Patents

Literature

1150 results about "Materials management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

'Materials management is a core supply chain function and includes supply chain planning and supply chain execution capabilities. Specifically, materials management is the capability firms use to plan total material requirements. The material requirements are communicated to procurement and other functions for sourcing. Materials management is also responsible for determining the amount of material to be deployed at each stocking location across the supply chain, establishing material replenishment plans, determining inventory levels to hold for each type of inventory (raw material, WIP, Finished Goods), and communicating information regarding material needs throughout the extended supply chain.

Maintenance, repair and overhaul management

A framework for maintenance, repair and overhaul business management includes a first layer identifying business areas in an MRO business, a second layer identifying one or more processes within each business area and a third layer identifying one or more sub-processes within each process wherein the business area include flight operations management, maintenance execution, maintenance management, engineering and maintenance support, material management, product development, enterprise management, strategic management, and demand generation.

Owner:ACCENTURE GLOBAL SERVICES GMBH

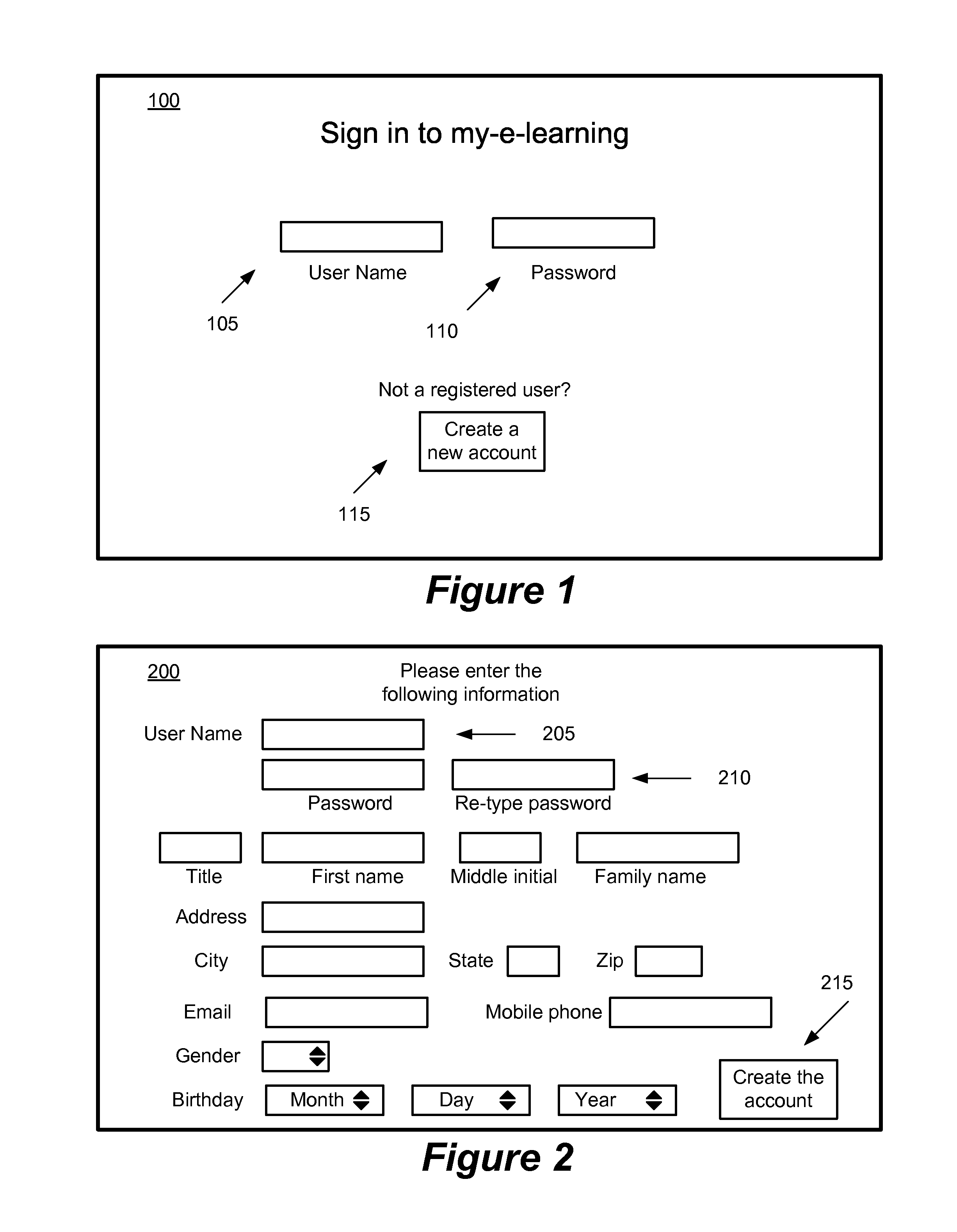

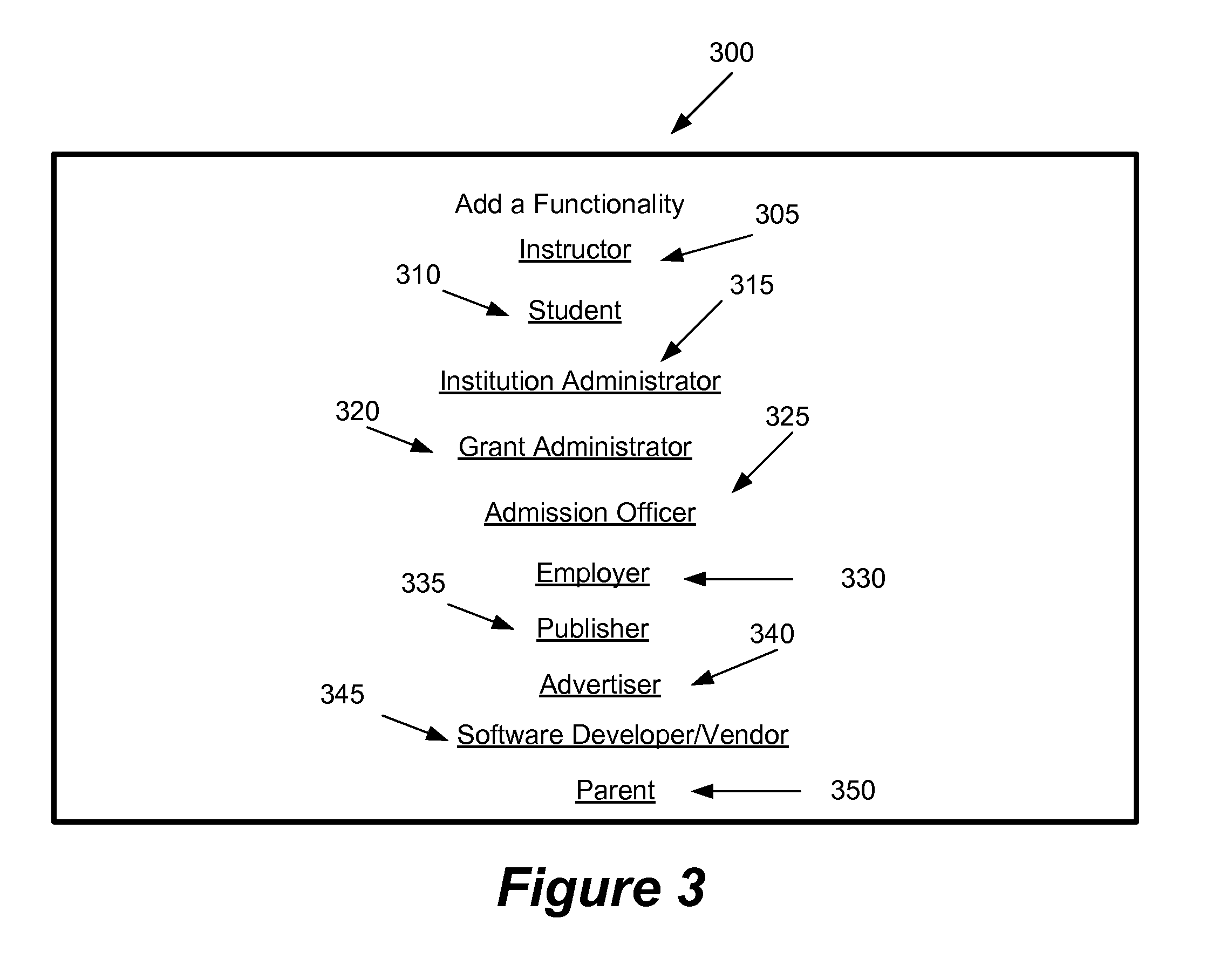

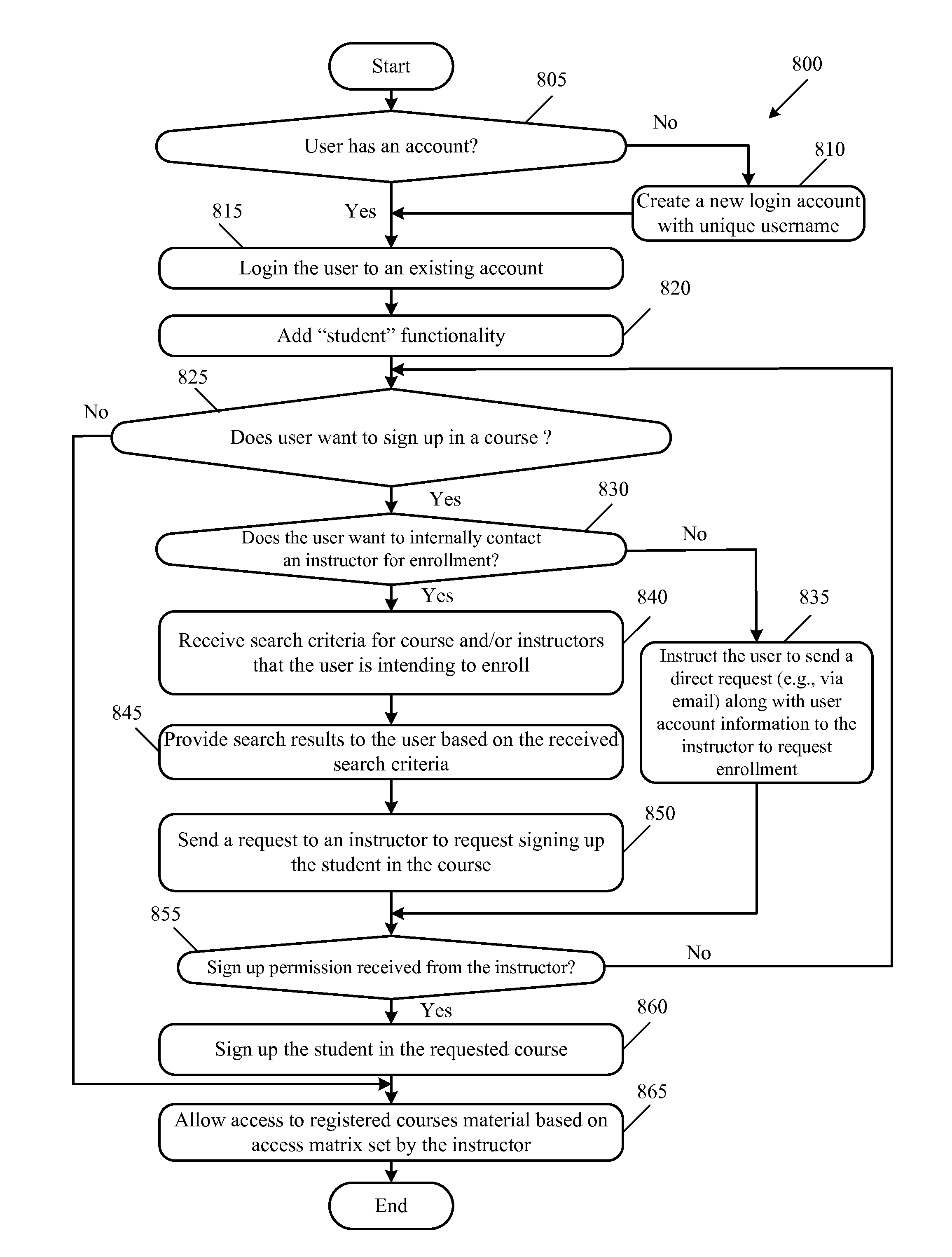

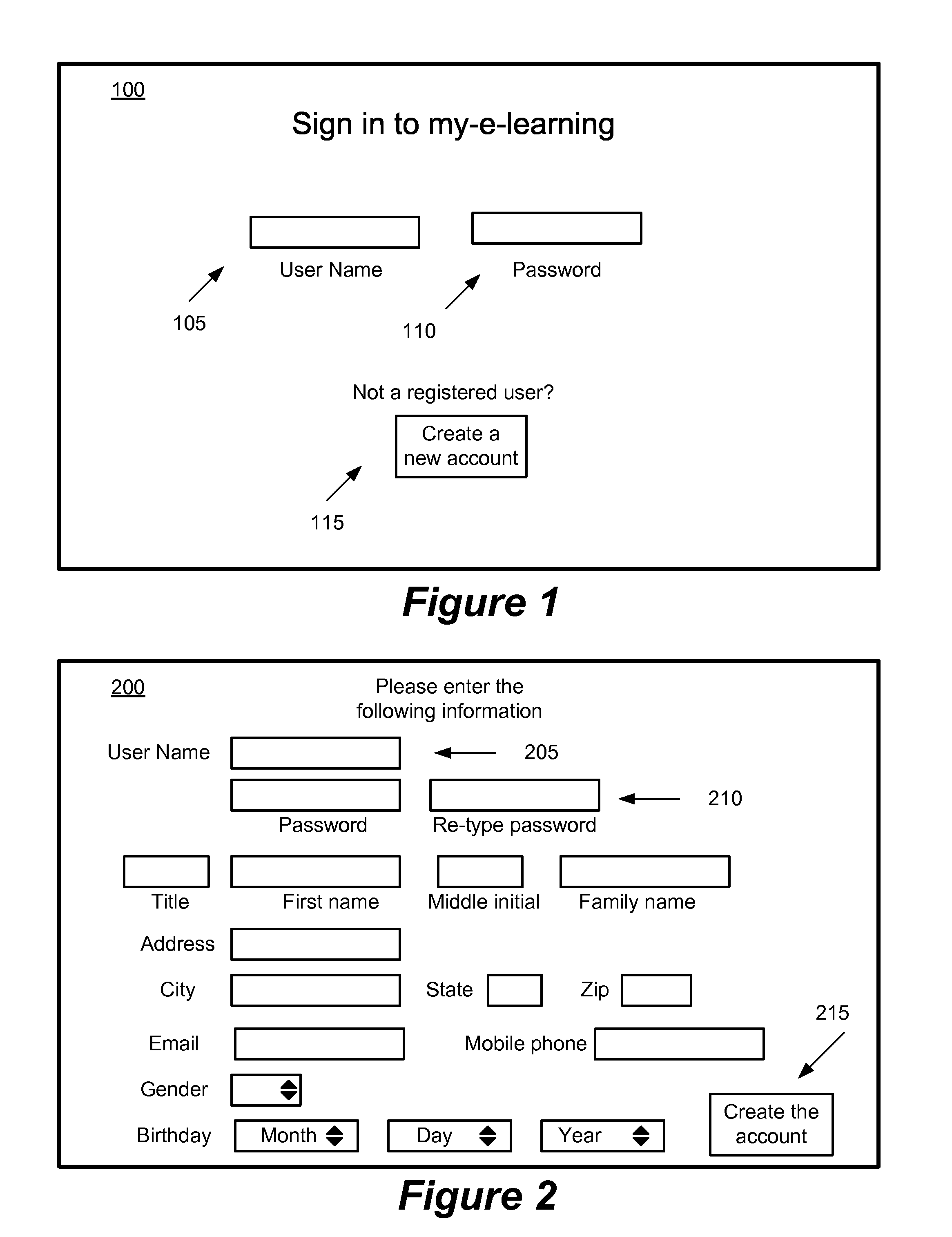

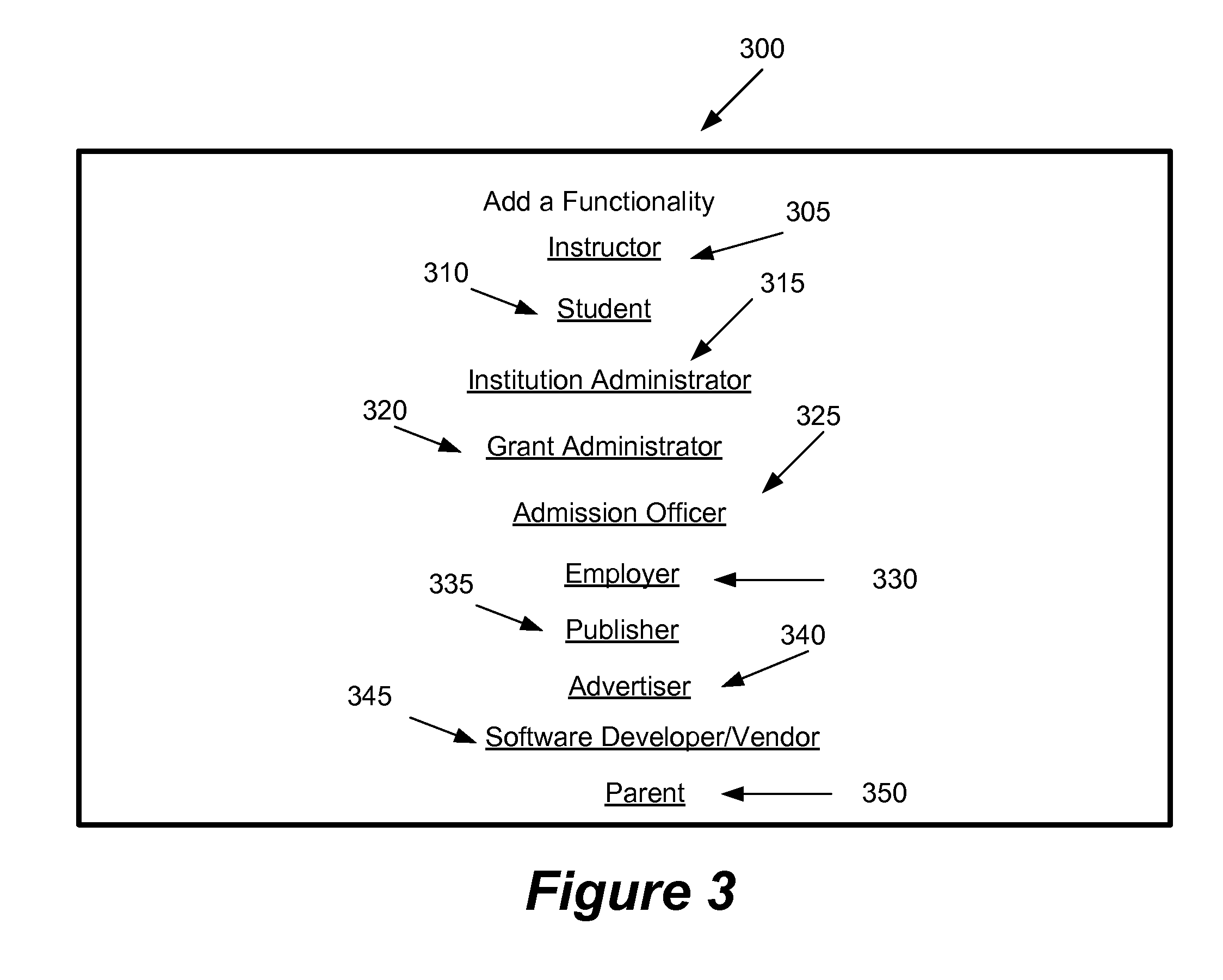

Method and system for sharing and networking in learning systems

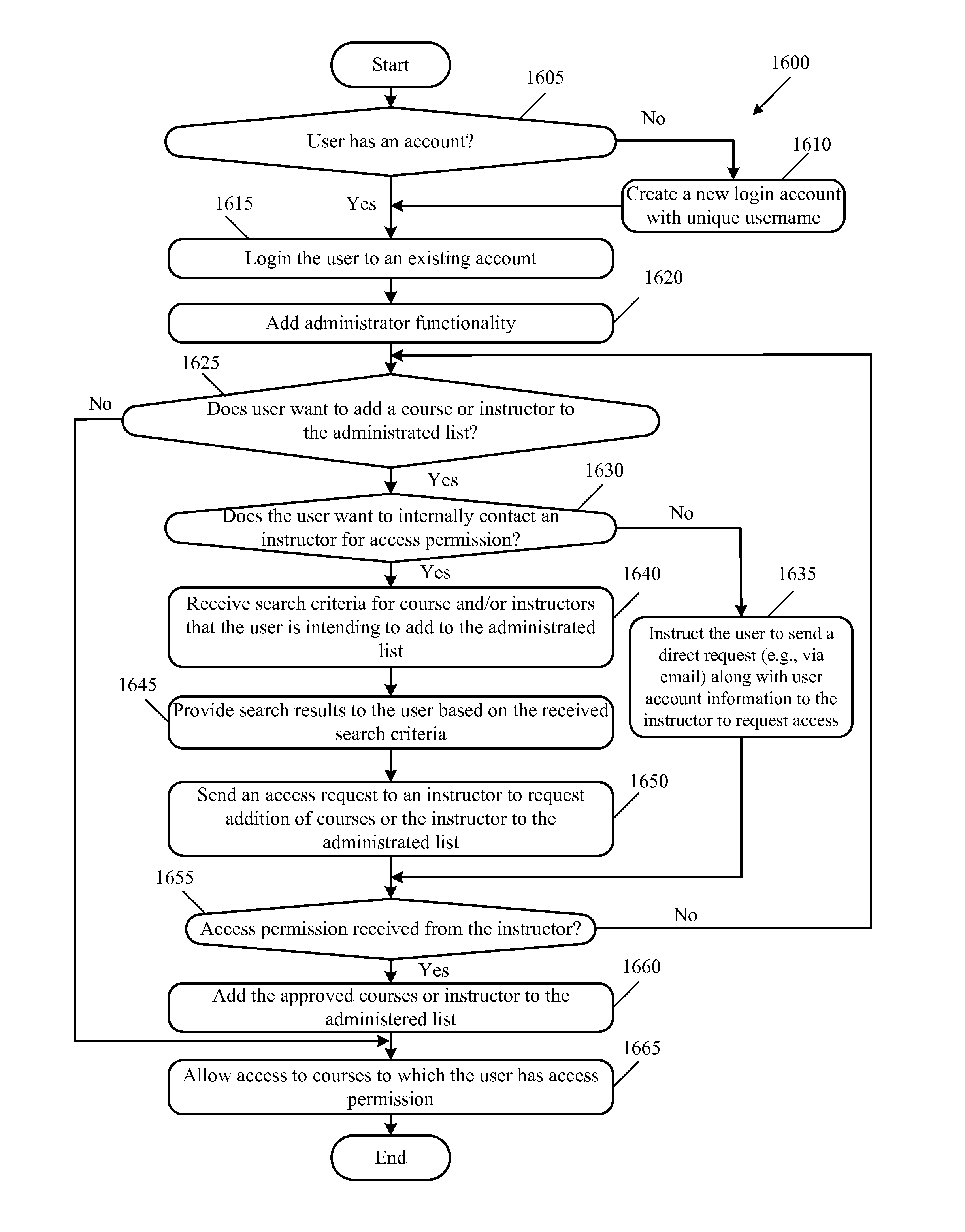

Online course and learning material management system and methods are provided where students, instructors, publishers, administrators, publishers, software vendors, and industry partners utilize the disclosed systems' databases and networking features to interact, to network, to improve learning outcome, and to exchange information elements. The system furthermore allows for networking among different user categories based on users' roles, professional profiles, and professional interests.

