Patents

Literature

69results about How to "Irregular shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Generation of depth map for an image

InactiveUS20100046837A1Increase varietyImprove imaging depthImage enhancementImage analysisImaging processingSelf adaptive

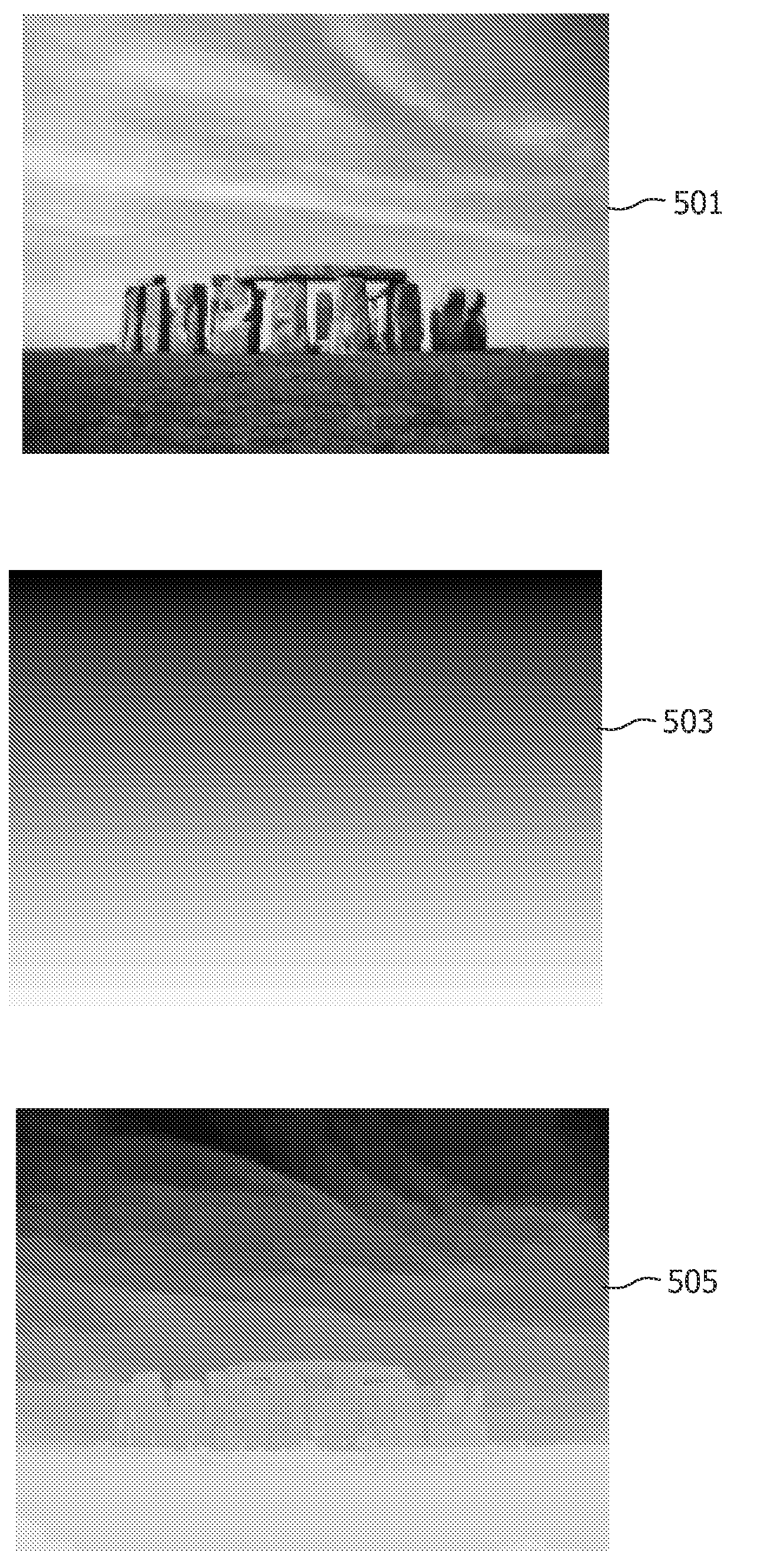

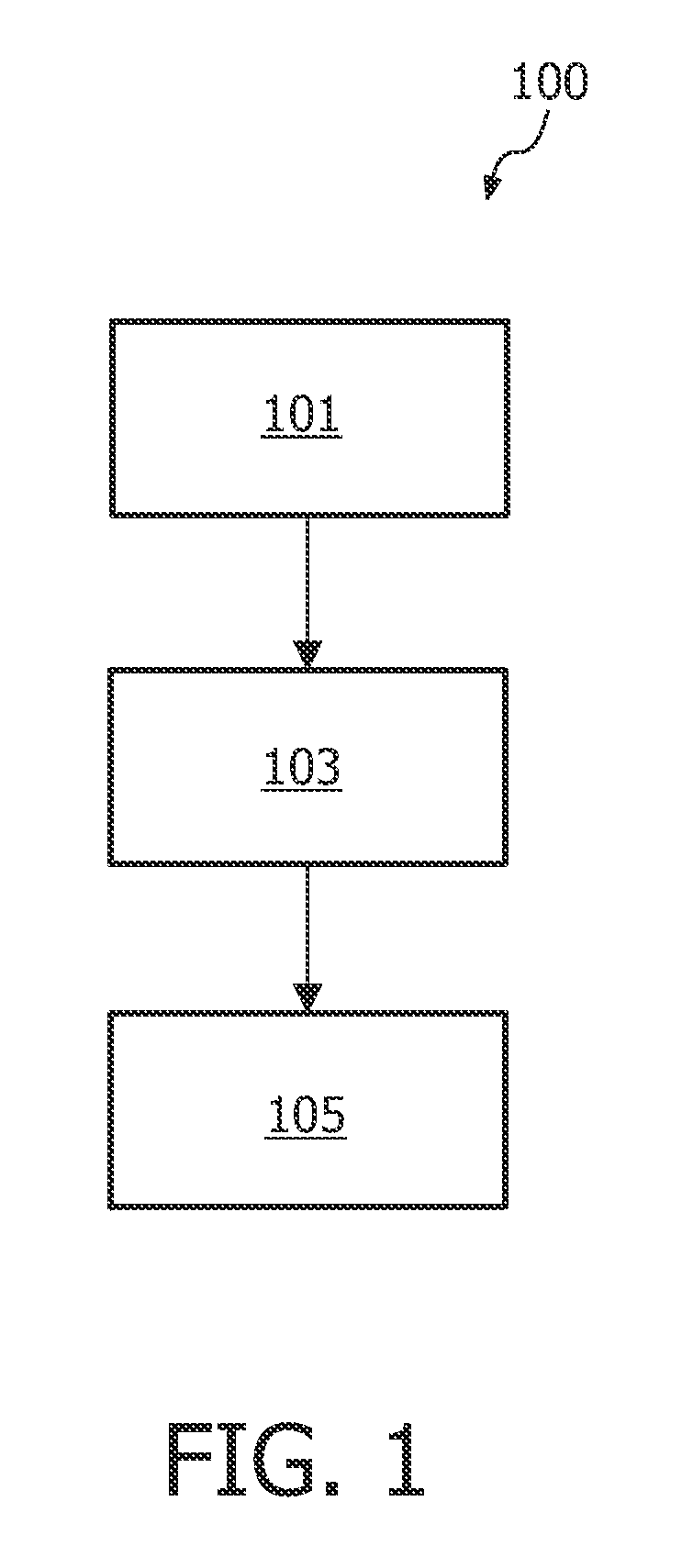

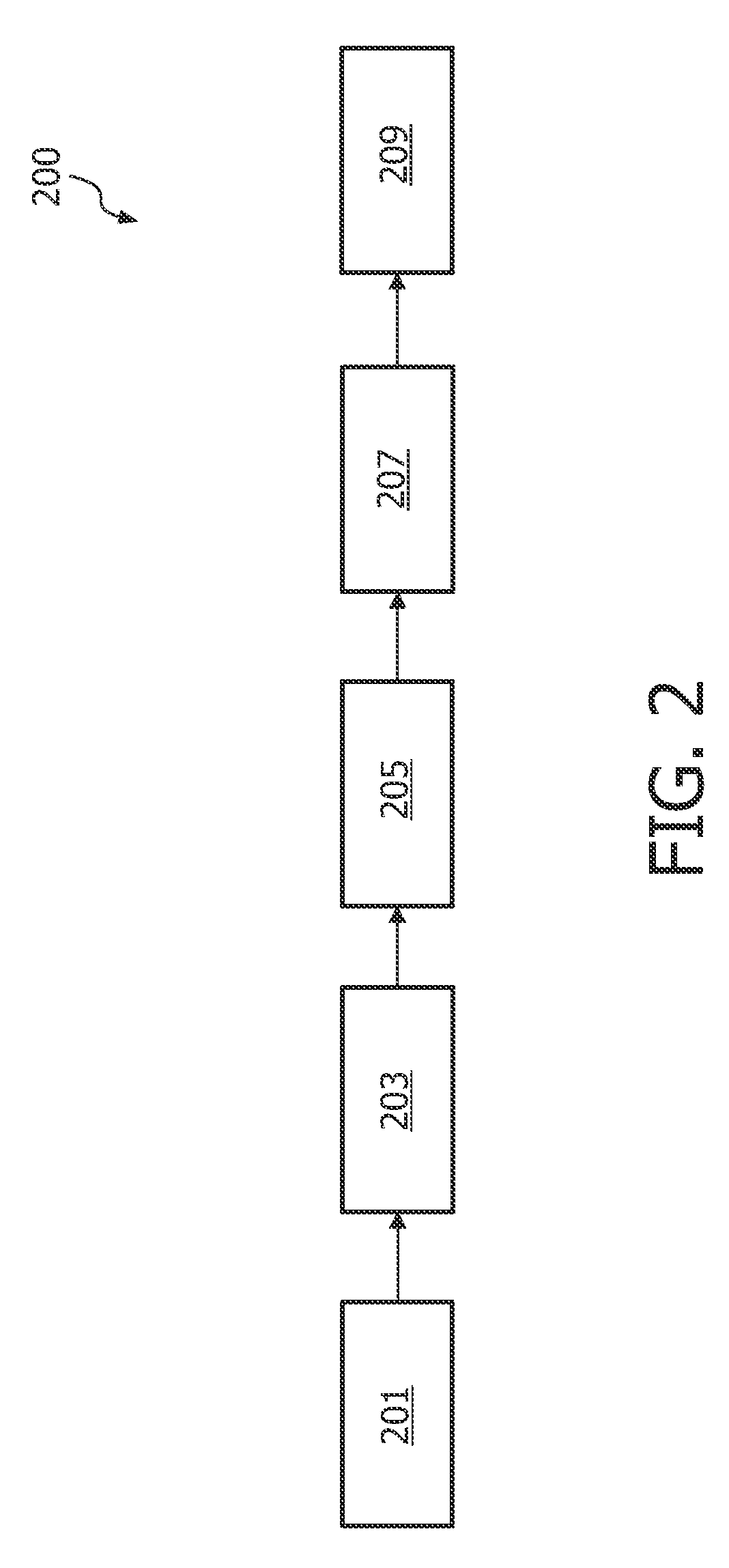

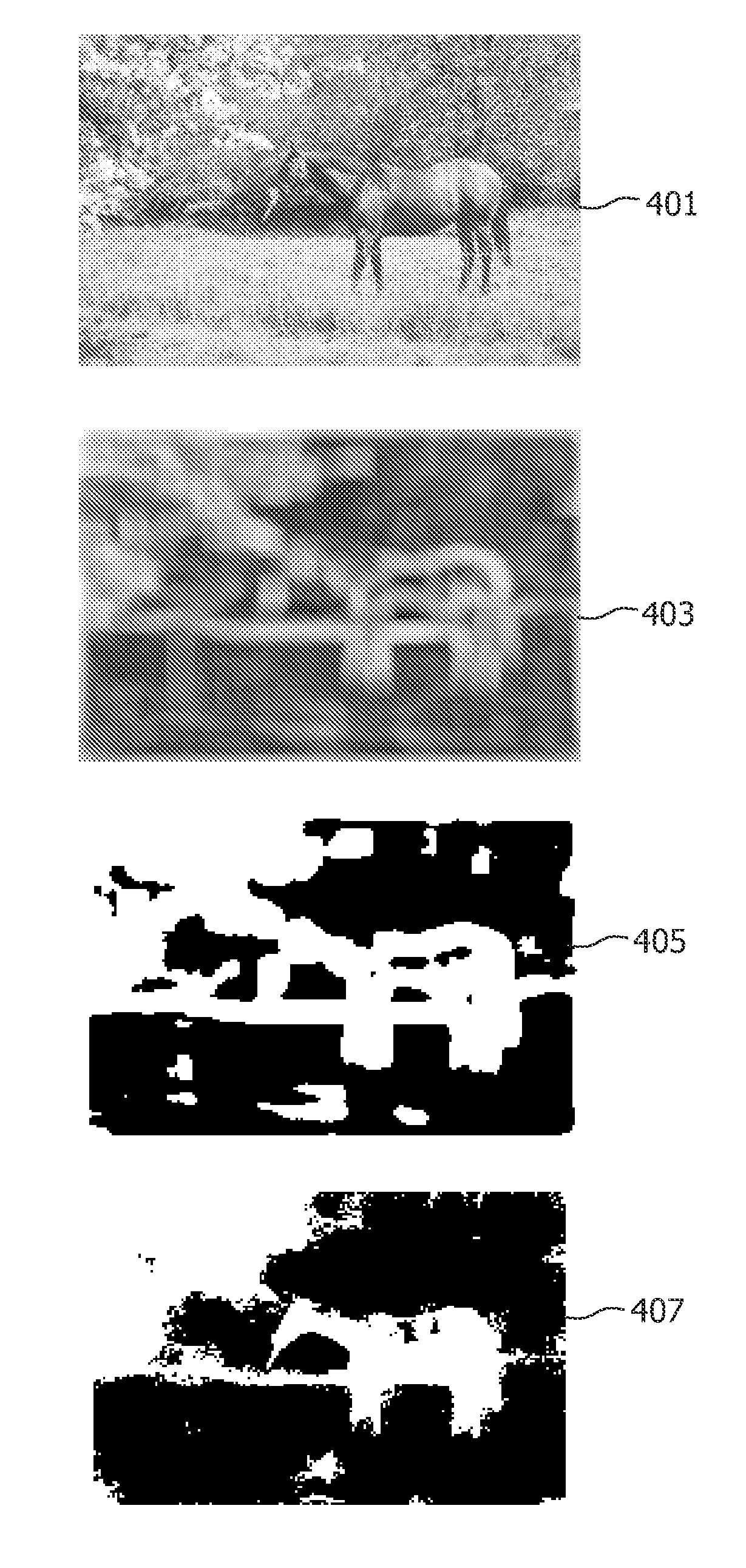

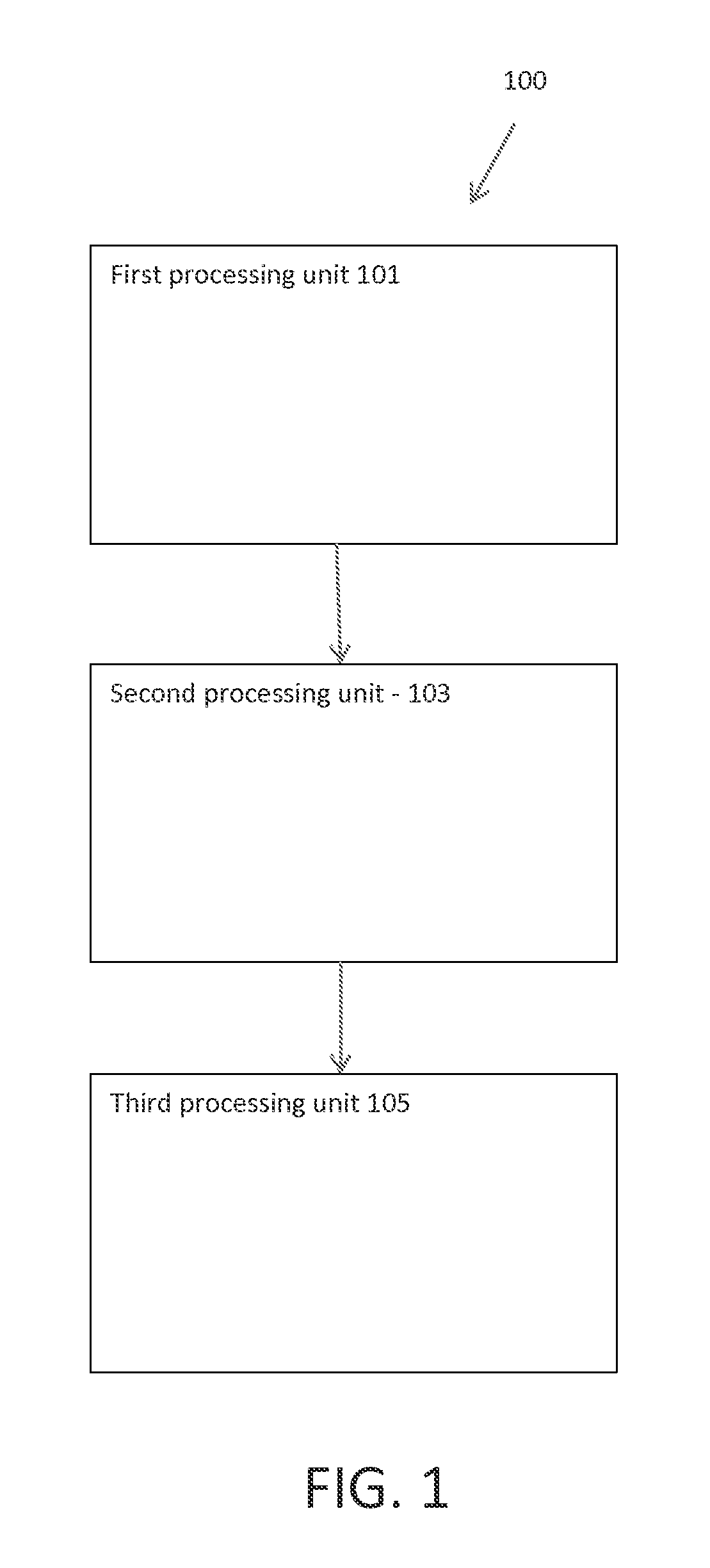

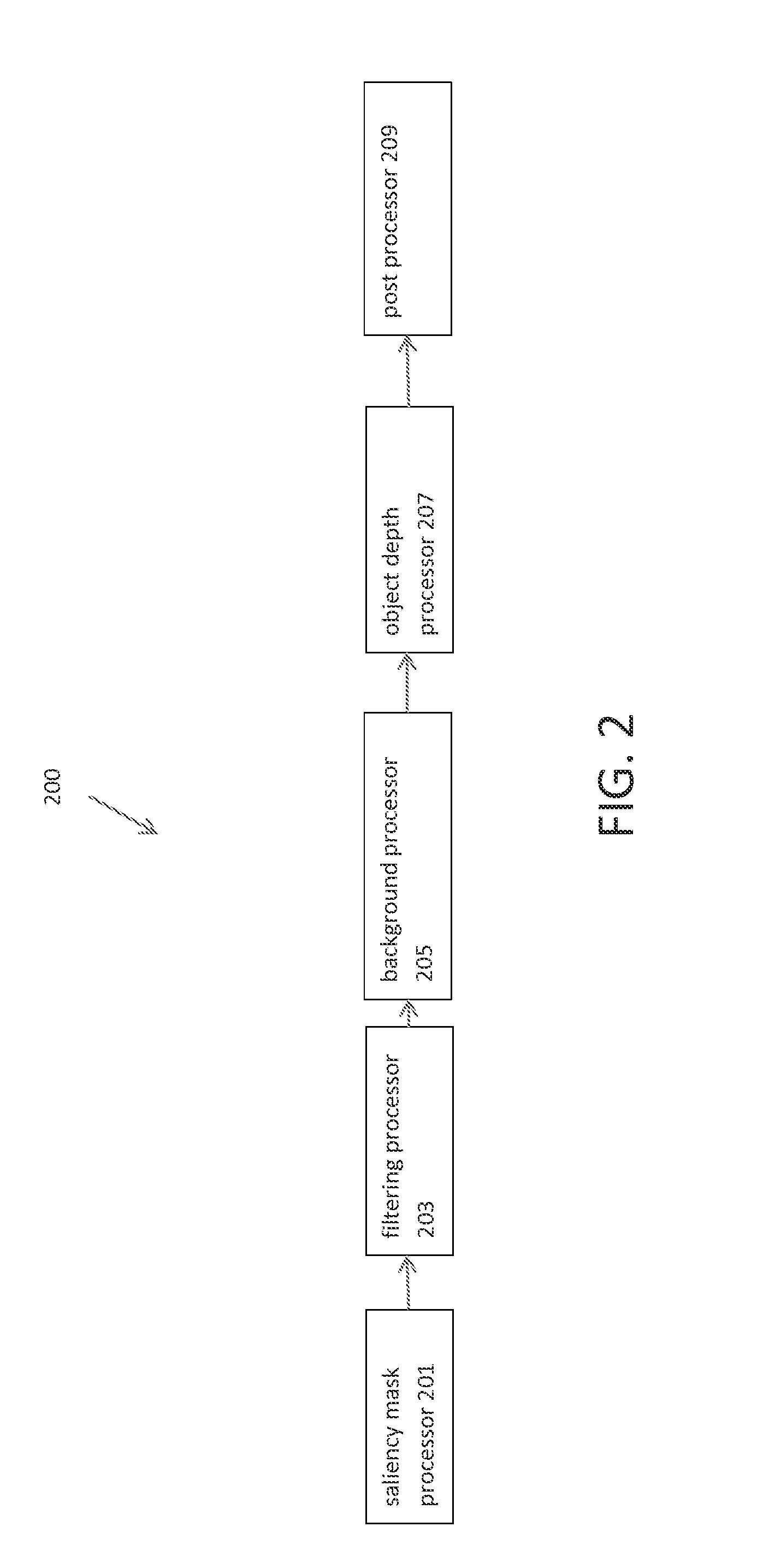

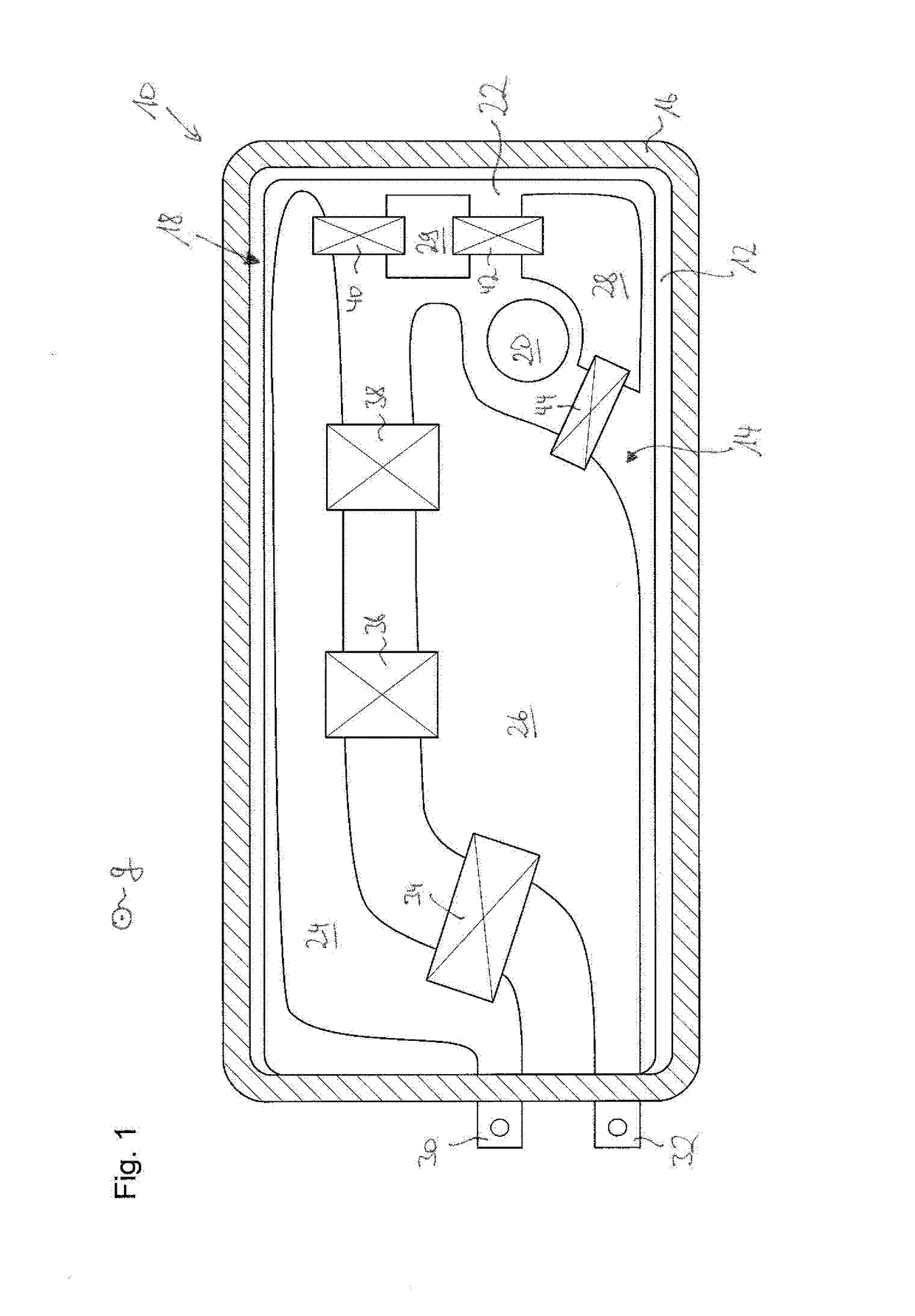

An image processing unit comprises a first processing unit (101) which generates a depth indication map for an image. The depth indication map may be, for example, an image object separation mask or a predetermined depth profile or background depth map. A second processing unit (103) generates a modified depth indication map by filtering the depth indication map in response to image characteristics of the image. The image adaptive filtering may, for example, provide a more accurate separation mask and / or may modify the predetermined depth profile to reflect the specific image. A third processing unit (105) generates an image depth map for the image in response to the modified depth indication map. The image depth map comprises data representing a depth of at least one image region of the image. The invention leads to the generation of an improved depth map for an image.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

