Agitated fluidized bed type drying machine

A technology of agitated flow and dryer, applied in hearth furnaces, drying solid materials, heating to dry solid materials, etc., can solve the problem of inability to maintain consistent particle size, damage to nutritional factors and biological activity, and different residence times. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The stirring fluidized bed dryer of the present invention will be further described in detail in conjunction with the accompanying drawings.

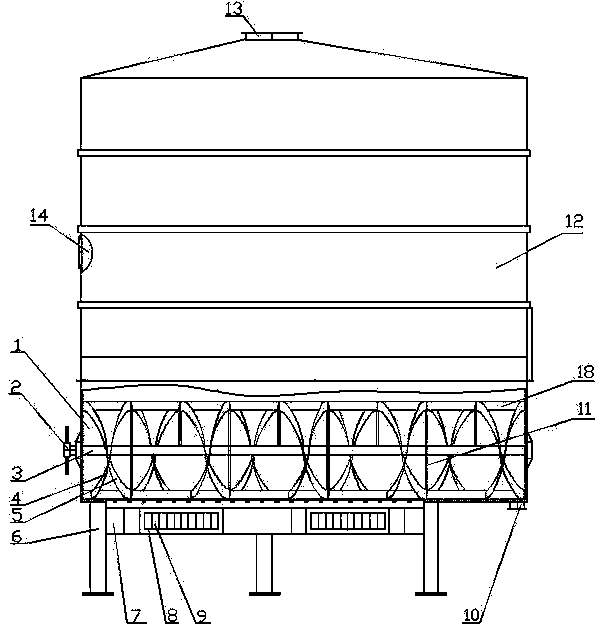

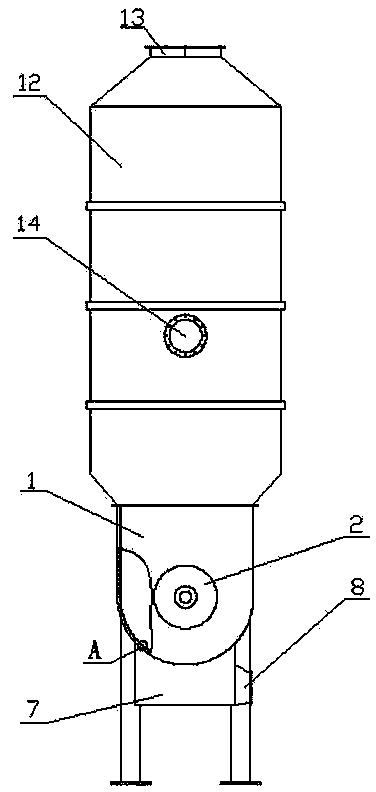

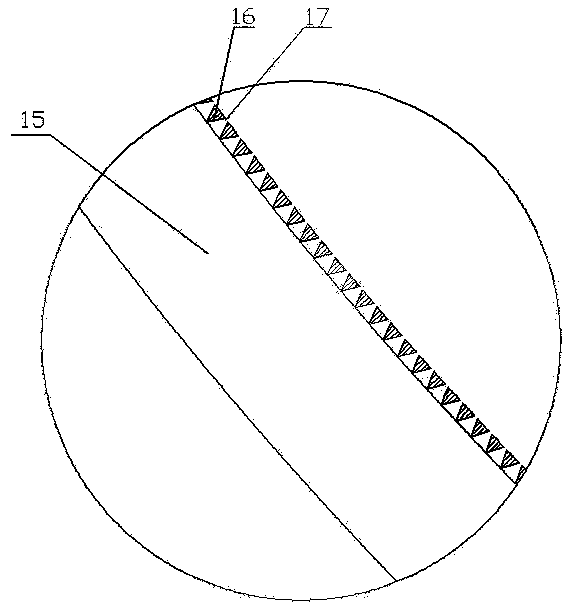

[0017] Such as figure 1 , figure 2 with image 3As shown, the stirring fluidized bed dryer of the present invention includes a drying chamber 1, the upper part of the drying chamber 1 is a rectangular box, and the lower part of the drying chamber 1 is a semi-cylindrical box that is arranged horizontally and protrudes downwards. The lower end of the box body and the upper end of the semi-cylindrical box body are both open and of the same size, and the rectangular box body and the semi-cylindrical box body are connected up and down to form the drying chamber 1 . An air inlet chamber 7 is connected to the bottom of the drying chamber 1 close to one end thereof, and the connection between the drying chamber 1 and the air inlet chamber 7 is densely covered with drying holes 17 . The groove wall of the semi-cylindrical box of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com