Patents

Literature

230 results about "User Facility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

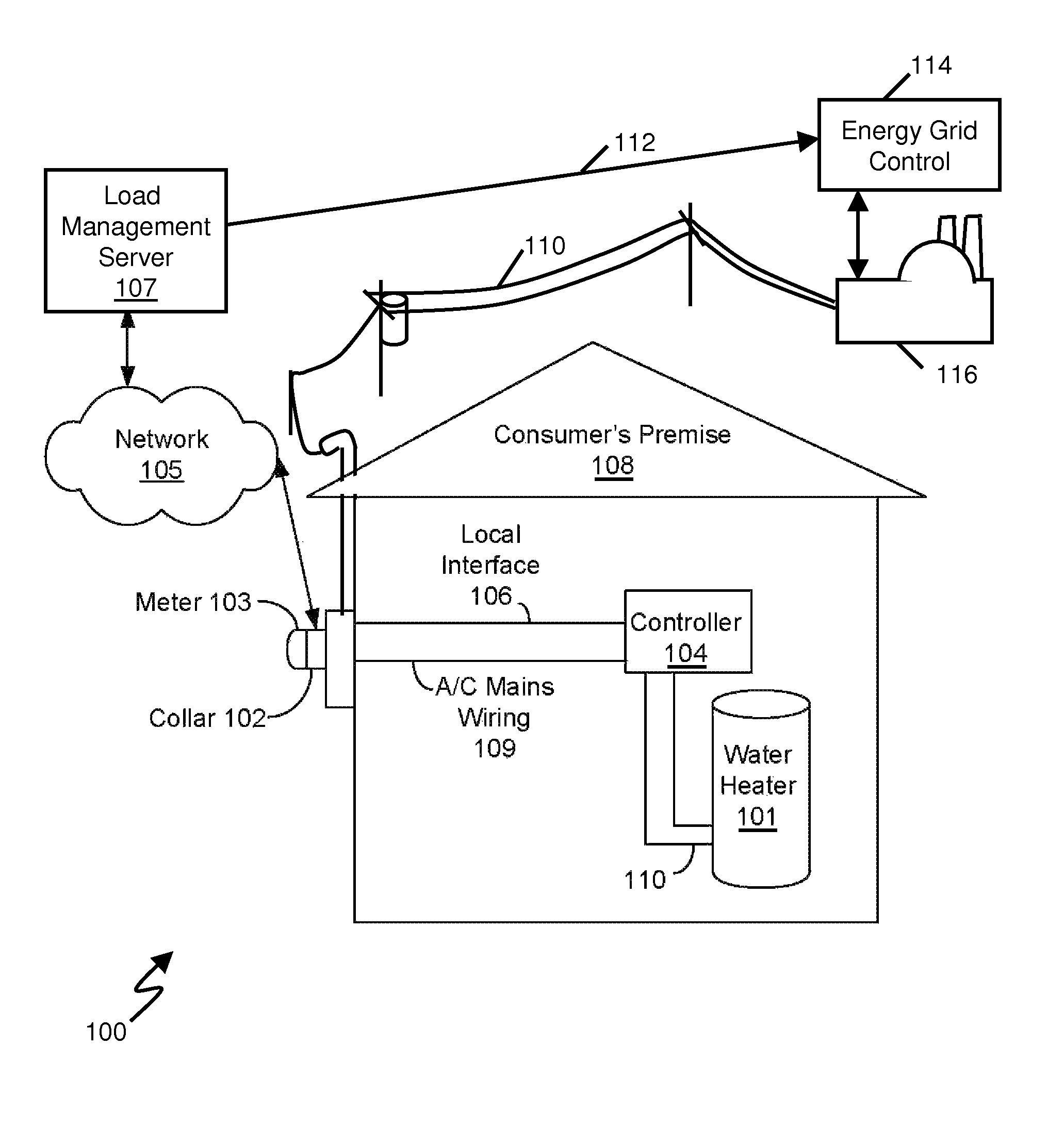

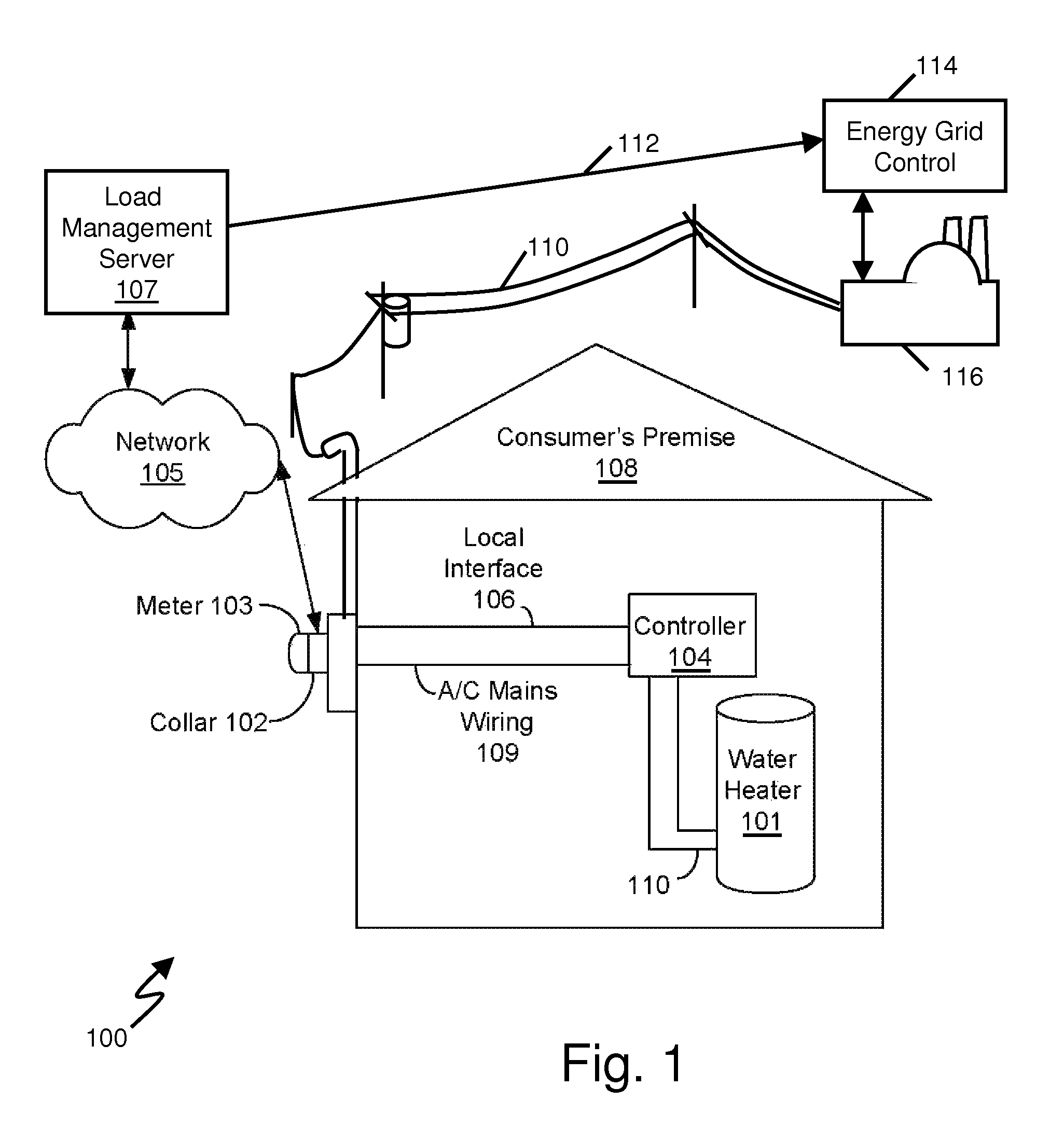

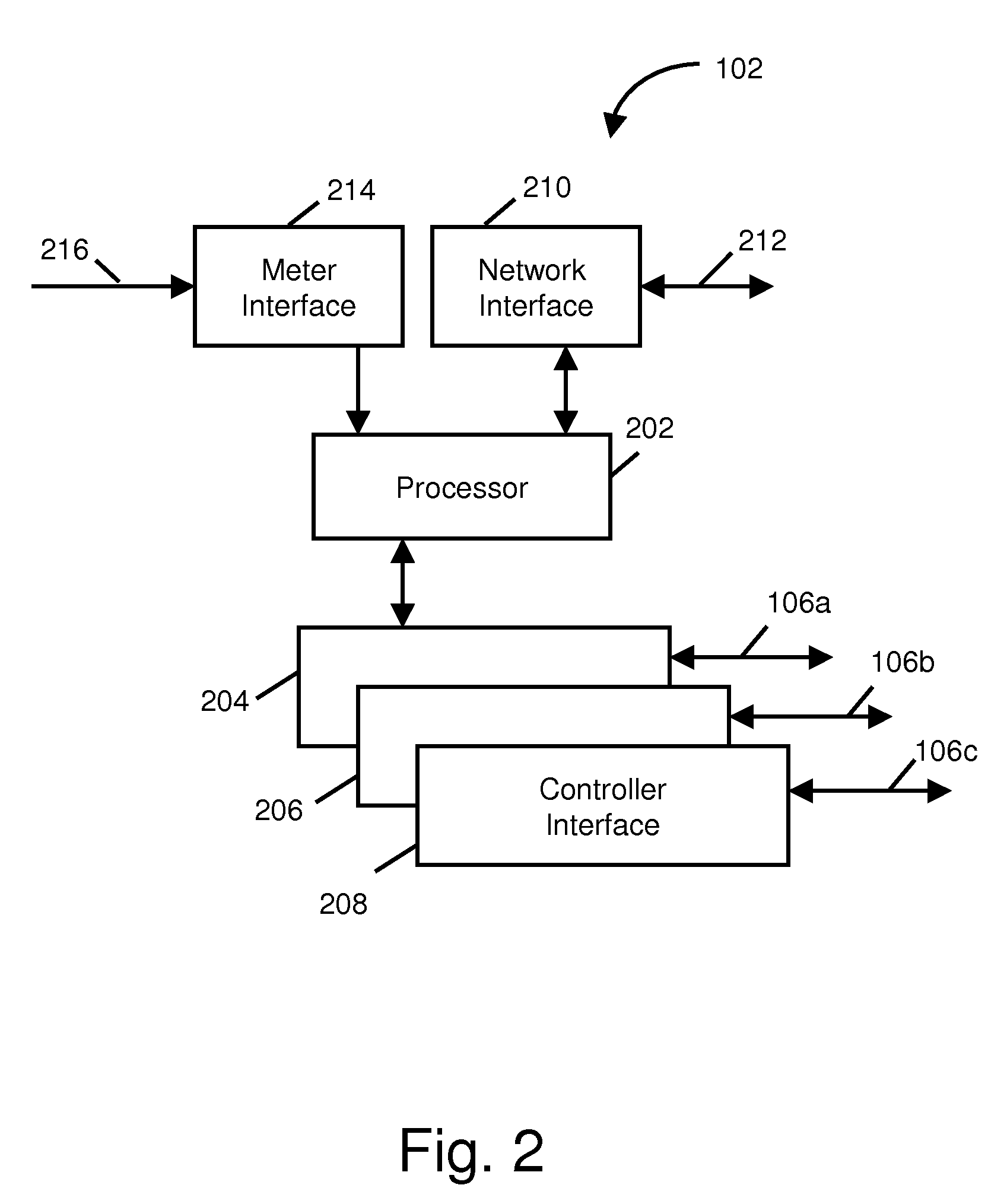

Water Heater Demand Side Management System

ActiveUS20100004790A1Reduce network trafficLevel controlVolume/mass flow measurementQuality of serviceEngineering

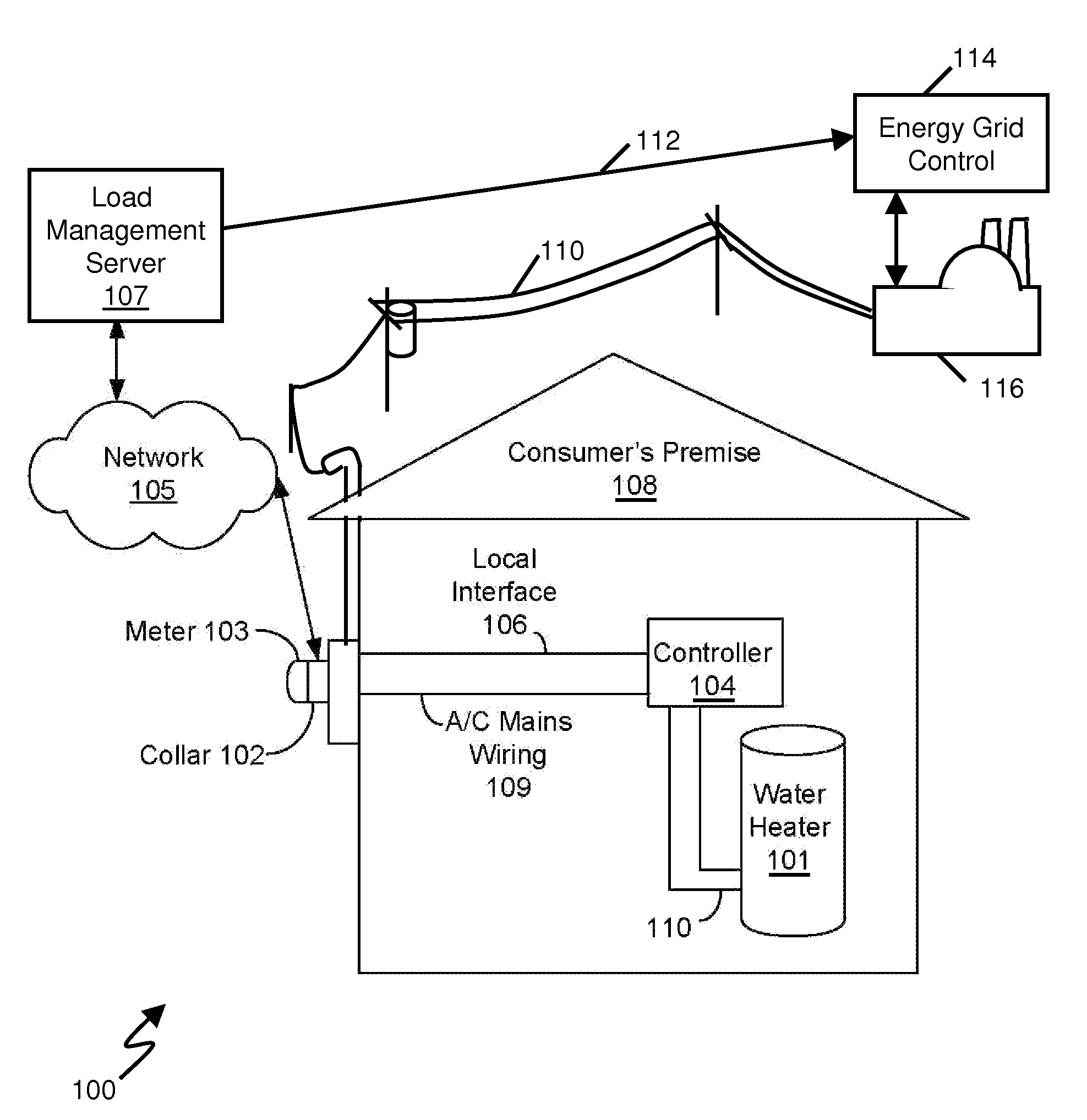

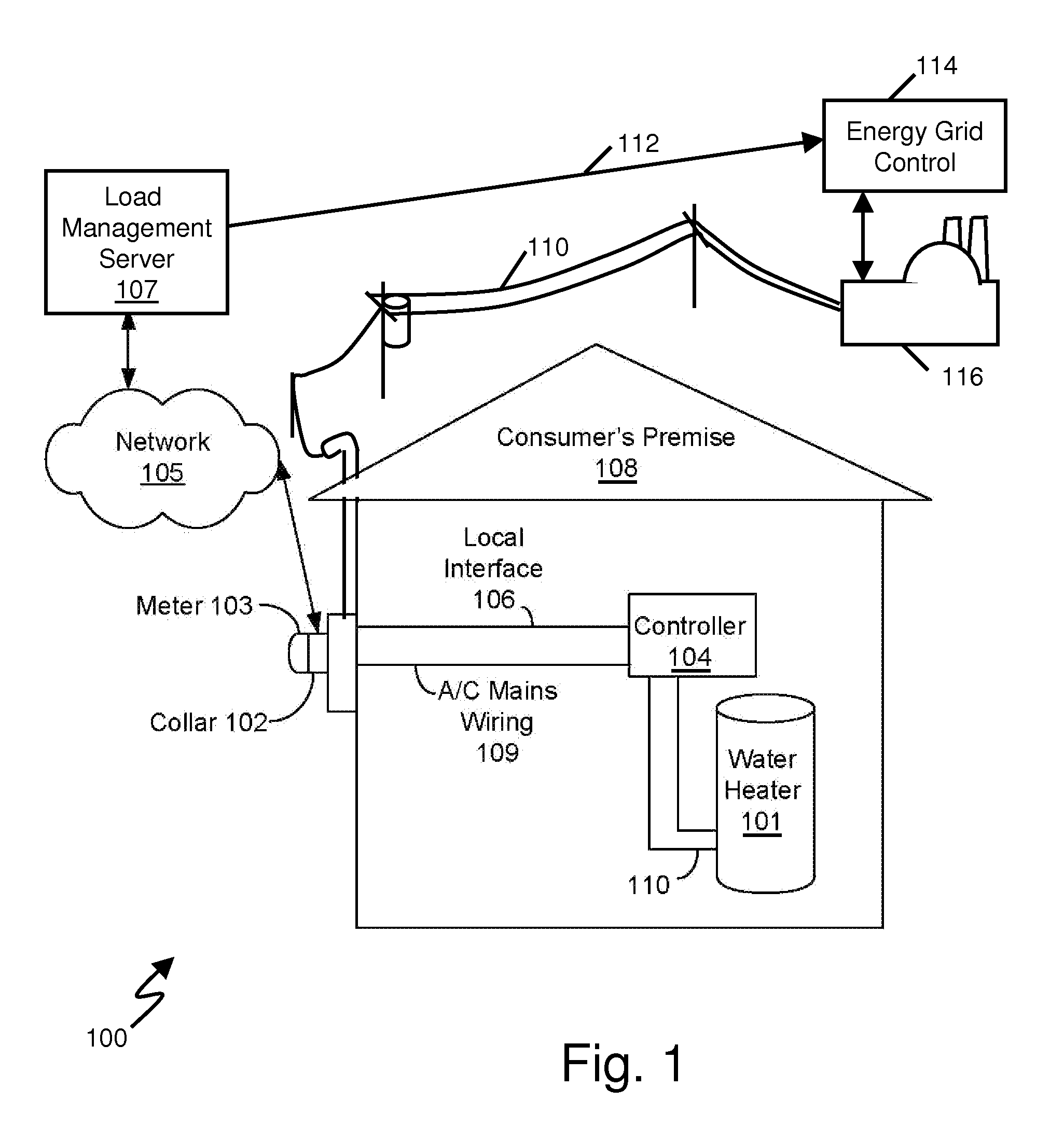

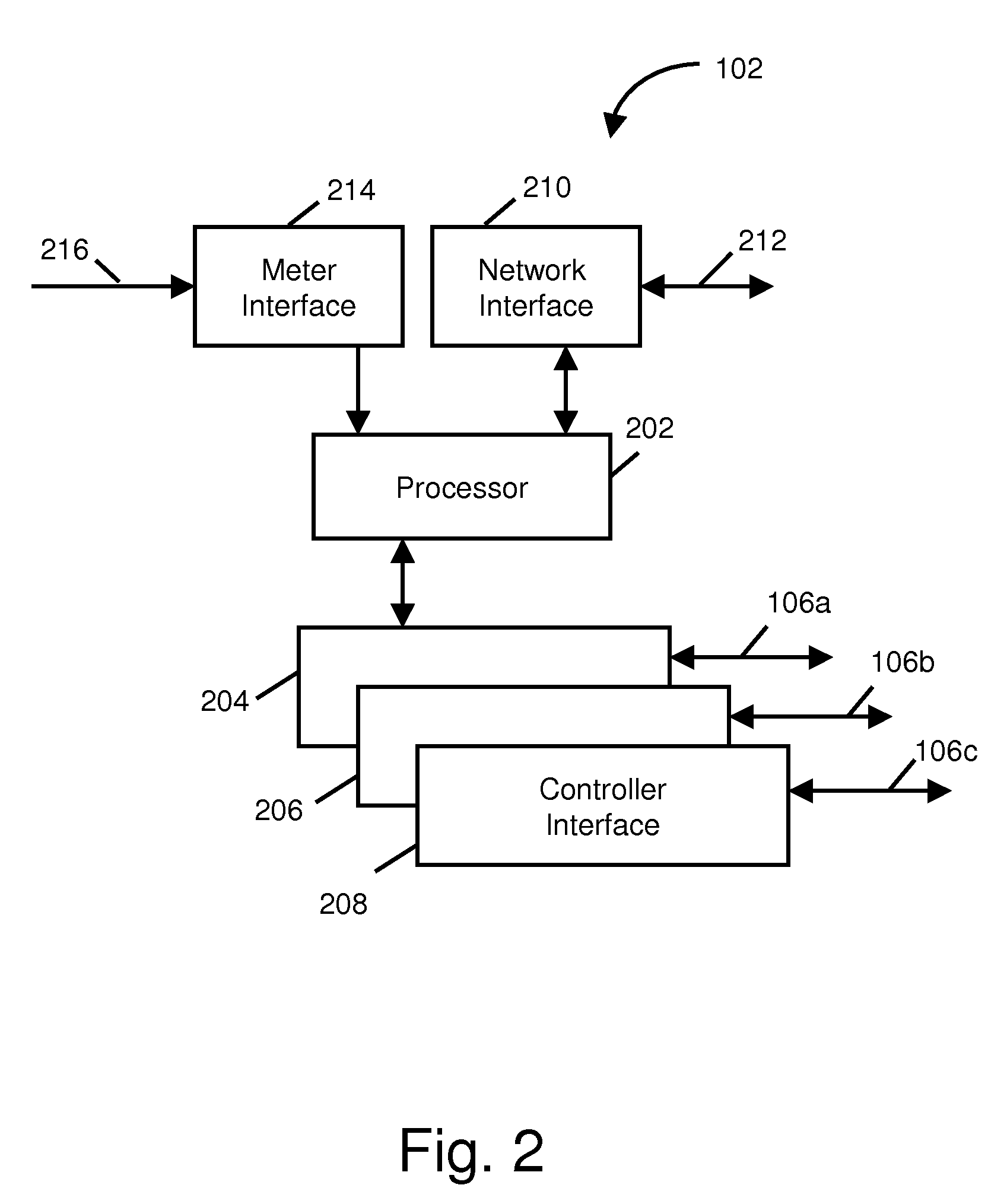

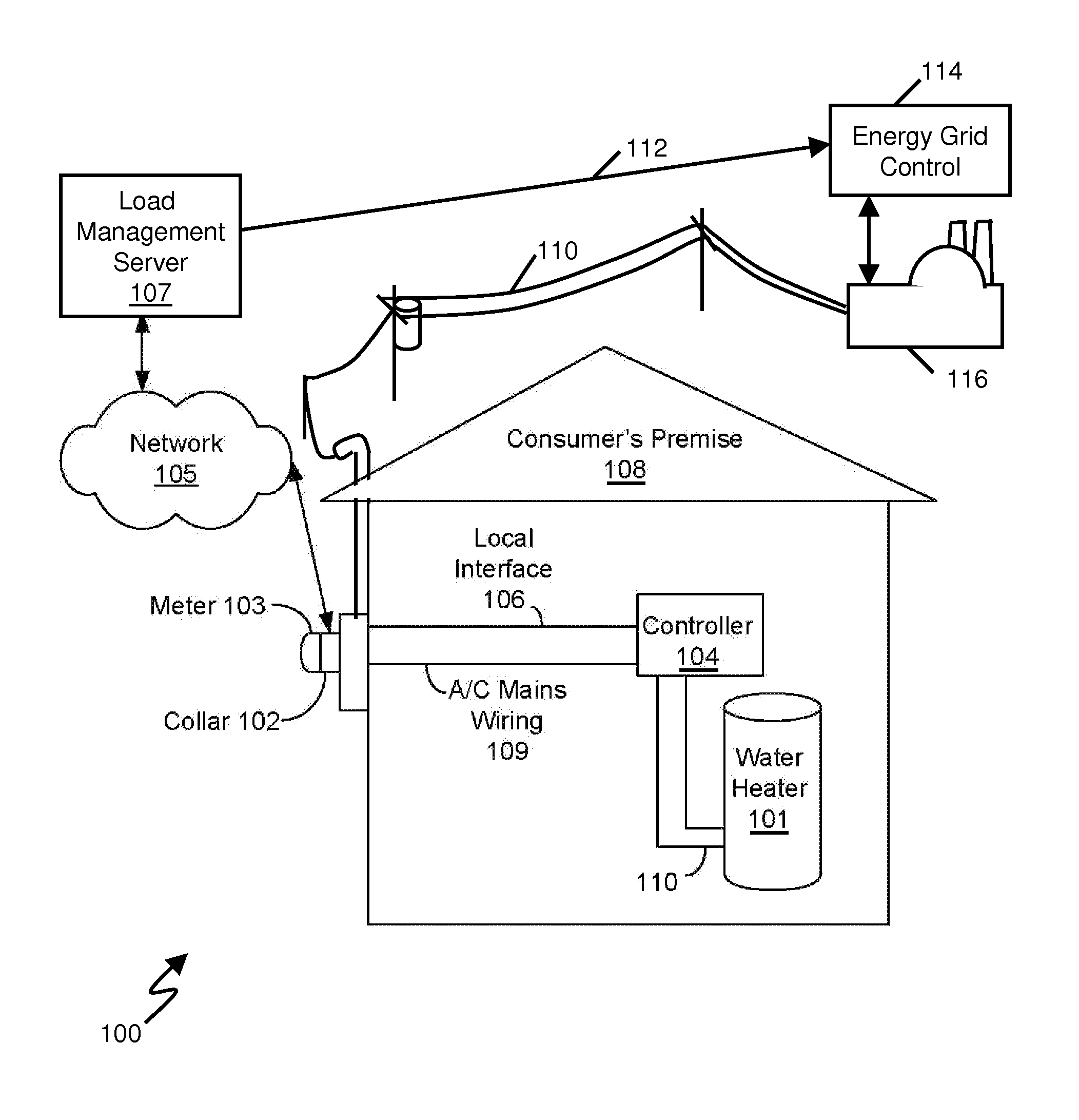

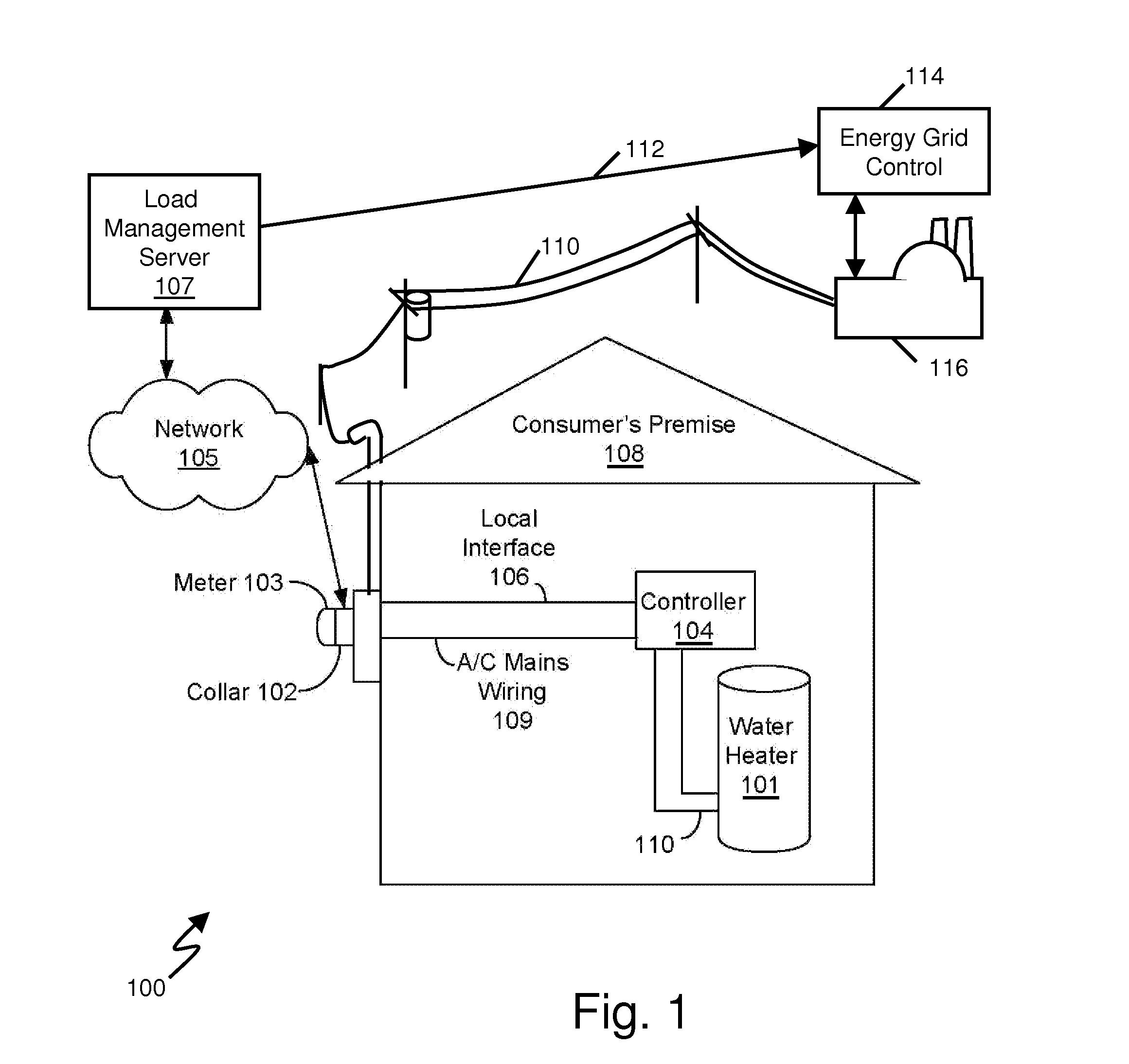

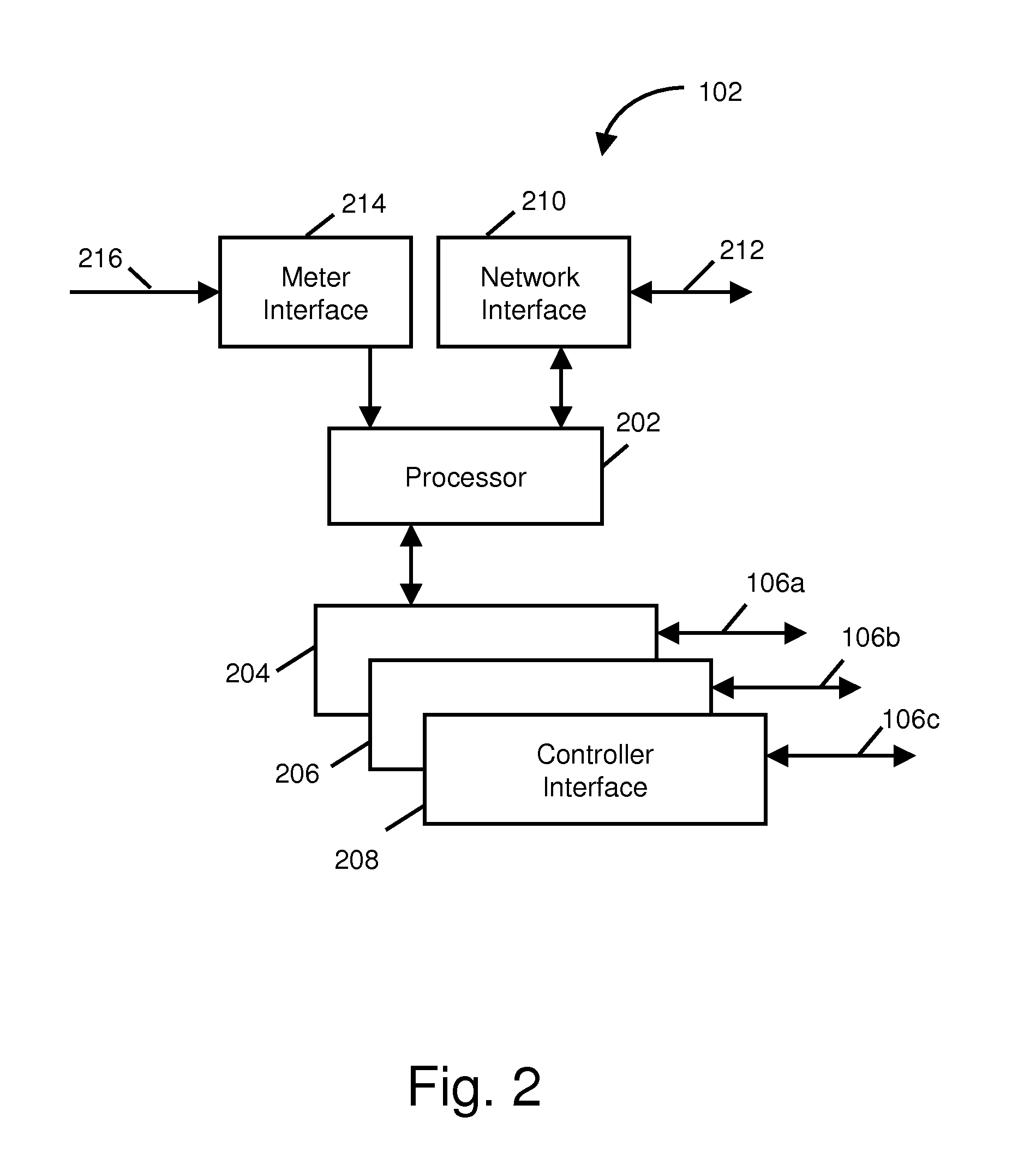

A system for shifting energy demand from on-peak time windows to off-peak time windows by using hot water heater load shifting, while providing the end user with the level of service (i.e., availability of hot water) according to the user's customary use described by service quality criteria. The shift is accomplished by a controller located at the end user establishment and in communication with a central control server. The controller monitors local water heater upper and / or lower temperature and controls upper and / or lower water heater heating elements in accordance with a demand shift process commanded by the central control server. The controller may determine usage and remaining capacity for reporting back to the central control server. A volumetric capacity and usage determination is disclosed. The control server may select water heaters according to use patterns and / or measured capacity. One embodiment is adapted for use with existing water heaters without disrupting safety features of the existing water heater.

