Patents

Literature

294 results about "Silicon electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

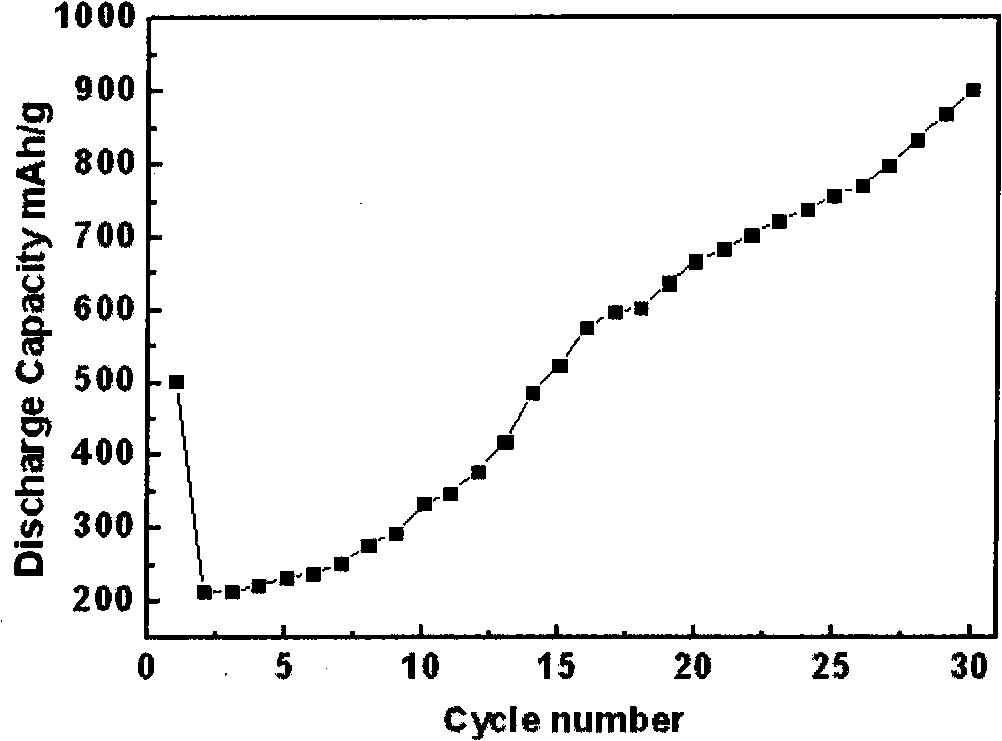

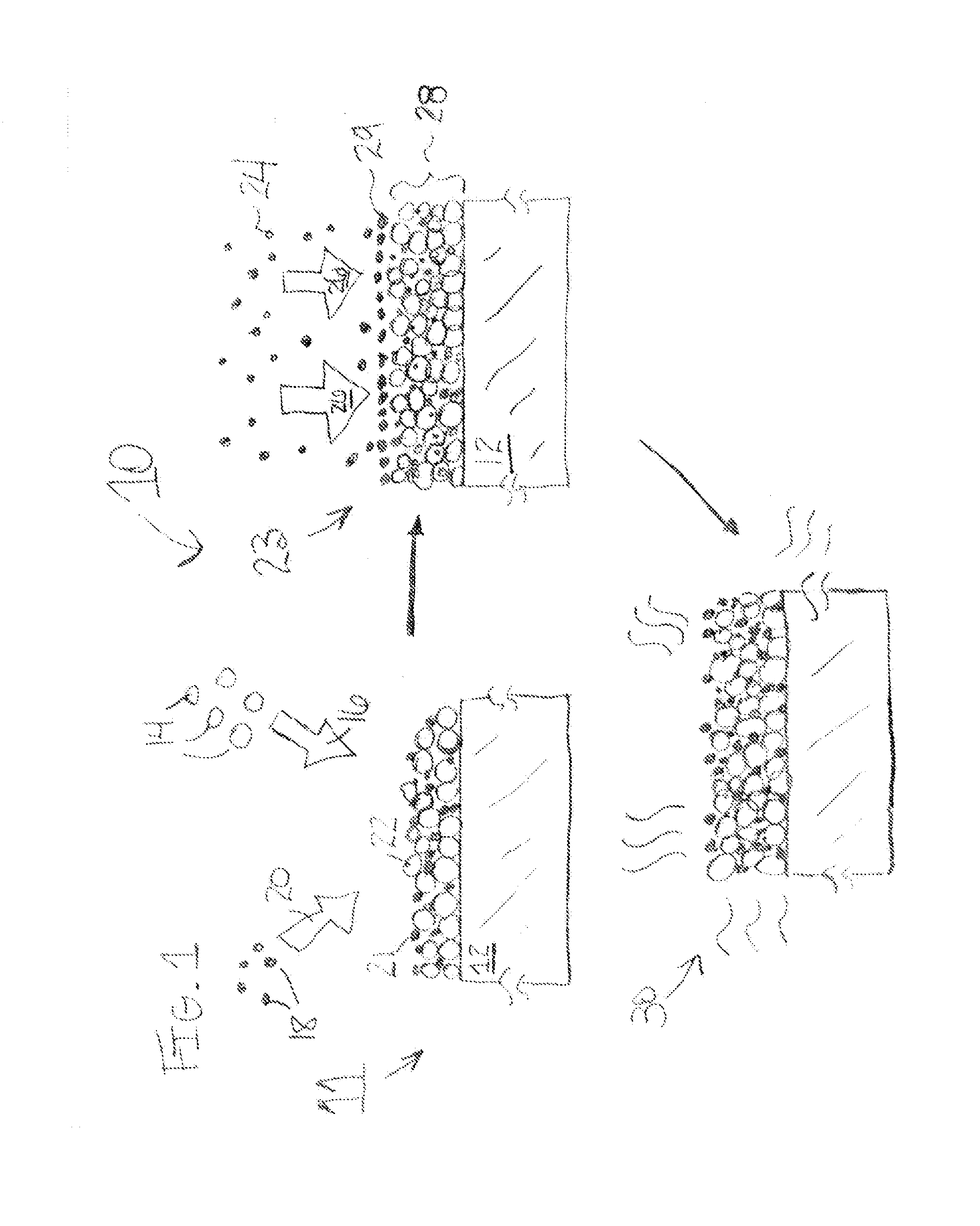

Carbon/silicon/carbon nano composite structure cathode material and preparation method thereof

The invention discloses a carbon / silicon / carbon nano composite structure cathode material and a preparation method thereof, belonging to the technical field of electrochemical power supply technologies. The cathode material consists of a carbon-based conductive substrate, nano silicon and a nano carbon coating layer, wherein the nano silicon is uniformly distributed on the carbon-based conductive substrate; the nano carbon coating layer is arranged on the surface of the nano silicon; the carbon-based conductive substrate is porous carbon, a carbon nanotube or graphene; the nano silicon exists in the state of nanoparticles or nano films; the weight percentage of the nano silicon in the cathode material is 10-90 percent; and the thickness of the nano carbon coating layer is 0.1-10 nanometers. The preparation method comprises the following steps of: depositing nano silicon on the carbon substrate in a reaction space in oxygen-free atmosphere by adopting a chemical vapor deposition process; and coating nano carbon on the surface of the nano silicon by adopting the chemical vapor deposition process. In the obtained carbon / silicon / carbon composite cathode material, the volume change of a silicon electrode material is controlled effectively in the charging and discharging processes, the electrode structure is kept complete, the circulation volume is large, the circulation service life is long, and the electrochemical performance is high.

Owner:TSINGHUA UNIV

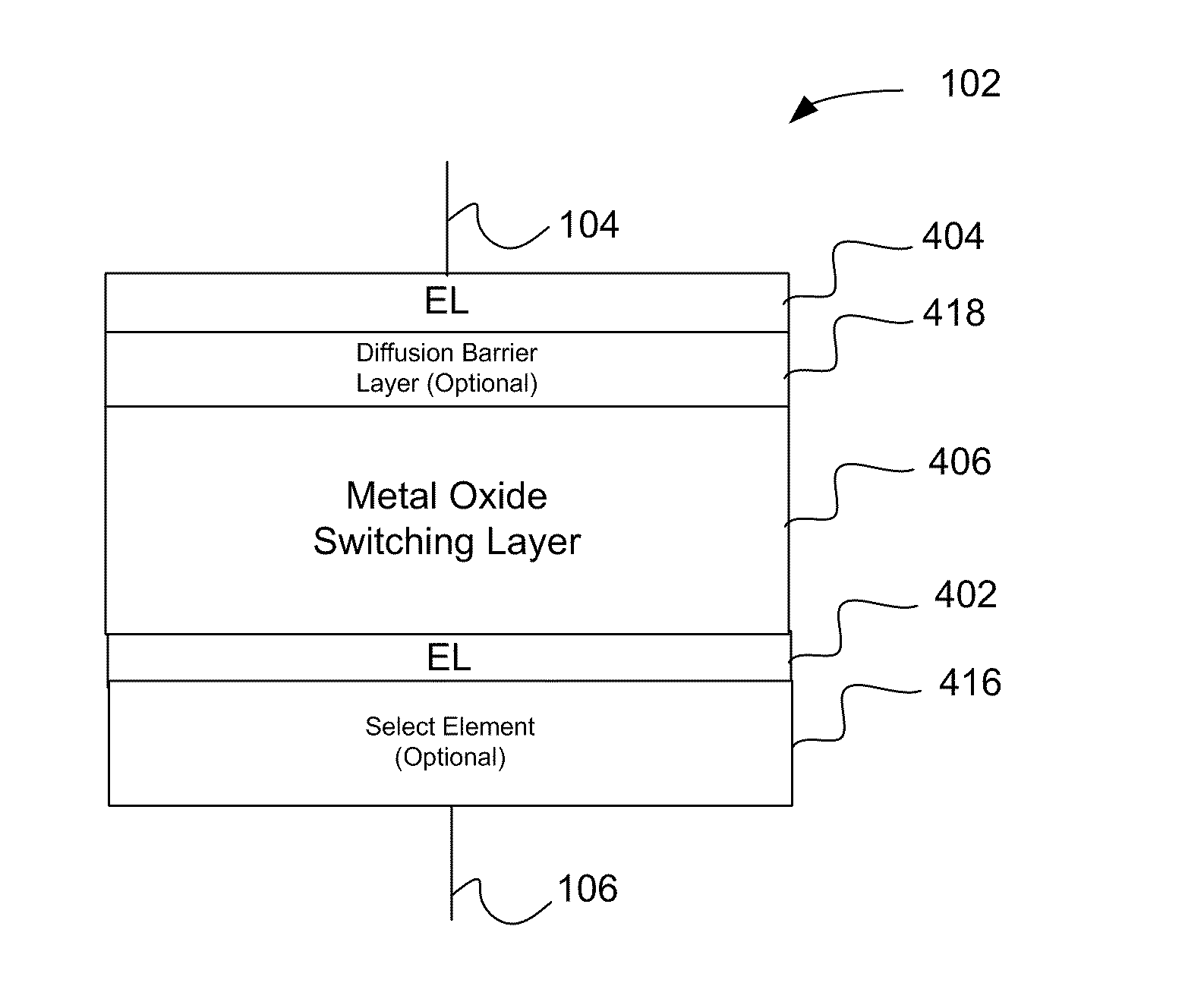

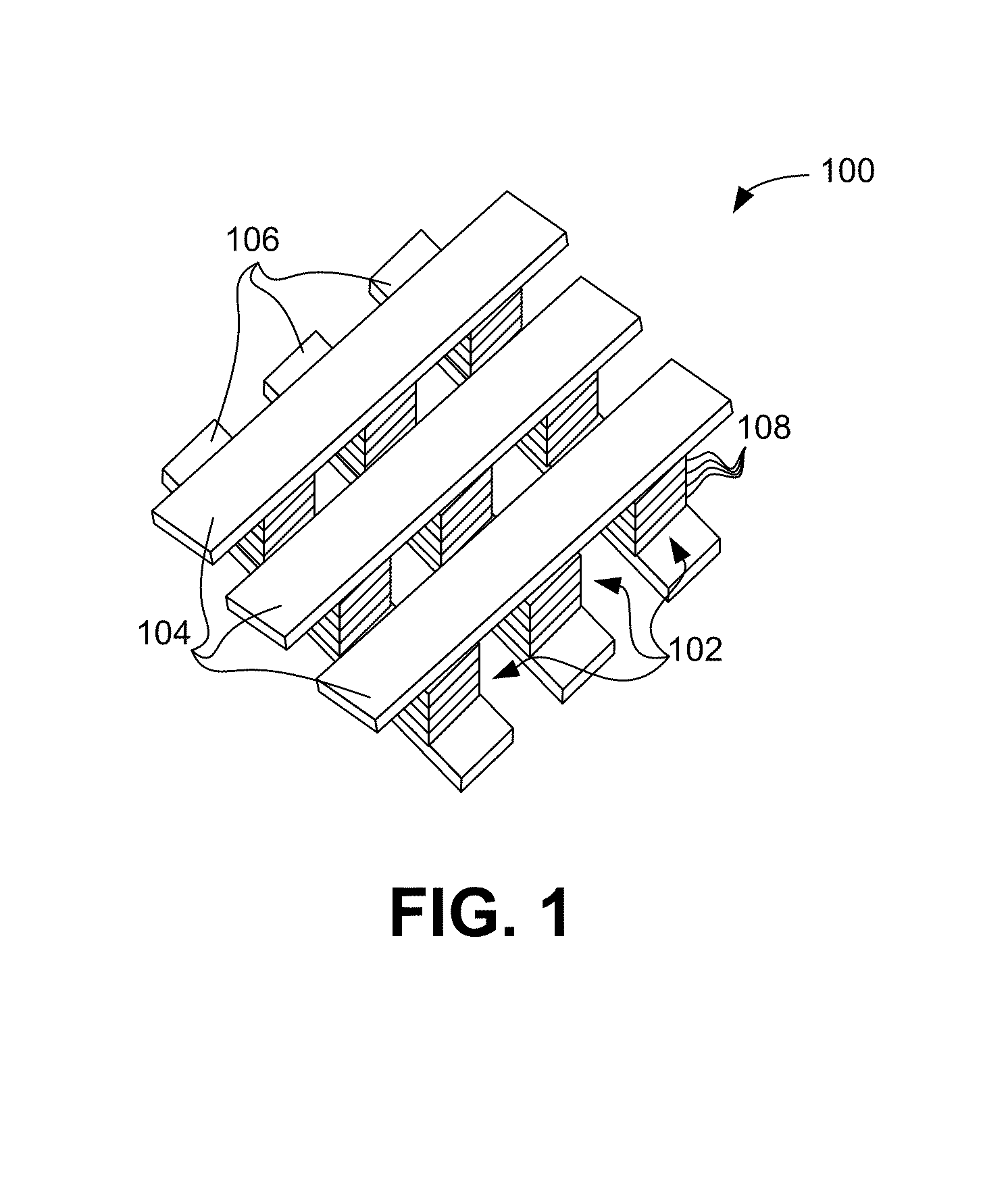

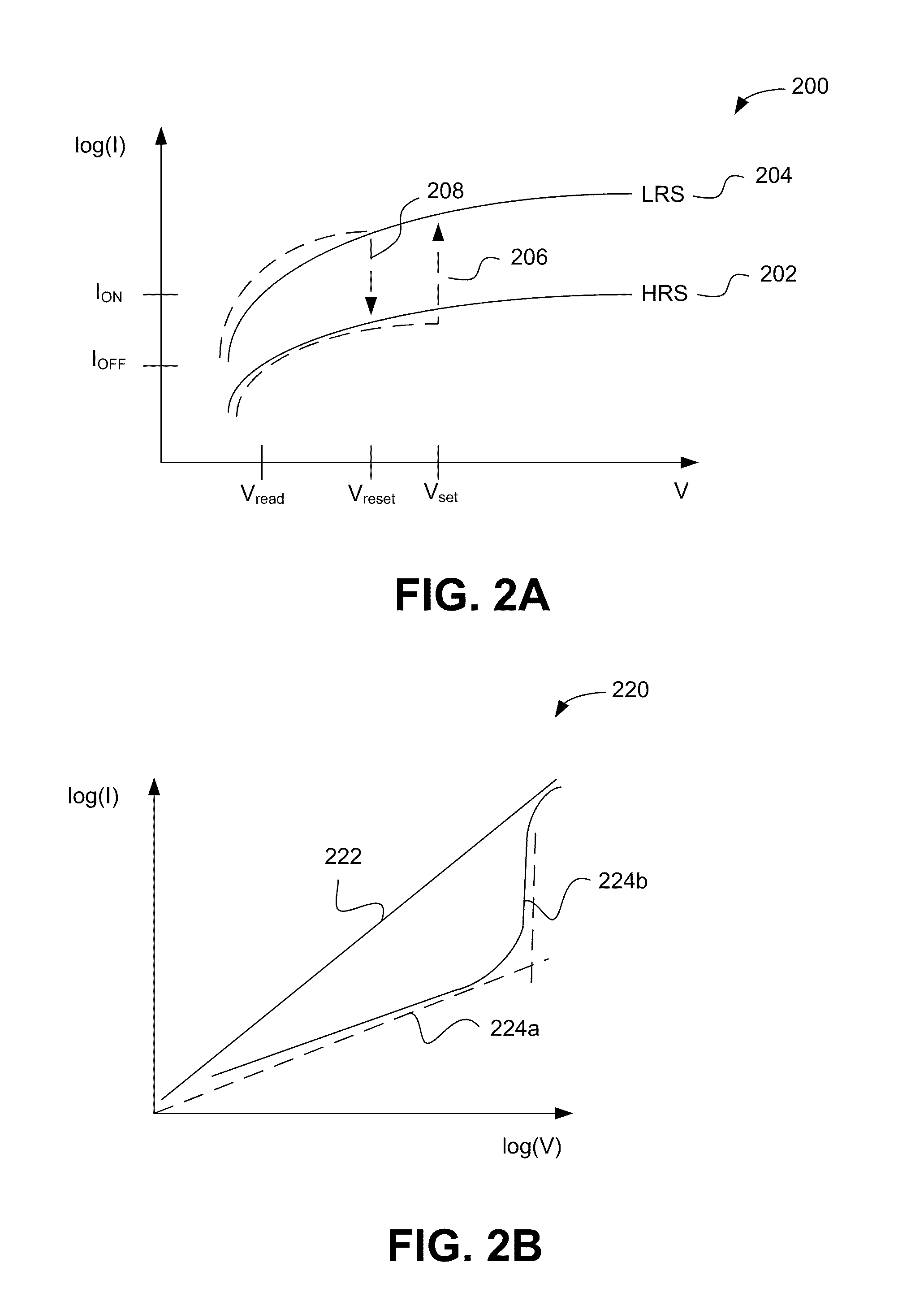

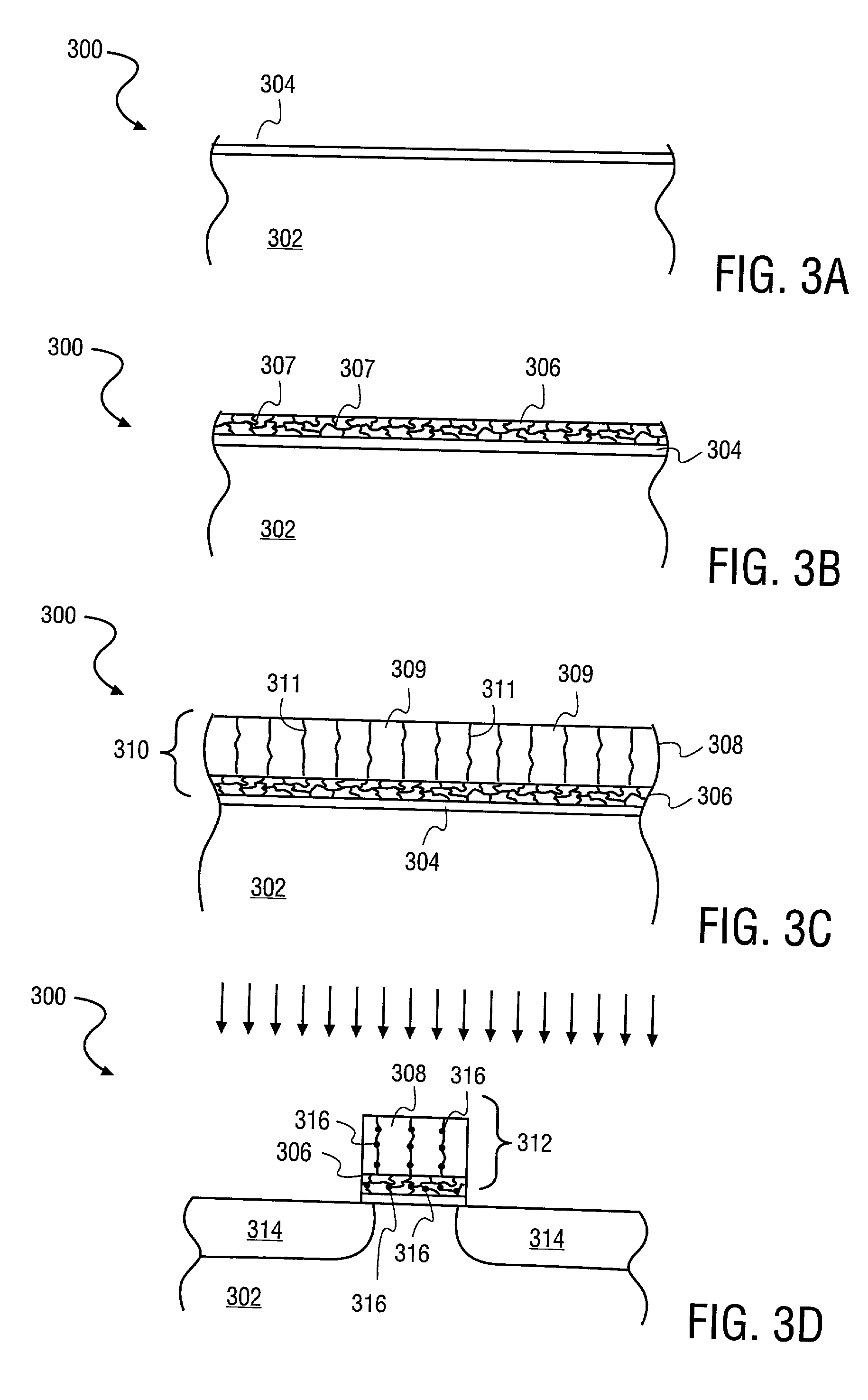

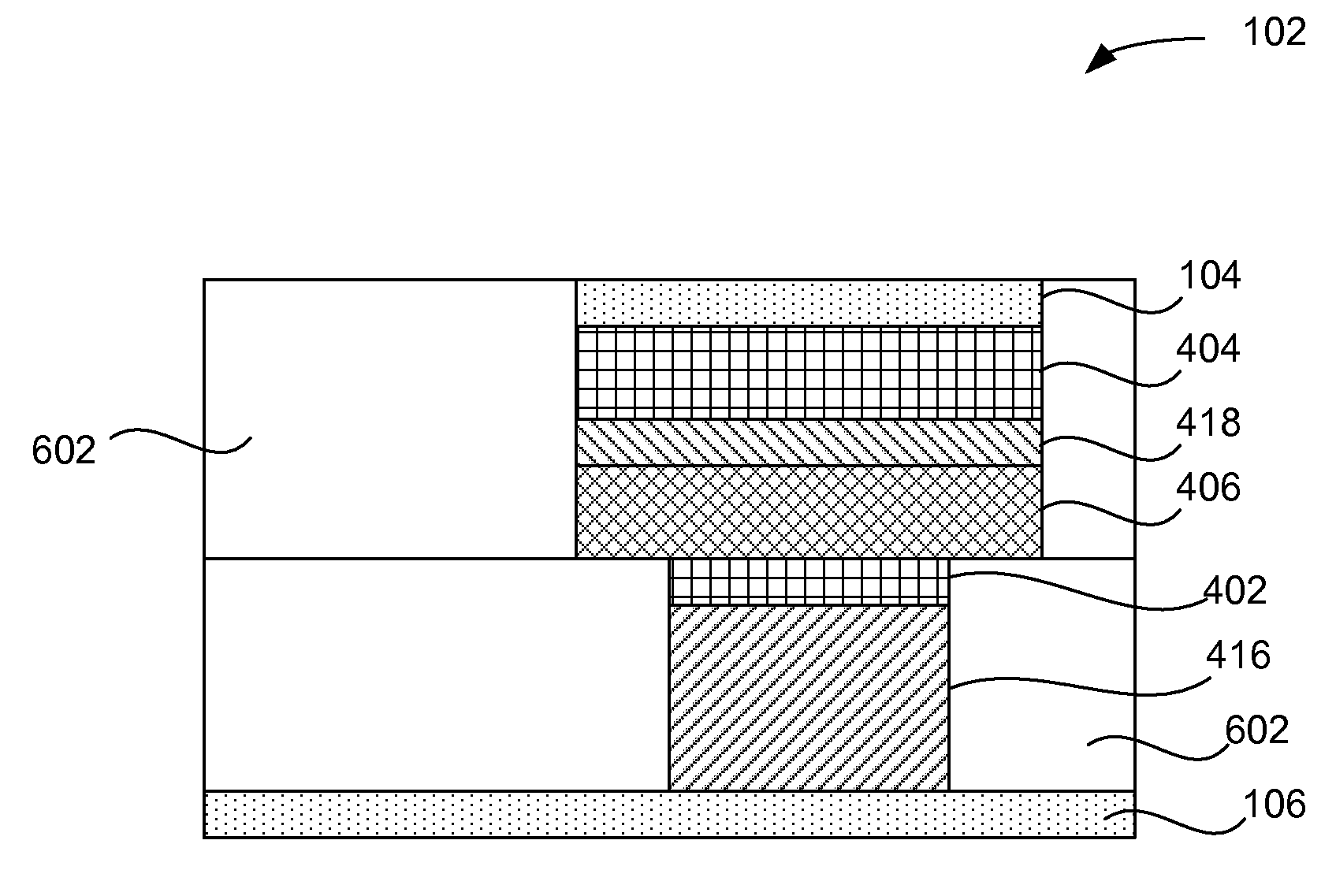

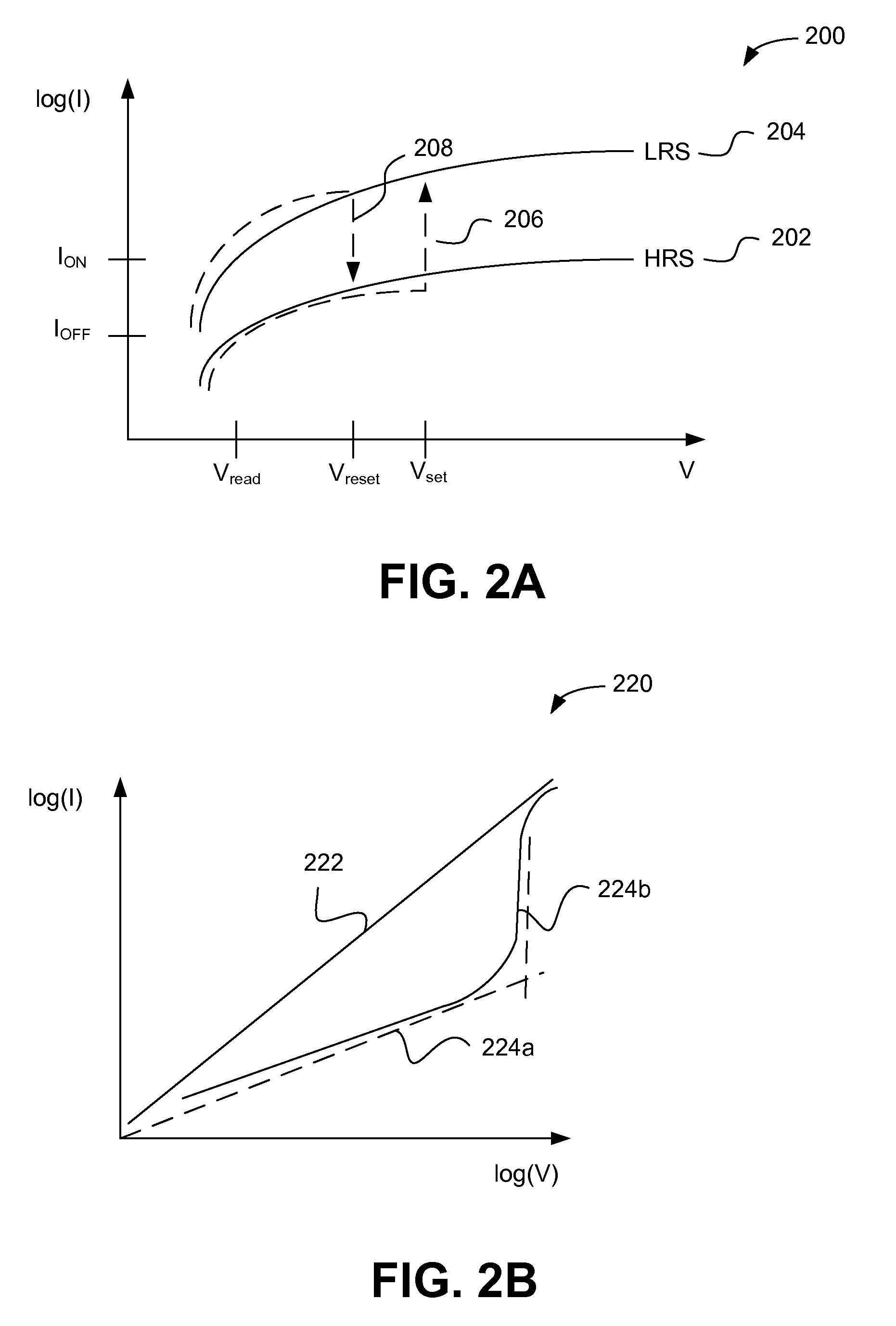

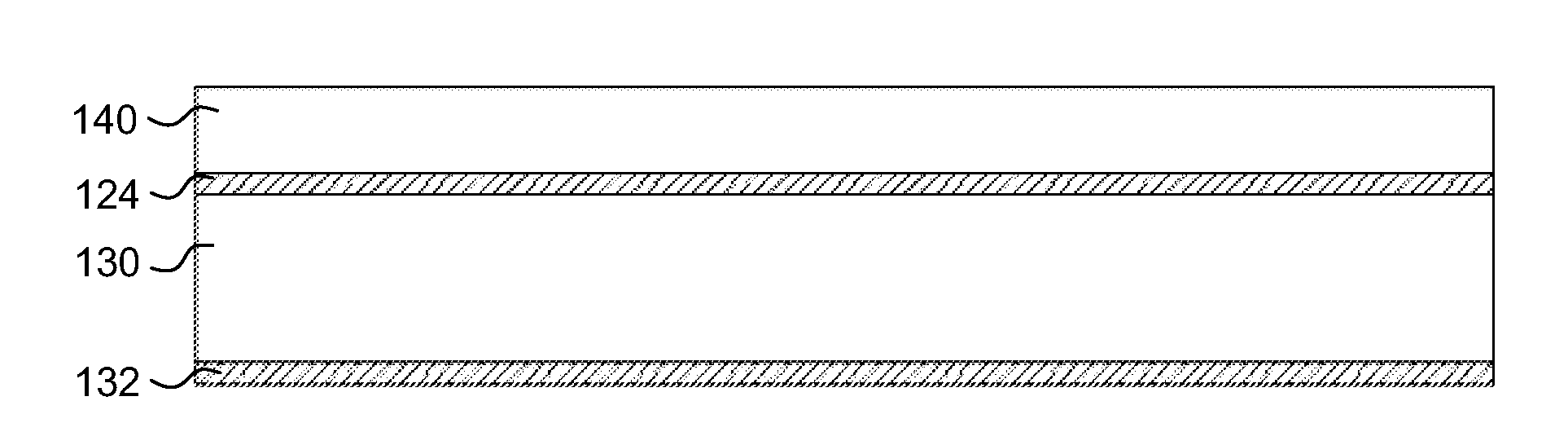

Resistive switching memory element including doped silicon electrode

A resistive switching memory element including a doped silicon electrode is described, including a first electrode comprising doped silicon having a first work function, a second electrode having a second work function that is different from the first work function by between 0.1 and 1.0 electron volts (eV), a metal oxide layer between the first electrode and the second electrode, the metal oxide layer switches using bulk-mediated switching and has a bandgap of greater than 4 eV, and the memory element switches from a low resistance state to a high resistance state and vice versa.

