Beneficiation method for high-oxidation-rate copper-molybdenum paragenic ores

A beneficiation method and oxidation rate technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of difficult flotation process enrichment, high oxidation rate of copper and molybdenum, improve density, reduce acid and alkali, The effect of promoting thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

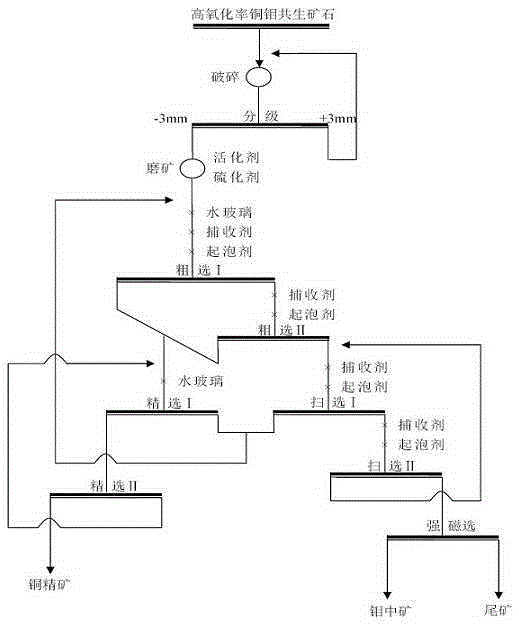

[0036] Using copper-molybdenum symbiotic ore with a high oxidation rate of 0.32% Cu and 0.25% Mo as raw material, the oxidation rate of Cu is 95.92%, and the oxidation rate of Mo is 87.50%. Utilize process technology of the present invention, carry out following steps, as figure 1 :

[0037] (1) Crushing: The raw ore is crushed and screened by a crusher, and the raw ore with a particle size of +3mm is returned for crushing until the particle size of all the raw ore reaches the -3mm level;

[0038] (2) Grinding: For the crushed -3mm raw ore, use a rod mill or a ball mill for closed-circuit grinding. At the same time, add ammonium sulfate 2000g / t and sodium sulfide 500g / t to the mill, and grind the raw ore to -0.075mm content of 65.0%;

[0039] (3) Flotation roughing operation; for the raw ore sample that has been ground, firstly stir and adjust the pulp to control the pulp concentration to 35%, and then add water glass 900g / t, penta-nine hydroxamic acid 75g / t, butyl xanthate ...

Embodiment 2

[0045] The copper-molybdenum symbiotic ore with a Cu content of 0.35% and a Mo content of 0.22% is used as a raw material. The Cu oxidation rate is 90.45%, and the Mo oxidation rate is 85.37%. Utilize process technology of the present invention, carry out following steps, as figure 1 :

[0046] (1) Crushing: The raw ore is crushed and screened by a crusher, and the raw ore with a particle size of +3mm is returned for crushing until the particle size of all the raw ore reaches the -3mm level;

[0047] (2) Grinding: For the crushed -3mm raw ore, use a rod mill or a ball mill for closed-circuit grinding. At the same time, add 2300g / t of ethylenediamine phosphate and 720g / t of sodium polysulfide to the mill, and grind the raw ore to -0.075mm content of 75.0%;

[0048] (3) Flotation roughing operation; for the raw ore sample that has been ground, firstly stir and adjust the pulp to control the pulp concentration to 32%, and then add water glass 1100g / t, benzylhydroxamic acid 90g / ...

Embodiment 3

[0054] The copper-molybdenum symbiotic ore with a Cu content of 0.27% and a Mo content of 0.21% is used as a raw material. The Cu oxidation rate is 92.45%, and the Mo oxidation rate is 89.97%. Utilize process technology of the present invention, carry out following steps, as figure 1 :

[0055] (1) Crushing: The raw ore is crushed and screened by a crusher, and the raw ore with a particle size of +3mm is returned for crushing until the particle size of all the raw ore reaches the -3mm level;

[0056] (2) Grinding: For the crushed -3mm raw ore, use a rod mill or a ball mill for closed-circuit grinding. At the same time, add 2000g / t of benzotriazole and 500g / t of sodium hydrosulfide to the mill, and grind the raw ore to -0.075mm content of 70.0%;

[0057] (3) Flotation roughing operation; for the raw ore sample that has been ground, firstly stir and adjust the pulp to control the concentration of the pulp to 38%, and then add 800g / t of water glass, 70g / t of salicylic hydroxami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com