Patents

Literature

189results about How to "Reduce package" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

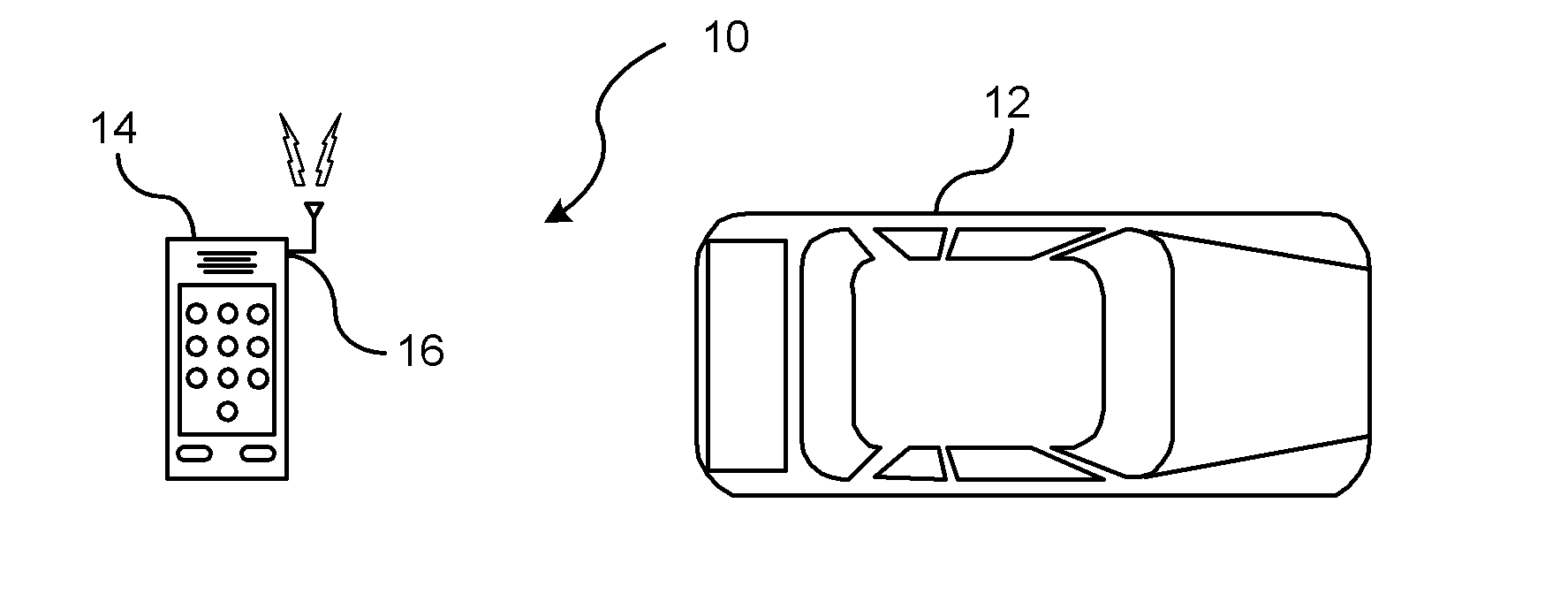

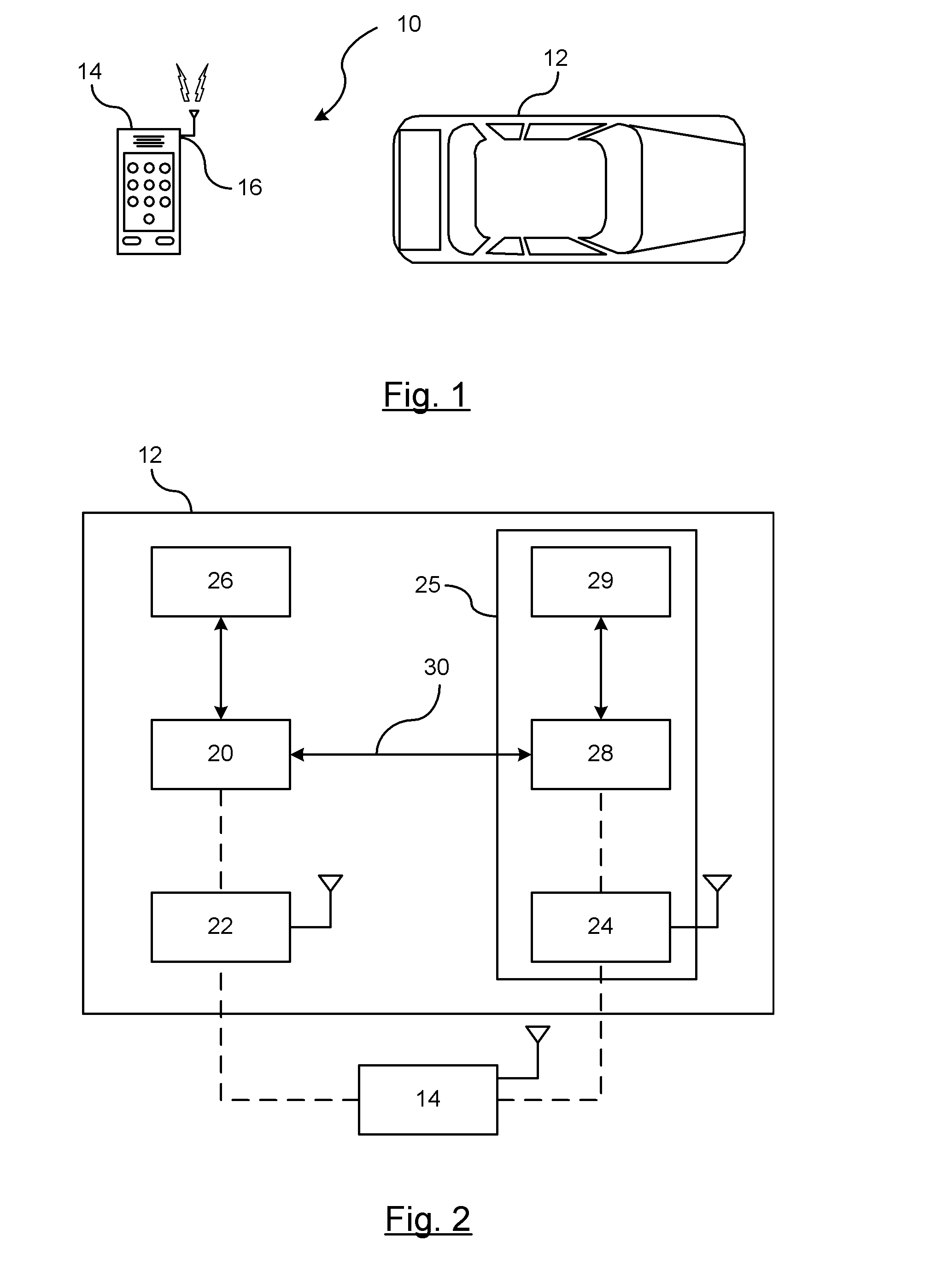

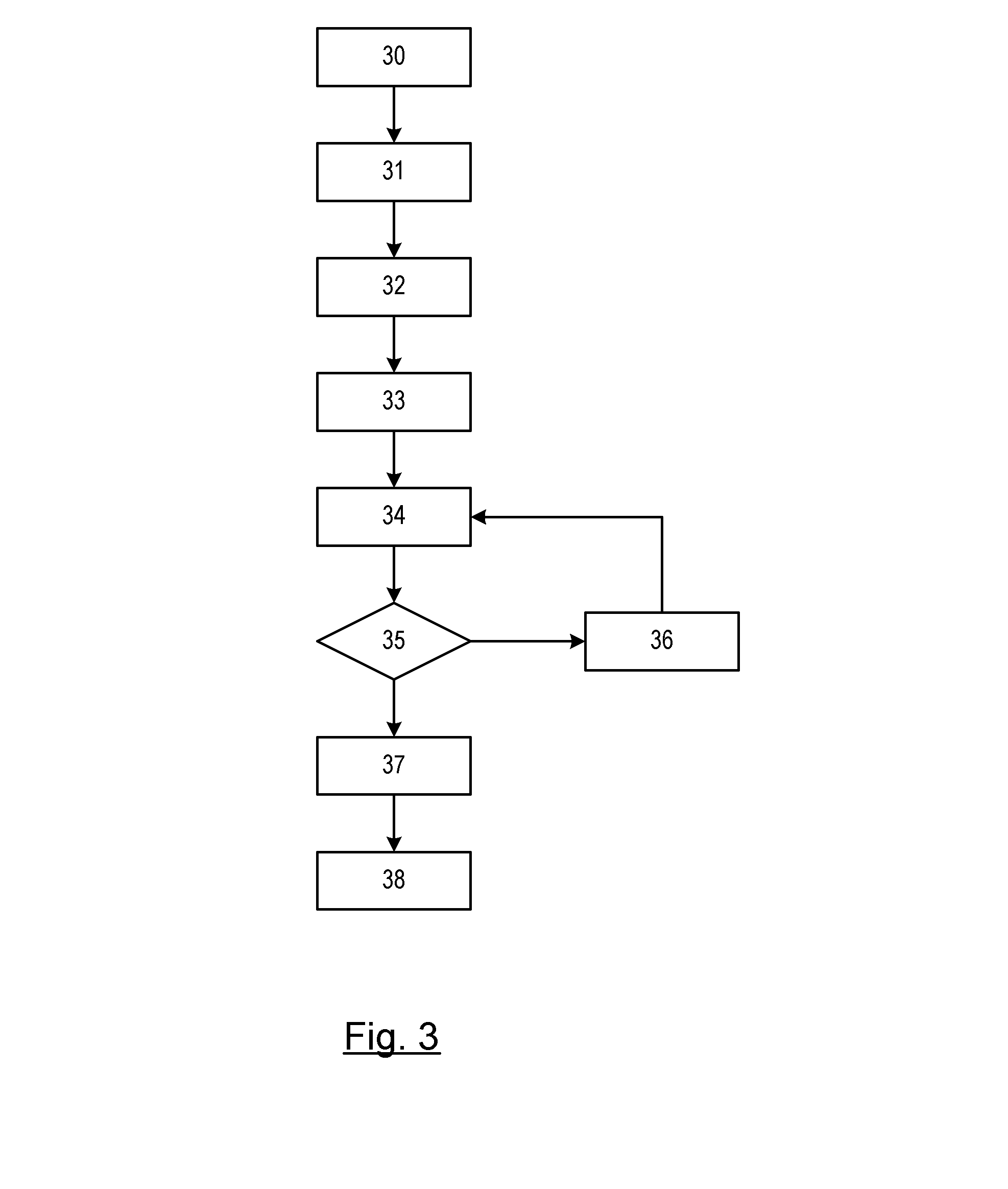

Bluetooth low energy approach detections through vehicle paired capable devices

ActiveUS20130017816A1Reduce complexityReduce packagePower managementNetwork topologiesTelecommunicationsHigh energy

A method of enabling communications between a Bluetooth low energy master communication device in a vehicle and a slave communication device. The slave communication device is successfully paired with a Bluetooth high energy master communication device in the vehicle. An identifier of the slave communication device is stored when it is successfully paired with the Bluetooth high energy master communication device. The Bluetooth low energy master communication device identifies an advertising event broadcast by the slave communication device. The advertising event relates to a notification by the slave communication device of the availability of its services. A determination is made whether the identifier of the slave communication device matches the stored identifier. Wireless communications between the Bluetooth low energy master communication device and the slave communication device is autonomously established without a manual pairing operation in response to an identifier of the slave communication device matching the stored identifier.

Owner:GM GLOBAL TECH OPERATIONS LLC

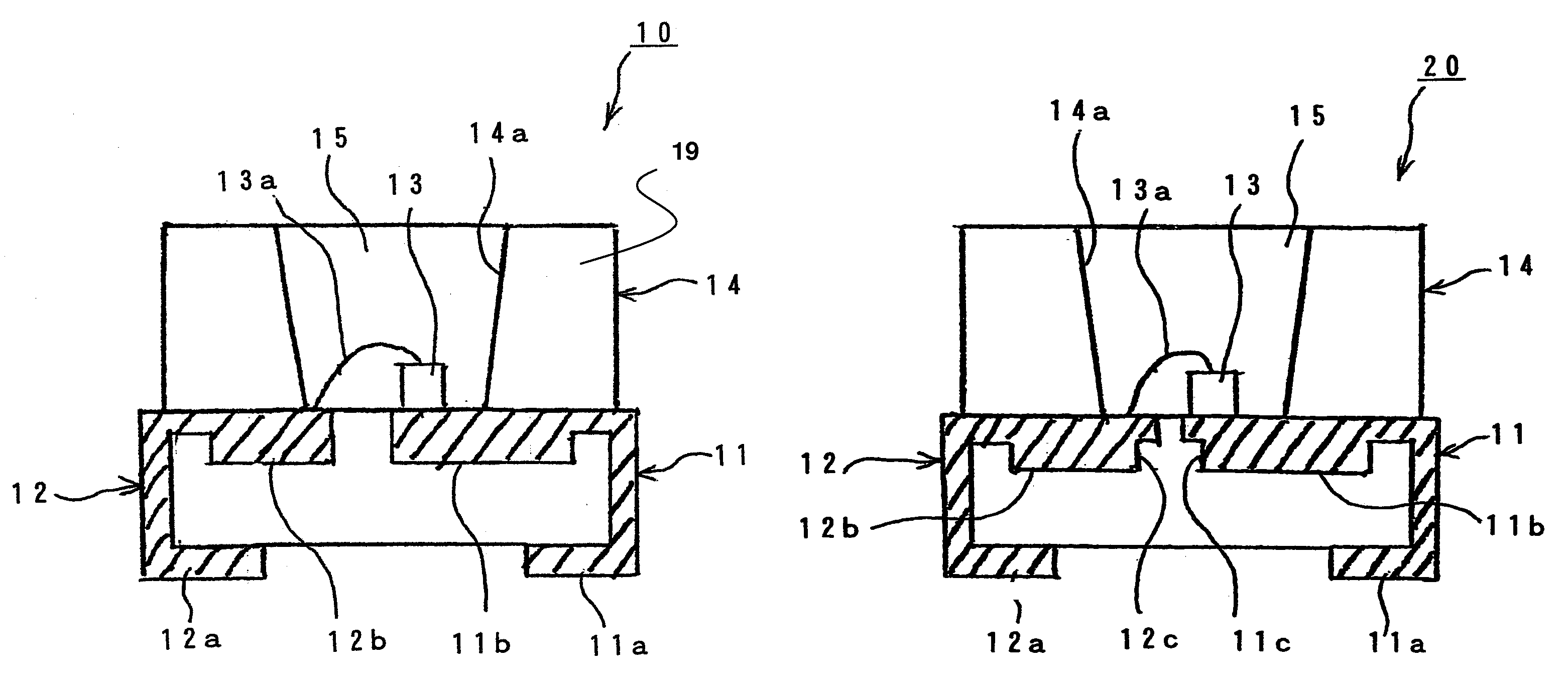

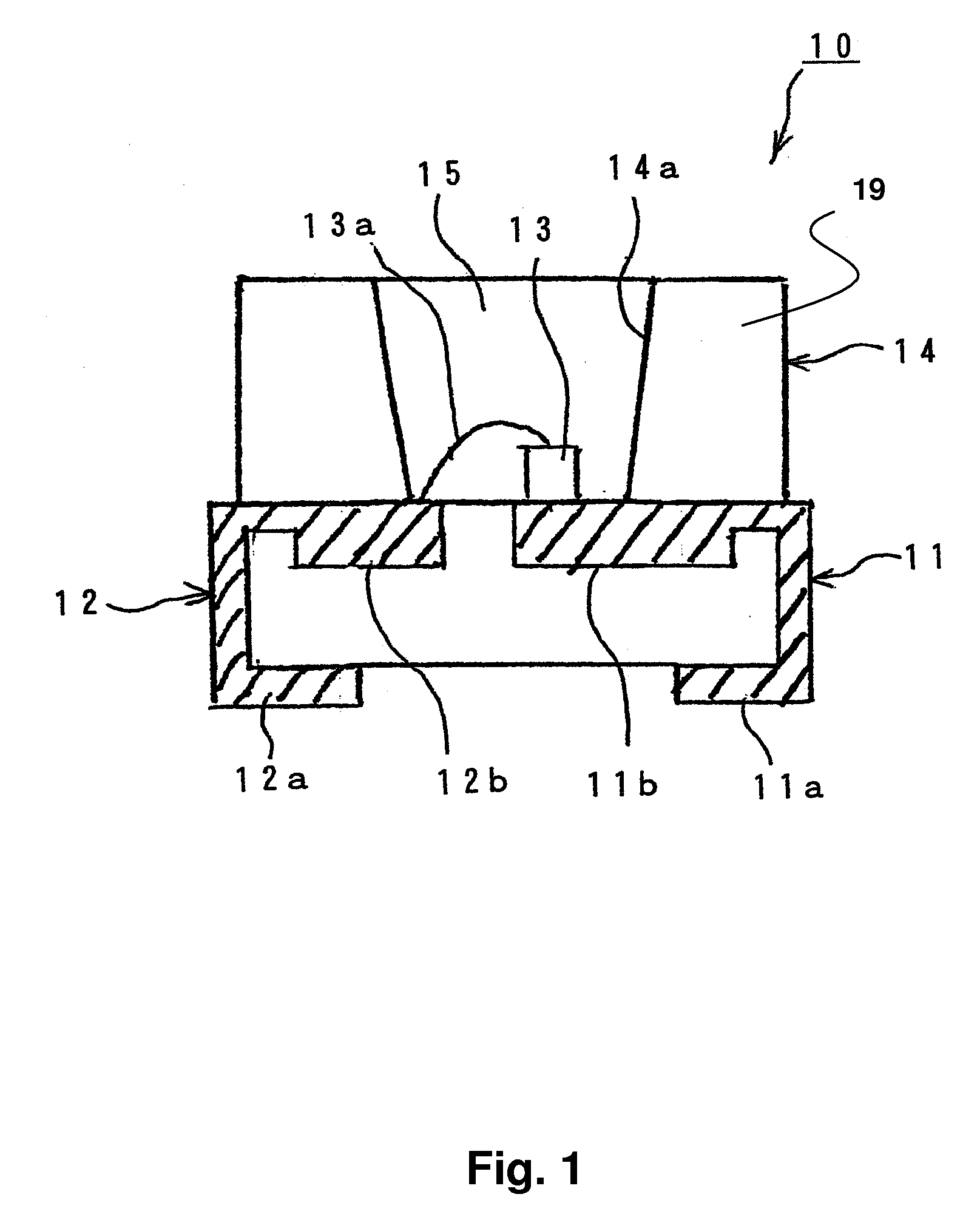

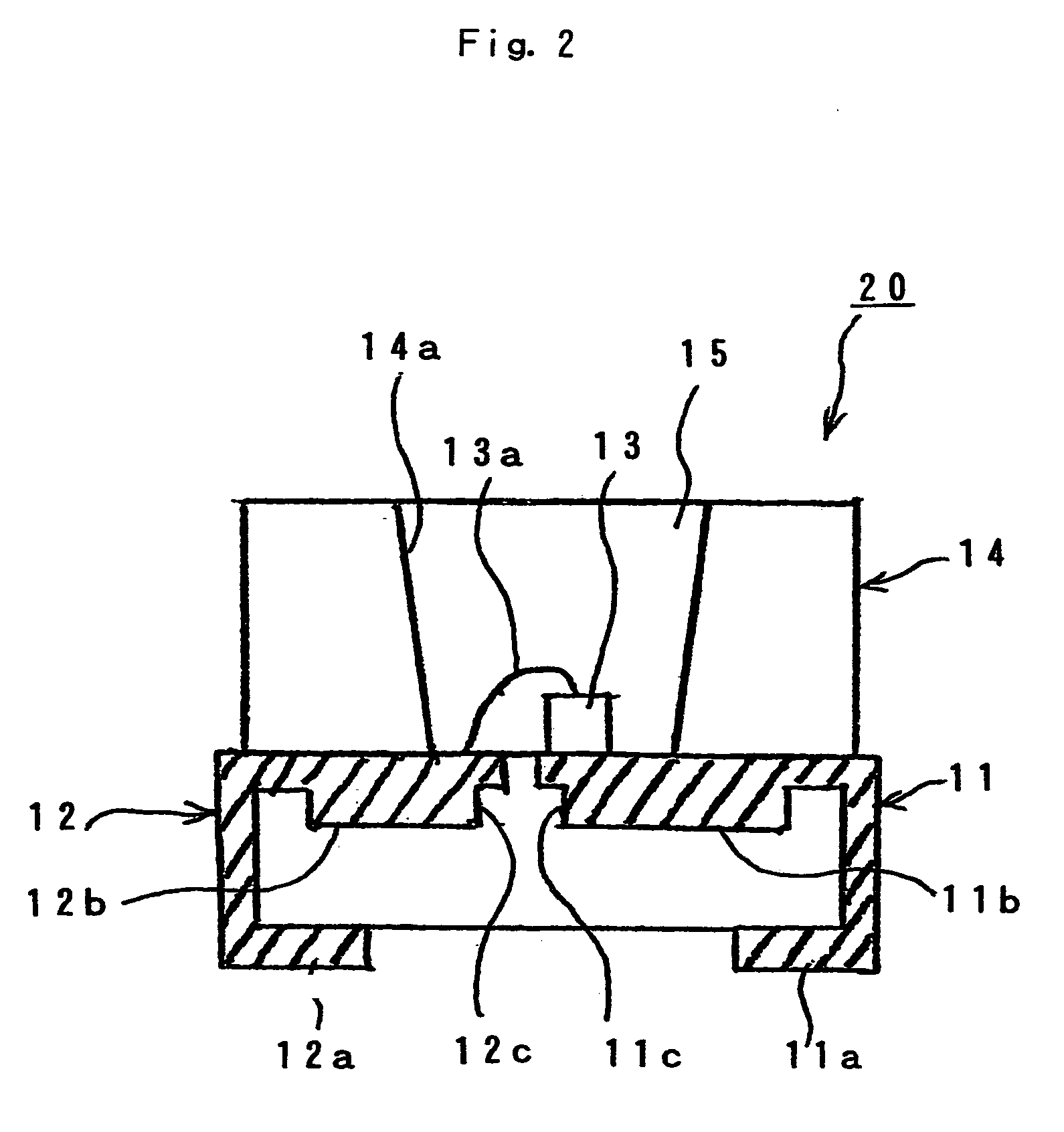

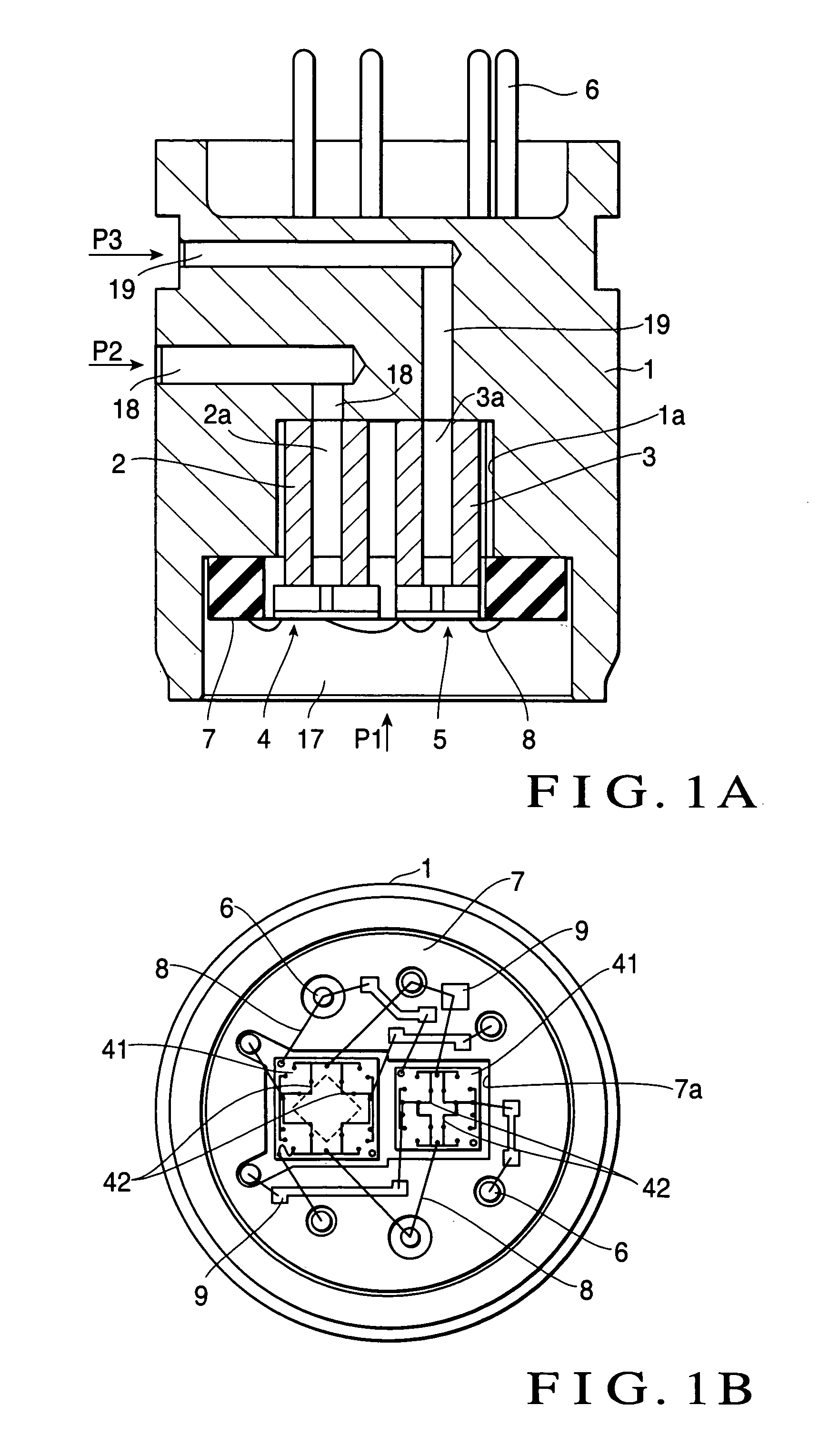

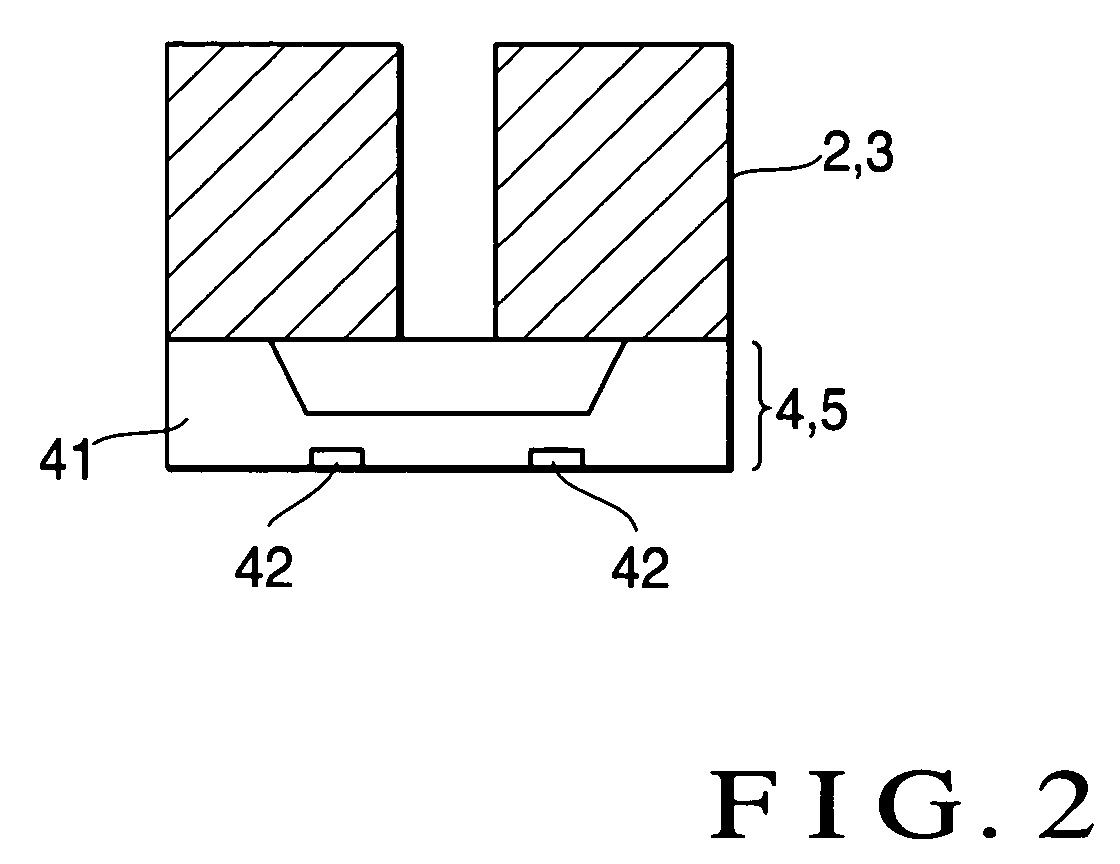

Surface mount type semiconductor device and lead frame structure thereof

ActiveUS7282785B2Increase heatRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesLead bondingSurface mounting

A surface mount type semiconductor device can be configured to include a pair of lead frames that are butted to each other with a spacing such that ends of the lead frames are opposite to each other. A bare chip can be mounted on a chip mount portion on one end side of one of the lead frames, and wire-bonded to a connection portion on an end side of the other lead frame. A housing can be insert-molded to an end side of both of the lead frames, and the lead frames can be shaped such that they extend along the side and bottom surfaces of the housing and form surface mounting terminal portions. The lead frames are preferably formed to be thin at least at the regions that are to be bent, and other regions thereof are preferably formed to be thick to improve heat radiating effect.