Owner:CARINA TECH +1

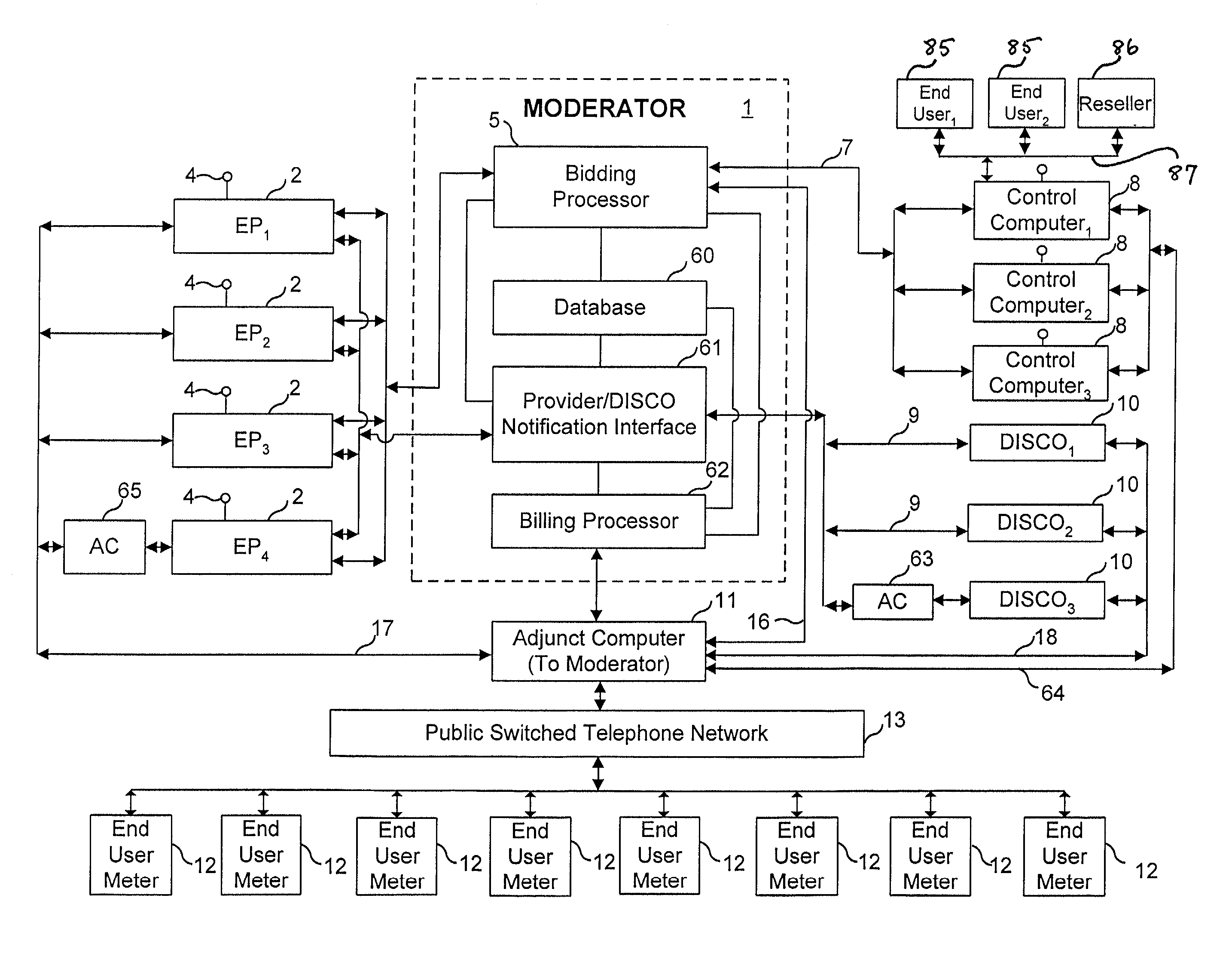

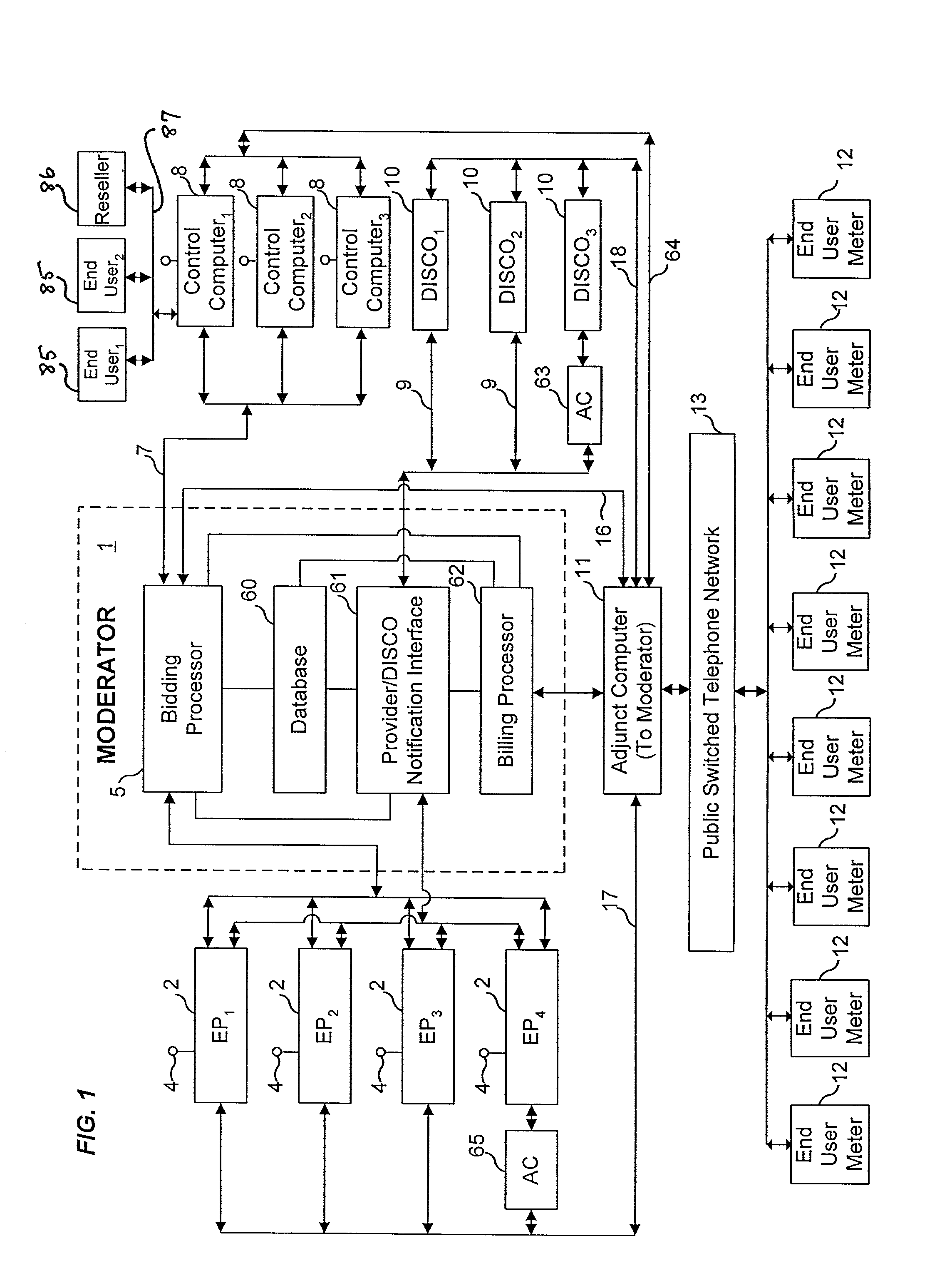

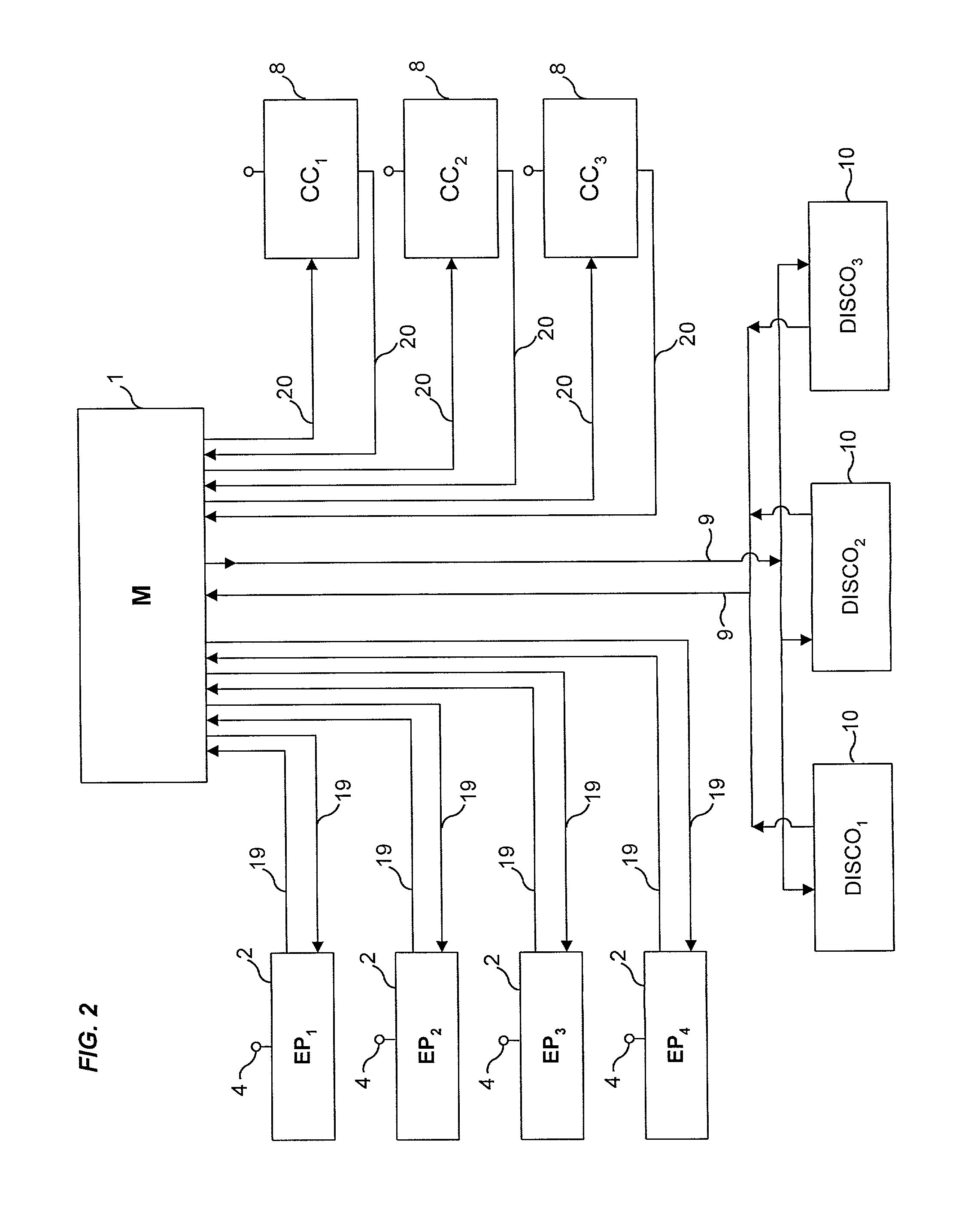

Bidding for Energy Supply

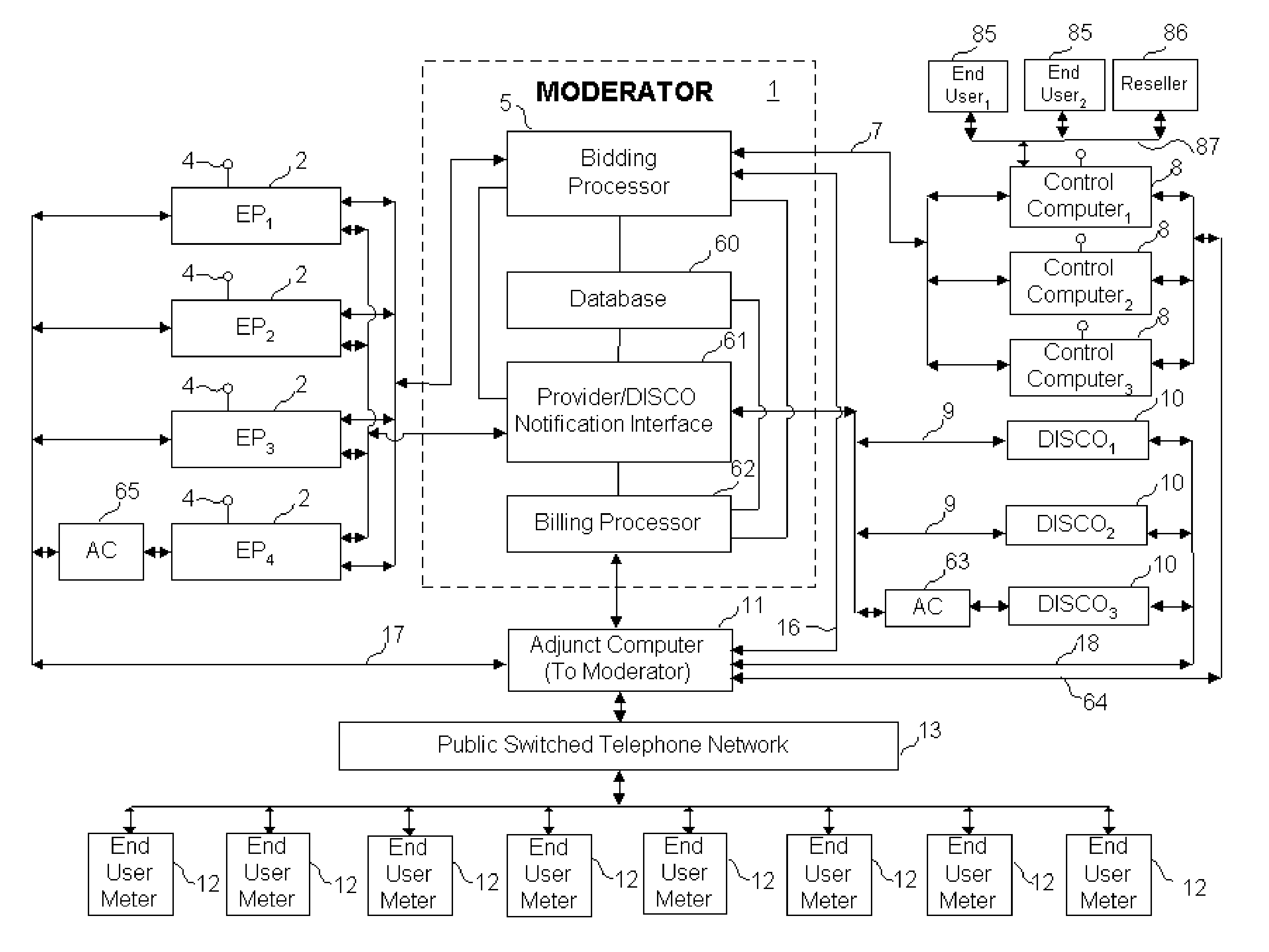

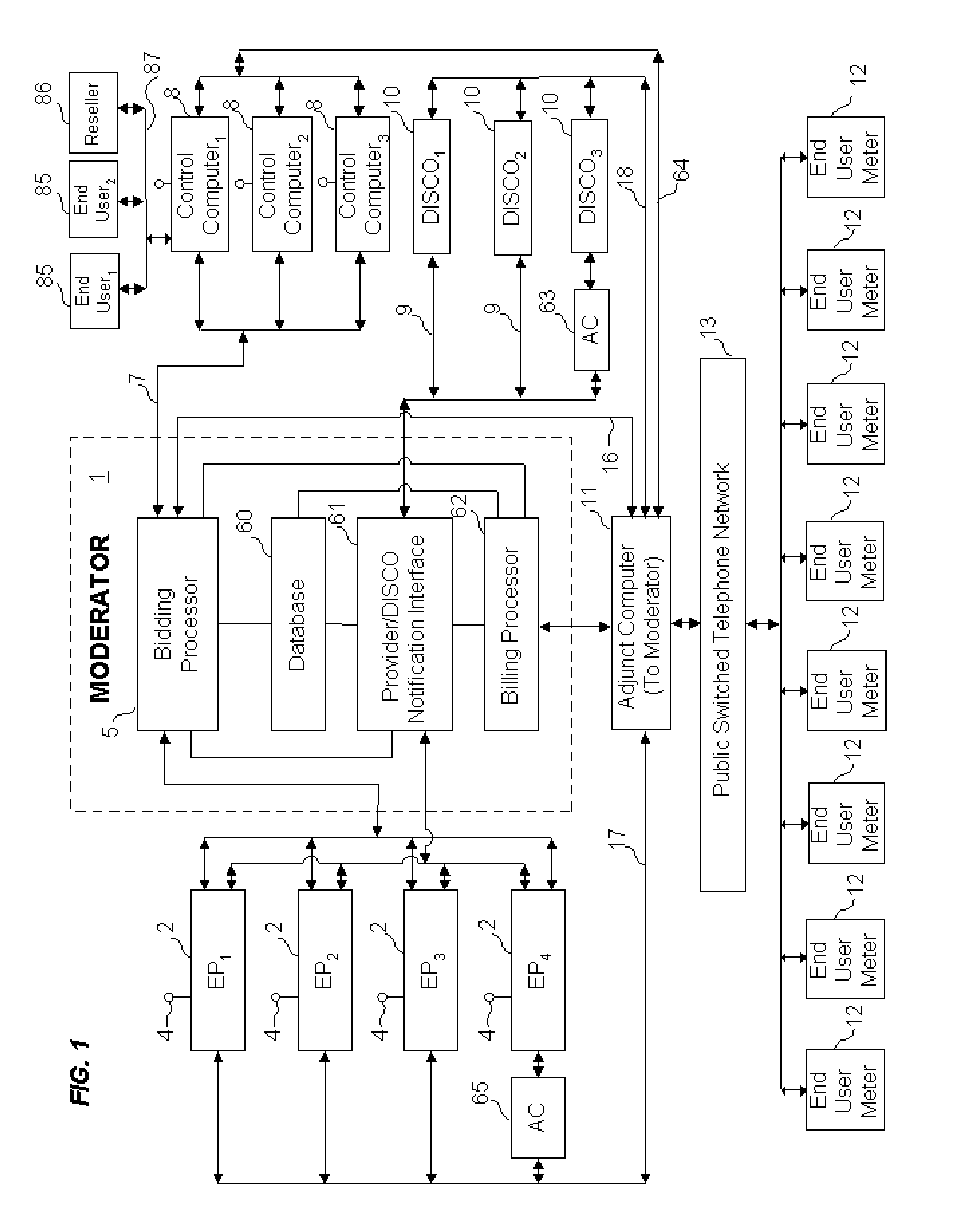

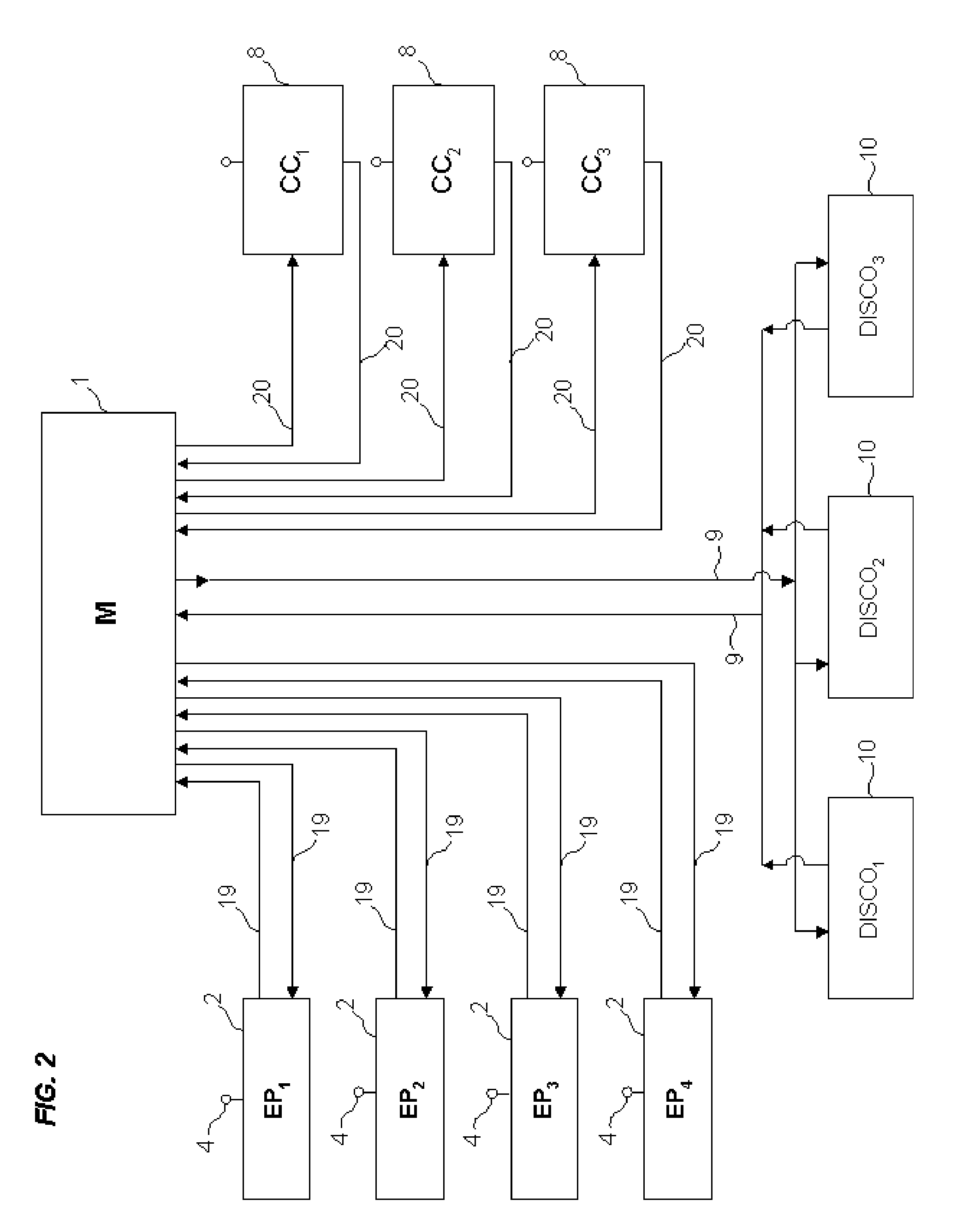

<heading lvl="0">Abstract of Disclosure< / heading> An auction service is provided that stimulates competition between energy suppliers (i.e., electric power or natural gas). A bidding moderator (Moderator) receives offers from competing suppliers specifying the economic terms each is willing to offer to end users for estimated quantities of electric power or gas supply (separate auctions). Each supplier receives feedback from the Moderator based on competitors offers and has the opportunity to adjust its own offers down or up, depending on whether it wants to encourage or discourage additional energy delivery commitments in a particular geographic area or to a particular customer group. Each supplier s offers can also be changed to reflect each supplier s capacity utilization. The Moderator selects at least two suppliers to provide energy to each end user, with each supplier providing a portion of the energy to be used by each end user at an end-user facility during a specific future time interval.

Owner:GEOPHONIC NETWORKS

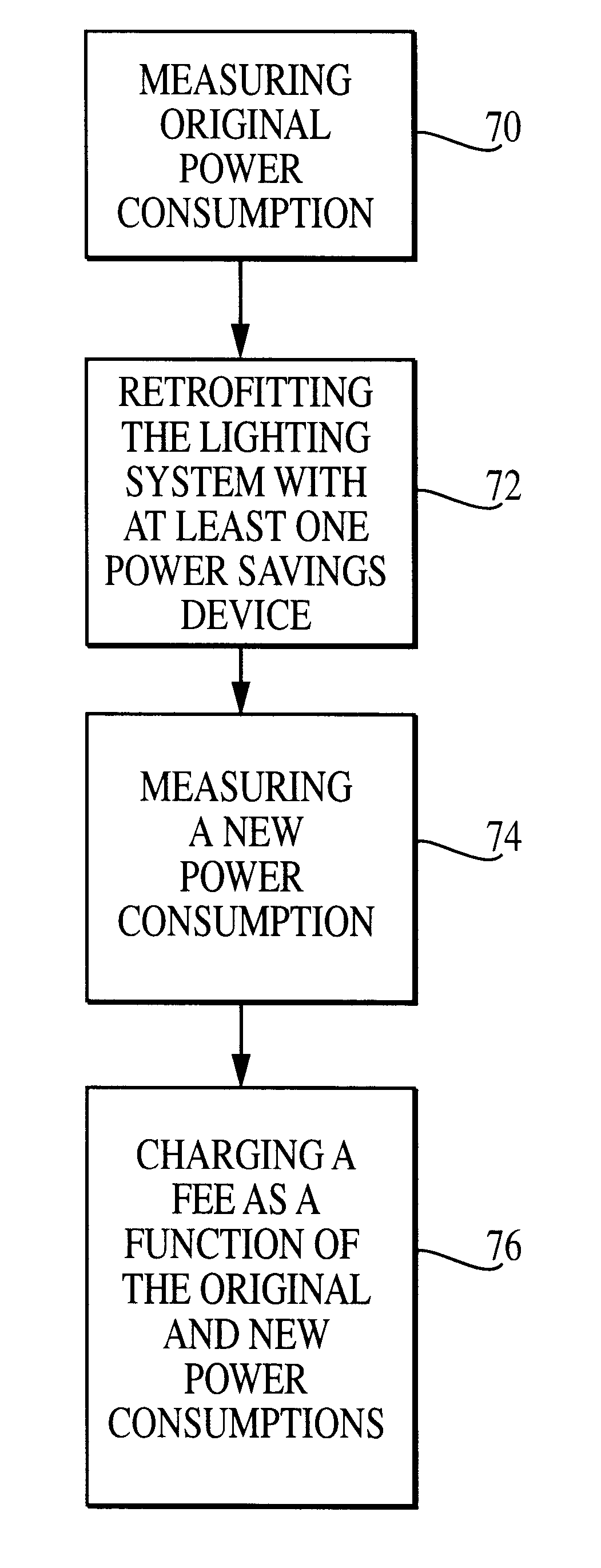

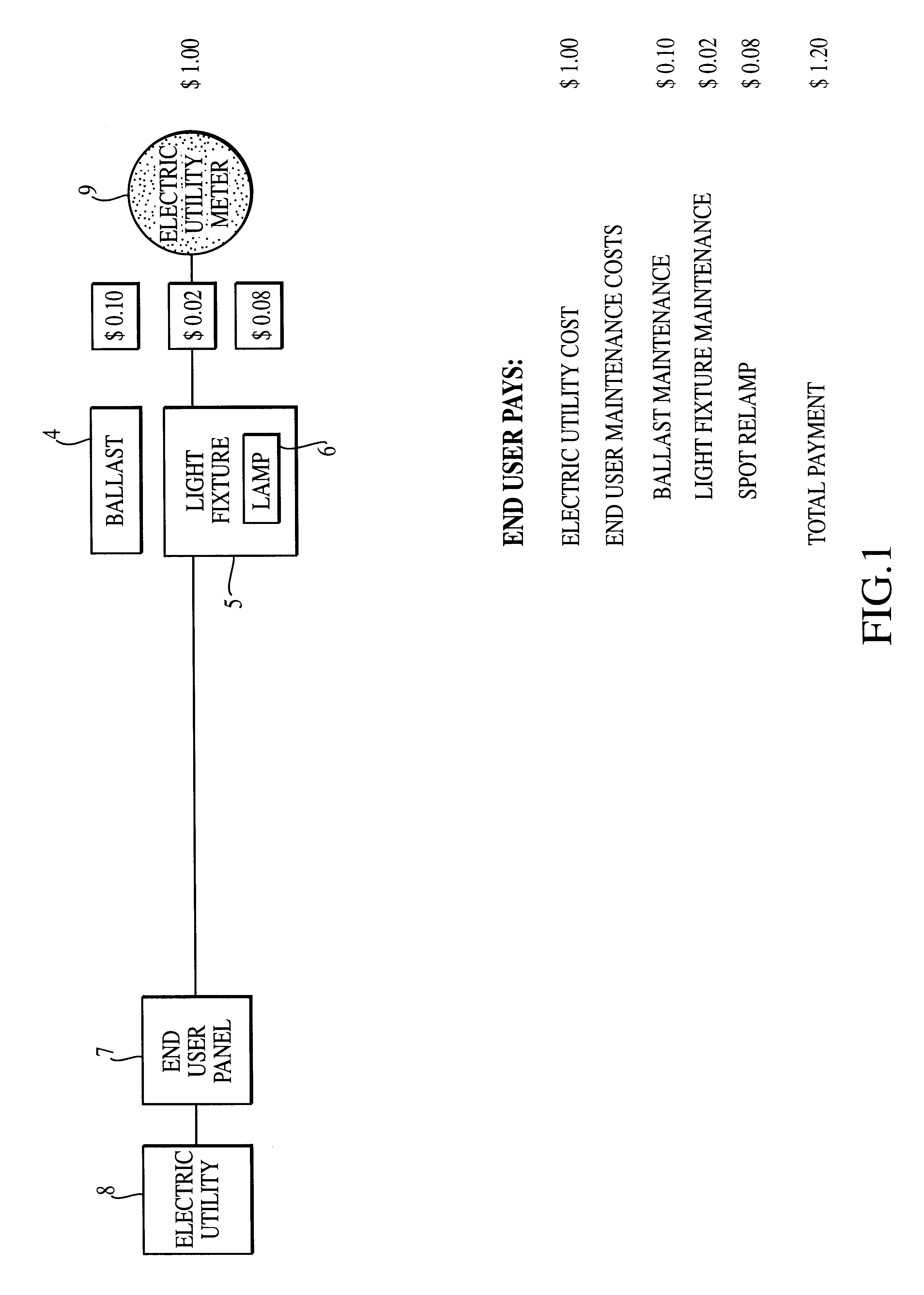

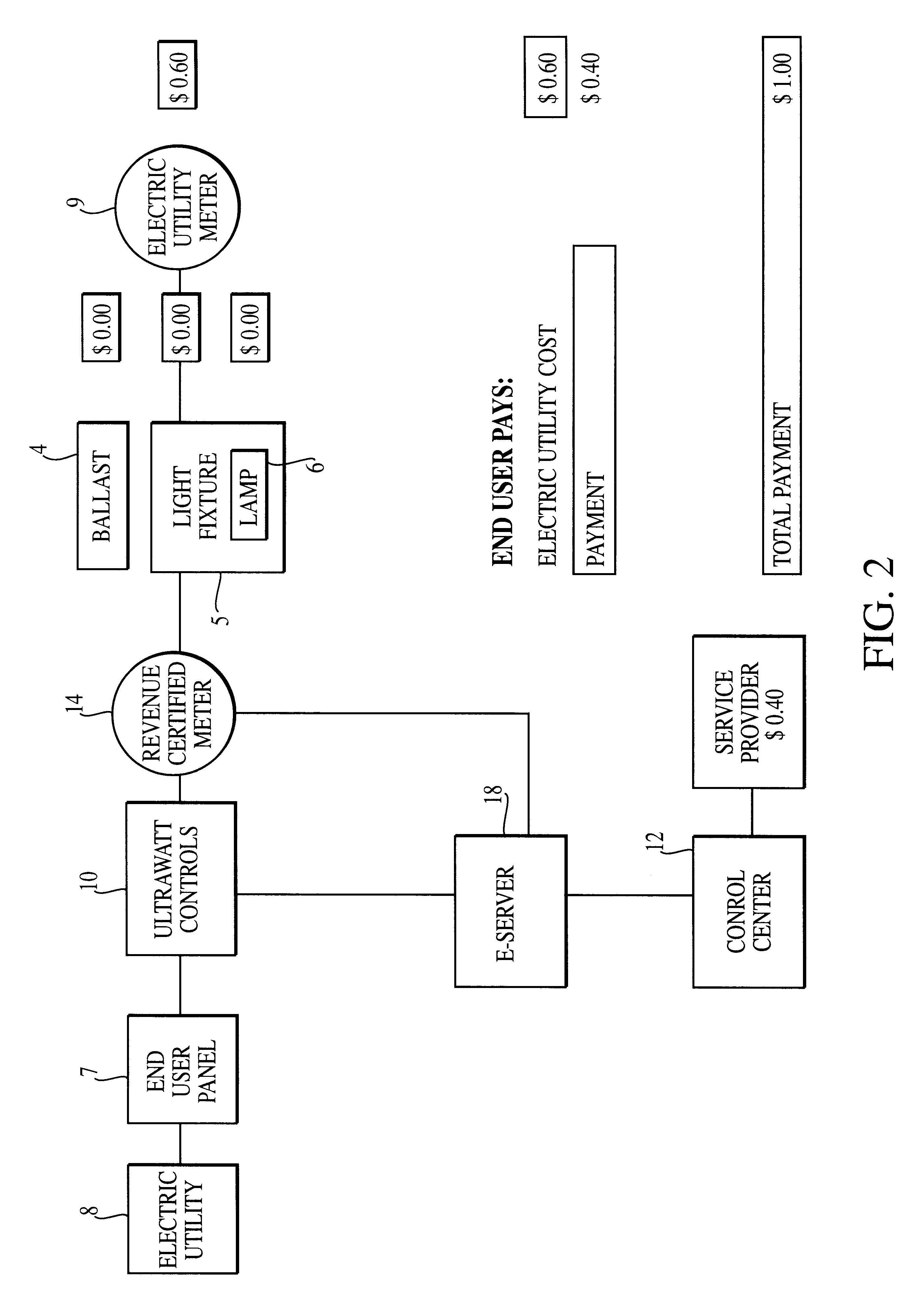

System and method for monitoring lighting systems

A method and system for charging a fee to an end user where a service company services a lighting system of the end user's facility. To determine the fee, an original power consumption of the facility is determined before the lighting system is retrofitted with at least one power savings device. Thereafter, the lighting system is retro-fitted with the at least one power saving device. Then, a new power consumption is measured of the facility. Finally, the fee is charged to the end user, such that the fee is a function of a difference between the original power consumption and the new power consumption.

Owner:LTI INT

Bidding for energy supply

An auction service is provided that stimulates competition between energy suppliers (i.e., electric power or natural gas). A bidding moderator (Moderator) receives offers from competing suppliers specifying the economic terms each is willing to offer to end users for estimated quantities of electric power or gas supply (separate auctions). Each supplier receives feedback from the Moderator based on competitors' offers and has the opportunity to adjust its own offers down or up, depending on whether it wants to encourage or discourage additional energy delivery commitments in a particular geographic area or to a particular customer group. Each supplier's offers can also be changed to reflect each supplier's capacity utilization. The Moderator selects at least two suppliers to provide energy to each end user, with each supplier providing a portion of the energy to be used by each end user at an end-user facility during a specific future time interval.

Owner:GEOPHONIC NETWORKS

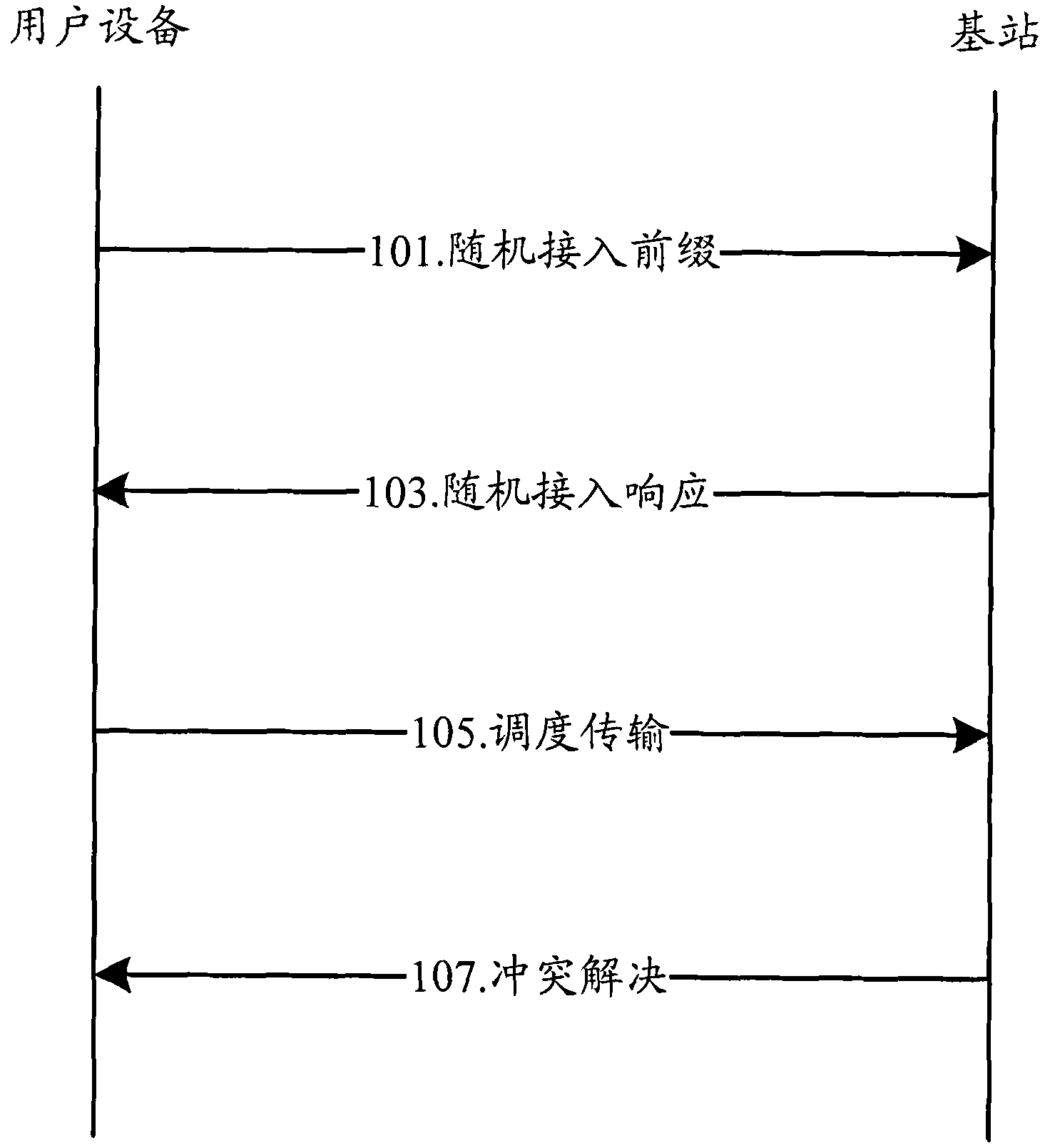

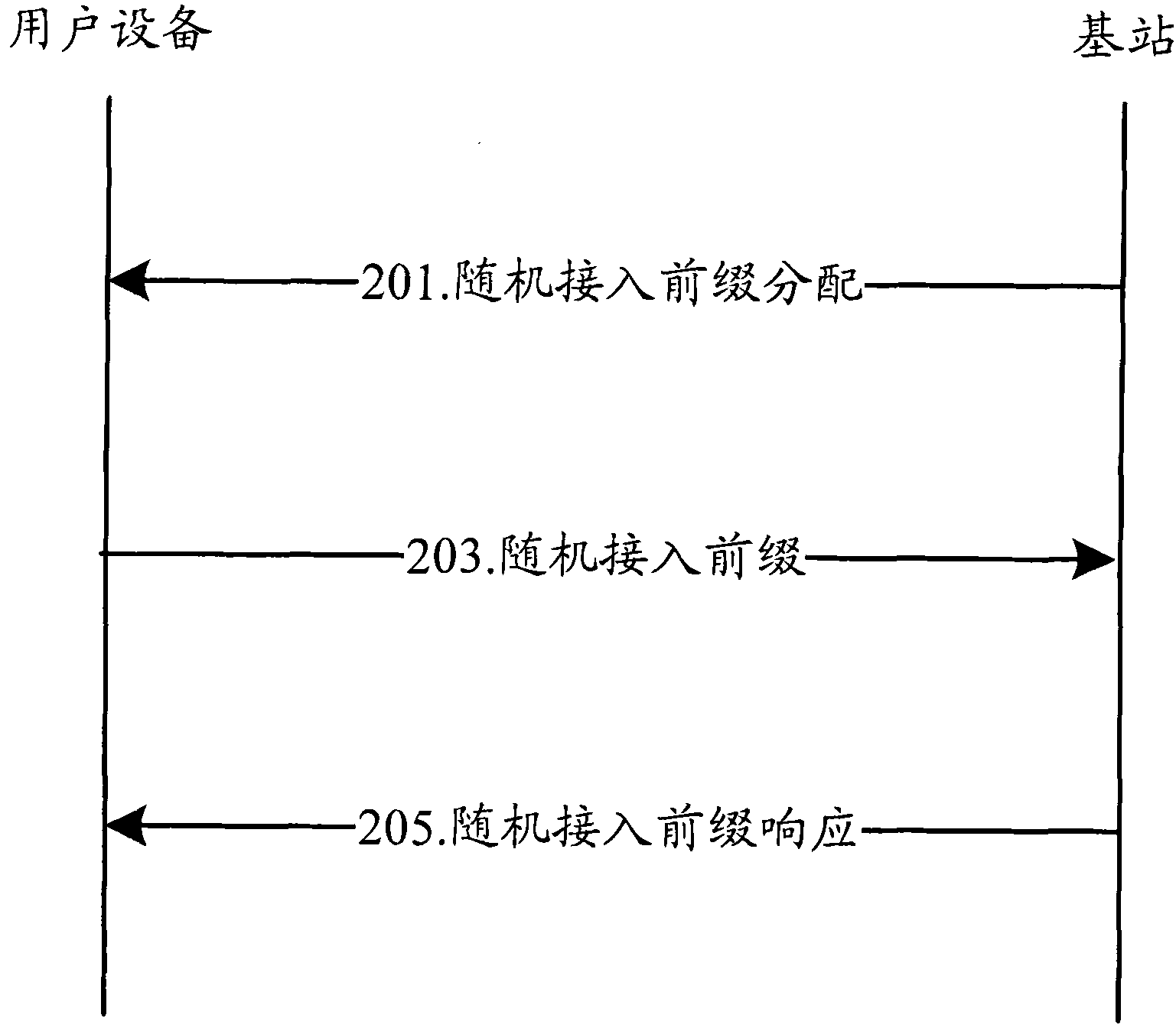

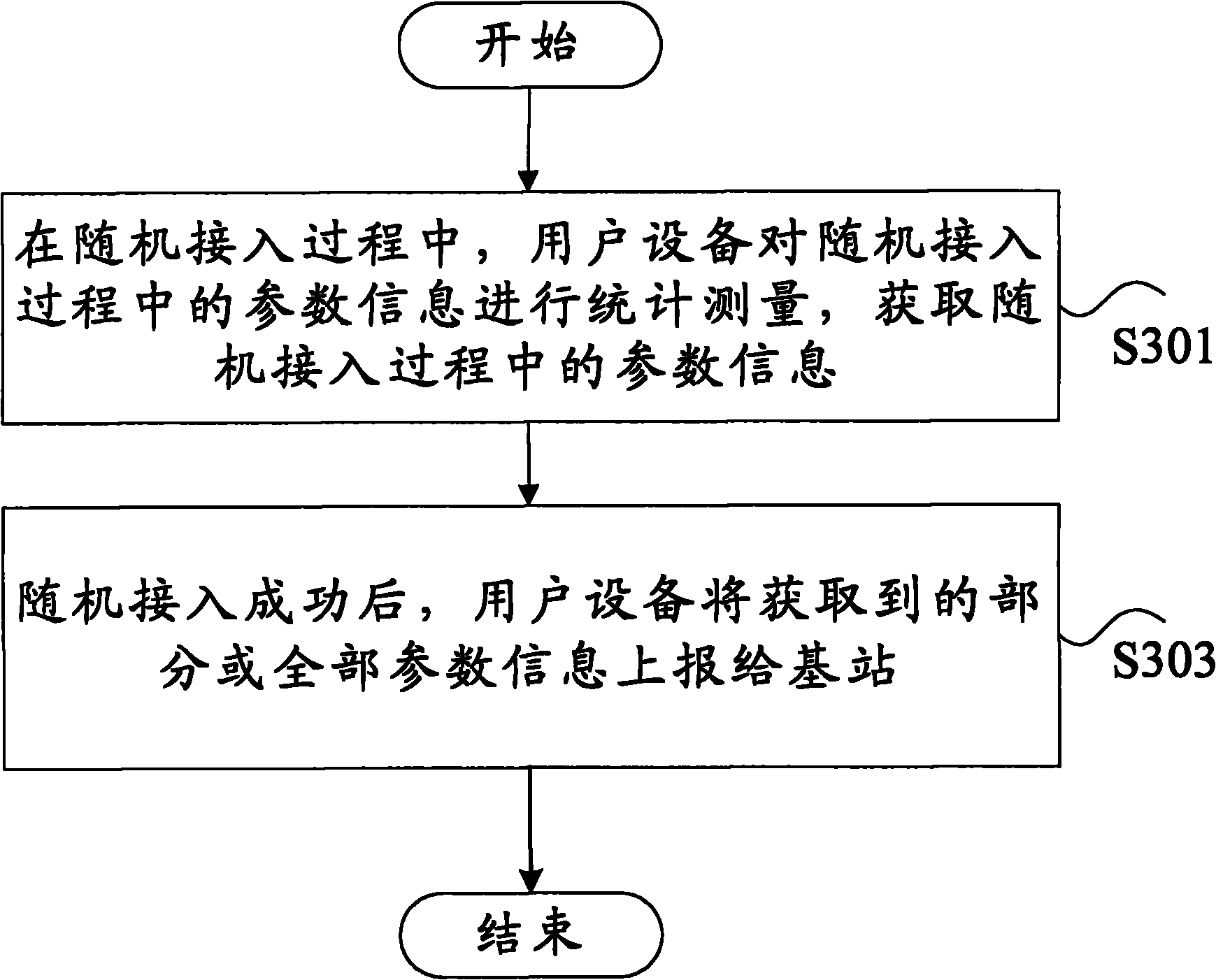

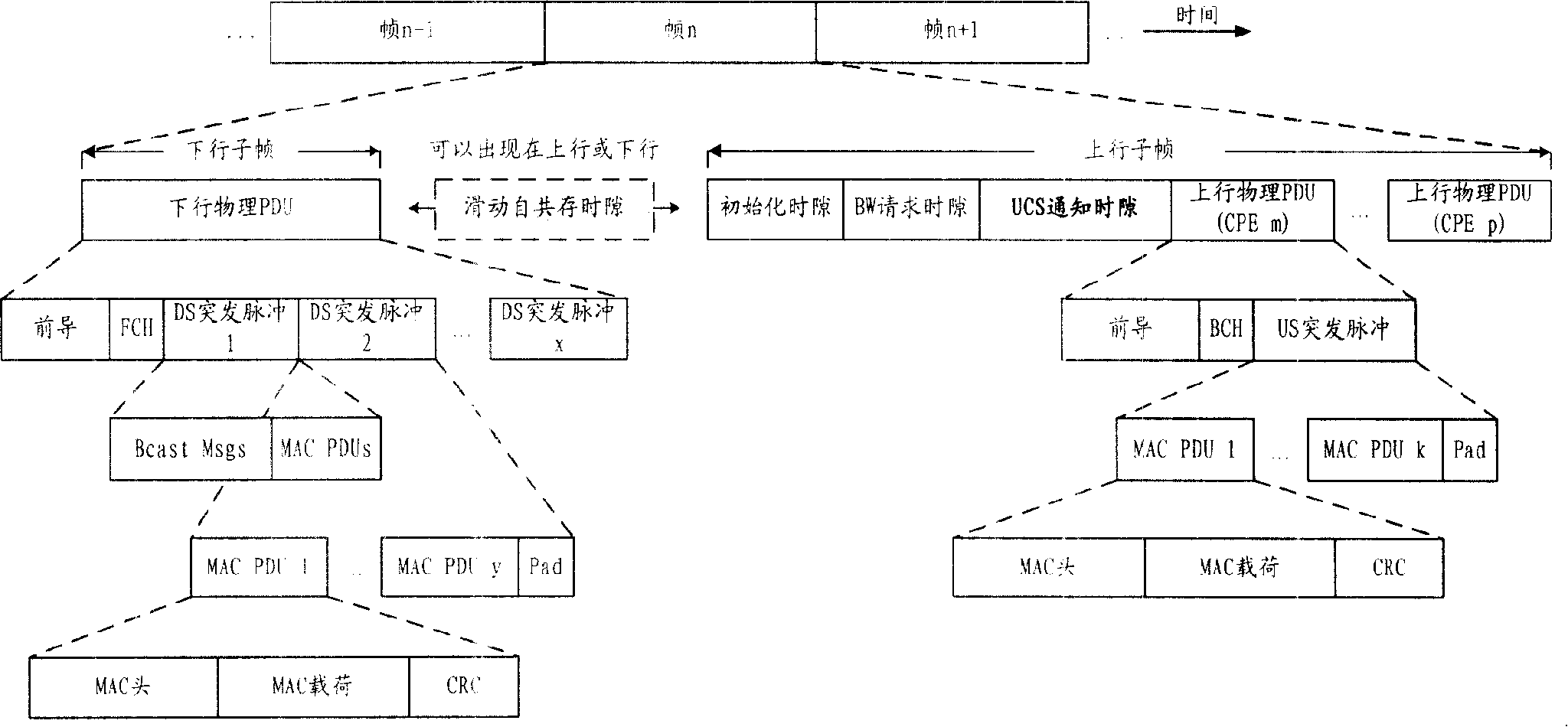

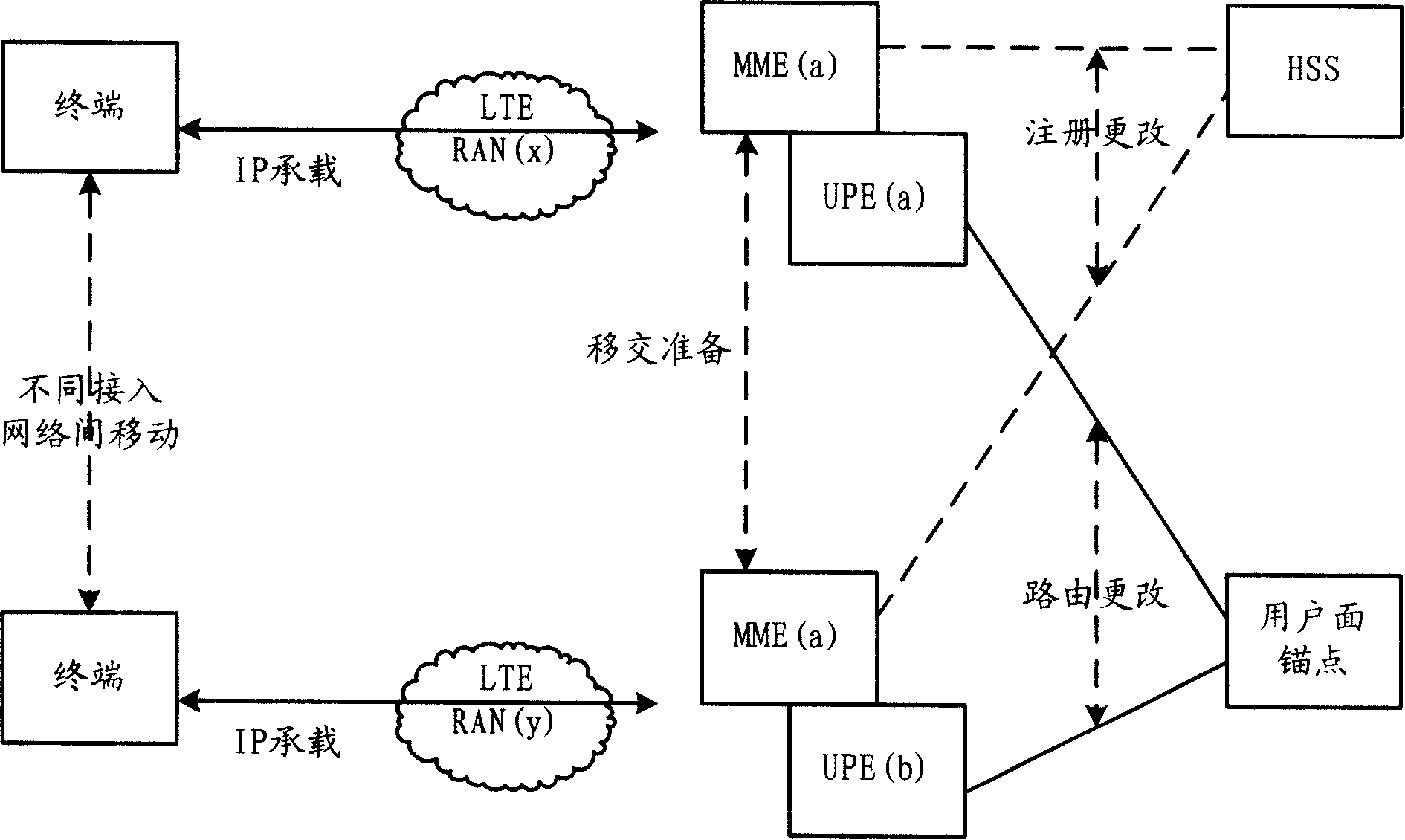

Method for acquiring random access information and user facility

ActiveCN101841889AAccurate and comprehensive collectionImprove accuracyAssess restrictionComputer scienceUser equipment

The invention discloses a method for acquiring random access information and a user facility. The method comprises the following steps: in the process of random access, the user facility measures parameter information and acquires the parameter information; and after the random access is successful, the user facility reports part or all of the acquired parameter information to a base station. By using the invention, the base station can optimize the random access according to the parameter information reported by a terminal, and the accuracy of random access optimization is enhanced.

