Patents

Literature

137results about "Antimony oxides/hydroxides/oxyacids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing fine particles of metal oxide

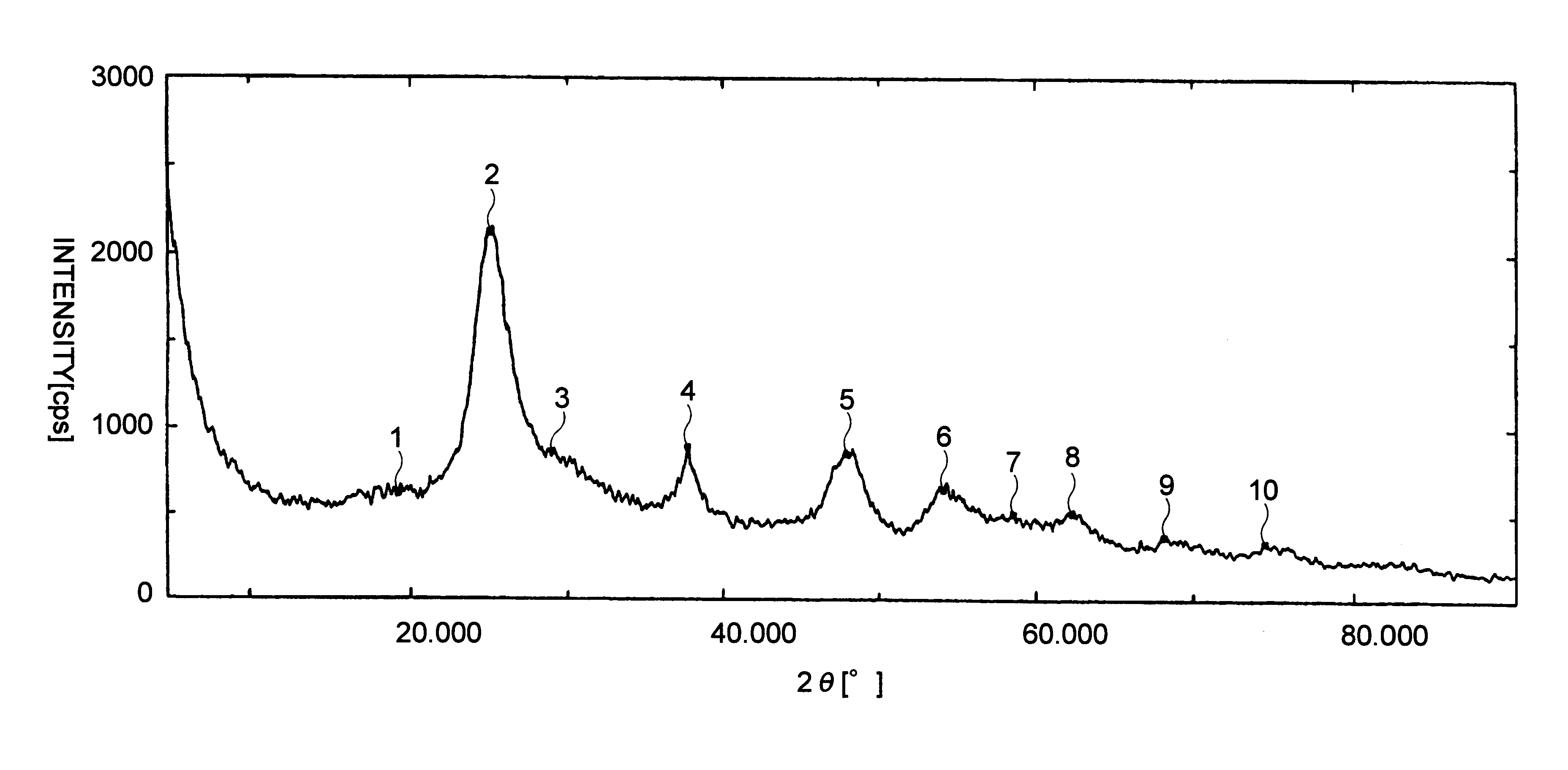

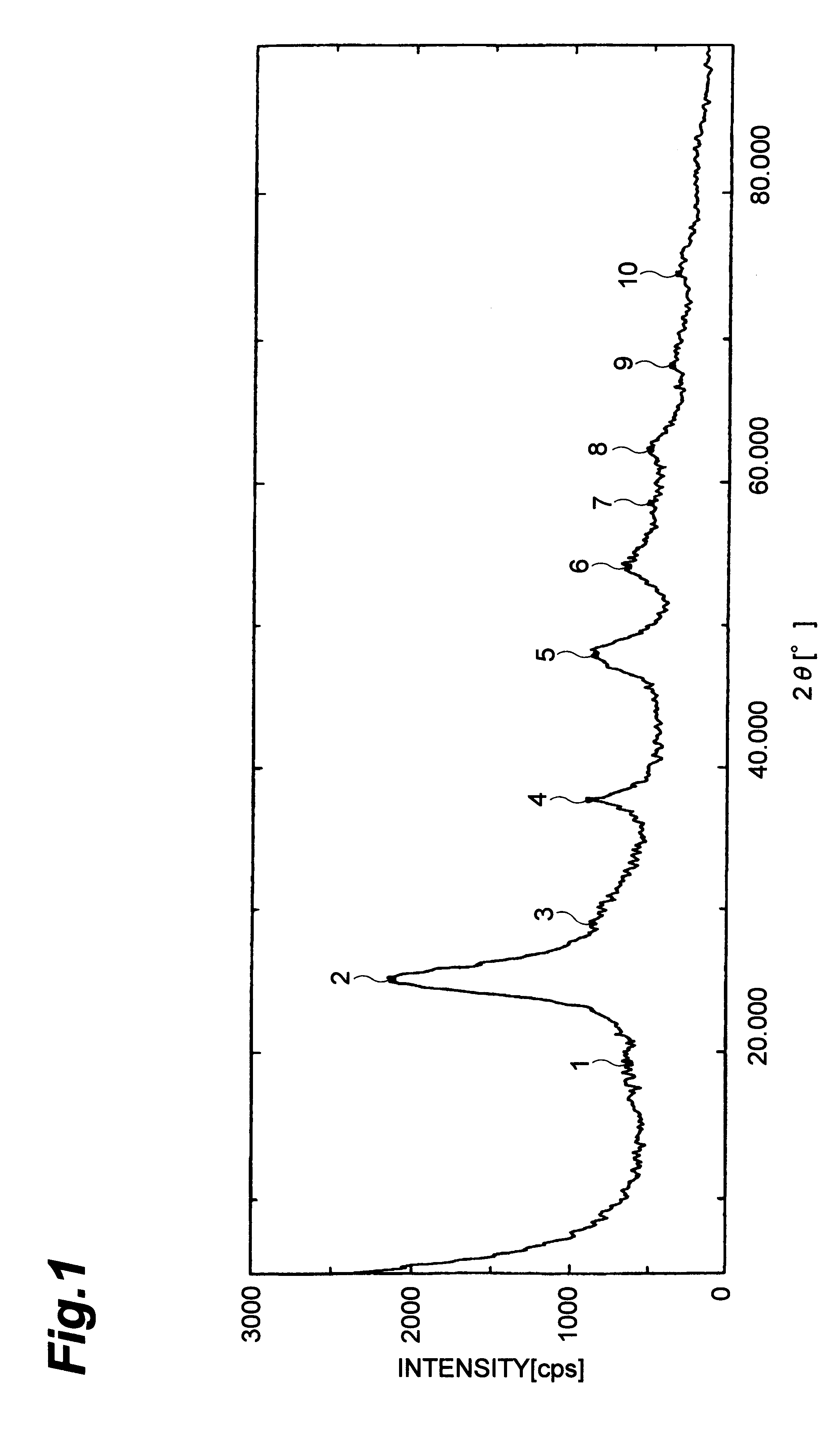

A method for producing fine particles of metal oxide characterized in that metal halide is hydrolyzed in the presence of organic solvent. According to this invention, under hydrolysis of titanium tetrachrolide, anatase type titanium oxide can be obtained by selecting hydrophilic organic solvent, and rutile type titanium oxide can be obtained by selecting hydrophobic organic solvent.

Owner:SHOWA DENKO KK

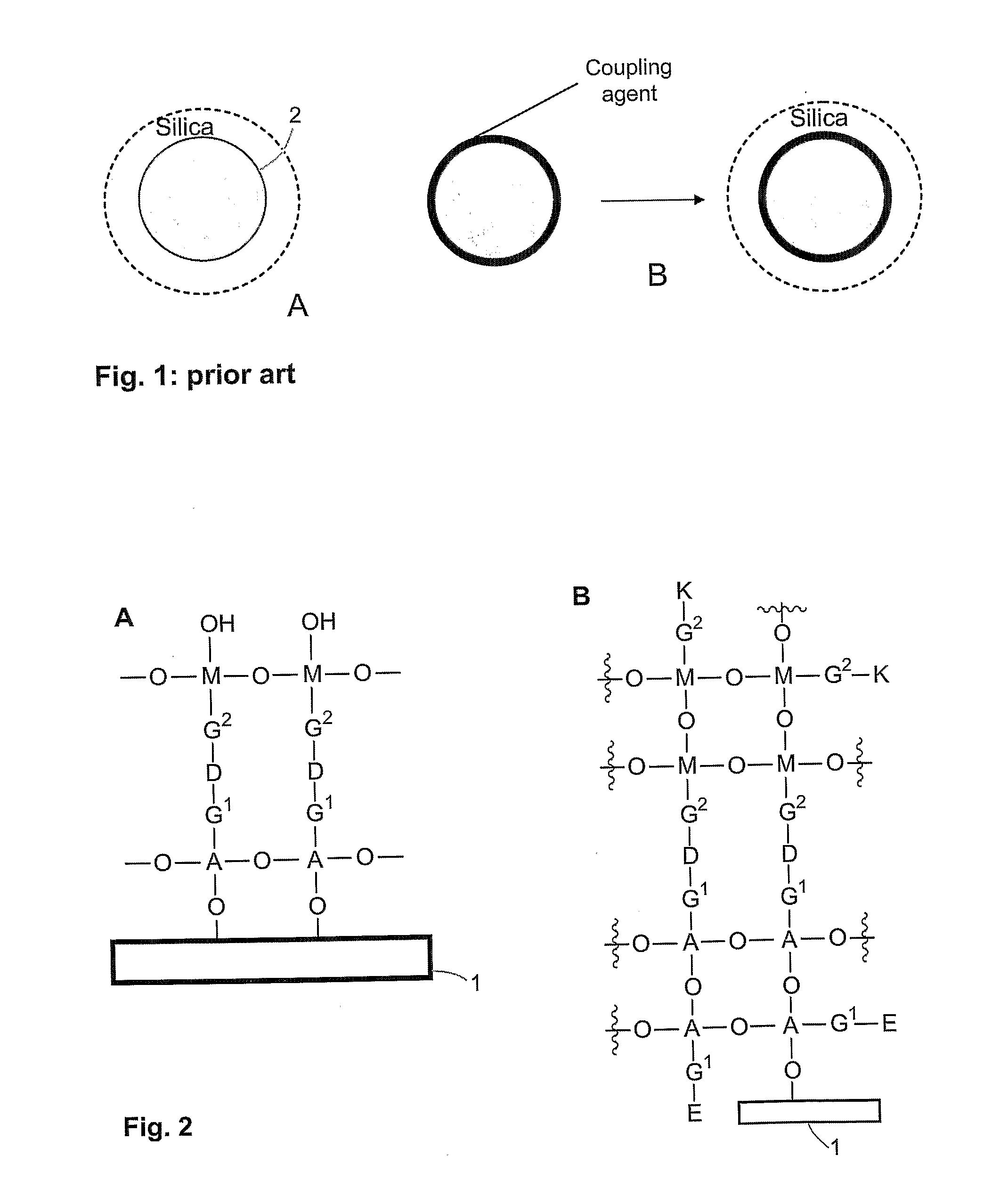

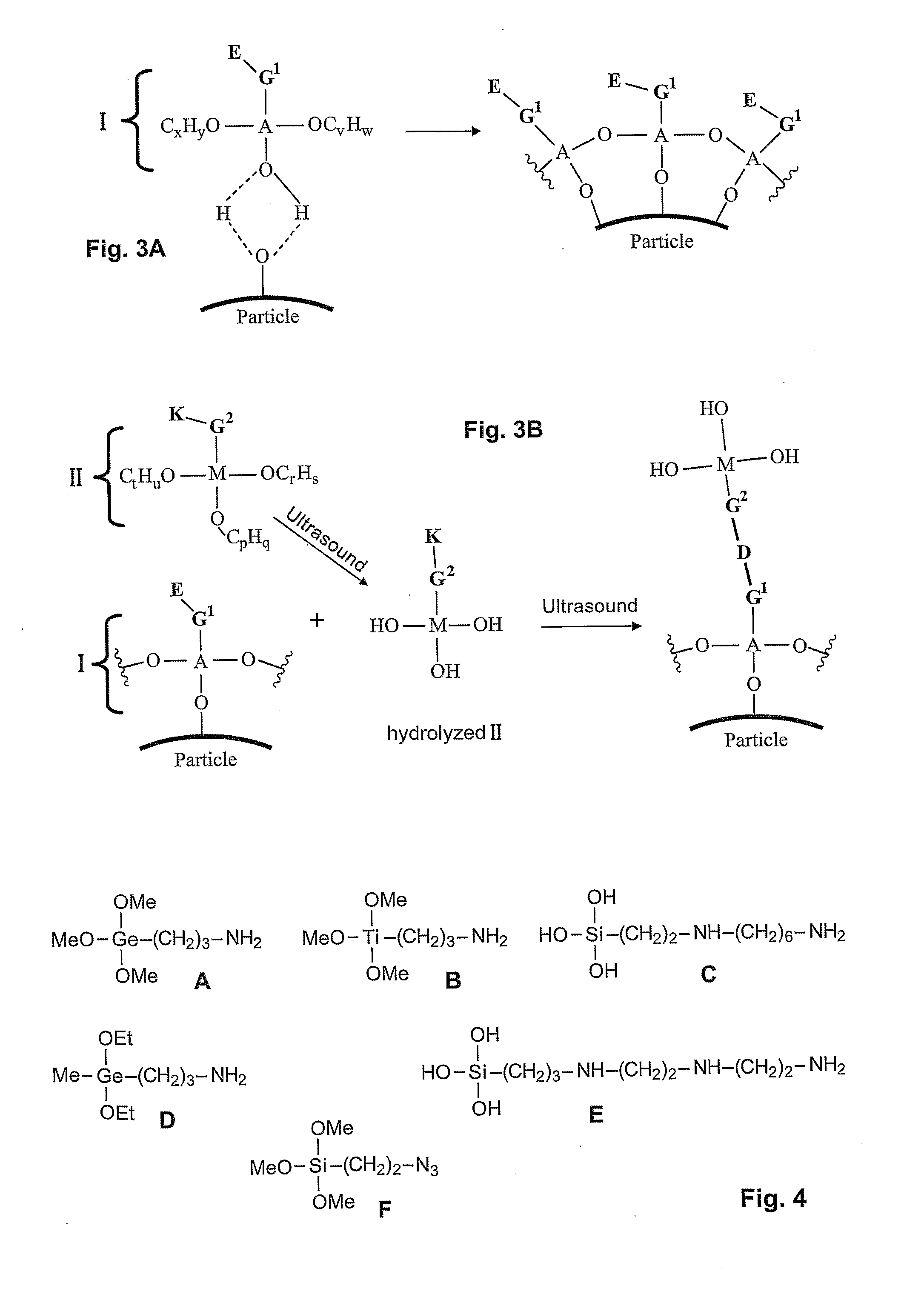

Method of coating a particle

Disclosed is a method of coating a particle, the method comprising contacting (i) a particle, wherein the surface of the particle comprises functional groups suitable to undergo a coupling reaction with at least a hydroxyl group, a halogen group or an alkoxy group, with (ii) molecules of formula (Ia) and / or (Ib): (Ia) or (Ib) wherein A is a metal or a metalloid, R1 and (in formula (Ia)) R2 are halogen or an alkoxy group and R20 is OH, halogen or an alkoxy group. G1 is an aliphatic; cycloaliphatic, aromatic, arylaliphatic or arylcycloaliphatic spacer and E is a functional group. Molecules of the compound of general formula (Ia) and / or (Ib) are immobilized on the surface of the particle by a coupling reaction between functional groups on the surface of the particle and moieties R20.

