Patents

Literature

251results about "Mechanically variable capacitor details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

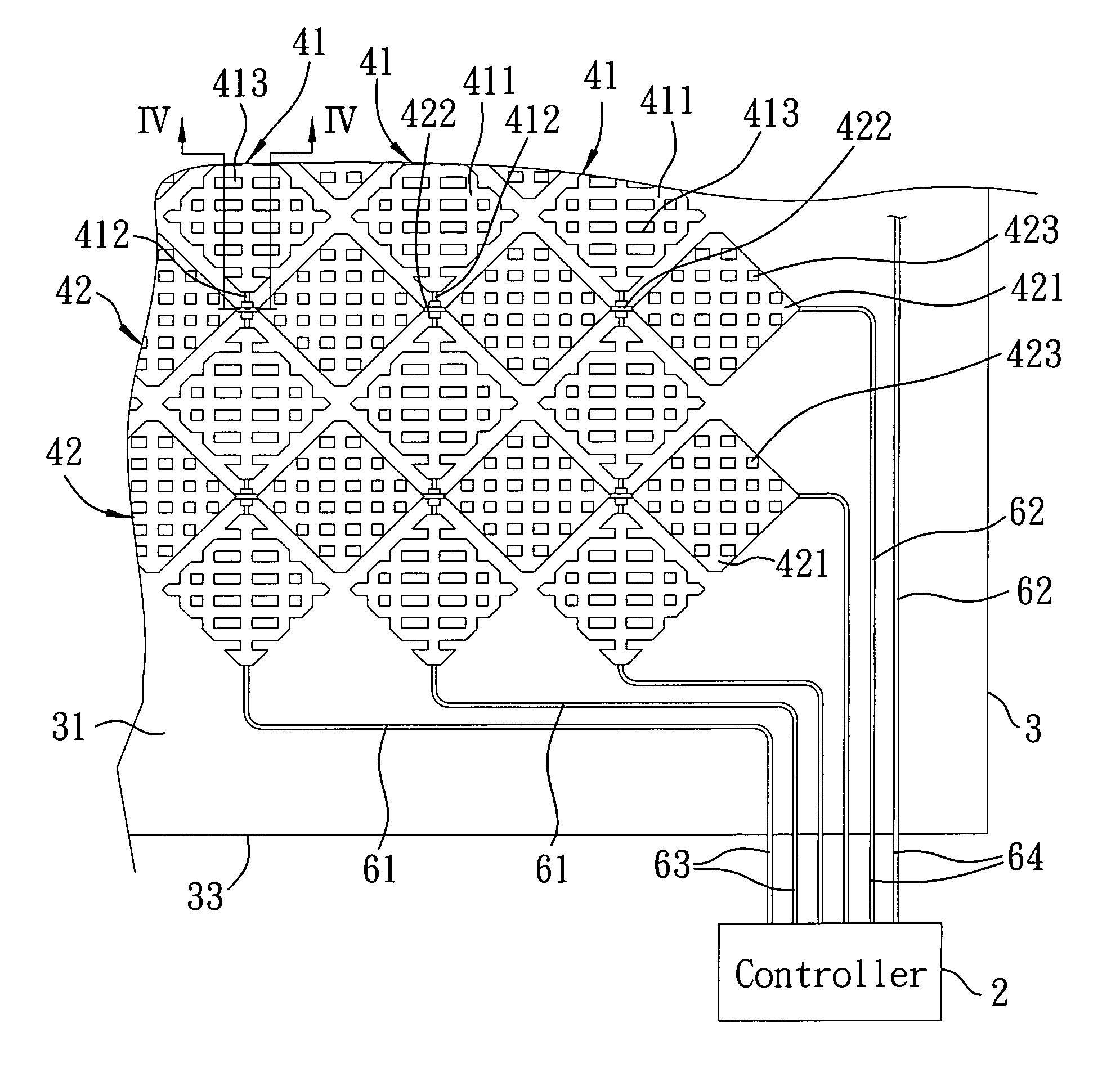

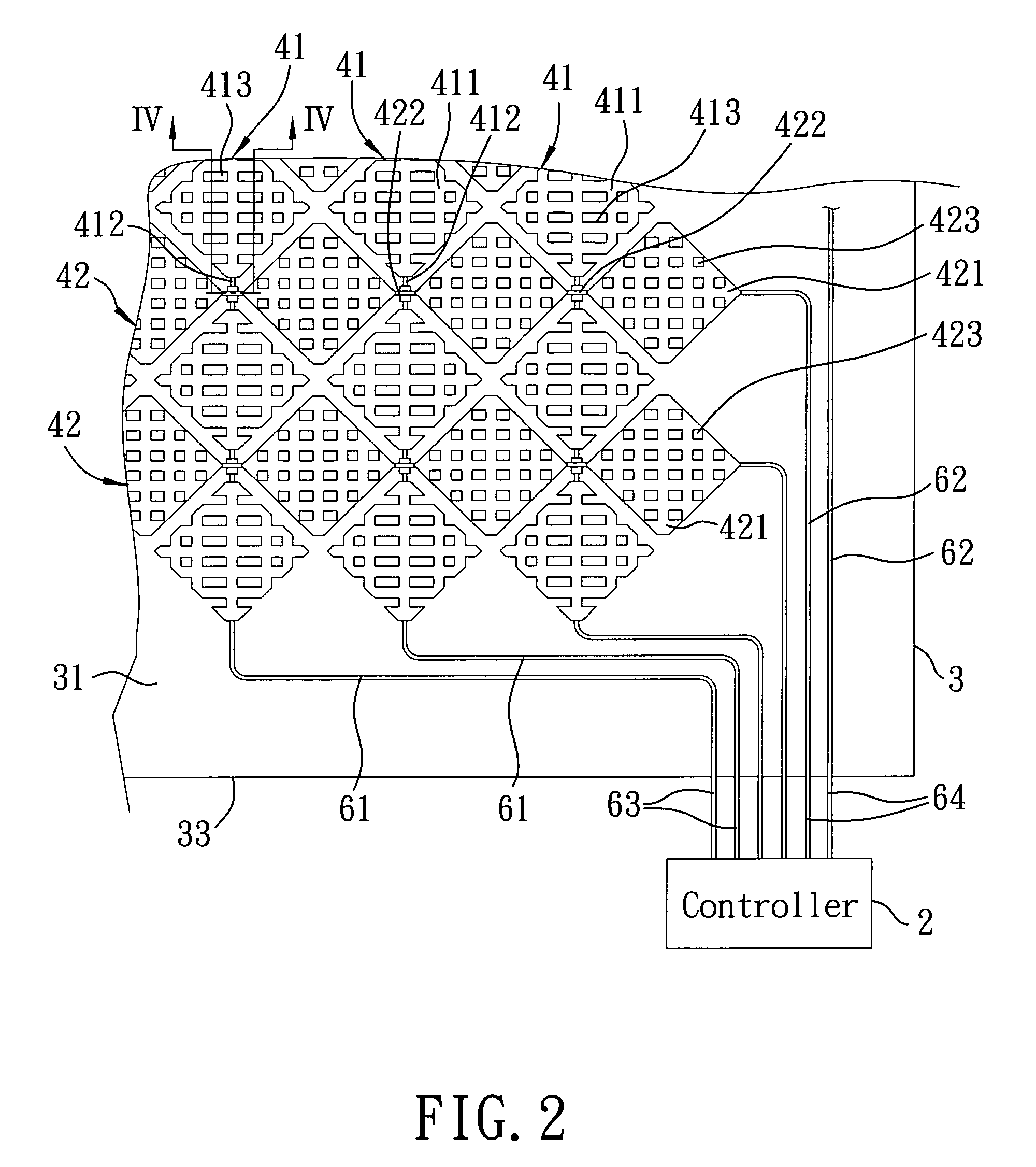

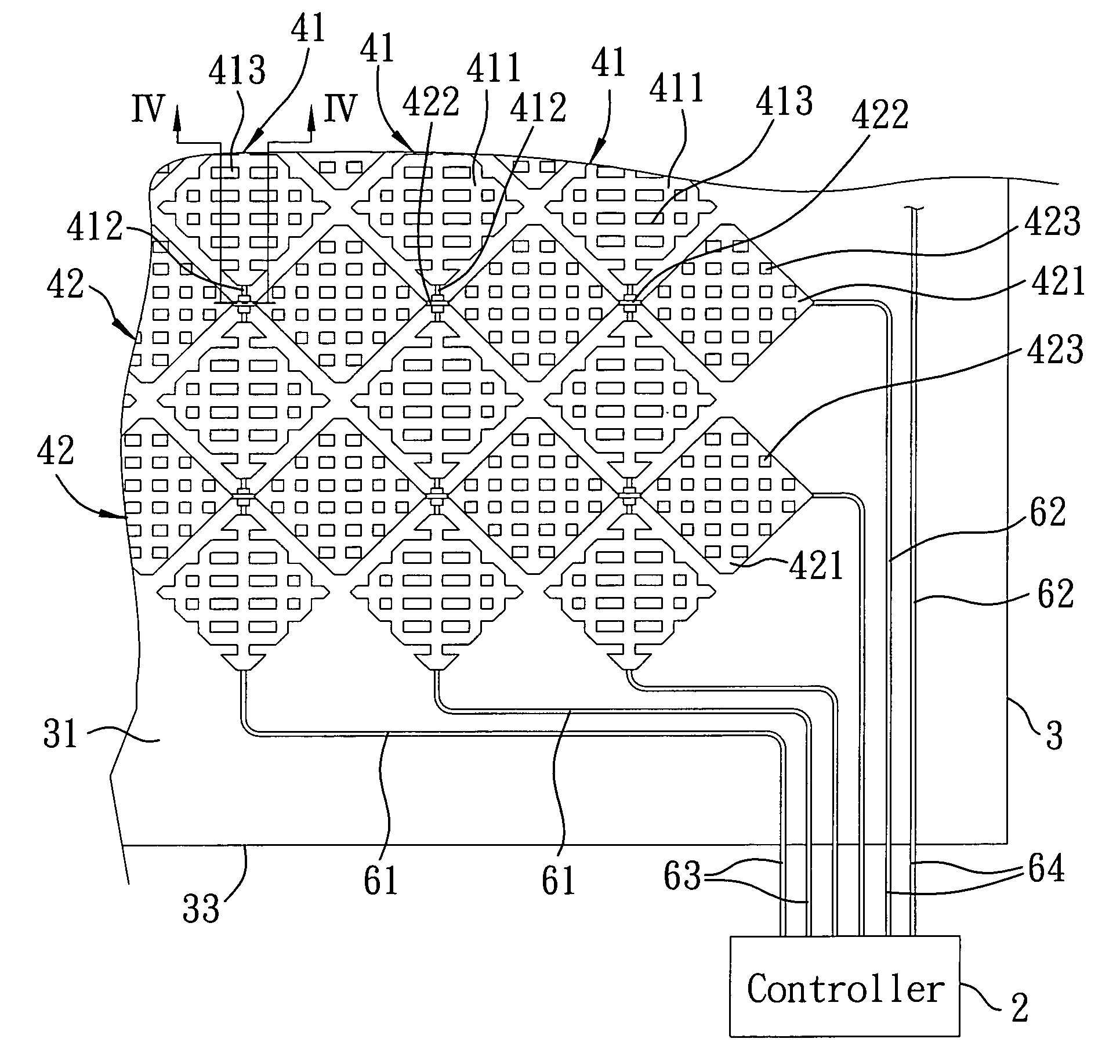

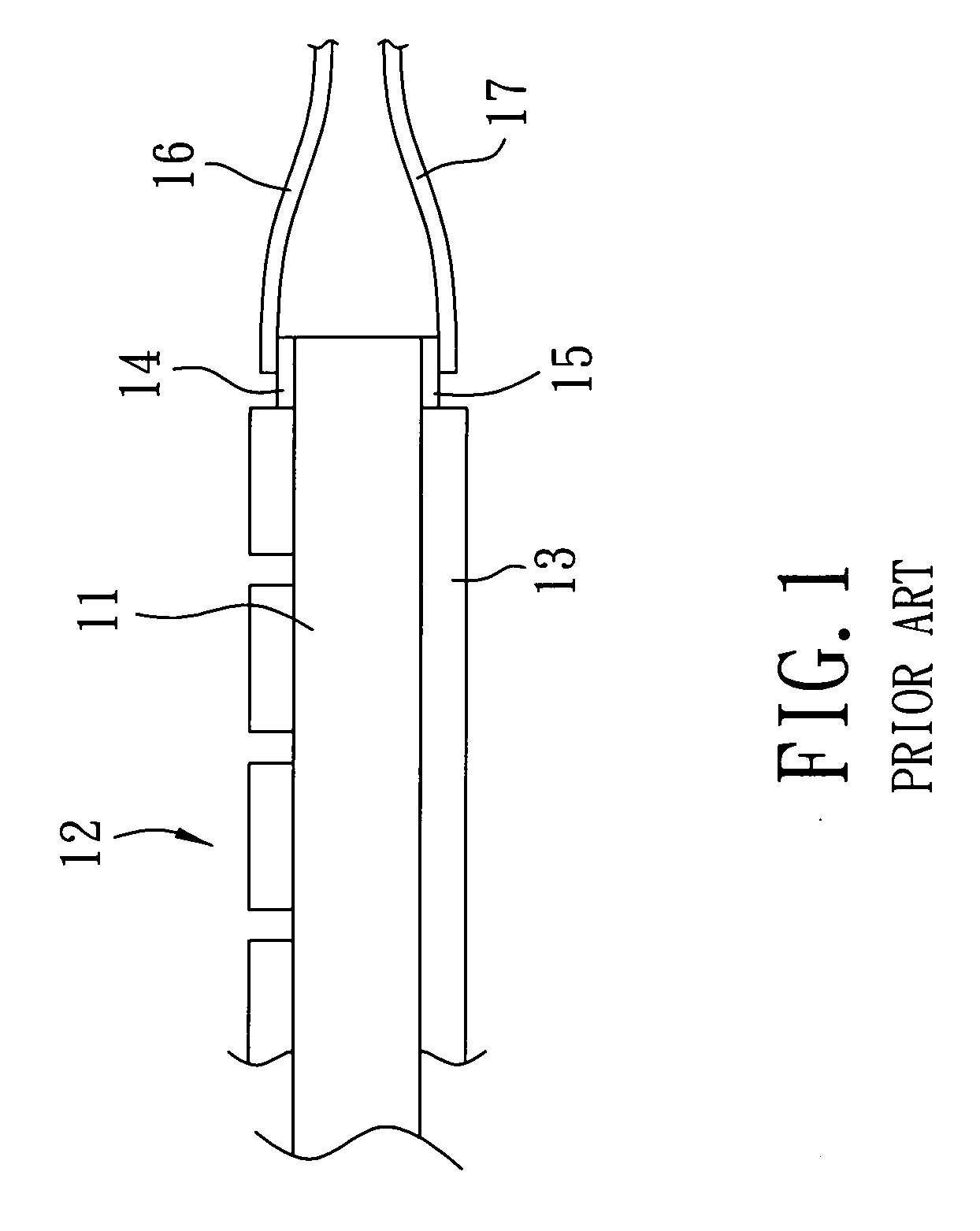

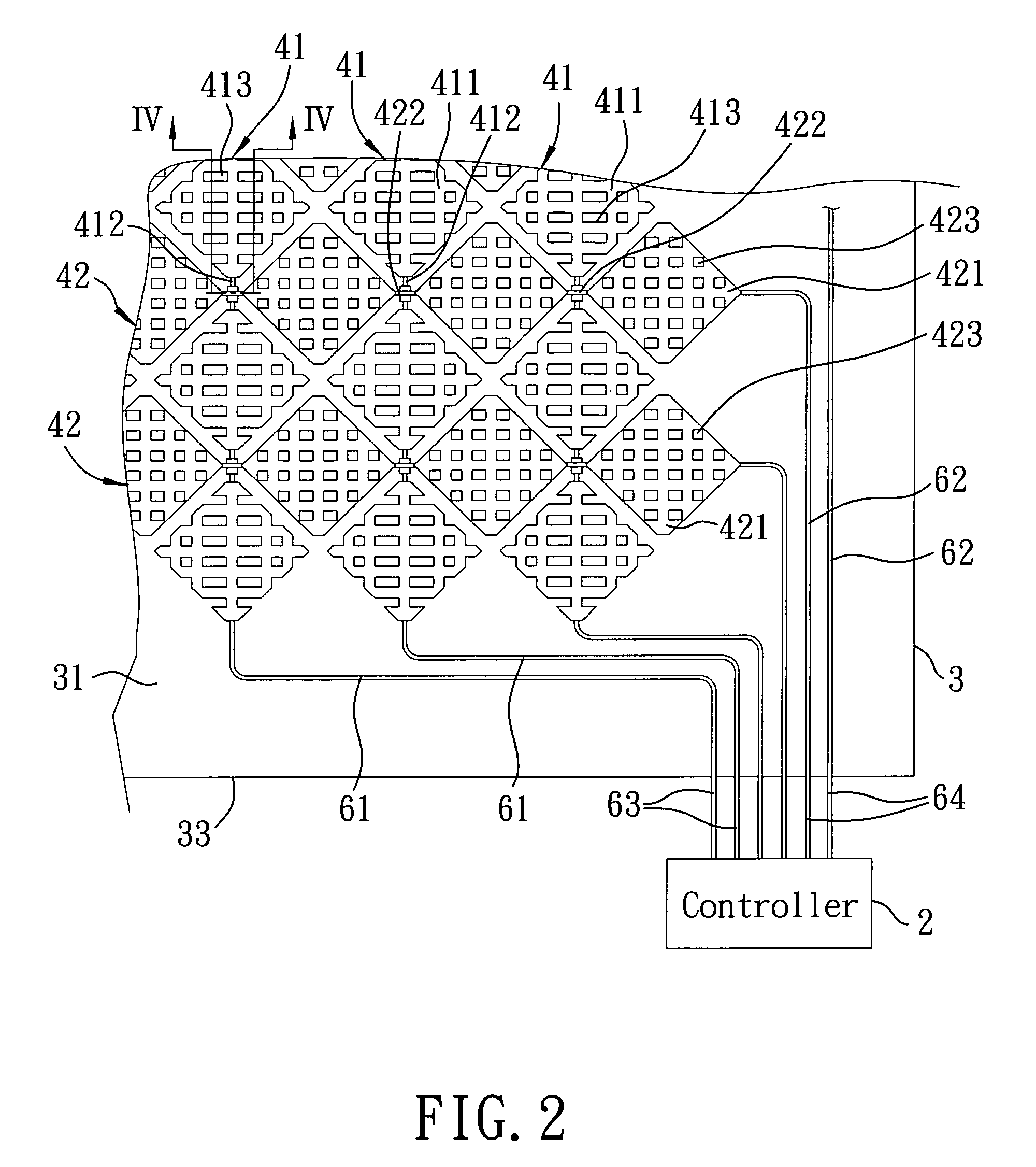

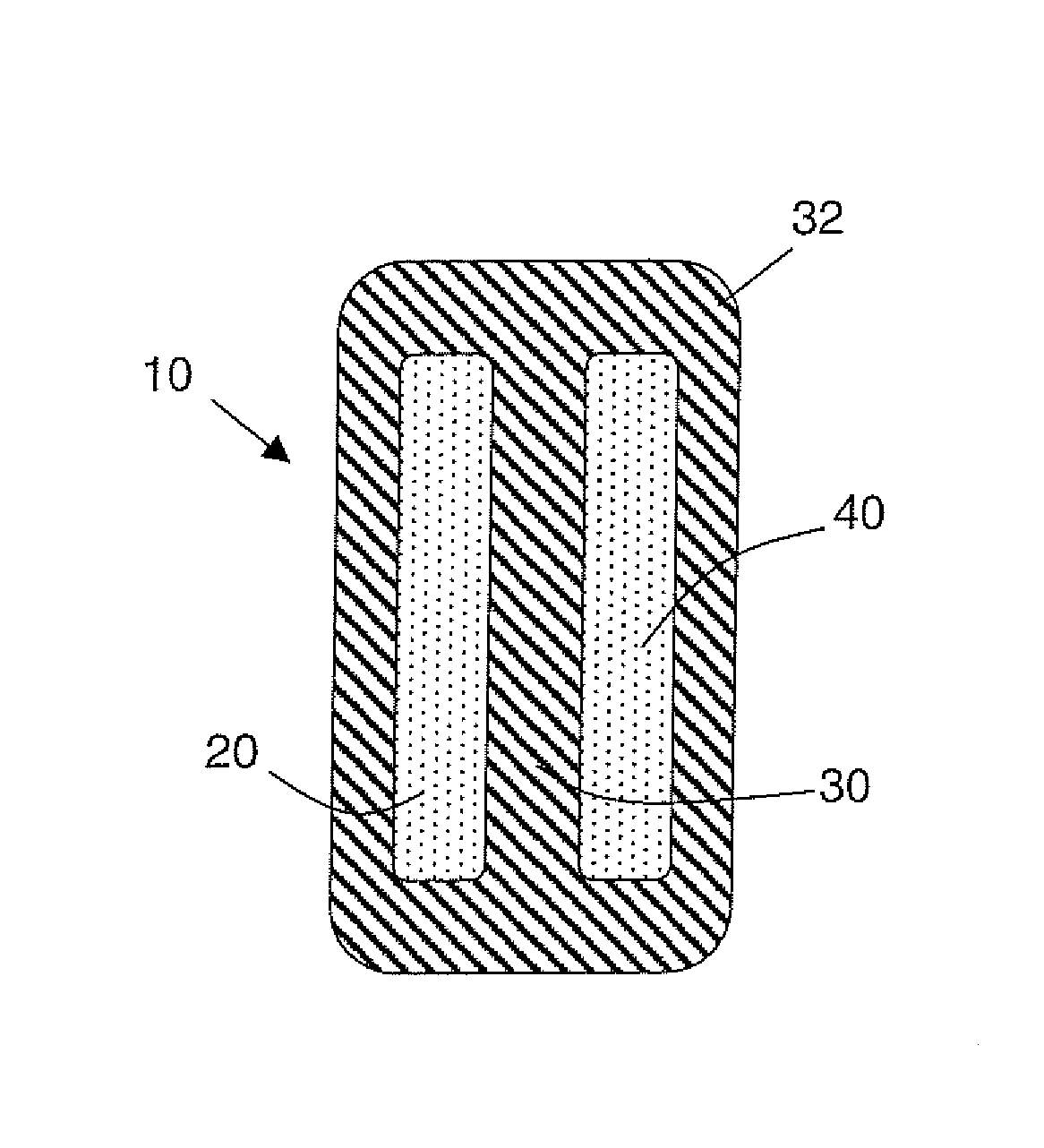

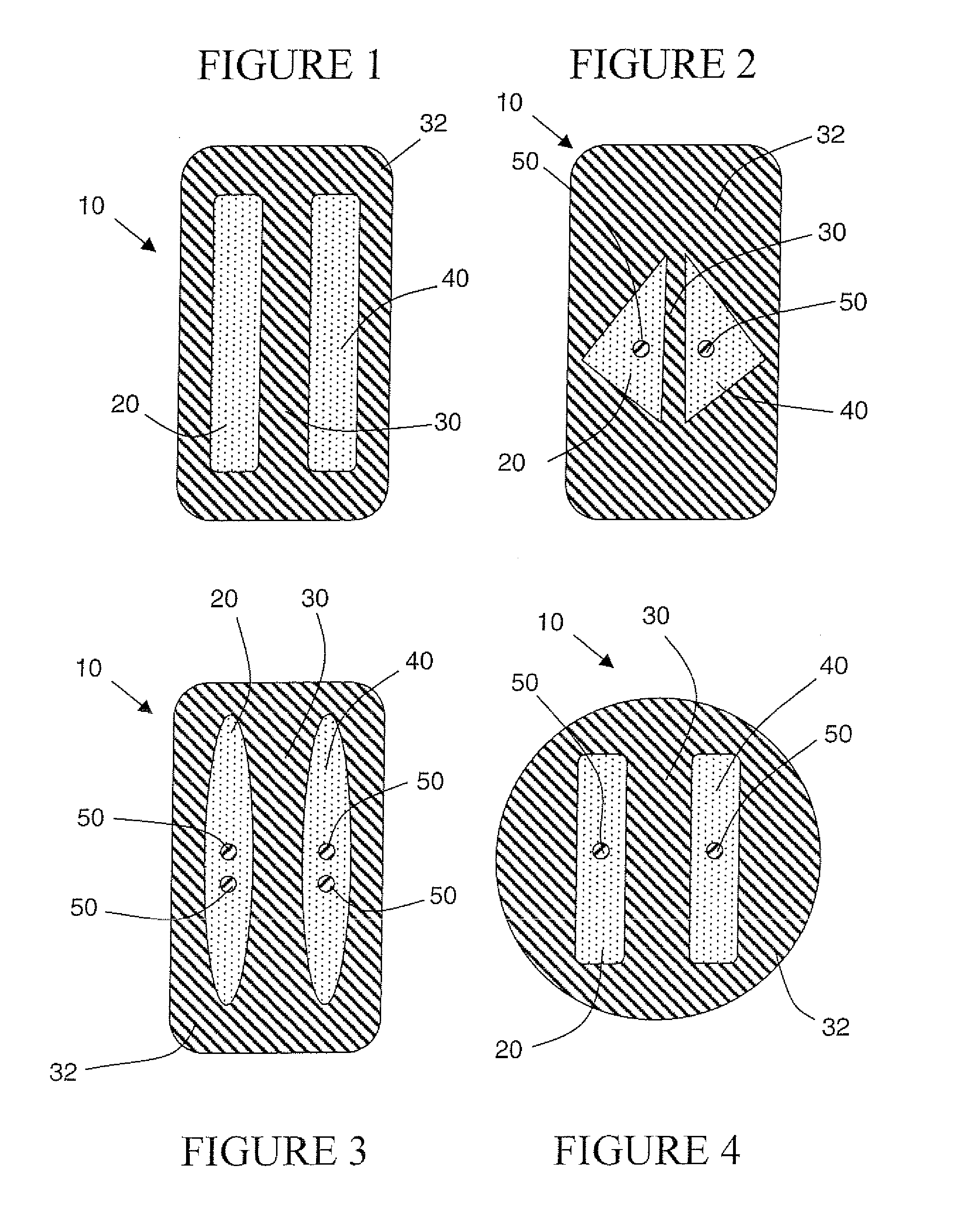

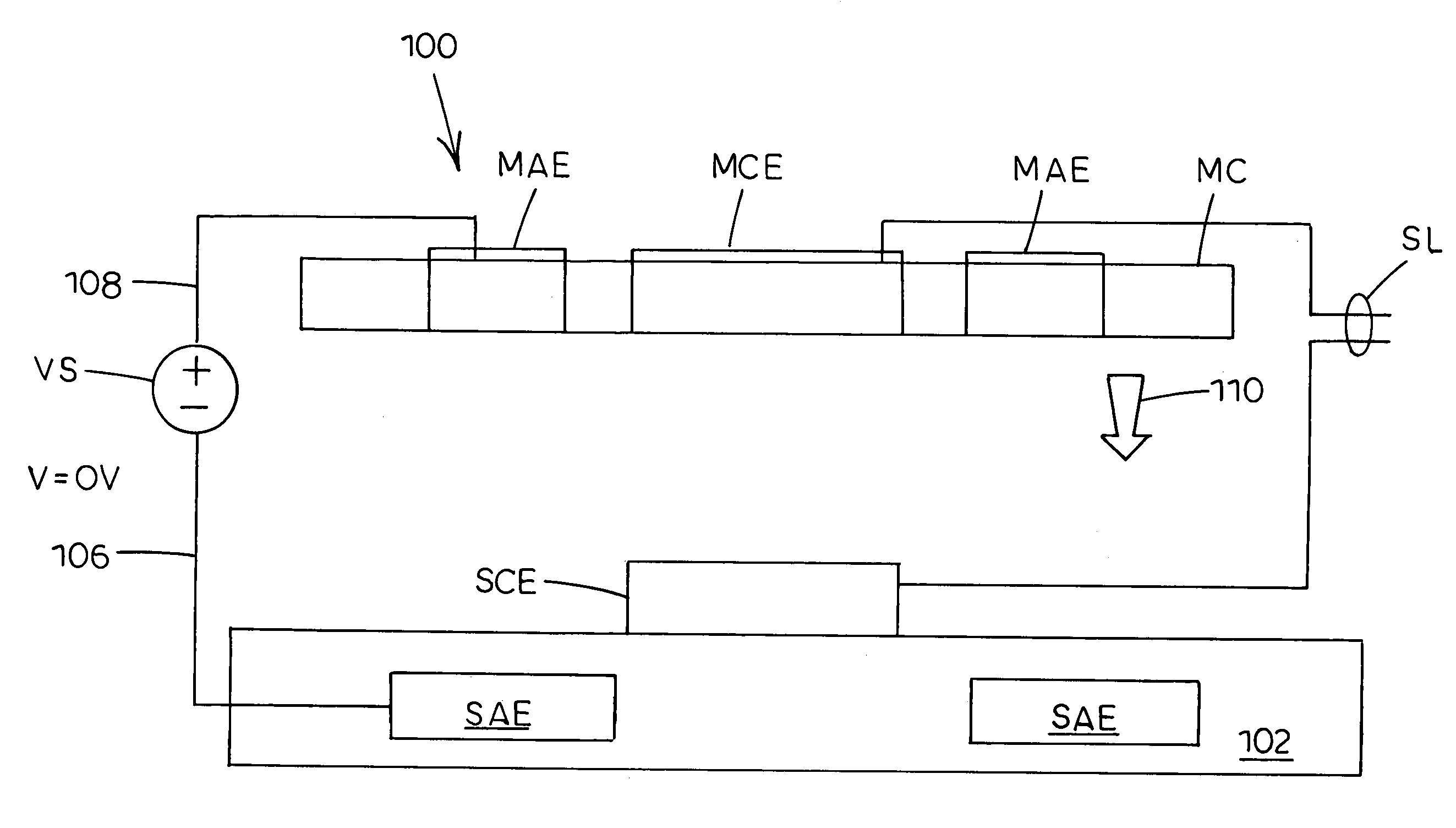

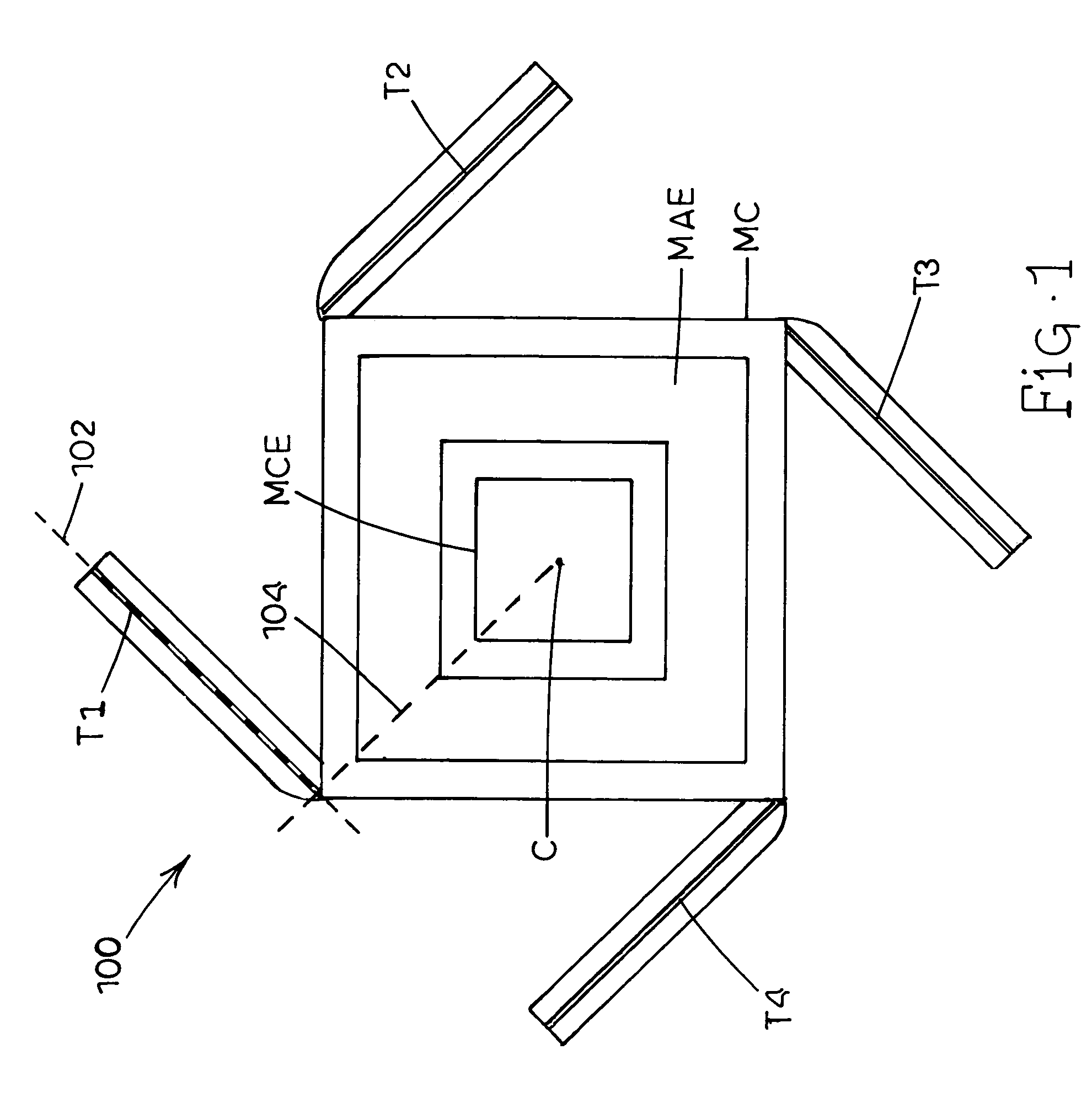

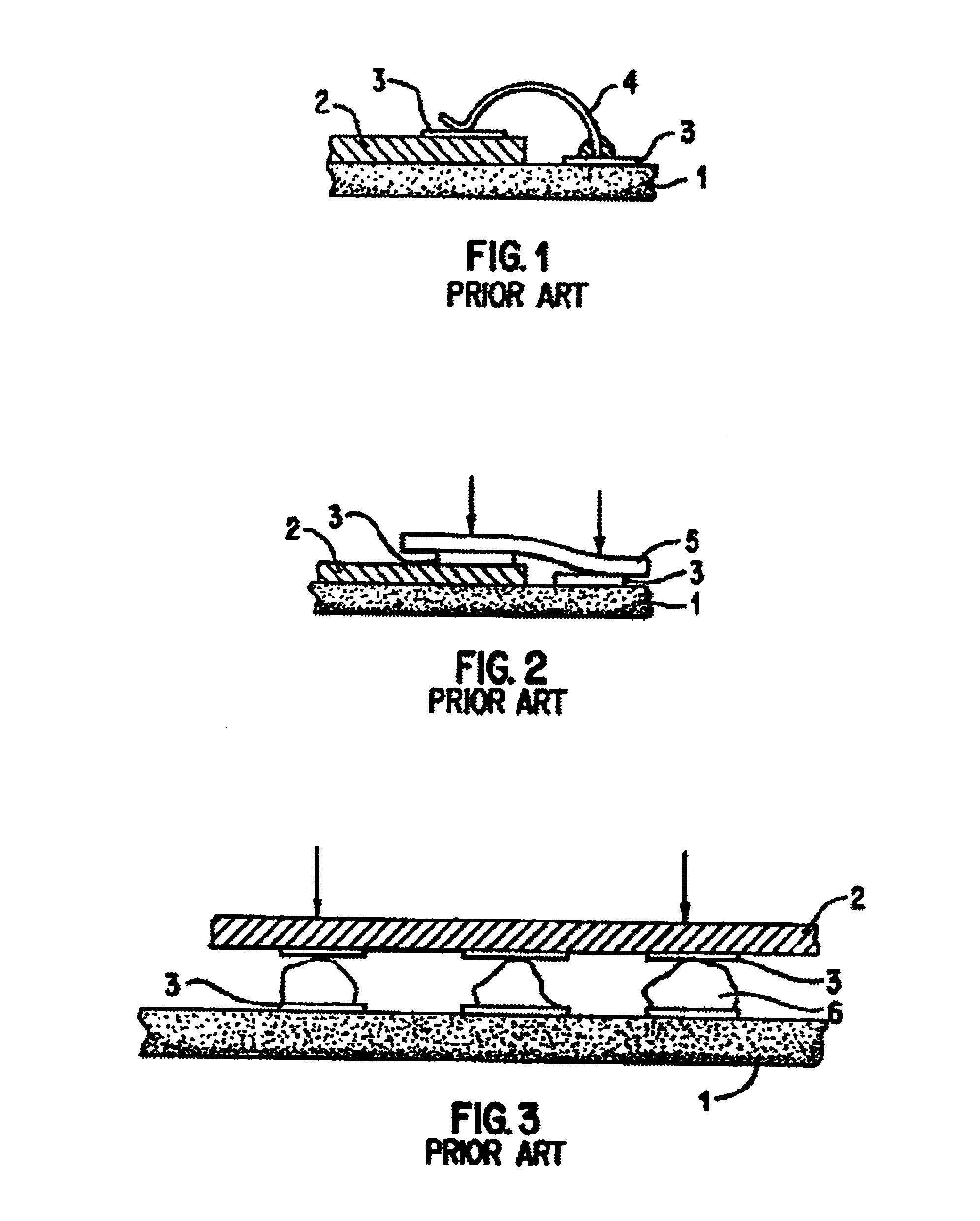

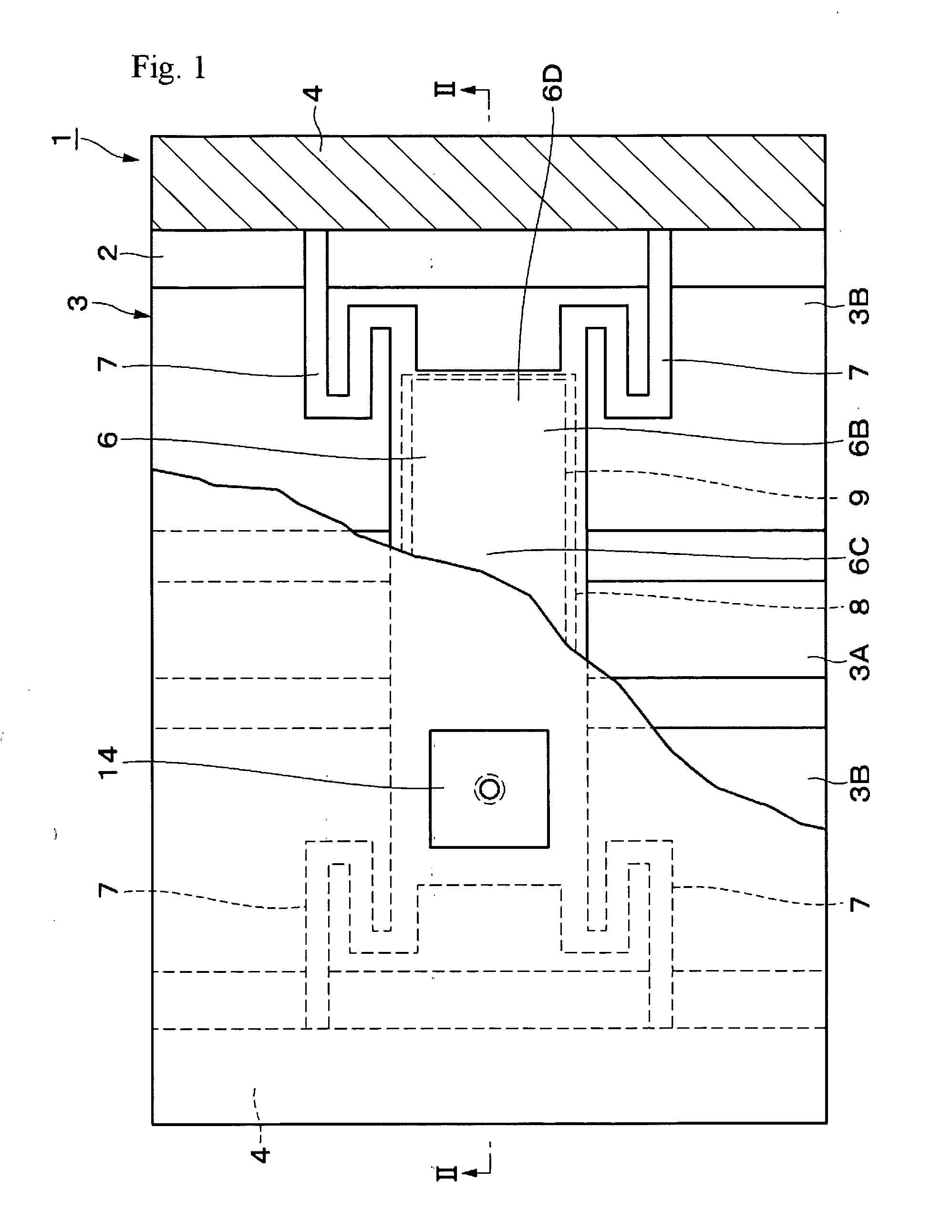

Capacitive type touch panel

ActiveUS7864503B2Overcomes drawbackContact materialsMechanically variable capacitor detailsElectrical conductorEngineering

A capacitive type touch panel includes: a transparent substrate; an array of first conductors formed on a surface of the transparent substrate; an array of second conductors formed on the surface of the transparent substrate; a plurality of conductive first bridging lines, each of which interconnects two adjacent ones of the first conductors; a plurality of conductive second bridging lines, each of which interconnects two adjacent ones of the second conductors and each of which intersects insulatively a respective one of the first bridging lines; and a plurality of spaced apart insulators, each of which is disposed at an intersection of a respective one of the first bridging lines and a respective one of the second bridging lines to separate the respective first and second bridging lines.

Owner:TAZIK SOLUTIONS (SUZHOU) LTD

Capacitive type touch panel

ActiveUS20080277259A1Overcomes drawbackContact materialsMechanically variable capacitor detailsElectrical conductorTouch panel

A capacitive type touch panel includes: a transparent substrate; an array of first conductors formed on a surface of the transparent substrate; an array of second conductors formed on the surface of the transparent substrate; a plurality of conductive first bridging lines, each of which interconnects two adjacent ones of the first conductors; a plurality of conductive second bridging lines, each of which interconnects two adjacent ones of the second conductors and each of which intersects insulatively a respective one of the first bridging lines; and a plurality of spaced apart insulators, each of which is disposed at an intersection of a respective one of the first bridging lines and a respective one of the second bridging lines to separate the respective first and second bridging lines.

