Electrode plate and lithium ion battery

A technology of electrode sheet and conductive layer, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of electrode structure damage capacity, loss of electron and ion channels, hidden dangers of battery safety, etc., and achieve good stability and interfacial contact properties, high gram capacity and energy density, avoidance of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

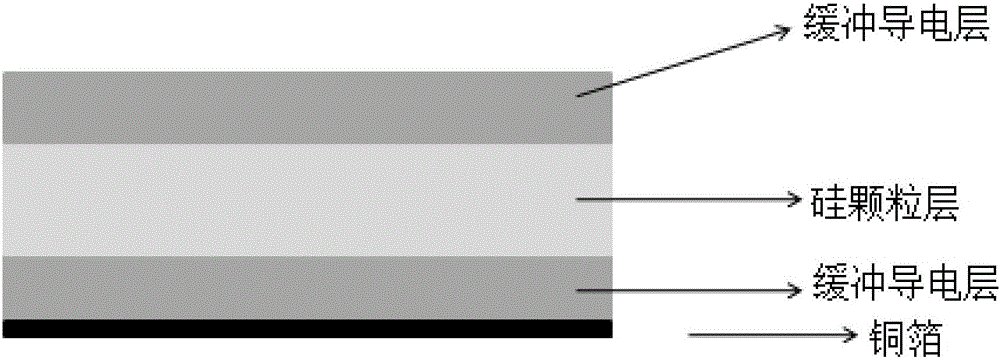

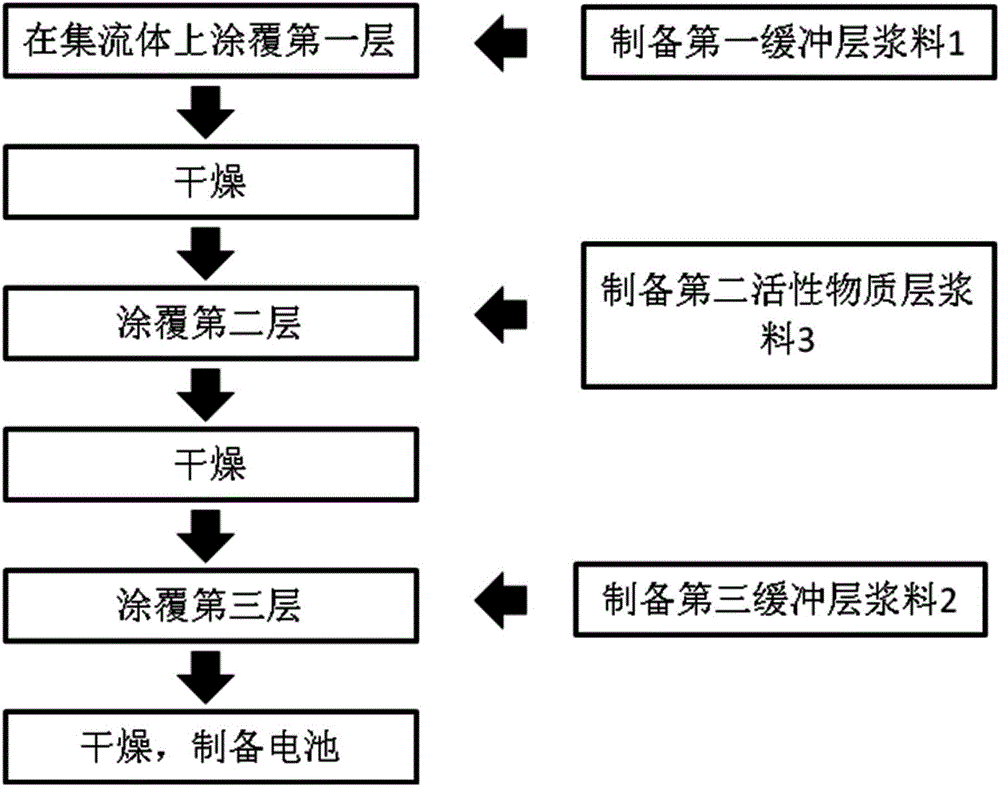

[0070] The process flow chart of the electrode sheet preparation method provided by the embodiment of the present invention is as follows figure 2 shown, including:

[0071] Coating the first conductive layer slurry (first buffer layer slurry) on the surface of the current collector and drying to obtain the first conductive layer;

[0072] Coating the first silicon material layer slurry (second active material layer slurry) on the surface of the first conductive layer and then drying to obtain the first silicon material layer;

[0073] The outer conductive layer slurry (third buffer layer slurry) is coated on the surface of the first silicon material layer and then dried to form an outer conductive layer to obtain an electrode sheet.

