Patents

Literature

71results about How to "Dwell time is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

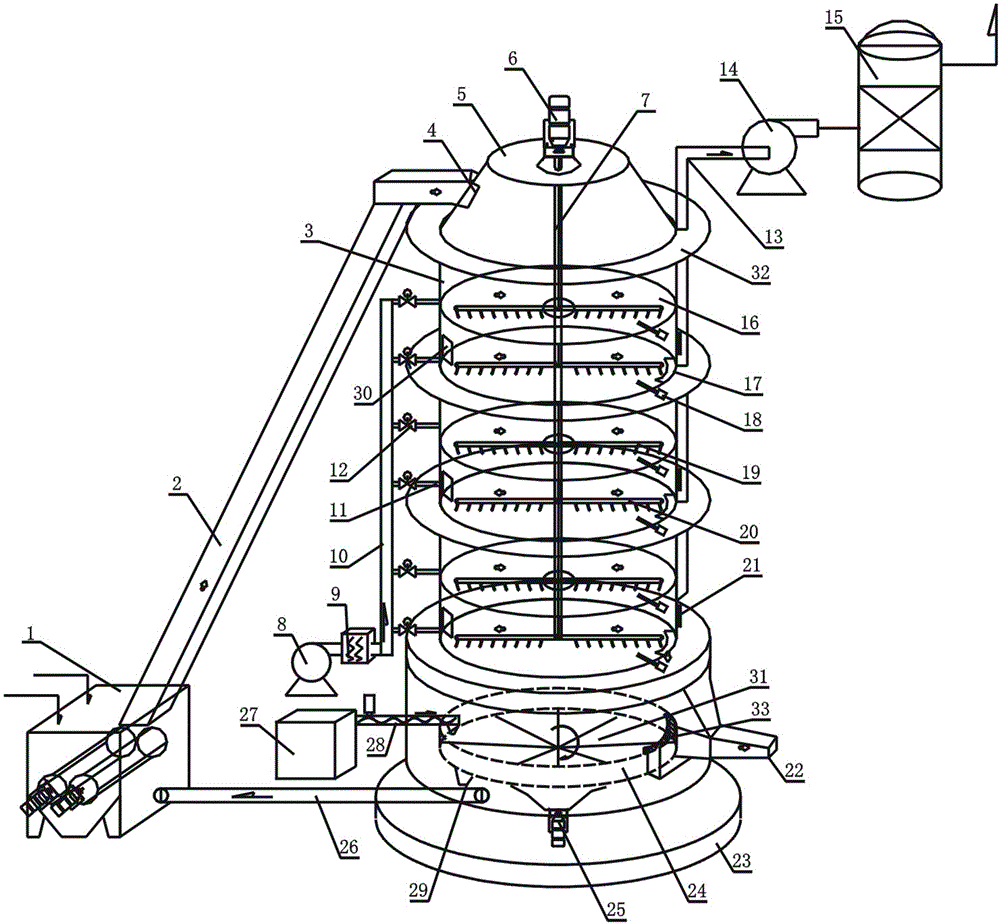

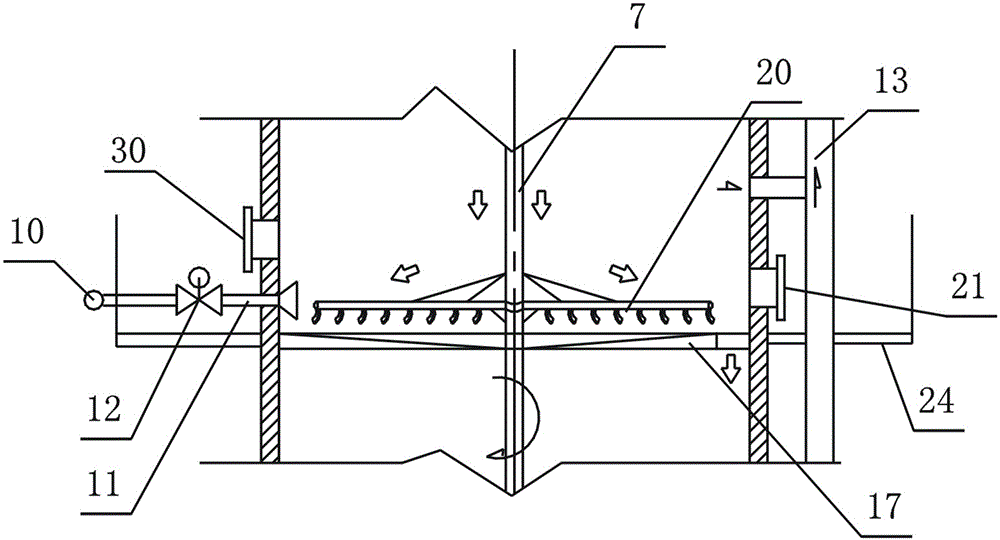

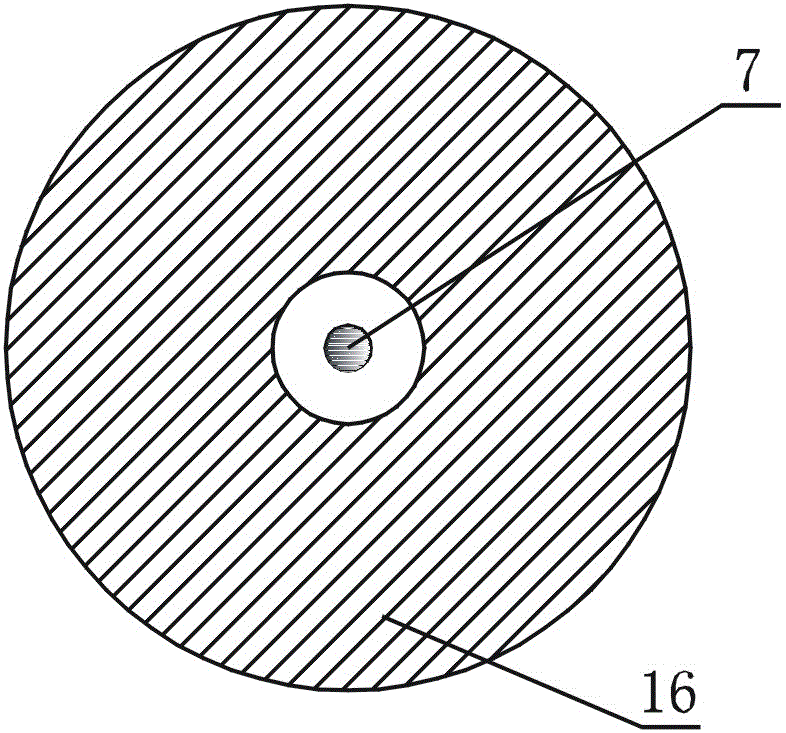

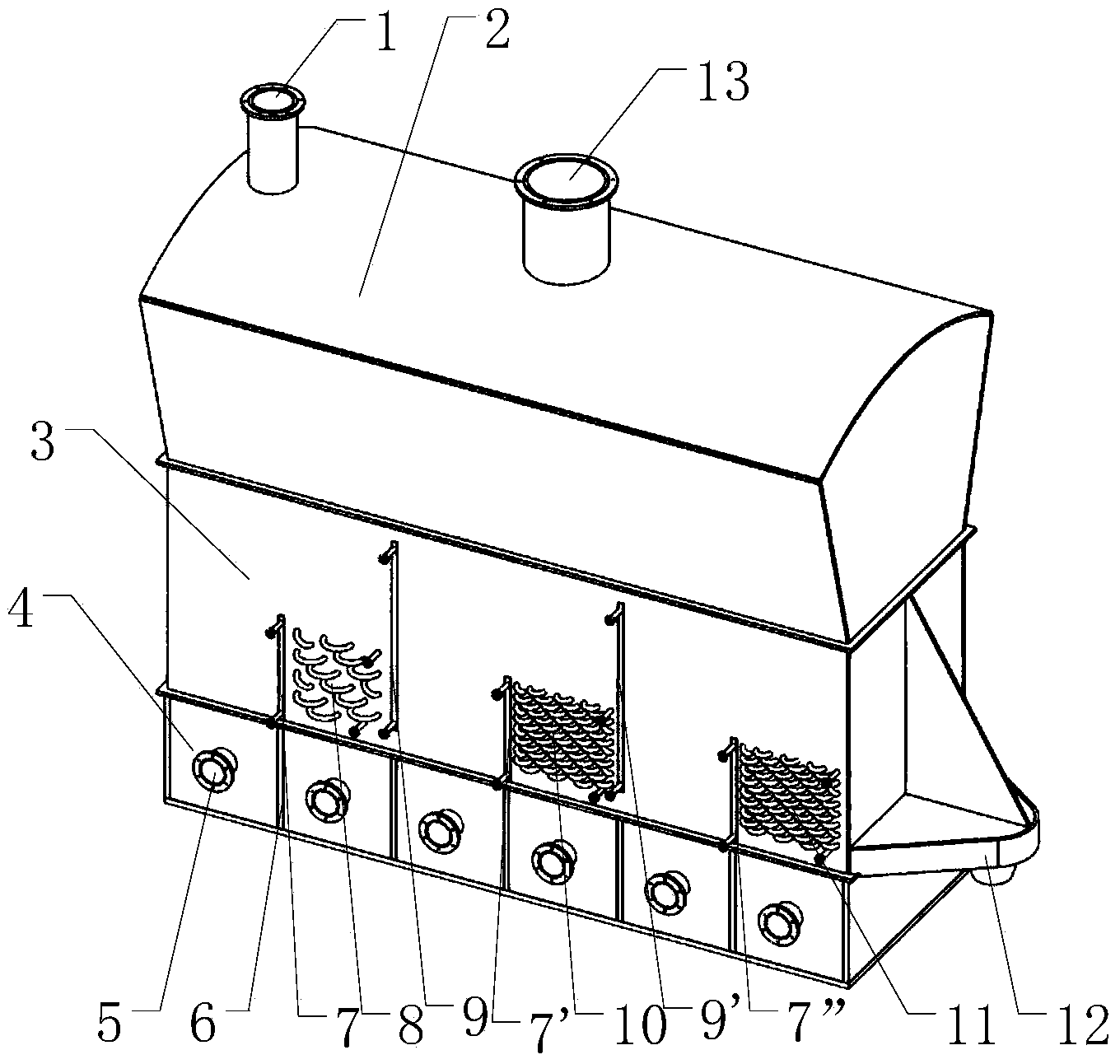

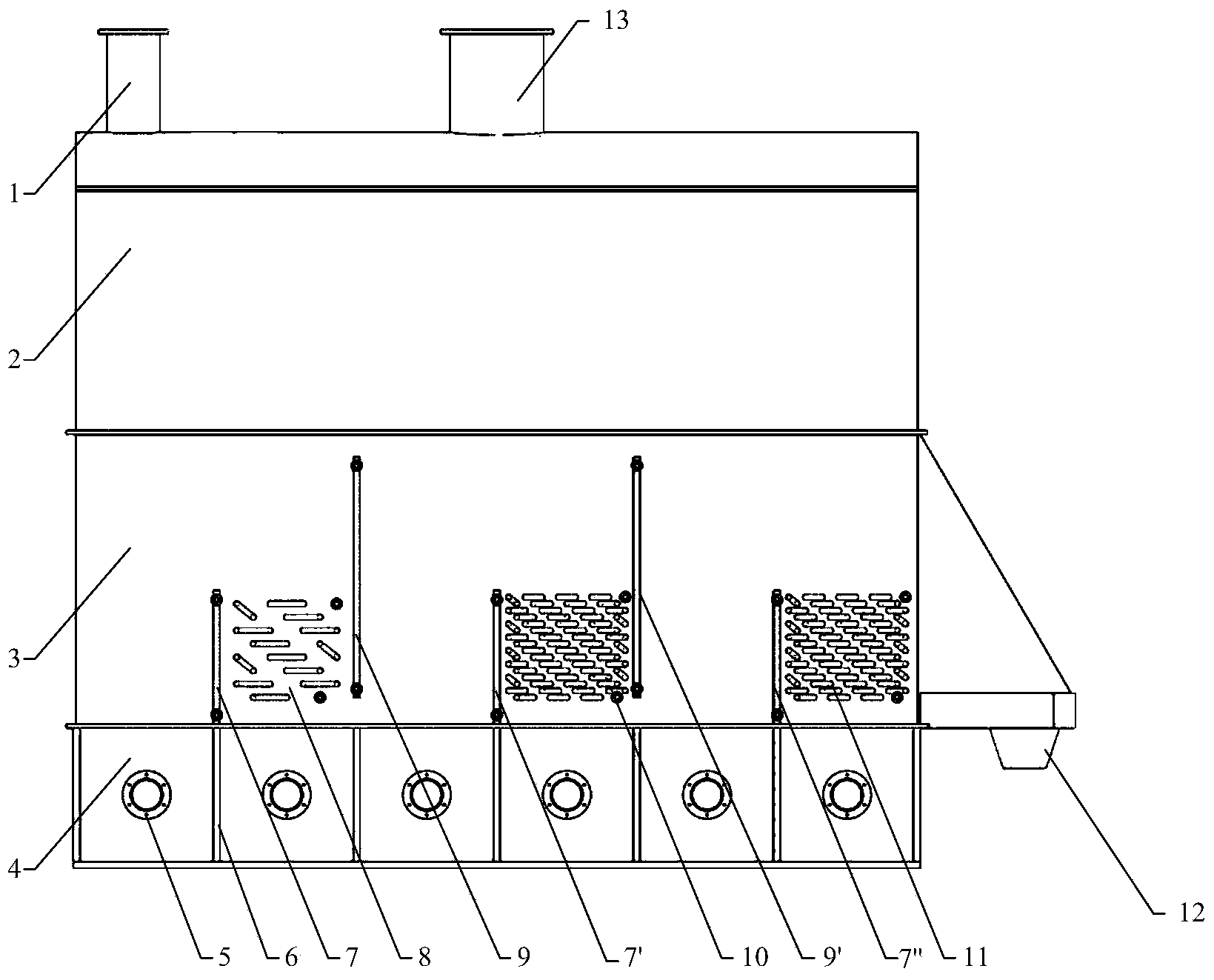

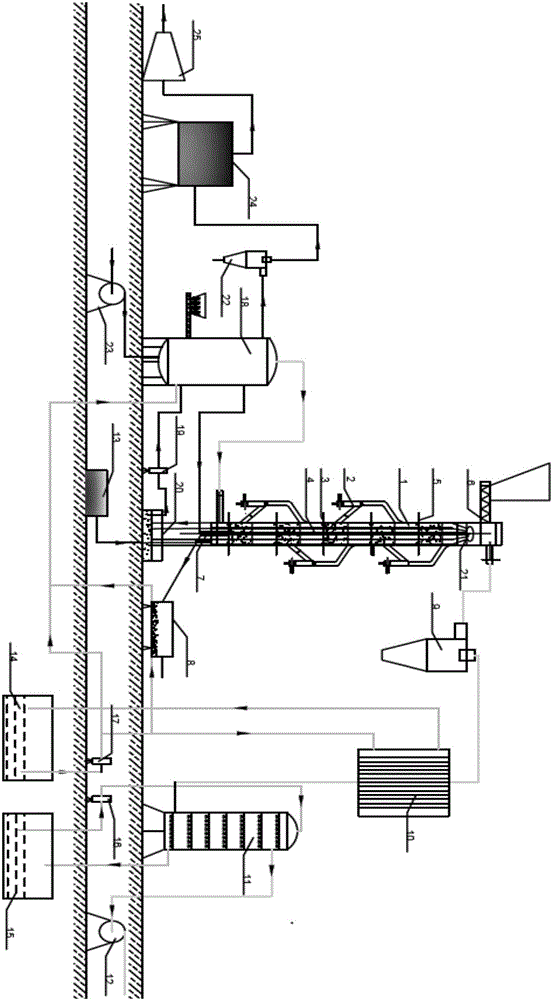

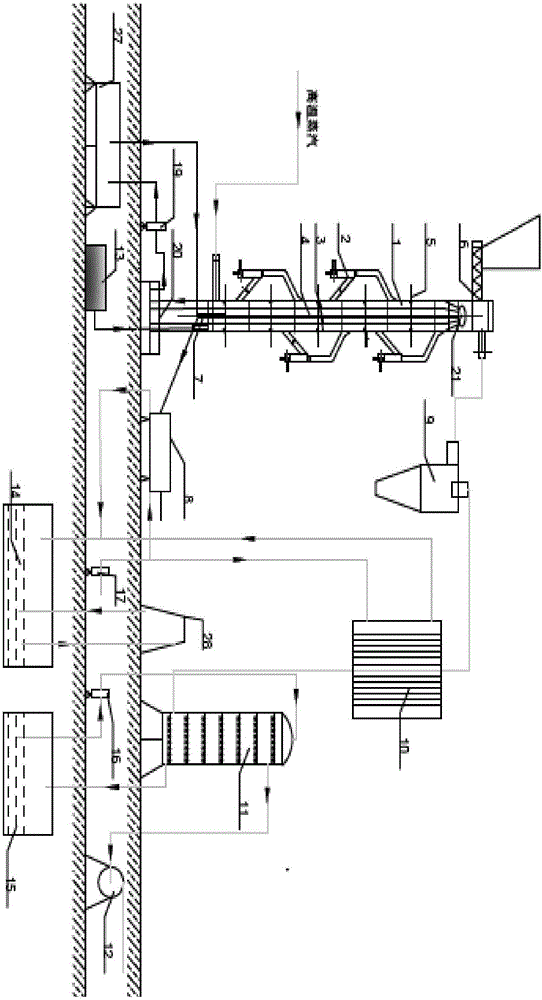

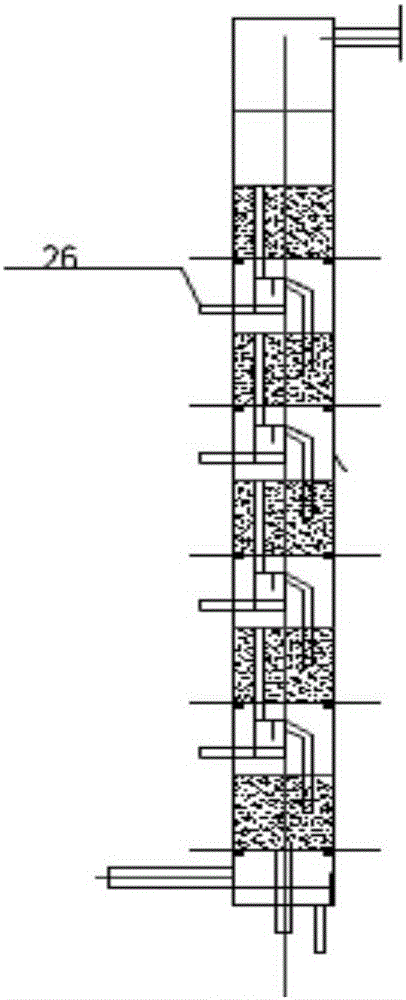

Aerobic composting device for organic solid waste

ActiveCN103145467ARealize resource utilizationAchieve reductionBio-organic fraction processingOrganic fertiliser preparationTemperature controlAir blower

The invention discloses an aerobic composting device for organic solid waste, which comprises a feeding mixer, a conveyor, a fermentation tower, a scraper blade drive device, an air blower, a heating device, an exhaust fan, a waste gas processing device, centre discharge trays, periphery discharge trays, a swivel type granulator, a granulator drive device, a return conveyor, a granulating agent adding device and a spiral conveyor. The aerobic composting device is characterized in that a conical sealing cover is arranged above the fermentation tower, the swivel type granulator is arranged below the fermentation tower; the feeding mixer is connected with the feeding opening in the side surface of the sealing cover through the conveyor; an inward scraper blade is arranged above the centre discharge tray, and an outward scraper blade is arranged above the periphery discharge tray; and two or more groups of the centre discharge trays and the periphery discharge trays are arranged in the fermentation tower from top to bottom. The aerobic composting device for the organic solid waste disclosed by the invention has the characteristic of processing the organic solid waste in a quantity-reduction, stable and harmless manner to realize resource recycling; in addition, the device occupies a small space and also has the characteristics of automatic feeding, granulating, self-control venting, temperature controlling and tail gas processing.

