Patents

Literature

475 results about "Tool management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tool management is needed in metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. Tool data management consists of specific data fields, graphics and parameters that are essential in production, as opposed to managing general production equipment.

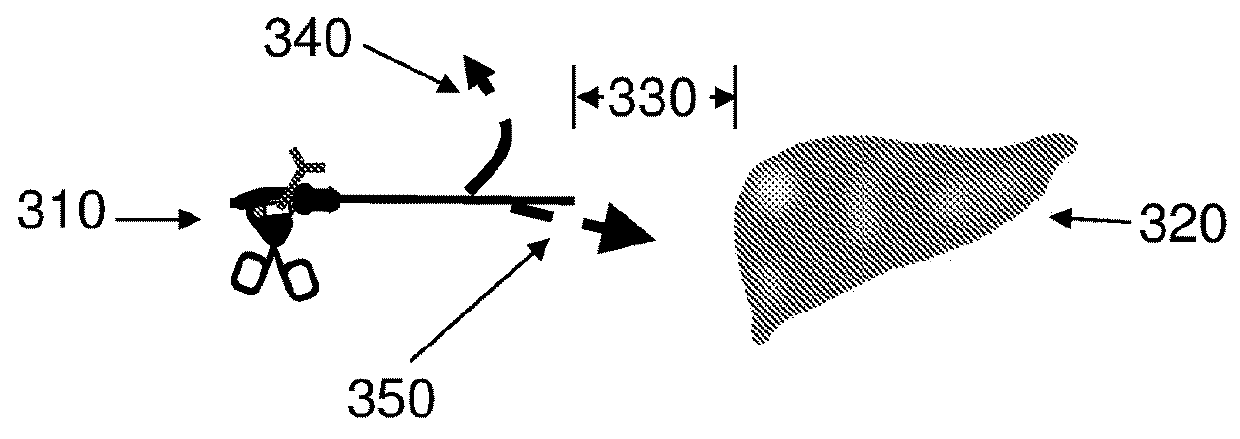

Intelligent surgical tool control system for laparoscopic surgeries

An intelligent surgical tool control system, comprising a tool management system; an indicating means to indicate at least one surgical event; a communicable database for storing, for each item of interest, its identity, its present 3D position and at least one previous 3D position; and at least one processor to identify, from a surgical event, an output surgical procedure. The tool management system can comprise a maneuvering mechanism to maneuver a surgical tool in at least two dimensions; and a controller to control at least one of activation and deactivation of a surgical tool and articulation of a surgical tool. The indicating means can indicate a surgical event selected from movement of a moving element and presence of an item of interest, where movement is determinable if the current 3D position of the moving element is substantially different from a previous 3D position of the same.

Owner:TRANSENTERIX EURO SARL

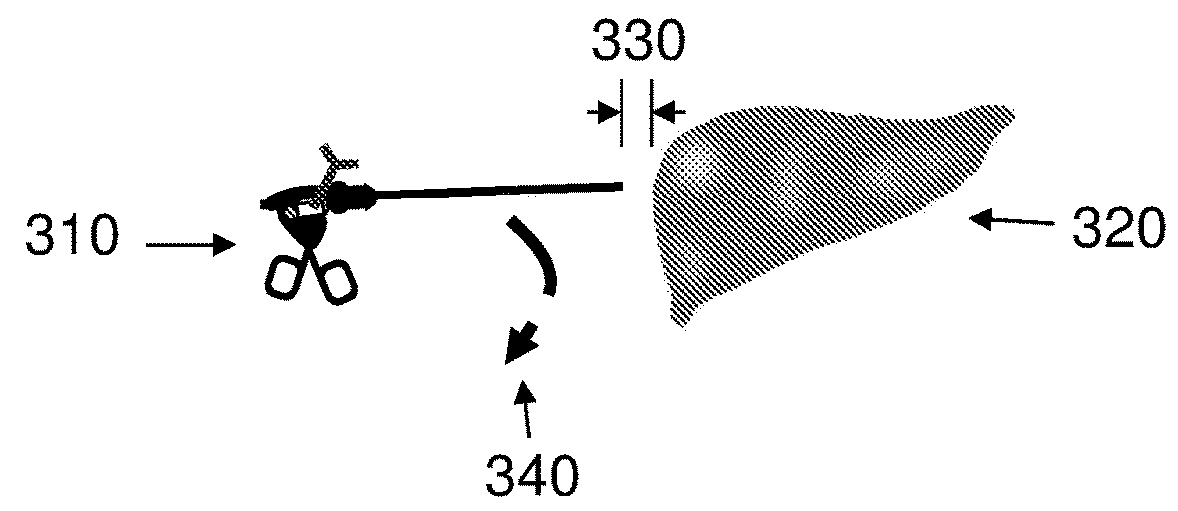

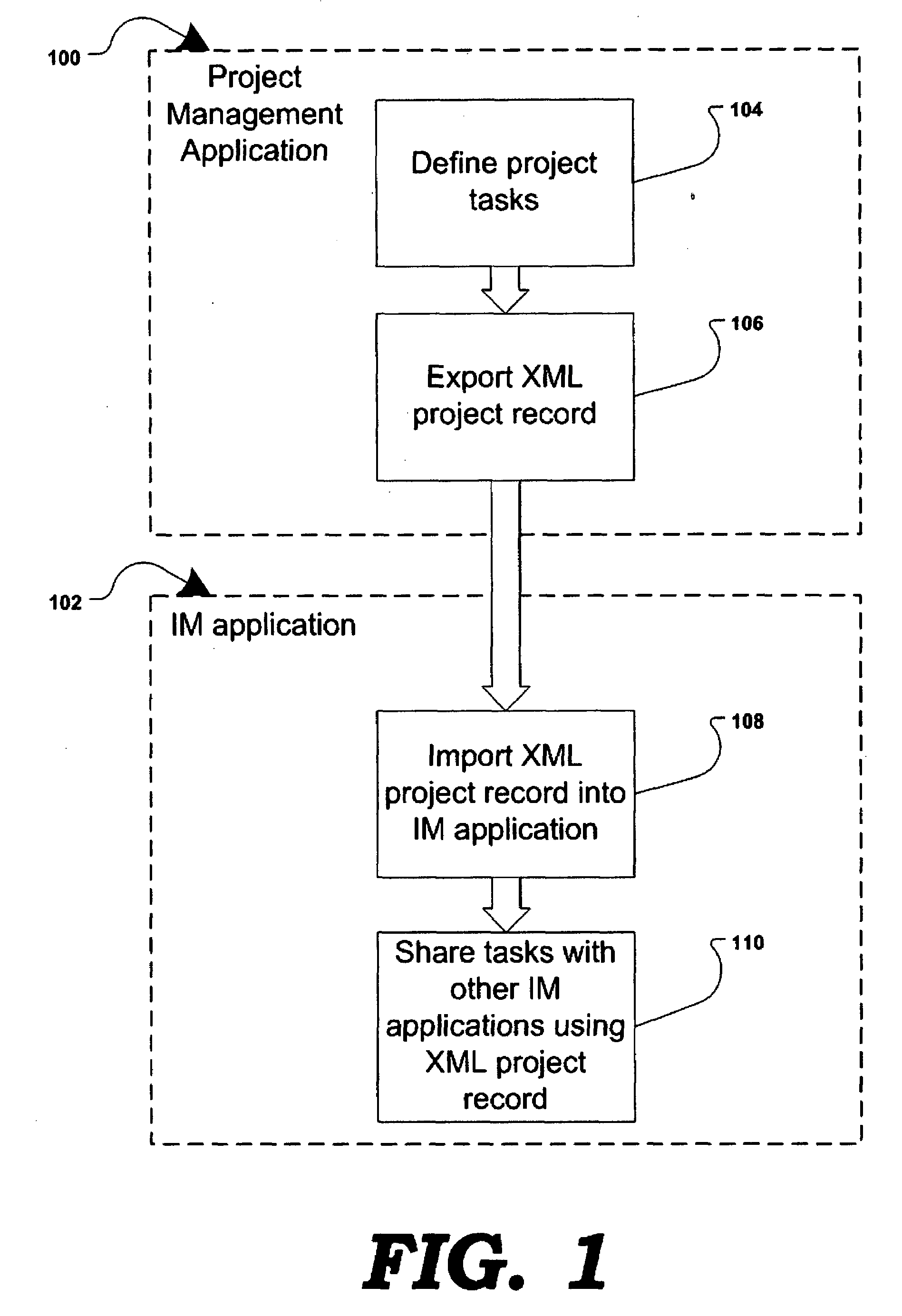

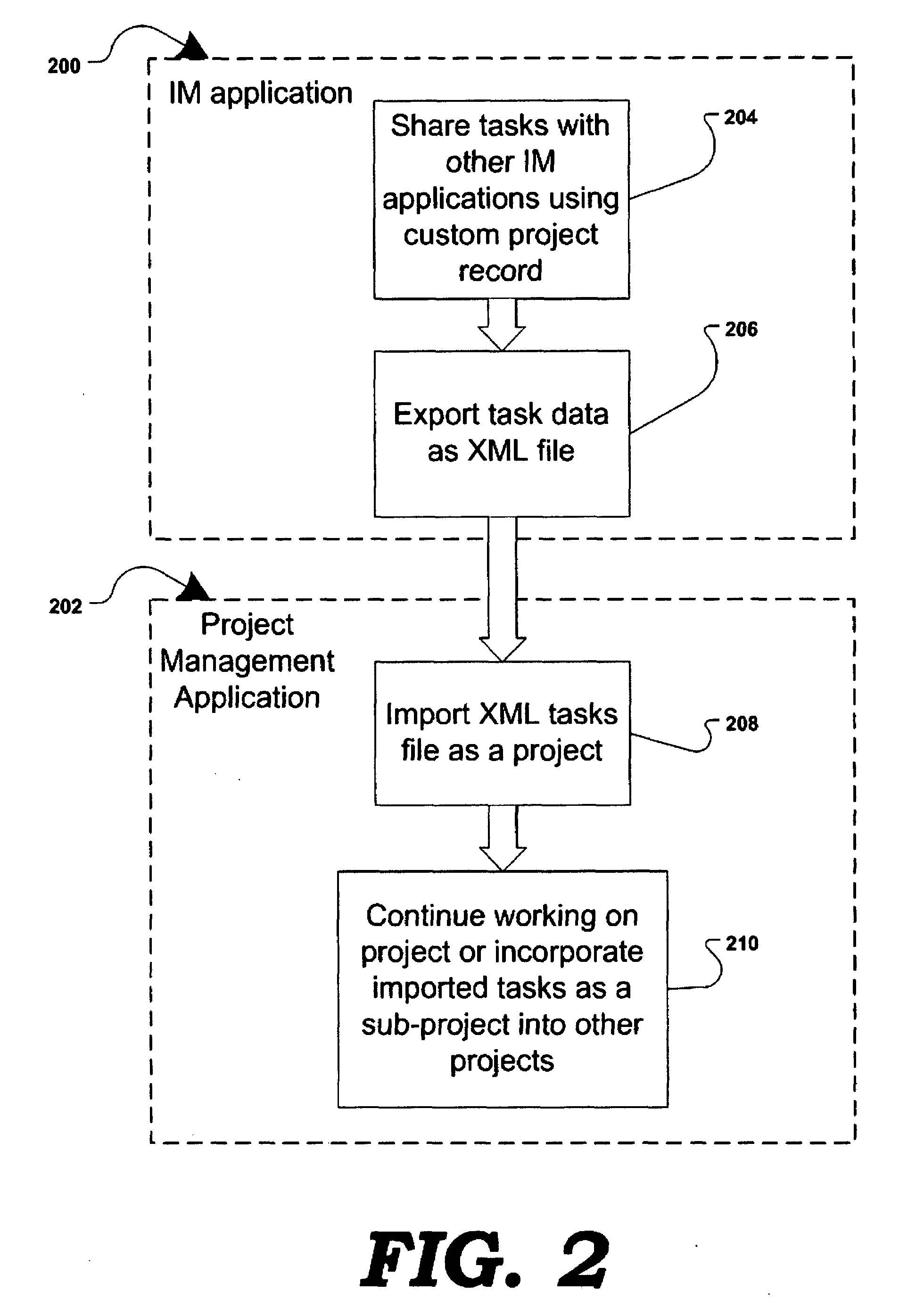

Method and system of project management and task collaboration over instant messenger

InactiveUS20080209417A1Multiprogramming arrangementsMultiple digital computer combinationsWork taskMilestone

Owner:JAKOBSON GABRIEL

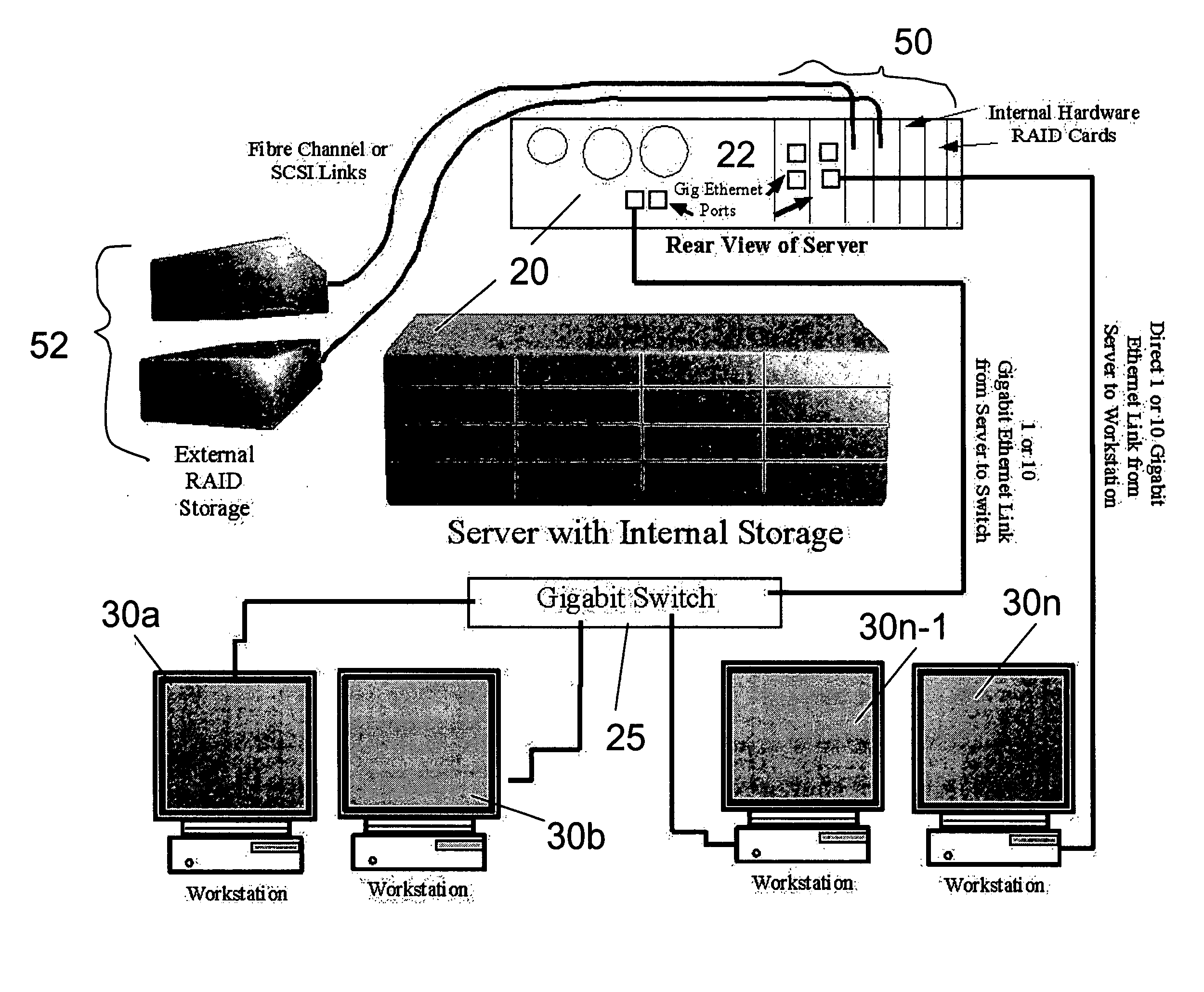

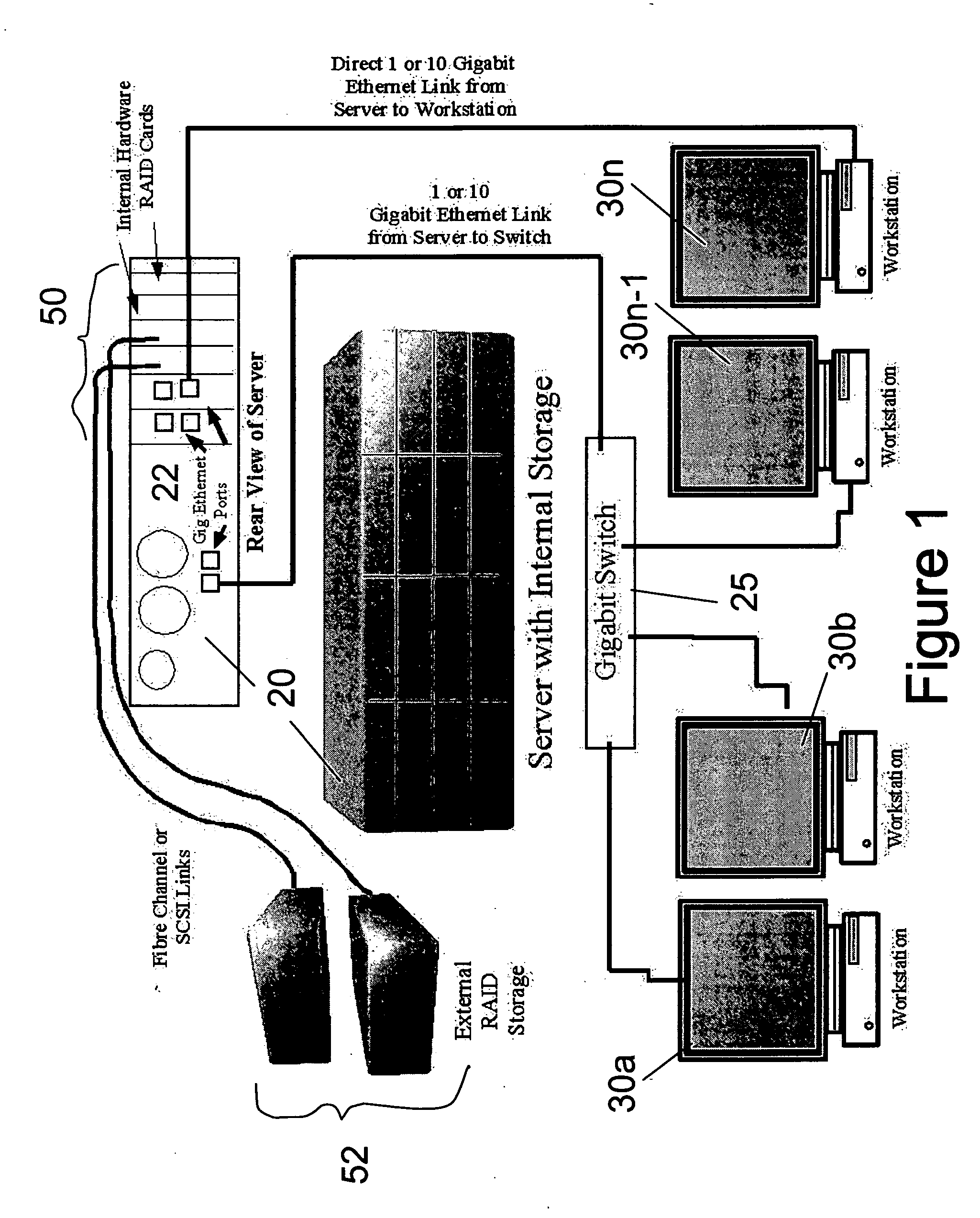

Novel media file access and storage solution for multi-workstation/multi-platform non-linear video editing systems

ActiveUS20060184673A1Digital data processing detailsElectronic editing digitised analogue information signalsSymbolic linkMulti platform

Owner:EDITSHARE LLC

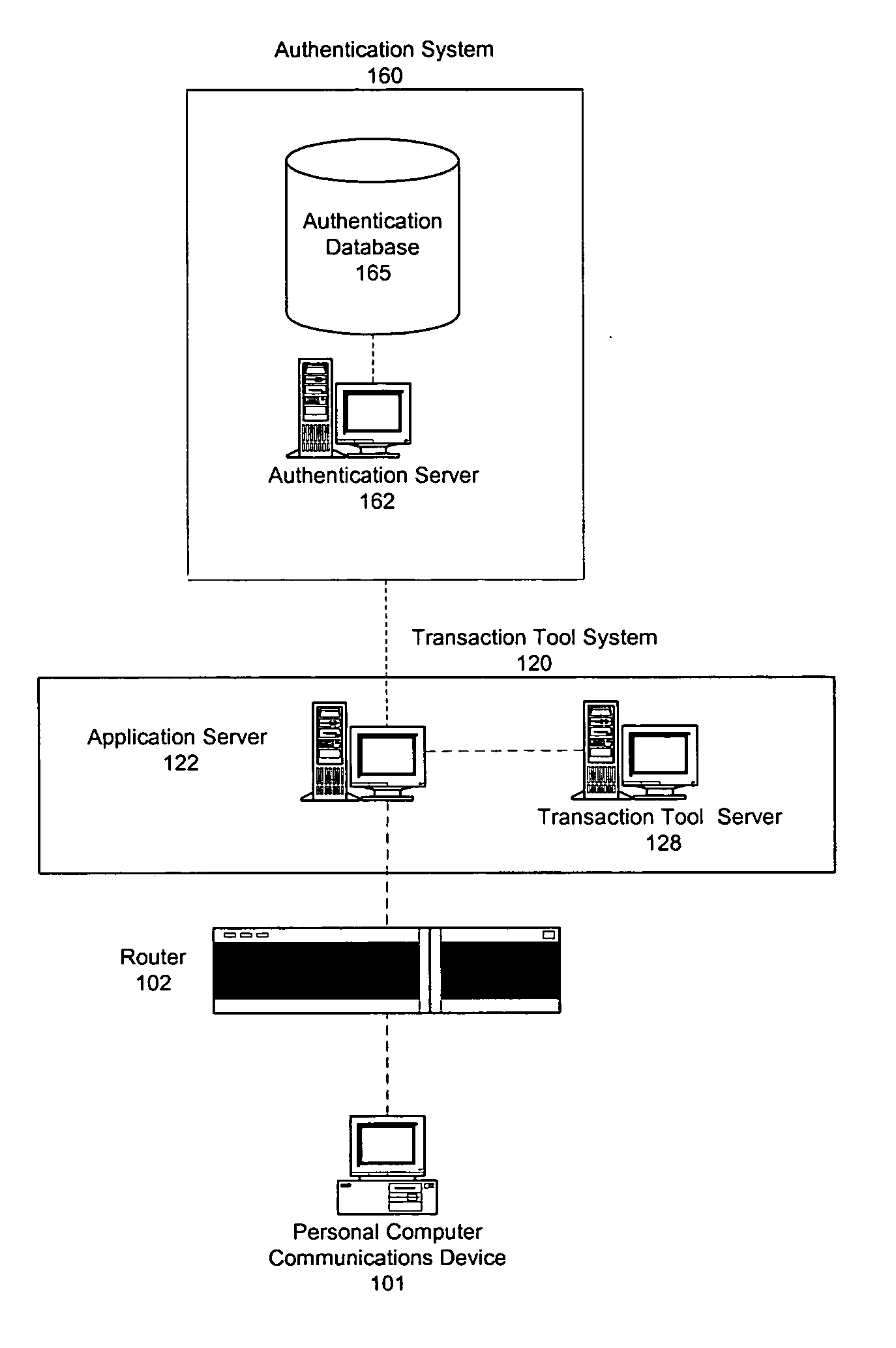

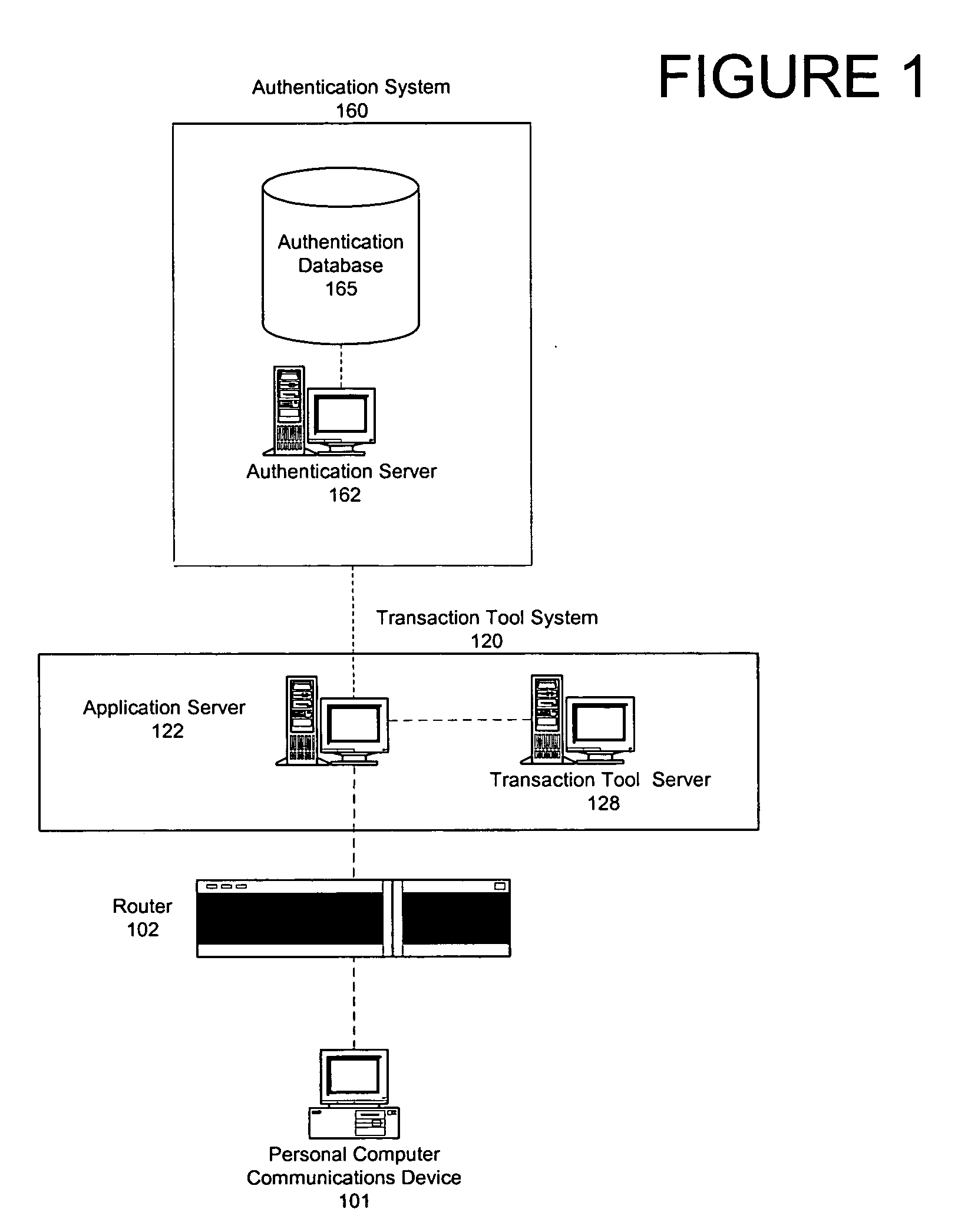

Pluggable authentication for transaction tool management services

InactiveUS20060041507A1Data processing applicationsDigital data authenticationAuthenticationTool management

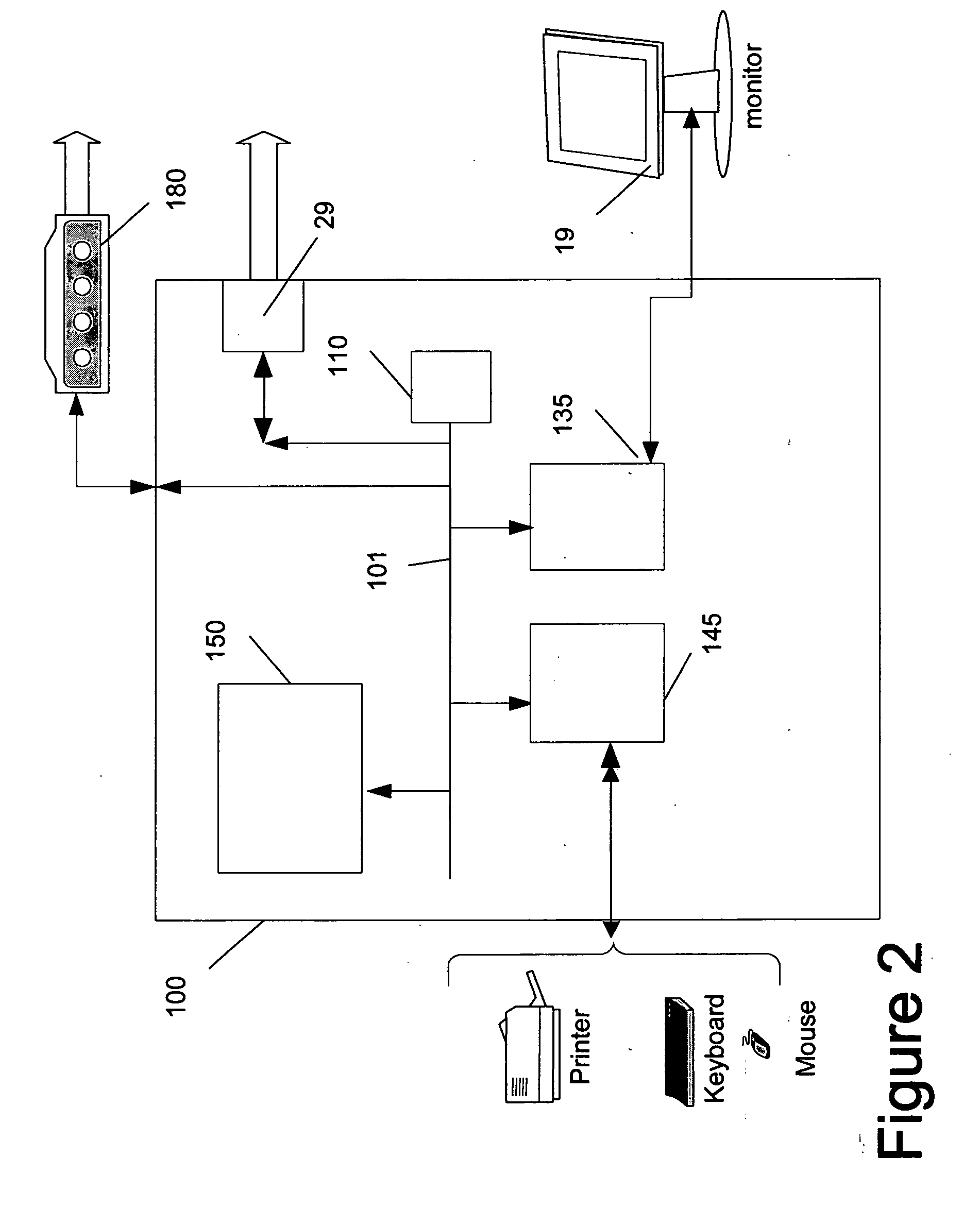

A system is provided for managing a transaction tool for an individual. The system includes a receiver that receives a request from the individual to initiate a process for managing the transaction tool. A processor analyzes the request from the individual and dynamically selects, based upon the requested process, at least one authentication method to be used for authenticating the identity of the individual before the request can be honored. The selected authentication method(s) are used to verify the identity of the individual.

