Method for drying poly carbonate (PC)

A polycarbonate, drying technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of complex equipment structure, long drying time, low drying efficiency, etc., and achieve controllable residence time and avoid Inflammable and explosive, avoiding the effect of accident hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

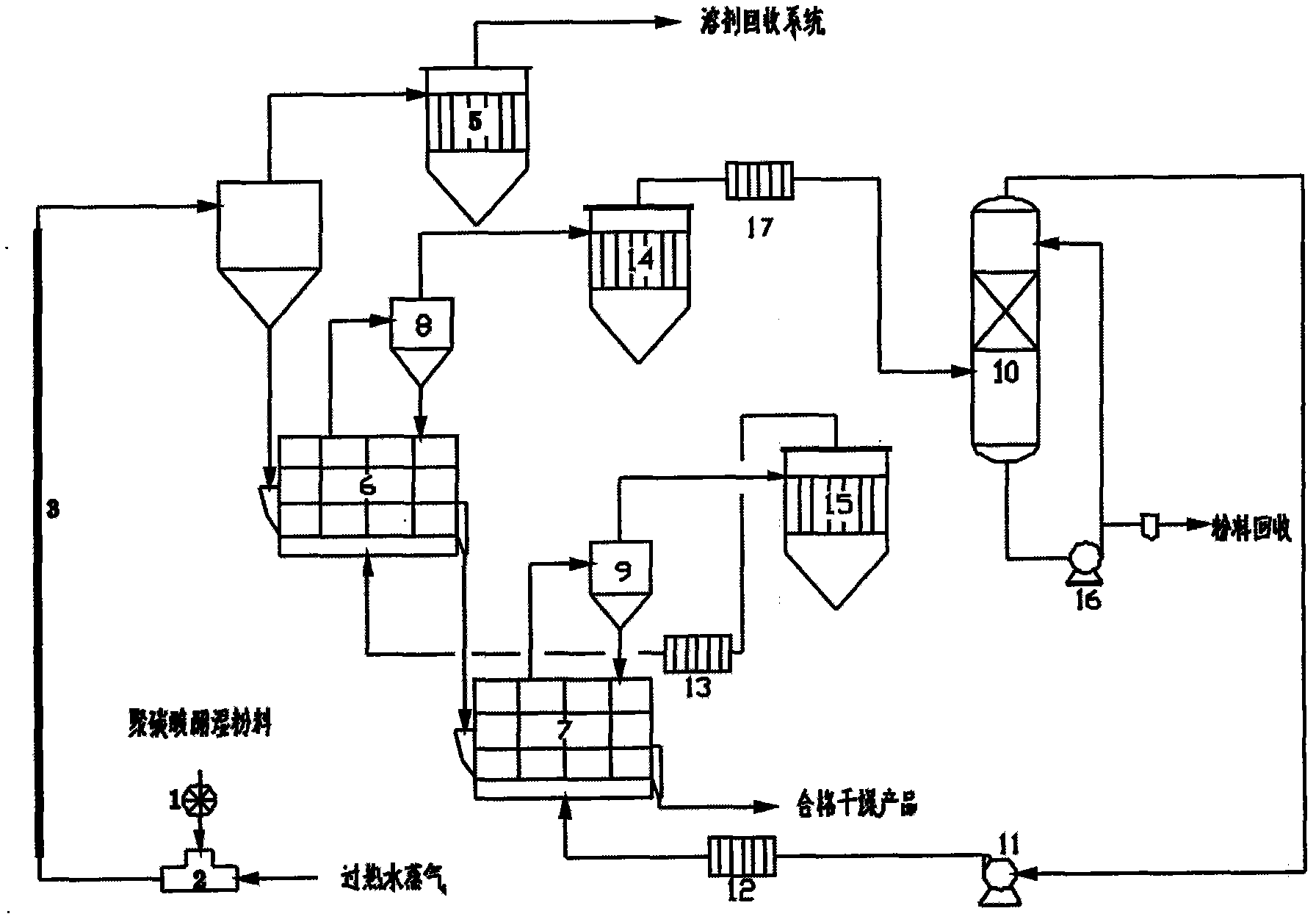

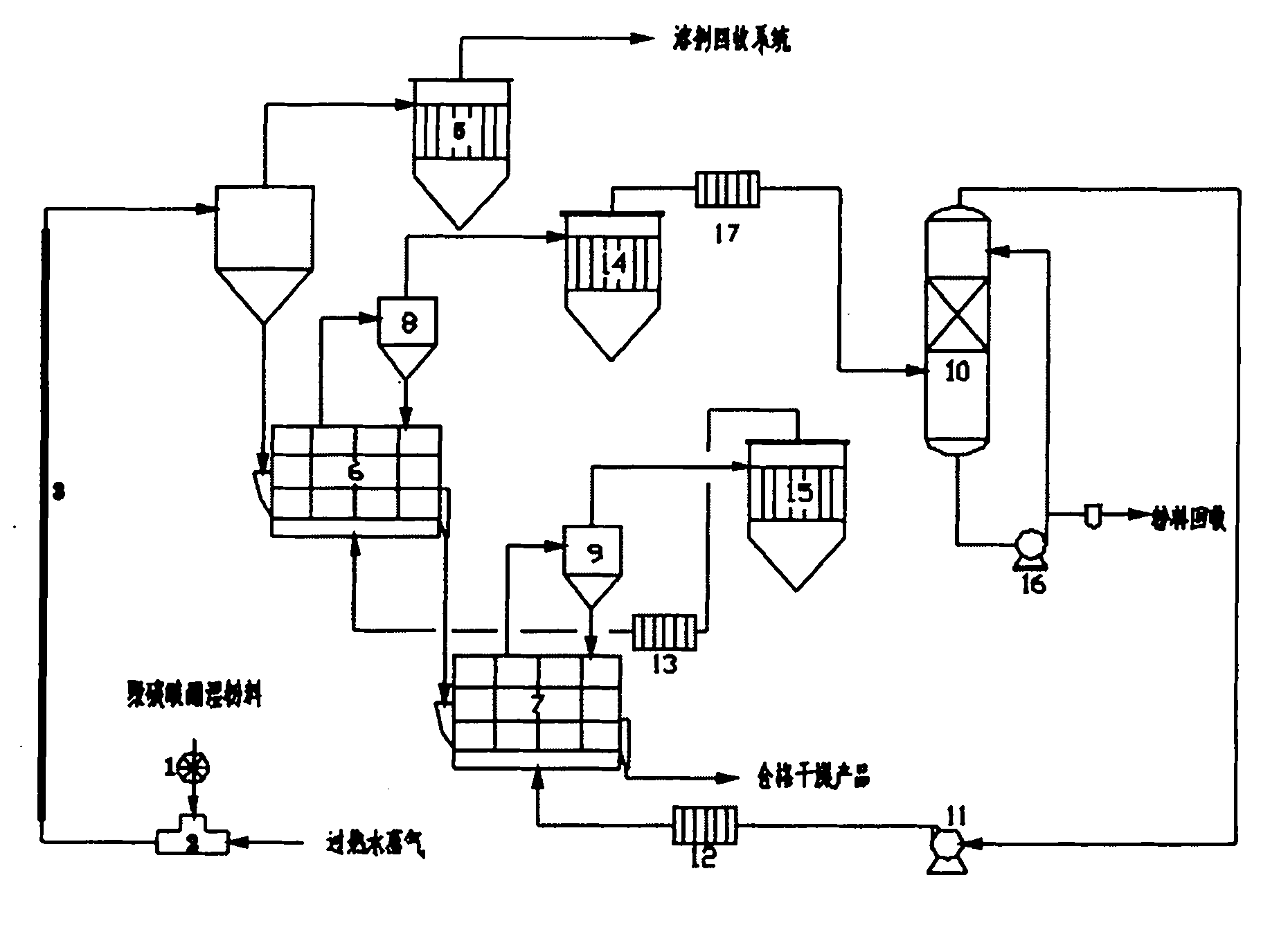

[0021] Example 1: see figure 1

[0022] A method for drying polycarbonate, which is characterized in that polycarbonate powder is dried by a combination of one-stage airflow drying and two-stage fluidized bed drying, and the specific steps are as follows:

[0023] a. The dichloromethane solvent in the polycarbonate powder is removed and recovered by primary air drying: the polycarbonate wet powder generated by the steam precipitation method, that is, the PC powder, is passed through the star feeder 1 and fed The tee 2 enters the air dryer 3, and the residence time is 2.5~4.5S; at the same time, the superheated steam of 0.5~1.0Mpa is sent into the air dryer 3, and the solid-gas mass ratio of the PC powder to the superheated steam is 1~ 10. Control the temperature of the airflow dryer 3 at 100-130°C. After the PC wet powder is fluidized and dried by water vapor in the airflow dryer 3, it is sent to the primary cyclone separator 4 to complete the primary airflow drying. At this ...

Embodiment 2

[0031] Example 2, see figure 1 :

[0032]The previous process uses steam spraying method to generate 128kg / h of PC powder, which contains 25.6kg / h of moisture and 6.4kg / h of organic solvent, and enters the airflow drying through star feeder 1 and feeding tee 2 3, the residence time is 2.5 ~ 4.5S; at the same time, 0.5 ~ 1.0Mpa superheated steam is sent to the air dryer 3, the solid-gas mass ratio of PC powder to superheated steam is 1 ~ 10, and the air flow dryer is controlled. 3. The temperature is 100-130°C. After the PC wet powder is fluidized and dried by water vapor in the airflow dryer 3, it is transported to the first-stage cyclone separator 4 to complete the first-stage airflow drying. At this time, the water content in the PC powder 5-10%, the methylene chloride solvent content is 10-50ppm; the dichloromethane solvent in the PC powder is vaporized and then enters the solvent recovery system after being treated by the first-stage bag filter 5; the powder enters the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com