Owner:STANLEY ELECTRIC CO LTD

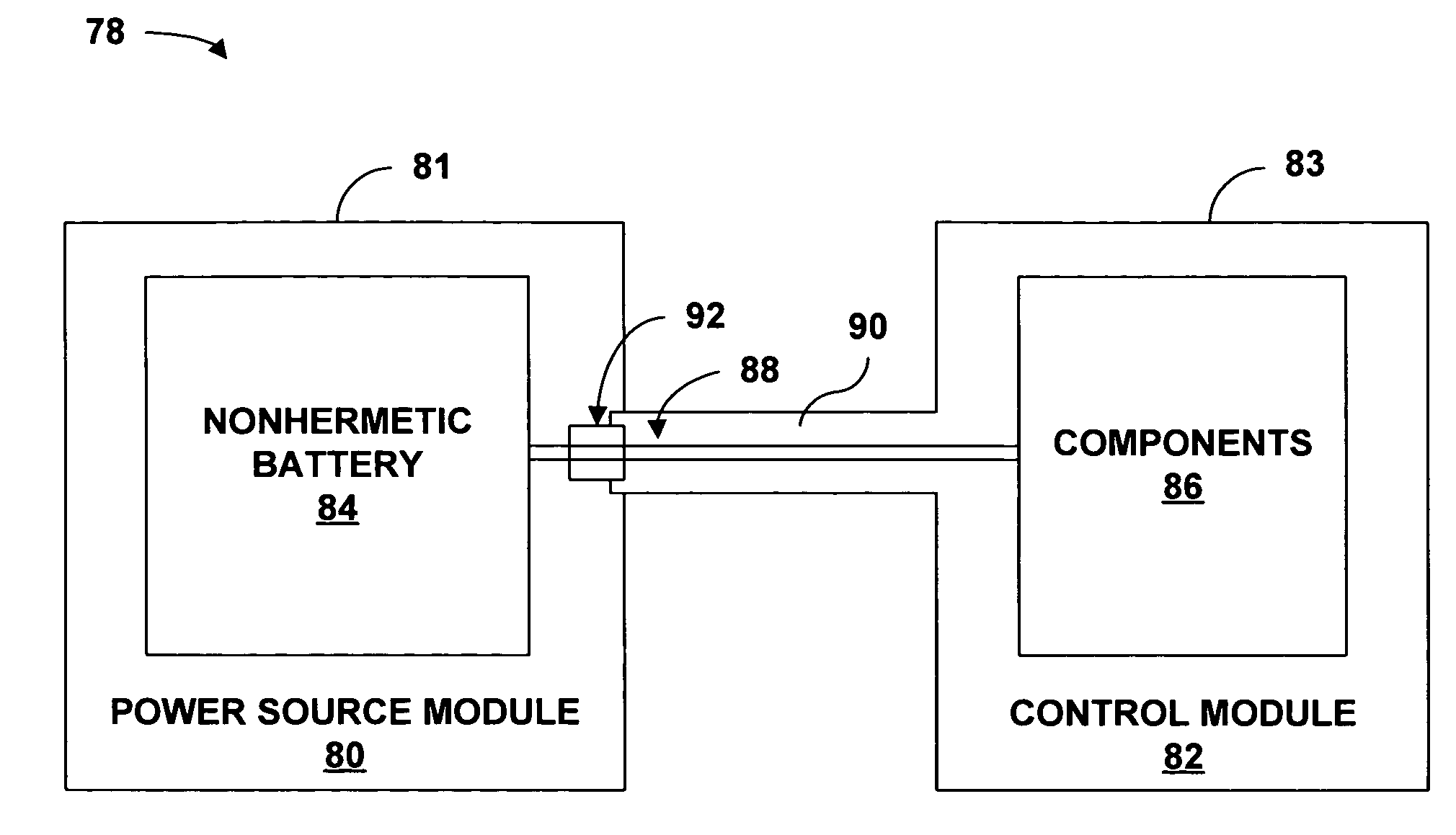

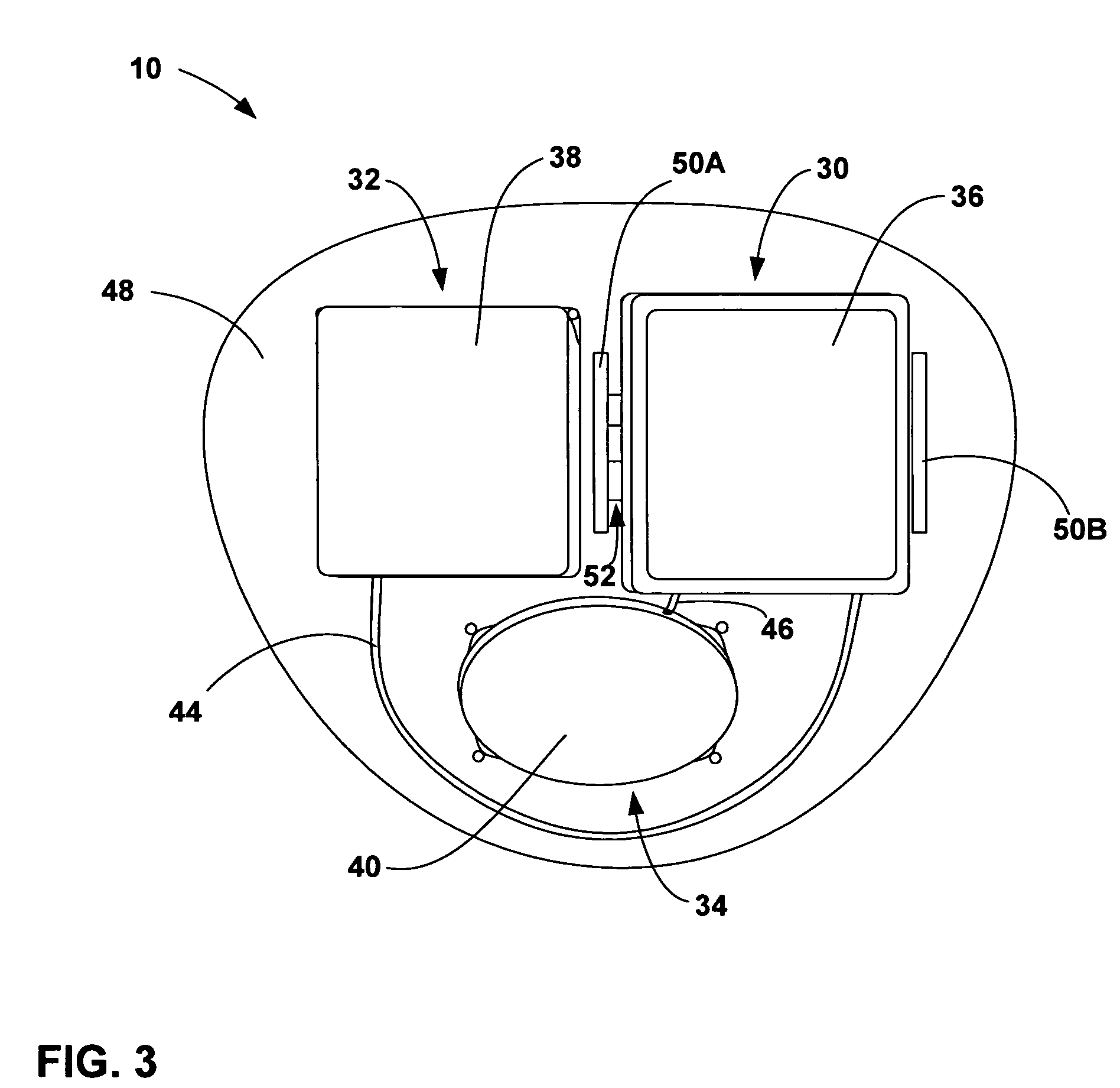

Implantable medical device with a nonhermetic battery

InactiveUS7263401B2Damage to componentEasy to useInternal electrodesHermetically-sealed casingsElectrical batteryEngineering

An implantable medical device (IMD) including a nonhermetic battery is described. The IMD includes components and a power source module that includes the nonhermetic battery. The IMD also includes a barrier to substantially impede movement of substances from the nonhermetic battery to the components. The barrier may include a hermetic feedthrough, a gel, a polymer, or a solid electrolyte within the nonhermetic battery, and a seal member. The barrier may also be a material that encapsulates the nonhermetic battery and a getter within the IMD. In some embodiments, the IMD comprises a modular IMD including an interconnect member. In that case, the barrier may include a material that fills at least a portion of a void defined by the interconnect member. A length and a cross-sectional area of the interconnect member may also act as a barrier.

Owner:MEDTRONIC INC

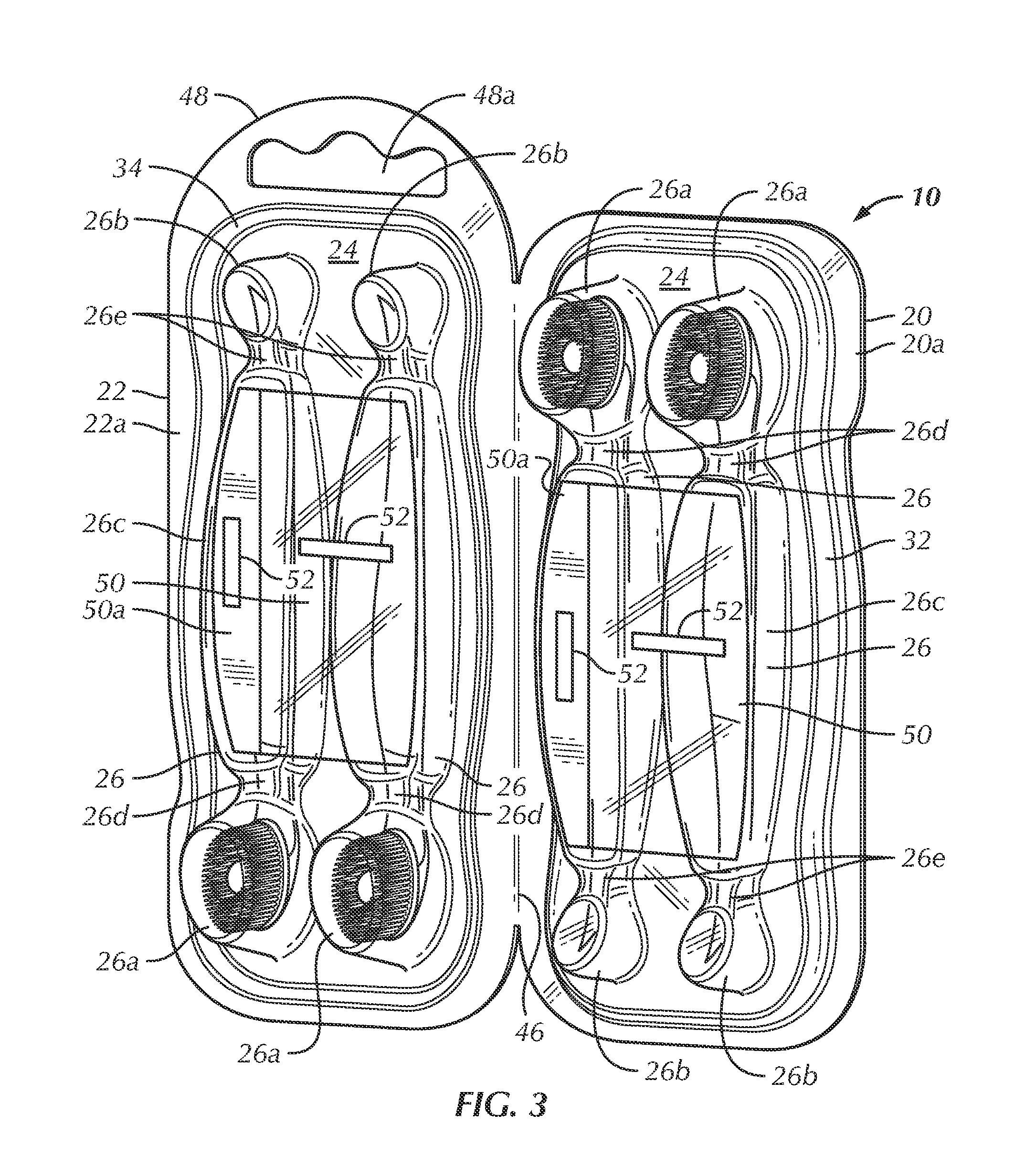

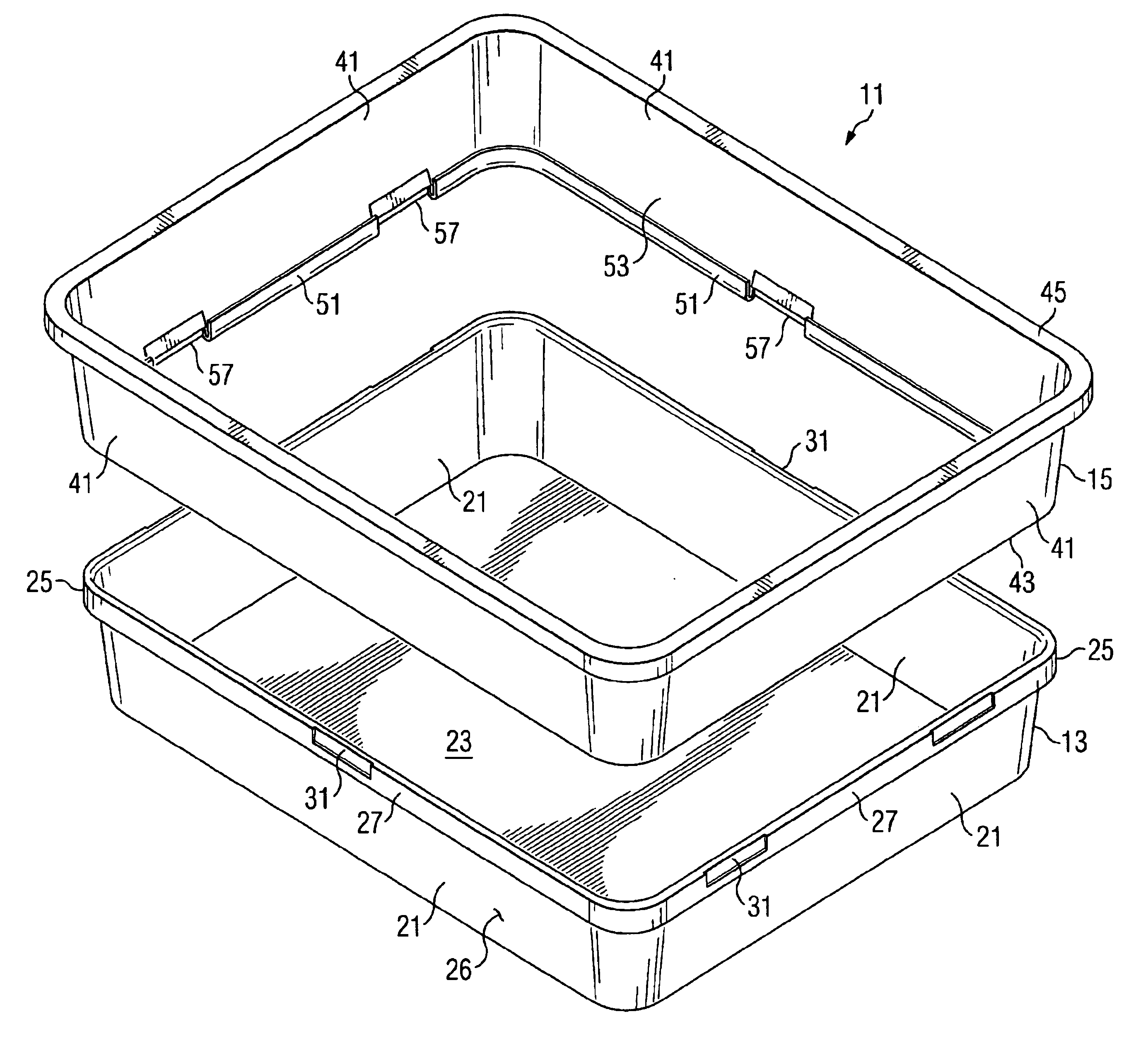

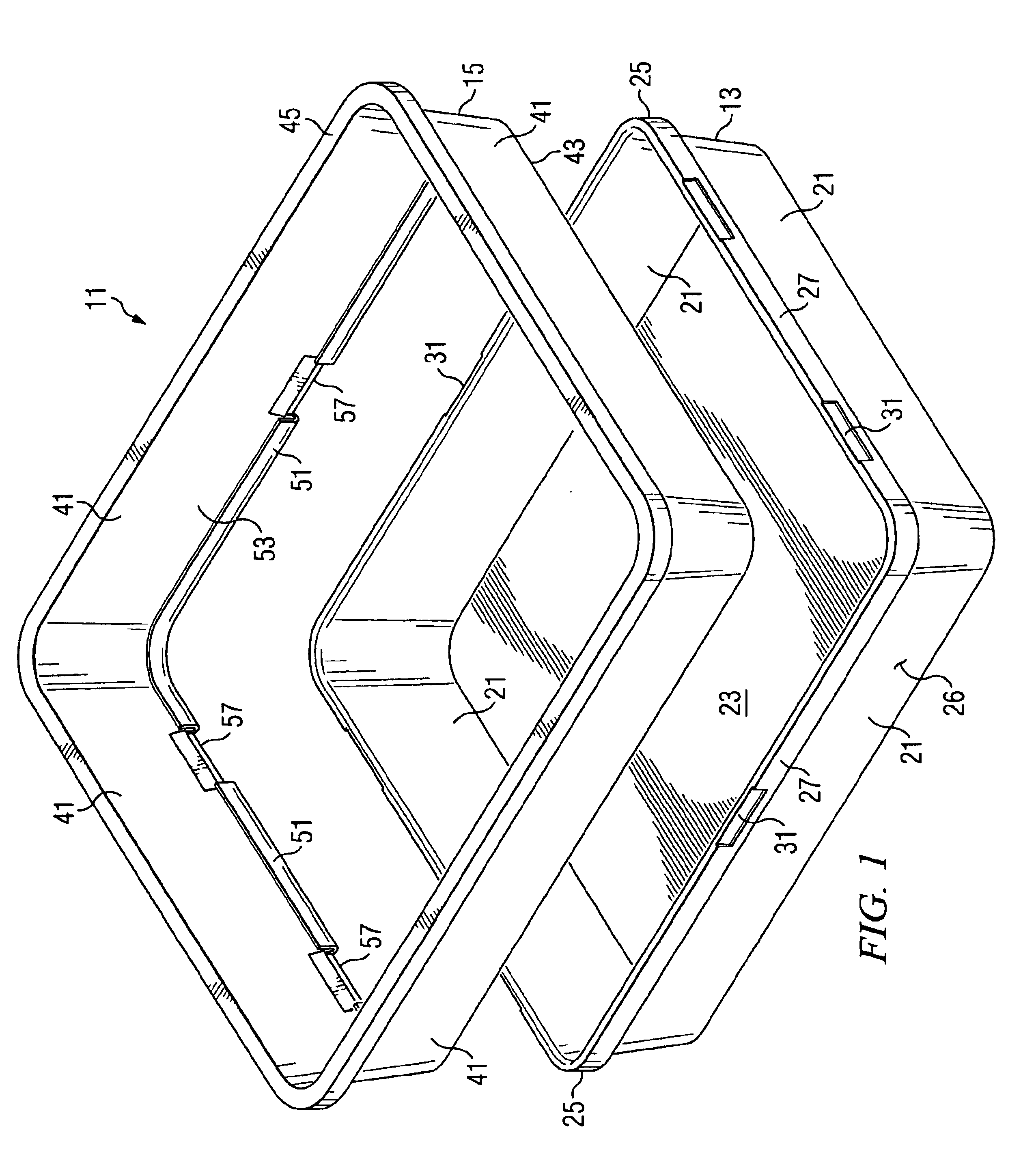

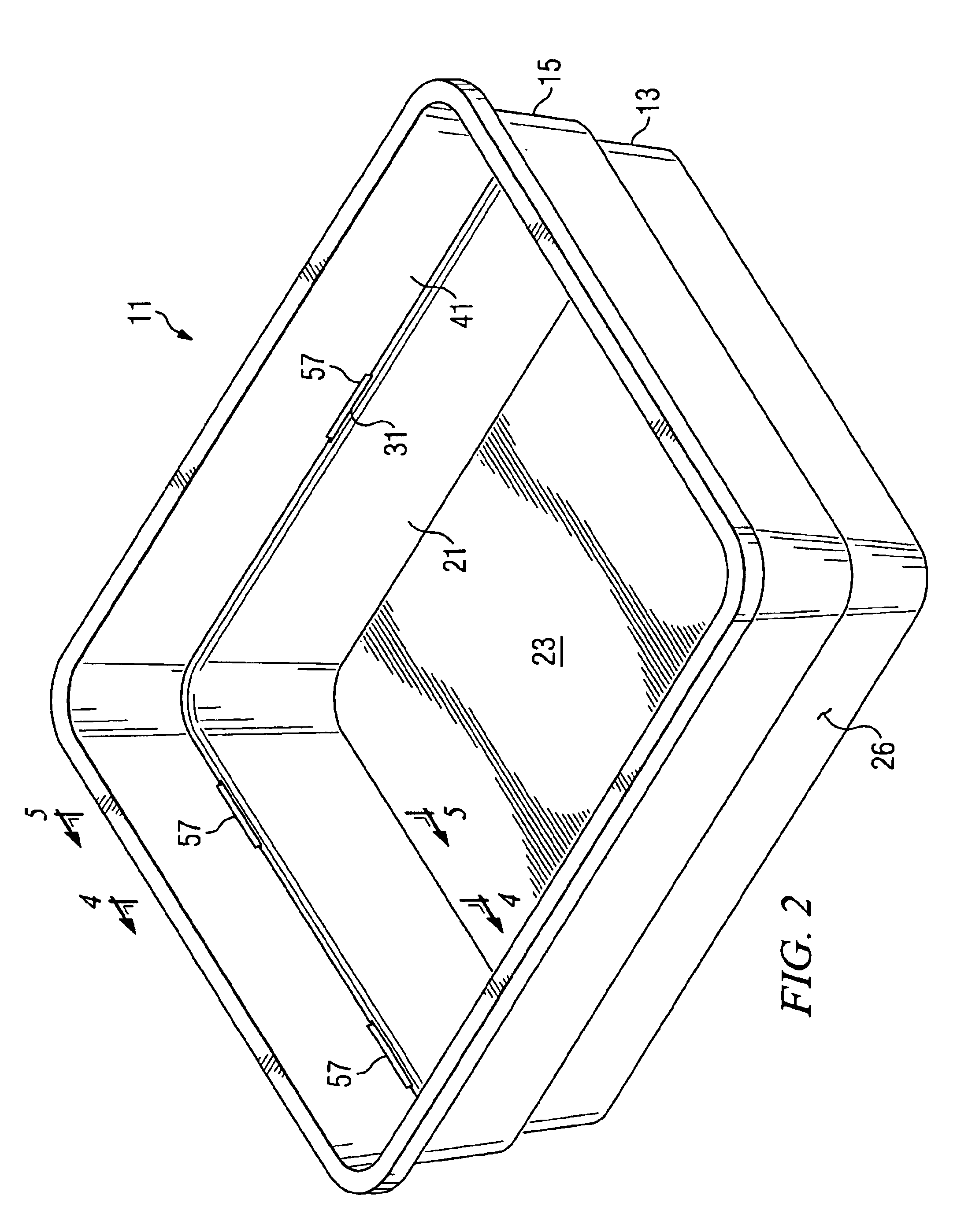

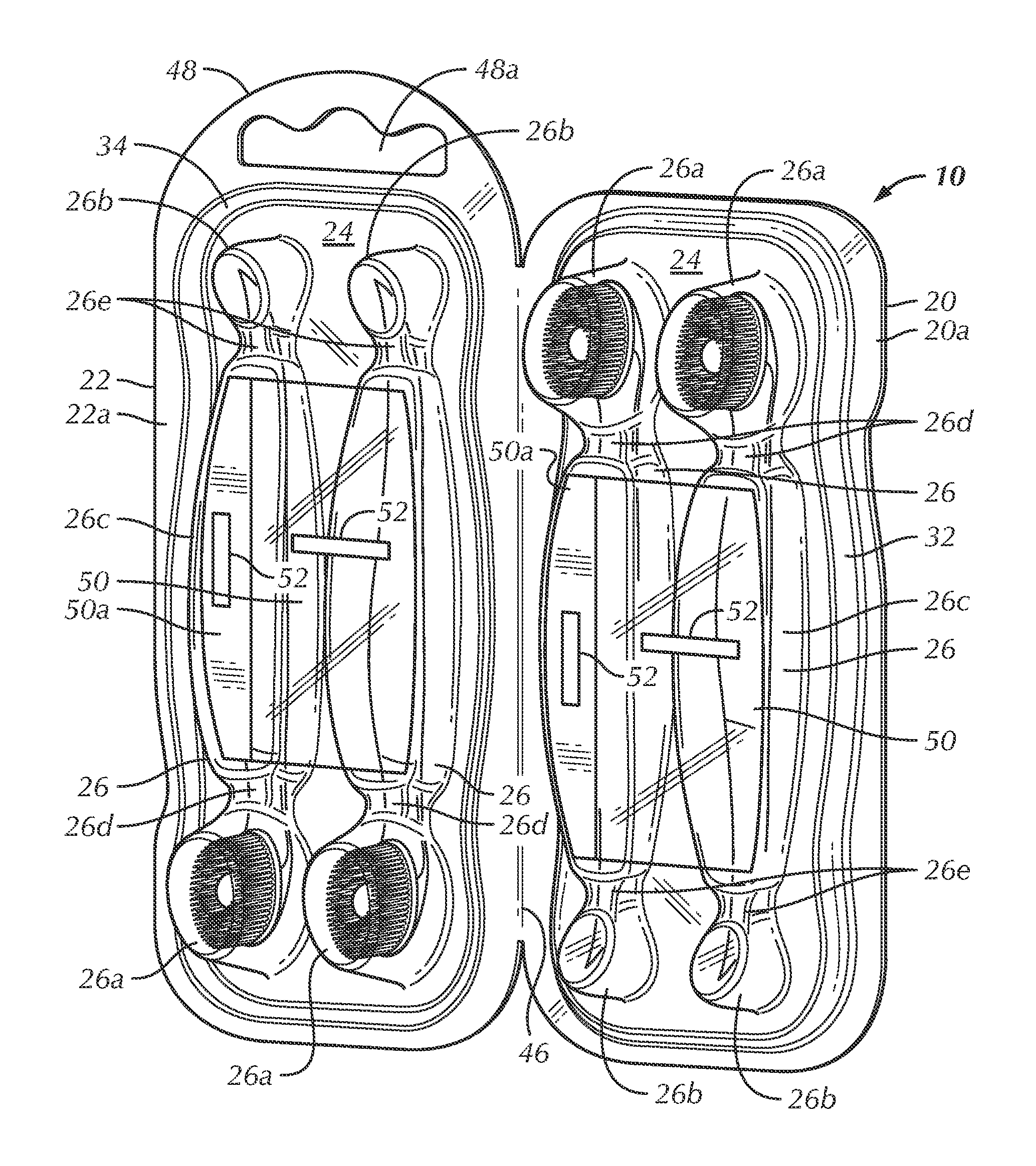

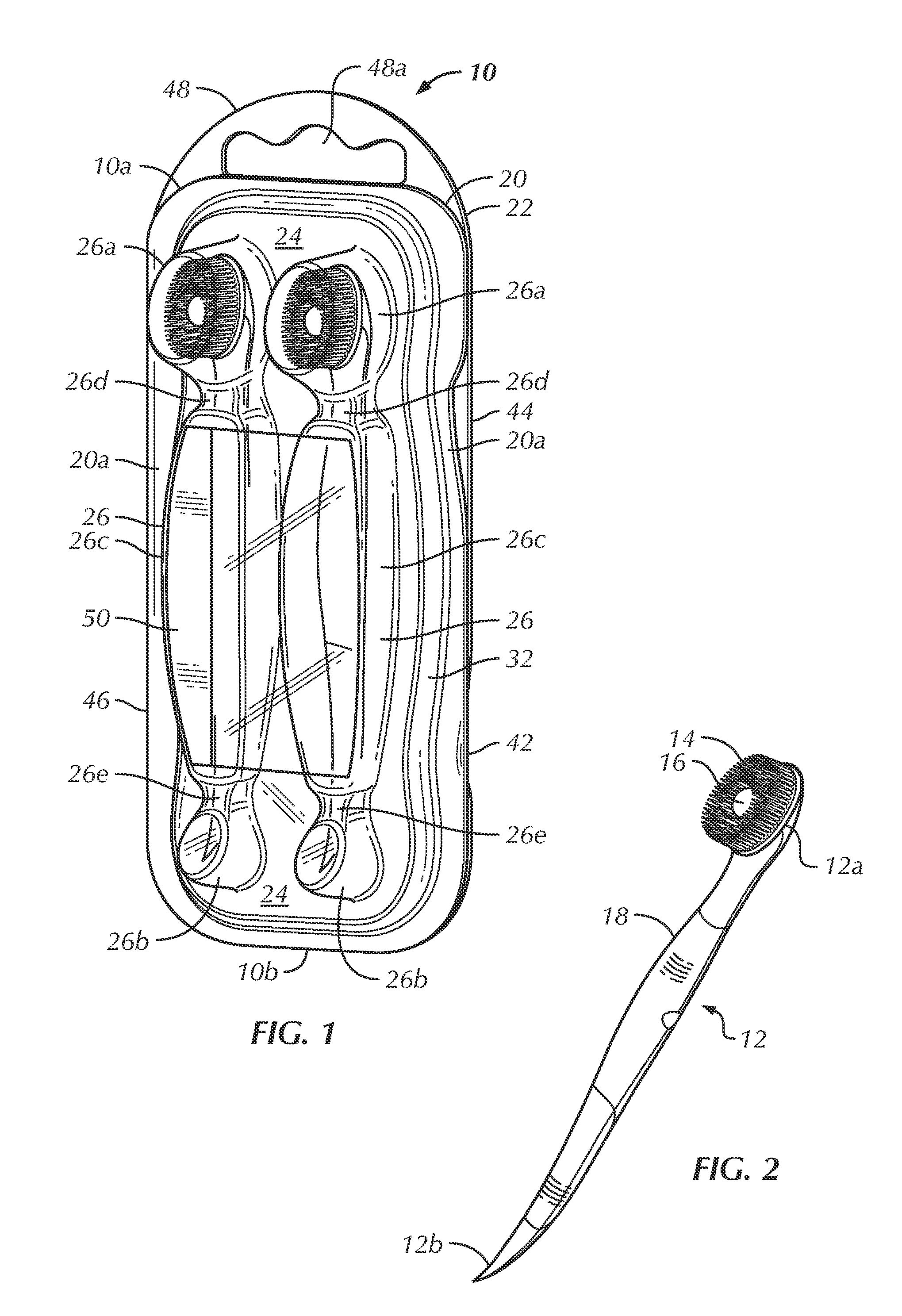

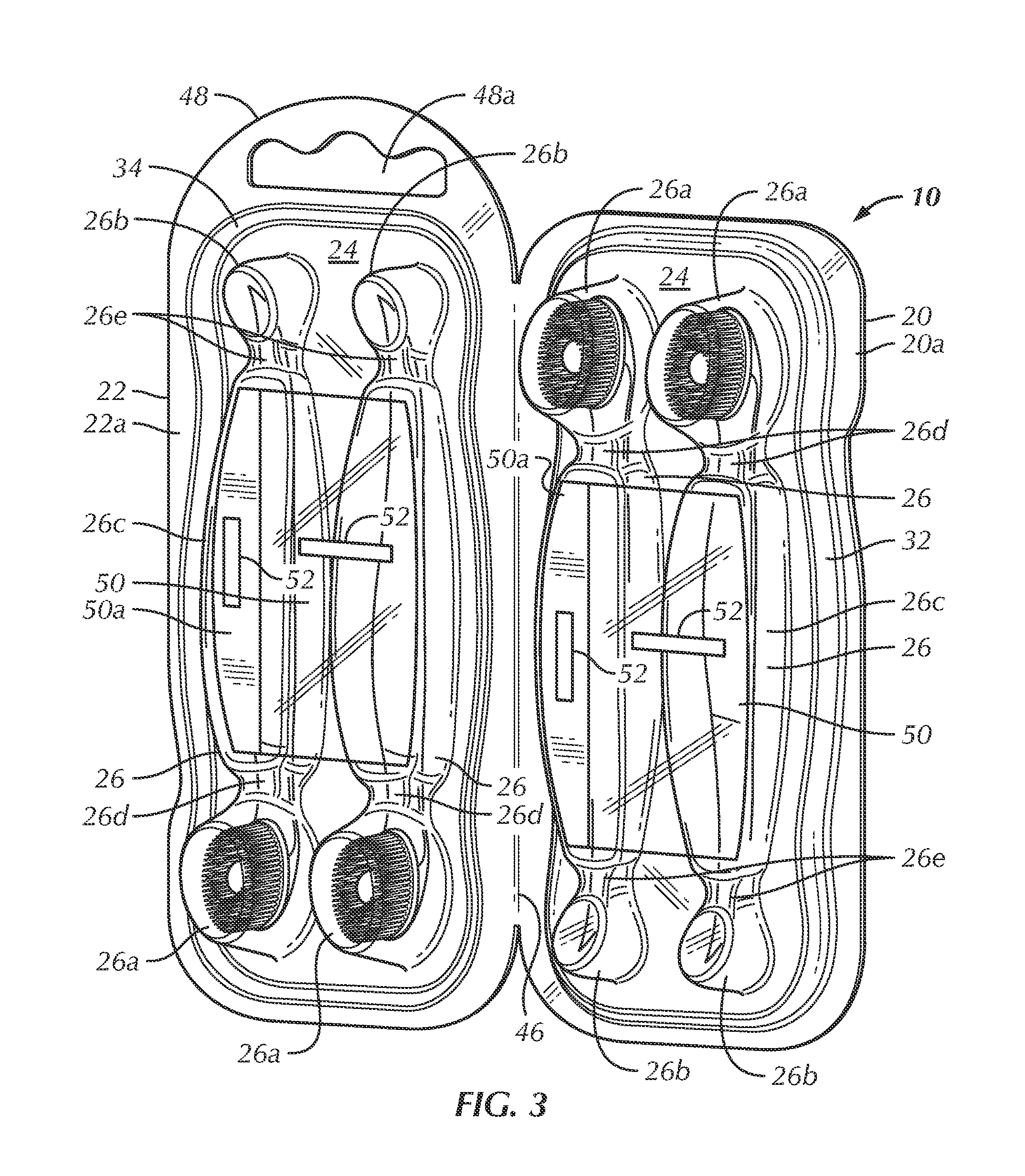

Display package

InactiveUS20100230312A1High degreeImprove sustainabilityContainer decorationsLevel indicationsEngineeringMechanical engineering

A package for displaying a plurality of items where the package has first and second containers connectable between an open position and a closed position, each container having an outer surface having at least one elongated protrusion, the at least one protrusion having a head end and a tail end, the head end extending further outwardly from the package than the tail end, and an inner surface having at least one inner cavity aligned with the at least one protrusion, the cavity having a depth varying along the protrusion and configured to receive one of the plurality of items, wherein the head end of the at least one protrusion of the first container is proximate the tail end of the at least one protrusion of the second container in the closed position.

