Patents

Literature

37results about How to "Repressive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

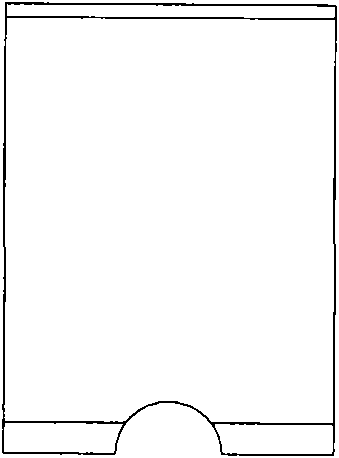

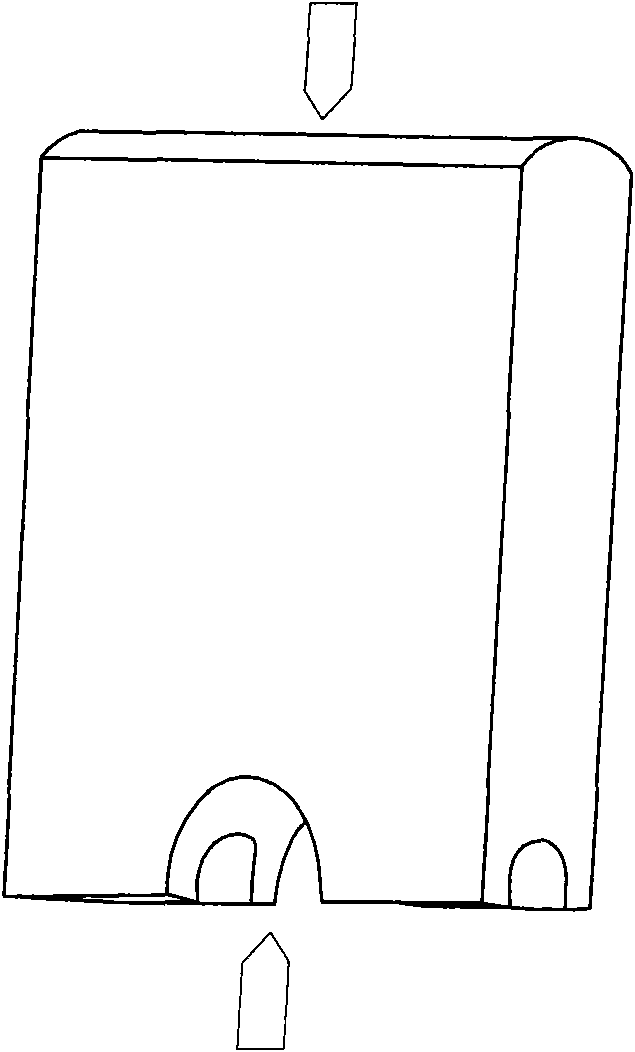

Preparation method of powder-metallurgy refrigeration compressor valve sheet

ActiveCN102380613AHigh forming densityImprove production continuityTurbinesOther manufacturing equipments/toolsRefrigeration compressorAlloy

The invention relates to a preparation method of a powder-metallurgy refrigeration compressor valve sheet. The preparation method is characterized by comprising the following steps of: mixing iron powder, high-alloy main powder, graphite powder, manganese sulfide powder and zinc stearate powder according to certain proportion, leading the weight percentage of all elements in the total components to be as follows: 0.5-2.0% of carbon, 3.0-6.5% of cobalt, 2.5-4.5% of chromium, 2.5-4.5% of molybdenum, 0.5-2.0% of nickel, 0.2-1.0% of vanadium, less than 3% of impurities and the balance of iron; using a mold to press and form the mixture to obtain a powder-metallurgy green blank; putting the green blank in a sintering furnace to sinter for more than 5 minutes with the sintering temperature being 1150-1250 DEG C; carrying out repressing and finishing on the sintered blank; carrying out quenching and annealing under the protective atmosphere; and carrying out grinding on the valve sheet. In the preparation method, the problems of the adding mode and effective alloying of the powder-metallurgy high alloy are solved, and higher forming density needed by the powder-metallurgy valve sheet material under higher alloy content is realized, so that the powder-metallurgy refrigeration compressor valve sheet achieves the needed wear resistance. The prepared powder-metallurgy refrigeration compressor valve sheet has the advantages of low material cost, high material utilization ratio and suitability for large-batch production.

Owner:NBTM NEW MATERIALS GRP

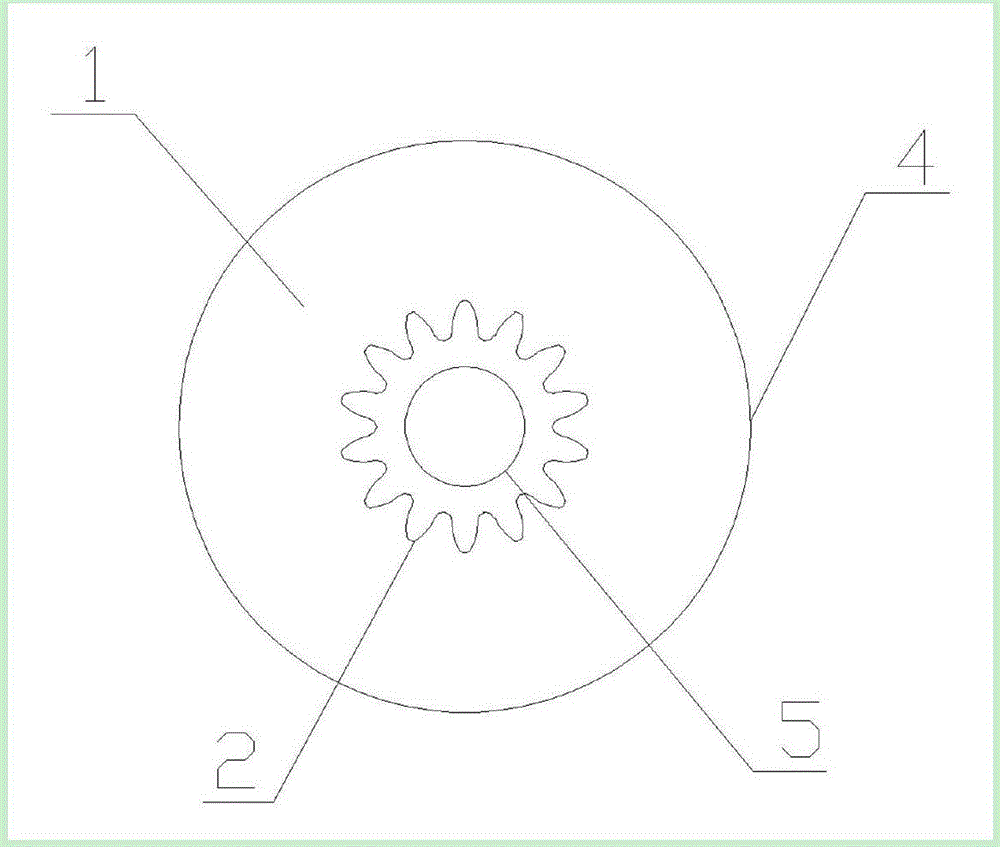

Powder metallurgy production method of internal helical gear

The invention relates to a powder metallurgy production method of an internal helical gear. The powder metallurgy production method comprises the following steps: 1) preparing metal powder raw materials in proportion; 2) putting the prepared metal powder raw materials into a mould of a powder extrusion moulding machine for moulding by rotary extrusion to form a mould green compact; 3) putting the mould green compact into a high temperature mesh belt furnace for sintering treatment; and 4) putting a sintered product into a carburizing furnace for carburizing treatment. The powder metallurgy production method helps produce the internal helical gear with easy production and operation, less cost, high production efficiency, high material utilization rate and high product accuracy.