Owner:AGENCY FOR SCI TECH & RES

Substrate with Hard Coat Film and Coating Solution for Forming Hard Coat Film

ActiveUS20090061183A1Improve stabilityEasily adjusted in refractive indexMaterial nanotechnologyMixing methodsRefractive indexHardness

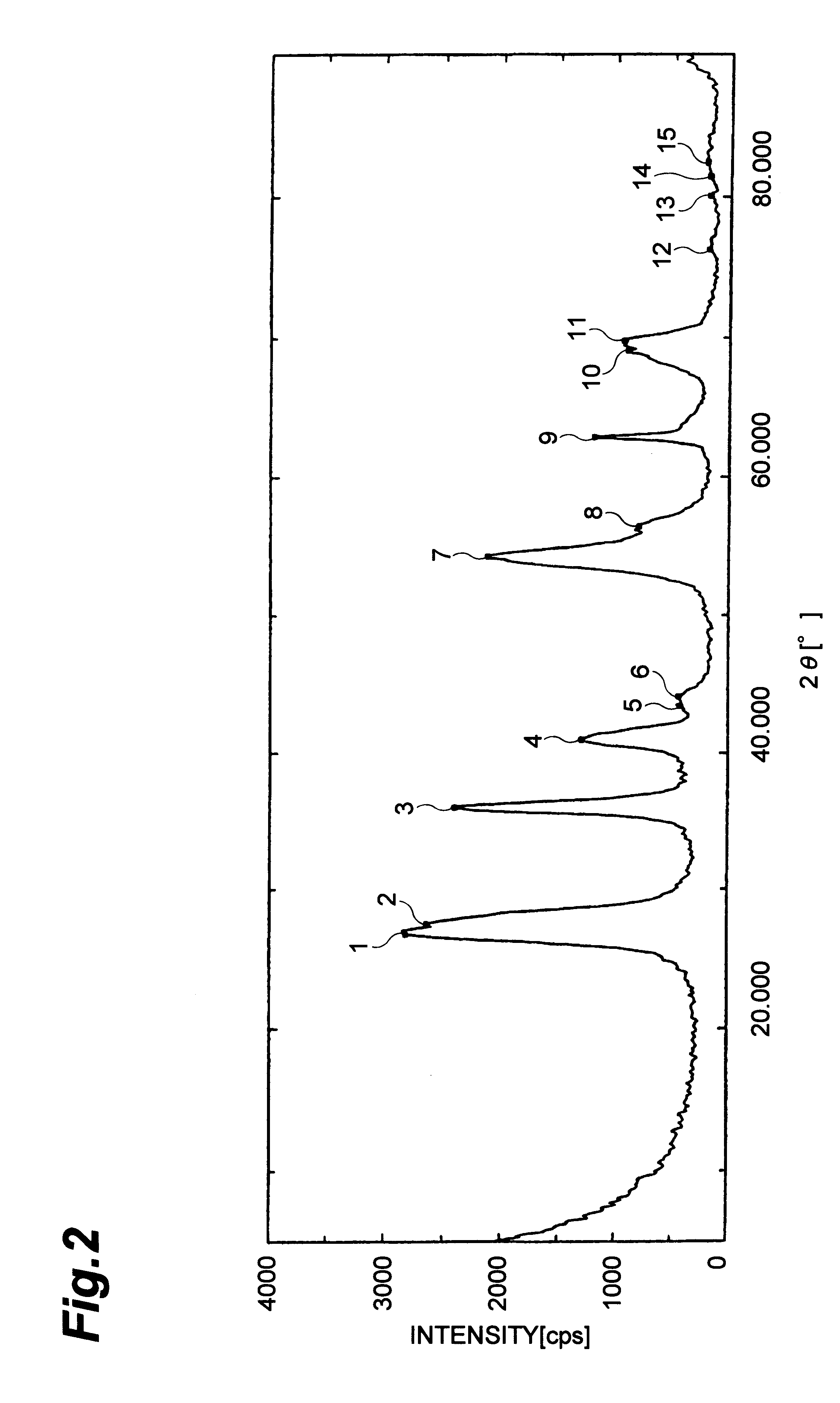

The present invention provides modified zirconia fine particles which are stable in an acidic region as well as in an alkaline region, and which may be readily adjusted in refractive index in a predetermined range. The present invention further provides a substrate with a hard coat film excellent in adhesiveness with the substrate, abrasion resistance, scratch strength, pencil hardness and the like without interference fringes and a coating solution which may form the hard coat film.The substrate with a hard coat film is composed of composite oxide particles formed on at least one surface of the substrate and a matrix component, wherein the composite oxide particles are composite oxide particles having a core-shell structure composed of a core formed from zirconium oxide and a shell formed from antimony pentoxide and / or silica.

Owner:JGC CATALYSTS & CHEM LTD

Metal oxide composite sol, coating composition, and optical member

InactiveCN101815675AGood weather resistanceGood light fastnessMaterial nanotechnologyPigmenting treatmentRefractive indexOxide composite

To provide a sol of metal oxide composite colloidal particles which are almost completely inhibited from being discolored by photoexcitation, contain titanium oxide excellent in light resistance and weatherability, and have a high refractive index. [MEANS FOR SOLVING PROBLEMS] The metal oxide composite colloidal particles comprise titanium oxide / tin oxide / zirconium oxide / tungsten oxide composite colloidal particles which have a primary-particle diameter of 2-50 nm and have an SnO2 / TiO2 molar ratio of 0.1-1.0, ZrO2 / TiO2 molar ratio of 0.1-0.4, and WO3 / TiO2 molar ratio of 0.03-0.15.

Owner:NISSAN CHEM CORP

Process for Producing Antimony Pentaoxide

InactiveUS20080038187A1Increase concentrationMaterial nanotechnologyOther chemical processesReaction temperatureAntimony trioxide

The invention relates to a process for producing diantimony pentoxide having a high oxidation purity. A process for producing an aqueous sol of diantimony pentoxide, which comprises mixing diantimony trioxide (Sb2O3) and an aqueous hydrogen peroxide solution in an aqueous medium, and after the temperature has reached from 50 to 80° C., reacting the diantimony trioxide with the aqueous hydrogen peroxide solution while keeping the reaction temperature at a level not higher by at least 10° C. than a desired set temperature in the temperature range, to thereby obtain a sol having dispersed in the aqueous medium diantimony pentoxide particles which have a primary particle size of from 2 to 50 nm and which have a diantimony trioxide / diantimony pentoxide weight ratio of not higher than 5 wt %.

Owner:NISSAN CHEM IND LTD

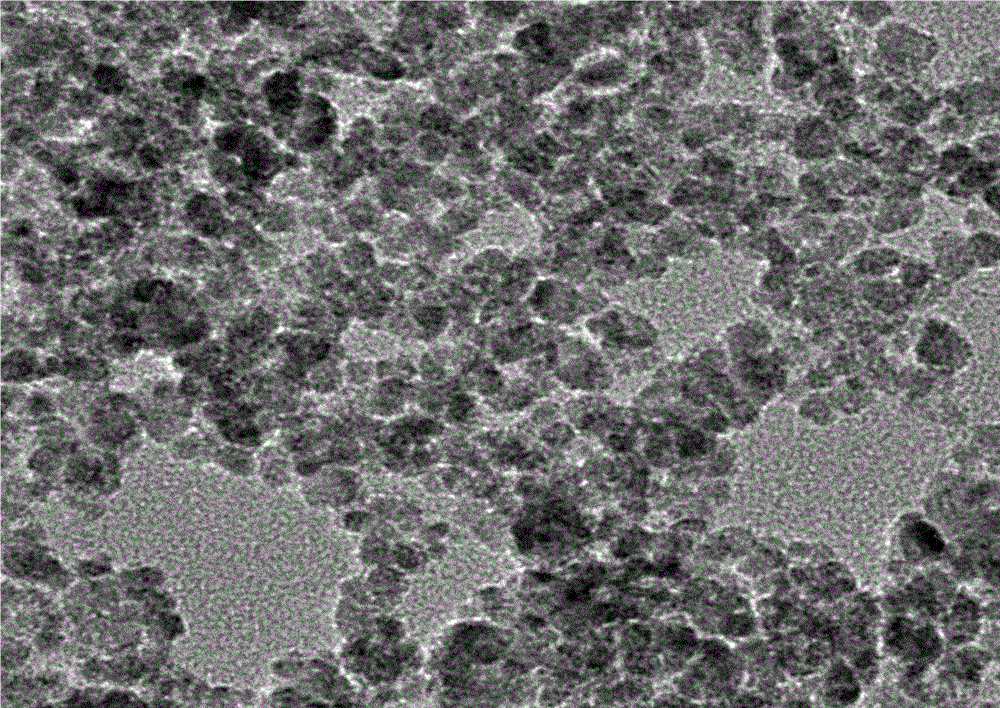

Chain inorganic oxide fine particle groups, process for preparing dispersion of the fine particle groups, and uses of the fine particle groups

InactiveUS20050116205A1High transparencyImprove antistatic performanceMaterial nanotechnologyAluminium silicatesSilica particleAntimonate

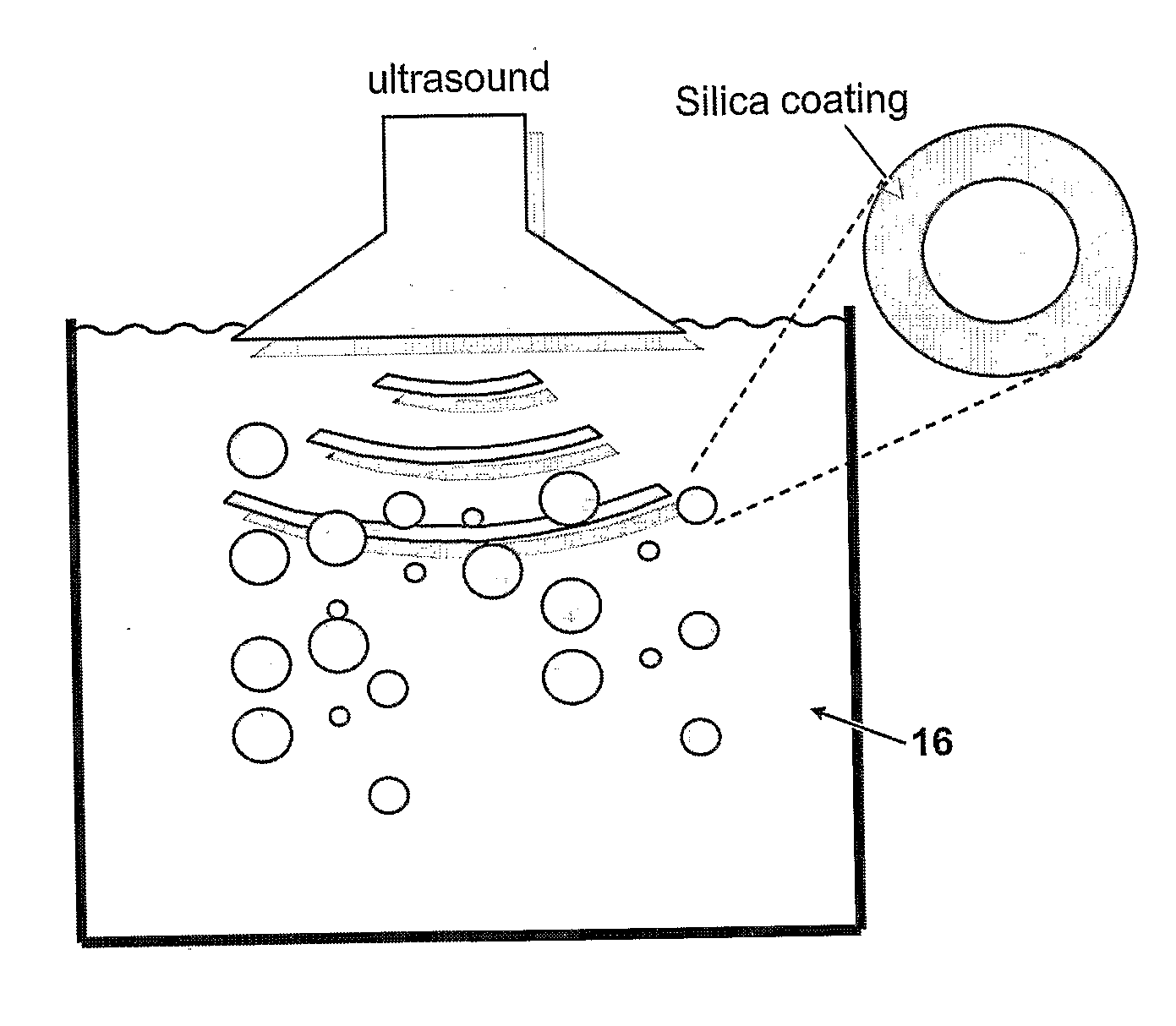

A chain antimony oxide fine particle group comprising antimony oxide fine particles which have an average particle diameter of 5 to 50 nm, are connected in the form of a chain and have an average connection number of 2 to 30 and preferably used for forming a hard coating film. The fine particle group can be prepared by a process comprising treating an alkali antimonate aqueous solution with a cation exchange resin to prepare an antimonic acid (gel) dispersion and then treating the dispersion with an anion exchange resin and / or adding a base to the dispersion. Also provided is a substrate with a film comprising a substrate and a hard coating film. The hard coating film includes a chain inorganic oxide fine particle group, in which inorganic oxide fine particles of 2 to 30 on the average are connected in the form of a chain, and a matrix. The inorganic oxide particles may be silica particles, silica-alumina particles being preferable, and porous particles and / or hollow particles having a cavity inside being more preferable.

