Cu-Al alloy powder, alloy paste utilizing same, and electronic component

A technology of alloy powder and electronic components, applied in printed circuit parts, electrical components, electric solid devices, etc., can solve the problems of weather resistance deterioration, material cost increase, electronic component products are not applicable, etc., and achieve migration resistance Excellent effect of suppressing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This example shows an example of controlling the crystal particle size distribution of Cu—Al alloy powder, which is important for cost reduction in the manufacturing process of forming electrodes, wiring, and / or contact members of electronic components. In the present invention, in the Cu-Al alloy powder manufacturing process of melting of the above-mentioned Cu-Al alloy, powderization by nozzle spraying, drying of the powder, classification of the powder, mixing of the classified powder, and deoxidation-dehydration, Cu - Al alloy powder (spherical) particle size distribution of the maximum diameter of 30 μm or less, the average particle size of the alloy powder is 5 μm or less, then the yield of the raw material into the alloy dissolved in more than 90%. An example of the particle size distribution of the Cu-Al alloy powder at this time is shown in Figure 11 . In addition, the flaky Cu-Al alloy powder is manufactured from the above-mentioned powder using a ball mill, e...

Embodiment 2

[0068] In the Cu-Al alloy powder manufacturing process of melting of Cu-Al alloy by nozzle spraying, drying of powder, classification of powder, mixing of classified powder, and deoxidation-dehydration of Cu-Al alloy powder of the present invention, this example shows An example of a classification method implementing Cu-Al alloy powder particle size distribution control. First, as an example of wet classification, the present embodiment in which classification is carried out by a low-cost natural sedimentation method is used as follows. The present invention produced by the method includes melting of the Cu-Al alloy related to the present invention, powderization by nozzle spraying, drying of the powder, classification of the powder, mixing of the classified powder, and deoxidation-dehydration steps. Cu-Al alloy powder particles (Al: 8wt%, density 8.4g / cm 3 ) 200g, surfactant polyacrylic acid to 0.8wt% of particles, and pure water to 1000g, put into polymerization container....

