Intelligent warehousing device and warehousing method

A technology of intelligent warehousing and equipment, applied in the field of industrial warehouse warehouse management, can solve the problems of insufficient warehousing equipment and warehousing methods, taking away other items on the same tray, wasting manpower, etc., so as to facilitate management and review work and save labor. The effect of managing costs and simplifying the picking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

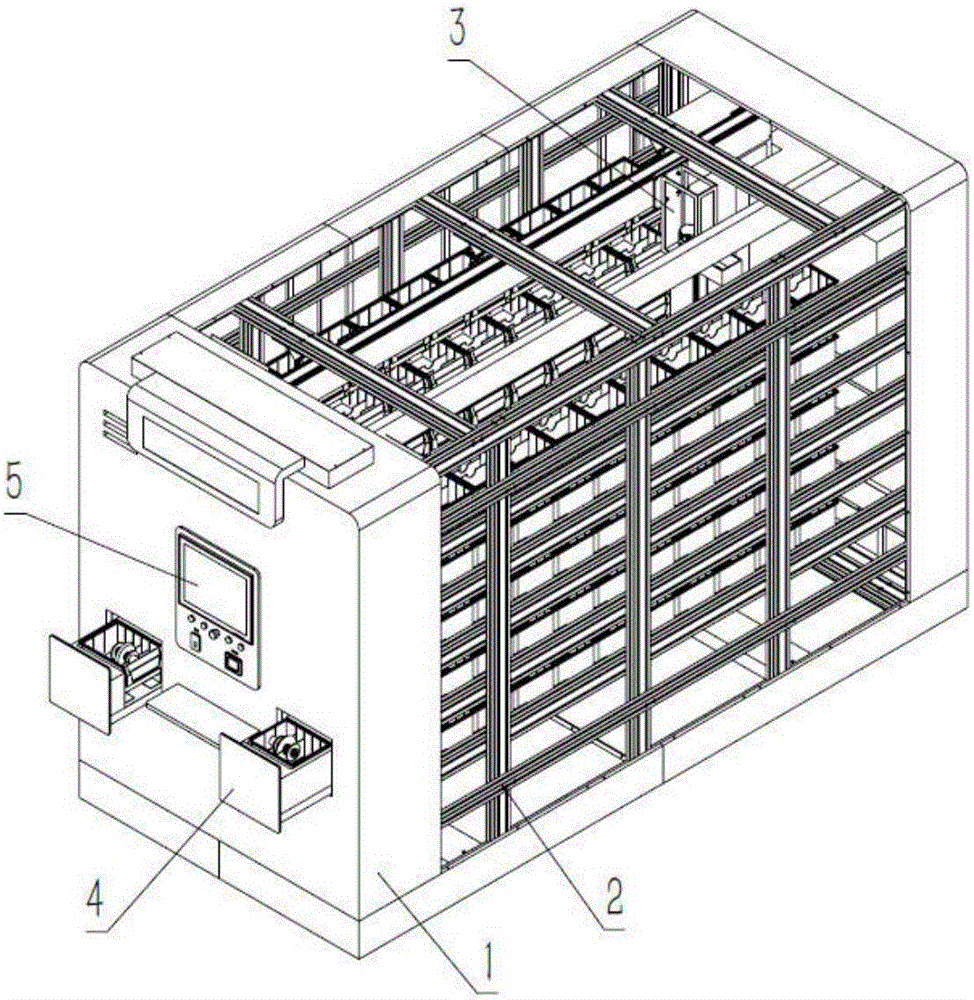

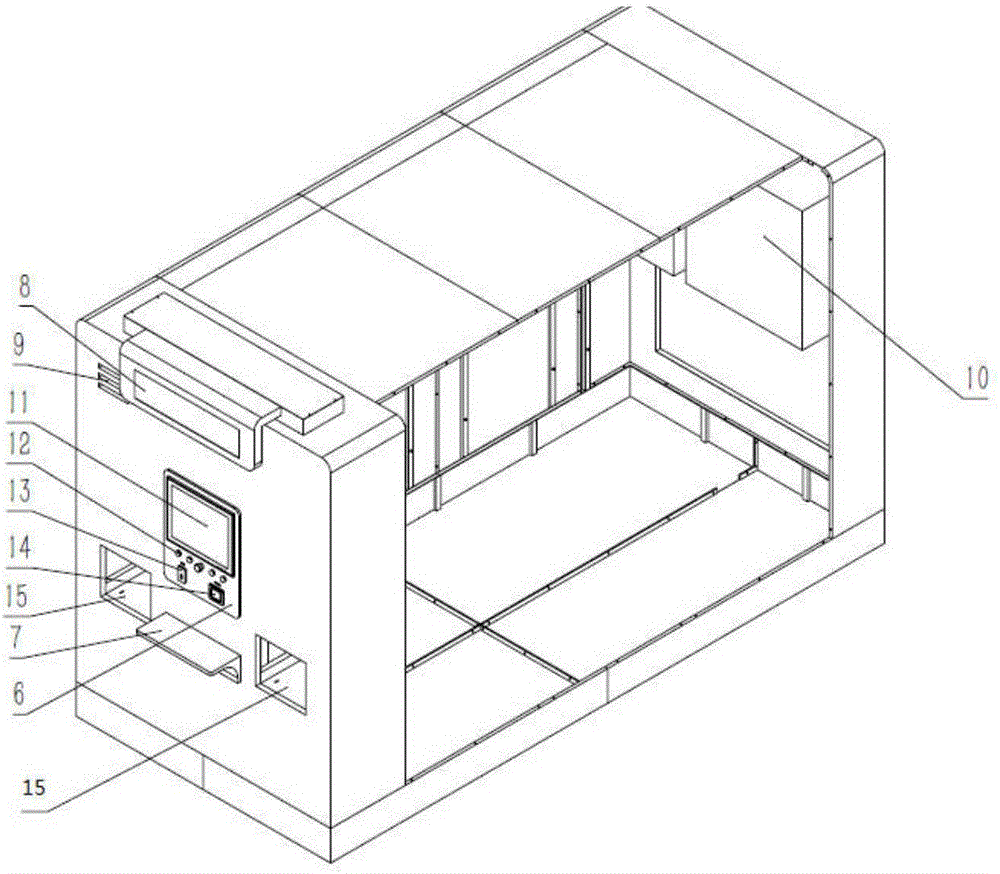

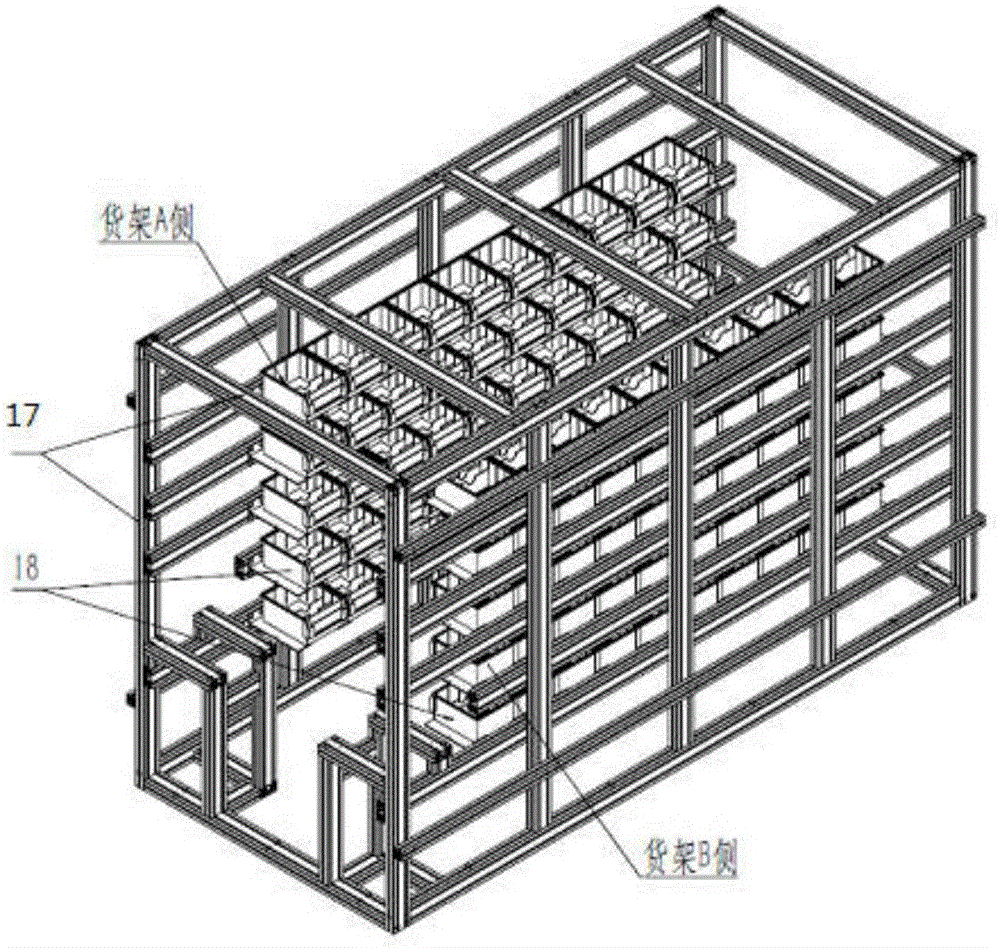

[0025] Embodiment of the present invention: an intelligent storage device, the intelligent storage device is composed of a cover 1, a shelf 2, a pick-up device 3, a storage drawer box 4 and a control system 5, and the cover 1 is fixedly installed on the outside of the shelf 2 Around, on the outer cover 1 are provided with an operation panel 6, an object stage 7, a display screen 8, an indicator light 9, an electrical cabinet 10 and a drawer window 15, and the shelf 2 is built into a rectangular frame structure by aluminum profiles 17, and the The pick-up device 3 is fixed at the middle position inside the shelf 2, and the storage drawer box 4 is arranged in the drawer windows 15 on both sides under the operation panel of the outer cover 1 .

[0026] The operation panel 6 is provided with an ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com