Owner:扬州保来得科技实业有限公司

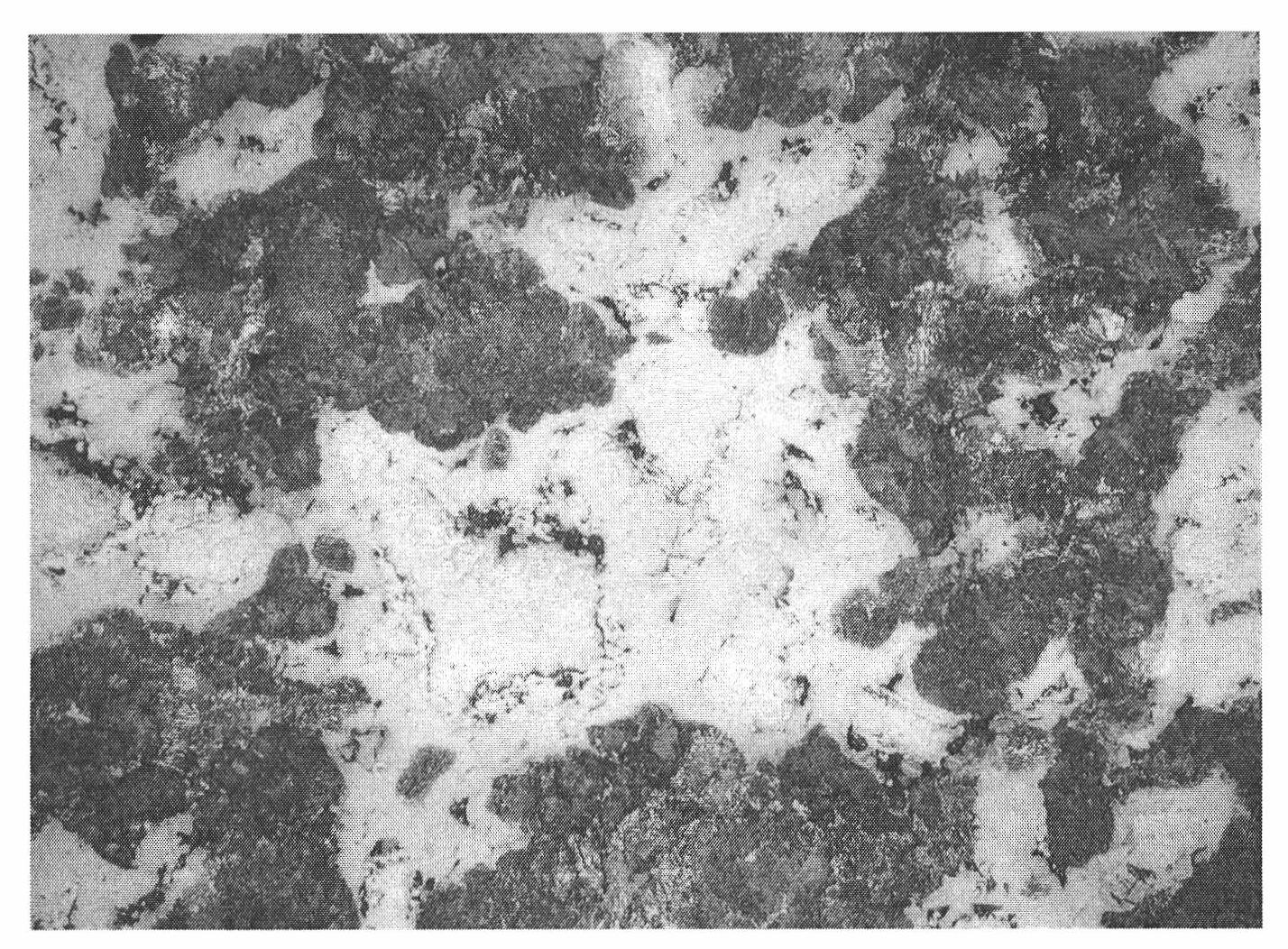

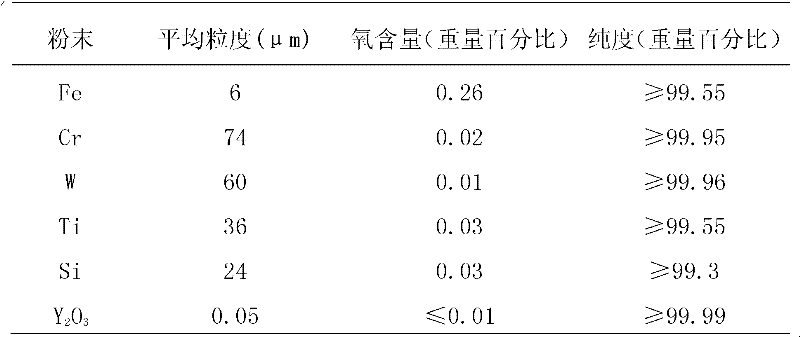

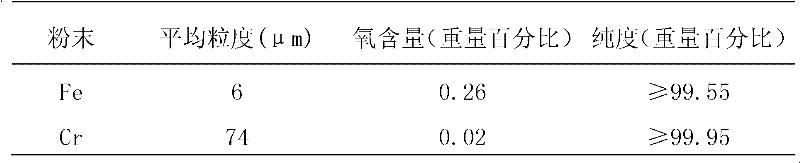

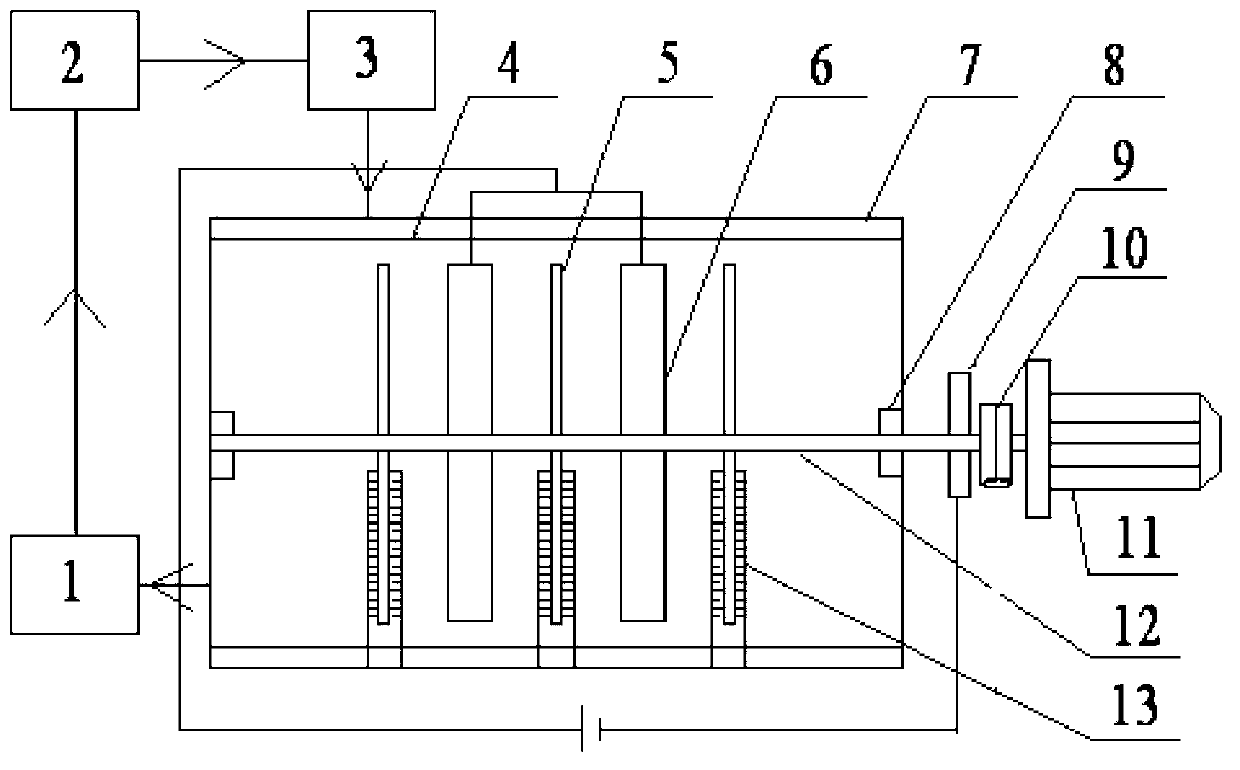

A kind of anti-oxidation iron-based superalloy and preparation method thereof

InactiveCN102286694AIncrease working temperatureIncrease productivityNuclear fusionOxidation resistant

An anti-oxidation iron-based superalloy and a preparation method thereof, which belong to superalloys and a preparation method thereof, solve the problem of unsatisfactory oxidation resistance of existing iron-based superalloys under high-temperature conditions, so as to improve serviceability and broaden high-temperature application fields. The anti-oxidation iron-based superalloy of the present invention has the composition mass percentages of: 12%≤Cr≤14%, 2%≤W≤3%, 0.3%≤Ti≤0.4%, 0.2%≤Si≤2%, 0.25%≤ Y2O3≤0.3%, the balance is Fe; it is made by mechanical alloying, molding and vacuum sintering, and the matrix of the final sintered body is α-(Fe, Cr) single-phase solid solution with uniformly distributed oxides in the matrix. The invention has high production efficiency and low cost, and the prepared anti-oxidation iron-based superalloy has reduced oxidation weight gain and improved anti-oxidation ability under the atmospheric condition of 850°C; the tensile strength at room temperature is ≥600MPa, and the elongation rate is ≥25%, which meets the requirements of automobiles. Requirements for the use of high-temperature structural parts such as engines and gas turbines, nuclear fission fuel cladding tubes, and first wall structural materials of nuclear fusion reactors.

Owner:HUAZHONG UNIV OF SCI & TECH

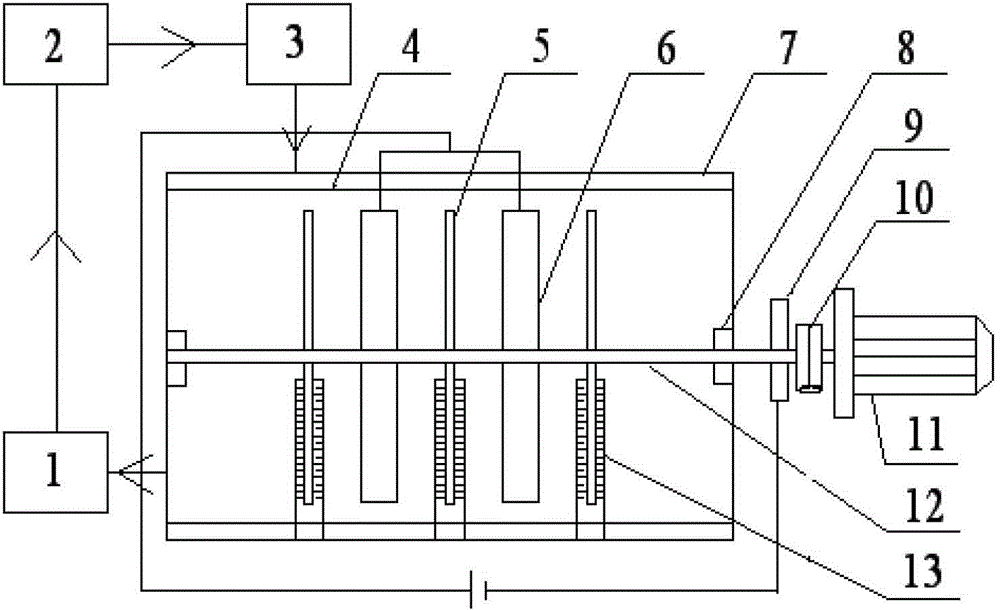

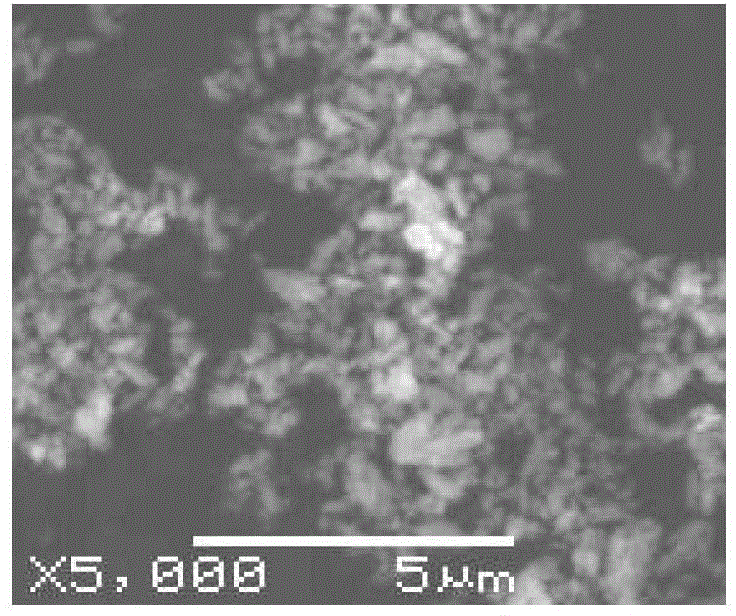

Iron-silicon-chromium soft magnetic powder, preparation method and application thereof

The invention discloses iron-silicon-chromium soft magnetic powder, a preparation method and application thereof. The preparation method comprises the following steps: 1) iron-silicon-chromium soft magnetic alloy powder raw materials are added in a medium-frequency induction furnace for atmospheric smelting to obtain alloy liquid; and 2) under the condition of nitrogen protection, the alloy liquid is fed in an atomization tower; in the feeding process, two atomization mediums of ultrahigh-pressure atomization water and low-pressure vortex gas synchronously acts on the alloy liquid; and the alloy liquid is strongly crushed as a lot of fine metal molten drops, and is cooled and condensed as the iron-silicon-chromium soft magnetic alloy powder. The iron-silicon-chromium soft magnetic powder with high loose packing density, high tap density, low oxygen content and higher inductance value and magnetic conductivity can be prepared; and the iron-silicon-chromium soft magnetic powder can serve as a raw material of a micro inductor, and is widely applied.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

