Patents

Literature

38results about How to "Enable high-volume manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Horizontal axis micromechanical gyroscope and its preparation method

InactiveCN1828223ASmall dampingHigh sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesElectricityCapacitance

The product comprises: an outer / inner frame, a drive electrode and a drive feedback electrode both with two group of lateral comb-tooth capacitors and movable electrodes connected to the outer frame, a drive-modal elastic beam, a detection electrode with two group of unequal vertical comb-tooth capacitors for difference detection with movable electrode connected to the inner frame, a detect-modal elastic beam as four group of combined torsion beams everyone with ends connected to former inner / outer frame respectively, and an anchor point fixed on substrate bottom and connected to the outer frame through the drive-modal beam. This invention is simple and fit to large-scale production, compatible to Z-axis gyro and accelerometer, and can be used for MIMU.

Owner:PEKING UNIV

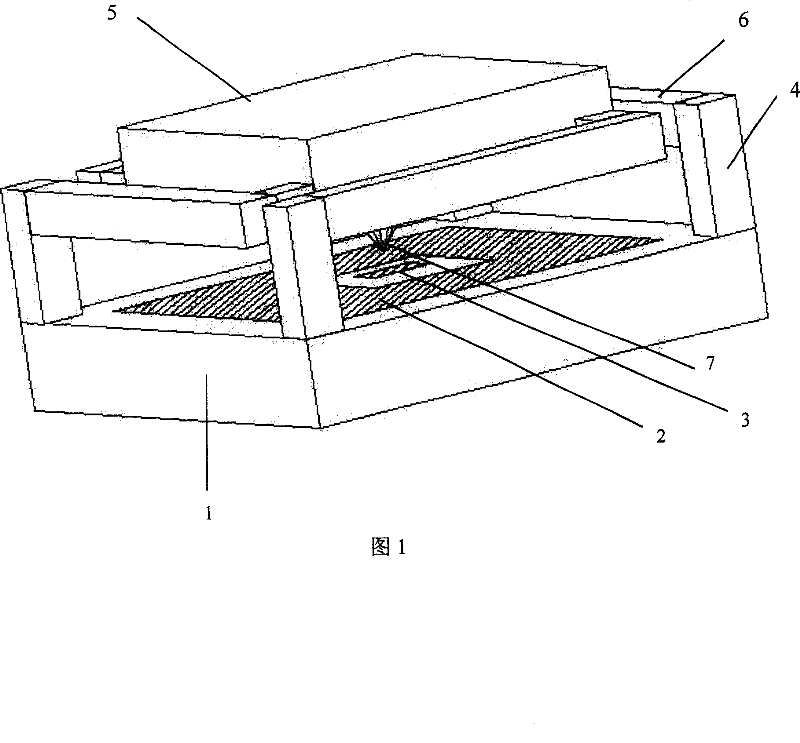

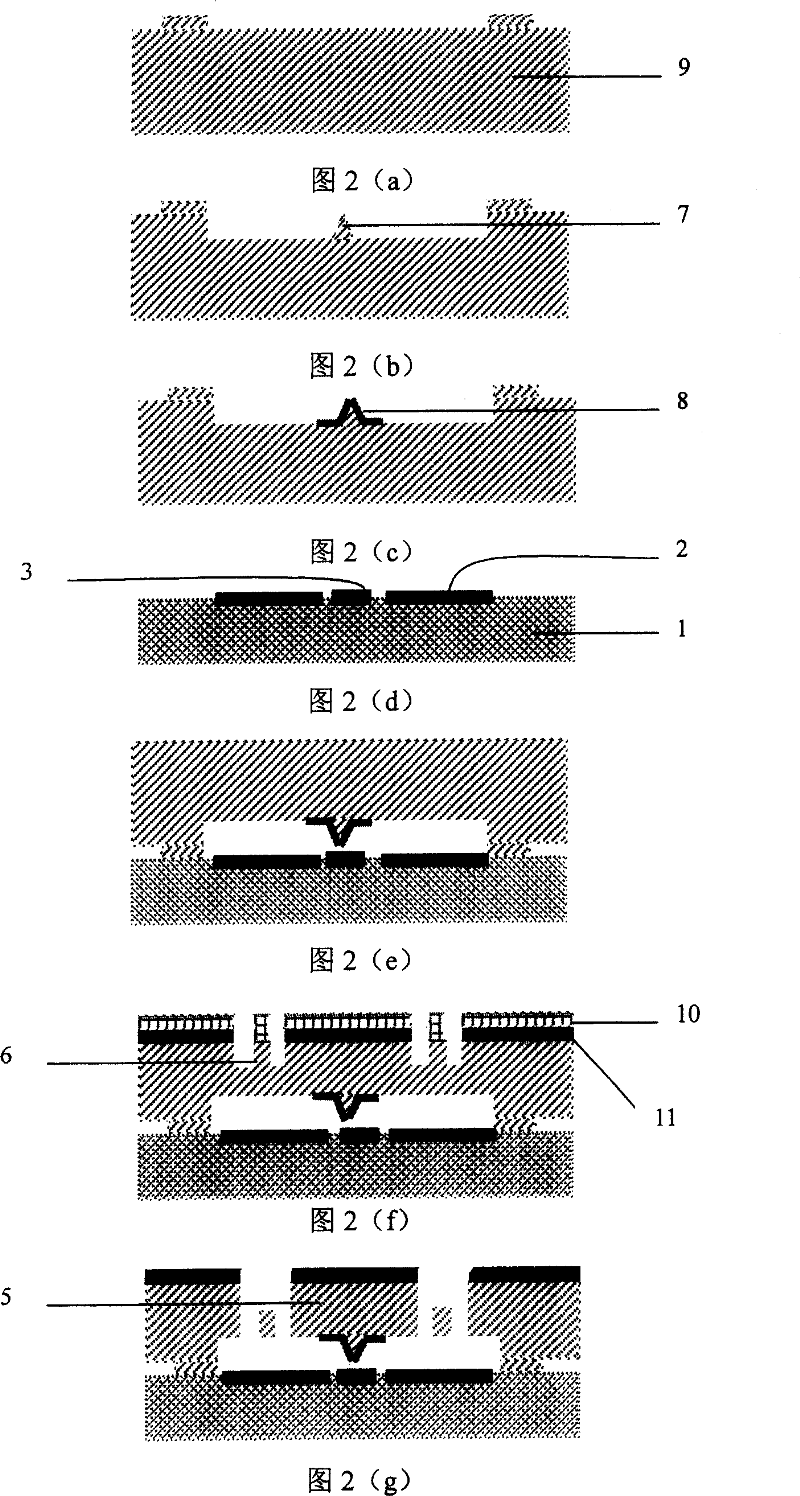

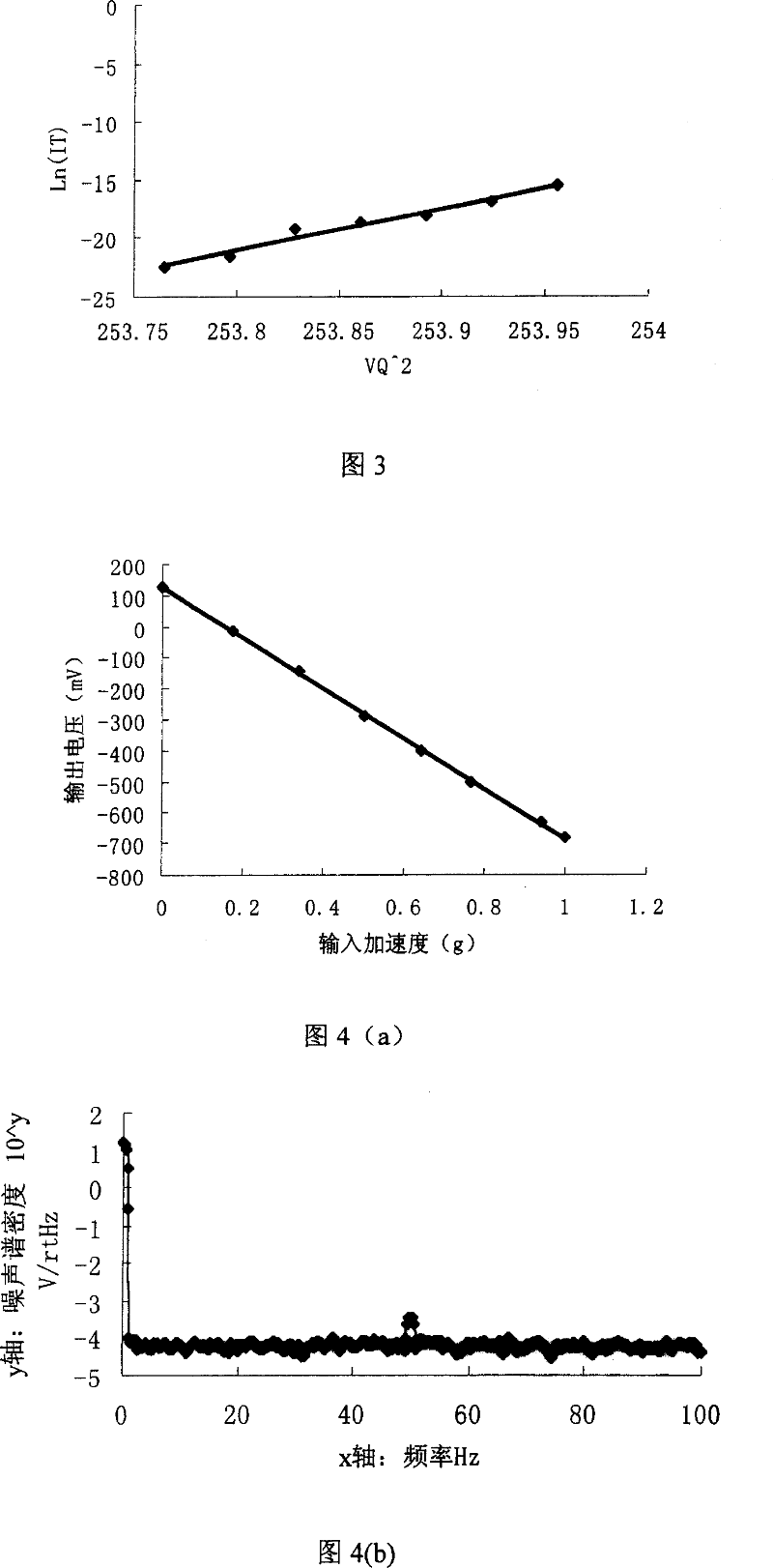

High precision tunnel type accelerometer and preparation method thereof

InactiveCN1635381AHigh sensitivityReduce internal stressAcceleration measurement using interia forcesAccelerometerAnodic bonding

This invention provides a high accurate tunnel accelerometer structure and its process method, which comprises the following steps: first etching on the silicon pad and determining the initial distance between tunnel head to the electrode; keeping etching the tunnel head and depositing metal on the head as tunnel current emission electrode; processing drive electrode and tunnel head electrode on the glass underlay; positive electrode bonding to realize the underlay and silicon pad alignment and sticking; etching the silicon back with dry deep groove etching process to generate supportive beam; keeping etching silicon pad back to generate mass block and releasing structure to get the accelerometer.

Owner:PEKING UNIV

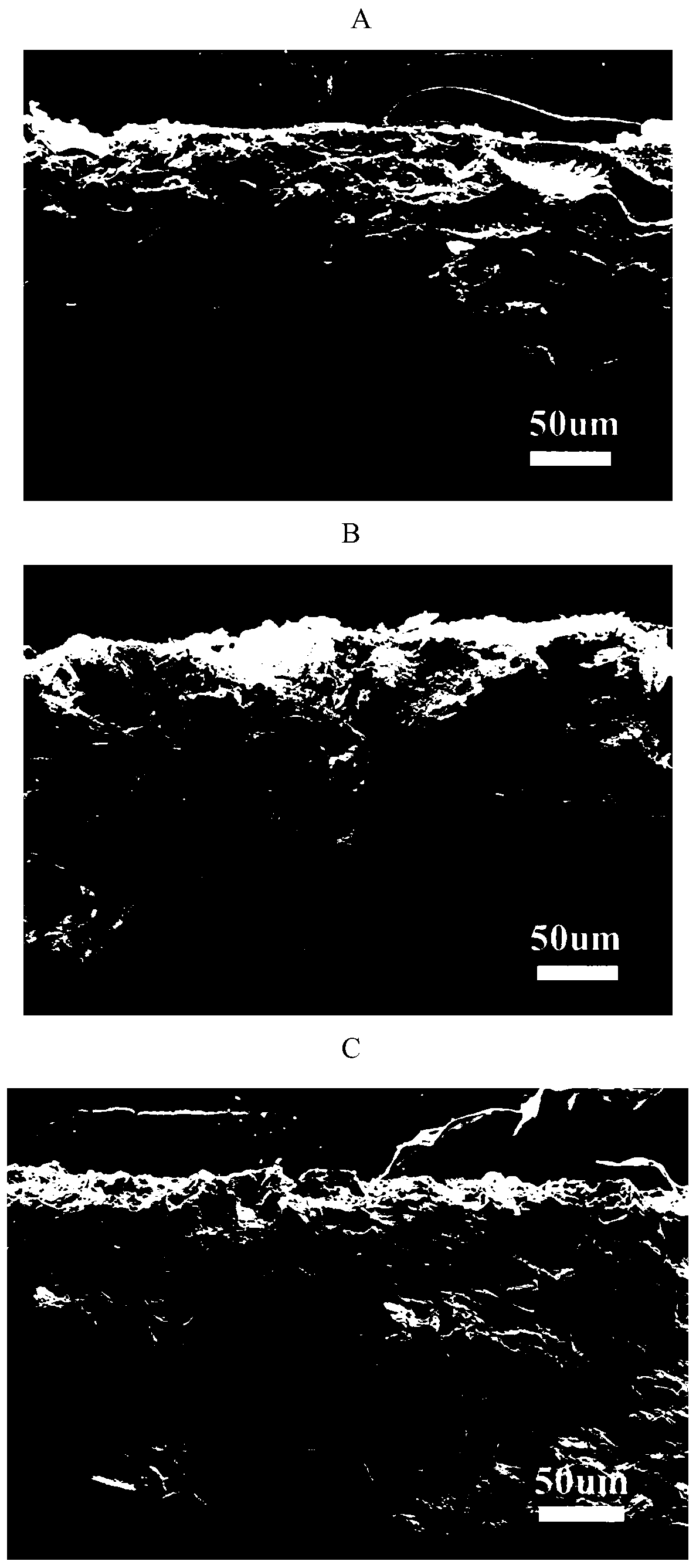

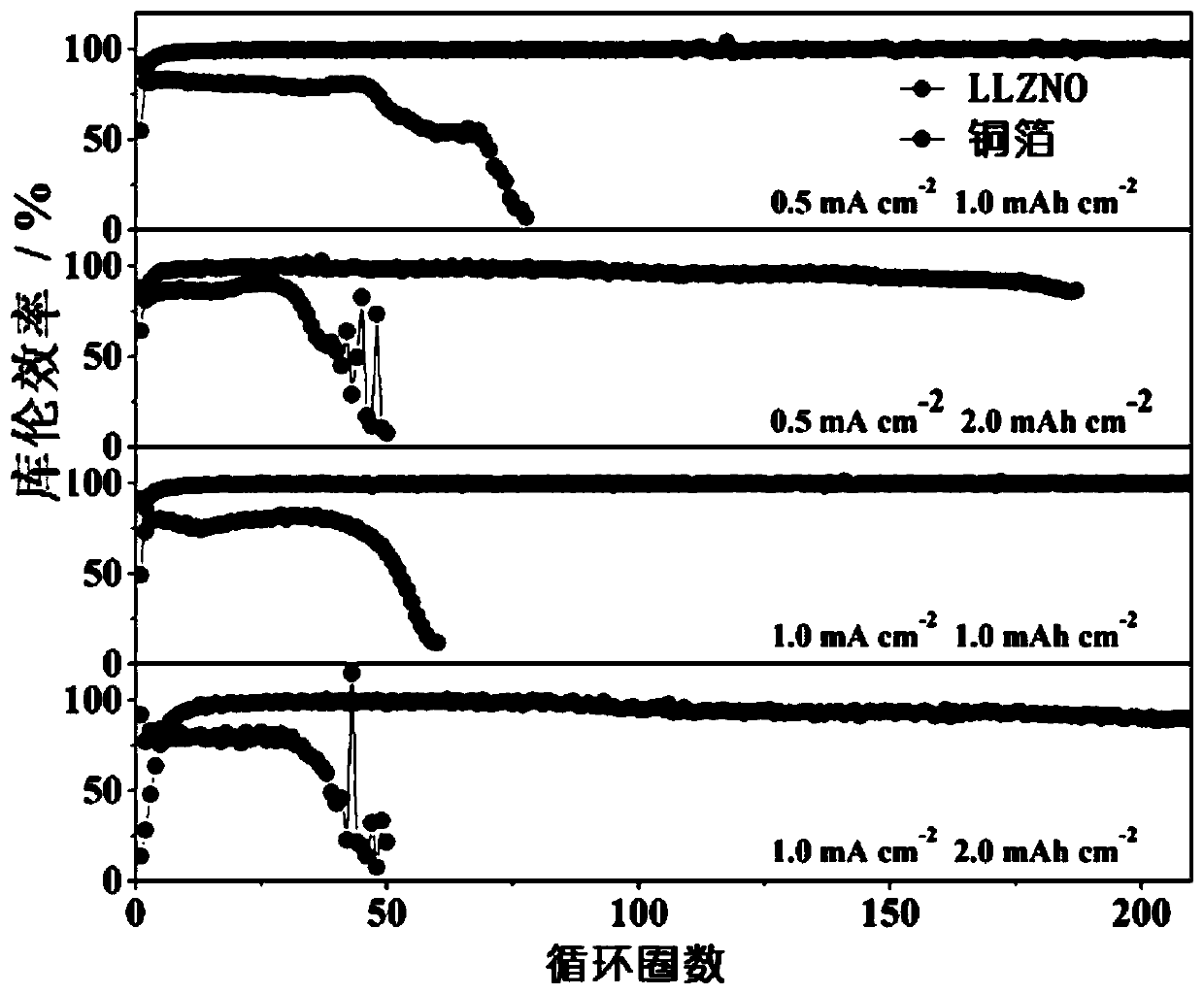

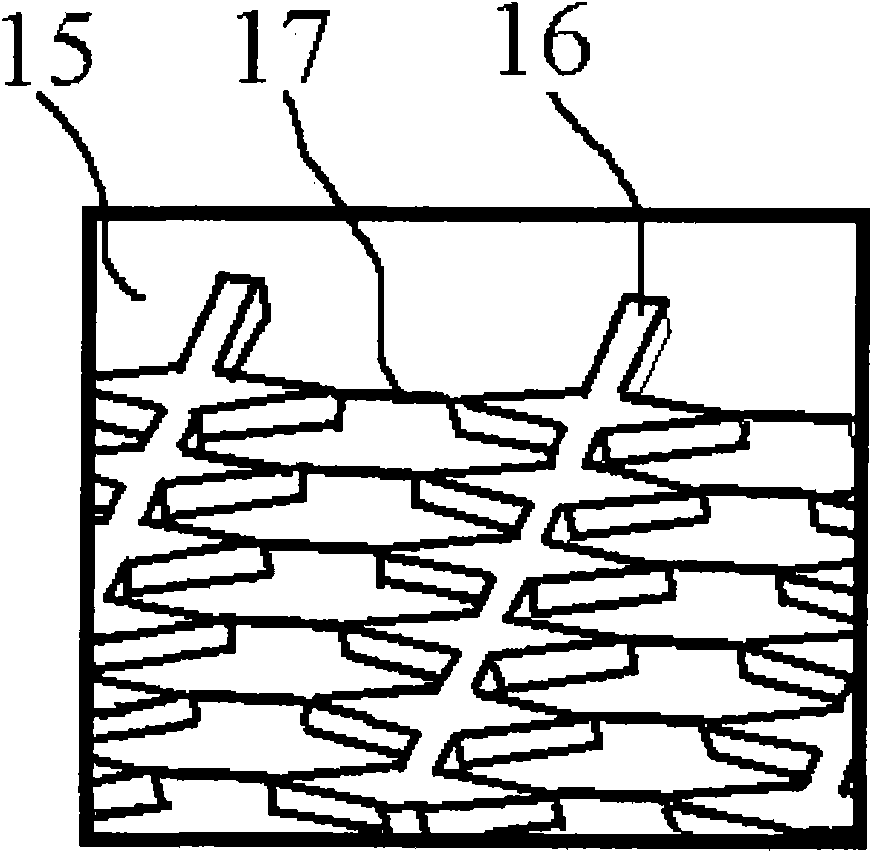

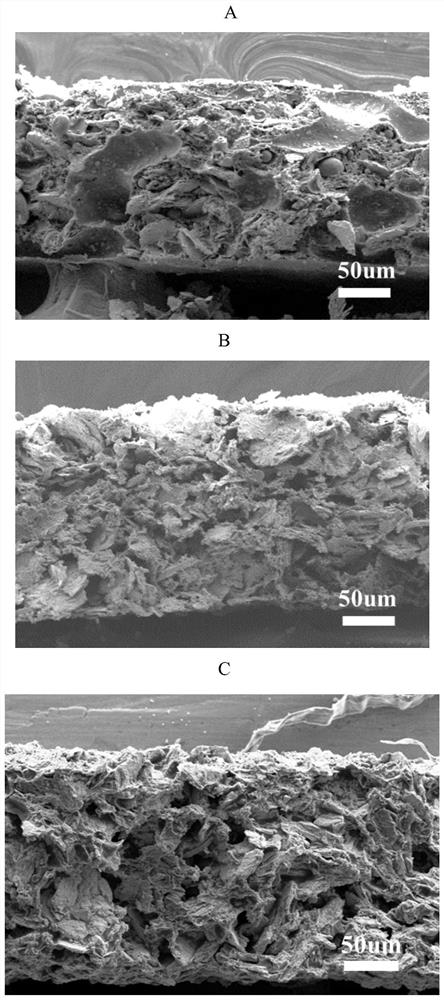

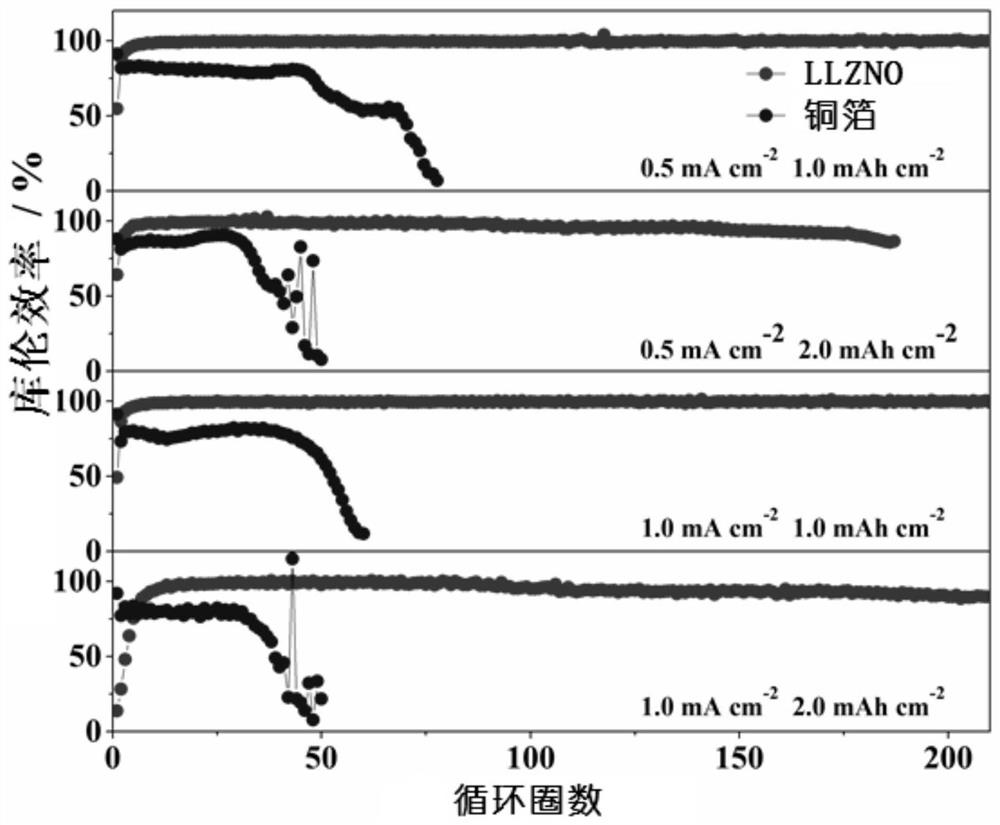

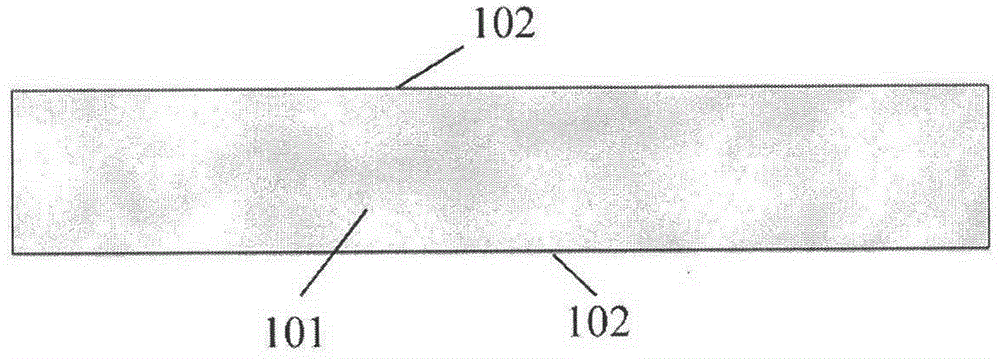

Porous ceramic composite lithium metal negative electrode and preparation method thereof

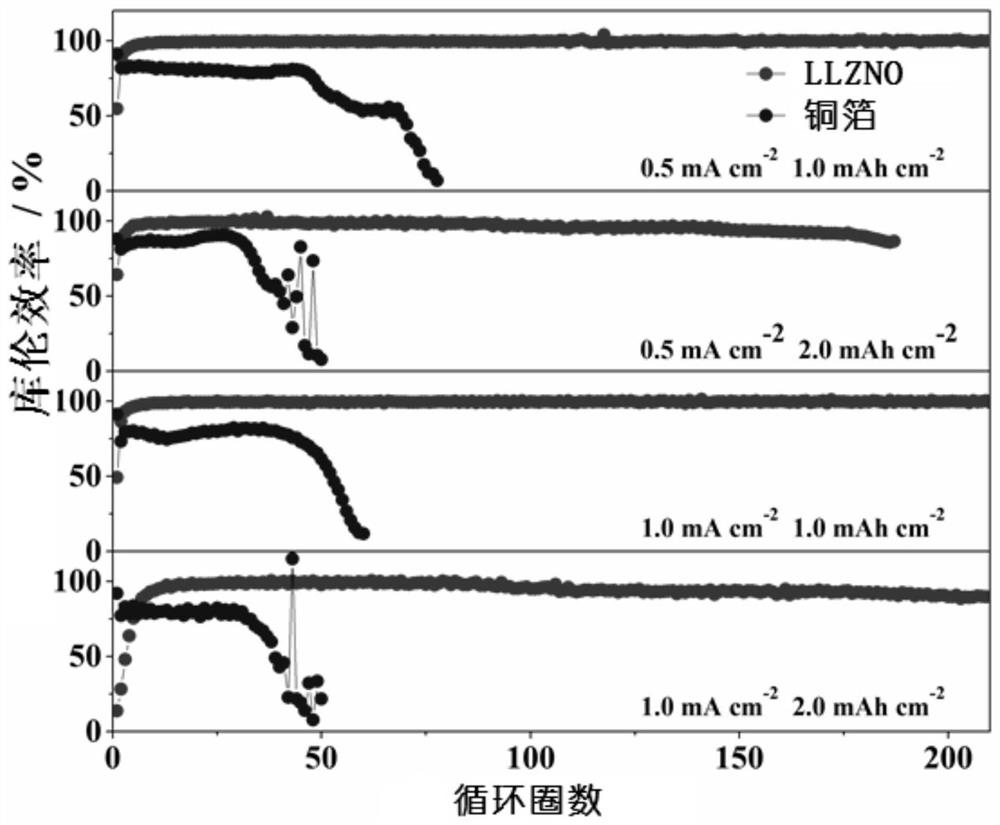

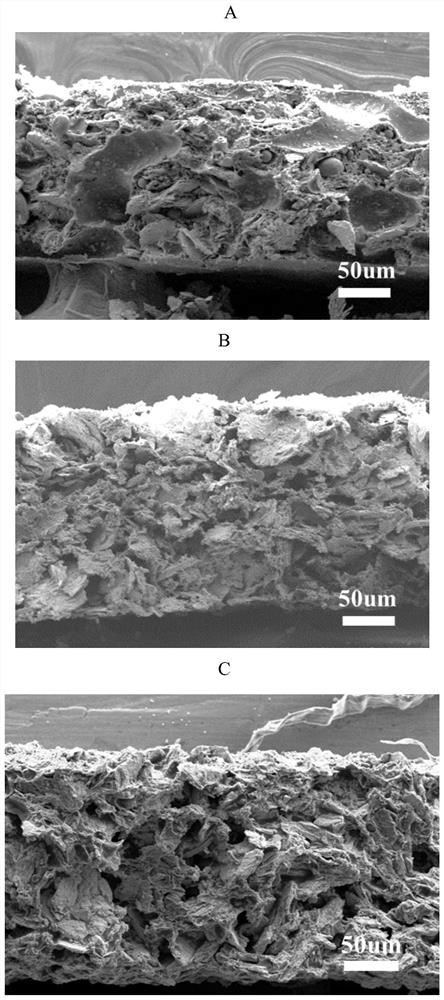

ActiveCN110957477ASolve insufficient storage spaceEnsure structural stabilityFuel and secondary cellsNegative electrodesAll solid stateLithium–air battery

The invention belongs to the field of high-specific-energy lithium metal batteries, and particularly discloses a porous ceramic composite lithium metal negative electrode and a preparation method thereof. The porous ceramic lithium metal negative electrode is composed of a porous ceramic skeleton, a conductive layer and lithium metal, and compared with a traditional lithium sheet negative electrode, the porous ceramic lithium metal negative electrode disclosed by the invention has the advantages that the porosity of the porous ceramic skeleton can provide sufficient storage space for the lithium metal; the rigidity of the porous ceramic skeleton can maintain the structural stability of the lithium metal negative electrode; the large specific surface area attribute of the porous ceramic skeleton can effectively reduce the local current density of the lithium metal negative electrode and relieve the growth problem of lithium dendrites; the composite negative electrode has the characteristics of high structural strength, high coulombic efficiency, low polarization, no lithium dendrites, good cycling stability and the like, meanwhile, the preparation method is simple, and large-batch manufacturing can be realized. The porous ceramic lithium metal composite negative electrode can be used for preparing a high-specific-energy lithium metal secondary battery, including an organic electrolyte system lithium ion battery, a lithium-air battery, an all-solid-state lithium ion battery, a lithium-air battery and the like.

