Nano-composite fiber material and preparation method thereof

A nano-composite fiber and nano-technology, which is applied in the field of fiber materials, can solve the problems of organic carriers being easily corroded by light, difficult to recycle, and reduced in activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

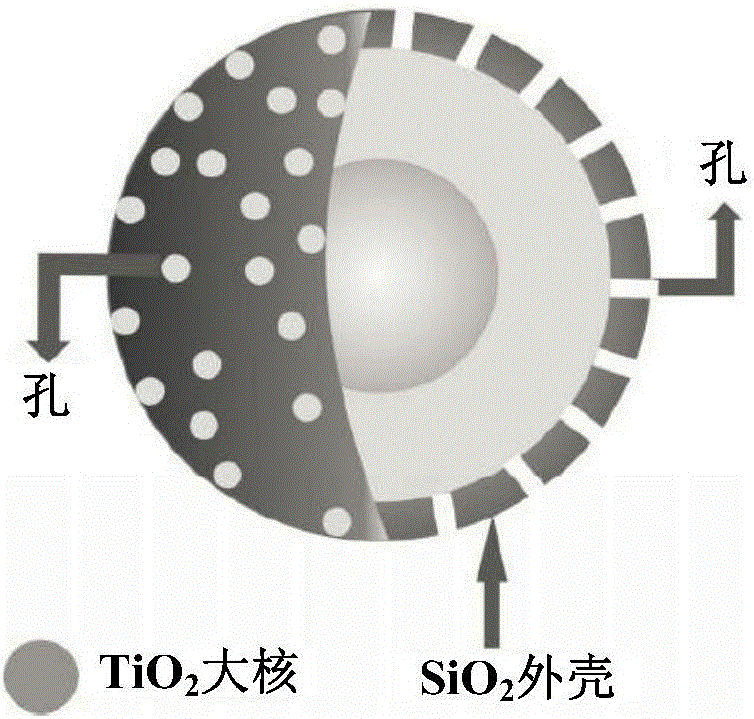

[0052] This embodiment provides a preparation method of titanium dioxide polyester composite fiber material, comprising the following steps:

[0053] Step (1) dispersing a plurality of nanometer titanium dioxide particles in ethanol to form a suspension of nanometer titanium dioxide particles;

[0054] Step (2) provides a molten polyester; specifically, extruding the polyester dry slices through a screw extruder into a thin stream of polyester melt through a spinneret to obtain the molten polyester;

[0055] In step (3), the nano-titanium dioxide particle suspension is heated to 50° C., and sprayed to the polyester melt stream from around the polyester melt stream at a flow rate of 0.1 m / s, so that the poly A nano-titanium dioxide particle floats on the surface of the polyester melt stream to obtain a molten titanium dioxide-polyester composite material;

[0056] Step (4) solidifying the molten titanium dioxide polyester composite material into titanium dioxide polyester comp...