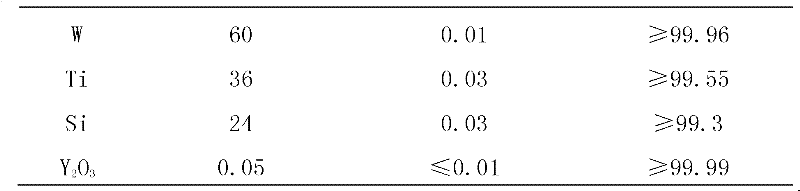

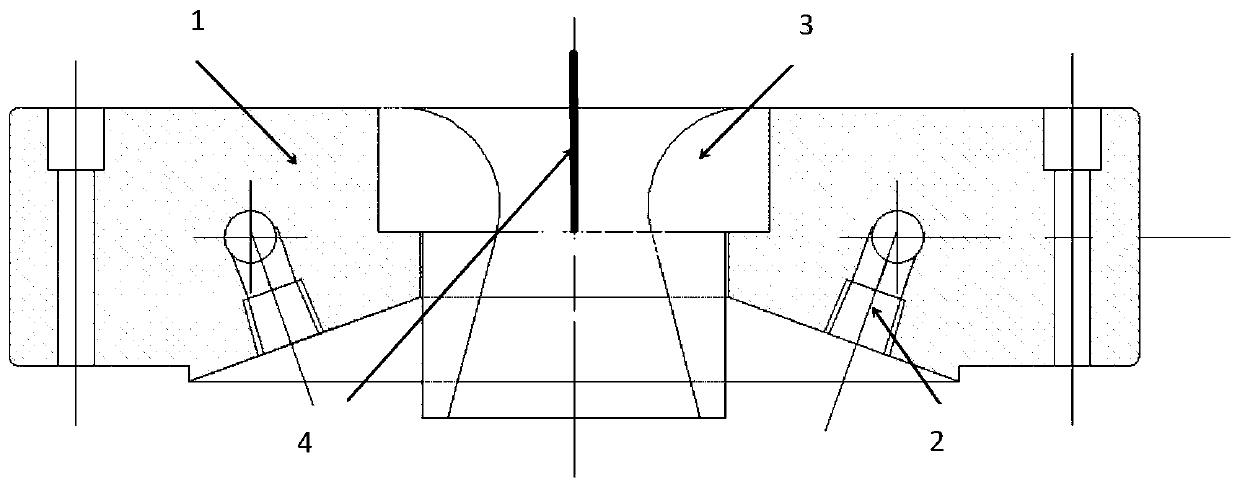

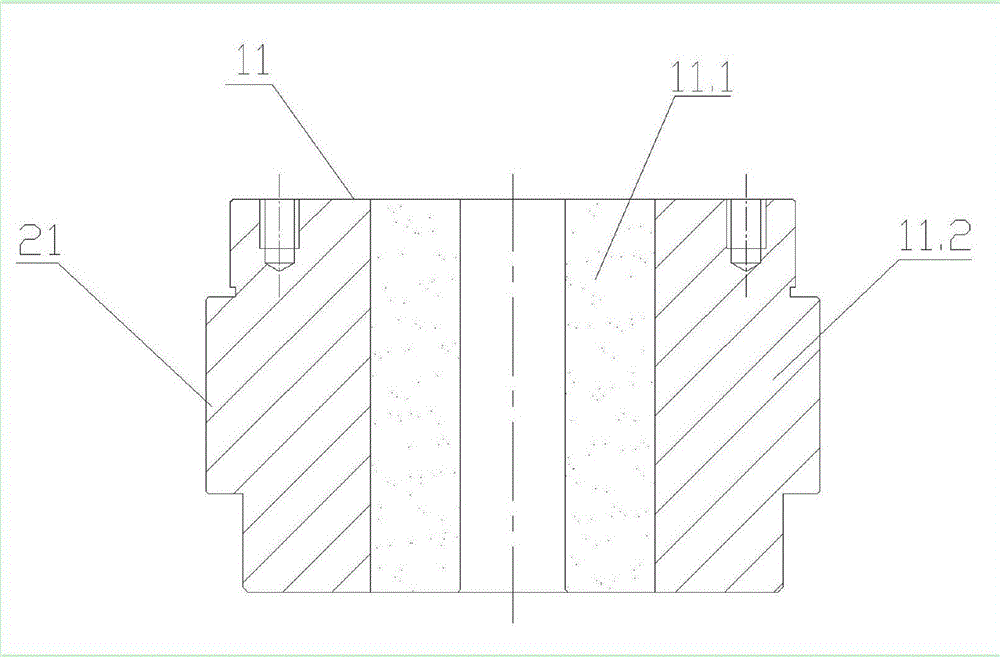

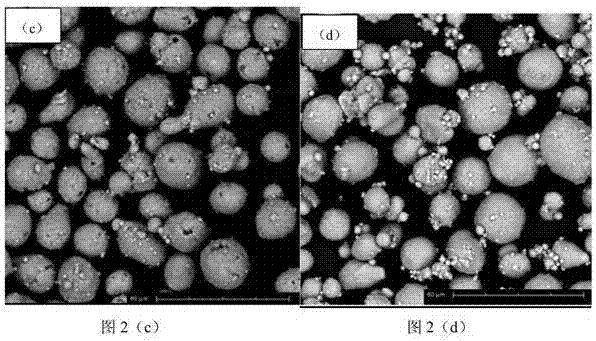

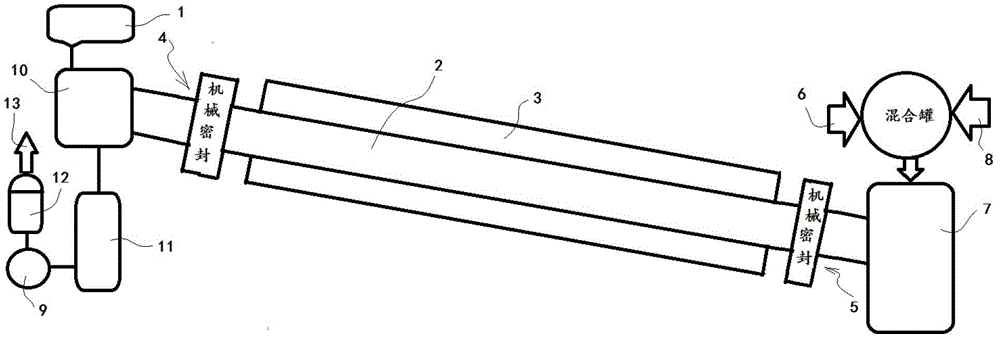

Method for preparing copper or nickel powder and electrolysis device based on same

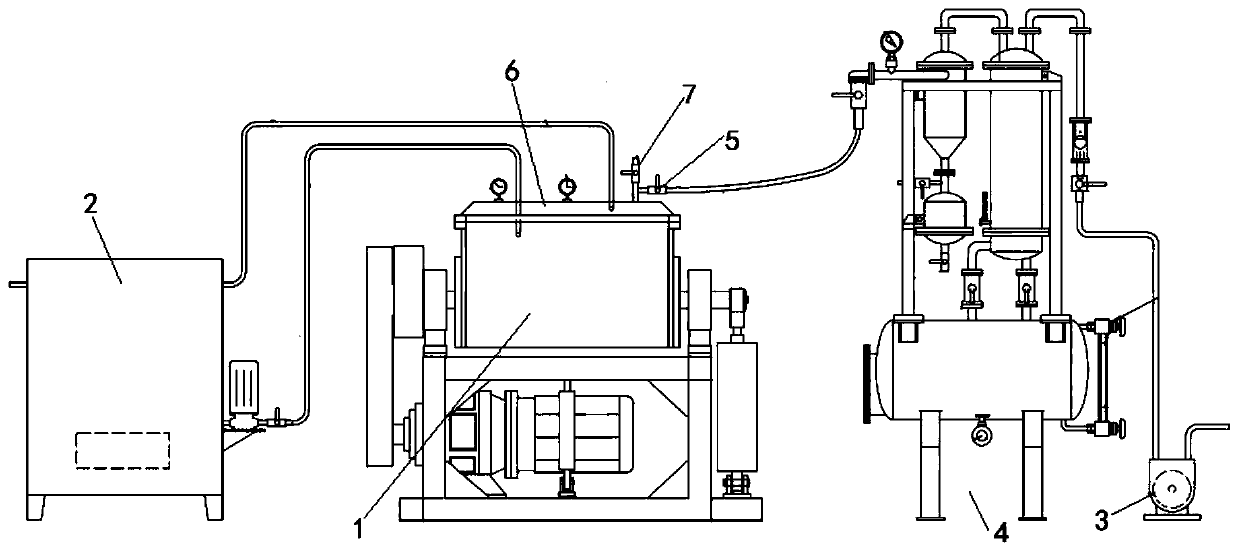

The invention discloses a method for preparing copper or nickel powder and an electrolysis device based on the same, so as to achieve continuous large-scale production. The method comprises the steps of: preparing electrolyte; clearing metal particles or turning scraps to be powdered to obtain a metal raw material; putting the metal raw material as a sacrificial anode into an electrolysis basket for electrolysis; continuously sending a suspension solution of the metal powder and the electrolyte out to filter and separate the metal powder; cleaning the filtered metal powder with deionized water; vacuum drying the metal powder; mechanically grinding the dried metal powder; and examining a finished product. The electrolysis device comprises an electrolysis tank, a cathode assembly plate, a conductive spindle, a ceramic bearing, a collector, an insulating coupling, a speed reduction motor, the anode basket, a bracket, a scraping brush, a separation tank, an acid-resistant pump and an overhead tank. The device has a compact structure, and the effective cathode area is enlarged by more than five times compared with the roller type electrolysis tank with the equal capacity, so that the working efficiency is greatly improved, and the labor intensity is reduced.

Owner:辽宁索研科技有限公司

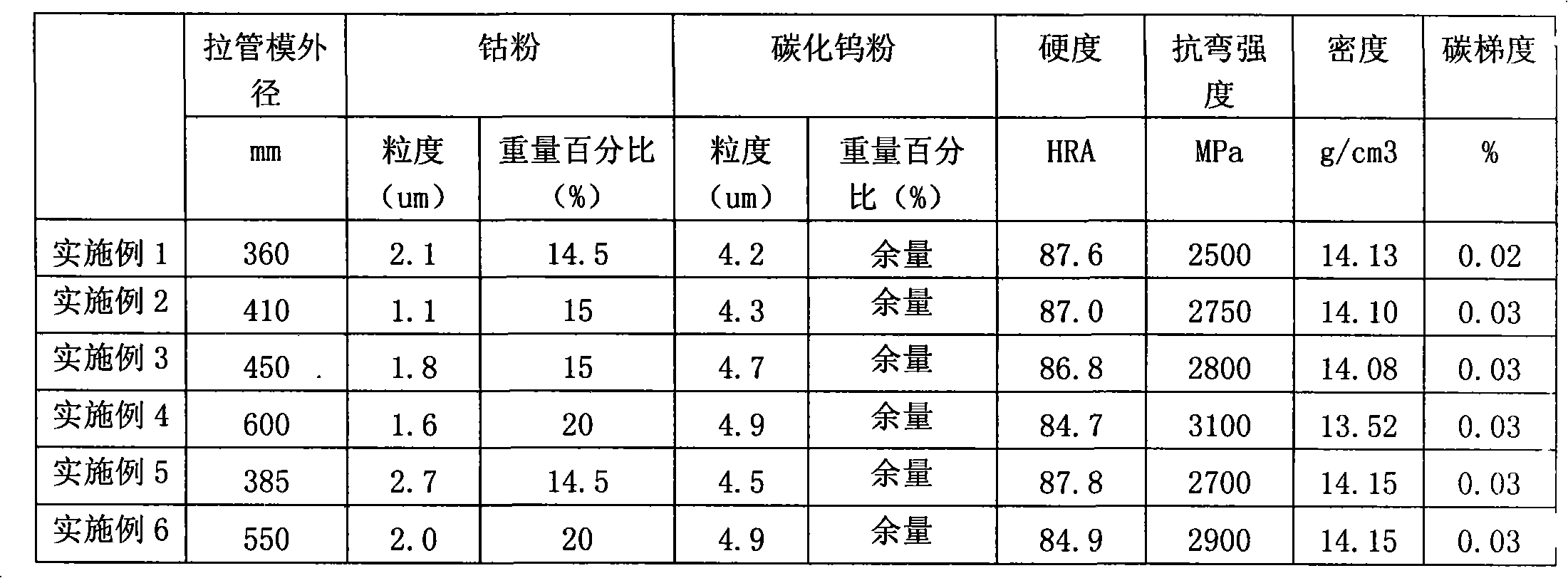

Hard alloy large pipe drawing mold and preparation method

InactiveCN101892408AHigh product strengthGuaranteed hardness and wear resistanceDrawing profiling toolsWaxCemented carbide

The invention provides a hard alloy large pipe drawing mold and a preparation method. The hard alloy large pipe drawing mold comprises the following raw material ingredients in percentage by weight: 14 to 20 percent of cobalt with a particle size of 1.0 to 3.0mu m, and the balance of tungsten carbide with a particle size of 4 to 5mu m. The preparation method comprises: raw material preparation, wet milling, drying, pressing, forming agent removal and sintering, wherein in the drying step, wax or butadiene rubber is used as the forming agent; the drying with the wax as the forming agent is spray drying; the forming agent remove is performed in a dewaxing and sintering integrated furnace or bell-type furnace; and the sintering is pressure sintering, and during the sintering, the temperature is raised within 11 to 13 hours till a liquid phase of the product appears, then about 40 mbars of high-purity argon is introduced into the furnace till the final sintering temperature of 1,390 to 1,400 DEG C, the temperature is kept for 50 to 60 minutes, then about 50 to 60 bars of high-purity argon is introduced, the temperature is kept continuously for 50 to 60 minutes, and the product is cooled to room temperature. The Rockwell hardness of the hard alloy large pipe drawing mold of the invention is more than or equal to 83HRA, the bending strength of the hard alloy large pipe drawing mold is more than or equal to 2,200MPa, and the density of the hard alloy large pipe drawing mold is 13.40 to 14.20g / cm<3>. And the hard alloy large pipe drawing mold has the advantages of high hardness, high wear resistance, uniform product performance, fragmentation resistance and long service life.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

