Lithium supplementing slurry for lithium ion energy storage device, and preparation method and application of lithium supplementing slurry

A lithium-ion and lithium-replenishing technology, used in electrical components, structural parts, electrochemical generators, etc., can solve the problems of difficulty in large-scale production, combustion and explosion, and high danger, and achieve improved energy density and service life, charging and discharging. Efficiency and cycle life improvement, effect of compensating for irreversible capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of Lithium Oxalate Lithium Supplement Slurry

[0035] 1.1 In this embodiment, water is used as a solvent, lithium nickel manganese oxide (LNMO) is used as a catalyst, a copolymer of styrene and butadiene (SBR) and sodium carboxymethyl cellulose (CMC) are used as a binder, and carbon black is used as a catalyst. Conductive additives were used to prepare lithium-supplementing slurries with different lithium oxalate contents.

[0036] 1. Measure 5g of deionized water into a beaker, weigh 0.25g of CMC and add it into deionized water and stir to dissolve. At the same time, weigh 2.5g of lithium oxalate, 1g of LNMO and 1g of carbon black, grind and mix, and then add the mixture to the above solution Stir until evenly dispersed, and finally weigh 1 g of SBR (solid content: 25%) and add it into the above dispersion liquid and continue stirring until a uniform slurry is obtained, which is recorded as a1.

[0037]2. Measure 5g of deionized water into a b...

Embodiment 2

[0075] Example 2 Preparation of LiNi 0.5 mn 1.5 o 4 / Lithium oxalate positive electrode sheet

[0076] In this example, the electrode sheet supplemented with active lithium was prepared by directly adding the lithium oxalate slurry prepared in Example 1 into the positive electrode slurry.

