Patents

Literature

118 results about "Part program" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The part program is a sequence of instructions, which describe the work, which has to be done on a part, in the form required by a computer under the control of computer numerical control (CNC) software. It is the task of preparing a program sheet from a drawing sheet. All data is fed into the CNC system using a standardized format. Programming is where all the machining data are compiled and where the data are translated into a language which can be understood by the control system of the machine tool.

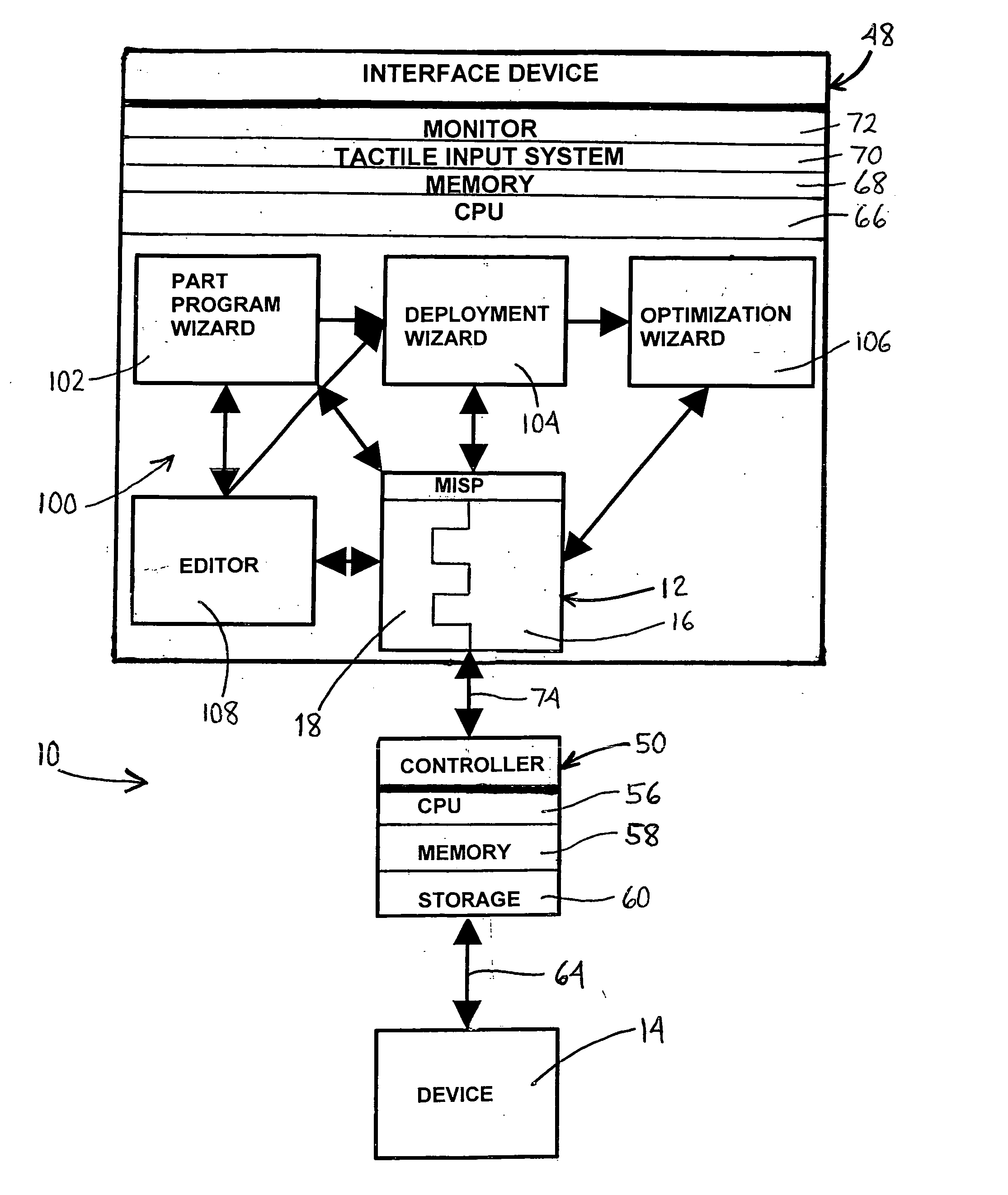

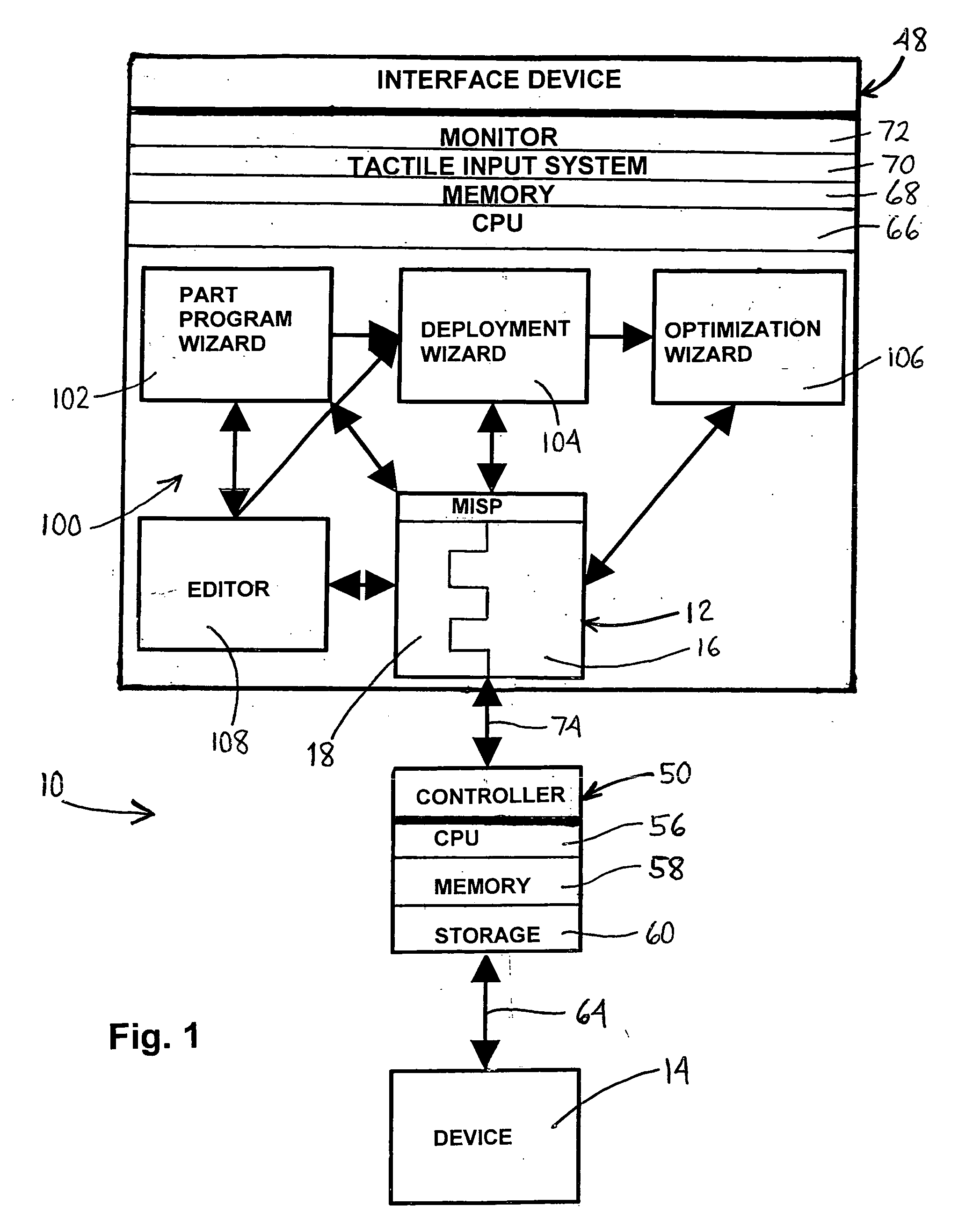

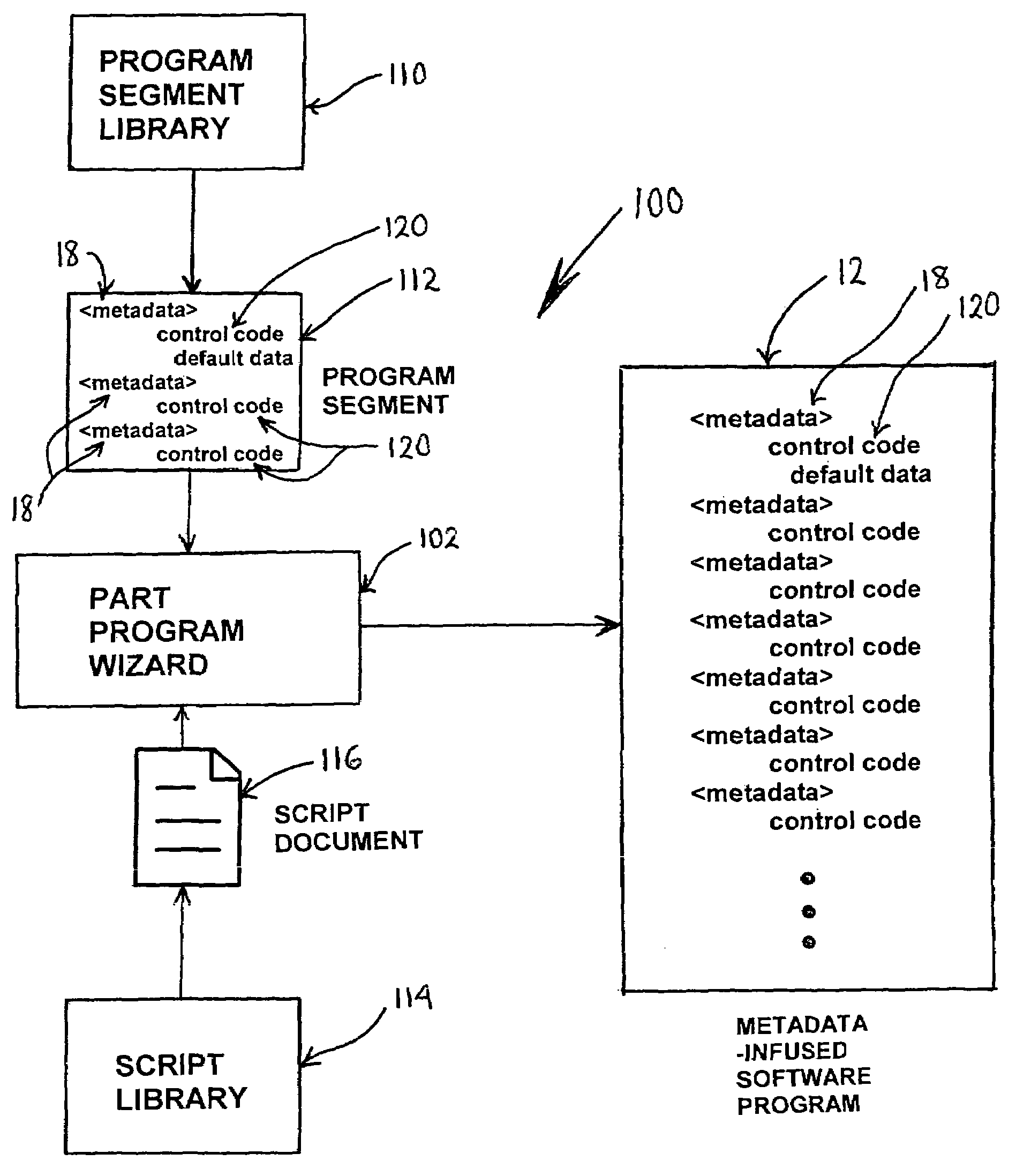

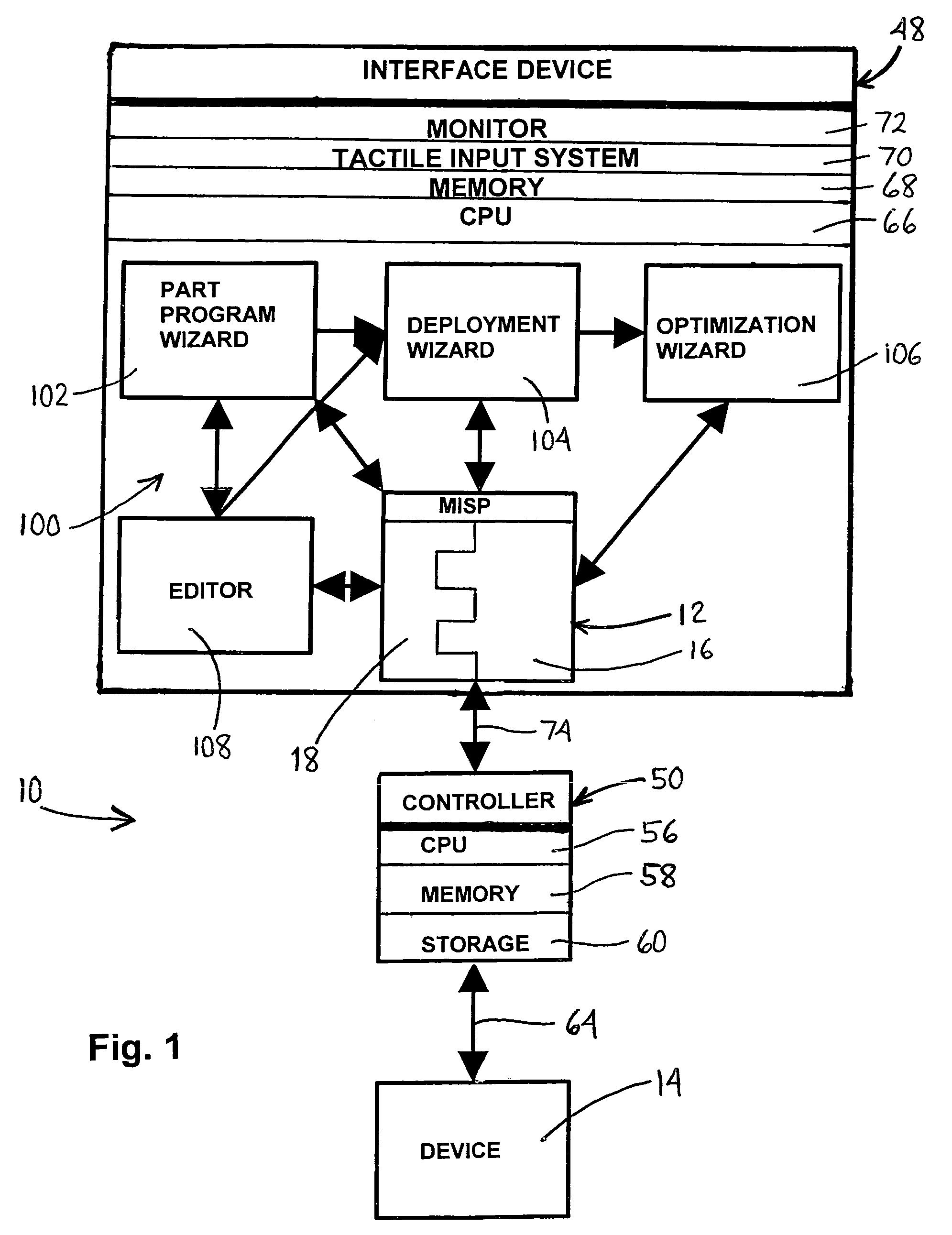

Method and apparatus for developing a software program

The present invention is directed to a method and apparatus for developing a metadata-infused software program for controlling a device, such as a robot. A first library of software segments with metadata and a second library of script documents are provided. A part program wizard uses a script document selected from the second library to display queries on a screen of an interface device. Using input information received in response to the queries, the part program wizard selects and combines software segments from the first library to produce the metadata-infused software program. The metadata identifies the selected software segments and includes statuses of the selected software segments. A graphical representation of the metadata infused software program is displayed on the screen and conveys the statuses of the software segments. A deployment wizard is utilized to teach data points for the metadata-infused software program.

Owner:ABB RES LTD

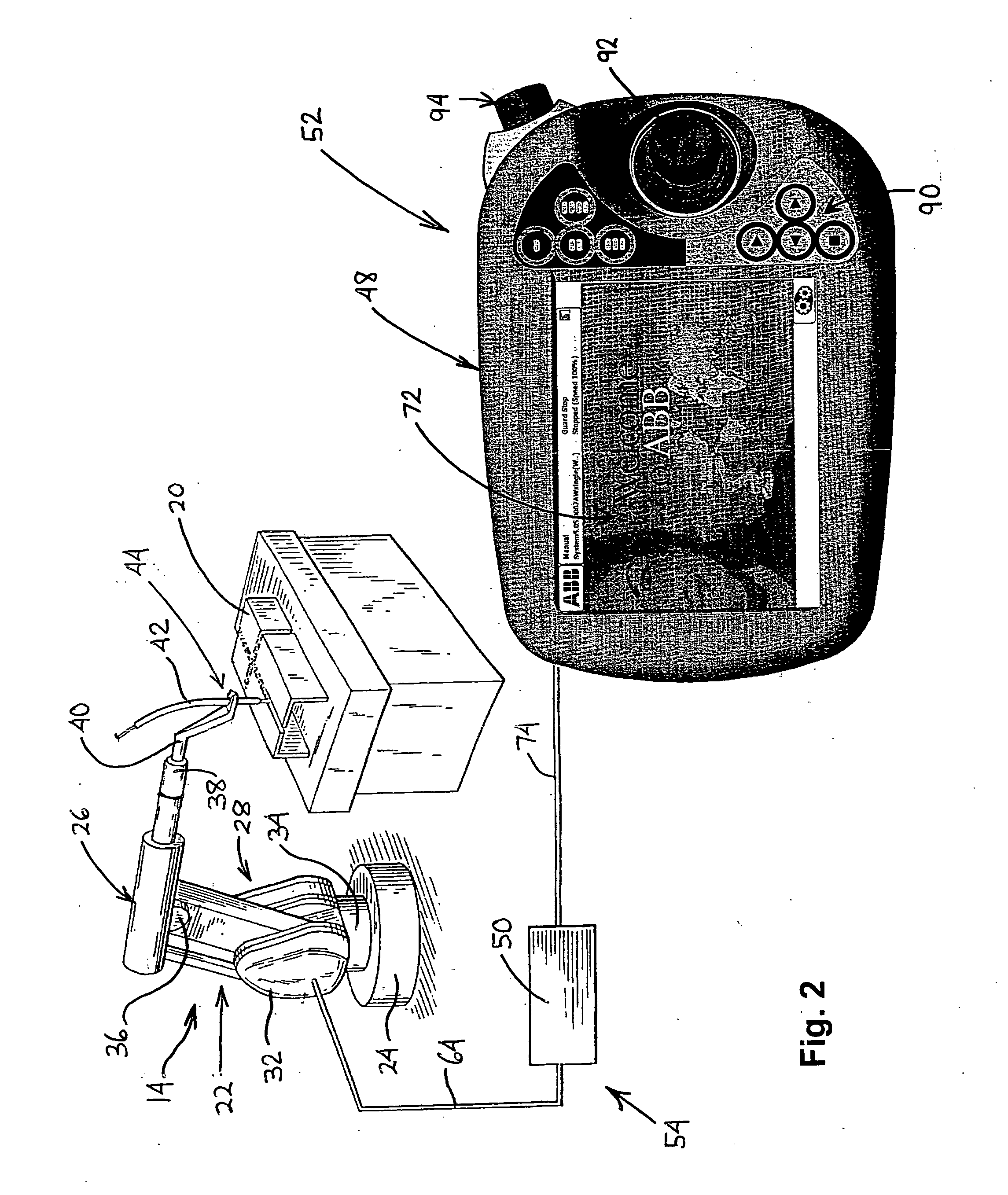

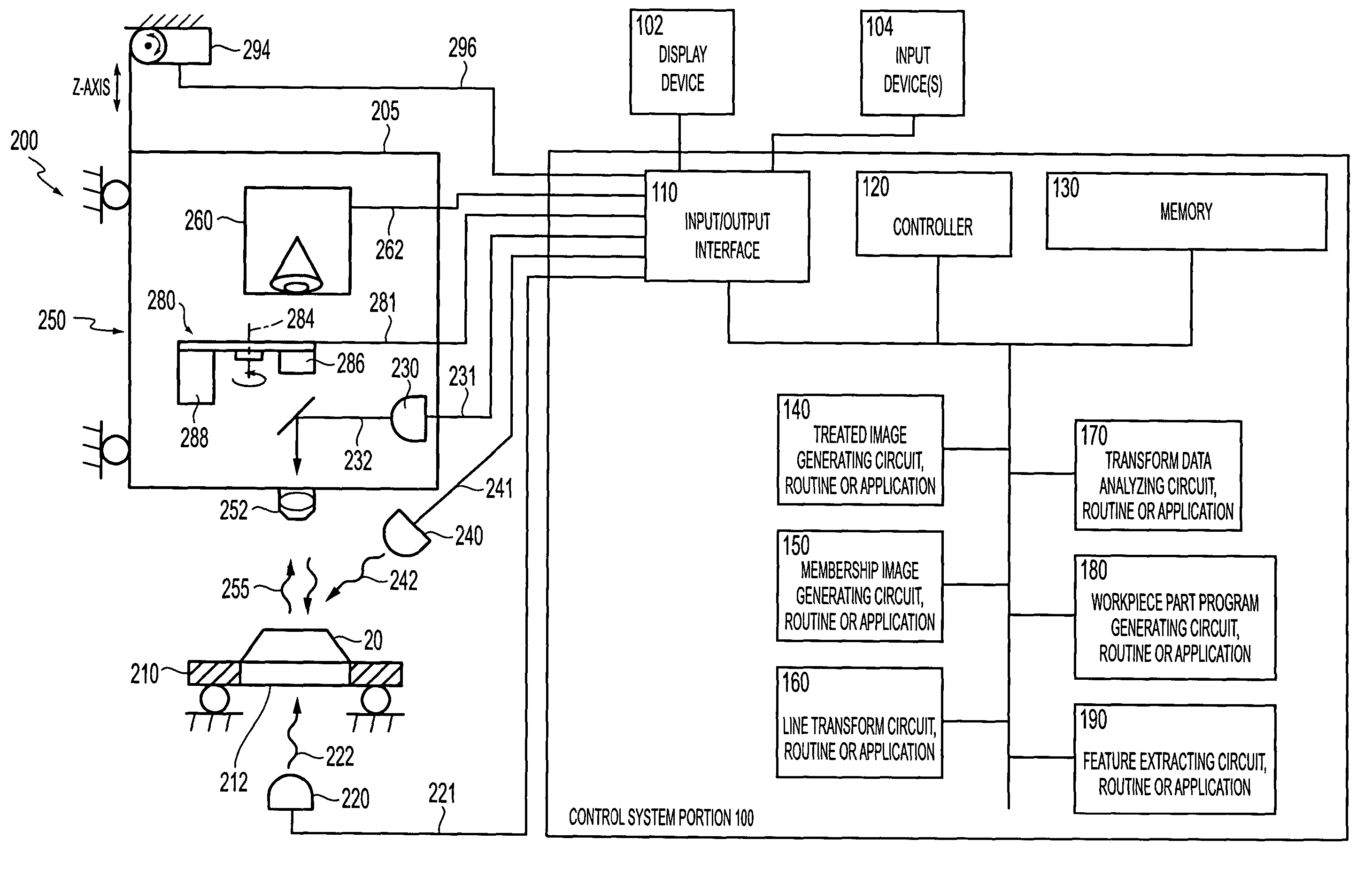

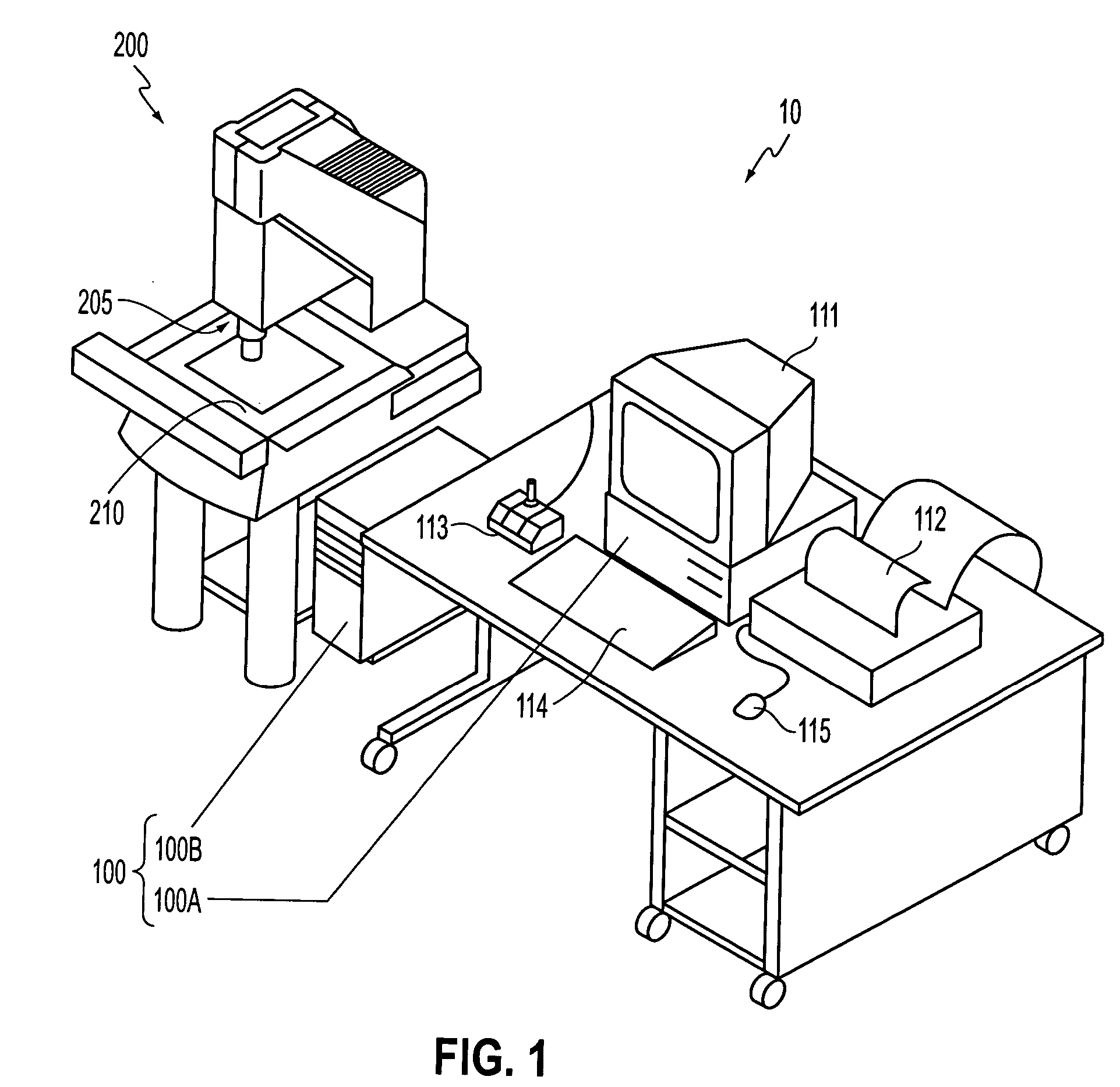

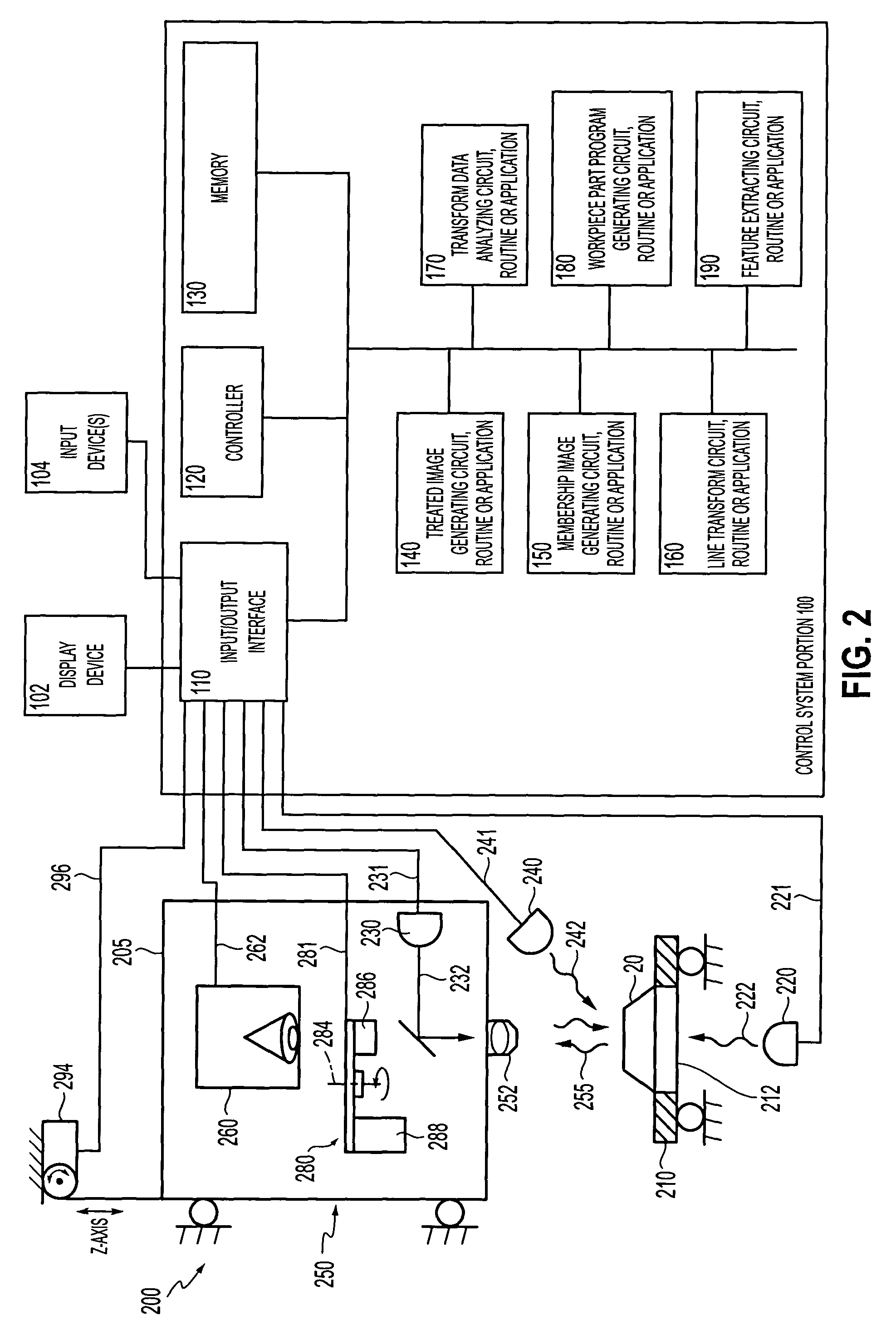

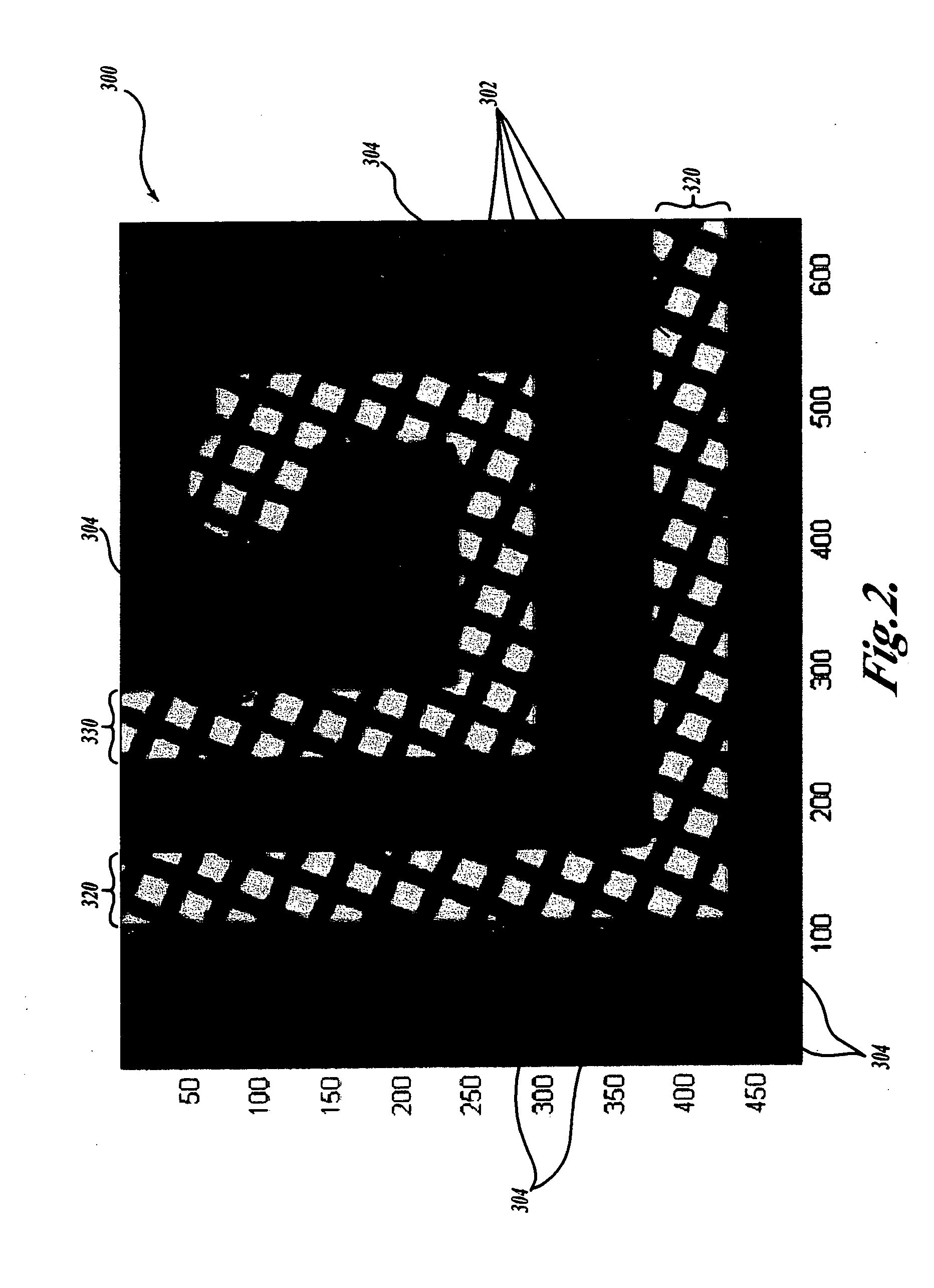

Methods and apparatus for inspection of lines embedded in highly textured material

InactiveUS20050031191A1Improve abilitiesLack of precisionImage enhancementImage analysisMachine visionData set

A machine vision inspection system is programmed and operated to identify one or more lines appearing in a highly-textured and / or low-contrast surface of a workpiece. In a learning mode, a line-enhancing image is generated from a captured image of the workpiece. In various embodiments, the enhanced image is based on a previously determined technique governed by a selected value for an associated parameter. A line transform is used to transform the enhanced image. The transformed data is analyzed to identify local extrema corresponding to the lines to be identified. Part program instructions are created to automatically generate the line-enhancing image, to transform it, and to analyze the transformed data set to identify the lines to be detected. Line constraint(s) that characterize a consistent line arrangement are used to improve the speed and reliability of the line detection.

Owner:MITUTOYO CORP

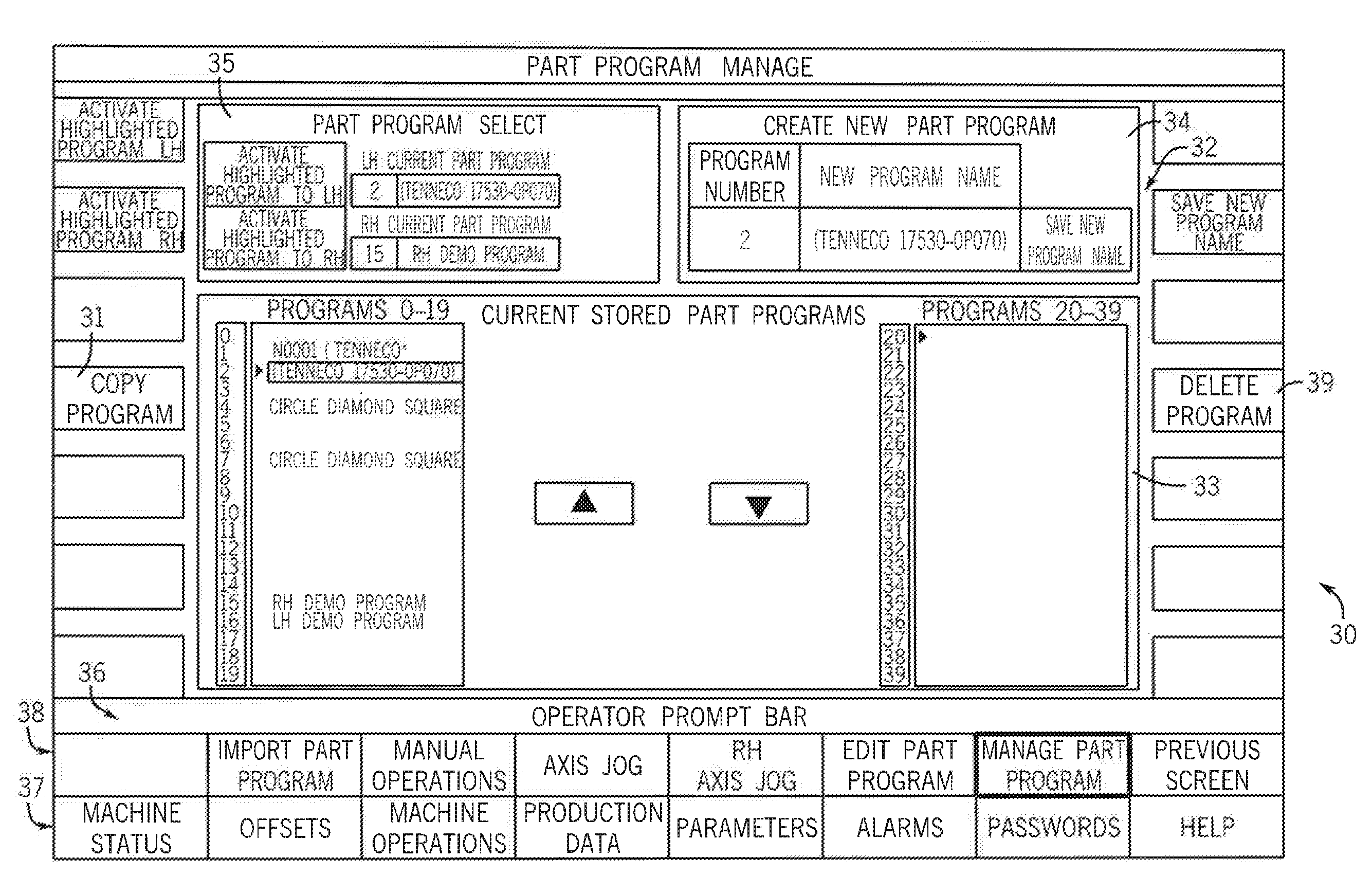

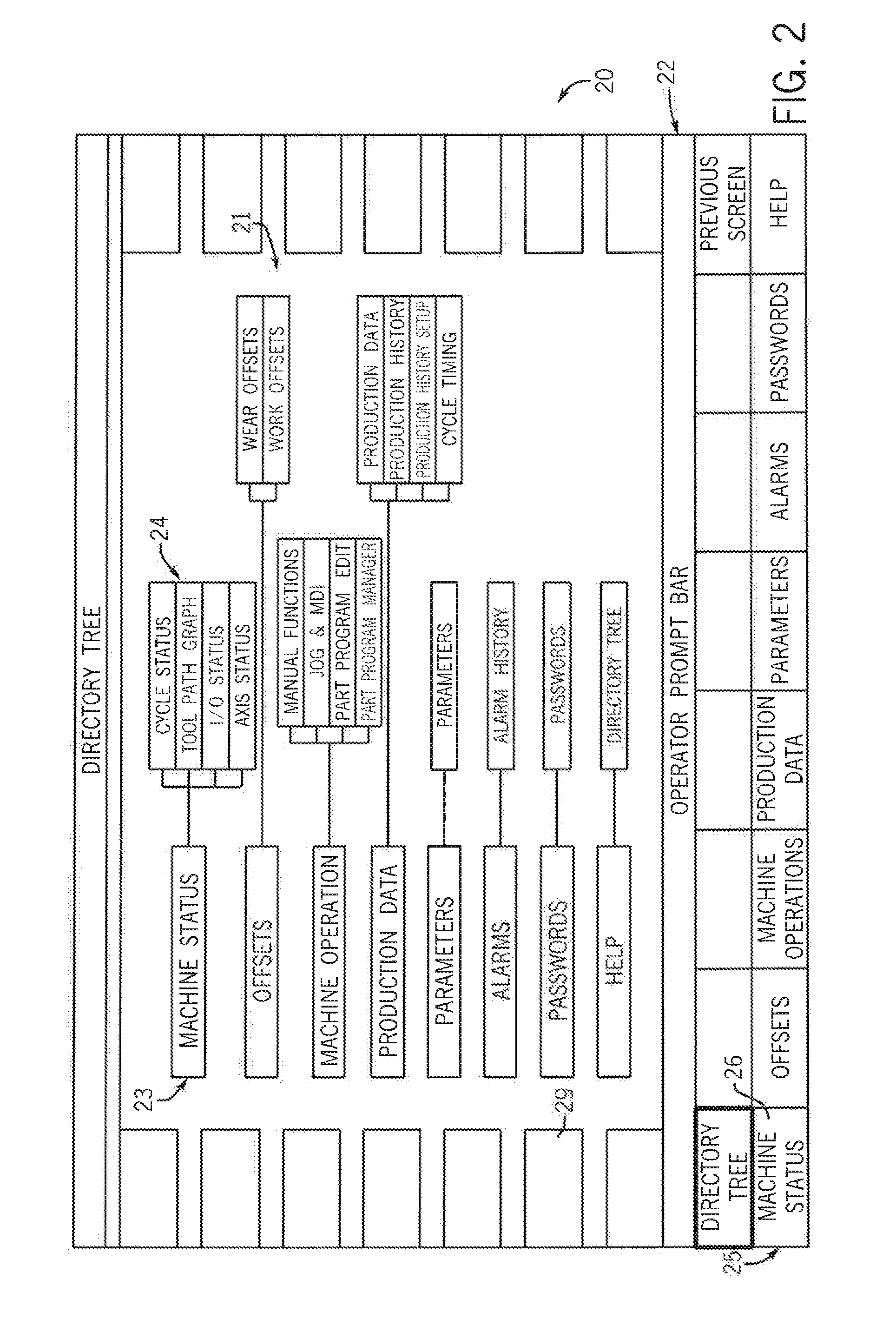

Method and System for Programmable Numerical Control

ActiveUS20100063608A1Programme control in sequence/logic controllersSpecial data processing applicationsNumerical controlOperator interface

A method of controlling a machine tool and other controlled devices, as well as a programmable numerical control (PNC) system, are disclosed. In at least one embodiment, the method of controlling includes receiving a first part program at a programmable logic controller (PLC), and storing the first part program in a string array library of a memory portion of the PLC. The method further includes communicating information between the PLC and an operator interface regarding the first part program, and providing a first signal from the PLC to a first port so as to cause the first machine tool to be operated in accordance with the first part program. Also, in at least some embodiments, the PNC system allows for control of multiple machine tools and / or other controlled devices, by way of one or more part programs, and / or for editing of a part program while that program is being executed.

