Silver powder surface modification processing method

A technology of surface modification and treatment method, applied in the direction of coating, etc., can solve the problem of ion migration of silver conductor paste, etc., and achieve the effect of smooth surface, short time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

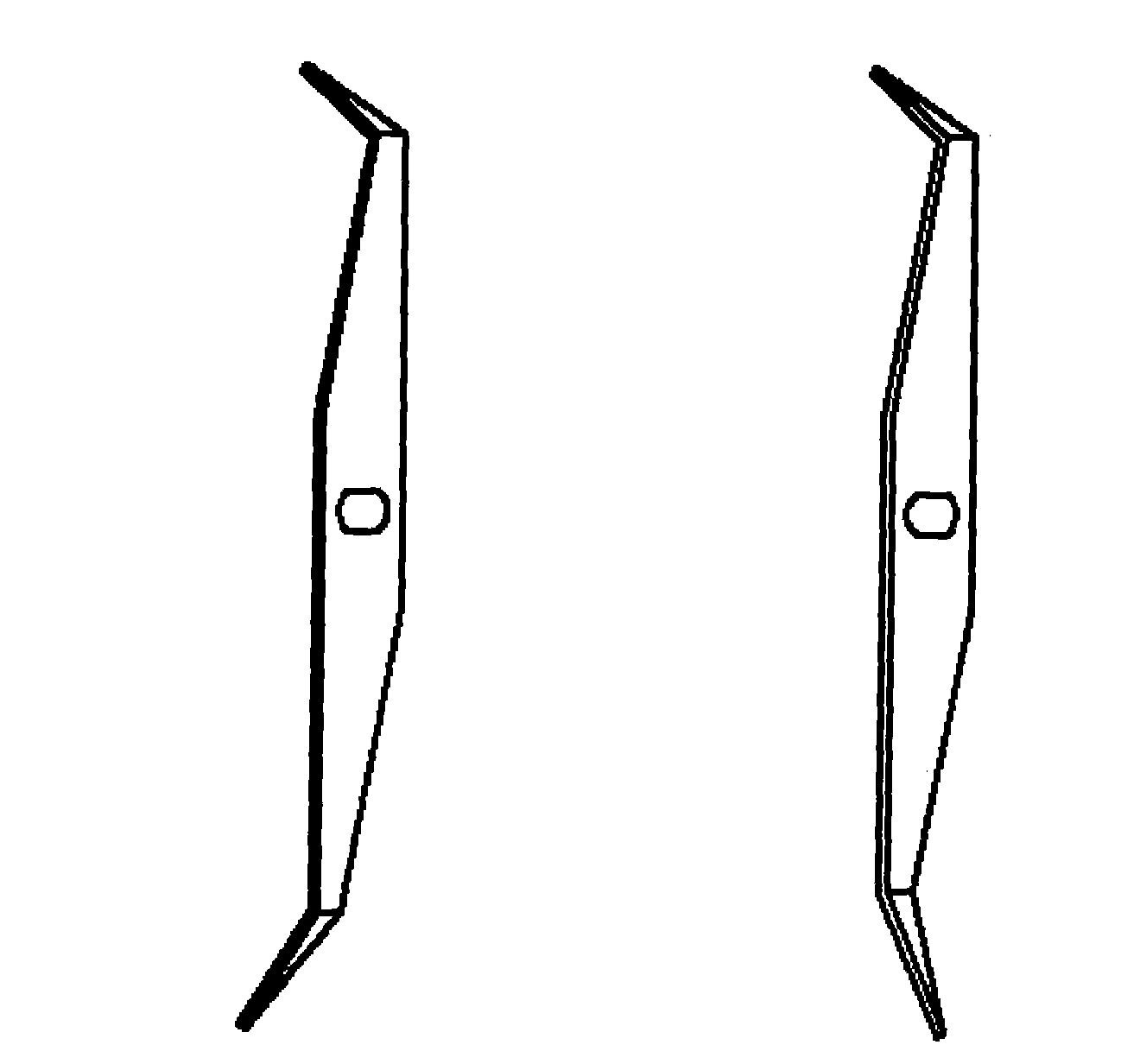

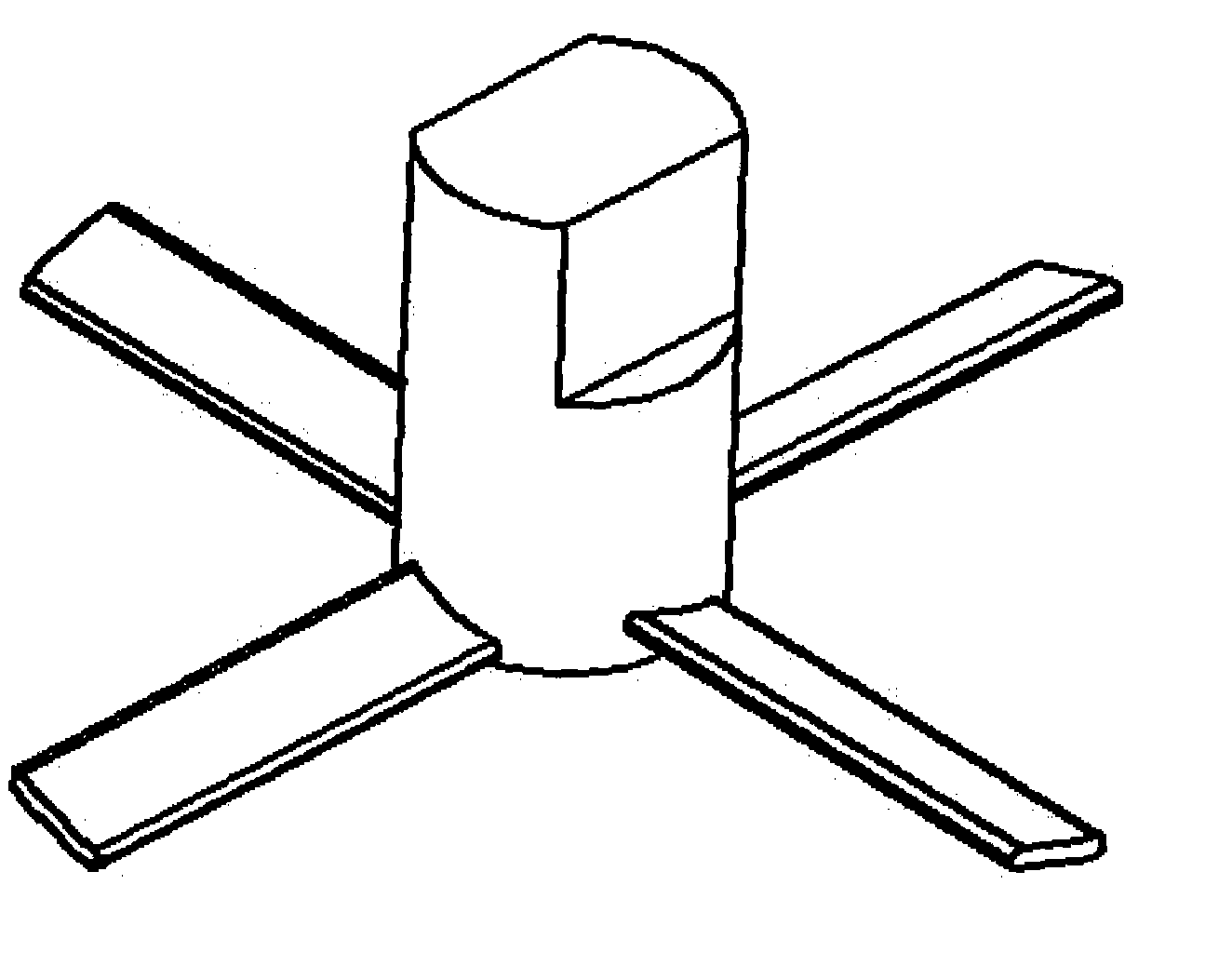

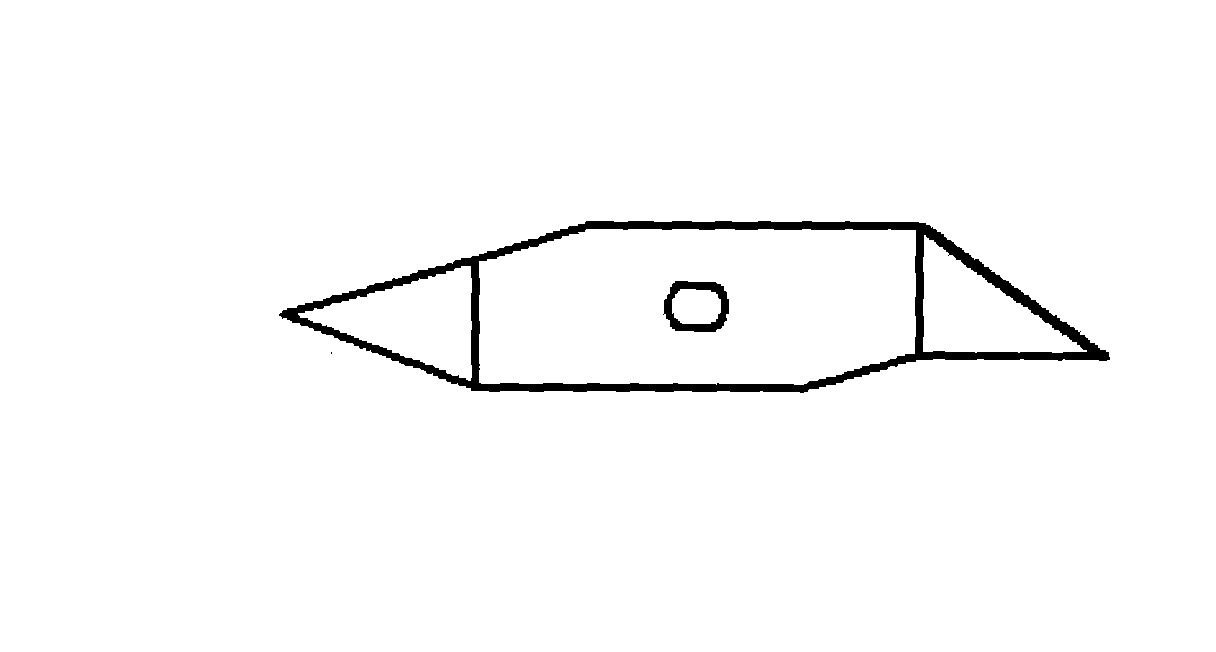

[0020] Example 1. Weigh 18.18g of silver powder with an average particle size of 10nm and 181.82g of silver powder with an average particle size of 1μm, and pour (10:100) into the sample tank of the coating machine. figure 1 The left is the No. 1 blade, the right is the No. 2 blade, Figure 2-4 Corresponding to No. 3-5 cutter heads respectively. Select the No. 5 and No. 3 cutter heads for assembly, adjust the coating machine speed to 5000r / min, the revolution speed to 30r / min, and the operation time to 3min. Start the operation. After the end, pour out the silver powder. Either shuttle-shaped or superimposed up and down with the annular blade and rotates together. The revolution is provided by the cladding machine itself.

