Patents

Literature

58 results about "Comb finger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

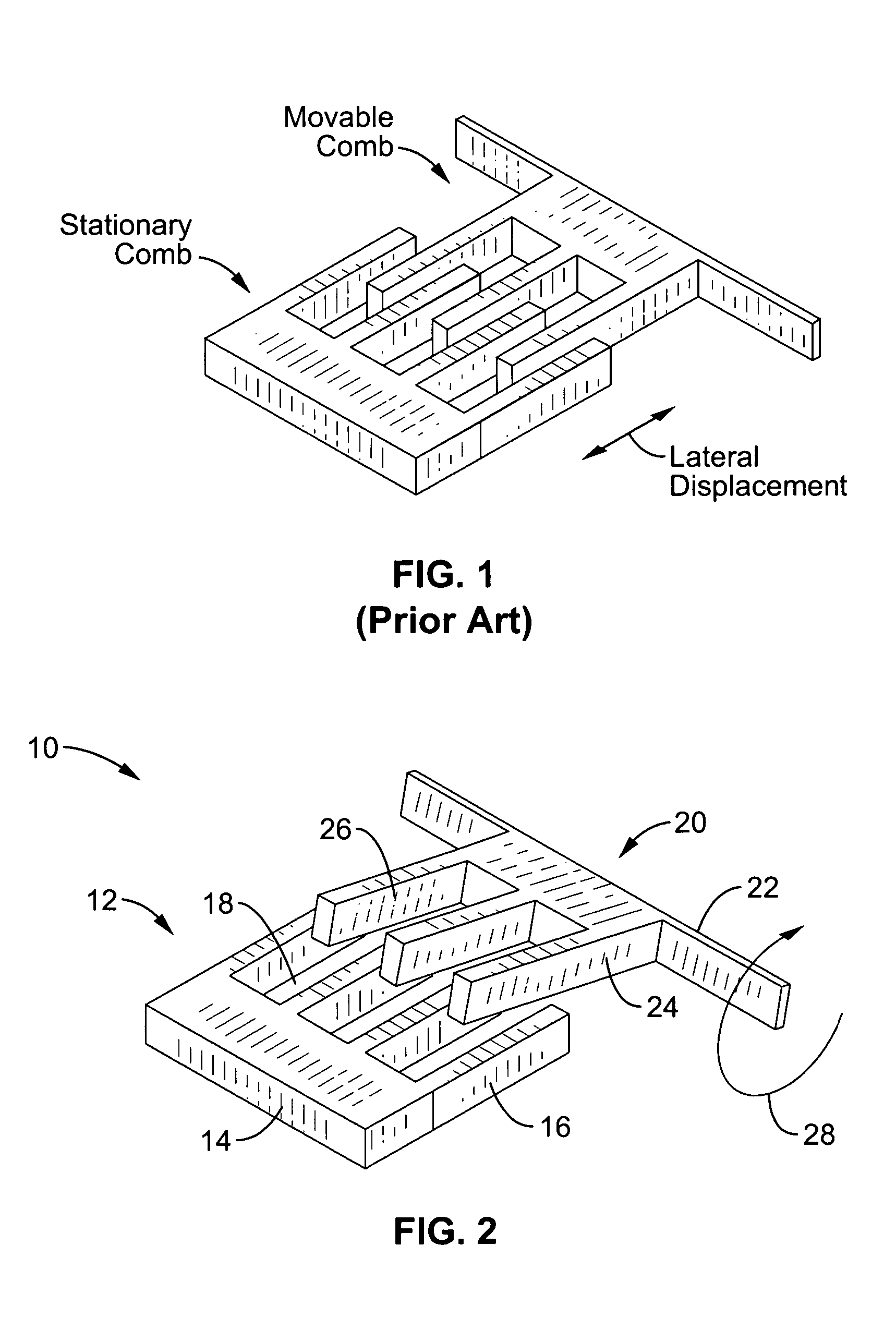

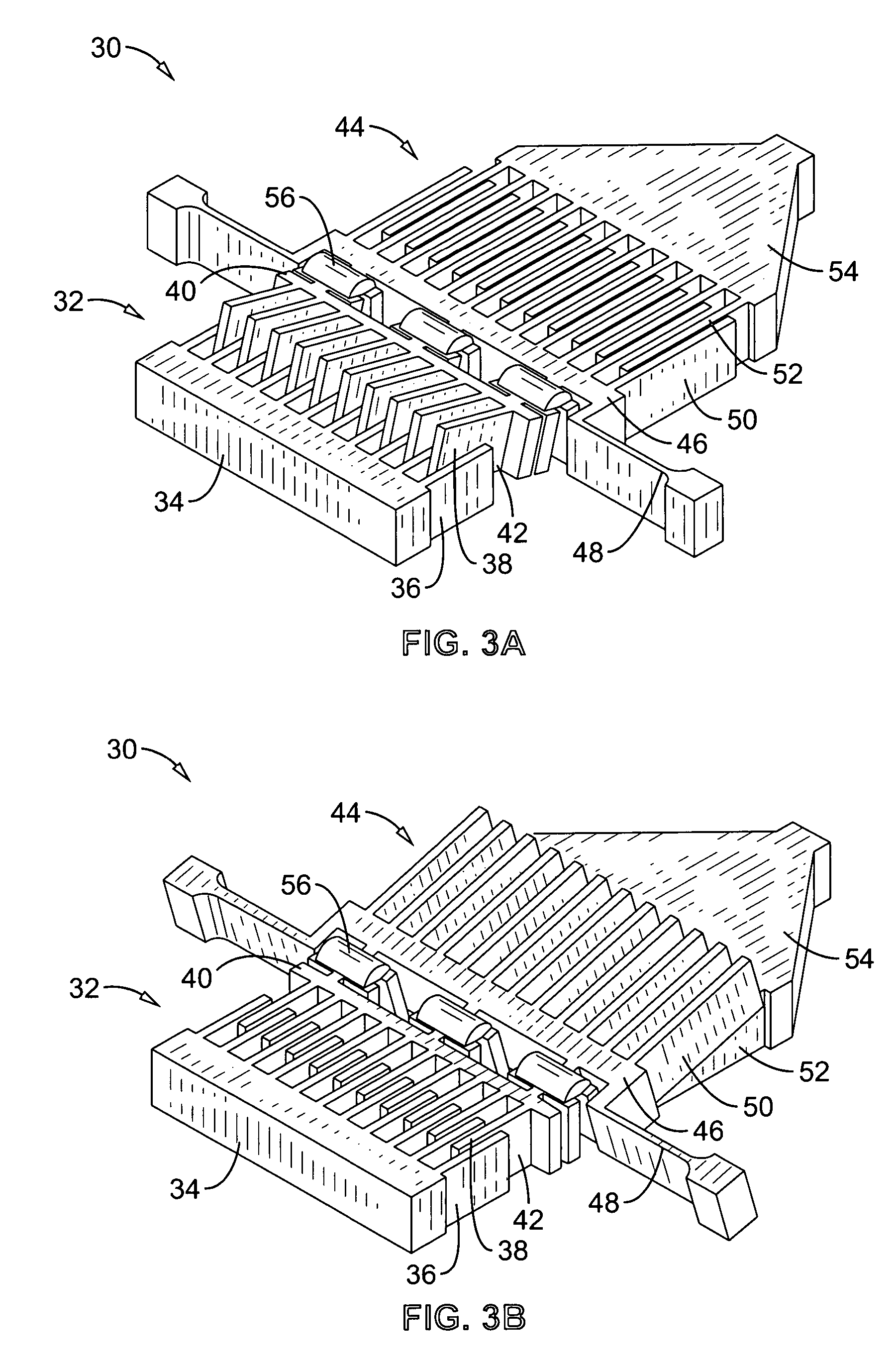

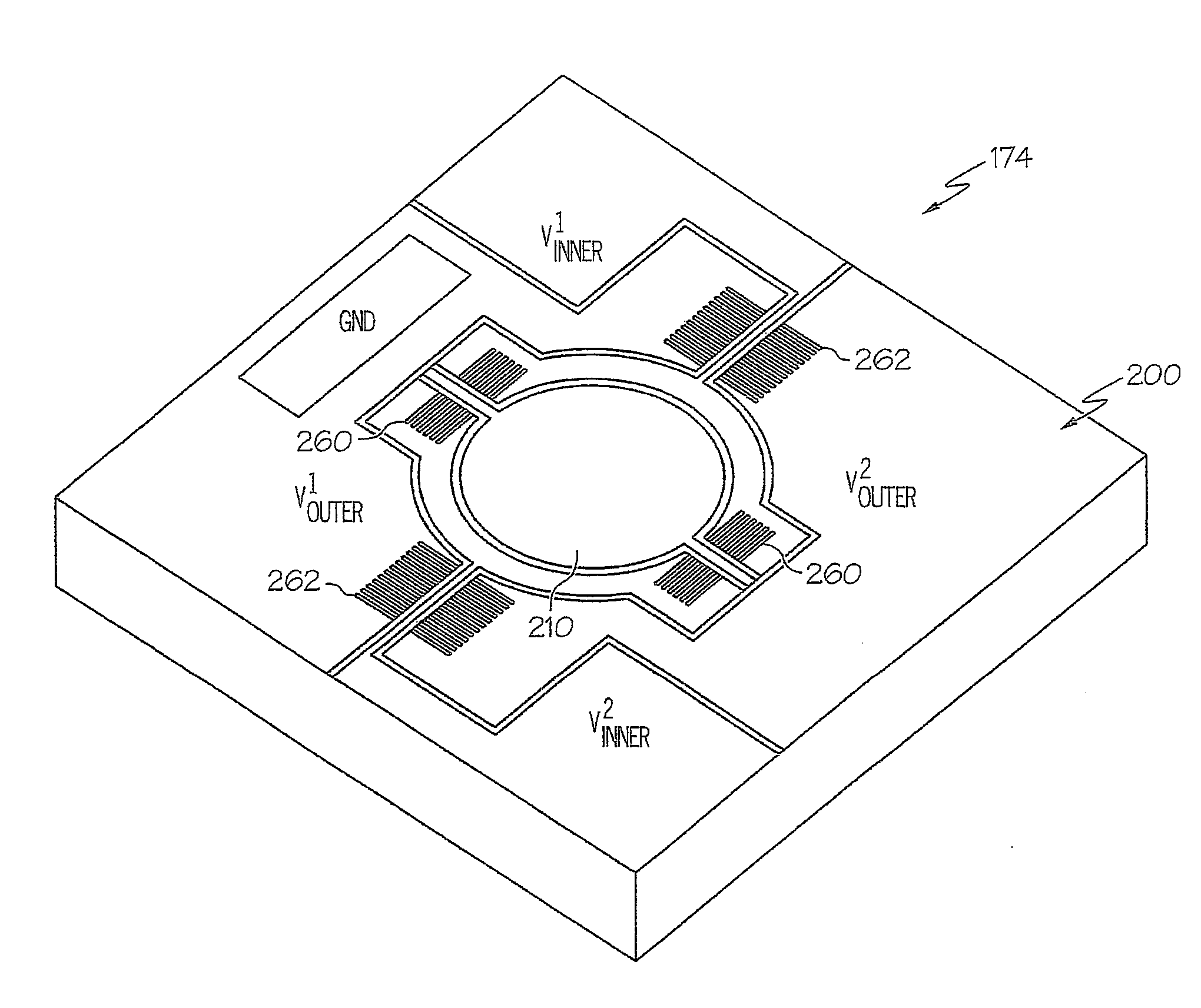

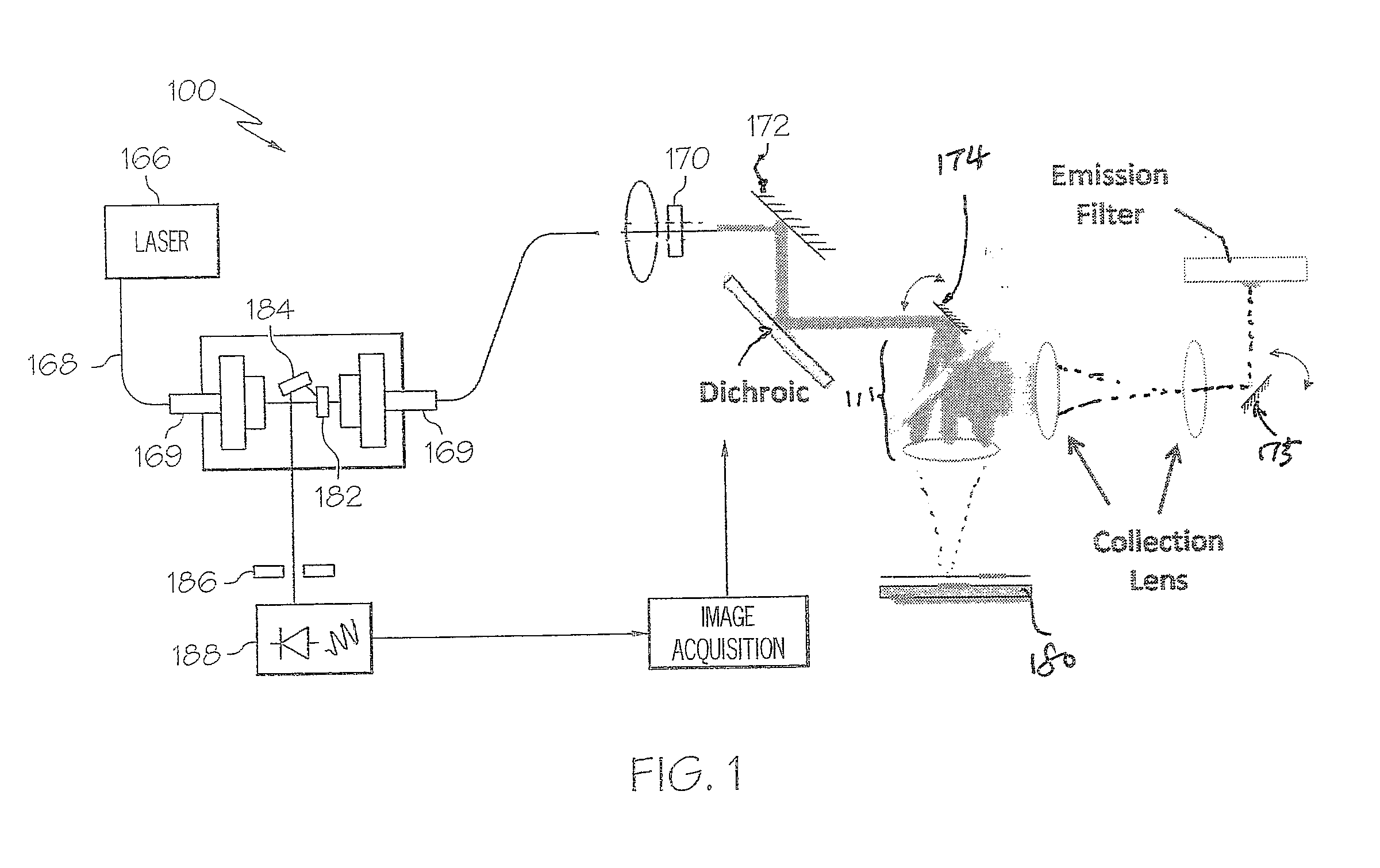

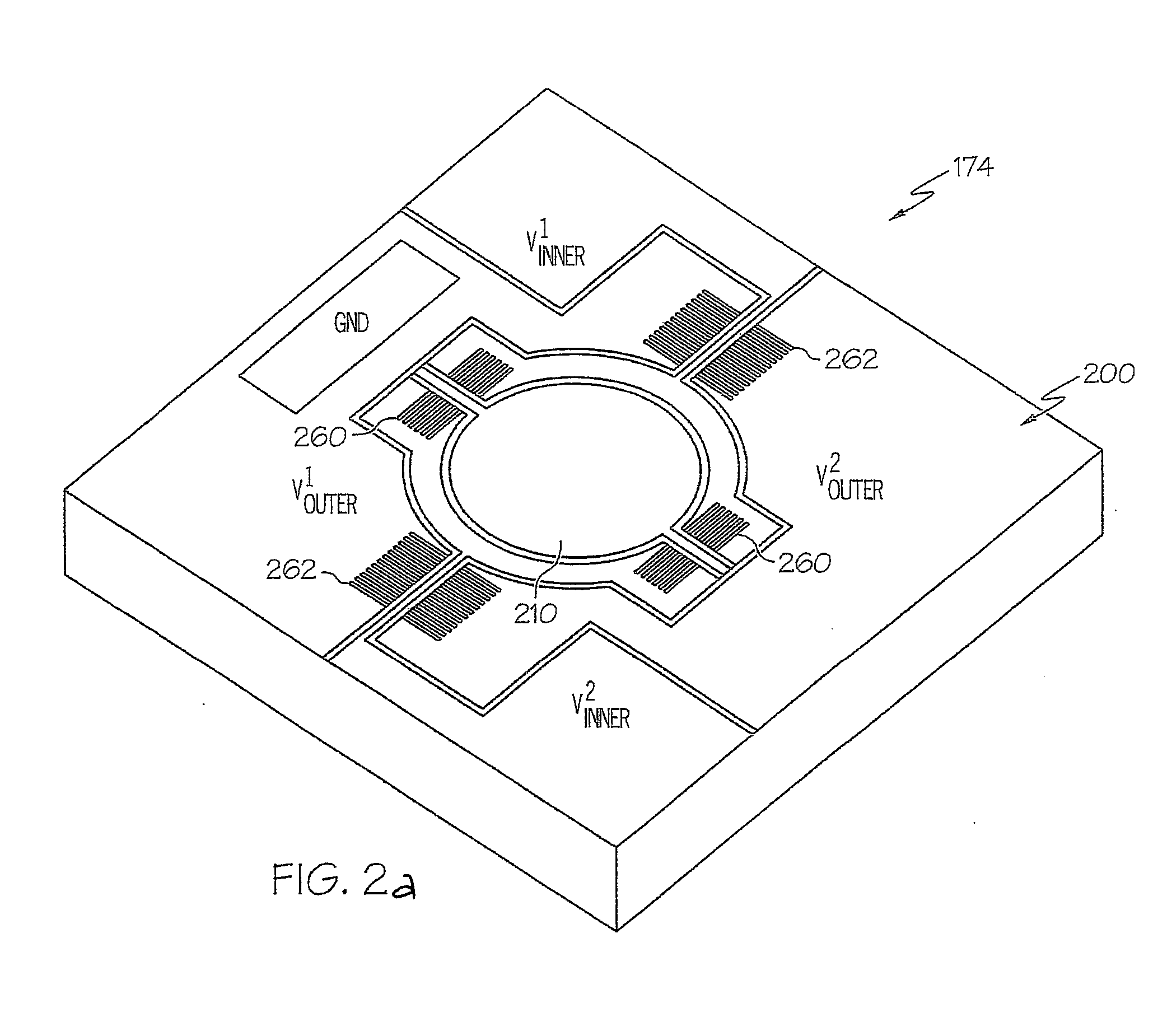

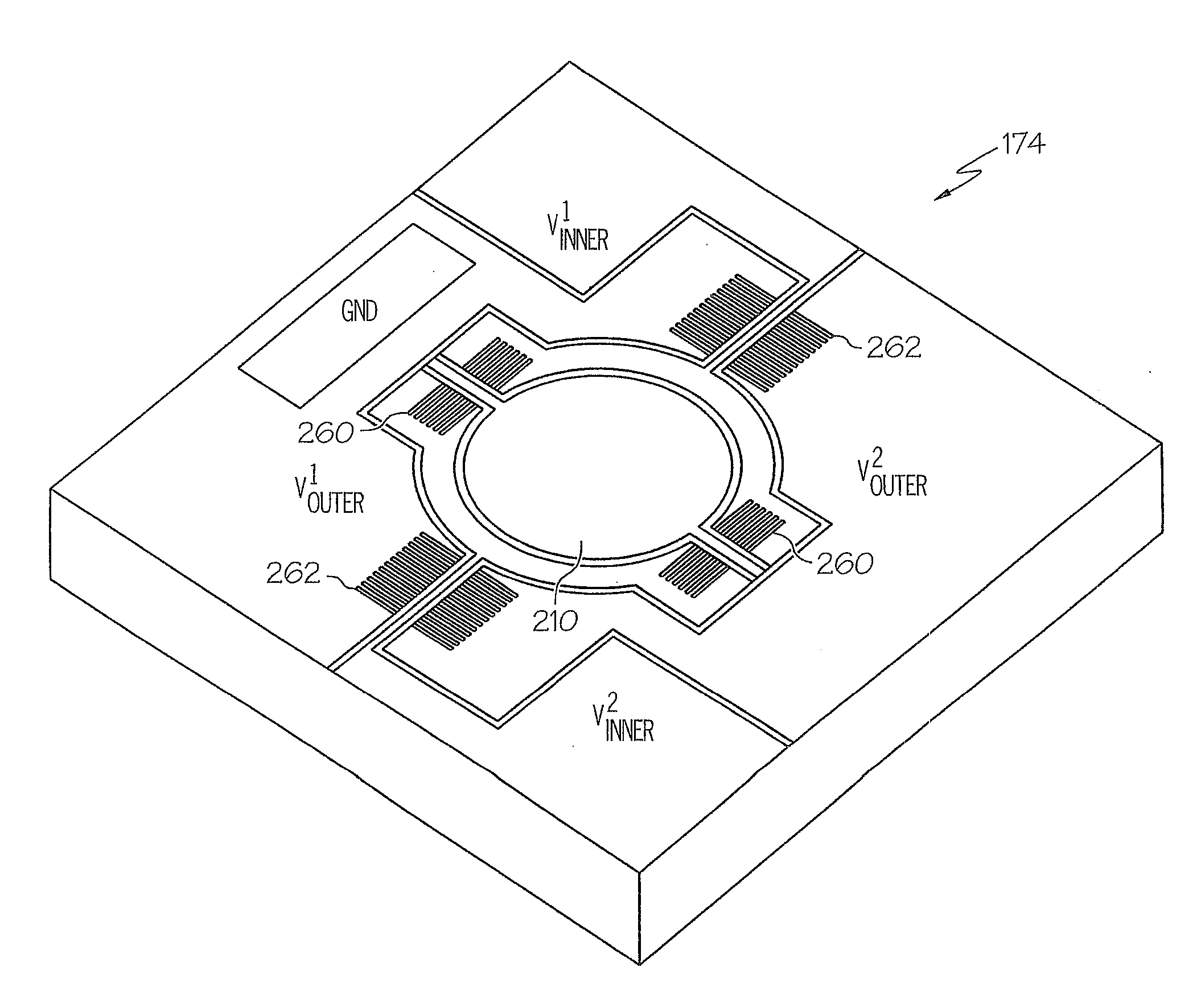

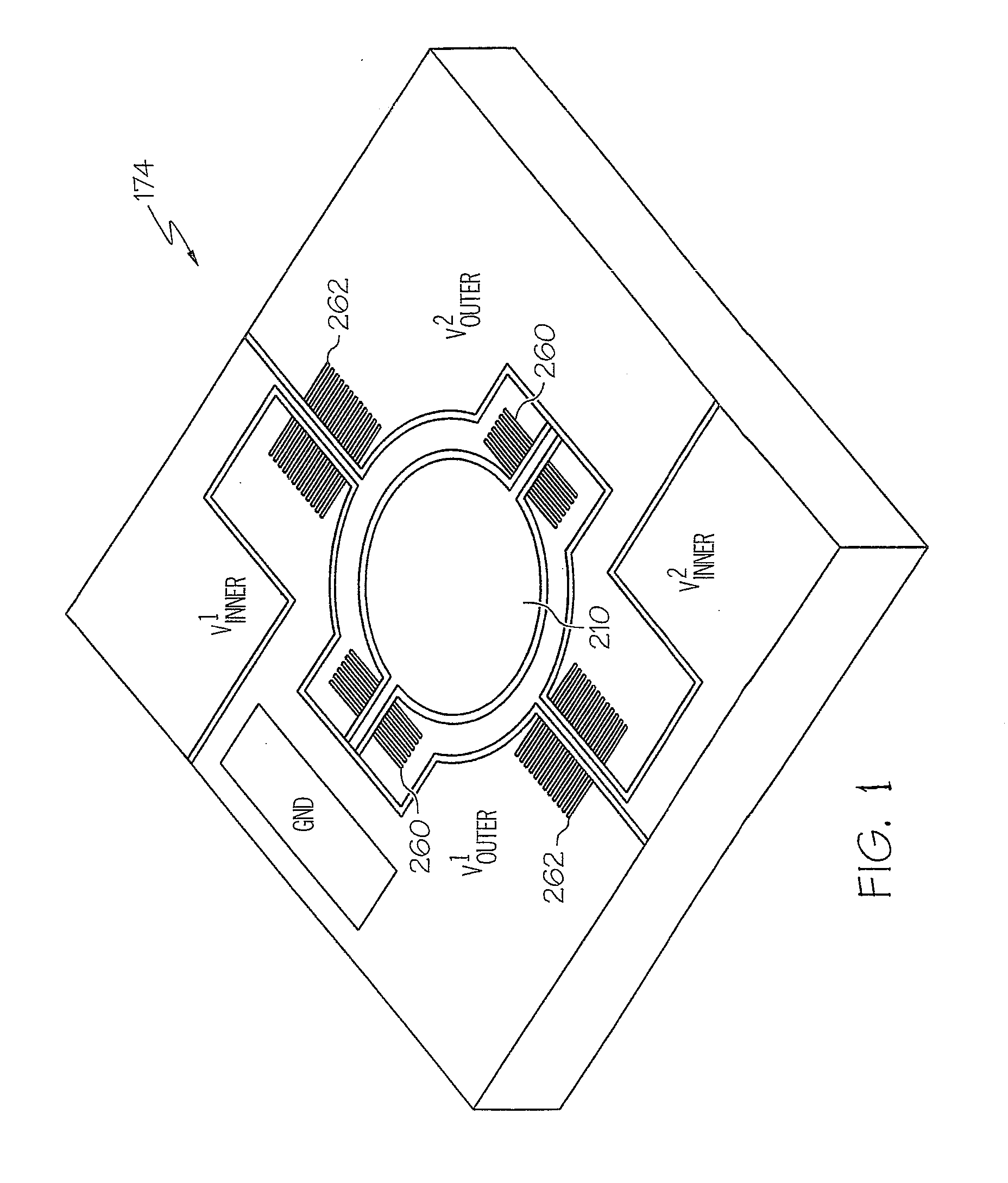

MEMS tunable capacitor based on angular vertical comb drives

InactiveUS7085122B2Appreciates the drawbacks inherent in lateral drive MEMS capacitorsIncrease tuning rangeMultiple-port networksMechanically variable capacitor detailsCapacitanceComb finger

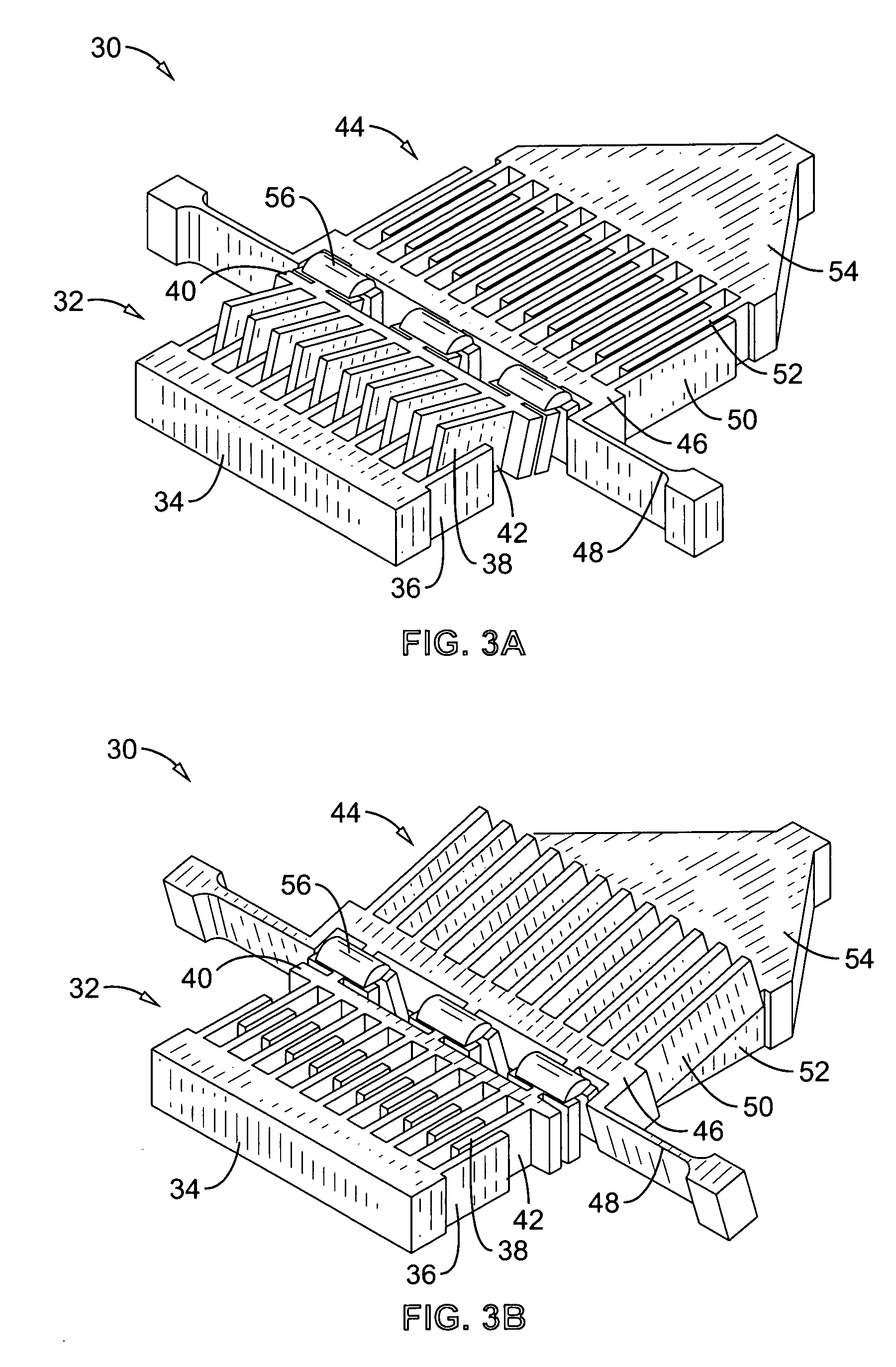

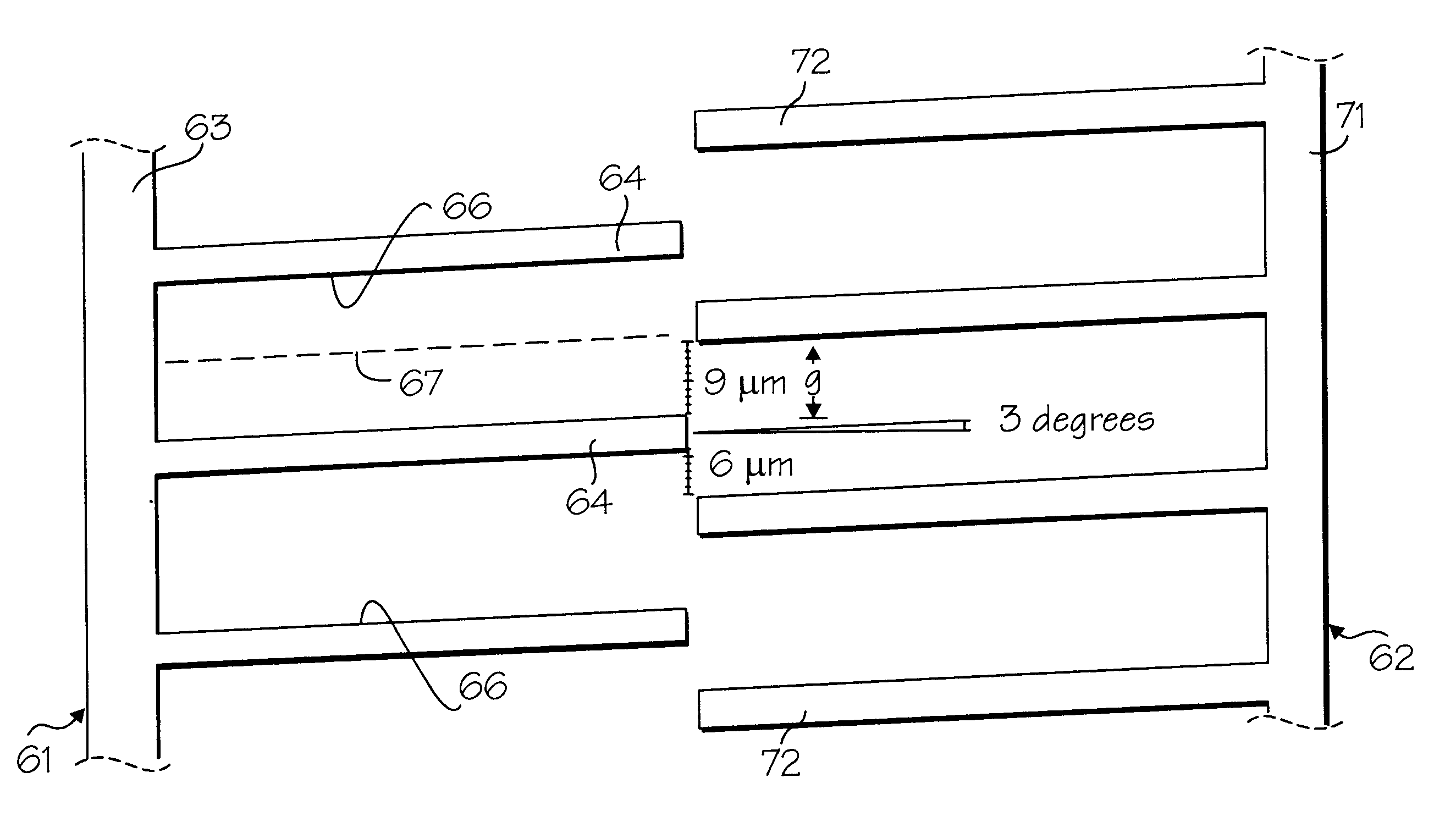

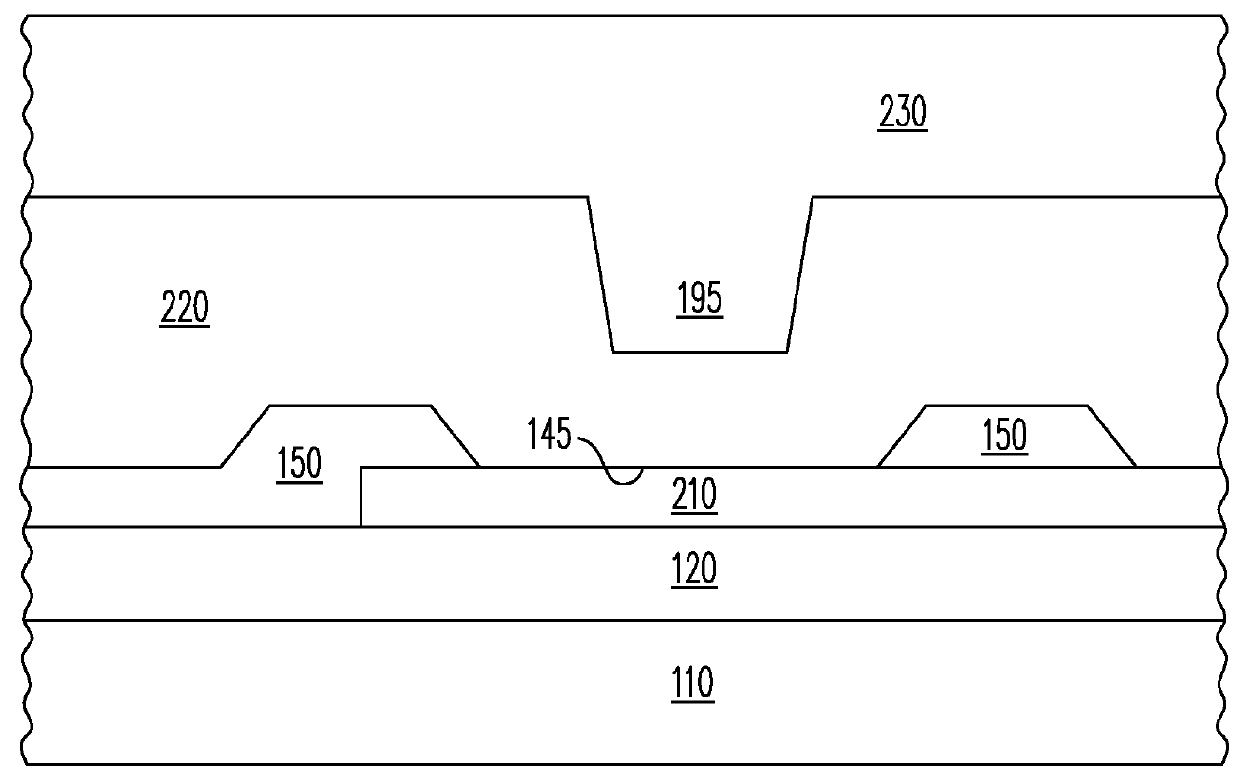

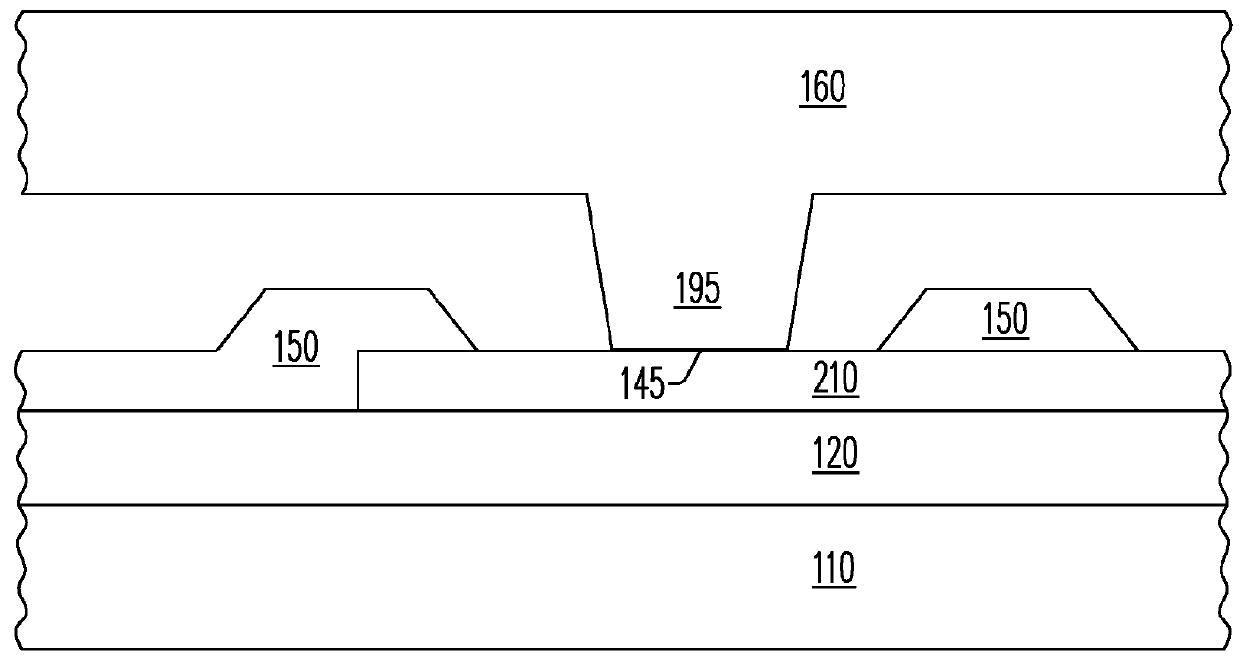

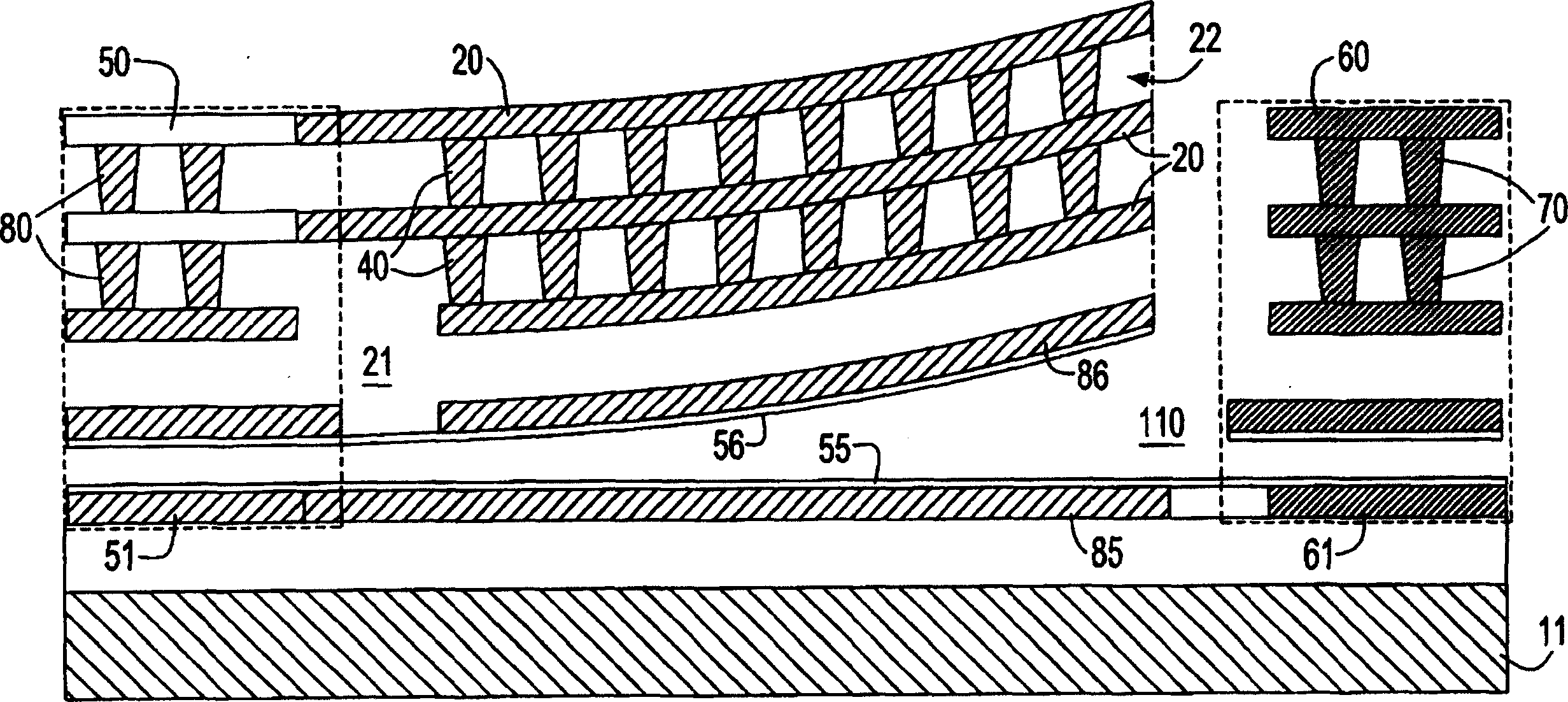

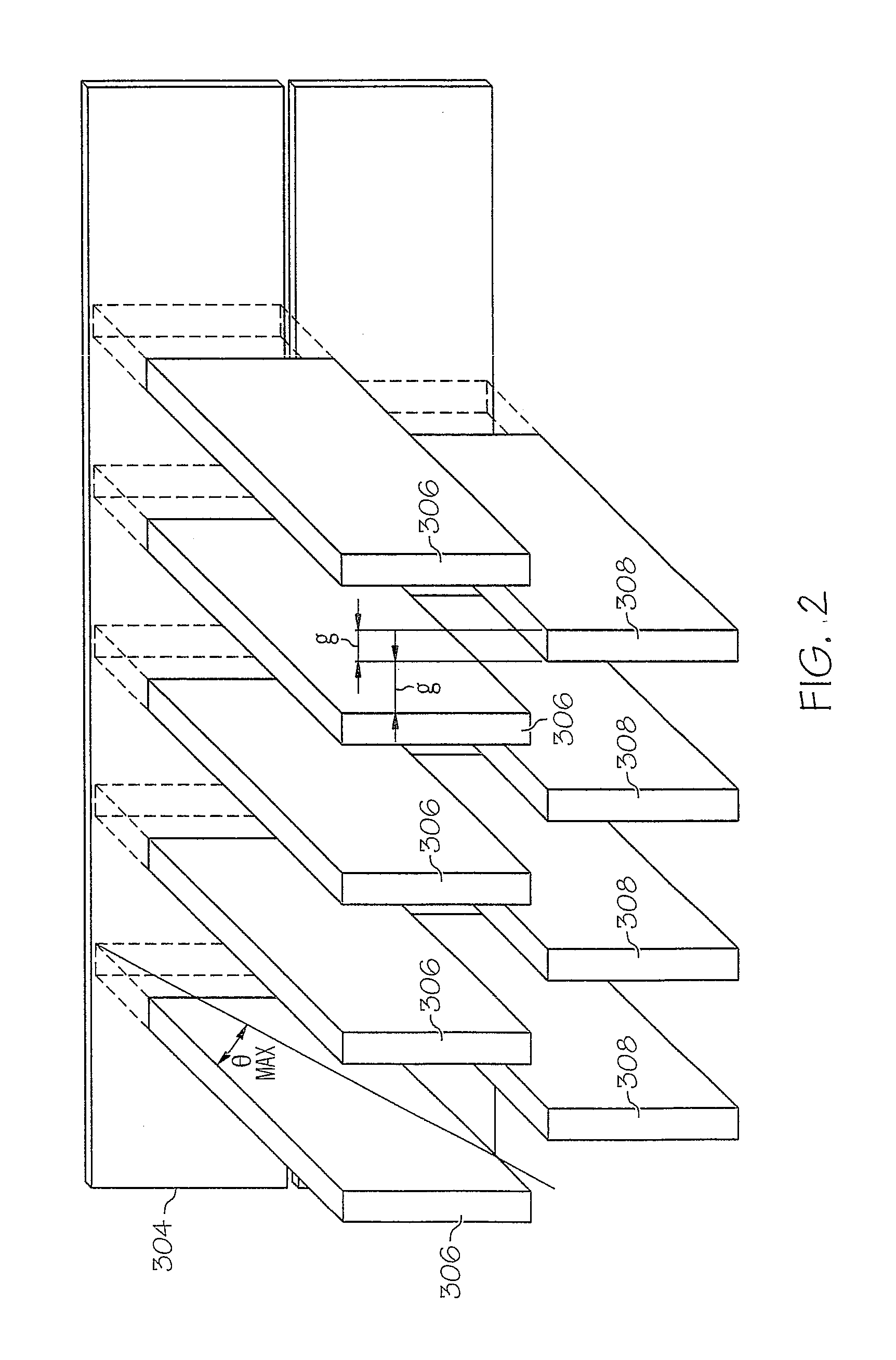

A MEMS tunable capacitor with angular vertical comb-drive (AVC) actuators is described where high capacitances and a wide continuous tuning range is achieved in a compact space. The comb fingers rotate through a small vertical angle which allows a wider tuning range than in conventional lateral comb drive devices. Fabrication of the device is straightforward, and involves a single deep reactive ion etching step followed by release and out-of-plane assembly of the angular combs.