Owner:TAZIK SOLUTIONS (SUZHOU) LTD

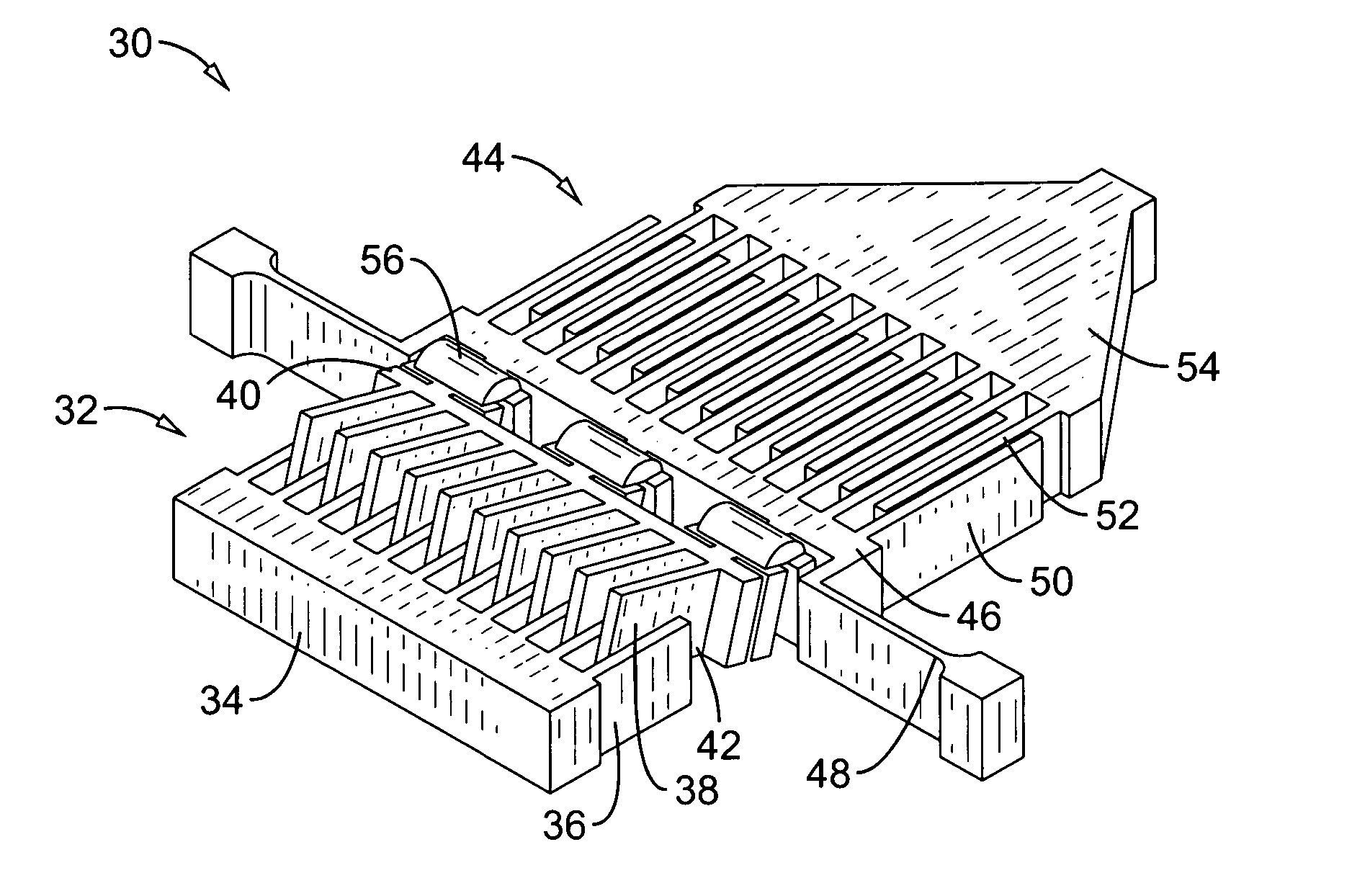

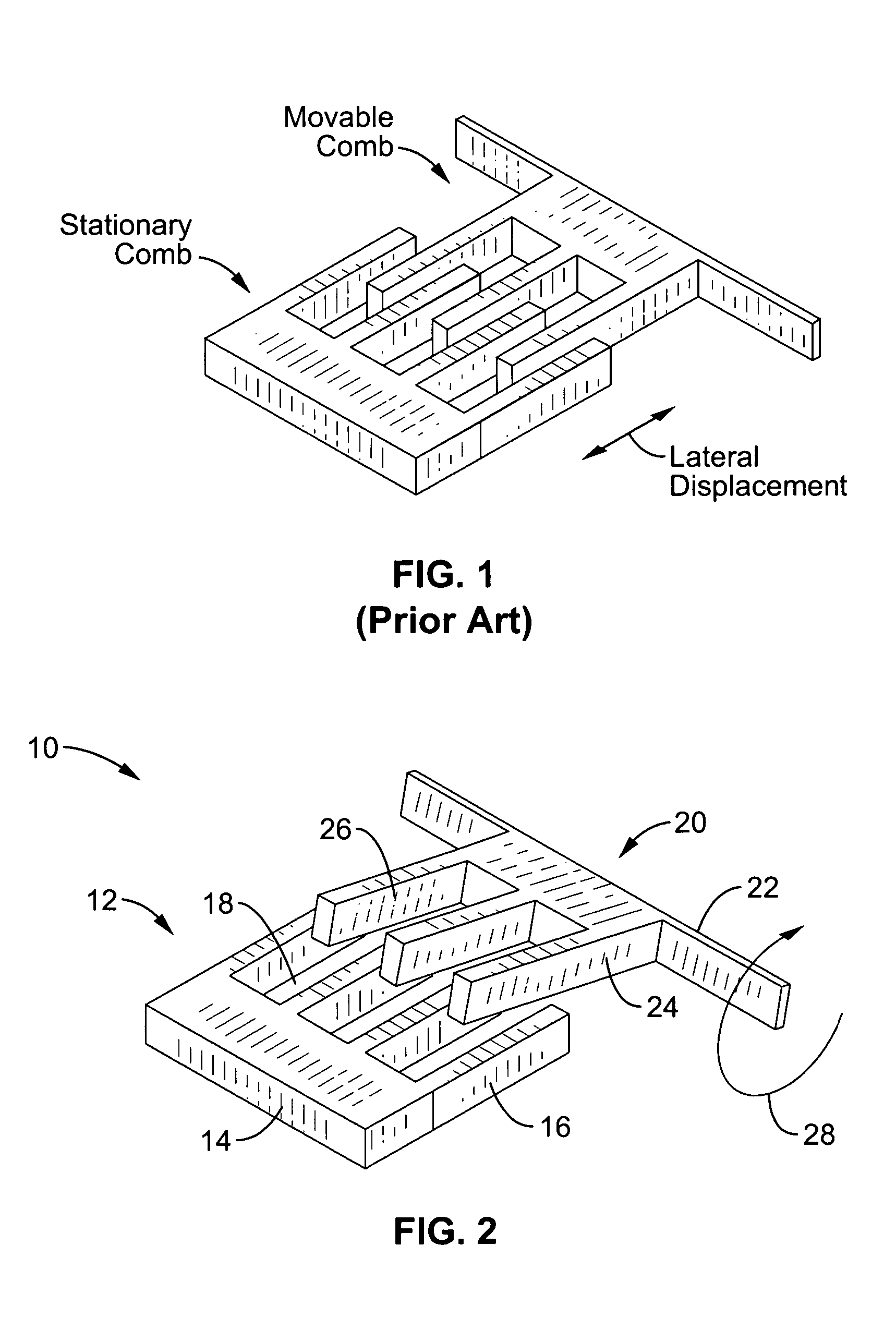

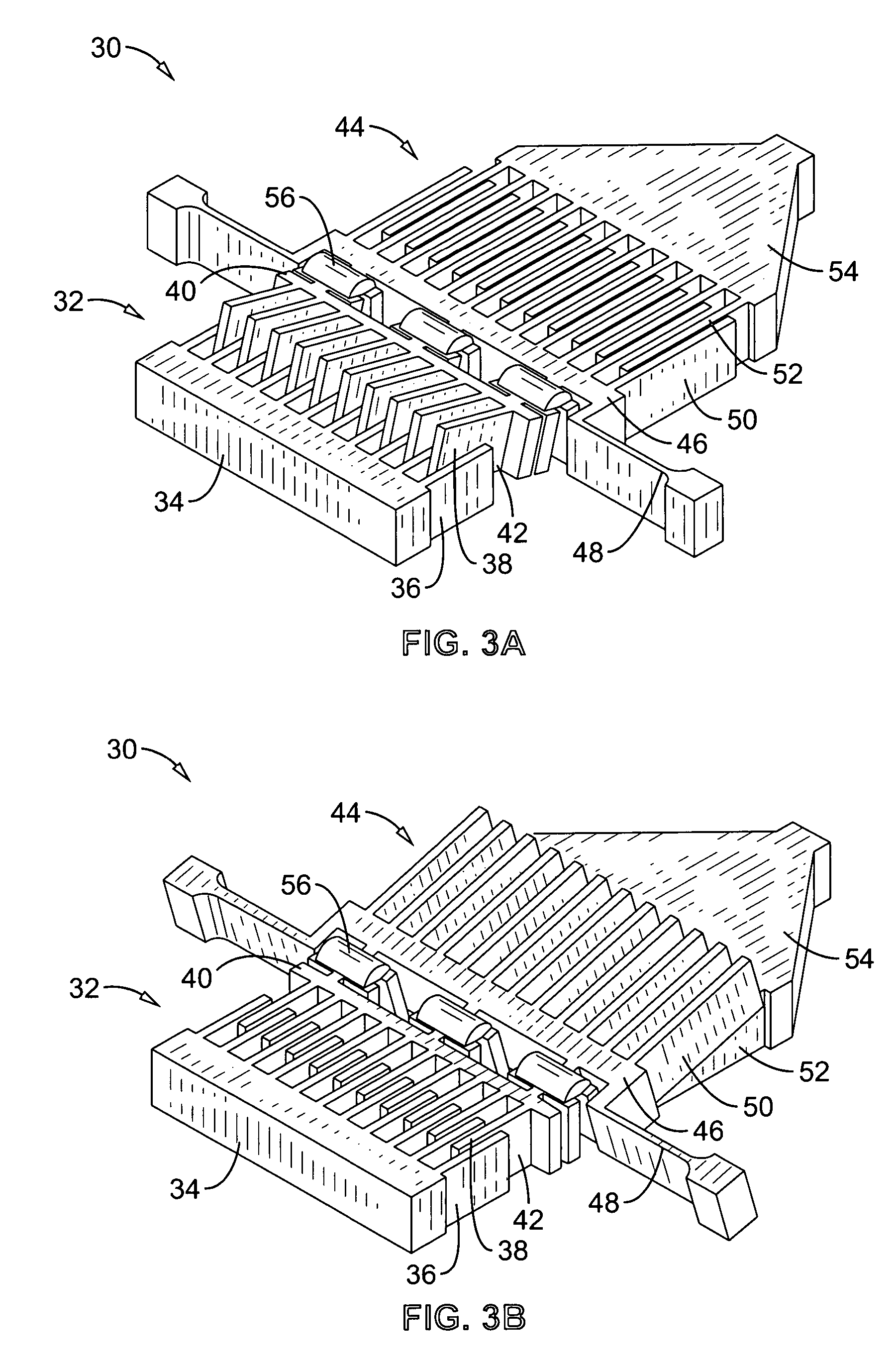

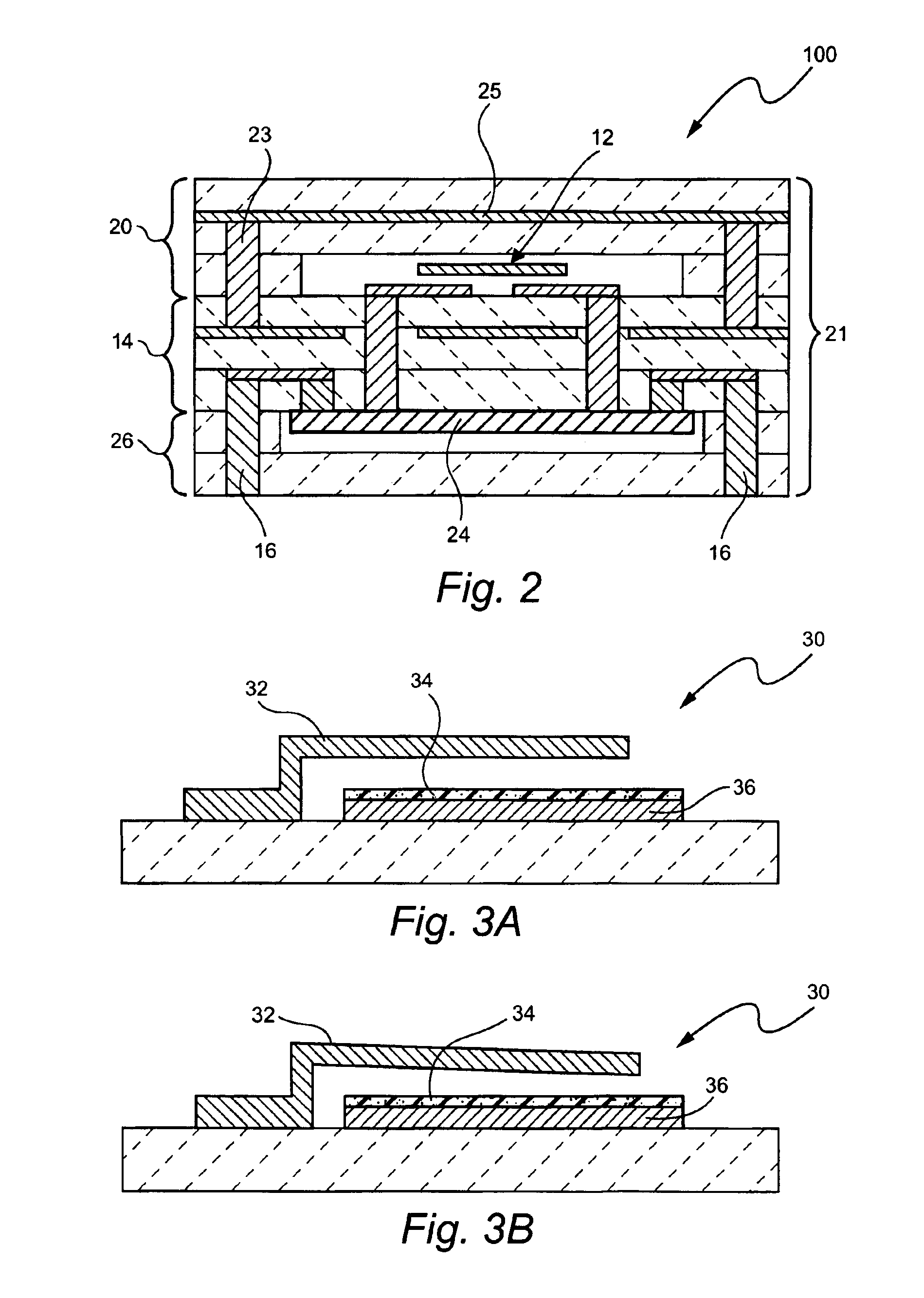

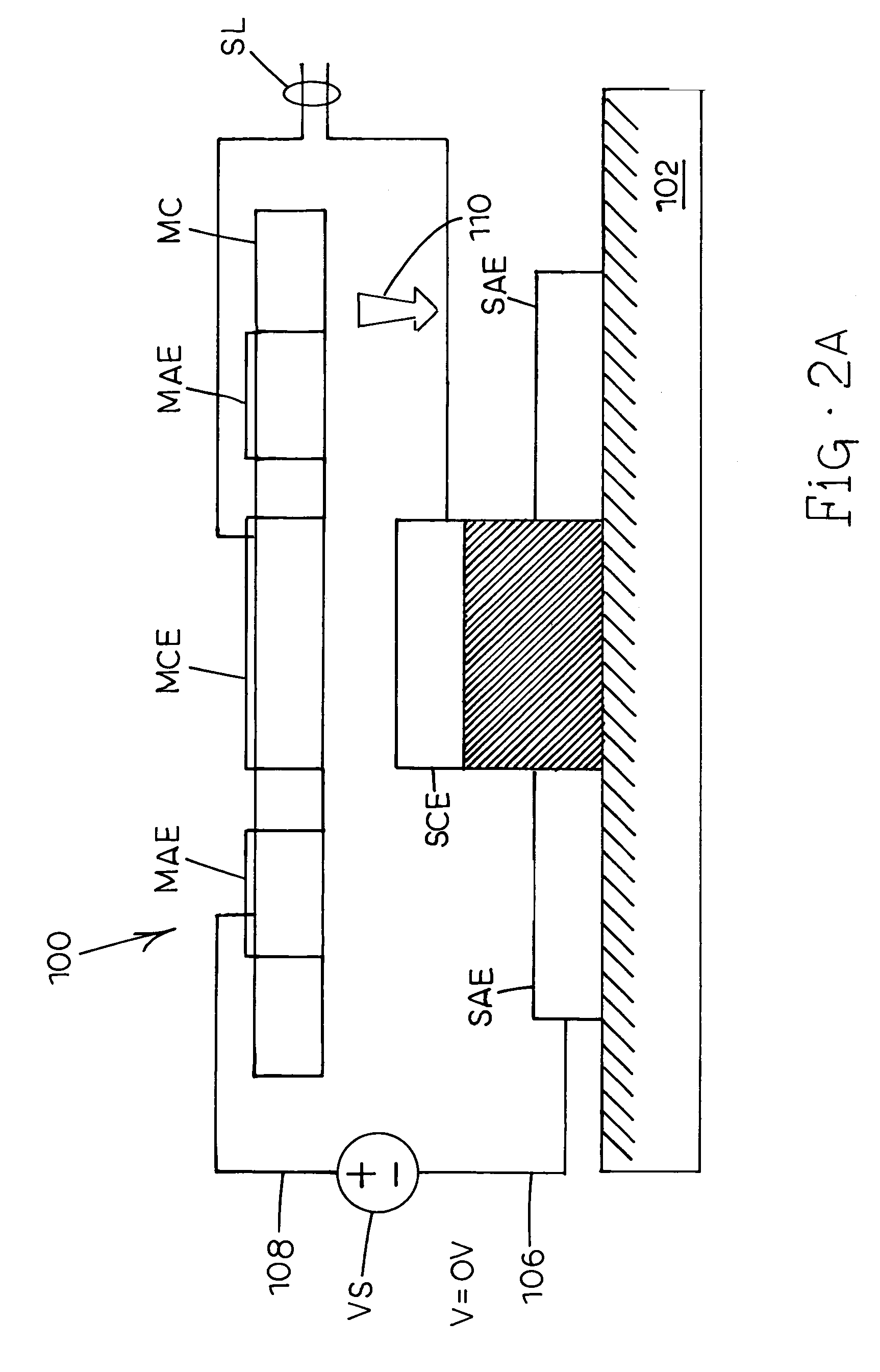

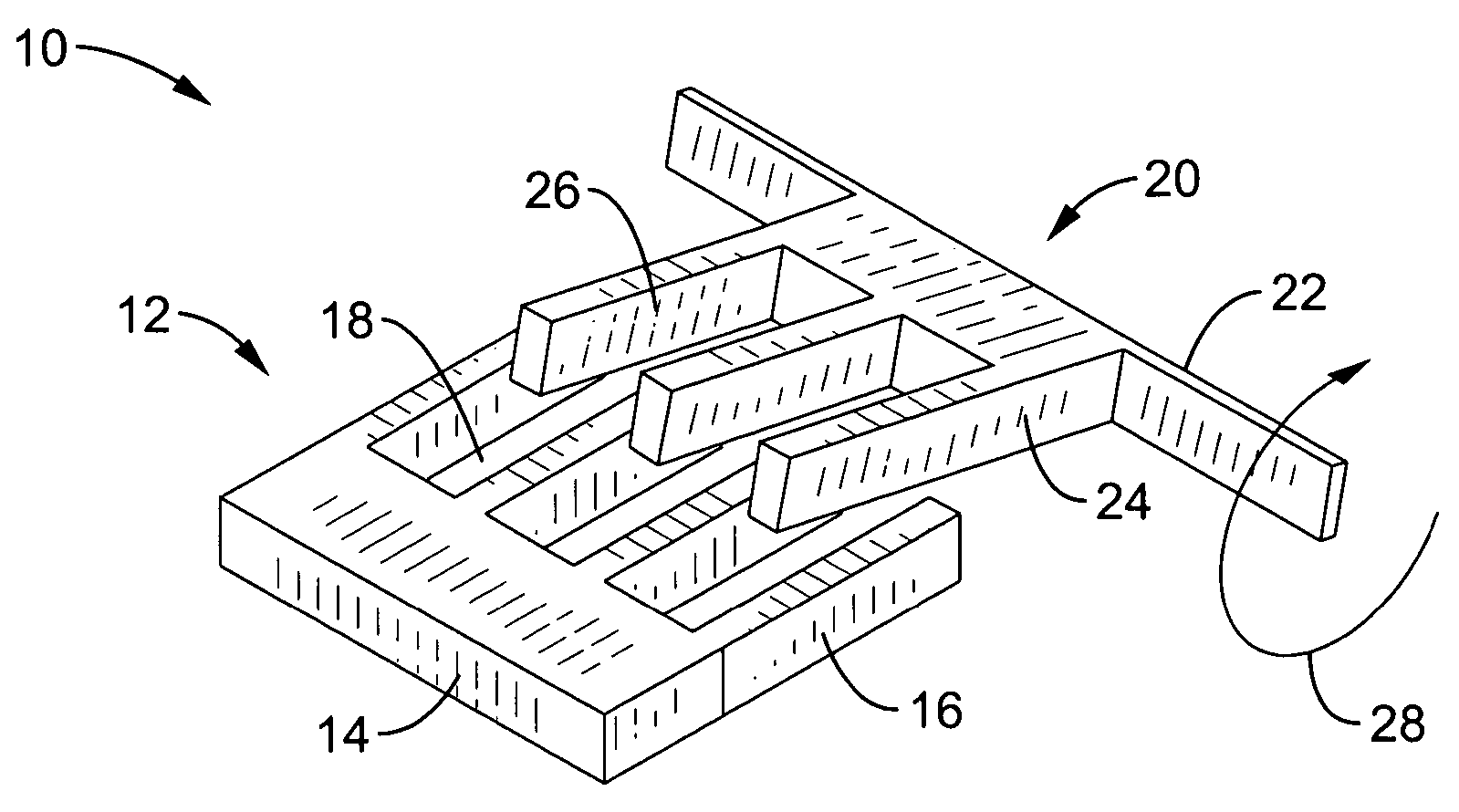

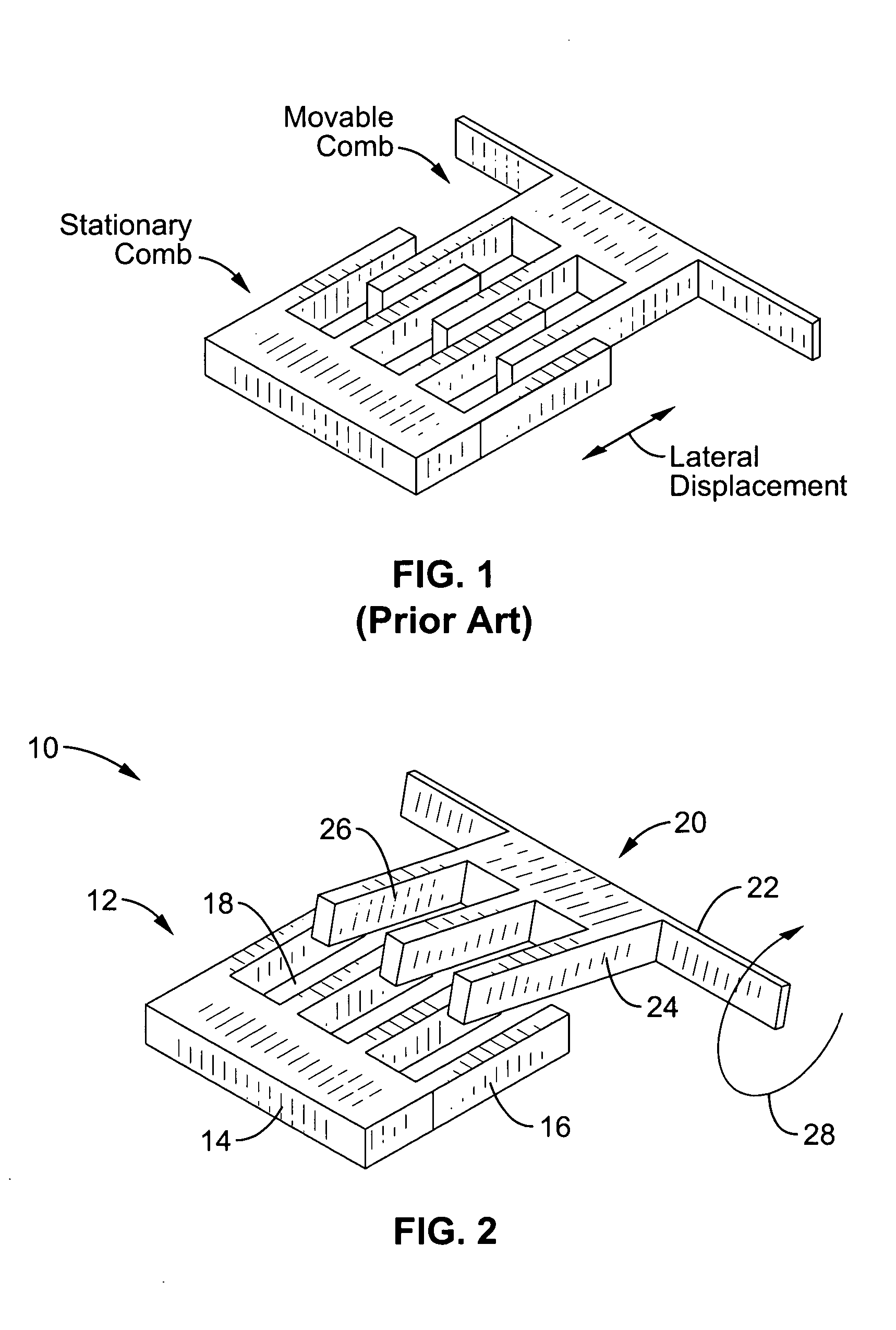

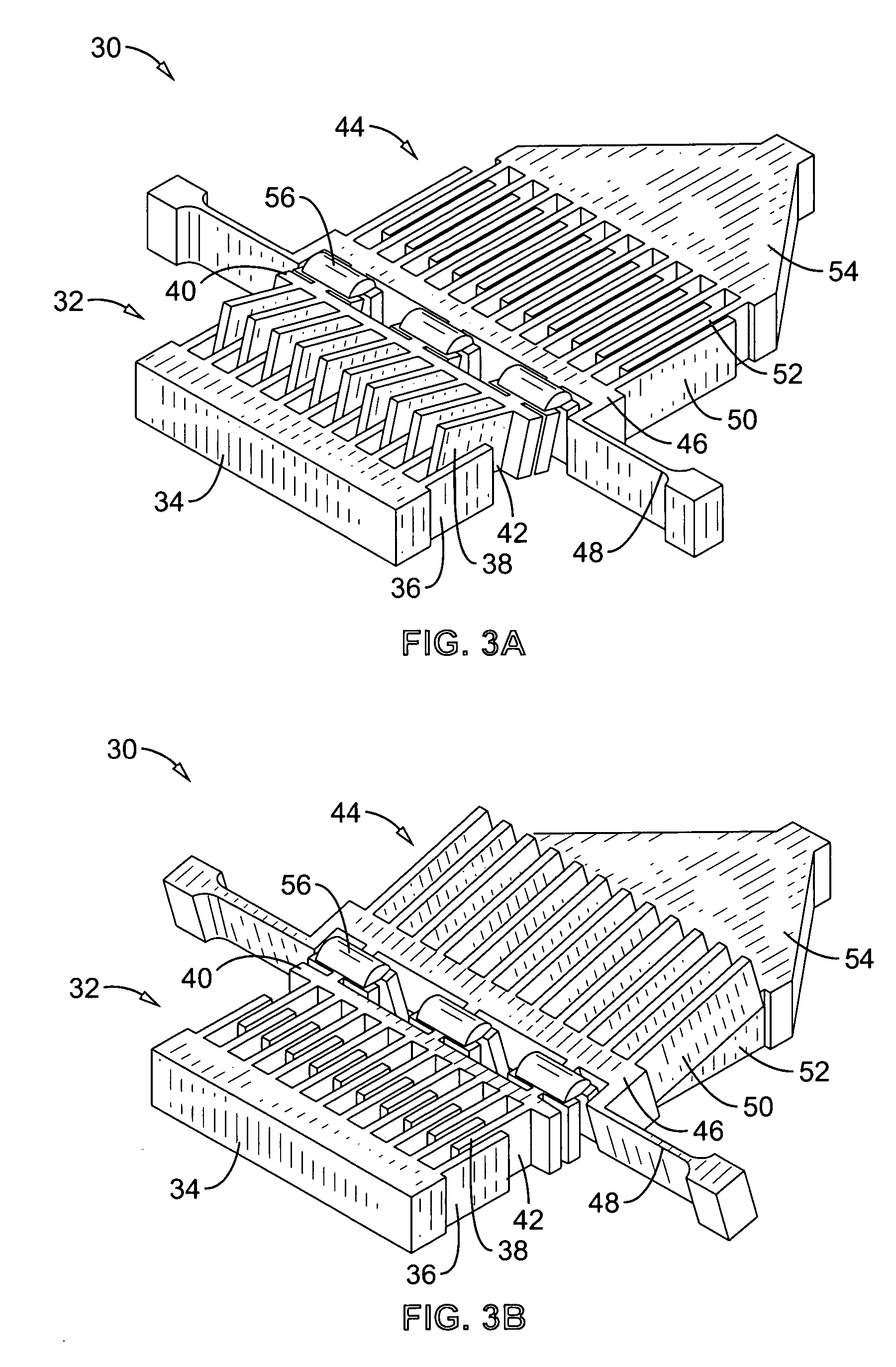

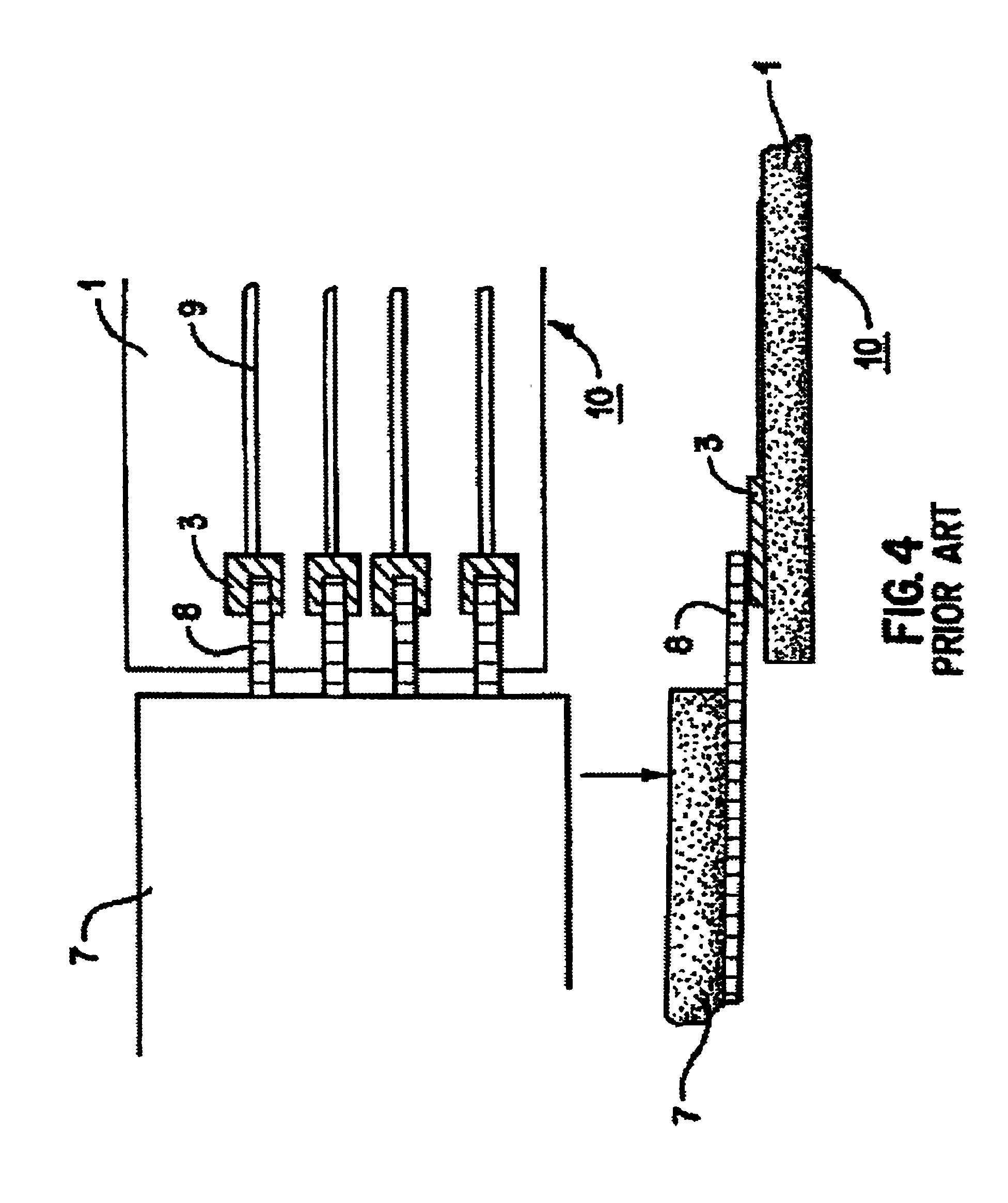

MEMS tunable capacitor based on angular vertical comb drives

InactiveUS7085122B2Appreciates the drawbacks inherent in lateral drive MEMS capacitorsIncrease tuning rangeMultiple-port networksMechanically variable capacitor detailsCapacitanceComb finger

A MEMS tunable capacitor with angular vertical comb-drive (AVC) actuators is described where high capacitances and a wide continuous tuning range is achieved in a compact space. The comb fingers rotate through a small vertical angle which allows a wider tuning range than in conventional lateral comb drive devices. Fabrication of the device is straightforward, and involves a single deep reactive ion etching step followed by release and out-of-plane assembly of the angular combs.

Owner:RGT UNIV OF CALIFORNIA

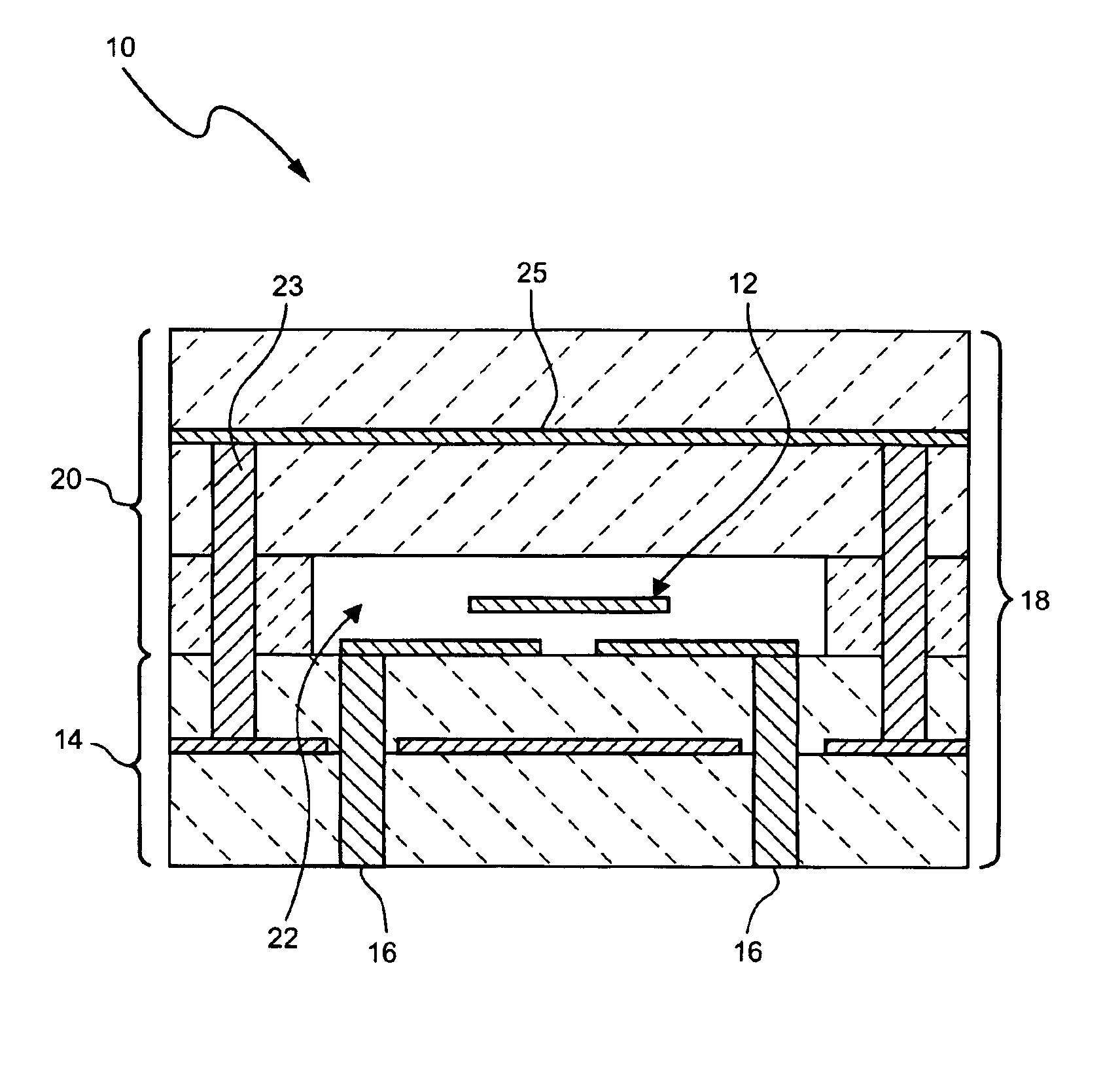

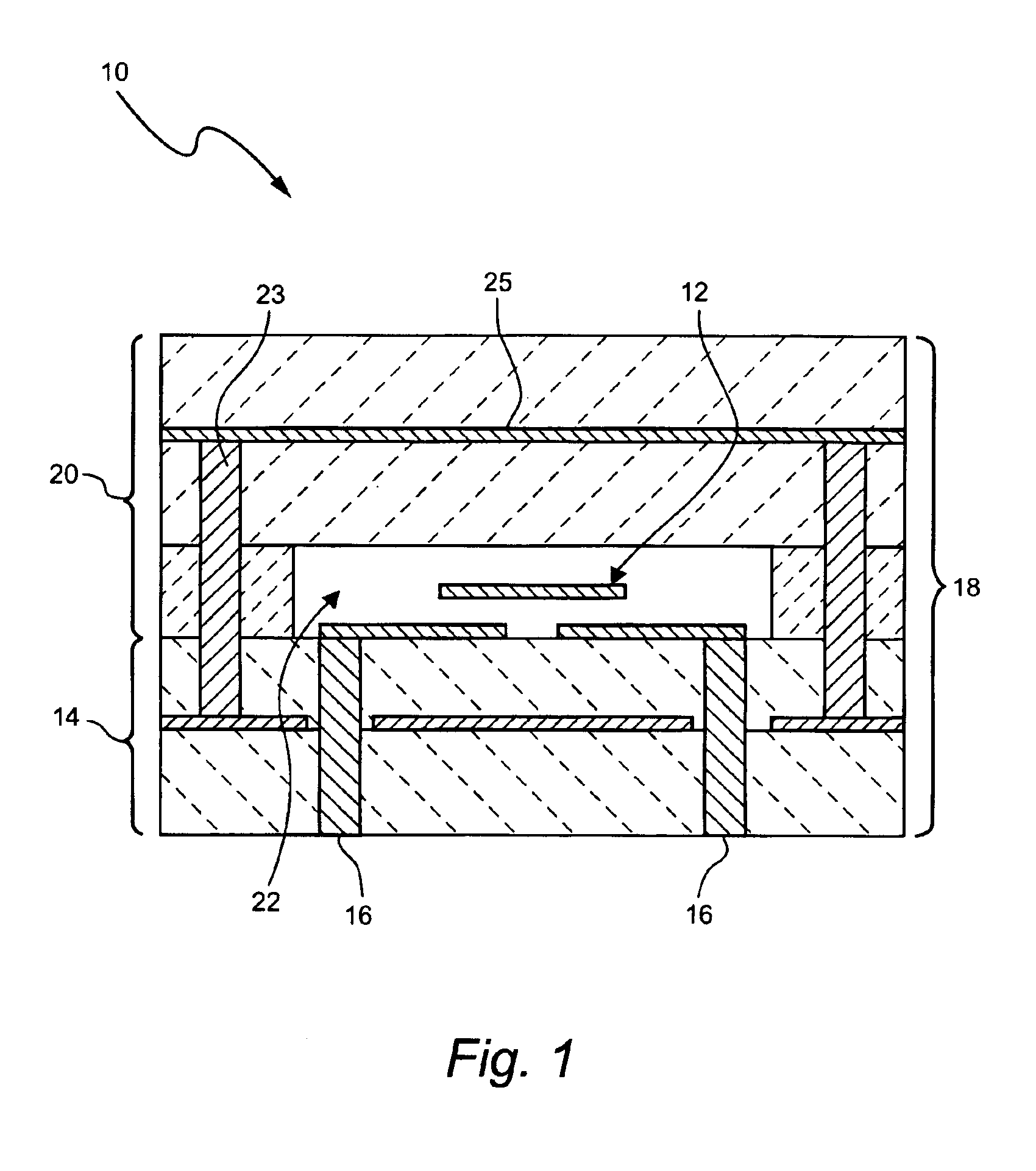

Micro-electro-mechanical system (MEMS) variable capacitor apparatuses and related methods

