Real-time emulation storage material management system

A real-time simulation and management system technology, applied in logistics, data processing applications, instruments, etc., can solve problems such as inability to assist warehouse patrol management work, single function, and inconvenient daily management of staff, so as to achieve strict logistics management and less error-prone , Saving the effect of warehouse patrol time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

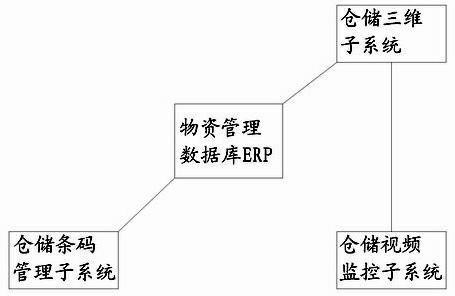

[0035] The real-time simulation storage material management system includes a material management database ERP, and is characterized in that it includes a storage three-dimensional subsystem, a storage barcode management subsystem and a storage video monitoring subsystem.

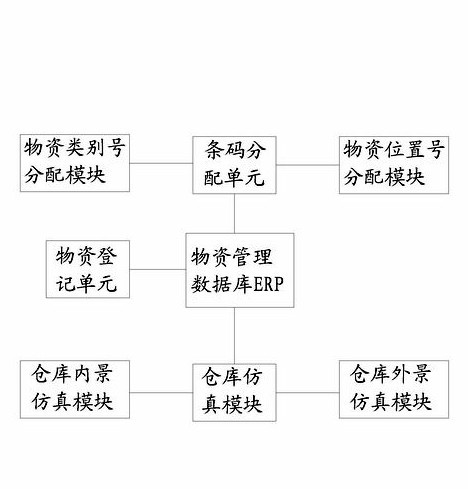

[0036] The warehouse 3D subsystem is used to create warehouse simulation images, including warehouse internal structure simulation images and material simulation images. The warehouse and materials are displayed on the computer in the form of simulated 3D images. Simulate the materials recorded in the management database ERP;

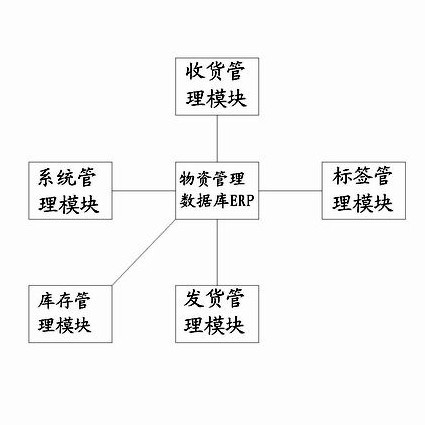

[0037] The warehouse barcode management subsystem assigns a unique barcode number to each warehouse material, and stores the relevant information in the material management database ERP;

[0038] The storage video monitoring subsystem controls the cameras installed in the war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com