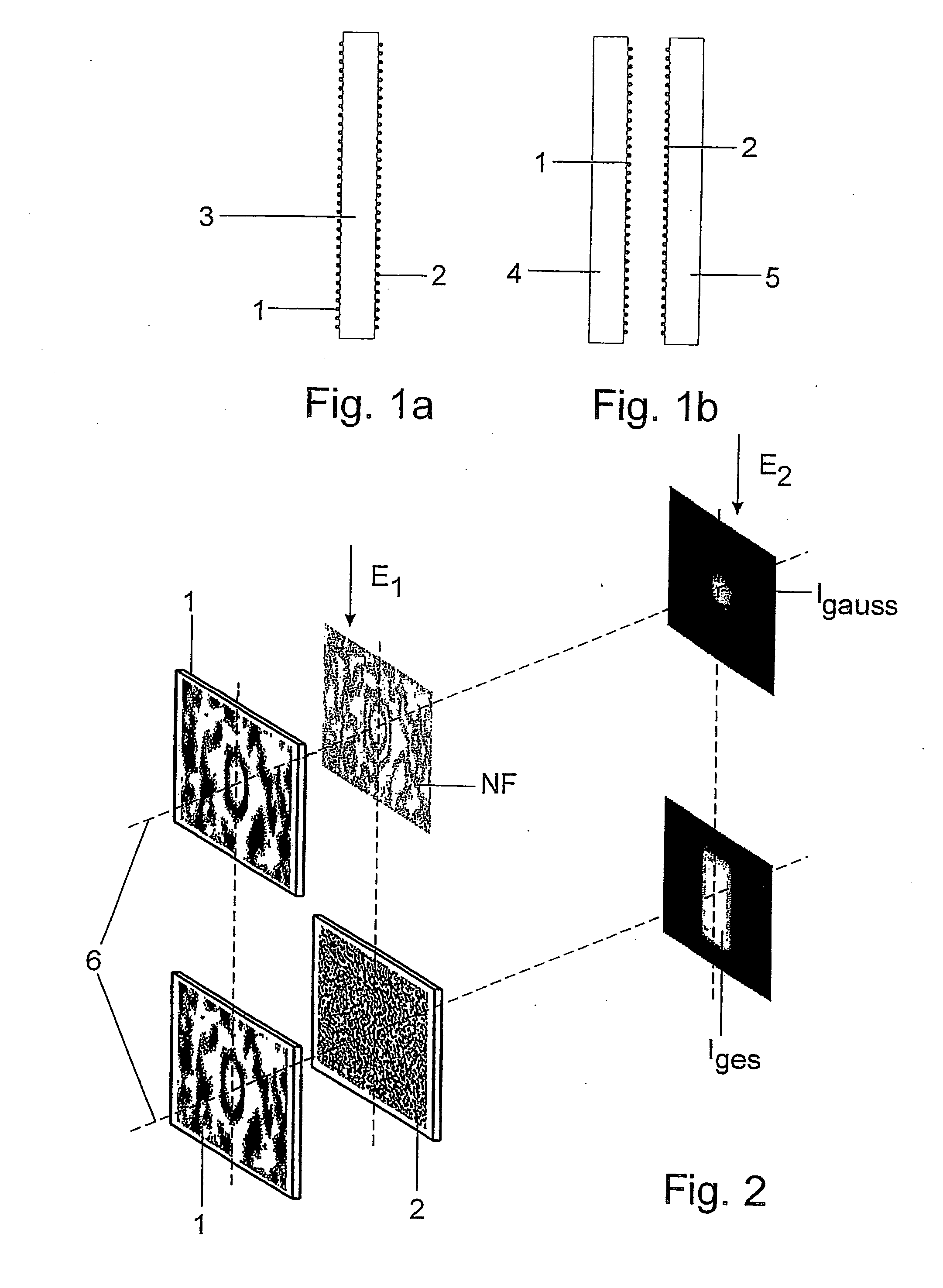

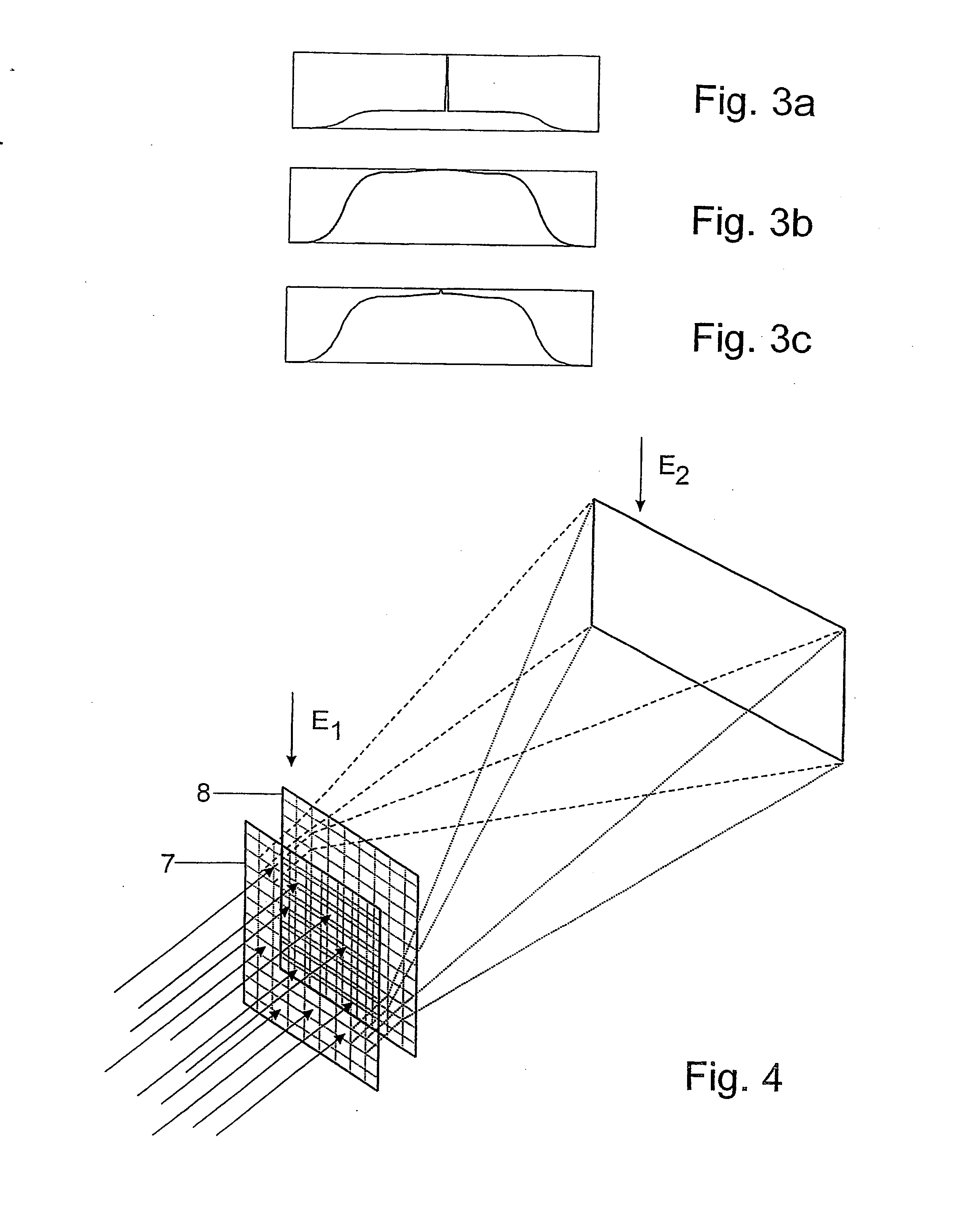

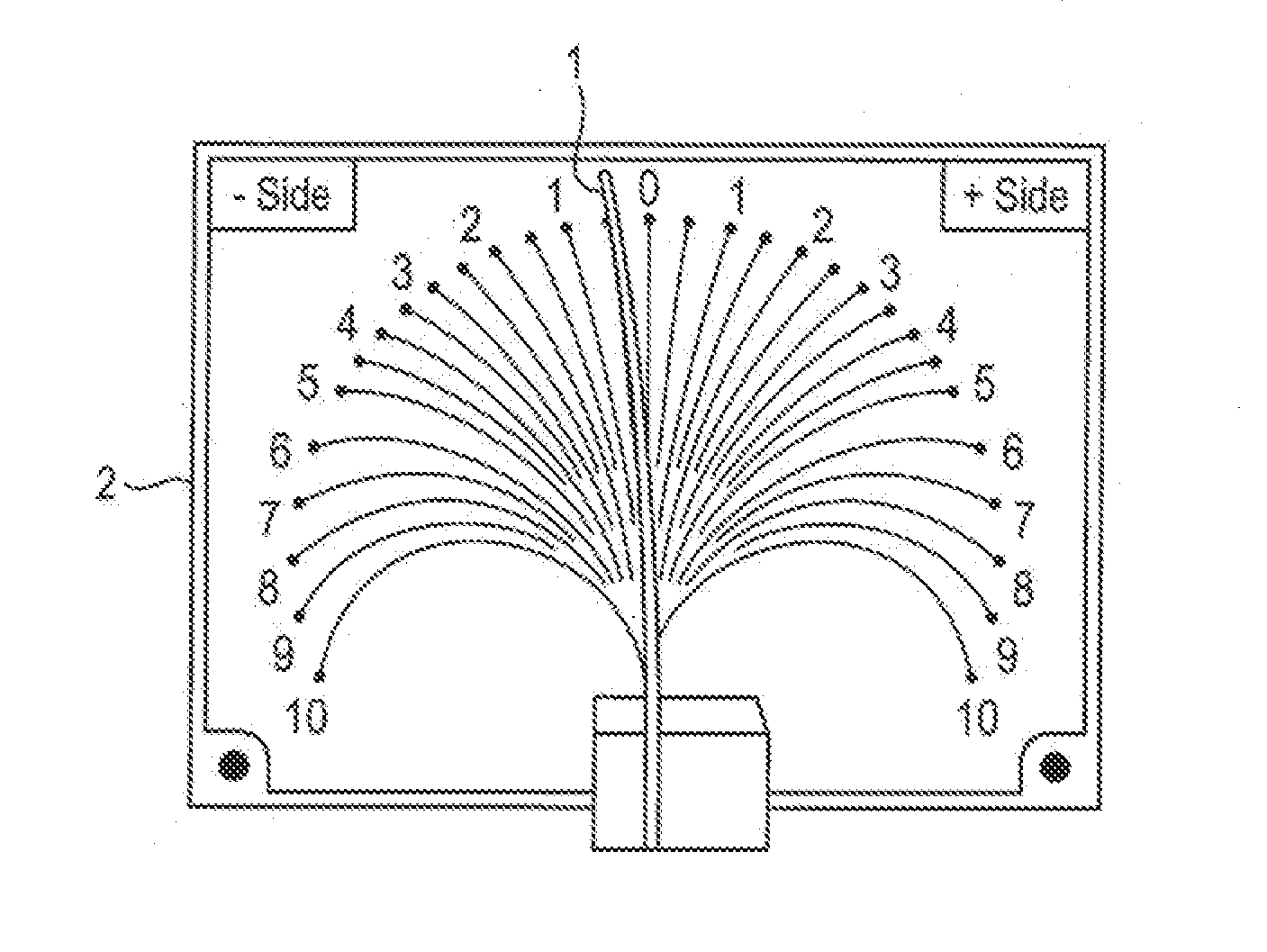

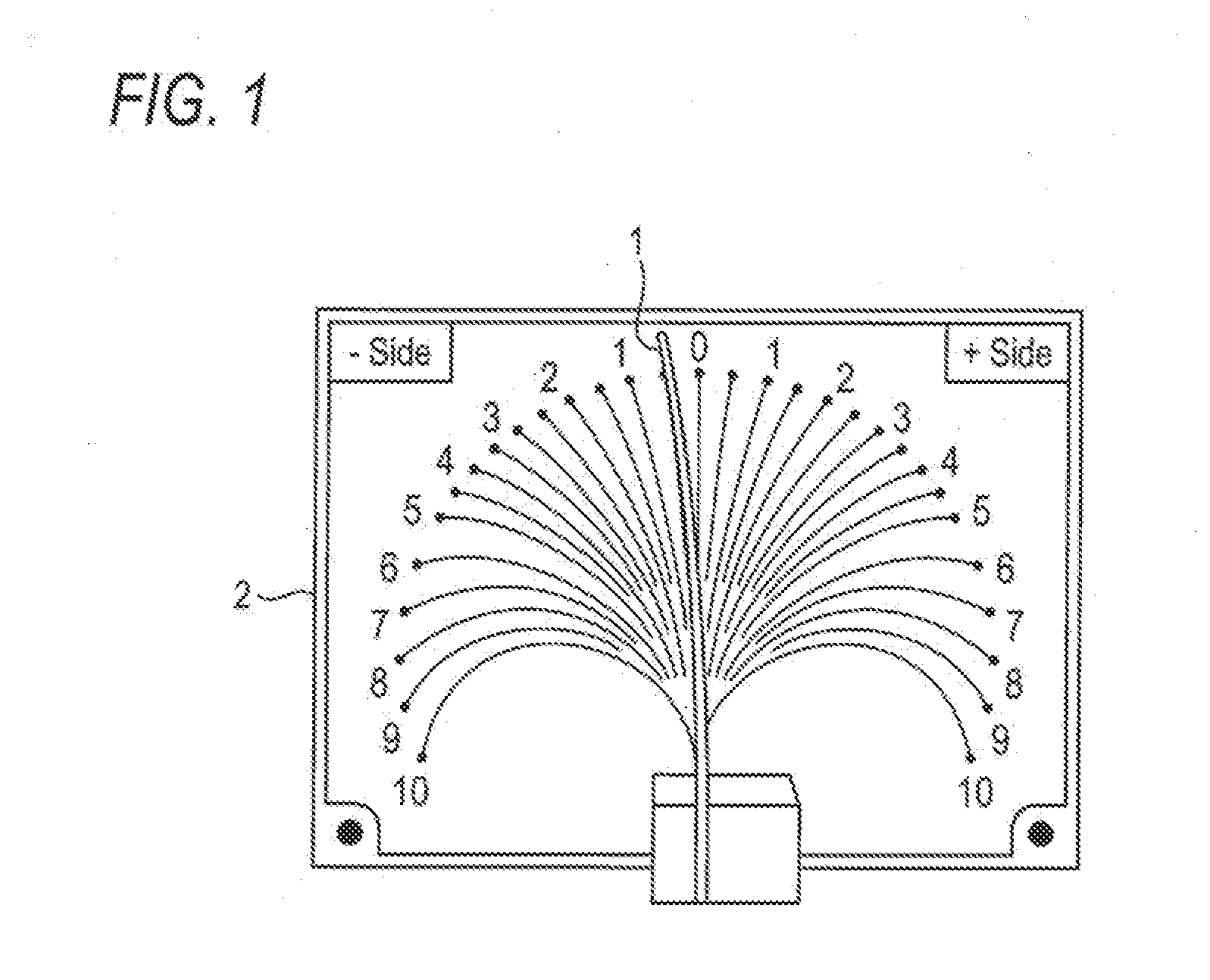

Optical System For Converting A Primary Intensity Distribution Into A Predefined Intensity Distribution That Is Dependent On A Solid Angle

InactiveUS20080074746A1Reduce destructive effectsHigh apertureOptical elementsDiffraction orderUltimate tensile strength

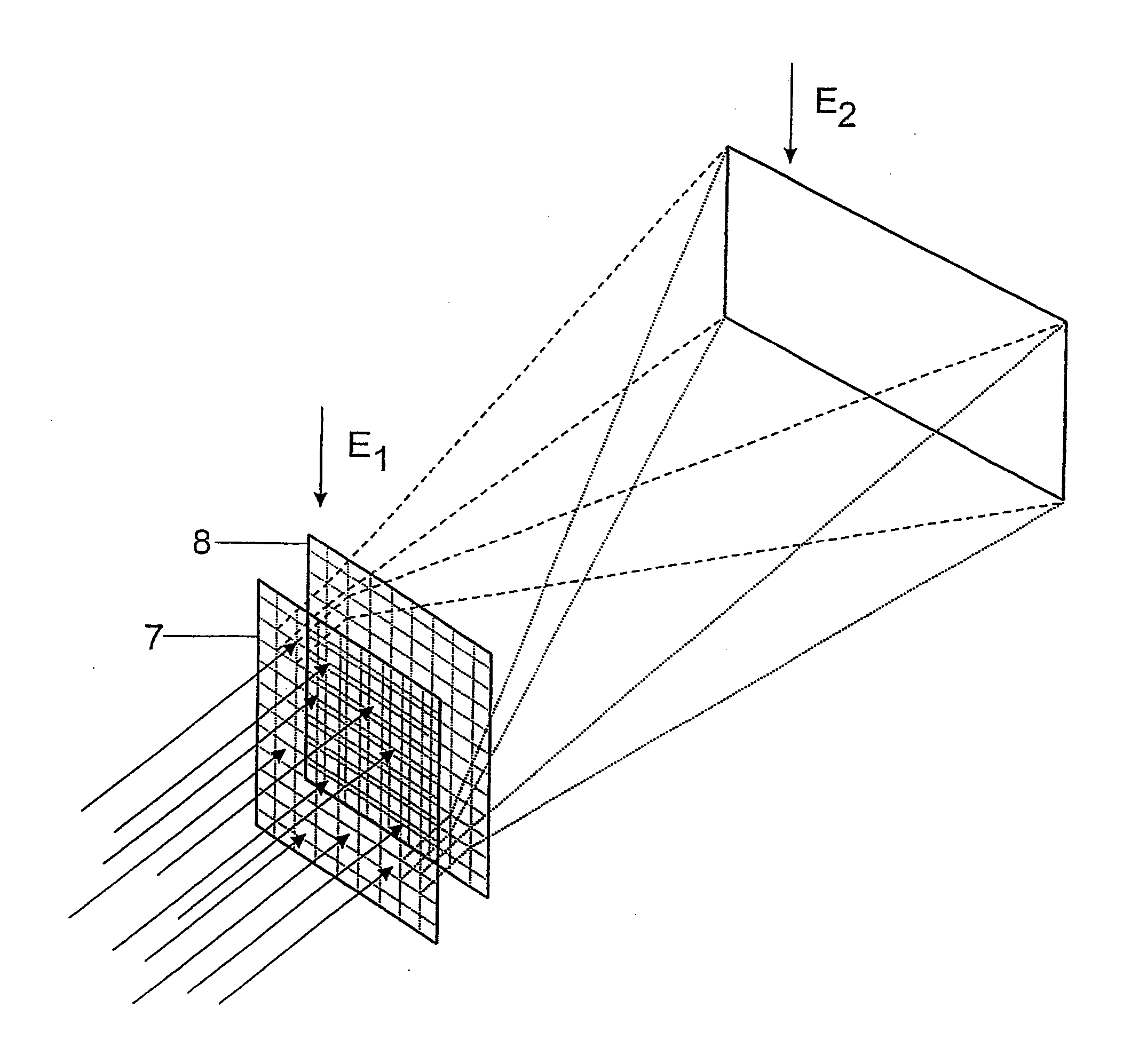

It is the object of an optical system and a method for converting a primary intensity distribution into a predetermined intensity distribution dependent on a solid angle to reduce the disruptive influence of the zeroth diffraction order beyond the limits imposed by the manufacturing accuracy in the manufacture of the diffractive structures, also with increasingly higher apertures, while making use of the advantages of diffractive structures in providing variously shaped intensity distributions. In a first plane, in which first micro-optic homogenization structures generate a finely structured amplitude distribution and phase distribution from the primary intensity distribution, there are arranged second diffractive micro-optic homogenization structures which are adapted to the finely structured amplitude distribution and phase distribution and which generate the predetermined solid angle-dependent intensity distribution in a second plane from the finely structured amplitude distribution and phase distribution.

Owner:JENOPTIK LASER OPTIK SYST

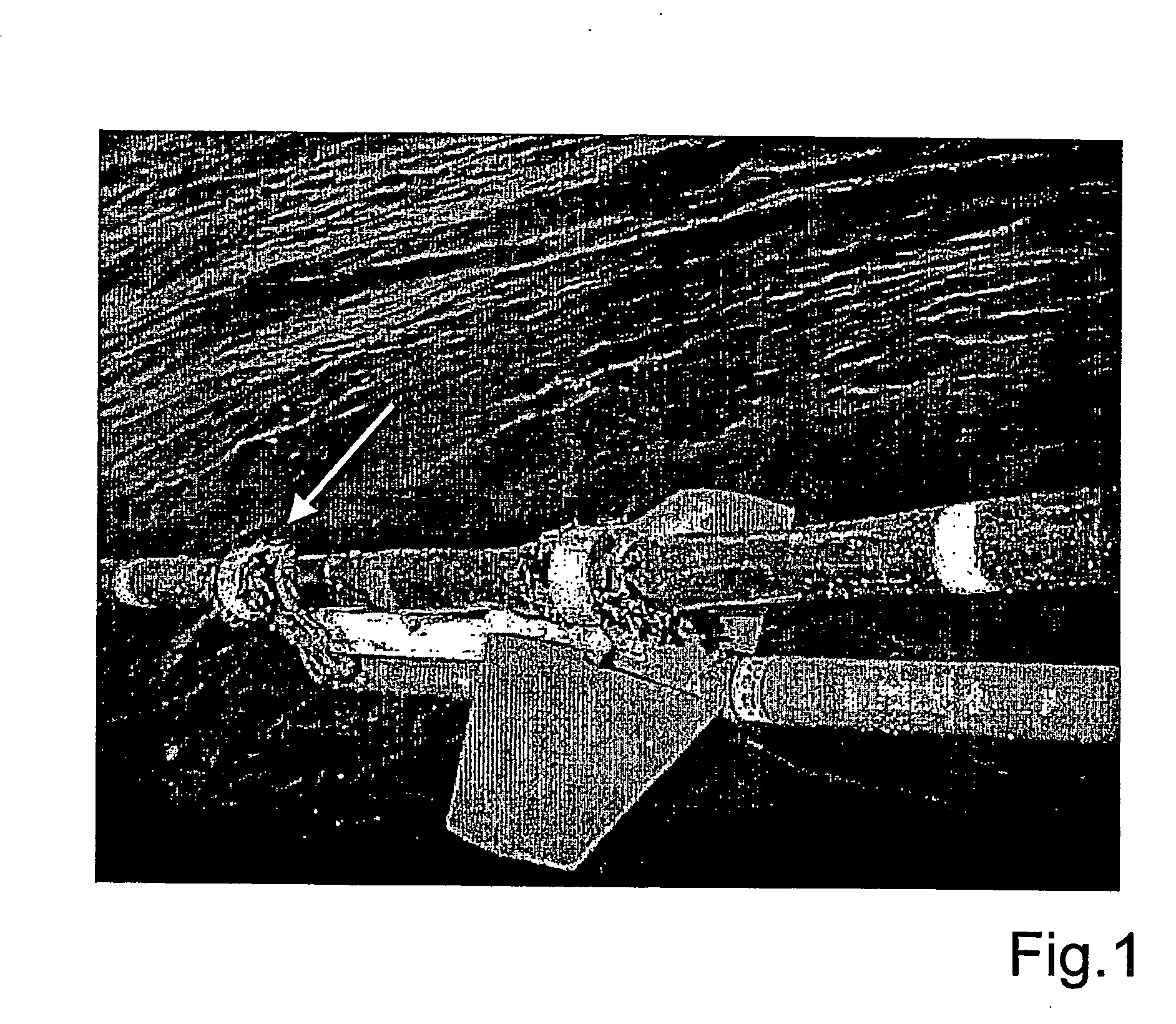

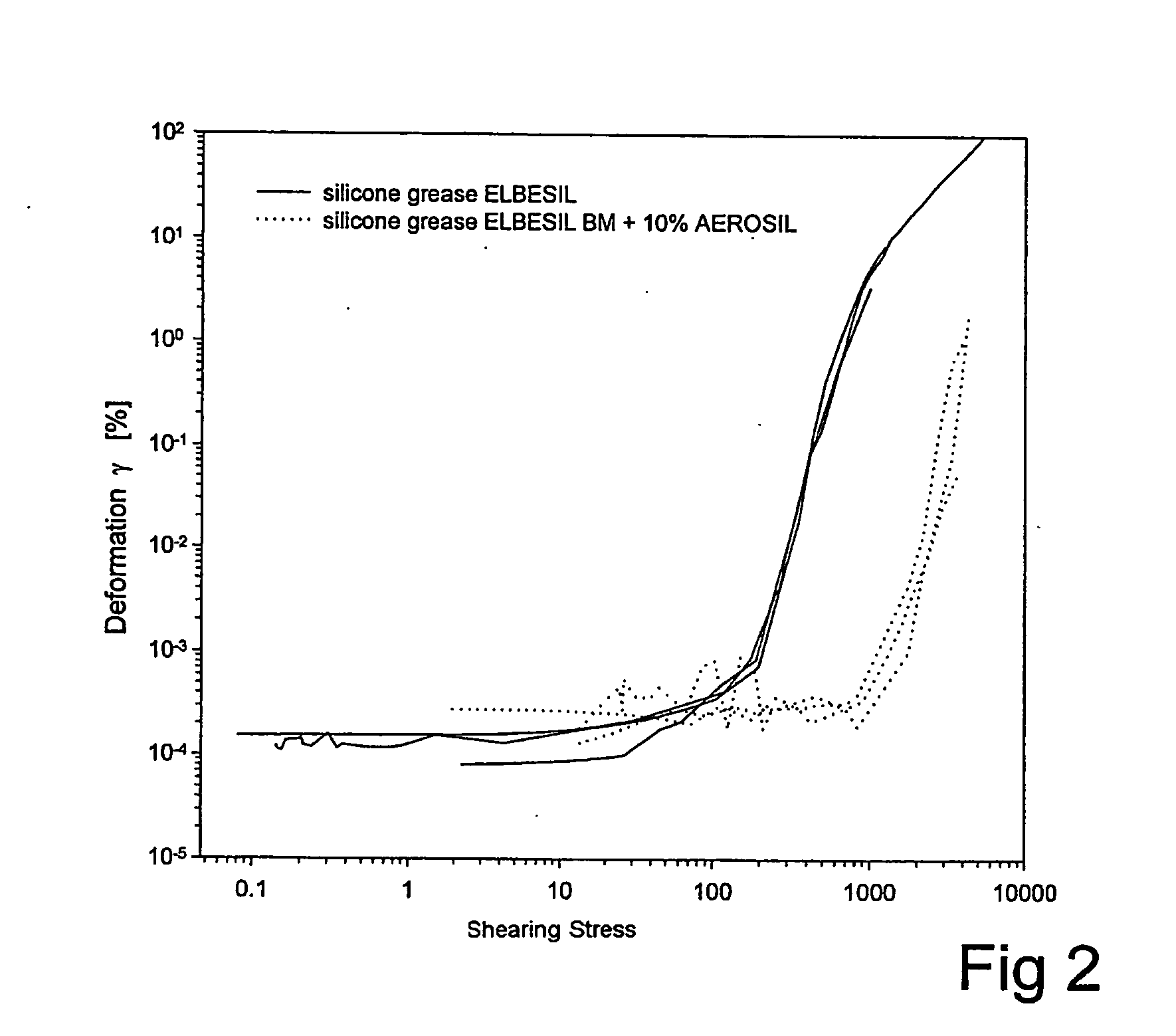

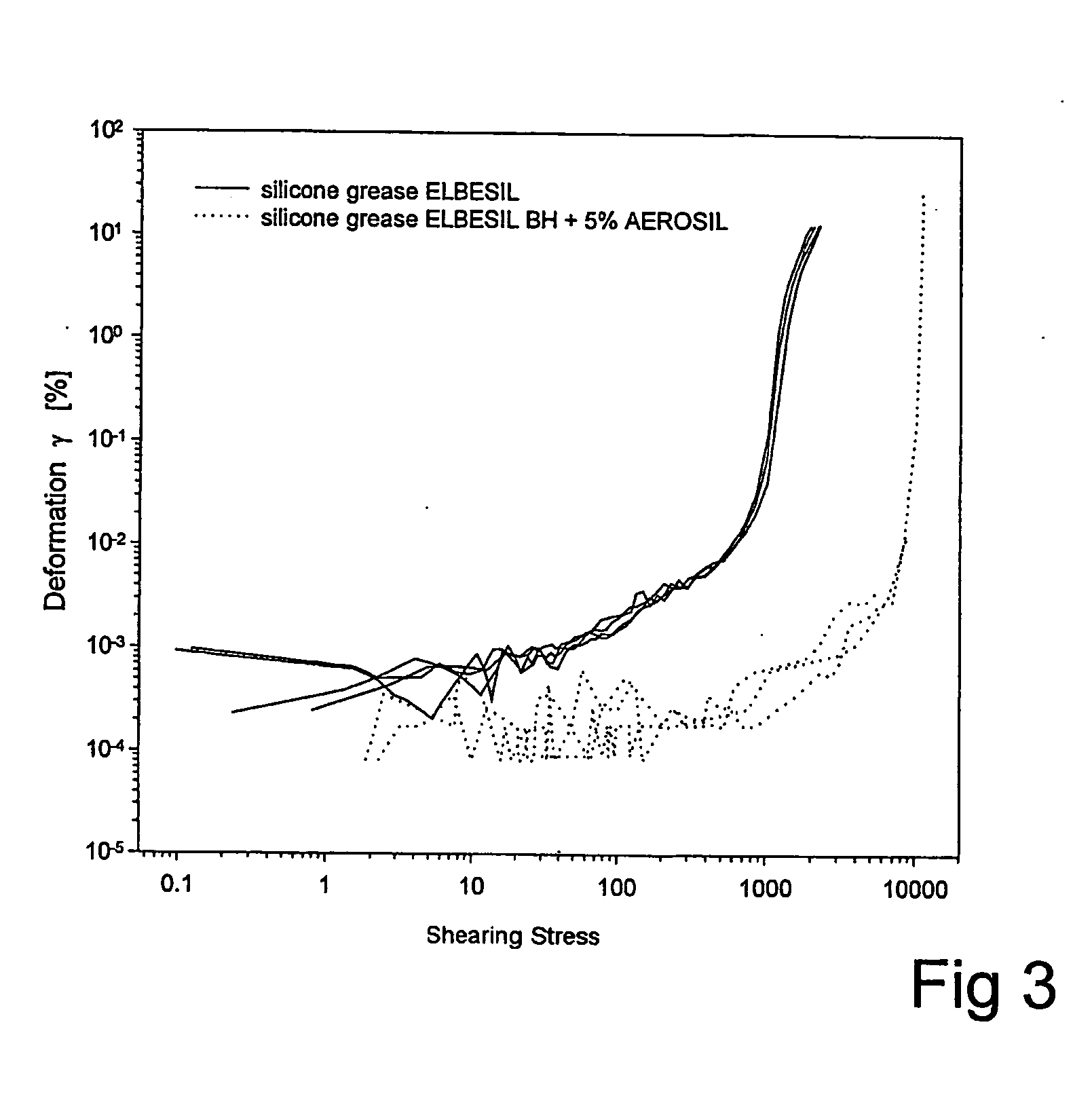

Viscoelastic coating paste for protecting against macrofouling and method for producing a coating

InactiveUS20060144286A1Improve antifouling performanceConvenient coatingFireproof paintsAntifouling/underwater paintsWall shearMacroscopic scale

A non-toxic anti-fouling coating paste having a rheologic switching behavior based on a flow point, which can be set to the hydrodynamic and biological environmental conditions of a submarine component to be protected and which is between 5 Pa and 2,000 Pa above the wall shearing stress of the unfouled component to form a substrate which prevents colonization by marine fouling organisms.