Owner:JGC CATALYSTS & CHEM LTD

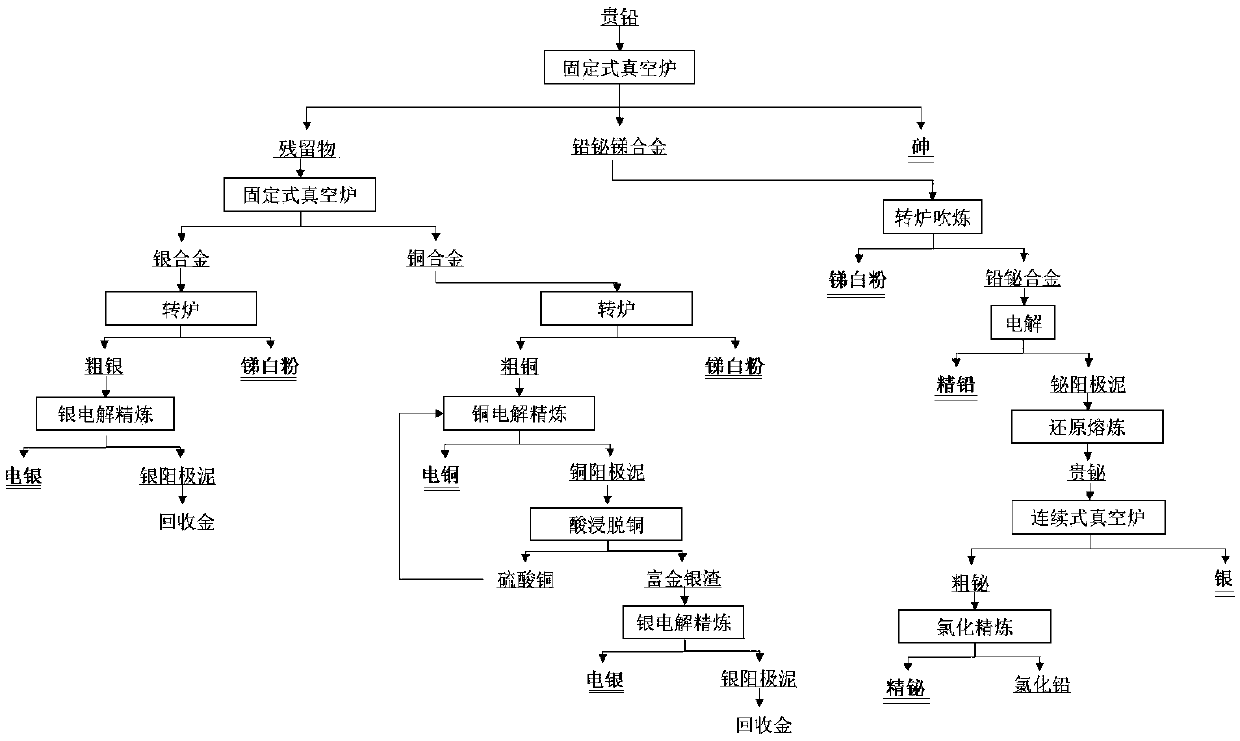

Bullion lead comprehensive treatment method

ActiveCN110172578AAchieve enrichmentImprove direct yieldAntimony oxides/hydroxides/oxyacidsLead halidesElectrolysisAntimony trioxide

The invention belongs to the technical field of solid waste recycling and reusing and particularly relates to a bullion lead comprehensive treatment method. Through the bullion lead comprehensive treatment method provided by the invention, open-circuit of arsenic, lead, bismuth and antimony and high-efficiency enrichment of precious metals gold and silver are realized through twice vacuum distillation, and elementary arsenic, a lead-bismuth-antimony alloy, a silver alloy and a copper alloy can be obtained respectively; the lead-bismuth-antimony alloy, the silver alloy and the copper alloy aretreated through oxidizing refining, electrolytic refining and chlorination refining to obtain refined lead, refined bismuth, antimony trioxide and electrolytic silver and electrolytic silver, and goldenrichment is realized; the bullion lead comprehensive treatment method has the advantages of being high in metal direct yield, low in energy consumption, short in flow, simple in equipment and the like in the whole treatment process; and moreover, vacuum distillation belongs to the physical process; the alloys can be separated through the saturated vapor pressure difference of the metals withoutgeneration of waste water, waste gas and waste residues, and industrialization, automation and continuity of bullion lead treatment can be achieved easily.

Owner:KUNMING UNIV OF SCI & TECH +1

Modified metal-oxide composite sol, coating composition, and optical member

InactiveCN101815676AGood weather resistanceGood light fastnessPigmenting treatmentMaterial nanotechnologyRefractive indexOxide composite

Owner:NISSAN CHEM IND LTD

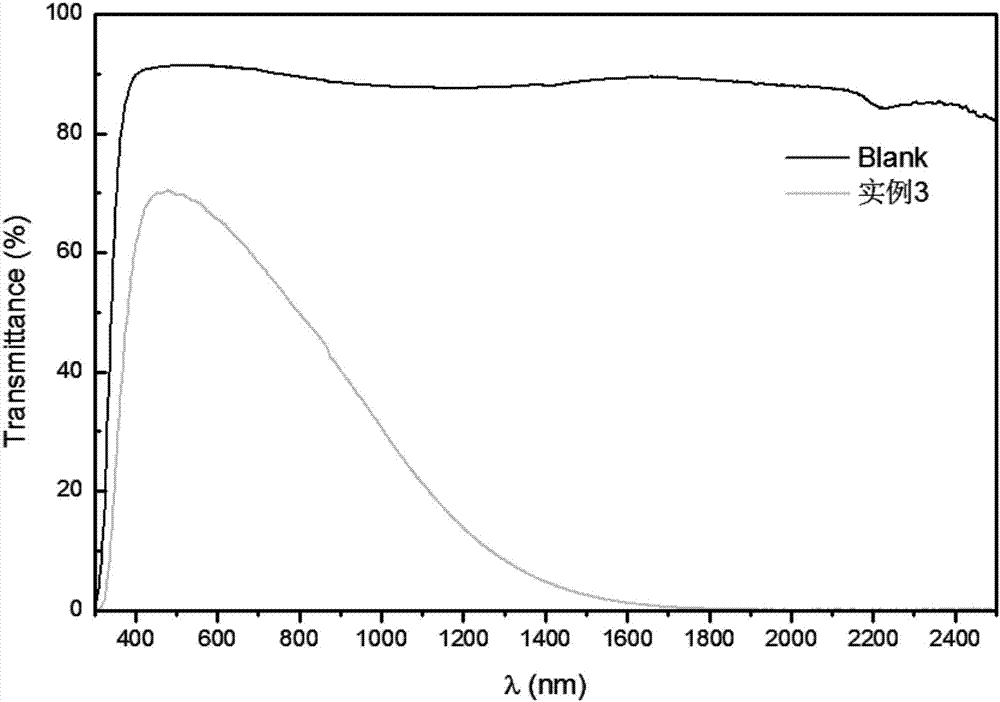

Method for preparing nanoscale graphene doped tin antimony oxide thermal insulation dispersion liquid

ActiveCN105925018AMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsThermal insulationPyrrolidinones

The invention discloses a method for preparing nanoscale graphene doped tin antimony oxide (ATO) thermal insulation dispersion liquid. ATO is prepared through combustion of an ethylenediaminetetraacetic acid-citric acid (EDTA-CA) bi-functional chelating agent, then nanoscale graphene and nanoscale ATO are added to a proper amount of N-methyl pyrrolidone (NMP), particle aggregation is inhibited through PH value regulation, and stirring is conducted to enable graphene and ATO to be quickly dispersed in NMP respectively; the two kinds of NMP dispersion liquid are mixed, PH value is regulated again, ultrasonic treatment and ball milling are conducted to enable graphene, ATO and solvent to be mixed quickly and fully, high dispersibility and high stability on the micro-scale level are realized, and the obtained nanoscale graphene doped ATO material can be used for manufacturing high-thermal-conductivity thermal insulation paint.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

