Sodium ion battery formation method and preparation method, and sodium ion battery

A sodium-ion battery, a technology for the formation method, which is applied in the manufacture of electrolyte batteries, secondary battery charging/discharging, secondary batteries, etc. Charging efficiency, improving initial charge capacity, preventing electrolyte decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

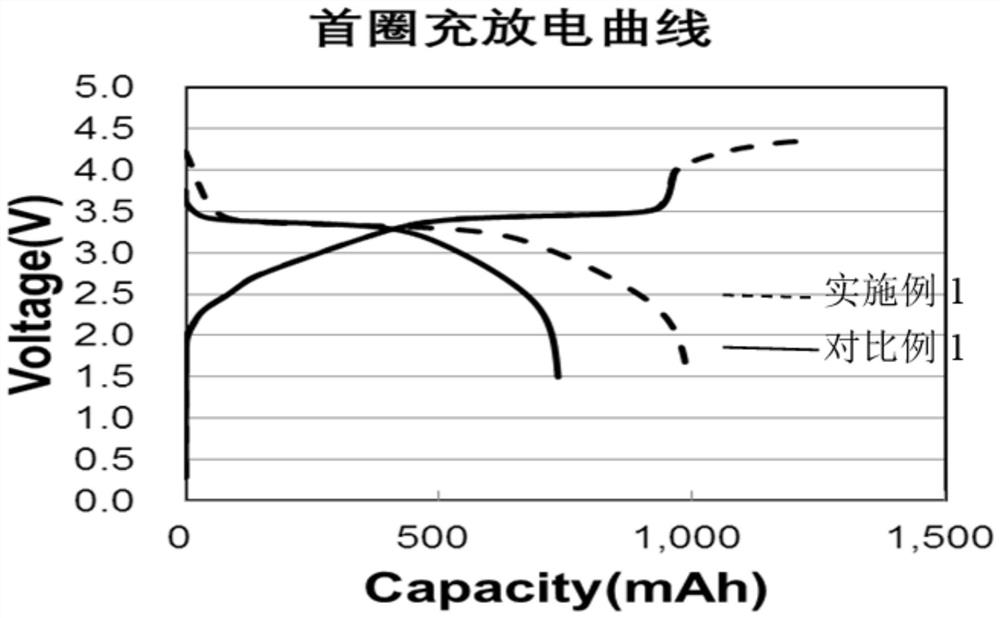

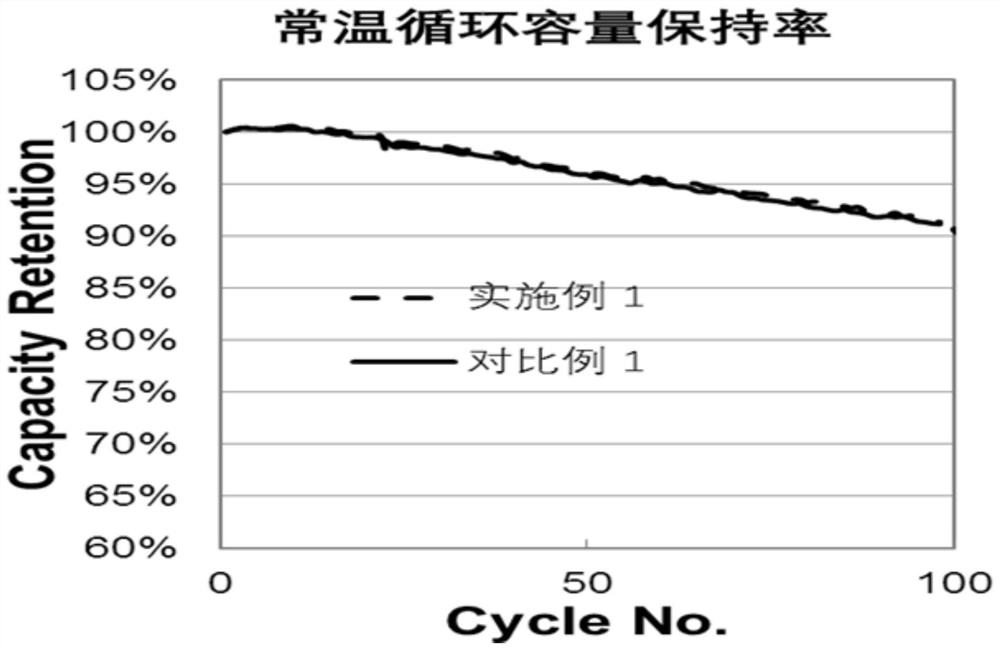

Embodiment 1

[0037] A preparation method of sodium ion battery, comprising the following steps:

[0038] 1) Preparation of positive electrode sheet: Na 1.92 Fe[Fe(CN) 6 ]·0.08H 2 O: acetylene black: super-P: PVDF is slurried according to the mass ratio of 90:2.5:2.5:5, coated, dried, and rolled to obtain the positive electrode sheet.

[0039] 2) Preparation of the negative electrode sheet: hard carbon: super-P: PVDF is mixed according to the mass ratio of 90:5:5, coated, dried, and rolled to obtain the negative electrode sheet. The capacity ratio of the positive electrode sheet to the negative electrode sheet is 1:1.2.

[0040] 3) Diaphragm: polyethylene diaphragm.

[0041] 4) Electrolyte: Propylene carbonate (PC): ethylene carbonate (EC) with a volume ratio of 1:1 is used as the solvent, and 1.2M NaPF is used for the sodium salt 6 , 4% fluoroethylene carbonate (FEC) and 5% pentafluoroethoxycyclotriphosphazene (PFPN) are used as additives.

[0042] 5) Battery assembly: Assemble the p...

Embodiment 2

[0046] The difference from Example 1 is the setting of the electrolyte.

[0047] 4) Electrolyte: Use propylene carbonate (PC): ethylene carbonate (EC) with a volume ratio of 1:1 as the solvent, and use 1.8M NaPF for the sodium salt 6 , 4% fluoroethylene carbonate (FEC) and 5% pentafluoroethoxycyclotriphosphazene (PFPN) are used as additives.

[0048] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0050] The difference from Example 1 is the setting of the electrolyte.

[0051] 4) Electrolyte: Propylene carbonate (PC): ethylene carbonate (EC) with a volume ratio of 1:1 is used as solvent, 1.8M NaTFSI is used for sodium salt, 4% fluoroethylene carbonate (FEC) and 5 % Pentafluoroethoxycyclotriphosphazene (PFPN).

[0052] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com