Owner:INTERMOLECULAR

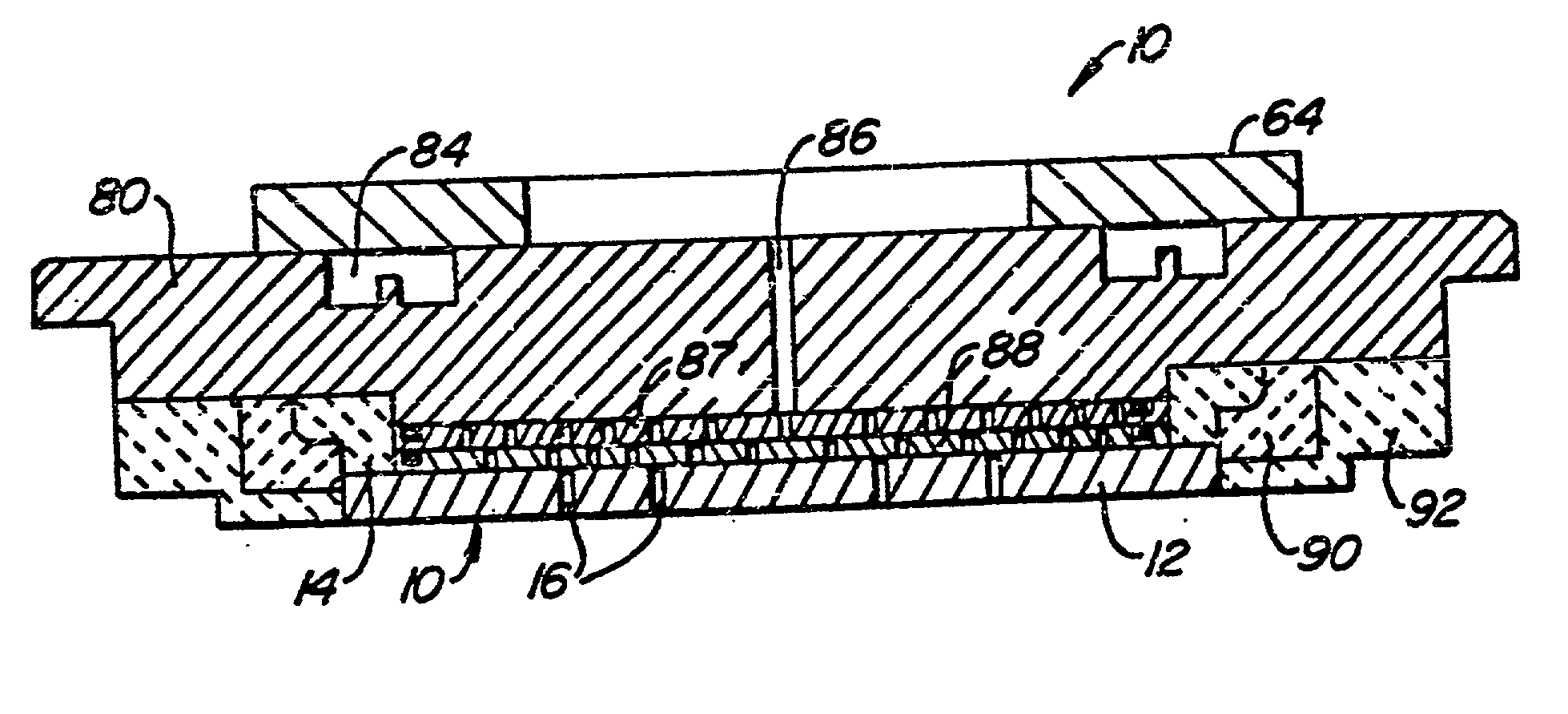

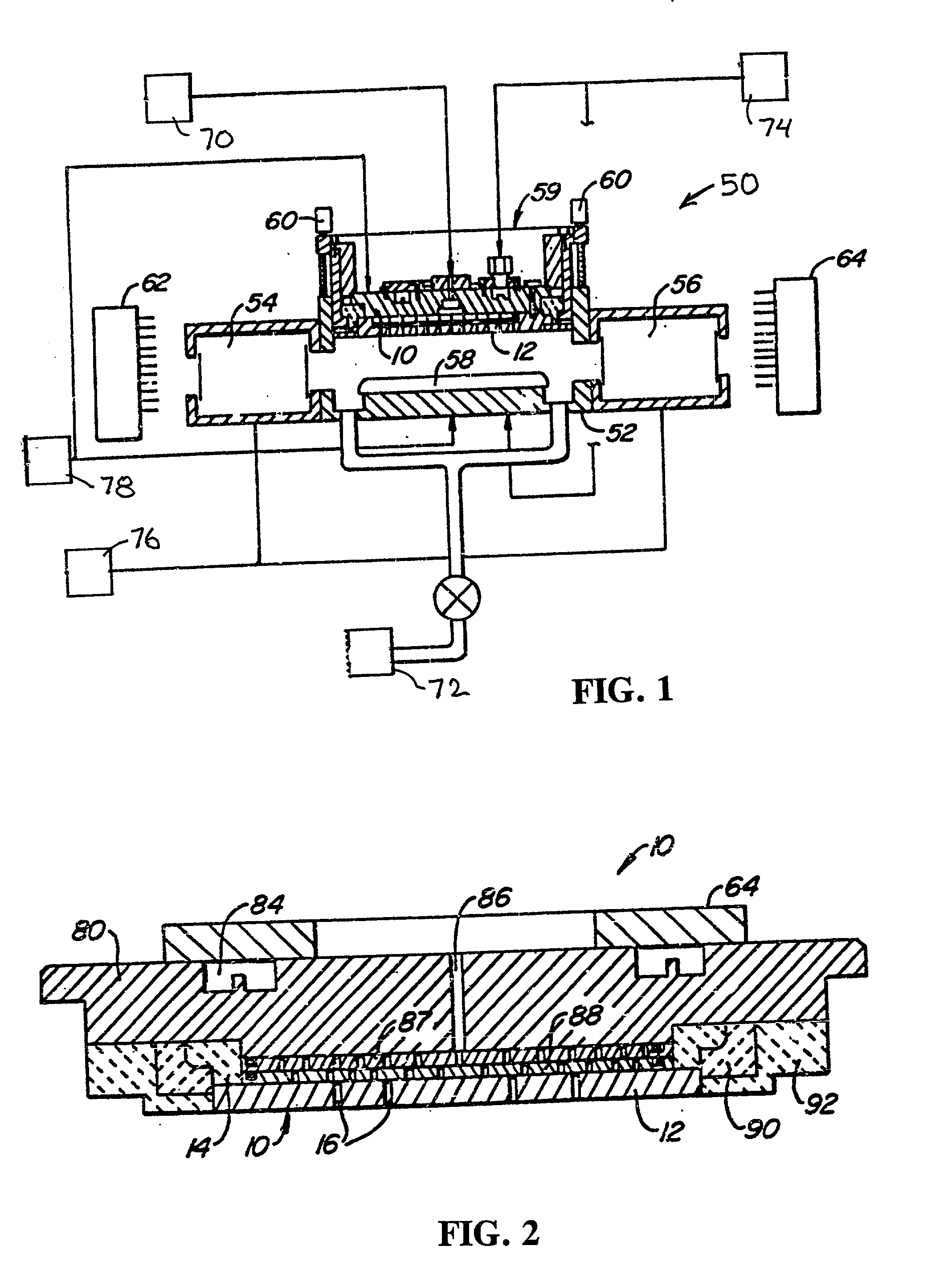

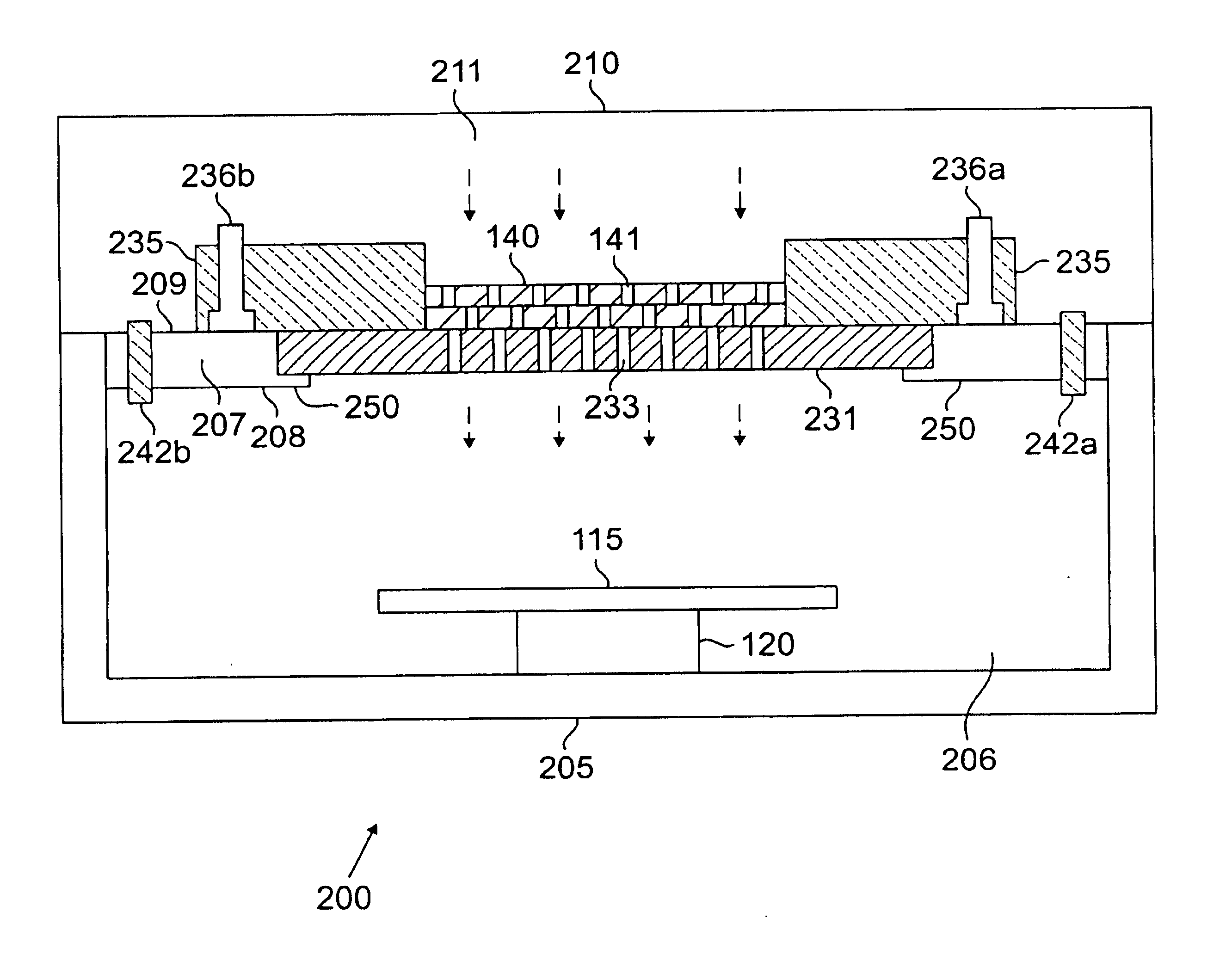

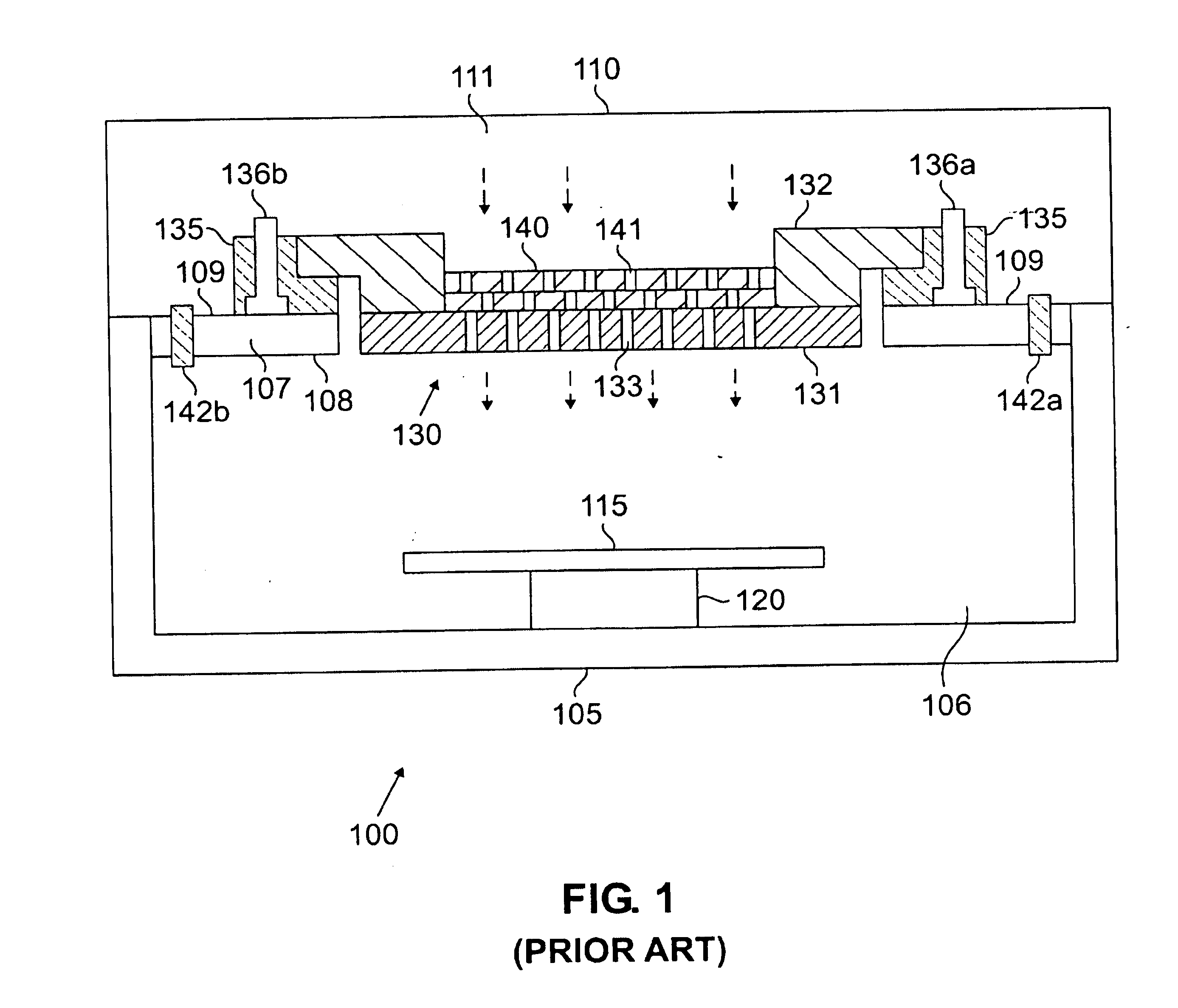

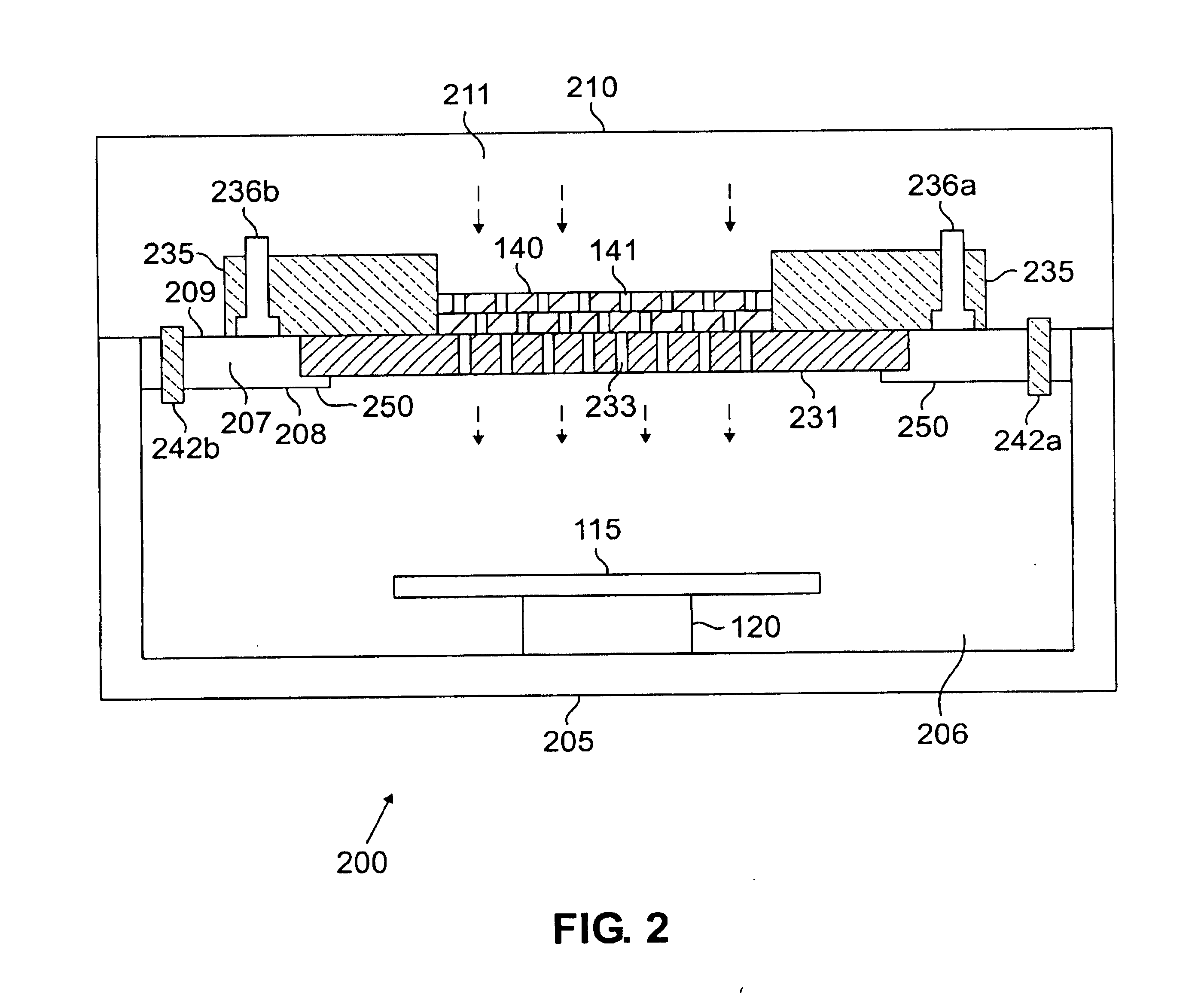

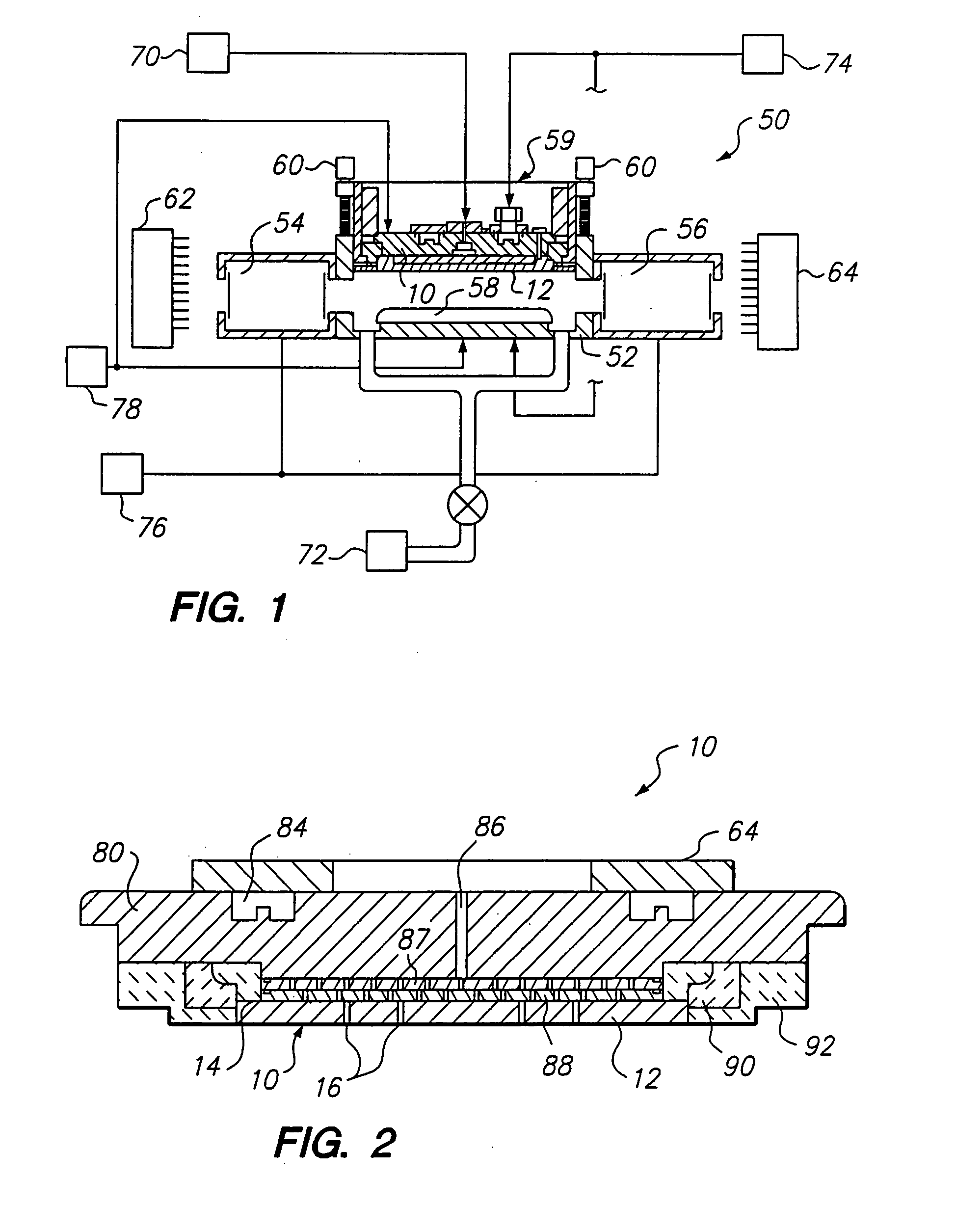

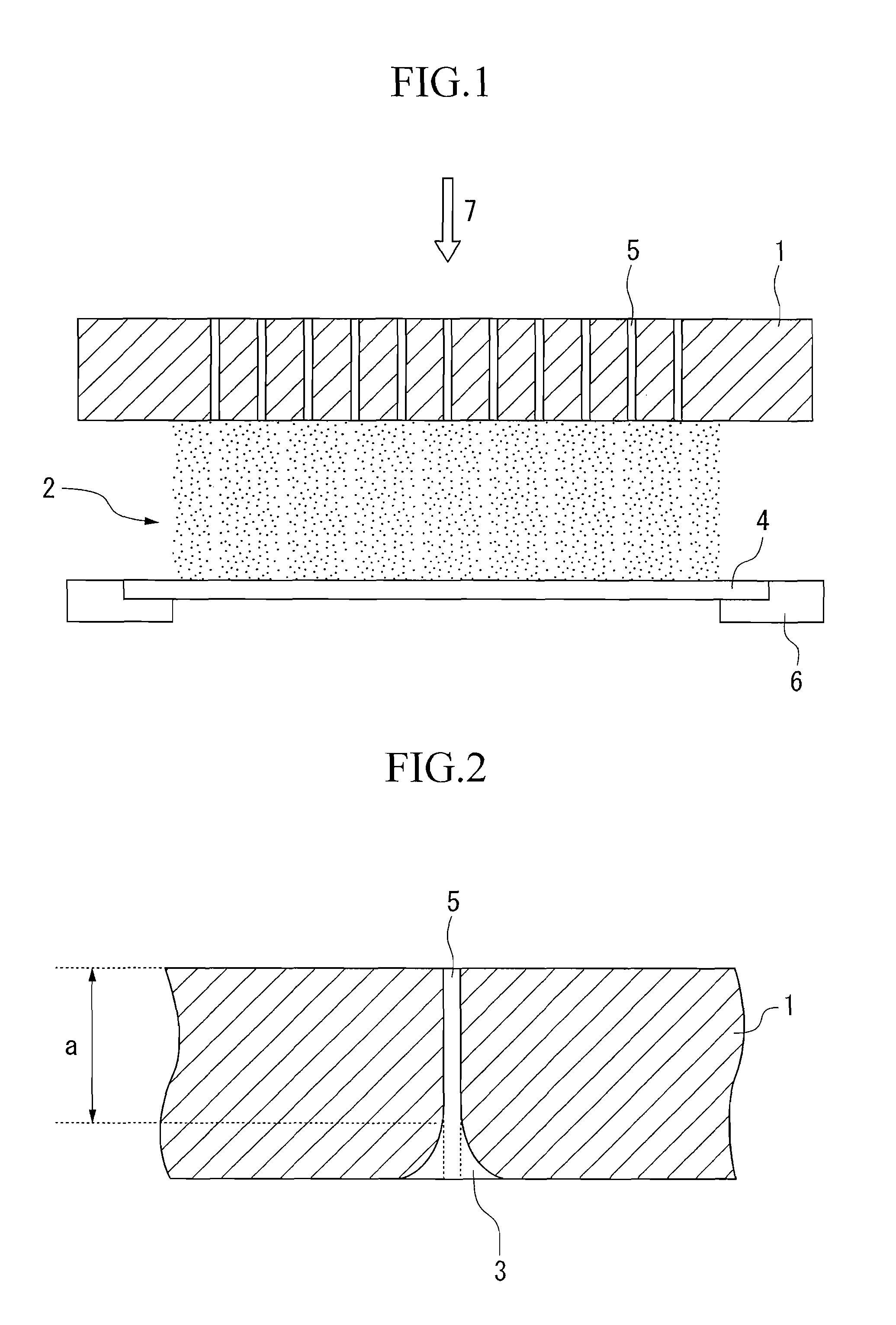

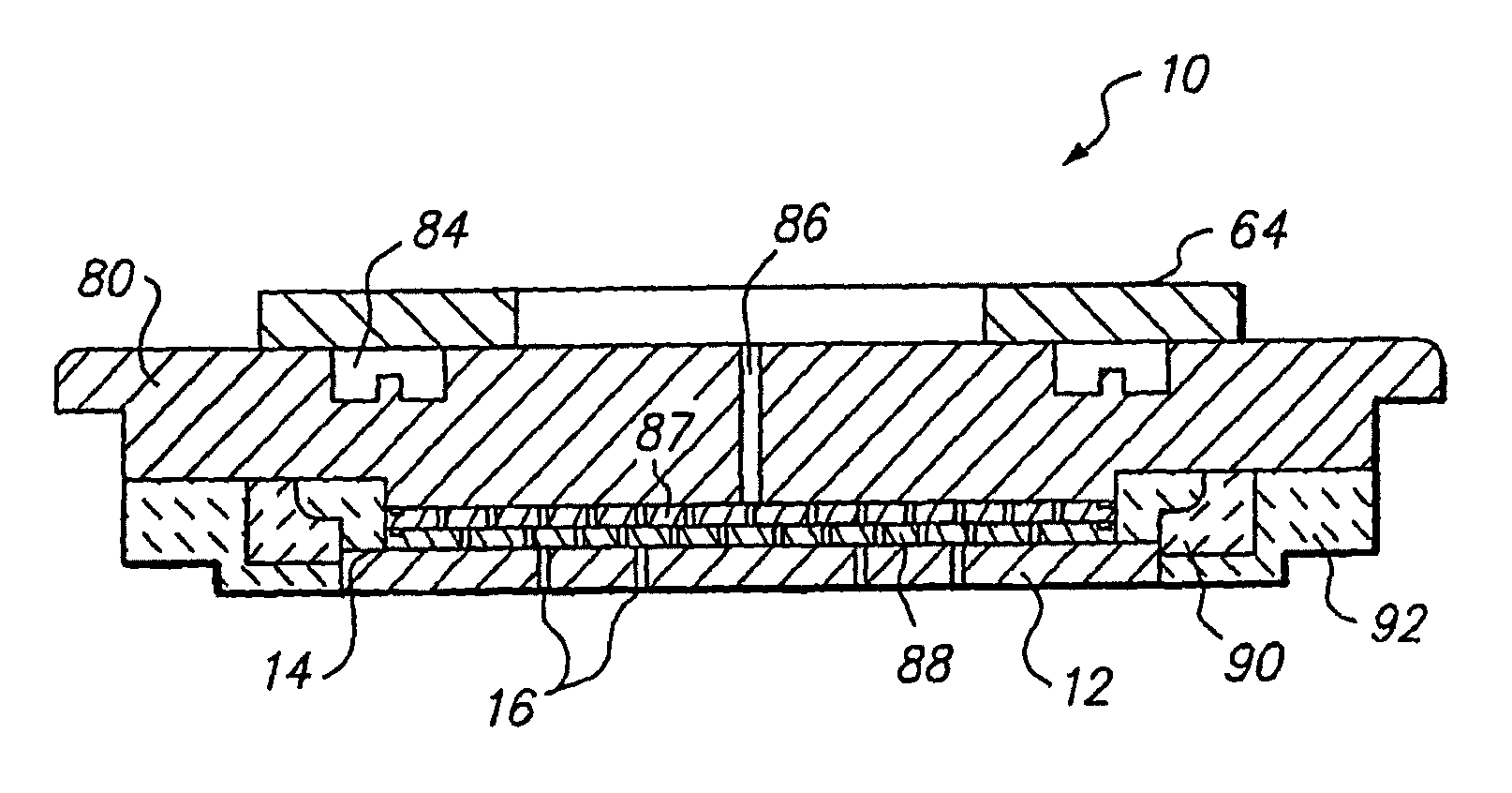

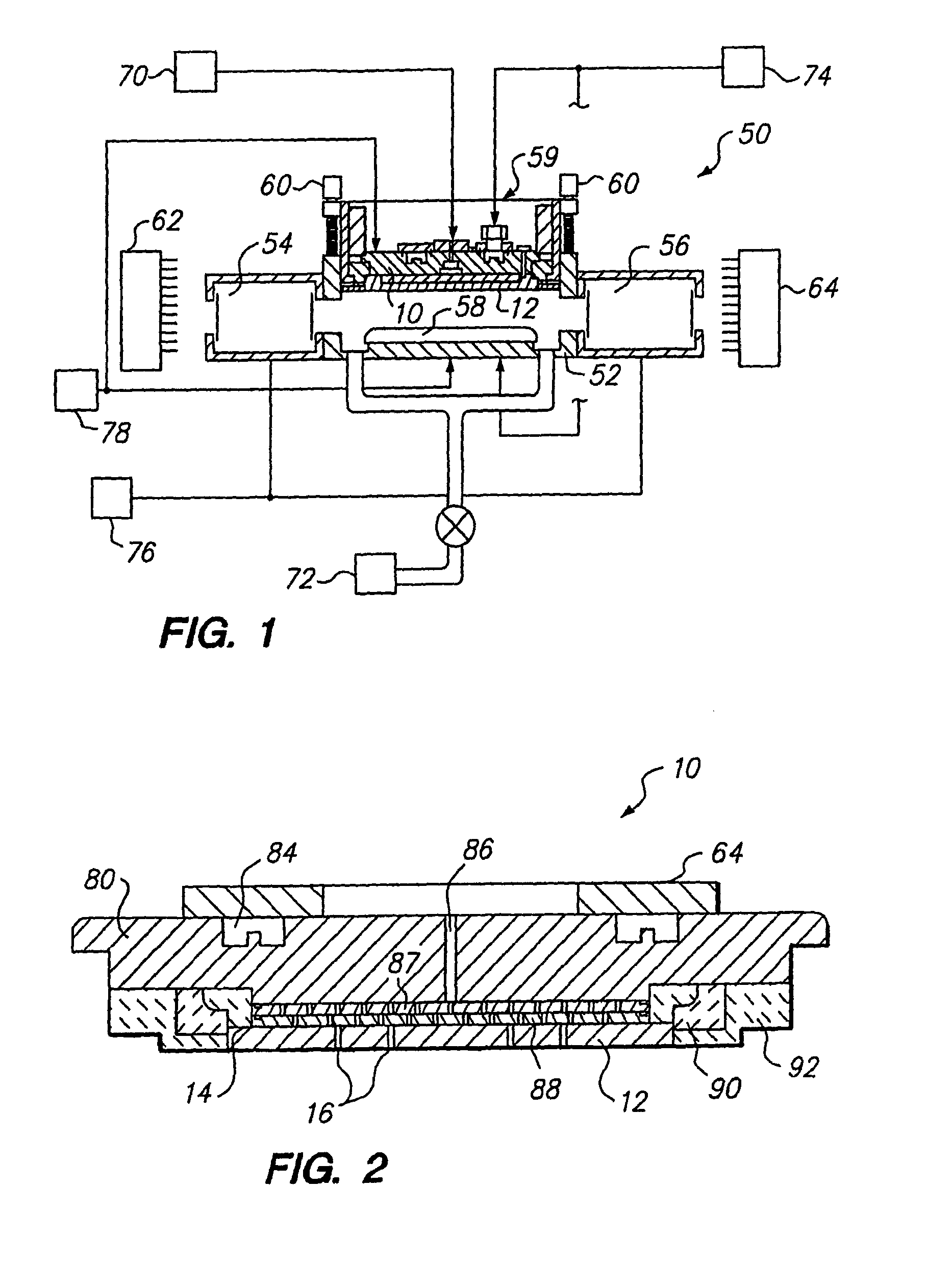

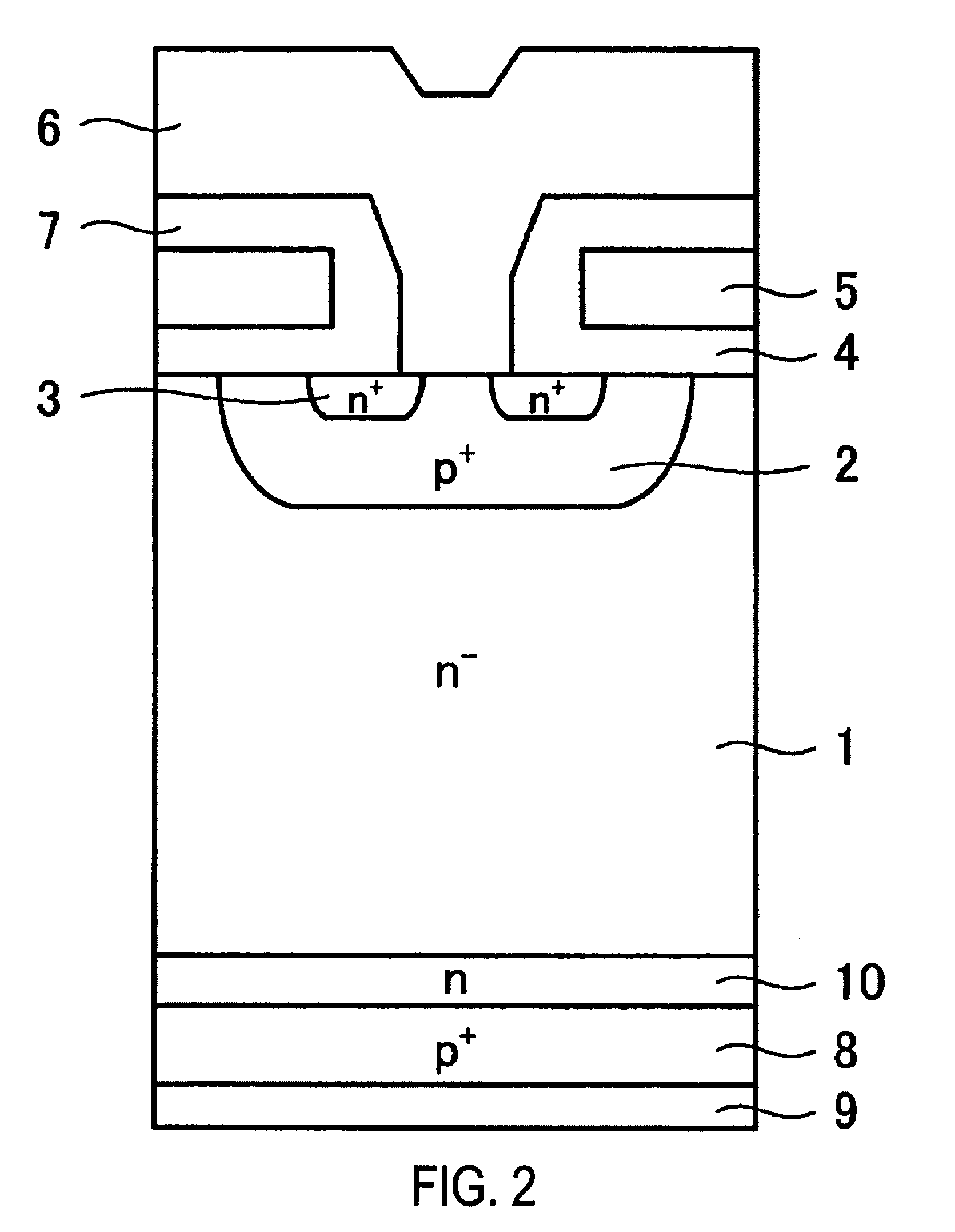

Electrode for plasma processes and method for manufacture and use thereof

InactiveUS20020127853A1Less heat-upReduce accumulationElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlSilicon electrode

A silicon electrode for a plasma reaction chamber wherein processing of a semiconductor substrate such as a single wafer can be carried out and a method of processing a semiconductor substrate with the electrode. The electrode is a low resistivity electrode having an electrical resistivity of less than 1 ohm-cm. The electrode can be a zero defect single crystal silicon or silicon carbide electrode such as a showerhead electrode bonded or clamped to support such as a temperature controlled plate or ring. The showerhead electrode can be in the form of a circular disk of uniform thickness and an elastomeric joint can be provided between a support ring and the electrode. The electrode can include gas outlets having 0.020 to 0.030 inch diameters.