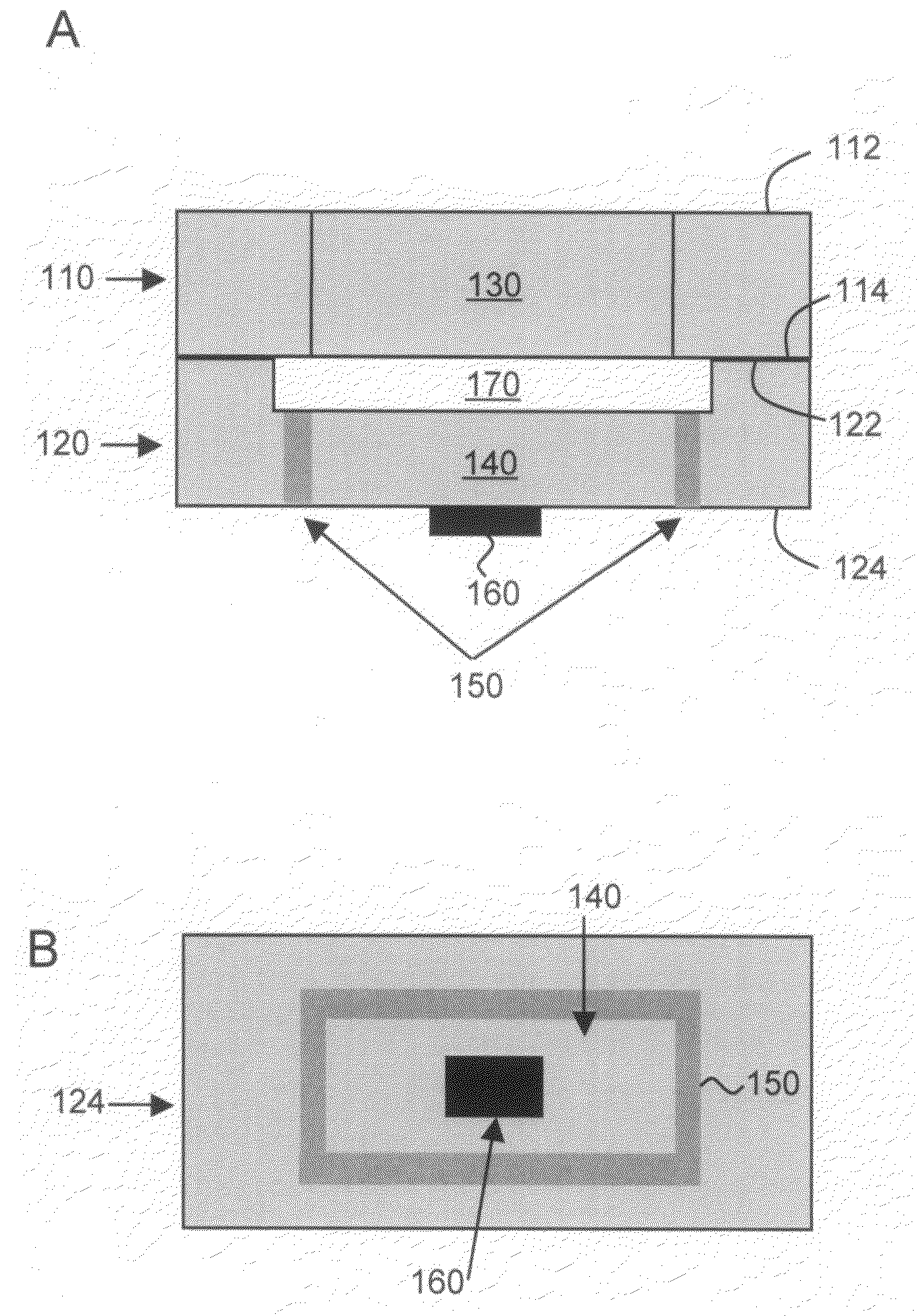

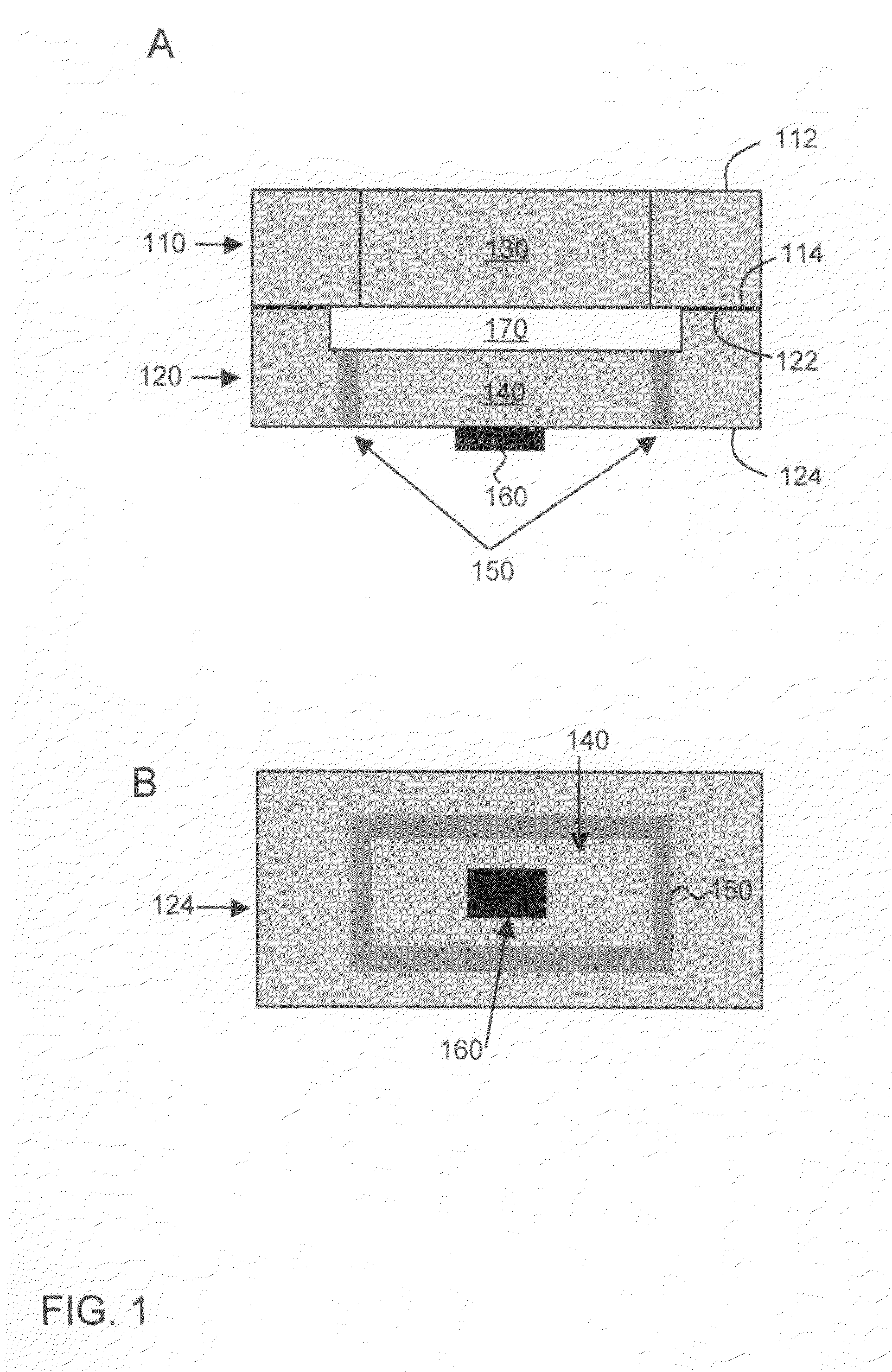

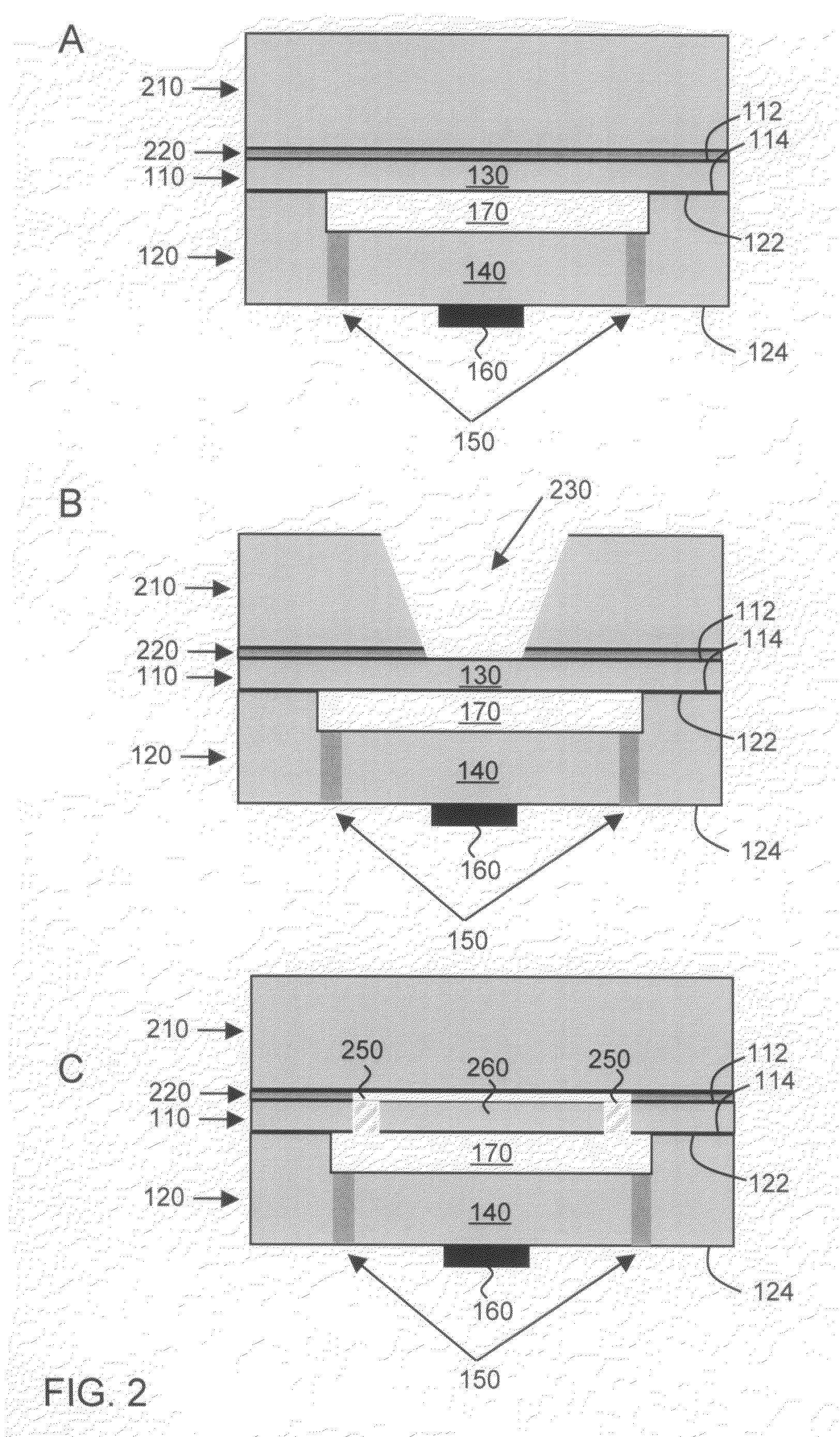

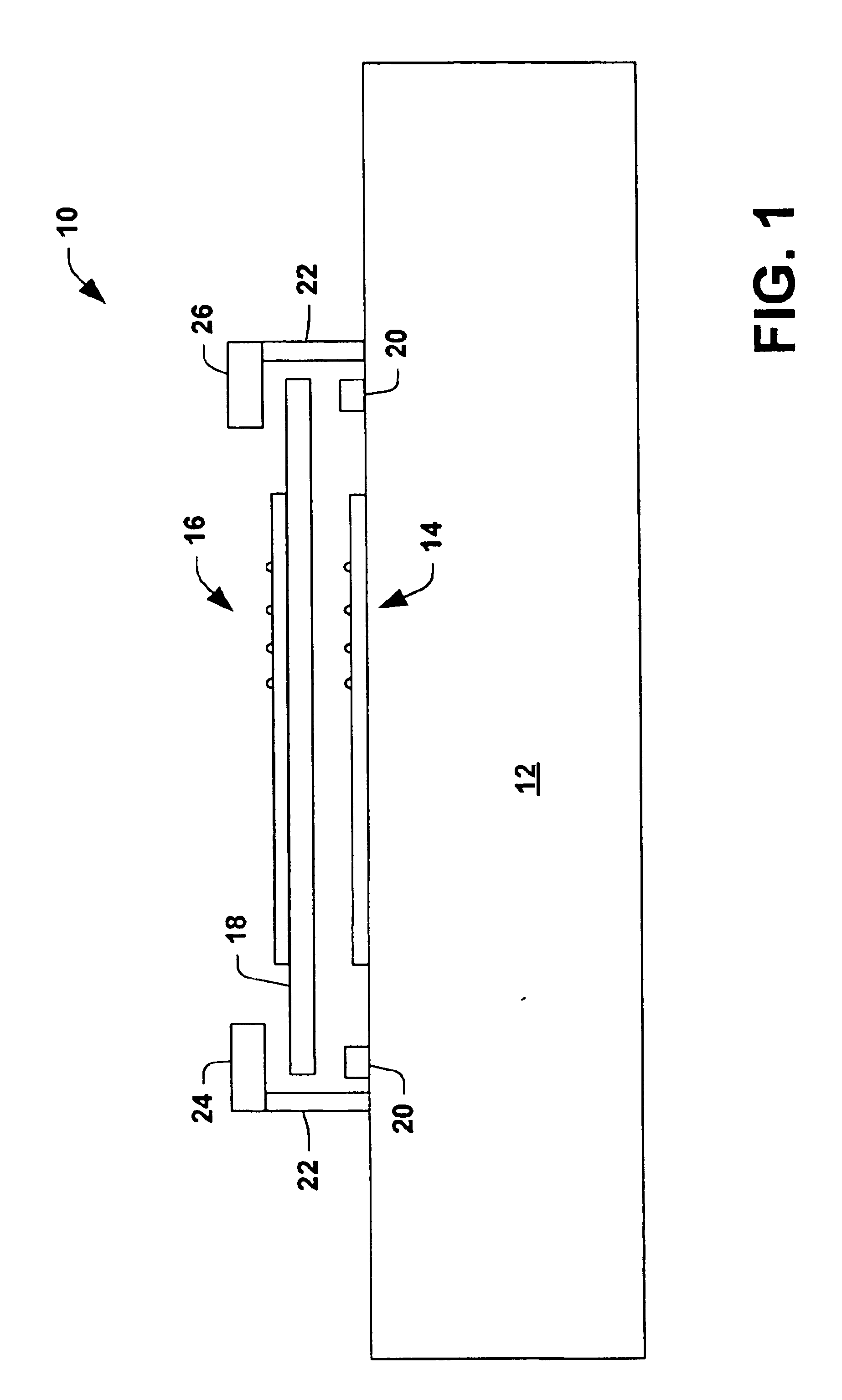

Micro-Electro-Mechanical System (MEMS) Variable Capacitor Apparatus and Related Methods. According to one embodiment, a MEMS variable capacitor is provided. The variable capacitor can include first and second electrodes being spaced apart, and at least one of the electrodes being movable when a voltage is applied across the first and second electrodes. The variable capacitor can also include a first conductive plate attached to and electrically isolated from the first electrode. Furthermore, the variable capacitor can include a second conductive plate attached to the second electrode and spaced from the first conductive plate for movement of at least one of the plates with respect to the other plate upon application of voltage across the first and second electrodes to change the capacitance between the first and second plates.

Owner:AAC TECH PTE LTD

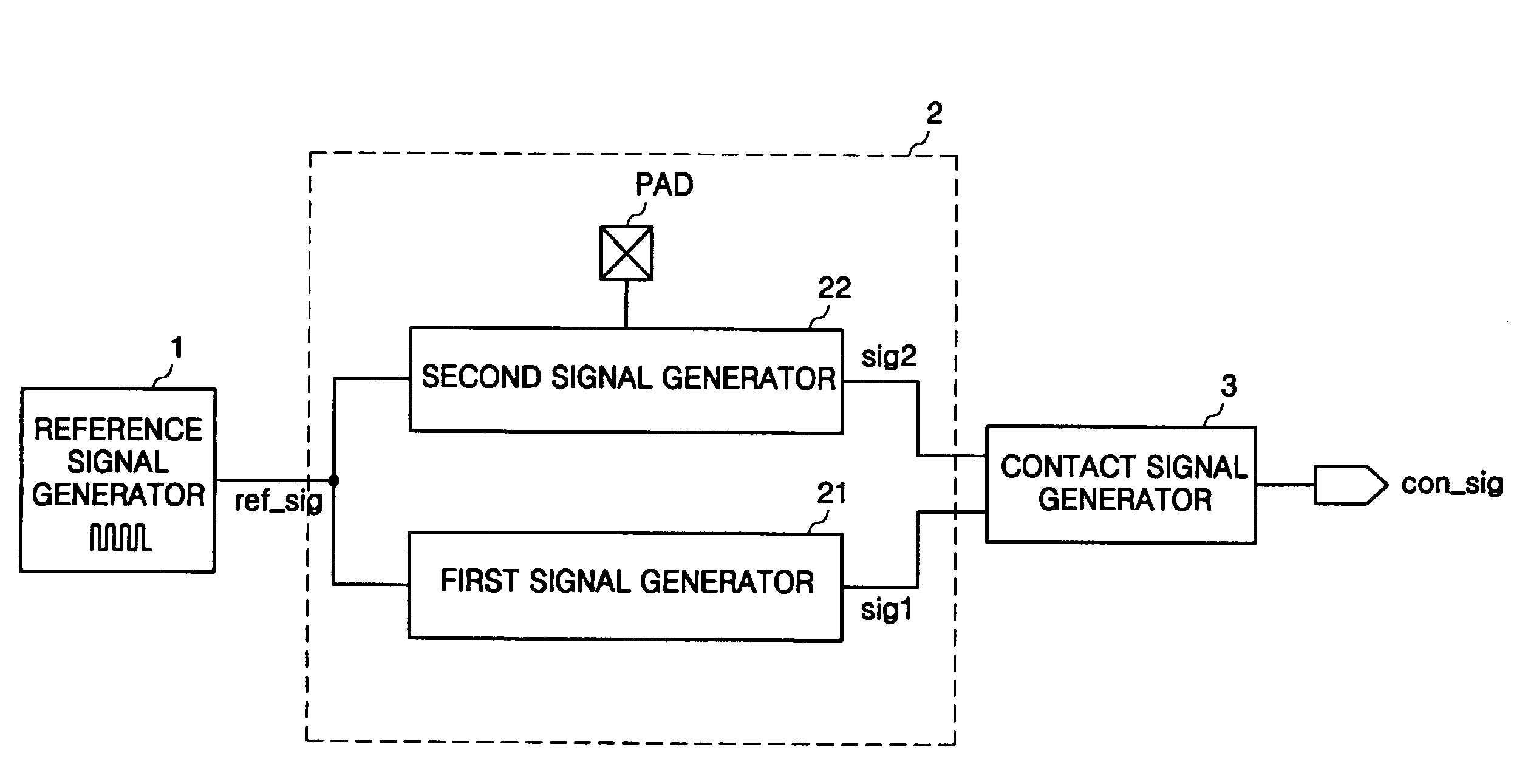

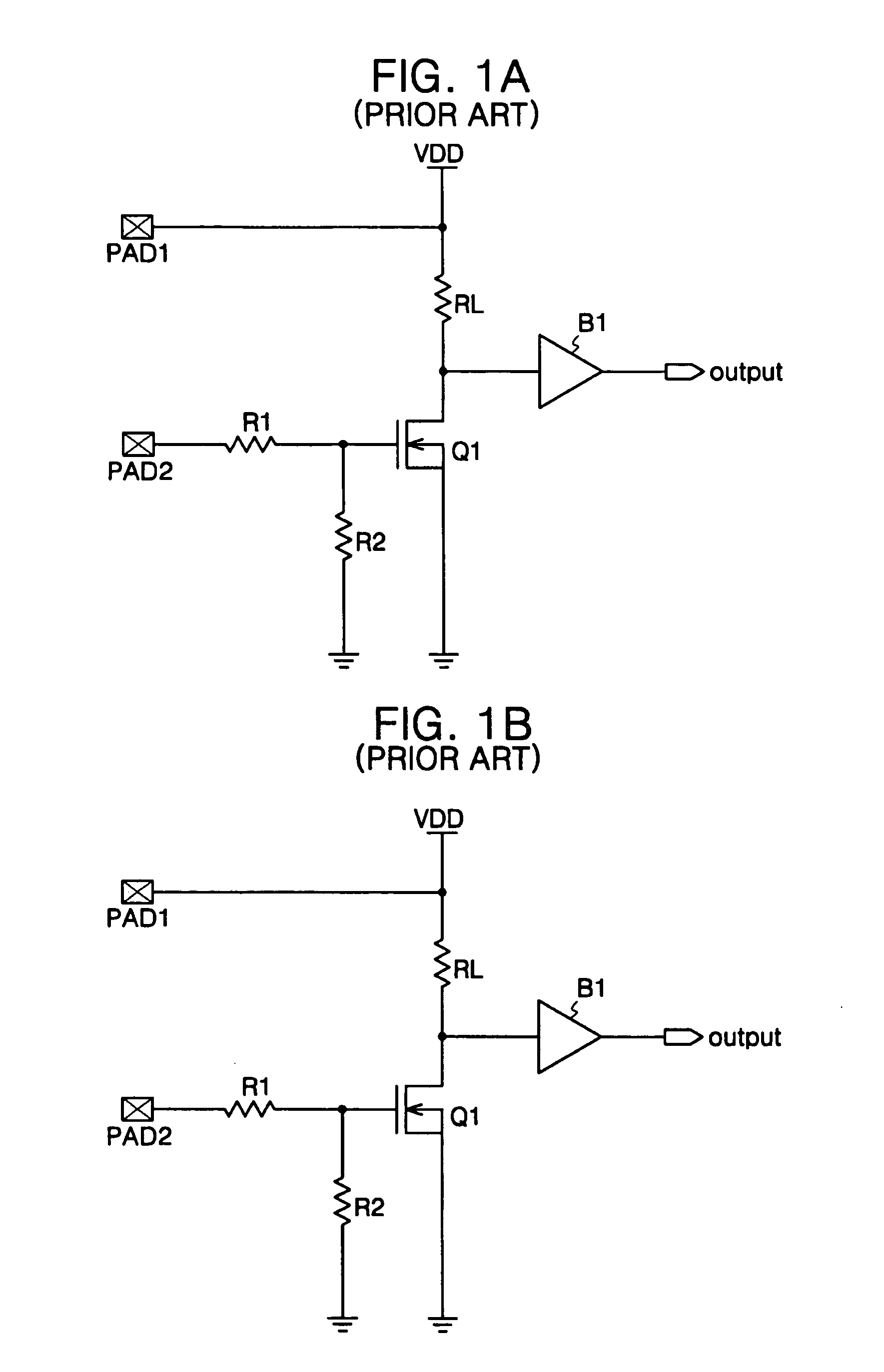

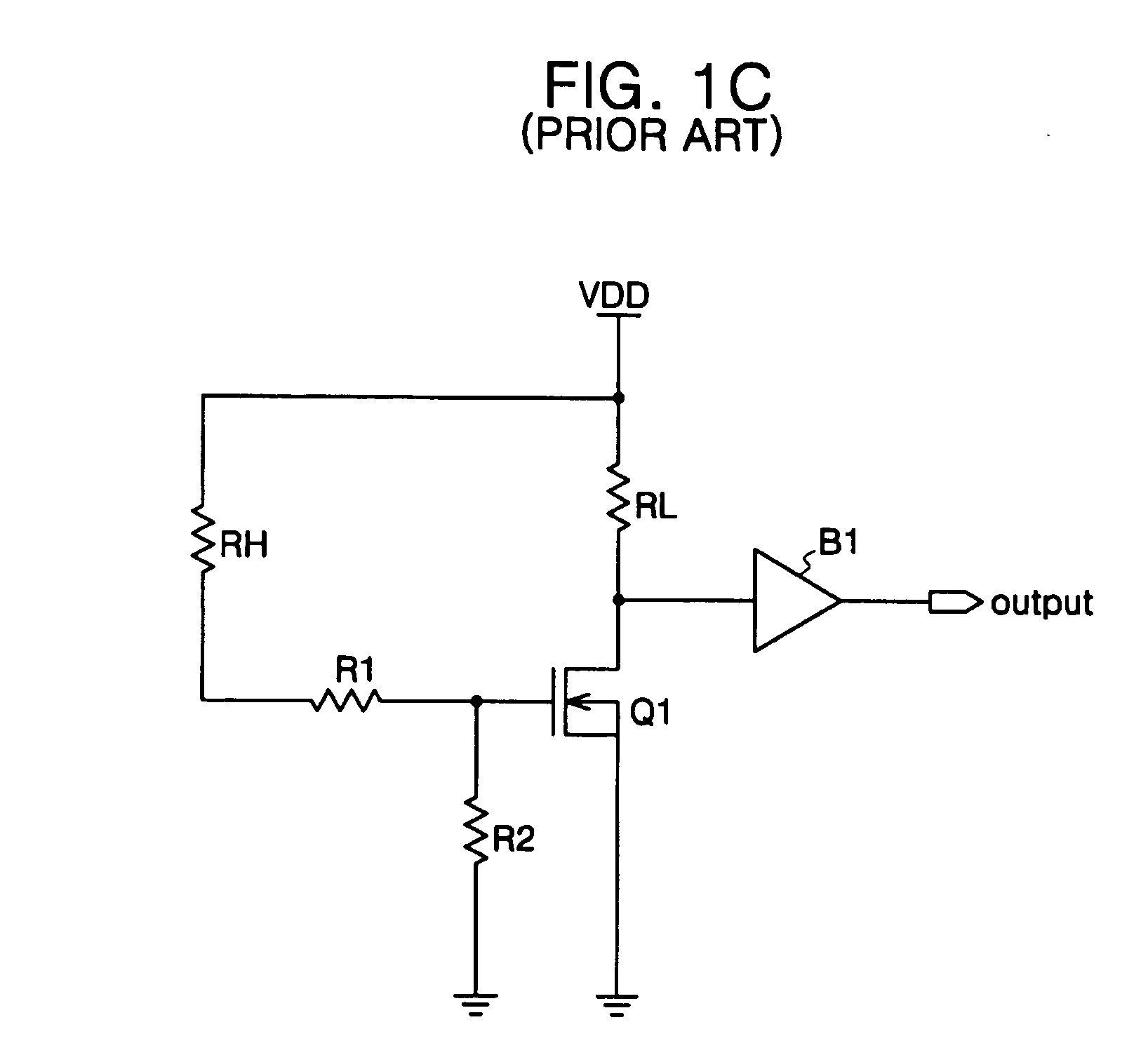

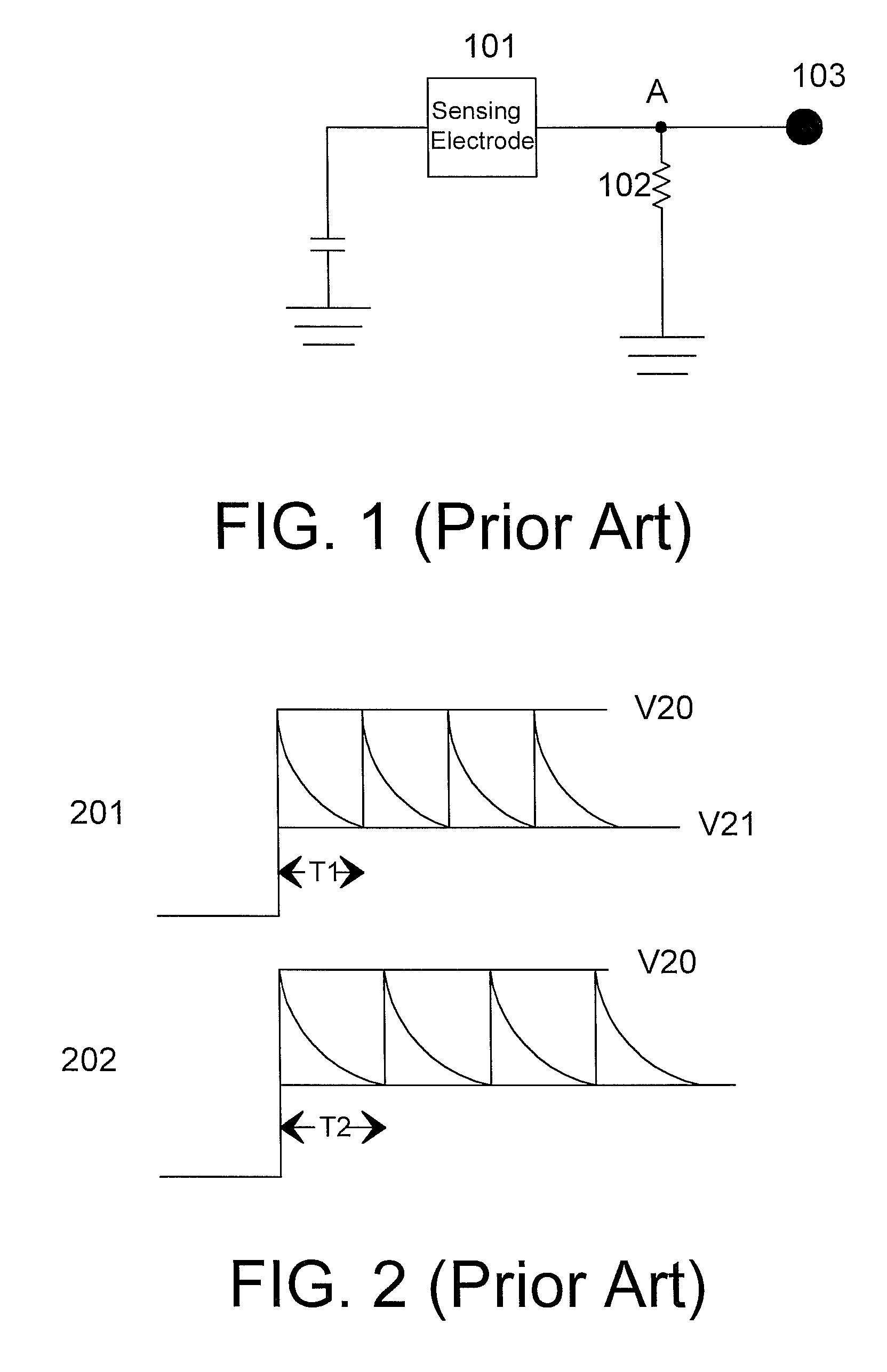

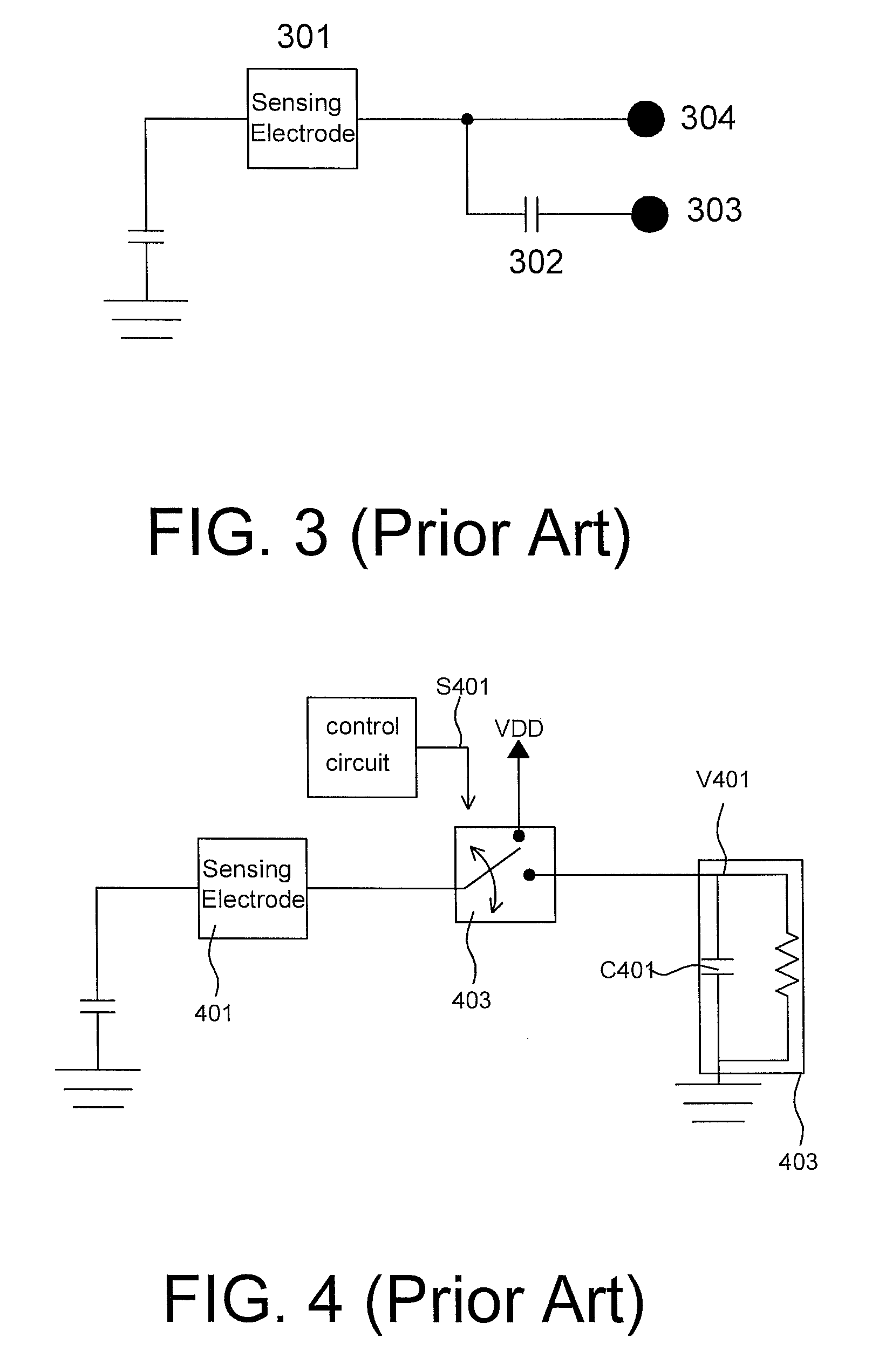

Electrical touch sensor and human interface device using the same

ActiveUS20060007181A1Accurate detectionMechanically variable capacitor detailsCapacitor with electrode distance variationTouchpadSignal generator

An electrical touch sensor is provided. The electrical touch sensor includes: a touch detection part having at least one touch pad and generating a first signal having a same delay time regardless of whether the object is in contact with the touch pad and a second signal having a varied delay time according to whether the object is in contact with the touch pad; and a contact signal generator generating a contact signal in response to the delay time-difference between the first and second signals. Therefore, it is possible to increase operation reliability by precisely determining whether the object is in contact with the pad, when the object has charge accumulation characteristics more than a certain level, although its conductive is insufficient. In addition, the electrical touch sensor can determine whether the object is in contact with the pad using only one pad to reduce a layout area of a product.

Owner:III HLDG 2

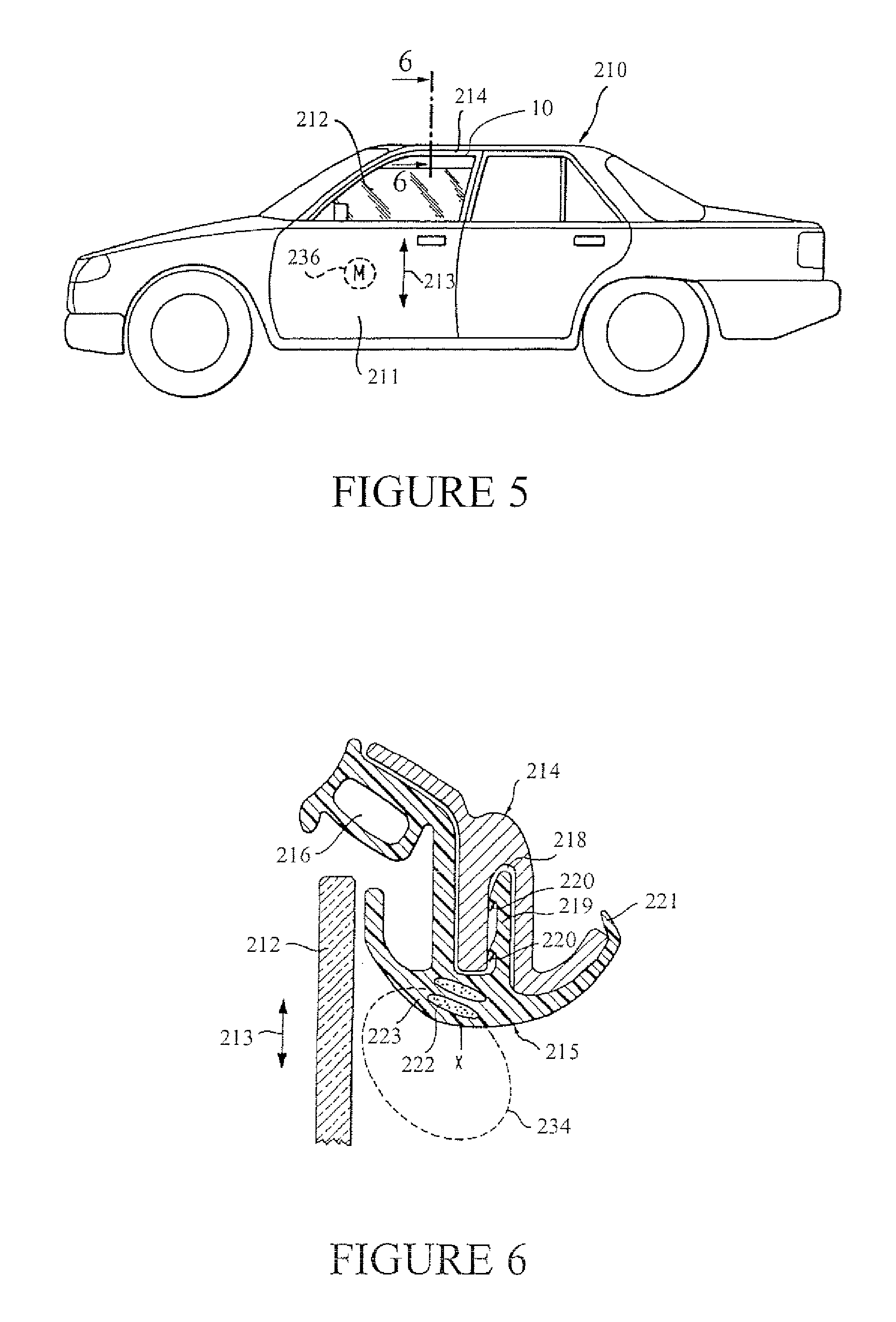

Capacitive sensor having flexible polymeric conductors

InactiveUS7215529B2Avoid displacementConstant separationAnti-noise capacitorsEngine sealsElectrical conductorCapacitive sensing

A capacitive sensor having a first and a second polymeric conductor are embedded within a non conducting body, wherein the body maintains a fixed separation distance between the first and the second polymeric conductor. The body can include a non conducting web, wherein the web substantially precludes variation in the spacing of the polymeric conductors during use in the intended operating environment.