Owner:湖南洁源生物能源科技有限公司

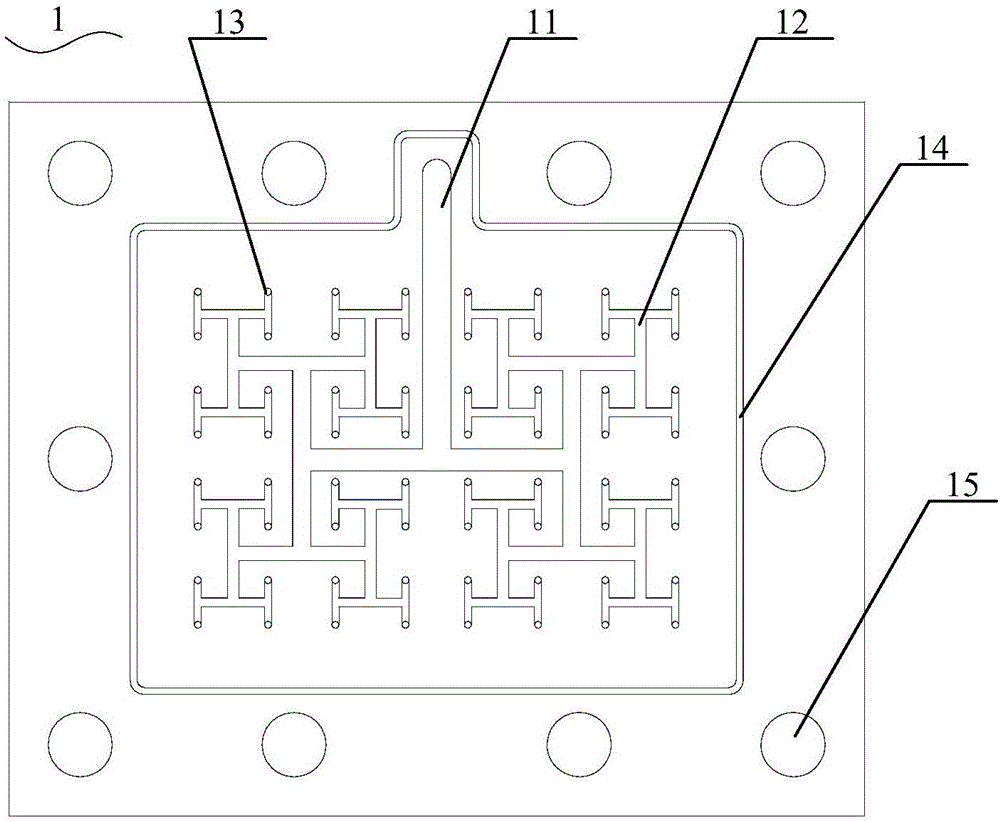

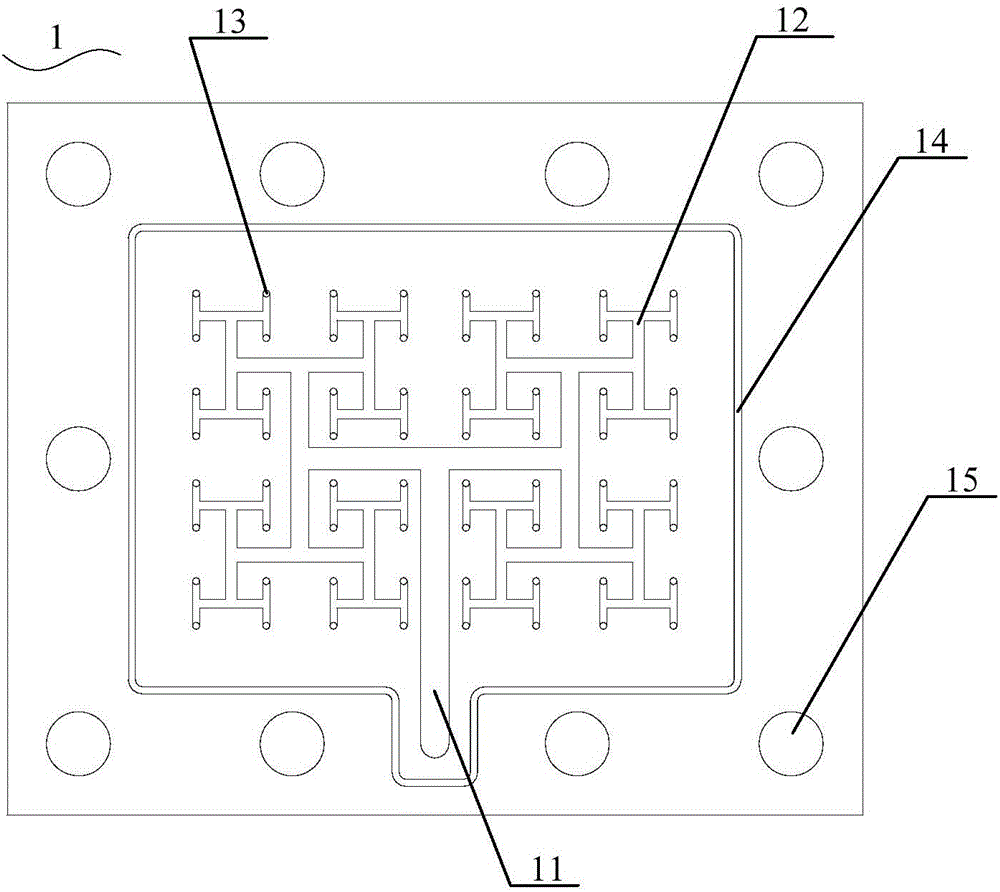

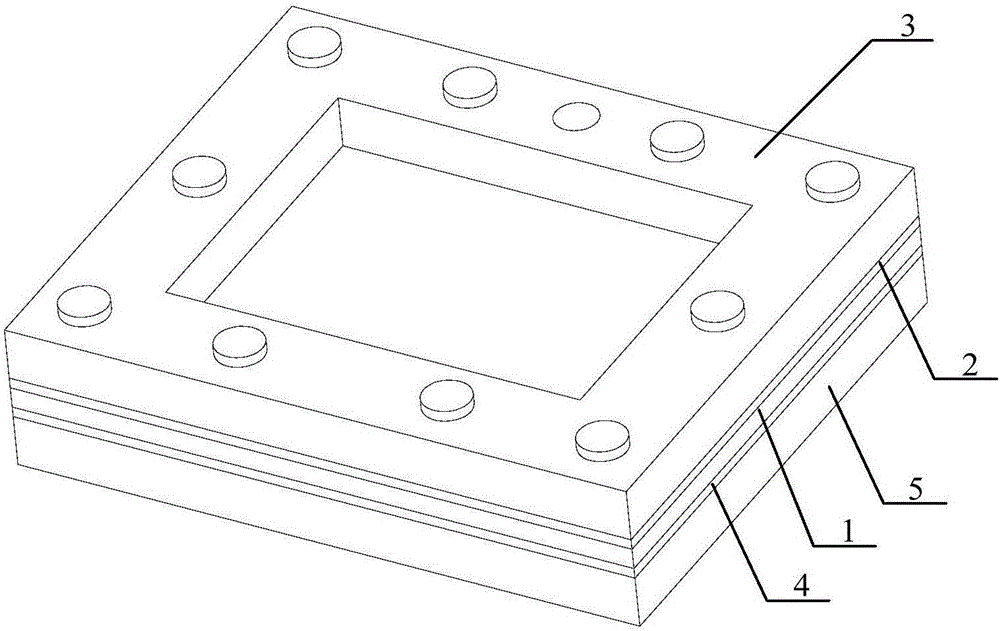

Microchannel plate with fractal structure, photocatalytic reactor and application thereof

InactiveCN106311110AControl flowControl dwell timeChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionThree-phase

The invention provides a microchannel plate with a fractal structure, a photocatalytic reactor and an application thereof. The microchannel plate with the fractal structure comprises a first surface and a second surface which are opposite; the first surface and the second surface of the microchannel plate with the fractal structure each is provided with a main pipeline microchannel and multistage H-shaped fractal bifurcated microchannels which are connected with one end of the corresponding main pipeline microchannel, and the H-shaped fractal bifurcated microchannels of the first surface of the microchannel plate with the fractal structure communicate with those of the second surface of the microchannel plate with the fractal structure through connecting through holes. According to the microchannel plate with the fractal structure, the photocatalytic reactor and the application thereof, through forming fractal-structured microchannels in the upper and lower surfaces of the microchannel plate with the fractal structure, three phases, i.e., gas, liquid and solid phases can be effectively distributed, heat transfer and mass transfer are strengthened, the problem in collection of reactants of fractal distribution can be effectively solved, meanwhile, the length of the microchannels can be increased, and the control on reaction flux and reactant residence time is better facilitated.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

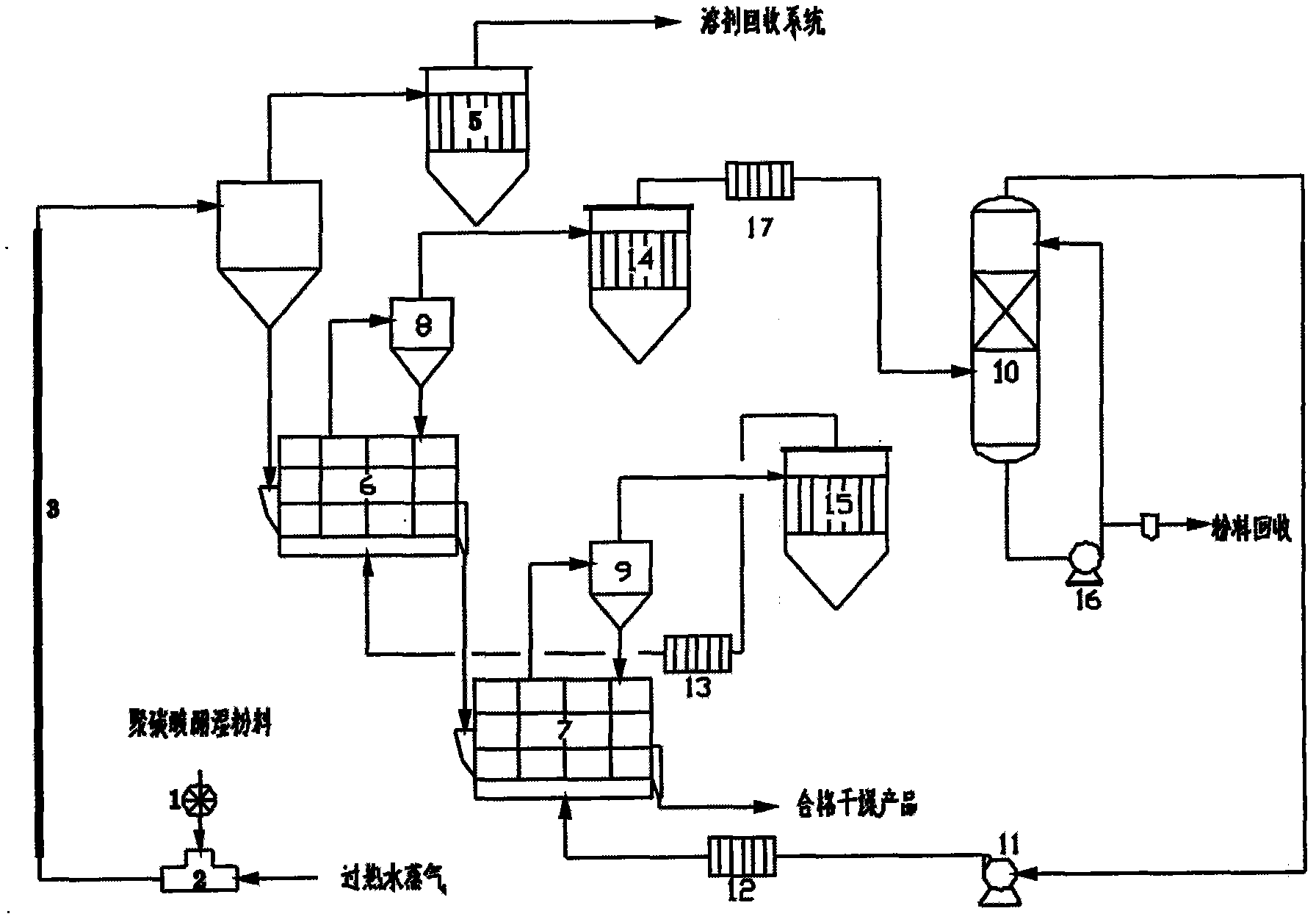

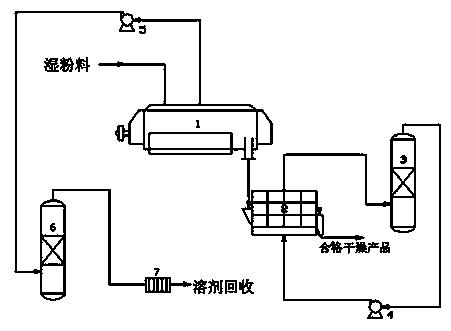

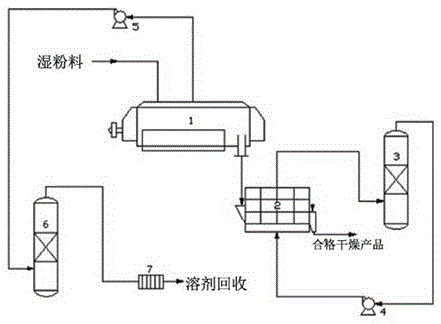

Method for drying poly carbonate (PC)

InactiveCN102620526ASolving Recycling ProblemsAvoid accident hazardsDrying solid materials with heatHearth type furnacesFluidized bed dryingThree stage

The invention relates to a method for drying polycarbonate (PC), which is characterized in that PC powder is subjected to drying treatment by adopting a one-stage pneumatic drying and two-stage fluid bed drying combined way, and overhot vapor is used as the drying medium in the one-stage drying process; and hot nitrogen gas is used as the drying medium in the fluid bed drying process, the nitrogen gas is recycled through processes such as washing, cooling, dehumidifying, pressurizing, heating and the like, and the PC powder in washing water is recycled. The water content of a product dried in the three-stage draying combined way can meet the later processing requirement, accident potentials such as dust explosion and the like caused in the drying process of the PC powder can be effectively solved, and the quality of the product can be improved.

Owner:甘肃银光聚银化工有限公司 +1

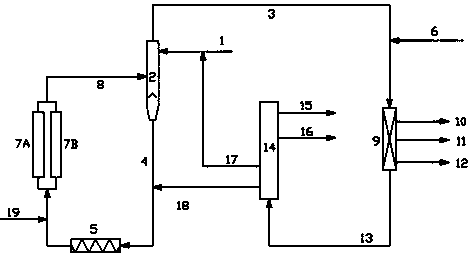

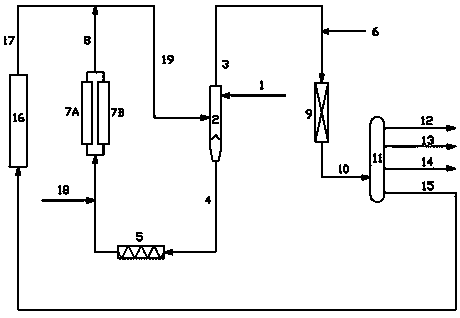

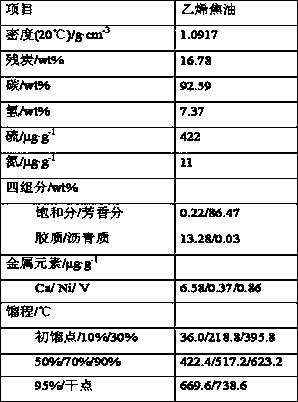

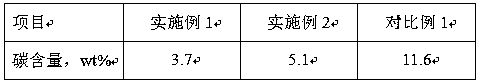

Process and system for treating ethylene tar

ActiveCN109929592APlay a role in strippingRestricted accessTreatment with hydrotreatment processesCracking reactionTreatment system

The invention discloses a process and a system for treating ethylene tar. According to the process, preheated ethylene tar contacts a coking reaction effluent from a delayed coking reaction system ina pretreatment reactor, and a light component and a heavy component are obtained after separation; the heavy component enters the delayed coking reaction system, and the generated coking reaction effluent enters the pretreatment reactor; the light component and hydrogen enter a hydrogenation reaction system, and the reaction effluent is separated to obtain gas, gasoline distillate, diesel oil distillate and heavy oil distillate; and the heavy oil distillate enters a catalytic cracking reaction system, and the catalytic diesel oil obtained after separation enters the pretreatment reaction. Thetreatment system comprises the pretreatment reactor, the coking reaction system, the hydrogenation reaction system, and the catalytic cracking reaction system. With the process and the system of the present invention, the stable long-cycle operation of the whole treatment system can be ensured, and the yield of the light oil product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

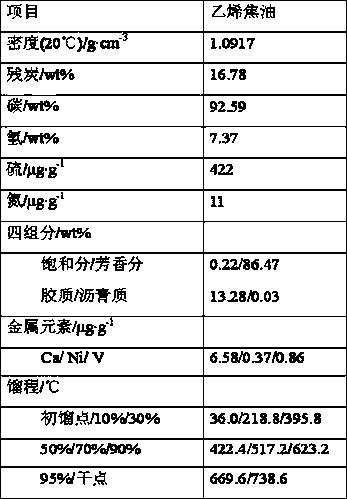

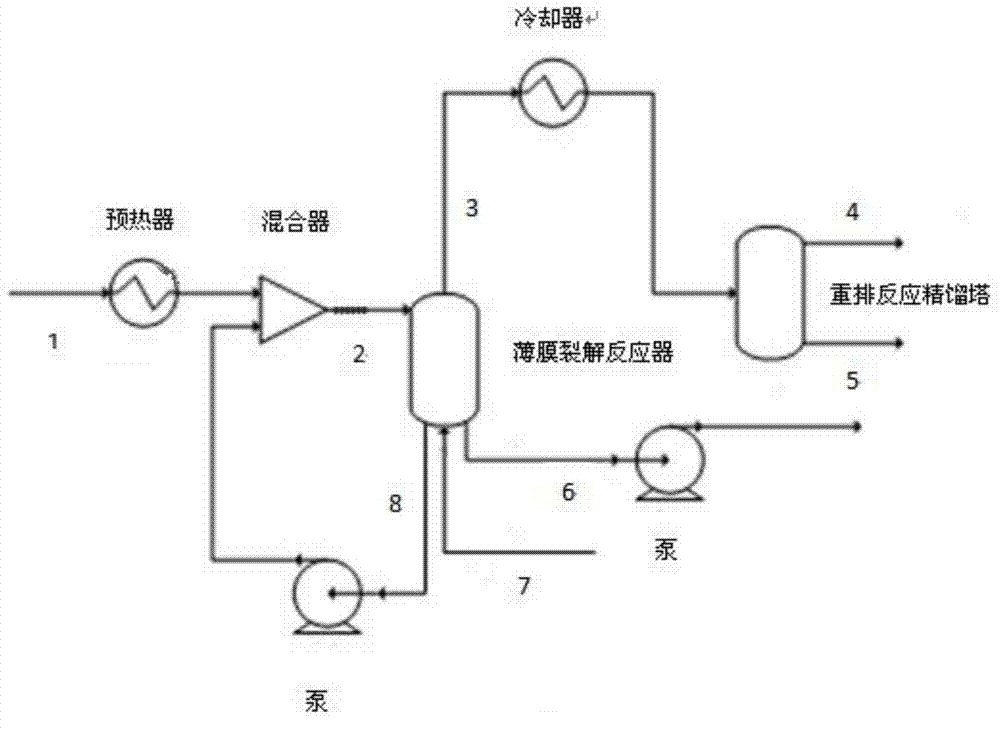

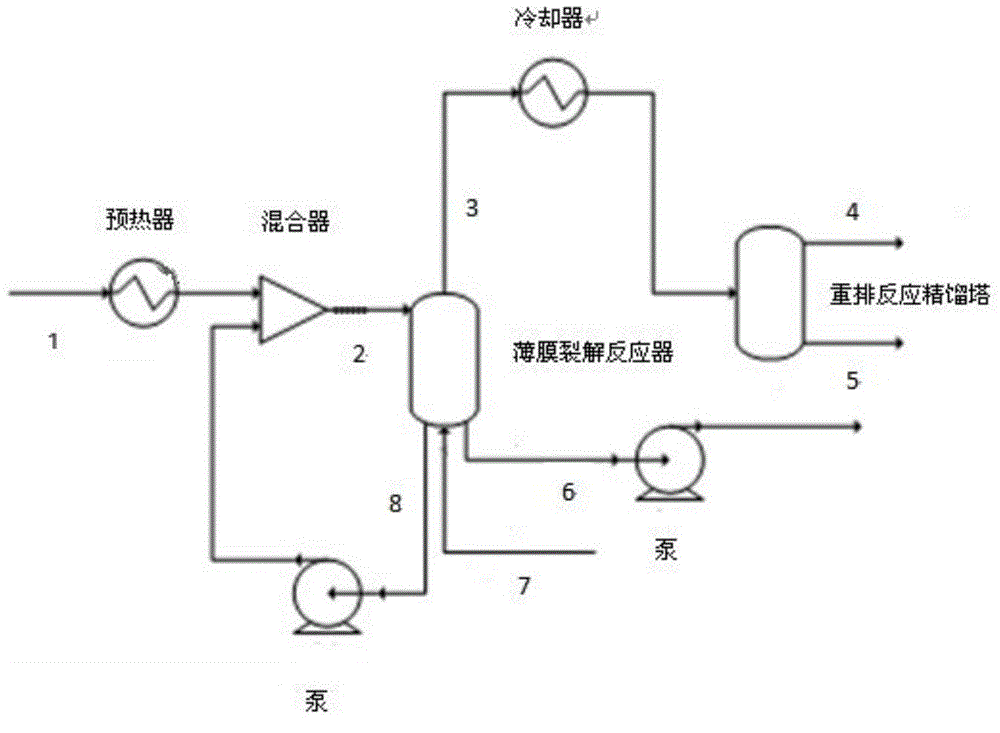

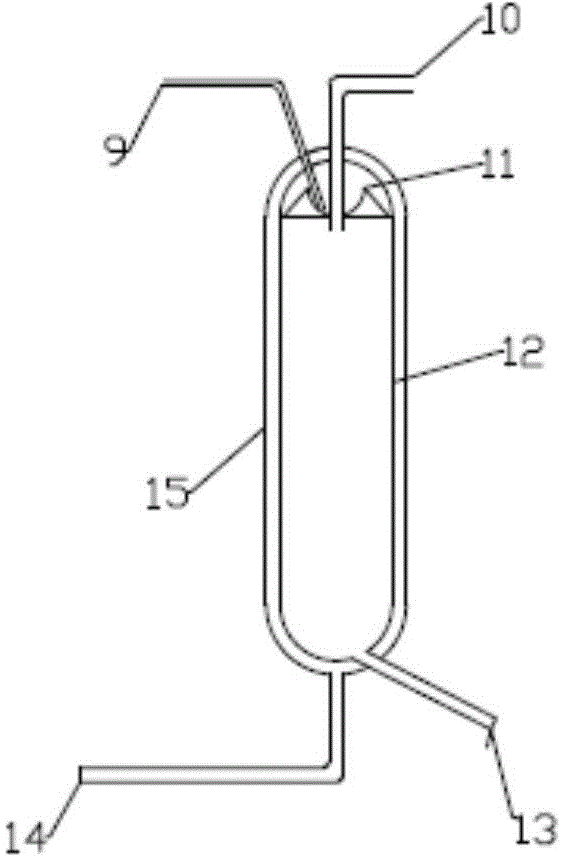

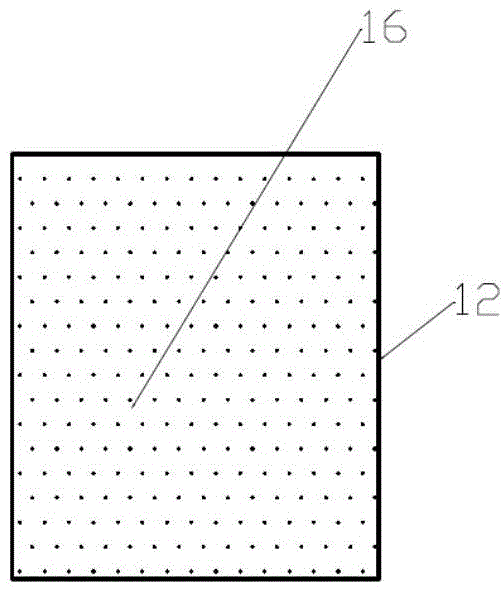

Preparation method of citral

ActiveCN103787852ASmall liquid holding capacityIncrease reaction rateOrganic compound preparationCarbonyl compound preparationAlcoholNitrogen gas

The invention discloses a preparation method of citral. The preparation method comprises the following steps: reacting 3-methyl-2-butene-1-aldehyde diisopentenyl acetal in a film cracking reactor with a nitrogen gas stripping function to obtain prenyl alcohol and prenyl isopentenyl ether, adding a mixture of the prenyl alcohol and the prenyl isopentenyl ether into a reactive rectifying tower, continuously extracting the prenyl alcohol from the top of the tower and continuously extracting from the citral from the bottom of the tower. According to the method, the residence time of an intermediate under high-temperature and acidic conditions can be remarkably shortened, byproducts are reduced, and the citral selection performance can be more than 98%.