Owner:LAM RES CORP

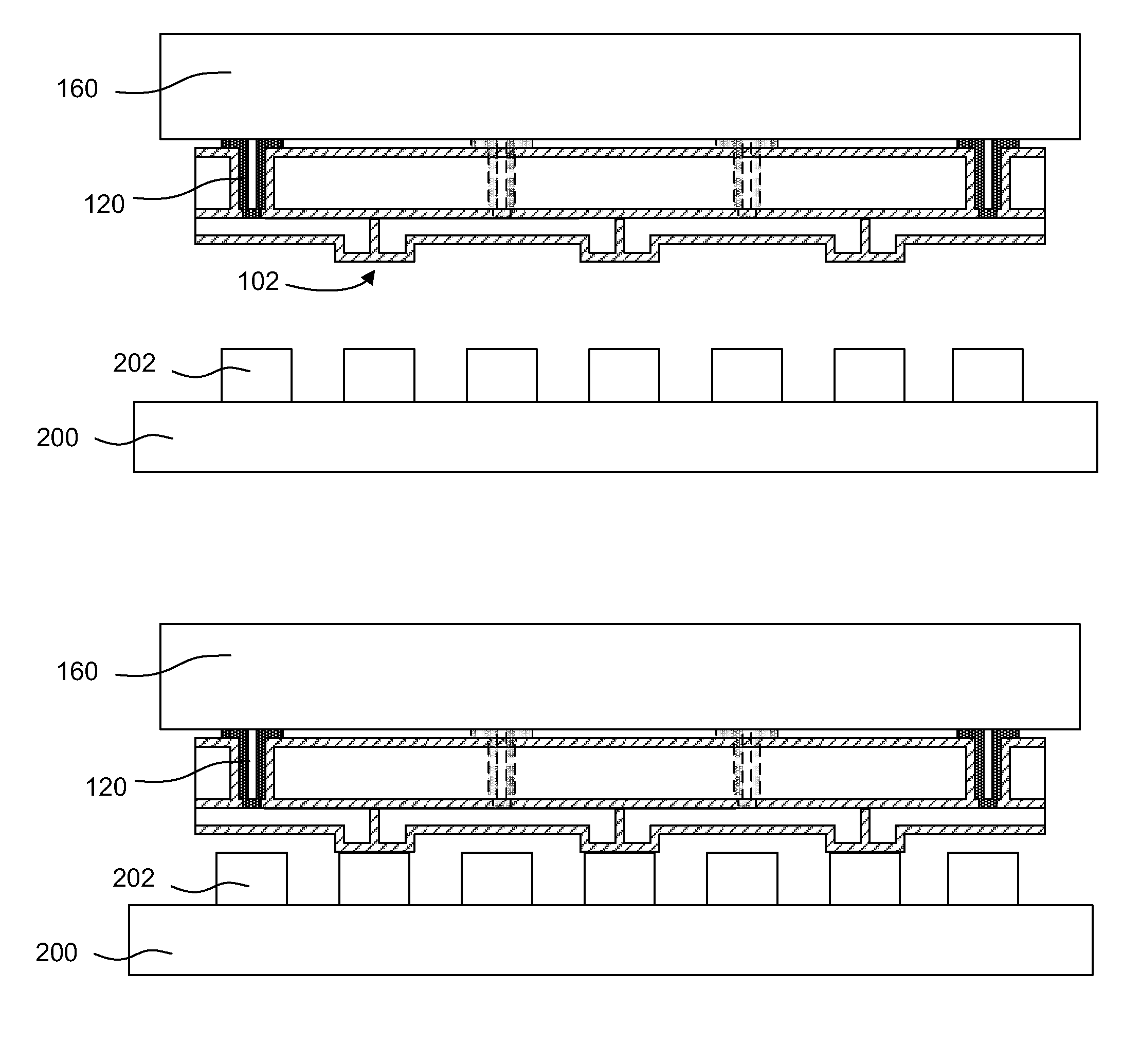

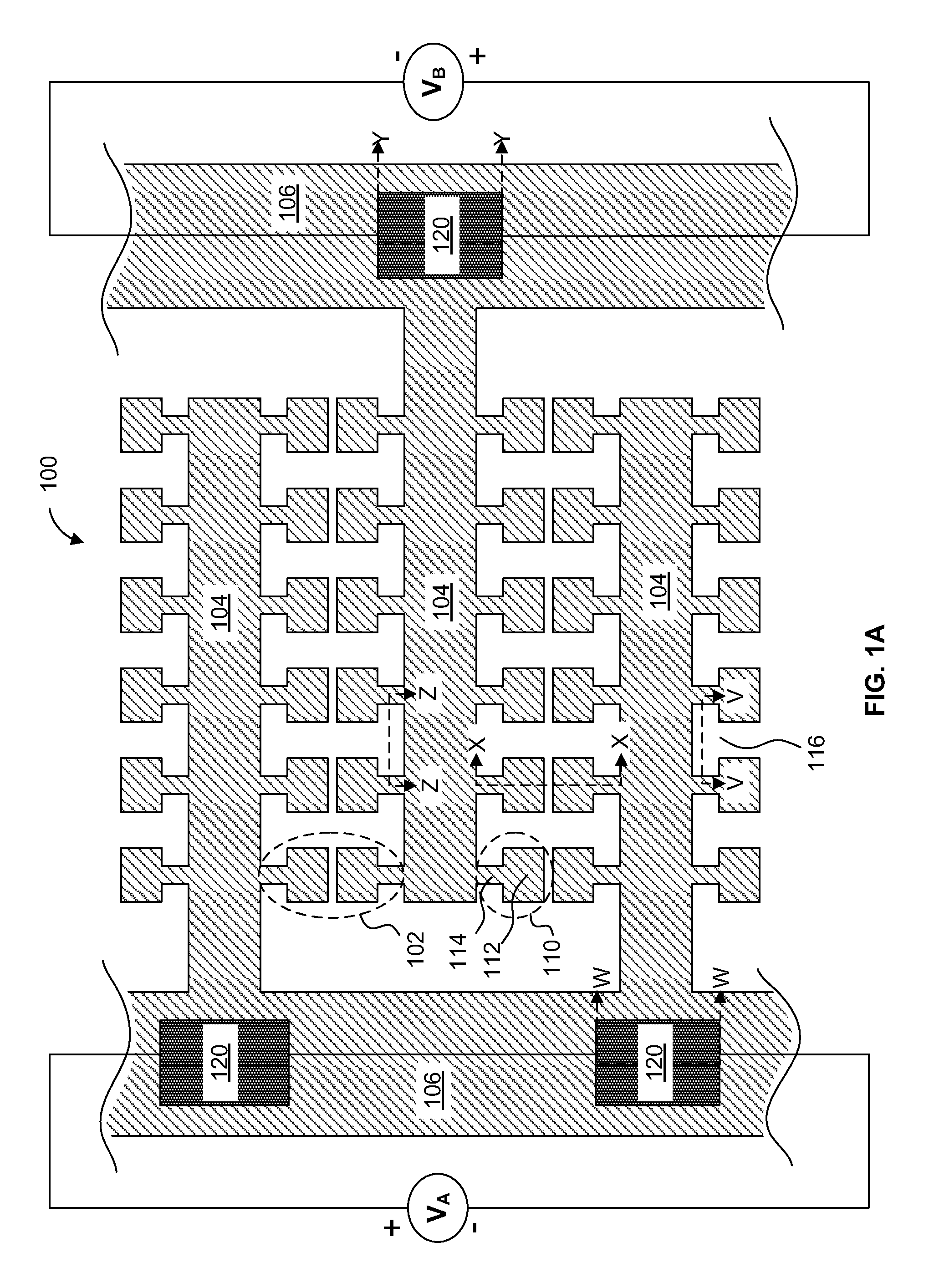

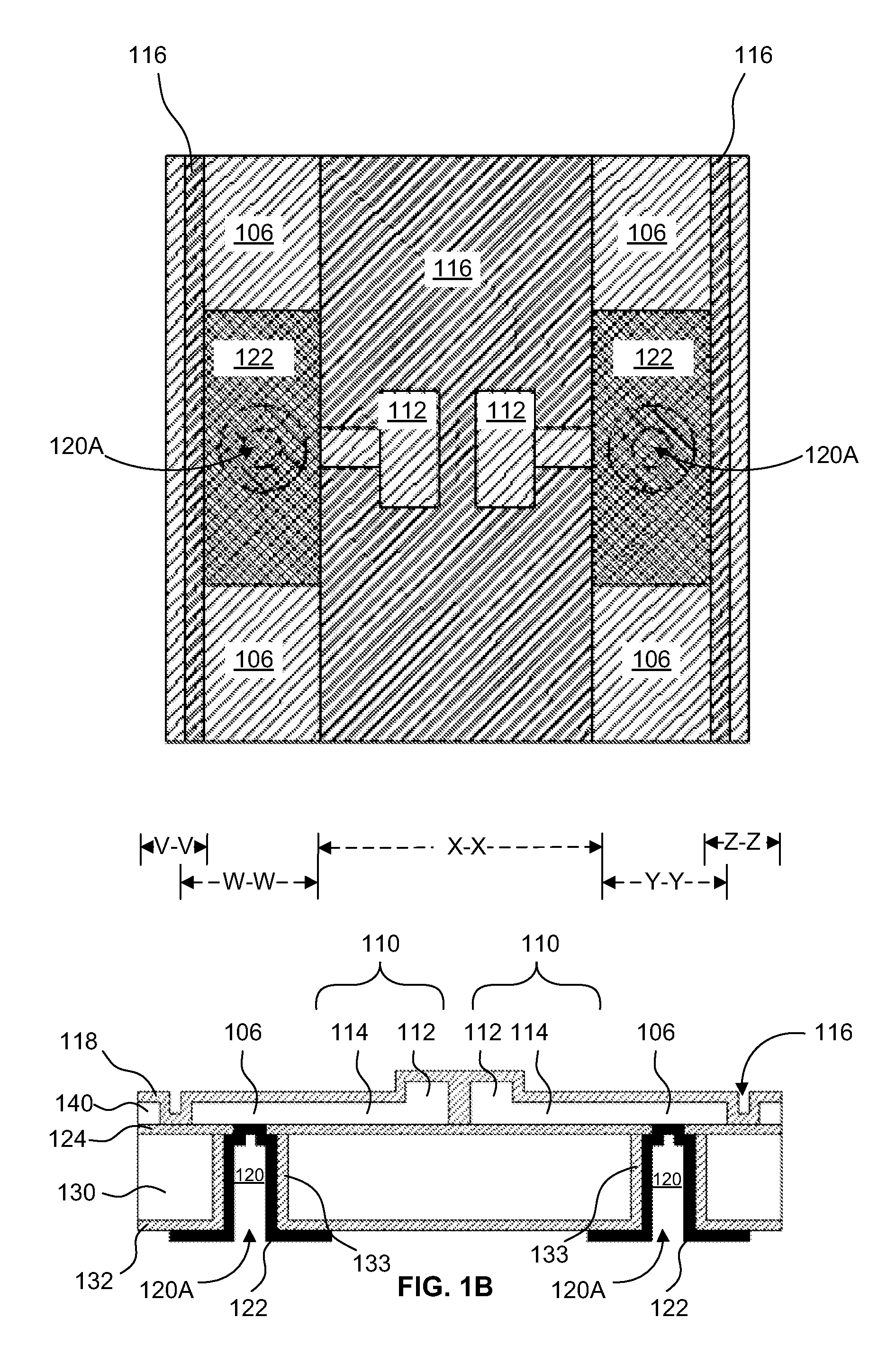

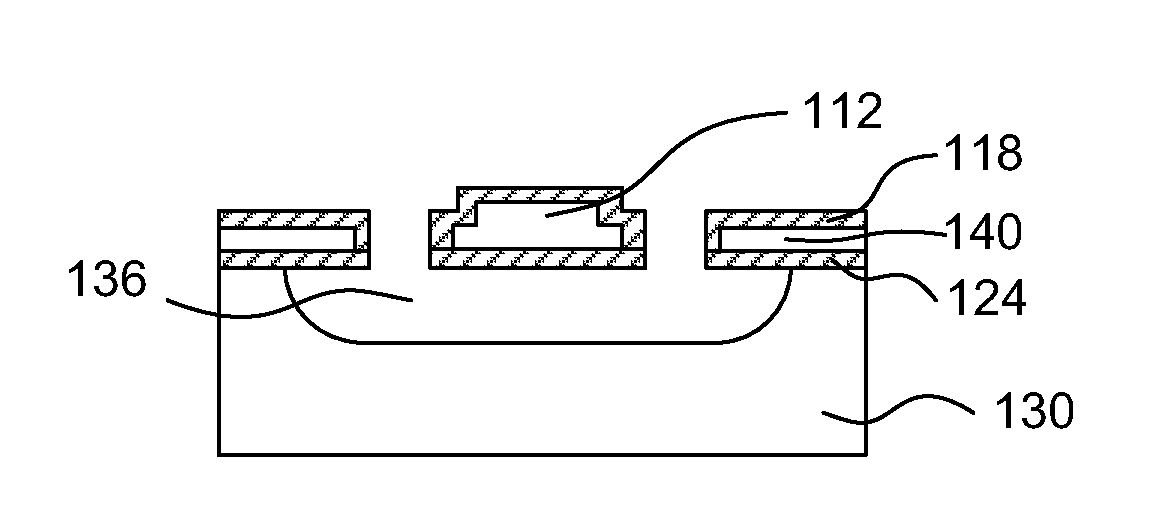

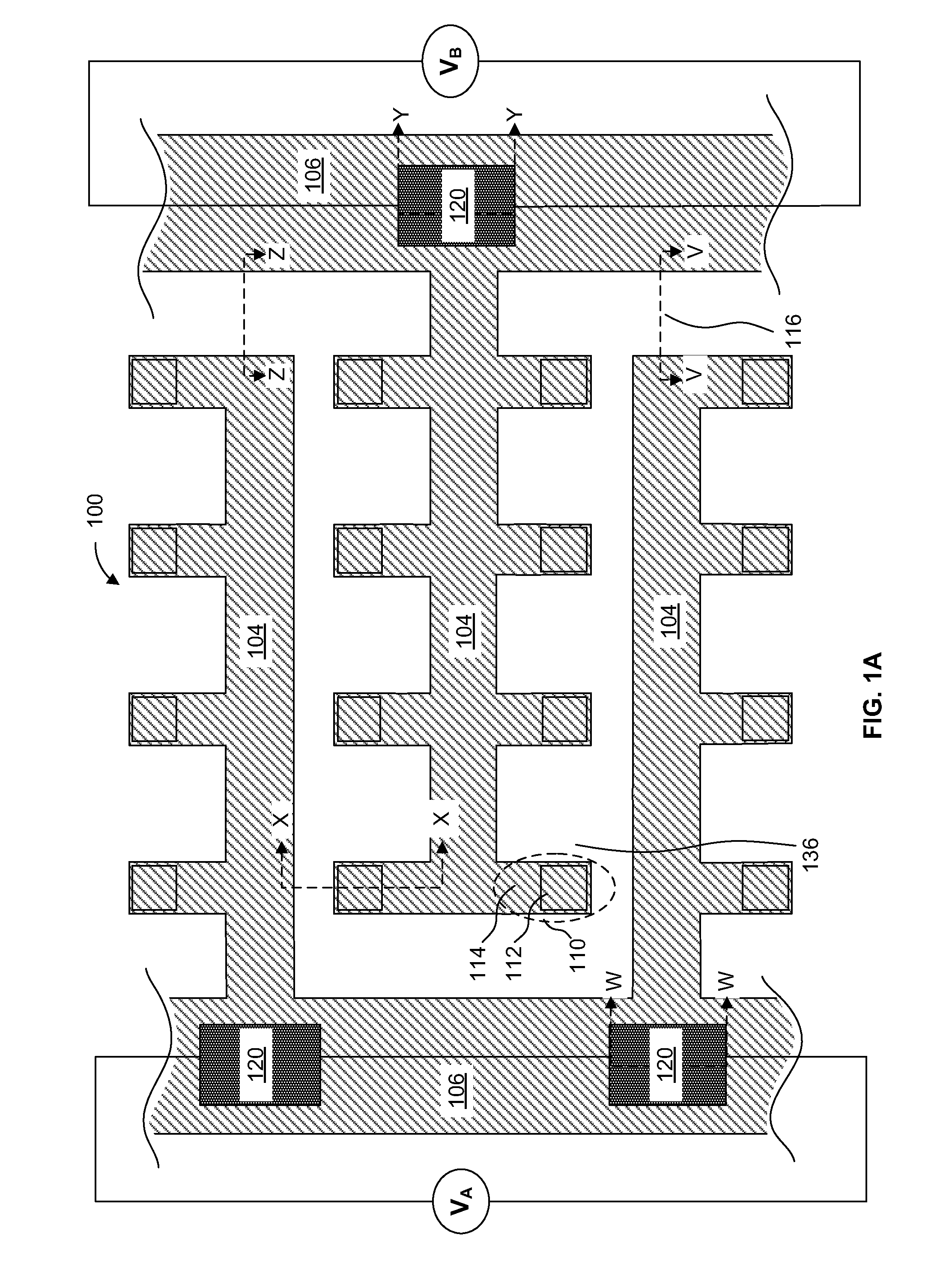

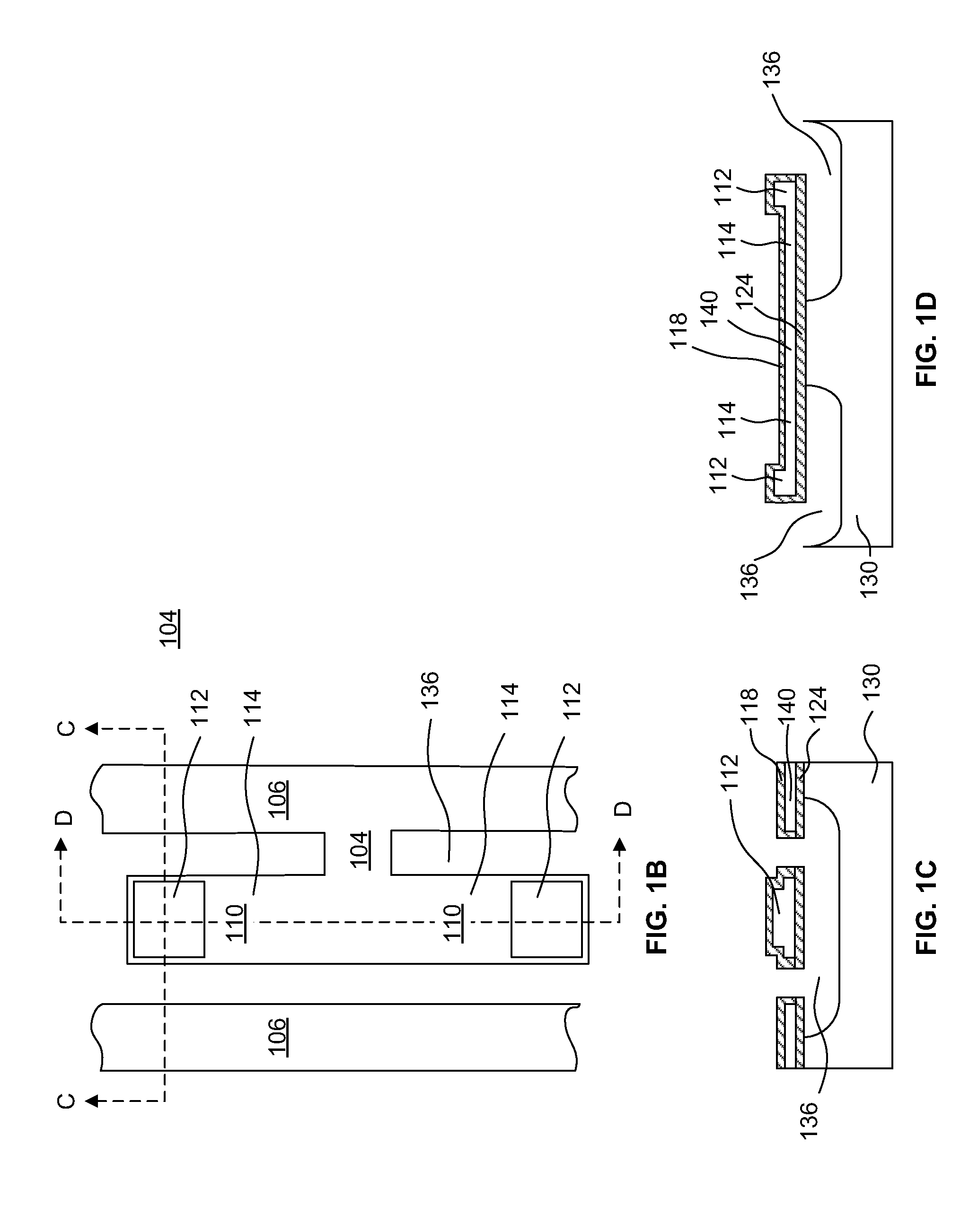

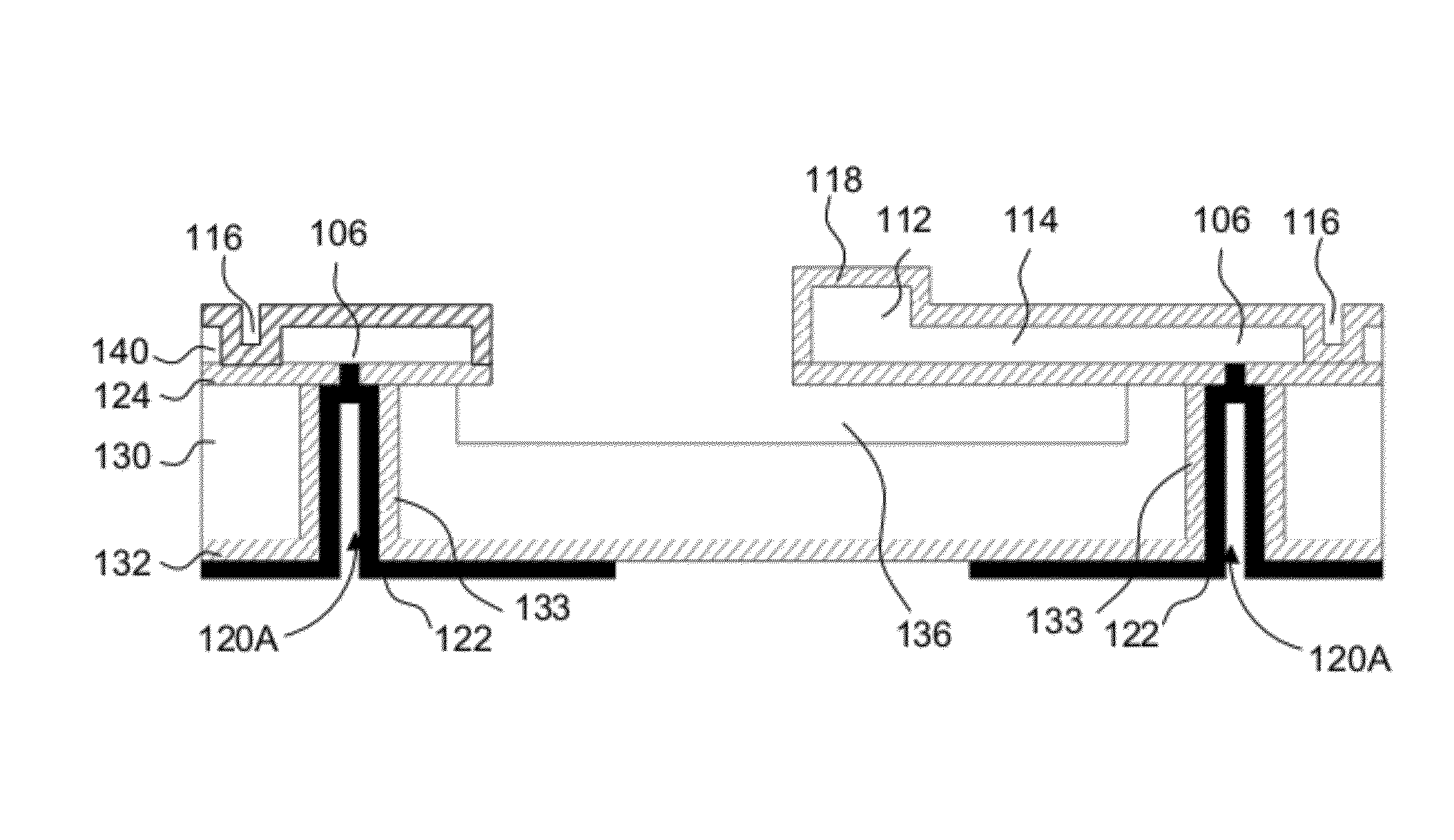

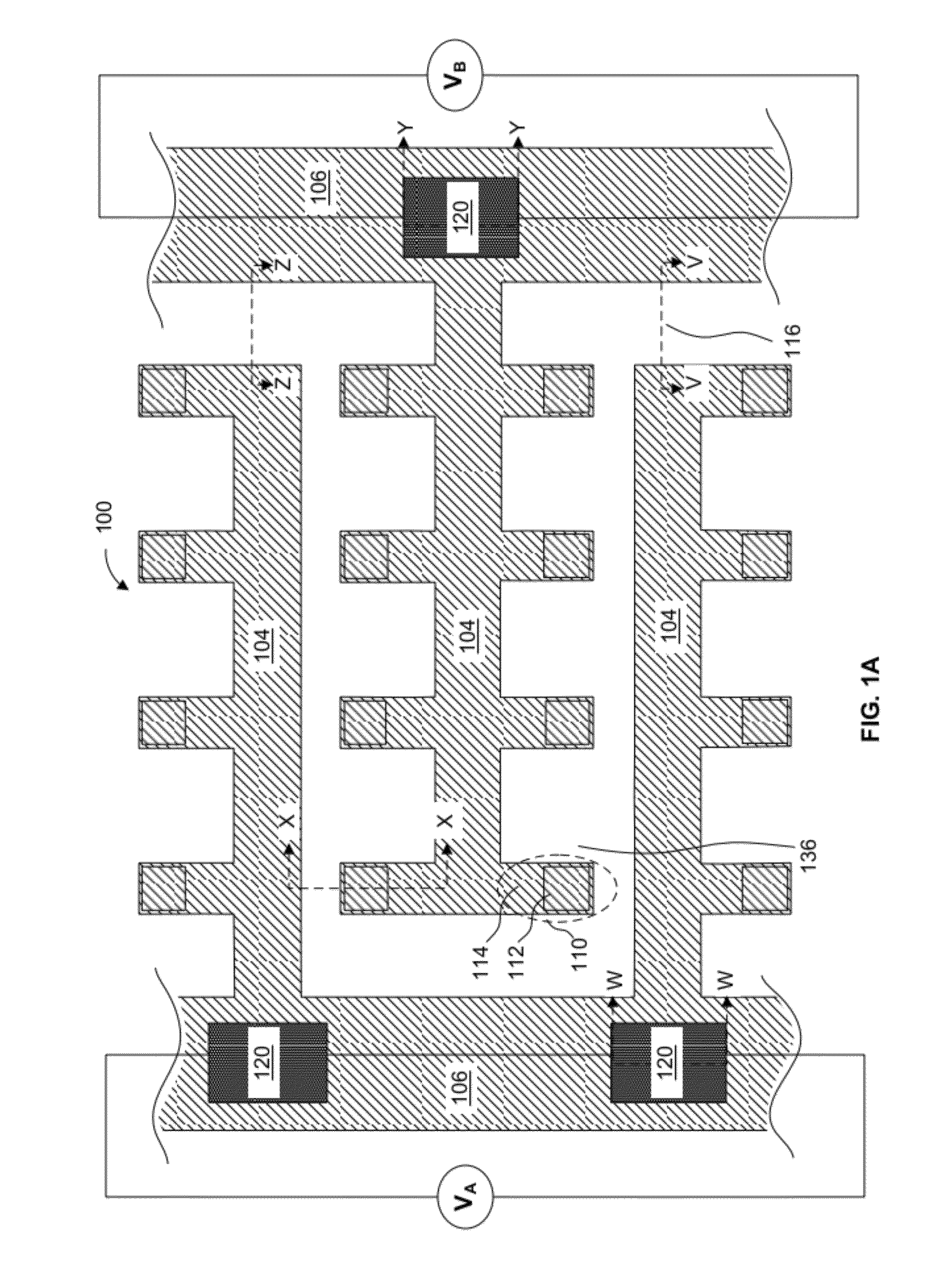

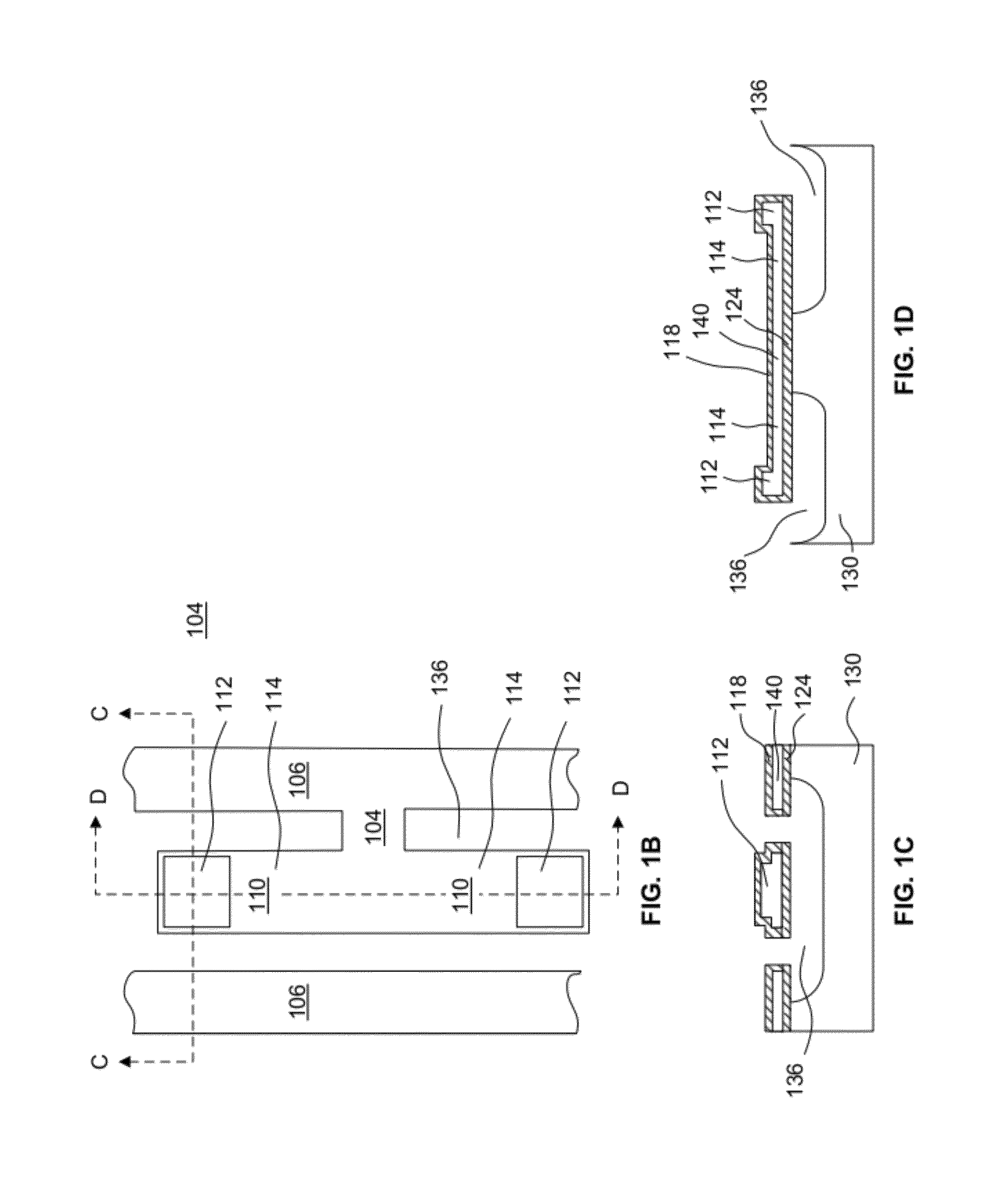

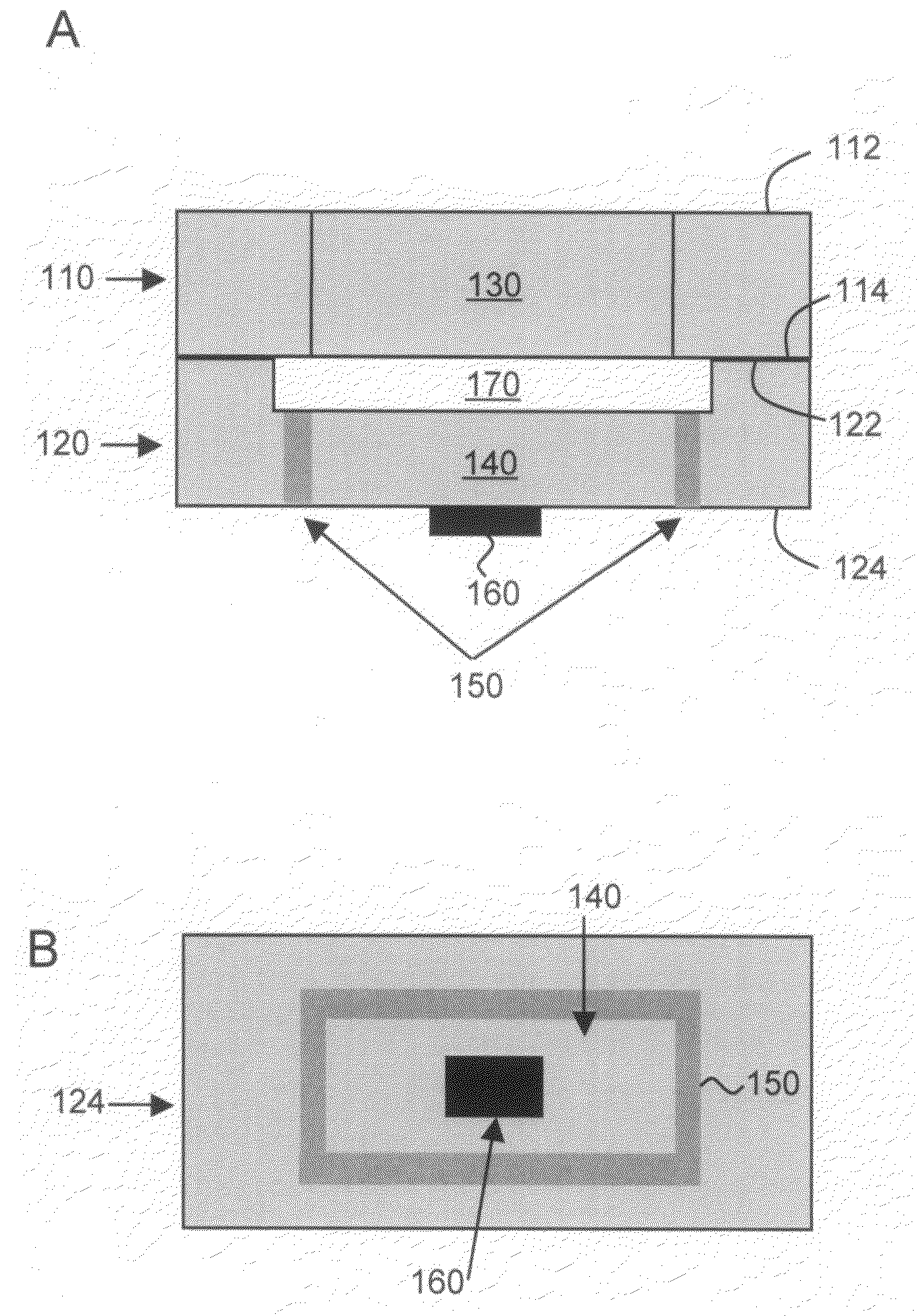

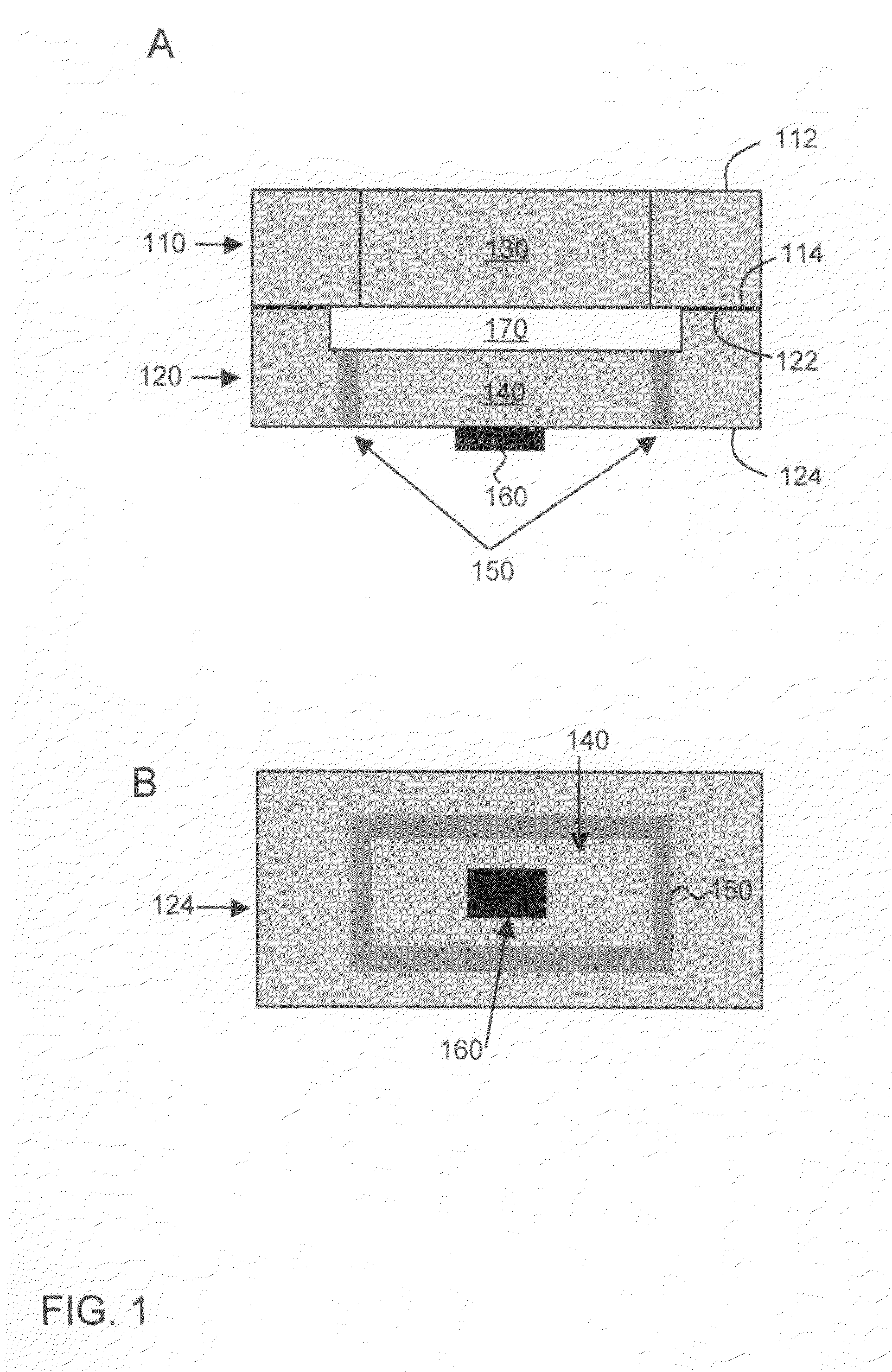

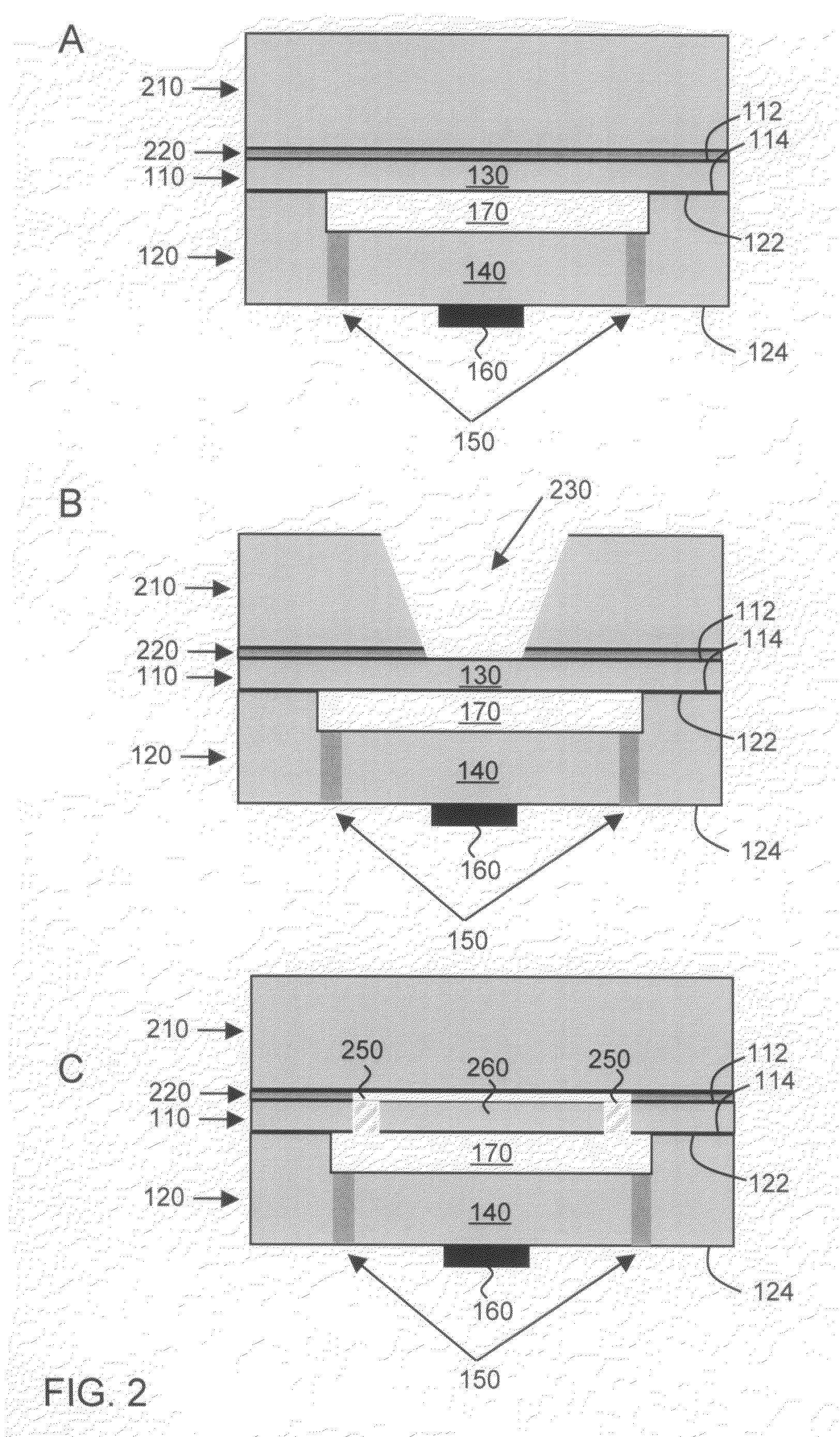

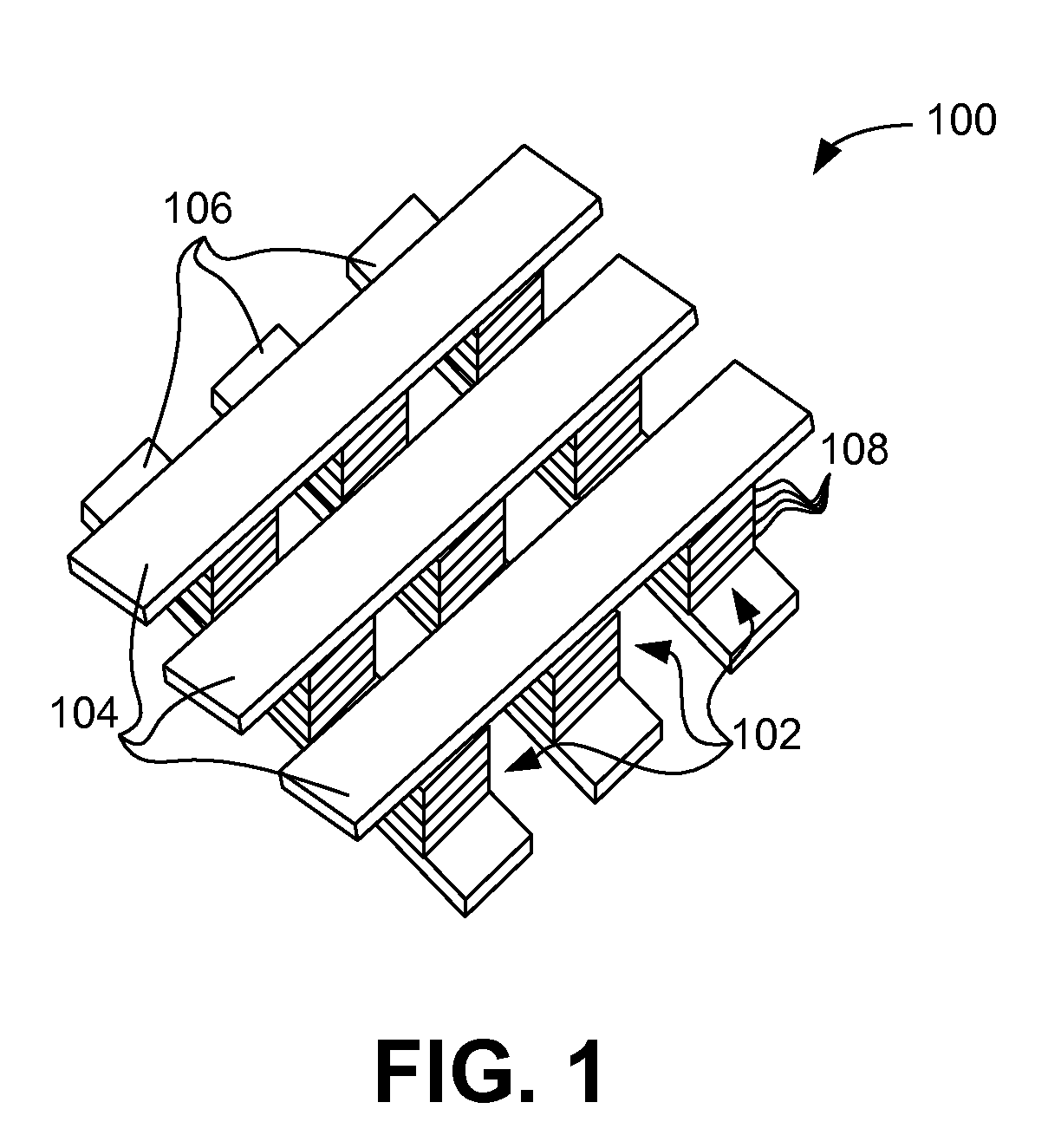

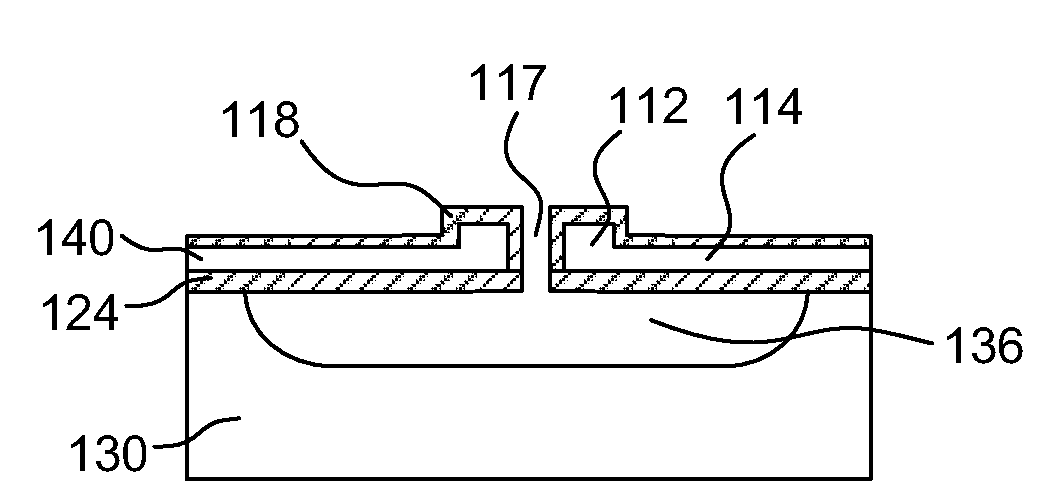

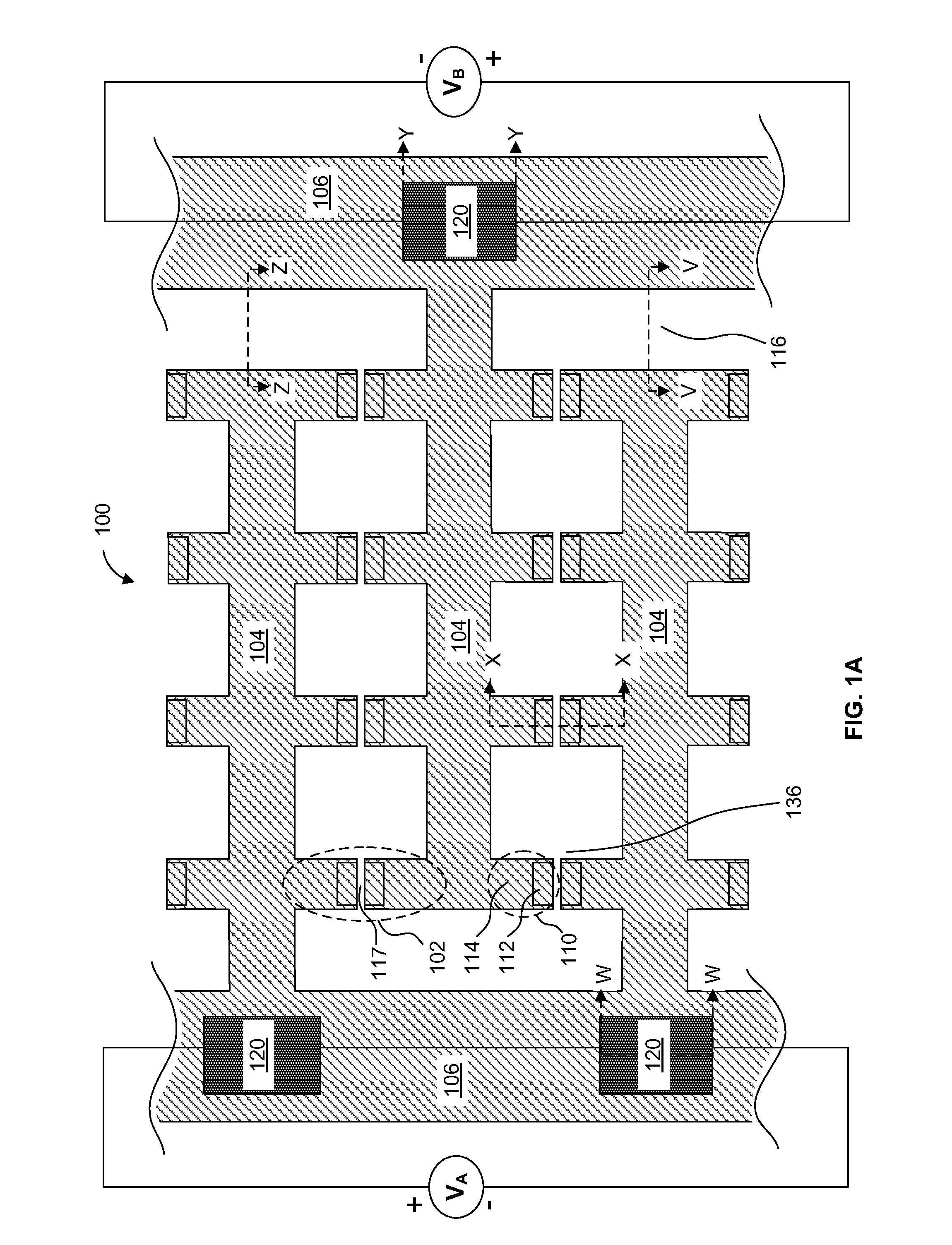

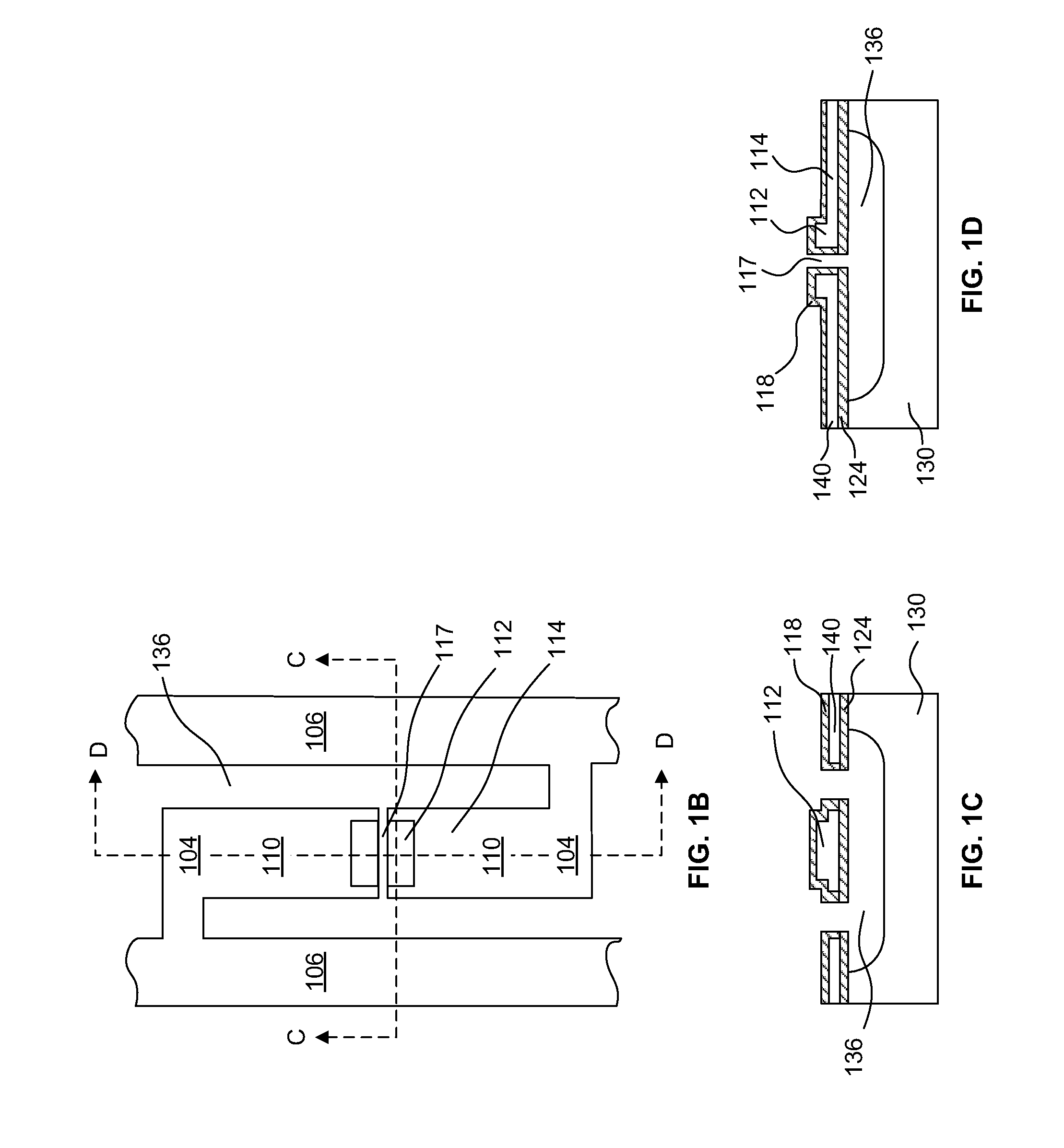

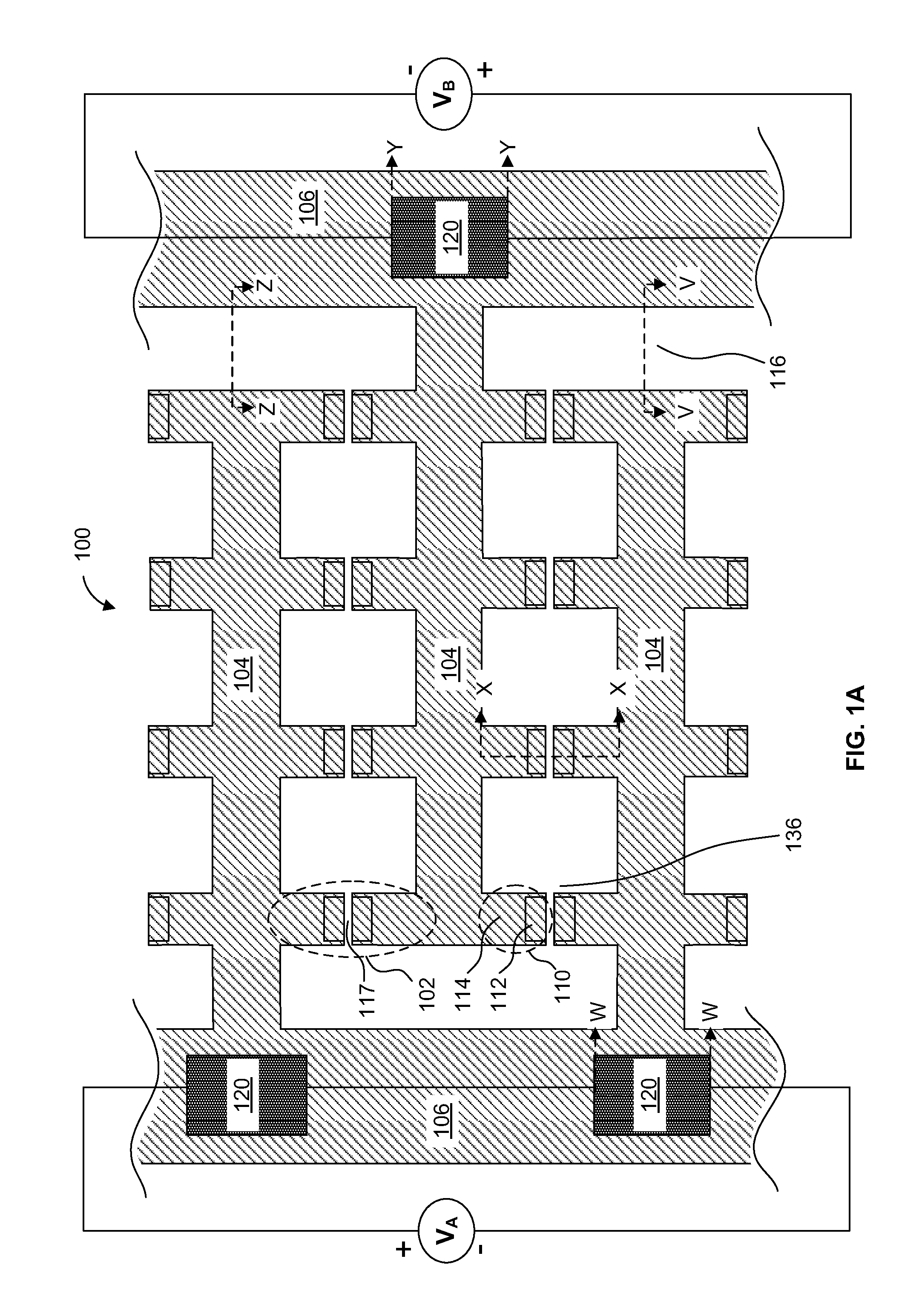

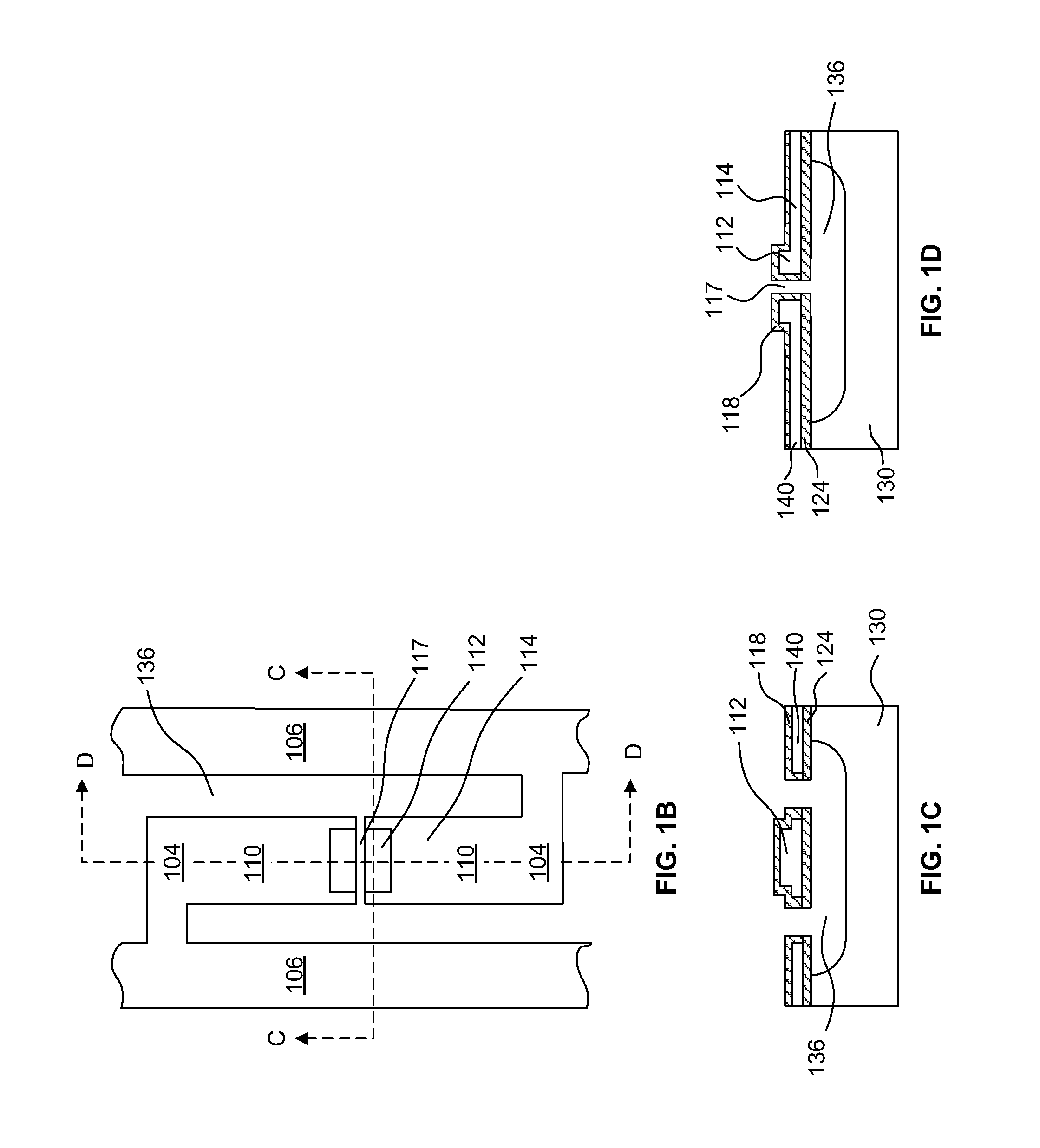

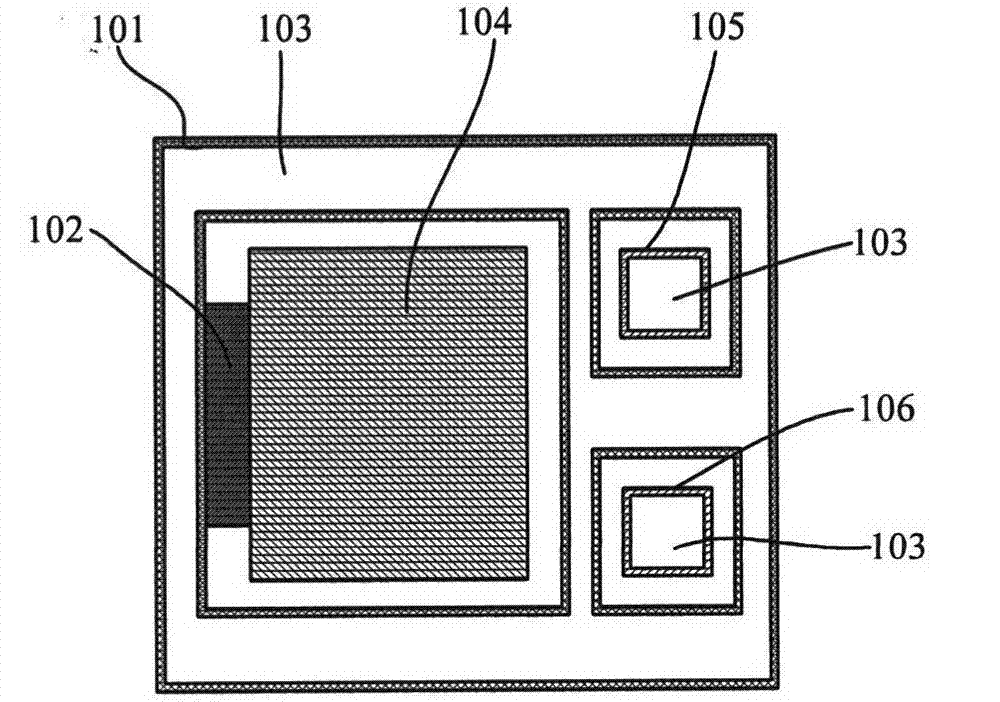

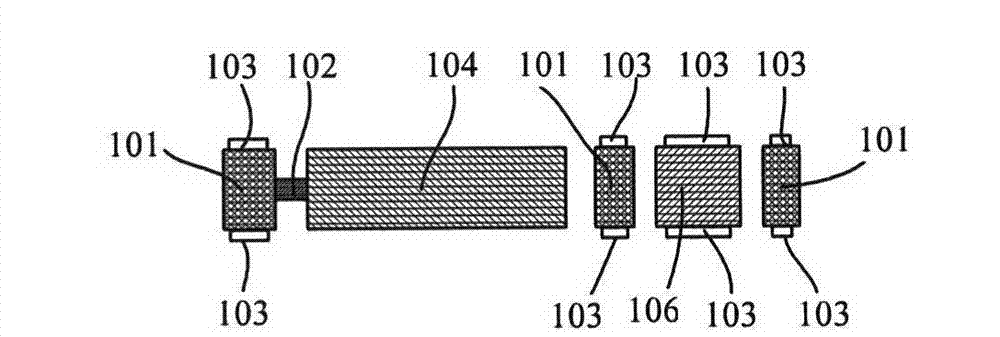

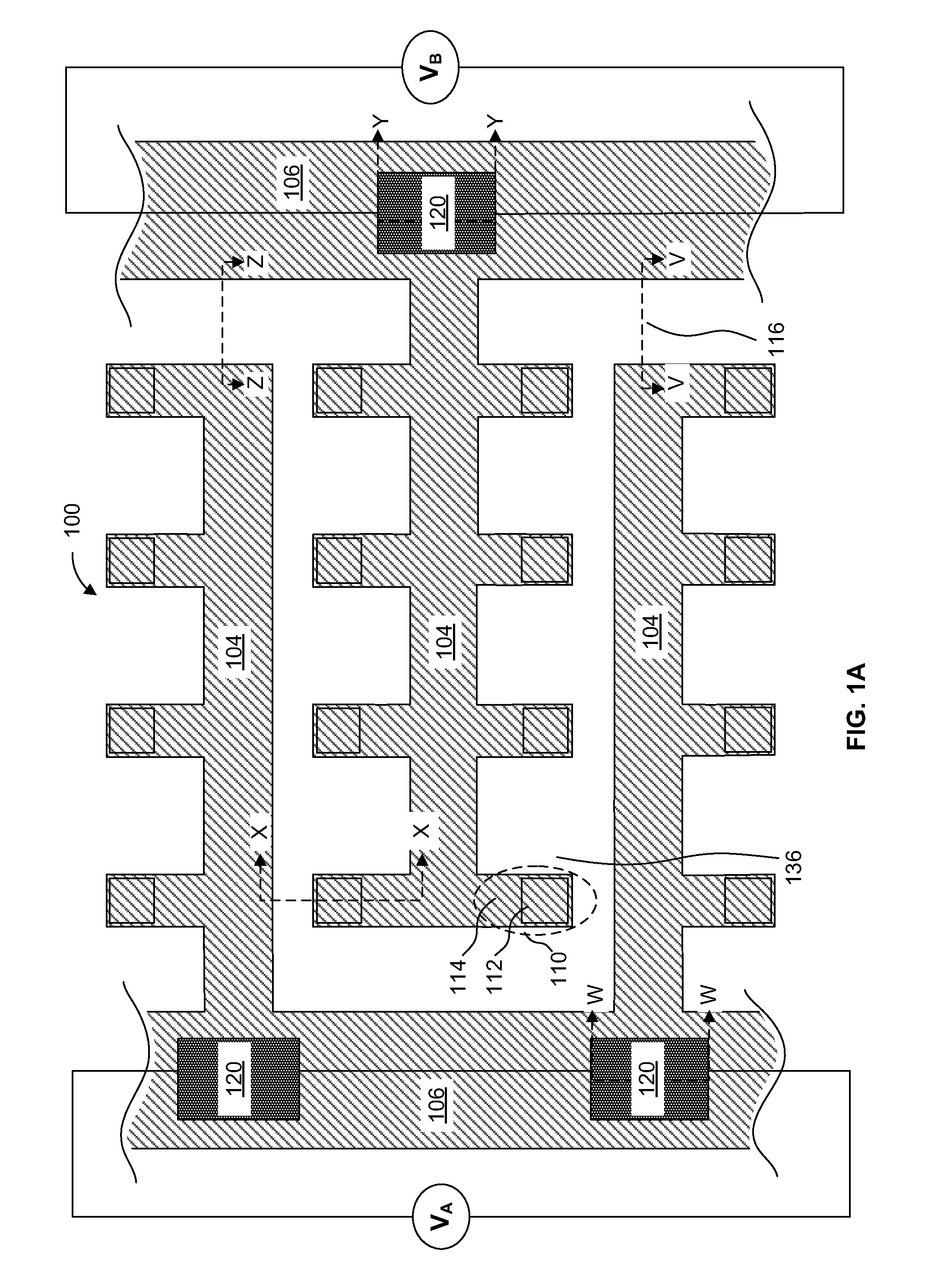