Owner:SUZHOU UNIV

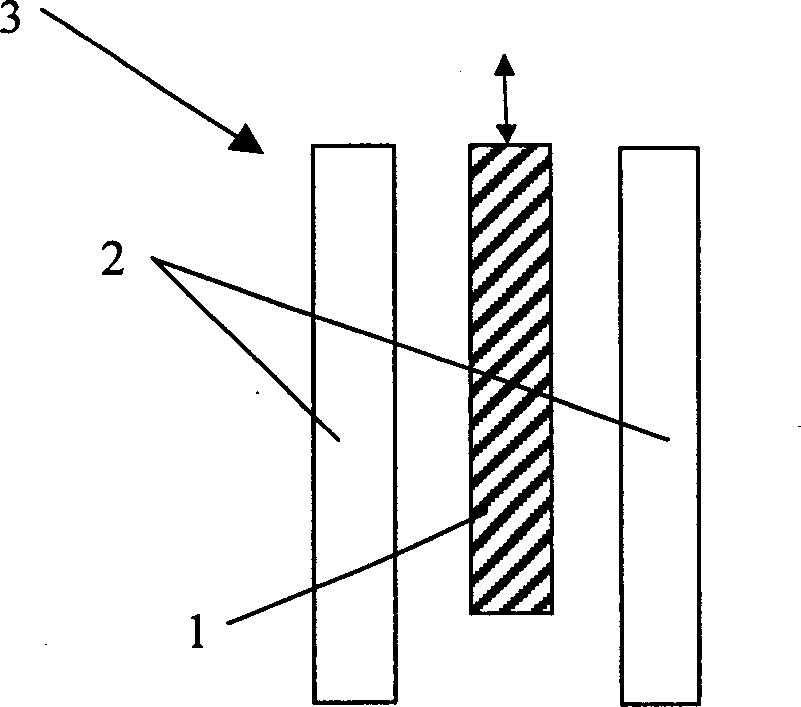

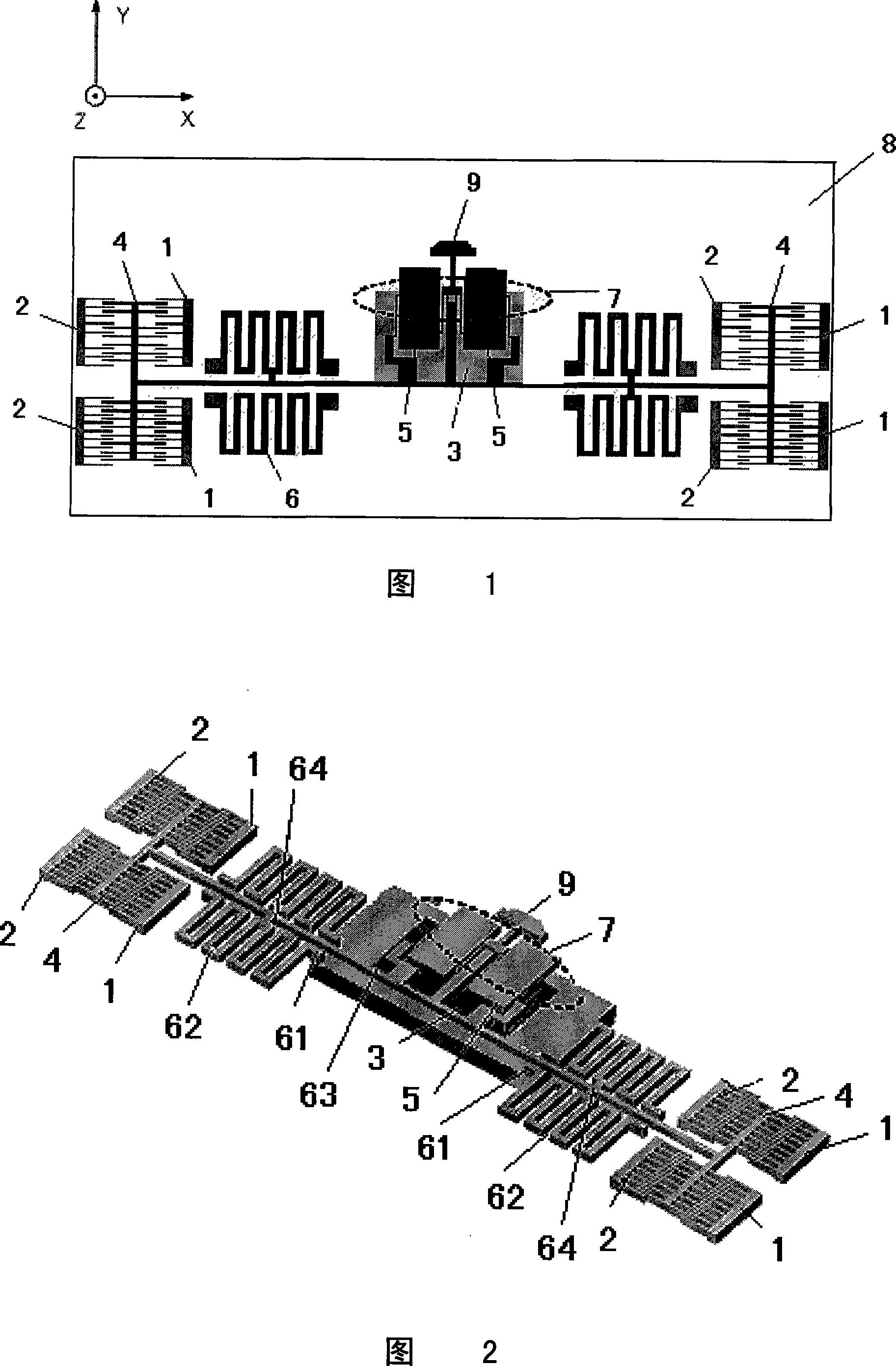

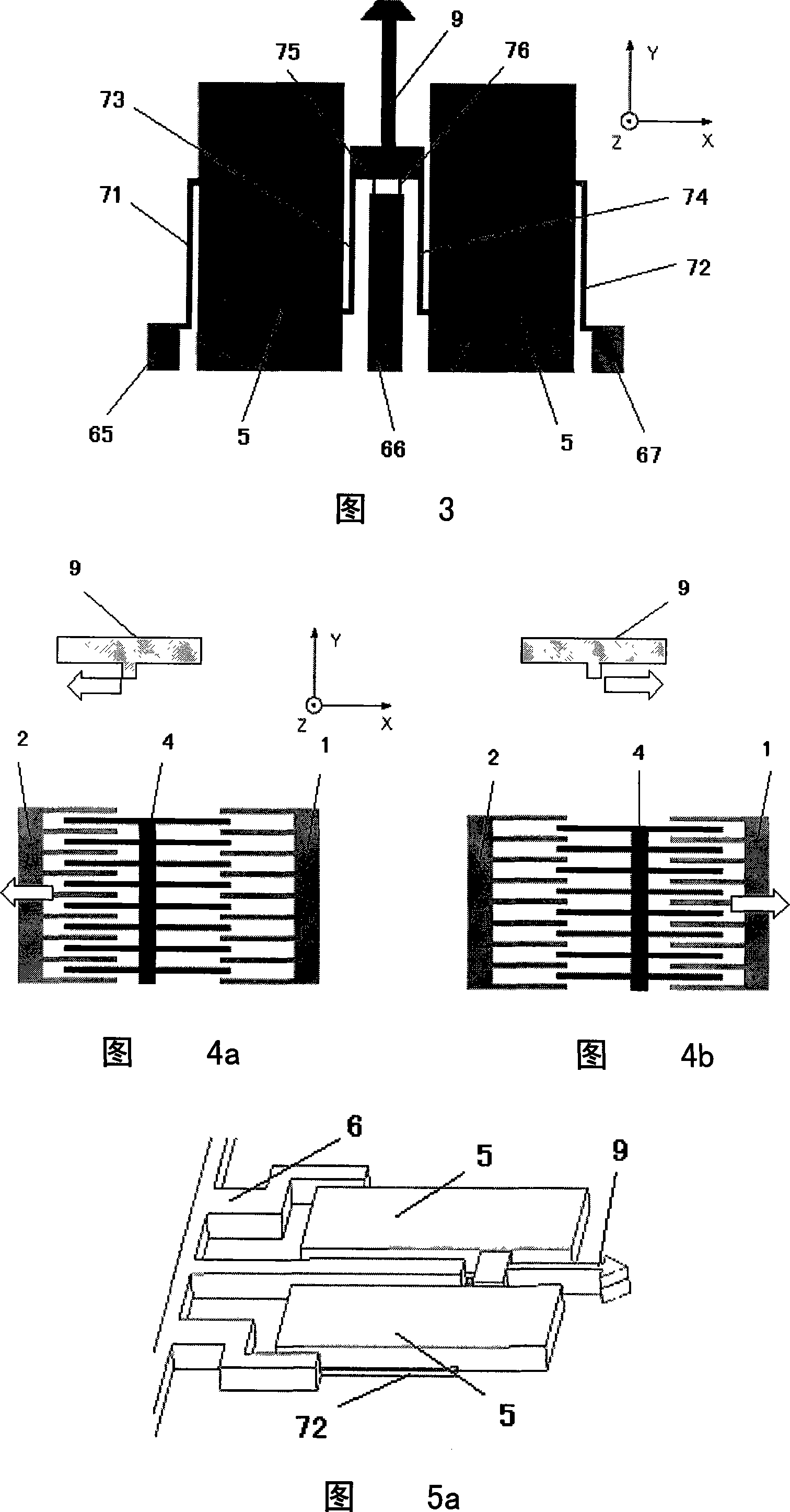

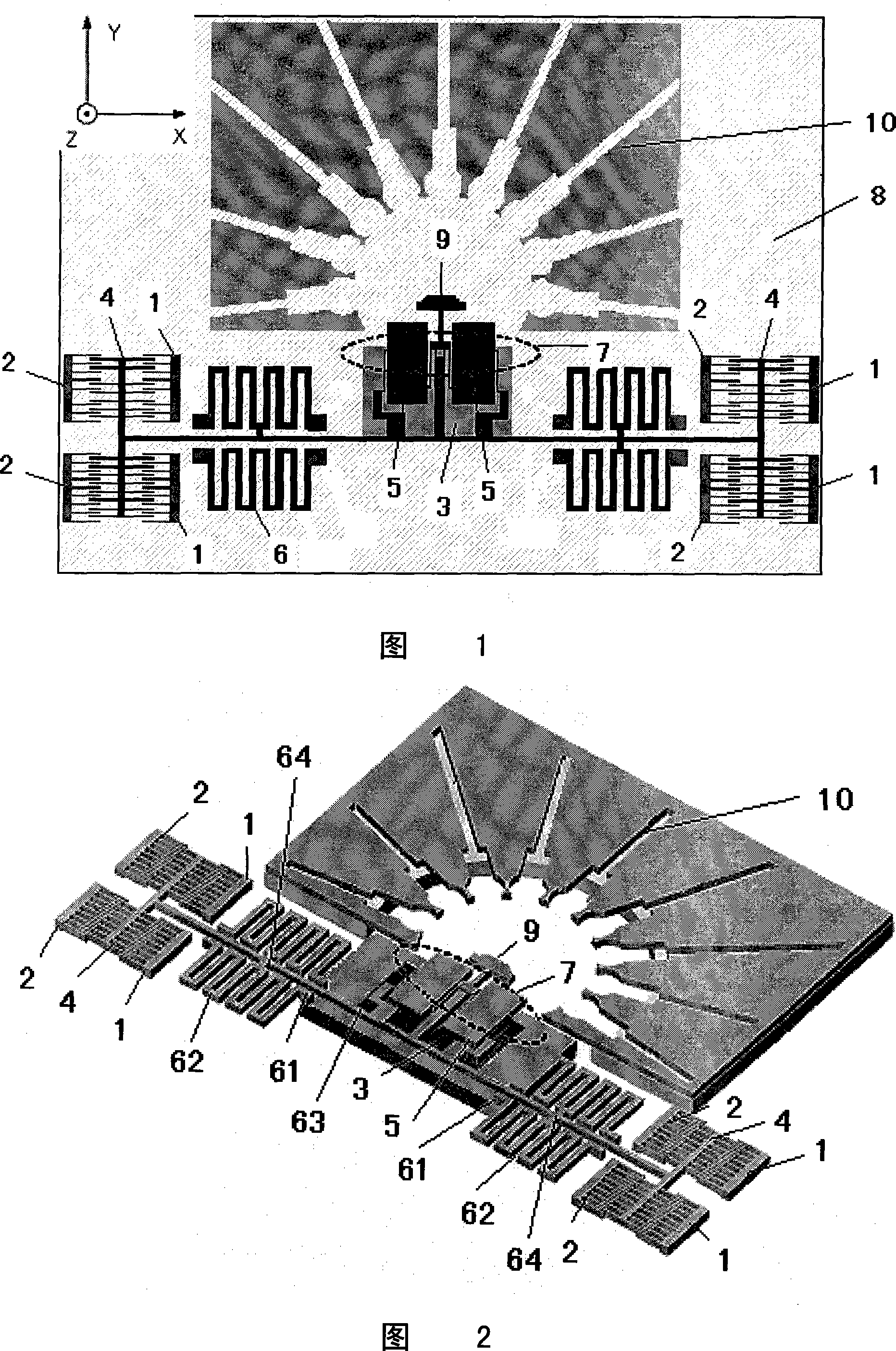

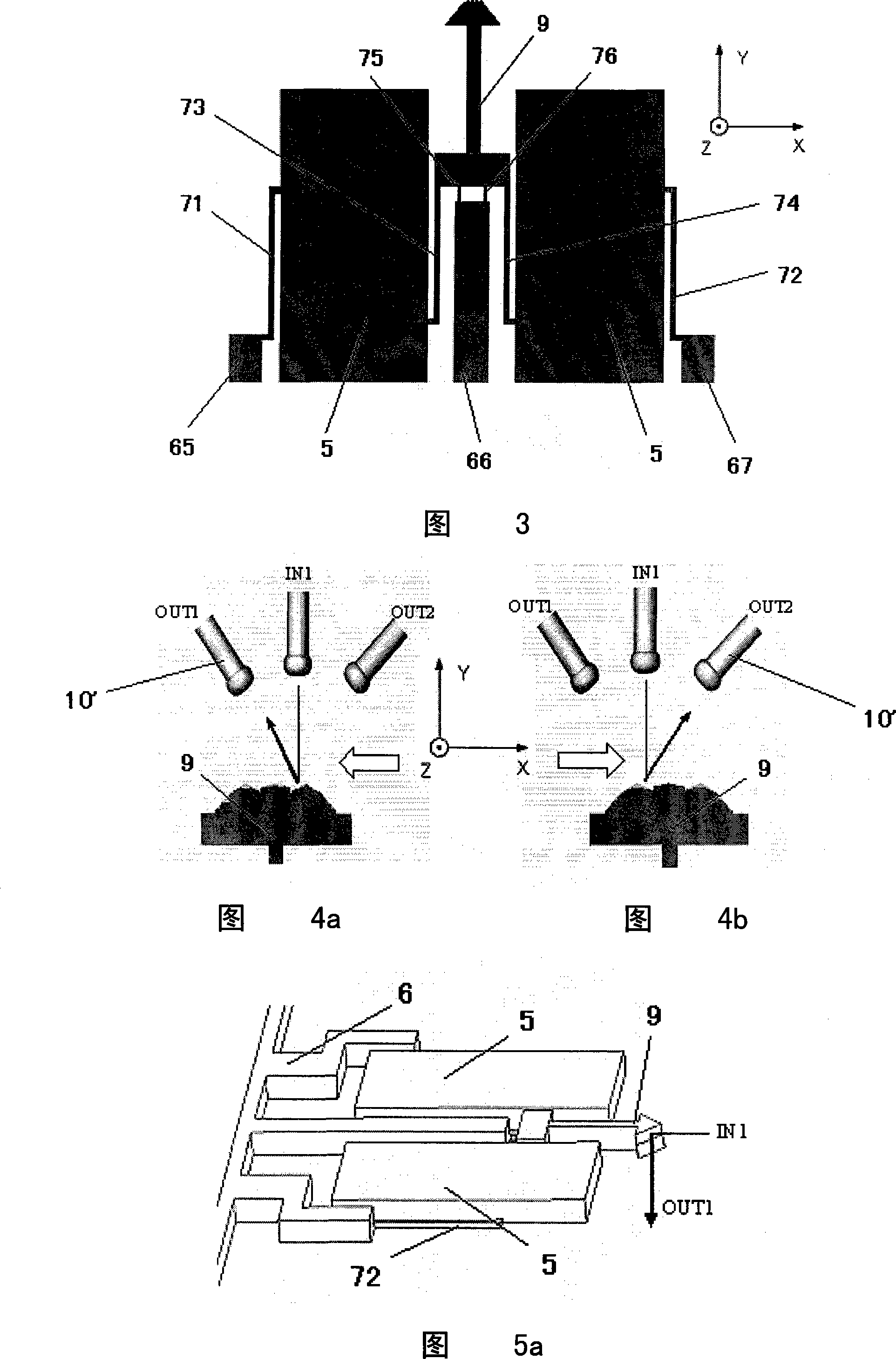

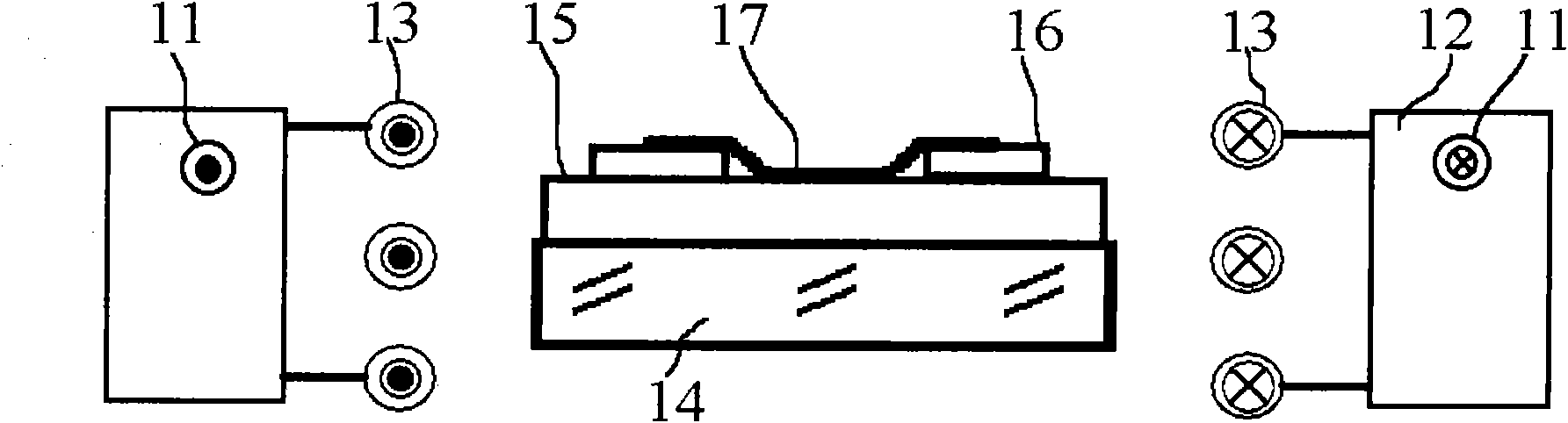

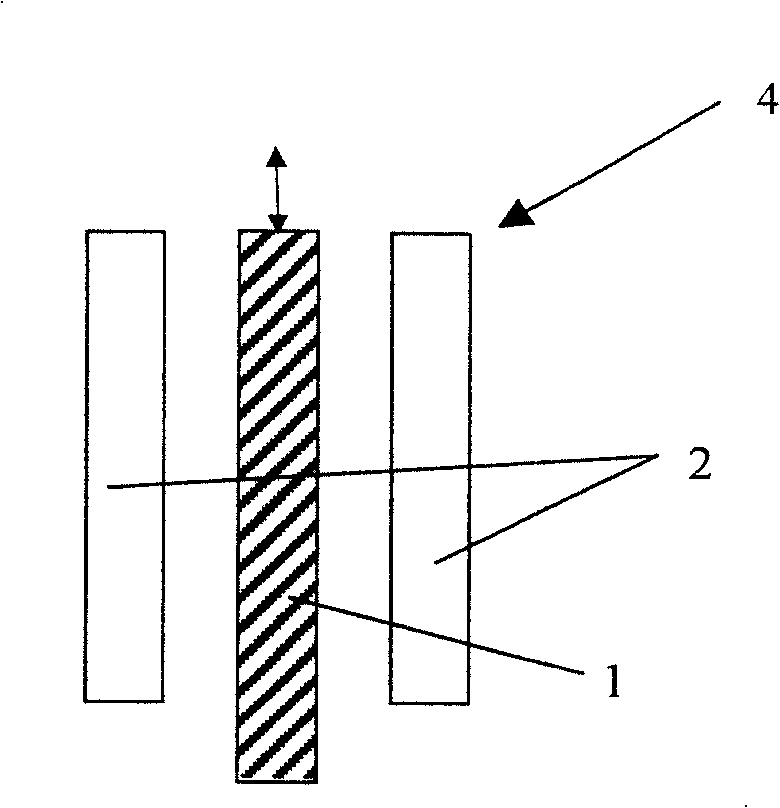

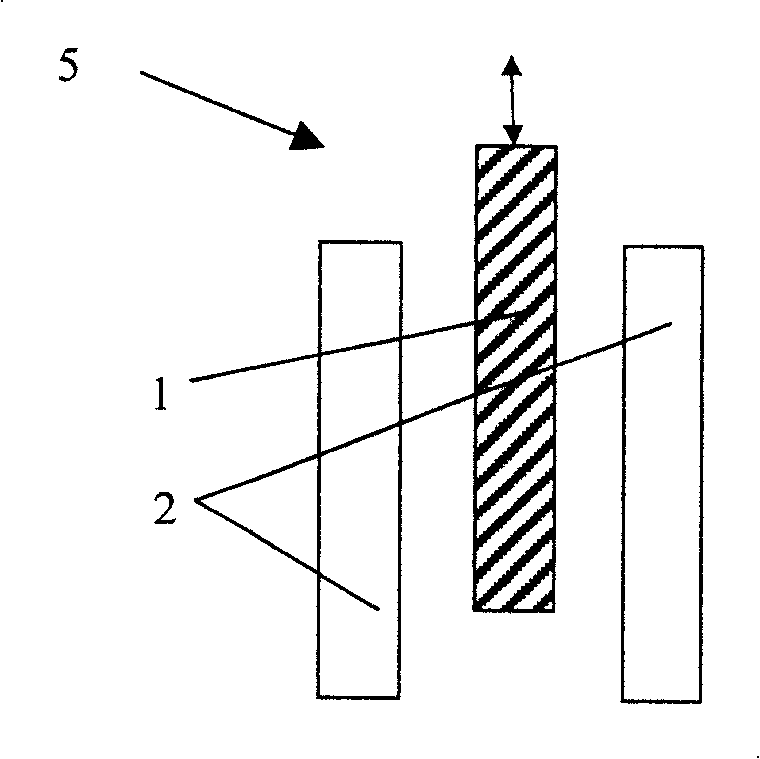

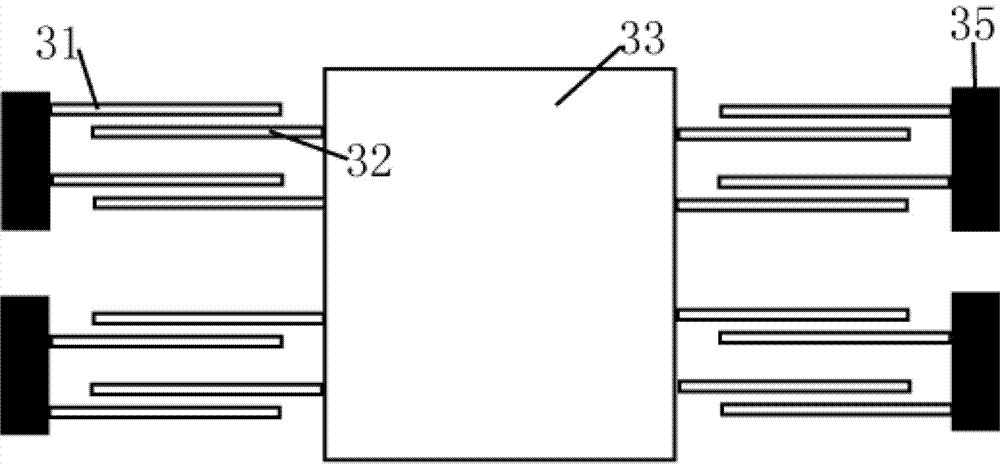

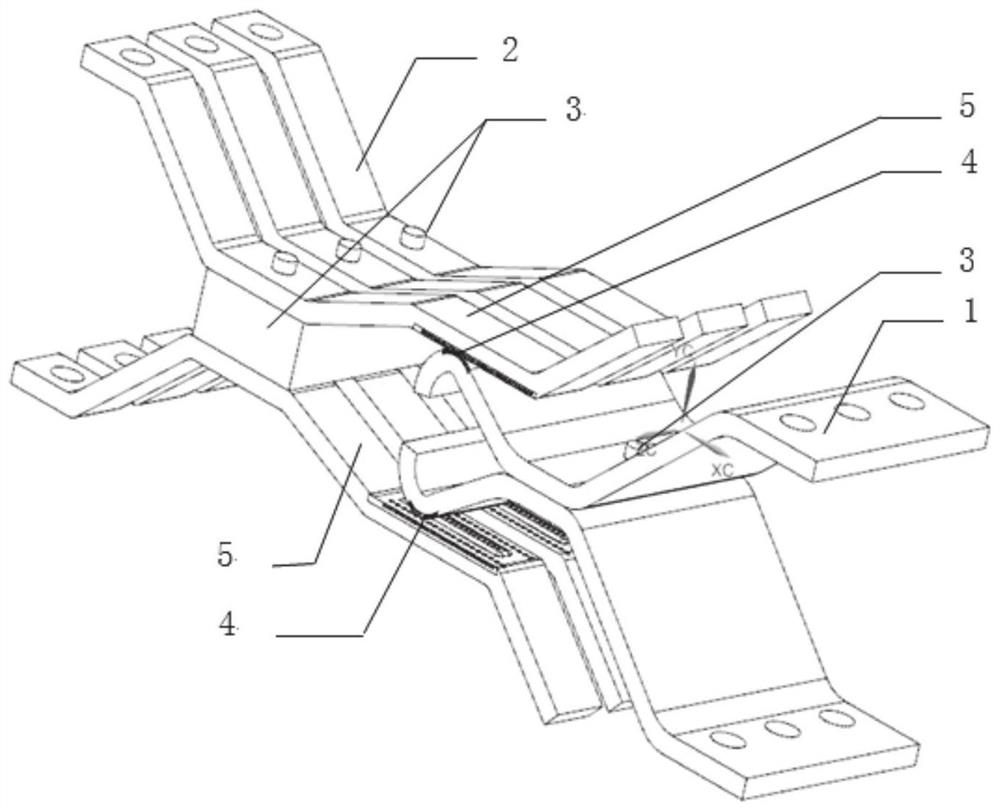

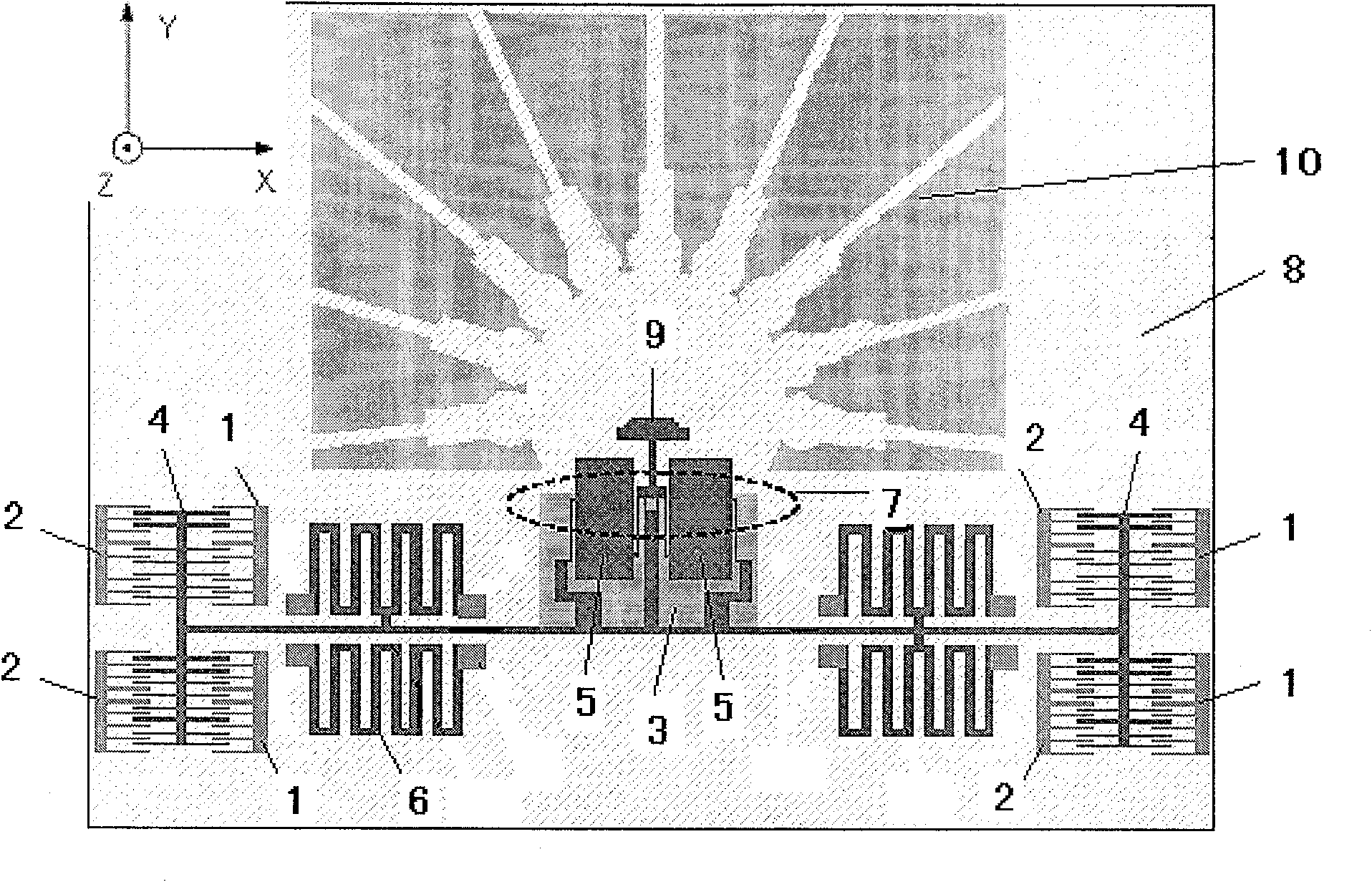

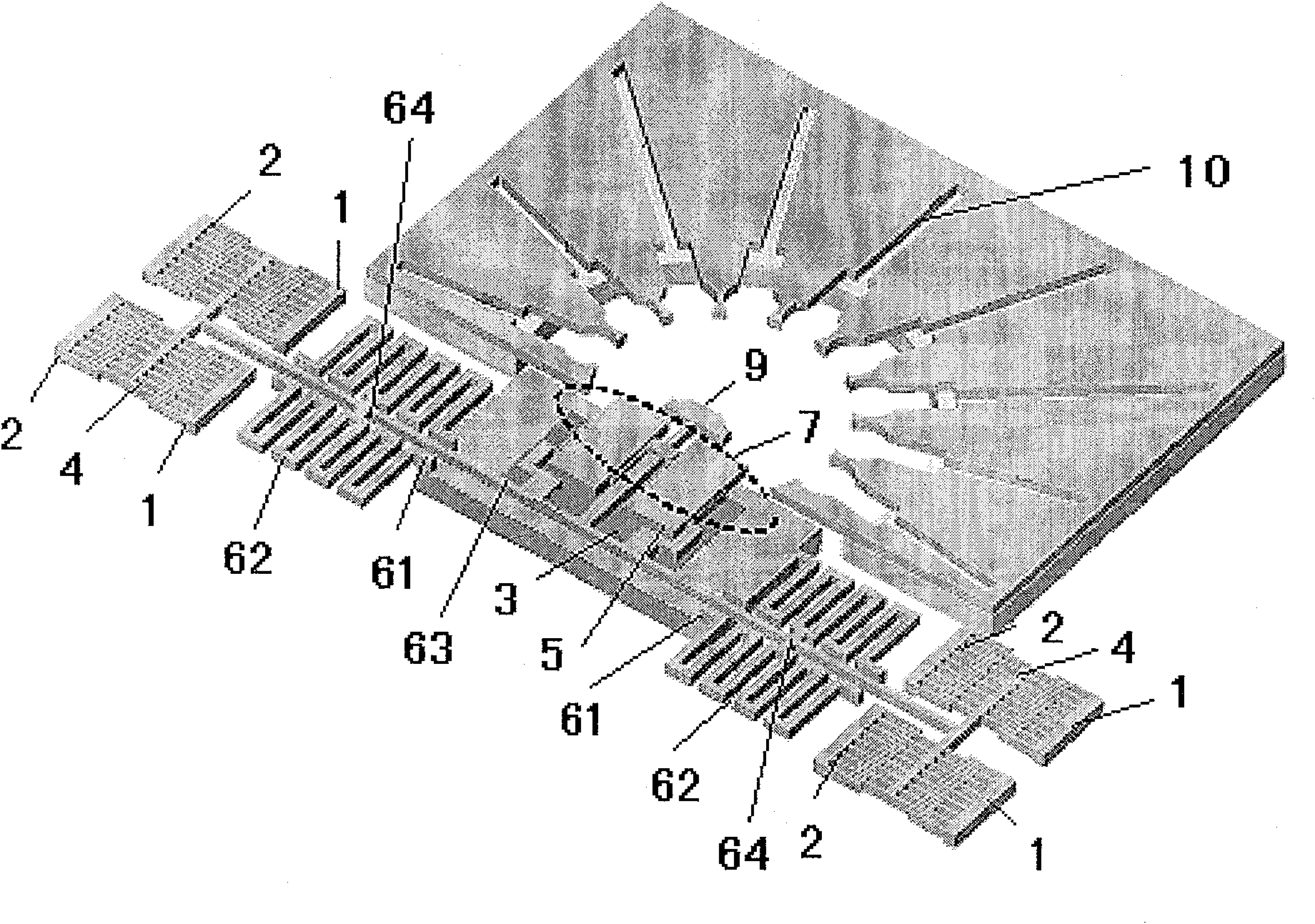

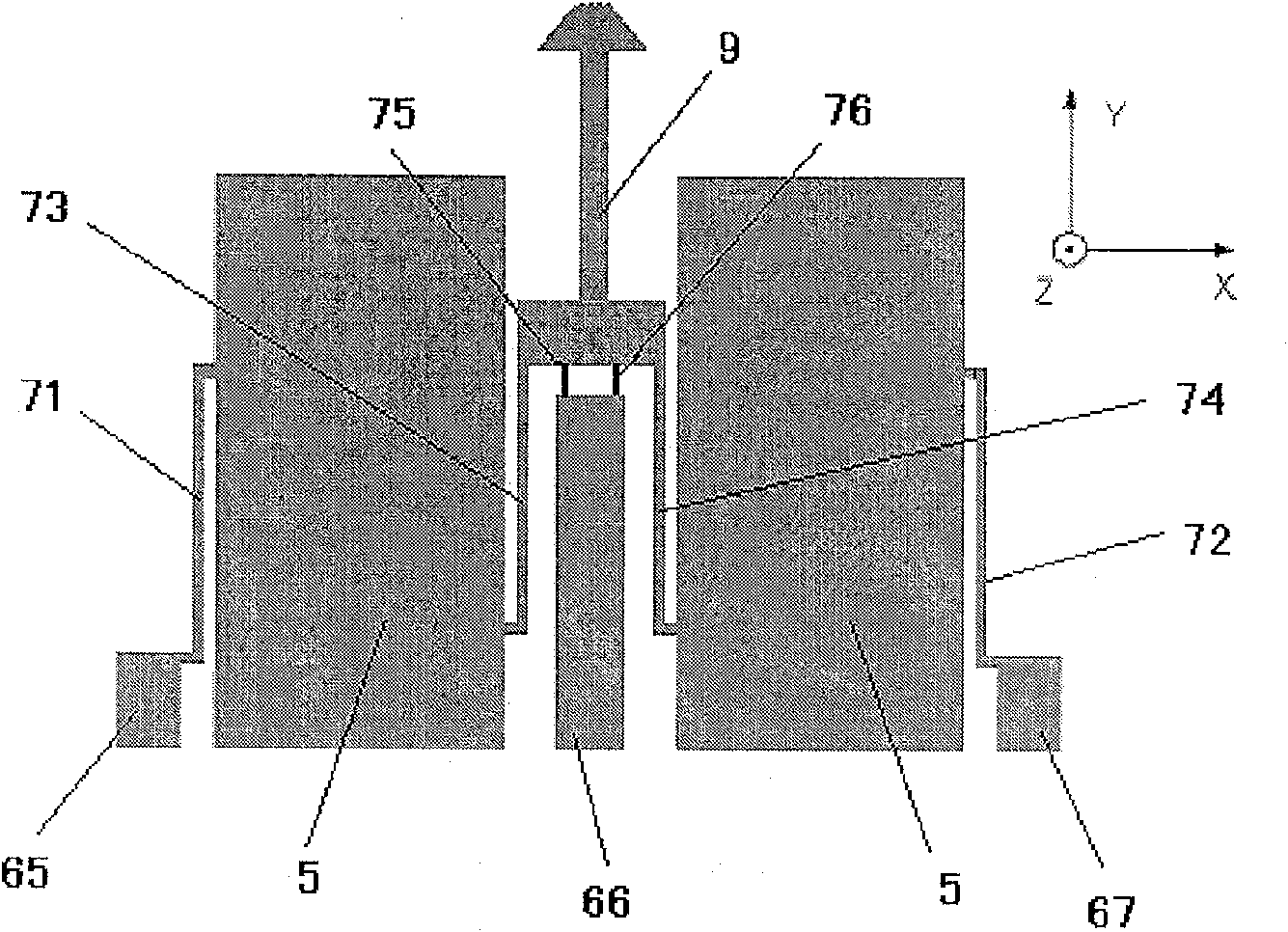

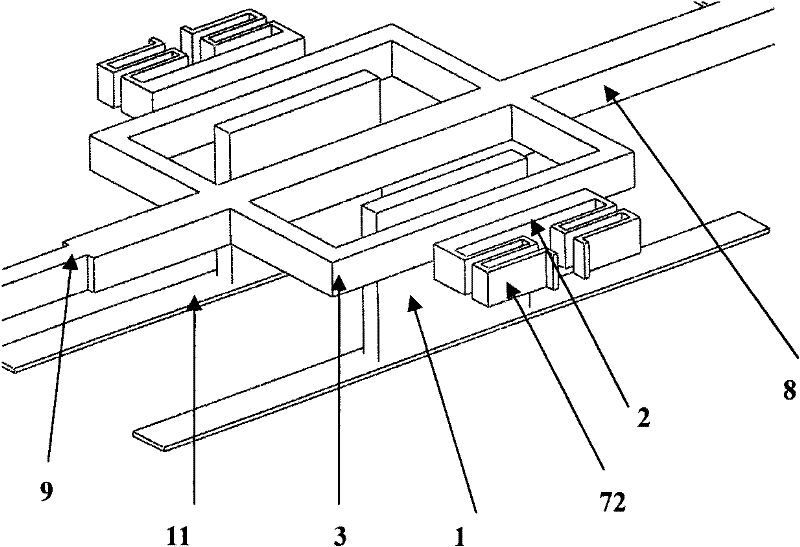

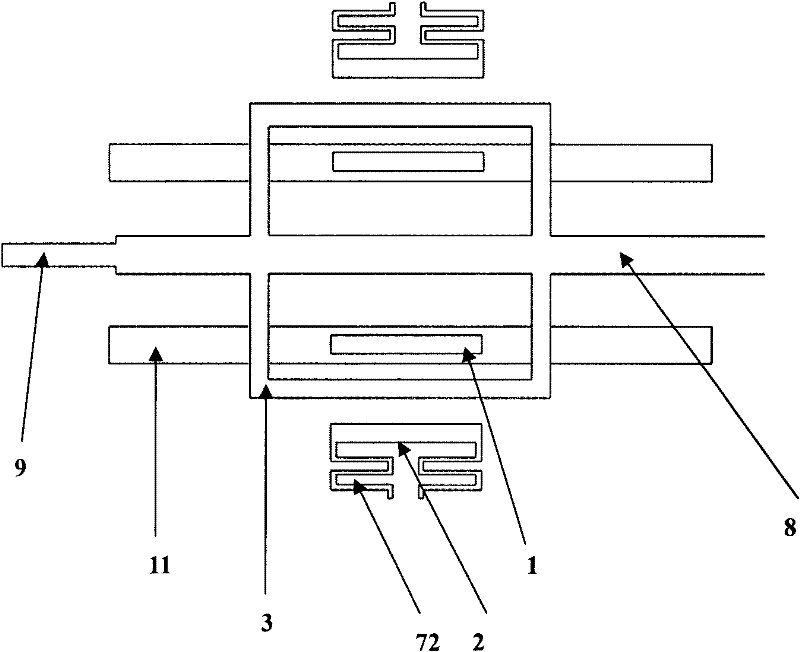

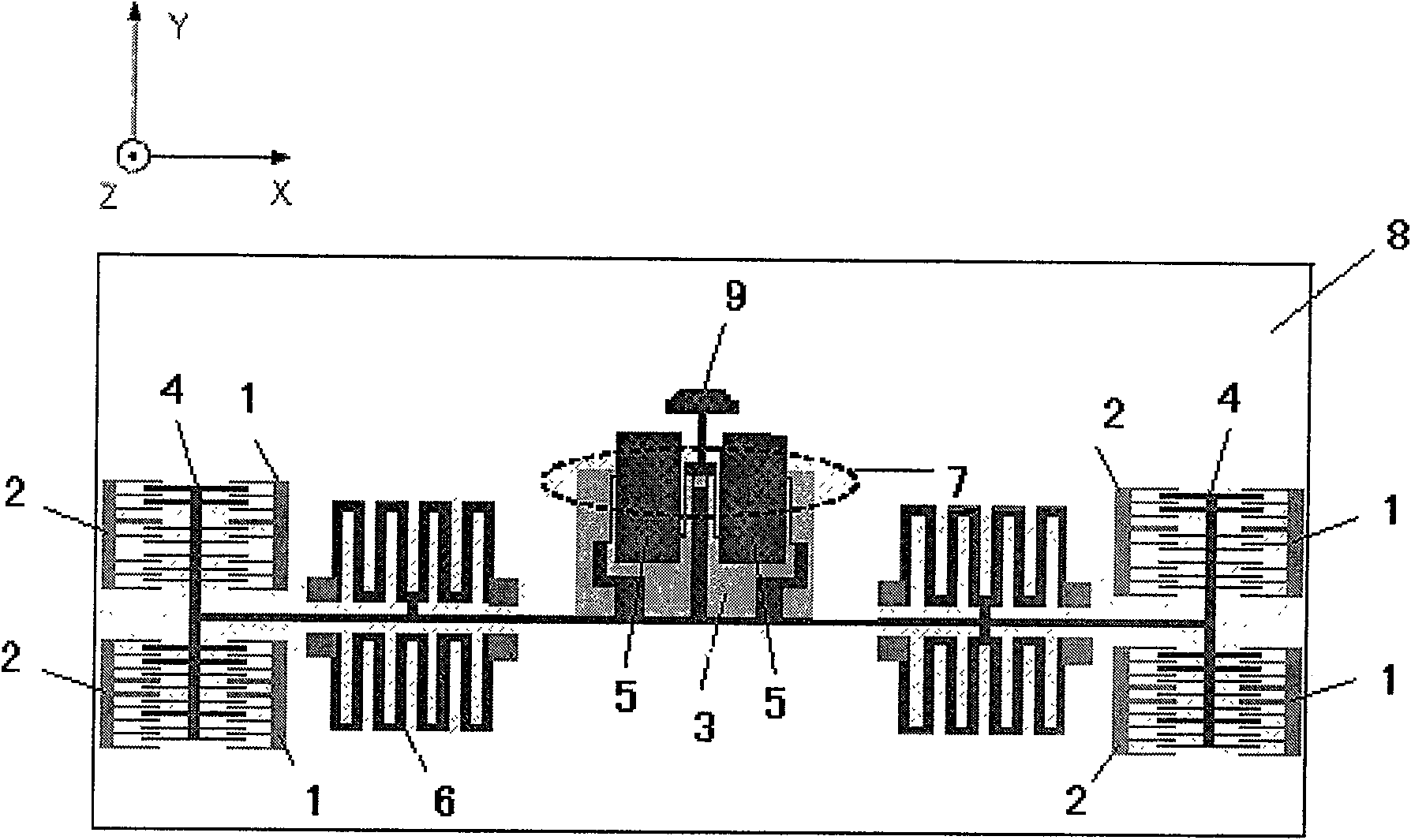

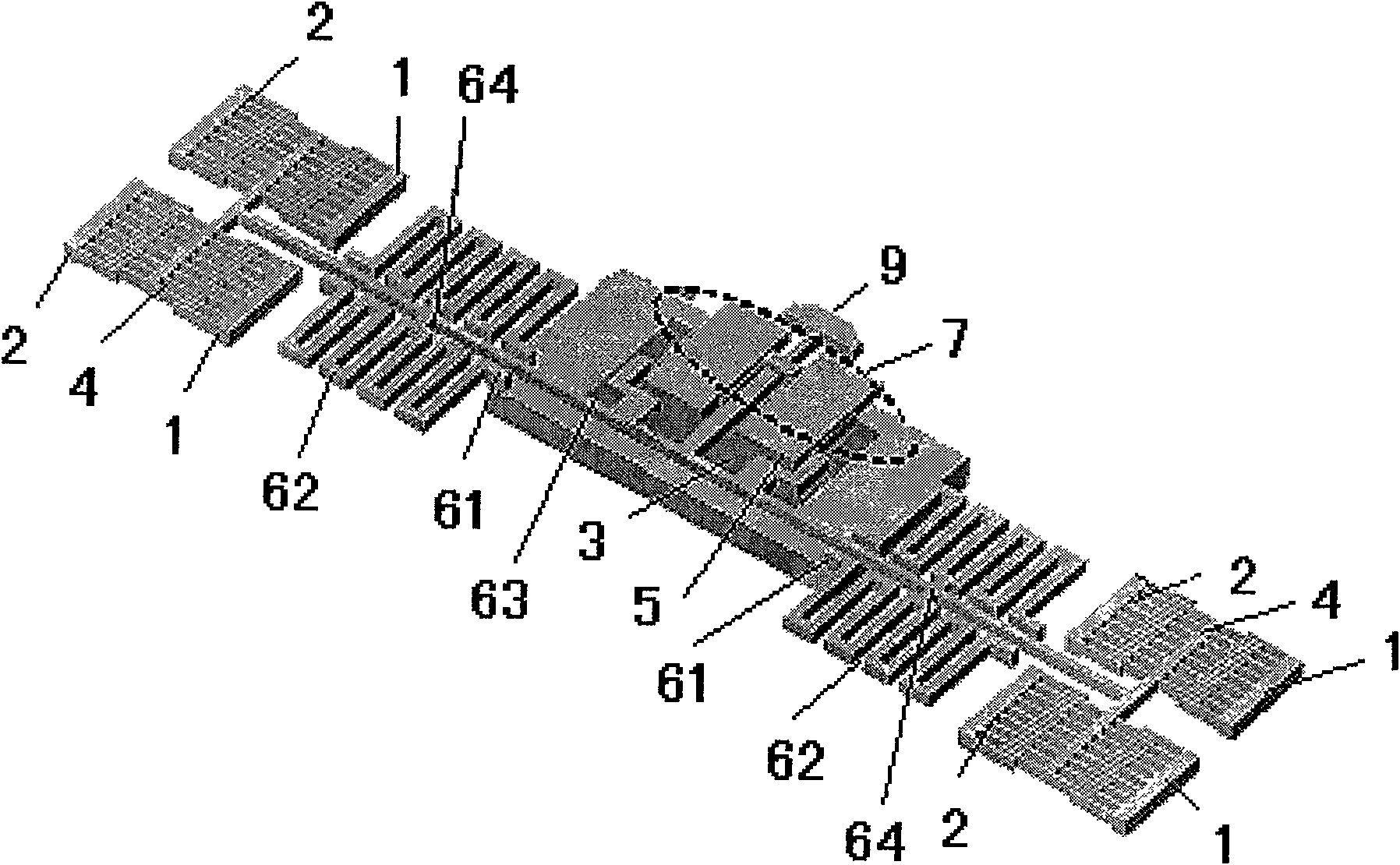

Micro-drive structure for implementing coplane and off-plane movement

ActiveCN101244801AReduce internal stressQuality improvementTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesComb fingerEngineering

The invention relates to a coplanar and off-plane micro driving structure and the preparation method. The driving structure comprises fixed electrodes, movable electrodes, support beams, a glass base and a drive output, wherein the fixed electrodes comprise a comb-finger fixed electrode connected at both sides of the glass base top surface and a flat plate fixed electrode which is fixed at the central section of the glass base top surface; the movable electrodes comprise two comb-finger movable electrodes which insert in the comb-finger fixed electrode and two flat plate movable electrodes respectively arranged above the flat plate fixed electrode; the support beams comprise a folded beam and a composite torsion beam. The coplanar and off-plane micro driving structure can not only realize the coplanar movement along the X axis direction through the interaction between the comb-finger movable electrodes and the fixed electrodes, but also realize the off-plane torsion movement of the driving output through the interaction between the movable electrodes and the fixed electrodes. The coplanar and off-plane micro driving structure has the advantages of simple processing and is compatible with a plurality of MEMS devices process, thus applicable to glimmer integrated system with more powerful function.