Owner:SCHLEGEL

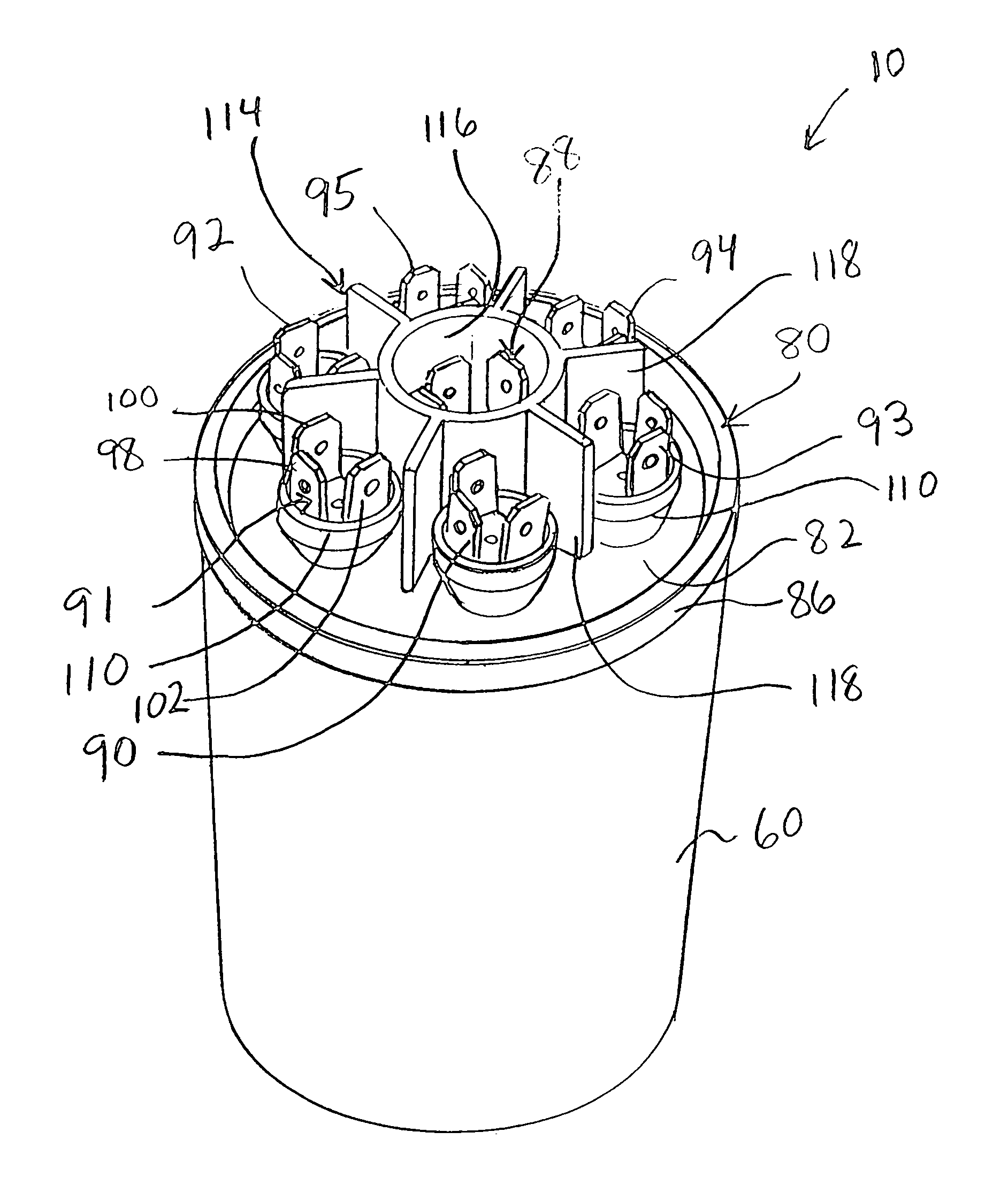

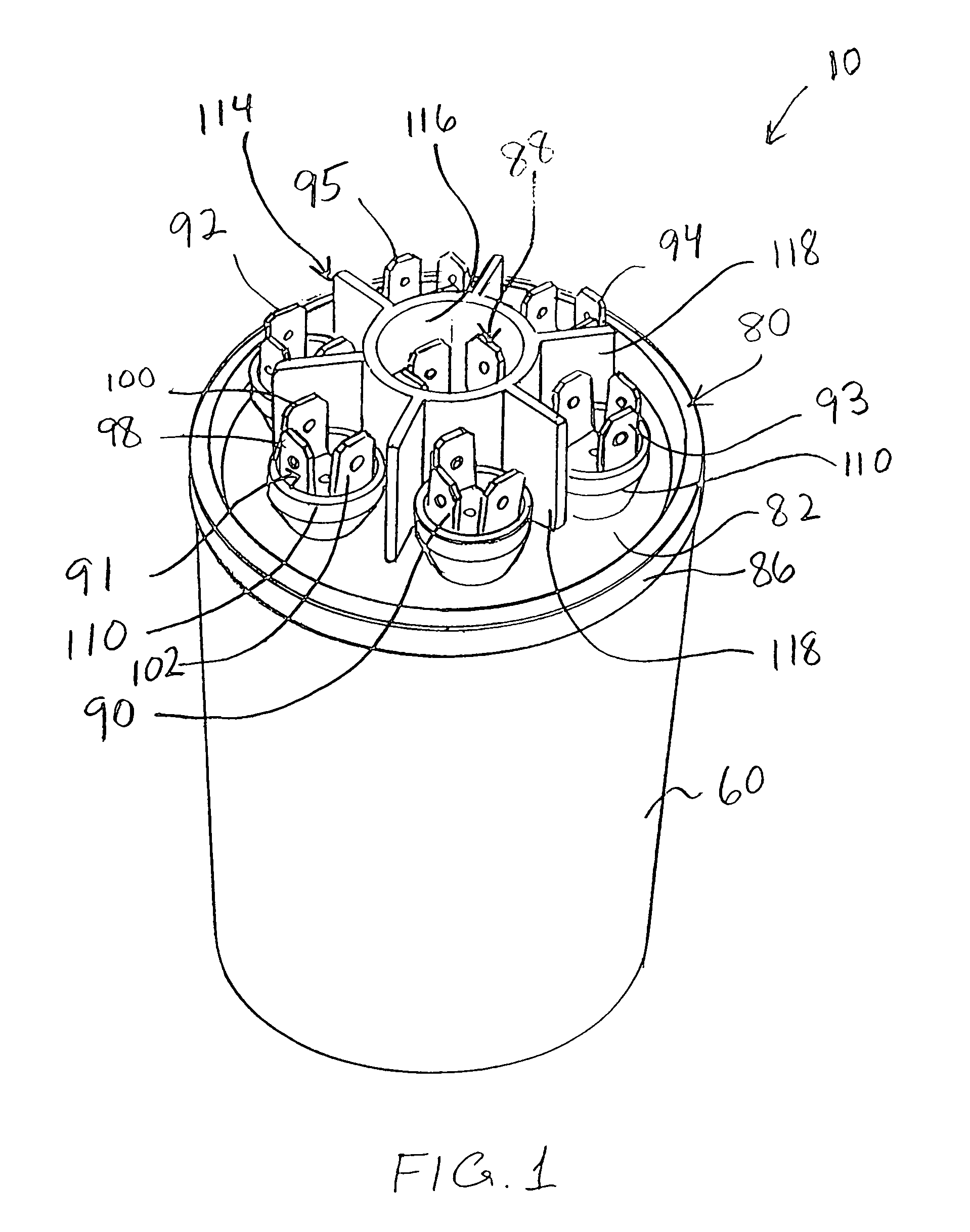

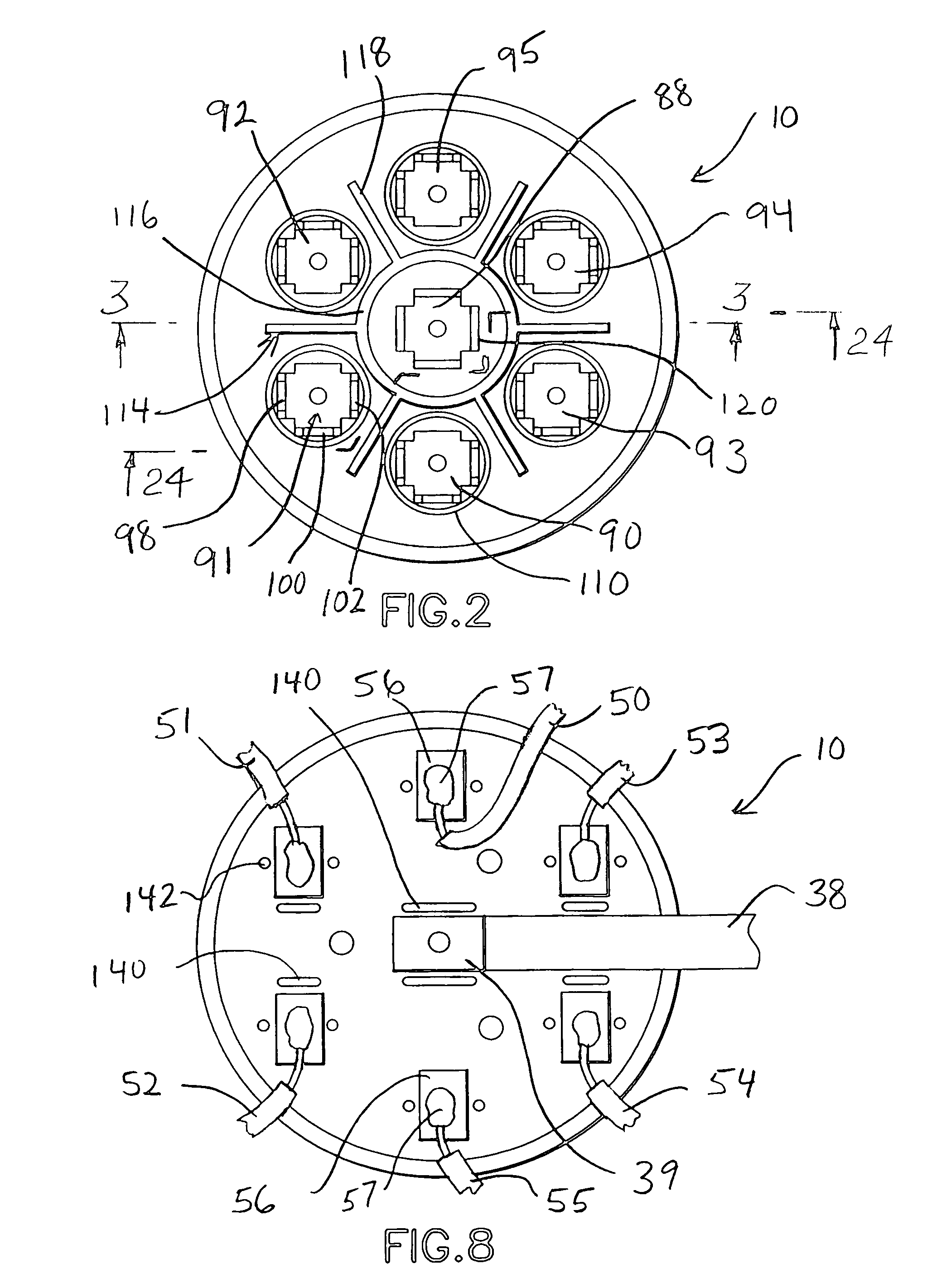

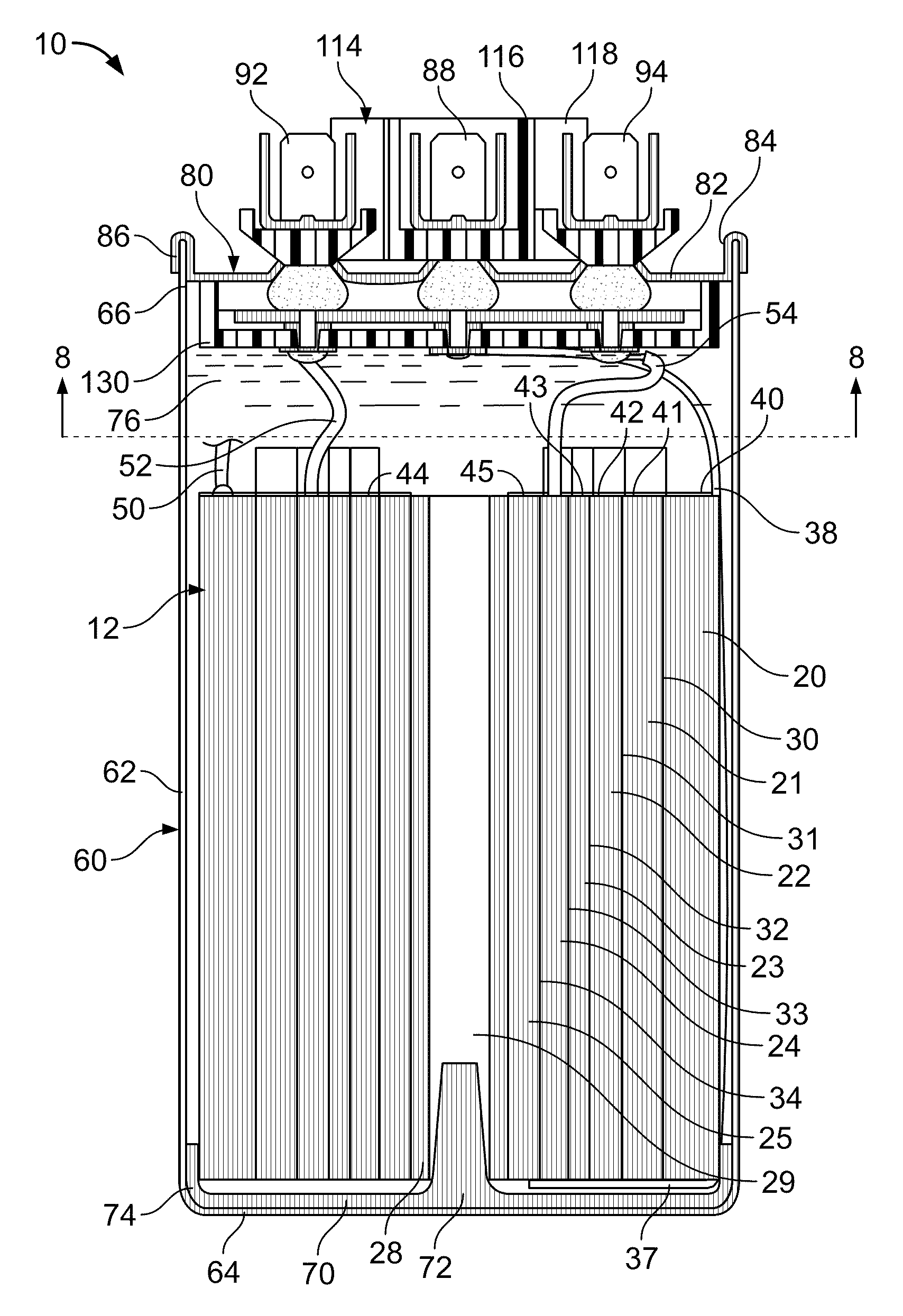

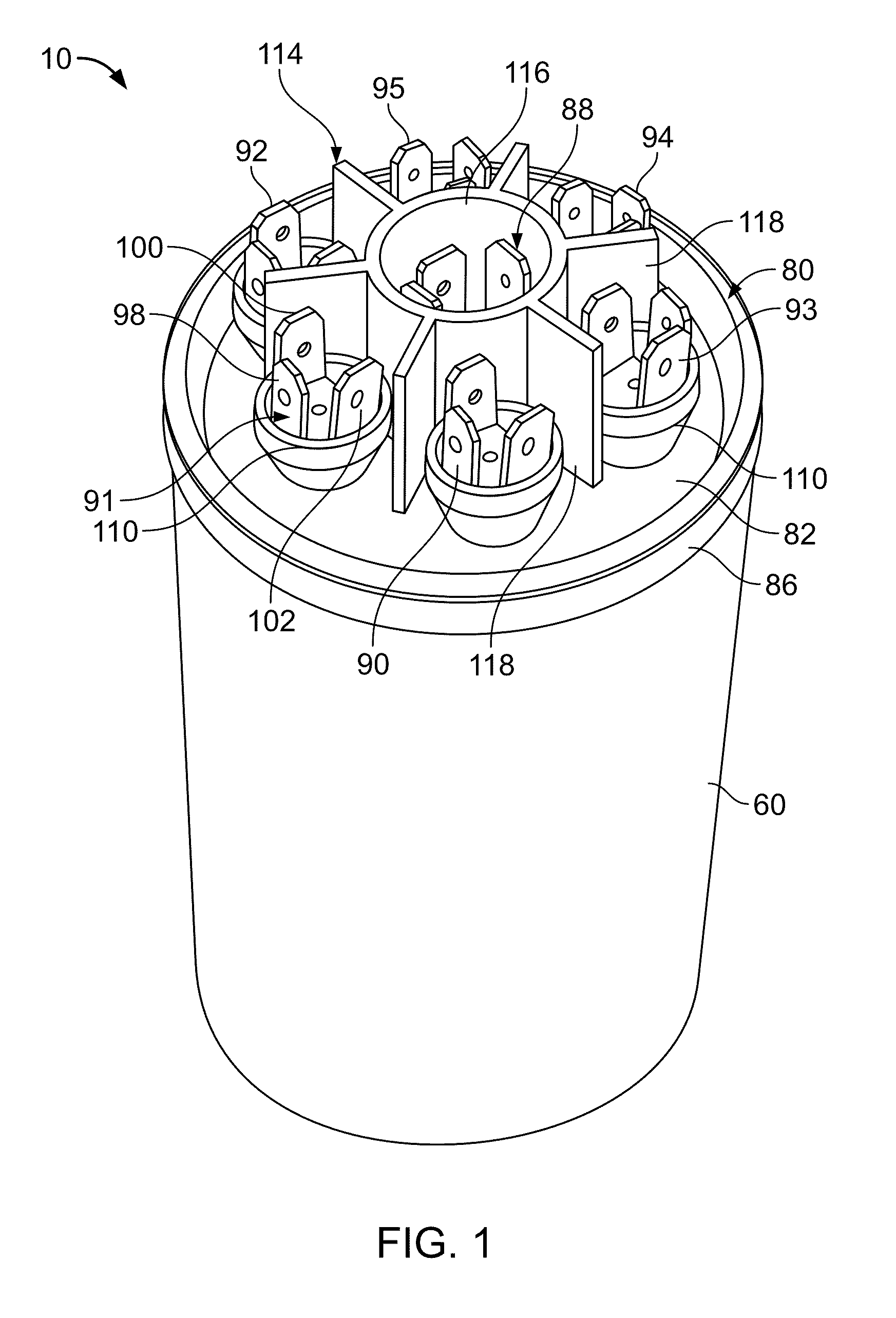

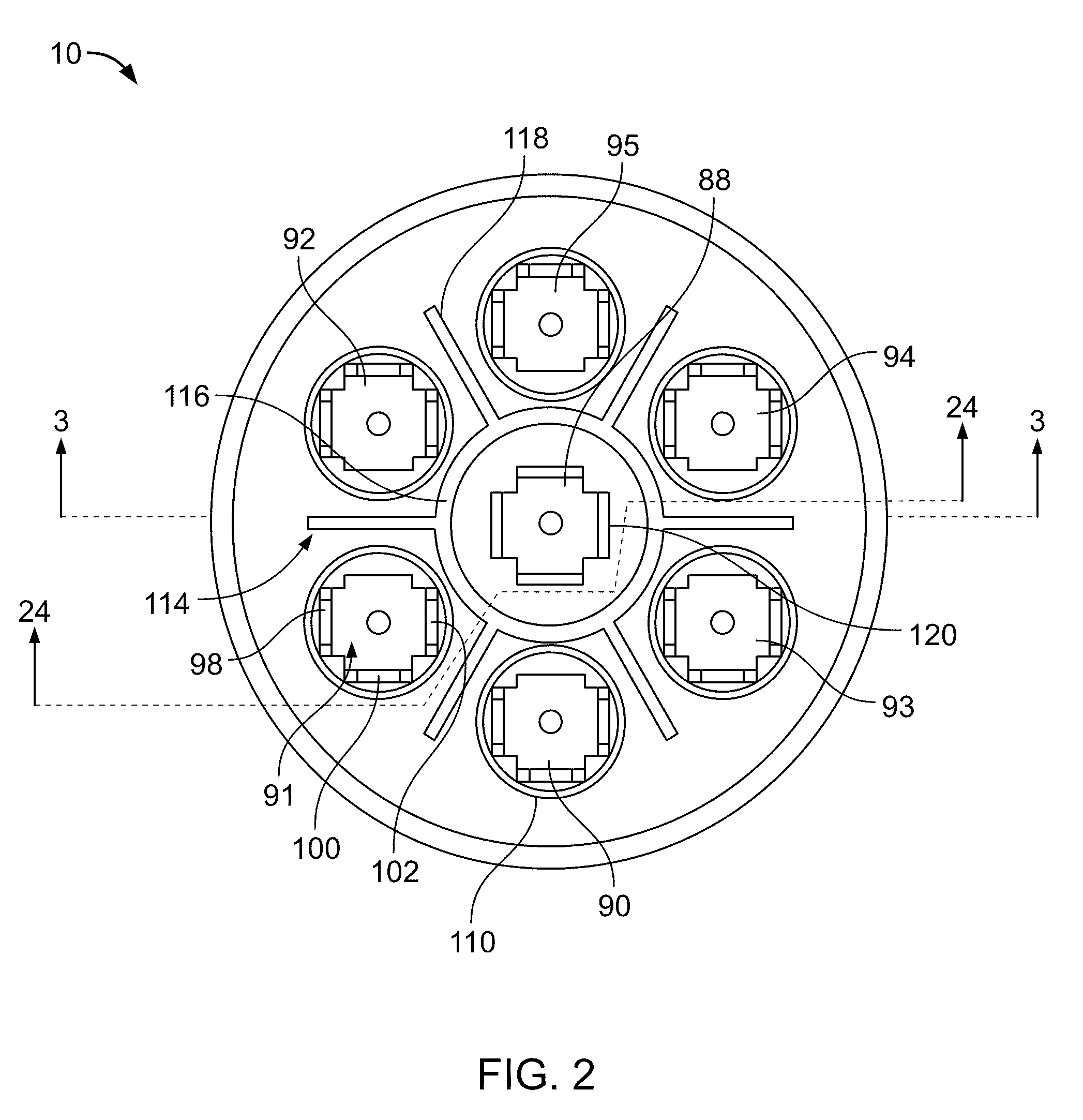

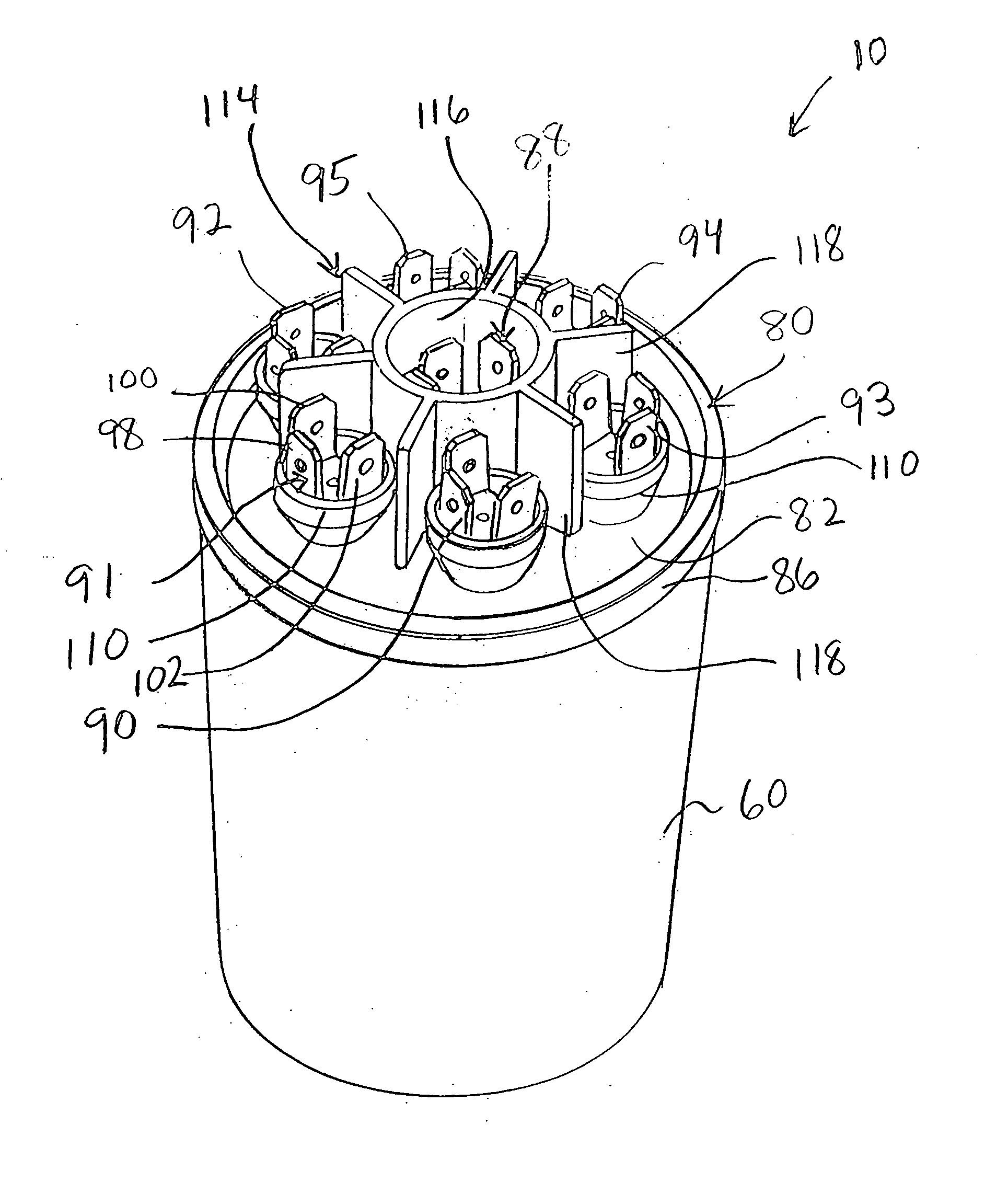

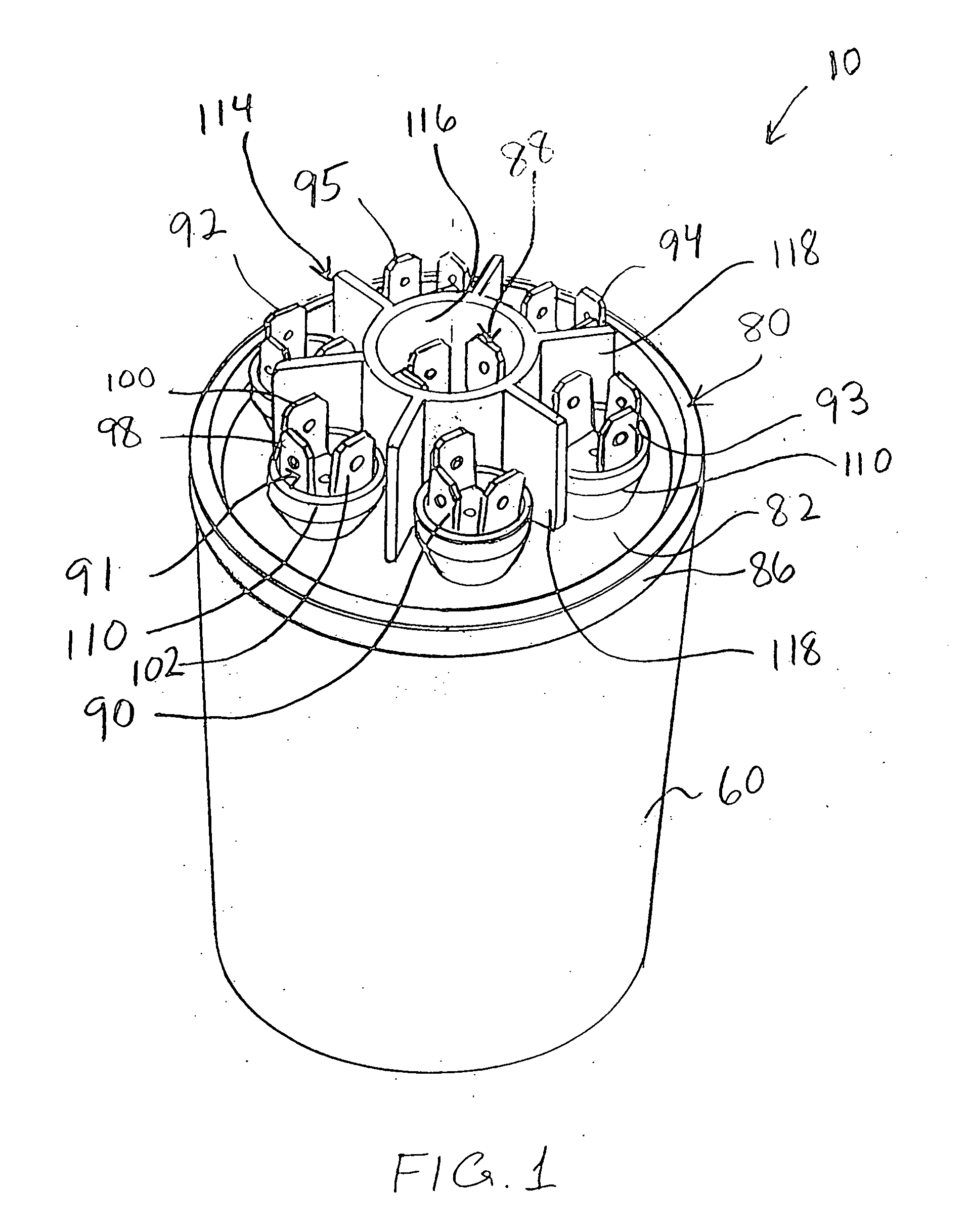

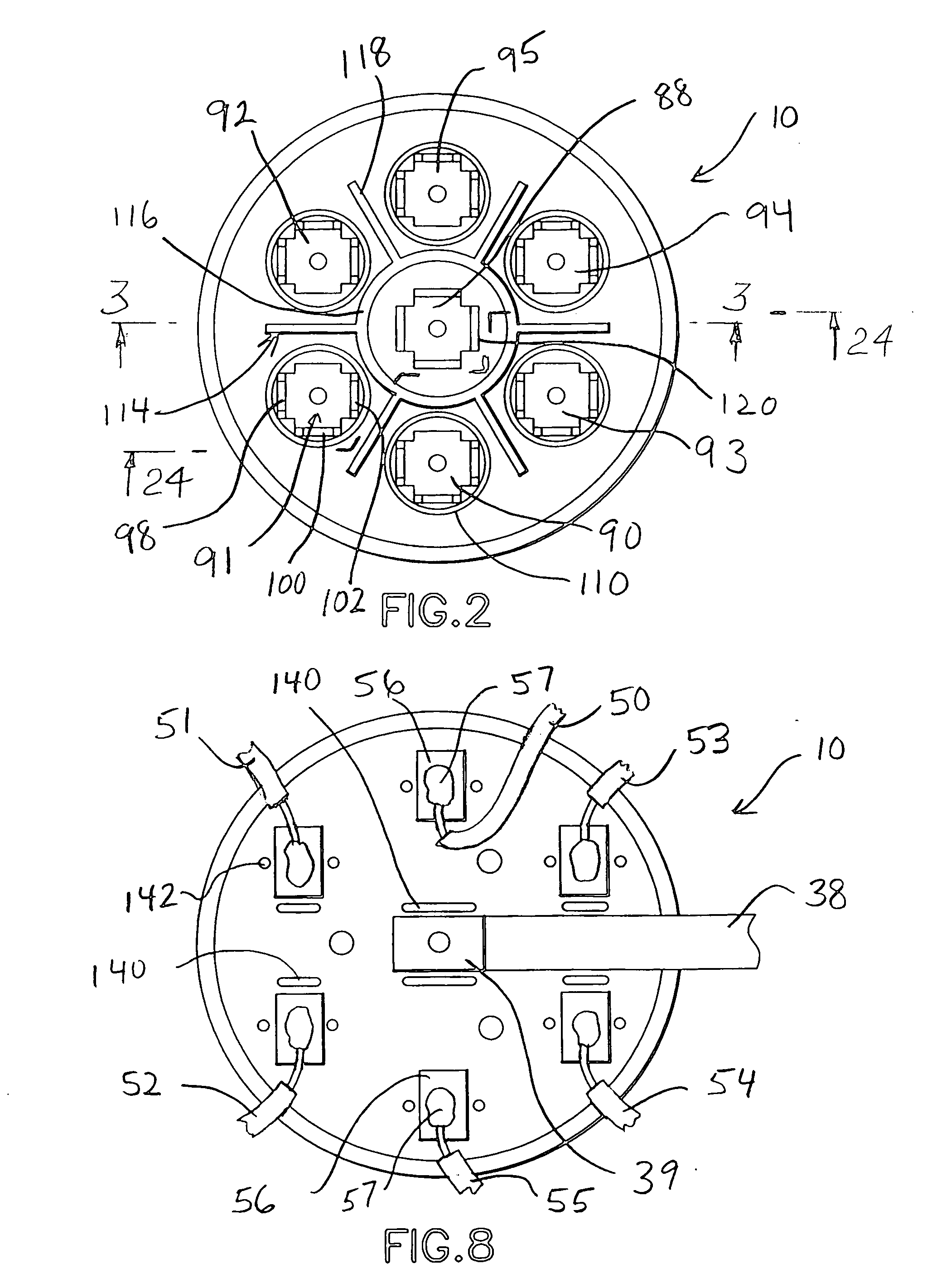

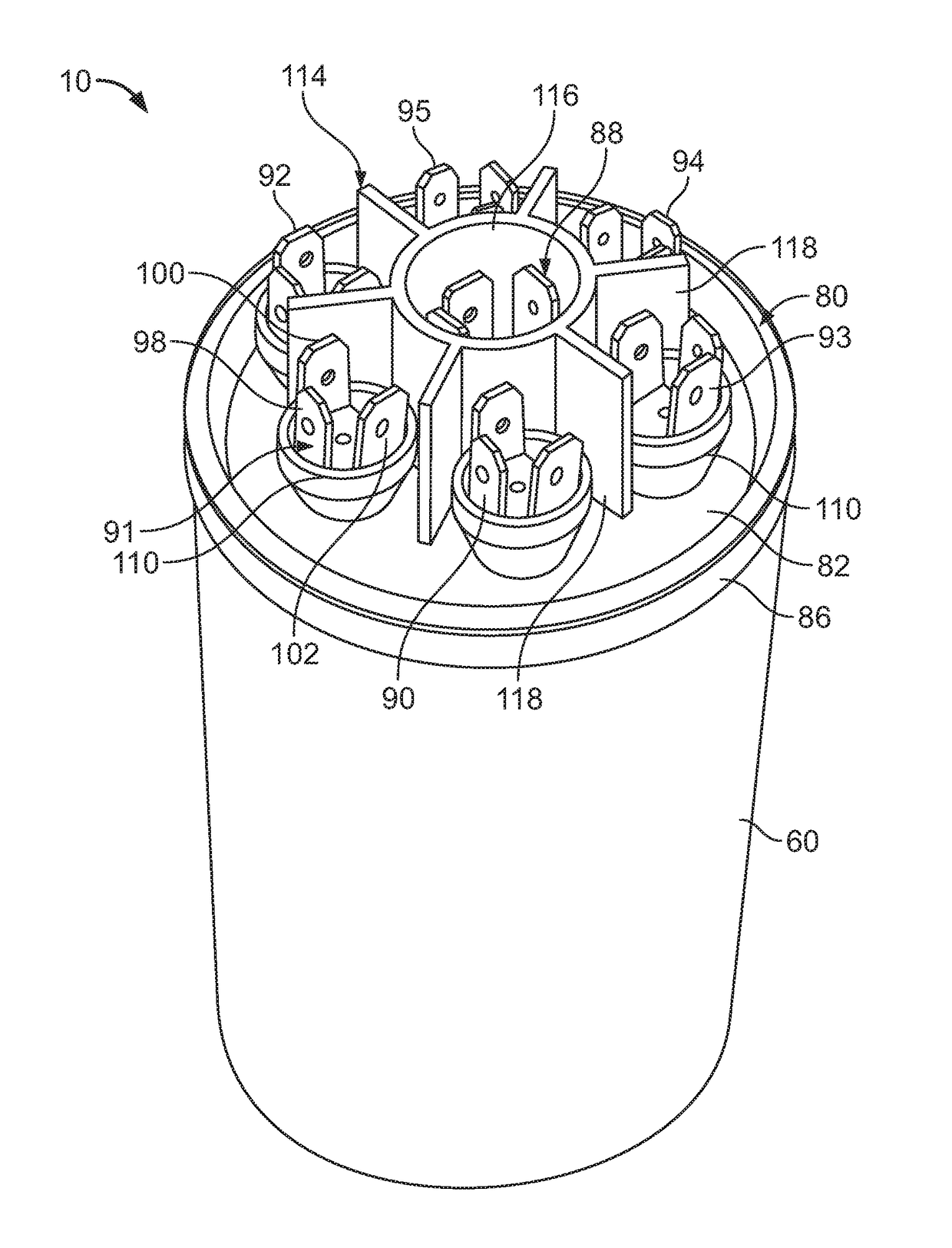

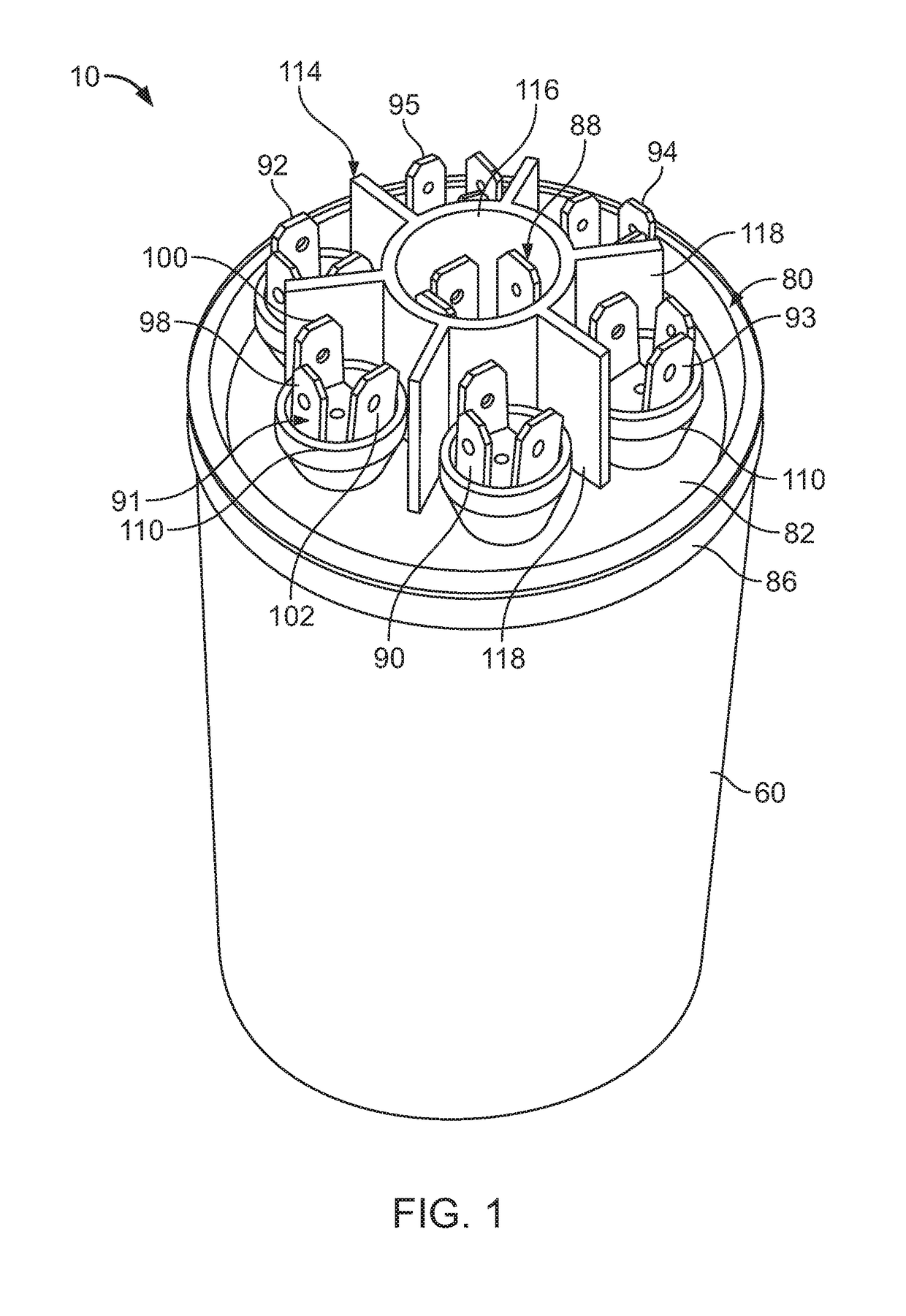

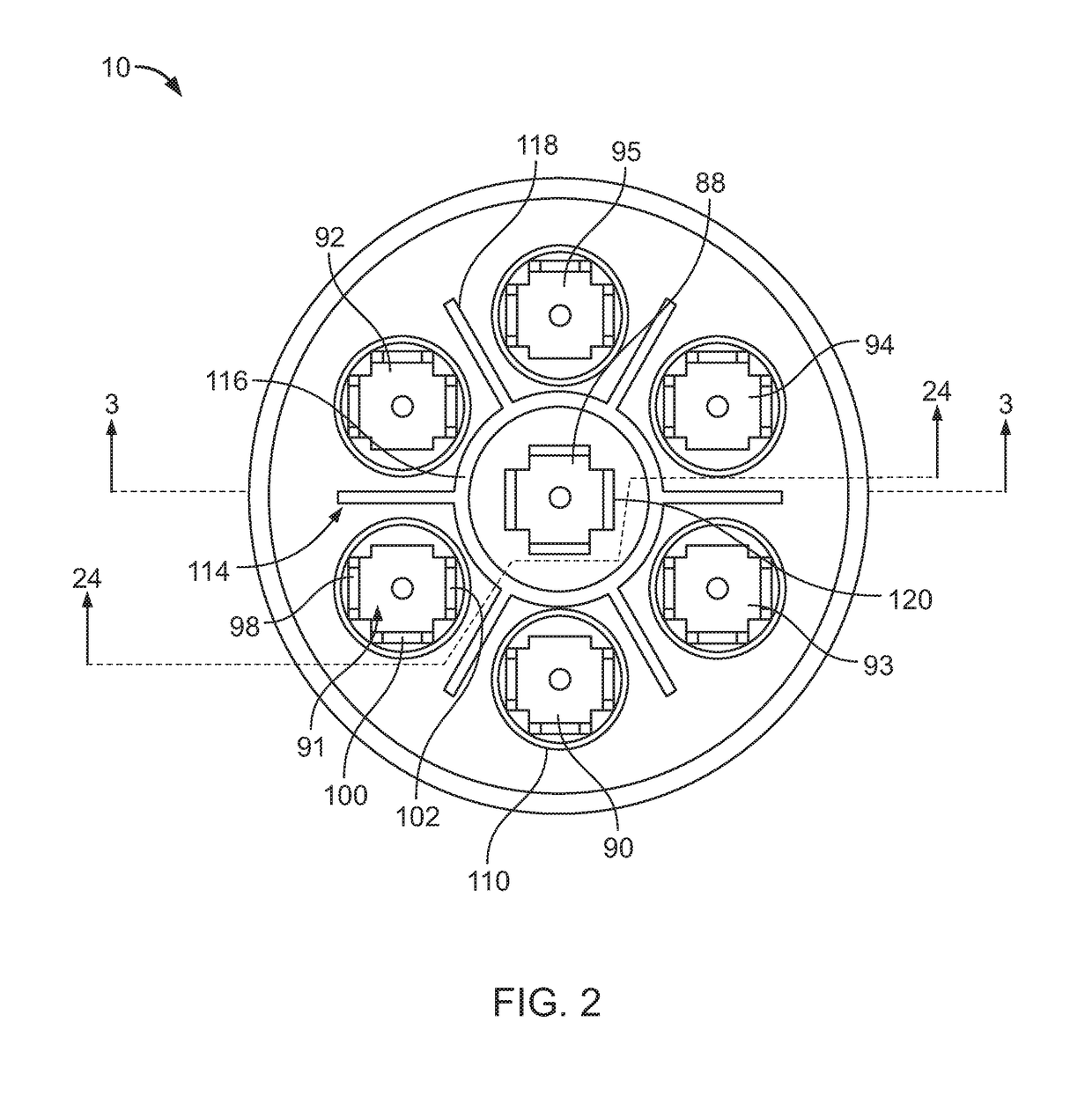

Capacitor with multiple elements for multiple replacement applications

ActiveUS7423861B2Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six capacitor sections of a capacitive element each having a capacitance value. The capacitor sections are provided in a plurality of wound cylindrical capacitive elements. Two vertically stacked wound cylindrical capacitance elements may each provide three capacitor sections. There may be six separately wound cylindrical capacitive elements each providing a capacitor section. The capacitor sections have a common element terminal. A pressure interrupter cover assembly is sealingly secured to the open end of case for the elements and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitor section to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover terminals.

Owner:AMRAD MFG LLC

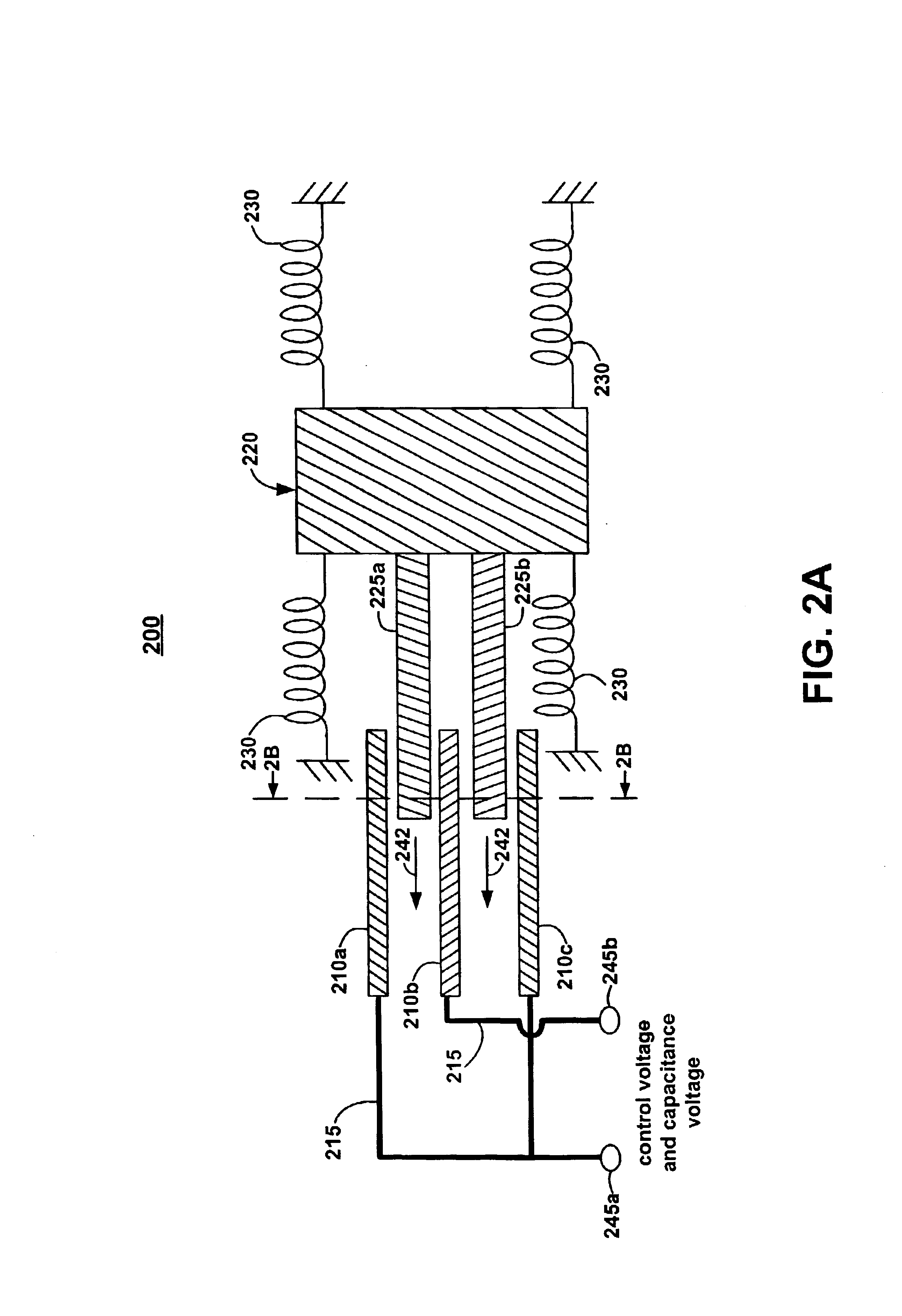

MEMS-based variable capacitor

ActiveUS6909589B2Low loss tangentSimple processMechanically variable capacitor detailsSemiconductor/solid-state device detailsCapacitanceClosed loop

A variable capacitor device using MEMS or micromachining techniques wherein thin-films of materials are deposited, patterned and etched to form movable micromechanical elements on the surface of a substrate composed of either semiconductor, glass, metal, or ceramic material. In one embodiment of the present invention to achieve higher frequency performance as well as other benefits, the substrate is comprised of Low-Temperature Co-Fired Ceramics (LTCC). The variable capacitor is an electrostatically actuated micromechanical device and if fabricated on a LTCC multi-layered substrate material has continuous electrical connections through the layers. The same LTCC substrate material can also be used to enclose the device by selectively removing a portion of the upper substrate so as to form a cavity. The two substrates are then bonded together to enclose and protect the variable capacitor. An integrated circuit can be incorporation onto the multi-level substrate structure to enable a electronic closed-loop controlled variable capacitor module. The integrated circuit is flip-chip bonded at the bottom of the substrate structure with appropriate electrical connections between the integrated circuit and the MEMS variable capacitor device. A variation of the present invention utilizes a zipper actuation method wherein the tuning ratio of the variable capacitor is increased to very high levels. Yet another variation of the present invention utilizes a differential gap between the top and bottom electrodes such that the actuation electrodes do not physically contact one another. Yet another implementation of the present invention uses an extra set of electrodes or mechanical mechanism so as to lock the value of the capacitor indefinitely. Yet another implementation uses shaped actuation electrodes so as to linearize the relationship between the applied actuation voltage and the resultant capacitance of the device.