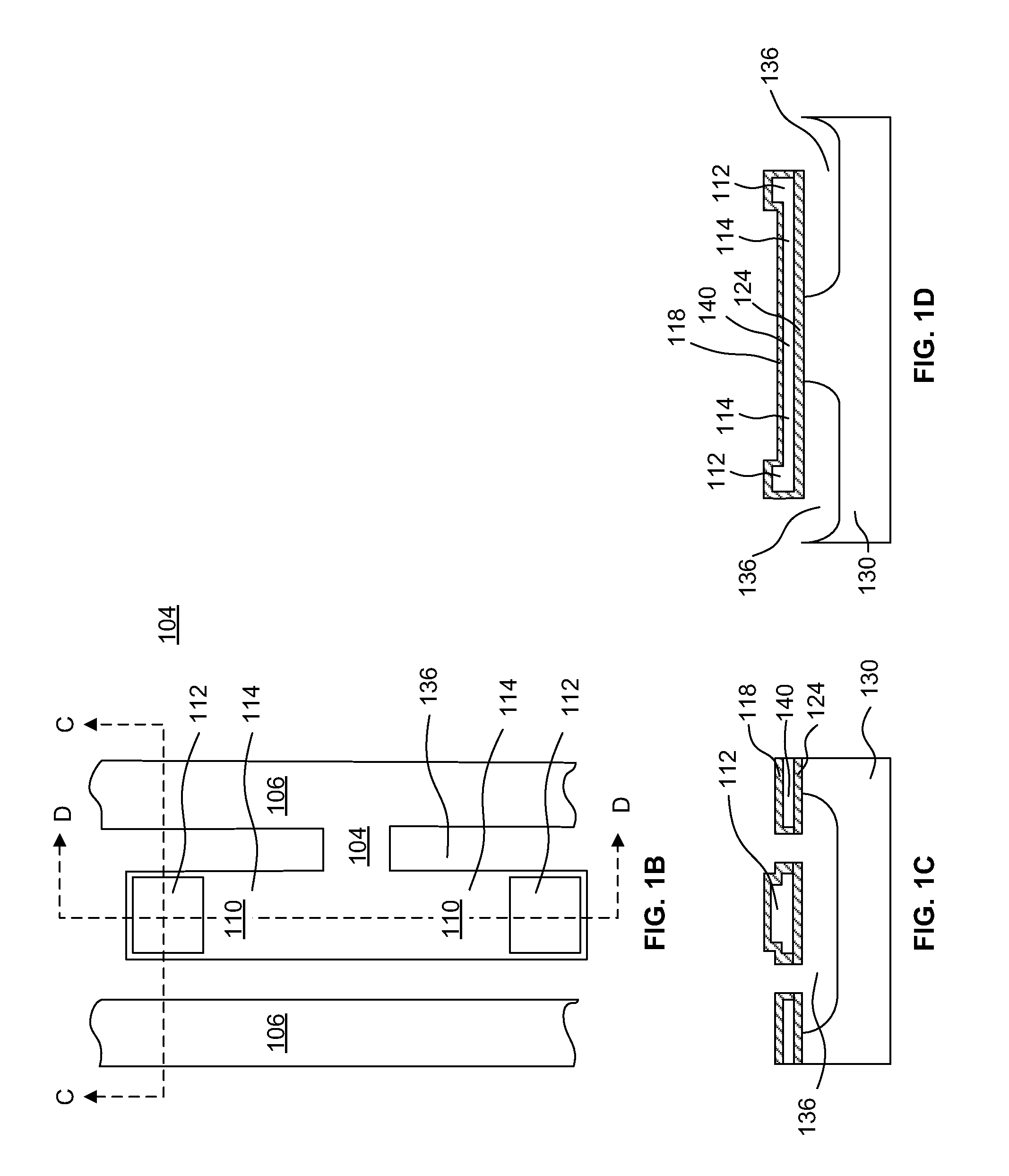

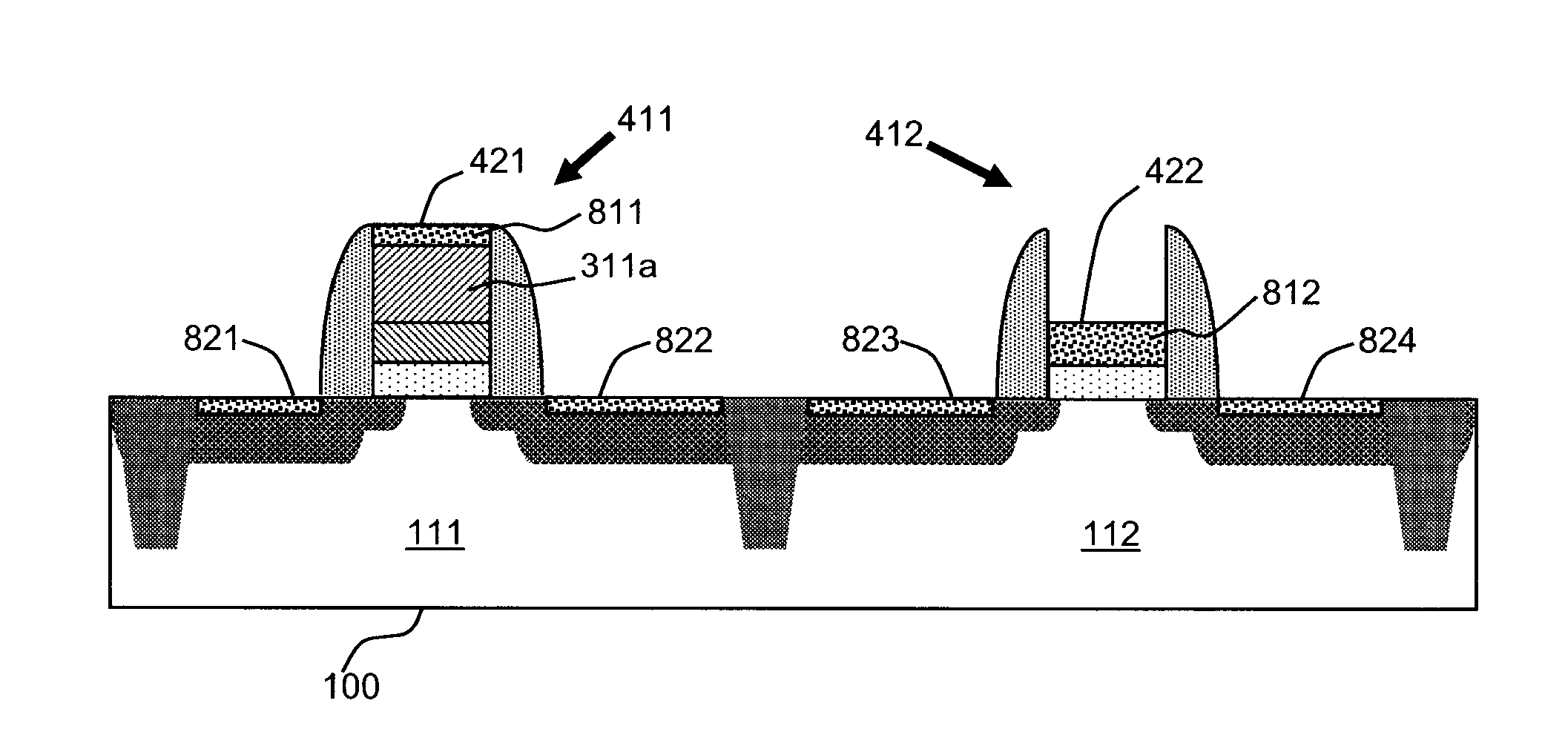

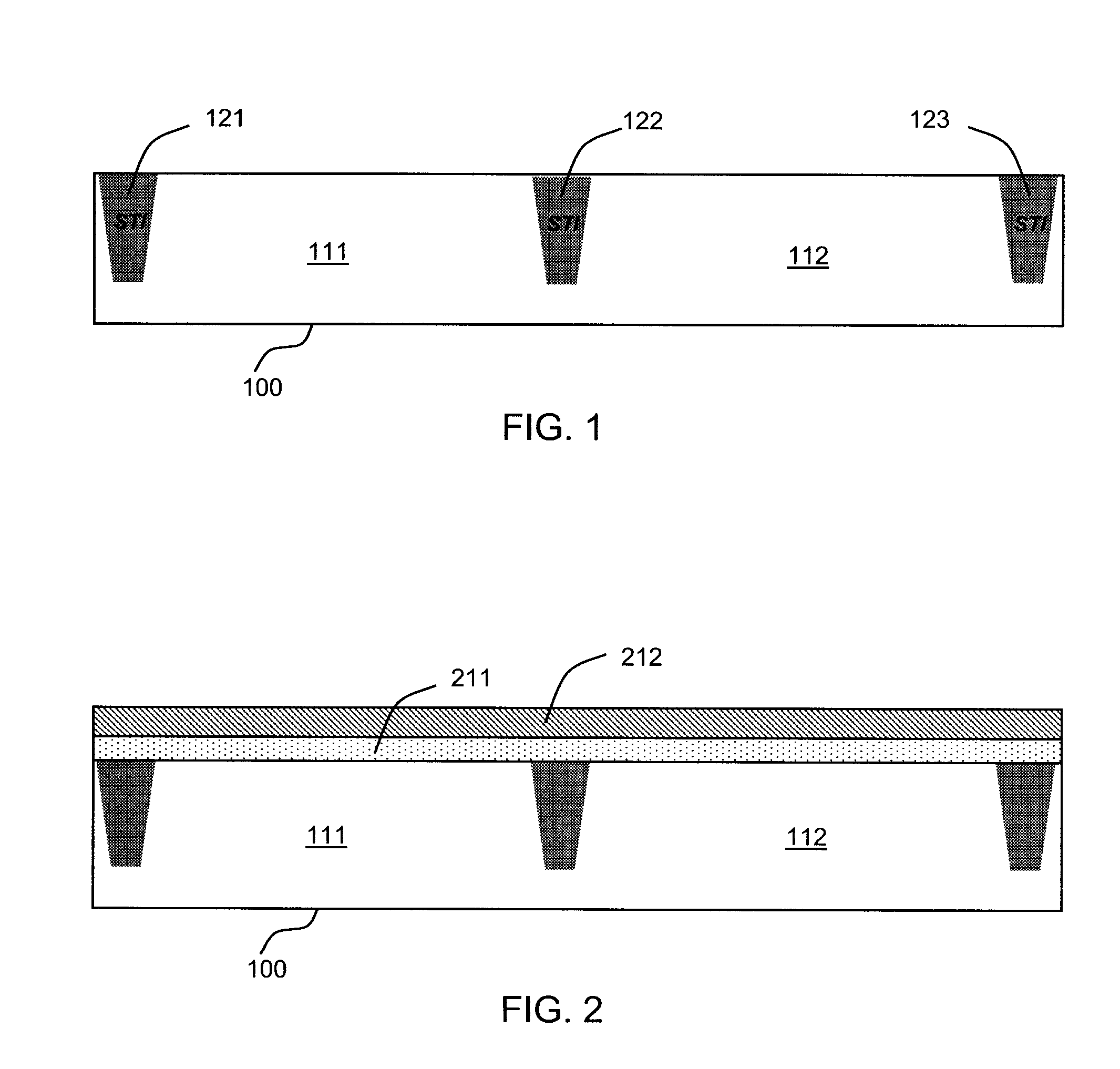

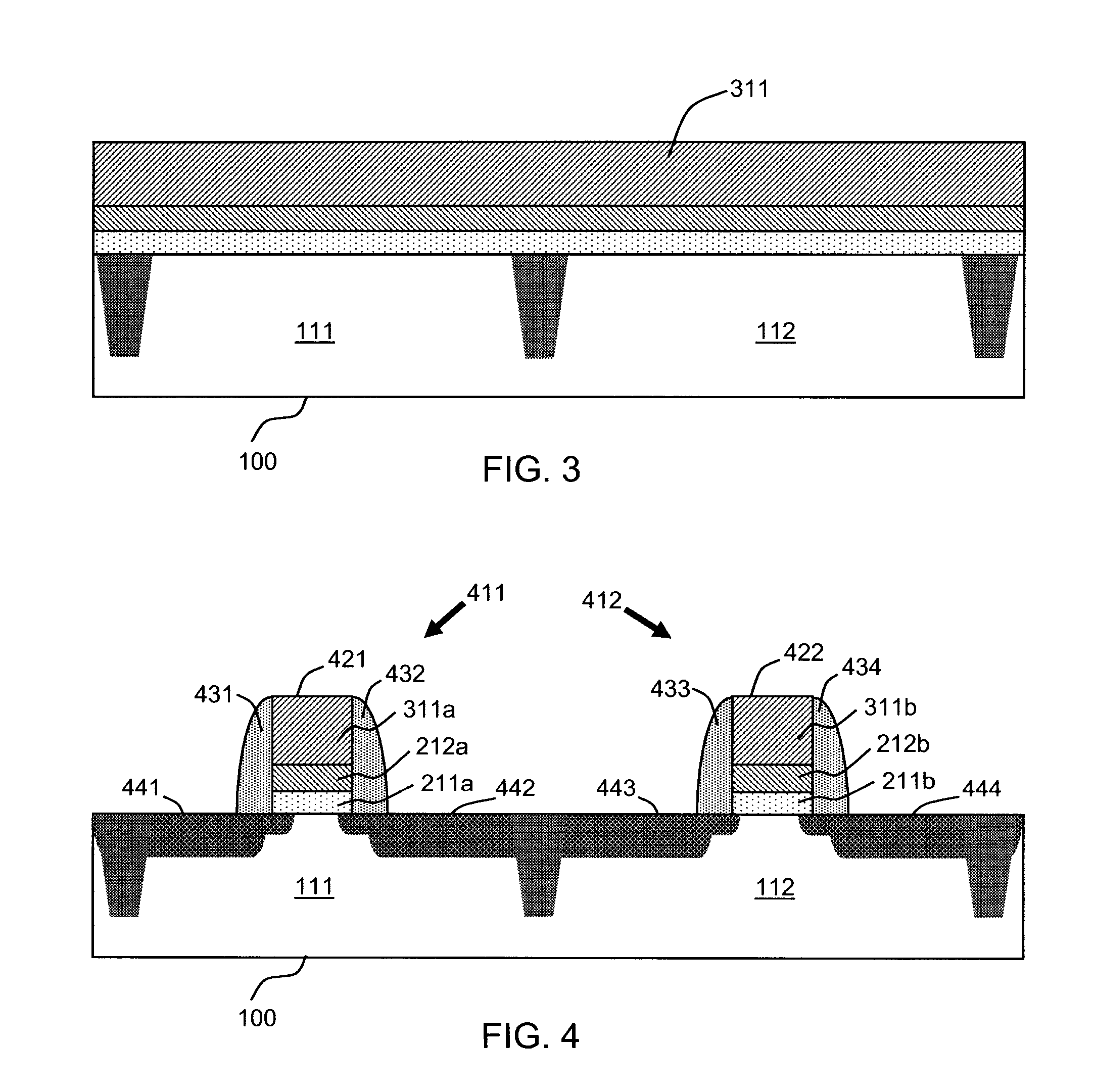

Micro device transfer head with silicon electrode

ActiveUS8415771B1Solid-state devicesSemiconductor/solid-state device manufacturingSilicon electrodeSoi substrate

A micro device transfer head array and method of forming a micro device transfer array from an SOI substrate are described. In an embodiment, the micro device transfer head array includes a base substrate and a patterned silicon layer over the base substrate. The patterned silicon layer may include a silicon interconnect and an array of silicon electrodes electrically connected with the silicon interconnect. Each silicon electrode includes a mesa structure protruding above the silicon interconnect. A dielectric layer covers a top surface of each mesa structure.