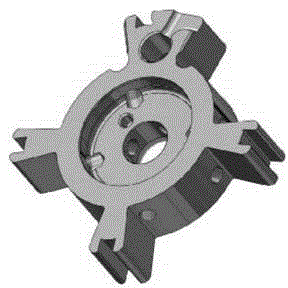

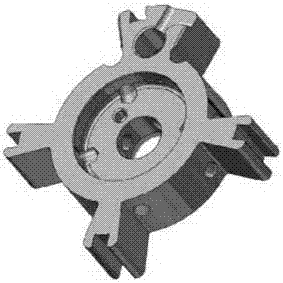

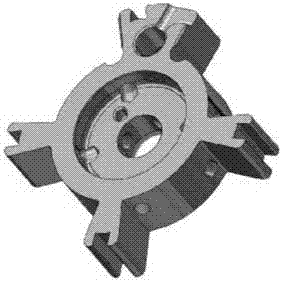

Preparation method for manufacturing rotor of phaser through powder metallurgy

The invention discloses a preparation method for manufacturing a rotor of a phaser through powder metallurgy. The preparation method comprises the steps that aluminum powder, high alloy base powder, copper powder, nickel powder and organic lubricant are mixed according to the following mass proportions of 4.0%-5.0% of copper, 0.5%-1.0% of magnesium, 0.5%-1.0% of iron, 2.0%-2.5% of nickel, 0.5%-1.0% of silicon, 0.8%-1.5% of the organic lubricant, no more than 2% of unavoidable impurities, and the balance aluminum; and powder metallurgy green bodies are obtained through pressing forming and are subjected to sintering, solid solution and quenching treatment, repressing, finishing and aging treatment, and turning machining is conducted on the rotor at last to meet the final size requirement. Compared with a sintered steel rotor, the rotor prepared through the preparation method is good in pressing property, higher in speed and low in pressing cost. The temperature for sintering aluminum alloy is much lower than the temperature for sintering steel; the energy consumption in the sintering process is reduced, and the powder metallurgy aluminum rotor is better in machining property and no surface protection treatment is needed in the transportation and storage process. Compared with a diecast or an extruded aluminum alloy rotor, the powder metallurgy is a near-net forming technology, and the use ratio of aluminum alloy raw materials is high; the production efficiency is high; the production cost is low.

Owner:NBTM NEW MATERIALS GRP

cBN-high speed steel composite material and preparation method thereof

The invention discloses a high speed steel precursor powder mixture used for preparing a cBN-high speed steel composite material. The high speed steel precursor powder mixture comprises, by mass, 3%-15% of Co powder, 32%-75% of Fe powder, 20%-50% of carbide powder selected from Group 4 metal, Group 5 metal and Group 6 metal of the periodic table of the elements, and 0-2% of C powder. The cBN-high speed steel composite material comprises, by mass, 1%-30% of cBN, 2.7%-13.5% of Co, 1.7%-5.4% of C, 14%-45% of Group 4 metal, Group 5 metal and Group 6 metal selected from the periodic table of the elements, and 40.6%-67.5% of Fe. Non-atomized powder is adopted to replace atomized powder, a local eutectic liquid phase can be avoided, erosion to cBN by the local eutectic liquid phase is prevented, the cBN can be kept stable, and therefore usability of the final cBN-high speed steel composite material is improved.

Owner:长沙市萨普新材料有限公司

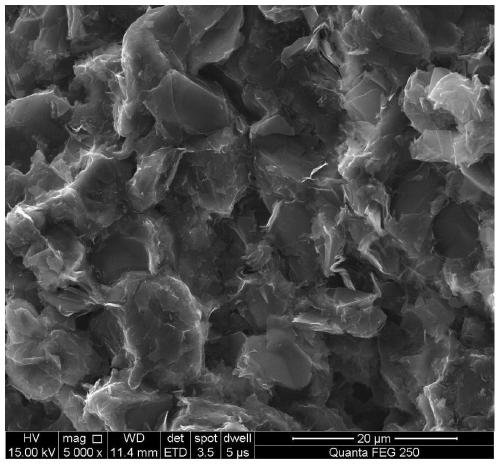

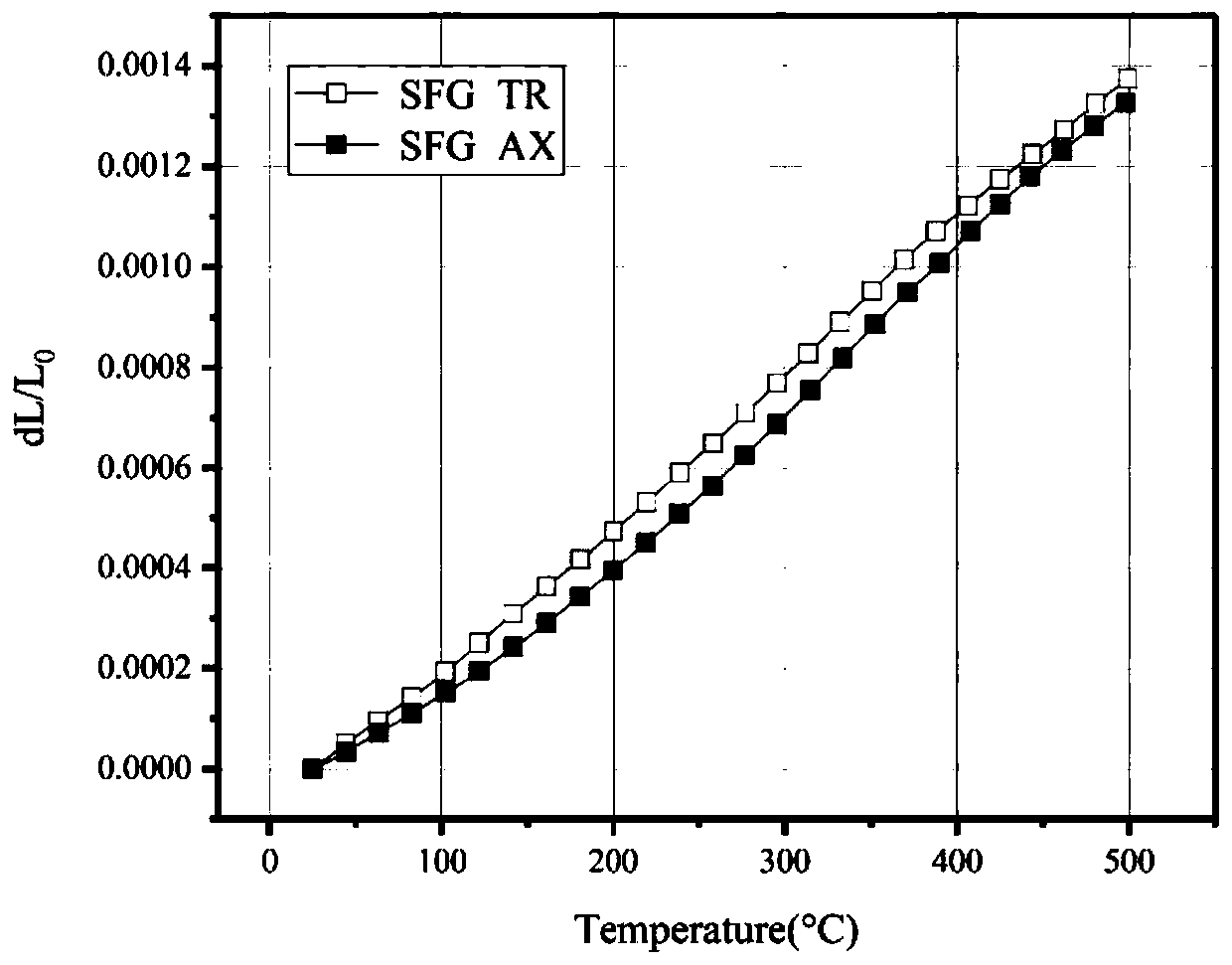

Novel isotropic nuclear-grade graphite material and preparation method thereof

The invention discloses a novel isotropic nuclear-grade graphite material and a preparation method thereof. The novel isotropic nuclear-grade graphite material is prepared by using spheroidized natural crystalline flake graphite as an aggregate, and the proportion of the spheroidized natural crystalline flake graphite in the aggregate is 50-100 wt%. The preparation method comprises the following steps: spheroidizing treatment, purification, mixing kneading, secondary crushing and screening, forming, primary roasting, dipping, secondary roasting, and graphitizing treatment. The isotropic nuclear-grade graphite material is prepared by spheroidizing natural crystalline flake graphite, has the characteristics of high density, high thermal conductivity, low expansion coefficient and excellent isotropy, and shows good application prospects in the fields of nuclear energy, thermal management, machinery, chemical engineering and the like.

Owner:HUNAN UNIV

High-performance self-lubricating copper-based pantograph pan material and preparation method thereof

ActiveCN111360243ALower sintering temperatureImproved high temperature stability and ablation resistanceTransportation and packagingMetal-working apparatusGunmetalCopper matrix

The invention relates to a high-performance self-lubricating copper-based pantograph pan material and a preparation method thereof, and belongs to the technical field of high-speed carrying equipmentdevelopment. The self-lubricating copper-based pantograph pan material is prepared from, by mass, 40-70 parts of copper-tin alloy powder, 10-30 parts of pure copper powder, 4-12 parts of iron-copper alloy powder, 2-6 parts of copper-chromium alloy powder, 5-9 parts of lead powder, 1-4 parts of graphite powder and 1-3 parts of molybdenum disulfide. According to the preparation method, the copper-tin alloy powder, the iron-copper alloy powder and the copper-chromium alloy powder are adopted to replace elemental tin powder, iron powder, chromium powder and the like to serve as a reinforcing phase, the sintering temperature can be effectively reduced, and the problem of loss of the low-melting-point elemental tin powder in the sintering process is avoided. Through reinforcement, the high-temperature stability and anti-ablation capability of a copper matrix are improved, the deformation and adhesion of a pan in a high-temperature environment caused by friction are suppressed, the loss of the pan is reduced, and the friction resistance of the pan is improved.

Owner:长沙迈特锐新材料有限公司

Method for directly manufacturing heavy pressure blank strength tungsten powder with ammonium metatungstate

The invention discloses a preparation method of high pressed compact strength tungsten powder by ammonium metatungstate (AMT) direct hydrogen reduction. The tungsten powder prepared by the invention is directly formed into high-intensity pressed compacts without adding any forming agents, and the transverse rupture strength of the pressed compacts reaches 2.5 to 4.0MPa. The tungsten powder prepared by the invention can be widely used for preparing large tungsten products and tungsten alloy products. In the method, ammonium metatungstate is used for direct reduction, and calcination and other intermediate processes are not necessary, thereby process is simple and energy consumption is low. The granularity of the tungsten powder prepared by the method is controlled to be homogeneous and the sintering activity is high, thereby being benefit for the preparation of high-performance tungsten products.