Owner:WANHUA CHEM GRP CO LTD +1

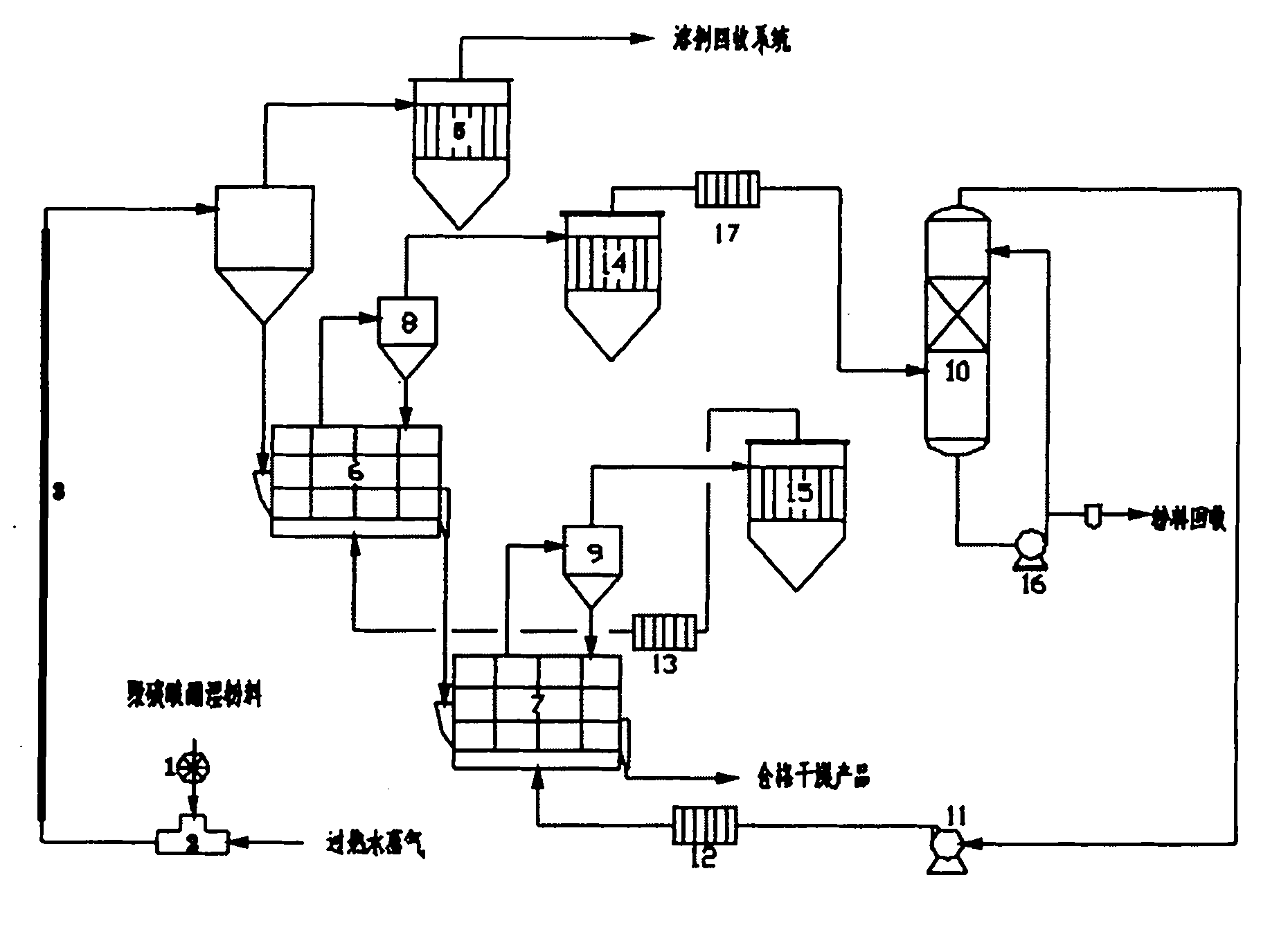

Method for drying polycarbonate

ActiveCN103640108AReduce pipeline corrosionReduce energy consumptionDrying solid materials with heatHalogenated hydrocarbon separation/purificationPolycarbonateChemistry

The invention relates to a method for drying polycarbonate. The method for drying polycarbonate is characterized by comprising the following steps: a. firstly, desorbing and recycling a dichloromethane solvent in polycarbonate powder by a paddle dryer; and b. then drying the polycarbonate powder deeply by a fluidized bed dryer, wherein cycling thermal nitrogen serves as a fluidized bed drying medium. The polycarbonate powder is dried by adopting a two-stage drying technology method, and the recycling issue of the dichloromethane solvent in the process of drying the polycarbonate powder is solved effectively as well as the drying effect is achieved; the accident hazard of flammable and combustible dust of the polycarbonate drying system is prevented; and the safety of the polycarbonate drying system is improved.

Owner:甘肃银光聚银化工有限公司

Automatic chain belt conveyor

InactiveCN101823614AAdjustable conveying speedAccurate stay positionConveyorsControl devices for conveyorsElectricityDrive wheel

The invention relates to the technical field of conveyors, in particular to an automatic chain belt conveyor. The automatic chain belt conveyor comprises a frame, a driving wheel, a driven wheel, and a speed regulation motor which drives the driving wheel to rotate, wherein the driving wheel, the driven wheel and the speed regulation motor are arranged on the frame, the driving wheel drives the driven wheel to rotate via a transmission belt. The automatic chain belt conveyor also comprises an inductive switch, a timer and a control circuit, wherein the speed regulation motor, the inductive switch and the timer are respectively and electrically connected with the control circuit. The invention can prevent the product on a supporting plate from vibrating, can adjust the conveyance speed of the supporting plate, can prevent the misplacing of the product, can prevent the false operation of the product, can realize accurate stop position of the supporting plate, can control the stop time of the supporting plate, and can operate fully automatically by being matched with an ultrasonic machine, a soldering machine, a transfer printing machine, an oiling gun and other mechanical devices. In addition, the invention has firm overall structure and can be moved freely.

Owner:覃其凤

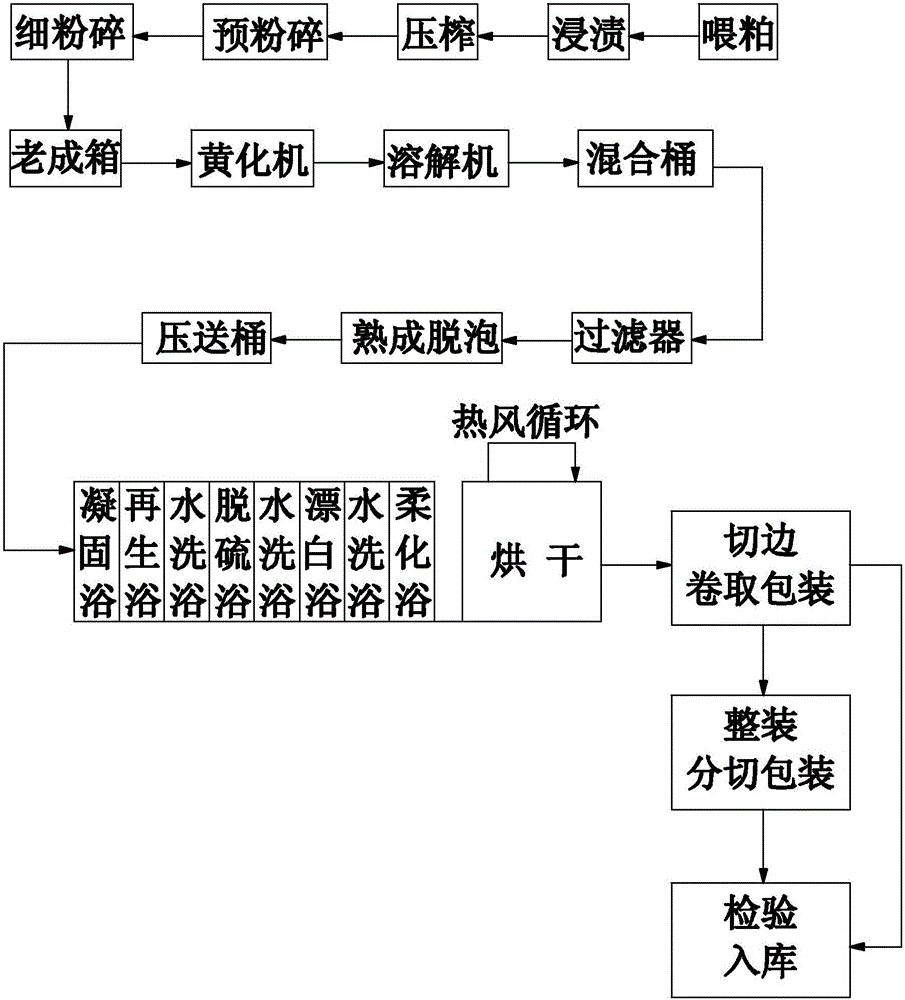

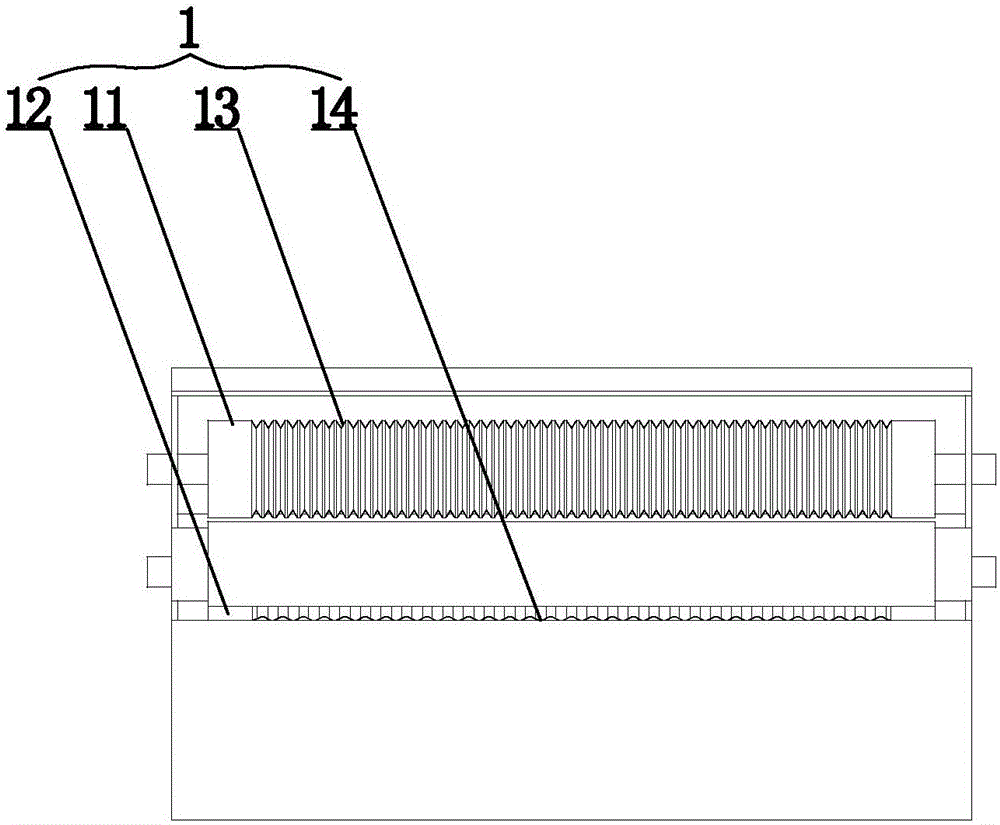

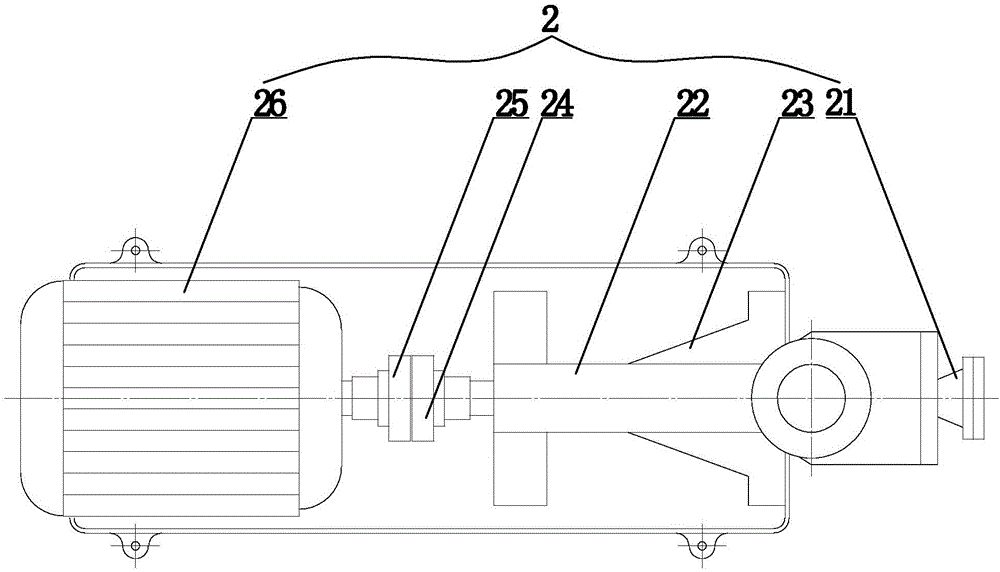

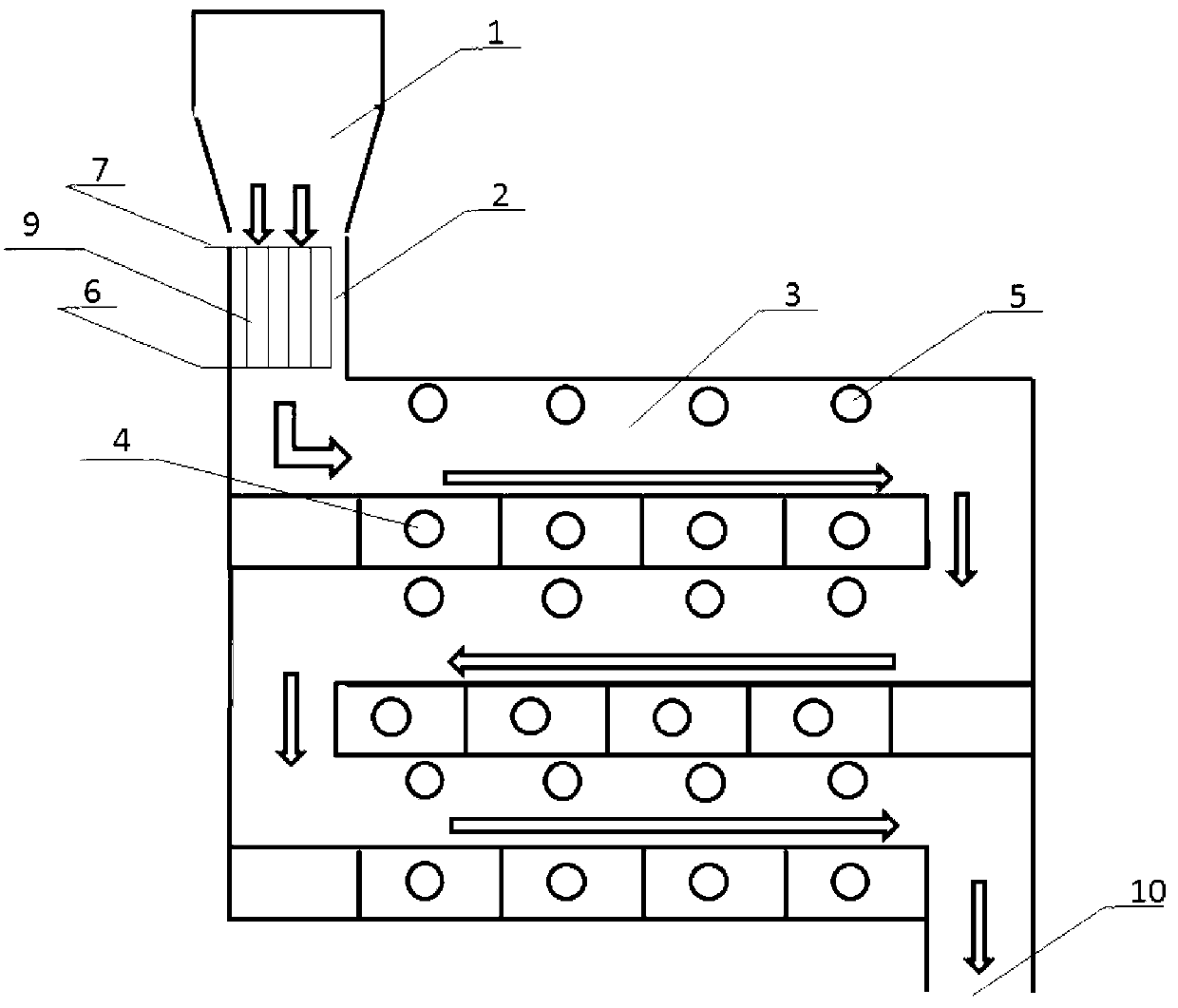

Preparation method of food package paper

The invention relates to a preparation method of a food package paper and belongs to the technical field of inorganic substance or its complex-based treatment on fibers, yarn, wires, fabrics or their fiber products. The preparation method utilizes pulp as a raw material and comprises dipping, squeezing, crushing, aging, yellowing, dissolution, curing, solidification in a solidification bath, primary washing, desulphurization, rinsing, secondary washing, softening, drying and rolling. The preparation method is used for cellulose membrane food package paper processing and has the advantages of stable mechanical properties and high safety.

Owner:SHAOXING CHUNMING NATURAL CELLULOSE MEMBRANE CO LTD

Moving bed brown coal drying method and device

ActiveCN102997634AAdaptableFully contactedDrying solid materials with heatHearth type furnacesBrown coalRetention time

The invention discloses a moving bed brown coal drying method and device, and relates to the technical fields of brown coal drying techniques and devices. Brown coal enters a direct drying chamber of a horizontal moving bed to remove moisture after being dried by an indirect drying chamber of a vertical moving bed firstly; and high-temperature hot air inside the indirect drying chamber indirectly transfers the heat to brown coal particles when flowing through a pipeline arranged in the movement direction of a coal bed. Therefore, a rapid drying process is achieved; the floor space and the height of a drying system can be reduced; and safe operation of the system can be ensured. A direct drying chamber adopts a one-layer or multi-layer horizontal moving bed structure; the hot gas and the brown coal are directly subjected to heat exchange; the moisture content of a terminal dry product is conveniently controlled by controlling the retention time of the brown coal particles; and the adaptability of the drying system on raw coal is more excellent. The entire device does not generate a fluidization control problem; treatment of large-grain brown coal particles is facilitated; the particle sizes of the particles of the terminal product and controllable moisture content are guaranteed; and the system is simpler, more stable and safer to operate.

Owner:TSINGHUA UNIV

Environmentally-friendly transport vehicle for fresh and live aquatic products

PendingCN107627941APhysiological signs are stableRealize environmental protectionAir-treating devicesWater contaminantsMonitoring systemAquatic product

The invention provides an environmentally-friendly transport vehicle for fresh and live aquatic products. The environmentally-friendly transport vehicle comprises a carriage, a solar cooling system isarranged on the carriage, the carriage is internally provided with keep-alive boxes with a water cycle device, and a solar power system used for power supply is provided; the water cycle device comprises a water pump, a water inlet of the water pump is communicated with the keep-alive boxes, a water outlet of the water pump is connected with a filtering and sterilization box, the filtering and sterilization box is connected with a cool-heat-exchanger through a foam separation device, the cool-heat-exchanger is communicated with the keep-alive boxes, and the water pump is connected with a controller. According to an inner-box environment monitoring system of the transport vehicle, optical fiber sensors are applied to measurement of oxygen, the temperatures and ammonia-nitrogen in water inan aquatic product transporting process, so that the transport environments of the aquatic products are accurately monitored in real time; according to the transport vehicle, the multiple keep-alive boxes are independently controlled, and the appropriate environments are provided for each kind of aquatic products, so that the transporting keep-alive rate of the fresh and live aquatic products is effectively improved.

Owner:SHANDONG INST OF COMMERCE & TECH

Preparation method of citral

ActiveCN103787852BShort stayAvoid side reactions such as polymerizationOrganic compound preparationCarbonyl compound preparationAlcoholNitrogen gas

The invention discloses a preparation method of citral. The preparation method comprises the following steps: reacting 3-methyl-2-butene-1-aldehyde diisopentenyl acetal in a film cracking reactor with a nitrogen gas stripping function to obtain prenyl alcohol and prenyl isopentenyl ether, adding a mixture of the prenyl alcohol and the prenyl isopentenyl ether into a reactive rectifying tower, continuously extracting the prenyl alcohol from the top of the tower and continuously extracting from the citral from the bottom of the tower. According to the method, the residence time of an intermediate under high-temperature and acidic conditions can be remarkably shortened, byproducts are reduced, and the citral selection performance can be more than 98%.