Owner:CGGVERITAS SERVICES HLDG U S +1

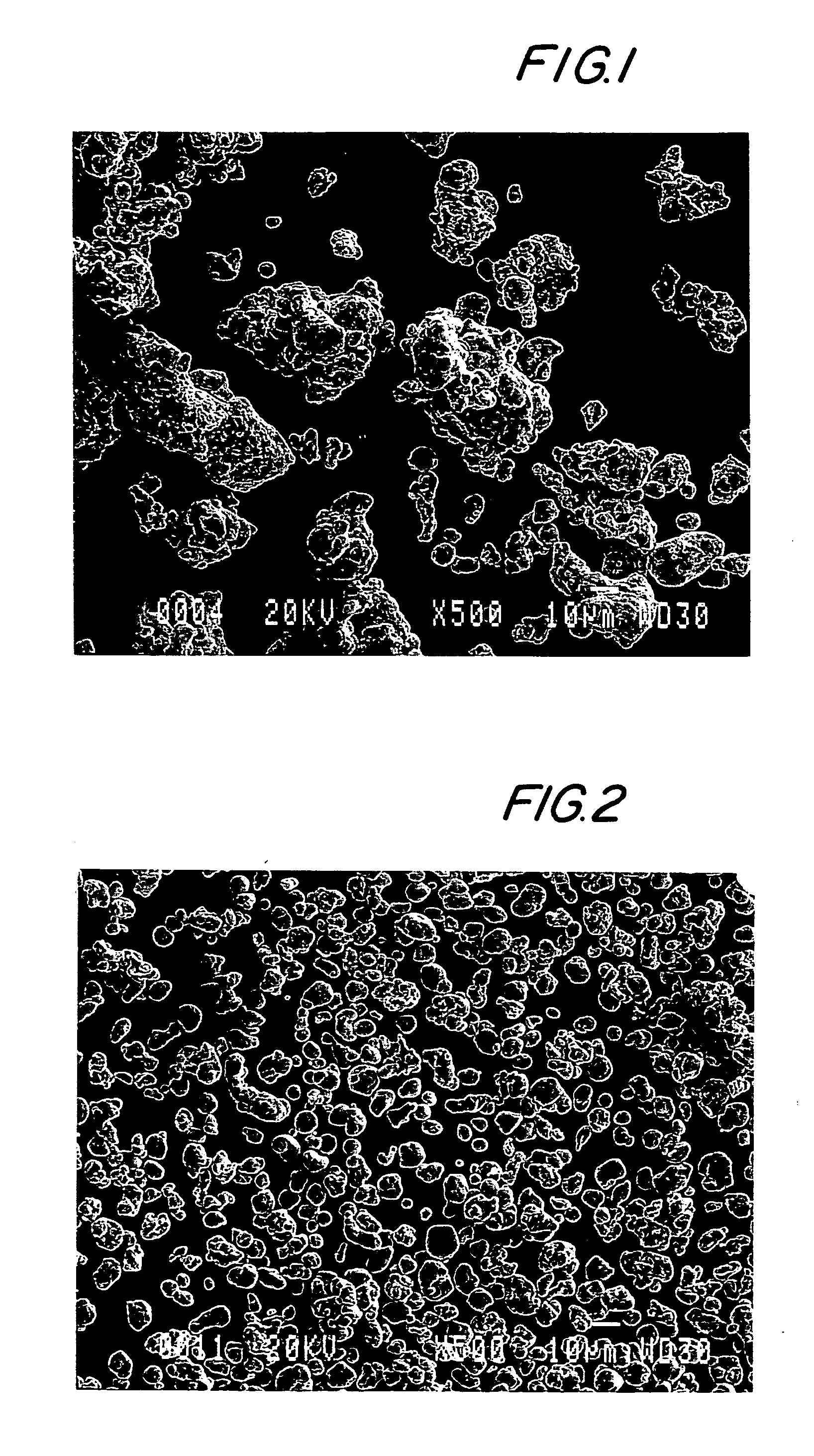

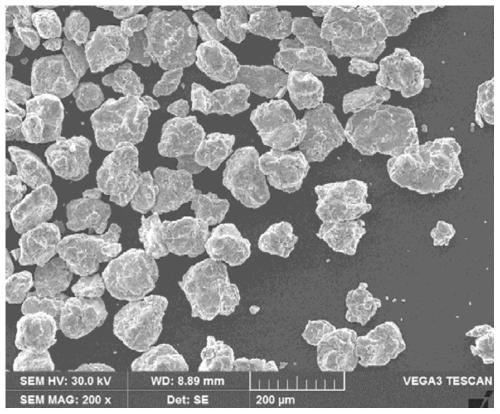

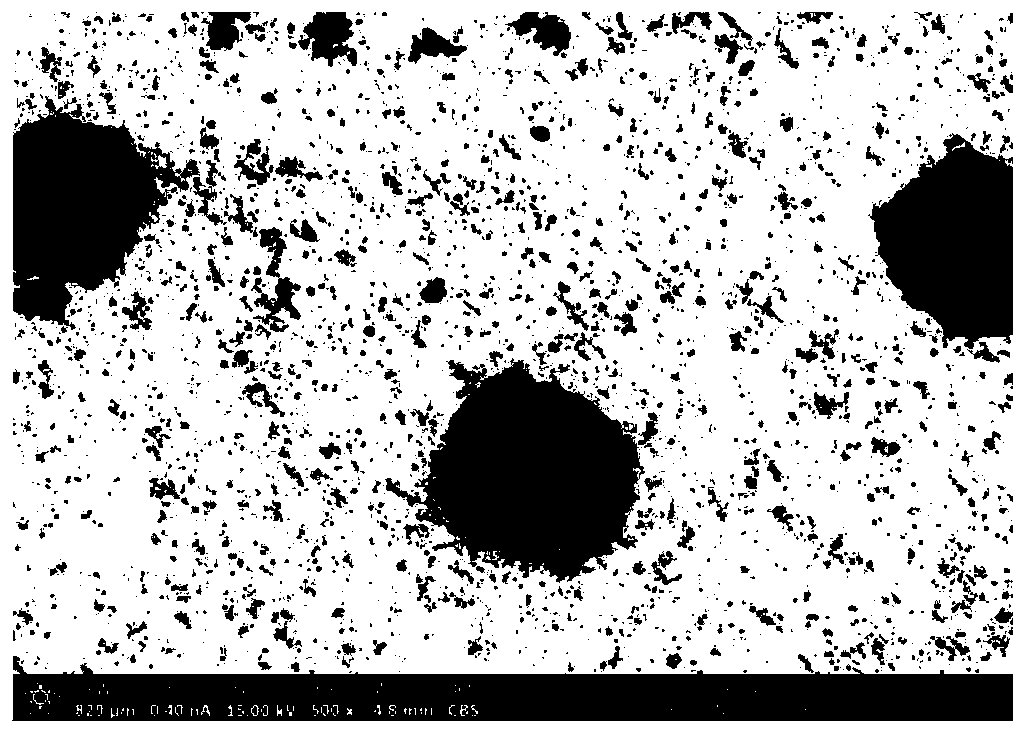

Irregular shaped copper particles and methods of use

InactiveUS20050182161A1Improve conductivityIrregular shapePrinted circuit assemblingTransportation and packagingAdhesiveCopper

The present invention provides water atomized copper powder comprising substantially irregular shaped copper particles having at least a median D50 particle size of from about 20 μm or greater to about 50 μm. The powders of the present invention are suitable for use in electrically conductive compositions, such as copper-based adhesives. The present invention also provides methods of making these copper powders.

Owner:SCM METAL PRODUCTS INC

Antiglare film, method for producing the same, polarizing plate and image display device

InactiveUS20130258481A1Good anti-glare effectHigh densityDiffusing elementsPolarising elementsOrganic solventChemical compound

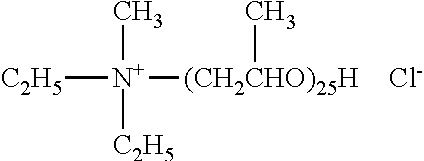

An antiglare film includes an antiglare layer having a thickness of from 3 to 10 μm and a transparent support having a thickness from 20 to 70 μm, and the antiglare layer is formed by applying a composition containing the following components (A) to (D) on the transparent support, drying and curing the applied composition: (A) a resin particle having an average particle size of from 1.0 to 3.0 μm, (B) a curable compound having two or more curable functional groups in a molecule, (C) a smectite clay organic complex in which a smectite clay is intercalated with a quaternary ammonium salt represented by the formula (1) as defined herein, and (D) a volatile organic solvent.

Owner:FUJIFILM CORP

Generation of depth map for an image

InactiveUS8340422B2Increase varietyImprove imaging depthImage enhancementImage analysisImaging processingSelf adaptive

An image processing unit comprises a first processing unit (101) which generates a depth indication map for an image. The depth indication map may be, for example, an image object separation mask or a predetermined depth profile or background depth map. A second processing unit (103) generates a modified depth indication map by filtering the depth indication map in response to image characteristics of the image. The image adaptive filtering may, for example, provide a more accurate separation mask and / or may modify the predetermined depth profile to reflect the specific image. A third processing unit (105) generates an image depth map for the image in response to the modified depth indication map. The image depth map comprises data representing a depth of at least one image region of the image. The invention leads to the generation of an improved depth map for an image.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Zinc oxide nanoparticle preparation method based on silk fibroin bio-template regulation

ActiveCN107089677AHigh surface energyImprove antibacterial propertiesZinc oxides/hydroxidesNanotechnologyZincateNanoparticle

The invention relates to the technical field of biomedical materials, and in particular to a zinc oxide nanoparticle preparation method based on silk fibroin bio-template regulation, which includes the following steps: (S1) after being degummed, silkworm cocoons are dissolved, so that aqueous silk fibroin solution is prepared; (S2) zincate solution and alkaline solution are blended, so that mixed solution is obtained; (S3) the aqueous silk fibroin solution obtained step S1 is added into the mixed solution in step S2 to sufficient react; (S4) after solution after the reaction in step S3 is washed and dried, zinc oxide nanoparticles are obtained. Silk fibroin is adopted as a bio-template to regulate the size and morphology of the zinc oxide nanoparticles, the grain size of the obtained zinc oxide nanoparticles is small, the morphology is irregular, the antibacterial property is enhanced, moreover, the operation method is simple, and the cost is low.

Owner:XUANWU HOSPITAL OF CAPITAL UNIV OF MEDICAL SCI

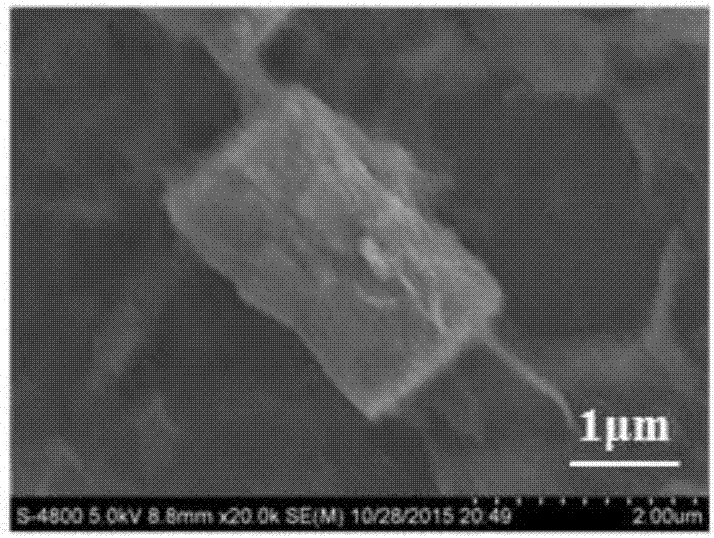

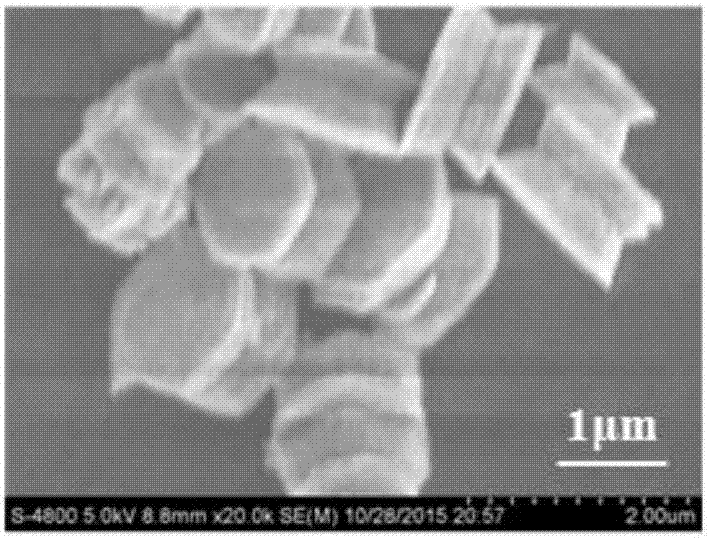

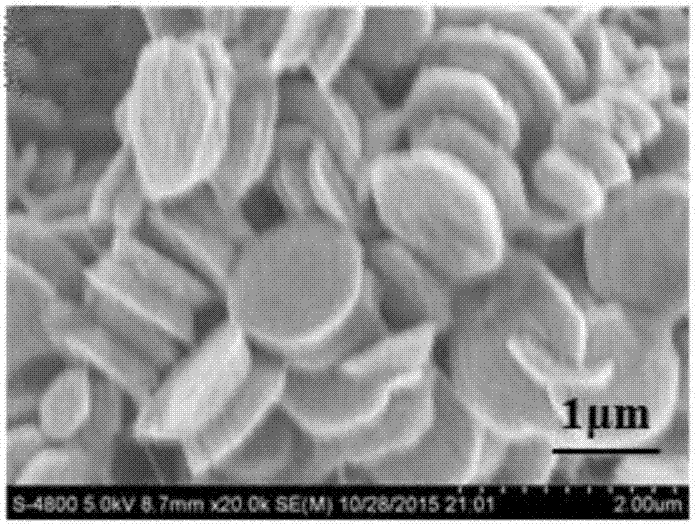

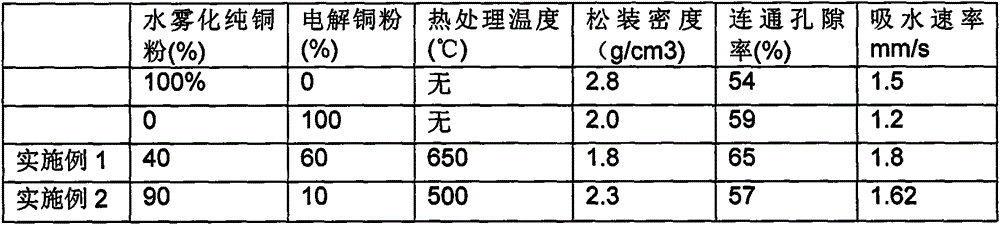

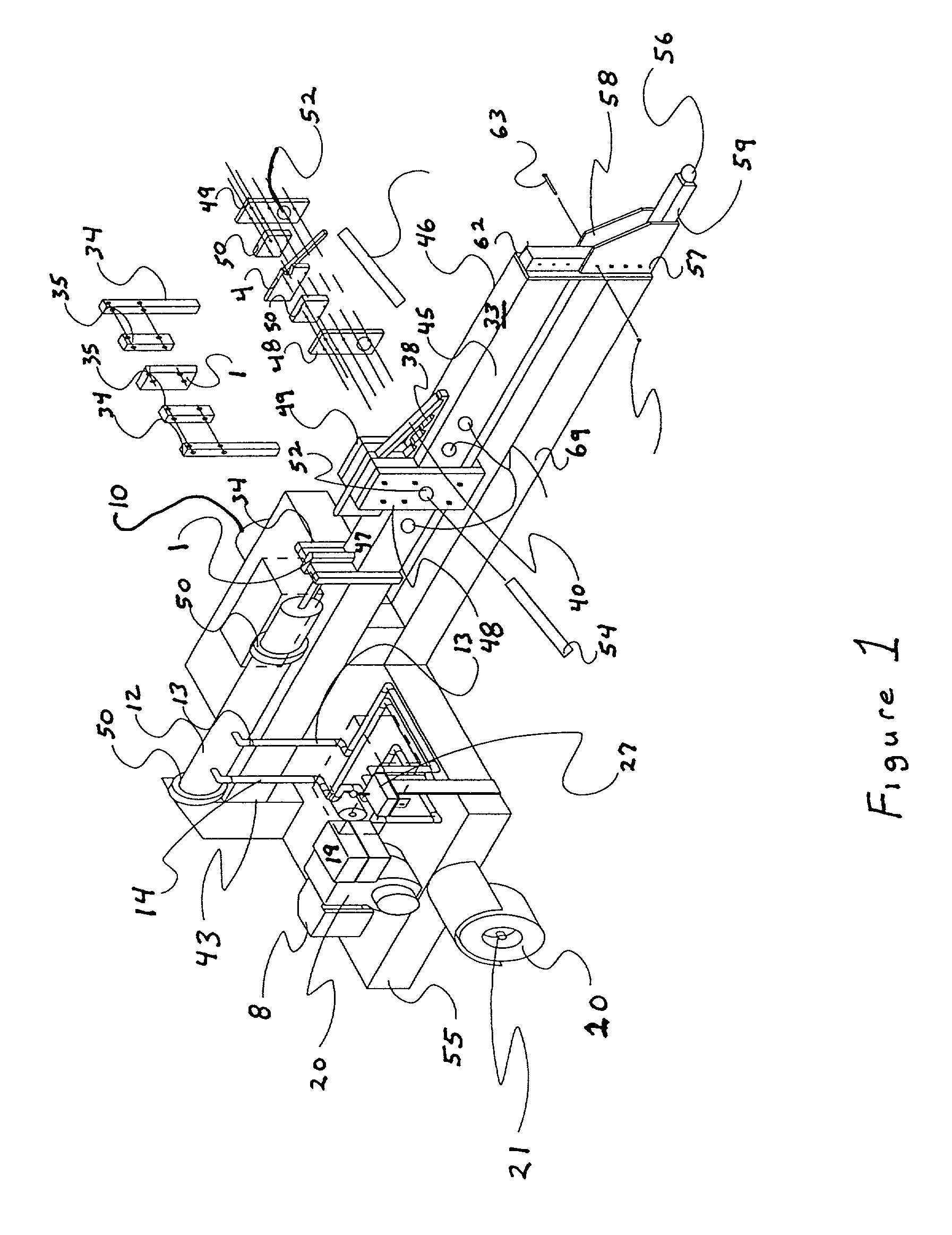

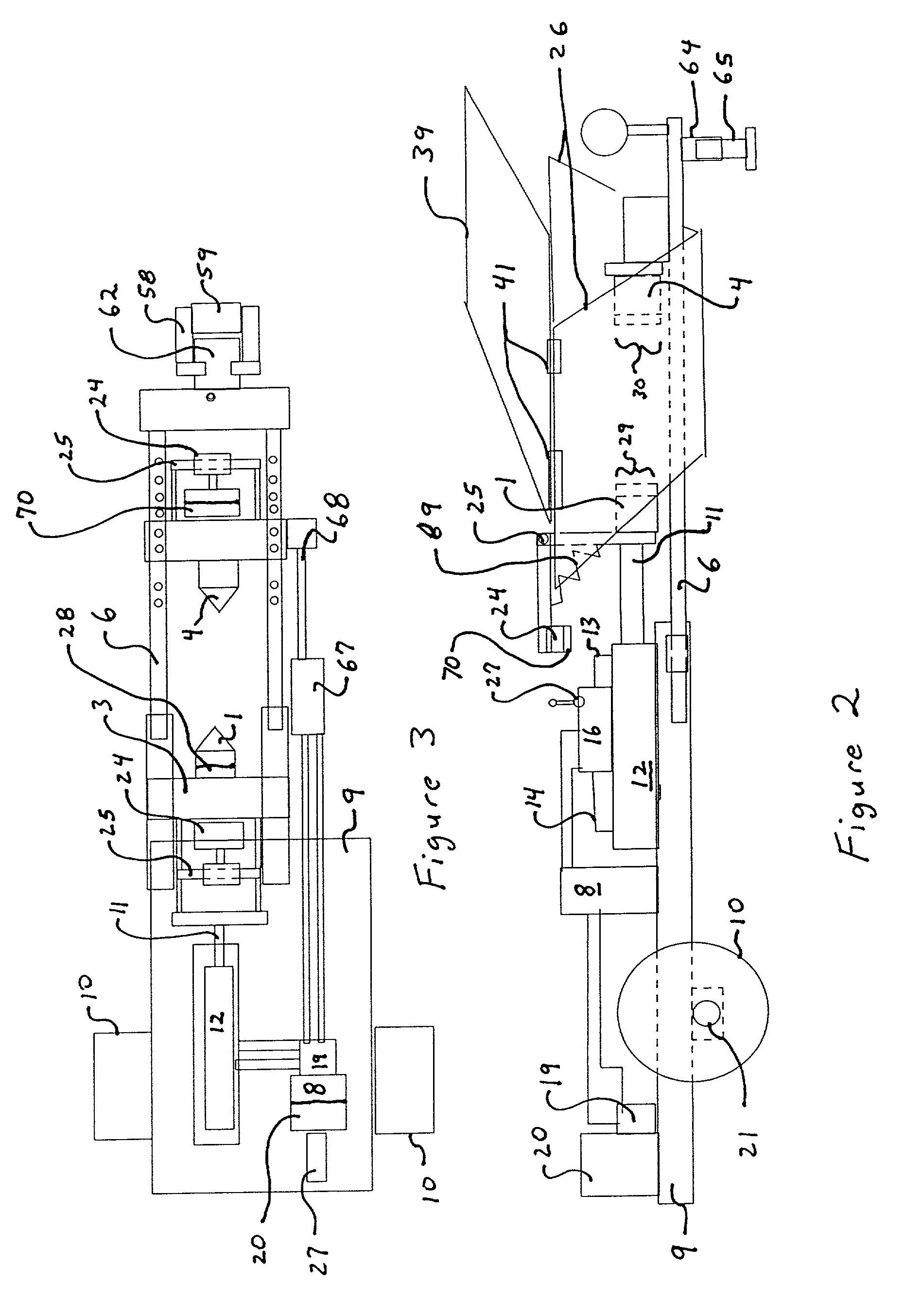

Method for producing composite copper powder for ultrathin heat pipe

The invention provides a method for producing composite cooper powder for an ultrahigh heat pipe. The method for producing the composite copper powder for the ultrahigh heat pipe comprises the steps of powder blending, heat treatment, smashing, oxidant treatment and screening. The composite copper powder produced according to the method is formed in the mode that after electrolytic copper powder and water atomized copper powder are mixed, heat treatment, smashing, oxidant treatment and screening are conducted on the mixture. After compaction and sintering are conducted on the composite copper powder, a capillary structural layer with high communication porosity and high capillary water absorption rate can be obtained, and the heat conduction efficiency of the ultrathin heat pipe is improved.