Owner:ZTE CORP

Water heater demand side management system

A system for shifting energy demand from on-peak time windows to off-peak time windows by using hot water heater load shifting, while providing the end user with the level of service (i.e., availability of hot water) according to the user's customary use described by service quality criteria. The shift is accomplished by a controller located at the end user establishment and in communication with a central control server. The controller monitors local water heater upper and / or lower temperature and controls upper and / or lower water heater heating elements in accordance with a demand shift process commanded by the central control server. The controller may determine usage and remaining capacity for reporting back to the central control server. A volumetric capacity and usage determination is disclosed. The control server may select water heaters according to use patterns and / or measured capacity. One embodiment is adapted for use with existing water heaters without disrupting safety features of the existing water heater.

Owner:CARINA TECH +1

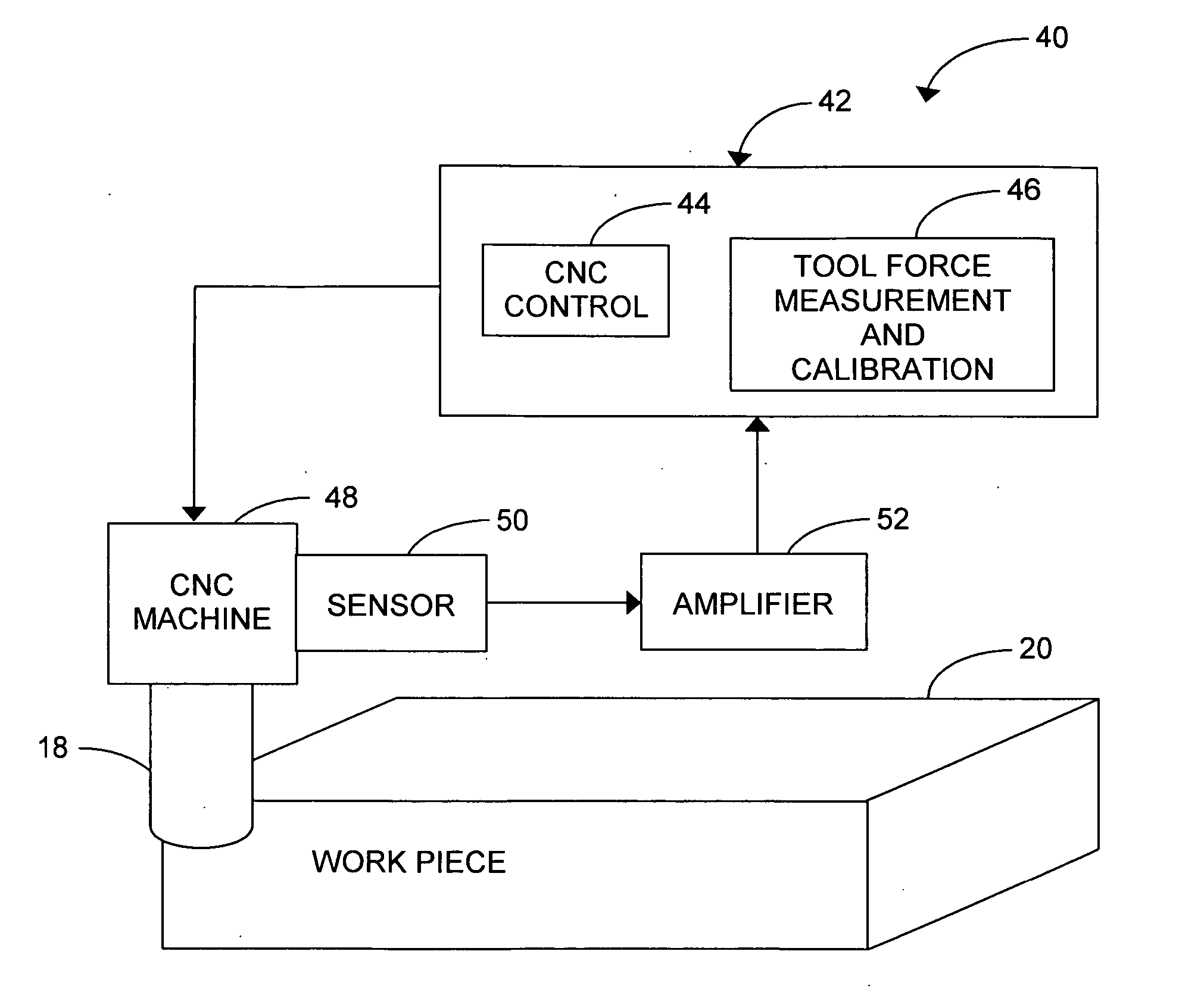

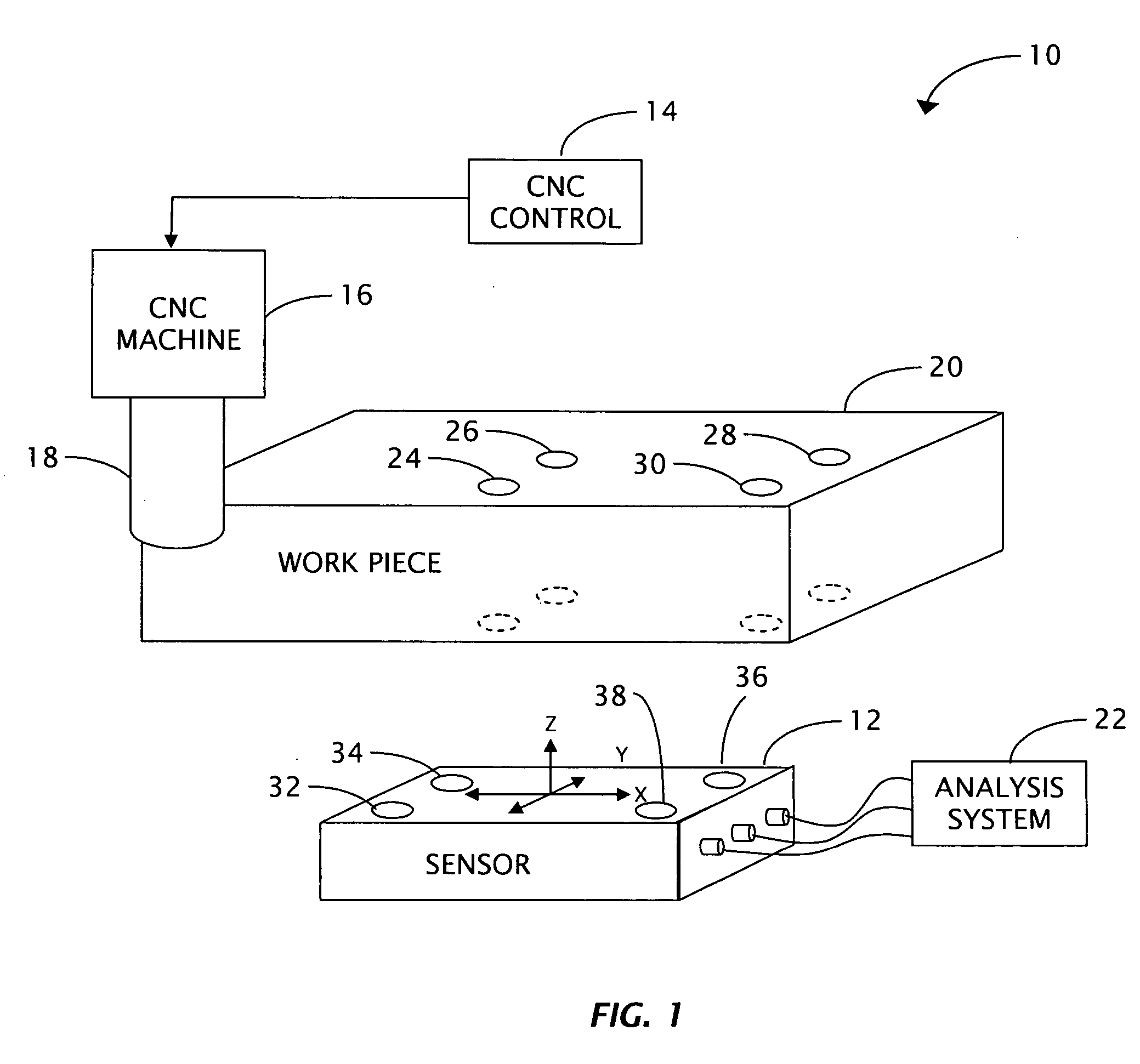

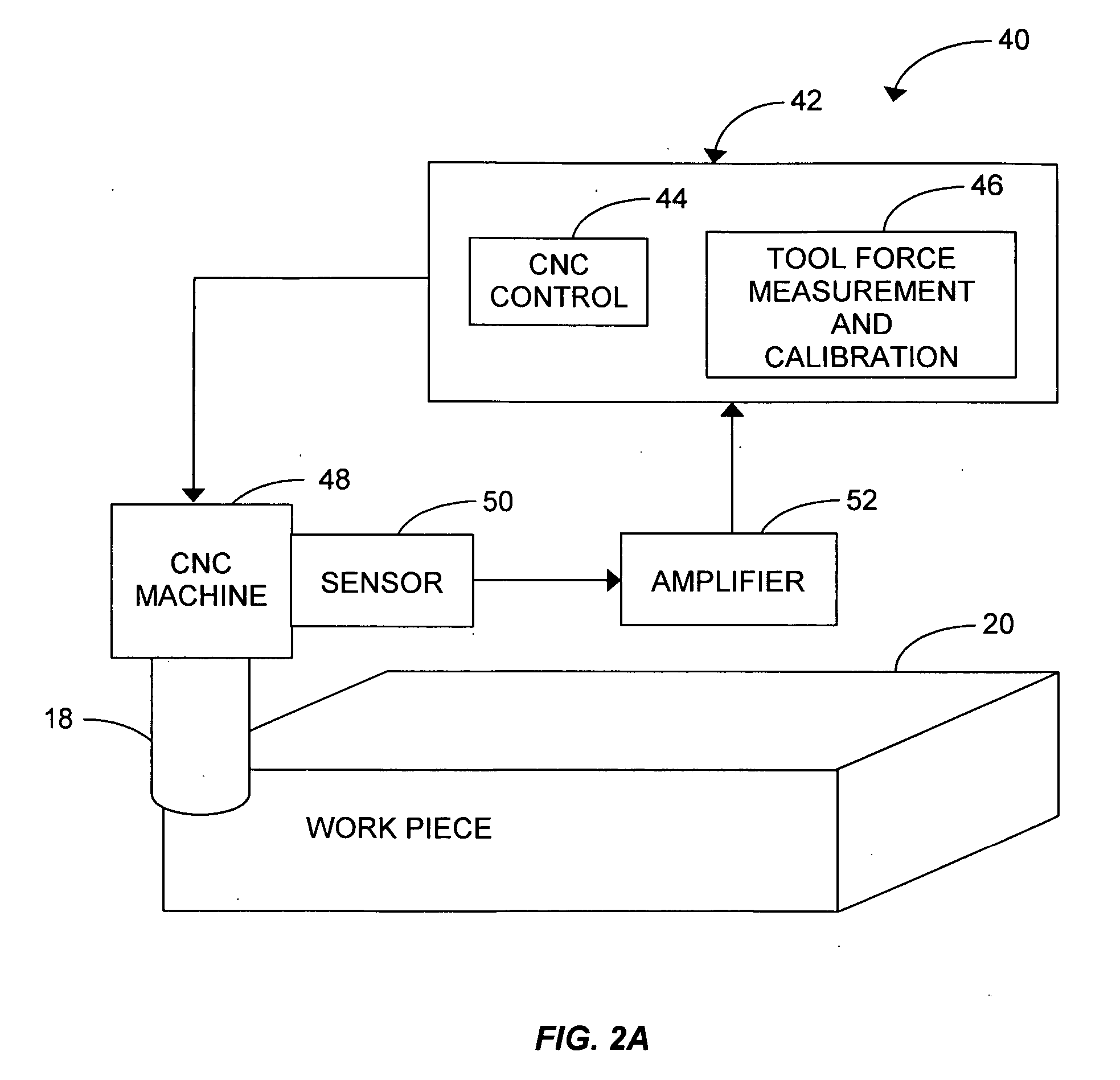

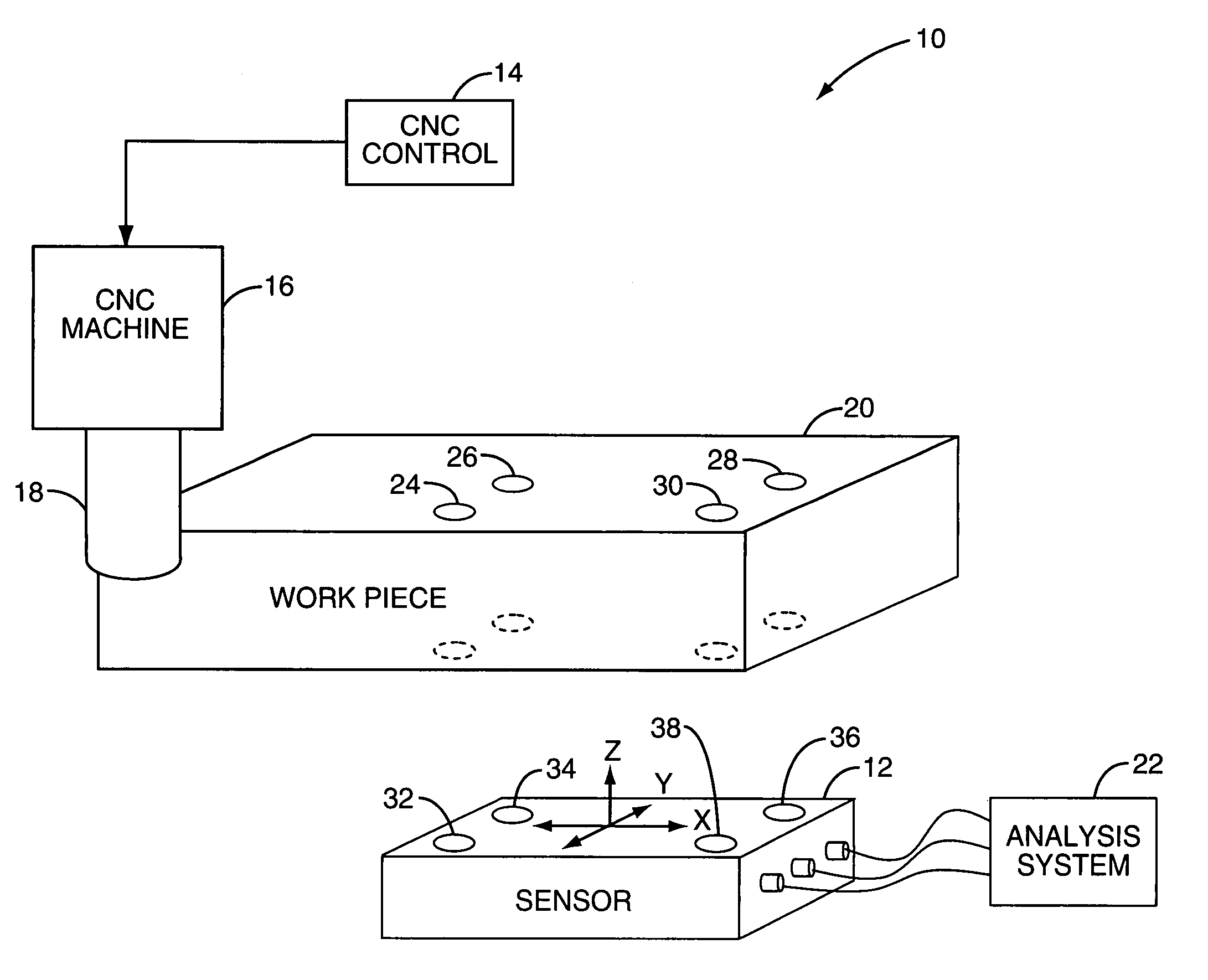

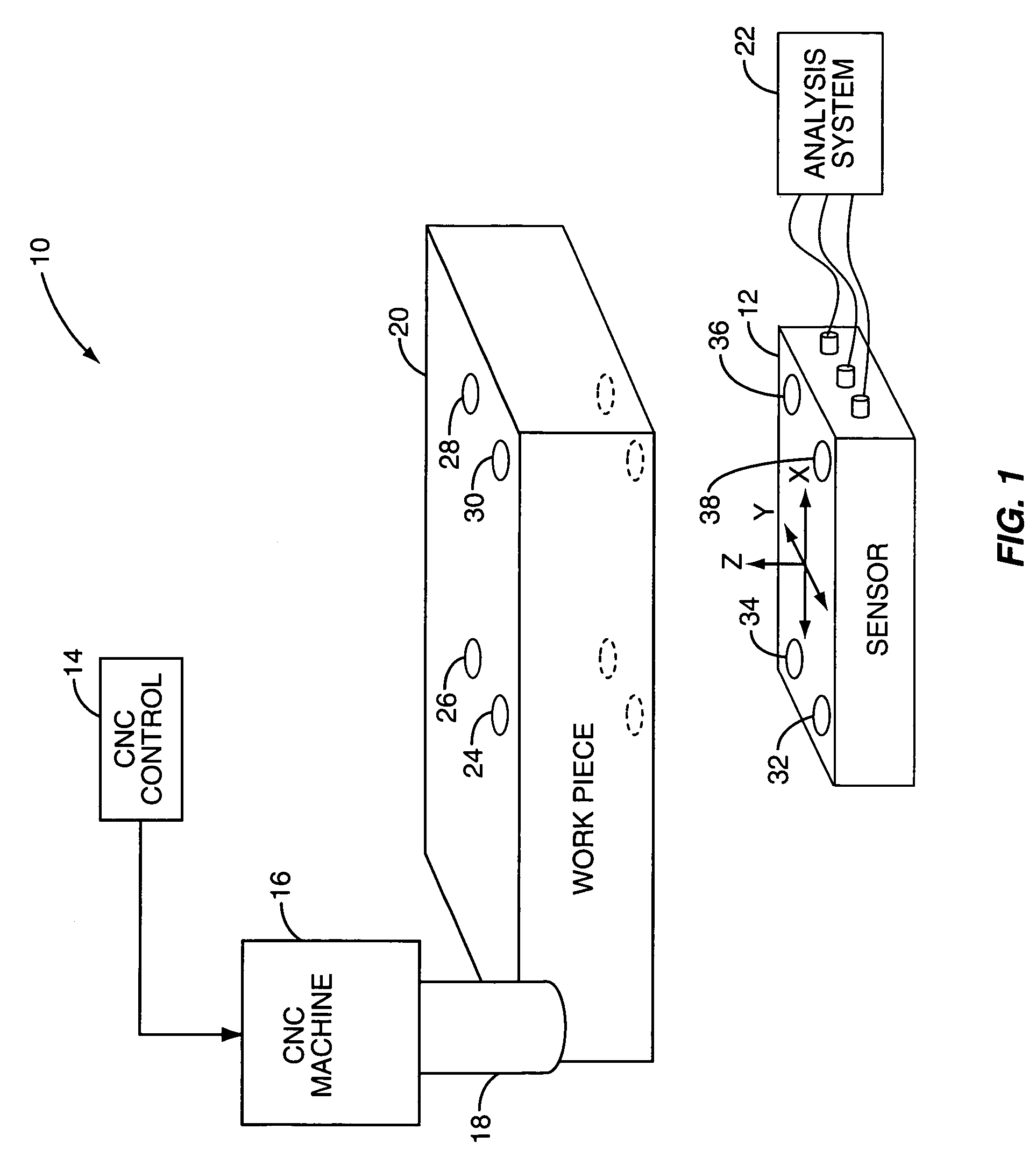

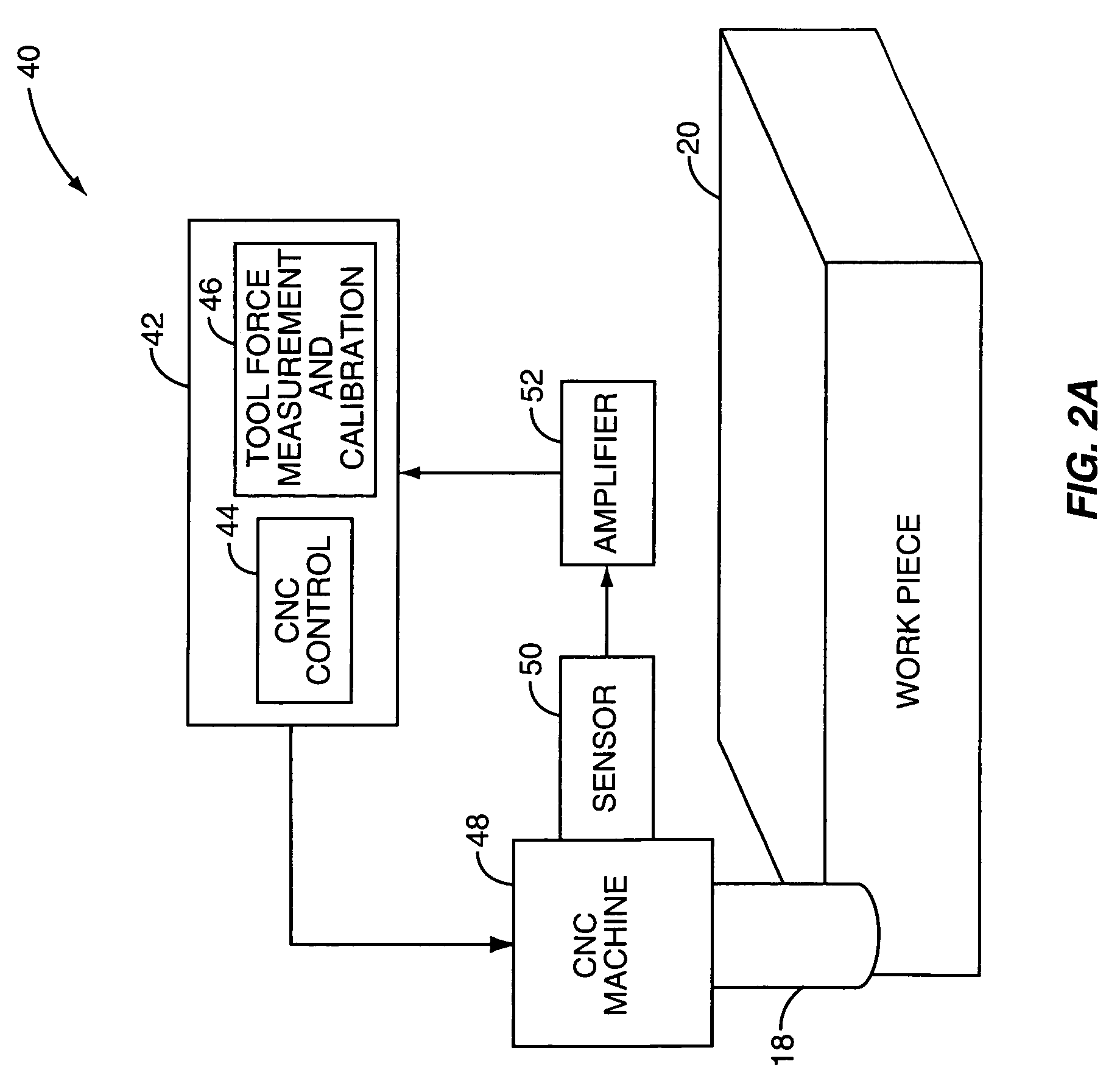

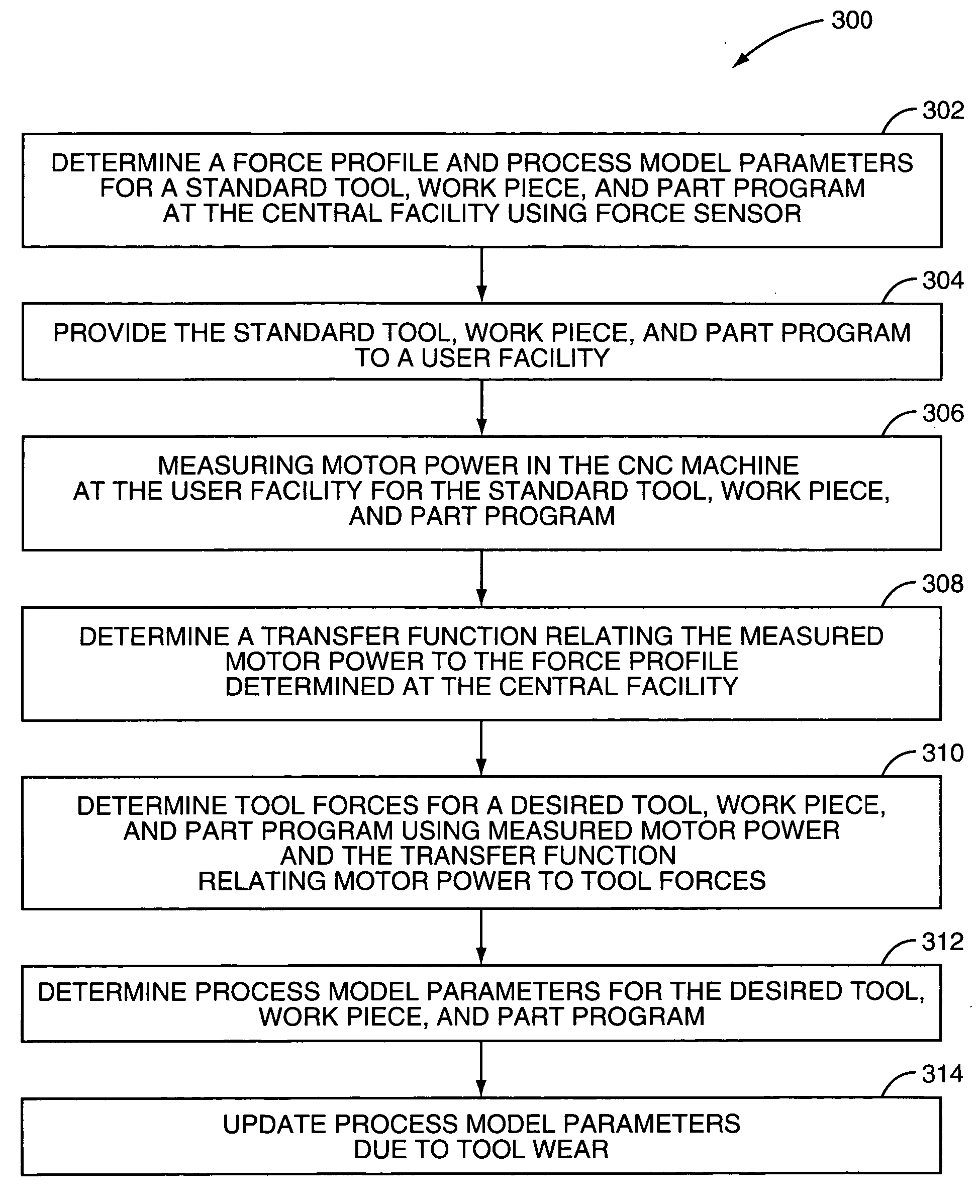

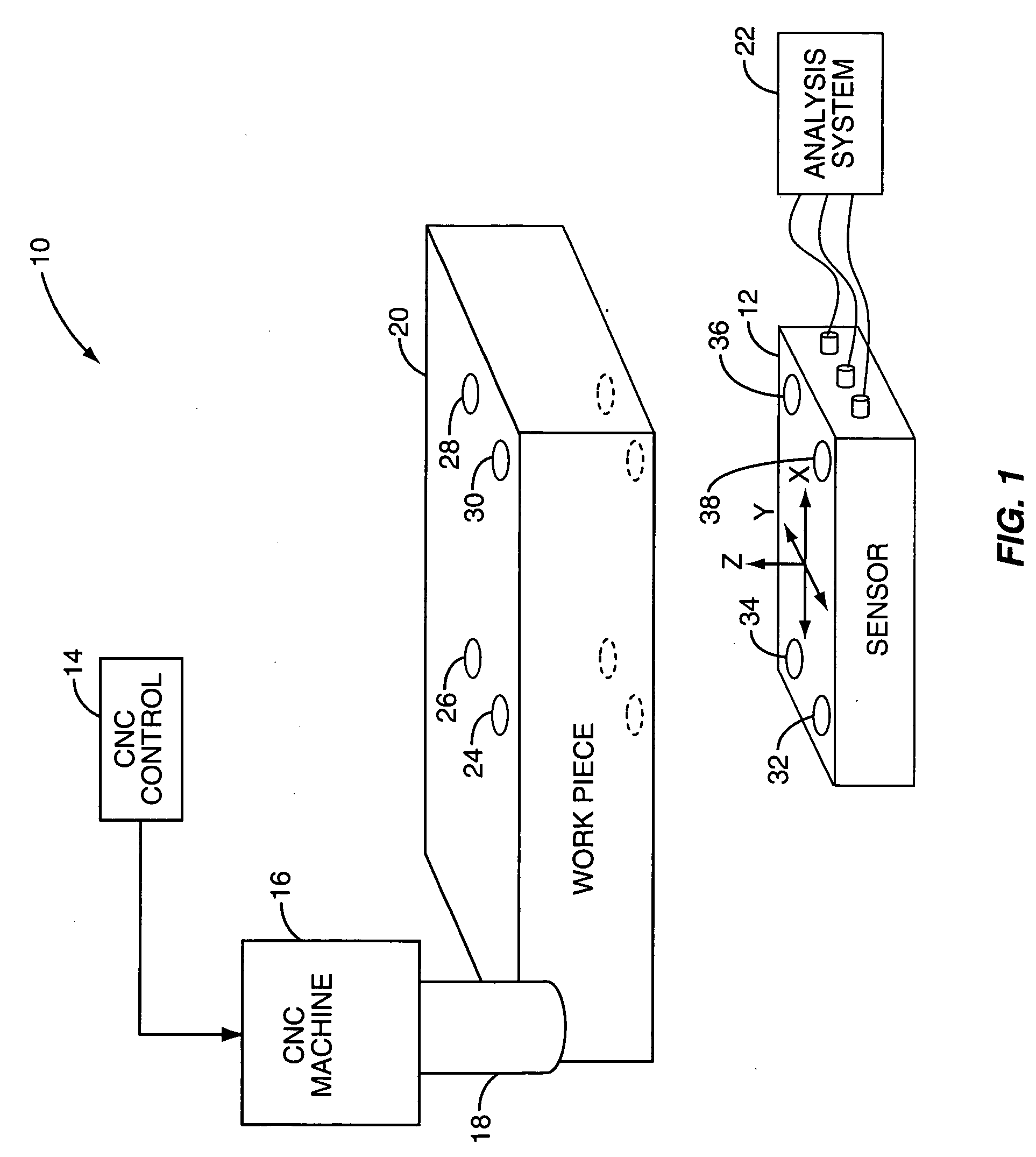

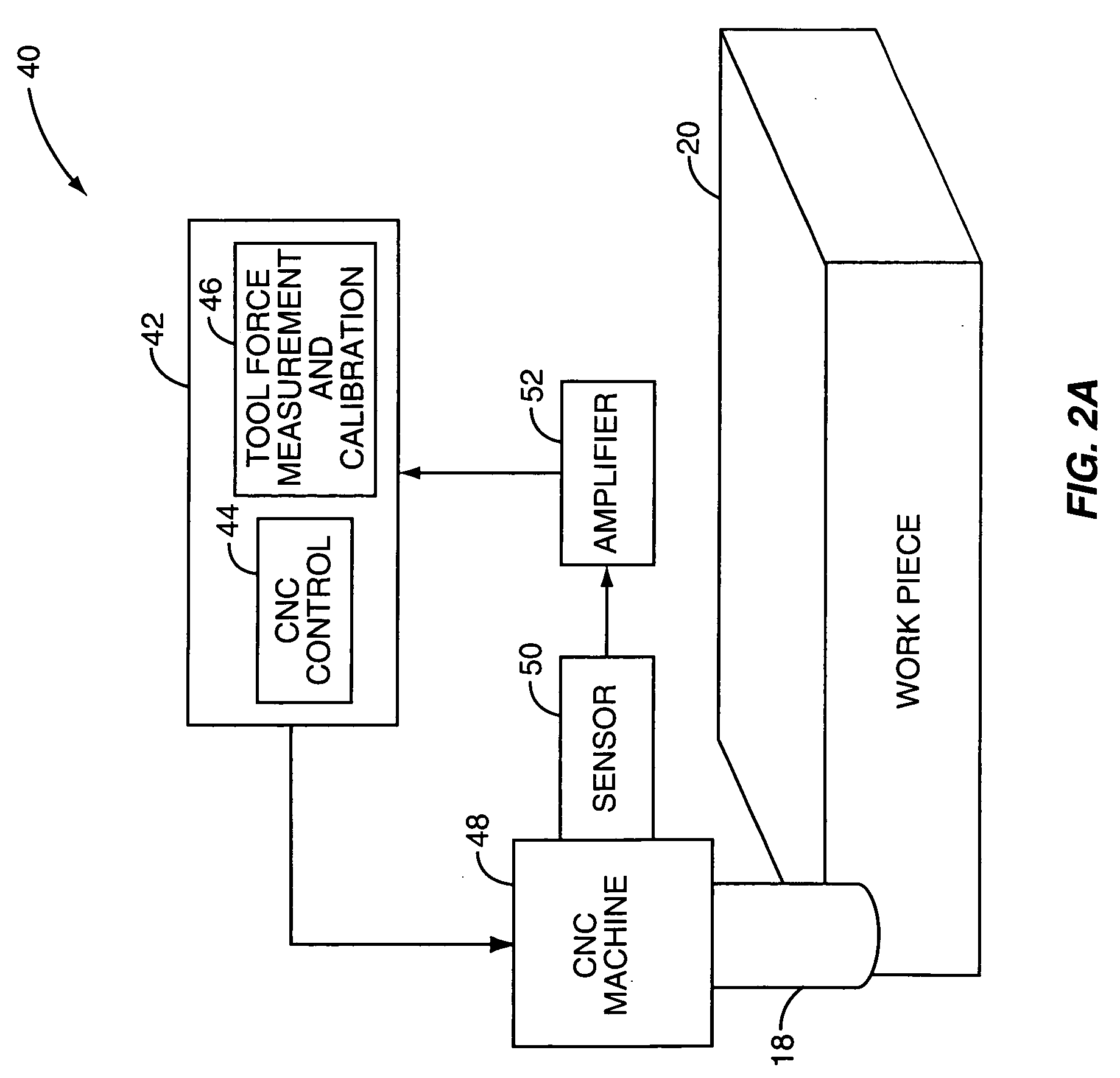

Sensor-based measurement of tool forces and machining process model parameters

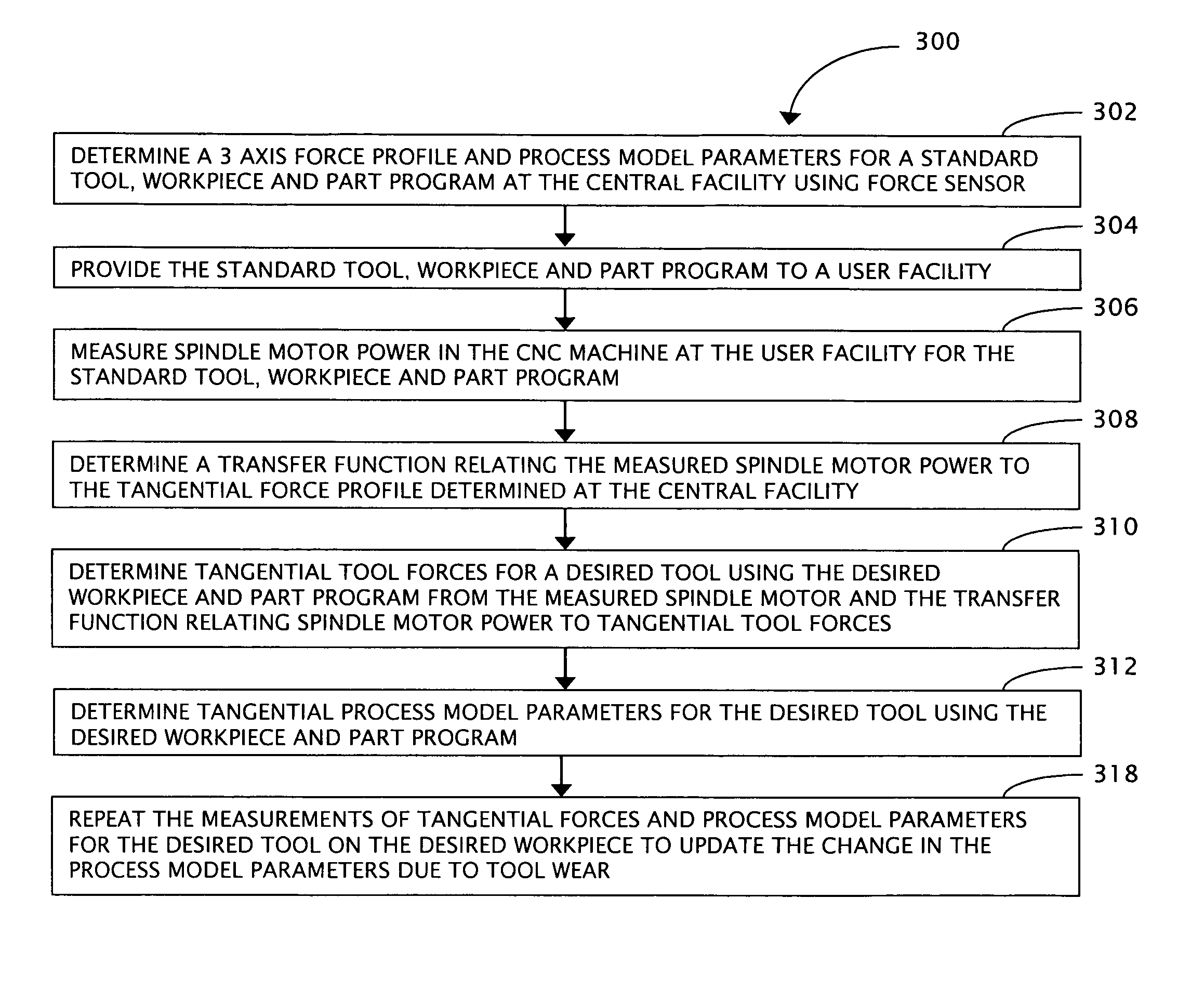

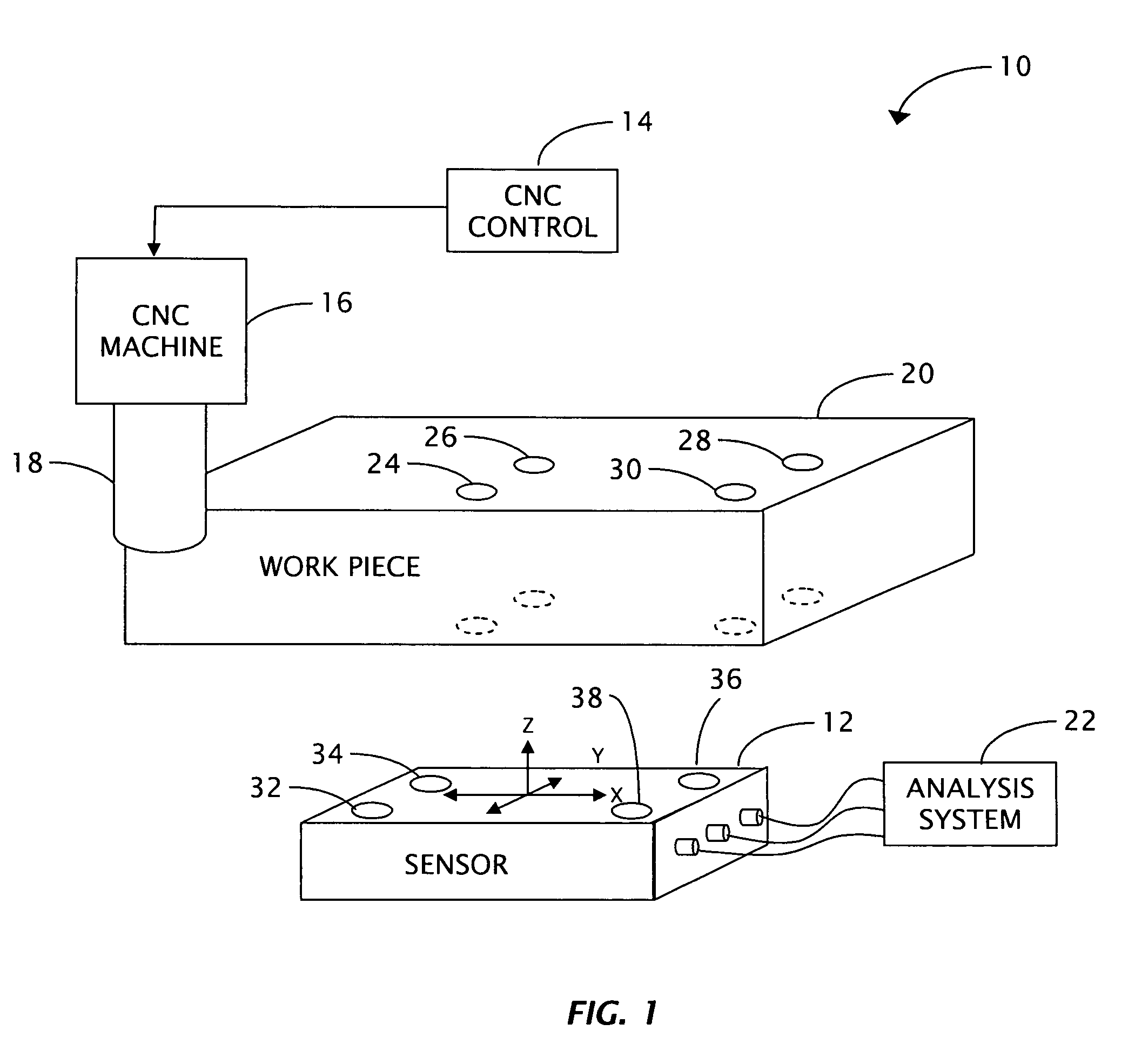

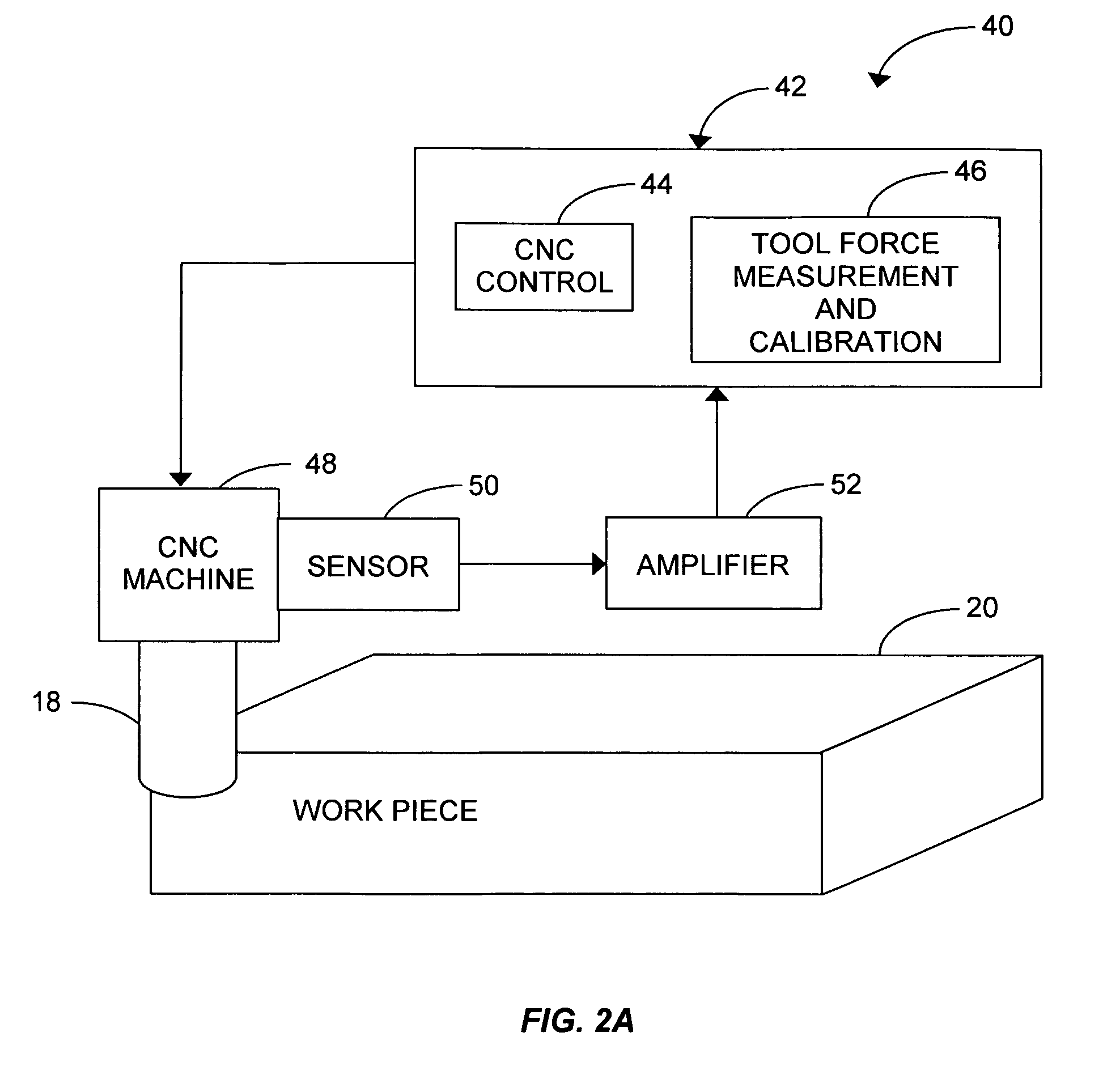

InactiveUS20070016325A1Inexpensive but accurate monitoringAddressing Diversity InsufficiencyProgramme controlForce measurementSacrificial partElectric machinery

A system and method are provided for real-time measurement of tool forces. A relationship between a sensor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The sensor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the sensor characteristic and tool forces is determined. Thereafter, the sensor characteristic of the CNC machine is measured for a work piece, part program and desired tool and converted to tool forces using the relationship between the sensor characteristic and tool forces. The resulting tool forces may be combined with a process model to obtain process model parameters or cutting energies for the work piece and the desired tool. In cases where the sensor is not conveniently attached to the work piece or when the part program is not sufficiently robust in cutting conditions to accurately determine the process model parameters, the work piece and part program are replaced by a sacrificial work piece and sacrificial part program. The sacrificial work piece and sacrificial part program are selected to both accommodate the sensors and to provide sufficient robustness in cutting conditions to accurately determine the process model parameters for the sacrificial work piece. The process model parameters for the desired work piece are obtained from the process model parameters by, first, obtaining the averaged tangential tool forces for the desired work piece and for the sacrificial work piece by measuring the spindle motor power and applying the relationship between spindle motor power and tangential tool forces for each work piece, second, obtaining a ratio of the averaged tangential tool forces for the desired work piece and the sacrificial work piece and, third, applying this ratio to the process model parameters for the sacrificial work piece to obtain predicted values for the tool forces and the process model parameters for the desired tool and desired work piece.

Owner:UNIVERSITY OF NEW HAMPSHIRE