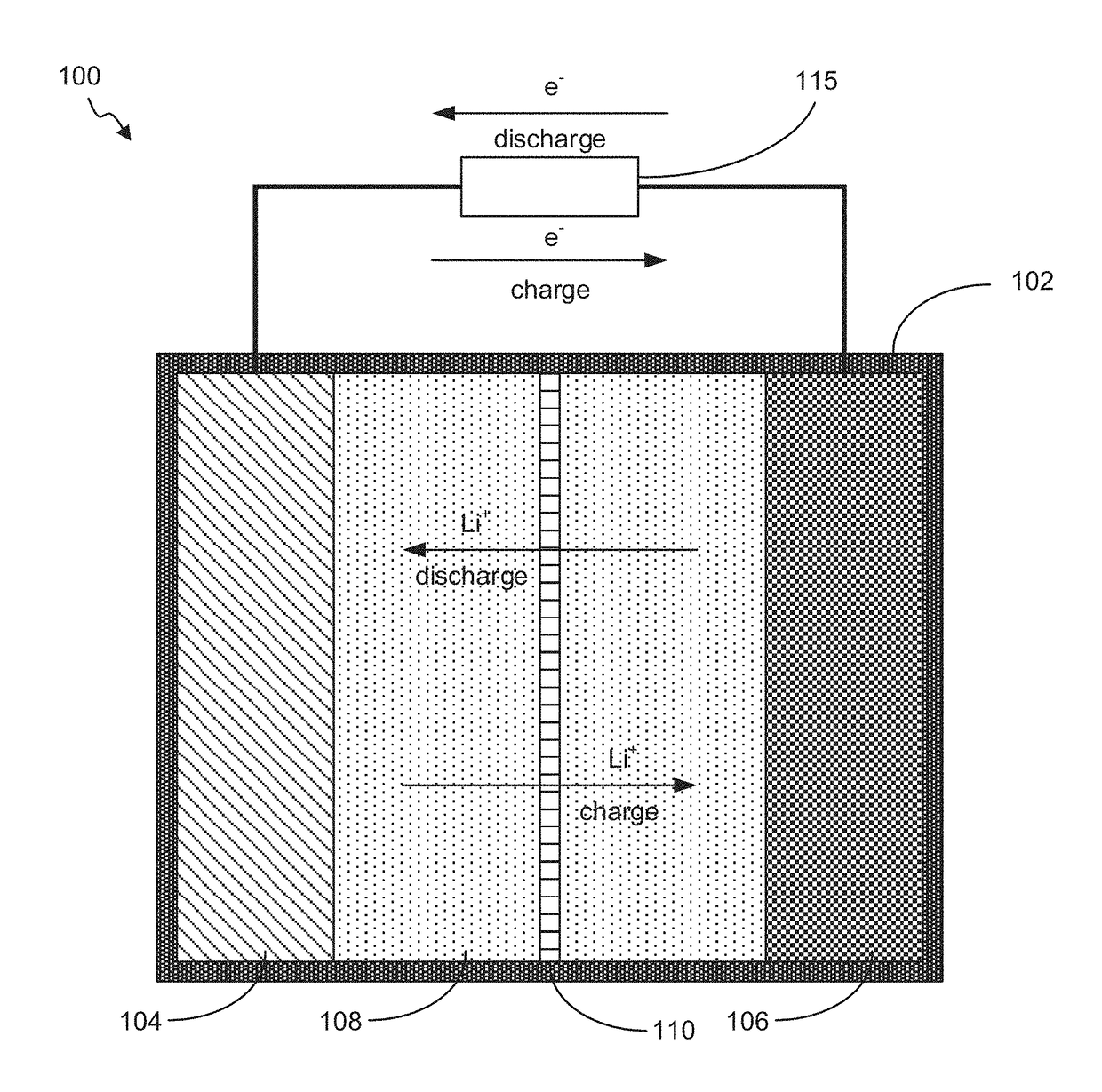

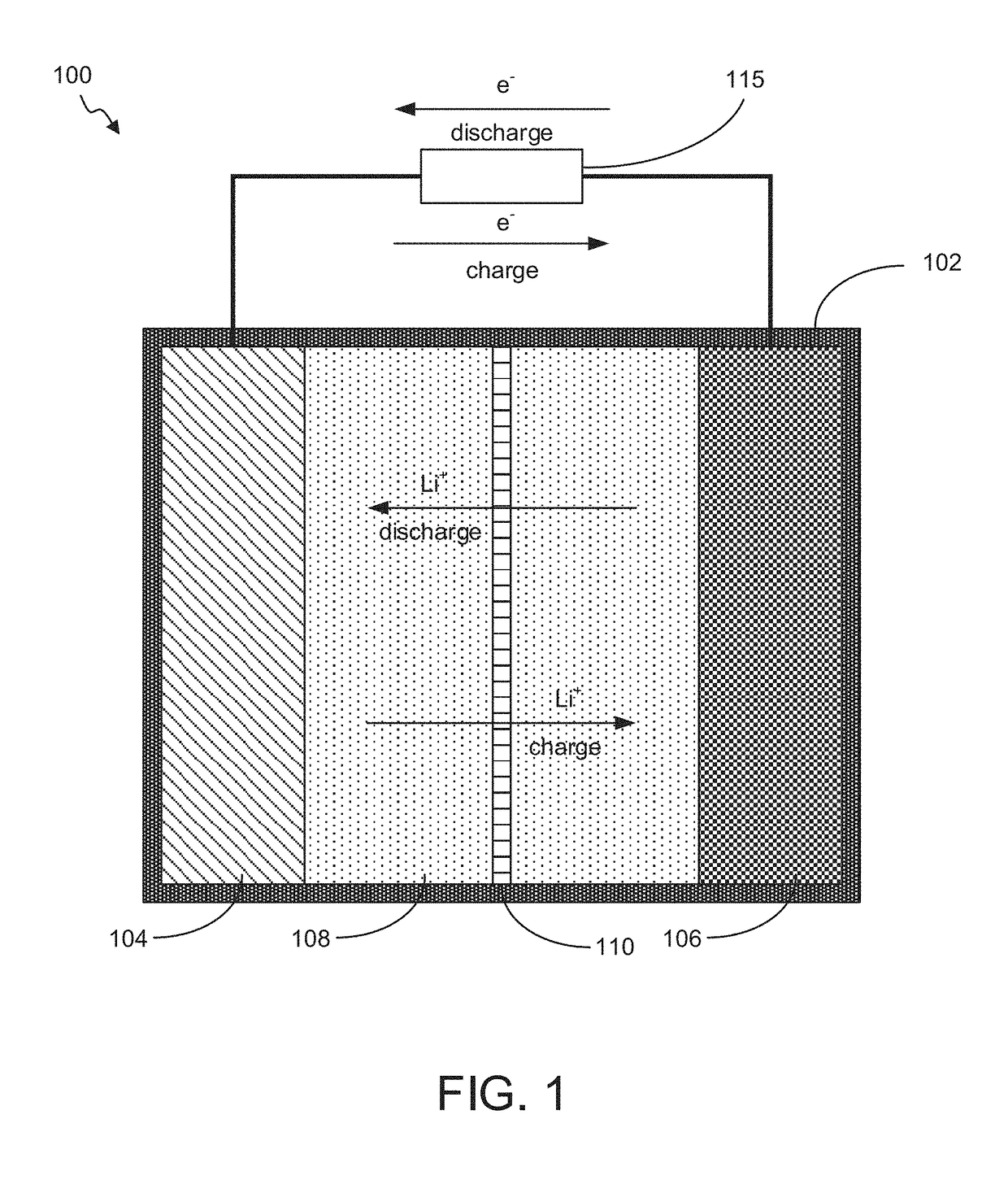

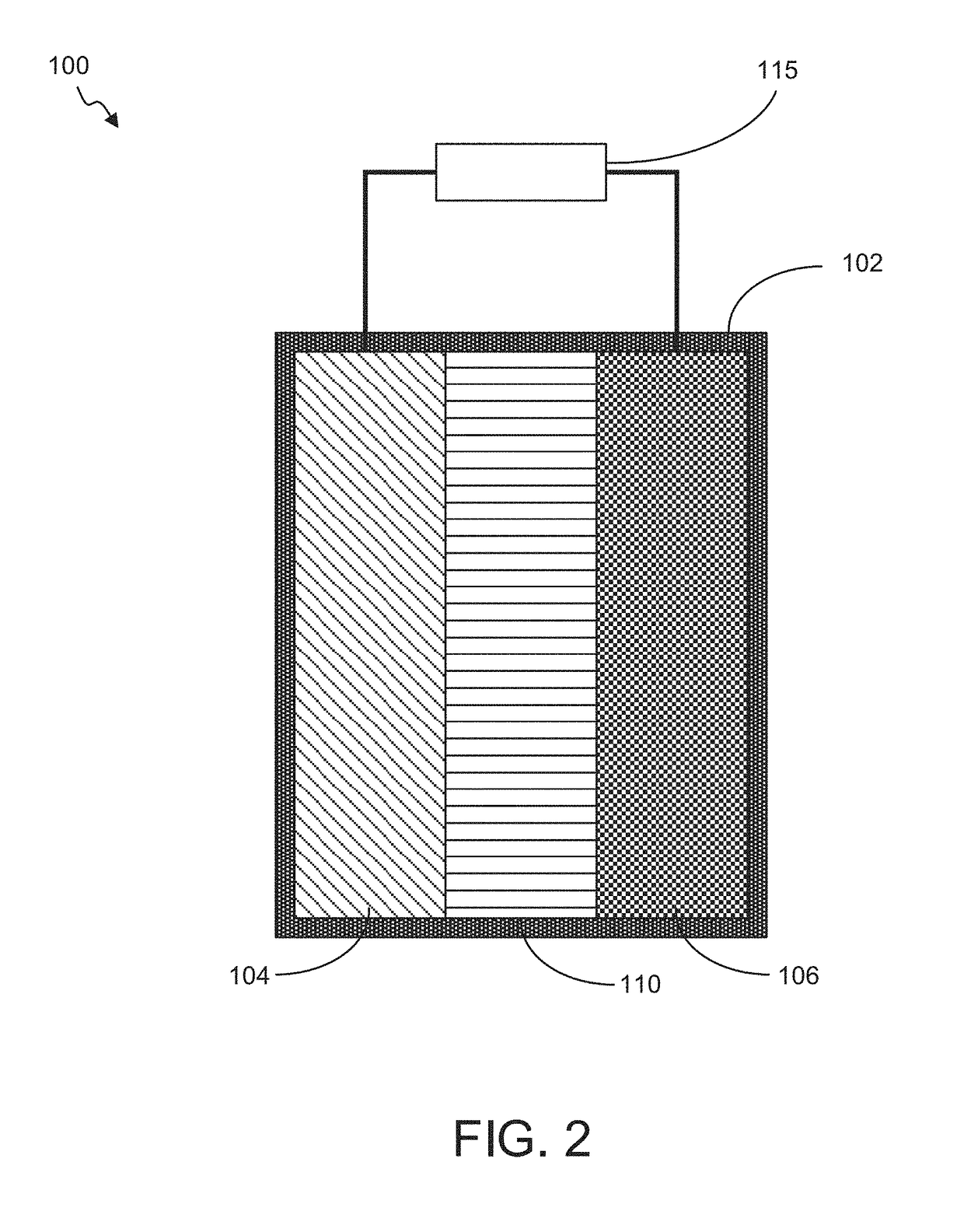

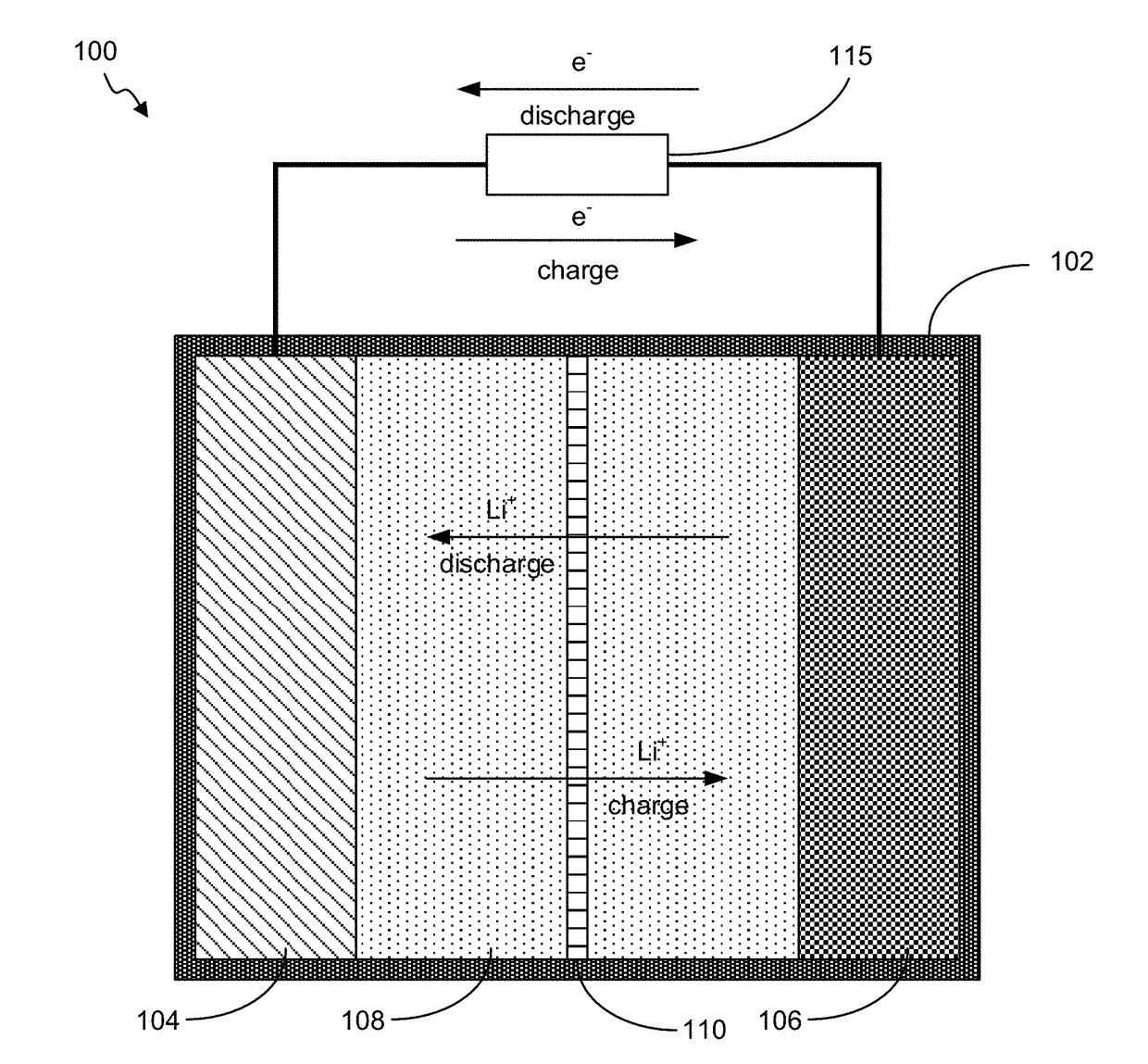

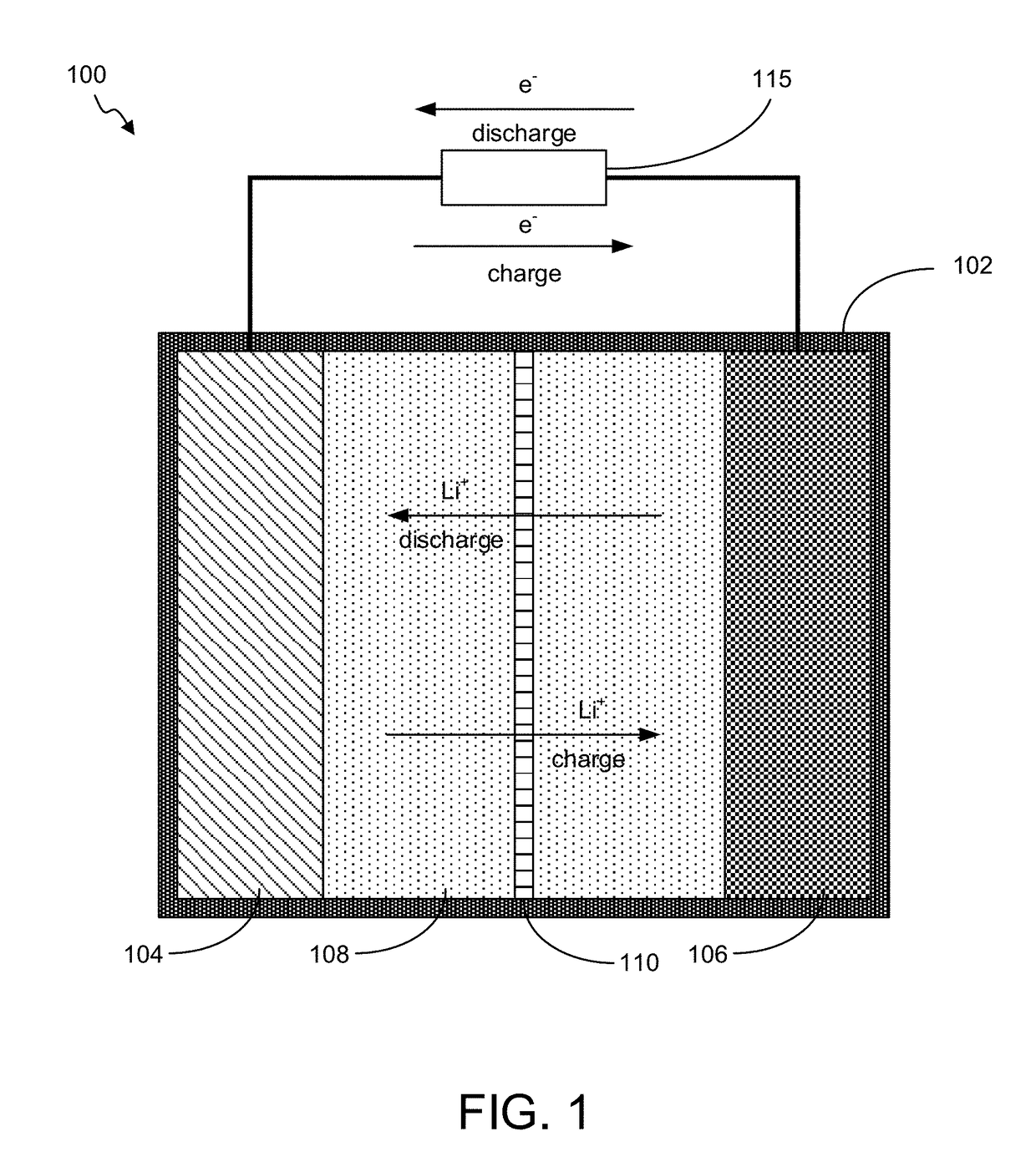

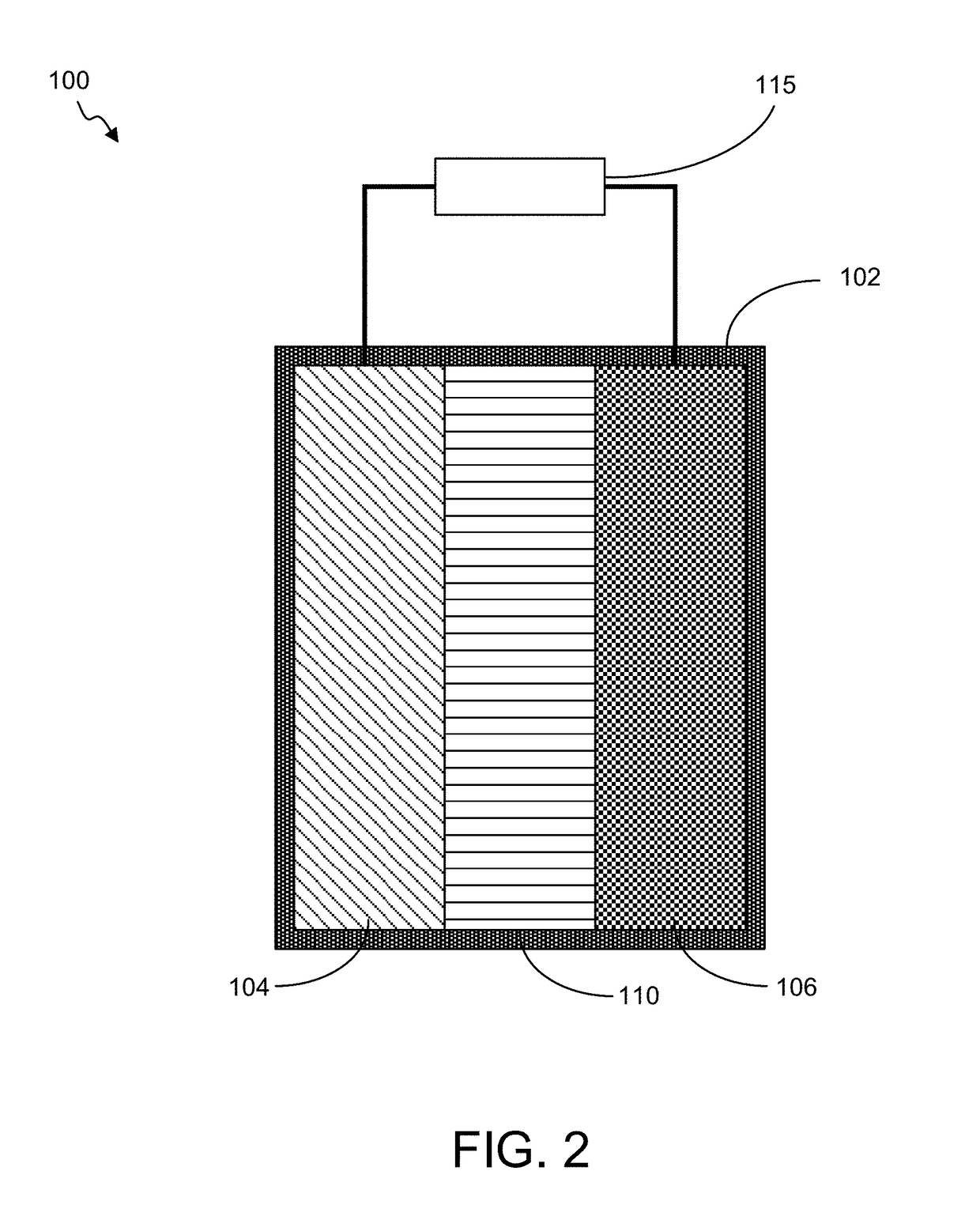

Battery Cell with Novel Construction

ActiveUS20180337405A1Increase profitIron oxides/hydroxidesGallium/indium/thallium compoundsAqueous solutionNanometre

Owner:HHELI LLC

Modified metal-oxide composite sol, coating composition, and optical member

InactiveUS20100221556A1High refractive indexGood dispersionMaterial nanotechnologyPigmenting treatmentWeather resistanceOxide composite

There is provided a sol of modified metal oxide composite colloidal particles including titanium oxide having a high refractive index and excellent light resistance and weather resistance that discoloration of the colloidal particles by photoexcitation is almost completely inhibited. A modified metal oxide composite colloidal particle comprises; a titanium oxide-tin oxide-zirconium oxide-tungsten oxide composite colloidal particle (A) having a primary particle diameter of 2 to 50 nm and having a SnO2 / TiO2 molar ratio of 0.1 to 1.0, a ZrO2 / TiO2 molar ratio of 0.1 to 0.4, and a WO3 / TiO2 molar ratio of 0.03 to 0.15, as a core; and a tungsten oxide-tin oxide-silicon dioxide composite colloidal particle (B) having a primary particle diameter of 1 to 7 nm with which a surface of the core is coated.