Owner:RGT UNIV OF CALIFORNIA

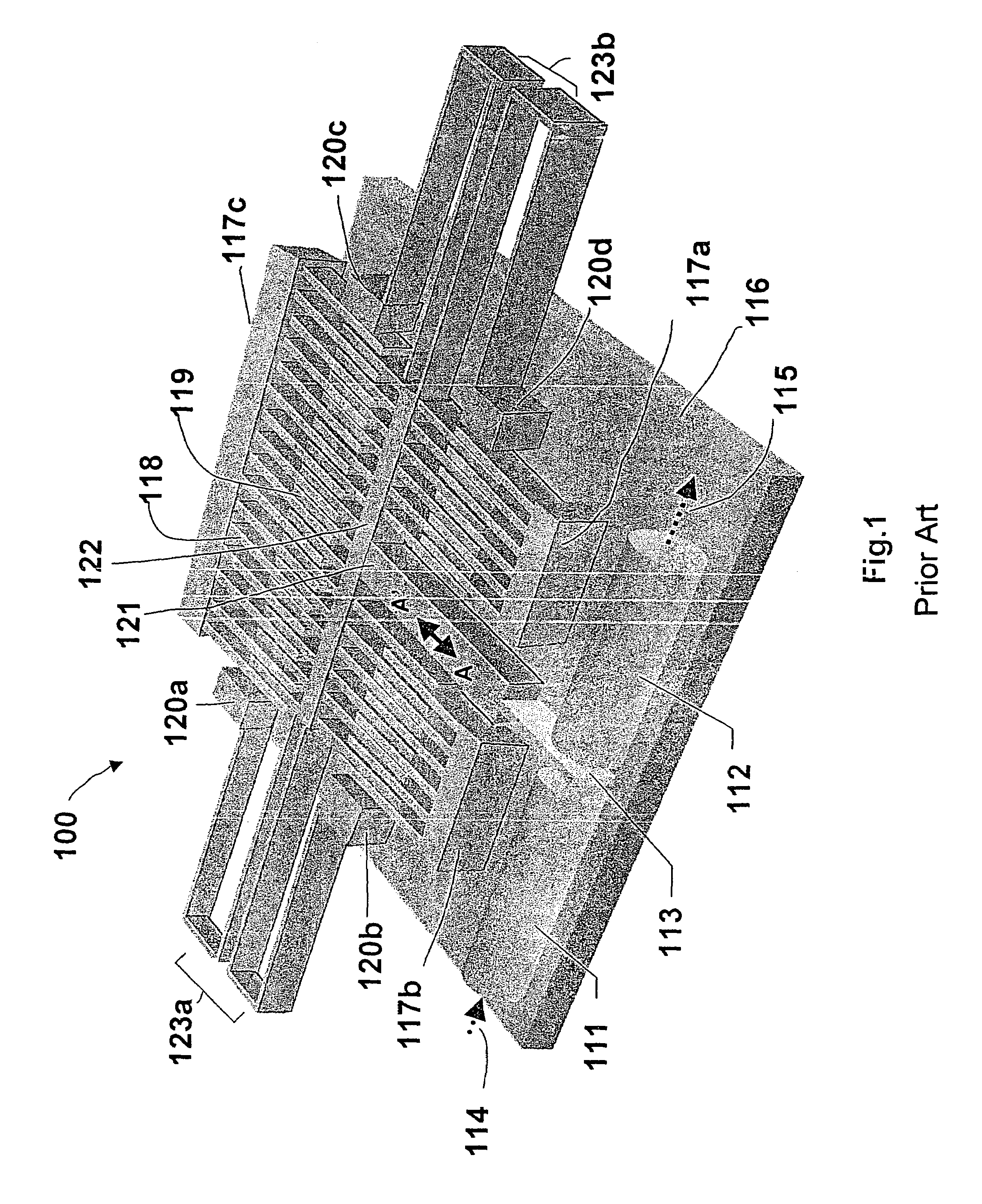

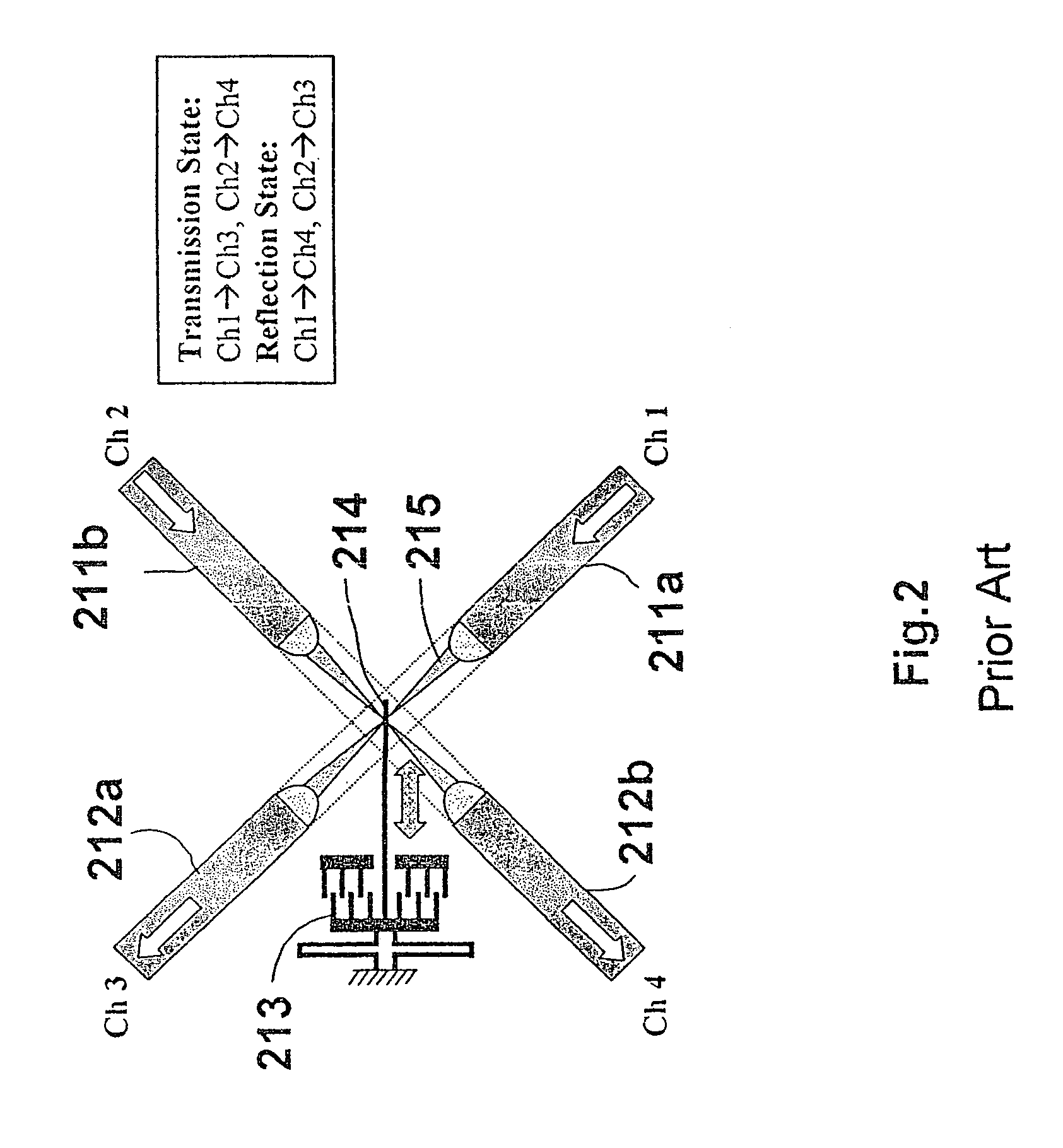

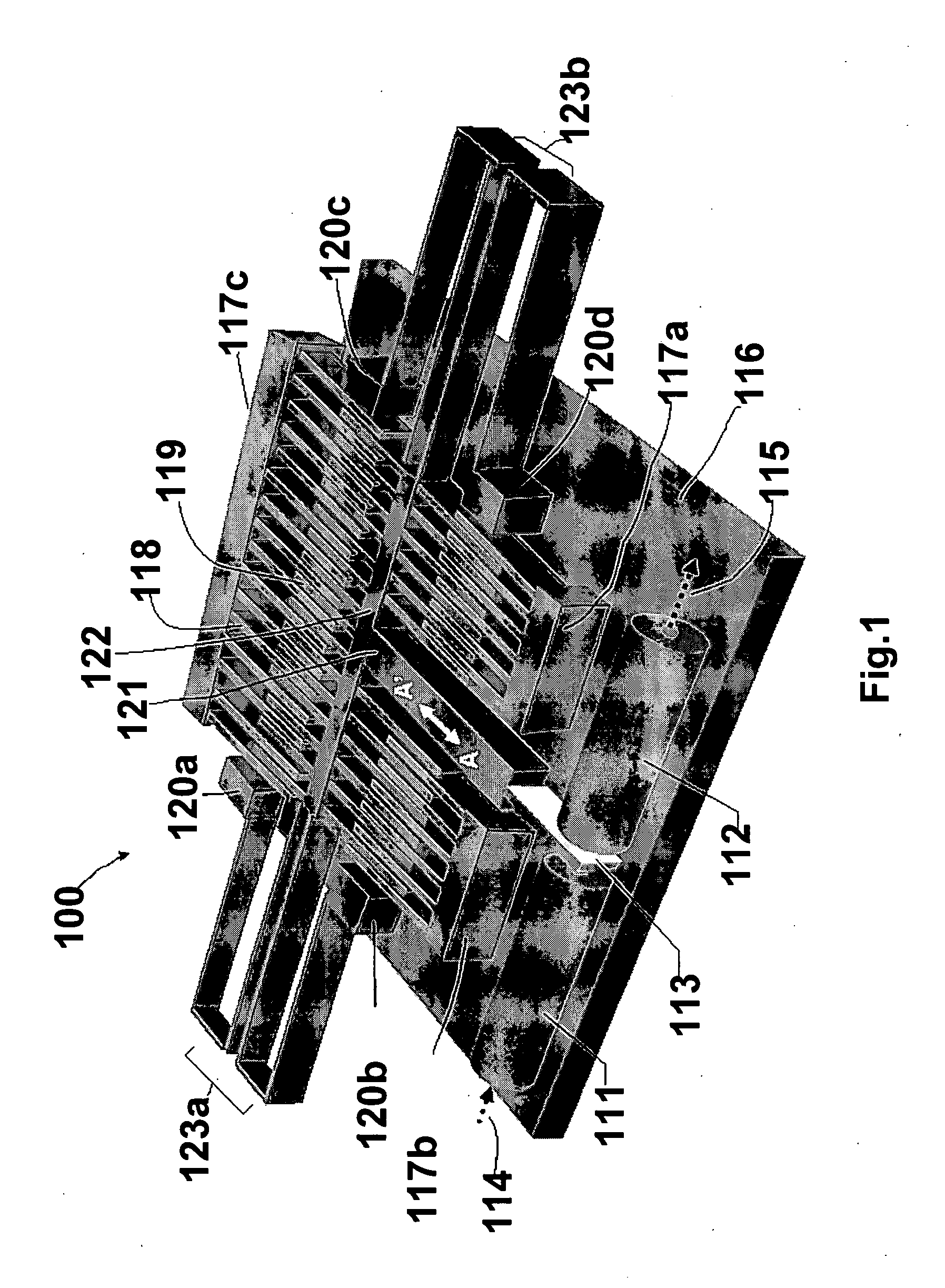

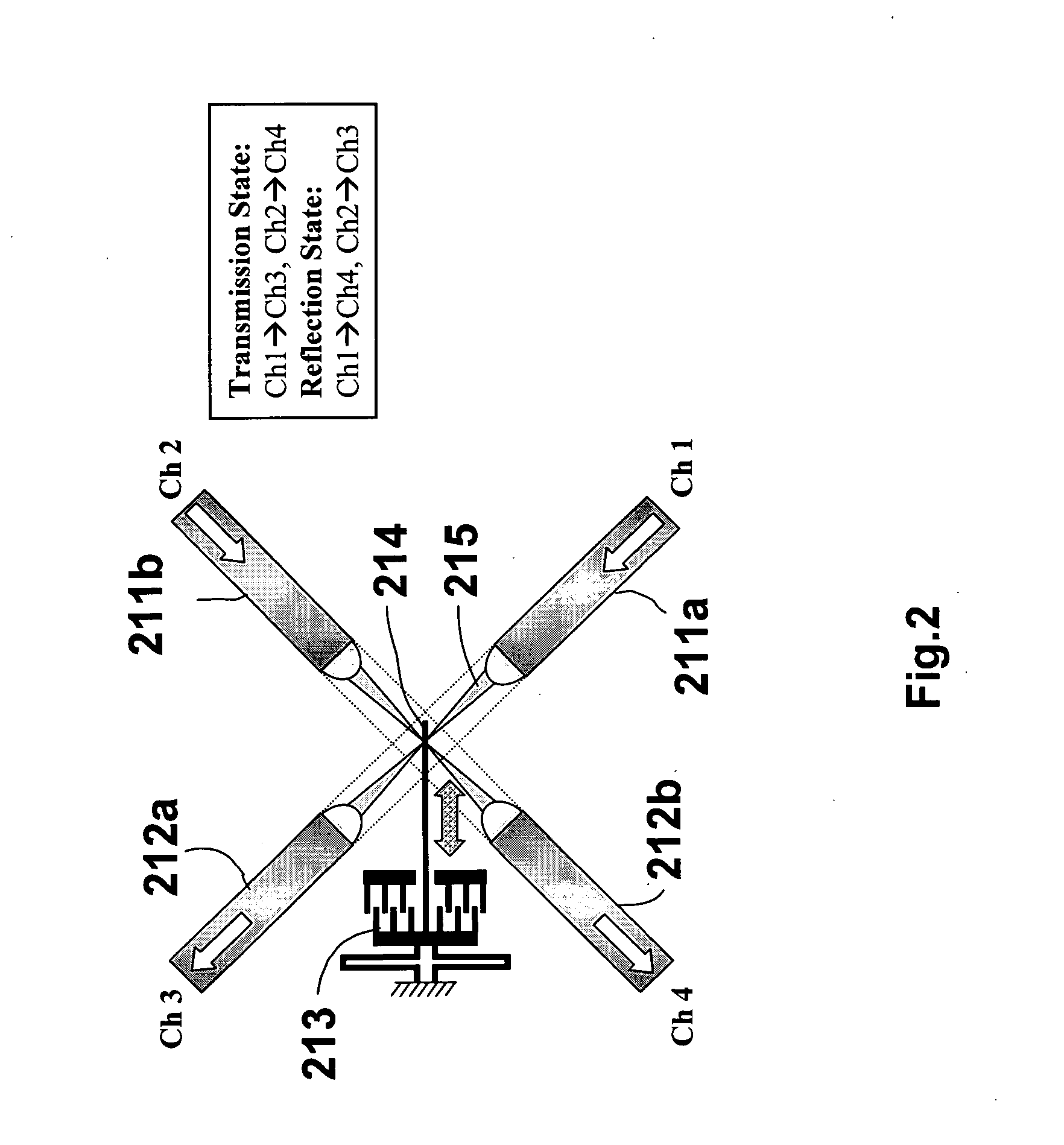

Electrostatically operated micro-optical devices and method for manufacturing thereof

Electrostatically operated micro-optical devices and method of manufacturing such devices is disclosed. In a preferred embodiment, the micro-optical devices using electrostatic comb drive actuators having new spring designs to overcome side instability and exhibit enlarged displacement, having new designs of comb finger electrode shapes to generate larger force output, and having new clip type latch mechanism to control the corresponding device at certain states in an analog manner without electrical power consumption. Based on the proposed optical path and device configurations, integration and assembly of a plurality of reflective micro-mirrors in conjunction with proposed new comb drive actuators is very promising way to provide micro-optical devices to get good optical performance and suitable for multi-channel applications. We also disclose several process techniques to manufacture the micro-optical devices with said electrostatic comb drive actuator in a mass production manner with higher yield.

Owner:ASIA PACIFIC MICROSYST

MEMS tunable capacitor based on angular vertical comb drives

InactiveUS20050013087A1Increase tuning rangeAppreciates the drawbacks inherent in lateral drive MEMS capacitorsMultiple-port networksMechanically variable capacitor detailsCapacitanceComb finger

A MEMS tunable capacitor with angular vertical comb-drive (AVC) actuators is described where high capacitances and a wide continuous tuning range is achieved in a compact space. The comb fingers rotate through a small vertical angle which allows a wider tuning range than in conventional lateral comb drive devices. Fabrication of the device is straightforward, and involves a single deep reactive ion etching step followed by release and out-of-plane assembly of the angular combs.

Owner:RGT UNIV OF CALIFORNIA

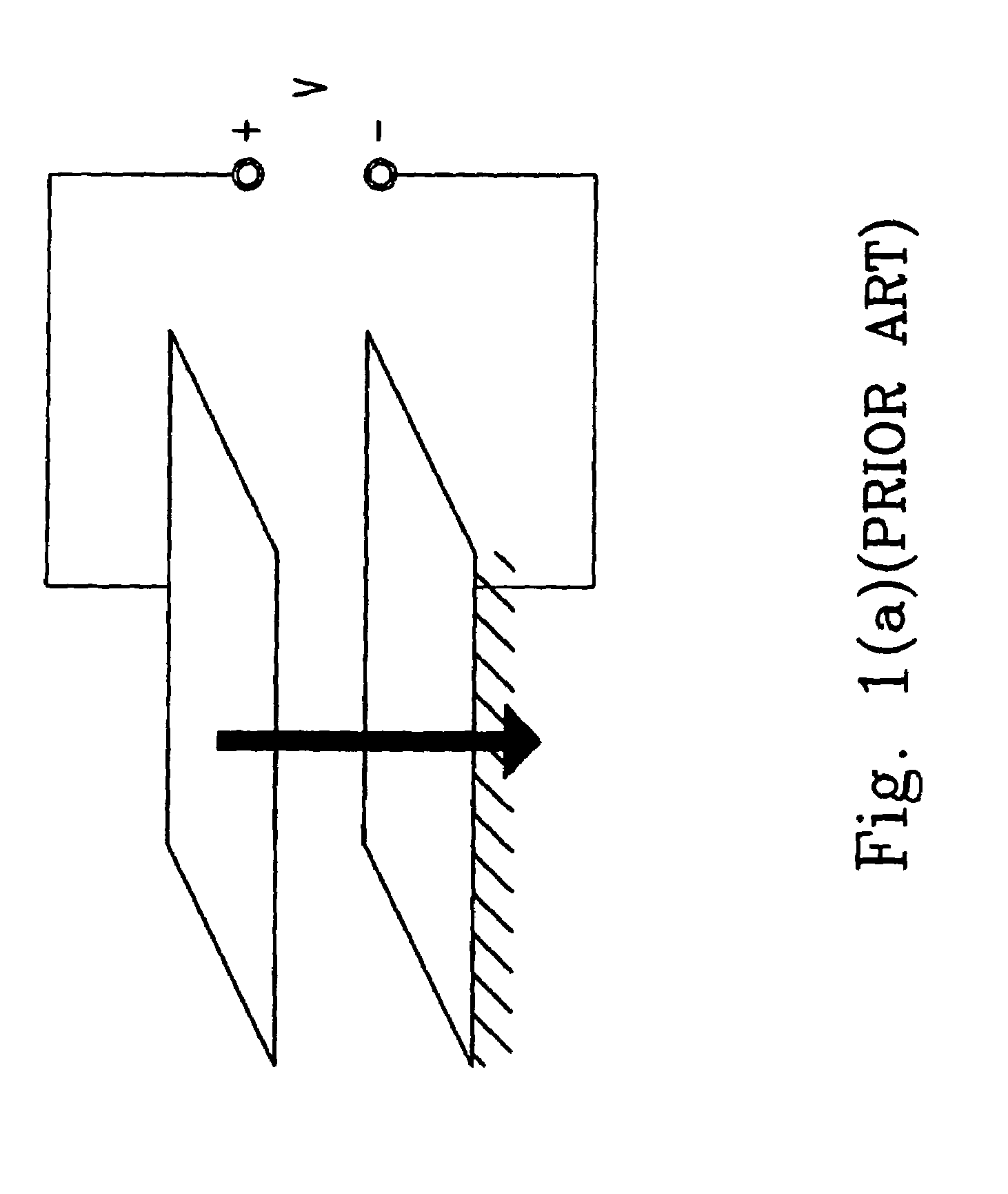

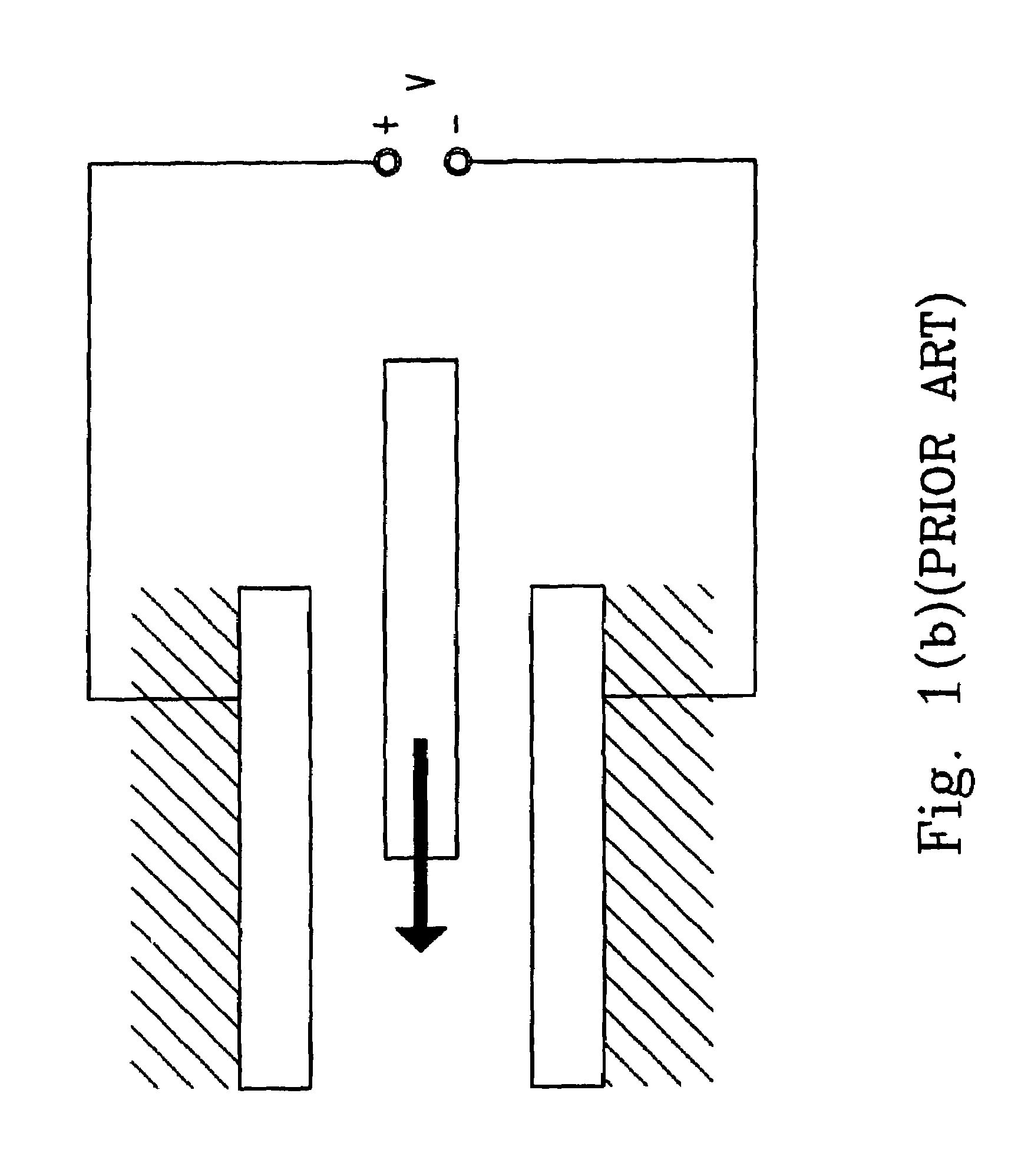

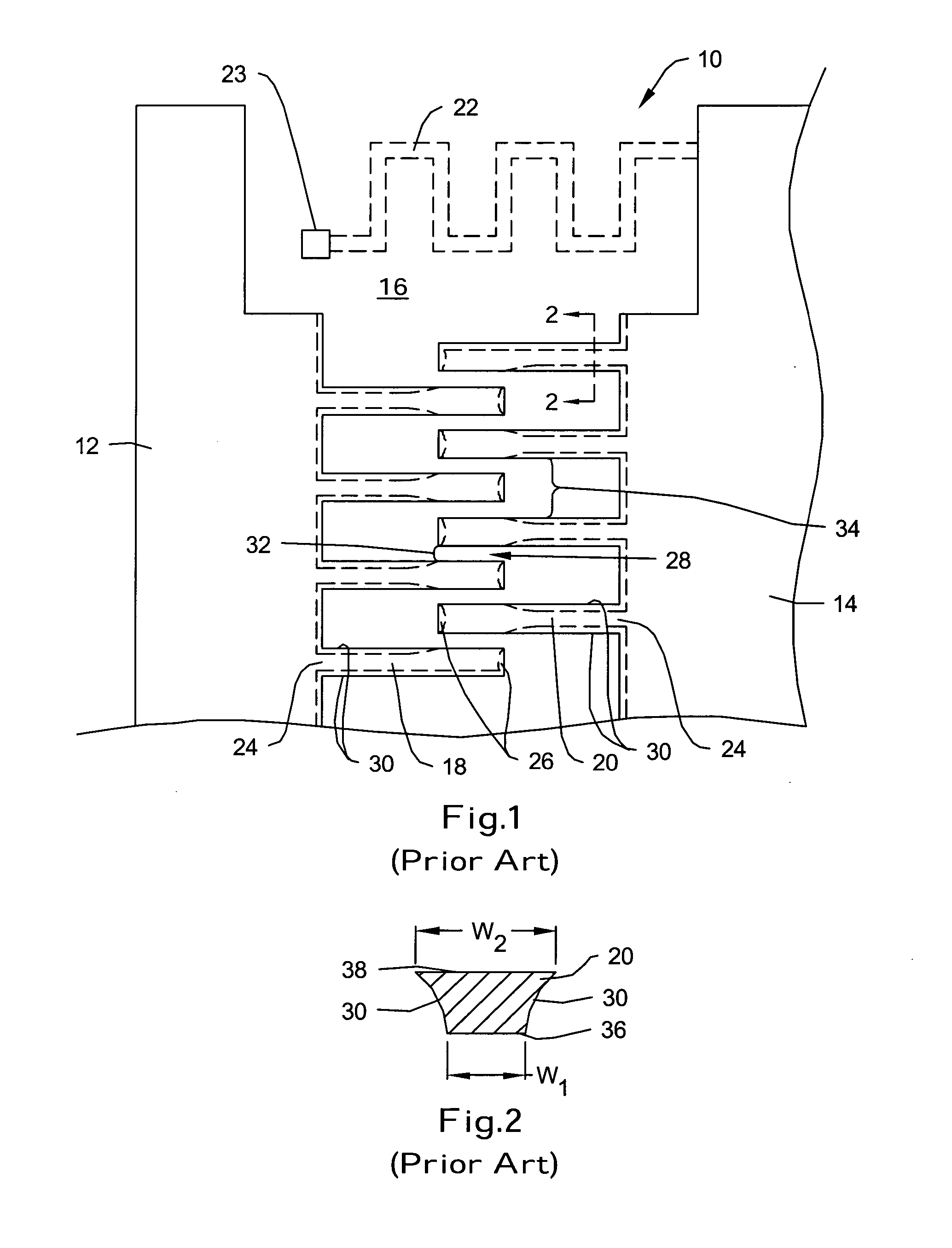

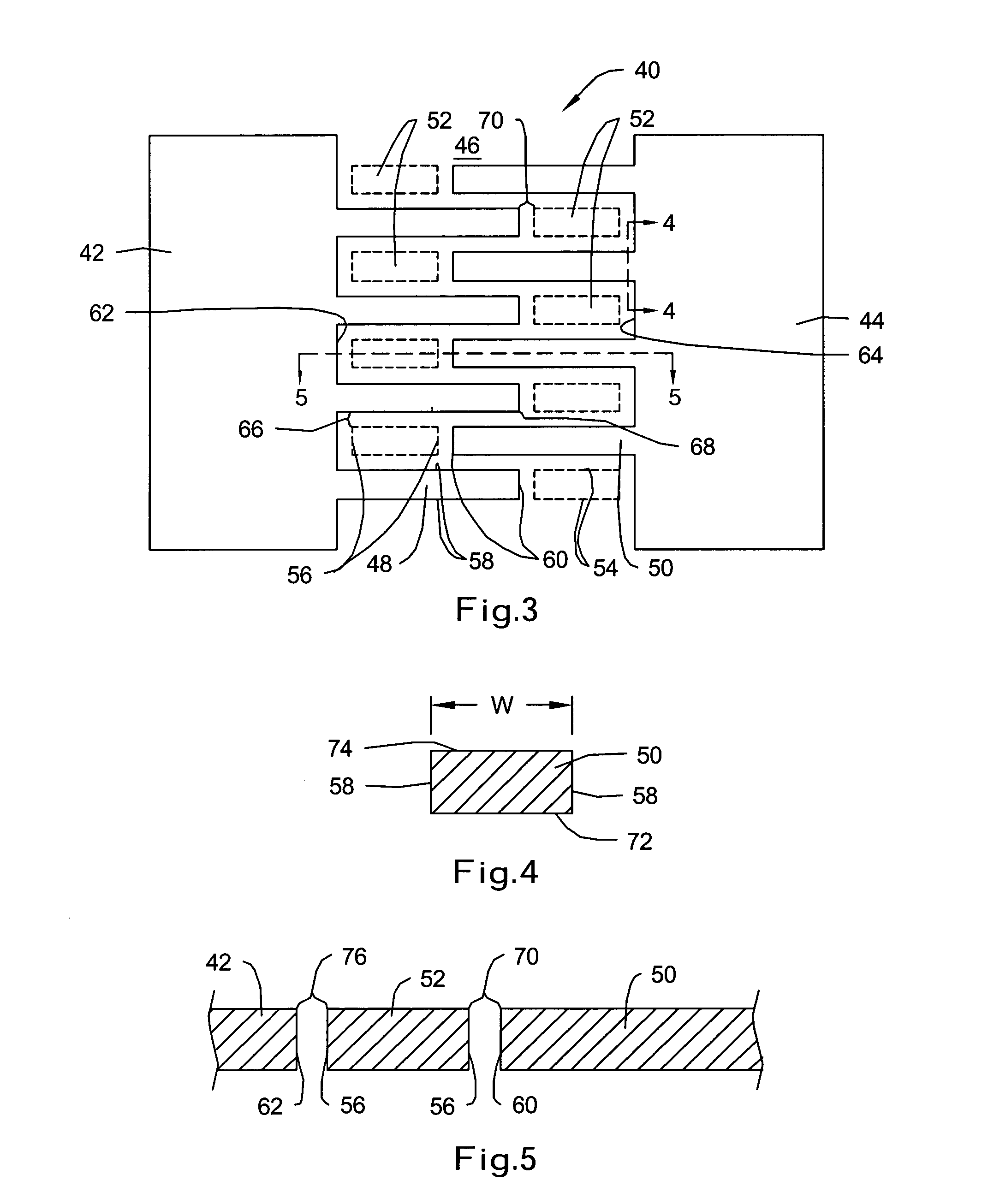

Electrostatic microactuator with offset and/or inclined comb drive fingers

InactiveUS6384510B1Minimizing sidewise movementMinimizing snapoverRecord information storageCoupling light guidesComb fingerEngineering

An electrostatic microactuator comprising a substrate and at least one comb drive assembly having a first comb member mounted on the substrate and a second comb member overlying the substrate. The first comb member has a plurality of first comb fingers. The second comb member has a plurality of second comb fingers. The second comb member is movable between a first position in which each second comb finger is not substantially fully interdigitated with an adjacent pair of first comb fingers and a second position in which each such second comb finger is substantially fully interdigitated with such adjacent pair of first comb fingers. Each of the second comb fingers is offset relative to the midpoint between the adjacent pair of first comb fingers when in the first position and is substantially centered on such midpoint when in the second position.

Owner:COHERENT INC

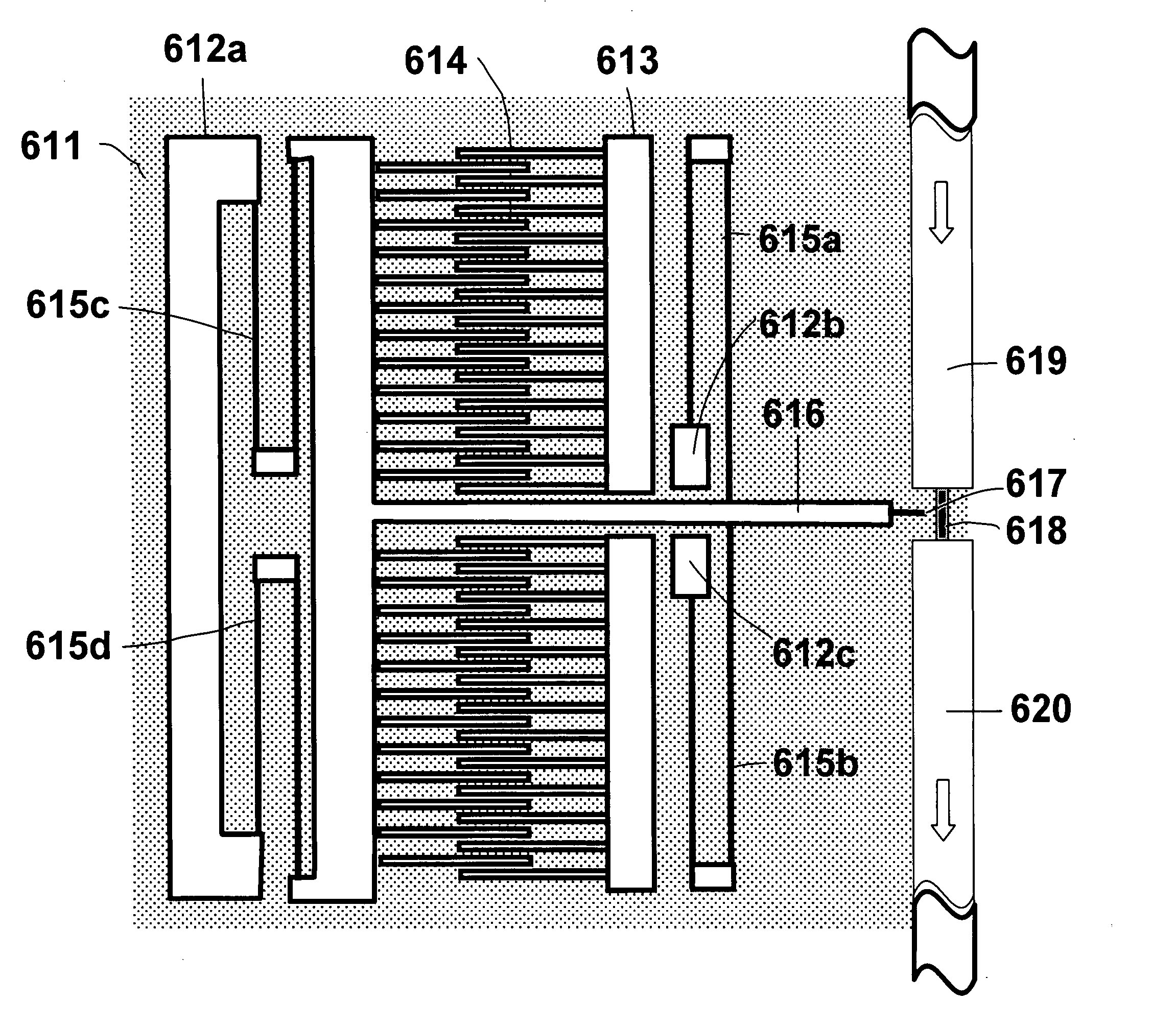

Electrostatically operated micro-optical devices and method for manufacturing thereof

ActiveUS20050047721A1Increase displacementLarge force outputCoupling light guidesComb fingerInstability

Electrostatically operated micro-optical devices and method of manufacturing such devices is disclosed. In a preferred embodiment, the micro-optical devices using electrostatic comb drive actuators having new spring designs to overcome side instability and exhibit enlarged displacement, having new designs of comb finger electrode shapes to generate larger force output, and having new clip type latch mechanism to control the corresponding device at certain states in an analog manner without electrical power consumption. Based on the proposed optical path and device configurations, integration and assembly of a plurality of reflective micro-mirrors in conjunction with proposed new comb drive actuators is very promising way to provide micro-optical devices to get good optical performance and suitable for multi-channel applications. We also disclose several process techniques to manufacture the micro-optical devices with said electrostatic comb drive actuator in a mass production manner with higher yield.