Owner:PEKING UNIV

Method for manufacturing silicon-penetrating coaxial line for microwave frequency band

InactiveCN102097672ASmall mechanical propertiesLittle physical damageSemiconductor/solid-state device manufacturingWaveguidesCoaxial lineCoaxial transmission line

The invention relates to a method for manufacturing a silicon-penetrating coaxial line for a microwave frequency band. The method is characterized by comprising the following steps of: photoetching a coaxial line pattern on an oxide layer at the A side of a silicon slice (1) and etching coaxial line through holes by using a deep reactive plasma etching process, wherein the depth of each coaxial line through hole is smaller than the thickness of the silicon slice; sputtering a seed layer on the A side of a silicon slice (2), covering a layer of photoconductive BCB (Benzocyclobutene) and photoetching to obtain the plated pattern of the coaxial line; then, aligning the A sides of the silicon slices (1 and 2) by using a BCB linkage process and linking at a low temperature; grinding the B side of the silicon slice (1) by using a chemical mechanical polishing process until through holes are exposed, and plating the coaxial line; and finally, grinding the silicon slice (2) from the B side to remove metal on the seed layer. By adopting wafer-level processes compatible with a microelectronics process, such as photoetching, and the like, the invention ensures the accuracy of a transmission line and can realize the mass manufacture. The silicon-penetrating coaxial transmission line lessens the influence on the microwave performance when a signal passes by the silicon slice in high-density three-dimensional encapsulation and avoids the great loss of the silicon-penetrating transmission line.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