Owner:APPLE INC

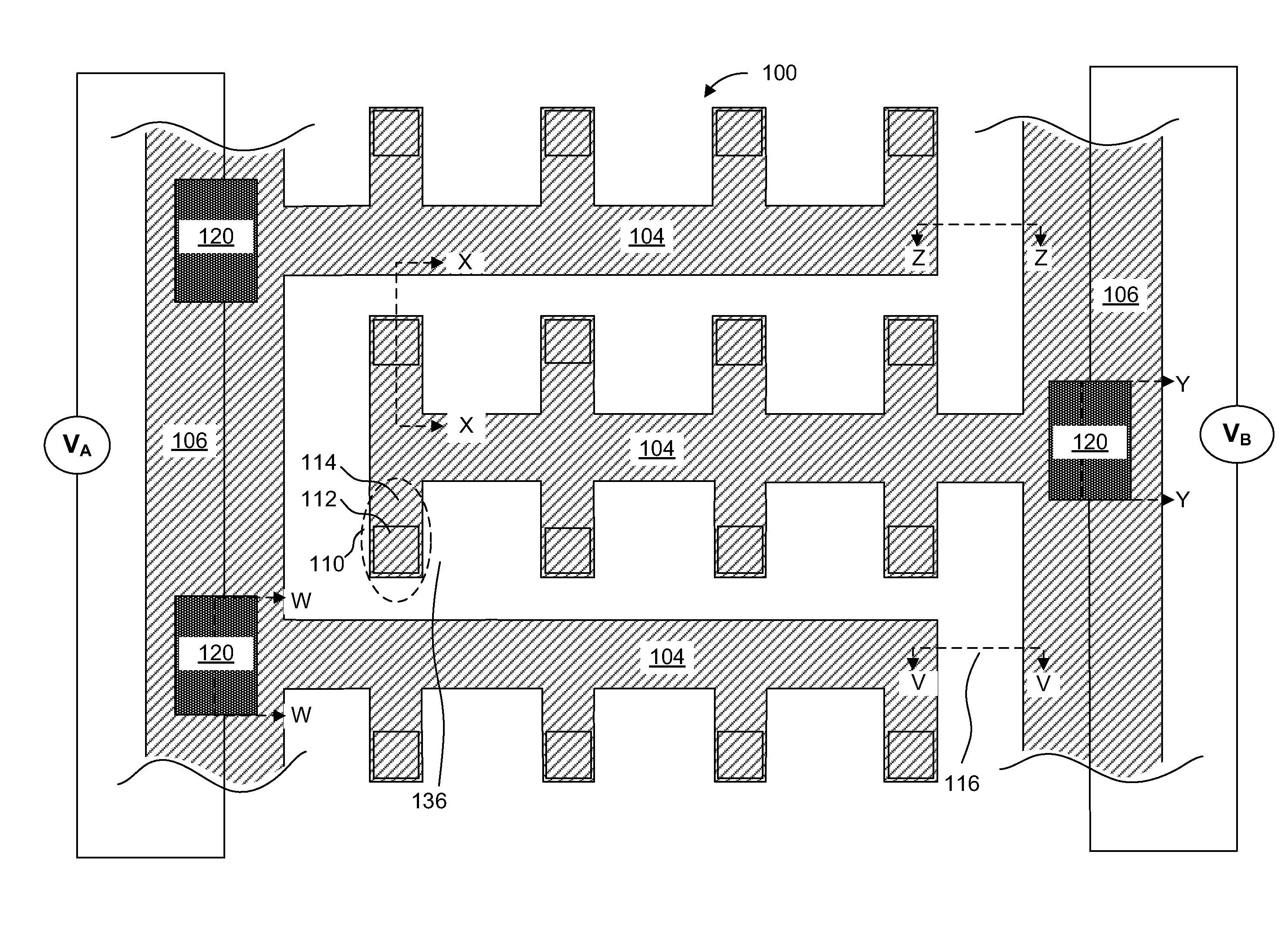

Compliant monopolar micro device transfer head with silicon electrode

ActiveUS8415768B1Lamination ancillary operationsSemiconductor/solid-state device detailsSilicon electrodeSoi substrate

A compliant monopolar micro device transfer head array and method of forming a compliant monopolar micro device transfer array from an SOI substrate are described. In an embodiment, the micro device transfer head array including a base substrate and a patterned silicon layer over the base substrate. The patterned silicon layer may include a silicon interconnect and an array of silicon electrodes electrically connected with the silicon interconnect. Each silicon electrode includes a mesa structure protruding above the silicon interconnect, and each silicon electrode is deflectable into a cavity between the base substrate and the silicon electrode. A dielectric layer covers a top surface of each mesa structure.

Owner:APPLE INC

Method of forming a compliant monopolar micro device transfer head with silicon electrode

ActiveUS8383506B1Semiconductor/solid-state device detailsSolid-state devicesSilicon electrodeSoi substrate

A compliant monopolar micro device transfer head array and method of forming a compliant monopolar micro device transfer array from an SOI substrate are described. In an embodiment, the micro device transfer head array including a base substrate and a patterned silicon layer over the base substrate. The patterned silicon layer may include a silicon interconnect and an array of silicon electrodes electrically connected with the silicon interconnect. Each silicon electrode includes a mesa structure protruding above the silicon interconnect, and each silicon electrode is deflectable into a cavity between the base substrate and the silicon electrode. A dielectric layer covers a top surface of each mesa structure.

Owner:APPLE INC

Capacitive micro-electro-mechanical sensors with single crystal silicon electrodes

ActiveUS7539003B2Mechanically variable capacitor detailsCapacitor with electrode area variationIn planeAccelerometer

The devices presented herein are capacitive sensors with single crystal silicon on all key stress points. Isolating trenches are formed by trench and refill forming dielectrically isolated conductive silicon electrodes for drive, sense and guards. For pressure sensing devices according to the invention, the pressure port is opposed to the electrical wire bond pads for ease of packaging. Dual-axis accelerometers measuring in plane acceleration and out of plane acceleration are also described. A third axis in plane is easy to achieve by duplicating and rotating the accelerometer 90 degrees about its out of plane axis Creating resonant structures, angular rate sensors, bolometers, and many other structures are possible with this process technology. Key advantages are hermeticity, vertical vias, vertical and horizontal gap capability, single crystal materials, wafer level packaging, small size, high performance and low cost.

Owner:SAMSUNG ELECTRONICS CO LTD

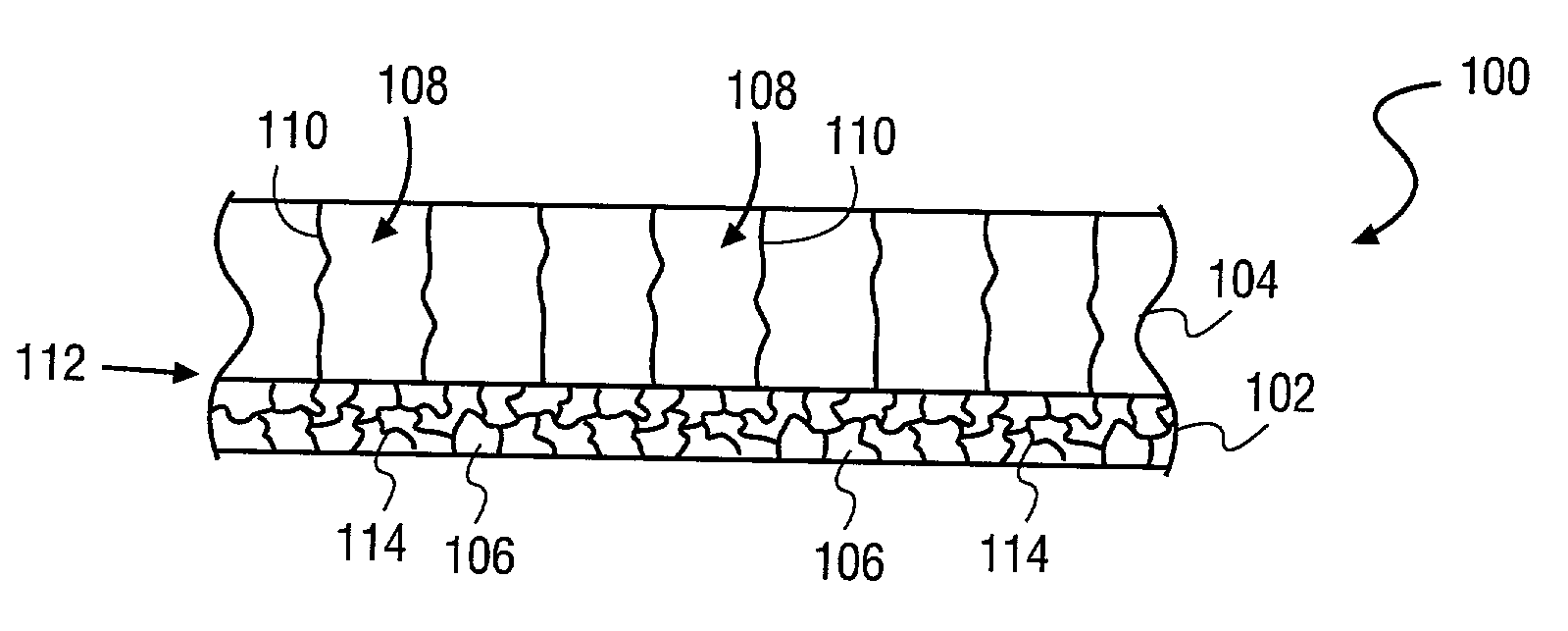

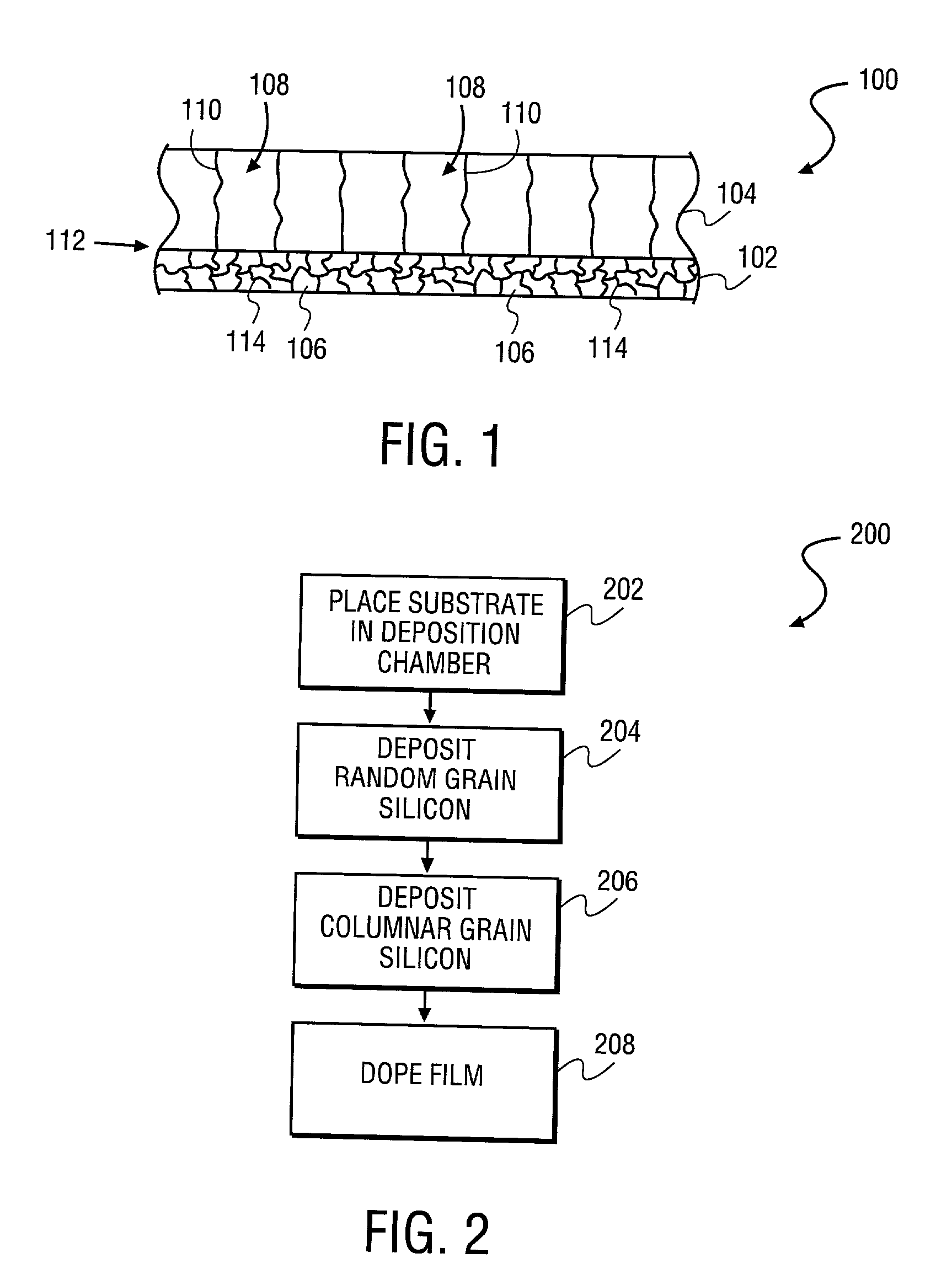

Bi-layer silicon film and method of fabrication

InactiveUS20030047734A1Reduces and slows dopant diffusionDiffusion fastTransistorSolid-state devicesSilicon electrodePolycrystalline silicon

A bi-layer silicon electrode and its method of fabrication is described. The electrode of the present invention comprises a lower polysilicon film having a random grain microstructure, and an upper polysilicon film having a columnar grain microstructure.

Owner:APPLIED MATERIALS INC

Resistive switching memory element including doped silicon electrode

ActiveUS20100258781A1Solid-state devicesBulk negative resistance effect devicesHigh resistanceElectrical resistance and conductance

A resistive switching memory element including a doped silicon electrode is described, including a first electrode comprising doped silicon having a first work function, a second electrode having a second work function that is different from the first work function by between 0.1 and 1.0 electron volts (eV), a metal oxide layer between the first electrode and the second electrode, the metal oxide layer switches using bulk-mediated switching and has a bandgap of greater than 4 eV, and the memory element switches from a low resistance state to a high resistance state and vice versa.

Owner:INTERMOLECULAR

Method of forming a compliant bipolar micro device transfer head with silicon electrodes

ActiveUS8569115B1Lamination ancillary operationsSemiconductor/solid-state device detailsSilicon electrodeSoi substrate

A compliant bipolar micro device transfer head array and method of forming a compliant bipolar micro device transfer array from an SOI substrate are described. In an embodiment, a compliant bipolar micro device transfer head array includes a base substrate and a patterned silicon layer over the base substrate. The patterned silicon layer may include first and second silicon interconnects, and first and second arrays of silicon electrodes electrically connected with the first and second silicon interconnects and deflectable into one or more cavities between the base substrate and the silicon electrodes.

Owner:APPLE INC

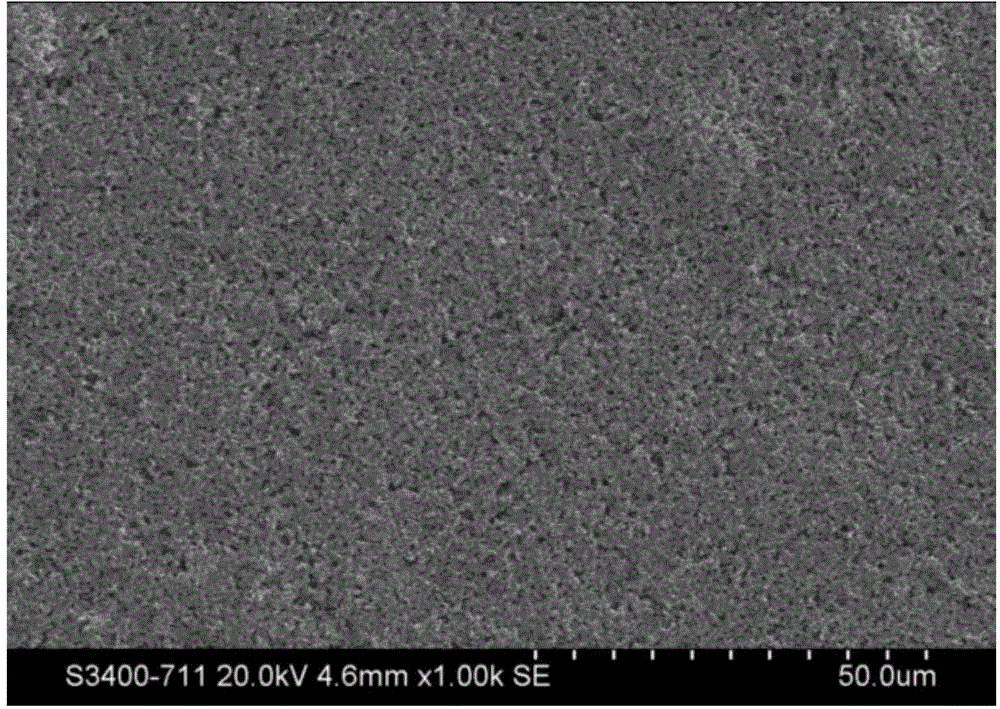

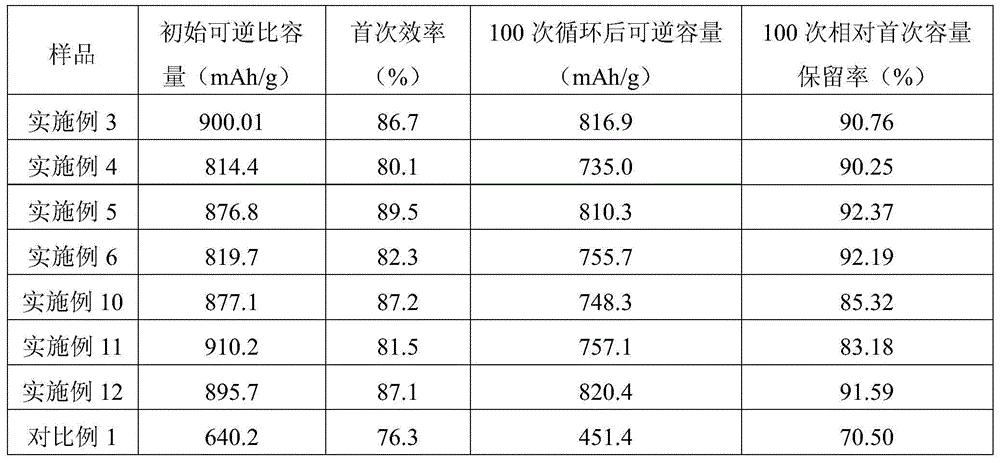

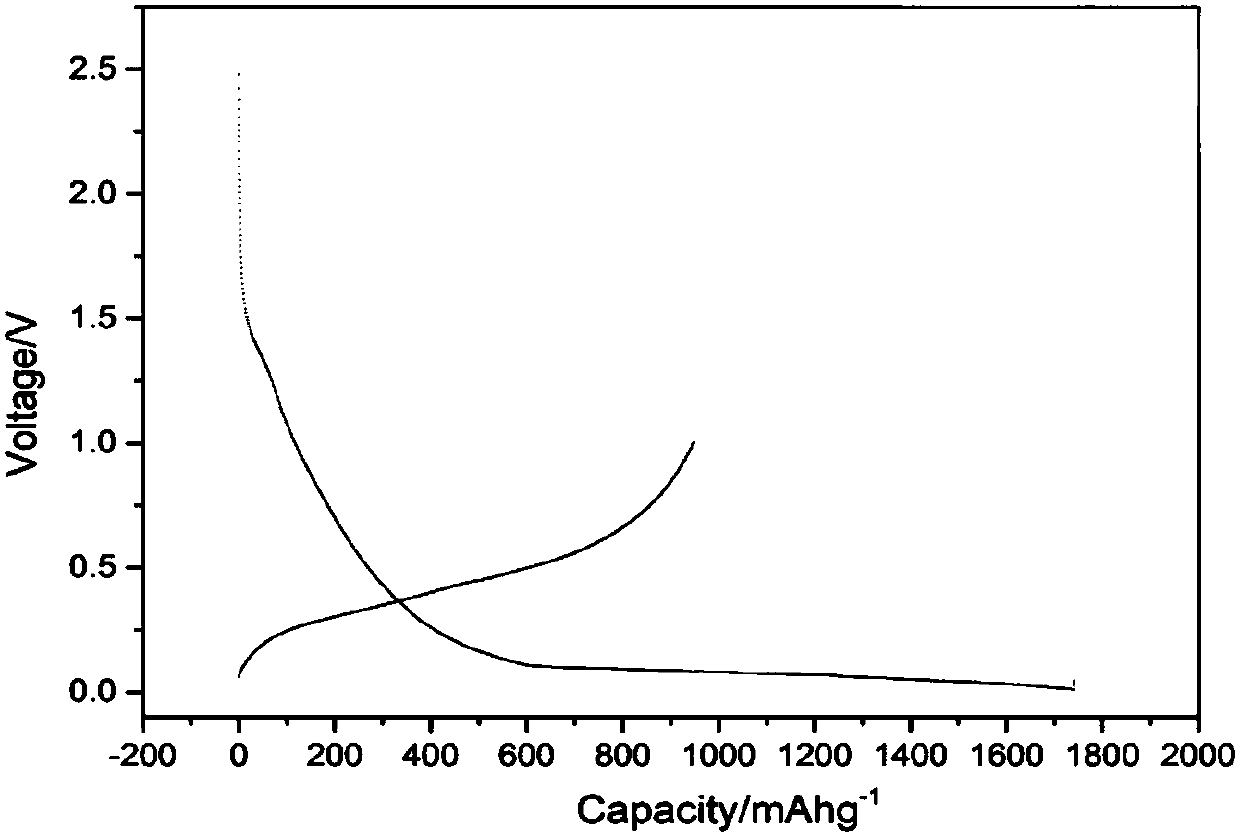

Nano-silicon amorphous carbon composition lithium ion battery cathode material and preparation method therefor

InactiveCN101527357ALarge capacityImprove cycle lifeElectrode manufacturing processesCarbonizationSolvent

The invention relates to a nano-silicon amorphous carbon composition lithium ion battery cathode material and a preparation method therefore, belonging to the field of electrochemistry power supply. The cathode material consists of a substrate and granules distributed evenly thereon, wherein, cores of the nano-granules are nano-silicon while shells thereof are amorphous carbon obtained by pyrogenation of organic substance; and the substrate thereof is obtained by pyrogenation and carbonization of organic electrospun fibre; wherein, content range of monomer silicon is 10%-50% and content range of amorphous carbon is 90%-50%. The preparation method comprises that nano-silicon granules and electrospun-available organic substances are uniformly stirred and mixed in solvent; high-voltage static electrospun is carried out to obtain fibrous composition; temperature is maintained at 80-200 DEG C, so as to volatilize the solvent completely; and carbonization is then carried out at 400-1000 DEG C. The silicon / carbon composition cathode material prepared by the method can effectively control volume change of silicon electrode material in charging and discharging process. Therefore, the electrode structure is maintained integral; the volume is released gradually. And the silicon / carbon composition cathode material has large circular volume, long circular service life and excellent electrochemical performance.