Owner:湖南省天心博力科技有限公司

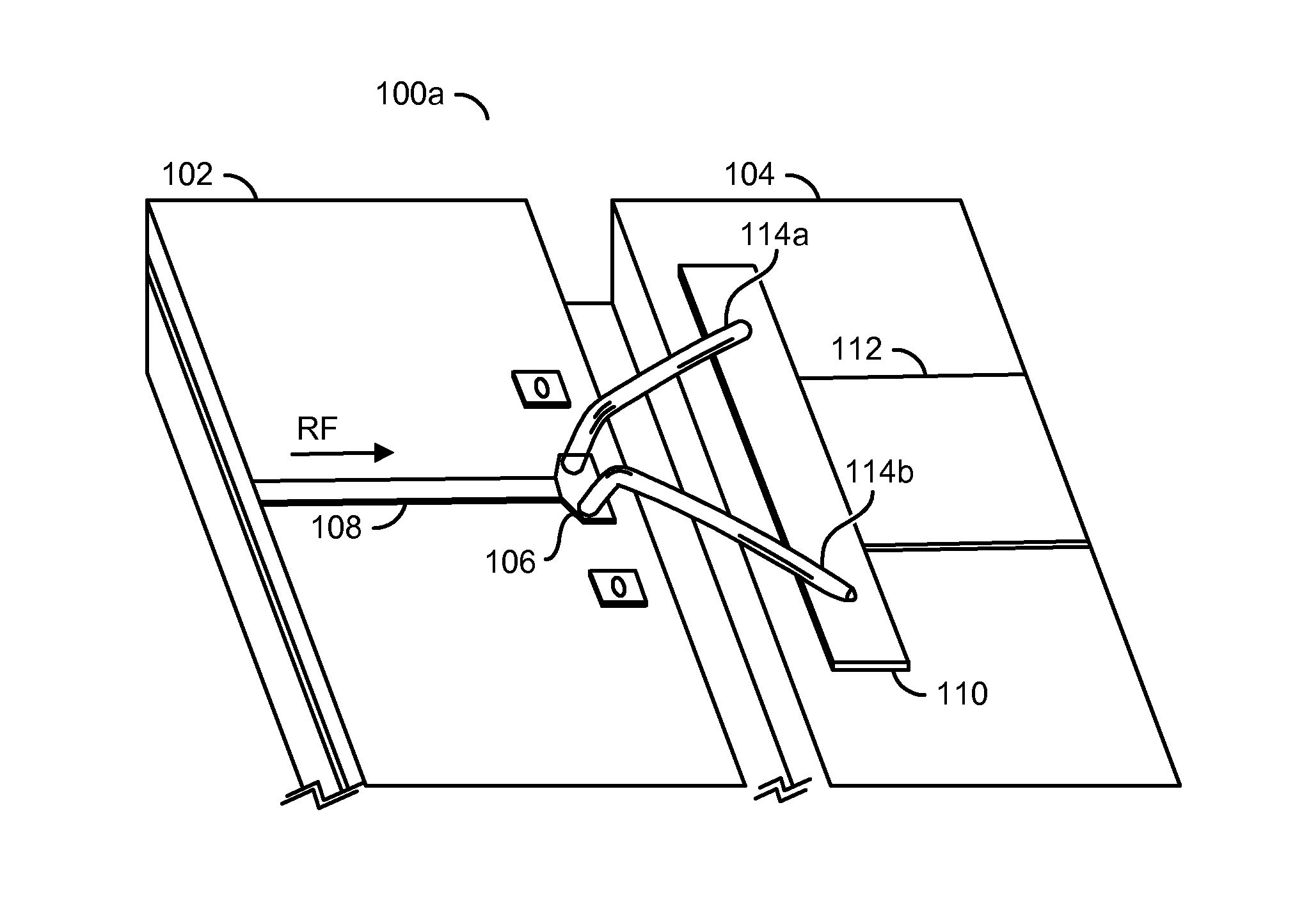

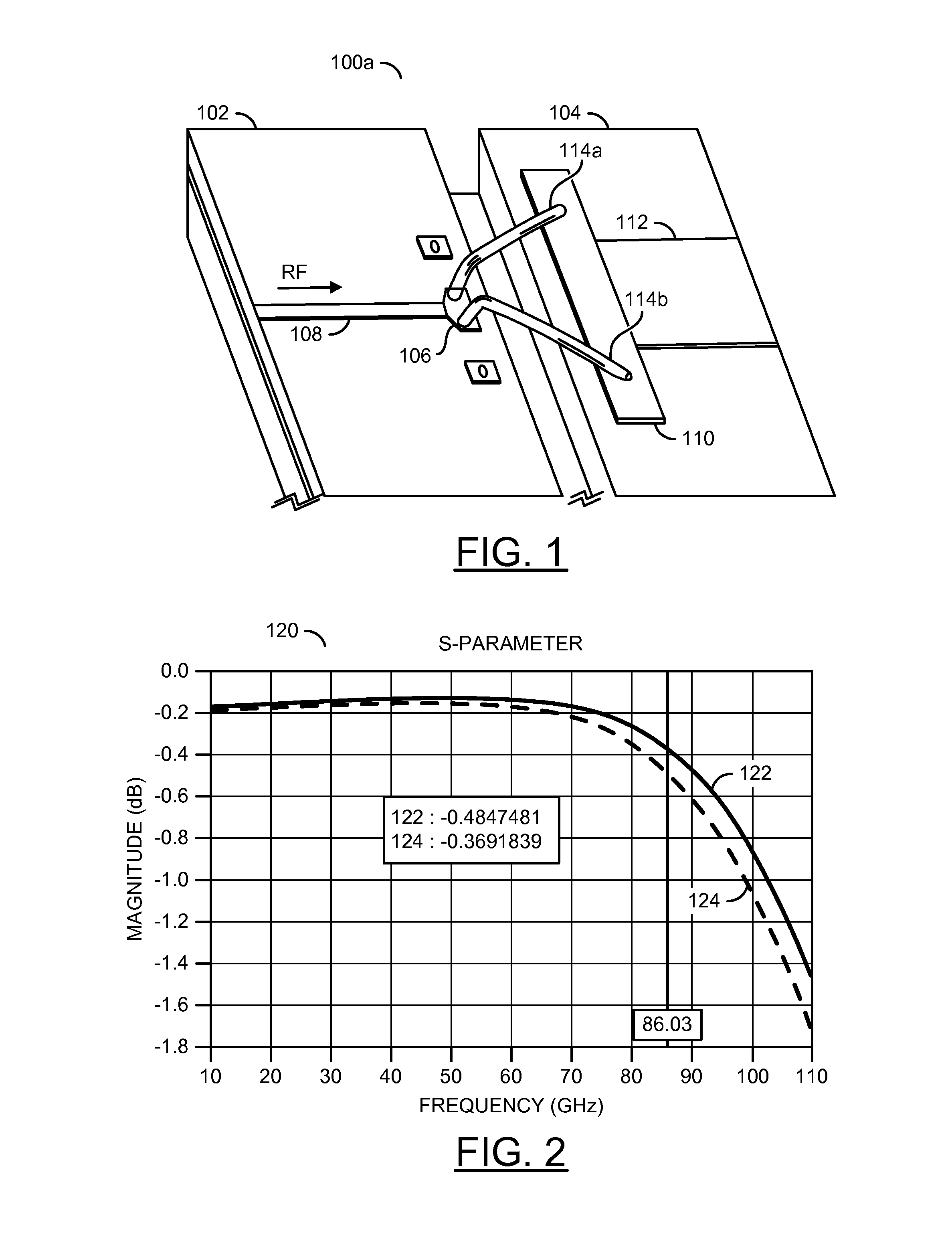

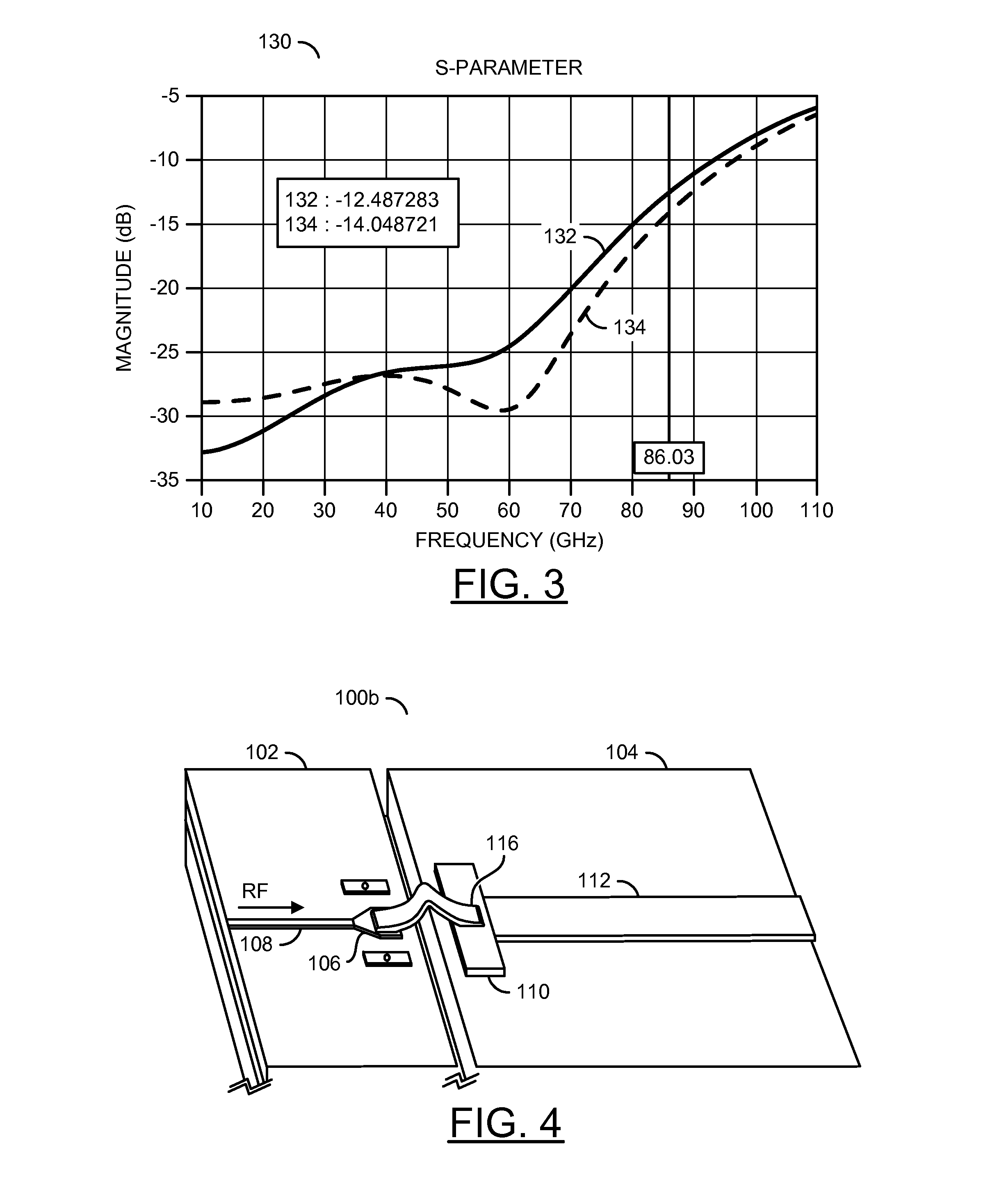

High frequency monolithic microwave integrated circuit connection

InactiveUS8970017B1Reduce radio frequency pad sizeIncrease surface areaSemiconductor/solid-state device detailsSolid-state devicesMicrowave frequency rangeElectrical conductor

An apparatus having a bonding pad and a conductor is disclosed. The bonding pad may be formed in a conductive layer of an integrated circuit. The bonding pad generally has (i) a bond region, (ii) an interface edge sized to match a transmission line and (iii) a tapered region between the bond region and the interface edge. The interface edge may be narrower than the bond region. The tapered region generally has a non-rectangular shape that spans from the bond region to the interface edge. The conductor may be bonded to the bond region. The conductor is generally configured to exchange a signal with the bond region. The signal may be in a microwave frequency range.

Owner:MACOM TECH SOLUTIONS HLDG INC

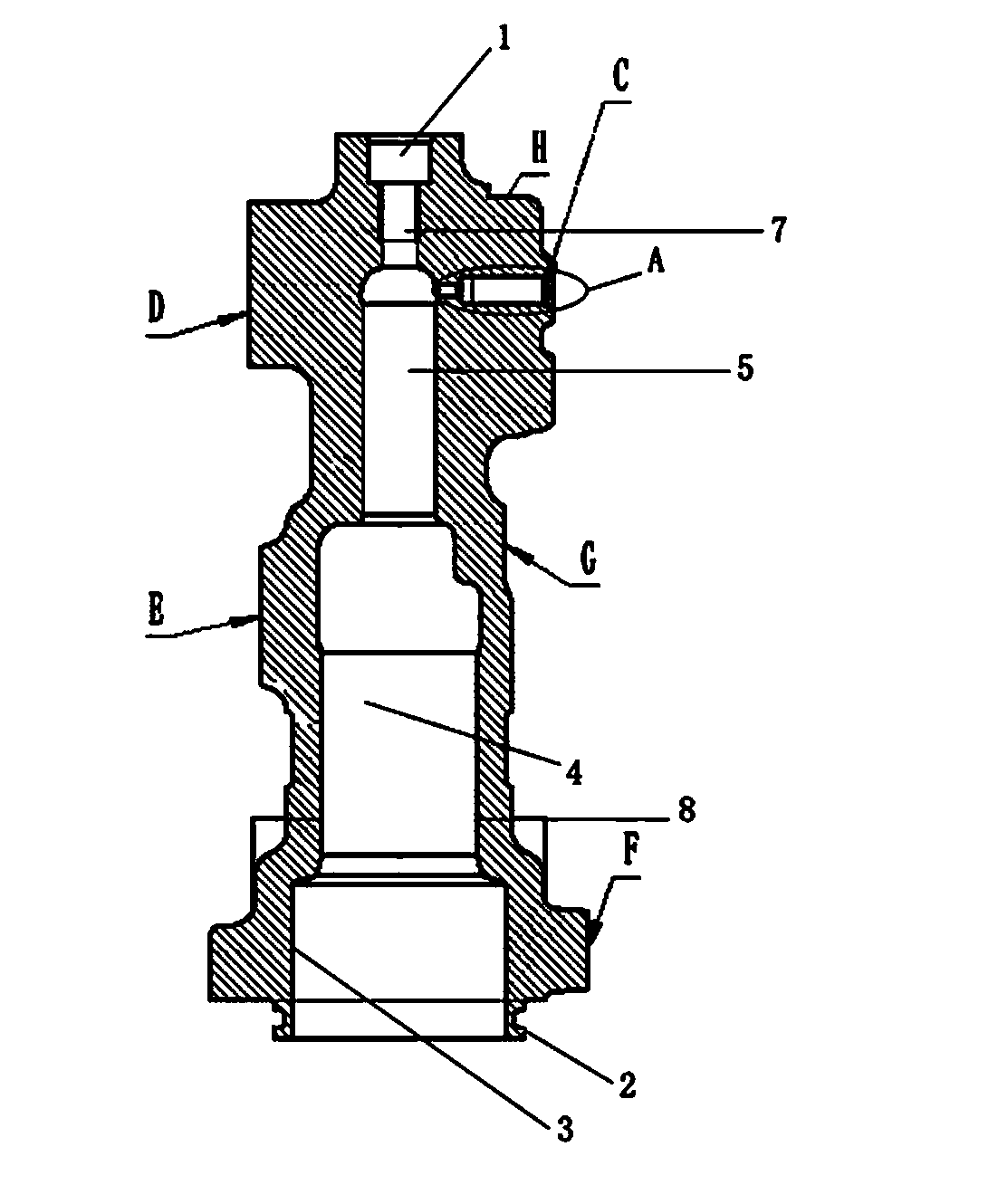

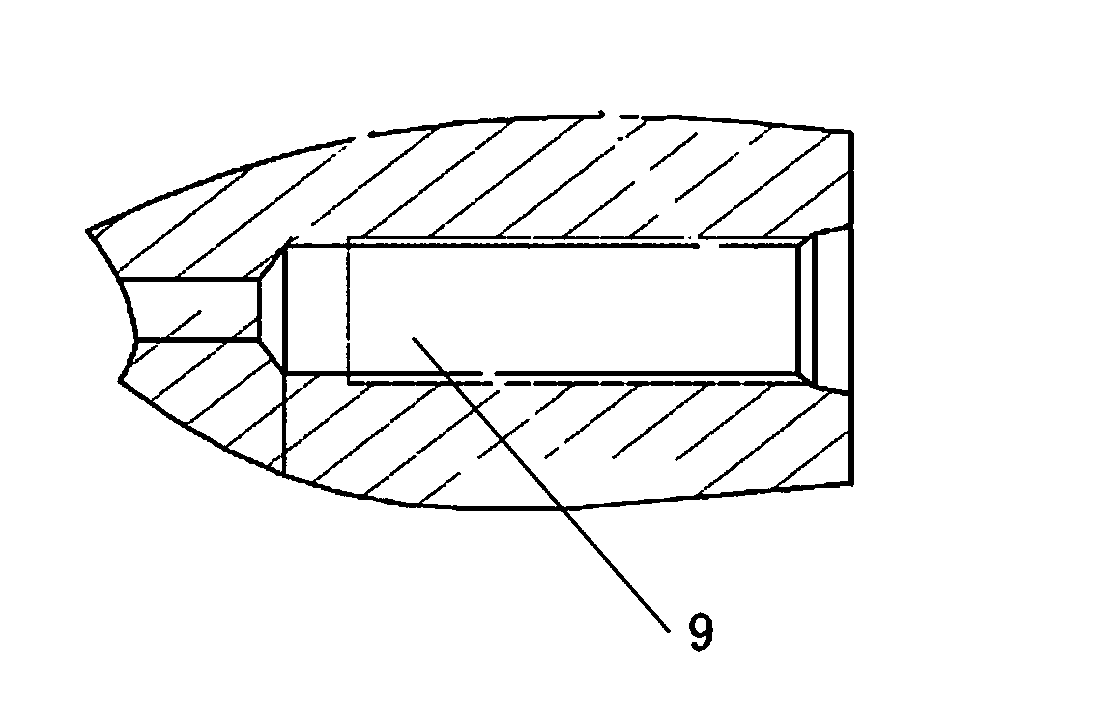

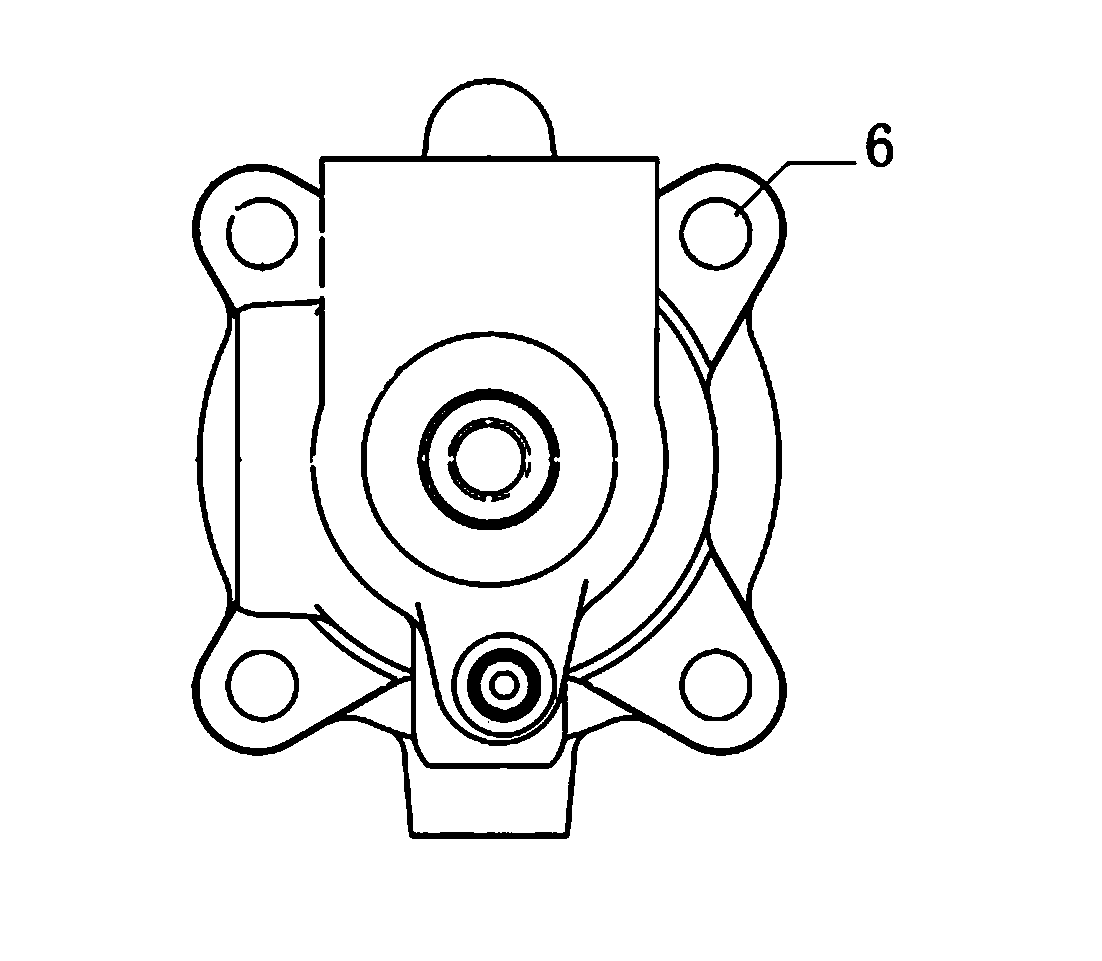

Manufacturing method for diesel engine exhaust valve upper seat

The invention discloses a manufacturing method for a diesel engine exhaust valve upper seat. The manufacturing method comprises the steps of processing a center hole after workblank polishing; drawing every horizontal curve, every round line and every lug processing line; processing inner holes at one end with a small diameter after correction; milling every excircle lug; enabling the inner holes at the end with the small diameter to be located through cylinder ejector pins, adjusting tooling screws to be aligned with the round lines at one end with a large diameter, first enabling a cutter retracting groove hole to undergo rough turning to be smooth, and then using a dill and a forming drill to process the inner holes and a cutter retracting groove; performing lineation and adjustment on excircles at one end with the large diameter; processing a process screw hole; performing high-pressure pumping pressure and low-pressure pumping pressure on a workpiece; processing small holes; performing finish machining on every inner hole and every excircle after pouring fusible alloy; processing locating pins; processing every hole on the side; performing deburring, and honing the inner holes; cleaning parts, and performing rust prevention treatment and inspection. The manufacturing method can effectively improve product processing quality and efficiency.

Owner:KUNSHAN JIANGJIN MACHINERY

Vegetable insecticide and preparation method thereof

InactiveCN106900768AThoroughly modifiedHigh activityBiocideAnimal repellantsBacillus thuringiensisBiology

The invention discloses a vegetable insecticide and a preparation method thereof and relates to the technical field of insecticides. The vegetable insecticide is prepared from 80-90 parts of attapulgite, 55-75 parts of sepiolite powder, 55-65 parts of natural plant extracts, 45-50 parts of kieselguhr, 15-30 parts of bacillus thuringiensis, 10-20 parts of veratrine, 10-15 parts of additive and 250-300 parts of water. The vegetable insecticide is good in insecticidal efficacy and long in action time, the raw materials are easy to obtain, and the vegetable insecticide is safe, environmentally friendly and harmless to the human body.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