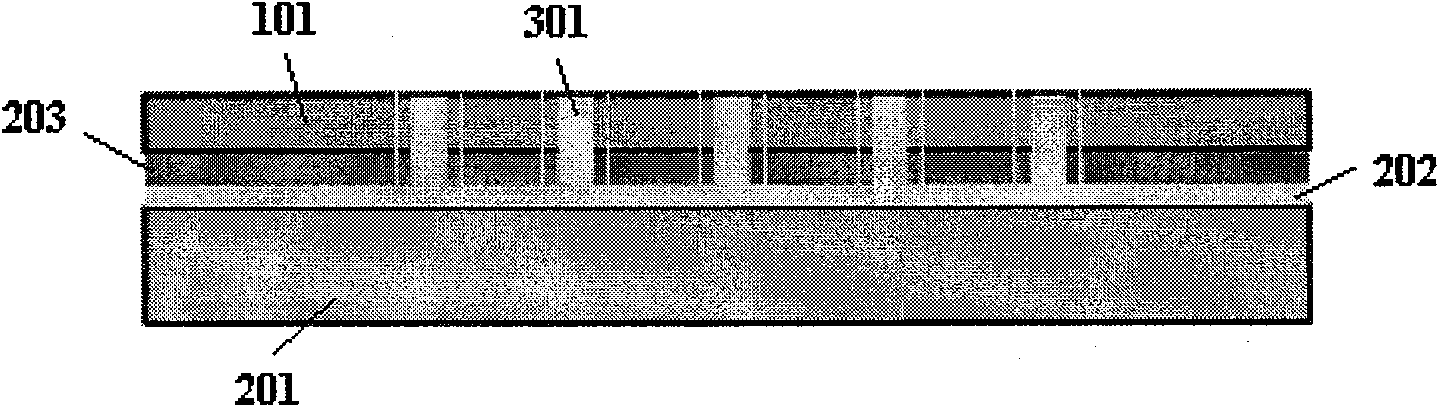

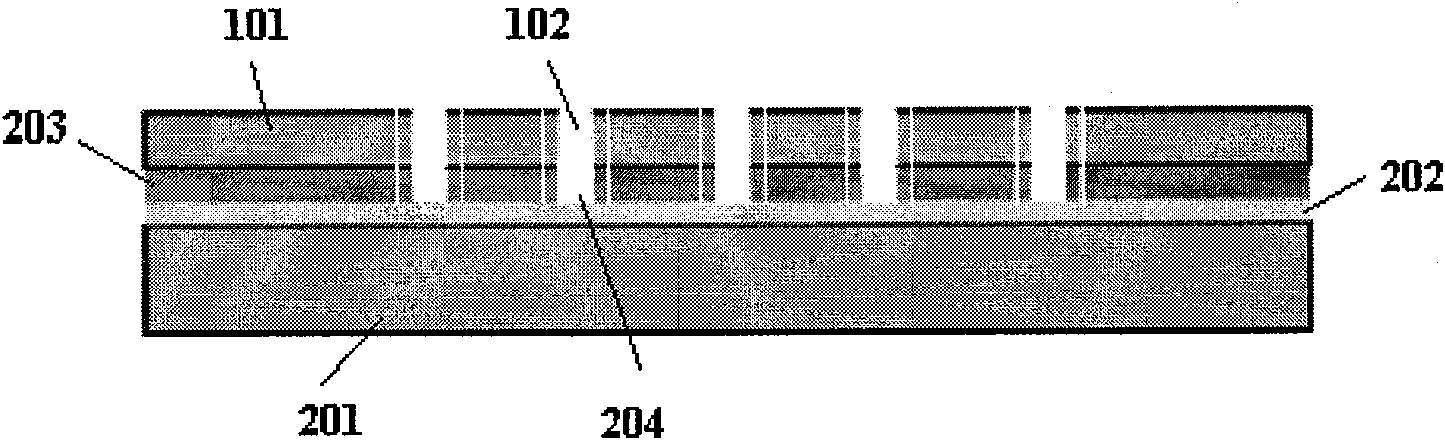

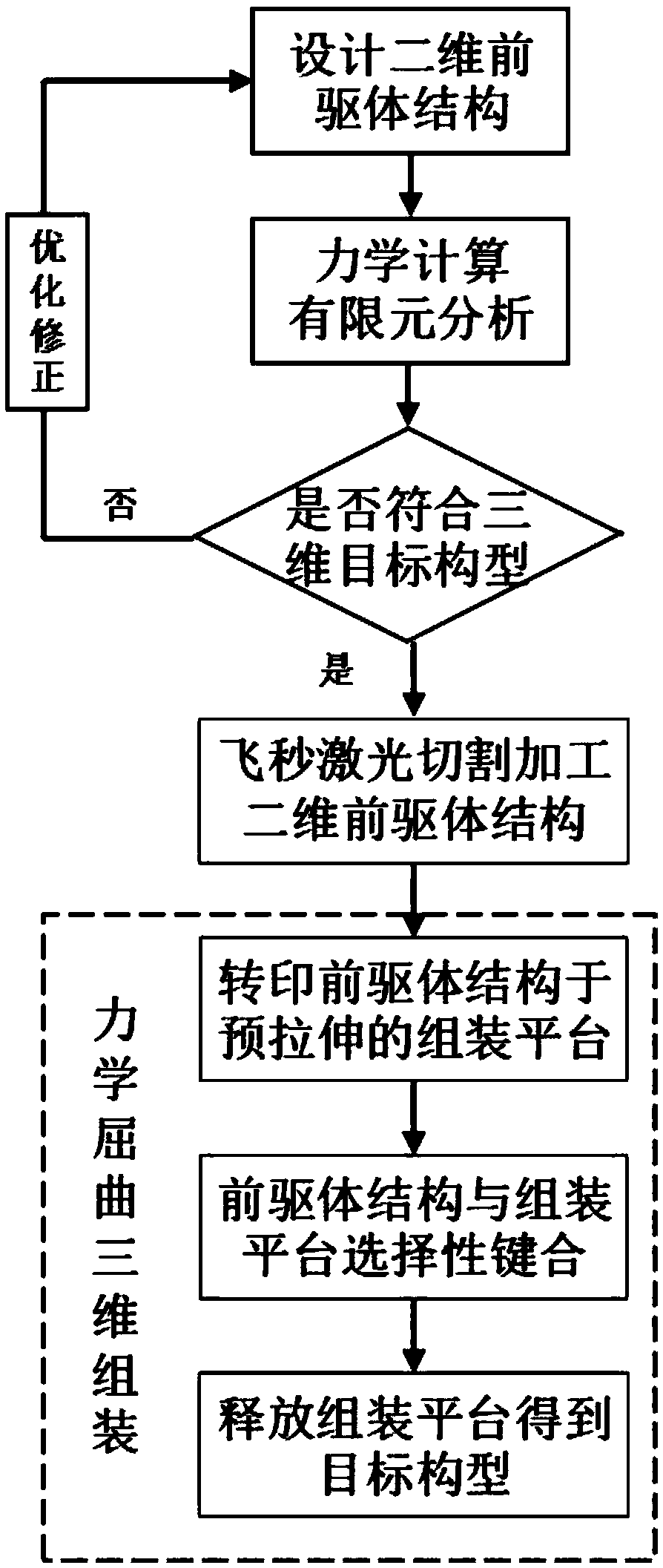

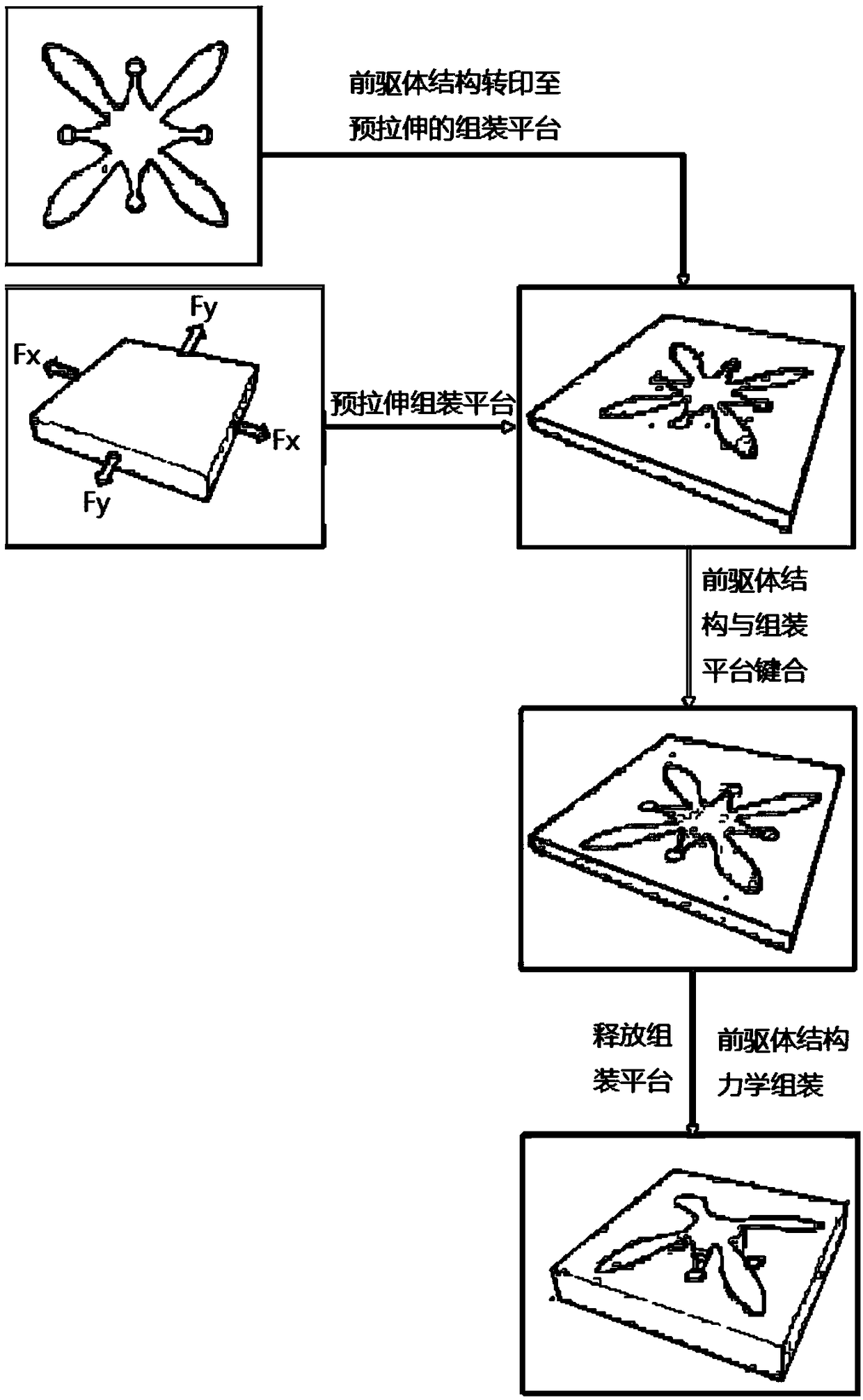

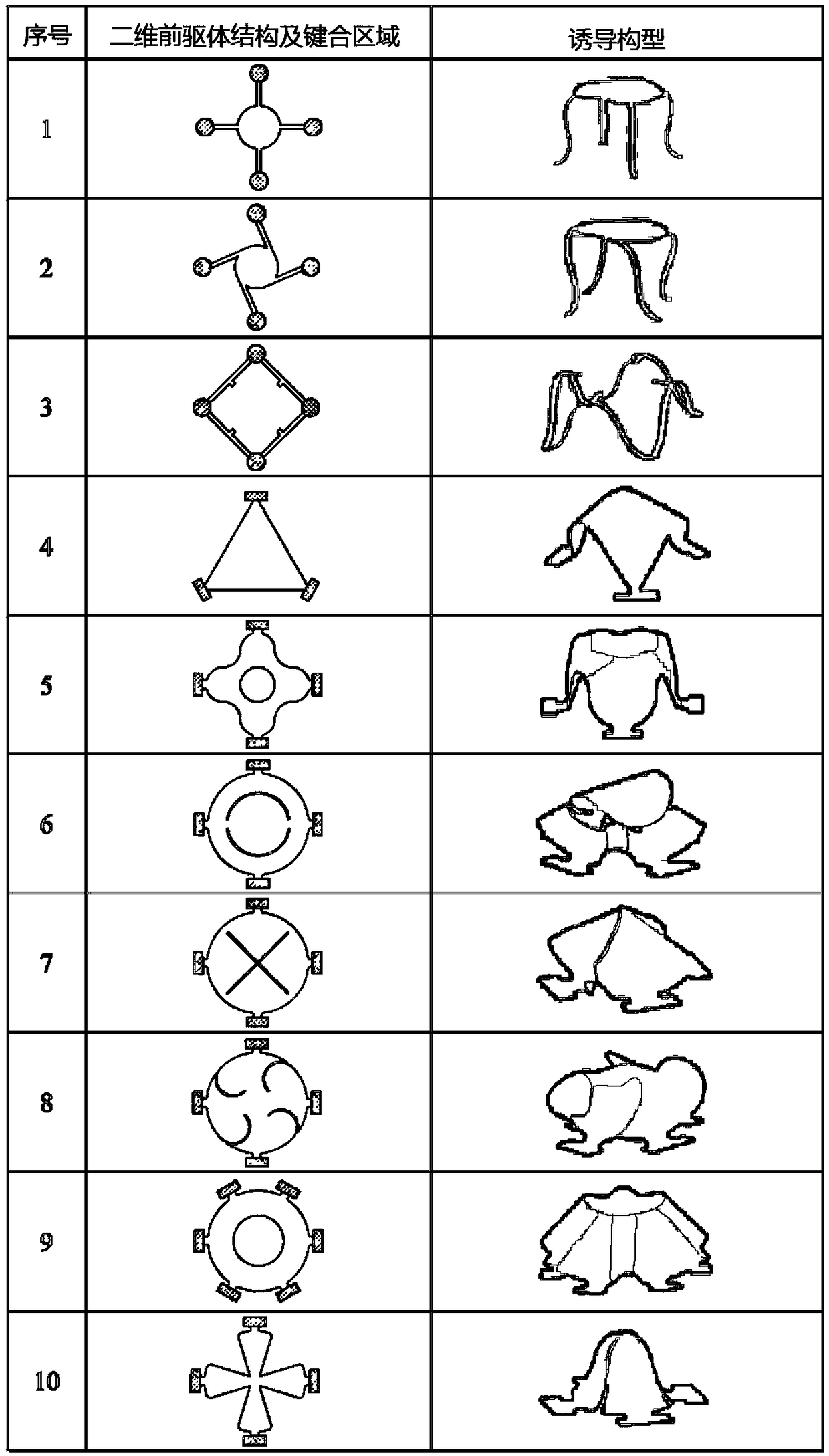

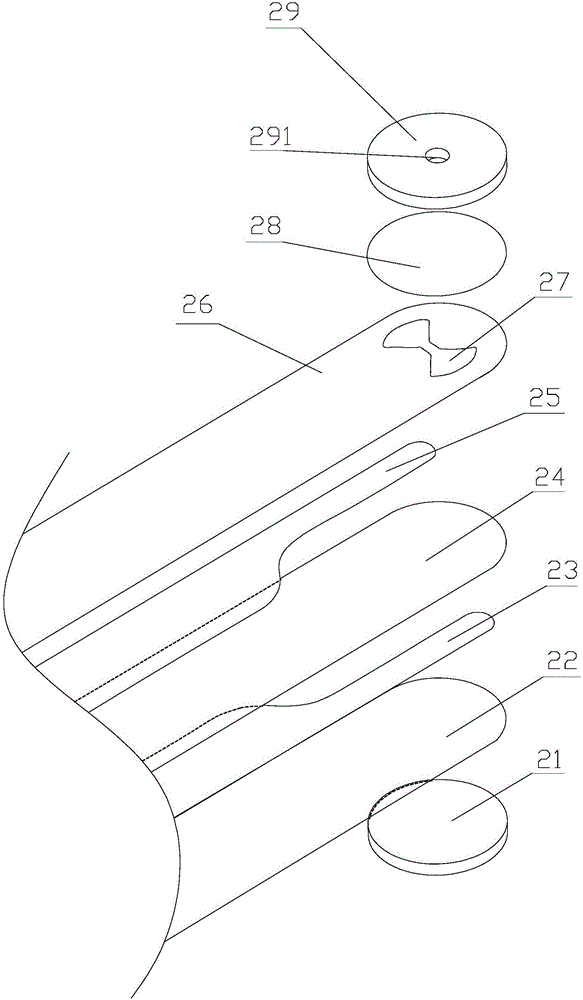

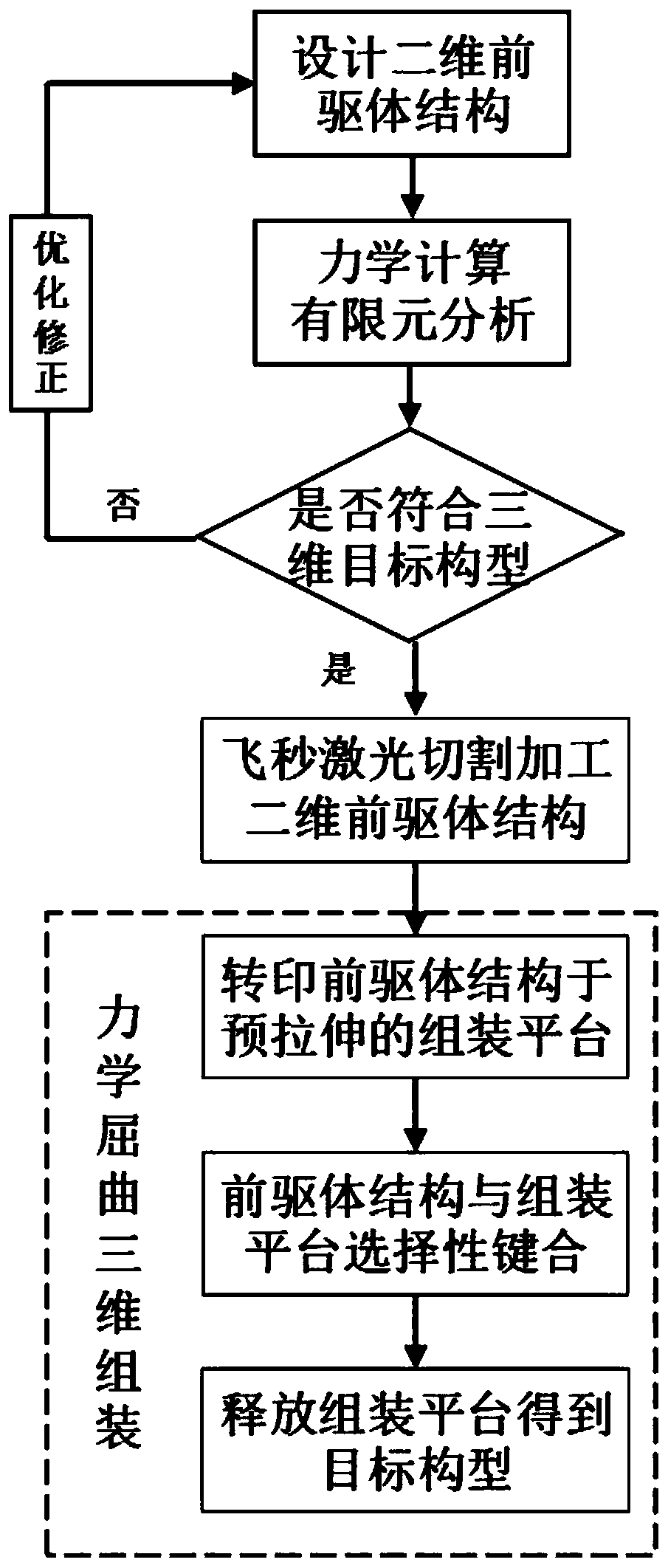

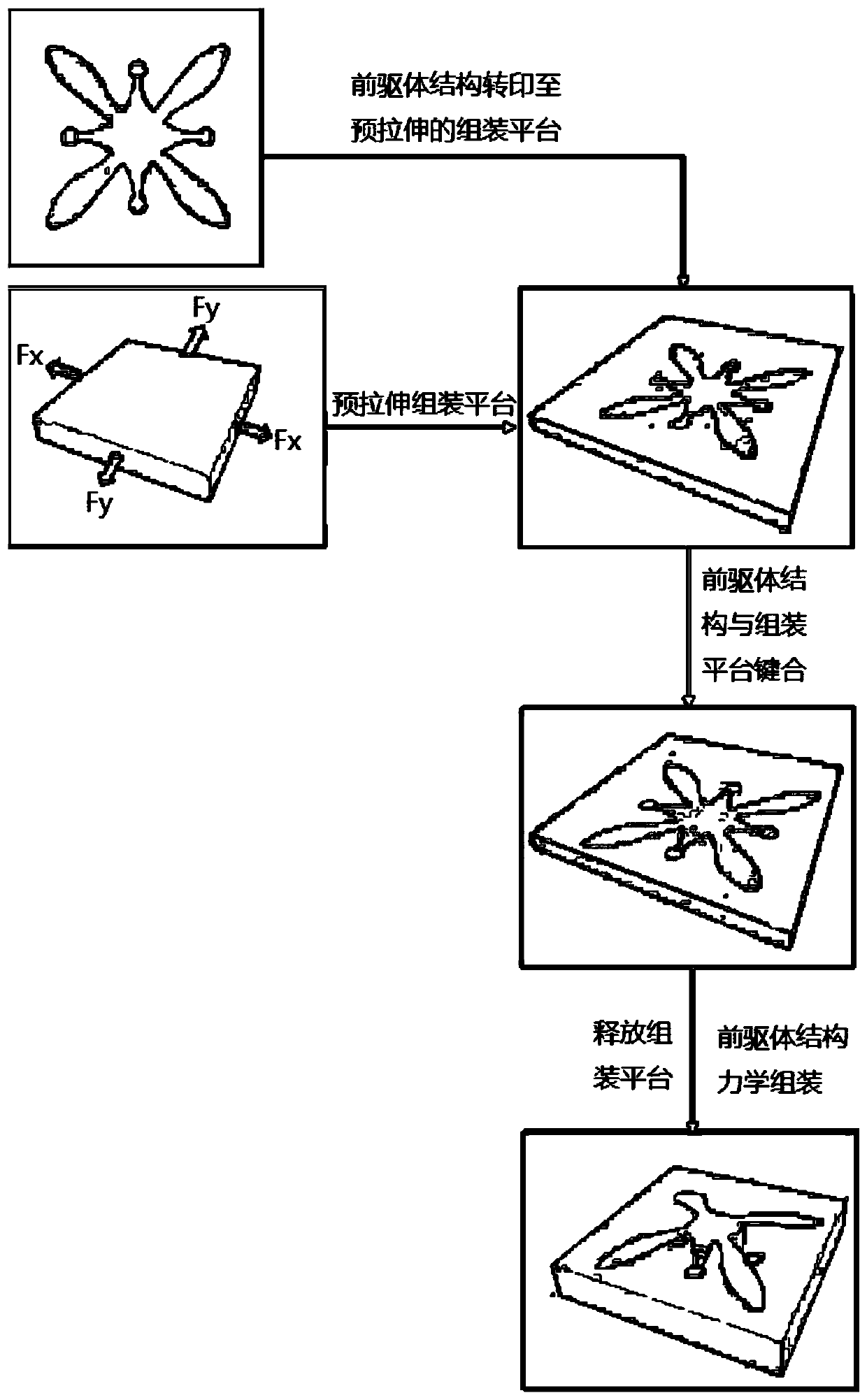

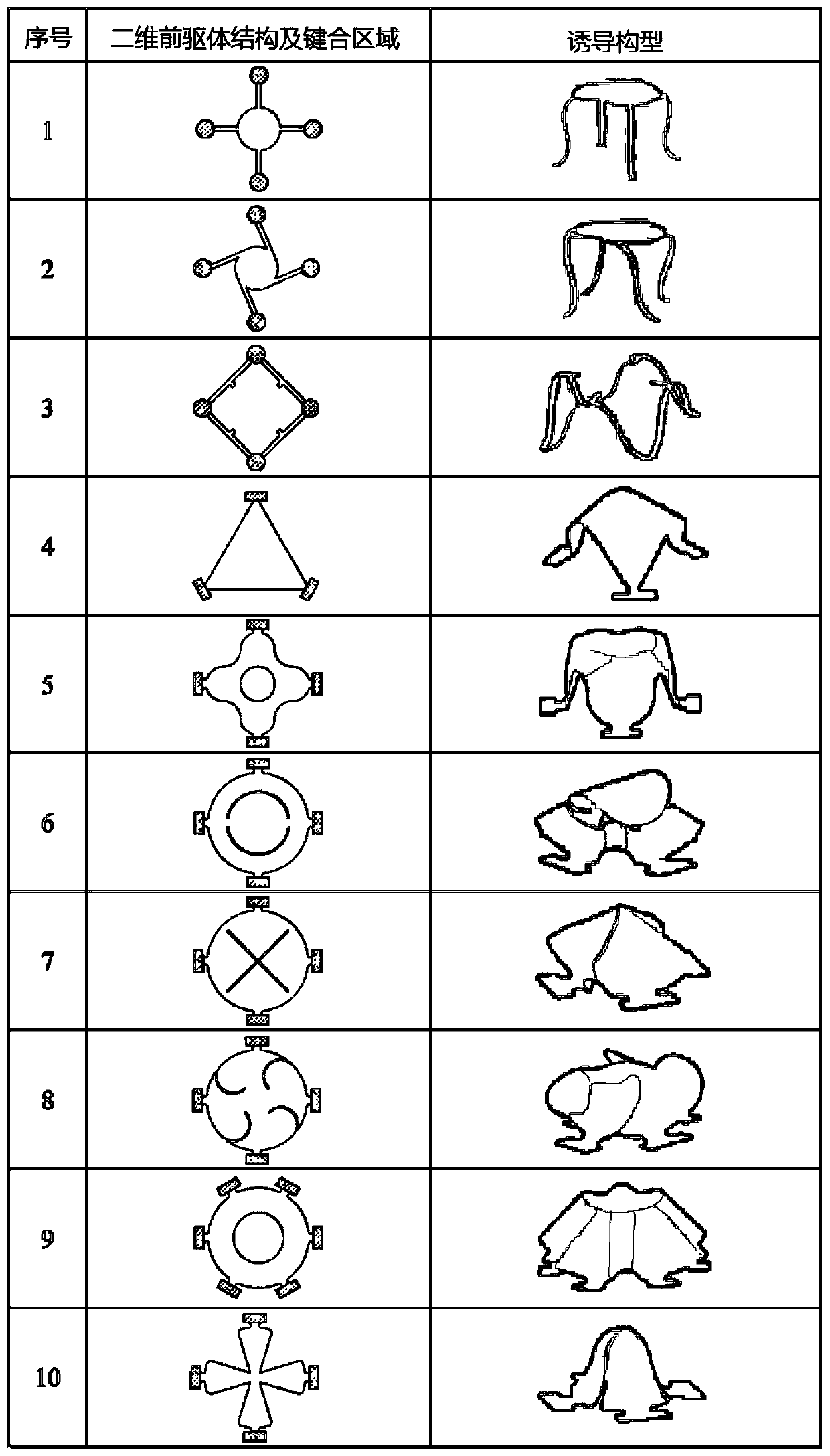

Non-photolithographic mesoscopic scale structure mechanical assembling and forming method

ActiveCN109455665APerformance not affected by processingImprove machining accuracyPrecision positioning equipmentDecorative surface effectsManufacturing technologyScale structure

The invention provides a non-photolithographic mesoscopic scale structure mechanical assembling and forming method used for obtaining a mesoscopic scale three-dimensional target configuration. The method comprises the following steps: a design step of designing a two-dimensional precursor structure corresponding to the target configuration and a pre-stretching dependent variable of an assembly platform used for forming the target configuration with the two-dimensional precursor structure through mechanical assembling and forming; a manufacturing step of cutting a two-dimensional planar material through femtosecond laser to form the two-dimensional precursor structure; a mechanical assembling and forming step of fixing the two-dimensional precursor structure at the assembly platform havingthe pre-stretching dependent variable, releasing the assembly platform to enable the two-dimensional precursor structure to at least partially flex and deform, and consequently forming the target configuration. The preparation method has high processing precision and is suitable for various high-performance materials, can efficiently and economically produce the mesoscopic scale structure with less chemical reagent, is environmental-friendly, and can be compatible to a semiconductor manufacturing technology.

Owner:TSINGHUA UNIV

High-precision anti-symmetric bimorph structure shape memory alloy and a preparation method thereof

ActiveCN109748233AWith shape memory functionAvoid external force interferenceDecorative surface effectsChemical vapor deposition coatingEtchingEvaporation

The invention relates to a high-precision anti-symmetric bimorph structure shape memory alloy and a preparation method thereof. A shape memory alloy film structure is manufactured by using a method ofelectron beam evaporation (E-beam Evaporation) and photoresist stripping (Lift-off Rest). A traditional ion sputtering method is not adopted to deposit the shape memory alloy thin film and then the structure is obtained through wet etching. Therefore, the structural feature size precision obtained by the preparation method provided by the invention only depends on the precision of the photoresist, and as the wavelength of the UV light of the exposure photoresist adopted by the invention is about 500 nanometers, the overall structural size precision reaches 0.5 micrometer and is 100 times of the precision (50 micrometers) of the current manufacturing method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

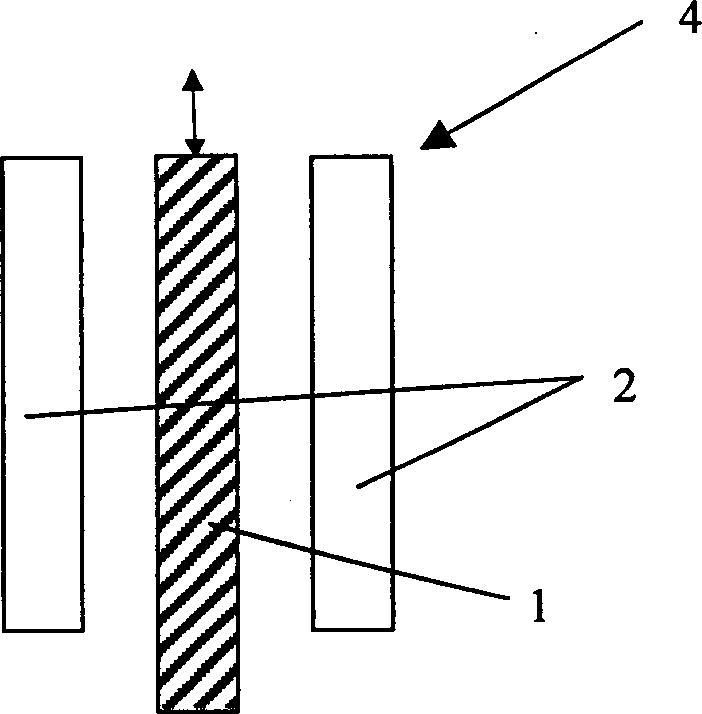

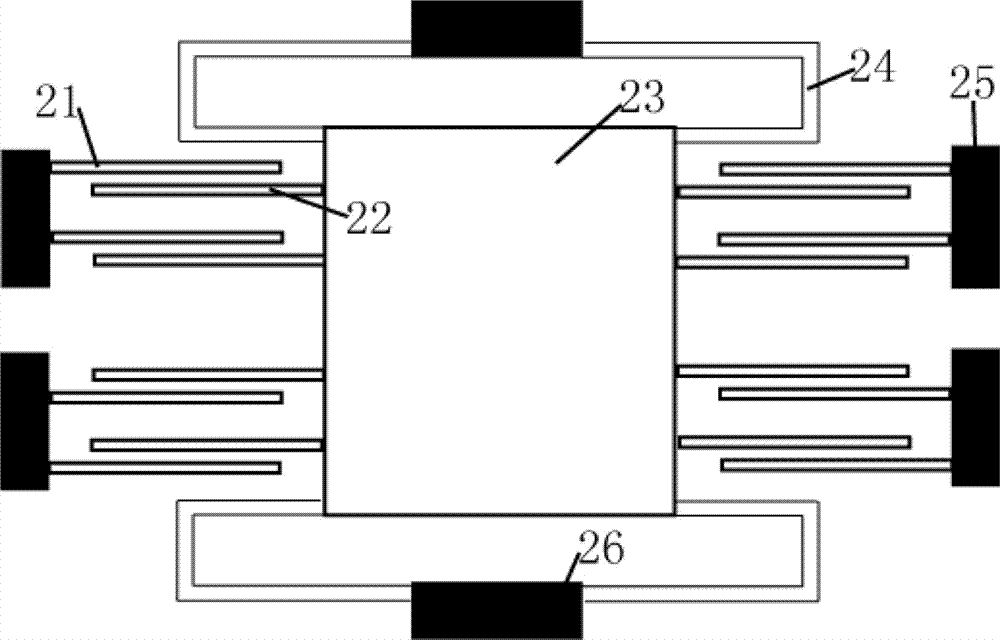

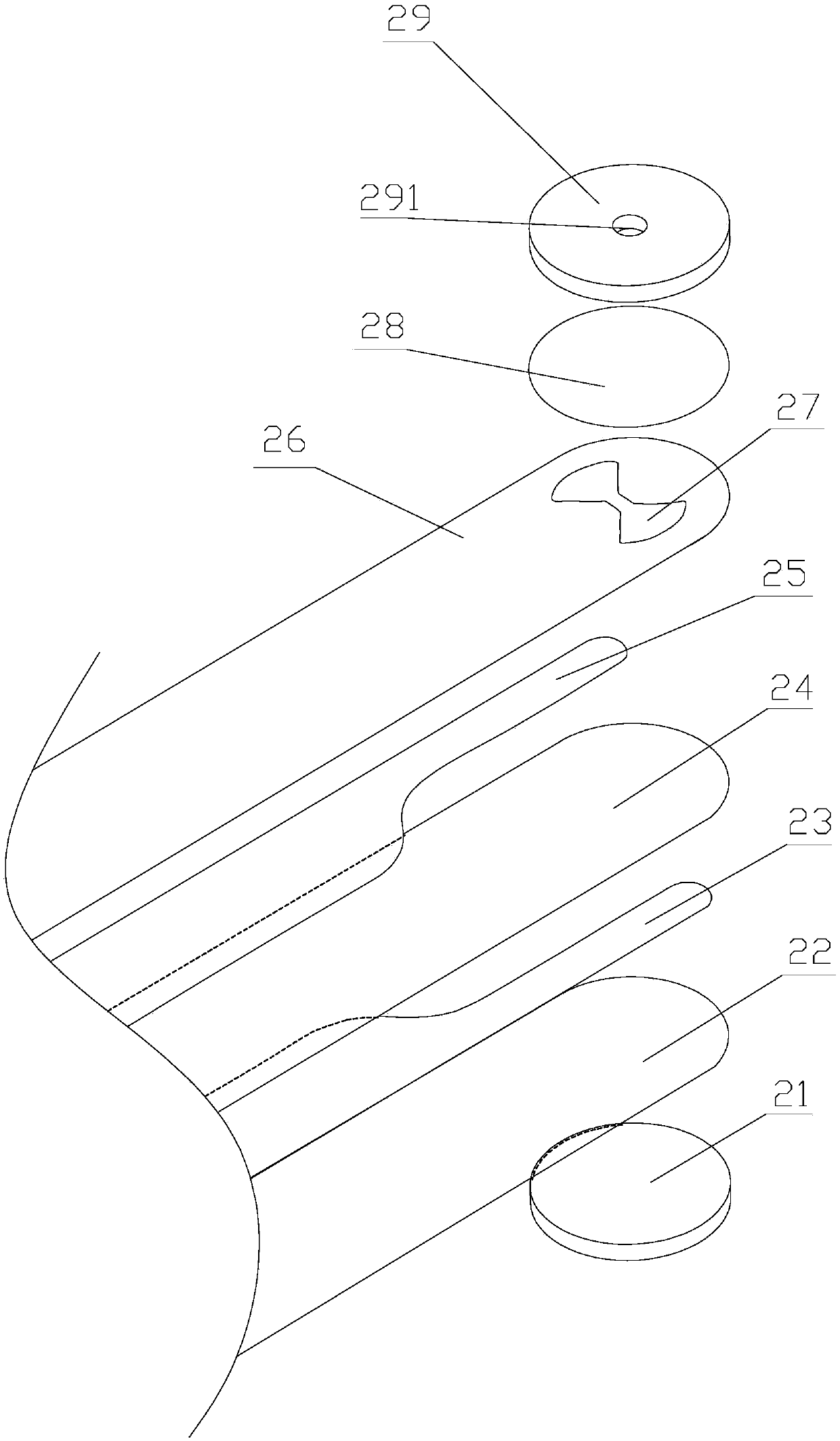

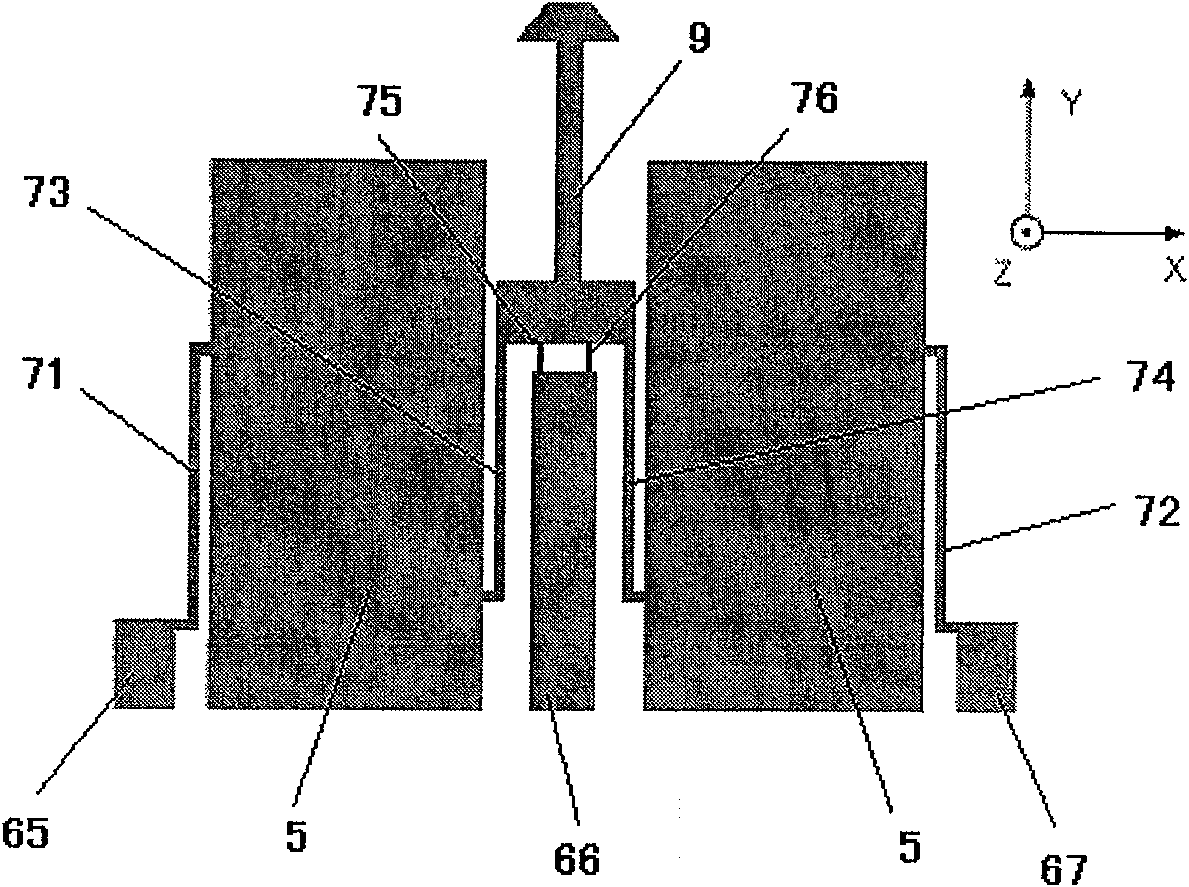

Minitype optical device and method for producing the same

ActiveCN101246259ASelf-aligningImprove controllabilityDecorative surface effectsPhotomechanical apparatusFiberComputer module

The invention relates to a micro type optics apparatus and the preparing process thereof, which is characterized in that: the apparatus includes fixed electrode, moveable electrode, supporting beam, glass substrate, light reflecting module and fiber fixed module; the fixed electrode includes the comb type fixed electrode connected to the double sides of the top surface of the glass substrate and the flat type fixed electrode fixed to the middle part of the glass substrate top surface; the moveable electrodes are two comb type moveable electrodes inserted equipped between the comb type fixed electrodes and two flat type movable electrodes equipped above the flat type fixed electrode; the supporting beam includes folding beam and combined torsion beam, the light reflecting module is the center above the fiber fixed module which is equipped with several fiber grooves in radiation type, and every fiber groove is separately focused to one of many light reflecting surfaces above the light reflecting module. The invention is easy to prepare, and is compatible with many kinds of types of MEMS components processes, which can be used for realizing more powerful micro optical integrated system.