Owner:TSINGHUA UNIV

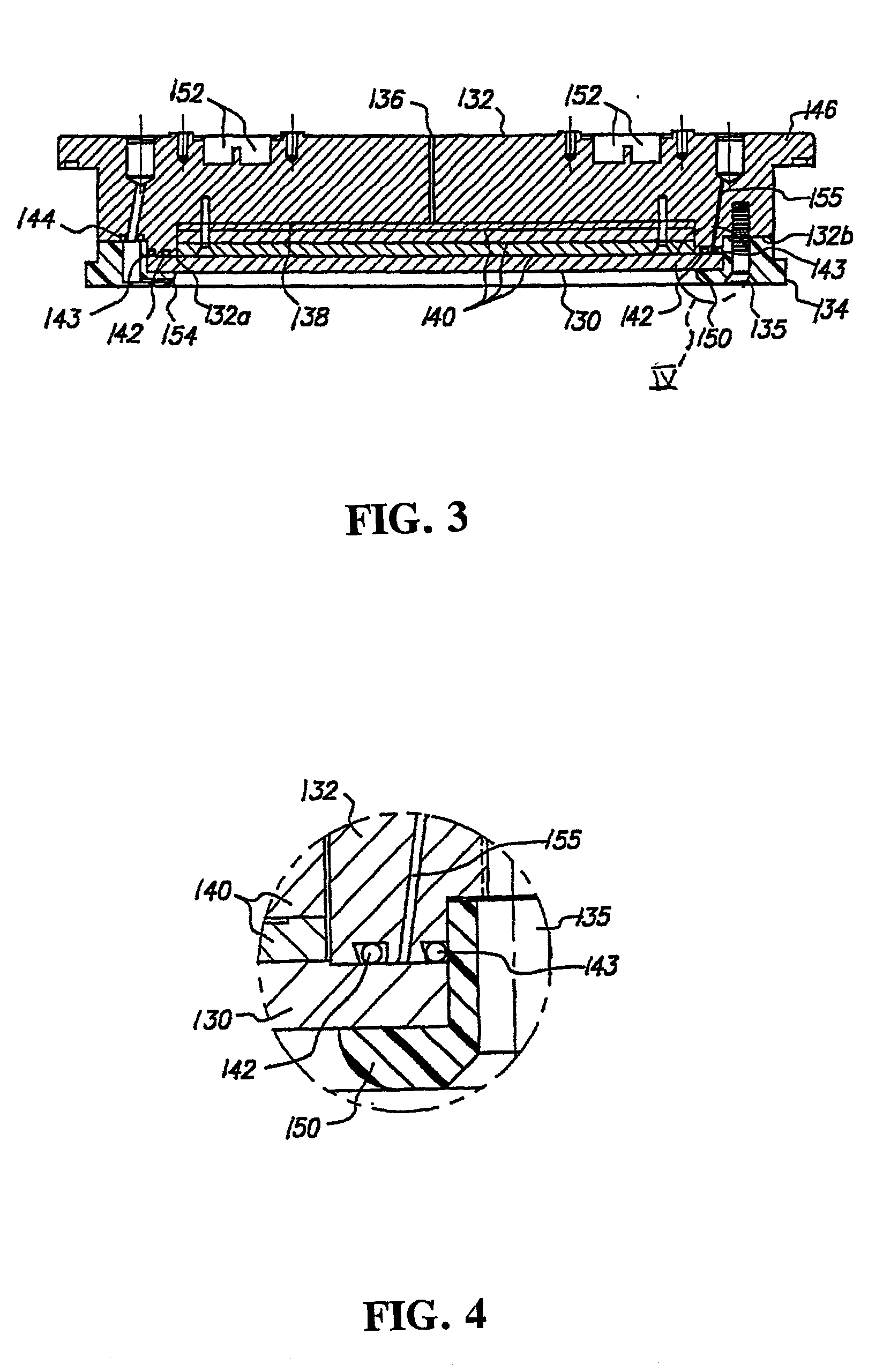

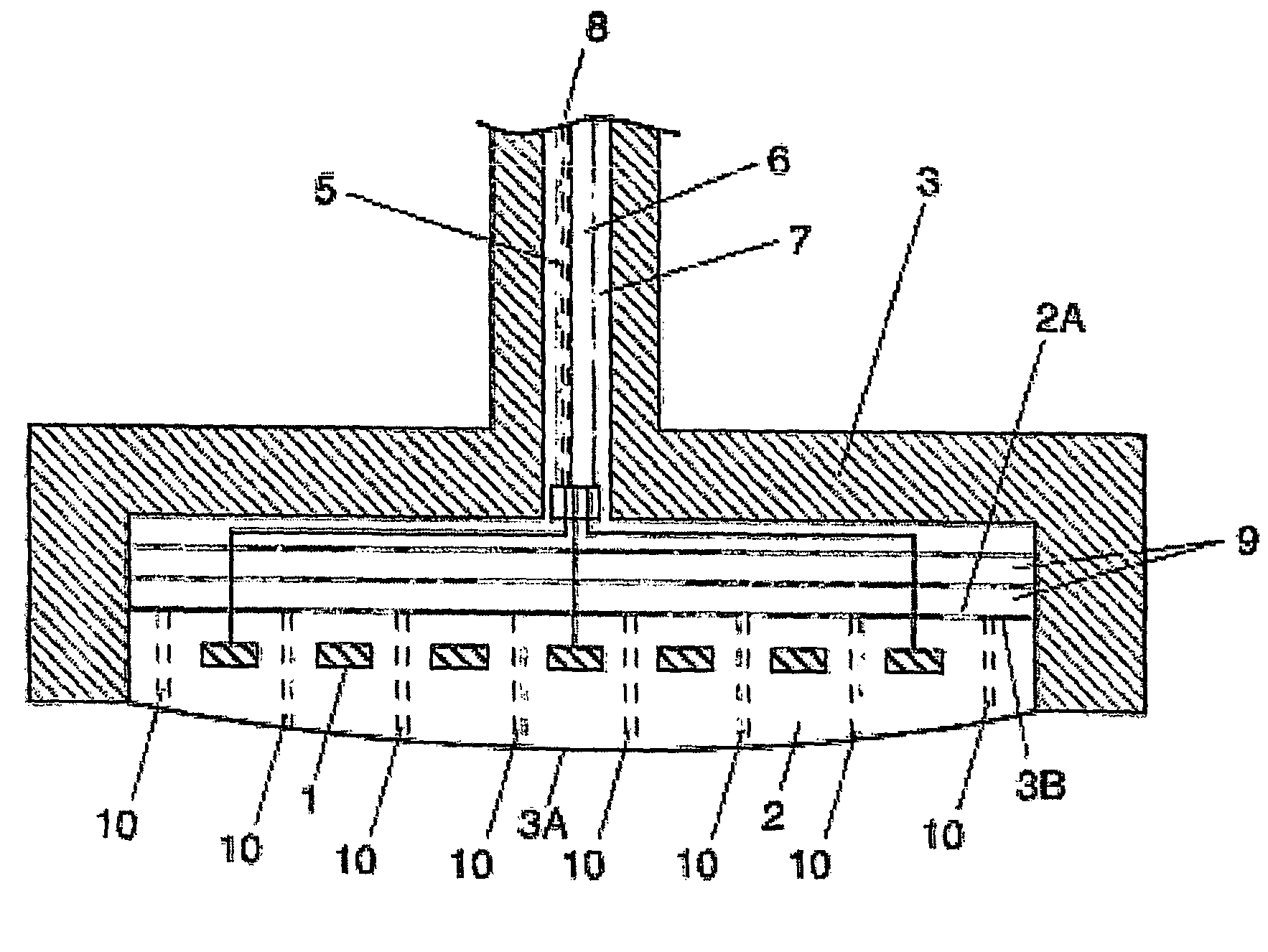

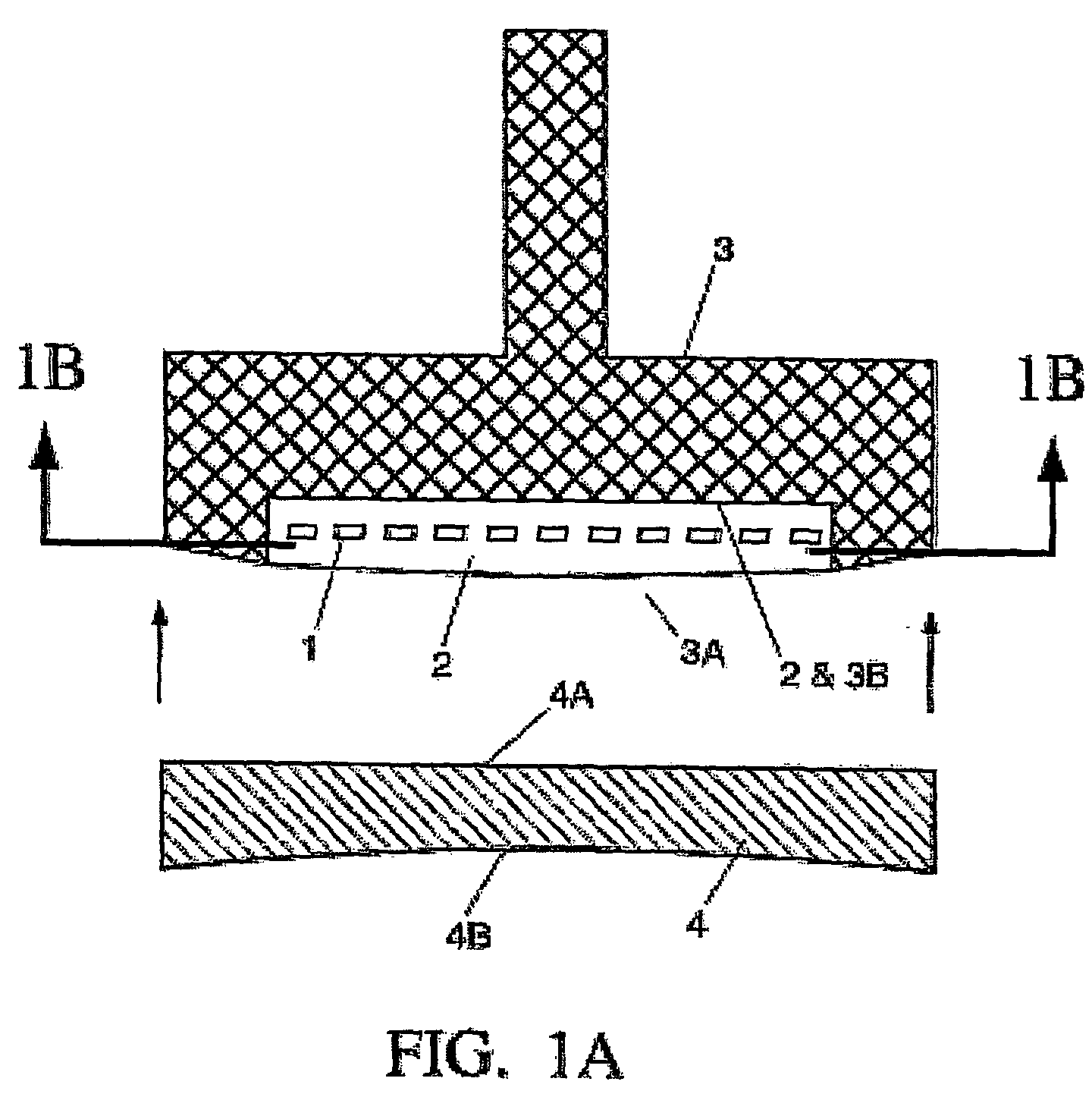

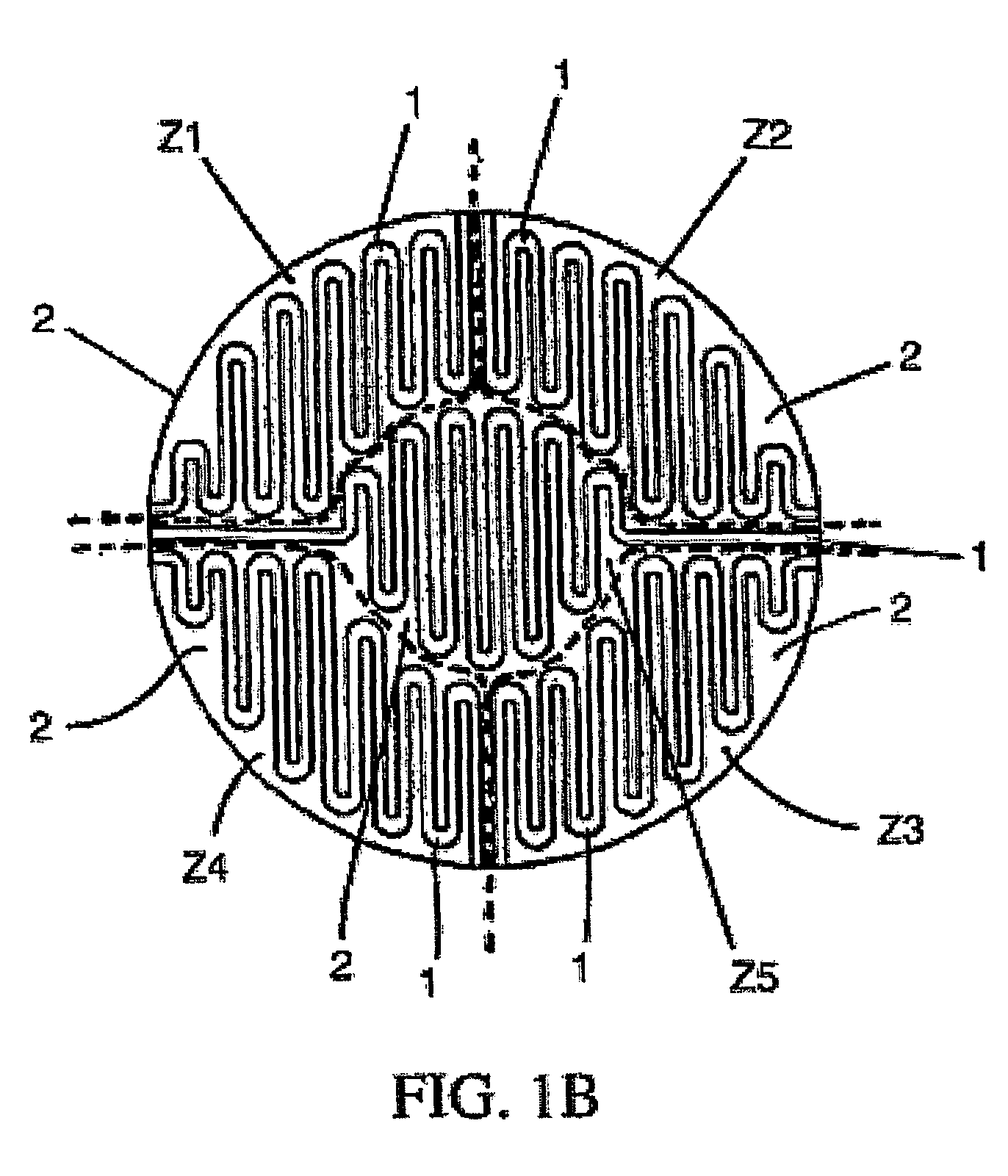

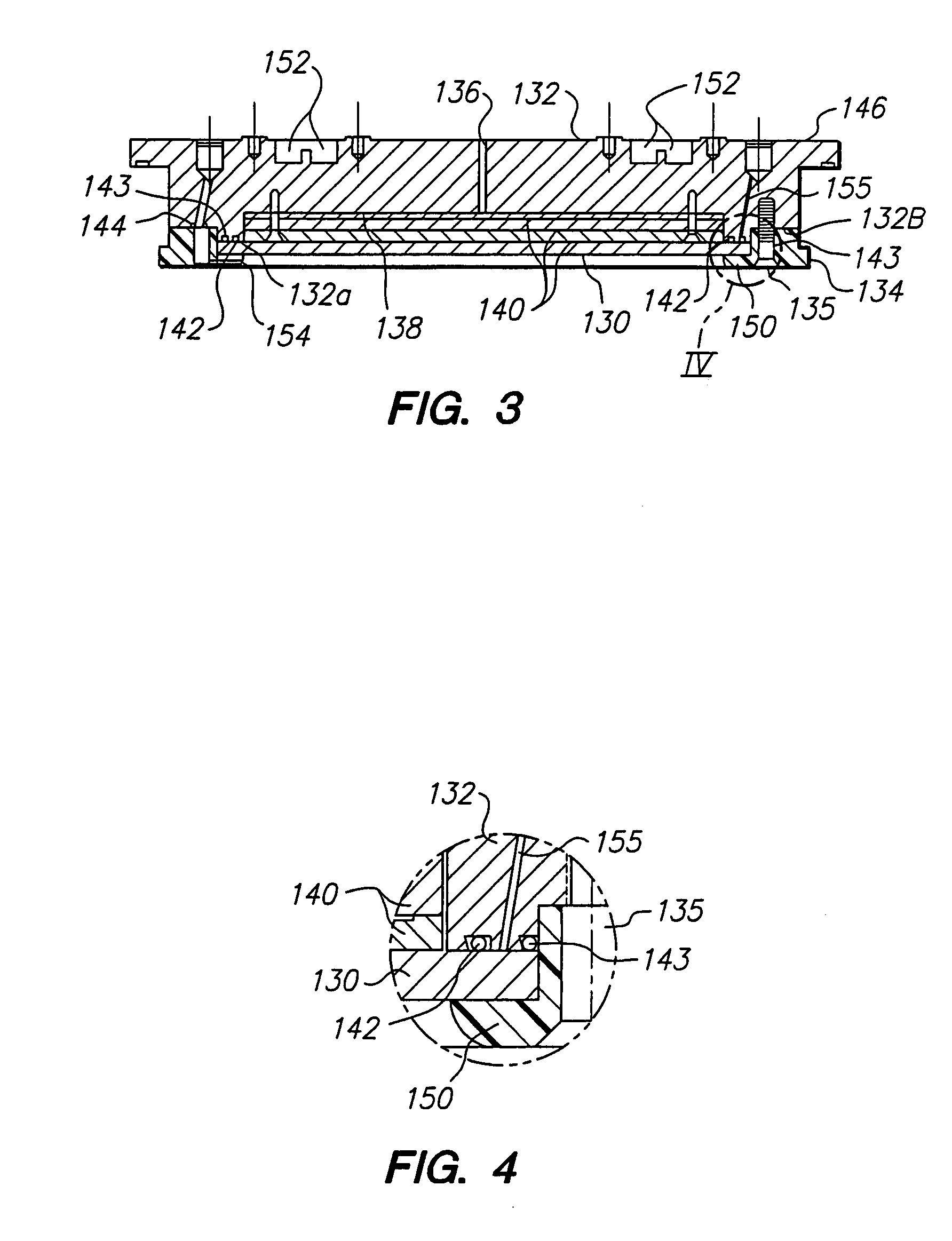

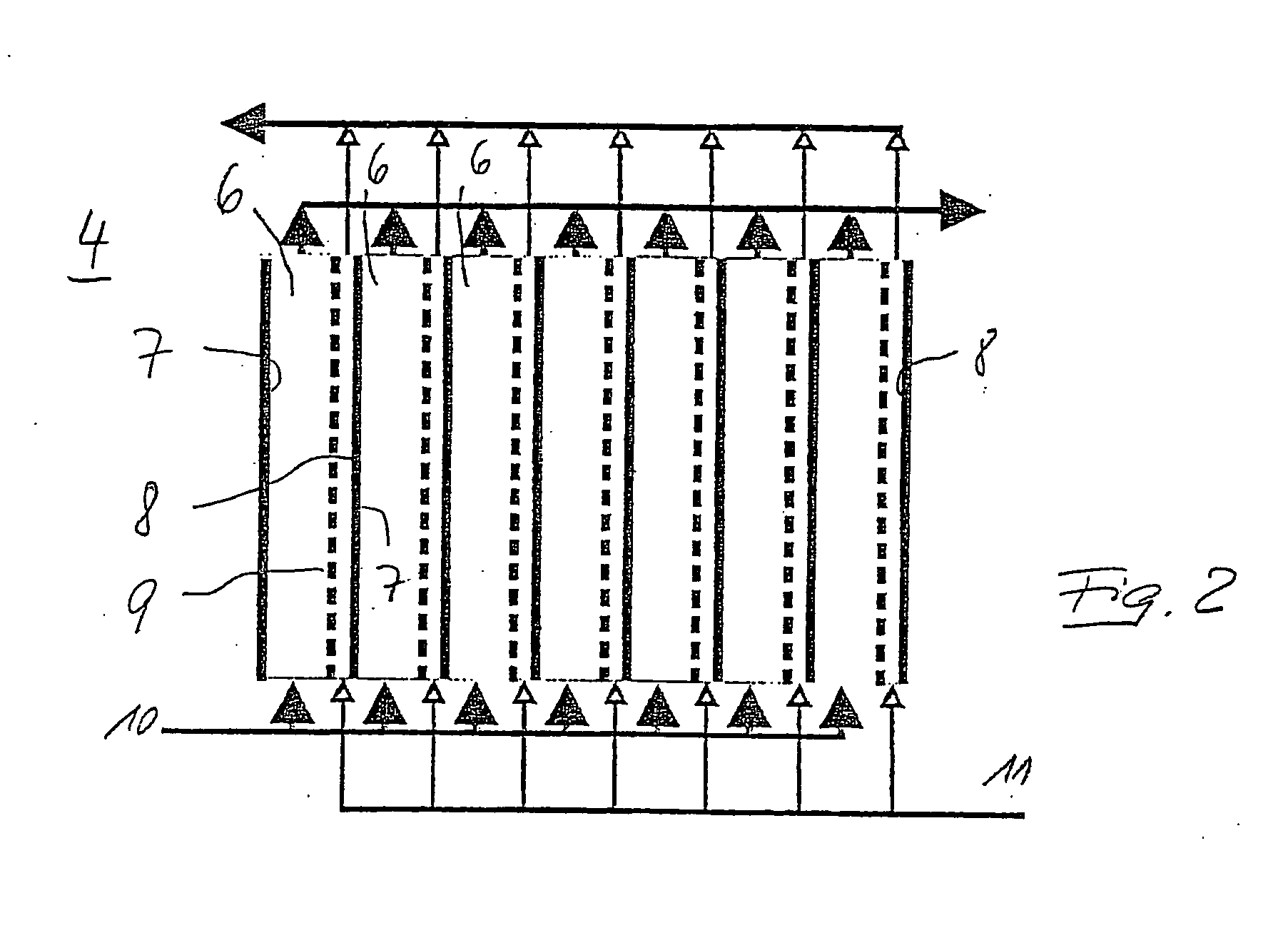

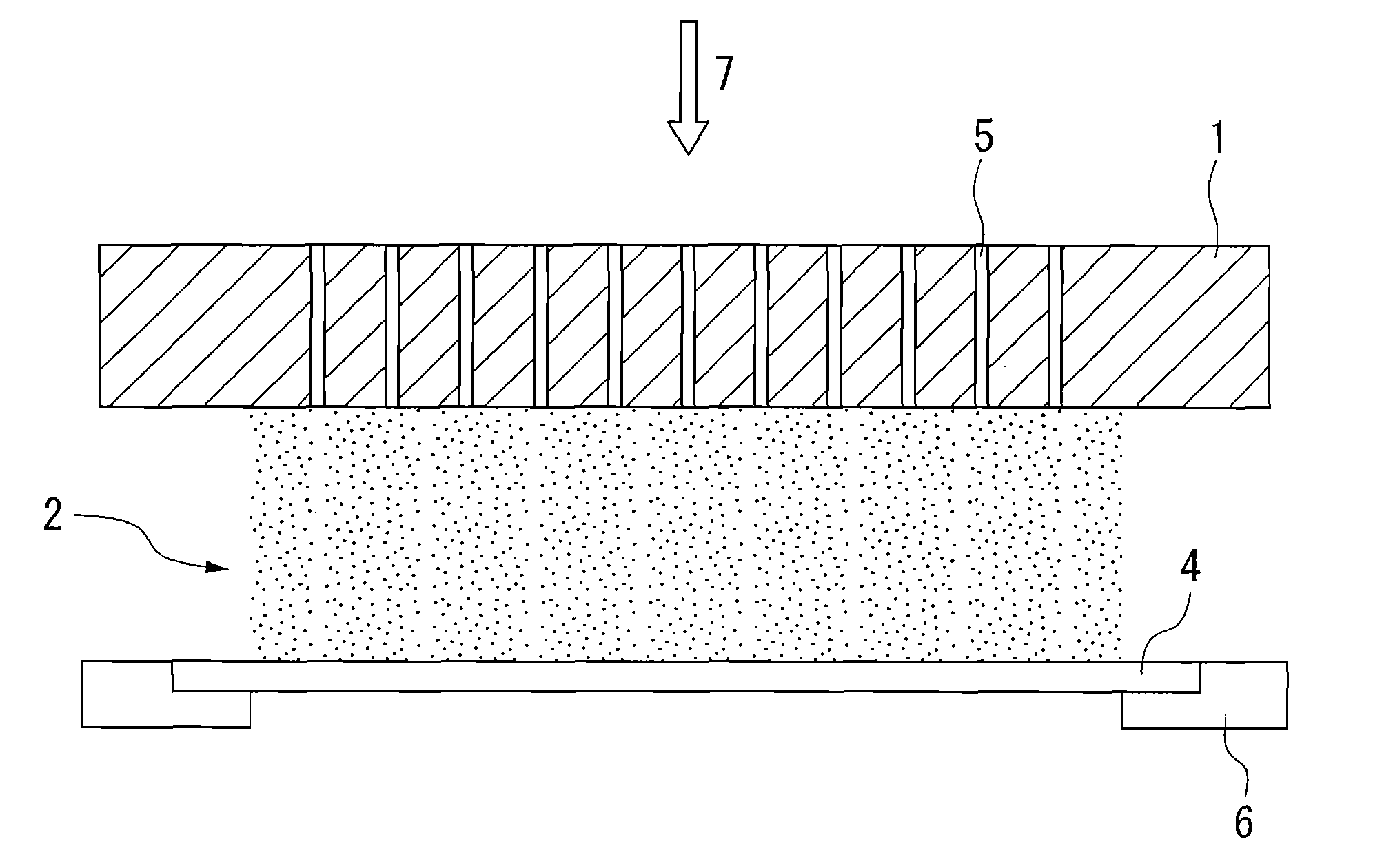

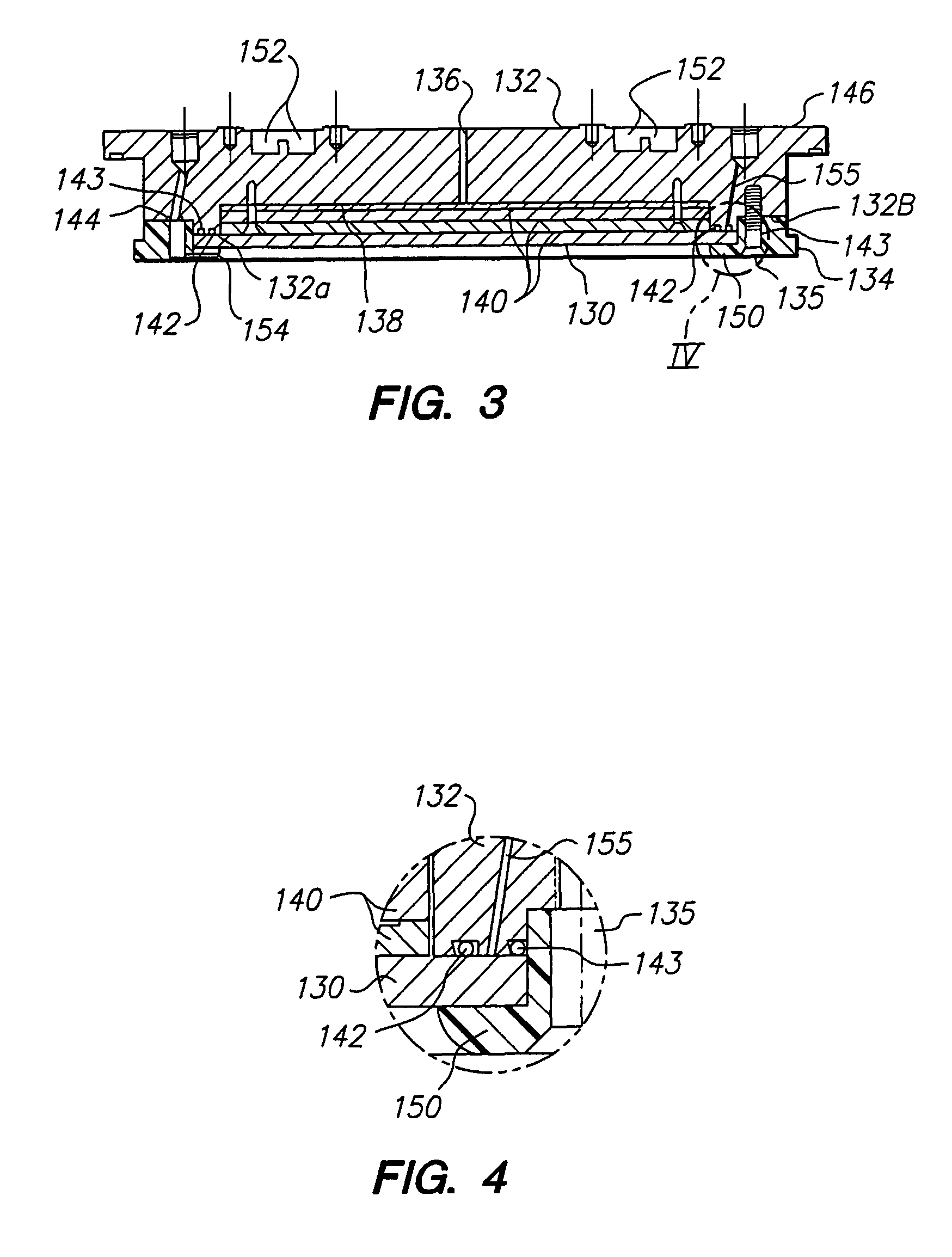

Method of and structure for controlling electrode temperature

InactiveUS7075031B2Minimizing temperatureHeating up fastElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceEtching

A method of and a structure for controlling the temperature of an electrode (4). The electrode is heated prior to etching the first wafer and both a (temporally) stationary and a (spatially) homogeneous temperature of the silicon electrode are maintained. Resistive heater elements (1) are either embedded within the housing of the electrode (3) or formed as part of the electrode. The resistive heater elements form a heater of a multi-zone type in order to minimize the temperature non-uniformity. The resistive heater elements are divided into a plurality of zones, wherein the power to each zone can be adjusted individually, allowing the desirable temperature uniformity of the electrode to be achieved. Preheating the electrode to the appropriate operating temperature eliminates both the “first wafer effect” and non-uniform etching of a semiconductor wafer.

Owner:TOKYO ELECTRON LTD

Compliant bipolar micro device transfer head

ActiveUS20140048909A1Lamination ancillary operationsSolid-state devicesSilicon electrodeSoi substrate

A compliant bipolar micro device transfer head array and method of forming a compliant bipolar micro device transfer array from an SOI substrate are described. In an embodiment, a compliant bipolar micro device transfer head array includes a base substrate and a patterned silicon layer over the base substrate. The patterned silicon layer may include first and second silicon interconnects, and first and second arrays of silicon electrodes electrically connected with the first and second silicon interconnects and deflectable into one or more cavities between the base substrate and the silicon electrodes.

Owner:APPLE INC

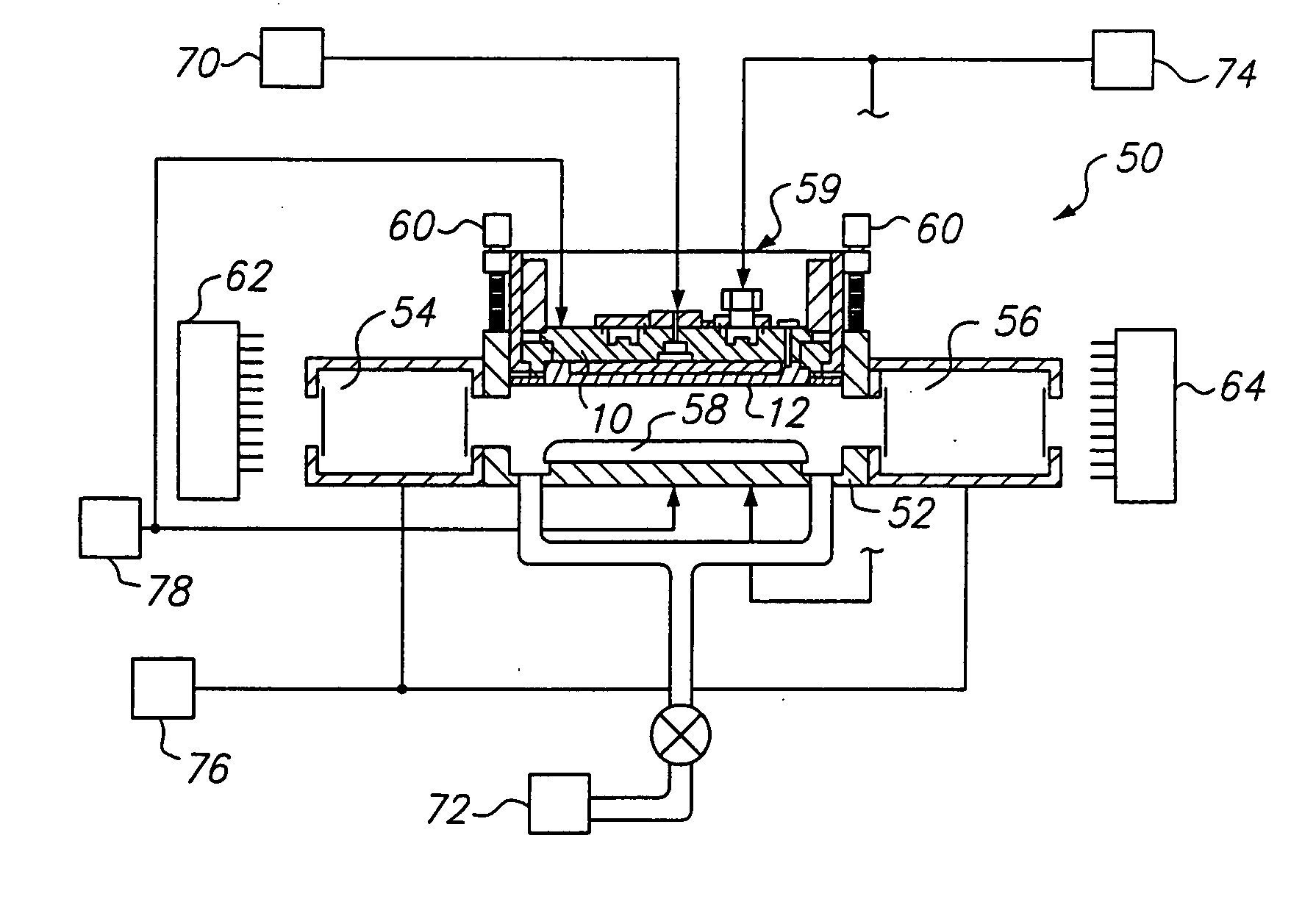

Plasma reaction chamber and captive silicon electrode plate for processing semiconductor wafers

InactiveUS20060108069A1Electric discharge tubesSemiconductor/solid-state device manufacturingSilicon electrodeEngineering

A plasma processing system for etching a semiconductor wafer comprises: 1) a plasma chamber in which the semiconductor wafer may be mounted; 2) an upper ring capable of being mounted on an upper opening of the plasma chamber, wherein a central portion of the upper ring forms a hole; and 3) an electrode plate having a plurality of vias therethrough. The electrode plate is disposed in the hole in the upper ring, wherein the central portion of the upper ring further forms a shelf for supporting the electrode plate in the hole.

Owner:SAMSUNG AUSTIN SEMICON +1

High-performance binder for silicon materials for lithium ion batteries and preparation method thereof

ActiveCN104538635AImprove conductivityImprove microscopic compositionCell electrodesCyclic processAcrylonitrile

The invention provides a high-performance binder for silicon materials for lithium ion batteries, which is a polyacrylonitrile copolymer, a polymeric monomer of the copolymer comprises acrylonitrile, also comprises a second monomer and / or a third monomer; and the second monomer is a monobutyl itaconate monomer, and the third monomer is selected from a mixture of one or more of an itaconic acid, sodium allylsulfonate, acrylamide, amino, a pyridyl or acylamino monomer, n-butyl acrylate or methyl acrylate. The invention also provides a preparation method of the binder. Compared with existing binders, the binder disclosed by the invention has better binding power, can effectively improve the expansion of silicon materials in the processes of charging and discharging, and can improve the performance of a silicon electrode in the process of cycling. Meanwhile, the binder is simple in preparation method, low in cost and good in repeatability, and can achieve the practical need of mass production.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Electrode for plasma processes and method for manufacture and use thereof

ActiveUS20080026589A1Reduce accumulationMore powerLiquid surface applicatorsElectric discharge tubesTemperature controlSilicon electrode

A silicon electrode for a plasma reaction chamber wherein processing of a semiconductor substrate such as a single wafer can be carried out and a method of processing a semiconductor substrate with the electrode. The electrode is a low resistivity electrode having an electrical resistivity of less than 1 ohm-cm. The electrode can be a zero defect single crystal silicon or silicon carbide electrode such as a showerhead electrode bonded or clamped to support such as a temperature controlled plate or ring. The showerhead electrode can be in the form of a circular disk of uniform thickness and an elastomeric joint can be provided between a support ring and the electrode. The electrode can include gas outlets having 0.020 to 0.030 inch diameters.

Owner:LAM RES CORP

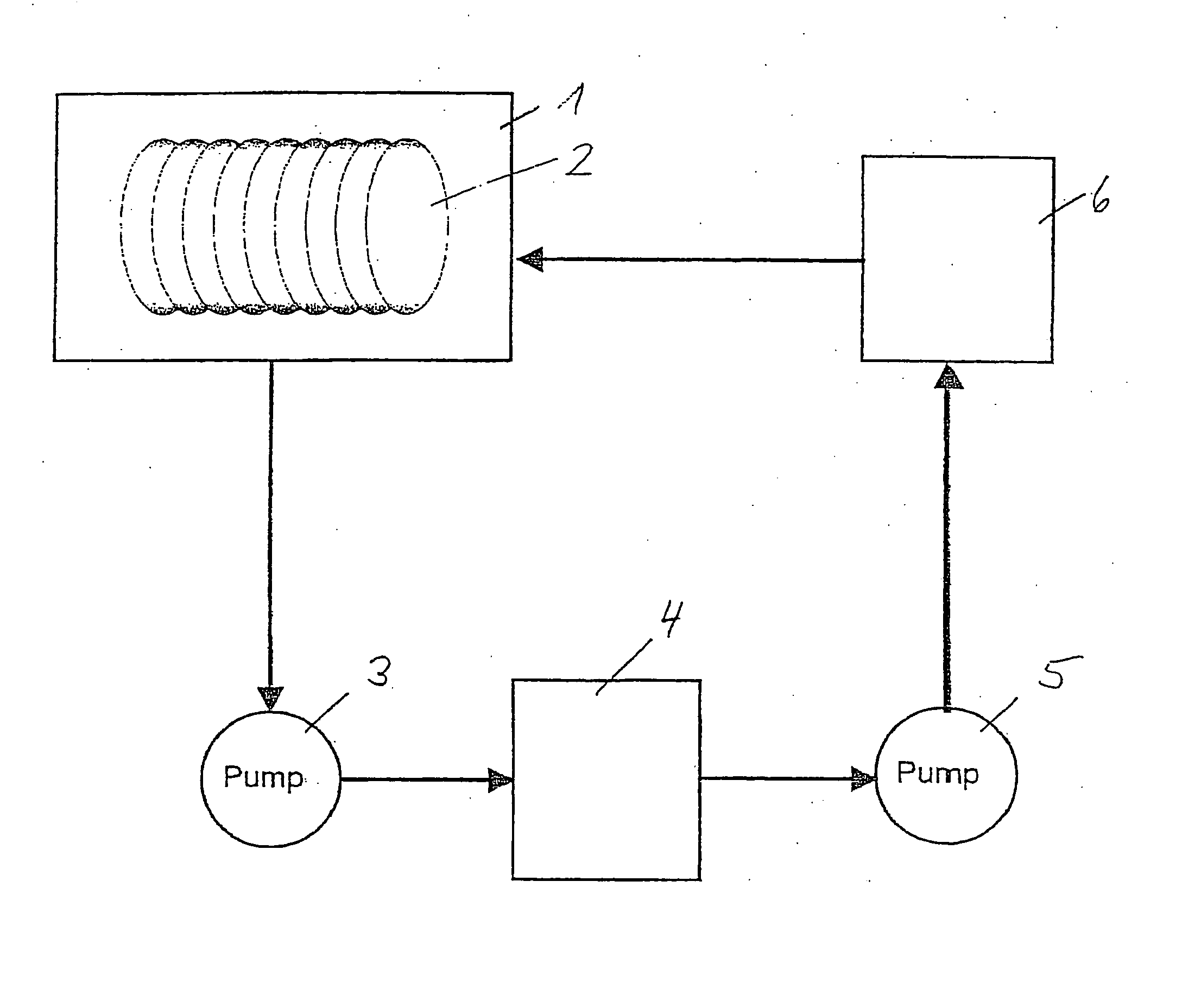

Method for the oxidative treatment of components comprised of or containing elementary silicon and/or substantially inorganic silicon compounds

InactiveUS20050139487A1Electrolysis componentsLiquid separation by electricityOvervoltageSilicon electrode

In a method for the treatment of an object made of silicon or an inorganic, optionally organically modified, silicon compound, an oxidizing agent is prepared by electrolysis of an aqueous solution in an electrolysis device. The anode of the electrolysis device is a silicon electrode. The anode has an overvoltage for oxygen so that upon electrolysis of water the formation of hydrogen peroxide is preferred over that of oxygen. The aqueous solution used in electrolysis contains at least one reactive component or a constituent that is converted by electrolysis of the solution into a reactive component. The object to be treated is contacted with the freshly prepared oxidizing agent. The oxidizing agent is circulated and returned into the electrolysis device to be regenerated.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

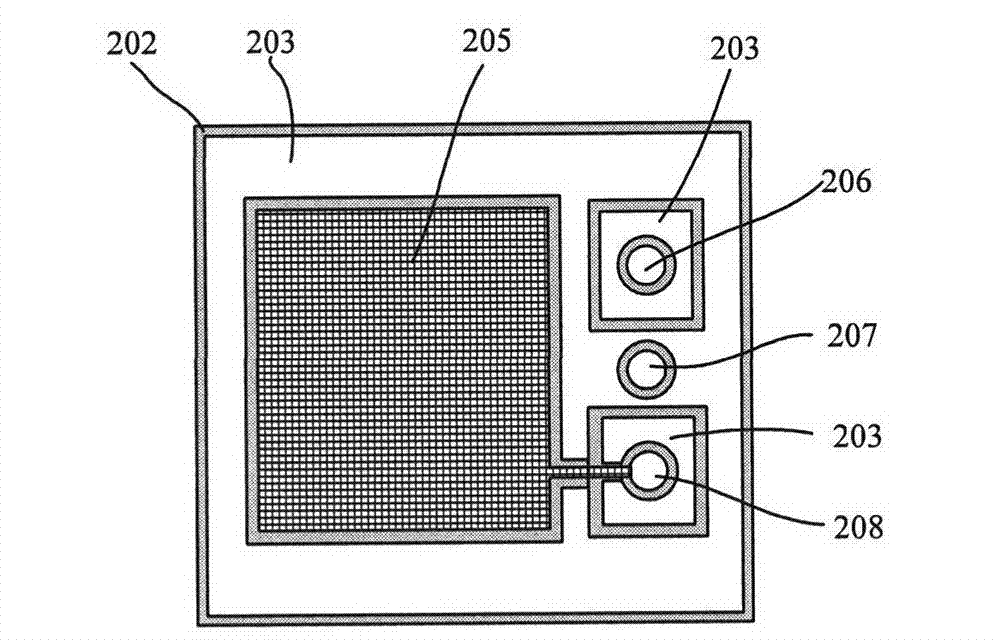

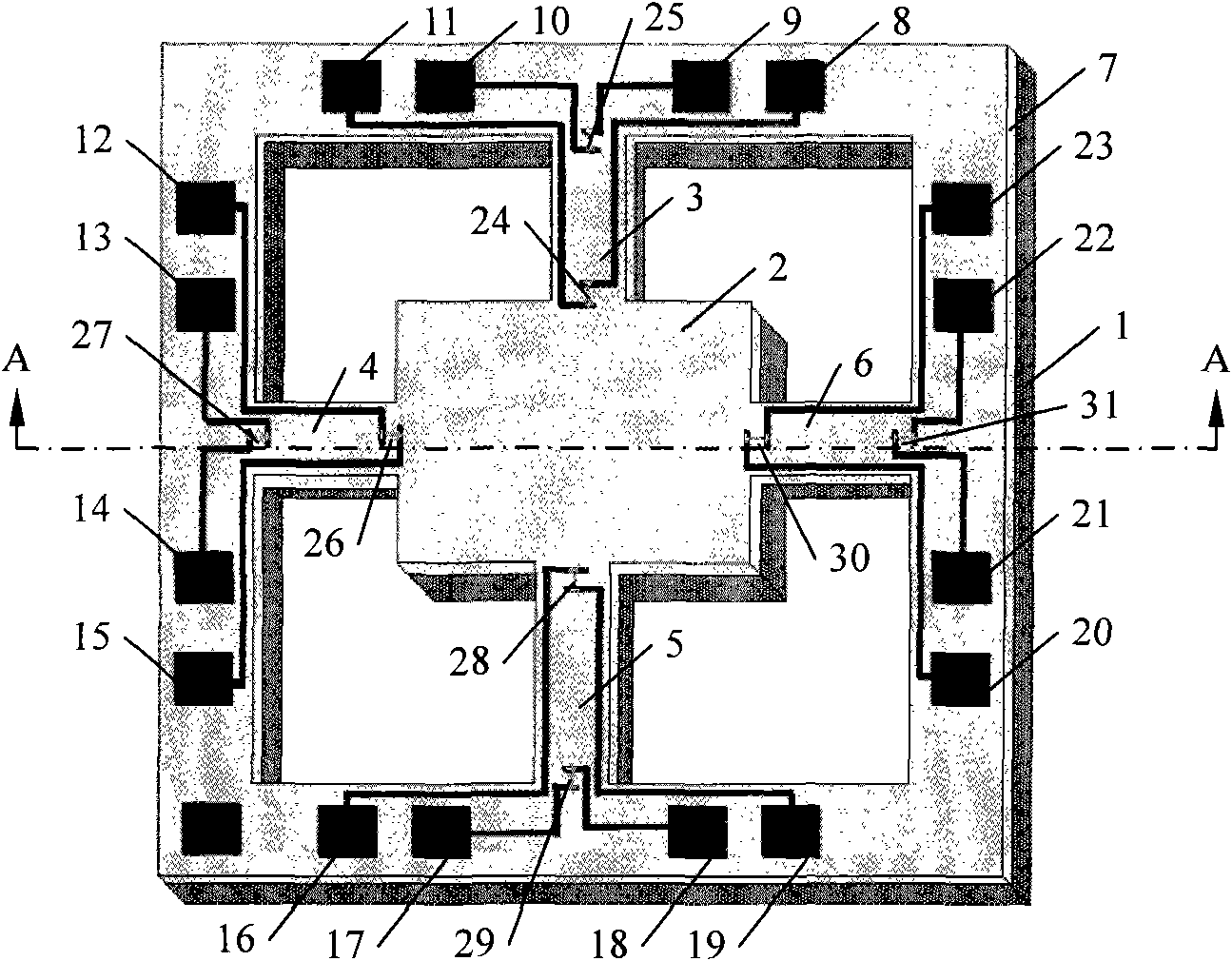

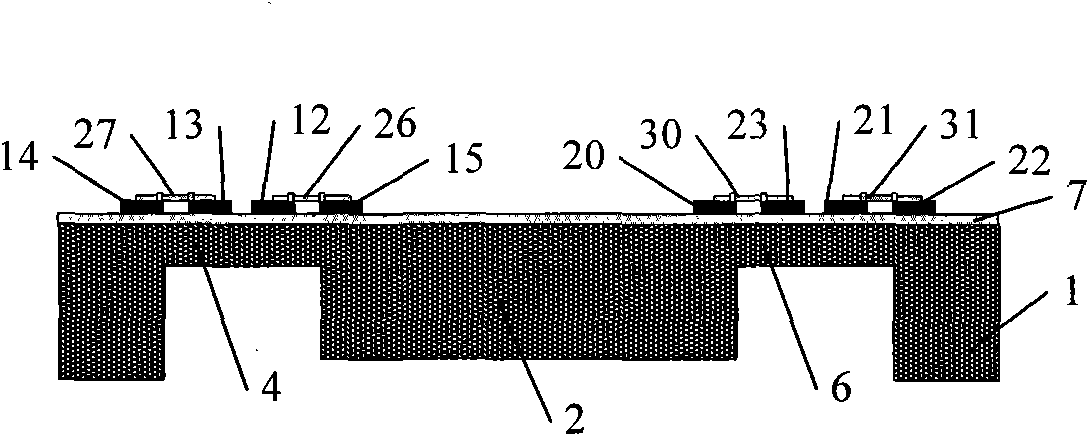

Capacitive micro-electromechanical system (MEMS) accelerometer and manufacturing method thereof

ActiveCN102759636AFlexible packagingFlexible interconnectionAcceleration measurementAccelerometerSilicon electrode

The invention provides a capacitive micro-electromechanical system (MEMS) accelerometer, which comprises a first silicon cover plate layer, a middle silicon layer and a second silicon cover plate layer which are arranged in sequence, wherein the middle silicon layer comprises a first silicon island and a second silicon island; the silicon islands are formed inside a silicon framework and separated from the silicon framework at intervals; the first silicon island is contacted with a metal electrode of the first silicon cover plate layer; the second silicon island is contacted with a metal electrode of the second silicon cover plate layer; the first silicon cover plate layer further comprises a first metal electrode through hole, a second metal electrode through hole and a silicon electrode through hole which are formed in a first silicon substrate; the first metal electrode through hole corresponds to the position of the first silicon island; the second metal electrode through hole corresponds to the position of the second silicon island; the silicon electrode through hole corresponds to the position of the silicon framework; and an insulating layer is arranged on the inner wall of each through hole, and each through hole is filled with metal electrically conductive material. By adopting the capacitive MEMS accelerometer, all electrodes of the accelerometer can be led out on the same silicon surface, so that wafer level bonding of the accelerometer is realized and the accelerometer can be packaged by adopting the flip chip technology.