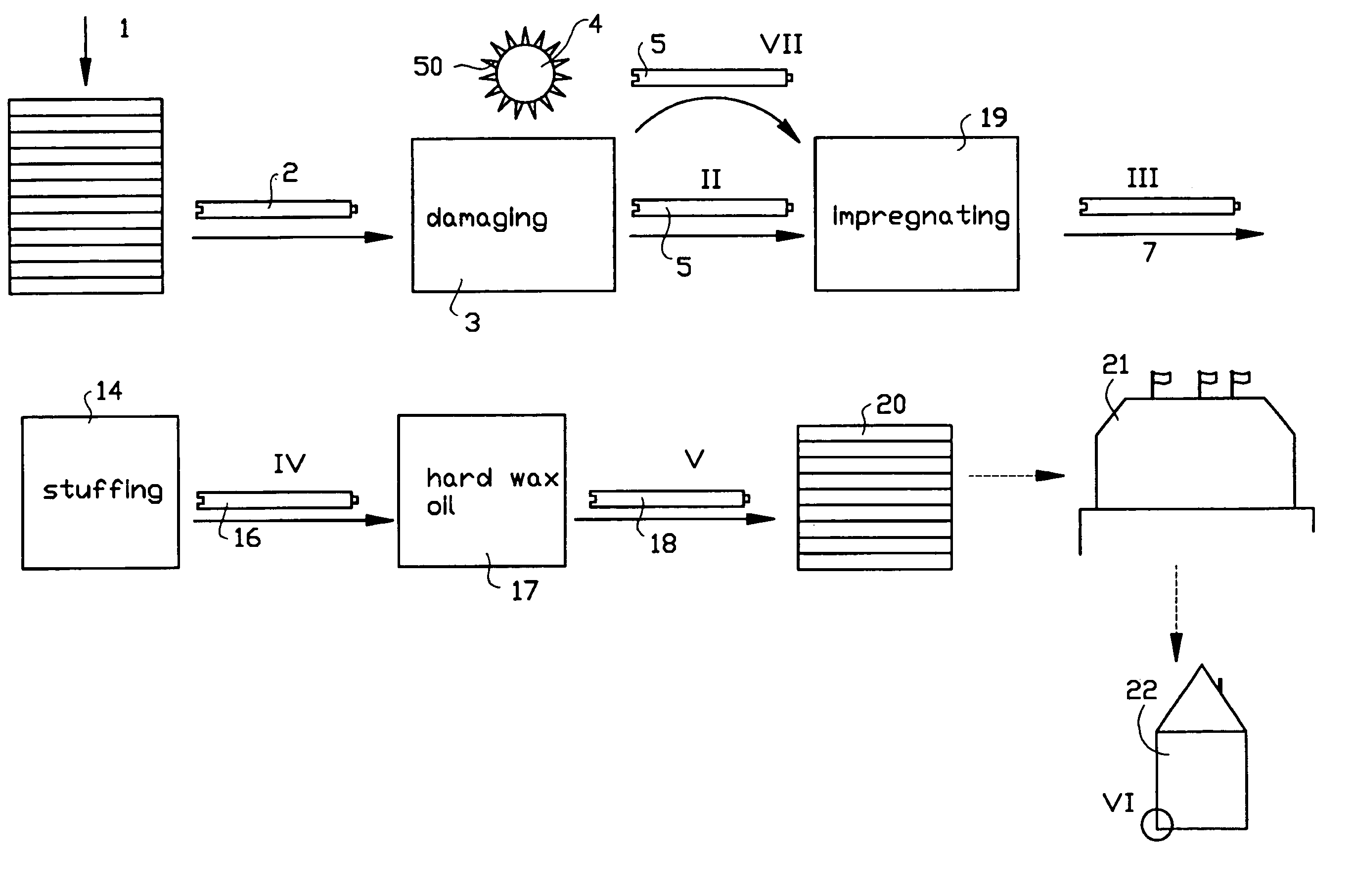

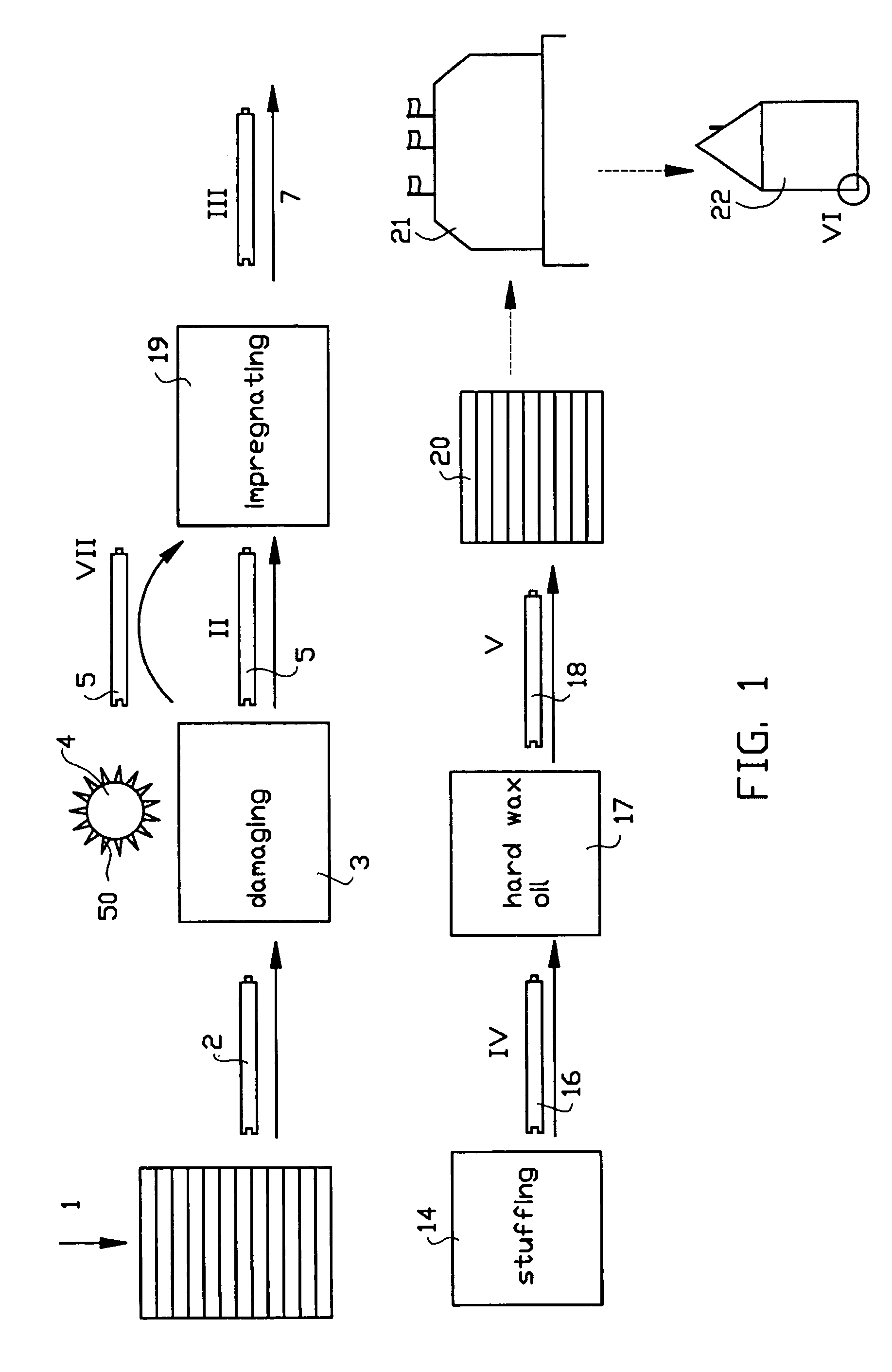

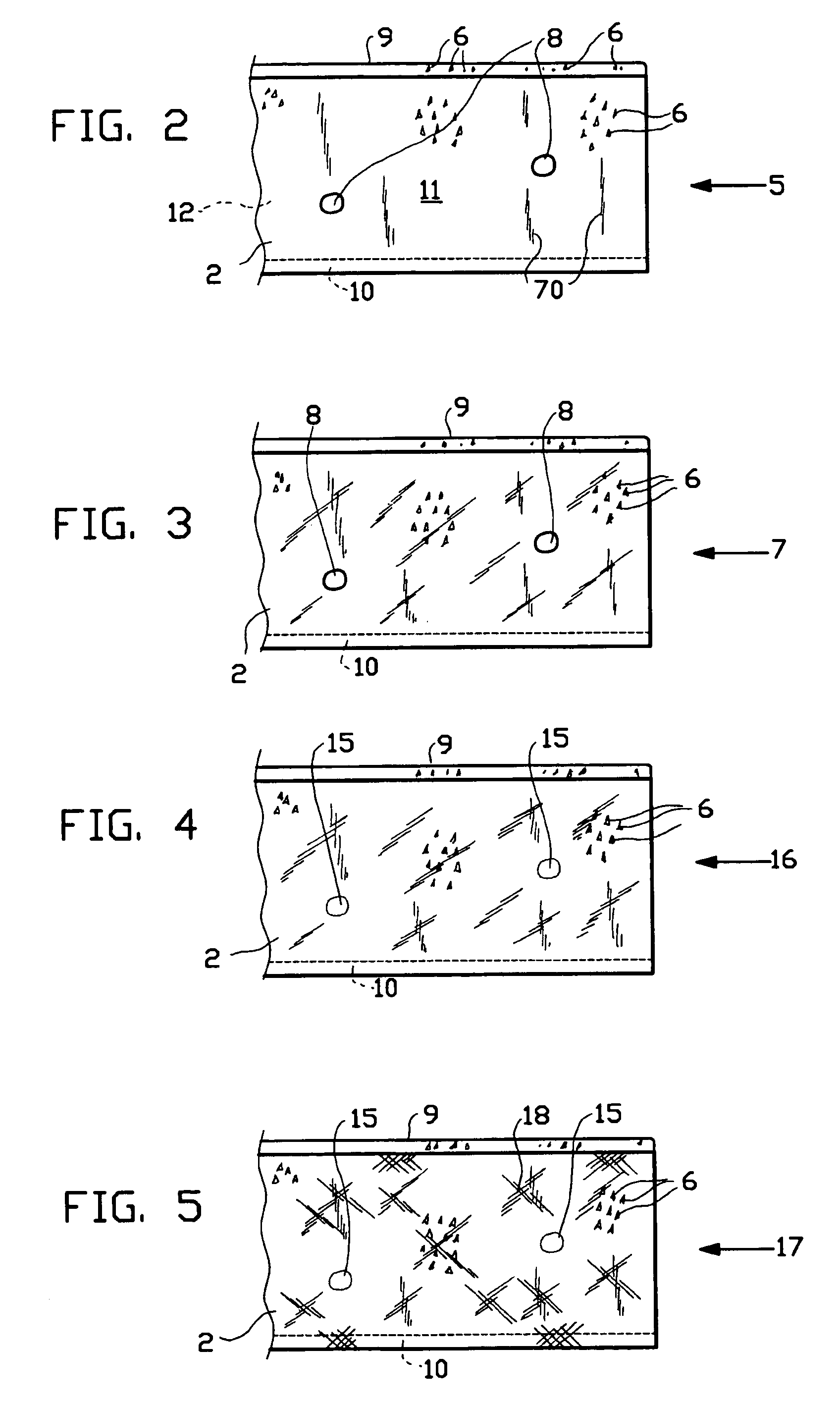

Method for manufacturing floor boards

InactiveUS6978814B2Good effectMaximal diversityMechanical surface treatmentSpecial ornamental structuresChemical treatmentWax

Method for manufacturing wooden floor boards having an antique and used look, the boards of planed new wood being subjected to a mechanical treatment for making damages in its circumferential surface, and after that to a chemical treatment of at least the entire top surface. The chemical treatment comprises the impregnation of at least the entire top surface and applying a hard wax oil after that.

Owner:HOUTIND SCHIJNDEL

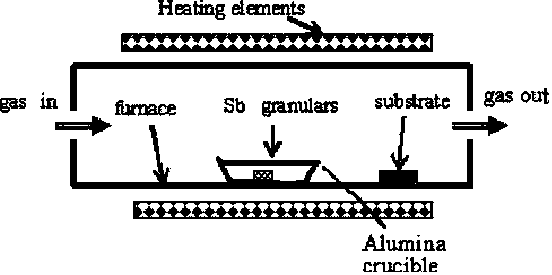

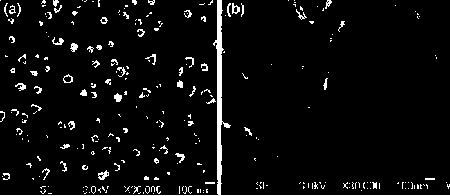

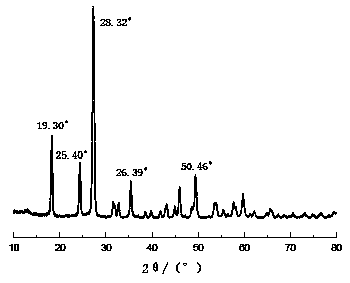

Method for preparing diantimony trioxide nano-particles by mechanochemical modification technology

PendingCN110963527AEasy to upgradeSimple processAntimony oxides/hydroxides/oxyacidsGrain treatmentsActive agentAqueous ethanol

The invention relates to a method for preparing diantimony trioxide nano-particles by a mechanochemical modification technology. The method comprises the following steps: (1) mixing and ball-milling micrometer diantimony trioxide, small hard alloy steel balls and distilled water to obtain nano-Sb2O3 particles; (2) washing, drying and sieving the nano-Sb2O3 particles to obtain a nano-Sb2O3 sample;(3) mixing the nano-Sb2O3 sample, small hard alloy steel balls and distilled water, adjusting the pH value, adding hexadecyltrimethylammonium bromide, carrying out ball milling, and cleaning, filtering and drying the obtained mixture to obtain cationic surfactant CTAB modified nano-Sb2O3 particles; (4) adding the cationic surfactant CTAB modified nano-Sb2O3 particles into an ethanol-water solution, and carrying out ultrasonic dispersion so as to obtain cationic surfactant CTAB modified nano-Sb2O3 particles; and (5) mixing and ball-milling the cationic surfactant CTAB modified nano-Sb2O3 particles, a silane coupling agent KH580, small hard alloy steel balls and anhydrous ethanol, and cleaning, filtering and drying the obtained mixture to obtain CTAB and KH580 compounded modified nano-Sb2O3.The method has the advantages of simple process, high yield, high operability, and easiness in realization of industrial production.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

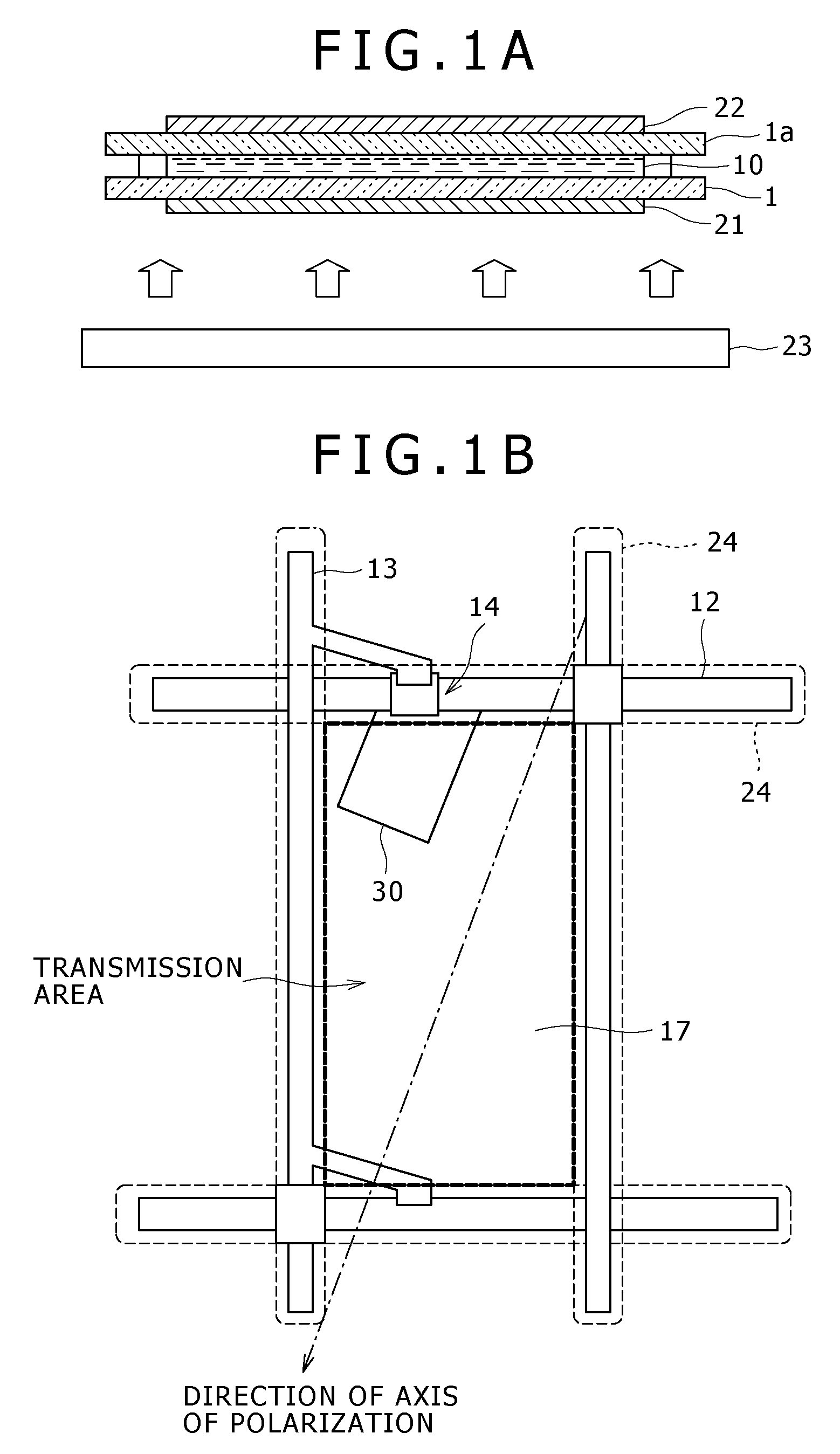

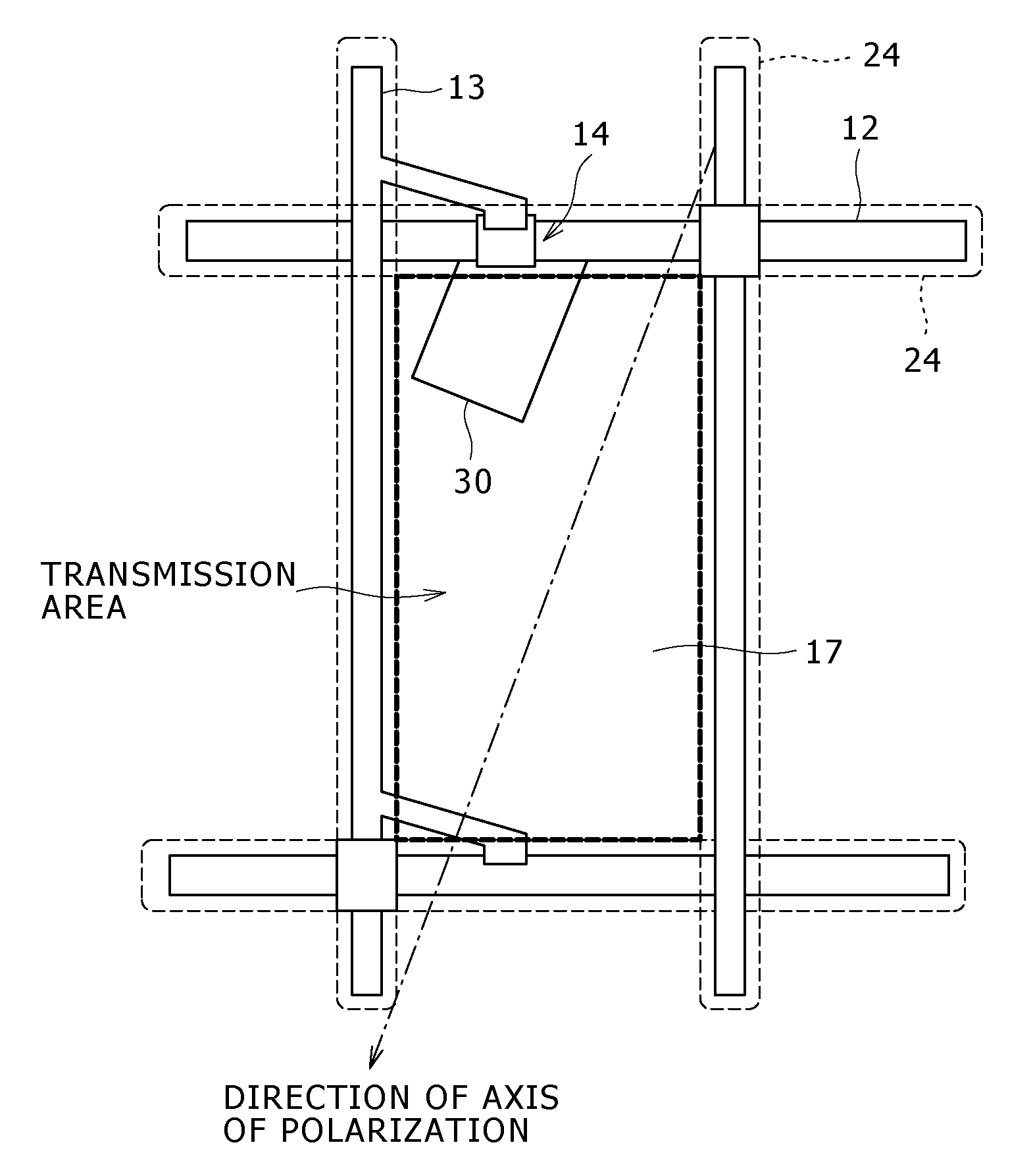

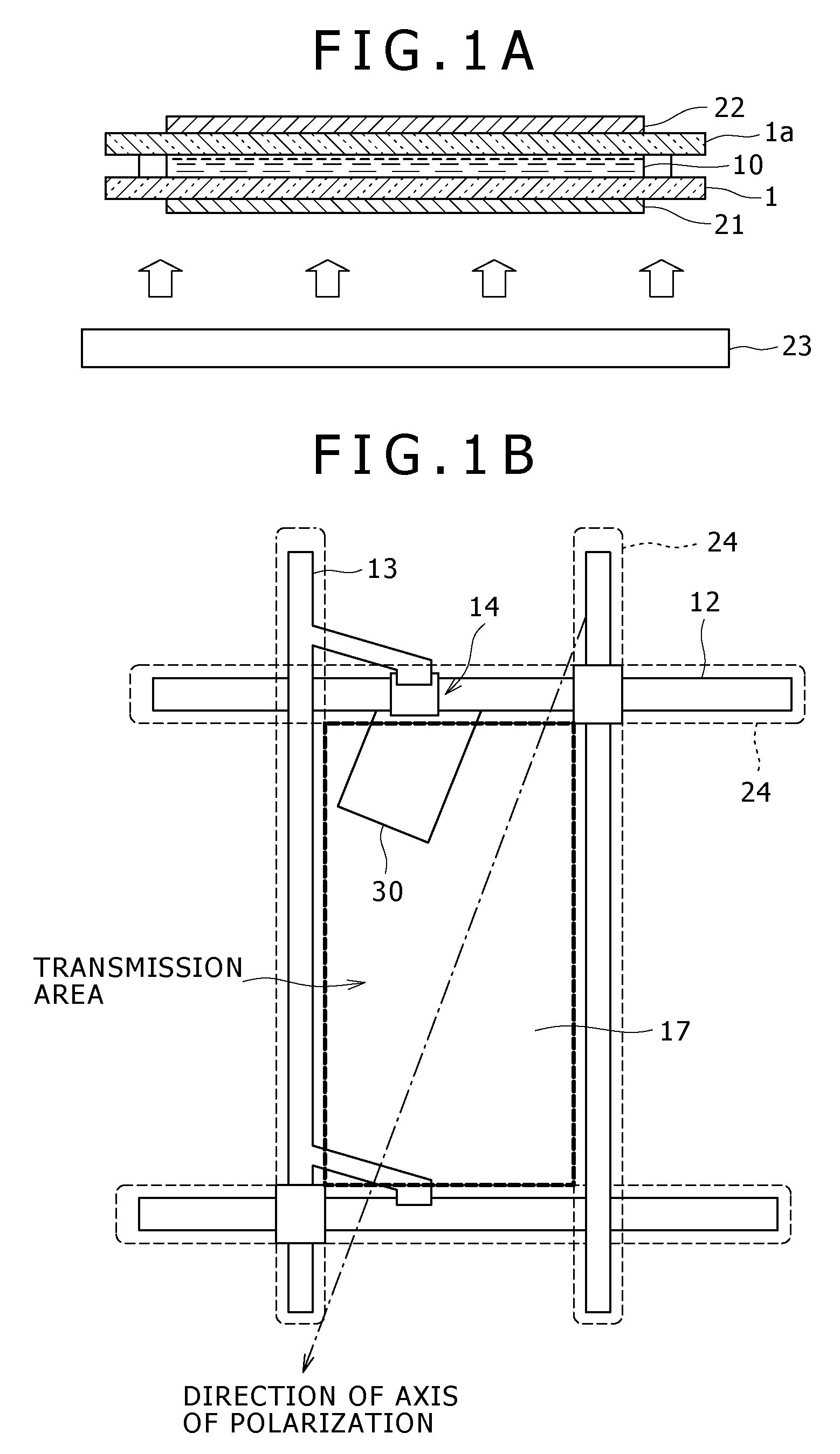

Liquid crystal display

ActiveUS20090284705A1Lower performance requirementsAvoid light leakageNon-linear opticsLiquid-crystal displayEngineering

Disclosed herein is a liquid crystal display including a pair of substrates; a liquid crystal held between the substrates; and a polarizing plate disposed on the side of one of the substrates.

Owner:JAPAN DISPLAY WEST

Peparation of water dispersed soft particle of pesticide

InactiveCN1679392AIrregular shapeEvenly distributedBiocideAnimal repellantsDispersityOrganic solvent

A water-dispersive soft particle of agricultural chemical is prepared from vegetative agricultural chemical or chemical pesticide, carrier, adhesive (poloxamer), wetting agent and disintegrant. Its advantages are high flow ability, dispersity and water affinity, good suspending nature, and high disintegrating speed.

Owner:馥稷生物科技发展(上海)有限公司

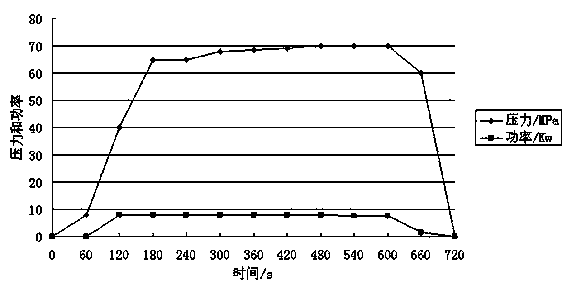

Coarse particle polycrystalline diamond synthesizing technology

ActiveCN103949187AIrregular shapeRough surfaceUltra-high pressure processesMetallurgyPolycrystalline diamond

The invention discloses a coarse particle polycrystalline diamond synthesizing technology. Coarse particle polycrystalline diamond is generated by controlling the variation of heating power and pressure intensity. The coarse particle polycrystalline diamond synthesizing technology provided by the invention has the beneficial effects that the synthesized polycrystalline diamond is irregular in shape, is rough in surface, has large particles and little impurities, is dark green, and has extremely good self-sharpening capability and good thermal stability.

Owner:HENAN FAMOUS DIAMOND IND CO LTD

Novel catalytic agent for diamond synthesis and preparation method thereof

InactiveCN106076324ACost-effectiveIncrease molding particle sizeMetal/metal-oxides/metal-hydroxide catalystsRheniumGranularity

The invention discloses a novel catalytic agent for diamond synthesis and a preparation method thereof. The novel catalytic agent comprises the following components in percentage by weight: 15-25% of aluminum, 2-3% of rhenium, 2-4% of chromium, less than or equal to 0.02% of carbon, less than or equal to 0.001% of boron, less than or equal to 0.003% of silicon and the balance of Fe. According to the novel catalytic agent disclosed by the invention, the formula design is reasonable, the cost performance of the catalytic agent is improved, the molding granularity and crystal color purity of diamond are improved, and the novel catalytic agent has excellent self-sharpening ability and high thermal stability.