Owner:PEKING UNIV

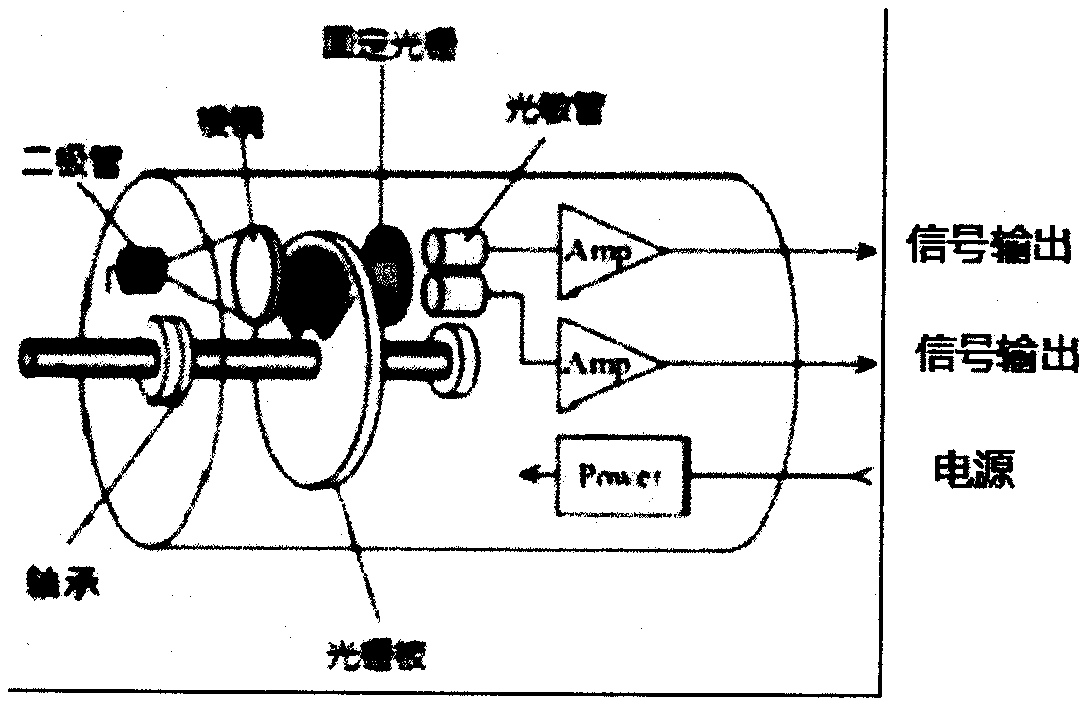

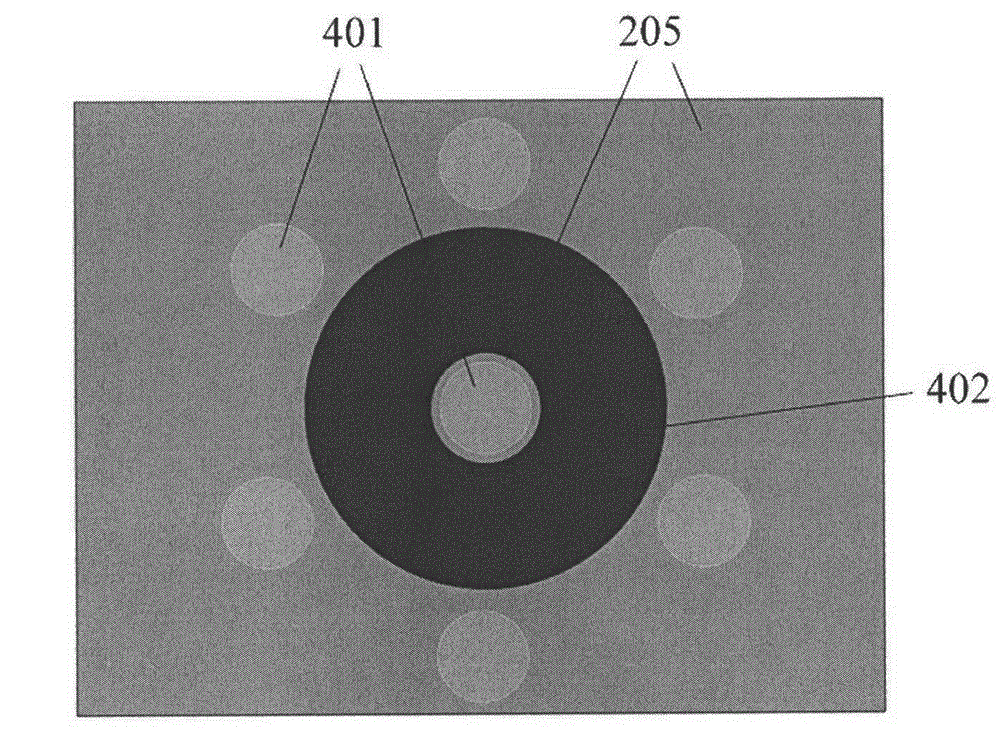

High-speed and high-precision photoelectric encoder with two-piece deployment

InactiveCN109357692AReduce installation componentsLarge installation toleranceConverting sensor outputIncremental encodingElectric machine

The invention relates to a photoelectric encoder suitable for various motors, in particular high-speed and high-precision motors, and supports 32 million lines and 600,000 rpm. The photoelectric encoder is divided into a passive optical coding component mounted on a rotor, a light source + photoelectric conversion + a data acquisition processing module mounted on a stator. The encoder supports absolute and incremental encoding. The passive optical components of different specifications are manufactured through mass production or precision machining in the form of matryoshka dolls by using integrated circuits or micro-electromechanical and precision mold processes. Higher speeds and resolutions are supported as the manufacturing processes are improved. The encoder uses a microlens array toincrease sensitivity, and uses the microlens array to form a spot of a special pattern, thereby increasing a tolerance threshold and facilitating to install and use. The performance indicators of thelight source, a photosensor, a lens array, the passive optical coding component, etc. used by the encoder are related to coding accuracy, the speed, and device size.

Owner:尹登庆 +1

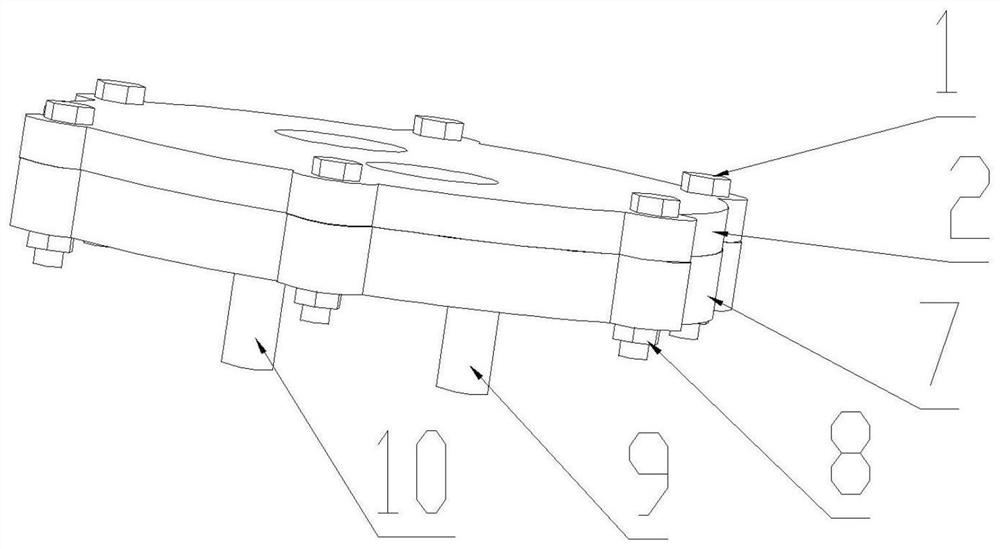

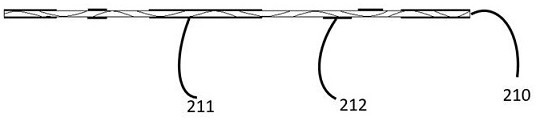

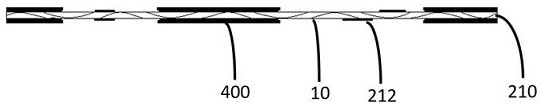

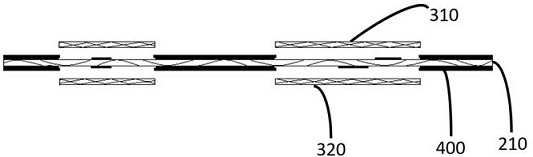

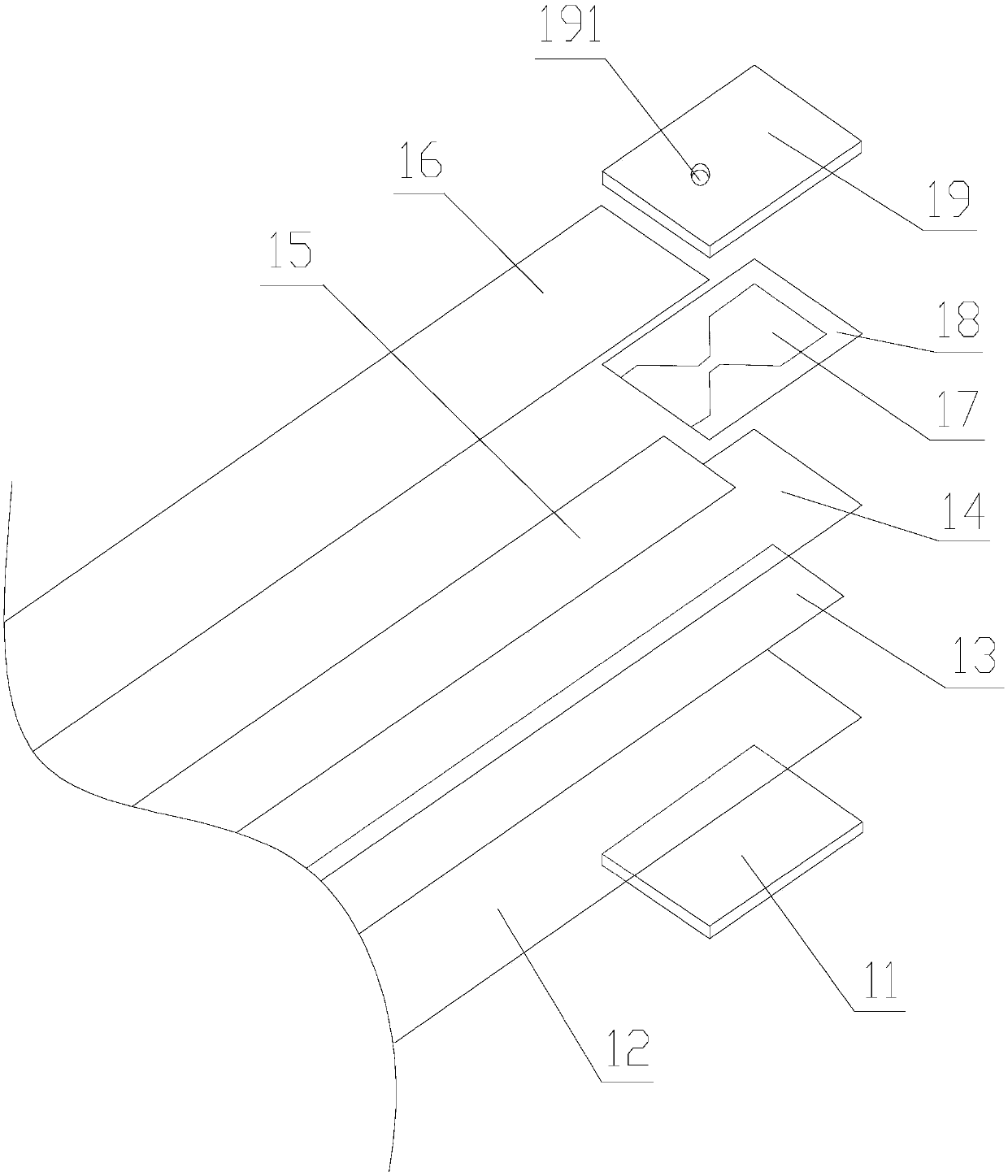

Integrated electrode slapper exploder

The invention discloses an integrated electrode slapper exploder. The integrated electrode slapper exploder comprises an integrated electrode assembly and an acceleration bore. A reflector plate is arranged on the lower surface of the end of the integrated electrode assembly in a matched mode. The acceleration bore is arranged on the upper surface of the end of the integrated electrode assembly. The end of the integrated electrode assembly is tightly clamped between the acceleration bore and the reflector plate. A slapper layer and explosion foil are stacked up and down to be located between the acceleration bore and the end of the integrated electrode assembly. An acceleration bore hole is formed in the position, corresponding to the center of the explosion foil, of the acceleration bore. The integrated electrode assembly is formed by sequentially pressing a lower insulating layer, a lower electrode core layer, a middle insulating layer, an upper electrode core layer, an upper insulating layer, the explosion foil and the slapper layer. The lower electrode core layer is in circuit connection with one end of the explosion foil, and the upper electrode core layer is in circuit connection with the other end of the explosion foil. According to the integrated electrode slapper exploder, the upper electrode core layer, the explosion foil and the lower electrode core layer form a circuit loop. After the explosion foil is powered up, electrical explosion can generate plasma to impact the slapper layer, the slapper layer is made to fly out of the acceleration bore hole of the acceleration bore, and percussion charging is performed to achieve the detonation function of slappers.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Large-scale welding method for carbon nano tube devices

InactiveCN102115029AFast welding speedNo damage to other structuresNanostructure manufactureDielectrophoresisElectrode pair

The invention relates to a large-scale welding method for carbon nano tube devices. A carbon nano tube is deposited on a wafer including a graphical electrode by adopting a dielectrophoresis method, the wafer is placed on a carrying table of a radio-frequency induction heating system for heating for a short time, the wafer is cooled under the condition of vacuum or protective gas, a heating coil is set according to an electrode pattern. The welding method includes the following steps of: A. dispersing carbon nano tubes; B. connecting a positioning and orientating bridge of the nano tubes between an electrode pair; and C. connecting the carbon nano tubes with the electrode in a welding manner. The large-scale welding method has the advantages of adopting a radio-frequency induction heating method, being simple in process, fast in welding speed, good in repeatability and high in reliability, and being capable of realizing production on a large scale, and realizing large-scale effective welding of the wafer-level carbon nano tube devices.