Embodiment 2

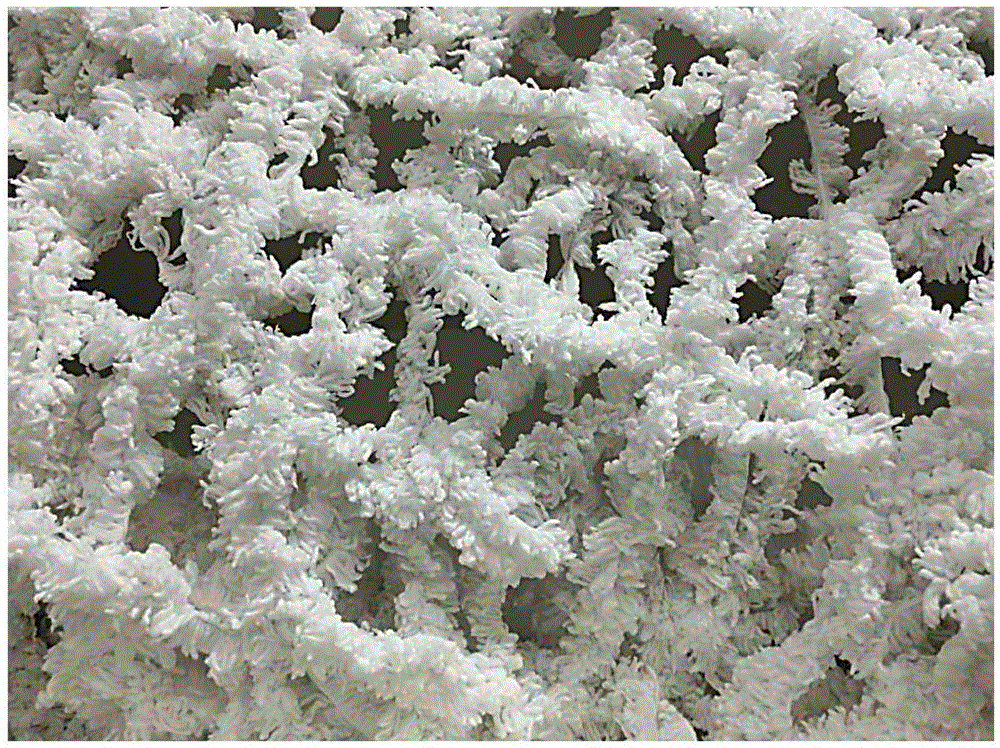

[0059] This example provides a preparation method of a silica-polyamide composite fiber material, which is basically the same as the preparation method of the titanium dioxide polyester composite fiber material provided in Example 1, except that this example uses nano-polyamide Silicon particles are used as functional nanoparticles, and polyamide materials are used as organic polymer flexible carriers; in addition, in steps (3) and (4), the nano-calcium oxide particle suspension is heated to 100 ° C and heated at 0.3m / s The flow rate is sprayed from the surroundings of the polyamide melt stream to the polyamide melt stream, and solidified to obtain a silica-polyamide composite filament; the silica-polyamide composite filament is twisted into a strand with 10-80 strands. root bulky thick fibers, and weave to form a continuous loop structure with a diameter of about 0.5-3cm, that is, to obtain the silica polyamide composite fiber material, wherein, in the silica polyamide composi...

Embodiment 3

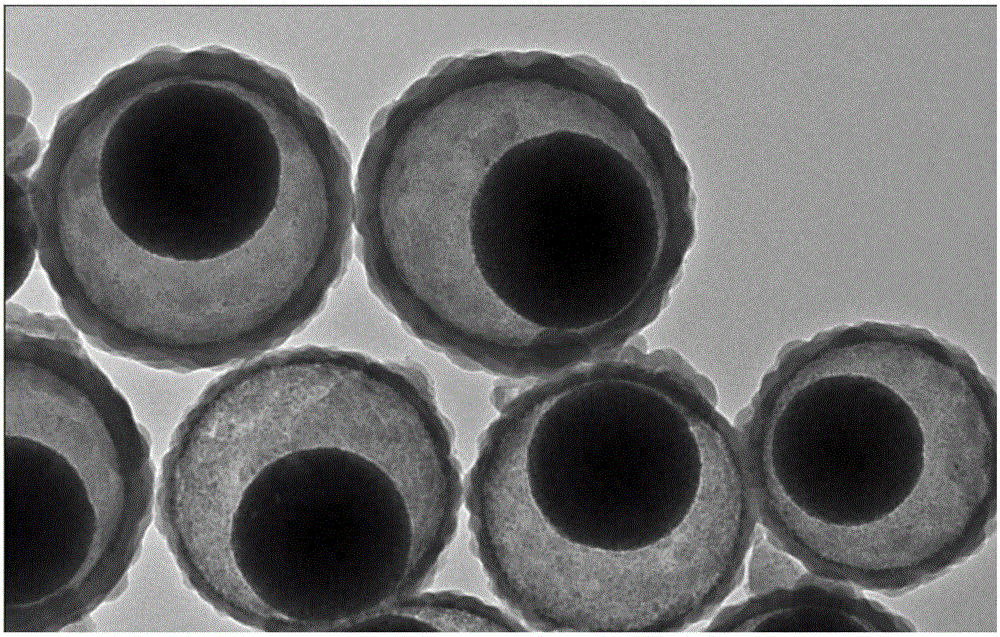

[0062] This example provides a method for preparing a porous hydroxyapatite polyester composite fiber material, which is basically the same as the preparation method for the titanium dioxide polyester composite fiber material provided in Example 1, except that this example uses nanoporous The hydroxyapatite particles are used as functional nanoparticles; in addition, in step (3), the flow velocity of the nanoporous hydroxyapatite particle suspension to the polyester molten stream is 0.4m / s.

[0063]In the porous hydroxyapatite polyester composite fiber material provided in this embodiment, the plurality of porous hydroxyapatite particles are evenly embedded in the polyester material. It is measured that in the porous hydroxyapatite polyester composite fiber material, the loading capacity of nanoporous hydroxyapatite particles is 5% to 10% of the mass of the polyester material; the porous hydroxyapatite polyester composite fiber material The specific surface area is 100m 2 / g~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com