Owner:ROCKWELL AUTOMATION TECH

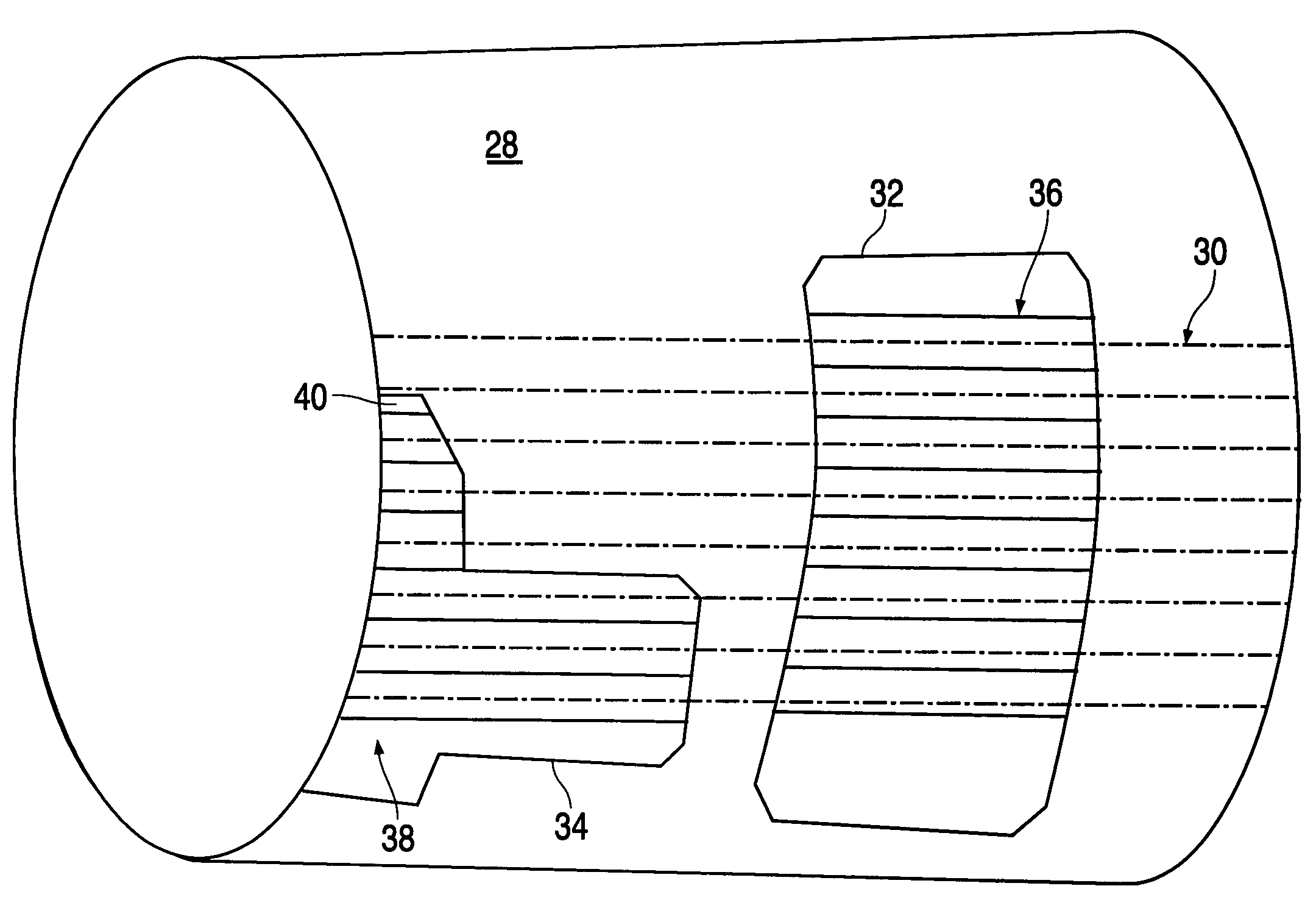

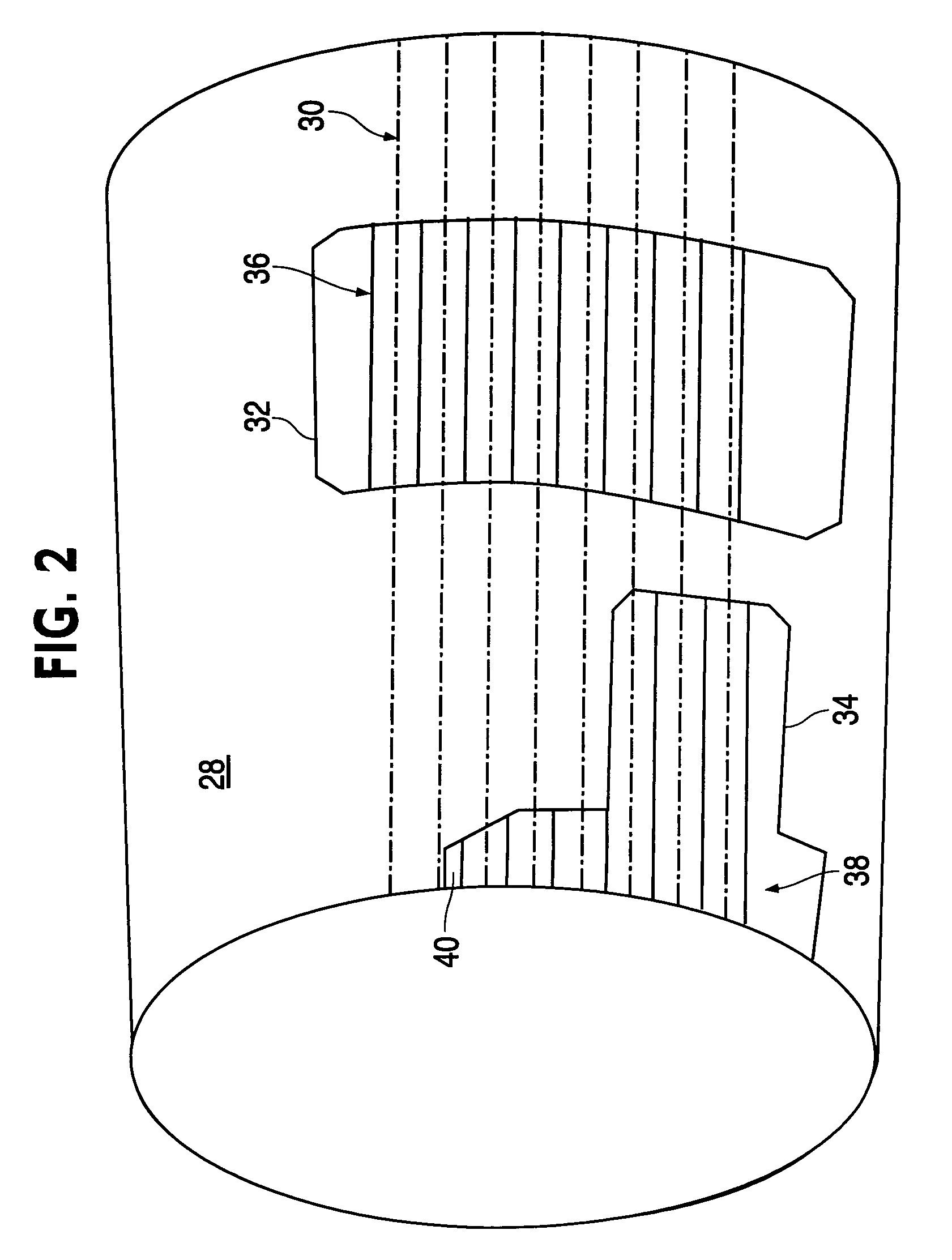

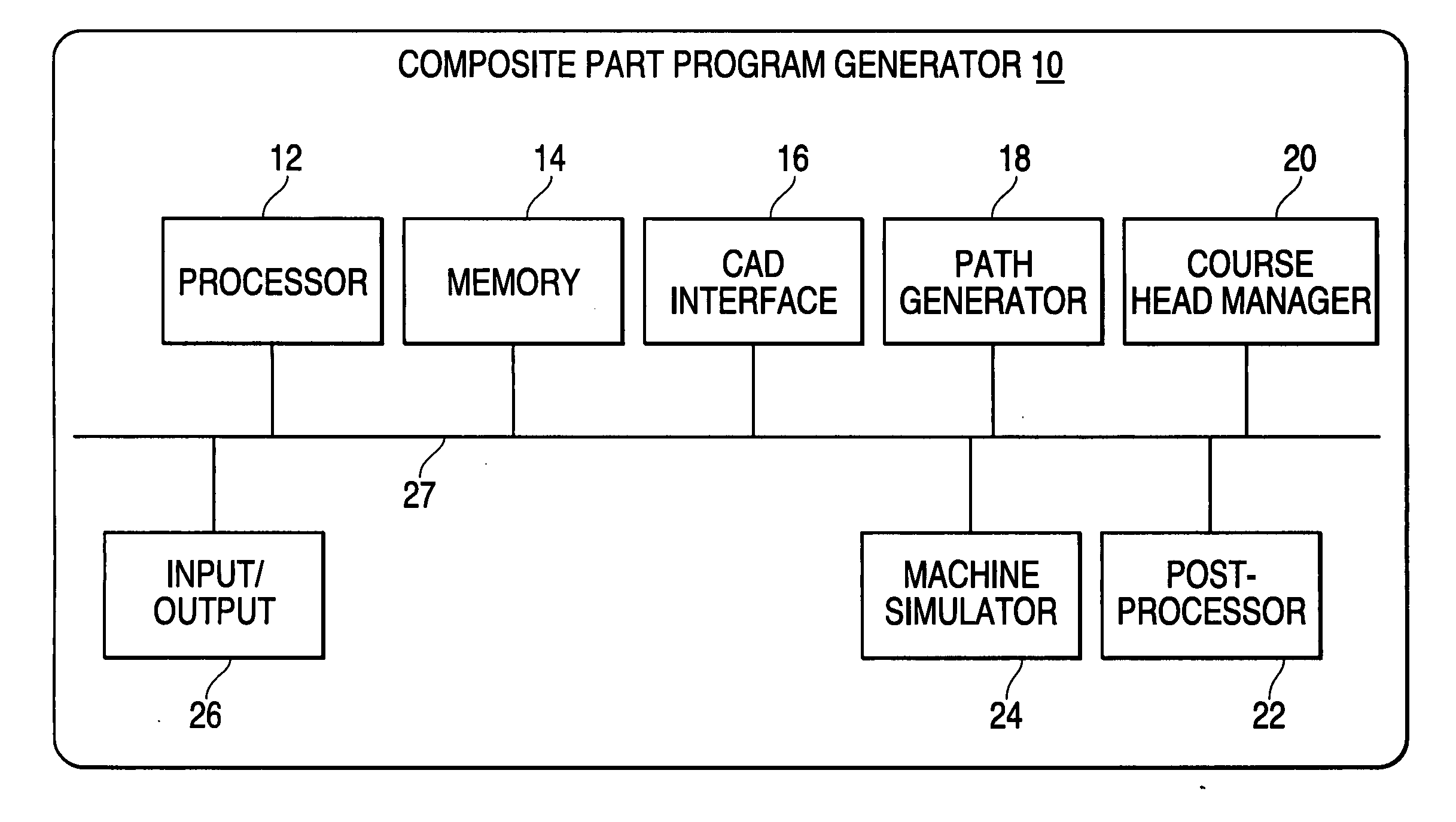

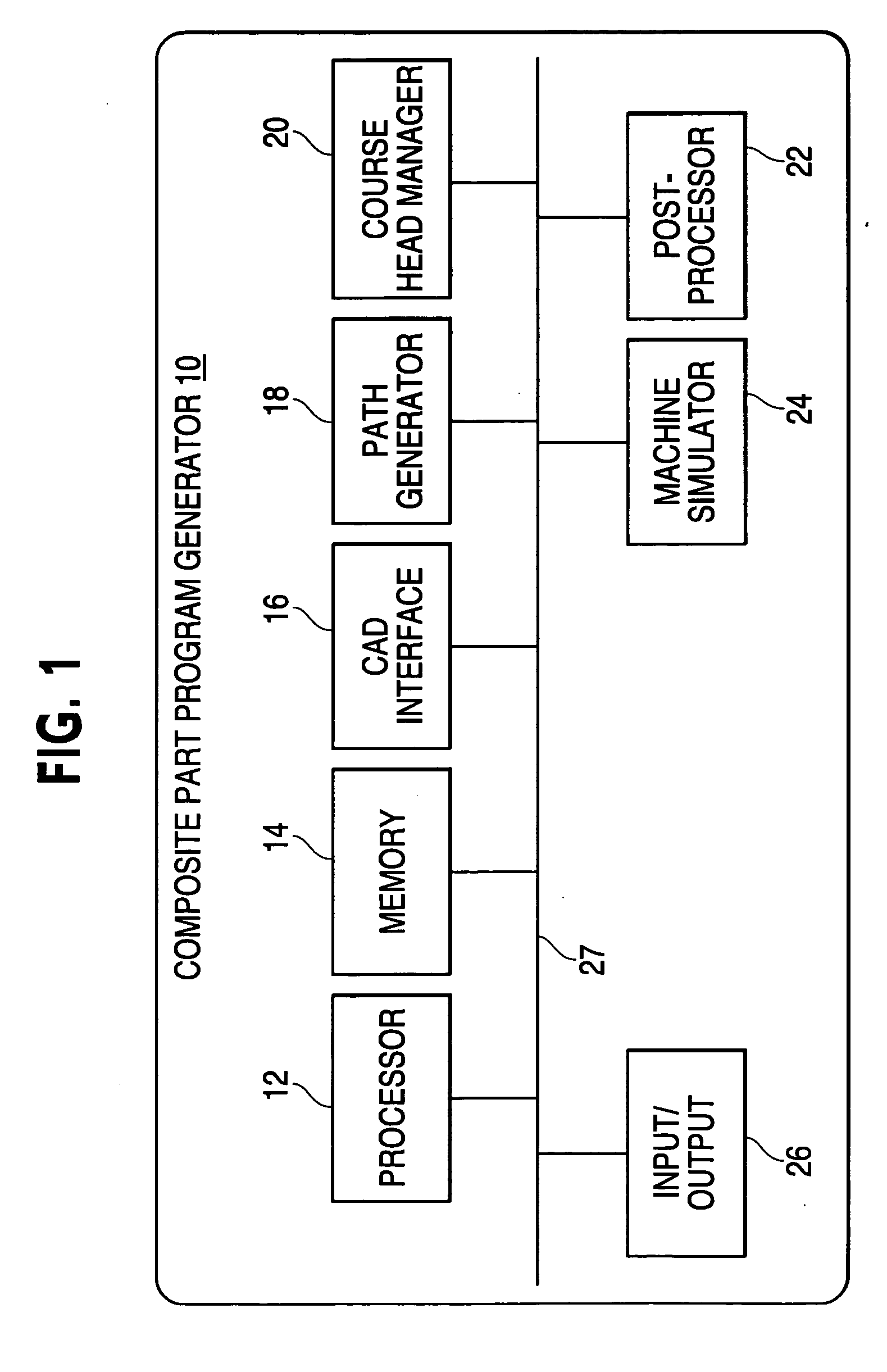

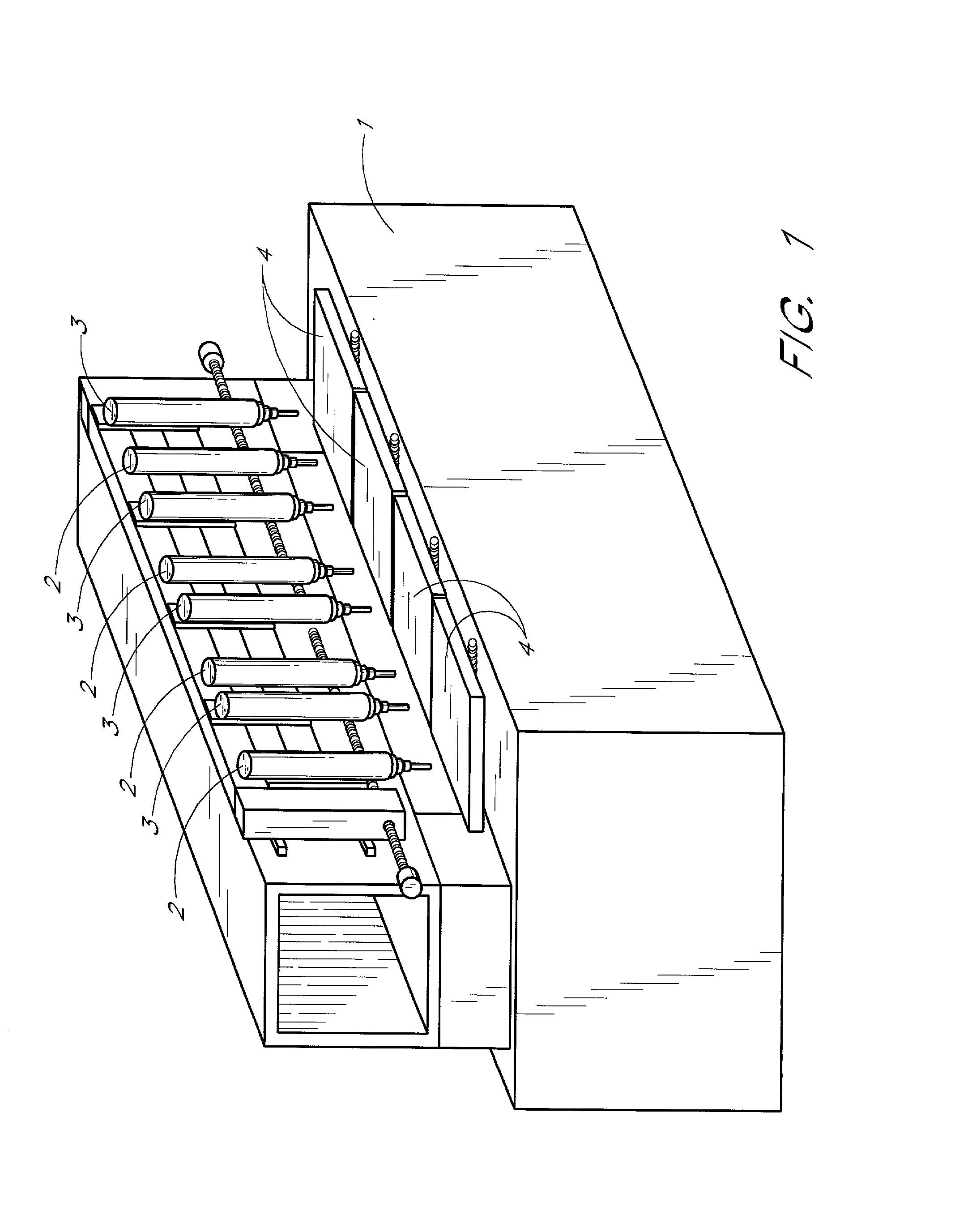

Multihead composite material application machine programming method and apparatus for manufacturing composite structures

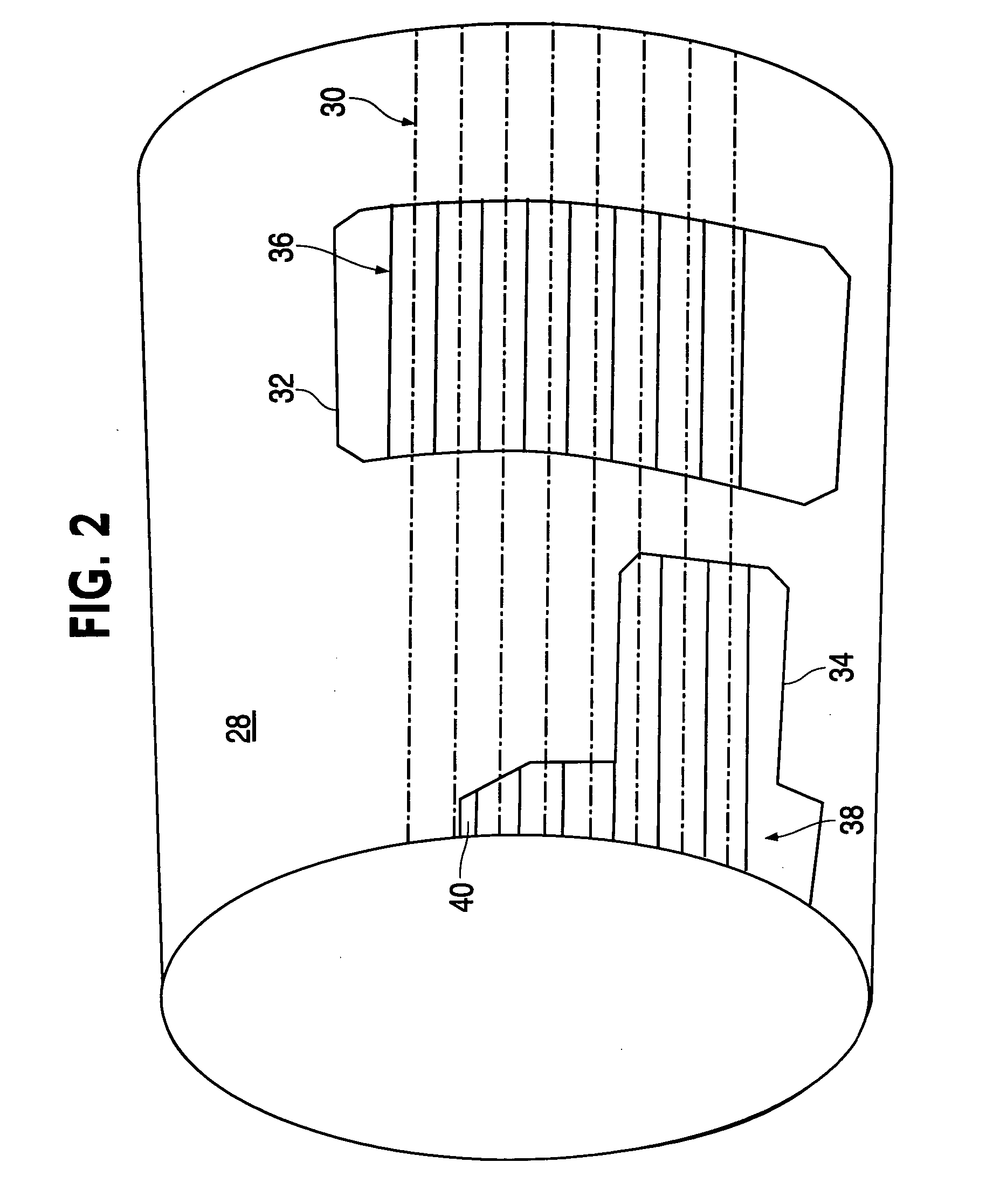

ActiveUS7376480B2Efficient productionProgramme controlControlling laminationComputer Aided DesignFiber

A composite part program generator includes a computer-aided design (CAD) system interface, a path generator, a course head manager, a post-processor and a machine simulator. The composite part program generator produces composite part programs for use on a multihead composite material application machine, such as a composite tape lamination machine or an automated fiber placement (AFP) machine, to manufacture a complex composite parts, including relatively flat, contoured, or generally cylindrical composite parts. This programming method can reduce the labor and time required to produce a composite part program for a multihead composite material application machine by an order of magnitude with respect to manual or existing automated programming methods.

Owner:THE BOEING CO

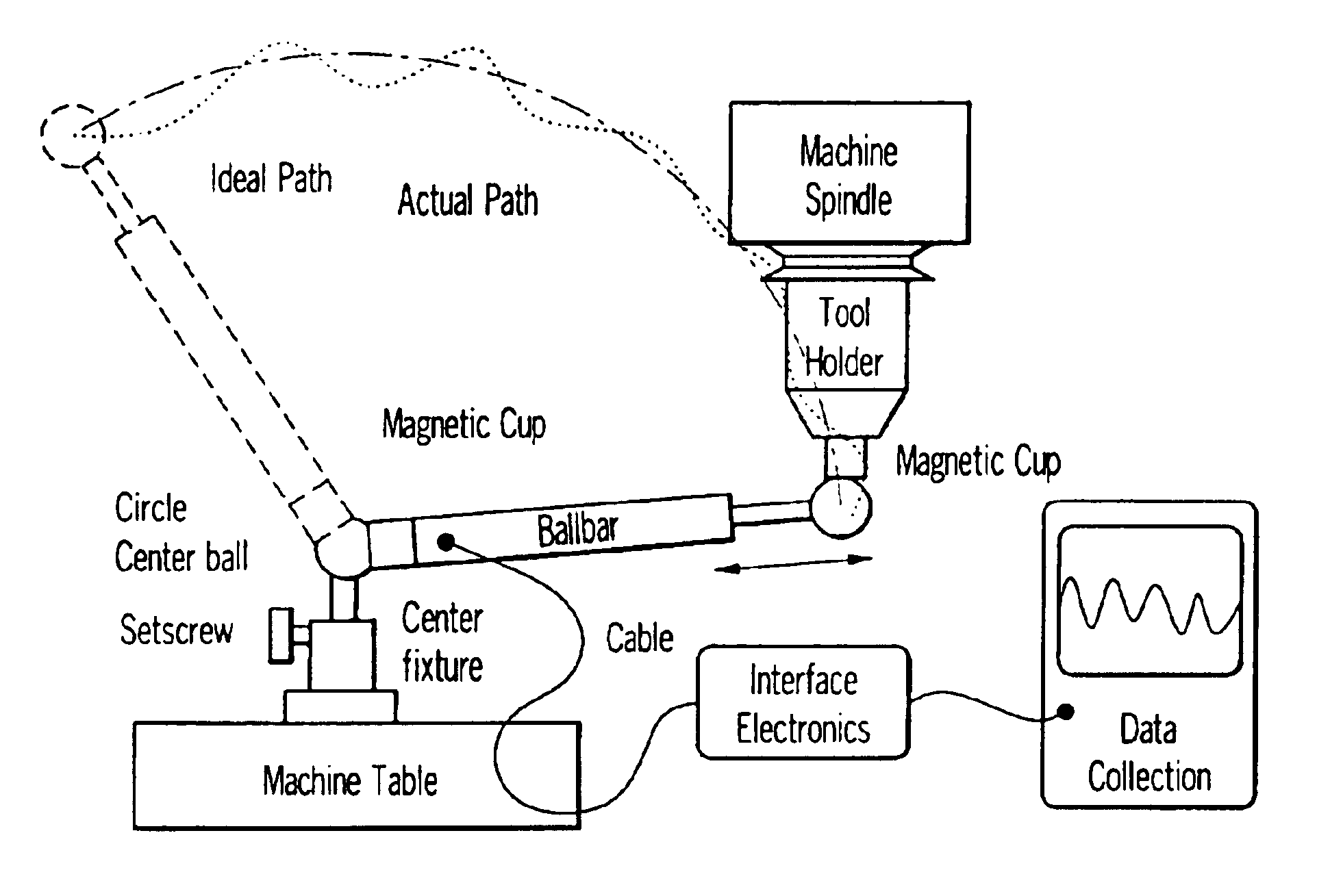

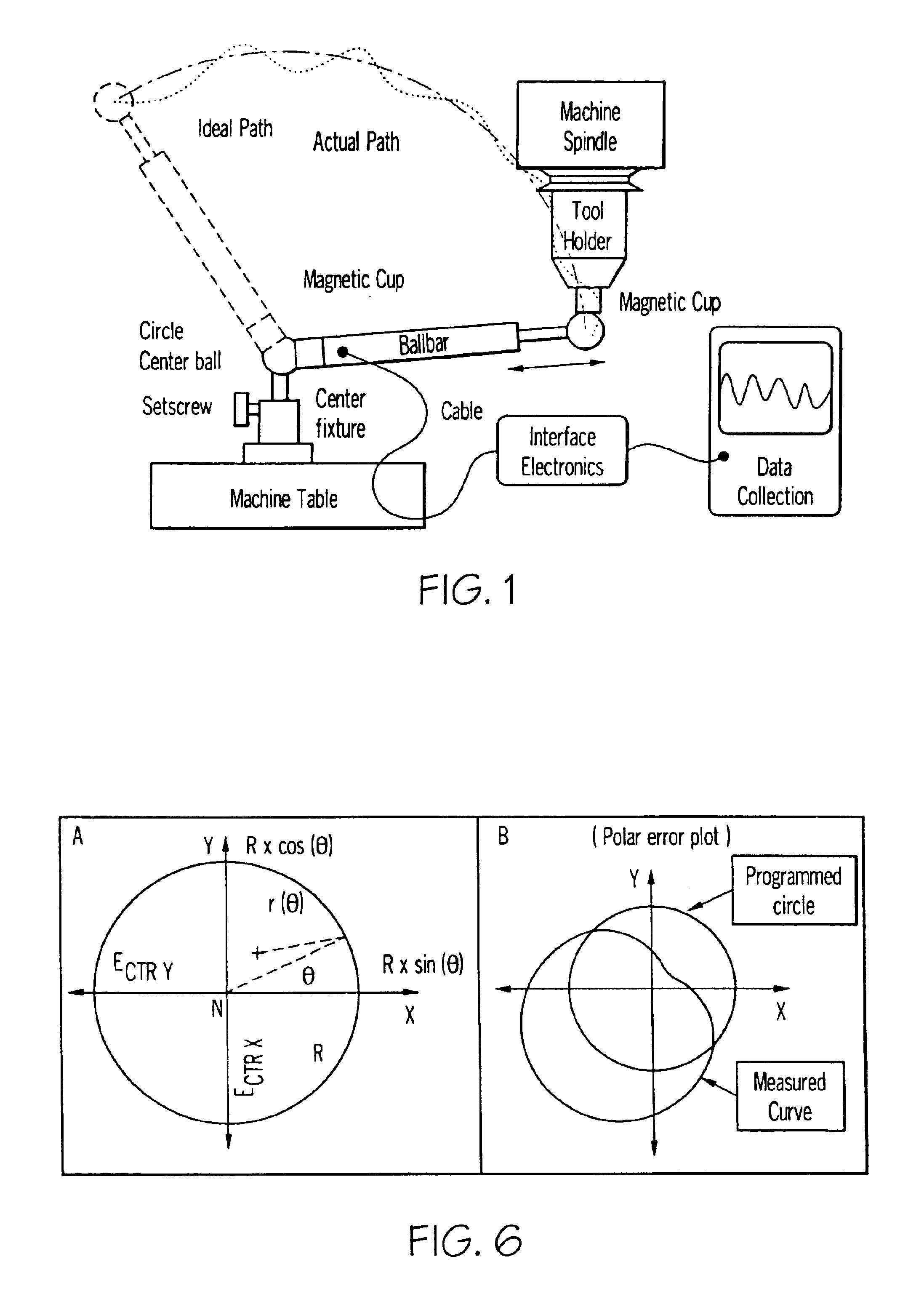

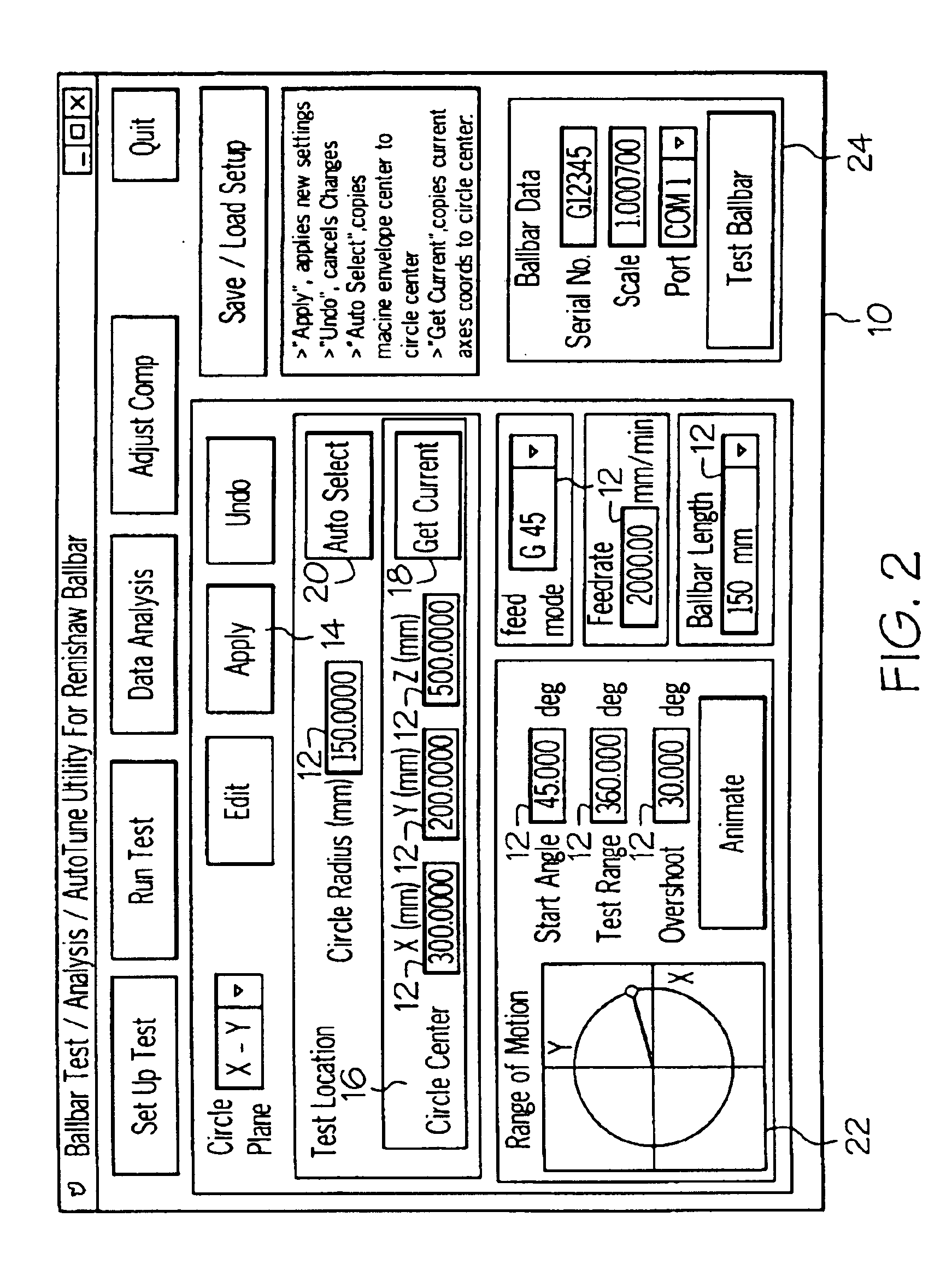

Method and apparatus for self-calibrating a motion control system

In one embodiment, a method of and apparatus for self-calibrating a motion control system is provided. The method includes the steps of receiving a test parameter, ensuring a reasonable test can be executed based on the test parameter, generating a part program based upon the test parameter, instructing a user of the motion control system regarding set up of a device capable of acquiring data associated with the test, and executing the test, wherein the part program is executed as part of the test.

Owner:SIEMENS ENERGY & AUTOMATION INC

Multihead composite material application machine programming method and apparatus for manufacturing composite structures

ActiveUS20070106418A1Efficient productionProgramme controlTotal factory controlFiberComputer Aided Design

A composite part program generator includes a computer-aided design (CAD) system interface, a path generator, a course head manager, a post-processor and a machine simulator. The composite part program generator produces composite part programs for use on a multihead composite material application machine, such as a composite tape lamination machine or an automated fiber placement (AFP) machine, to manufacture a complex composite parts, including relatively flat, contoured, or generally cylindrical composite parts. This programming method can reduce the labor and time required to produce a composite part program for a multihead composite material application machine by an order of magnitude with respect to manual or existing automated programming methods.

Owner:THE BOEING CO

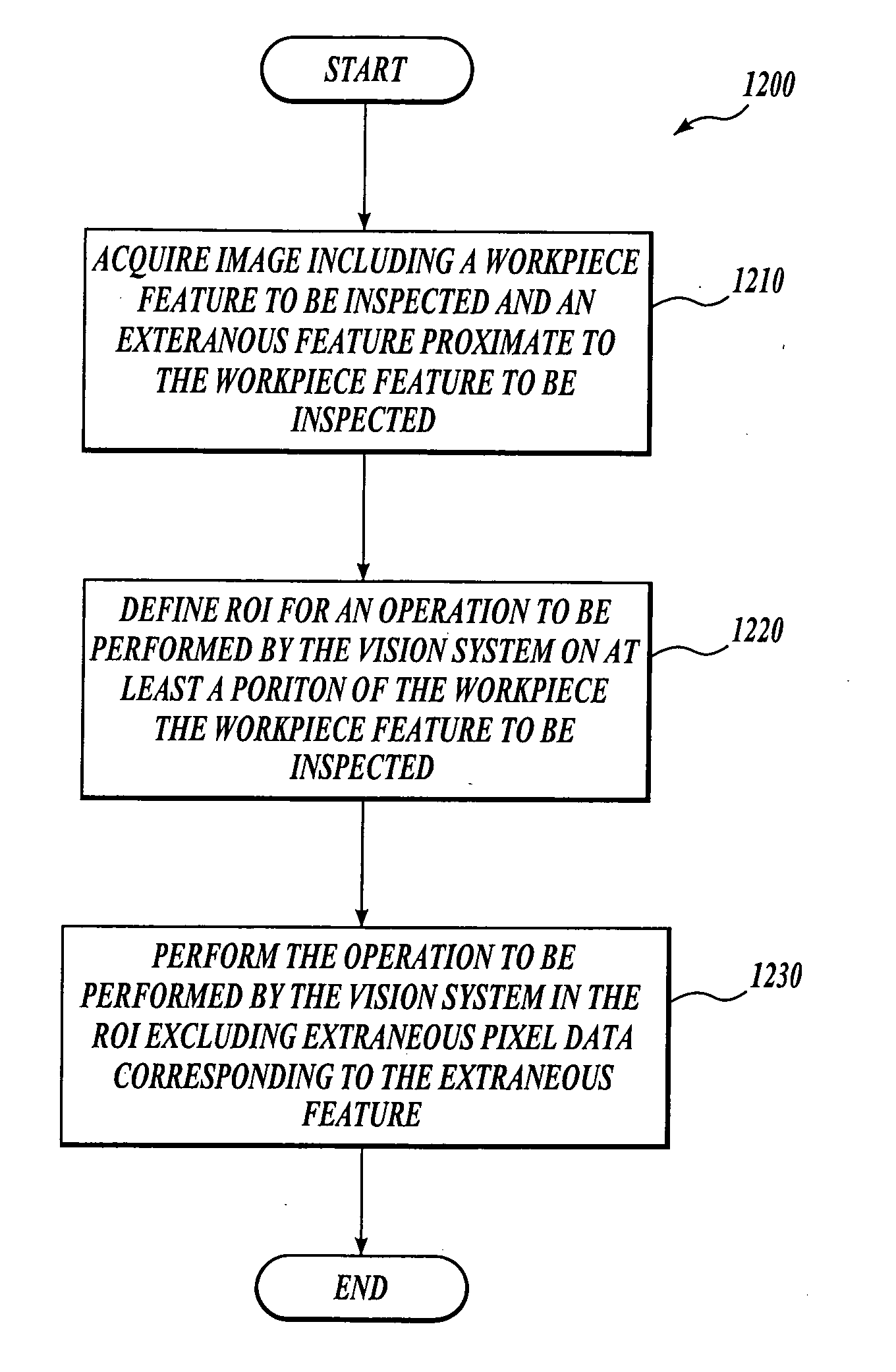

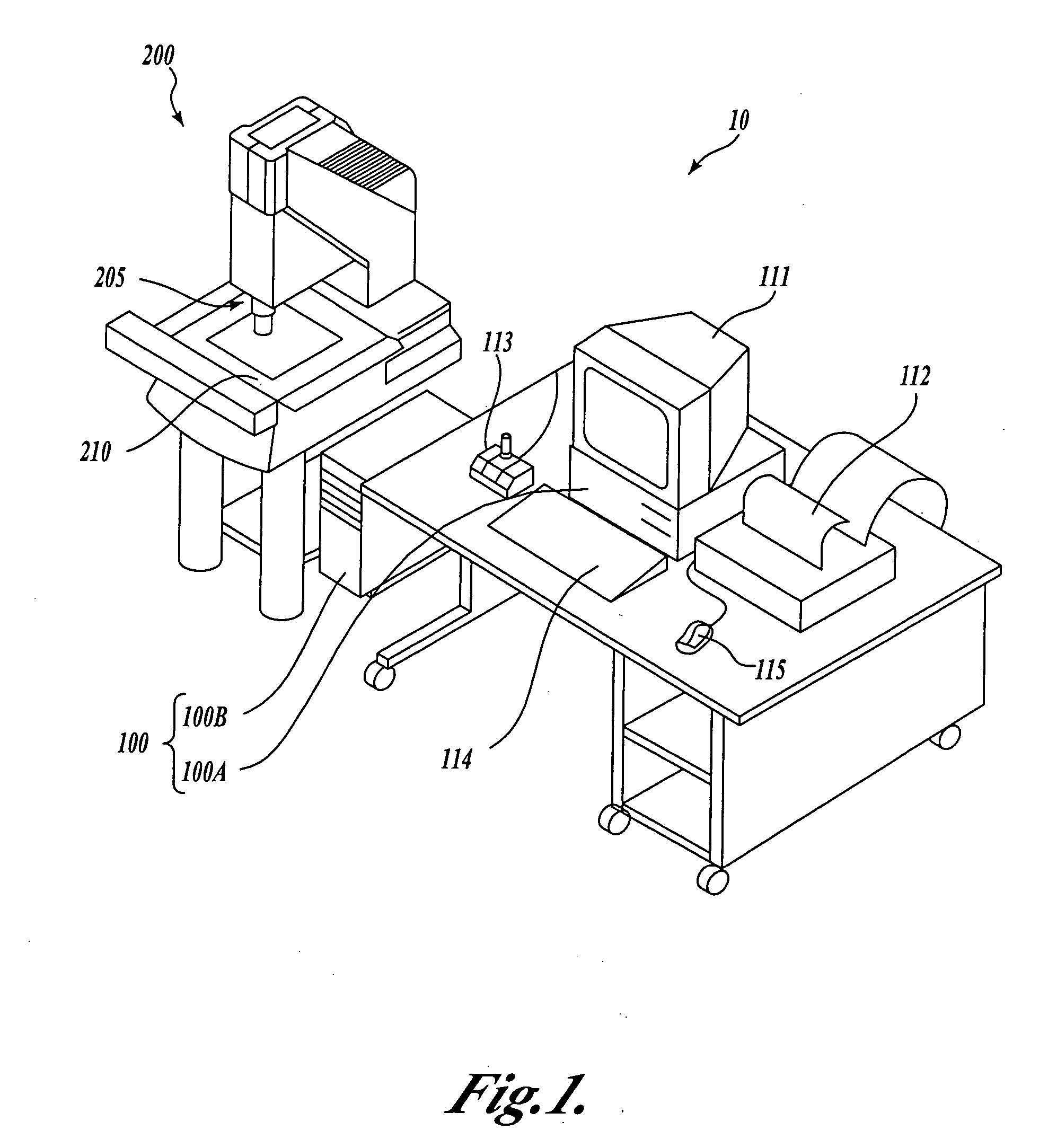

System and method for excluding extraneous features from inspection operations performed by a machine vision inspection system

ActiveUS20050213807A1Prevent proliferationEasy maintenanceImage enhancementImage analysisMetrologyImaging Feature

Systems and methods for a machine vision metrology and inspection system are provided for excluding extraneous image features from various inspection or control operations of the machine vision system. The extraneous image features may be in close proximity to other image features to be inspected. One aspect of various embodiments of the invention is that no filtering or other image modifications are performed on the “non-excluded” original image data in the region of the feature to be inspected. Another aspect of various embodiments of the invention is that a region of interest associated with a video tool provided by the user interface of the machine vision system can encompass a region or regions of the feature to be inspected, as well as regions having excluded data, making the video tool easy to use and robust against reasonably expected variations in the spacing between the features to be inspected and the extraneous image features. In various embodiments of the invention, the extraneous image excluding operations are concentrated in the region of interest defining operations of the machine vision system, such that the feature measuring or characterizing operations of the machine vision system operate similarly whether there is excluded data in the associated region of interest or not. Various user interface features and methods are provided for implementing and using the extraneous image feature excluding operations when the machine vision system is operated in a learning or training mode used to create part programs usable for repeated automatic workpiece inspection. The invention is of particular use when inspecting flat panel display screen masks having occluded features to be inspected.