Owner:NISSAN CHEM IND LTD

Battery with Novel Components

ActiveUS20180294479A1Increase profitImprove performanceIron oxides/hydroxidesGallium/indium/thallium compoundsAqueous solutionBattery cell

A battery cell having an anode or cathode comprising an acidified metal oxide (“AMO”) material, preferably in monodisperse nanoparticulate form 20 nm or less in size, having a pH<7 when suspended in a 5 wt % aqueous solution and a Hammett function H0>−12, at least on its surface.

Owner:HHELI LLC

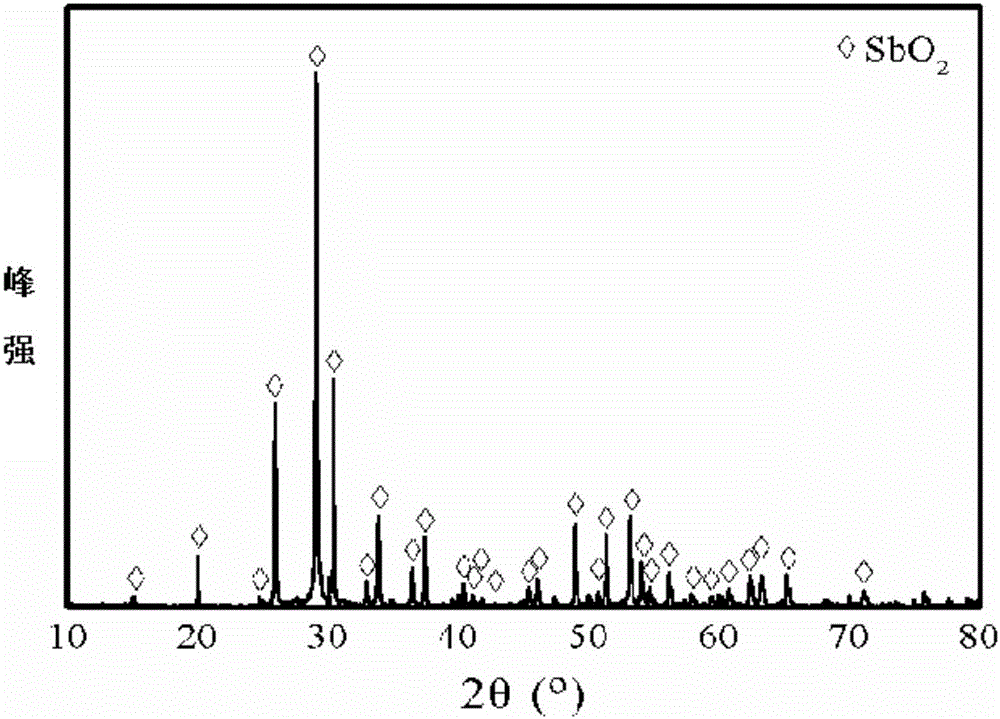

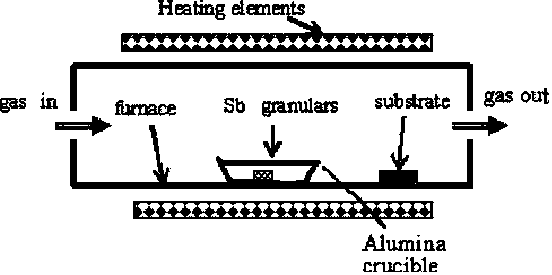

Method of using solution atomization method to prepare superfine Sb oxide

ActiveCN105858724ASimple processShort manufacturing processAntimony oxides/hydroxides/oxyacidsMaterials preparationSpray pyrolysis

The invention discloses a method of using a solution atomization method to prepare superfine Sb oxide. The method comprises the following steps: (1) trivalent Sb is added into a hydrochlric solution to prepare a Sb solution with the molar concentration of 0.05-0.8 mol / L; (2) clean oxidant is used to oxidize the solution obtained in step (1), and a pentavalent Sb solution is obtained; (3) Sb oxide powder is obtained after spray pyrolysis of the pentavalent Sb solution is obtained in step (2). According to the invention, trivalent Sb solution is used as a raw material, superfine Sb oxide powder materials are directly prepared through oxidization and spray pyrolysis, and the technological process is simple. Alternatively, lixivium from the conventional process of using an acid method in antimony smelting is directly used as the raw material. Therefore, the process of preparing the superfine Sb oxide powder materials is shortened; the conventional metallurgical process and the material preparation process are effectively combined; added value of products from conventional non-ferrous metal metallurgy is significantly increased; recycling of hydrochloric acid from lixivium is realized.

Owner:CENT SOUTH UNIV

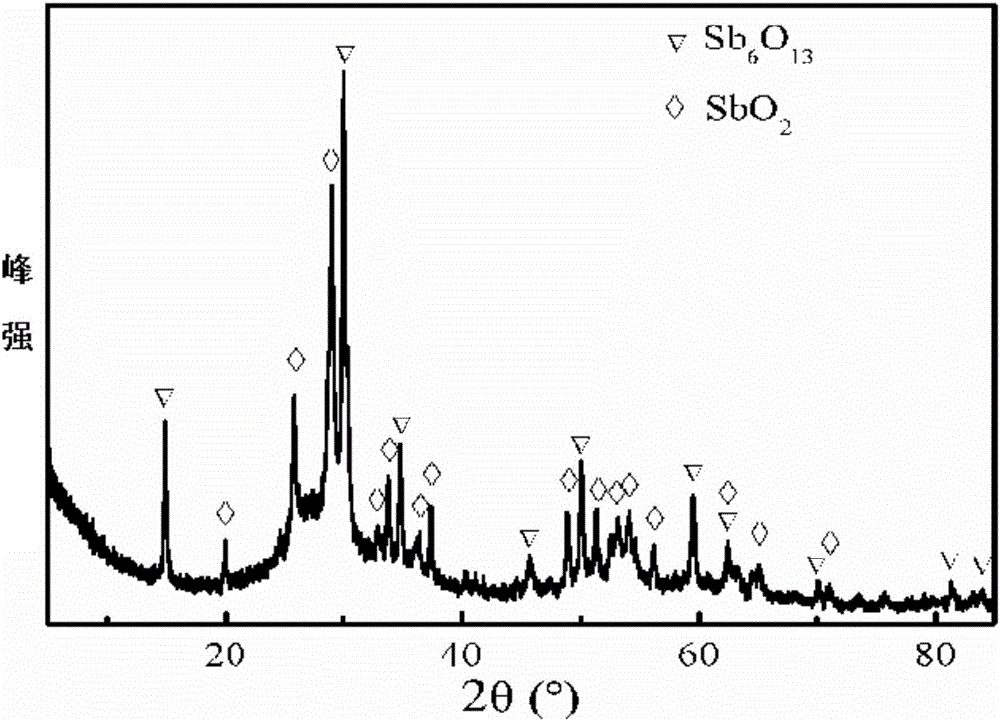

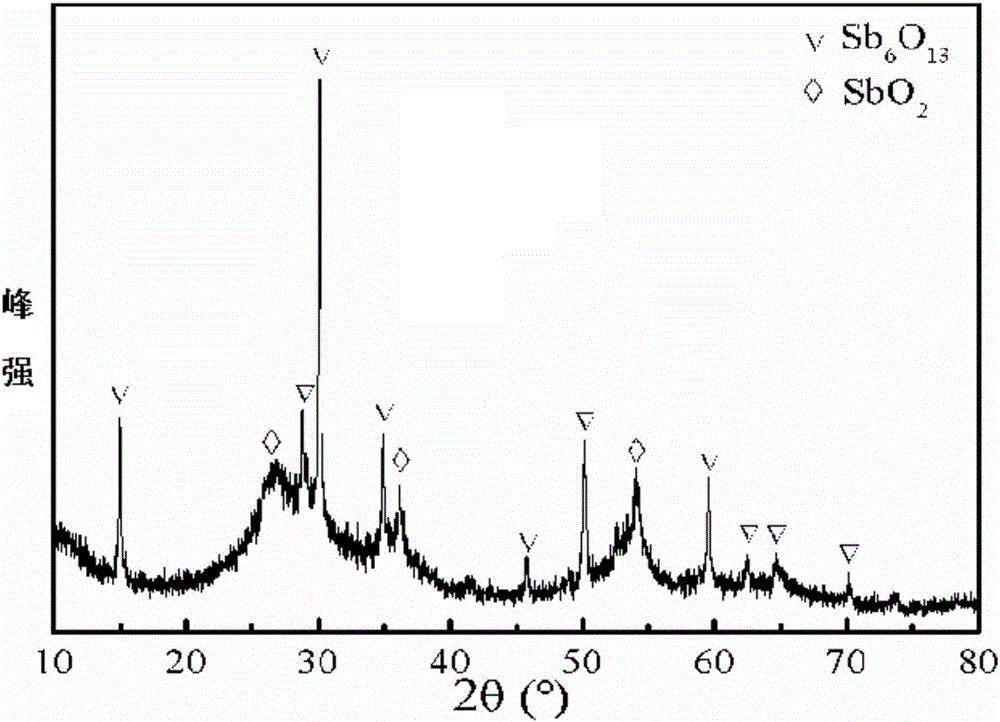

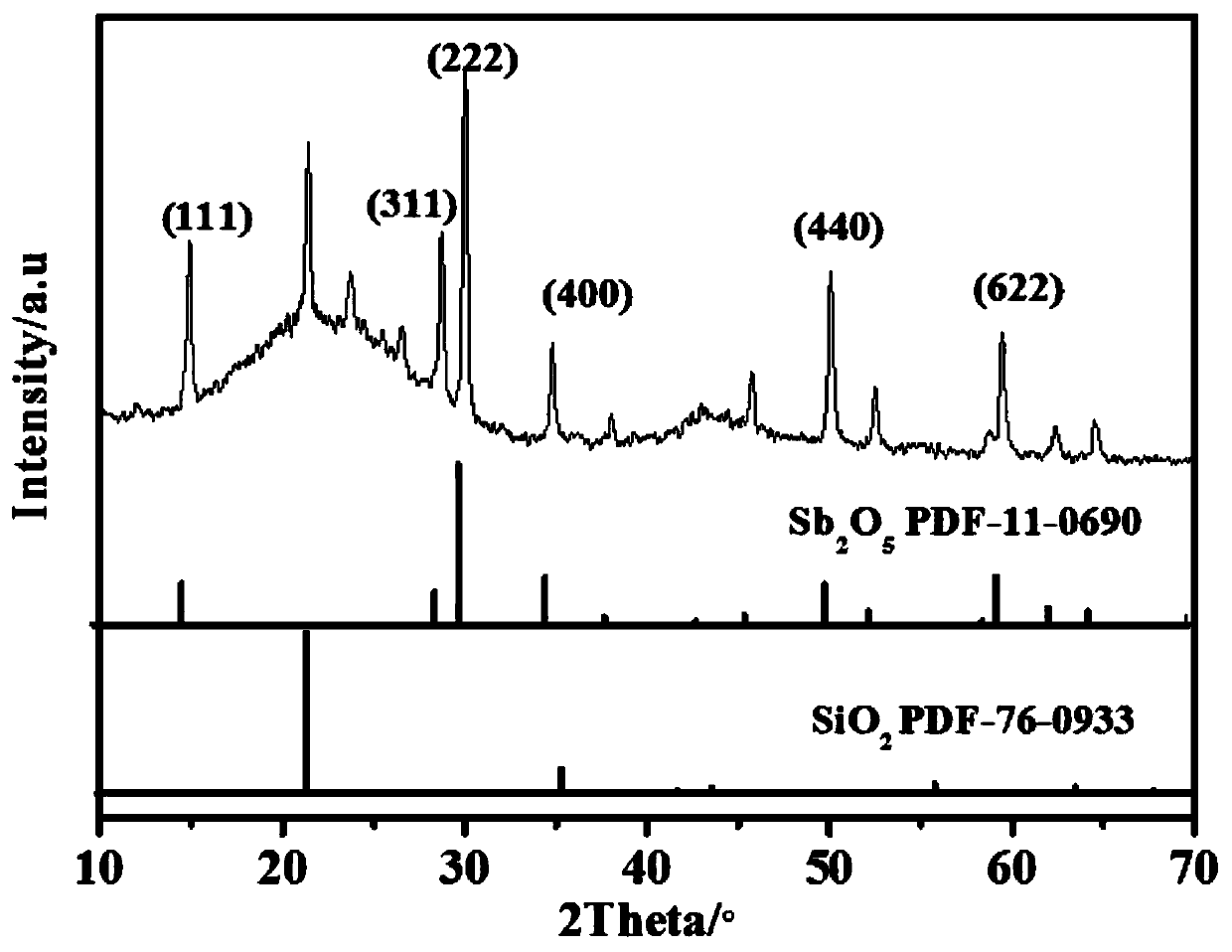

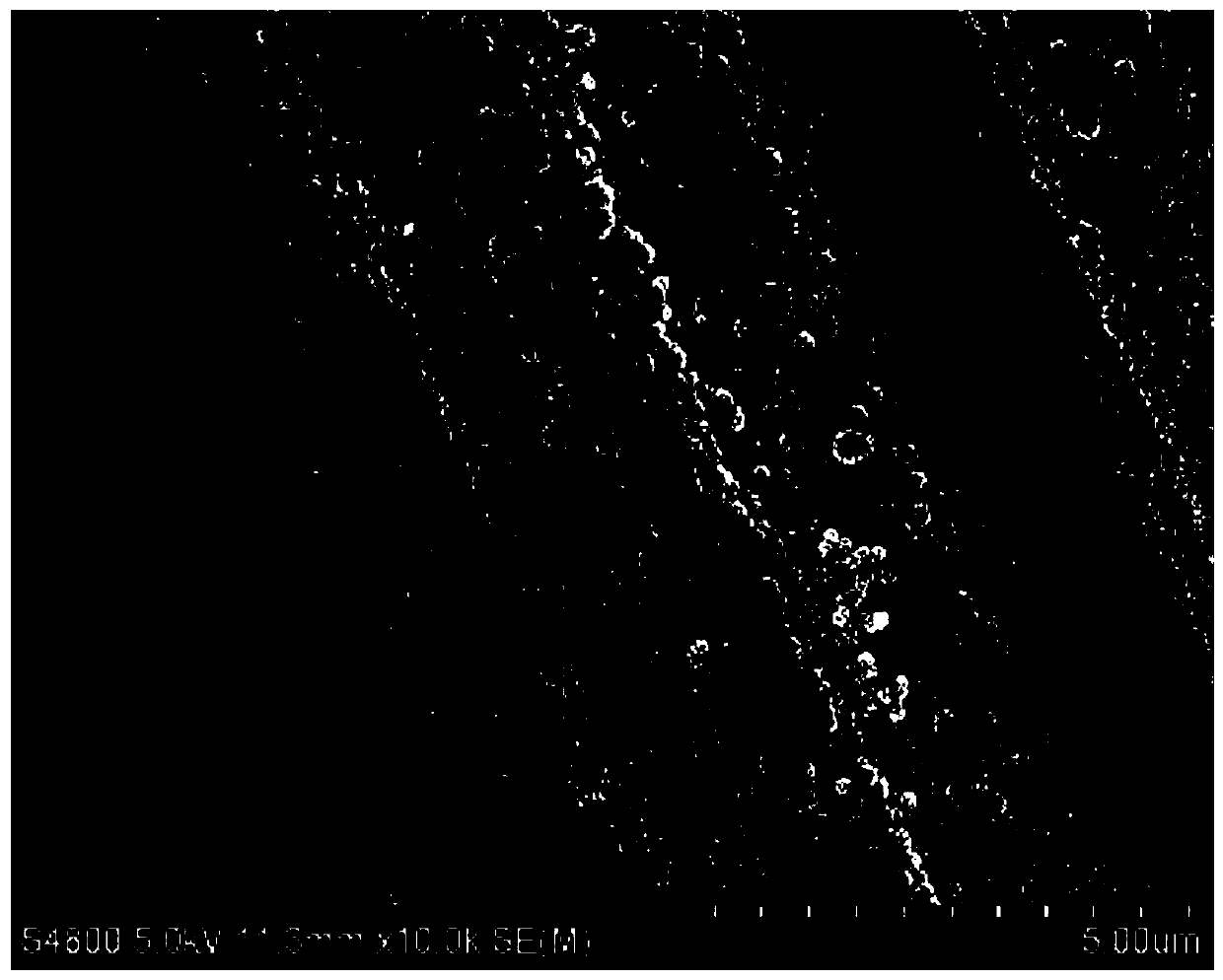

Preparation of antimony pentoxide/silicon dioxide/carbon cloth flexible material and application thereof as negative electrode of sodium-ion battery