Owner:ASIA PACIFIC MICROSYST

Active lateral force stiction self-recovery for microelectromechanical systems devices

ActiveUS20140345380A1Acceleration measurementPiezoelectric/electrostrictive devicesSelf recoveryComb finger

A mechanism for recovering from stiction-related events in a MEMS device through application of a force orthogonal to the stiction force is provided. A small force applied orthogonal to the vector of a stiction force can release the stuck proof mass easier than a force parallel to the vector of the stiction force. Example embodiments provide a vertical parallel plate or comb-fingered lateral actuator to apply the orthogonal force. Alternate embodiments provide a proof mass of a second transducer to impact a stuck MEMS actuator to release stiction.

Owner:NXP USA INC

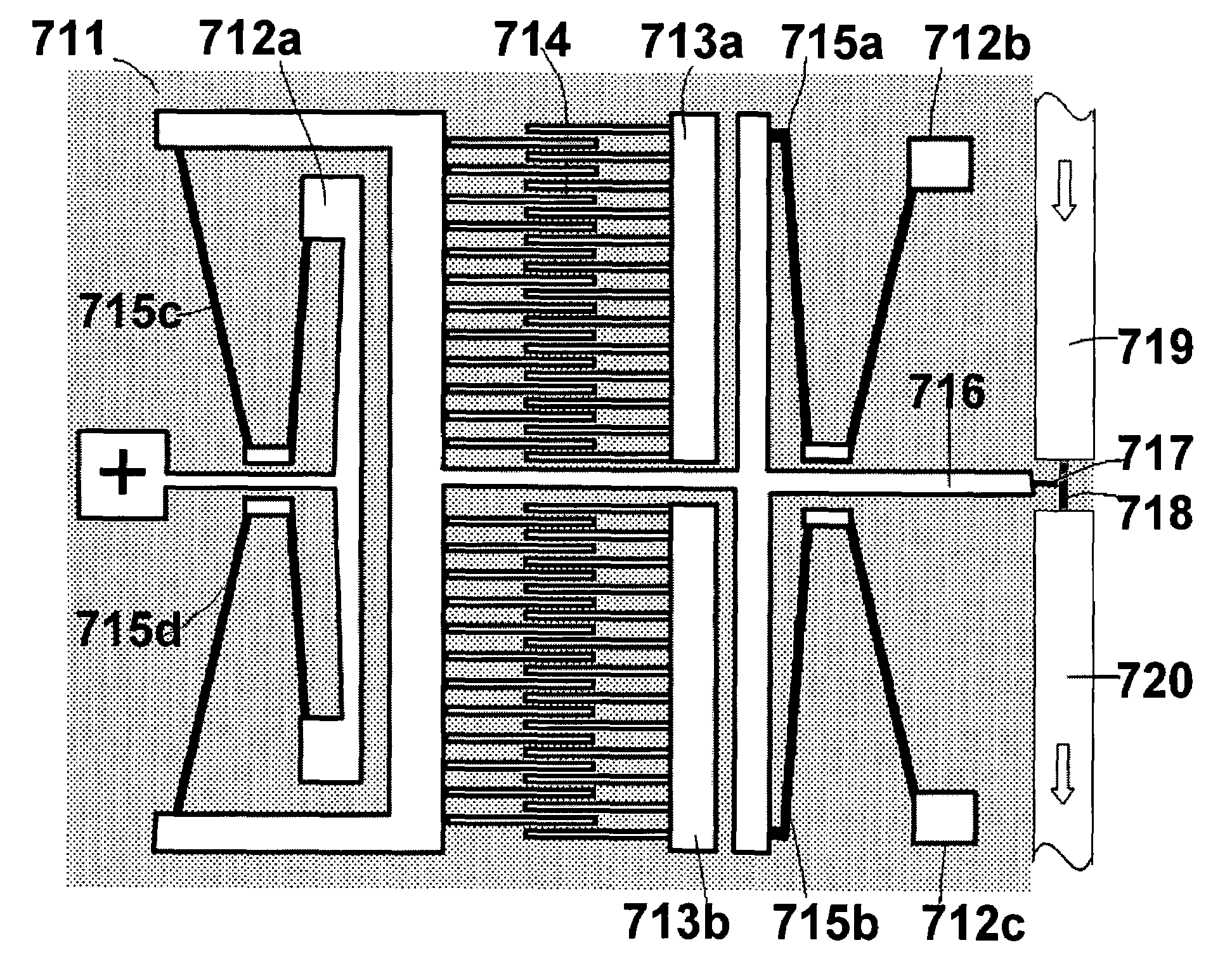

Micro electro-mechanical variable capacitor

InactiveCN1716639AEnhanced capacitance regulationCapacitor with electrode distance variationSolid-state devicesDielectricCapacitance

The invention relates to a micro electromechanical variable capacitor, wherein, movable comb electrodes with opposite polarities which are simultaneously manufactured on a same substrate are independently actuated. The polarities are formed into cross comb form to maximize the capacitance of a device. The change of the lateral wall overlapping area between cross comb fingers provides the expected capacitance regulation of the device. The stiffness of the electrodes is lowered through using thin supporting structures on the end parts of the electrodes. The three-dimensional features of the device are beneficial to realize larger surface area. Larger capacitance change and regulation range are obtained through independently actuating the electrode fingers. A plurality of working modes of the device result in wider flexibility and larger performance advantage of the device. During the manufacturing of the device, single substrates with etched dielectrics are used for packaging the device. Thus, no additional packaging is required. In addition, the alignment and the conjugation can be finished in the wafer scale. Therefore, the improved device yield can be obtained with low cost.

Owner:GLOBALFOUNDRIES INC

Off-plane electrostatic driver and production method thereof

InactiveCN103288034AIncrease stiffnessImprove reliabilityDecorative surface effectsChemical vapor deposition coatingComb fingerEngineering

The invention relates to an MEMS (Micro-electromechanical Systems) comb-finger off-plane electrostatic driver structure with low driving voltage and a production method thereof. The driver structure comprises a fixed electrode, a movable electrode, an anchor, a combined torsion beam, a driving output part and a signal lead out bonding pad, wherein the fixed electrode is a comb-finger electrode fixed on a substrate; the movable electrode is a comb-finger electrode connected to the driving output part; and the combined torsion beam comprises two groups of foldable torsion beams and one bracket cross beam, and is suspended and fixed on the substrate. According to the driver structure, angular displacement is converted into linear displacement through the adoption of the combined torsion beam, so that not only can large-stroke off-plane motion under low driving voltage be achieved, but also the influence of the electrostatic pull-in effect can be refrained, and the reliability of the driver can be improved. The off-plane electrostatic driver and the production method have the advantages that the technological process is simple and is compatible with various types of MEMS device technologies, and integration with other micro-optic-electro-mechanical systems can be achieved.

Owner:PEKING UNIV

Liquid crystal display panel and liquid crystal display device

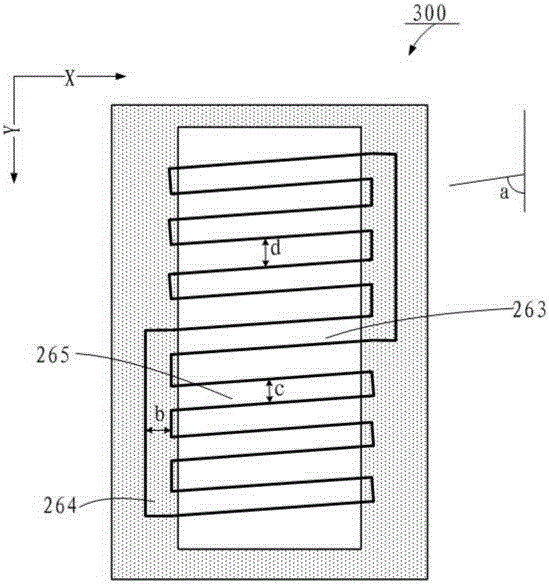

ActiveCN106444171AImprove color mixingThe range of change in penetration rate is the sameNon-linear opticsComb fingerColor film

The invention discloses a liquid crystal display panel and a liquid crystal display device. The liquid crystal display panel and the liquid crystal display device have the advantages that a comb-shaped first portion and a comb-shaped second portion are arranged, an electric field generated by comb finger portions and a third portion drives liquid crystal molecules in a region to rotate to transmit light, and an electric field generated by connecting portions drives liquid crystal molecules in the region not to rotate to block the light, so that a central region of each of pixel units is light-transmitting but an edge region thereof blocks the light to improve that the edge region of one pixel unit emits the light to an adjacent pixel unit to cause color mixing between the two adjacent pixel units when contraposition bias exists between a color film substrate and an array substrate; the first portion and the second portion are shaped in comb, the connecting portions of the first portion and the second portion are arranged on two sides of each pixel unit oppositely, and accordingly the region where each pixel unit suffers from penetration rate loss when the contraposition bias exists between the color film substrate and the array substrate is a region of the connecting portions and extension portions thereof, the penetration rate variation amplitudes corresponding to all the pixel units are basically consistent, and good display effects are guaranteed.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

