Preparation method of food package paper

A technology for food wrapping paper and finished products, applied in wrapping paper, wrapping paper, packaging, etc., can solve the problems of cellulose film bacteria content, strength and toughness affecting the use effect, etc., to improve hot air circulation efficiency, high heat dissipation efficiency, and speed Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

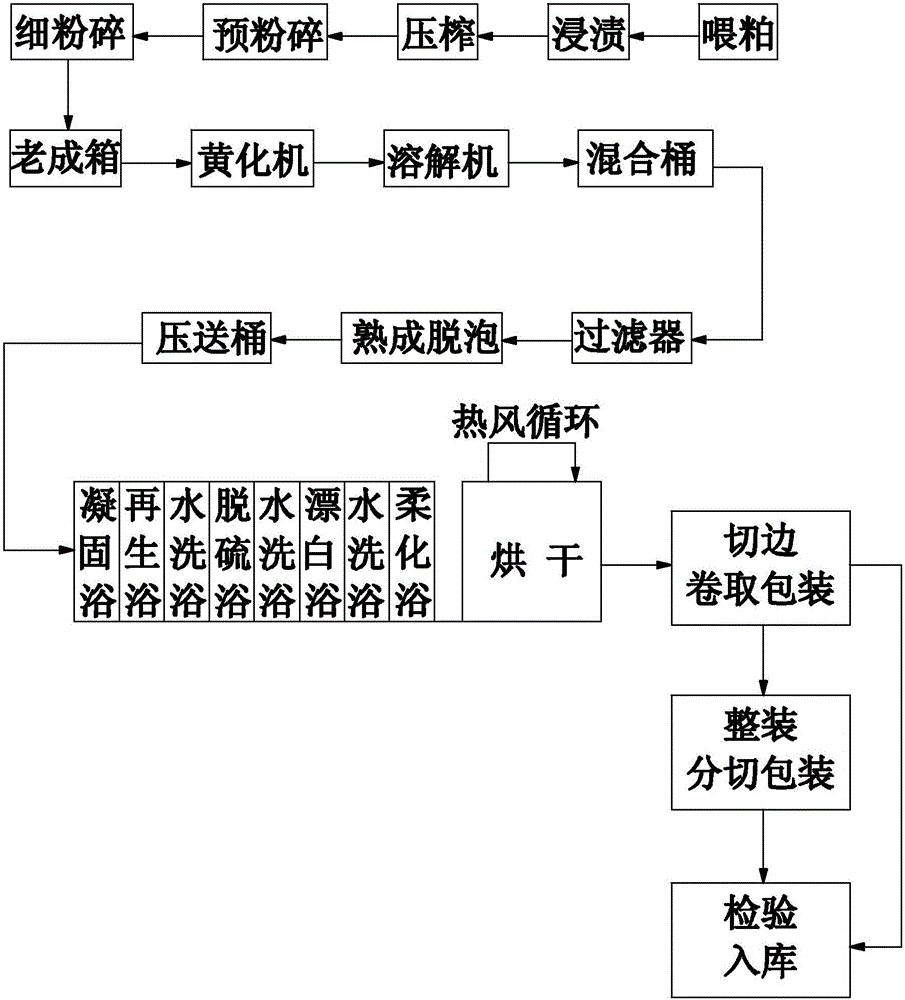

[0034] The preparation method of present embodiment food packaging paper, combines figure 1 The wood pulp is sequentially impregnated→pressed→crushed→aged→yellowing→dissolved→cured→coagulated in a coagulation bath→one water washing→desulfurization→rinsing→second water washing→softening→drying→high and low temperature humidity control→rolling to obtain finished product, of which:

[0035] (1) Dipping: Stir the pulp and lye to form a porridge; the concentration of lye is 235±5g / L, the mass ratio of pulp to lye is about 1:2, the immersion temperature is 50°C, and the immersion time is 30 minutes.