Owner:COLGATE PALMOLIVE CO

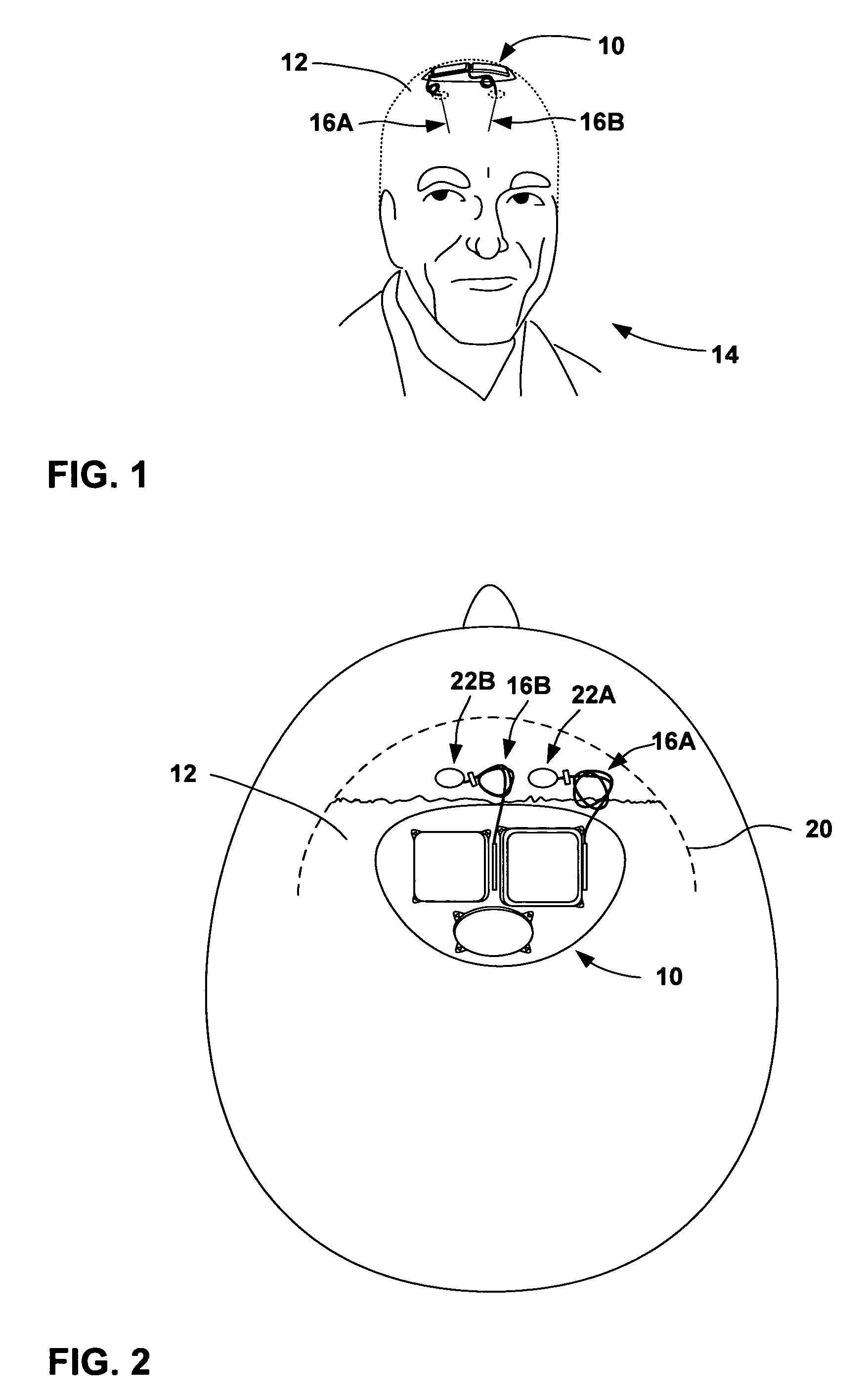

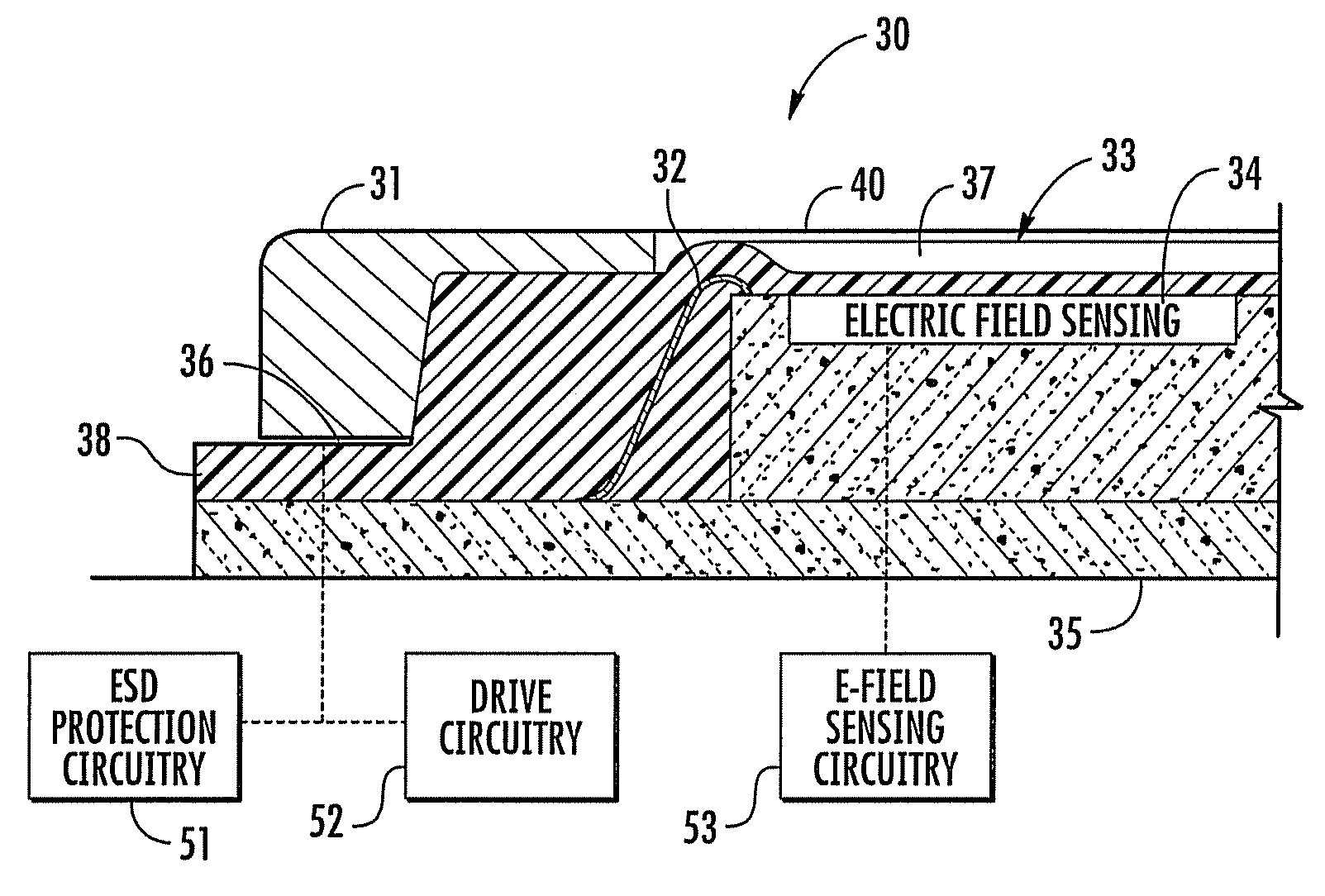

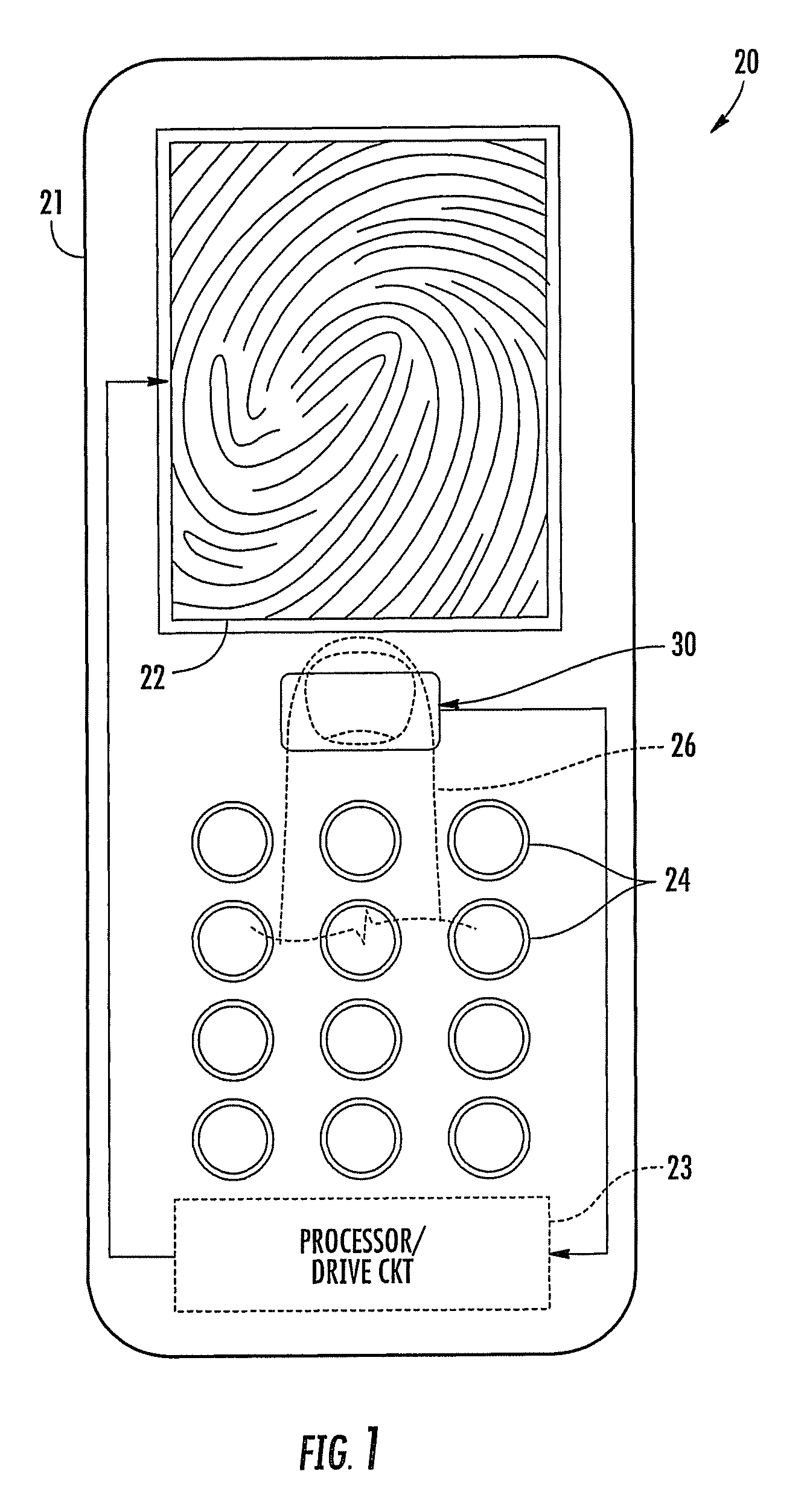

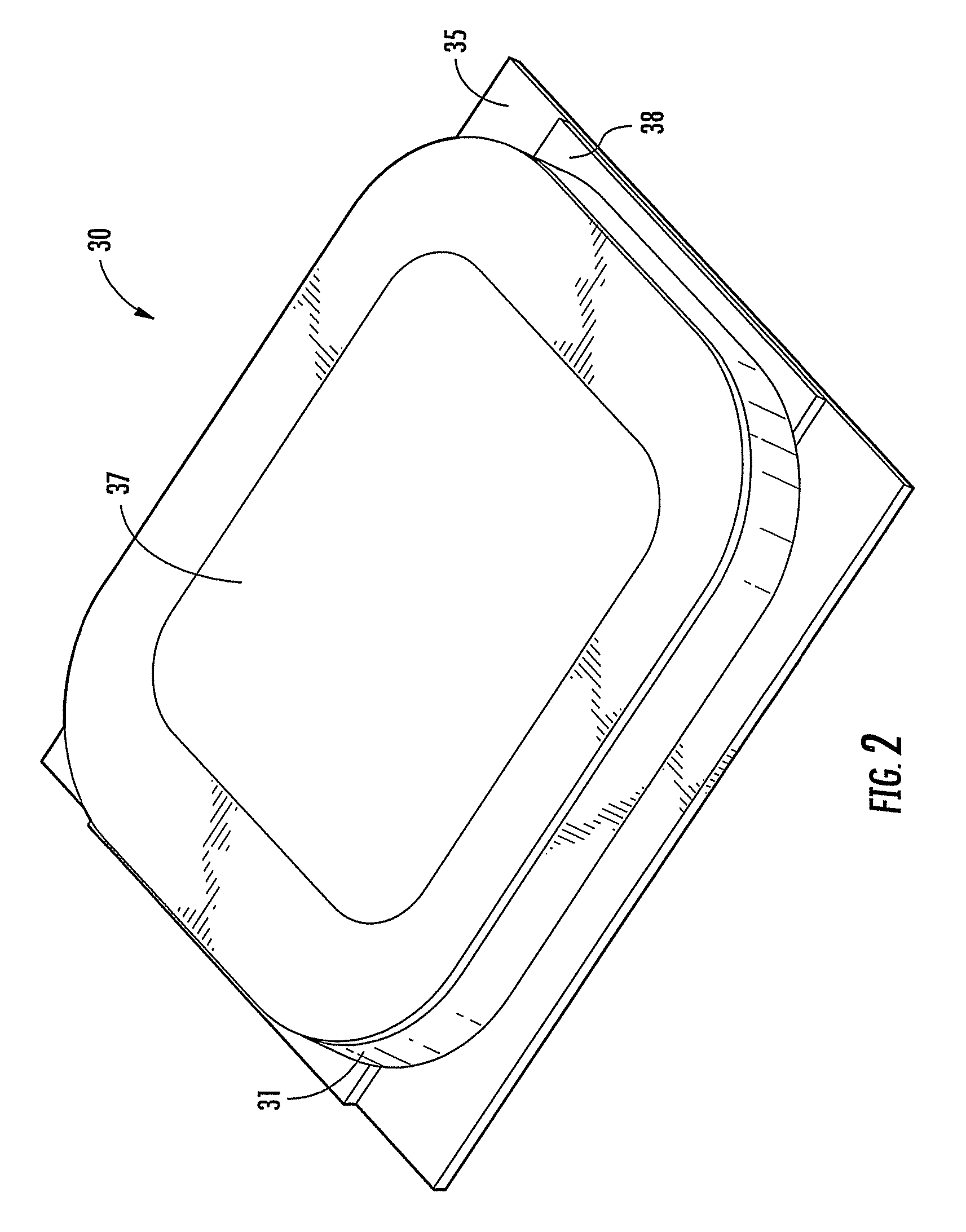

Finger sensor including encapsulating layer over sensing area and related methods

InactiveUS8736001B2Reduce packageReduced mechanical robustnessSemiconductor/solid-state device detailsSolid-state devicesEngineeringFingerprint

A fingerprint sensor may include a substrate, and a finger sensing IC on the substrate and including a finger sensing area on an upper surface thereof for sensing an adjacent finger. The fingerprint sensor may include an encapsulating material on the finger sensing IC and covering the finger sensing area, and a bezel adjacent the finger sensing area and on an uppermost surface of the encapsulating layer.