Owner:MITUTOYO CORP

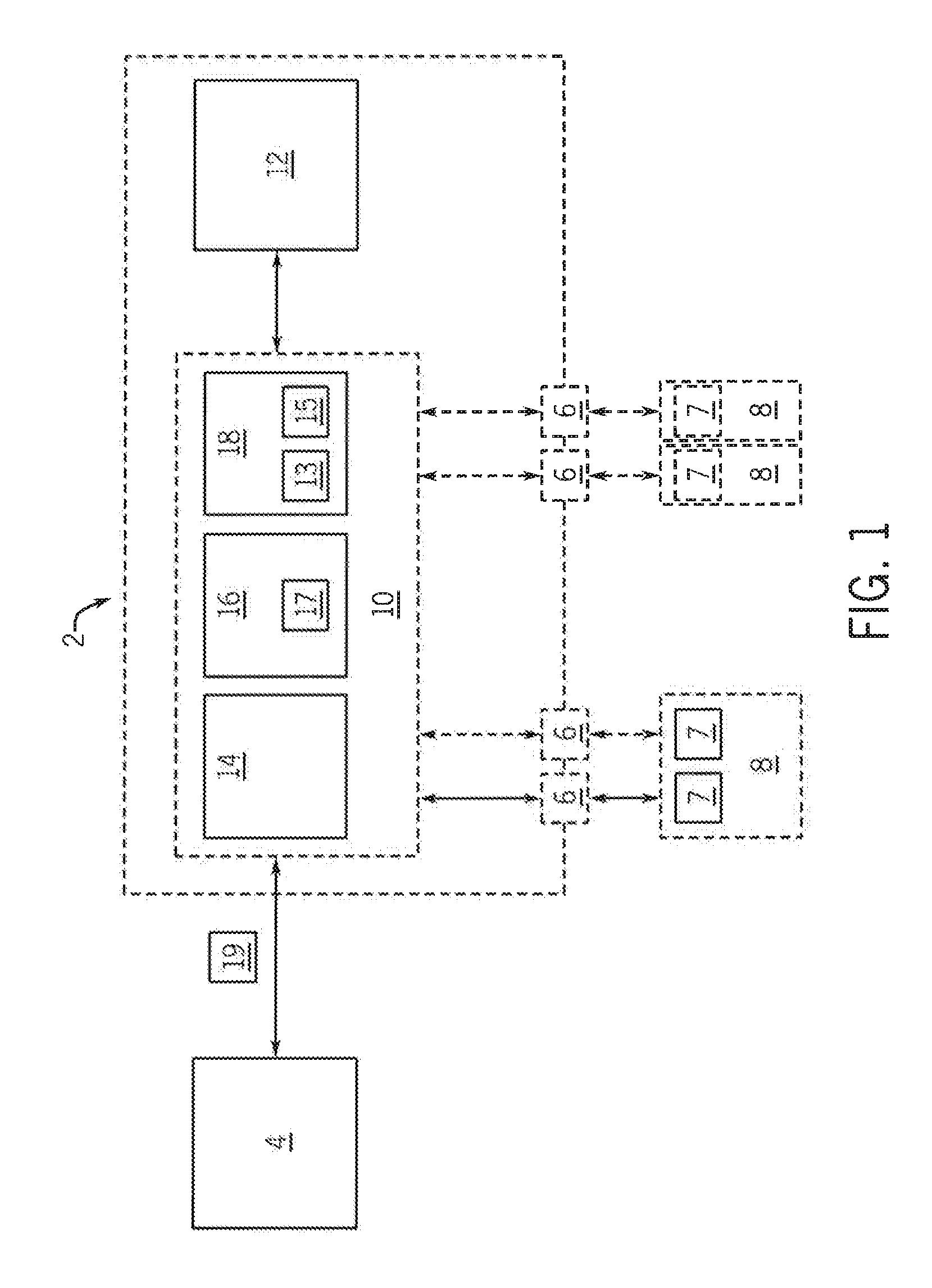

Method and apparatus for developing a metadata-infused software program for controlling a robot

The present invention is directed to a method and apparatus for developing a metadata-infused software program for controlling a device, such as a robot. A first library of software segments with metadata and a second library of script documents are provided. A part program wizard uses a script document selected from the second library to display queries on a screen of an interface device. Using input information received in response to the queries, the part program wizard selects and combines software segments from the first library to produce the metadata-infused software program. The metadata identifies the selected software segments and includes statuses of the selected software segments. A graphical representation of the metadata infused software program is displayed on the screen and conveys the statuses of the software segments. A deployment wizard is utilized to teach data points for the metadata-infused software program.

Owner:ABB RES LTD

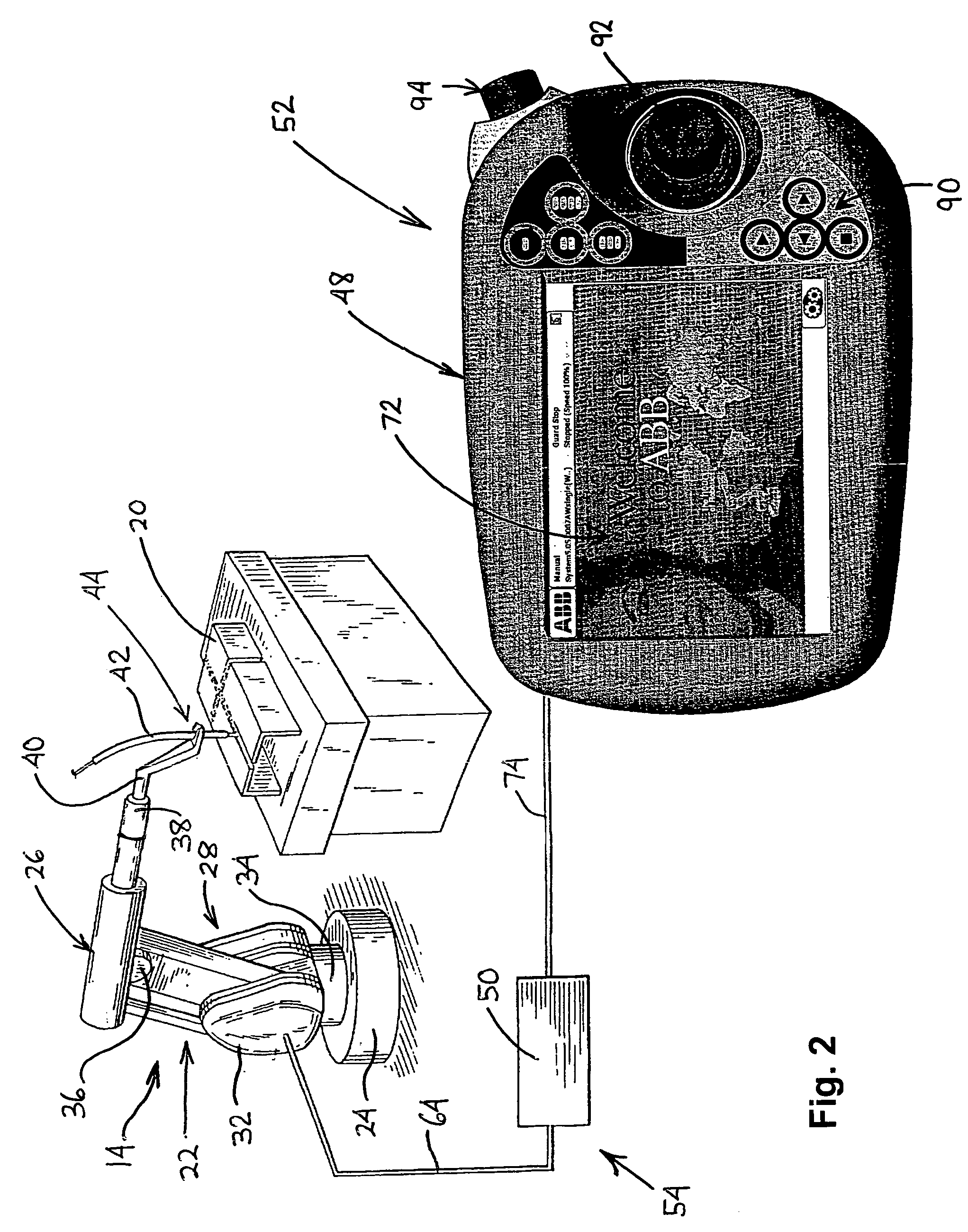

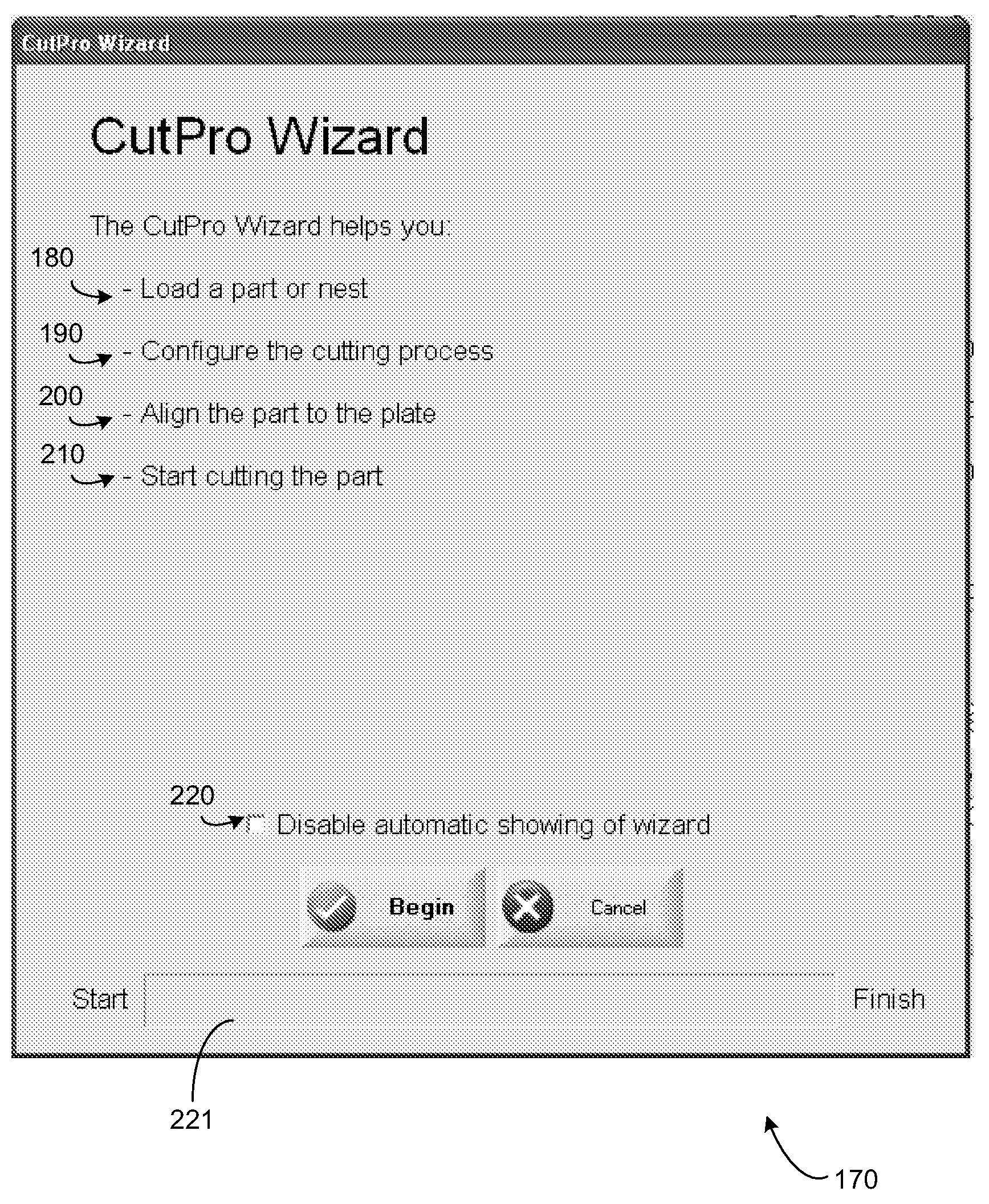

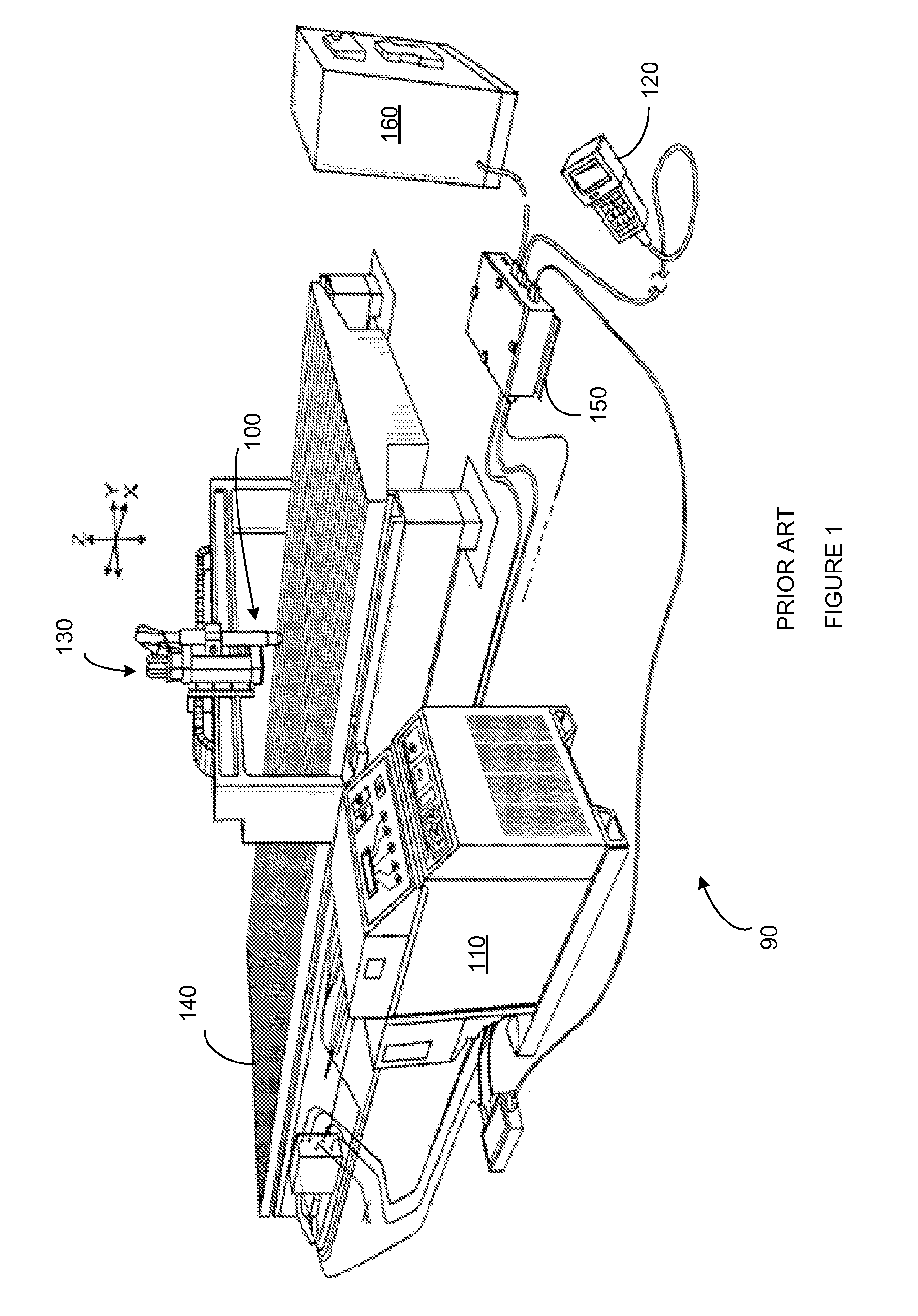

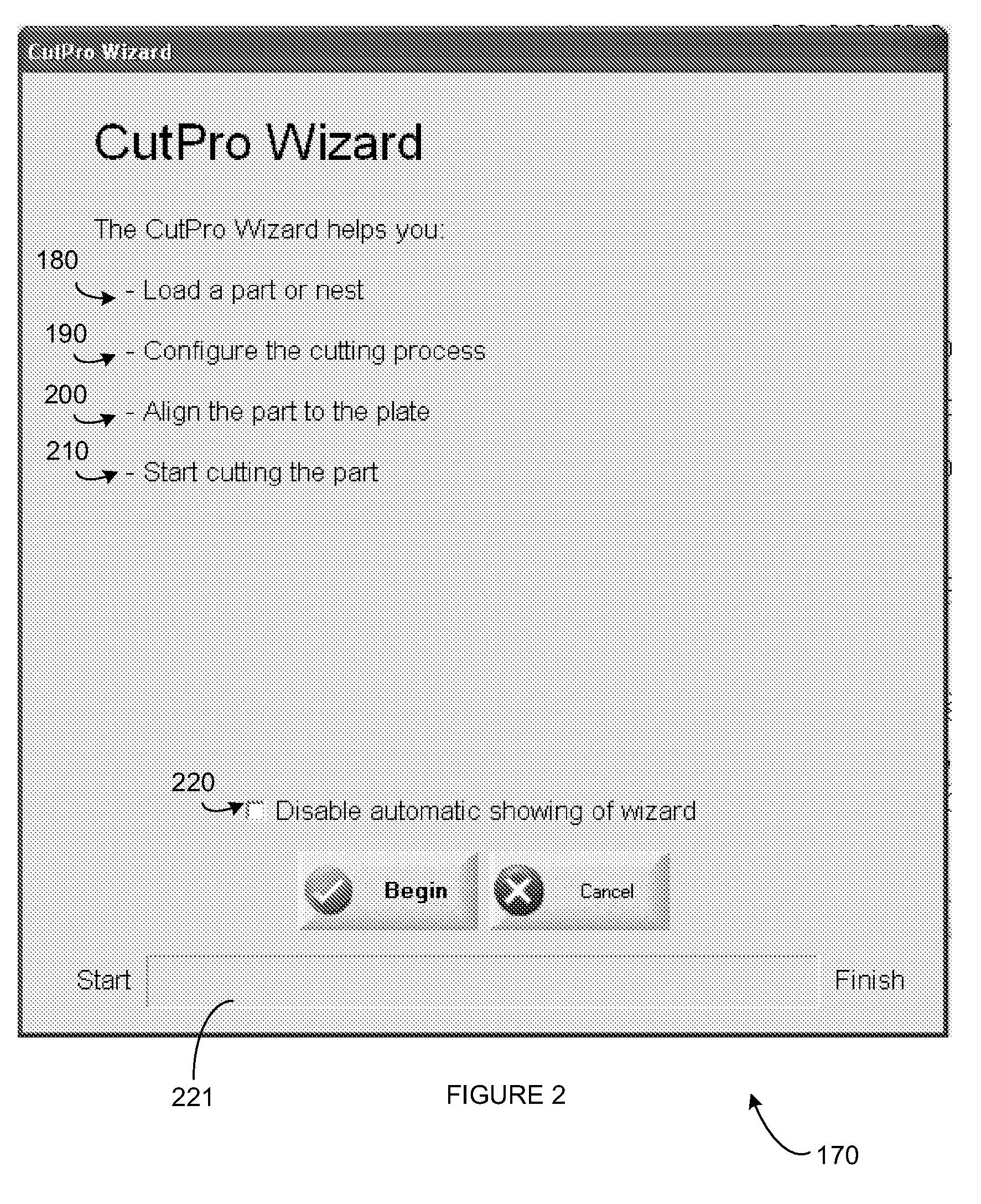

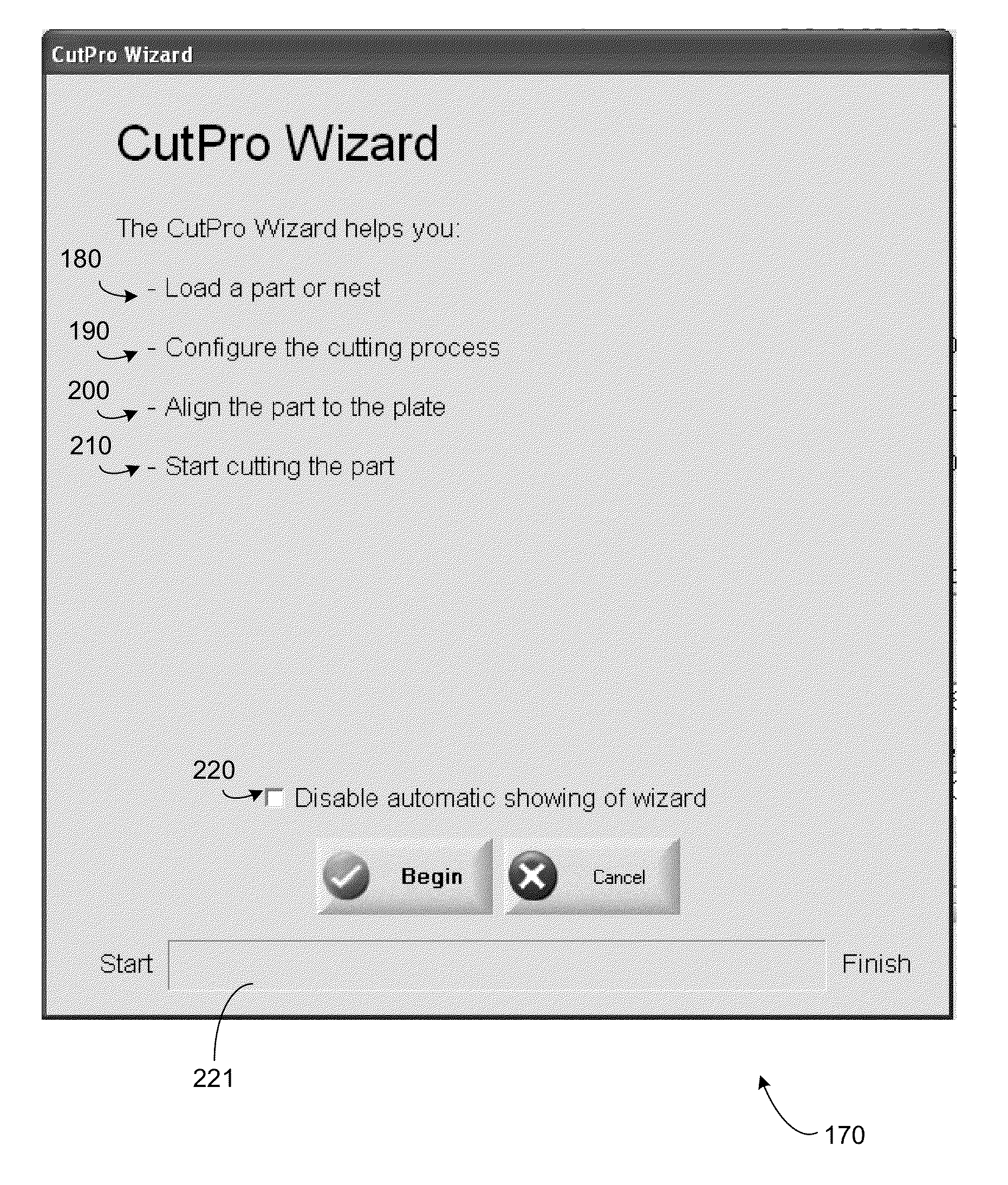

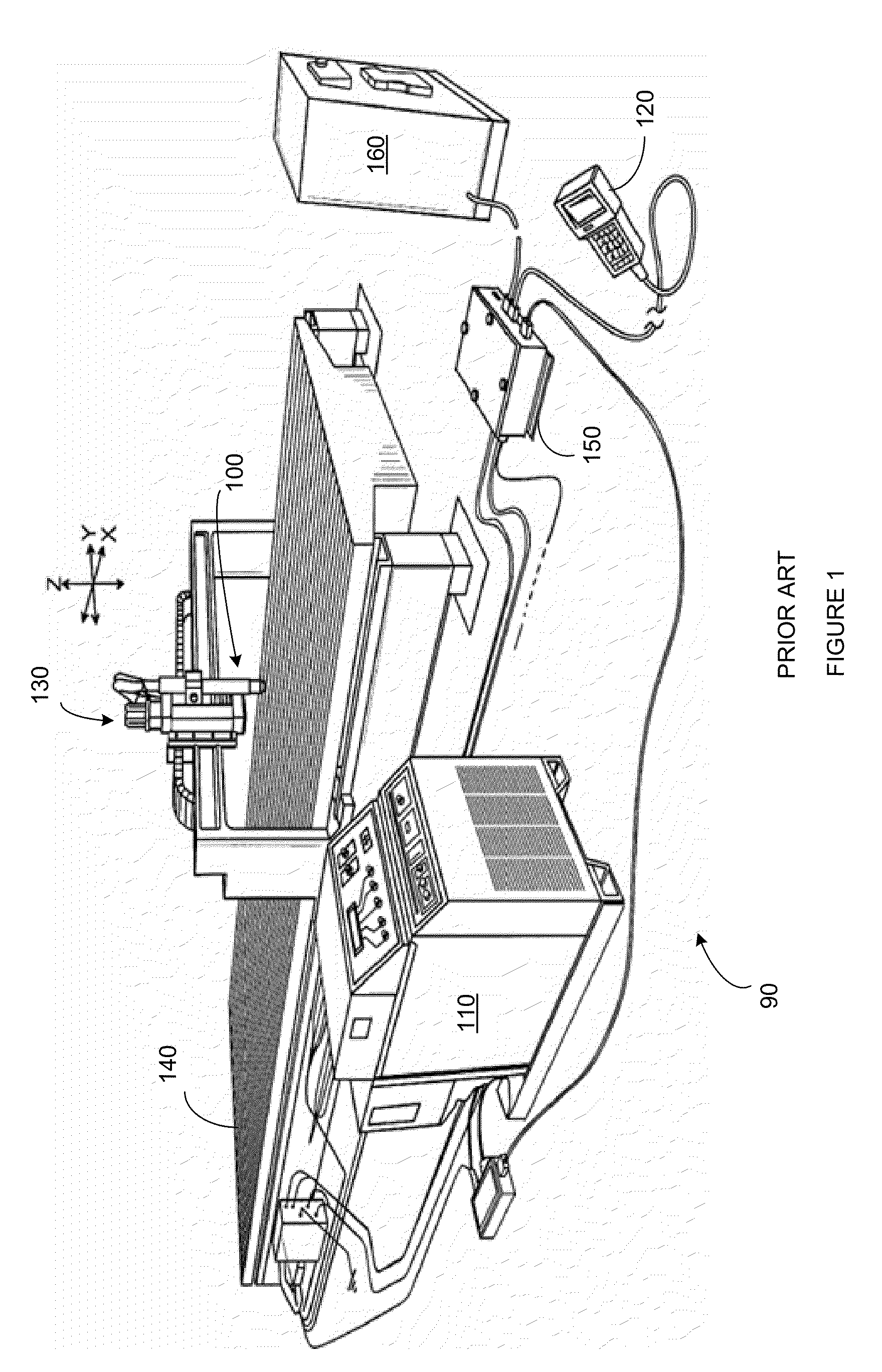

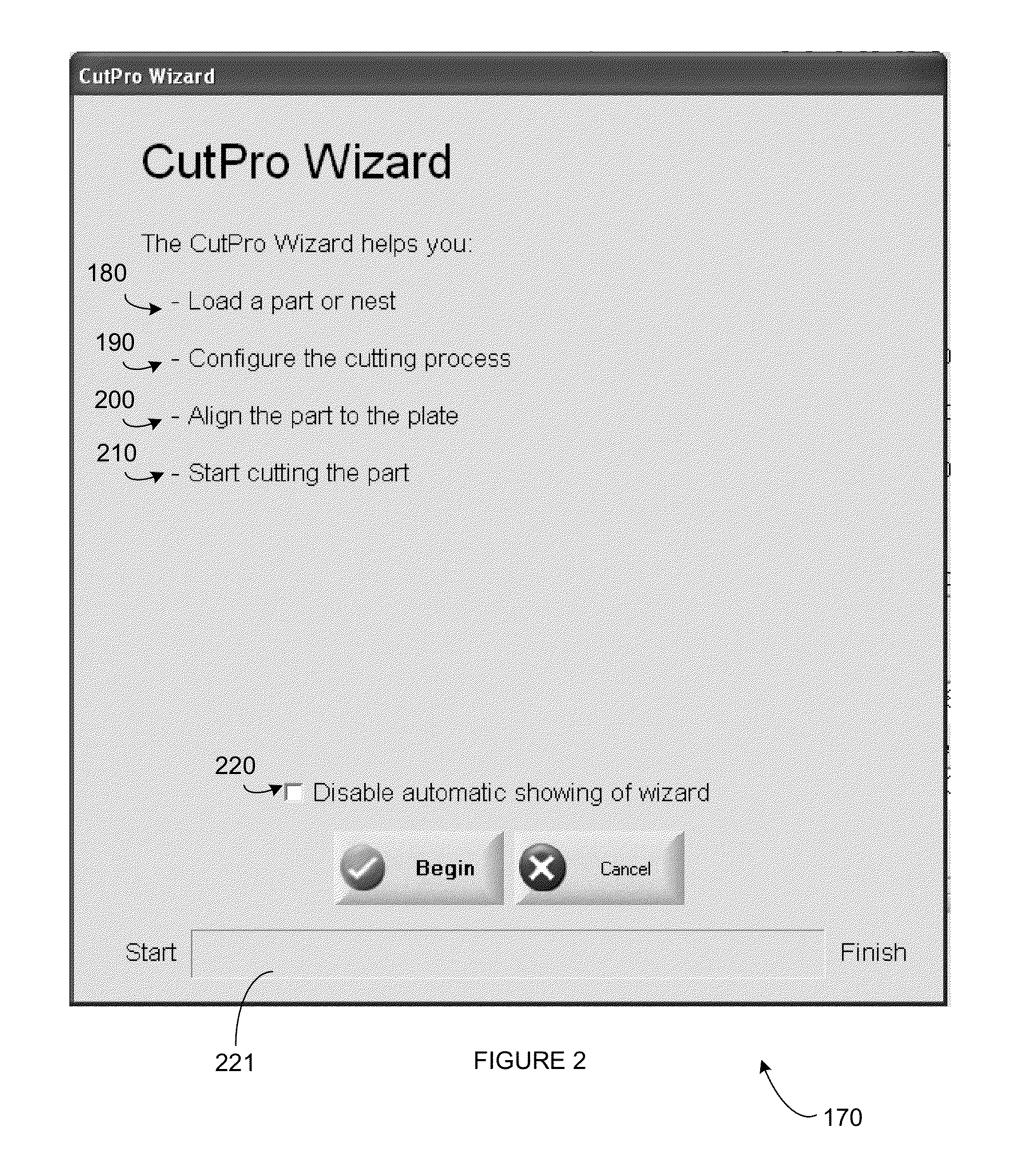

Method and Apparatus for Operating an Automated High Temperature Thermal Cutting System

ActiveUS20090240368A1Arc welding apparatusSpecial data processing applicationsGraphicsGraphical user interface

A method for setting up a cutting table for an automated high temperature thermal cutting system can include providing a computer-readable product to, for example, a digital signal processor (e.g., CNC). The computer-readable product can include data for at least one part to be cut from a workpiece (e.g., a part program). A user can be prompted to select values from a menu of mandatory operating parameters (e.g., using a graphical user interface) for a shape of the part to be cut from the workpiece. Mandatory operating parameters can include at least one of an operating current, a gas flow, a thickness of the workpiece, or a material of the workpiece.

