Industrial production method for pigment yellow 81

A production method and technology for pigment yellow, applied in the direction of organic dyes, etc., can solve the problems of poor heat resistance, light resistance, poor application performance, low pigment yield, and narrow application range, and achieve low equipment requirements, short reaction time, enhanced The effect of application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

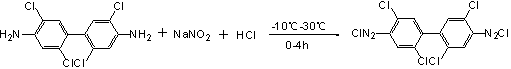

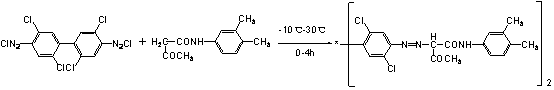

Method used

Image

Examples

Embodiment 1

[0028] 1) Put 175Kg of TCB into a common reaction kettle, add 2000Kg of water and 500Kg of ice cubes, beat 50Kg of zeolite at 0°C to form salt for 1 hour; quickly add 400Kg of 30% hydrochloric acid, and then slowly add 40% of nitrous acid at 0°C 200Kg of sodium solution was diazotized and stirred for 2 hours, and excess sodium nitrite was removed with sulfamic acid to obtain diazonium solution;

[0029] 2) Inject 233Kg AAMX into the coupling reaction kettle, add 200Kg dilute lye, stir until 2,4-dimethyl-N-acetoacetanilide is dissolved, add 24.5Kg surfactant SF-1 and 14KgSF to the coupling reaction kettle -2, hydrochloric acid acid precipitation at 0°C to a pH of 6.0;

[0030] 3) After filtering the diazo solution to remove the active adsorbent, add it to the coupling reaction kettle at 5°C for coupling reaction. After adding the diazo solution, stir for 30 minutes; post-treatment, heat up to 90°C, keep it warm for 30 minutes, cool down and filter, Drying at 90°C, the obtained...

Embodiment 2

[0033] 1) Pour 175Kg TCB into a common reactor, add 2000Kg water, 500Kg ice cubes and 50Kg kaolin, beat at -10°C for 3 hours; quickly add 400Kg of 30% hydrochloric acid, and then quickly add 40% nitrous acid at 10°C 200Kg of sodium solution was diazotized, reacted for 1 hour, and excess sodium nitrite was removed with sulfamic acid;

[0034] 2) Pour 233Kg AAMX into the coupling reaction kettle, add 200Kg dilute lye, stir to dissolve. Add 24.5Kg surfactants SF-1 and 14KgSF-2 to the coupling reaction kettle, hydrochloric acid acid analysis at 0°C until the pH is 5.0; filter the diazo solution to remove the adsorbent and add it to the coupling reaction kettle at 5°C for coupling reaction. Stir for 30 minutes after adding the diazonium solution; post-treatment, raise the temperature to 90°C, keep it warm for 30 minutes, cool down and filter, and dry at 90°C. The yield of the obtained pigment is 389.5Kg, the yield is 95.1%, and the appearance of the pigment is bright. Pigment ap...

Embodiment 3

[0036] Inject 175Kg of TCB into a high-speed stirring reactor, add appropriate amount of water and 87.5Kg of diatomaceous earth, beat for 2 hours at 0°C; quickly add 400Kg of 30% hydrochloric acid, and then quickly add 200Kg of 40% sodium nitrite solution at 0°C Nitriding, react for 1 hour, remove excess sodium nitrite with sulfamic acid; inject 250Kg AAMX into the coupling reaction kettle, add 200Kg dilute lye, stir to dissolve. Add 24.5Kg surfactants SF-1 and 14KgSF-2 to the coupling reaction kettle, hydrochloric acid acid analysis at 0°C until the pH is 5.5; filter the diazo solution to remove the adsorbent and add it to the coupling reaction kettle at 5°C for coupling reaction. Stir for 30 minutes after adding the diazonium solution; post-treatment, raise the temperature to 90°C, keep it warm for 30 minutes, cool down and filter, and dry at 90°C. The yield of the obtained pigment: 405.9 Kg, the yield rate is 99.0%, the appearance of the pigment is bright, the application ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid resistance | aaaaa | aaaaa |

| alkali resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com