Owner:WANHUA CHEM GRP CO LTD +1

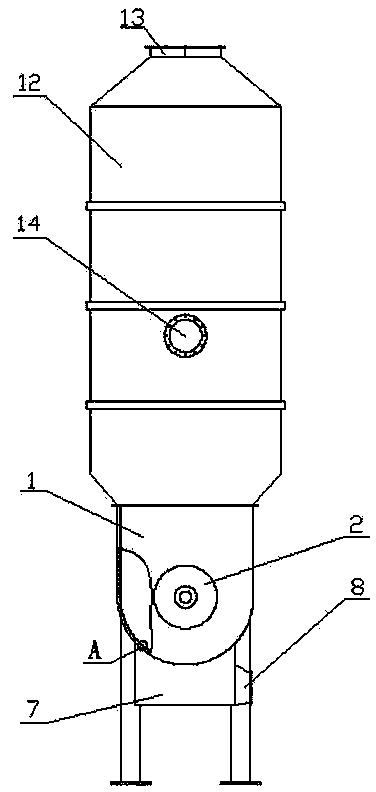

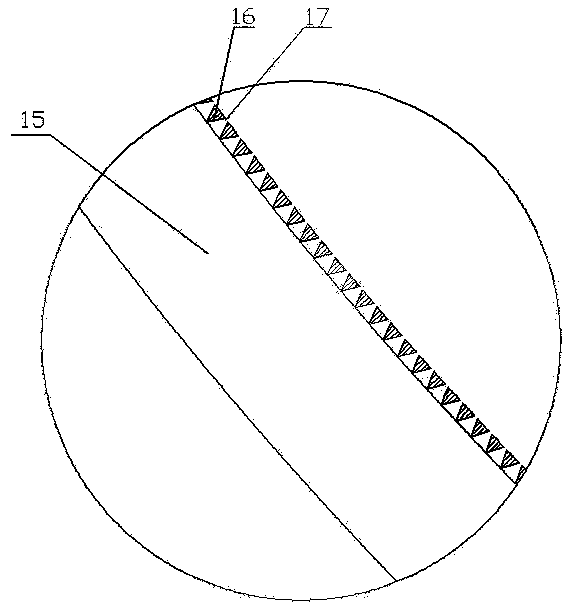

Non-uniform air distribution interconnected fluidized bed drying device

ActiveCN103542694AEliminates uneven drying or overheatingReduce wear and tearDrying solid materials with heatDrying gas arrangementsEngineeringEnergy consumption

The invention discloses a non-uniform air distribution interconnected fluidized bed drying device which comprises a separation section, a fluidization section, an air distribution section, built-in heat exchangers and partition plate heat exchangers. The separation section comprises a feeding port and an air outlet. The air distribution section comprises an air inlet, a partition plate and an air distribution plate. The fluidization section is connected between the separation section and the air distribution section and provided with the built-in heat exchangers and the partition plate heat exchangers. The built-in heat exchangers can be classified as low-density arranged built-in heat exchangers for drying, high-density arranged built-in heat exchangers for drying and built-in heat exchangers for cooling according to effect and arrangement density. The partition plate heat exchangers can be classified as low-position partition plate heat exchangers and high-position partition plate heat exchangers according to effect and position. The non-uniform air distribution interconnected fluidized bed drying device enables dried materials to be subjected to interconnected fluidization in non-uniform air distribution and regional fluidization modes and has the advantages of being high in fluidization quality, low in energy consumption, reliable in operation and the like.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

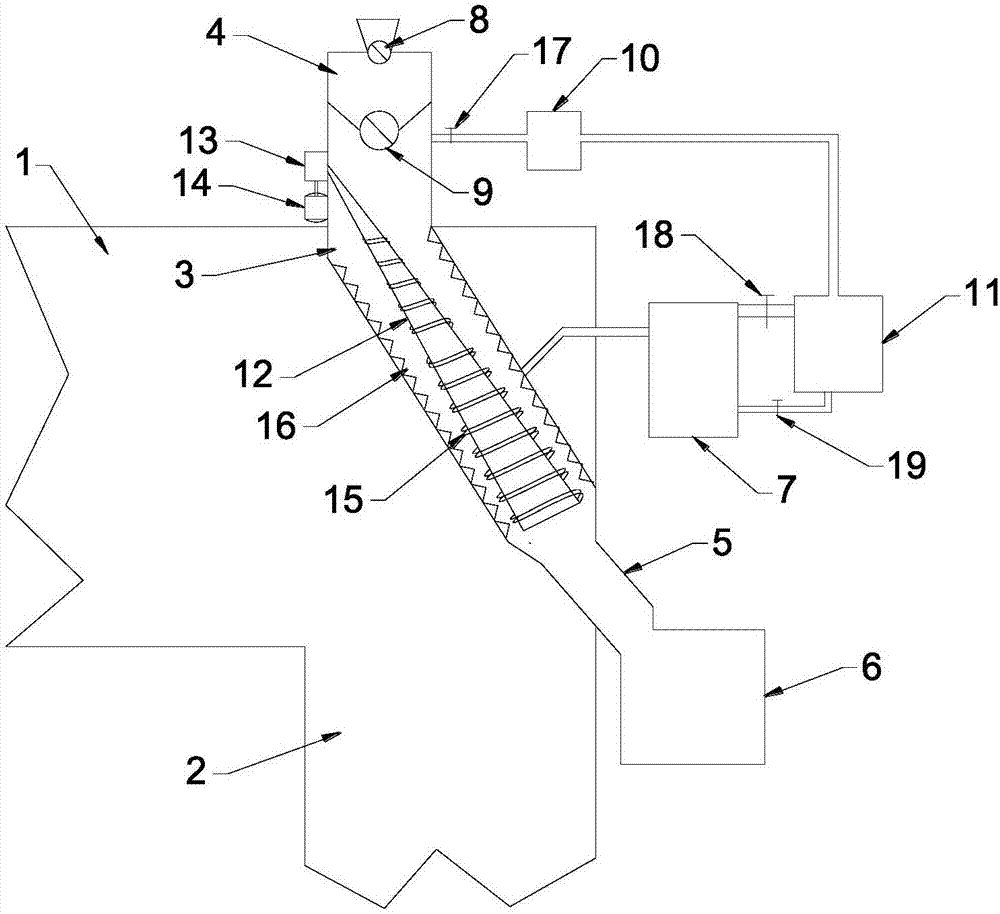

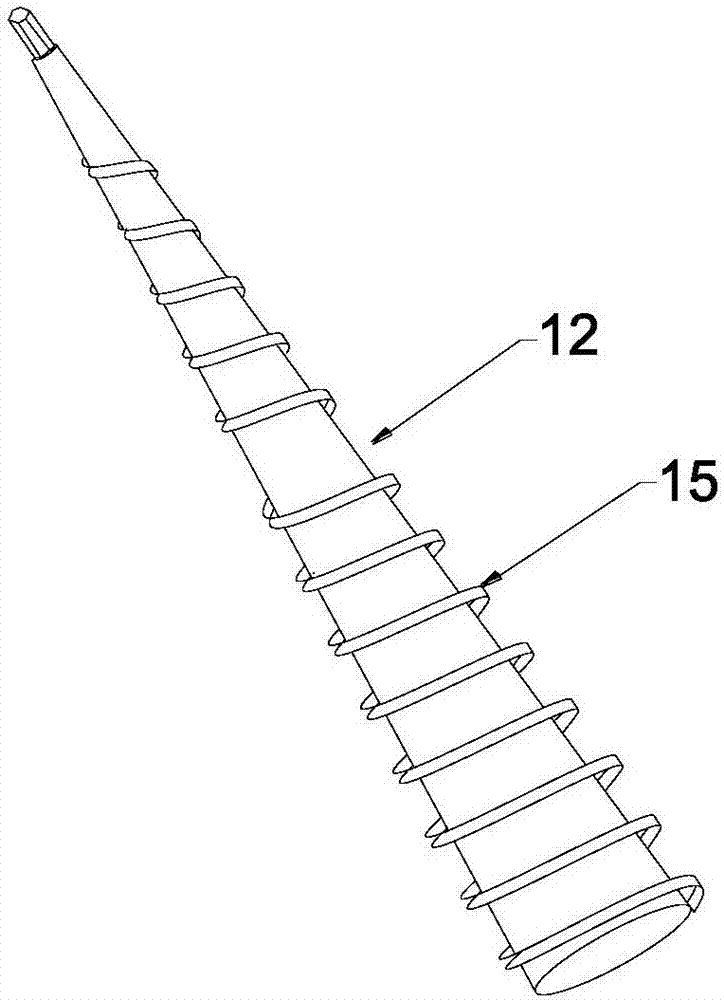

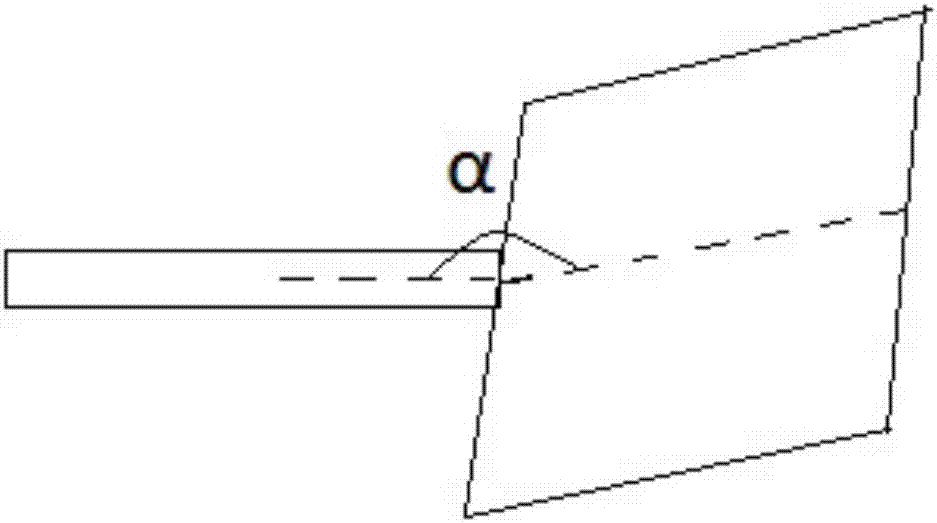

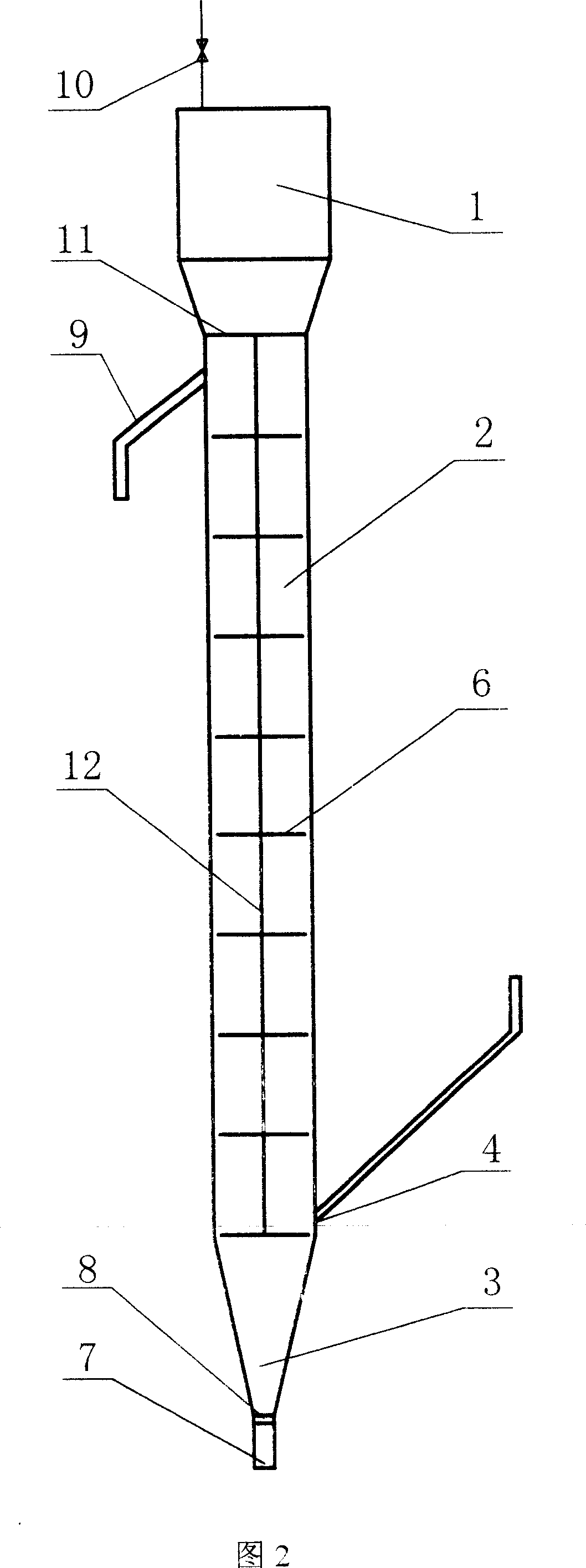

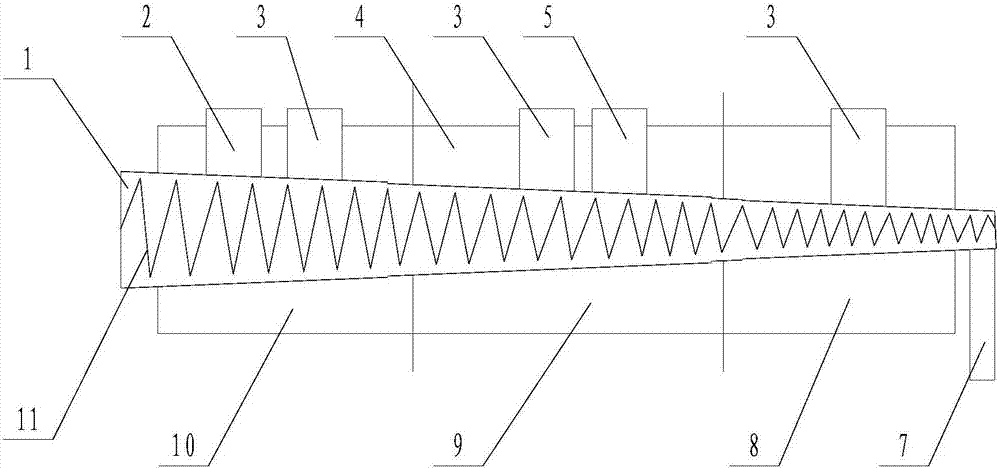

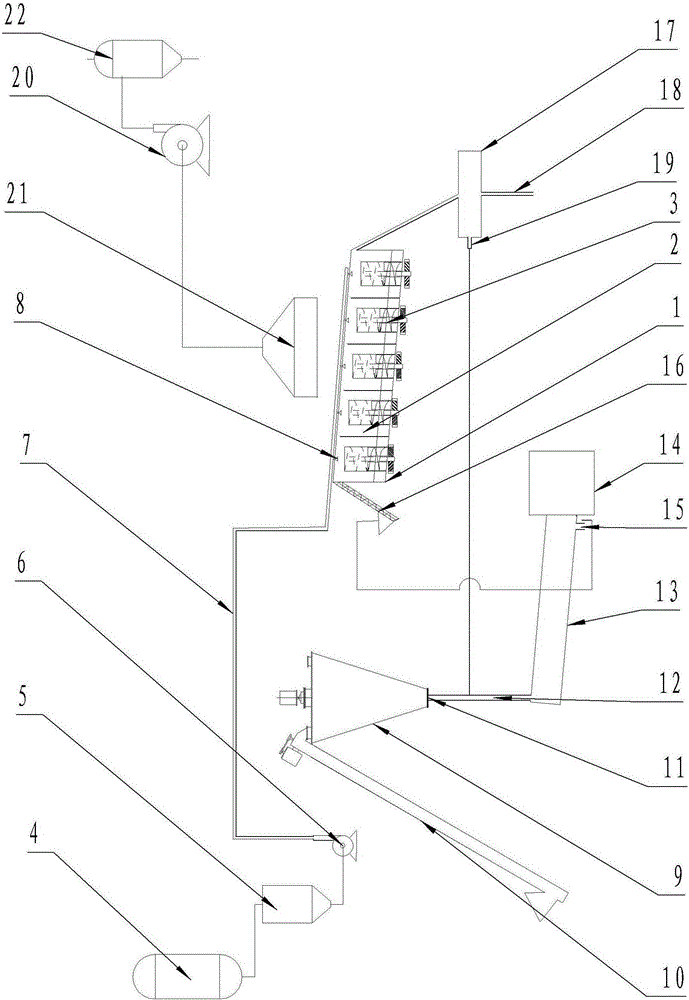

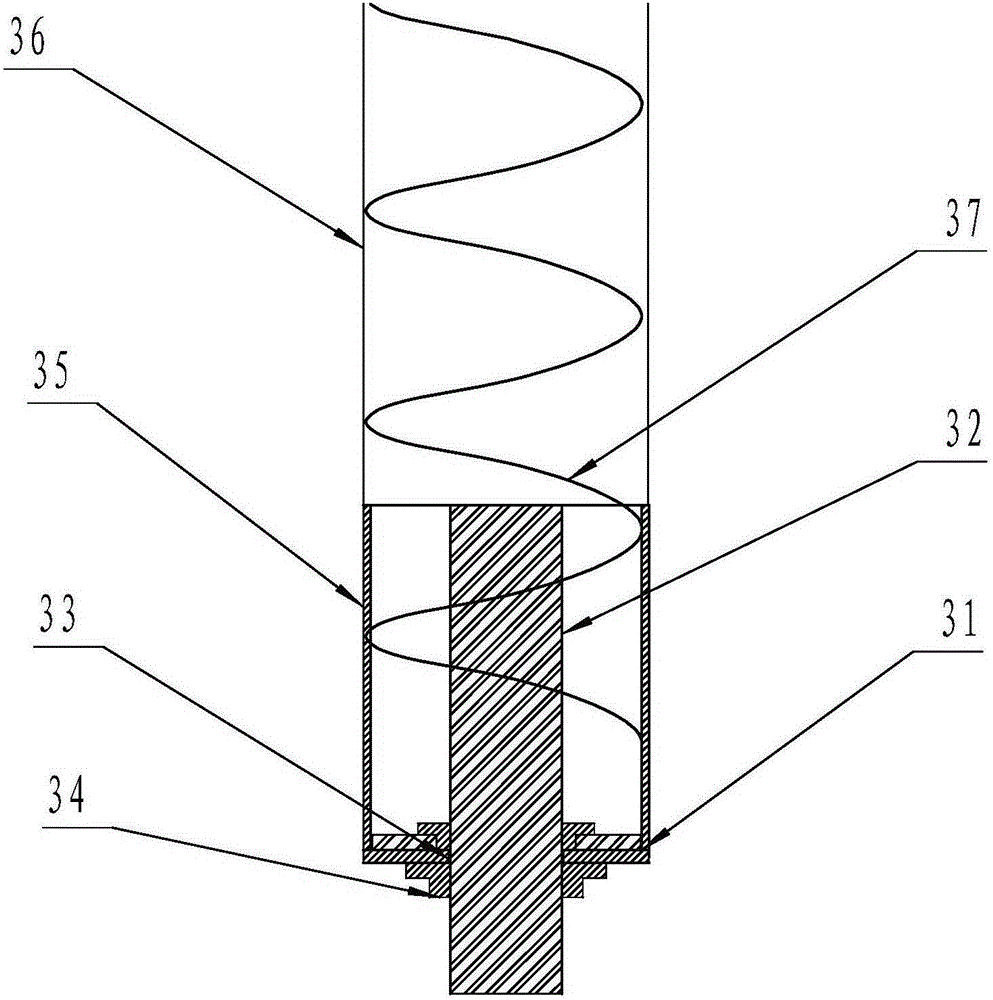

Gradually expanding type screw-feed thermal decomposition furnace integrated in vertical shaft flue behind pulverized coal boiler

ActiveCN107964405AIncrease added valueEfficient use ofEnergy inputSpecial form destructive distillationWater vaporTar

The invention relates to a gradually expanding type screw-feed thermal decomposition furnace integrated in a vertical shaft flue after a pulverized coal boiler. The furnace comprises a cylindric furnace body which is arranged at a connecting part between a horizontal flue and the vertical shaft flue; the upper end of the furnace body protrudes from an upper wall or a sidewall of the horizontal flue and is communicated with a feed chamber, and the lower end of the furnace body is communicated with a charcoal collecting bin which is arranged outside the vertical shaft flue through a charcoal outlet slideway; the upper part of a sidewall in the middle area of the furnace body is provided with a tar gas outlet and is communicated with a tar gas condensation bin, and a sidewall at the upper endof the furnace body is provided with a water vapor outlet and is communicated with a combustible gas collecting bin through a water vapor separator; and a spiral pushing arm whose radial dimension isgradually increased from up to bottom along an axial direction is arranged in the furnace body, and the upper end of the spiral pushing arm is connected with a motor in transmission connection through a gear case. The product is advantageous in that the furnace body is inclinedly arranged at a connecting part of the horizontal flue and the vertical flue, in order to effectively utilize waste heatof the flue; the spiral pushing arm with gradually increased radial dimension is arranged in the furnace body, in order to guarantee smooth feeding and effective fragmentation of the raw materials.