Owner:APPLE INC

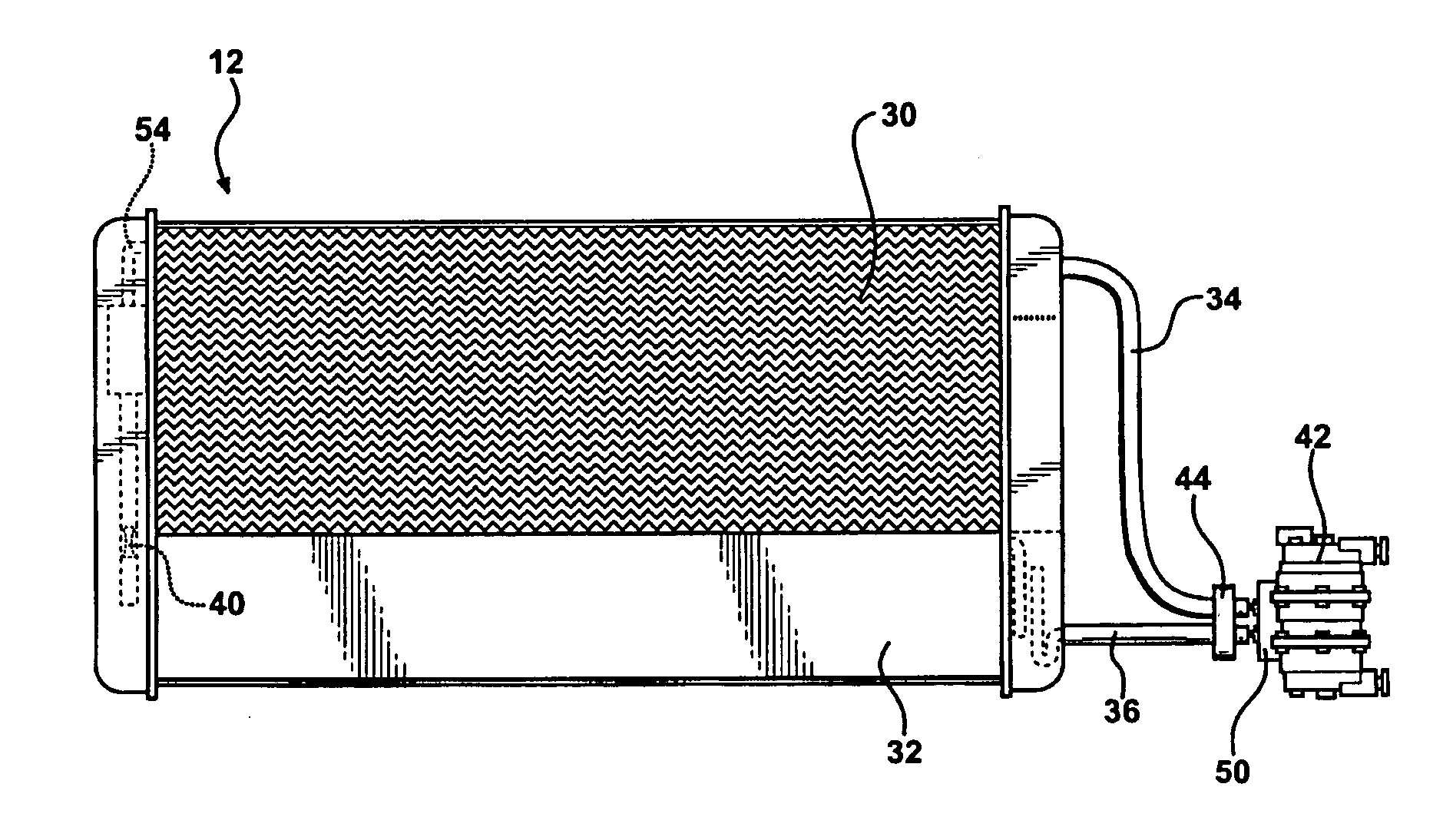

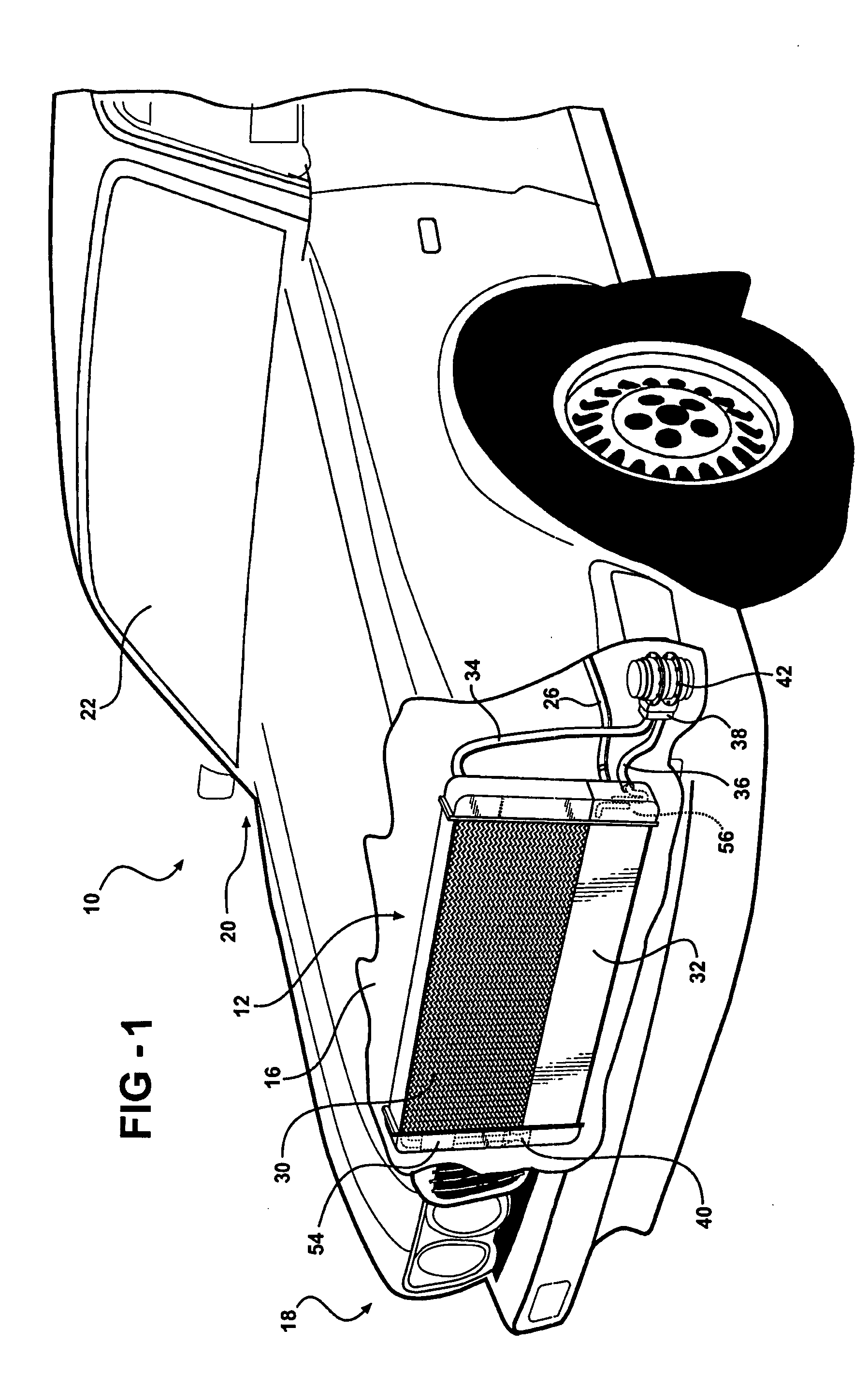

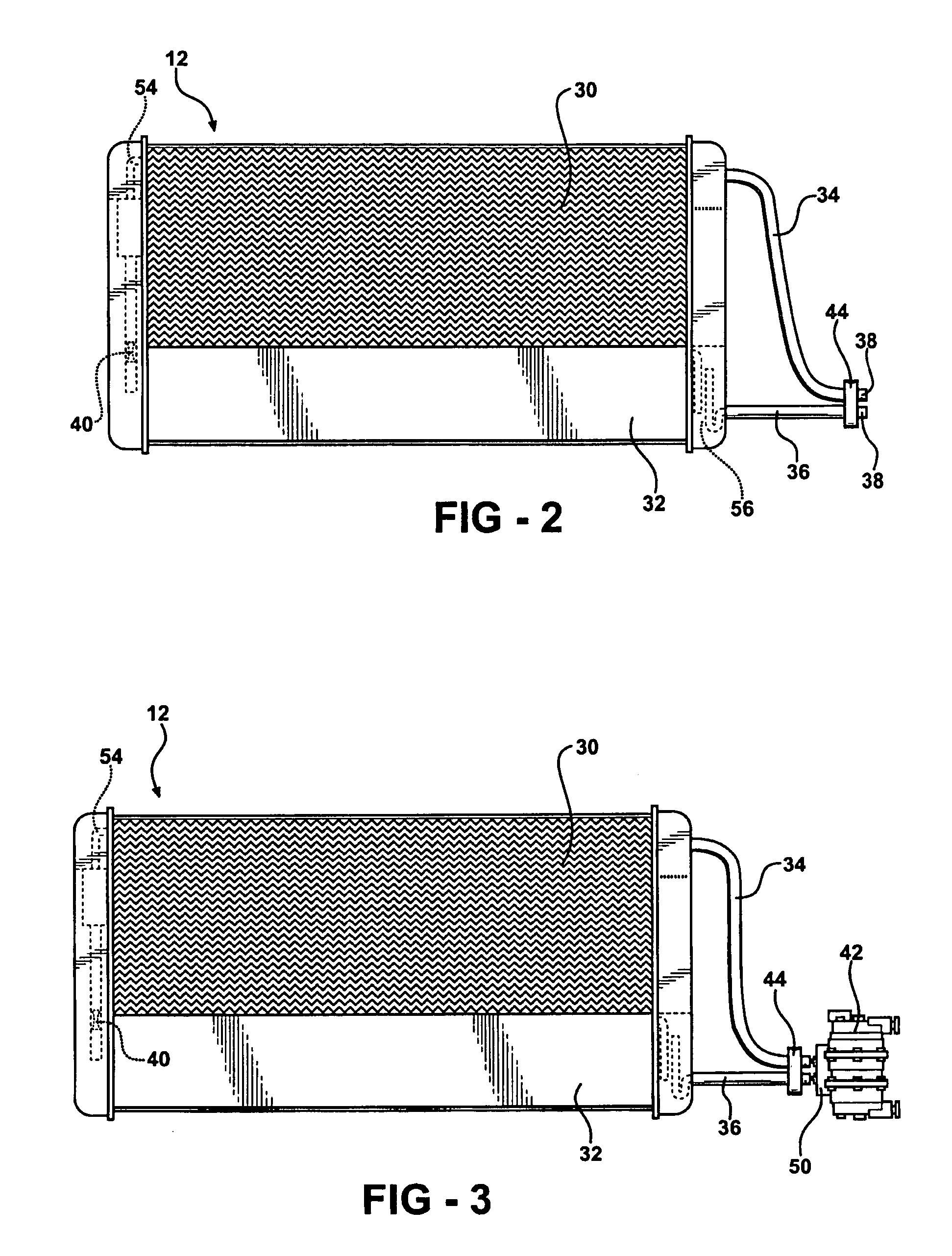

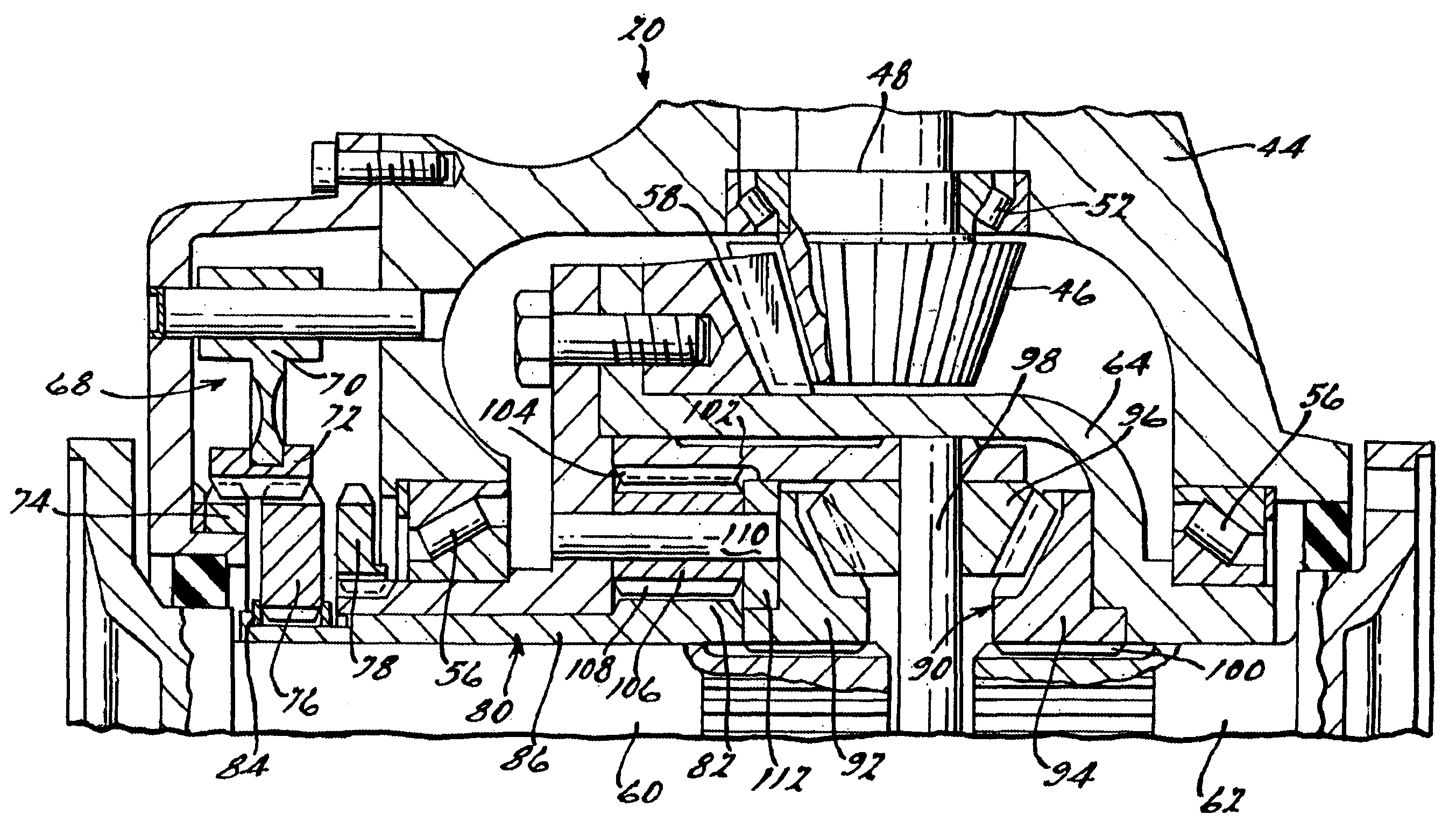

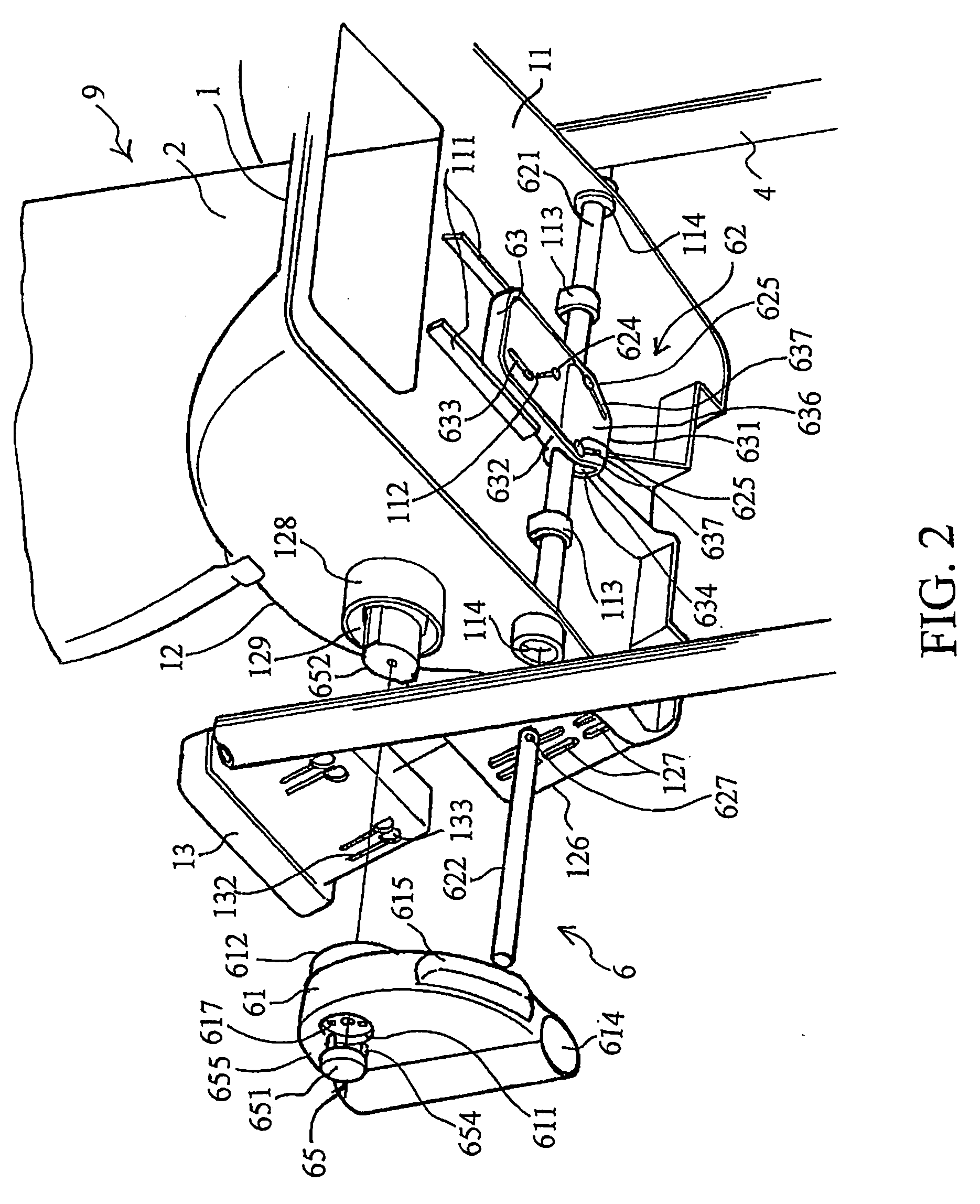

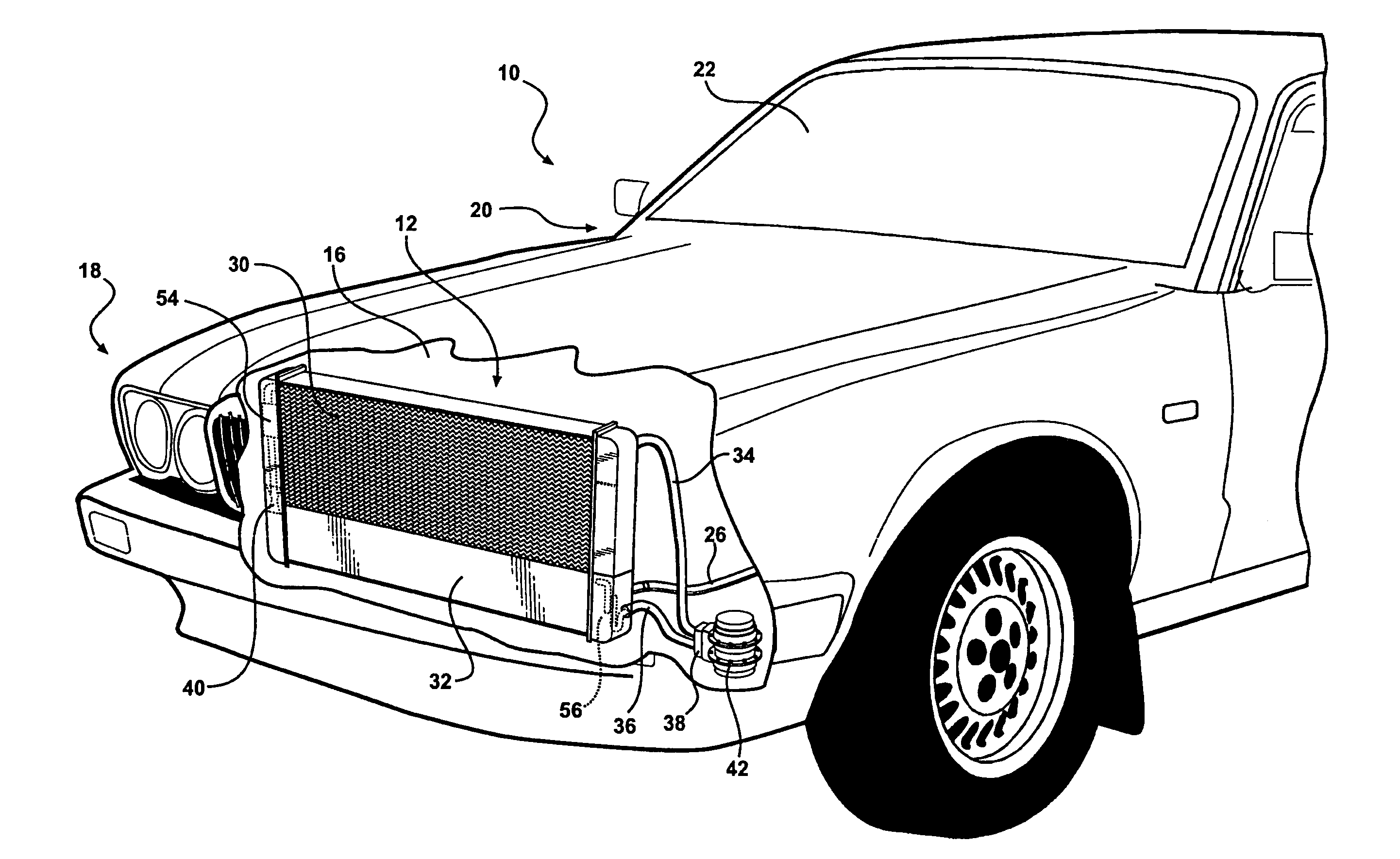

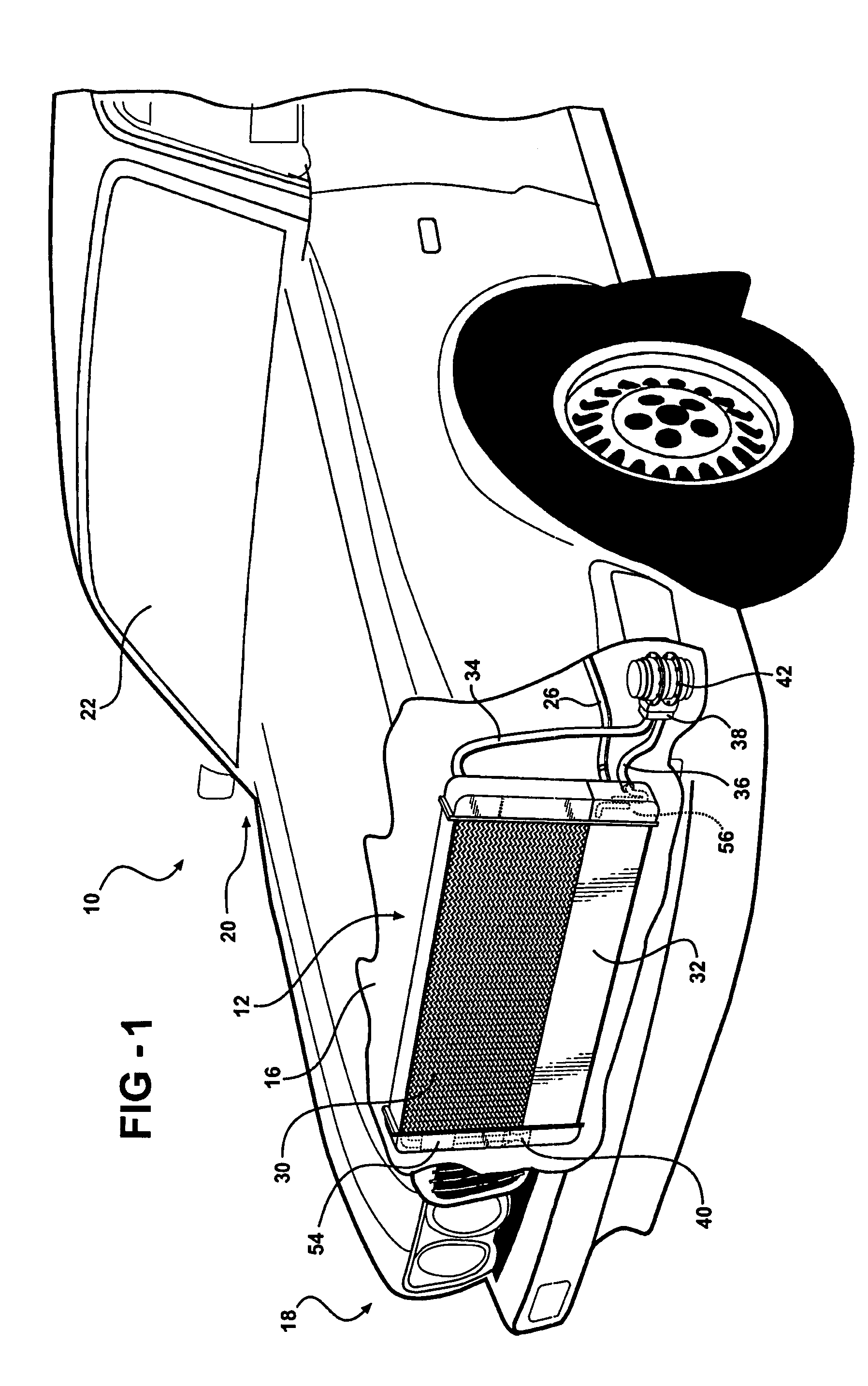

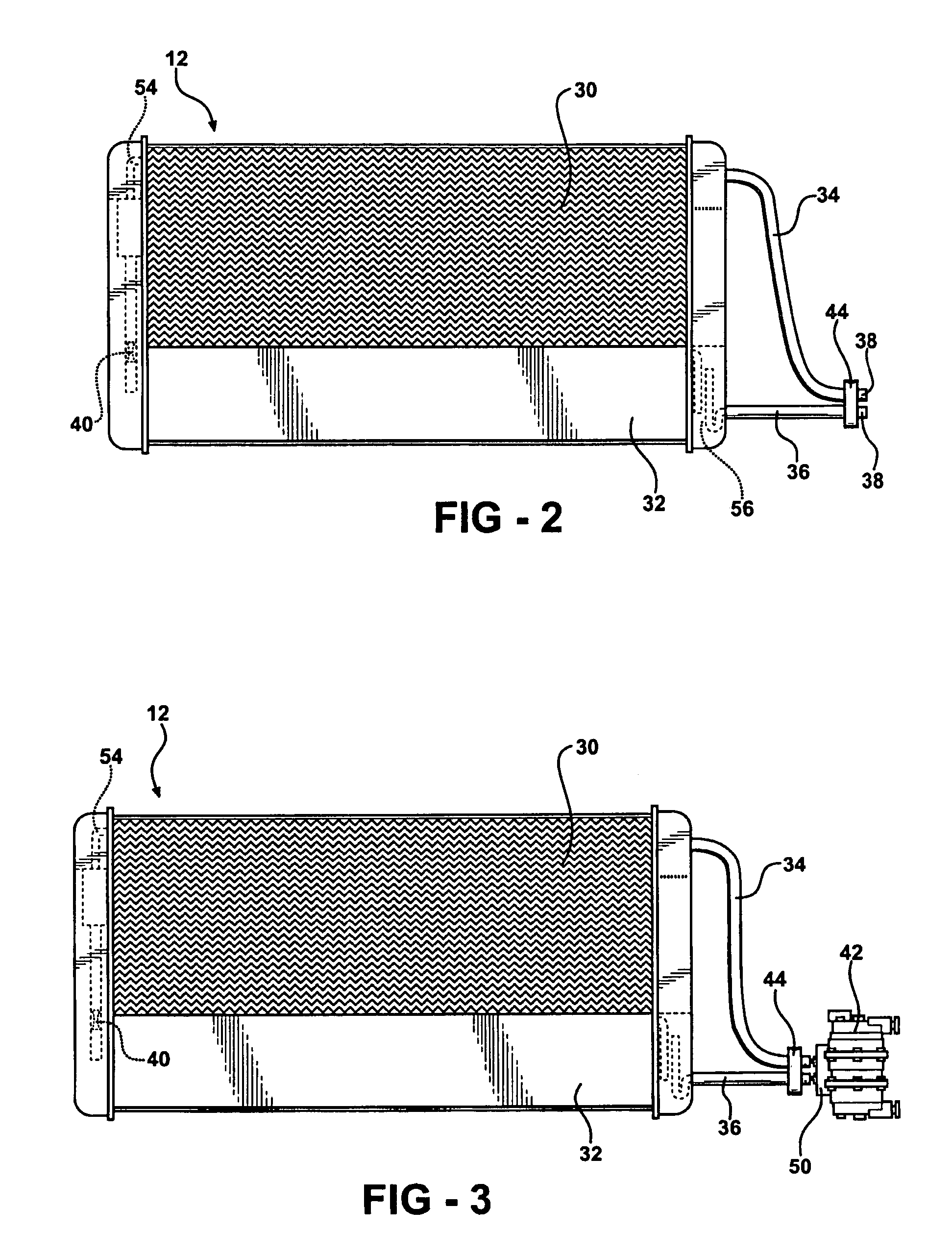

Front-end integral air-conditioning unit

ActiveUS20050016196A1Facilitate easeReduce packageAir-treating devicesEvaporators/condensersCouplingPre-charge

A sub-unit for a vehicle air conditioning system is shipped with a condenser, chiller and fluid lines. Snap together couplings are placed on free ends of the fluid lines whereby the sub-unit can be pre-charged, shipped, installed into the front end of a vehicle engine compartment and connected to an air conditioning compressor.

Owner:MAHLE INT GMBH

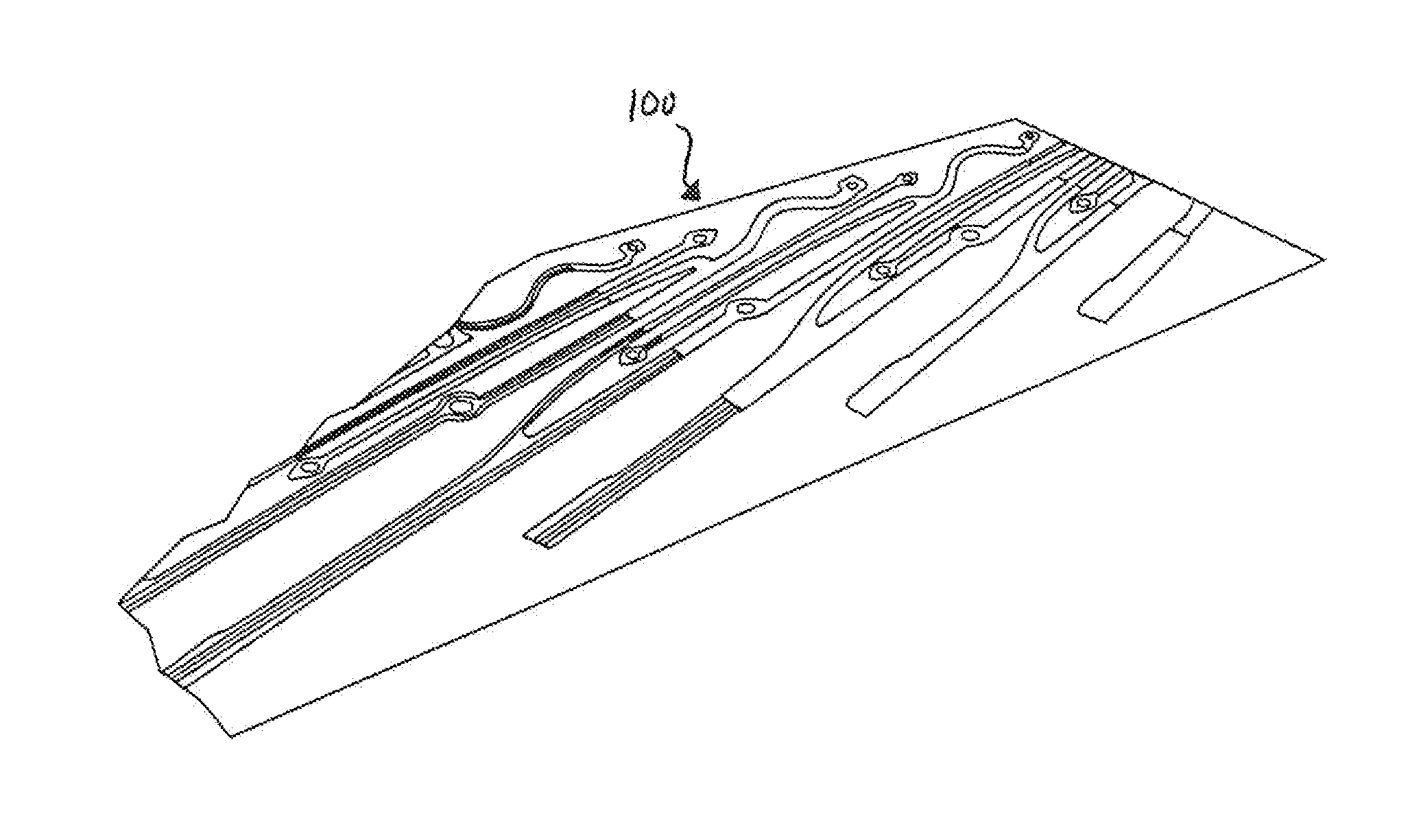

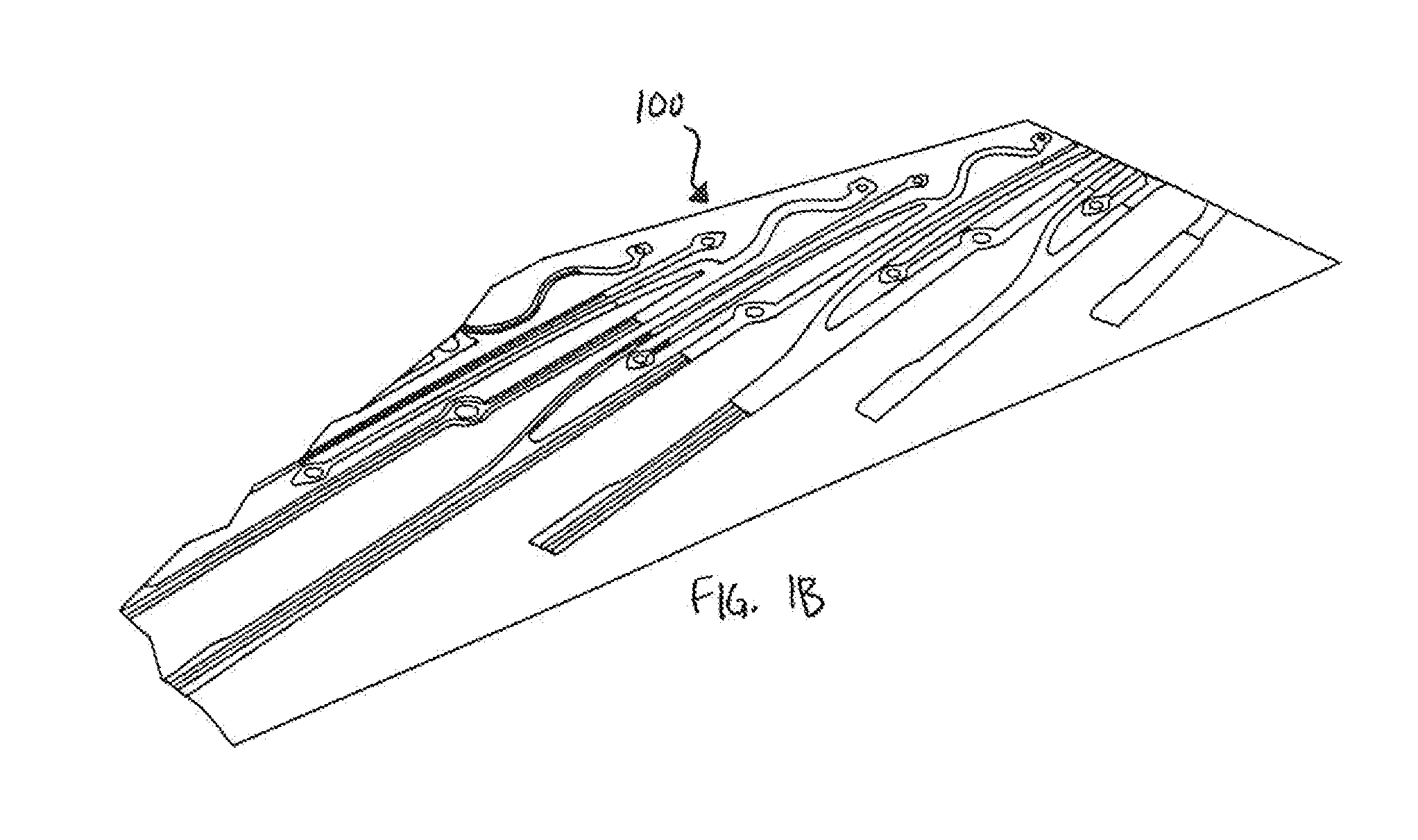

Physical contact layer for body-worn leadware using selective deposition

ActiveUS20130248226A1Reduce material costsAvoid partialElectrotherapyBioelectric signal measurementConductive materialsContact layer

A printed electrical circuit and methods for additively printing electrical circuits. Patterned layers of conductive, insulating, semi-conductive materials, and other materials are print deposited on a flexible or rigid substrate to form electrical circuits. A buffering layer is selectively deposited to cover or encapsulate these materials to comprise a comfort layer that provides a soft and comfortable interface to the skin of a wearer. The comfort layer can be selectively deposited on the same press that the conductive, insulating, semi-conductive materials, and other materials are deposited. Further, the comfort layer is selectively deposited only where it is desired and exactly where it is desired.

Owner:MOLEX INC

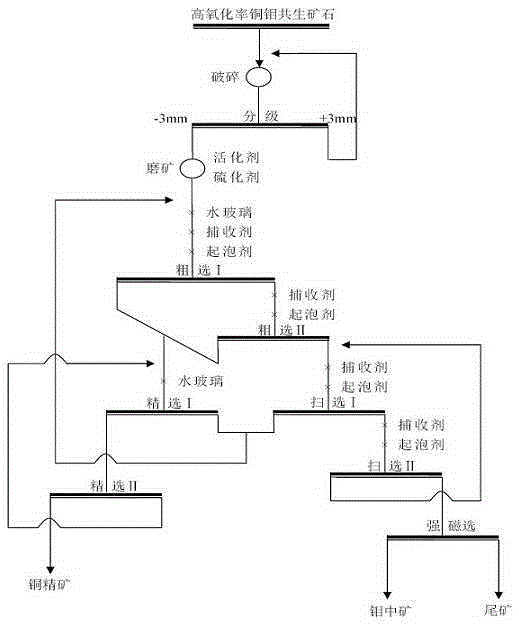

Beneficiation method for high-oxidation-rate copper-molybdenum paragenic ores

The invention discloses a beneficiation method for high-oxidation-rate copper-molybdenum paragenic ores. The beneficiation method comprises the following steps: (1) crushing: adopting a crusher to crush and screen raw ores, returning the raw ores with a particle size of (+)3mm to crush until the particle size of all raw cores reaches (-)3mm level; (2) carrying out ore grinding: adding the crushed raw ores with the particle size of (-)3mm into raw ore grinding equipment to carry out closed-hoop ore grinding operation, adding an activator with concentration being 1000-3000g / t and a vulcanizing agent with concentration being 250-900g / t into a grinder for grinding the raw cores until raw cores with the particle size of (-)0.075mm account for 55-80%; (3) carrying out primary flotation operation; (4) carrying out flotation scavenging operation; (5) carrying out flotation concentration operation; and (6) carrying out strong magnetic separation operation. The beneficiation method can be adopted to carry out beneficiation enrichment and recovery on copper oxide minerals and molybdenum oxide minerals in the high-oxidation-rate copper-molybdenum paragenic ores so as to obtain high-quality qualified copper concentrate and relatively enriched molybdenum middlings which can be used as raw materials for producing an ammonium molybdate product by chemical wet-process leaching, so that molybdenum oxide resources in the ores are recycled.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

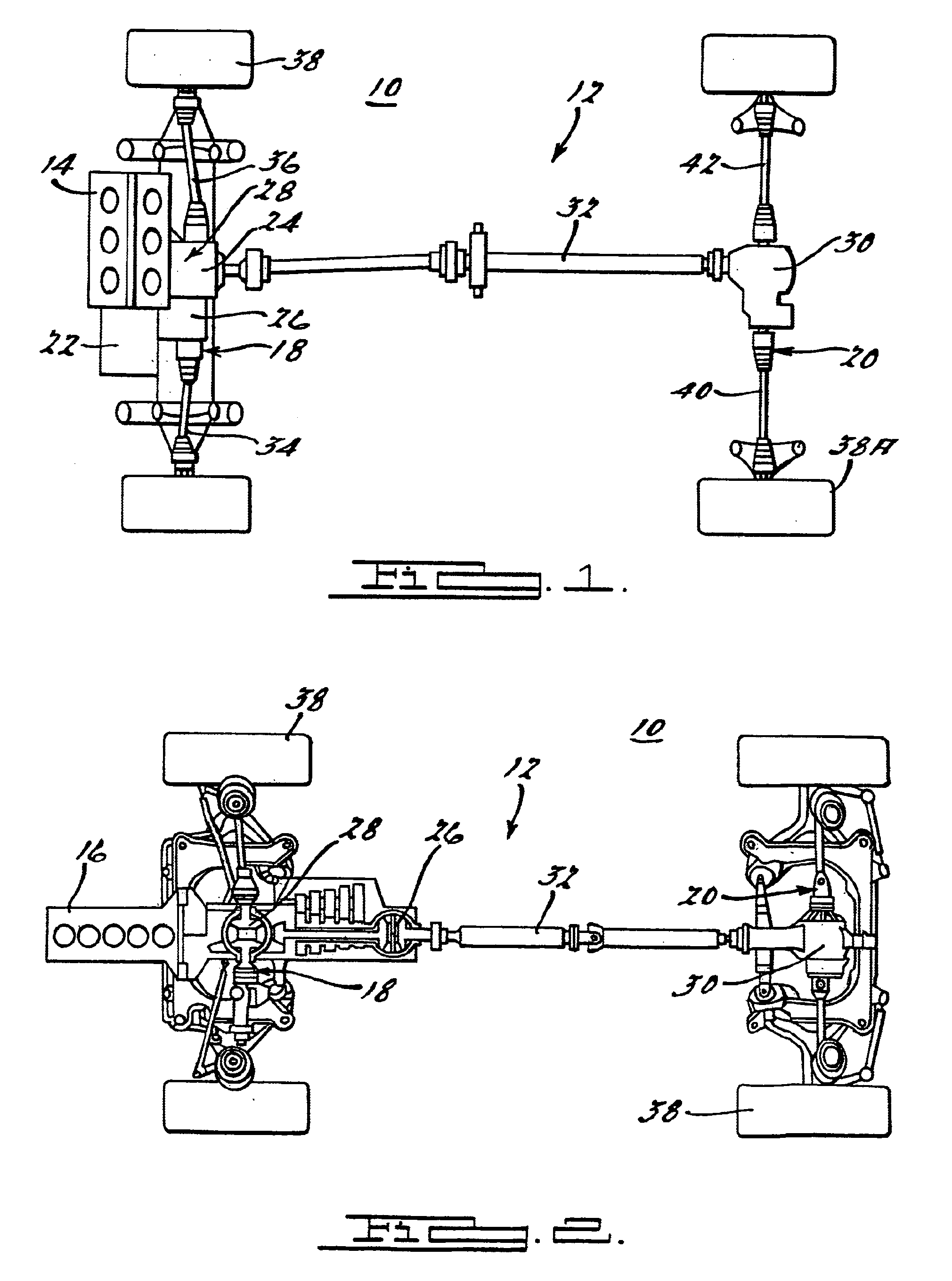

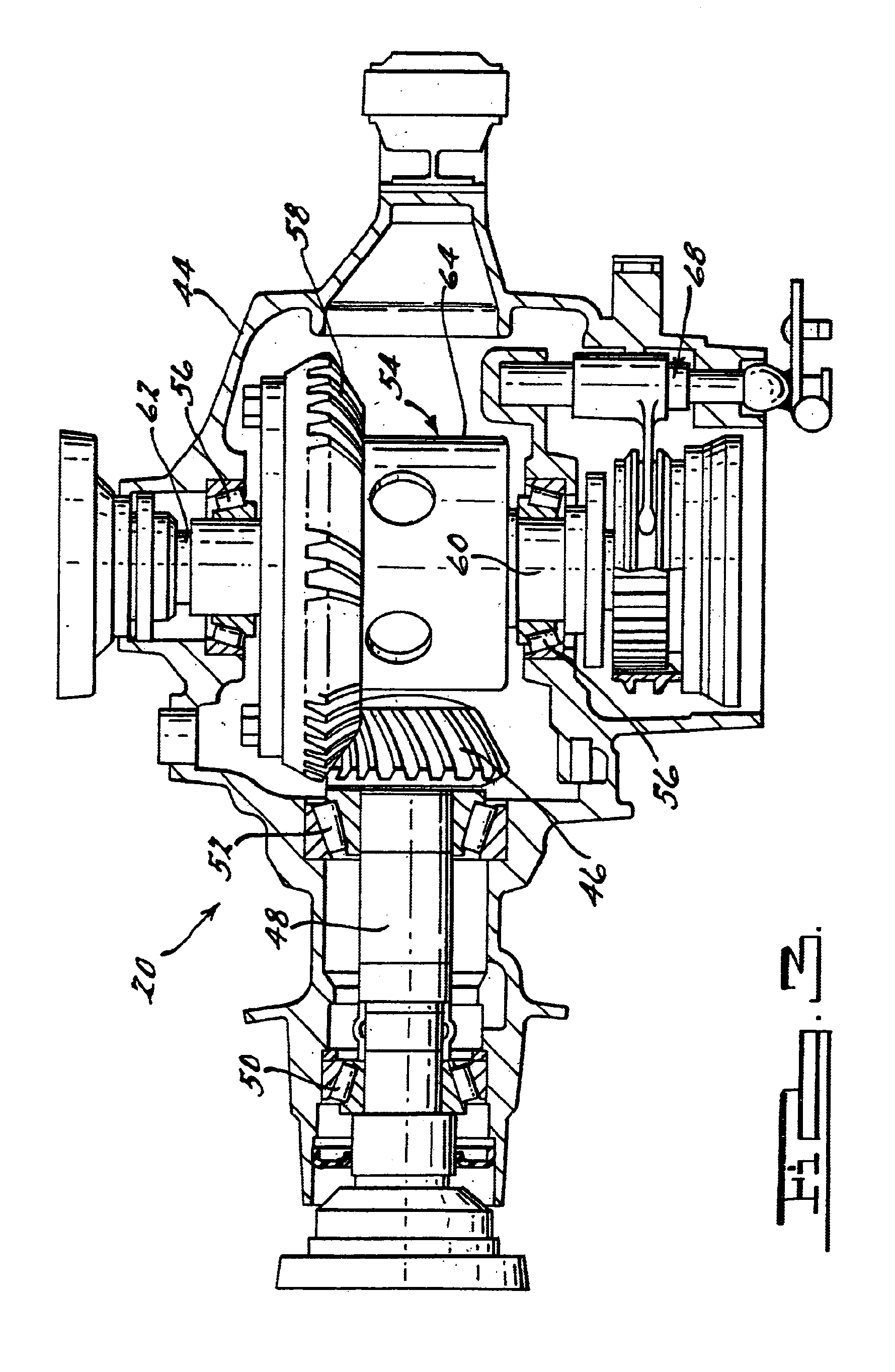

Full time all wheel drive system

InactiveUS6851501B2Small and simpler transferReduce weightDifferential gearingsControl devicesDrive shaftAll-wheel drive

An all wheel drive system for use in a vehicle where that system includes a front axle having a front differential. The all wheel drive system also includes a center differential connected to the front differential via a prop shaft. The all wheel drive system also includes a rear axle having a rear differential wherein the rear differential is connected to the center differential. The rear differential having a reduction gear integrated therein.

Owner:GKN DRIVELINE NORTH AMERICA

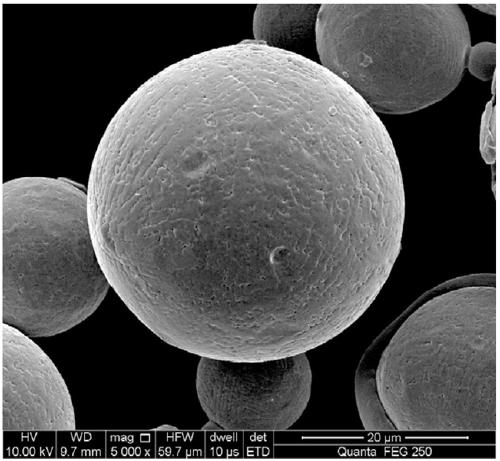

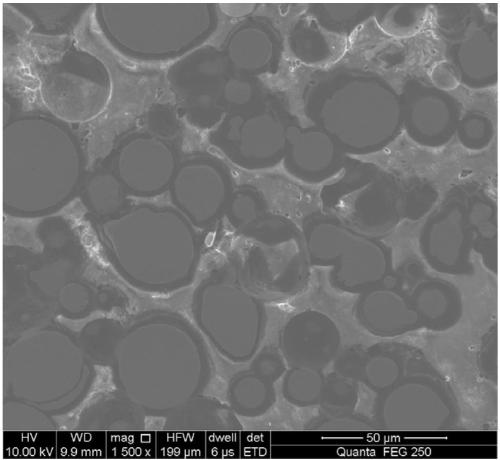

Preparation method for nickel-base superalloy powder for laser forming

ActiveCN108941588AHigh sphericityHigh yieldAdditive manufacturing apparatusTransportation and packagingOxygen contentHot Temperature

The invention discloses a preparation method for nickel-base superalloy powder for laser forming, and belongs to the field of superalloy and powder metallurgy. According to the preparation method, vacuum induction melting and argon atomization powder making technologies are adopted, and the nickel-base superalloy powder suitable for laser forming is prepared. The nickel-base superalloy powder prepared through the method is high in small grain size powder, high in degree of sphericity, low in oxygen content, good in flowing performance, free of hollow defects, less in satellite powder and capable of meeting the technical requirement for laser forming.