Owner:BEIJING MXTRONICS CORP +1

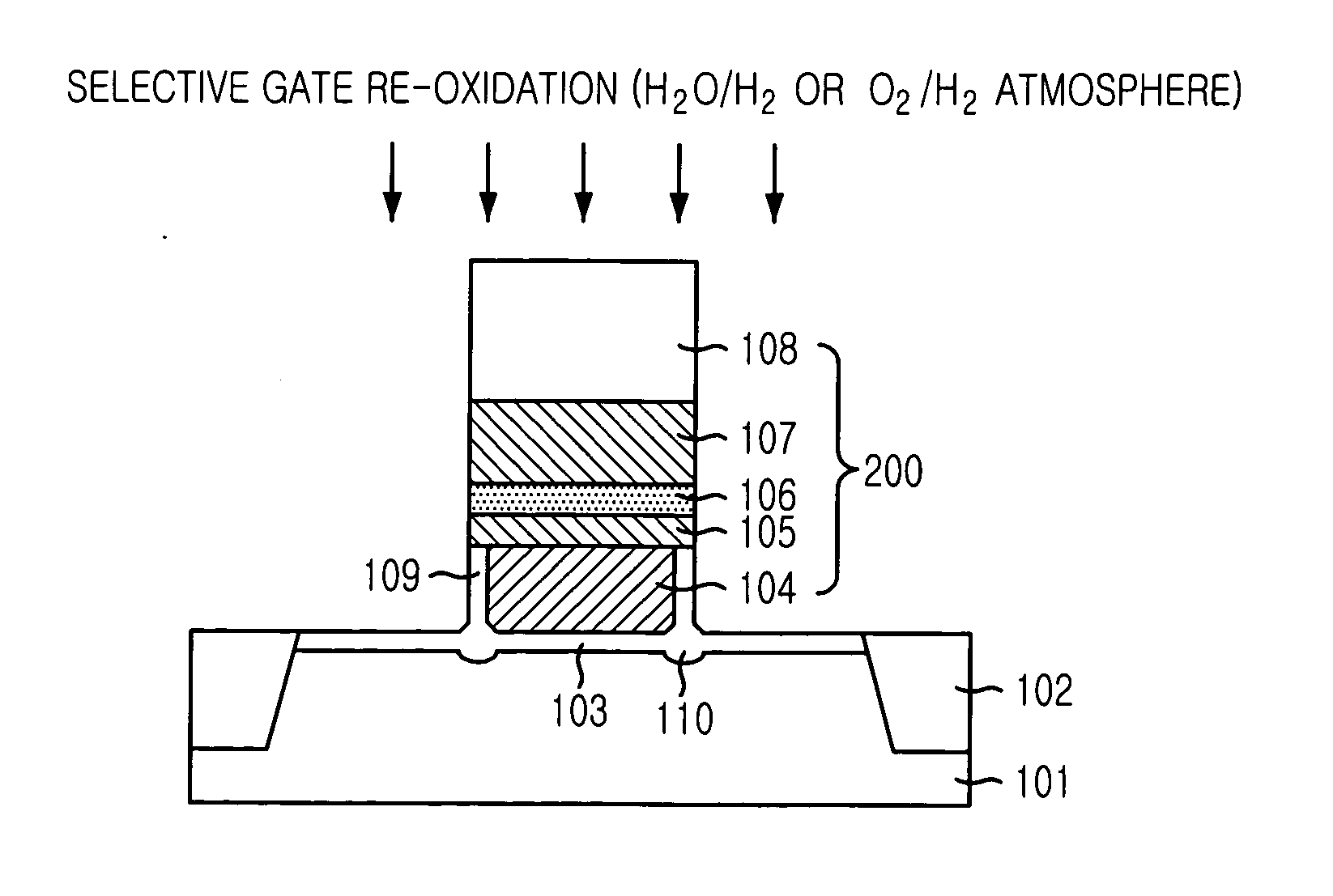

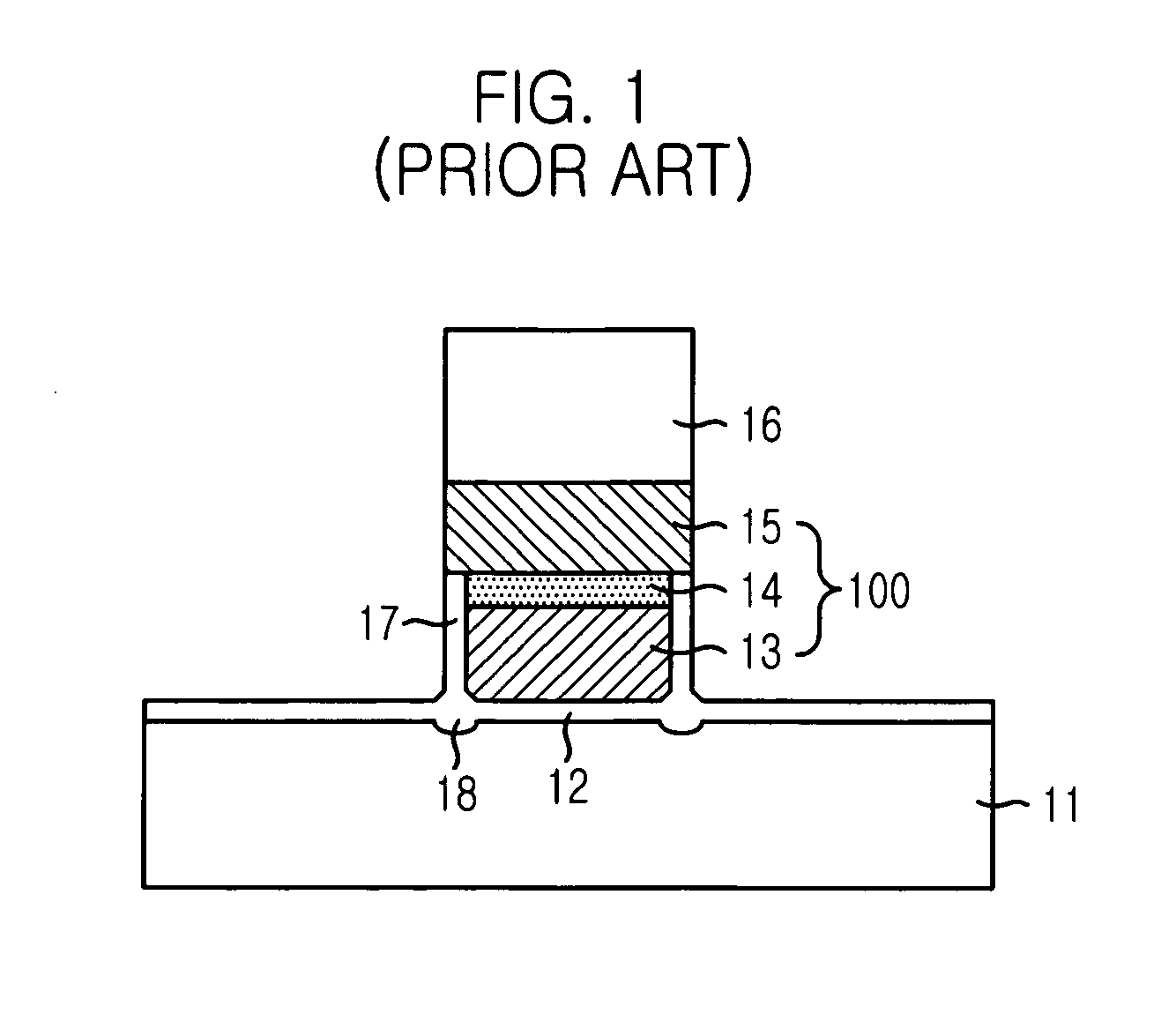

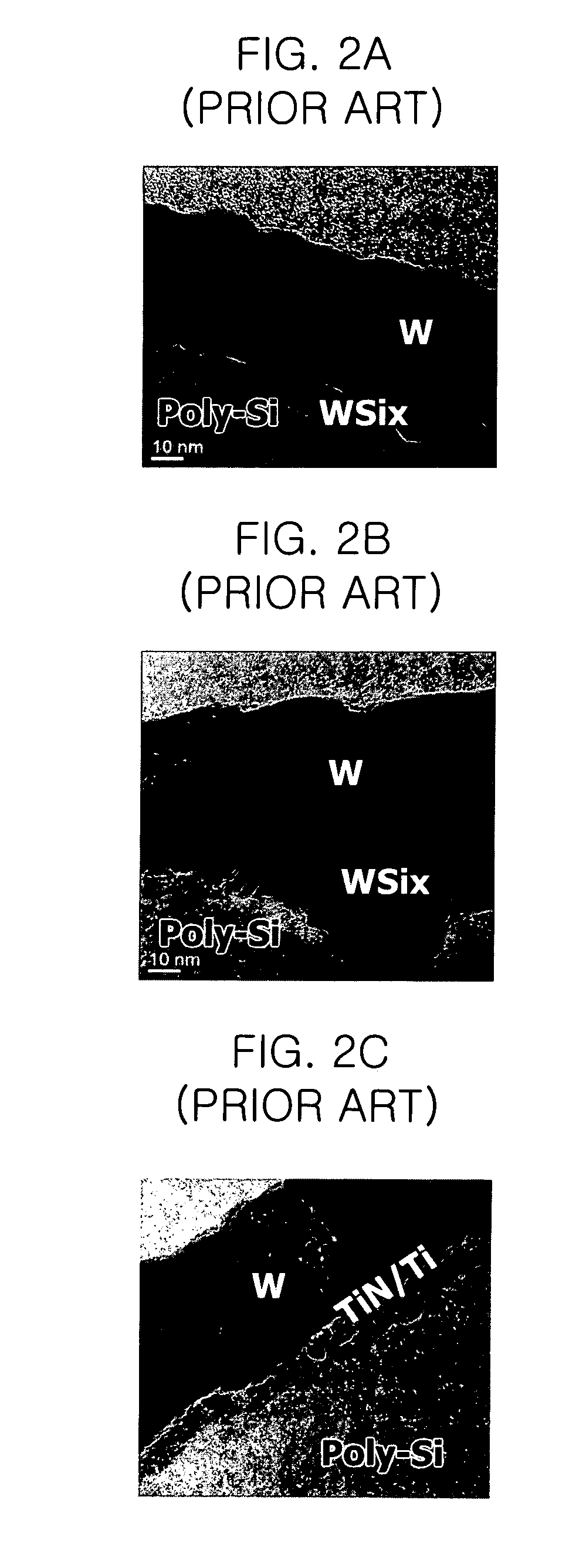

Gate electrode with double diffusion barrier and fabrication method of semiconductor device including the same

InactiveUS20070001246A1Improve thermal stabilityInhibition formationSemiconductor/solid-state device manufacturingSemiconductor devicesTungsten nitrideSilicon electrode

Owner:SK HYNIX INC

Silicon electrode plate for plasma etching with superior durability

ActiveUS20070181868A1Reduce replacement frequencyElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon electrodeSingle crystal

This silicon electrode plate for plasma etching is a silicon electrode plate for plasma etching with superior durability including silicon single crystal which, in terms of atomic ratio, contains 3 to 11 ppba of boron, and further contains a total of 0.5 to 6 ppba of either or both of phosphorus and arsenic.

Owner:SUMCO CORP +1

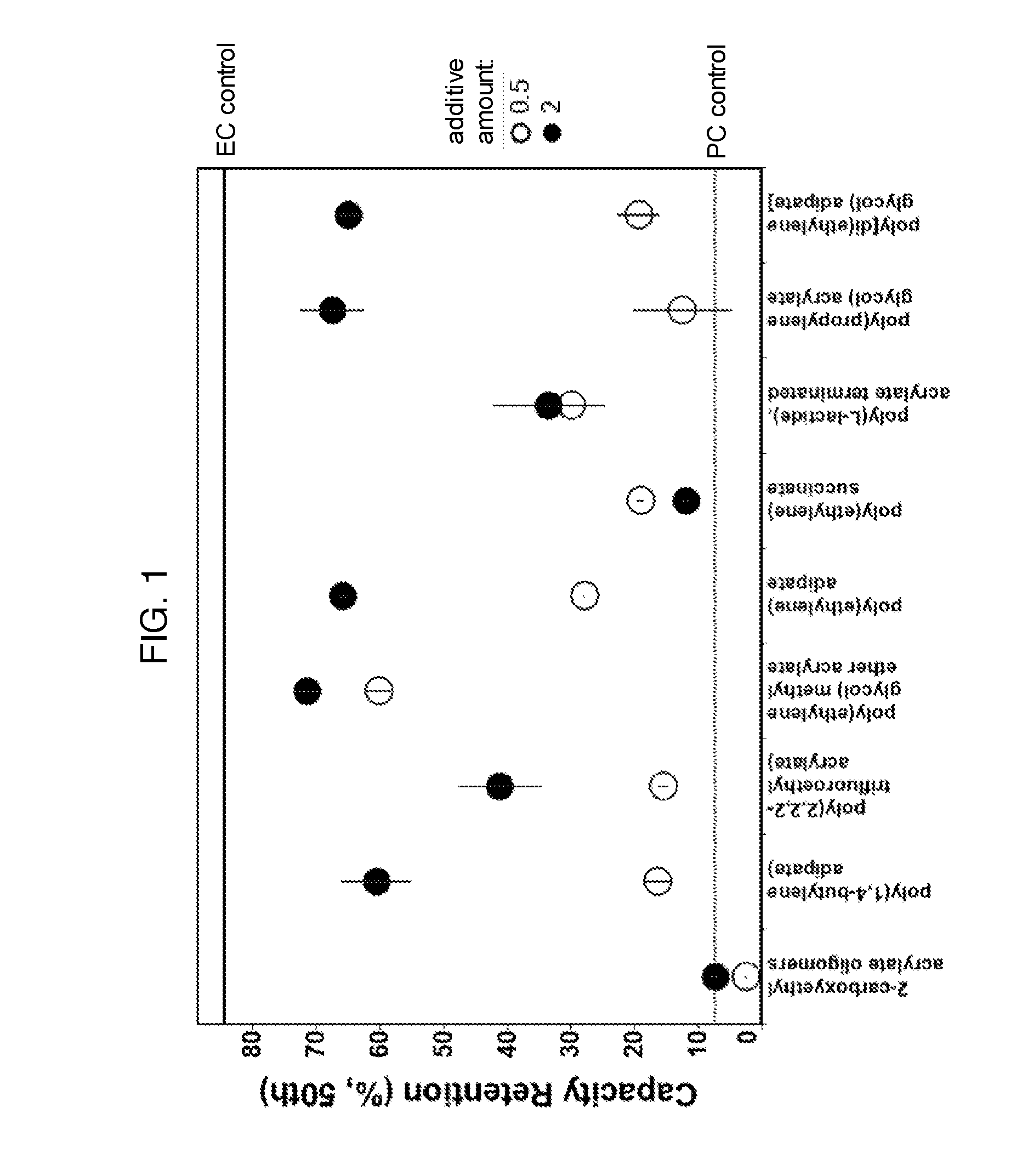

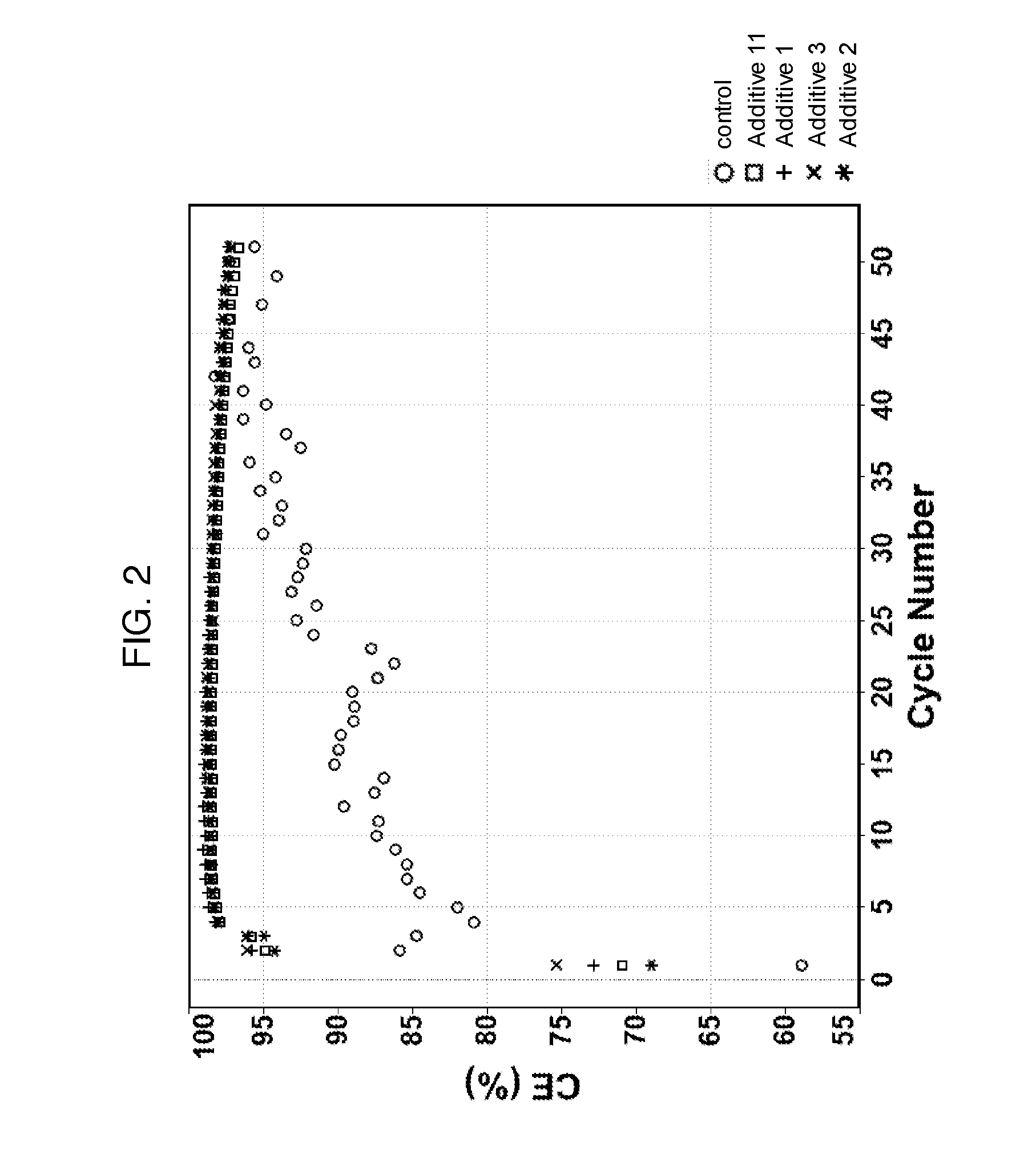

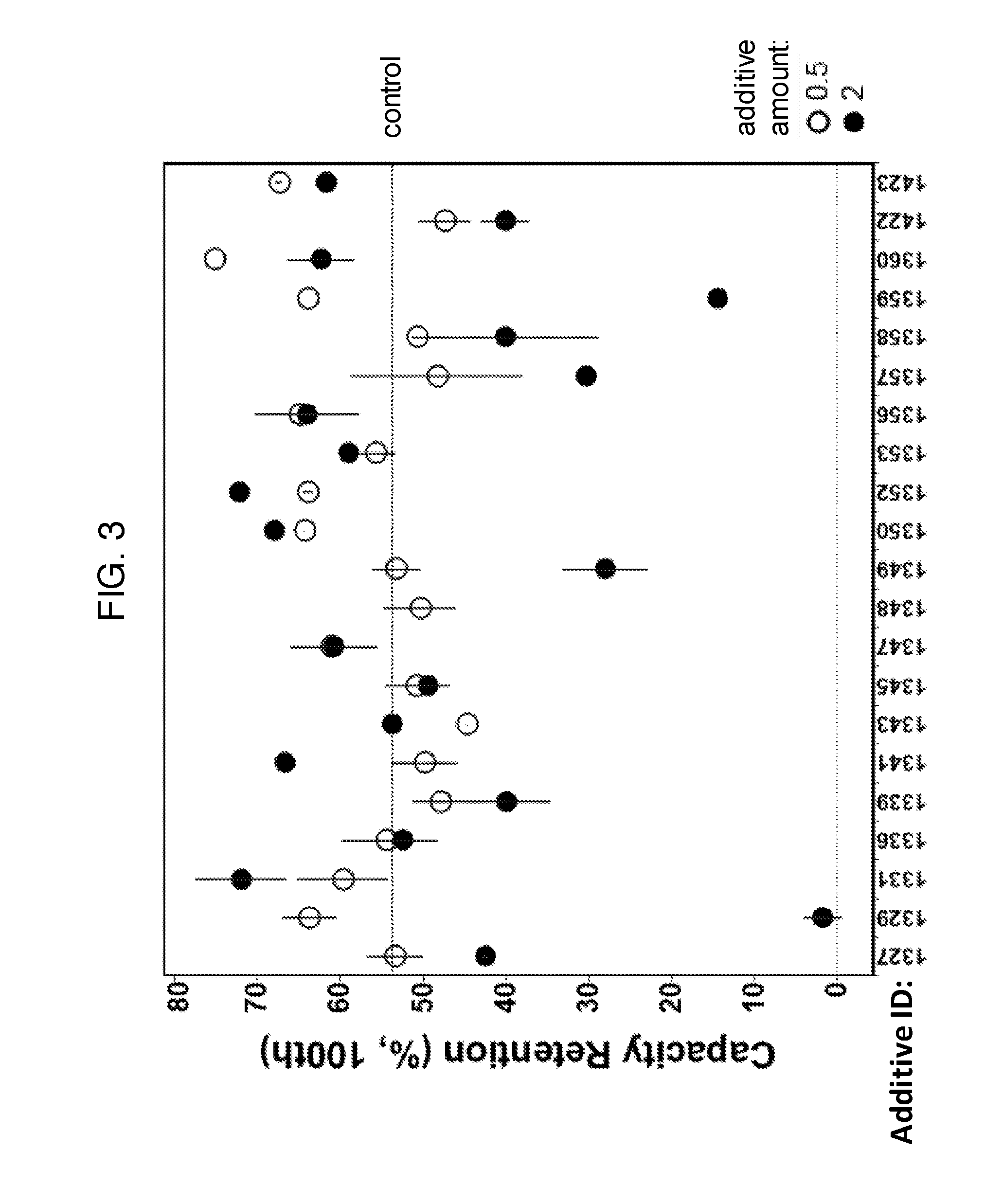

Electrolyte Formulations For Electrochemical Cells Containing A Silicon Electrode

ActiveUS20160240889A1Improve Coulombic efficiencyMore robust SEI filmsCell electrodesLi-accumulatorsSilicon electrodeElectrochemical cell

Additives to electrolytes that enable the formation of comparatively more robust SEI films on silicon anodes. The SEI films in these embodiments are seen to be more robust in part because the batteries containing these materials have higher coulombic efficiency and longer cycle life than comparable batteries without such additives.

Owner:WILDCAT DISCOVERY TECH

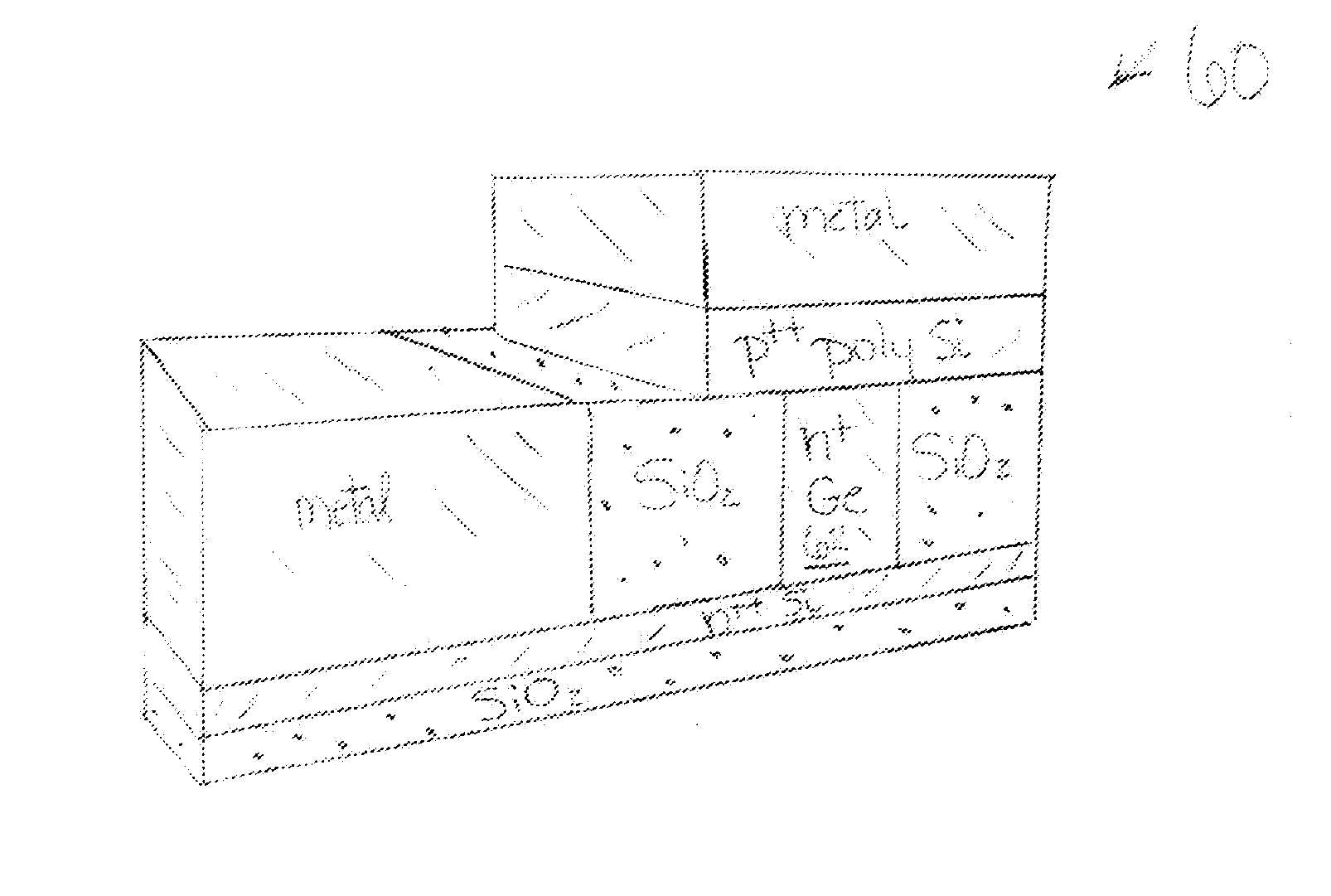

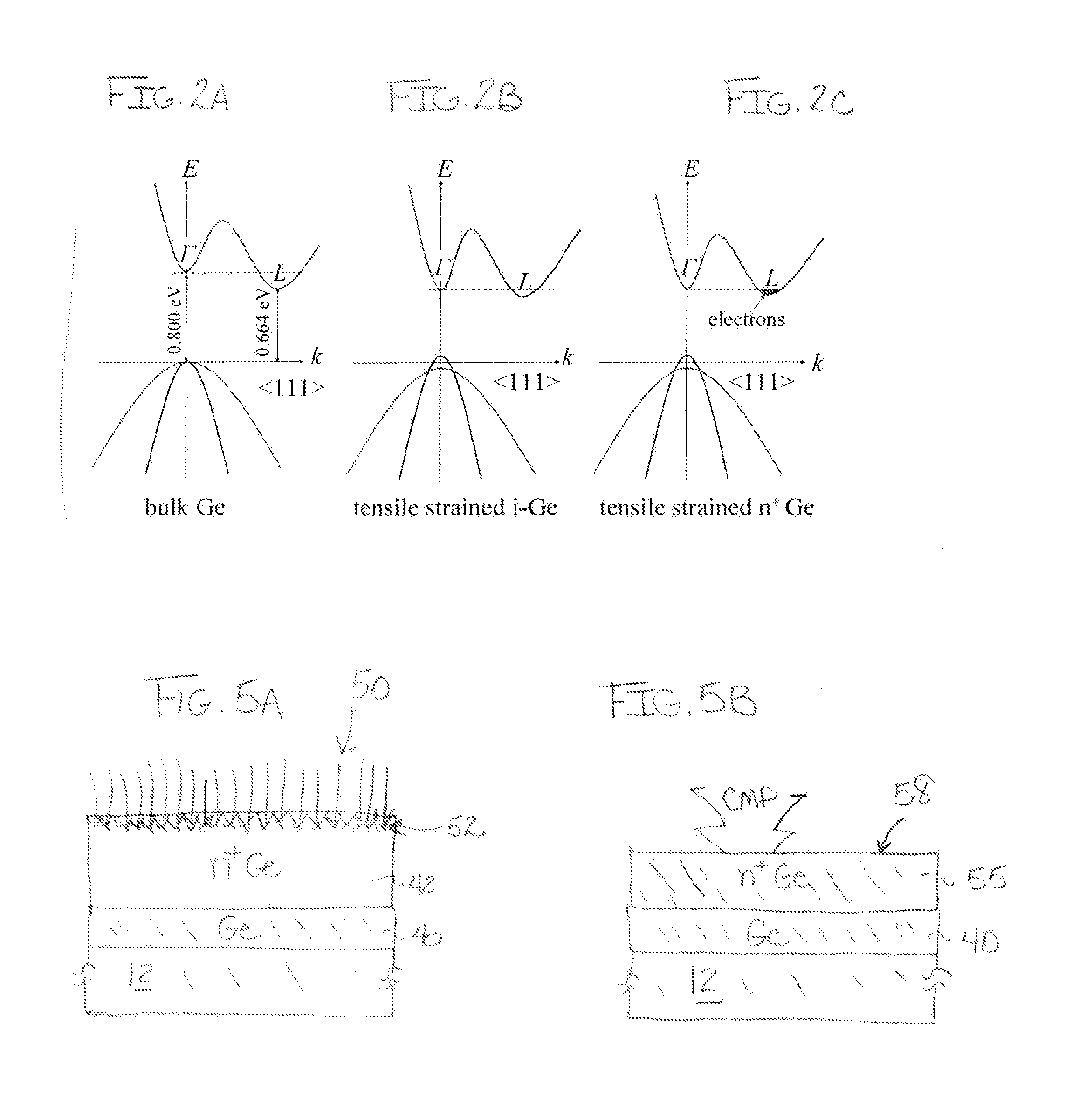

High-Concentration Active Doping in Semiconductors and Semiconductor Devices Produced by Such Doping

In a method of forming a photonic device, a first silicon electrode is formed, and then a germanium active layer is formed on the first silicon electrode while including n-type dopant atoms in the germanium layer, during formation of the layer, to produce a background electrical dopant concentration that is greater than an intrinsic dopant concentration of germanium. A second silicon electrode is then formed on a surface of the germanium active layer. The formed germanium active layer is doped with additional dopant for supporting an electrically-pumped guided mode as a laser gain medium with an electrically-activated n-type electrical dopant concentration that is greater than the background dopant concentration to overcome electrical losses of the photonic device.

Owner:MASSACHUSETTS INST OF TECH

Compliant monopoloar micro device transfer head with silicon electrode

ActiveUS20140008813A1Lamination ancillary operationsSemiconductor/solid-state device detailsSilicon electrodeSoi substrate

Owner:APPLE INC

Electrode for plasma processes and method for manufacture and use thereof

ActiveUS8845855B2Reduce accumulationMore powerLiquid surface applicatorsElectric discharge tubesTemperature controlSilicon electrode

A silicon electrode for a plasma reaction chamber wherein processing of a semiconductor substrate such as a single wafer can be carried out and a method of processing a semiconductor substrate with the electrode. The electrode is a low resistivity electrode having an electrical resistivity of less than 1 ohm-cm. The electrode can be a zero defect single crystal silicon or silicon carbide electrode such as a showerhead electrode bonded or clamped to support such as a temperature controlled plate or ring. The showerhead electrode can be in the form of a circular disk of uniform thickness and an elastomeric joint can be provided between a support ring and the electrode. The electrode can include gas outlets having 0.020 to 0.030 inch diameters.

Owner:LAM RES CORP

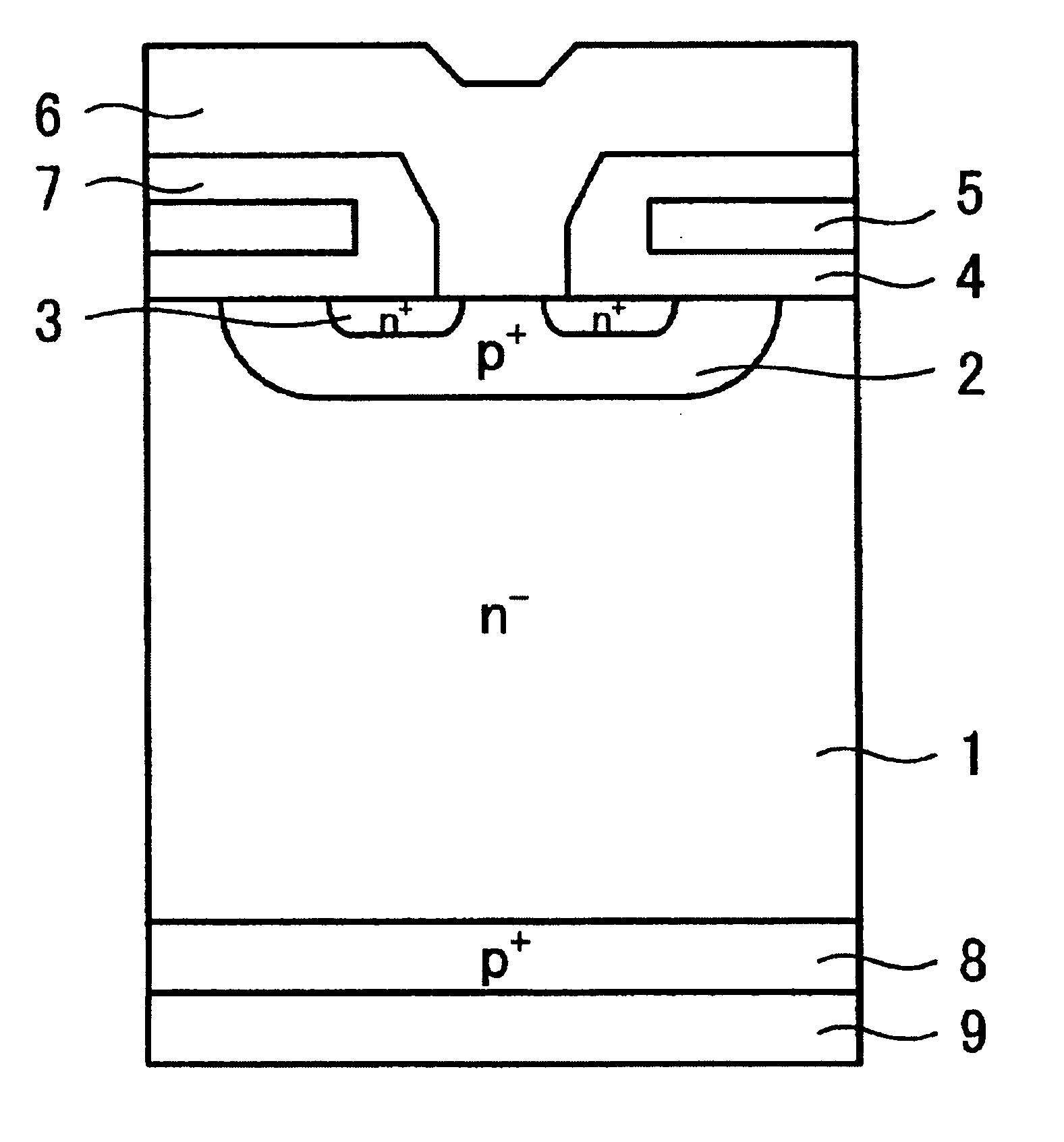

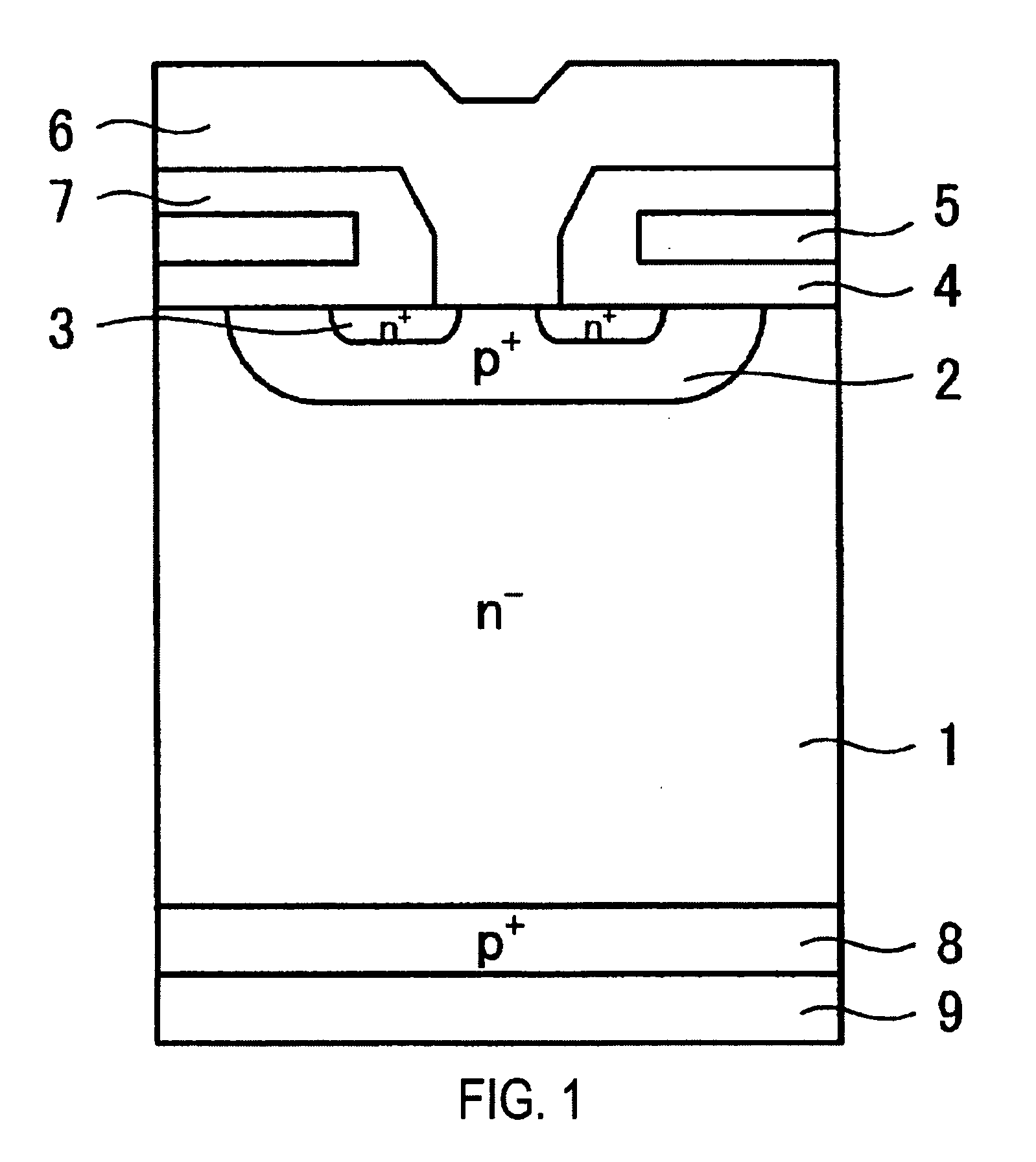

Method of producing a semiconductor device with an aluminum or aluminum alloy electrode

InactiveUS20070004098A1Avoid it happening againHigh proportionTransistorSemiconductor/solid-state device manufacturingSilicon electrodeDevice material

A method of producing a semiconductor device having a thickness of 90 μm to 200 μm and with an electrode on the rear surface, which achieves a high proportion of non-defective devices by optimizing the silicon concentration and thickness of the aluminum-silicon electrode. A surface device structure is formed on a first major surface of a silicon substrate. A buffer layer and a collector layer are formed on the second major surface after grinding to reduce the thickness of the substrate. On the collector layer, a collector electrode is formed including a first layer of an aluminum-silicon film having a thickness of 0.3 μm to 1.0 μm and a silicon concentration of 0.5 percent to 2 percent by weight, preferably not more than 1 percent by weight.