Owner:HYPERTHERM INC

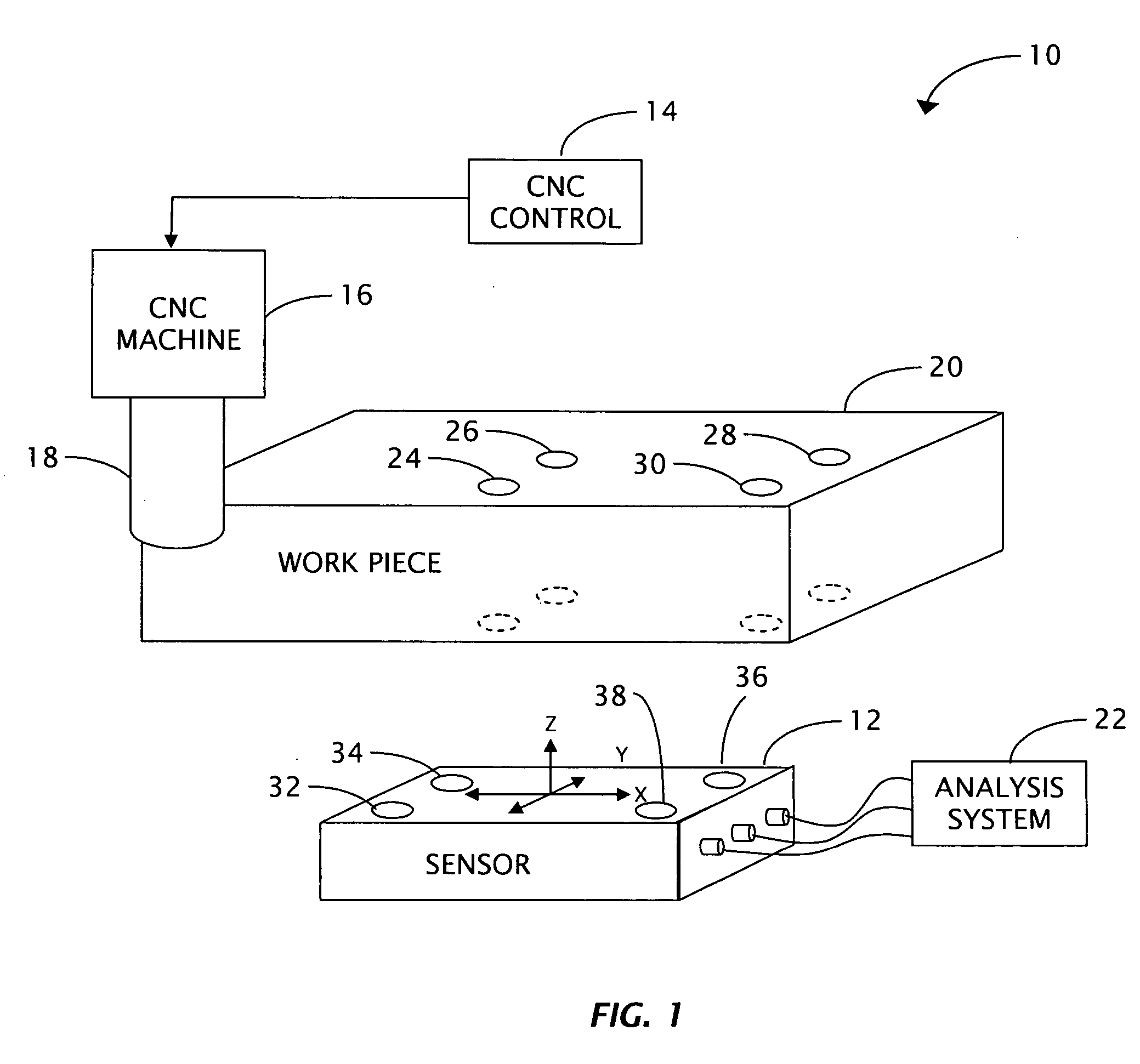

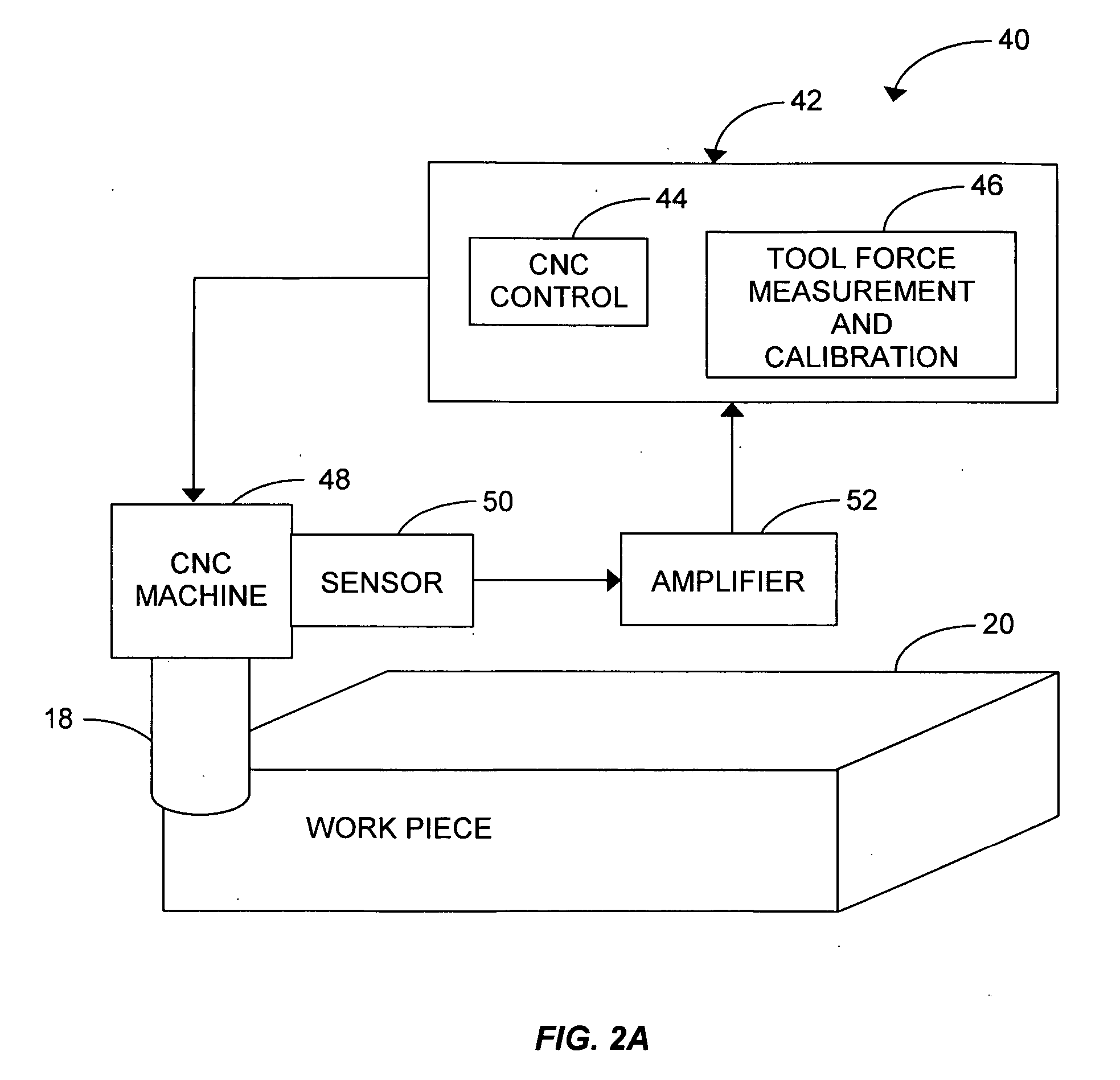

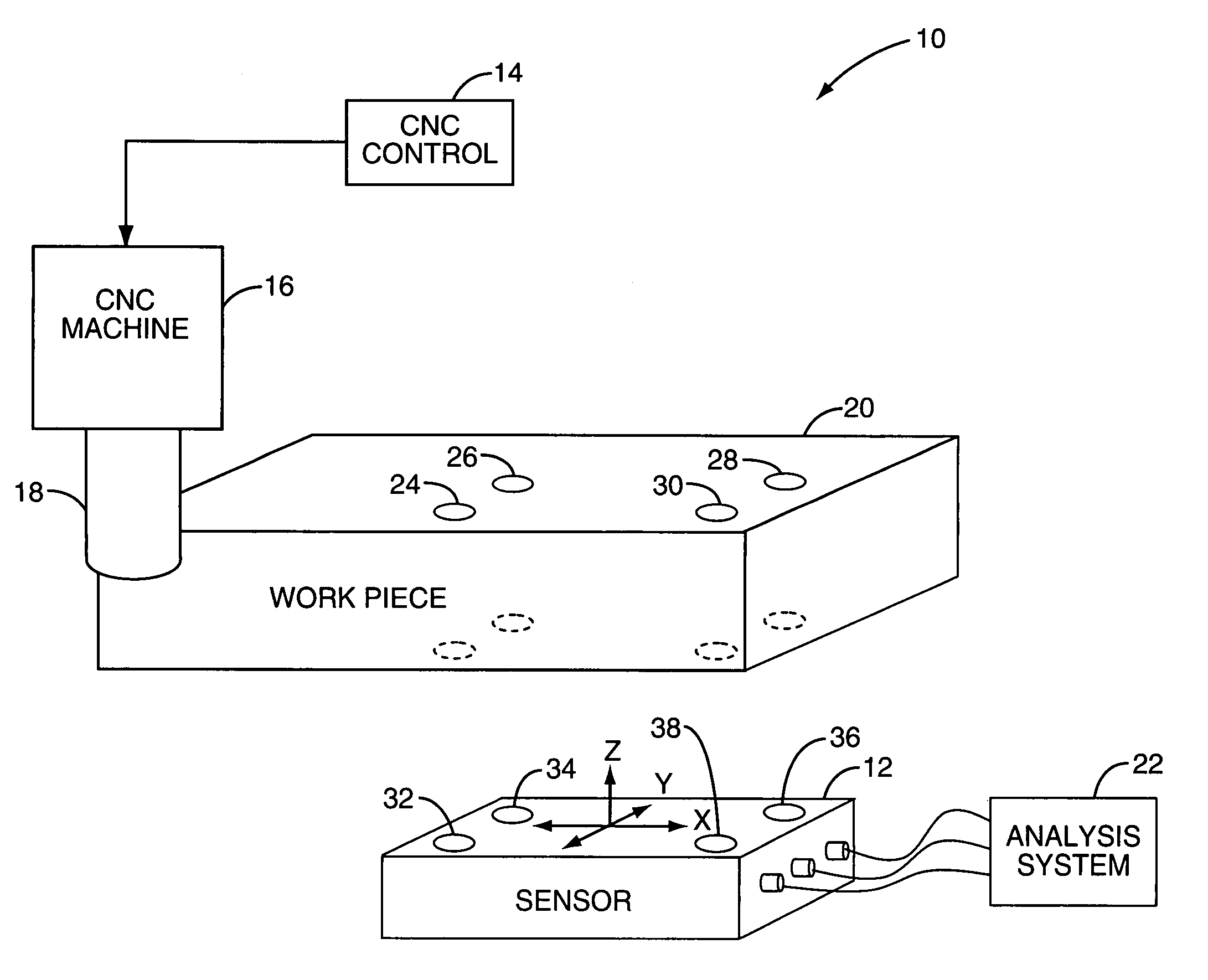

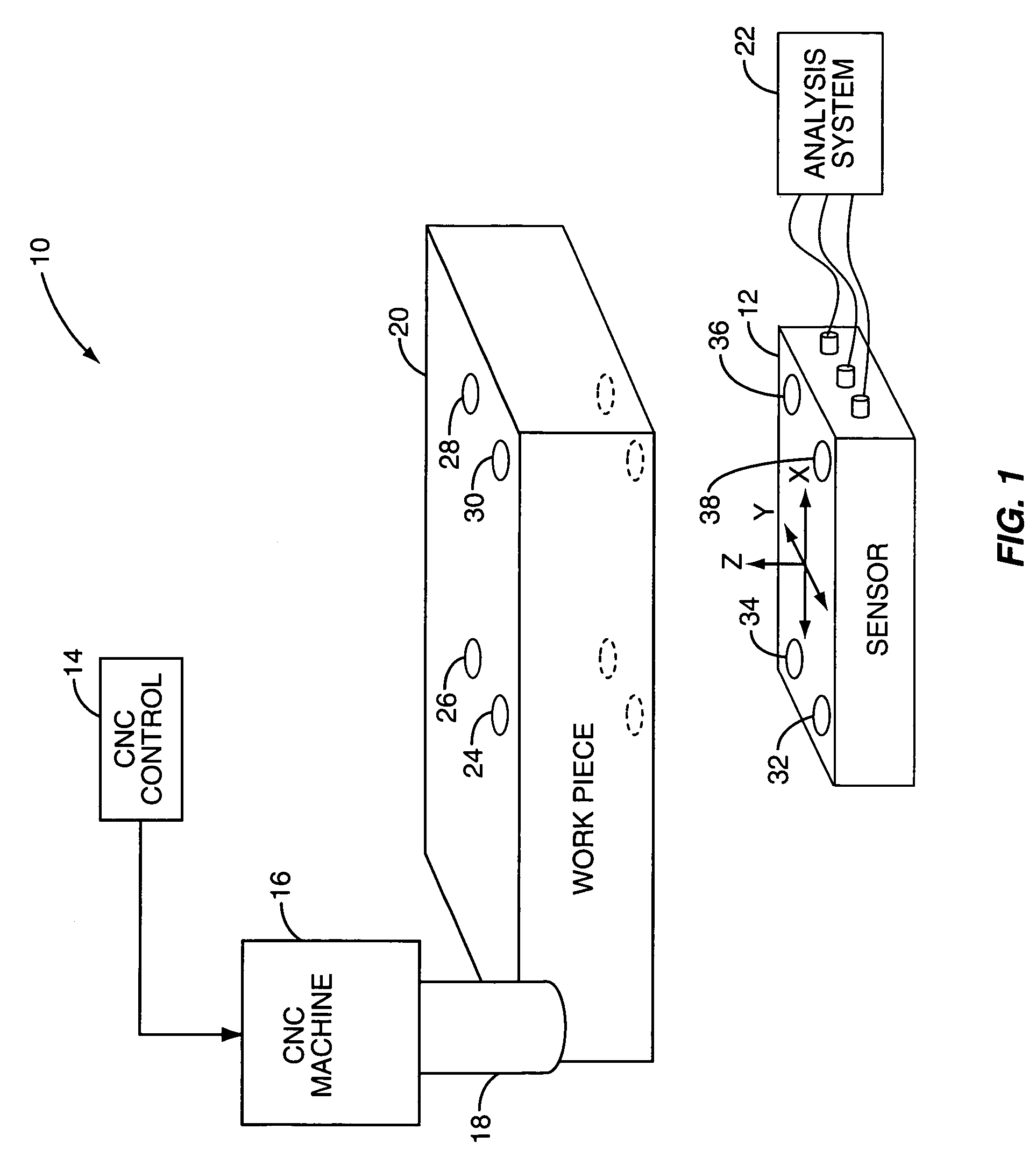

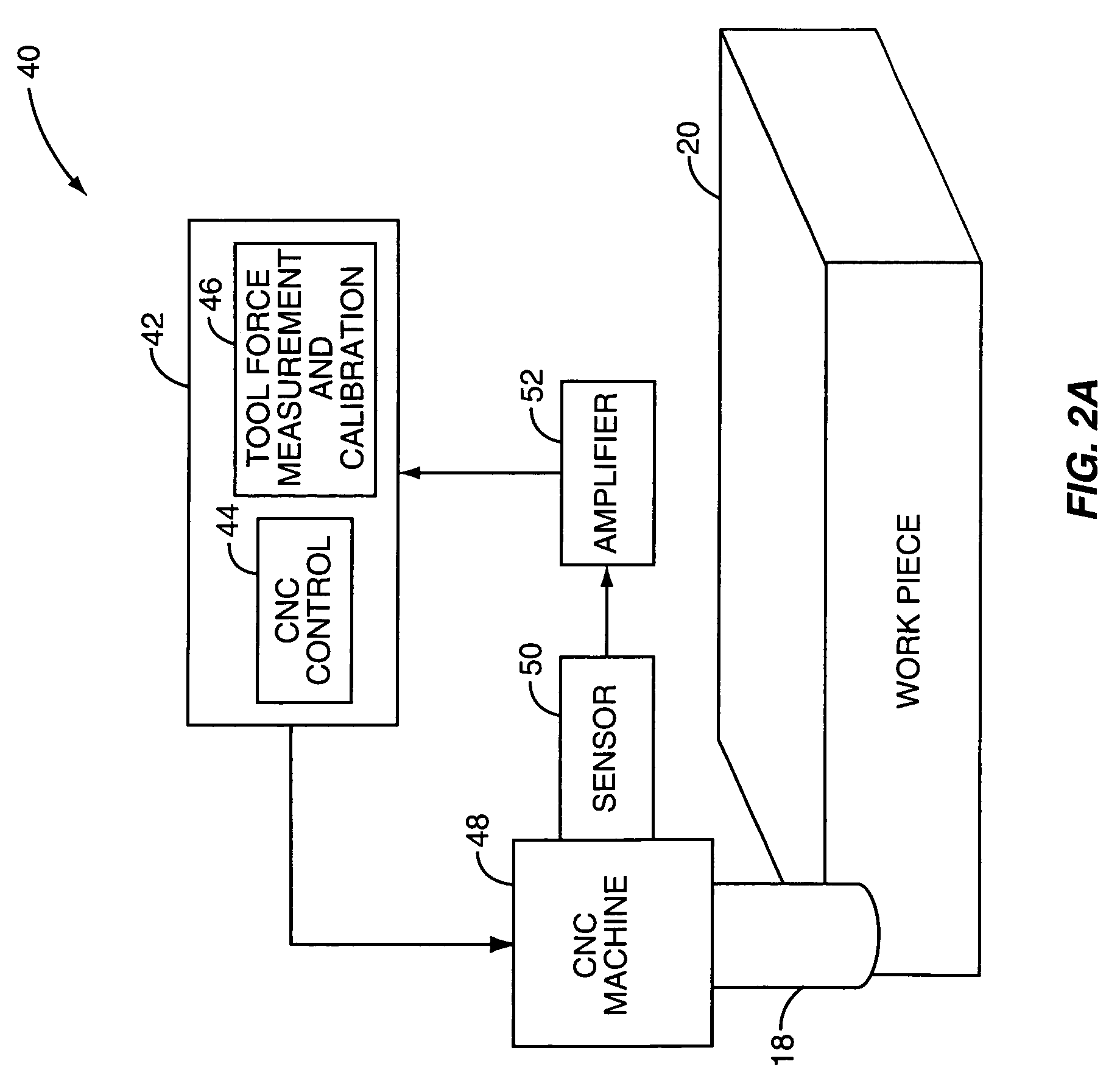

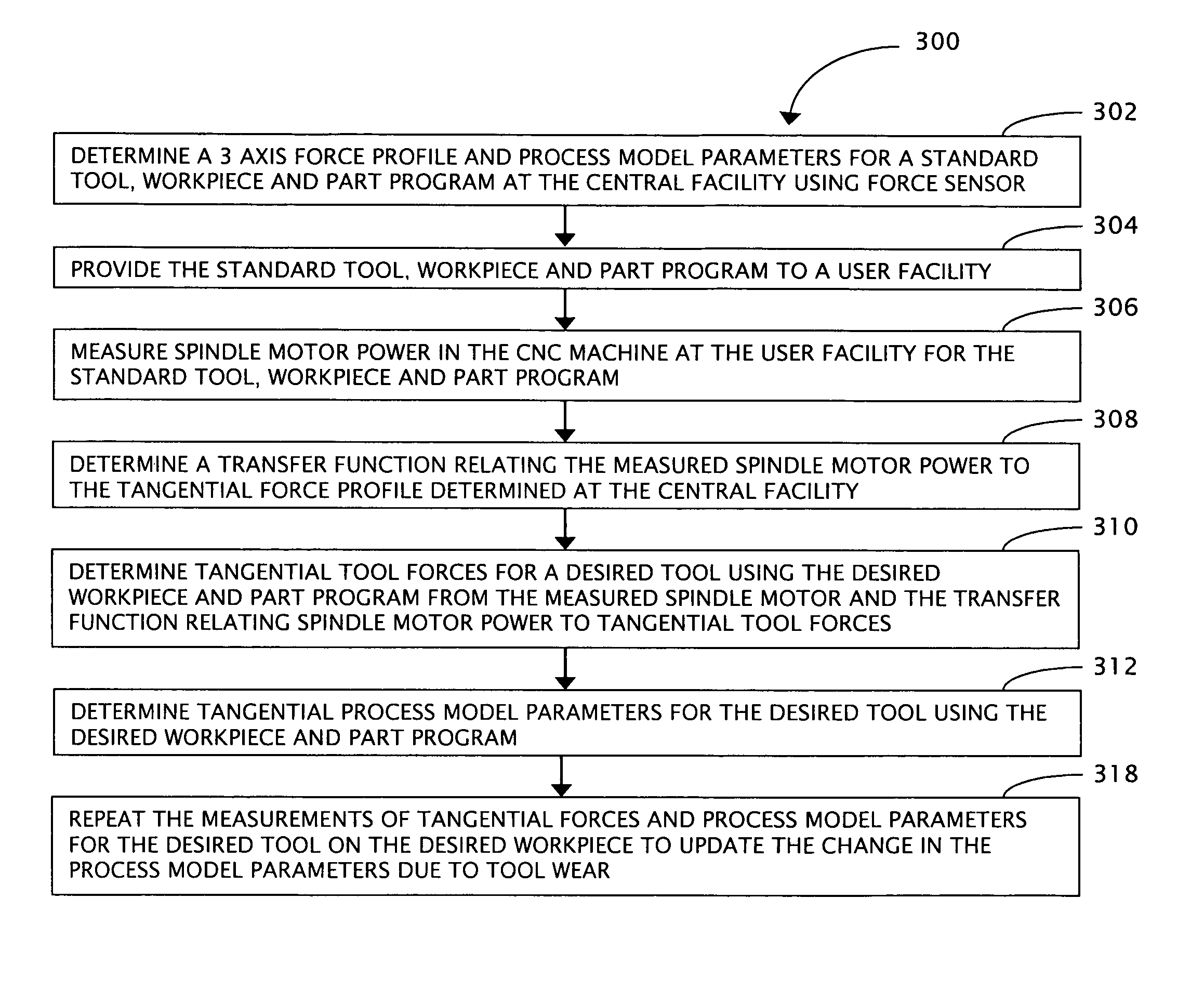

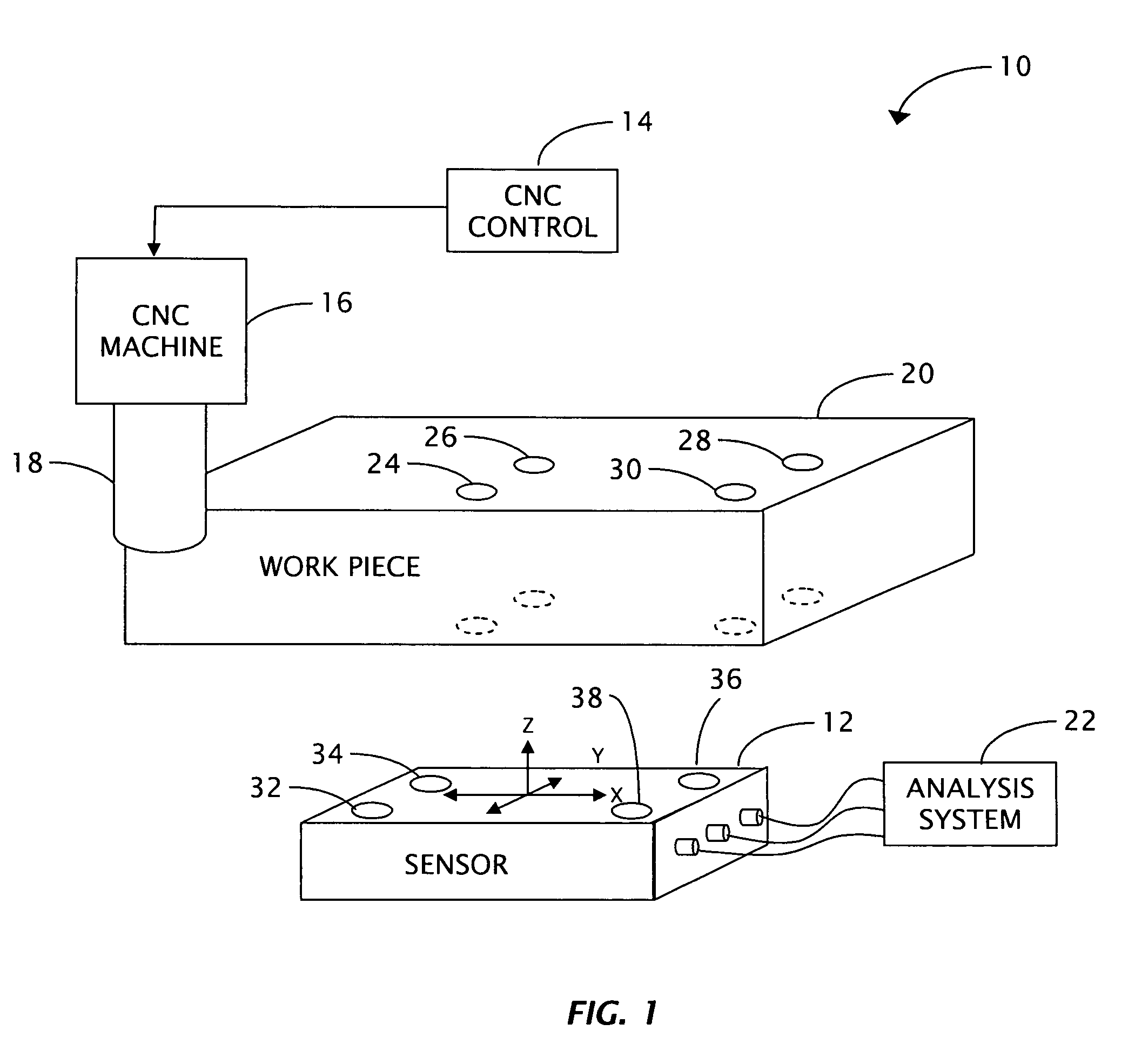

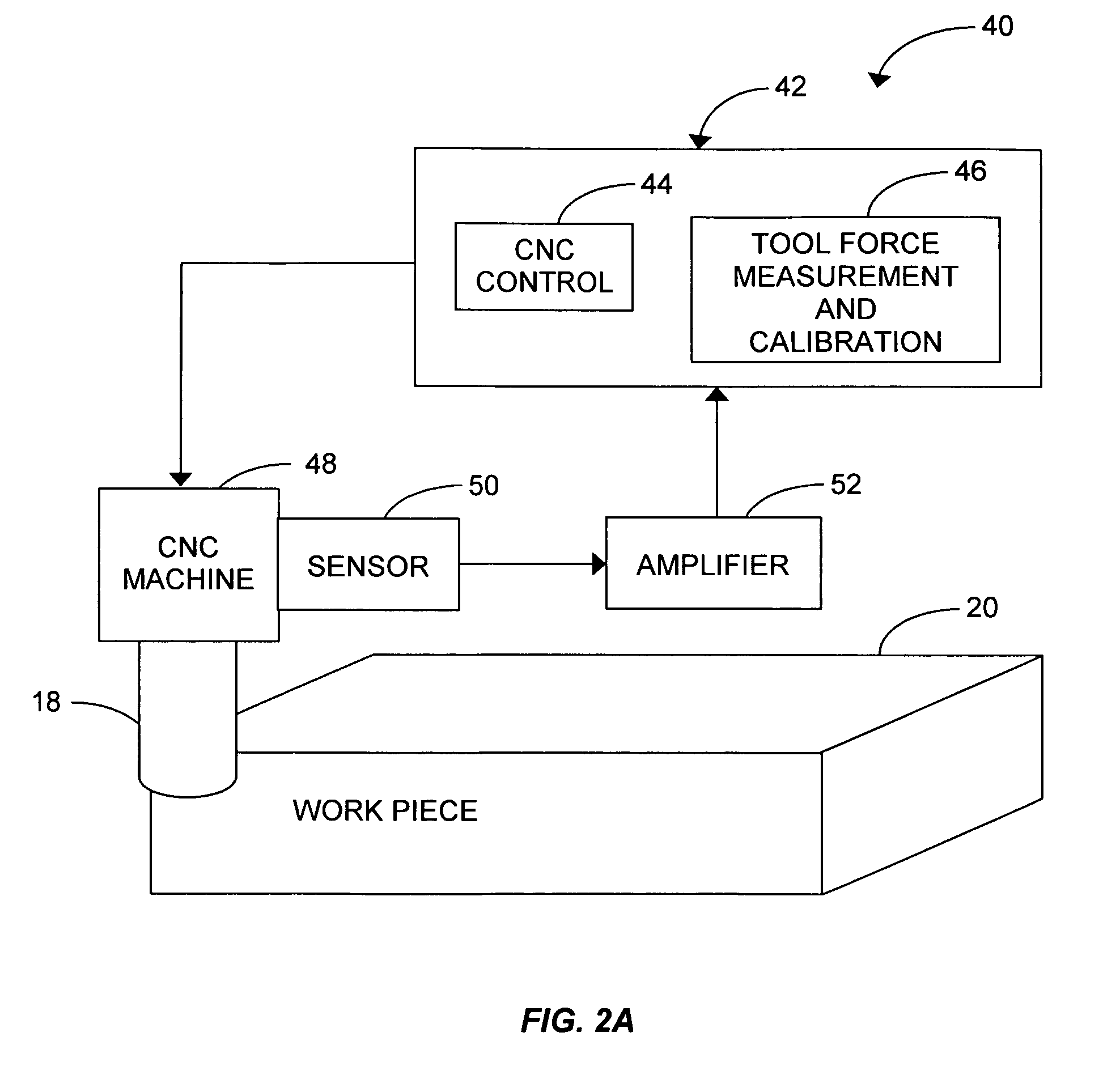

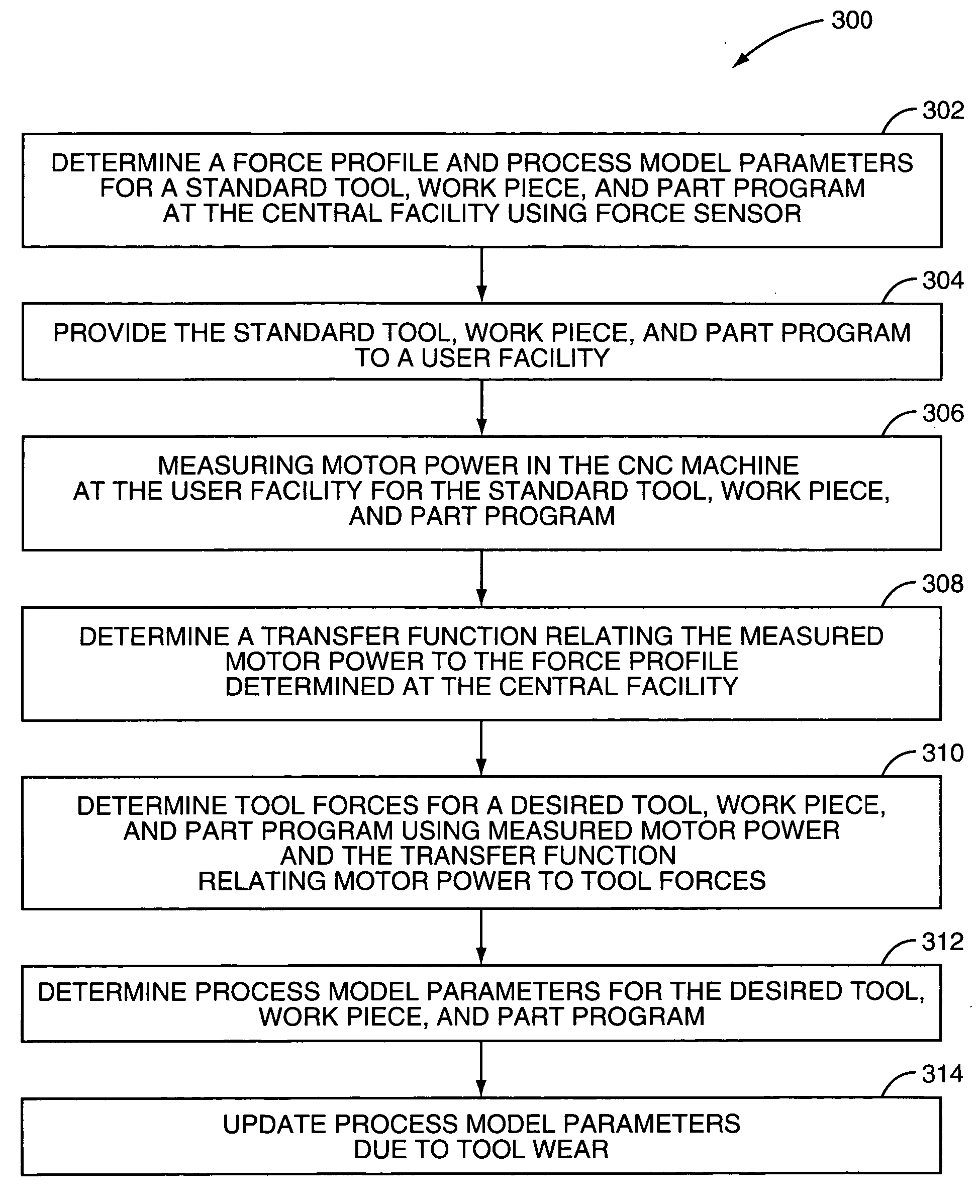

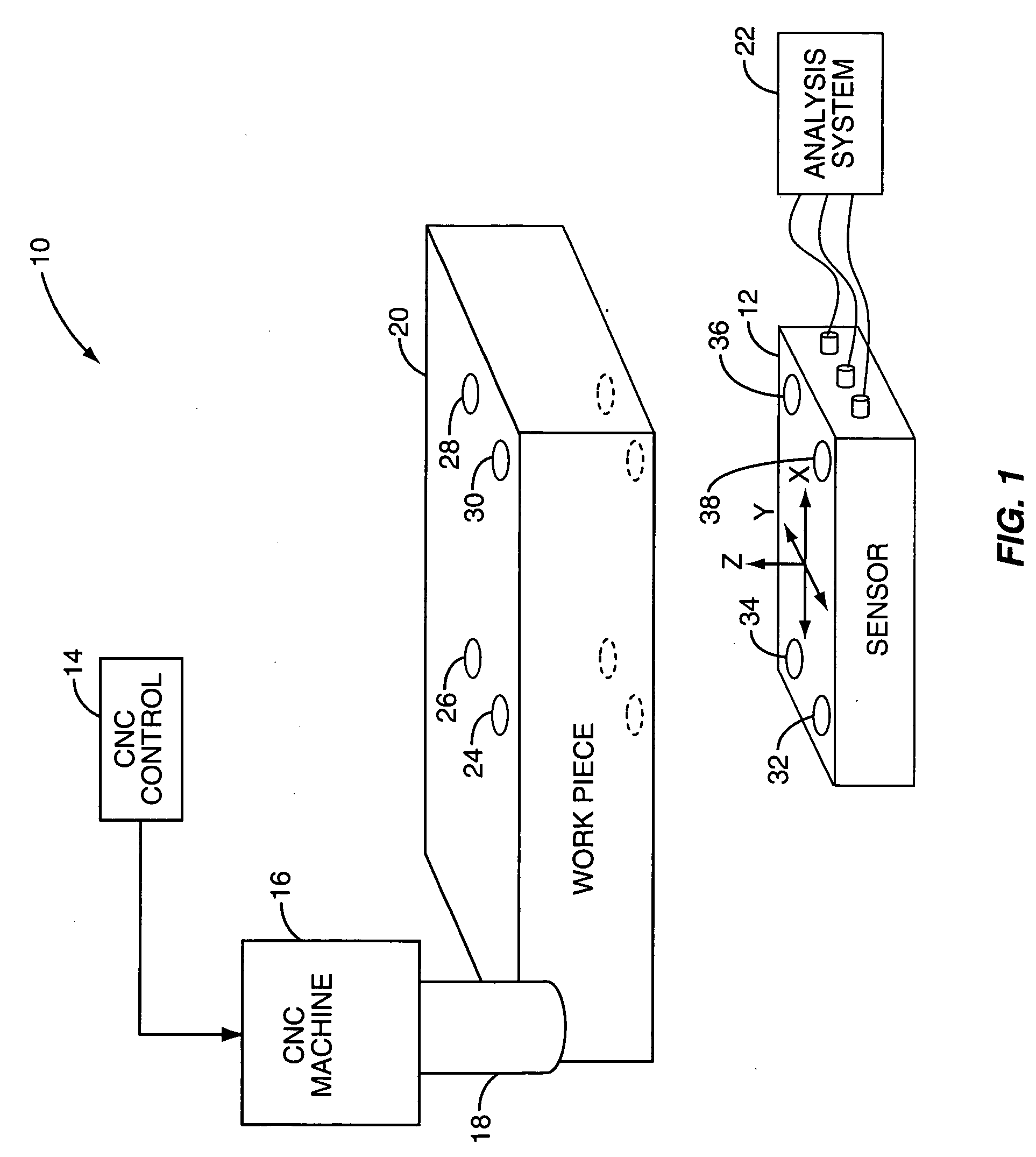

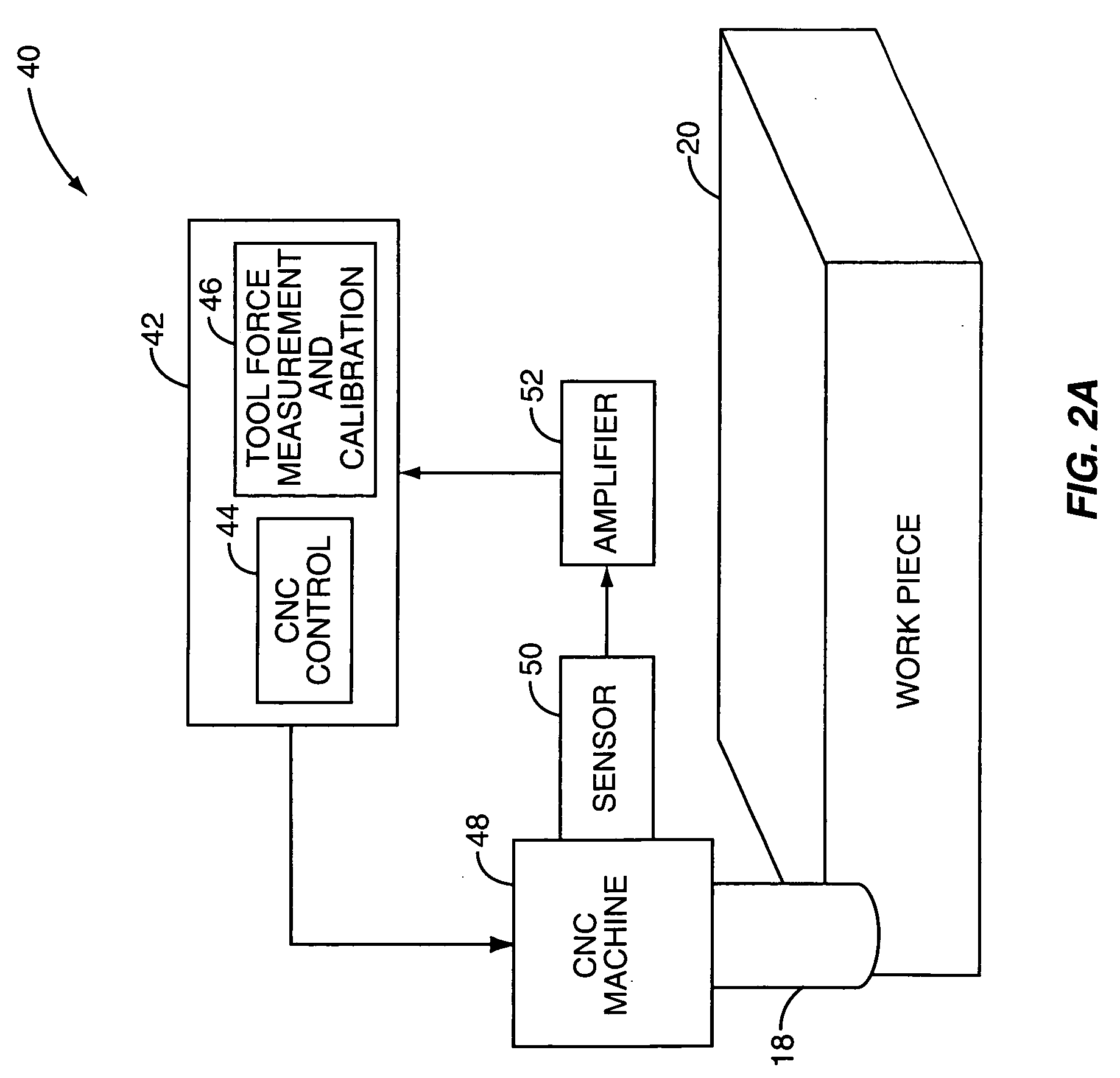

Sensor-based measurement of tool forces and machining process model parameters

InactiveUS20070016325A1Inexpensive but accurate monitoringAddressing Diversity InsufficiencyProgramme controlForce measurementSacrificial partElectric machinery

A system and method are provided for real-time measurement of tool forces. A relationship between a sensor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The sensor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the sensor characteristic and tool forces is determined. Thereafter, the sensor characteristic of the CNC machine is measured for a work piece, part program and desired tool and converted to tool forces using the relationship between the sensor characteristic and tool forces. The resulting tool forces may be combined with a process model to obtain process model parameters or cutting energies for the work piece and the desired tool. In cases where the sensor is not conveniently attached to the work piece or when the part program is not sufficiently robust in cutting conditions to accurately determine the process model parameters, the work piece and part program are replaced by a sacrificial work piece and sacrificial part program. The sacrificial work piece and sacrificial part program are selected to both accommodate the sensors and to provide sufficient robustness in cutting conditions to accurately determine the process model parameters for the sacrificial work piece. The process model parameters for the desired work piece are obtained from the process model parameters by, first, obtaining the averaged tangential tool forces for the desired work piece and for the sacrificial work piece by measuring the spindle motor power and applying the relationship between spindle motor power and tangential tool forces for each work piece, second, obtaining a ratio of the averaged tangential tool forces for the desired work piece and the sacrificial work piece and, third, applying this ratio to the process model parameters for the sacrificial work piece to obtain predicted values for the tool forces and the process model parameters for the desired tool and desired work piece.

Owner:UNIVERSITY OF NEW HAMPSHIRE

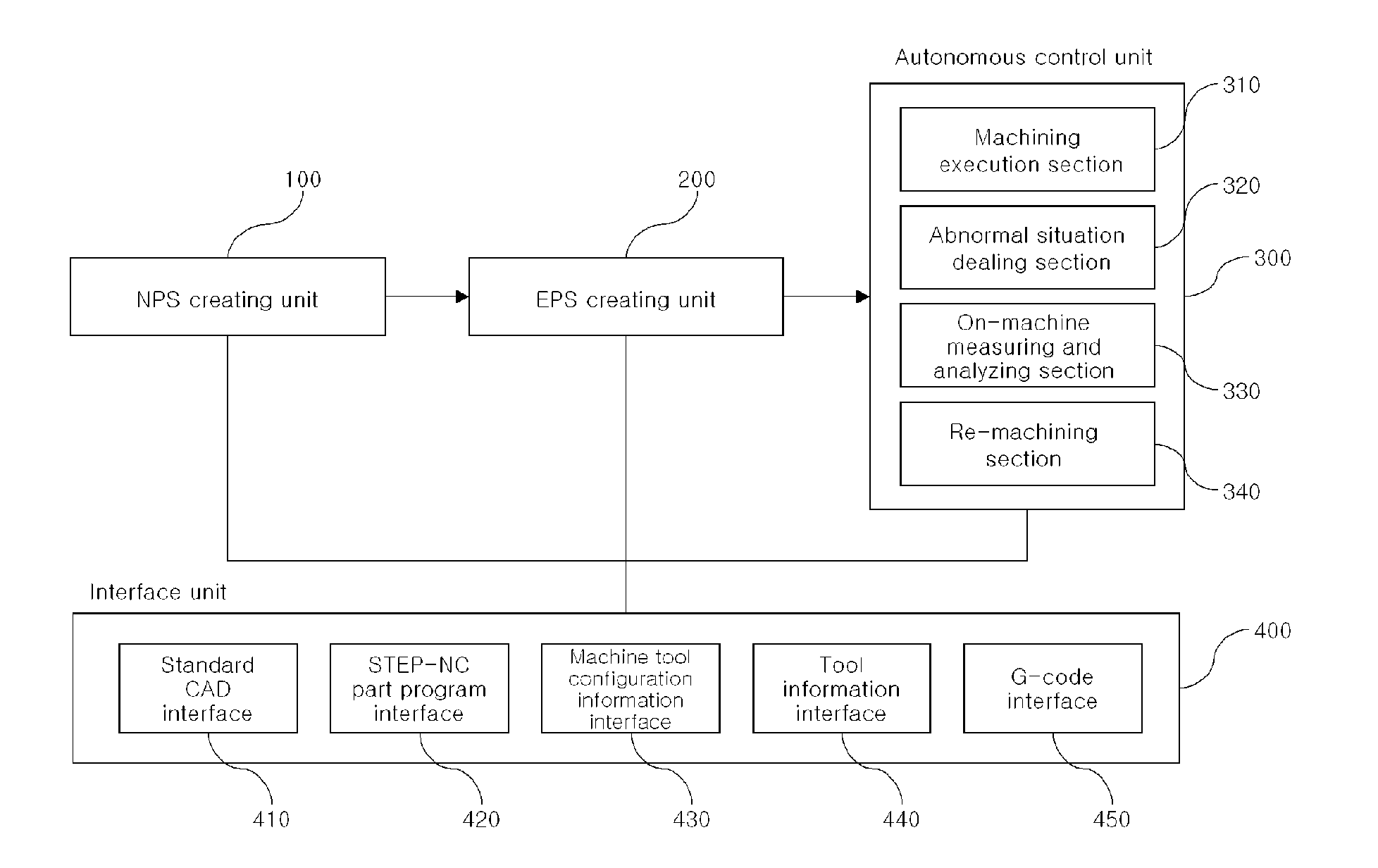

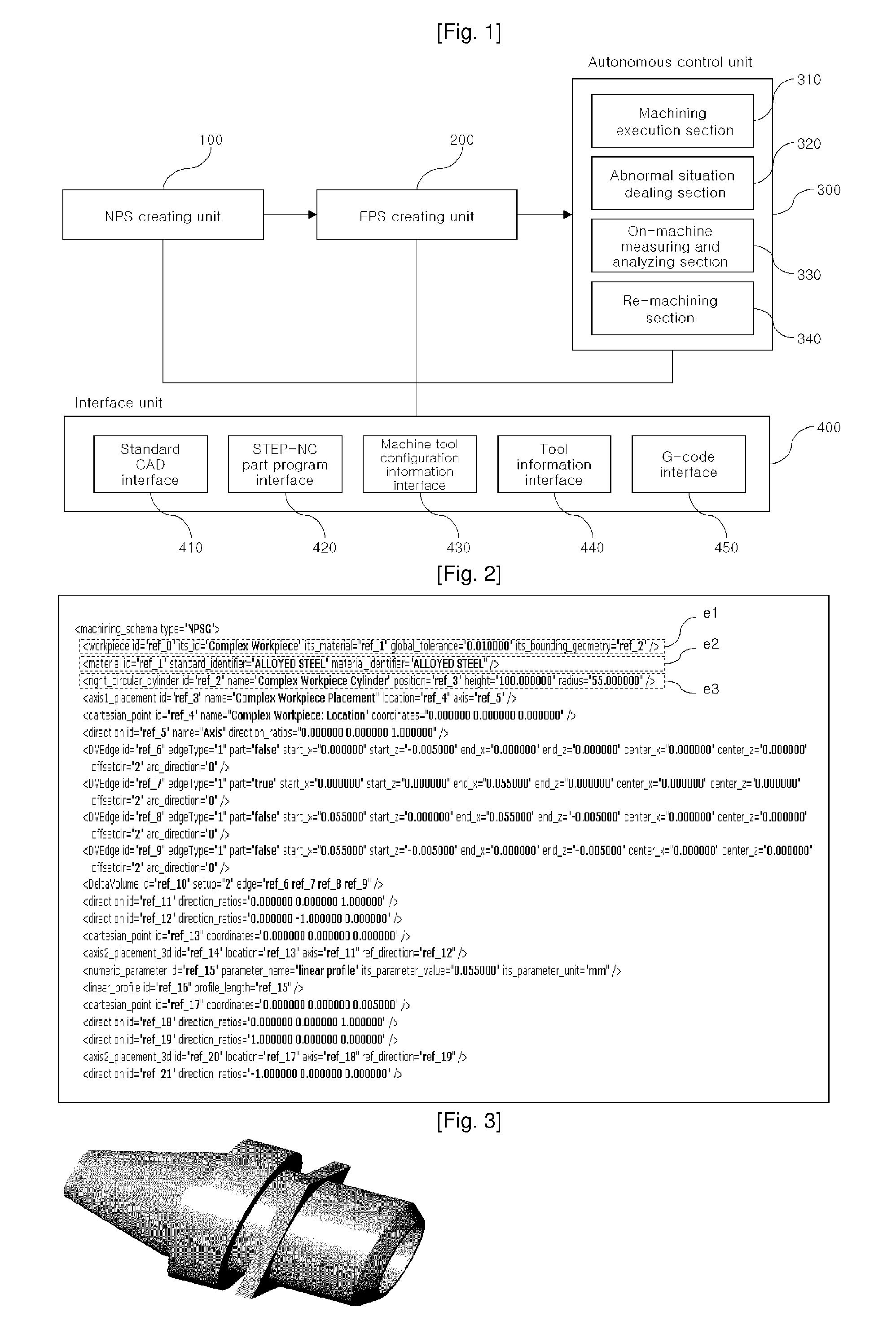

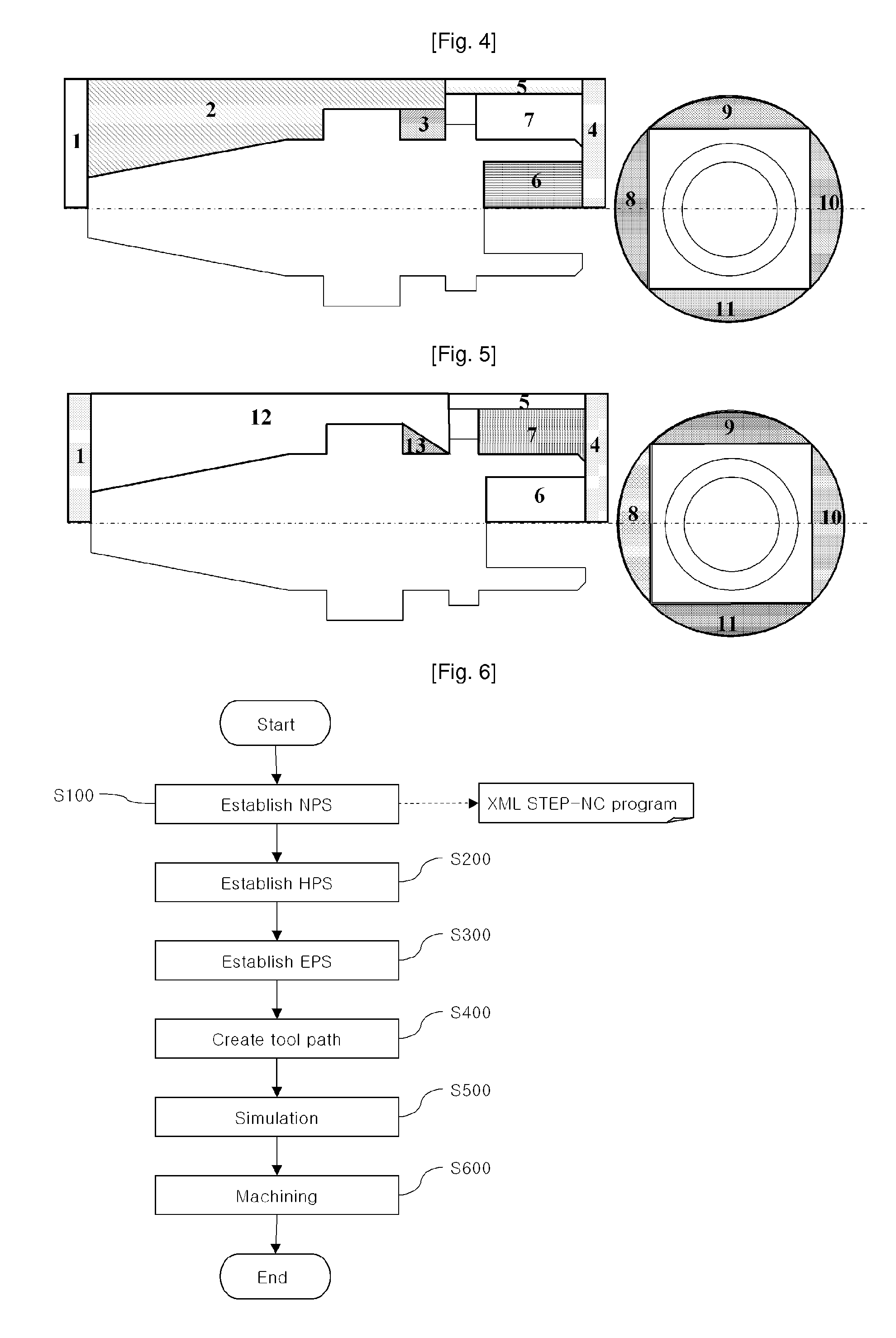

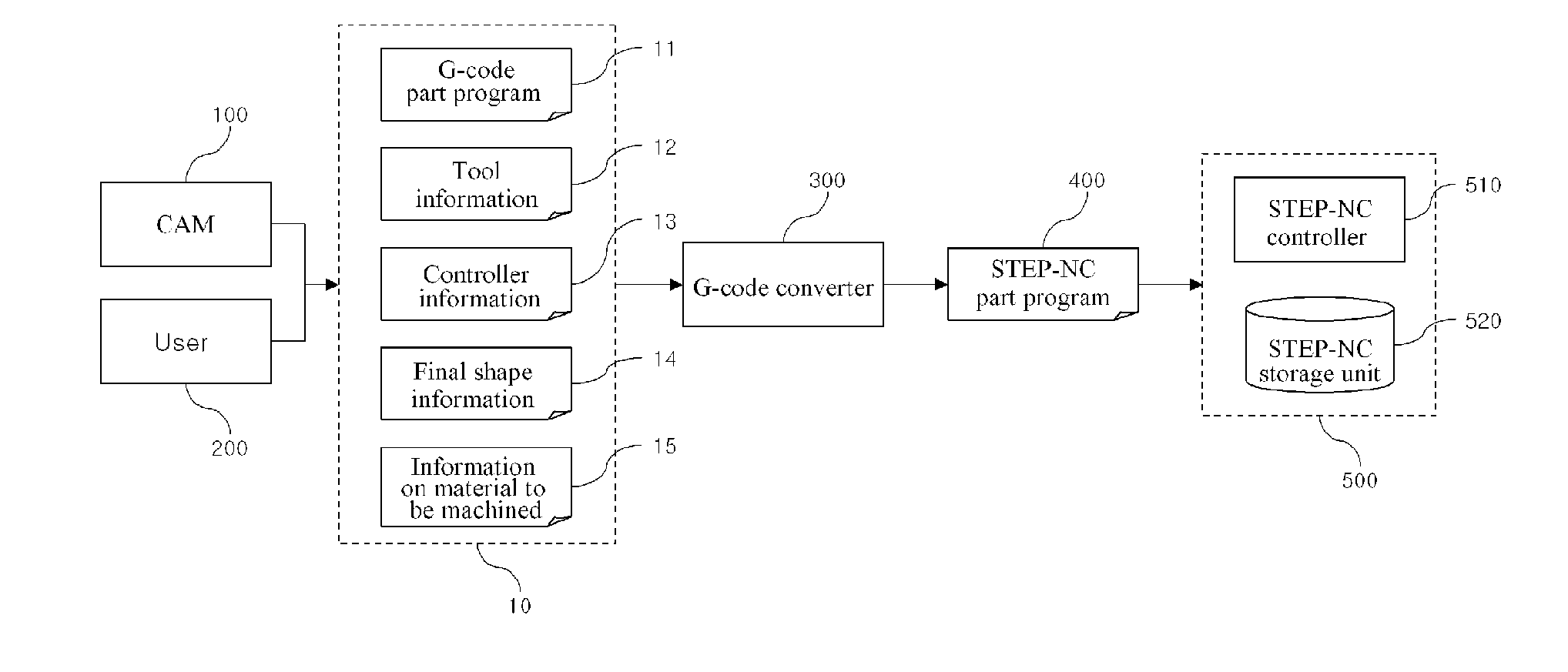

Method of Non-Linear Process Planning and Internet-Based Step-Nc System Using the Same

InactiveUS20080281463A1Decrease productivityEasy constructionProgramme controlSpecial data processing applicationsSTEP-NCAlternative process

The present invention relates to a method of creating a non-linear process plan and an Internet-based STEP-NC system using the same, and more particularly, to a method of creating a non-linear process plan, wherein the non-linear process plan including information on a variety of alternative processes and machining sequences is established in consideration of situations in the field, thereby autonomously dealing with abnormal situations while executing optimal machining, and to an Internet-based STEP-NC system, wherein a STEP-NC part program in an XML format is created based on the established process plan so that process information can be easily exchanged with other systems via the Internet. Since the present invention provide a plurality of machining alternatives to the field, and thus, allow a STEP-NC machine tool to execute machining optimized depending on field situations and to autonomously deal with abnormal situations that may occur during machining.