Owner:SBC KNOWLEDGE VENTURES LP

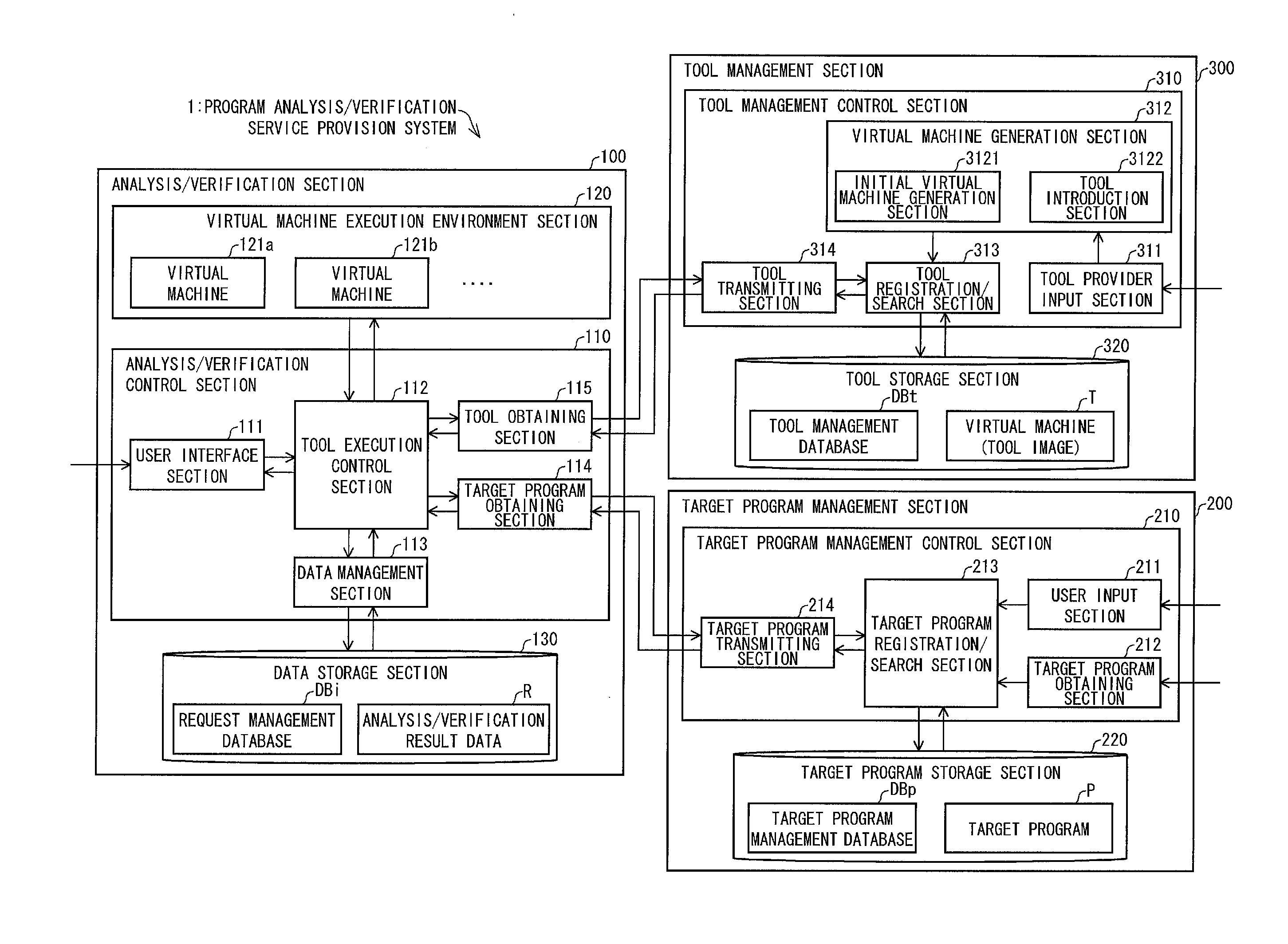

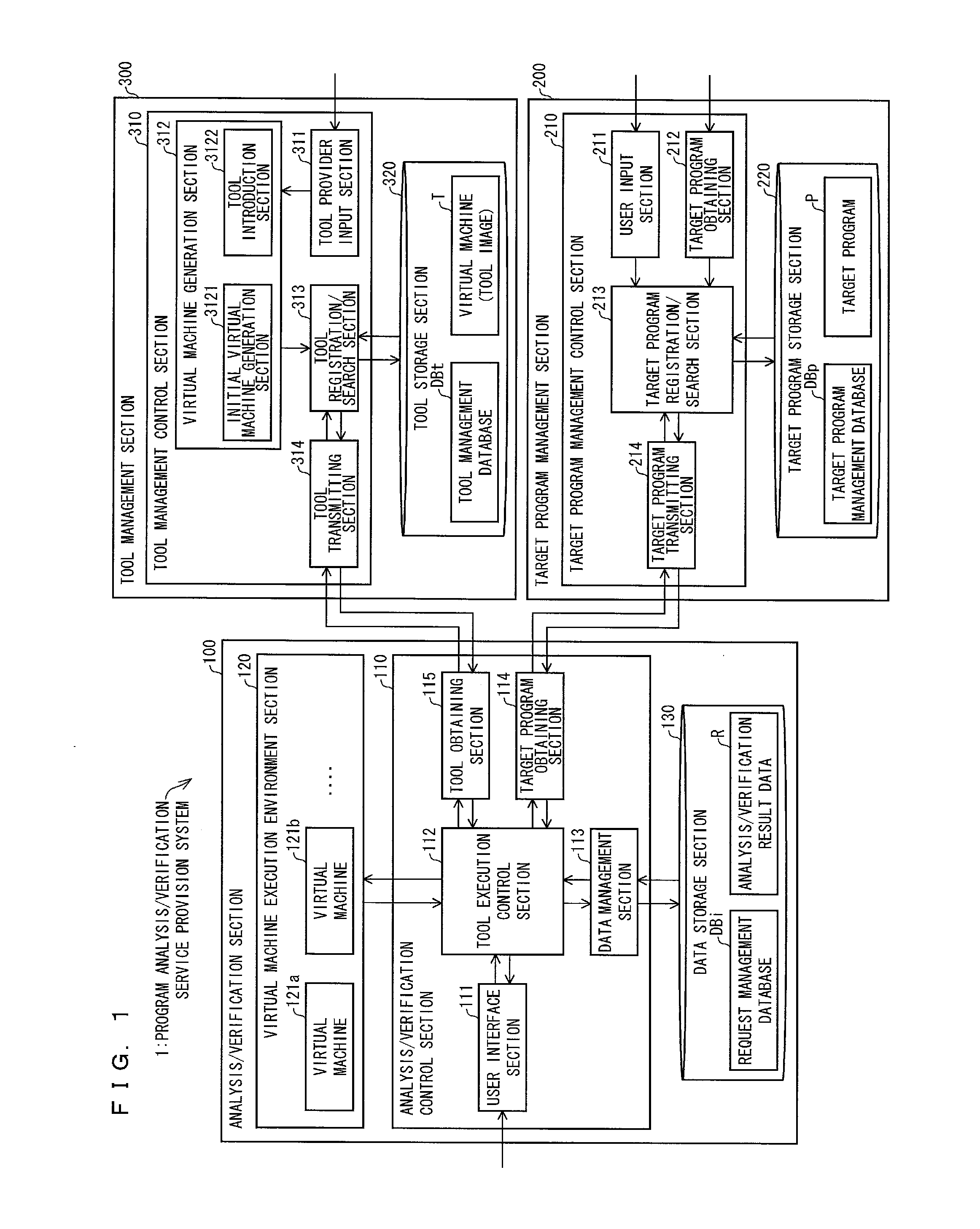

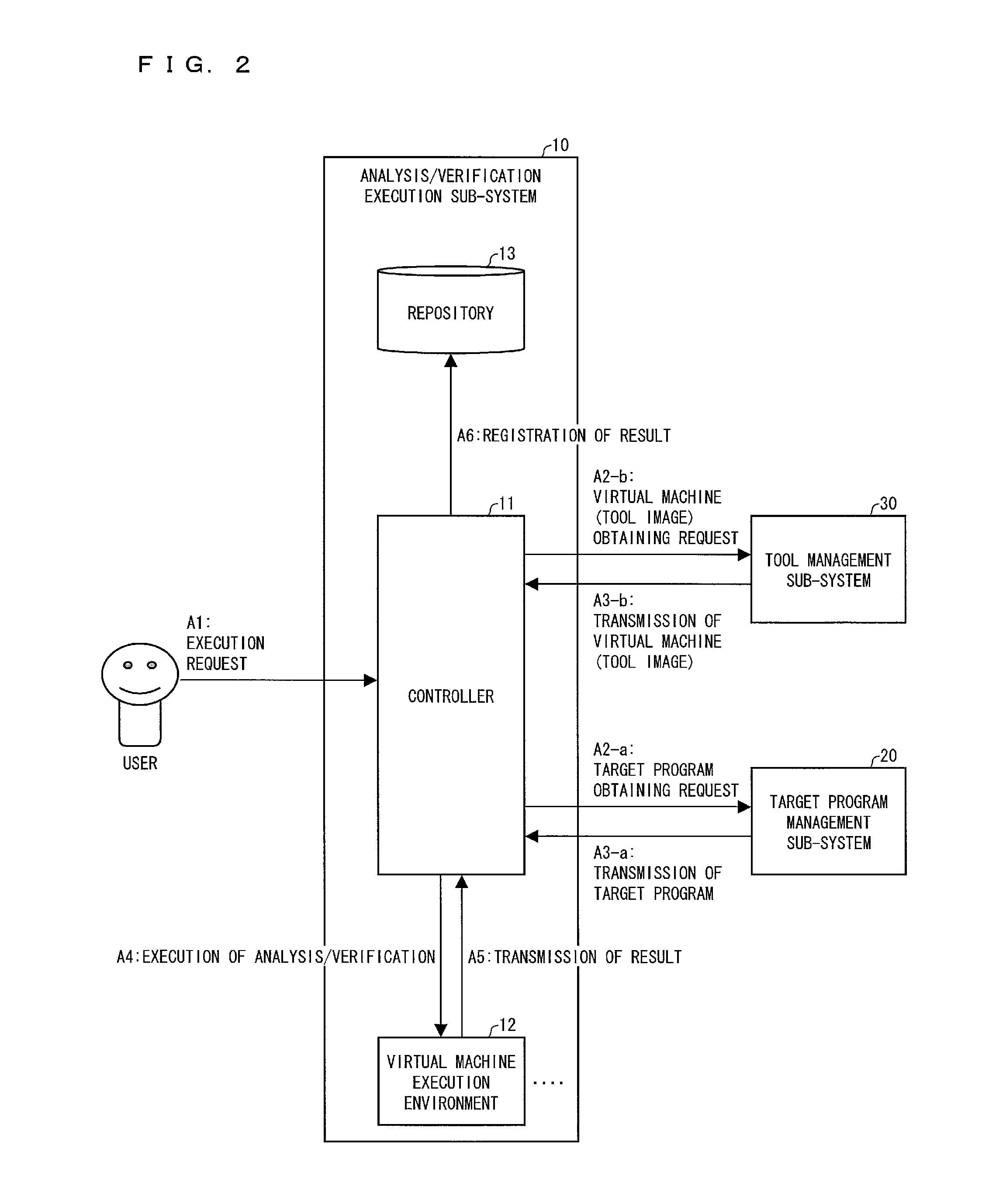

Program analysis/verification service provision system, control method for same, control program, control program for directing computer to function, program analysis/verification device, program analysis/verification tool management device

ActiveUS20140304815A1Easily analyze/verifyMemory loss protectionError detection/correctionService provisionProgram analysis

A program analysis / verification service provision system (1) includes: a tool registration / search section (313) for extracting, from a plurality of program analysis / verification tools (virtual machines) stored in a tool storage section (320), a virtual machine (T) in which a program analysis / verification tool for use in analysis / verification of a target program (P) has been installed and set; and a virtual machine execution environment section (120) for analyzing / verifying the target program (P) with use of the virtual machine (T) thus extracted.

Owner:JAPAN SCI & TECH CORP

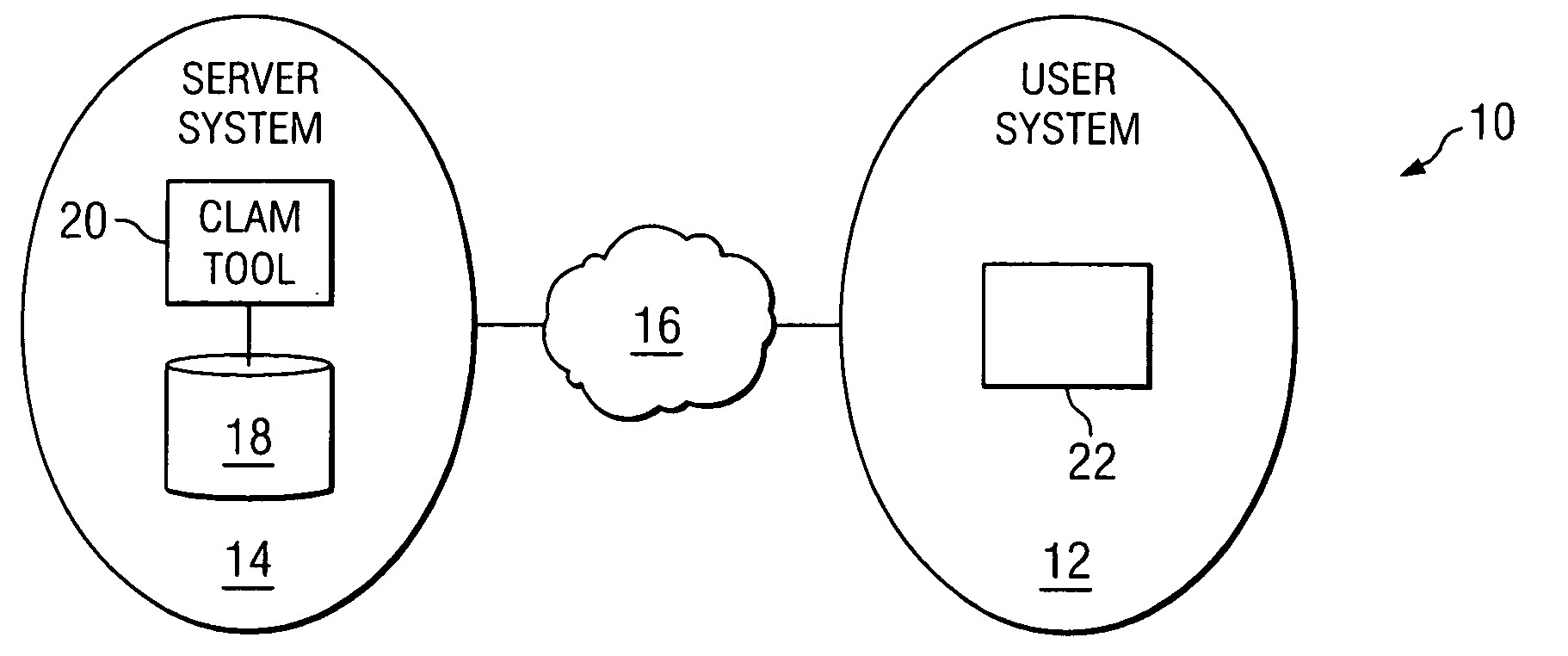

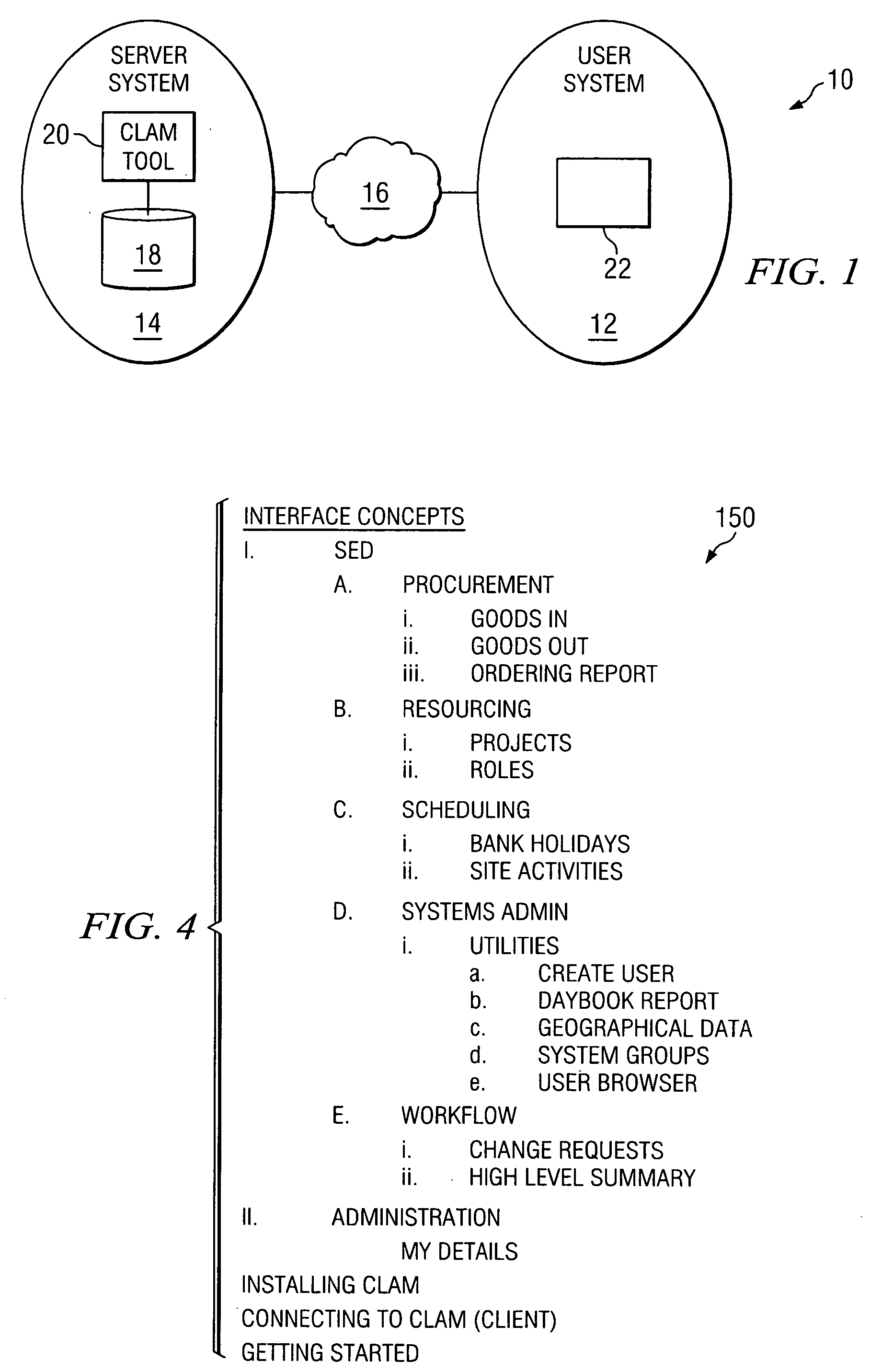

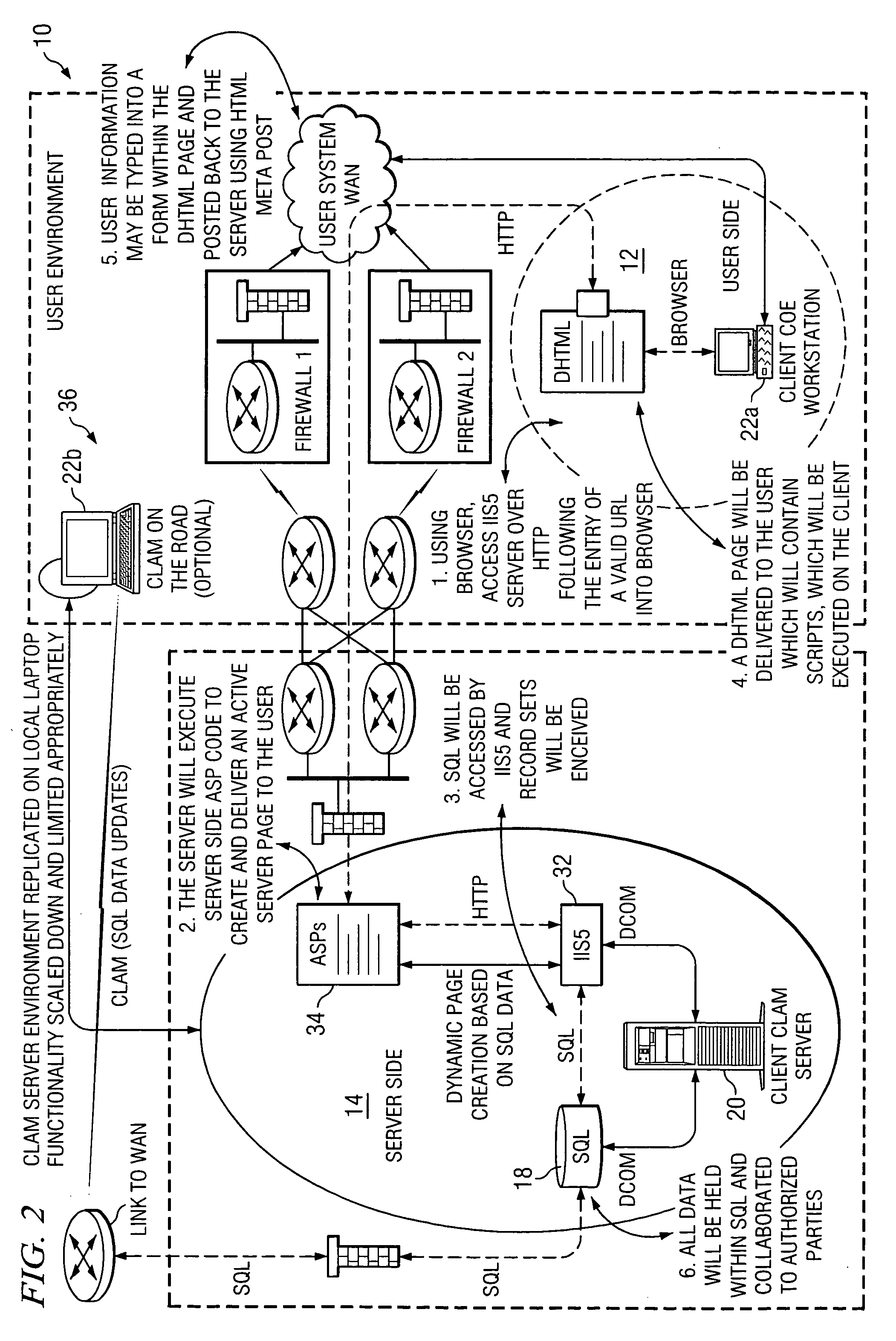

Managing information technology (IT) infrastructure of an enterprise using a centralized logistics and management (CLAM) tool

InactiveUS20050159969A1Disadvantages can be reduced eliminatedReducing and eliminating ambiguity and misunderstandingSpecial data processing applicationsLogistics managementKnowledge management

In one embodiment, a process for managing information technology (IT) infrastructure of an enterprise includes: (1) capturing and storing IT infrastructure information regarding the IT infrastructure of the enterprise; (2) defining a plurality of roles within the enterprise, each role specifying a particular job function within the enterprise; (3) associating items of IT infrastructure with roles within the enterprise such that each role is associated with one or more predetermined items of IT infrastructure; (4) assigning roles to one or more employees of the enterprise such that each of the one or more employees is associated with one or more roles and is assigned the one or more predetermined items of IT infrastructure associated with each of these one or more roles; (5) automatically modeling a change in the IT infrastructure for one or more impacted employees; and (6) automatically initiating deployment of one or more IT infrastructure assets for the one or more impacted employees by organizing delivery of the one or more IT infrastructure assets to the one or more impacted employees to implement the change modeled.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

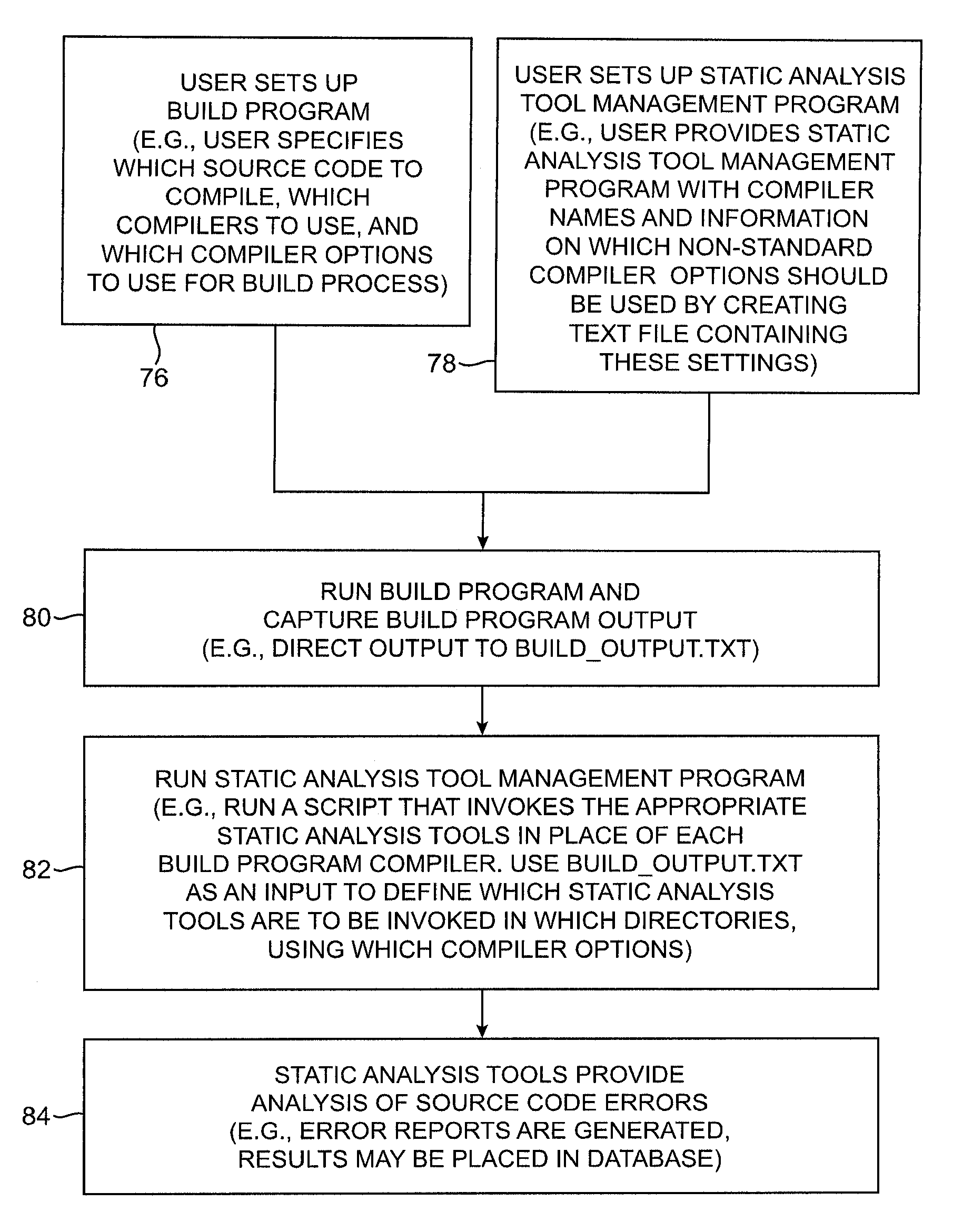

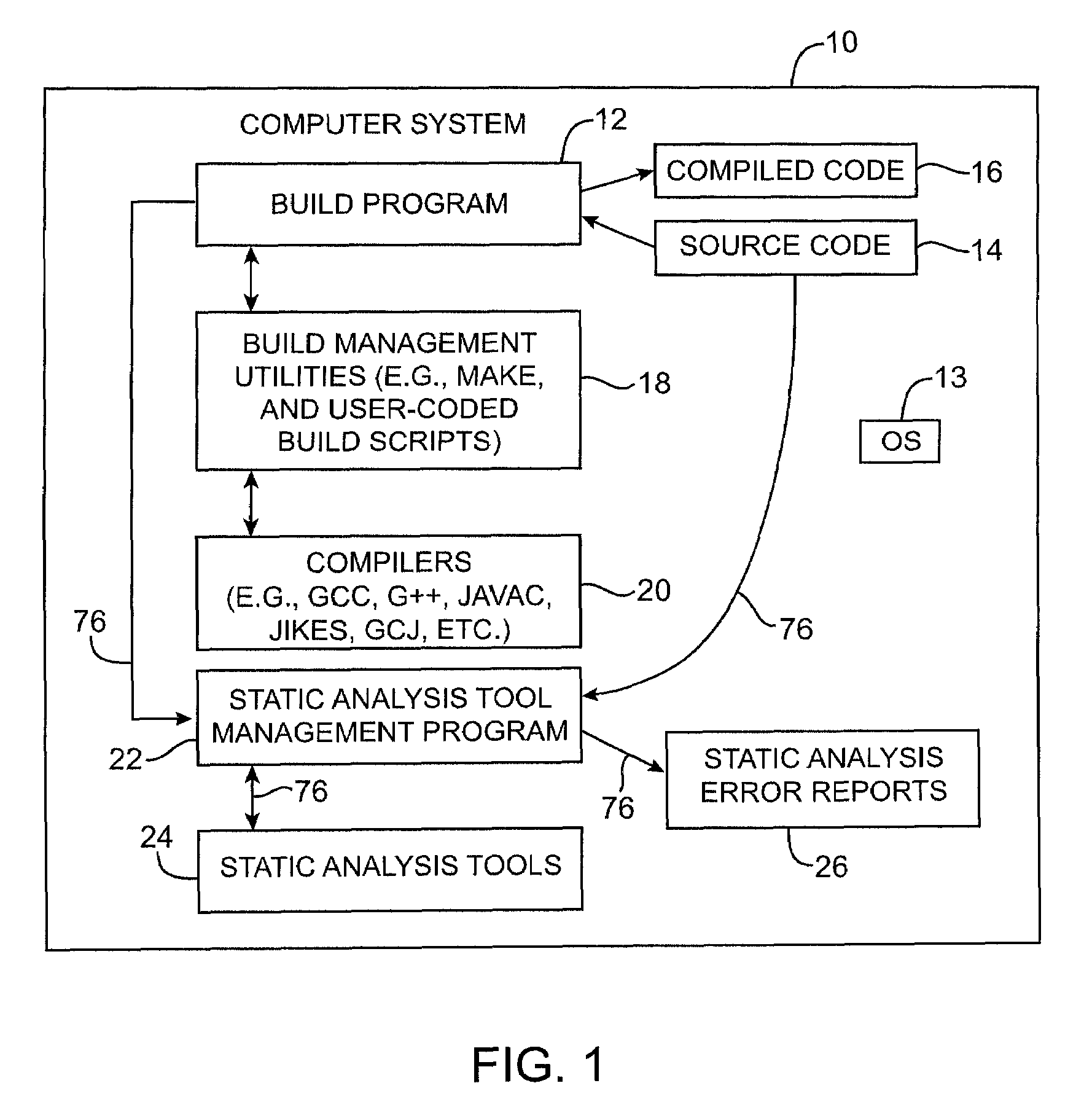

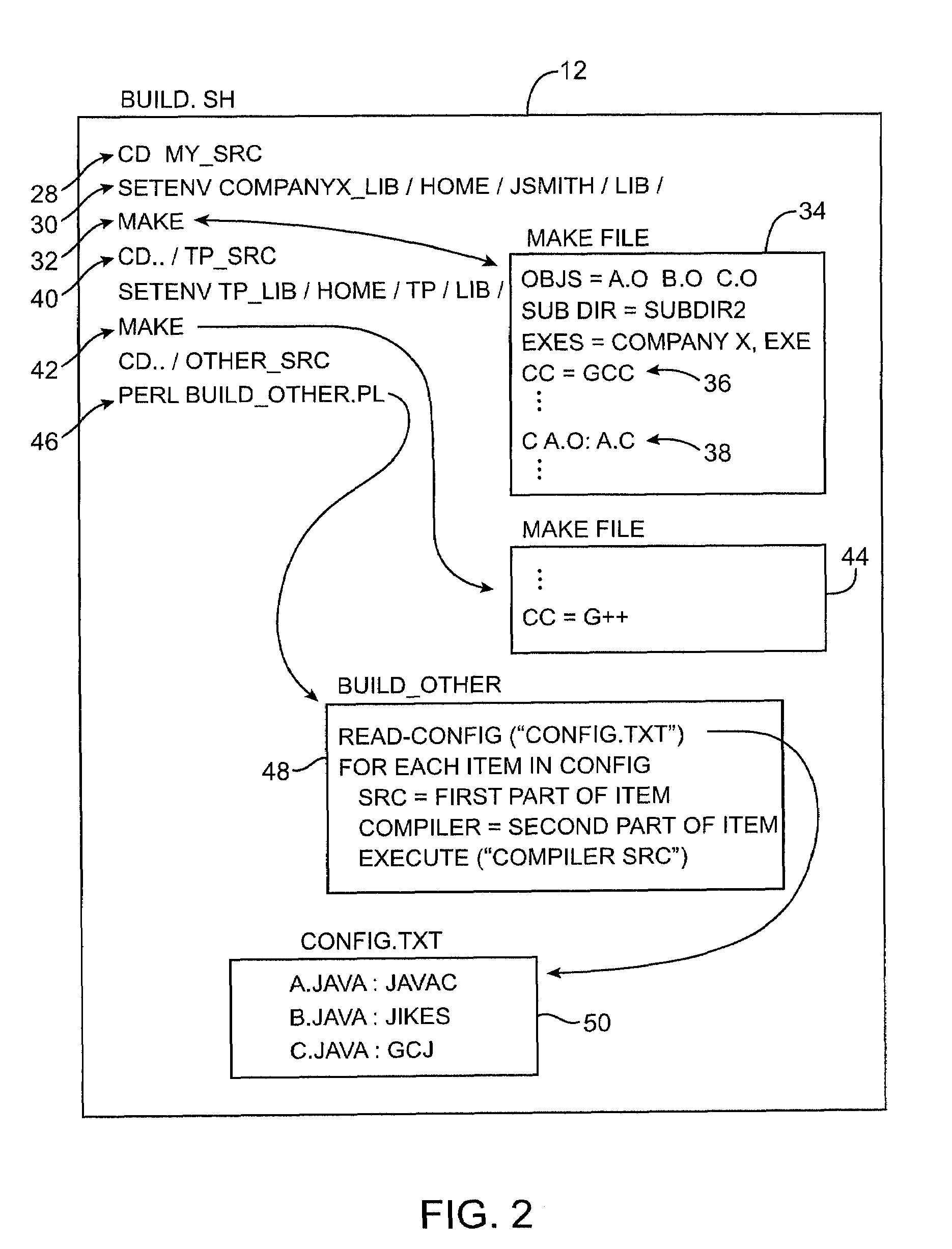

Systems and methods for performing static analysis on source code

Systems and methods are provided for performing static error analysis on source code. A computer system having an operating system may contain a number of source code files. During a normal build process, a build program may be used to set various compilation options and to invoke appropriate compilers that compile the source code files into executable code. Static analysis debugging tools may be used to perform static analysis on the source code files. The appropriate static analysis tools may be invoked using a static analysis tool management program. Directory, path and name modification may be used to invoke the analysis tools. A monitoring program may be used to determine how to invoke the tools. The operating system may be modified so that the static analysis tools are invoked in place of the compilers when the build program is run.