Owner:FUJI ELECTRIC CO LTD

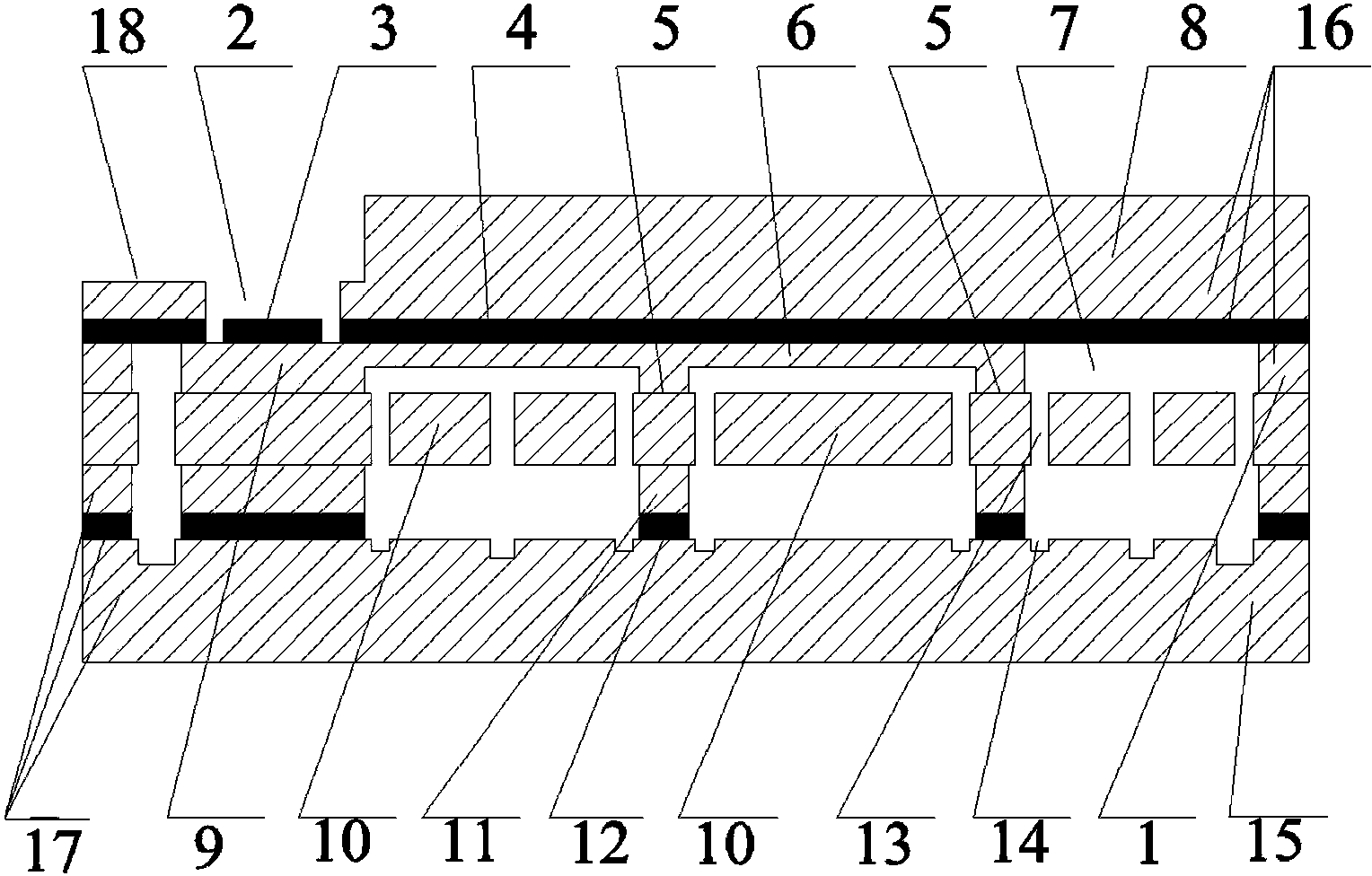

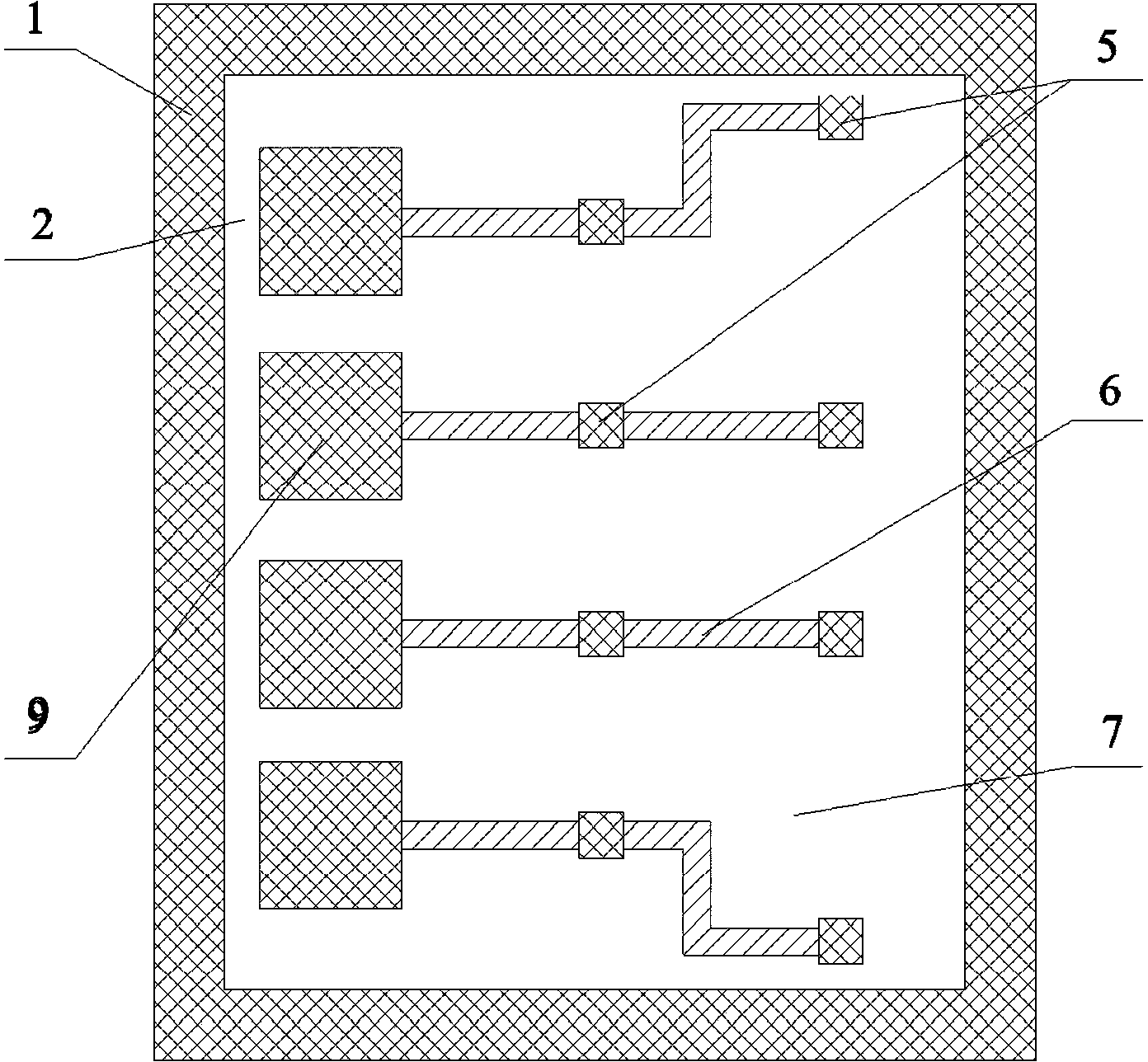

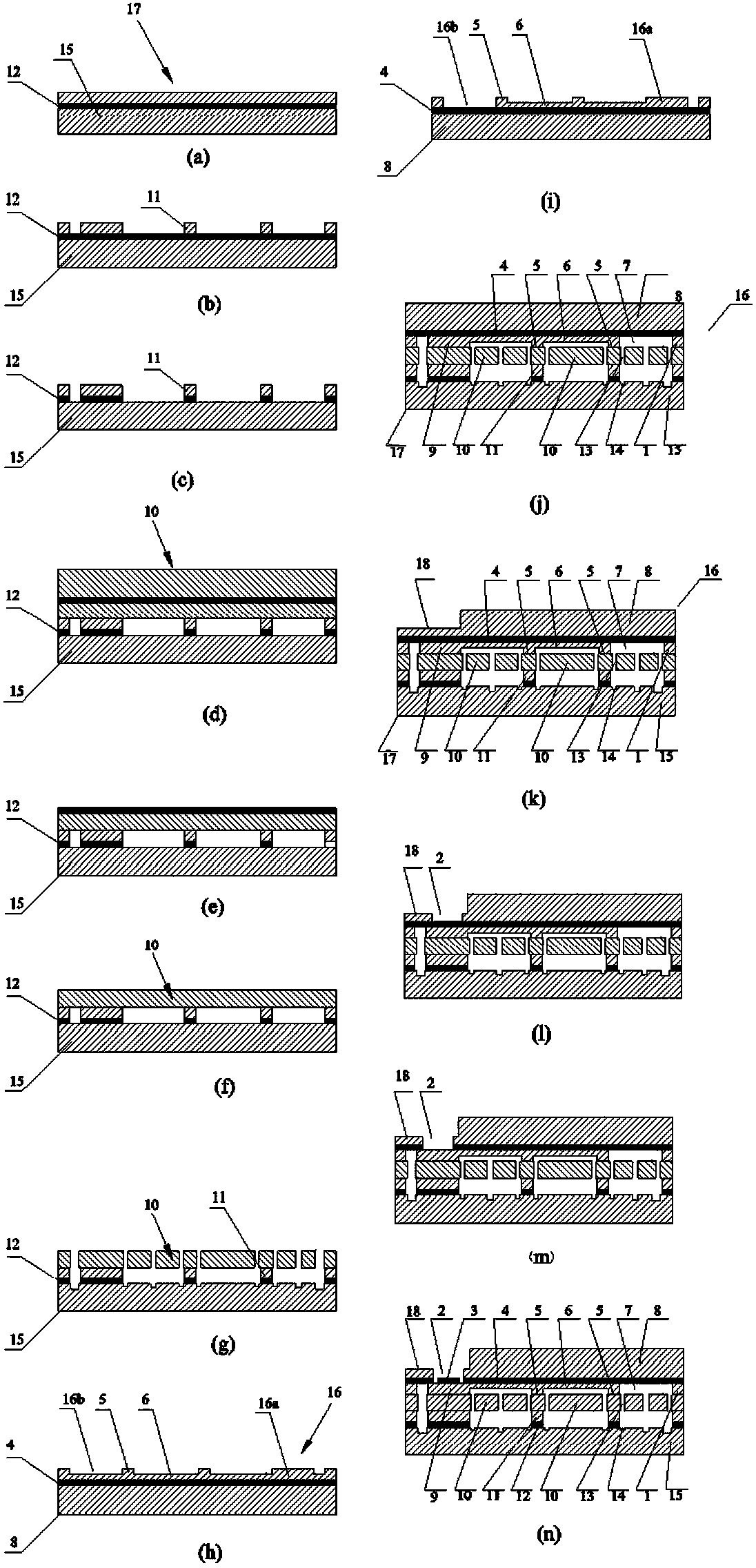

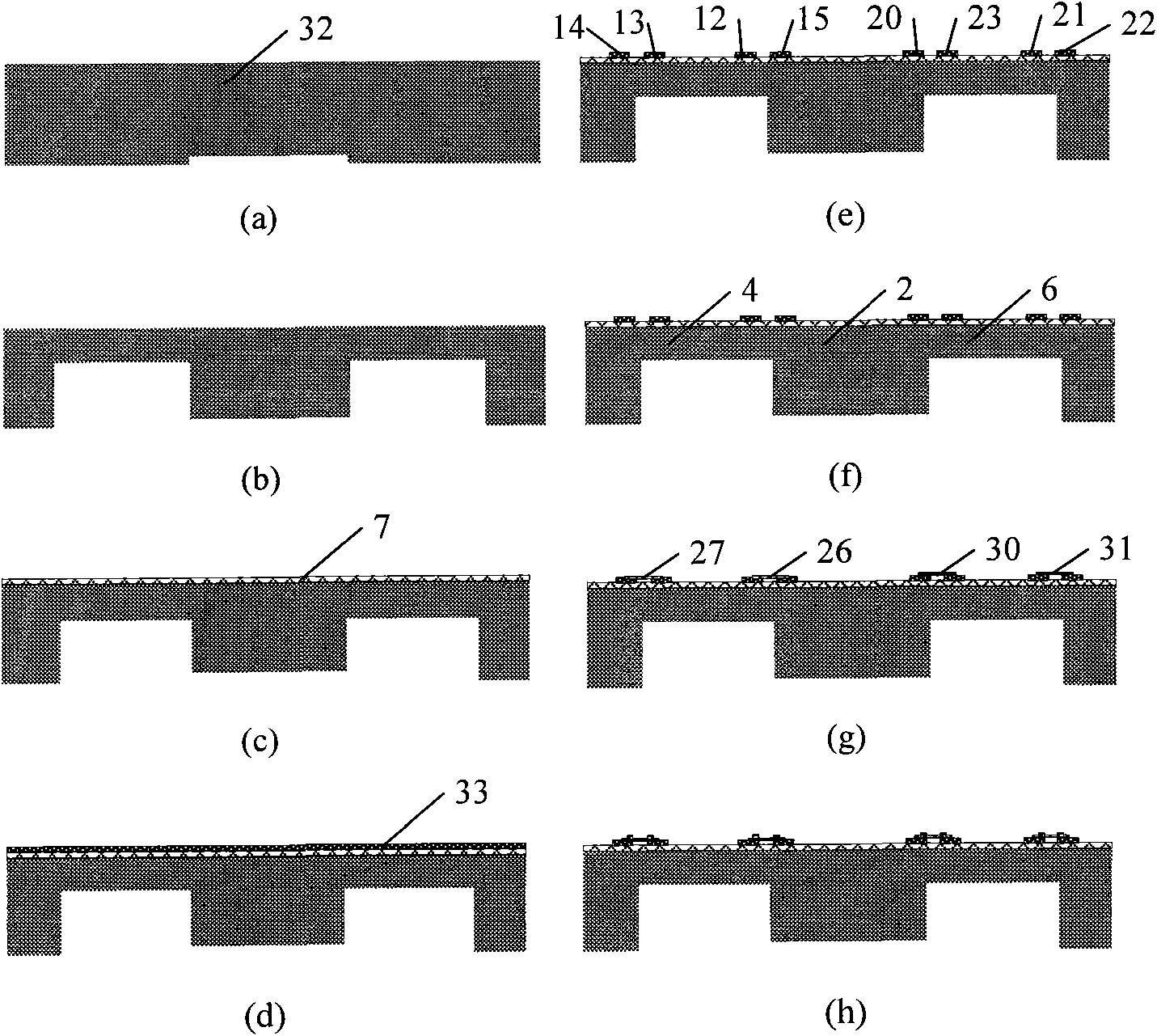

All-silicon MEMS device structure and manufacture method thereof

ActiveCN104355286AHighly precise controlGuaranteed to elicitTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesSilicon electrodeSilicon chip

The invention relates to an all-silicon MEMS (Micro Electro-Mechanical Systems) device. The all-silicon MEMS device consists of a liner SOI silicon chip (17), a structural layer silicon chip (10) and a nut cap SOI silicon chip (16) which are subjected to direct silicon-silicon bonding, and is characterized in that a top silicon (6) of the structural layer silicon chip (10) and the nut cap SOI silicon chip are low-resistance silicon; the top silicon (6) of the nut cap SOI silicon chip is made into an electric interconnection wire and subjected to direct silicon-silicon bonding with the structural layer silicon through a bonding face (5); an electrical signal of the structural layer is led to a silicon electrode (9) in the nut cap SOI silicon chip through the electric interconnection wire and is electrically connected with a pressure welding point (3) on the silicon electrode (9); the silicon electrode (9) is subjected to direct silicon-silicon bonding with the structural layer silicon. The all-silicon MEMS device has the advantages that as the nut cap layer bulk silicon wires are adopted, the structural layer is prevented from pickling splash damage; as twice direct silicon-silicon bonding is adopted, residual stress is eliminated; the direct silicon-silicon bonding is good in airtightness; a getter does not need to be additionally added during vacuum packaging, so that the cost is effectively reduced.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

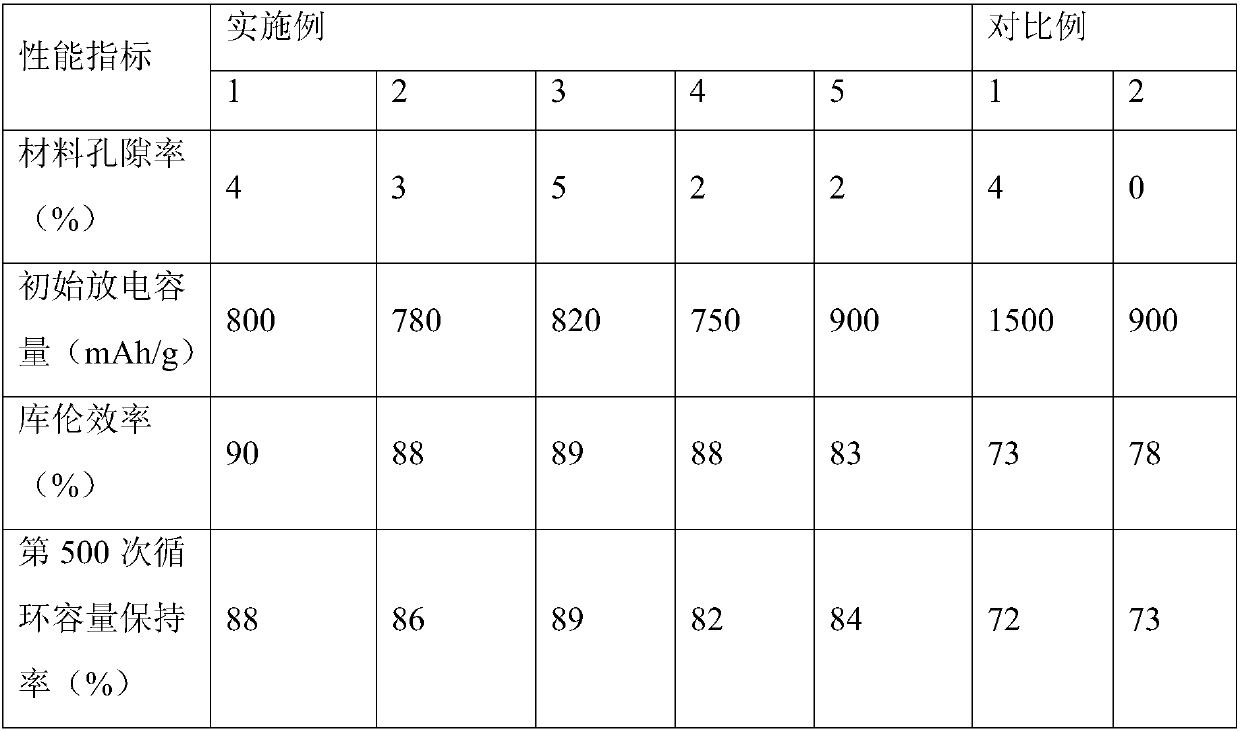

Negative electrode composite material of lithium ion battery and preparation method thereof

ActiveCN107623116ANovel structureControl volume expansionSecondary cellsNegative electrodesNano siliconSilicon monoxide

The invention relates to a negative electrode composite material of a lithium ion battery. The material comprises a core body, an intermediate layer that is coated outside the core body and has pores,and an outer layer coated outside the intermediate layer, wherein the core body is nano silicon, the intermediate layer is silicon monoxide compounded with graphite, and the outer layer is amorphouscarbon. According to the scheme of the invention, a negative electrode composite material with a novel structure is obtained through the improvement of a preparation method, the negative electrode composite material can control the volume expansion of silicon in a certain space, effectively prevent silicon electrodes from being pulverized, and improve the cycling stability, and can be used as a negative electrode material of a high-capacity lithium battery. The preparation method has a simple process and is suitable for industrial production.

Owner:SUZHOU GINET NEW MATERIAL TECH CO LTD

Fully silicided gate electrodes and method of making the same

InactiveUS7297618B1Reduce doping concentrationReduce and eliminate gate depletionSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon electrodeField-effect transistor

The present invention relates to a method of selectively fabricating metal gate electrodes in one or more device regions by fully siliciding (FUSI) the gate electrode. The selective formation of FUSI enables metal gate electrodes to be fabricated on devices that are compatible with workfunctions that are different from conventional n+ and p+ doped poly silicon electrodes. Each device region consists of at least one Field Effect Transistor (FET) device which consists of either a polysilicon gate electrode or a fully silicided (FUSI) gate electrode. A gate electrode comprised of silicon and a Ge containing layer is used in combination with a selective removal process of the Ge containing layer. The Ge containing layer is not removed on devices with threshold voltages that are not compatible with the FUSI workfunction. Devices that are compatible with the FUSI workfunction have the Ge containing layer removed prior to the junction silicidation step. The remaining thin silicon layer of the gate electrode becomes fully silicided during the same step as the junction silicidation step.

Owner:GLOBALFOUNDRIES INC

An acceleration transducer based on nano-resonator and method of producing the same

InactiveCN101551404AHigh resolutionHigh precisionIndividual molecule manipulationAcceleration measurementBasementMetallic electrode

The present invention discloses an acceleration transducer based on nano-resonator, including four supporting beams, mass block and basement, which are covered by insulation layer, the impending mass block is connected with the basement via four supporting beams; upper the insulation layer ends of the four supporting beams are provided with eight pair electrodes, nano-resonant beams are respectively related joint and fixed to the corresponding electrode couple, the nano-resonant beam applies semiconductor nano-wire or semiconductor nano-tube; the nano-resonant beam, upper metallic electrode couple and the lower silicon electrode constitute field-effect tranisistor structure, the lower silicon electrode and the upper metallic electrode couple is separated by insulation layer, and the upper metallic electrode couple are respectively source and drain, the lower silicon electrode is gate electrode. The invention also discloses a method of producing the acceleration transducer and method of measuring acceleration by using the acceleration transducer. The invention applies the semiconductor nano-wire or semiconductor nano-tube as the nano-resonant beam to implement high-sensitivity measurement of transducer via frequency mixing phase-lock technique.

Owner:TSINGHUA UNIV

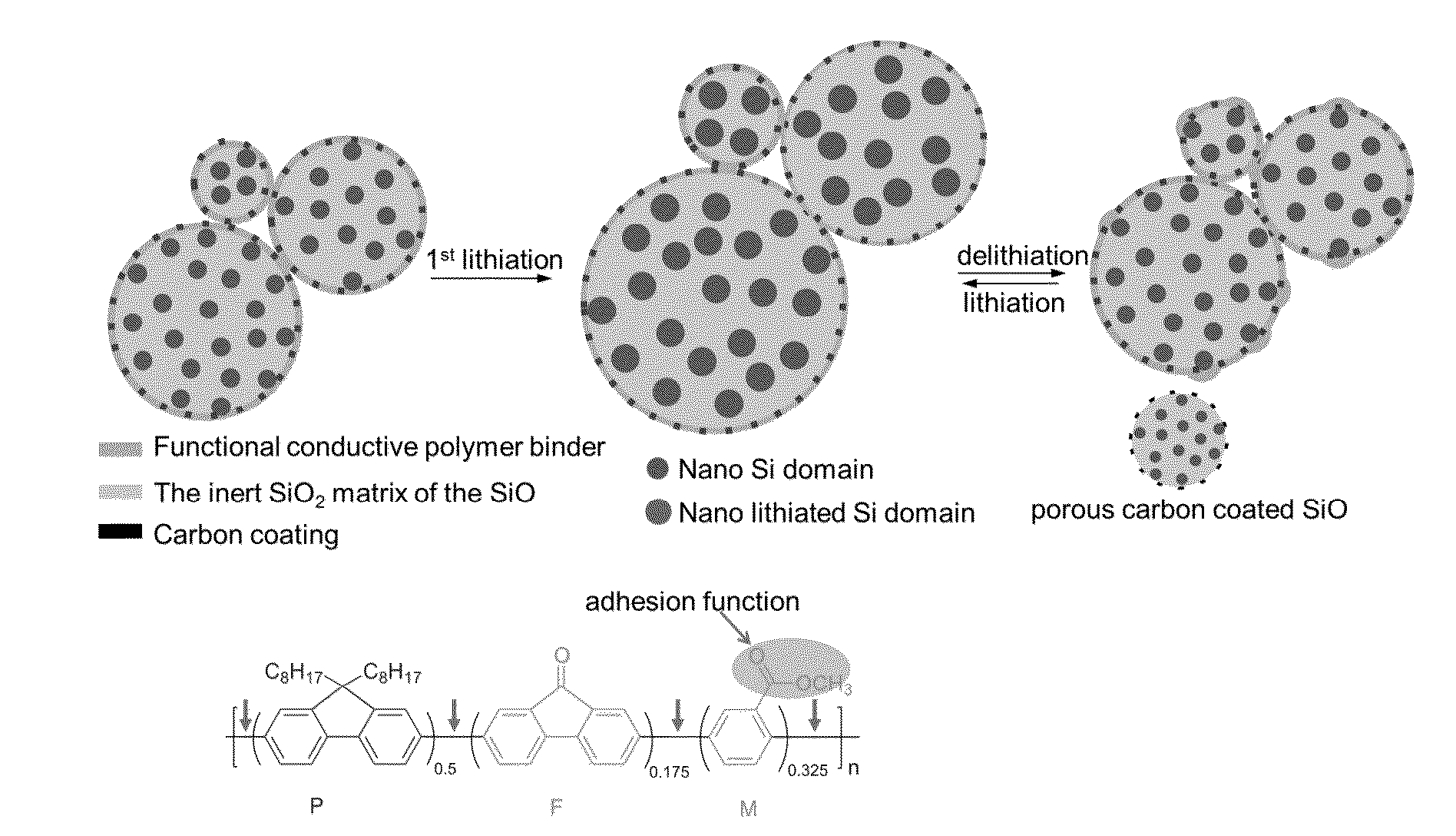

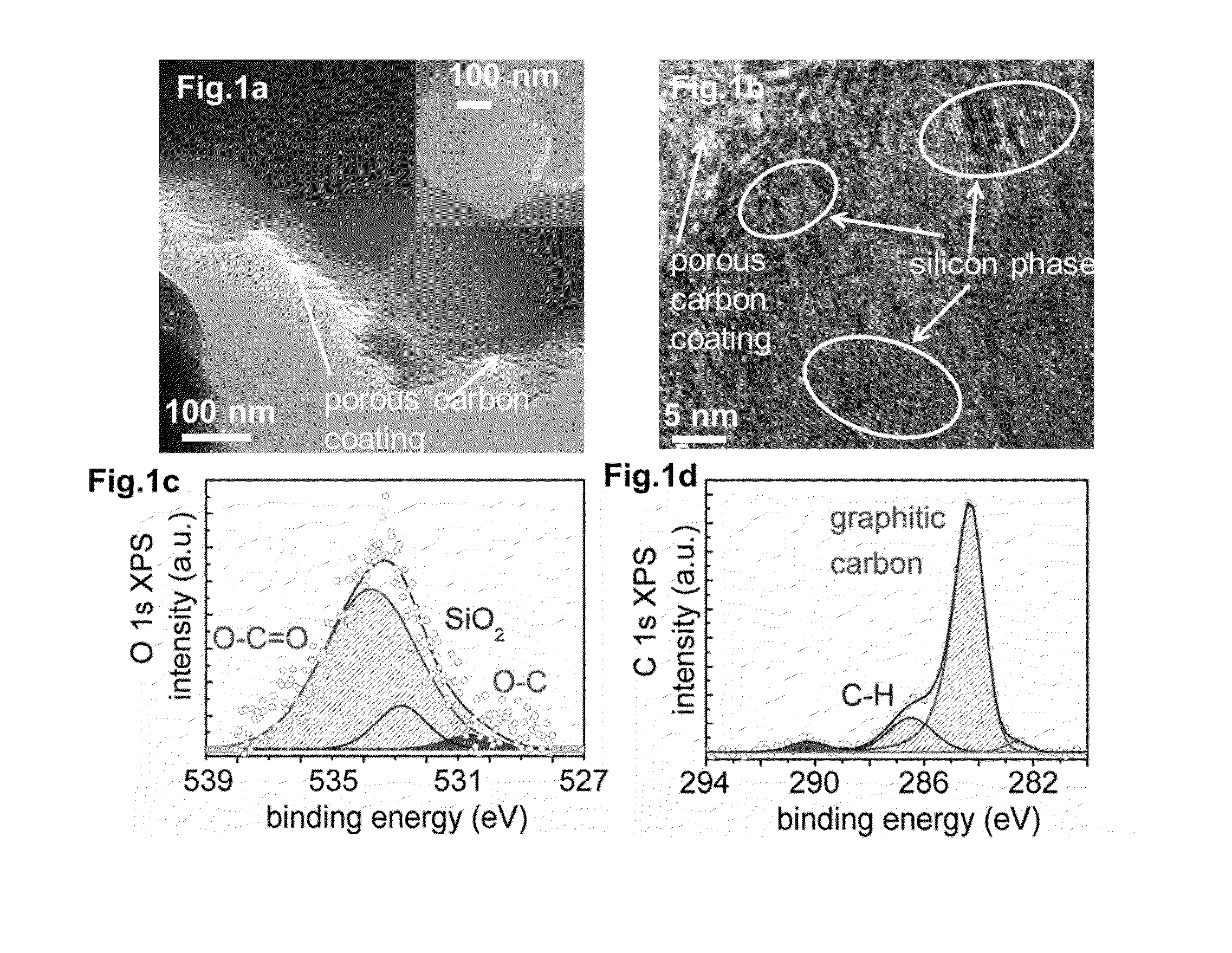

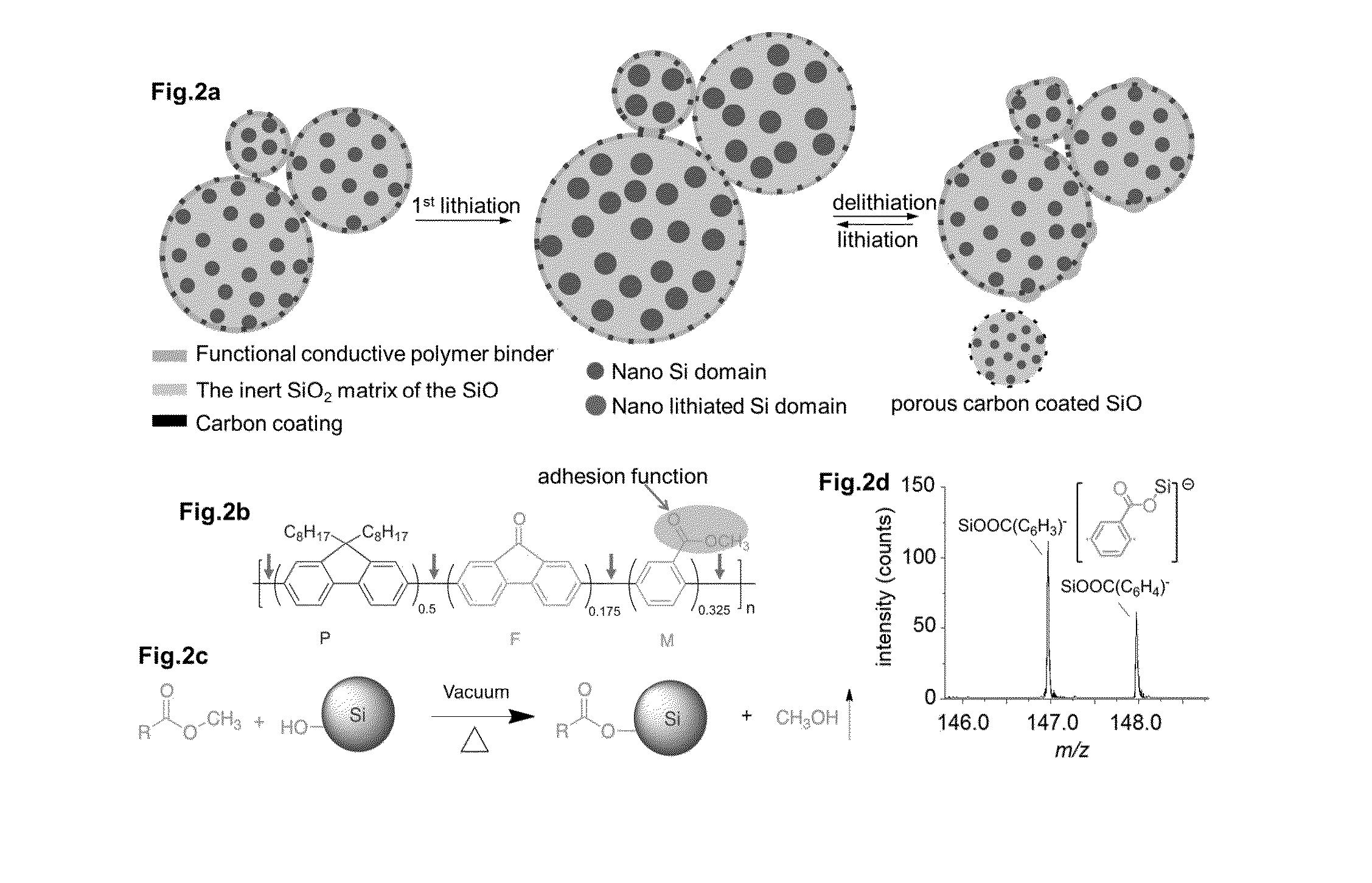

Porous Silicon Oxide (SiO) Anode Enabled by a Conductive Polymer Binder and Performance Enhancement by Stabilized Lithium Metal Power (SLMP)

ActiveUS20160164073A1Electrode carriers/collectorsConductive materialSilicon monoxidePerformance enhancement

The invention demonstrates that only 2% functional conductive polymer binder without any conductive additives was successfully used with a micron-size silicon monoxide (SiO) anode material, demonstrating stable and high gravimetric capacity (>1000 mAh / g) for ˜500 cycles and more than 90% capacity retention. Prelithiation of this anode using stabilized lithium metal powder (SLMP®) improves the first cycle Coulombic efficiency of a SiO / NMC full cell from ˜48% to ˜90%. This combination enables good capacity retention of more than 80% after 100 cycles at C / 3 in a lithium-ion full cell. We also demonstrate the important connection between porosity and the loading of silicon electrodes. By employing a highly porous silicon electrode, a high areal capacity (3.3 mAh / cm2) is obtained. This method works well to achieve high loading of other high-capacity alloy anodes, the state-of-art graphite anode, as well as a high loading of positive electrodes for LIBs.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com