[0021] 65% (weight ratio) of the above-mentioned modified silver powder, 5% of black lead-free glass powder, 5% of photosensitive monomer, 5% of photoinitiator, and 20% of organic carrier are dispersed and mixed uniformly. After the material is printed,...

Embodiment 2

[0022] Example 2. Weigh 1.00 g of copper powder with an average particle size of 20 nm and 199.00 g of silver powder with an average particle size of 1 μm

[0023] (1:100), pour it into the sample tank of the coating machine, select the No. 3 cutter head and the No. 4 cutter head to assemble, adjust the mixing knife speed of the coating machine to 10000r / min, the revolution speed of the sample tank to 30r / min, and the running time is 2.5min, start running, after the end, pour out the silver powder.

[0024] 65% (weight ratio) of the above-mentioned modified silver powder, 5% of black lead-free glass powder, 5% of photosensitive monomer, 5% of photoinitiator, and 20% of organic carrier are dispersed and mixed uniformly. After the material is printed, dried and sintered, the test is carried out. The test results are shown in Table 1.

Embodiment 3

[0025] Example 3. Weigh 2.96g of nickel powder with an average particle size of 40nm and 197.04g of silver powder with an average particle size of 5μm

[0026] (1.5∶100), pour it into the sample tank of the coating machine, select the No. 5 shuttle cutter head and the No. 3 cutter head to assemble, adjust the coating machine speed to 14000r / min, revolution speed to 30r / min, and run time to 30s. Start the operation, and after the end, pour out the silver powder.

[0027] 65% (weight ratio) of the above-mentioned modified silver powder, 5% of black lead-free glass powder, 5% of photosensitive monomer, 5% of photoinitiator, and 20% of organic carrier are dispersed and mixed uniformly. After the material is printed, dried and sintered, the test is carried out. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com