Owner:SYNOPSYS INC

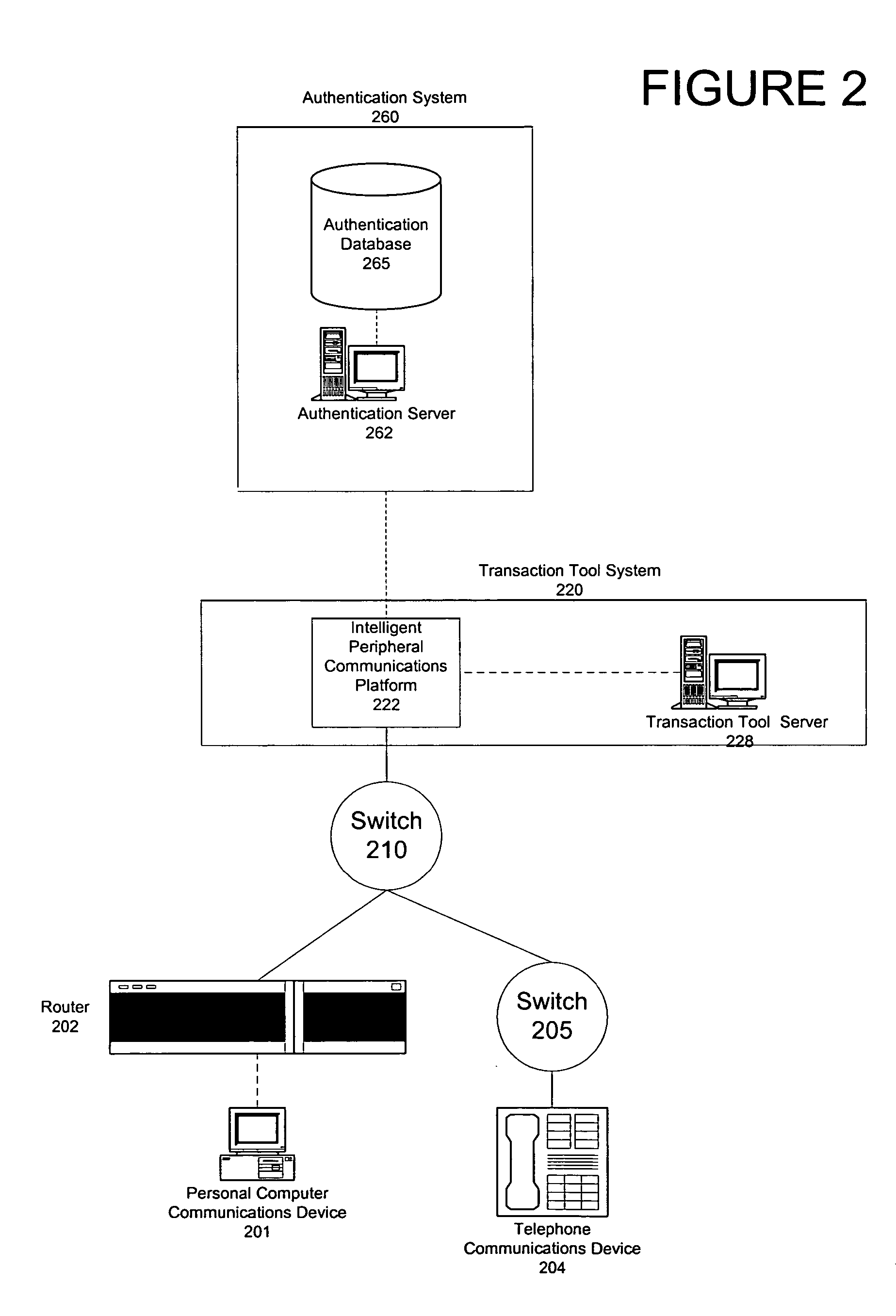

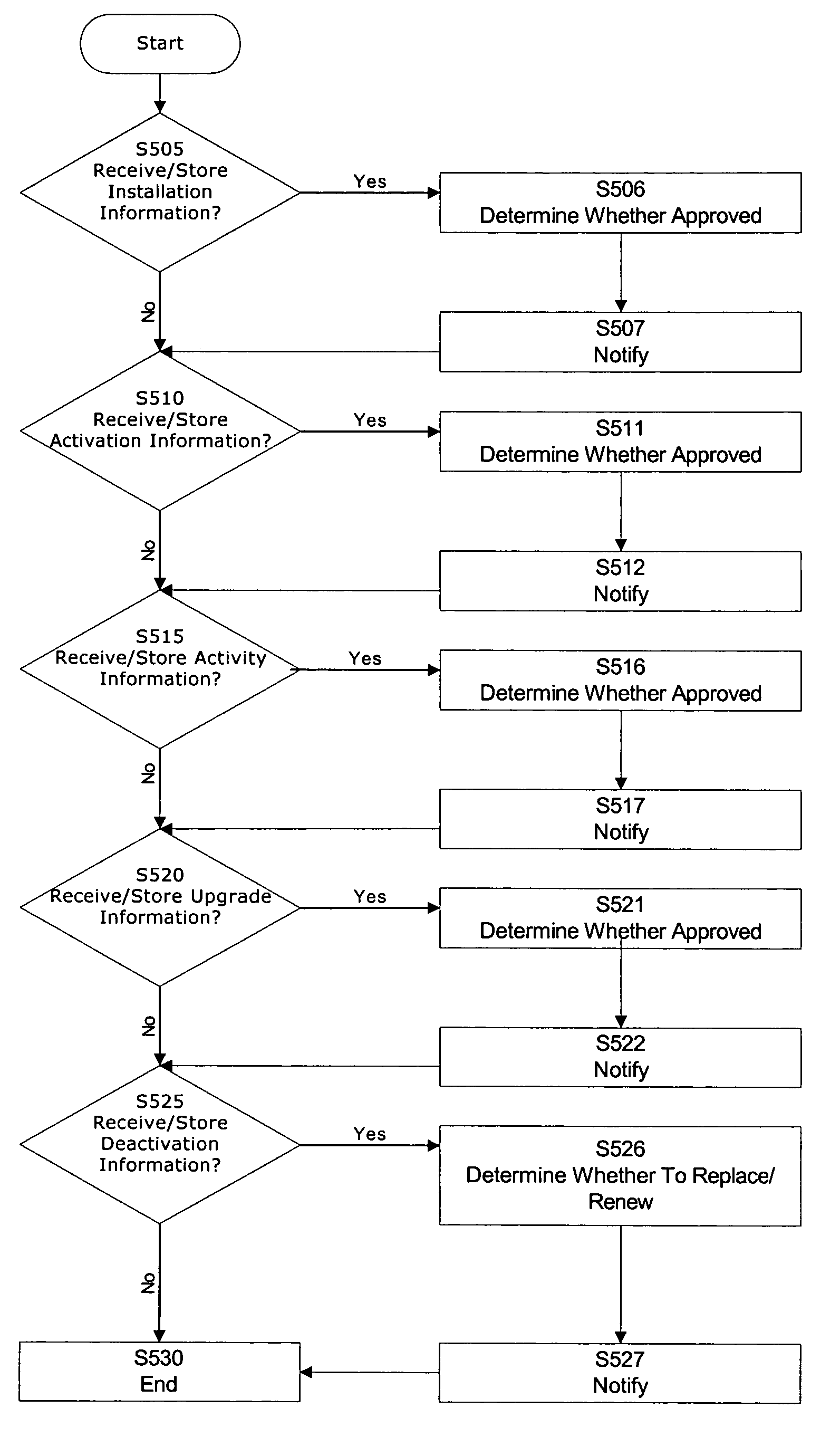

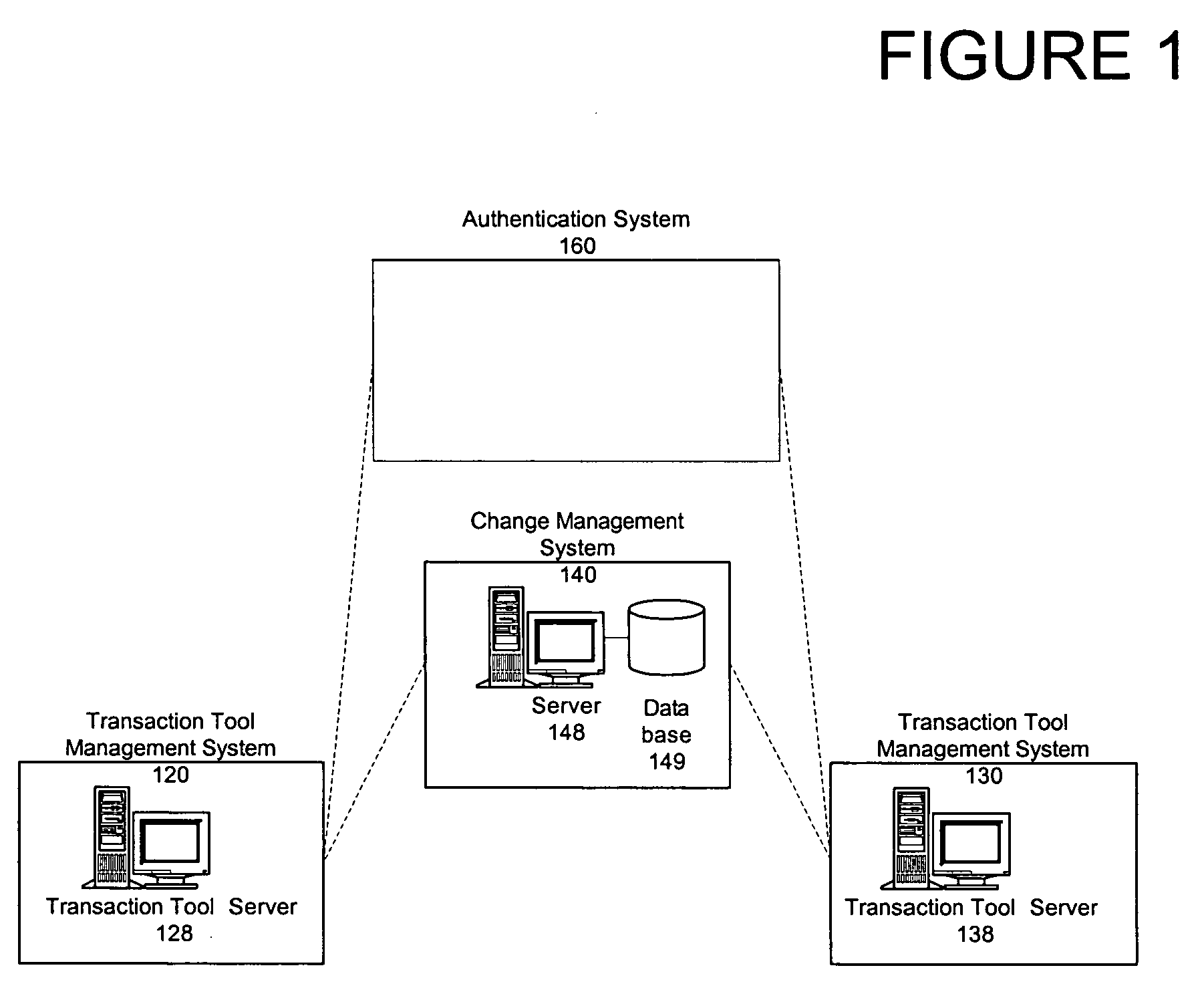

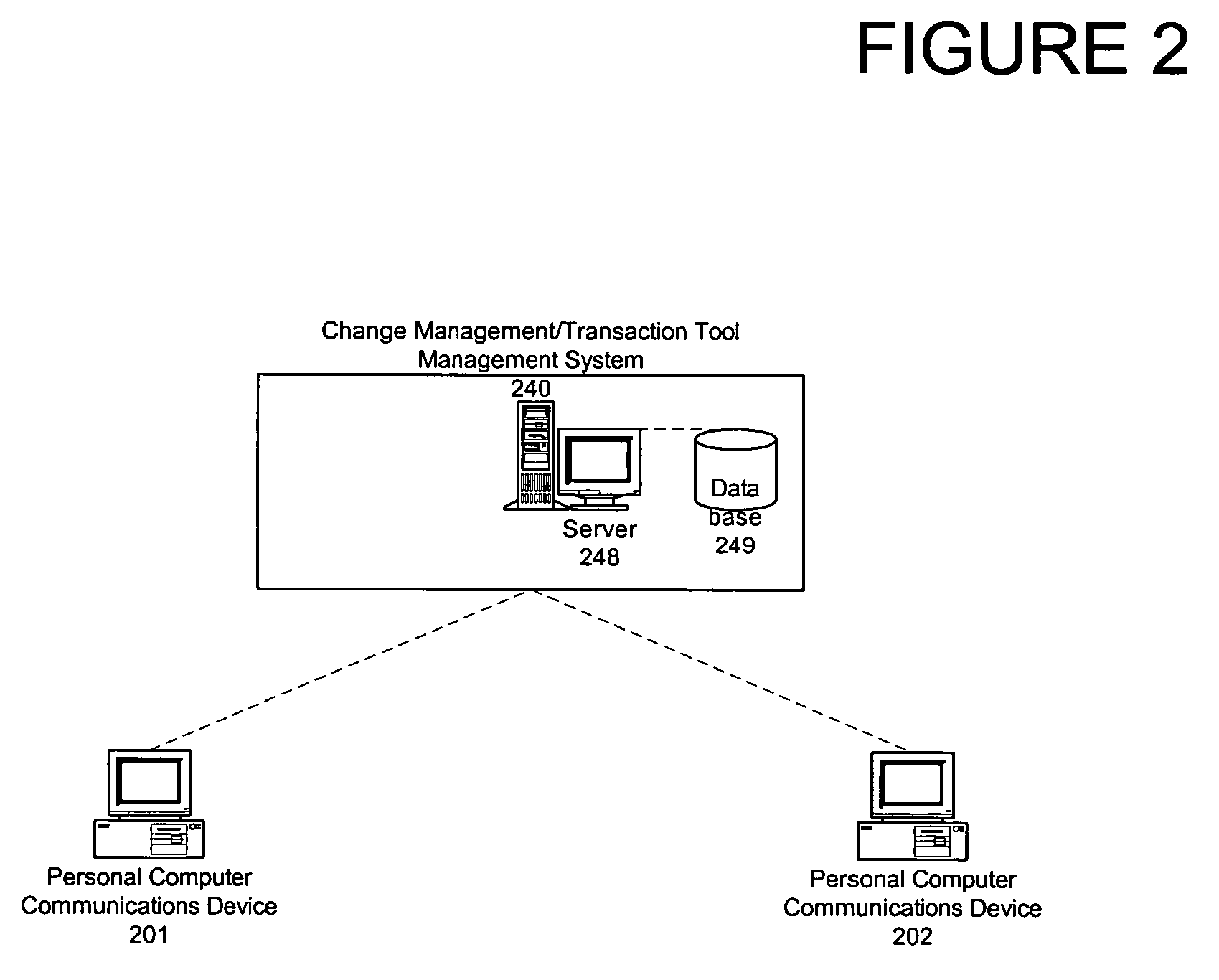

Transaction tool management integration with change management

InactiveUS20060095923A1Multiprogramming arrangementsMultiple digital computer combinationsChange managementManagement system

A change management system coordinates information of a transaction tool managed by a transaction tool management system. The system includes a receiver that receives, over a communications network, activity information and / or lifecycle event information for the transaction tool. The system also includes a storage that stores the received information. Additionally, the system includes a processor that manages a change in a status of the transaction tool based on the received information.

Owner:SBC KNOWLEDGE VENTURES LP

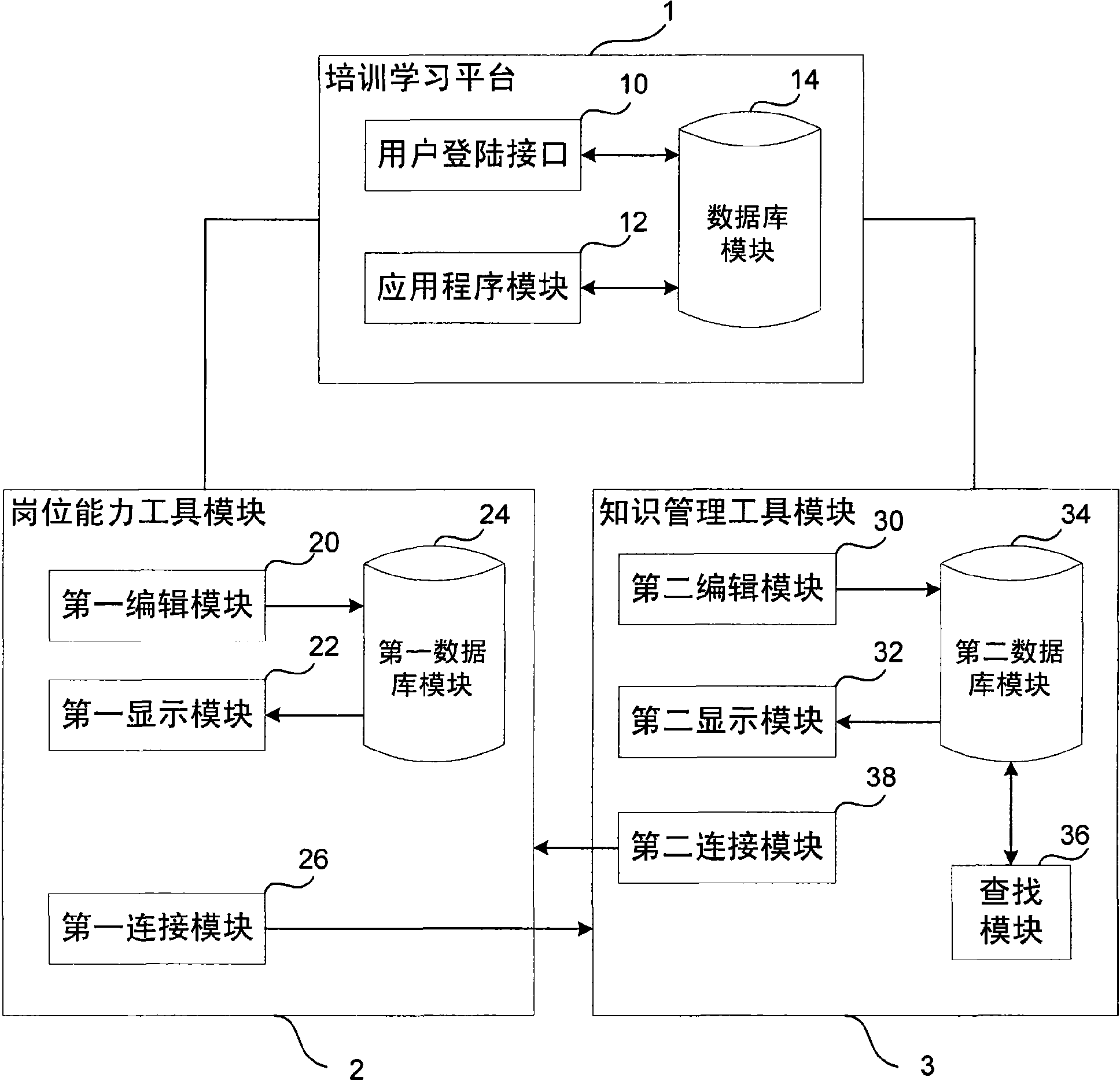

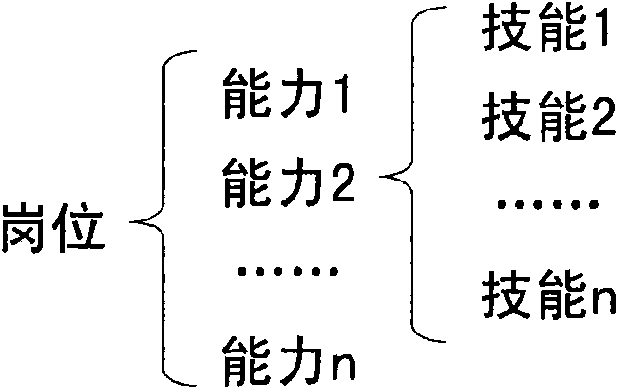

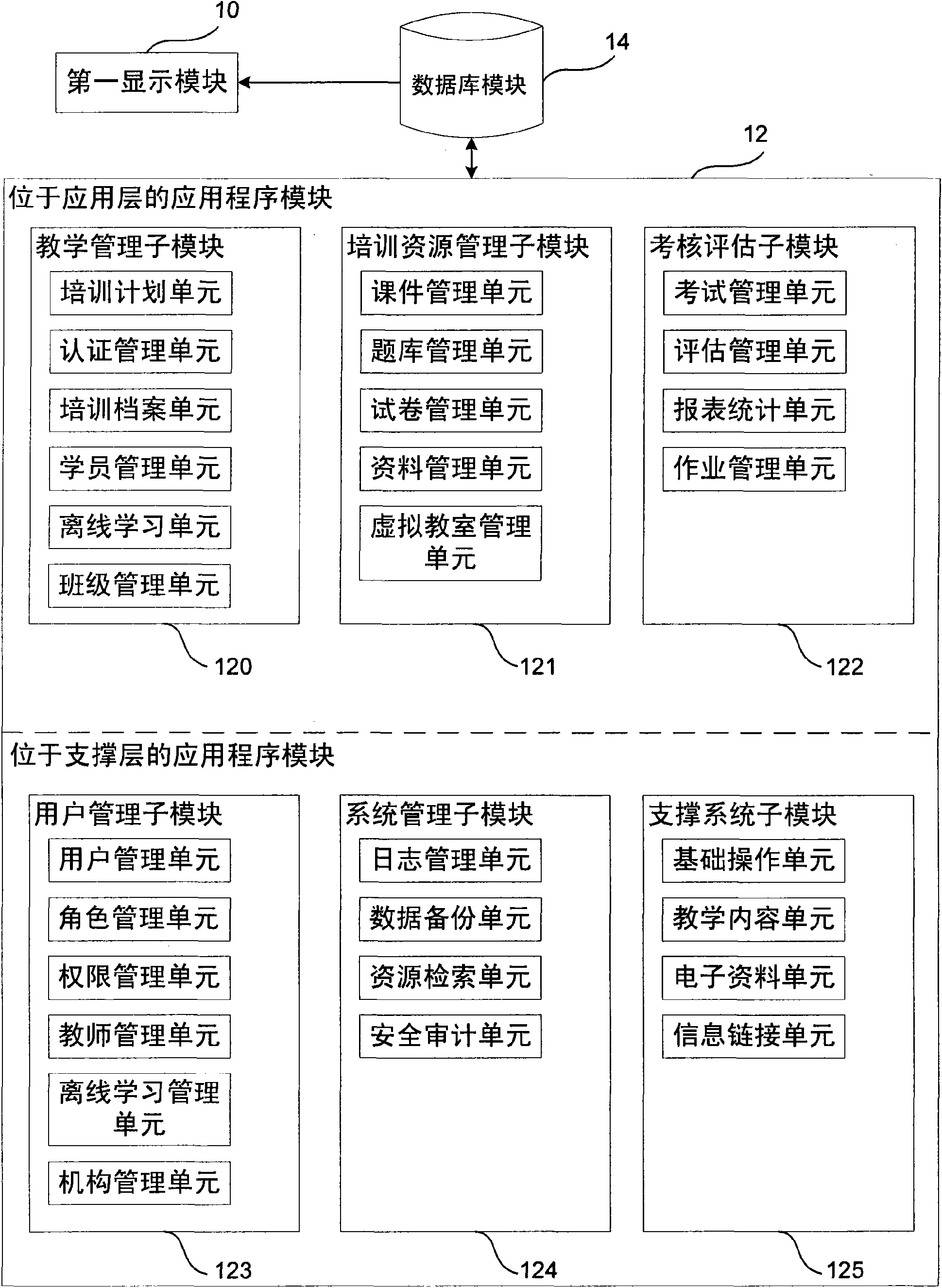

Learning management system based on competency model and knowledge management

InactiveCN101661589AMeet Career DevelopmentGuaranteed pertinenceData processing applicationsElectrical appliancesManagement toolButt joint

The invention discloses a learning management system based on a competency model and knowledge management, which realizes butt joint of enterprise strategies and learning. The technical scheme is as follows: the system comprises a training and learning platform comprising a user login interface; an application program module comprising a trainee information addition module and a database module; apost capability tool module comprising a first database module for storing posts, capability and skills; a first editting module for editing correlation of the posts, the capability and the skills; afirst display module for displaying correlation of the posts, the capability and the skills; a first connecting module for allowing knowledge point operation to enter a knowledge management tool module, wherein, the knowledge management tool module comprises a second database module for storing the knowledge points and courses; a second editing module for editing correlation of the knowledge points and the skills, the knowledge points and the courses; a second display module for displaying correlation of the skills, the knowledge points and the courses and knowledge point contents; and a second connecting module for allowing skill operation to enter the post capability tool module.

Owner:上海一佳一网络科技有限公司

System for creating, managing and executing computer testing and task management applications

InactiveUS7343587B2Easy to createImprove development efficiencyError detection/correctionMultiprogramming arrangementsTest suiteParallel computing

A system stored on a computer-readable storage medium for testing computer software, including: a plurality of heterogeneous test tools; a testing application that provides an interface that enables a user to collectively access each of said plurality of heterogeneous test tools; and a plurality of modules that interact with the testing application for creating and modifying, via said interface, a test that is implemented with said plurality of test tools, including: a tool manager module for selecting one or more tools, from among said plurality of test tools, to be employed in a test; a case manager module for selecting test cases, each comprising an elemental executable test, that are performed by selected tools, for inclusion in the test; and a suite manager module for creating, modifying and selecting test suites, each comprising at least one group of selected test cases, to be executed during the test.

Owner:APPLE INC

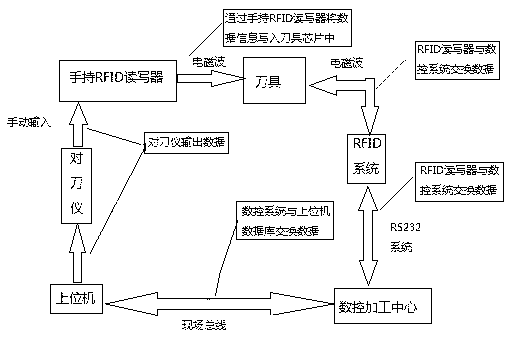

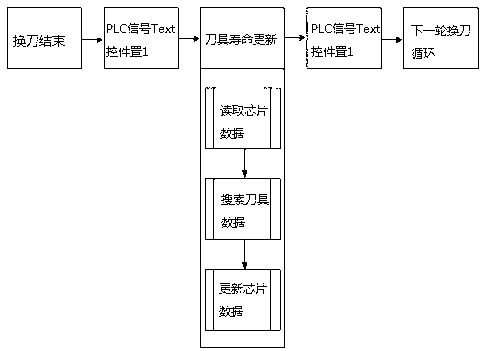

RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of Siemens 840D numerical control system

InactiveCN103076764AImprove entry efficiencyImprove accuracyProgramme controlComputer controlTerra firmaReader writer

The invention belongs to the technical field of machine tools and particularly relates to an RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of a Siemens 840D numerical control system. Through research on an RFID automatic identification technology and integration with a numerical control system, a tool in a machining center is automatically identified. An RFID reader-writer selected by the invention is a BIS-C-600 type reader-writer produced by Germany BALLUFF company, an automatic tool identification technology is integrated in a numerical control system, tool information is automatically identified and tool key data is read and input to the numerical control system of the machining center, and thus the accuracy and efficiency of tool information entry are effectively improved; and life monitoring data in the numerical control system is written an RFID chip, thus a tool which is discarded or approaches the life limit is effectively prevented from being misused, and the risks that the machining quality of products is reduced and even the production safety accidents are caused are avoided. The firm foundation is laid for further realizing the tool network-based management of the whole workshop.

Owner:TONGJI UNIV

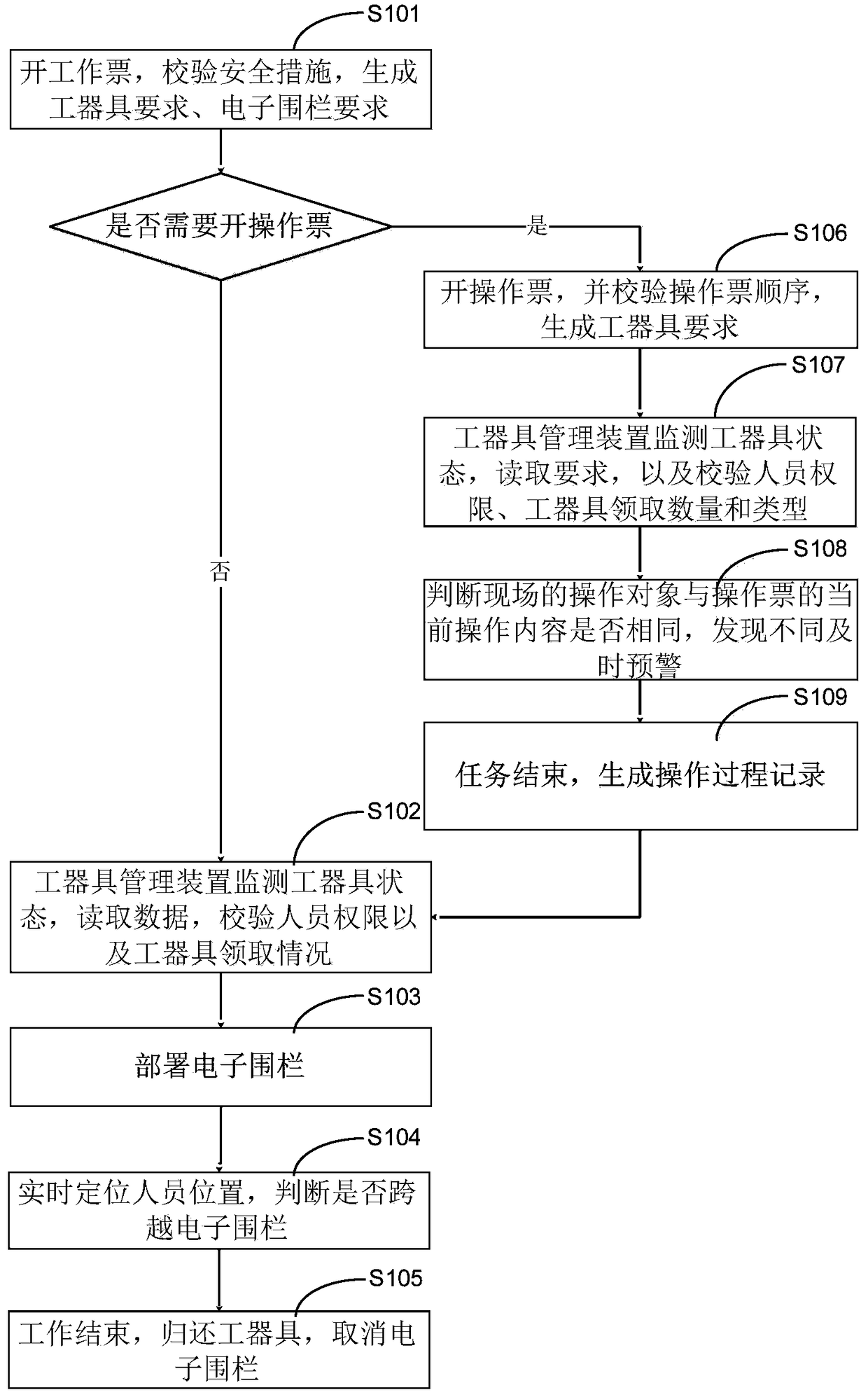

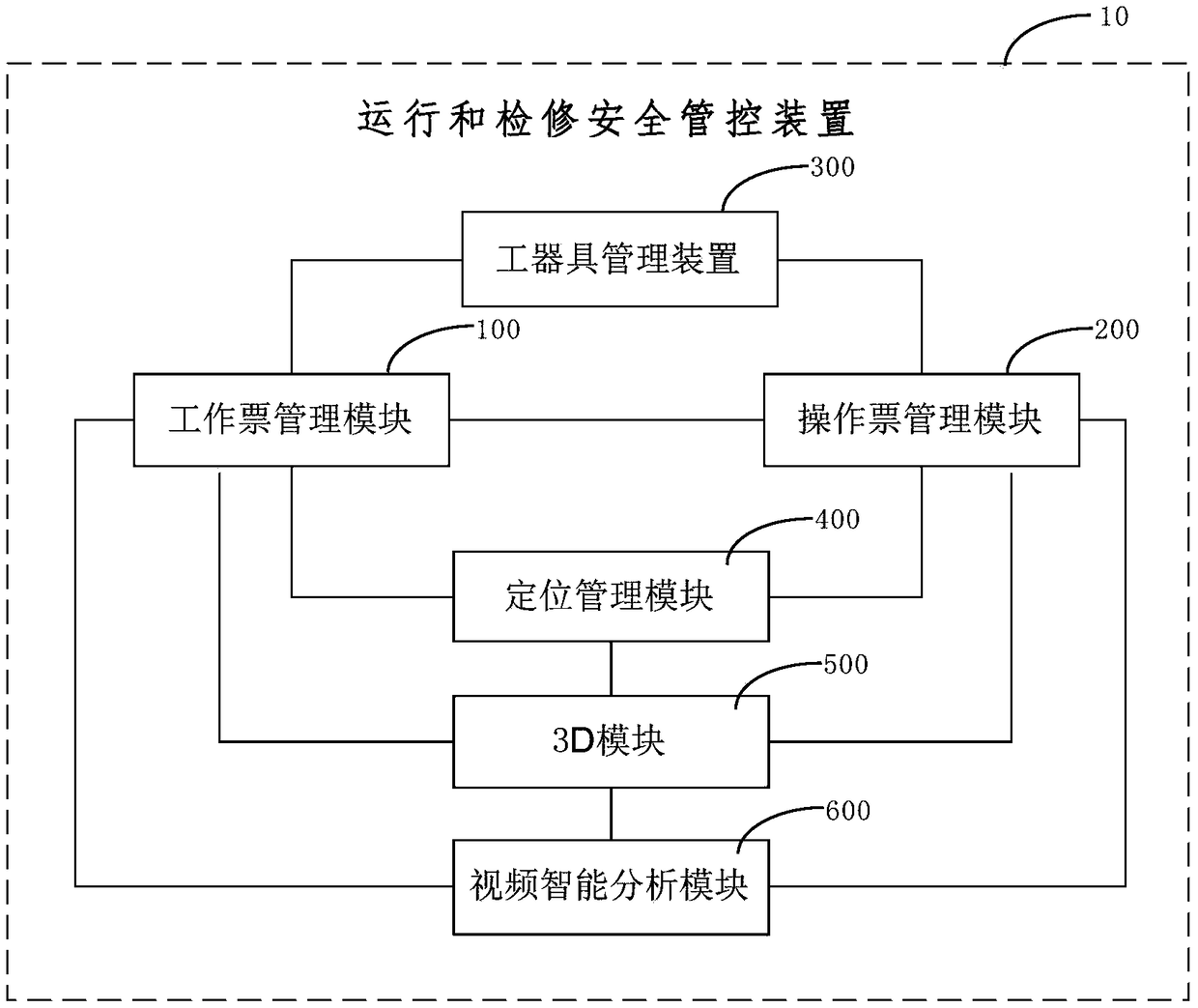

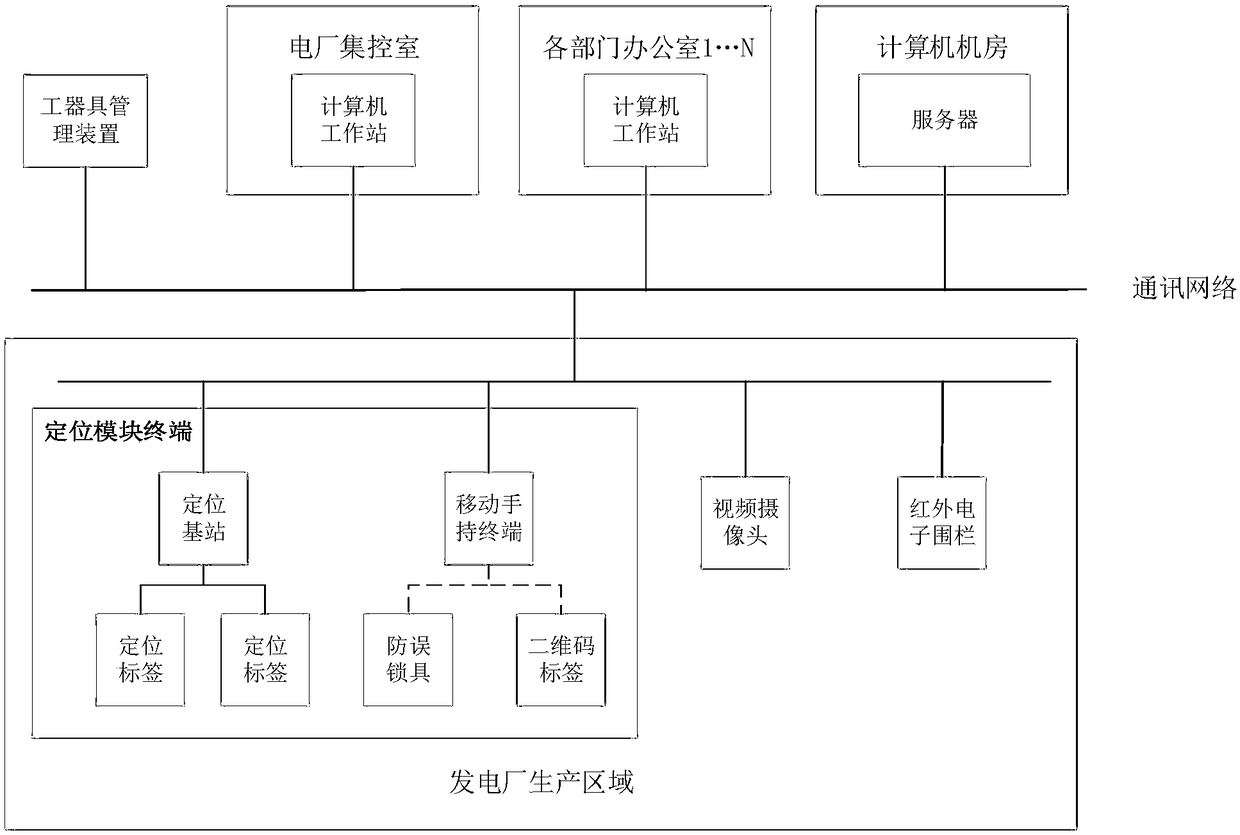

Operation and maintenance safety control device, system and method

ActiveCN108960554AComprehensive understanding of comprehensive dynamic informationReal-time grasp of production process risksResourcesSafety controlSecurity Measure

The present invention provides an operation and maintenance safety control device, system and method. A work ticket and an operation ticket of a main production task are taken as a main line. The total process control method from a billing source to execution ending comprises the following steps of: making out a work ticket, verifying a safety measure item, generating a tool requirement comprisingthe number, the type and the personnel access, and generating an electronic fence requirement comprising the deployment position, the range, the time and the personnel access; monitoring a safety tool state by a tool management device, reading the tool requirement, and verifying a tool receiving tool comprising the number, the type and the personnel access of the tool; deploying the electronic fence according to the electronic fence requirement; locating the personnel position in real time, determining the personnel access passing through the electronic fence, wherein alarm for prompting is performed if authorized officers pass through the electronic fence, or else, the alarm is not performed; finishing the work, and cancelling the electronic fence.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

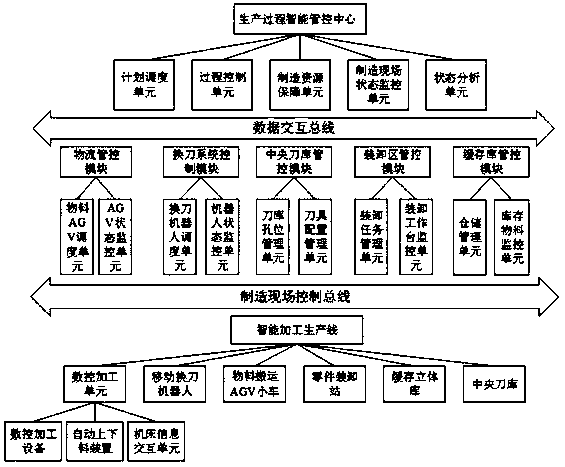

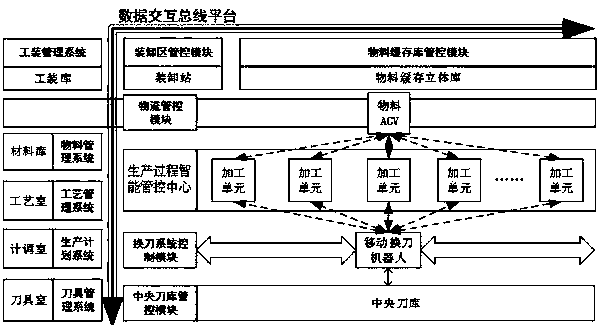

Intelligent control system for large-scale structural component automatic production line

ActiveCN109917770AReasonable architecture designRealize scientific managementElectric/hybrid propulsionTotal factory controlData acquisitionTool management