Owner:HUAZHONG UNIV OF SCI & TECH

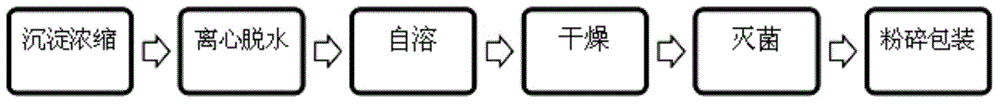

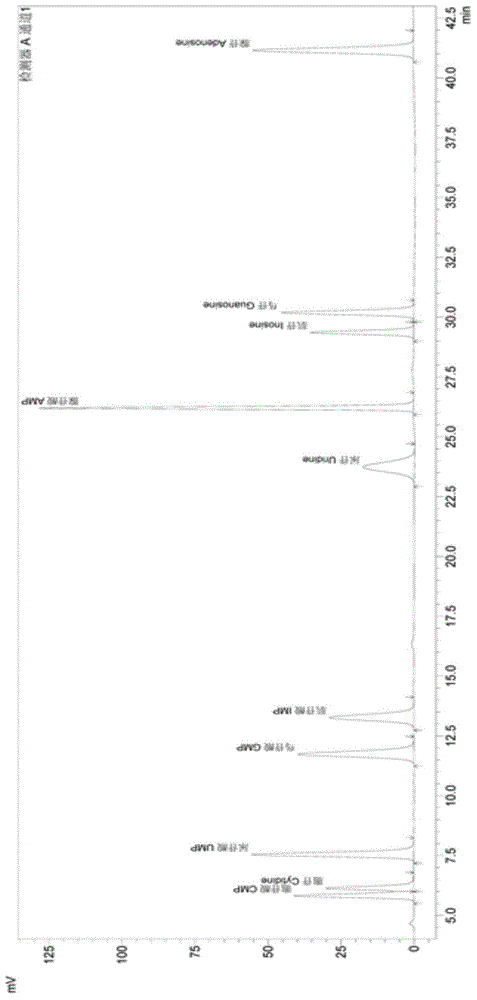

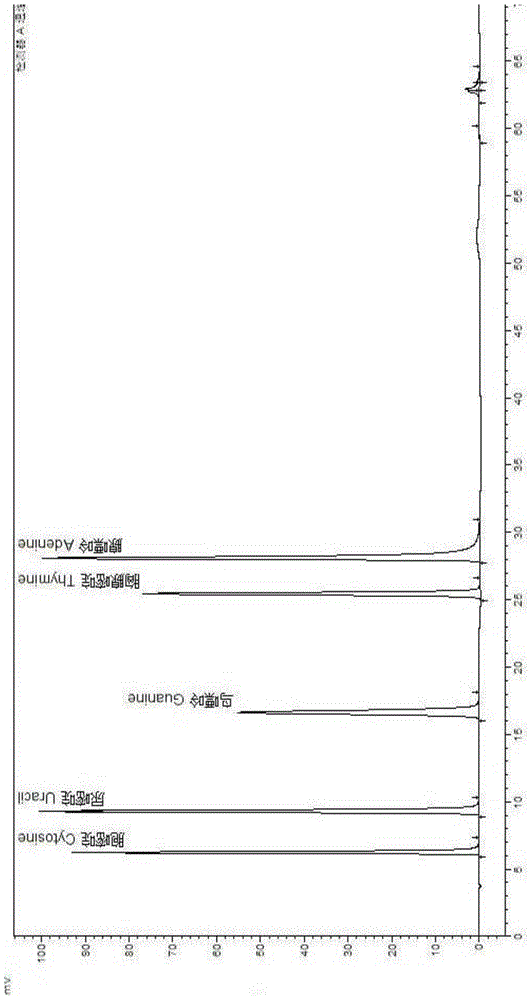

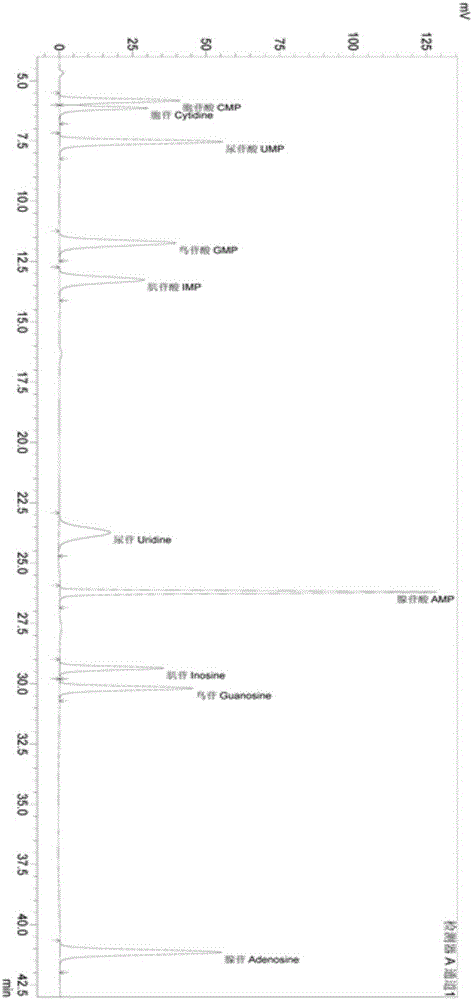

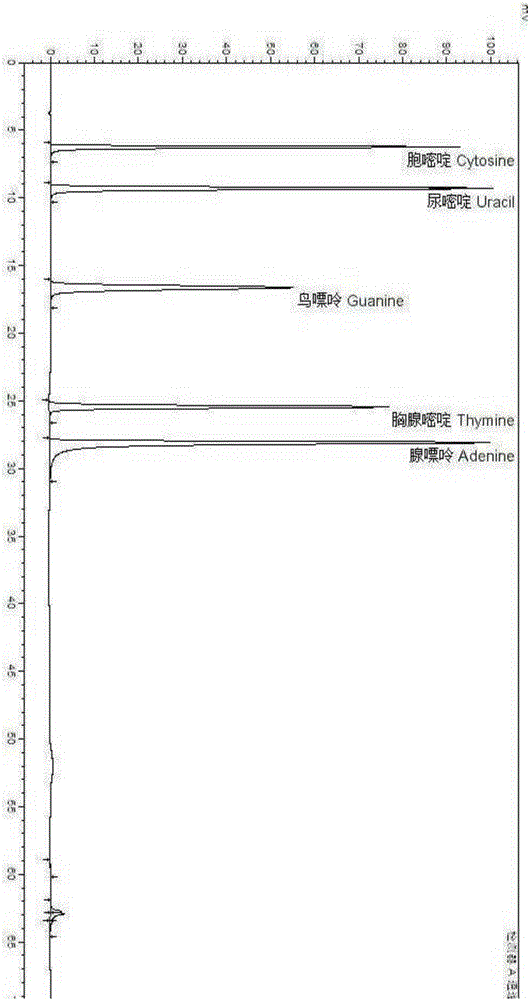

Method for producing aerobic type single-cell protein through autolysis process

PendingCN104893976AEnsure outflowImprove efficiencyMicroorganism lysisPeptide preparation methodsCell wall polysaccharideSingle-cell protein

The invention relates to the technical field of single-cell protein processing, in particular to a method for producing aerobic type single-cell protein through an autolysis process. The method comprises the steps of settling concentration, centrifugal dewatering, drying, sterilization and smashing and packaging, wherein autolysis and drying are carried out on materials with the moisture content of 78 percent to 85 percent obtained after the step of centrifugal dewatering in sequence. The autolysis process is adopted in the process and the manufactured product, autolytic enzymes fully decompose macromolecule nutrients and cell walls in the autolysis process, and high-content free amino acid and free nucleotide can be generated through autolysis. Meanwhile, polysaccharide of the cell walls is decomposed, so that cells are permeable, it is guaranteed that active substances can flow out of the cells, and therefore the active substances can be directly absorbed and utilized by animals. Autolysis is carried out after centrifugal dewatering, and the high efficiency of autolysis can be ensured; the content of moisture needing to be removed in a drying process after autolysis can be reduced, and therefore drying cost is lowered.

Owner:TAIZHOU ICELL BIO TECH CO LTD

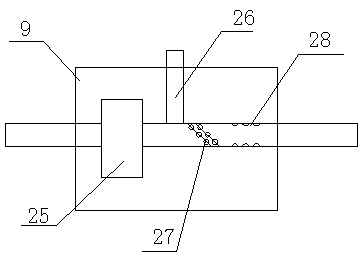

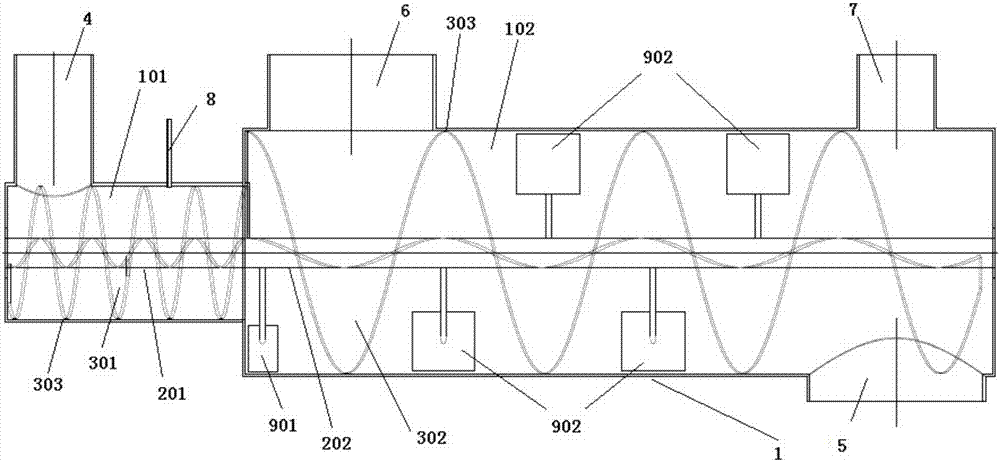

Horizontal mixed material conveying and/or reacting device and mixed material conveying and/or reacting method

InactiveCN107469759AReduce breakage rateSimple structureProcess control/regulationRotary stirring mixersFill rateChemical industry

The invention relates to the field of manufacturing chemical industry and metallurgy devices, and discloses a horizontal mixed material conveying and / or reacting device. The device includes a material cylinder internally provided with a seal chamber and a rotating shaft passing through the seal chamber. The seal chamber is divided into a first chamber and a second chamber communicating with the first chamber. The cross-sectional area of the first chamber is smaller than that of the second chamber. The first chamber is provided with a cold material inlet, and the second chamber is provided with a mixed material outlet and a gas outlet. A hot carrier inlet formed in the second chamber is formed between the cold material inlet and the mixed material outlet. The first chamber rotating shaft is provided with a first spiral belt sheet, and the second chamber rotating shaft is provided with a second spiral belt sheet. The invention further relates to a mixed material conveying and / or reacting method through adoption of the device above. Through adoption of a diameter-variable spiral structure and a sectional material feeding manner, material separation at different conveying sections is achieved, and through varying pitch design, different standing time and filling rates in each section are controlled.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

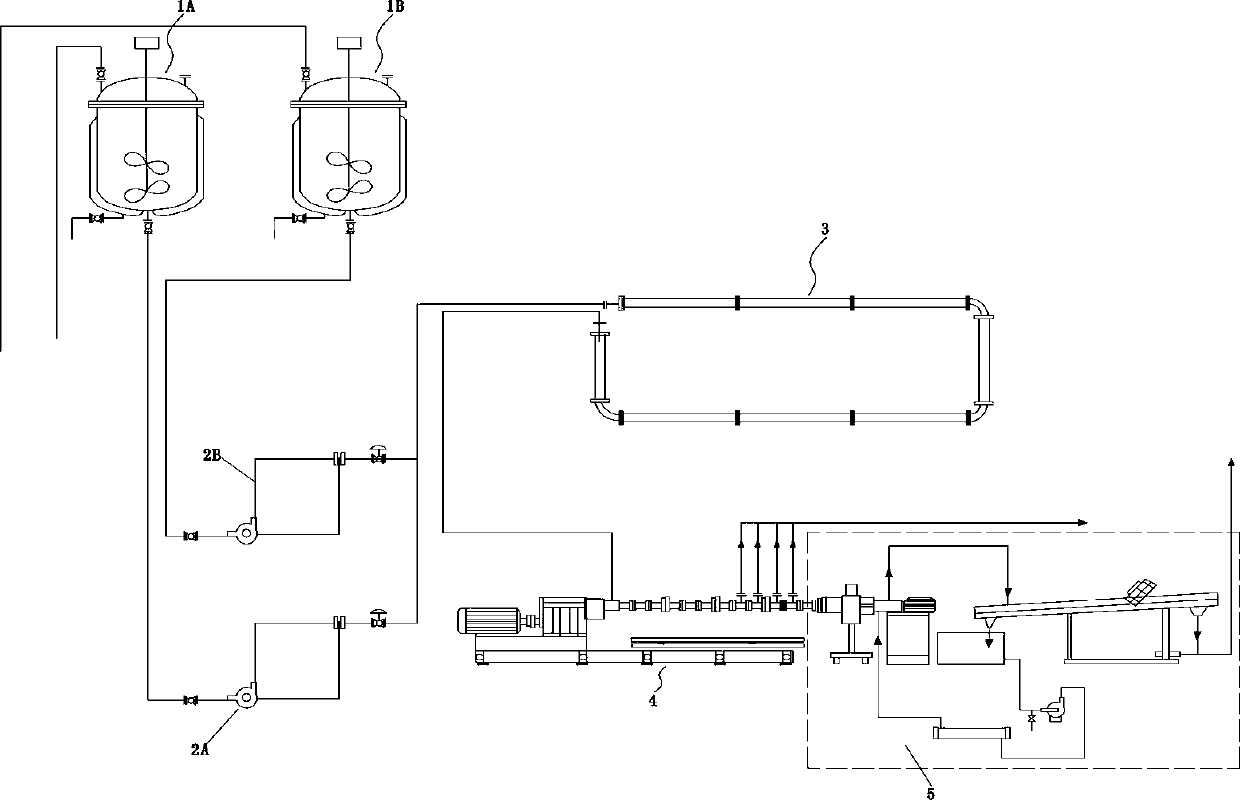

Method for preparing water-based crylic acid resin by continuous extruding process and production equipment for realizing method

The invention provides a method for preparing water-based crylic acid resin by a continuous extruding process and production equipment for realizing the method. The method is characterized in that anannular pipe type reactor and a twin-screw extrusion reactor are connected in series to be used as a continuous reactor; firstly, monomers, initiating agents and optional molecular weight modifiers are sucked into a mixed raw material preparation tank from each raw material barrel under the negative pressure; then, the materials in the preparation tank are conveyed to the annular pipe type reactorwith the temperature being 120 DEG C by a material conveying pump at the speed of 50 to 150kg / h; the detention time of the materials in the annular pipe type reactor is 15 minutes; after the materials enter the twin-screw extrusion reactor, the screw rotating speed is controlled to be 20 to 50 turns / min; a devolatilization section valve is opened so that the materials are subjected to vacuum devolatilization at the third stage; the product after devolatilization is subjected to underwater pelleting and drying at the temperature being 30 DEG C or below, and then passes through a cyclone separator; next, packaging is performed. The crylic acid resin prepared by the method has the characteristics that the quality stability is good; the molecular weight is great; the distribution is narrow. The invention also provides the production equipment for realizing the method.

