Graphene-tin antimony oxide composite material and dry-method preparation method thereof

A technology of tin and antimony oxide and composite materials, applied in graphene, chemical instruments and methods, antimony oxide/antimony hydroxide/antimony oxyacid and other directions, can solve problems such as affecting the performance of composite materials, and achieve low cost, good electrical Chemical properties, reducing the effect of subsequent processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

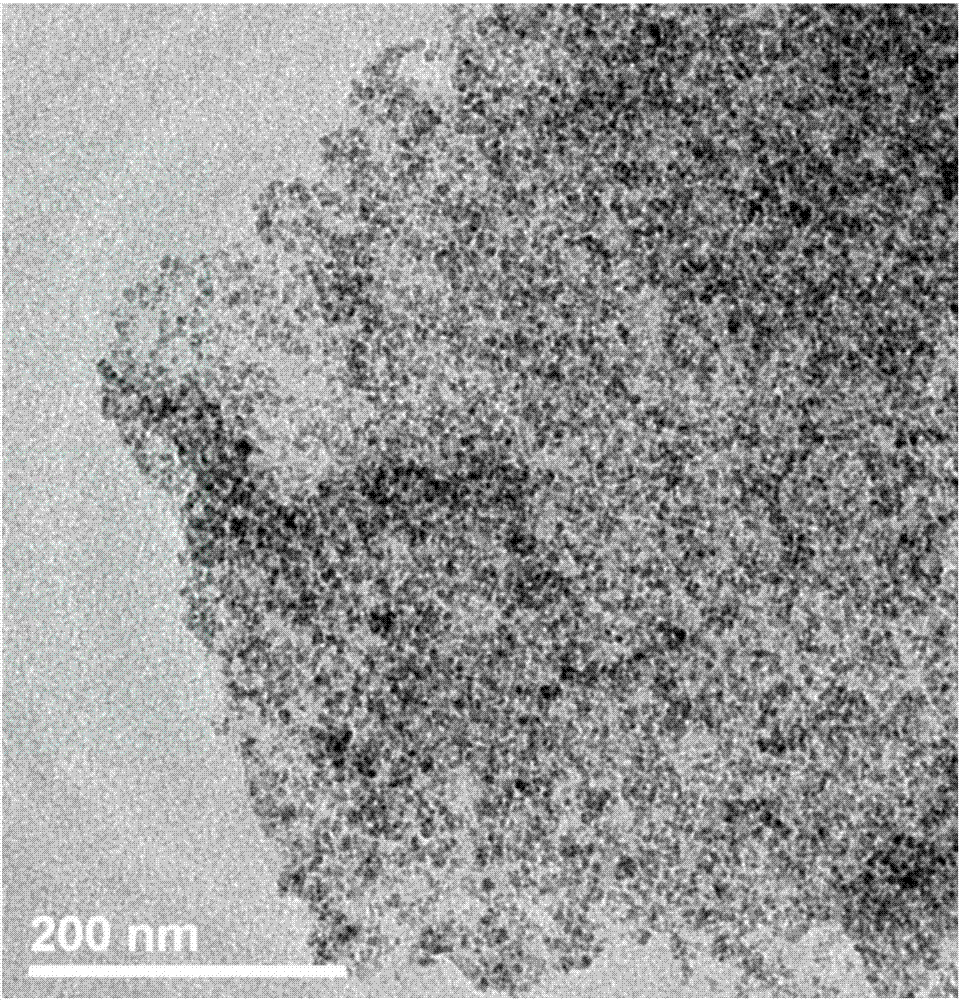

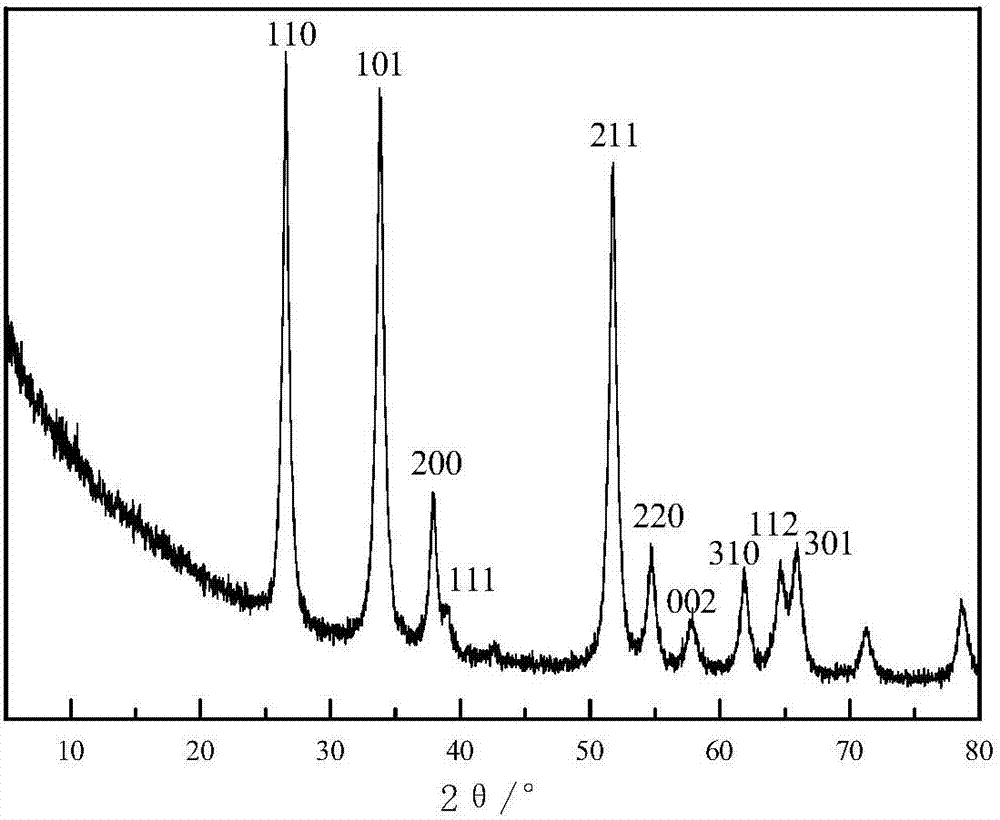

[0052] The graphene-tin-antimony oxide composite material provided in this embodiment is mainly made of graphene oxide and tin-antimony oxide composite. Wherein, the mass ratio of the graphene oxide water body to the tin-antimony oxide composite is 1:1.

[0053] This embodiment also provides a method for preparing graphene-tin antimony oxide composite material:

[0054] Add 27g of concentrated sulfuric acid to 5g of graphite flakes, and slowly add 10g of potassium permanganate during electric stirring to obtain a mixture of concentrated sulfuric acid / graphite flakes / potassium permanganate, which is the first mixed solution, wherein the average particle size of graphite flakes is 1 μm . Continue electric stirring of the first mixed solution and raise the temperature of the water bath to 60° C. and keep it for 5 hours, stop the electric stirring, pour the first mixed solution into 35 g of ice-water mixture, then slowly add 60 g of hydrogen peroxide to it and manually stir until...

Embodiment 2

[0058] The graphene-tin-antimony oxide composite material provided in this embodiment is mainly made of graphene oxide and tin-antimony oxide composite. Wherein, the mass ratio of the graphene oxide water body to the tin-antimony oxide composite is 1:5.