Embodiment 3

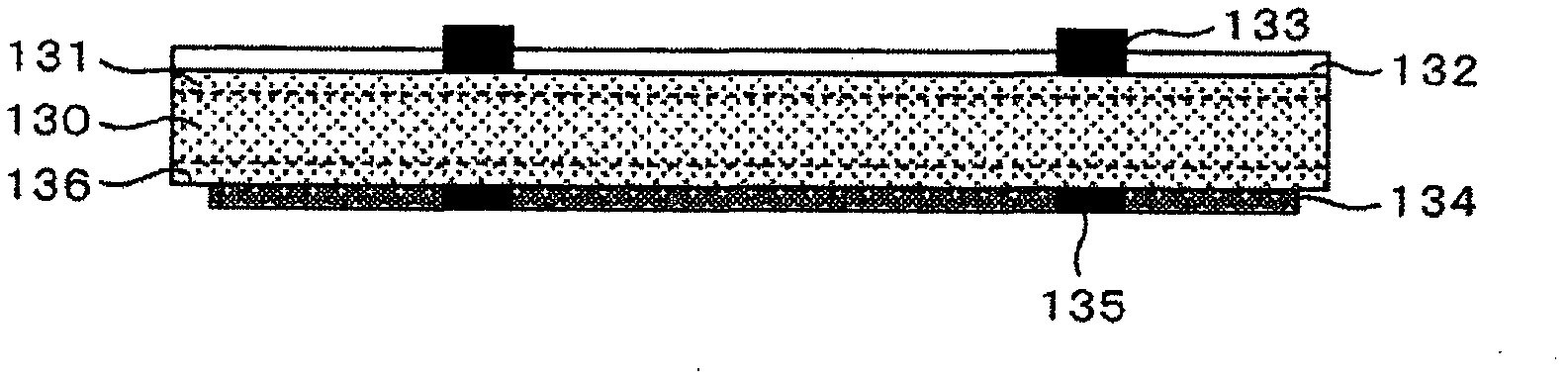

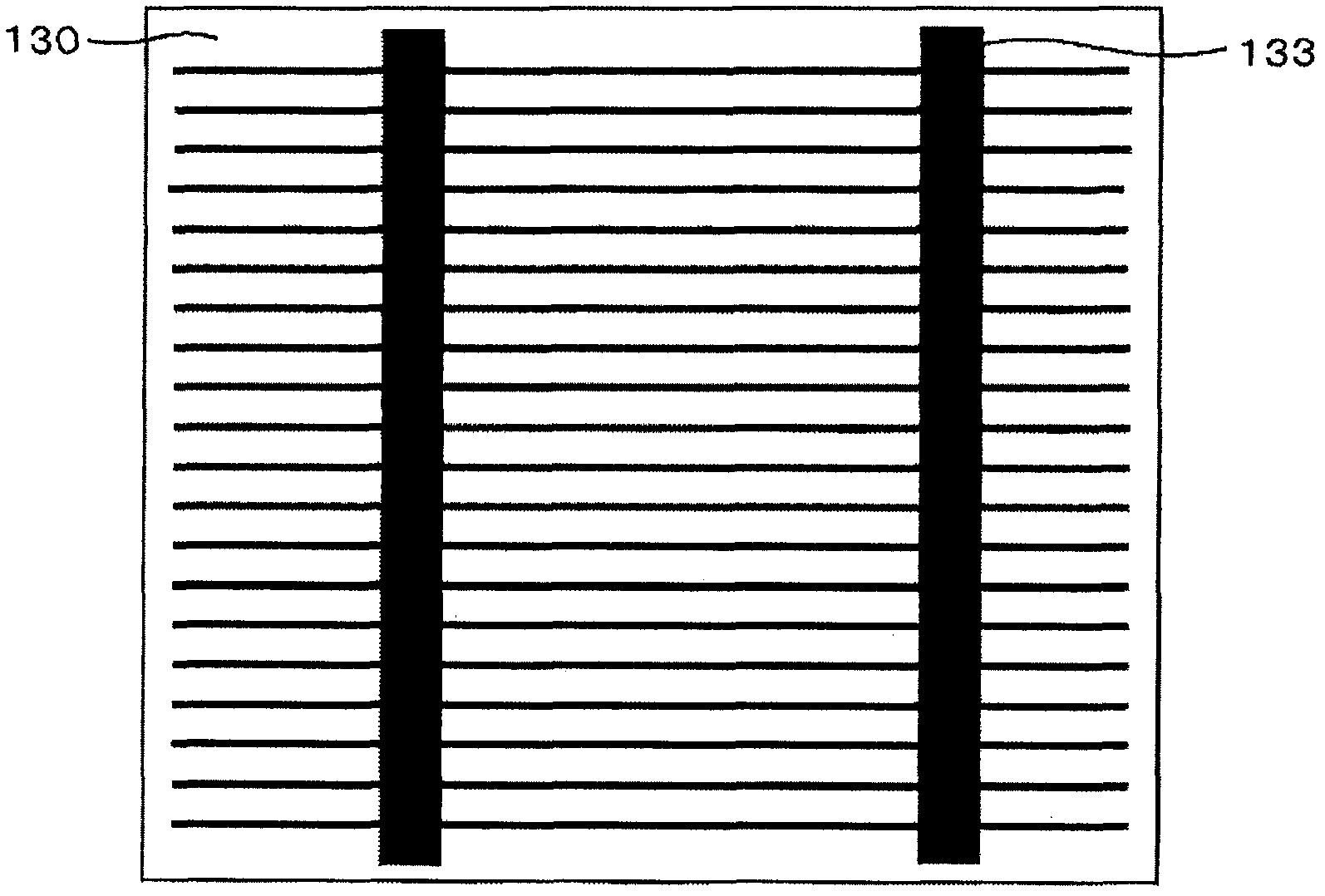

[0071] An example in which the electrode of the present invention is used in the double-sided electrode crystalline silicon (Si) solar cell element of the present invention will be described. A cross-sectional view of a typical solar cell element, and an outline of the light-receiving surface and the back surface are shown in figure 2 , image 3 and Figure 4 .

[0072] Generally, single crystal or polycrystalline Si or the like is used for the semiconductor substrate 130 of the solar cell element. The semiconductor substrate 130 contains boron or the like, and forms a p-type semiconductor. On the light-receiving side, unevenness is formed by etching to suppress reflection of sunlight. This light-receiving surface is doped with phosphorus or the like to form an n-type semiconductor diffusion layer 131 with a thickness of nanometers, and at the same time, a pn junction is formed at the boundary with the p-type entire portion. In addition, an antireflection layer 132 made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com