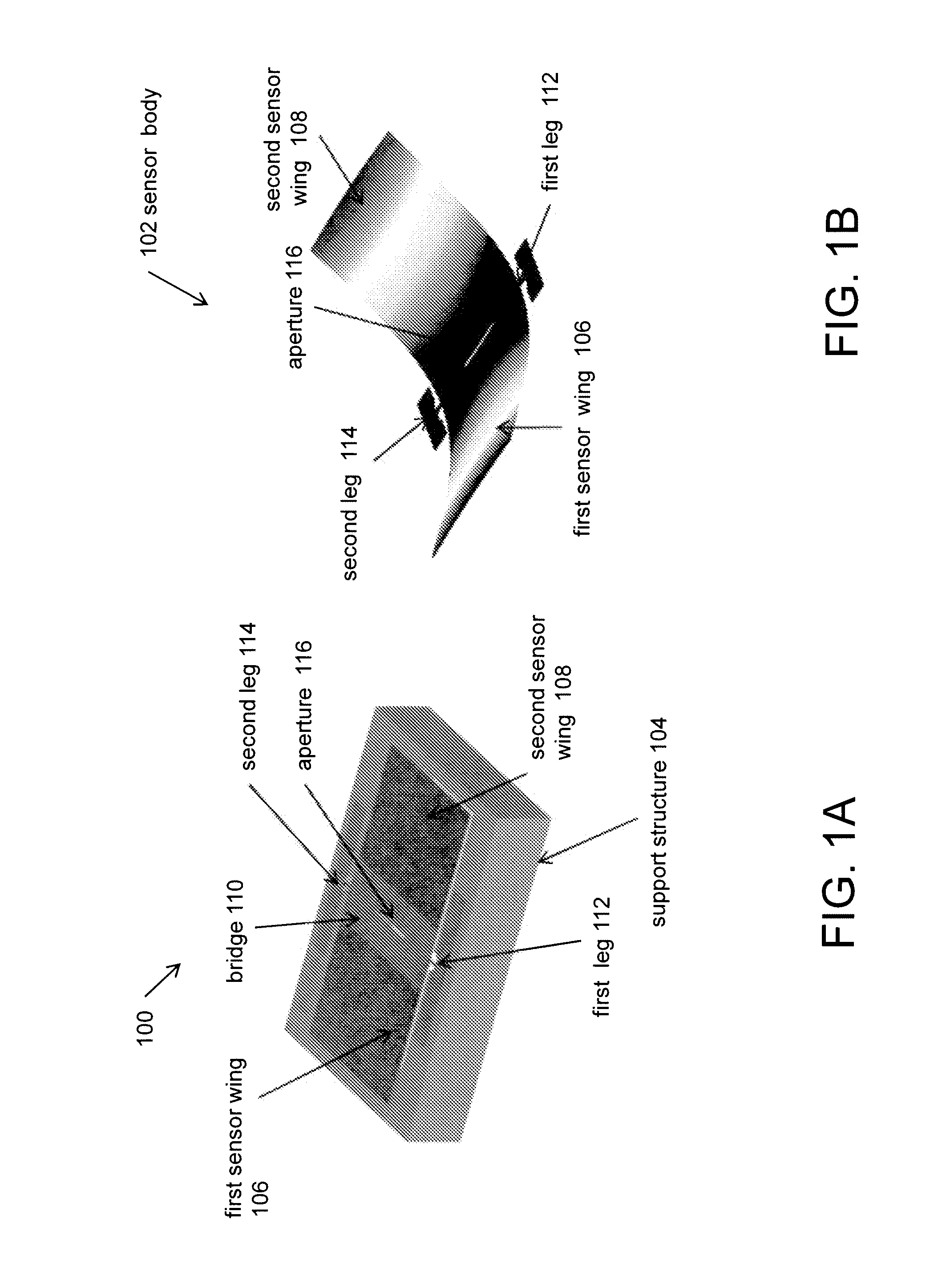

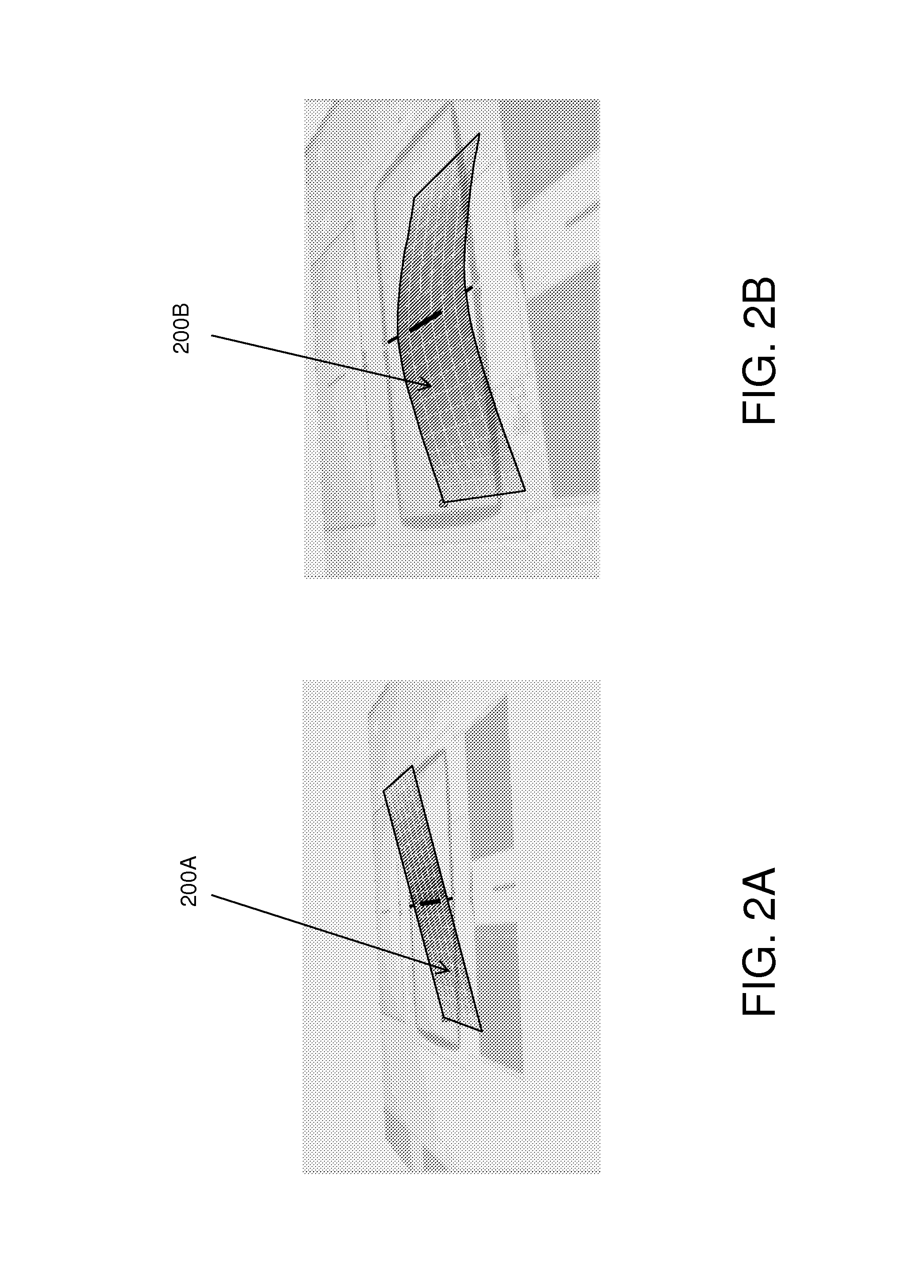

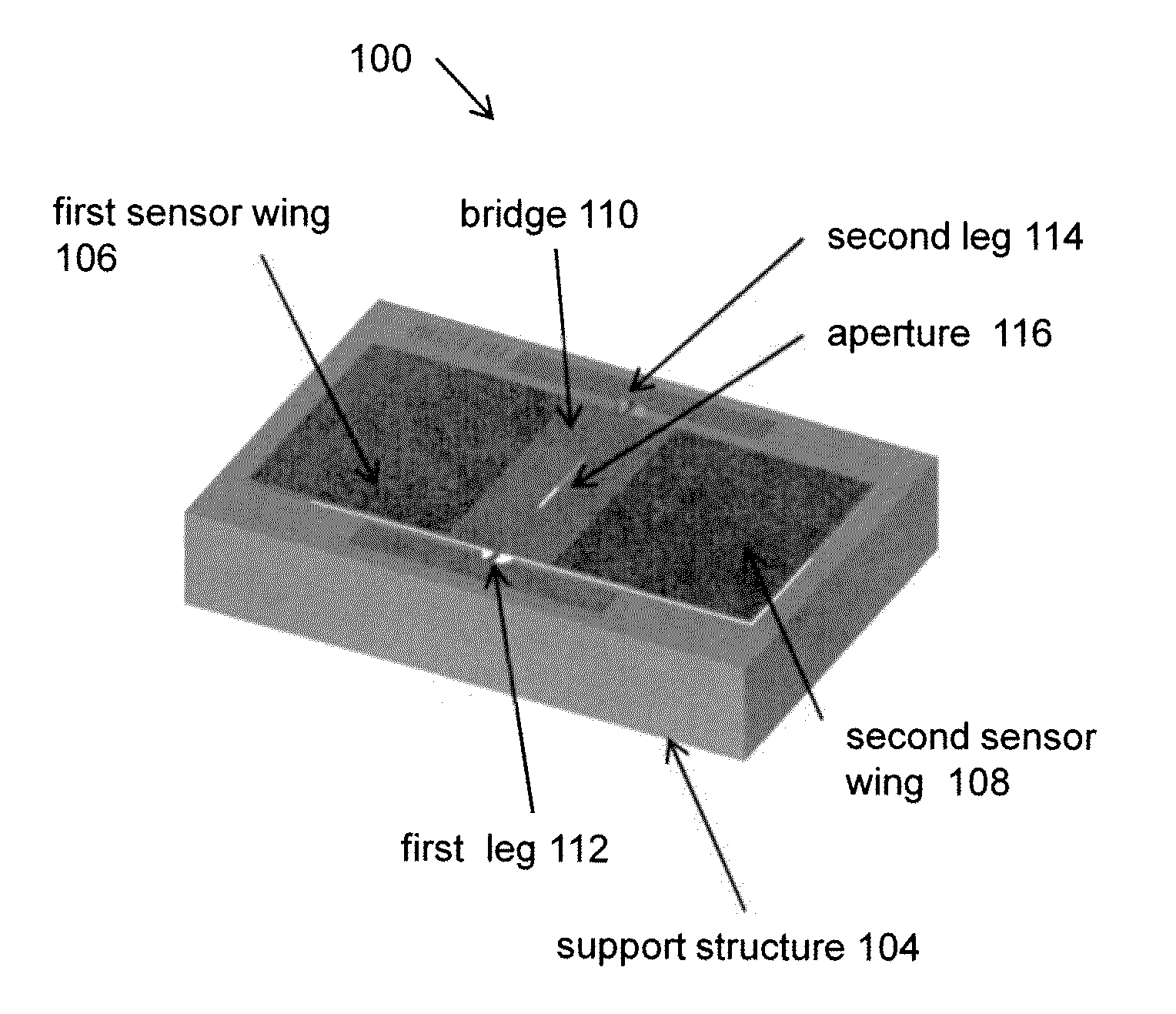

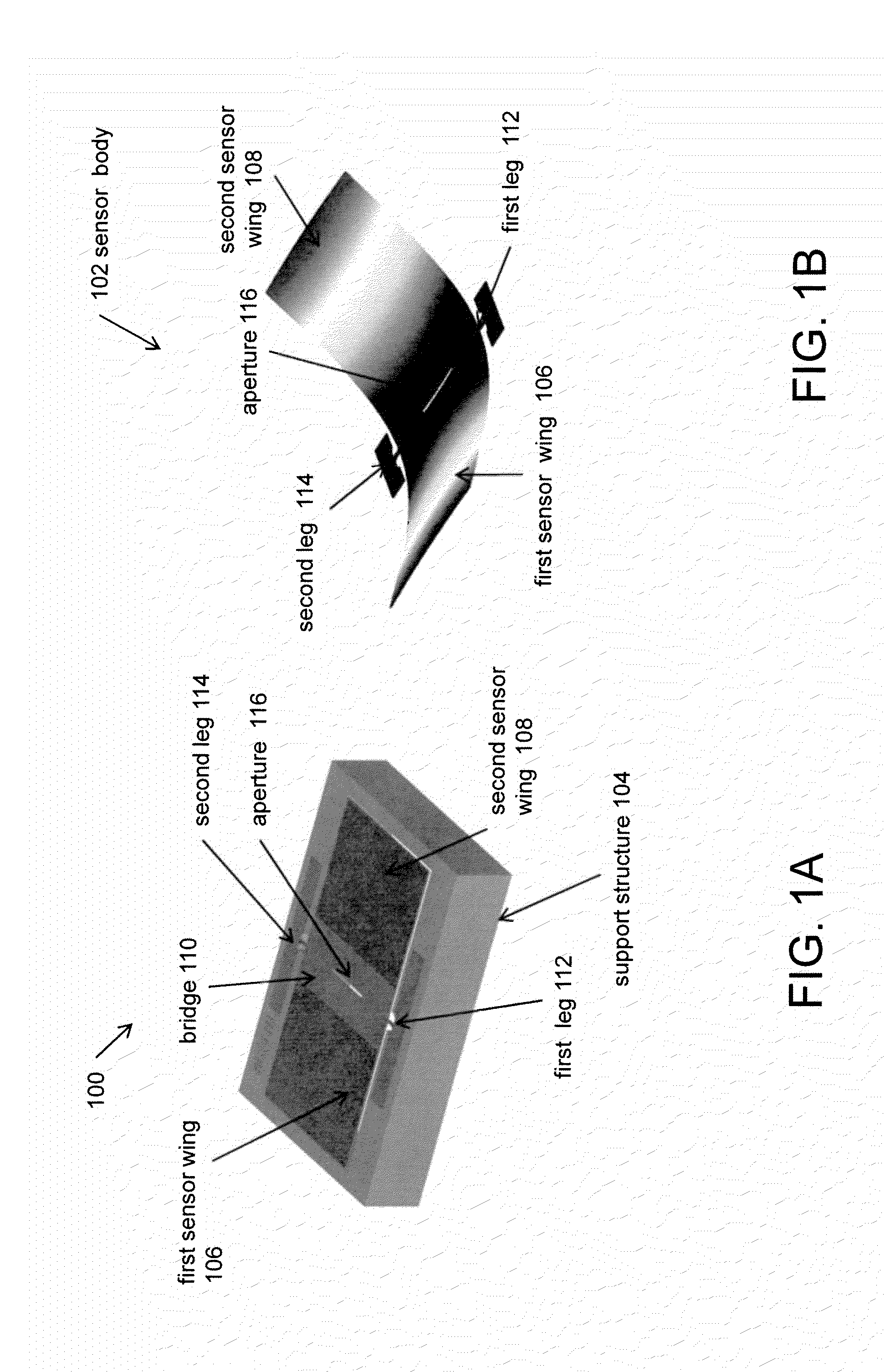

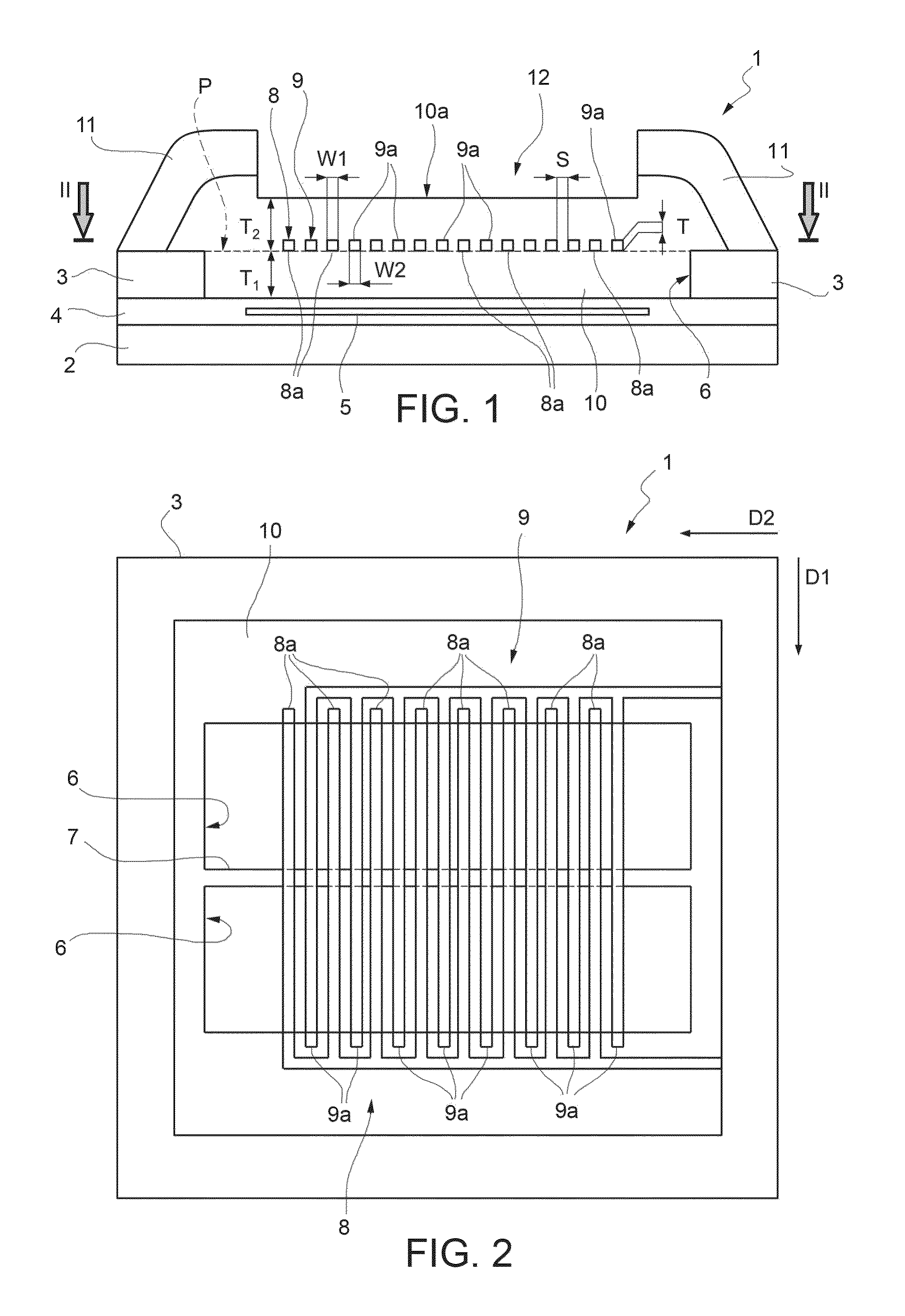

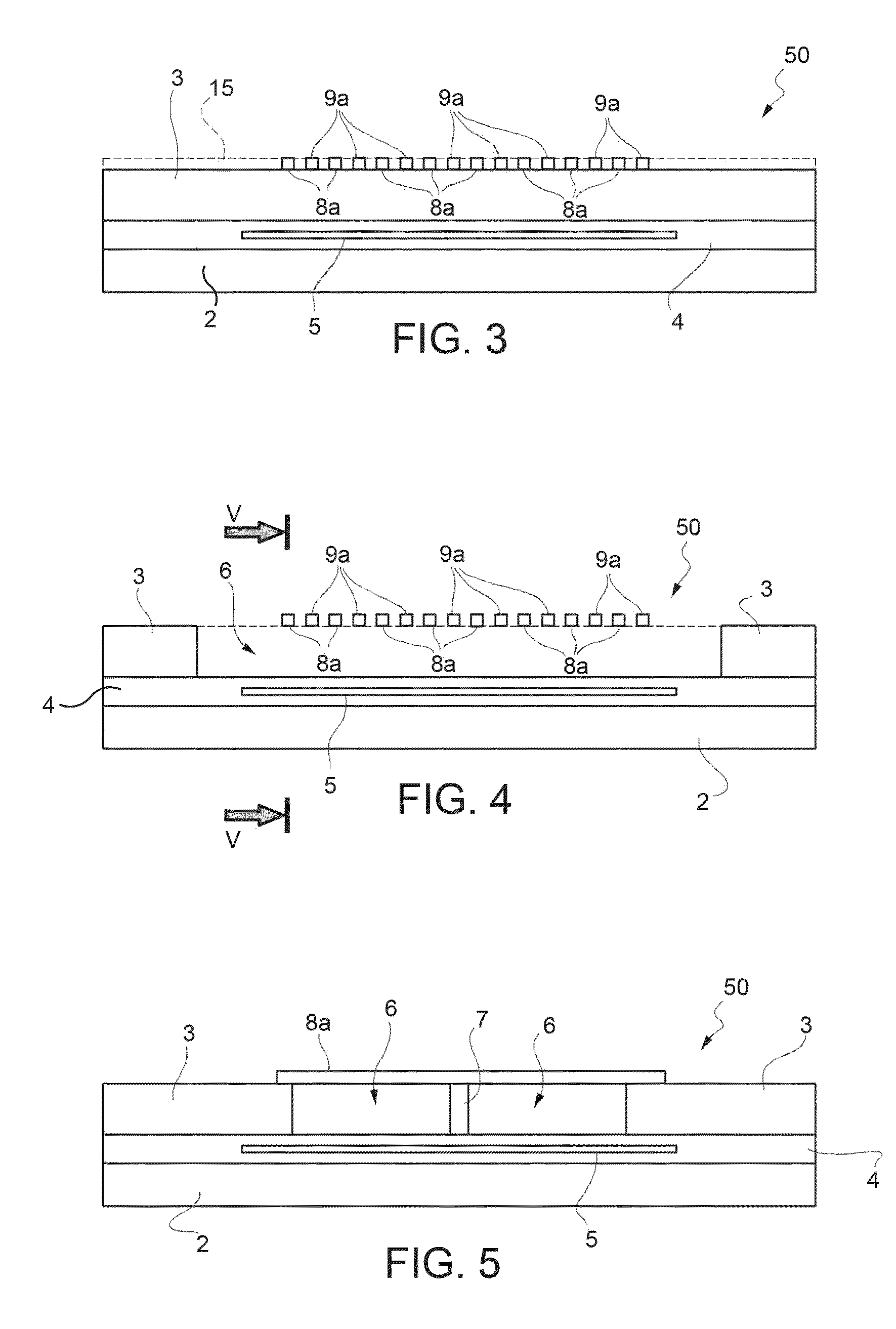

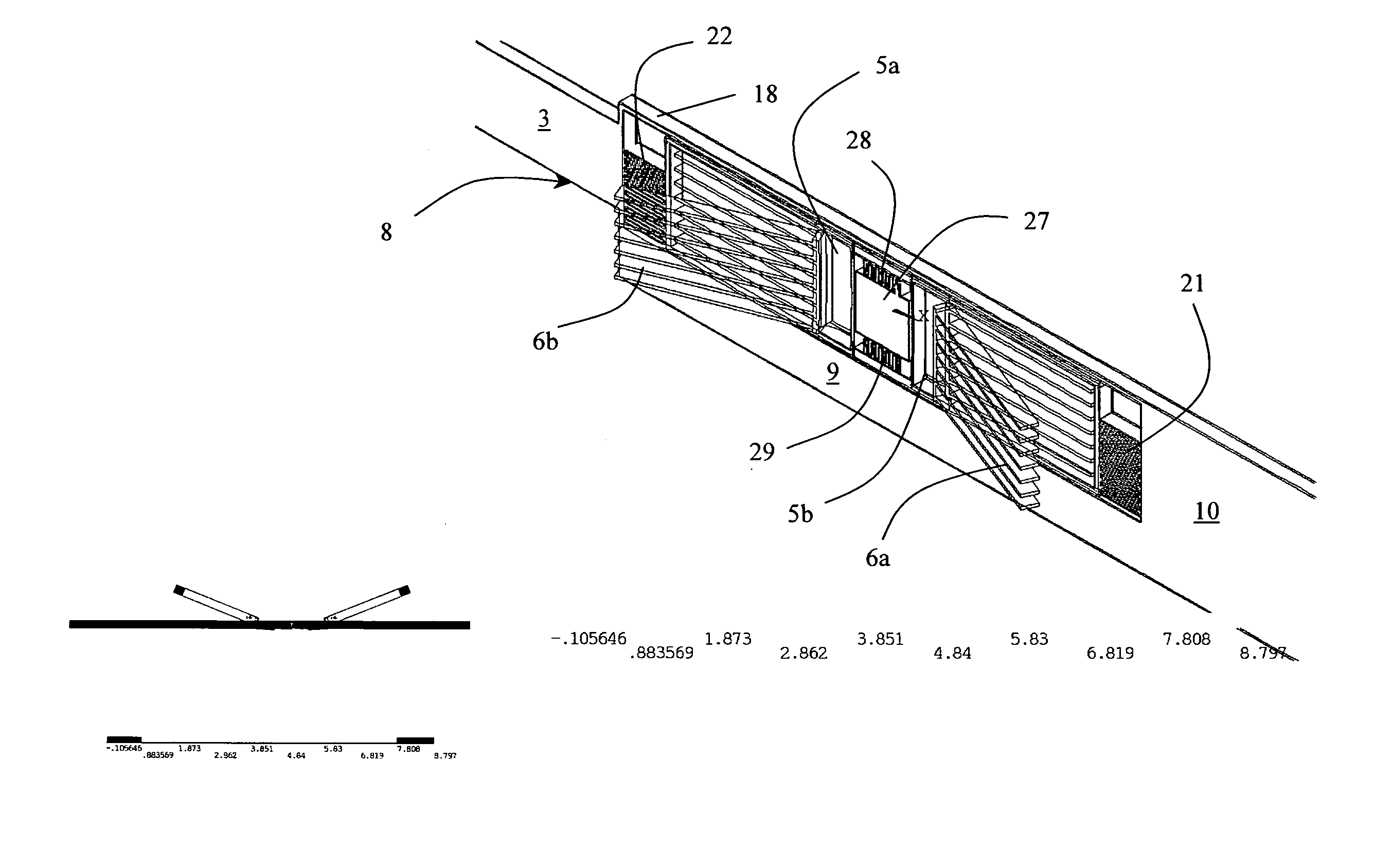

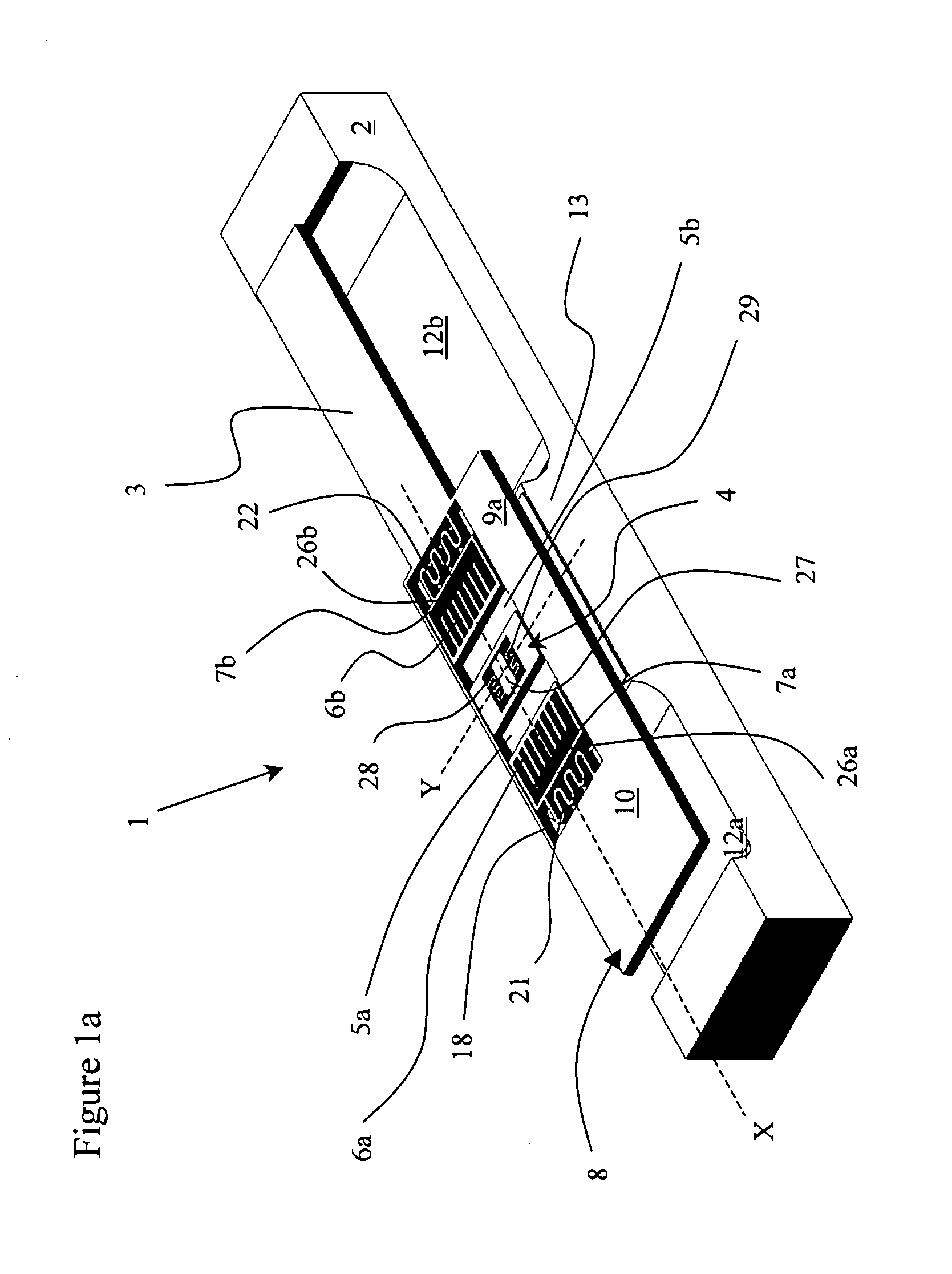

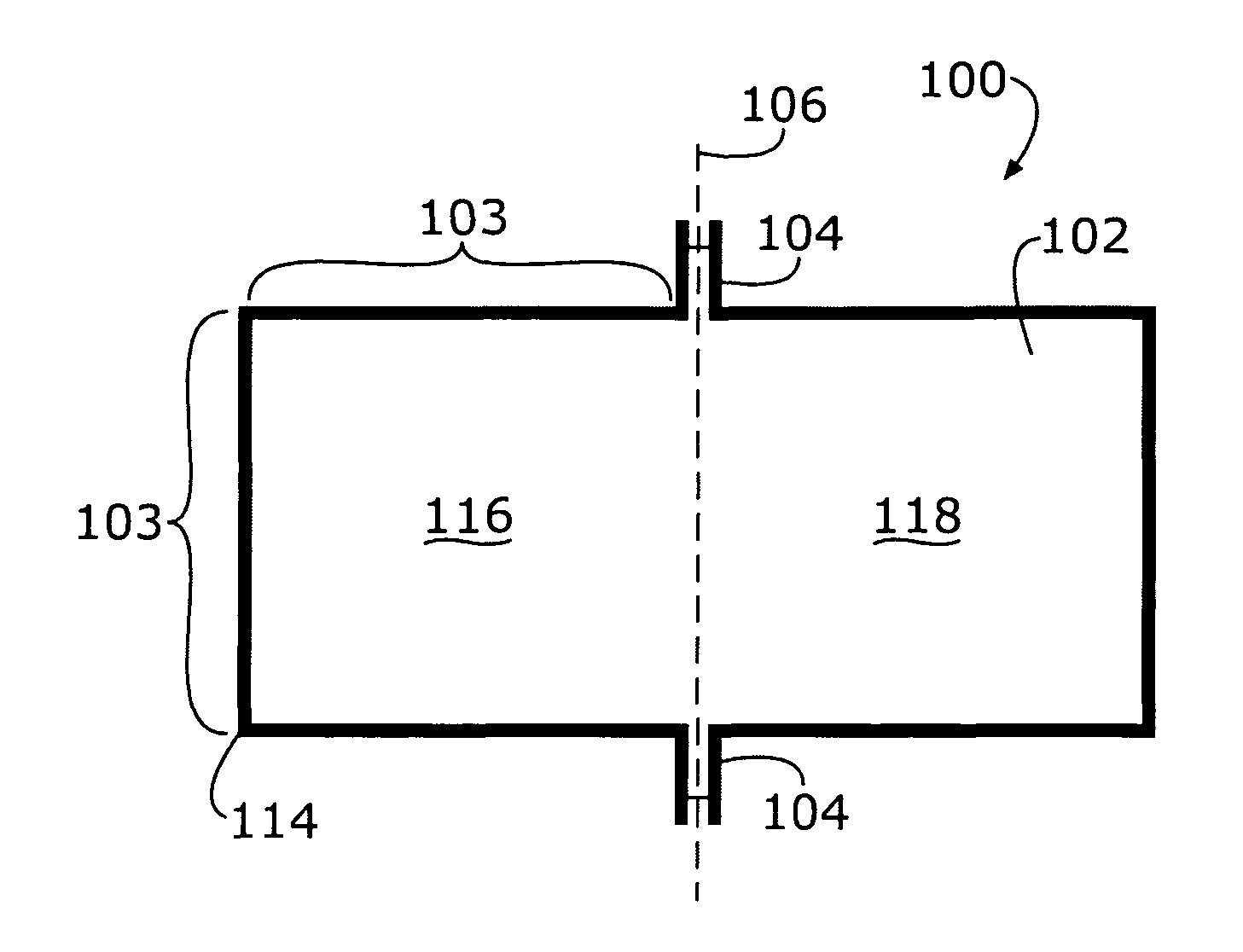

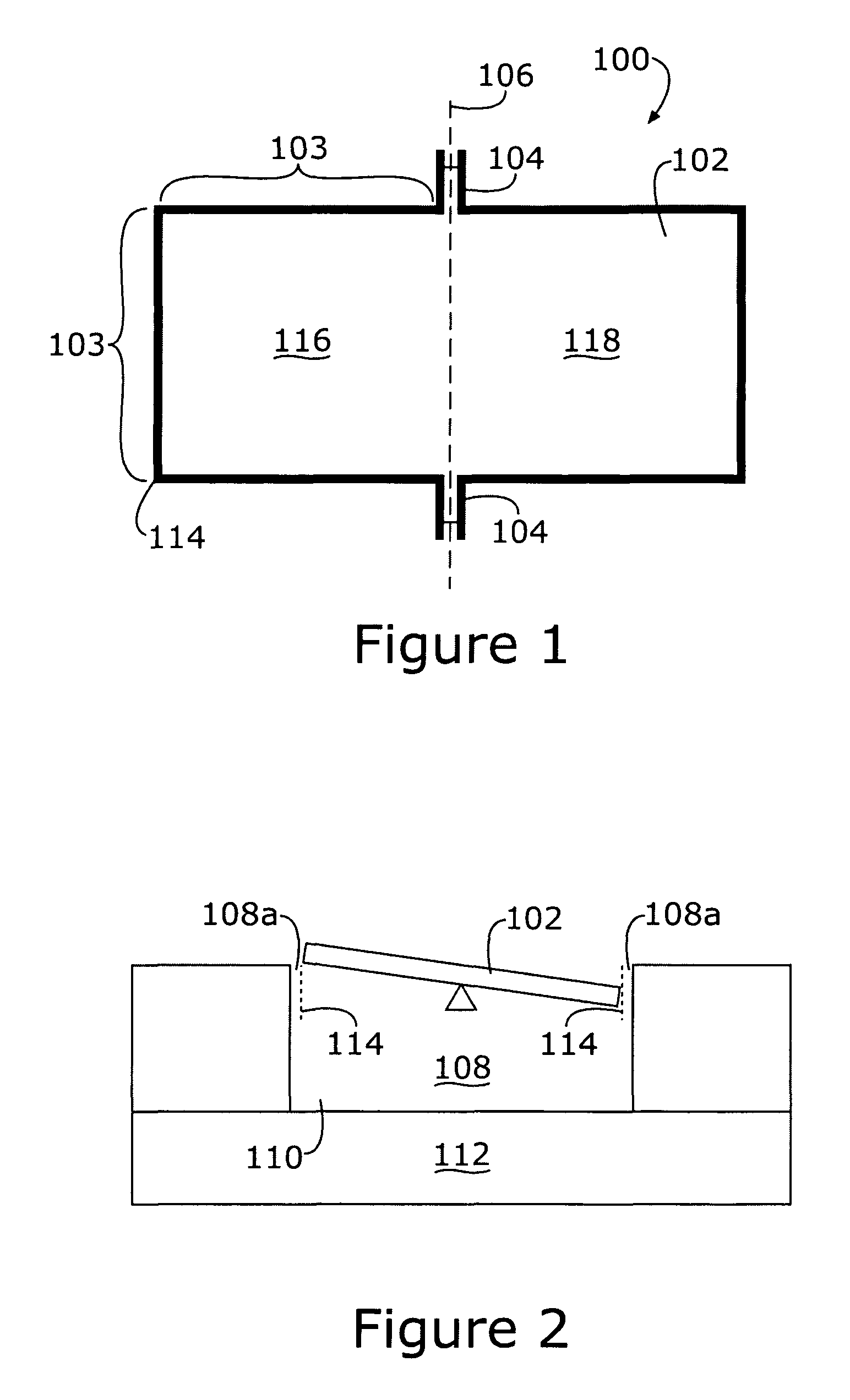

Miniature micro-electromechanical system (MEMS) based directional sound sensor

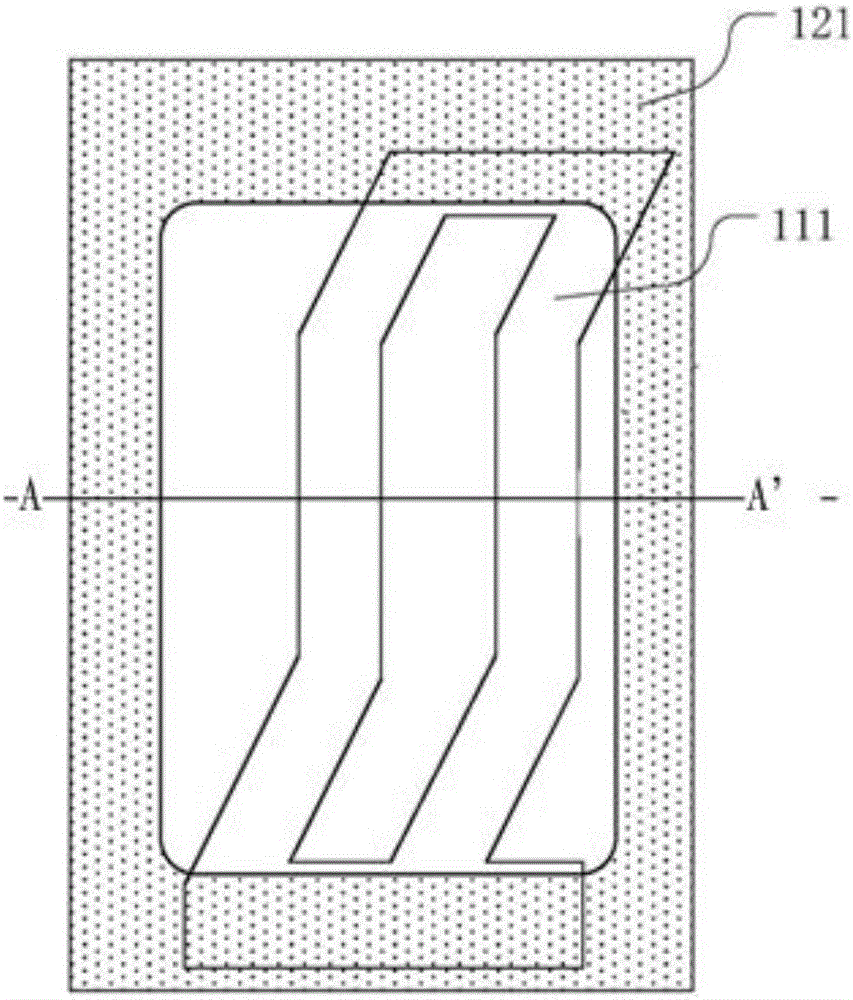

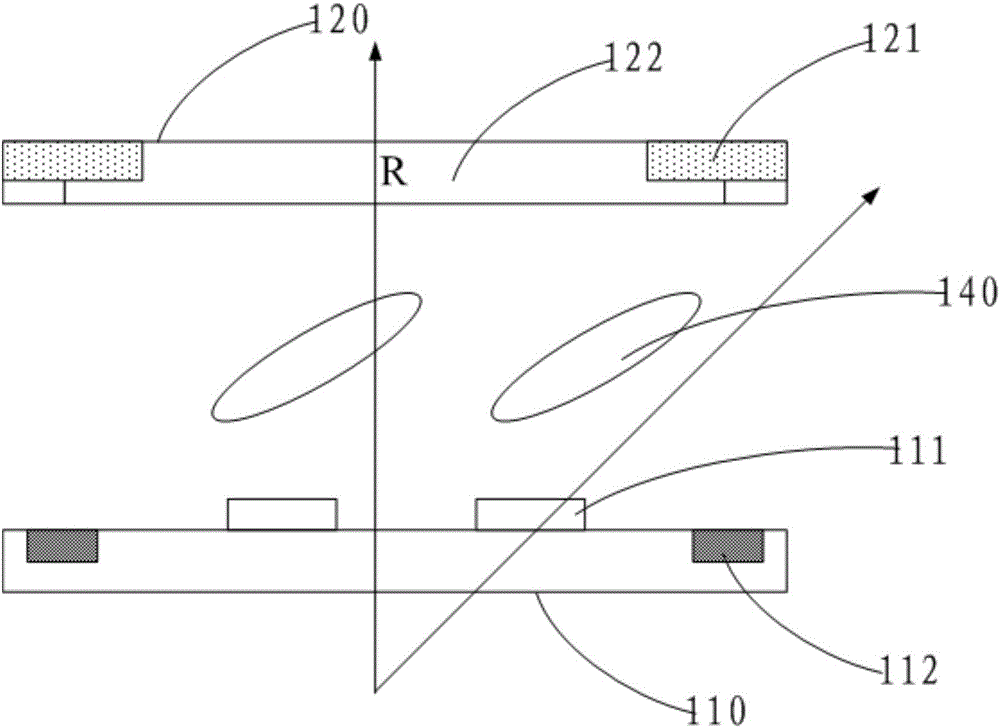

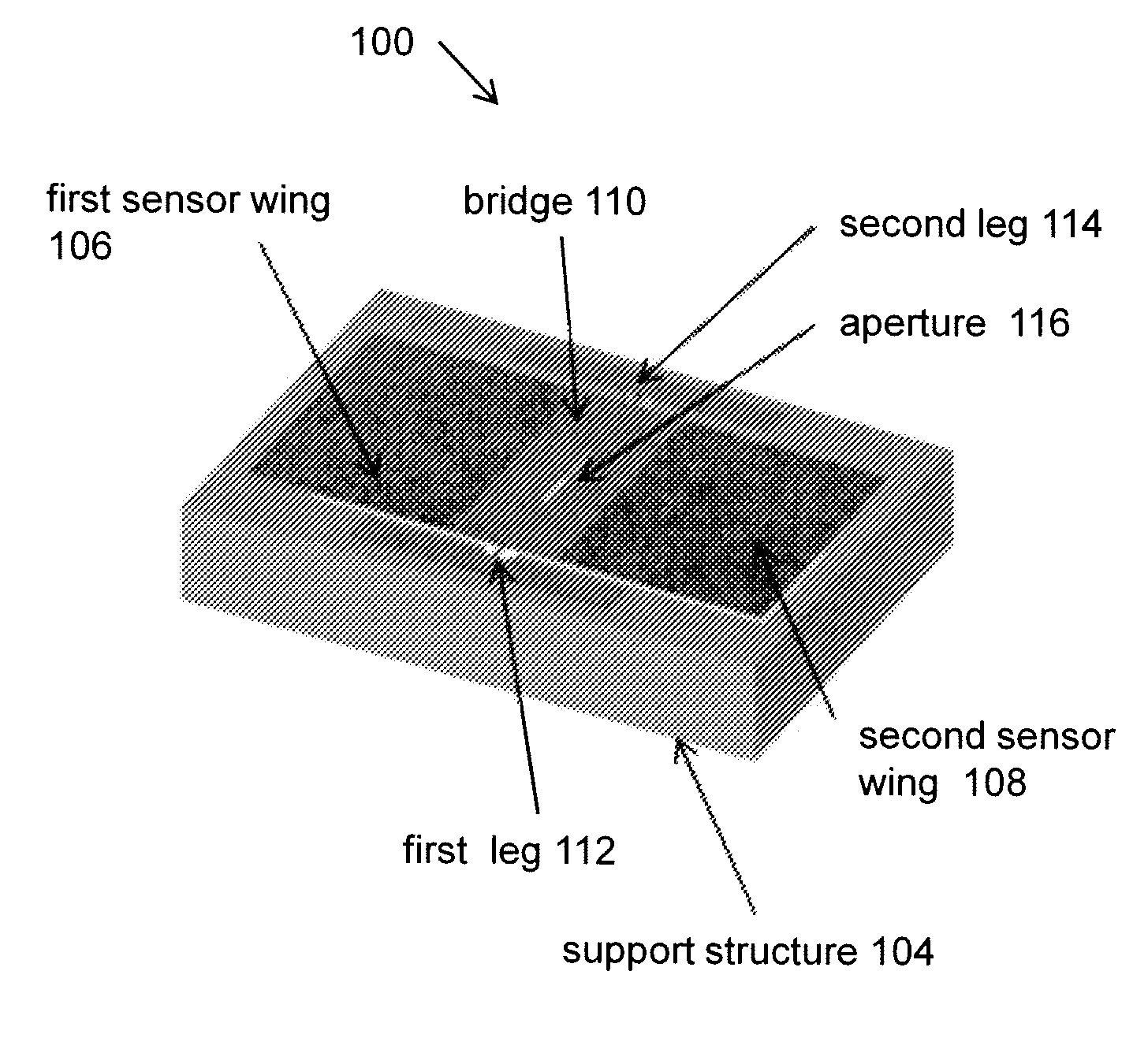

ActiveUS8467548B2Solid-state devicesSemiconductor/solid-state device manufacturingCapacitanceComb finger

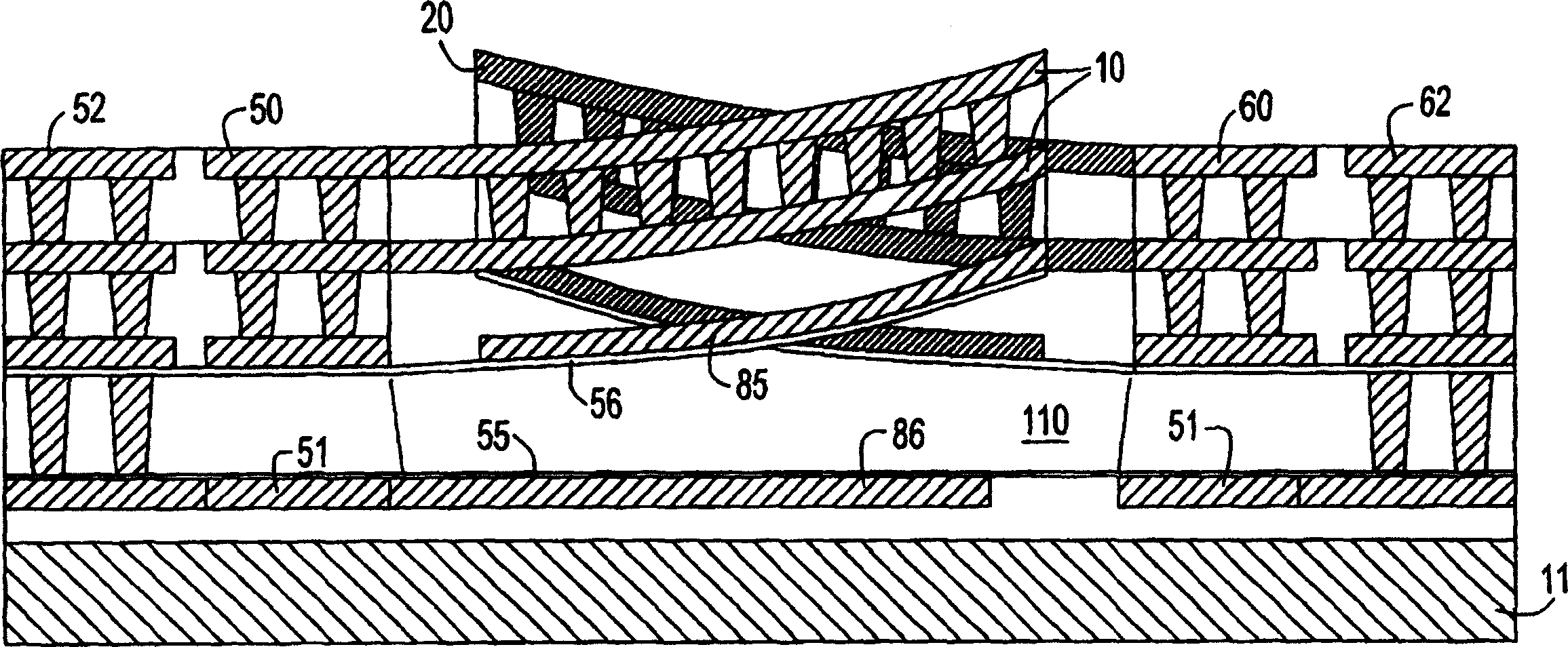

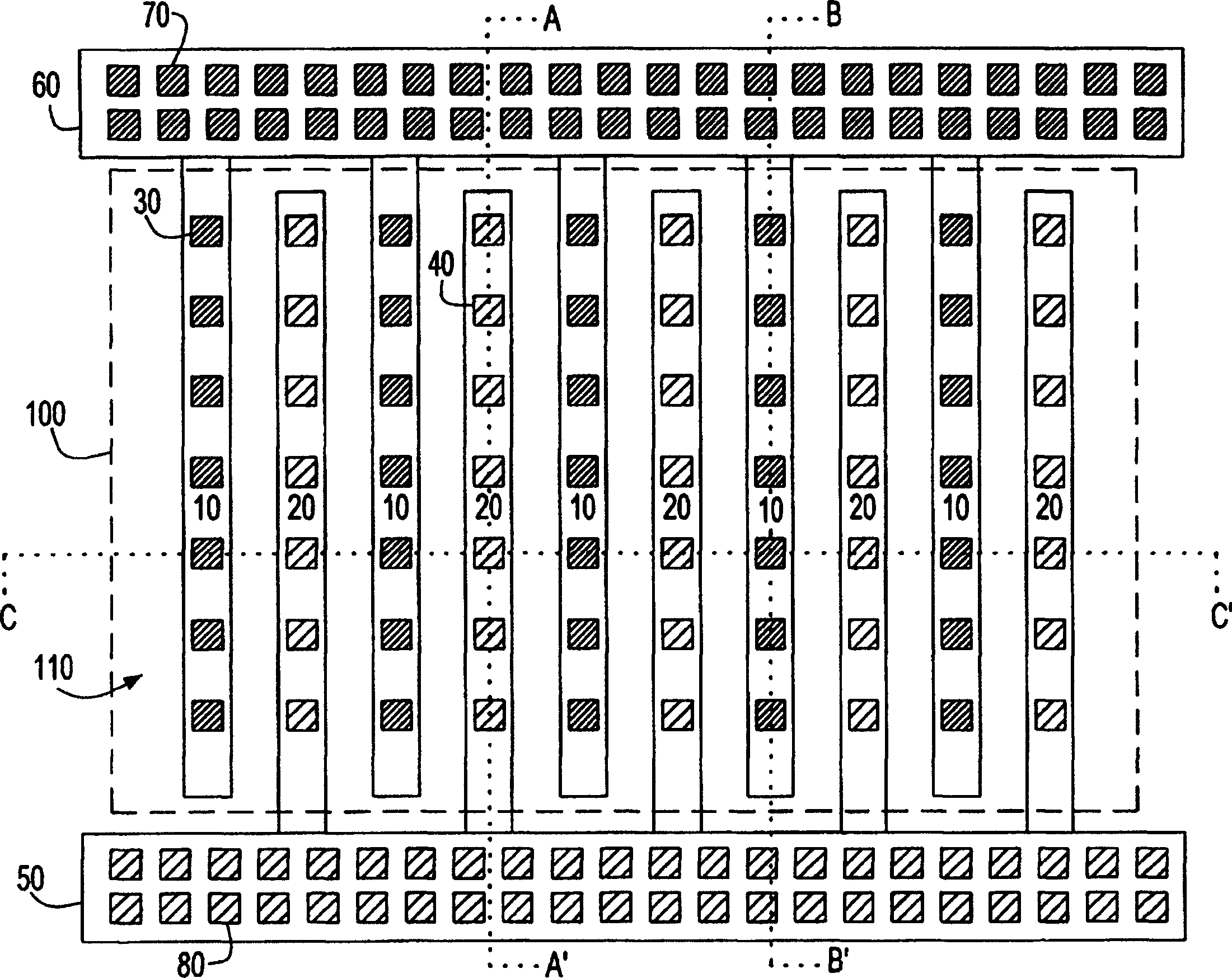

A micro-electromechanical (MEMS) based directional sound sensor includes a two sensor wings attached to a surrounding support structure by two legs. The support structure is hollow beneath the sensor wings allowing the sensor wings to vibrate in response to sound excitation. In one embodiment, interdigitated comb finger capacitors attached on the sensor wing edges and the support structure enable an electrostatic (capacitive) readout related to the vibrations of the sensor which allows determination of the sound direction.