The invention discloses an intelligent control system for a large-scale structural component automatic production line. The intelligent control system is characterized by comprising an intelligent machining production line, a production process intelligent control center, a logistics control module, a tool change system control module, a central tool magazine control module, a loading and unloading area control module, a material cache library management module, a tooling management system, a material management system, a process management system, a production planning system and a tool management system. Through the reasonable design of the overall architecture, the intelligent control system structures the overall intelligent management and control mode of a workshop automation production line manufacturing site from three aspects of manufacturing site state data acquisition, process intelligent decision, and overall operational state analysis, so as to solve the large-scale structural component automatic production line manufacturing resources guarantee problem.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Paper-free three-dimensional assemblage process document accomplishing method

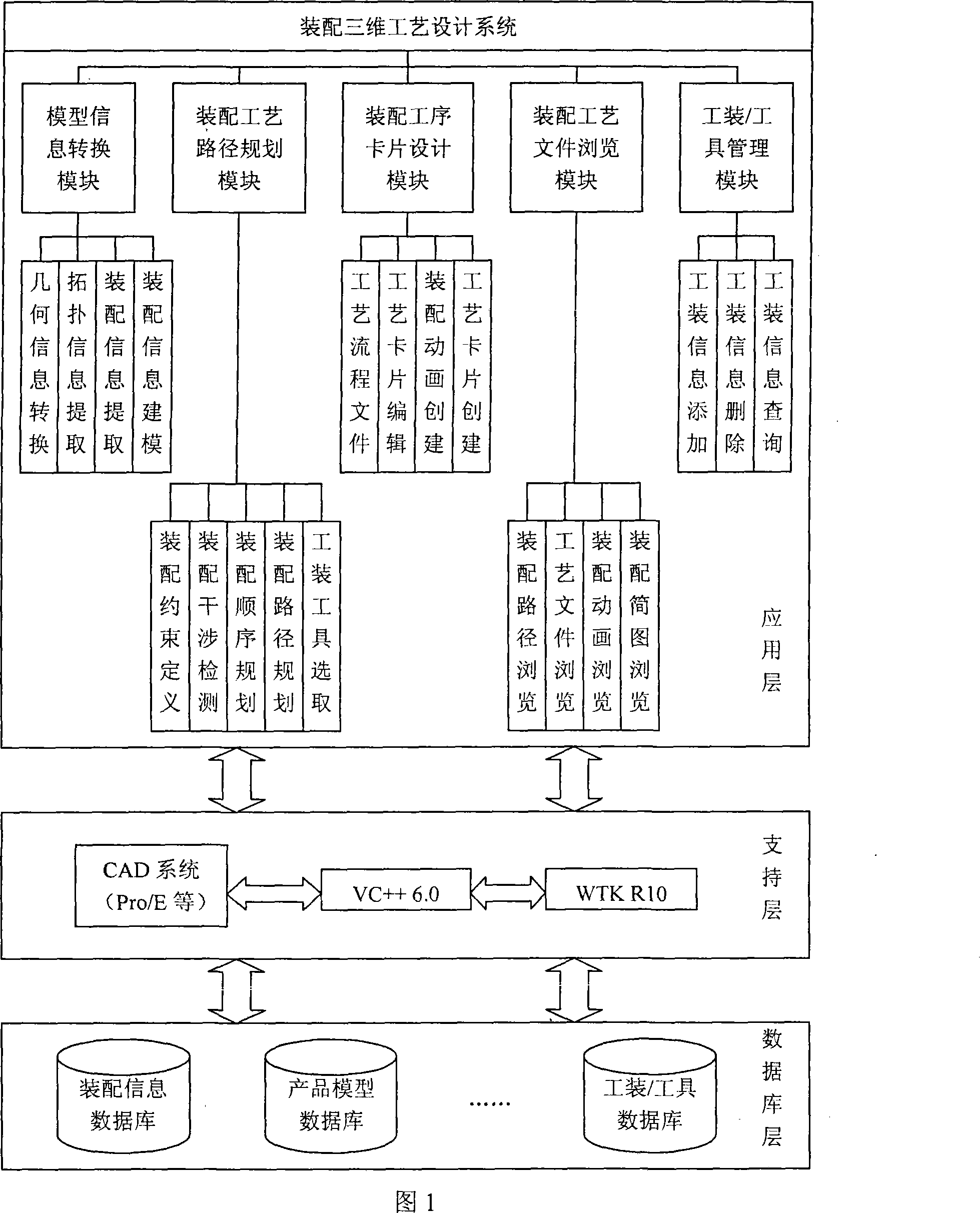

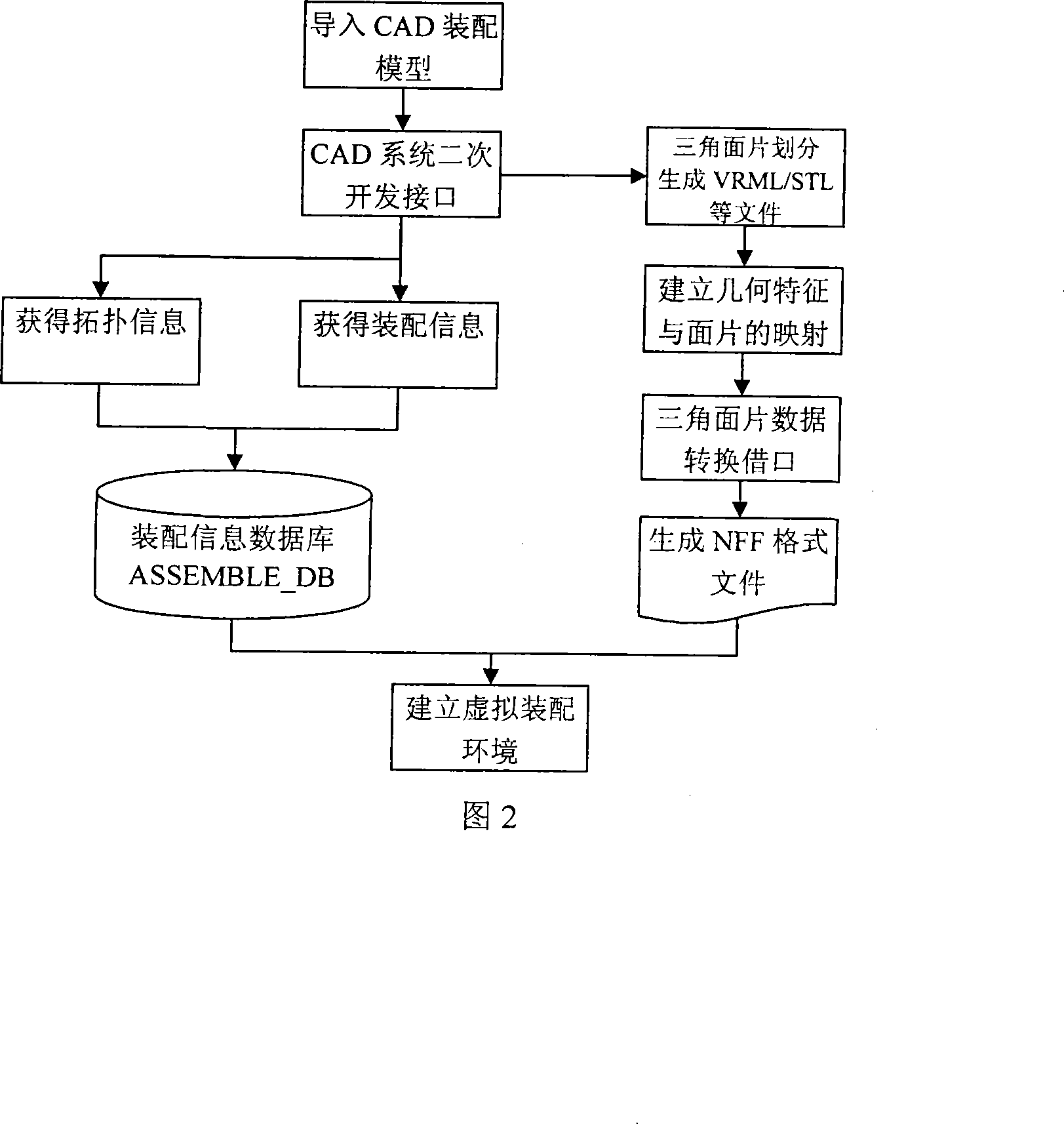

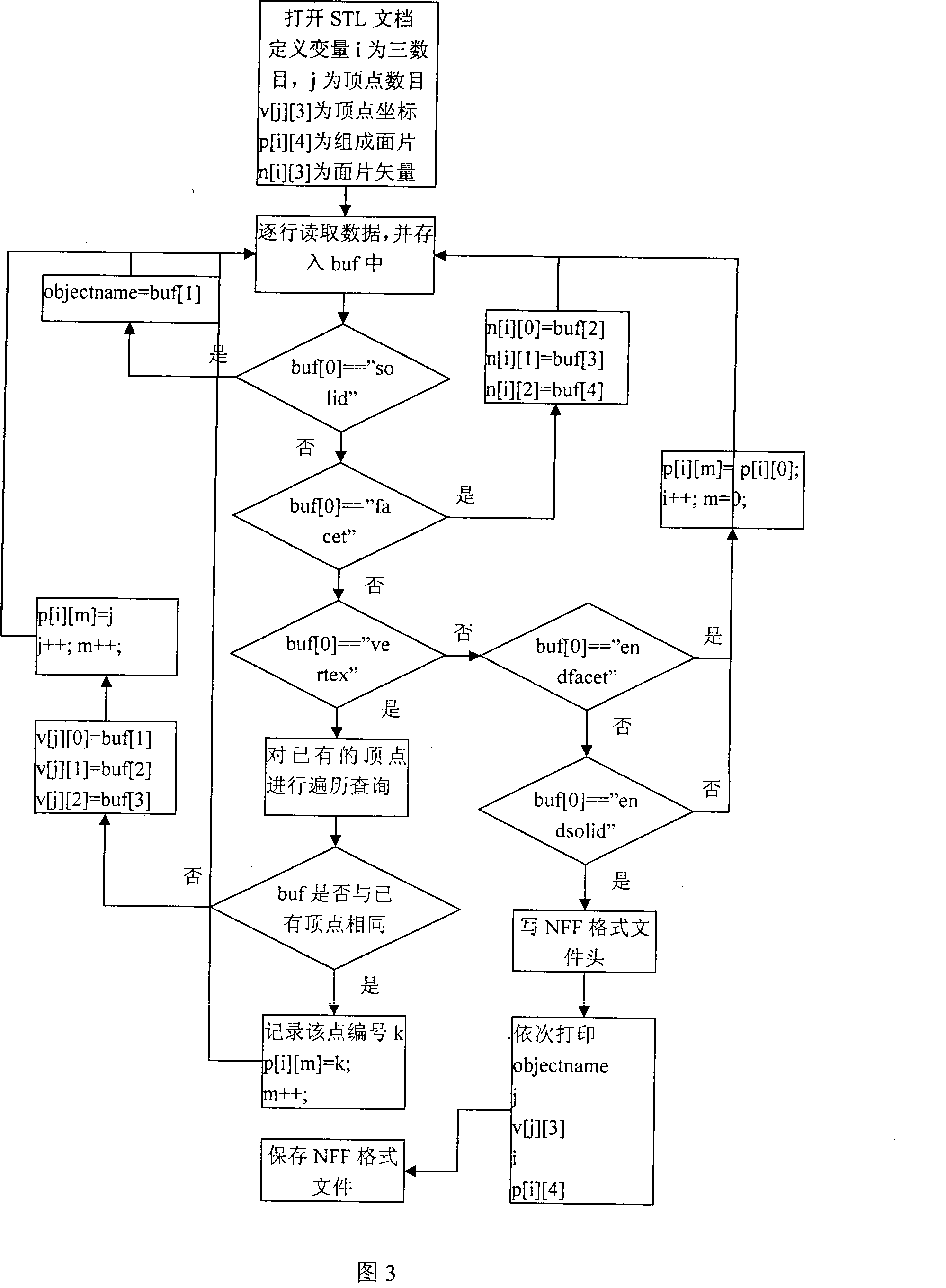

InactiveCN101216862AVerify feasibilityEasy to compileSpecial data processing applicationsFile designAnimation

Aiming to meet the current demand of three-dimensional assembly system and to address the problem that the two-dimensional paper process file cannot reflect the assembly details and requirements intuitively, the invention discloses a non-paper three-dimensional assembly-process file design method which makes three-dimensional process planning for the assembly resources of model products intuitively and interactively and generates three-dimensional assembly cards and assembly process animation. The software comprises (1) a model information conversion module, (2) an assembly process path planning module, (3) an assembly process card design module, (4) an assembly process file browsing module and (5) frock or tool management module. The invention solves the problem that two-dimensional paper process file cannot reflect the assembly details and requirements intuitively and is not beneficial for operators understanding and using. The invention is characterized by good intuition and interaction, through which the process operators can establish three-dimensional process files easily by introducing CAD design model and which acts as a teaching role to the operators on assembly site.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

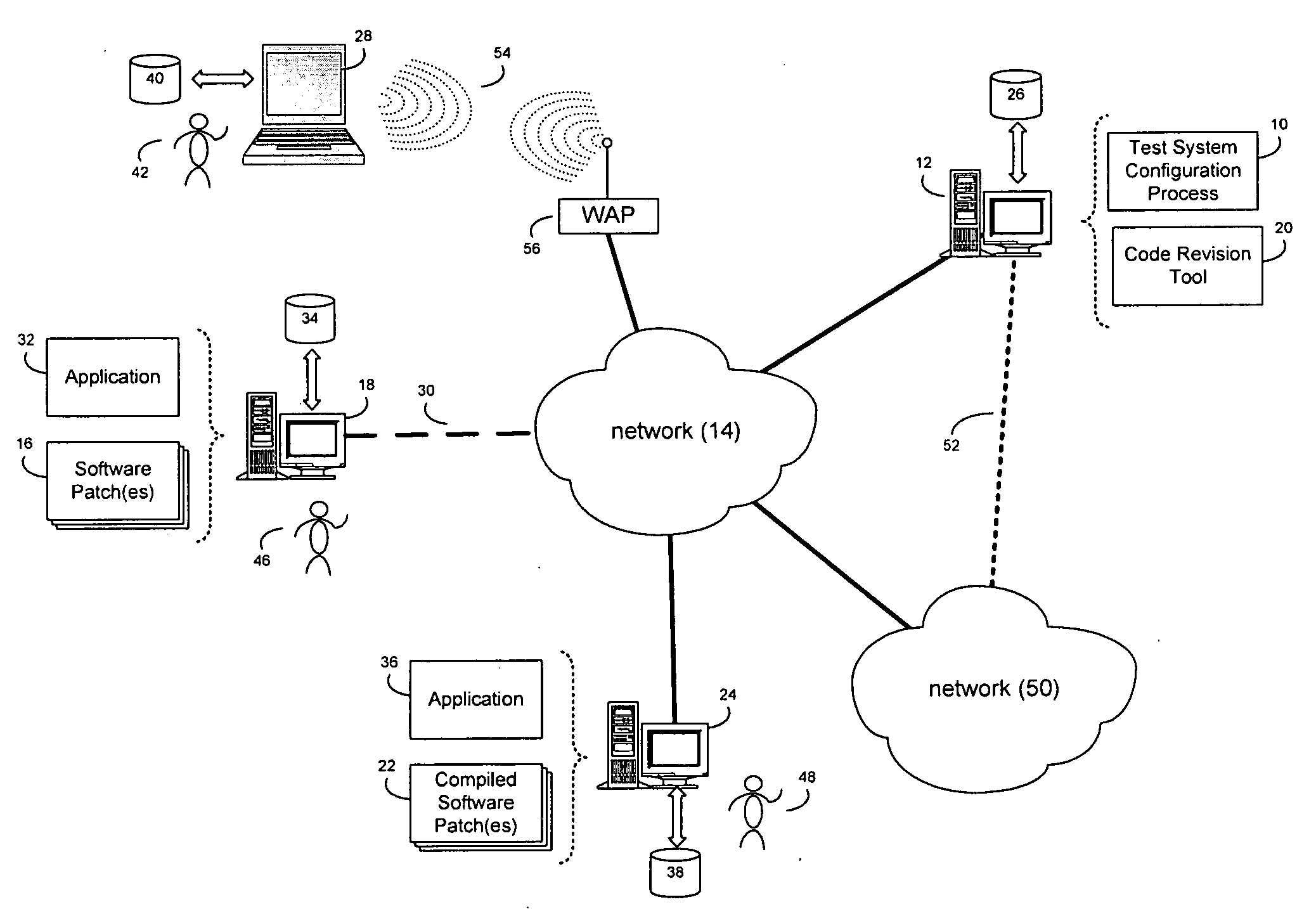

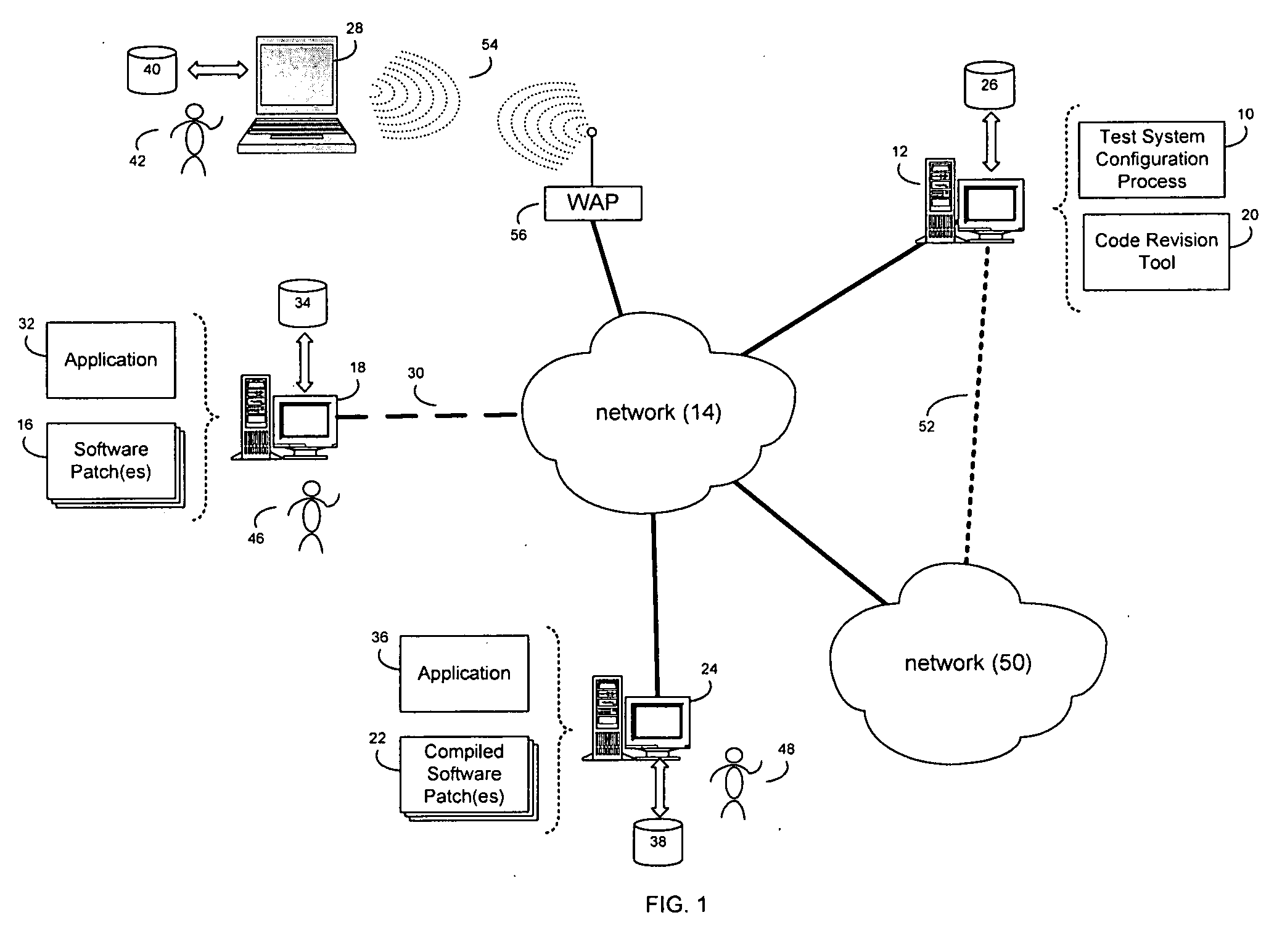

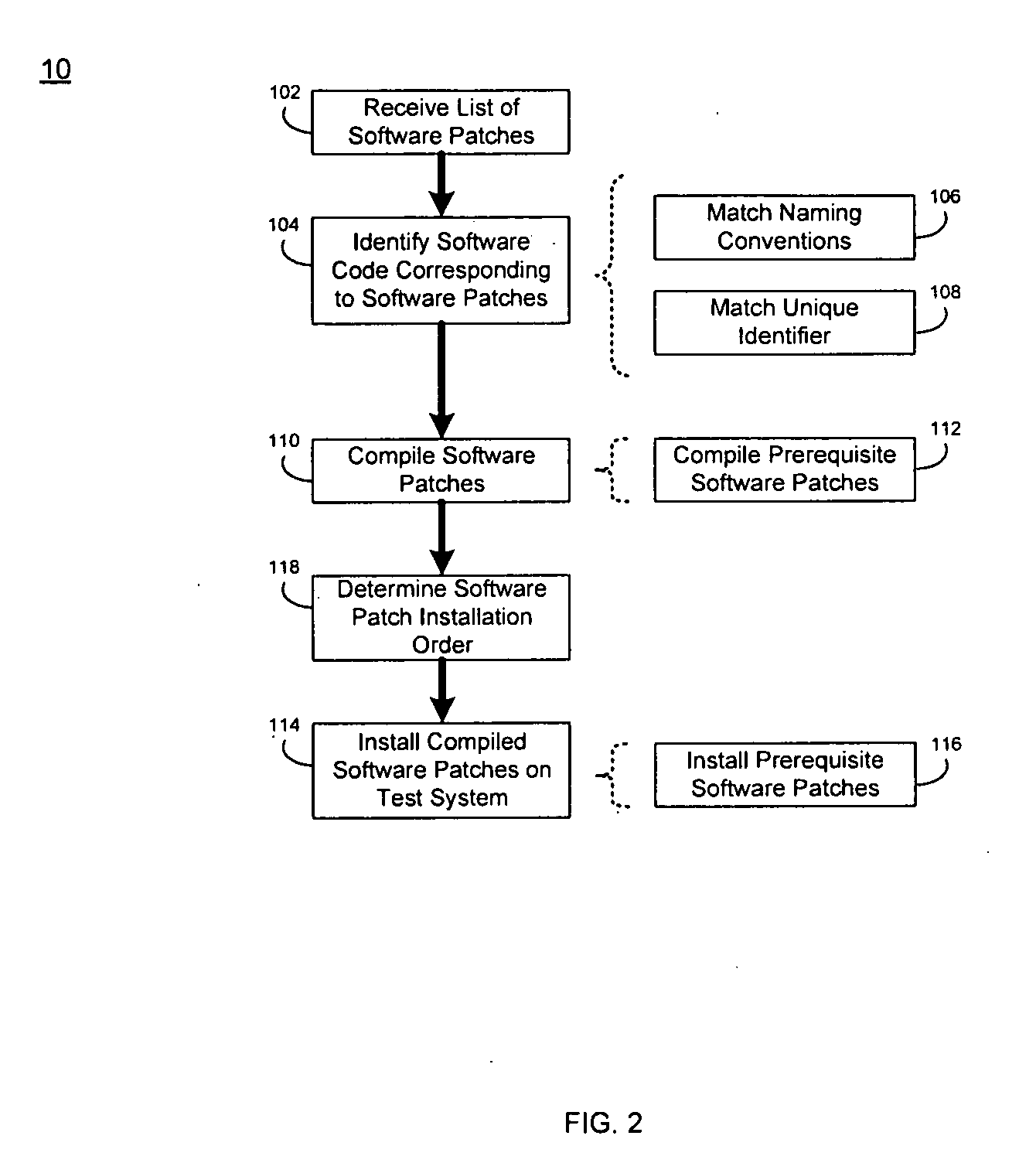

Test system configuration method and system

InactiveUS20100218176A1Error detection/correctionVersion controlComputerized systemSystem configuration

This disclosure relates to computer test systems and, more particularly, to automatically configuring computer test systems. A method, computer program product, and system receives a list of one or more software patches installed on an in-field computer system, the list including a version of each of the one or more software patches. Source code, managed by a source code revision tool, corresponding to the version of each of the one or more software patches, is identified. A compiling and installation system compiles one or more newly compiled software patches from the source code managed by the source code revision tool for each of the software patches installed on the in-field computer system. The compiling and installation system automatically installs the one or more newly compiled software patches on a test computer system to replicate the in-field computer system.

Owner:IBM CORP

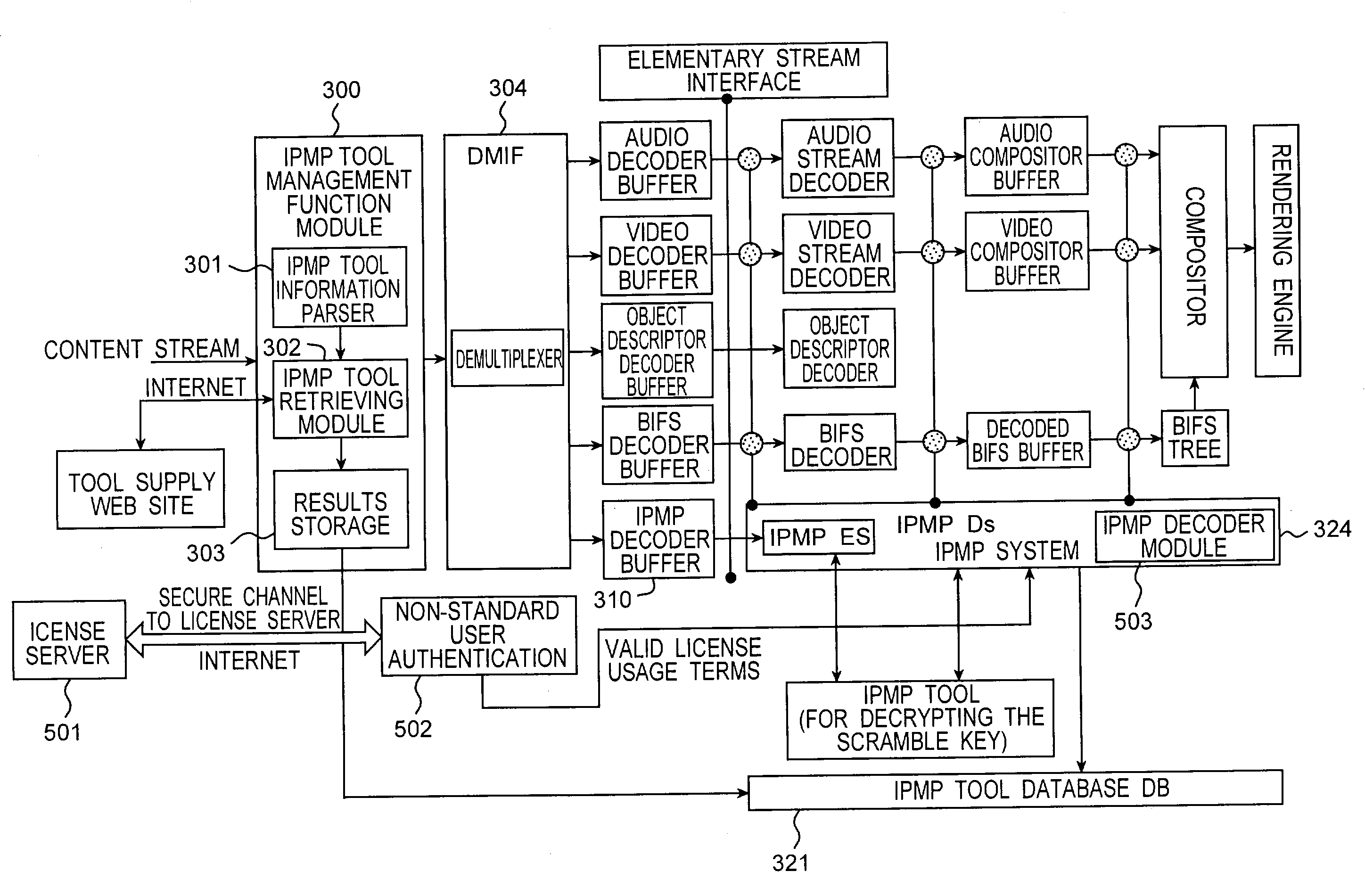

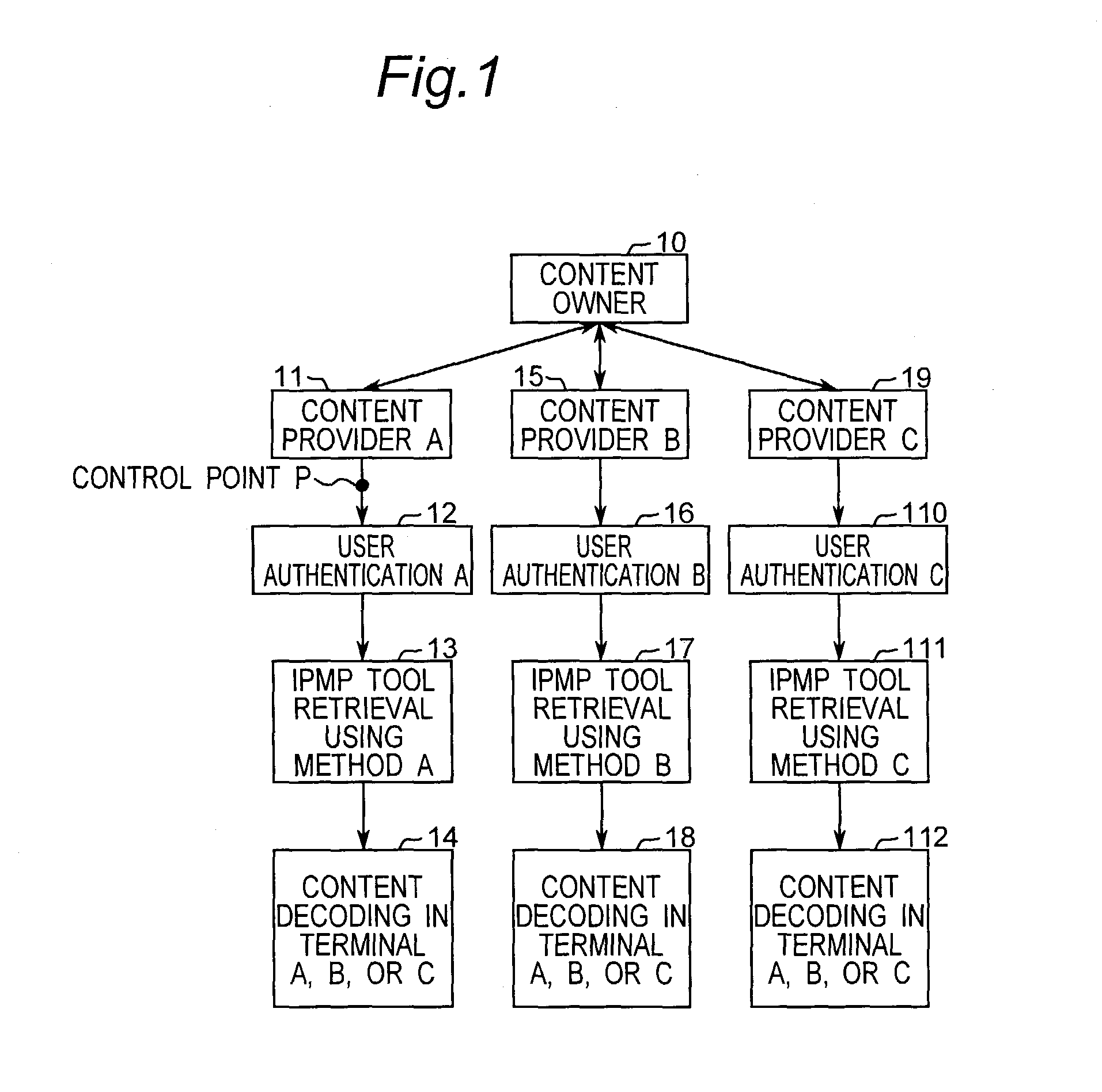

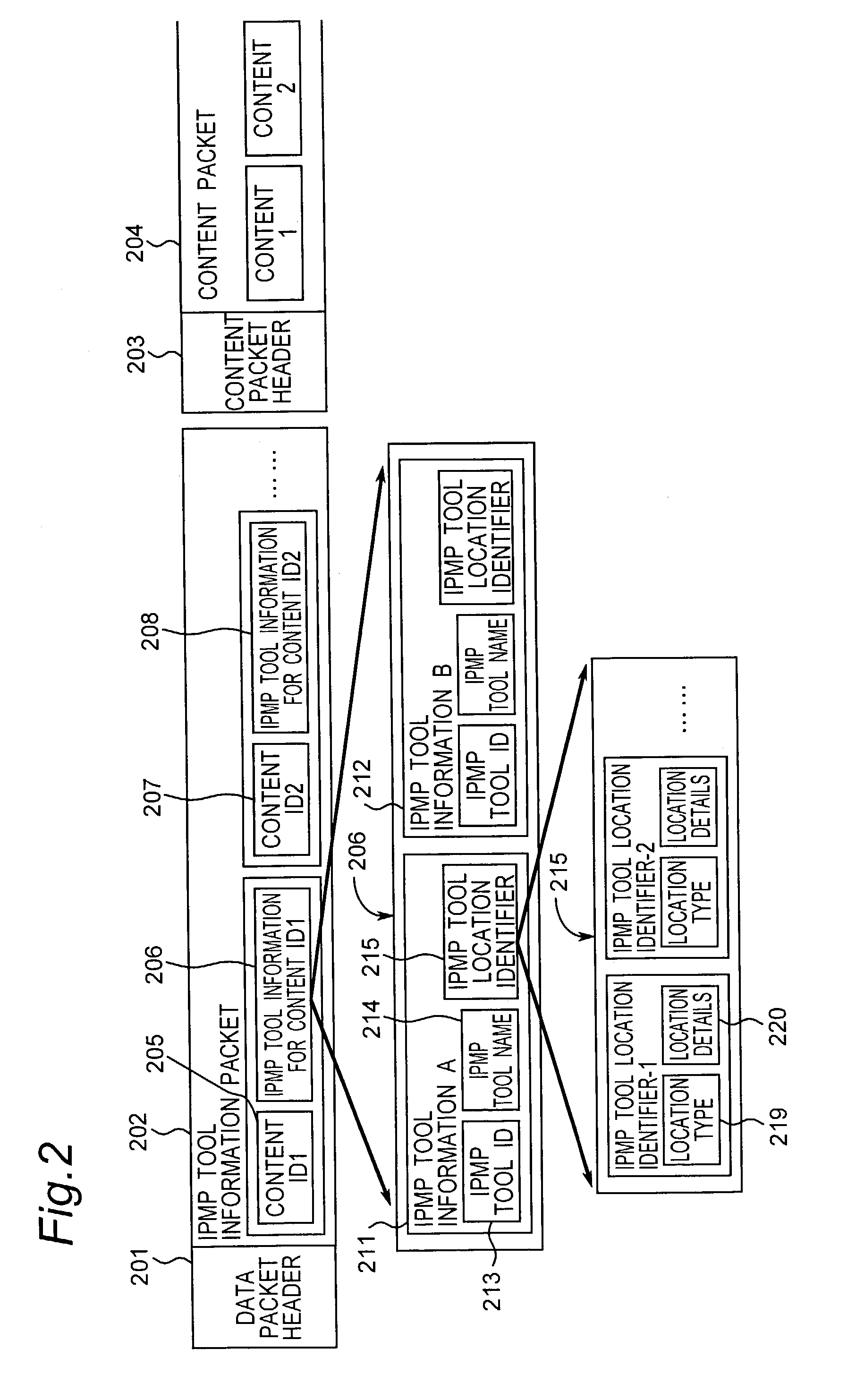

Content distribution/protecting method and apparatus

InactiveUS7689823B2Improve securityEnables compatibilityKey distribution for secure communicationMultiple keys/algorithms usageContent distributionSoftware engineering