Owner:FOR NAT RES INITIATIVES

Capacitive micro-electro-mechanical sensors with single crystal silicon electrodes

ActiveUS7539003B2Mechanically variable capacitor detailsCapacitor with electrode area variationIn planeAccelerometer

The devices presented herein are capacitive sensors with single crystal silicon on all key stress points. Isolating trenches are formed by trench and refill forming dielectrically isolated conductive silicon electrodes for drive, sense and guards. For pressure sensing devices according to the invention, the pressure port is opposed to the electrical wire bond pads for ease of packaging. Dual-axis accelerometers measuring in plane acceleration and out of plane acceleration are also described. A third axis in plane is easy to achieve by duplicating and rotating the accelerometer 90 degrees about its out of plane axis Creating resonant structures, angular rate sensors, bolometers, and many other structures are possible with this process technology. Key advantages are hermeticity, vertical vias, vertical and horizontal gap capability, single crystal materials, wafer level packaging, small size, high performance and low cost.

Owner:SAMSUNG ELECTRONICS CO LTD

Capacitor with multiple elements for multiple replacement applications

ActiveUS20090219665A1Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

Owner:AMRAD MFG LLC

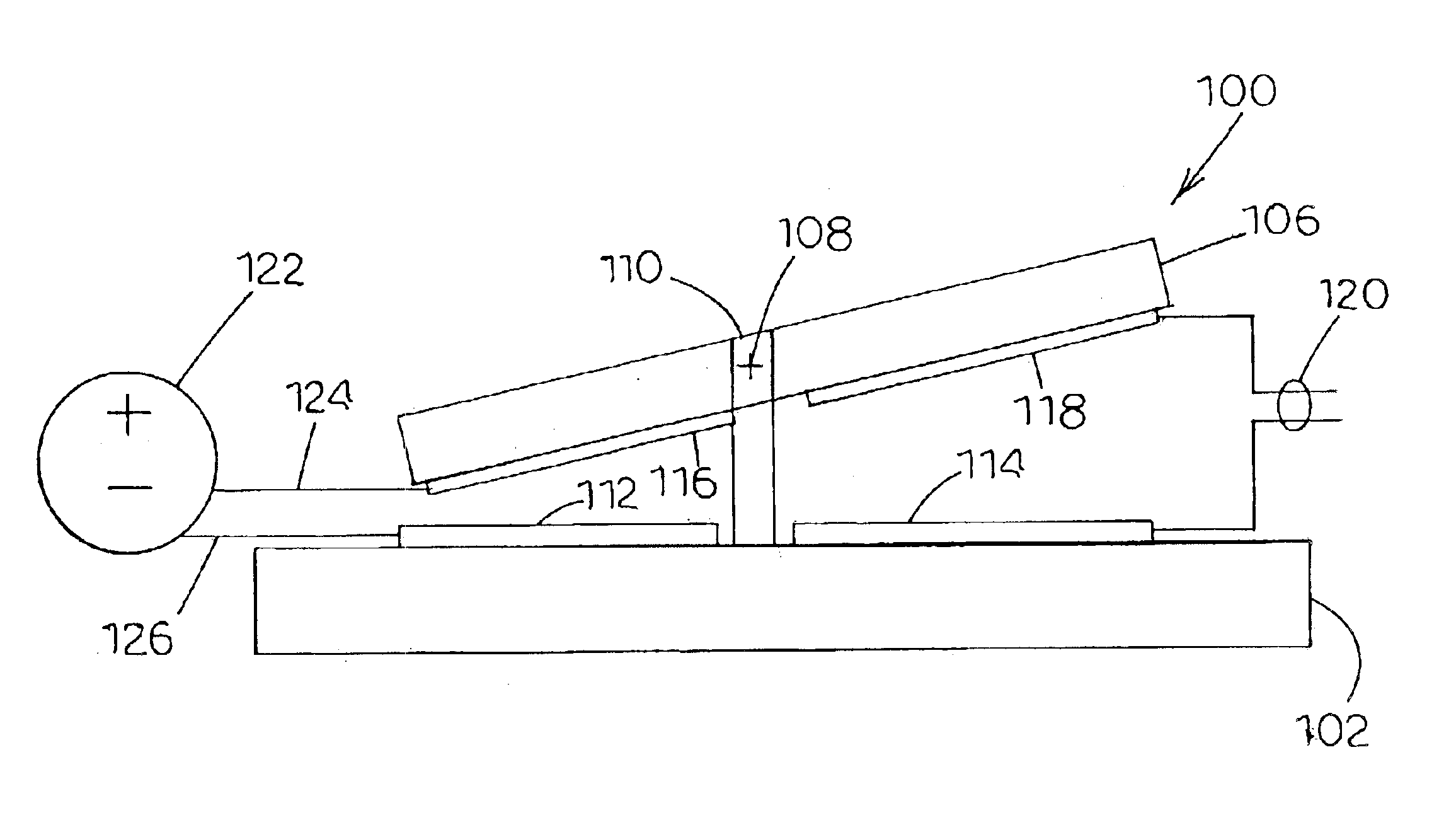

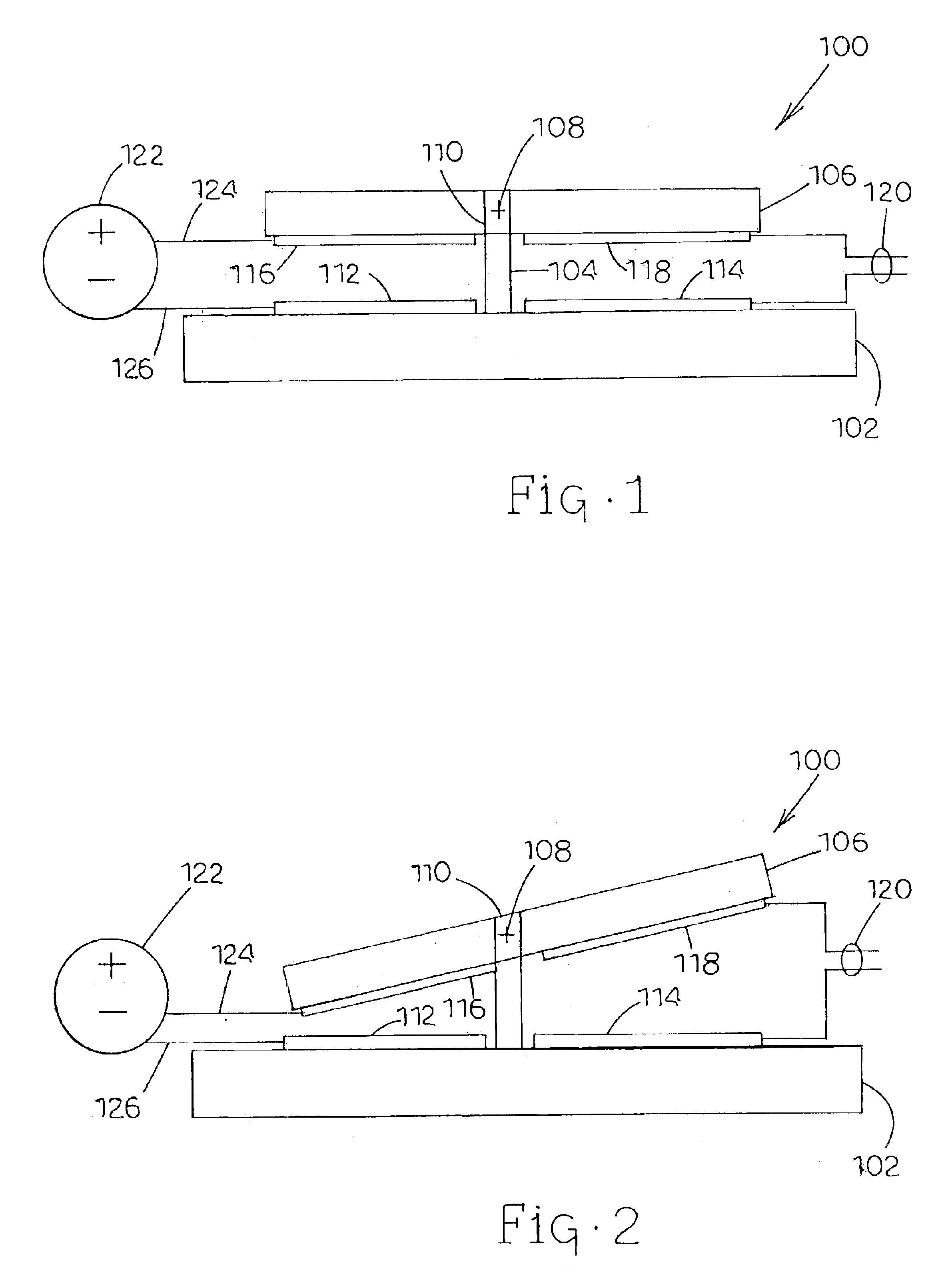

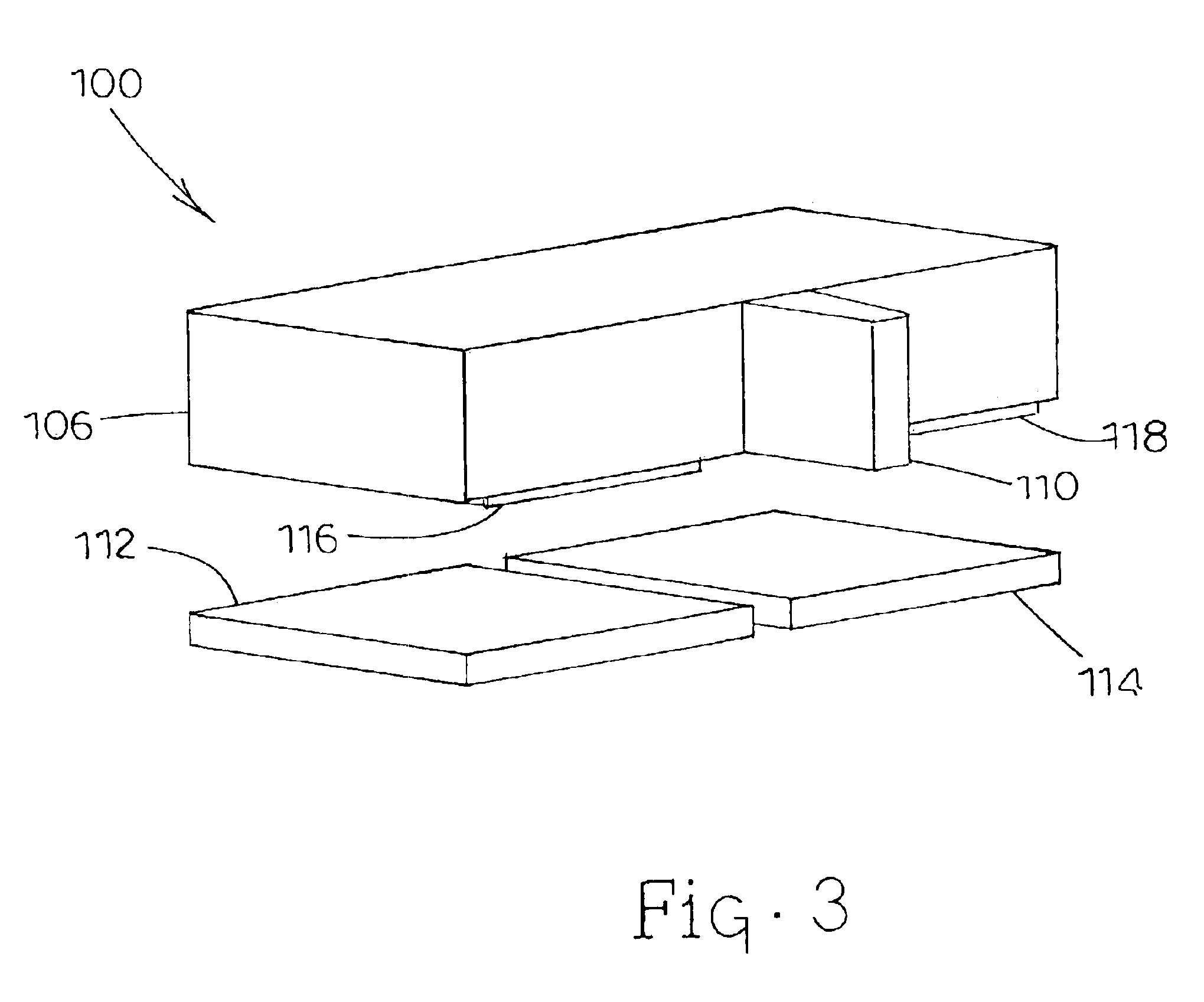

Tunable capacitor

InactiveUS6853534B2Mechanically variable capacitor detailsCapacitor with electrode area variationCapacitanceFixed capacitor

A tunable capacitor. The tunable capacitor has a first fixed capacitor electrode and a second fixed capacitor electrode opposite to one another. The tunable capacitor also has a movable element formed of a conductive material. The movable element is moveable between the first fixed capacitor electrode and the second fixed capacitor electrode to adjust the capacitance between the first fixed capacitor electrode and the second fixed capacitor electrode.

Owner:AGILENT TECH INC

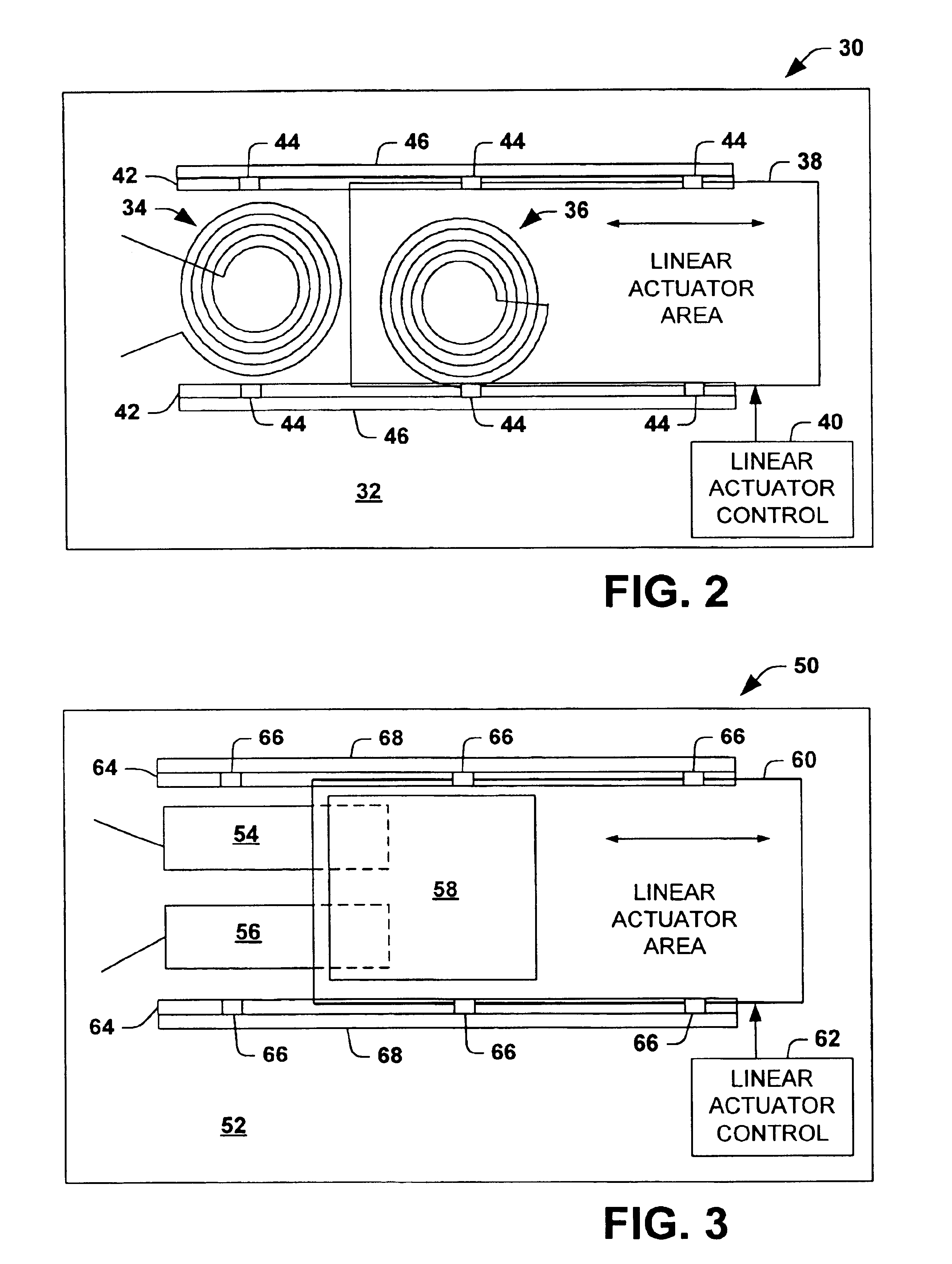

Micro-electro-mechanical system (MEMS) variable capacitor apparatuses, systems and related methods

InactiveUS7180145B2Reducing electrostatic instabilityMechanically variable capacitor detailsPiezoelectric/electrostriction/magnetostriction machinesElectrical and Electronics engineeringMechanical system

Micro-electro-mechanical system (MEMS) variable capacitor apparatuses, system and related methods are provided.

Owner:AAC TECH PTE LTD

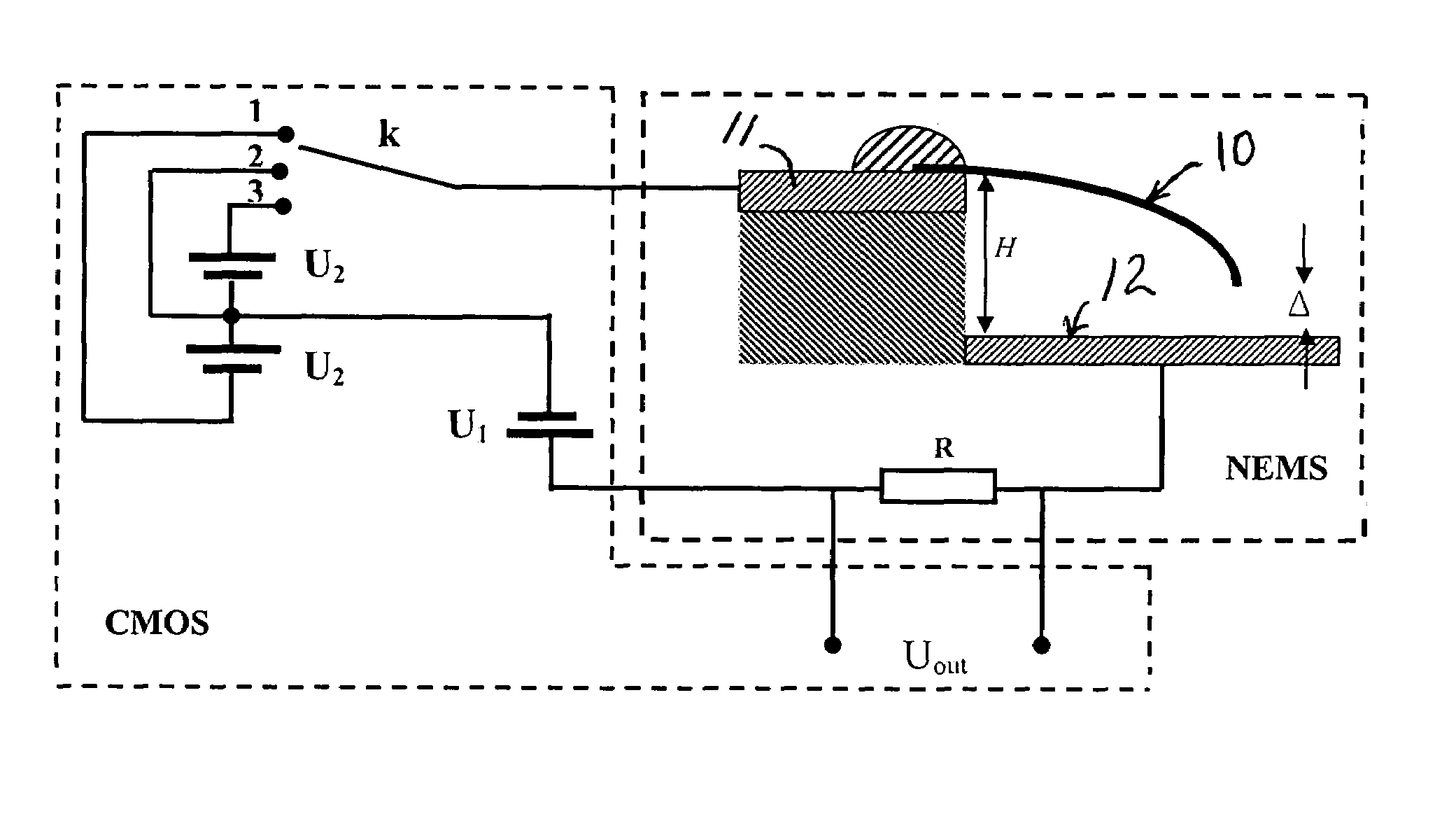

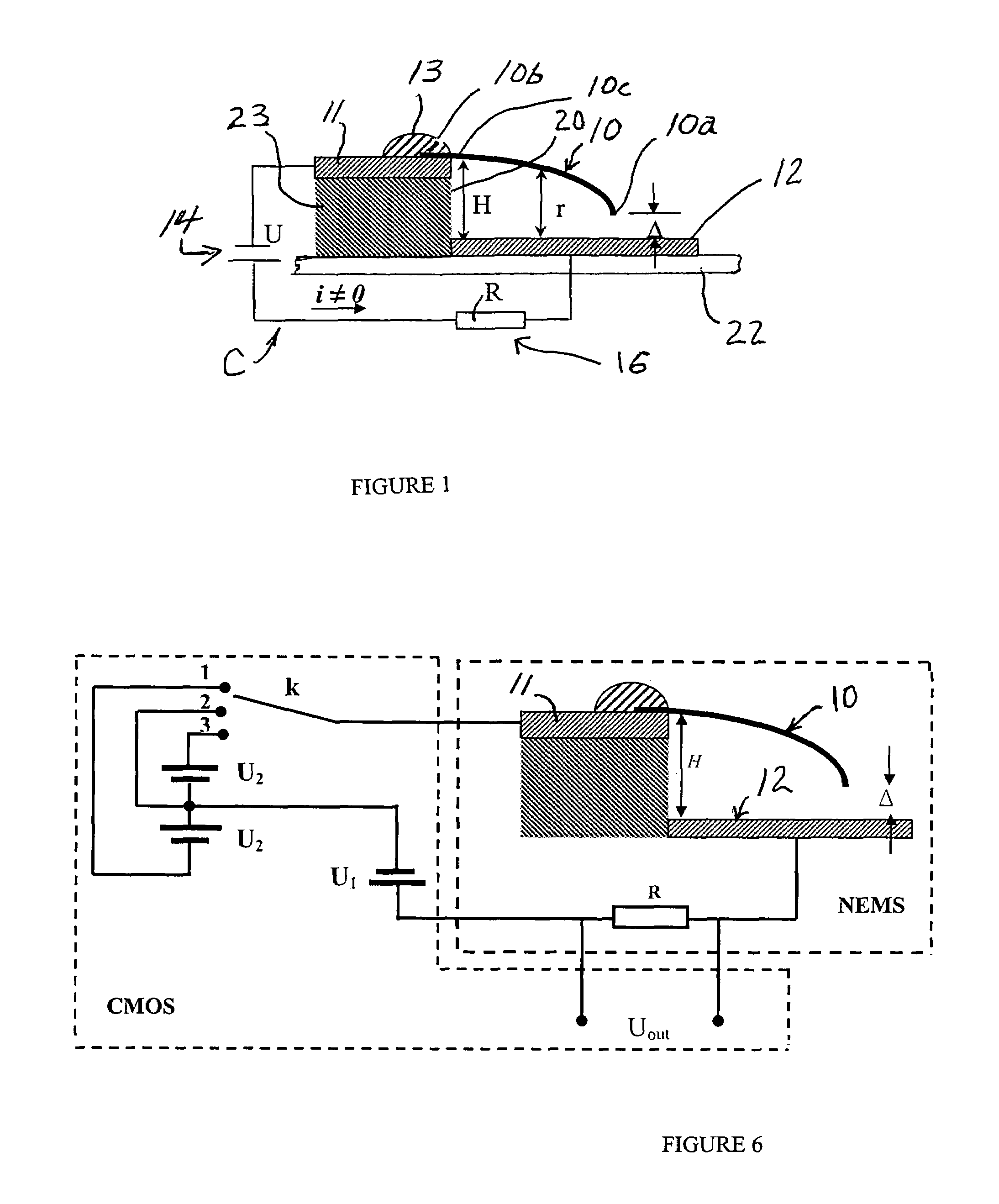

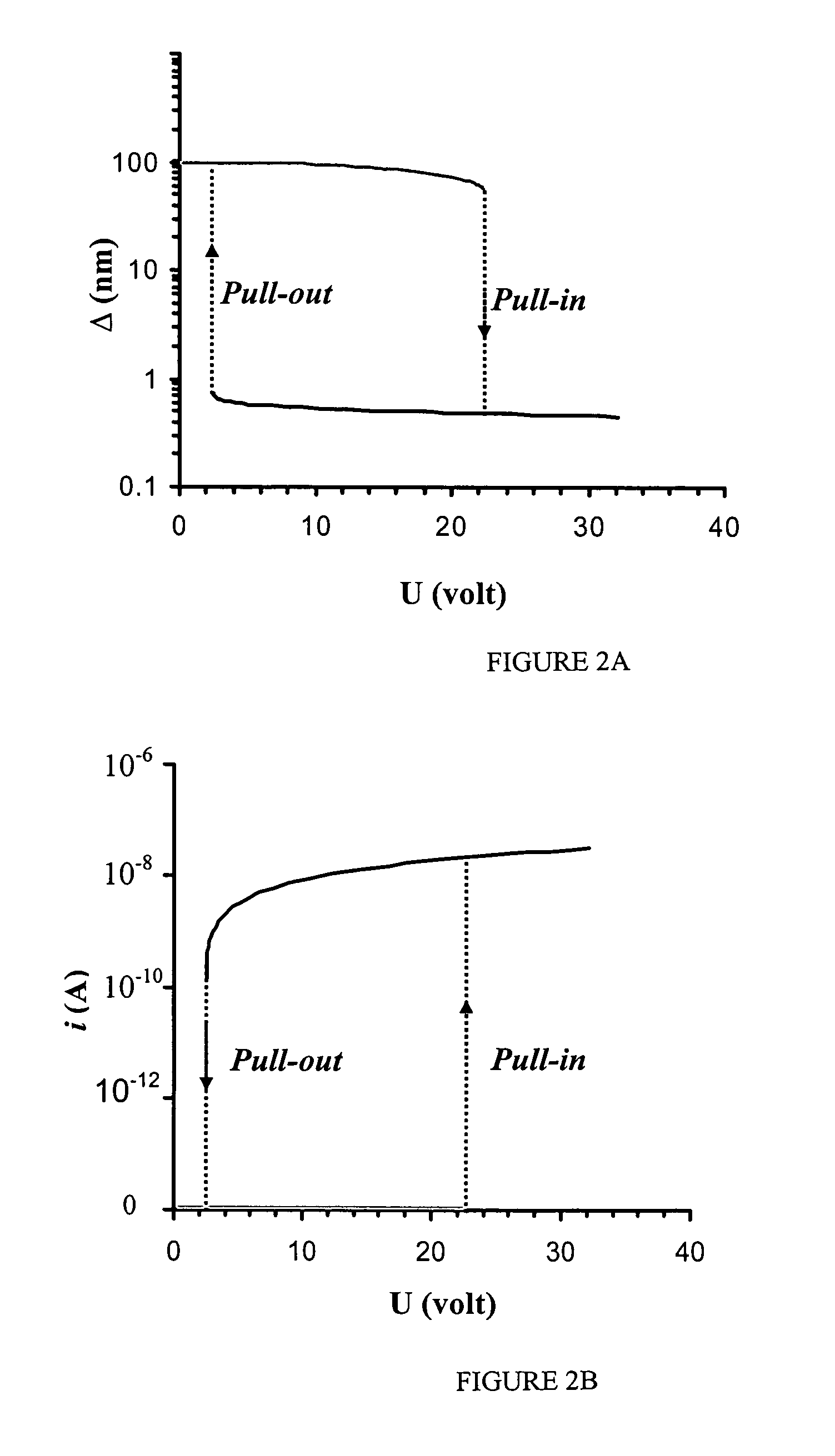

Nanoelectromechanical bistable cantilever device

InactiveUS7612424B1Stable positionMechanically variable capacitor detailsNanoelectromechanical switchesHysteresisWave detection

Nano-electromechanical device having an electrically conductive nano-cantilever wherein the nano-cantilever has a free end that is movable relative to an electrically conductive substrate such as an electrode of a circuit. The circuit includes a power source connected to the electrode and to the nano-cantilever for providing a pull-in or pull-out voltage therebetween to effect bending movement of the nano-cantilever relative to the electrode. Feedback control is provided for varying the voltage between the electrode and the nano-cantilever in response to the position of the cantilever relative to the electrode. The device provides two stable positions of the nano-cantilever and a hysteresis loop in the current-voltage space between the pull-in voltage and the pull-out voltage. A first stable position of the nano-cantilever is provided at sub-nanometer gap between the free end of the nano-cantilever and the electrode with a pull-in voltage applied and with a stable tunneling electrical current present in the circuit. A second stable position of the nano-cantilever is provided with a pull-out voltage between the cantilever and the electrode with little or no tunneling electrical current present in the circuit. The nano-electromechanical device can be used in a scanning probe microscope, ultrasonic wave detection sensor, NEMS switch, random access memory element, gap sensor, logic device, and a bio-sensor when the nano-cantilever is functionalized with biomolecules that interact with species present in the ambient environment be them in air or aqueous solutions. In the latest case, the NEMS needs to be integrated with a microfluidic system.

Owner:NORTHWESTERN UNIV

MEMS tunable capacitor based on angular vertical comb drives

InactiveUS20050013087A1Increase tuning rangeAppreciates the drawbacks inherent in lateral drive MEMS capacitorsMultiple-port networksMechanically variable capacitor detailsCapacitanceComb finger

A MEMS tunable capacitor with angular vertical comb-drive (AVC) actuators is described where high capacitances and a wide continuous tuning range is achieved in a compact space. The comb fingers rotate through a small vertical angle which allows a wider tuning range than in conventional lateral comb drive devices. Fabrication of the device is straightforward, and involves a single deep reactive ion etching step followed by release and out-of-plane assembly of the angular combs.

Owner:RGT UNIV OF CALIFORNIA

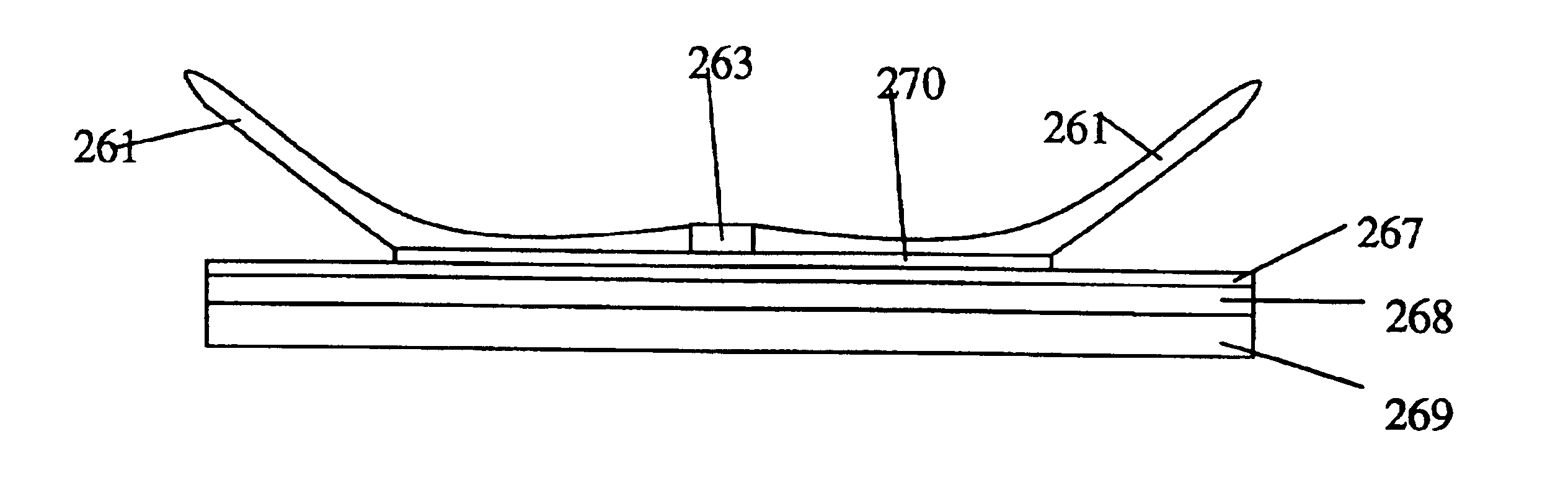

Photolithographically-patterned variable capacitor structures and method of making

InactiveUS6922327B2Speed and easeEliminate needAnti-noise capacitorsMechanically variable capacitor detailsCapacitanceDielectric layer

A new type of high-Q variable capacitor includes a substrate, a first electrically conductive layer fixed to the substrate, a dielectric layer fixed to a portion of the electrically conductive layer, and a second electrically conductive layer having an anchor portion and a free portion. The anchor portion is fixed to the dielectric layer and the free portion is initially fixed to the dielectric layer, but is released from the dielectric layer to become separated from the dielectric layer, and wherein an inherent stress profile in the second electrically conductive layer biases the free portion away from the dielectric layer. When a bias voltage is applied between the first electrically conductive layer and the second electrically conductive layer, electrostatic forces in the free portion bend the free portion towards the first electrically conductive layer, thereby increasing the capacitance of the capacitor.

Owner:XEROX CORP

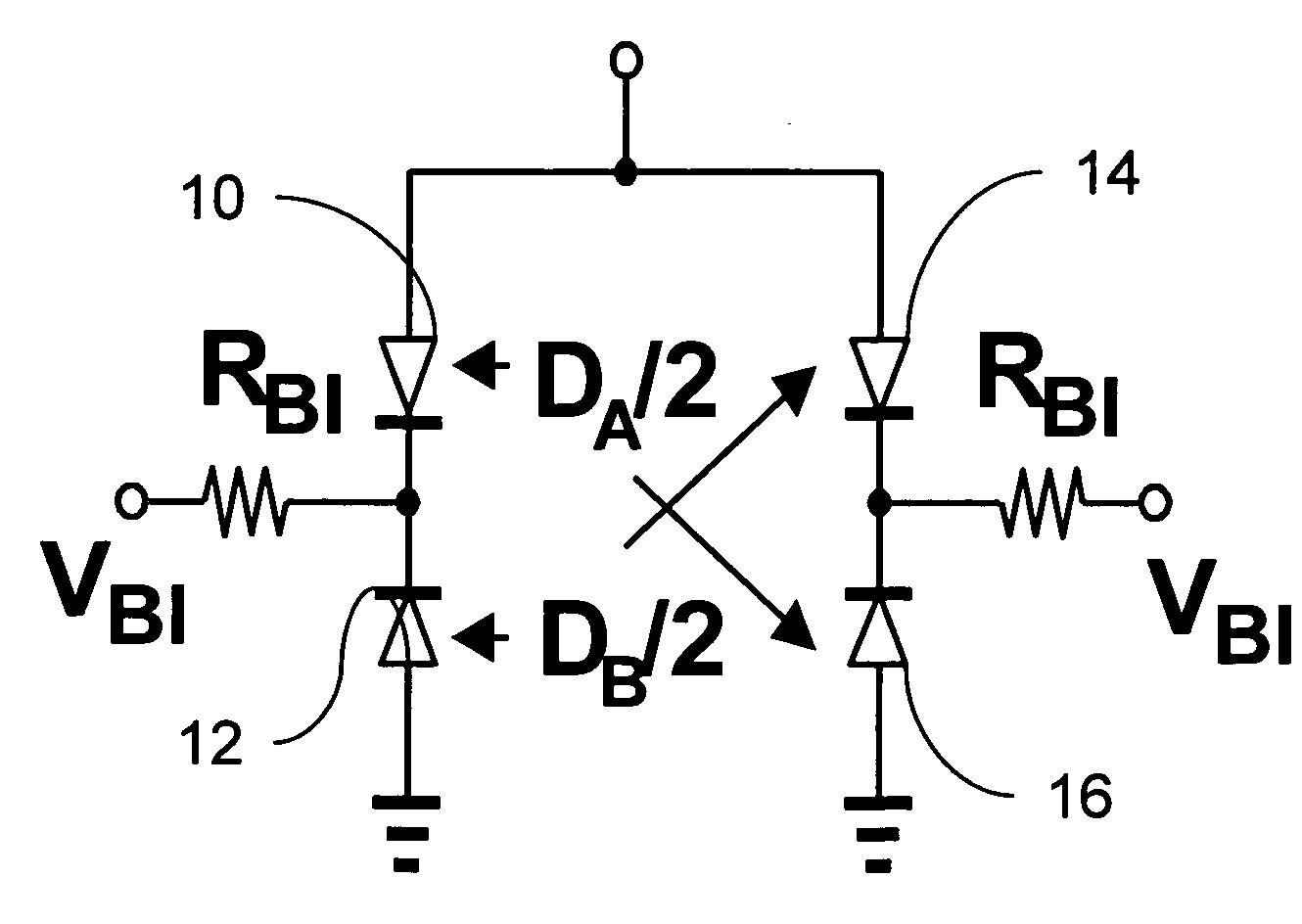

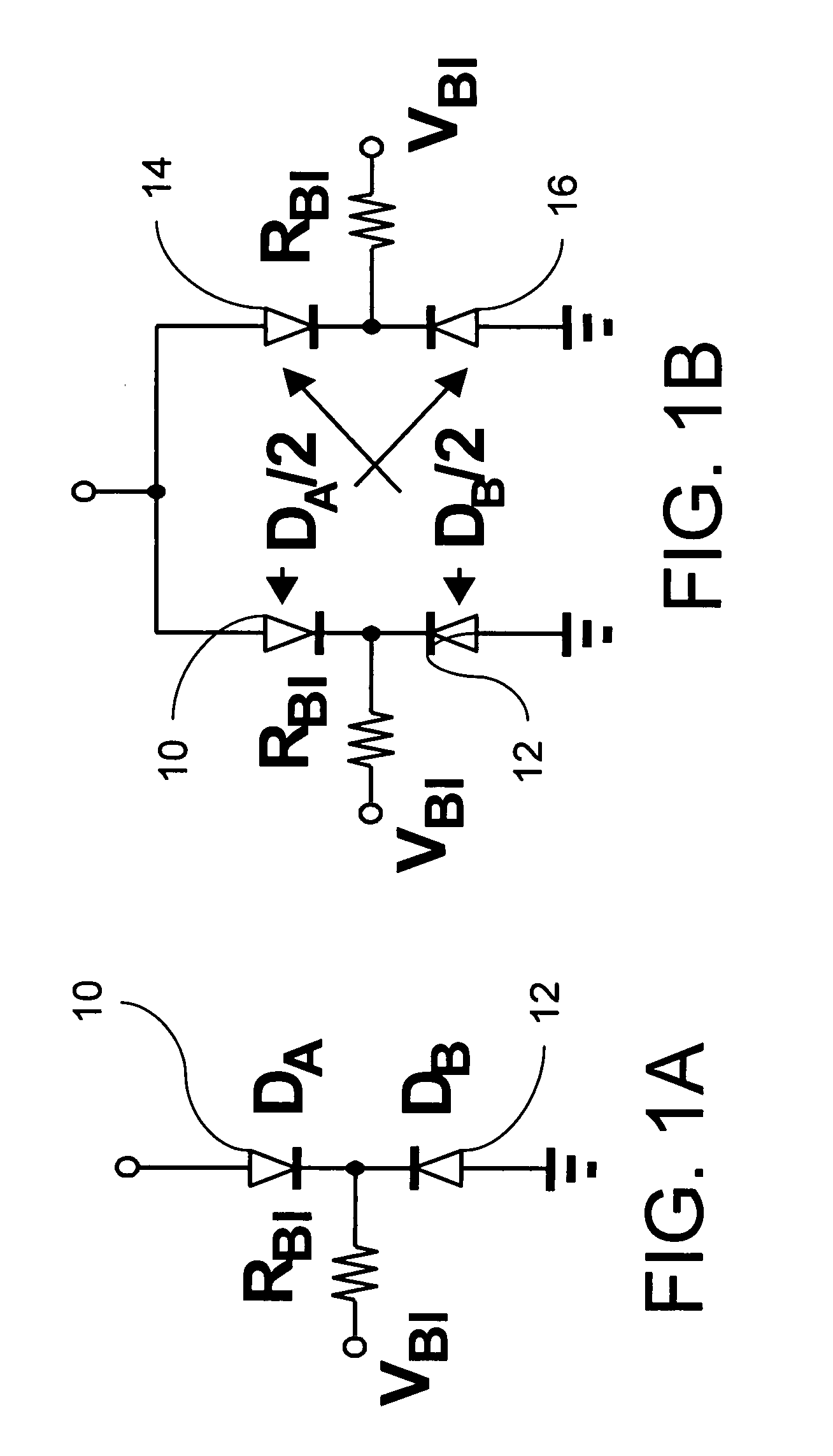

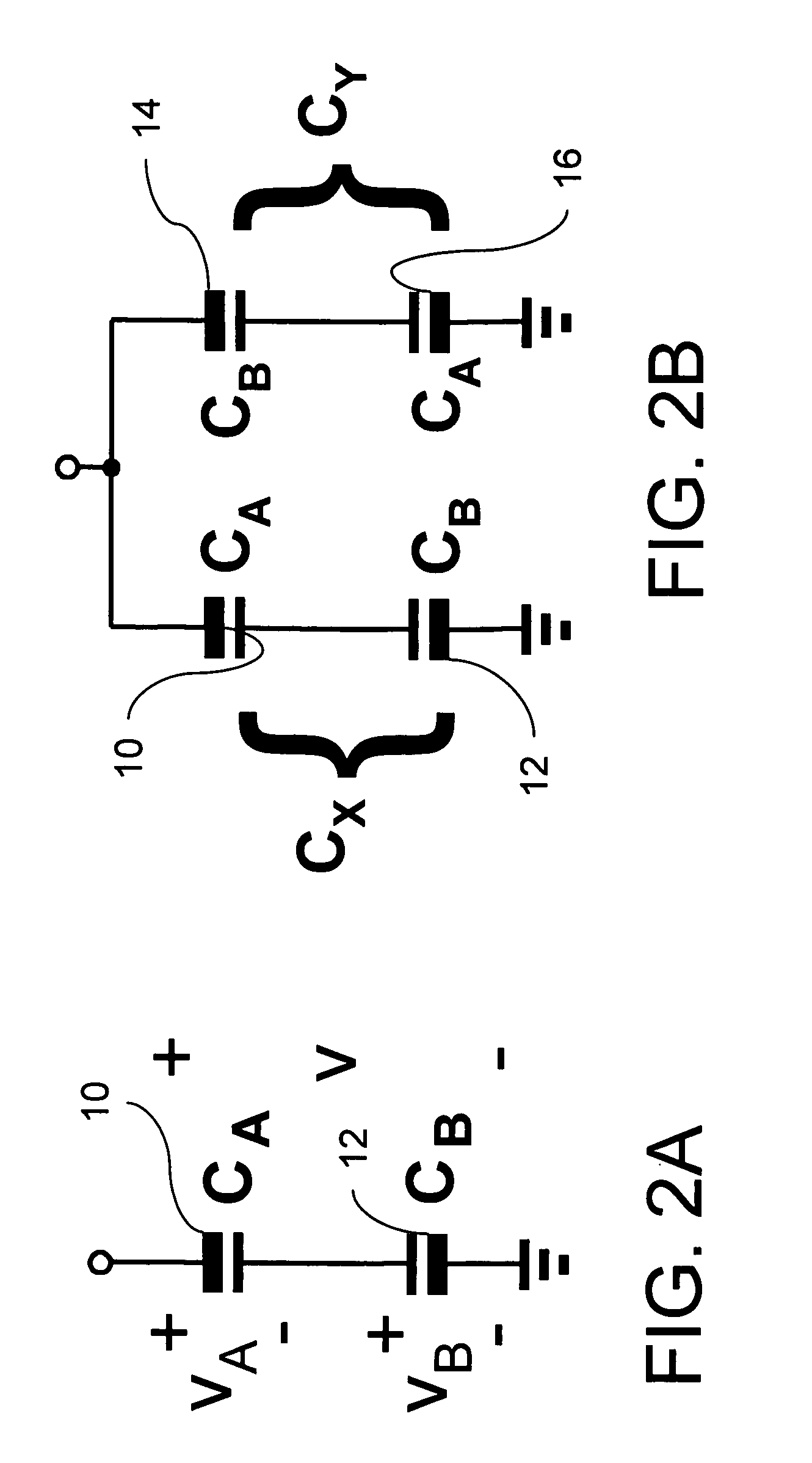

Linear variable voltage diode capacitor and adaptive matching networks

InactiveUS20090134960A1Reduce distortion problemsHighly linear voltage variableTransistorMultiple-port networksSize ratioAdaptive matching

An integrated variable voltage diode capacitor topology applied to a circuit providing a variable voltage load for controlling variable capacitance. The topology includes a first pair of anti-series varactor diodes, wherein the diode power-law exponent n for the first pair of anti-series varactor diodes in the circuit is equal or greater than 0.5, and the first pair of anti-series varactor diodes have an unequal size ratio that is set to control third-order distortion. The topology also includes a center tap between the first pair anti-series varactor diodes for application of the variable voltage load. In preferred embodiments, a second pair of anti-series varactor diodes is arranged anti-parallel to the first pair of anti-series varactor diodes so the combination of the first pair of anti-series varactor diodes and the second pair of anti-series varactor diodes control second-order distortion as well.