Owner:ANQING KAILI DIAMOND TECH

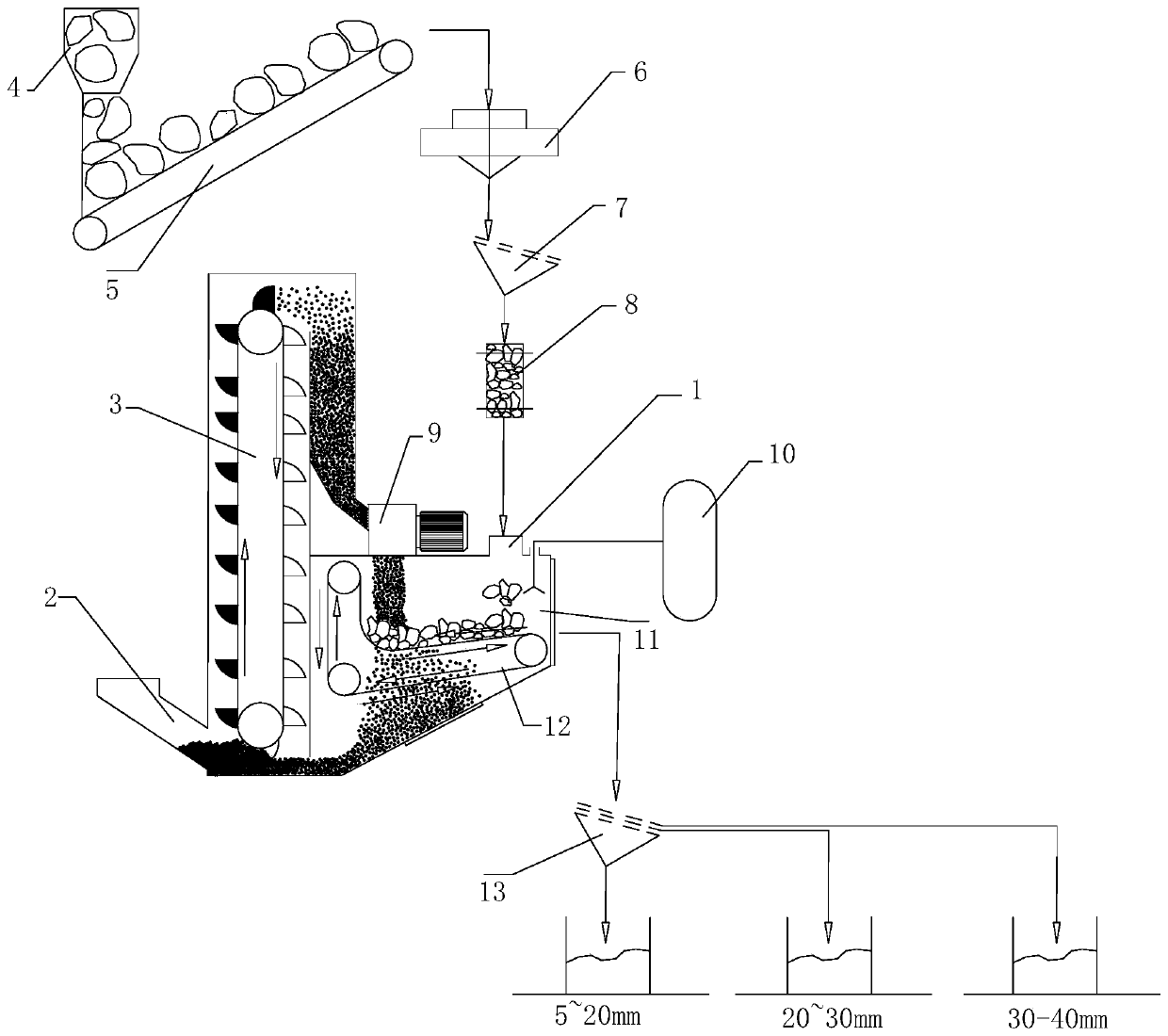

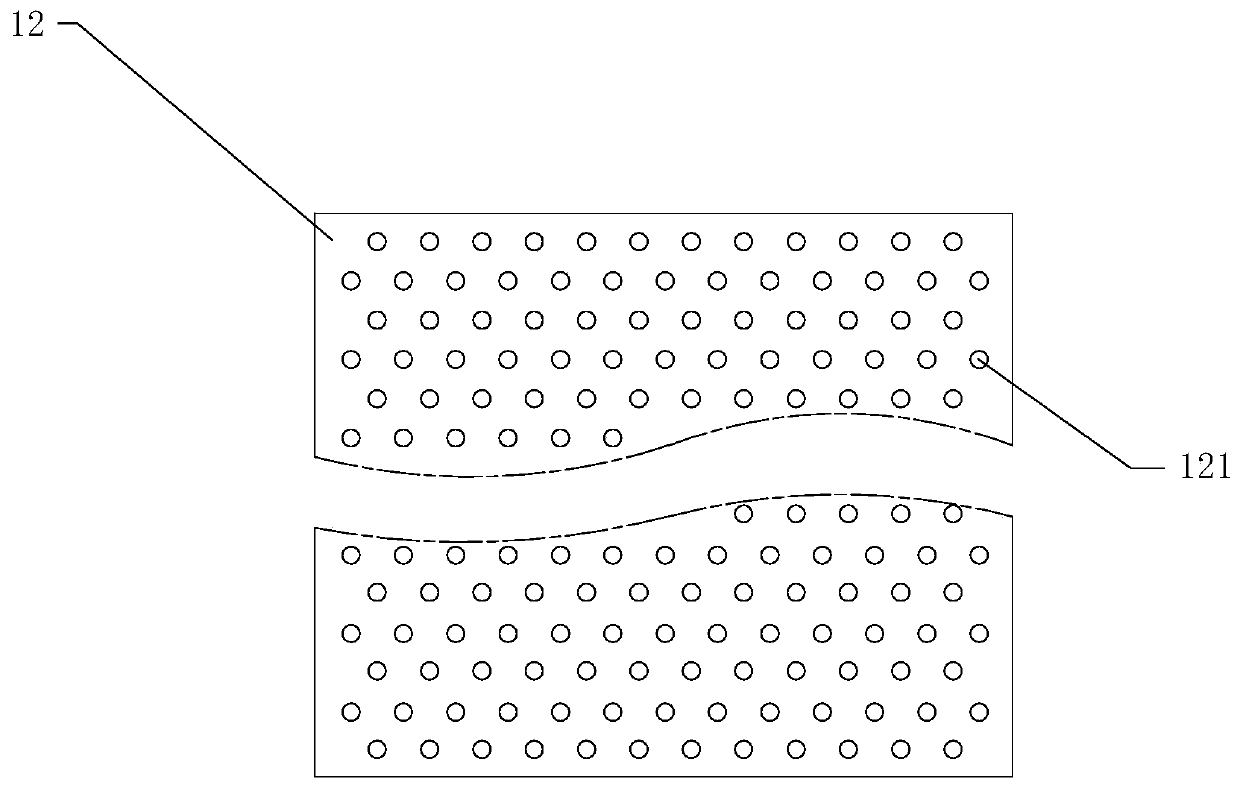

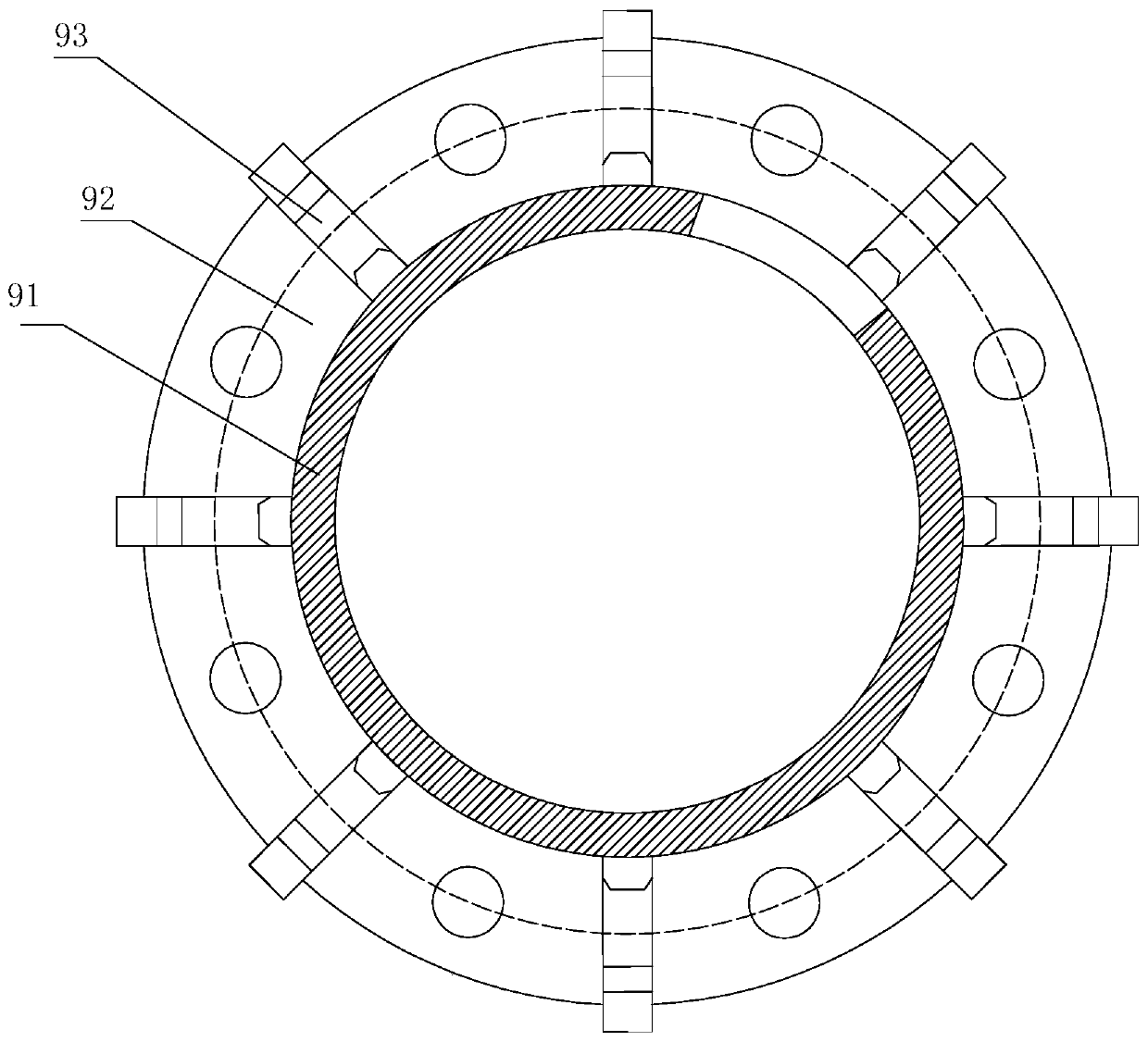

System for preparing recycled aggregate from waste concrete on basis of particle impact crushing

ActiveCN109704606AQuality improvementHigh speedSolid waste managementGrain treatmentsAccelerated particleHeating furnace

The invention provides a system for preparing recycled aggregate from waste concrete on basis of particle impact crushing. Concrete blocks enter a crusher through a conveyor belt for being crushed, then the crushed concrete blocks are screened to be concrete particles through a first vibrating screen, the concrete particles enter a heating furnace to be heated, and the heated concrete particles enter an air abrasion chamber through a first feeding port and are transmitted to a position below an outlet of a particle accelerator by a crawler belt; the air abrasion chamber is further provided with a second feeding port, and air abrasion particles enter the air abrasion chamber from the second feeding port and are lifted by a lifting device to enter the particle accelerator; and the air abrasion particles sprayed out of the particle accelerator collide with the concrete particles, and then mortar on the surfaces of the concrete particles are stripped, so that the high-quality recycled aggregate is prepared.

Owner:HUAQIAO UNIVERSITY

Polycrystalline diamond catalyst and thermal treatment process thereof

InactiveCN103949269AChange grain structureIncreased Synthetic Contact RangeUltra-high pressure processesCatalyst activation/preparationSurface oxidationManganese

The invention discloses a polycrystalline diamond catalyst and a thermal treatment process thereof. The polycrystalline diamond catalyst comprises the following chemical components in percentage by weight: 3-4 percent of cobalt, 27-34 percent of iron, 27-31 percent of manganese, 18-22 percent of nickel, 13-17 percent of silicon and 3-4 percent of carbon. The catalyst is thermally treated for certain time at certain temperature to form a novel catalyst. The polycrystalline diamond catalyst and the thermal treatment process thereof have the beneficial effects that after the catalyst is thermally treated, the surface of the catalyst is roughened by oxidization, a grain structure of the catalyst is changed, and the synthesis contact range of the catalyst is widened; the catalyst treated by using the thermal treatment process has the advantages of wide synthesis pressure range, wide synthesis temperature range, high yield per unit, short time and controllability of the synthesis process when being used for synthesizing polycrystalline diamond; the synthesized polycrystalline diamond is irregularly shaped, has the rough surface and few impurities, is dark green, and is excellent in self-sharpening capacity and high in thermal stability.

Owner:HENAN FAMOUS DIAMOND IND CO LTD

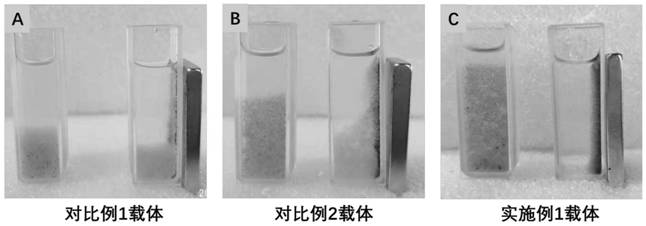

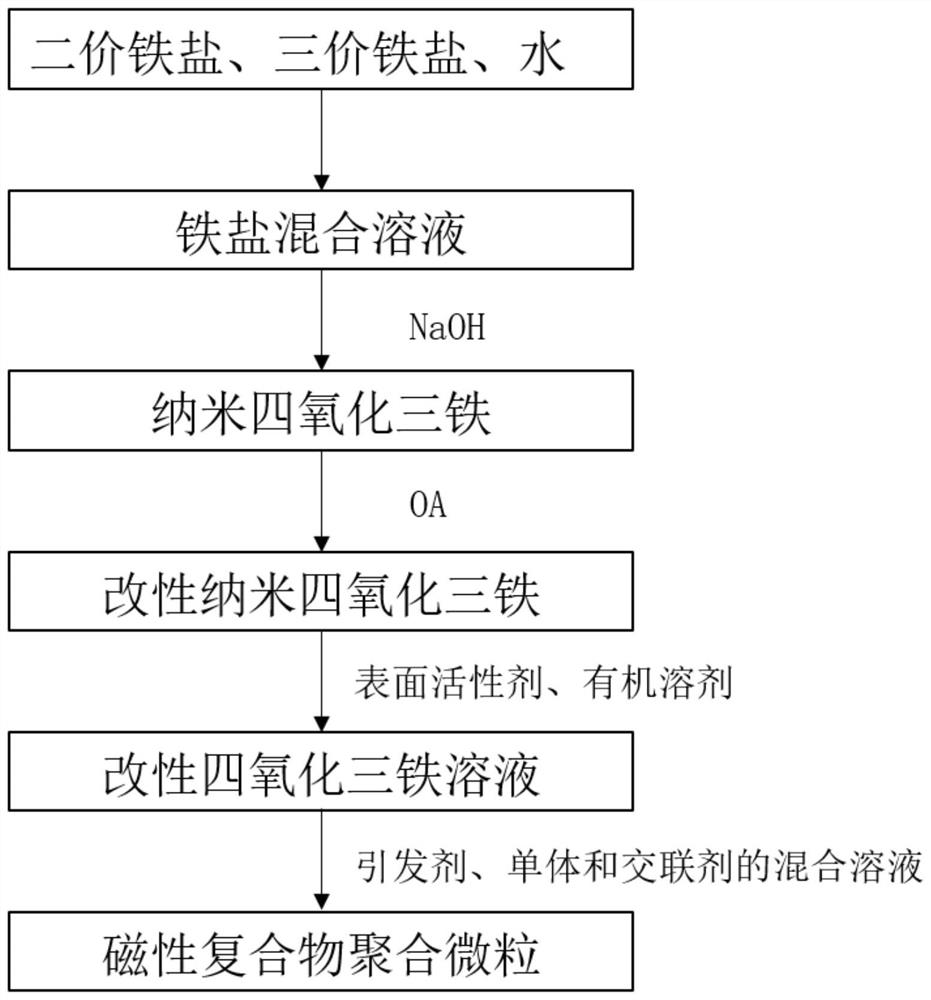

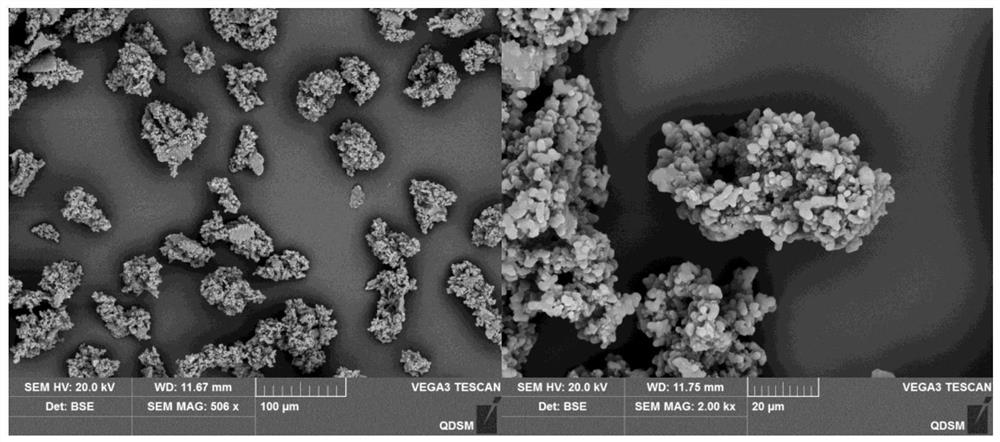

Magnetic polymer composite particle as well as preparation method and application thereof

PendingCN113908783AUniform particle size distributionGood superparamagneticMicroballoon preparationMicrocapsule preparationPolymer sciencePolymer chemistry

The invention discloses a magnetic polymer composite particle as well as a preparation method and application thereof, and relates to the technical field of composite materials. According to the technical scheme, the preparation method of the magnetic polymer composite particle is provided, and compared with the prior art, the method has the advantages that the method is environment-friendly, the production process is simple, and the magnetic polymer composite particles can be prepared by a one-pot method. The invention also provides a magnetic polymer composite particle. The particle size of the magnetic polymer composite particle is 50-250 [mu] m, and the magnetic polymer composite particle is formed by aggregating a plurality of small particles with the diameter of 1-10 [mu]m and has a macroporous structure. The invention also provides an application of the magnetic polymer composite particle. The magnetic polymer composite particle can be used as a carrier for microbial immobilization.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Light hollow ceramsite and production method thereof

ActiveCN102936127BHigh mechanical strengthThe protective effect is obviousCeramic materials productionClaywaresPolymer scienceSludge

The invention provides a light hollow ceramsite and a production method thereof and belongs to the technical field of artificial lightweight aggregate processing. The light hollow ceramsite is made of a ceramic forming material and a template material, wherein the ceramic forming material is composed of waste paper papermaking dry sludge, fly ash and clay, and the template material is composed of polyphenyl foam particles. The obtained light hollow ceramsite is spherical or similar to a sphere in appearance, a middle cavity is spherical or similar to a sphere, and the middle cavity is separated from the outside through a ceramic structure with wall thickness to be 0.5-2.5mm. According to the light hollow ceramsite, barrel pressure strength is 33MPa, stacking bulk weight is 300-500kg / m<3> and particle size is 5-20mm, and therefore the light hollow ceramsite can be used for preparing high performance light aggregate concrete or suspended bio-film ceramic filter materials used for sewage treatment.

Owner:CHINA MCC17 GRP

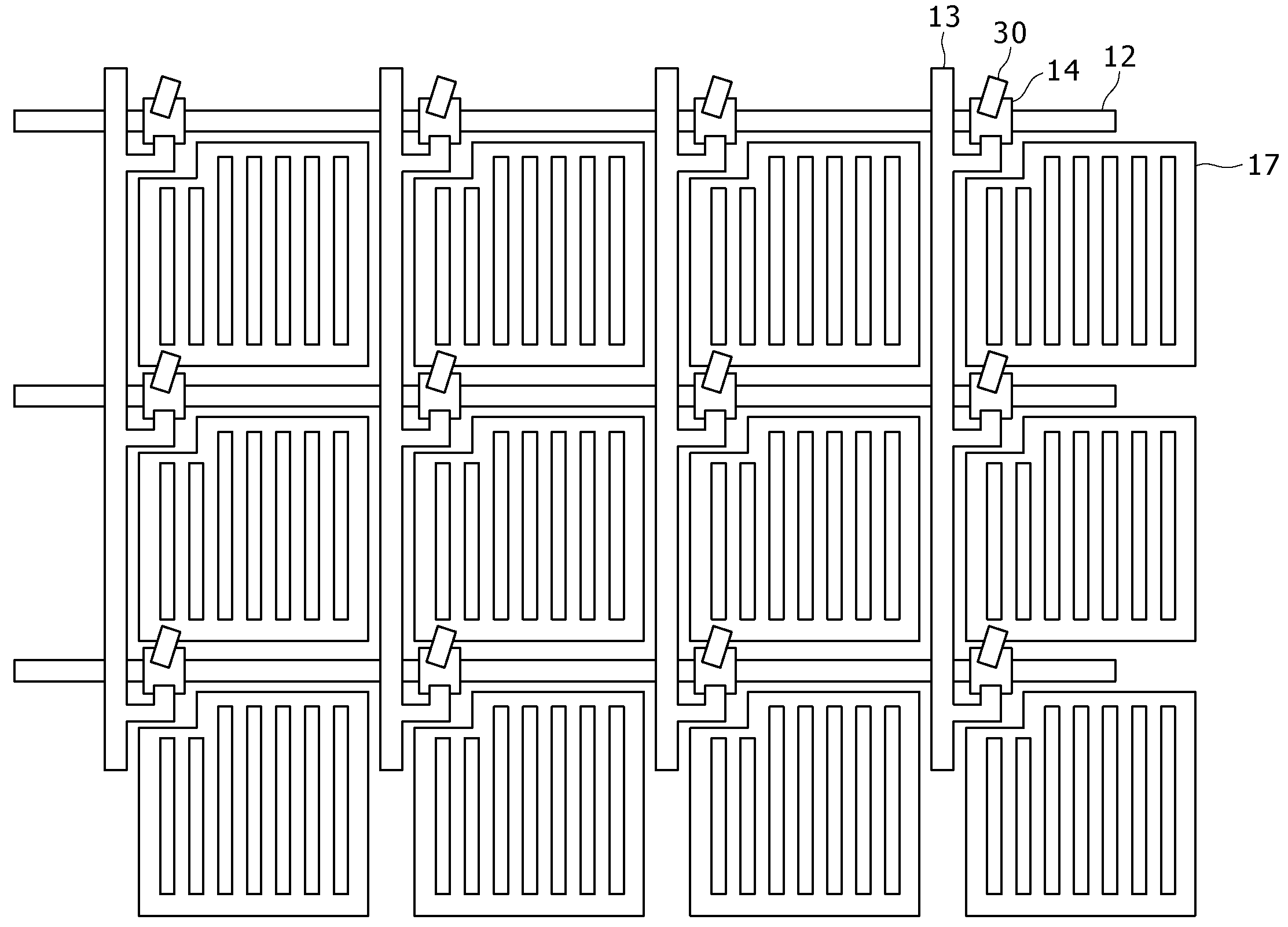

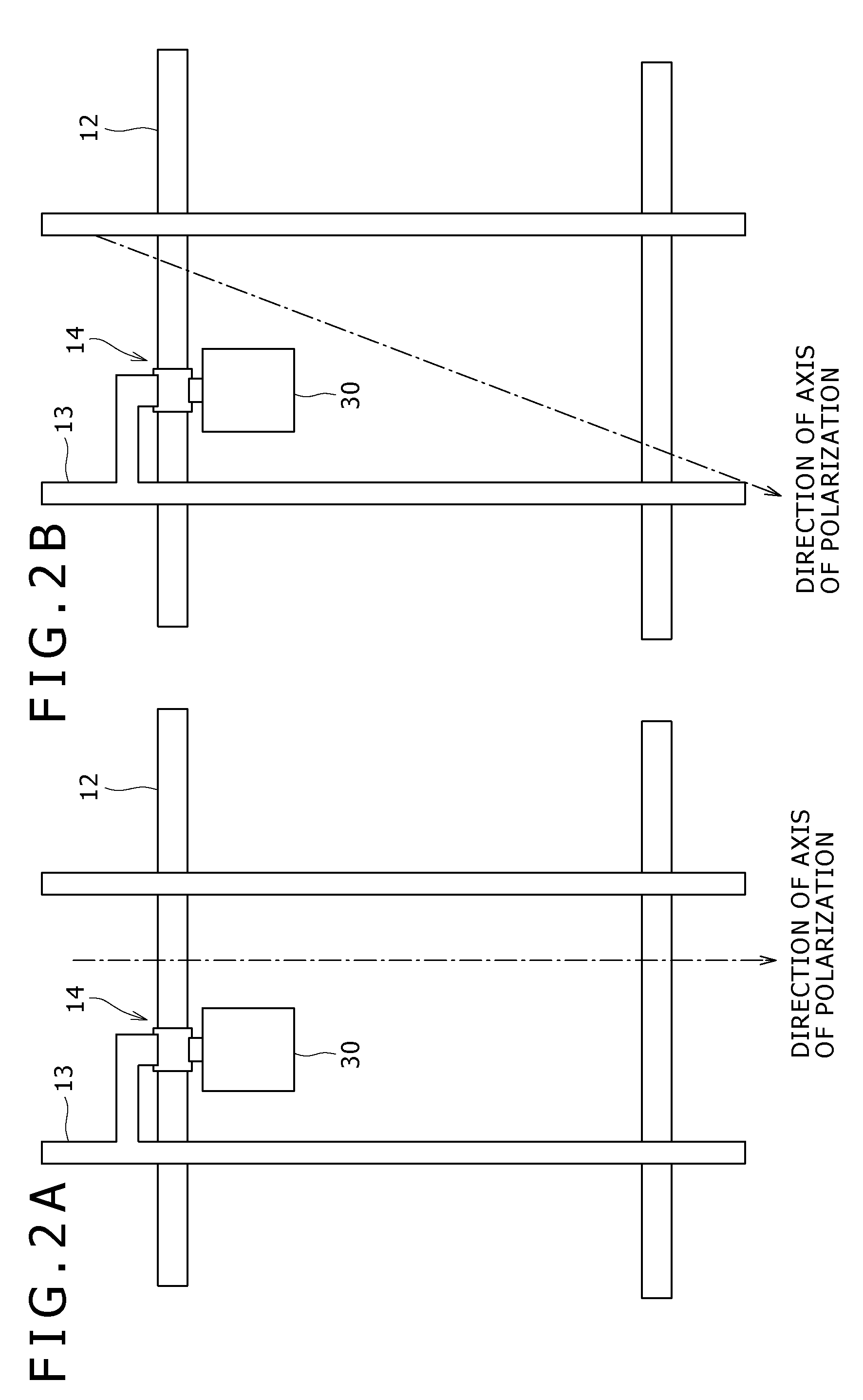

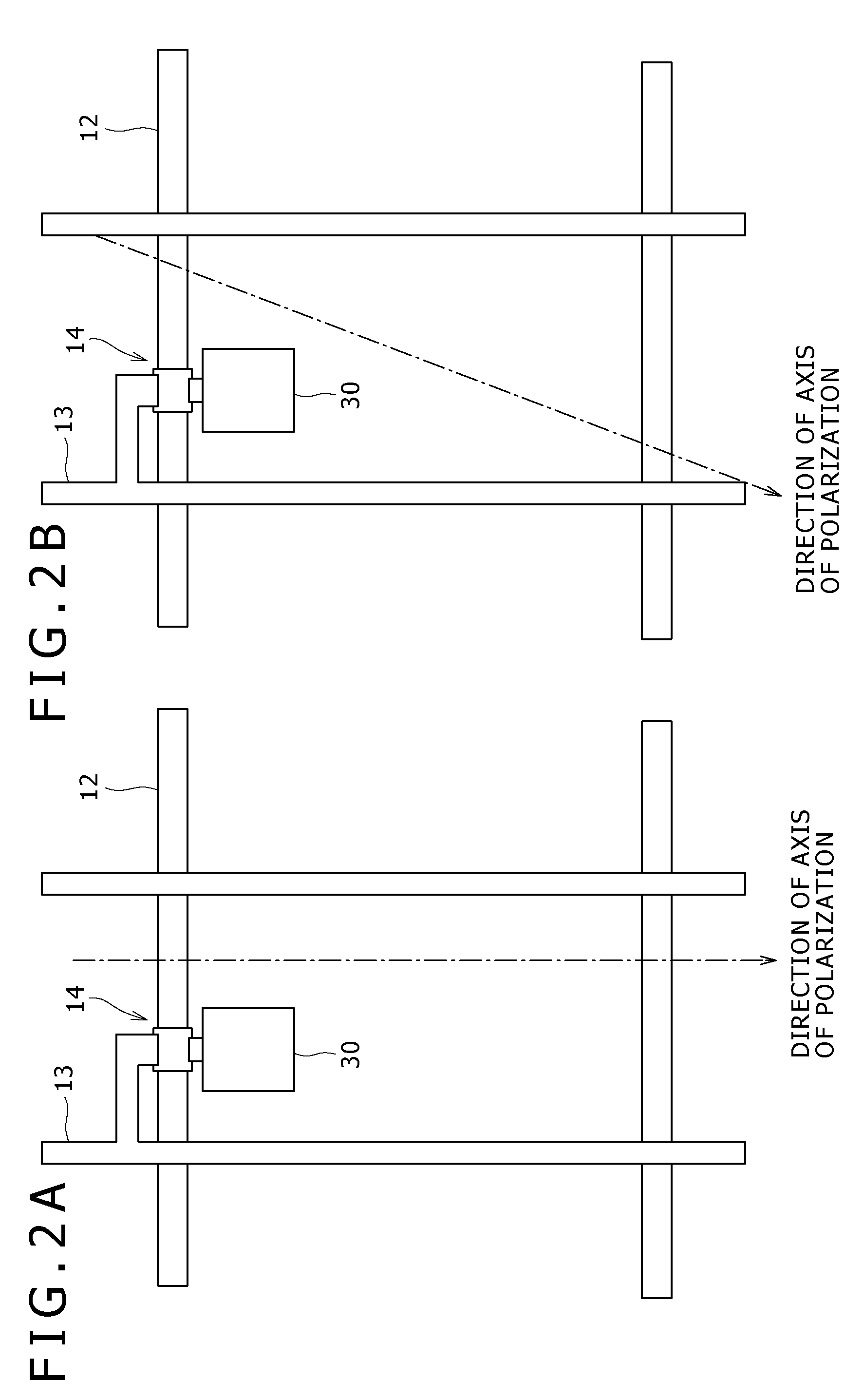

Liquid crystal display

ActiveUS8094283B2Lower performance requirementsAvoid light leakageNon-linear opticsLiquid-crystal displayScan line

A liquid crystal display including a polarizing plate having a linear polarization axis slanted in relation to a scan line, a transparent pixel electrode, an active element which drives the transparent pixel electrode, and a wire for connecting the active element and the transparent pixel electrode. The wire has an end part so shaped as to be slanted in a direction parallel to or perpendicular to the linear polarization axis.