Owner:UNITED STATES OF AMERICA

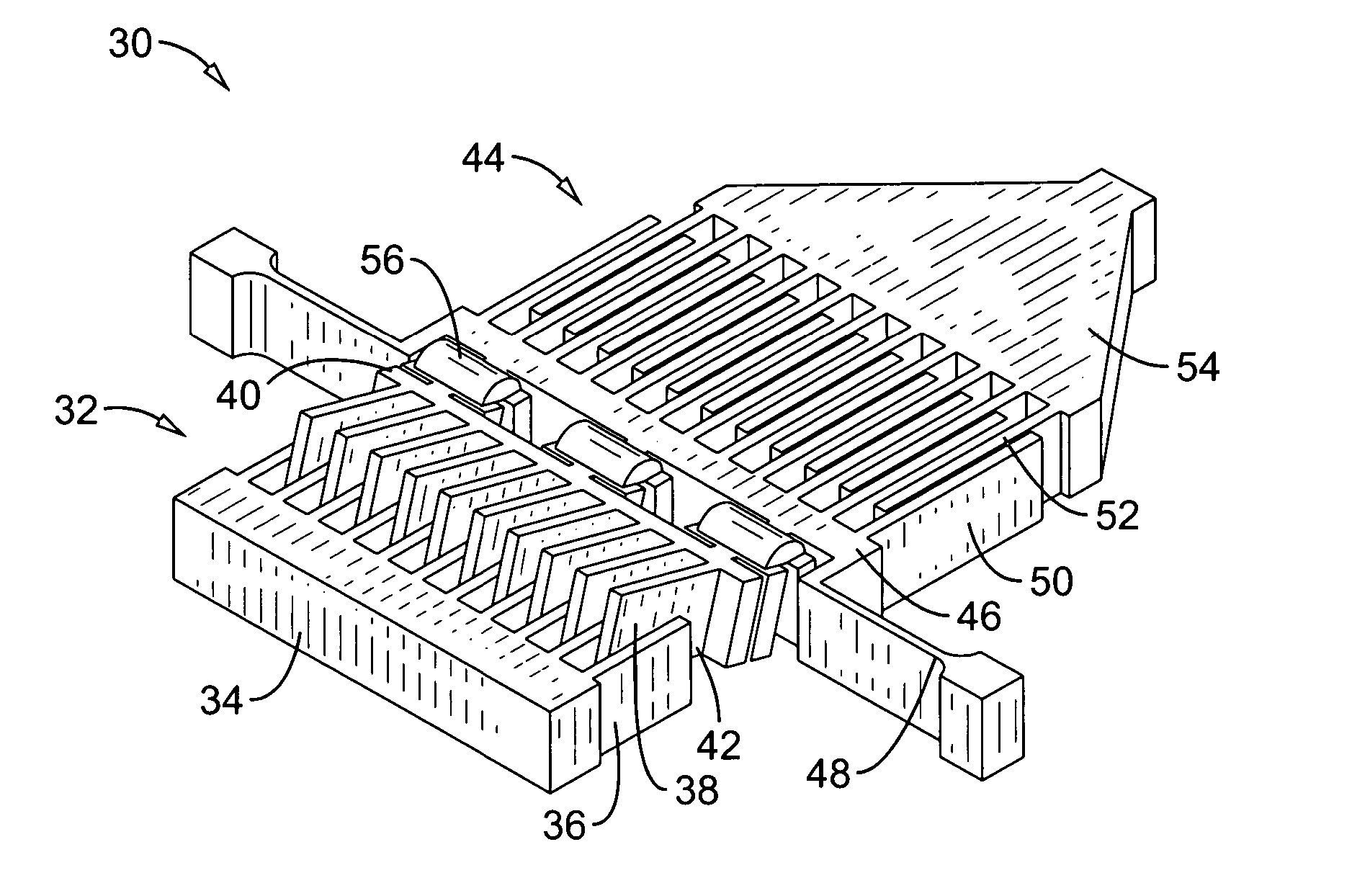

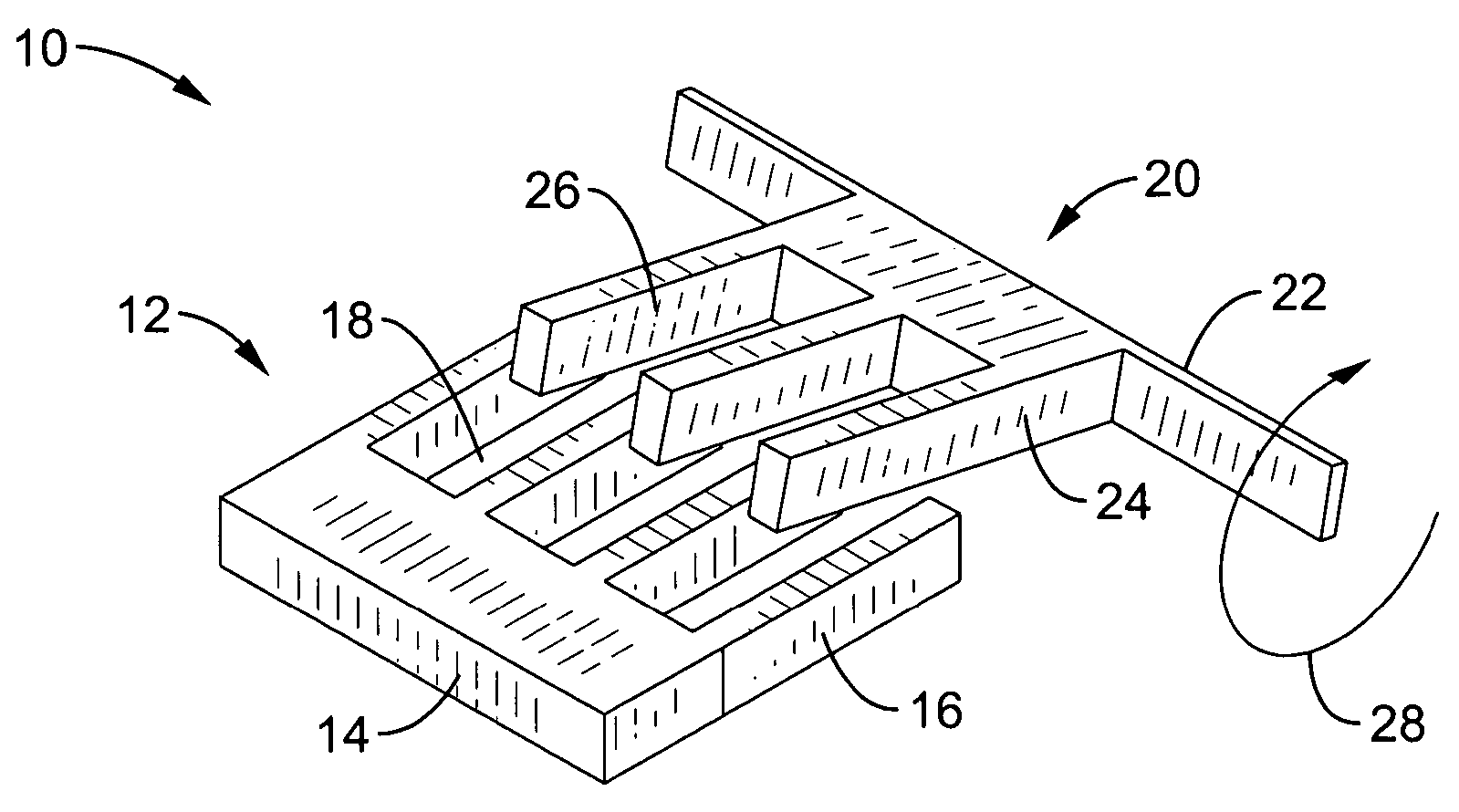

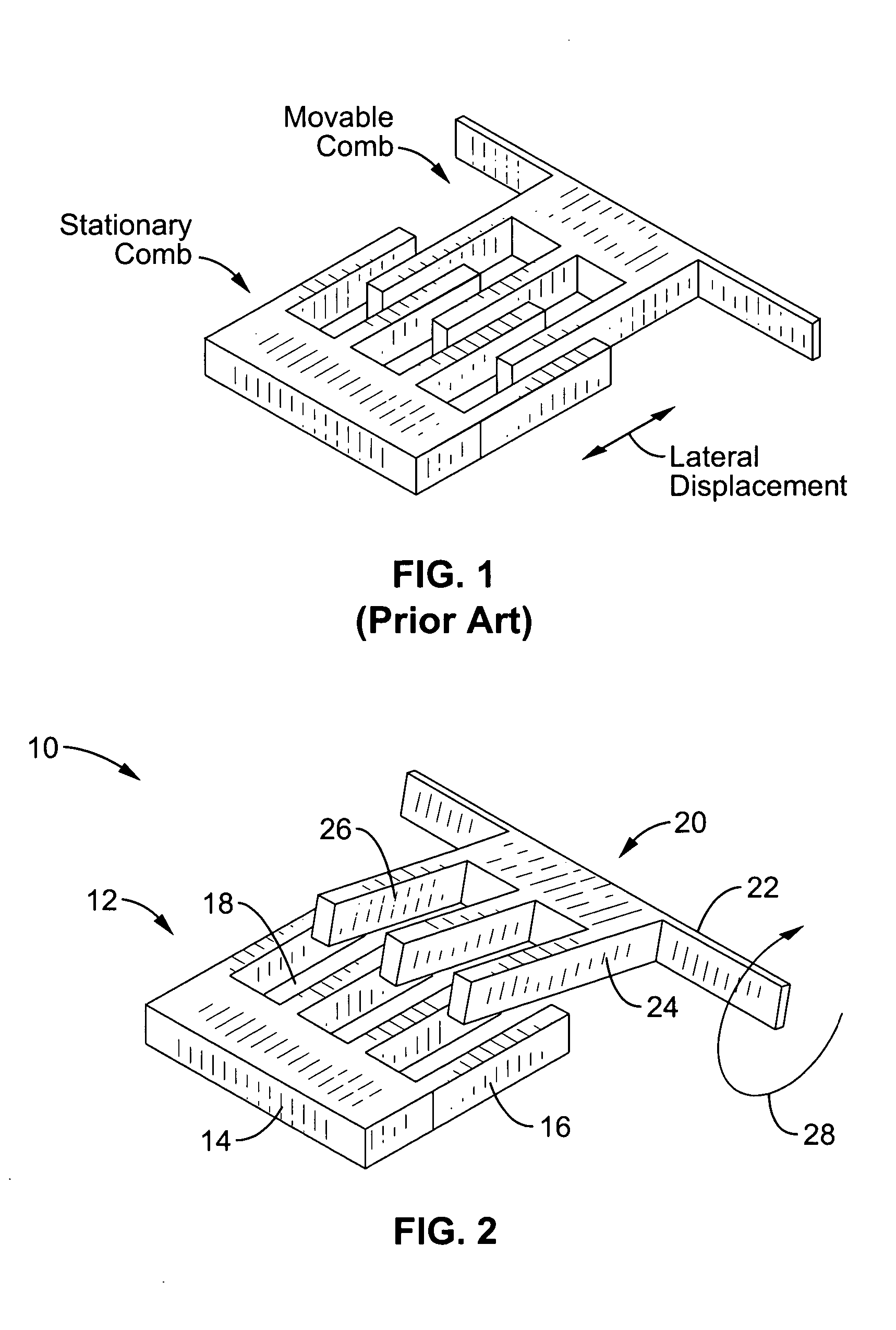

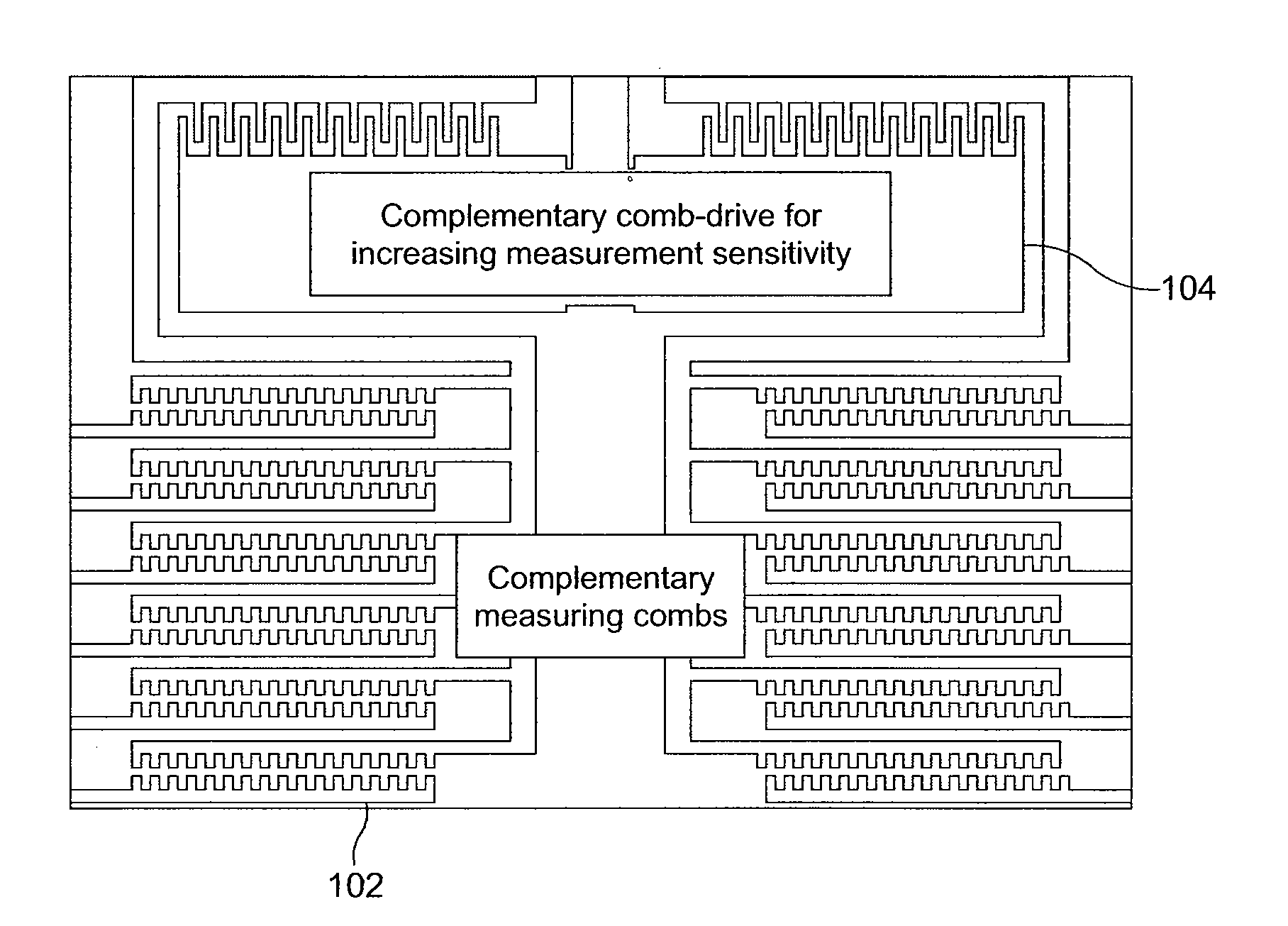

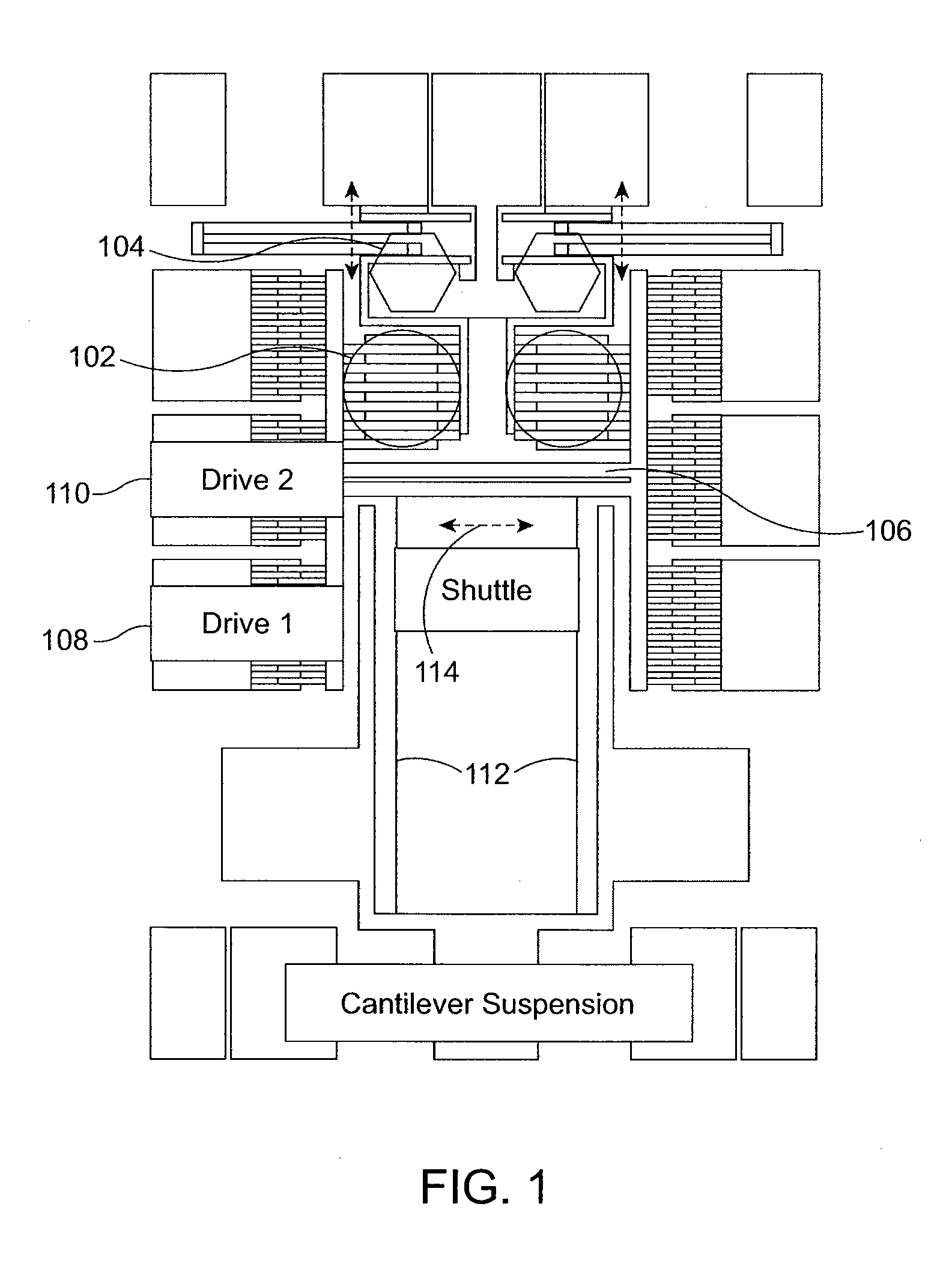

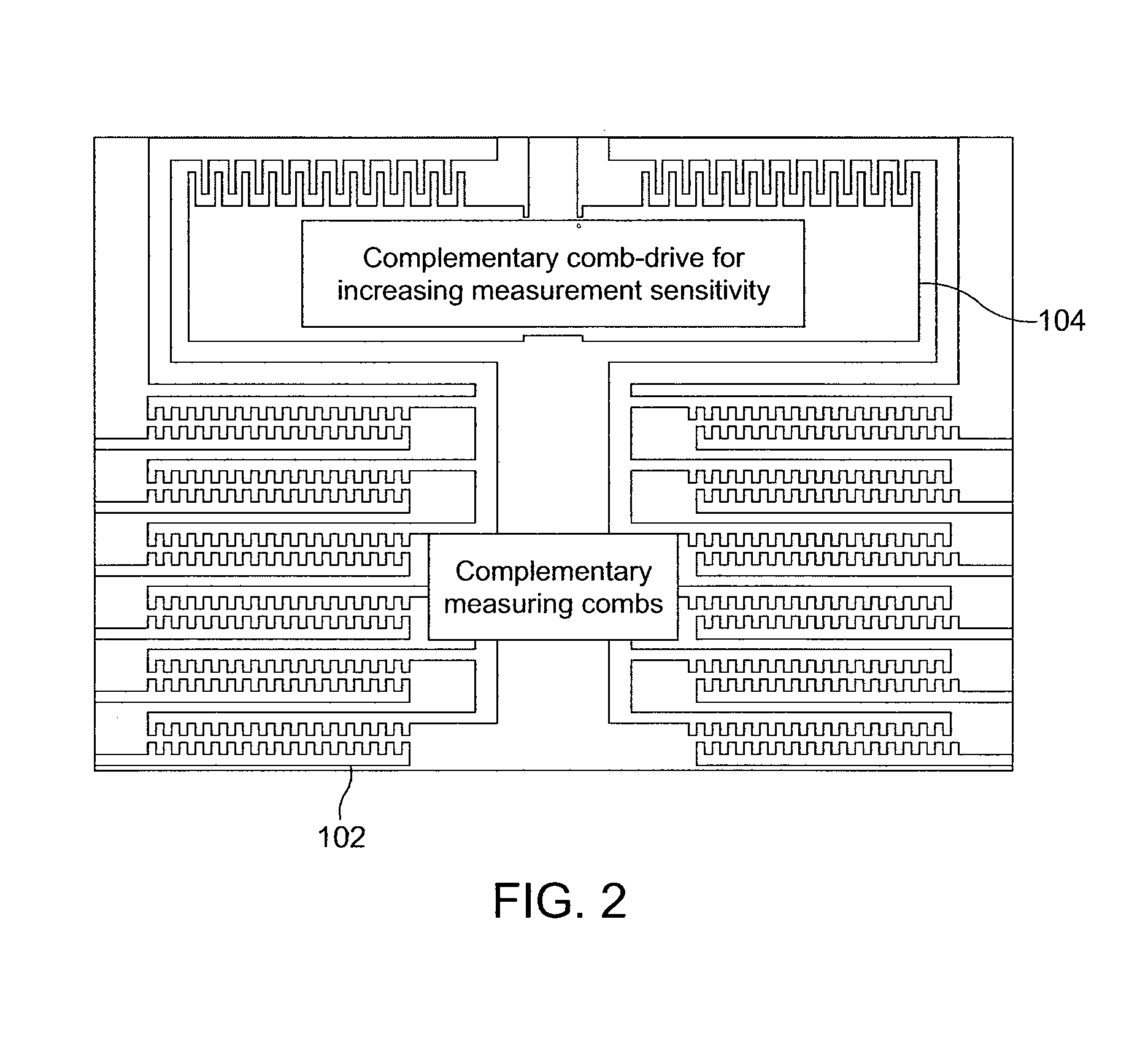

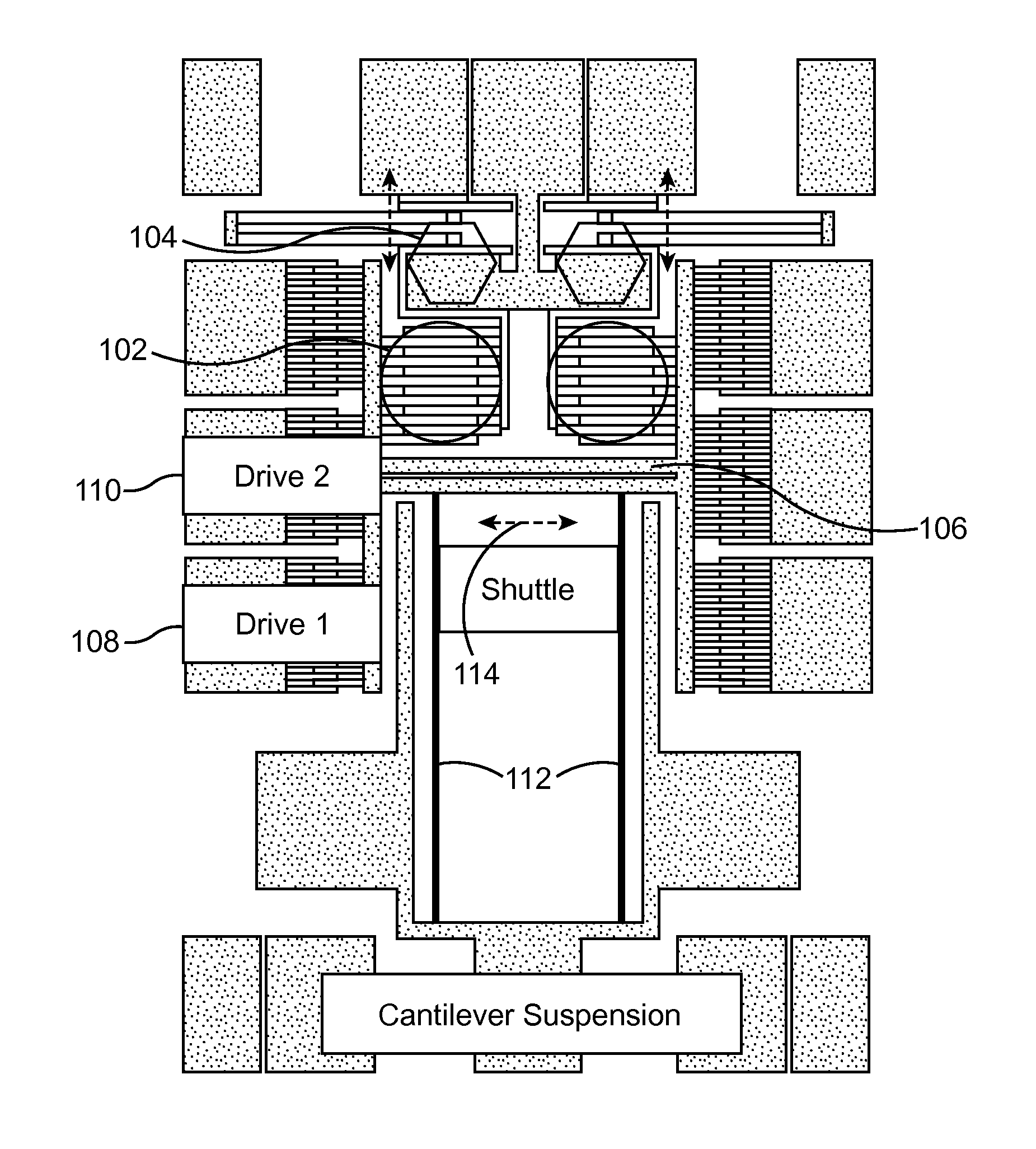

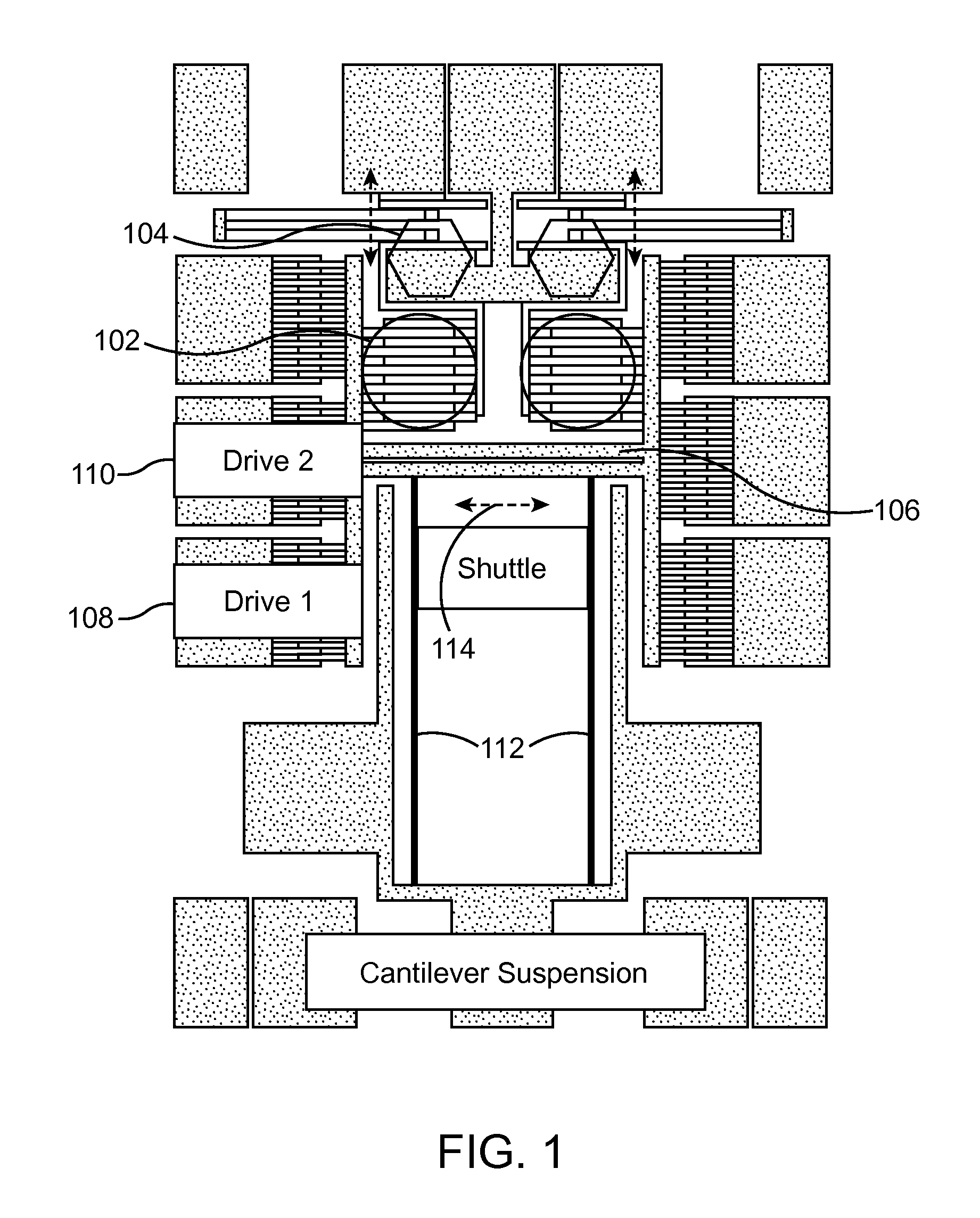

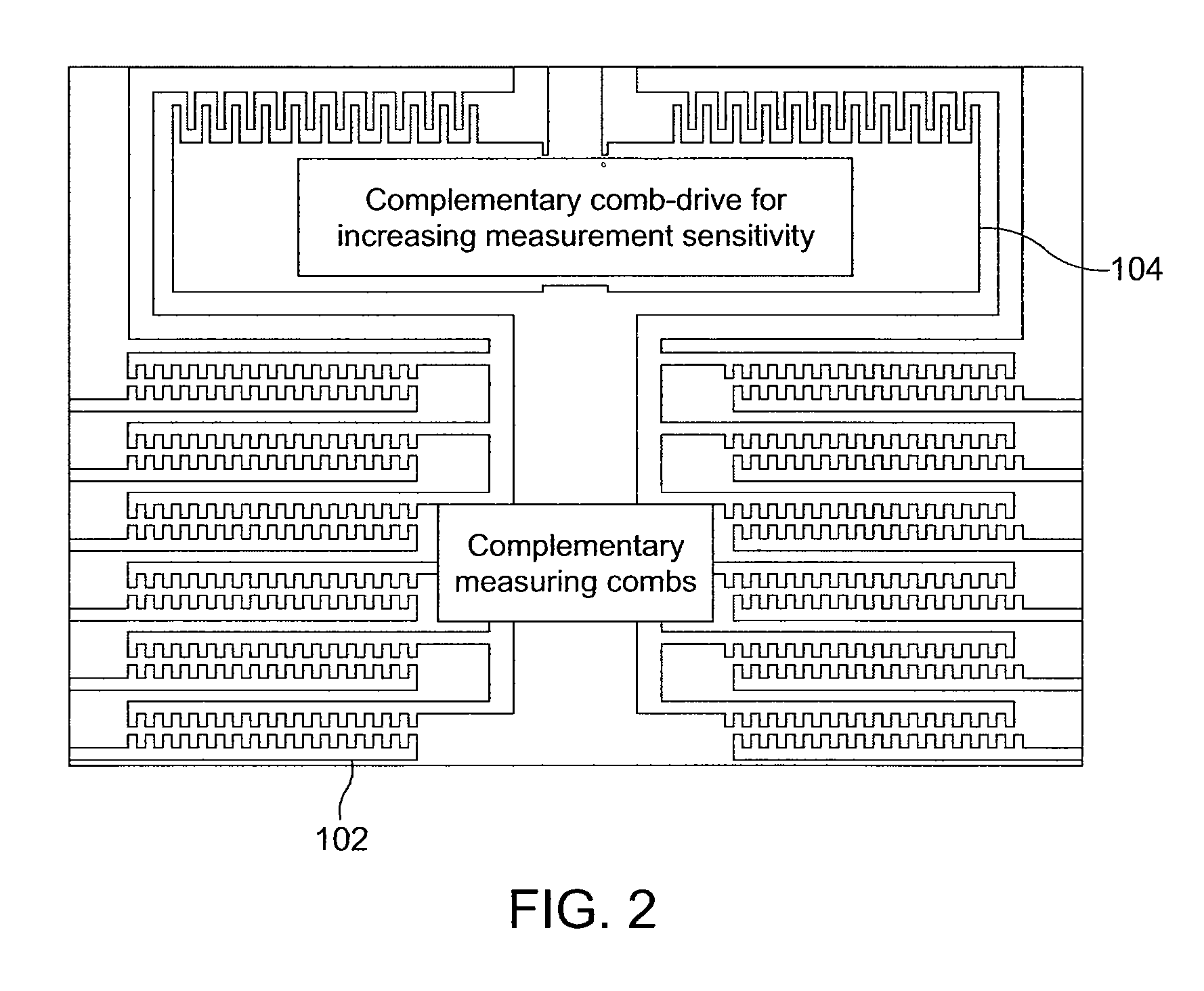

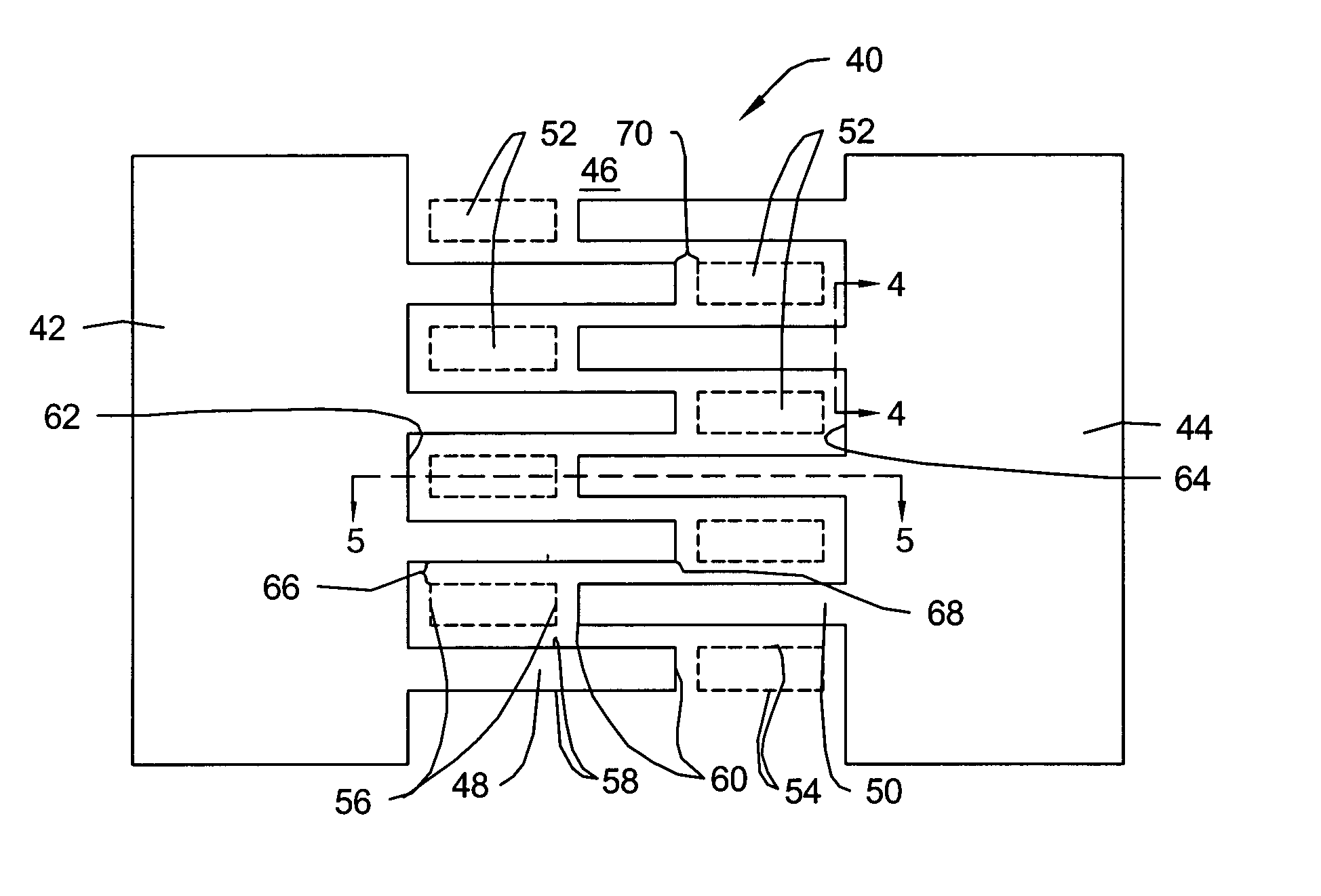

Integrated MEMS metrology device using complementary measuring combs

InactiveUS20090322365A1Small sizeAccurate measurementAcceleration measurement using interia forcesElectrical testingCapacitanceMetrology

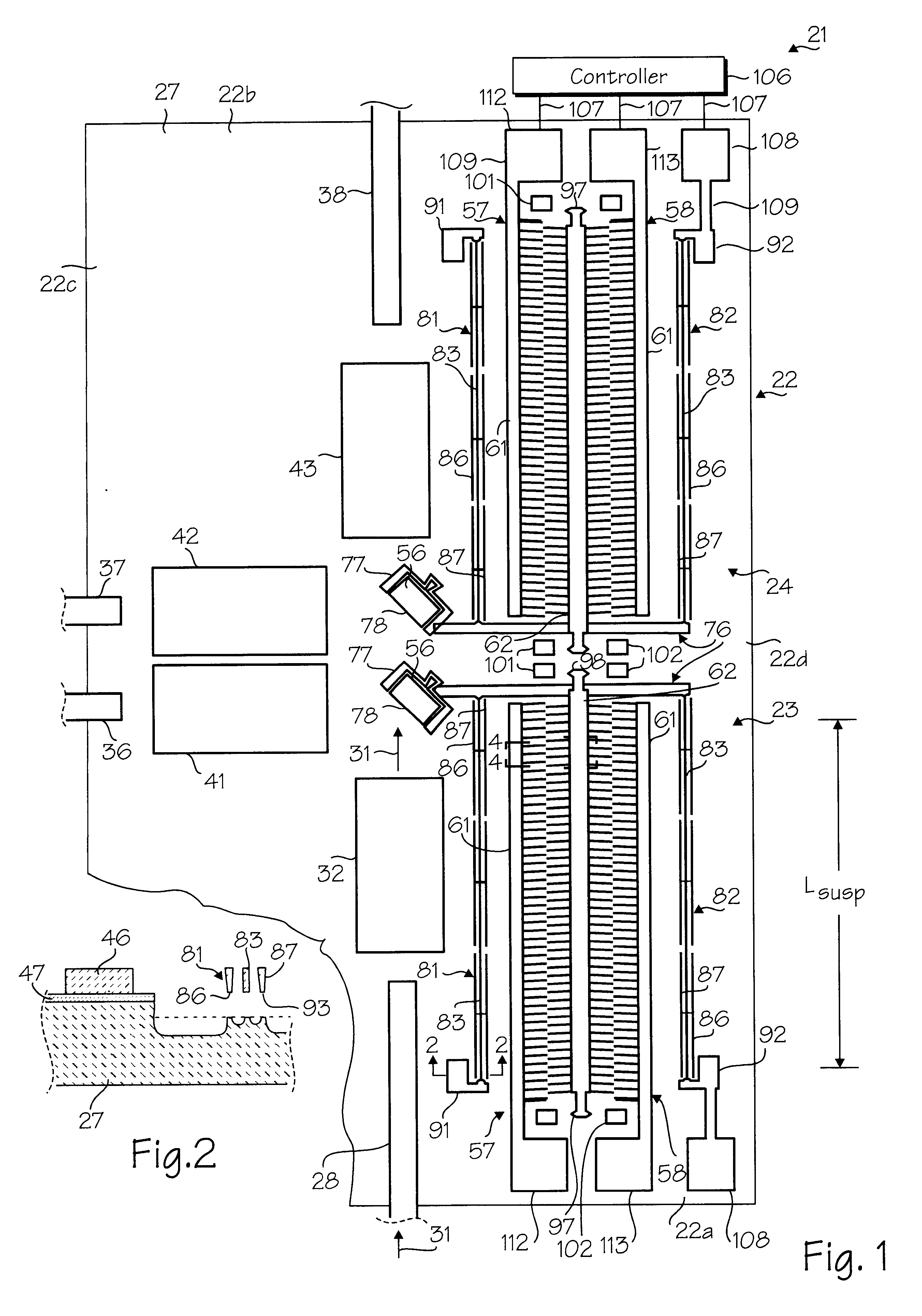

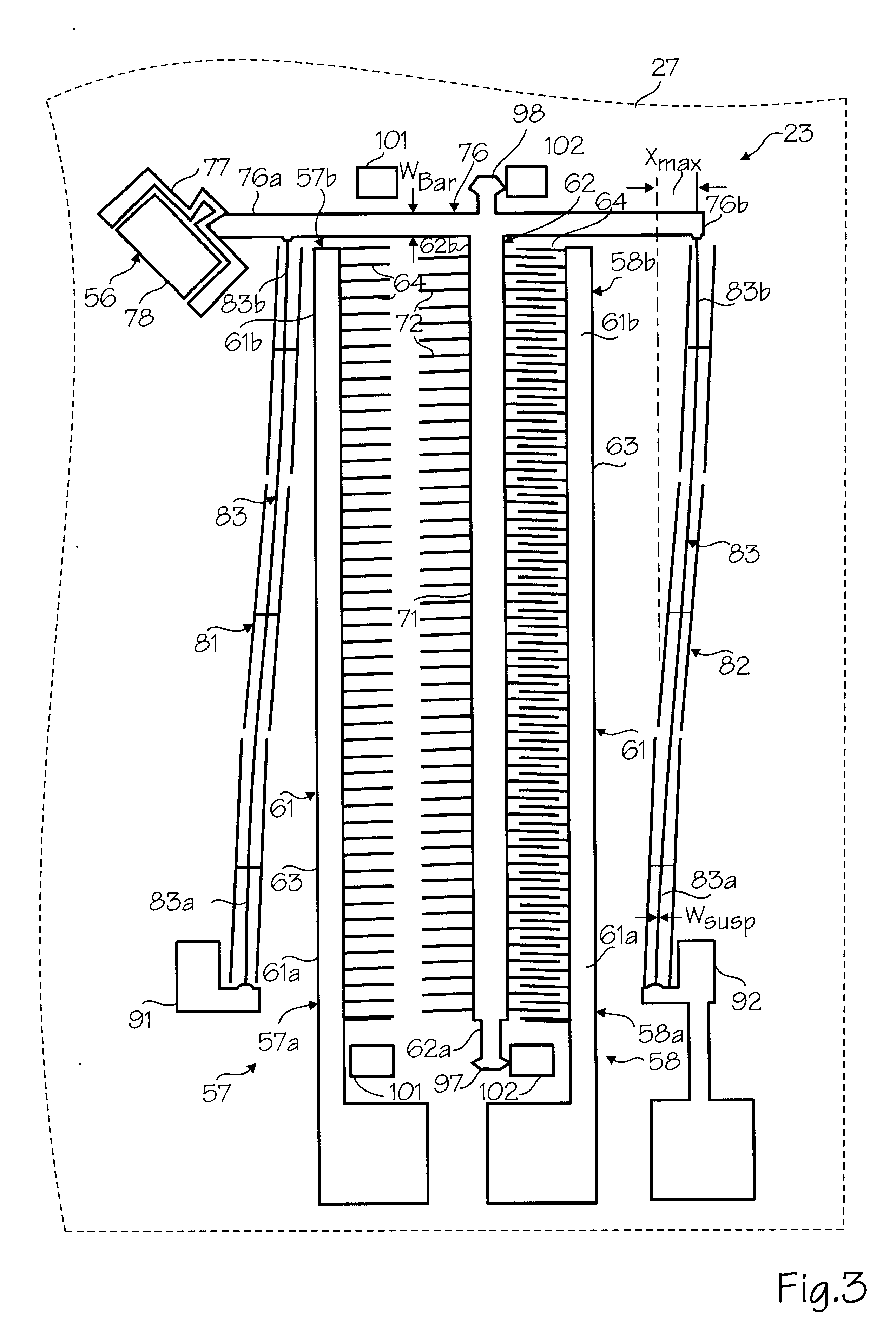

The present invention provides a device for in-situ monitoring of material, process and dynamic properties of a MEMS device. The monitoring device includes a pair of comb drives, a cantilever suspension comprising a translating shuttle operatively connected with the pair of comb drives, structures for applying an electrical potential to the comb drives to displace the shuttle, structures for measuring an electrical potential from the pair of comb drives; measuring combs configured to measure the displacement of the shuttle, and structures for measuring an electrical capacitance of the measuring combs. Each of the comb drives may have differently sized comb finger gaps and a different number of comb finger gaps. The shuttle may be formed on two cantilevers perpendicularly disposed with the shuttle, whereby the cantilevers act as springs to return the shuttle to its initial position after each displacement.

Owner:RGT UNIV OF CALIFORNIA

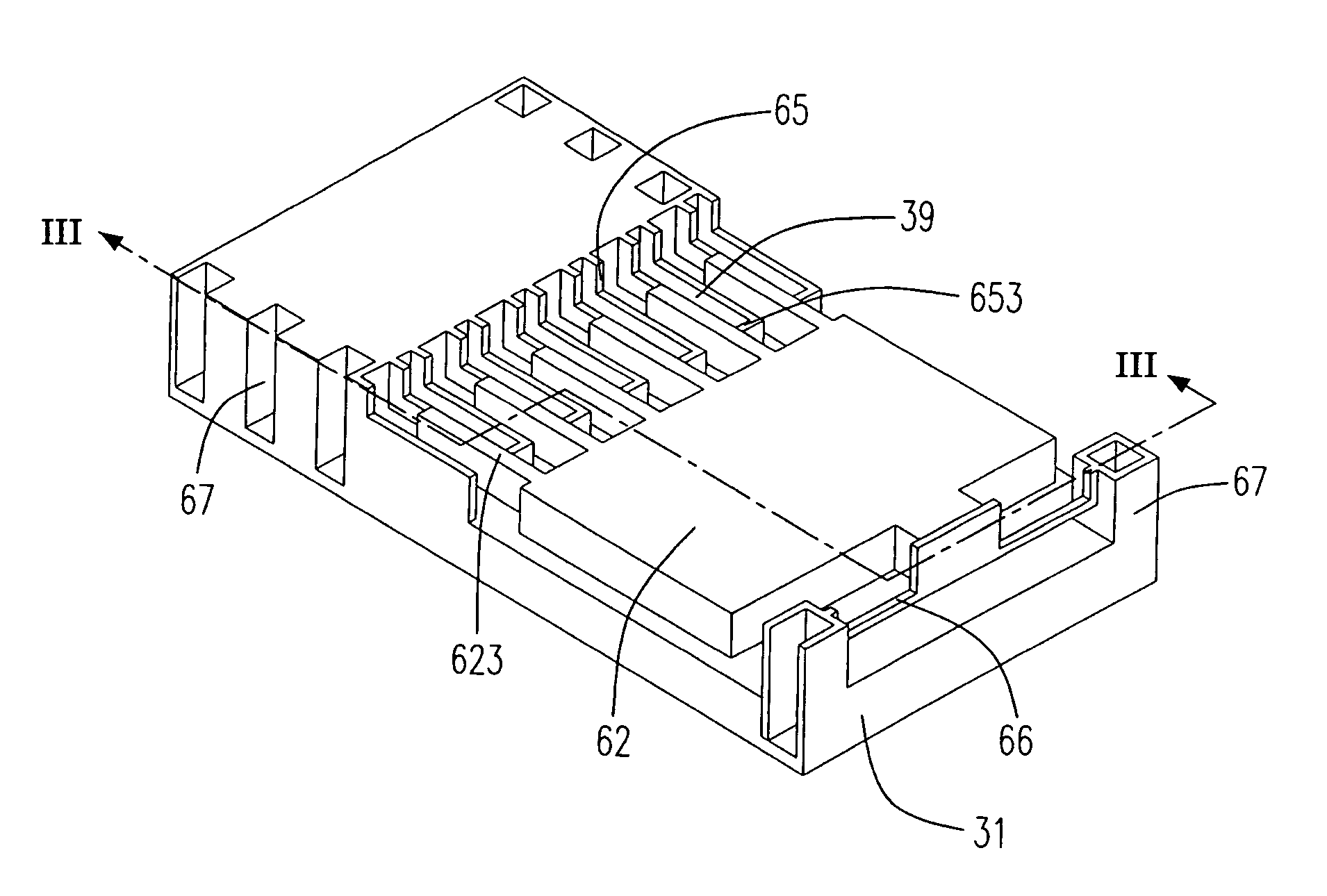

High-aspect-ratio-microstructure (HARM)

InactiveUS7088030B2Provide protectionSimple manufacturing processFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingComb fingerHeight difference

A high-aspect-ratio-microstructure (HARM) is provided. The structure includes: a substrate; a lower structure with a comb shape fixedly mounted on said substrate and having first plural comb fingers, wherein each of the first plural comb fingers has a thin slot thereon; an upper structure with a comb shape having second plural comb fingers, wherein the lower structure and the upper structure have a height difference therebetween so as to form an uneven surface; and a lateral strengthening structure formed at vertically peripheral walls of the first plural comb fingers and the second plural comb fingers for protecting the plural first and second comb fingers.

Owner:WALSIN LIHWA

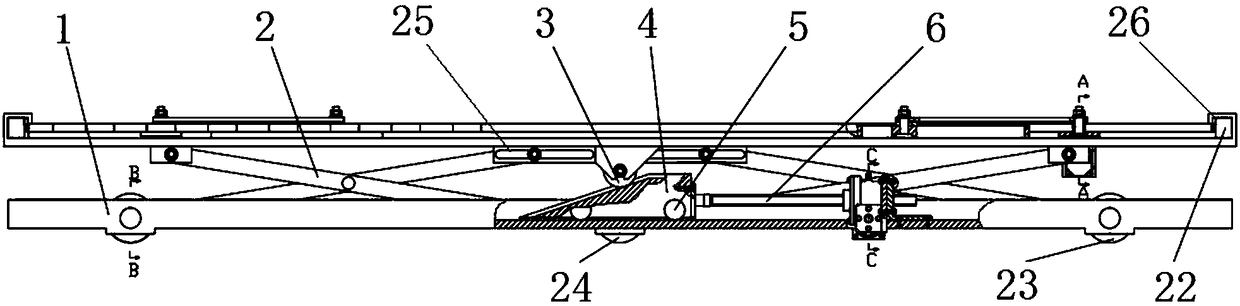

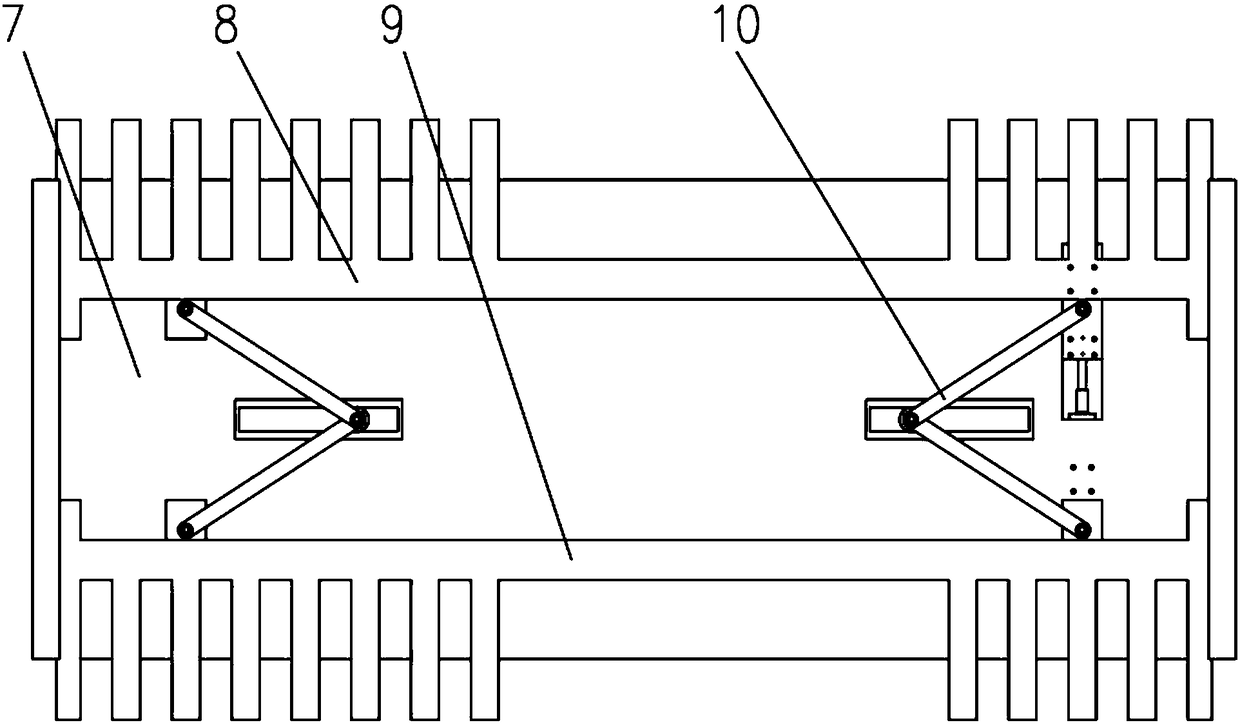

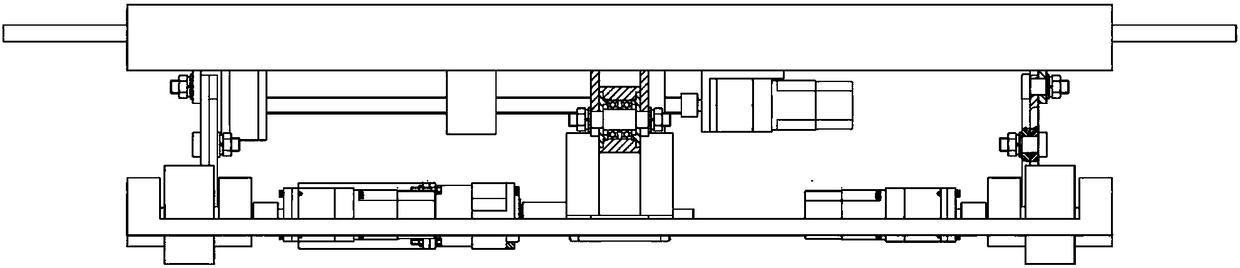

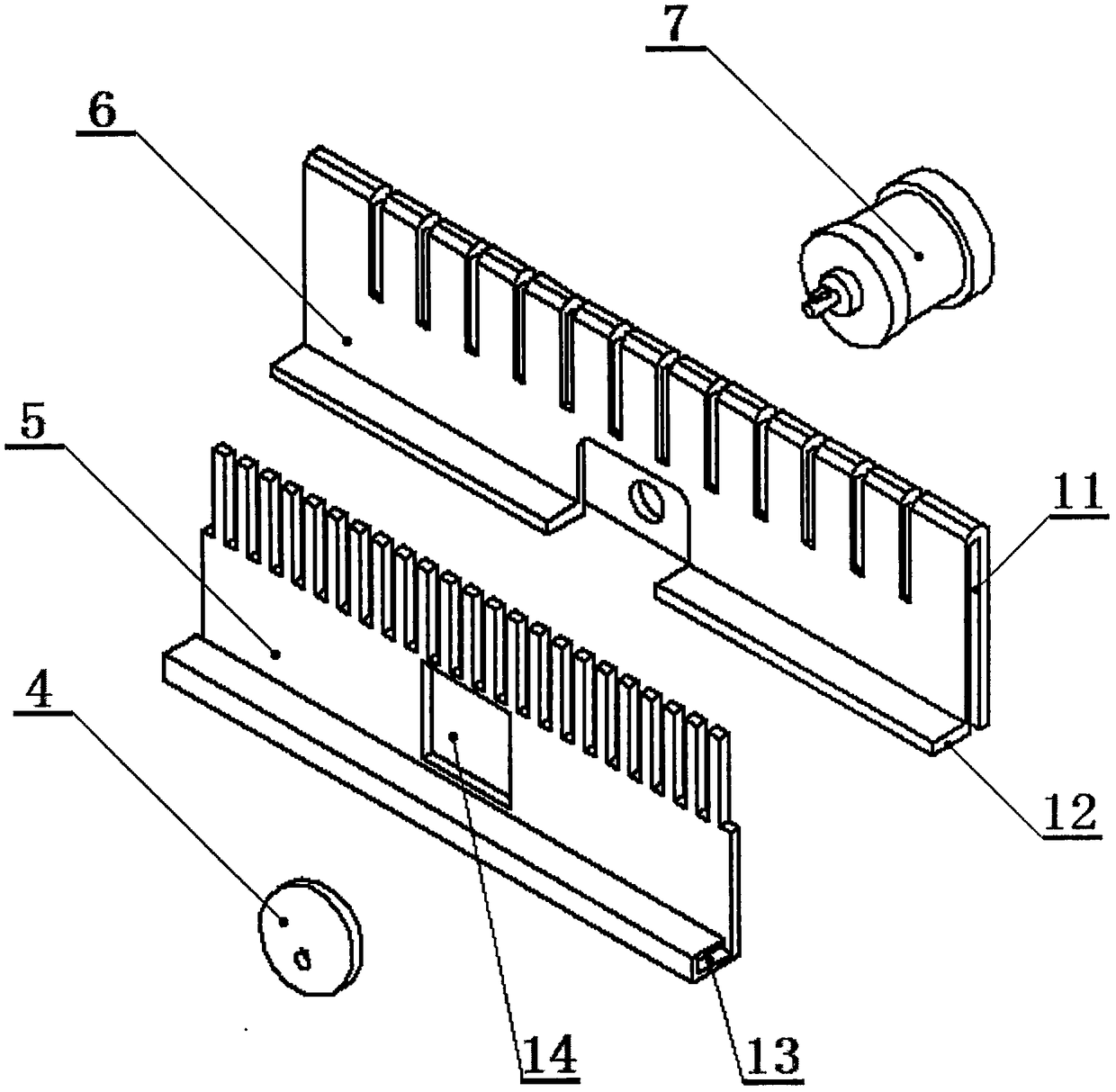

Comb-finger stereo garage carrying trolley and method

ActiveCN108442776APick up the car automaticallyAutomatically complete the carParkingsVehicle frameComb finger

The invention discloses a comb-finger stereo garage carrying trolley and a method. The comb-finger stereo garage carrying trolley and the method solve the problems that in the prior art, a carrying trolley travels on a fixed track and cannot walk freely on a garage plane, the laying of the fixed track increases the construction cost, and car garage space is wasted. The effects that the comb-fingerstereo garage carrying trolley can be applied to an aisle-stack stereo garage, the handling safety of handling equipment and the transmission ratio of a lifting mechanism are improved, and the utilization rate of garage space is improved are achieved. According to the technical scheme, the comb-finger stereo garage carrying trolley includes a bottom frame and an upper car frame, and a plurality of sets of travelling mechanisms is arranged at the bottom of the bottom frame. The upper car frame is connected with the bottom frame through a plurality of shear type support frames. A lifting and elevating mechanism for controlling lifting of the upper car frame is installed between the upper car frame and the bottom frame. Comb-finger frames are slidably connected to two sides of the upper carframe. The comb-finger frames are controlled by a telescopic mechanism to extend or retract, and after the comb-finger frames are extended, the lifting and elevating mechanism controls the upper car frame to rise, so that a car to be carried is rose and separated from a parking frame.

