Plasma reaction chamber and captive silicon electrode plate for processing semiconductor wafers

a technology of reaction chamber and silicon electrode plate, which is applied in the direction of electrical equipment, basic electric elements, electric discharge tubes, etc., can solve the problems of increasing the cost of using a dry plasma etching system, affecting the effect of the etching process, and prohibitively expensive showerhead electrodes that are commonly used in the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

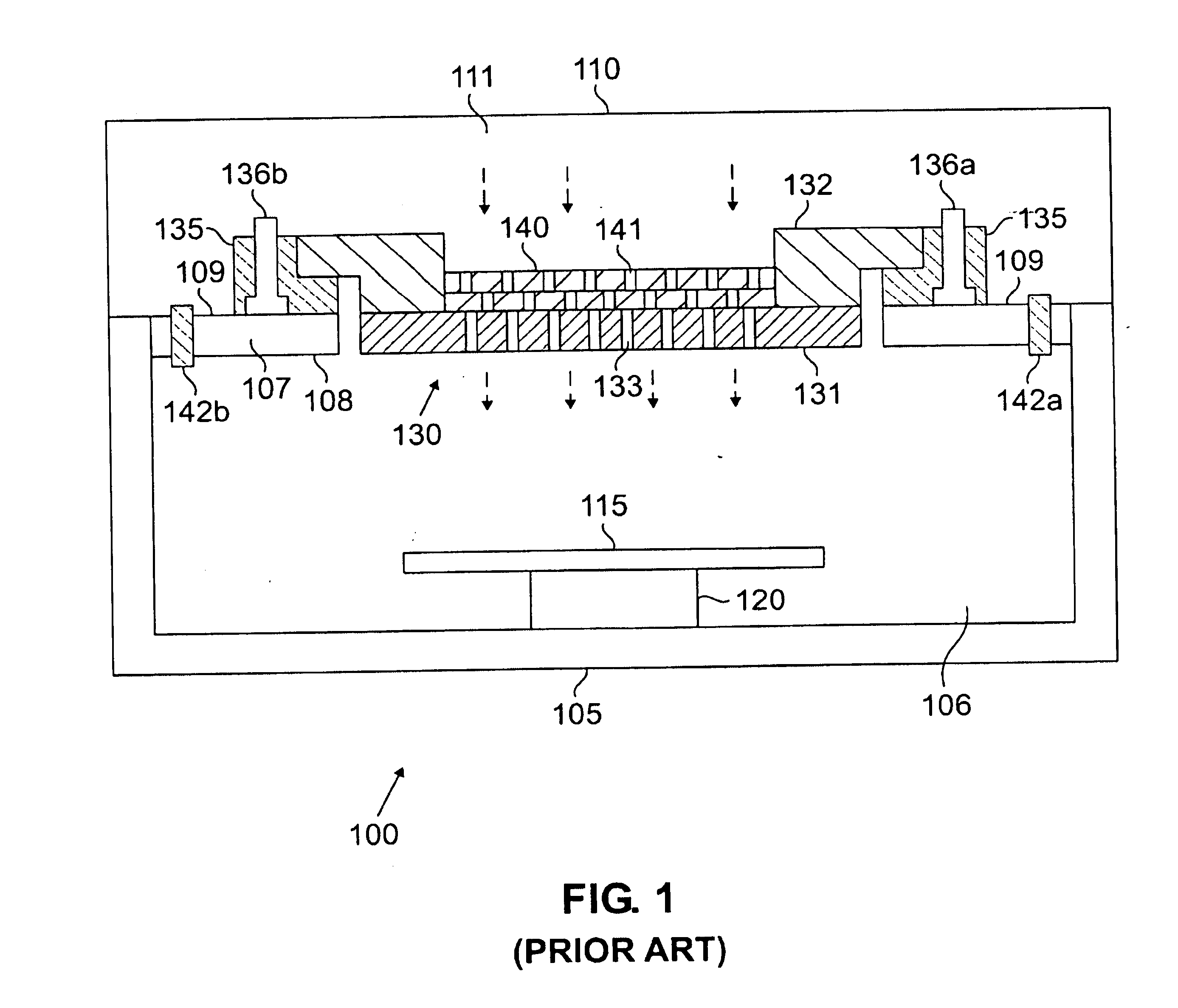

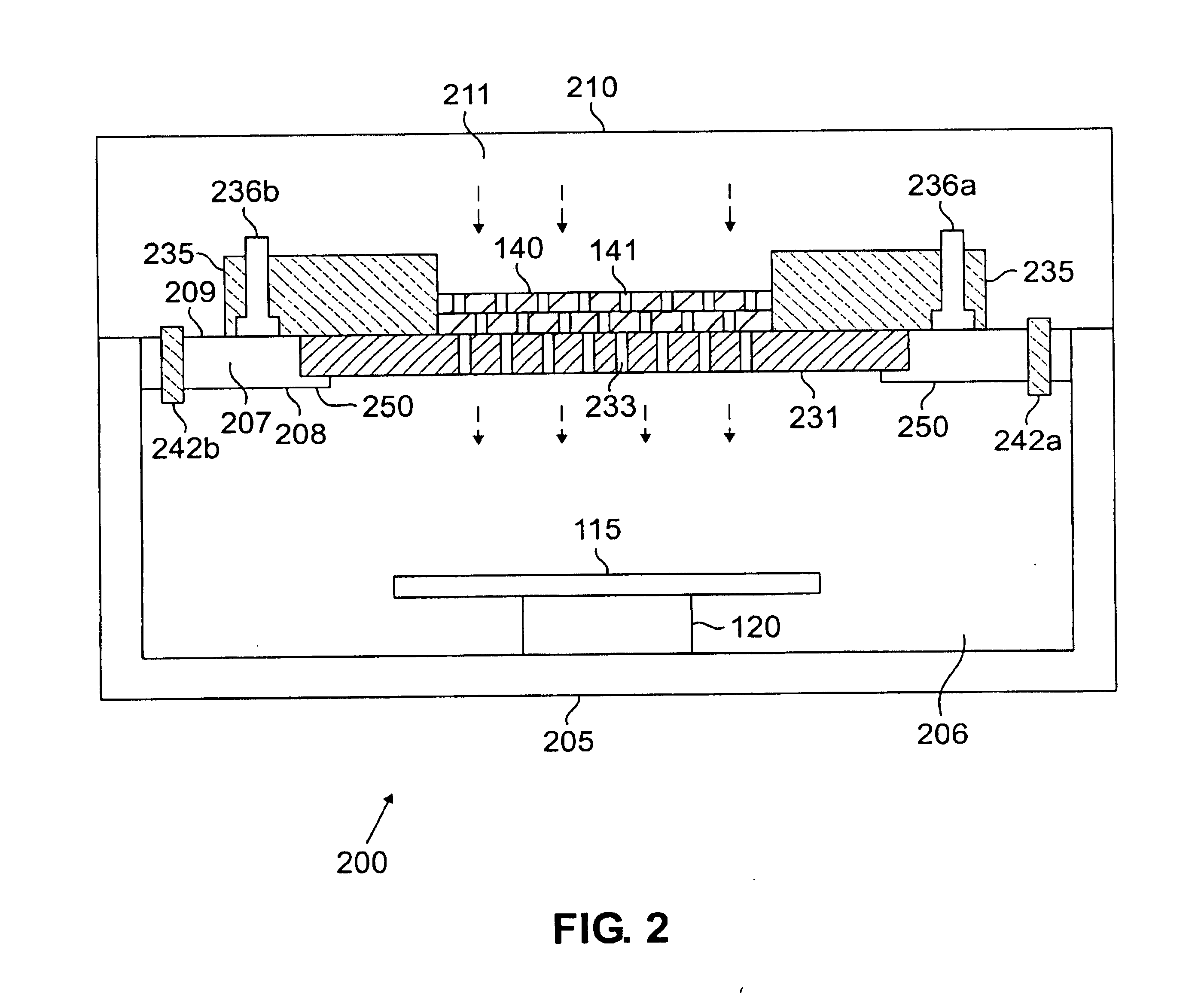

[0023]FIGS. 1 through 4, discussed below, and the various embodiments used to describe the principles of the present invention in this patent document are by way of illustration only and should not be construed in any way to limit the scope of the invention. Those skilled in the art will understand that the principles of the present invention may be implemented in any suitably arranged plasma processing system.