Owner:JAPAN DISPLAY WEST

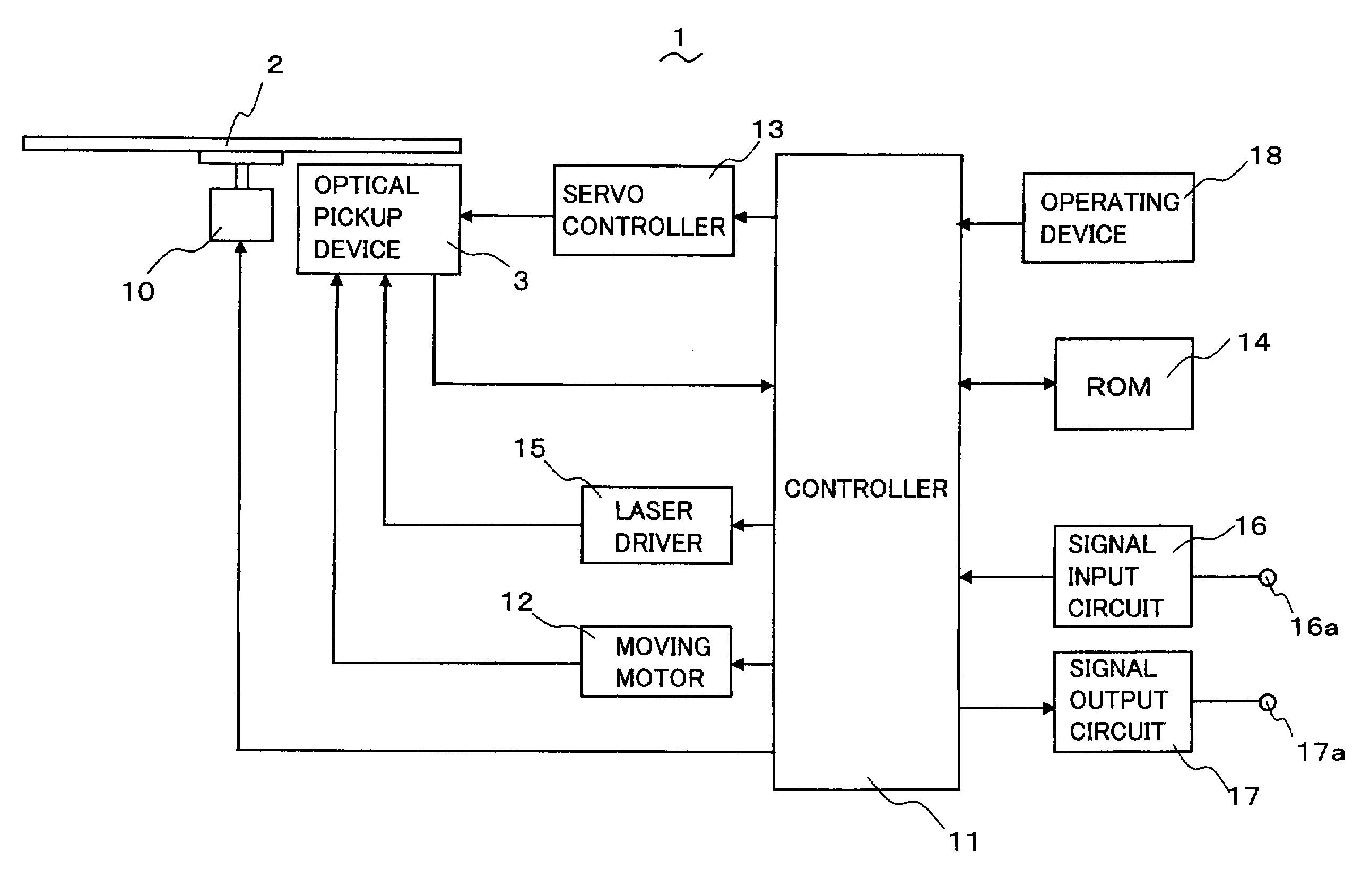

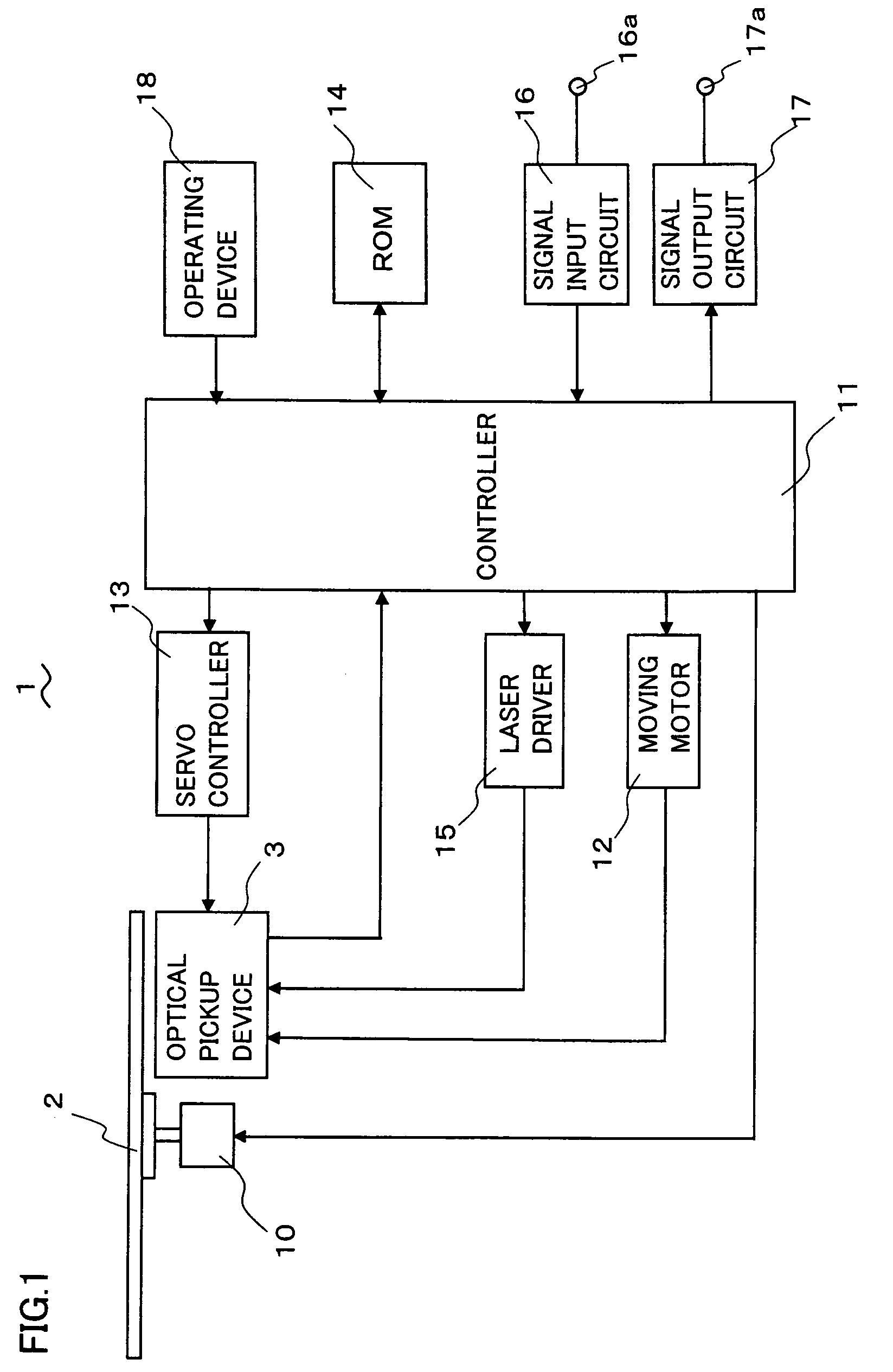

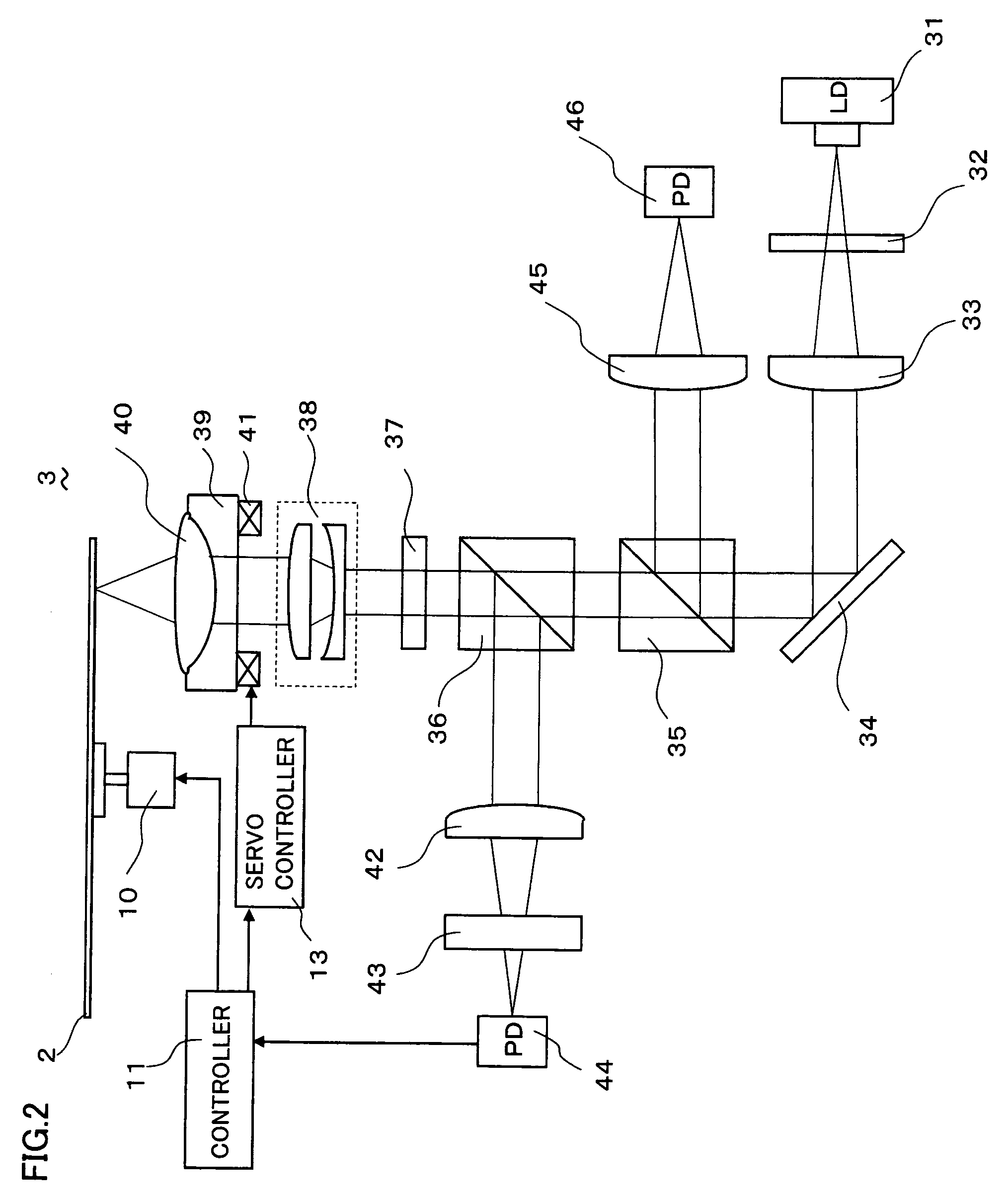

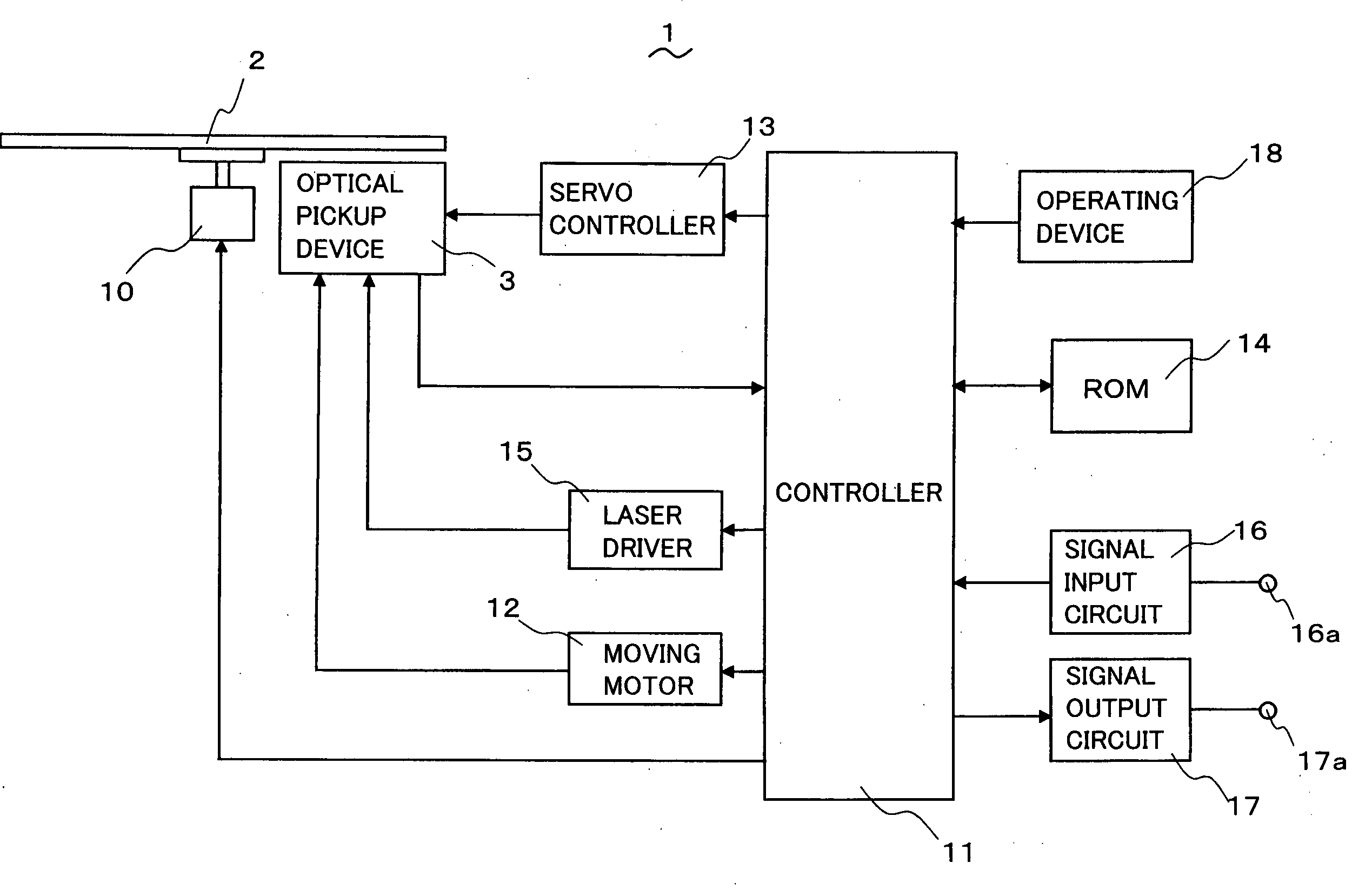

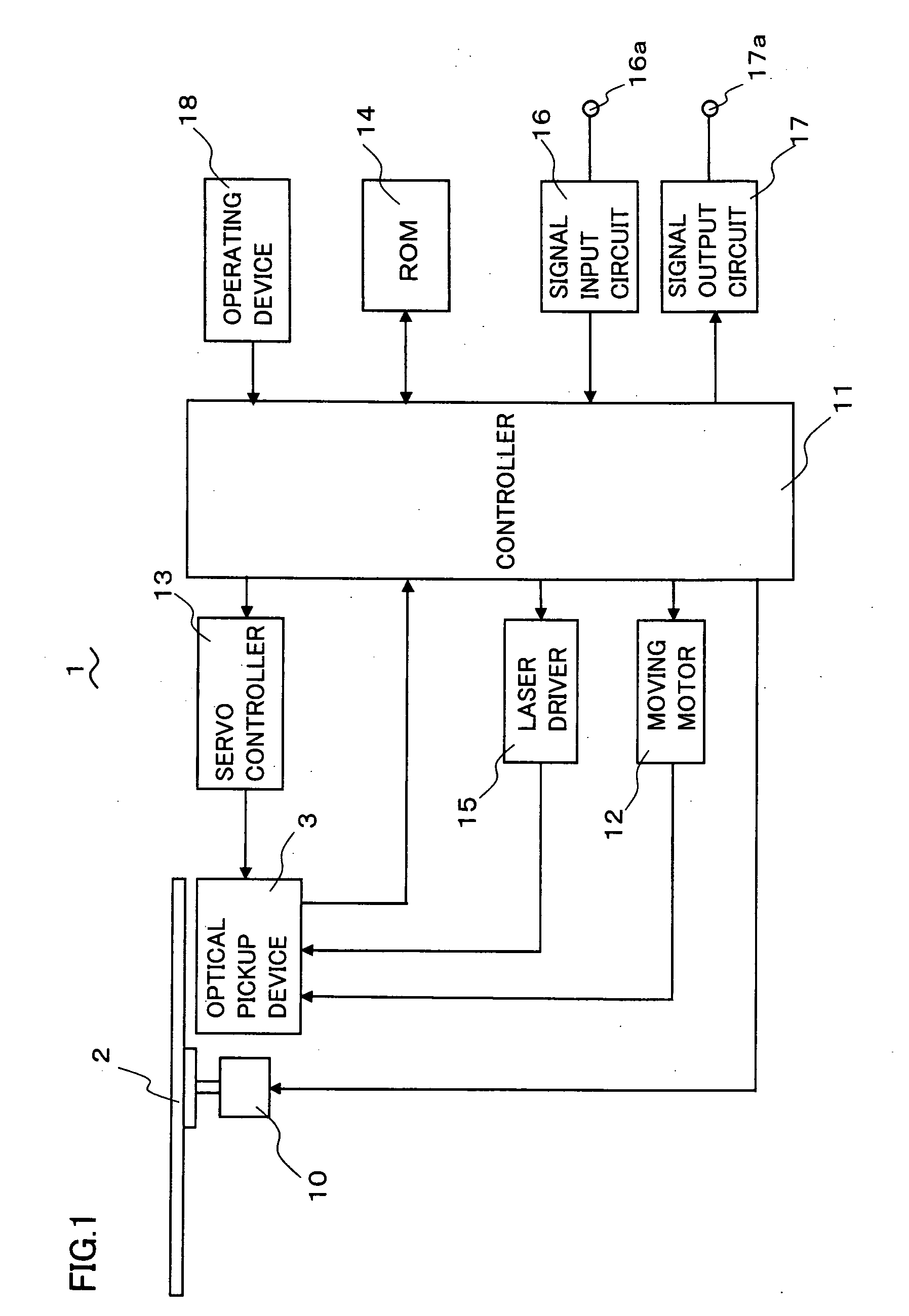

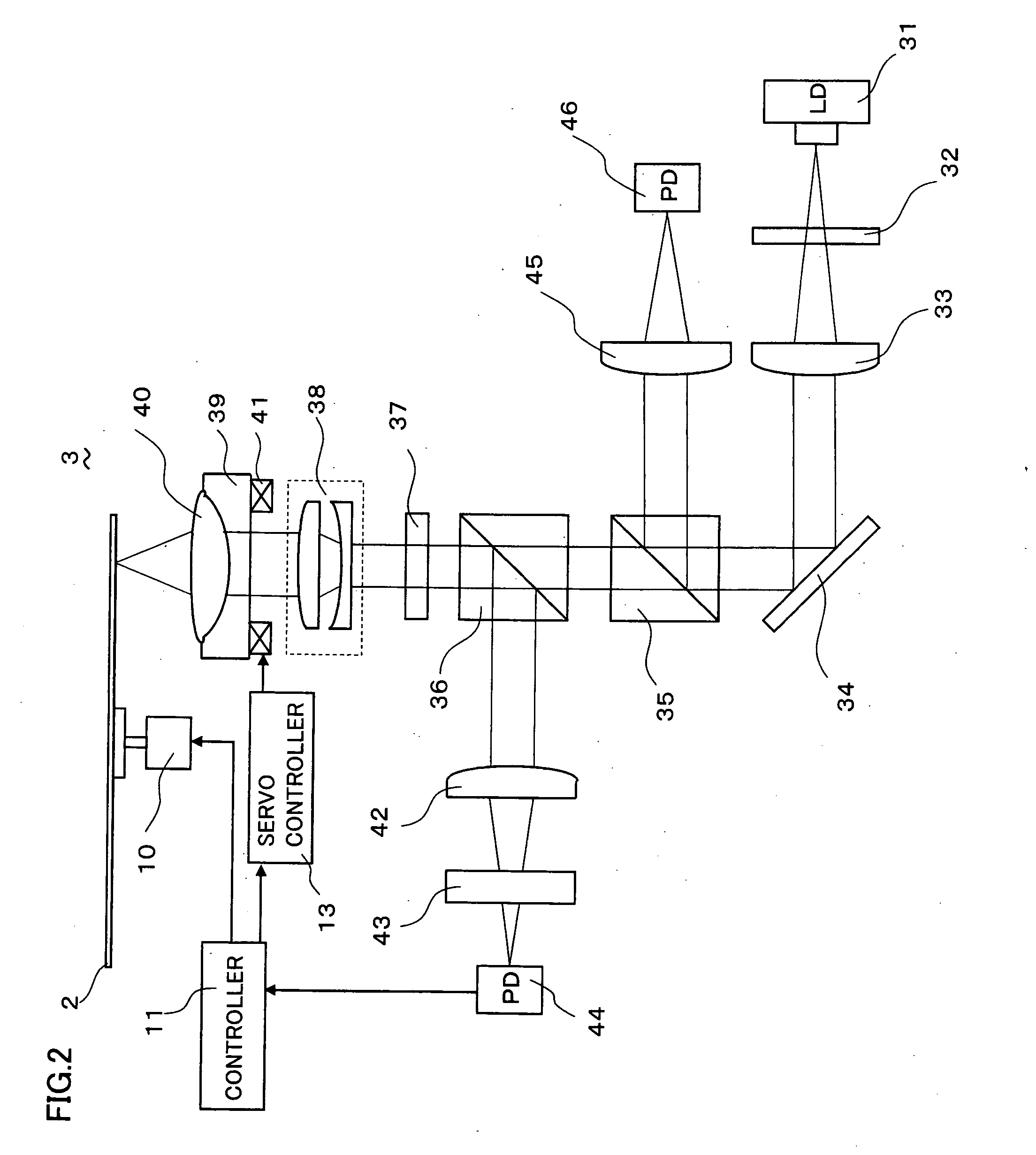

Method of focus error signal adjustment in optical disk device and optical disk drive

InactiveUS7630279B2Increase amplitudeIrregular shapeRecord information storageOptical recording/reproducingDVD-RAMComputer science

A method for a focus error signal adjustment in an optical disk device which shapes a focus error signal and enables a high-accuracy focus servo is provided.In a DVD-RAM having an emboss data zone and a rewritable data zone, a focus error signal is generated with the DVD-RAM remaining still in a position where an emboss pit is not formed in the rewritable data zone, and a waveform of the FE signal is shaped so that the waveform is symmetrical with respect to a reference point. Then, the FE signal is generated in the emboss data zone and an amplitude of the FE signal is adjusted. The amplitude of the signal which is obtained by increasing the the amplitude of the FE signal whose amplitude is adjusted by approximately 6 dB is applied to the amplitude of the focus error signal in the rewritable data zone. Consequently, a high-accuracy focus servo based on the FE signal, whose amplitude is adjusted and waveform is shaped, can be achieved without an error caused by the emboss pit.

Owner:FUNAI ELECTRIC CO LTD

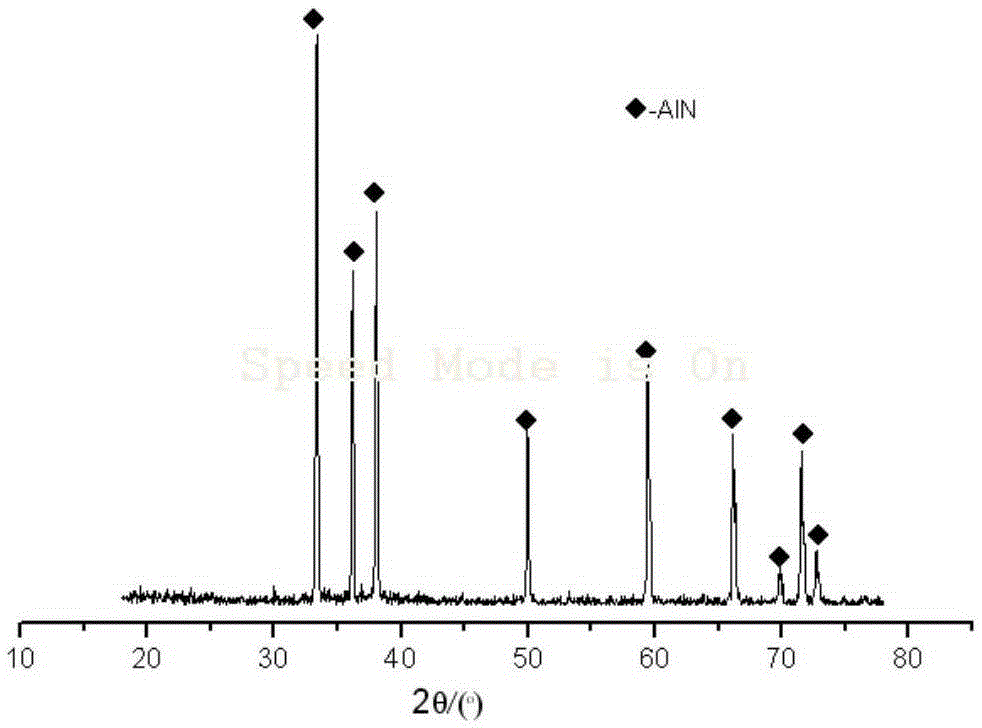

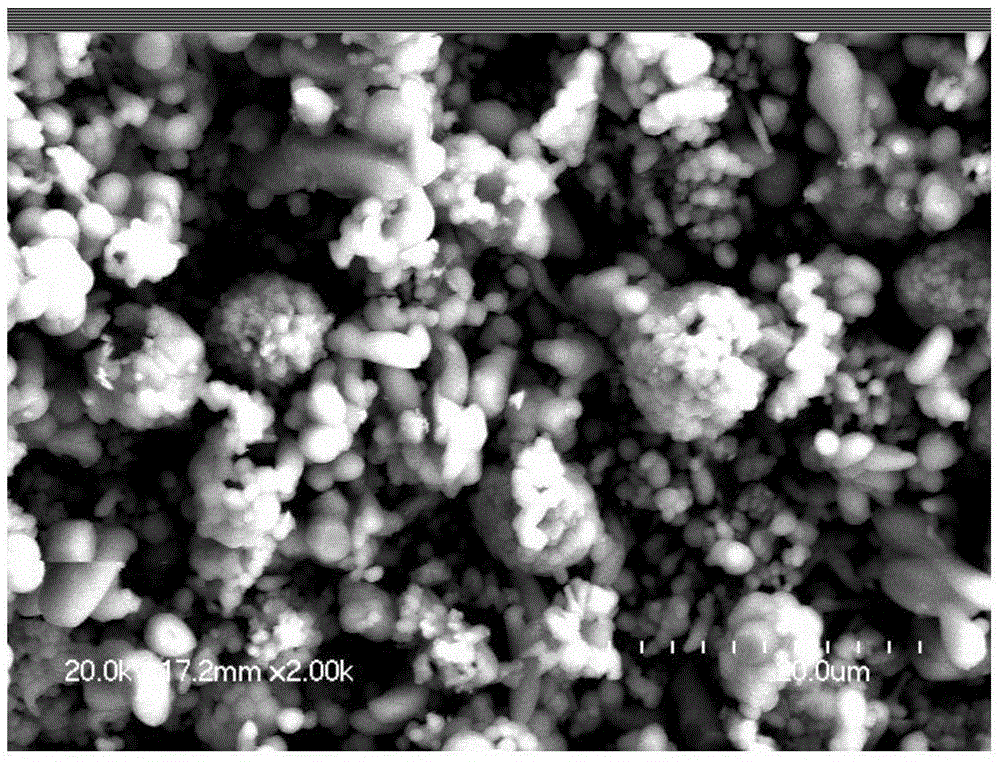

Method for compounding high-quality low-oxygen low-iron aluminium nitride powder

InactiveCN105399065AEasy to sinterDiffuse fullyNitrogen compoundsSelf-propagating high-temperature synthesisHigh pressure

The invention relates to a method for compounding high-quality low-oxygen low-iron aluminium nitride powder, which comprises steps: aluminite powder, aluminium nitride and ammonium salt are uniformly mixed to obtain a mixture according to quality radio of (5-10): (10-40), the mixture is uniformly spread into an aluminium nitride ceramic saggar, then carbon power is uniformly spread on the surface layer of the mixture, the quality radio of the aluminite powder and the carbon powder is 60:1-180:1, a reactor is vacuumized to 1*10-4MPa through a vacuum pump, the aluminium nitride ceramic saggar which is filled with materials is put into a reactor cavity, nitrogen which is pretreated is pumped into the aluminium nitride ceramic saggar for 15-30 min in 5-8MPa, and fully diffuses to contact with the aluminite powder, is compounded in a self-propagating mode by being ignited to obtain a reactant, and the reactant is the high-quality low-oxygen low-iron aluminium nitride powder after being cooled. The method for compounding high-quality low-oxygen low-iron aluminium nitride powder breaks down reaction barriers to fully diffuse by adding the carbon power, vacuumizing the reactor in advance, treating nitrogen, pumping the nitrogen into the reactor in advance and keeping the nitrogen in high pressure for 15-30min, and is low in energy consumption, high in efficiency and obvious in oxygen removal effect.