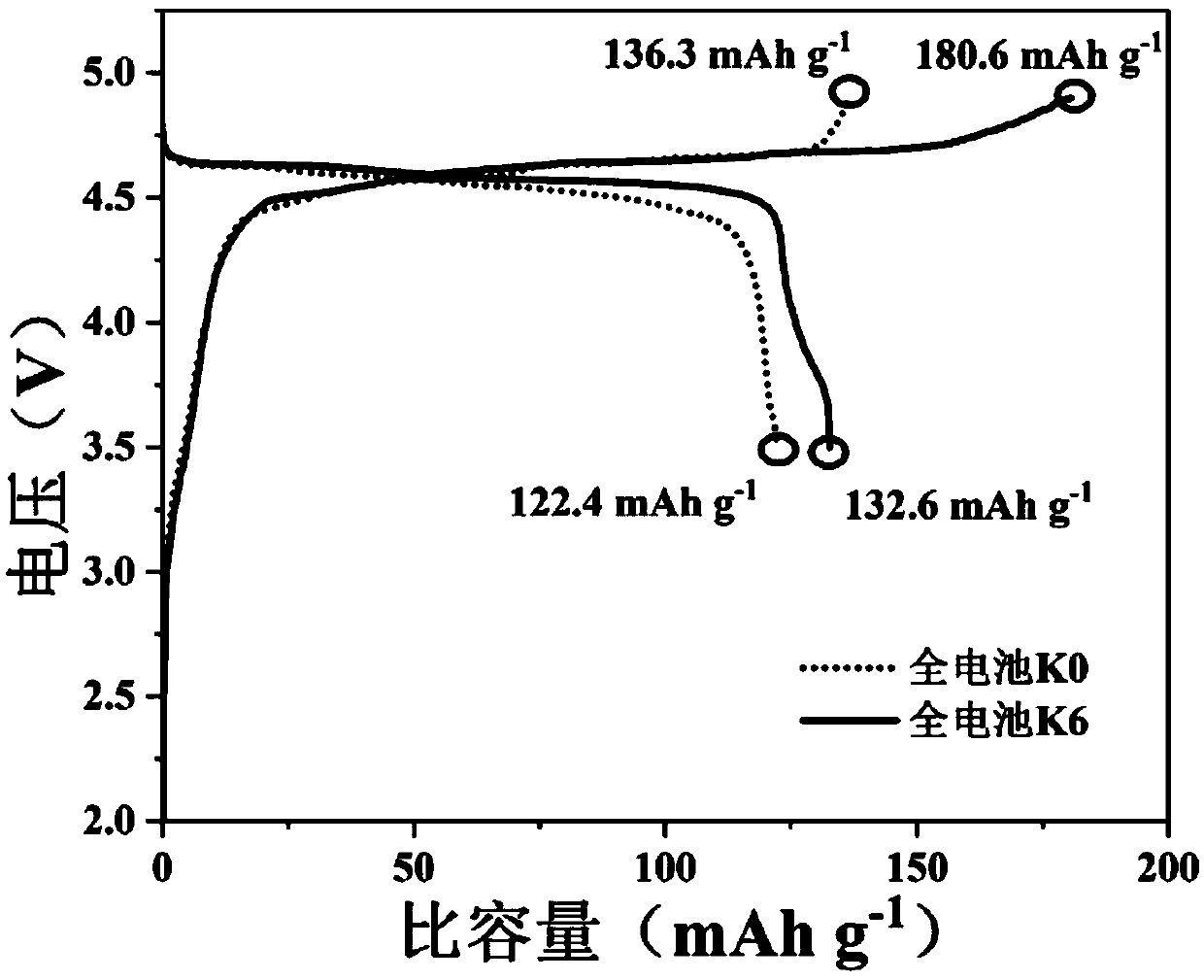

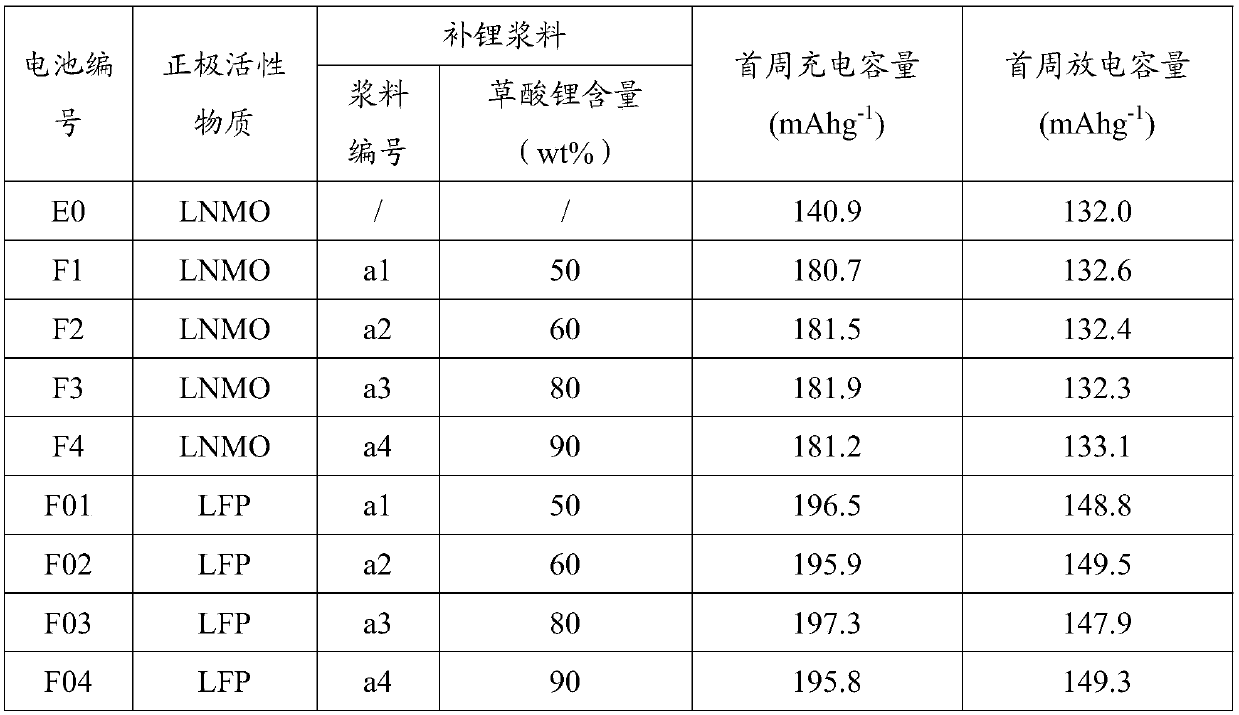

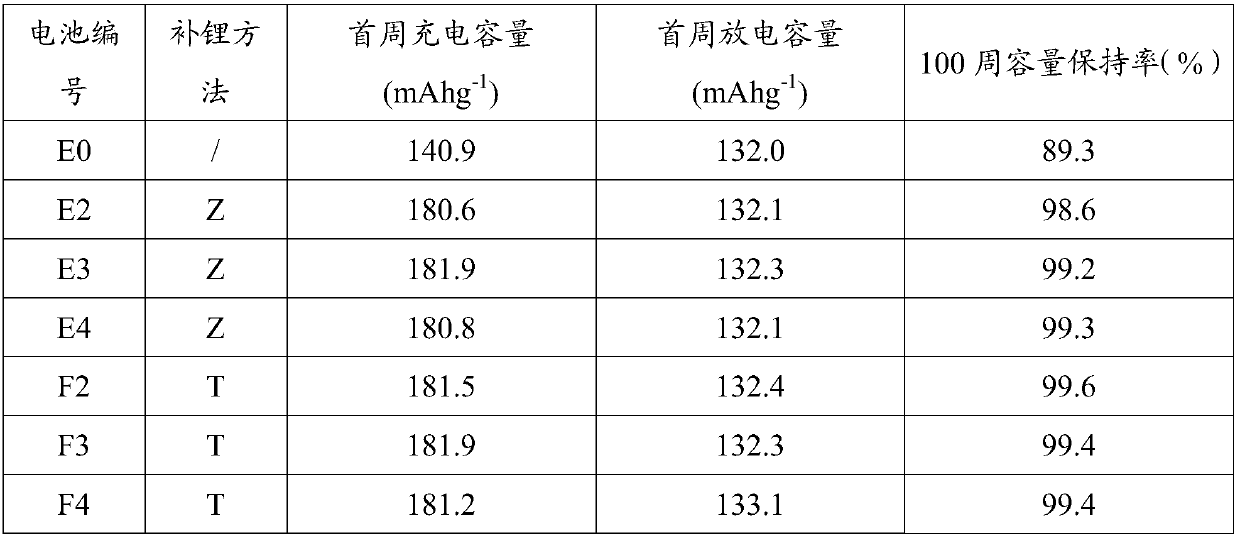

[0077] Will LiNi 0.5 mn 1.5 o 4 (LNMO) is used as the positive electrode active material, and carbon black is used as the conductive additive at the same time, with SBR and CMC as the binder, according to the mass ratio active material: conductive additive: CMC: SBR = 92:5:1:2 in deionized water and mix evenly , prepared into a homogeneous slurry 1. Then, the corresponding volumes of a1-a9 slurries containing lithium oxalate whose mass is 10% of the mass of the LNMO used were respectively added to the slurry 1 to obtain the slurry 2. Coat the slurry 2 evenly on the aluminum foil current collector, dry it at 55°C, and cut the pole piece into a diameter of The wafers were placed in...

Embodiment 3

[0078] Example 3 Preparation of LiNi 0.5 mn 1.5 o 4 / lithium oxalate and LFP / lithium oxalate positive electrode sheet

[0079] In this example, the slurry prepared in Example 1 is applied to LiNi 0.5 mn 1.5 o 4 Or lithium iron phosphate (LFP) to obtain pole pieces supplemented by active lithium.

[0080] Will LiNi 0.5 mn 1.5 o 4 (LNMO) as positive electrode active material, carbon black as conductive additive, with SBR and CMC as binder, according to mass ratio active material: conductive additive: CMC: SBR=92:5:1:2 in deionized water and mix uniformly, Prepare a homogeneous slurry. Evenly coat the uniform positive electrode slurry on the aluminum foil current collector, dry it at 55°C, and cut the pole piece into a diameter of The wafers were placed in a vacuum oven and baked at 120°C for 6 hours. After cooling naturally, they were taken out and placed in a glove box to be used as positive electrodes (referred to as A0).

[0081] Lithium iron phosphate (LFP) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com