Owner:广东龙湖科技股份有限公司

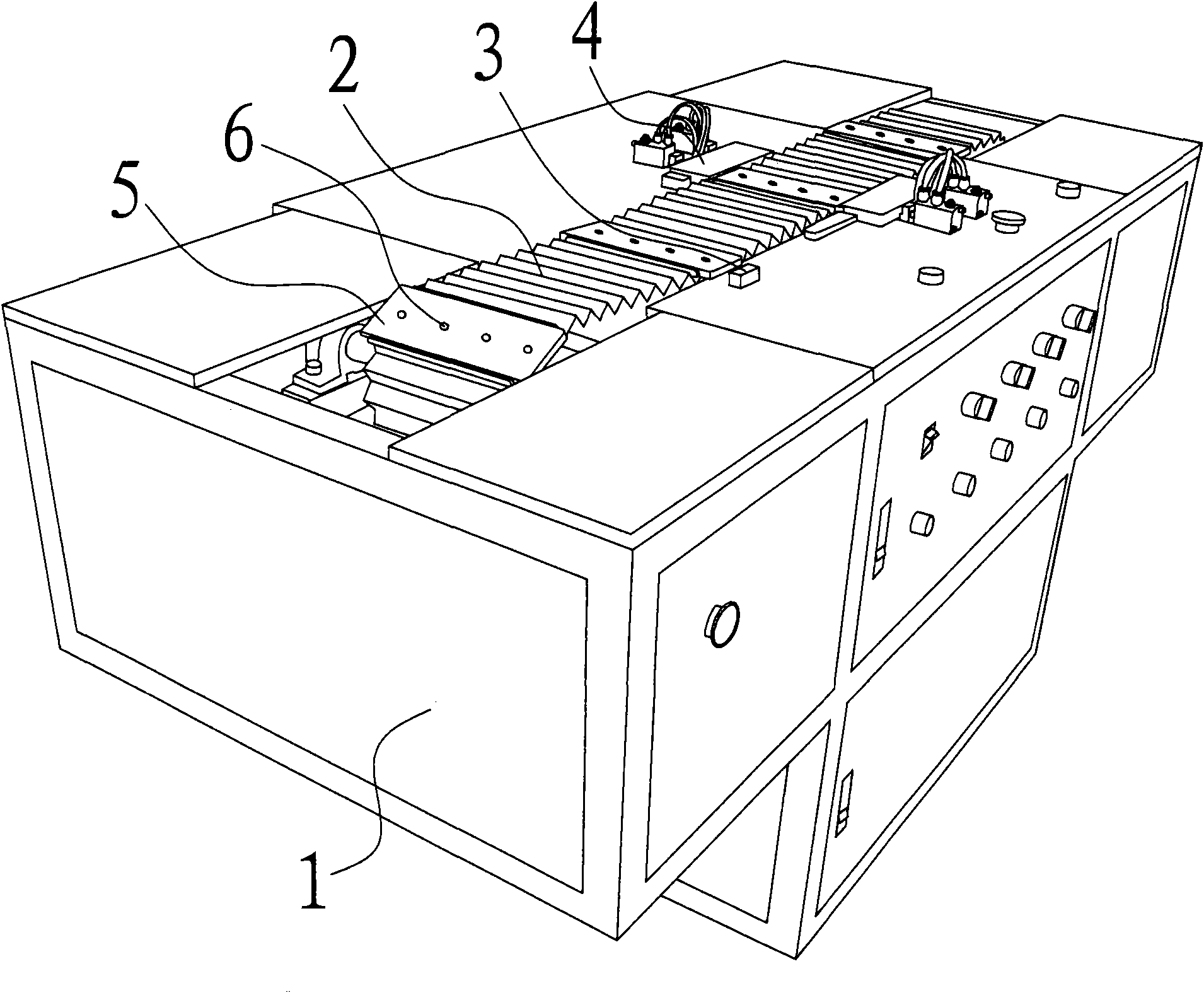

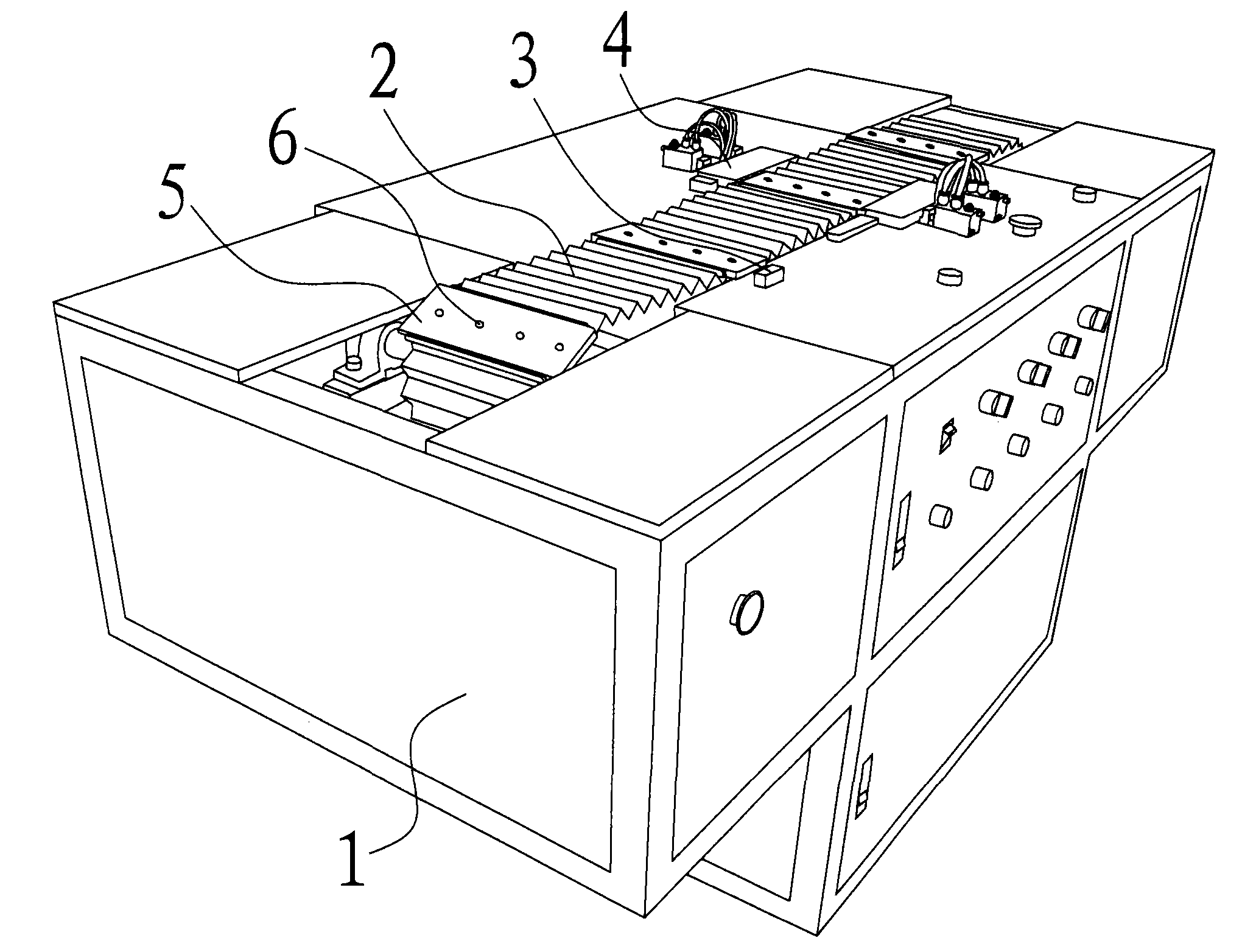

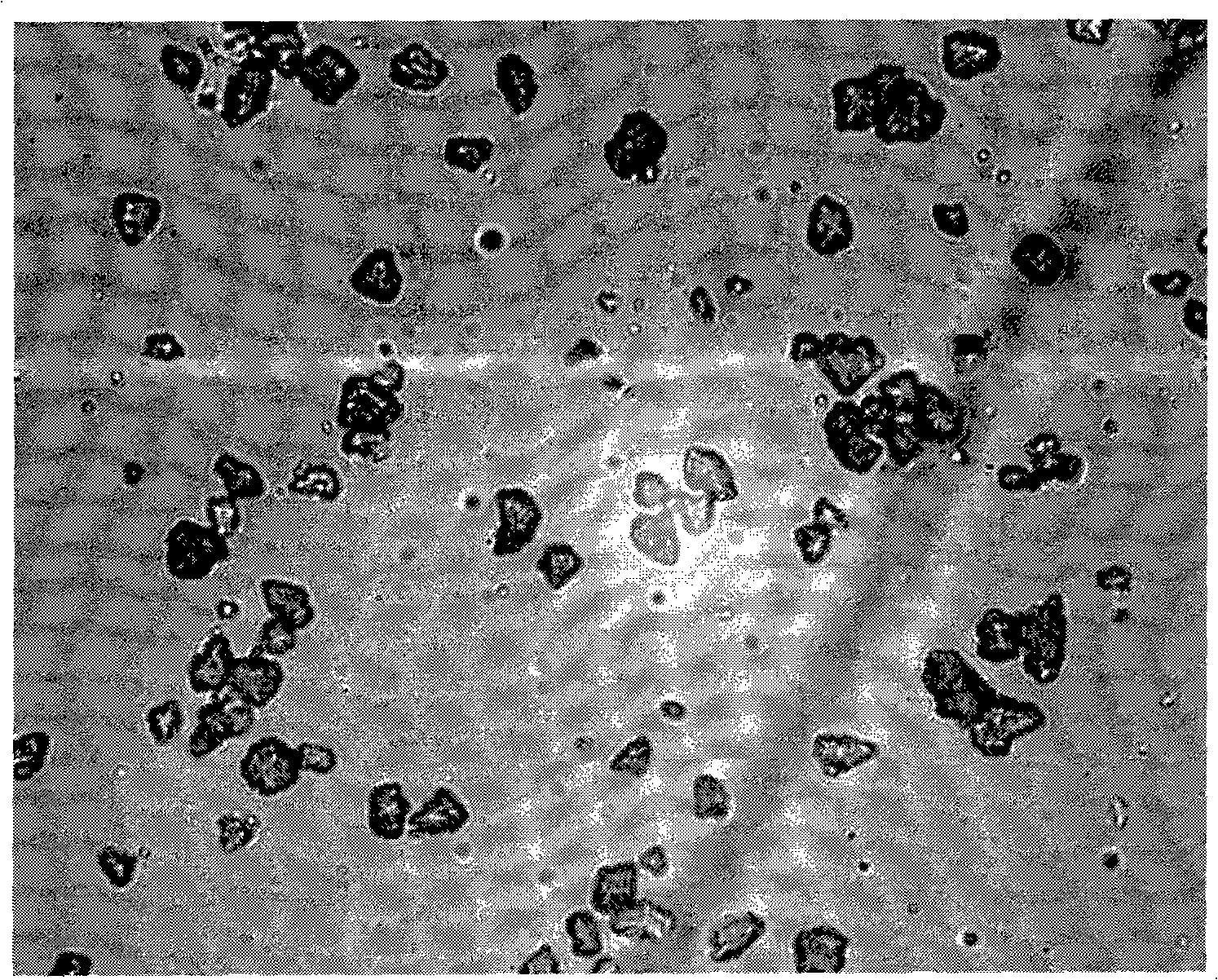

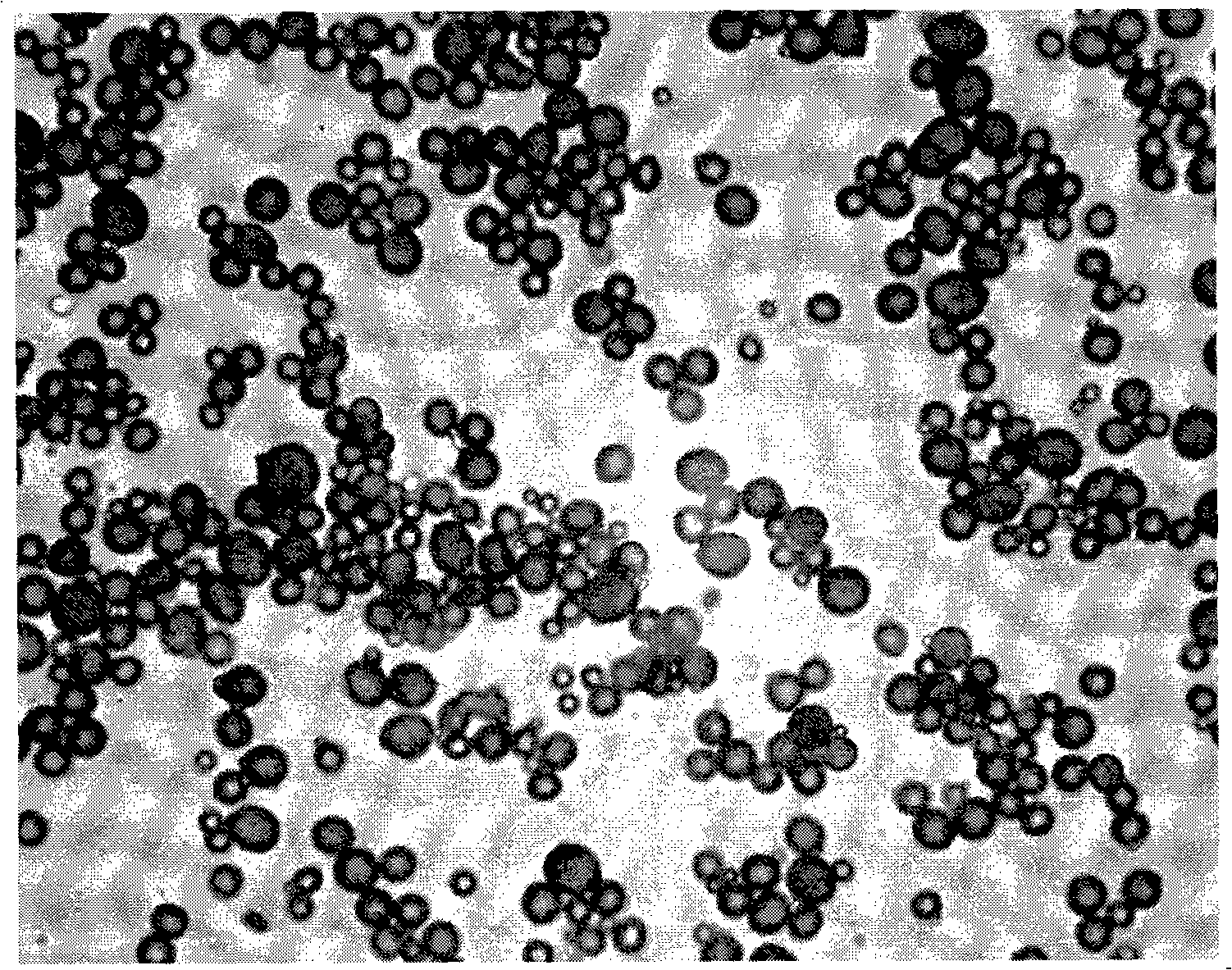

Production method of spherical toner

InactiveCN101271286AEvenly dispersedDwell time is easy to controlDevelopersEngineeringSpherical form

A spherical toner manufacturing method comprises a heating glomeration working procedure that irregular shaped toner powder is spread in water and is heated and mixed to ensure the glomeration of the irregular shaped toner power and a post processing working procedure that a product obtained from the heating glomeration working procedure is filtered, washed and dried to obtain the toner. The spherical toner manufacturing method has the advantages of the simple method and the practicability etc.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

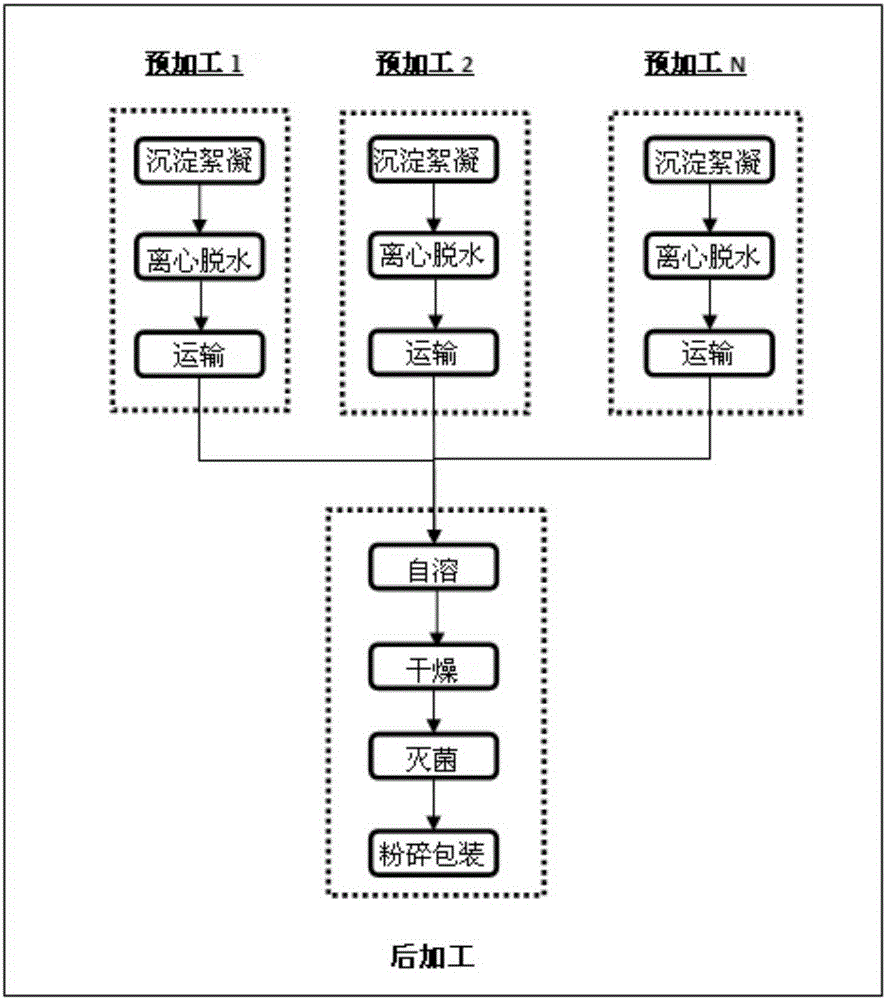

Method for high yield production of aerobic single-cell protein by autolysis process

InactiveCN105166322AEnsure outflowImprove efficiencyMicroorganism/unicellular-algae proteins working-upCell wall polysaccharideSingle-cell protein

The invention relates to the technical field of single-cell protein processing, in particular to a method for high yield production of aerobic single-cell protein by an autolysis process. The process is characterized in that in each pre-processing unit, the material obtained by a centrifugal dewatering step is transported to a post-processing unit to conduct centralized treatment, and the post-processing unit consists of an autolysis step, a drying step, a sterilization step and a crushing and packaging step. The technology and the prepared product involved in the invention employ the autolysis process, during autolysis, autolytic enzyme fully decomposes macromolecular nutrients and cell walls, autolysis can produce high content free amino acid and free nucleotide, and at the same time cell wall polysaccharides are decomposed, and cells can produce permeability so as to ensure that active substances can flow out of cells to as to be directly absorbed and utilized by animals. Autolysis is carried out after centrifugal dewatering, high efficiency of autolysis can be ensured, and the content of water needing to be removed in a drying process after autolysis can be reduced, thereby reducing the cost of drying.

Owner:TAIZHOU ICELL BIO TECH CO LTD

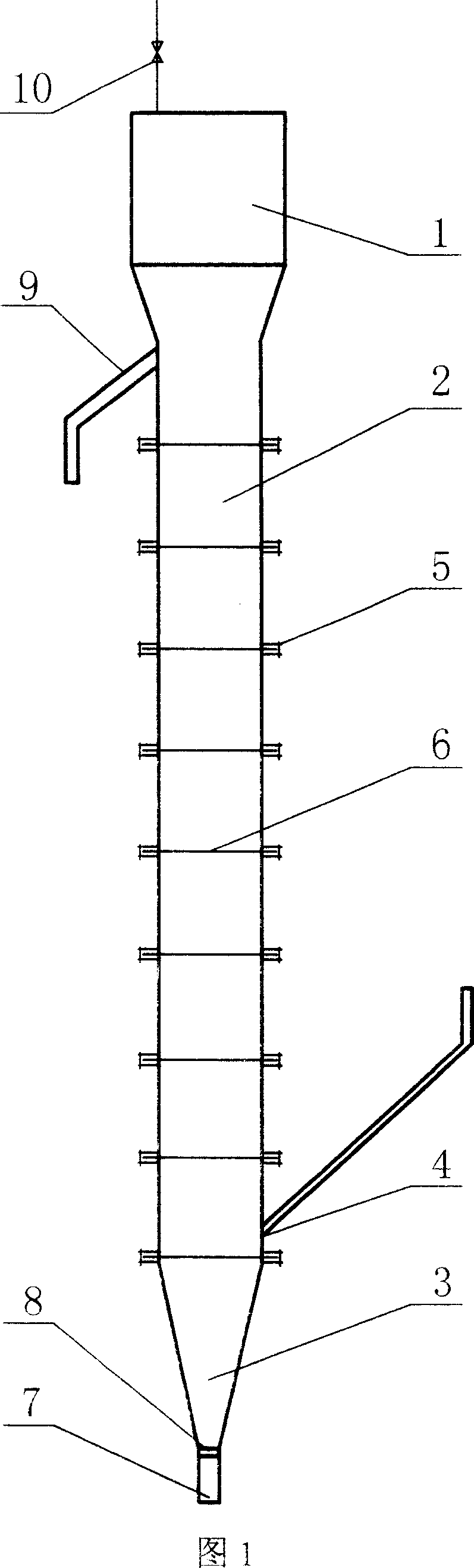

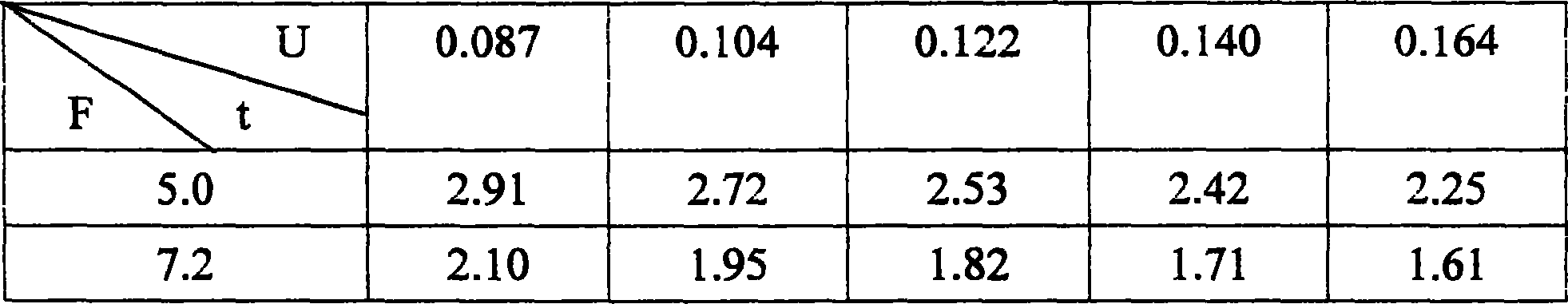

Fluid-bed reactor for oxido-reduction sintering of high calcium magnesium titanium slag

InactiveCN101117665AReduce axial backmixingImproved solid phase residence time distributionFluidised-bed furnacesProcess efficiency improvementOxido reductionMagnesium

The present invention relates to a fluidized bed reactor used for oxidizing and deoxidizing and baking high calcium magnesium titanium slag to remove calcium for improving the titanium inert solid grade, and comprises a cylindrical column material settlement section, a cylindrical column material reaction section, and a coniform column air preheating section. The main body of the cylindrical fluidized bed reactor is the cylindrical column material reaction section, and the top part is of a horn mouth shape, the top part of the horn mouth column body is connected with the cylindrical column material settlement section, the bottom end of the reaction is connected with the air preheating section. The upper part of the air preheating section is provided with a material feeding port, and the bottom part is arranged with an air distribution plate under which an air inlet is provided. The lower part of the material reaction is provided with a material discharging port, and the top part is provided with an air outlet. More than one baffle with holes is arranged in the material reaction. The present invention can make the residence time of particles of the high calcium magnesium titanium slag prolong following the increase of the grain size to satisfy the requirements of the reaction time of different grain sizes of particles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

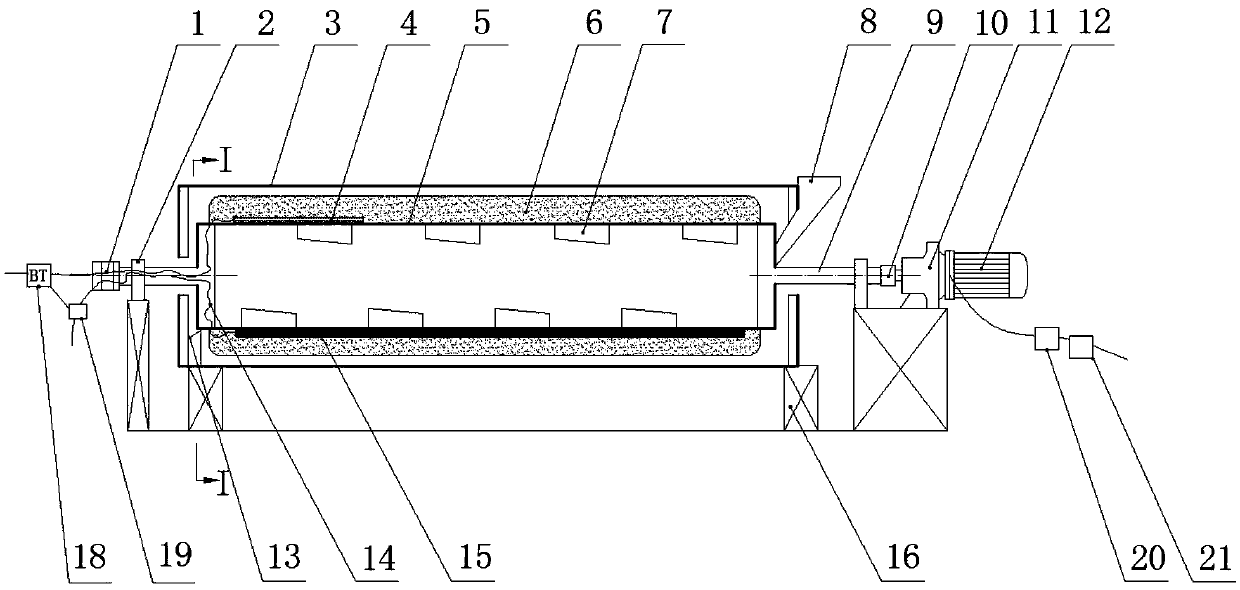

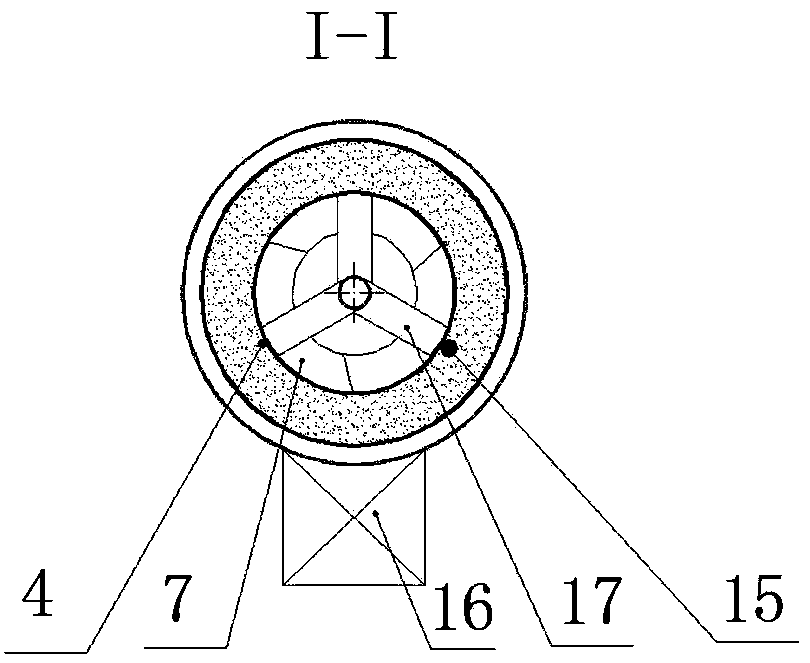

Lotus seed electric heating drum drying device

PendingCN108679994AAchieve constant temperatureAchieve dryingDrying chambers/containersDrying solid materialsElectric heatingResidence time

The invention discloses a lotus seed electric heating drum drying device. The lotus seed electric heating drum drying device comprises a rotating electrical heating cylinder, hollow shafts are connected with both ends of the rotating electric heating cylinder, and the hollow shafts are mounted on bearing seats on a bracket. A feeding port is formed on the right side of the rotating electric heating cylinder, a discharging port is formed on the left side of the rotating electric heating cylinder, a rotating conductive slip ring is connected to the tail end of the left side of the left hollow shaft, and a coupling and a reducer are sequentially connected to the tail end of the right side of the right hollow shaft. A variable frequency motor controlled by a forward and reverse controller is connected to the reducer, insulation cotton is arranged between an inner drying cylinder and an outer fixing cylinder in a filled mode as an insulation layer, and a silicone rubber high temperature resistant cable penetrates through the hollow shaft on the left side. One end of the silicone rubber high temperature resistant cable is connected to the rotating conductive slip ring in sequence and connected with an external power supply, and the other end of the silicone rubber high temperature resistant cable is connected to a relay-controlled electric heating tube. A temperature controller is connected to a temperature sensor and a relay separately. According to the lotus seed electric heating drum drying device, energy consumption is saved, constant temperature or variable temperature drying of lotus seeds can be realized, high quality products are produced, the residence time of lotus seeds in the drying cylinder can be controlled, and uniform drying of the lotus seeds are realized.