Owner:CENT SOUTH UNIV

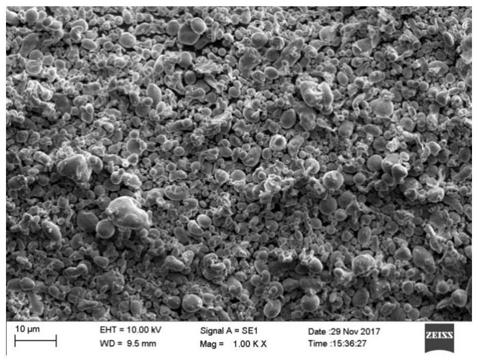

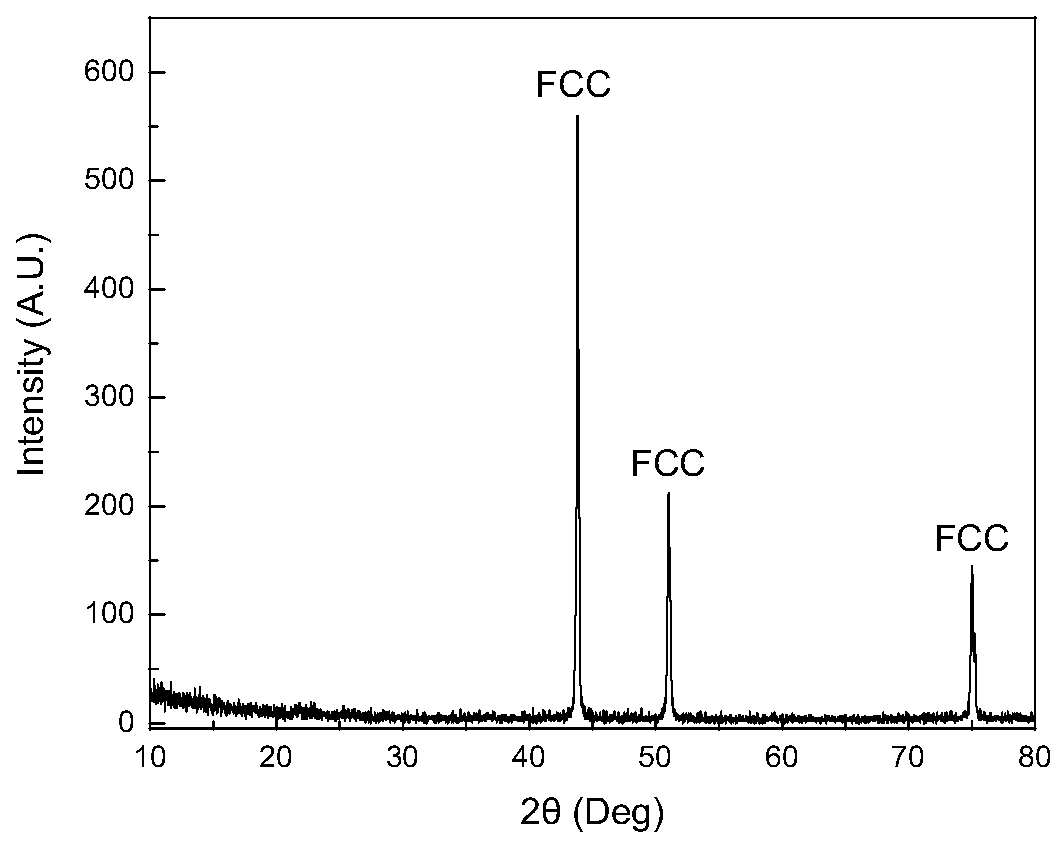

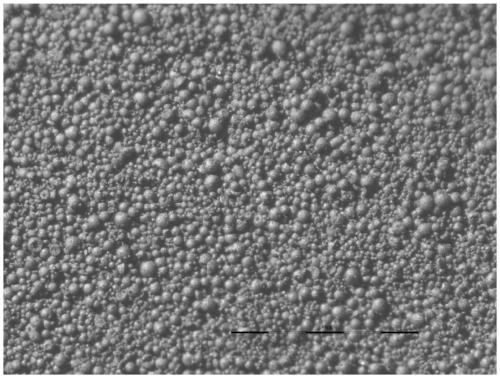

Annular inductance element, FeSiCr soft magnetic alloy powder and preparation method of FeSiCr soft magnetic alloy powder applied to annular inductance part

PendingCN110004382AGood sphericityReduce oxygen contentTransportation and packagingMetal-working apparatusApparent densityOxygen content

The invention discloses an annular inductance element, FeSiCr soft magnetic alloy powder and a preparation method of the FeSiCr soft magnetic alloy powder applied to the annular inductance part. An alloy comprises the following components of, in percentage by mass, 4.0%-8.0% of Cr, 2.0%-8.0% of Si, 1.2%-2.0% of Ni, 0.5%-0.8% of Mo, and 85%-92.3% of Fe. According to the method, the prepared FeSiCrsoft magnetic alloy powder is less in impurity content, uniform in alloying component and an organization structure, low in carbon and oxygen content, good in powder sphericity and in a spherical-likeshape, good in apparent density, and high in tap density; and a prepared product is good in pressing property, high in inductance value, low in power loss, good in rust resistance, and the FeSiCr soft magnetic alloy powder is capable of being widely applied as a raw material of the annular inductance element.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

A kind of composite material of high-entropy alloy holding abrasive particles and its preparation method and application

The invention relates to a composite material of a high-entropy alloy holding abrasive particle as well as a preparation method and application thereof, and belongs to the technical field of high-entropy alloy application. The high-entropy alloy holds the abrasive particle in a tyre body form. The high-entropy alloy is prepared from the following ingredients through being metered by atomic percentage: 10 to 30 percent of Fe, 10 to 30 percent of Co, 10 to 30 percent of Cr, 10 to 30 percent of Ni, 10 to 30 percent of Cu and 0 to 8 percent of Mo. The preparation method is characterized in that after the high-entropy alloy raw material powder is prepared and taken according to the designed ingredients, high-entropy alloy powder is prepared by a gas atomization method and a mechanical alloyingmethod; then, a SPS process is combined; the composite material with excellent performance is obtained. The composite material is particularly suitable for being used for manufacturing a cutter head.The high-entropy alloy is used as a tyre body for holding abrasive particles for the first time; the ingredient design is reasonable; the preparation process is scientific and controllable; the performance of the product is excellent; the large-scale industrial application is convenient.

Owner:江西咏泰粉末冶金有限公司

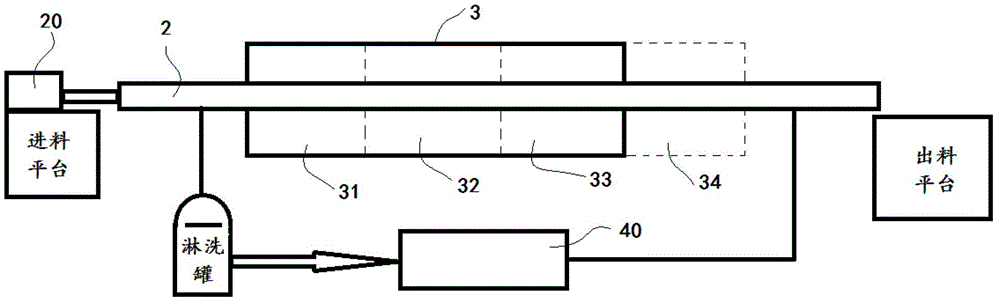

Method for preparing cemented carbide mixture by adopting modified wax forming agent

ActiveCN108838386AGood dispersionEasy to expandTransportation and packagingMetal-working apparatusParaffin waxAlcohol

A method for preparing a cemented carbide mixture by adopting an modified wax forming agent is characterized in that the method sequentially comprises the following steps that 1, all raw materials forforming the cemented carbide mixture are put into a ball-milling chamber of ball-milling equipment according to the requirements of weight parts, wherein the cemented carbide mixture is composed of 90-99 parts of cemented carbide powder, 1-10 parts of modified wax forming agent and 10-50 parts of alcohol, and the modified wax forming agent comprises paraffin, a complexing agent and an impregnating compound; 2, the mixture of all the raw materials is ball-milled; and 3, all the ball-milled raw materials are dried, and the cemented carbide mixture is obtained after drying. In the process of preparing the cemented carbide mixture through the modified wax forming agent, the modified wax forming agent is dispersed quite easily in an alcohol solvent, the fluidity of the powder is good during spraying, the powder is uniform, and powder pressing performance is good.

Owner:武汉新锐合金工具有限公司

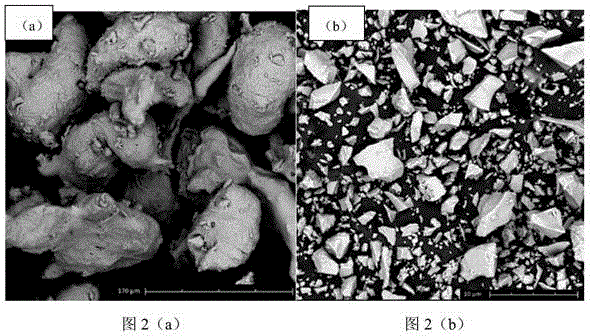

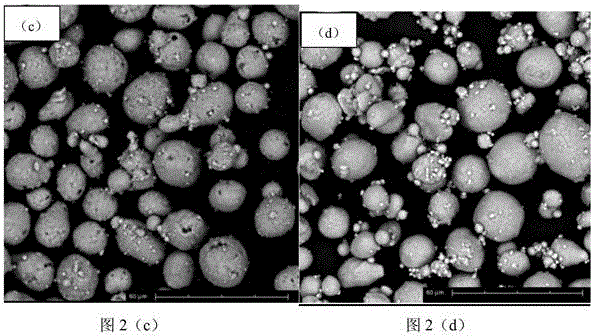

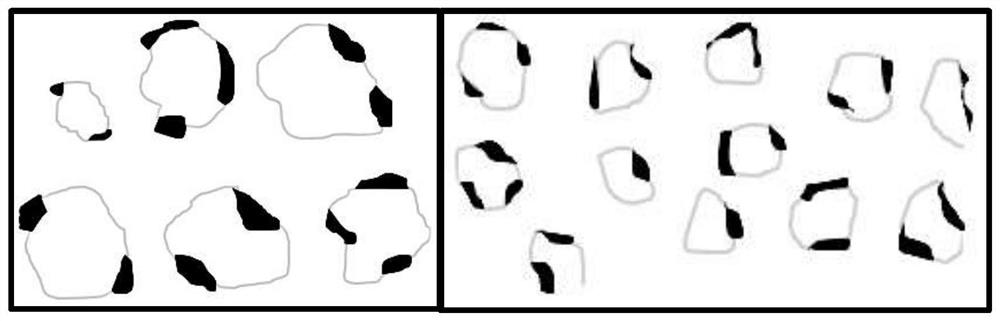

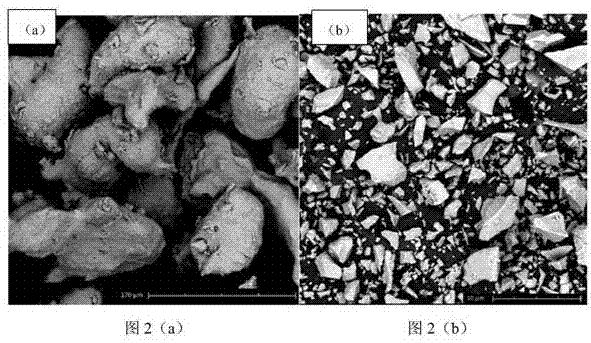

Method for improving fluidity of spray powder particles of hard alloy mixture

InactiveCN111421140AReduce drynessReduce fine particle powder moreTransportation and packagingMetal-working apparatusAlcoholCrazing

The invention relates to a method for improving the fluidity of spray powder particles of a hard alloy mixture. Raw materials are prepared into the hard alloy mixture, a wet milling medium, an alloy bar and a forming agent are added for ball milling, and fatty acid diethanolamide and oleamide are added in the ball milling process; and mixture slurry obtained after wet milling is screened, spray-dried and pelletized, and the hard alloy spray particles smooth in surface and good in fluidity are prepared. The fatty acid diethanolamide and the oleamide are added, and in combination with ball milling and spray production processes matched with the fatty acid diethanolamide and the oleamide, the fatty acid diethanolamide can be fully fused with paraffin and ethyl alcohol; polar groups and non-polar groups in the fatty acid diethanolamide are combined with a ball milling medium and the paraffin correspondingly, and stable suspension is formed; the prepared mixture slurry is uniform and is notlikely to precipitate, the spraying efficiency is high, and the spray powder particles are good in uniformity; the spray powder particles are regular in morphology, smooth in surface and good in fluidity; and the prepared powder is good in pressing performance, and cracks and other defects are not likely to be generated.