Owner:DELART TECH SERVICES

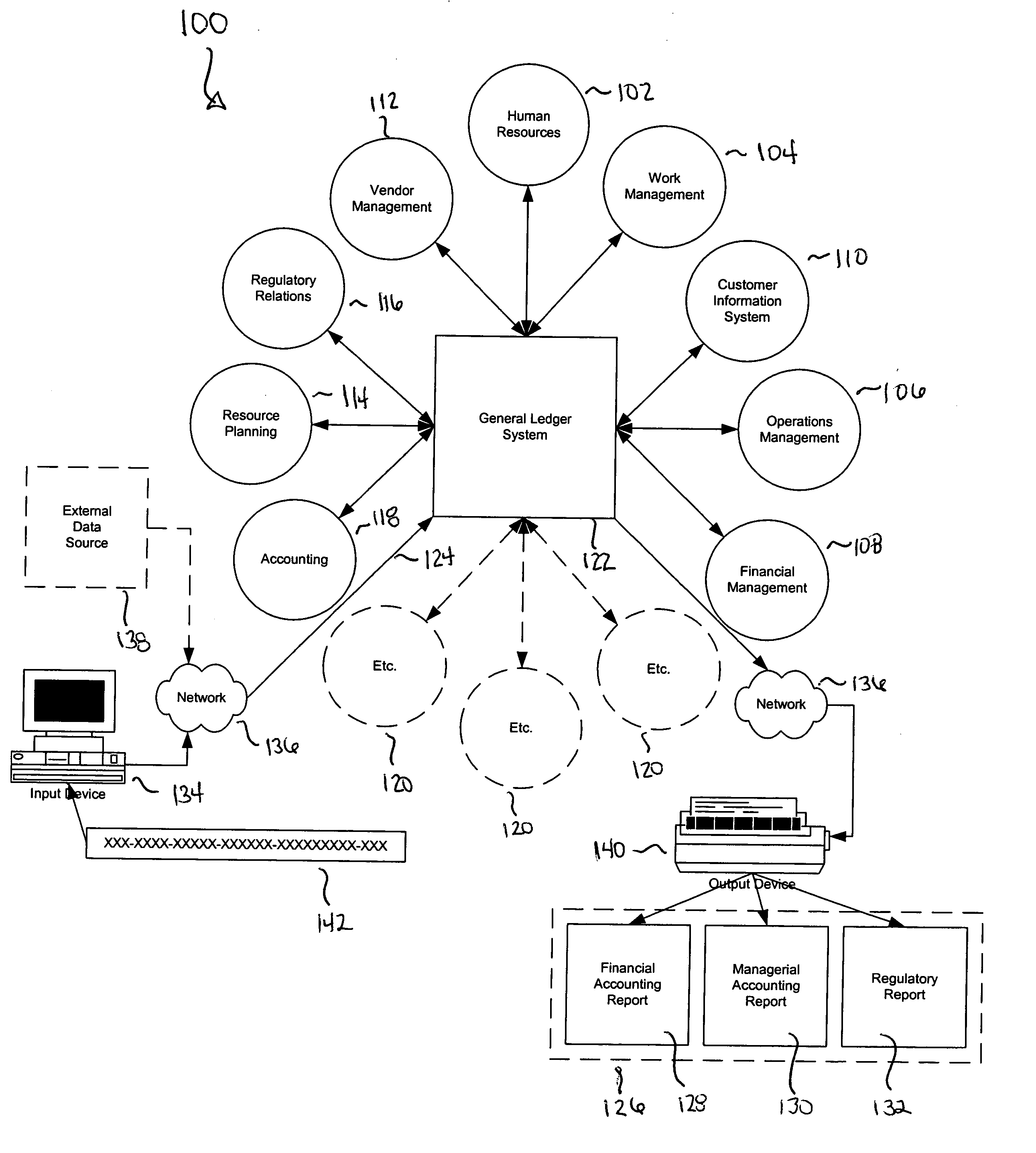

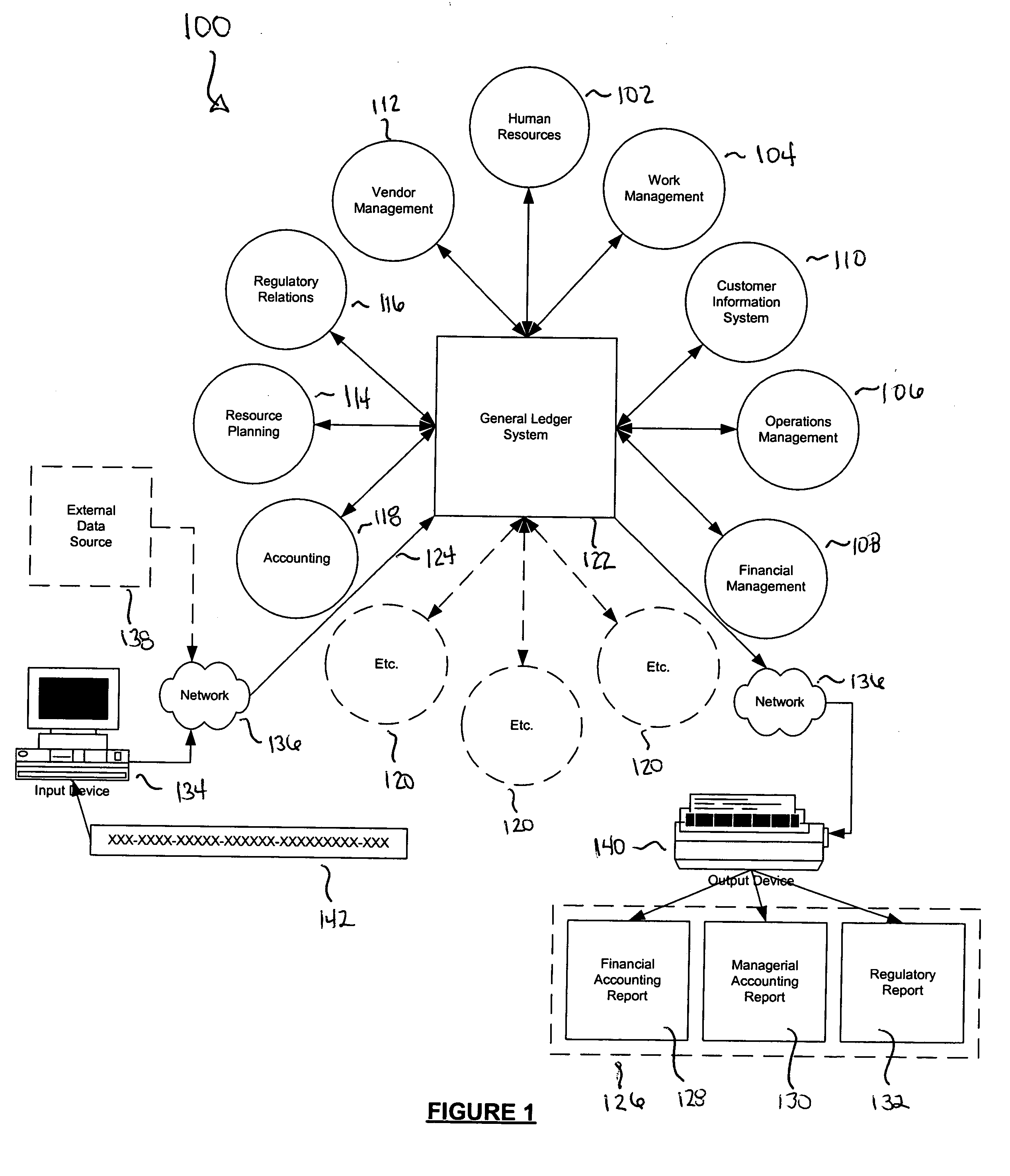

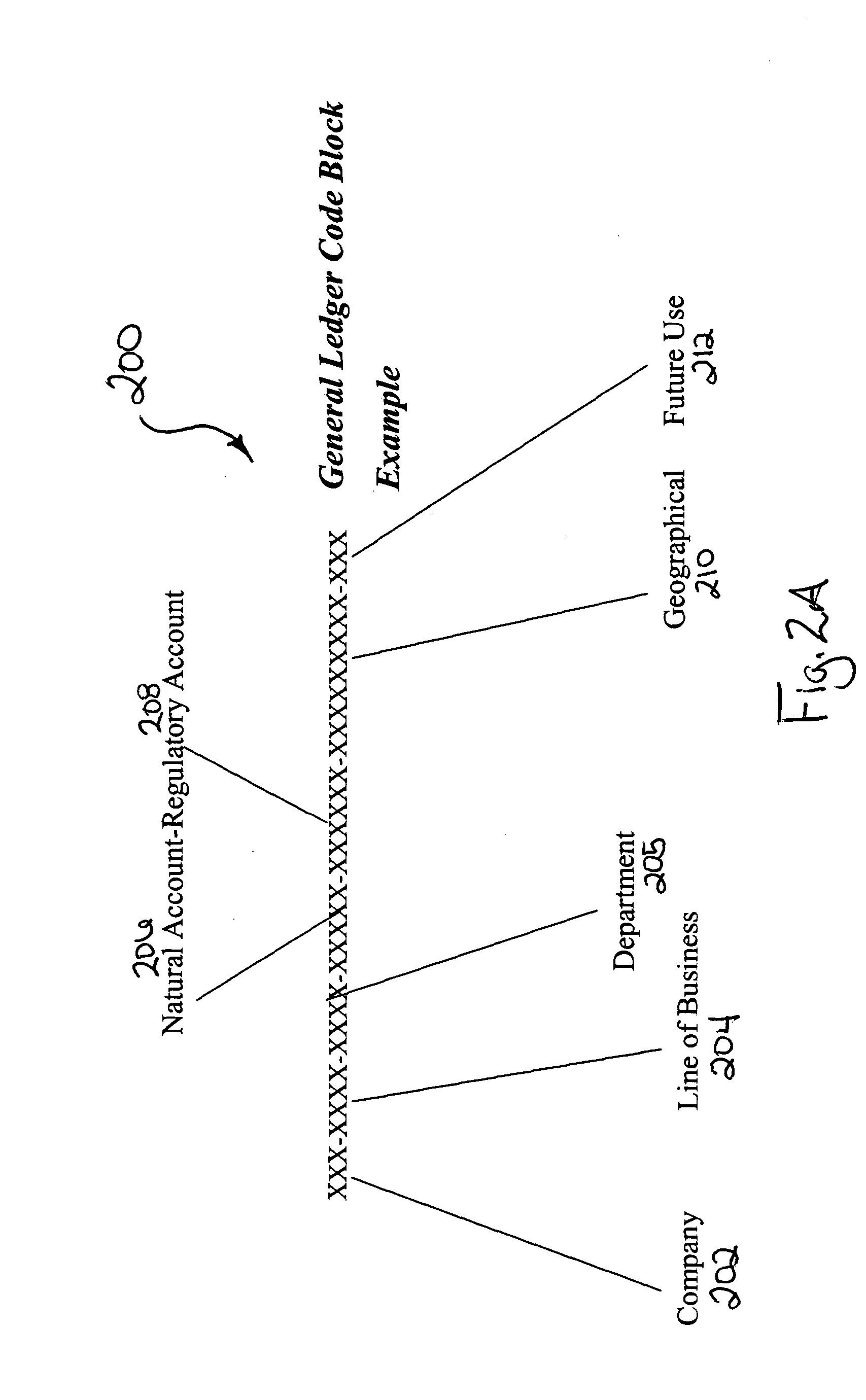

Integrated utility accounting, materials management, work management and regulatory reporting software

InactiveUS20050038721A1Avoid mistakesNeed to accountComplete banking machinesFinanceLevel of detailSoftware system

The invention is an integrated software system that provides one set of books for work management, accounting and regulatory reporting functions. The account structure of the general ledger is shared across the various entities (or departments) of the utility such that they all record the same information about activities, transactions and balances, thus sharing the same ledger structure comprised of a very limited number of segments, generally five to seven. The segments form an account flexfield. Certain segments of the account flexfield, if not supplied, may be derived from the other segments. The system is based on commercially available database software and allows for single ledger entries that are integrated throughout the accounting and reporting system of the utility. Account flexfields are entered into the system at a certain level of detail, such as, for example, activity, work order, natural account and regulatory account levels and may be summarized at a level of detail other than the one entered. The system provides reports in either an accounting format (financial and managerial) or in the form required by regulatory bodies without having to re-enter or reconcile data or keep separate sets of books.

Owner:WEBSOURCEIT

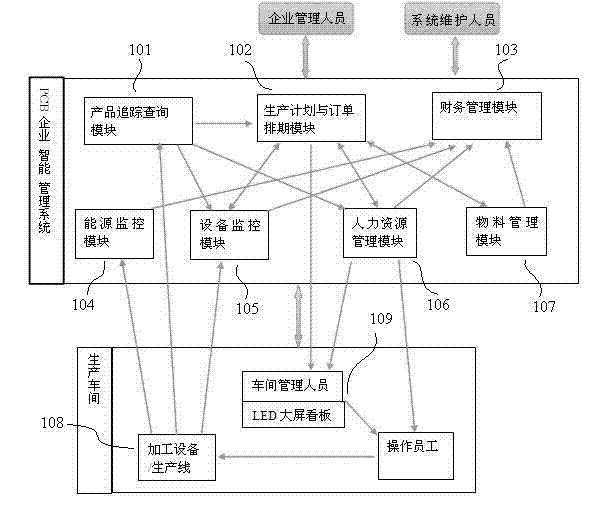

Intelligent management system of flexible production enterprise

InactiveCN104331770AReduce manufacturing costMonitor usage in real timeTechnology managementResourcesHuman resource managementProgram planning

The invention provides an intelligent management system of a flexible production enterprise. The system comprises a product tracing inquiry module, an order management and production planning module, an equipment monitoring module, a material management module, an energy monitoring module, a human resource management module, a financial management module and an information exchange platform, wherein the product tracing inquiry module is used as a basis and the order management and production planning module is a core to intelligently realize automatic generation of a production plan, whole-course on-line tracing recording of a processing process, monitoring of equipment and hydroelectric energy and plan management of human, material and money. By using the intelligent management system of the flexible production enterprise, the flexible production enterprise can perform true product quality tracing, master the use conditions of the equipment and the hydroelectric energy in real time and fully utilize the capacities of the equipment, the human, the energy and the like of the enterprise, so that the production cost of the enterprise is reduced.

Owner:叶校然

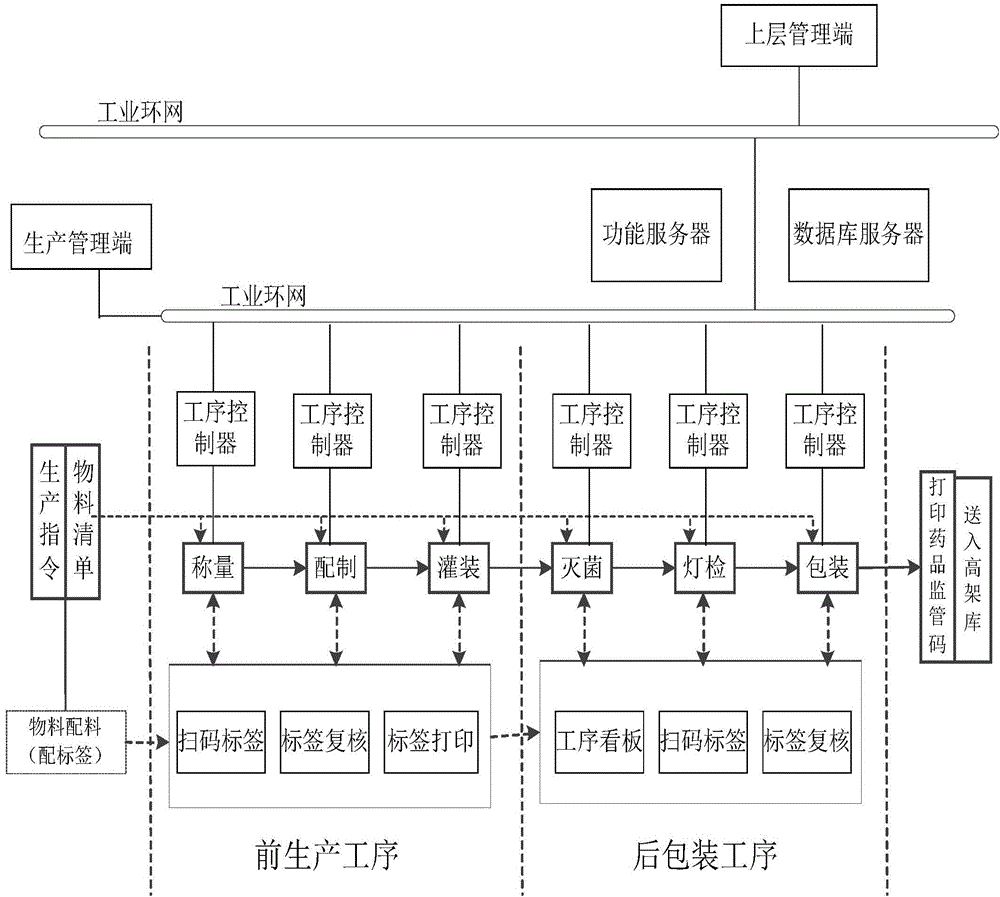

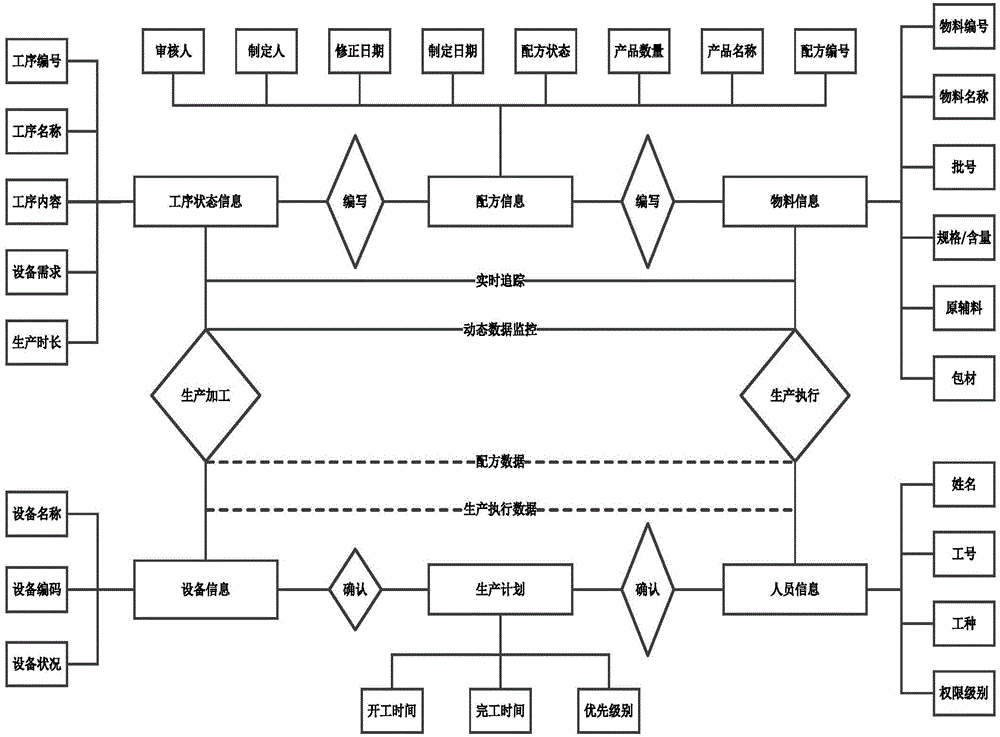

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Intelligent material warehousing and fetching method

The invention discloses an intelligent material warehousing and fetching method. The method comprises the following steps: coding the material; delivering a material tray filled with the material to a material placement platform at a material inlet window of an intelligent warehouse by a loader; automatically capturing the material by a manipulator of the intelligent warehouse and storing the material to a freight space in the intelligent warehouse, of which the address is designated by a material management software system; when the material is discharged, fetching the material tray at the freight space address designated by the warehousing system by the manipulator and delivering the material tray to a material conveyor belt of the intelligent warehouse; conveying the material tray to a discharge hole of the intelligent warehouse through the material conveyor belt to finish material discharging from the intelligent warehouse. The intelligent material warehousing and fetching method disclosed by the invention combines the intelligent warehouse with the material management software system to realize accurate storage and fetch of multiple materials or the single material, is high in degree of automation, free of wrong material fetching or material loss, capable of reducing the idle stock problem, and high in material storage and fetch efficiency, saves labor, and is beneficial to improvement of the production efficiency and reduction of the production cost.

Owner:SUZHOU I STOCK INTELLIGENT TECH

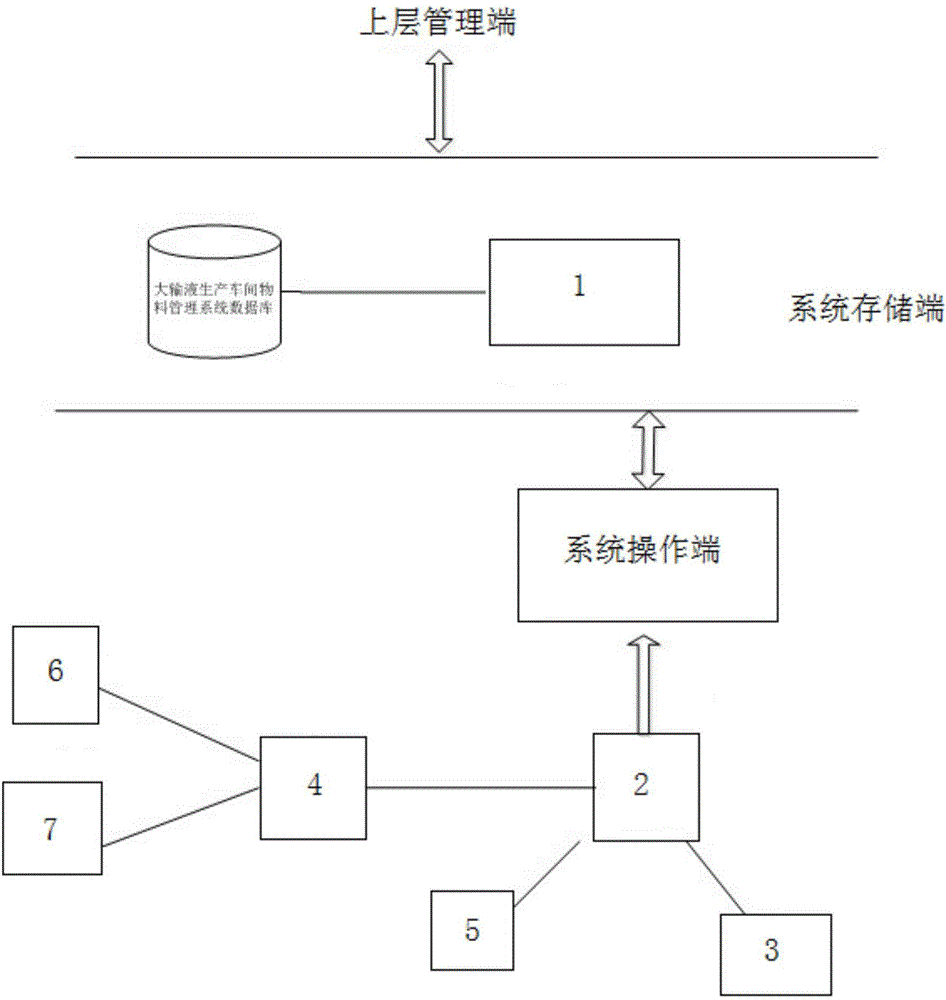

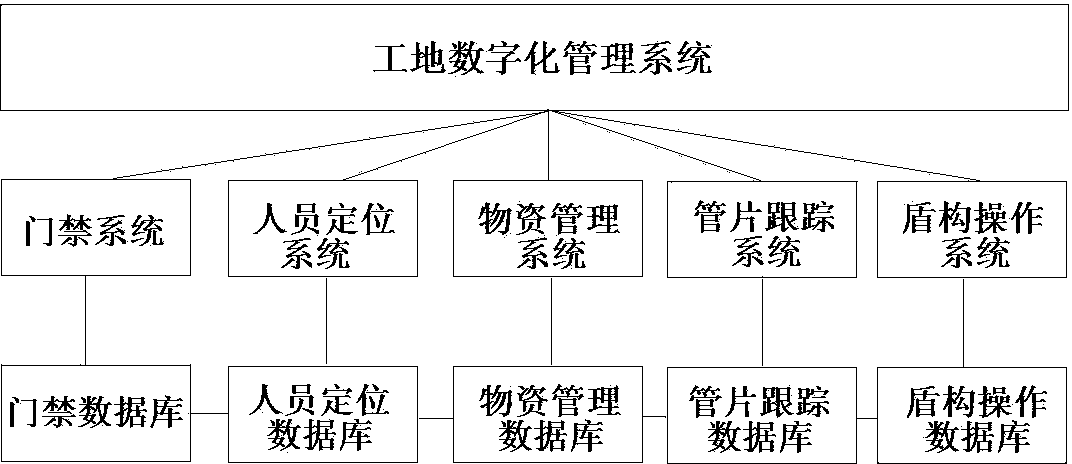

Construction site digital management system and application method thereof

ActiveCN103390255AGuarantee quality and safetyGuarantee authenticityData processing applicationsSensing record carriersOperational systemDigital rights management

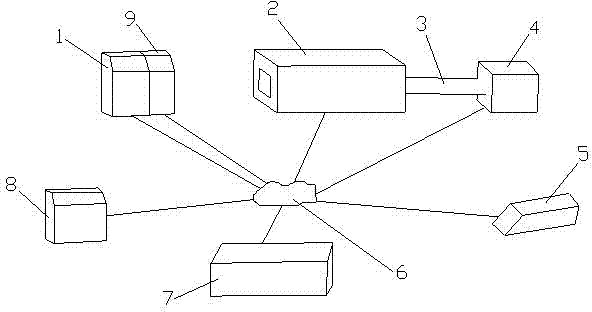

The invention belongs to the technical field of construction site digital management and particularly relates to a construction site digital management system and an application method thereof. The management system comprises five sub systems, namely, a PLS (personnel location system), an access control system, a material management system, a shield operating system and a duct piece tracking system, wherein all the sub systems are connected with a remote database server, five sub database corresponding to the five sub systems are established in the remote database server, all the sub systems perform read-write operation on a main management object in a construction site range by using an RFID (radio frequency identification) technology, read data are uploaded to all corresponding sub databases in real time, and the operating authorization of a handheld RFID read head and the operating authorization of a shield machine are obtained through cross verification of data among all main sub databases. The management system and the application method have the advantages as follows: conventional extensive management is improved, the management responsibility is cleared, the management level is improved, and engineering information management, digital management and visual management are realized.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