A method for appropriately defining standards for implementing an MPEG-n intellectual property management and protection (IPMP) system introduces IPMP Tool Information located at the beginning of the content stream, and an IPMP Tool management function as a pre-processing module located at the start of the content decoder, and retrieves IPMP Tools based on the IPMP Tool Information. To improve security and enable interoperability between terminals in different IPMP systems, a two-layer security structure and user authentication output format are further defined. Implementation on terminals of different complexity is enabled by further defining different profiles for IPMP Tool retrieval.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

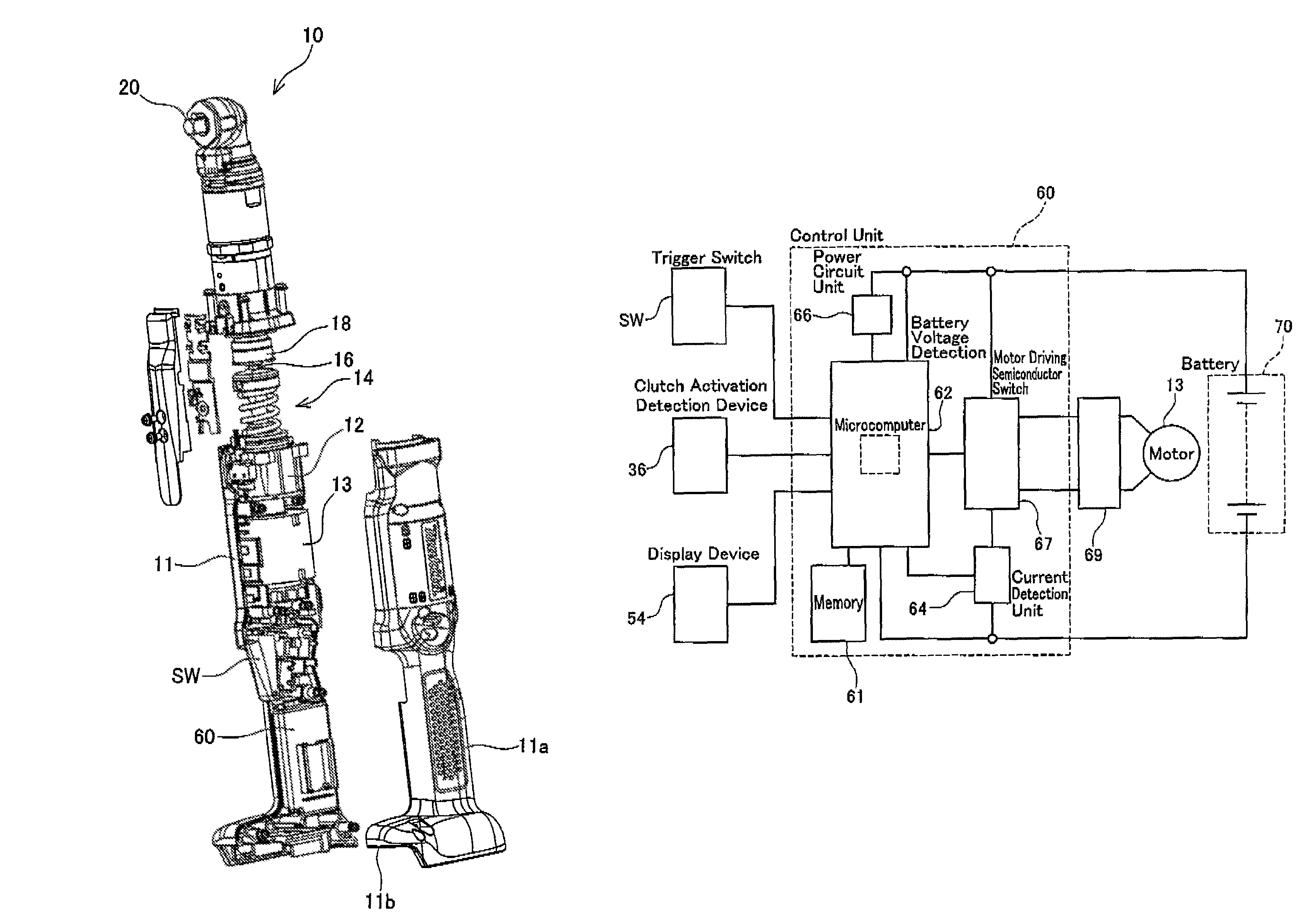

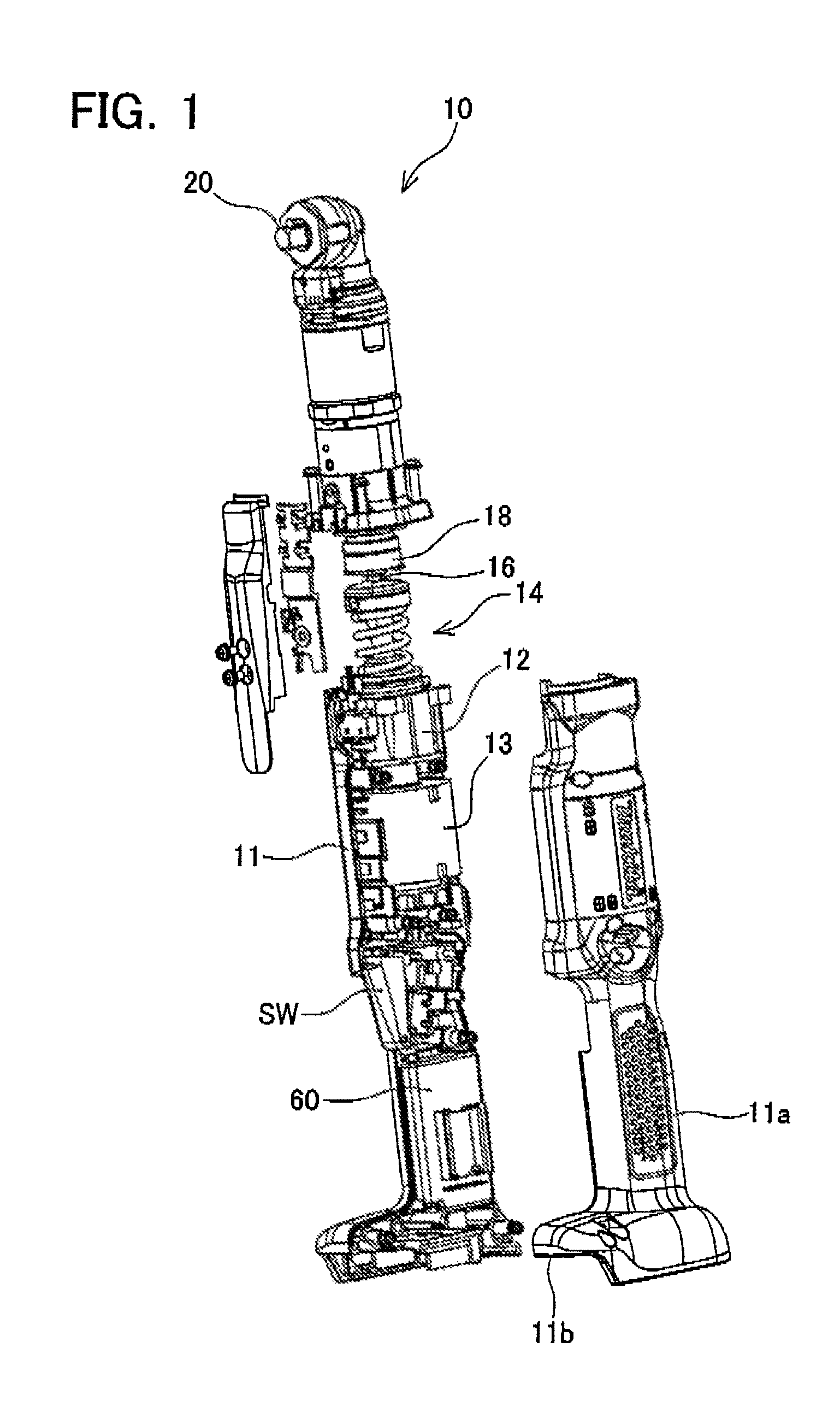

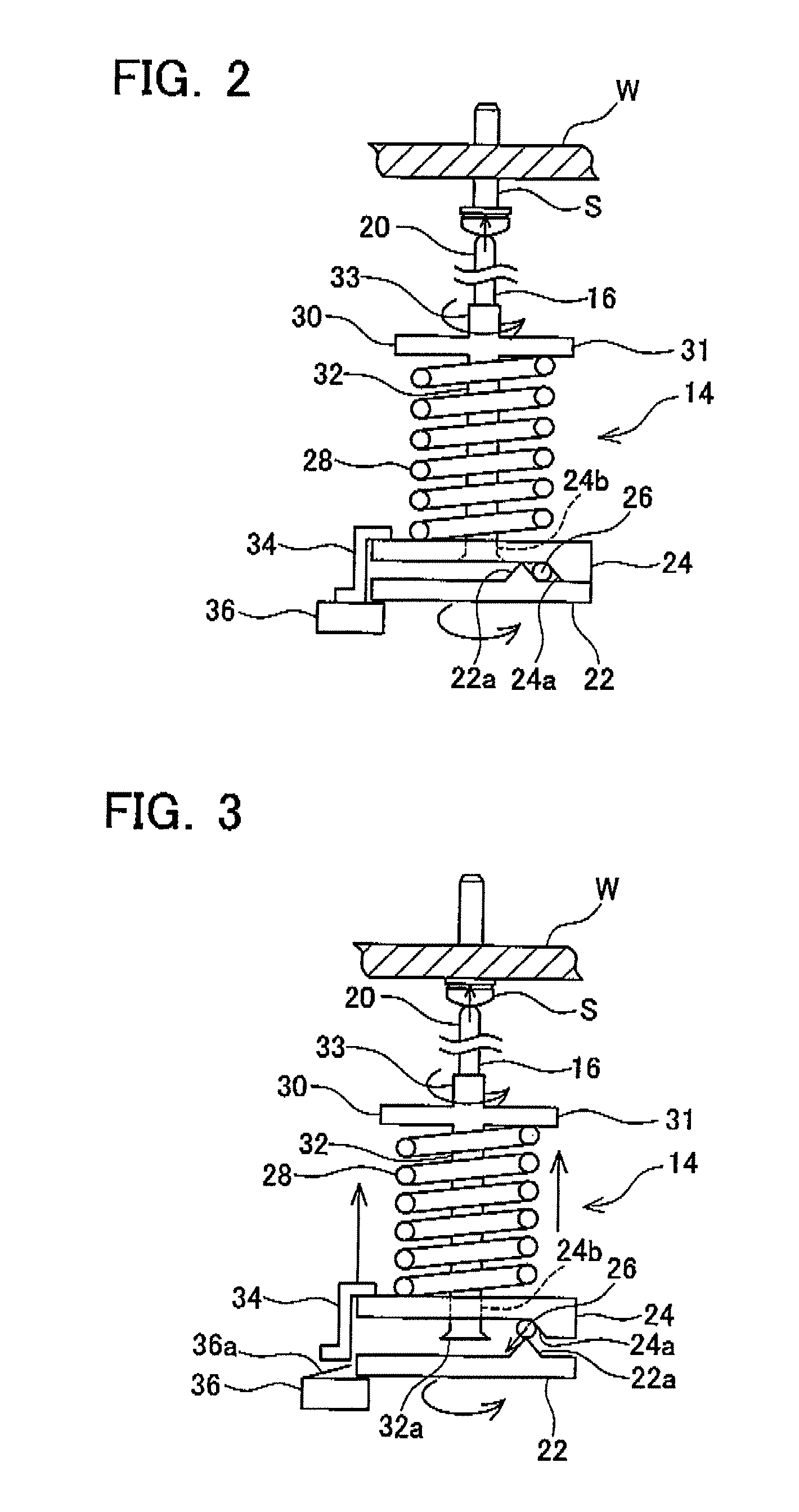

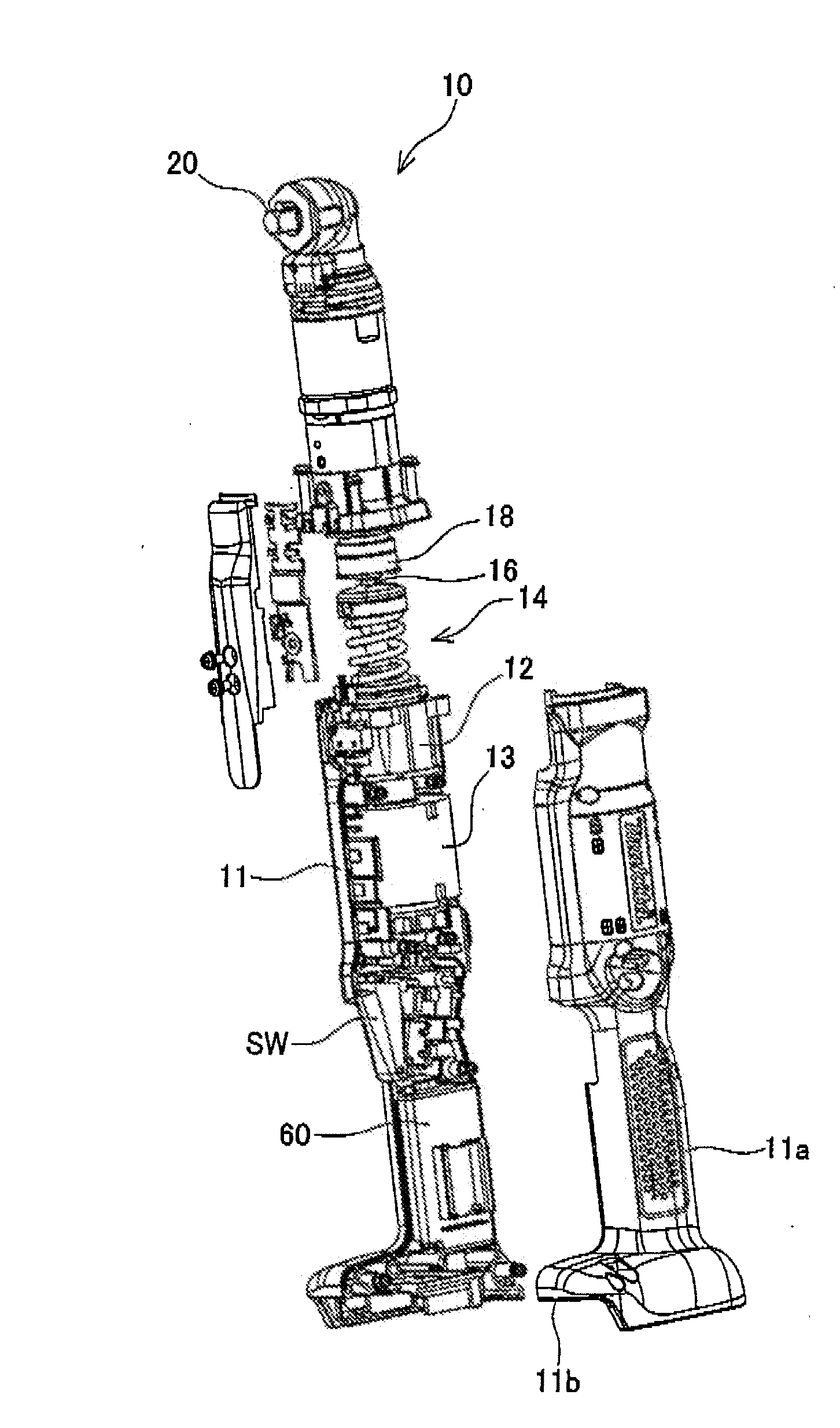

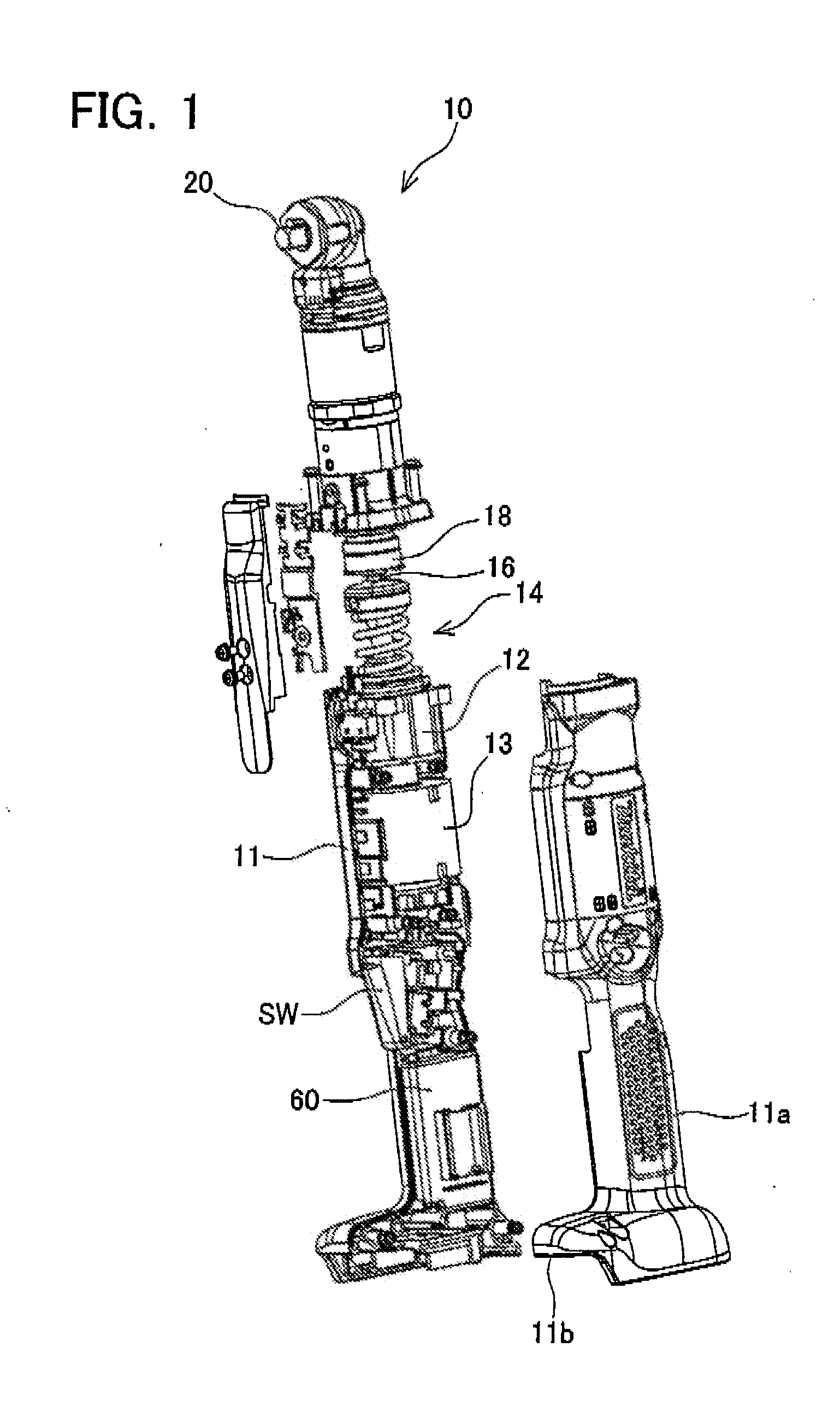

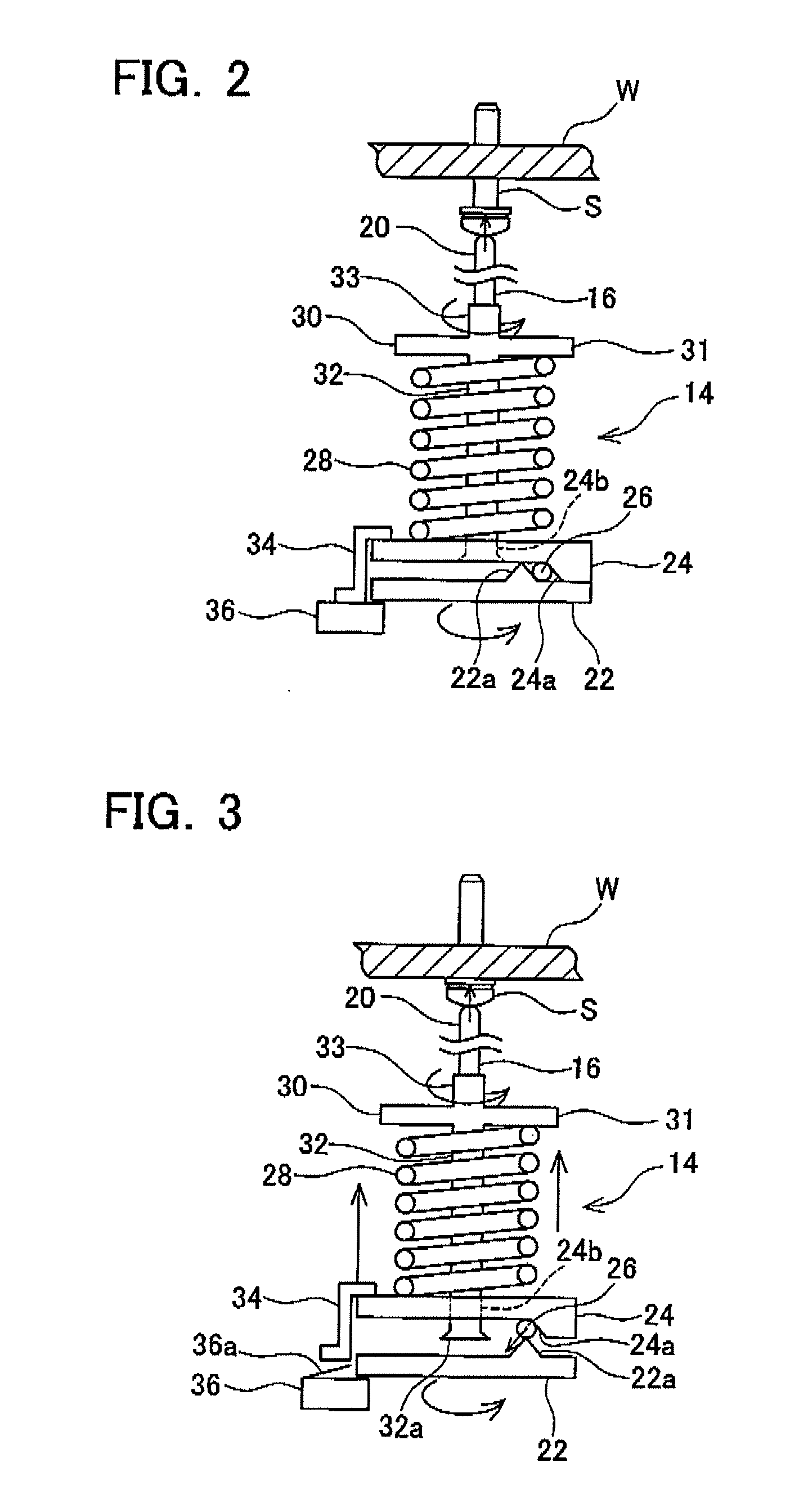

Tightening tool and tightening tool management system

InactiveUS7556103B2Low costReduce forceDerricks/mastsMeasurement arrangements for variablePower flowTorque transmission

A fastening tool with a clutch for shutting off transmission of torque, capable of self-diagnosing fastening torque of a screw or the like at low cost without using expensive elements such as a torque sensor, etc. A fastening tool (10) has a motor (13), a main shaft (20) engaging with a screw or the like, and a clutch (14) interposed between the motor (13) and the main shaft (20). The clutch (14) transmits torque from the motor (13) to the main shaft (20) when a load acting on the main shaft (20) is less than a predetermined value, and shuts off torque transmission from the motor (13) to the main shaft (20) when a load acting on the main shaft (20) is equal to or greater than the predetermined value. The fastening tool (10) further has a control unit (60) for controlling the motor (13). The control unit (60) monitors a current flowing to the motor (13) and determines whether fastening torque is normal or not based on a motor current when transmission of torque from the motor (13) to the main shaft (20) is shut off.

Owner:MAKITA CORP

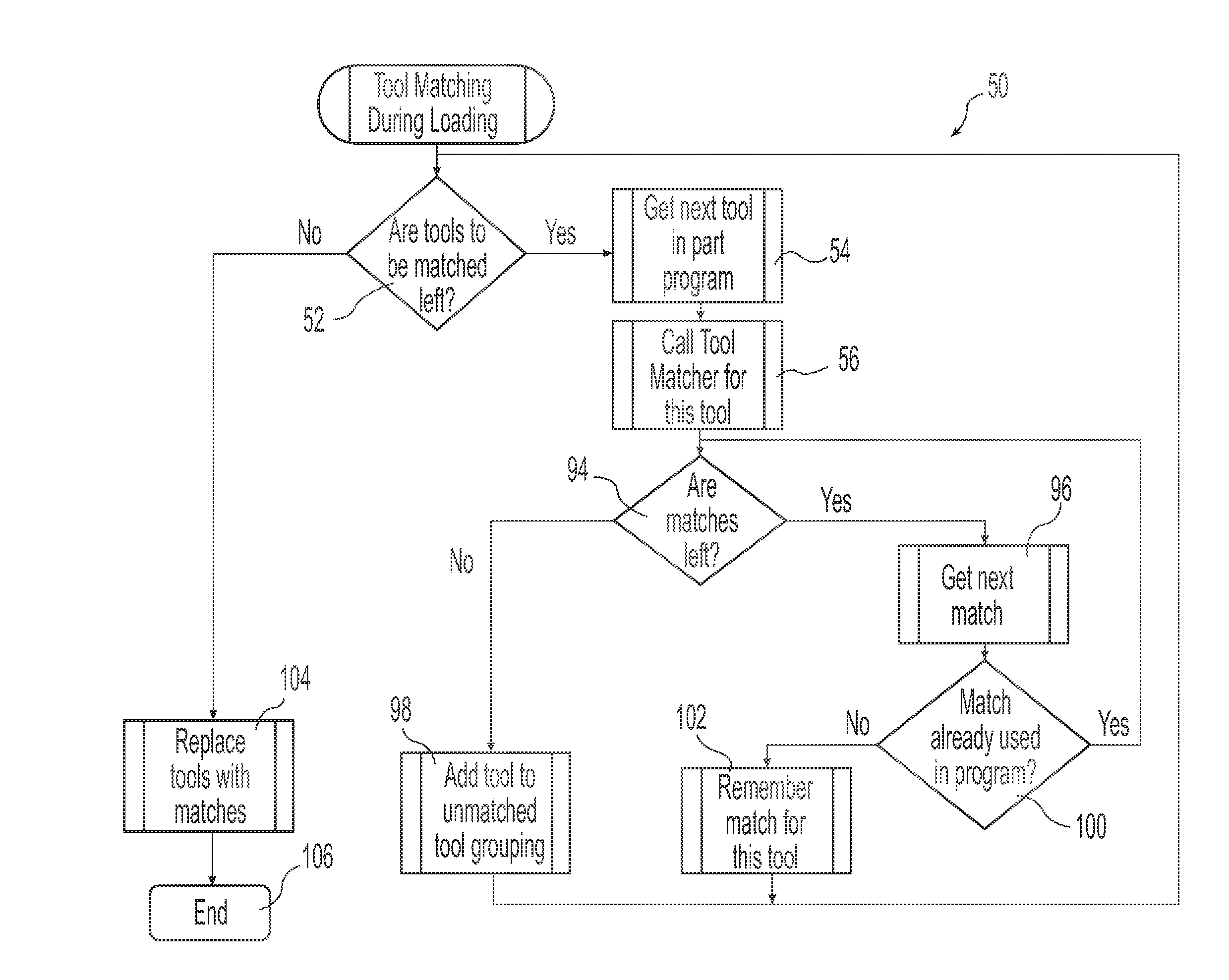

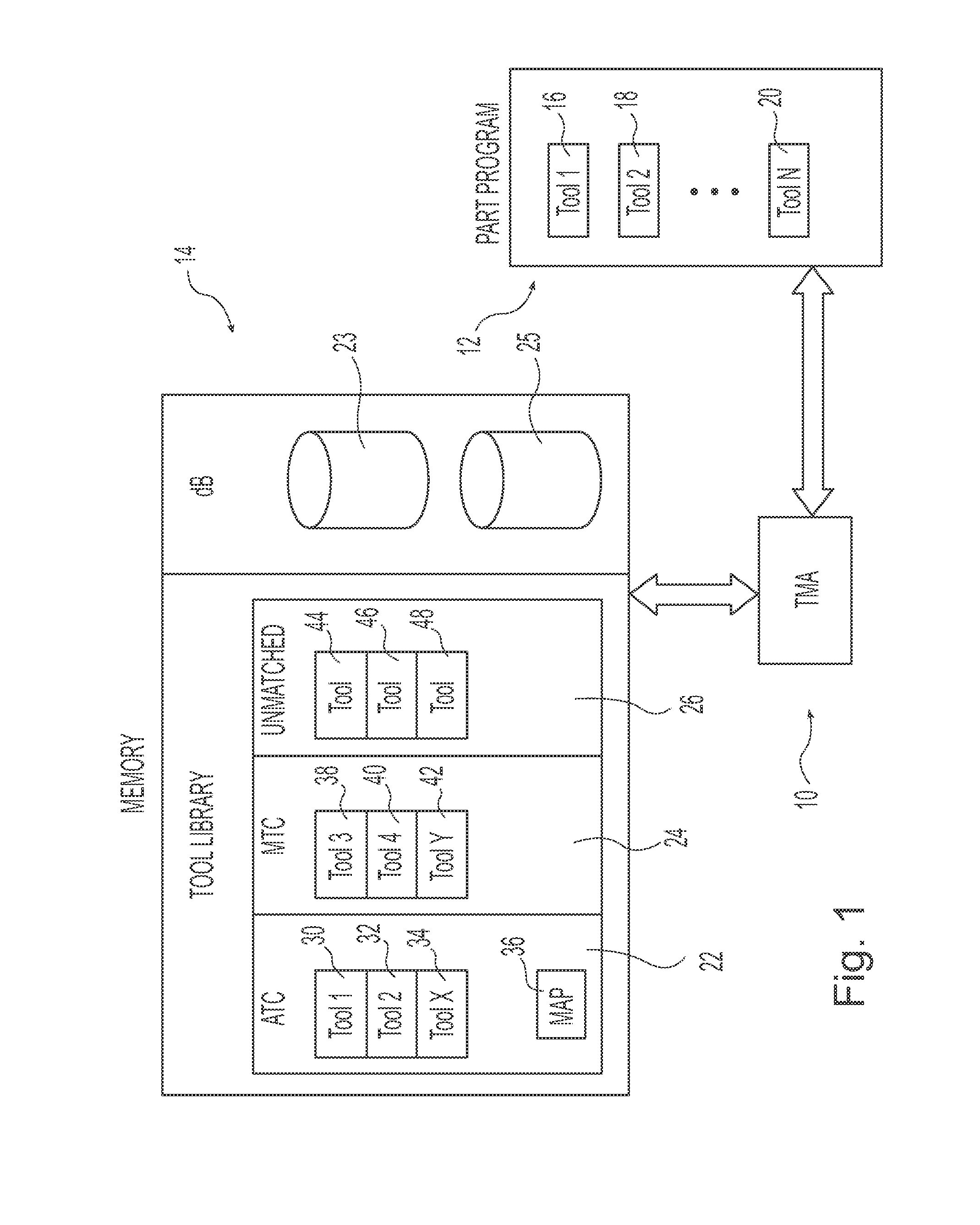

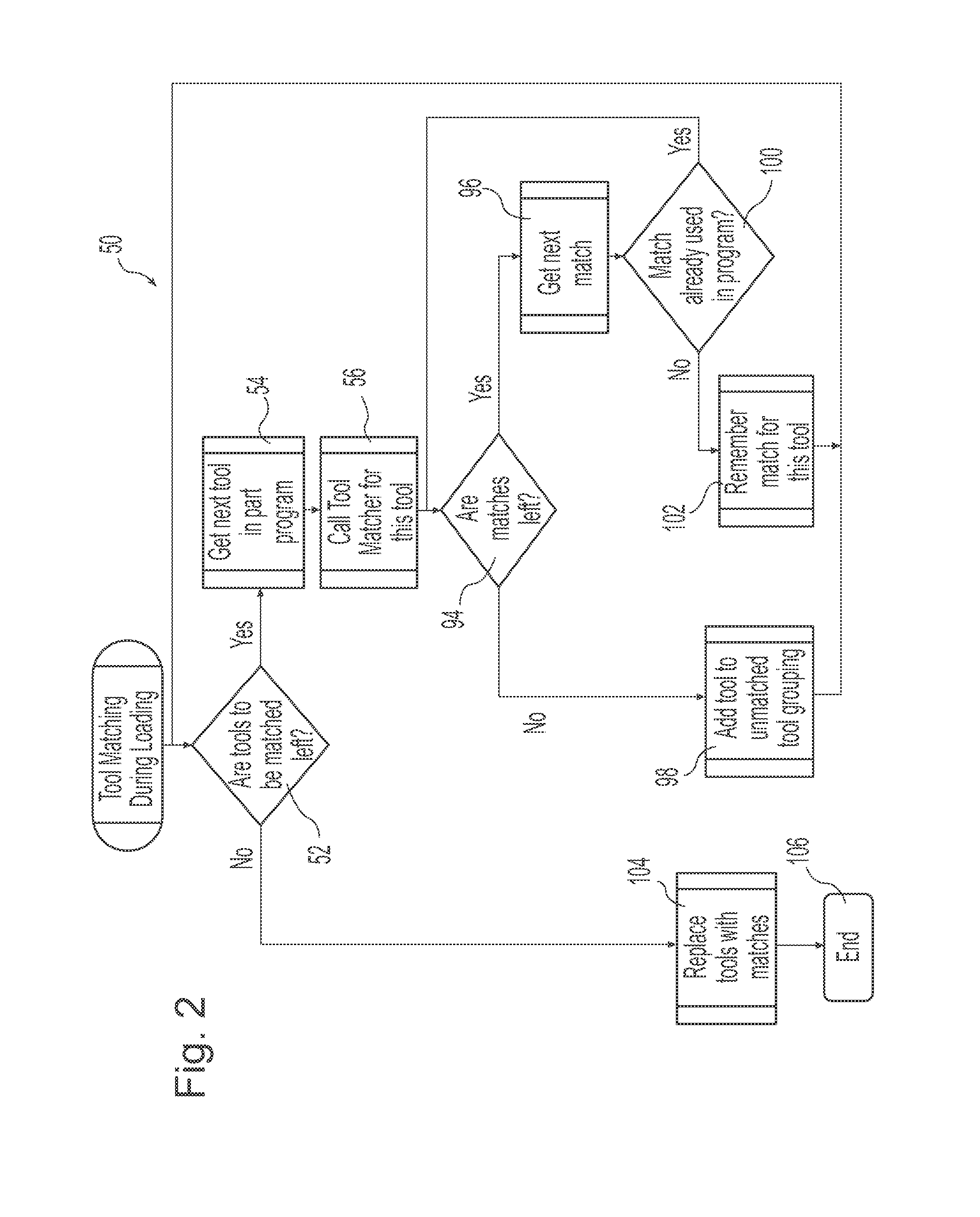

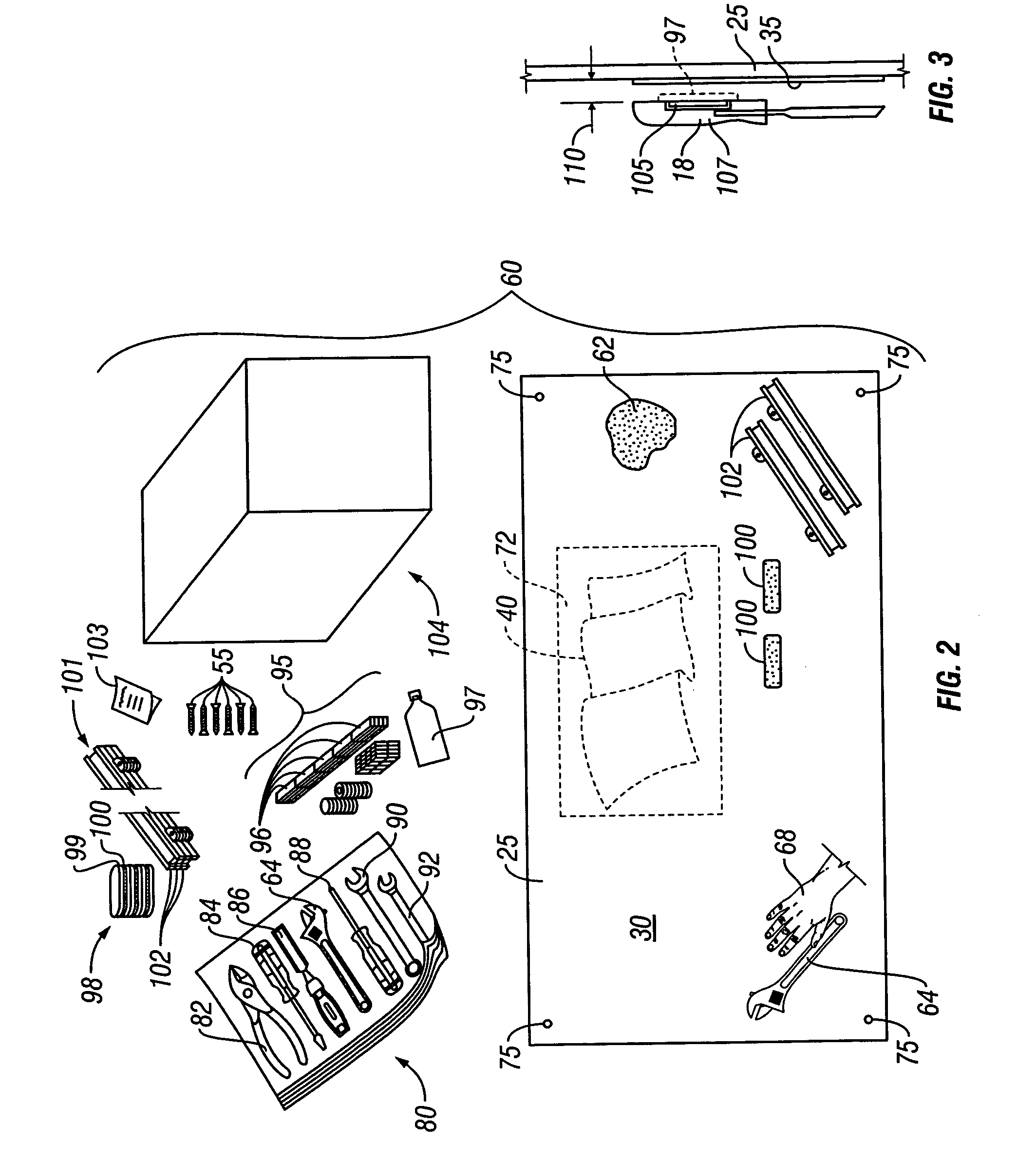

System and method for tool use management

The present invention provides a system and method for tool use management wherein a CNC machine retains information identifying the tools associated with the machine as well as their current locations (if any), and executes an algorithm for determining the source tools needed by a part program and matching the source tools with the available tools.

