Production method of spherical toner

A manufacturing method and toner technology, which can be applied in the directions of developer, electrography, optics, etc., can solve the problems of difficult residence time, complex structure, powder adhesion and uneven spheroidization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

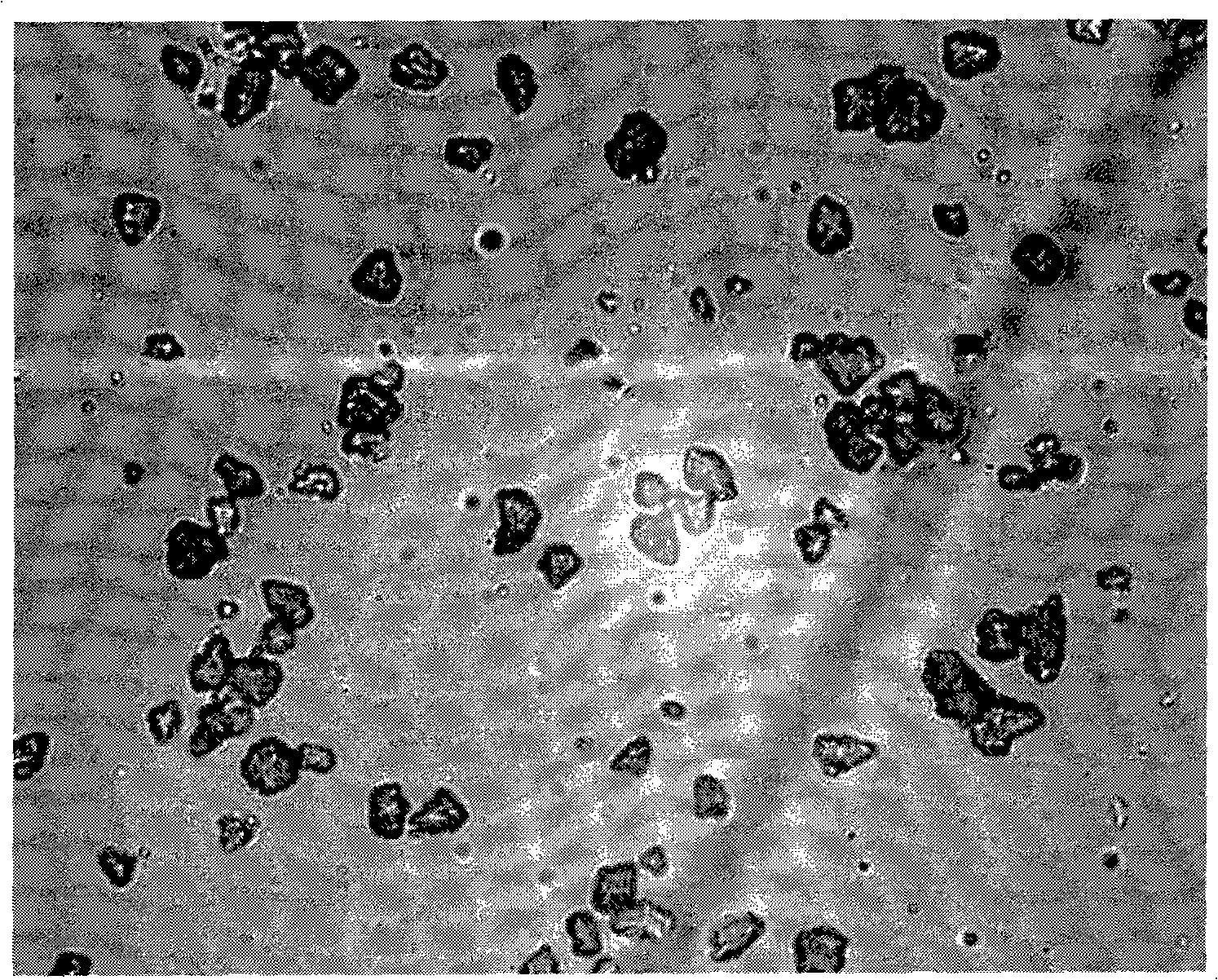

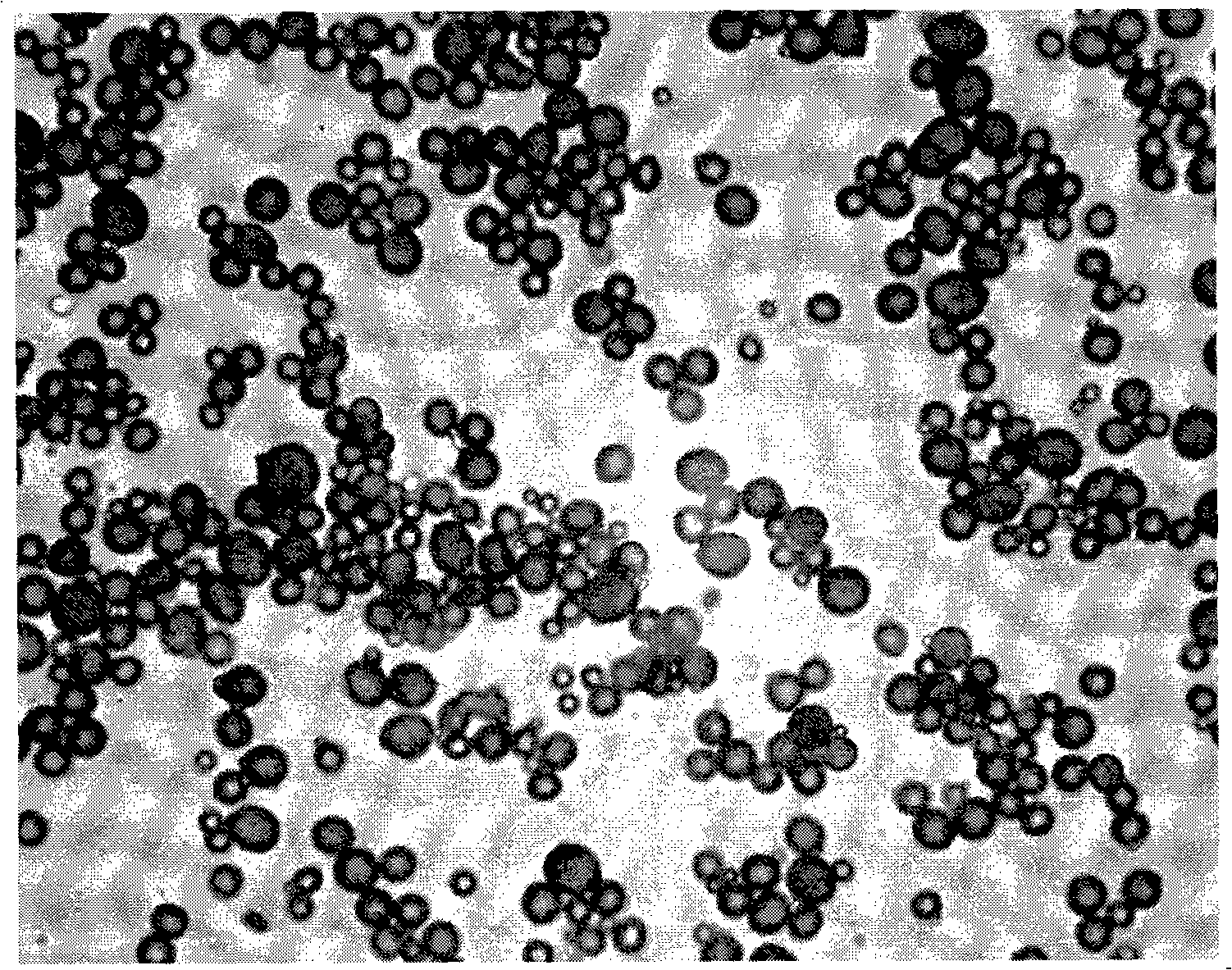

[0026] Take 5 parts by weight of magenta toner (TE01) with a particle size range of 5-20 μm after airflow classification and a softening point temperature of 85° C. into the container, add 50 parts by weight of industrially pure water, It is best to add a small amount of surfactant, such as 0.1-0.5 parts of sodium dodecylbenzenesulfonate, disperse with ultrasonic waves for 10-20 minutes, take samples and observe the dispersion effect and particle shape under a biological microscope. Such as figure 1 As shown, the toner powder at this time is in an irregular shape with edges and corners. Put the container containing the dispersion into a constant temperature water bath at 90-100°C, and at the same time stir with an electric mixer at a speed of 250 rpm for about 5 hours, then stop stirring. At this time, samples were taken and observed under a microscope, such as figure 2 As shown, the shape of the toner is spherical or ellipsoidal. The finished spherical toner can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com