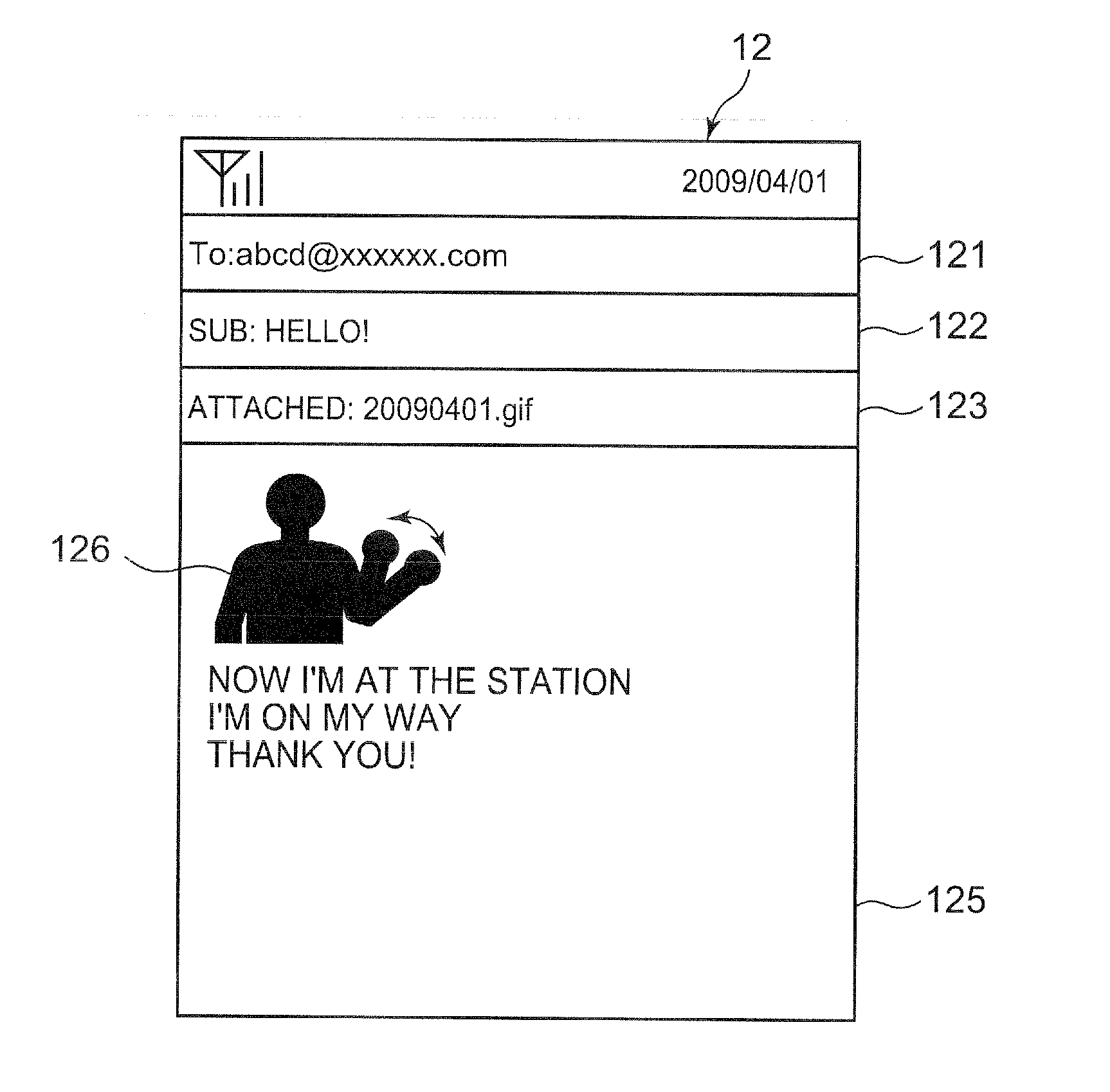

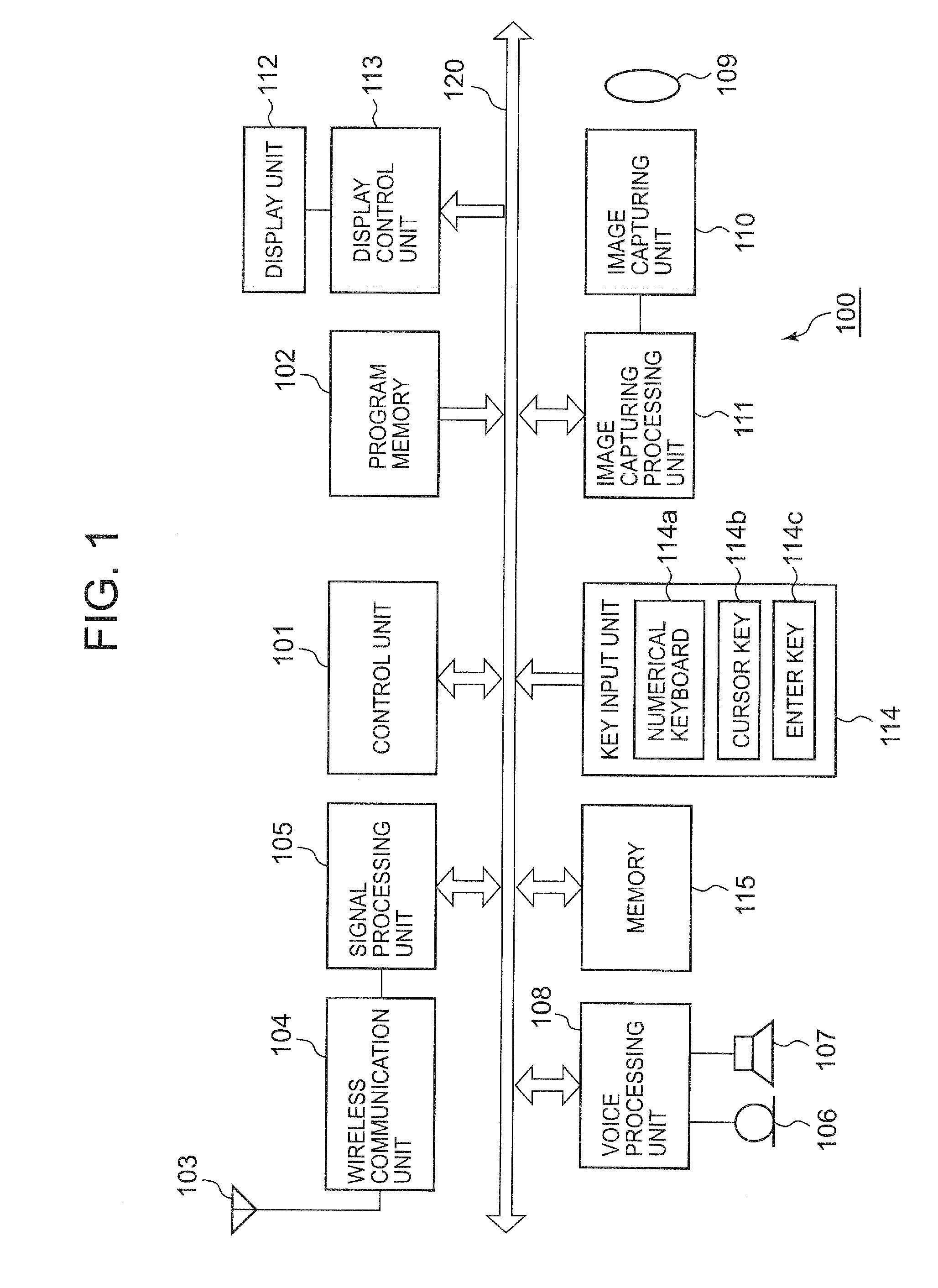

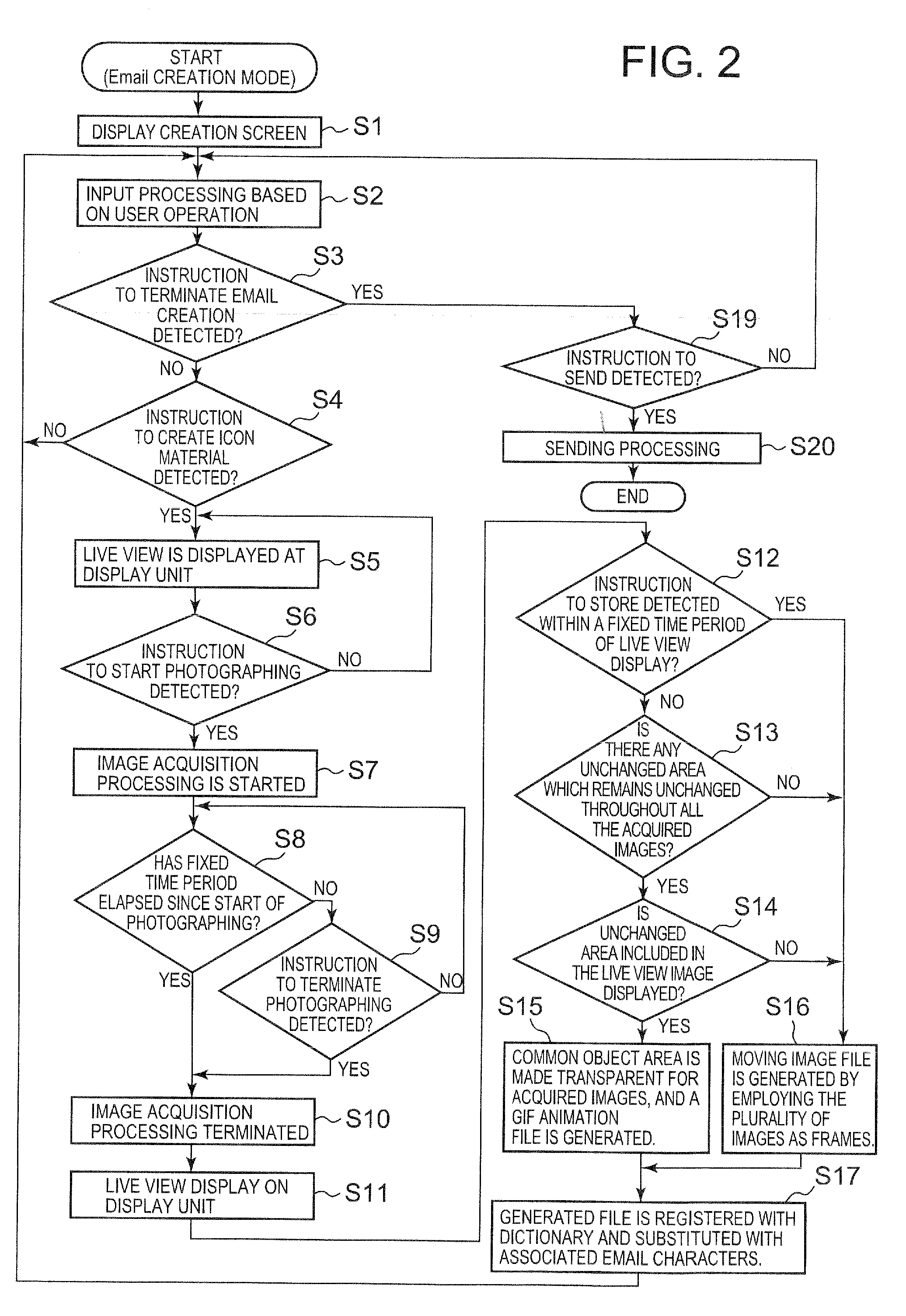

Mobile terminal, icon material management system, and icon material management method

InactiveUS20110176010A1Television system detailsColor television detailsImaging processingComputer graphics (images)

A mobile terminal 100 includes an image capturing unit 110, an image processing unit 111, a control unit 101, and a key input unit 114. The image capturing unit 110 captures an image. The image processing unit continuously drives the image capturing unit and acquires data of a plurality of images. The control unit 101 generates decorative data based on the plurality of image data, the decorative data including image data indicative of an image having only an object common to the plurality of images nontransparent. The key input unit 114 inputs a character from an external operation. The control unit 101 determines whether or not character information associated with decorative information is contained in a text constituted by the character information inputted by the key input unit 114, and substitutes the character information with the decorative data associated therewith if it is determined that the character information is included.

Owner:CASIO COMPUTER CO LTD

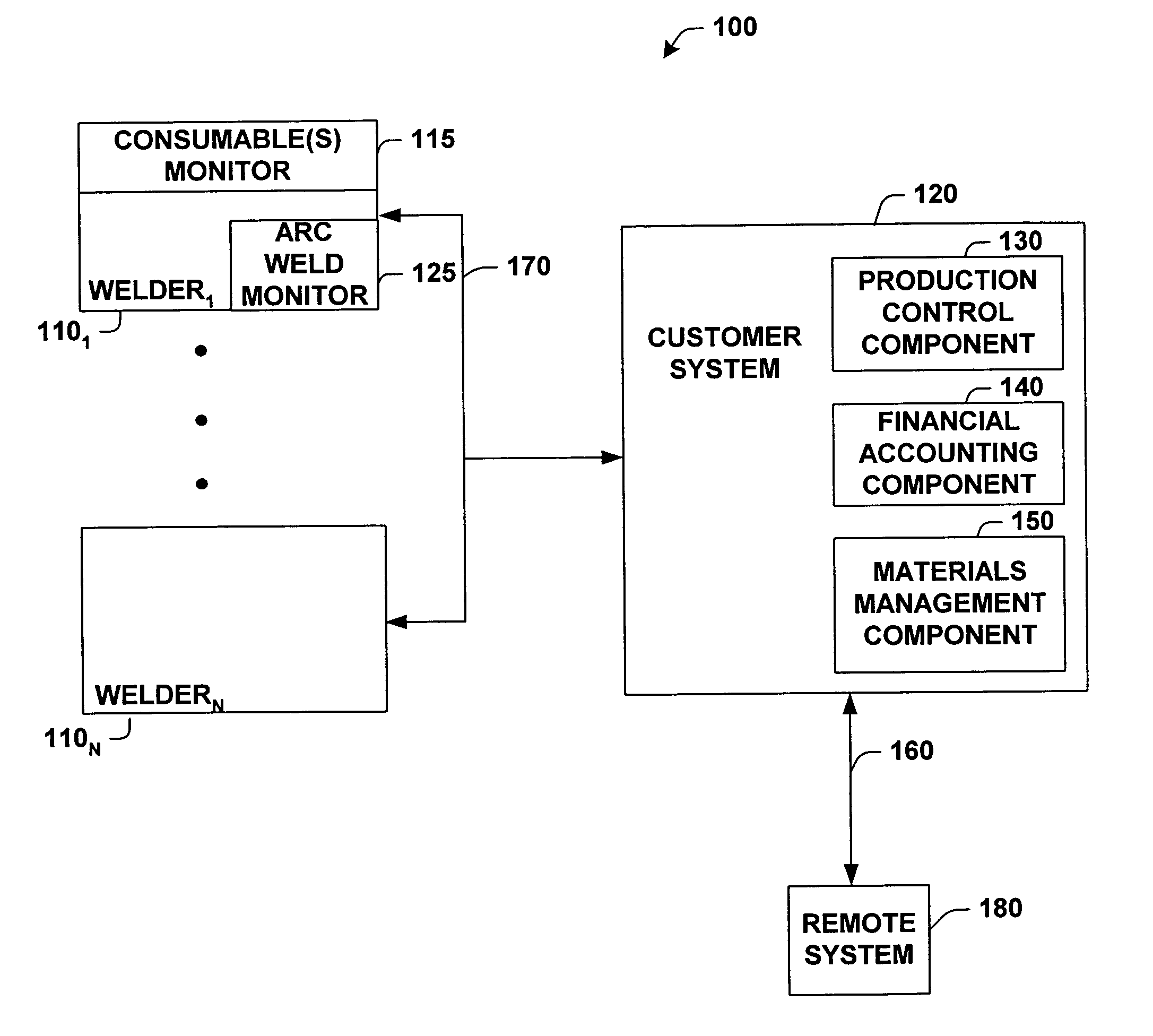

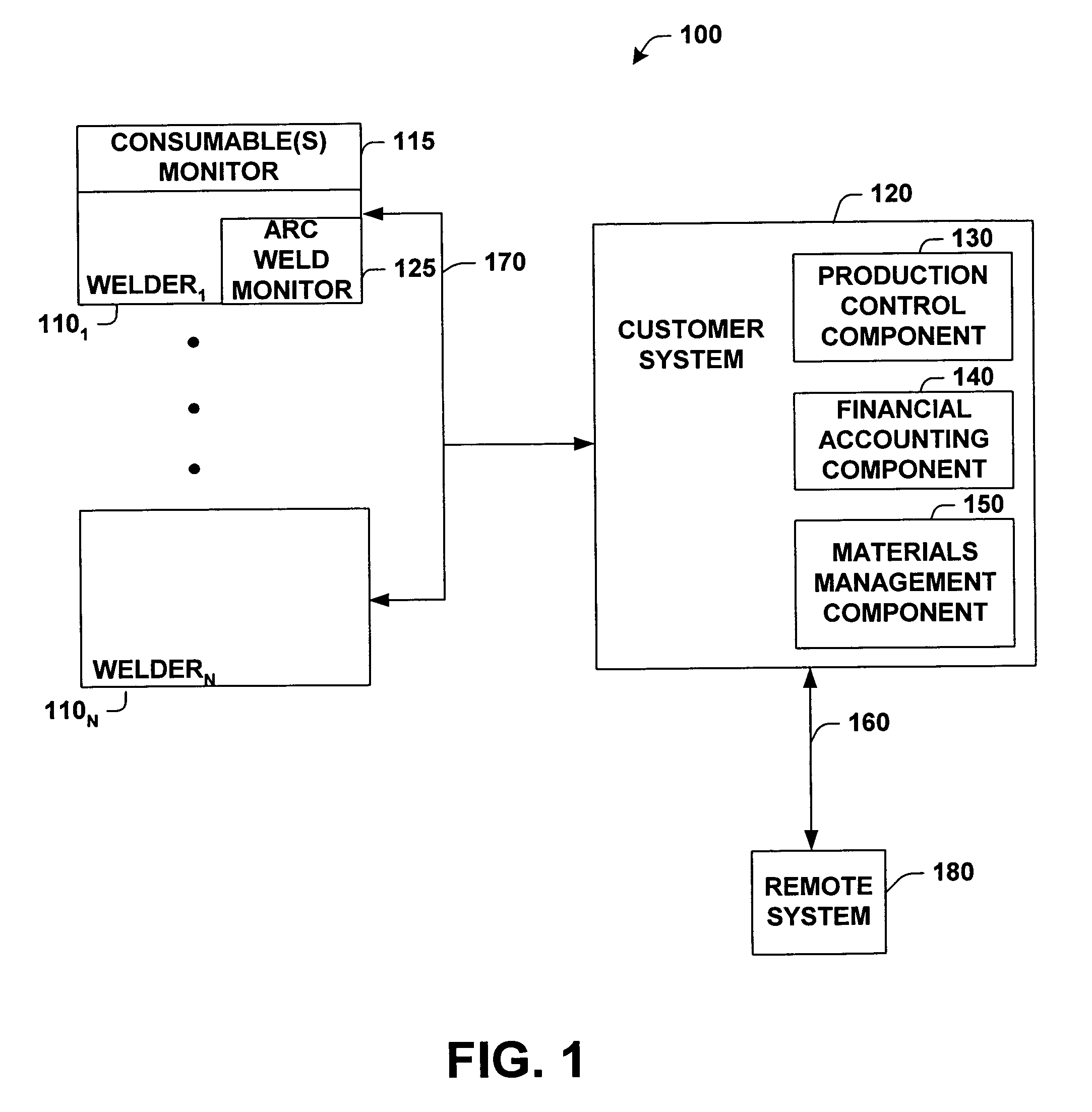

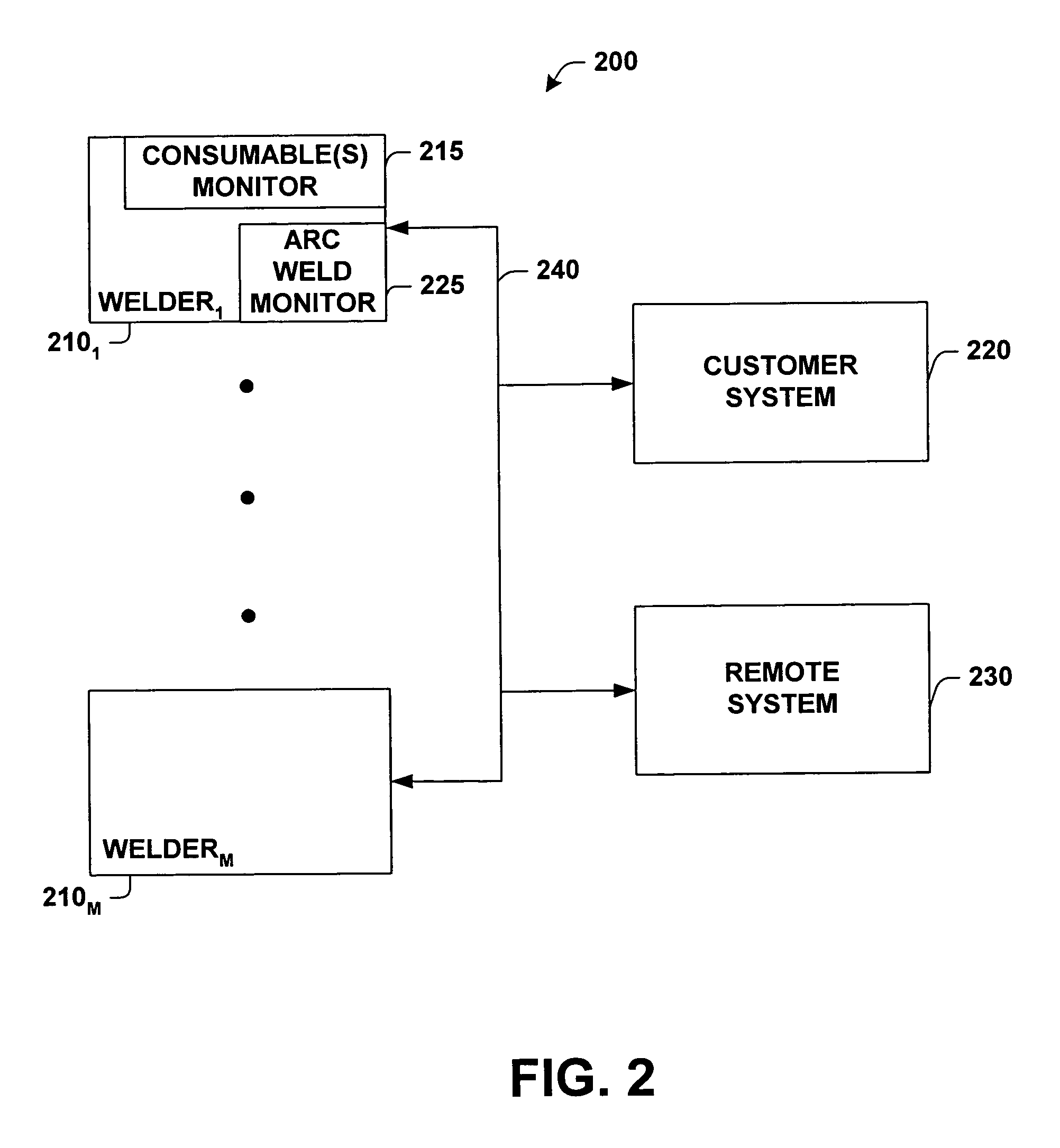

System and method for managing welding consumables

InactiveUS7761336B1Facilitate inventory controlDecrease stockArc welding apparatusElectron beam welding apparatusRemote systemInvoice

A system and method for managing welding consumable(s) is provided. The invention includes a welder having a consumable(s) monitor, a customer system and / or a remote system. The invention further provides for monitoring of welding consumable(s) usage and ordering of welding consumable(s) from suppliers, distributors and / or manufacturers. The invention further provides for an optional arc / weld quality monitor that provides information regarding weld quality. The invention further provides for invoicing a customer for welding consumable(s) as the consumable(s) are used by the customer. The invention further provides for invoicing of customers for welding consumable(s) that produce acceptable welds. The invention further provides for remote management of customer welding consumable(s) inventory based at least in part upon information received regarding welding consumable(s) usage. The invention further provides for communication with a production component, financial accounting component and / or materials management component in order to facilitate automation of welding consumable(s) management.