Owner:SHAREATE TOOLS

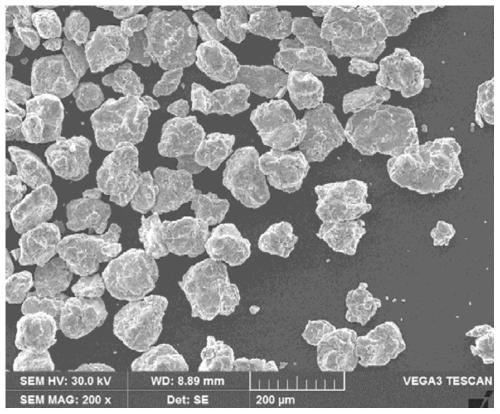

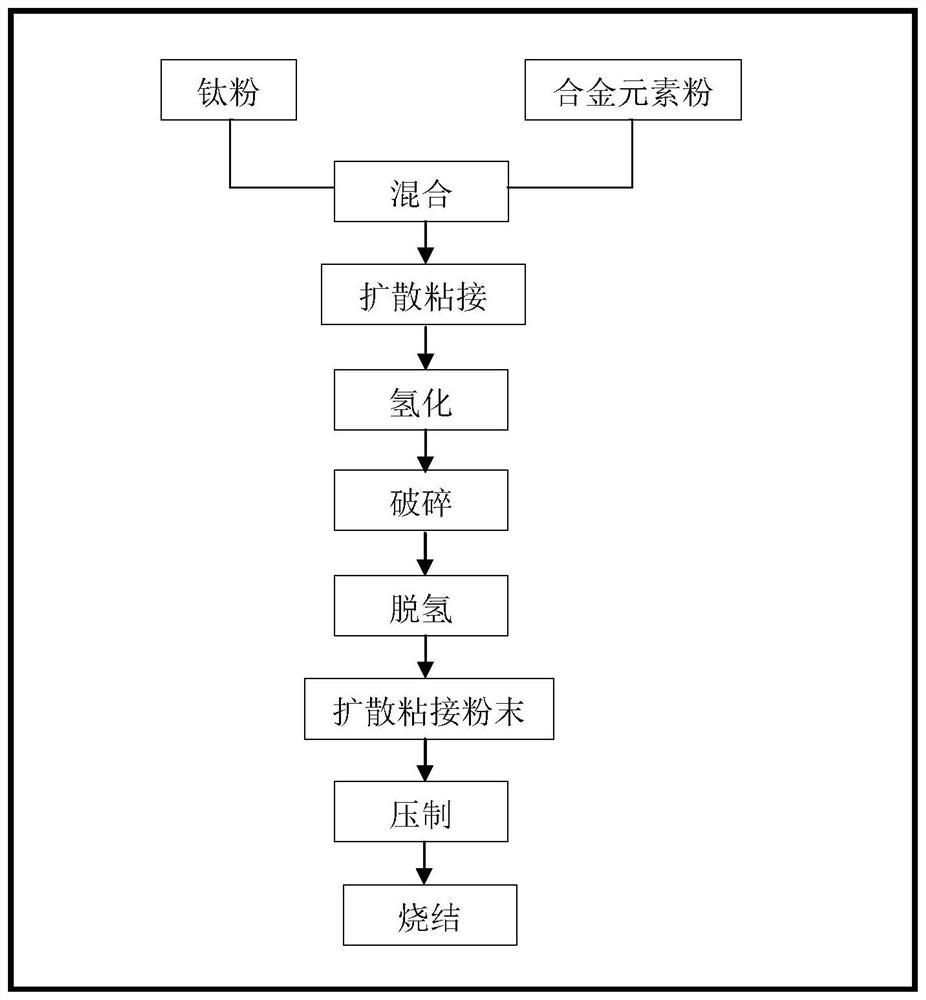

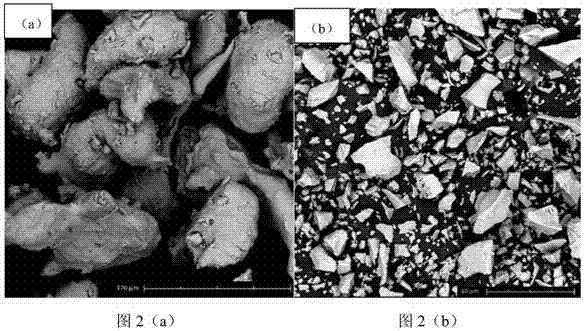

Preparation method of diffusion bonding titanium powders

ActiveCN112453384AReduce oxygen contentPromote fragmentationTransportation and packagingMetal-working apparatusTitanium alloyTitanium powder

The invention relates to a preparation method of diffusion bonding titanium powders, in particular to a method for producing powders for high performance powder metallurgy titanium alloys. The preparation method comprises the following steps that coarse particle titanium powders and elemental powders or alloy powders are used as raw materials to be mixed according to the proportion of required components, obtained mixed powders are subjected to diffusion bonding treatment, and hydrogen is introduced to form titanium hydride; and then the titanium hydride is taken out of a furnace, ball millingand crushing are carried out to obtain powders with the required particle size, and finally dehydrogenating is carried out to obtain the diffusion bonding titanium alloy powders. According to the preparation method, the cost of titanium alloy powders is obviously reduced, and the cost is only 1 / 10-1 / 2 that of the prior art; the preparation method has the advantages of low equipment requirement, less fixed asset investment, high production efficiency and simple and controllable production process; obtained products have low oxygen content and few impurities; and products obtained after sintering have stable performance, low oxygen content and uniform component structures.

Owner:CENT SOUTH UNIV

High magnetic permeability soft magnetic alloy powder, inductance part and preparation method thereof

ActiveCN106205934BReduce power lossHigh Intrinsic Insulation ResistanceTransformers/inductances detailsMagnetic materialsApparent densityInductor

The invention discloses high-magnetoconductivity soft magnetic alloy powder. The alloy consists is prepared from the following components in parts by mass: 25.0 to 80.0 parts of Fe, 3.0 to 8.0 parts of Si, 15 to 55 parts of Ni, 1.0 to 7.0 parts of B and 1.0 to 5.0 parts of P. The invention further discloses an inductance piece prepared from the high-magnetoconductivity soft magnetic alloy powder, a preparation method of the high-magnetoconductivity soft magnetic alloy powder and a preparation method of the inductance piece. By the adoption of the preparation method disclosed by the invention, the soft magnetic alloy powder with various particle sizes can be prepared, and the soft magnetic alloy powder is high in magnetoconductivity, lower in power loss, higher in apparent density, high in tap density, lower in oxygen content, high in product pressing performance and high in magnetic ring density. Due to small oxygen content, few impurities, small carbon content, uniform alloy components and high sphericity degree, the high-magnetoconductivity soft magnetic alloy powder can be widely used as a raw material of a novel sintered inductor.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

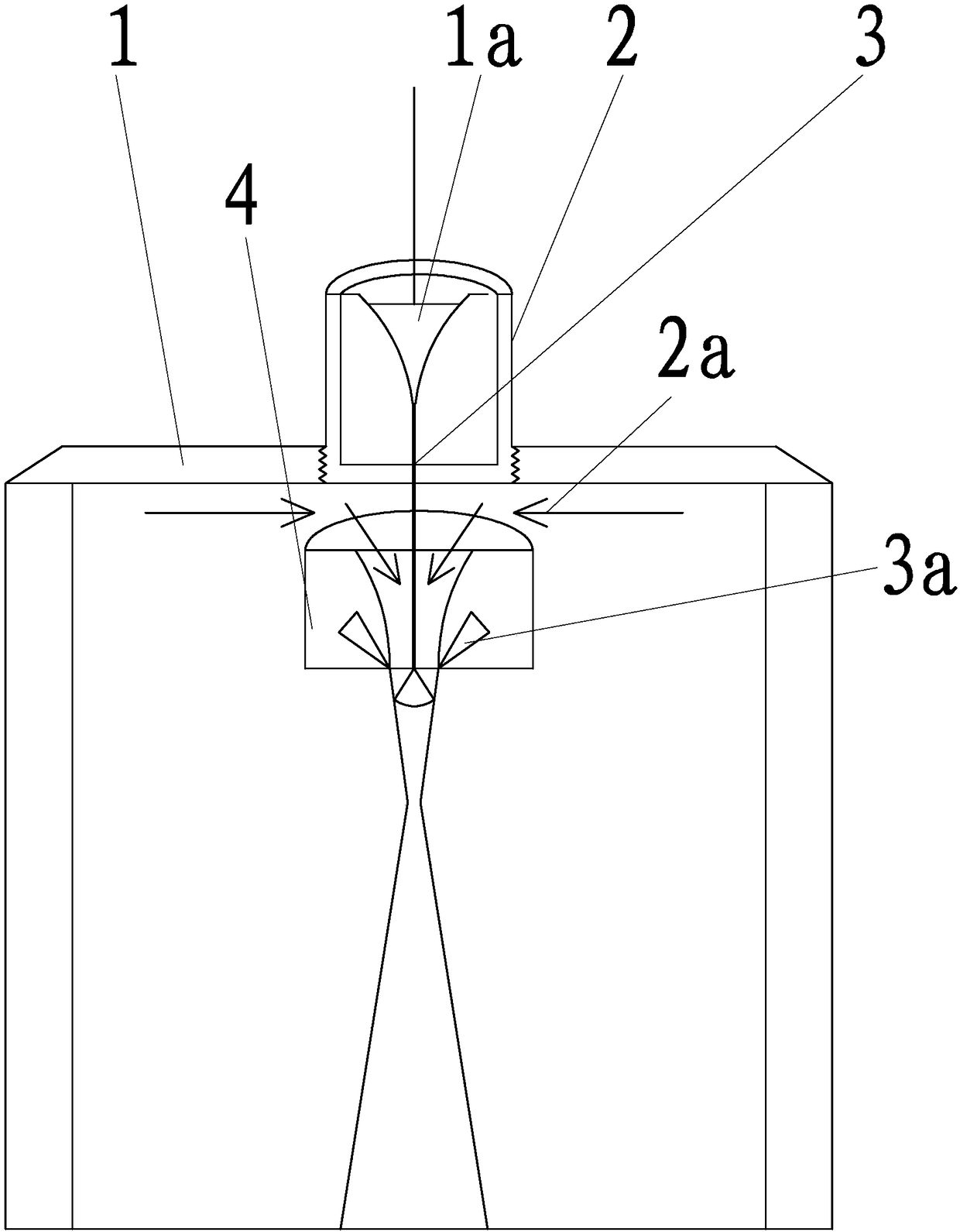

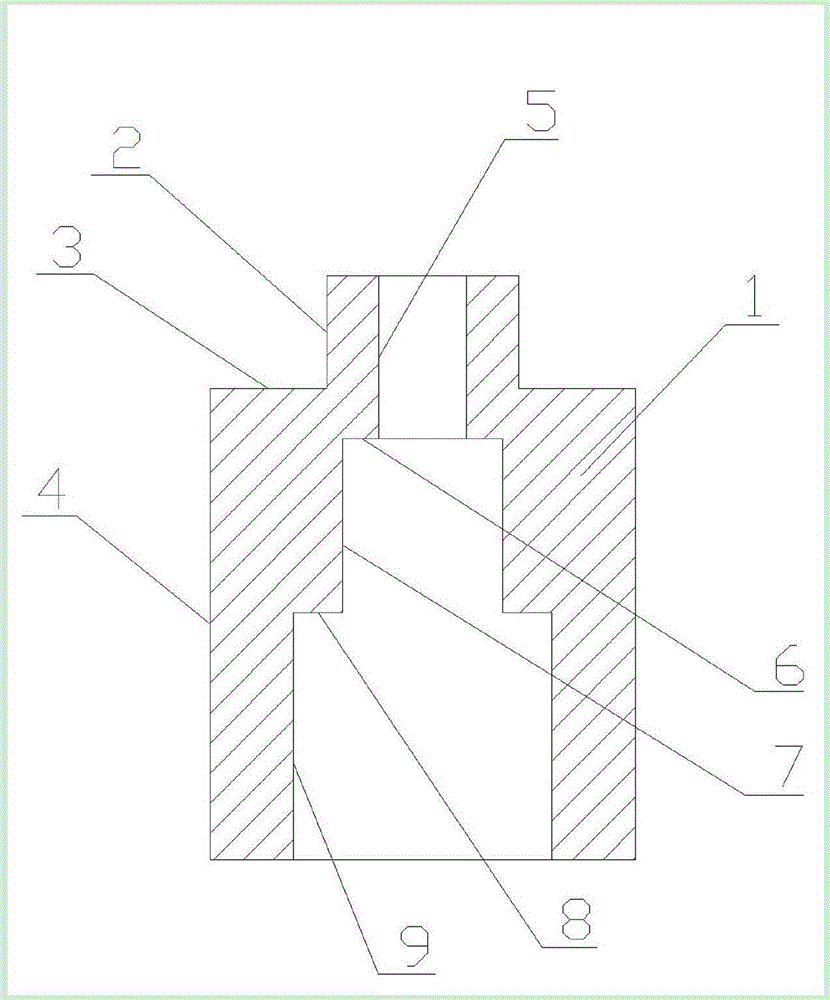

A mold for processing a gear bushing and a method for processing a gear bushing using the mold

ActiveCN104117679BImprove liquidityRepressiveBearing componentsNumerical controlVolumetric Mass Density

Owner:宁波金钟粉末冶金有限公司

A preparation method of powder metallurgy phaser rotor

A method for preparing a powder metallurgy phaser rotor, the steps of: mixing aluminum powder, high-alloy mother powder, copper powder, nickel powder and an organic lubricant according to the following mass ratios: copper 4.0-5.0%, magnesium 0.5-1.0% , iron 0.5-1.0%; nickel 2.0-2.5%, silicon 0.5-1.0%, organic lubricant: 0.8-1.5%, unavoidable impurities not exceeding 2%, the balance being aluminum; powder metallurgy green body obtained by pressing, Then sintering, solution quenching, repressing finishing, aging treatment, and finally turning the rotor to meet the final size requirements. Compared with the rotor made of sintered steel, the present invention has better pressing performance, faster speed and lower pressing cost; the temperature of sintered aluminum alloy is much lower than that of sintered steel, the energy consumption in the sintering process is reduced, and the processing performance of the powder metallurgy aluminum rotor is better Well, there is no need for surface protection treatment during transportation and storage; compared with die-casting or extruded aluminum alloy rotors, powder metallurgy is a near-net-shaping technology, with high utilization of aluminum alloy raw materials, high production efficiency, and low production costs Low.