Owner:POSTECH ACAD IND FOUND

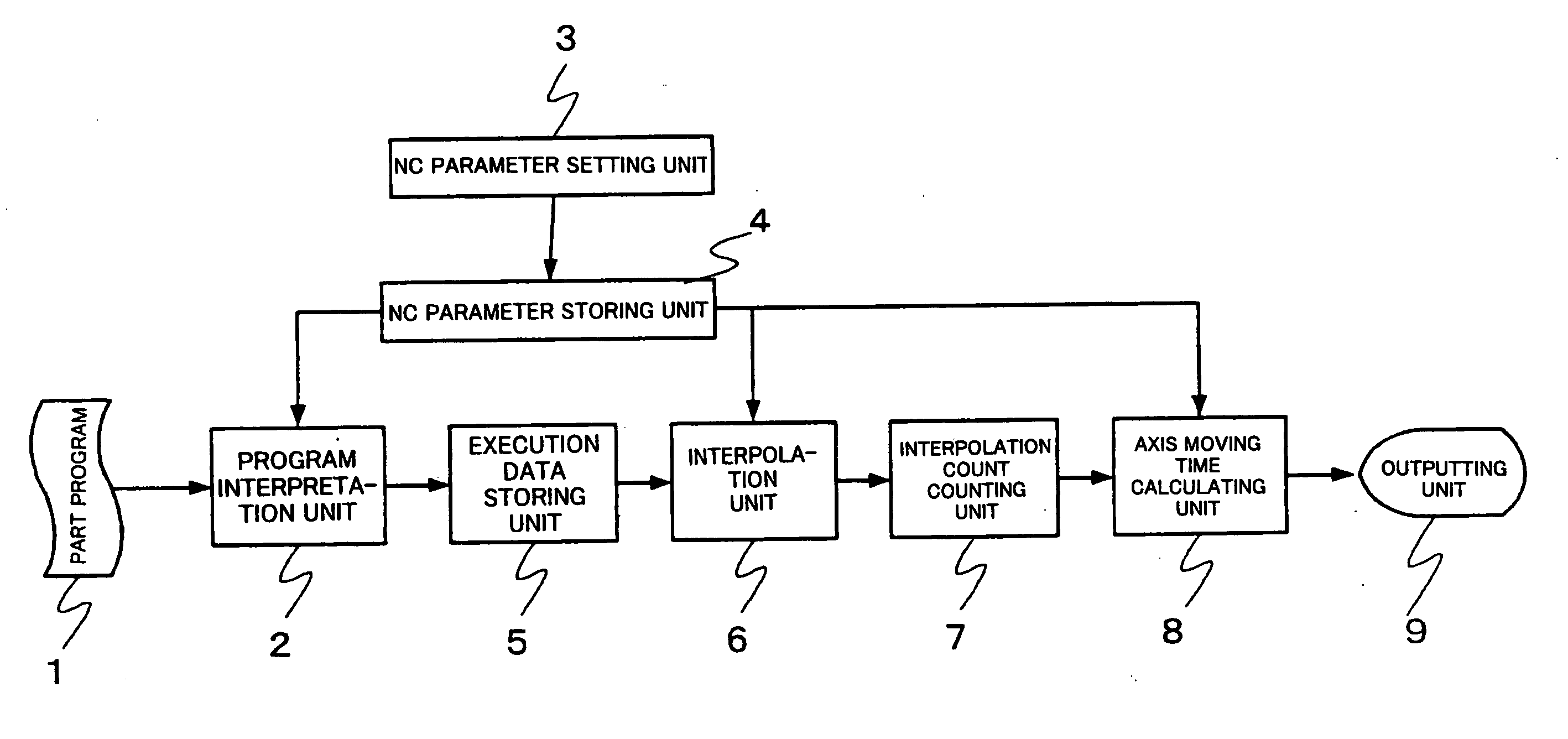

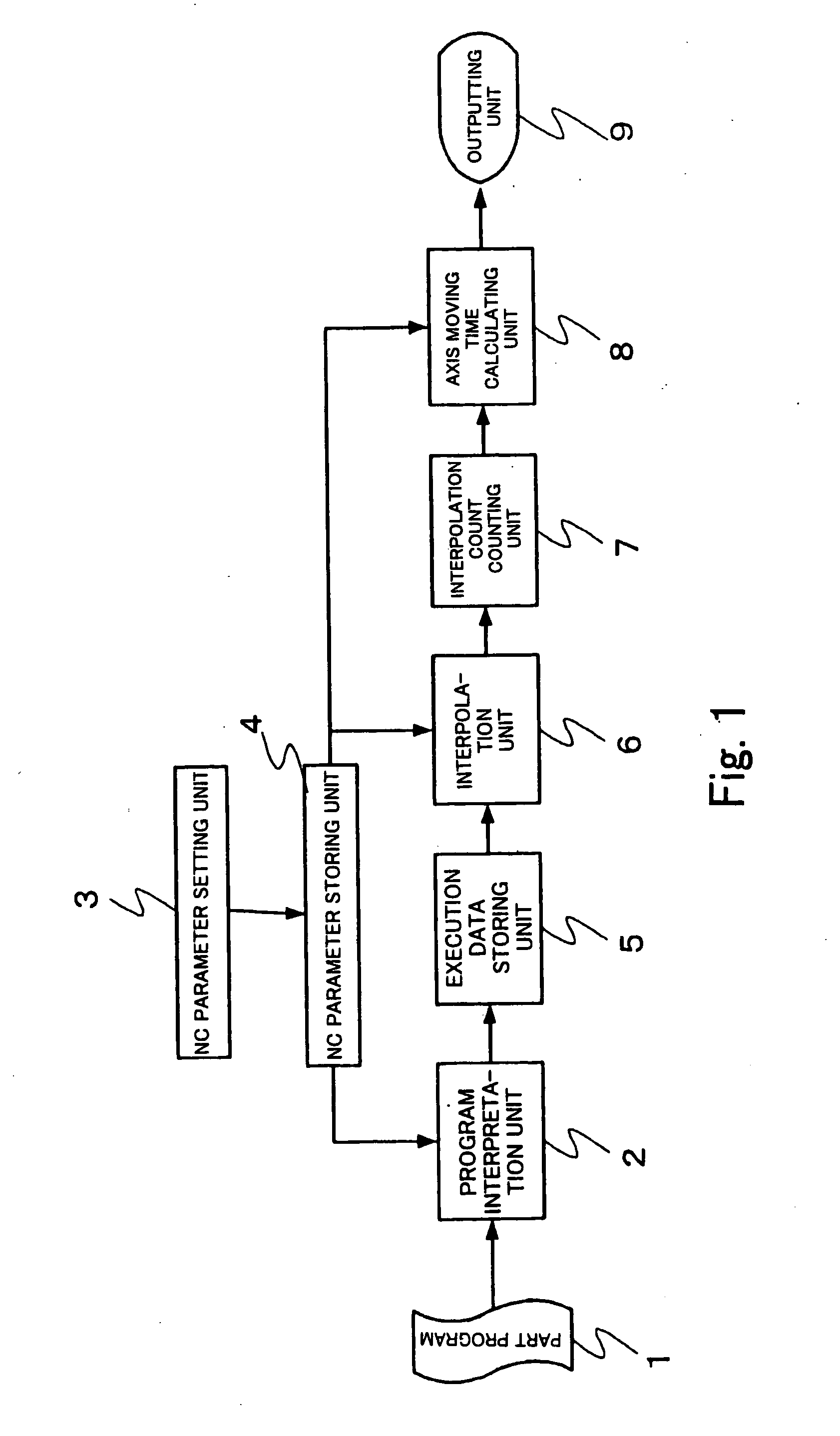

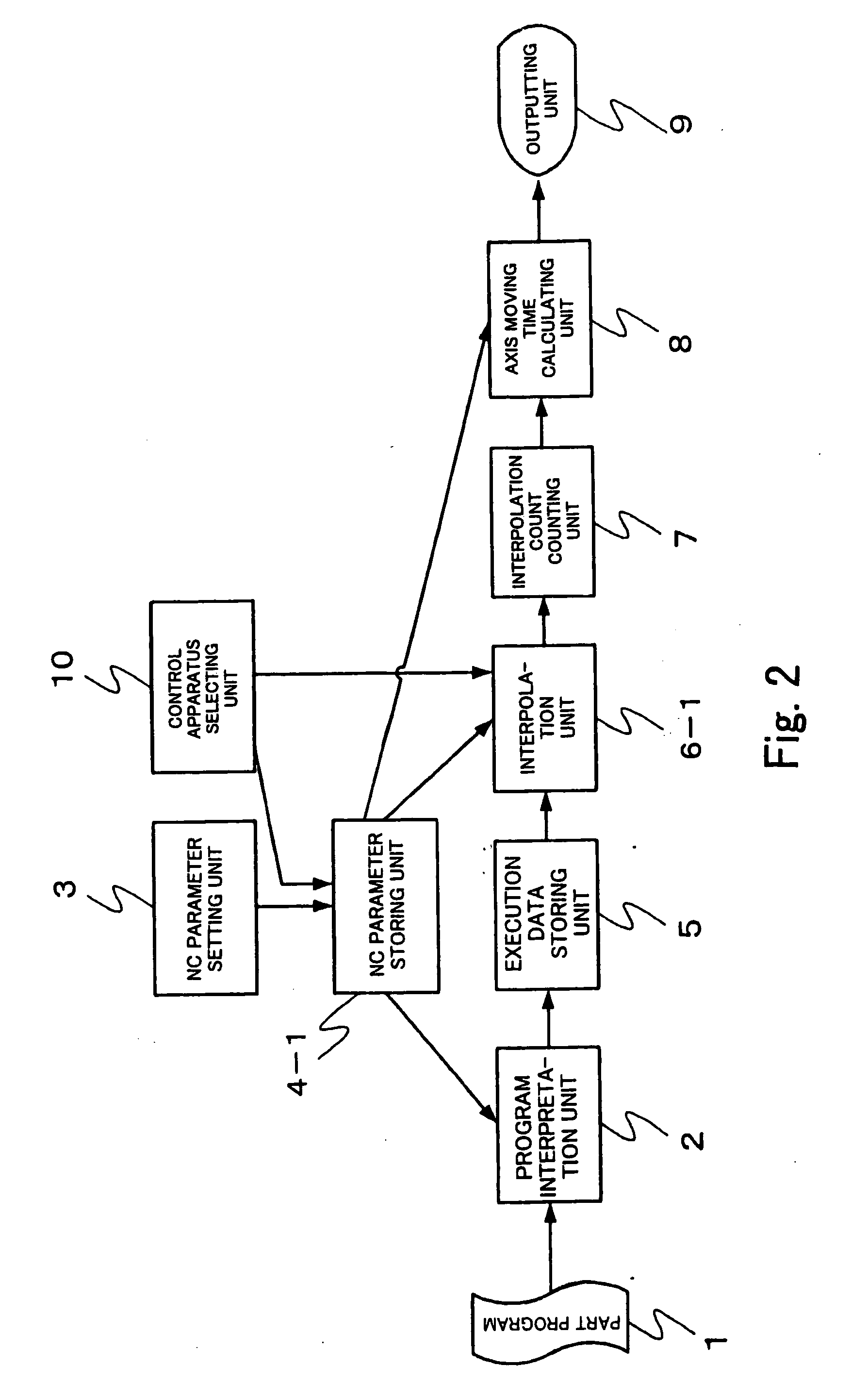

Machining time calculating apparatus

ActiveUS20050228533A1Accurate calculationHigh precisionProgramme-controlled manipulatorTime indicationNumerical controlComputer architecture

A structure having a parameter storing unit which stores a parameter to be used when a numeric control apparatus drives and controls the numeric control machine tool, a program interpretation unit which reads a part program to generate machining data for each block, an interpolation unit which interpolates a movement path instructed in an axis moving instruction referring to a parameter stored in the parameter storing unit and using an interpolation algorithm which is identical to a driving and controlling interpolation algorithm of the numeric control apparatus, an interpolation count counting unit which counts an interpolation count in the movement path, and an axis moving time calculating unit which multiplies an interpolation cycle when the numeric control apparatus drives and controls the numeric control machine tool and the counted interpolation count to calculate an axis moving time.

Owner:OKUMA CORP

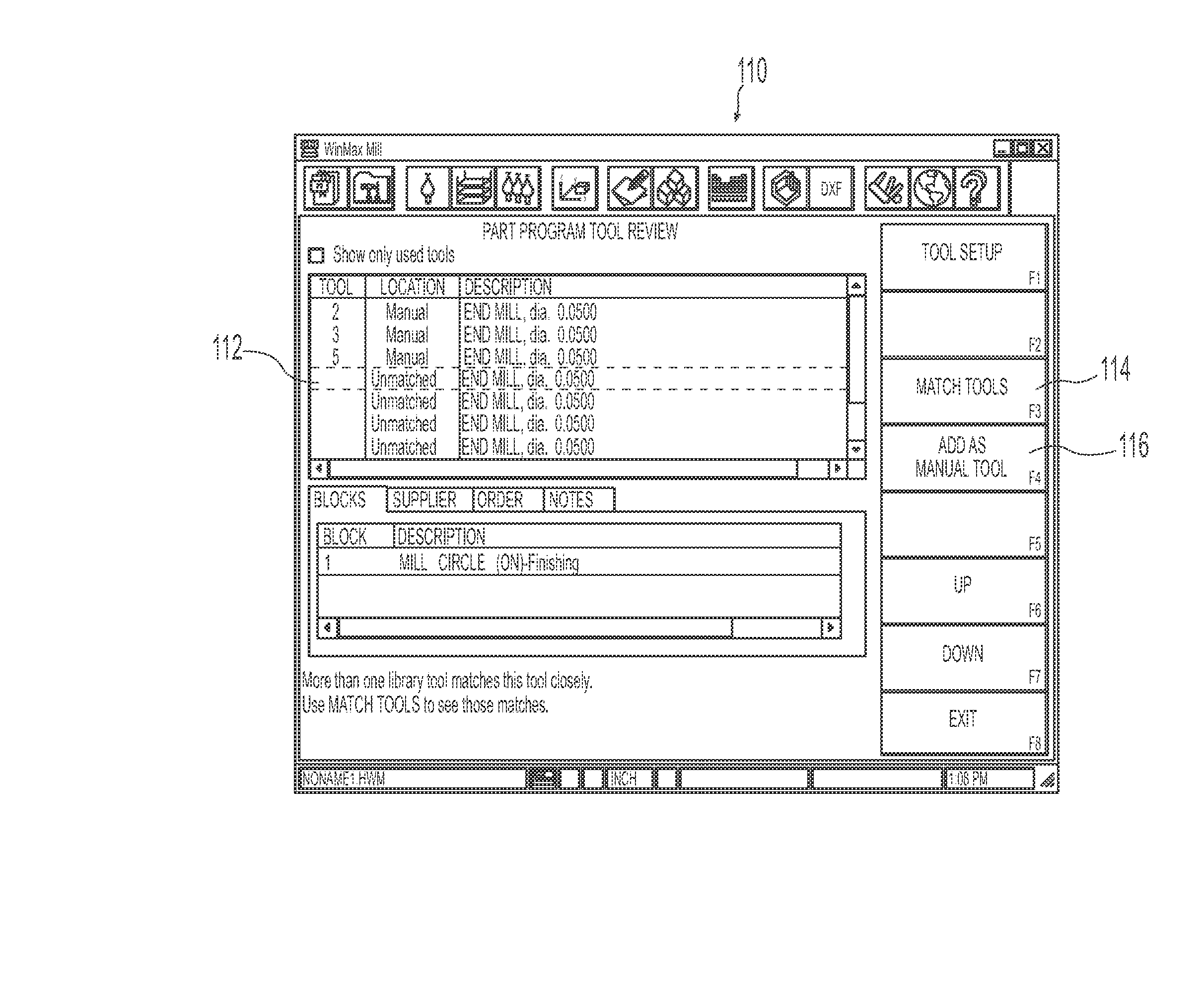

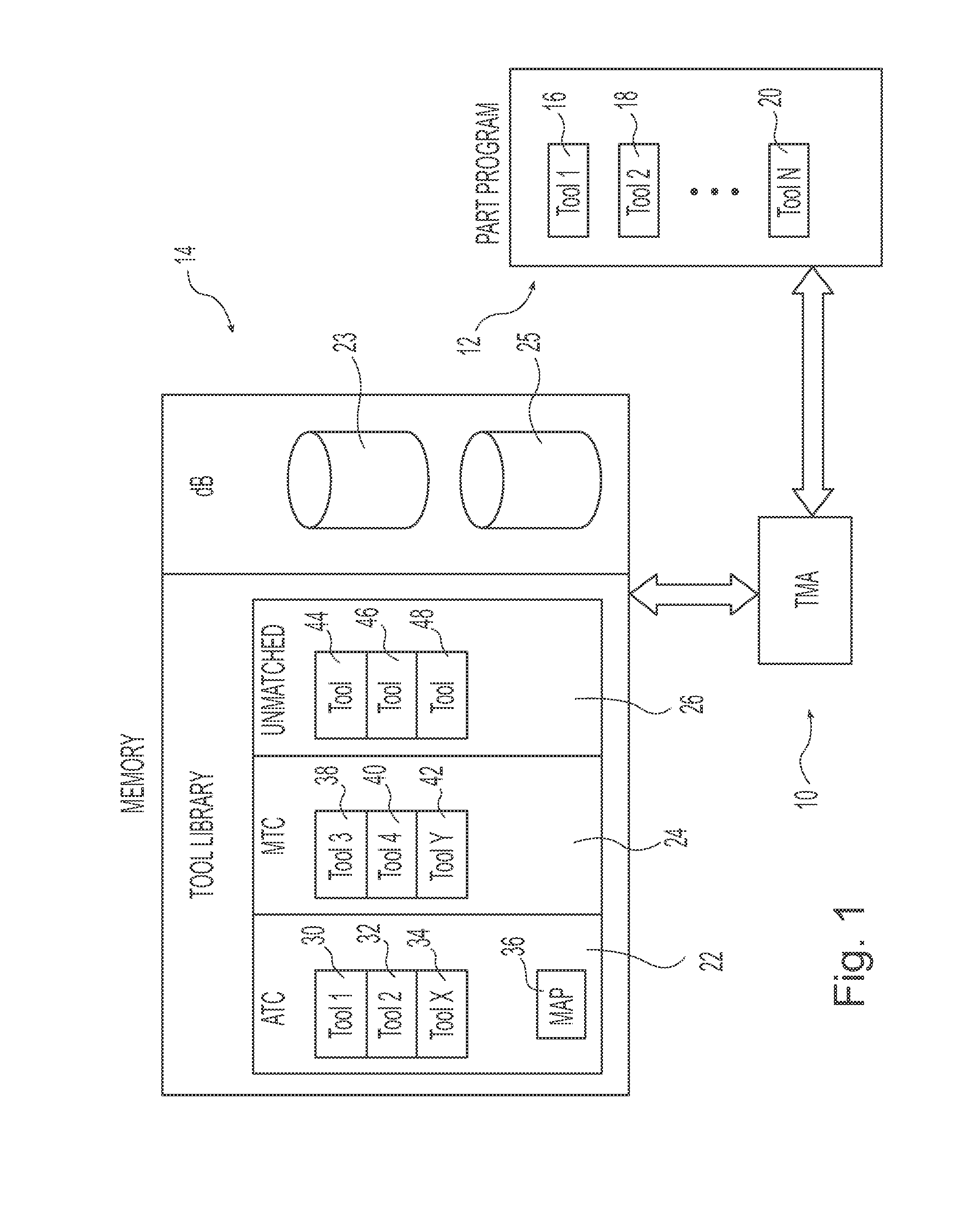

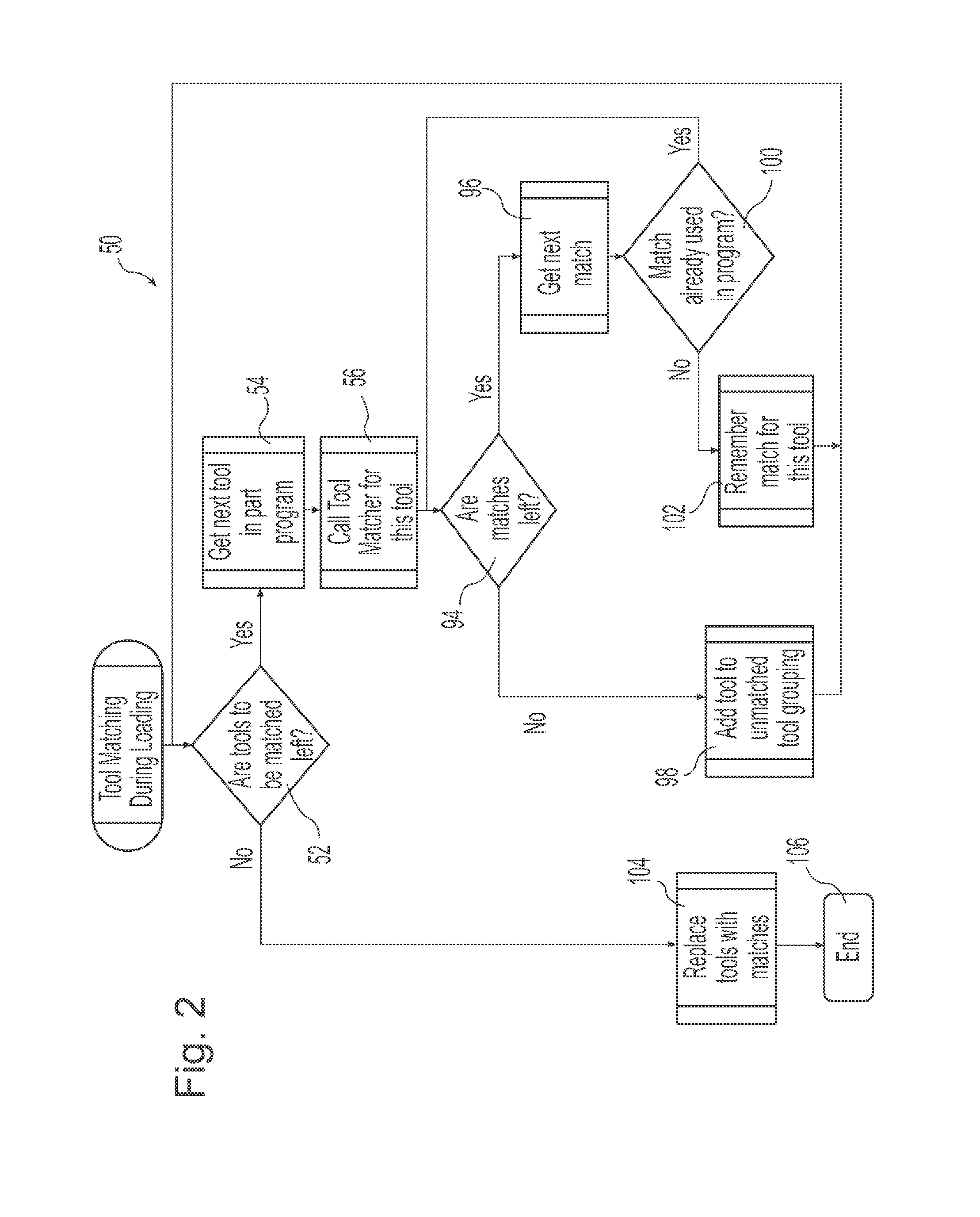

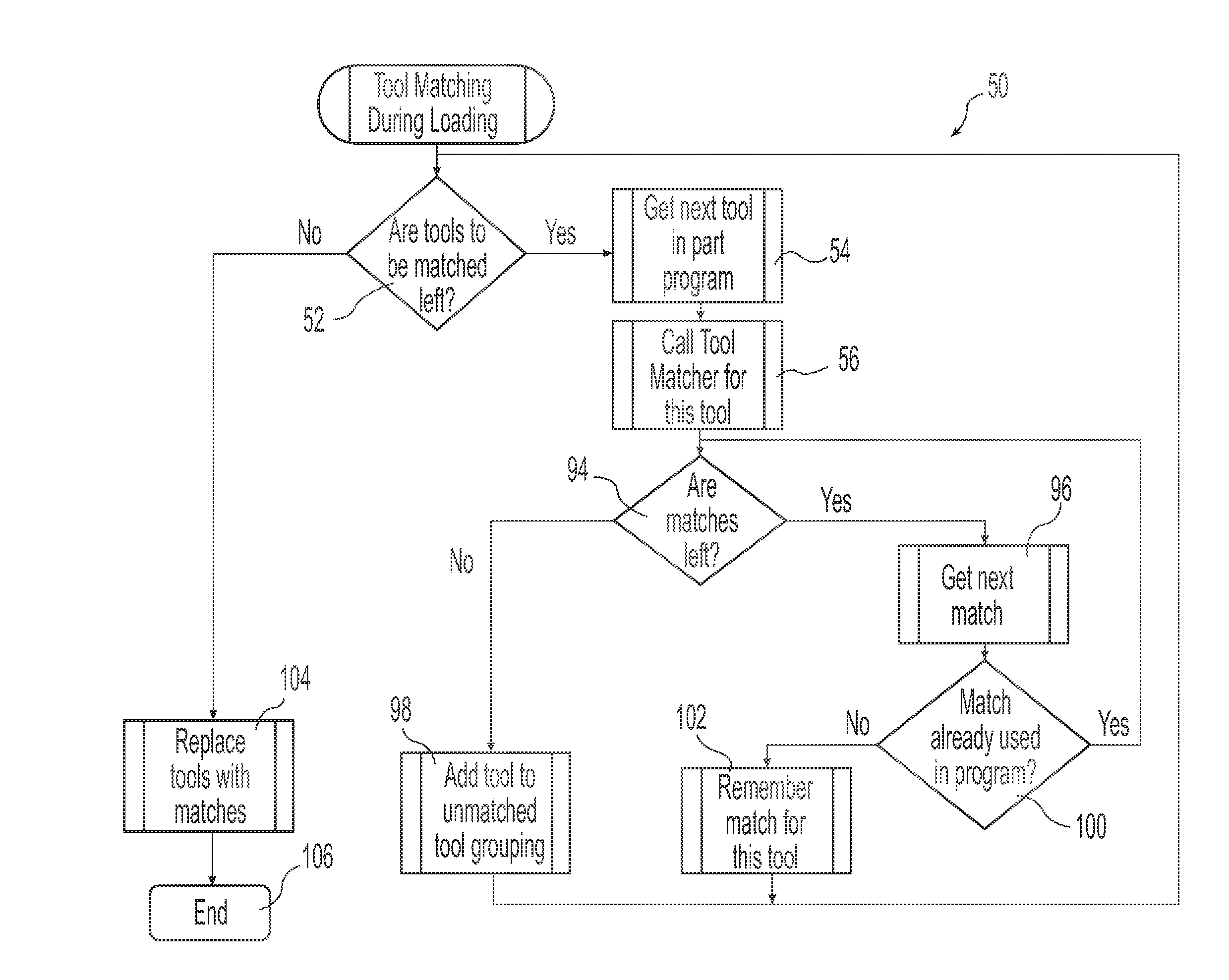

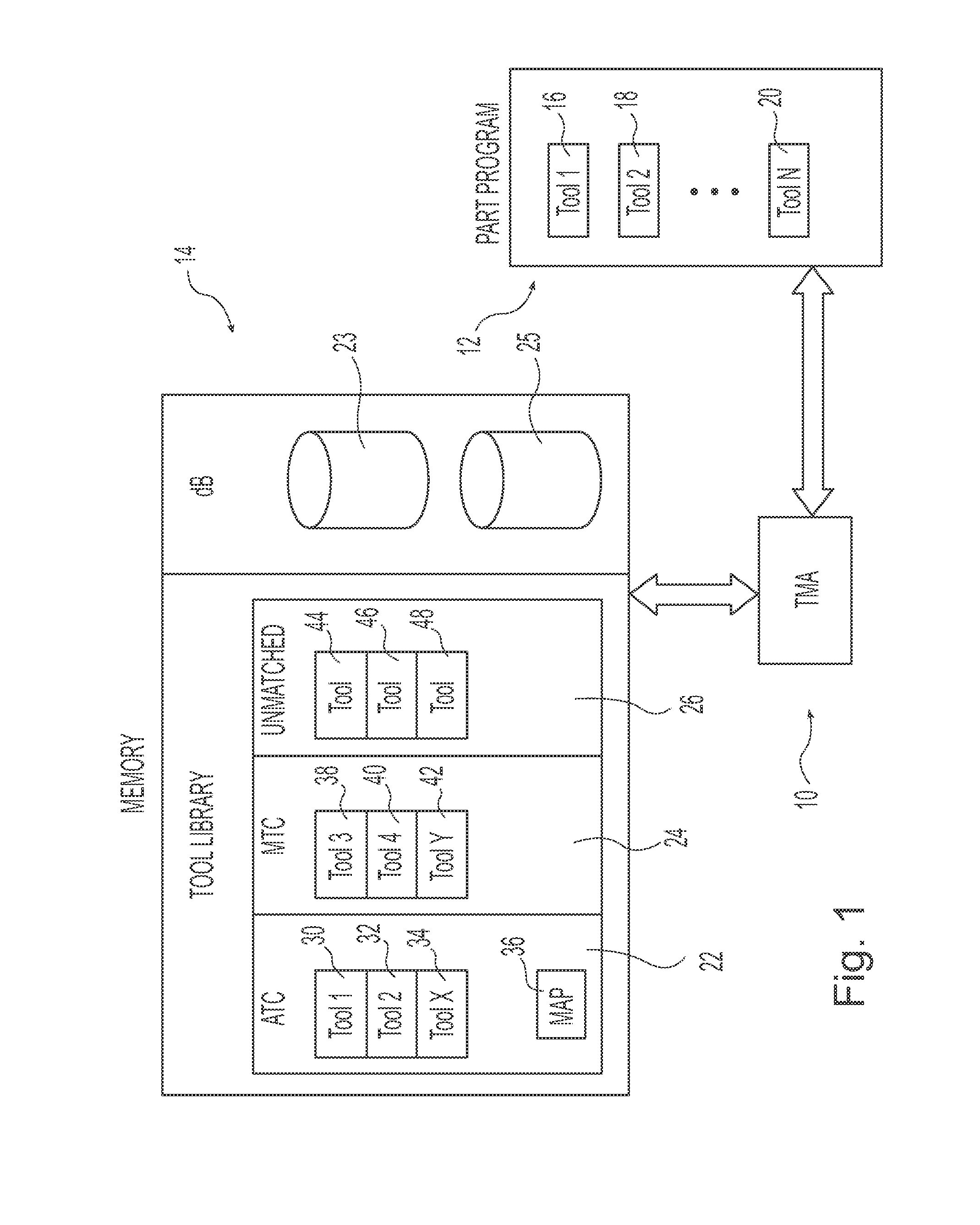

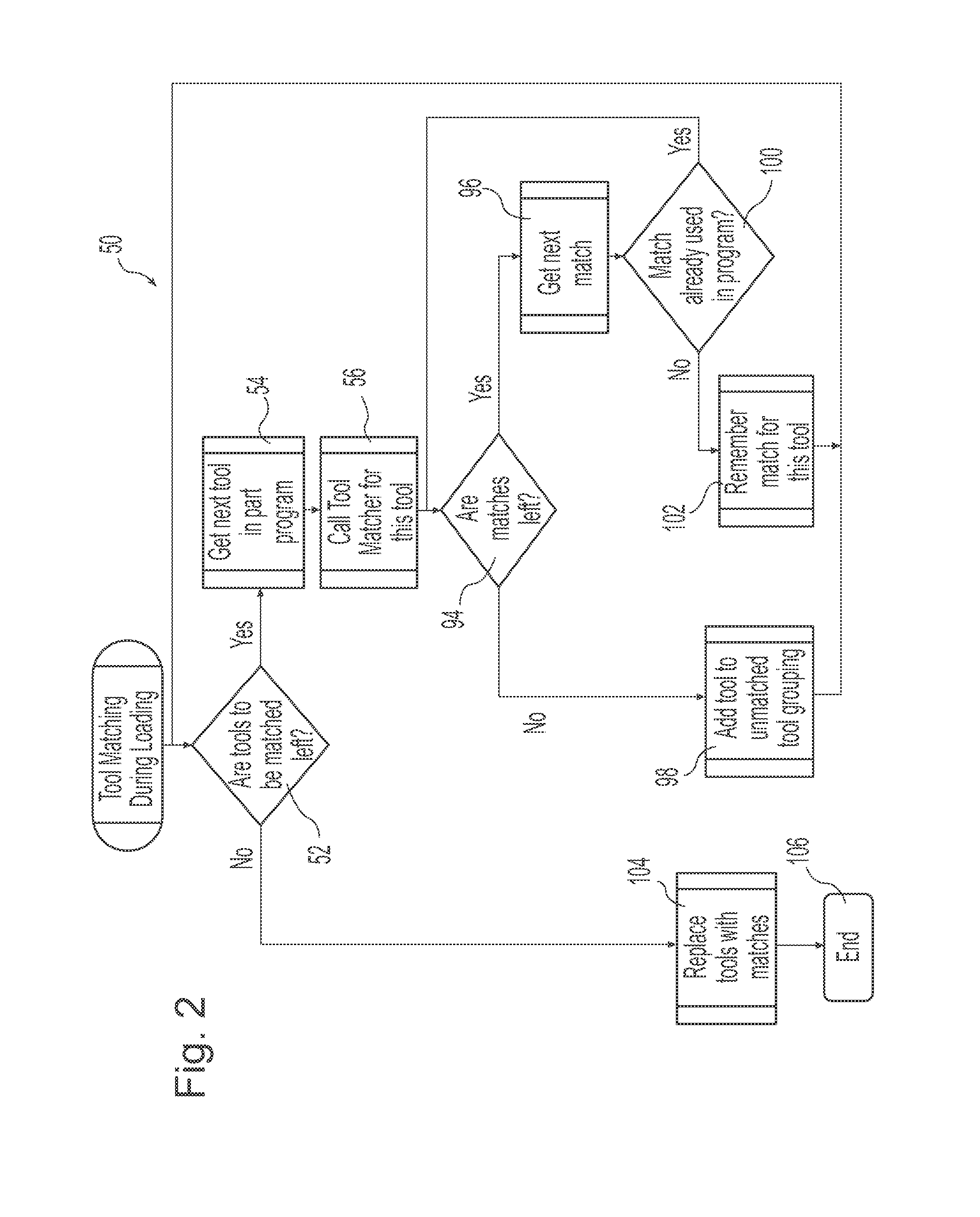

System and method for tool use management

The present invention provides a system and method for tool use management wherein a CNC machine retains information identifying the tools associated with the machine as well as their current locations (if any), and executes an algorithm for determining the source tools needed by a part program and matching the source tools with the available tools.

