High-precision anti-symmetric bimorph structure shape memory alloy and a preparation method thereof

A memory alloy and bimorph technology, which is applied in the field of shape memory alloys with a high-precision antisymmetric bimorph structure and its preparation, can solve the problems of inability to manufacture a high-precision three-dimensional structure, undercutting phenomenon, poor dimensional accuracy, etc. The effect of mass production, lower production costs, and avoidance of external force interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

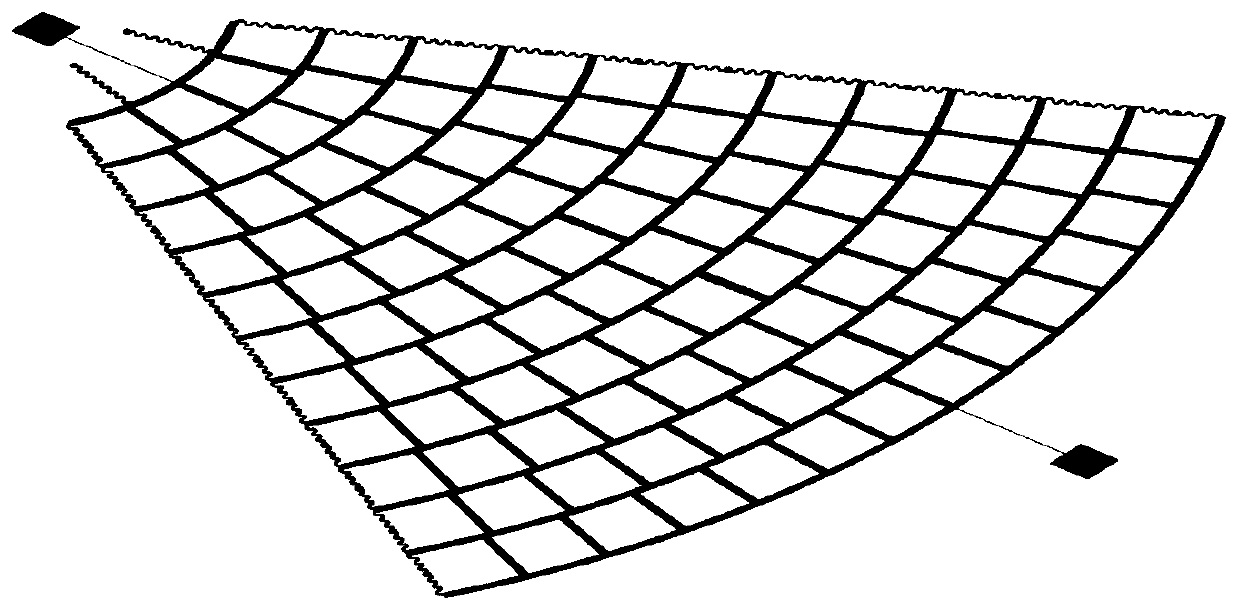

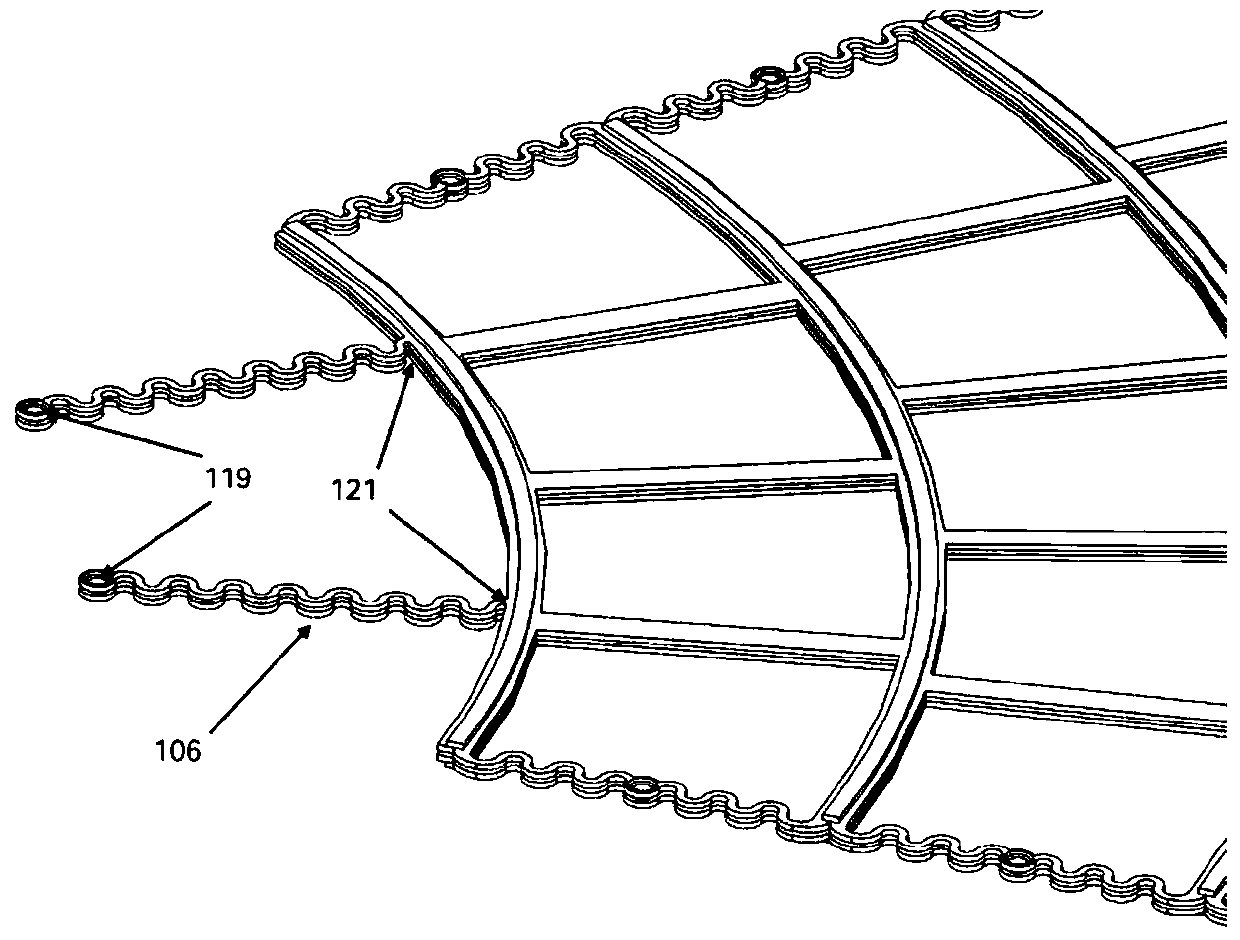

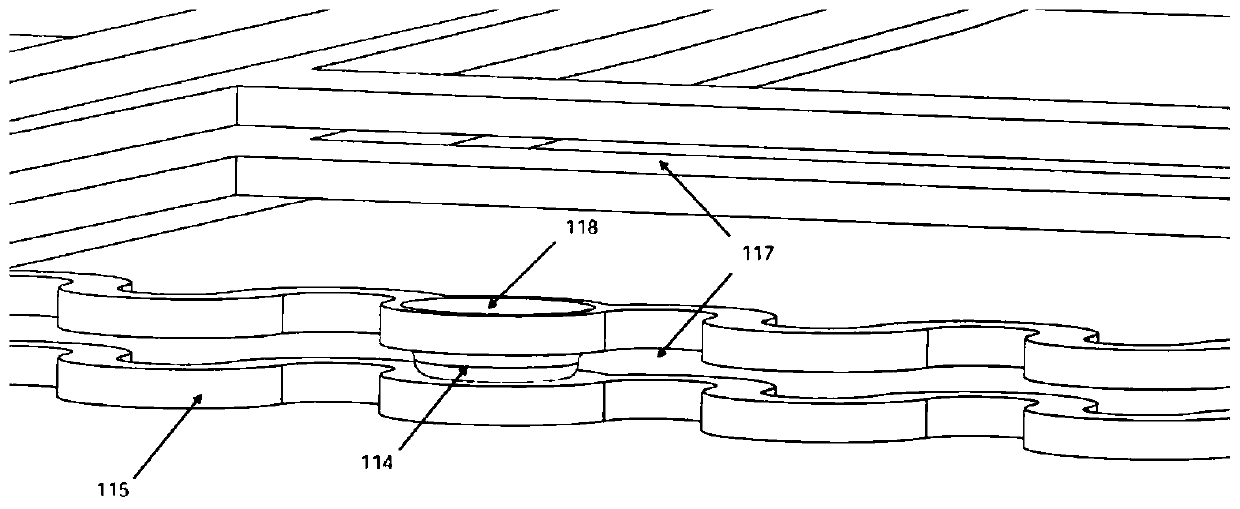

[0041] The specific structure of the embodiment is an anti-symmetric bimorph (Bimorph) structure, including a bottom bimorph shape memory alloy film, a top bimorph shape memory alloy film, and a driving electrode, wherein the driving electrode and the bottom bimorph shape memory alloy film pass through The support beams are fixedly connected, the driving electrodes are fixed on the silicon wafer, the bottom and top double-chip shape memory alloy film structures are antisymmetric, and the two parts are fixedly connected up and down through the anchor point (Anchor), except for the anchor point, the upper and lower double-chip shape The memory alloy thin film does not have any contact points and has gaps, and the shape memory alloy thin film at the bottom is not in contact with the silicon chip and has gaps. The antisymmetric bimorph (Bimorph) structure shape memor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com