[0059] The concentrated sulfuric acid that present embodiment adopts is 35g, flake graphite is 3g, and the average particle diameter of flake graphite is 3 microns, and potassium permanganate is 12g. The heating temperature is 65° C., the holding time is 4 hours, the amount of ice water added is 20 g, and the amount of hydrogen peroxide added is 70 g. The standing time is 20 hours, the amount of dilute hydrochloric acid added is 8g, the amount of deionized water added is 120g, the centrifugation speed is 13000r / min, the centrifugation time is 20 minutes, and the pH is 6.4.

[0060] 1.6g of graphene oxide was mixed with 9.646g of stannous chloride dihydrate and 2.438g of antimony chloride in a ball mill for 40min. Wherein, t...

Embodiment 3

[0062] The graphene-tin-antimony oxide composite material provided in this embodiment is mainly made of graphene oxide and tin-antimony oxide composite. Wherein, the mass ratio of the graphene oxide water body to the tin-antimony oxide composite is 1:10.

[0063] The concentrated sulfuric acid that present embodiment adopts is 20g, flake graphite is 4g, and the average particle diameter of flake graphite is 2 microns, and potassium permanganate is 15g. The heating temperature is 55° C., the holding time is 3 hours, the amount of ice water added is 40 g, and the amount of hydrogen peroxide added is 80 g. The standing time was 30 hours, the amount of dilute hydrochloric acid added was 10 g, the amount of deionized water added was 80 g, the rotational speed of centrifugation was 12500 r / min, the centrifugation time was 17 minutes, and the pH value was 5.5.

[0064] 1 g of graphene oxide was ground and mixed with 12.06 g of stannous chloride dihydrate and 3.047 g of antimony chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com