The invention discloses preparation of an antimony pentoxide / silicon dioxide / carbon cloth flexible material and an application thereof as a negative electrode of a sodium-ion battery, which comprisesthe following steps: grinding silicon dioxide, adding the silicon dioxide into deionized water for dissolution to obtain a solution A; adding antimony trichloride into the ethanol solution for dissolution to obtain an antimony trichloride solution, and adding a sodium hydroxide aqueous solution into the antimony trichloride solution to adjust the pH value of the antimony trichloride solution to obtain a solution B; adding the solution A into the solution B and stirring to obtain a solution C; impregnating the activated carbon cloth in the solution C, transferring the solution C and the carboncloth into a reaction kettle for hydrothermal reaction, cooling the carbon cloth to room temperature, moving out the carbon cloth, and cleaning and drying the carbon cloth to obtain the antimony pentoxide / silicon dioxide / carbon cloth flexible sodium ion battery negative electrode material. The method is simple to operate and low in cost, and the silicon material can be applied to the negative electrode material of the sodium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of adhesive coating, wear resistant and flame resistant floor leather for vehicle

InactiveCN105504598AImprove wear resistanceNo harmAntimony oxides/hydroxides/oxyacidsPressure sensitive film/foil adhesivesWear resistantSolvent

The invention relates to a preparation method of adhesive coating, wear resistant and flame resistant floor leather for a vehicle, and belongs to the field of floor leather preparation. The preparation method lies in that melamine resin-coated nanometer antimony trioxide is taken as a fire retardant, silicon carbide micro powder is taken as an antiwear filler, through processes such as tanning and hot pressing, finally the adhesive coating, wear resistant and flame resistant floor leather for the vehicle is prepared by being sequentially coated with a hot-melt pressure-sensitive adhesive and an isolating membrane layer, wherein as melamine resin-coated nanometer antimony trioxide is taken as a flame resistant material, the fire resistance is greatly improved, silicon carbide micro powder is hot pressed on the leather surface, and the floor leather surface abrasion resistance is also improved; besides, due to use of the hot-melt pressure-sensitive adhesive, the harm to a human body caused by an organic solvent in the solvent adhesive is avoided, and therefore the floor leather is excellent in comprehensive performance, and has a broad application prospect.

Owner:CHANGZHOU QINGFA IND GAS CO LTD

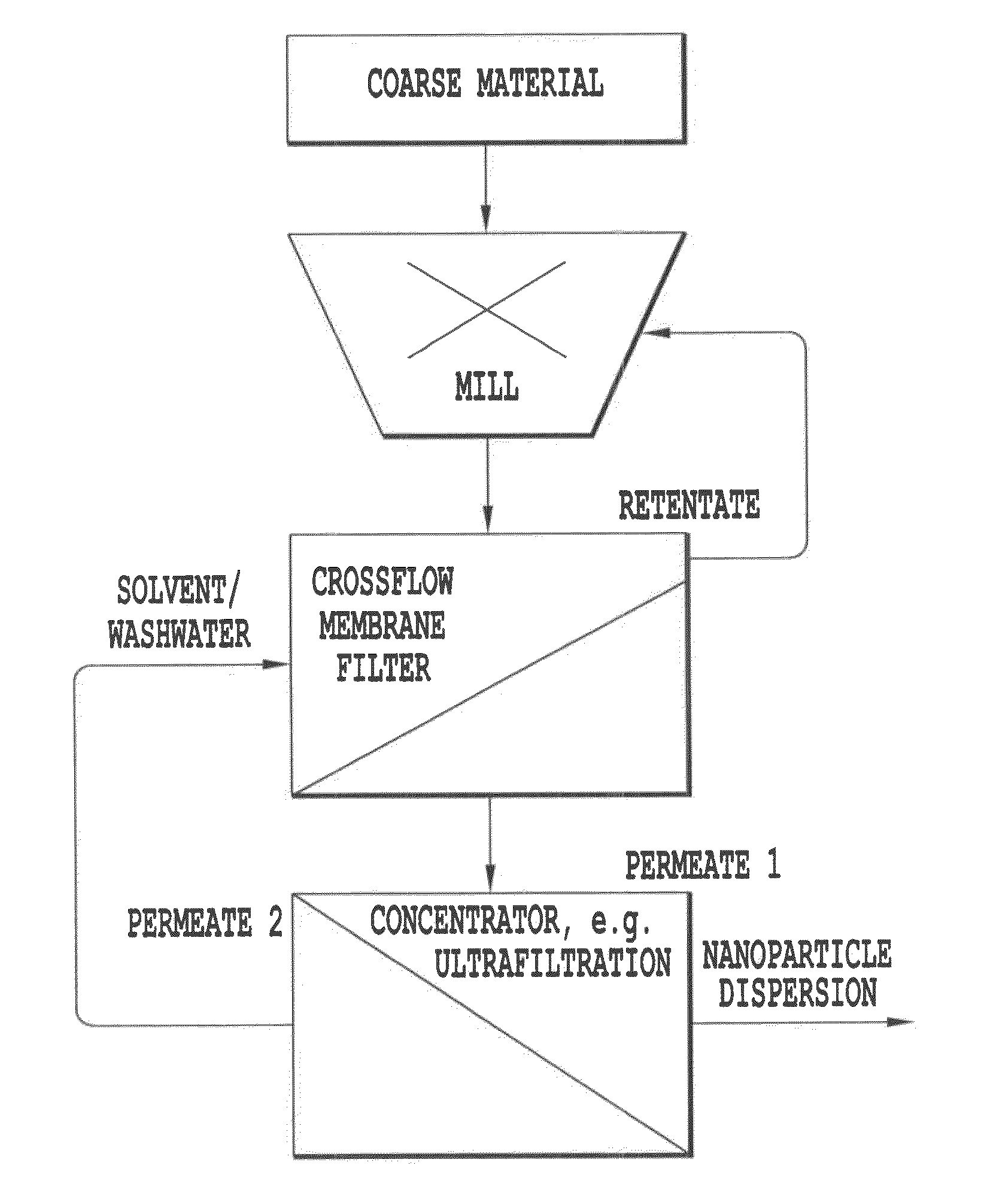

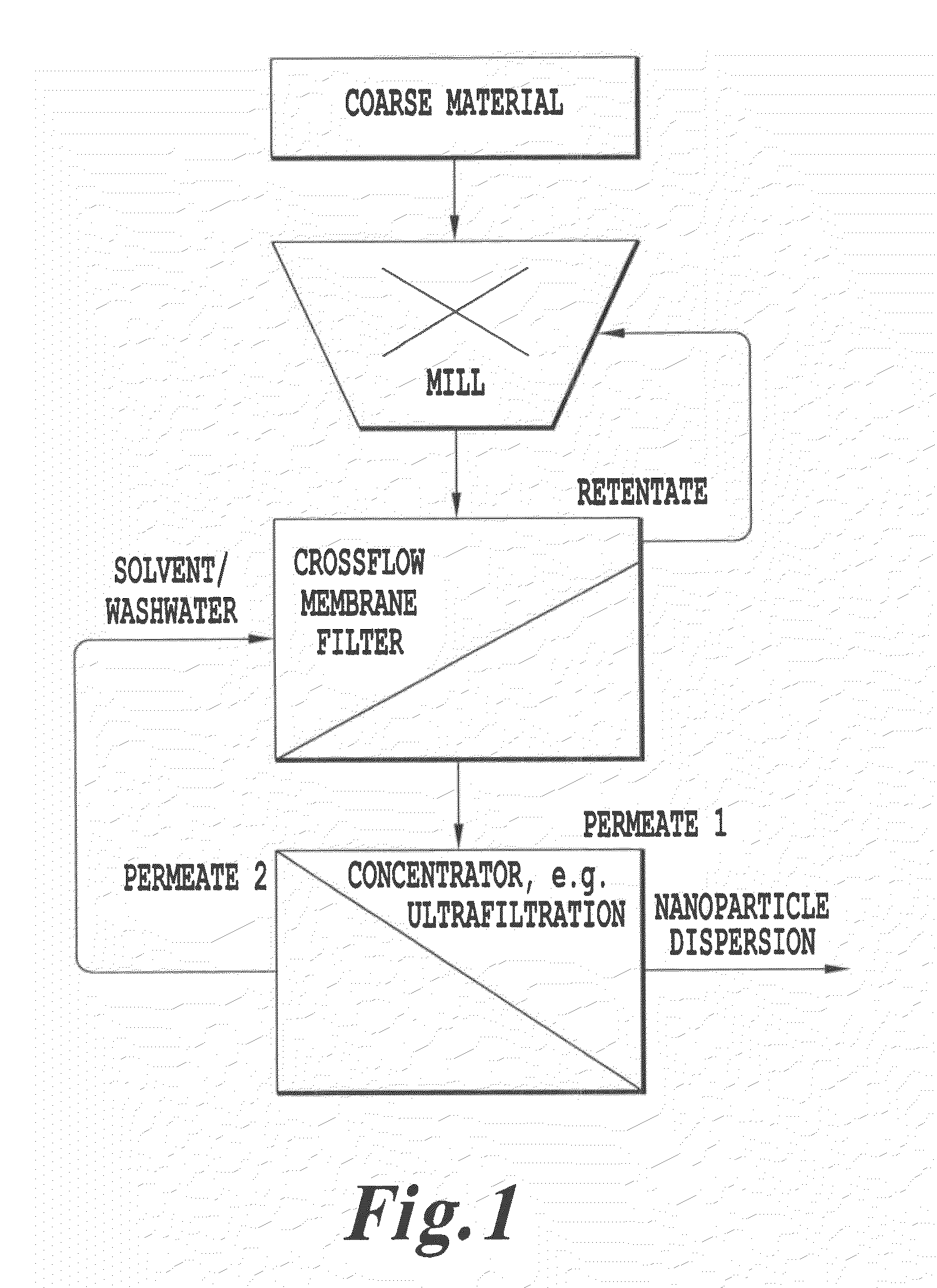

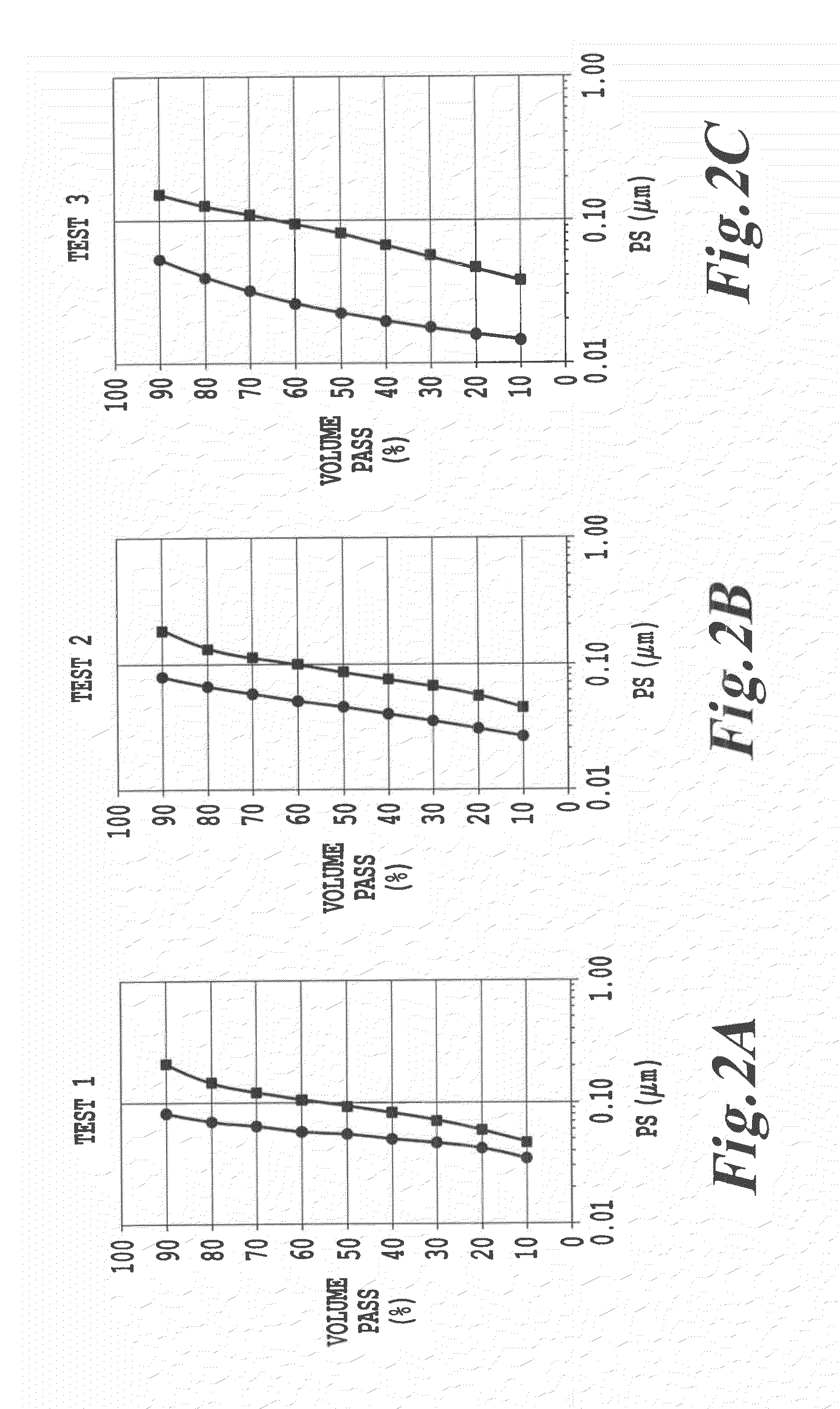

Method of fractionating oxidic nanoparticles by crossflow membrane filtration

ActiveUS20100187174A1Overcome disadvantagesAvoid accumulationAlkaline earth titanatesMembranesFiltrationNanometre

A method of fractionating a dispersion of oxidic nanoparticles wherein at least one step of the method is a membrane crossflow filtration step, the flow of the dispersion over the membrane being brought about by means of driven rotating parts; and dispersions of oxidic nanoparticles that are obtainable by the method.