Owner:TECH UNIV DELFT +1

Micro electro-mechanical variable capacitor

InactiveUS6906905B1Increase capacitanceHigh quality factorMechanically variable capacitor detailsCapacitor with electrode area variationDielectricCapacitance

A three-dimensional micro electro-mechanical (MEMS) variable capacitor is described wherein movable comb electrodes of opposing polarity are fabricated simultaneously on the same substrate are independently actuated. These electrodes are formed in an interdigitated fashion to maximize the capacitance of the device. The electrodes are jointly or individually actuated. A separate actuation electrode and a ground plane electrode actuate the movable electrodes. The voltage potential between the two electrodes provides a primary mode of operation of the device. The variation of the sidewall overlap area between the interdigitated fingers provides the expected capacitance tuning of the device. The interdigitated electrodes can also be attached on both ends to form fixed-fixed beams. The stiffness of the electrodes is reduced by utilizing thin support structures at the ends of the electrodes. The three dimensional aspect of the device avails large surface area. Large capacitance variation and tuning ranges are obtained by independent actuation of the electrode fingers. A plurality of modes of operation of the device provides wide flexibility and greater performance advantage for the device. Upon fabrication of the device, a separate substrate with etched dielectric is used to encapsulated the device. The MEMS device is then completely encapsulated, requiring no additional packaging of the device. Further, since alignment and bonding can be done on a wafer scale, an improved device yield is obtained at a lower cost.

Owner:GLOBALFOUNDRIES INC

Capacitor with multiple elements for multiple replacement applications

ActiveUS20070025051A1Making safeMaintenance safetyMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six capacitor sections of a capacitive element each having a capacitance value. The capacitor sections are provided in a plurality of wound cylindrical capacitive elements. Two vertically stacked wound cylindrical capacitance elements may each provide three capacitor sections. There may be six separately wound cylindrical capacitive elements each providing a capacitor section. The capacitor sections have a common element terminal. A pressure interrupter cover assembly is sealingly secured to the open end of case for the elements and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitor section to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover terminals.

Owner:AMRAD MFG LLC

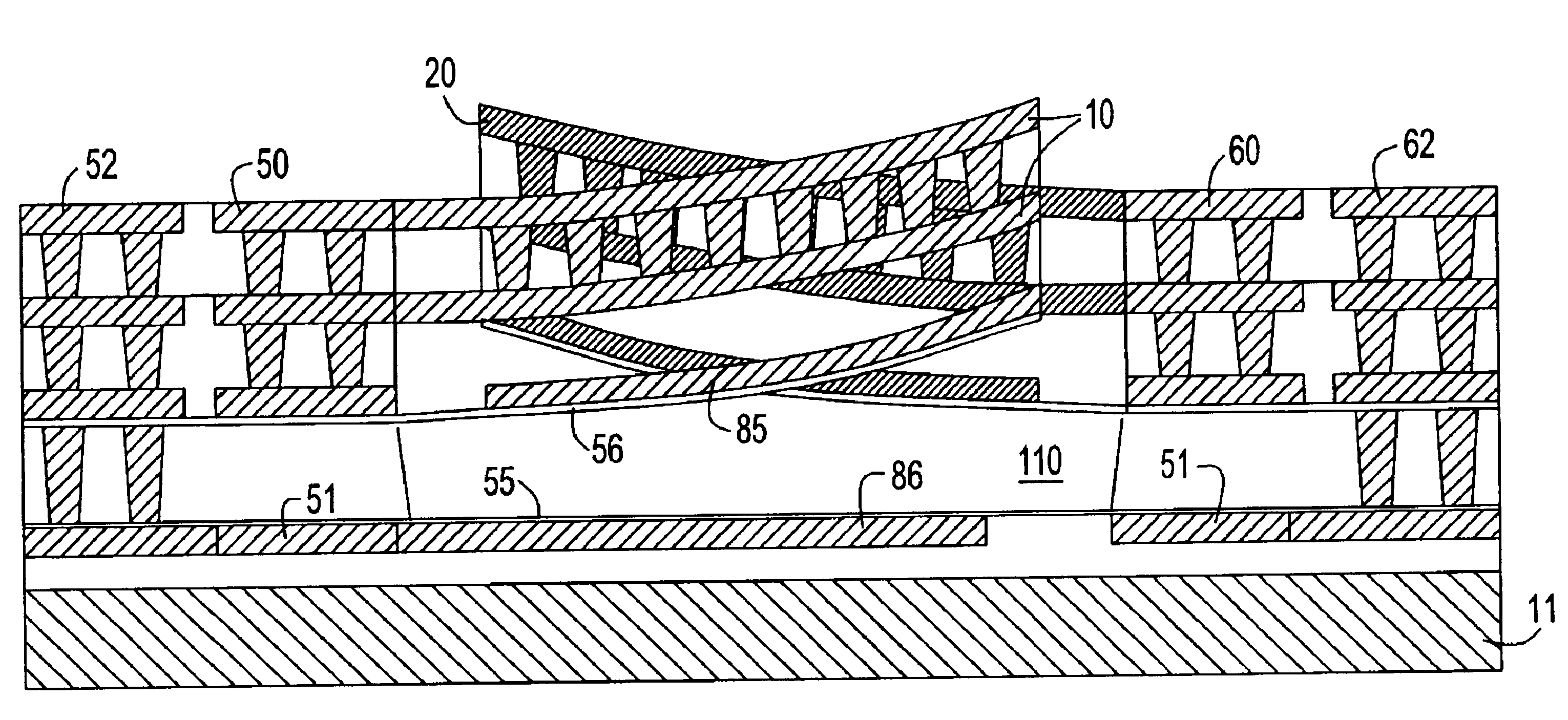

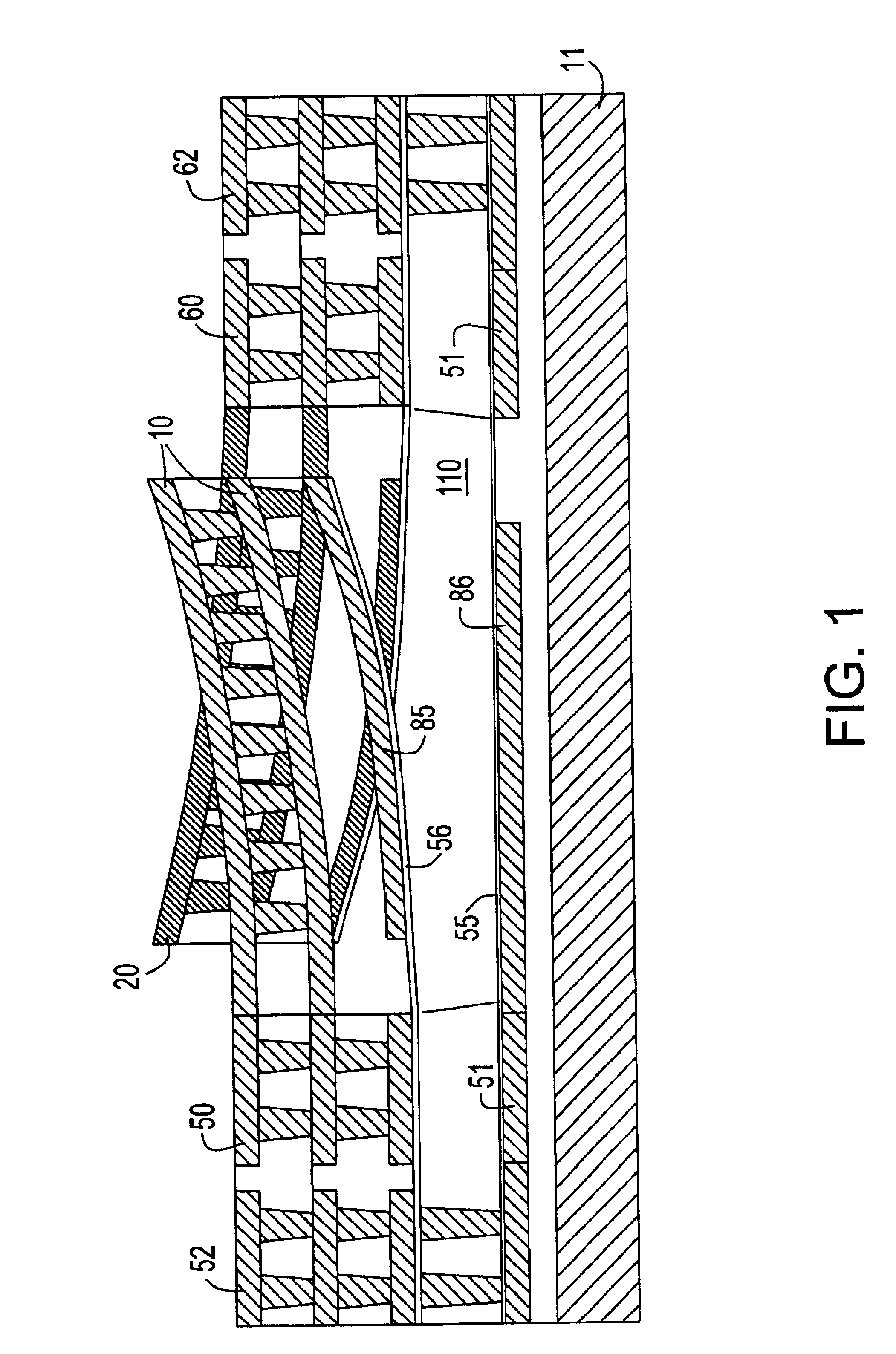

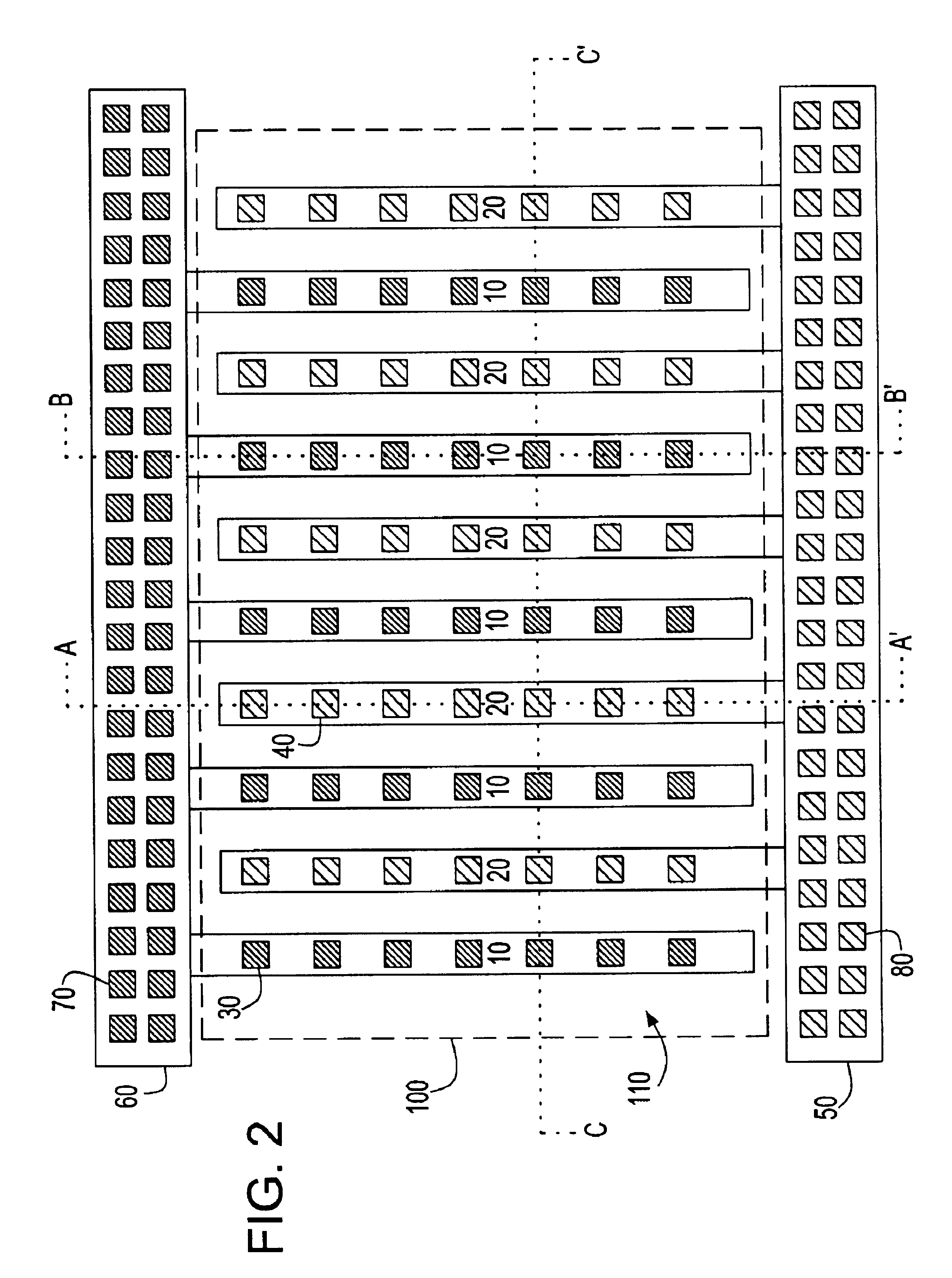

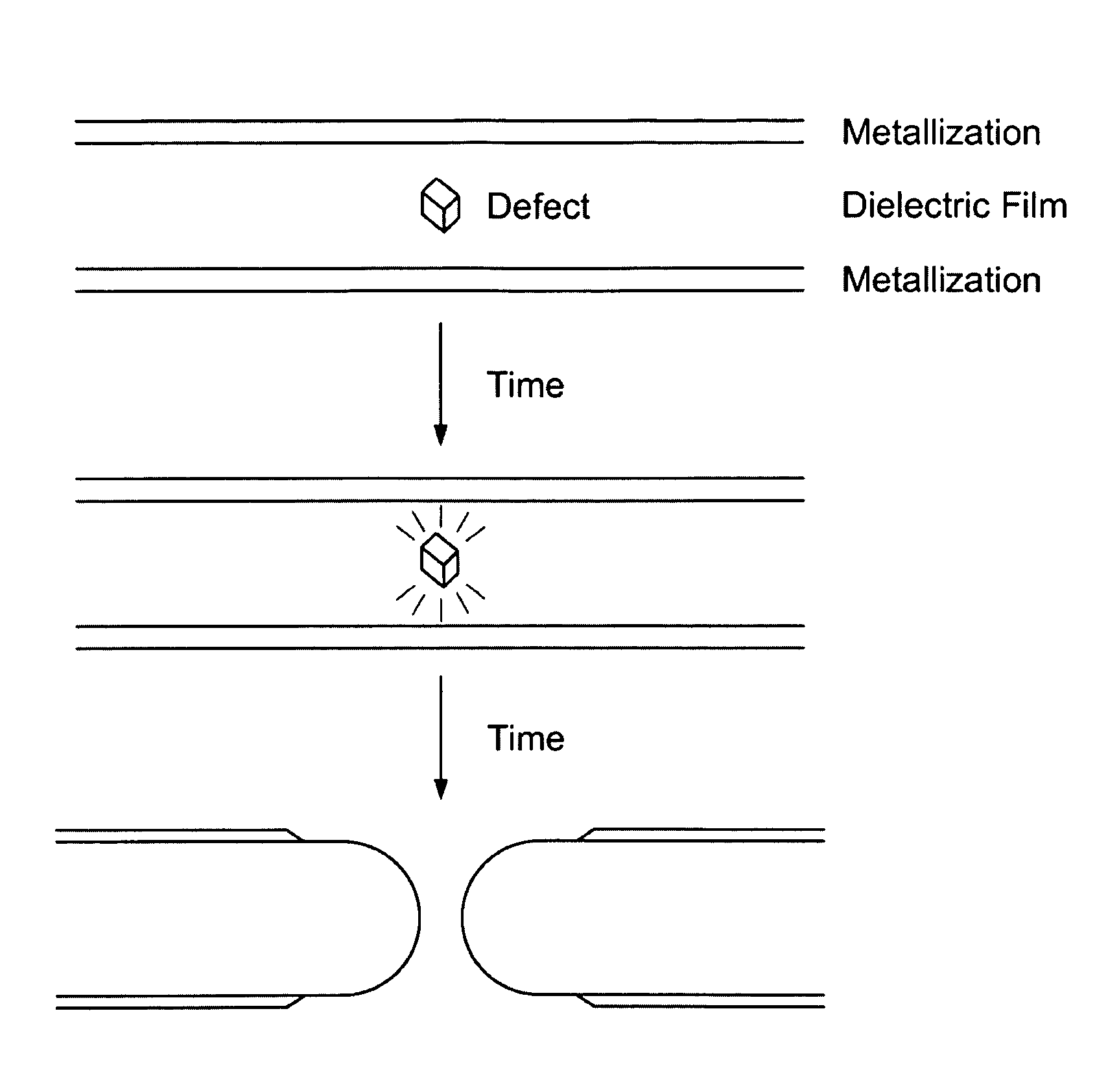

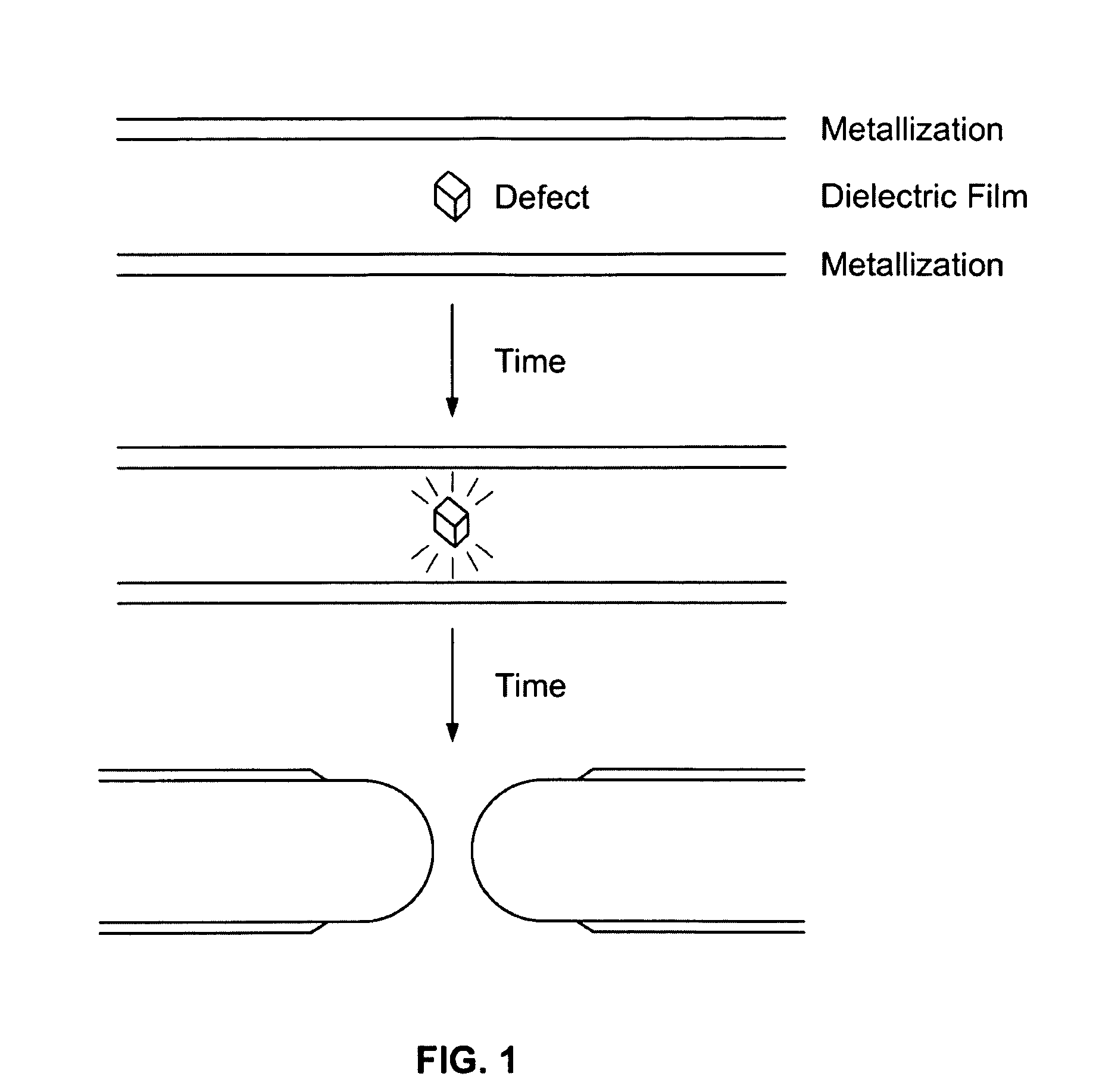

Fault-tolerant materials and methods of fabricating the same

ActiveUS7911761B2Effectively and efficiently isolateOptimize fault tolerancePiezoelectric/electrostrictive device manufacture/assemblyMechanically variable capacitor detailsSelf-healingMaterials science

The present invention provides compliant / stretchable electroactive materials and devices made from those materials which exhibit fault-tolerant properties, i.e., self-healing / clearing properties. The present invention also provides systems, which incorporate the subject materials and / or devices, as well as methods of fabricating the subject materials and devices.

Owner:COVESTRO DEUTSCHLAND AG

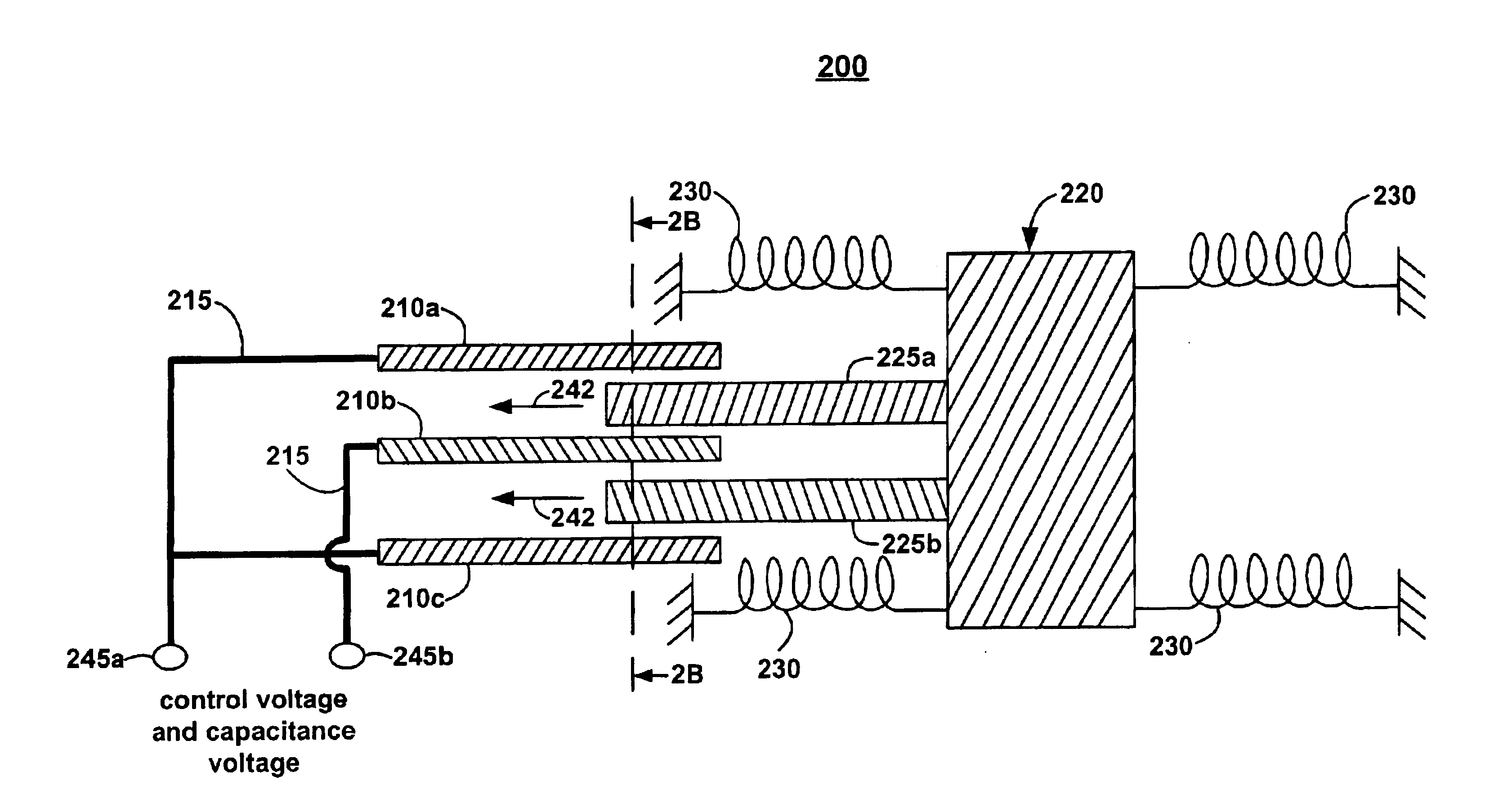

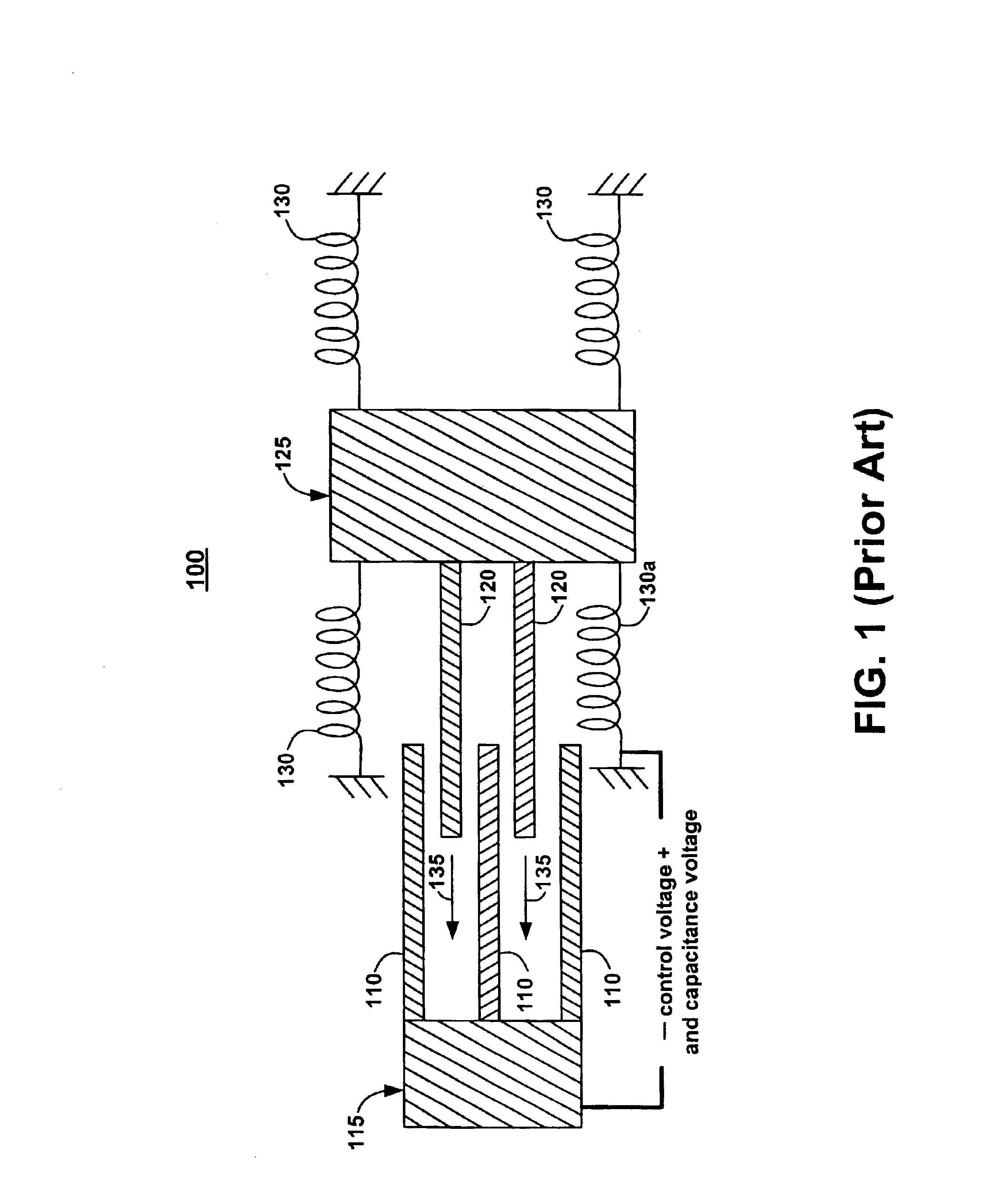

Capacitors adapted for acoustic resonance cancellation

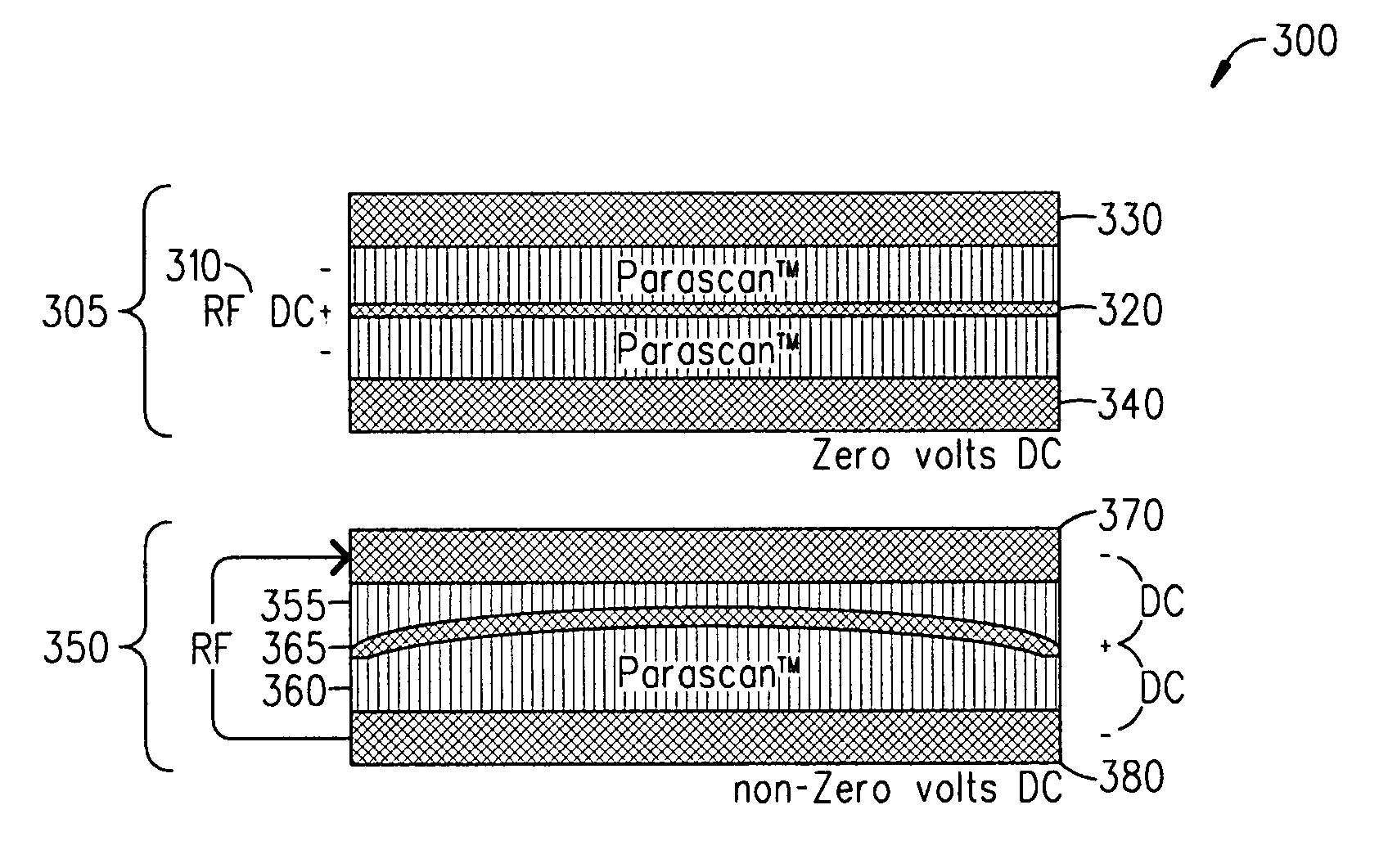

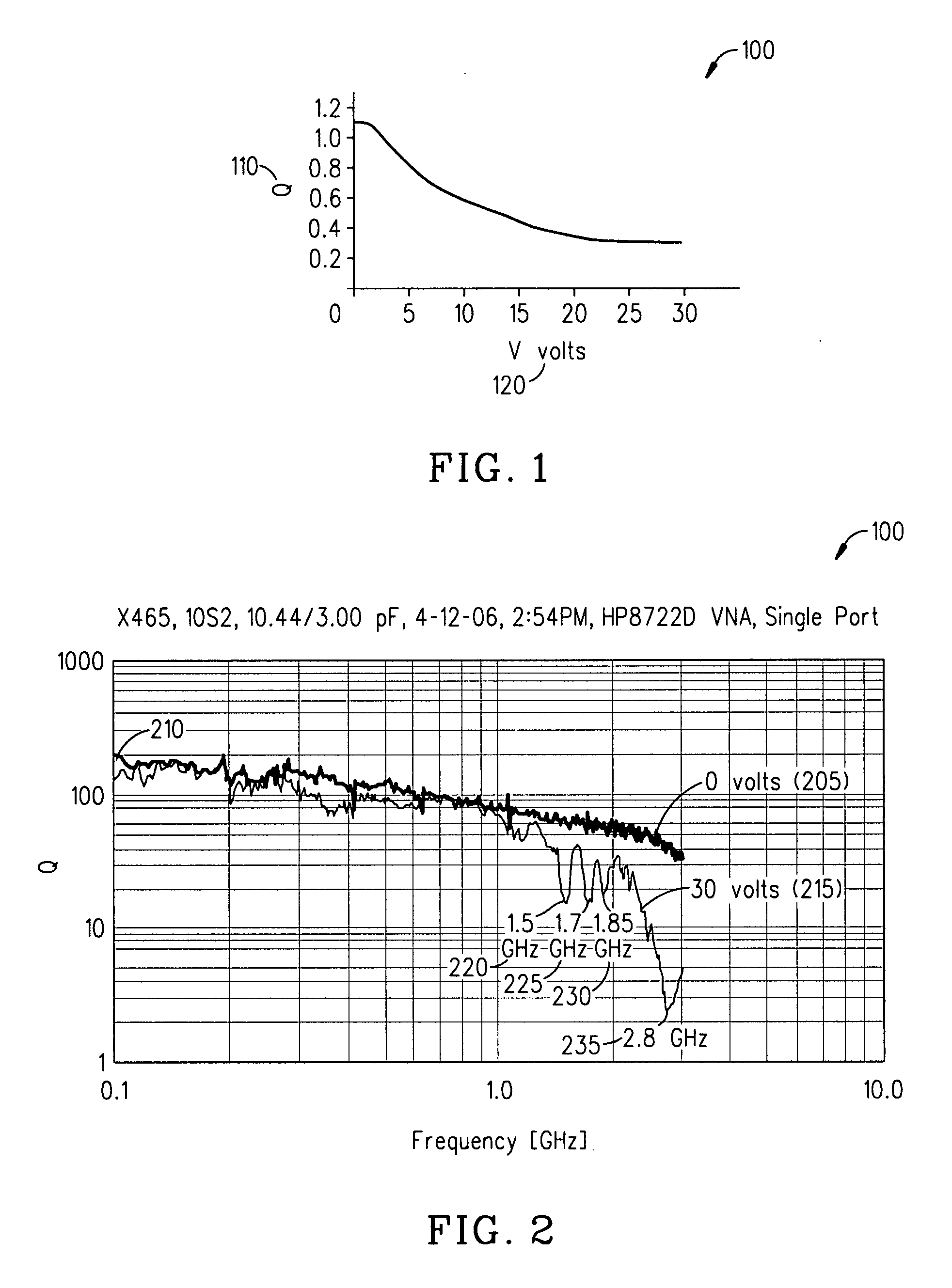

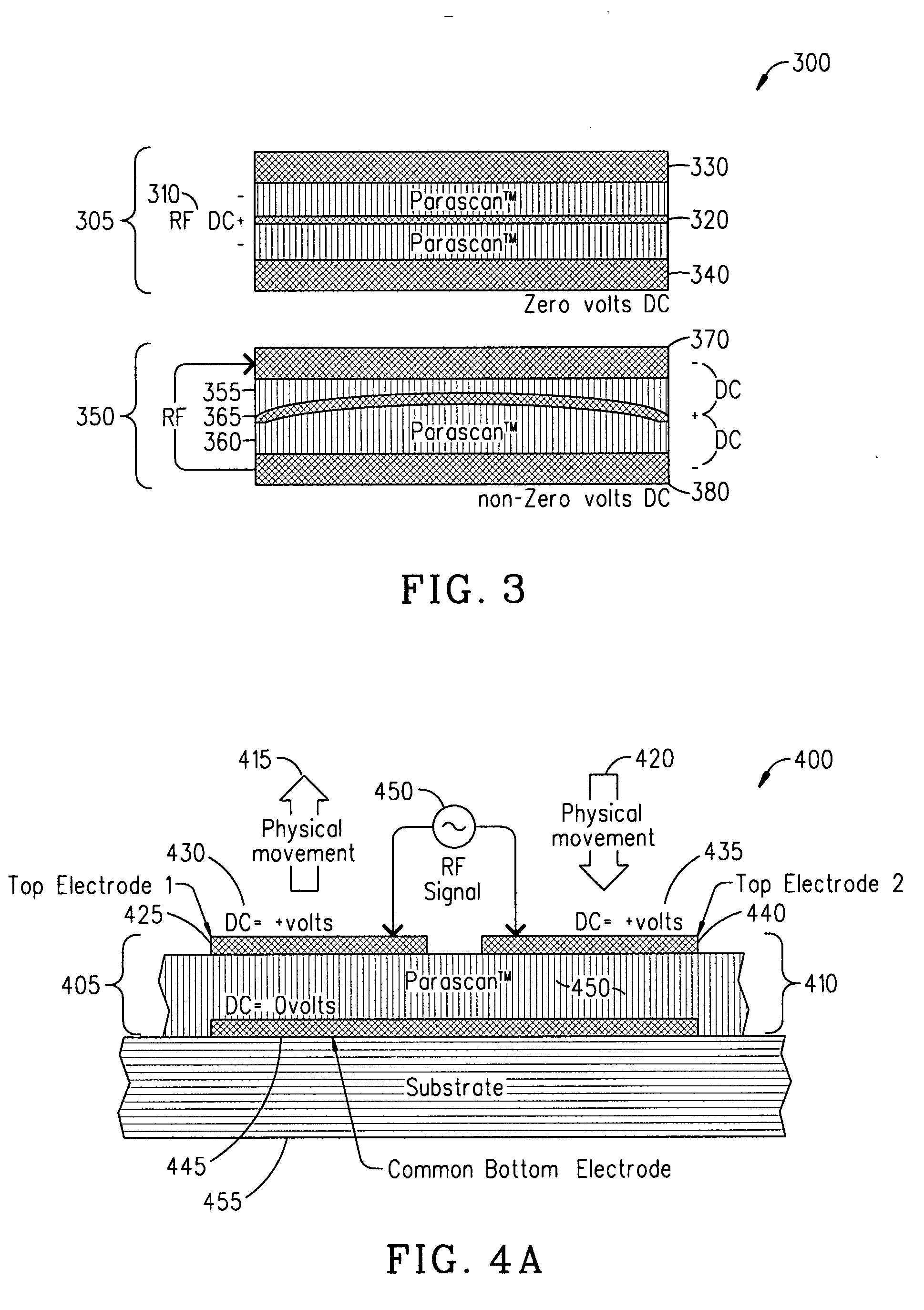

ActiveUS20080232023A1Reduce lossesImproving QMechanically variable capacitor detailsFixed capacitor electrodesAcousticsDielectric permittivity

An embodiment of the present invention provides a device, comprising a multilayered tunable dielectric capacitor, wherein said multilayers of tunable dielectric are adapted to be DC biased to reduce the dielectric constant; and wherein the DC bias is arranged so that the number of layers of tunable dielectric biased positively is equal to the number of layers of tunable dielectric biased negatively.