Owner:HUAZHONG UNIV OF SCI & TECH

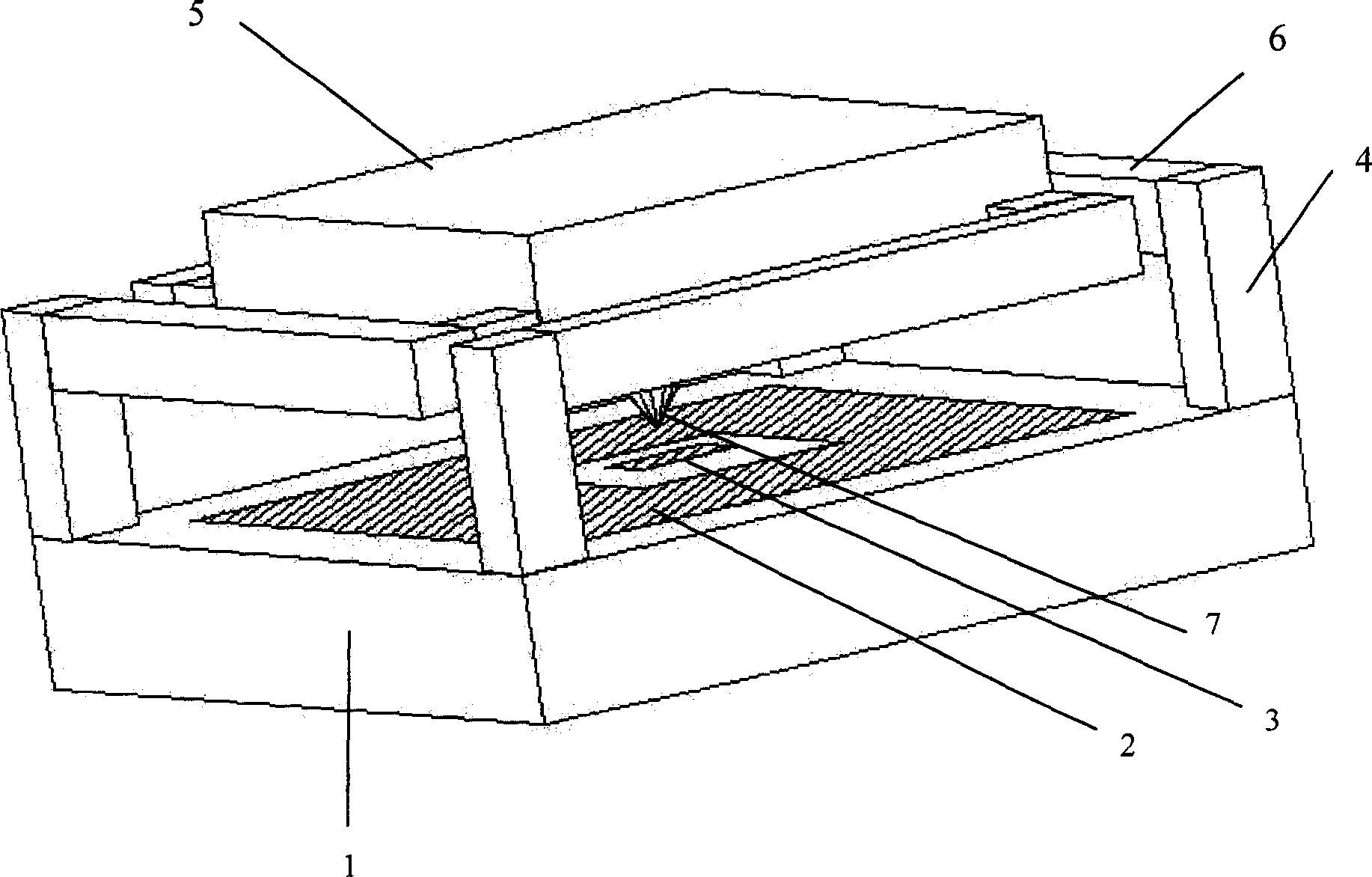

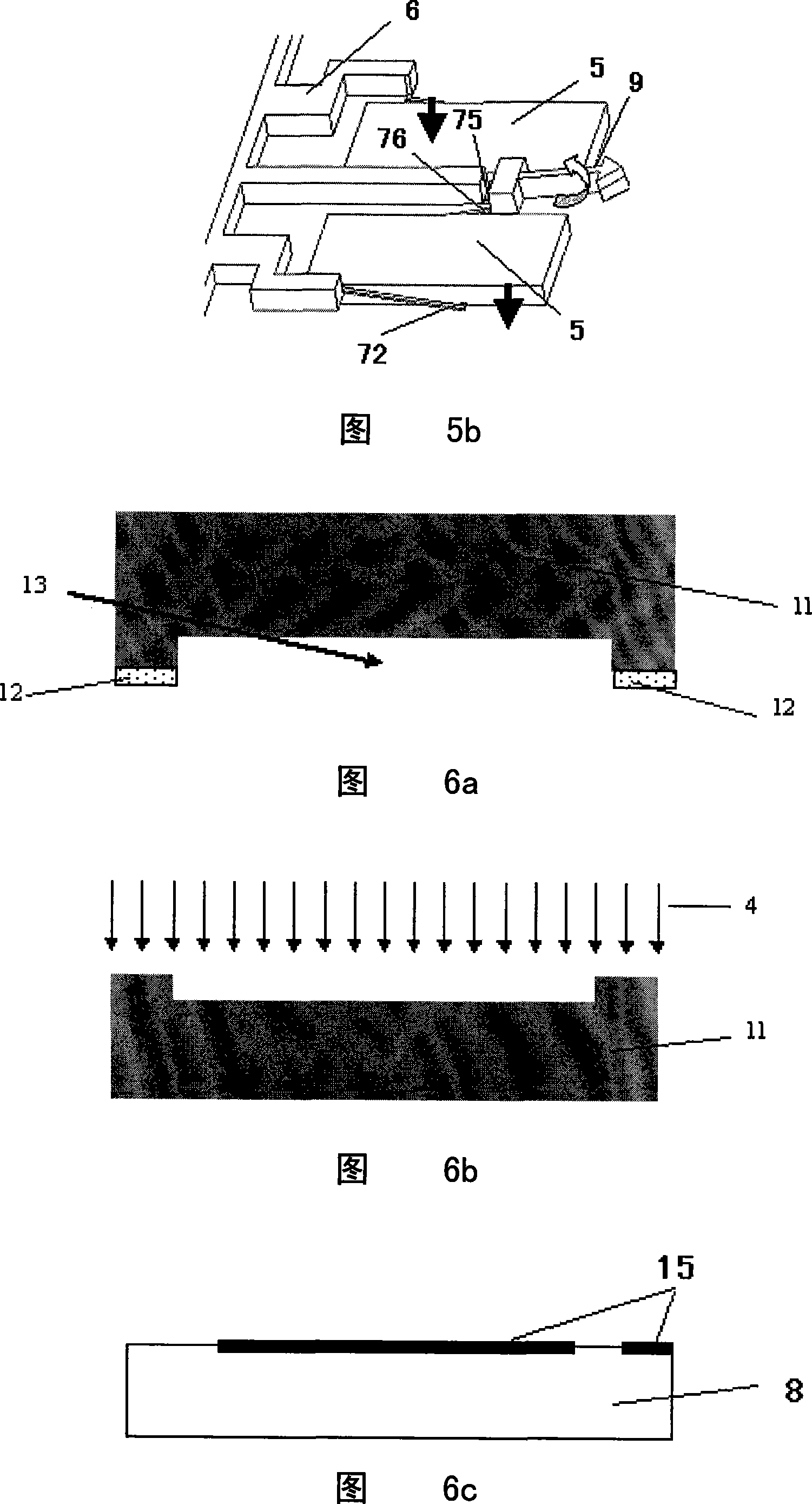

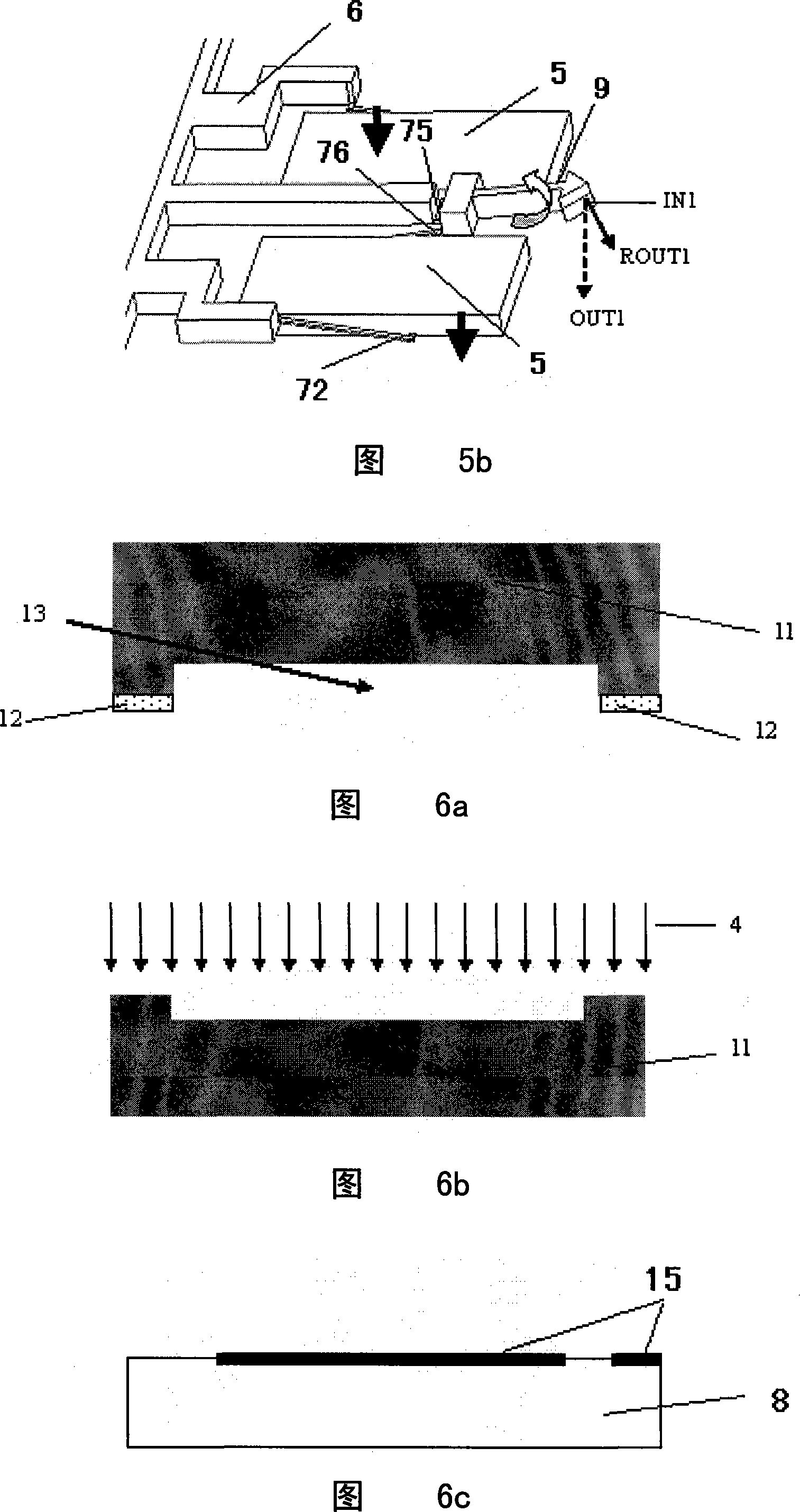

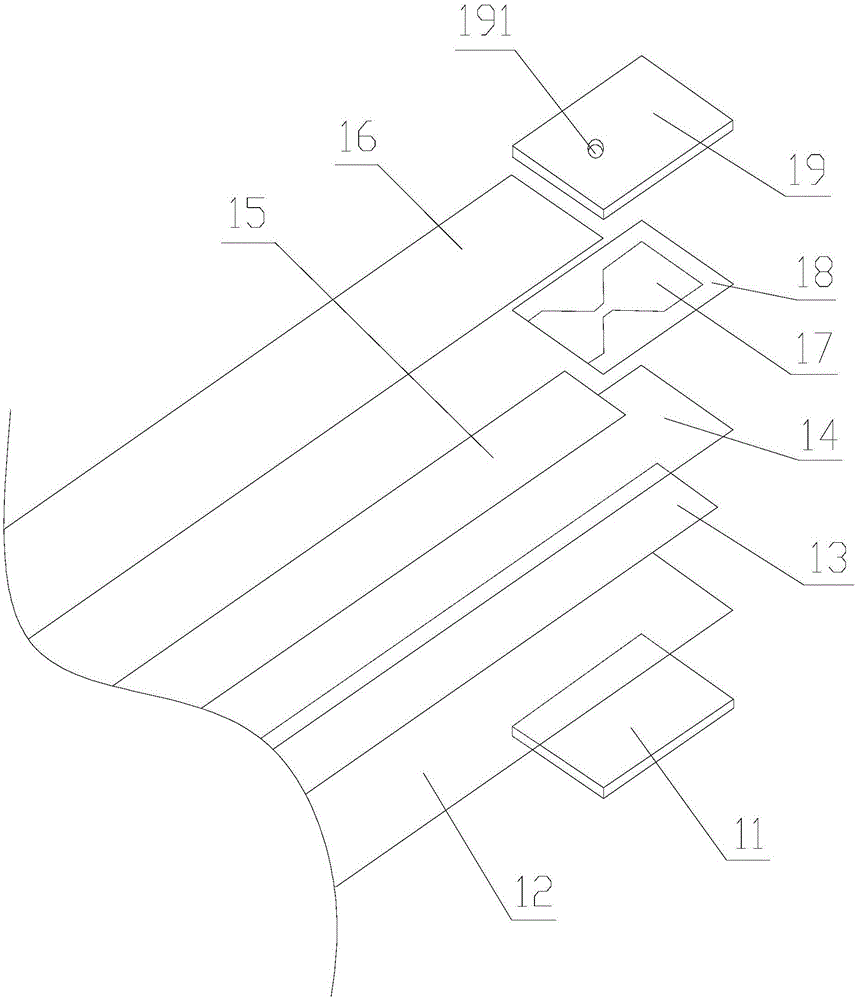

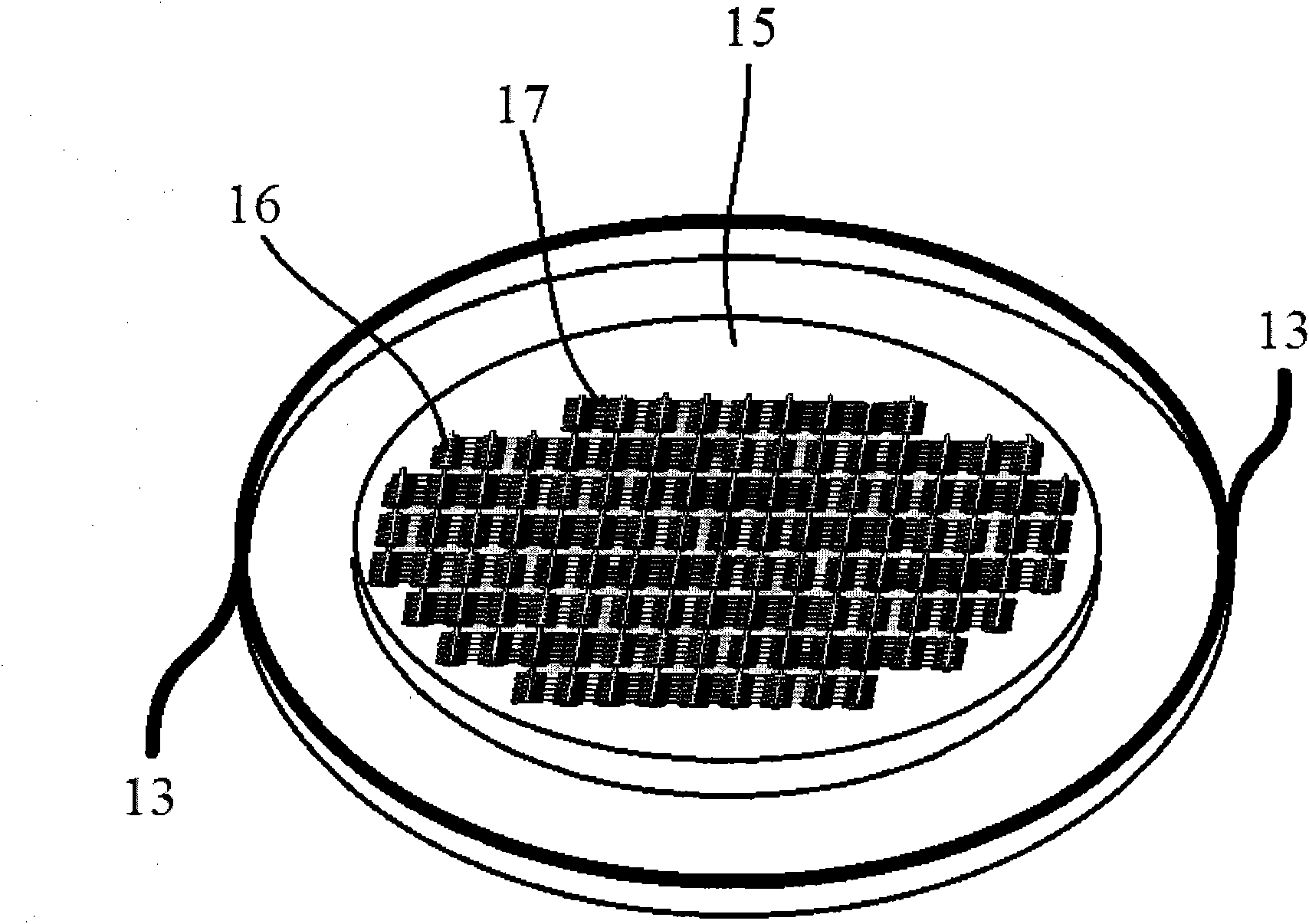

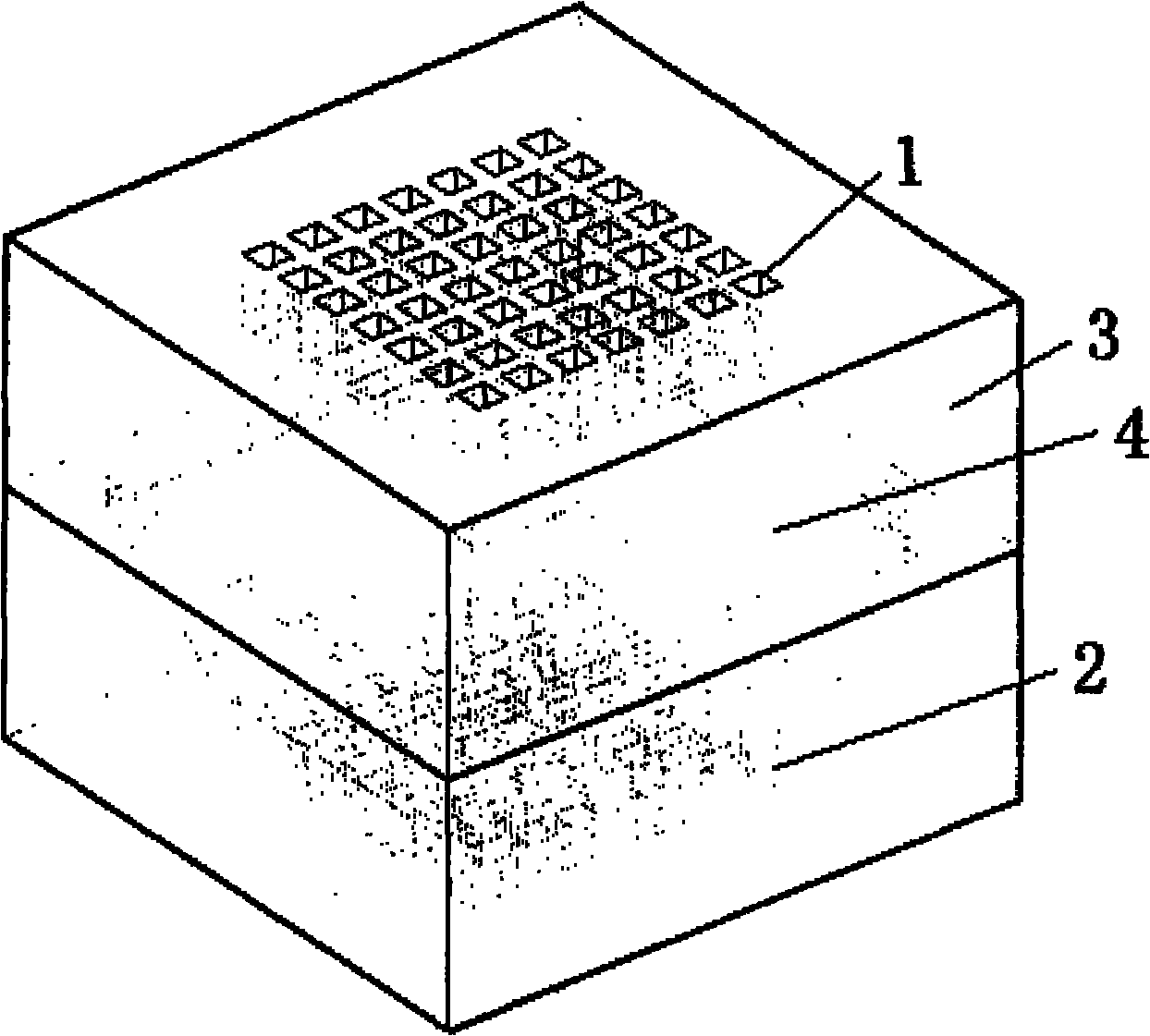

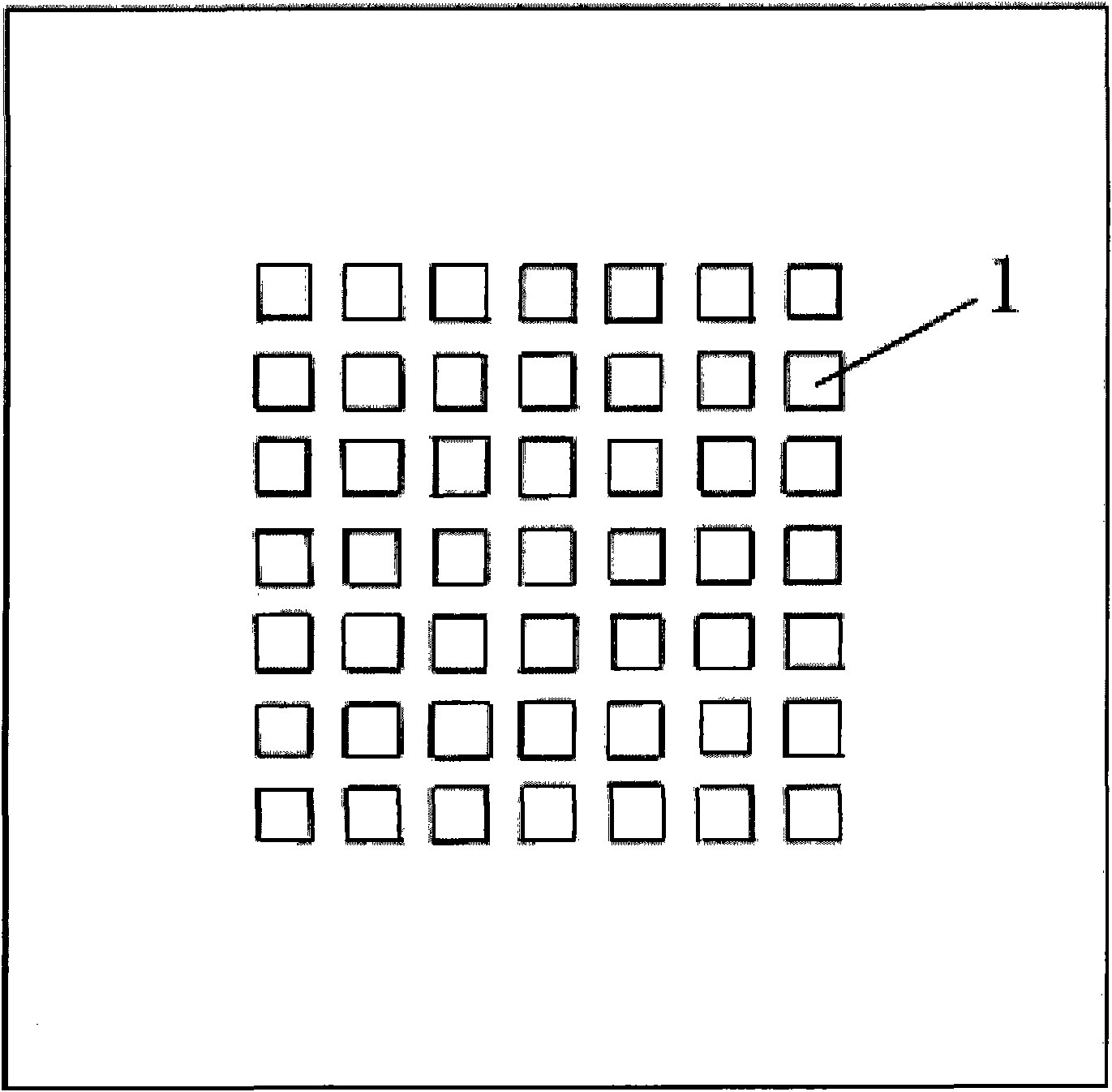

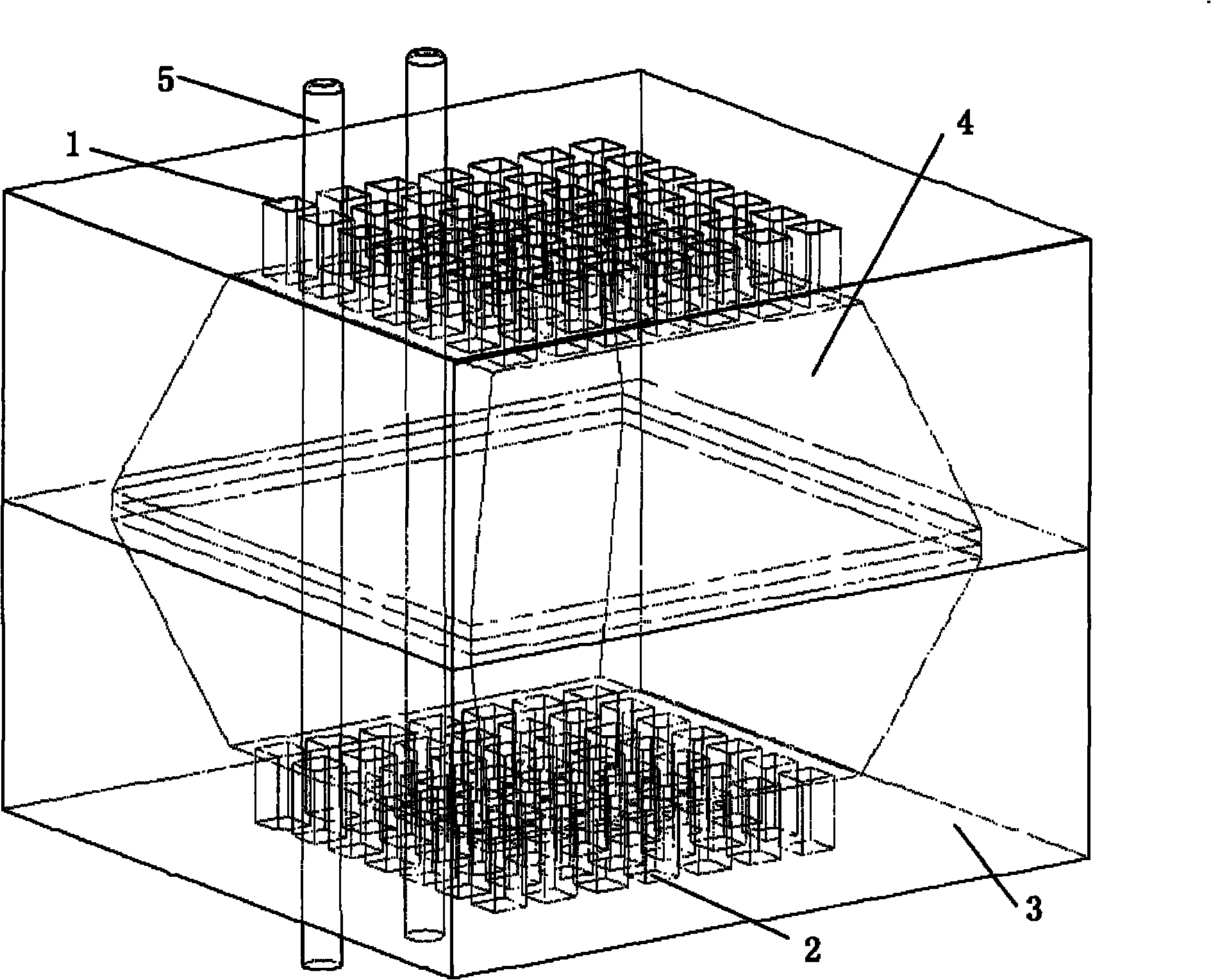

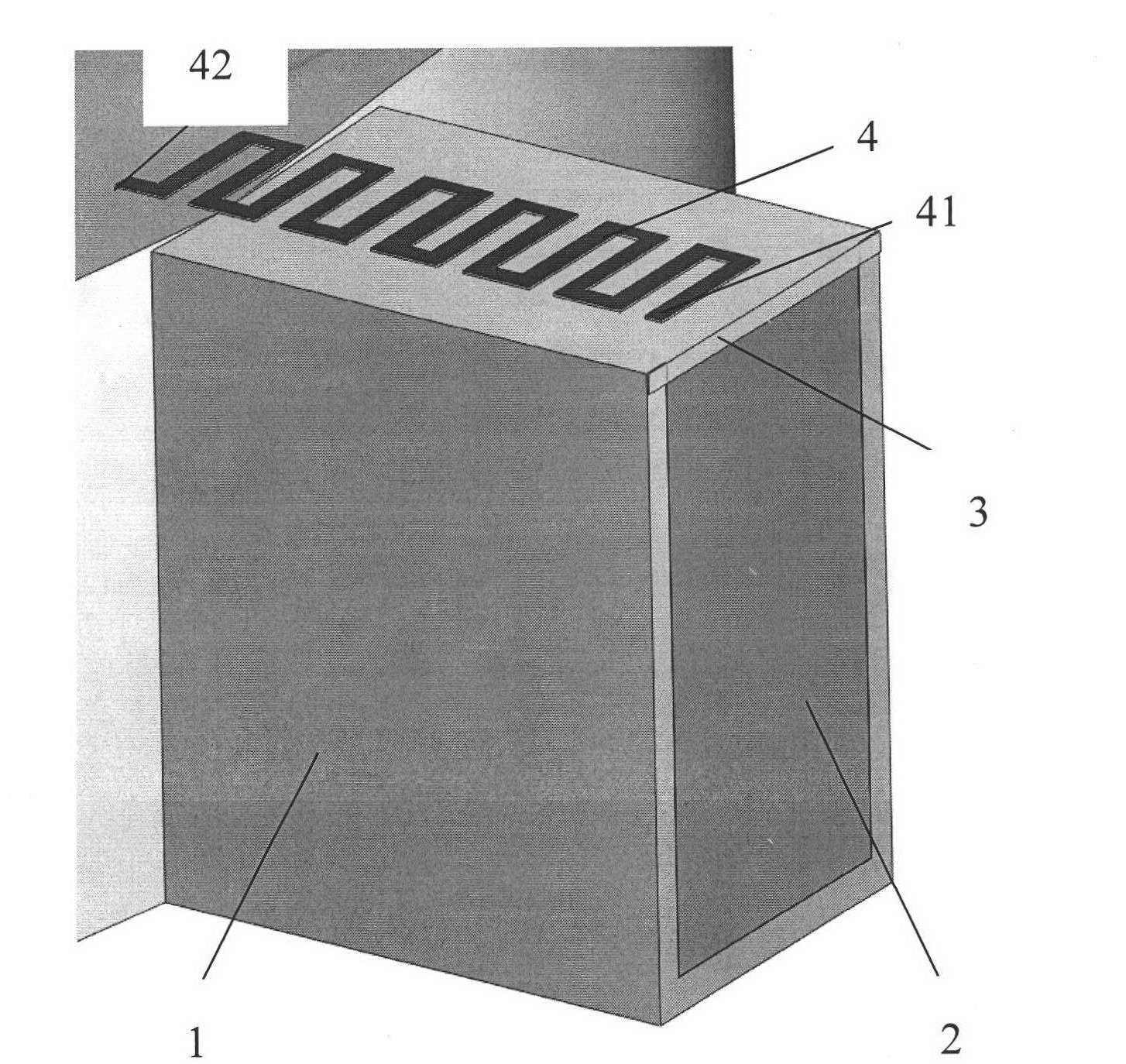

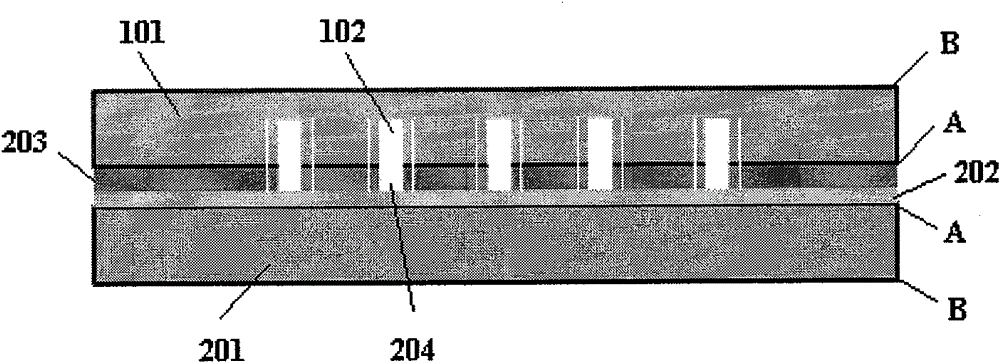

Optical fiber array fixing device and manufacturing method thereof

InactiveCN102062897APrecise positioningReduce difficultyOptical waveguide light guideProcess equipmentFiber array

The invention relates to an optical fiber array fixing device and a manufacturing method thereof. The optical fiber array fixing device comprises a base, and an optical fiber fixing hole array which consists of a plurality of the same optical fiber fixing holes, wherein the optical fiber fixing hole array is arranged on upper and lower end faces of the base; the optical fiber fixing holes of the upper and lower end faces are in one-to-one correspondence; and a cavity is formed between the optical fiber fixing holes of the upper and lower end faces. The optical fiber array fixing device is suitable for medium-scale and large-scale two-dimensional (2D) optical switches, large-scale three-dimensional (3D) optical switches and the like, and has high expandability; optical fibers can be accurately and stably positioned by the optical fiber fixing holes defined by high-precision photolithography, so that the difficulty and cost of encapsulation are reduced. In the manufacturing method, the conventional micro-electromechanical system (MEMS) process equipment can be adopted, large-scale manufacturing is realized, the process is simple, and the manufacturing method is compatible with various types of MEMS device processes and can be used for realizing a micro-optical integrated system with wider and stronger functions.

Owner:PEKING UNIV

Horizontal axis micromechanical gyroscope and its preparation method

InactiveCN100449265CSmall dampingHigh sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesElectricityCapacitance

The product comprises: an outer / inner frame, a drive electrode and a drive feedback electrode both with two group of lateral comb-tooth capacitors and movable electrodes connected to the outer frame, a drive-modal elastic beam, a detection electrode with two group of unequal vertical comb-tooth capacitors for difference detection with movable electrode connected to the inner frame, a detect-modal elastic beam as four group of combined torsion beams everyone with ends connected to former inner / outer frame respectively, and an anchor point fixed on substrate bottom and connected to the outer frame through the drive-modal beam. This invention is simple and fit to large-scale production, compatible to Z-axis gyro and accelerometer, and can be used for MIMU.

Owner:PEKING UNIV

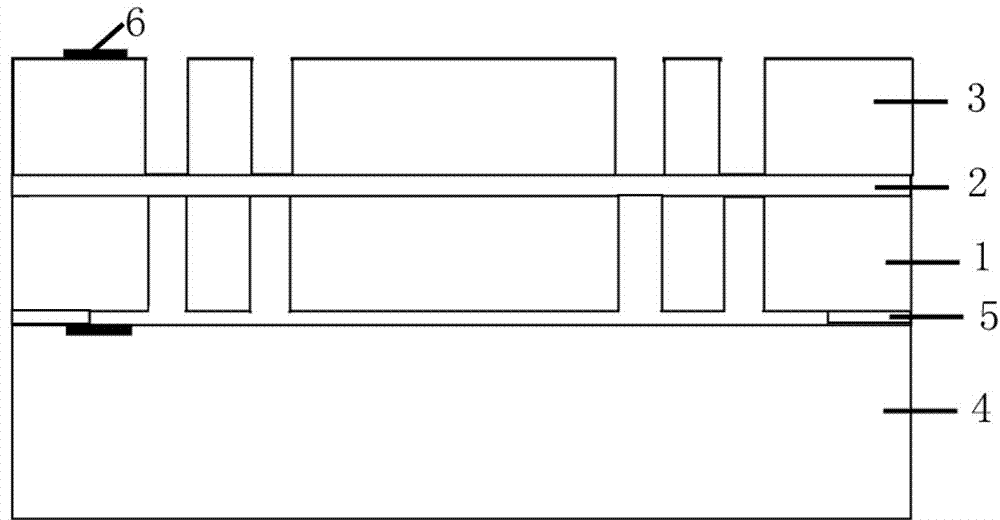

Comb capacitive micro accelerometer

InactiveCN104133080BIncrease the areaQuality improvementAcceleration measurementCapacitanceAccelerometer

The invention discloses a comb-tooth capacitive micro-accelerometer, which comprises a substrate layer, an insulating layer, a structural layer and a base layer arranged from top to bottom, the insulating layer is arranged between the substrate layer and the structural layer; Both are equipped with metal lead electrodes. The invention doubles the detection capacitance without increasing the area of the device, increases the weight of the mass block, increases the flexibility of the design, can improve the measurement accuracy, and can use dry etching, with good size control and simple process, and can realize Manufactured in high volumes.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

A non-lithographic method for mechanical assembly and molding of mesoscopic-scale structures

ActiveCN109455665BPerformance not affected by processingImprove machining accuracyPrecision positioning equipmentDecorative surface effectsManufacturing technologyEngineering

The invention provides a non-photolithographic mesoscopic scale structure mechanical assembling and forming method used for obtaining a mesoscopic scale three-dimensional target configuration. The method comprises the following steps: a design step of designing a two-dimensional precursor structure corresponding to the target configuration and a pre-stretching dependent variable of an assembly platform used for forming the target configuration with the two-dimensional precursor structure through mechanical assembling and forming; a manufacturing step of cutting a two-dimensional planar material through femtosecond laser to form the two-dimensional precursor structure; a mechanical assembling and forming step of fixing the two-dimensional precursor structure at the assembly platform havingthe pre-stretching dependent variable, releasing the assembly platform to enable the two-dimensional precursor structure to at least partially flex and deform, and consequently forming the target configuration. The preparation method has high processing precision and is suitable for various high-performance materials, can efficiently and economically produce the mesoscopic scale structure with less chemical reagent, is environmental-friendly, and can be compatible to a semiconductor manufacturing technology.

Owner:TSINGHUA UNIV

High precision tunnel type accelerometer and preparation method thereof

InactiveCN100356177CHigh sensitivityReduce internal stressAcceleration measurement using interia forcesAccelerometerAnodic bonding

This invention provides a high accurate tunnel accelerometer structure and its process method, which comprises the following steps: first etching on the silicon pad and determining the initial distance between tunnel head to the electrode; keeping etching the tunnel head and depositing metal on the head as tunnel current emission electrode; processing drive electrode and tunnel head electrode on the glass underlay; positive electrode bonding to realize the underlay and silicon pad alignment and sticking; etching the silicon back with dry deep groove etching process to generate supportive beam; keeping etching silicon pad back to generate mass block and releasing structure to get the accelerometer.

