RFID (Radio Frequency Identification Device) technology-based dynamic tool management method of Siemens 840D numerical control system

A technology of numerical control system and tool management, applied in general control system, control/regulation system, program control, etc., can solve problems such as loss, negligence, error and omission of production time and money, to prevent product scrap, improve stability and safety , the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

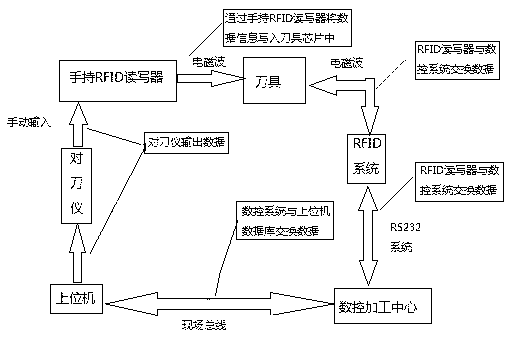

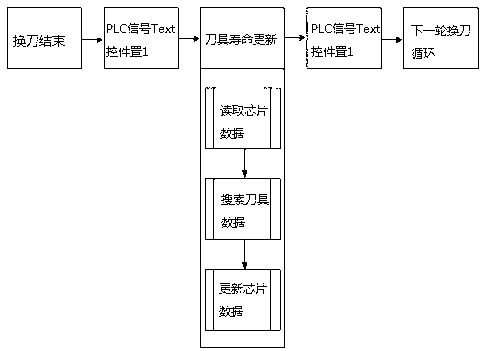

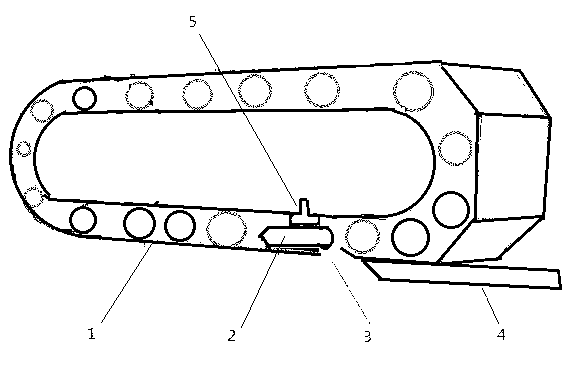

[0038] Embodiment 1: The numerical control machining center used in this embodiment is a certain turning-milling composite numerical control machining center currently being developed by Shenyang Machine Tool Group, which will use a Siemens 840D numerical control system. The tool magazine of the machining center is a chain tool magazine with an automatic tool change position. The RFID read-write antenna can be installed at the automatic tool change position to facilitate the update of tool life data during tool exchange, such as image 3 Shown.

[0039] The RFID reader is placed in a position with ample space at the rear of the machining center, and is connected to the CNC system through the RS232 interface. The machining center uses Sandvik's Coromant Caputo modular combination tool. The RFID chip can be installed in the gap of the tool change holding slot on the side of the connection pair. Sandvik can customize the connection pair with the chip installation position reserved a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com