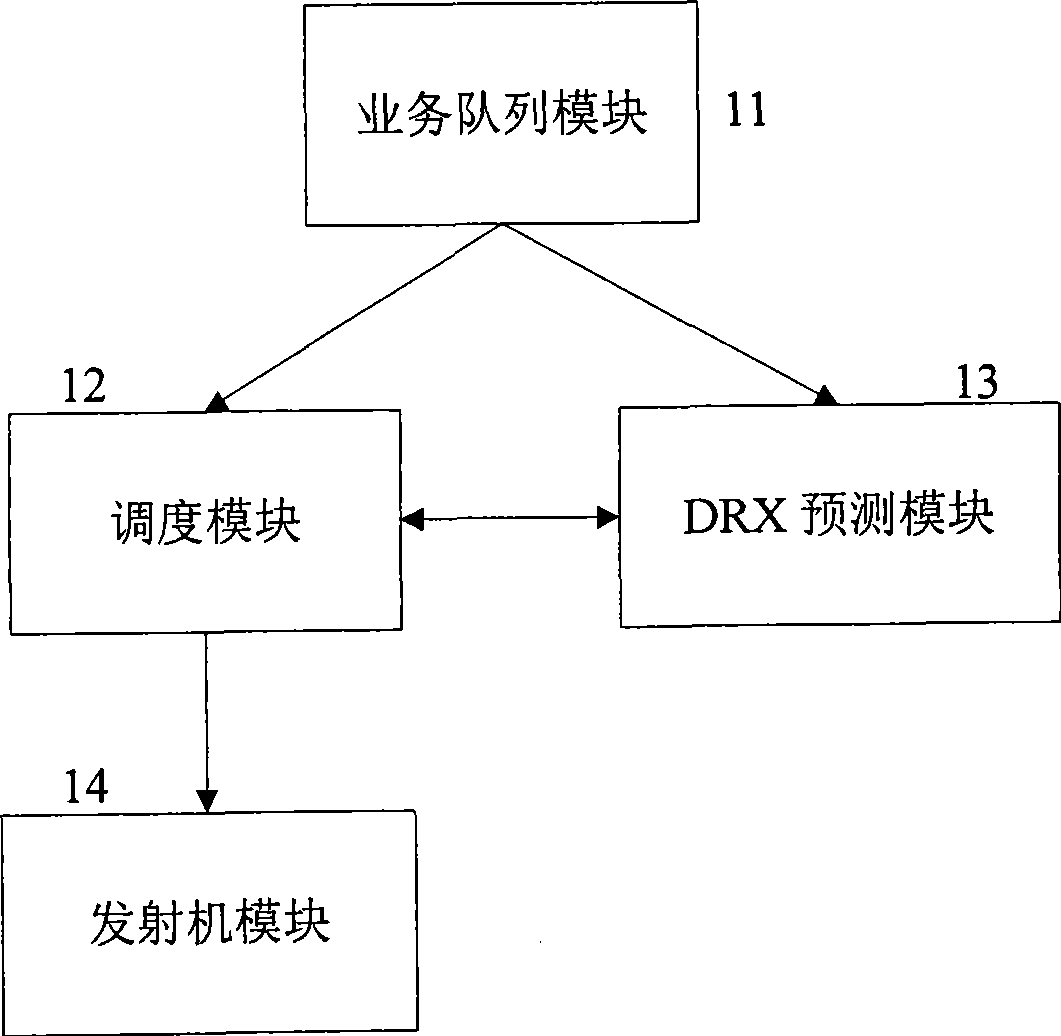

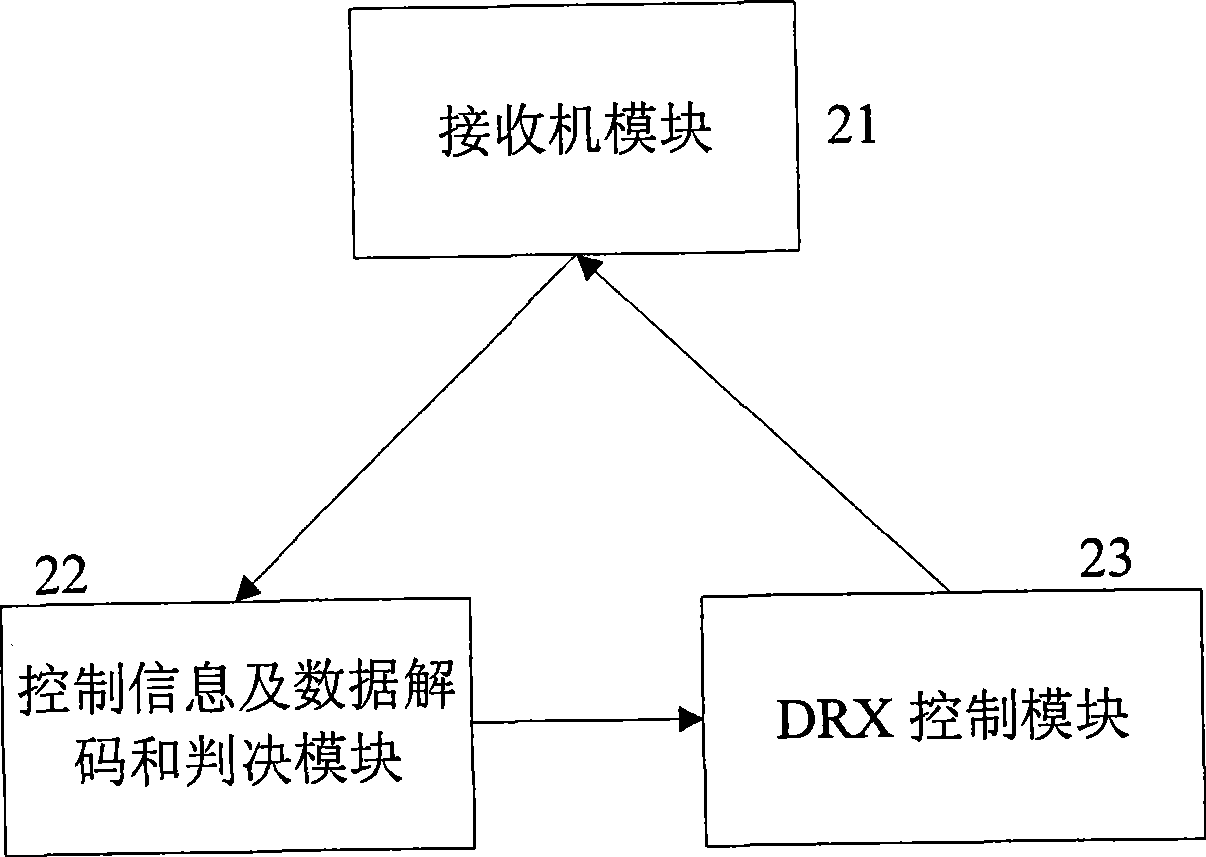

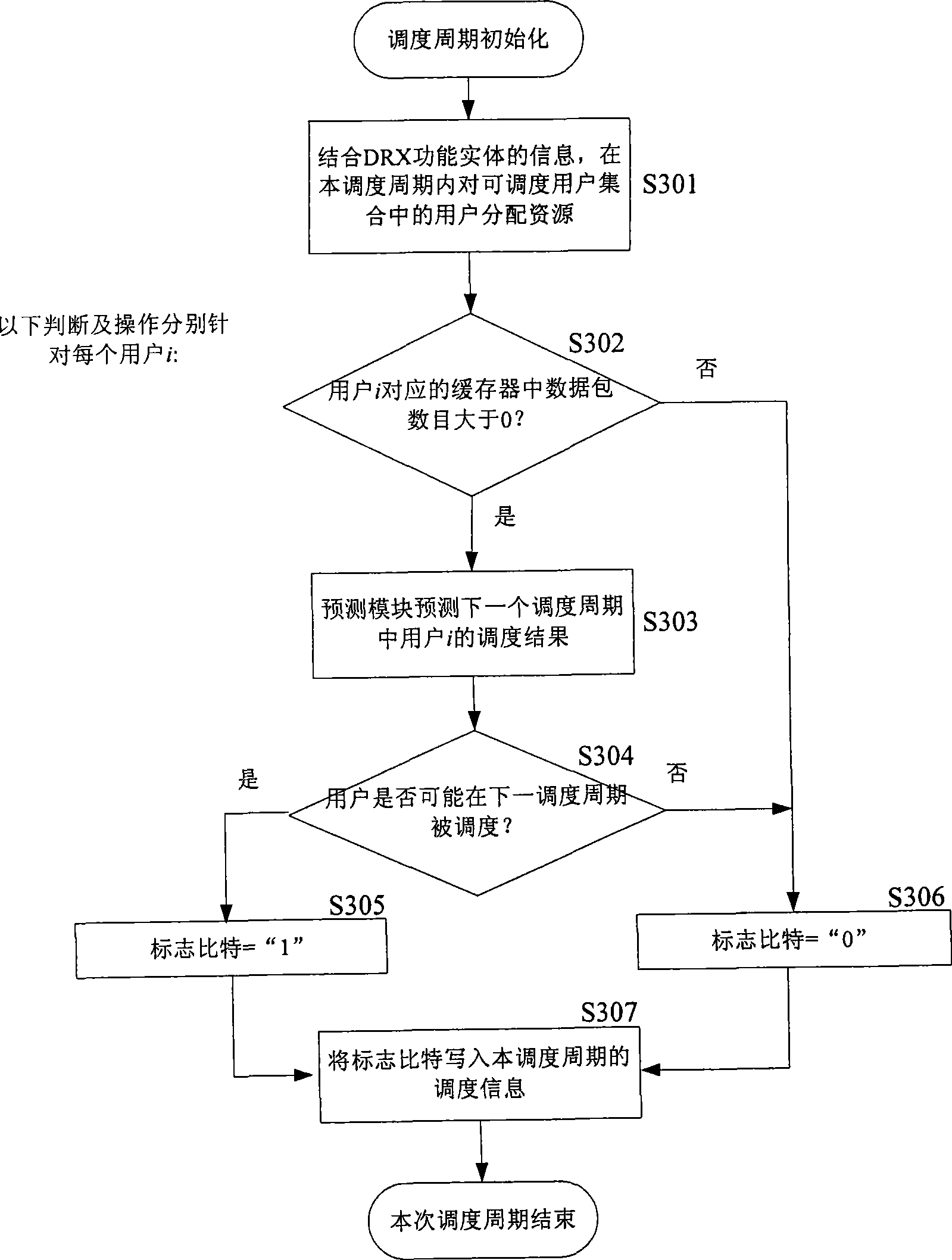

Method and apparatus for dynamically controlling uncontinuous receiving

ActiveCN101483446AEasy to adjustEfficient acquisitionEnergy efficient ICTTransmissionBiological activationSelf adaptive

The present invention discloses a method for dynamically controlling the non-continuous receiving of user facility with a self-adapting mode. The invention comprises the following steps: allocating resource for the schedulable user facility at the network side in scheduling period, and confirming whether the data to be transmitted to each schedulable user facility exists after present scheduling period; indicating a token indicating whether the data to be transmitted to the user facility exists for the user facility according to the confirmation result, and transmitting the set token and scheduling information together to the user facility; and controlling the receiver to enter into a dormancy stage or continue in the activation period by the user facility according to the received token, wherein when the token shows that the data to be transmitted to the user facility exist at the network side, the user facility controls the receiver in the activation period. When the token shows that data to be transmitted to the user facility do not exist, the user facility controls the receiver to enter the dormancy stage.

Owner:NTT DOCOMO INC

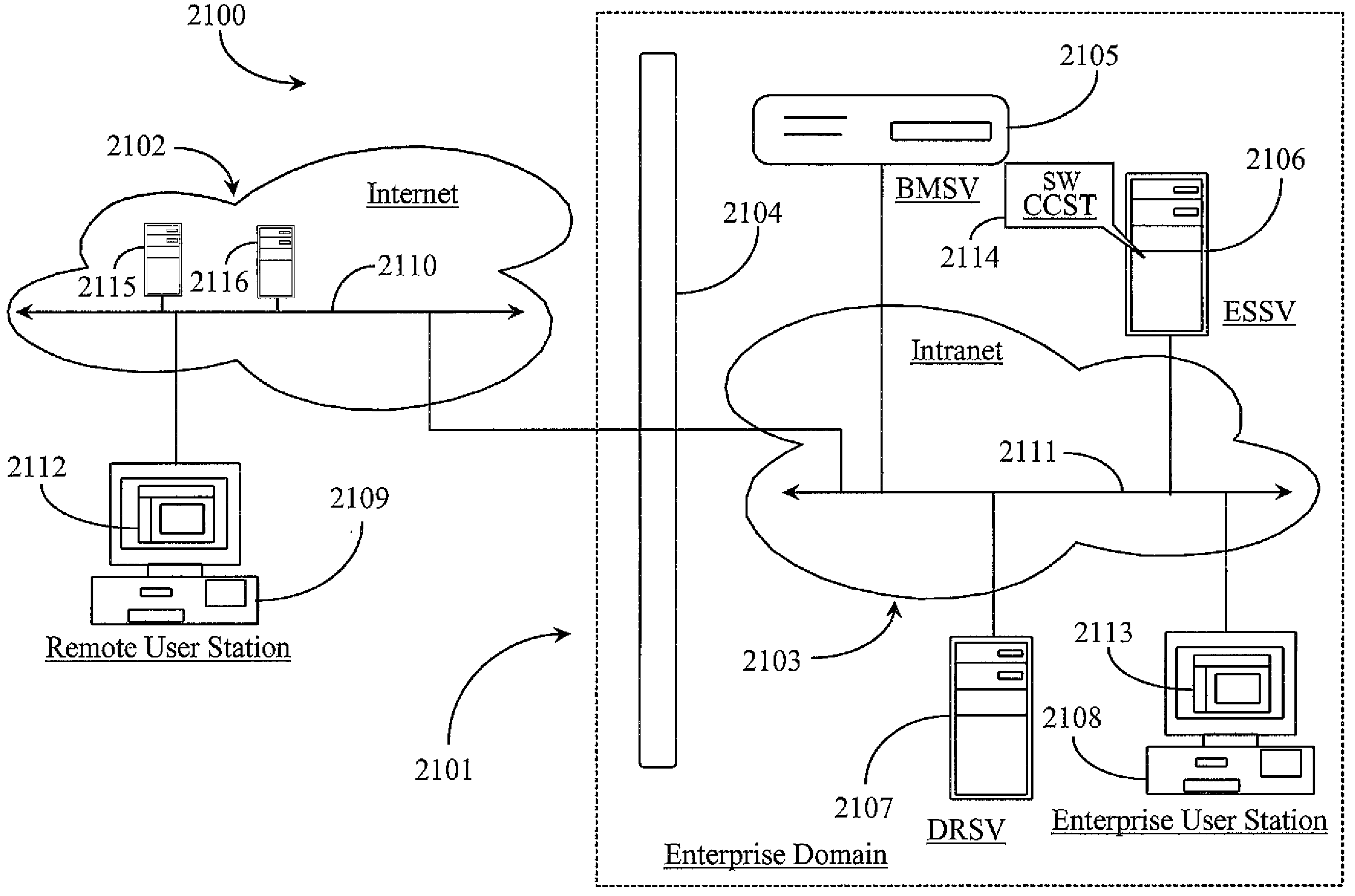

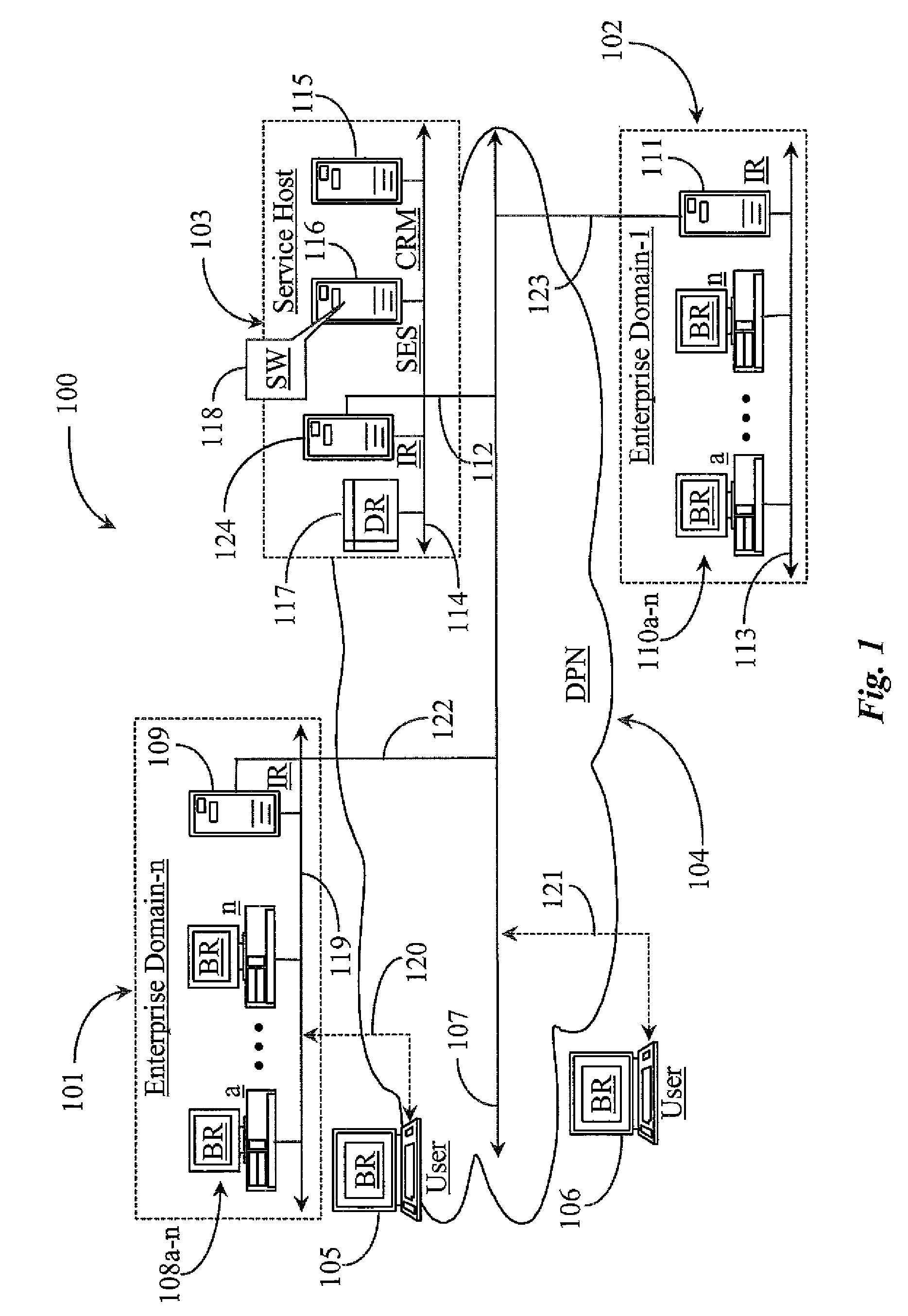

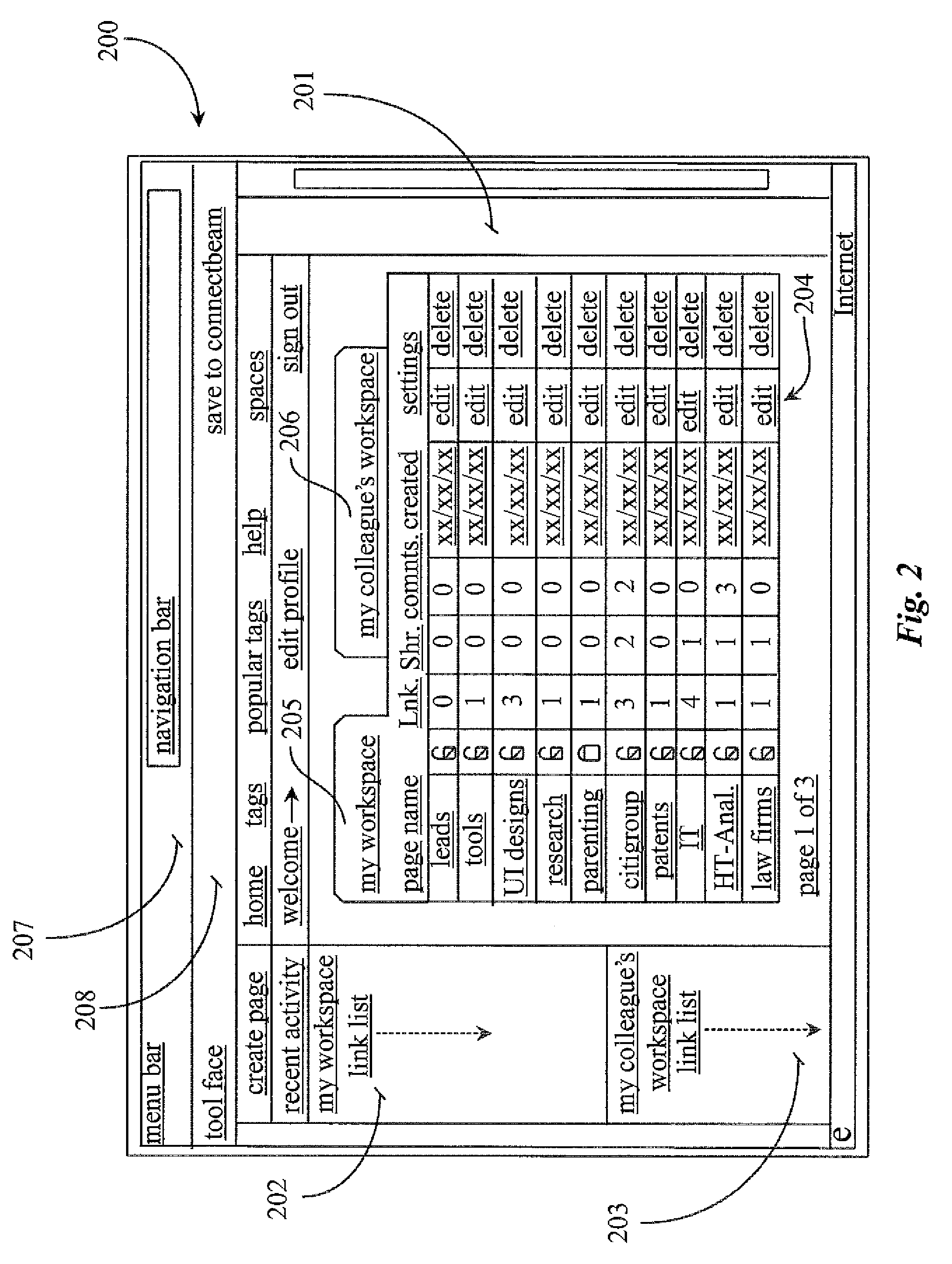

Knowledge Management System with Collective Search Facility

InactiveUS20090083229A1Digital data processing detailsMetadata multimedia retrievalUser FacilityManagement system

A search facility includes a computerized appliance coupled to one or more private enterprise networks with connected data repositories, the appliance executing software from a machine-readable media, and a portal from one of the one or more private enterprise networks to one or more networks external to the enterprise. The software provides an interactive interface on a display of the appliance, the interface providing an input mechanism for a user to enter search criteria and an initiation mechanism for the user to initiate a search using the entered criteria, and wherein a search thus initiated searches both the data repositories within the enterprise, and sources outside the enterprise accessible by the one or more networks external to the enterprise.

Owner:INTELLECTUAL ADVANCE

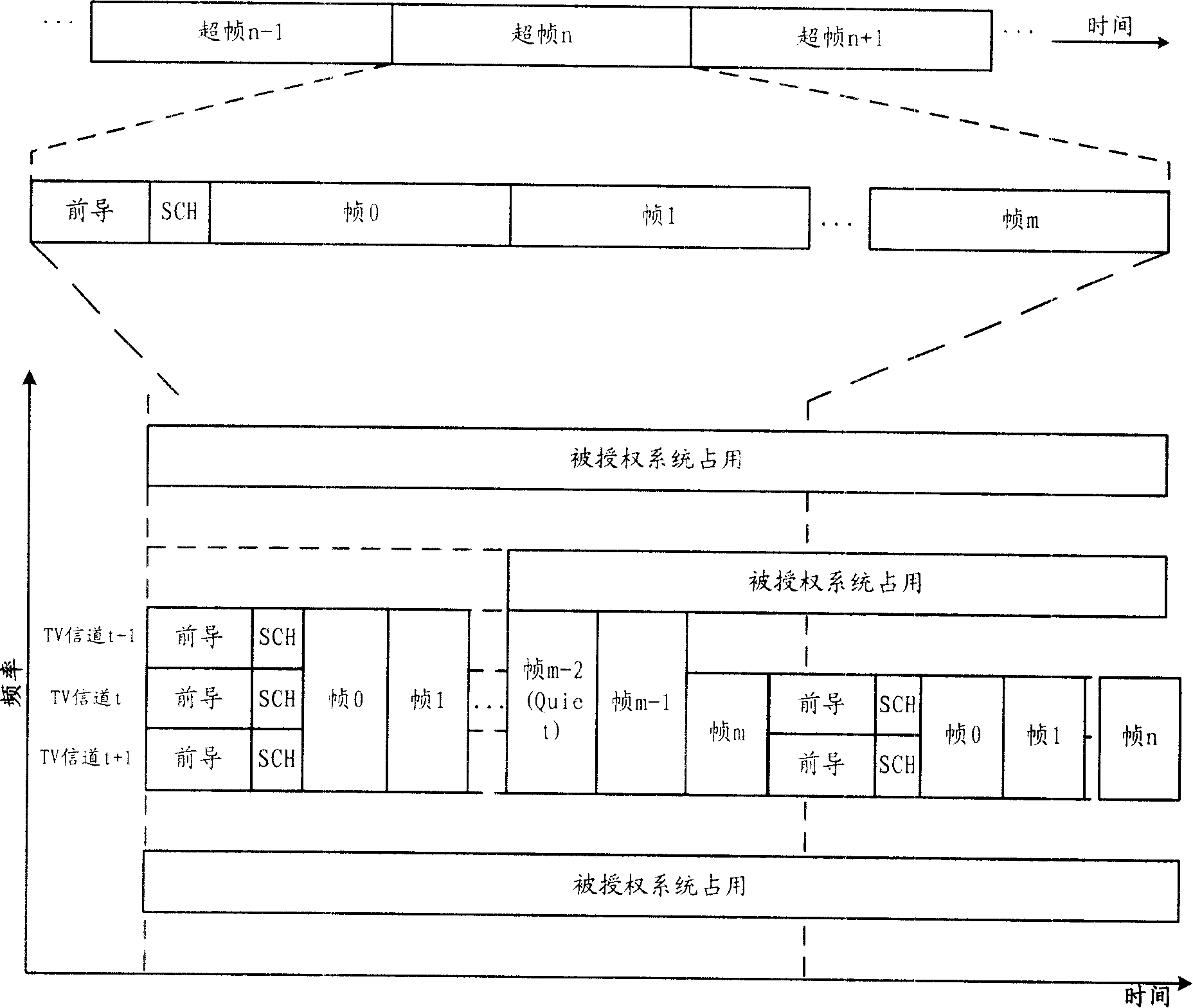

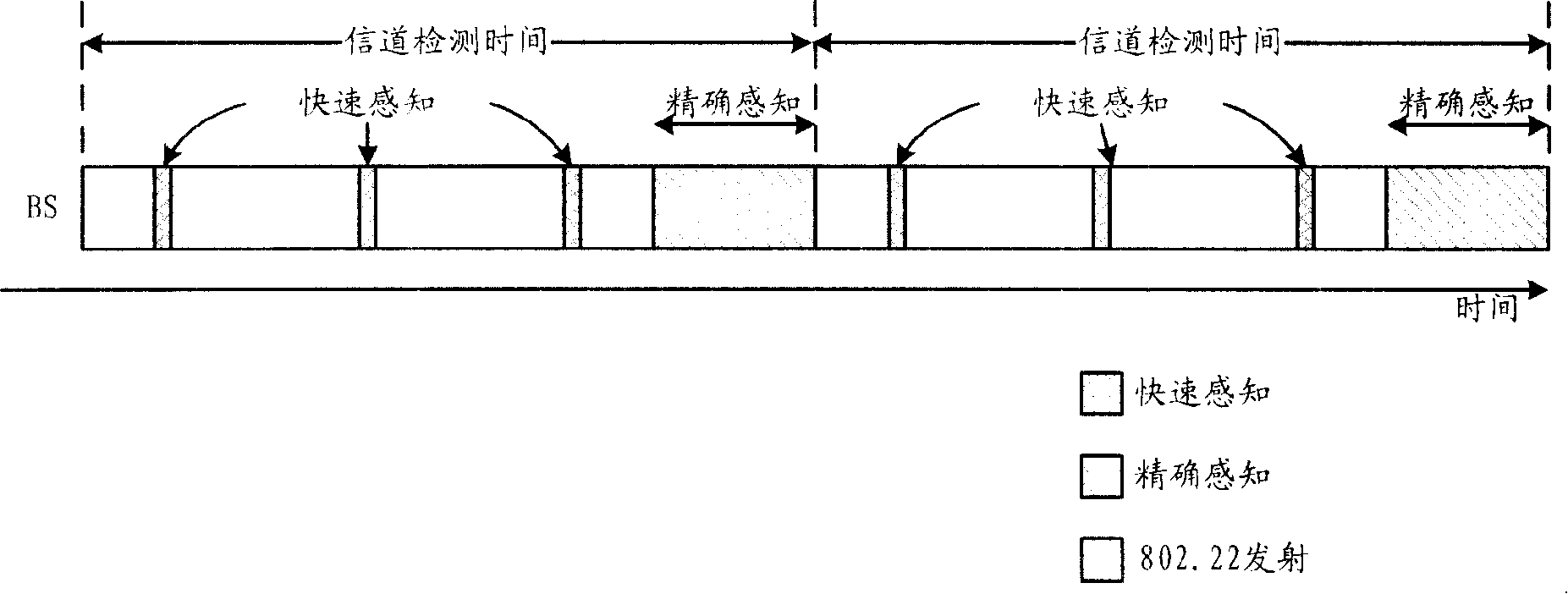

Frequency spectrum detecting and sharing method, system, user facility and device

InactiveCN101184324AAccurate judgmentQuality improvementRadio/inductive link selection arrangementsRadio transmission for post communicationFrequency spectrumComputer science

The invention relates to a wireless communication field, disclosing a frequency spectrum detection and sharing method, system, user equipment and device. In the invention, when the network receives at least two CPE sensing detection reports, whether frequency spectrum occupancy occurs or not currently can be judged synthetically according to the CPE sensing detection reports and CPE sensing capability, thereby performing the judgment of sensing detection reports more accurately and improving the quality of judgment result. The CPE sensing capability comprises CPE sensing detection method, for the sensing detection report for sensing same type signal, the network distributes higher credibility for higher level sensing detection report according to the CPE sensing detection method, and judges the sensing detection reports comprehensively according to the credibility.