Owner:LINCOLN GLOBAL INC

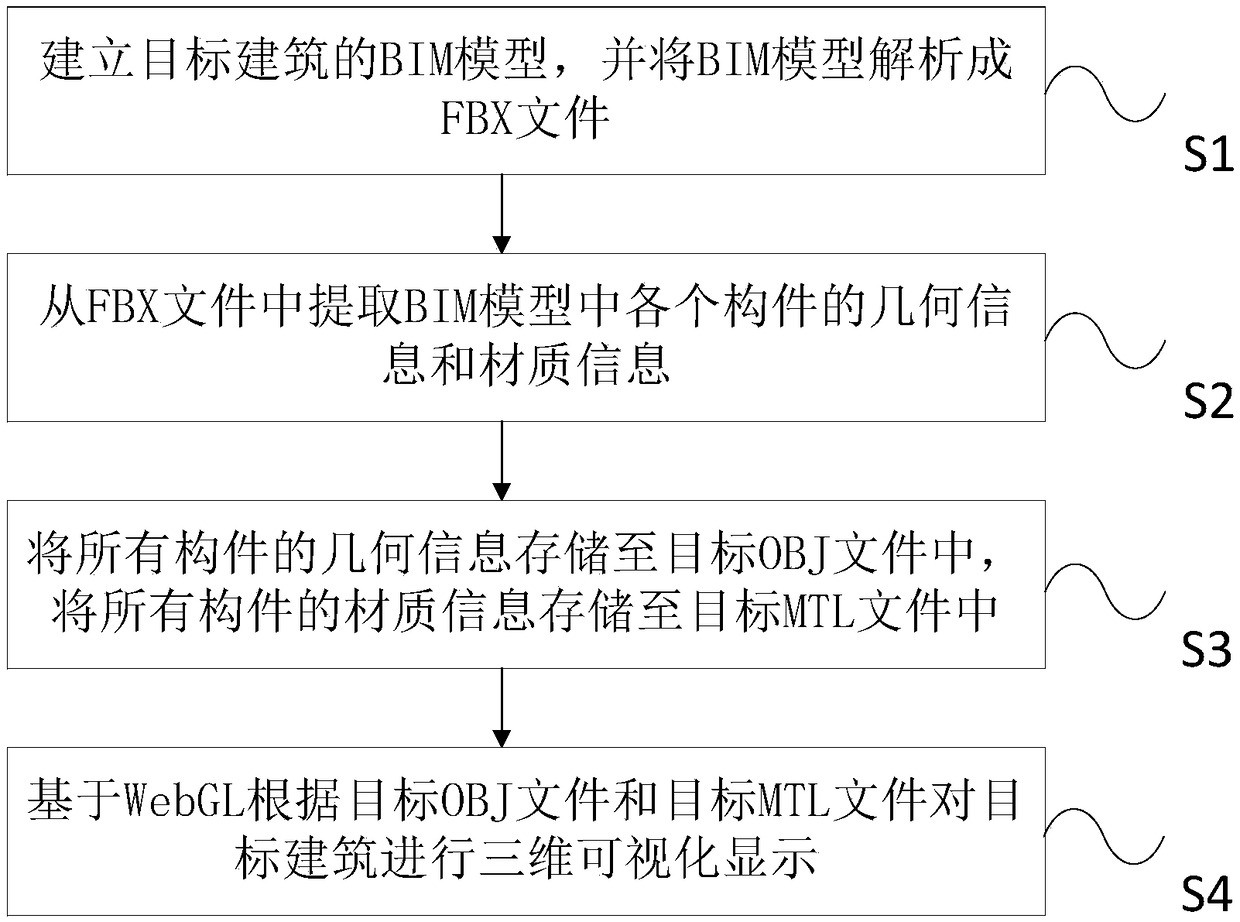

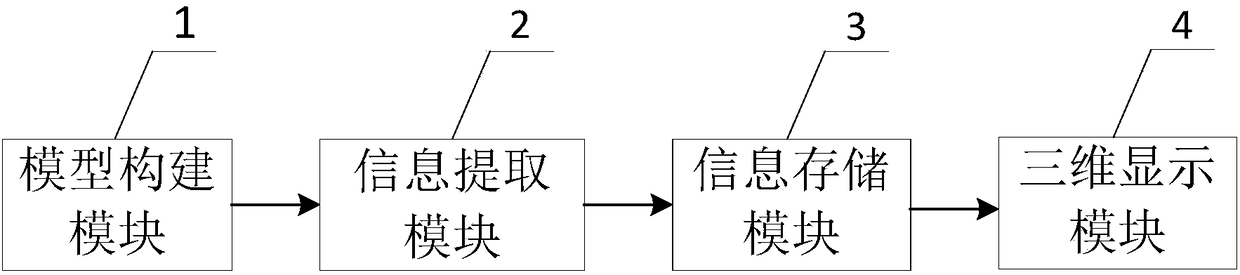

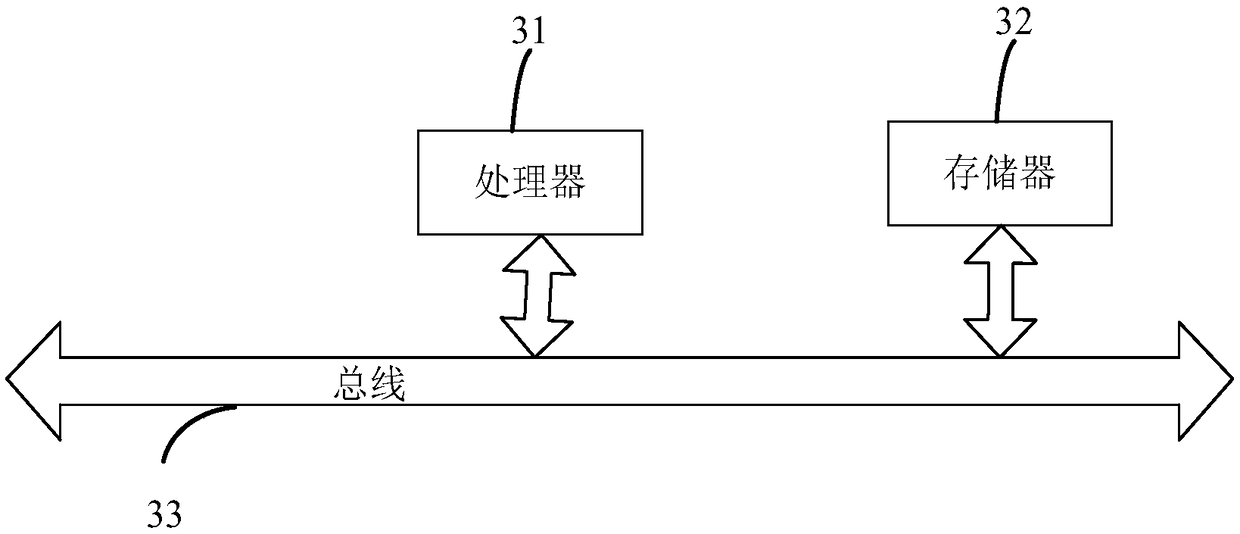

Method and system for building information modeling light weight and three-dimensional scene visualization

ActiveCN108710739AAchieve lightweightReduce redundancyGeometric CADSpecial data processing applicationsComputer terminalMaterials management

The invention provides a method and a system for building information modeling light weight and three-dimensional scene visualization. The method comprises the following steps that: establishing the BIM (Building Information Modeling) of a target building, and analyzing the BIM into an FBX (FilmBoX) file; extracting the geometric information and the material information of each construction memberin the BIM from the FBX file; storing the geometric information of all construction members into a target OBJ file, and storing the material information of all construction members into an MTL (Material Management System) file; and on the basis of a WebGL (Web Graphics Library), according to the target OBJ file and the target MTL file, carrying out three-dimensional visualization display on the target building. By use of the method and the system, target BIM light weight is effectively realized, the redundancy of the BIM data is lowered, and efficiency for the intelligent mobile terminal to organize and display the BIM data can be improved to a certain degree. In addition, the three-dimensional visualization display of the target building on the intelligent mobile terminal can be served as a basic three-dimensional map of indoor positioning, and a foundation is laid for realizing the indoor positioning of the intelligent mobile terminal.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

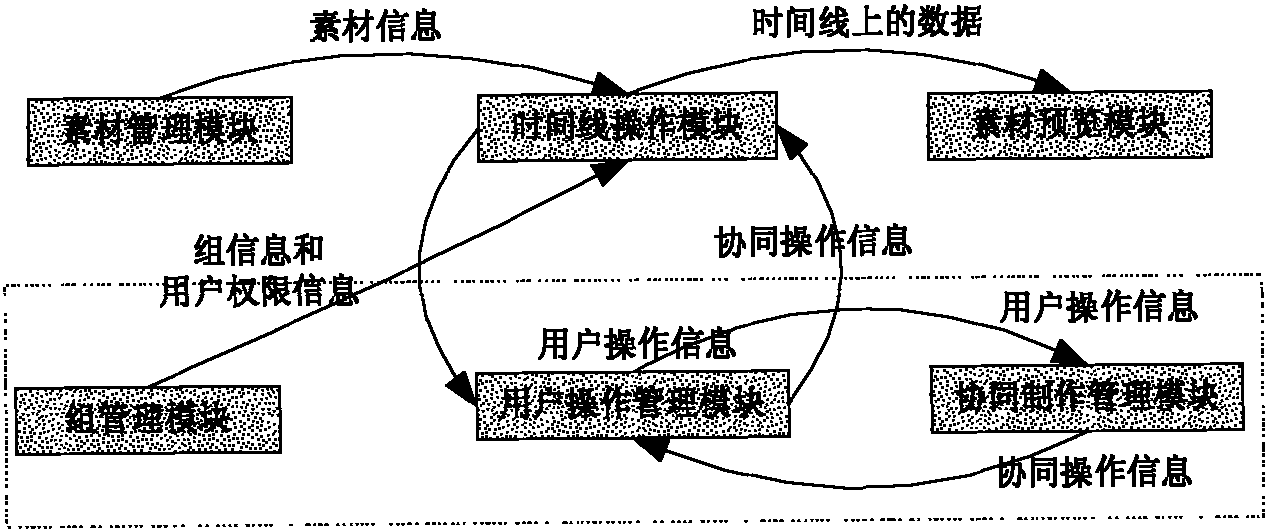

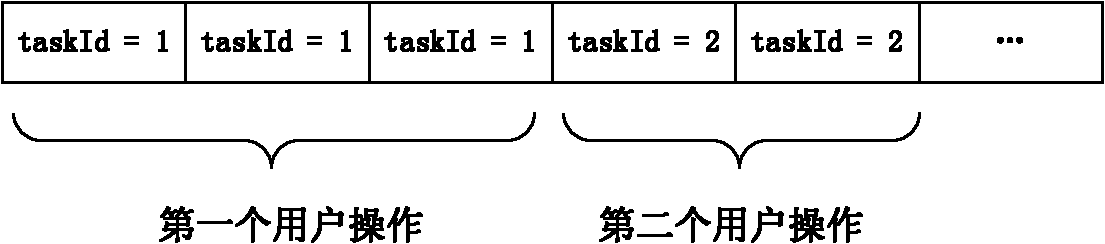

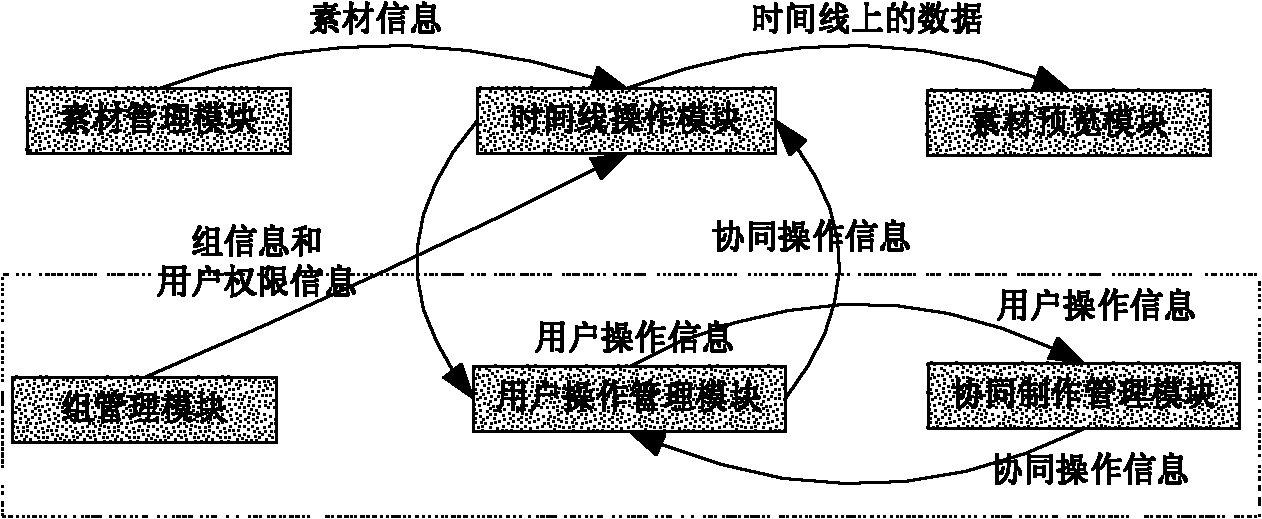

On-line collaborative nolinear editing system

ActiveCN102081946AAchieve sharingSolve the problem of collaborative editing and productionTelevision system detailsCarrier editingInformation processingTeam management

The invention discloses an on-line collaborative nolinear editing system belonging to the technical field of Internet media information processing. The on-line collaborative nolinear editing system comprises a manufacture team management module, a material management module, a timeline operation module, a material previewing module, a user operation management module and a collaborative manufacture management module. Edition operation for respective video of each person is shared by the on-line collaborative nolinear editing system to realize the on-line collaborative nolinear edition system for more people, the efficiency on collaborative edition manufacture of the on-line video program is improved, and the collaborative edition manufacture for more people under different environments can be realized.

Owner:SHANGHAI NAT ENG RES CENT OF DIGITAL TELEVISION

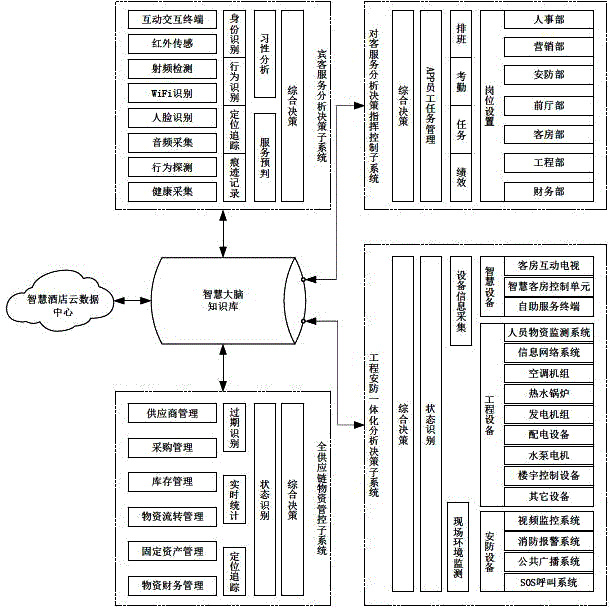

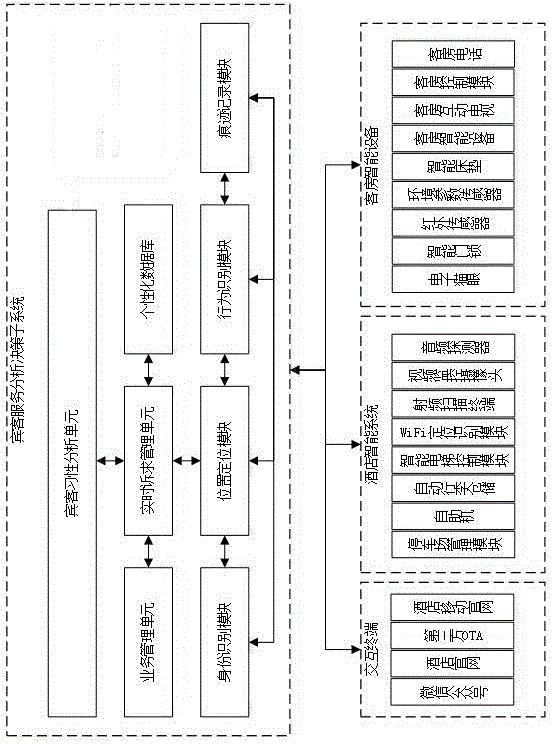

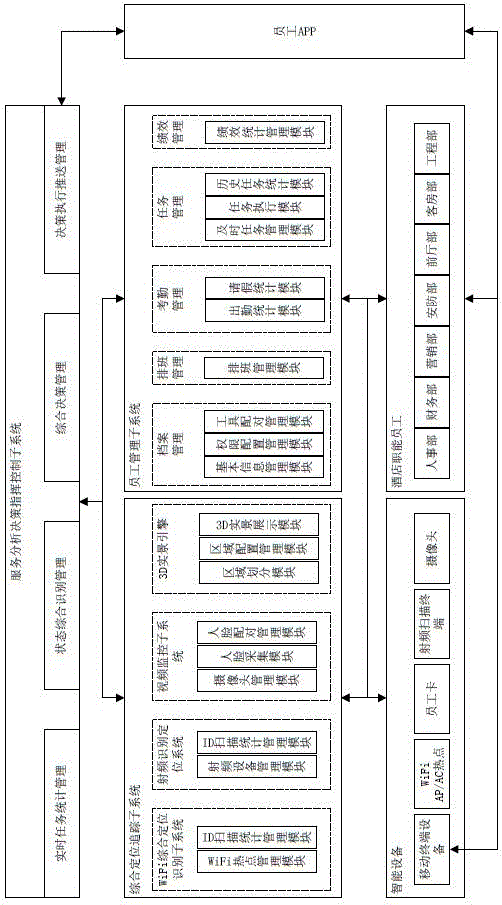

Intelligent hotel management system based on Internet of everything

InactiveCN106570641AImprove availabilityEfficient serviceResourcesTransmissionCommand and controlEcological data

The invention discloses an intelligent hotel management system based on the Internet of everything, which comprises an intelligent hotel cloud data center, an intelligent knowledge base and a plurality of intelligent hotel systems, and is characterized in that the intelligent hotel cloud data center is used for integrating hotel related data of all of the intelligent hotel systems and forming a database; the intelligent knowledge base is used for collecting data of the intelligent hotel systems in real time on the one hand, performing data interaction with the intelligent hotel cloud data center on the other hand, and performing analysis and decision-making on an intelligent hotel system according to field data of the intelligent hotel systems and the data integrated by the intelligent hotel cloud data center; and the intelligent hotel system comprises a guest service analysis and decision-making subsystem, a guest service analysis and decision-making command and control subsystem, a whole supply chain material management and control subsystem, an engineering security and protection integrated analysis and decision-making subsystem. The intelligent hotel management system explores values of data which includes facility and equipment operation data, guest behavior data and hotel business district ecological data; and real-time and accurate data enables hotel services and management decision-making to be more efficient and more scientific.

