Heat-resistant recycled asphalt concrete and preparation method thereof

A technology for recycling asphalt and concrete, applied in the field of highway engineering, can solve the problems of affecting the service life of asphalt pavement, poor temperature stability of asphalt pavement, easy absorption of heat and melting of asphalt pavement, etc. Good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

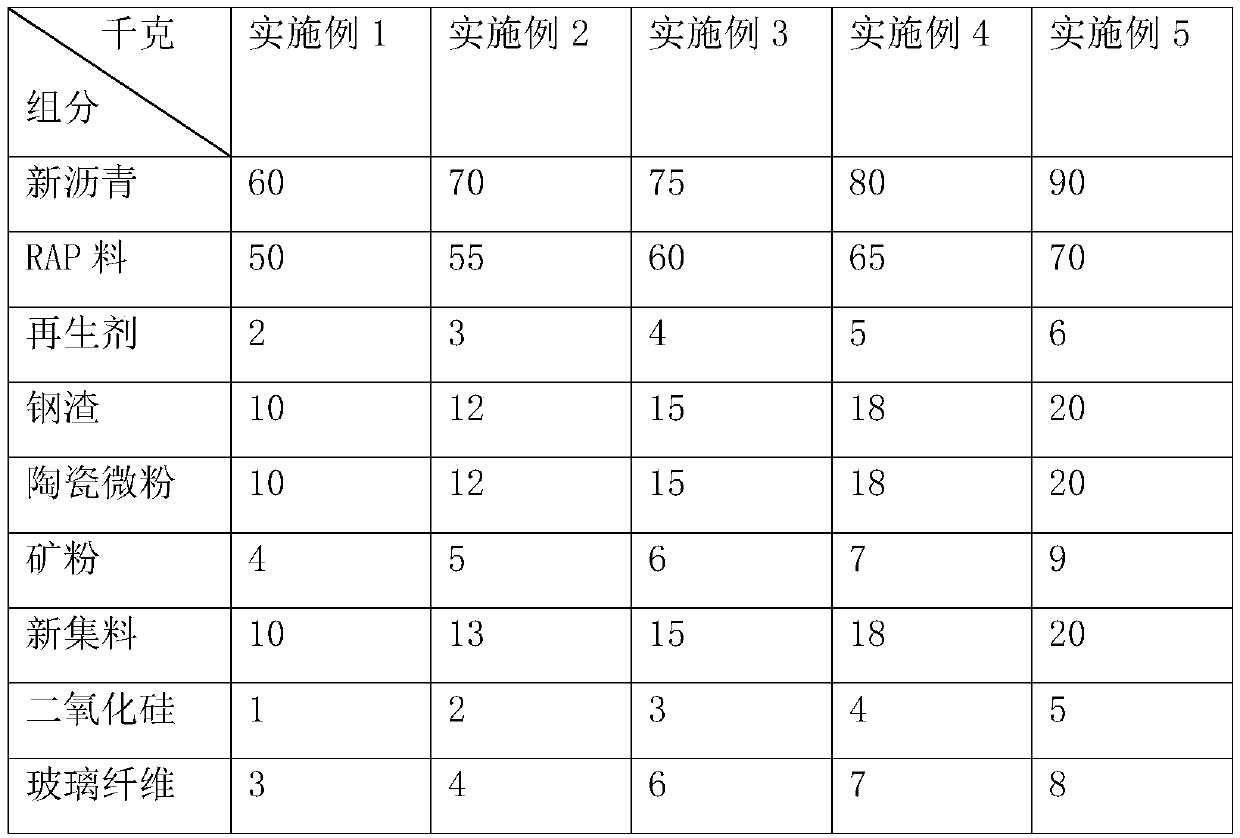

Examples

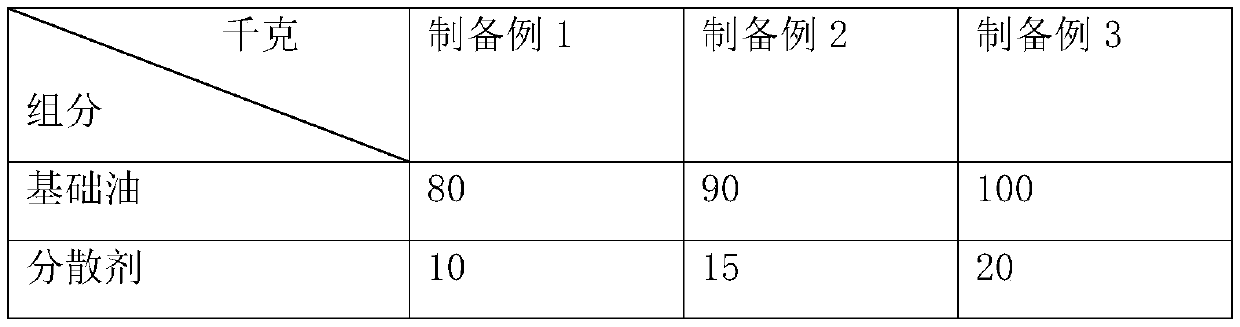

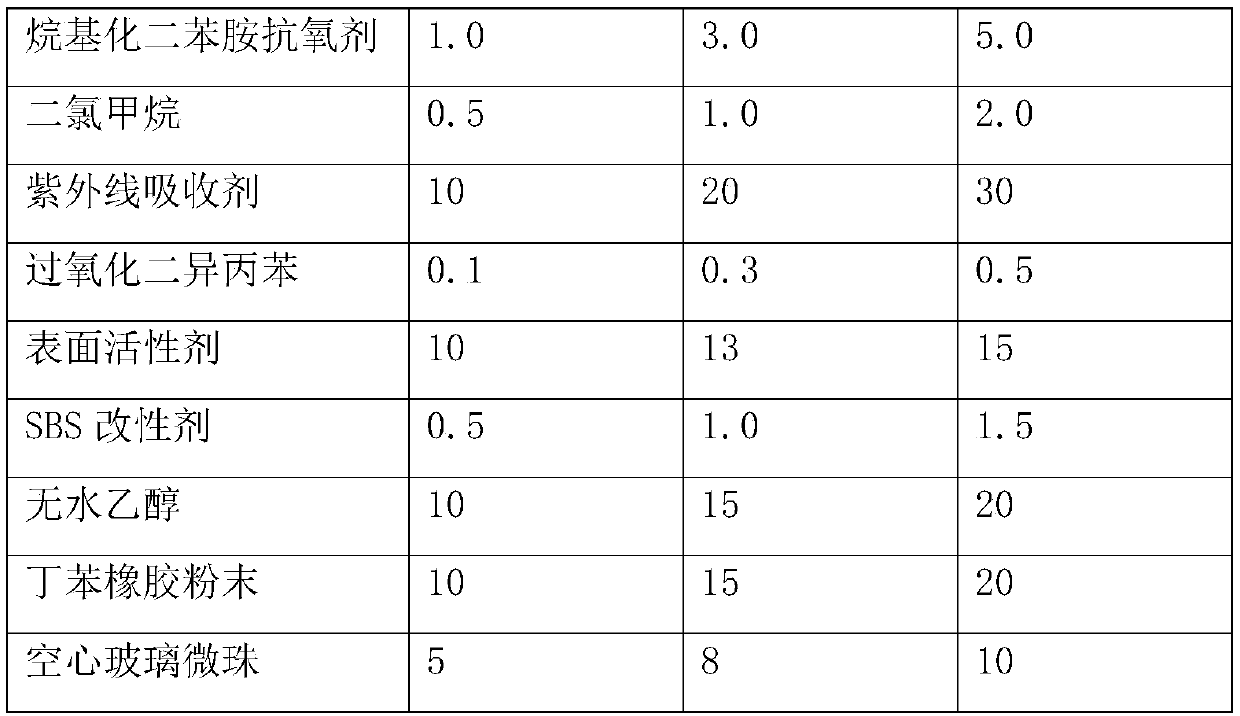

preparation example 1-3

[0043] Tung oil in Preparation Example 1-3 is selected from lc-0001 type tung oil sold by Shandong Greentown Chemical Co., Ltd., and turpentine is selected from AOX-68 type turpentine sold by Jinan Aoxiang Chemical Co., Ltd., and naphthenic rubber oil is selected from Shanghai Judao Chemical Co., Ltd. The KN4010 naphthenic rubber oil and alkylated diphenylamine antioxidant sold by the company are selected from the T534 alkylated diphenylamine antioxidant sold by Jinzhou Shengda Chemical Co., Ltd. The YH-801 SBS modifier and UV absorber sold by Jiang Shengbang Plastic Raw Materials Management Department are selected from the UV-531 UV absorber sold by Dongguan Kangjin New Material Technology Co., Ltd., and the styrene-butadiene rubber powder is selected from Beijing Yuda Industrial Co., Ltd. The YDH-SBR styrene-butadiene rubber powder and hollow glass microspheres sold by Trading Co., Ltd. are selected from the hollow glass microspheres sold by Fengheng Mineral Products Processi...

preparation example 1