Owner:HUAWEI TECH CO LTD

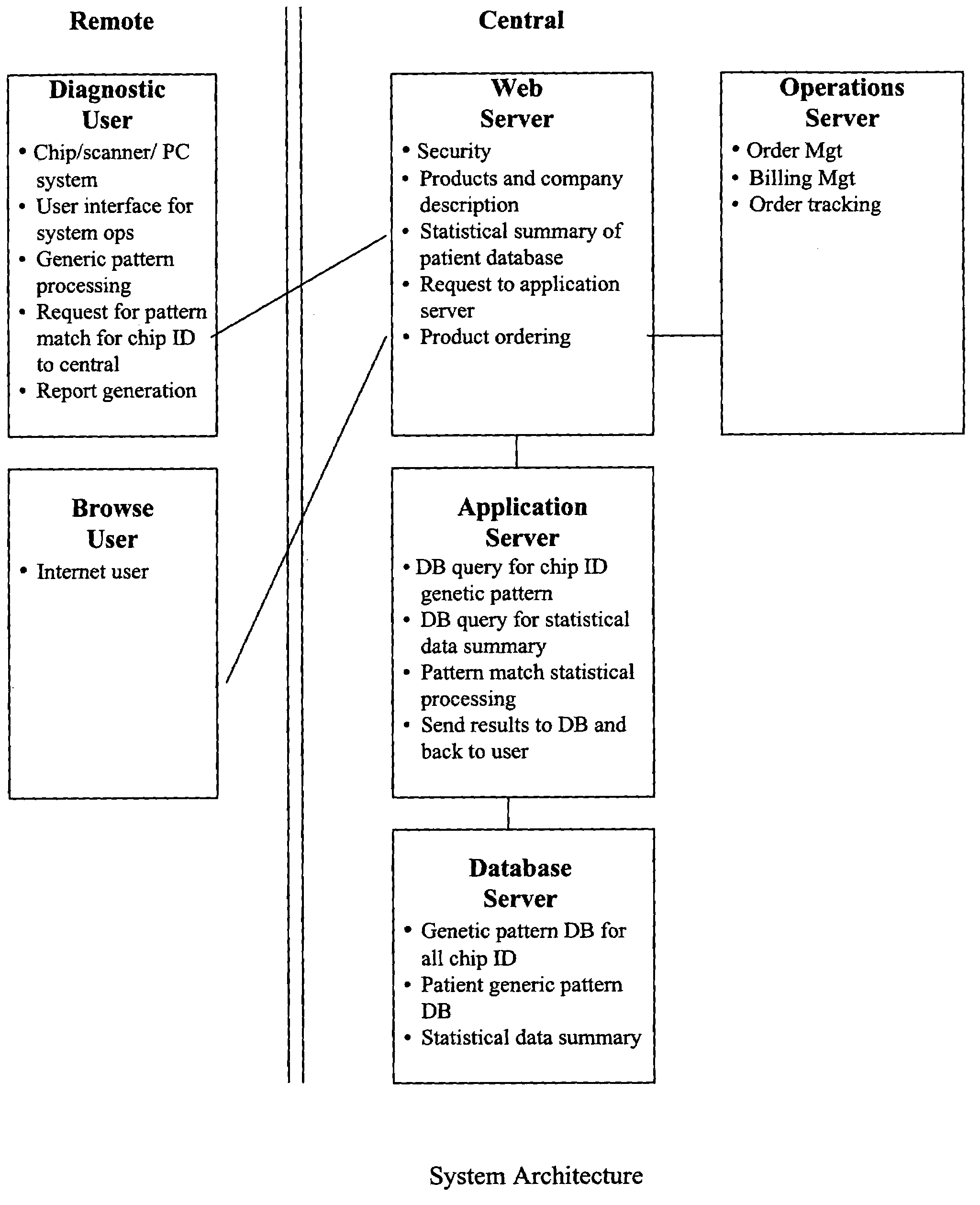

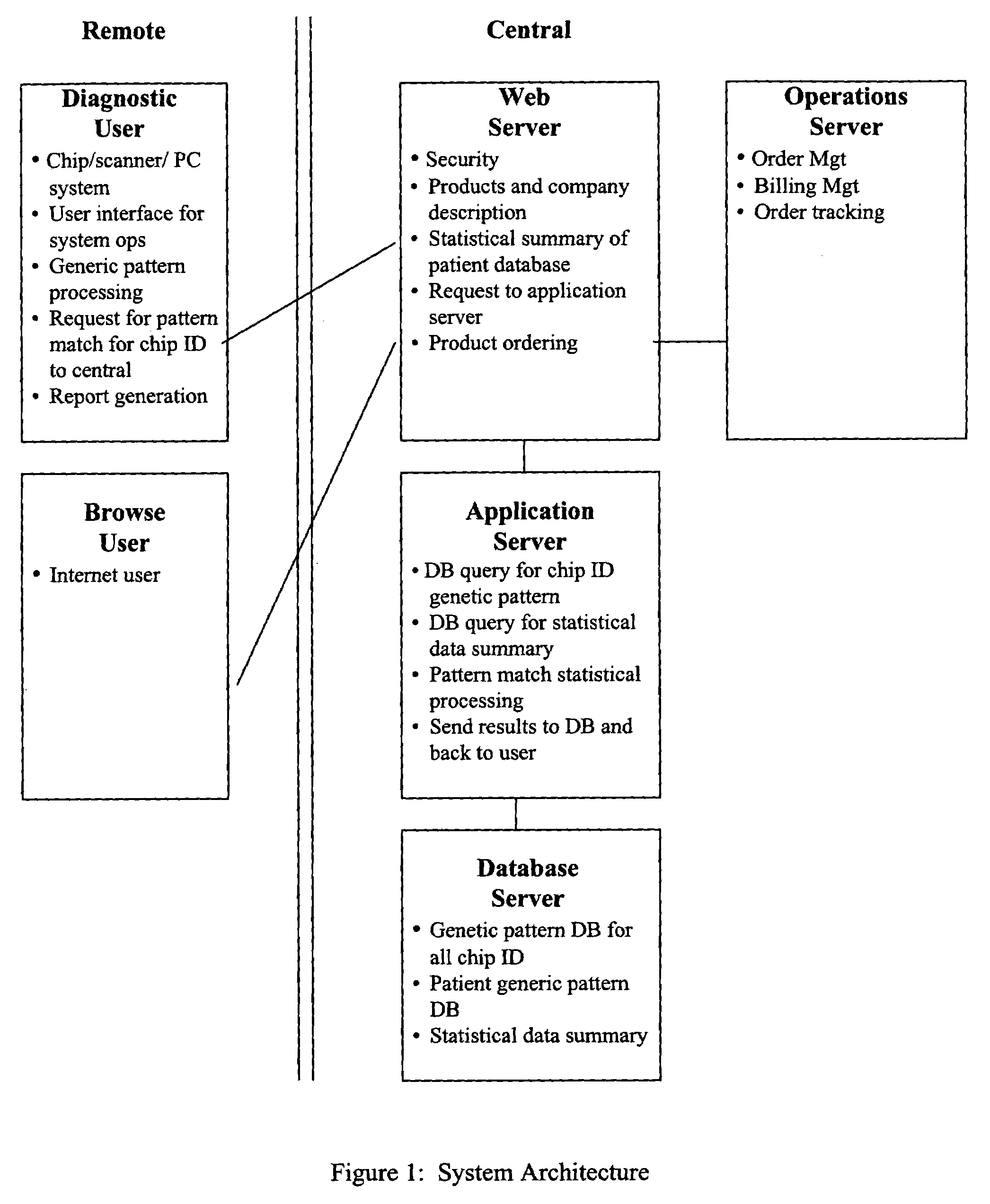

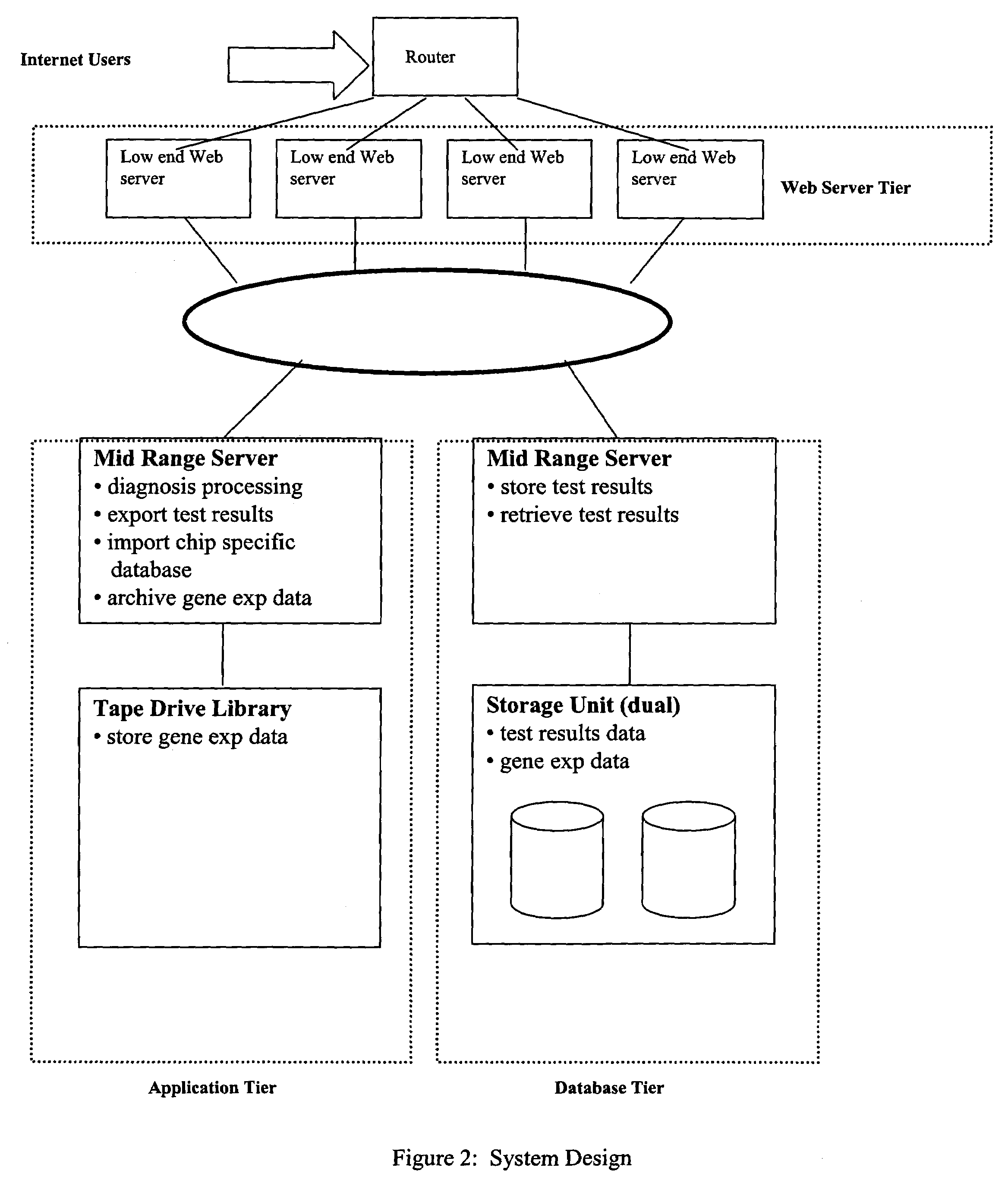

Artificial intelligence system for genetic analysis

InactiveUS7062076B1Interpreting informationAcquiring/recognising microscopic objectsProteomicsData conversionUser Facility

The present invention provides a complete artificial intelligence system for the acquisition and analysis of nucleic acid array hybridization information. The system is divided into at least one central data processing facility and one or more user facilities, linked by encrypted network connections or similar links. Each user facility may include an optical scanning system to collect hybridization signals from a nucleic acid array, an image processing system to convert the optical data into a set of hybridization parameters, a connection to a data network, and a user interface to display, manipulate, search, and analyze hybridization information. This system reads data from a gene chip or DNA microarray, or a proteomics chip, analyzes test results based on maintained parameters, evaluates patient risk for various ailments, recommends methods of treatment, presents information to medical and / or private individuals, and notifies test participants when new treatment becomes available. The test results may be used to perform individual diagnostics, longitudinal studies, population studies, or a wide variety of statistical analyses of patient data. The automated artificial intelligence system is a real time, dynamic decision making tool that can be used not only in conjunction with a clinical analysis system, but also with the information obtained in a research and development environment. Access to this system allows the user(s) to look at both clinical and non-clinical information. Most importantly, the system is intelligent and possesses the capability to interpret the information obtained. The system presents the information primarily via a secured encrypted Web interface, such as the Internet. The information is also presented in a retrievable format, such as electronic or paper format, using various computing technologies.

Owner:IRIS BIOTECH

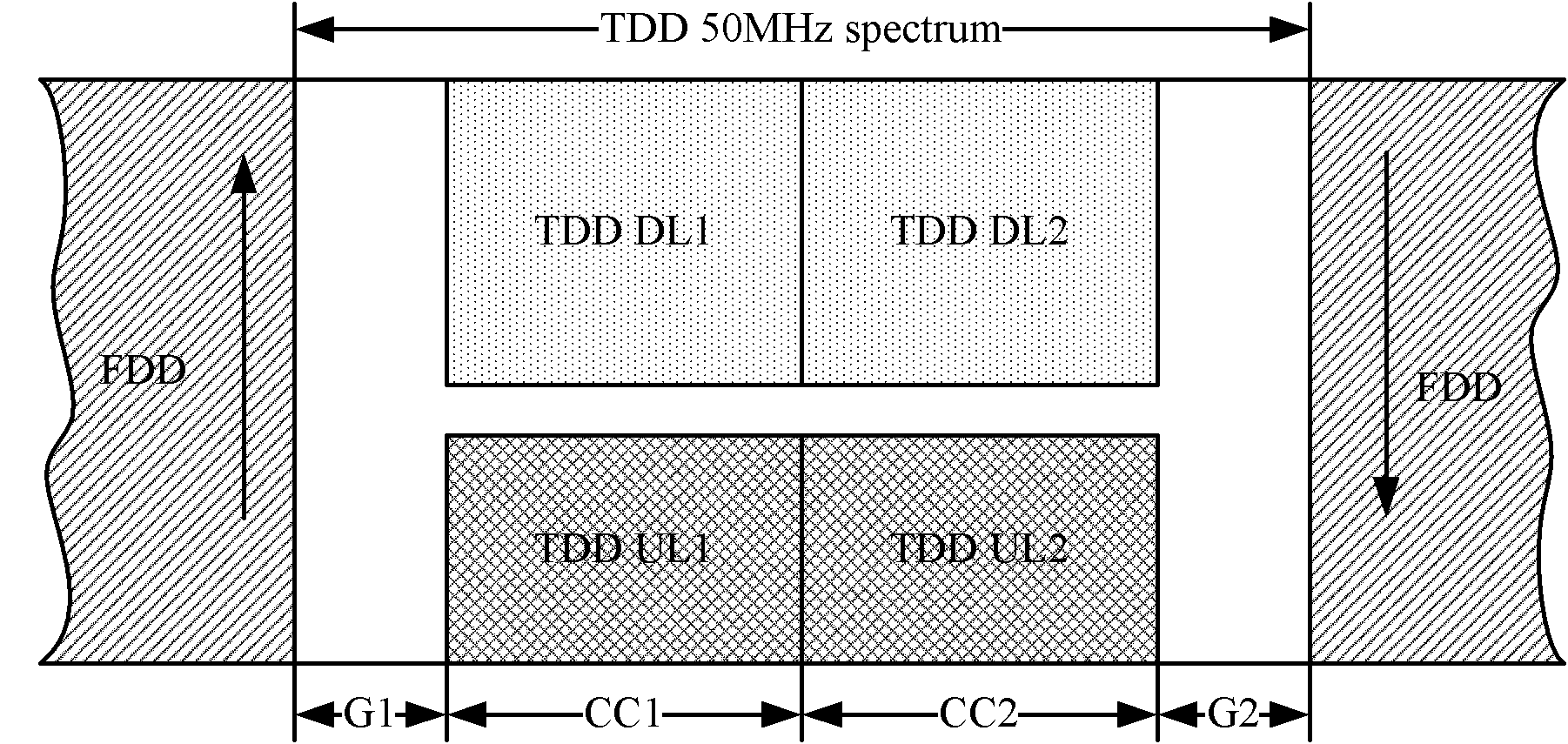

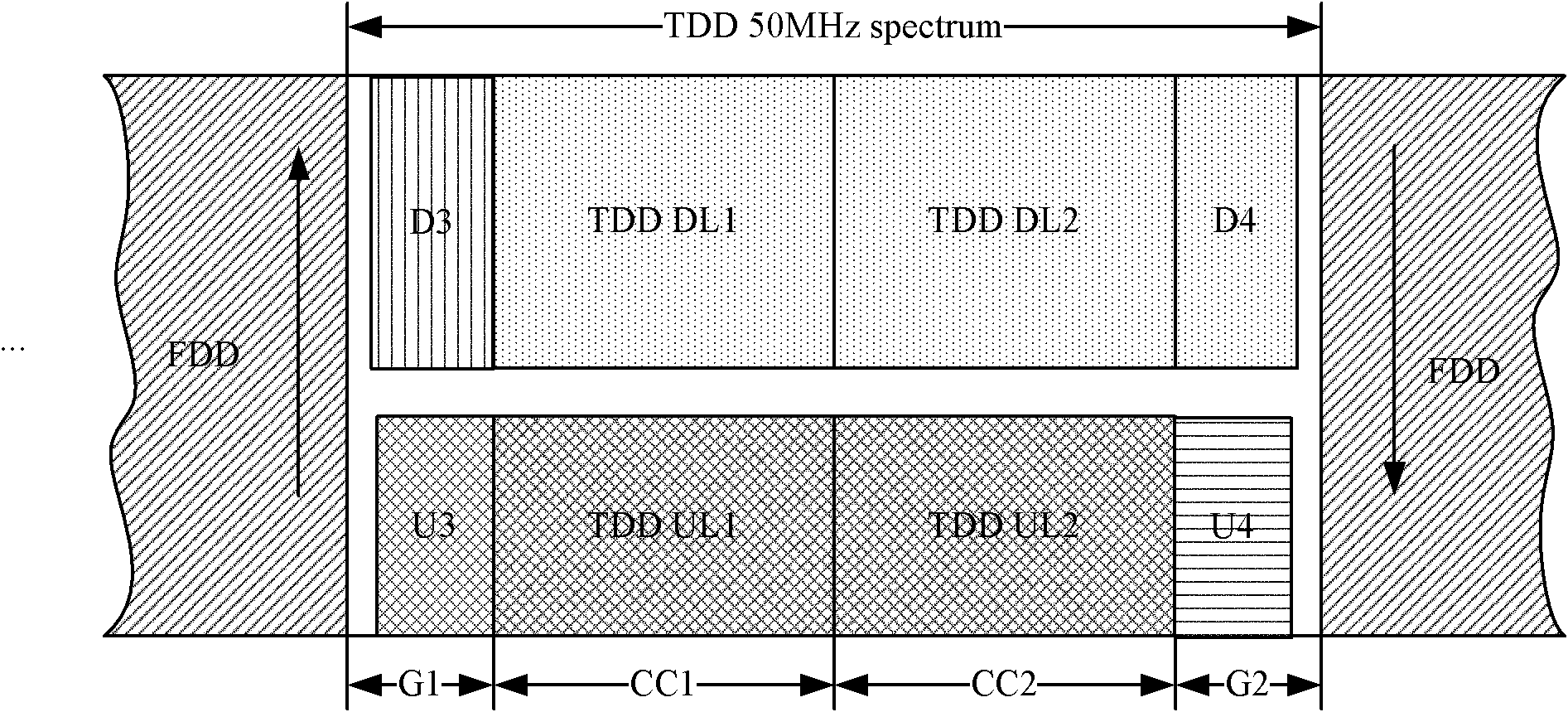

Method and device for processing frequency spectrum resources

ActiveCN102026208AImprove efficiencyLow costNetwork traffic/resource managementTransmission path divisionFrequency spectrumCarrier signal

The invention discloses a method and a device for processing frequency spectrum resources. The method comprises that a base station determines frequency spectrum resources needing to be processed, the frequency spectrum resources can be used for uplink data transmission, and downlink frequency spectrum resources without corresponding relationship of uplink and downlink are used for downlink data transmission; and the base station notifies the user facility of using a carrier wave aggregation technology to polymerize the frequency spectrum resources after determining that the frequency spectrum resources are used for the uplink data transmission. The user facility polymerizes the frequency spectrum resources by utilizing the carrier wave aggregation technology according to notification. The invention has the advantages that terminals can operate in cells within protection bandwidth, the using efficiency of a time division duplex frequency spectrum is improved, and system cost is lowered.

Owner:DATANG MOBILE COMM EQUIP CO LTD

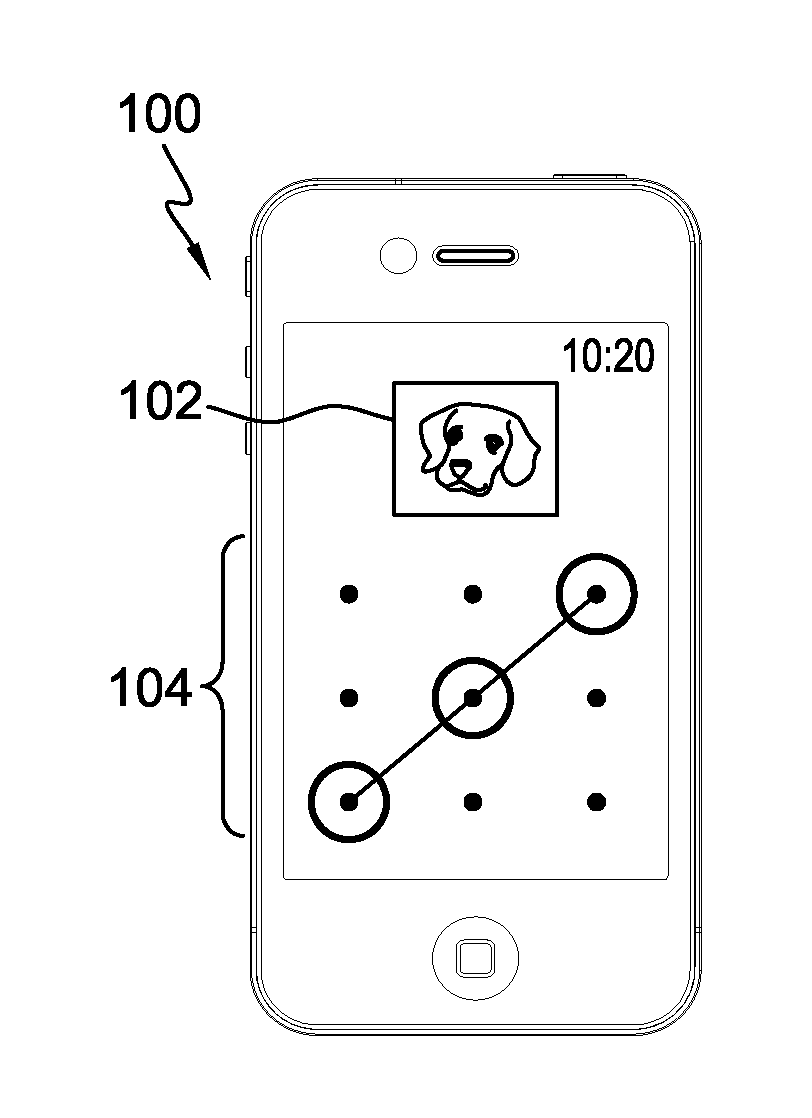

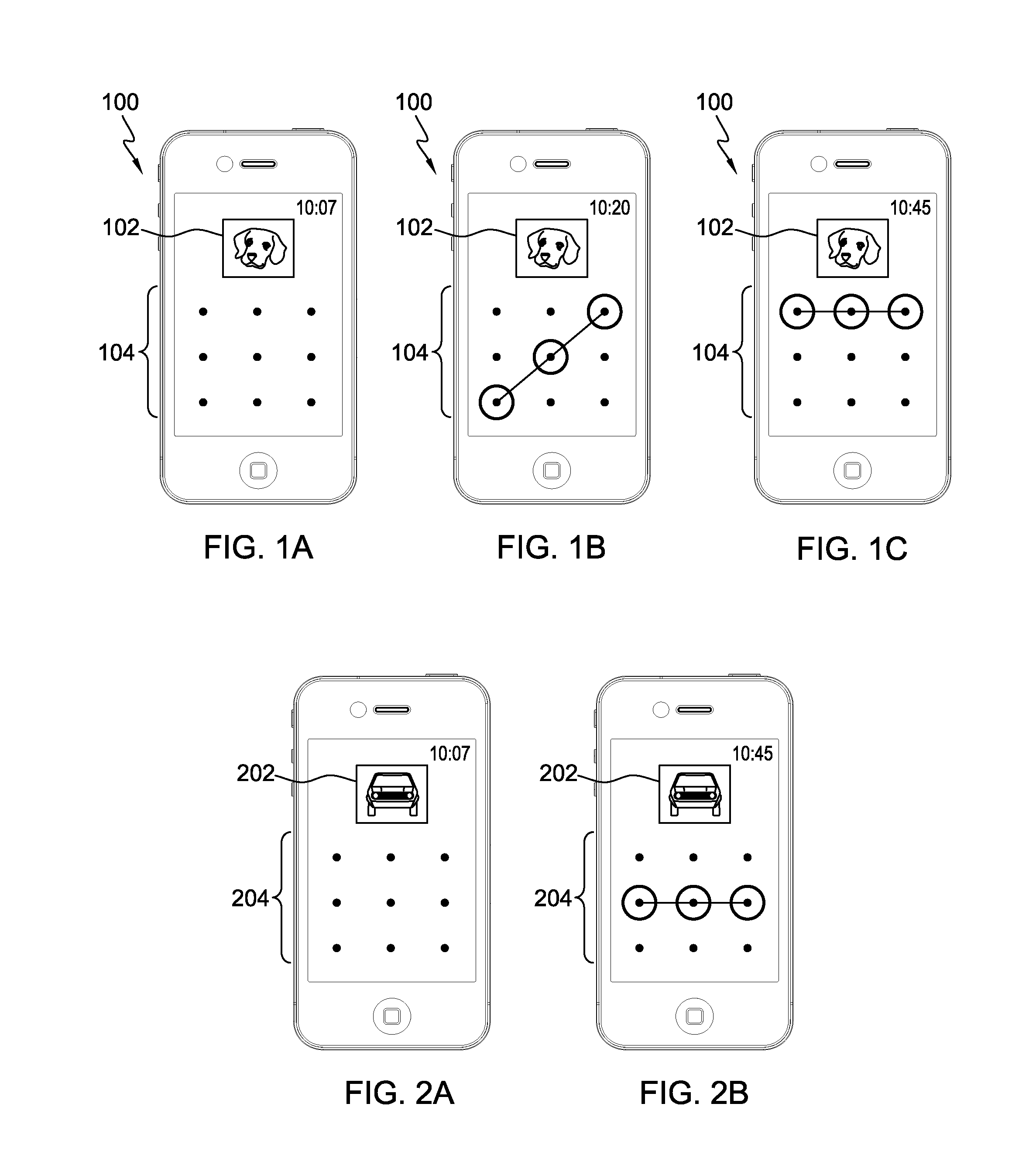

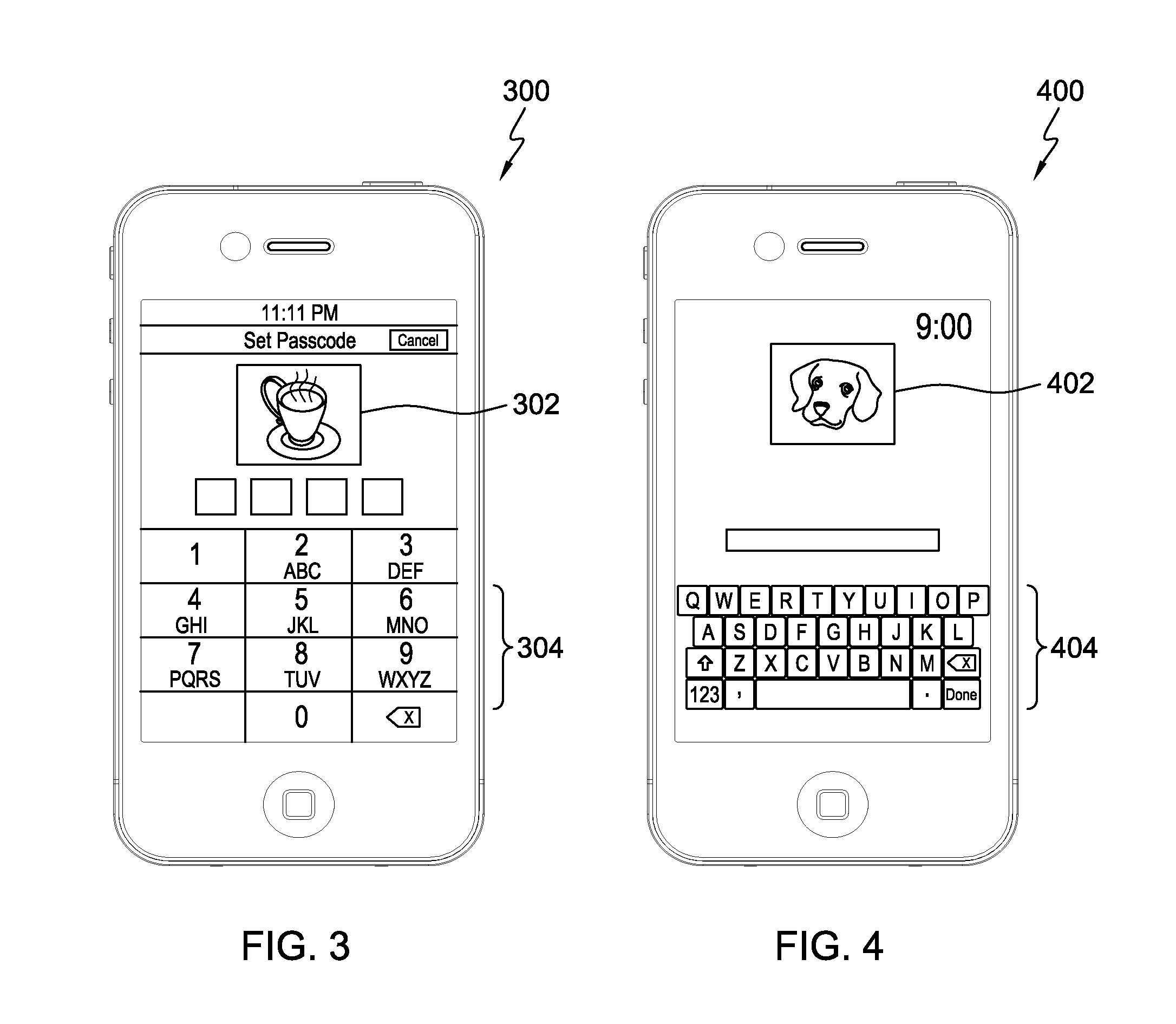

Variable image presentation for authenticating a user

ActiveUS20160132673A1Improvement against over-the-shoulderImprovement other attackDigital data protectionDigital data authenticationGraphicsInternet privacy

Facilities are provided herein for authenticating a user to use a processing device. A user predefines authenticators of one or more types and associates these with graphical images. Upon on attempt to activate the processing device, a graphical image, of the graphical images, is selected for presentation to the user. The selected graphical image is presented to the user, who then provides input to authenticate with the device. A determination is made as to whether the user is authenticated to use the device. The determination is made based on input received from the user and based further on the authenticator associated with the selected graphical image. Varying the selection of image(s), each associated with a predefined authenticator and authentication type, enables variability in the authenticator that is suitable for unlocking a device at a given time, providing greater security to the authentication process.

Owner:IBM CORP

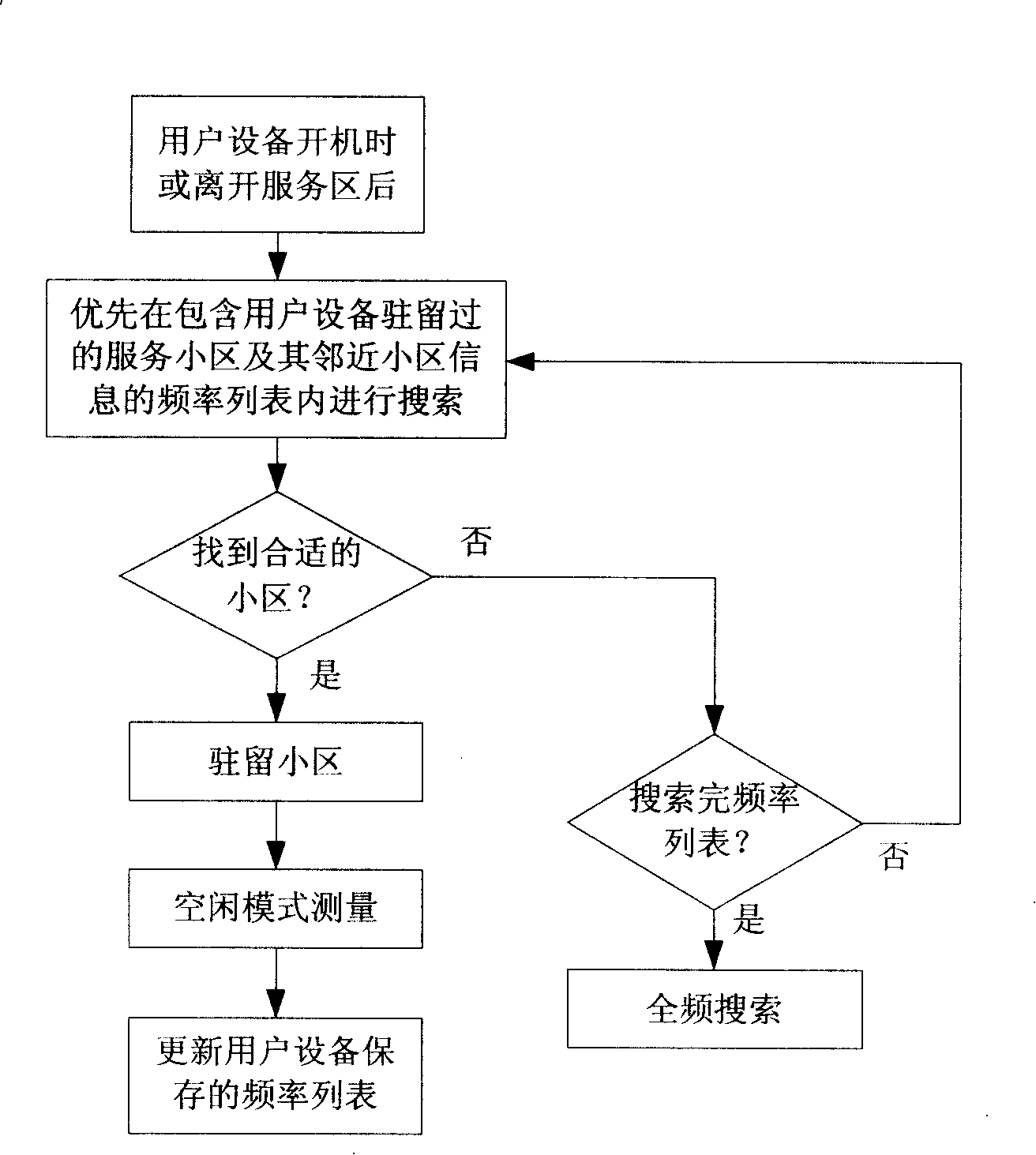

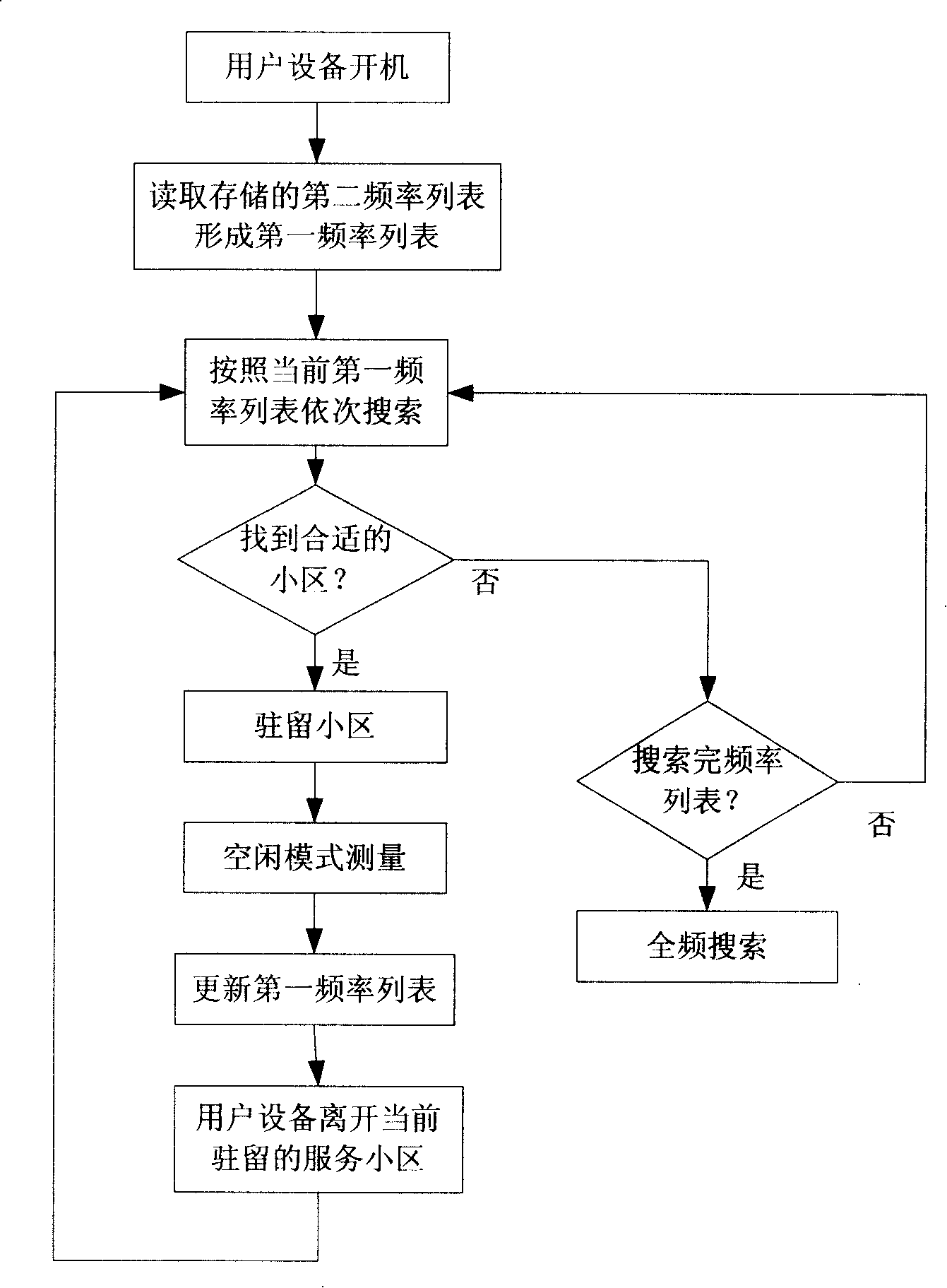

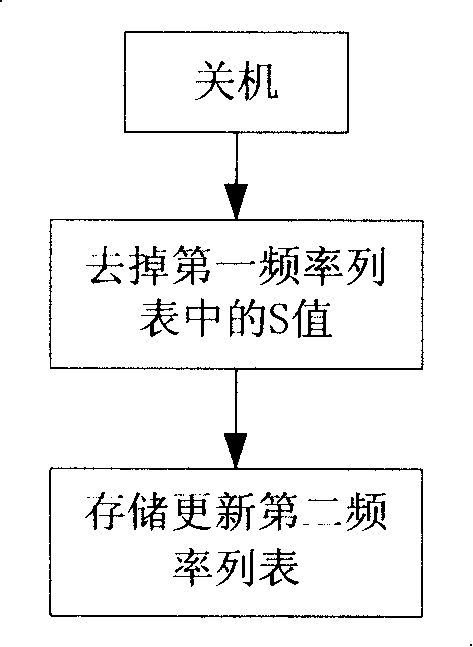

Method for searching district frequency

InactiveCN101227204AFewer searchesShorten the timeAssess restrictionTransmissionUser FacilityElectricity

The invention discloses a frequency searching method for a community, wherein the method preferentially carries out community frequency search in a frequency table which contains a serviced community and the adjacent community information which are resided in a user facility, next adaptive community frequency search is accelerated after opening machine or leaving off a service area, therefore the adaptive community frequency can be effectively searched, the time that a user facility is connected to the network is shortened, searching times of the community frequency are reduced, therefore the purpose of electricity saving is achieved.