Owner:HURCO

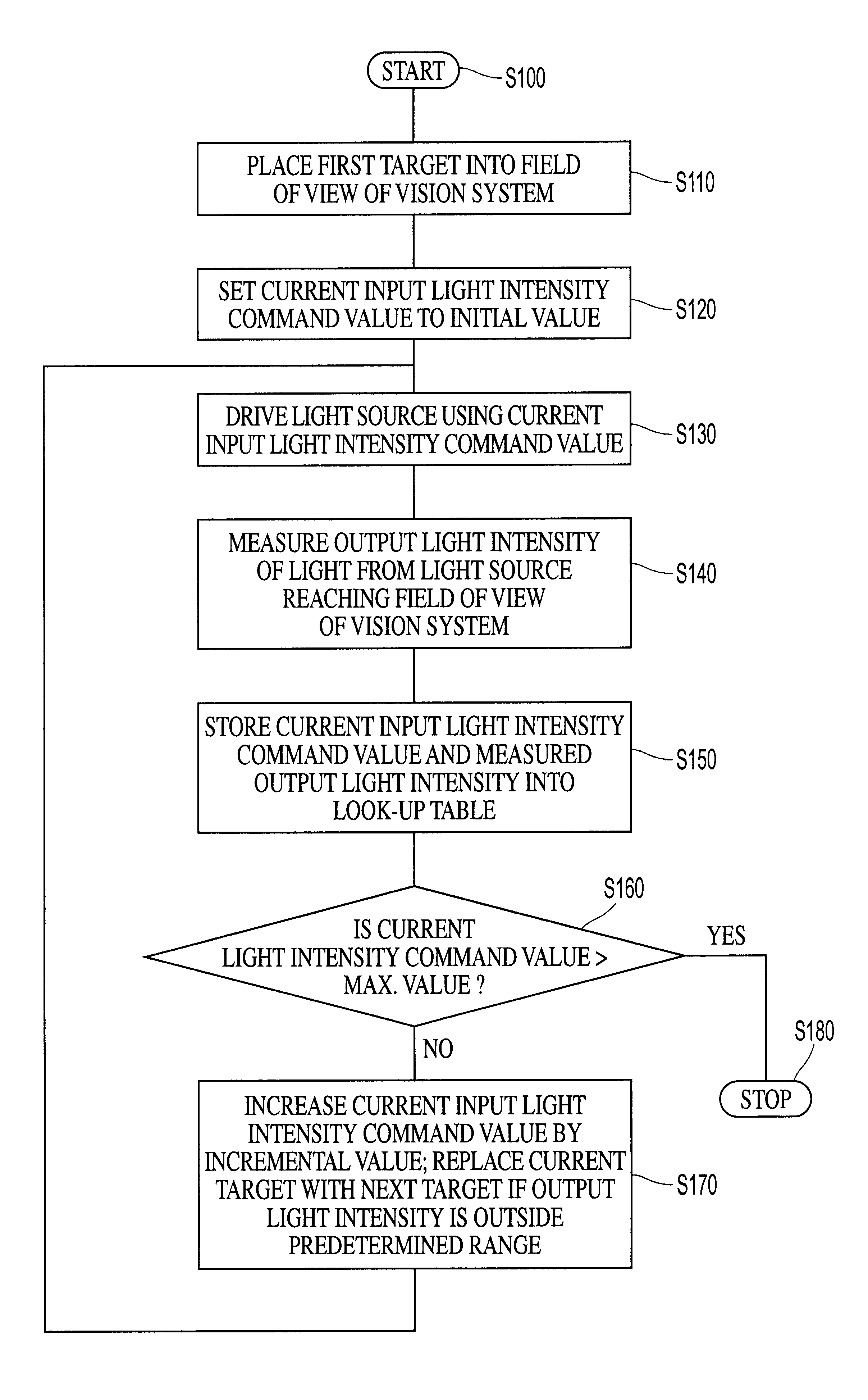

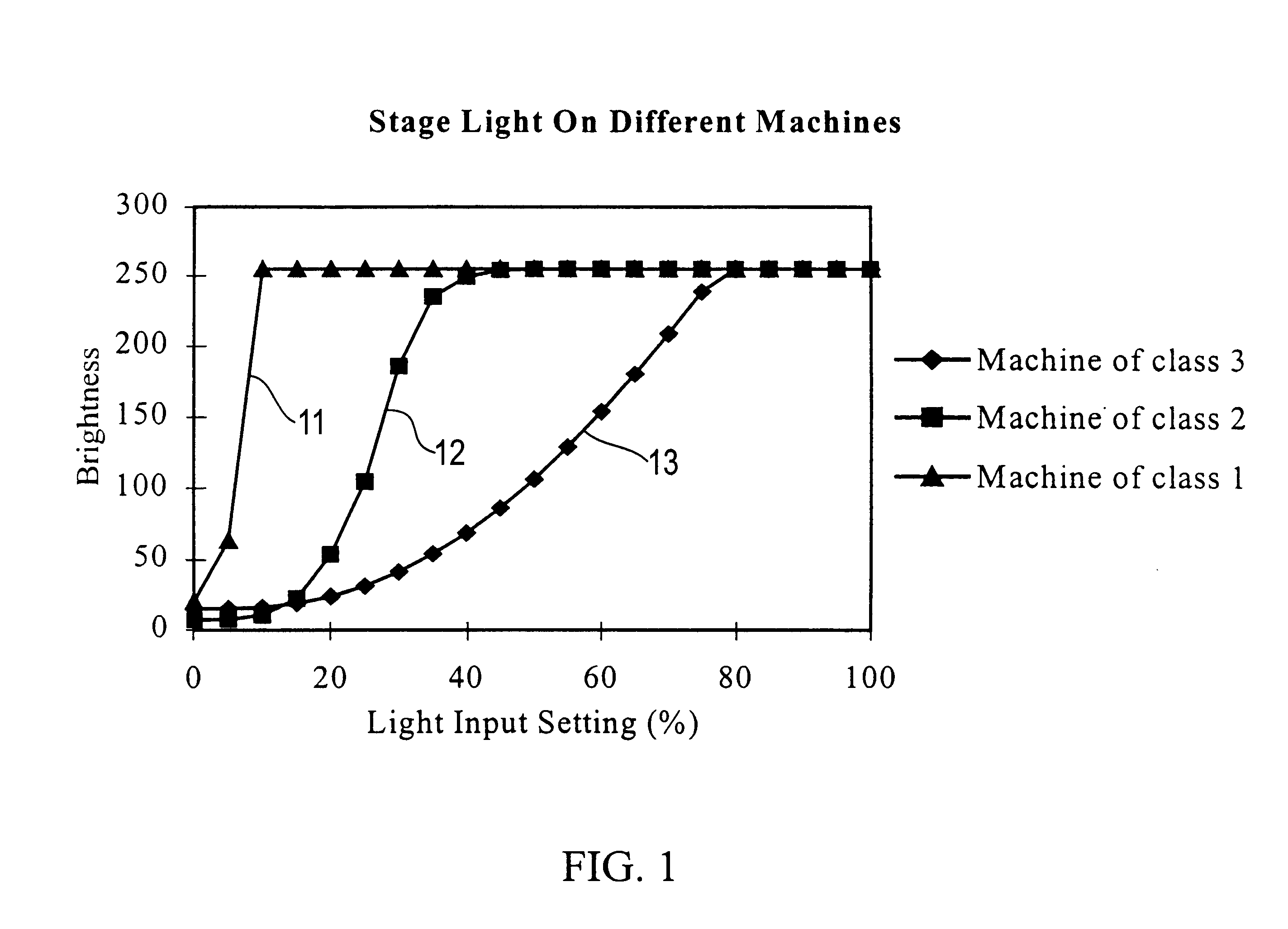

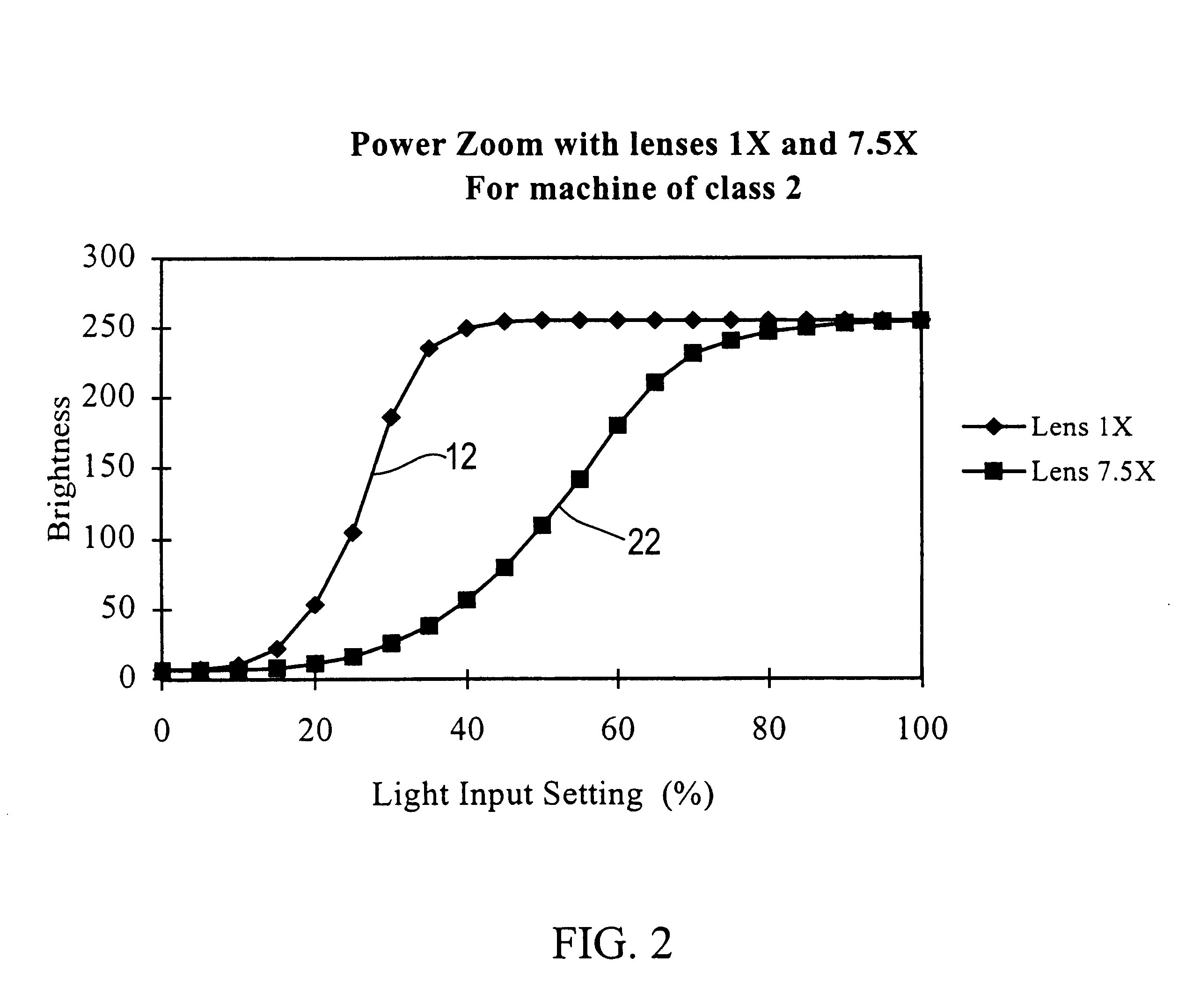

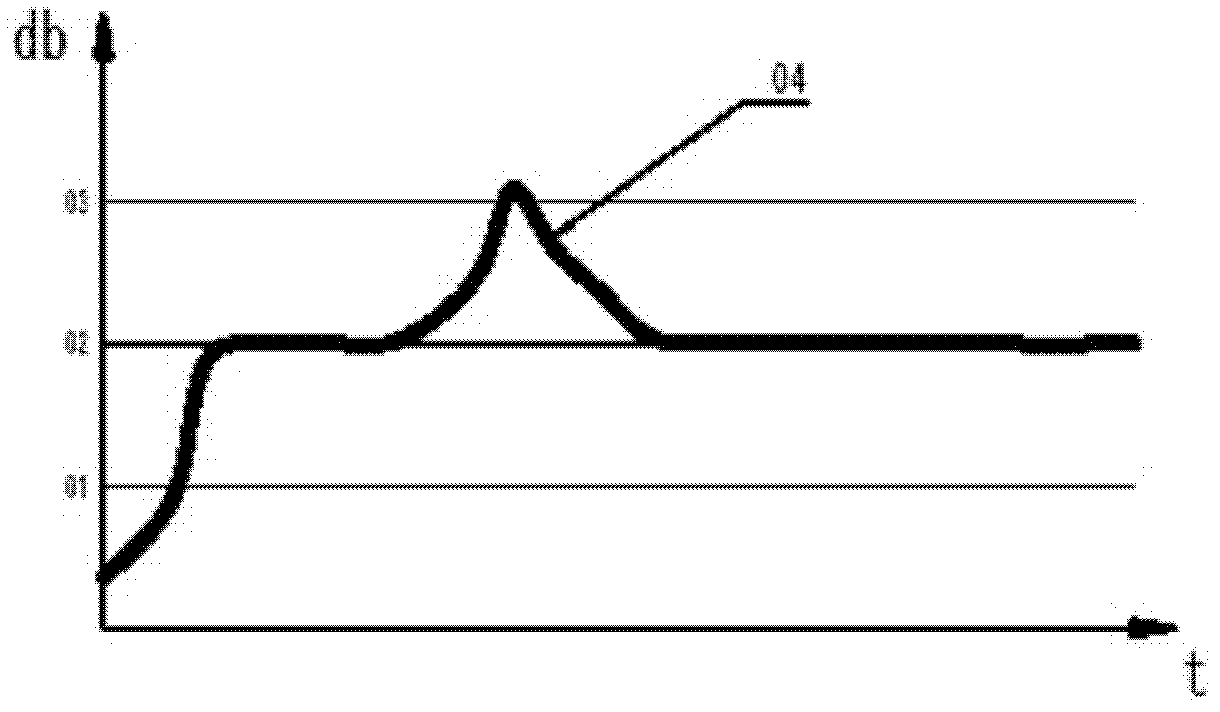

Open-loop light intensity calibration systems and methods

InactiveUS6239554B1Reduce lightReduce inconsistencyPhotometry using reference valuePhotometry using wholly visual meansEffect lightVisual perception

The input light settings in many vision systems often do not correspond to fixed output light intensities. The relationships between the measured output light intensity and the input light intensity are inconsistent between vision systems or within a single vision system over time. This inconsistency makes it difficult to interchange part-programs even between visions systems of one model of vision systems, because a part program with one set of light intensity values might produce images of varying brightness on another vision system. However, many measurements depend on the brightness of the image. To solve this problem, a reference lighting curve is generated for a reference vision system, relating an input light intensity value to a resulting output light intensity. A corresponding specific lighting curve is generated for a specific vision system that corresponds to the reference vision system. A calibration function is determined that converts a reference input light intensity value into a specific input light intensity value. Accordingly, when an input light intensity value is input, the specific vision system is driven at a corresponding specific input light intensity value such that the output light intensity of the specific vision system is essentially the same as the output light intensity of the reference vision system when the reference vision system is driven at the input light intensity value. Thus, in a vision system calibrated using these lighting calibration systems and methods, the specific lighting behavior of that vision system is modified to follow a pre-defined, or reference, lighting behavior.

Owner:MITUTOYO CORP

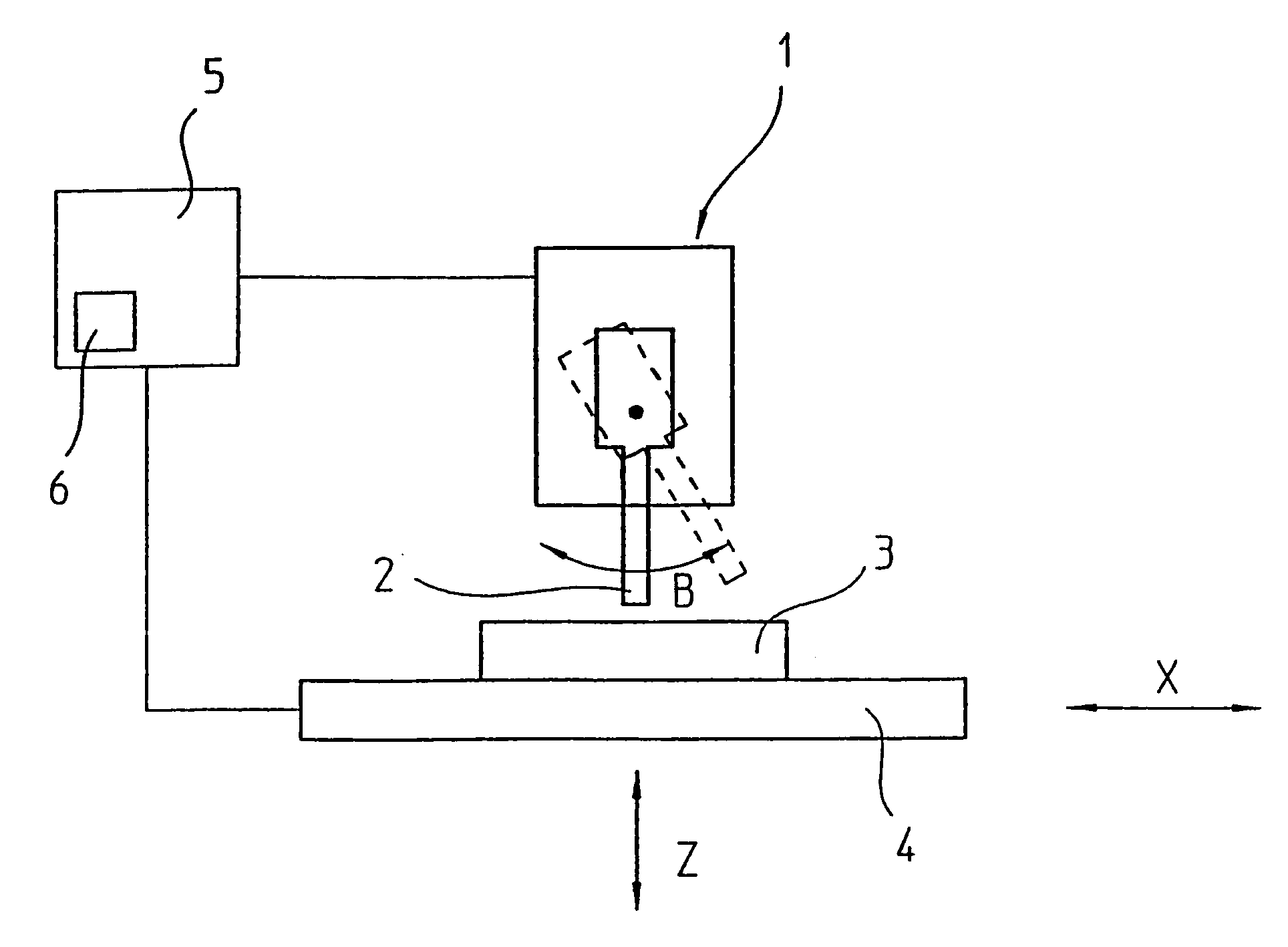

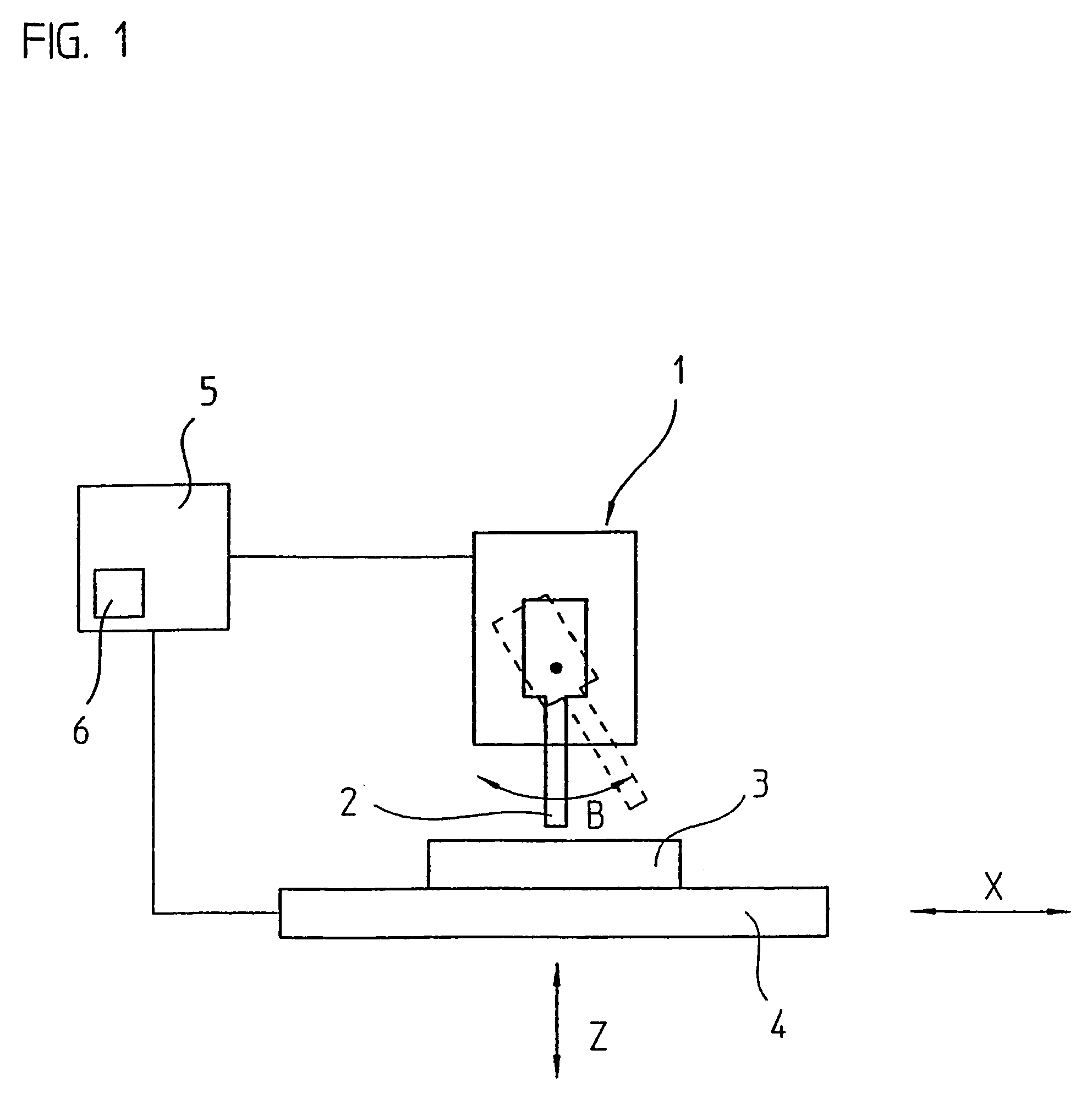

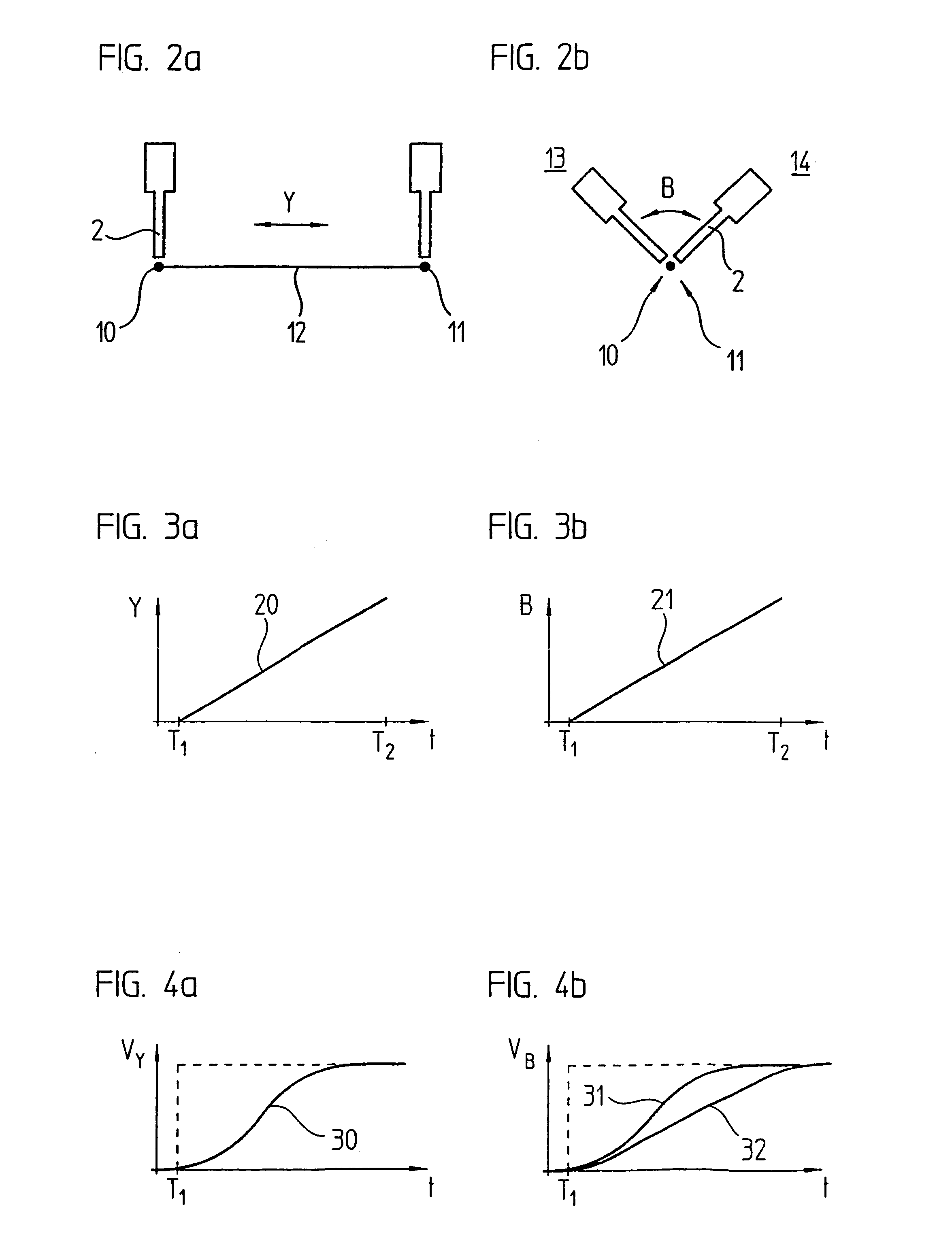

Method for continuous-path control

InactiveUS7012395B2Improve surface qualityMachine becomes highComputer controlSimulator controlNumerical controlRounding

In a method for continuous-path control in at least two linear axes and at least one angle axis, the movement of a tool relative to a workpiece is predefined by a parts program for a numerical control. The velocity control in the numerical control is performed separately for the linear axes and the angle axes. Deviations in the movement between the tool and the workpiece resulting due to the separate velocity control may be corrected by compensation movements of the linear axes. The separate velocity control for the linear axes and the angle axes may be achieved by rounding the velocity profiles in the angle axes more significantly than the velocity profiles in the linear axes. A measure for the rounding for velocity profiles may be predefined separately for the angle axes and the linear axes.

Owner:DR JOHANNES HEIDENHAIN GMBH

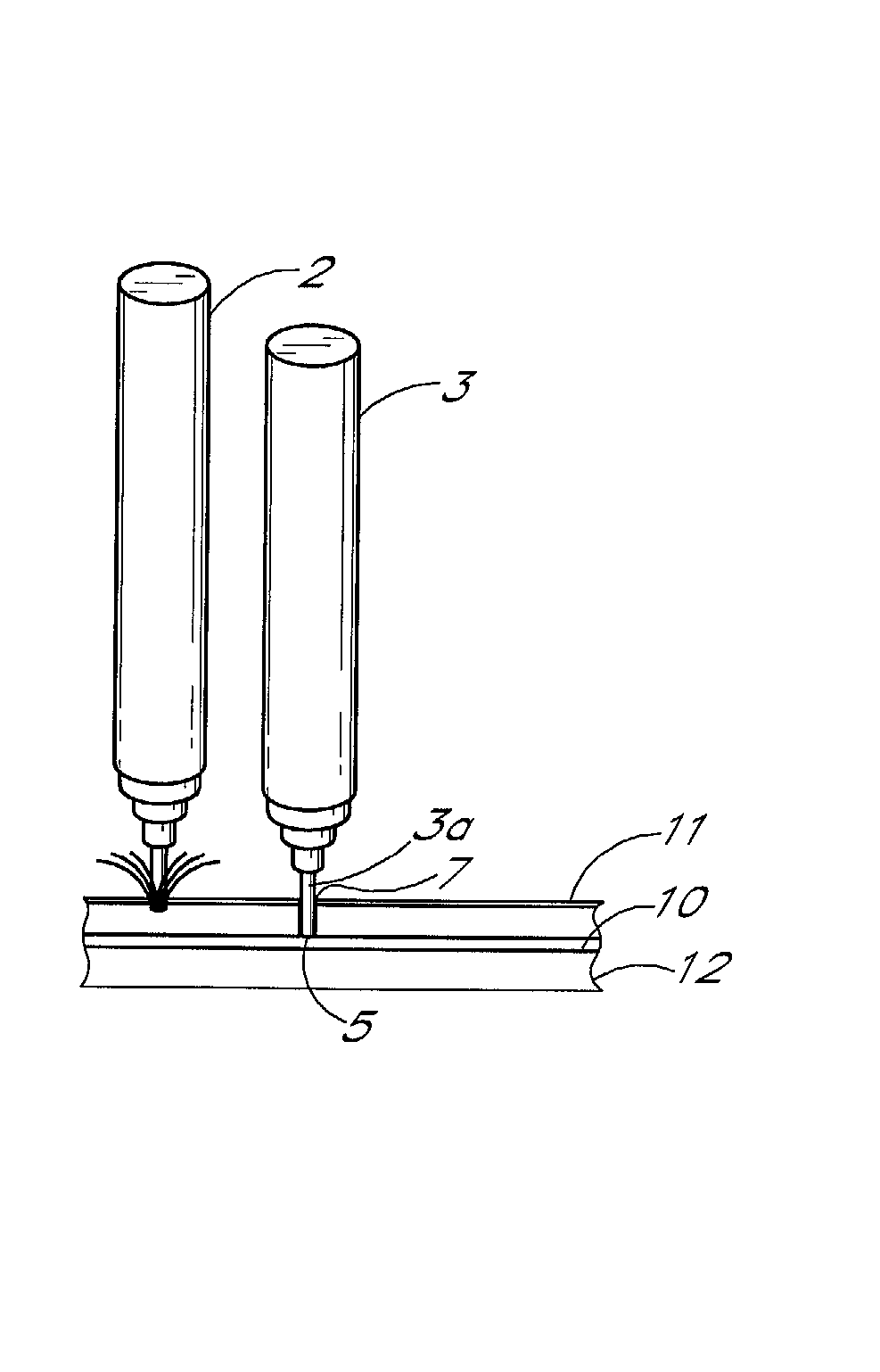

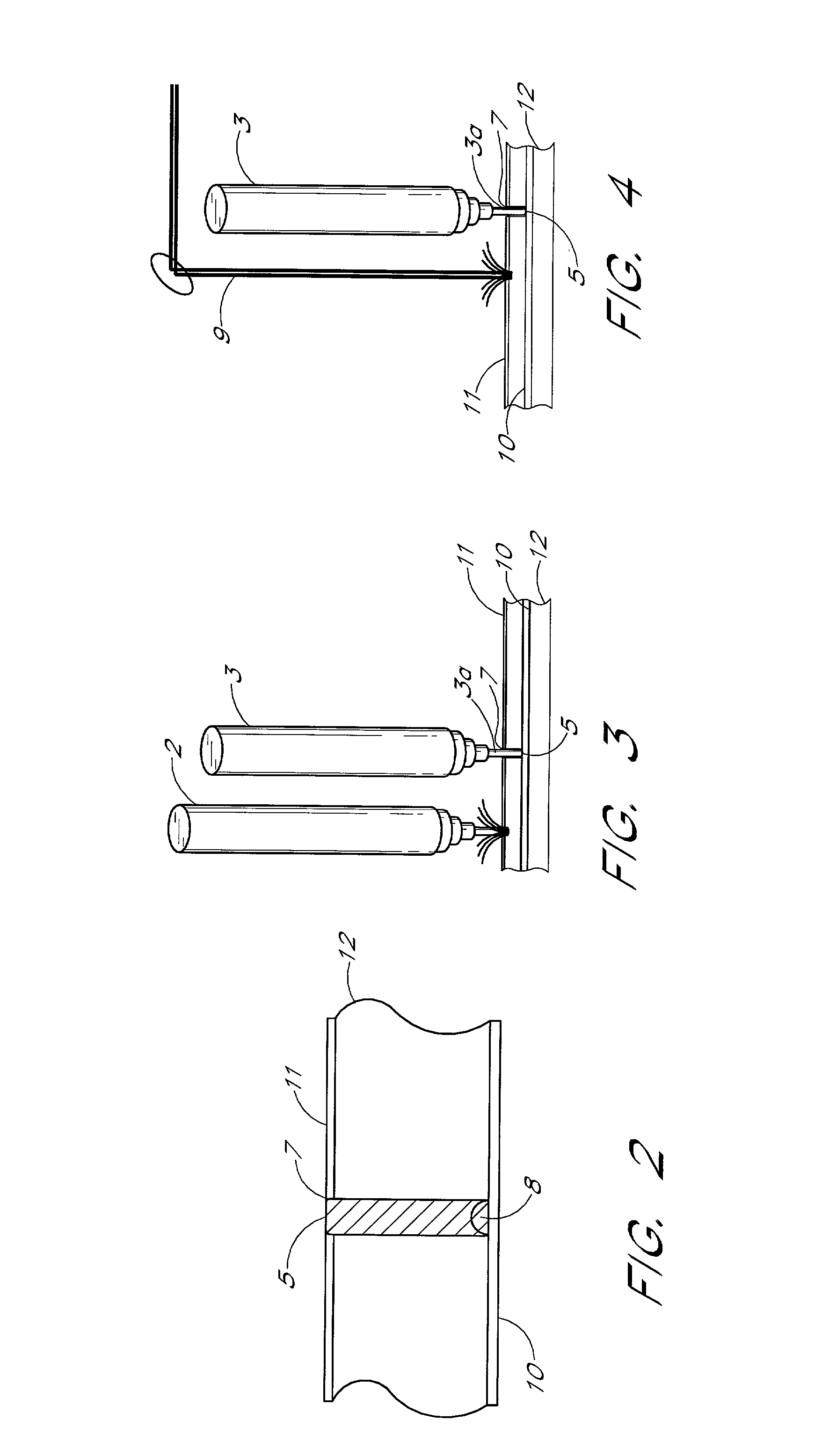

System and method for metalization of deep vias

InactiveUS20020066179A1Eliminate needReduce complicationsLiquid surface applicatorsPrinted circuit aspectsEpoxyEngineering

In a method of injecting an electrically conductive epoxy into blind vias during drilling or shortly thereafter in order to avoid oxidation of the copper or other metal of the imbedded layer, a machine tool is provided with at least one controllable spindle and at least one injection device. Alternatively, two machine tools, one with at least one controllable spindle and one with at least one injection device, may be provided. A printed circuit board mounted on the machine tool table for drilling is registered in the usual way for the particular machine tool. The machine tool part program then drills a particular pattern for the circuit board for mounting of circuit board components. All of the blind vias as well as through hole vias are drilled at one time by the machine tool by the tools mounted in the spindle or by laser drilling systems, but may also be drilled and filled in any sequence. The drilling operation is followed by the epoxy injecting operation in which a controlled operating device, comprising a reservoir, a pumping mechanism, a hollow needle through which the conductive epoxy flows to the bottom of the hole, a control mechanism, and sensors detect various mechanism operations and when hole fill is completed.

Owner:EXCELLON AUTOMATION

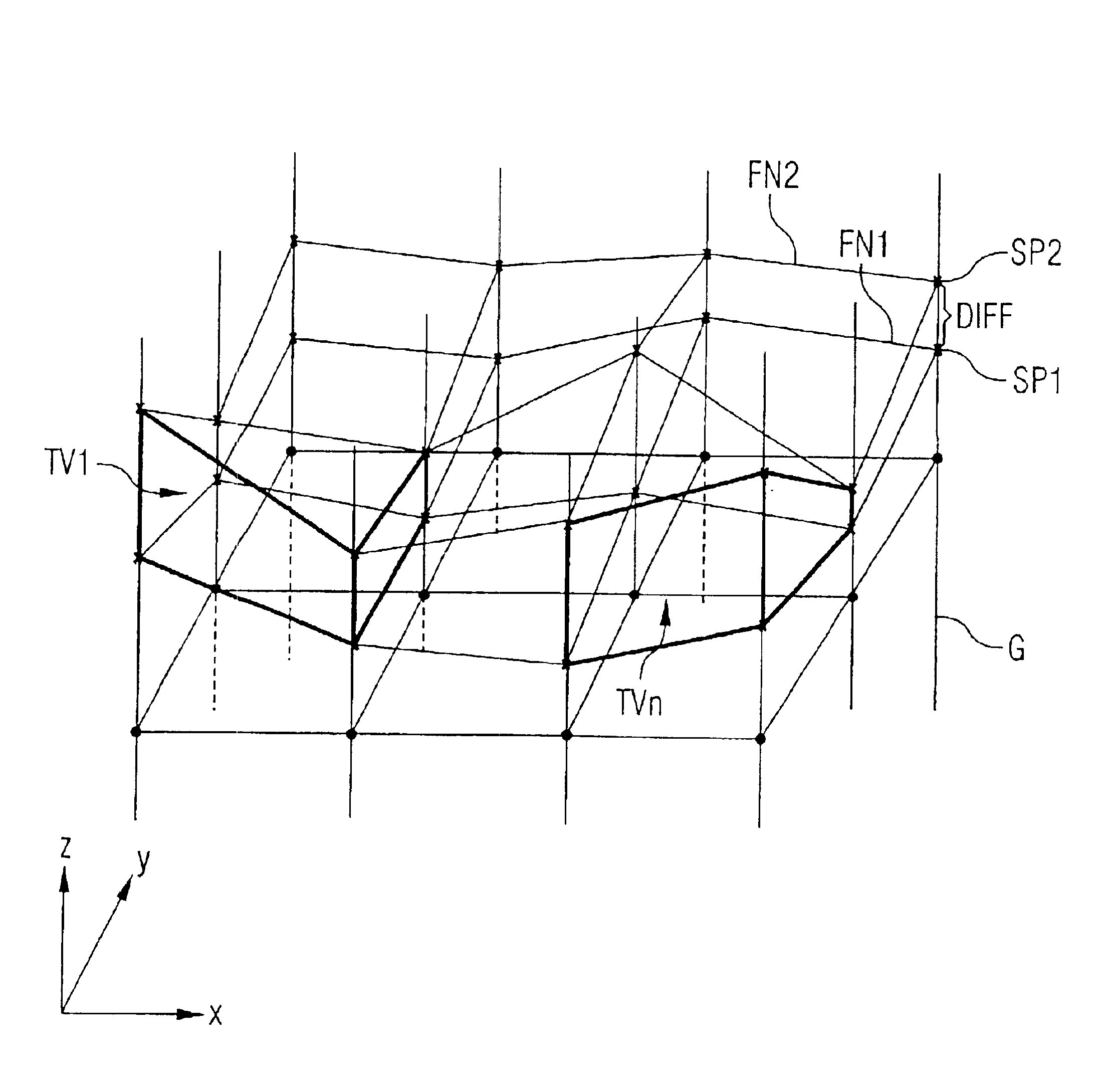

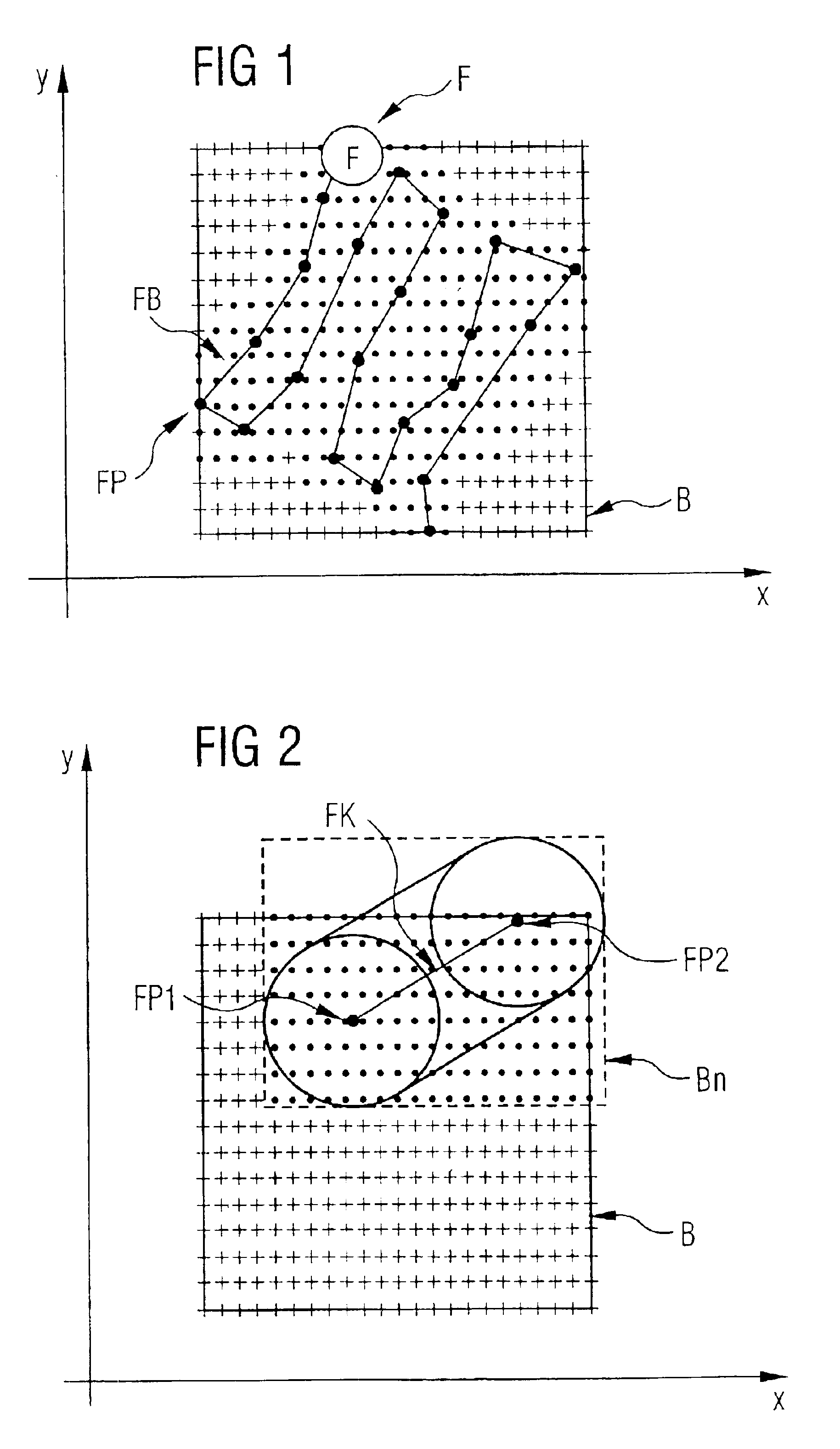

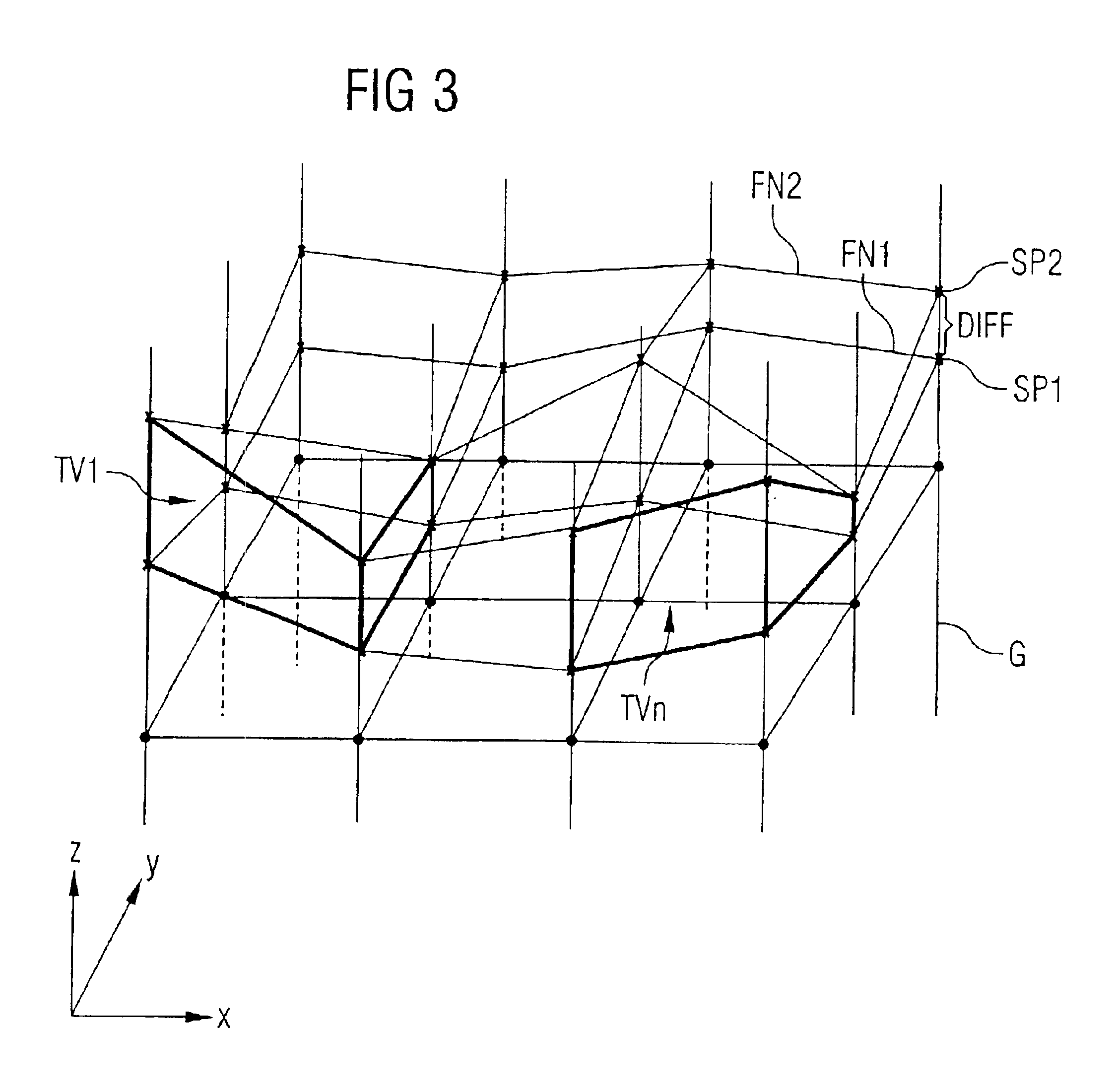

Evaluating excessive tolerances in NC parts programs

In a process for determining when tolerances are exceeded during generation of NC parts programs, the defined CAD geometry is converted into an equivalent grid, preferably a triangular grid. A surface corresponding to the NC parts programs in form of a triangular grid is generated after conversion of the CAD geometry. The parts program takes into consideration the geometric attributes of the milling tool (diameter, shape, etc.). After two triangular grids have been generated from the starting data, i.e. the CAD geometry and the NC parts program, the distance between the two grids can be calculated and visualized.