Owner:烟台同立高科新材料股份有限公司

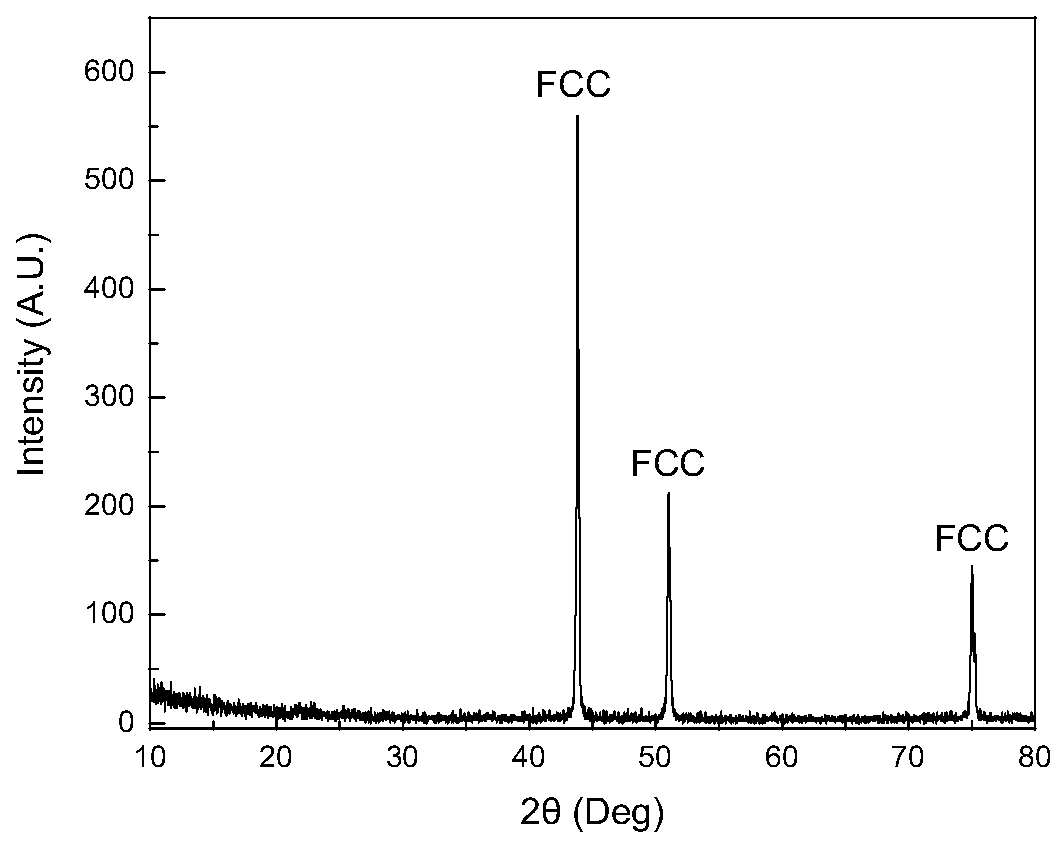

A kind of composite material of high-entropy alloy holding abrasive particles and its preparation method and application

The invention relates to a composite material of a high-entropy alloy holding abrasive particle as well as a preparation method and application thereof, and belongs to the technical field of high-entropy alloy application. The high-entropy alloy holds the abrasive particle in a tyre body form. The high-entropy alloy is prepared from the following ingredients through being metered by atomic percentage: 10 to 30 percent of Fe, 10 to 30 percent of Co, 10 to 30 percent of Cr, 10 to 30 percent of Ni, 10 to 30 percent of Cu and 0 to 8 percent of Mo. The preparation method is characterized in that after the high-entropy alloy raw material powder is prepared and taken according to the designed ingredients, high-entropy alloy powder is prepared by a gas atomization method and a mechanical alloyingmethod; then, a SPS process is combined; the composite material with excellent performance is obtained. The composite material is particularly suitable for being used for manufacturing a cutter head.The high-entropy alloy is used as a tyre body for holding abrasive particles for the first time; the ingredient design is reasonable; the preparation process is scientific and controllable; the performance of the product is excellent; the large-scale industrial application is convenient.

Owner:江西咏泰粉末冶金有限公司

Stone cutter

InactiveUS20010035174A1Easy to useIrregular shapeStone-like material working toolsPistonKnife blades

A rock cutter for splitting stones is disclosed which shows a support surface for holding the rock and (a) a first blade and (b) a second blade which may be position to hold the rock between the first and second blades and on the support surface along with a means for moving the first blade towards the second blade. The means for moving comprises a hydraulicly driven piston having a piston arm to which the first blade is mounted. The invention also includes shock means for applying a sudden force to the first blade. The rock cutter also has a cover which is used in conjunction with a means for receiving pieces at an angle after the split.

Owner:ONEAL ROY G +2

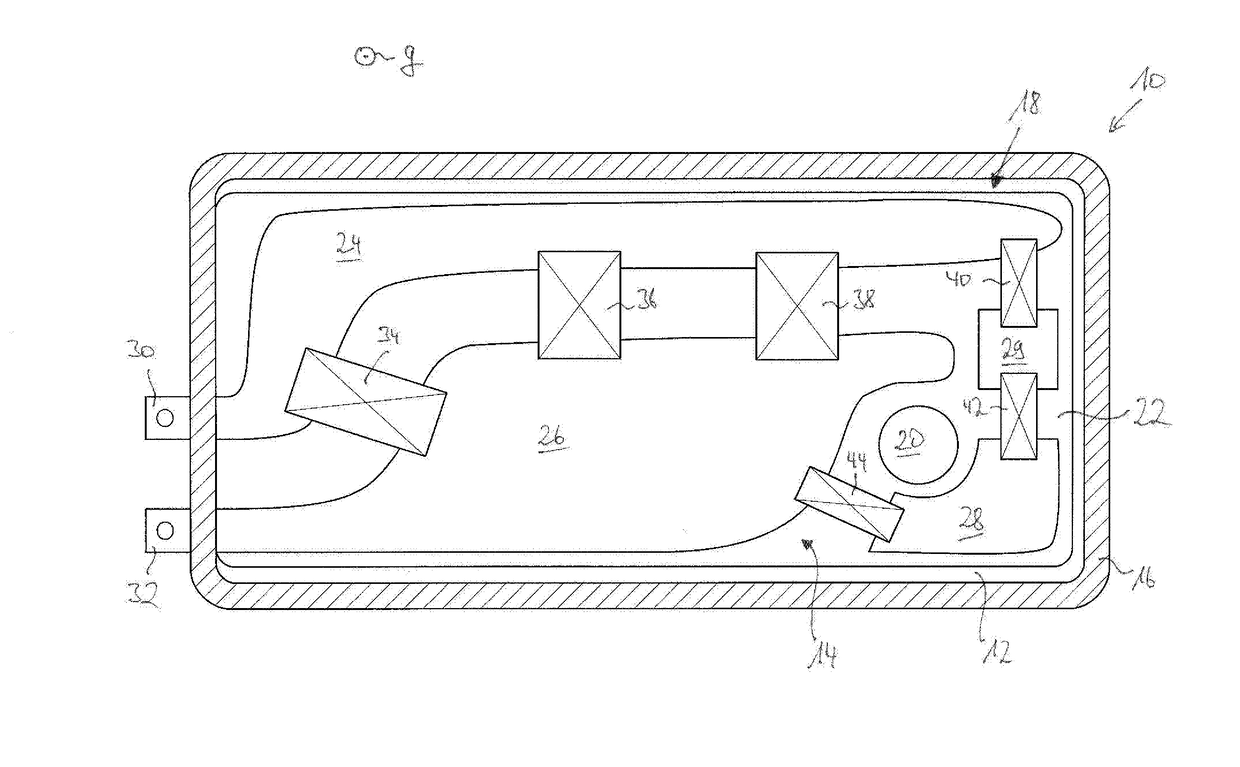

Electrical heating device with PTC element and electrical supply lines as heat conductor and operating fluid tank with such a heating device

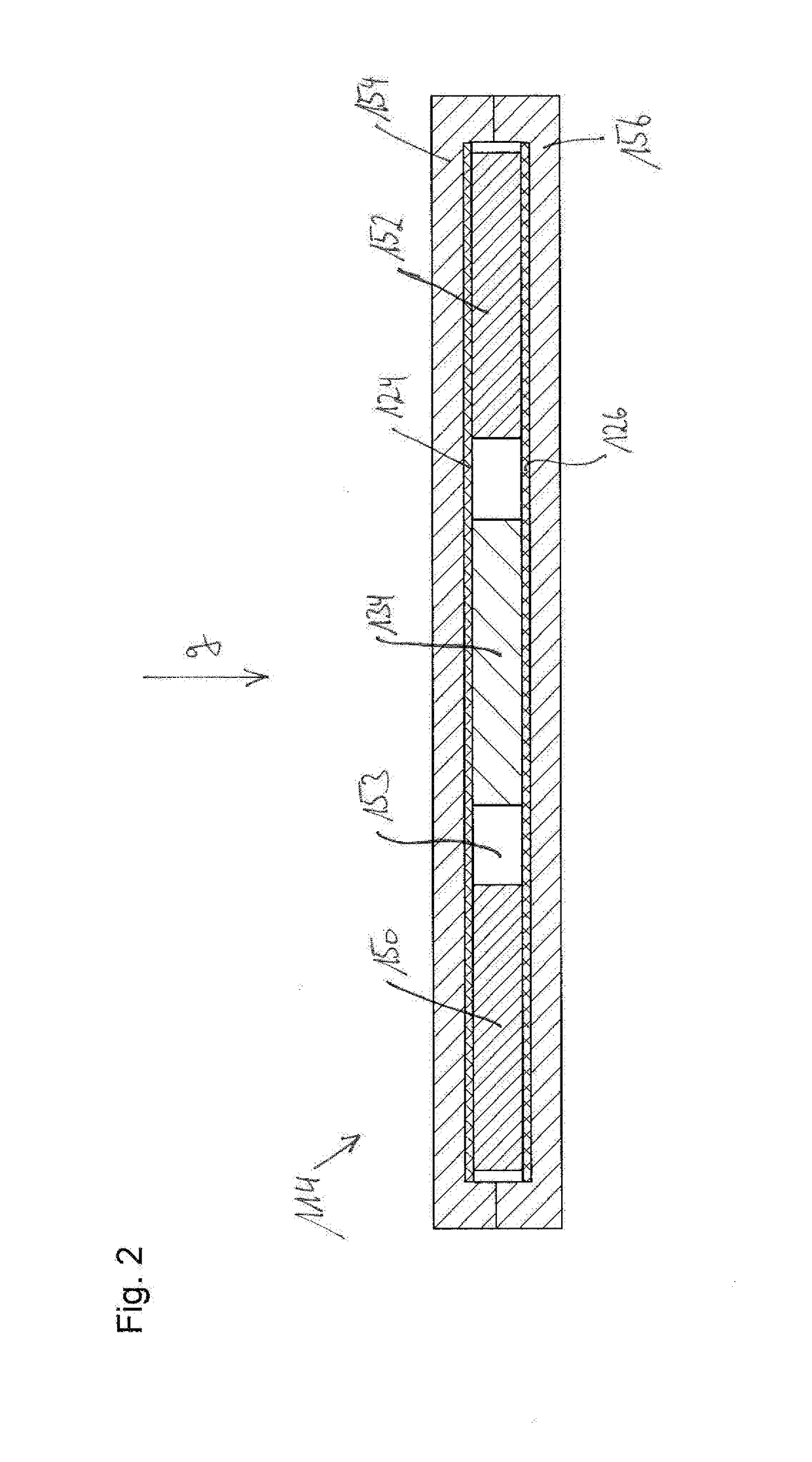

InactiveUS20170257911A1Easy to useIrregular shapeInternal combustion piston enginesExhaust apparatusUreaElectrically conductive

An electrical heating device (14) for an operating fluid tank (10) of a motor vehicle, in particular for a tank (10) for storing aqueous urea solution, having at least one PTC element (34, 36, 38, 40, 42, 44), that is disposed connecting two electrical conductors (24, 26, 28, 29), characterized in that the electrical heating device (14) comprises a multitude of PTC elements (34, 36, 28, 40, 42, 44), of which each is connectively arranged to two electrical conductors (24, 26, 28, 29), wherein at least one of the electrical conductors (24, 26, 28, 29) is configured as a laminar conductor component and forms a heat conductor for transferring the heat produced in the PTC element (34, 36, 38, 40, 42, 44) to a volume portion of the outside environment (18) of the electrical heating device (14), which is adjacent to the electrical heating device (14).

Owner:ROCHLING AUTOMOTIVE SE

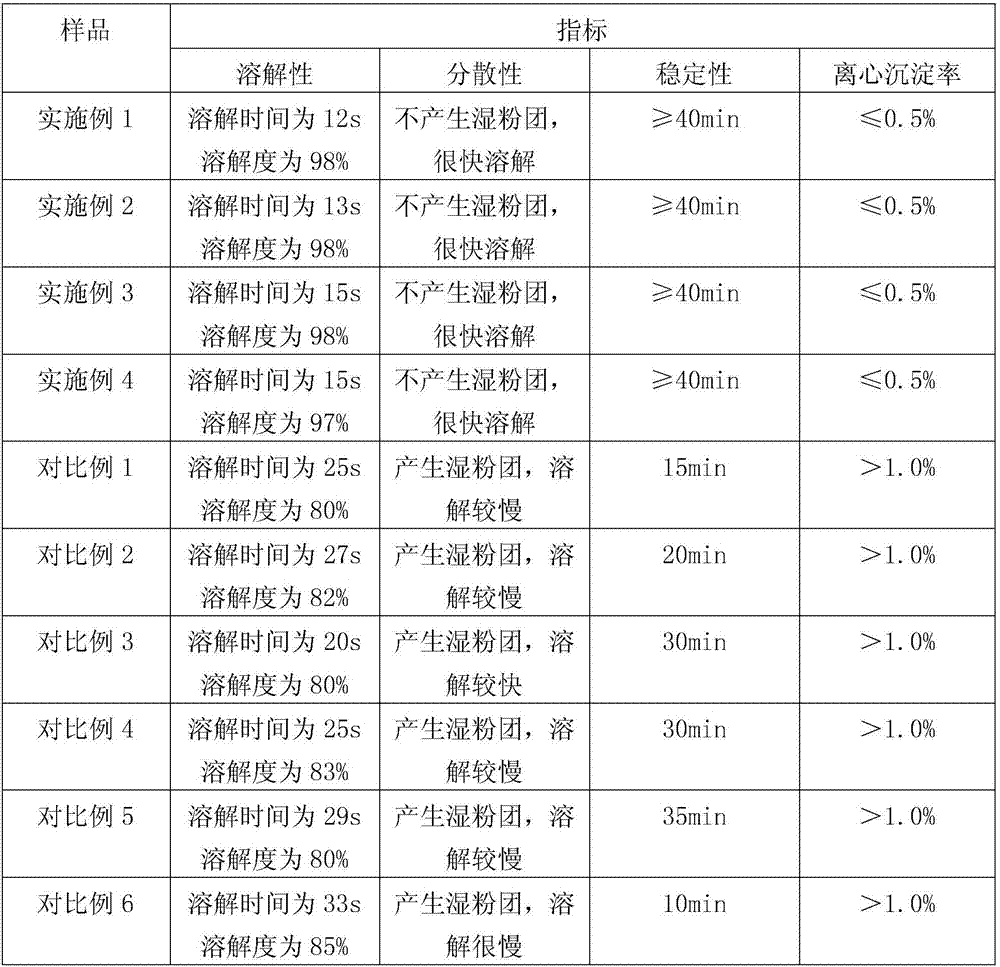

Preparation method of special soybean protein particles for liquid beverage

ActiveCN107319244AImprove solubilityGood dispersionFood coatingLipidic food ingredientsFlavorHydrolysate

The invention discloses a preparation method of special soybean protein particles for a liquid beverage. The preparation method comprises the following steps of dissolving soybean protein into water; regulating pH by alkali liquor; adding prolease for enzymolysis; performing heating enzyme deactivation to obtain the soybean protein hydrolysate solution; performing shearing homogenization, spray drying and sieving to obtain enzymolysis soybean protein powder; preparing spraying coating liquid: dissolving soybean power phospholipid, sucrose fatty acid ester and calcium chloride into water; performing shearing homogenization to obtain spray coating liquid; performing spraying coating granulation on the obtained enzymolysis soybean protein powder; obtaining the special soybean protein particles. The preparation process is simple; the operation is easy; the method is suitable for mass production; the prepared soybean protein particles are applied to the liquid beverage, and have the functional characteristics of good solubleness, fast dispersion, high stability, low centrifugal sedimentation rate and the like; the original flavor of the soybean protein can be remained.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

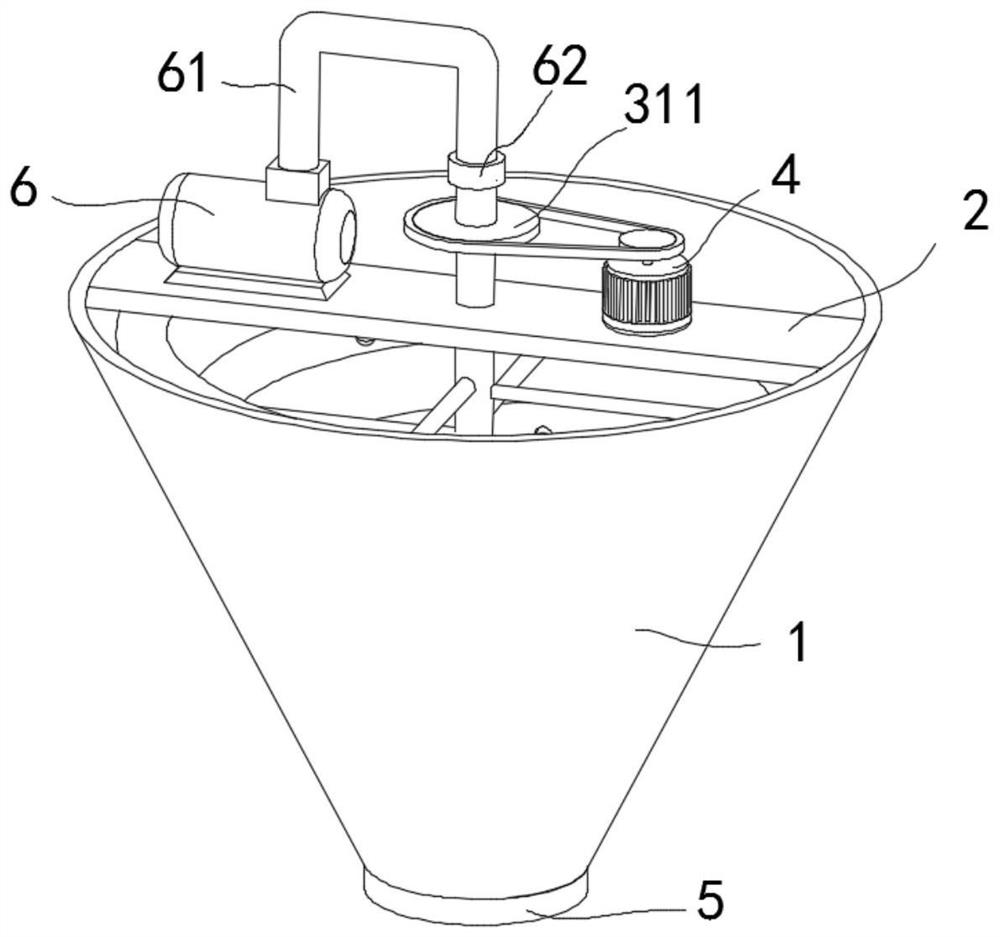

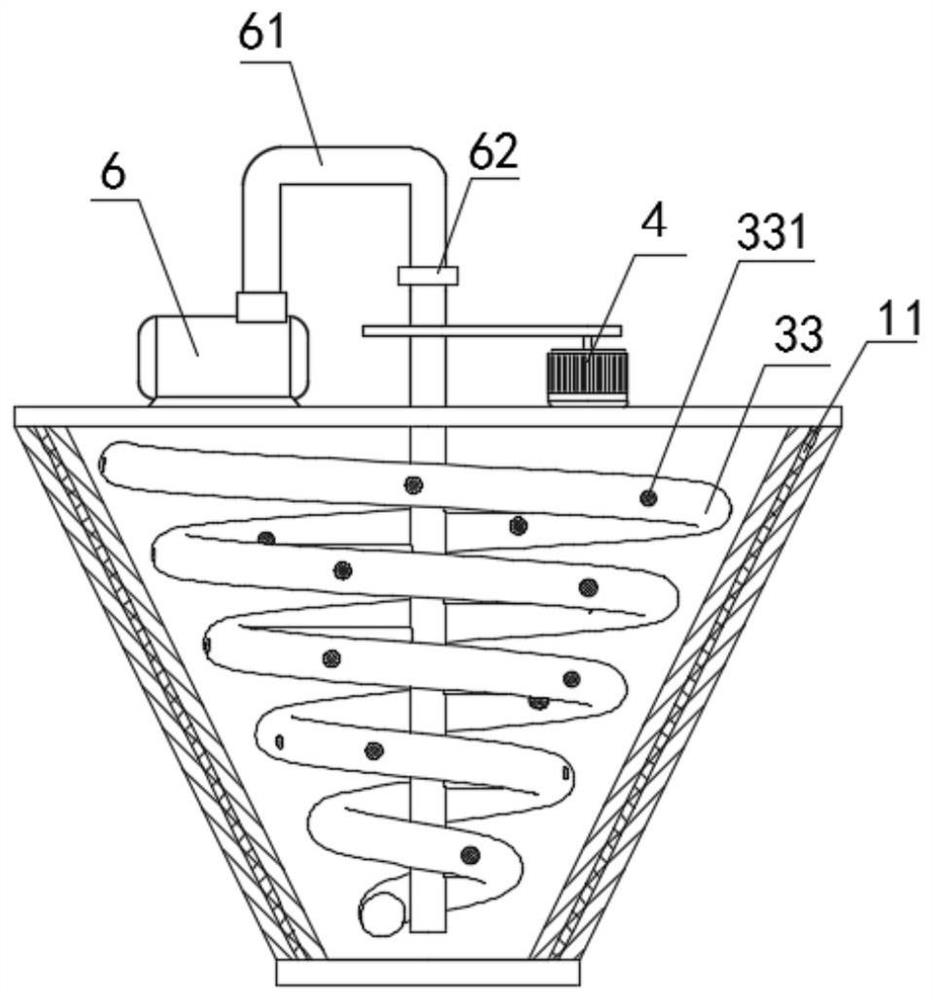

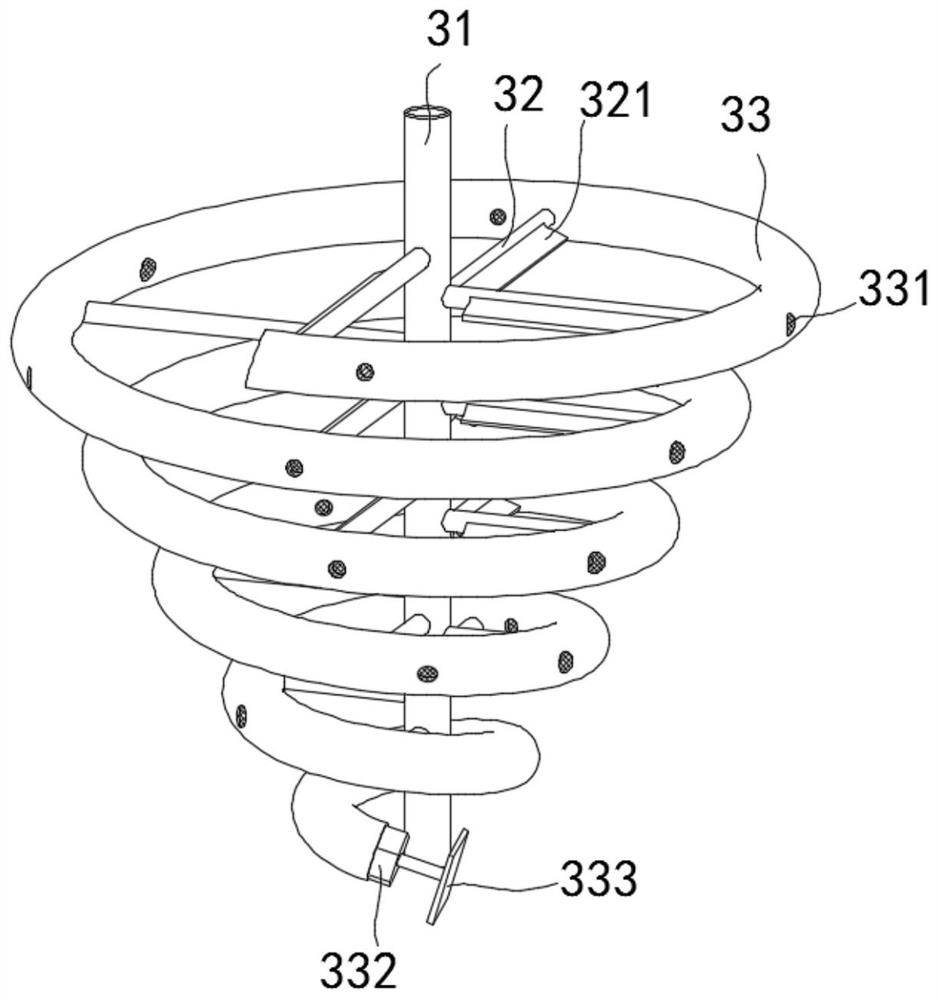

Spiral stirring type rice frying mechanism

PendingCN113331342AStir fry to achieveIncrease loading capacityFood scienceElectric machineEngineering

The invention provides a spiral stirring type rice frying mechanism. The spiral stirring type rice frying mechanism comprises an electric heating barrel body, a supporting plate, a spiral stirring device, a rotating motor and an opening and closing plate. The electric heating barrel body is an inverted conical barrel with an upper opening and a lower opening, a main body of the spiral stirring device is a spiral round pipe arranged in the electric heating barrel body, the supporting plate is arranged above the electric heating barrel body, the rotating motor is arranged on the supporting plate and drives the spiral stirring device to rotate, and the opening and closing plate is movably connected with the bottom of the barrel body and seals the bottom of the barrel body. The spiral stirring type rice frying mechanism can realize automatic rice frying, and has a relatively good stir-frying effect.

Owner:三江县埼玉农业发展有限公司

Method of focus error signal adjustment in optical disk device and optical disk device

InactiveUS20070127330A1Precise processIncrease amplitudeRecord information storageOptical recording/reproducingDVD-RAMComputer science

A method for a focus error signal adjustment in an optical disk device which shapes a focus error signal and enables a high-accuracy focus servo is provided. In a DVD-RAM having an emboss data zone and a rewritable data zone, a focus error signal is generated with the DVD-RAM remaining still in a position where an emboss pit is not formed in the rewritable data zone, and a waveform of the FE signal is shaped so that the waveform is symmetrical with respect to a reference point. Then, the FE signal is generated in the emboss data zone and an amplitude of the FE signal is adjusted. The amplitude of the signal which is obtained by increasing the the amplitude of the FE signal whose amplitude is adjusted by approximately 6 dB is applied to the amplitude of the focus error signal in the rewritable data zone. Consequently, a high-accuracy focus servo based on the FE signal, whose amplitude is adjusted and waveform is shaped, can be achieved without an error caused by the emboss pit.

Owner:FUNAI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com