Owner:PEKING UNIV

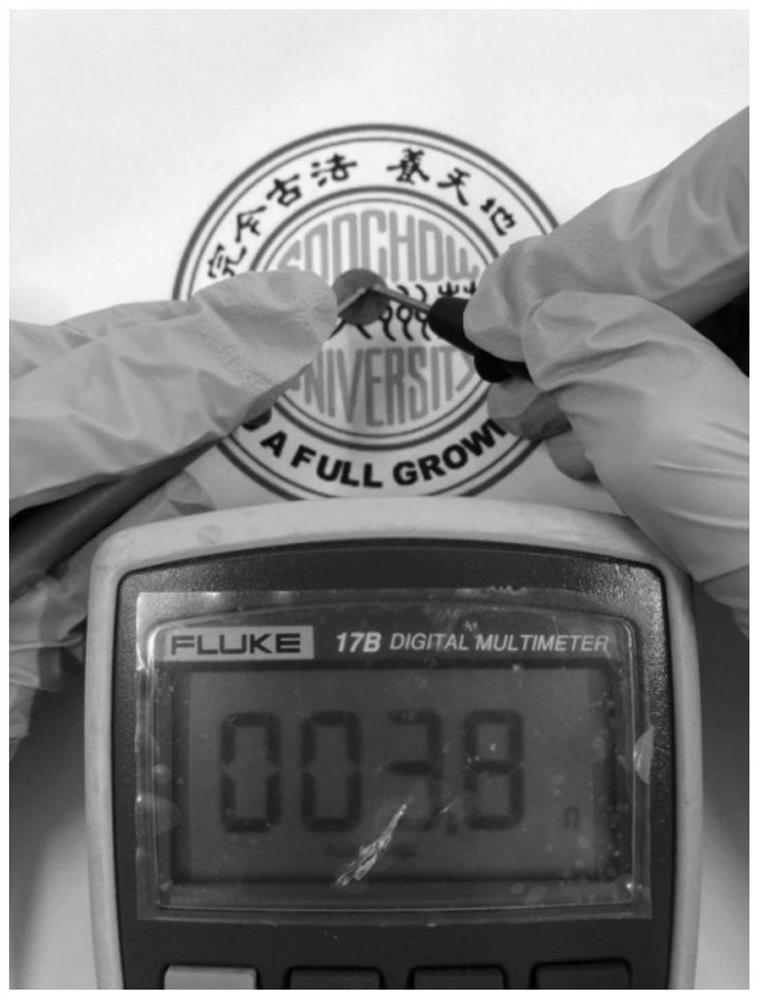

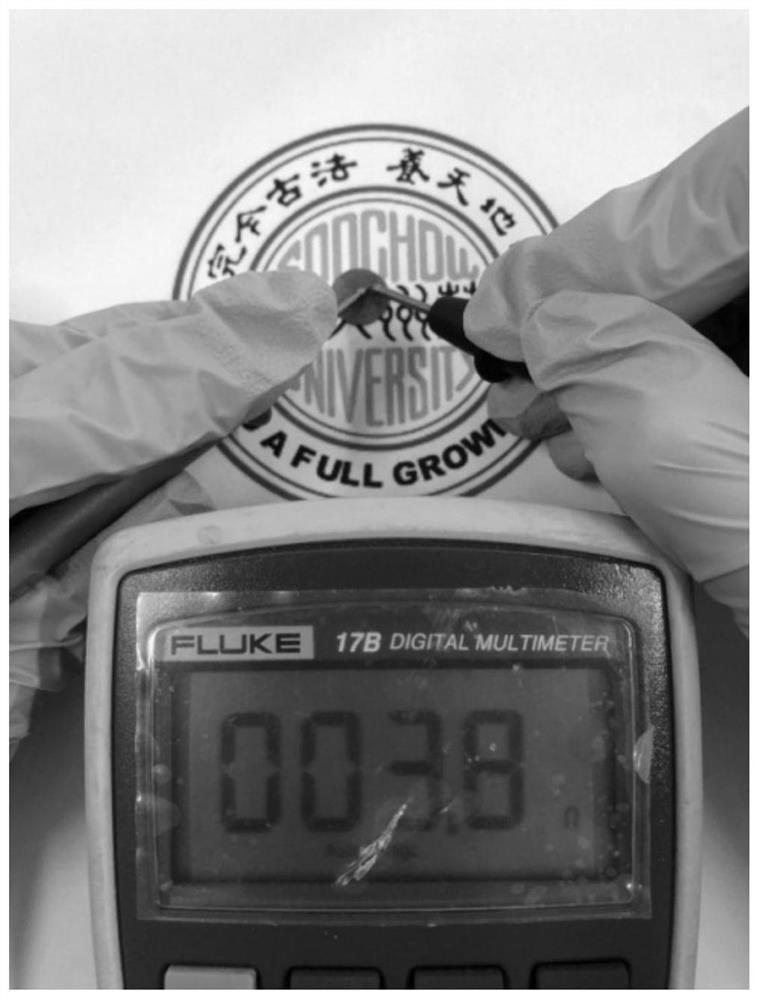

Lithium metal secondary battery based on porous ceramic composite lithium metal negative electrode and preparation method thereof

ActiveCN110890530BSolve insufficient storage spaceEnsure structural stabilityCell electrodesFinal product manufacturePorous ceramicsBattery cell

The invention belongs to the field of high specific energy lithium metal batteries, and specifically discloses a lithium metal secondary battery based on a porous ceramic composite lithium metal negative electrode and a preparation method thereof; the porous ceramic lithium metal negative electrode consists of a porous ceramic skeleton, a conductive layer, a lithium metal Composition, compared with the traditional lithium sheet negative electrode, the advantage of the porous ceramic lithium metal negative electrode disclosed by the present invention is: the porosity of the porous ceramic framework can provide sufficient storage space for lithium metal; the rigidity of the porous ceramic framework can maintain the lithium metal negative electrode Structural stability; the large specific surface area of the porous ceramic framework can effectively reduce the local current density of the lithium metal anode and alleviate the growth of lithium dendrites. Based on the above advantages, the porous ceramic lithium metal composite negative electrode of the present invention can be used to prepare high specific energy lithium metal secondary batteries, and at the same time, the preparation method is simple, and mass production can be realized.

Owner:SUZHOU UNIV

A kind of porous ceramic composite lithium metal negative electrode and preparation method thereof

ActiveCN110957477BSolve insufficient storage spaceEnsure structural stabilityFuel and secondary cellsNegative electrodesAll solid stateElectrical battery

The invention belongs to the field of high specific energy lithium metal batteries, and specifically discloses a porous ceramic composite lithium metal negative electrode and a preparation method thereof; the porous ceramic lithium metal negative electrode is composed of a porous ceramic skeleton, a conductive layer, and lithium metal, and is the same as a traditional lithium sheet Compared with the negative electrode, the advantages of the porous ceramic lithium metal negative electrode disclosed by the present invention are: the porosity of the porous ceramic skeleton can provide sufficient storage space for lithium metal; the rigidity of the porous ceramic skeleton can maintain the structural stability of the lithium metal negative electrode; the porous ceramic The large specific surface area of the framework can effectively reduce the local current density of the lithium metal anode and alleviate the growth of lithium dendrites; the composite anode has high structural strength, high Coulombic efficiency, low polarization, no lithium dendrites, and good cycle stability. characteristics, at the same time, the preparation method is simple, and mass production can be realized. The porous ceramic lithium metal composite negative electrode of the present invention can be used to prepare high specific energy lithium metal secondary batteries, including organic electrolyte system lithium-ion batteries and lithium-air batteries, all-solid lithium-ion batteries and lithium-air batteries, and the like.

Owner:SUZHOU UNIV

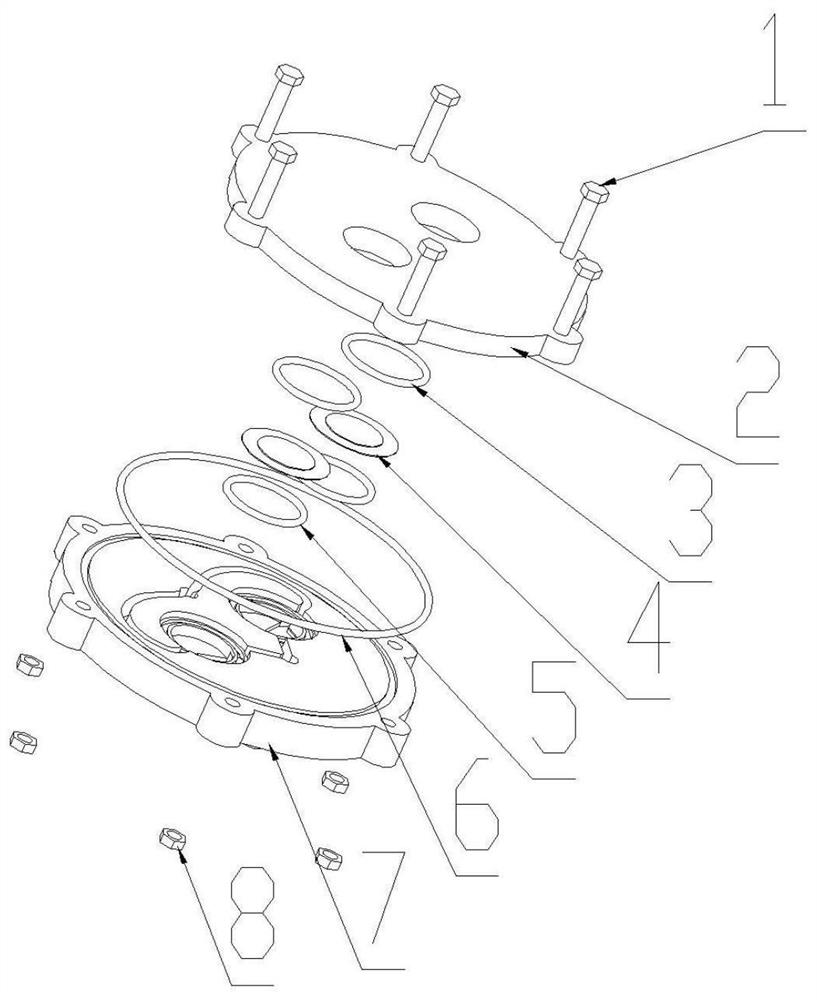

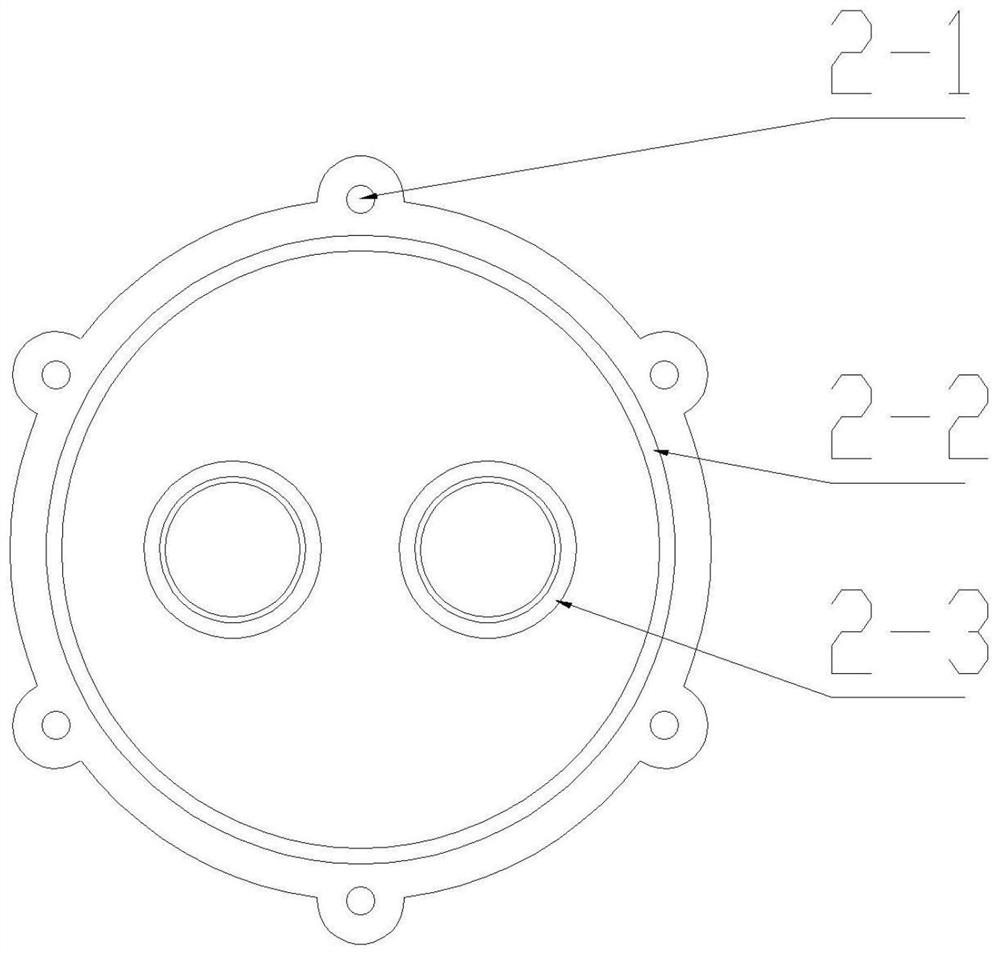

Double-cavity valveless piezoelectric pump provided with convolution line flow pipes and having computer CPU water cooling function

InactiveCN113107818ASimple structureSmall structurePositive displacement pump componentsDigital data processing detailsEngineeringMechanical engineering

The invention discloses a double-cavity valveless piezoelectric pump provided with convolution line flow pipes and having a computer CPU water cooling function. The double-cavity valveless piezoelectric pump comprises a hexagon head bolt, a pump cover, an O-shaped ring, a piezoelectric vibrator, an annular ring, a sealing ring, a pump body, a nut, an inlet pipe and an outlet pipe. The pump body is provided with a hexagonal head bolt hole, a sealing ring groove, a second flow channel, an annular ring groove, a pump cavity, a first flow channel, a liquid inlet and a liquid outlet. The pump body and the piezoelectric vibrator are connected in a sealed manner. The bottom of the pump cavity protrudes to form a sector with the central angle of 225 degrees. The piezoelectric pump utilizes the piezoelectric vibrator to generate volume change of the pump cavity so as to realize directional conveying of fluid; the two convolution line flow pipes and the sector-shaped pump cavity are arranged, so that the pump-out amount is increased; the piezoelectric pump has the advantages of small size, low power consumption, no electromagnetic interference, simple structure and the like; and the piezoelectric pump has the wide market prospects in the fields of computer chip cooling and the like.