Owner:SIEMENS AG

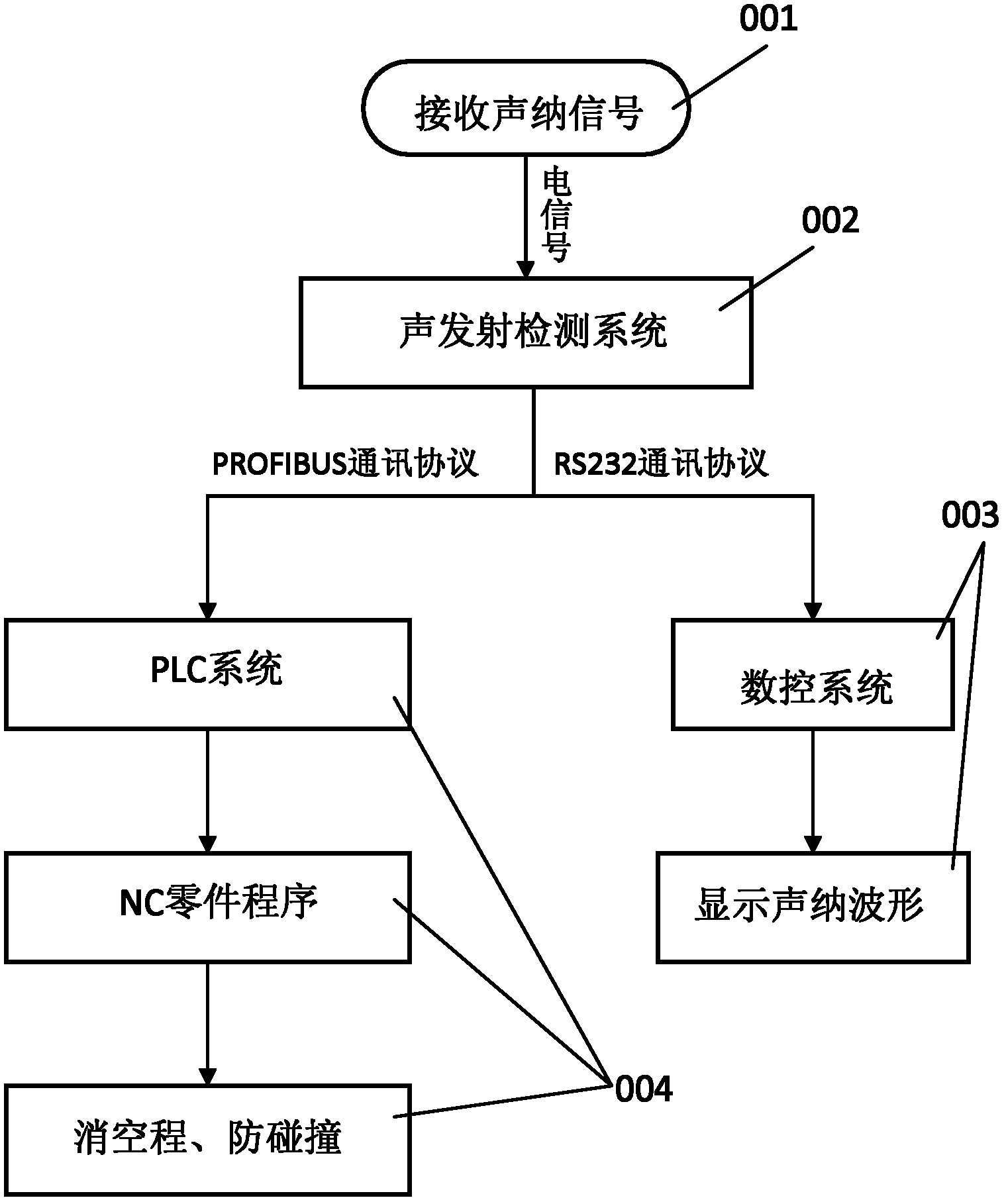

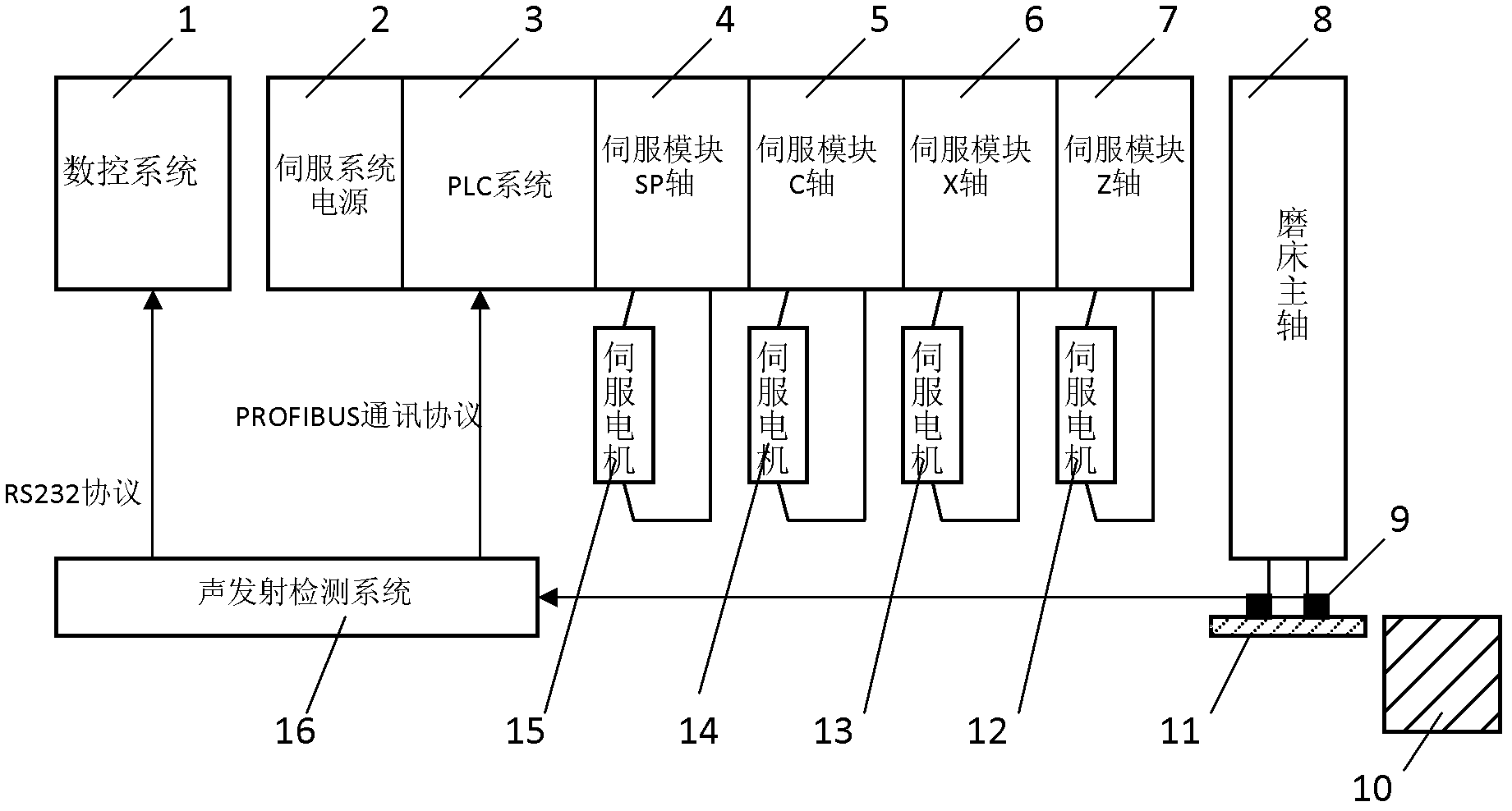

Monitoring method and monitoring system for detecting grinding machine processing status

InactiveCN102275131AMonitor the whole process of processingReal-timeGrinding feed controlSignal onEmbedded system

A monitoring method and a monitoring system for detecting a processing state of a grinding machine are disclosed. A sonar sensor is employed to receive a sonar signal which is sent by a numerical control grinding machine during the processing of a work piece, and then to convert the sonar signal into an electric signal; an acoustic emission detection system is employed to convert the detected electric signal which is output by the sonar sensor into an RS232 communication protocol signal and a PROFIBUS communication protocol signal, respectively; the RS232 communication protocol signal is transmitted to a numerical control system on the grinding machine, and then the numerical control system displays the received RS232 protocol signal on a screen in the form of dynamic waveform, thereby realizing visualization of the grinding process; and the PROFIBUS communication protocol signal is transmitted to a PLC (Programmable Logic Control) system for PLC logic programming, and a collision signal and a contact signal of the grinding machine and the work piece which are output by the PLC system are transmitted to the part program of the numerical control system, thereby realizing collision prevention and idle running elimination. The monitoring method and the monitoring system of the invention are capable of monitoring the whole processing of the numerical control grinding machine, so that the grinding process can be optimized; and the grinding quality and efficiency are improved.

Owner:SHANGHAI SANY PRECISION MACHINERY

System and method for tool use management

The present invention provides a system and method for tool use management wherein a CNC machine retains information identifying the tools associated with the machine as well as their current locations (if any), and executes an algorithm for determining the source tools needed by a part program and matching the source tools with the available tools.

Owner:HURCO

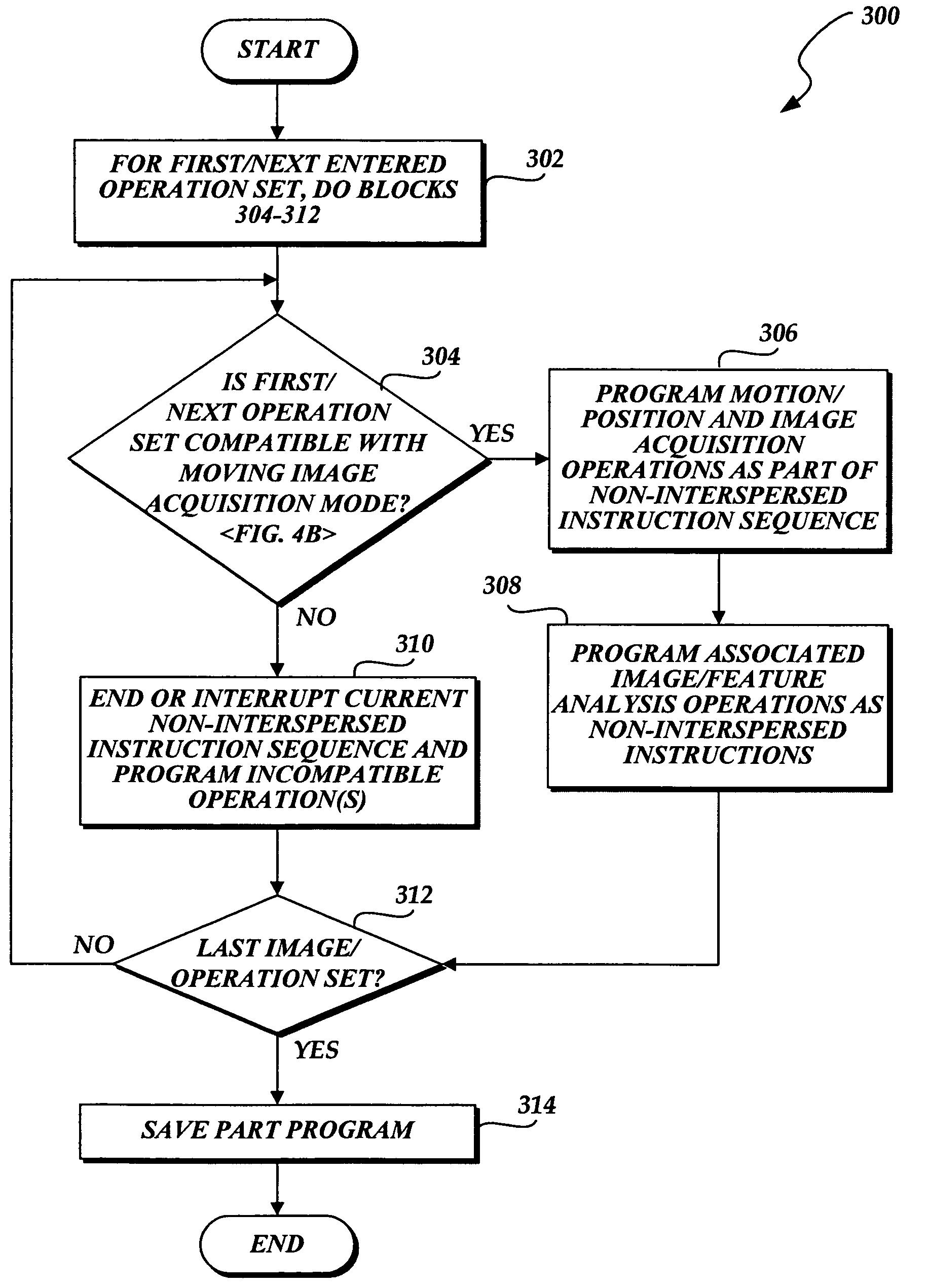

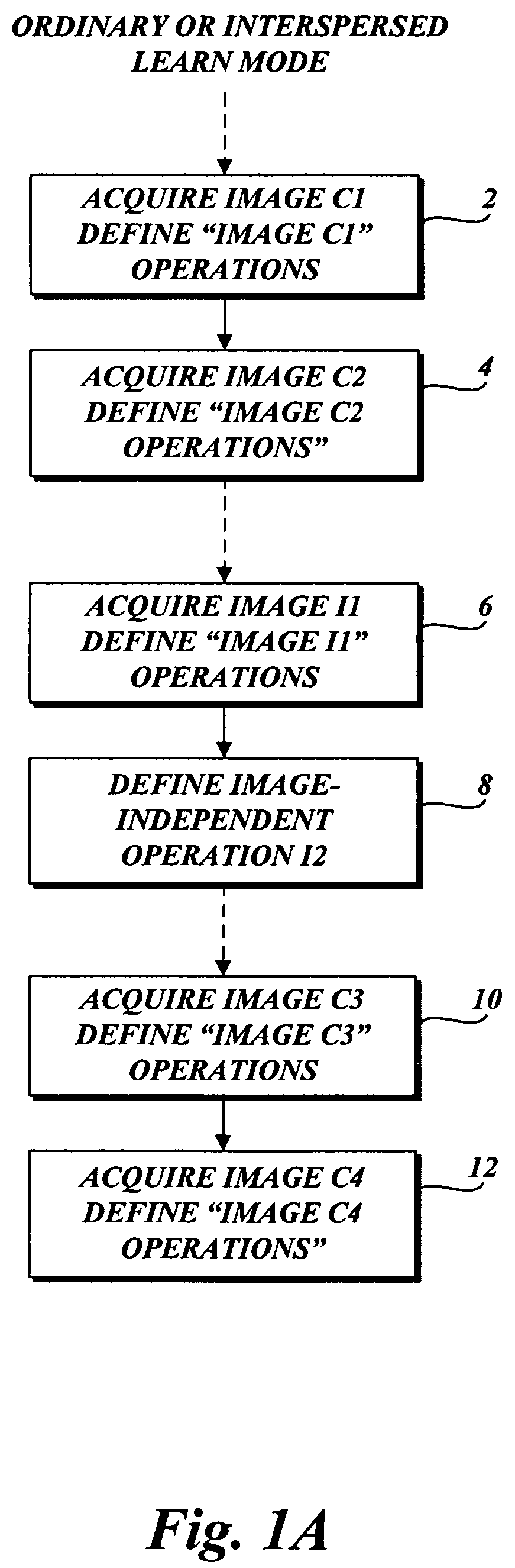

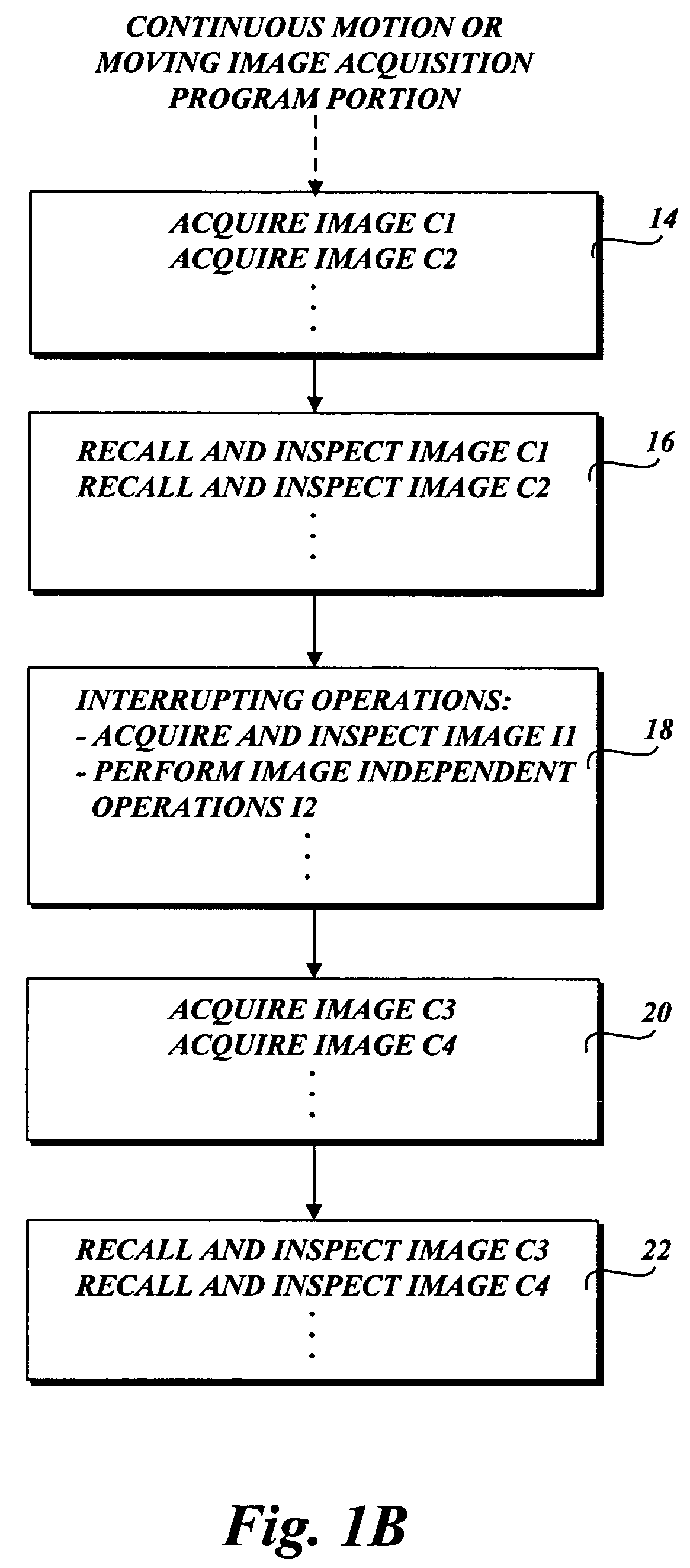

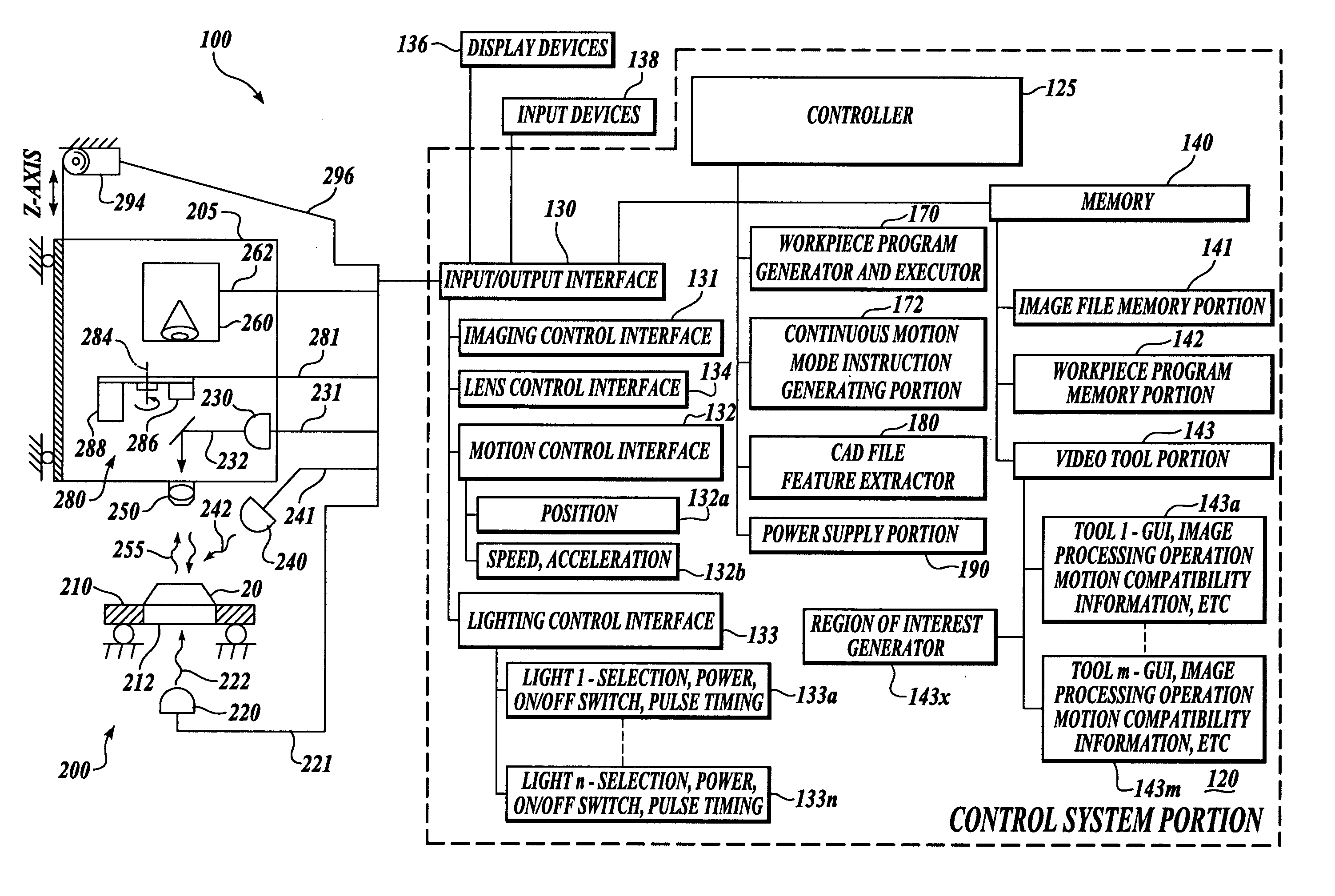

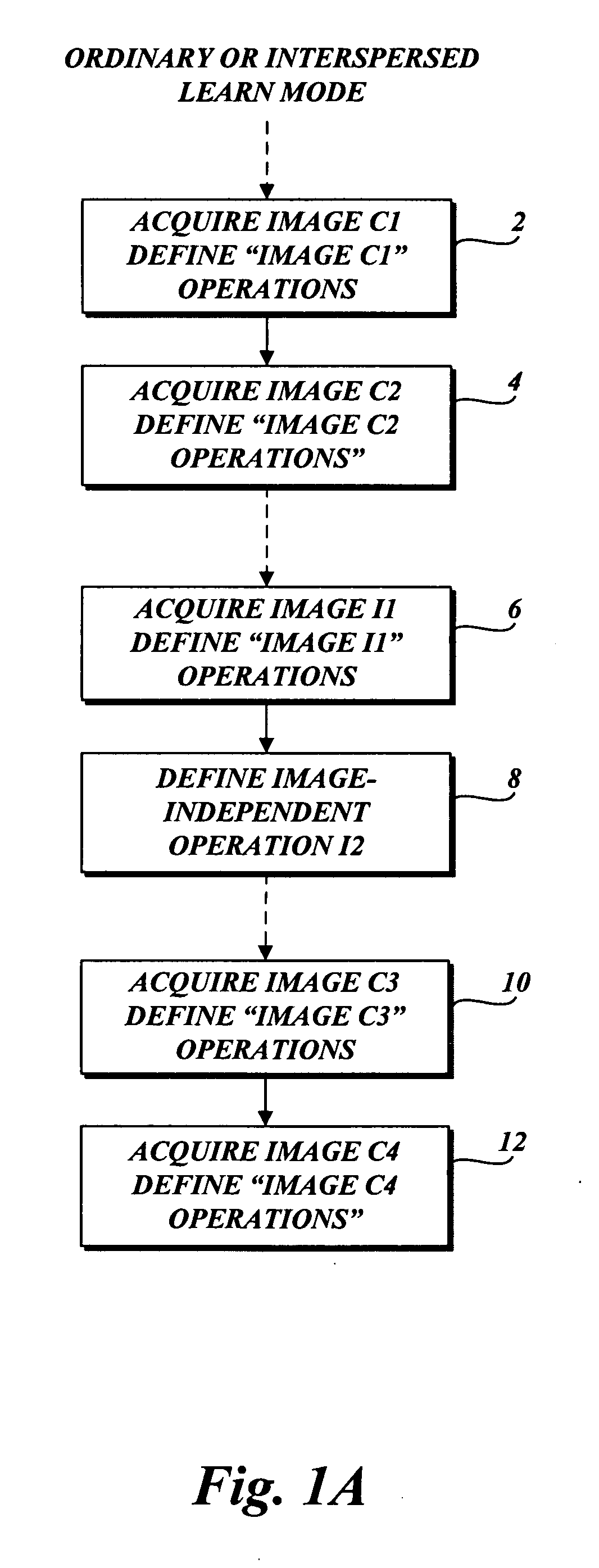

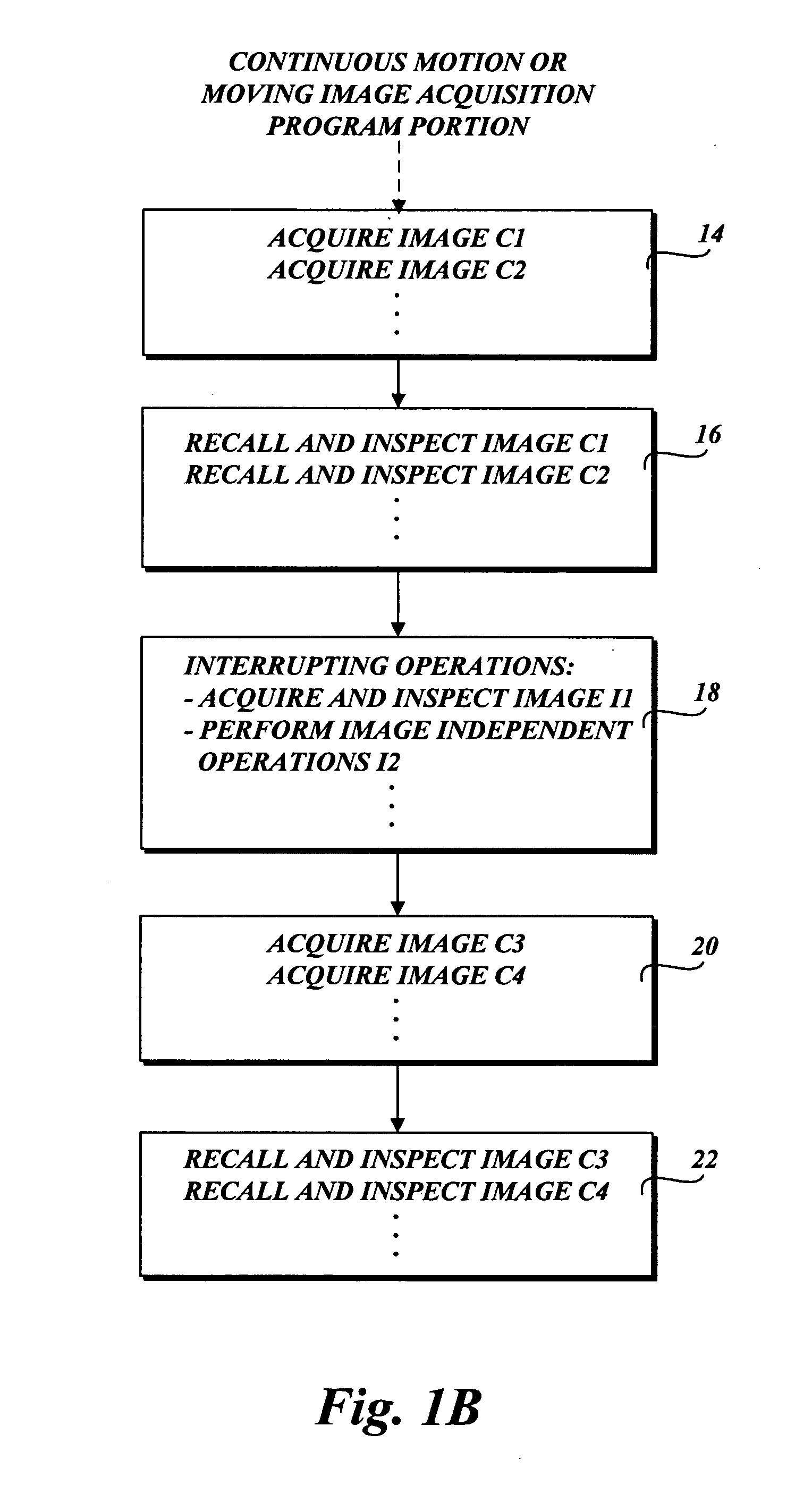

System and method for programming interrupting operations during moving image acquisition sequences in a vision system

ActiveUS7590276B2Facilitate rapid programmingImage enhancementImage analysisMachine visionImaging analysis

Methods and systems of part programming for machine vision inspection systems are provided, which permit a user to readily define multiple image acquisition operations interspersed with associated image analysis and / or inspection operations during learn mode operations and in the resulting part program image acquisition operations for at least some of the images are arranged into a continuous motion image acquisition sequence that acquires images and stores images in a “non-interspersed” manner in order to increase the throughput of the machine vision inspection system. Image analysis / inspection operations associated with the stored images are performed subsequently by recalling the store images. The programming systems and methods disclosed herein may operate automatically to facilitate rapid programming for a variety of workpieces by relatively unskilled users, wherein the resulting programs include continuous motion image acquisition sequences.

Owner:MITUTOYO CORP

Method and apparatus for operating an automated high temperature thermal cutting system

ActiveUS8204618B2Arc welding apparatusSpecial data processing applicationsGraphicsGraphical user interface

A method for setting up a cutting table for an automated high temperature thermal cutting system can include providing a computer-readable product to, for example, a digital signal processor (e.g., CNC). The computer-readable product can include data for at least one part to be cut from a workpiece (e.g., a part program). A user can be prompted to select values from a menu of mandatory operating parameters (e.g., using a graphical user interface) for a shape of the part to be cut from the workpiece. Mandatory operating parameters can include at least one of an operating current, a gas flow, a thickness of the workpiece, or a material of the workpiece.

Owner:HYPERTHERM INC

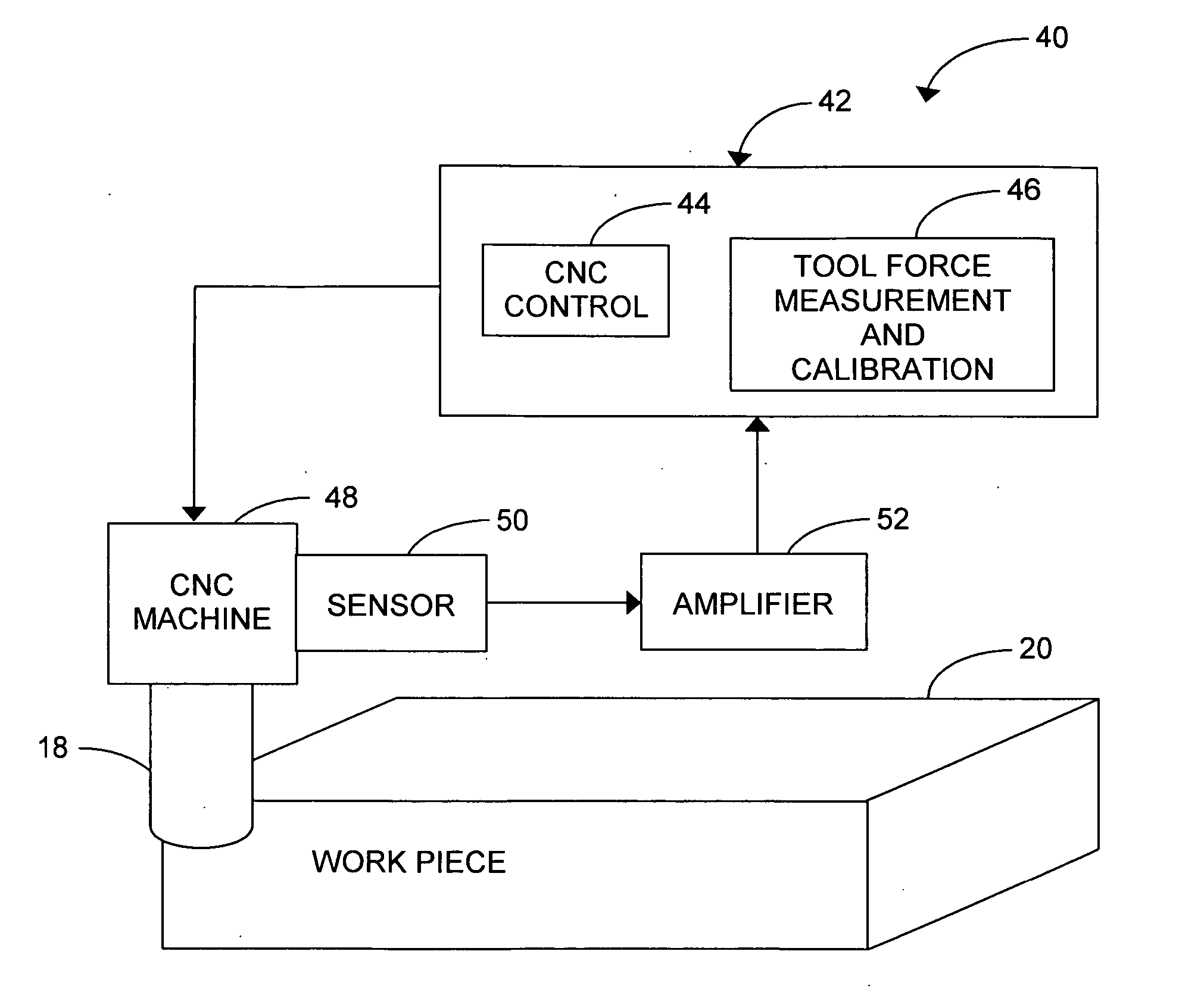

Real-time measurement of tool forces and machining process model parameters

A system and method are provided for real-time measurement of tool forces. A relationship between a motor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The motor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the motor characteristic and tool forces is determined. Thereafter, the motor characteristic of the CNC machine is measured for a desired tool, work piece, and part program and converted to tool forces using the relationship between the motor characteristic and tool forces.

Owner:UNIVERSITY OF NEW HAMPSHIRE +1

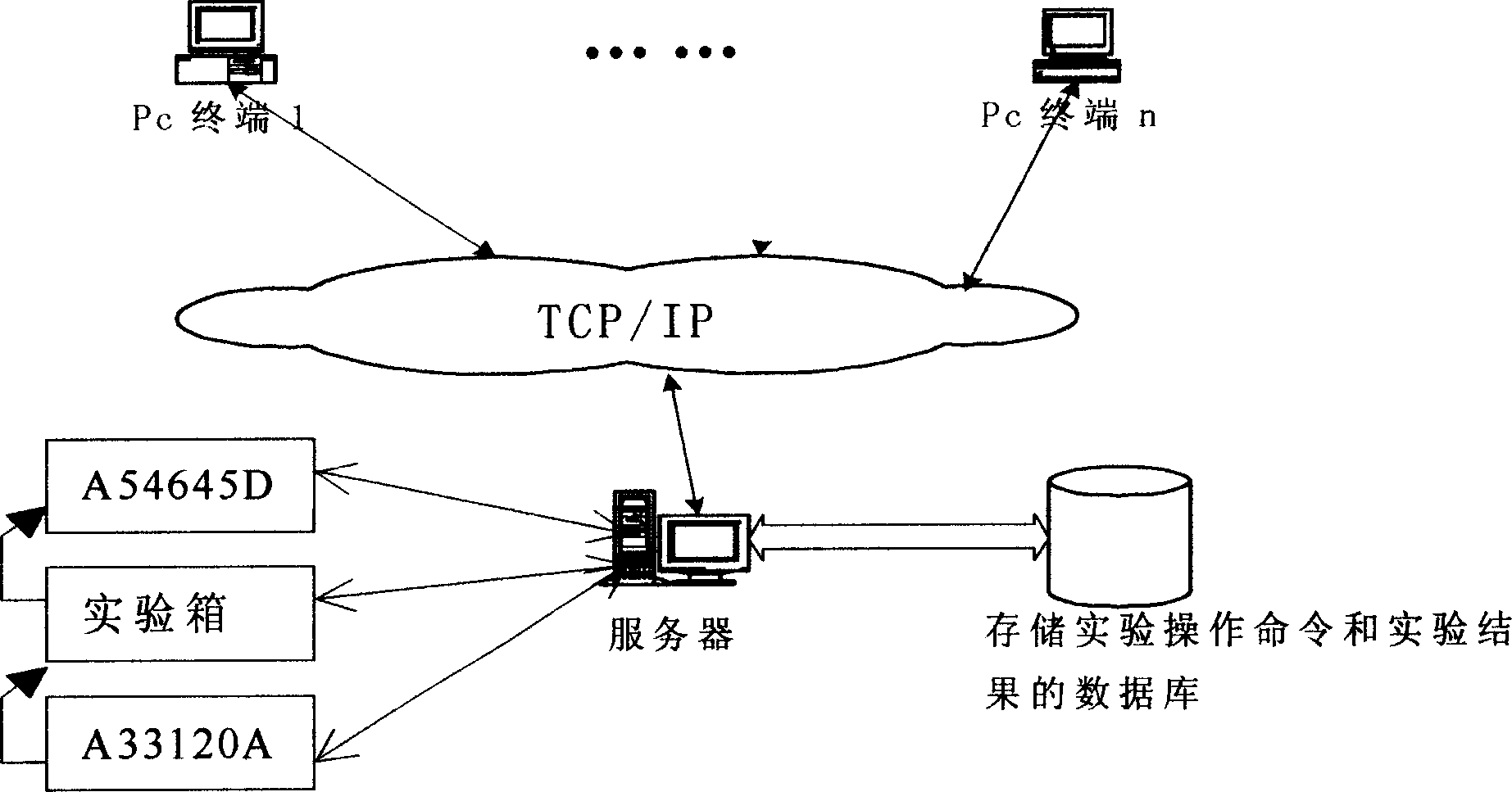

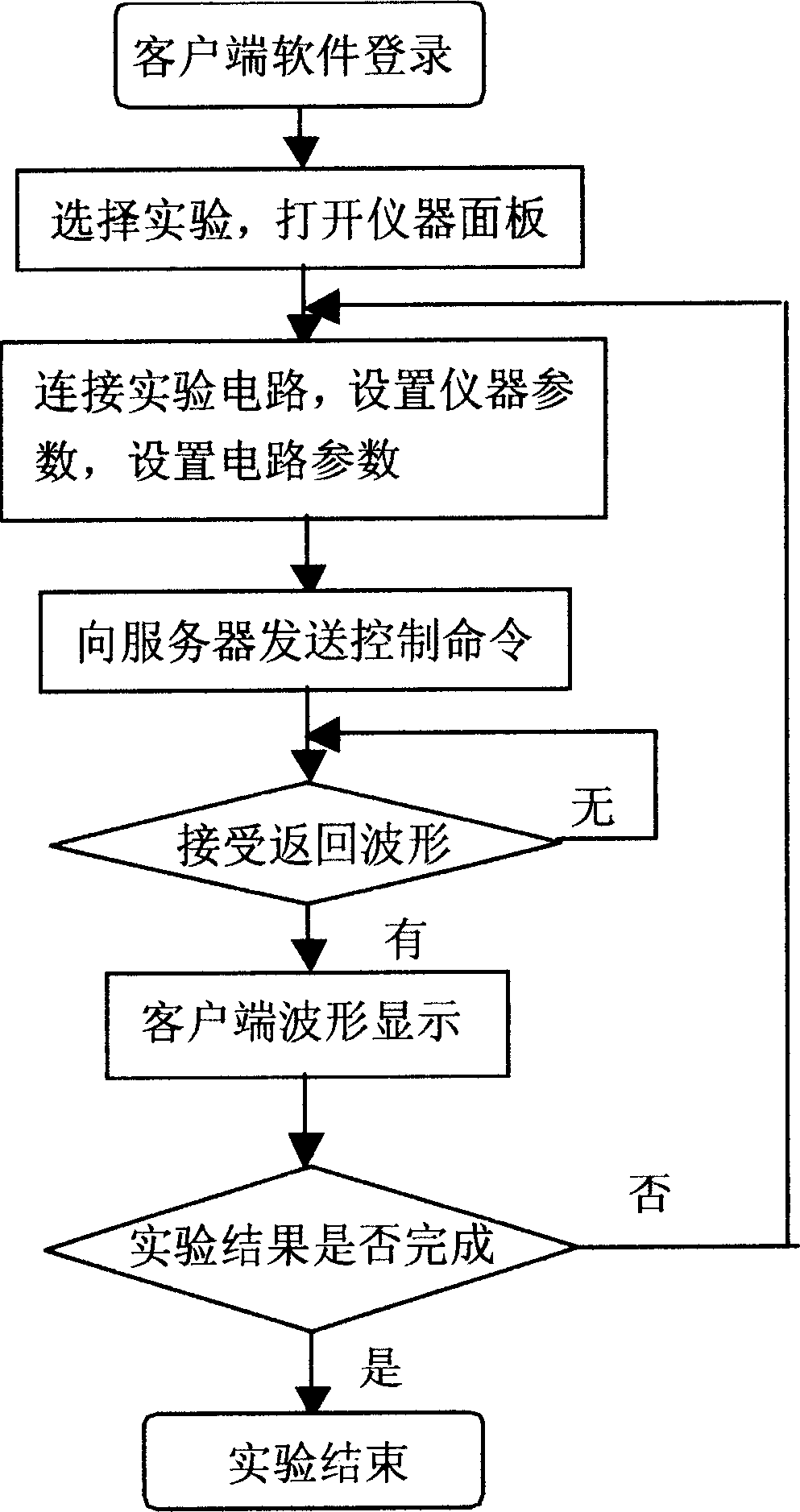

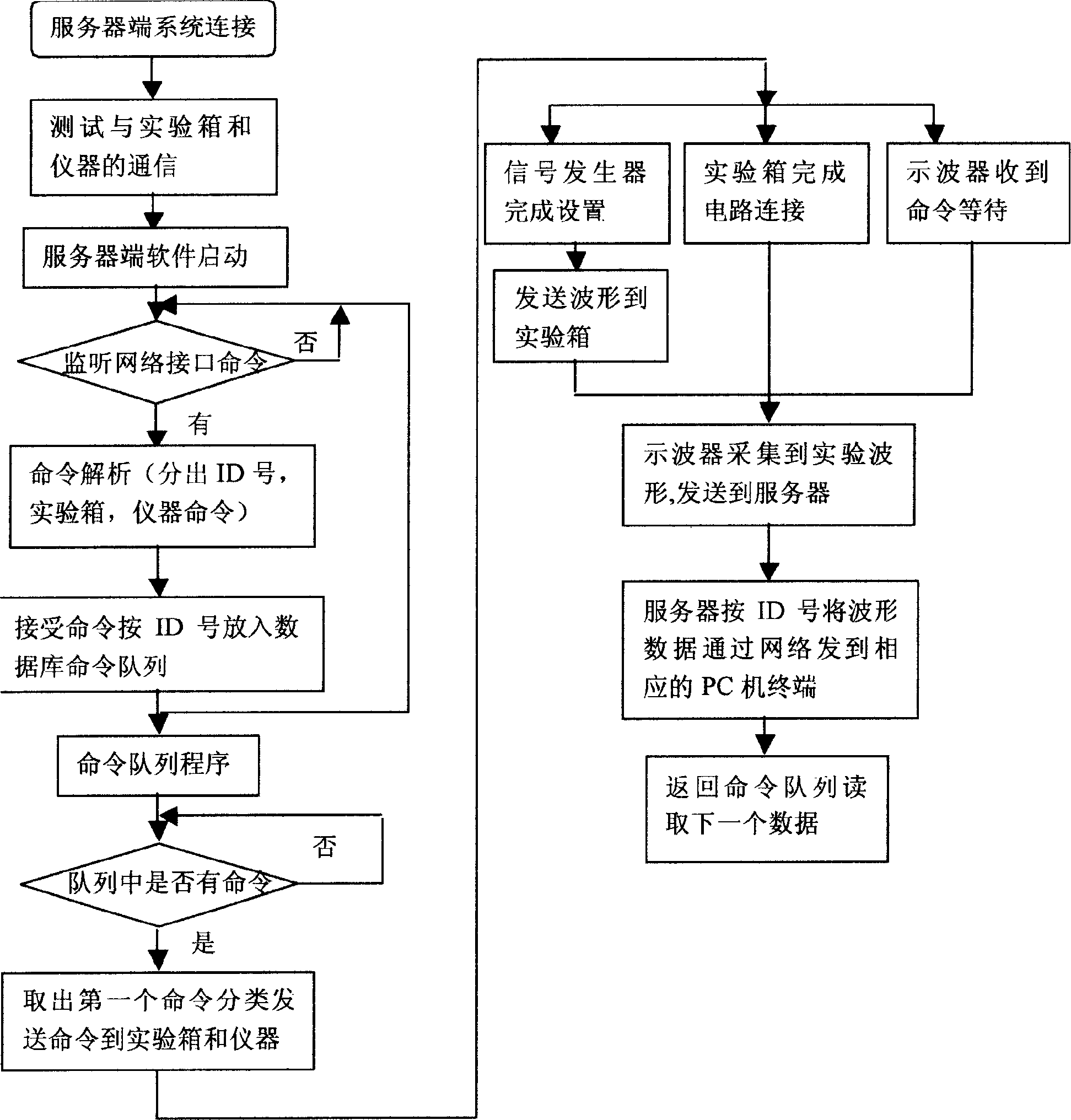

Network-based remote electronic circuit experimental method and system

InactiveCN1804948AIncrease spaceIncrease profitEducational modelsSpecial data processing applicationsExperimental methodsRemote control

The invention relates to a remote electronic circuit experimental approach and system based on network. The client end program device provides the remote operating apparatus, the user interface of the combining experiment circuit and achieves the remote control, control measuring apparatus and circuit; the client end program device comprises a function generator part program device, an oscillation detector part program device and an experiment circuit part program device; the function generator part program device simulates the basic function of the function generator and generates the control order. The oscillation detector part program device simulates the basic function of the oscillation detector and generates the control order. The experiment circuit part program device provides the operating interface of the experiment circuit and finishes the choosing and setting of the circuit; the server program device receives the client end sent control operating order information and stores it in the database.