Owner:NBTM NEW MATERIALS GRP

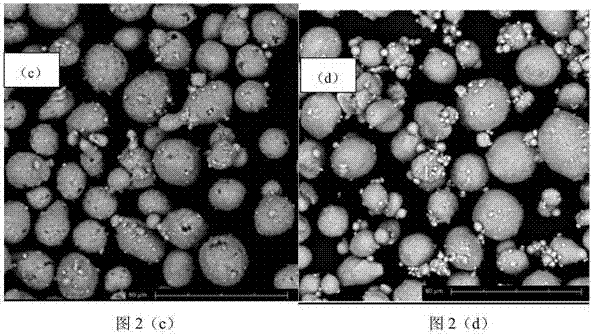

A kind of preparation method of FeSiCr soft magnetic powder

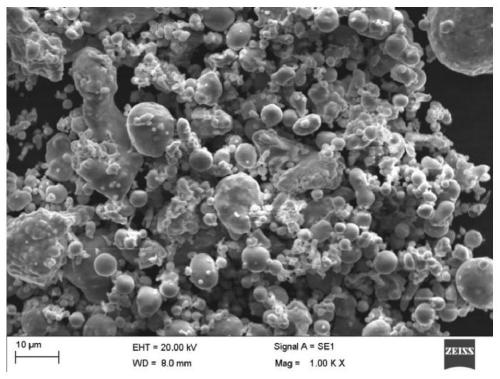

ActiveCN105945294BPowder with high oxygen contentGood sphericityMagnetic materialsUltra high pressureIntermediate frequency

The invention discloses a preparation method of iron-silicon-chromium soft magnetic powder. The steps of the preparation method are as follows: 1) adding iron-silicon-chromium soft magnetic alloy powder raw materials into an intermediate frequency induction furnace, and smelting in the atmosphere to obtain alloy liquid; 2) under the condition of nitrogen protection Then, the alloy liquid is sent to the atomization tower. During the feeding process, the two atomization media, ultra-high pressure atomized water and low-pressure vortex gas, act on the alloy liquid at the same time, and the alloy liquid is strongly broken into a large number of small metal melts. drops, and then cools and solidifies into Fe-Si-Cr soft magnetic alloy powder. It can prepare Fe-Si-Cr alloy powder with high bulk density, high tap density, low oxygen content, high inductance value and magnetic permeability. It can be widely used as a raw material for miniature inductors.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

A method for preparing copper powder or nickel powder and its electrolysis device

The invention discloses a method for preparing copper or nickel powder and an electrolysis device based on the same, so as to achieve continuous large-scale production. The method comprises the steps of: preparing electrolyte; clearing metal particles or turning scraps to be powdered to obtain a metal raw material; putting the metal raw material as a sacrificial anode into an electrolysis basket for electrolysis; continuously sending a suspension solution of the metal powder and the electrolyte out to filter and separate the metal powder; cleaning the filtered metal powder with deionized water; vacuum drying the metal powder; mechanically grinding the dried metal powder; and examining a finished product. The electrolysis device comprises an electrolysis tank, a cathode assembly plate, a conductive spindle, a ceramic bearing, a collector, an insulating coupling, a speed reduction motor, the anode basket, a bracket, a scraping brush, a separation tank, an acid-resistant pump and an overhead tank. The device has a compact structure, and the effective cathode area is enlarged by more than five times compared with the roller type electrolysis tank with the equal capacity, so that the working efficiency is greatly improved, and the labor intensity is reduced.

Owner:辽宁索研科技有限公司

A production method and system for high billet strength tungsten powder

Disclosed is a method for producing high compact strength tungsten powder. Ammonium paratungstate and purple tungsten oxide serving as raw materials are uniformly mixed according to a certain proportion, mixed powder is placed into a hydrogen reduction furnace, the thickness of a material bed is 5-25mm, the mixed powder is heated up to 700-1100 DEG C at the speed of 5-20 DEG C / min and is directly reduced with hydrogen, holding time is 1-5 hours, the dew-point temperature of the hydrogen ranges from -40 DEG C to -65 DEG C, and finally, reduced powder is sieved to obtain the high compact strength tungsten powder. The tungsten powder produced by the method can be pressed into high-strength compact without adding any forming agents, the compact strength of the tungsten powder is as high as 3.0-5.0MPa, and a tungsten product made of the tungsten powder has the advantages of high density, fine high-temperature resistance, stable quality and the like. The preparation method and preparation steps are quite simple, and technological parameters of the preparation process are easily controlled.

Owner:赣州江钨友泰新材料有限公司

Mixture preparation process

The invention discloses a mixture preparation process. Rapid and continuous stirring is carried out in the state that the vacuum degree of a vacuum drying stirrer ranges from -0.06- -0.08 so that the drying speed can be increased and oxidation and / or excessive hardness of a mixture can be prevented; when stirring enables the temperature in the vacuum drying stirrer has an obvious rising process and the mixture is in a half-dry state, continuous stirring is stopped, the vacuum degree of the vacuum drying stirrer is reduced to 0- -0.05, the mixture is prevented from being broken, so that follow-up pelletizing is facilitated; and the mixture particles produced and discharged in such a way are soft, fragile and good in pressing performance, holes of sintered products can reach A02 or below, WC grows completely, and metallographic structures are uniform.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

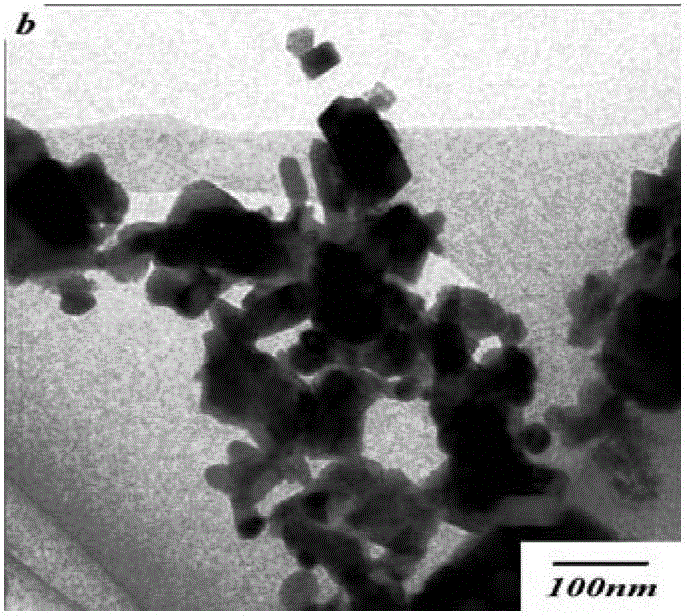

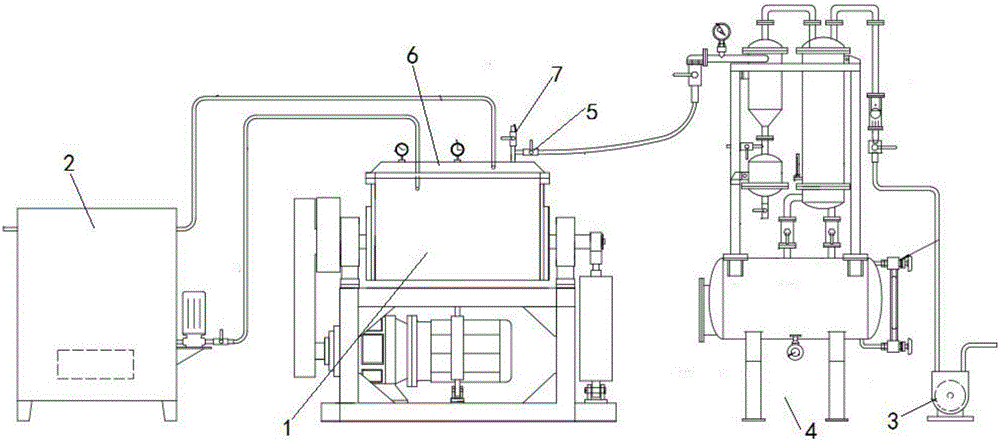

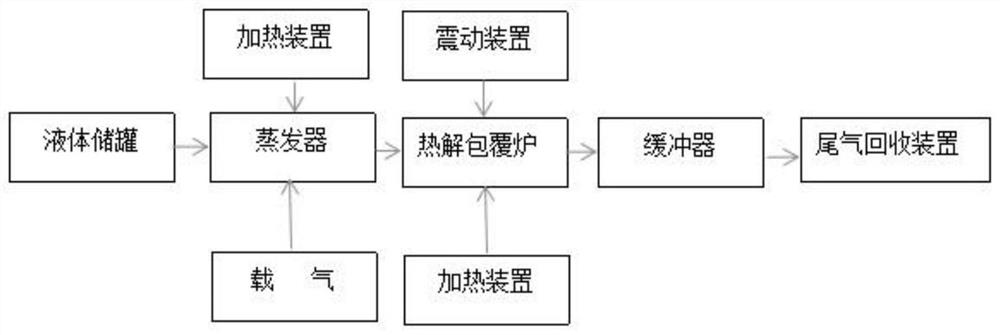

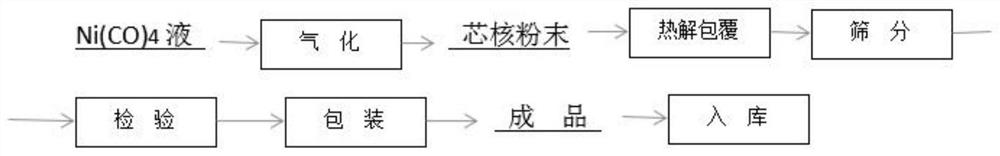

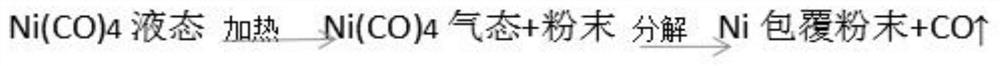

Method for preparing nickel-coated powder by carbonyl vapor deposition

ActiveCN110976850BHigh purityImprove responseTransportation and packagingMetal-working apparatusChemical reactionNickel Carbonyl

The invention relates to a method for preparing nickel-coated powder by carbonyl vapor deposition. First, under normal pressure and 40-100°C, carbon monoxide reacts with active metal nickel to generate a carbonyl nickel liquid; then the carbonyl nickel liquid is heated to 150-100°C. At 300°C, the nickel carbonyl liquid is vaporized into nickel carbonyl gas; finally, the nickel carbonyl gas is mixed with the carrier gas, loaded into the vibrating pyrolysis coating furnace, and reacts with the coated material in the vibration pyrolysis coating furnace, and the nickel carbonyl The gas thermally decomposes and deposits metallic nickel on the surface of the coated material to obtain nickel-coated powder; the nickel coating method in the present invention has high selectivity, and the powder produced by this method has large surface area, high purity, uniform particles, and dispersed Good resistance, high chemical reactivity and activity, and has excellent compressibility and sinterability.