Owner:江西省科学院食品工程创新中心

A kind of method of drying polycarbonate

ActiveCN103640108BSolving Recycling ProblemsAvoid flammable and explosive accident hazardsDrying solid materials with heatHalogenated hydrocarbon separation/purificationFluidized bed dryingNitrogen

Owner:甘肃银光聚银化工有限公司

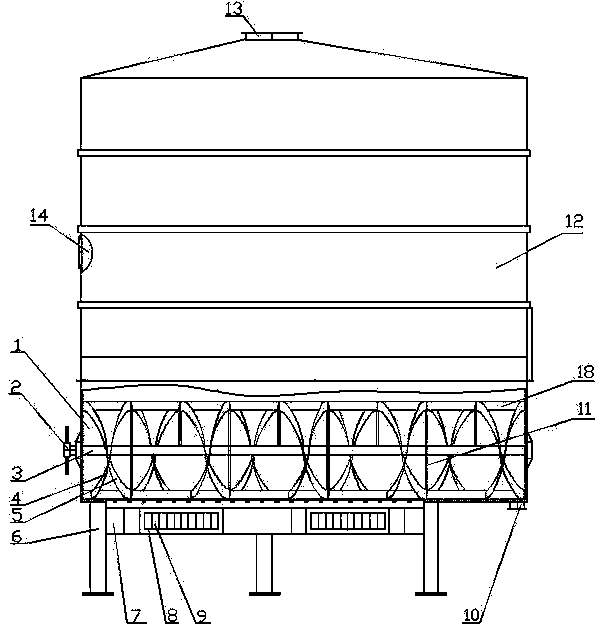

Agitated fluidized bed type drying machine

ActiveCN103968645ADry evenlyThe feed is heated and dried evenly in the drying roomDrying solid materials with heatHearth type furnacesBand shapeFluidized bed

The invention relates to an agitated fluidized bed type drying machine. The agitated fluidized bed type drying machine comprises a drying chamber, wherein the lower portion of the drying chamber is connected with an air inlet chamber; a hot wind inlet is formed in the air inlet chamber; drying holes are densely distributed in the position where the drying chamber and the air inlet chamber are connected. An agitating shaft is arranged inside the drying chamber; the two ends of the agitating shaft and the two ends of the drying chamber are in rotating fit; one end of the agitating shaft extends out and is connected with a drive sprocket. The position, inside the drying chamber, of the agitating shaft is provided with banded propulsion leaves which are continuously arranged. The outer edges of the banded propulsion leaves are evenly provided with knockout plates in the circumferential direction of the agitating shaft. The upper end of the drying chamber is open and is connected with an upper tank, the side wall of one end, corresponding to the air inlet chamber, of the upper tank is provided with a feed port, the end, away from the air inlet chamber, of the bottom of the drying chamber is provided with a discharge port, and the top of the upper tank is provided with an air outlet. When the agitated fluidized bed type drying machine dries biological fermentation feed, the drying efficiency is high, drying is even, and nutrient factors and biological activity of the biological fermentation feed are not destroyed when the biological fermentation feed is dried.

Owner:孙甫兴

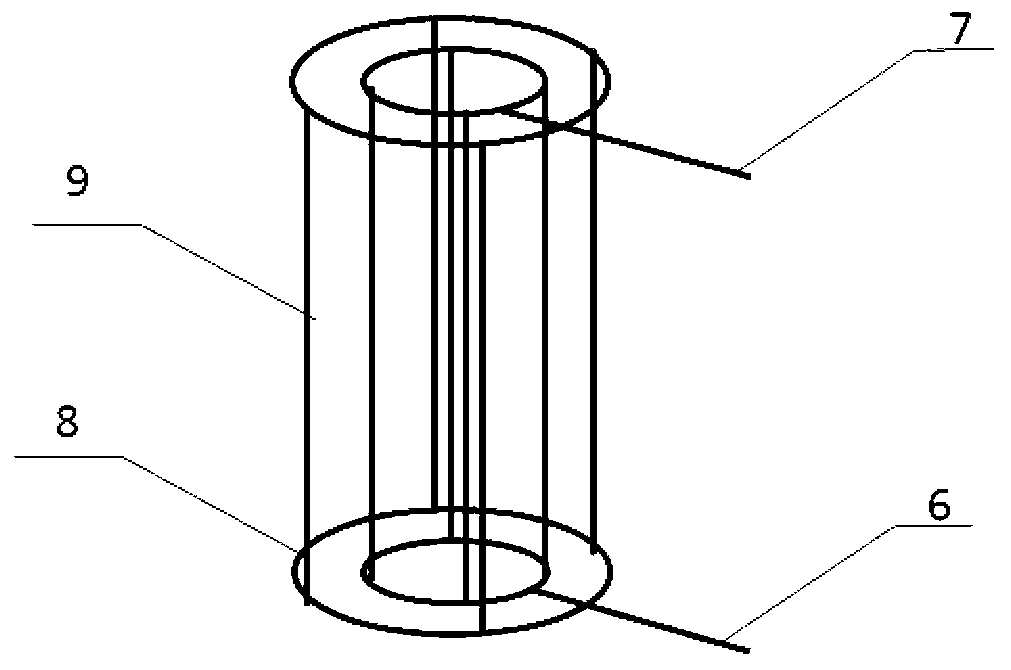

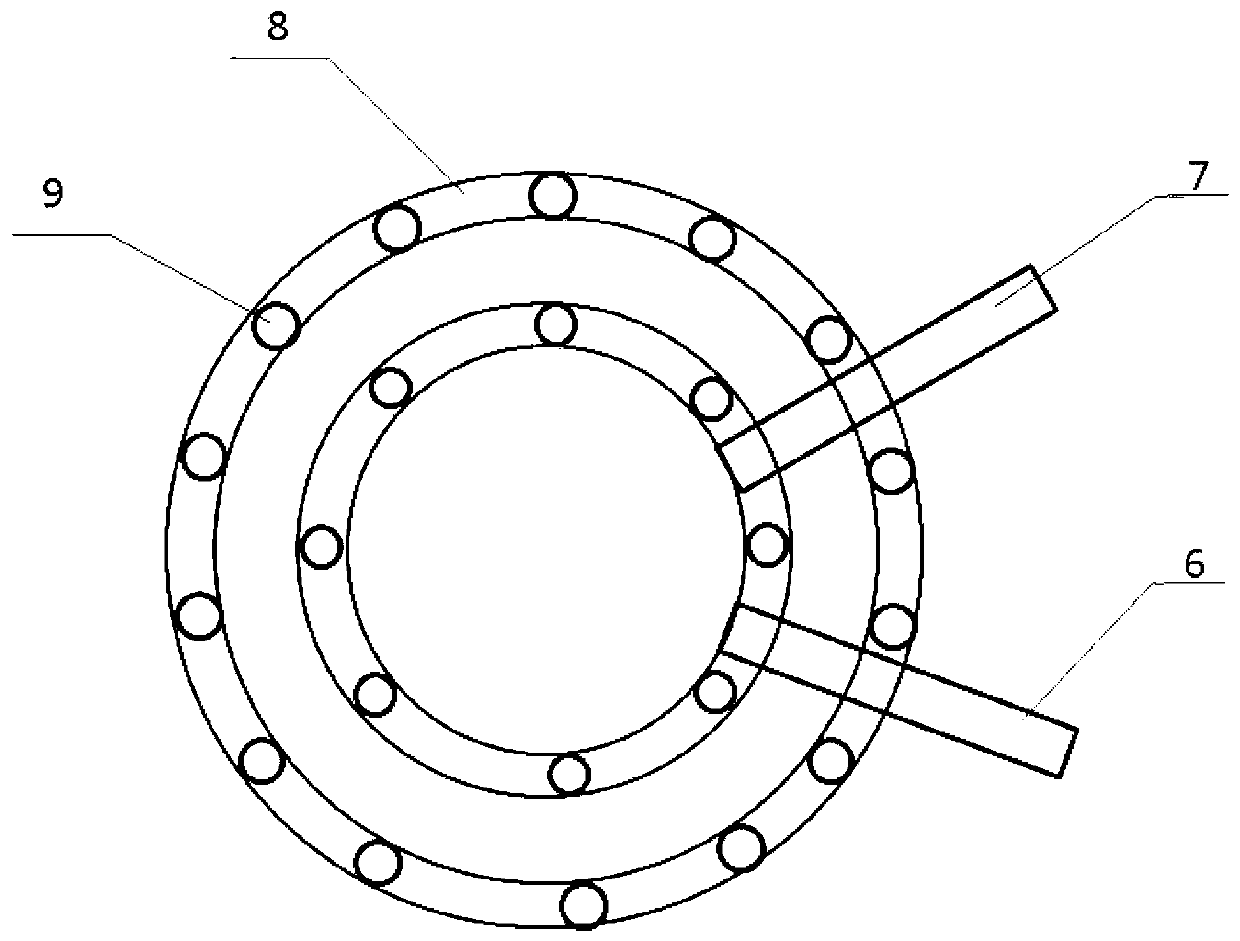

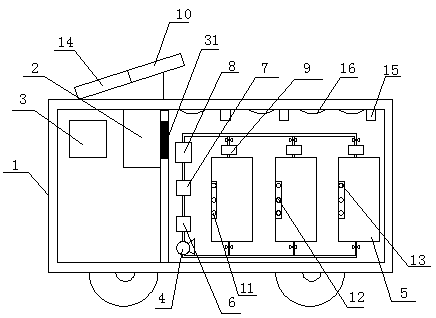

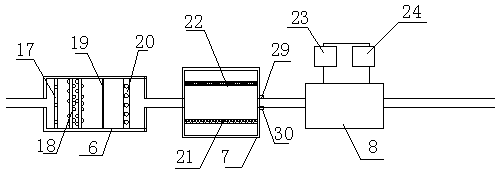

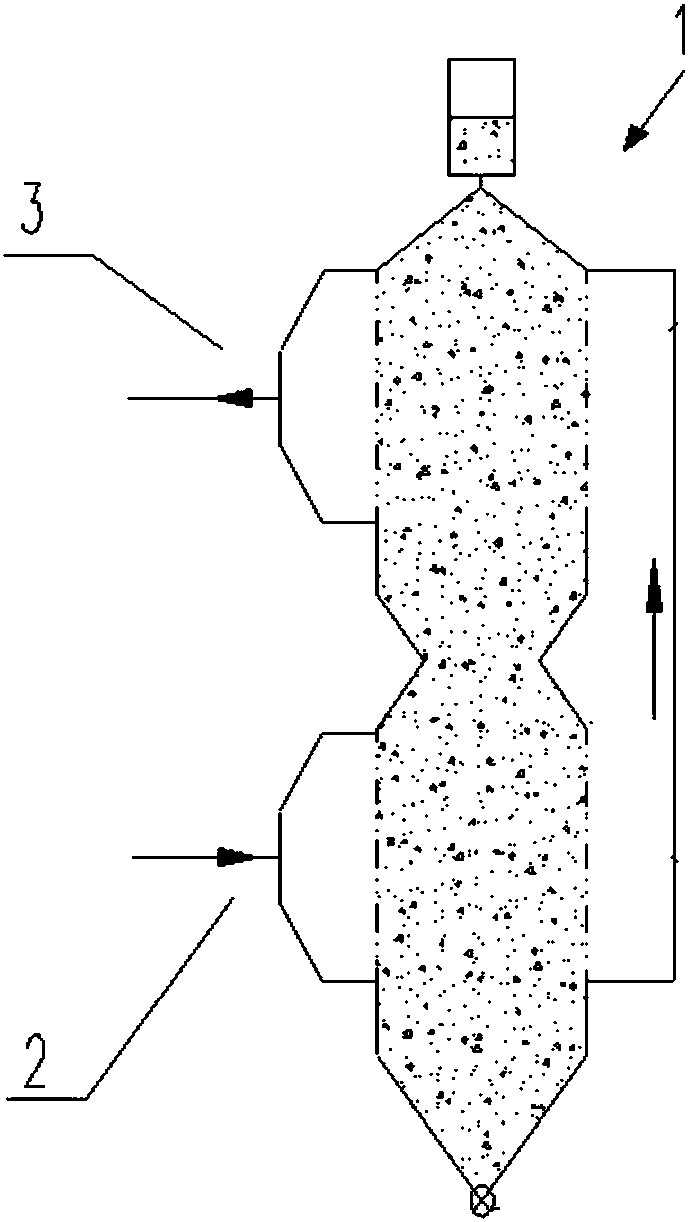

Multilayer fluidized bed parsing device for conducting pneumatic material return through row tube type heat exchange and coupling of molten salt

PendingCN105709710AHigh heat transfer efficiencyIncrease floor area ratioGas treatmentOther chemical processesSlagHeat transfer efficiency

The invention discloses a multilayer fluidized bed parsing device for conducting pneumatic material return through row tube type heat exchange and coupling of molten salt. The multilayer fluidized bed parsing device comprises a screw feeder (6), a multilayer fluidized bed (1), a slag cooler (8), a separator, a heat exchanger (10), a heat supply device, a water vapor generating unit and a spraying unit. The multilayer fluidized bed parsing device has the advantages of being high in heat transfer efficiency, high in plot ratio, even in heat exchange, controllable in stay time and the like and has an obvious advantage on the aspect of small granular activated coke compared with a traditional technology.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

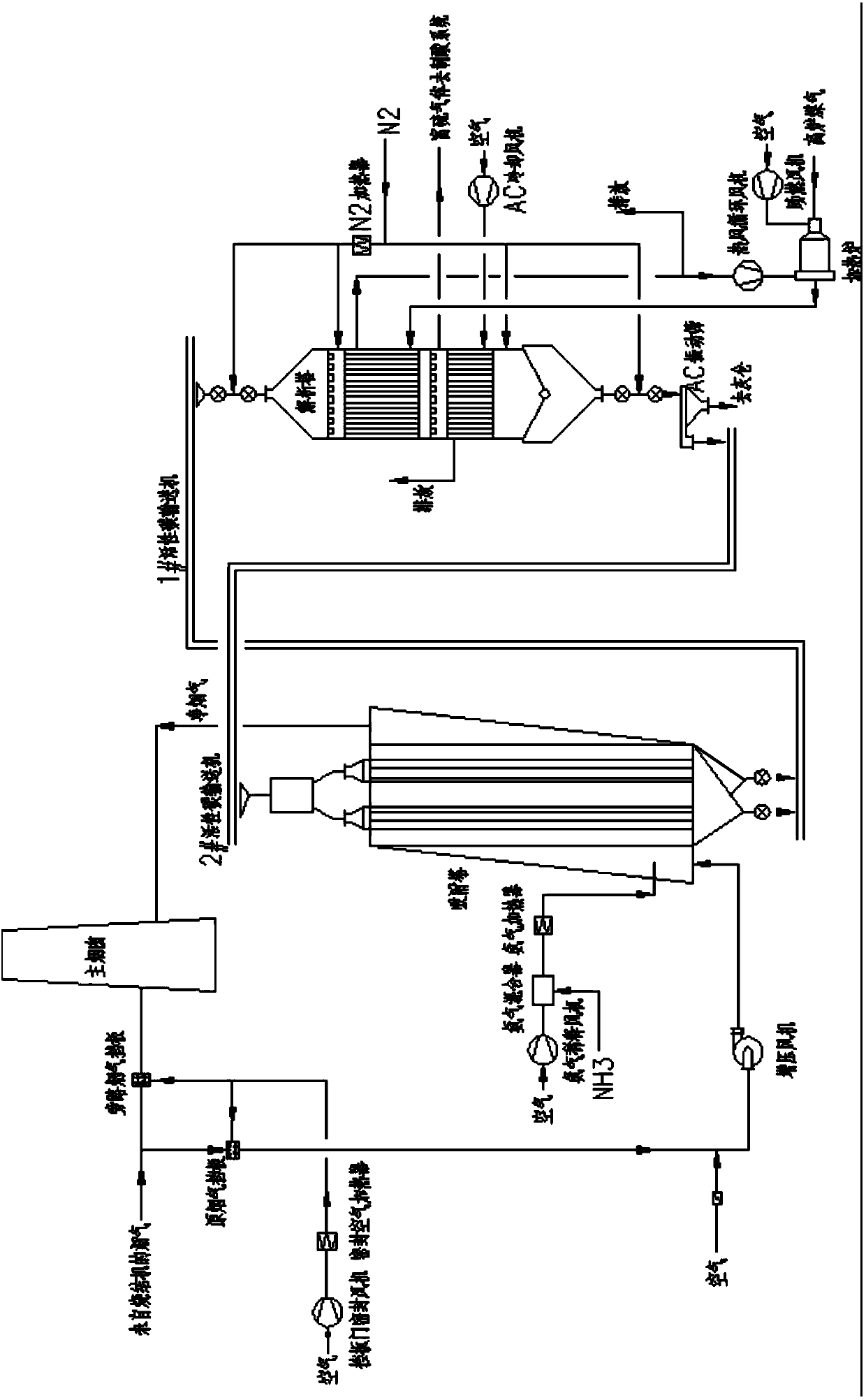

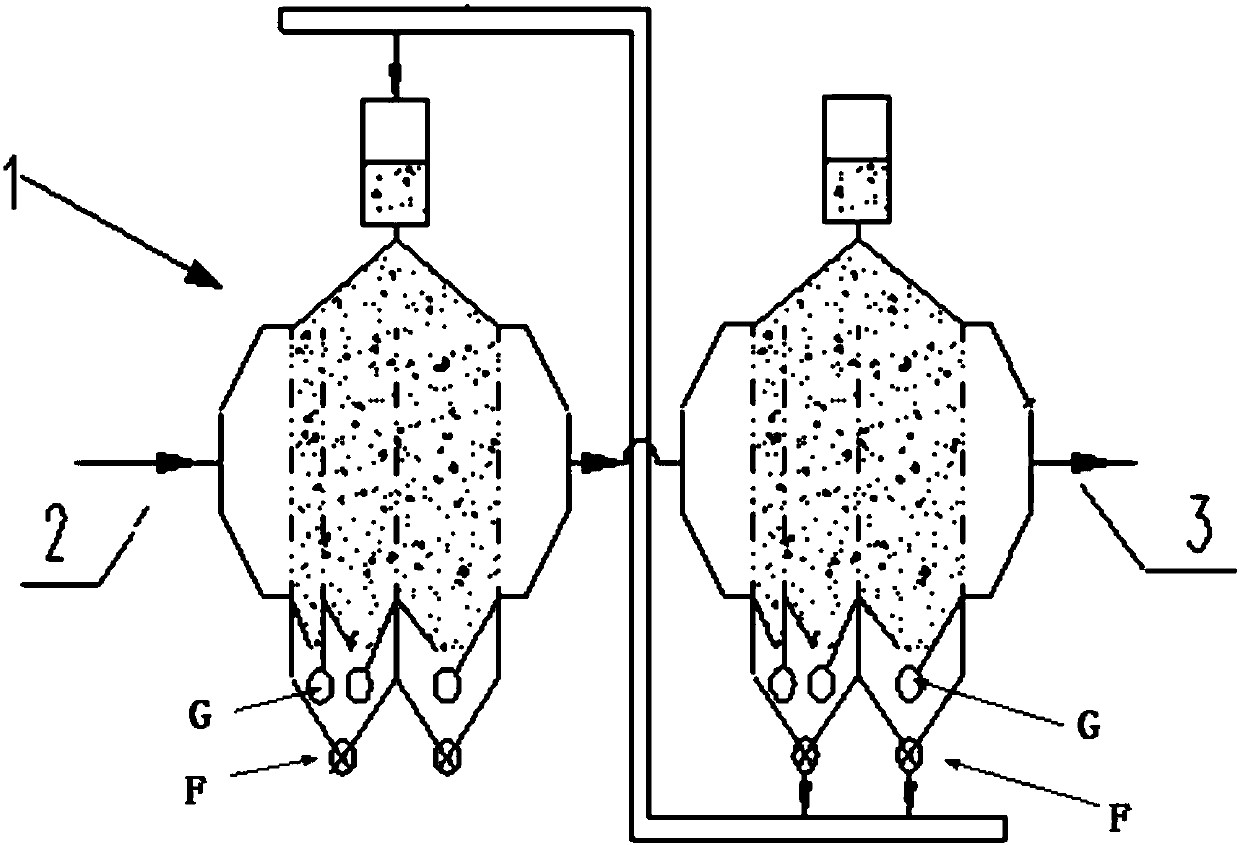

Activated carbon adsorption tower and flue gas purification method

ActiveCN109772097AIncrease throughputReduce manufacturing costGas treatmentDispersed particle separationActivated carbonPurification methods

The invention provides a double-tower type activated carbon adsorption tower. A left tower and a right tower respectively comprise an activated carbon bed layer part at the lower part, an activated carbon bed layer part at the upper part and a middle transition area between the two parts. The activated carbon adsorption tower further comprises a first gas chamber, a second gas chamber, a third gaschamber and a fourth gas chamber; each activated carbon bed layer part at the lower part comprises a lower first material chamber, a lower second material chamber and a lower third material chamber;each activated carbon bed layer part at the upper part comprises an upper first material chamber, an upper second material chamber and an upper third material chamber; the lower first material chambers and the upper first material chambers are communicated with each other through a row of first discharging channels, the lower second material chambers and the upper second material chambers are communicated with each other through a row or a plurality of rows of second discharging channels, and the lower third material chambers and the upper third material chambers are communicated with each other through a row of discharging channels. The adsorption tower disclosed by the invention can obviously improve smoke treating quality, reduces equipment manufacturing and operating cost and maintaining cost and saves electric energy and thermal energy.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