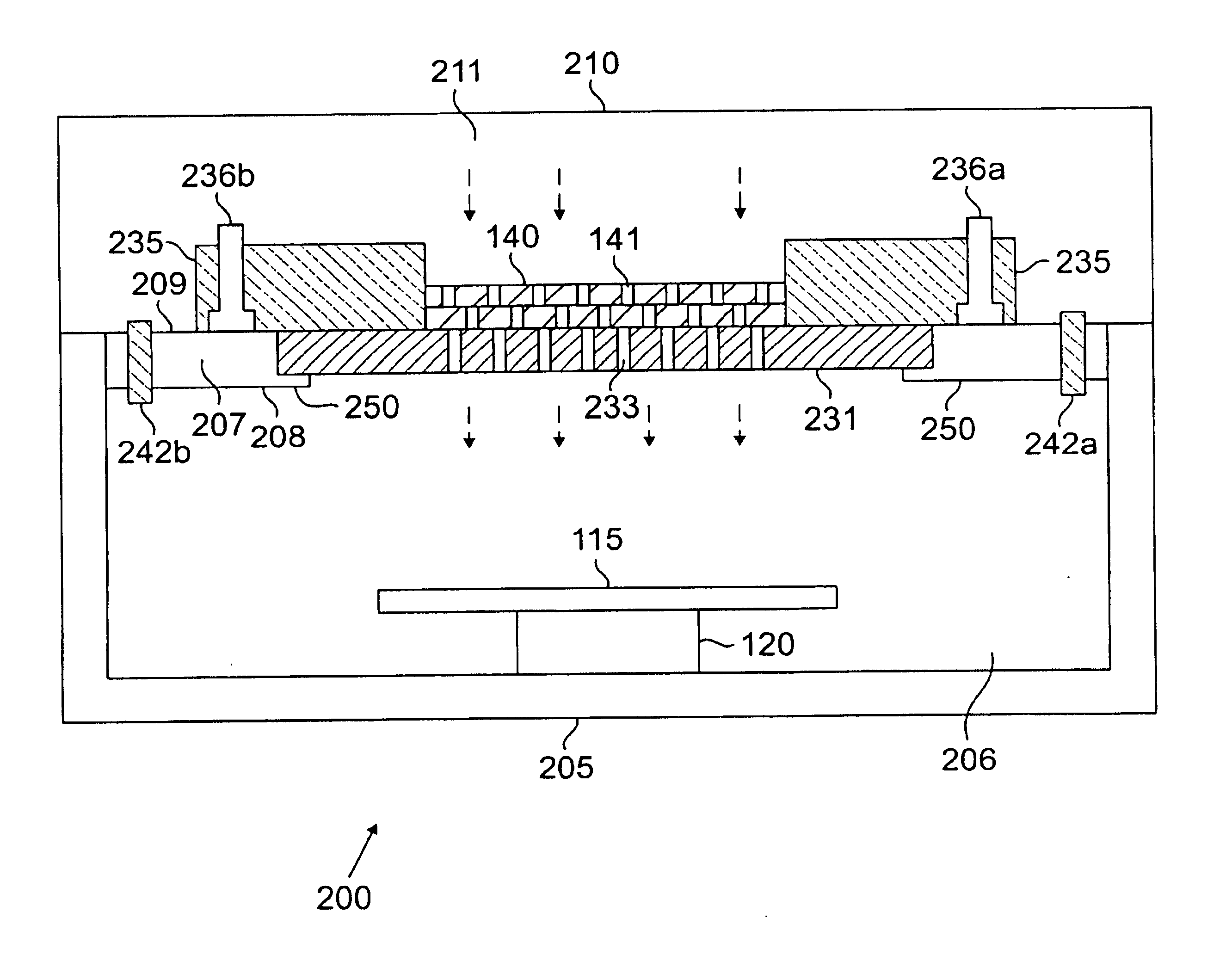

[0024]FIG. 1 illustrates a cross-sectional view of selected portions of conventional plasma etching system 100 according to an exemplary embodiment of the prior art. Plasma etching system 100 comprises plasma chamber 105, which encloses empty space 106. Semiconductor wafer 115 is mounted on support 120 on the bottom wall (floor) of plasma chamber 105. Plasma etching system 100 further comprises showerhead electrode assembly 130 and housing 110. Showerhead electrode assembly 130 comprises electrode plate 131 (diagonal line shading) and graphite ring 132 (lattice shading), whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| semiconductor | aaaaa | aaaaa |

| etch rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com