[0044] Preparation Example 1: According to the proportioning in Table 1, (1) 80kg base oil, 10kg surfactant and 10kg dispersant were added to the reactor, heated to 150°C, stirred at 1000r / min for 20min, and stirred evenly, wherein The base oil is a mixture of tung oil, turpentine and rubber oil with a mass ratio of 2:1:3, the rubber oil is naphthenic rubber oil, the surfactant is cetyltrimethylammonium chloride, and the dispersant is mass A mixture of stearylamide and n-butanol at a ratio of 0.5:15;

[0045] (2) Stir 10kg of styrene-butadiene rubber powder and 5kg of hollow glass microspheres at a speed of 500r / min for 30min, add them to the reactor, then add 0.1kg of dicumyl peroxide and 10kg of absolute ethanol to the reactor At 140°C, stir at 800r / min for 30min, and add 0.5kg of dichloromethane, 0.5kg of SBS modifier, 10kg of ultraviolet absorber and 1.0kg of alkylated diphenylamine anti-oxidant when it is naturally cooled to 60°C. Oxygen agent, continue to stir for 30 mi...

preparation example 2

[0049] Preparation Example 2: According to the proportioning in Table 1, (1) 90kg of base oil, 13kg of surfactant and 15kg of dispersant were added to the reactor, heated to 160°C, stirred at 1300r / min for 25min, and stirred evenly, wherein The base oil is a mixture of tung oil, turpentine and rubber oil with a mass ratio of 3:1.3:4, the rubber oil is naphthenic rubber oil, the surfactant is octadecyltrimethylammonium chloride, and the dispersant is mass A mixture of stearylamide and n-butanol at a ratio of 0.8:18;

[0050] (2) Stir 15kg of styrene-butadiene rubber powder and 8kg of hollow glass microspheres at a rotating speed of 700r / min for 35min, add them to the reactor, then add 0.3kg of dicumyl peroxide and 15kg of absolute ethanol to the reactor At 160°C, stir at 900r / min for 40min, and add 1.0kg of dichloromethane, 1.0kg of SBS modifier, 20kg of ultraviolet absorber and 3.0kg of alkylated diphenylamine anti-oxidant when naturally cooling to 70°C. Oxygen agent, continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com