Owner:CENT SOUTH UNIV

Collapsible storage bin

InactiveUS6908004B2Small space volumeReduce packageLarge containersVariable capacity containersEngineeringMechanical engineering

Owner:KIDKRAFT

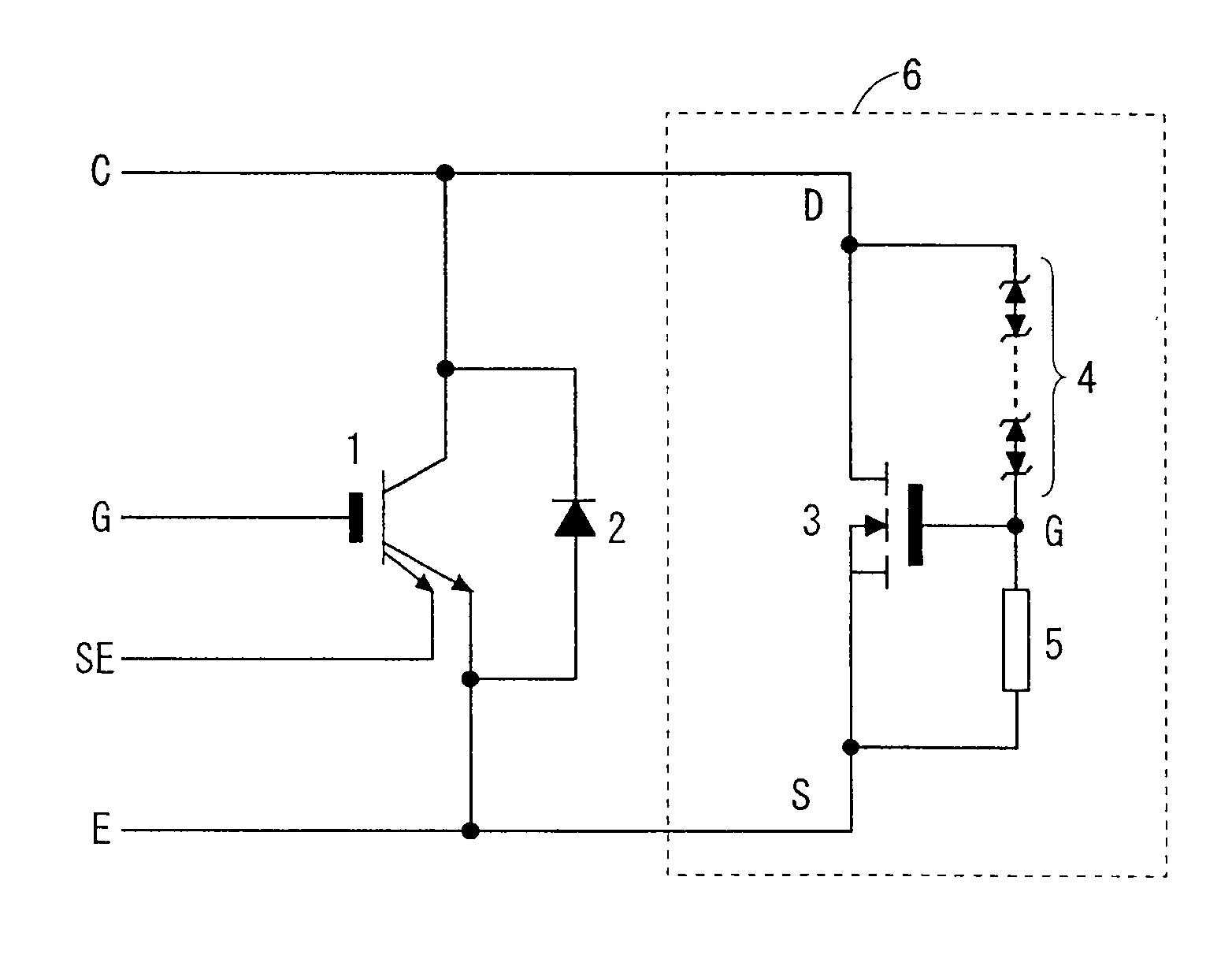

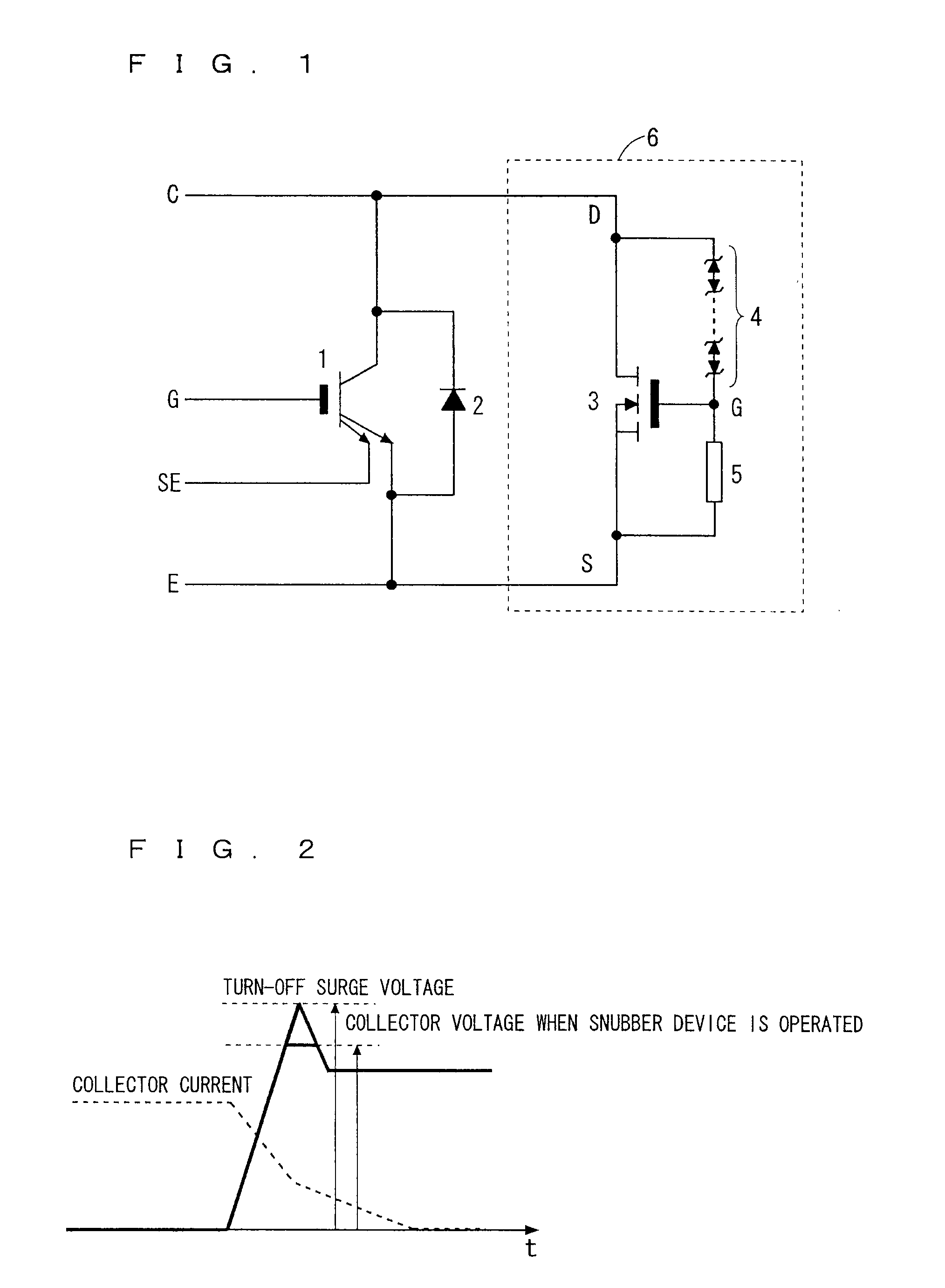

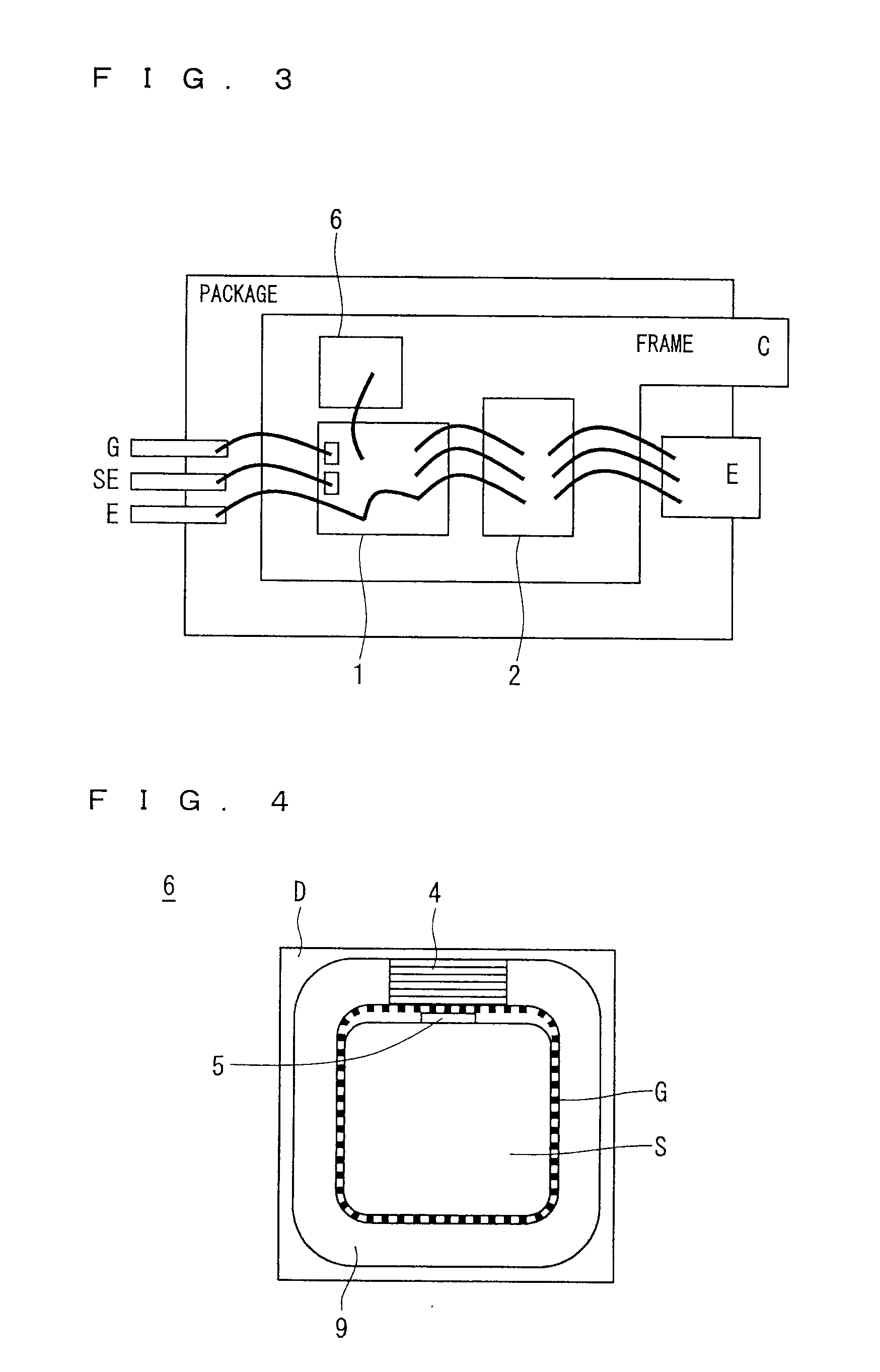

Semiconductor device and snubber device

ActiveUS20110310645A1Cost containmentReduce packageTransistorEfficient power electronics conversionMOSFETPower semiconductor device

A semiconductor device of the present invention includes a switching transistor, and a recovery diode and a snubber device which are mounted on a single conductive substrate (frame) on which the switching transistor is also mounted. The snubber device includes a SiC-MOSFET connected between an output terminal C and a reference terminal E of the switching transistor, a Zener diode formed between a gate terminal G and a drain terminal D of the SiC-MOSFET, and a resistor formed between the gate terminal G and a source terminal S of the SiC-MOSFET. The reference terminal E of the switching transistor, the source terminal S of the SiC-MOSFET, and an anode terminal of the recovery diode are commonly connected.

Owner:MITSUBISHI ELECTRIC CORP

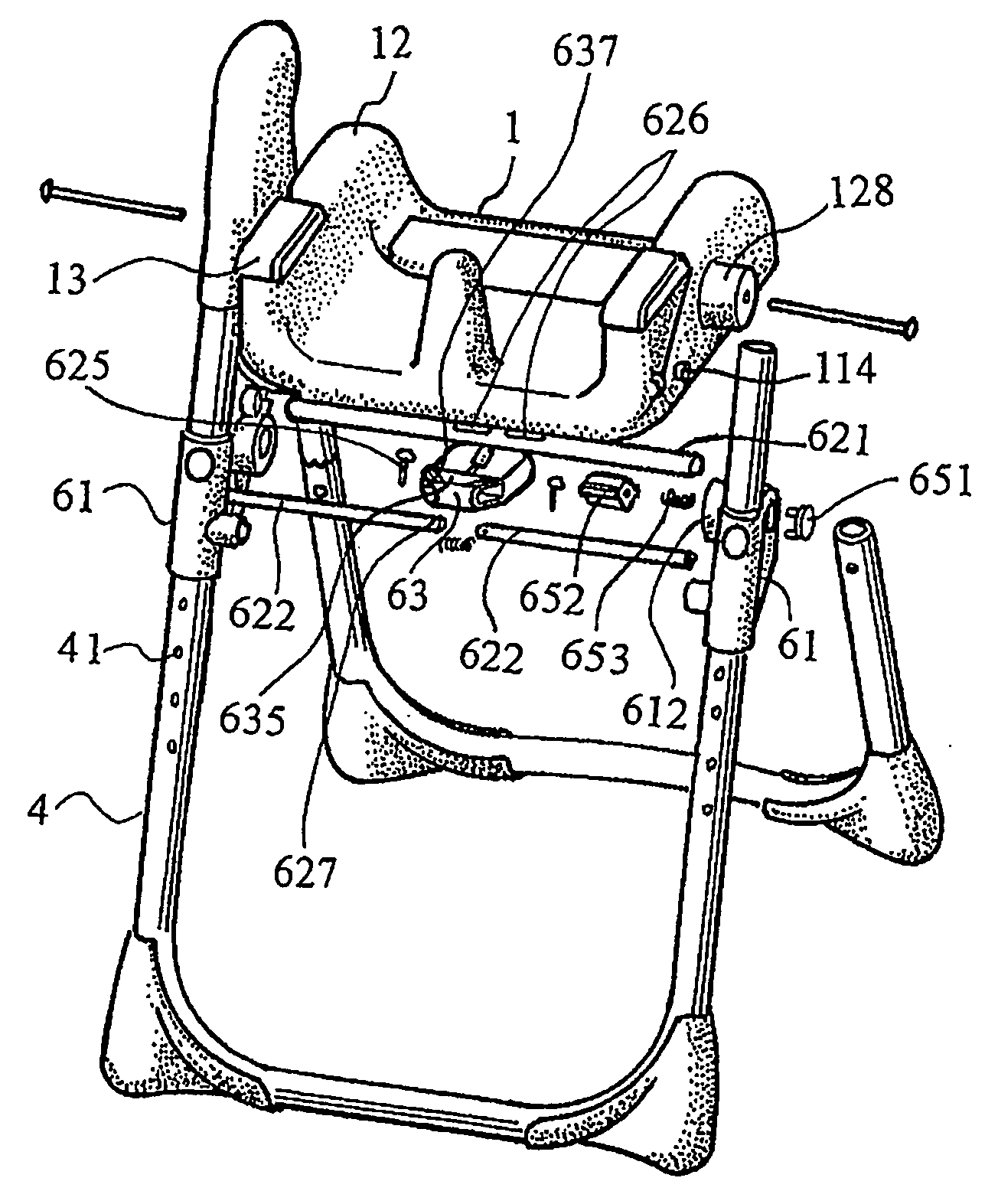

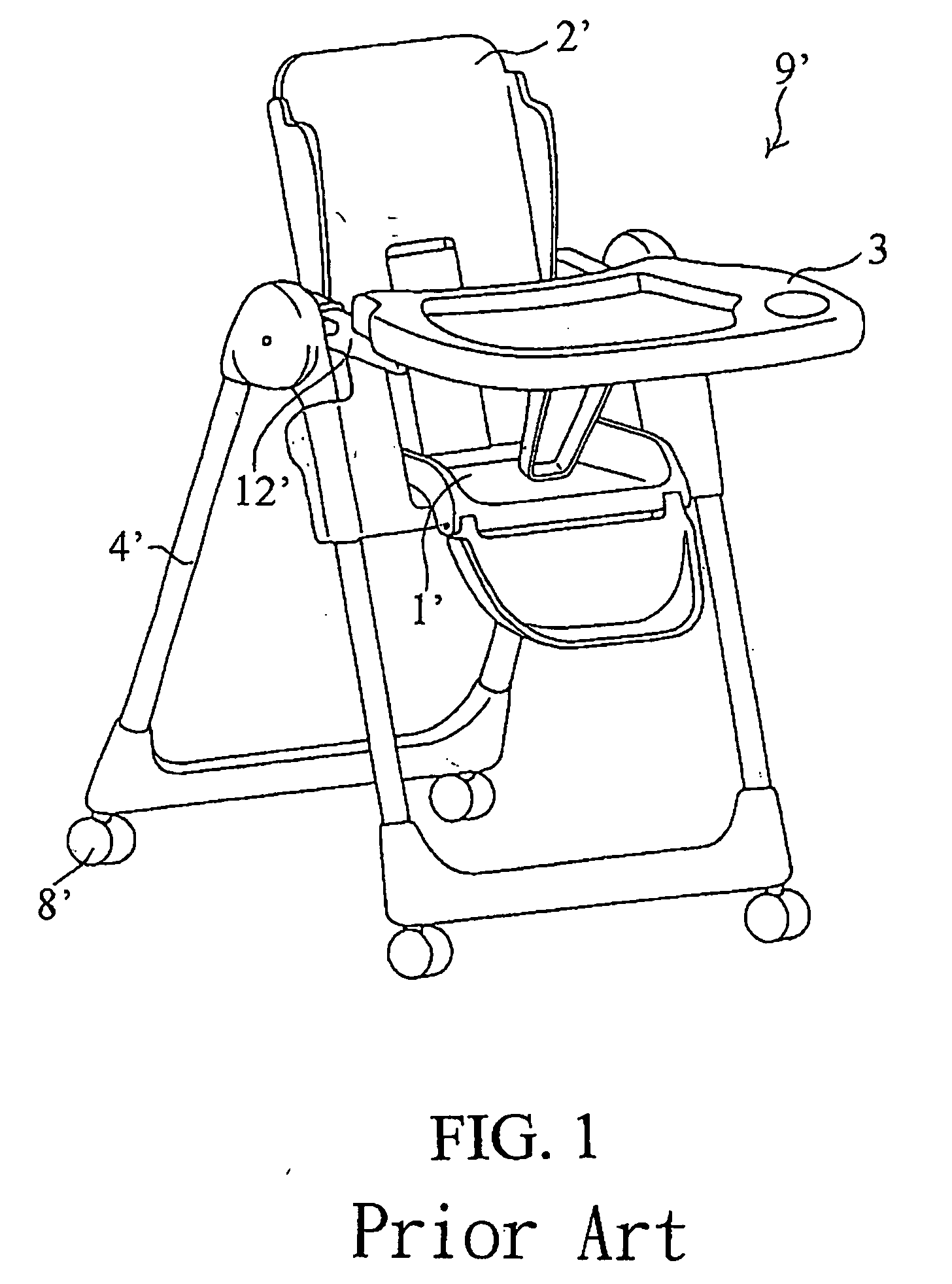

Collapsible high chair for children

ActiveUS20070024095A1Easy to carryReduce packageOperating chairsFoldable chairEngineeringMechanical engineering

A collapsible high chair for children comprises a frame, a seat portion, a backrest and an adjusting mechanism, all of which are sequentially connected with. The adjusting mechanism further comprises a pivotal member and a first engaging unit for connecting the seat portion with the frame at a first portion and a second portion of the pivotal member. Two actuating pieces of the first engaging unit respectively cooperate with two rods and make the rods be removed from the pivotal member at the first portion so as to allow the seat portion being pivotally rotated about the second portion. Also, the backrest can be rotated relative to the seat portion, so that the volume of the collapsed high chair is very small. Besides, the seat portion includes at least a movable piece with a bump for be engaged into the slits with different height at the arm of the seat portion to adjust the tray in height.

Owner:WONDERLAND NURSERYGOODS CO LTD

Preparation process of urea-formaldehyde resin adhesive

InactiveCN100999652AReduce manufacturing costReduce packageAldehyde/ketone condensation polymer adhesivesReaction temperatureResin adhesive

The present invention is process of preparing urea-formaldehyde resin adhesive. The preparation process includes the following steps: 1. adding formaldehyde in 420-600 weight portions into a reaction kettle and regulating pH value to 7.0-9.0 with alkali; 2. adding liquid urea from a urea synthesizing apparatus in 185-395 weight portions into the reaction kettle, reaction at 90-95 deg.c for 0.5-1.5 hr, regulating pH value to 4.0-5.5 with acid and further reaction until the solution becomes turbid and has viscosity of 15-20 CP; 3. regulating pH value to 7.0-7.6 with alkali and adding liquid urea of other 10-15 weight portions; 4. decompression dewatering, adding liquid urea of other 5-10 weight portions and modifier of 3-30 weight portions at temperature not higher than 70 deg.c and absolute pressure of 0.08-0.19 atm; and 5. regulating pH value to 7.5-8.5 with alkali, cooling to below 50 deg.c, discharging and packing.

Owner:水煤浆气化及煤化工国家工程研究中心

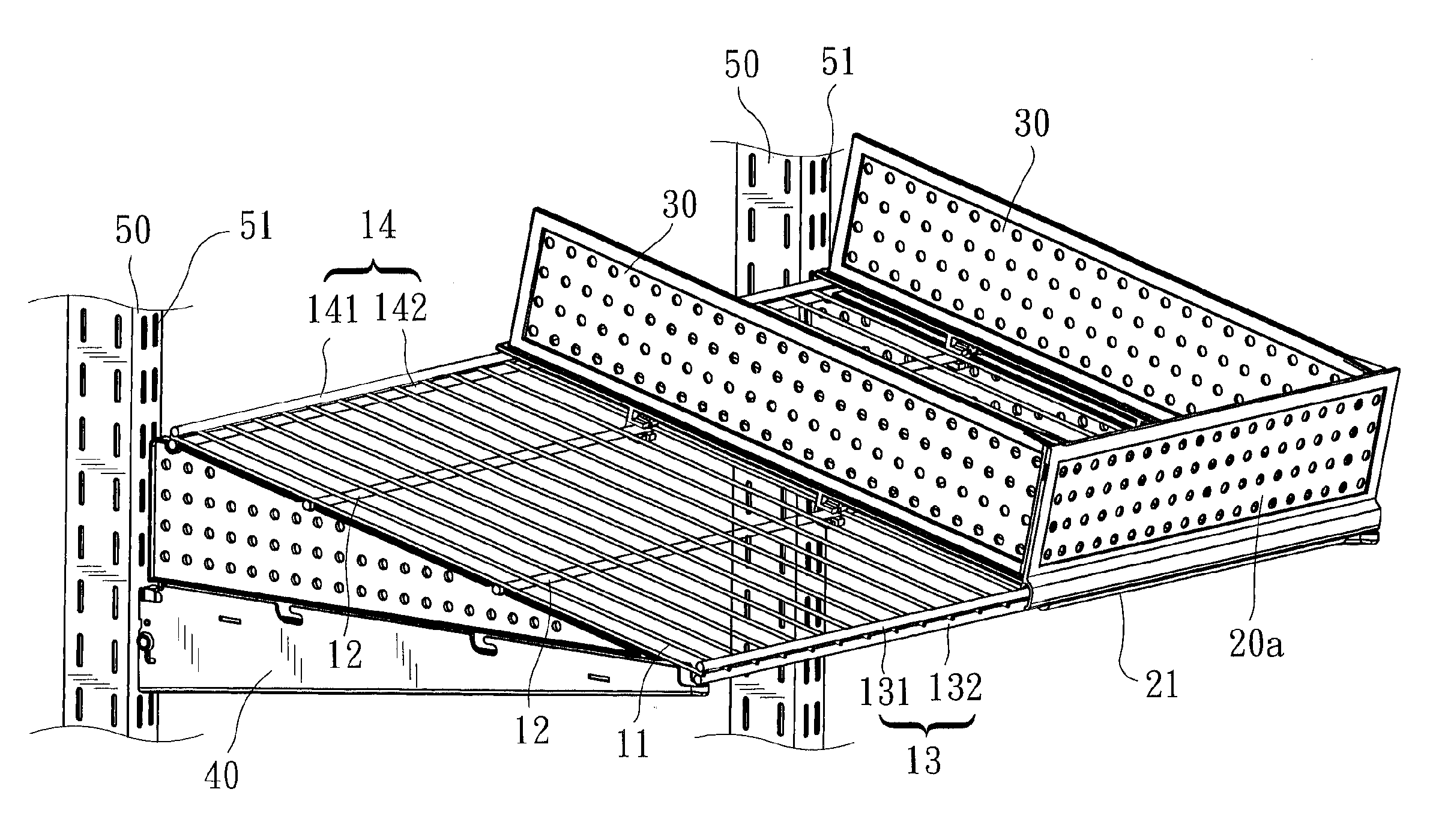

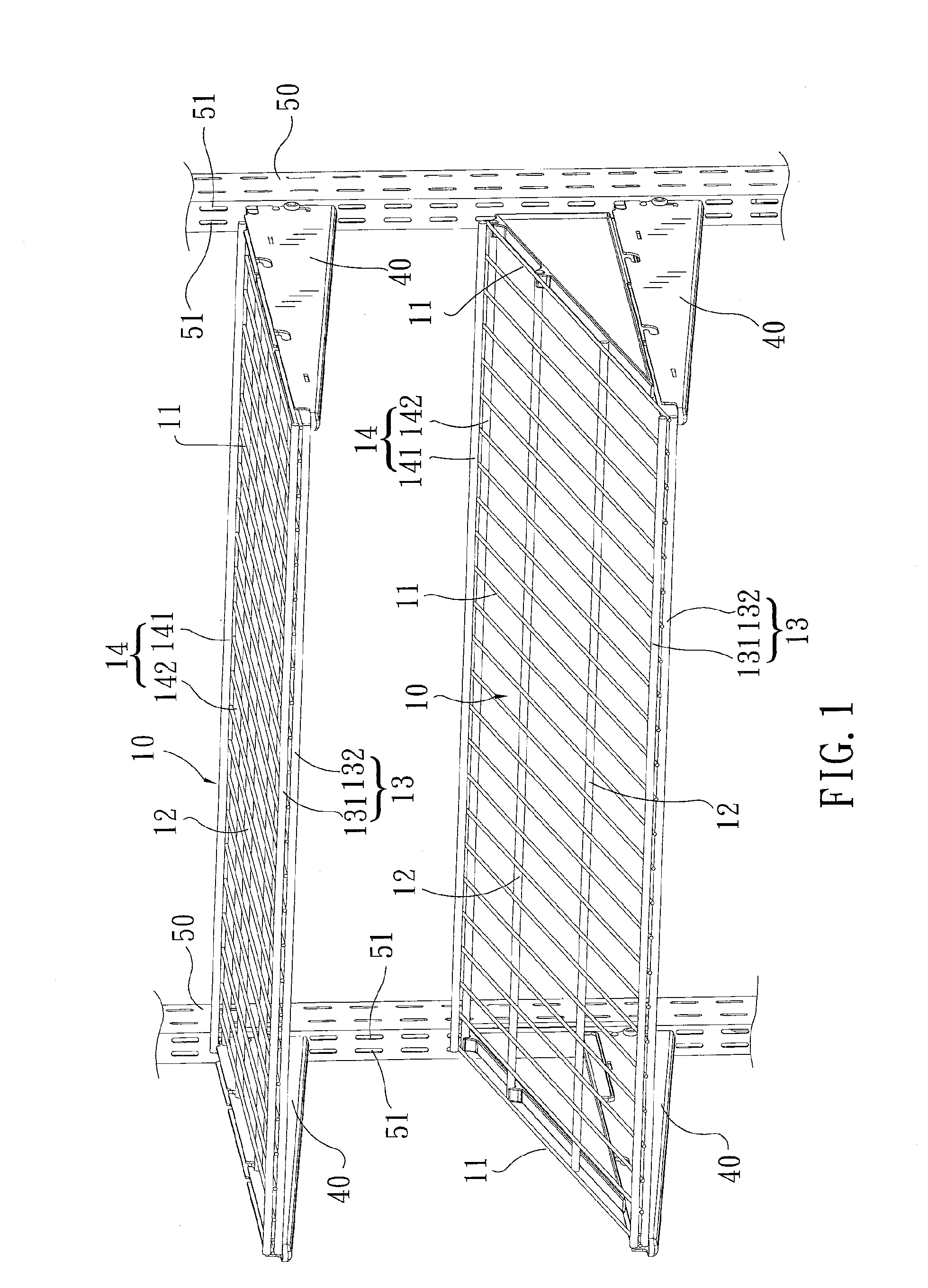

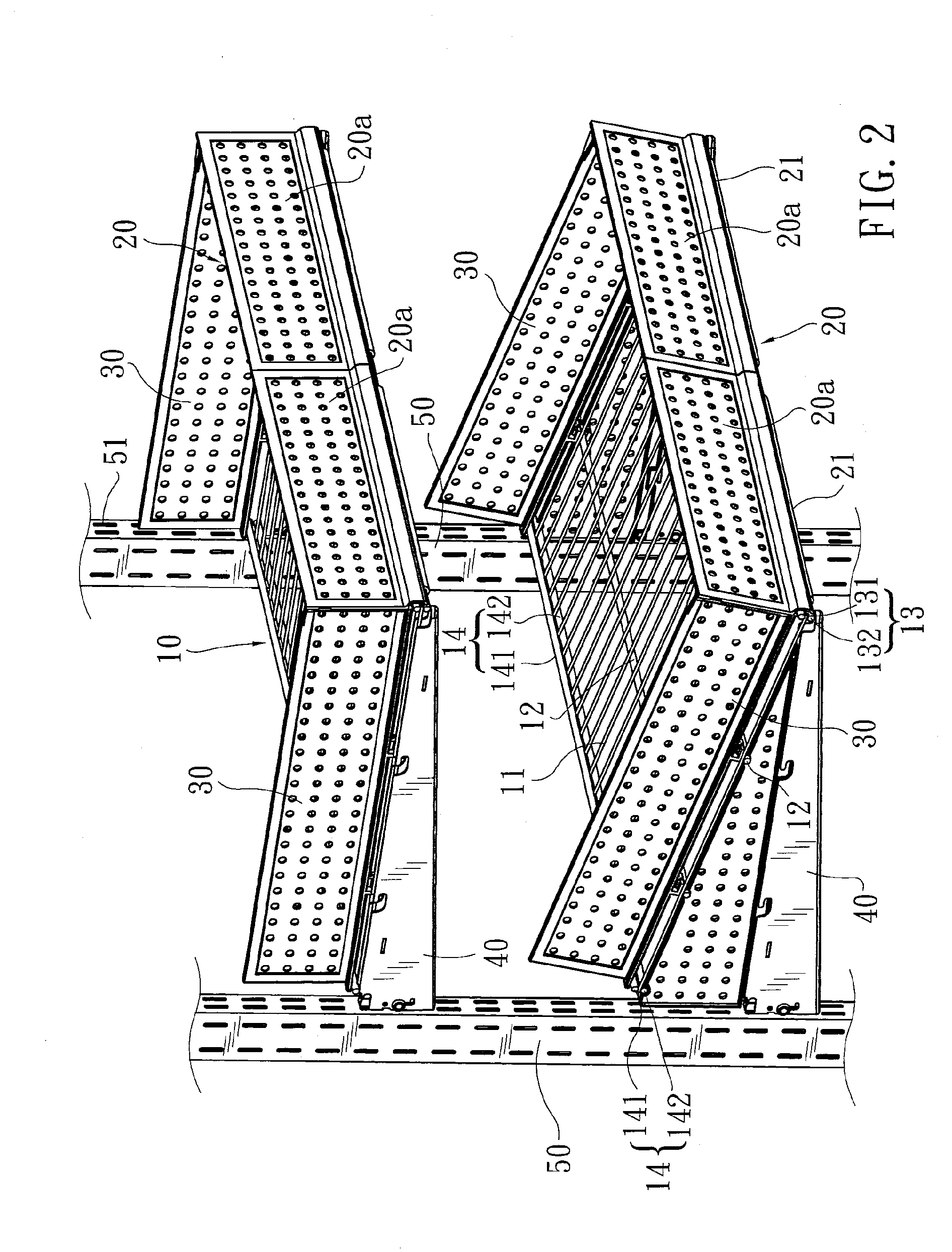

Stop wall structure for removably mounting to a metal-wire shelf

A stop wall structure includes a front stop wall and two side stop walls for removably mounting to a front edge and two lateral edges of a metal-wire shelf for a sectional rack. The front stop wall is formed along a lower edge with a tongue portion and a plurality of clamping member spaced behind the tongue portion, so that a retaining space is formed between the tongue portion and the clamping members for engaging with a transverse front metal-bar set of the metal-wire shelf therein. The side stop walls each are provided along a lower edge with a plurality of C-shaped clamping members for each receiving and holding a transverse metal bar of the metal-wire shelf therein. With the stop wall structure mounted to the metal-wire shelf, articles positioned on the metal-wire shelf are protected against falling therefrom.