Owner:NXP USA INC

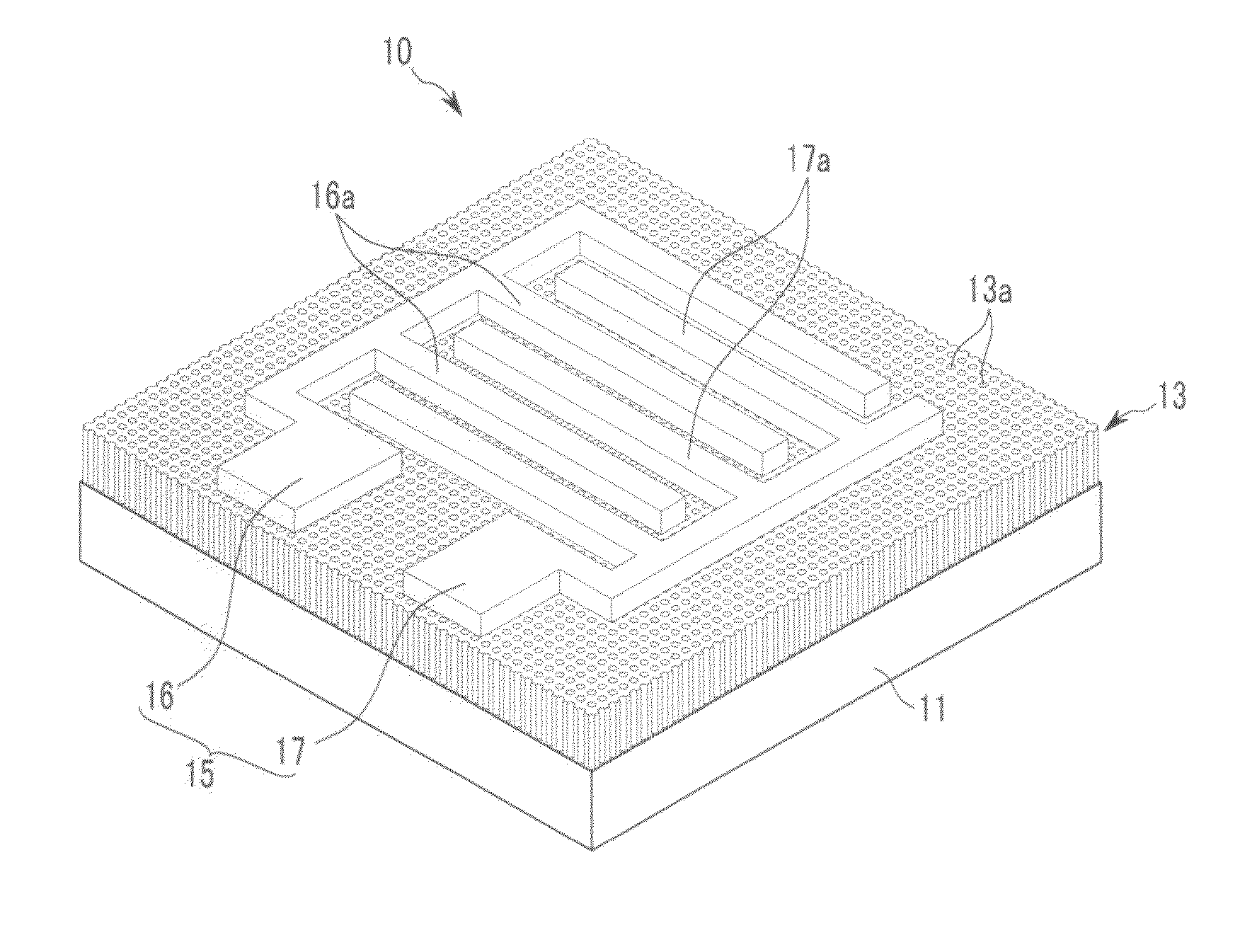

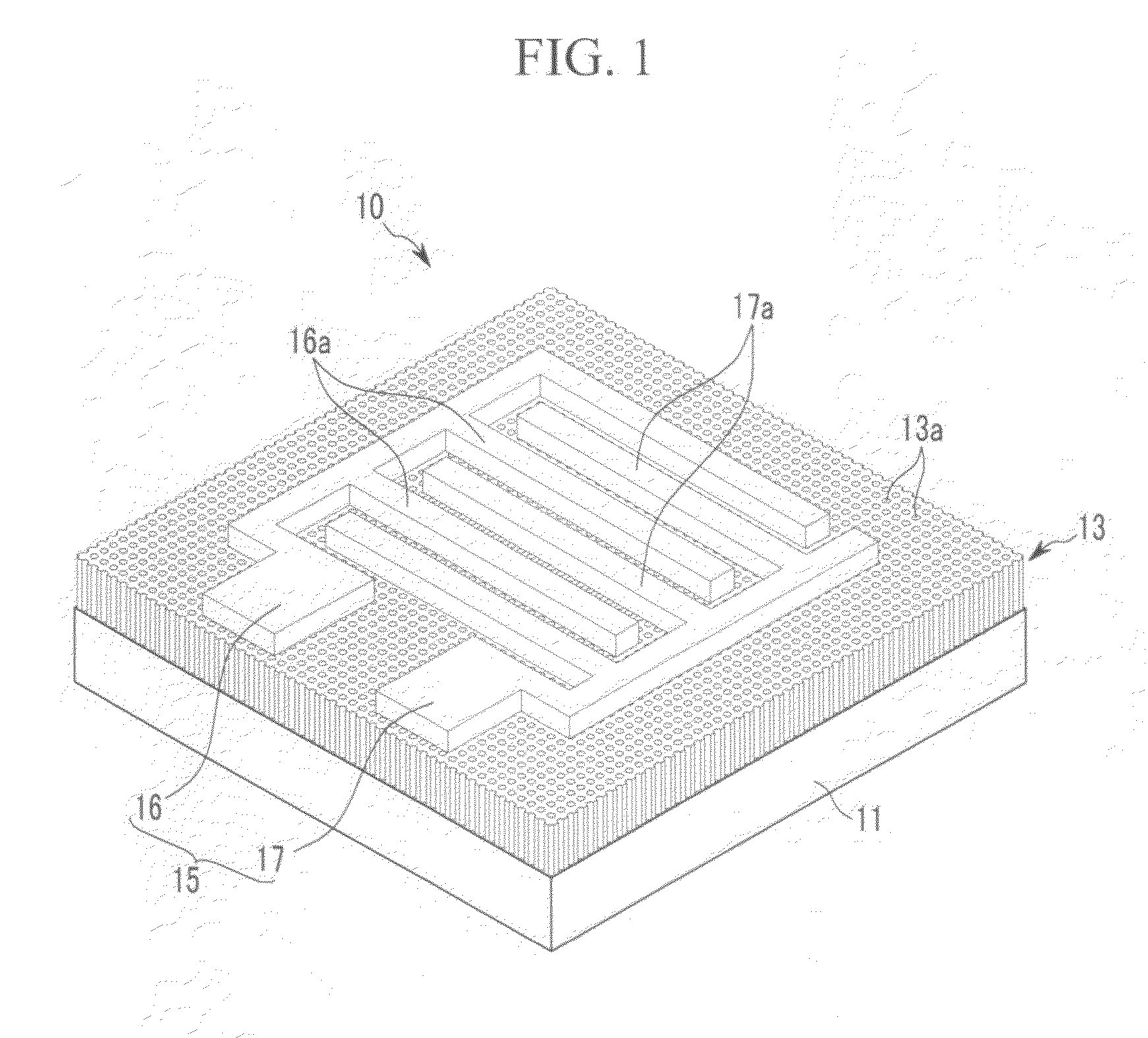

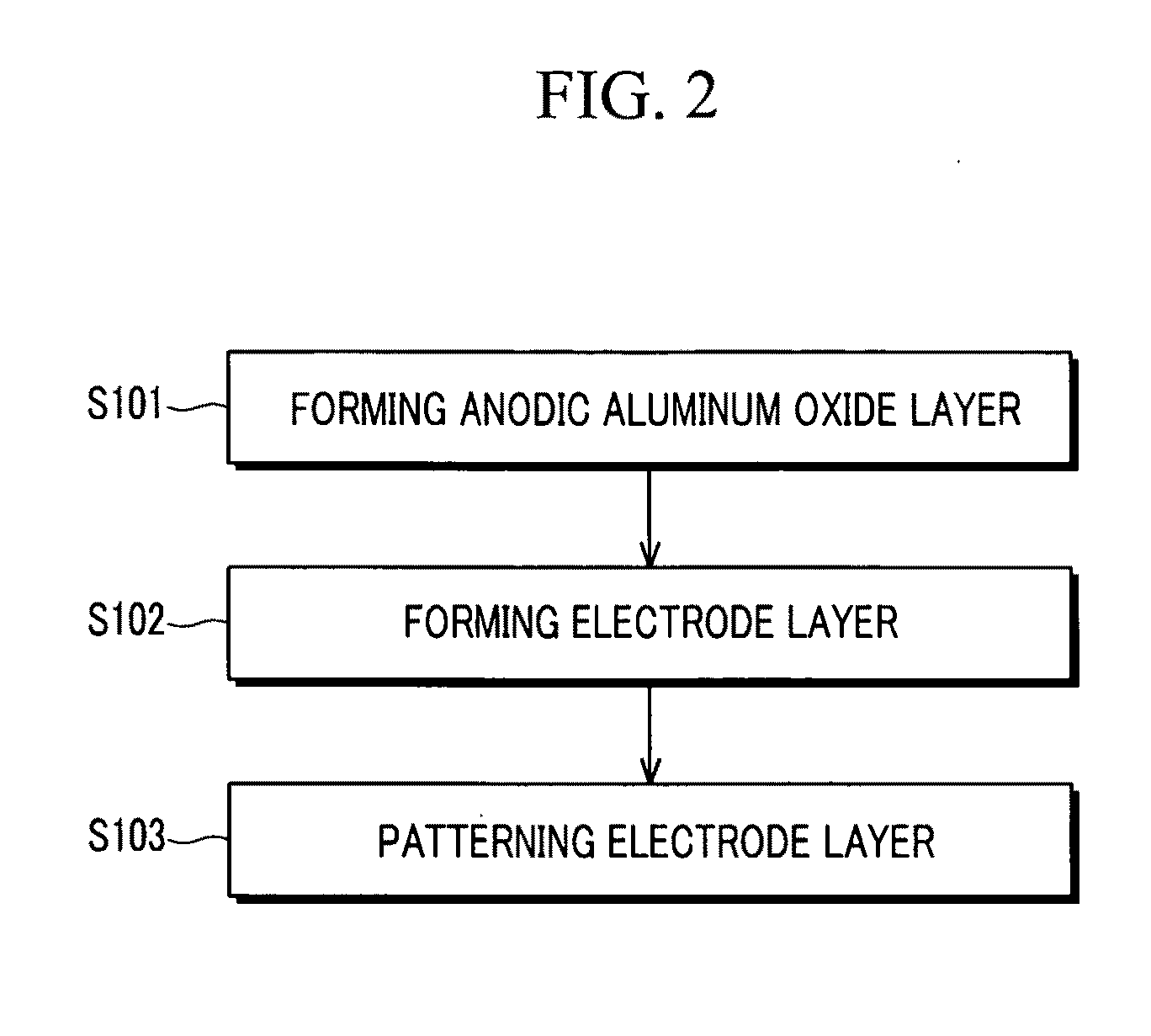

Humidity sensor having anodic aluminum oxide layer, and fabricating method thereof

InactiveUS20100134948A1High sensitivityImprove accuracyMechanically variable capacitor detailsCapacitor with electrode area variationOptoelectronicsMoisture sensor

Disclosed are a humidity sensor and a fabricating method thereof. The humidity sensor includes a substrate, an anodic aluminum oxide layer formed on the substrate and having a plurality of holes, and electrodes formed on the anodic aluminum oxide layer, in order to improve sensitivity and accuracy of the humidity sensor. Further, the fabricating method of a humidity sensor includes preparing an aluminum substrate, forming an anodic aluminum oxide layer by oxidizing the aluminum substrate, and forming electrodes on the anodic aluminum oxide layer.

Owner:POSTECH ACAD IND FOUND

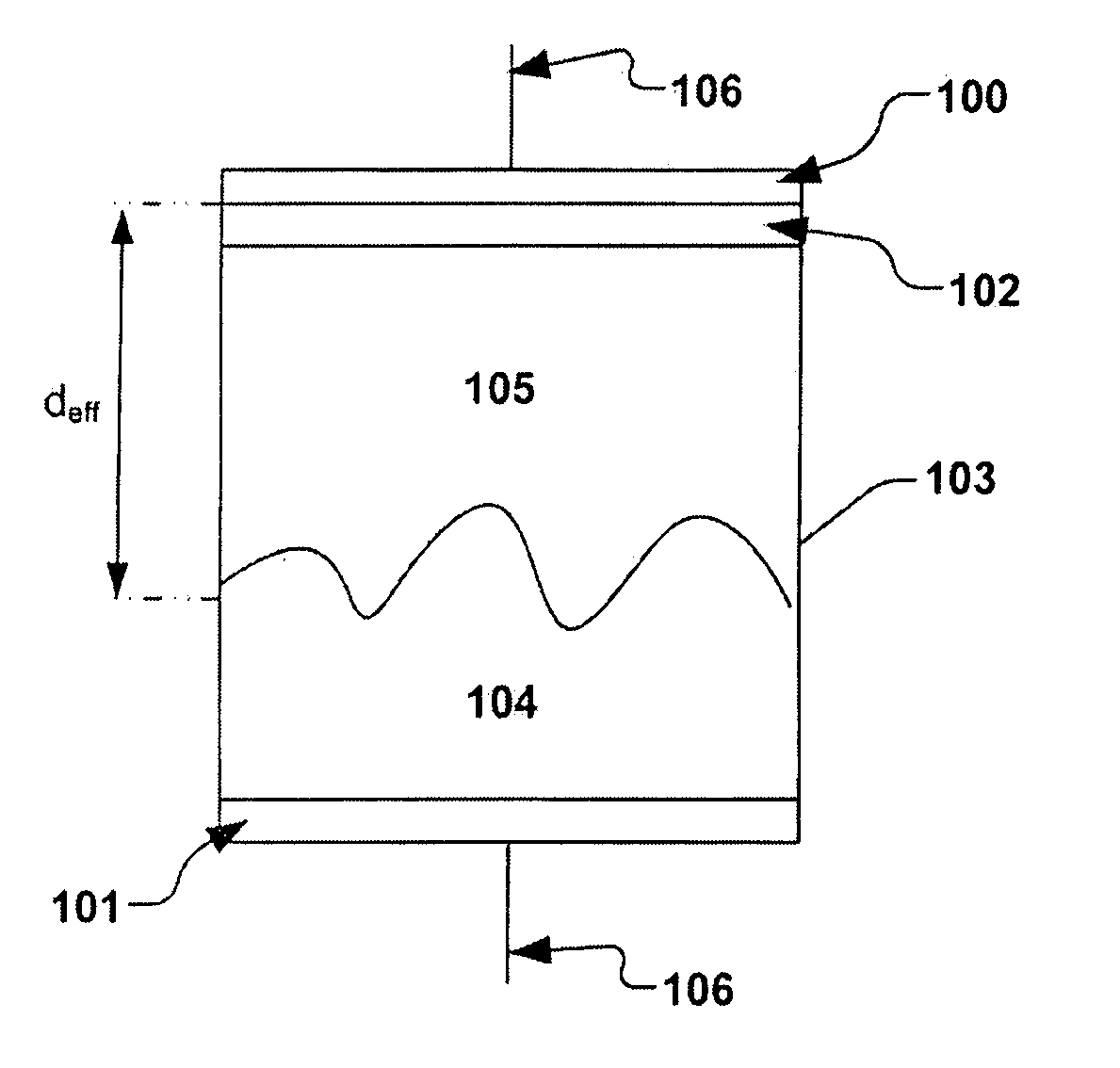

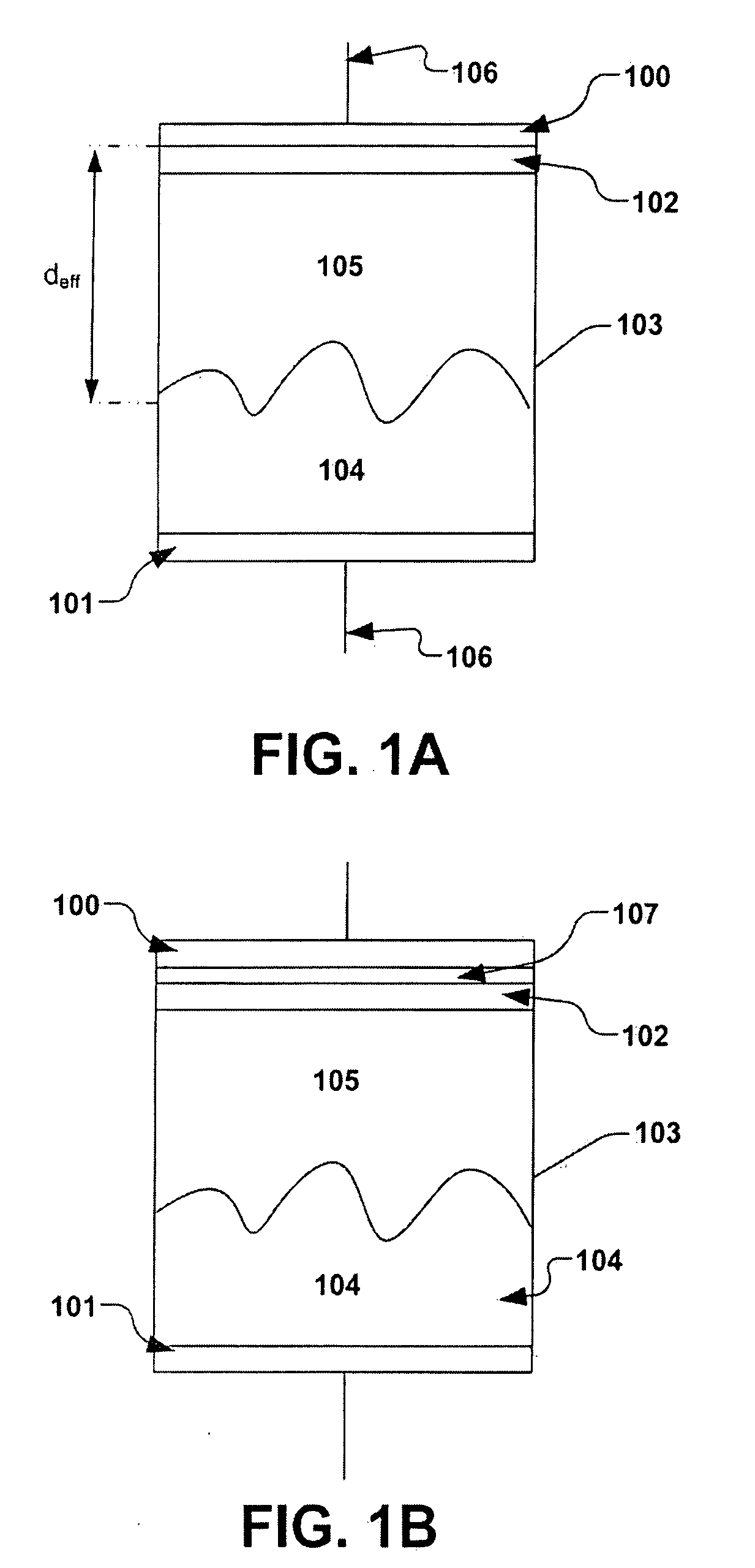

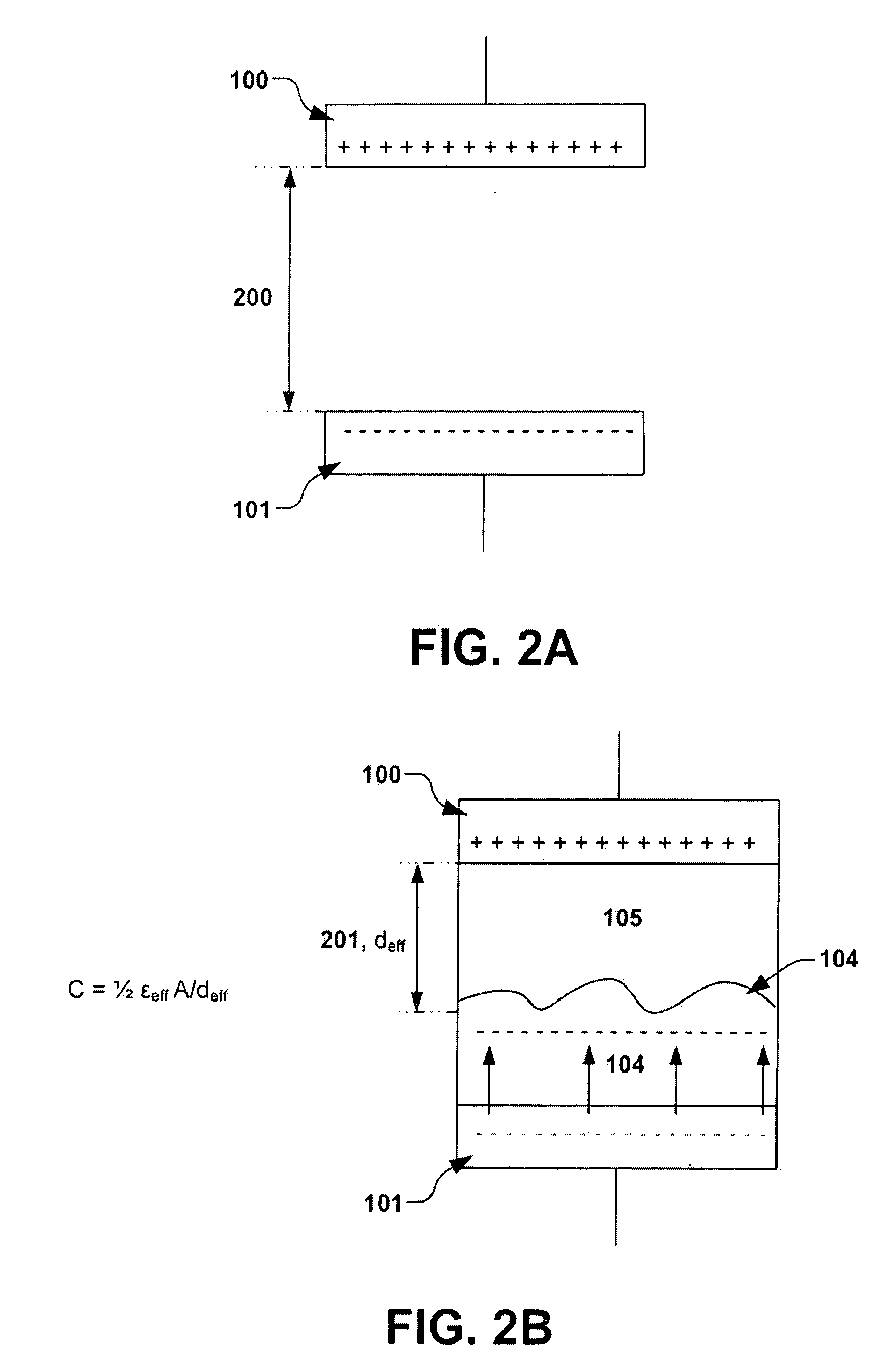

Fluidic electrostatic energy harvester

InactiveUS20090080138A1Mechanically variable capacitor detailsCapacitor with electrode area variationCapacitanceEnergy harvester

One embodiment of the present invention relates to a variable capacitor that operates without moving mechanical parts. In this capacitor electrically conductive electrodes are separated by an enclosed chamber filled with an electrically conductive material. The electrically conductive material can freely vary its position within the chamber. The capacitance of the device will vary as position of the conductive material changes due to external mechanical motion (ex: rotation vibration, etc.) of the device. Other embodiments of this device are also disclosed.

Owner:INFINEON TECH AG

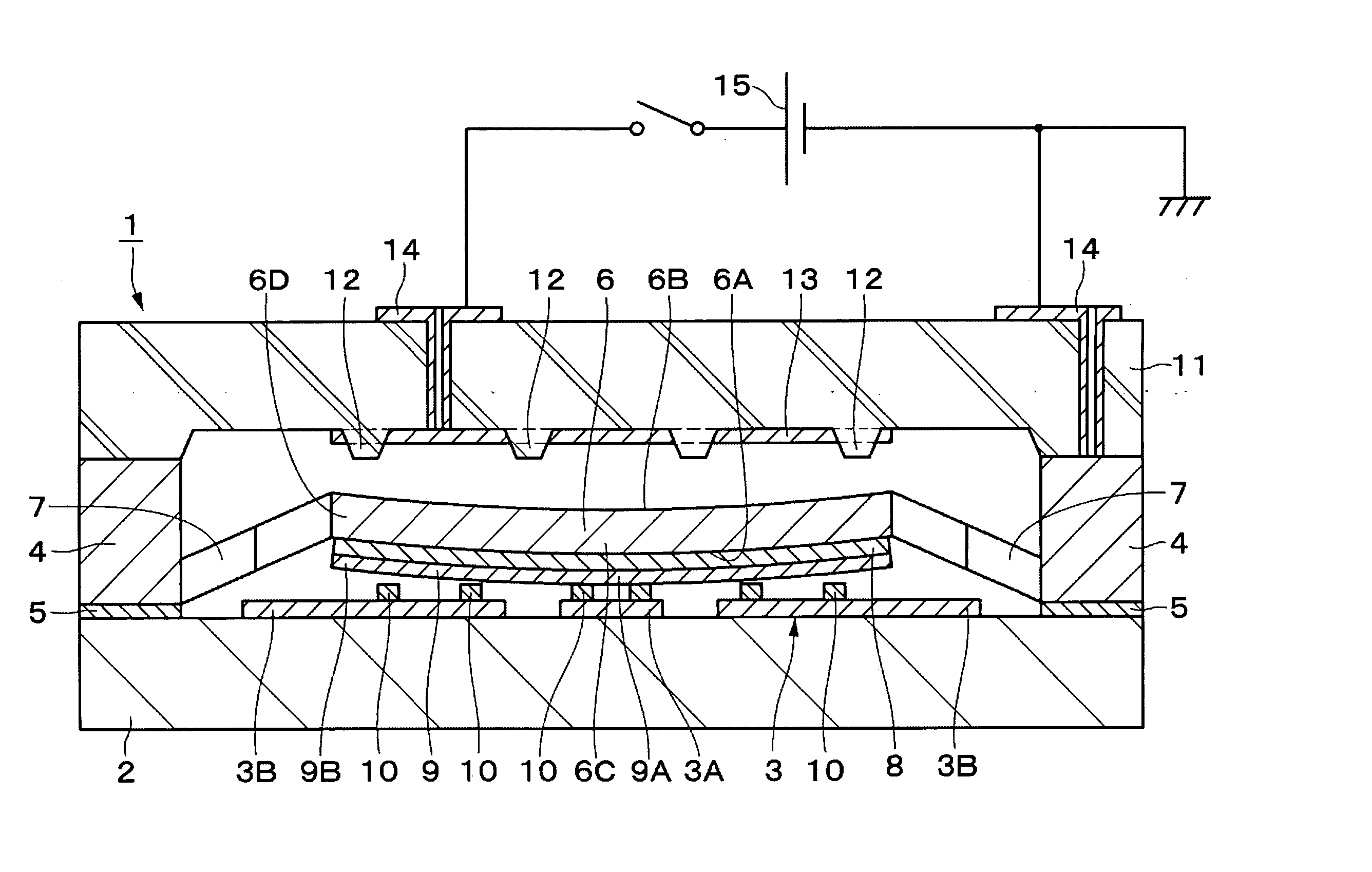

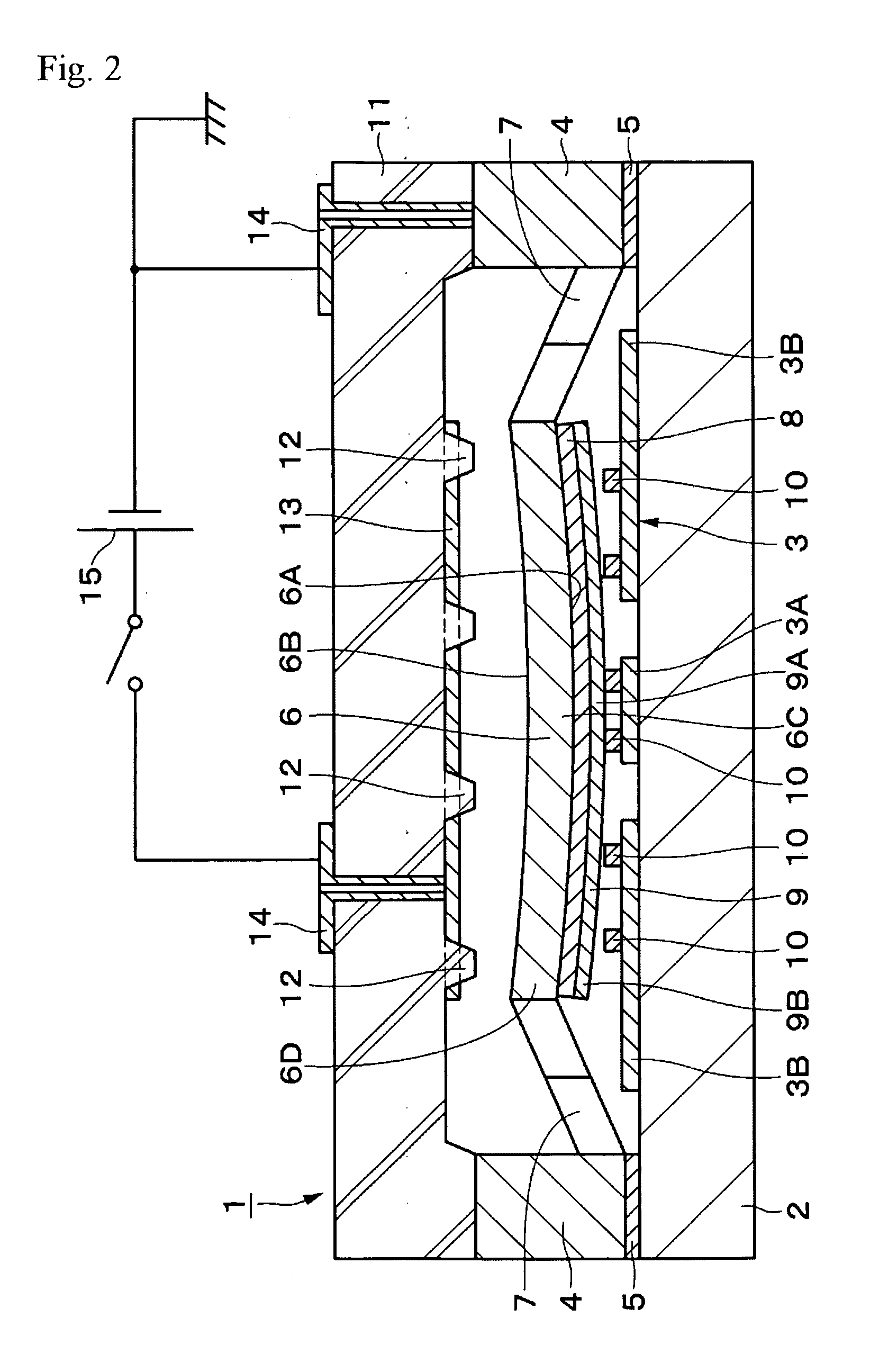

Variable capacitance element

InactiveUS20060056132A1Improve running characteristicsStable changeMultiple-port networksMechanically variable capacitor detailsCapacitanceElectrical conductor

A variable capacitance element includes a movable element provided above a substrate using supporting portions and support beams so as to be displaced from the substrate. An insulating film and a movable electrode are provided on a conductor facing surface of the movable element. A driving electrode is arranged to displace the movable element, between a signal cutoff position and a signal passage position, whereby a high frequency signal transmitted through a transmission line is cut off or allowed to pass. The insulating film uses compressive stress to warp the movable element and the movable electrode in a direction of warping in a convex form toward the transmission line, and maintains this warping direction.

Owner:MURATA MFG CO LTD

Capacitor with multiple elements for multiple replacement applications

ActiveUS20180261391A1Making safeMaintenance safetyMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceCapacitor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six capacitor sections of a capacitive element each having a capacitance value. The capacitor sections are provided in a plurality of wound cylindrical capacitive elements. Two vertically stacked wound cylindrical capacitance elements may each provide three capacitor sections. There may be six separately wound cylindrical capacitive elements each providing a capacitor section. The capacitor sections have a common element terminal.

Owner:AMRAD MFG LLC

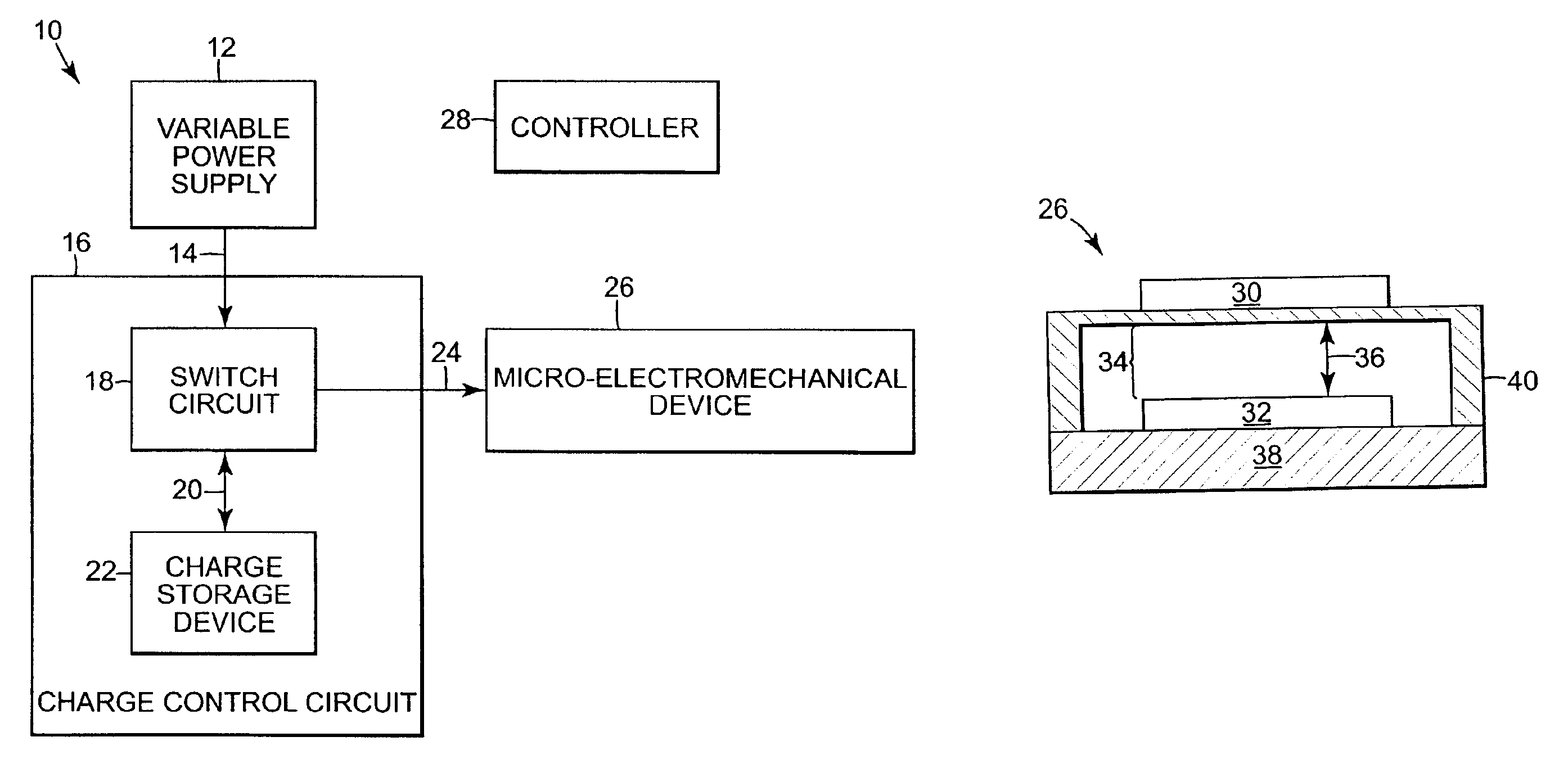

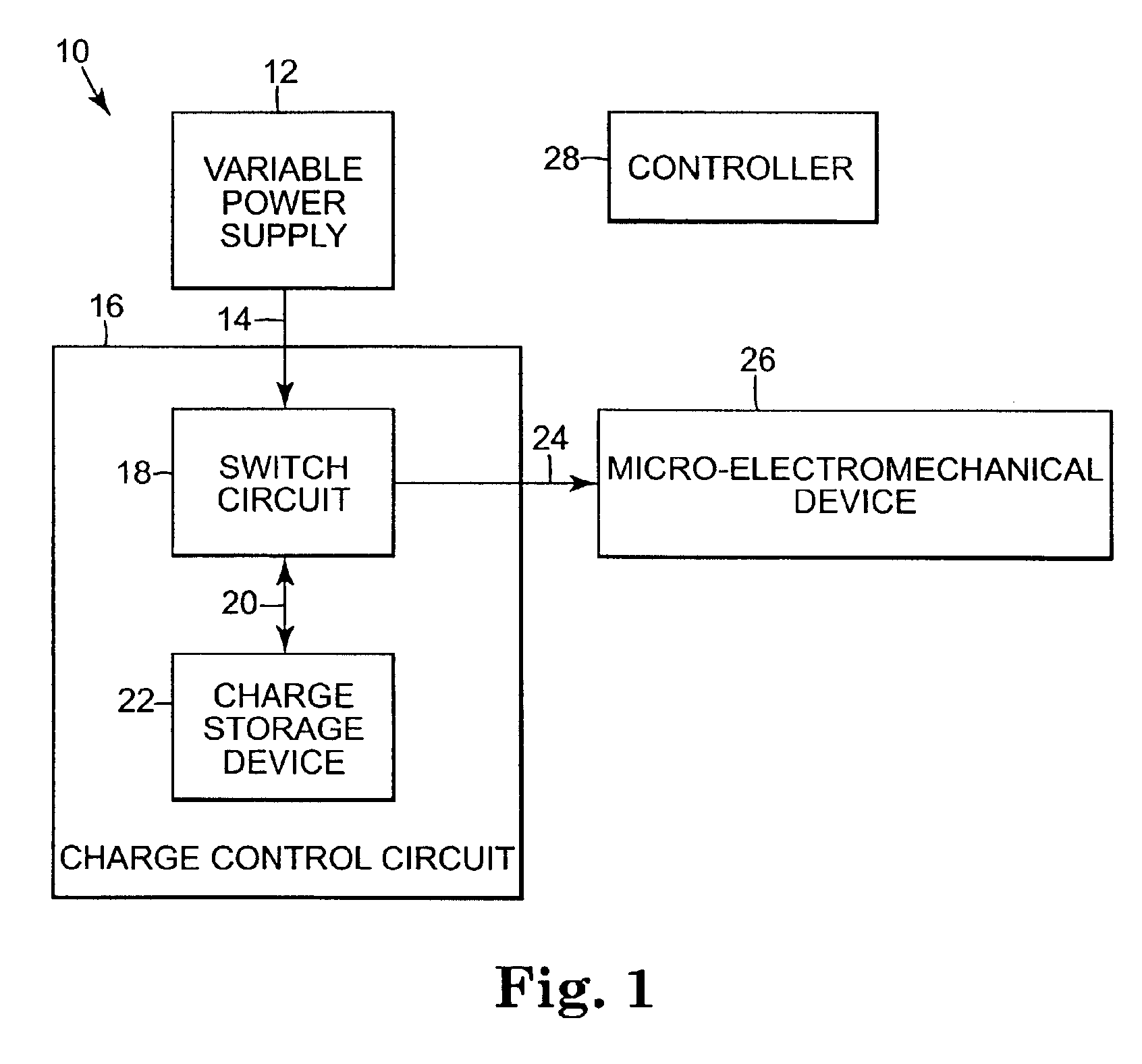

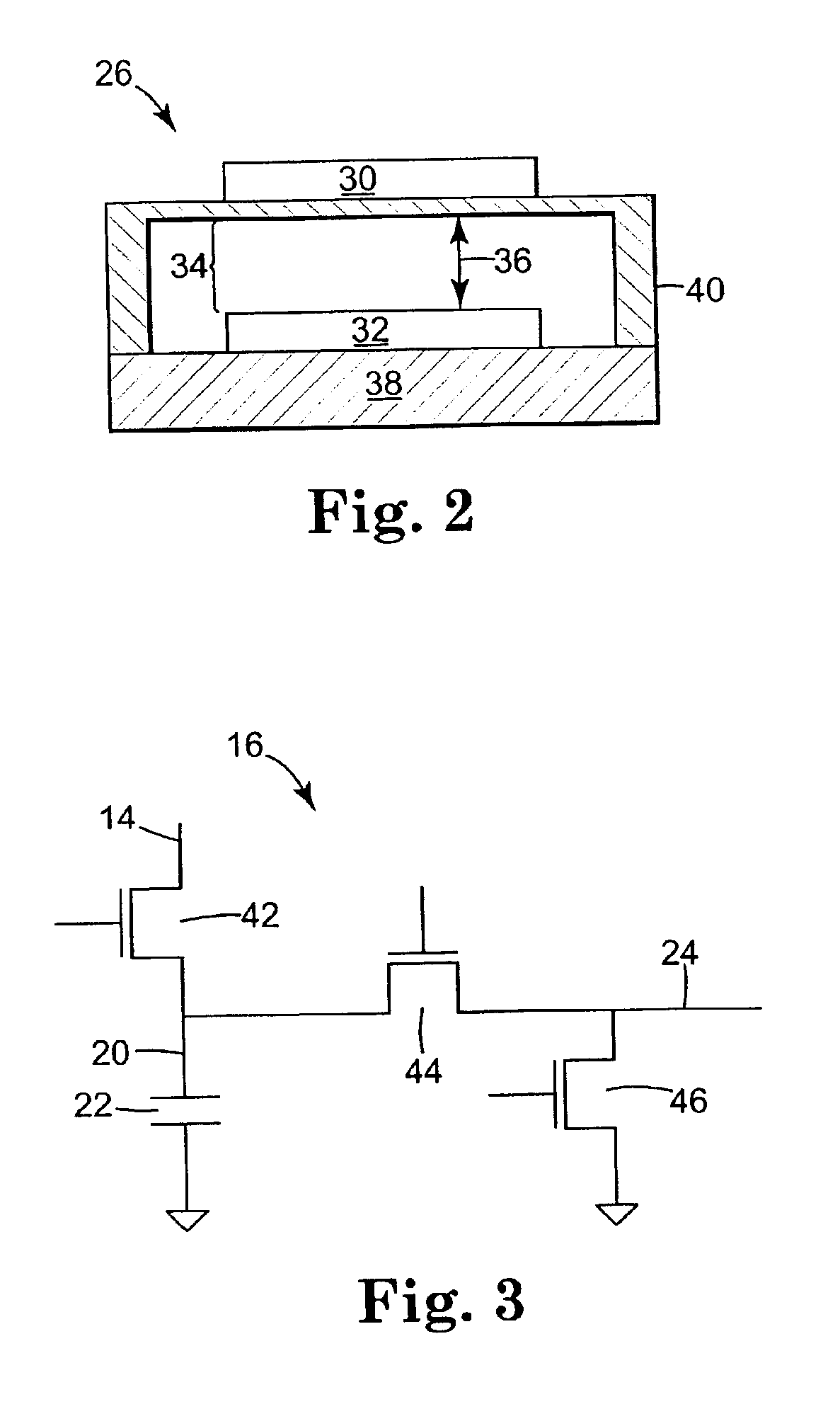

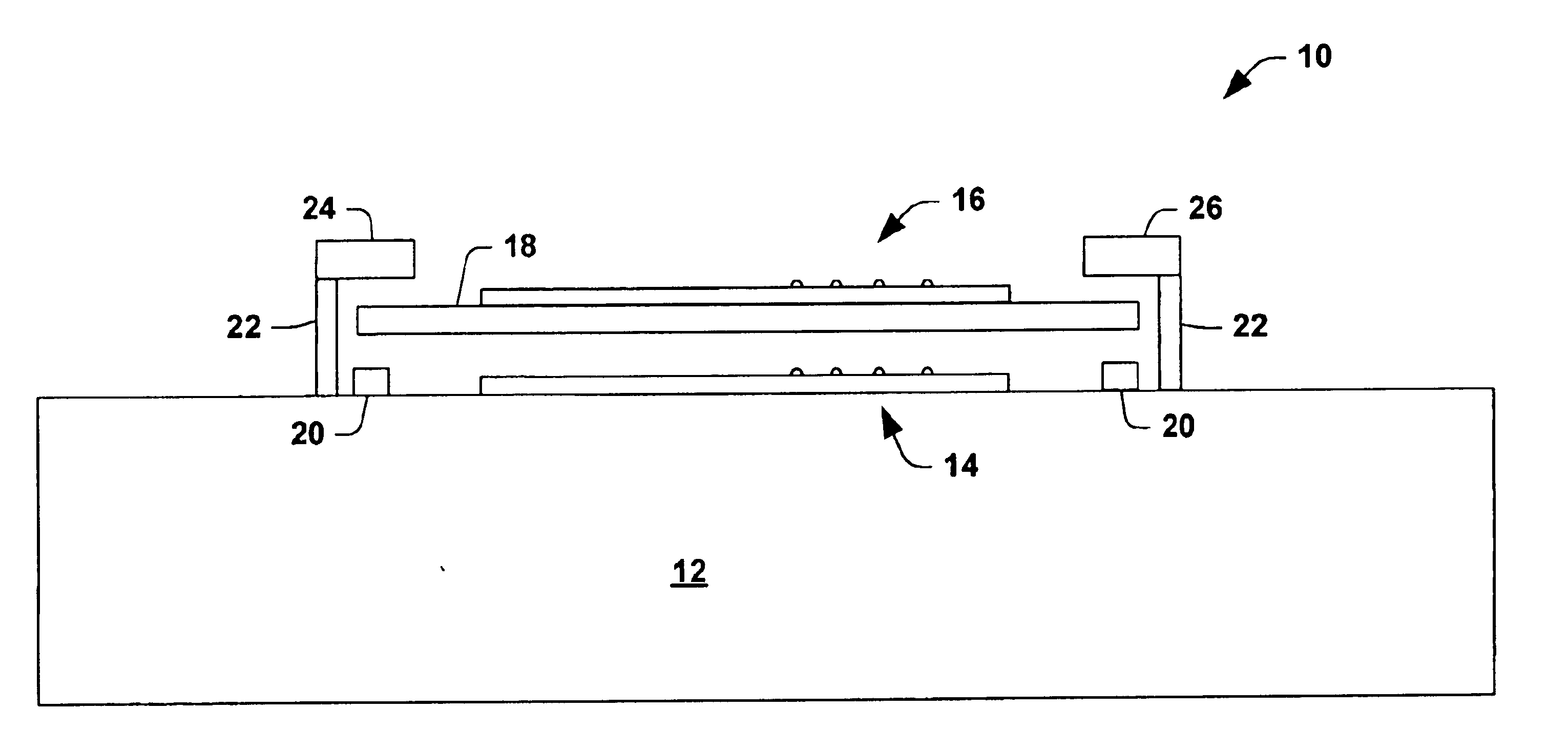

Charge control circuit for a micro-electromechanical device

Owner:HEWLETT PACKARD DEV CO LP

MEMS variable inductor and capacitor

InactiveUS6856499B2Maintaining gapReduce connectionsMultiple-port networksMechanically variable capacitor detailsCapacitanceDielectric plate

A variable passive component is provided for fabrication on a microelectromechanical system (MEMS) device. A conductive portion is provided on a low-profile sliding dielectric sheet that cooperates with a conductive portion disposed on a substrate to provide a variable passive component. The passive component can be a variable inductor provided by moving a shorted spiral inductor formed on the dielectric sheet over a spiral inductor on the substrate with varying degrees of overlap causing varying inductance values. The passive component can be a variable capacitor that consists of a large conductive pad on a dielectric plate which slides over two adjacent pads on the substrate with varying overlap causing varying capacitance values.