Owner:BEIJING JIAOTONG UNIV

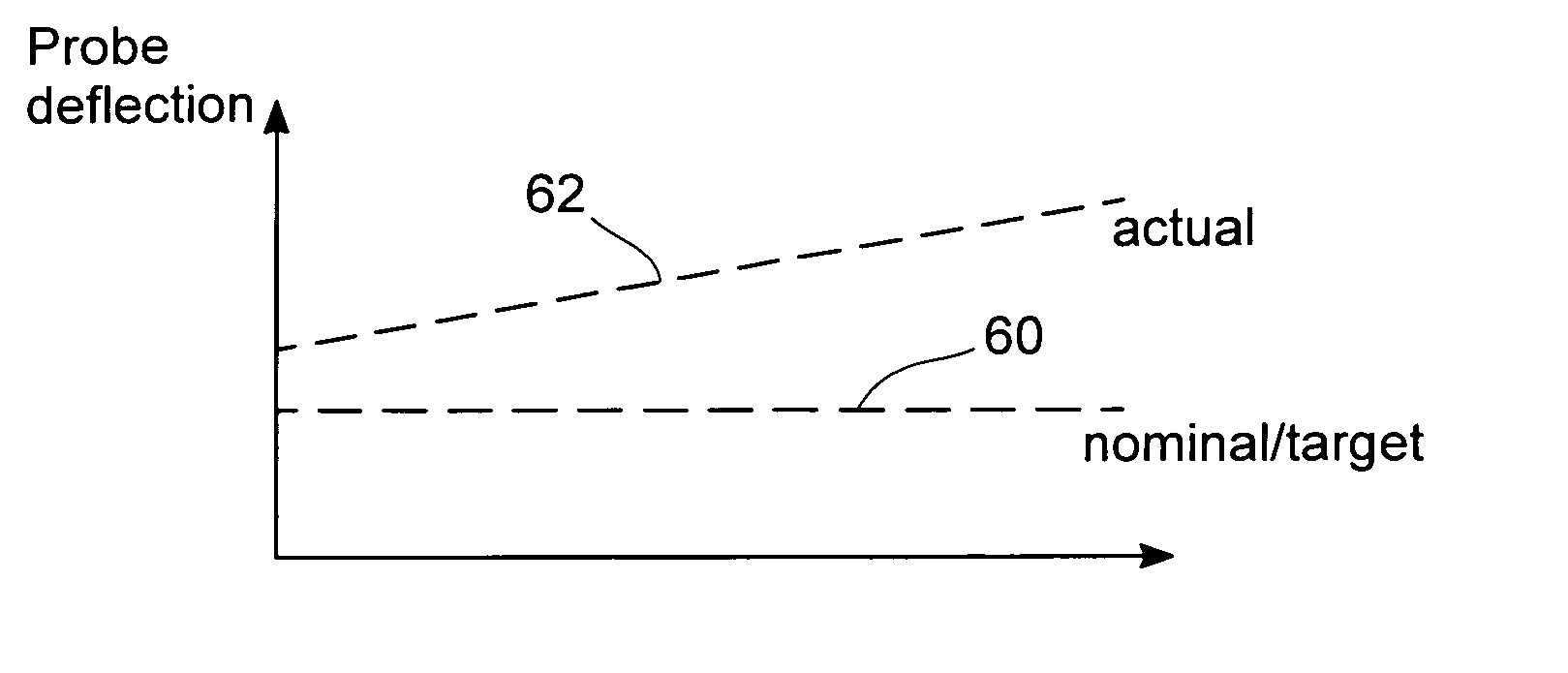

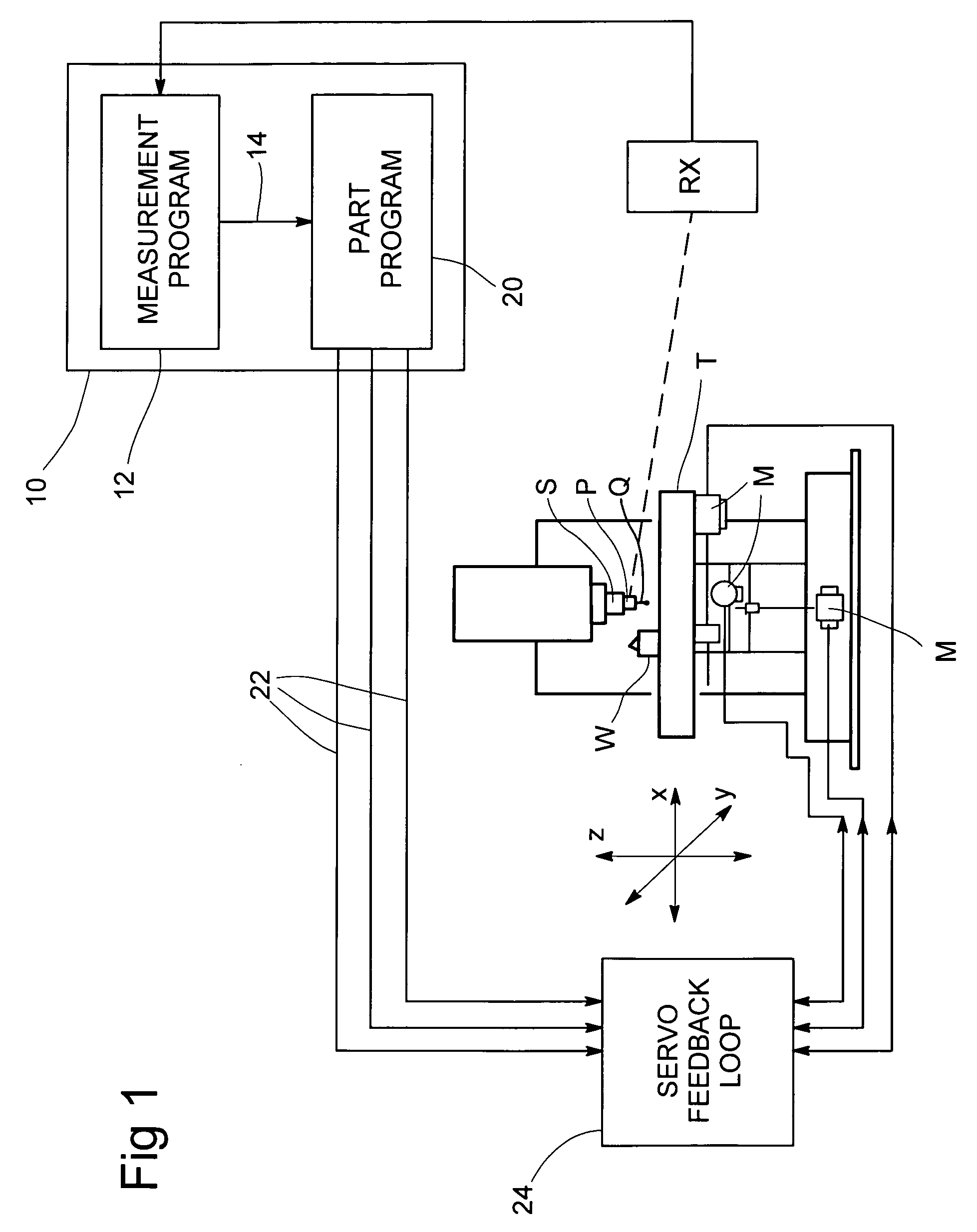

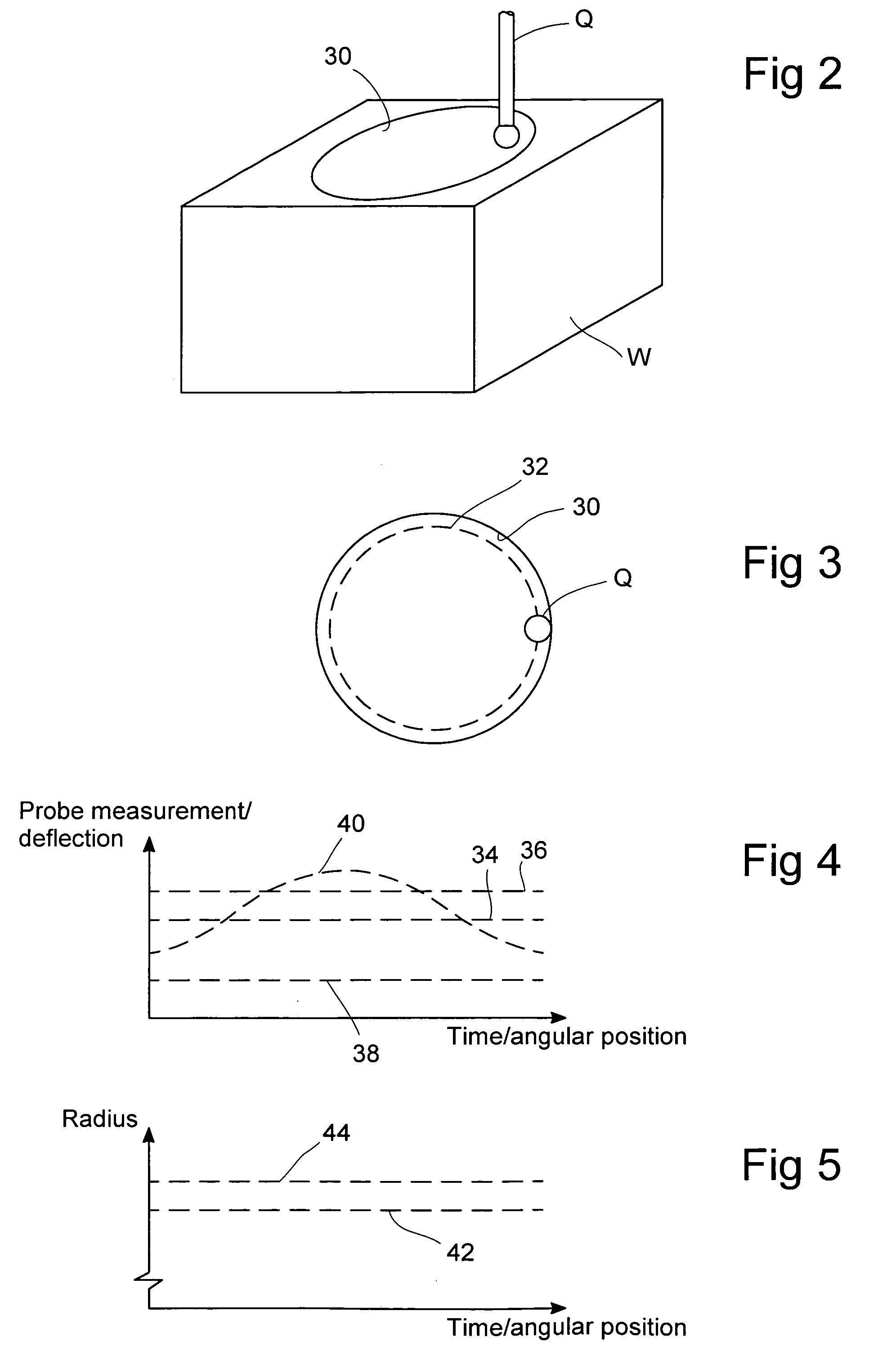

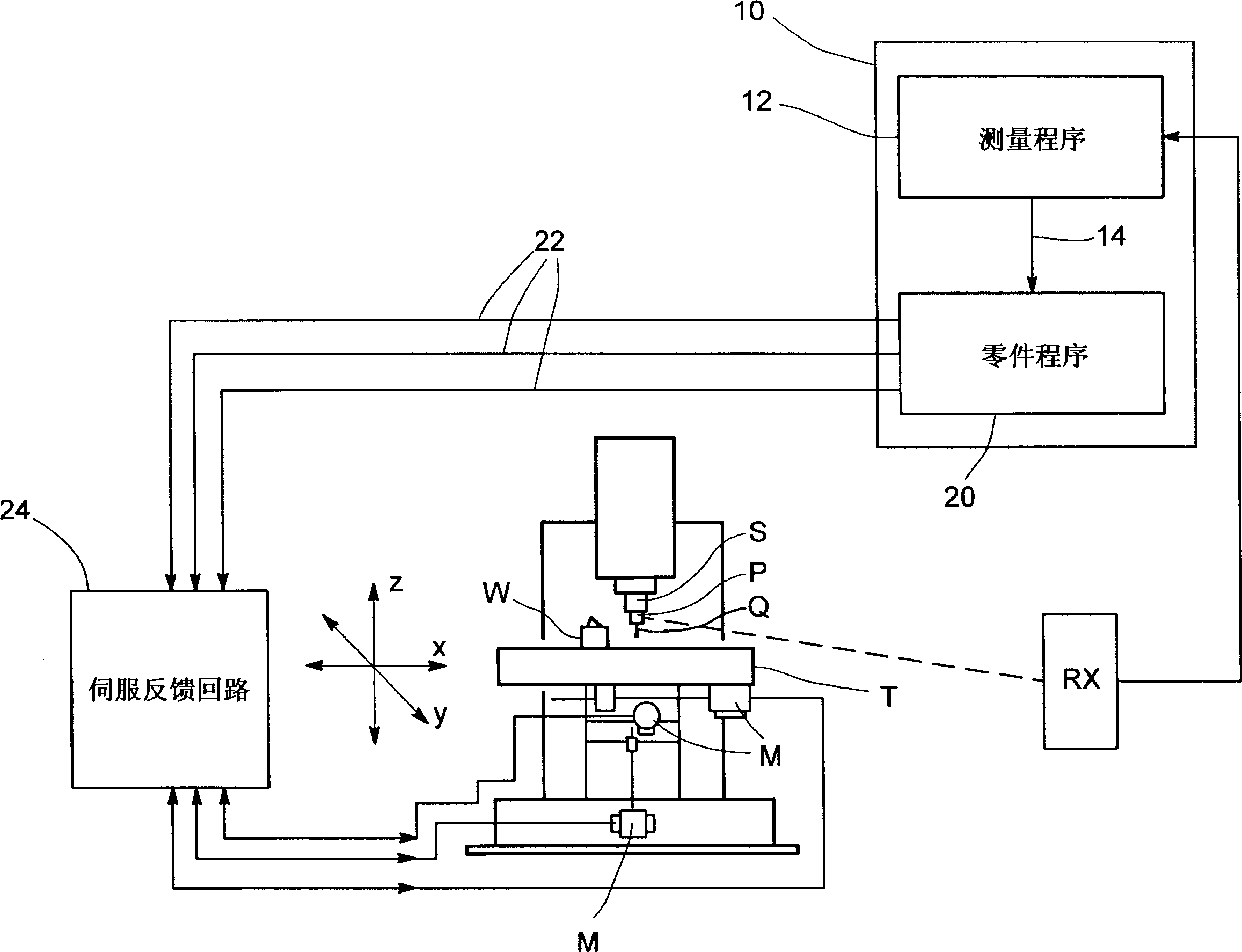

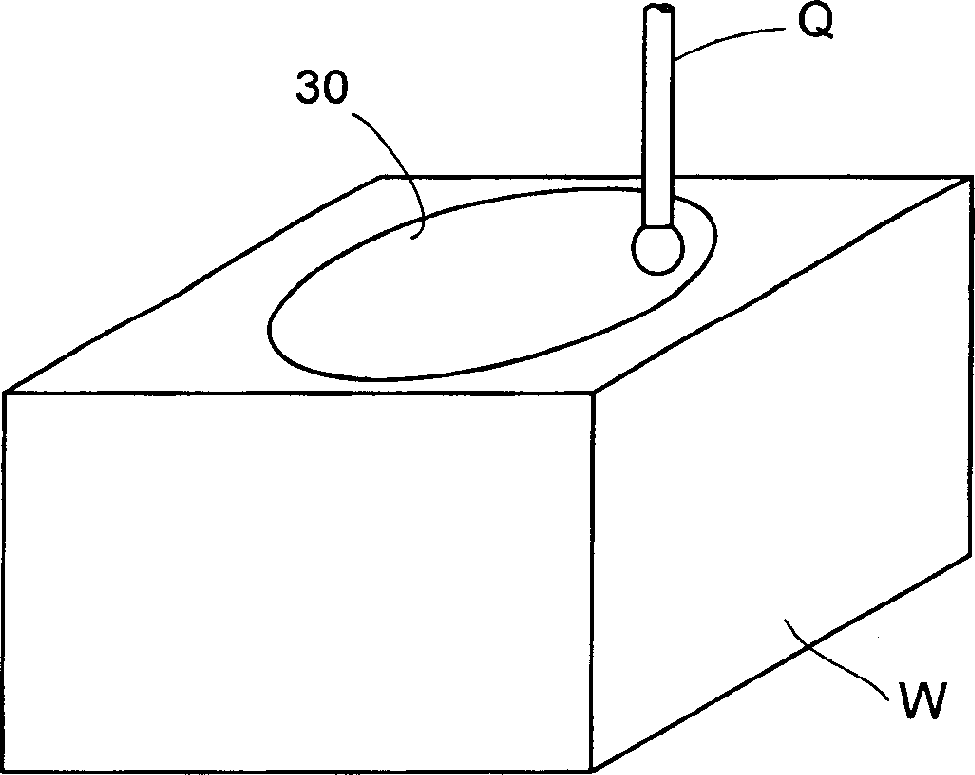

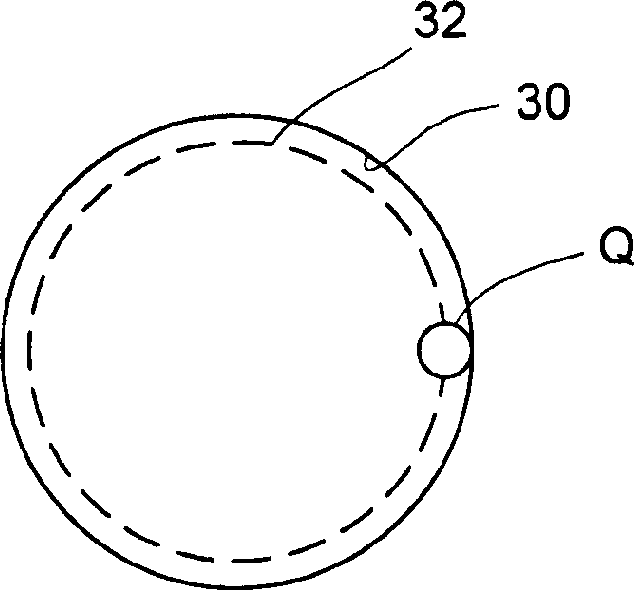

Measuring methods for use on machine tools

ActiveUS7523561B2Mechanical counters/curvatures measurementsWind musical instrumentsEngineeringMachine tool

Owner:RENISHAW PLC

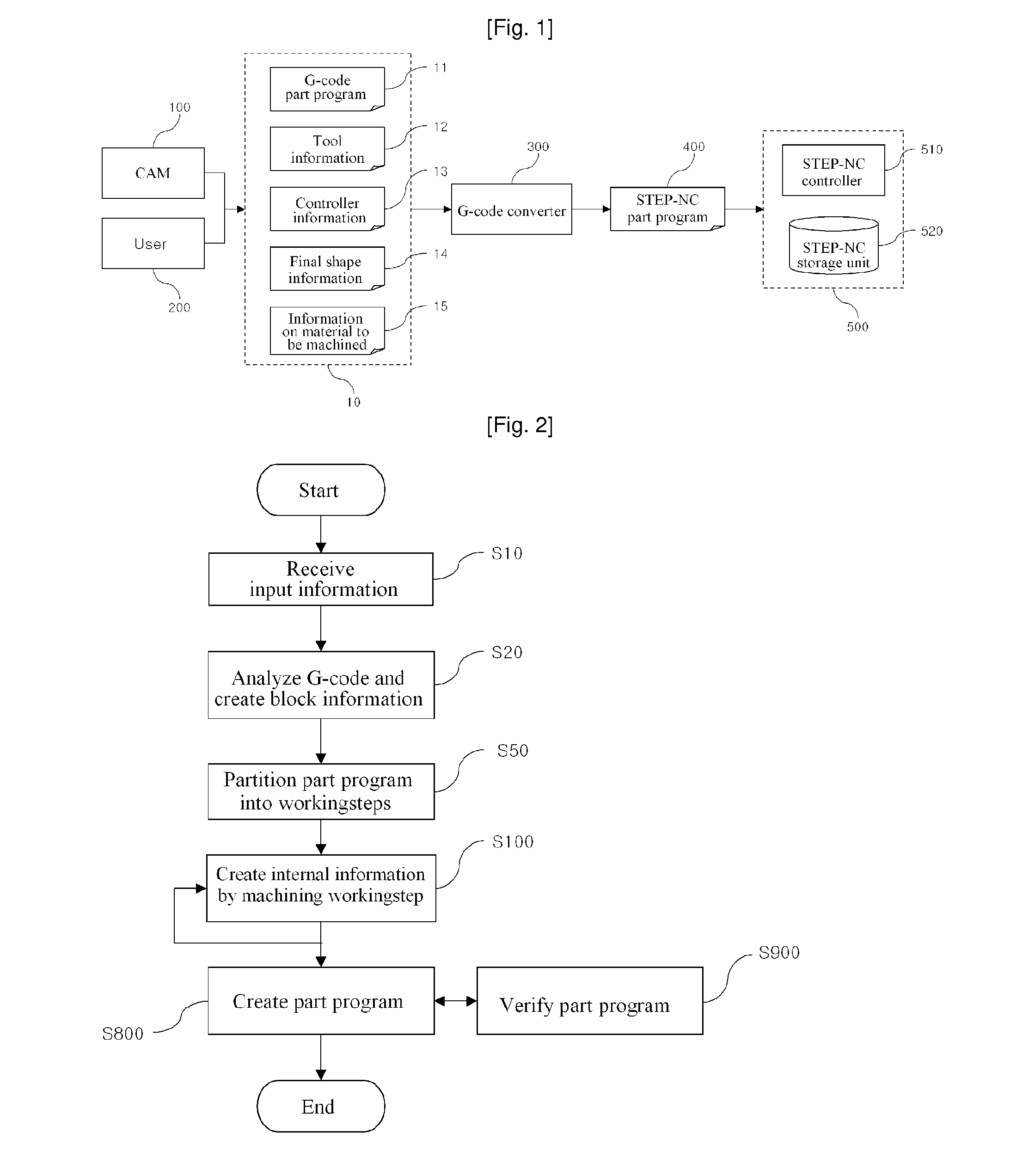

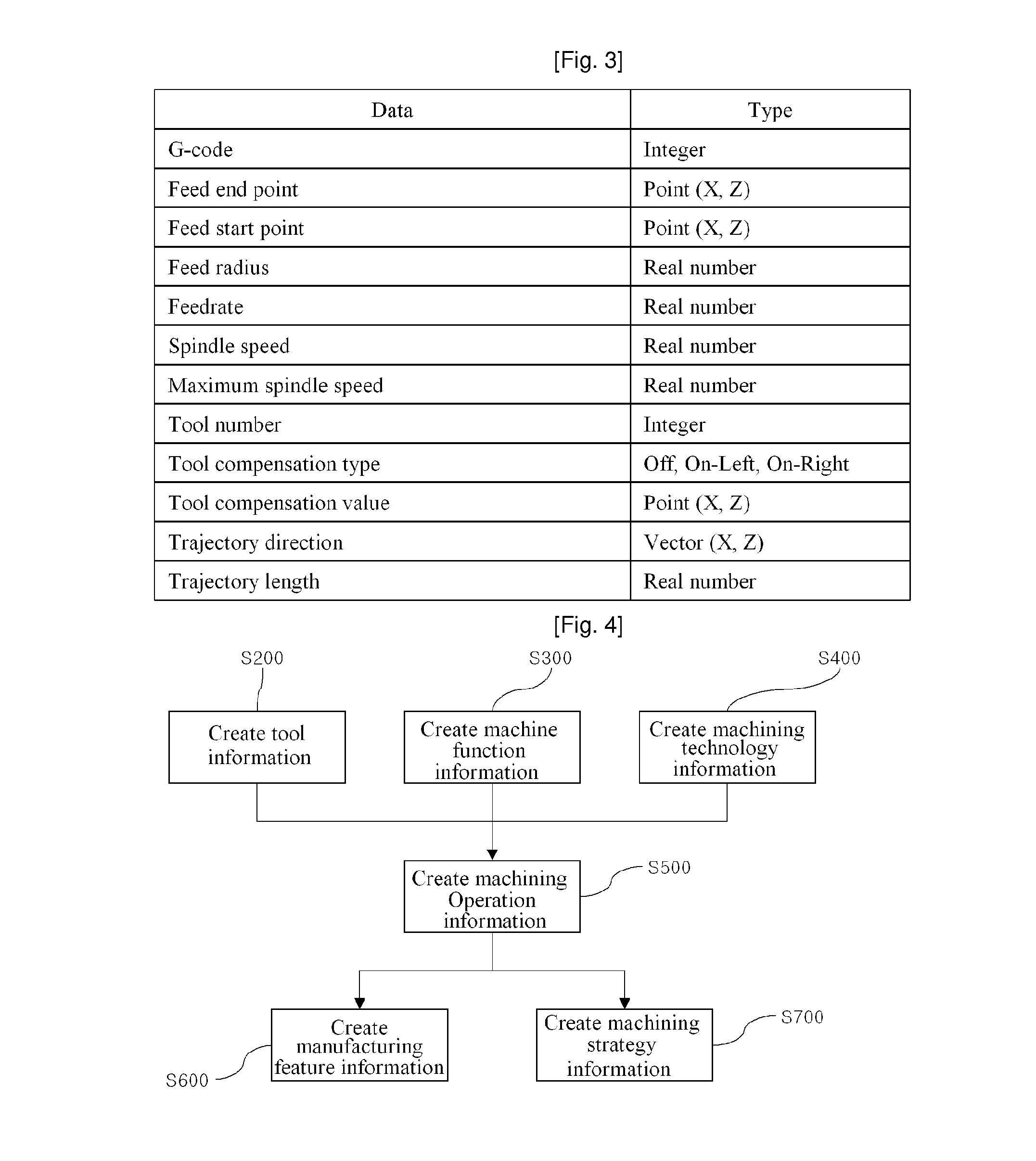

Transformation Method Of G-Code Into Step-Nc Part Program

A method of transforming a G-code type part program into a STEP-NC language type part program is provided and more particularly, a method is provided for enabling a G-code type part program mainly used in the field to be easily applied to a STEP-NC controller without a troublesome correction. A STEP-NC language type part program is automatically created, which is composed of machining operation information, manufacturing feature information, machining strategy information and the like, through a process of analyzing G-codes from the G-code type part program and tool information. A method of transforming a G-code into a STEP-NC part program includes receiving a G-code part program, tools and a numerical controller; creating G-code block information, and partitioning the entire part program on a workingstep basis. The method further includes creating machining strategy information and creating the STEP-NC part program by arranging the machining workingsteps.

Owner:POSTECH ACAD IND FOUND

Sensor-based measurement of tool forces and machining process model parameters

InactiveUS7536237B2Inexpensive but accurate monitoringAddressing Diversity InsufficiencyProgramme controlForce measurementSacrificial partModel parameters

A system and method are provided for real-time measurement of tool forces. A relationship between a sensor characteristic and tool forces is determined by directly measuring tool forces for a standard tool, work piece, and part program. The sensor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program, providing a relationship between the sensor characteristic at the user facility and tool forces. If the sensor is not conveniently attached to the work piece or the part program is not sufficiently robust in cutting conditions, the work piece and part program are replaced by a sacrificial work piece and sacrificial part program. The sacrificial work piece and sacrificial part program are selected to accommodate the sensors and to provide sufficient robustness in cutting conditions to accurately determine the process model parameters for the sacrificial work piece.

Owner:UNIVERSITY OF NEW HAMPSHIRE

Measuring methods for use on machine tools

Owner:RENISHAW PLC

System and method for programming interrupting operations during moving image acquisition sequences in a vision system

ActiveUS20060133663A1Facilitate rapid programmingImage enhancementImage analysisMachine visionImaging analysis

Methods and systems of part programming for machine vision inspection systems are provided, which permit a user to readily define multiple image acquisition operations interspersed with associated image analysis and / or inspection operations during learn mode operations and in the resulting part program image acquisition operations for at least some of the images are arranged into a continuous motion image acquisition sequence that acquires images and stores images in a “non-interspersed” manner in order to increase the throughput of the machine vision inspection system. Image analysis / inspection operations associated with the stored images are performed subsequently by recalling the store images. The programming systems and methods disclosed herein may operate automatically to facilitate rapid programming for a variety of workpieces by relatively unskilled users, wherein the resulting programs include continuous motion image acquisition sequences.

Owner:MITUTOYO CORP

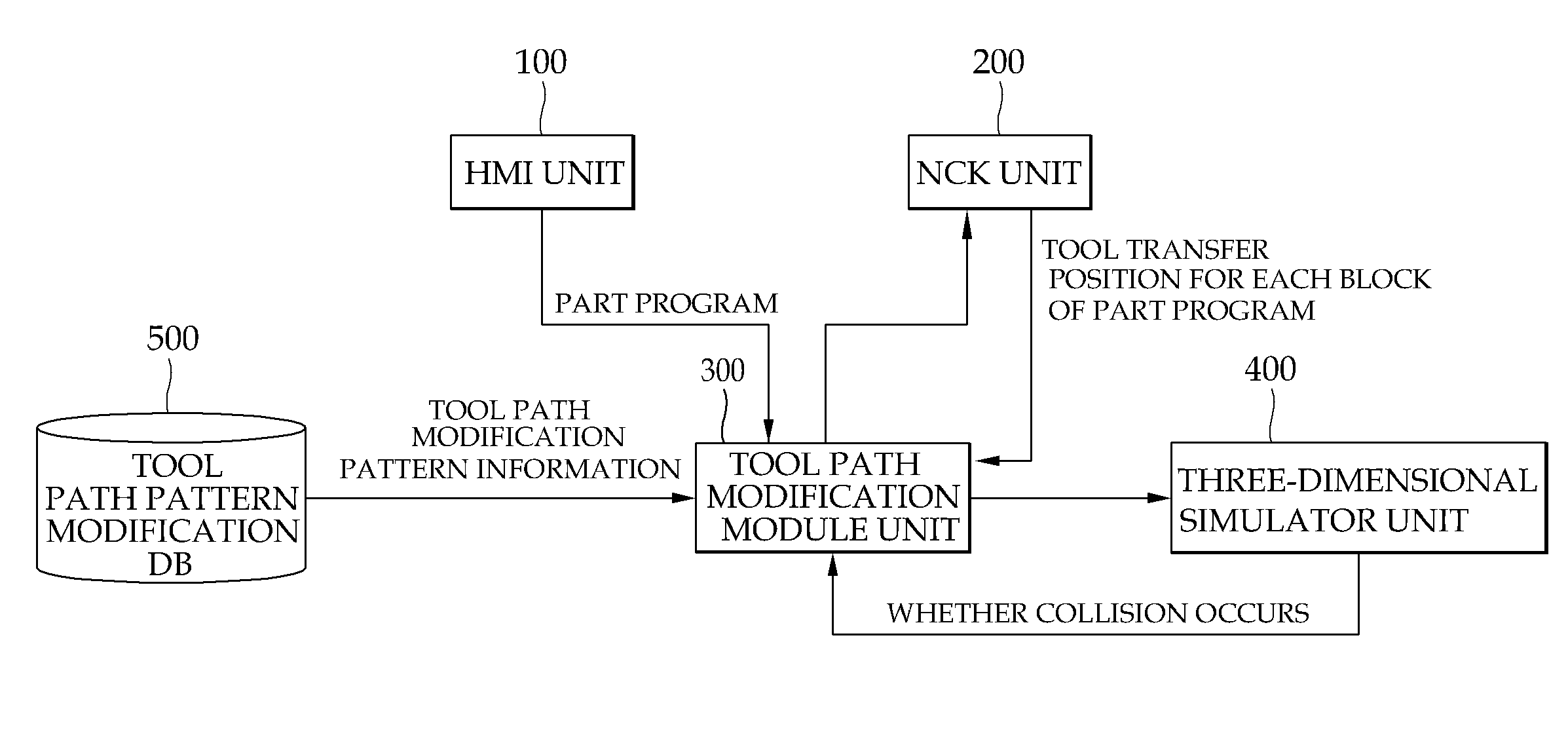

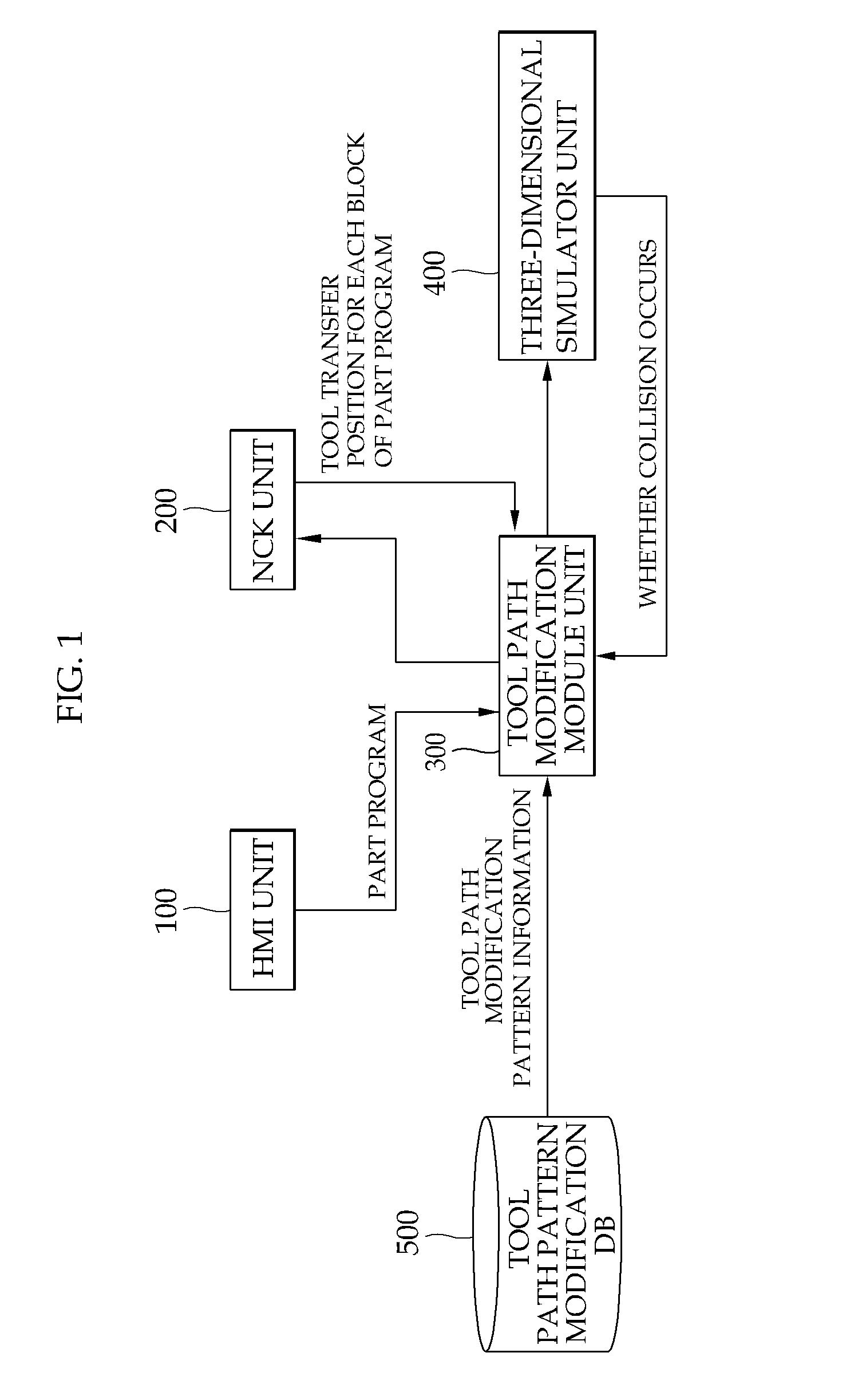

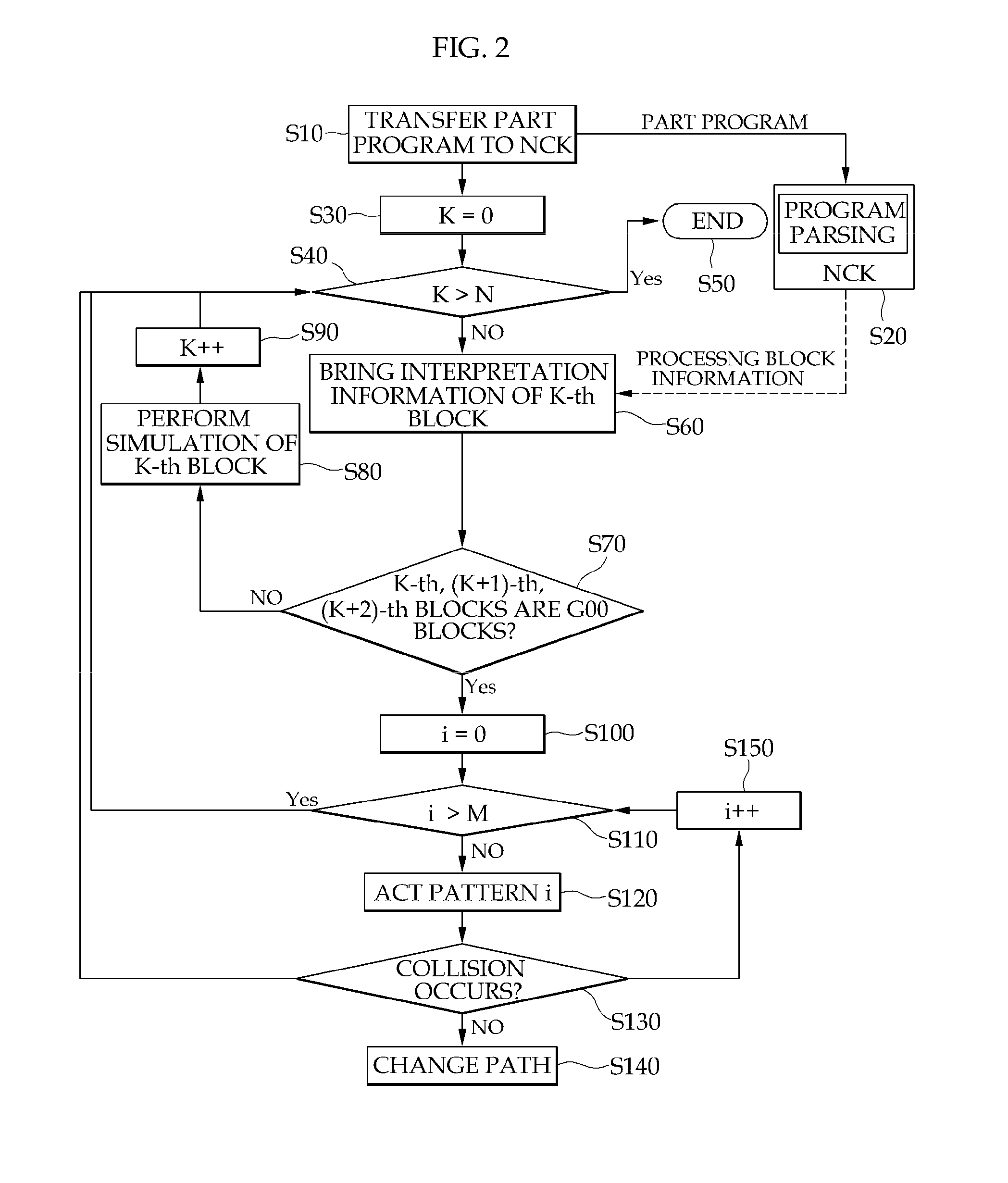

Tool path part program modification system of NC machine tool

ActiveUS20130253694A1Reduce processing timeReduce transfer timeProgramme controlComputer aided designNumerical controlParallel computing

A tool path part program modification system of an NC machine tool according to an aspect of the present disclosure, includes: an HMI unit which receives a tool path part program having one or more processing blocks which automate and perform tool paths for processing a work piece by using tools of the NC machine tool; an NC kernel unit which interprets the part program inputted to the HMI unit for each processing block, and generates each processing block information; a tool path modification module unit which sequentially calls the processing block information interpreted by the NC kernel unit, and modifies a consecutive rapid transfer processing block group such that tool paths are reduced and collision between the tool and the work piece does not occur, when the consecutive rapid transfer processing block group is present in which the predetermined reference number or more of processing blocks including rapid transfer commands are consecutively included; and a simulator unit which simulates the part program for each processing block interpreted by the NC kernel unit.

Owner:DN SOLUTIONS CO LTD

Real-time measurement of tool forces and machining process model parameters

A system and method are provided for real-time measurement of tool forces. A relationship between a motor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The motor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the motor characteristic and tool forces is determined. Thereafter, the motor characteristic of the CNC machine is measured for a desired tool, work piece, and part program and converted to tool forces using the relationship between the motor characteristic and tool forces.

Owner:UNIVERSITY OF NEW HAMPSHIRE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com