Owner:SHANDONG UNIV

Miniature micro-electromechanical system (MEMS) based directional sound sensor

ActiveUS20110299701A1Solid-state devicesSemiconductor/solid-state device manufacturingCapacitanceComb finger

A micro-electromechanical (MEMS) based directional sound sensor includes a two sensor wings attached to a surrounding support structure by two legs. The support structure is hollow beneath the sensor wings allowing the sensor wings to vibrate in response to sound excitation. In one embodiment, interdigitated comb finger capacitors attached on the sensor wing edges and the support structure enable an electrostatic (capacitive) readout related to the vibrations of the sensor which allows determination of the sound direction.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Micro electro mechanical system using comb and parallel plate actuation

The present invention combines electrostatic comb with parallel plate actuation in a novel design to create a robust low voltage MEMS Micromirror. Other unique advantages of the invention include the ability to close the comb fingers for additional reliability and protection during mirror snapping with over voltage.

Owner:MICROSYST

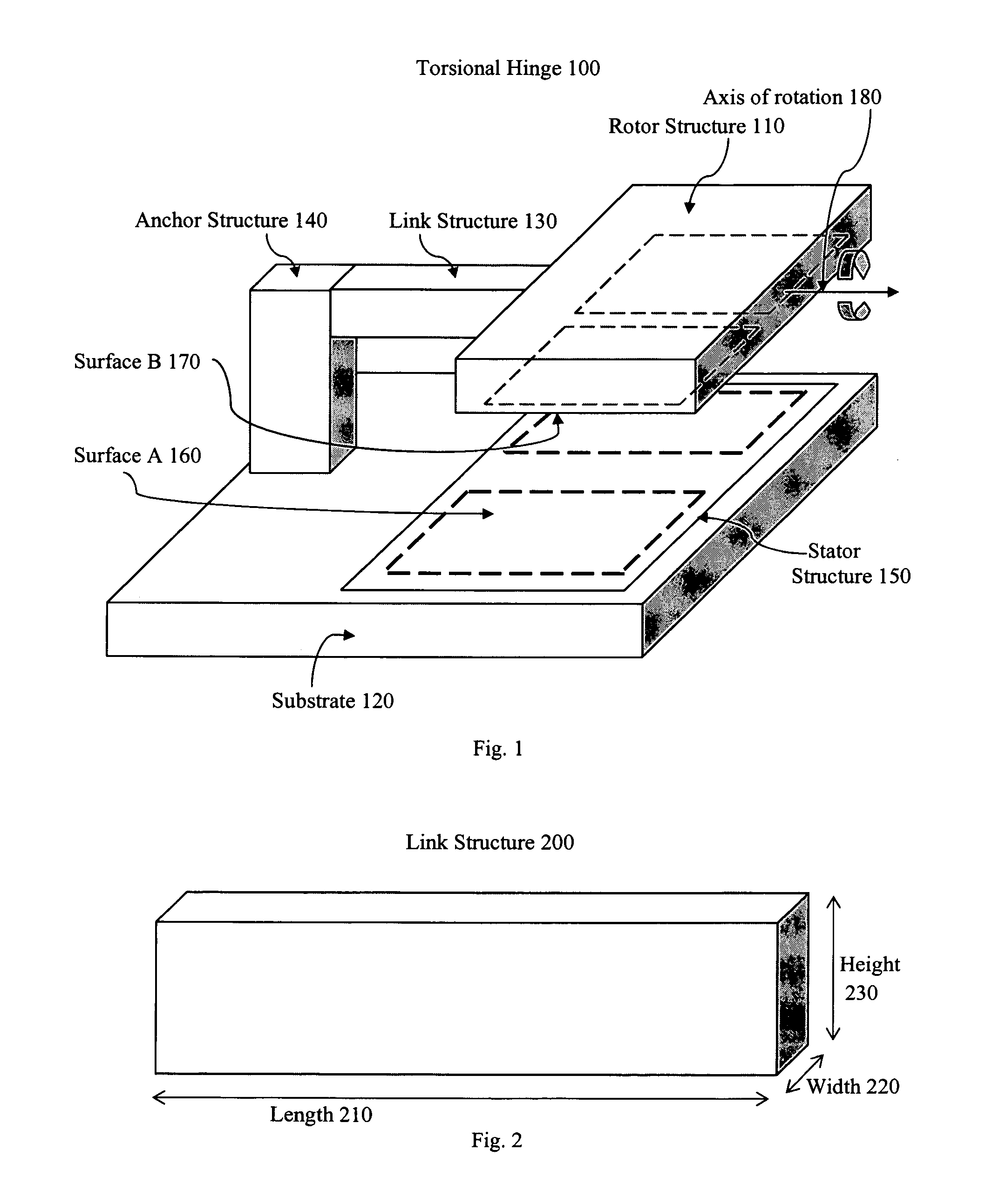

Frequency tunable micromirror

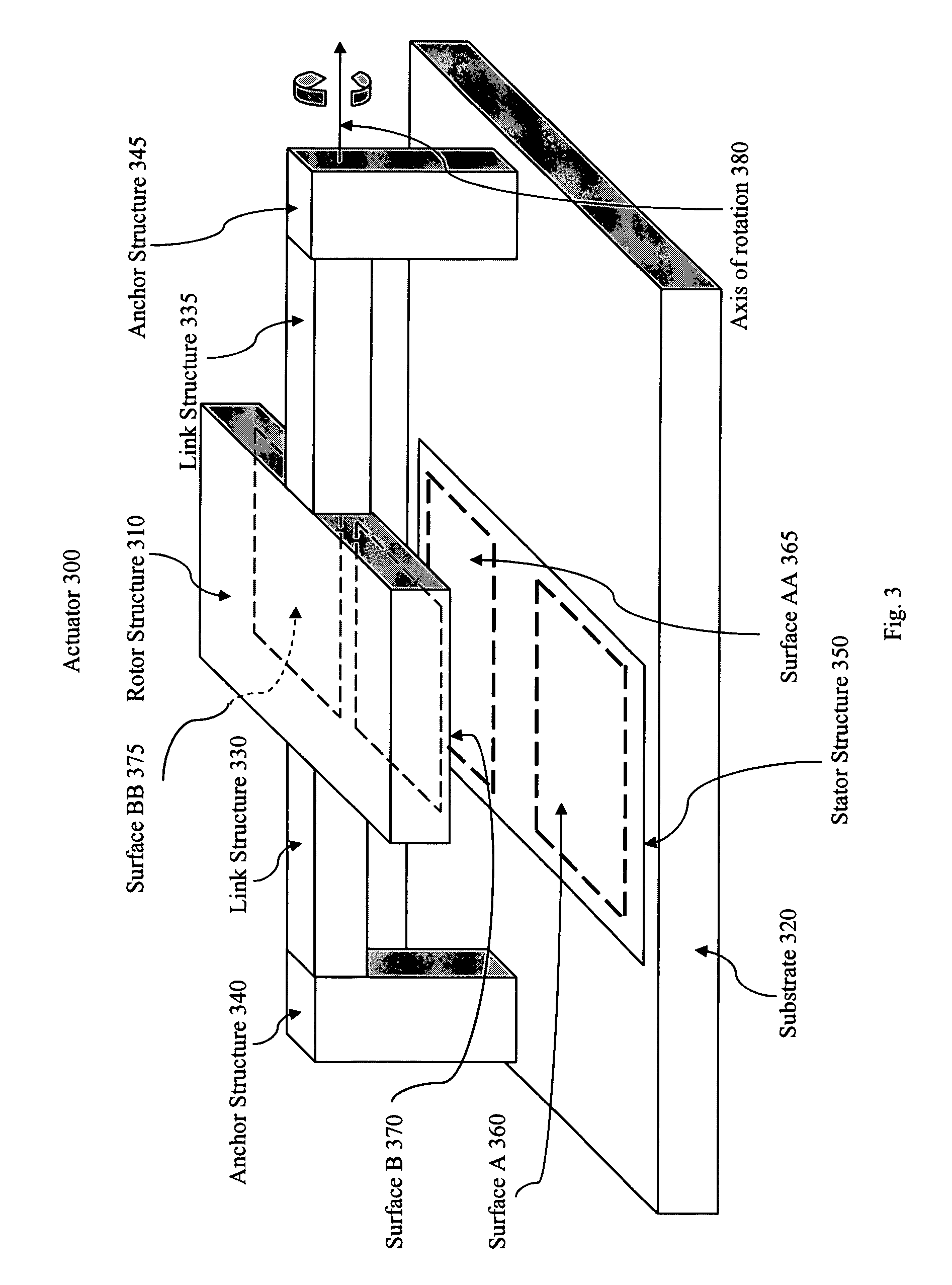

An optical imaging system having two micromirrors is disclosed. Each of the two micromirrors can be rotated by a first set of combdrive actuators along a first axis and a second set of combdrive actuators along a second axis. Each of the first and second set of combdrive actuators includes multiple stator comb fingers and multiple rotor comb fingers capable of rotating about a torsion bar. One of the micromirrors can be tuned by applying a current to the torsion bar to change the Young's modulus of the torsion bar via thermoelectrical heating of the torsion bar.

Owner:NANOLITE SYST

Method for Fabricating a Micromirror

A method for fabricating a micromirror is disclosed. A set of coarse features is formed in a low-temperature oxide (LTO) layer deposited on a front side of a wafer. A set of fine features is then formed in a photosensitive material layer deposited on top of the LTO layer. After removing a portion of the LTO layer to align the width of the coarse features with the width of the fine features, the first silicon dioxide layer and the first and second silicon device layers are etched to form stator comb fingers and rotor comb fingers accordingly. Finally, a portion of the substrate on a back side of the wafer is removed, and the silicon dioxide layers are removed from the front and back sides of the wafer to form a rotatable mirror.

Owner:ZHANG XIAOJING +3

Sensor of volatile substances and process for manufacturing a sensor of volatile substances

ActiveUS20150219581A1High sensitivityUsing mechanical meansMaterial capacitanceCapacitanceComb finger

A sensor of volatile substances includes: a first electrode structure and a second electrode structure capacitively coupled, comb-fingered, and arranged coplanar in a plane; and a sensitive layer, of a sensitive material that is permeable to a volatile substance and has electrical permittivity depending upon a concentration of the volatile substance absorbed by the sensitive material. The sensitive layer extends from opposite sides of the plane.

Owner:STMICROELECTRONICS INT NV

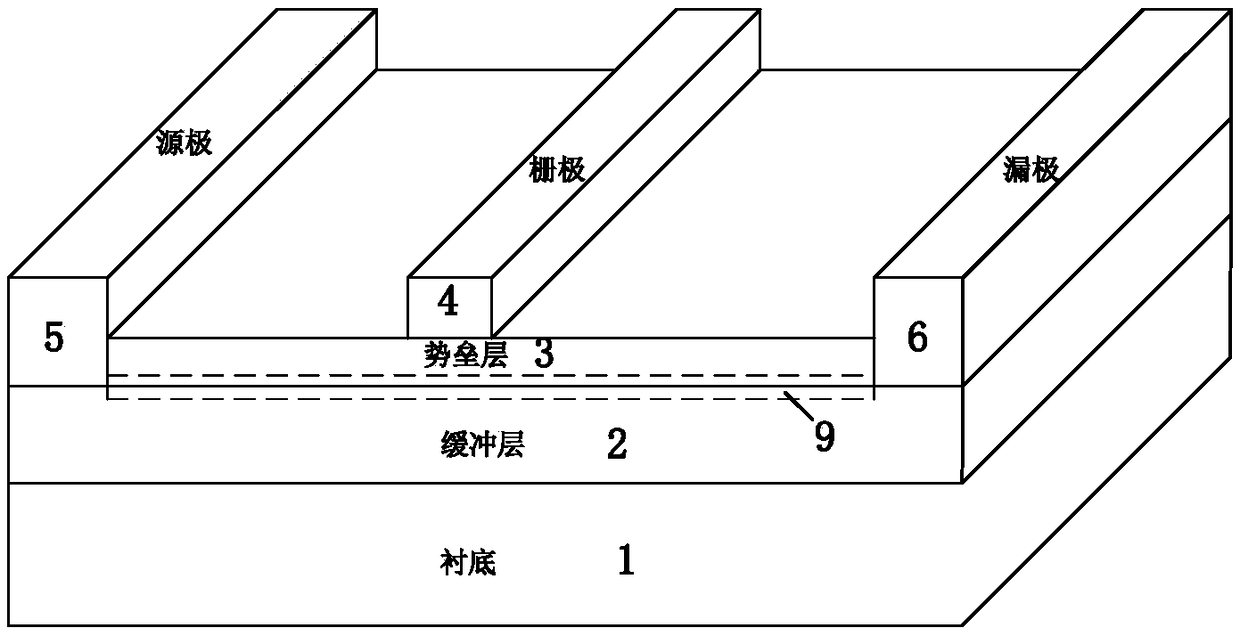

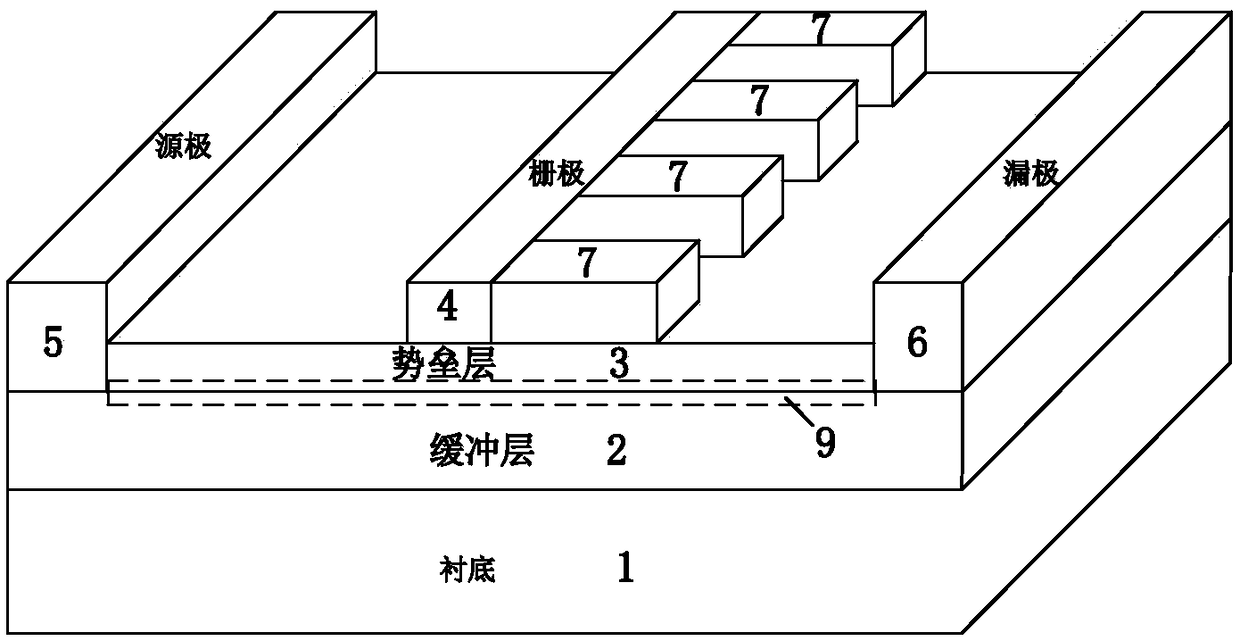

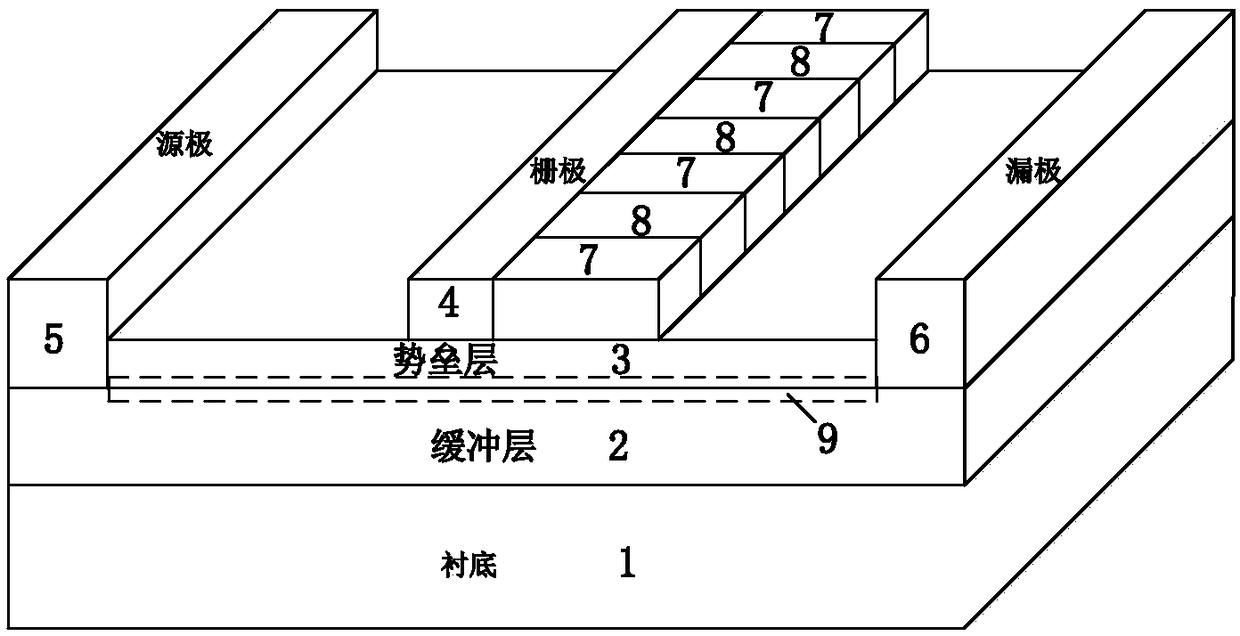

HEMT device containing high-dielectric coefficient medium block

The invention discloses a HEMT device containing high-dielectric coefficient medium blocks, and belongs to the technical field of the semiconductor. The HEMT device comprises a substrate, a buffer layer, a barrier layer, a grid electrode, a source electrode and a drain electrode; the buffer layer and the barrier layer are orderly arranged on the substrate, and a two-dimensional conducting channelis formed at an interface of the barrier layer and the buffer layer; the source electrode and the drain electrode are respectively arranged at two sides of the HEMT device and form ohmic contact withthe two-dimensional conducting channel; the grid electrode is arranged between the source electrode and the drain electrode, and the grid electrode is located on the barrier layer and the Schottky contact is formed on the barrier layer; multiple high-dielectric coefficient medium blocks are arranged at a region between the grid electrode and the drain electrode on the barrier layer; multiple high-dielectric coefficient medium blocks are connected with the grid electrode and extend along a grid drain direction, the grid electrode and multiple high-dielectric coefficient medium blocks form a comb-finger shaped structure; the high-dielectric coefficient medium blocks do not directly connect with the drain electrode, and the dielectric coefficient is greater than the dielectric coefficient ofthe barrier layer. The HEMT device provided by the invention has the feature of being high in breakdown voltage, and can satisfy the application with high working voltage and output power.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

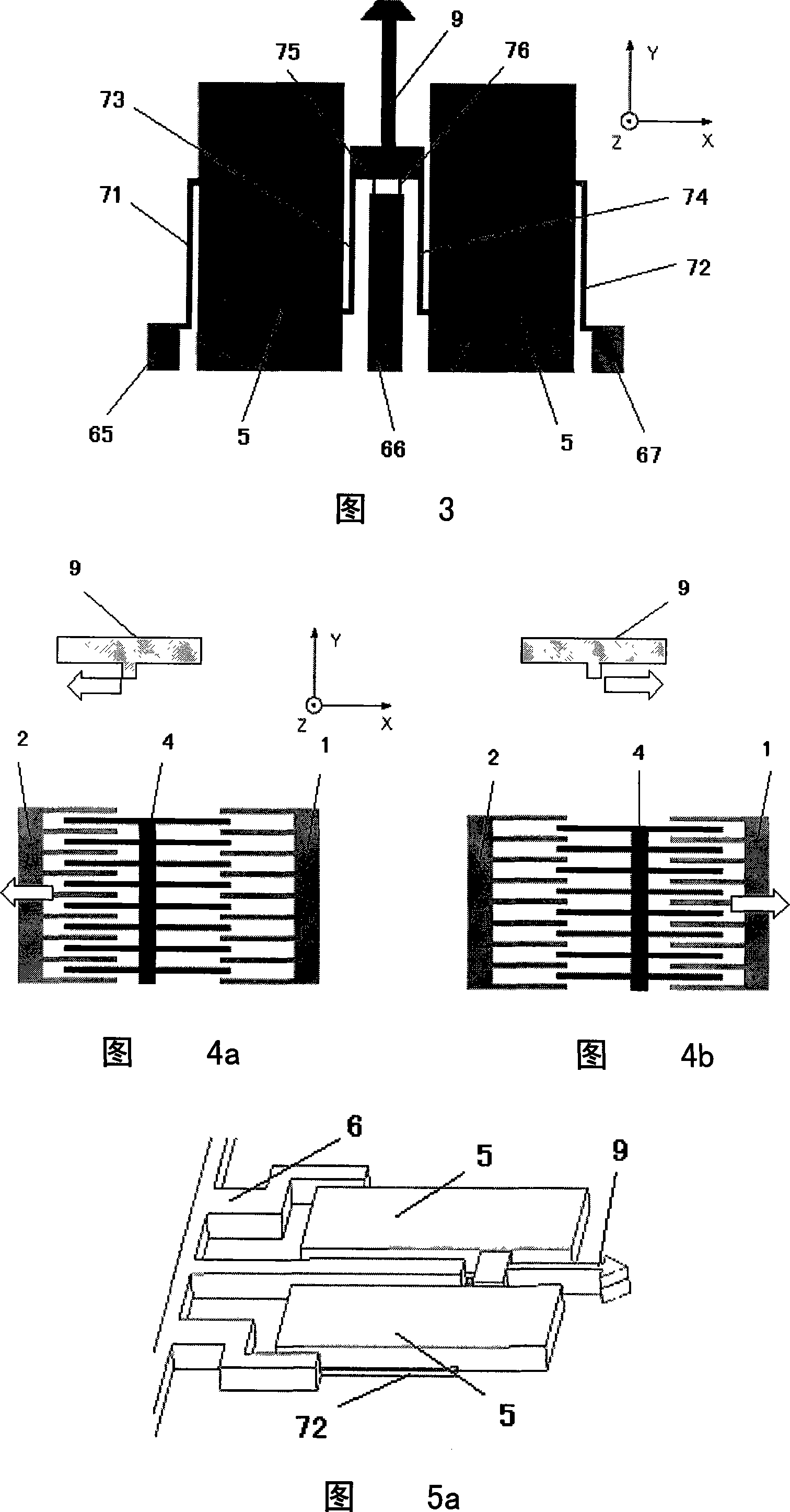

Micro-drive structure for implementing coplane and off-plane movement

ActiveCN101244801AReduce internal stressQuality improvementTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesComb fingerEngineering

The invention relates to a coplanar and off-plane micro driving structure and the preparation method. The driving structure comprises fixed electrodes, movable electrodes, support beams, a glass base and a drive output, wherein the fixed electrodes comprise a comb-finger fixed electrode connected at both sides of the glass base top surface and a flat plate fixed electrode which is fixed at the central section of the glass base top surface; the movable electrodes comprise two comb-finger movable electrodes which insert in the comb-finger fixed electrode and two flat plate movable electrodes respectively arranged above the flat plate fixed electrode; the support beams comprise a folded beam and a composite torsion beam. The coplanar and off-plane micro driving structure can not only realize the coplanar movement along the X axis direction through the interaction between the comb-finger movable electrodes and the fixed electrodes, but also realize the off-plane torsion movement of the driving output through the interaction between the movable electrodes and the fixed electrodes. The coplanar and off-plane micro driving structure has the advantages of simple processing and is compatible with a plurality of MEMS devices process, thus applicable to glimmer integrated system with more powerful function.

Owner:PEKING UNIV

Integrated MEMS metrology device using complementary measuring combs

InactiveUS8079246B2Accurate measurement and monitoringSmall sizeAcceleration measurement using interia forcesElectrical testingCapacitanceMetrology

The present invention provides a device for in-situ monitoring of material, process and dynamic properties of a MEMS device. The monitoring device includes a pair of comb drives, a cantilever suspension comprising a translating shuttle operatively connected with the pair of comb drives, structures for applying an electrical potential to the comb drives to displace the shuttle, structures for measuring an electrical potential from the pair of comb drives; measuring combs configured to measure the displacement of the shuttle, and structures for measuring an electrical capacitance of the measuring combs. Each of the comb drives may have differently sized comb finger gaps and a different number of comb finger gaps. The shuttle may be formed on two cantilevers perpendicularly disposed with the shuttle, whereby the cantilevers act as springs to return the shuttle to its initial position after each displacement.