Owner:PROTREND ENTERPRISE CO LTD

Method of preparing ceria by mixed precipitant

A method of preparing ceria by a mixed precipitant mainly comprises the steps of enabling a mixed solution of ammonium bicarbonate and ammonia as the precipitant to perform combined action with inoculating crystals, precipitating rare earth ions in a rare earth chloride solution to obtain a mixture with primary alkali type cerous carbonate and subsidiary cerous carbonate and cerium hydroxide, and further firing to prepare a rare earth ceria product. The prepared ceria accords with industry standards; reaction conditions of the method are mild; energy consumption during preparing process is obviously reduced, and the cost is low; meanwhile, the carbon dioxide emission is greatly reduced, and obvious social benefit and environmental benefit are achieved.

Owner:YANSHAN UNIV

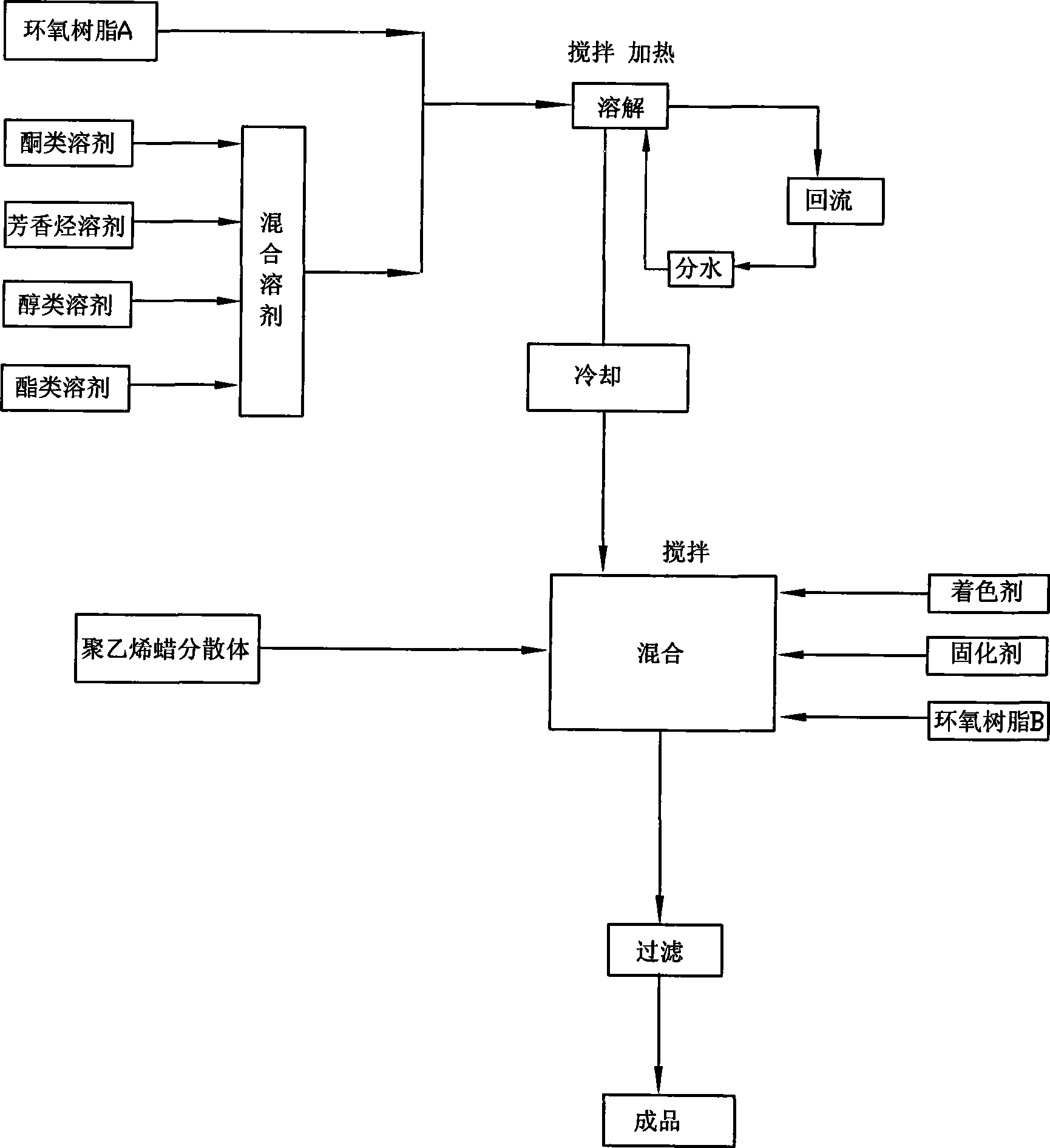

Adhesive for imperial crown cap polyolefin pad for beer or beverage and preparation thereof

InactiveCN101503606AGood environmental performanceSave resourcesNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventPolyolefin

The invention relates to the field of chemical engineering of adhesives, in particular to an adhesive for crown cap polyolefin gaskets for beer and beverage and a preparation method thereof. At present, crown cap gaskets for the national beer and beverage are mostly made of polyvinyl chloride (PVC) material, and compositions of the polyvinyl chloride material contain chemical substances which are harmful to human bodies. The adhesive for the crown cap polyolefin gaskets for the beer and beverage is prepared by compounding the following raw materials by weight portion: 18 to 43 portions of epoxy resin A, 3 to 11 portions of epoxy resin B, 43 to 57 portions of mixed solvent, 3 to 5 portions of polyethylene wax dispersion, 0.7 to 1.1 portions of colorant, and 4.9 to 10.3 portions of curing agent. The product has the advantages of no harm to human bodies, good hygienic property, firm adhesion and good sealing performance, realizes the successful substitution of new materials at the same time, and pushes the popularization and application of the crown cap polyolefin gaskets for the beer and beverage.

Owner:西安昌泰化工厂

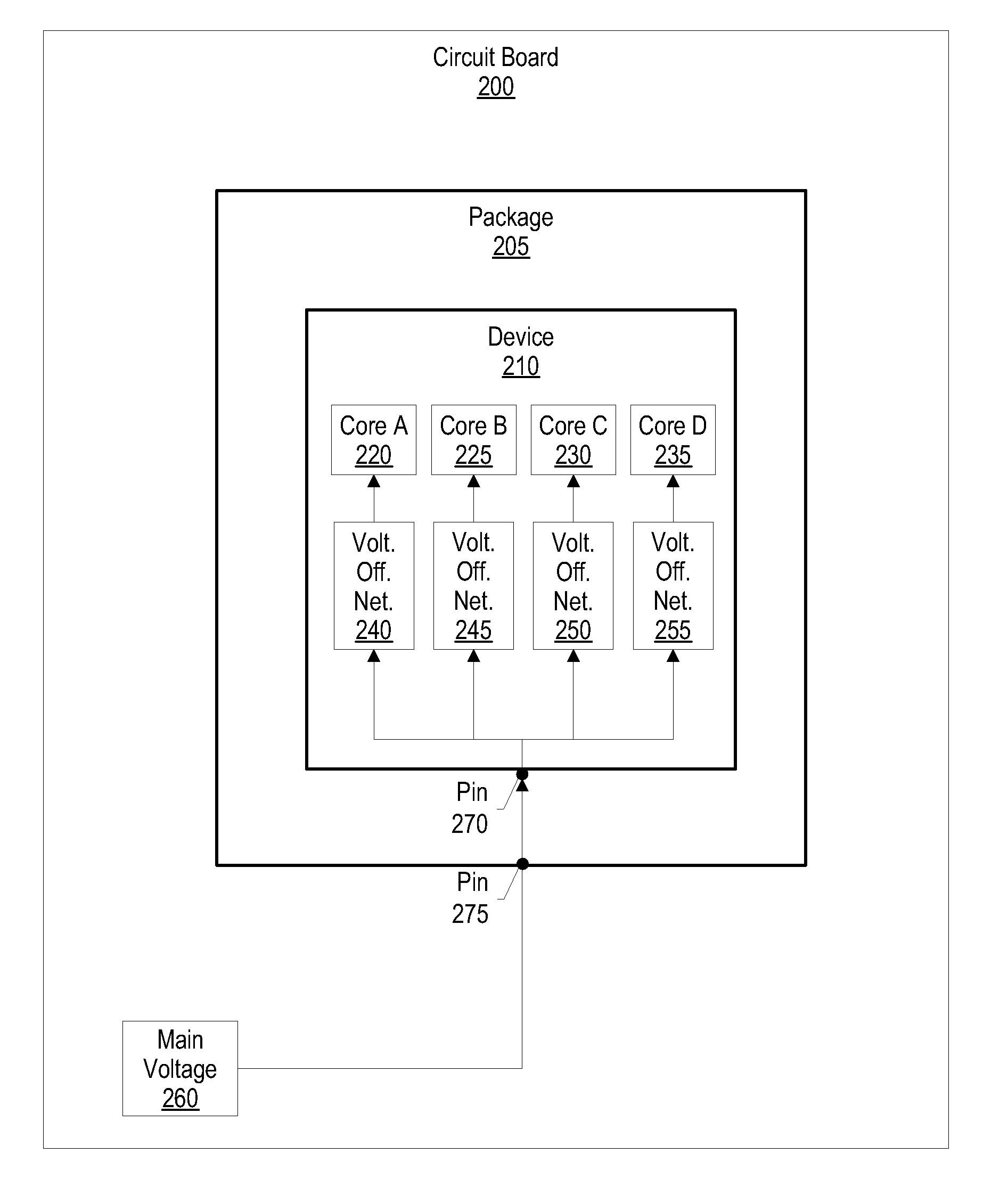

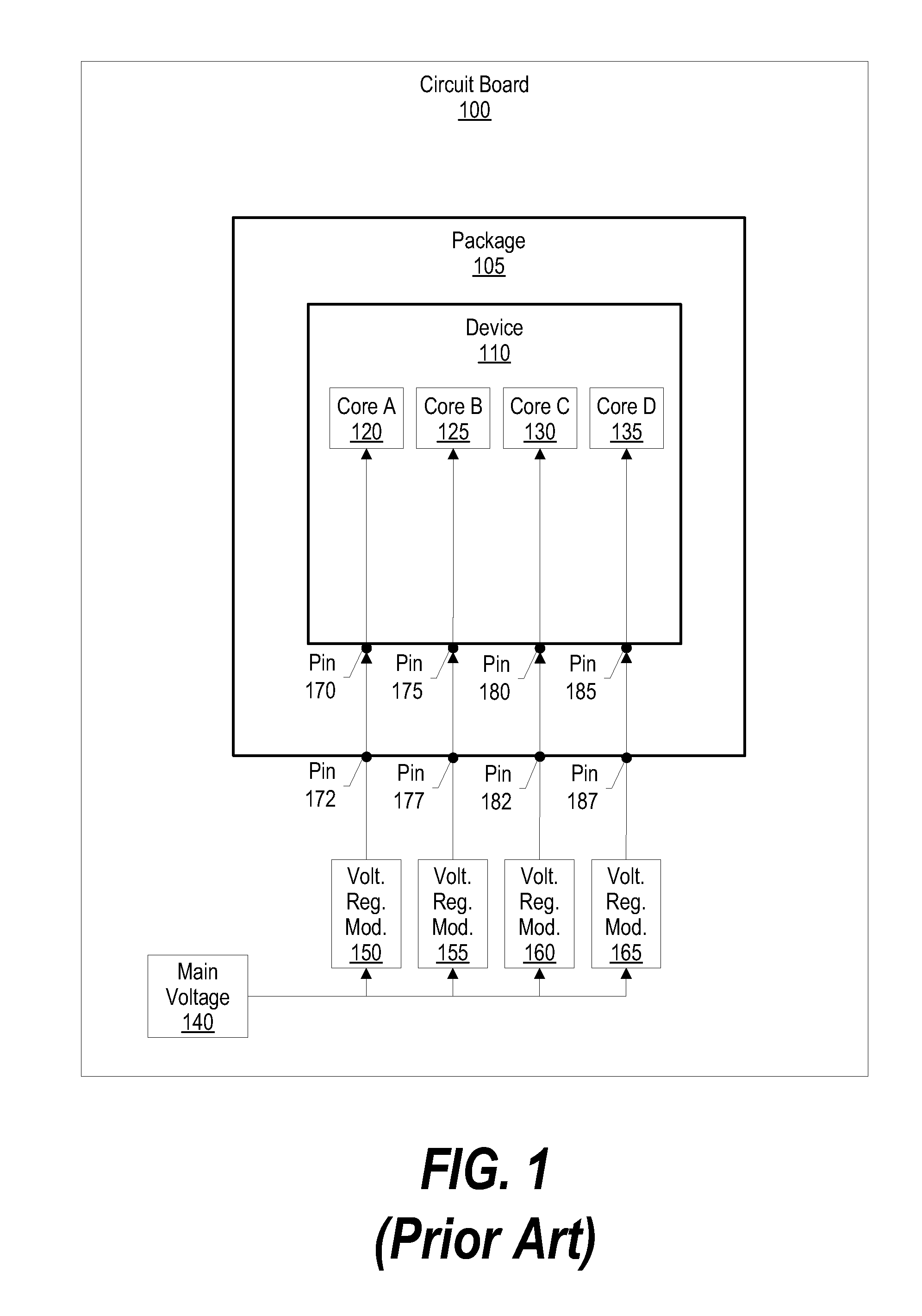

System and Method to Optimize Multi-Core Microprocessor Performance Using Voltage Offsets

InactiveUS20080052542A1Reduce packageReduces circuit board costMultiple-port networksPulse automatic controlVoltageEngineering

A system and method to optimize multi-core microprocessor performance using voltage offsets is presented. A multi-core device tests each of its processor cores in order to identify each processor core's optimum supply voltage. In turn, the device configures voltage offset networks for each processor core based upon each processor core's identified optimum supply voltage. As a result, the offset voltages produced by the voltage offset networks are subtracted from the multi-core device's main voltage, which results in the voltage offset networks supplying optimum supply voltages to each processor core. The voltage offset networks may include fuses to generate a fixed voltage offset, or the voltage offset networks may include a control circuit to dynamically adjust voltage offsets during the multi-core device's operation.

Owner:IBM CORP

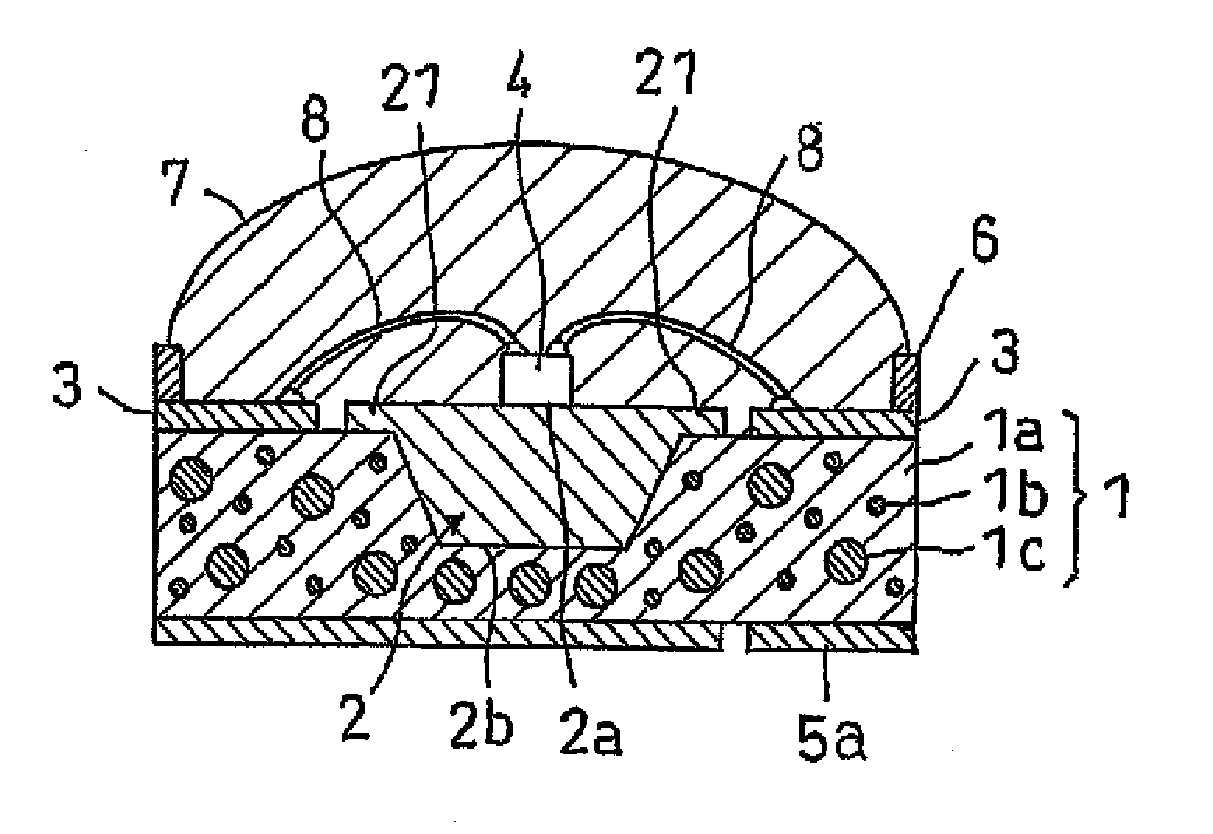

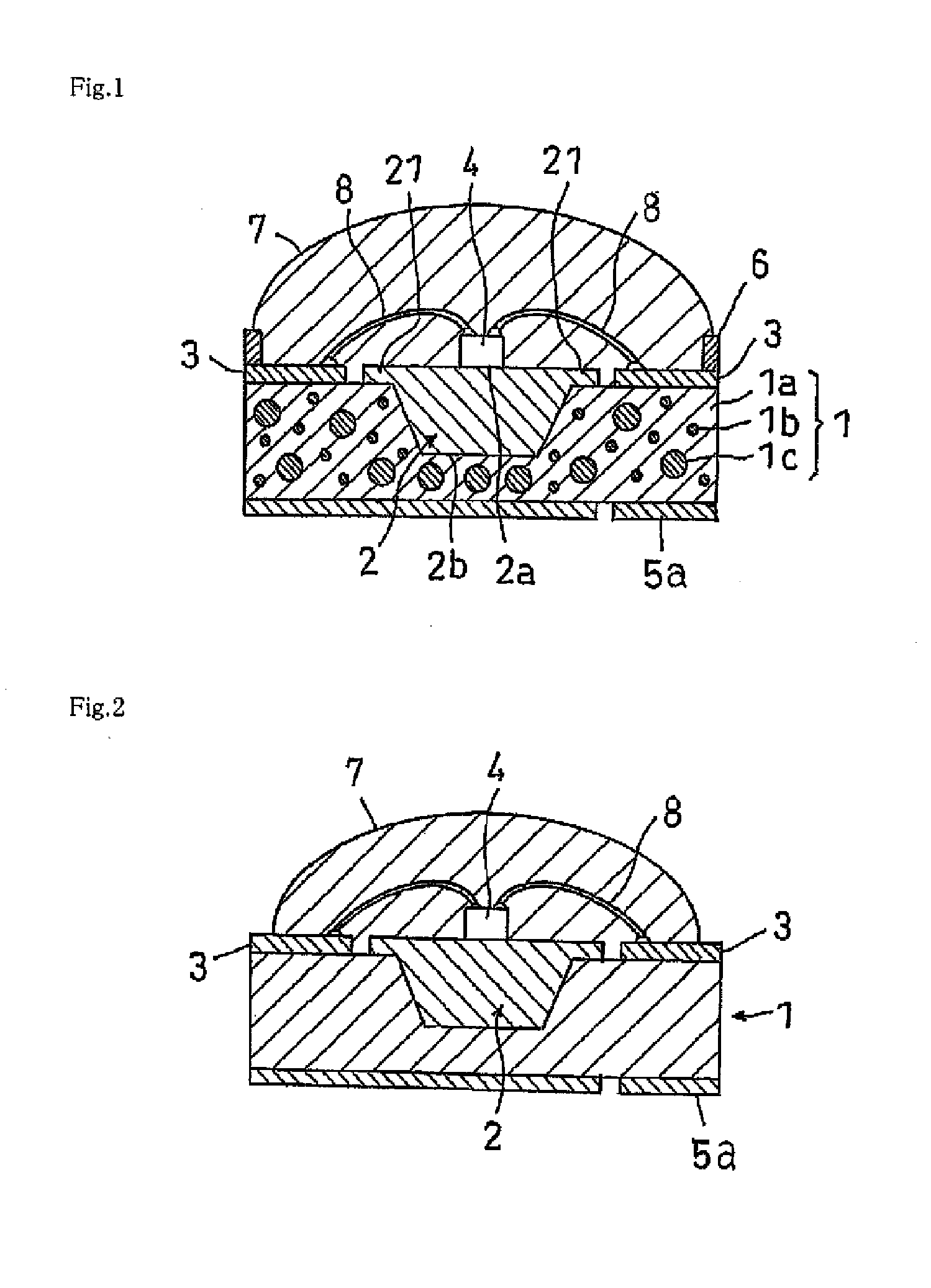

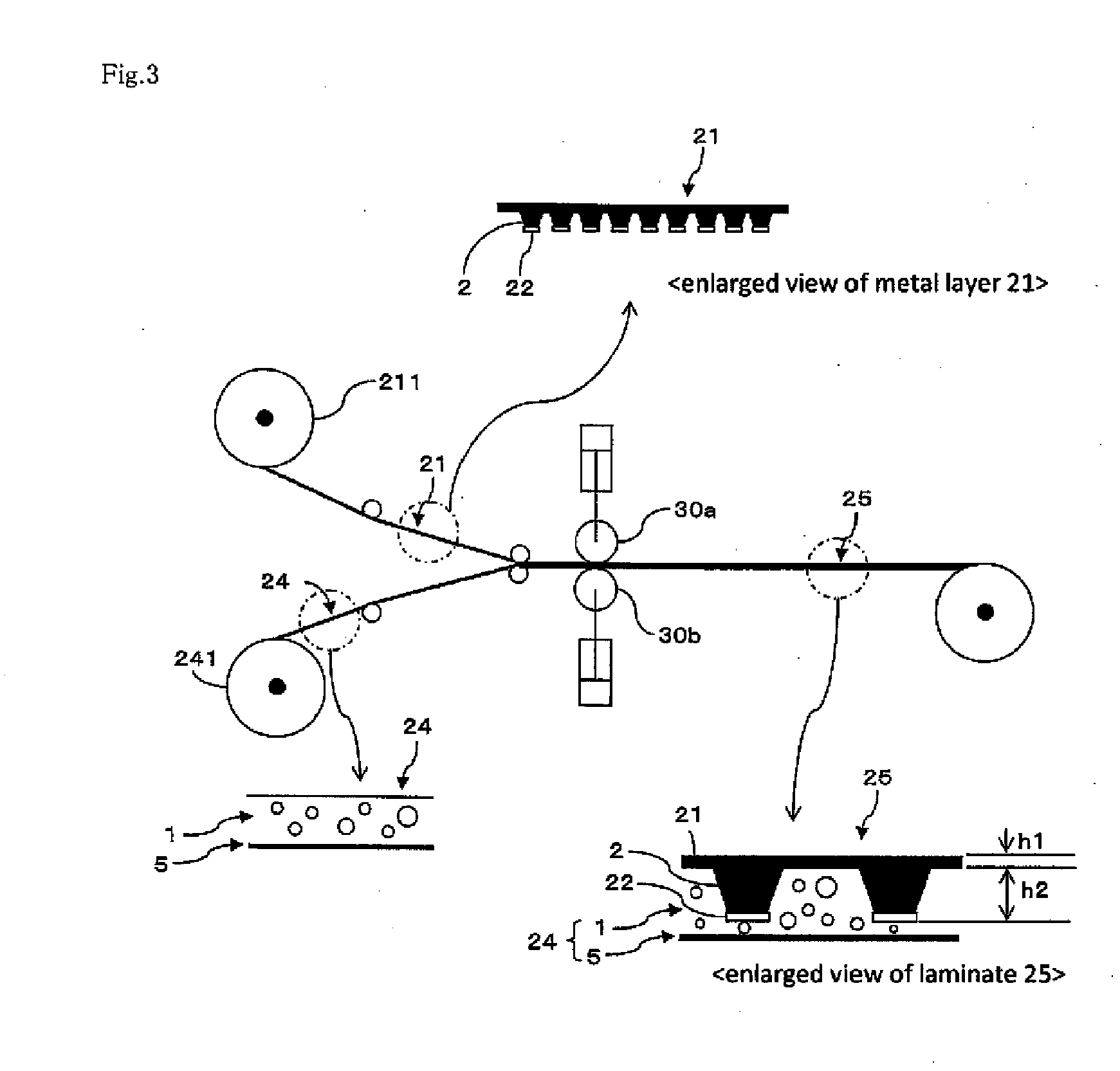

Method for manufacturing substrate for light emitting element package, and light emitting element package

InactiveUS20110311831A1Improve thermal conductivityEasy to carryPrinted circuit aspectsSolid-state devicesOptoelectronicsMetal

A method for manufacturing a substrate for a light emitting element package provided with a thick metal section formed under a mounting position of a light emitting element, having a lamination step of laminating and integrating a laminate having an insulating adhesive agent which is composed of a resin containing heat conductive fillers and has a heat conductivity of 1.0 W / mK or more and a metal layer member, with a metal layer member having a thick metal section while drawing out each member.

Owner:DENKA CO LTD

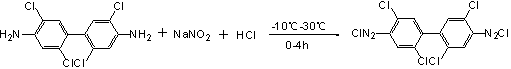

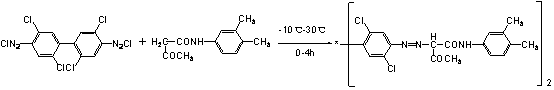

Industrial production method for pigment yellow 81

The invention discloses an industrial production method for pigment yellow 81 and belongs to the technical field of fine chemical synthesis. The industrial production method comprises the following steps of: pulping, diazotizing and coupling such materials as 2,2',5,5'-tetrachlorobiphenyl amine hydrochloride, 2,4-dimethyl-N-acetoacetanilide and the like; stirring the materials for 1 hour to 4 hours after the reaction is finished; heating up the reaction liquid to 80 DEG C to 100 DEG C, preserving the heat for reaction for 30 minutes; cooling the reaction liquid to the room temperature, filtering the reaction liquid; and drying the reaction liquid at 70 DEG C to 100 DEG C to obtain the pigment yellow 81. According to the industrial production method disclosed by the invention, the reaction conditions are gentle, the device requirements are low, the reaction time is short; moreover, the obtained product pigment yellow 81has a high yield of more than 90%, good performances, acid resistance of lever four or higher, alkali resistance of level four or high, weather resistance of level six or higher, and heat resistance to 200 DEG C or high, and so the pigment yellow 81 disclosed by the invention can be applied to rubber with high performance requirements and high-level paint.

Owner:CROWN CHEMICAL CORP

Front-end integral air-conditioning unit

ActiveUS7007493B2Reduce packageEasy to installAir-treating devicesEvaporators/condensersCouplingPre-charge

A sub-unit for a vehicle air conditioning system is shipped with a condenser, chiller and fluid lines. Snap together couplings are placed on free ends of the fluid lines whereby the sub-unit can be pre-charged, shipped, installed into the front end of a vehicle engine compartment and connected to an air conditioning compressor.

Owner:MAHLE INT GMBH

Particle material for producing beer and beverage crown cap polyolefin gasket and preparation method thereof

The invention relates to a particle material for producing a beer and beverage crown cap polyolefin gasket and a preparation method thereof. The material of the crown cap gasket for beer and beverage is mostly prepared from a polrvinyl chloride; and because the material of the crown cap gasket for beer and beverage contains a plasticizer, a stabilizer, vinyl chloride monomer residue in polrvinyl chloride and the like, the edible safety problem exists. The particle material is prepared by the following steps: mixing the following raw materials in parts by weight: 58.1-72.5 parts of low densitypolyethylene, 18.2-39.4 parts of thermoplastic elastomer, 2.5-8.5 parts of antioxidant master batch and 0-0.8 part of coloring master batch; and then extruding, granulating, water cooling, screening and drying; and finally cooling to form the particle material finished product. According to the invention, a safe material is adopted to replace an limited material, thus edible safety is ensured, and the particle material also has the advantage of good environmentally-friendly property and is beneficial to human body health, and food package amount is greatly reduced.

