Current collector, pole piece, lithium battery and preparation method of pole piece

A current collector and pole piece technology, applied in the field of lithium batteries, can solve the problems of hindering lithium battery capacity or energy density, increase the thickness of pole pieces, etc., and achieve the effect of making up for irreversible capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the above pole piece comprises the following process:

[0041] The first surface and the second surface of the current collector 10 are covered with a protective film. The protective film may be a PE film, and the thickness of the PE film may be 0.1mm˜0.5mm.

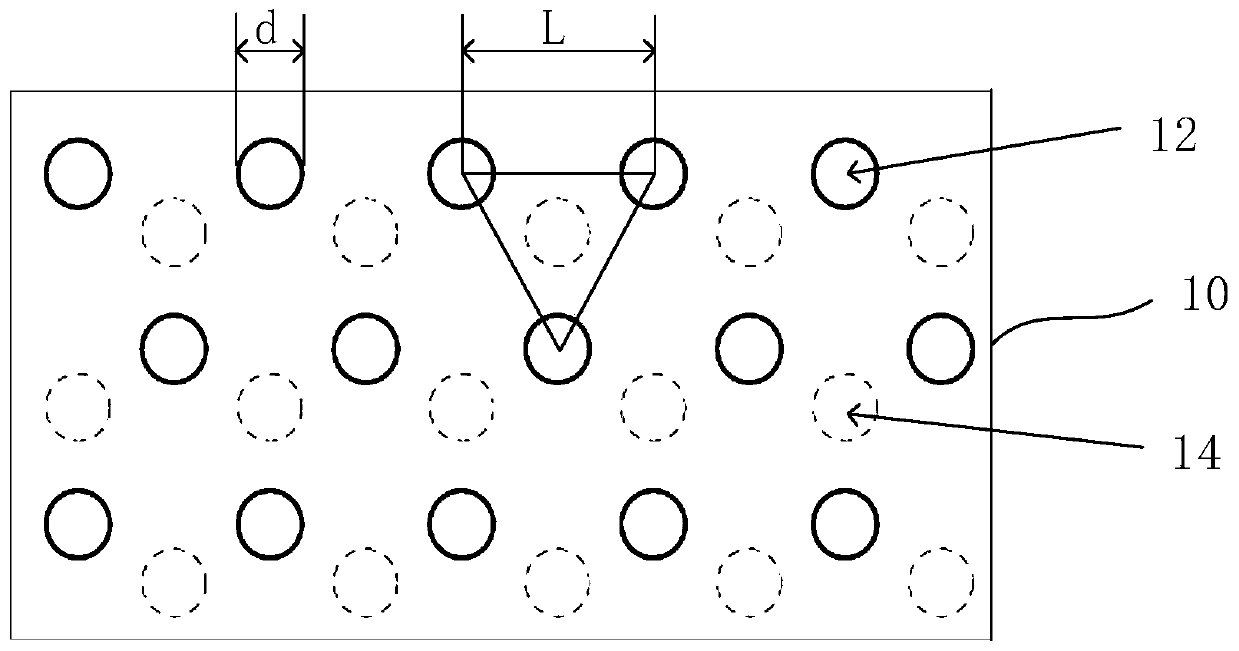

[0042] Laser processing technology is used to process the first blind hole 12 and the second blind hole 14 on the first surface and the second surface respectively.

[0043]Put the lithium-supplementing additive slurry in the first blind hole 12 and the second blind hole 14 , and dry to fix the lithium-supplementing additive slurry in the first blind hole 12 and the second blind hole 14 . The lithium supplement additive slurry is prepared by mixing the lithium supplement additive, a binder and a solvent. The binder may be polyvinylpyrrolidone or the like, and the solvent may be ethanol or the like. The lithium-supplementing additive slurry is coated or sprayed into the first blind hole ...

Embodiment 1

[0049] Using aluminum foil as the current collector, the thickness of the aluminum foil is 14μm, using PE film as the protective film, the thickness of the PE film is 0.1mm, covering both sides of the aluminum foil with PE film, using laser technology to make aluminum foil with PE film It has a structure with double-sided blind holes, the depth of which is 80% of the thickness of the aluminum foil, and the diameter d of both-sided blind holes is 20 μm. The projection of the blind hole of the second surface on the first surface does not overlap with the blind hole of the first surface, and the projection of the blind hole of the second surface on the first surface is located at the center of the equilateral triangle of the first surface, such as figure 1 shown. The distance L between adjacent blind holes is 30 μm, and the total area of the blind holes on the first surface is equal to the total area of the blind holes on the second surface.

[0050] Will Li 5 FeO 4 , poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com