Owner:EVONIK OPERATIONS GMBH

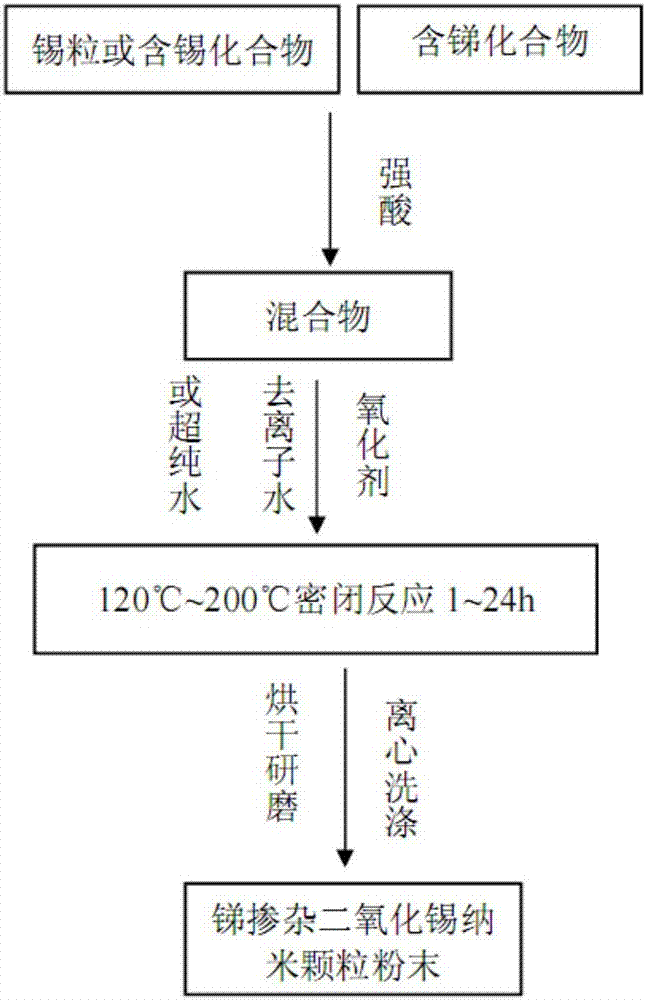

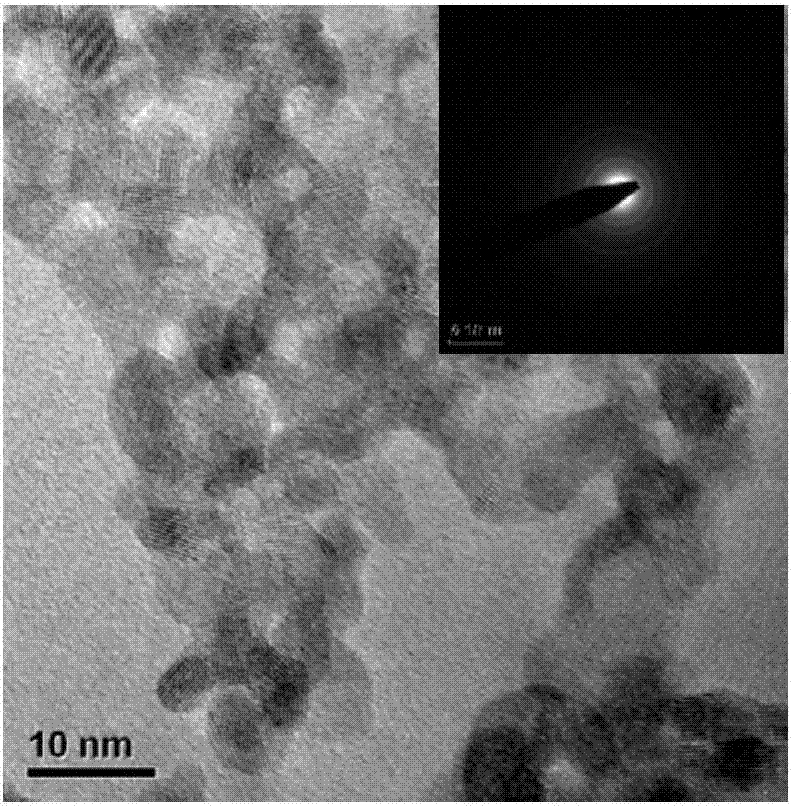

Preparation method of ultrafine high-purity antimony-doped tin oxide nanometer powder

InactiveCN107473263AWell mixedHigh purityMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsPrillLow emissivity

The invention relates to the field of nanomaterial synthesis, and discloses a preparation method for ultrafine high-purity antimony-doped tin oxide nanopowder, which comprises the following steps: taking tin particles or tin-containing compounds, antimony-containing compounds, adding strong acid, and then adding oxidizing agent and deionization Water or ultrapure water is then transferred to a closed reaction kettle, reacted at 120°C-200°C for 1-24h, cooled to room temperature, centrifuged and washed until neutral, dried, and ground to obtain antimony-doped tin dioxide nanoparticle powder. No anion impurity is introduced in the preparation process of the present invention, which ensures high purity of the prepared nanoparticles. The invention is easy to dope accurately and according to the amount, and solves the technical problems in the prior art that the doping is uneven, the particles contain anion impurities, and the particles are easy to agglomerate; the nano particles synthesized by the invention have high purity, small particle size and are easy to disperse. The coated glass prepared by the nano particles of the invention has high visible light transmittance, has the function of blocking infrared rays, and has low resistance, and can be applied to low-radiation glass and transparent conductive glass.

Owner:杭州聚力氢能科技有限公司

Preparation method of rhombic antimony (III) trioxide

InactiveCN104512926AEasy to removeEvenly distributedMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsFiberAntimony trioxide

Owner:QINGDAO SHOUSHENG IND

Method for preparing diantimony trioxide nano-particles by mechanochemical modification technology

PendingCN110963527AEasy to upgradeSimple processAntimony oxides/hydroxides/oxyacidsGrain treatmentsActive agentAqueous ethanol

The invention relates to a method for preparing diantimony trioxide nano-particles by a mechanochemical modification technology. The method comprises the following steps: (1) mixing and ball-milling micrometer diantimony trioxide, small hard alloy steel balls and distilled water to obtain nano-Sb2O3 particles; (2) washing, drying and sieving the nano-Sb2O3 particles to obtain a nano-Sb2O3 sample;(3) mixing the nano-Sb2O3 sample, small hard alloy steel balls and distilled water, adjusting the pH value, adding hexadecyltrimethylammonium bromide, carrying out ball milling, and cleaning, filtering and drying the obtained mixture to obtain cationic surfactant CTAB modified nano-Sb2O3 particles; (4) adding the cationic surfactant CTAB modified nano-Sb2O3 particles into an ethanol-water solution, and carrying out ultrasonic dispersion so as to obtain cationic surfactant CTAB modified nano-Sb2O3 particles; and (5) mixing and ball-milling the cationic surfactant CTAB modified nano-Sb2O3 particles, a silane coupling agent KH580, small hard alloy steel balls and anhydrous ethanol, and cleaning, filtering and drying the obtained mixture to obtain CTAB and KH580 compounded modified nano-Sb2O3.The method has the advantages of simple process, high yield, high operability, and easiness in realization of industrial production.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

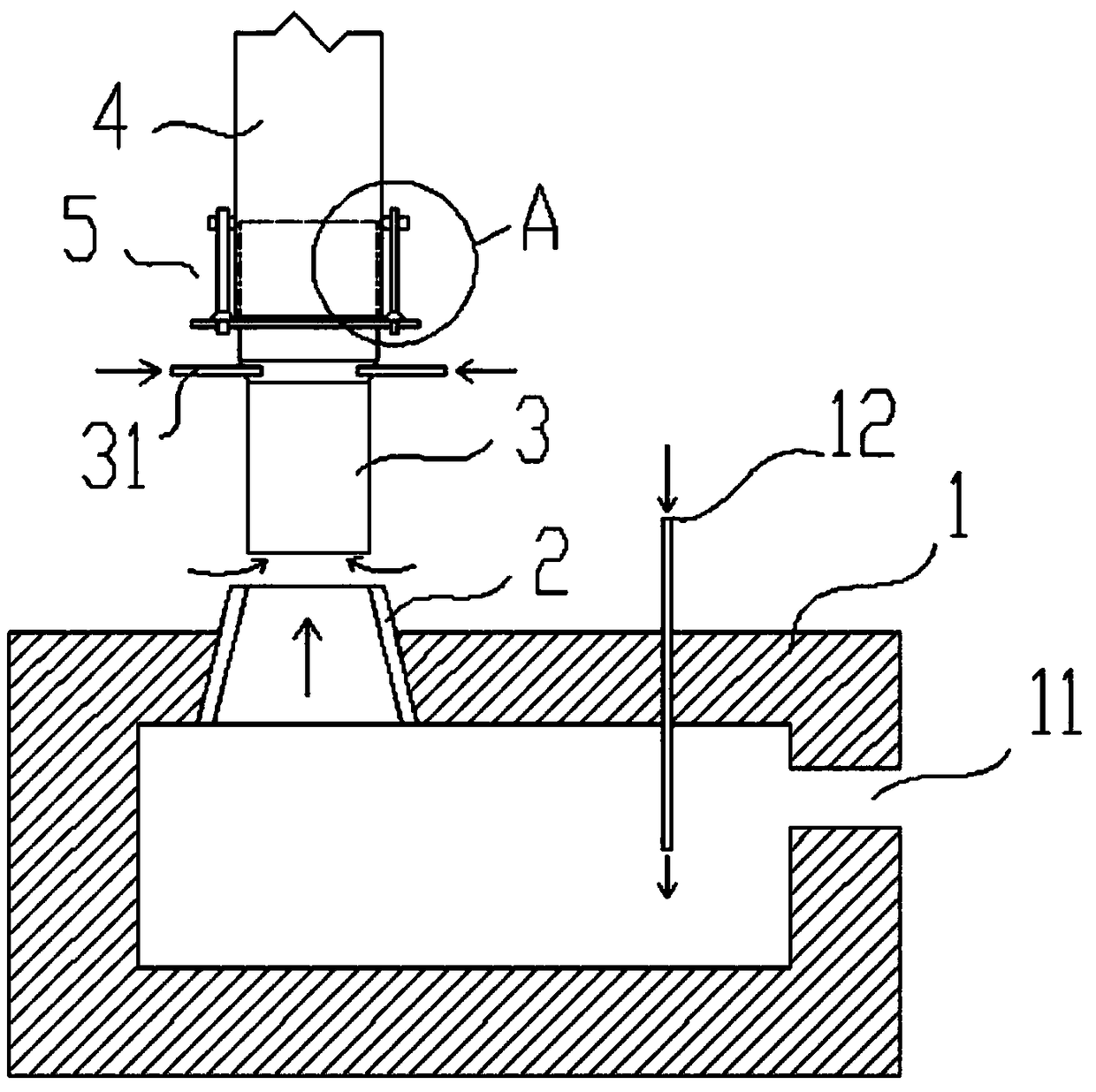

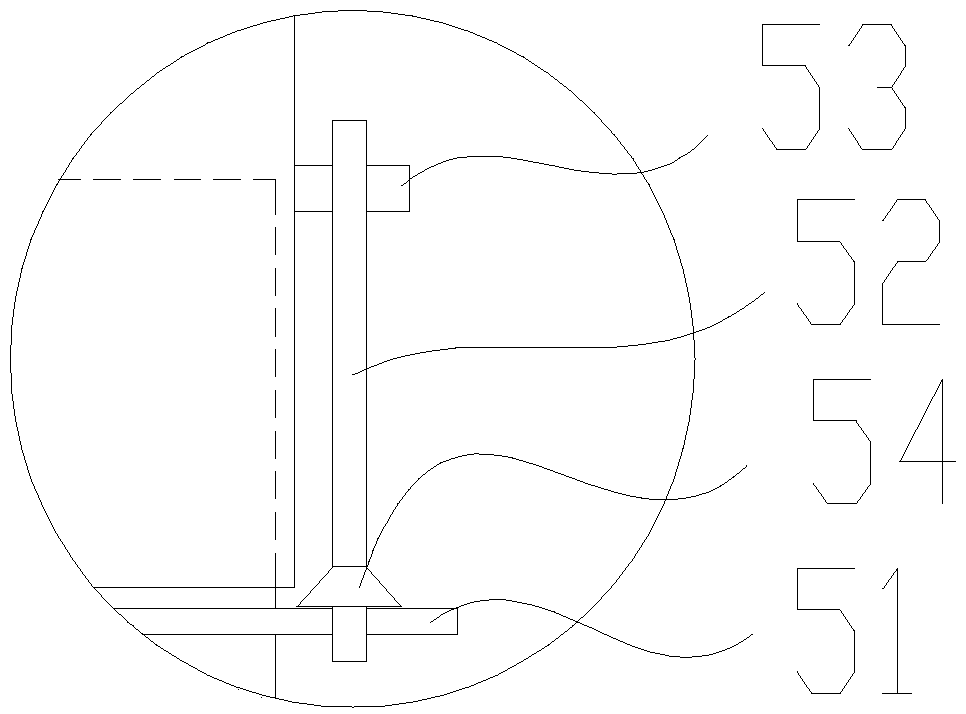

Antimonous oxide powder crystallization system

ActiveCN108622933AAdjustable lengthDwell time is easy to controlAntimony oxides/hydroxides/oxyacidsHeat exchange cooling cystallizationProduction lineFrequency conversion

The invention provides an antimonous oxide powder crystallization system. The antimonous oxide powder crystallization system comprises an antimony white furnace, a reactor, a crystallizer and a powdercollector, wherein the antimony white furnace is provided with an air hose and a feeding opening, a frequency conversion adjustable draught fan is arranged between the reactor and the crystallizer, the crystallizer and the powder collector are connected in a sleeving way and are fixed by using a regulating mechanism, and a low temperature air hose is arranged on the crystallizer. The length of the crystallizer is adjustable, the dwell time of an antimonous oxide material in a crystallization forming section is convenient to control, the crystal form and the grain size of an antimonous oxide power are further controlled, the product specifications of the antimonous oxide are guaranteed to be flexibly regulated on the same production line, the conversion of the crystal form is complete, theproduct quality is further controlled, the low-efficiency investment is avoided, the equipment production line is prevented from being left unused and being wasted, the difficulty in fund flow of theindustry is avoided, and due to the two-section air cooling mode, the whole system reaches rapid quenching, and the product index stably reaches the standard.

Owner:广东宇星阻燃新材股份有限公司

Preparation method of high-purity antimony trioxide

PendingCN113735169AGuaranteed not to be accidentally restoredGuaranteed treatment effectAntimony oxides/hydroxides/oxyacidsDistilled waterAntimony trioxide

The invention discloses a preparation method of high-purity antimony trioxide, which comprises the following steps: S1, dissolving: placing antimony trioxide in a container containing a sodium hydroxide solution, adjusting the pH value to 9-10, and stirring and dissolving for the first time; s2, filtering: filtering undissolved impurities in the container for the first time by using a filter screen, then adding a carbonic acid solution into the container, and adjusting the pH value to 6-6.5; s3, stirring: stirring the container for the second time, continuously stirring until the precipitate is separated out, and ensuring that the precipitate is completely separated out; s4, filtering and drying: filtering the separated antimony trioxide for the second time, then drying, then adding distilled water, and repeatedly filtering and drying for three to four times to obtain a dried precipitate; and S5, high-temperature smelting is conducted, specifically, the sediment is placed in a smelting furnace. The preparation method of the high-purity antimony trioxide not only can treat substances which are insoluble in alkali and easily soluble in acid, but also can assist in removing impurities from other substances.