Owner:RGT UNIV OF CALIFORNIA

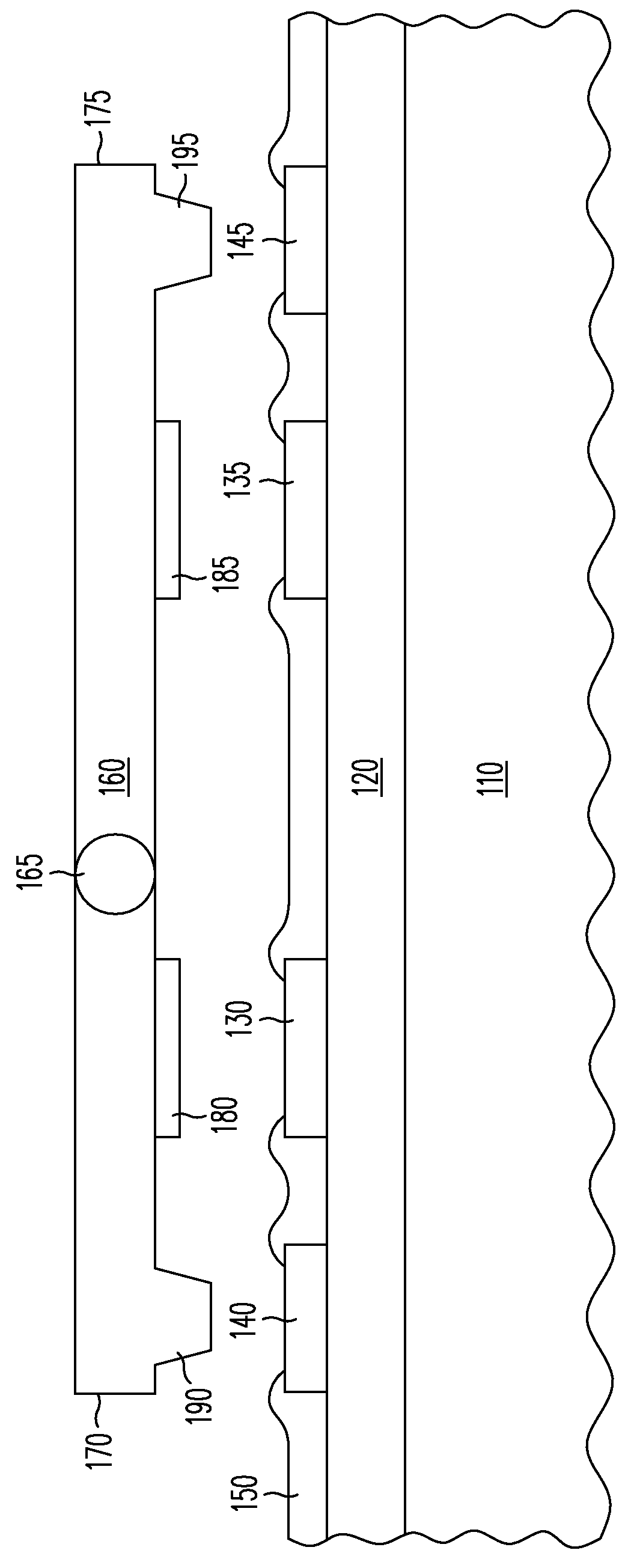

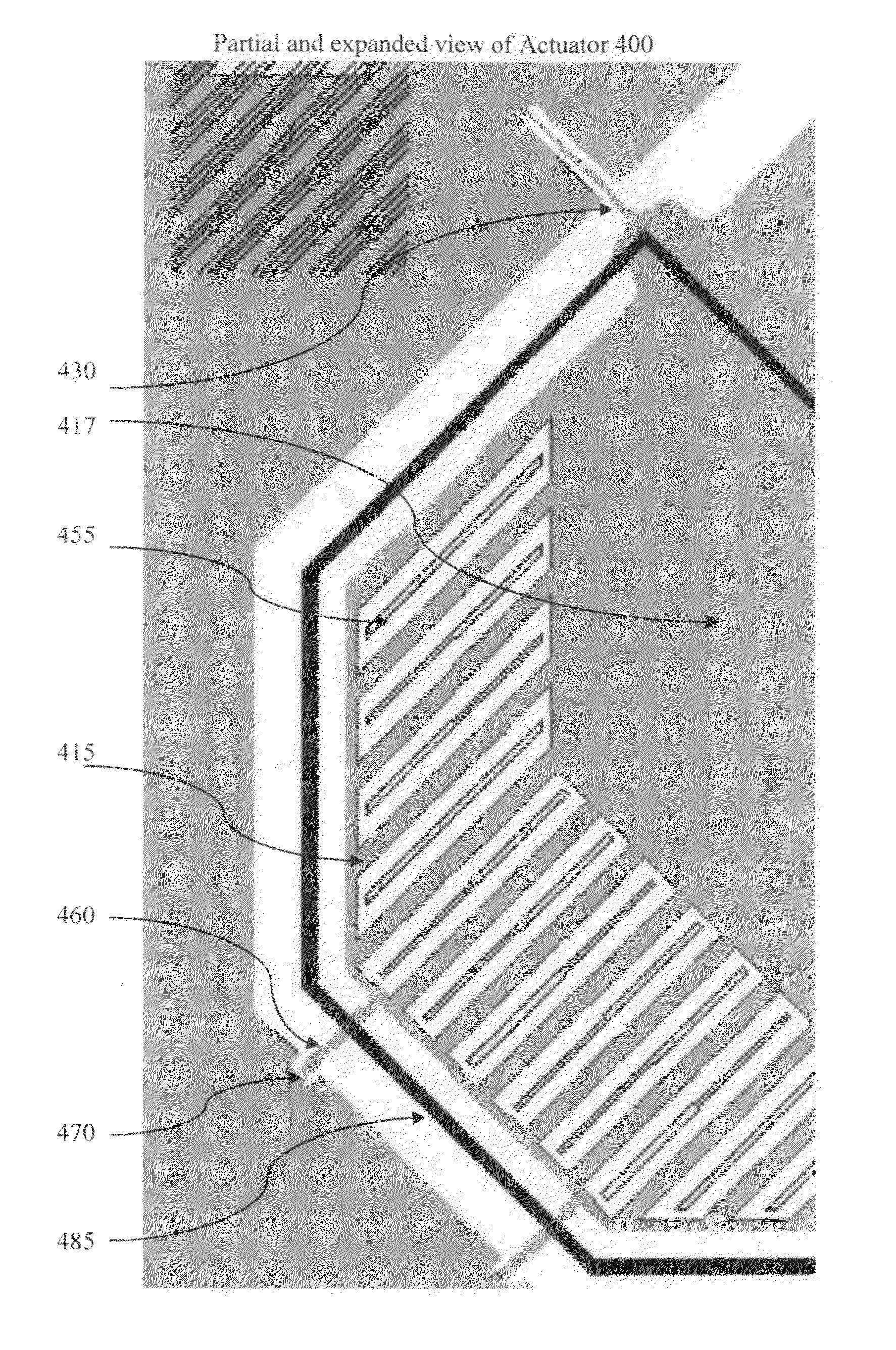

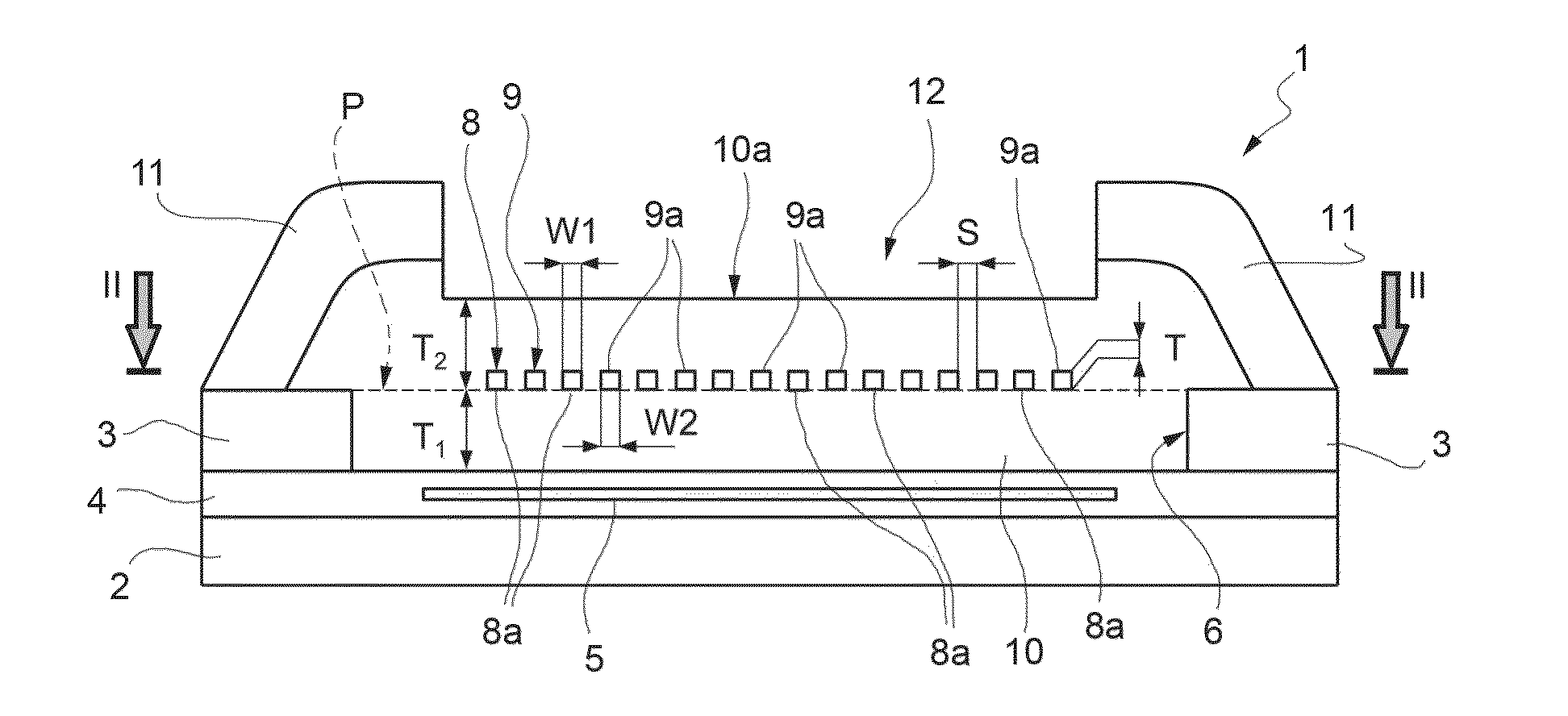

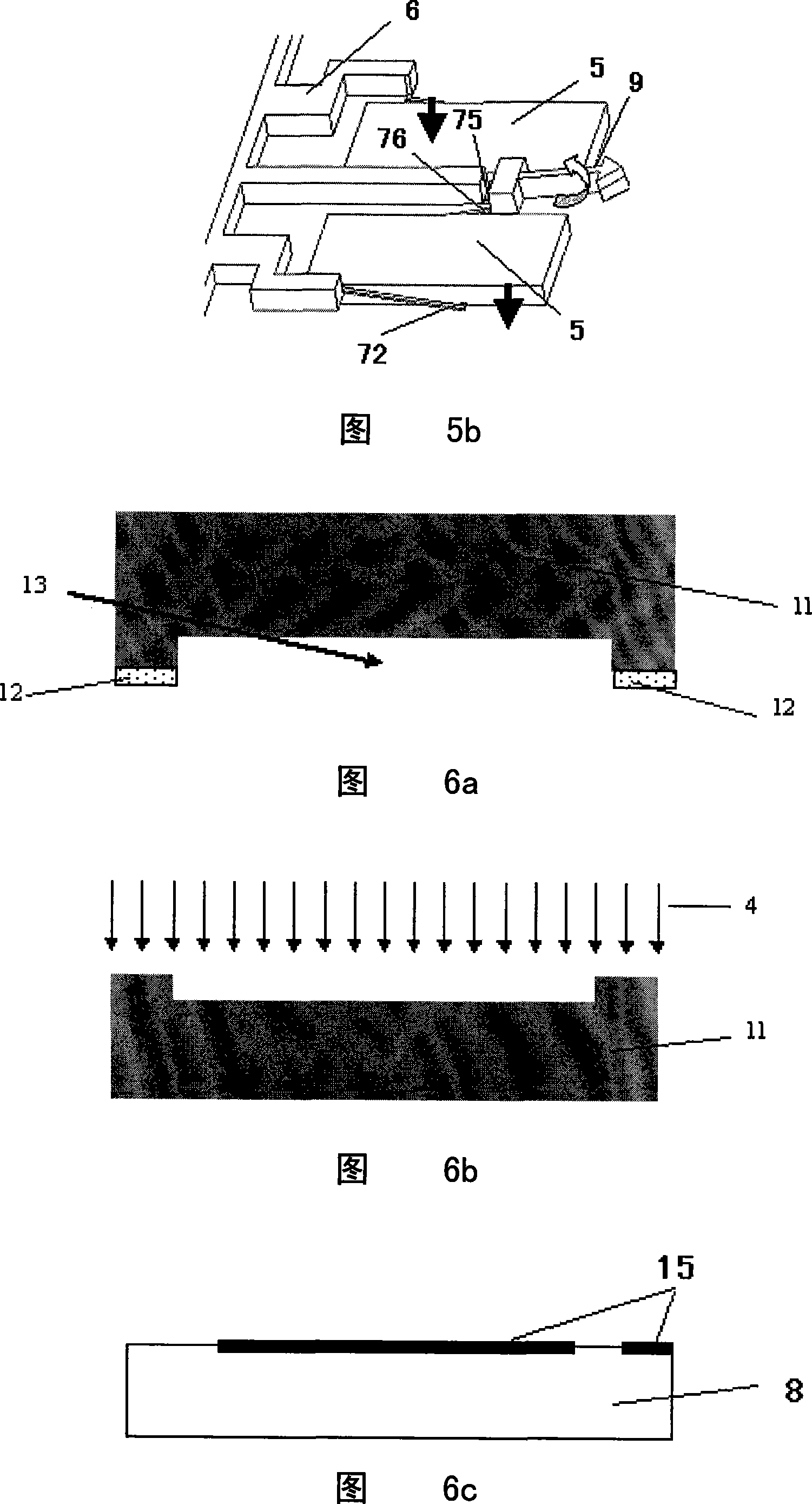

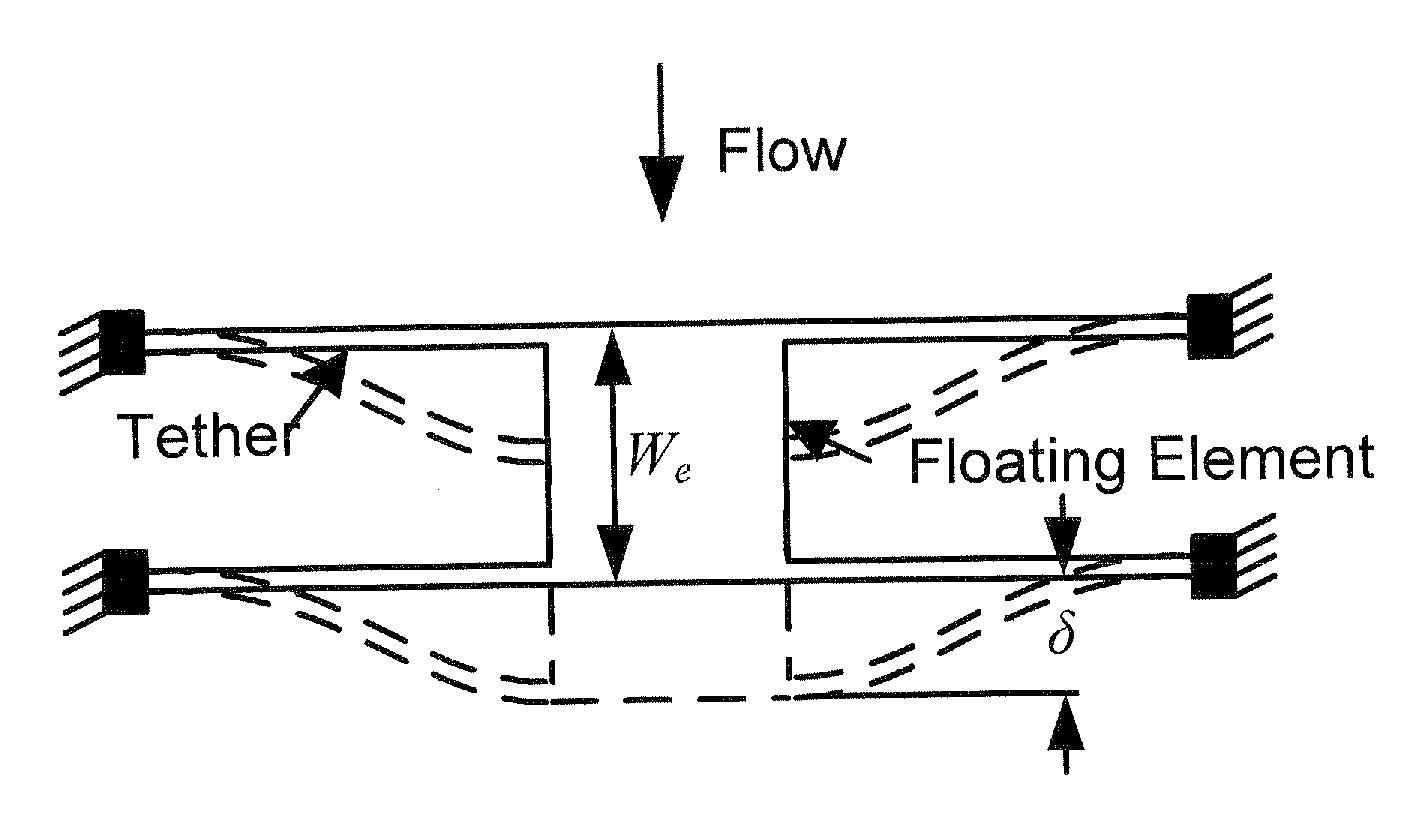

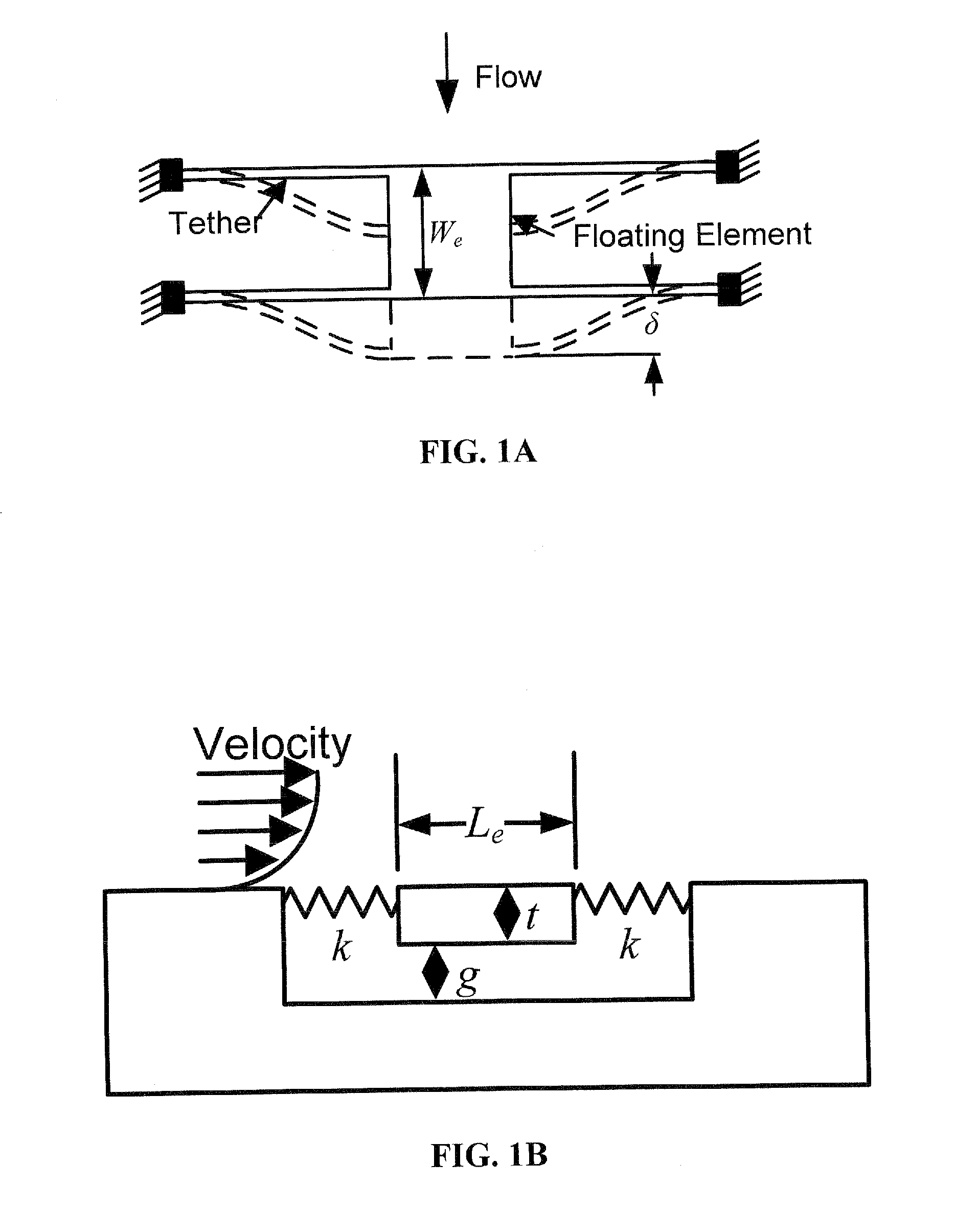

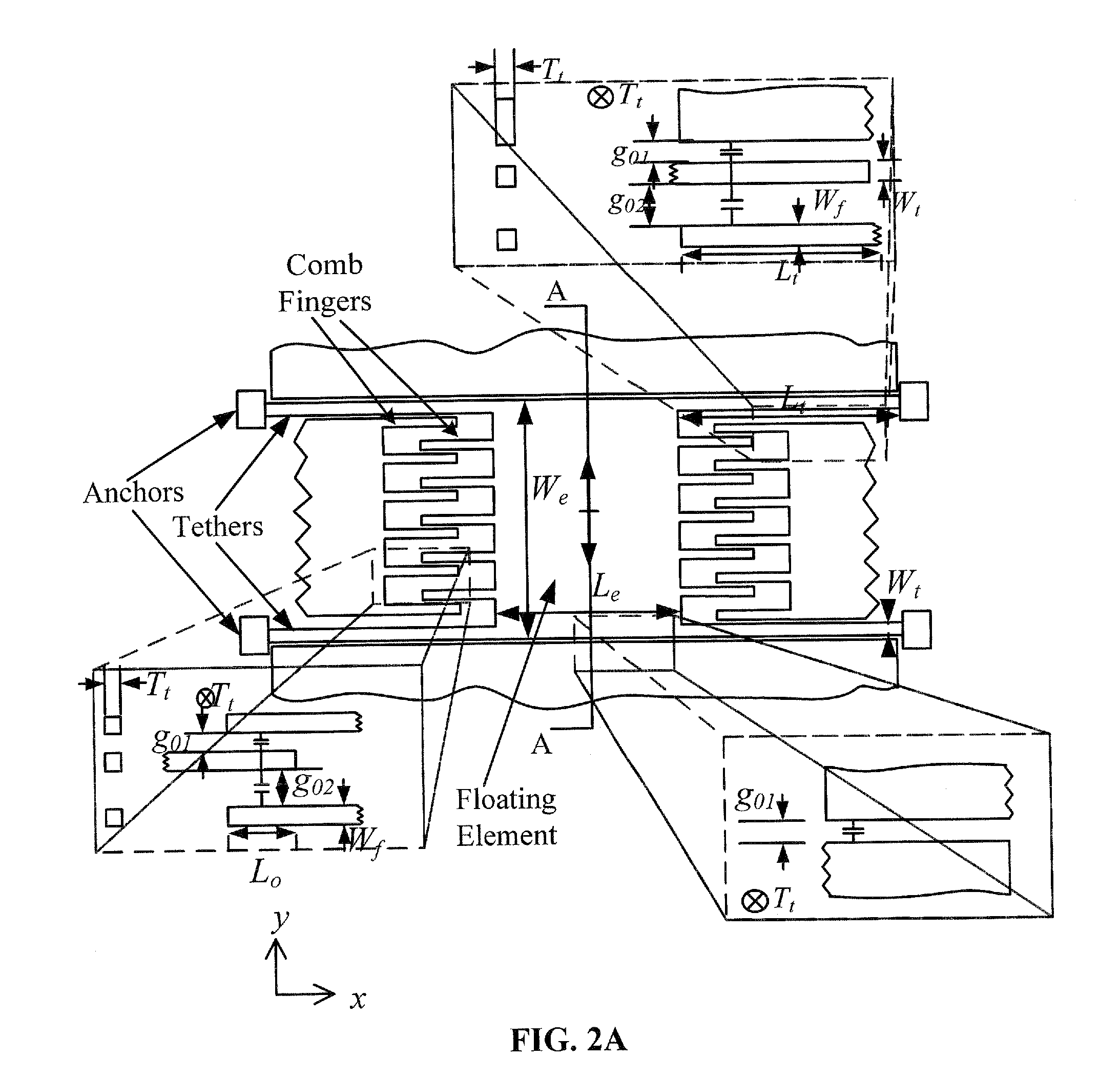

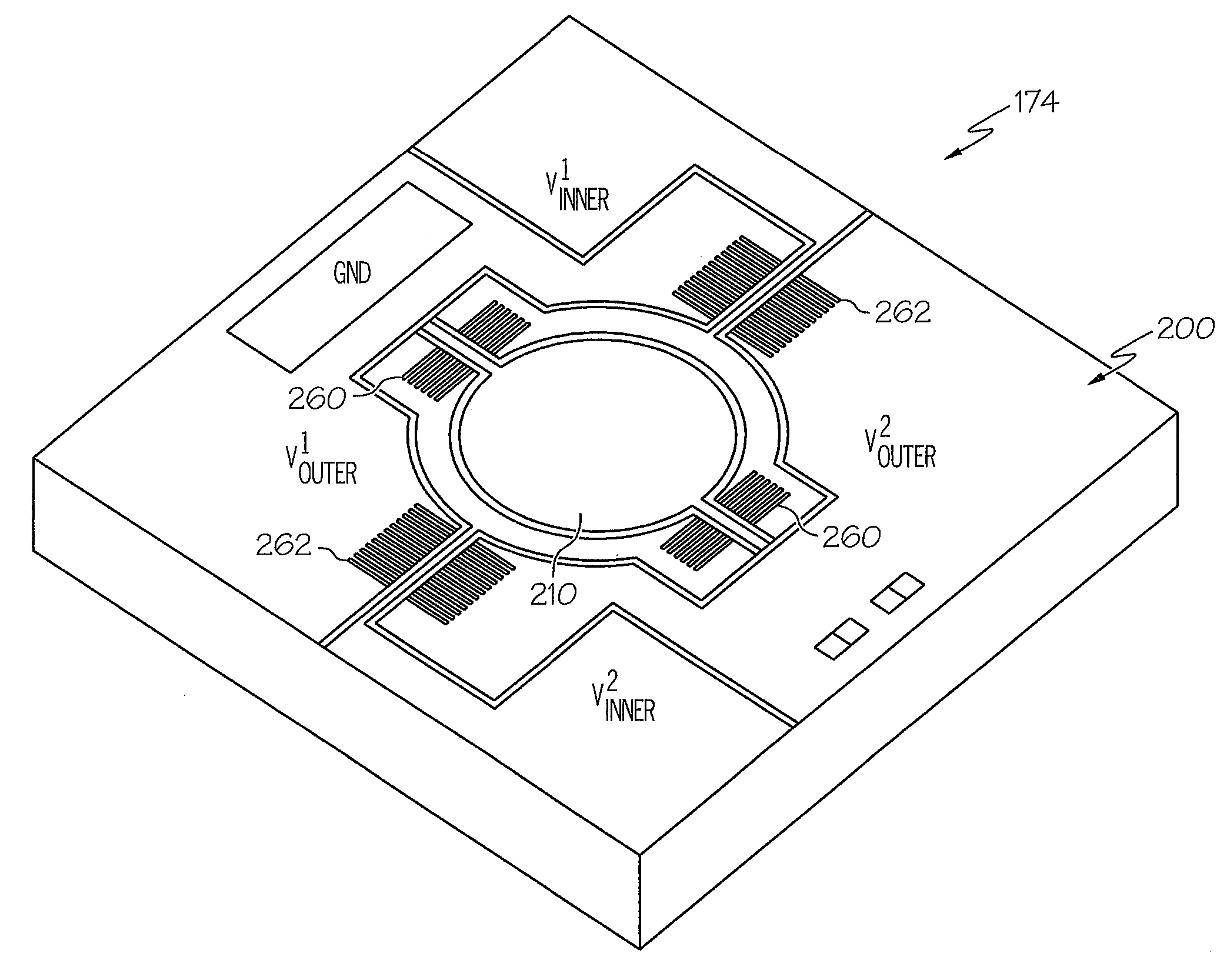

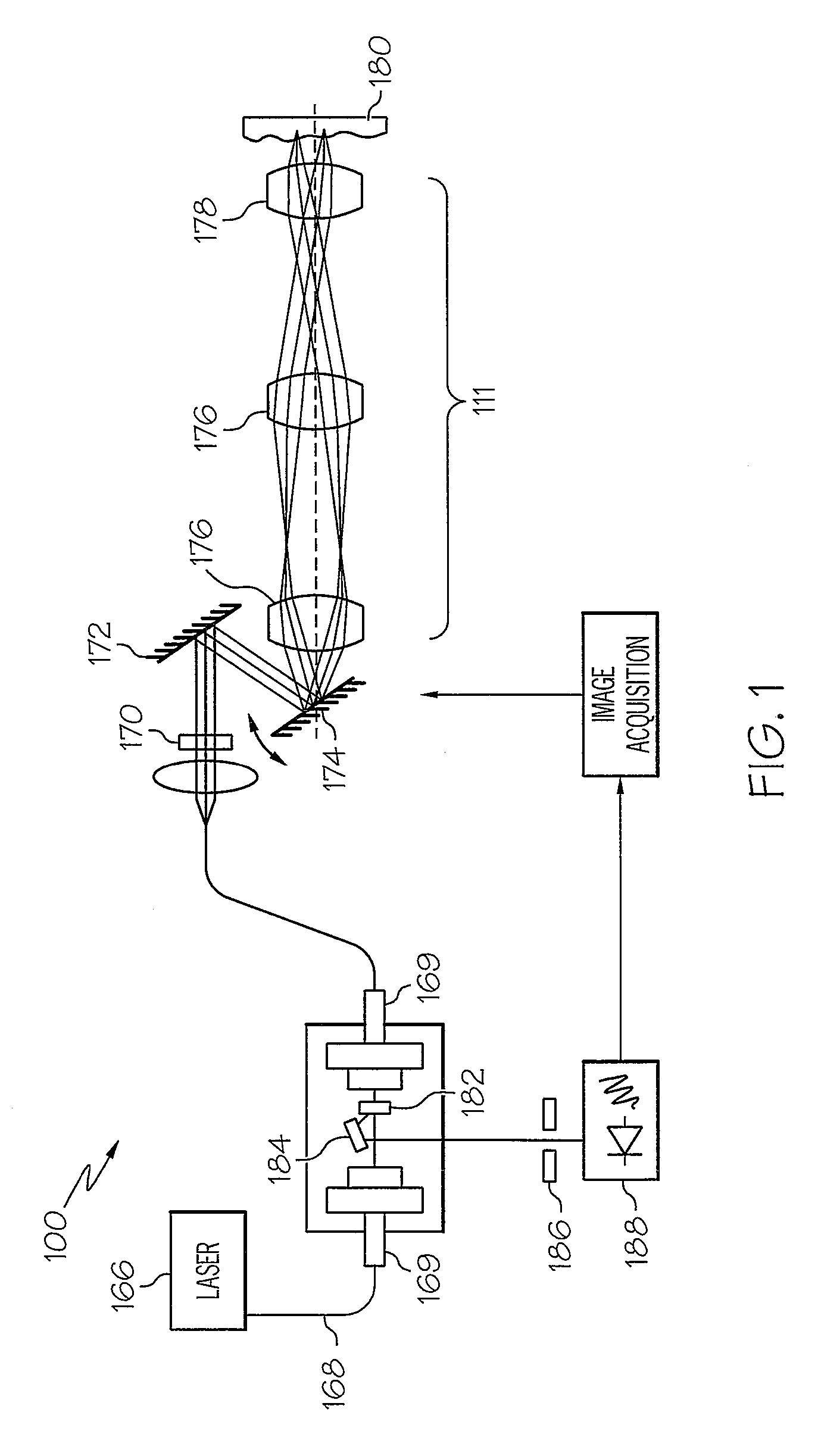

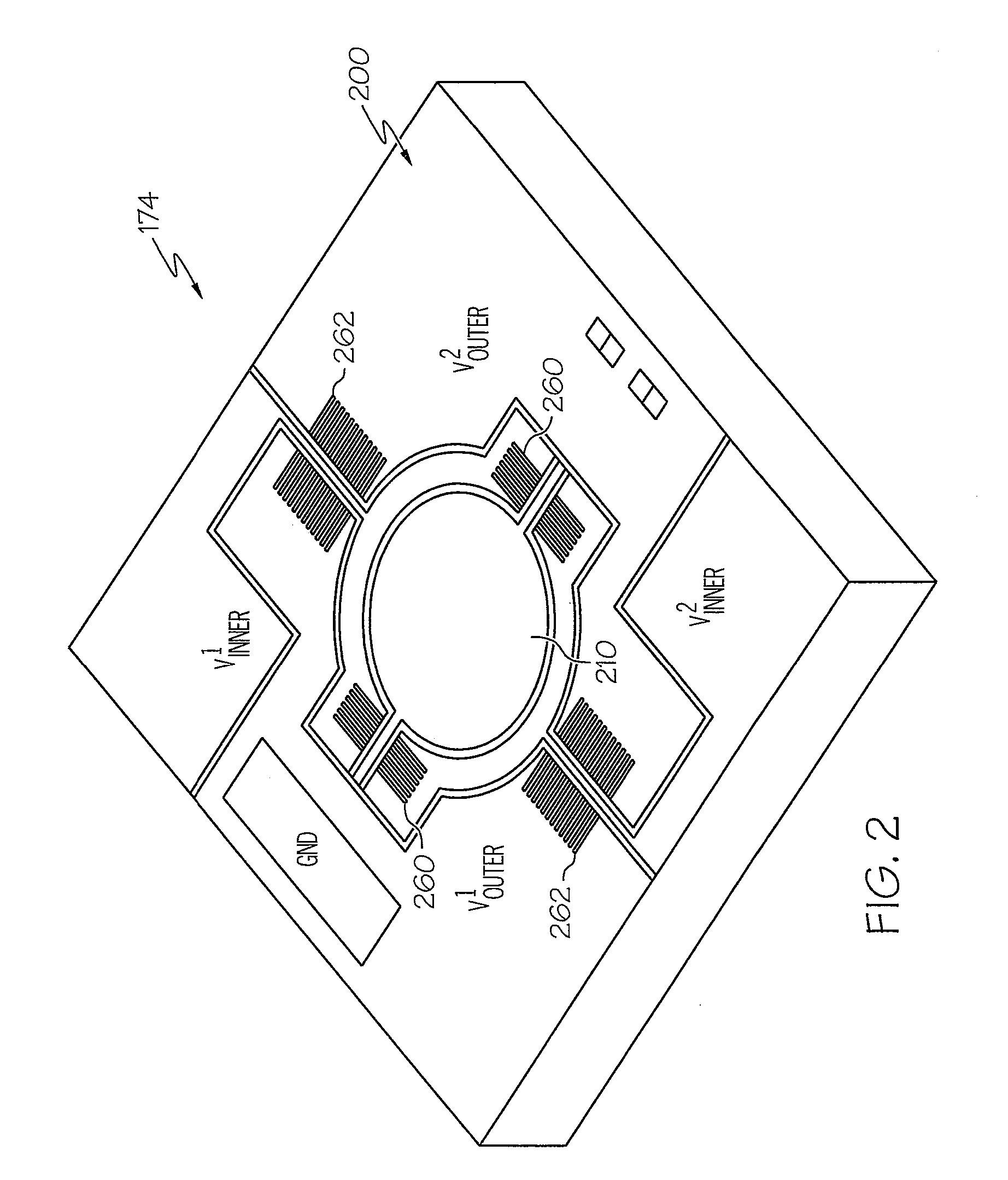

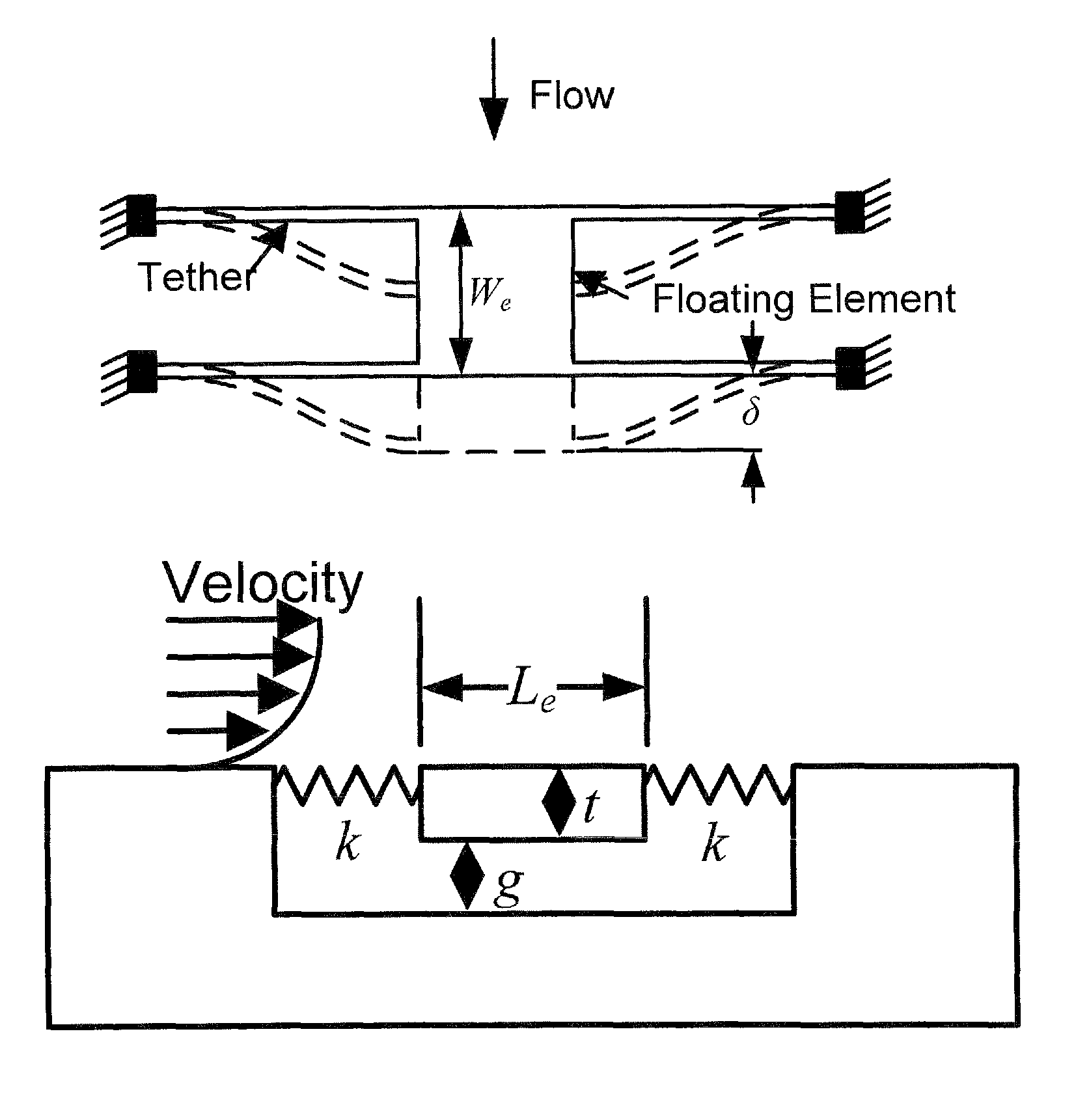

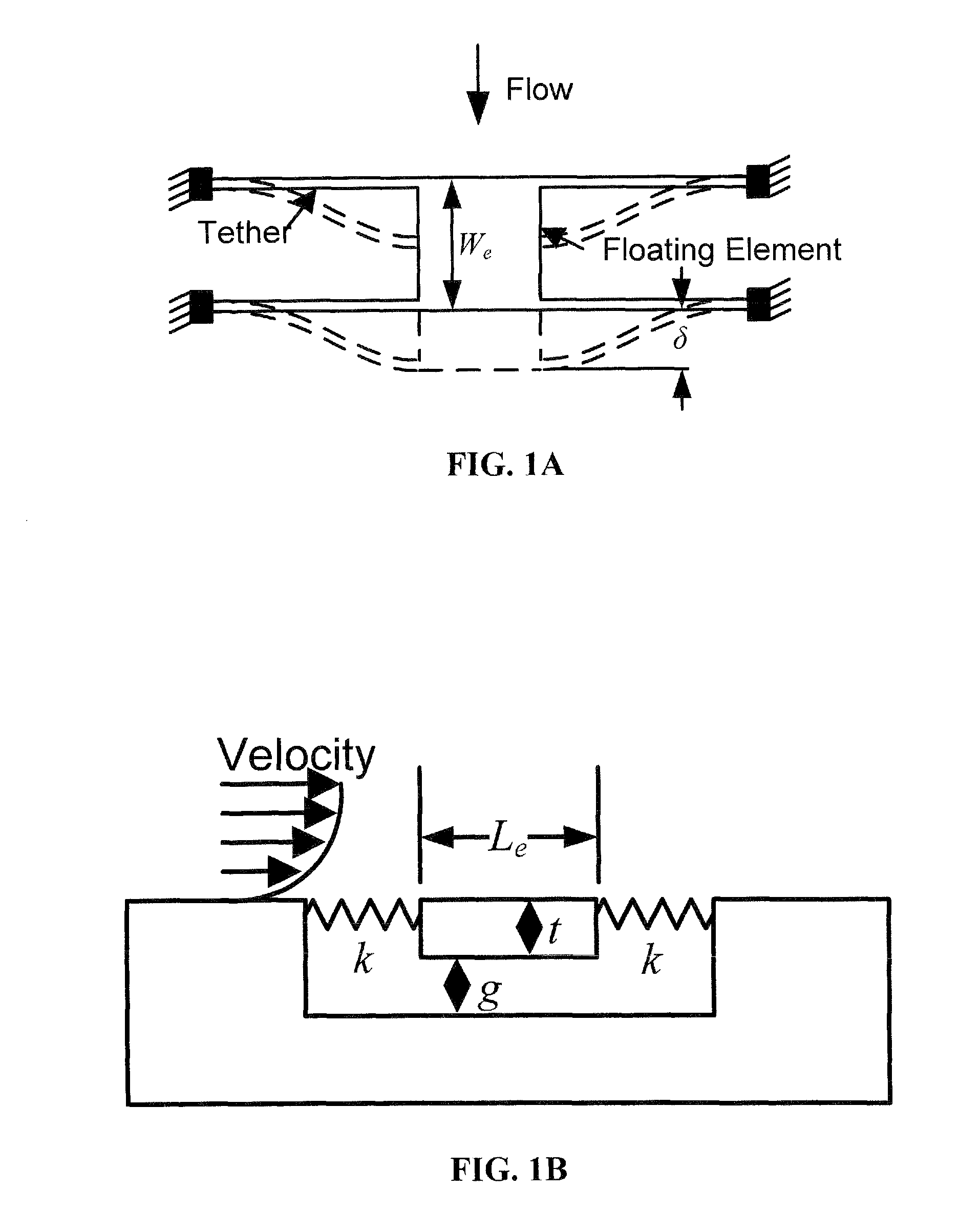

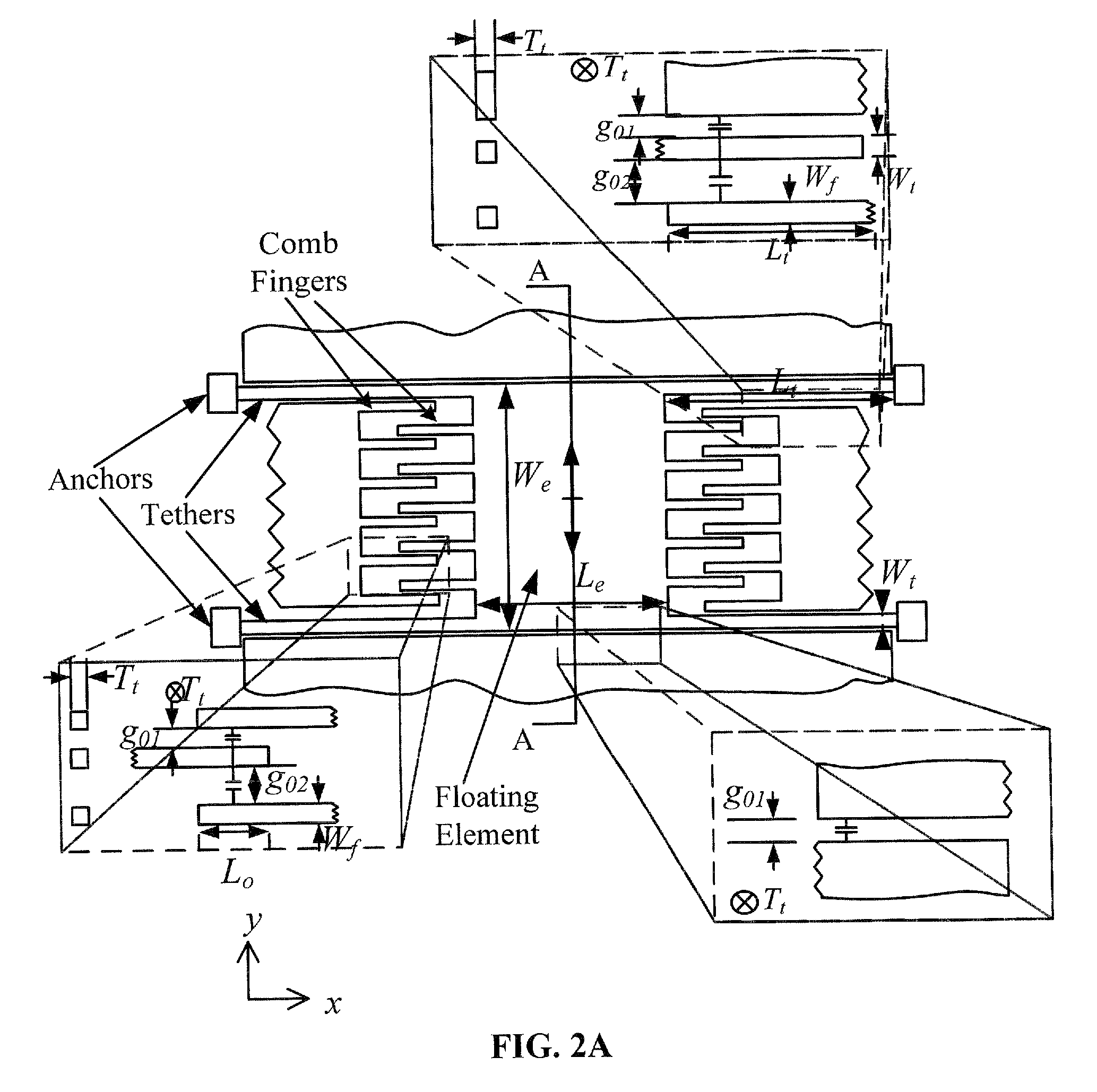

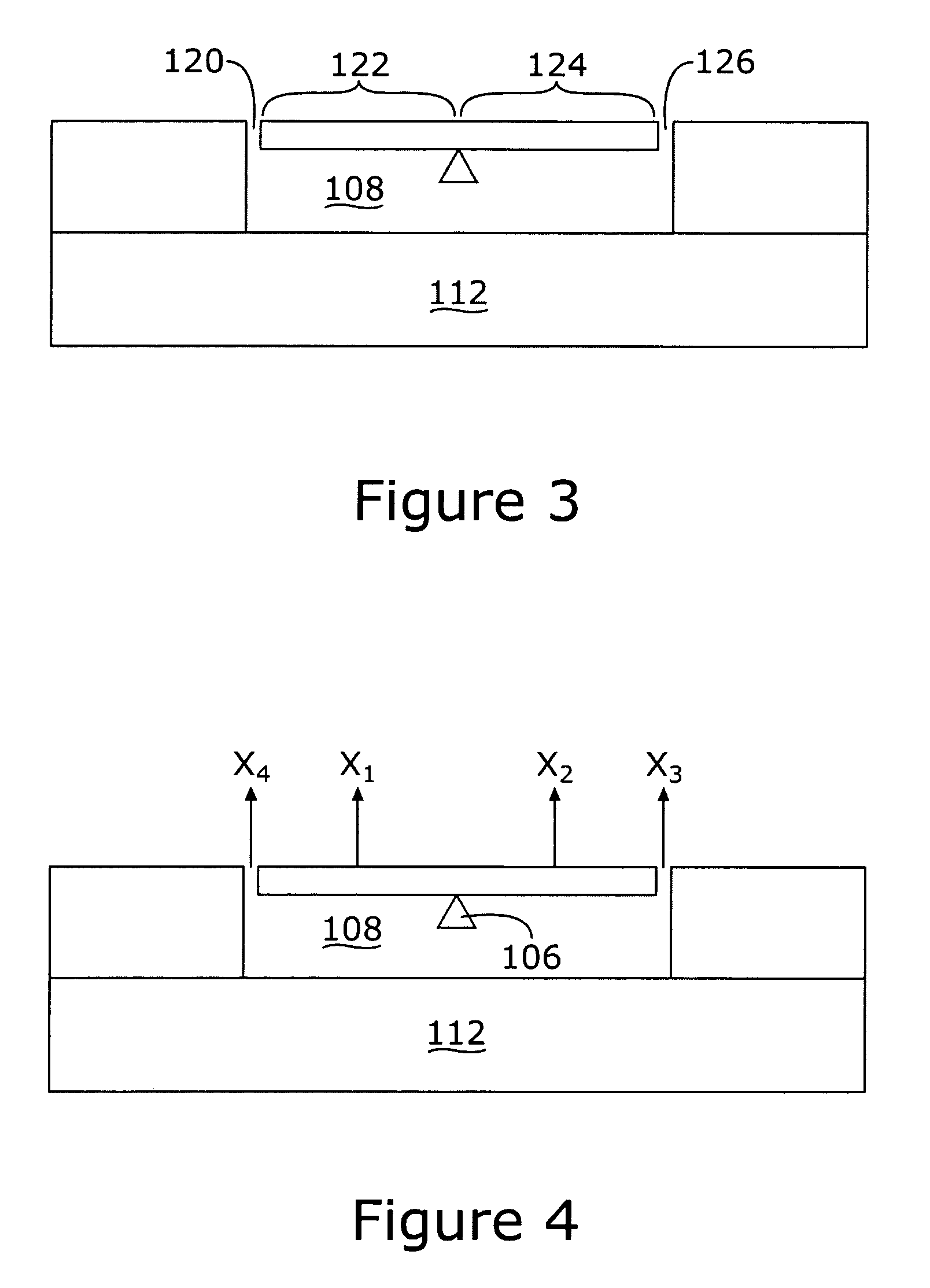

Structure and fabrication of a microscale flow-rate/skin friction sensor

ActiveUS20110314924A1Shorten the timeImprove efficiencySurface/boundary effectForce measurementCapacitanceShear stress

A floating element shear sensor and method for fabricating the same are provided. According to an embodiment, a microelectromechanical systems (MEMS)-based capacitive floating element shear stress sensor is provided that can achieve time-resolved turbulence measurement. In one embodiment, a differential capacitive transduction scheme is used for shear stress measurement. The floating element structure for the differential capacitive transduction scheme incorporates inter digitated comb fingers forming differential capacitors, which provide electrical output proportional to the floating element deflection.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Micromirror device with a hybrid actuator

A hybrid electro-static actuator for rotating a two-dimensional micro-electro-mechanical micro-mirror device about two perpendicular axes includes a vertical comb drive for rotating the micro-mirror about a tilt axis, and a parallel plate drive for rotating the micro-mirror about a roll axis. The rotor comb fingers of the comb drive extend from a sub-frame of the micro-mirror, which is only rotatable about the tilt axis, while one of the parallel plate electrodes is mounted on the underside of a main platform, which generally surrounds the sub-frame. The vertical comb drive rotates both the sub-frame and the main platform about the tilt axis, while the parallel plate drive only rotates the main platform about the roll axis.

