Integrated electrode slapper exploder

A technology integrating electrodes and impact plates, applied in the field of pyrotechnics, can solve problems such as the influence of the reliability of the detonator, and achieve the effect of remarkable effect, better electrical conductivity, and reduction of welding points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

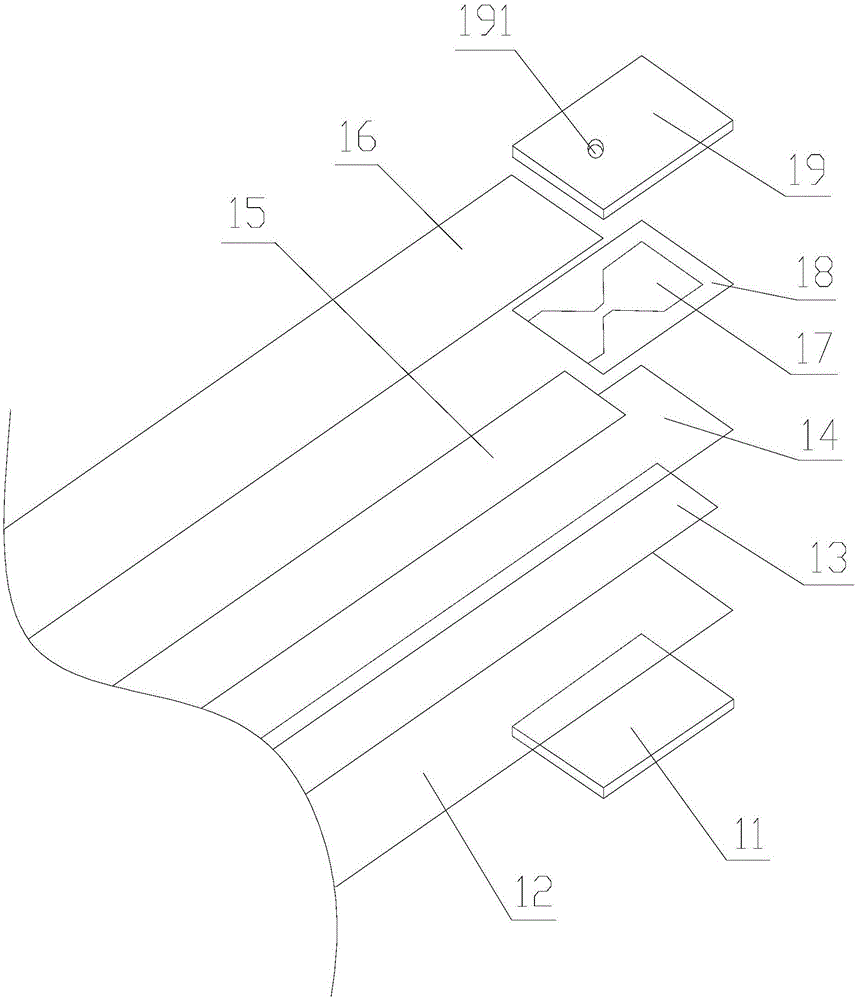

[0022] Such as figure 1 As shown, an integrated electrode impact sheet detonator includes a reflective sheet A11, an integrated electrode assembly, an explosive foil A17, a flyer layer A18 and an accelerating chamber A19. The upper surface of the integrated electrode assembly is provided with an explosive foil A17. Flyer layer A18 is stacked on top of foil A17, reflector A11 is fitted on the lower surface of the end of the integrated electrode assembly, and acceleration bore A19 is also provided on the upper surface of the end of the integrated electrode assembly, which is tightly clamped between the acceleration bore A19 and the reflector A11 Hold the end of the integrated electrode assembly, the flyer layer A18 and the explosive foil A17 are overlapped up and down between the lower surface of the acceleration chamber A19 and the upper surface of the end of the integrated electrode assembly. The acceleration chamber A19 corresponds to the center of the explosion foil A17 with an...

Embodiment 2

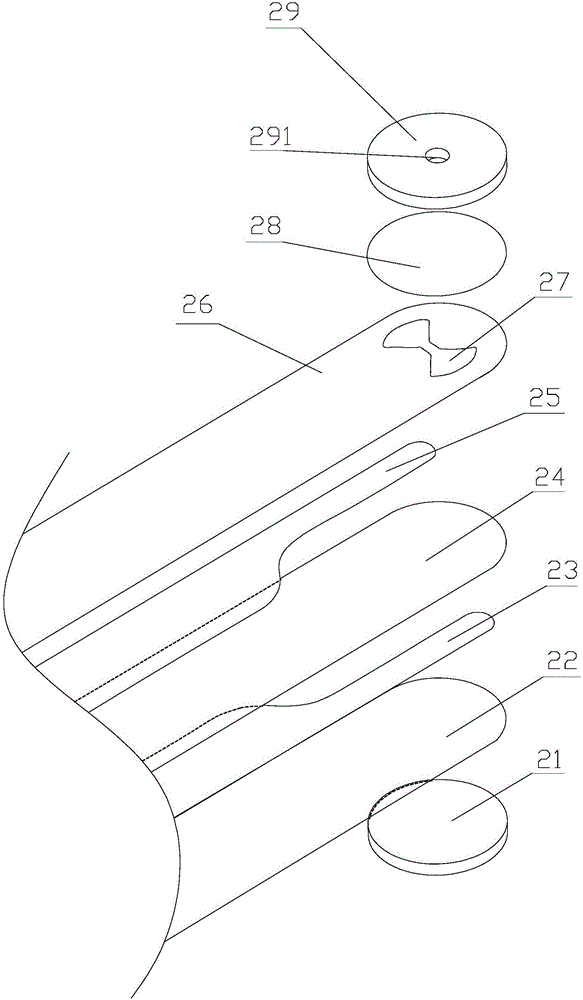

[0027] Such as figure 2 As shown, an integrated electrode impact sheet detonator includes a reflective sheet B21, an integrated electrode assembly, an explosive foil B27, a flyer layer B28 and an accelerating chamber B29. The upper surface of the integrated electrode assembly is provided with an explosive foil B27. Flyer layer B28 is stacked on top of foil B27, reflector B21 is fitted on the lower surface of the end of the integrated electrode assembly, and acceleration bore B29 is also provided on the upper surface of the end of integrated electrode assembly, which is tightly clamped between the acceleration bore B29 and reflector B21 Hold the end of the integrated electrode assembly, the flyer layer B28 and the explosive foil B27 are overlapped up and down between the lower surface of the accelerating chamber B29 and the upper surface of the end of the integrated electrode assembly. The accelerating chamber B29 corresponds to the center of the explosive foil B27 with an accel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com