Owner:苏州飞斯达化工有限公司

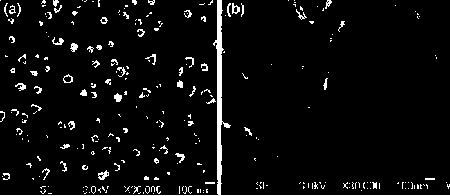

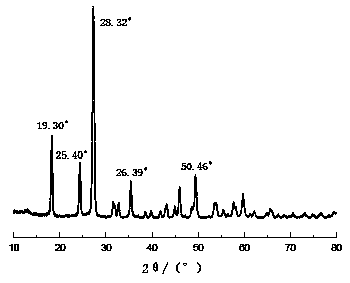

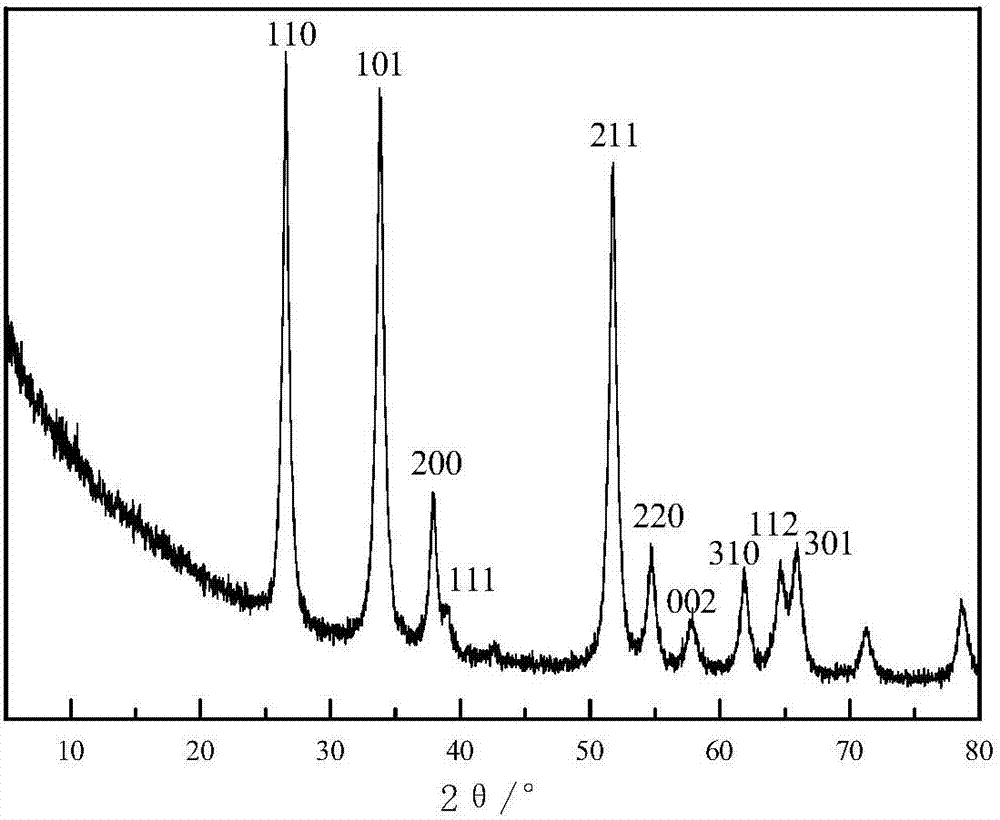

Neodymium and antimony codoped stannic oxide nano-powder and preparation and application thereof

ActiveCN106219598ASmall particle sizeUniform particle size distributionAntimony oxides/hydroxides/oxyacidsMaterial analysisDissolutionCalcination

The invention relates to a preparation method of neodymium and antimony codoped stannic oxide nano-powder. The preparation method comprises the steps that stannic chloride, antimony chloride, neodymium nitrate and ethyl alcohol are weighed, and stannic chloride is added into ethyl alcohol; neodymium nitrate is added into a solution, and stirring is conducted for sufficient dissolution; antimony chloride is added into the above-mentioned solution, and stirring is conducted for sufficient dissolution; the solution is warmed up, warming is kept for a period of time, ammonia water is dropwise added to adjust the PH to be about 7 so as to obtain solid powder, the solid powder is subjected to centrifugal washing, drying and high-temperature calcination, and neodymium and antimony codoped stannic oxide is obtained. Neodymium and antimony codoped stannic oxide obtained through the method is small in particle size and uniform in particle size distribution and has the excellent gas-sensitive sensitivity to acetone.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of antimony doped nanometer stannic oxide powder

ActiveCN107758741AFacilitate blendingLower surface energyMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsDispersityAlcohol

The invention discloses a preparation method of an antimony doped nanometer stannic oxide powder. The preparation method comprises the following steps: (1) mixing an antimonic salt and a tin salt, dissolving in an ethyl alcohol solution, and conducting ultrasonic concussion for 10-20 minutes at the room temperature to obtain a solution A; sequentially dissolving butanetetracarboxylic acid and ammonium dihydrogen phosphate into deionized water to obtain a solution B; (2) mixing the solution A and the solution B, conducting ultrasonic concussion for 5-10 minutes at the room temperature, adding alkali and diethanol amine at the stirring state, enabling the pH of the solution to reach 8-9, heating to 65-75 DEG C, reacting for 2-4 hours to obtain a precipitate precursor; and (3) washing, dryingand calcining the precipitate precursor to obtain the antimony doped nanometer stannic oxide powder. The prepared antimony doped nanometer stannic oxide powder is even in particle size distribution and good in dispersity, the average particle size of the prepared antimony doped nanometer stannic oxide powder is less than 120 nm, the electrical resistivity is less than 25 ohm.cm, the specific surface area is 4-6 m<2> / g, and the electrical conductivity is excellent.

Owner:广西生富锑业科技股份有限公司

Preparation method of antimony pentoxide composite powder

InactiveCN104355333AImprove stabilityImprove flame retardant performanceAntimony oxides/hydroxides/oxyacidsPhosphateCreatinol phosphate

The invention relates to a preparation method of an antimony pentoxide composite powder. The preparation method comprises the following steps: firstly, antimony trioxide is taken for refining; then the refined antimony trioxide dry powder is added into water, then creatinol-o-phosphate as a stabilizer and oxydol are added for oxidation reflux reaction, after the reaction, a reacting liquid is taken for dialysis for 2 to 3 times, redundant creation o-phosphate is removed, and an antimony pentoxide hydrosol is prepared; finally, the prepared antimony pentoxide hydrosol is added with zeolite powder, the mixture is stirred and then left to stand, precipitate is obtained through centrifugation, and the precipitate is filtered and dried so as to obtain the antimony pentoxide composite powder. The preparation method provided by the invention uses the creatinol-o-phosphate as the stabilizer, and the creatinol-o-phosphate contains a plurality of hydroxies and two inflaming retarding elements N and P, so that the stabilizing effect is good, the flame-retardant effect of the colloid of antimony pentoxide is improved, a zeolite powder is adopted for adsorbing the colloid of antimony pentoxide, so as to prepare the antimony pentoxide-zeolite powder composite powder, during the preparing process, the problem of much loss of antimony pentoxide dry powder during the drying process caused by relatively fine antimony pentoxide dry powder can be solved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Preparation method of antimony (III) trioxide cubic crystal

InactiveCN104512927ASave raw materialsSimple processAntimony oxides/hydroxides/oxyacidsFiberAntimony trioxide

The invention discloses a preparation method of an antimony (III) trioxide cubic crystal. The preparation method comprises the following steps: step one, dissolving antimony trichloride into glycol; step two, heating the solution to a temperature of 25-90 DEG C, and introducing ammonia gas into the solution until the pH value of the solution is greater than 8; step three, after the reaction, mixing the obtain solid-liquid mixture with distilled water, and stirring to carry out hydrolysis; step four, after the hydrolysis, carrying out centrifugal separation, washing the obtained substances until no chlorine ion exists on the substances, and drying so as to obtain the antimony (III) trioxide cubic crystals. The provided preparation method has the following advantages: (1) the raw materials are cheap, and the technology is simple; (2) the organic solvent can be recycle and reutilized, the recycling cost is low, and the production cost is reduced; (3) the crystal form of the obtained product is single, the crystallization is complete, and thus the crystals can be easily dispersed in plastic and paints and attached on fibers.

Owner:QINGDAO SHOUSHENG IND

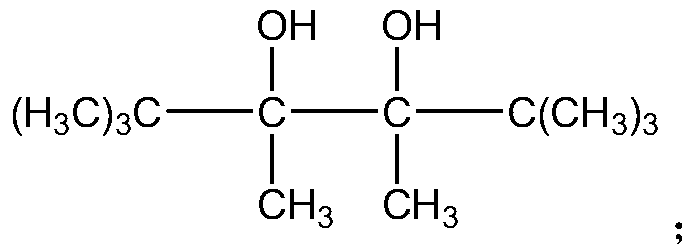

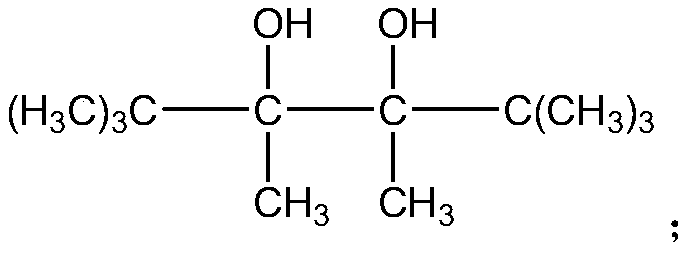

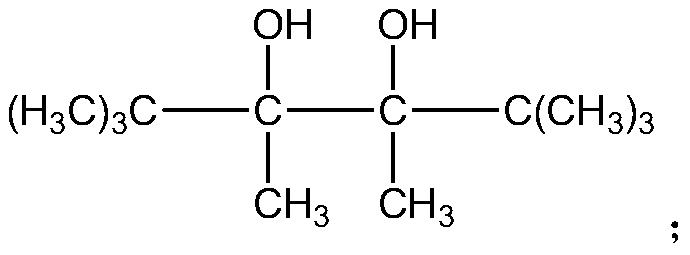

Easily-dyed porous modified polyester fiber and preparation method thereof

ActiveCN109735926AIncrease the void free volumeImprove permeabilityAntimony oxides/hydroxides/oxyacidsMonocomponent polyesters artificial filamentFiberDisiloxane

The invention relates to an easily-dyed porous modified polyester fiber and a preparation method thereof. The easily-dyed porous modified polyester fiber is prepared by a porous spinneret plate through an FDY process. The preparation method of modified polyester comprises the following steps: uniformly mixing terephthalic acid, glycol, dihydric alcohol with a silicon-containing main chain, 2,2,3,4,5,5-hexamethyl-3,4-hexanediol and a metal oxide doped and modified Sb2O3 powder, and sequentially carrying out esterification reaction and condensation polymerization reaction, wherein dihydric alcohol with the silicon-containing main chain is dimethylsilyl diol, dimethyl diphenyl disiloxane diol or tetramethyldisiloxane diol, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol isas follows: formula (shown in the description). The dyeing rate and K / S value of the prepared easily-dyed porous modified polyester fiber are high. The method is simple in process, and the finally prepared modified polyester fiber is good in dyeing performance and good in quality.

Owner:JIANGSU HENGLI CHEM FIBER

Composite core-shell structure nanopowder

ActiveCN107140687AGood dispersionThe experimental equipment is simpleMaterial nanotechnologySilicaCore shellSilicon dioxide

The invention discloses a composite core-shell structure nanopowder. The composite core-shell structure nanopowder comprises a first inner core, an intermediate layer and an outer layer, wherein the first inner core is antimony-doped stannic oxide nanopowder; the molar doping concentration of antimony in the antimony-doped stannic oxide nanopowder is 1-10%; the intermediate layer is a silicon dioxide layer coating the first inner core; the first inner core and the intermediate layer form intermediate powder; the outer layer is an antimony-doped stannic oxide nanopowder layer coating the intermediate powder; the molar doping concentration of antimony in the antimony-doped stannic oxide nanopowder layer is 5-15%. A preparation method of the composite core-shell structure nanopowder comprises the following steps: coating the surface of the nano antimony-doped stannic oxide particle with a silicon dioxide layer to form an intermediate powder medium, then coating with a layer of nano antimony-doped stannic oxide to prepare novel composite core-shell structure nanopowder. According to the composite core-shell structure nanopowder, experimental equipment and method are simple; the economic cost is low.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Preparation method of colloidal antimony pentoxide

InactiveCN104591278AUniform particle size distributionIncreased dispersionAntimony oxides/hydroxides/oxyacidsEvaporationPhosphoric acid

The invention discloses a preparation method of colloidal antimony pentoxide. The preparation method comprises following steps, step1, triethanolamine is delivered into a beaker filled with water, phosphoric acid is added, and triethanolamine phosphate is obtained via 10min of ultrasonic treatment; step 2, the obtained triethanolamine phosphate is delivered into a three-mouth flask filled with antimonous oxide powder, an obtained mixture is stirred, is heated to 95 to 100 DEG C, and is subjected to constant temperature heating, wherein the three-mouth flask is provided with a magnetic stirring apparatus and a reflux condensing tube; step 3, oxidizing agent hydrogen peroxide is added dropwise using a constant-pressure funnel with full stirring, and after adding, an obtained mixed material is subjected to oxidation refluxing for 30min; and step 4, colloidal antimony pentoxide dry powder is obtained via evaporation, condensation, and drying of an obtained hydrosol. The preparation method is simple; production period is short; energy consumption is low; particle size distribution of the obtained antimony pentoxide colloid particles is uniform; and colloid particle dispersion degree is high.

Owner:QINGDAO WANGYU RUBBER

Preparation method of low viscosity antimony pentoxide hydrosol

ActiveCN108793250AReduce dosageImprove liquidityAntimony oxides/hydroxides/oxyacidsSpecific gravityChemistry

The invention provides a preparation method of a low-viscosity antimony pentoxide hydrosol. The method comprises the following steps: (1) after water is heated, adding antimony trioxide for mixing, continuing heating and stirring, and adding hydrogen peroxide for reaction; and (2) concentrating, adding a stabilizer stepwise in the concentration process, immediately cooling after the concentrationis completed, and then adjusting the pH value to obtain the low-viscosity cerium pentoxide hydrosol. The method has the advantages that less stabilizer is used, and the prepared low-viscosity antimonypentoxide hydrosol is clearly milk white, yellowish and lustrous and has good fluidity, wherein the content of antimony pentoxide is 48-54%, the pH value is 6.1-6.8, the viscosity (25 DEG C) is lessthan 15mPa.s, the specific gravity (at room temperature) is 1.751-1.849, good stability is realized, and the direct yield of bismuth pentoxide from hydrosol to organosol is greater than or equal to 98.5%. The preparation method provided by the invention is simple, convenient to operate, low in cost, and environment-friendly.

Owner:锡矿山闪星锑业有限责任公司

Graphene-tin antimony oxide composite material and dry-method preparation method thereof

InactiveCN106927503ASynthesis fastImprove electrochemical performanceAntimony oxides/hydroxides/oxyacidsGrapheneLiquid wasteSurface-active agents

The invention relates to the field of graphene composite materials, in particular to a graphene-tin antimony oxide composite material and a dry-method preparation method thereof. The preparation method comprises the steps that oxidized graphene and a tin antimony oxide compound are mixed on the basis of the mass ratio being 1:(1-10) and ground to be calcinated, wherein the calcination time is 2-4 h, the calcination temperature is 400-800 DEG C. According to the method, no surface active agent or stabilizer or solvent needs to be added, and follow-up treatment processes and liquid waste generation are reduced. The material has the good electrochemical performance.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com