Owner:CHANGCHUN UNIV OF TECH

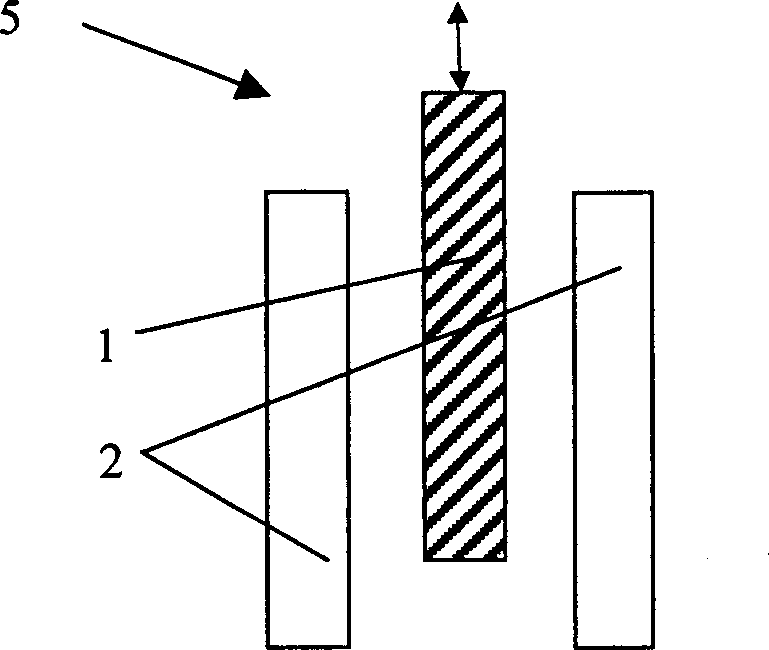

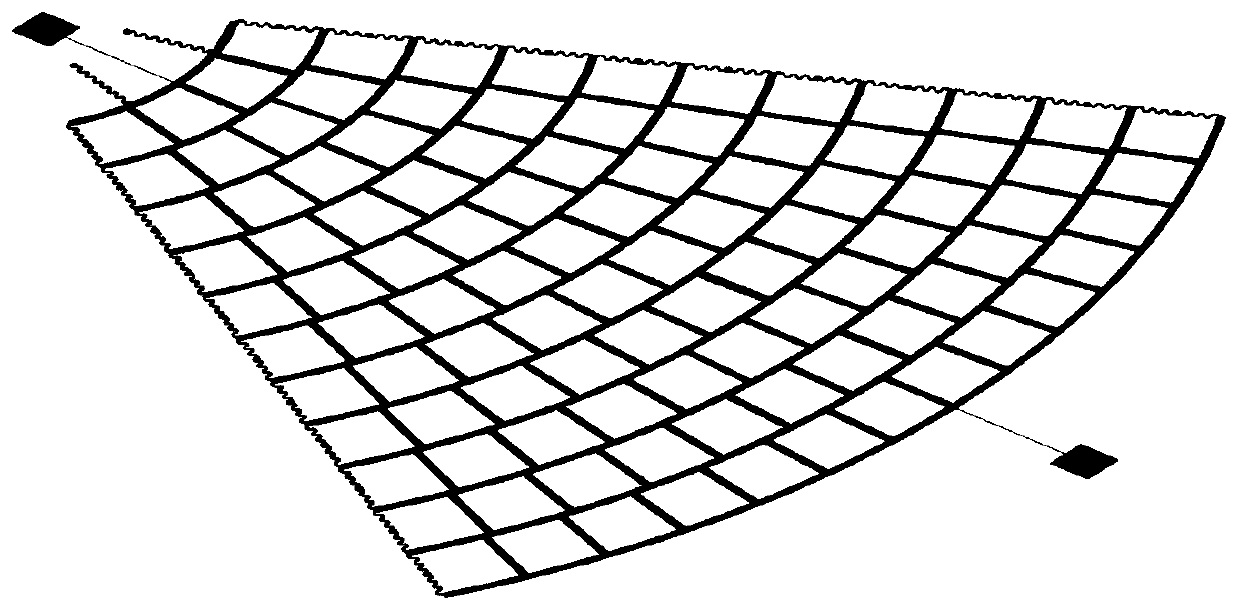

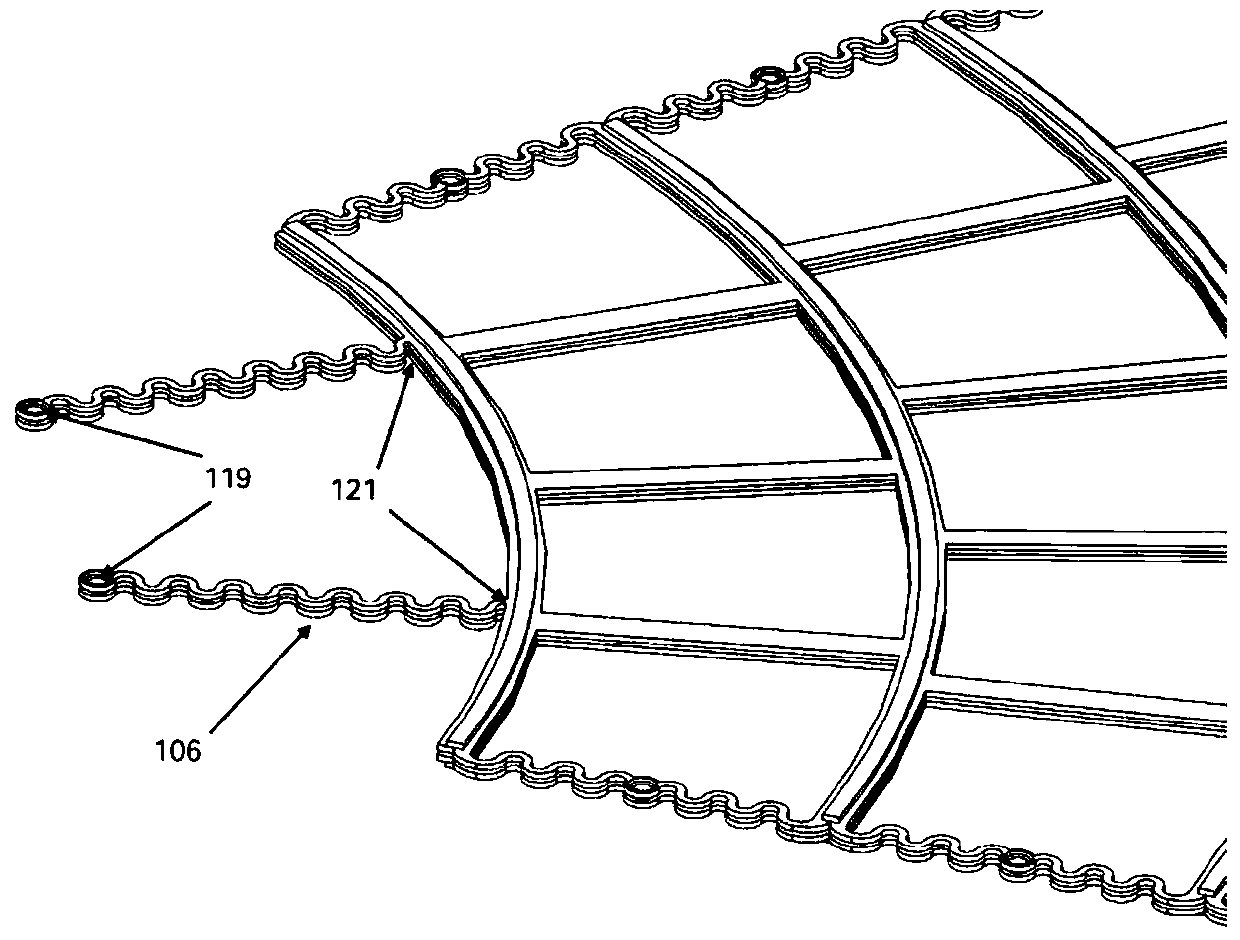

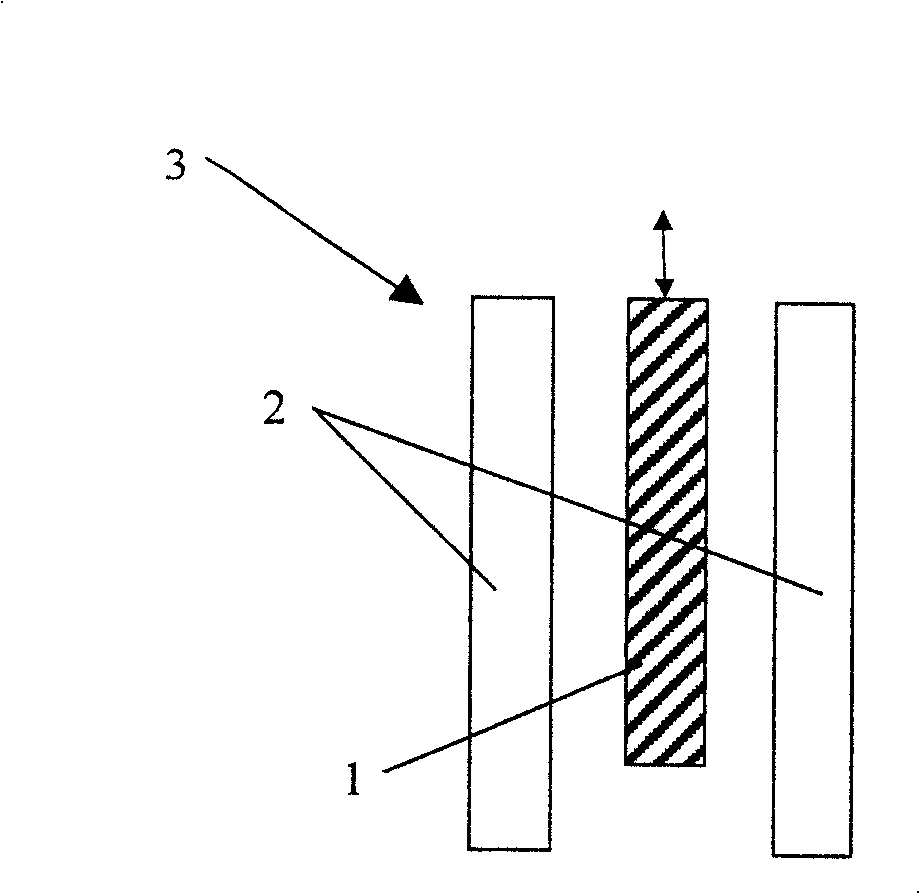

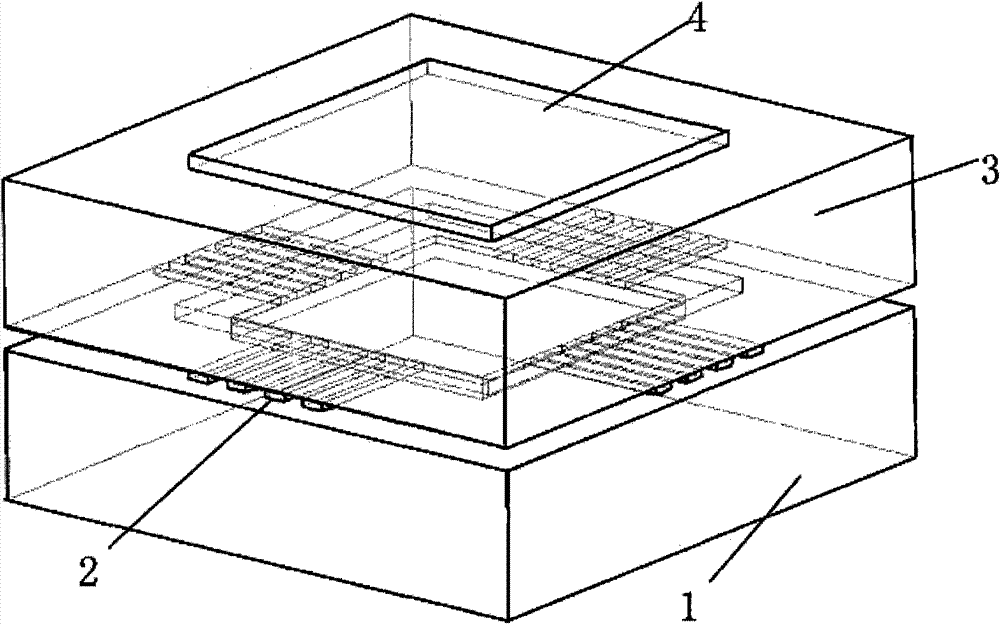

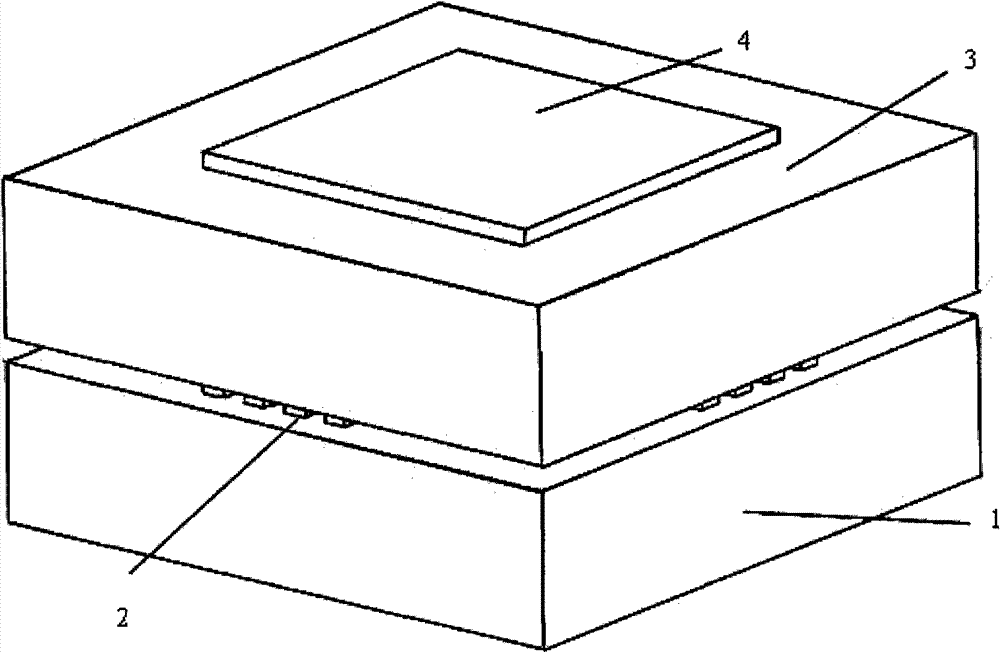

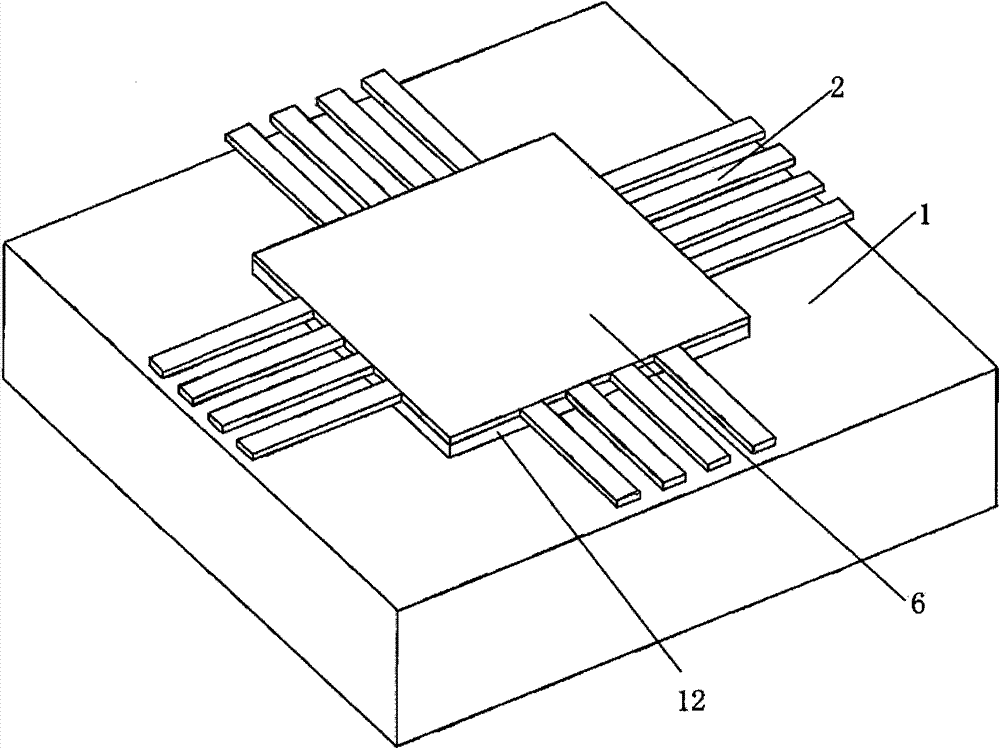

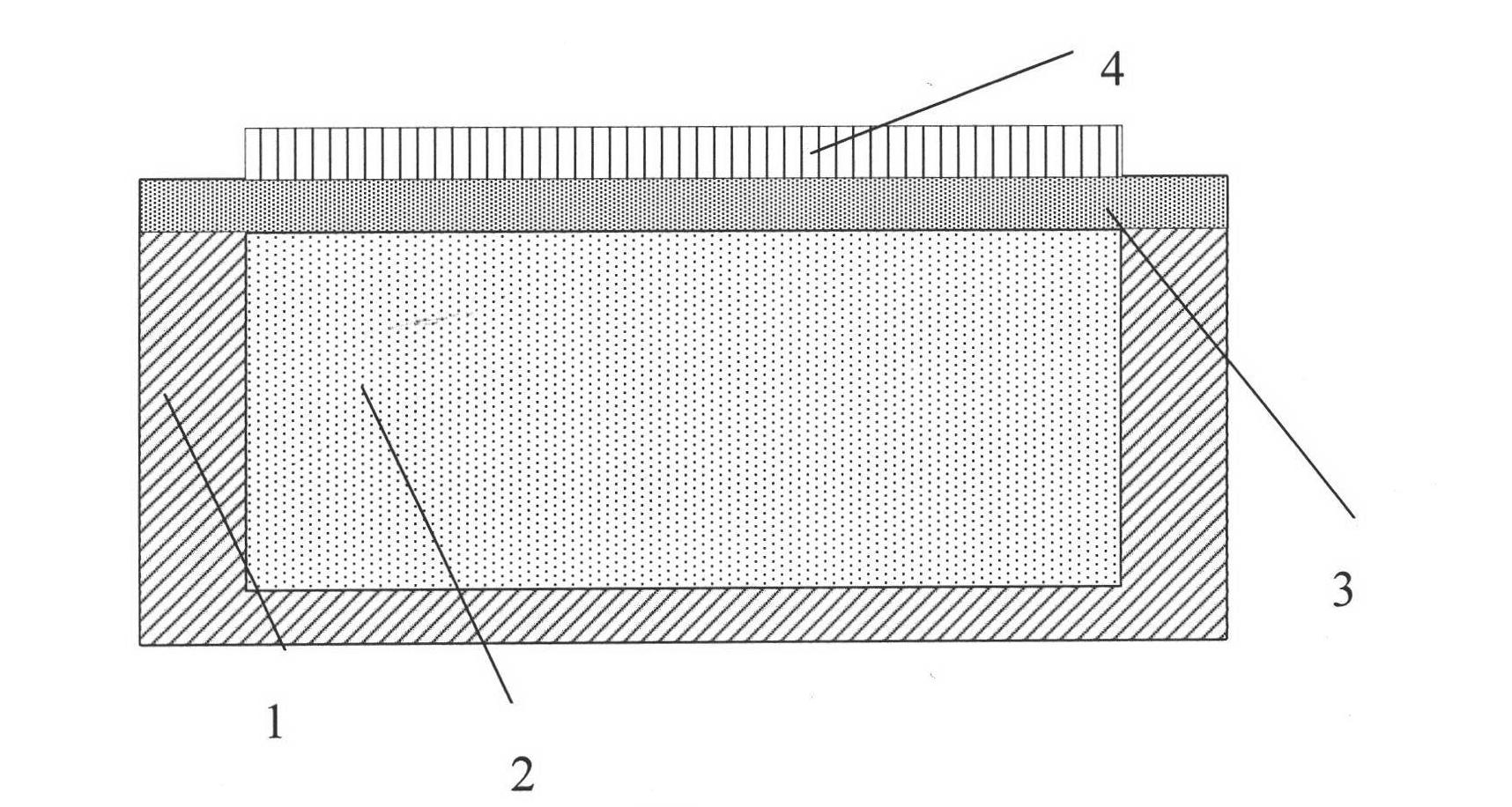

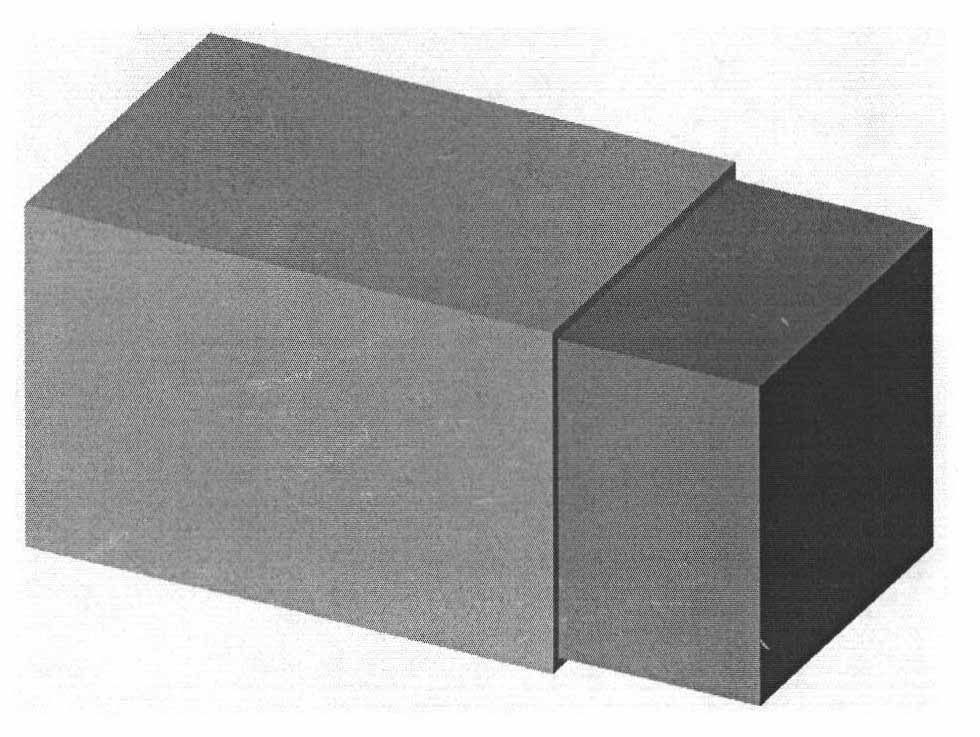

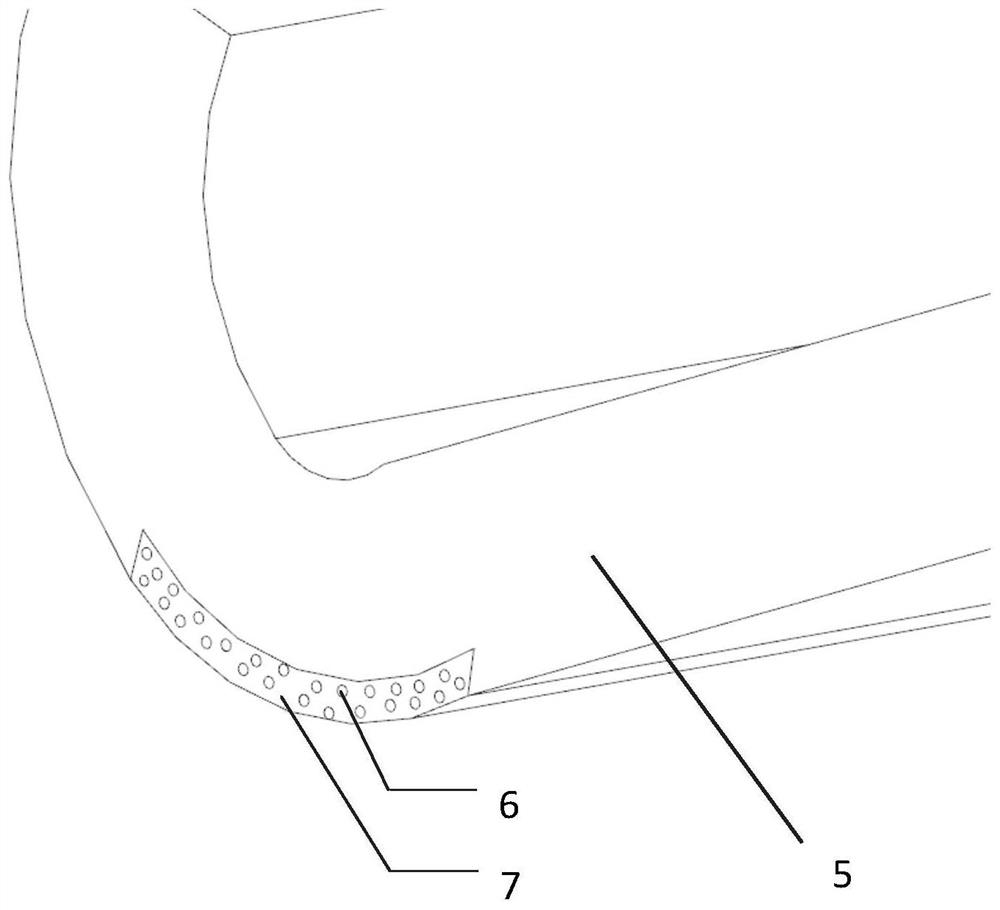

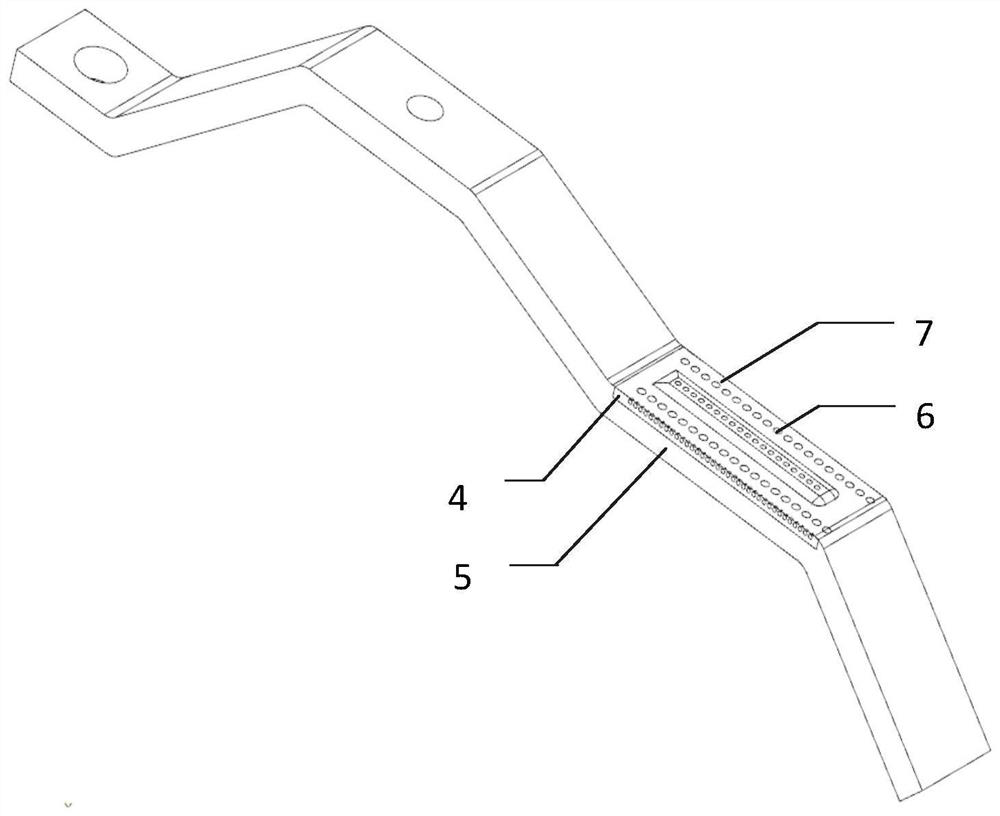

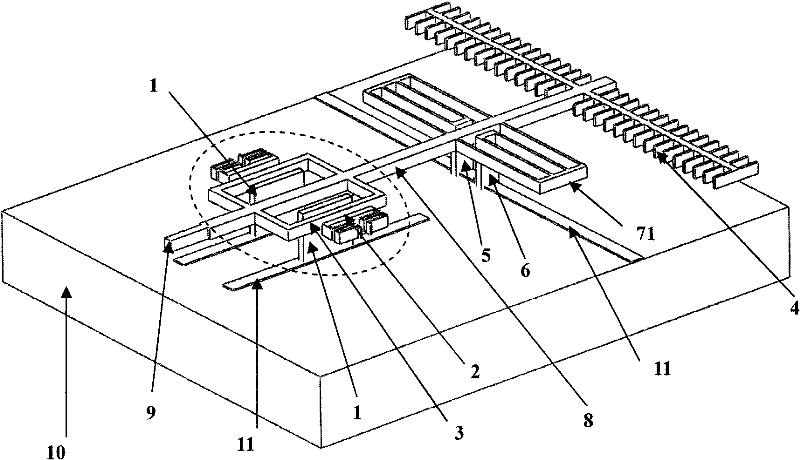

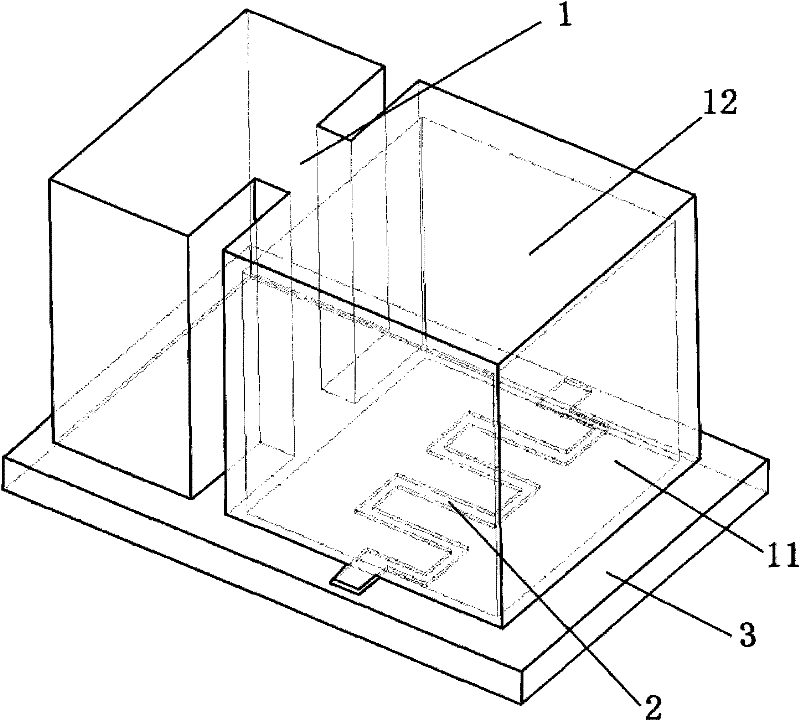

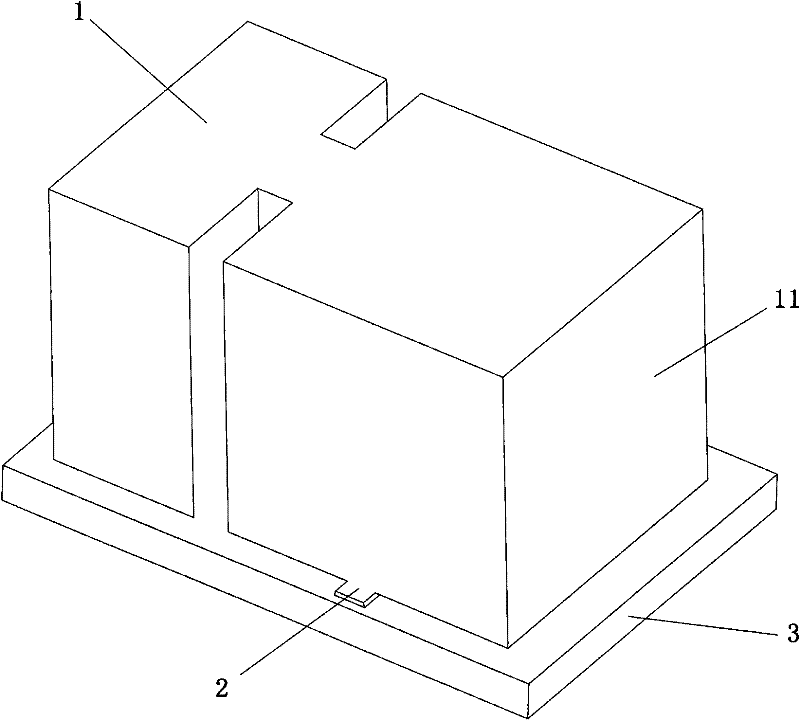

Anti-vibration device and preparation method thereof

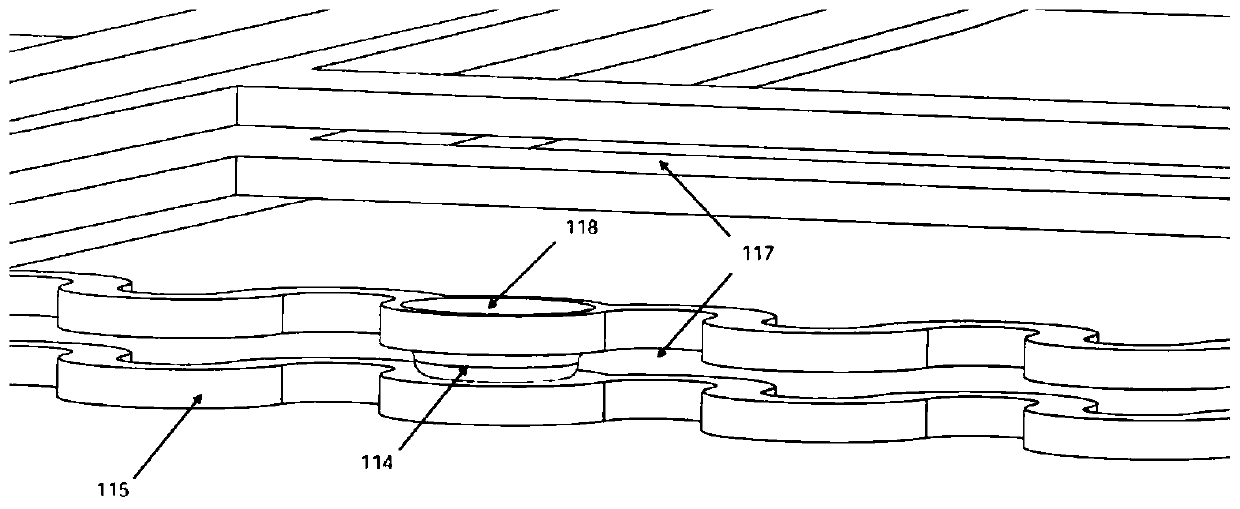

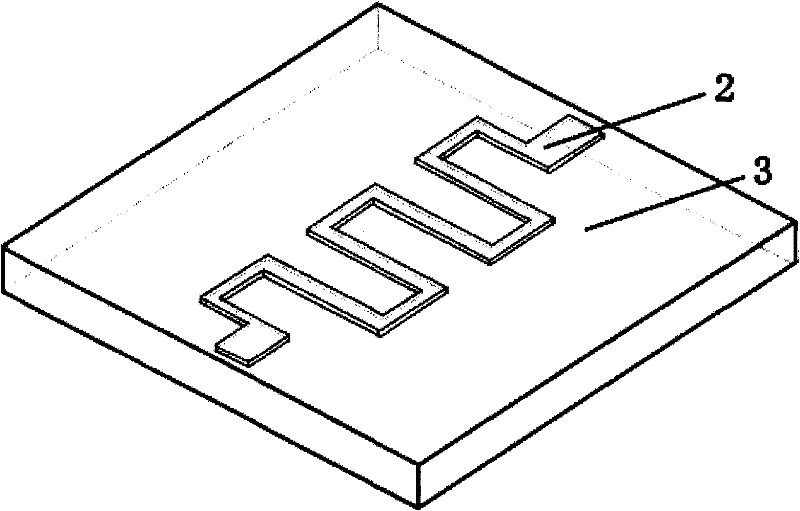

ActiveCN101880022BImprove applicabilityEnable high-volume manufacturingDecorative surface effectsChemical vapor deposition coatingCantilevered beamProcess equipment

The invention relates to an anti-vibration device and a preparation method thereof, and the device comprises a basal body and a device carrier, wherein an anti-vibration platform and a plurality of anti-vibration cantilever beams are arranged on the upper surface of the basal body, one end of each anti-vibration cantilever beam is fixedly connected with the anti-vibration platform and each anti-vibration cantilever beam extends in a manner of being not in contact with the upper surface of the basal body; and the upper surface of the device carrier is used for carrying a device to be protected, a groove is arranged on the lower surface of the device carrier, the device carrier is connected with the anti-vibration cantilever beams, and the groove is not in contact with the anti-vibration platform. The anti-vibration device and the preparation method thereof are applicable to applications of microelectronic circuit chips and MEMS movable devices in protection and the like under vibrationenvironment, and have very strong applicability; the anti-vibration device uses the physical way to realize the anti-vibration function, thereby being unnecessary to use a high-precision control circuit and further reducing the system cost. The preparation method can adopt the conventional MEMS process equipment and realize the mass manufacture; furthermore, the process flow is simple, and the preparation method can be compatible with a variety of types of MEMS device processes, thereby being used for realizing a microelectronic system with more extensive and more powerful functions.

Owner:PEKING UNIV

Variable rigidity beam, manufacturing method and actuating method thereof

ActiveCN101830425AReduce internal stressQuality improvementDecorative surface effectsChemical vapor deposition coatingAdditional valuesEngineering

Owner:PEKING UNIV

Method for manufacturing rigid-flex board with rigid board surrounded by flexible board

PendingCN114286543AIncrease widthReduce thicknessMultilayer circuit manufactureLaser cuttingMechanical engineering

The invention provides a manufacturing method of a rigid-flex board with a rigid board surrounded by a flexible board. The manufacturing method comprises the following steps: manufacturing a first inner-layer flexible board cutting cover film; pasting a covering film; fast pressing; quickly pressing the first soft board pasted with the cover film; baking the plate; baking the quickly pressed plate to obtain a soft plate layer; manufacturing a prepreg; performing laser cutting windowing on the first prepreg and the second prepreg corresponding to the first exposed area of the soft board and the rivet hole, wherein a connecting bridge connected with the hard board area needs to be designed in the laser cutting windowing; manufacturing a first inner-layer hard board; manufacturing a second inner-layer hard board; a first inner layer hard board depth control gong; controlling the depth of the second inner layer hard board; the steps are performed after integral pressing and before depth-controlled uncovering by using the prior art; opening the cover by controlling the depth; and forming, testing, appearance inspection and packaging are carried out on the uncovered rigid-flex board semi-finished product, and production of the rigid-flex board is completed.

Owner:江西强达电路科技有限公司

Preparation method of composite contact

The invention belongs to the technical field of contact preparation, and relates to a preparation method of a composite contact, which comprises the following steps: pre-pressing a contact material by using a powder metallurgy process to obtain a contact pre-pressing block, placing the contact pre-pressing block in a contact assembly mold, filling the contact assembly mold with a contact base material, pre-pressing to obtain a contact pre-pressing block, and carrying out hot pressing on the contact pre-pressing block to obtain the composite contact. Pressing and sintering the contact pre-pressing block in powder metallurgy equipment to prepare a contact assembly, and assembling the contact assembly to form a composite contact; the contact material comprises copper-chromium alloy powder and strengthening particles, and the strengthening particles are one of Cr2Nb powder, Al2O3 powder and WCu powder. The contact area of the moving contact and the static contact is replaced by the anti-ablation and anti-corrosion copper-chromium alloy dispersion reinforcing material, so that the anti-ablation and anti-corrosion performance of the area is improved by more than 50%.

Owner:ELECTRIC POWER RES INST OF EAST INNER MONGOLIA ELECTRIC POWER +2

A Shock Disc Detonator with Integrated Electrode

InactiveCN106643351BAchieve detonationDoes not affect the integration structureAmmunition fuzesDetonationSlapper detonator

The invention discloses an integrated electrode slapper exploder. The integrated electrode slapper exploder comprises an integrated electrode assembly and an acceleration bore. A reflector plate is arranged on the lower surface of the end of the integrated electrode assembly in a matched mode. The acceleration bore is arranged on the upper surface of the end of the integrated electrode assembly. The end of the integrated electrode assembly is tightly clamped between the acceleration bore and the reflector plate. A slapper layer and explosion foil are stacked up and down to be located between the acceleration bore and the end of the integrated electrode assembly. An acceleration bore hole is formed in the position, corresponding to the center of the explosion foil, of the acceleration bore. The integrated electrode assembly is formed by sequentially pressing a lower insulating layer, a lower electrode core layer, a middle insulating layer, an upper electrode core layer, an upper insulating layer, the explosion foil and the slapper layer. The lower electrode core layer is in circuit connection with one end of the explosion foil, and the upper electrode core layer is in circuit connection with the other end of the explosion foil. According to the integrated electrode slapper exploder, the upper electrode core layer, the explosion foil and the lower electrode core layer form a circuit loop. After the explosion foil is powered up, electrical explosion can generate plasma to impact the slapper layer, the slapper layer is made to fly out of the acceleration bore hole of the acceleration bore, and percussion charging is performed to achieve the detonation function of slappers.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

A wafer-level through-silicon transmission structure applicable to microwave frequency bands and its manufacturing method

InactiveCN103066040BSmall mechanical propertiesGuaranteed accuracySemiconductor/solid-state device detailsSolid-state devicesCoaxial lineEngineering

The present invention relates to a wafer-level through-silicon via (TSV) transmission structure applicable to the microwave band and a manufacturing method thereof. A TSV transmission cable structure using a high-frequency alternative coaxial cable structure is designed. In the structure, multiple TSVs surround a TSV core for signal transmission. The surrounding TSVs are grounded. A coaxial shielding layer similar to that of the coaxial cable is formed. Two opposite sides of the silicon piece between the grounded TSV and the TSV chip each use an isolation groove filled with low dielectric constant polymer. The number, size, and distance of the grounded via holes are determined through simulation of an actually applied frequency band. The structure realizes interconnection of the two sides of the silicon piece of the microwave band. The TSV transmission structure reduces the impact on the microwave band performance when a signal passes through a silicon piece in high-density three-dimensional package, and avoids excessive loss. The process has simple steps, and is compatible with other processes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Minitype optical device and method for producing the same

ActiveCN100561288CSelf-aligningImprove controllabilityDecorative surface effectsPhotomechanical apparatusFiberLight reflection

The invention relates to a micro-optical device and its preparation process, which is characterized in that it includes a fixed electrode, a movable electrode, a support beam, a glass substrate, a light reflection module and an optical fiber fixing module; the fixed electrode includes a Comb-tooth-type fixed electrodes on both sides of the top surface of the glass substrate and a plate-type fixed electrode fixed in the middle of the top surface of the glass substrate; the movable electrodes are two combs inserted between the comb-tooth-type fixed electrodes tooth-type movable electrodes and two flat-type movable electrodes respectively located above the flat-type fixed electrodes; the support beam includes a folding beam and a combined torsion beam, and the optical fiber fixing module is centered on the light reflection module, Several fiber grooves are arranged radially, and each of the fiber grooves is respectively aligned with one of the multiple light reflection surfaces on the light reflection module. The preparation method of the invention is simple in process, compatible with various types of MEMS device processes, and can be used to realize a micro-light integrated system with more powerful functions.

Owner:PEKING UNIV

Method for manufacturing silicon-penetrating coaxial line for microwave frequency band

InactiveCN102097672BSmall mechanical propertiesGuaranteed accuracySemiconductor/solid-state device manufacturingWaveguidesCoaxial lineCoaxial transmission line

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Static actuator and preparation method and instantaneous perturbation resistance method thereof

ActiveCN101704498BReduce internal stressQuality improvementTelevision system detailsImpedence networksEngineeringActuator

The invention relates to a static actuator and preparation method and instantaneous perturbation resistance method thereof. The static actuator comprises a fixed electrode, a first movable electrode and a second movable electrode, wherein the fixed electrode is a pad-shaped electrode of the lead electrode which is fixedly connected with a substrate; the first movable electrode is a pad-shaped electrode which is arranged above the substrate for a set height; the second movable electrode is rectangular box pad-shaped electrode and is arranged between the fixed electrode and the first movable electrode and on the same plane of the first movable electrode; and the first movable electrode and the second movable electrode are both connected with elastic parts. The static actuator of the invention has technical characteristics of monolithic integration, adaptability and the like and also has high precision positioning and high reliability so as to effectively overcome the impact perturbationintroduced by the external environment, especially the perturbation caused by instantaneous vibration.

Owner:PEKING UNIV

Variable optical attenuator and preparation method thereof

ActiveCN101881881BWide range of functionsSimple structureDecorative surface effectsChemical vapor deposition coatingOptoelectronicsOptical attenuator

The invention relates to a variable optical attenuator and a preparation method thereof. The variable optical attenuator comprises a silicon base and a glass base bonded with the silicon base, wherein the silicon base is provided with a heating hollow cavity and a vertical light reflecting surface as one lateral surface of the heating hollow cavity; the heating hollow cavity and part of the uppersurface of the glass base stand in a circle to form a closed cavity; and a heating component is arranged on the upper surface of the glass base in the closed cavity. Accordingly, the variable opticalattenuator of the invention is capable of meeting the requirement for the reliability of components in the vibration environment and has the advantages of low cost and high performance.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com