Owner:上海宇梦通信科技有限公司

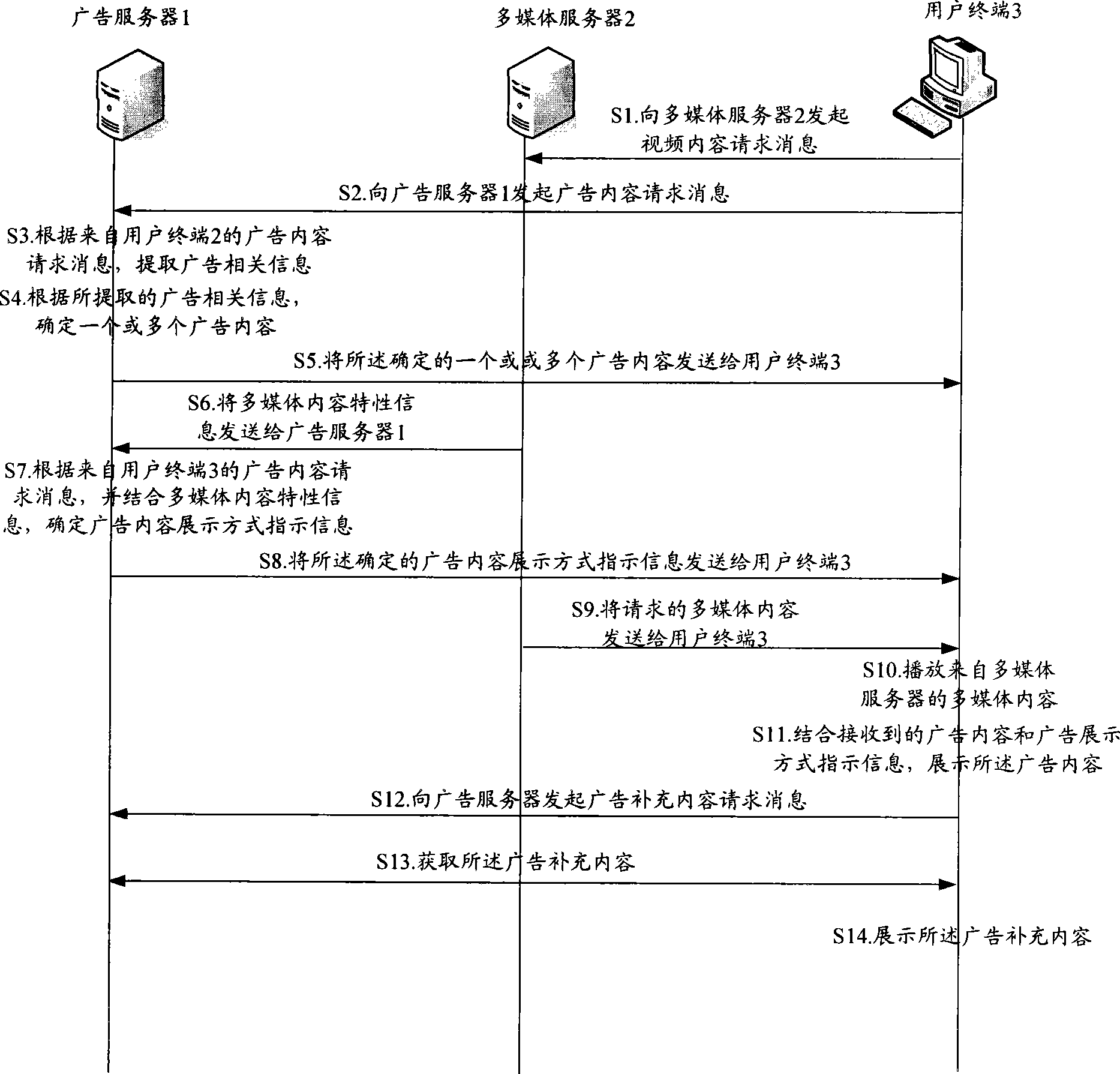

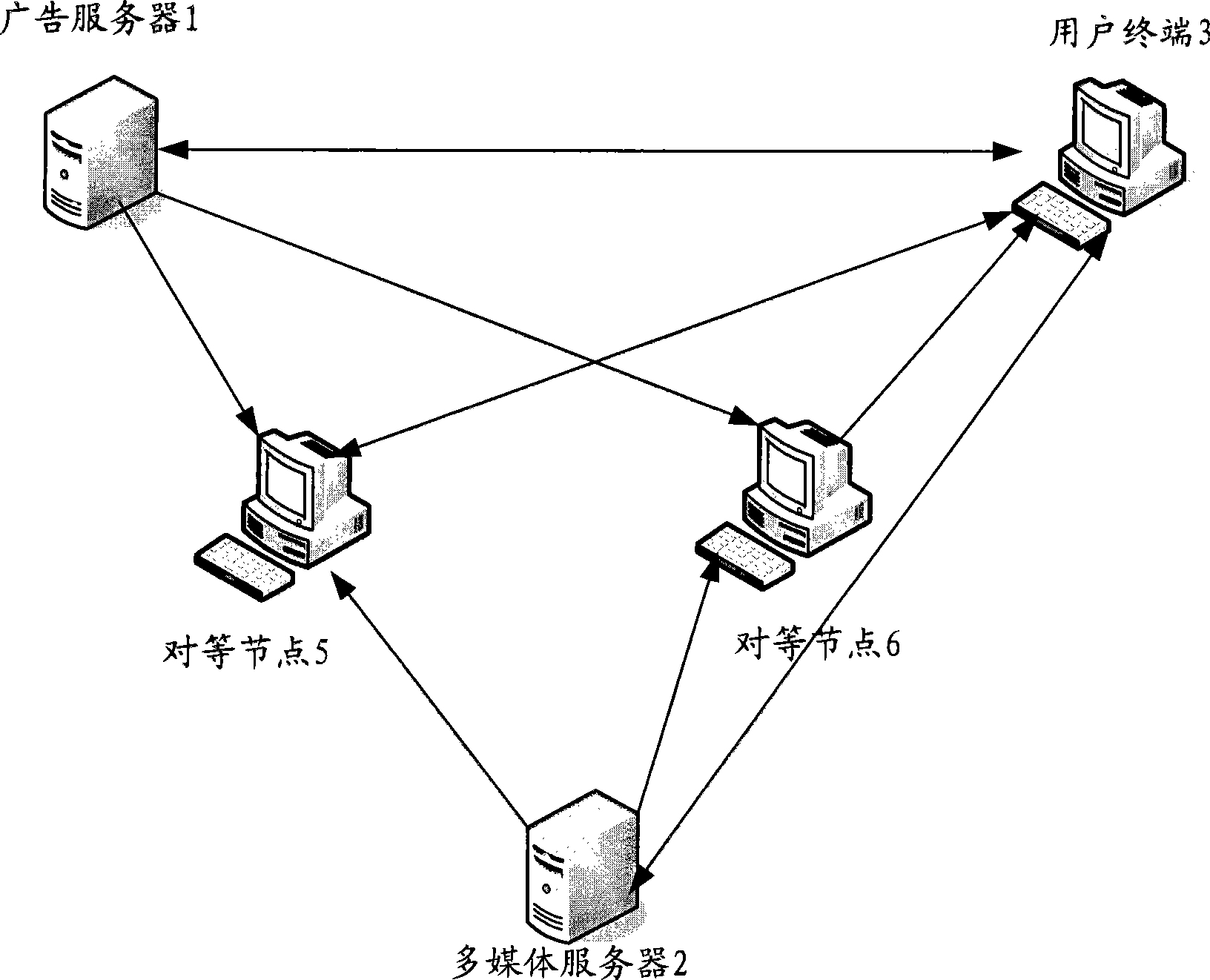

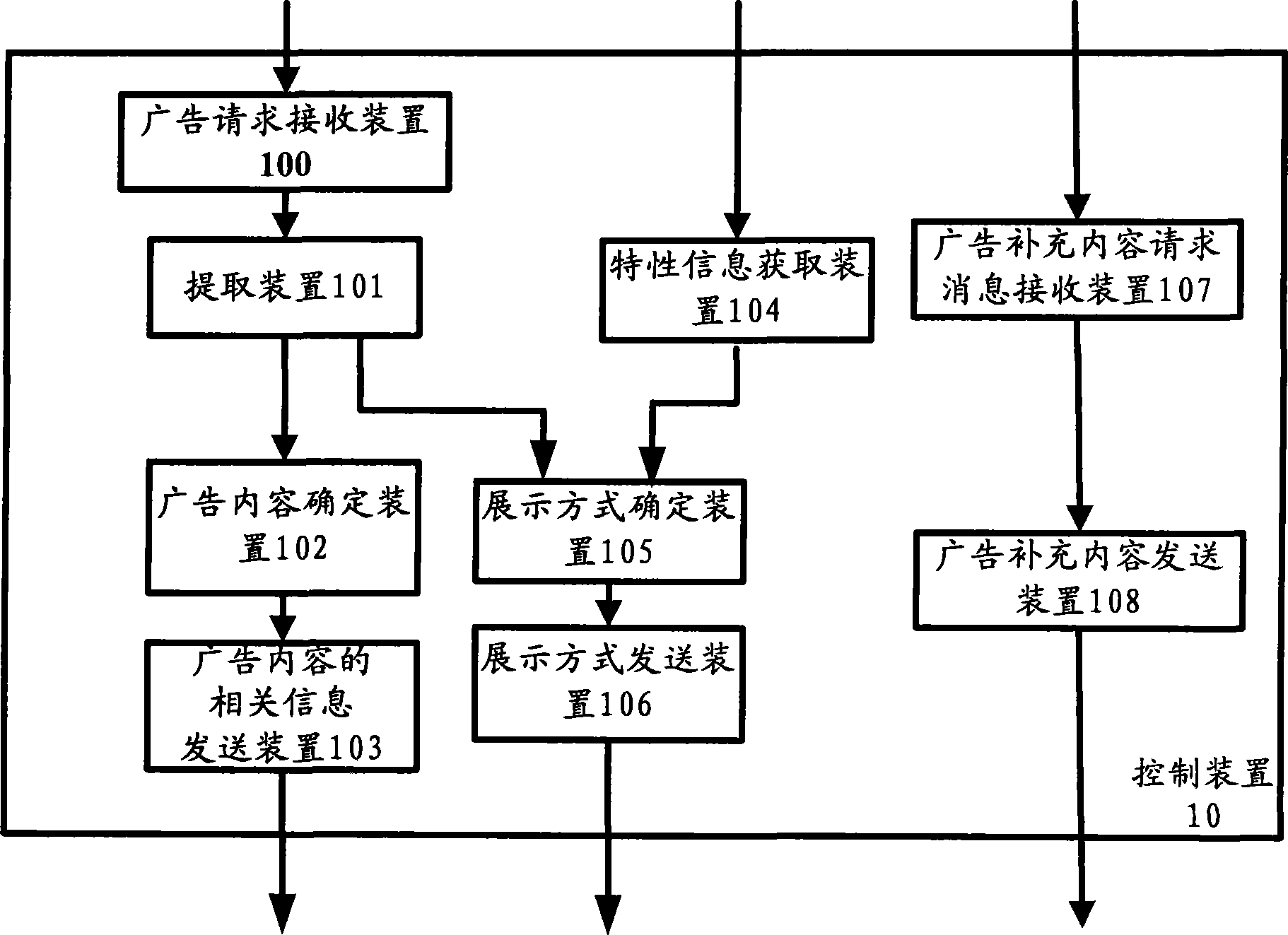

Method and apparatus for exhibiting advertisement in multimedia content based on user personalized information

InactiveCN101471802AImprove timelinessSolve the problem of no interactionSpecial service provision for substationCommercePersonalizationRelevant information

The invention provides a method and a device for showing advertisement contents based on a multi-media content request of a user to a user facility applying for receiving multi-media film and music contents or receiving the multi-media film and music contents according to individualized demands of the user. According to the technical scheme, an advertisement server extracts relevant advertisement information from advertisement content request information, determines one or a plurality of advertisement contents based upon the extracted relevant advertisement information, and determines the advertisement content displaying ways in terms of the characteristic information of multi-media contents obtained from a multi-media server; the determined one or a plurality of the advertisement contents and the advertisement content displaying ways are sent to the user facility; and the user facility sends advertisement request information to the advertisement server, and shows the received advertisement contents combining with the advertisement displaying ways correspondingly. Through the method and the device, the individualized advertisement service provided for the user can be achieved.

Owner:SHANGHAI SYNACAST MEDIA TECH

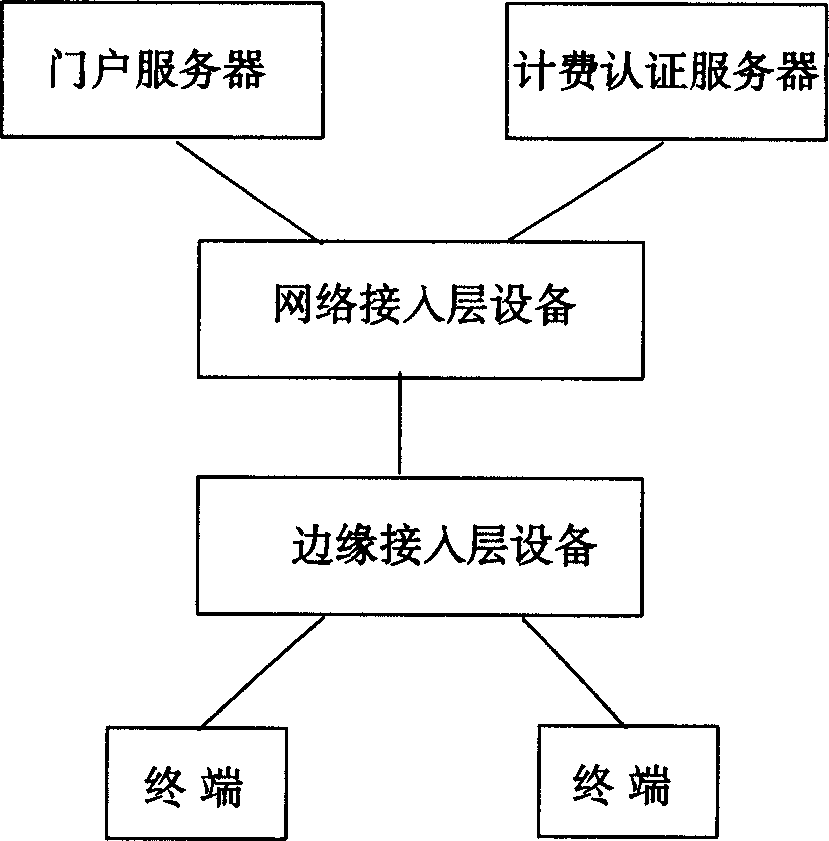

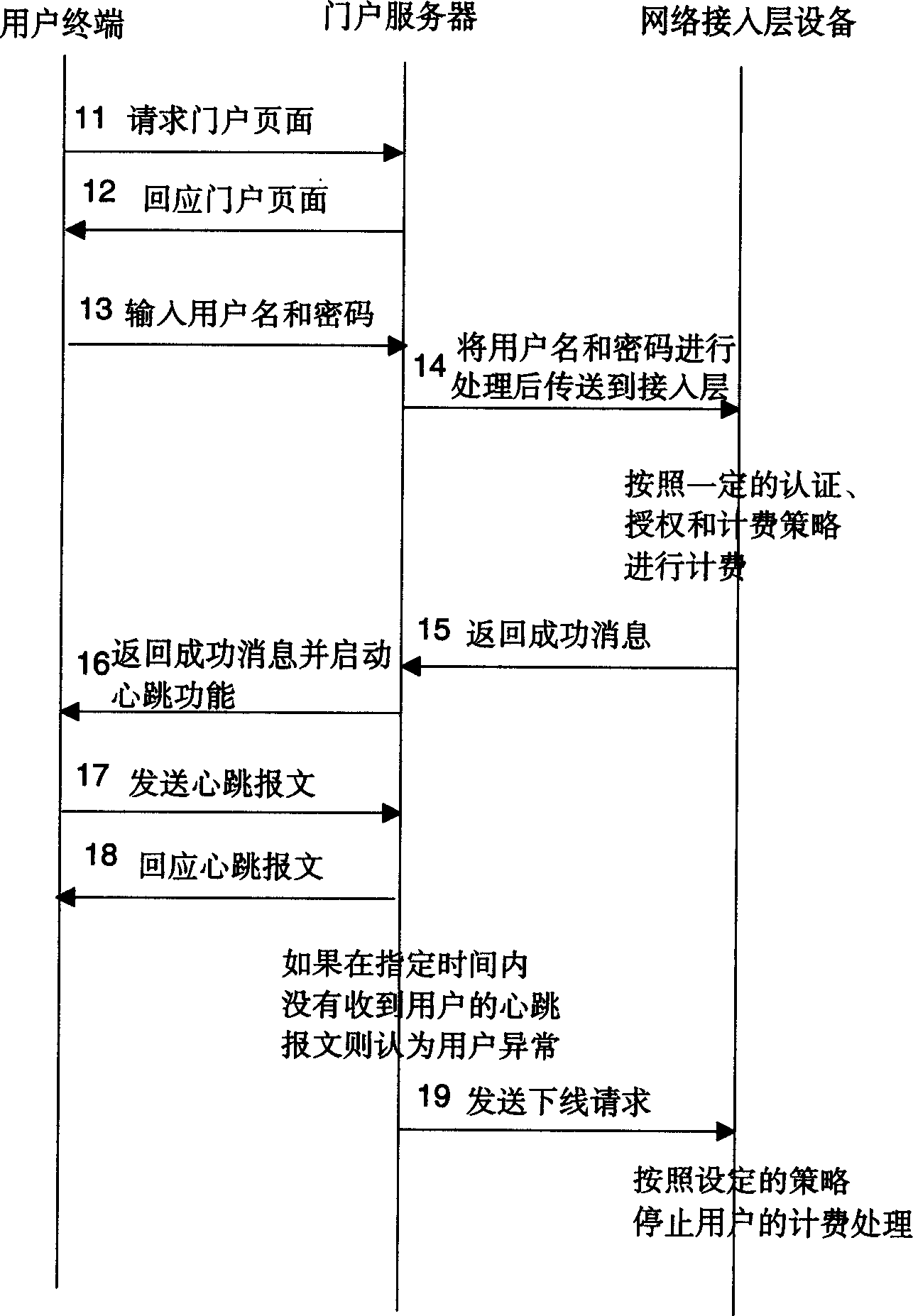

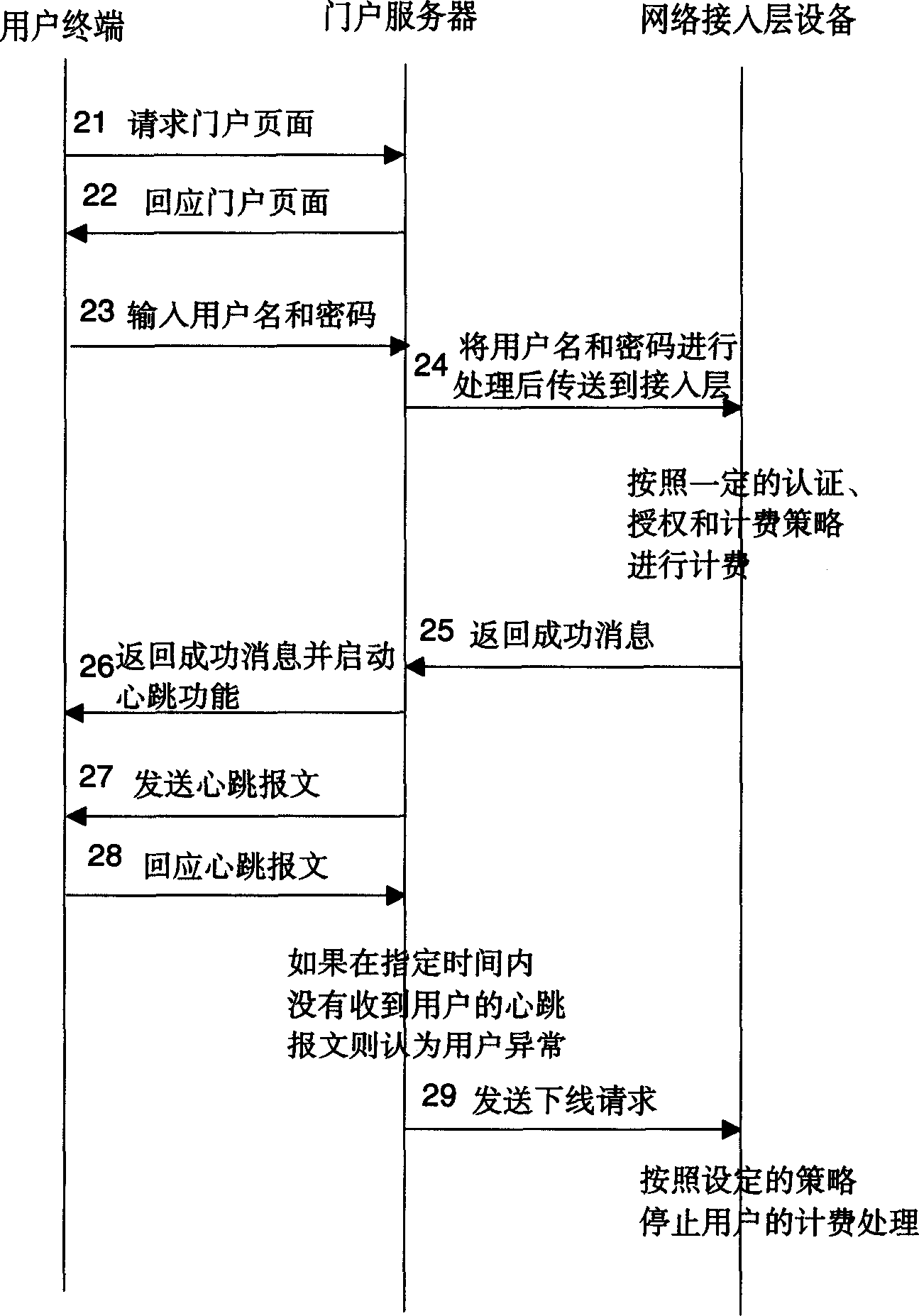

A method for detecting whether or not WEB authentication user is on line

InactiveCN1501636ARecord online timeTimely releaseData switching by path configurationNetwork access serverWeb authentication

The invention discloses a method for detecting whether a WEB identification user is online, wherein when the user proceeds internet connection, the network proceeds identification, authorization, and charging strategy processing, the gate server completes the user identification and feeds the result information back to the user facility, when the result information is an identification success information, a heartbeat processing flow path is initiated set by the user, then the user facility transmits heartbeat message periodically to the gate server, which feeds back the heartbeat response message periodically to the user facility. The method by the invention can user online time period more accurately.

Owner:HUAWEI TECH CO LTD

Water Heater Demand Side Management System

ActiveUS20160216007A1Reduce peak loadEasy to useTemperatue controlEfficient regulation technologiesQuality of serviceEngineering

A system for shifting energy demand from on-peak time windows to off-peak time windows by using hot water heater load shifting, while providing the end user with the level of service (i.e., availability of hot water) according to the user's customary use described by service quality criteria. The shift is accomplished by a controller located at the end user establishment and in communication with a central control server. The controller monitors local water heater upper and / or lower temperature and controls upper and / or lower water heater heating elements in accordance with a demand shift process commanded by the central control server. The controller may determine usage and remaining capacity for reporting back to the central control server. A volumetric capacity and usage determination is disclosed. The control server may select water heaters according to use patterns and / or measured capacity. Further embodiments may regulate load dependent properties of the power including voltage, phase and / or frequency.

Owner:CARINA TECH +1

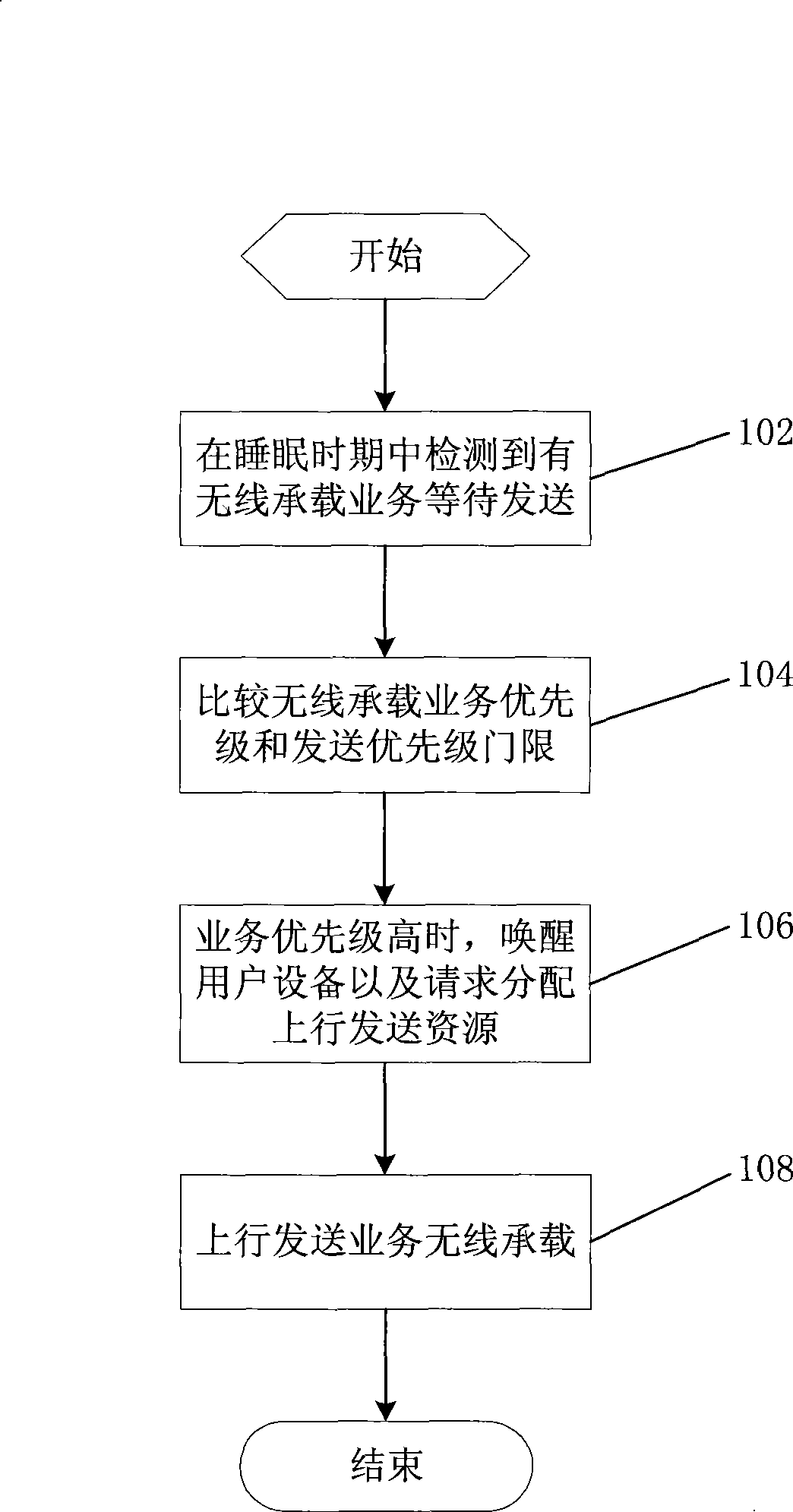

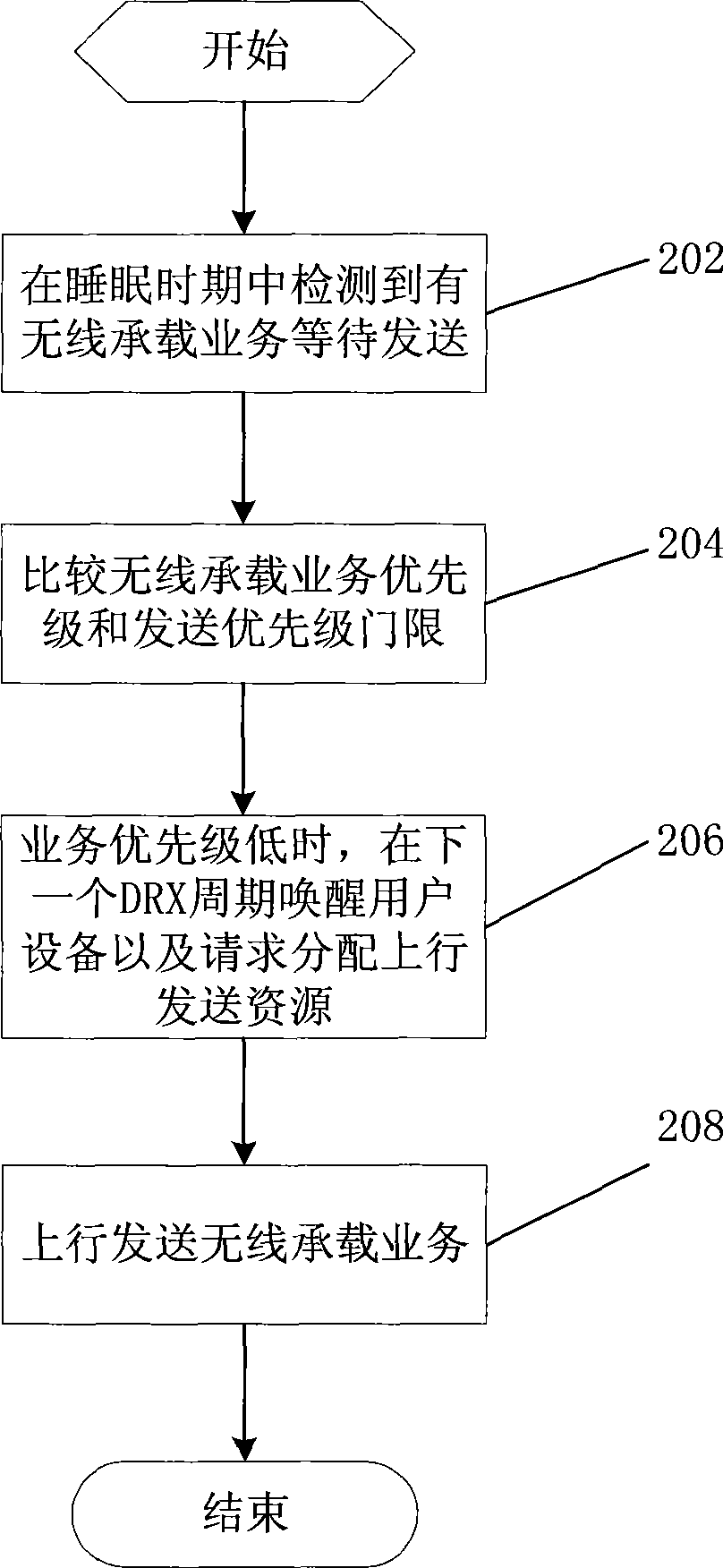

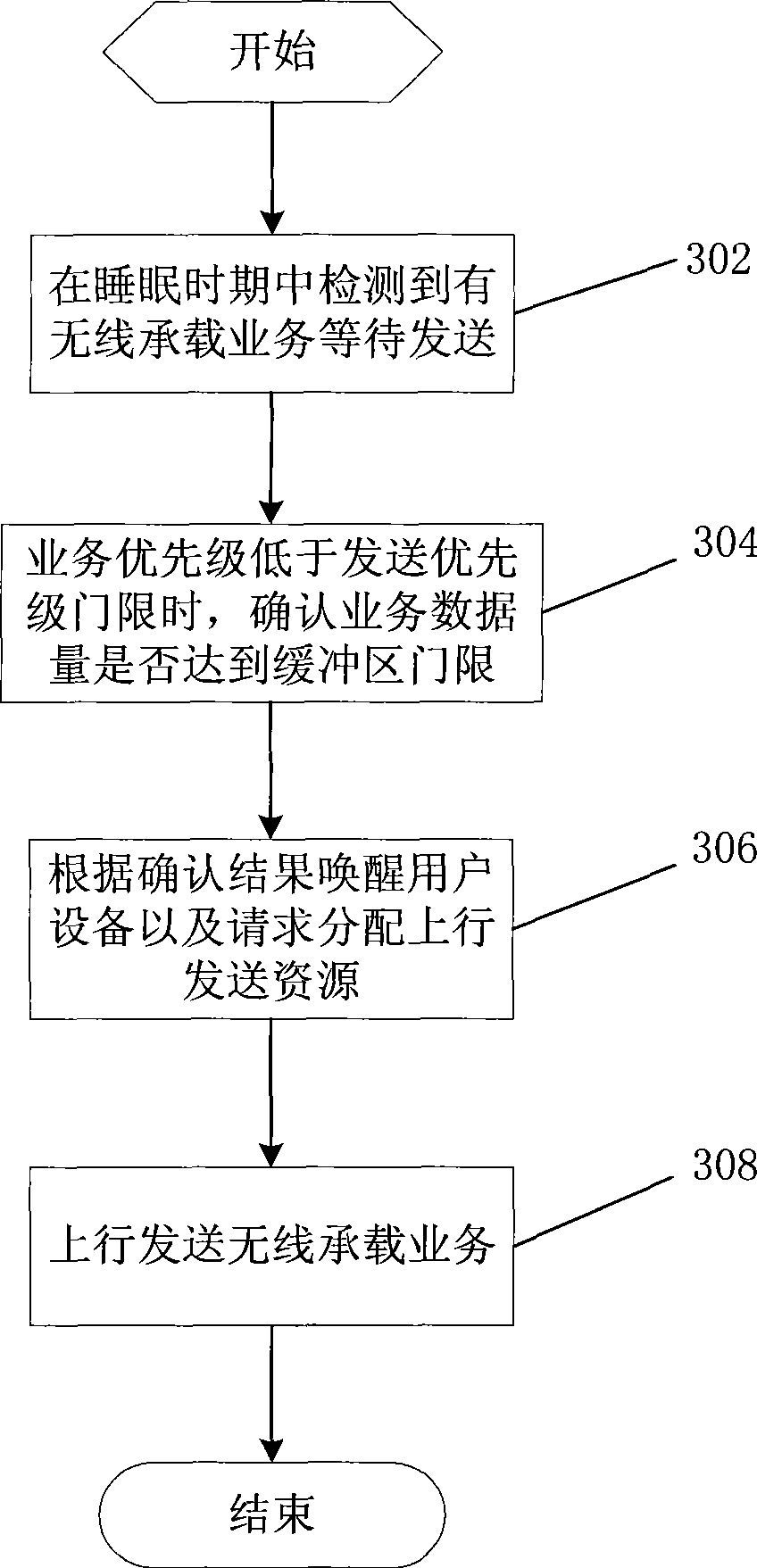

User equipment and uplink sending method under discontinuous receiving state

InactiveCN101500299AGuaranteed functionPower managementCurrent supply arrangementsTelecommunicationsUser Facility

The embodiment of the invention provides an uplink sending method under the DRX (Discontinuous Reception ) state, comprising the following steps of: detecting an uplink wireless bearer service to be sent in the Sleep mode under the DRX state; waking up a user facility and requesting to assign uplink sending resources, when the priority of the wireless bearer service to be sent is higher than or equal to the threshold of the sending priority; and sending the wireless bearer service to be sent by utilizing the assigned uplink sending resources. The embodiment of the invention further provides a user facility. The embodiment of the invention can lead the user facility to process services with high priority in time, thereby guaranteeing the normal function of the user facility.