Owner:成都科曦科技有限公司

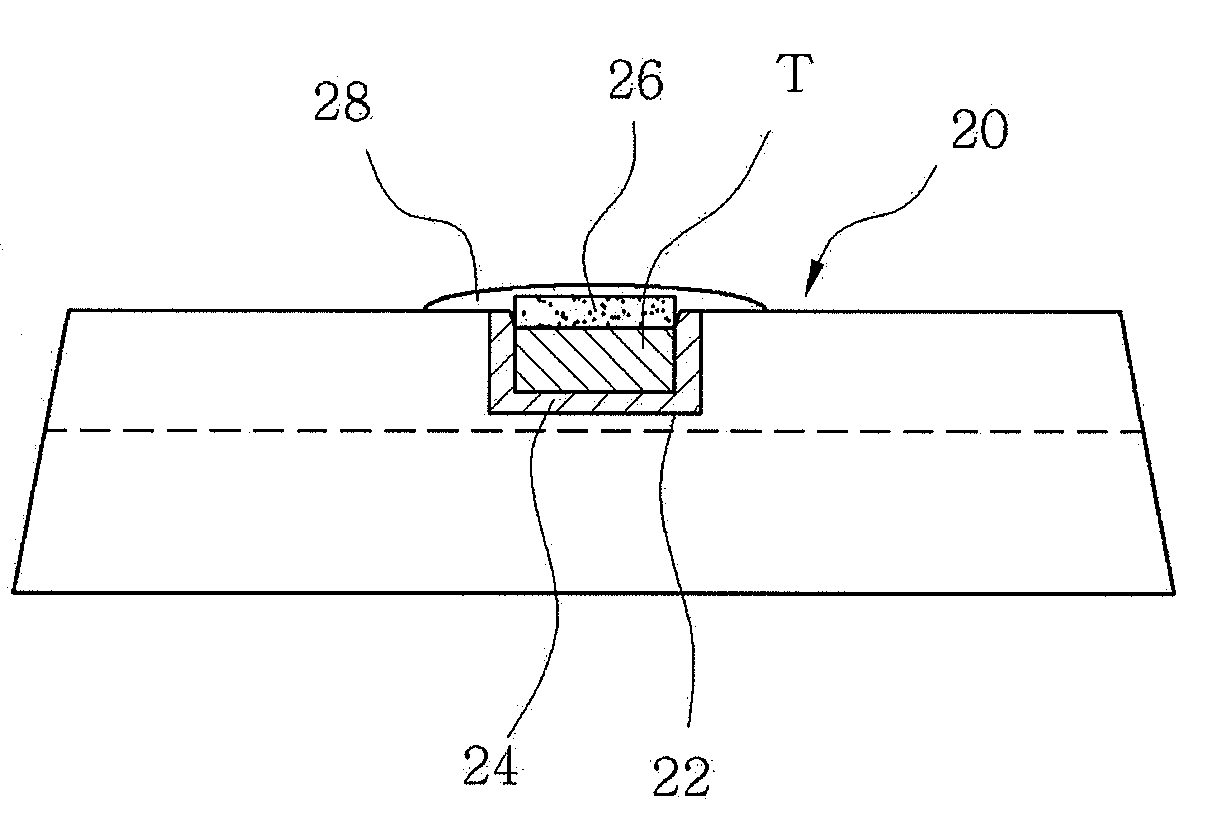

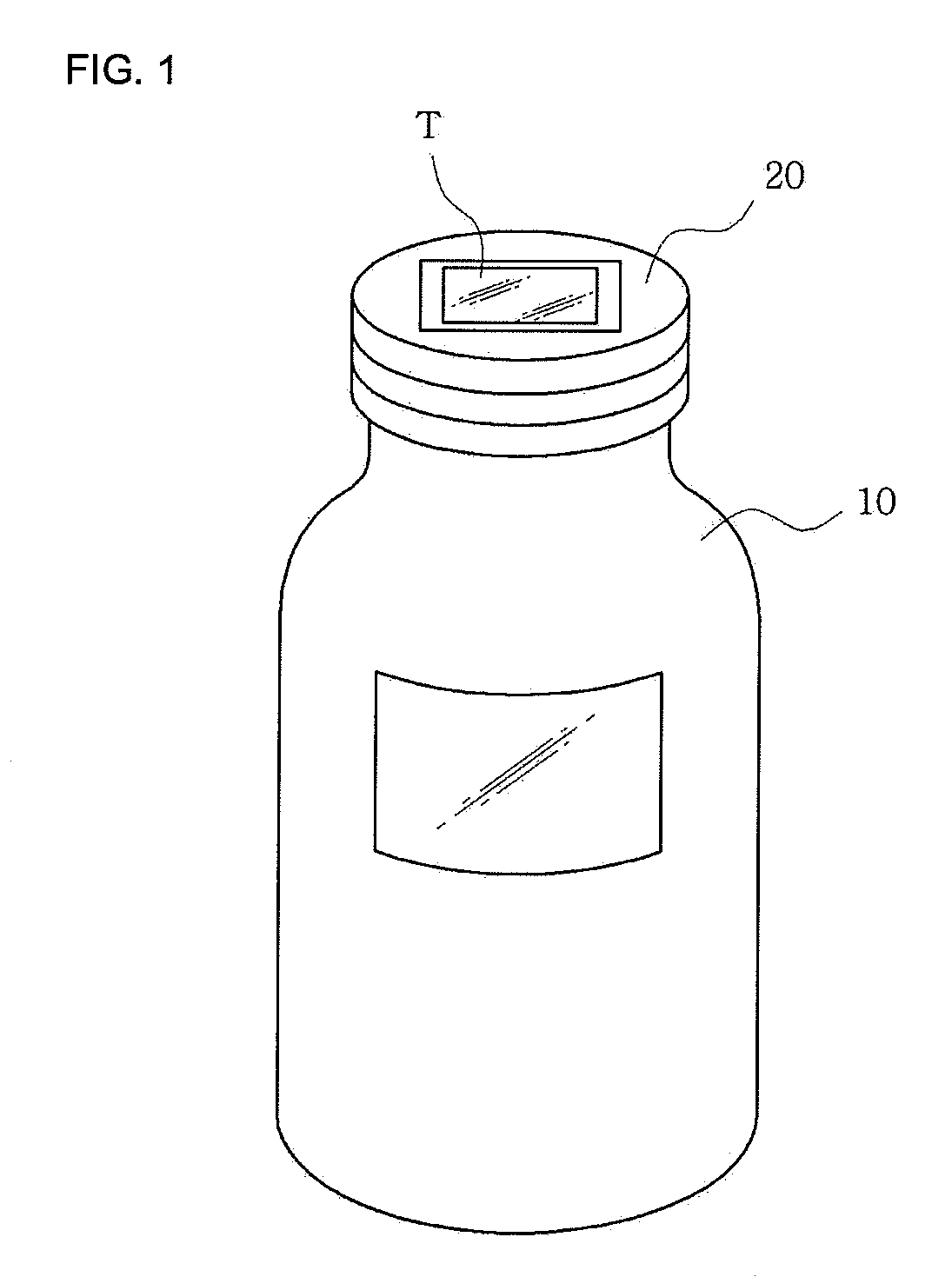

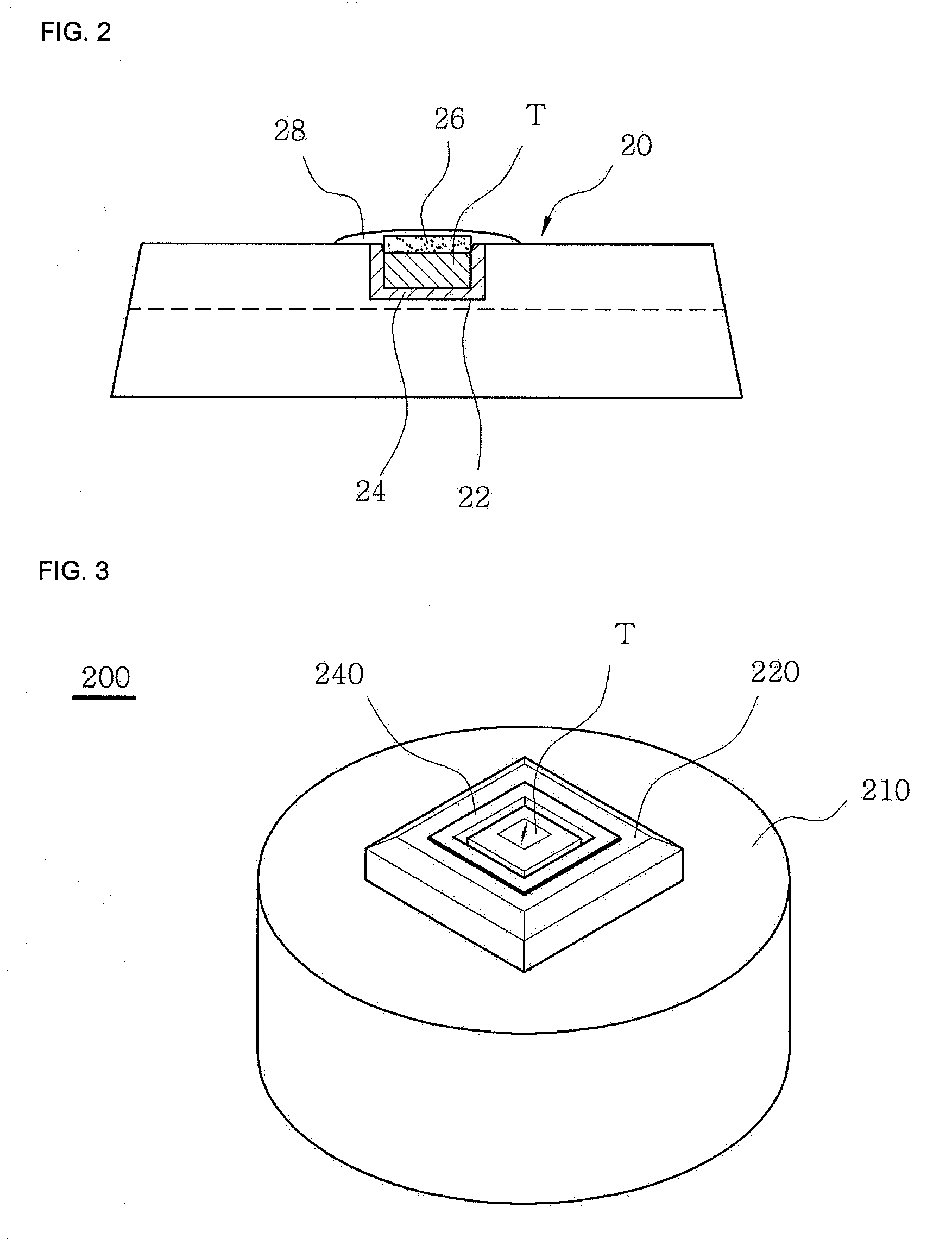

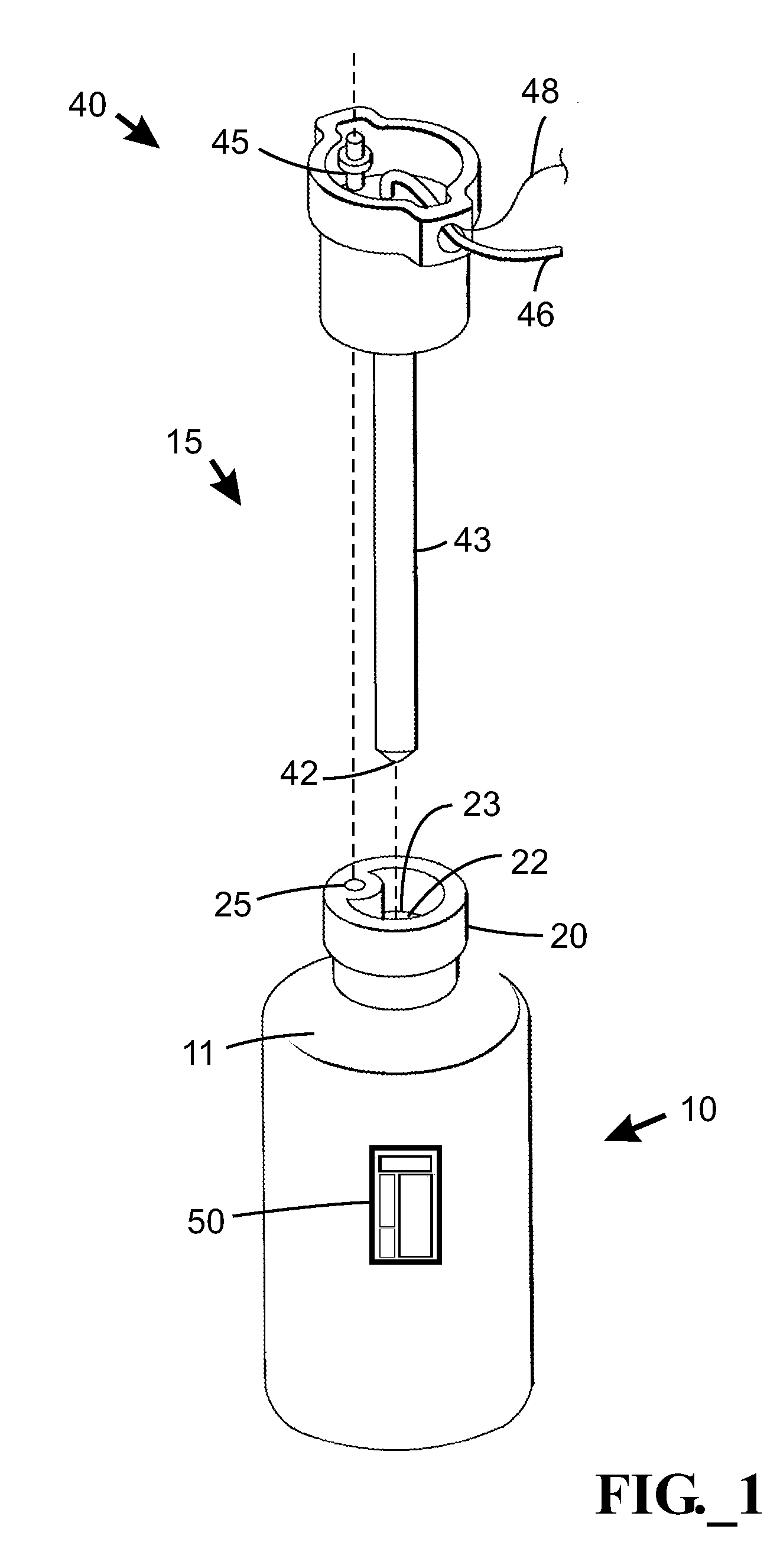

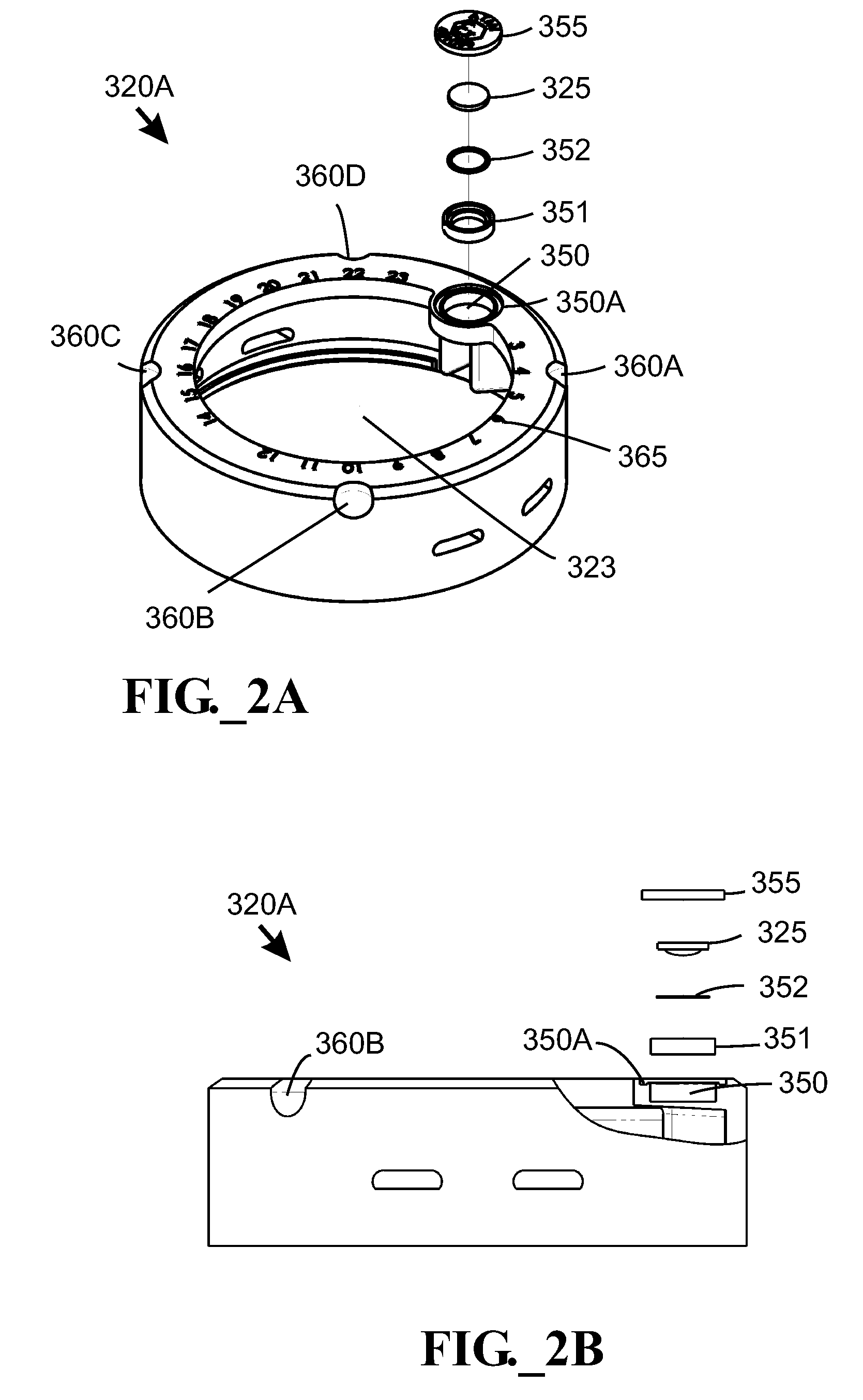

Container lid with a RFID tag

InactiveUS20100102967A1Easy to installAvoid failureContainer decorationsLevel indicationsEngineeringInventory management

The present invention provides a container lid with a removable built-in RFID tag which makes it easy to perform general management, such as information management, inventory management, use list management, hazardous material management, etc., of contents stored in the container. The container lid with the RFID tag according to the present invention includes a main body which covers an open end of a container, and a tag mount which protrudes from the upper surface of the main body. The tag mount is open on the upper end thereof and has therein an installation space, into which the RFID tag is inserted through the open upper end of the tag mount. The container lid further includes a tag holder which holds and supports the RFID tag in the tag mount, and a tag mount cover which covers the open upper end of the tag mount.

Owner:MINISTRY OF FOOD AND DRUG SAFETY

Method and system for collaborative on-line learning management with educational networking

InactiveUS20120231437A1Electrical appliancesMechanical appliancesKnowledge managementSoftware vendor

Online course and learning material management system and methods are provided where students, instructors, publishers, and industry partners utilize the disclosed systems' databases and networking features to interact and improve learning outcome. The system furthermore allows for networking among students, instructors, publishers, software vendors, and prospective employers.

Owner:FAKHRAI DELARAM

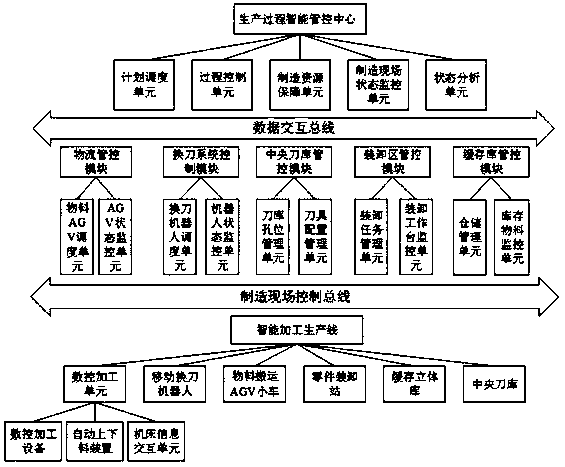

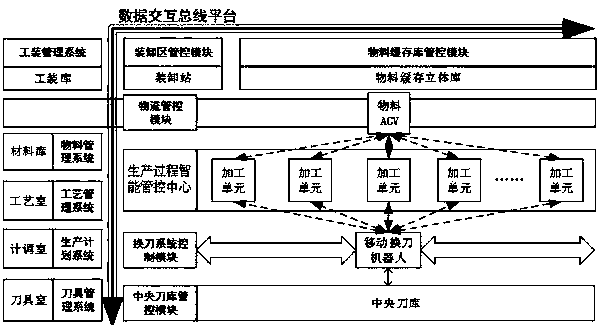

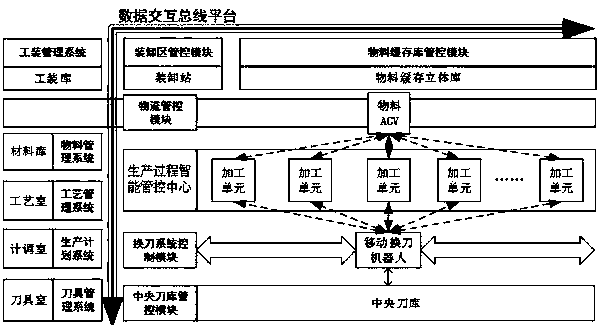

Intelligent control system for large-scale structural component automatic production line

ActiveCN109917770AReasonable architecture designRealize scientific managementElectric/hybrid propulsionTotal factory controlData acquisitionTool management

The invention discloses an intelligent control system for a large-scale structural component automatic production line. The intelligent control system is characterized by comprising an intelligent machining production line, a production process intelligent control center, a logistics control module, a tool change system control module, a central tool magazine control module, a loading and unloading area control module, a material cache library management module, a tooling management system, a material management system, a process management system, a production planning system and a tool management system. Through the reasonable design of the overall architecture, the intelligent control system structures the overall intelligent management and control mode of a workshop automation production line manufacturing site from three aspects of manufacturing site state data acquisition, process intelligent decision, and overall operational state analysis, so as to solve the large-scale structural component automatic production line manufacturing resources guarantee problem.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

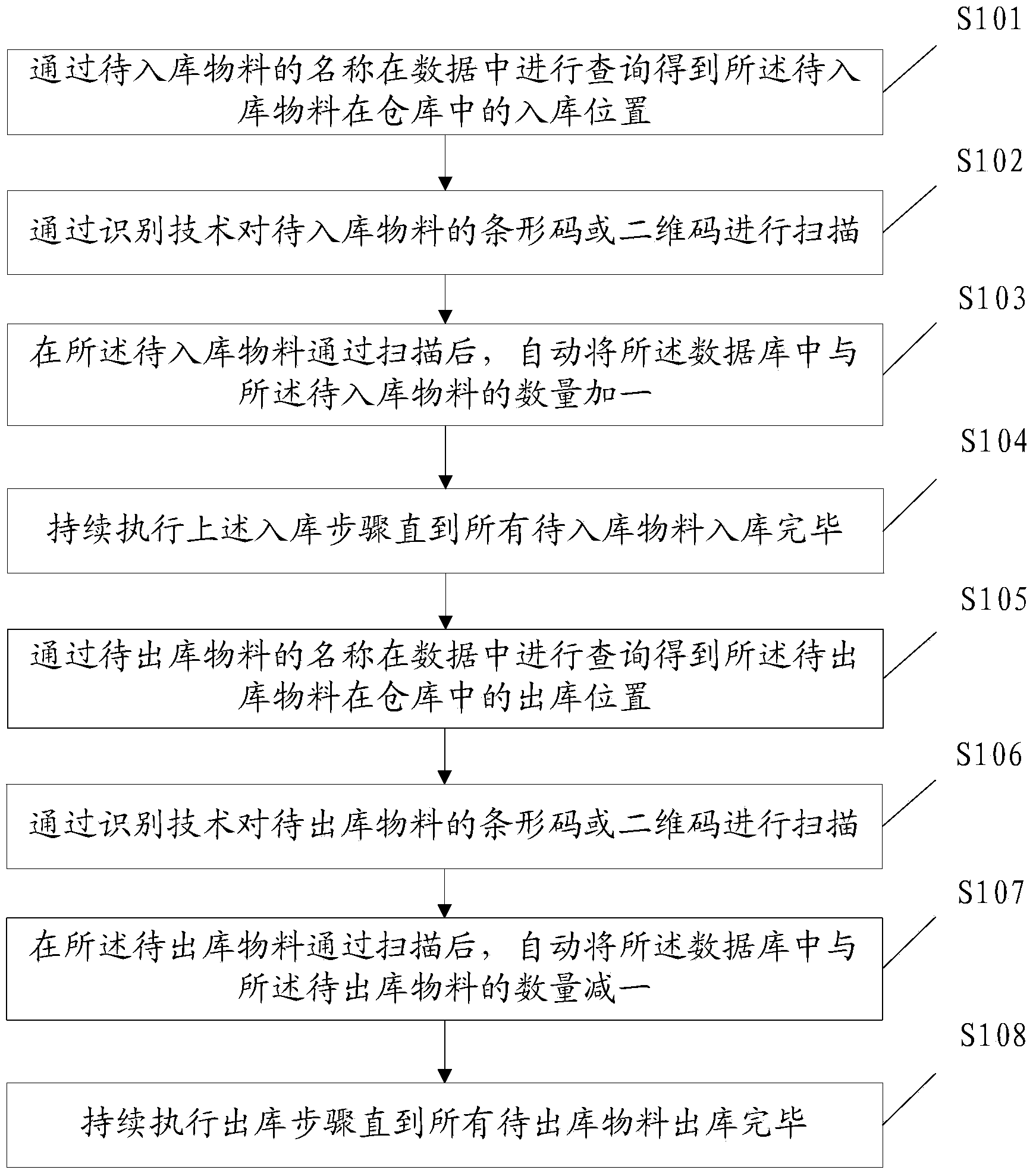

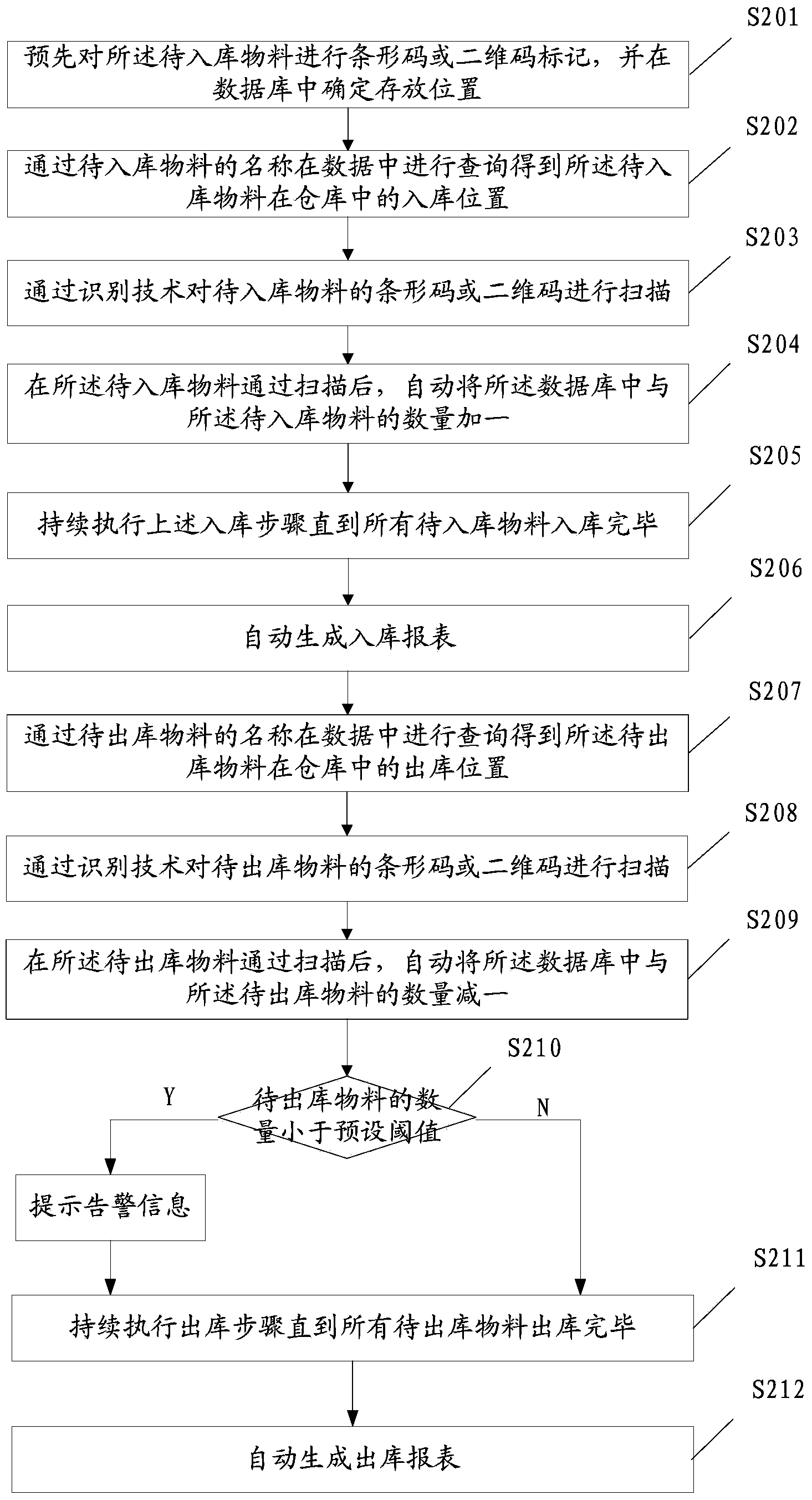

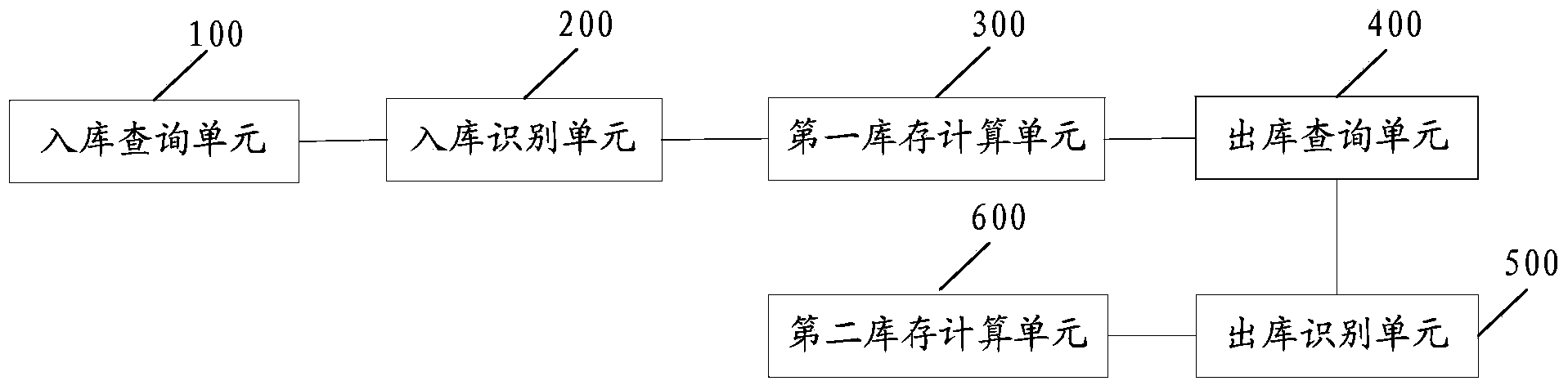

Material management method and device

InactiveCN103413211AAutomate managementRealize management workLogisticsSensing by electromagnetic radiationComputer scienceMaterials management