Owner:成都核八五七新材料有限公司

A kind of ultraviolet absorber for ultraviolet excitation LED device

ActiveCN107452859BGood effectBroad absorption spectrumMaterial nanotechnologySemiconductor devicesTO-18Film-forming agent

The invention discloses an ultraviolet absorber for an ultraviolet excitation LED device. The ultraviolet absorber comprises, by weight, 6 to 9 parts of mineral pressed powder, 5 to 8 parts of film-forming agent, 12 to 18 parts of nano aluminum hydroxide, 3 to 5 parts of nano zinc oxide, 4.5 to 7 parts of nano titanium dioxide, 2 to 3.5 parts of aminobenzoate, 1 to 3 parts of benzophenone derivatives, and 2 to 4 parts of methoxycinnamate. The formula of the ultraviolet absorber can be produced through a pressing process, the material is easy to obtain, the ultraviolet absorber is simple and efficient, and can be used for ultraviolet excitation light sources with wide ranges.

Owner:苏州轻光材料科技有限公司

A preparation method of powder metallurgy aluminum alloy phaser rotor

ActiveCN105234412BIncrease profitReduce manufacturing costTurbinesOther manufacturing equipments/toolsQuenchingNear net shape

A method for preparing a powder metallurgy aluminum alloy phaser rotor, the steps of: mixing aluminum powder, high-alloy mother powder, copper powder, nickel powder and an organic lubricant according to the following mass ratios: copper 1.8-3.0%, magnesium 1.0-2.0% %, iron 1.0-1.5%; nickel 0.8-2.0%, silicon 0.1-0.5%, organic lubricant: 0.8-1.5%, no more than 2% of unavoidable impurities, and the balance is aluminum; powder metallurgy green body obtained by pressing , then sintering, solution quenching, repressing finishing, aging treatment, and finally turning the rotor to meet the final size requirements. Compared with the rotor made of sintered steel, the present invention has better pressing performance, faster speed and lower pressing cost; the temperature of sintered aluminum alloy is much lower than that of sintered steel, the energy consumption in the sintering process is reduced, and the processing performance of the powder metallurgy aluminum rotor is better Well, there is no need for surface protection treatment during transportation and storage; compared with die-casting or extruded aluminum alloy rotors, powder metallurgy is a near-net-shaping technology, with high utilization of aluminum alloy raw materials, high production efficiency, and low production costs Low.

Owner:NBTM NEW MATERIALS GRP

Mixture preparation process

The invention discloses a mixture preparation process. Rapid and continuous stirring is carried out in the state that the vacuum degree of a vacuum drying stirrer ranges from -0.06- -0.08 so that the drying speed can be increased and oxidation and / or excessive hardness of a mixture can be prevented; when stirring enables the temperature in the vacuum drying stirrer has an obvious rising process and the mixture is in a half-dry state, continuous stirring is stopped, the vacuum degree of the vacuum drying stirrer is reduced to 0- -0.05, the mixture is prevented from being broken, so that follow-up pelletizing is facilitated; and the mixture particles produced and discharged in such a way are soft, fragile and good in pressing performance, holes of sintered products can reach A02 or below, WC grows completely, and metallographic structures are uniform.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

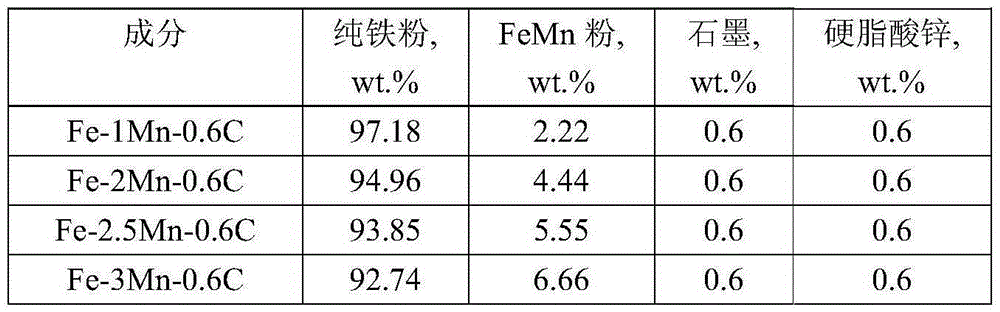

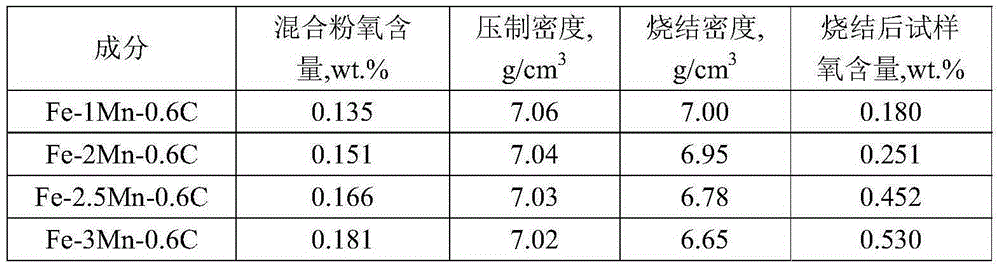

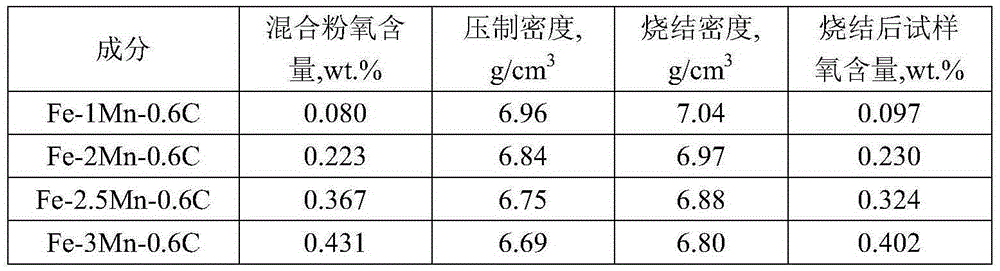

Mixed steel powder containing mn for powder metallurgy and preparation method thereof

The invention discloses Mn-contained mixture steel powder for powder metallurgy and a preparing method. The Mn-contained mixture steel powder is composed of water atomization pure iron powder, Mn-contained water atomization pre-alloyed steel powder, FeMn alloy powder, graphite powder and a lubricant, wherein the mass percentage content of Mn is lower than or equal to 3%. The preparing method includes the steps of preparing the components and mechanically and evenly mixing the components. The pressing performance and the sintered density of the prepared mixture steel powder are superior to the pressing performance and the sintered density of the Mn-contained water atomization pre-alloyed steel powder with the same components, and compared with a finished product obtained by sintering conventional Mn-contained mechanical mixture powder with the same contents, a sintered finished product is lower in oxygen content and high in density. The content of the Mn can be as high as 3%. The Mn-contained mixture steel powder is reasonable in component matching and high in Mn content, the prepared Mn-contained mixture steel powder combines the advantages of even Mn-element distribution in the Mn-contained pre-alloyed steel powder and the good pressing performance of the conventional Mn-contained mechanical mixture powder, the pressing performance is good, the sintered finished product is low in oxygen content and high in density, and the Mn-contained mixture steel powder is suitable for industrial production.

Owner:CENT SOUTH UNIV

Ultraviolet absorber for ultraviolet excitation LED device

ActiveCN107452859AGood effectBroad absorption spectrumMaterial nanotechnologySemiconductor devicesTO-18Film-forming agent

The invention discloses an ultraviolet absorber for an ultraviolet excitation LED device. The ultraviolet absorber comprises, by weight, 6 to 9 parts of mineral pressed powder, 5 to 8 parts of film-forming agent, 12 to 18 parts of nano aluminum hydroxide, 3 to 5 parts of nano zinc oxide, 4.5 to 7 parts of nano titanium dioxide, 2 to 3.5 parts of aminobenzoate, 1 to 3 parts of benzophenone derivatives, and 2 to 4 parts of methoxycinnamate. The formula of the ultraviolet absorber can be produced through a pressing process, the material is easy to obtain, the ultraviolet absorber is simple and efficient, and can be used for ultraviolet excitation light sources with wide ranges.

Owner:苏州轻光材料科技有限公司

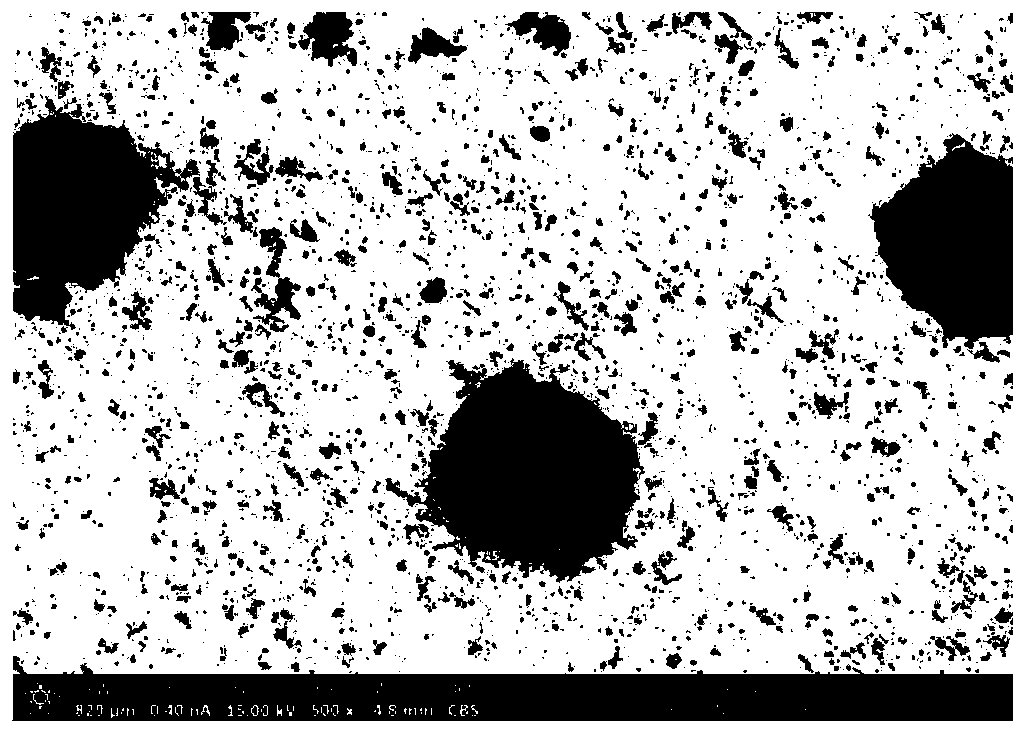

A kind of alcrfenisiti high entropy alloy porous material and preparation method thereof

ActiveCN110735077BDiffuse fullyInhibition of high temperature self-propagating reactionsTransportation and packagingMetal-working apparatusHigh entropy alloysLubricant

The invention belongs to the field of high-entropy alloy materials, and discloses an AlCrFeNiSiTi high-entropy alloy porous material and a preparation method thereof. The AlCrFeNiSiTi high-entropy alloy porous material of the present invention comprises Al: 10%-20%, Cr: 10%-20%, Fe: 10%-20%, Ni: 10%-20%, Si: 10%-20% according to atomic percentage 20%, Ti: 10%-20%, using the reaction synthesis method of element powder to prepare AlCrFeNiSiTi high-entropy alloy porous material, using the element powder of each principal element as raw material, only a small amount of lubricant needs to be added during the preparation process, which can Low consumption and low cost; make full use of the Kirkendall effect caused by partial diffusion between elements to generate pores, the controllability of the pore structure is good, and there is no need to add pore-forming agents, and there is no problem of subsequent removal of pore-forming agents. It has the characteristics of short process and high performance.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com