Owner:HUAWEI TECH CO LTD

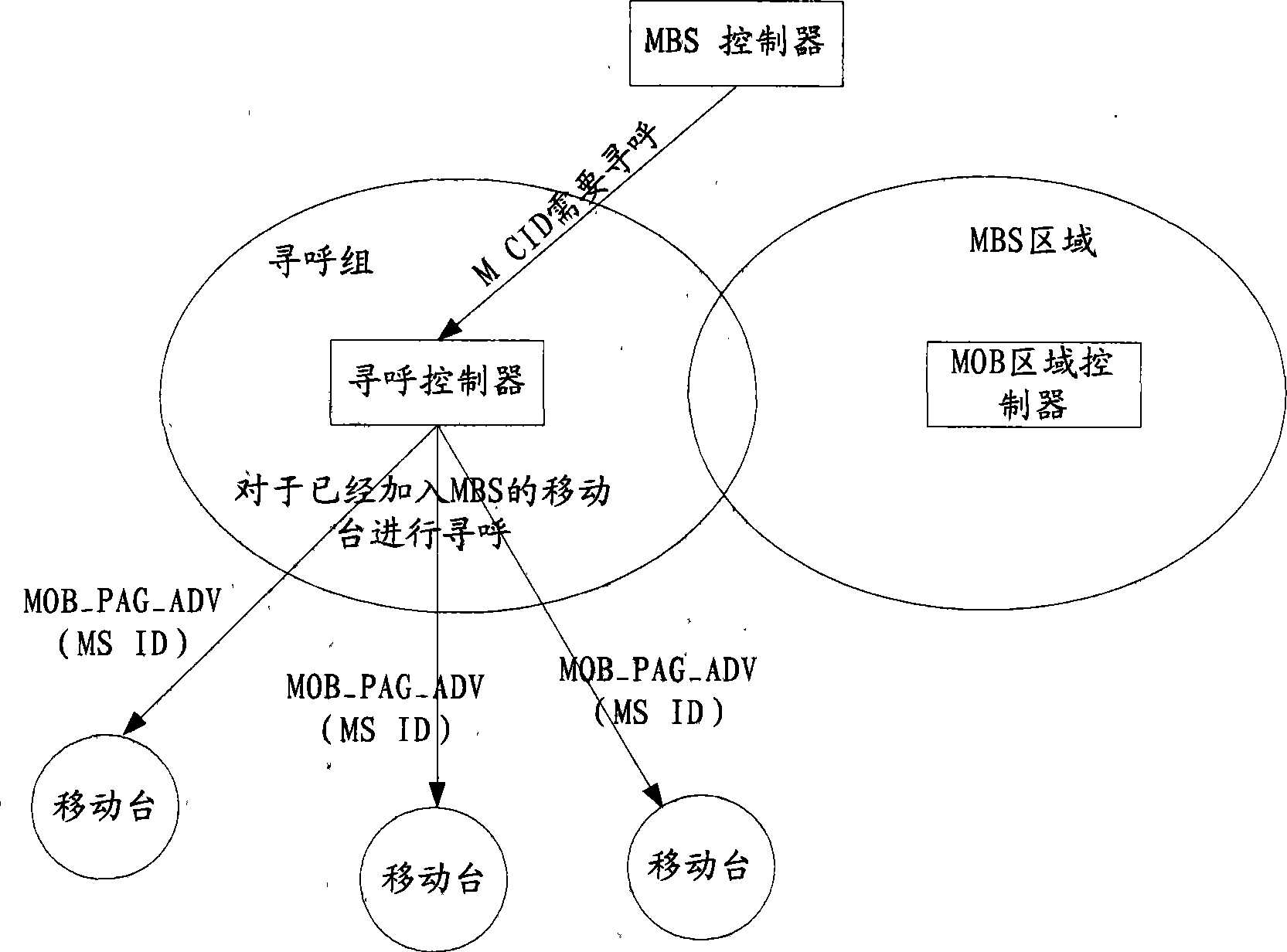

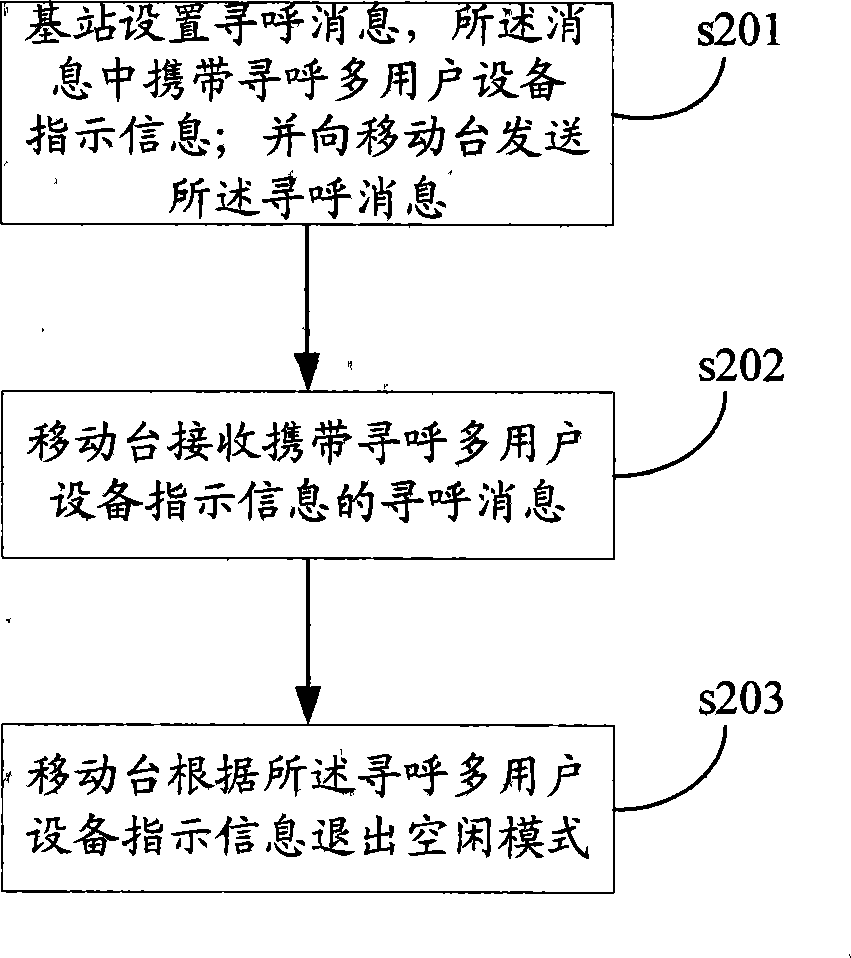

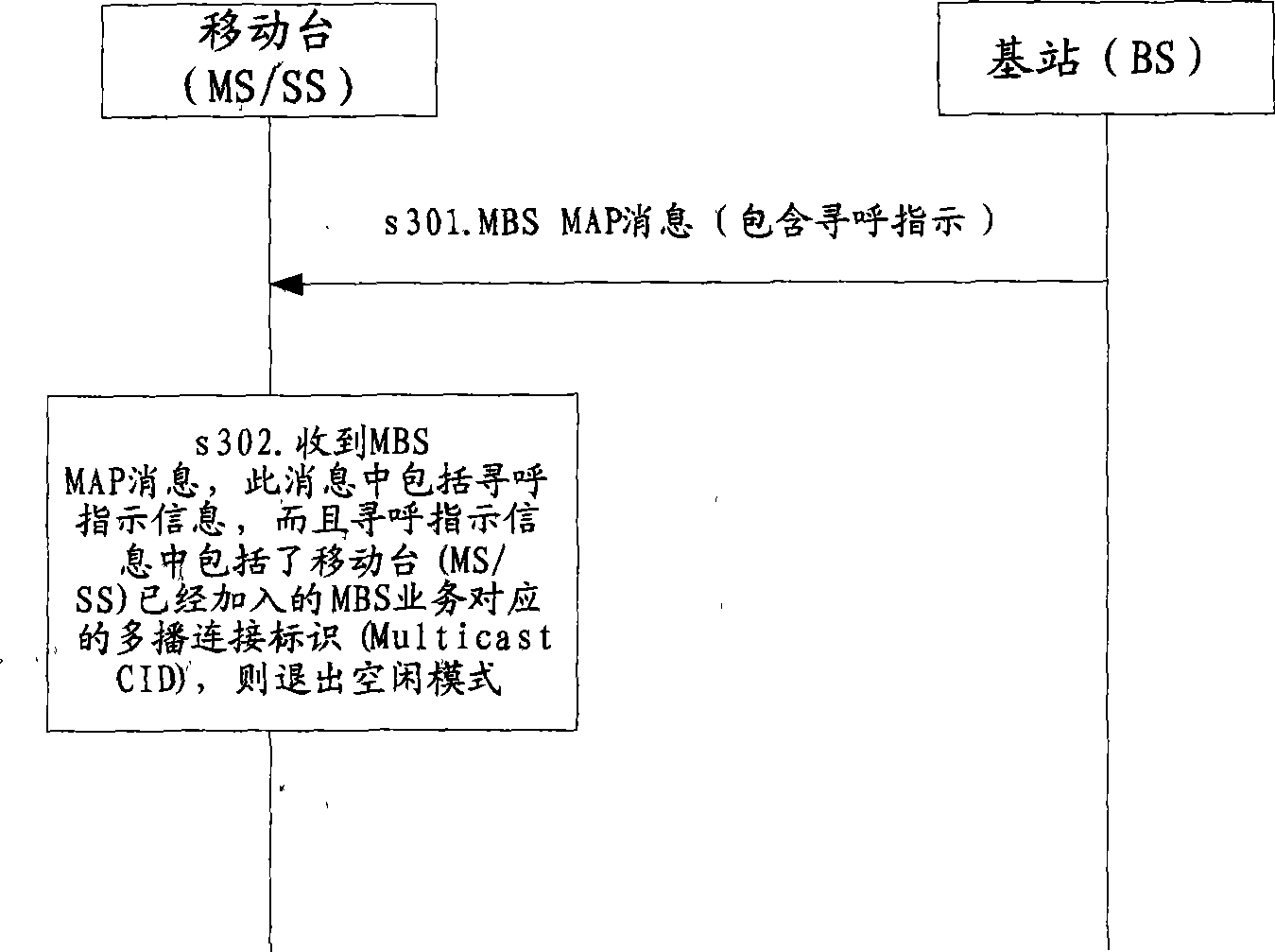

Method and apparatus for paging user equipment

The invention discloses a paging method used in a system consisting a user facility and a base station (BS). The method comprises the following steps: paging information is set in the BS, and the information carries paging multi-user facility indication information; the BS sends the paging information to the user facility, so that the user facility exits an idle mode according to paging multi-user facility indication information. The invention also discloses a user facility and a BS. In the embodiment of the invention, multiple MSes using MBS service can be paged at one time by carrying the paging indication information in MBS MAP, thus saving the expense on sending MBS_PAG_ADV information by a plurality of times; when the BS does not have the MBS service, the BS does not send any relevant paging signaling, thus saving air interfaces.

Owner:马丽

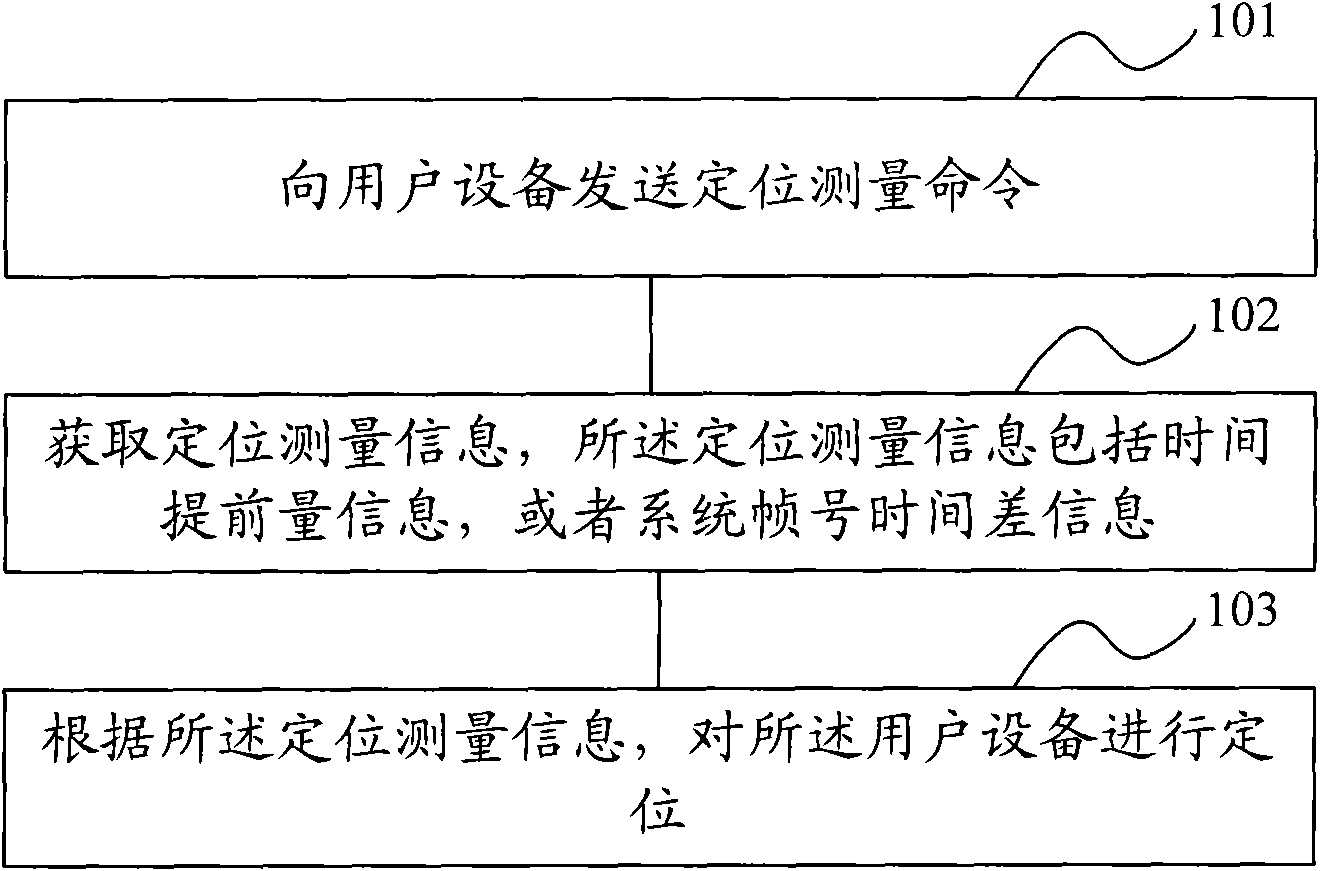

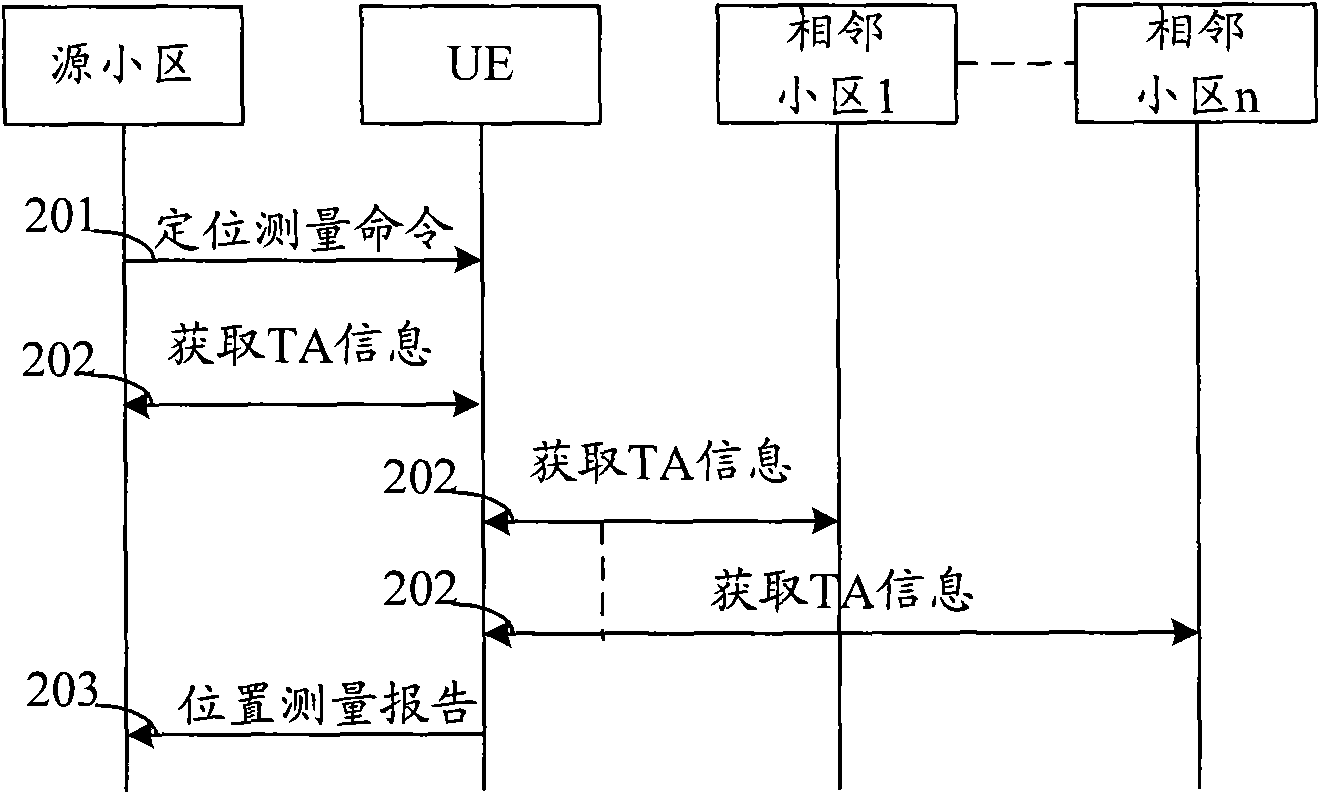

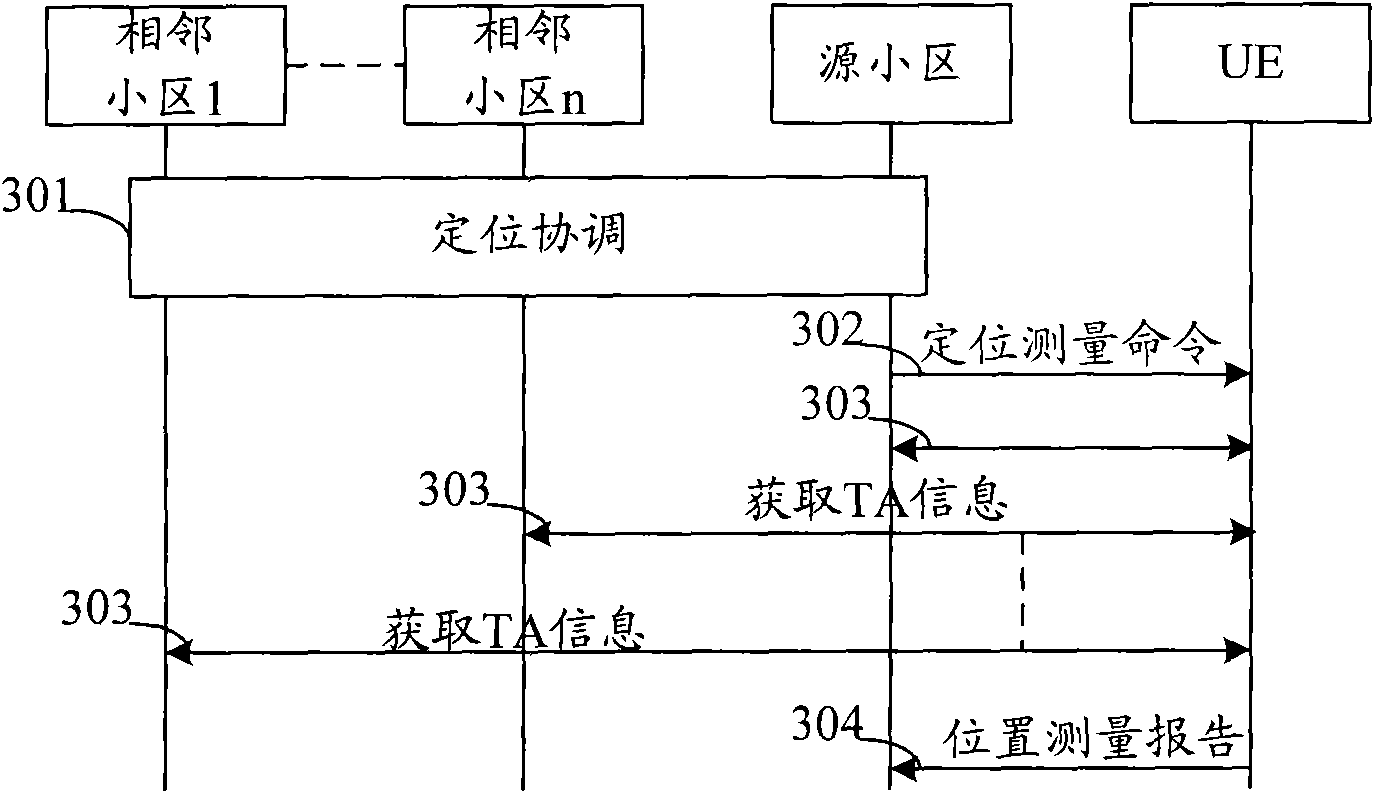

User facility positioning method and communication device

InactiveCN101772159AAchieve positioningPrecise positioningWireless communicationNumber timesComputer science

The invention relates to the wireless communication technical field, and discloses a user facility positioning method, the method comprises: transmitting a positioning measurement command to a user facility; acquiring positioning measurement information which includes timing advance information or system frame number time difference information; and positioning the user facility according to the positioning measurement information. The invention also provides a communication device. According to the scheme of the invention, the user facility can be conveniently and effectively positioned with low cost, thereby facilitating the application of user facility positioning services.

Owner:HUAWEI TECH CO LTD

Real-time measurement of tool forces and machining process model parameters

A system and method are provided for real-time measurement of tool forces. A relationship between a motor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The motor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the motor characteristic and tool forces is determined. Thereafter, the motor characteristic of the CNC machine is measured for a desired tool, work piece, and part program and converted to tool forces using the relationship between the motor characteristic and tool forces.

Owner:UNIVERSITY OF NEW HAMPSHIRE +1

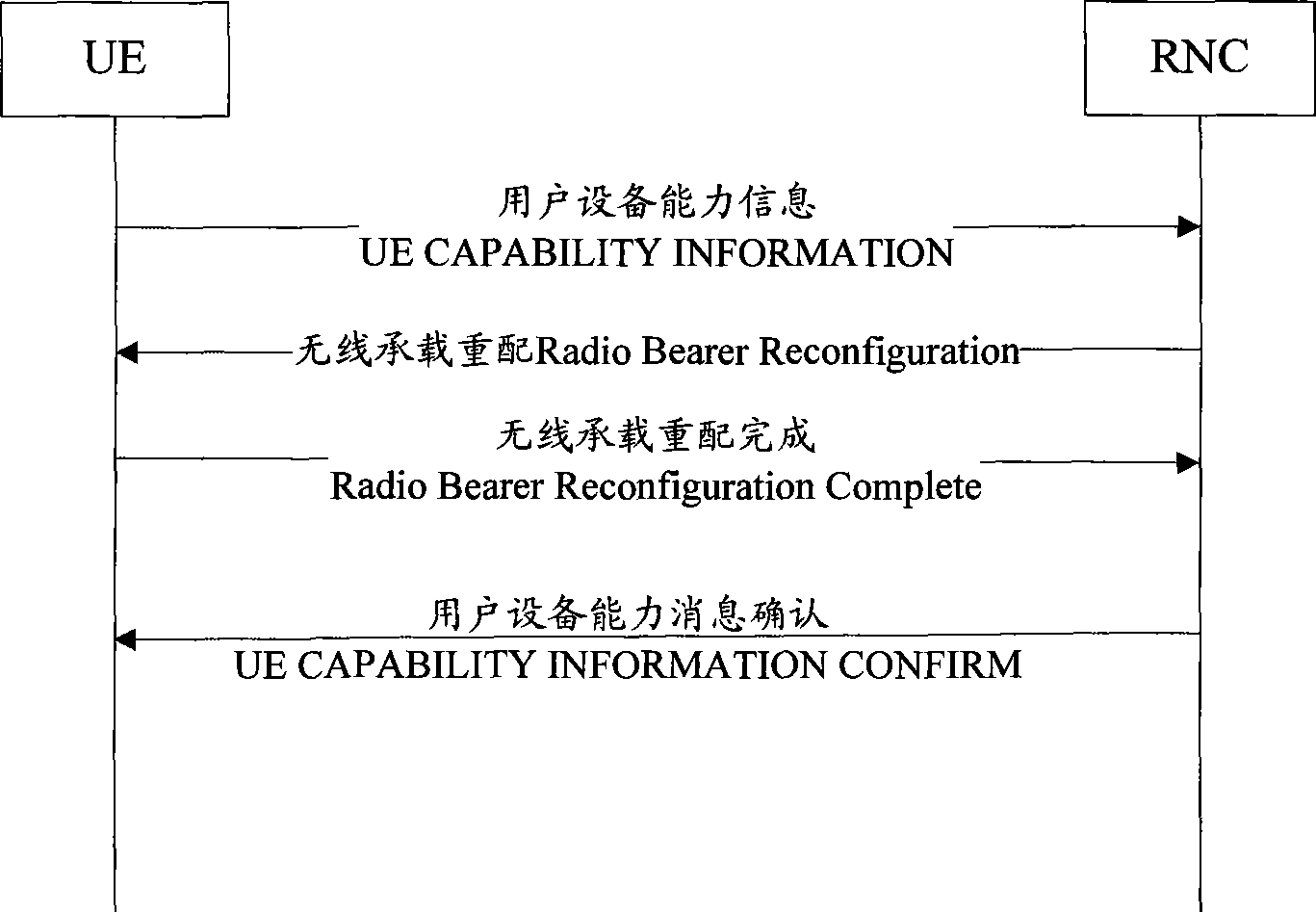

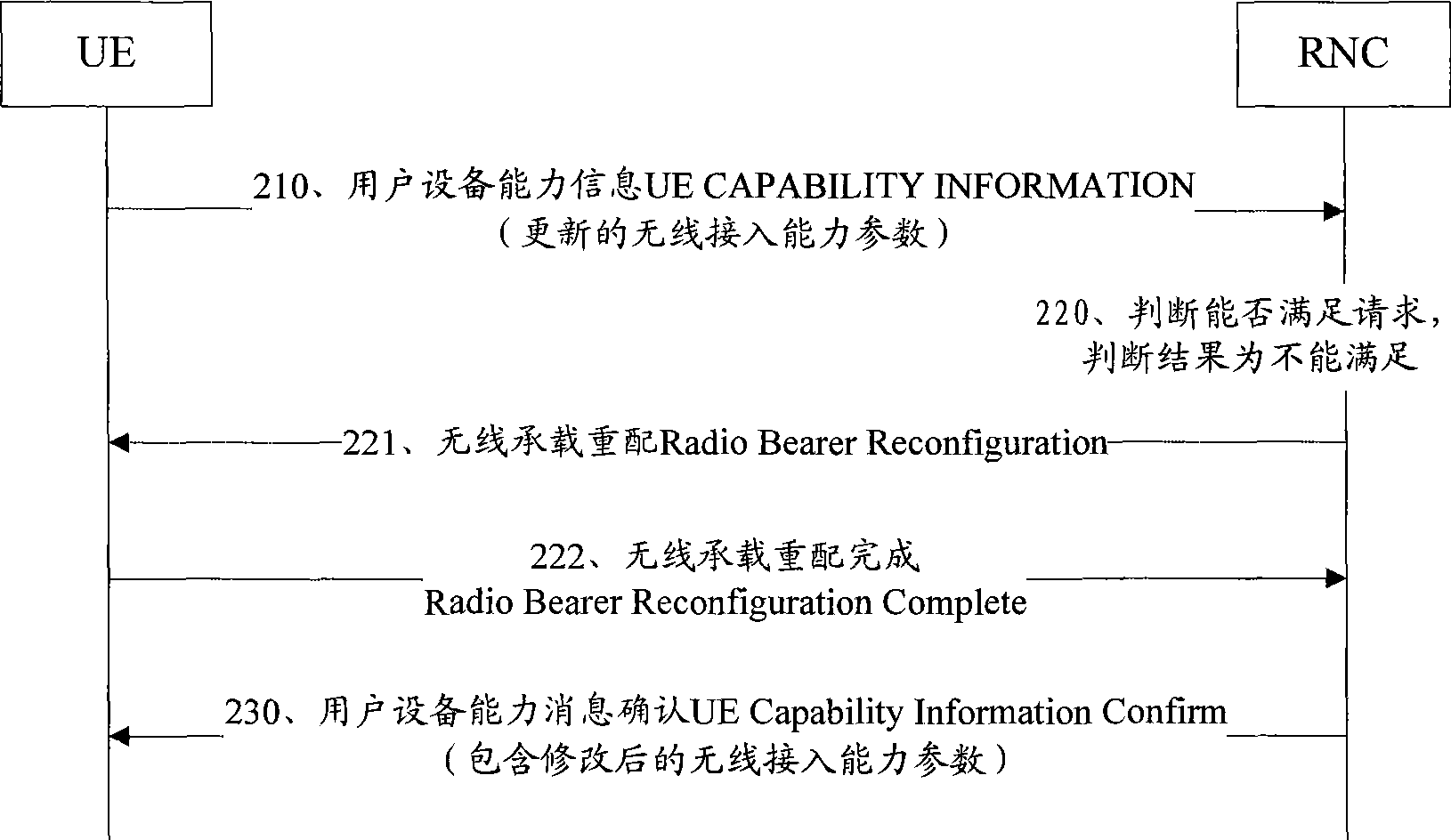

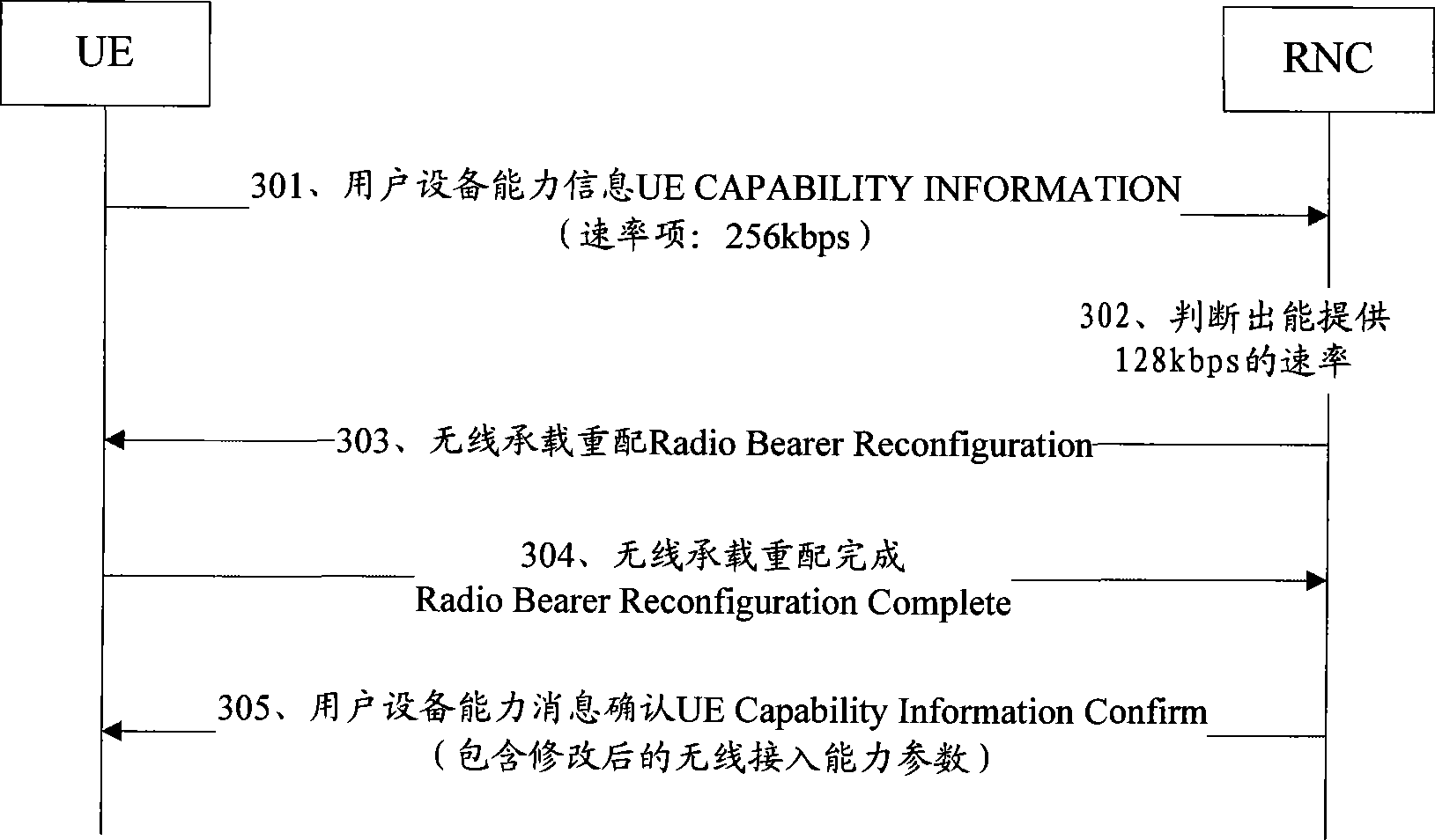

User equipment wireless access capability updating method, system and apparatus

InactiveCN101426256ASuit one's needsImprove user experienceNetwork traffic/resource managementAssess restrictionUser FacilityComputer network

The present invention provides a method, a system and a device for updating wireless access capability of user facility, wherein the method comprises the following procedures: receiving a wireless accessing capability parameter which is transmitted by user facility for requesting updating, determining in which the area where the user facility is can satisfy the wireless access capability requested by the user facility, modifying the wireless access capability parameter for requesting updating according to the network capability and resource state if not, and transmitting the modified wireless access capability parameter to the user facility. The method, system and device provided by the invention can return the modified wireless access capability parameter for the user facility when the network capability and resource state can not satisfy the request for updating the wireless access capability of the user facility. The requirement of user is satisfied furthest thereby increasing the using experience.

Owner:HUAWEI TECH CO LTD

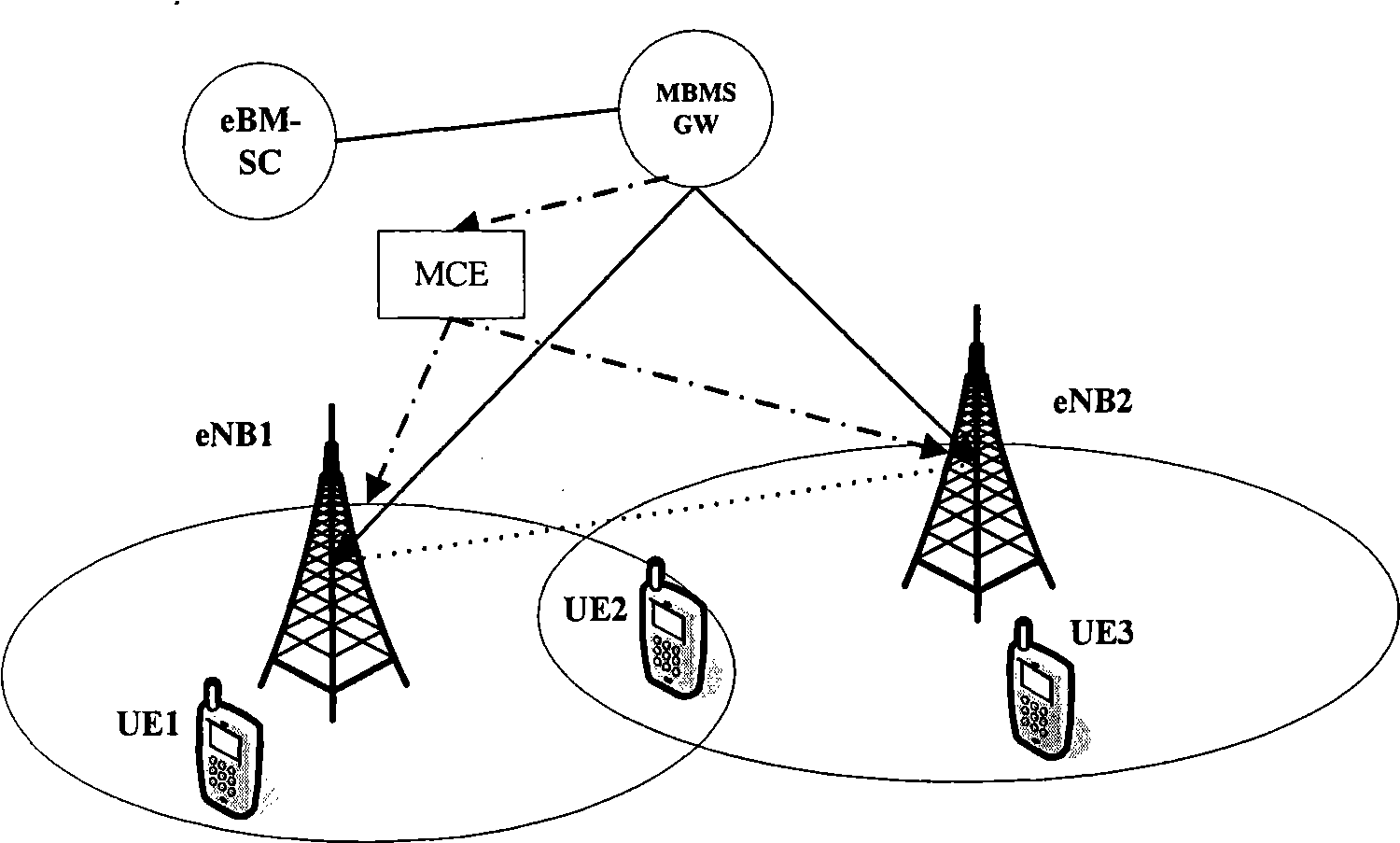

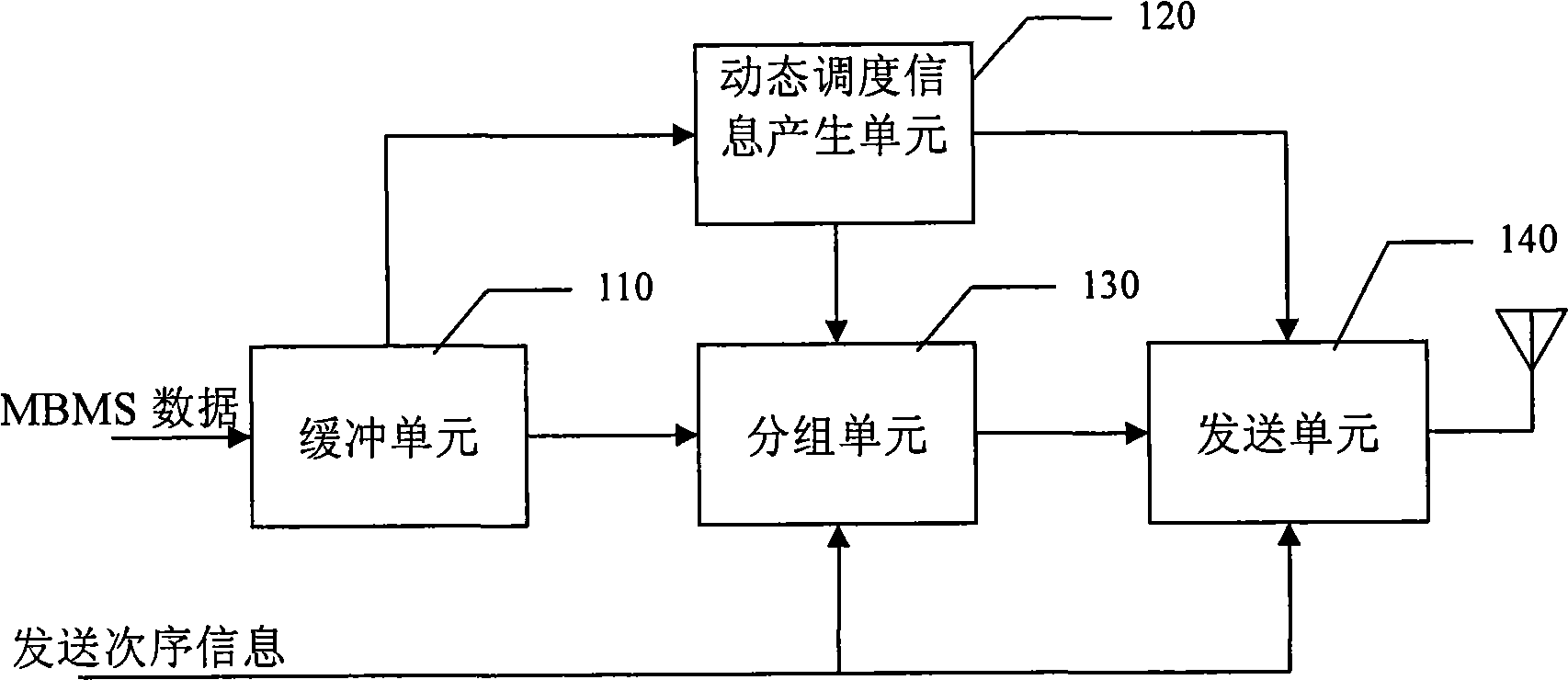

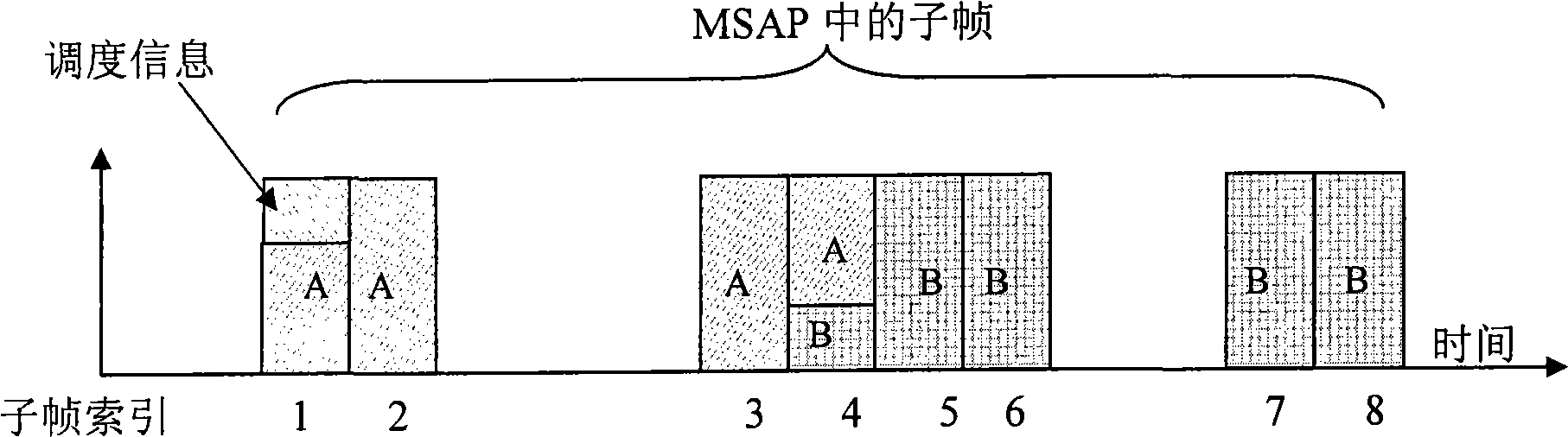

Multimedia service data sending and receiving method, base station apparatus and user equipment

ActiveCN101483810AImplement dynamic schedulingSave electricityNetwork traffic/resource managementBroadcast service distributionMultiplexingComputer science

The invention discloses a multimedia service data sending and receiving method, base station equipment and user equipment. The method includes following steps, receiving the information of sending sequences which show a plurality of multimedia service, generating starting index of each multimedia service and scheduling information in the corresponding number of the index; sending the data of each multimedia service based on the sending sequence information and scheduling information. The method and equipment of the invention can realize the dynamic scheduling of MBMS in a monochromatic network so as to save power of user facilities in the condition of discontinuous transmission and make statistic multiplexing processing easy.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