Owner:STATE GRID CORP OF CHINA +2

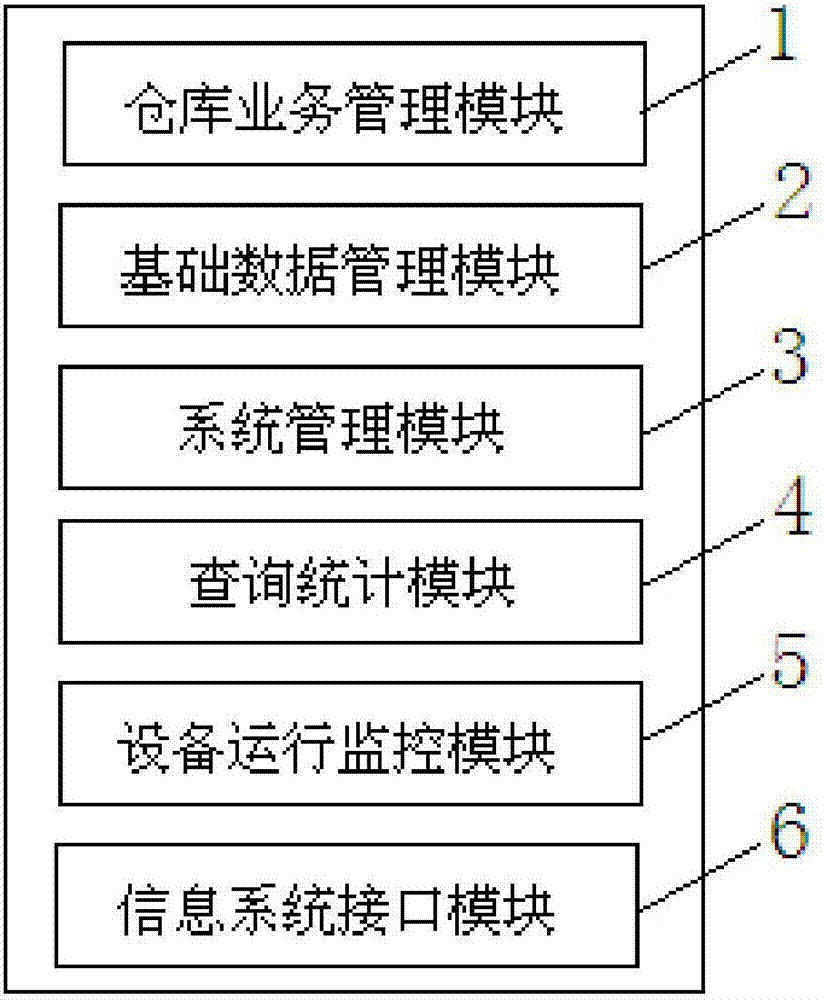

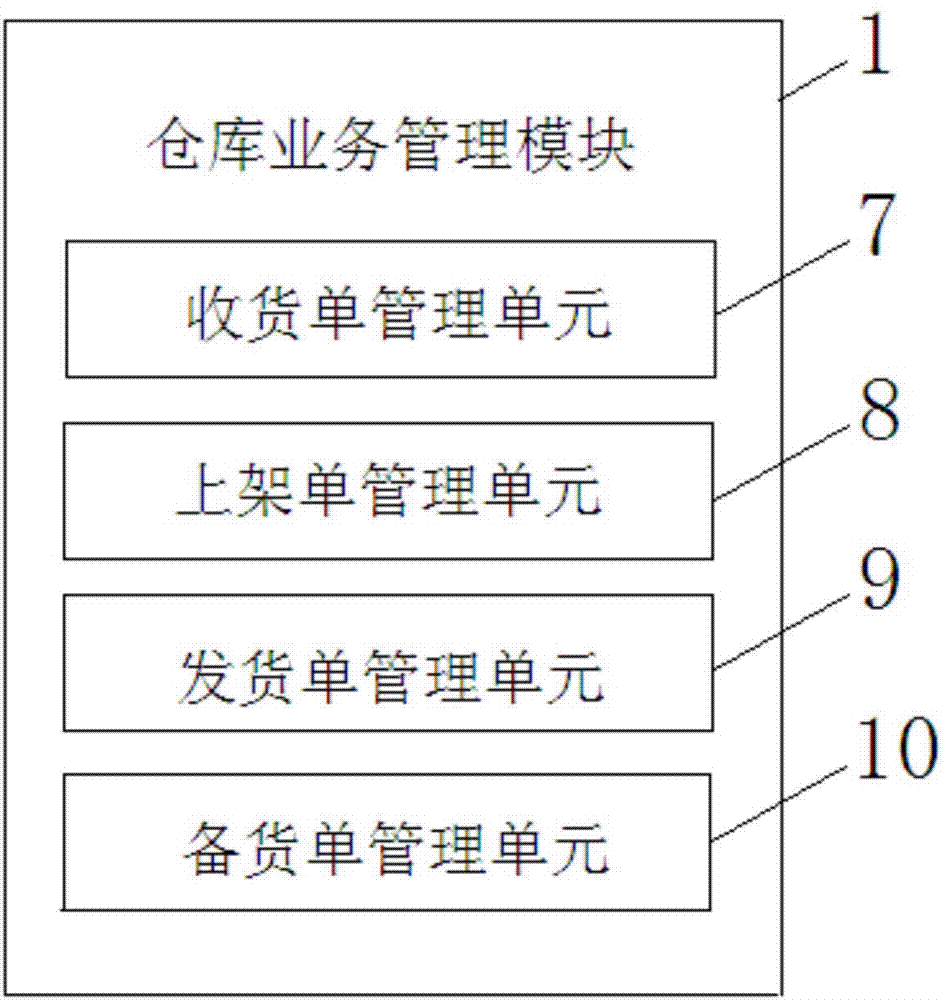

Warehouse management system

InactiveCN106920060AProcess digitizationProcess standardizationLogisticsSpecial data processing applicationsSystems managementManagement efficiency

The invention provides a warehouse management system which comprises the components of a warehouse service management module which is used for managing a warehousing service, a delivering-out-of-warehouse service and a storage service of materials and cargos; a basic data management module which is used for managing related data of the warehousing service, the delivering-out-of-warehouse service and the storage service of the materials and the cargos; a system management module which is used for managing user authorities and user operations; a searching and statistics module which is used for searching and performing statistics on operation historical information that is related with the warehousing service, the delivering-out-of-warehouse service and the storage service of the materials and the cargos, thereby searching and performing statistics on the cargo position visual map which is related with the materials and the cargos; an equipment operation monitoring module which is used for monitoring historical operation capability and current operation capability of the warehouse management system; and an information system interface module which is used for communication between the warehouse management system with an external system, wherein the modules perform communication between one another through Ethernet. The warehouse management system has a beneficial effect of improving stored material management efficiency and accuracy.

Owner:SHANGHAI LONGTENG TECH

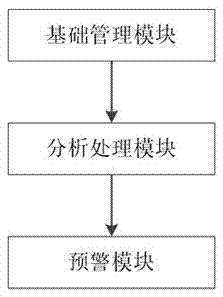

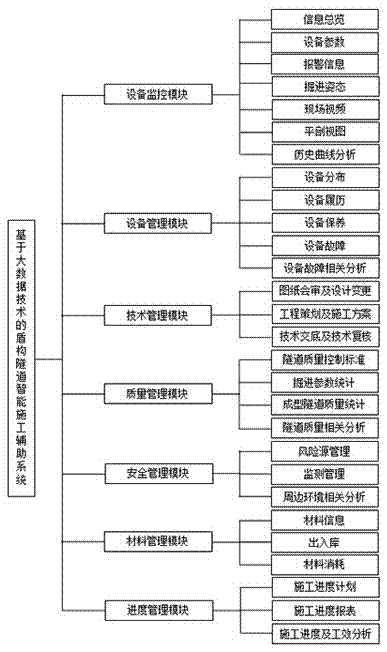

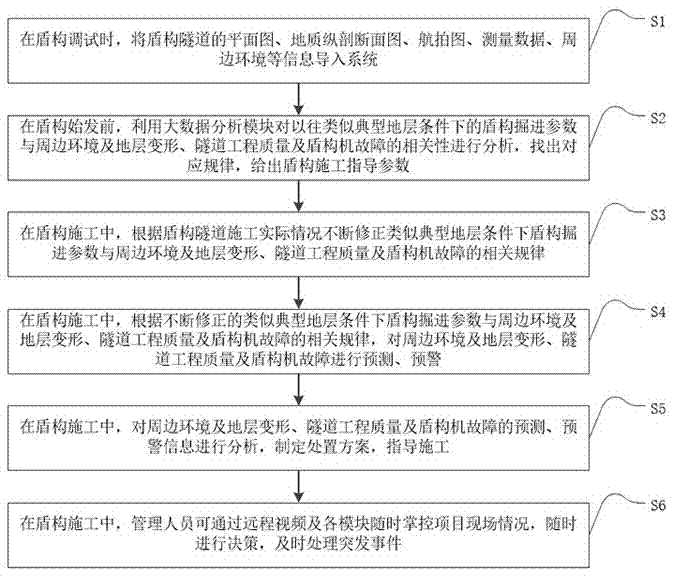

Shield tunnel intelligent construction auxiliary system based on big data technology and application method

ActiveCN107503757ATimely processingReduce unsafe behaviorTunnelsWireless networkEquipment monitoring

The invention discloses a shield tunnel intelligent construction auxiliary system based on the big data technology and an application method. The intelligent construction auxiliary system comprises a basic management module, an analyzing and processing module and a pre-warning module, wherein the basic management module is connected with the analyzing and processing module through a wireless network, and the analyzing and processing module is provided with a database, compares on-site basic management data with the database, performs analysis and outputs corresponding parameter control or performs pre-warning through the pre-warning module; the basic management module comprises an equipment monitoring module, an equipment management module, a technology management module, a quality management module, a safety management module, a material management module and a progress management module. The intelligent construction auxiliary system has the advantages that ambient environment and ground deformation, tunnel project quality and shield tunneling machine faults are predicted and pre-warned, unsafe behaviors during construction are reduced, the operation efficiency of shield tunneling equipment, the safety of tunnel construction and tunnel engineering quality are increased, and the construction cost of tunnel engineering is lowered.

Owner:CHINA CONSTR COMM ENG GRP UNITED

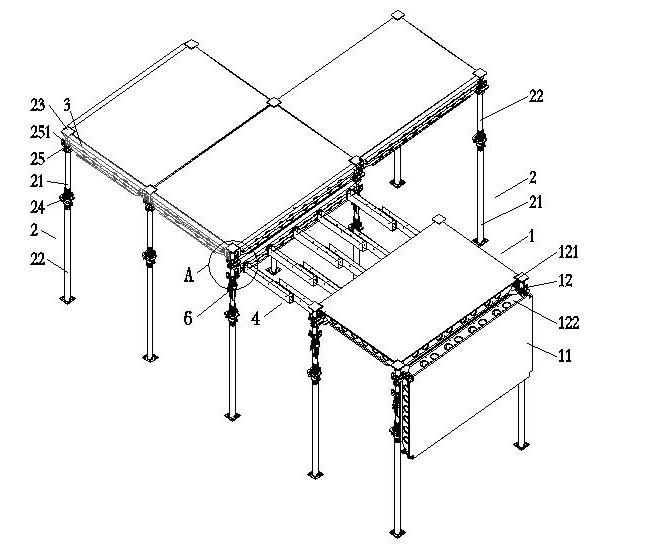

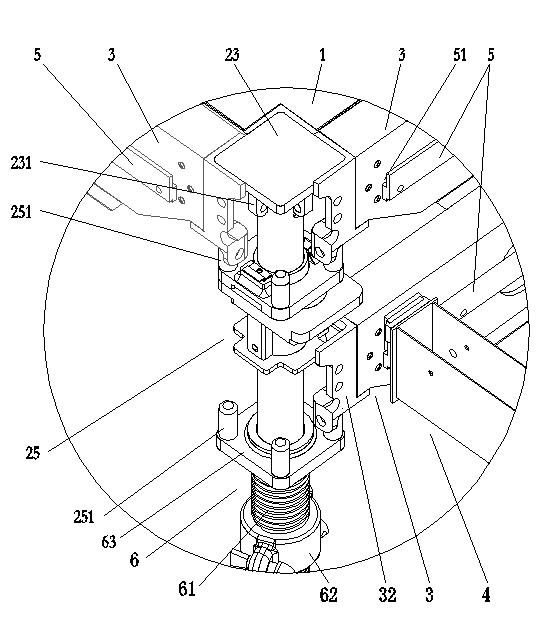

Early-removal formwork system for concreting of constructions comprising beams, plates and columns

ActiveCN102587647AReduce sizeReduce in quantityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStandard formMaterials management

The invention discloses an early-removal formwork system for concreting of constructions comprising beams, plates and columns. The early-removal formwork system comprises a plurality of rectangular standard forms, a plurality of early-removal support columns, a plurality of auxiliary beams and auxiliary forms. Each standard form comprises a face plate and a form frame, and the form frame is provided with L-shaped corner pieces at four corners. Each early-removal support column comprises an upper support column and a lower support column in telescopic connection, a rectangular top plate is disposed at the top end of the upper support column, one corner of the top plate and an internal corner of the optional L-shaped corner piece on each form frame are complementary, an unloading mechanism is connected between the upper support column and the lower support column, an early removal mechanism for early removal of the standard forms is disposed on the upper support column, short support posts for supporting one form frame are disposed at four corners of the early removal mechanism, and a structure for preventing the corresponding form frame to slip out is formed between each short support post and the corresponding L-shaped corner piece. The form frames, the auxiliary forms, the auxiliary beams and suspension beams are all in removal combined structures. The early-removal formwork system has the advantages that no secondary auxiliary beam or secondary auxiliary form is needed, specifications and amount of forms are reduced, transport and storage are facilitated, volume and capacity can be reduced effectively, and material management and cost reduction are benefited.

Owner:SHANDONG PRIMA FORMWORK CO LTD

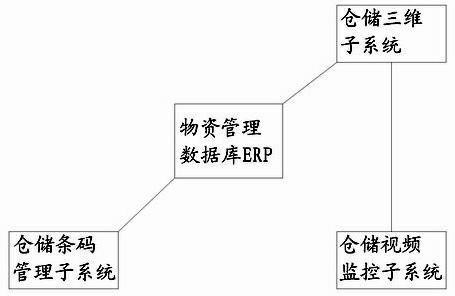

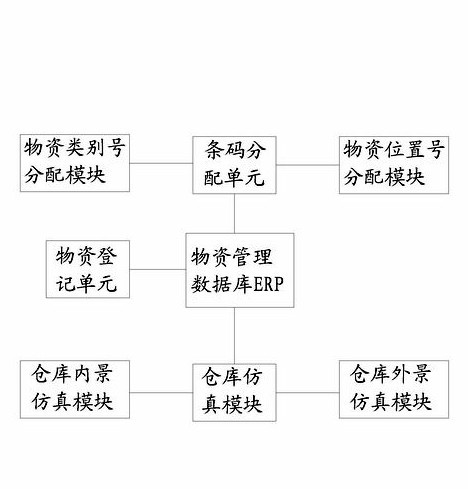

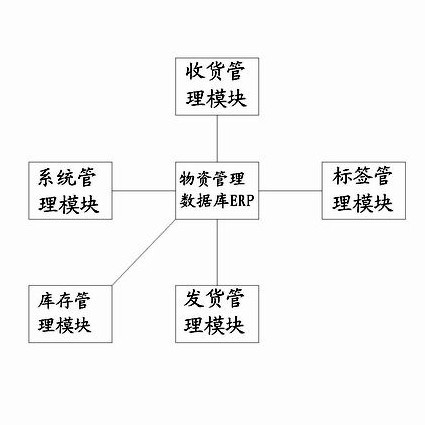

Real-time emulation storage material management system

InactiveCN102496099ASave warehouse rounds timeSave human effortLogisticsVideo monitoringReal-time simulation

A real-time emulation storage material management system comprises a material management database enterprise resource plan (ERP) and is characterized by comprising a storage three-dimensional subsystem, a storage bar code management subsystem and a storage video monitoring subsystem. The real-time emulation storage material management system enables managers to achieve simulation of storages and materials through the storage three-dimensional subsystem, conducts management on the storages and the materials in the simulation environment, and is combined with comparison of real-time videos of the storage video monitoring subsystem to finish the storage inspection work simply before a computer. The real-time emulation storage material management system remarkably saves storage inspection time and saves manpower. The bar code management subsystem distributes bar code numbers for every material, and the managers count and manage storage material information through the bar code numbers, so that material flow management is more rigorous and not prone to error.

Owner:STATE GRID CHONGQING ELECTRIC POWER +1

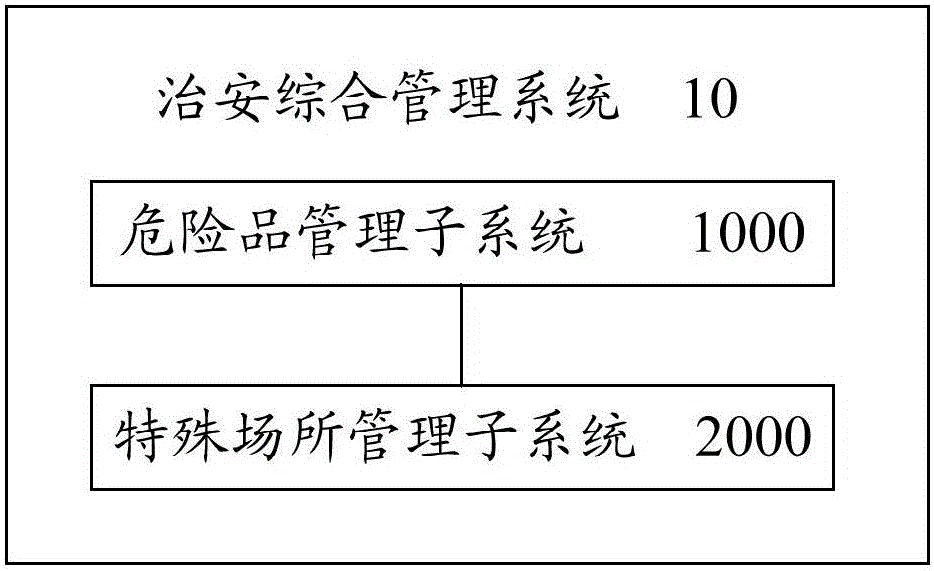

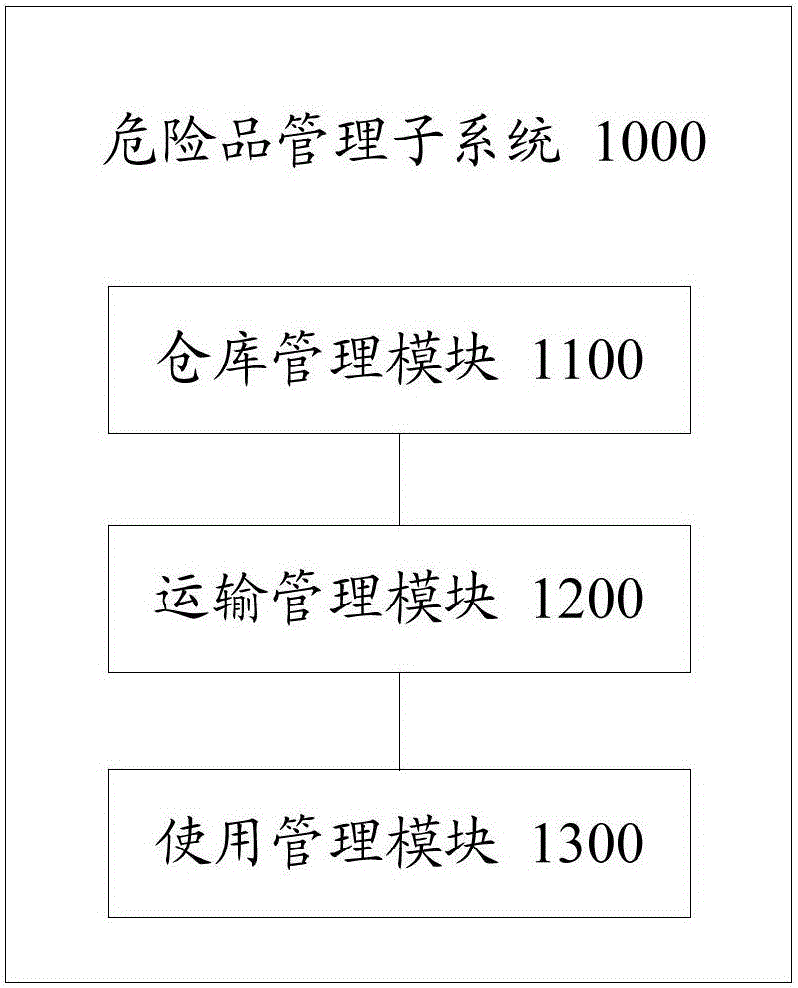

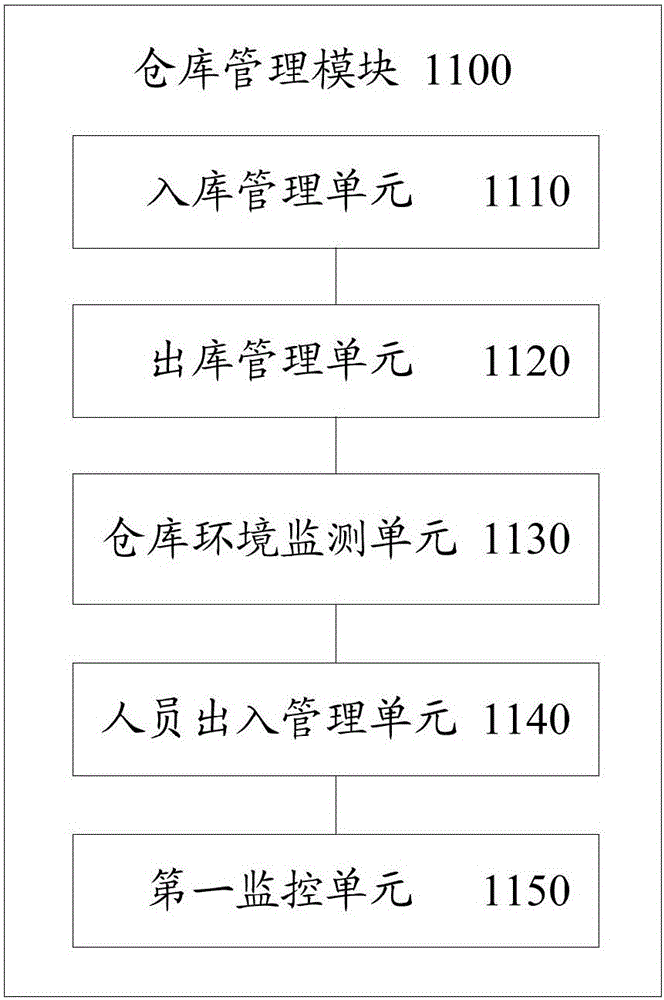

Public security integrated management system and public security integrated management method

InactiveCN105160514APrevent logistics accidentsConducive to security and stabilityLogisticsVideo monitoringInformation analysis

The invention provides a public security integrated management system and a public security integrated management method. the public security integrated management system comprises a dangerous material management subsystem for carrying out information acquisition, information analysis and video monitoring on a dangerous material warehouse-in process, a storage process, a warehouse-out process, a transportation process, a handover process, a distribution process and a use process, and a special place management subsystem for carrying out information acquisition, information analysis and video monitoring on an activity place and a fixing place. Prevention first and prior control serves as a rule, early warning, warning and alarming signals are sent out automatically through setting a threshold, graded management is realized in match with a provincial public security authority, a city public security authority, a county public security authority and an area public security authority, an information flow is used for guiding a material flow, various activities and places are monitored in real time through the information technology and a video point adjustment system, happening of dangerous material logistics accidents and special place emergencies and illegal events can be effectively prevented, and public security and social stability are facilitated.