Owner:LUMENTUM OPERATIONS LLC

Micromirror device with a hybrid actuator

Owner:LUMENTUM OPERATIONS LLC

Method for Fabricating a Micromirror with Self-Aligned Actuators

A method of fabricating a micromirror is disclosed. Initially, a set of coarse features is formed in a low-temperature oxide (LTO) layer deposited on a front side of a wafer. A set of fine features is then formed in a photosensitive material layer deposited on top of the LTO layer, and the fine features are constrained laterally within the coarse features. Next, a portion of the LTO layer is removed to align the width of the coarse features with the width of the fine features. The first silicon dioxide layer and the first and second silicon device layers are subsequently etched to form stator comb fingers and rotor comb fingers. Finally, a rotatable mirror is formed by removing a portion of the substrate on a back side of the wafer, and the silicon dioxide layers from the front and back sides of the wafer.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Structure and fabrication of a microscale flow-rate/skin friction sensor

ActiveUS8833175B2Minimizing sensitivityReduce complianceSurface/boundary effectForce measurementCapacitanceShear stress

A floating element shear sensor and method for fabricating the same are provided. According to an embodiment, a microelectromechanical systems (MEMS)-based capacitive floating element shear stress sensor is provided that can achieve time-resolved turbulence measurement. In one embodiment, a differential capacitive transduction scheme is used for shear stress measurement. The floating element structure for the differential capacitive transduction scheme incorporates inter digitated comb fingers forming differential capacitors, which provide electrical output proportional to the floating element deflection.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Surface micromachined differential microphone

ActiveUS7992283B2Low yieldIncreased complexityPiezoelectric/electrostrictive microphonesWave amplification devicesCapacitanceComb finger

A differential microphone having a perimeter slit formed around the microphone diaphragm that replaces the backside hole previously required in conventional silicon, micromachined microphones. The differential microphone is formed using silicon fabrication techniques applied only to a single, front face of a silicon wafer. The backside holes of prior art microphones typically require that a secondary machining operation be performed on the rear surface of the silicon wafer during fabrication. This secondary operation adds complexity and cost to the micromachined microphones so fabricated. Comb fingers forming a portion of a capacitive arrangement may be fabricated as part of the differential microphone diaphragm.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

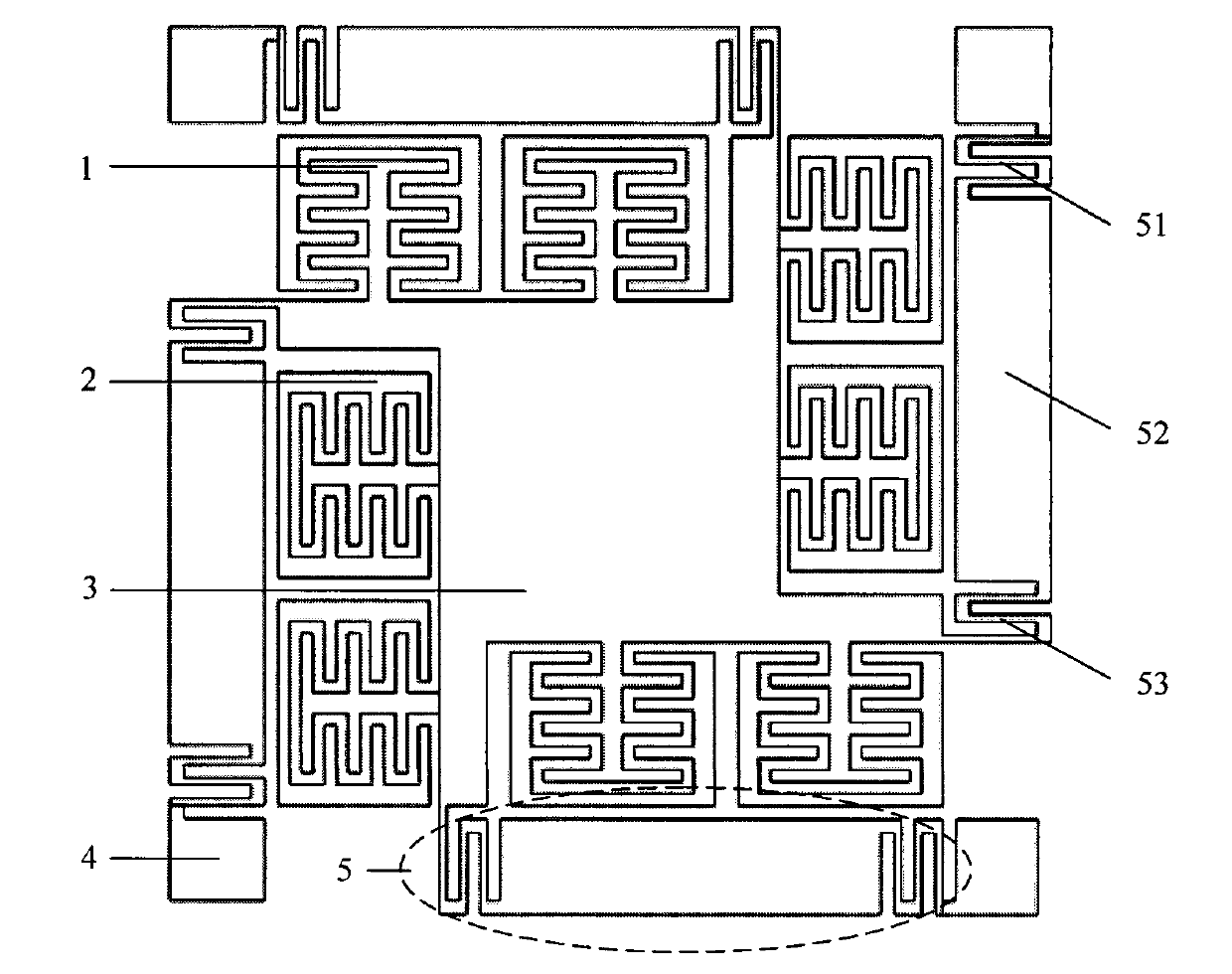

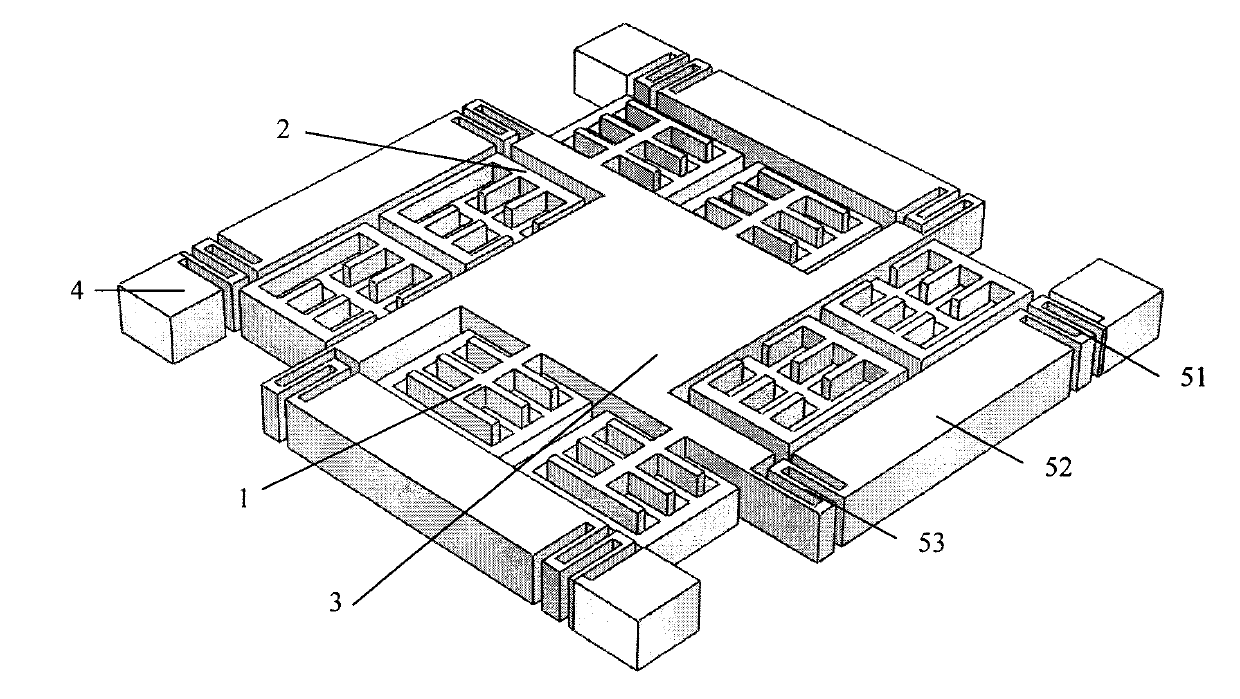

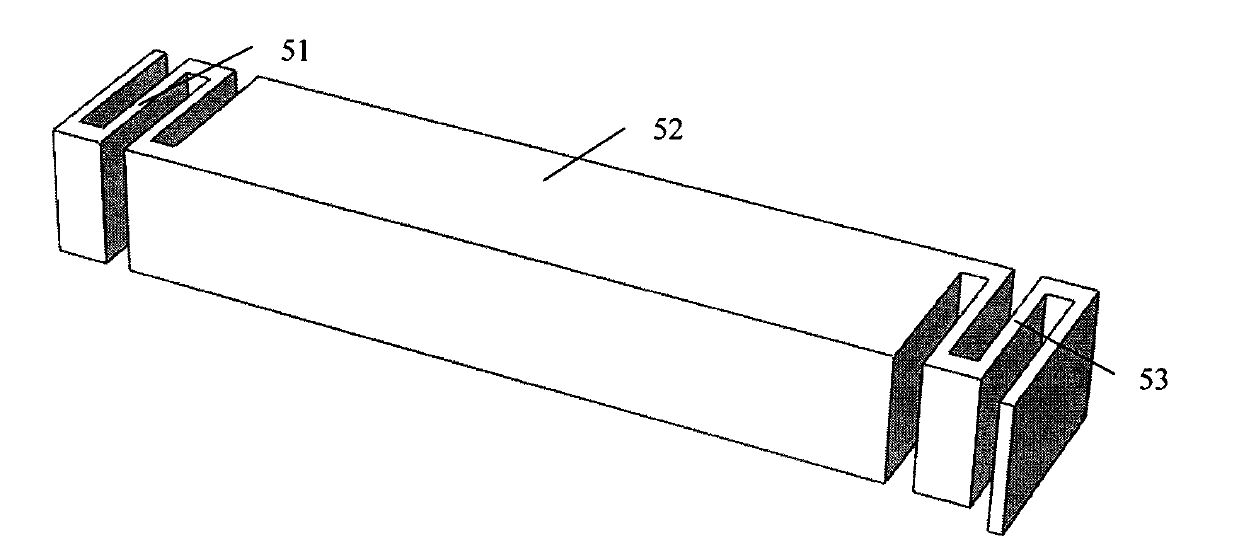

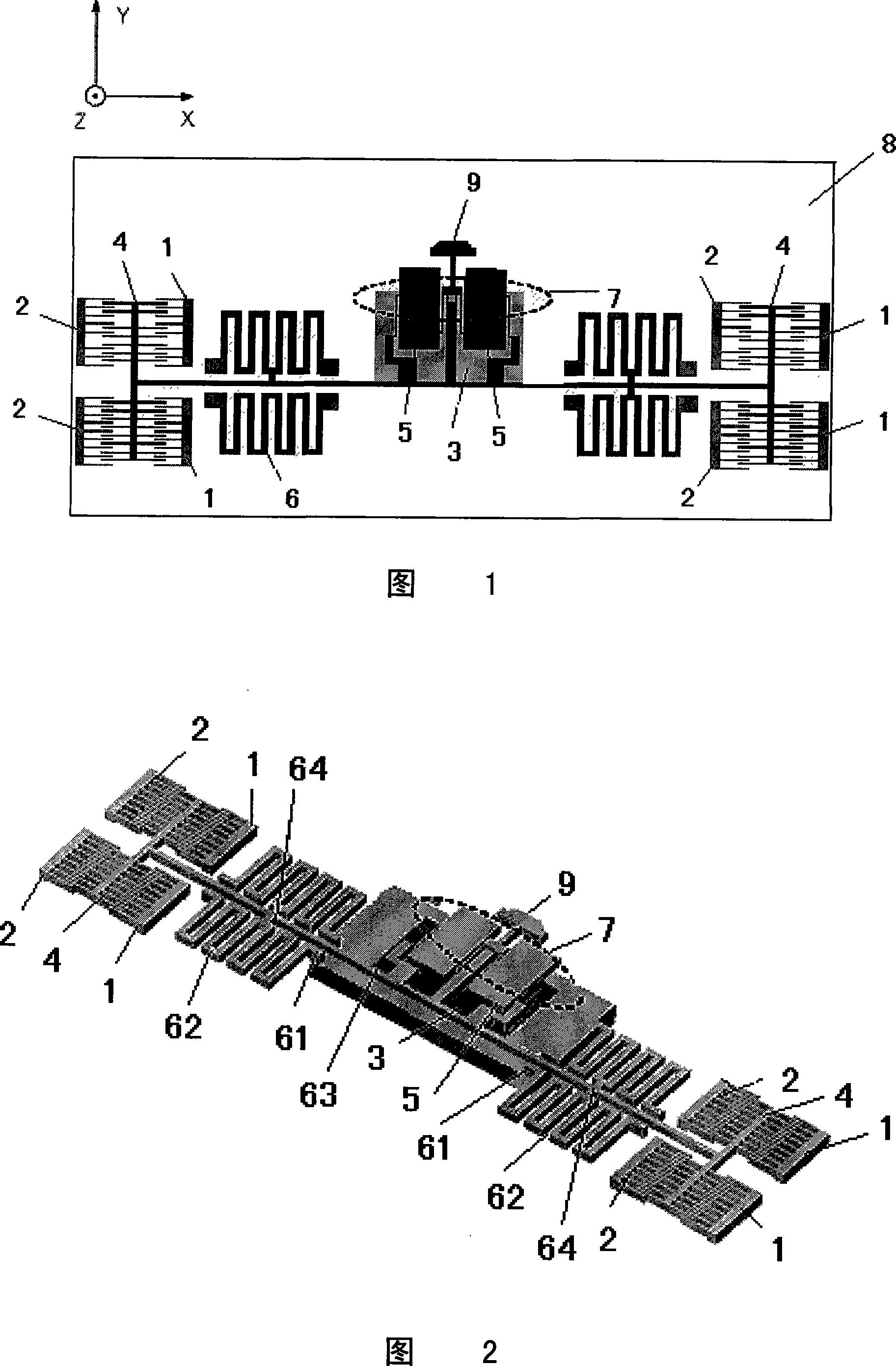

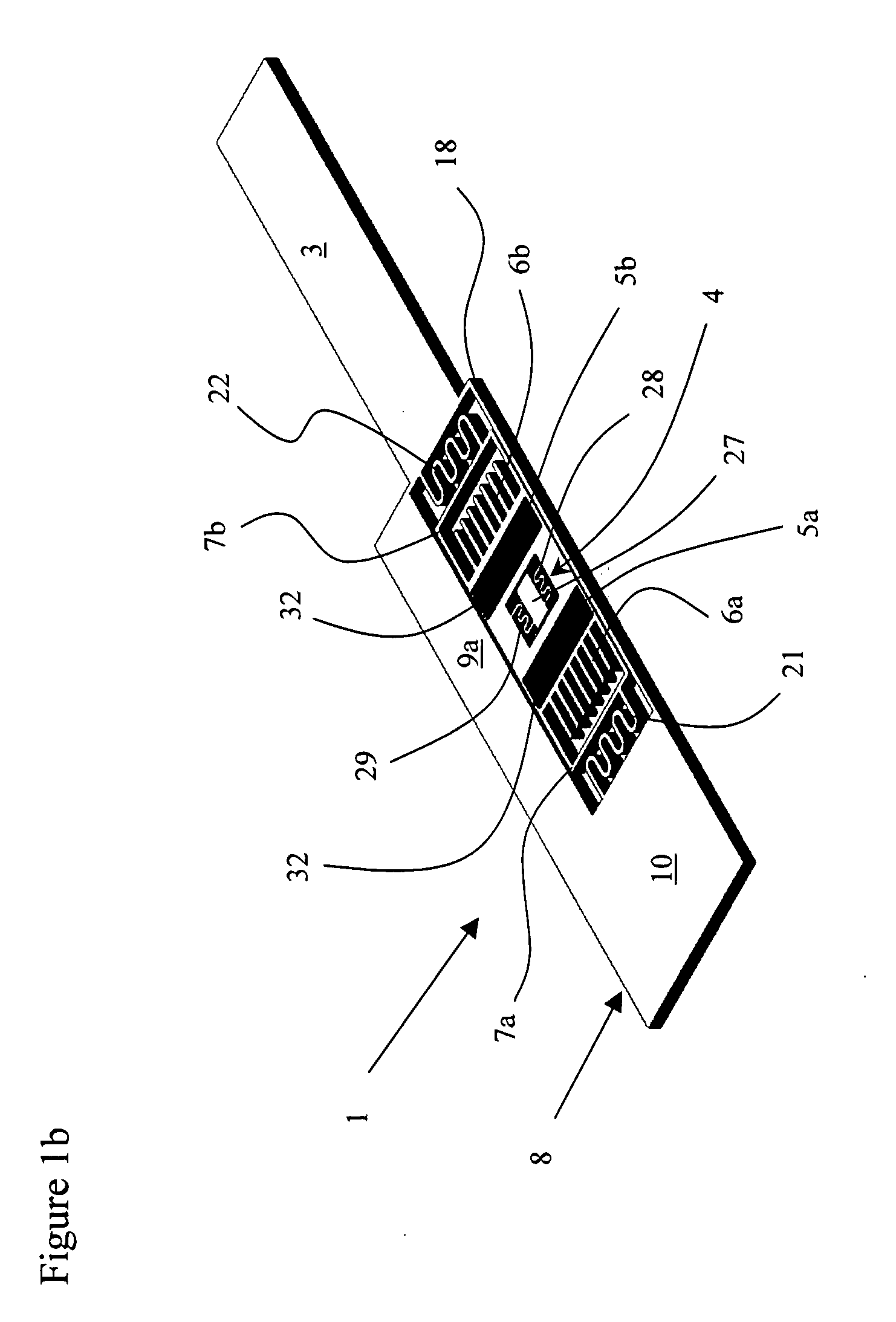

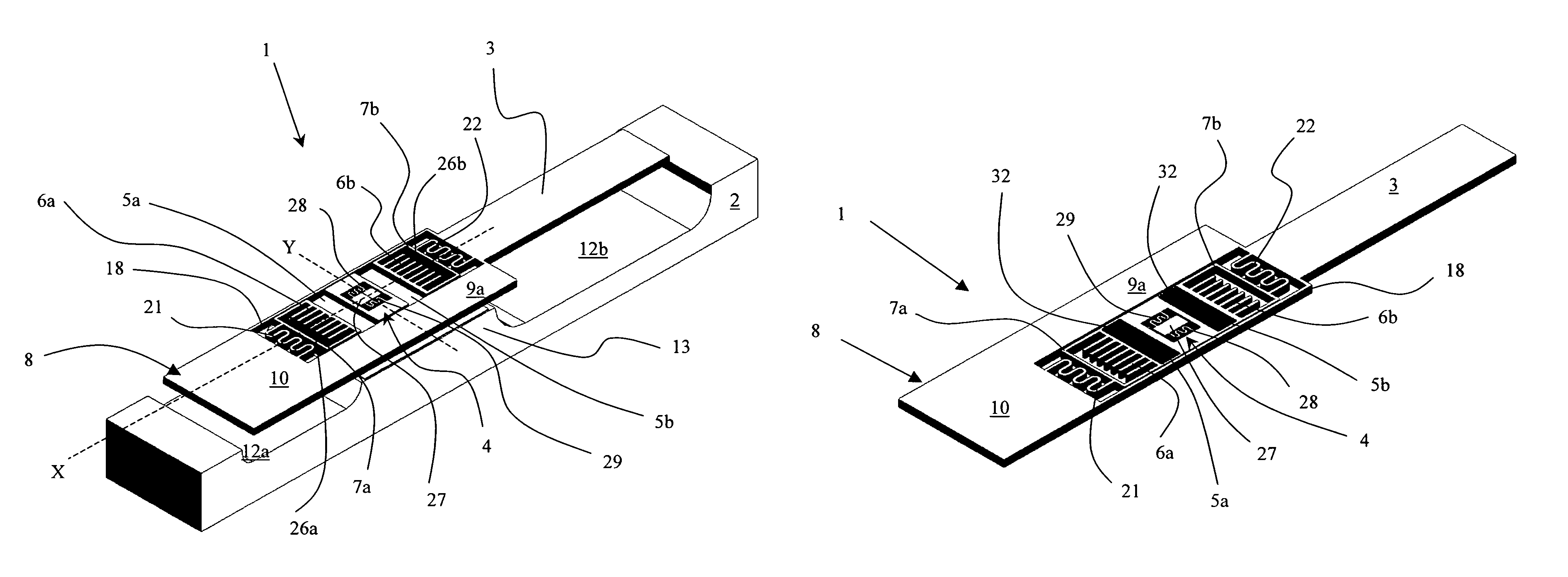

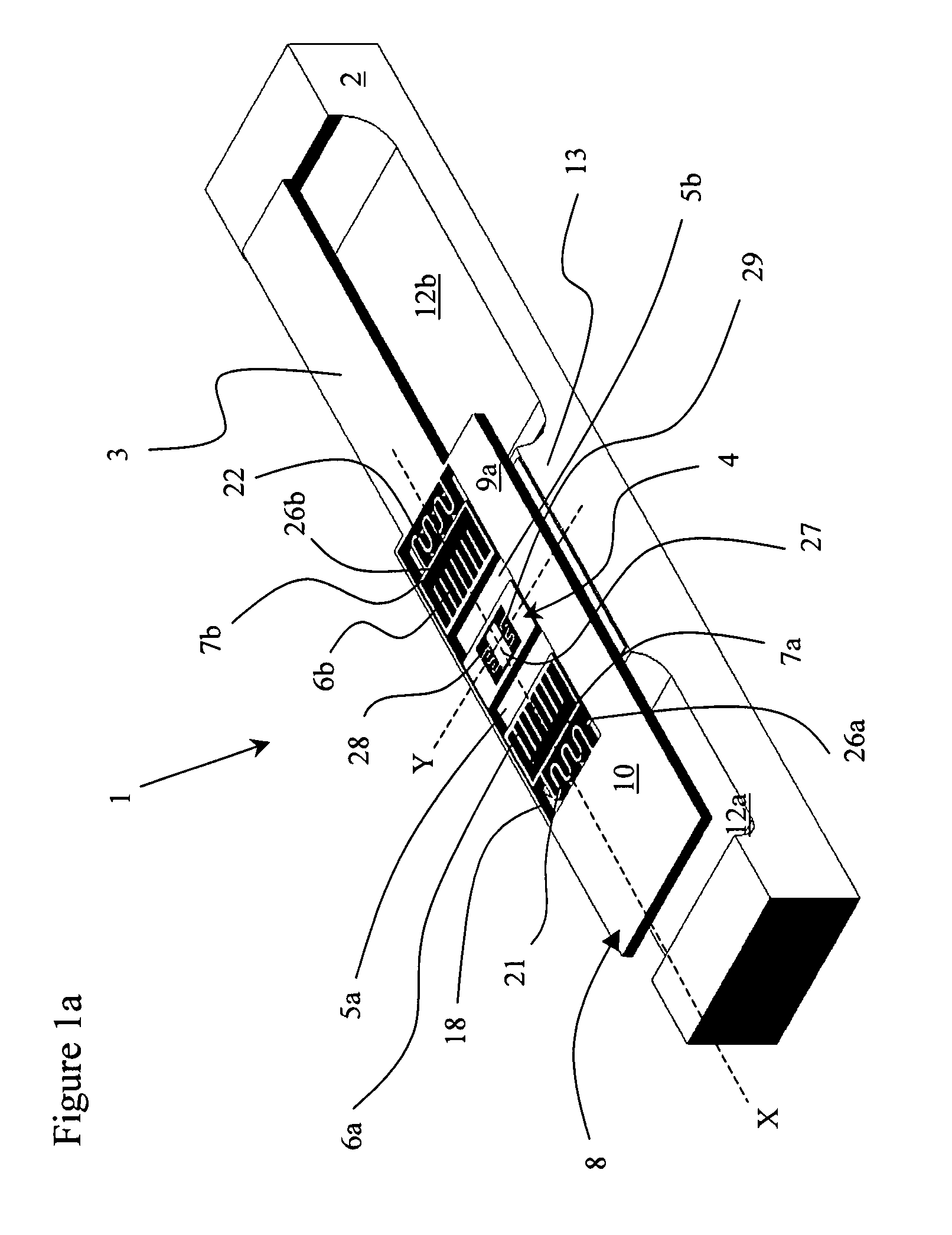

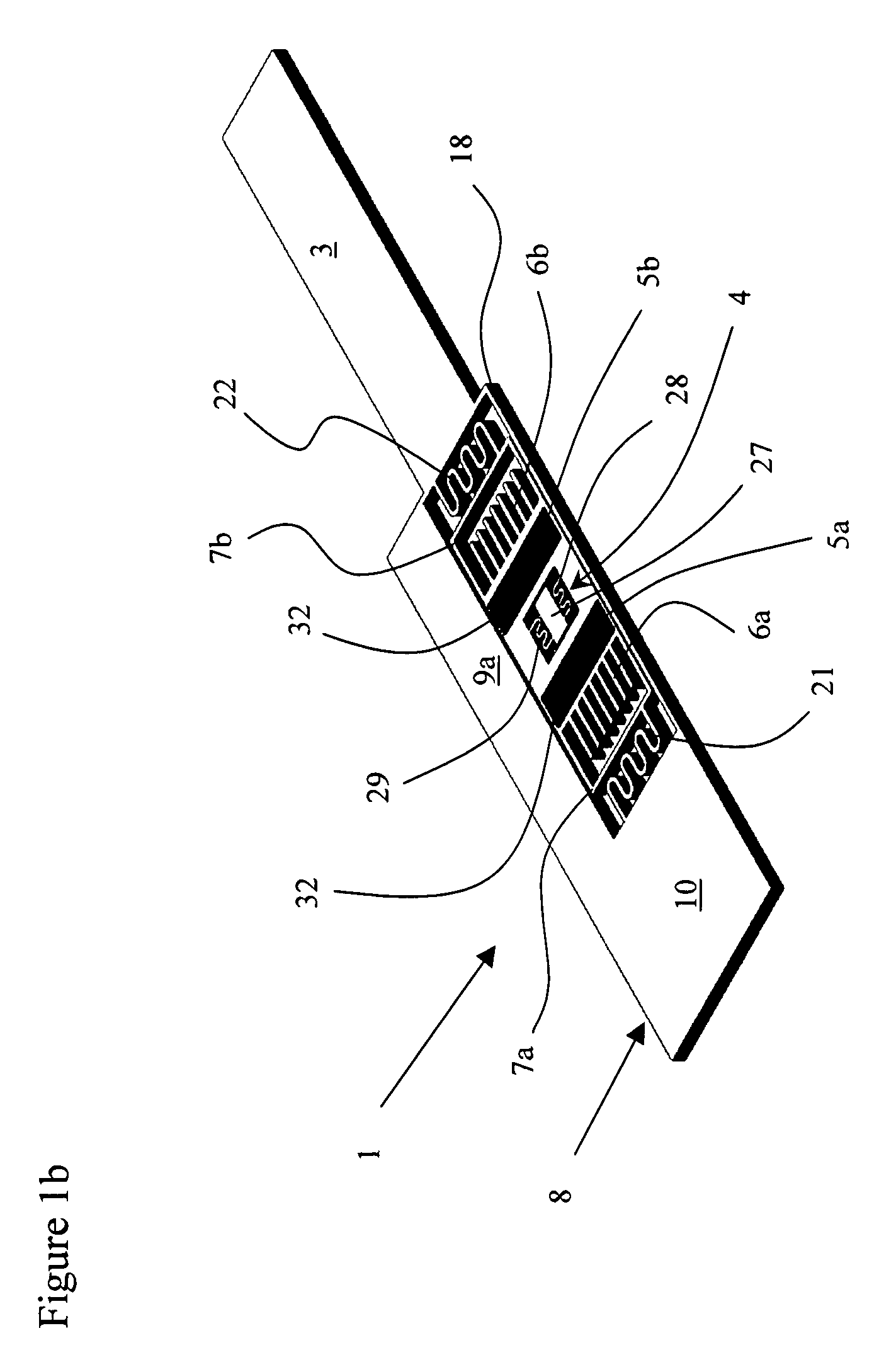

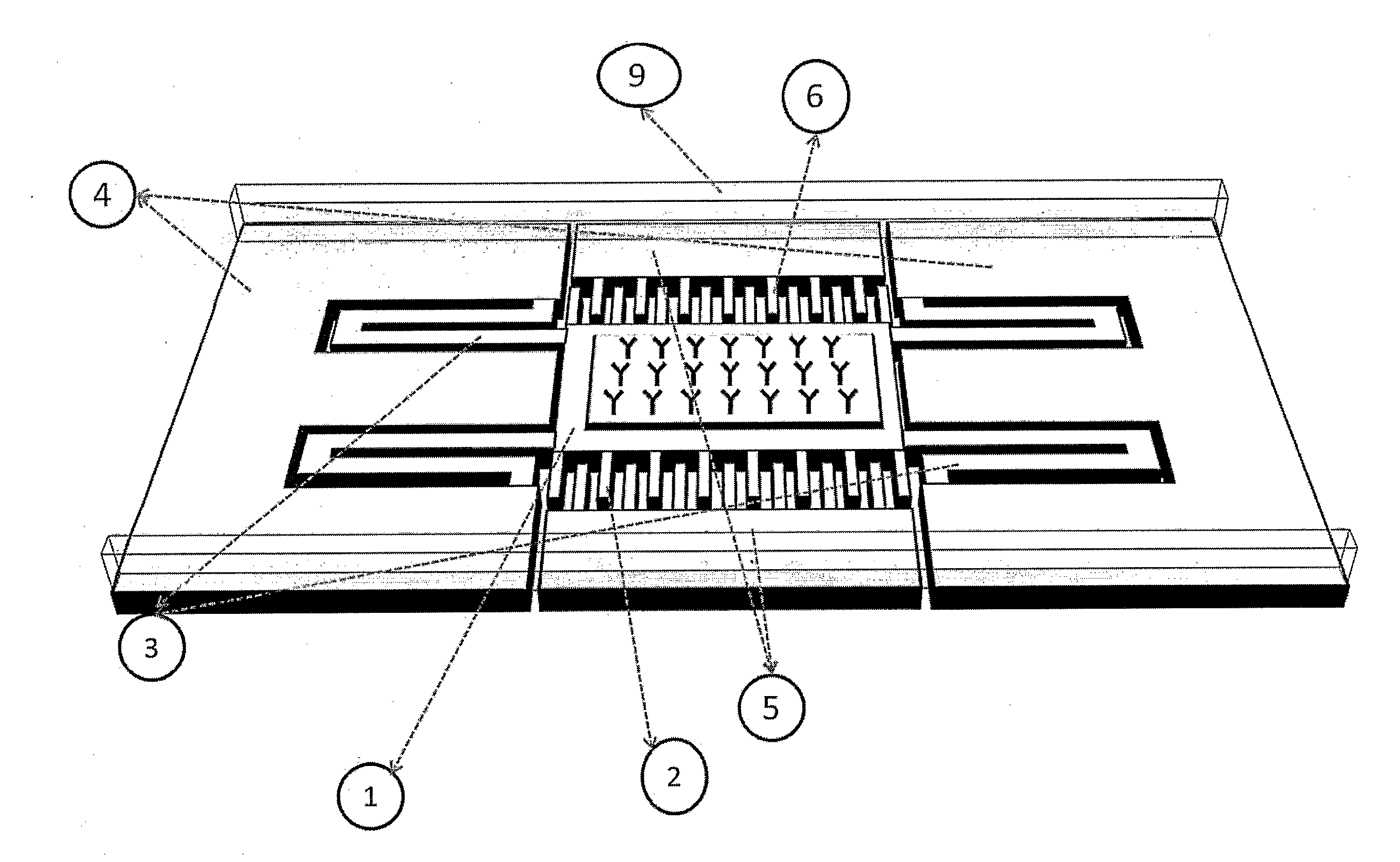

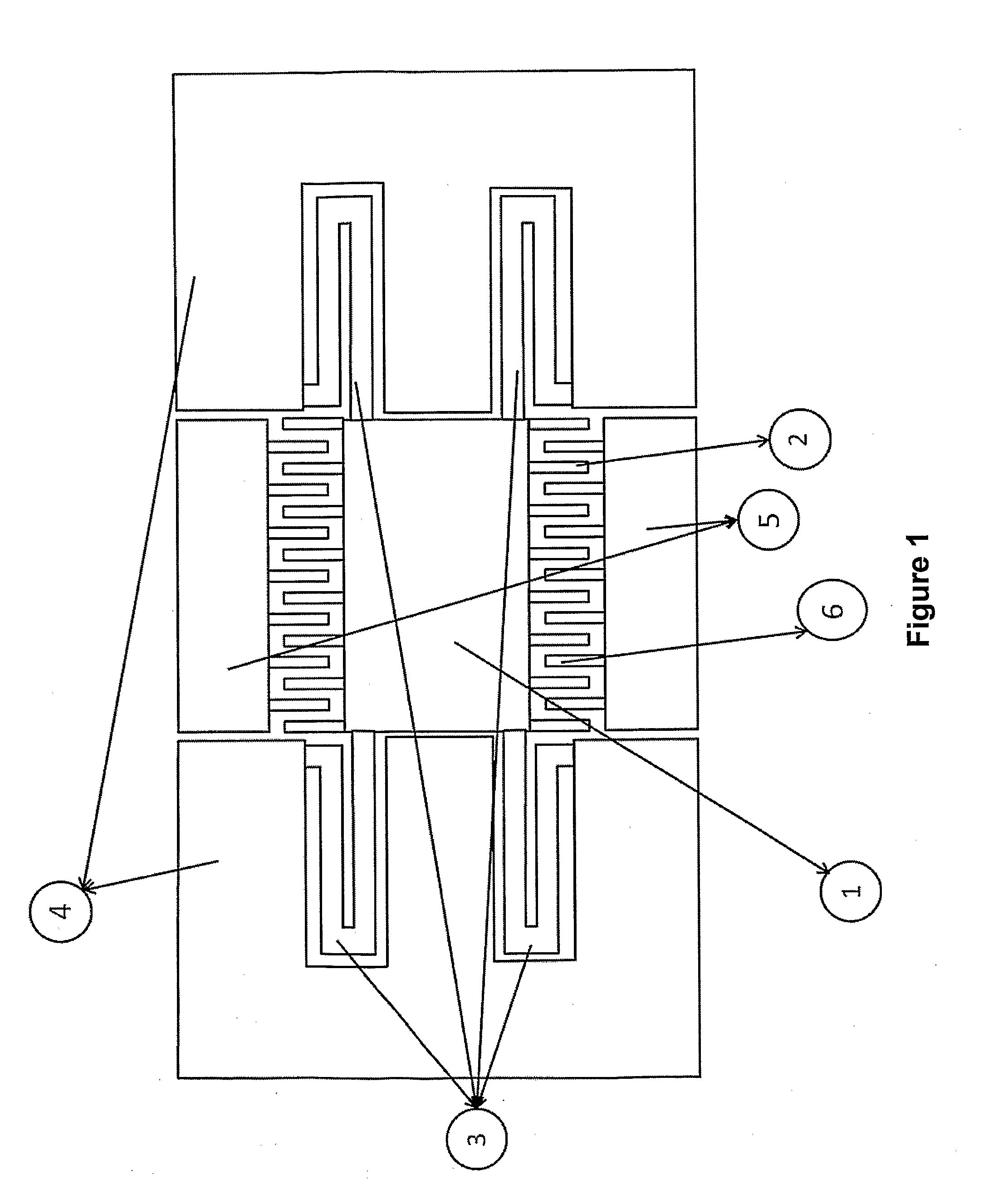

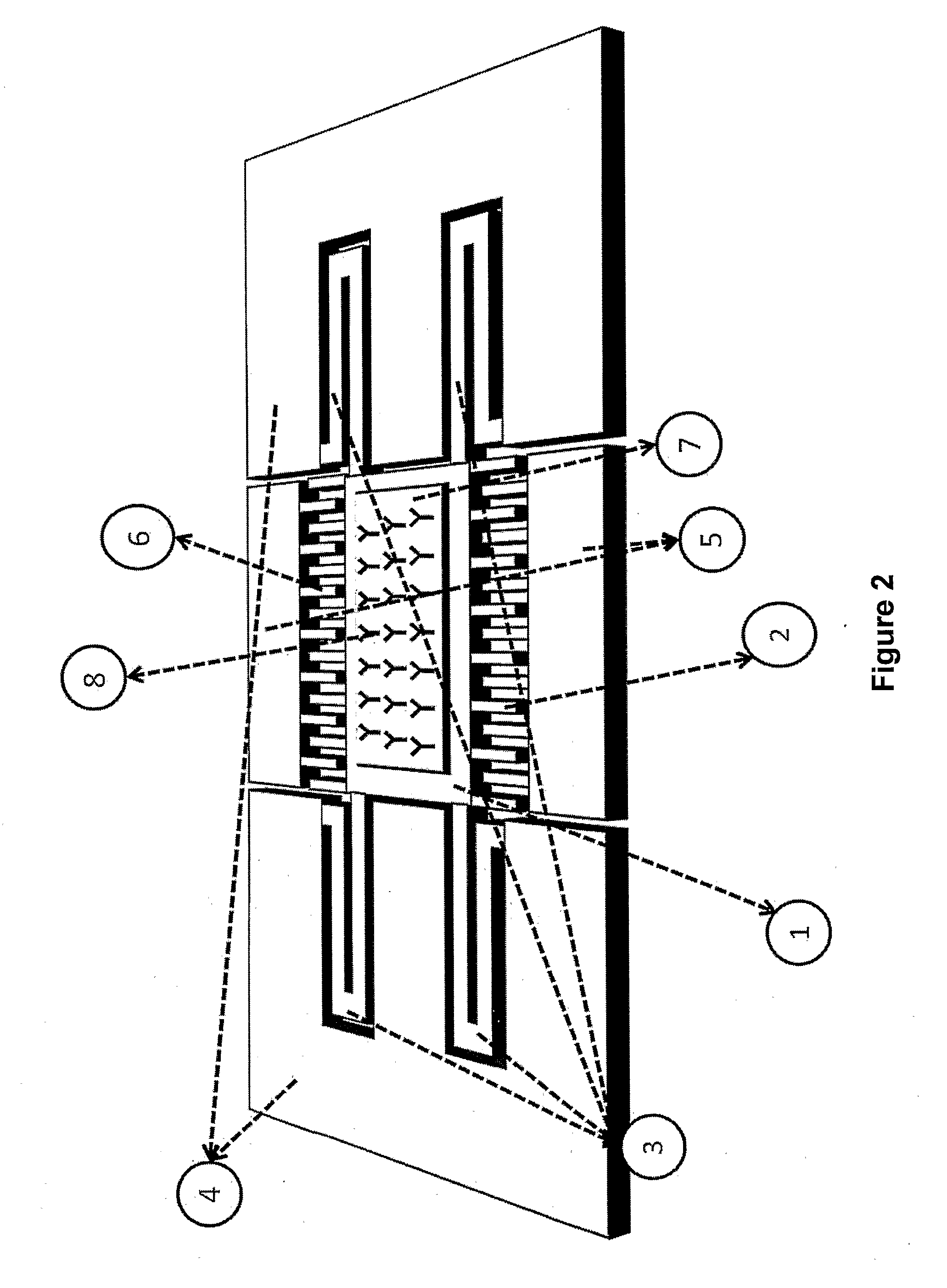

Microfluidic-channel embeddable, laterally oscillating gravimetric sensor device fabricated with micro-electro-mechanical systems (MEMS) technology

ActiveUS20120148448A1Easy to produceHigh quality factorAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersBiological cellAnalyte

Laterally oscillating gravimetric sensing device embeddable under micro-fluidic channels and fabricated with micro-electro mechanical systems (MEMS) technology, which detects biological cells and analytes by measuring the change of mass attached on its surface is composed of four main groups, namely a resonator that can be placed onto the basis of the channel, components of the resonator bio-activation, a micro fluidic channel, and the microfabrication techniques, and its main components are the proof mass (1), comb fingers fixed to proof mass (2), folded spring beams (3), channel floor and mechanical soil (4), stationary electrodes (5), comb fingers attached to the stationary electrodes (6), golden film deposited onto the mass (7), immobilized biologic recognition molecules (8), and micro fluidic channel placed on resonator structure (9).

Owner:MIKROBIYOSISTEMLER ELECTRONICS SAN & TIC AS

Method for reducing harmonic distortion in comb drive devices

InactiveUS20050136621A1Reduce and eliminate gapUniform etch rateSemiconductor/solid-state device detailsSolid-state devicesHarmonicComb finger

Methods of fabricating comb drive devices utilizing one or more sacrificial etch-buffers are disclosed. An illustrative fabrication method may include the steps of etching a pattern onto a wafer substrate defining one or more comb drive elements and sacrificial etch-buffers, liberating and removing one or more sacrificial etch-buffers prior to wafer bonding, bonding the etched wafer substrate to an underlying support substrate, and etching away the wafer substrate. In some embodiments, the sacrificial etch-buffers are removed after bonding the wafer to the support substrate. The sacrificial etch-buffers can be provided at one or more selective regions to provide greater uniformity in etch rate during etching. A comb drive device in accordance with an illustrative embodiment can include a number of interdigitated comb fingers each having a more uniform profile along their length and / or at their ends, producing less harmonic distortion during operation.

Owner:HONEYWELL INT INC

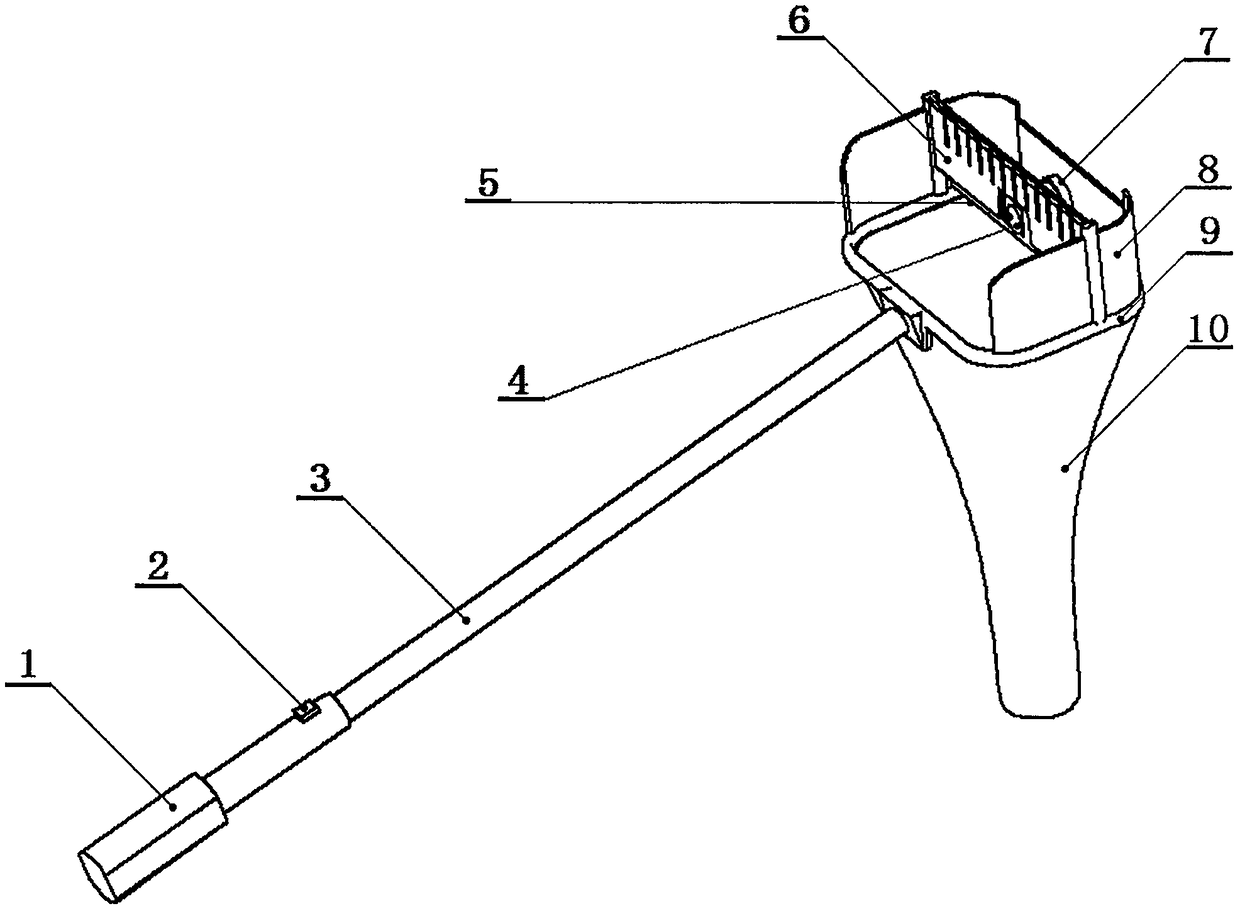

Comb finger-type fruit picking device

PendingCN108093863AReasonable and practical structureEasy to pickPicking devicesComb fingerAgricultural engineering

The invention relates to the field of agricultural machinery, and provides a comb finger-type fruit picking device. The device mainly includes a battery box, a switch, an operating rod, an eccentric wheel, a comb finger cutting plate, a double-layer comb finger fixing plate, a motor, a protective cover, a frame, a canvas bag, a bearing and a fastening bolt; the double-layer comb finger fixing plate is installed above the frame, the canvas bag is connected to the bottom of the frame, the double-layer comb finger fixing plate is provided with an interlayer and an insertion strip, the insertion strip is positioned at the lower edge of the double-layer comb finger fixing plate, the comb finger cutting plate is provided with an insertion groove and a rectangular through hole, the insertion groove is formed in the lower edge of the comb finger cutting plate, the motor is installed on the double-layer comb finger fixing plate, the eccentric wheel is installed on a motor shaft and positioned in the rectangular through hole of the comb finger cutting plate, the insertion strip and the insertion groove are matched with each other and can slide relatively, a comb finger cutting plate body ispositioned in the interlayer of the double-layer comb finger fixing plate and can slide relatively, and the sizes of the openings of comb fingers on the double-layer comb finger fixing plate are various.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com