Owner:HURCO

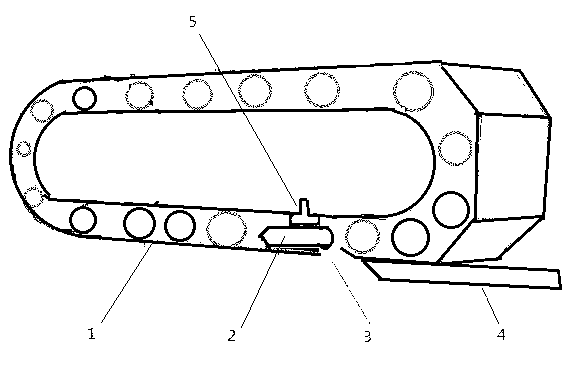

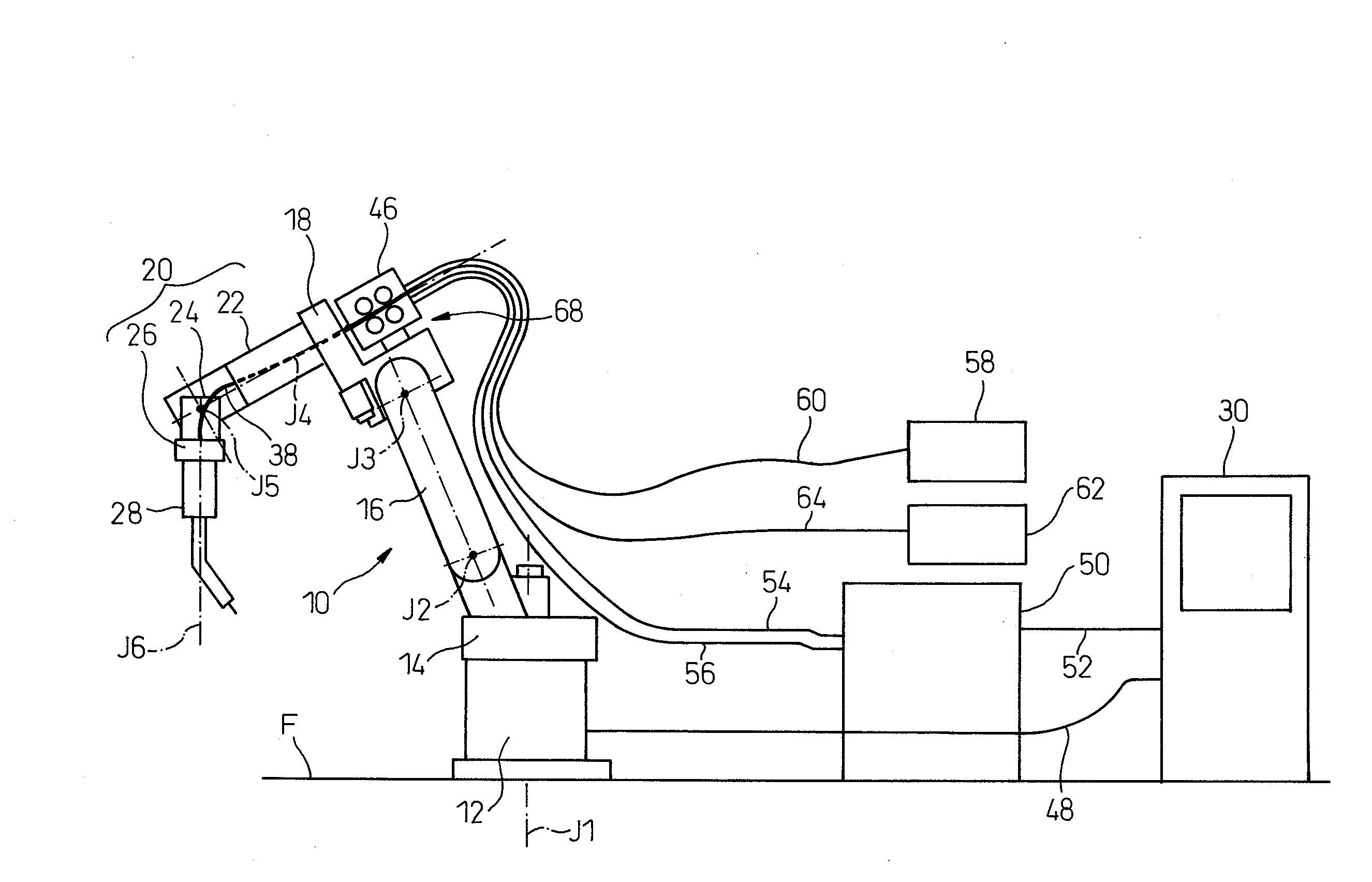

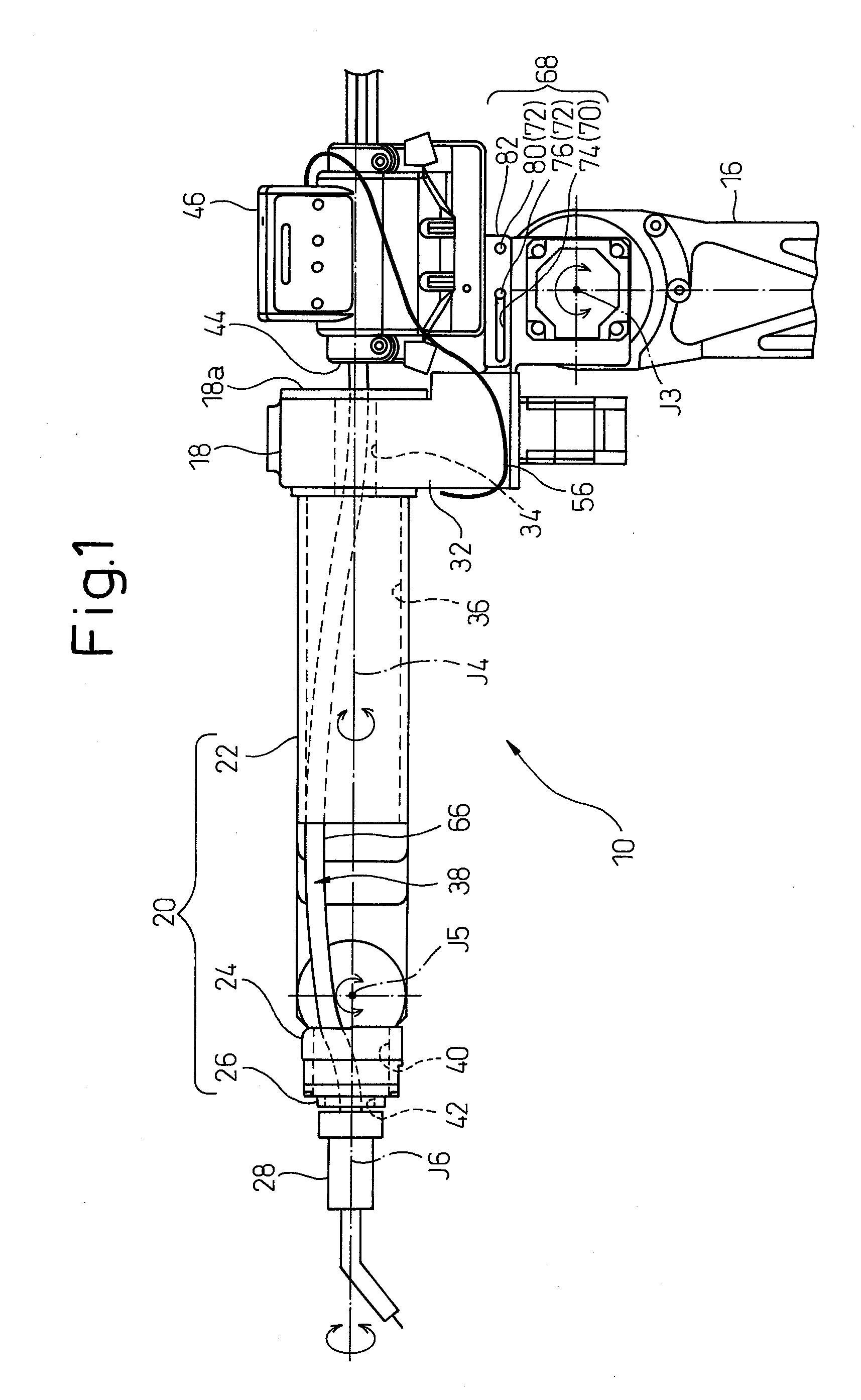

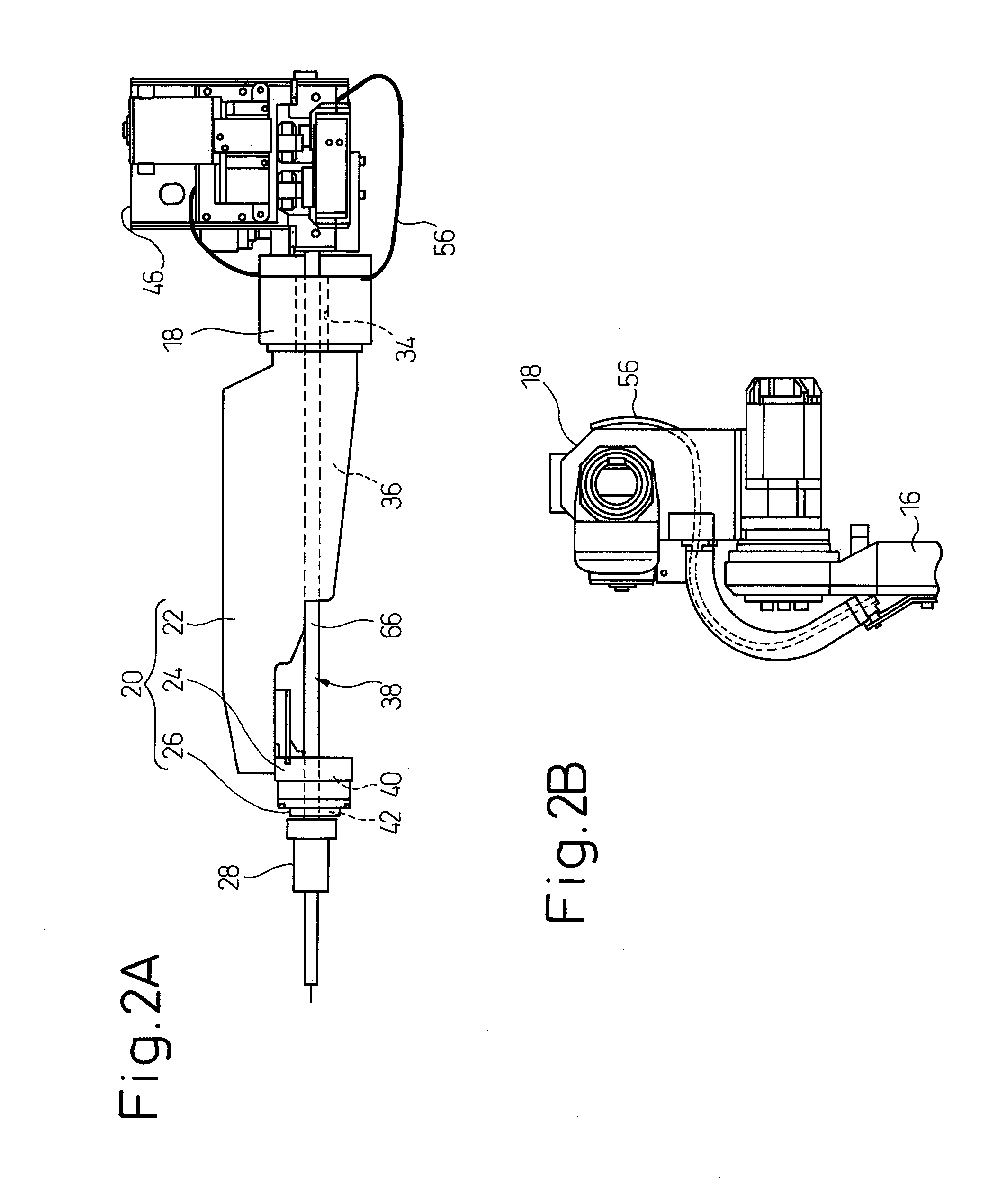

Robot having arm in which umbilical member is accomodated

A robot including a forearm section with a through passage, a wrist section articulated on the forearm section, and an umbilical member inserted through the through passage of the forearm section and provided along the wrist section. The robot includes a tool managing and relaying unit mounted on the forearm section close to the through passage and provided with a connection part to which the umbilical member is connected, and a mount mechanism carrying the tool managing and relaying unit movably between a first position where the connection part is disposed adjacent to an opening of the through passage and a second position where the connection part is spaced from the opening of the through passage, and releasably securing the tool managing and relaying unit to the forearm section at the first position.

Owner:FANUC LTD

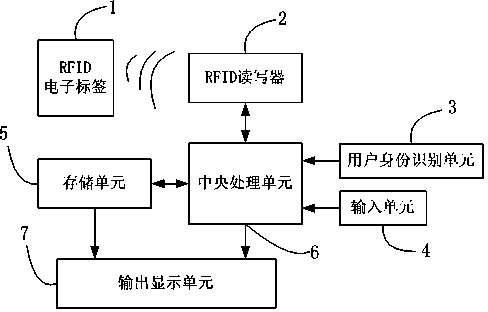

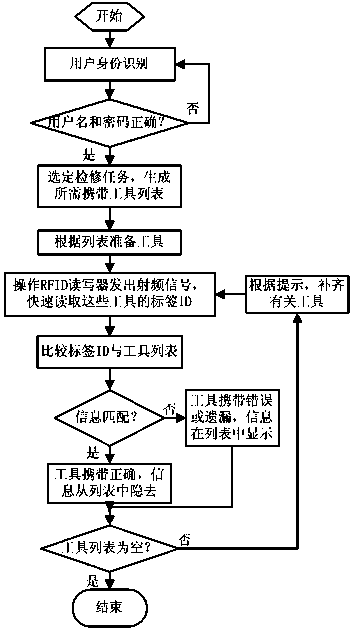

System and method for managing electric power overhauling tools

InactiveCN104268803AQuick checkReliable verificationData processing applicationsCo-operative working arrangementsTool managementIntensive management

The invention discloses a system for managing electric power overhauling tools. The system for managing the electric power overhauling tools comprises RFID labels, an RFID reader, a user identity recognition unit, an input unit, a storage unit, a central processing unit and an output and display unit. The matching relation between overhauling tasks and the overhauling tools is set in the central processing unit, and lists of the needed overhauling tools can be selected automatically according to different overhauling tasks. The invention also discloses a method for managing the electric power overhauling tools. The method comprises the steps of user management, tool management, label management and task management. According to the system and method, reasonable overhauling tool lists can be selected automatically according to different overhauling tasks, the tools can be checked rapidly and reliably, intensive management of the tools is achieved, the problems that people forget to bring the overhauling tools, bring the tools mistakenly and additionally, lose the tools and the like are solved, and the working efficiency and the working quality are improved.

Owner:STATE GRID CORP OF CHINA +1

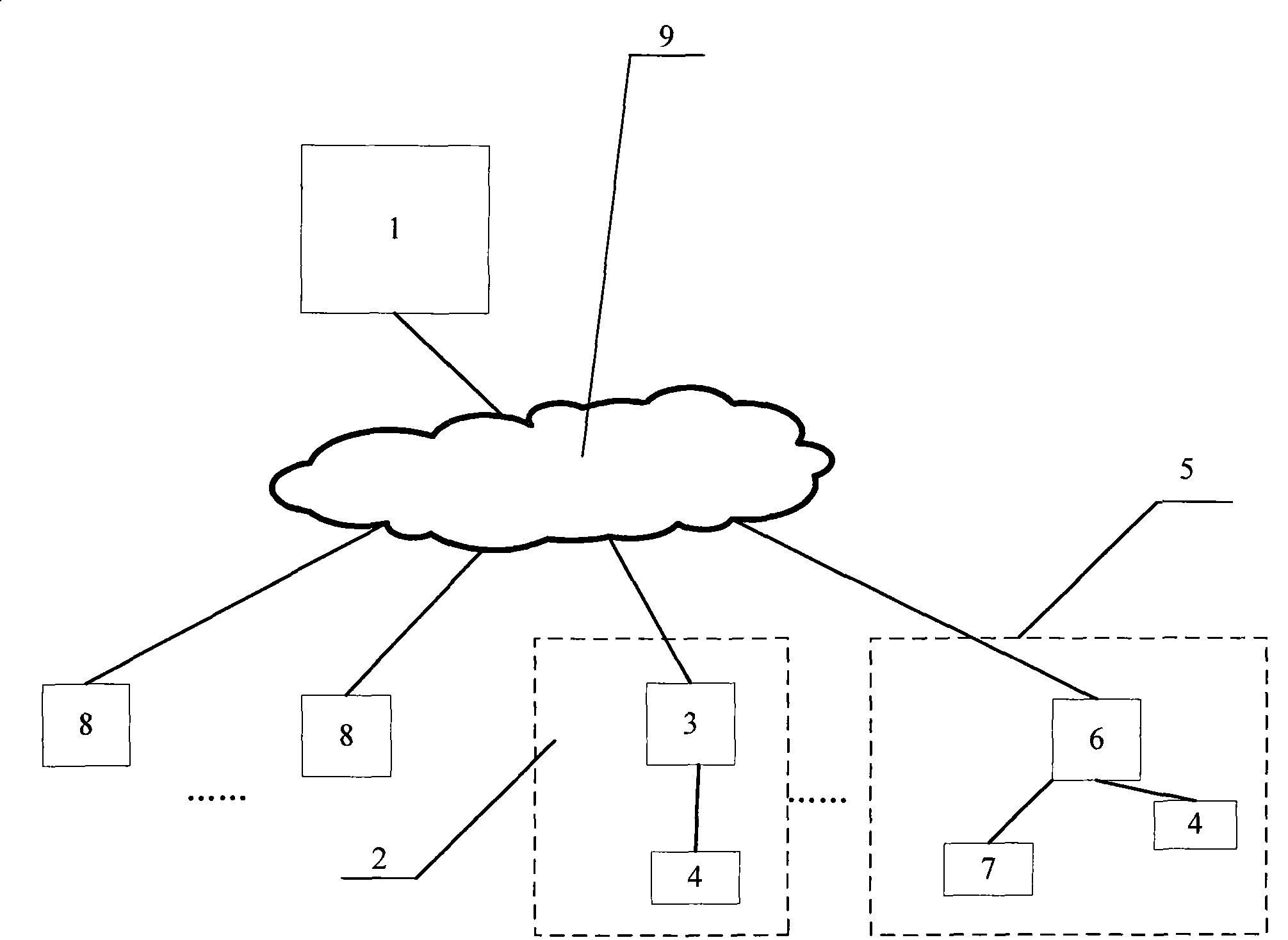

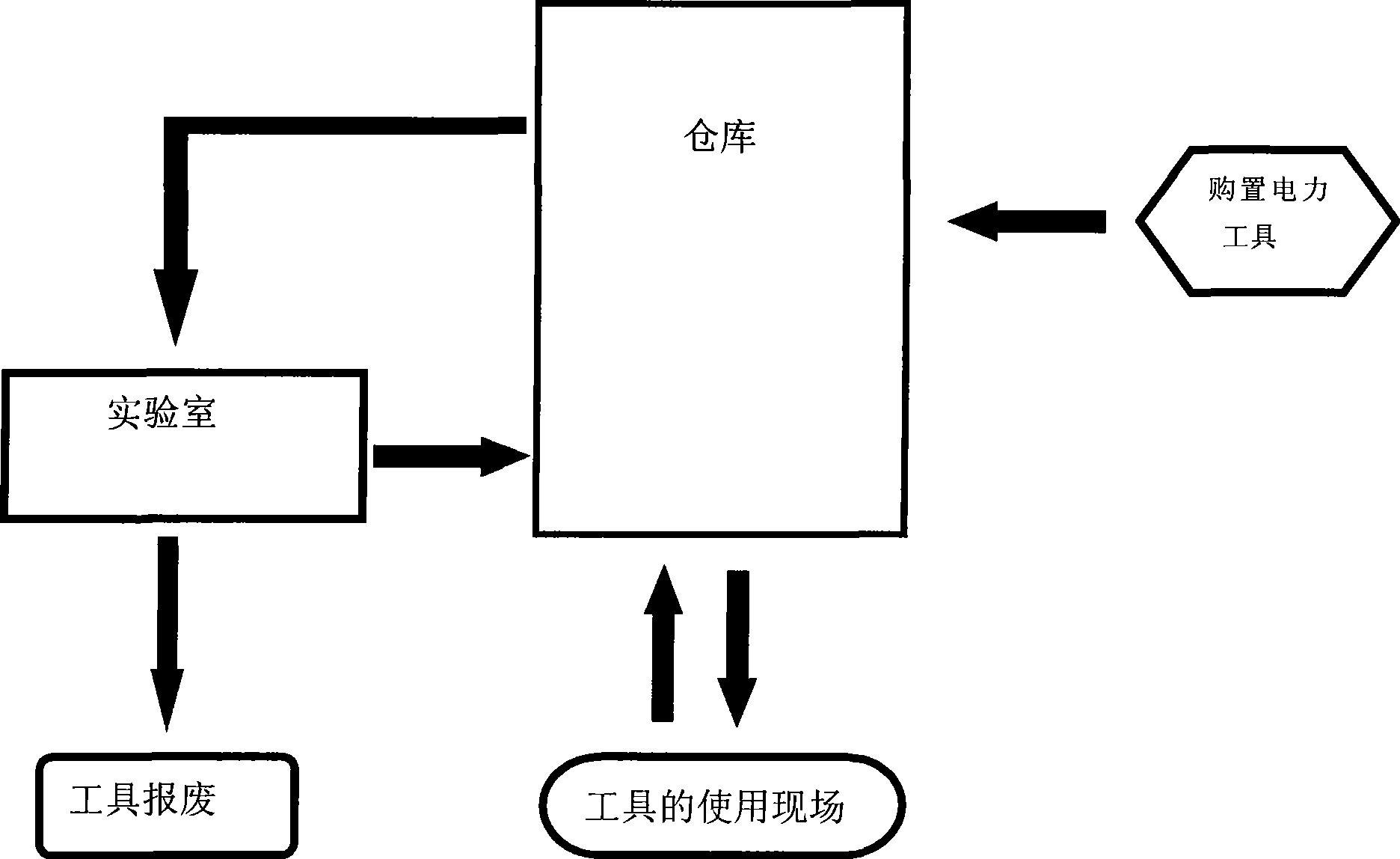

Full lofe cycle management system of electric power tools

InactiveCN101419689AEasy extractionEasy to operateData processing applicationsElectric power systemNetwork connection

An electric power tool life-cycle management system comprises the following components: a tool identification tag which is attached to an electric power tool, and is used for recording identity information of the electric power tool; a tool information database server which is used for storing event information related to the electric power tool; a client side which is used for extracting the event information related to the electric power tool from the tool information database server; a warehouse management subsystem which consists of a warehouse management operating host computer and an identity reading module connected with the warehouse management operating host computer; and a test management subsystem which consists of a test management operating host computer, a test device and an identity reading module that are respectively connected with the test management operating host computer; and the client side, the warehouse management subsystem and the test management subsystem are connected to the tool information database server by a network, and transmit the event information related to the electric power tool by network connection. The management system is simple in operation, is easy to be expanded, reduces burden from large-scale electric power tool management, and improves the management performance.

Owner:WUHAN FENJIN POWER TECH

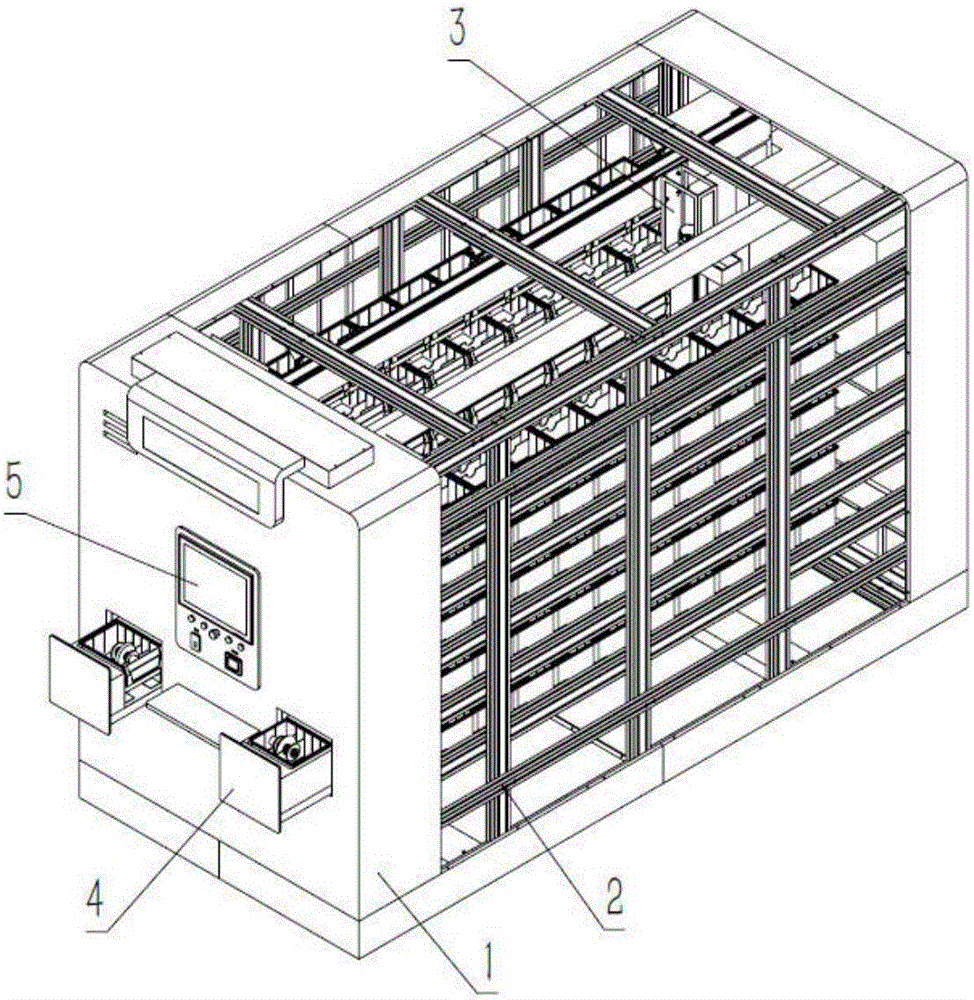

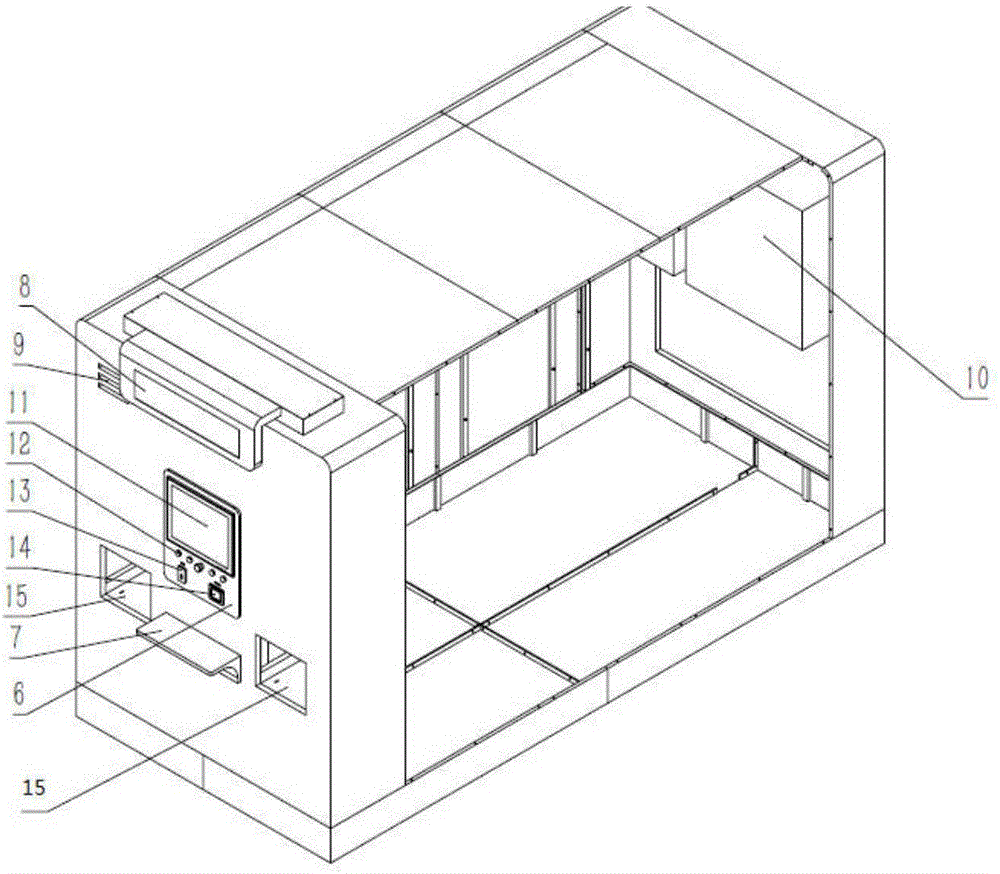

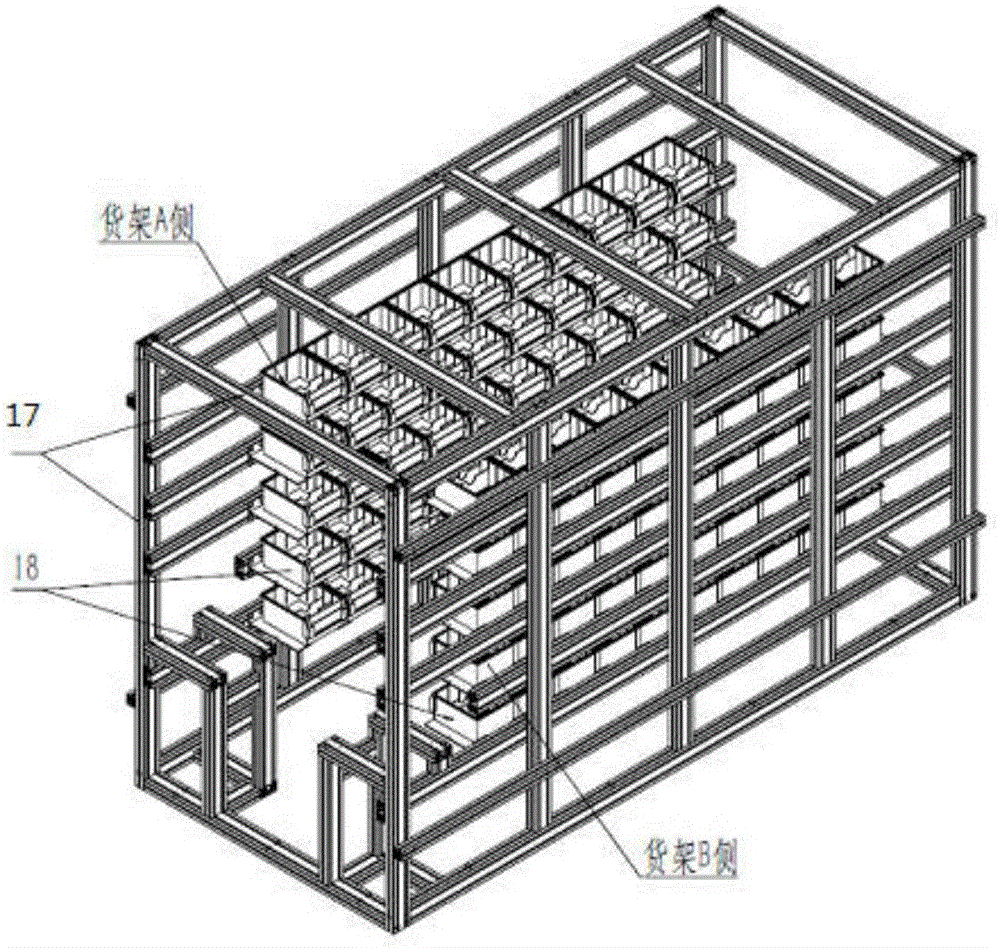

Intelligent warehousing device and warehousing method

InactiveCN106697707ASolve effective managementSimplify the picking processStorage devicesTool managementManufacturing engineering

The invention discloses an intelligent warehousing device and a warehousing method. The intelligent warehousing device is composed of an outer cover, a goods shelf, a goods taking device, storage drawer boxes and a control system. The outer cover is fixedly installed on the outer periphery of the goods shelf. An operation panel, a carrier platform, a display screen, an indication lamp, an electric appliance cabinet and drawer windows are arranged on the outer cover. The goods shelf is of a rectangular frame structure which is set up from aluminum profiles. The goods taking device is fixed to the middle position of the inner portion of the goods shelf. The storage drawer boxes are arranged inside the drawer windows in the two sides of the portion, below the operation panel, of the outer cover. When working, the intelligent warehousing device has the advantages that effective management of goods and tools on a production site of a factory can be effectively achieved, the material requisition process of workers is simplified at the same time, and the labor management cost is greatly reduced; meanwhile, the data including material storage and requisition information, material requisition personnel and the like can be uploaded to a tool management system in real time, process management and monitoring of the materials are achieved, and follow-up management and looking-up work are facilitated.