Owner:LIAONING CHENGYUAN BLASTING ENG

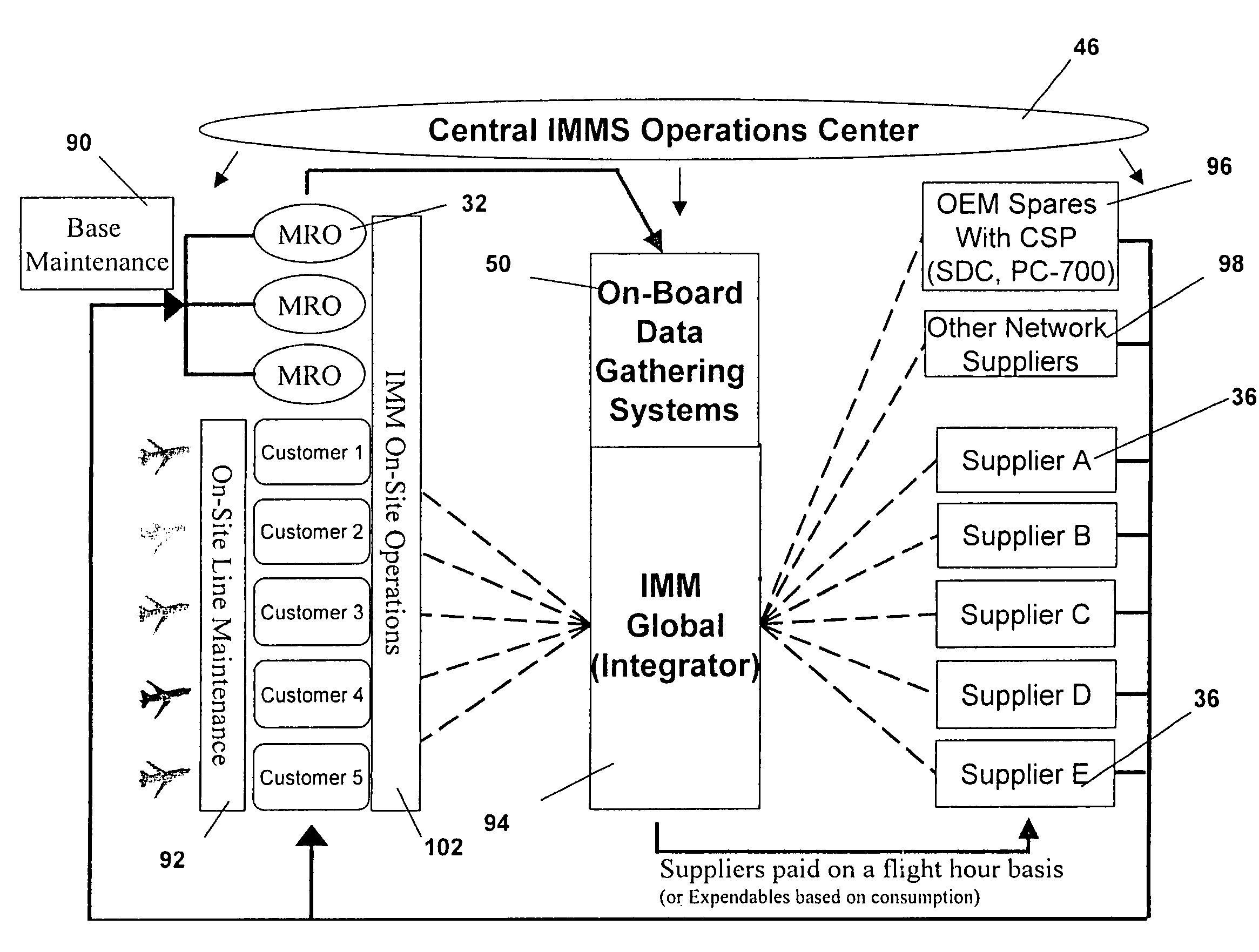

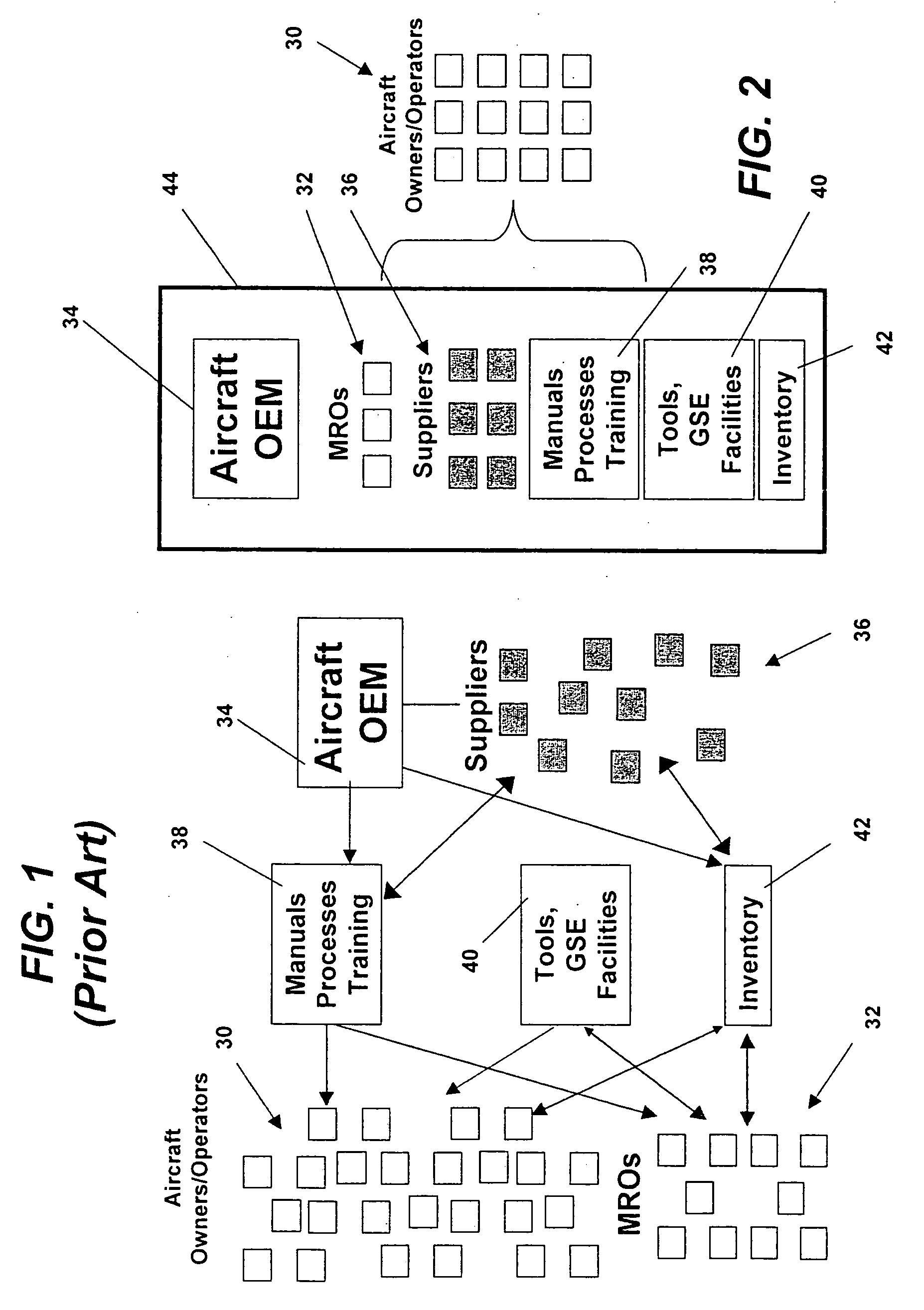

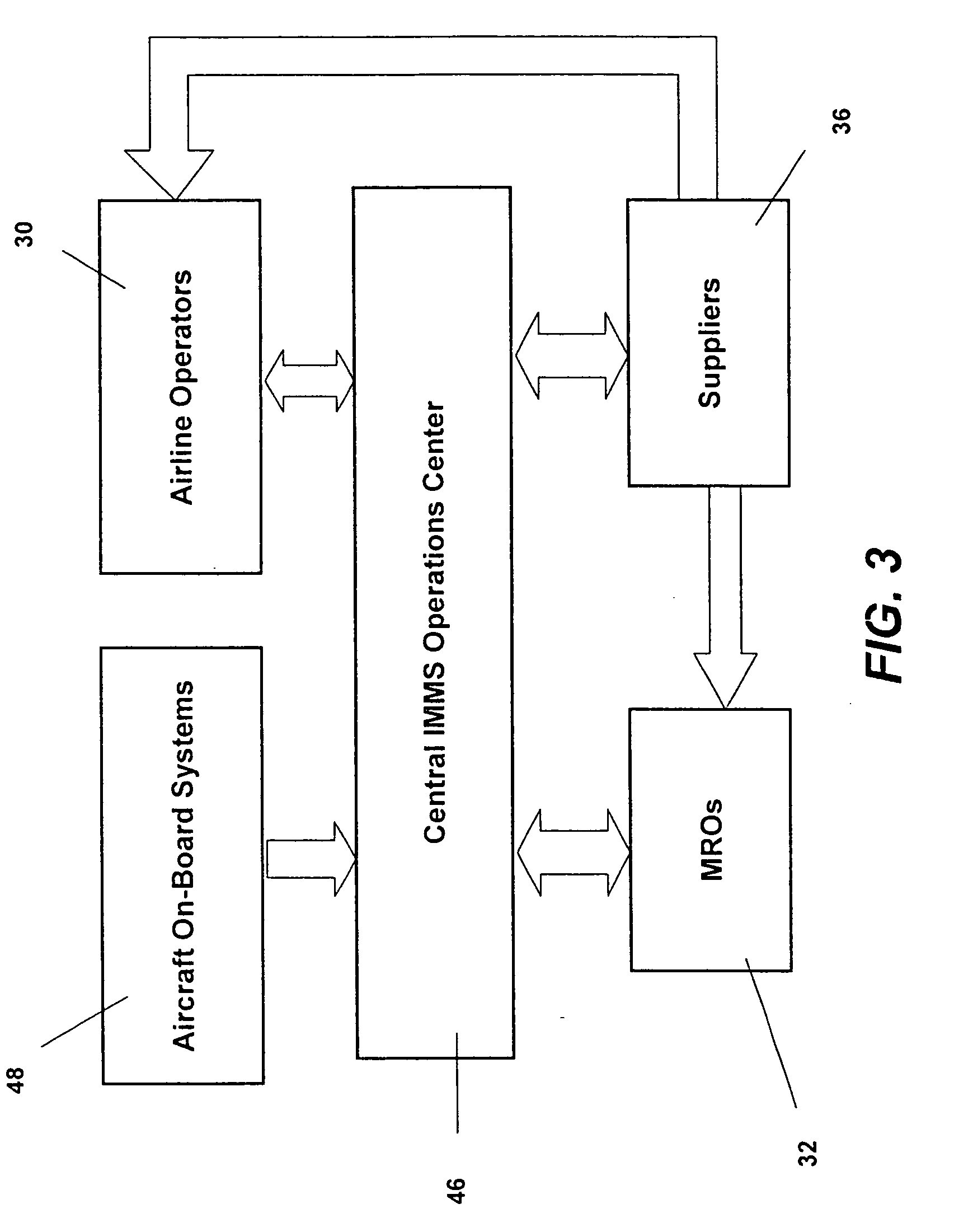

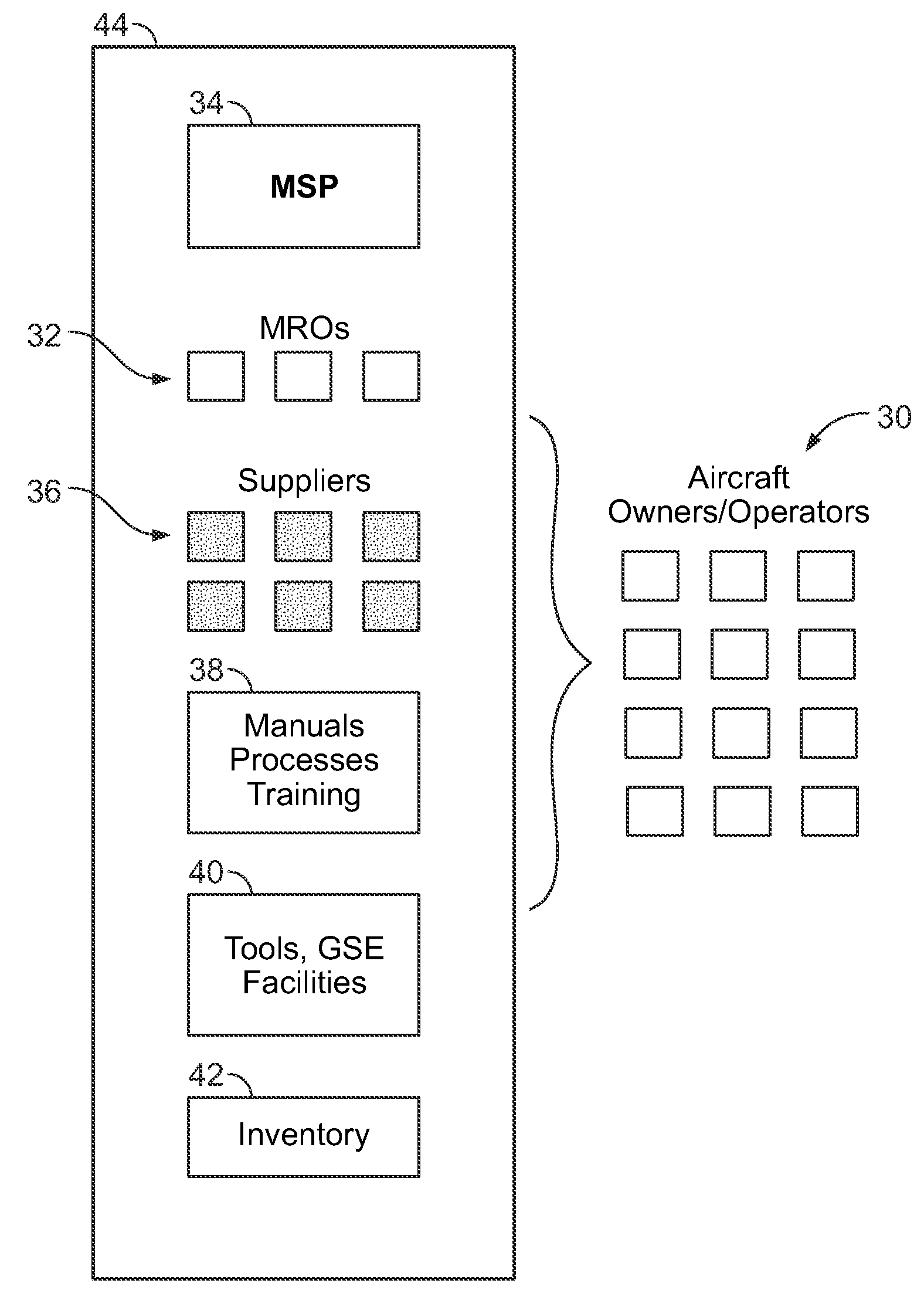

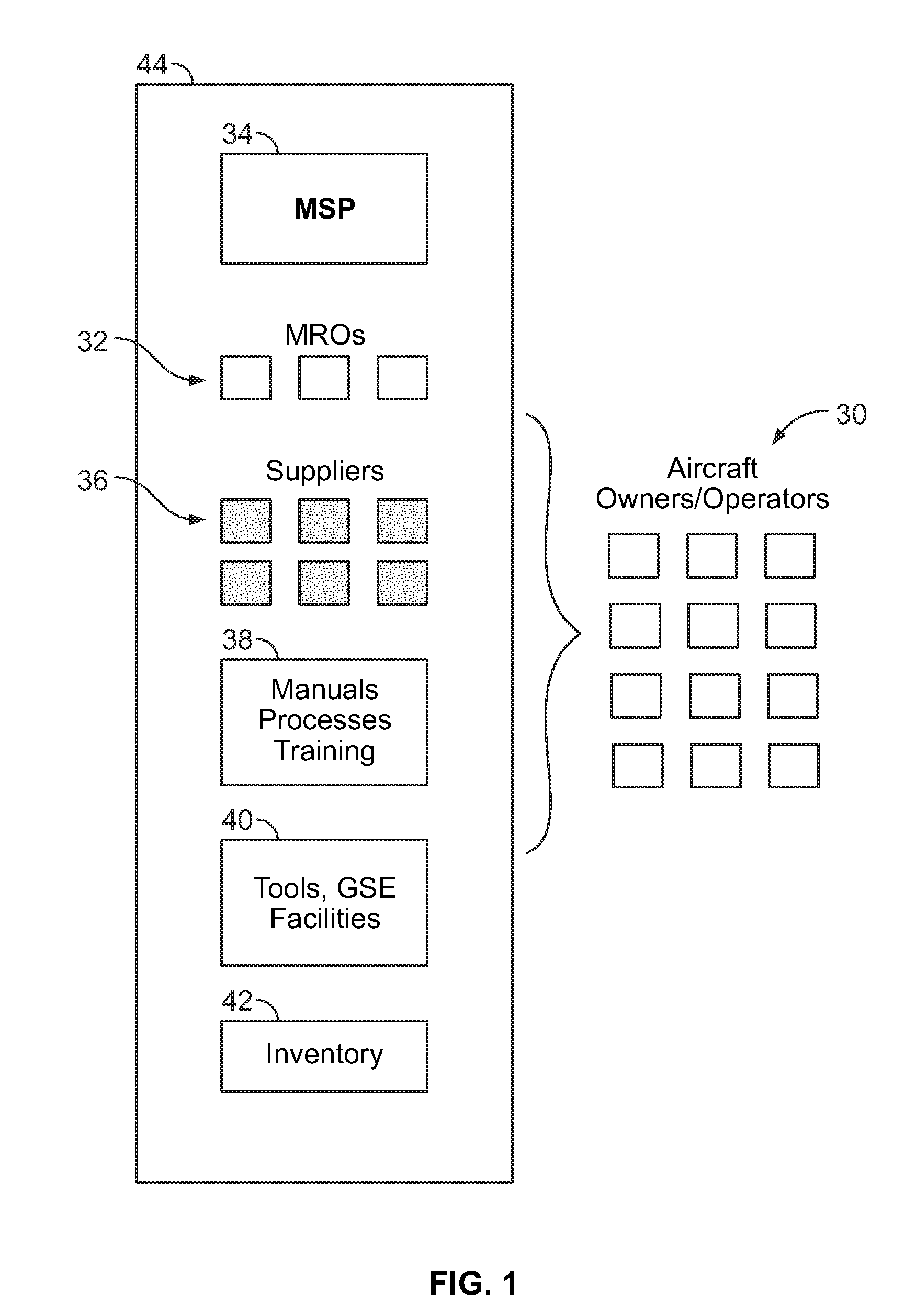

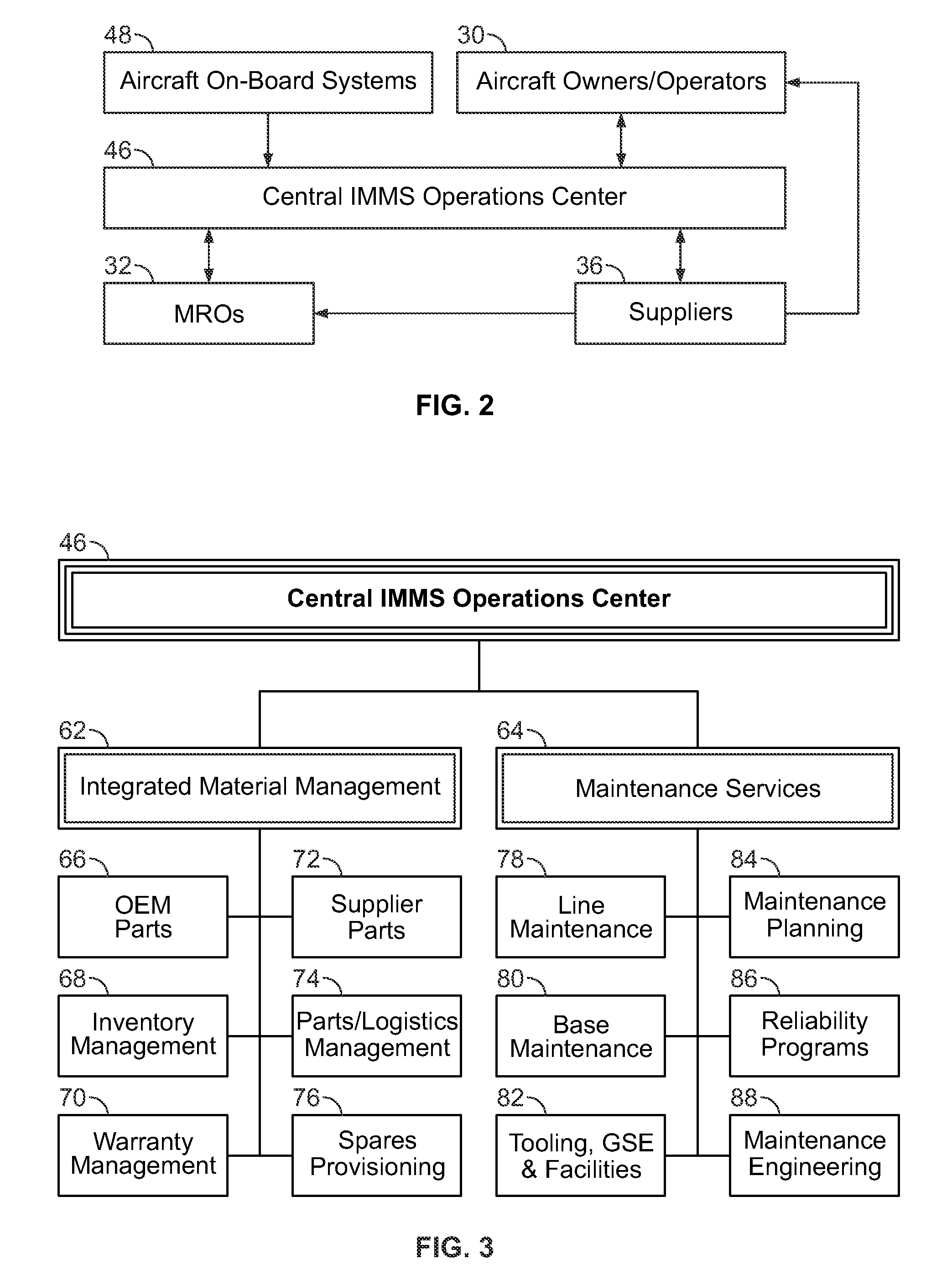

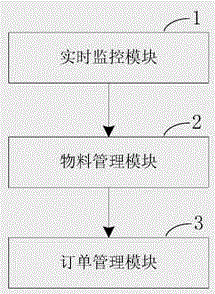

Integrated materials management for commercial aircraft fleets

ActiveUS20070124223A1Part demand informationImproves part inventory controlDigital data processing detailsAnimal feeding devicesMaintenance planningOn board

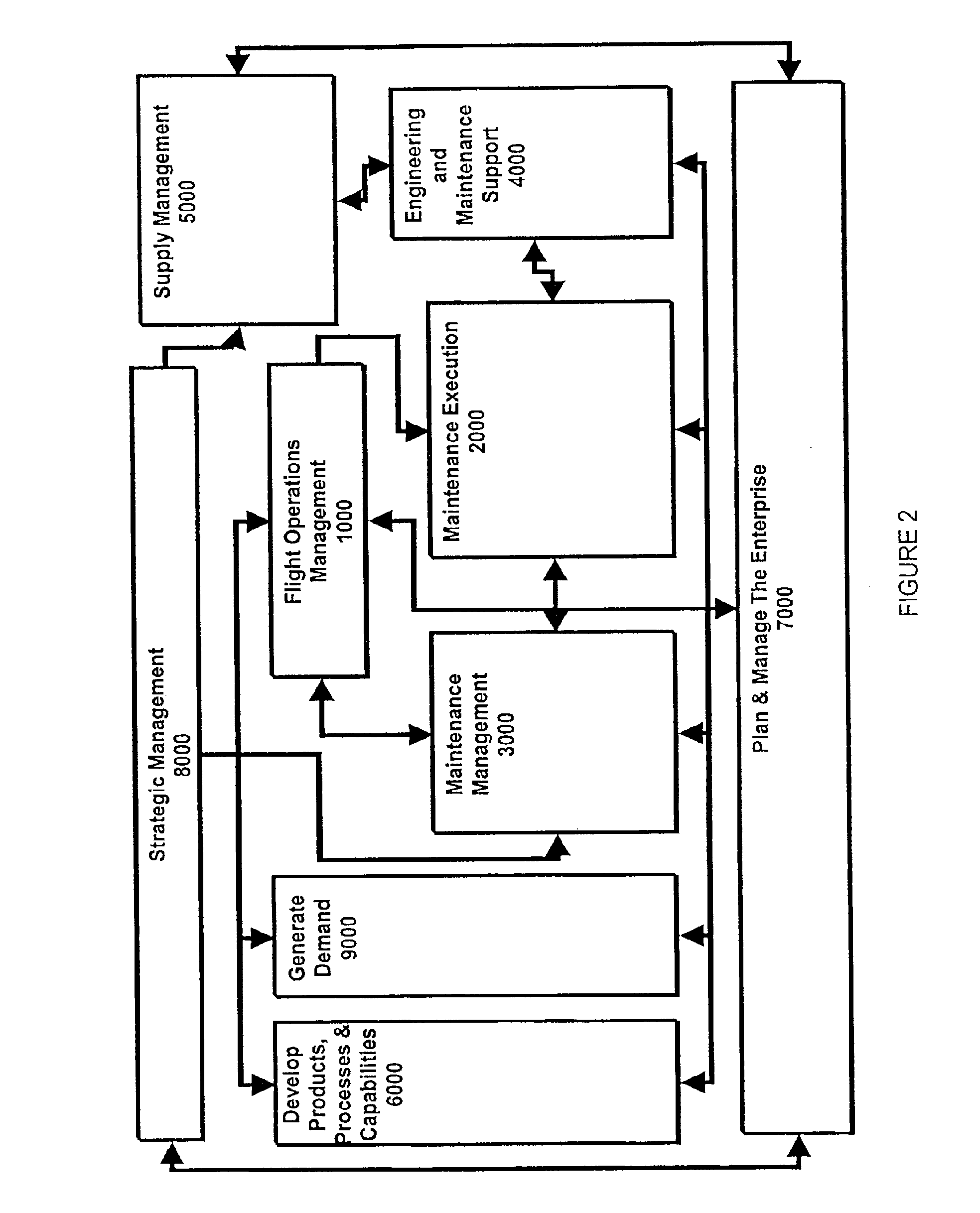

Turnkey maintenance of a customer's aircraft fleet is managed by a single management service provider (MSP) controlling integrated maintenance and materials services from a central operations site. The MSP converts data received directly from on-board aircraft systems into information it uses to manage maintenance service providers and parts suppliers. The MSP contracts with and manages maintenance, repair and overhaul organizations (MROs) who perform the maintenance on the customers' aircraft at line and base stations. The MSP either remotely manages part inventories at the customer's site, or manages suppliers who deliver the parts to the MROs. Maintenance planning, scheduling and execution information is exchanged between the MSP, MROs, part suppliers and the customers through a shared data communication network controlled by the MSP. The MSP charges the customer for the maintenance services based on a flat rate per unit of aircraft flying time.