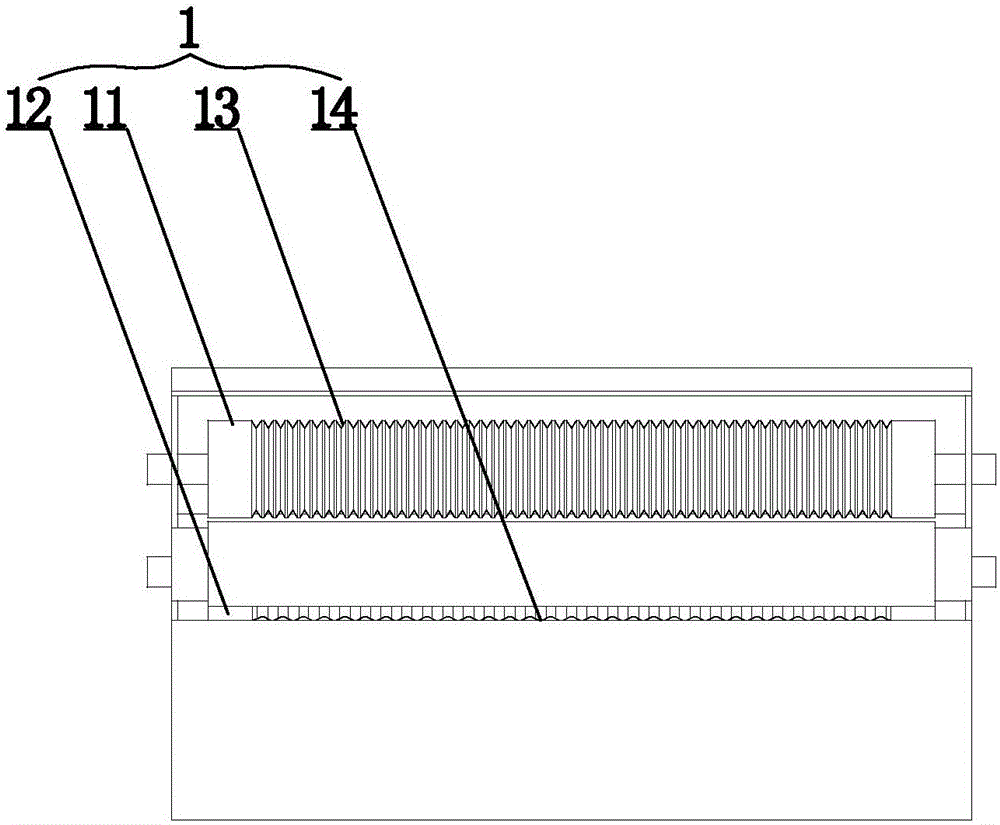

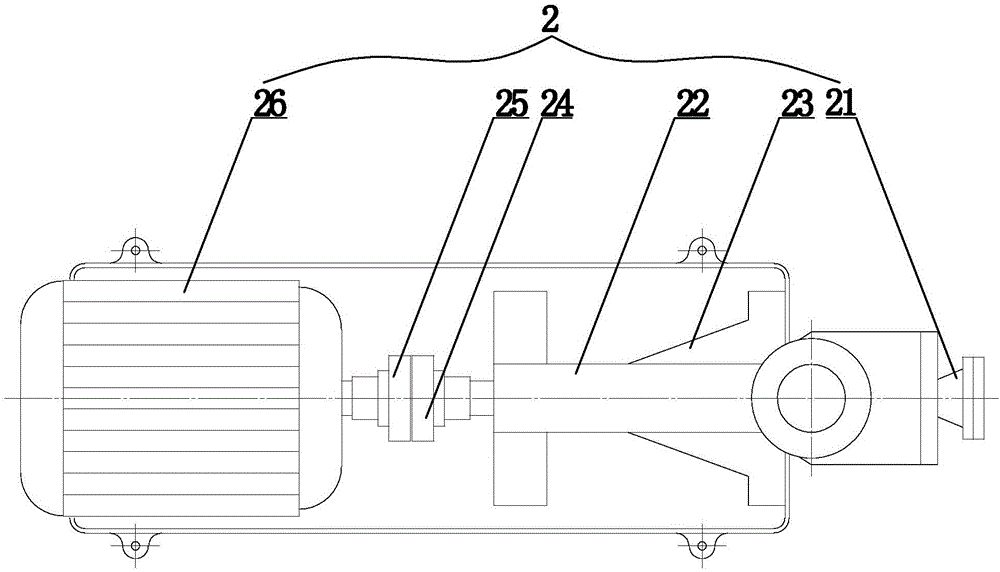

[0036] (2) Pressing and crushing: the porridge is sent into the press for pressing, combined with figure 2 , crushing is carried out between the bottom press roll 11 and the top press roll 12 of the press grinder 1, the top press roll 12 is provided with top press teeth 13, the top press teeth 13 are conical teeth, and the bottom press roll 11 is provided with bottom press teeth. Pr...

Embodiment 2

[0044] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0045] Post-processing: coagulate and regenerate the matured viscose in a coagulation bath to form a cellulose film, which is followed by high-temperature water washing, high-temperature desulfurization, normal temperature water washing 1, normal temperature rinsing, normal temperature water washing 2, after softening, drying, high and low temperature adjustment Wet, coiling is the finished product; the coagulation bath is a mixed solution of sulfuric acid with a concentration of 150g / L and sodium sulfate with a concentration of 235g / L, the temperature is 51°C, and the film-forming time is 6s; after the film is formed, the paper is milky white and opaque. Wash at high temperature until the paper surface is transparent. This time, the washing temperature is 85°C, and the washing time is 50s; then high-temperature desulfurization, the concentration of the de...

Embodiment 3

[0047] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0048] Post-processing: coagulate and regenerate the matured viscose in a coagulation bath to form a cellulose film, which is followed by high-temperature water washing, high-temperature desulfurization, normal temperature water washing 1, normal temperature rinsing, normal temperature water washing 2, after softening, drying, high and low temperature adjustment Wet, coiling is the finished product; the coagulation bath is a mixed solution of sulfuric acid with a concentration of 150g / L and sodium sulfate with a concentration of 235g / L, the temperature is 51°C, and the film-forming time is 6s; after the film is formed, the paper is milky white and opaque. Wash at high temperature until the paper surface is transparent. This time, the washing temperature is 85°C, and the washing time is 50s; then high-temperature desulfurization, the concentration of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com