Owner:XINAN TOOLS GUIZHOU PROV

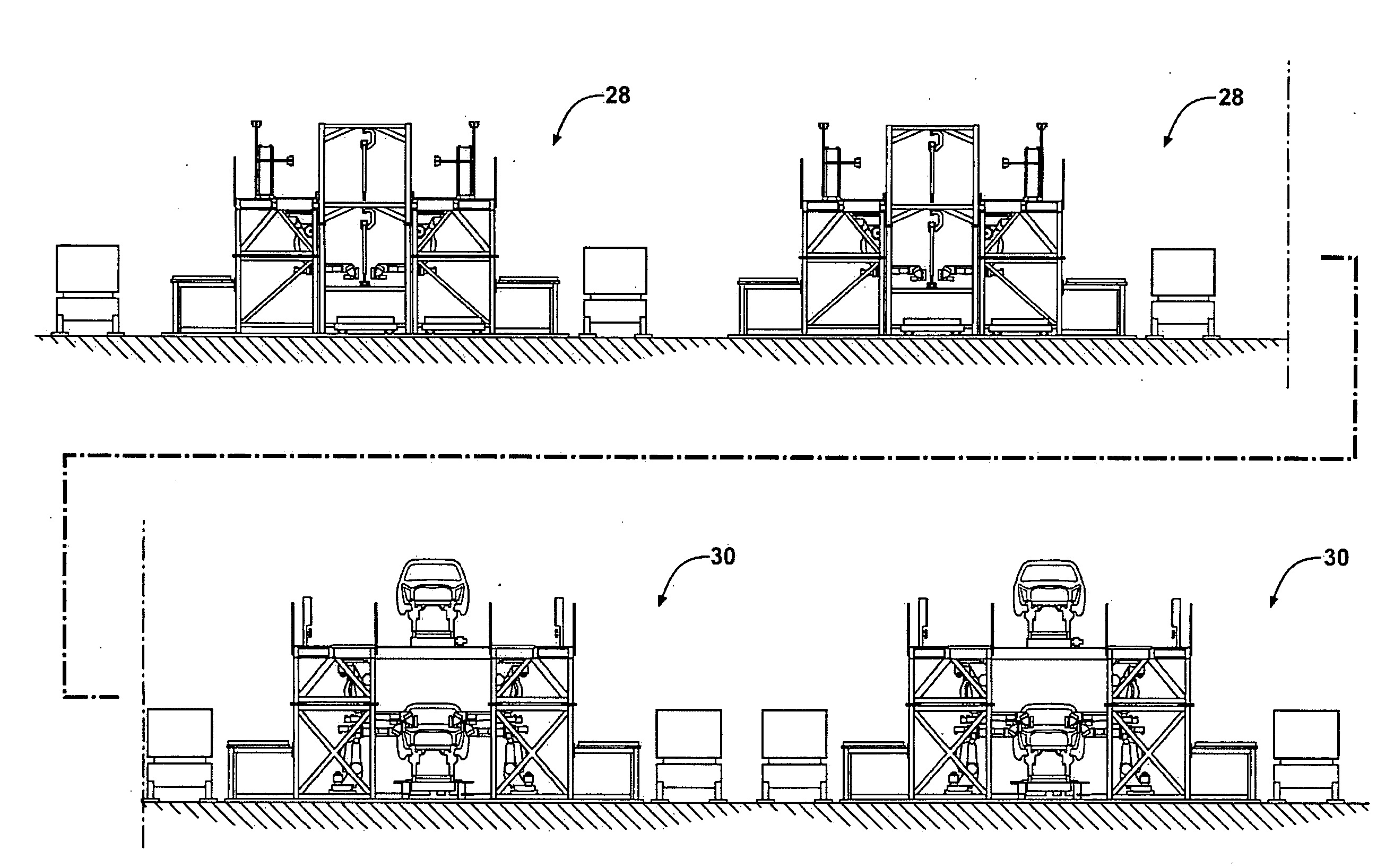

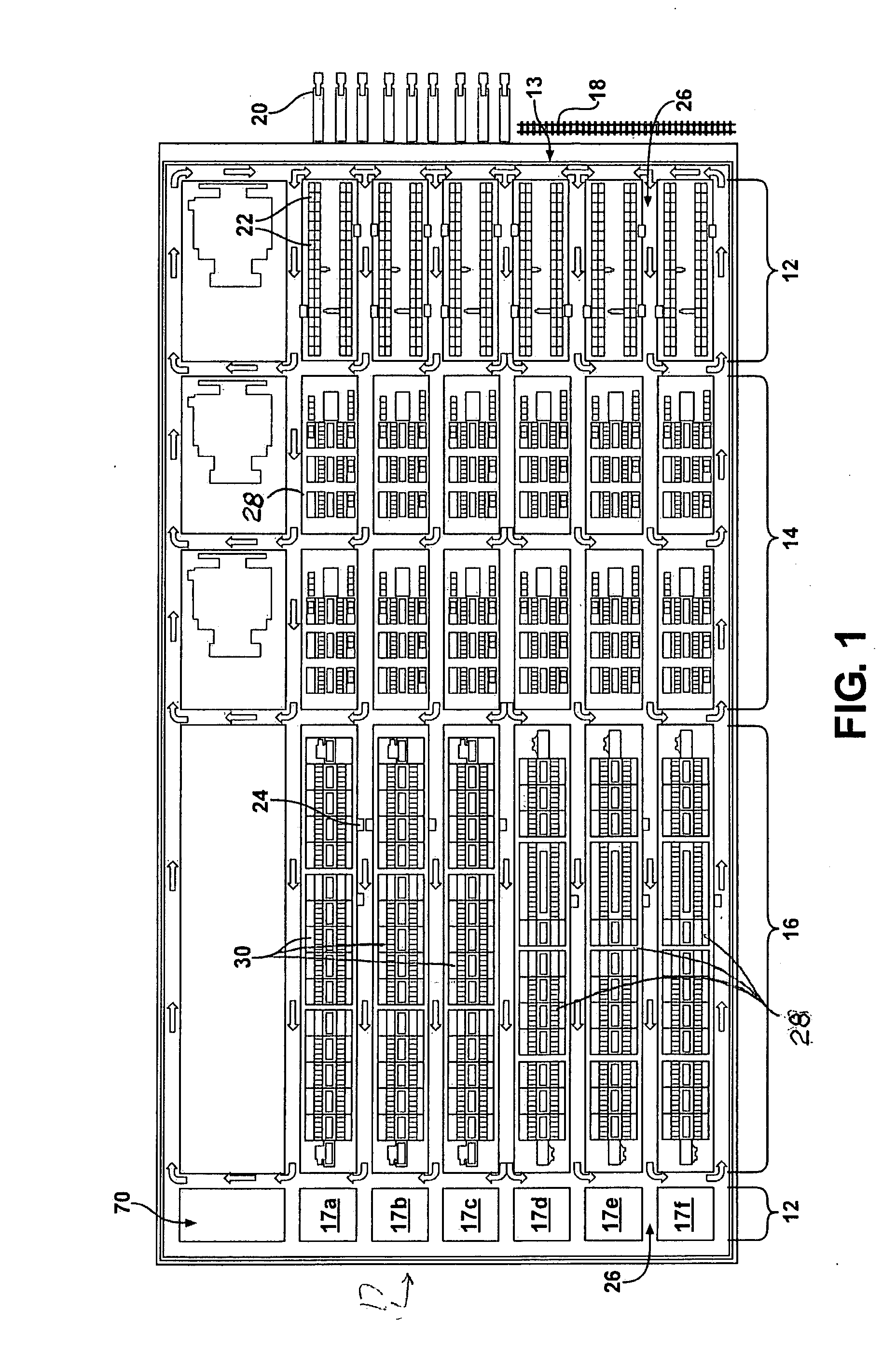

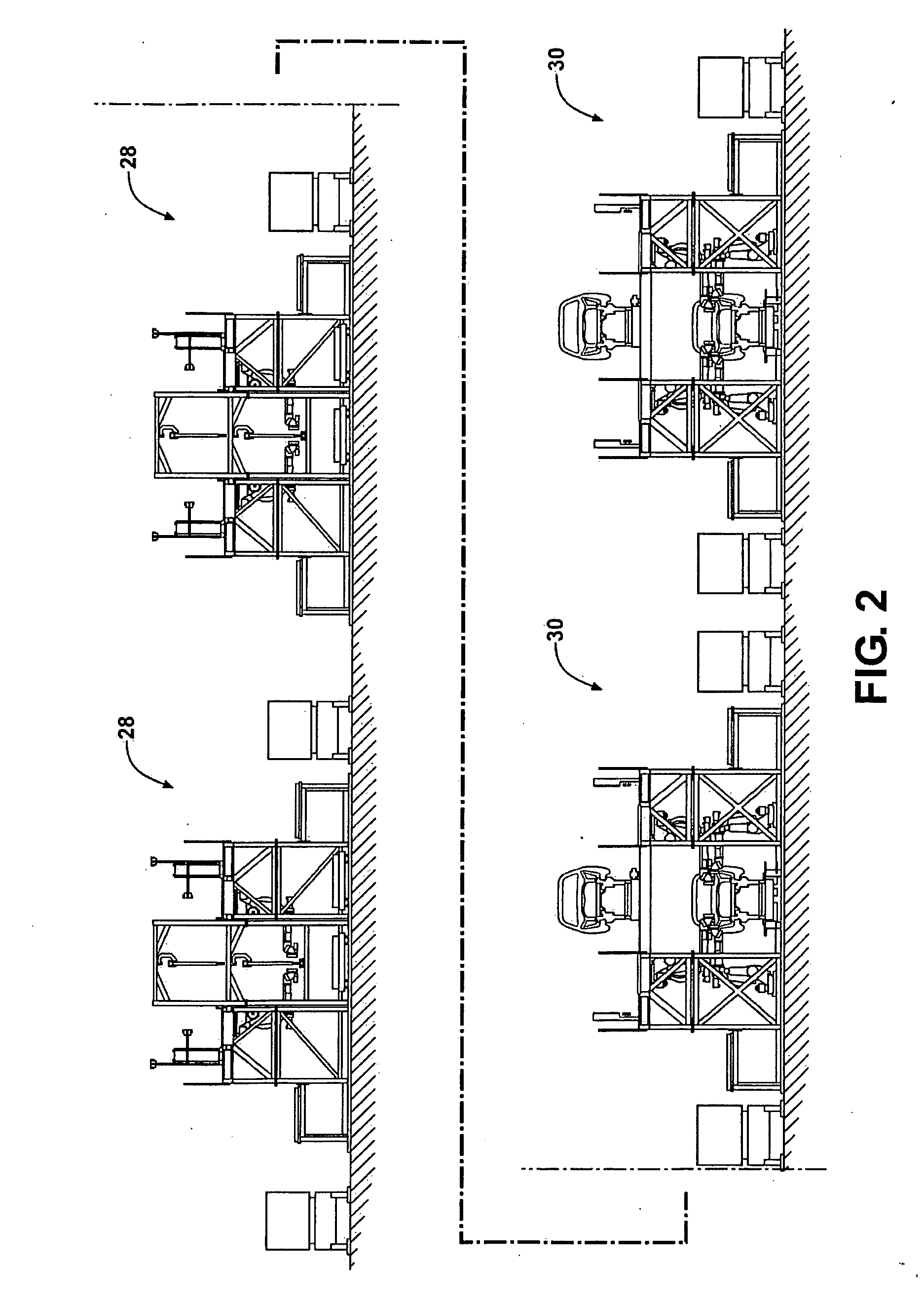

Robotic high density welding body shop

ActiveUS20090234488A1Unlimited flexibilityEasy constructionWelding/cutting auxillary devicesAssembly machinesMobile vehicleHigh density

A method and apparatus for managing the delivery of component parts and tooling to a robotic welding assembly positioned on a motor vehicle body assembly line. Automatic guided vehicles deliver component parts from a source of parts to a parts staging area on the robotic welding assembly including a substage awaiting area, a substage in-use area and a substage empty area, and further automatic guided vehicles deliver tooling from a tooling management area to the robotic welding assembly whereafter the tooling, upon model changeover, is moved to a tooling use area proximate the assembly line whereafter, upon further model changeover, the tooling is removed from the tooling use area and loaded onto an automatic guided vehicle for return to the tooling management area.

Owner:COMAU LLC

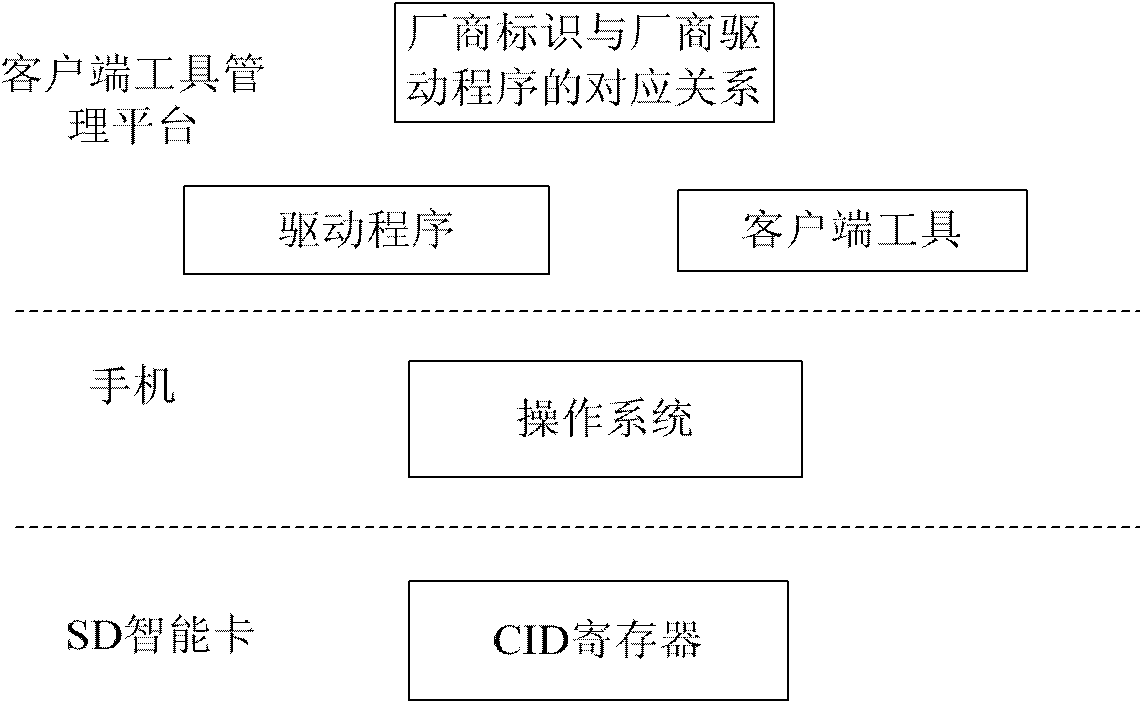

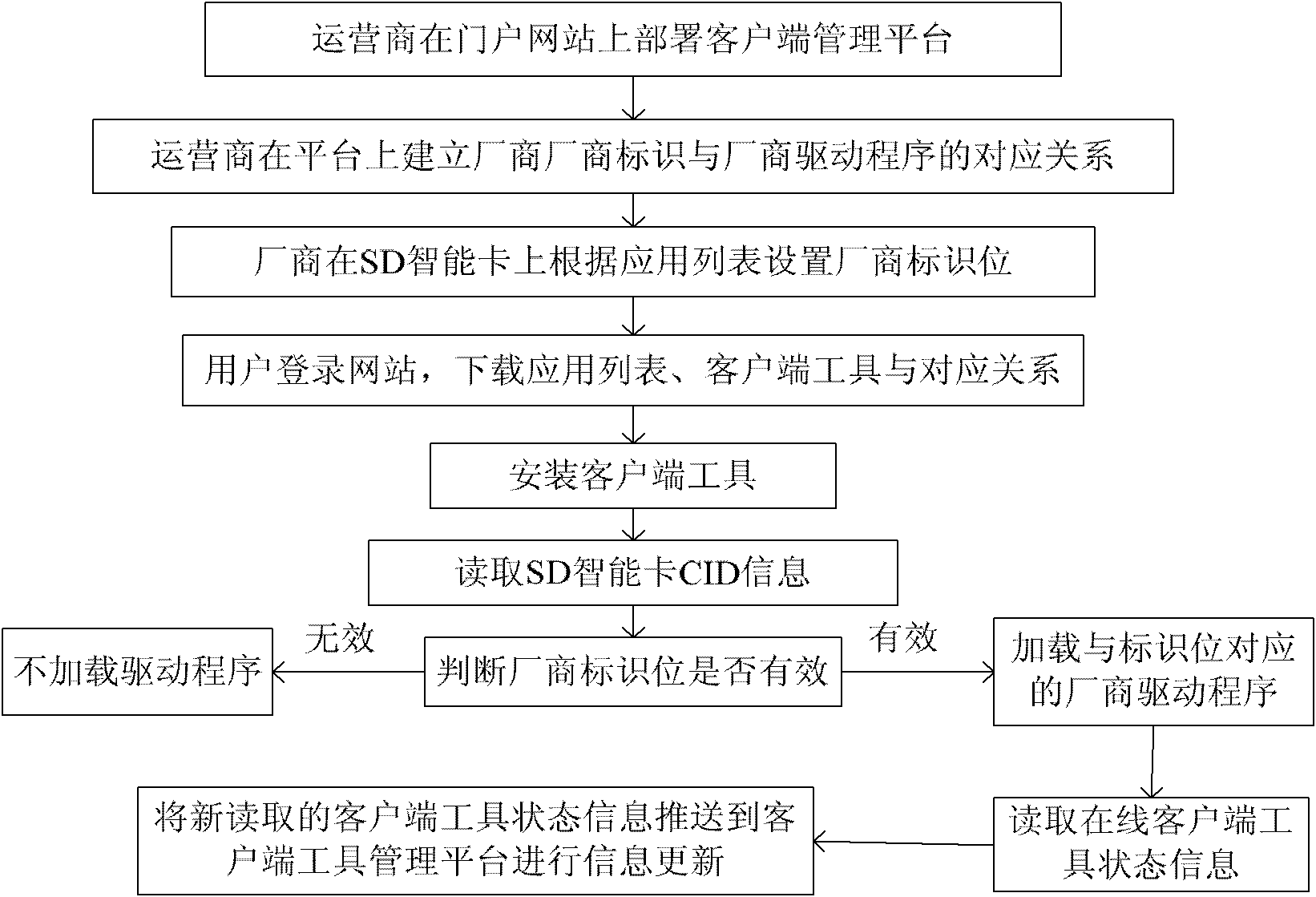

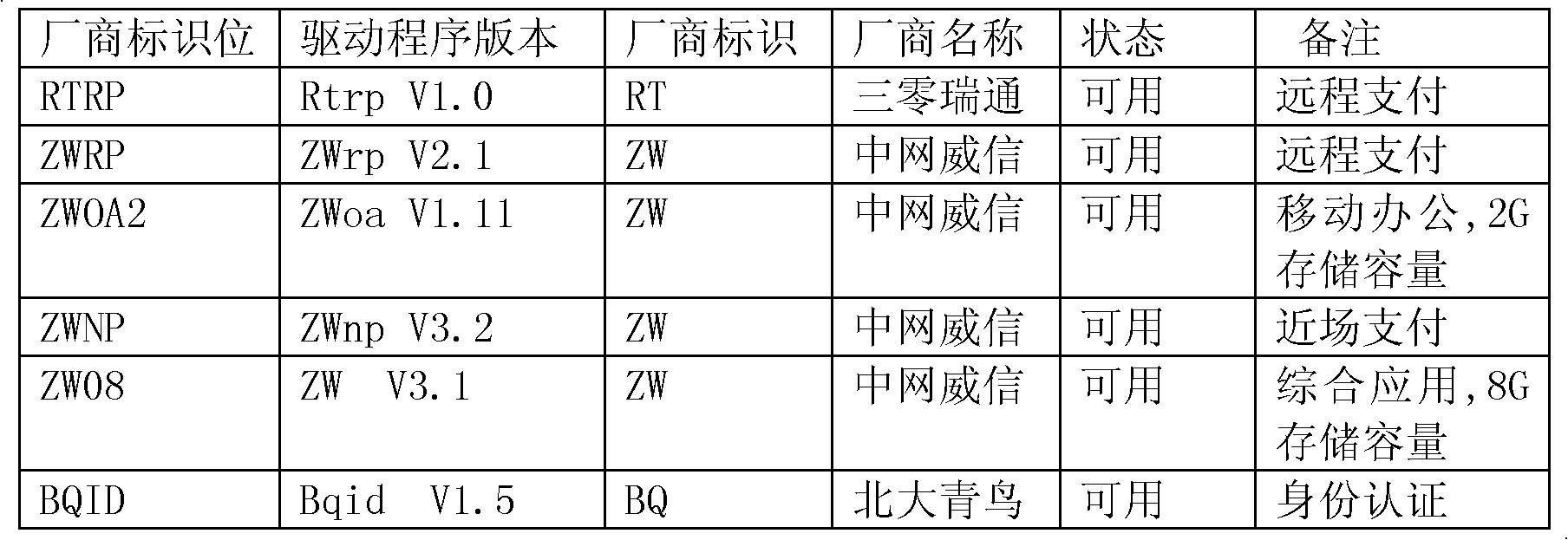

Identification and drive loading method and system of SD (Secure Digital) intelligent card

ActiveCN102184110ARealize plug and playProgram loading/initiatingTransmissionComputer hardwareClient-side

The invention discloses an identification and drive loading method and system of an SD (Secure Digital) intelligent card. The method comprises the steps of: deploying a client side tool management platform on a web portal by an operator, establishing correspondence between a manufacturer identification and a manufacturer drive program on the platform; setting a manufacturer identification location on the SD intelligent card by a manufacturer according to an application list; logging the web portal by a user through a mobile phone, downloading the application list from the web portal, and downloading a client side tool and the correspondence between the manufacturer identification and the manufacturer drive program from the client side tool management platform, and installing the client side tool, wherein the client side tool dynamically obtains insertion information of the SD intelligent card and reads and judges the manufacturer identification location; and if a field recorded by the read manufacturer identification location is in the application list, determining the manufacturer drive program corresponding to the manufacturer identification location, loading the manufacturer drive program, and if the field of the read manufacturer identification location is not in the application list, not loading the drive program.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD +1

Dockable Tool Framework for Interaction with Large Scale Wall Displays

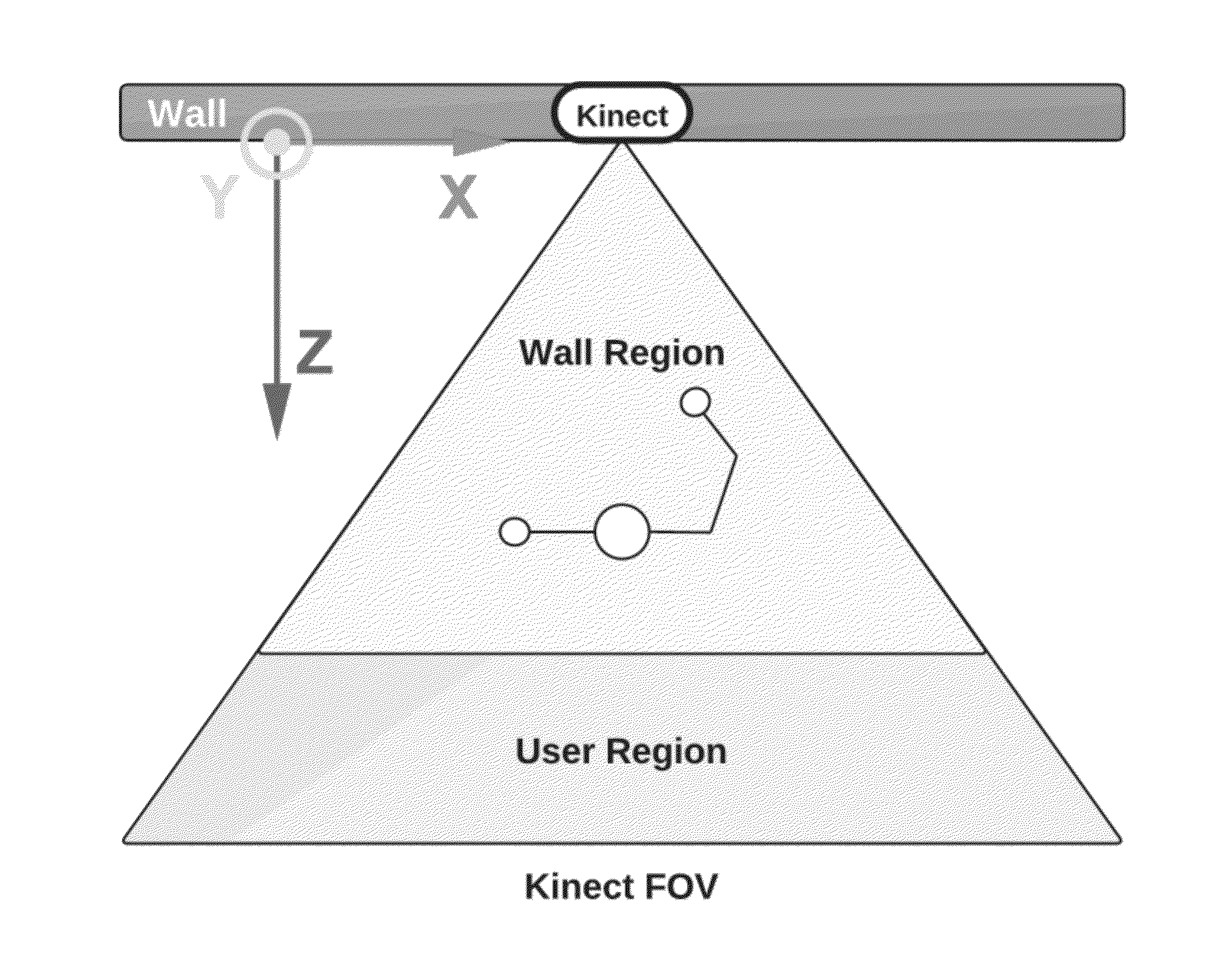

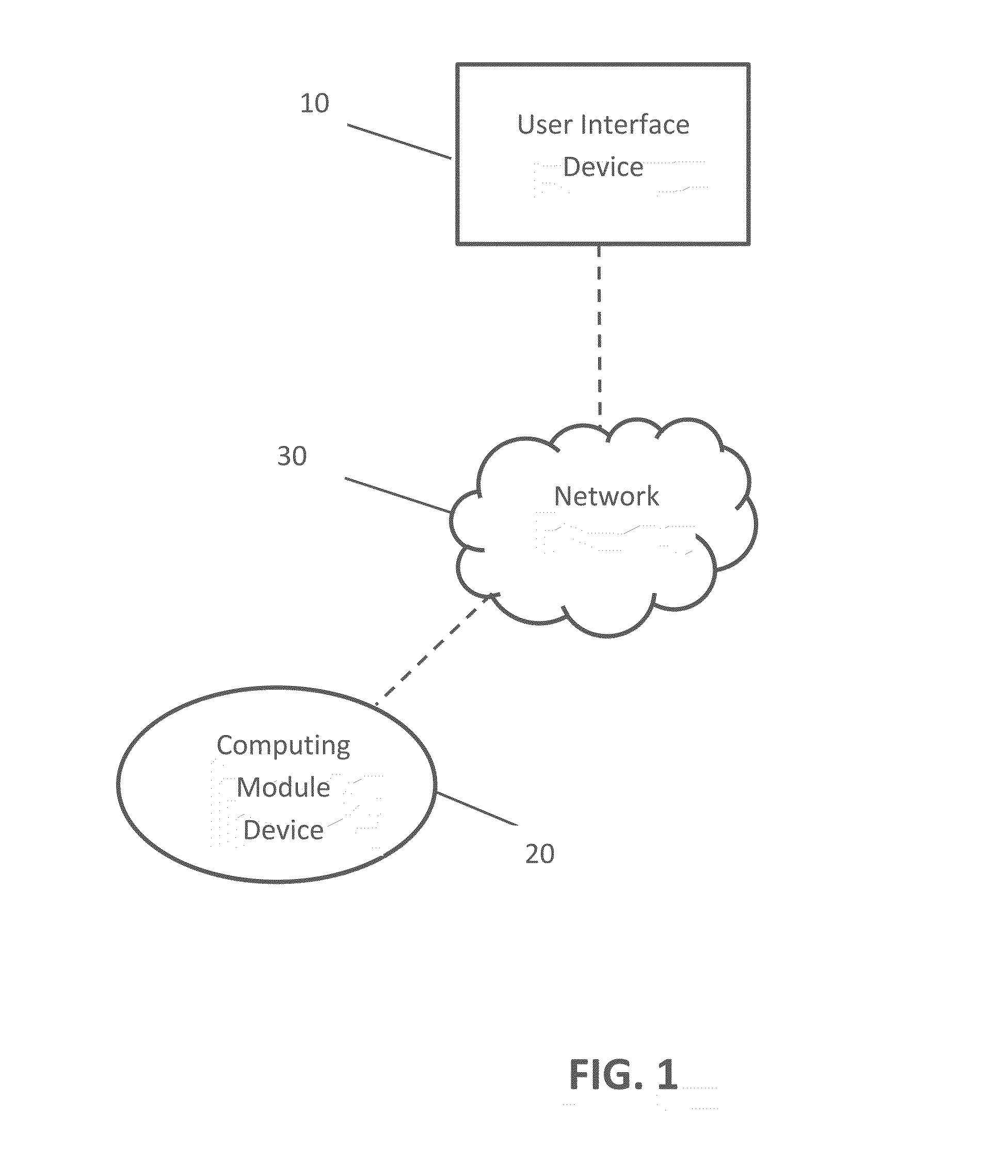

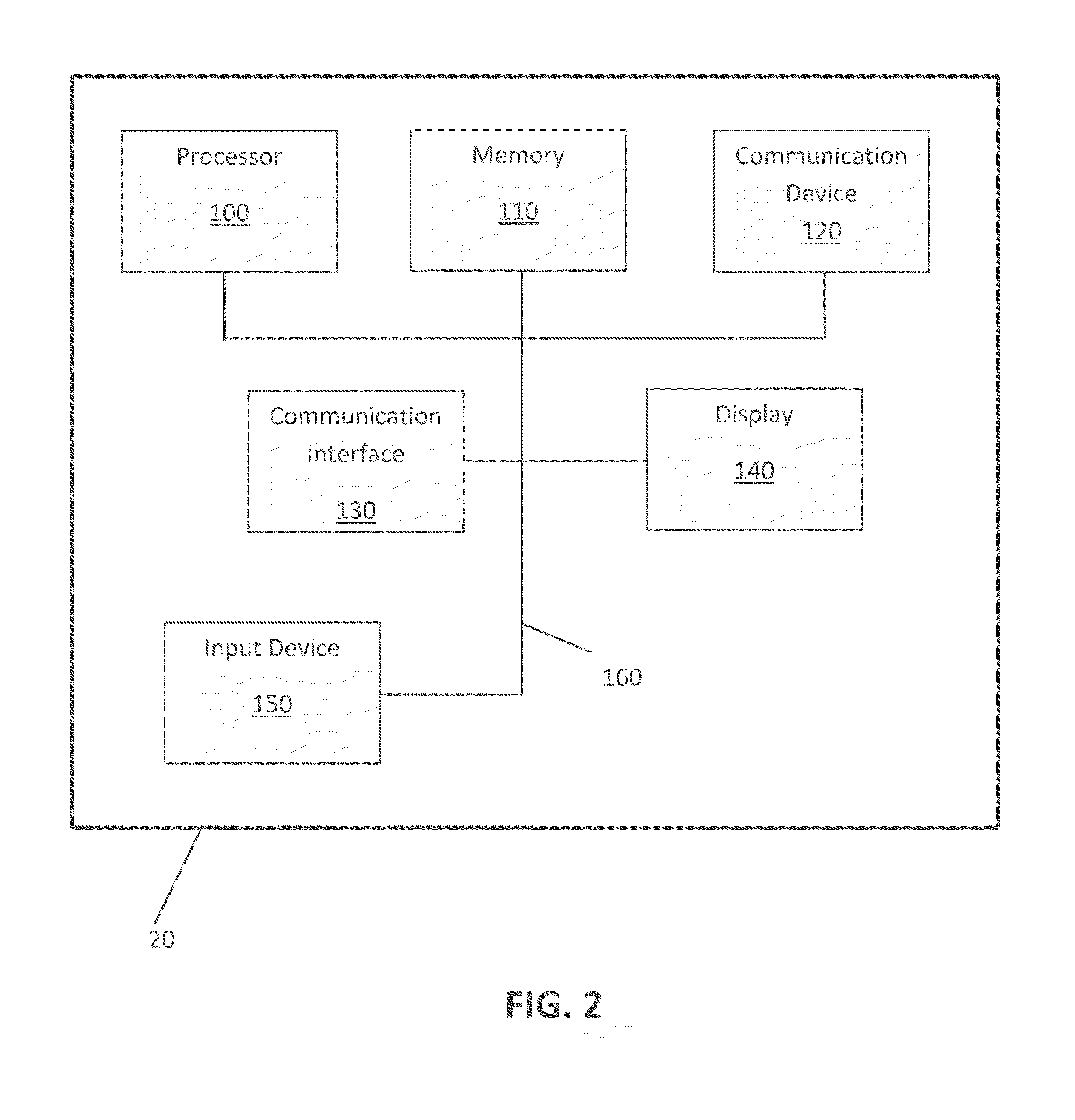

In accordance with an aspect of the present invention, a device and a method allows for body-based interaction with 3D applications on wall displays. The interface consists of virtual dockable tools which can be unholstered, used to manipulate geometry, and holstered on the user's body. The system also utilizes proprioceptive cues to allow the user to manipulate and holster tools without visual feedback. A 3D depth camera maps 3D user position to 3D coordinates in the virtual scene. Partitioning the physical work space into a region for interaction with geometry, and a region for tool management allows for intuitive mapping between the physical and virtual work space. The system can support multiple users, including simultaneous interaction with the environment, and tool exchange between users.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