Owner:XIAN CHANGTAI PACKAGE MATERIALS

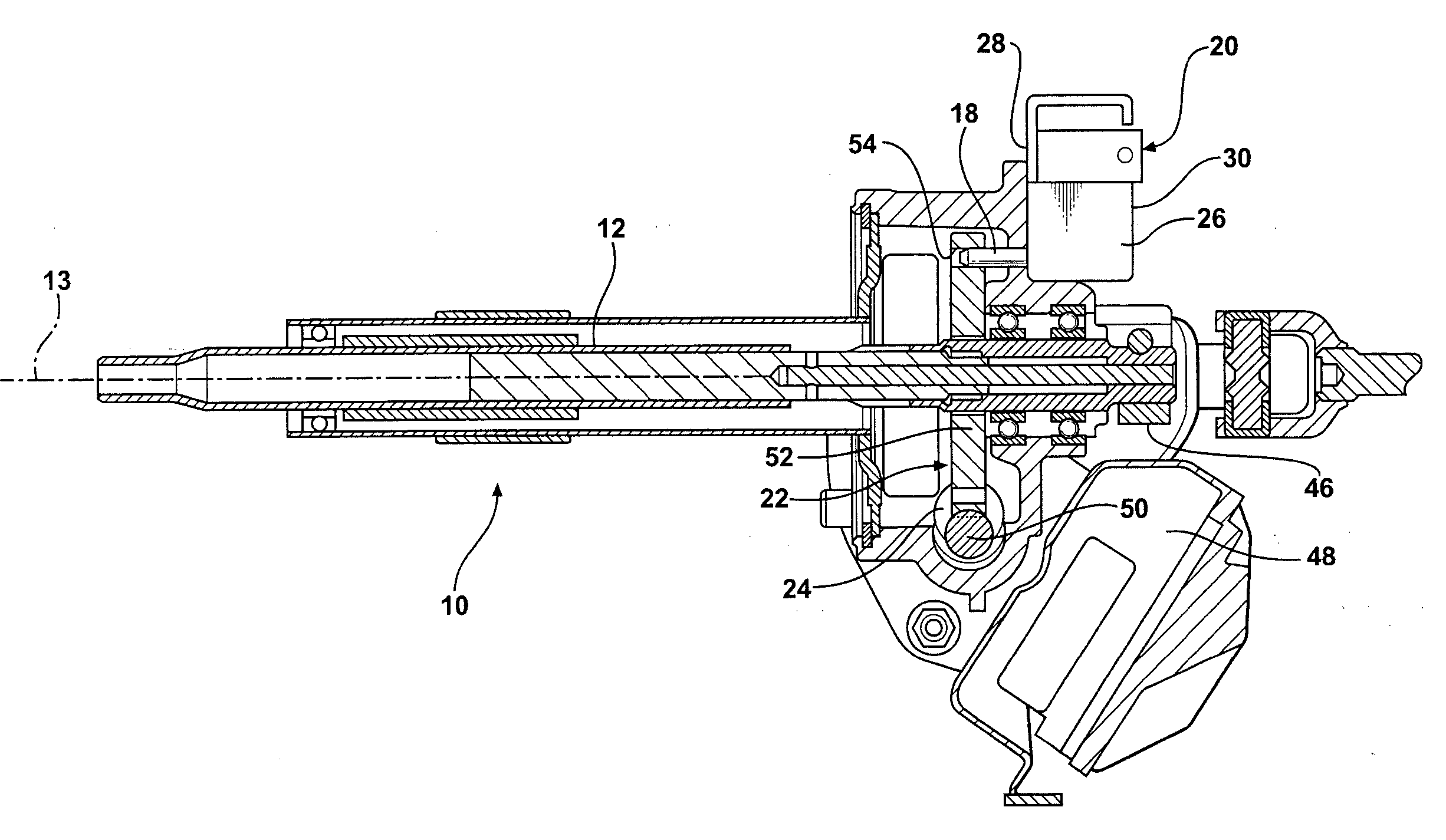

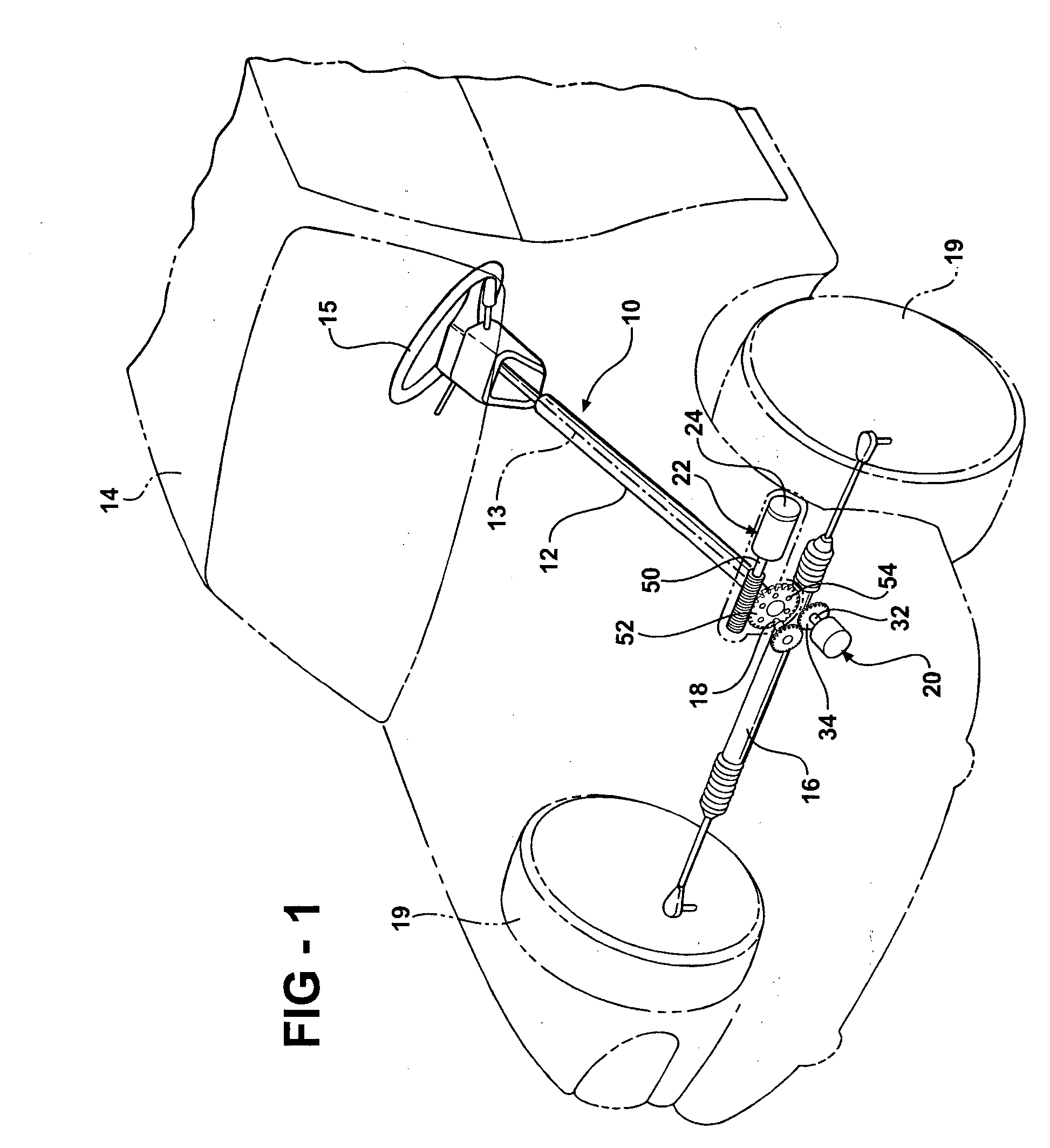

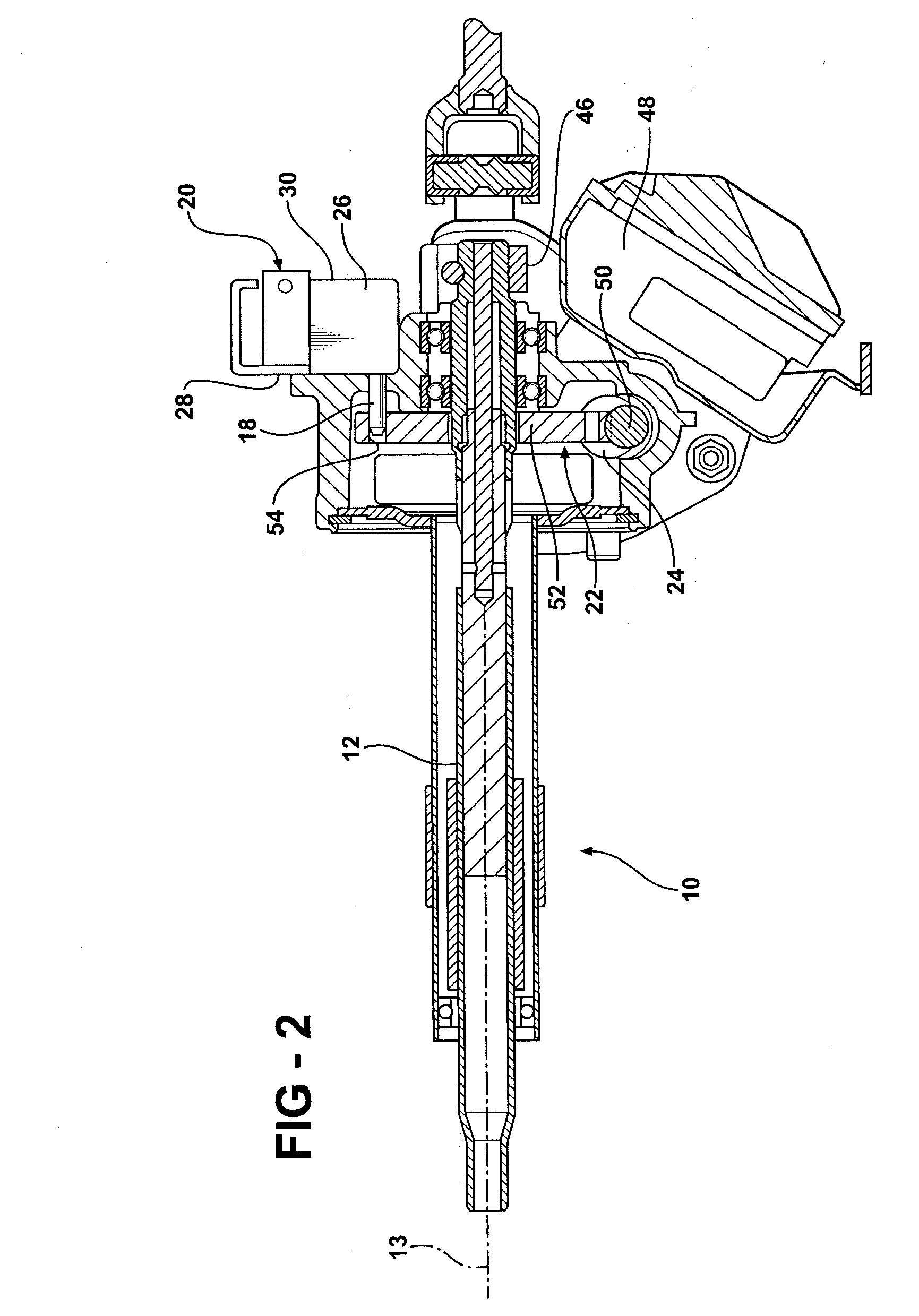

Column assembly of a vehicle having a steering column to be locked and unlocked

InactiveUS20050120761A1Reduce packageUnlocking of the steering column easierBuilding locksAnti-theft devicesSteering column

The subject invention provides a column assembly for releasably locking and unlocking a steering column of a vehicle. The assembly includes a steering column rotatable about a central axis for imparting a direction to the vehicle and a lock bolt moveable from an unlocked position to a locked position to lock the steering column against rotation. When in the locked position, the steering column is prevented from rotating which imparts a load to the lock bolt. A lock bolt drive is connected to the lock bolt to move the lock bolt from the locked position to the unlocked position. However, the load acting on the lock bolt prevents the lock bolt drive from being able to move the lock bolt from the locked position to the unlocked position. Therefore, a release mechanism is operative to reduce the load on the lock bolt sufficiently to enable the lock bolt drive to move the lock bolt from the locked position to the unlocked position.

Owner:DELPHI AUTOMOTIVE SYST

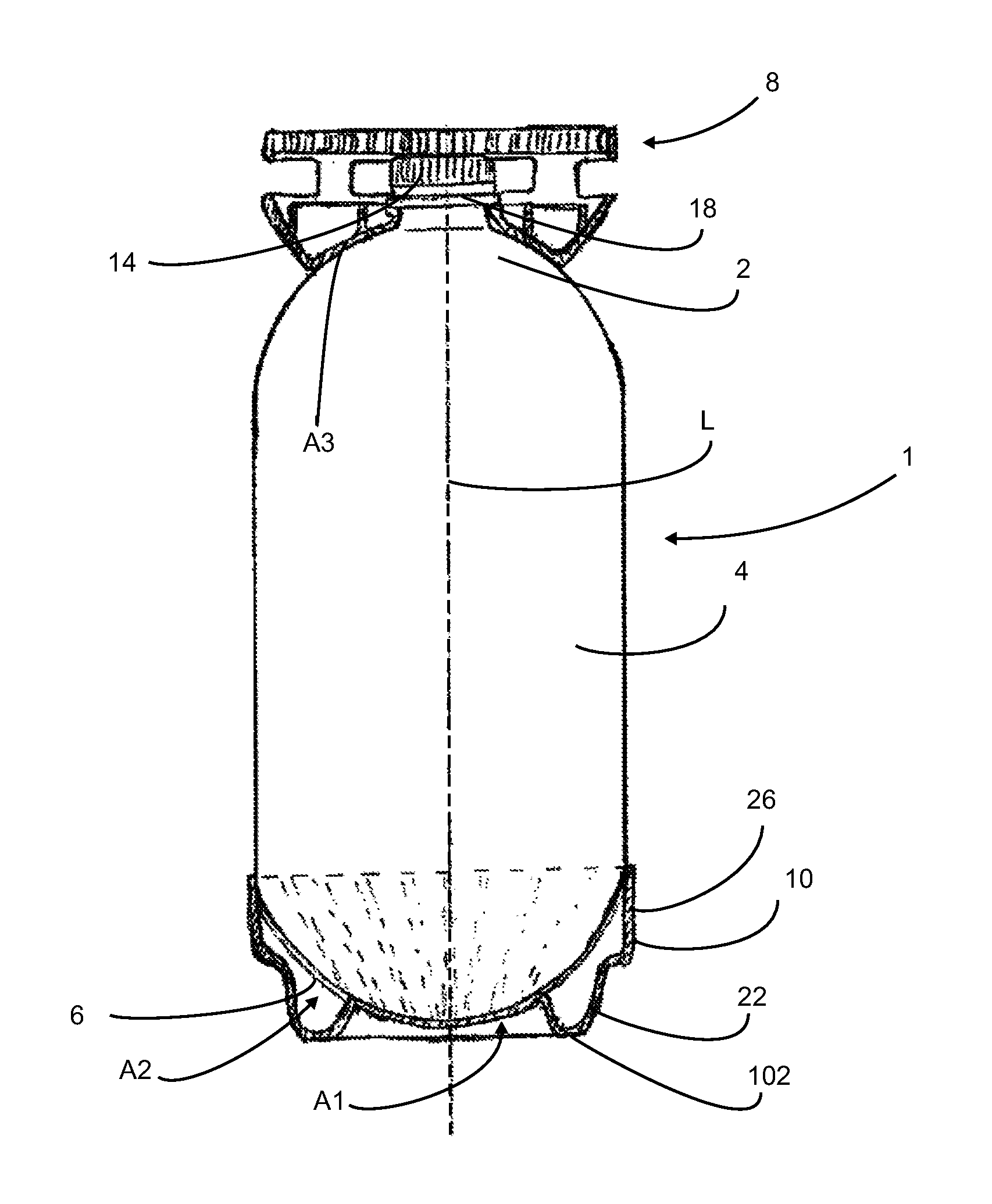

Compressible plastic container with base cup

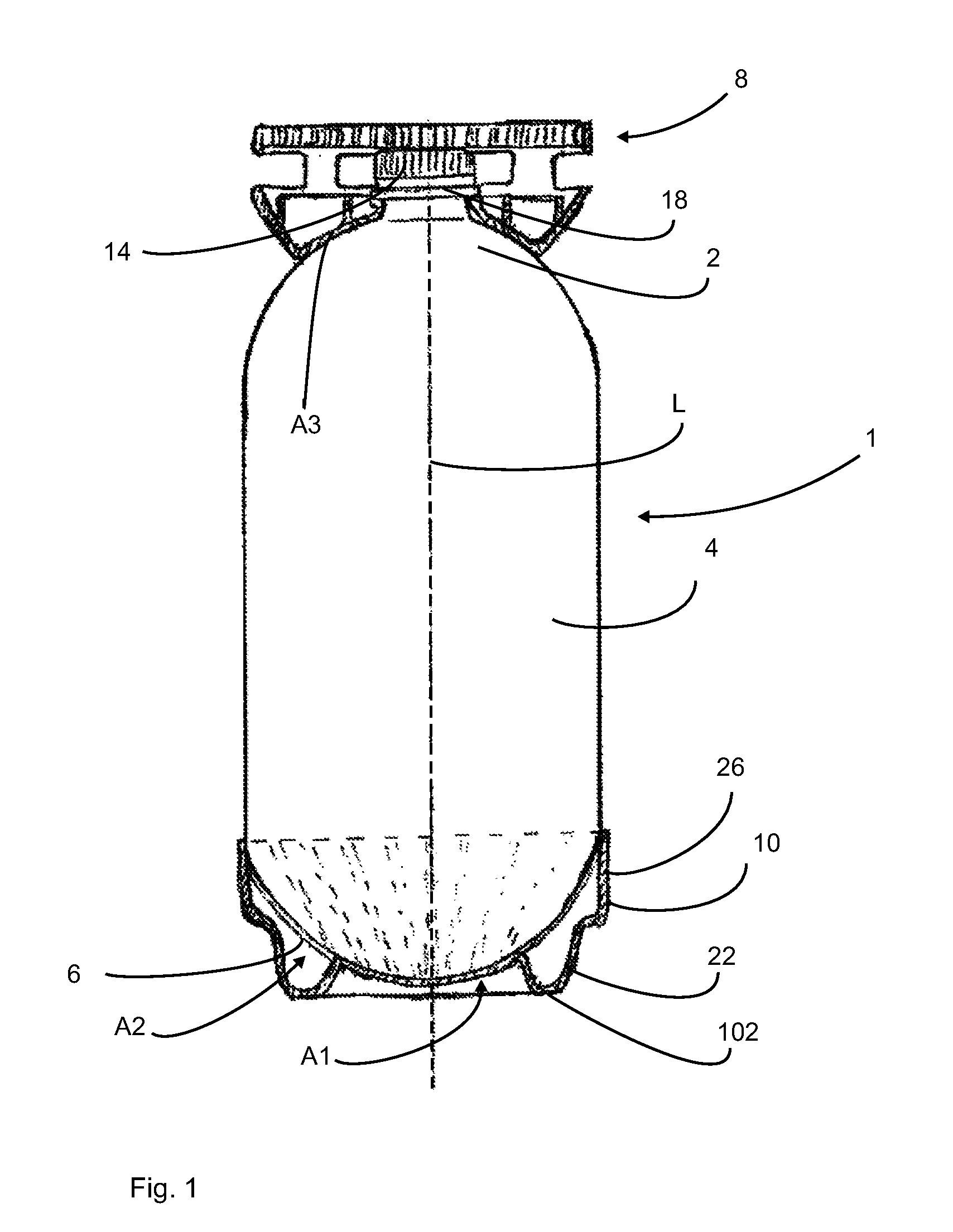

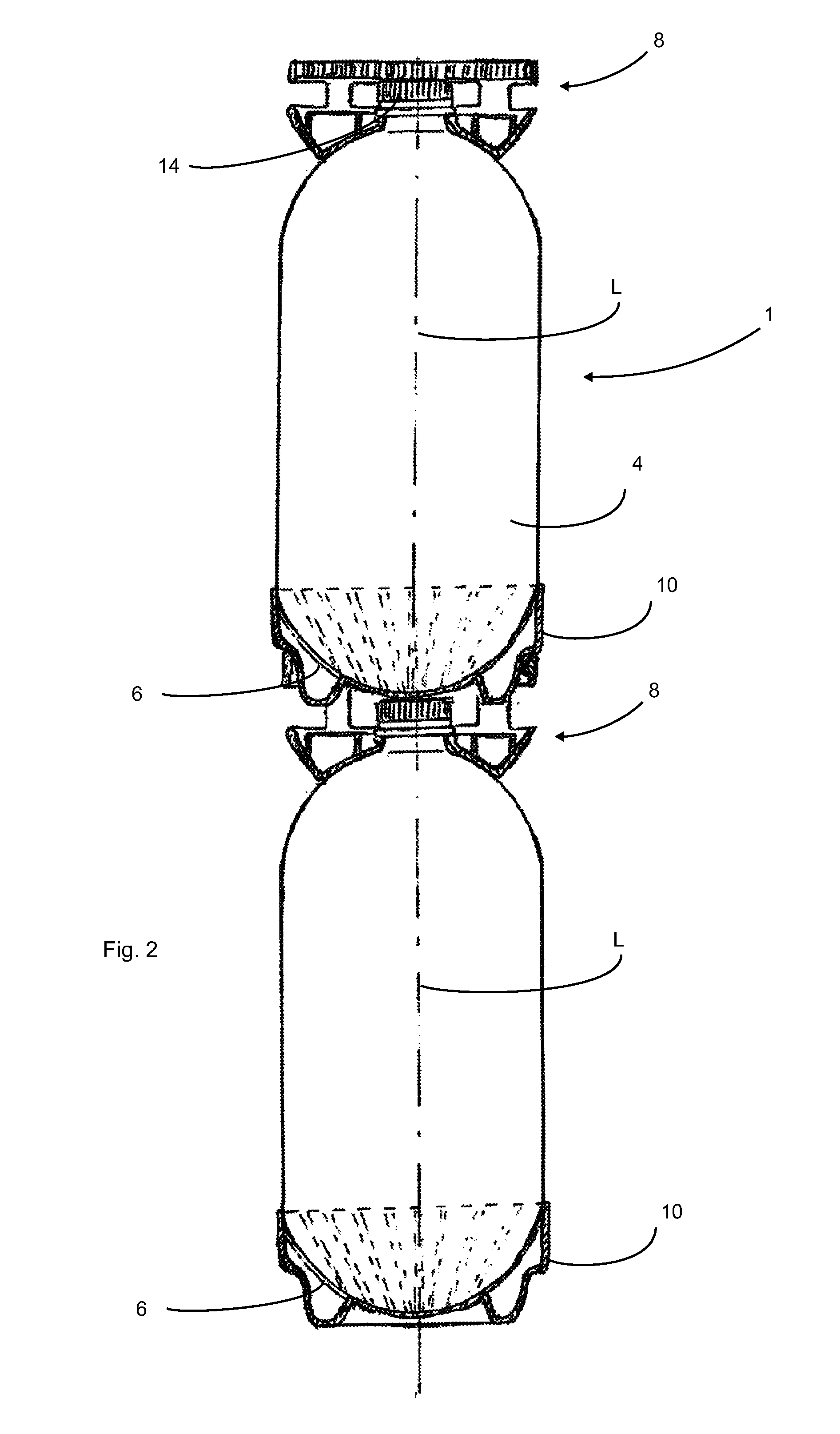

ActiveUS20160090215A1High market acceptanceLow costContainers for flexible articlesSupporting meansMechanical engineeringMouth region

A container, in particular a plastic container with a base region, a main body which adjoins this base region and is suitable to receive a volume of liquid, and with a mouth region, wherein the container can be compressed along its longitudinal direction for the removal of liquid located in the container is provided. On the base region a base cup is disposed which forms a base surface for the container and which when the container is compressed can also serve as a die element and / or die counter-element for compressing the container.

Owner:KRONES AG

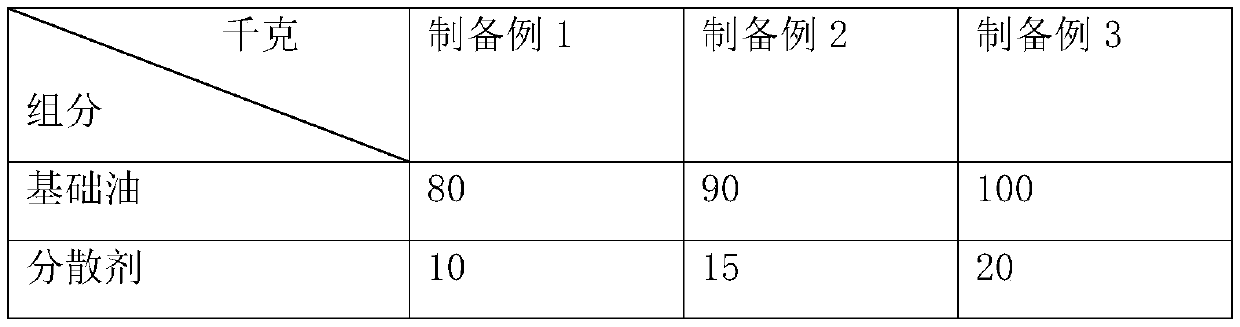

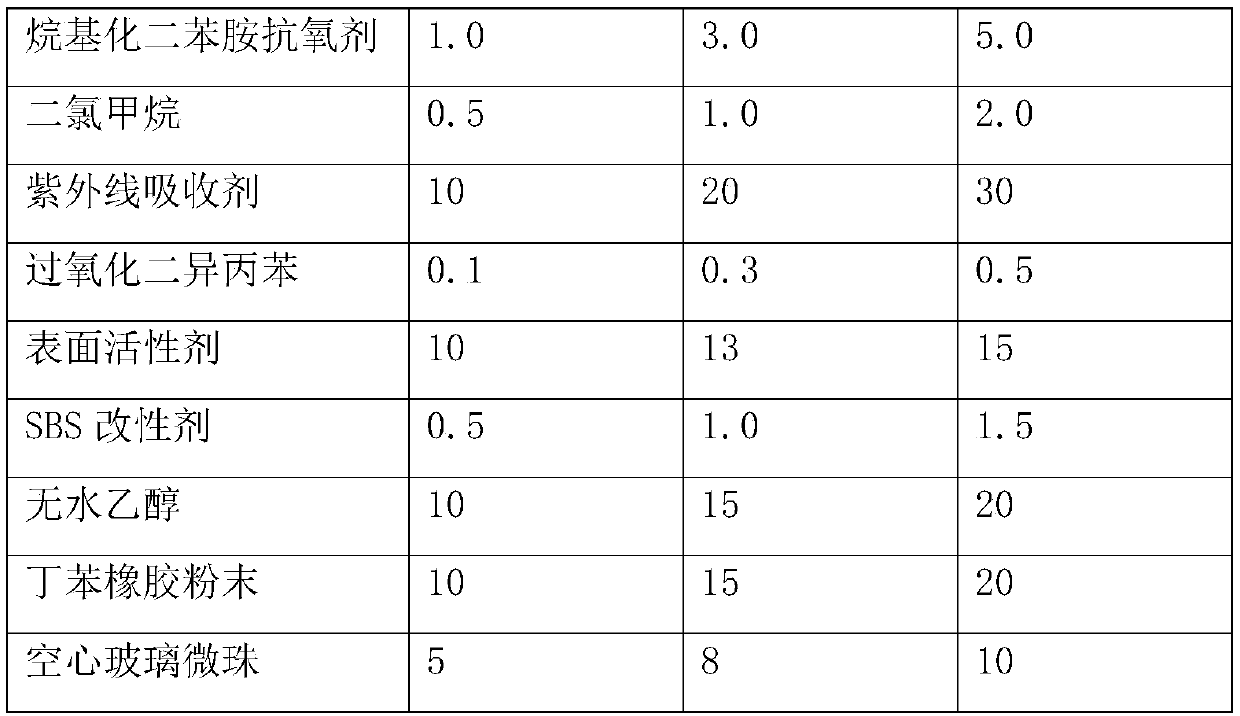

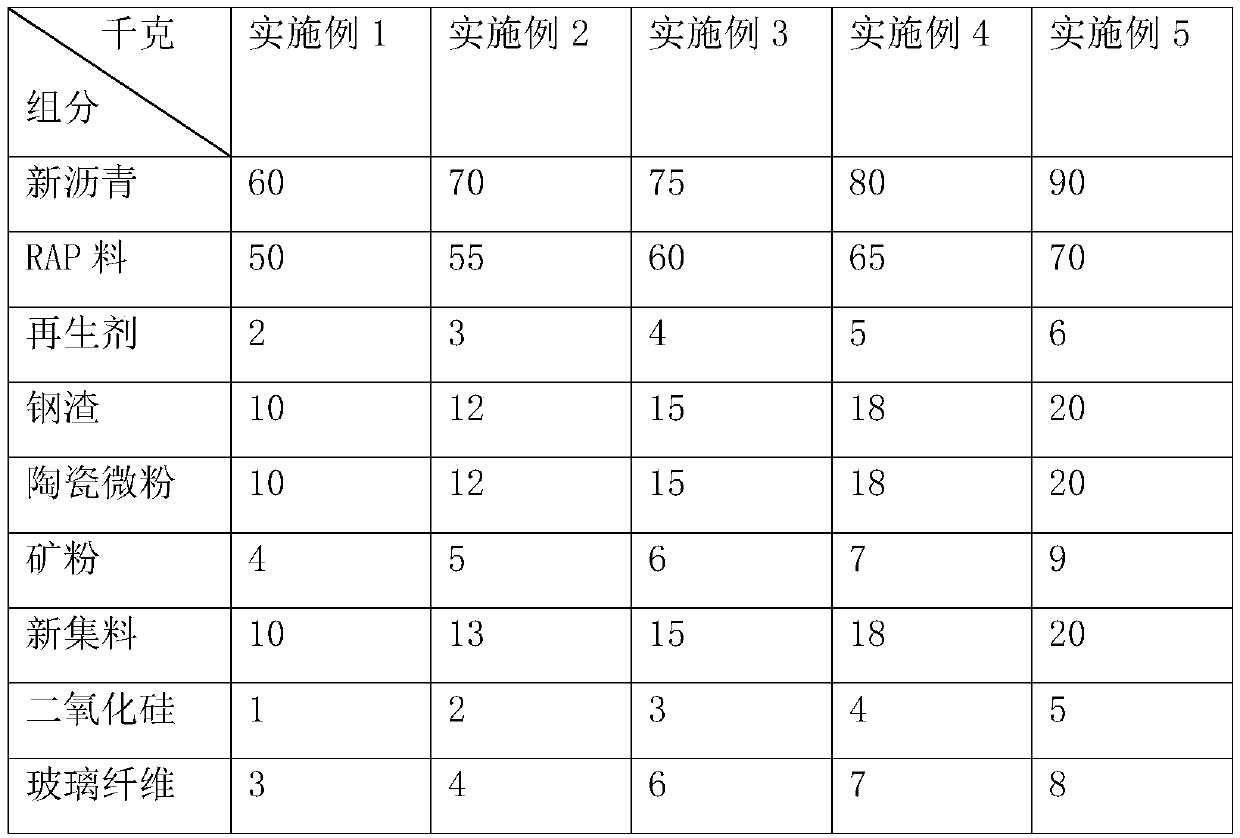

Heat-resistant recycled asphalt concrete and preparation method thereof

The invention discloses heat-resistant reclaimed asphalt concrete and a preparation method thereof. The heat-resistant reclaimed asphalt concrete comprises the following components: new asphalt, a RAPmaterial, a regenerant, steel slag, ceramic micropowder, mineral powder, a new aggregate, silica and glass fiber; the regenerant includes the following components: base oil, a dispersant, an alkylated diphenylamine antioxidant, dichloromethane, an ultraviolet absorber, dicumyl peroxide, a surfactant, a SBS modifier, anhydrous ethanol, styrene butadiene rubber powder and hollow glass microspheres;and the preparation thereof is as follows: S1, collecting the RAP material; S2, preparing a first mixture; S3, preparing a second mixture; S4, preparing a third mixture; and S5, preparing the finished product. The heat-resistant reclaimed asphalt concrete of the present invention is excellent in crack resistance, durability, and high-temperature and rutting deformation resistance; in addition, the preparation method of the present invention has the advantage of making asphalt distribution uniform.

Owner:江苏盛达飞建筑材料有限公司

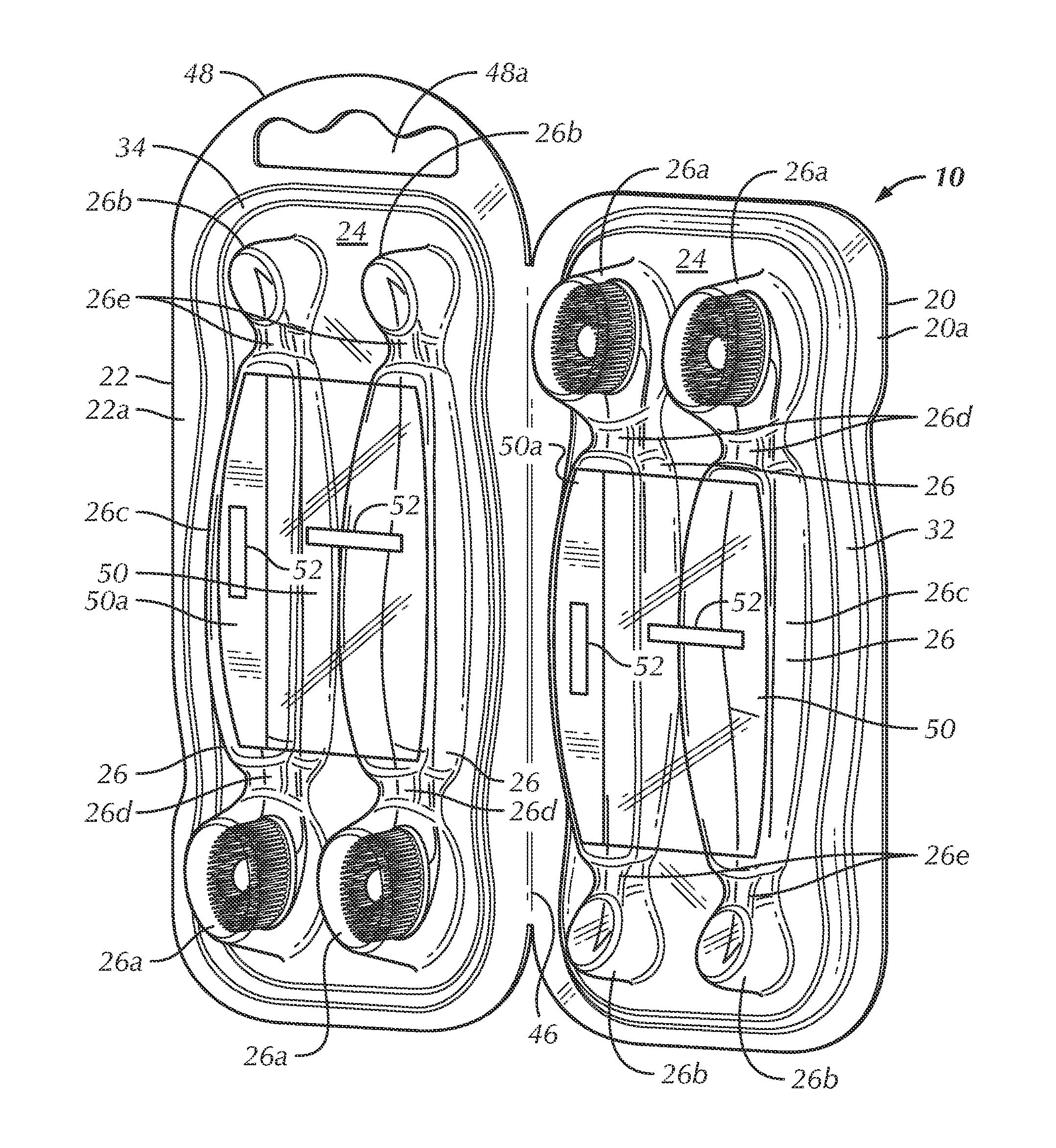

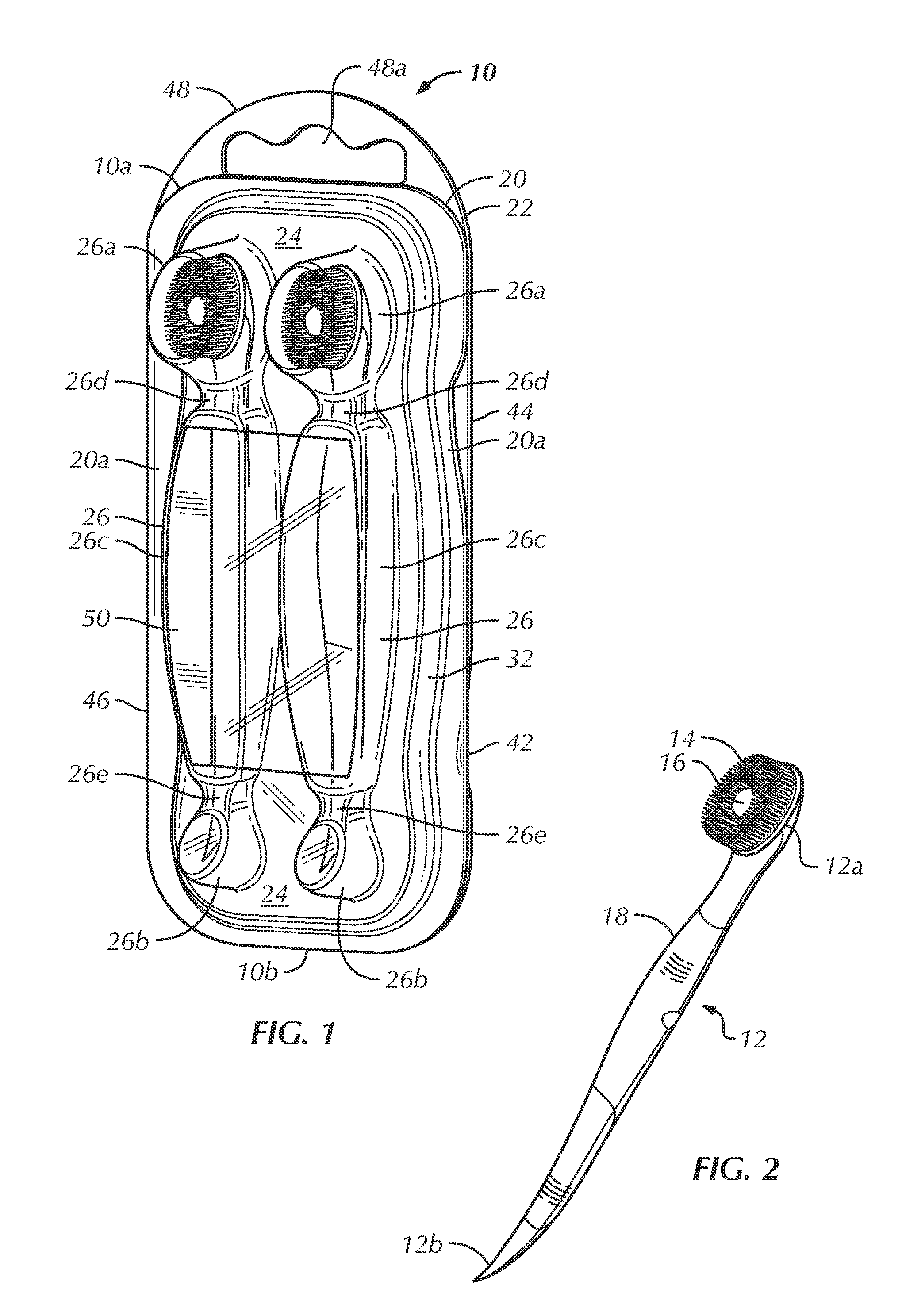

Display package

InactiveUS8245844B2Improve sustainabilityEfficient stackable profileContainer decorationsLevel indicationsEngineeringMechanical engineering

A package for displaying a plurality of items where the package has first and second containers connectable between an open position and a closed position, each container having an outer surface having at least one elongated protrusion, the at least one protrusion having a head end and a tail end, the head end extending further outwardly from the package than the tail end, and an inner surface having at least one inner cavity aligned with the at least one protrusion, the cavity having a depth varying along the protrusion and configured to receive one of the plurality of items, wherein the head end of the at least one protrusion of the first container is proximate the tail end of the at least one protrusion of the second container in the closed position.