Owner:THE BOEING CO

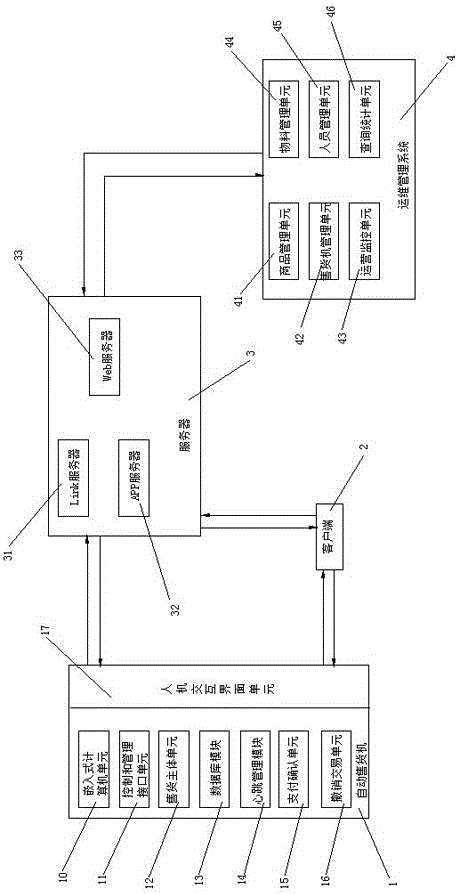

Automatic selling machine selling system based on embedded and mobile internet

InactiveCN105118159AReal-time monitoring of work and operation statusImprove service capabilitiesCoin-freed apparatus detailsBuying/selling/leasing transactionsManagement unitStatistical analysis

The invention discloses an automatic selling machine selling system based on an embedded and mobile internet. The selling system comprises an automatic selling machine, a server, a client and an operation and maintenance management system. The automatic selling machine comprises an embedded computer unit, a control and management interface unit, a selling body unit, a heartbeat management module and a human-computer interaction interface unit. A commodity management unit, a selling machine management unit, an operation monitoring unit, a material management unit, a personnel management unit and an inquiry statistics unit are arranged in the operation and maintenance management system. According to the embodiment of the automatic selling machine selling system based on the embedded and mobile internet, goods can be deployed and made according to user demands, and meanwhile operation and maintenance, real-time tracking monitoring and later-period data statistic analysis are facilitated.

Owner:HANGZHOU JINYE TECH

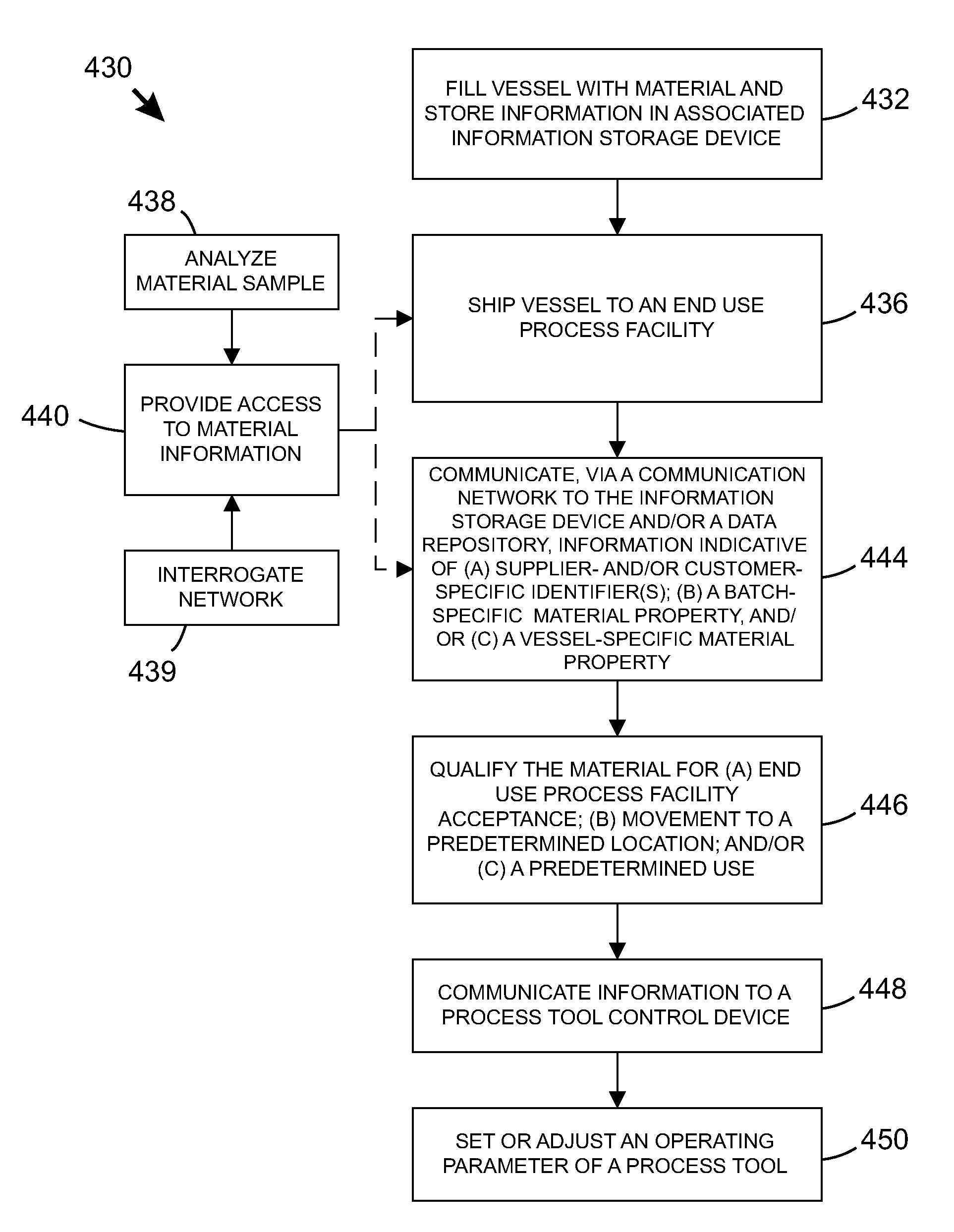

Systems and methods for managing material storage vessels having information storage elements

ActiveUS20100004772A1Error detection/correctionStructural/machines measurementRemote analysisElectronic information

Owner:ENTEGRIS INC

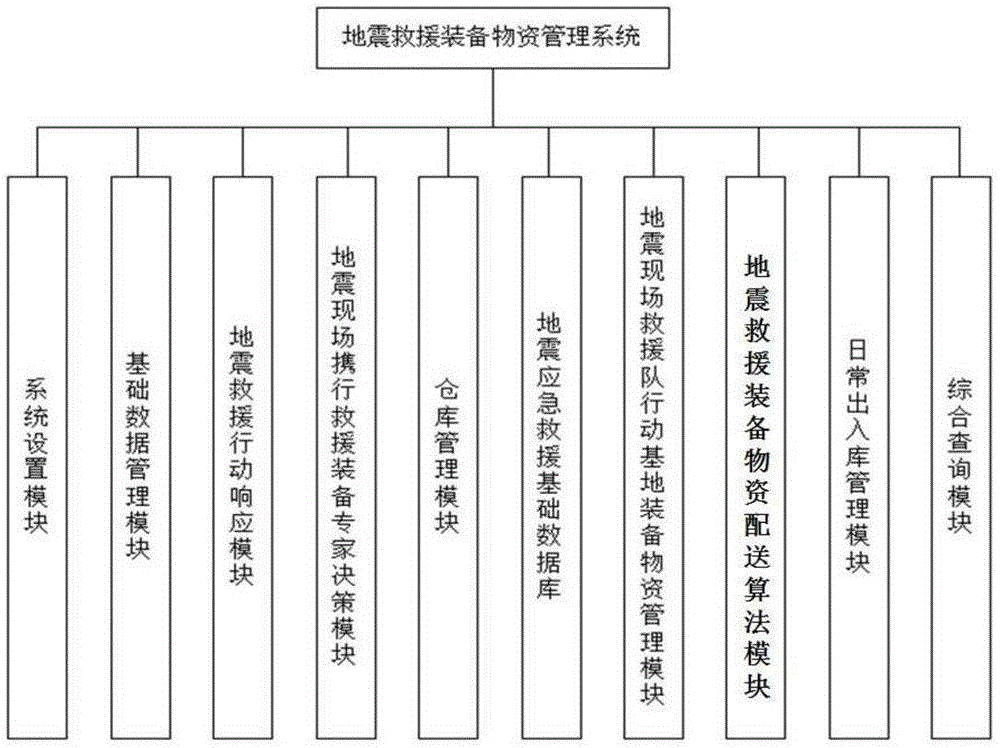

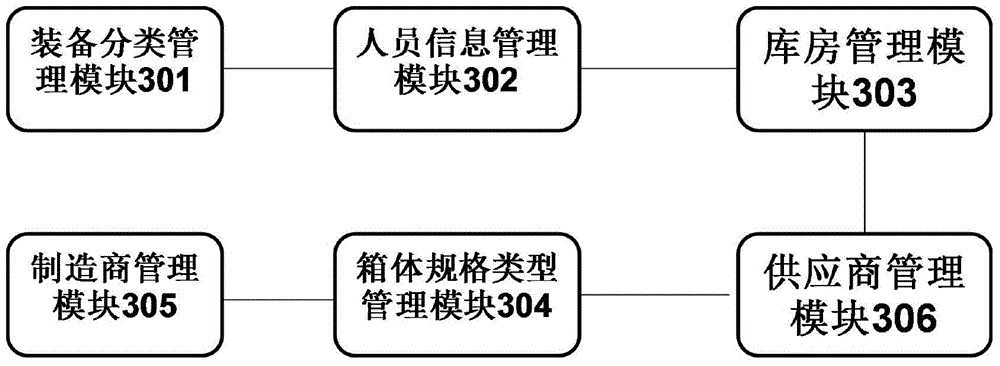

Earthquake rescue equipment material storage information system and material storage and distribution control method

InactiveCN105160515ARealize dynamic managementImprove management efficiencyLogisticsDistribution controlEmergency rescue

The invention discloses an earthquake rescue equipment material storage information system and a material storage and distribution control method. The information system comprises a system setting module, a basic data management module, a daily in and out of warehouse management module, an integrated query module, an earthquake rescue operation response module, an earthquake emergency rescue basic database module, a rescue equipment material distribution algorithm module, an earthquake site rescue target carrying rescue equipment expert decision module and an earthquake site rescue team operation base equipment material management module; and intelligent identification and allocation and dispatching of earthquake relief materials are achieved. According to the earthquake rescue equipment material storage information system and the material storage and distribution control method, dynamic management of earthquake rescue equipment material information can be achieved; the timeliness of counting, storing and dispatching the rescue equipment materials is improved; the management efficiency on the earthquake rescue equipment material information is improved; and a data support and a guarantee of equipment materials are provided for the rescue team.

Owner:胡卫建 +2

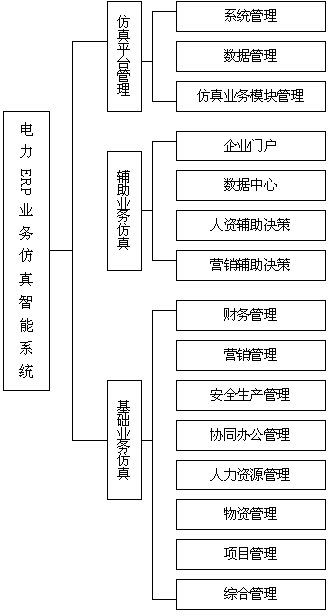

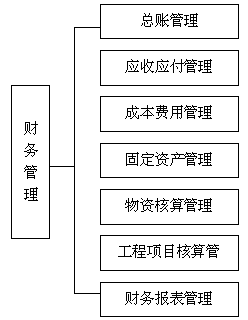

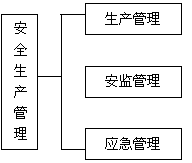

Intelligent simulation system for power ERP service

InactiveCN103021219AEnhance interestAccurate graspCosmonautic condition simulationsSimulatorsService flowData center

The invention discloses an intelligent simulation system for a power ERP service. The intelligent simulation system comprises three parts, namely simulation platform management, auxiliary service simulation and basic service simulation, wherein the simulation platform management comprises system management, data management and simulation service module management; the auxiliary service simulation comprises an enterprise portal, a data center, auxiliary human resource decisions and auxiliary marketing decisions; and the basic service simulation comprises financial management, marketing management, safety production management, cooperative office management, manpower resource management, material management, project management and integrated management. Complete simulation of an actual service scene flow, an operation mode and data association is realized and is completely same as an actual service flow, the operation mode and the data-related association mode, and the system has the characteristics of high flexibility, interestingness and the like and has an function of intelligent prompt.

Owner:国网四川省电力公司技能培训中心

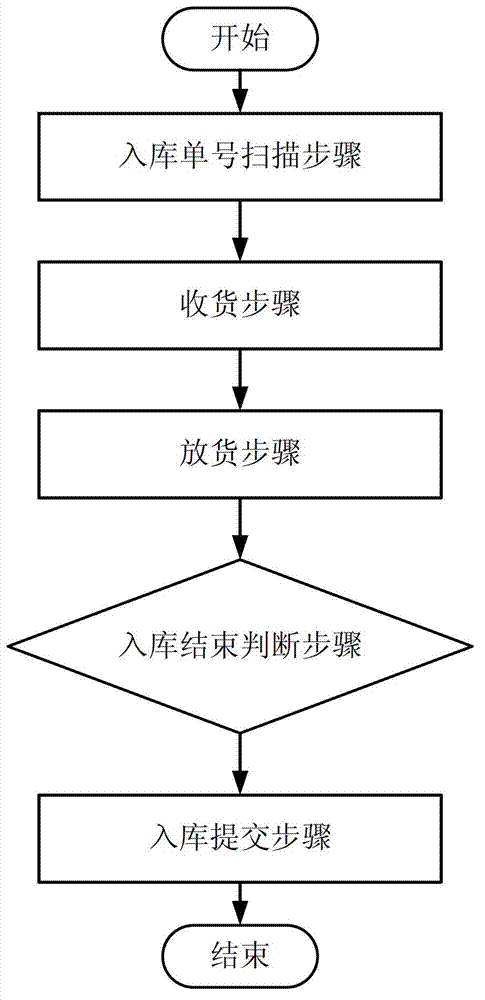

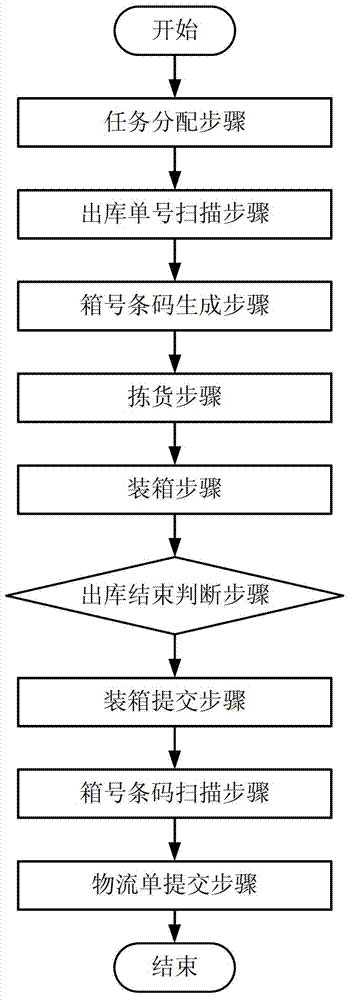

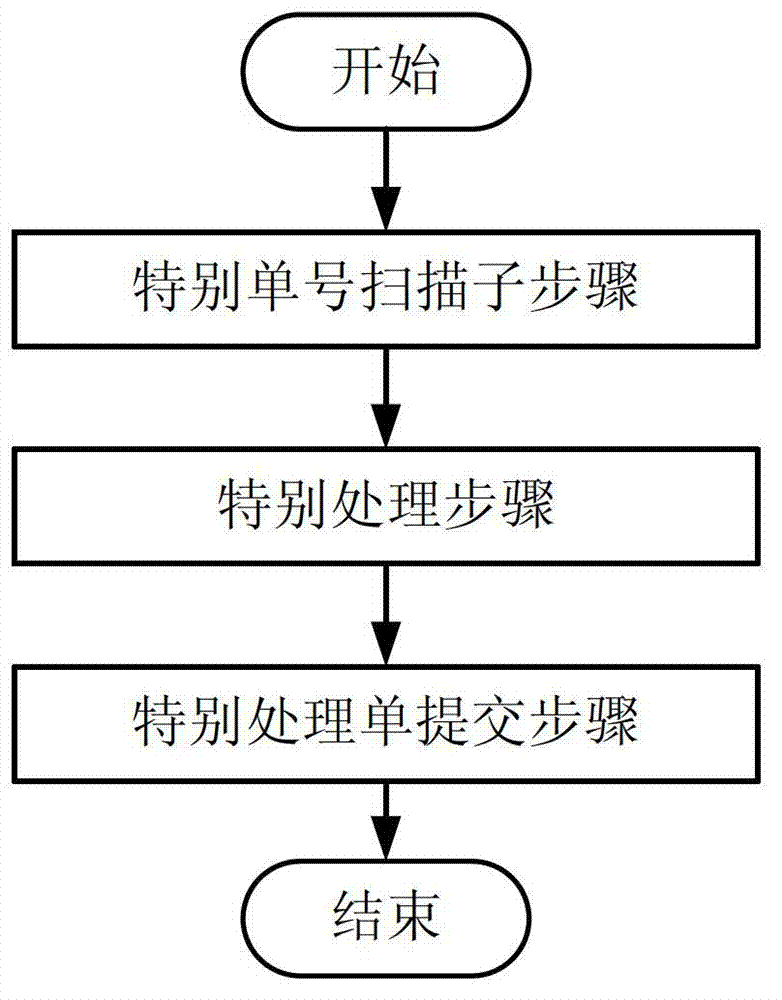

Management method and system for warehouse materials

The invention discloses a management method and a system for warehouse materials. The management method for the warehouse materials comprises a warehouse entering sub-method. The warehouse entering sub-method comprises the steps of (1) warehouse warrant number scanning steps, wherein warehouse warrant numbers displayed on a display screen of a server are scanned and recorded, (2) cargo receiving steps, wherein bar codes of materials to be entered a warehouse are scanned, a first numerical value which presents the total number of the bar codes of the materials is stored with the warehouse warrant numbers in an associated mode, and the first numerical value is recorded, (3) cargo releasing steps, wherein warehouse position bar codes of corresponding warehouse positions are scanned, bar codes of materials to be entered the warehouse positions are scanned, and a second numerical value which presents the total number of the bar codes of corresponding materials of the warehouse positions is recorded, (4) warehouse entering end judgment steps, wherein the cargo receiving steps are circularly conducted, if the sum of the second numerical value is equal to the first numerical value, judgment is finished, and (5) warehouse entering submission steps, wherein a warehouse warrant is generated and submitted to the server. According to the management method and the system for the warehouse materials, through the adoption of the technical scheme, the technical problems that labor cost is high, working efficiency is low and accuracy rate is low in the prior art are solved, and the technical effects that warehouse materials can be managed accurately, timely, rapidly and efficiently are achieved.

Owner:深圳市顶尖传诚科技有限公司

SMT material conveying method and system

ActiveCN104843486AImprove accuracySave human effortCharge manipulationConveyor partsProduction lineProcess engineering

The invention discloses an SMT material conveying method and system. The SMT material conveying method includes the steps of identity marking of materials, automatic warehousing and delivery in an intelligent warehouse, task distribution outside the warehouse, automatic conveying to a production line for use and re-identification warehousing of tailing. The SMT material conveying system comprises an automatic supplying machine, an automatic printing and labeling machine, the intelligent warehouse, an automatic printing and labeling module, a material conveying belt, an automatic feeding cart and automatic measurement and counting equipment, wherein the automatic supplying machine, the automatic printing and labeling machine, the intelligent warehouse and the automatic printing and labeling module are sequentially and linearly distributed, and the intelligent warehouse and the automatic printing and labeling module are connected through the material conveying belt. The SMT material conveying method and system can largely reduce labor, and are high in automation degree. The efficiency of storing, taking and conveying materials to the production line is high. The material management accuracy is high. The production cost is largely reduced. The production efficiency is improved.

Owner:SUZHOU I STOCK INTELLIGENT TECH

Method for testing a maintenance and materials management system

InactiveUS20080159158A1Aircraft health monitoring devicesError preventionTest managementData transmission

A method for testing an airplane maintenance system, which comprises the steps of: testing communications and data transmission between an aircraft operator and a management service provider; testing general communications and data transmission between internal systems of the management service provider; and testing communications and data transmission between the internal systems of the management service provider during for predetermined procedures.

Owner:THE BOEING CO

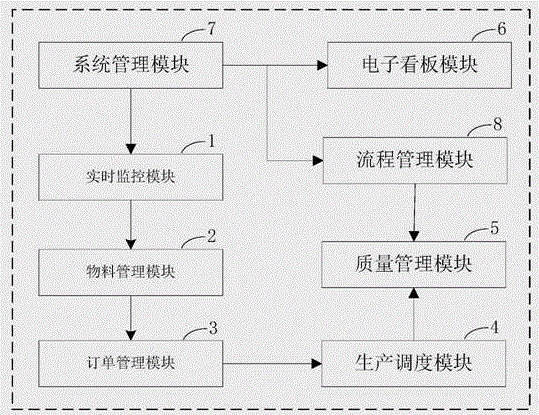

MES (Manufacturing Execution System) based on RFID (Radio Frequency Identification)

ActiveCN106779406AImprove the efficiency of obtaining informationImprove automationCo-operative working arrangementsResourcesManufacture execution systemProduction line

The invention provides an MES (Manufacturing Execution System) based on RFID (Radio Frequency Identification). The MES comprises a real-time monitoring module, a material management module and an order form management module, wherein the real-time monitoring module is used for monitoring the dynamic information of the process flow, the material accessories and the tooling equipment of each manufacturing shop in real time according to an RFID data collection system; the material management module is used for carrying out statistics on the material data of the produced product, the raw material accessories and the tooling equipment of each manufacturing shop according to the collected dynamic information; and the order form management module is used for receiving order form data, decomposing the order form data into a plurality of product order forms according to product categories according to production factors on the basis of the material data, configuring different ID (Identity) numbers according to product order forms, disassembling the products to form working procedure sections corresponding to the factors, and distributing composition factors onto the stations of a corresponding production line according to the working procedure sections to form an operational plan. Efficiency for the MES to obtain information is improved, the corresponding operational plan can be generated automatically according to the order form data, respective production capacity can be performed at a maximum degree according to the material data, and the automatic and intelligent level of the MES can be improved.

Owner:CHONGQING CHUANYI AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com