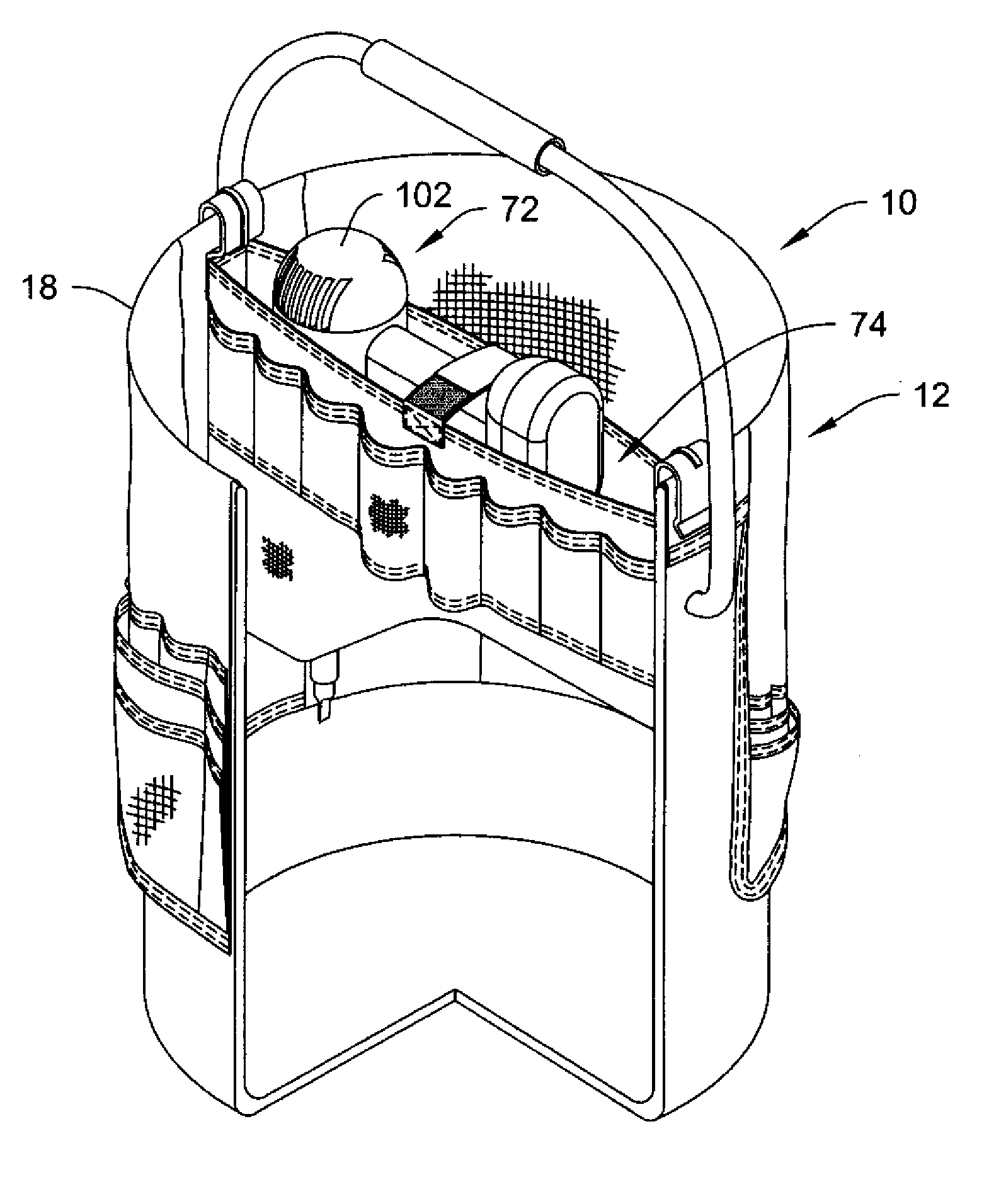

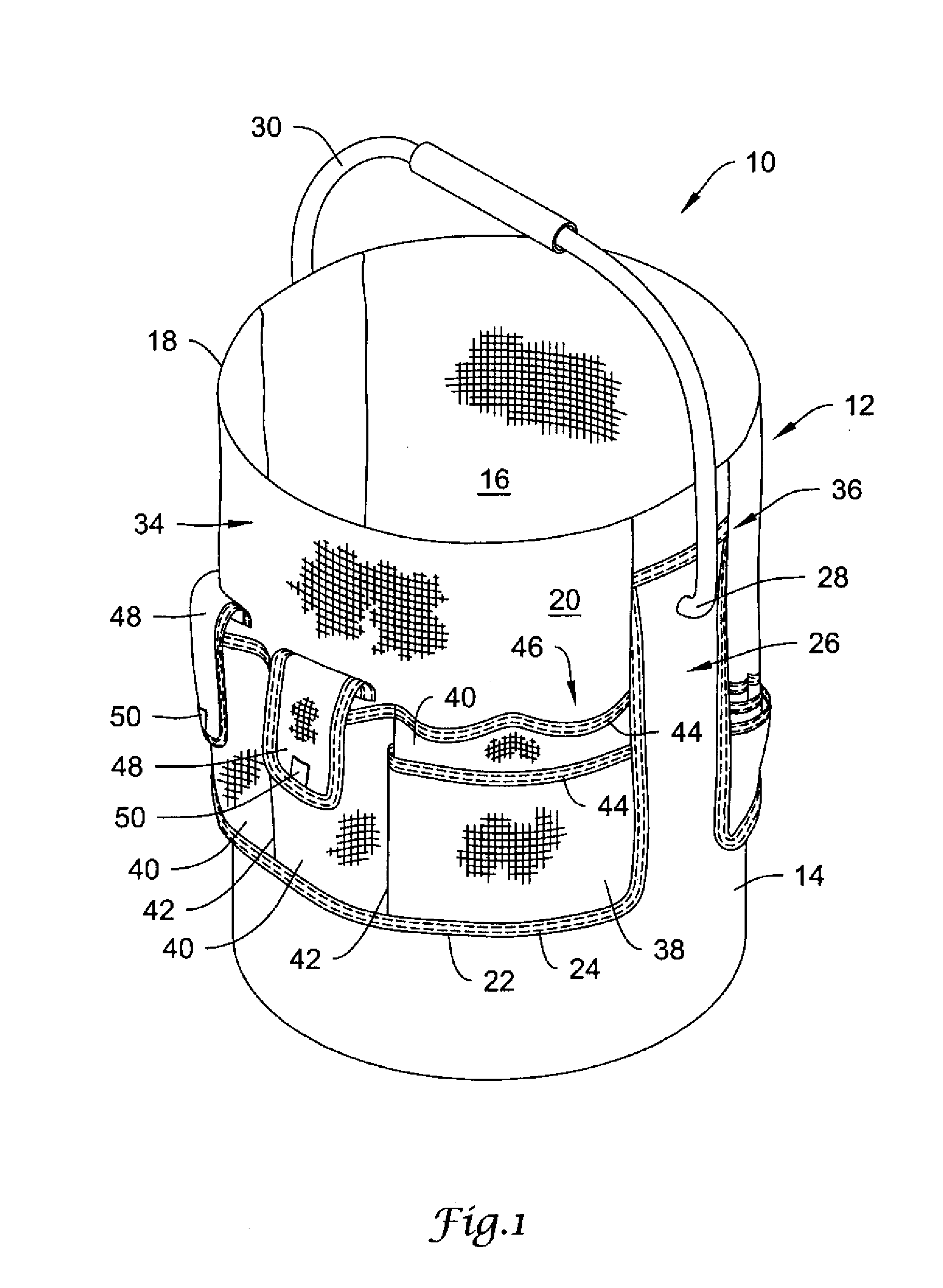

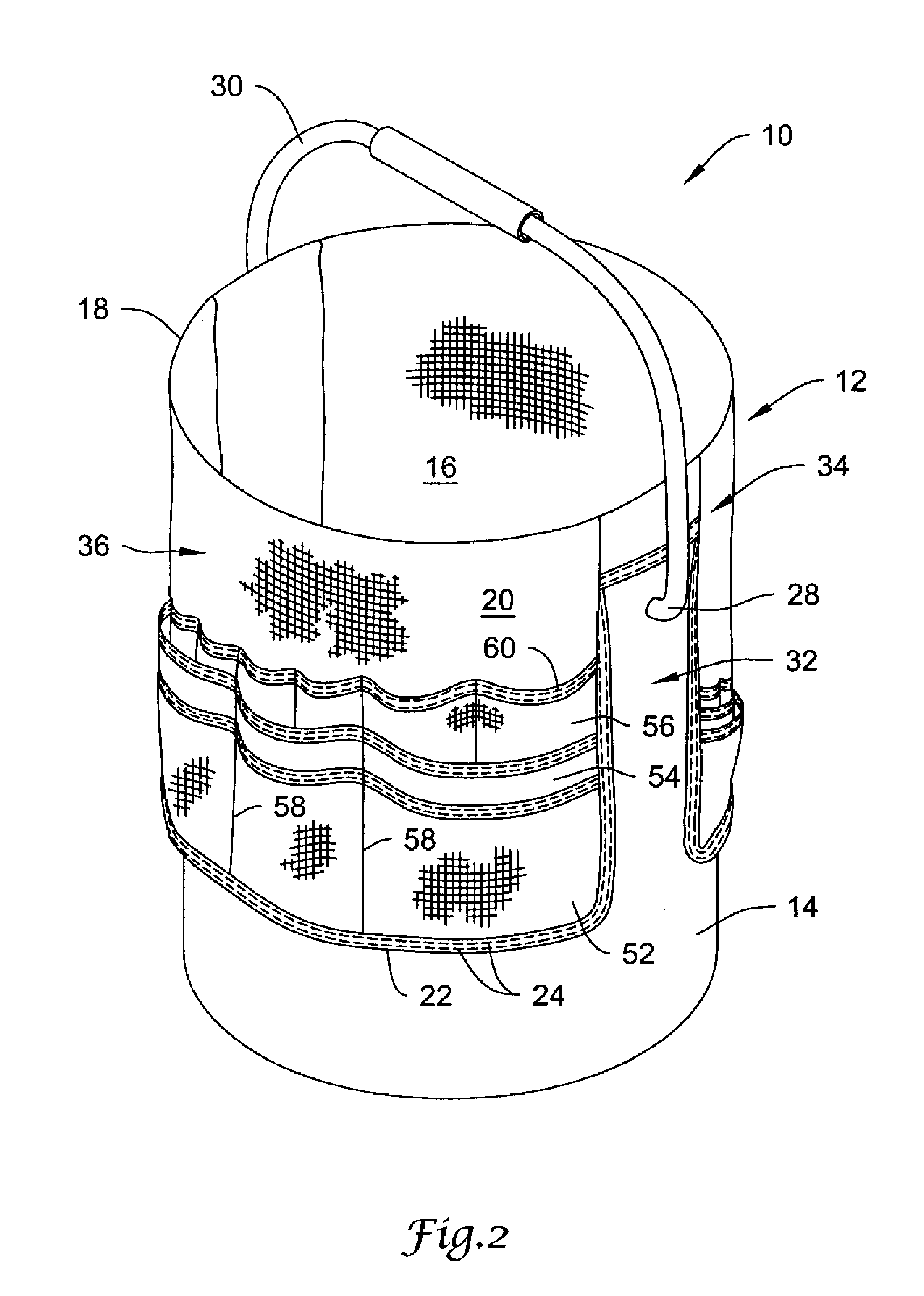

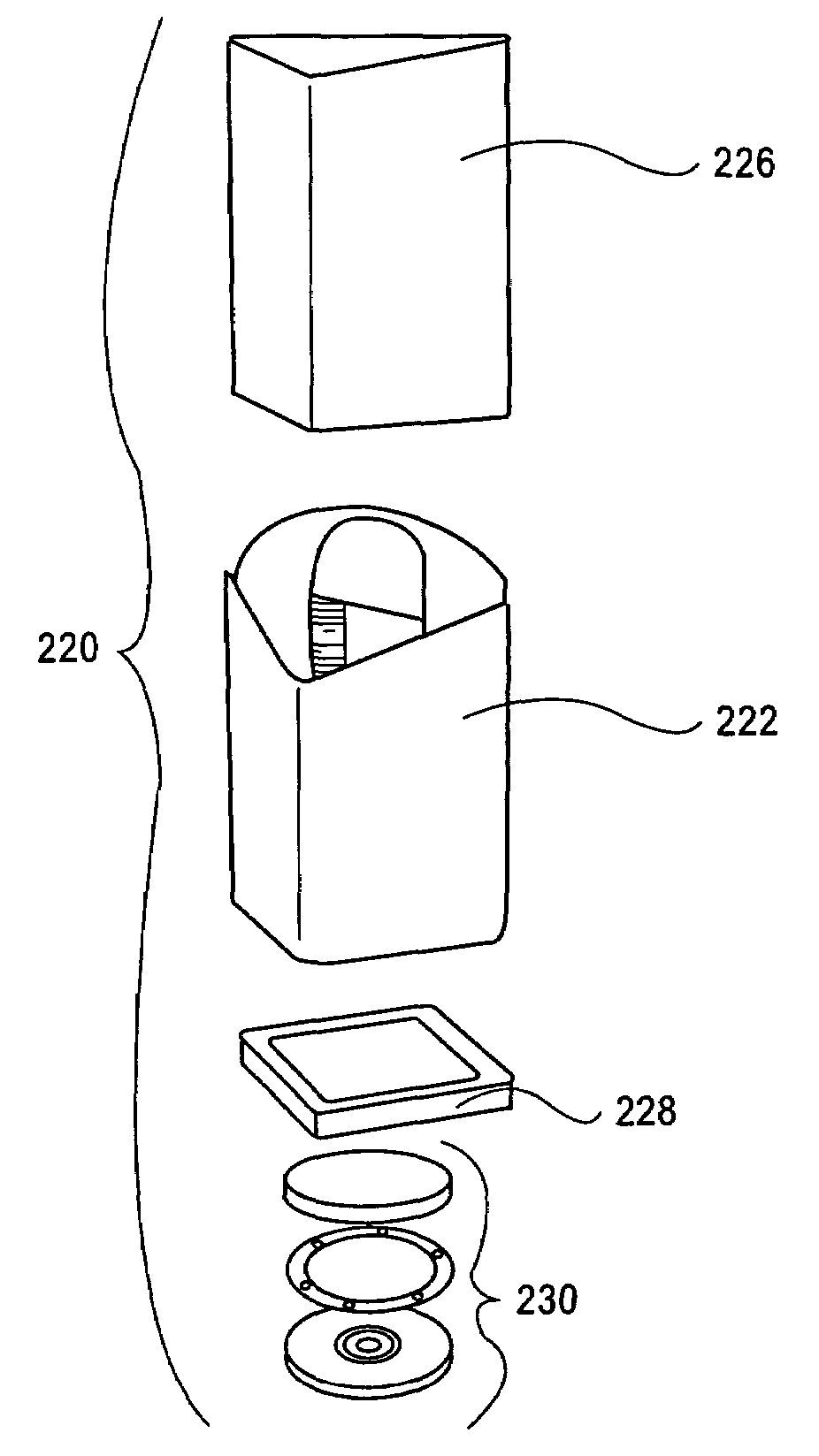

Bucket tool organizer with tool insert

InactiveUS20130037559A1Improve stabilityContainer/bottle contructionWork tools storageEngineeringPower tool

Owner:BOSS INNOVATIONS

Fastening Tool and Fastening Tool Management System

InactiveUS20080230245A1Low costReduce forceDerricks/mastsMeasurement arrangements for variablePower flowTorque transmission

A fastening tool with a clutch for shutting off transmission of torque, capable of self-diagnosing fastening torque of a screw or the like at low cost without using expensive means such as a torque sensor etc. A fastening tool (10) has a motor (13), a main shaft (20) engaging with a screw or the like, and a clutch (14) interposed between the motor (13) and the main shaft (20). The clutch (14) transmits torque from the motor (13) to the main shaft (20) when a load acting on the main shaft (20) is less than a predetermined value, and shuts off torque transmission from the motor (13) to the main shaft (20) when a load acting on the main shaft (20) is equal to or greater than the predetermined value. The fastening tool (10) further has a control unit (60) for controlling the motor (13). The control unit (60) monitors a current flowing to the motor (13) and determines whether fastening torque is normal or not based on a motor current when transmission of torque from the motor (13) to the main shaft (20) is shut off.

Owner:MAKITA CORP

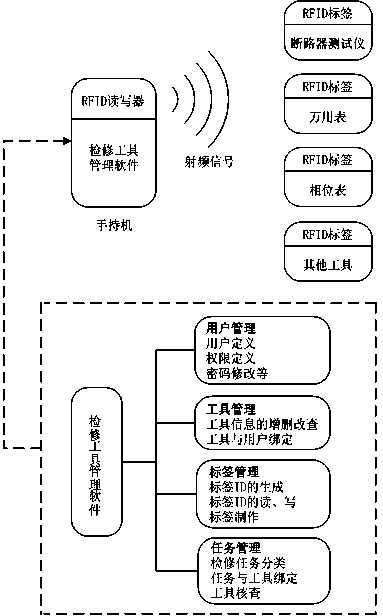

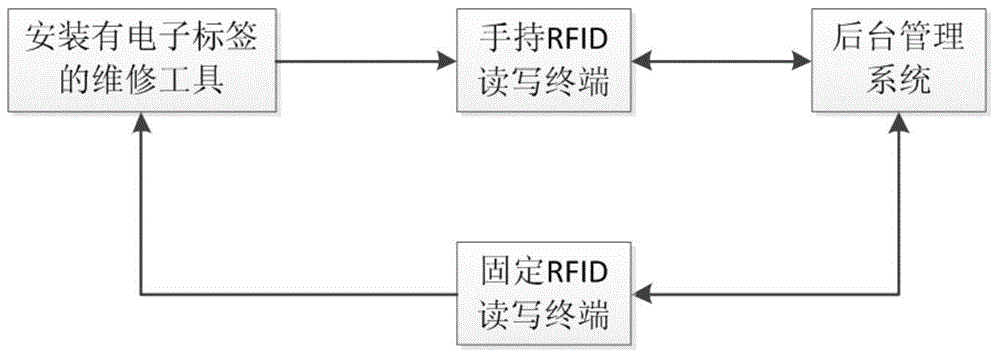

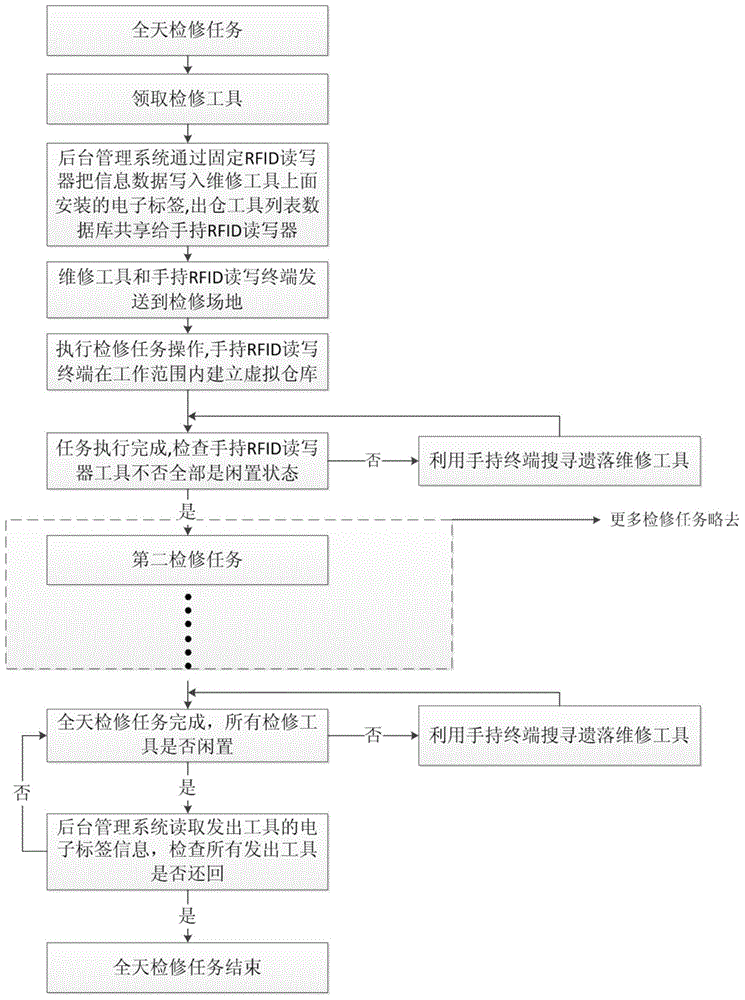

Aerial overhaul tool management system based on Internet of Things

InactiveCN104021453APrevent missing situations on the planeReduce flight hazardsSensing record carriersResourcesAviationThe Internet

The invention discloses an aerial overhaul tool management system based on the Internet of Things. The aerial overhaul tool management system comprises overhaul tools on which electronic tags are installed, a handheld RFID read-write terminal, a backstage management system and a fixed RFID read-write terminal. When the overhaul tools on which the electronic tags are installed are taken out of a warehouse, the backstage management system will use the fixed RFID read-write terminal for writing ex-warehouse information such as getting reasons and ex-warehouse time into internal storages of the electronic tags installed on the overhaul tools; after ex-warehouse is finished, the backstage management system shares an ex-warehouse tool list and ex-warehouse tool information with a database of the handheld RFID read-write terminal through wireless communication; the handheld RFID read-write terminal and the overhaul tools are together conveyed to a work site, the handheld RFID read-write terminal sets up a virtual warehouse in the 5 m-radius peripheral range with the handheld RFID read-write terminal as the center for warehousing and ex-warehouse management on the overhaul tools through the RFID communication technology, so that recover and usage of the overhaul tools are monitored, and it is prevented that the tools are lost on a plane and cause flight potential safety hazards.

Owner:海南赛龙网络科技有限公司

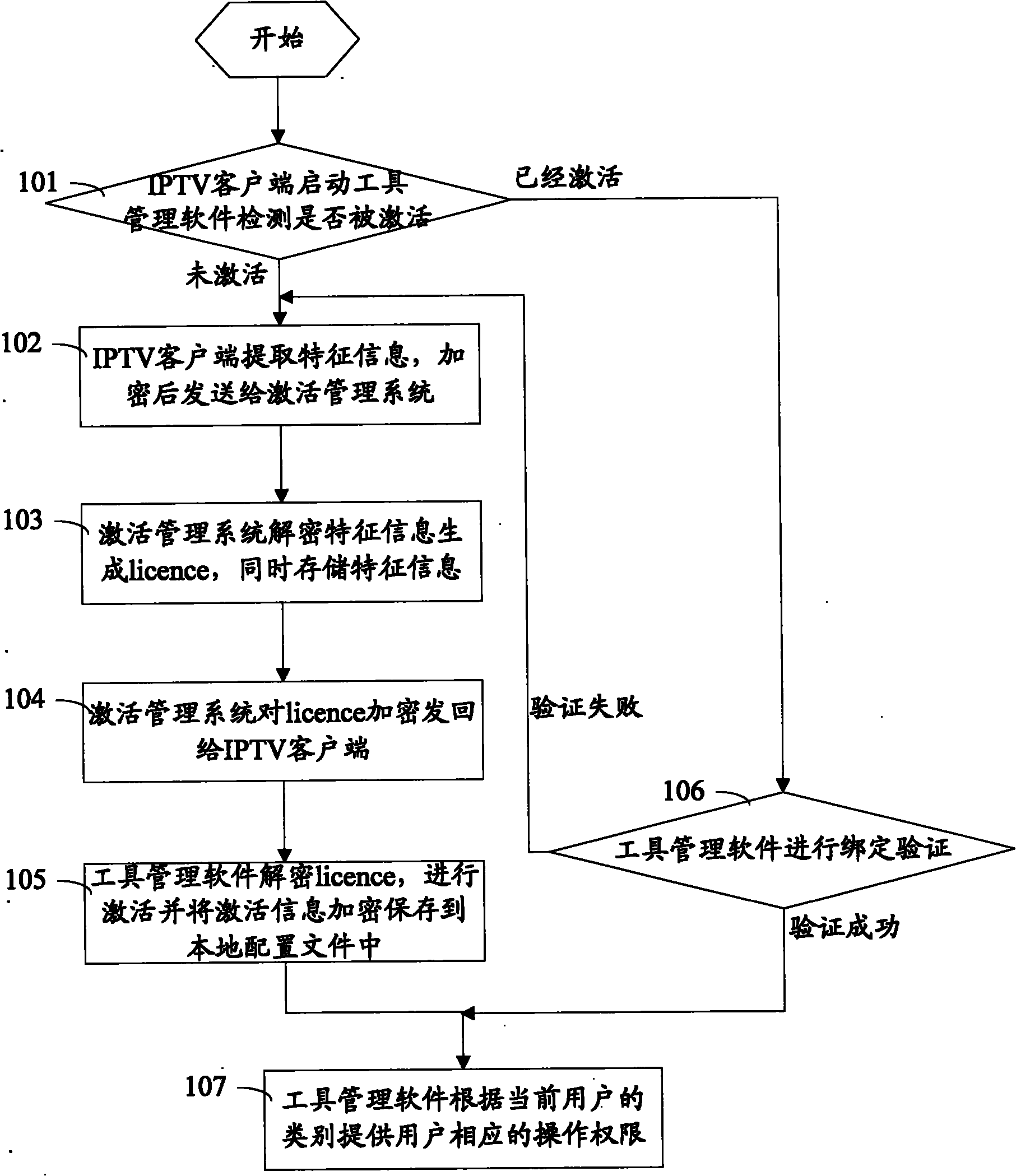

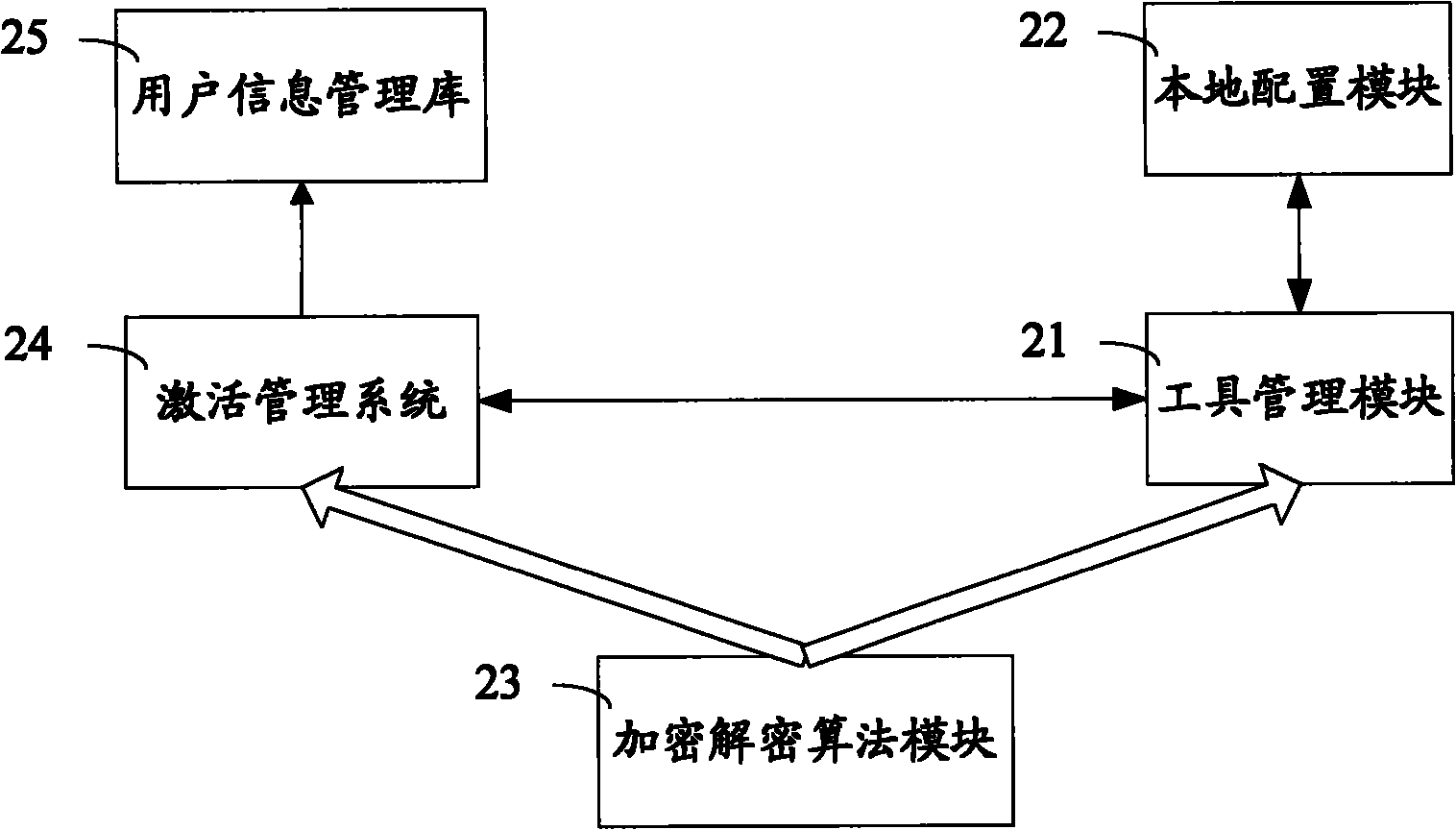

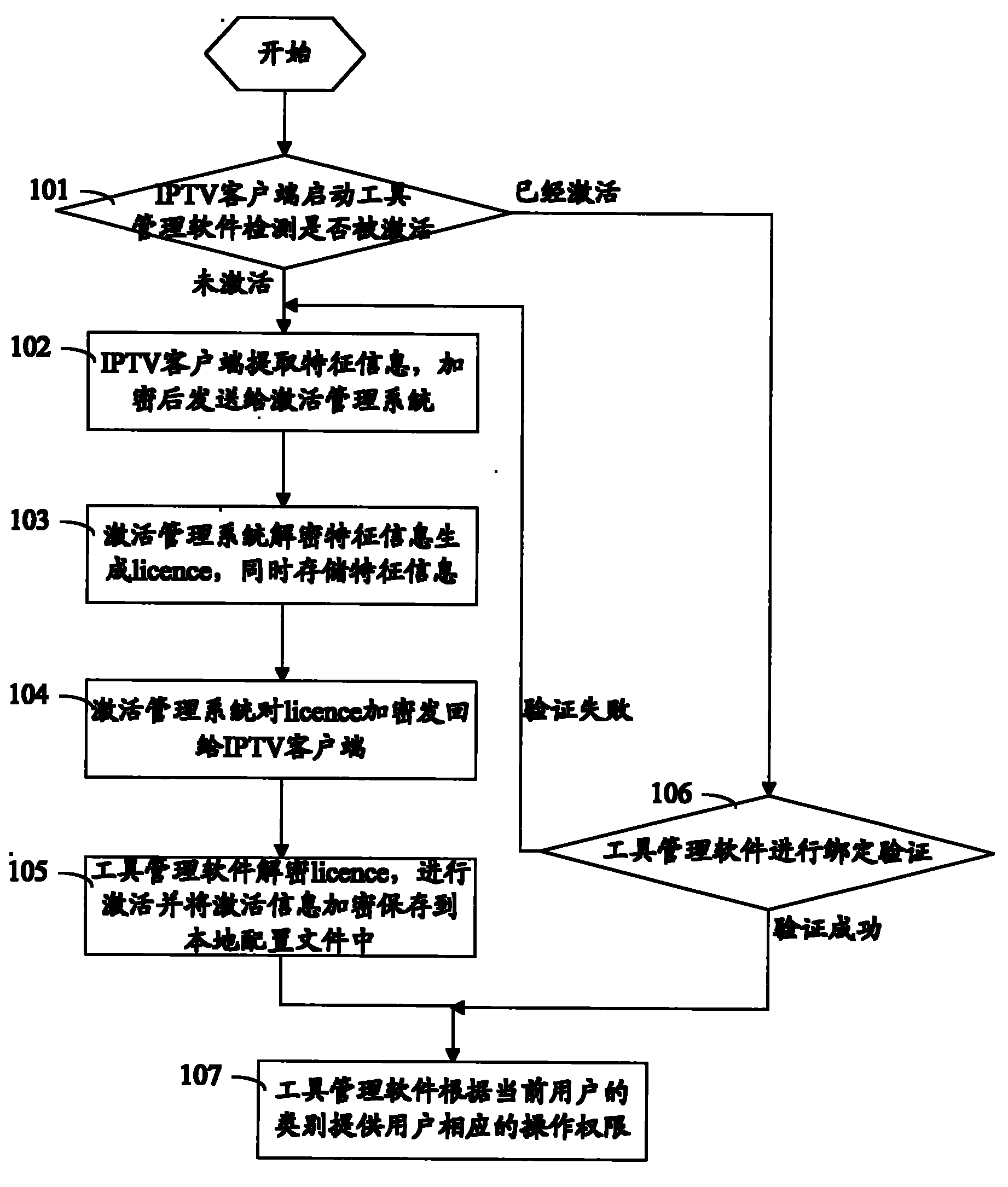

Method and system for activating and authenticating an internet protocol television client

InactiveCN101877702AImprove securityAvoid misuseUser identity/authority verificationTwo-way working systemsBiological activationClient-side

The invention discloses a method for activating and authenticating an internet protocol television (IPTV) client. The method comprises the following steps that: the IPTV client extracts the characteristic information of the client and transmits the information to an activation managing system after the characteristic information is encrypted; the activation managing system decrypts the characteristic information of the client, generates a license according to the characteristic information, encrypts the license and sends the encrypted license back to the IPTV client; and the IPTV client decrypts the received license, activates according to the information carried by the license, encrypts the activated information, stores the activated information into a local configuration file, and runs tool management software. The invention also discloses a system for activating and authenticating the IPTV client. Through the method and the system, the safety of the tool management software of the internet protocol television client can be improved and the use of the tool management software has more pertinence.

Owner:ZTE CORP

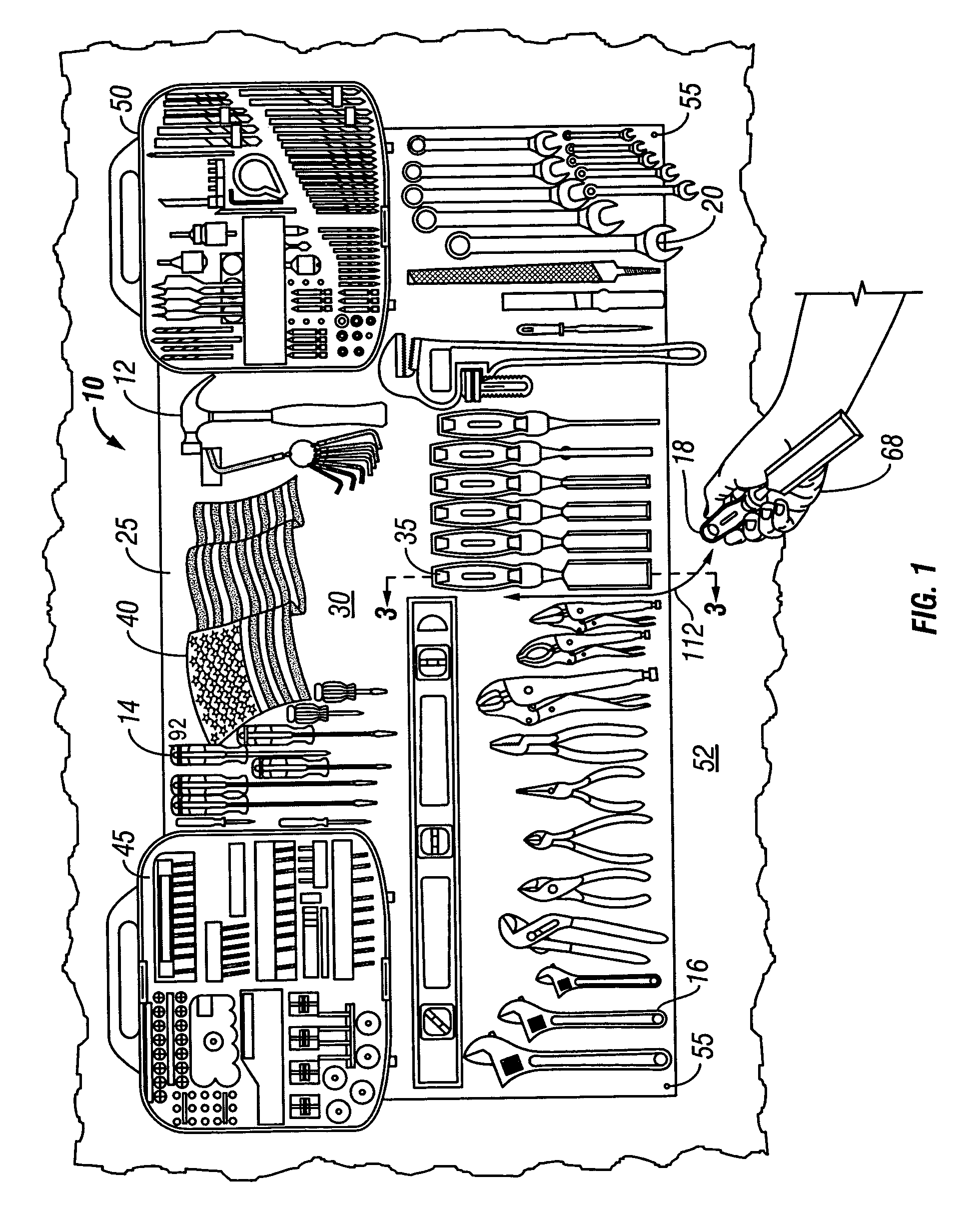

Tool attachment and organizer system and methods

InactiveUS7510092B2Easy to changeEnabling twisting reorientationRacksWork tools storageEngineeringMagnet

A tool organizer system has a flat sheet of magnetically attracted material that attracts magnets attached to tools to support the tools on the flat sheet. The system includes position indicators that can be attached at any orientation and position on the flat sheet. The system can be provided as a kit with one or more components. A method of organizing a set of tools provides for efficient use of space and clear association between a tool and a previously selected position and avoids loss of tools by placing them in previously selected positions. A method of making a tool organizer system includes making the system in accordance with requests from a customer. The tool organizer system includes a kitchen tool organizer system that has a container with at least one magnetically attractive side and a handle, allowing the container to retain kitchen tools within the container and magnetically on the side. Attachment tools may include a fastener attachment tool that couples to a tool and provides magnetic force and a magnetic bar coupled to a tool organizer to allow metal tools to be coupled to the bar.

Owner:SHOLEM STEVEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com