Owner:COLGATE PALMOLIVE CO

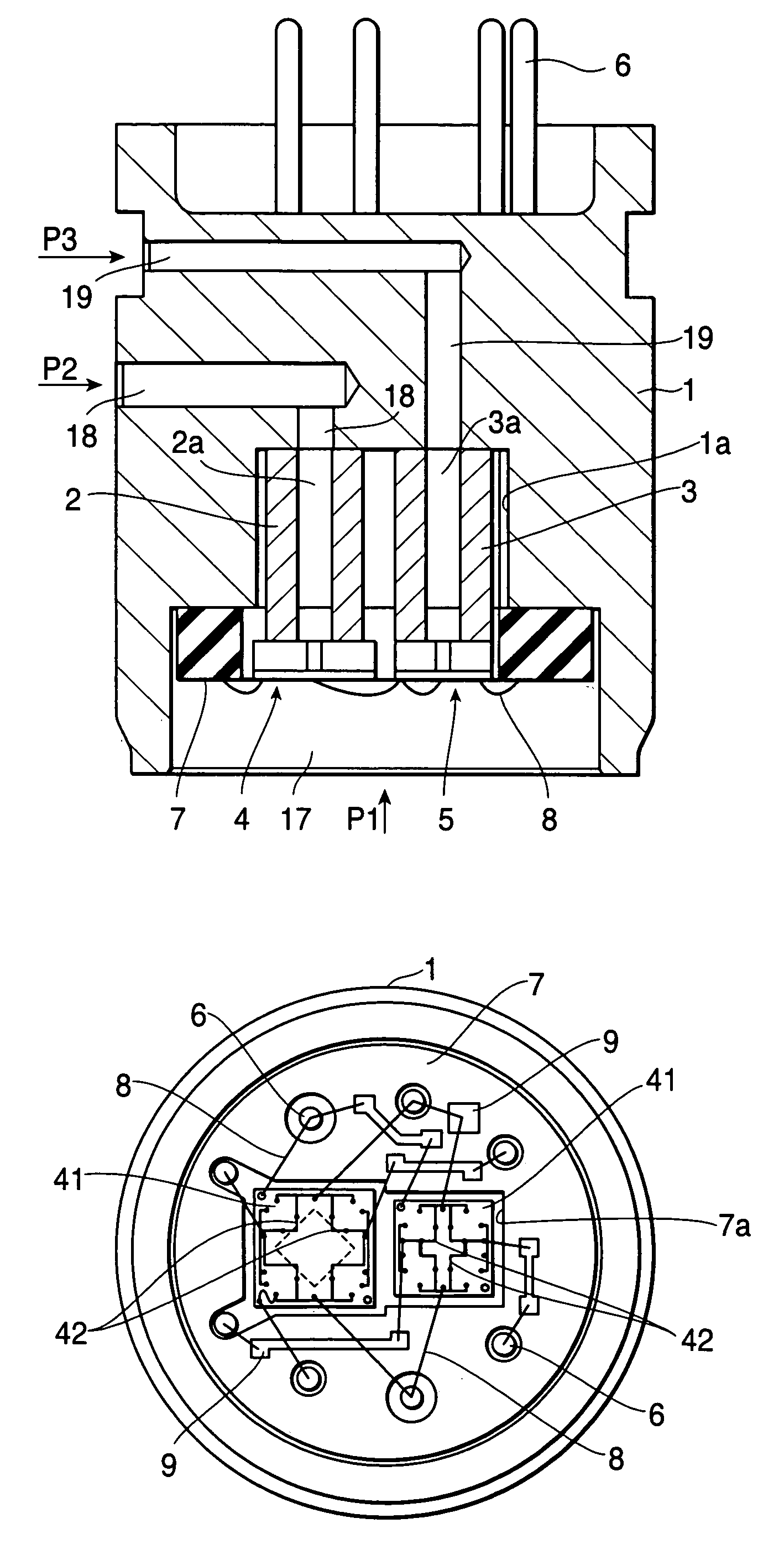

Pressure sensor

InactiveUS7013735B2Good temperature characteristicsWide pressure rangeFluid pressure measurement by electric/magnetic elementsForce measurementDifferential pressureEngineering

A differential pressure sensor chip (4) comprises a diaphragm for measuring a differential pressure and converts a pressure received by the diaphragm for measuring the differential pressure into an electrical signal. A static pressure sensor chip (5) comprises a diaphragm for measuring a static pressure and converts a pressure received by the diaphragm for measuring the static pressure into an electrical signal. The differential pressure sensor chip (4) and static pressure sensor chip (5) are mounted on a header (1) so that one surface of the differential pressure sensor chip (4) and one surface of the static pressure sensor chip (5) are exposed to the interior of a common pressure introducing chamber (17).

Owner:YAMATAKE HONEYWELL CO LTD

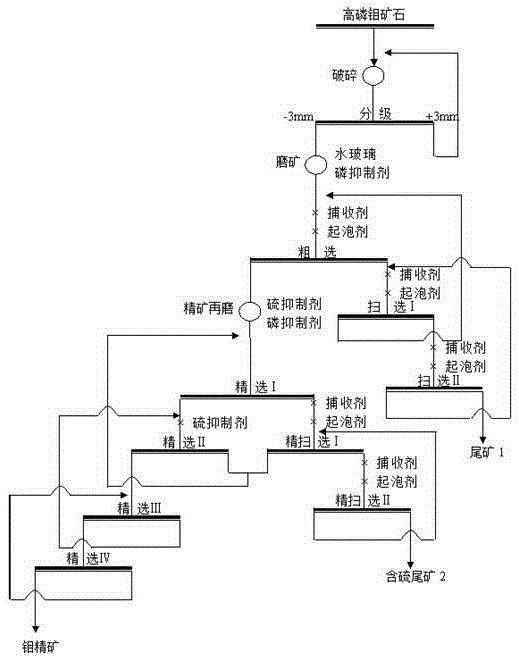

Physical concentration and phosphorus reduction method for skarn-type high-phosphorus molybdenum ore

The invention discloses a physical concentration and phosphorus reduction method for a skarn-type high-phosphorus molybdenum ore. The physical concentration and phosphorus reduction method comprises the following steps of (1) crushing, namely crushing raw ores by using a crusher, sieving, and returning a +3mm-grade raw ore to crush until the particle size of the raw ore is up to the -3mm grade; (2) grinding the ores, namely adding the crushed -3mm-grade raw ore into raw ore grinding equipment to carry out closed-circuit ore grinding operation, meanwhile, adding 500-1000g / t of water glass and 250-800g / t of a phosphate mineral inhibitor into a grinding machine, and grinding the raw ore until the particle size is up to the -0.075mm grade and the phosphorus content is up to 55-75%; (3) carrying out roughing operation; (4) carrying out scavenging operation; (5) regrinding a roughed molybdenum concentrate, namely adding 100-280g / t of a sulfur inhibitor and 150-300g / t of a phosphate mineral inhibitor to regrind the roughed molybdenum concentrate in roughed molybdenum concentrate regrinding equipment until the particle size is up to the -0.045mm grade and the phosphorus content is up to 70-95%; and (6) carrying out fine flotation operation. By using the physical concentration and phosphorus reduction method, the phosphorus content of a molybdenum concentrate product can be reduced to be lower than the standard, and a high-quality molybdenum concentrate product can be obtained.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

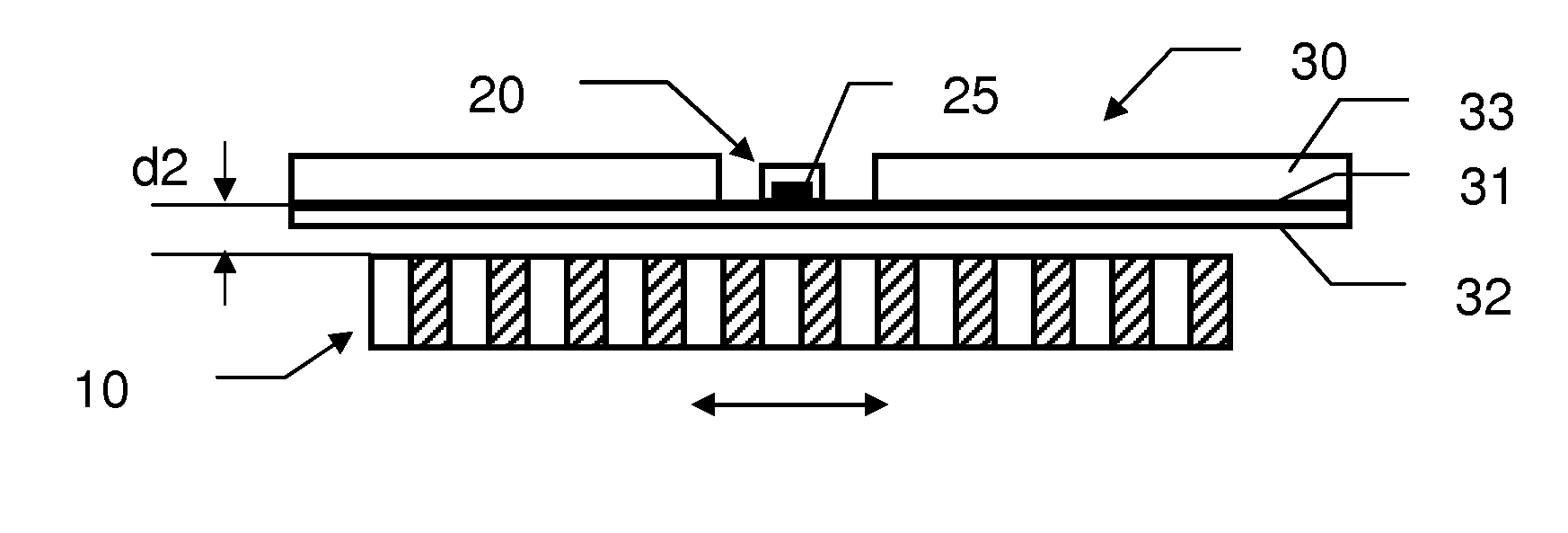

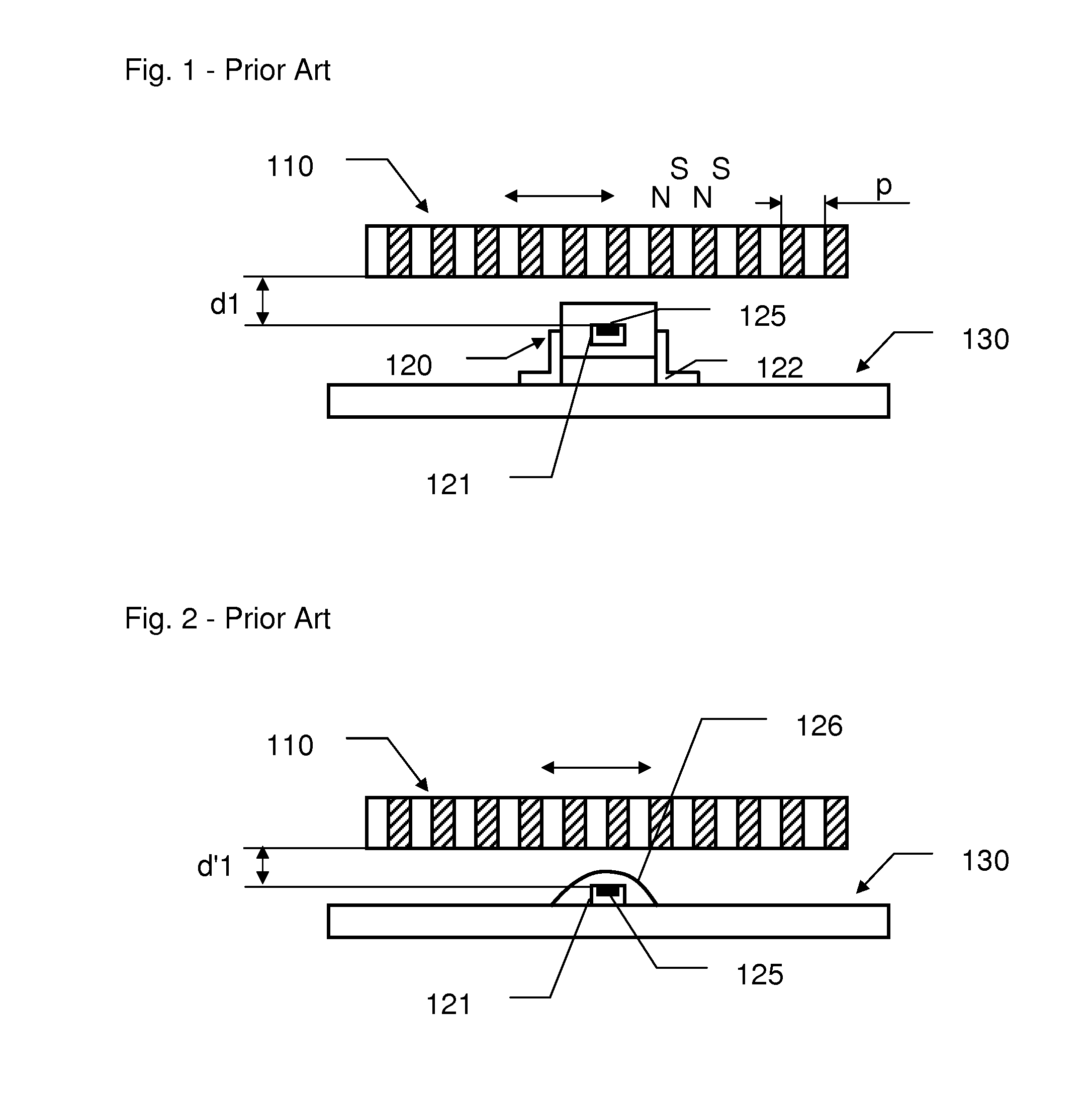

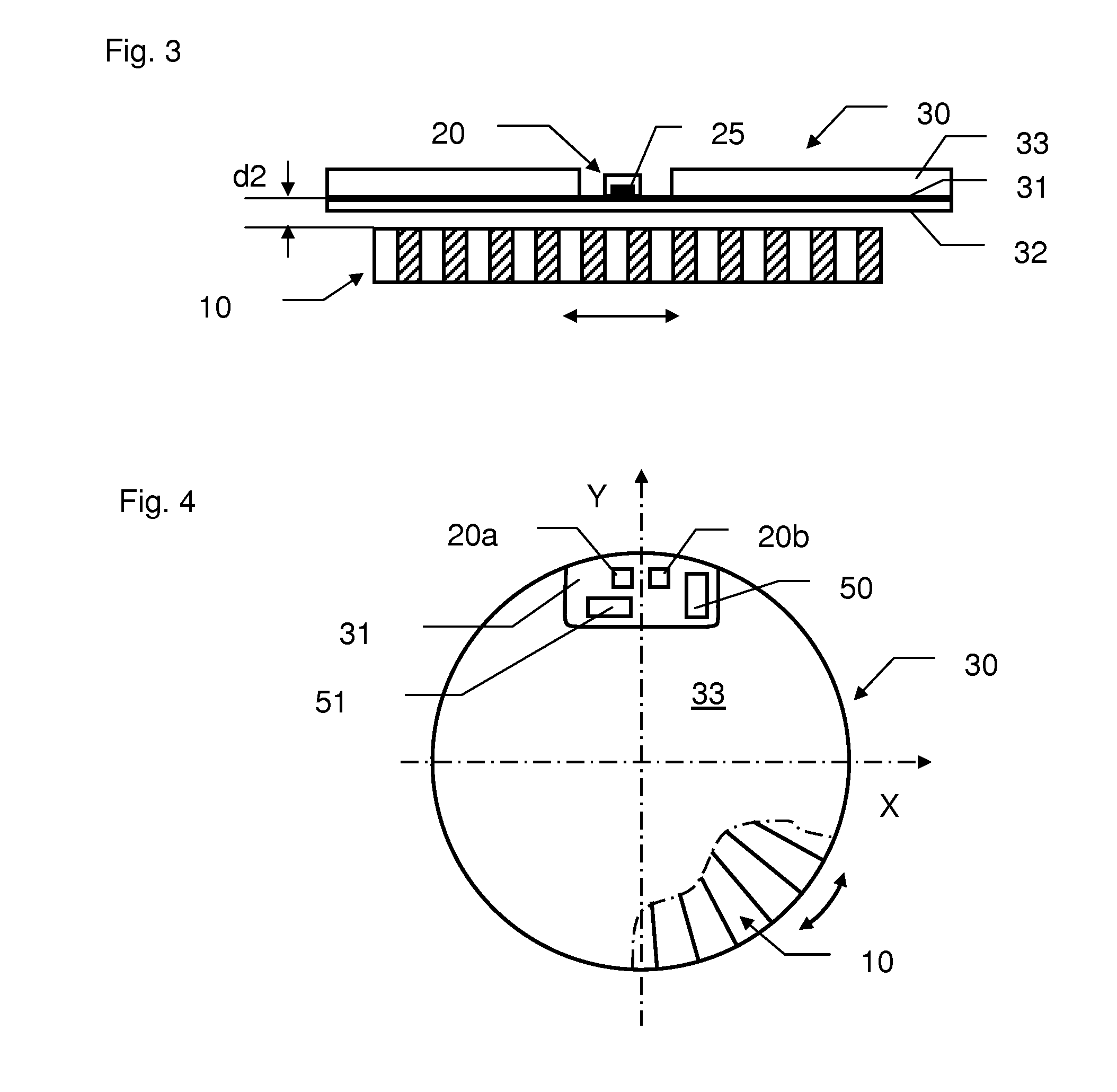

Magnetic encoder

ActiveUS20140132123A1Reduce packagingGood accuracy/resolutionMeasurement apparatus componentsSolid-state devicesPhysicsHall effect sensor

Encoder includinga moveable part with at least one magnetic dipole,at least one Hall Effect sensor with a sensitive area arranged to detect a magnetic field created by the magnetic dipole,at least one circuit board with a main thickness and having an attachment portion on which the Hall Effect sensor is mounted,where the Hall Effect sensor is a semiconductor die sensor with the sensitive area arranged on an external face of the semiconductor die,where the Hall Effect sensor is flip chip mounted onto the attachment portion of the circuit board, with the sensitive area in contact with the circuit board, and where the attachment portion is arranged between the Hall Effect sensor and the magnetic dipole and presents a reduced thickness compared to the main thickness of the rest of the circuit board.

Owner:PORTESCAP

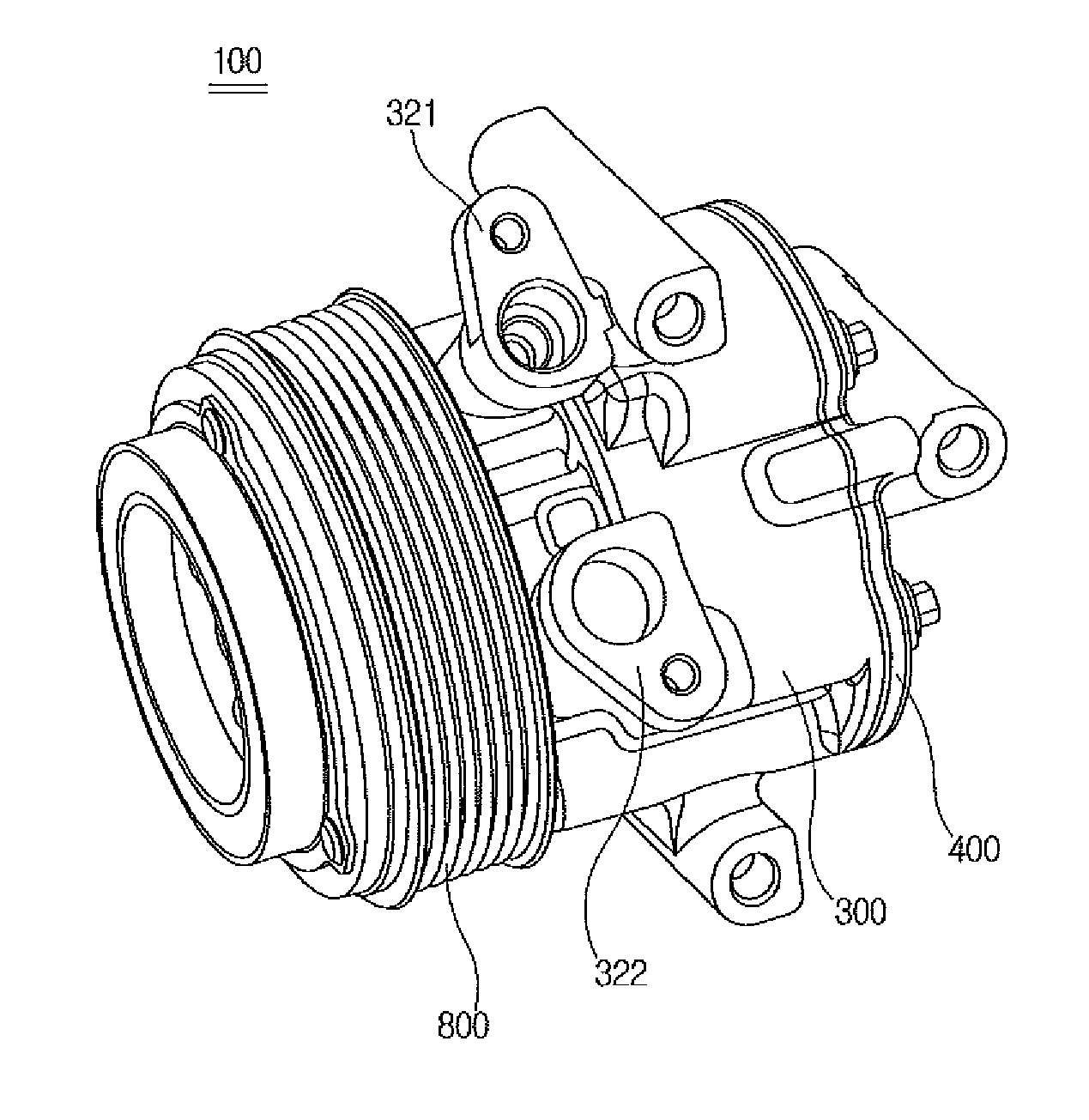

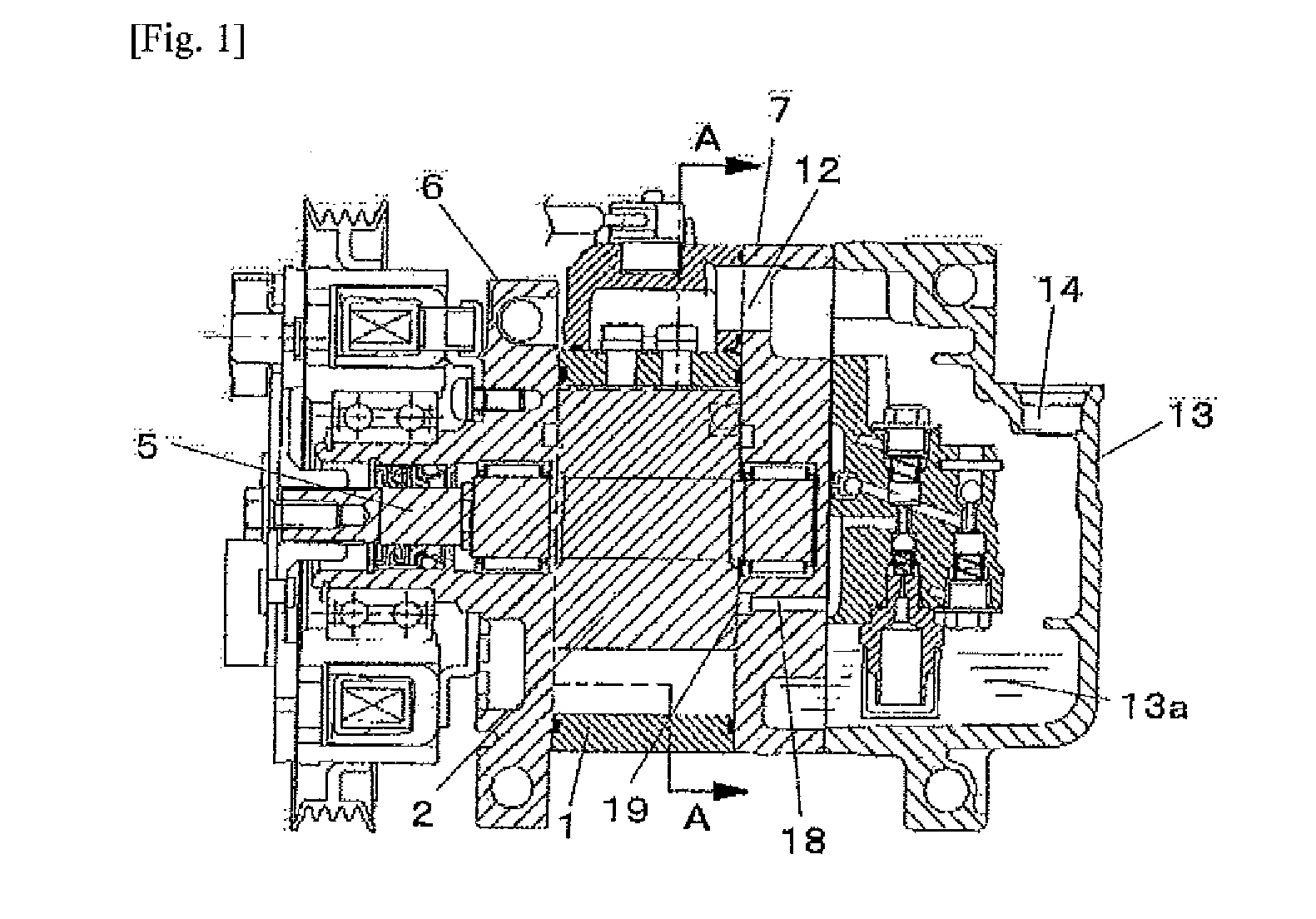

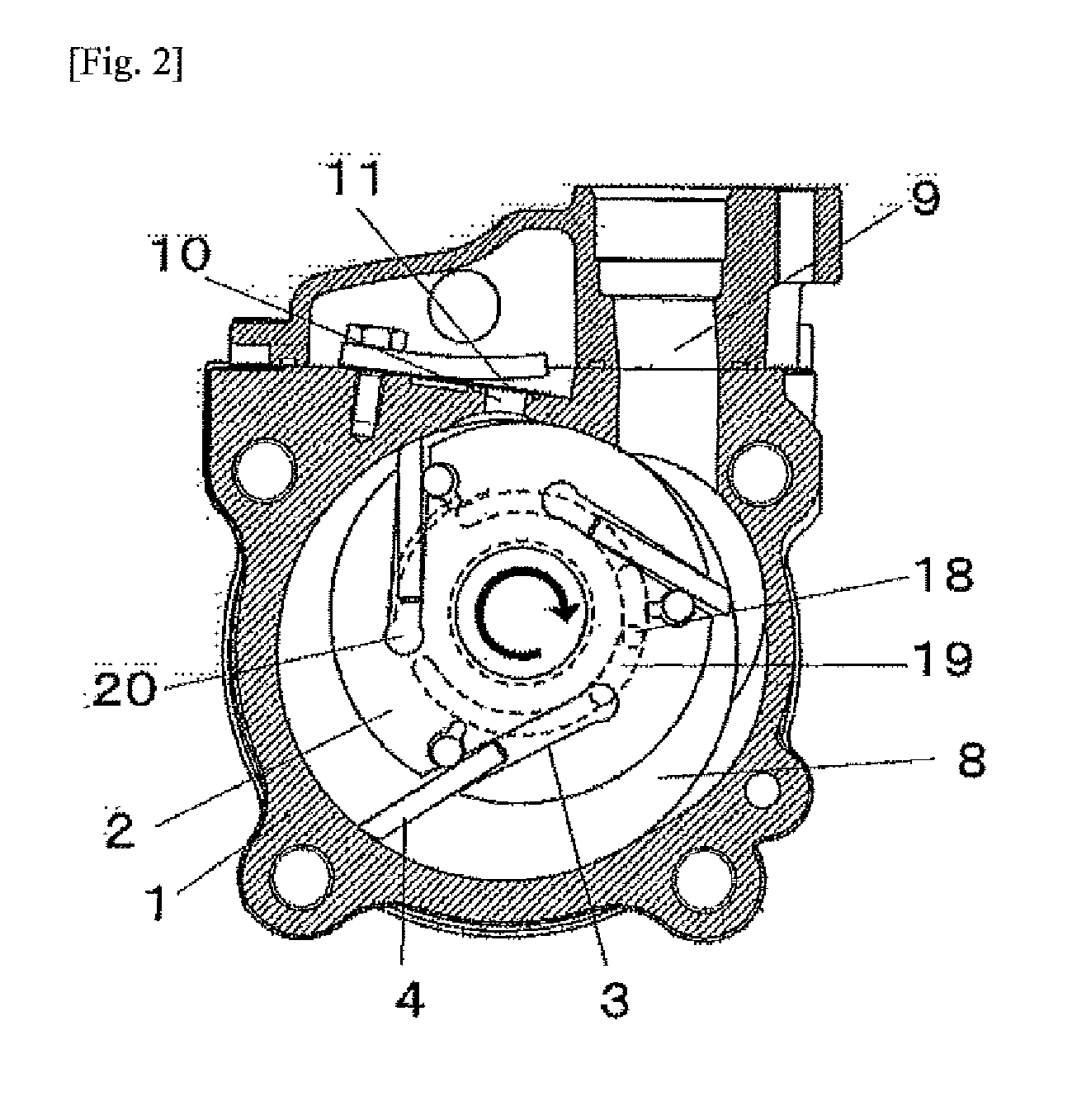

Vane rotary compressor

ActiveUS20140170010A1Improve performanceAvoid noiseOscillating piston enginesSealing arrangement for pumpsEngineeringRefrigerant

The present invention relates to a vane rotary compressor in which, while a rotor is rotating, the volume of a compressing chamber is reduced and a fluid such as a refrigerant is compressed. The vane rotary compressor according to one embodiment of the present invention is provided with the compressing chamber, the inner circumferential surface of which is formed in the shape of an involute curve, wherein the rotor is hinge-coupled with a plurality of cantilever vanes such that compression efficiency is high and noise is prevented from occurring during the operation of the compressor.

Owner:HANON SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com