Owner:NORTHROP GRUMMAN SYST CORP

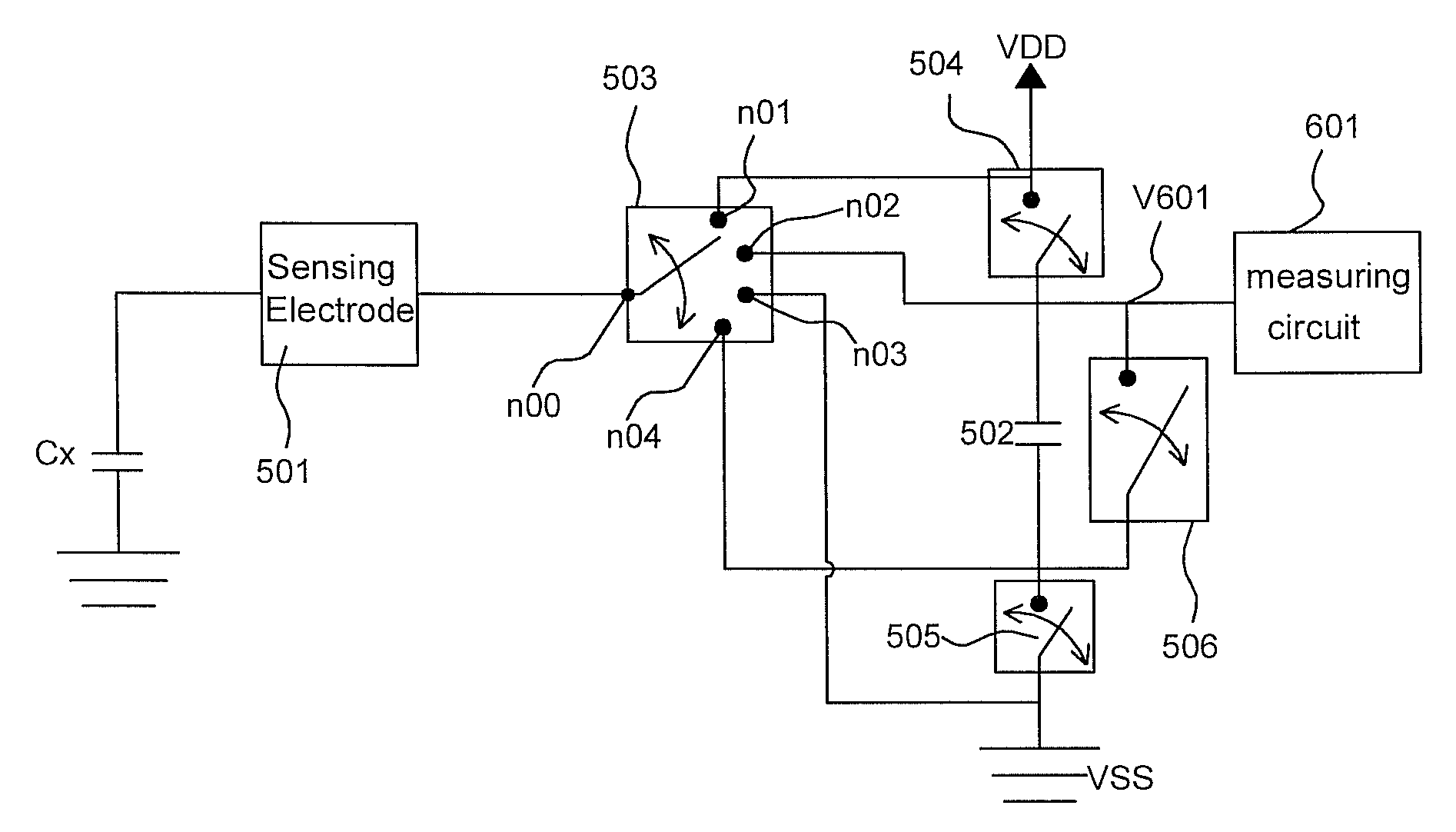

Capacitive sensor

InactiveUS7541816B1Avoid interferenceLow costTesting dielectric strengthMechanically variable capacitor detailsHigh frequencyCapacitive sensing

In a capacitive sensor, a sensing electrode is positively charged, the sensing electrode and a sensing capacitor are charge-balanced, the sensing electrode is negatively charged, and then the sensing electrode and the sensing capacitor are again charge-balanced. The sensing electrode is positively and negatively charged in the same period when the capacitive sensor is sensed. So, the invention can not only effectively improve the high-frequency external interference but also effectively resist the interference when an external direct current electrical field approaches.

Owner:GENERALPLUS TECH INC

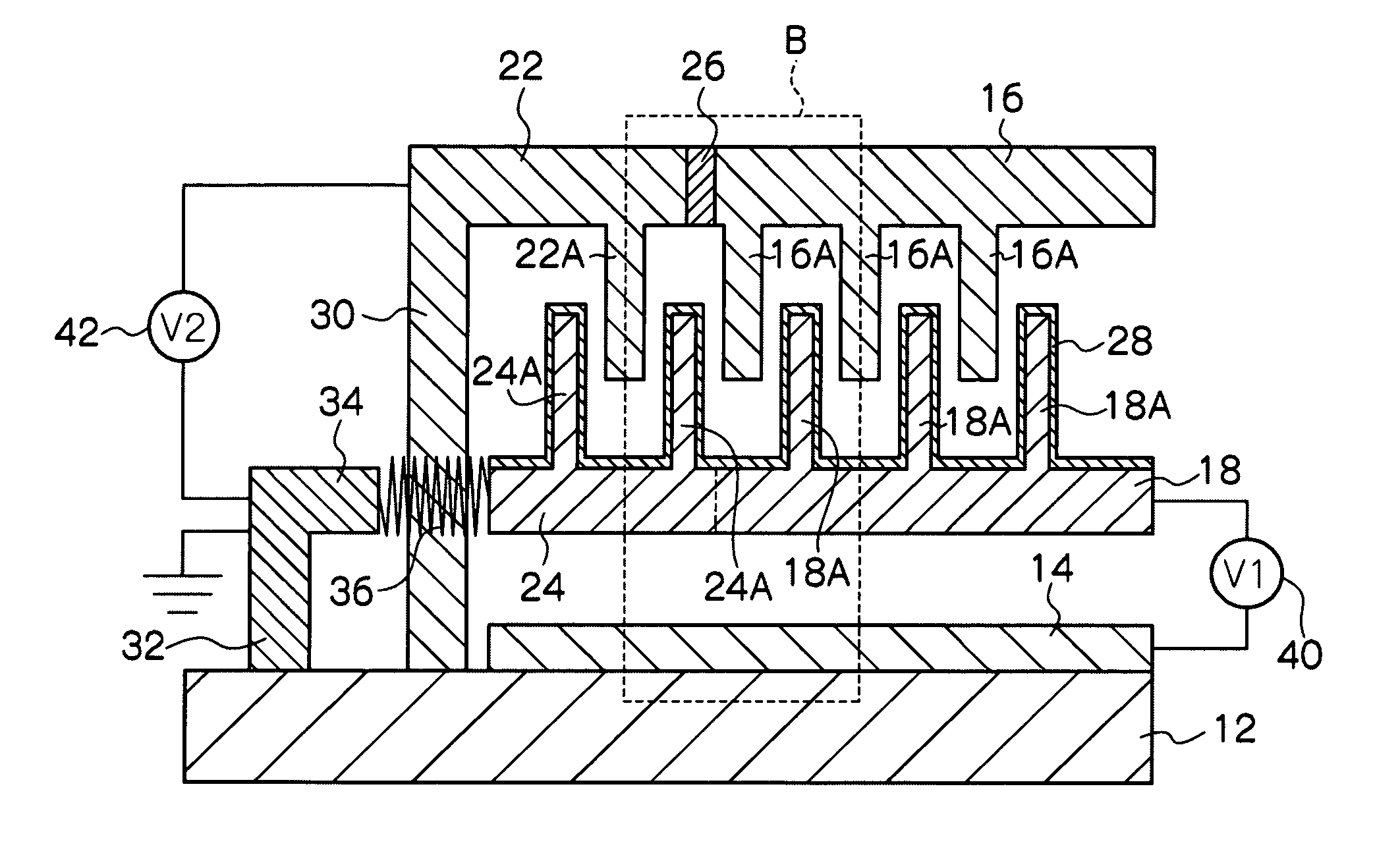

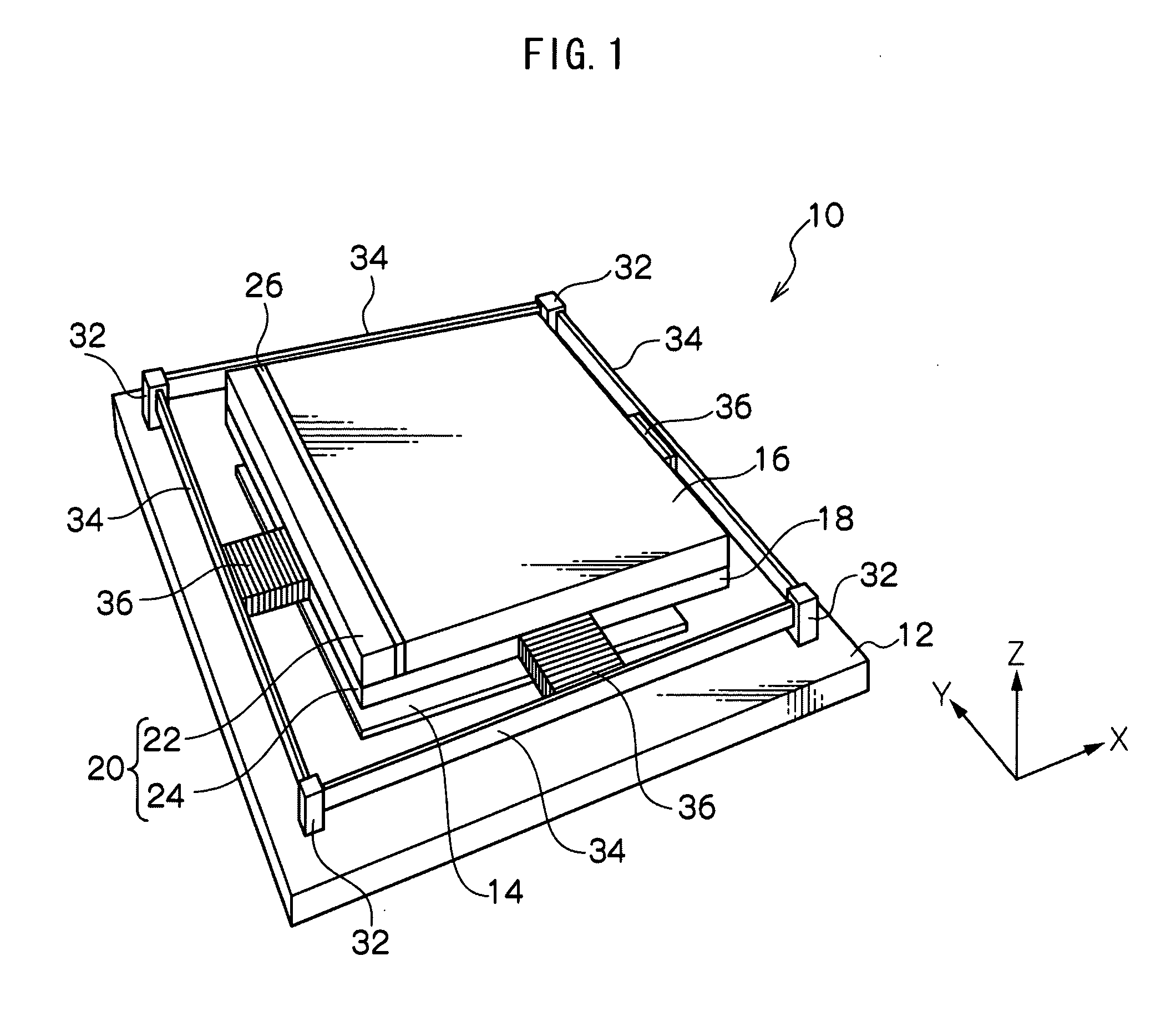

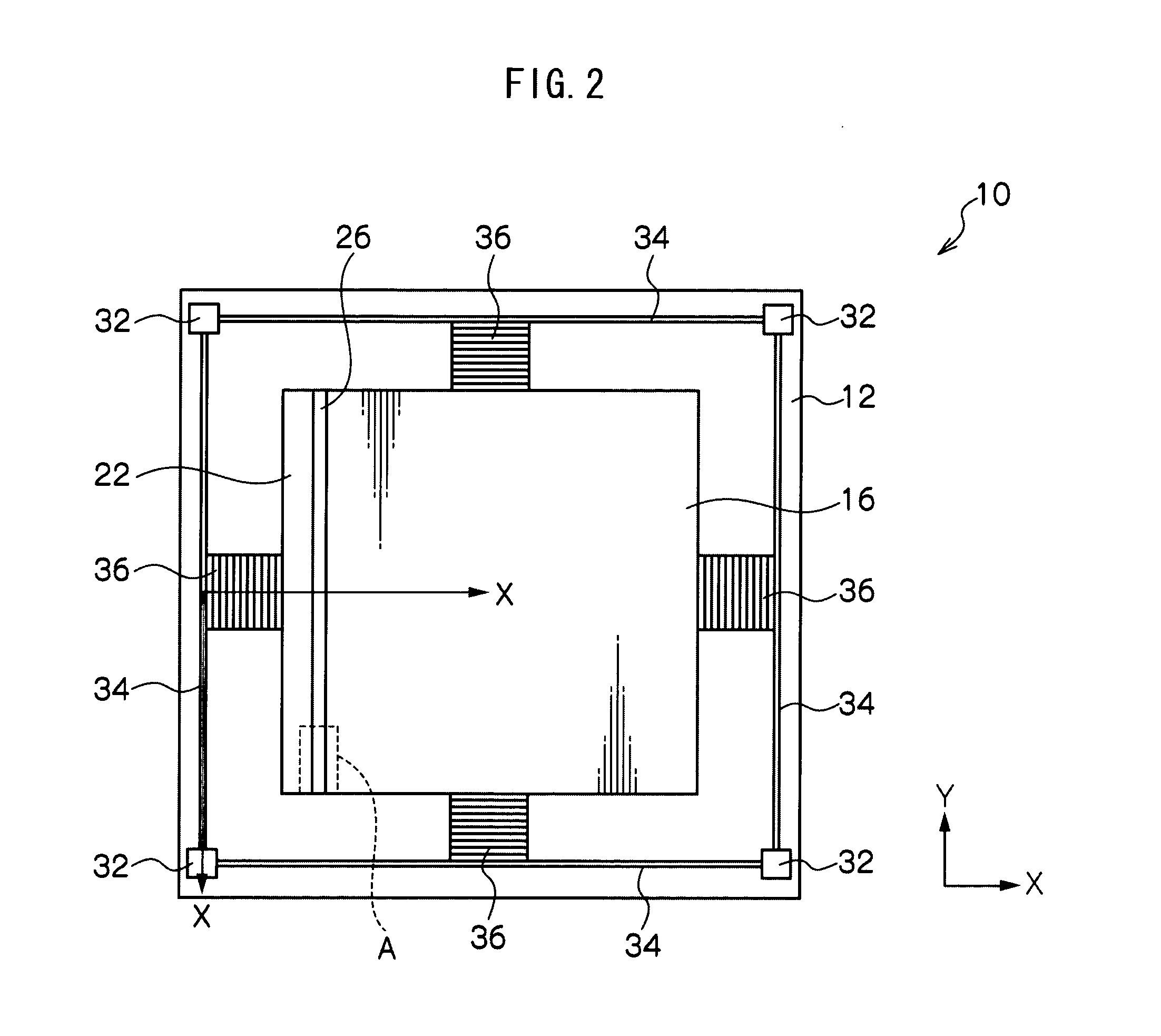

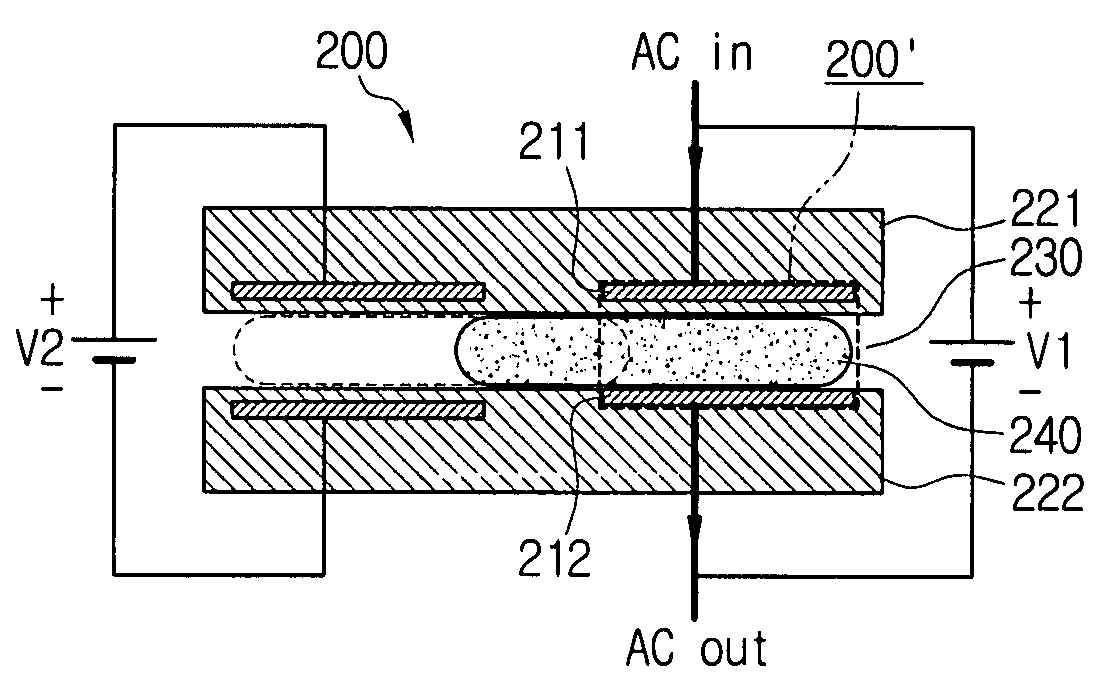

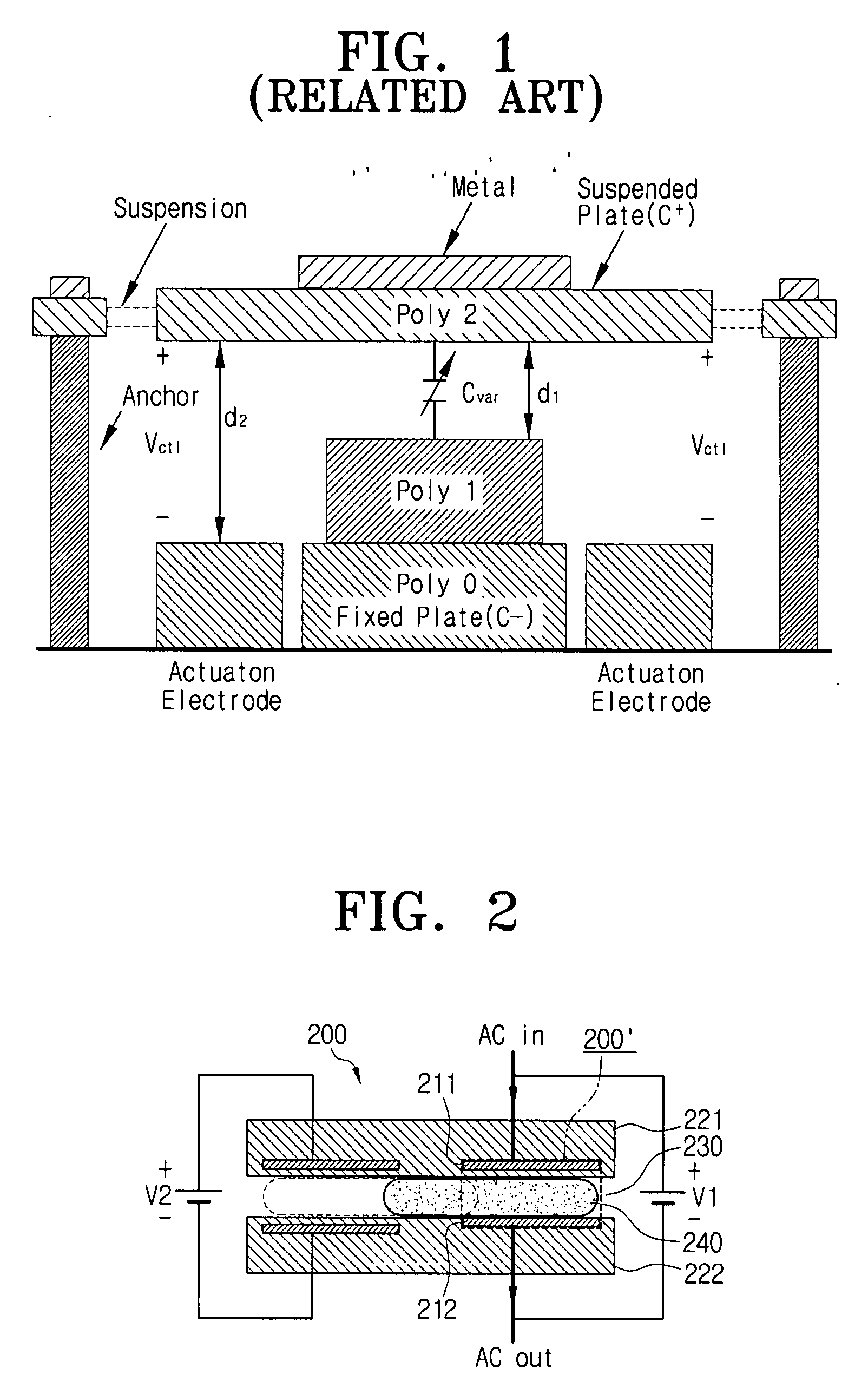

Variable capacitor employing MEMS technology

ActiveUS20100038753A1Avoid vibrationMechanically variable capacitor detailsCapacitor with electrode distance variationCapacitanceDielectric layer

When a positive voltage of V1 is applied to a drive capacitor with a braking voltage V2 at 0V, a moveable electrode moves toward the drive electrode, and a capacitance C of a tunable capacitor becomes smaller. When the braking voltage V2 is applied a lower portion brake electrode of the brake capacitor moves in a horizontal direction, such that the inter electrode separation distance between an upper portion brake electrode and the lower portion brake electrode becomes 0 μm. The moveable electrode configured integrally formed with the lower portion brake electrode also moves in the horizontal direction, and the inter electrode separation distance between the moveable electrode and a fixed electrode becomes 0 μm. Since the two electrodes make contact with each other with a dielectric layer interposed therebetween, the position of the moveable electrode can be stably maintained by frictional force between the electrodes.

Owner:LAPIS SEMICON CO LTD

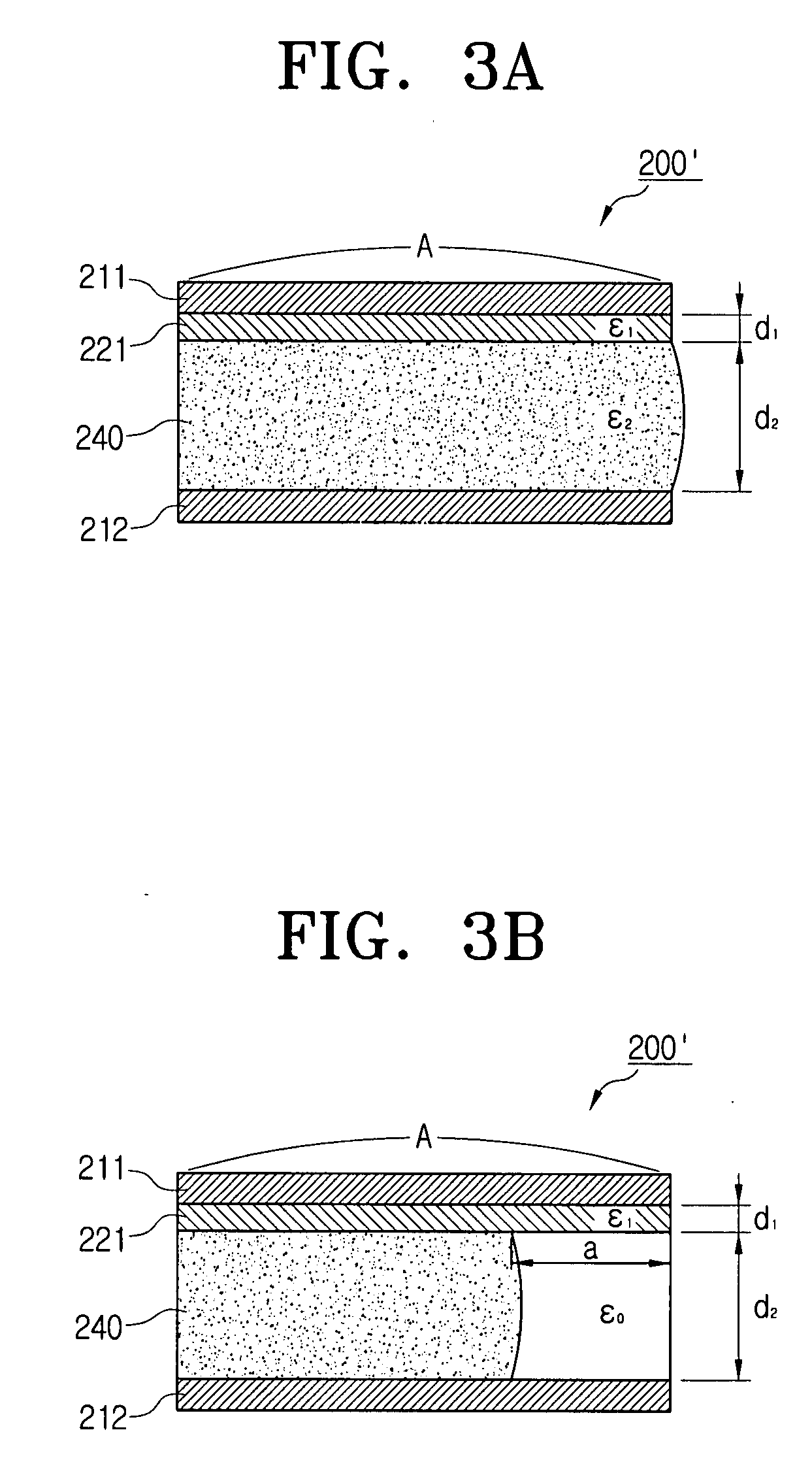

Tunable capacitor using electrowetting phenomenon

InactiveUS20080089005A1Simplify the manufacturing processImprove reliabilityMechanically variable capacitor detailsSemiconductor/solid-state device manufacturingPotential differenceCapacitor

A tunable capacitor using an electrowetting phenomenon includes a first electrode; a second electrode which is spaced apart from the first electrode and faces the first electrode; a fluidic channel which is disposed between the first electrode and the second electrode; a first insulating layer which is disposed between the first electrode and the fluidic channel; and a conductive fluid which is disposed in the fluidic channel and moves along the fluidic channel when a direct current (DC) potential difference occurs between the first and second electrodes. Accordingly, it is possible to fabricate the tunable capacitor with the simplified fabrication process, good reliability and durability, and no restriction on the tuning range.

Owner:SAMSUNG ELECTRONICS CO LTD

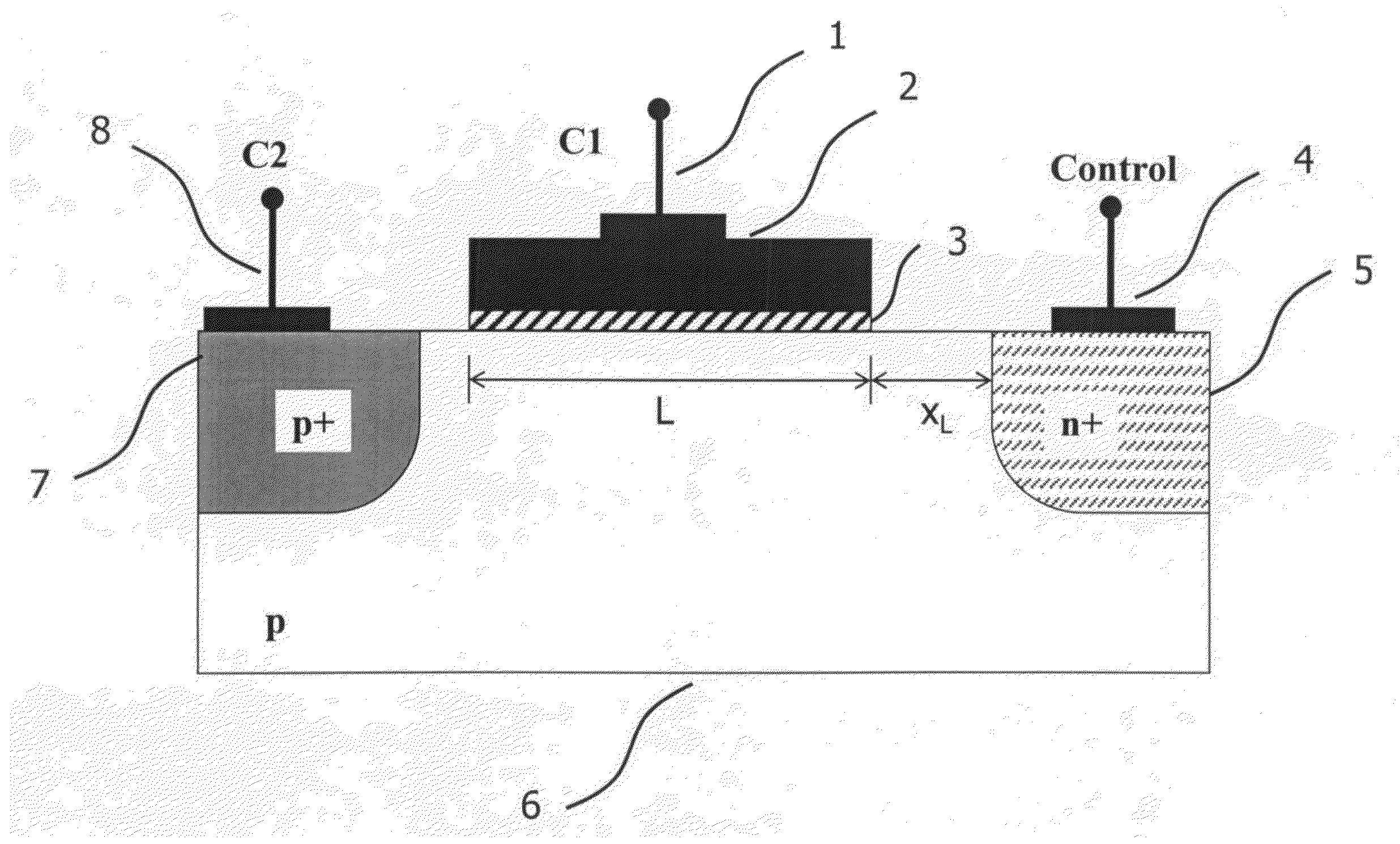

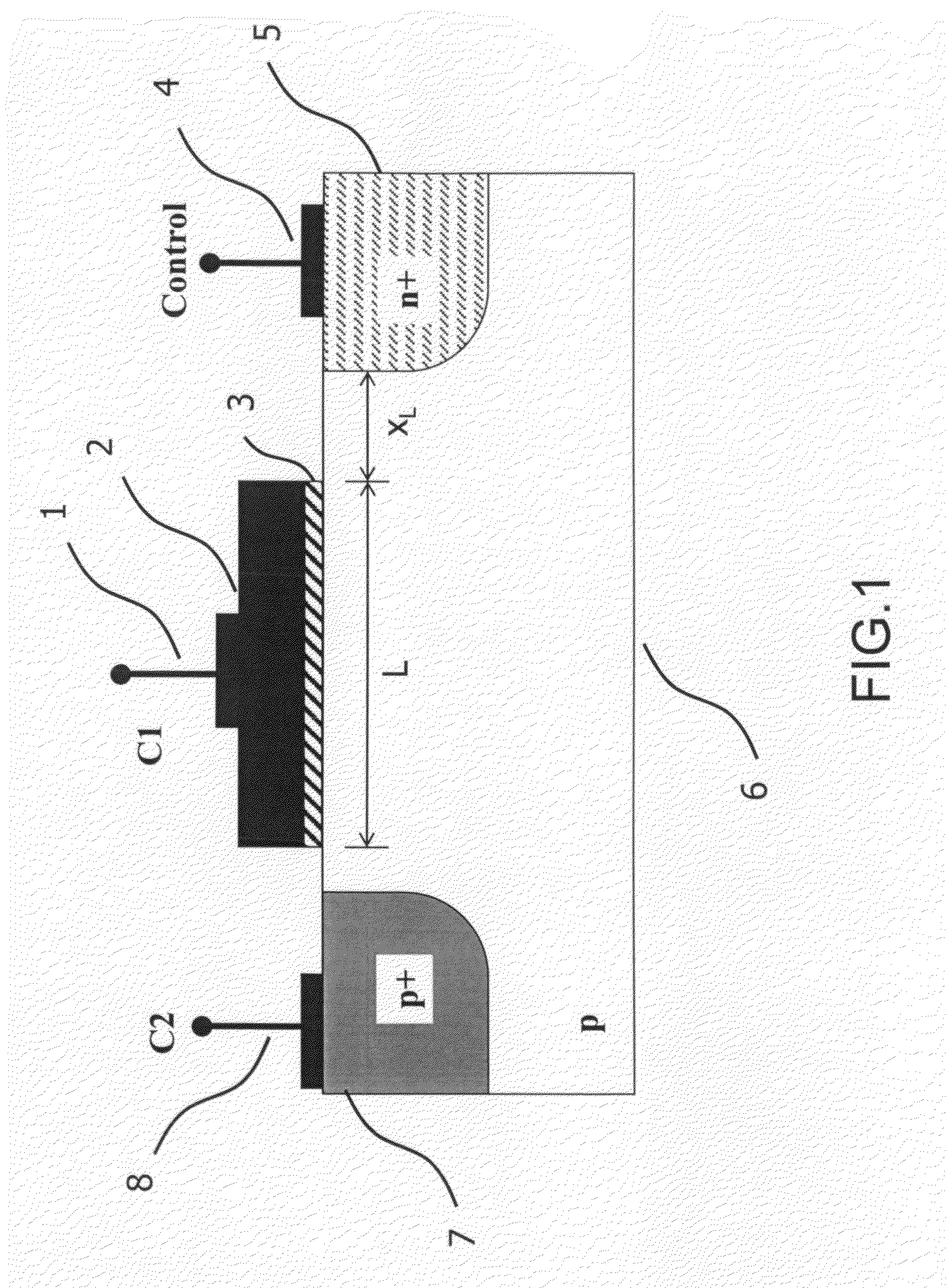

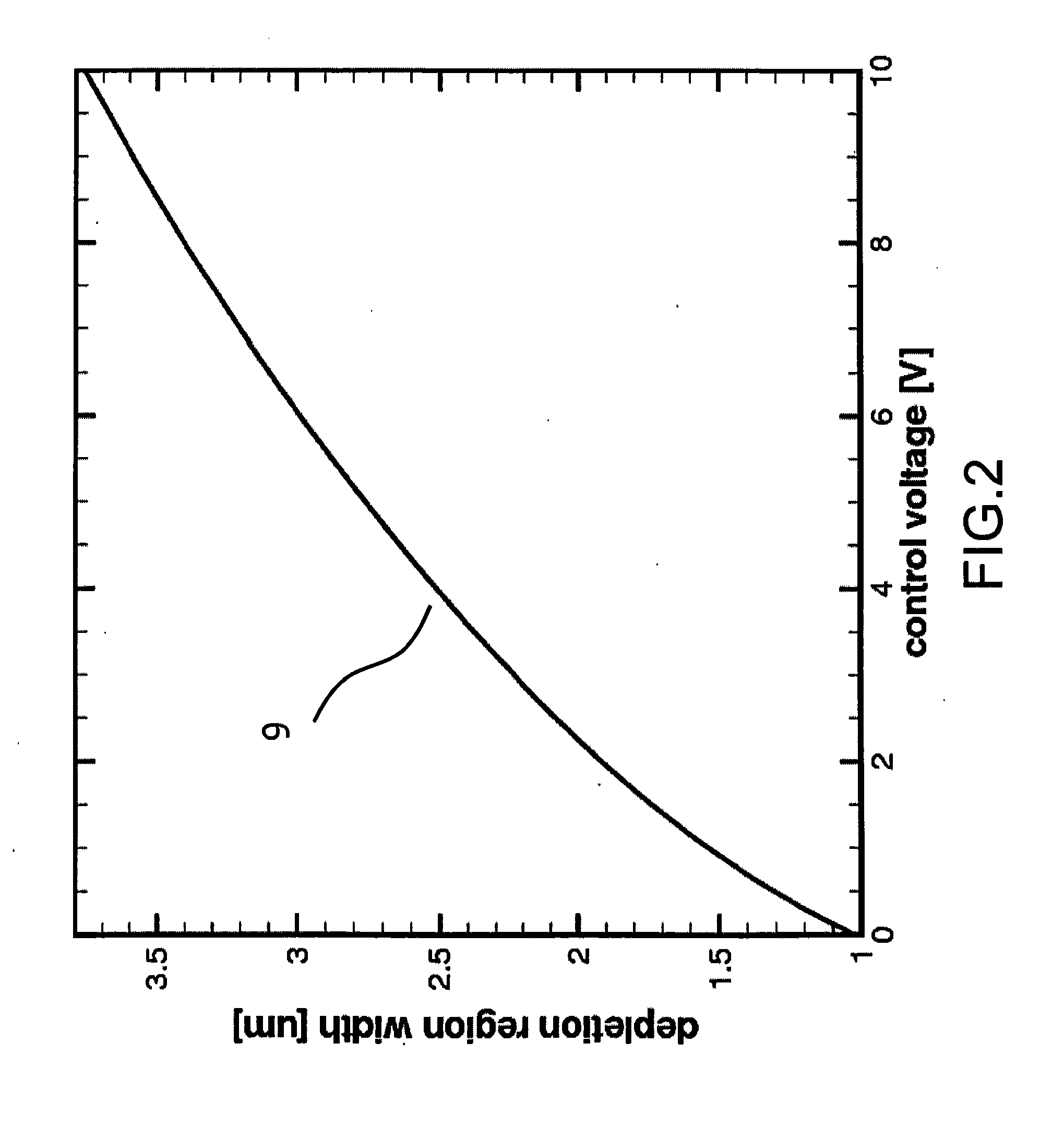

Semiconductor variable capacitor

ActiveUS20120281336A1Avoid distortionIncrease valueMechanically variable capacitor detailsCapacitor with electrode distance variationCapacitanceSemiconductor structure

A novel semiconductor variable capacitor is presented. The semiconductor structure is simple and is based on a semiconductor variable MOS capacitor structure suitable for integrated circuits, which has at least three terminals, one of which is used to modulate the equivalent capacitor area of the MOS structure by increasing or decreasing its DC voltage with respect to another terminal of the device, in order to change the capacitance over a wide ranges of values. Furthermore, the present invention decouples the AC signal and the DC control voltage avoiding distortion and increasing the performance of the device, such as its control characteristic. The present invention is simple and only slightly dependent on the variations due to the fabrication process. It exhibits a high value of capacitance density and, if opportunely implemented, shows a linear dependence of the capacitance value with respect to the voltage of its control terminal.

Owner:QUALCOMM INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com