Off-plane electrostatic driver and production method thereof

An electrostatic drive, out-of-plane technology, applied in the direction of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Drive application range and other issues to achieve the effect of improving reliability, reducing driving force and driving voltage, and realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, the following examples are only limited to explain the present invention, and the protection scope of the present invention should include the entire content of the claims.

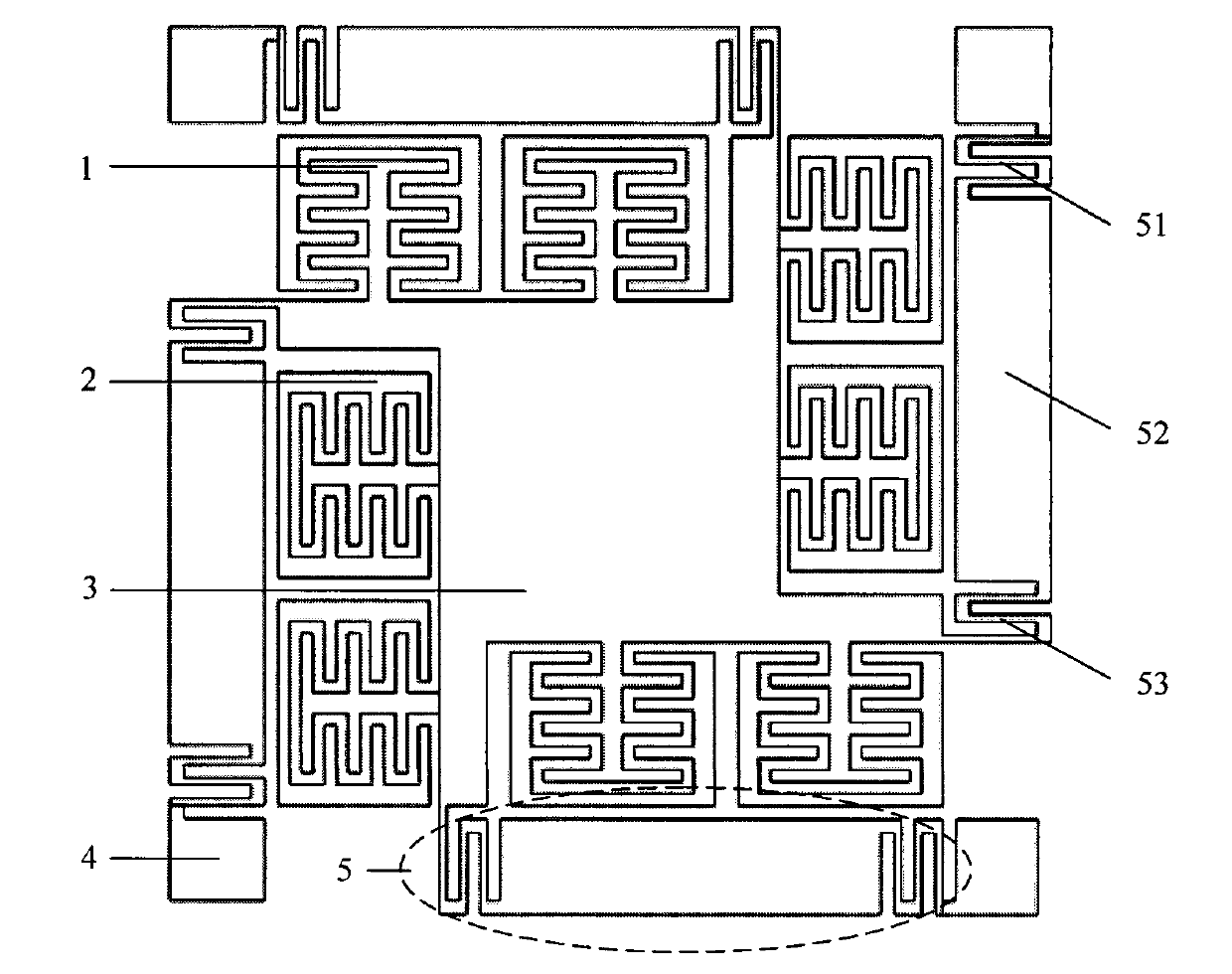

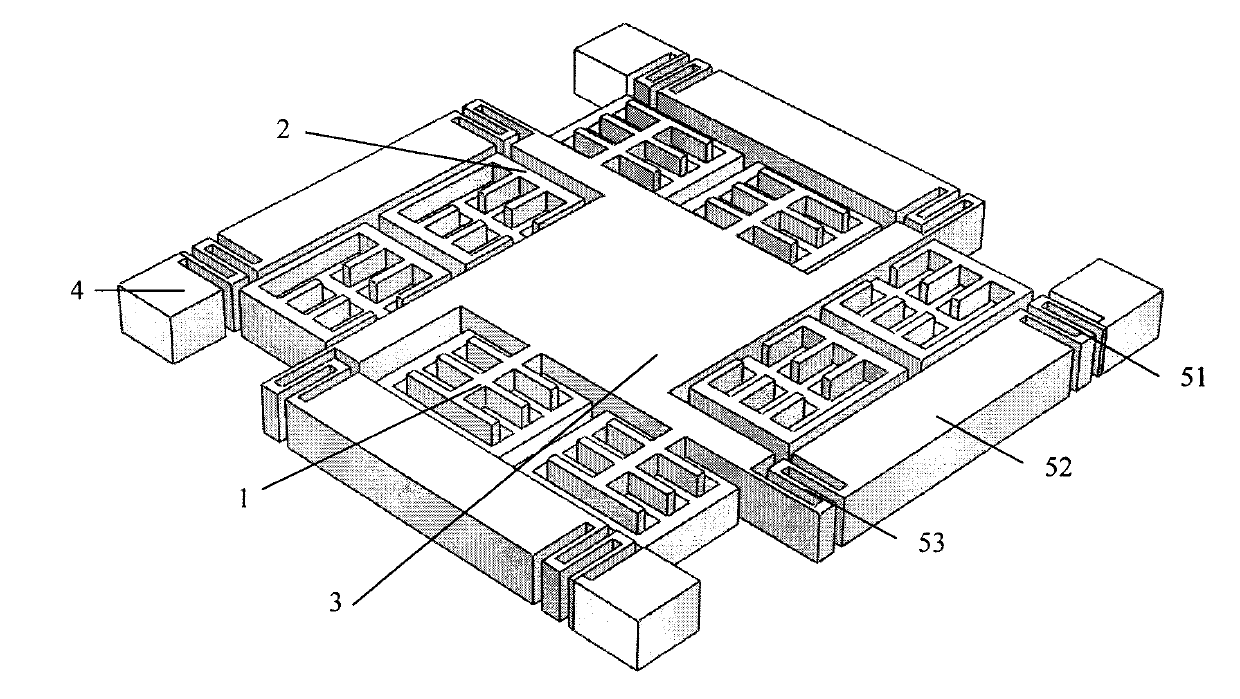

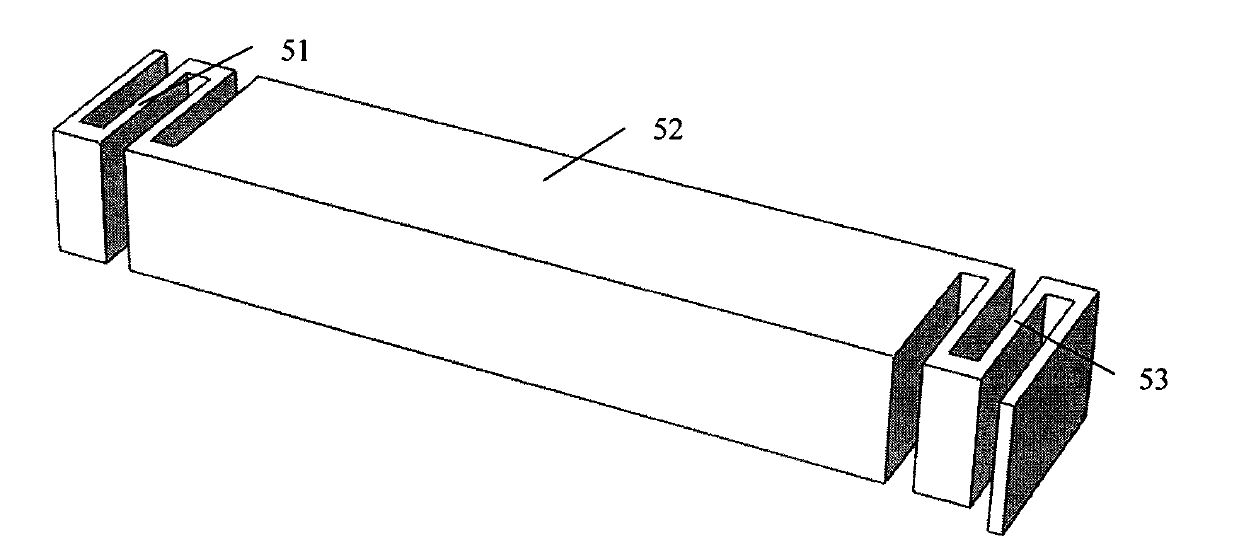

[0021] figure 1 Shown is a schematic diagram of the planar structure of the embodiment of the present invention, figure 2 Shown is a schematic diagram of the three-dimensional structure of the embodiment of the present invention. The size of this embodiment is 3000 μm×3000 μm, which is just for example, and the present invention is not limited thereto. The structure of the MEMS comb-tooth off-plane electrostatic driver in this embodiment includes a substrate (not shown in the figure), a movable electrode 1, a fixed electrode 2, a drive output part 3, an anchor point 4, a signal lead-out pad (not shown in the figure) and Twist composite beam 5.

[0022] The movable ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com