Optical fiber array fixing device and manufacturing method thereof

A technology for fixing devices and optical fiber arrays, which is applied in optical components, instruments, optics, etc., can solve the problems of unfavorable large-scale optical switches, high cost of precision mold opening, and increased system cost, achieving strong scalability, reducing difficulty and Cost, effect of a wide range of functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The optical fiber array fixing device and the preparation method thereof proposed by the present invention are described in detail as follows with reference to the accompanying drawings and embodiments.

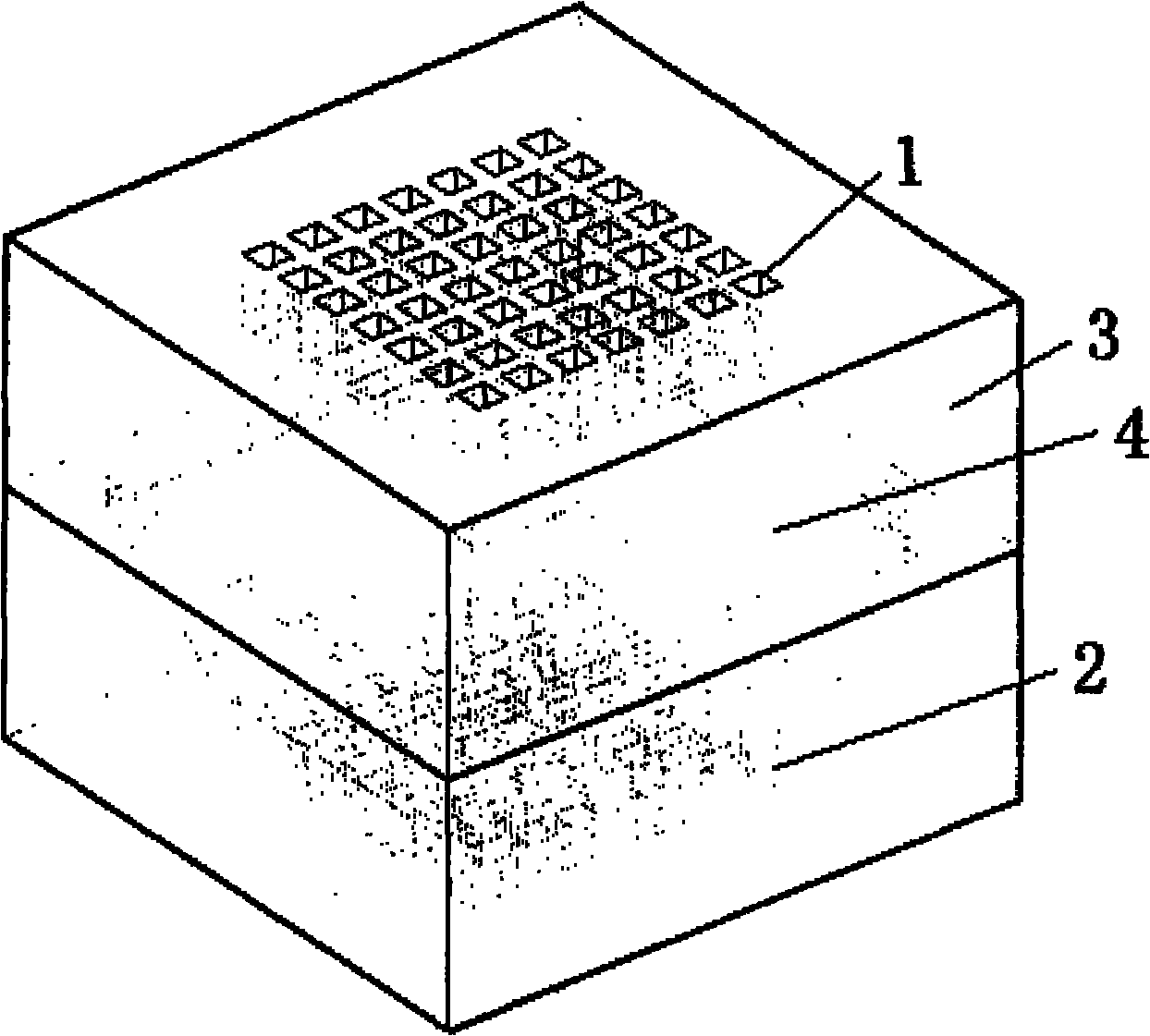

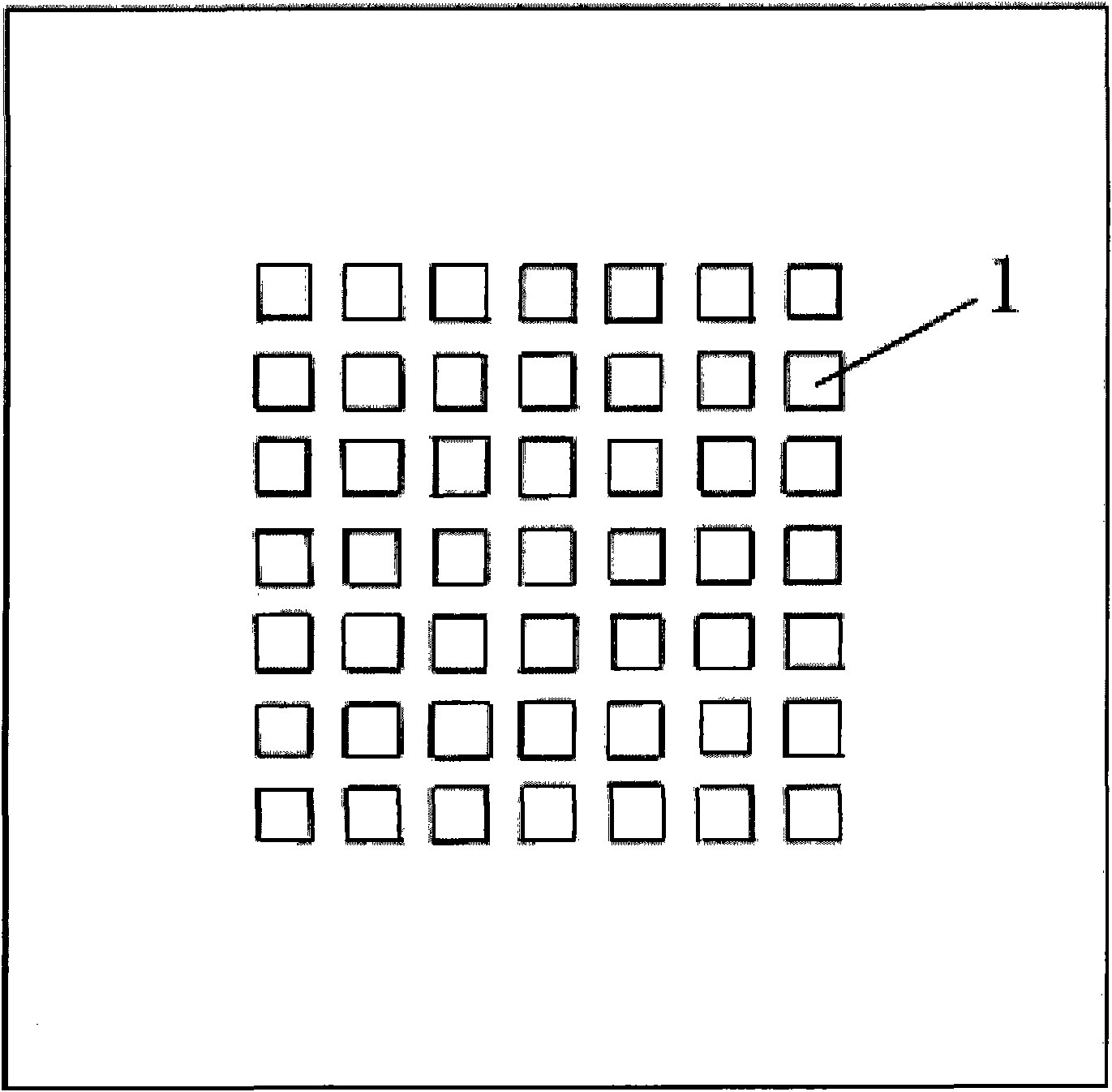

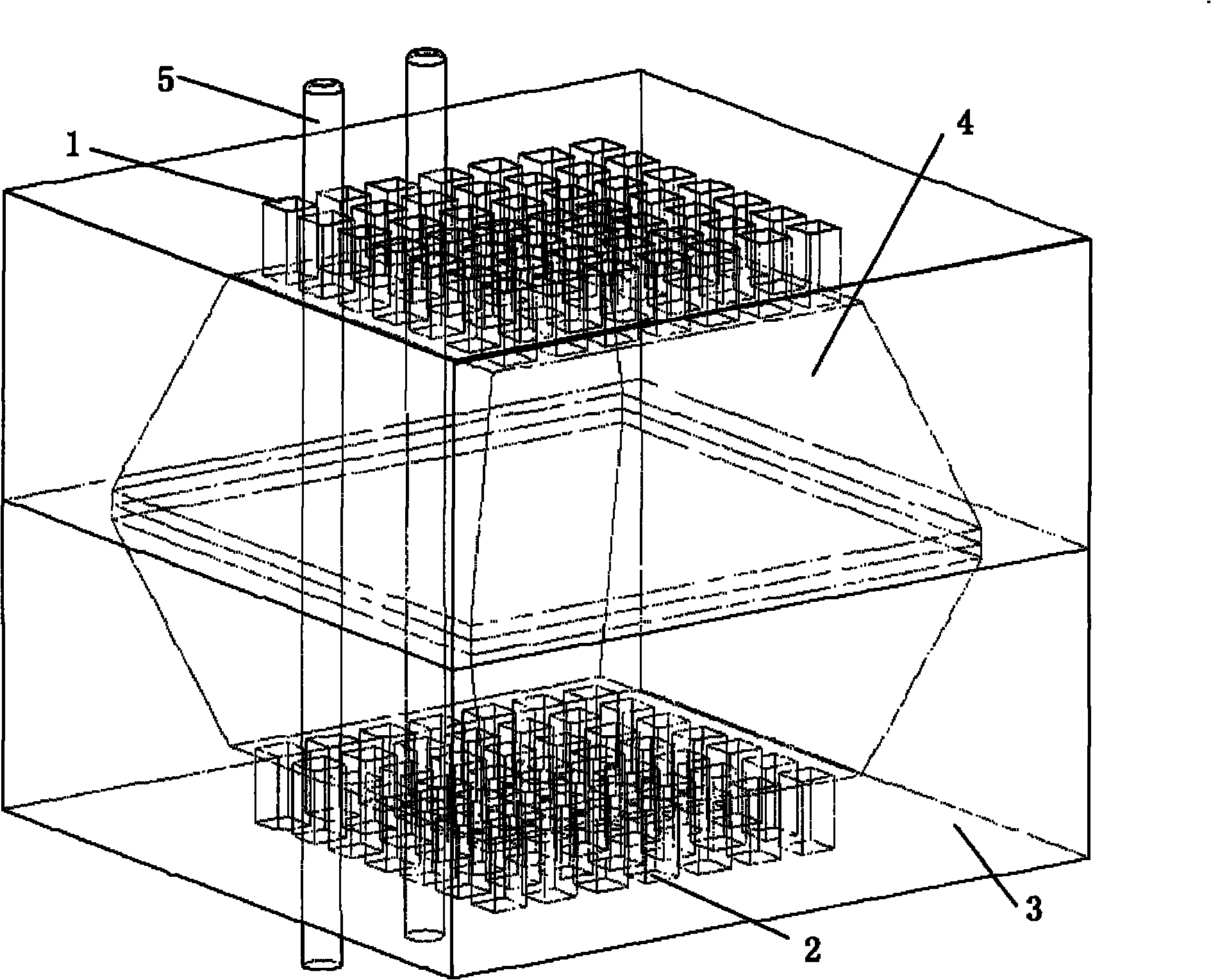

[0024] The optical fiber array fixing device of the invention is suitable for micro-optical devices such as medium and large-scale 2D optical switches and large-scale 3D optical switches. like figure 1 Shown is a perspective perspective view of an optical fiber array fixing device according to an embodiment of the present invention, the device includes: a base 3, and an optical fiber fixing hole array composed of several identical optical fiber fixing holes, and the optical fiber fixing holes are respectively arranged on the base. The upper and lower end faces of the base 3, and the optical fiber fixing holes 1 arranged on the upper end face and the optical fiber fixing holes 2 arranged on the lower end face correspond one-to-one. In order to achieve stable fixing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com