Clean and ecologically-degradable PVC (Polyvinyl Chloride) decorative artificial leather

A technology of artificial leather and PVC resin powder, which is applied in the field of artificial leather manufacturing, can solve the problems of non-environmental friendly materials and non-green manufacturing process, and achieve enhanced heat resistance, increased flame retardant and degradable ability, and good folding fastness to aging performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

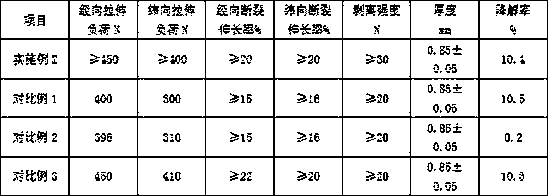

Examples

Embodiment 1

[0024] A clean and ecologically degradable PVC decorative artificial leather, made of the following raw materials in parts by weight: 100 parts of PVC resin powder, 30 parts of vinyl acetate resin, 38 parts of diacetyl epoxy soybean oleate, polycaprolactone-based polyurethane 20 parts of elastomer, 1 part of foaming agent, 20 parts of epoxy soybean oil, 20 parts of organically modified clay, 1 part of lubricant, 1 part of silicone masterbatch, 1 part of stabilizer, and 1 part of pigment.

[0025] A kind of preparation of clean ecological degradable PVC decorative artificial leather, it comprises the following steps:

[0026] (1) Put the weighed PVC resin powder, vinyl chloride resin, polycaprolactone-based polyurethane elastomer, lubricant, silicone masterbatch, and stabilizer into a high-speed kneader, then add epoxy soybean oil, Stir for 10 minutes, then add diacetylepoxy soybean olein, stir for another 10 minutes, add pigment, stir for another 3 minutes, add organically mod...

Embodiment 2

[0037] A clean and ecologically degradable PVC decorative artificial leather, made of the following raw materials in parts by weight: 100 parts of PVC resin powder, 30 parts of vinyl acetate resin, 36 parts of diacetyl epoxy soybean oleate, polycaprolactone-based polyurethane 15 parts of elastomer, 1 part of foaming agent, 24 parts of epoxy soybean oil, 22 parts of organically modified clay, 1 part of lubricant, 1 part of silicone masterbatch, 1 part of stabilizer, and 1 part of pigment.

[0038] A kind of preparation of clean ecological degradable PVC decorative artificial leather, it comprises the following steps:

[0039] (1) Put the weighed PVC resin powder, vinyl chloride resin, polycaprolactone-based polyurethane elastomer, lubricant, silicone masterbatch, and stabilizer into a high-speed kneader, then add epoxy soybean oil, Stir for 5-10 minutes, then add diacetylepoxy soybean olein, stir for another 10 minutes, add lubricant, pigment, stir for another 3 minutes, add or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weft tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com