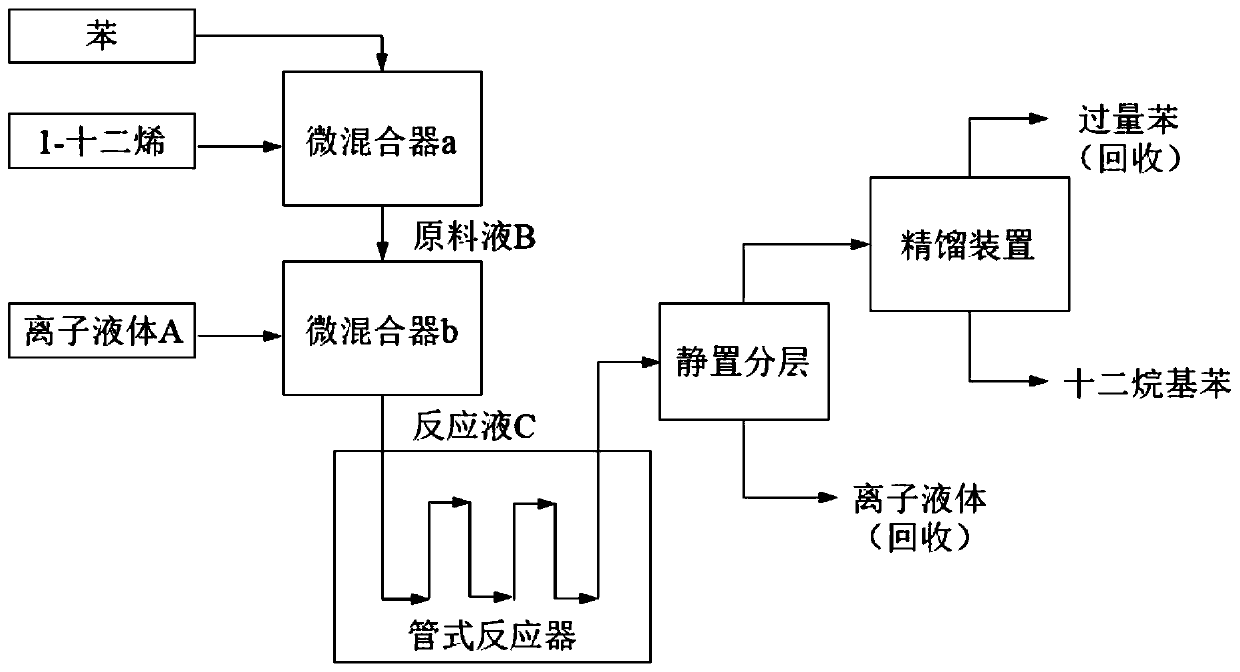

Method for continuously preparing dodecyl benzene

InactiveCN110283031AHigh synthesis efficiencyMix quickly and evenlyOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminium chlorideIonic liquid

The invention belongs to the technical field of chemical engineering, and relates to a method for continuously preparing dodecyl benzene. The method comprises the following steps that 1, trimethylamine hydrochloride and aluminum chloride are stirred and mixed according to a ratio to prepare an ionic liquid catalyst A; 2, benzene and 1-dodecene are introduced into a micro-mixer a to be quickly and evenly mixed in proportion to obtain a raw material liquid B; 3, a catalyst A and the raw material liquid B are continuously introduced into a micro-mixer b to be rapidly and uniformly mixed to obtain a reaction liquid C, and the reaction liquid C enters a tubular micro-reactor for reaction; 4, the product mixture stands still and is layered, and an ionic liquid A is recycled; 5, an upper layer organic phase obtained in step 4 is rectified to obtain the product dodecyl benzene. The method is environmentally friendly, and can effectively solve the problems of high corrosion, high pollution and the like in a traditional technology. Material flows are rapidly and uniformly mixed, the reaction efficiency is high, the yield of monoalkyl benzene is nearly 100% in a very short time, and the yield of two-position isomer can reach 44% or above; the reaction is conducted in the tubular micro-reactor, the reaction time can be accurately controlled, and the product quality is stable.

Owner:TSINGHUA UNIV

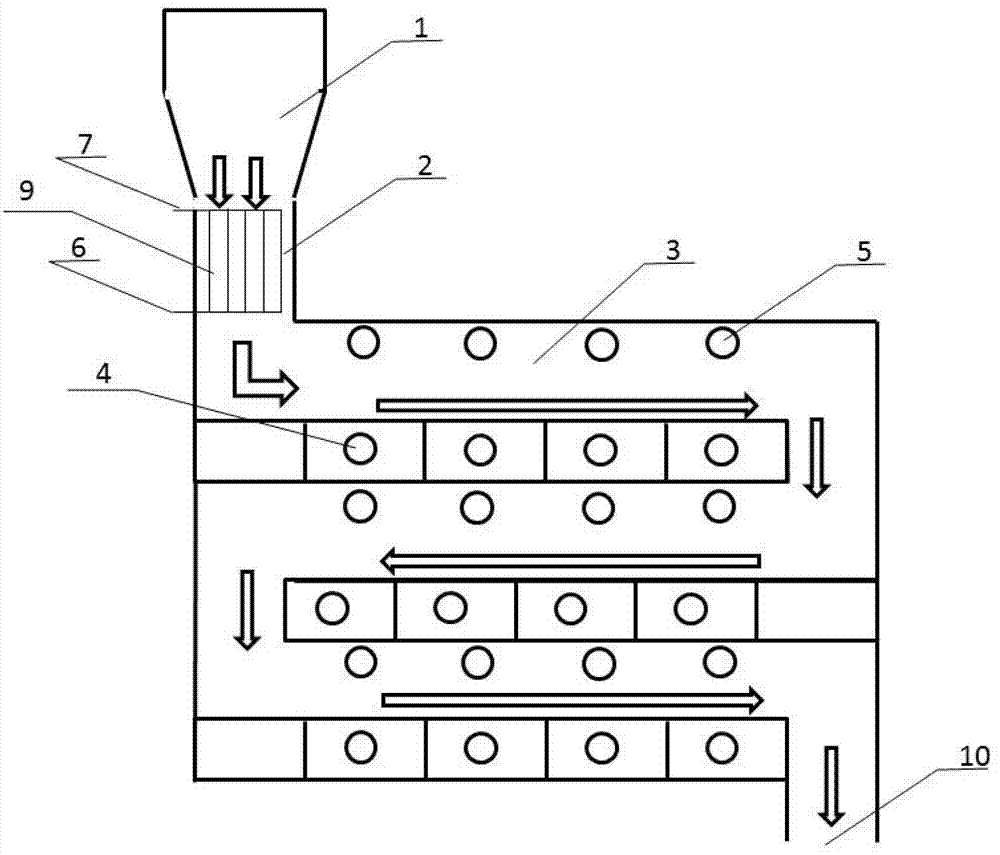

Moving bed brown coal drying method and device

ActiveCN102997634BAdaptableFully contactedDrying solid materials with heatHearth type furnacesBrown coalRetention time

The invention discloses a moving bed brown coal drying method and device, and relates to the technical fields of brown coal drying techniques and devices. Brown coal enters a direct drying chamber of a horizontal moving bed to remove moisture after being dried by an indirect drying chamber of a vertical moving bed firstly; and high-temperature hot air inside the indirect drying chamber indirectly transfers the heat to brown coal particles when flowing through a pipeline arranged in the movement direction of a coal bed. Therefore, a rapid drying process is achieved; the floor space and the height of a drying system can be reduced; and safe operation of the system can be ensured. A direct drying chamber adopts a one-layer or multi-layer horizontal moving bed structure; the hot gas and the brown coal are directly subjected to heat exchange; the moisture content of a terminal dry product is conveniently controlled by controlling the retention time of the brown coal particles; and the adaptability of the drying system on raw coal is more excellent. The entire device does not generate a fluidization control problem; treatment of large-grain brown coal particles is facilitated; the particle sizes of the particles of the terminal product and controllable moisture content are guaranteed; and the system is simpler, more stable and safer to operate.

Owner:TSINGHUA UNIV

Device and method for producing low-ash low-sulfur carbon black through pyrolysis of waste and old tires

InactiveCN106916601AFast heating rateHigh yieldPigmenting treatmentLiquid hydrocarbon mixture productionSulfurSynthetic rubber

The invention discloses a device and method for producing low-ash low-sulfur carbon black through pyrolysis of waste and old tires and belongs to the technical field of waste and old tire pyrolysis treatment. The device comprises a cracking chamber and an outer heating chamber. The cracking chamber comprises an initial cracking zone, a middle cracking zone and a rear cracking zone. The upper part of the initial cracking zone is provided with a raw material inlet. The tail end of the rear cracking zone is provided with a cracked carbon black outlet. The initial cracking zone, the middle cracking zone and the rear cracking zone are respectively provided with pyrolysis gas outlets. The method comprises natural rubber cracking in the initial cracking zone, synthetic rubber cracking in the middle cracking zone and pyrolysis of carbon black in the rear cracking zone. The device and method are suitable for production of low-ash low-sulfur carbon black through pyrolysis of waste and old tires.

Owner:山东铂铠环保科技有限公司

Ethylene tar treating method

ActiveCN109929589ARelieve blockageRestricted accessTreatment with hydrotreatment processesHydrogenation reactionTar

Owner:CHINA PETROLEUM & CHEM CORP +1

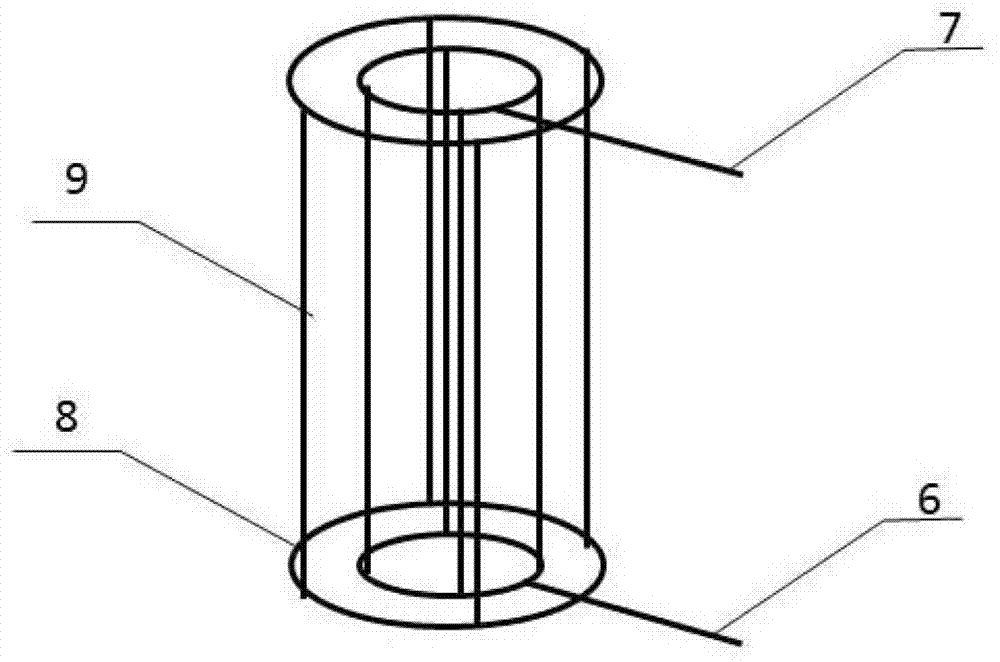

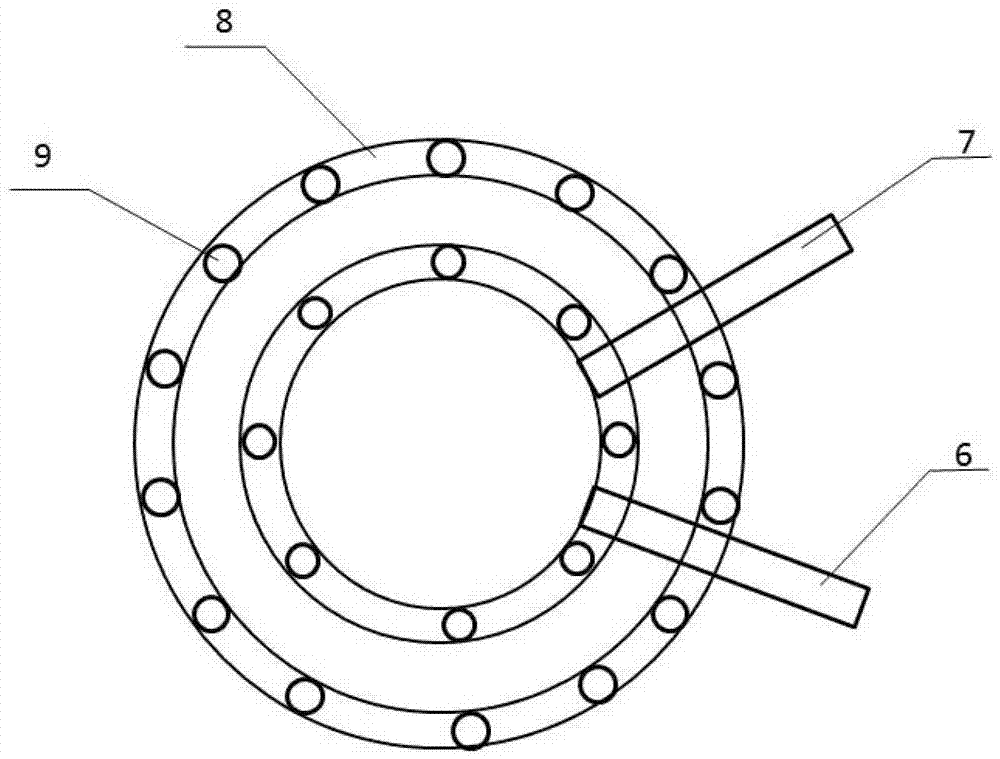

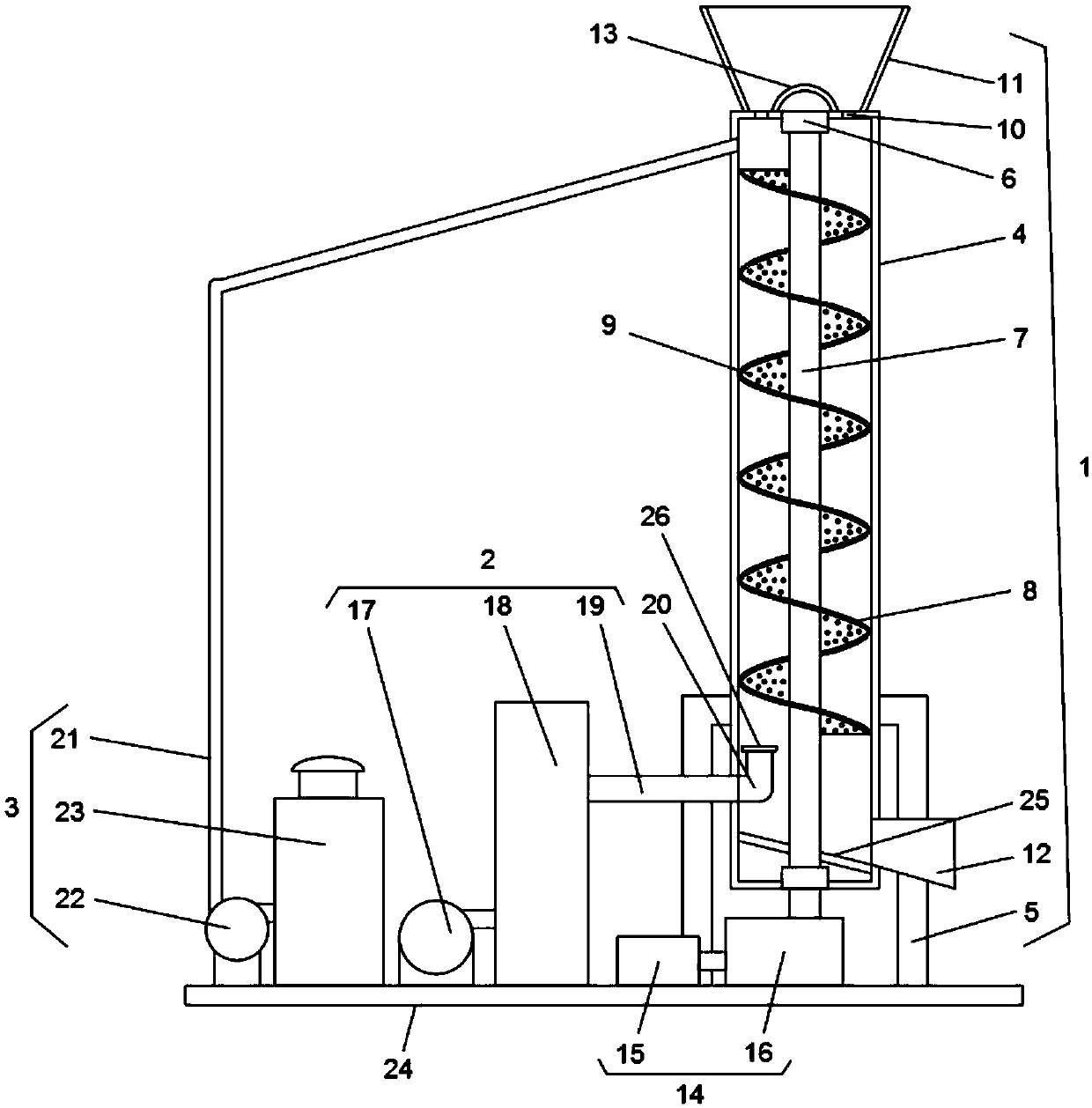

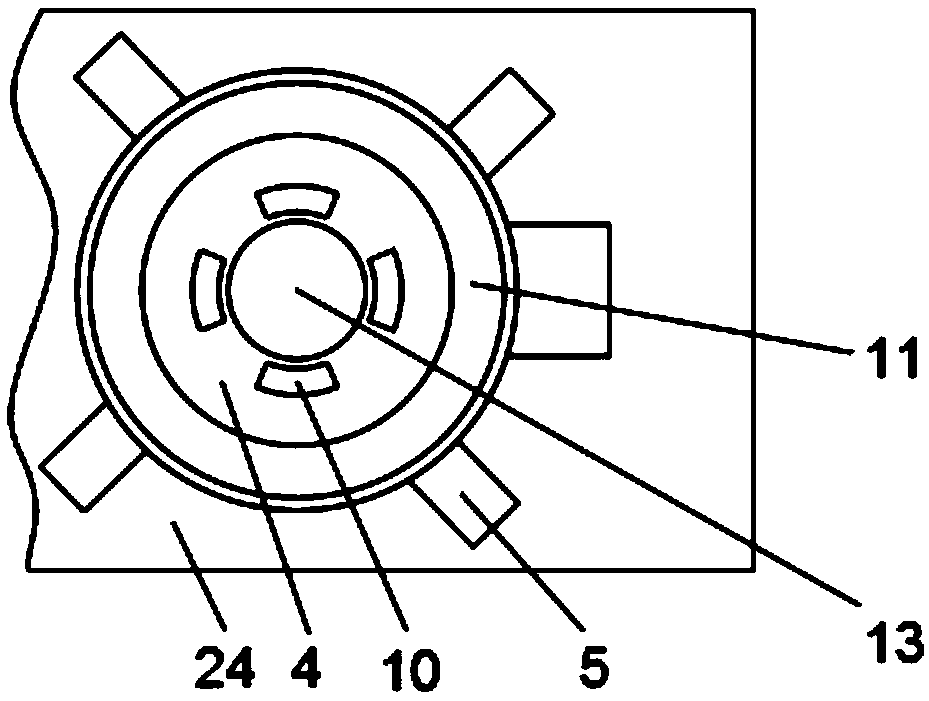

A kind of spiral fluidized bed granulation method and its equipment

ActiveCN104174331BReduce pollutionRealize fluidizationGranulation by powder suspensionAdhesiveProcess engineering

The invention discloses a spiral fluidized bed granulating method and equipment for realizing the spiral fluidized bed granulating method. The spiral fluidized bed granulating method comprises the following steps: A. melting granulating adhesive; B. mixing materials, heating and conveying to a spiral fluidized bed unit; C. granulating; D. screening granulated materials in the step C; and E. collecting dusts. The equipment for realizing the spiral fluidized bed granulating method comprises a granulating adhesive melting and conveying device, a material mixing, heating and conveying device, a granulating device, a screening device and a dust collecting device. The spiral fluidized bed granulating method and the equipment have the beneficial effects that a mechanical method is adopted to perform powdery material granulation, and the method and the equipment can be suitable for powdery material granulation, can overcome the defect that the traditional fluidized bed adopts wind powder as power and is not suitable for powdery material granulation, and can reduce dust pollution.

Owner:SHANDONG ZOETICLAND BIOLOGICAL TECH

Straw granule drying device

PendingCN109539755AGuaranteed efficiencyGuaranteed drying effectGranular material dryingDrying gas arrangementsExhaust gasPower component

The invention discloses a straw granule drying device. The straw granule drying device comprises a drying generating component, a hot gas generating component, an exhaust gas processing component, a power component and a first supporting plate; the drying generating component, the hot gas generating component, the exhaust gas processing component and the power component are all arranged on the upper surface of the first supporting plate; the hot gas generating component communicates with the drying generating component; the drying generating component communicates with the exhaust gas processing component; and the power component and the hot gas generating component are connected. Through the straw granule drying device, the drying effect and the drying efficiency of straw granules in a drying cylinder in the application process can be ensured, and the whole device is convenient and easy to operate and beneficial for drying of the straw granules.

Owner:颍上县聚鑫再生资源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com