[0074] In the present invention, the thickness of the coating is such that the thickness of the obtained first conductive layer is consistent with the thickness of the first conductive layer described in the above technical solution, which wil...

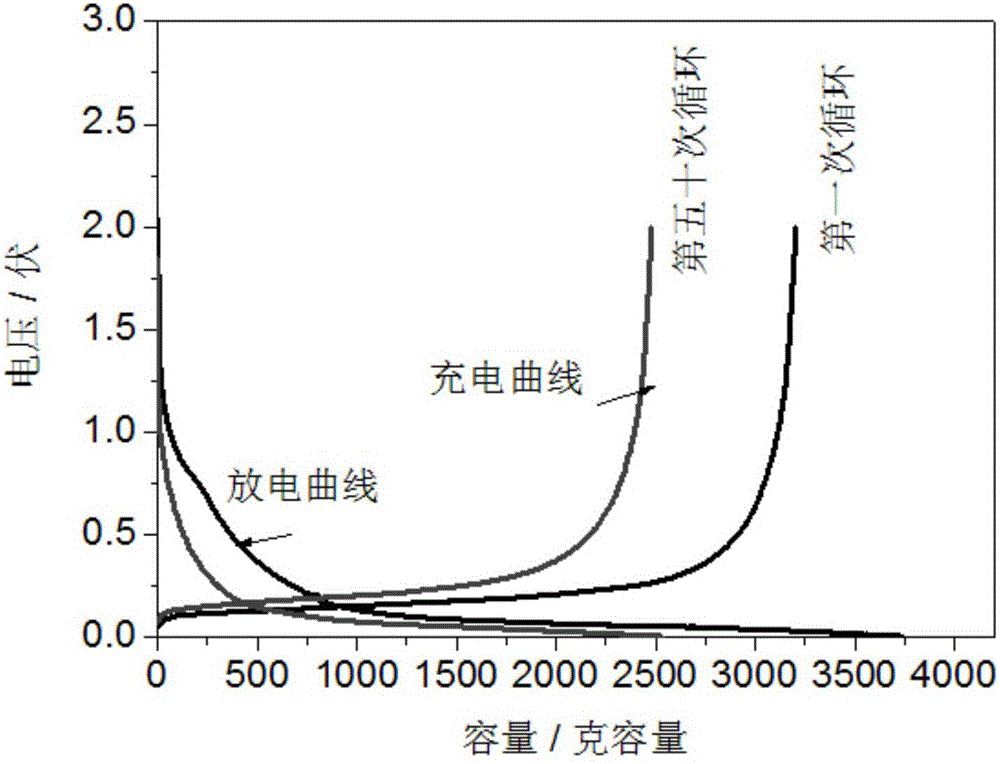

Embodiment 1

[0087] 60g of acetylene black (carbon material) and 40g of polyvinylidene fluoride (PVDF binder) were dissolved in 200g of NMP (N-methylpyrrolidone) solvent to obtain the first conductive layer slurry;

[0088] Prepare the outer conductive layer slurry according to the preparation method of the conductive layer slurry;

[0089] 80g, 325 mesh pure silicon granular material, 10g of acetylene black (conductive agent) and 10g of PVDF (binder) were dissolved in 100g of NMP solvent to obtain the first silicon material layer slurry;

[0090] Coating the conductive layer slurry on the surface of copper foil with a thickness of 15 microns and drying it in a hot air flow drier at 50° C. for 10 minutes to obtain a first conductive layer with a thickness of 100 microns;

[0091] Coating the silicon material layer slurry on the surface of the conductive layer with a doctor blade and drying in a hot air flow drier at 50° C. for 10 minutes to obtain a first silicon material layer with a thic...

Embodiment 2

[0095] The carbon nanotube (carbon material) of 60g and the carboxymethyl cellulose (CMC binding agent) of 40g are dissolved in the secondary water solvent of 200g, obtain the first conductive layer slurry;

[0096] Prepare the outer conductive layer slurry according to the preparation method of the conductive layer slurry;

[0097] 80g, 50nm of pure silicon particle material, 10g of carbon nanotubes (conductive agent) and 10g of CMC (bonding agent) were dissolved in 150g of secondary water solvent to obtain the first silicon material layer slurry;

[0098] Coating the conductive layer slurry on the surface of the copper foil with a thickness of 15 microns and drying at 50° C. for 10 minutes in a hot air flow drier to obtain a first conductive layer with a thickness of 50 microns;

[0099] Coating the silicon material layer slurry on the surface of the conductive layer with a doctor blade and drying in a hot air flow drier at 50° C. for 10 minutes to obtain a first silicon mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com