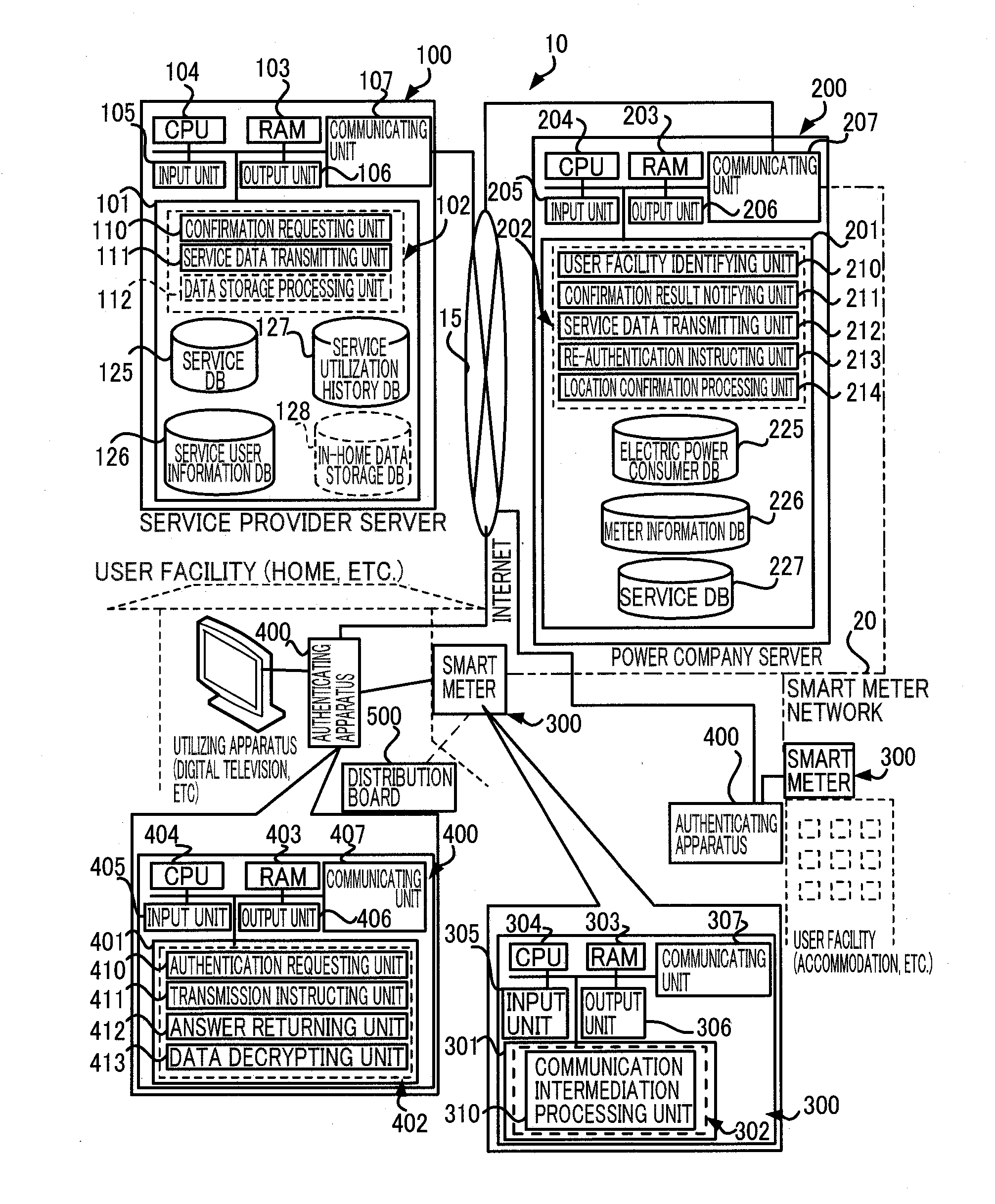

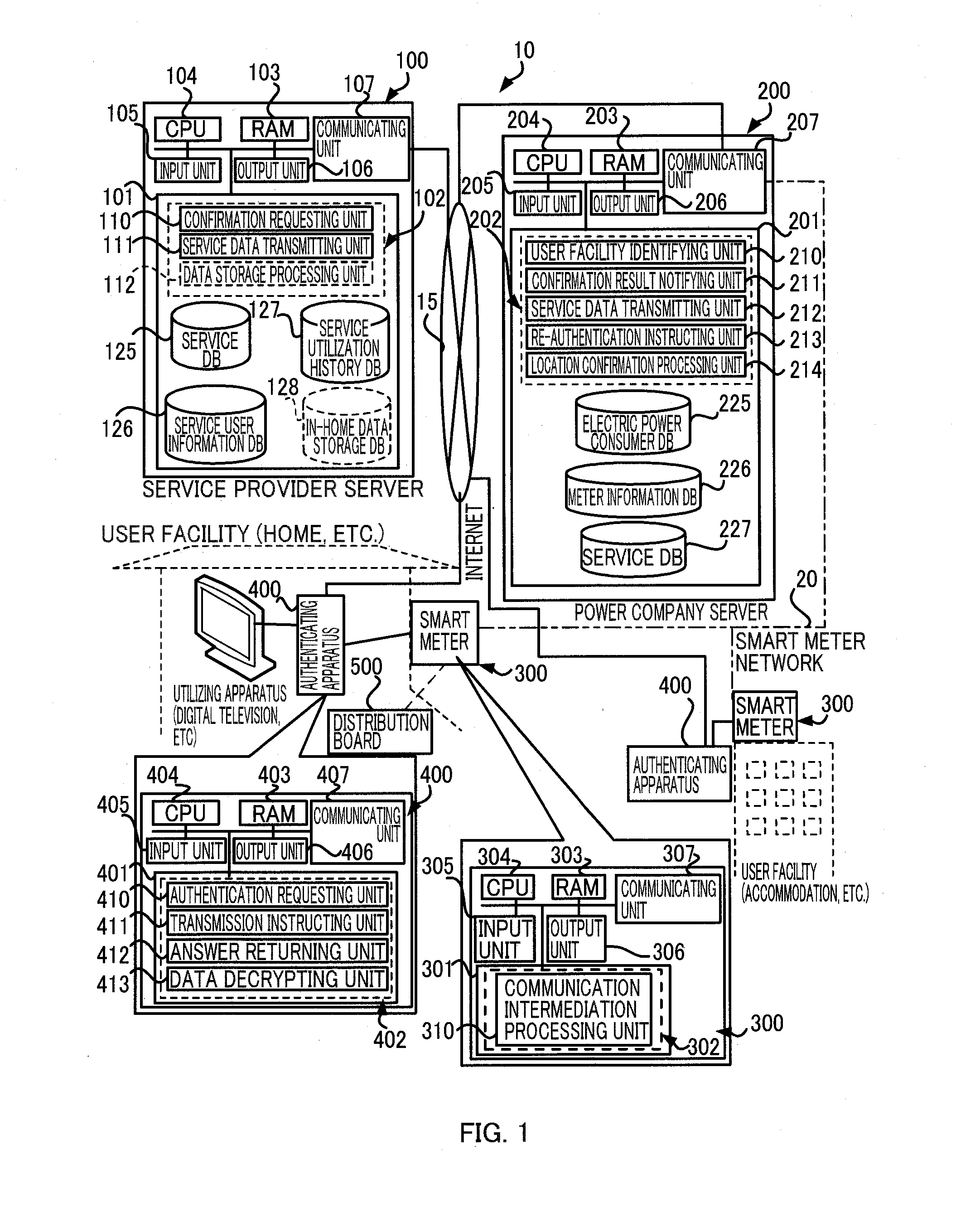

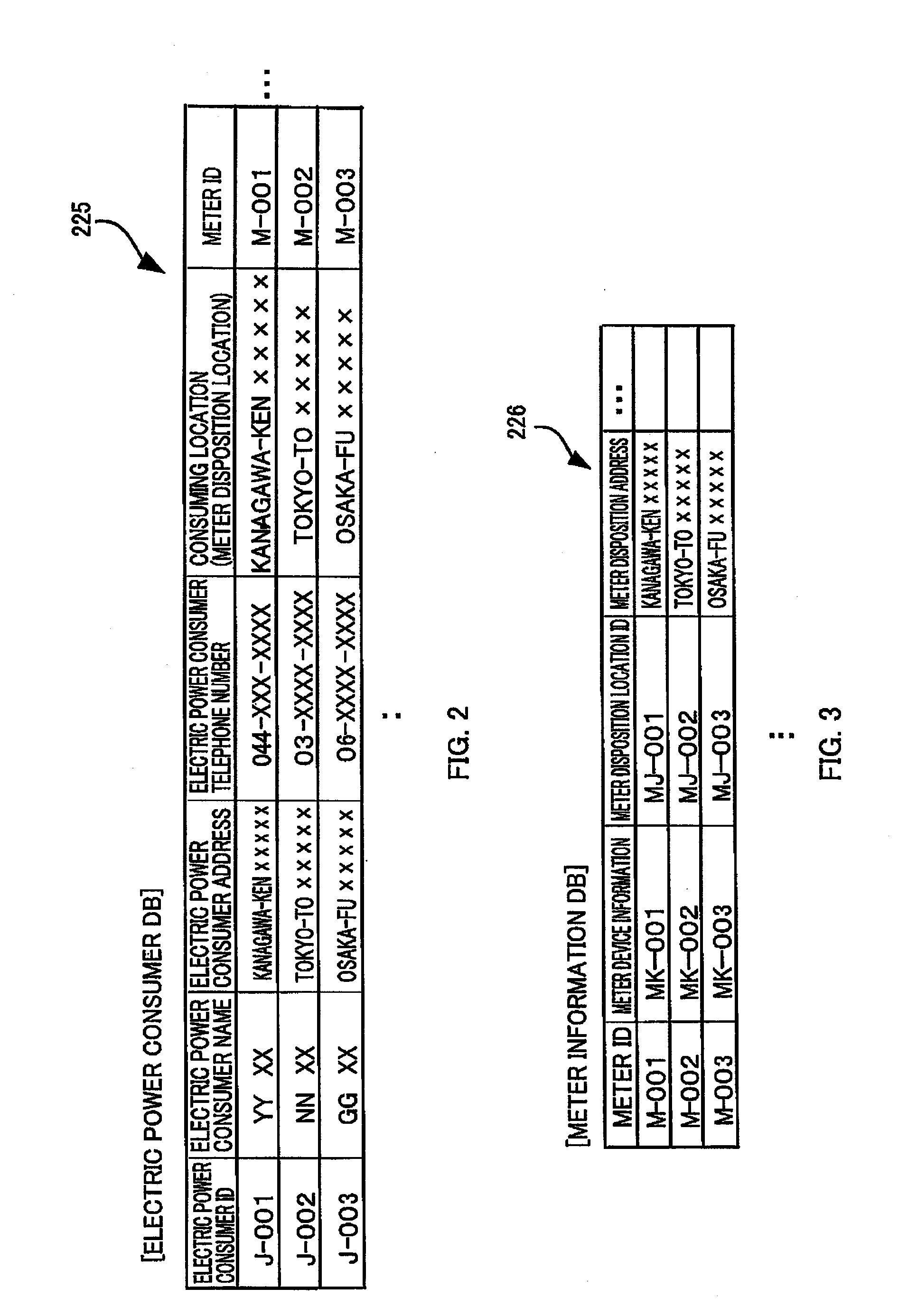

Information processing method and information processing system

ActiveUS20110016517A1Improve securityPrevent counterfeitingTariff metering apparatusDigital data processing detailsInformation processingDedicated line

A first server in a system includes confirmation requesting unit 110 that receives an authentication request from a predetermined apparatus 400 coupled through a public line and that sends a user confirmation request to a second server in the case where user authentication is successful. A second server includes a user facility identifying unit 210 that receives the user confirmation request from the first server and identifies location information of the user facility of the user and a confirmation result notifying unit 211 that receives a utilization request from a measuring apparatus linked through a dedicated line and identifies disposition location information of the measuring apparatus and that sends a notification of success of user confirmation including the identification information of the user to the first server 100 if the disposition location information of the measuring apparatus is identical to the user facility location information.

Owner:HITACHI LTD

Sensor-based measurement of tool forces and machining process model parameters

InactiveUS7536237B2Inexpensive but accurate monitoringAddressing Diversity InsufficiencyProgramme controlForce measurementSacrificial partModel parameters

A system and method are provided for real-time measurement of tool forces. A relationship between a sensor characteristic and tool forces is determined by directly measuring tool forces for a standard tool, work piece, and part program. The sensor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program, providing a relationship between the sensor characteristic at the user facility and tool forces. If the sensor is not conveniently attached to the work piece or the part program is not sufficiently robust in cutting conditions, the work piece and part program are replaced by a sacrificial work piece and sacrificial part program. The sacrificial work piece and sacrificial part program are selected to accommodate the sensors and to provide sufficient robustness in cutting conditions to accurately determine the process model parameters for the sacrificial work piece.

Owner:UNIVERSITY OF NEW HAMPSHIRE

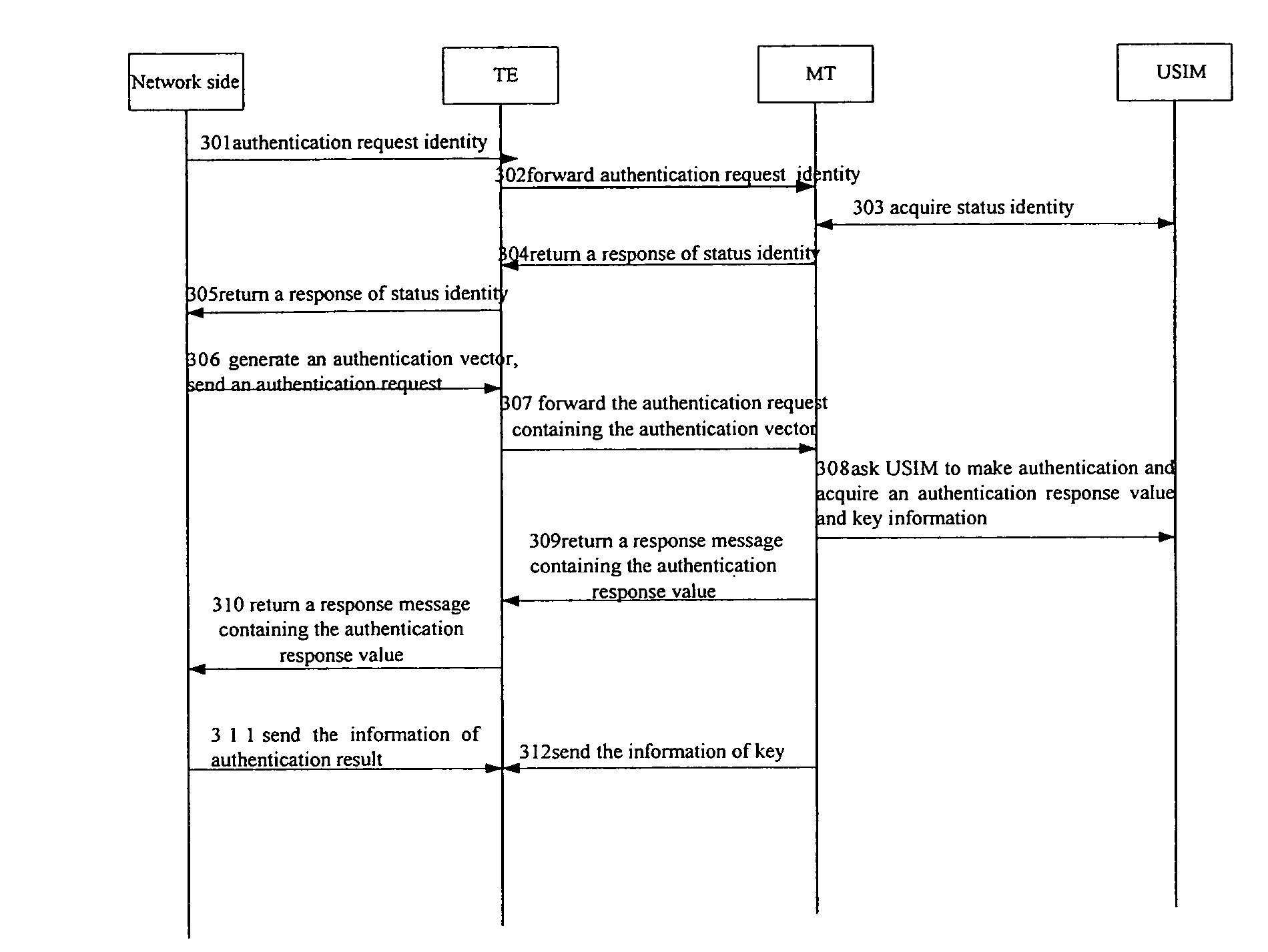

Method For Managing Local Terminal Equipment Accessing A Network

ActiveUS20080101276A1Save network resourcesFunction increaseUnauthorised/fraudulent call preventionEavesdropping prevention circuitsTerminal equipmentUser Facility

Methods for managing a local Terminal Equipment (TE) accessing a network are provided. One is to set in a Mobile Terminal (MT) a management list containing the identities of local TEs, and to decide according to the information of the management list whether to accept a request message from the TE, thereby implementing the management of local TE that accesses the network using resources of the MT, improving the function of the MT, and at the same time, enhancing the security of users' accounts. In accordance with this invention, a user is able to define an authority for the TE to access and learn the current state of the TE, which gives the user facilities for daily use. The other method is to modify the existing procedure such that the MT will not send the key(s) information to the TE until having received a notice of successful authentication from the TE or having decided that the message forwarded by the TE is a response message of successful authentication, which makes the procedure more reasonable and saves the network resources the method further includes a management list containing the identities of local TEs on the basis of the modified procedure.

Owner:HUAWEI TECH CO LTD

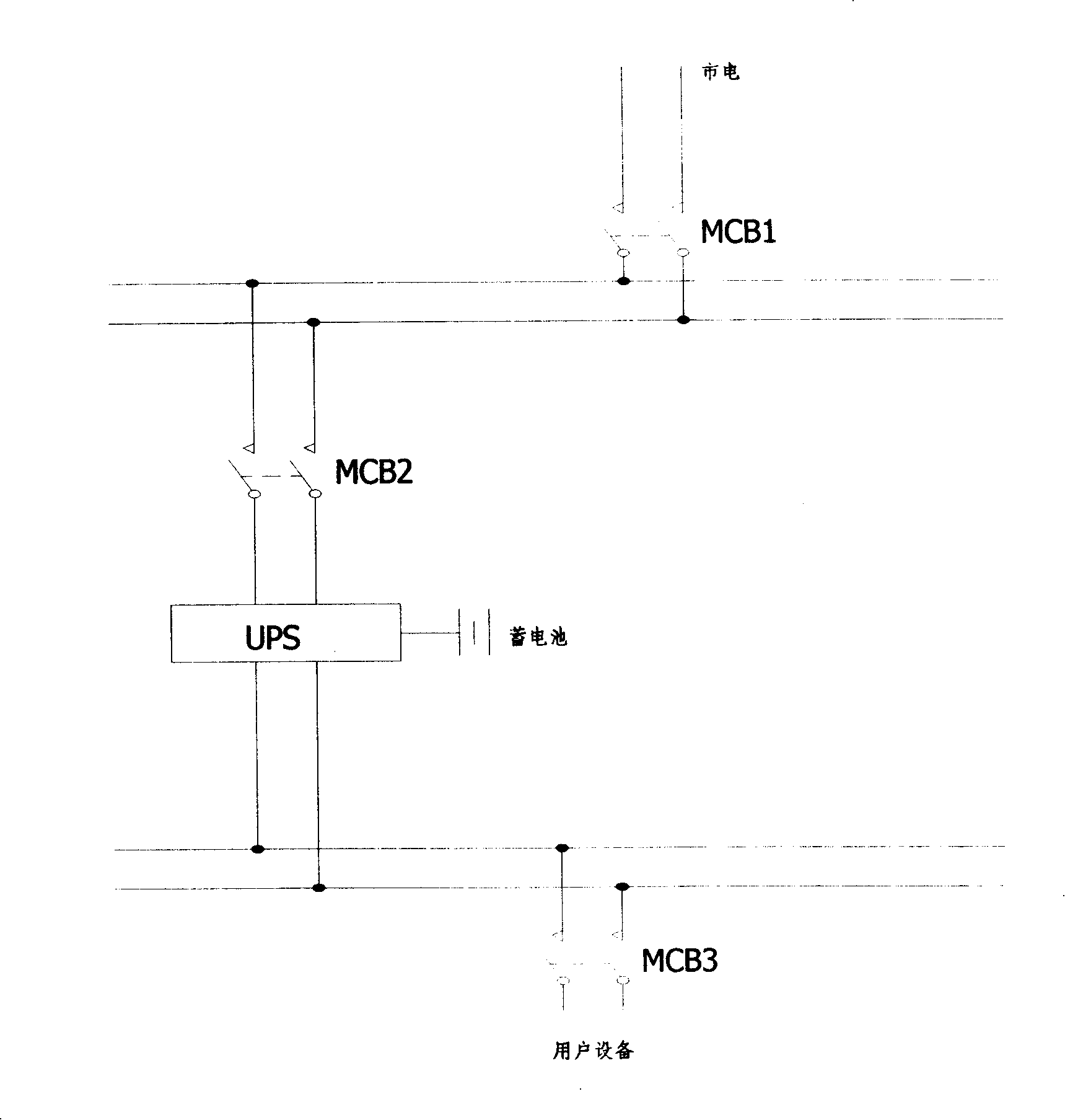

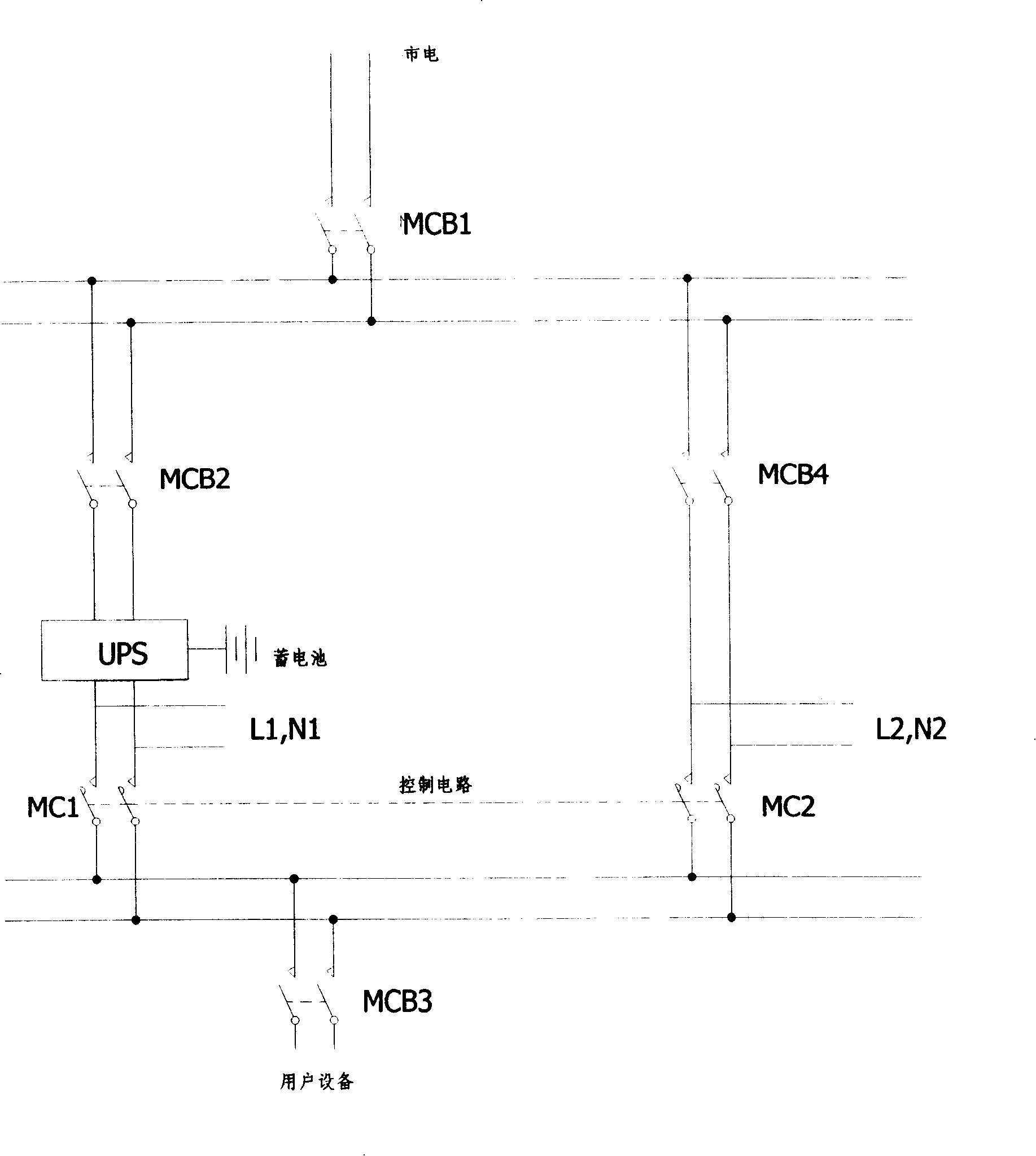

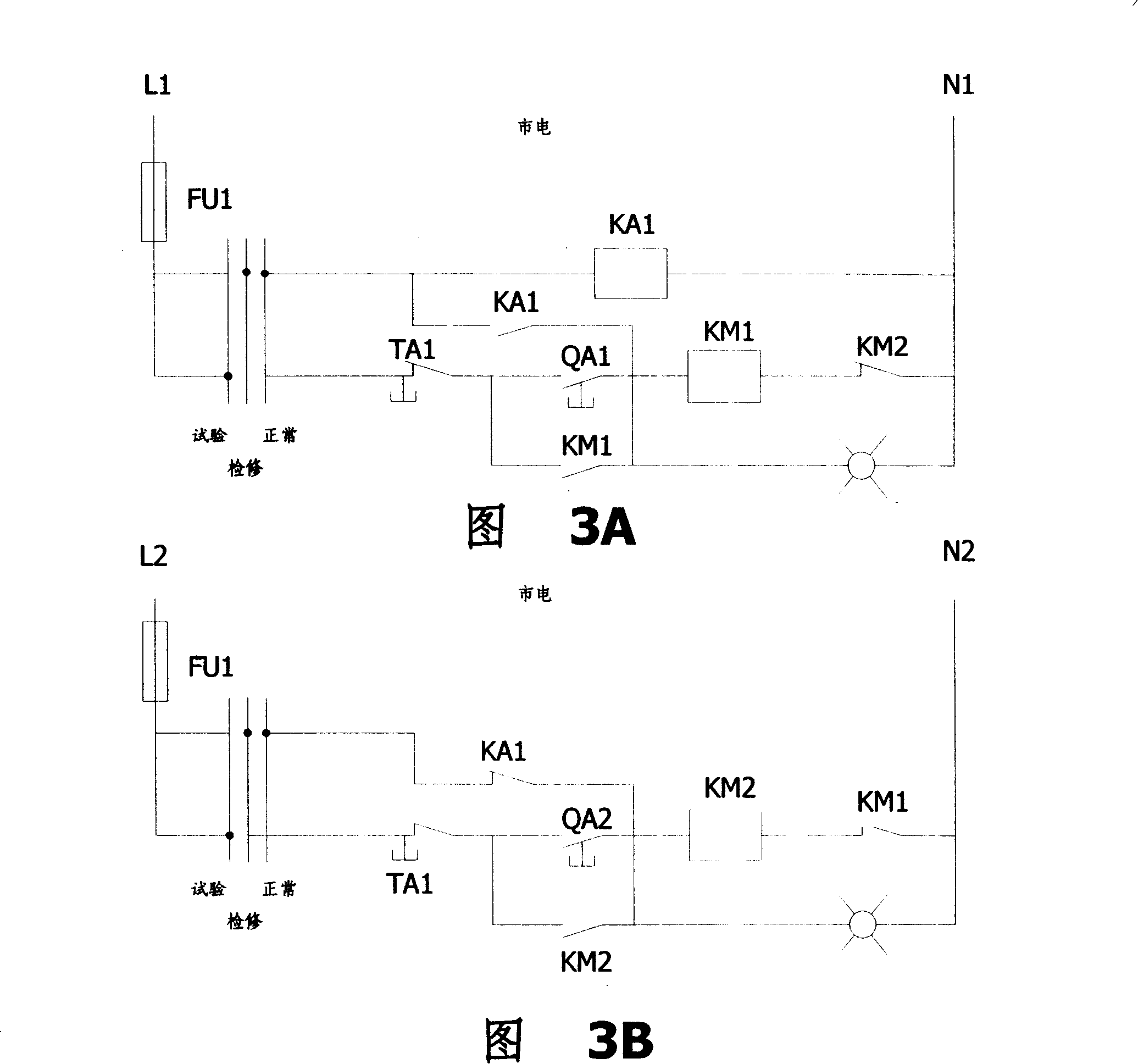

Device and method for on-line switching uninterrupted power supply

ActiveCN101222145AExtend or adjust the maintenance cycle at any timeLow failure rateBatteries circuit arrangementsElectric powerPower circuitsLine switching

The invention discloses an on-line switching UPS device and a method thereof. An input terminal of the UPS is connected to an input power supply loop through inputting a power switch MCB2 by the UPS device, wherein, the input power supply loop is connected to the commercial power circuit through a supply line switch MCB1, an output terminal of the UPS is connected to an output power supply loop, a user facility is connected to the output power supply loop by a user load switch MCB3. The device also comprises an outer shunt circuit connected in parallel with the UPS and a set of contactors, wherein, the outer shunt circuit is connected to the input power supply loop by an outer shunt circuit switch MCB4 and is connected with the output power supply loop; a first main contact point MC1 is connected in series between the output terminal of the UPS and the output power supply loop, a second main contact point MC2 is connected in series between the outer shunt circuit switch MCB4 and the output power supply loop; the contactors are switched between the UPS and the outer shunt circuit. The technical proposal of the invention realizes that the switching way of the controller is controlled by the joint point of a relay by adopting a small number of elements such as the set of controllers, the relay and the switch and basically realizes the very quick switching. Therefore, the invention is an economic and effective UPS on-line switching mode.

Owner:BAOSHAN IRON & STEEL CO LTD

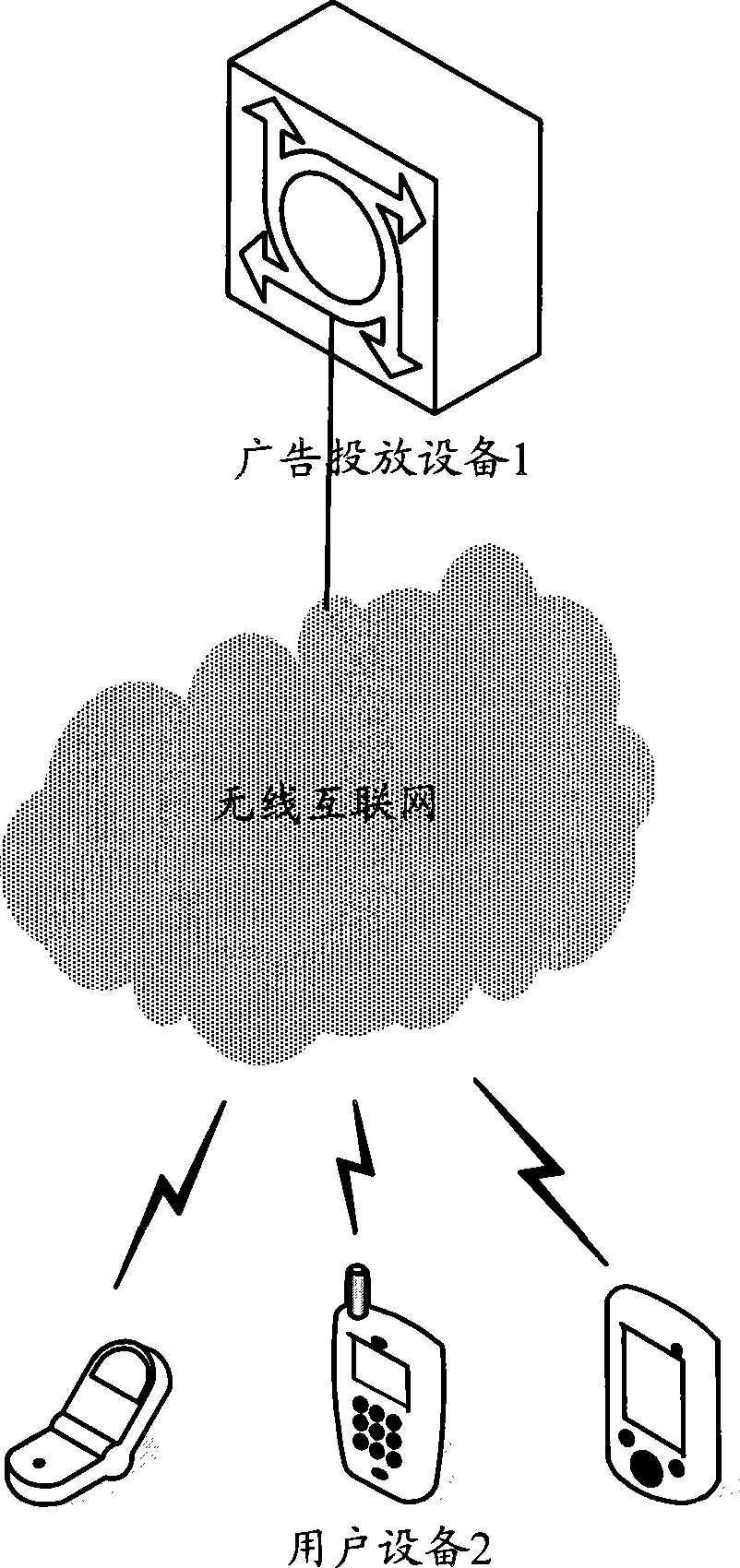

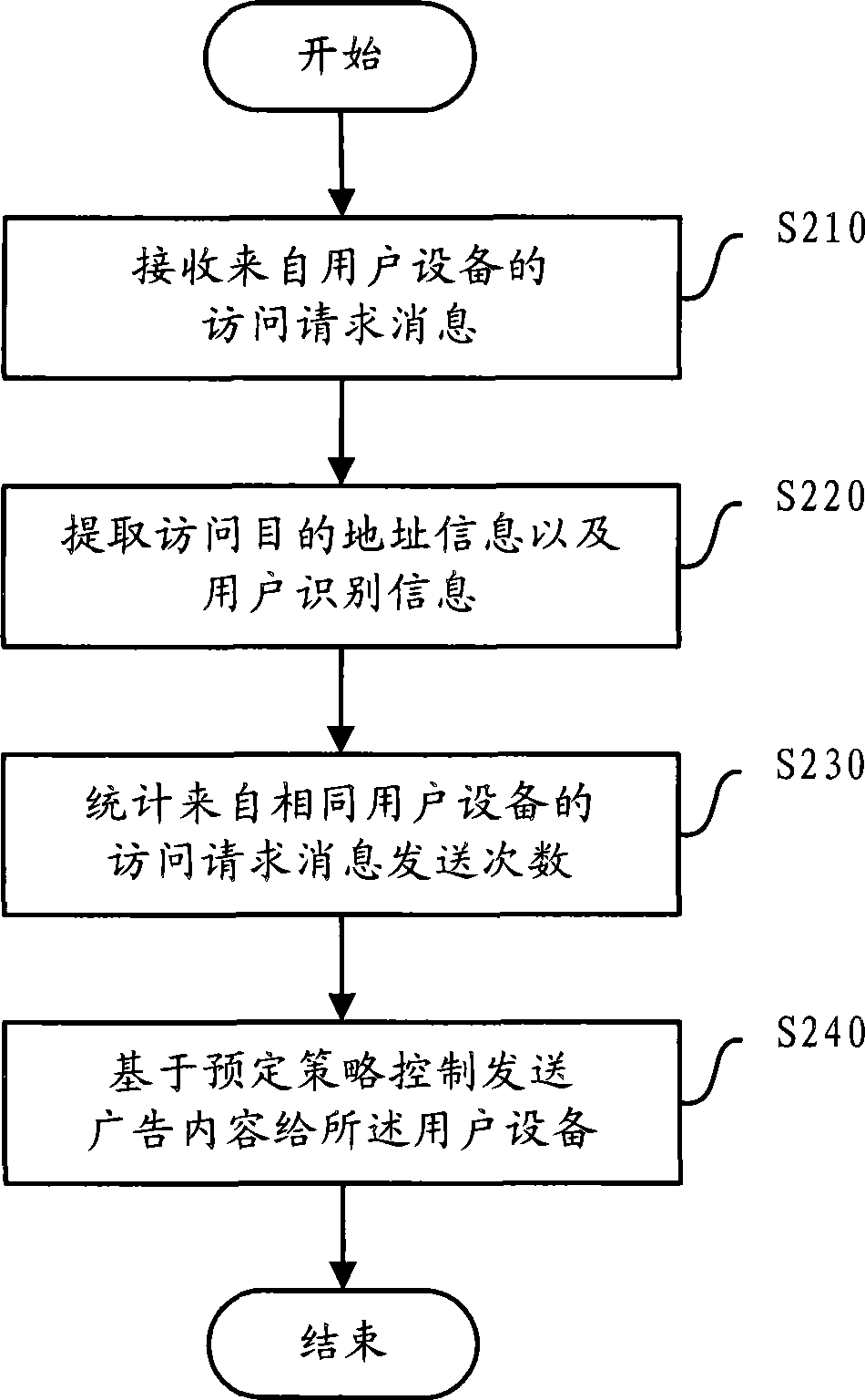

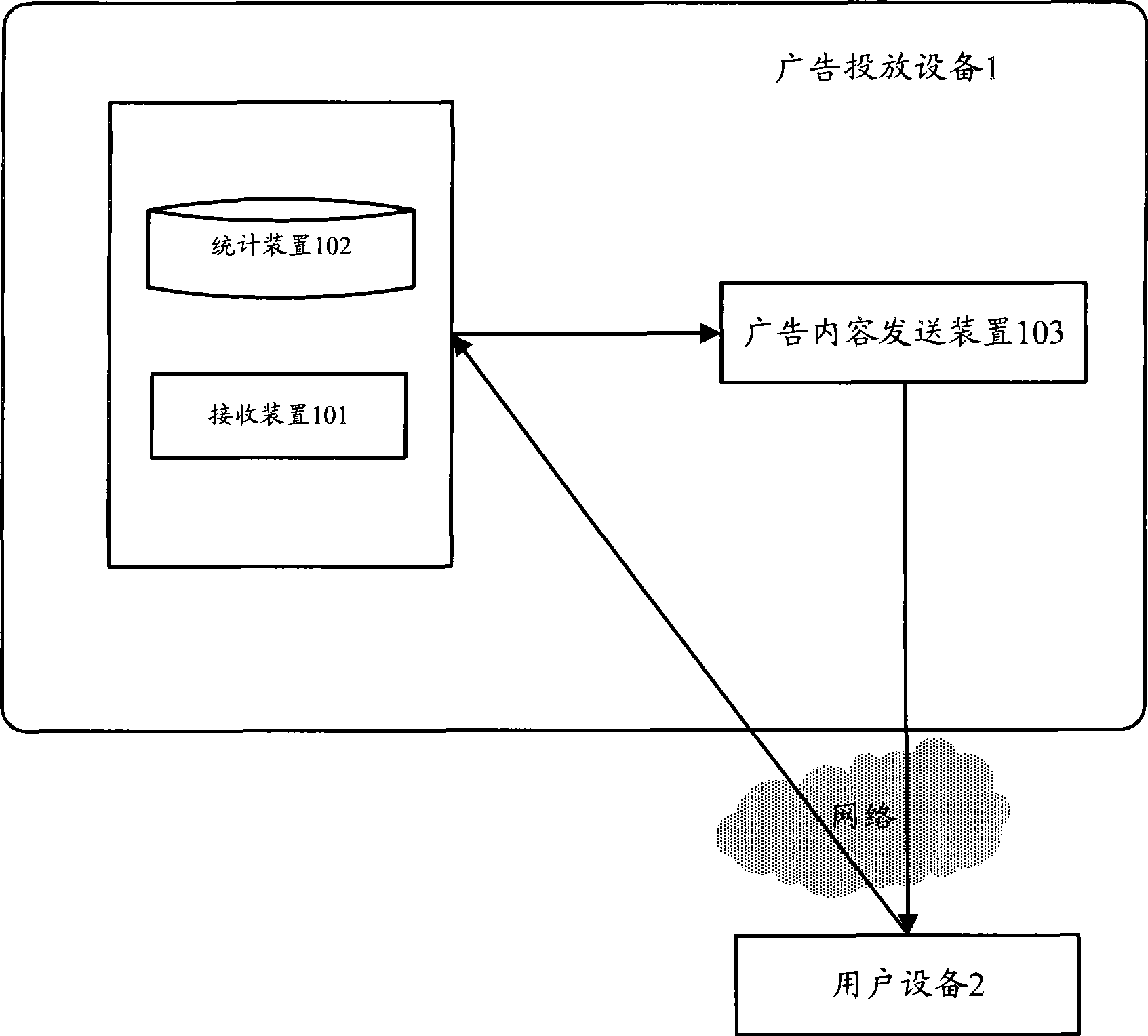

Advertisement delivery method and apparatus for preventing fault advertisement in wireless internet

InactiveCN101471801ALimit impressionsLimit the number of unsolicited clicks on your adSpecial service provision for substationBroadcast service distributionUser equipmentUser Facility

The invention provides an advertisement delivery method used for advertisement fraud prevention in a wireless Internet, which mainly comprises the steps as follows: access requesting information is received from a user facility, and the frequency that the user facility sends the access requesting information is counted; and then advertisement contents are controlled and sent to the user facility based on a preconcerted strategy according to the counted frequency for sending the access requesting information. The advertisement delivery method and a device for complementing the method can be used for preventing advertisement fraud, and avoiding advertisement resource waste.

Owner:上海亿动信息技术有限公司

Real-time measurement of tool forces and machining process model parameters

A system and method are provided for real-time measurement of tool forces. A relationship between a motor characteristic and tool forces is determined by first directly measuring tool forces for a standard tool, work piece, and part program in a central facility. A force profile indicative of the tool forces and the standard tool, work piece, and part program are provided to a user at a user facility. The motor characteristic for a CNC machine at the user facility is then measured for the standard tool, work piece, and part program. Based on the force profile determined at the central facility, the relationship between the motor characteristic and tool forces is determined. Thereafter, the motor characteristic of the CNC machine is measured for a desired tool, work piece, and part program and converted to tool forces using the relationship between the motor characteristic and tool forces.

Owner:UNIVERSITY OF NEW HAMPSHIRE +1

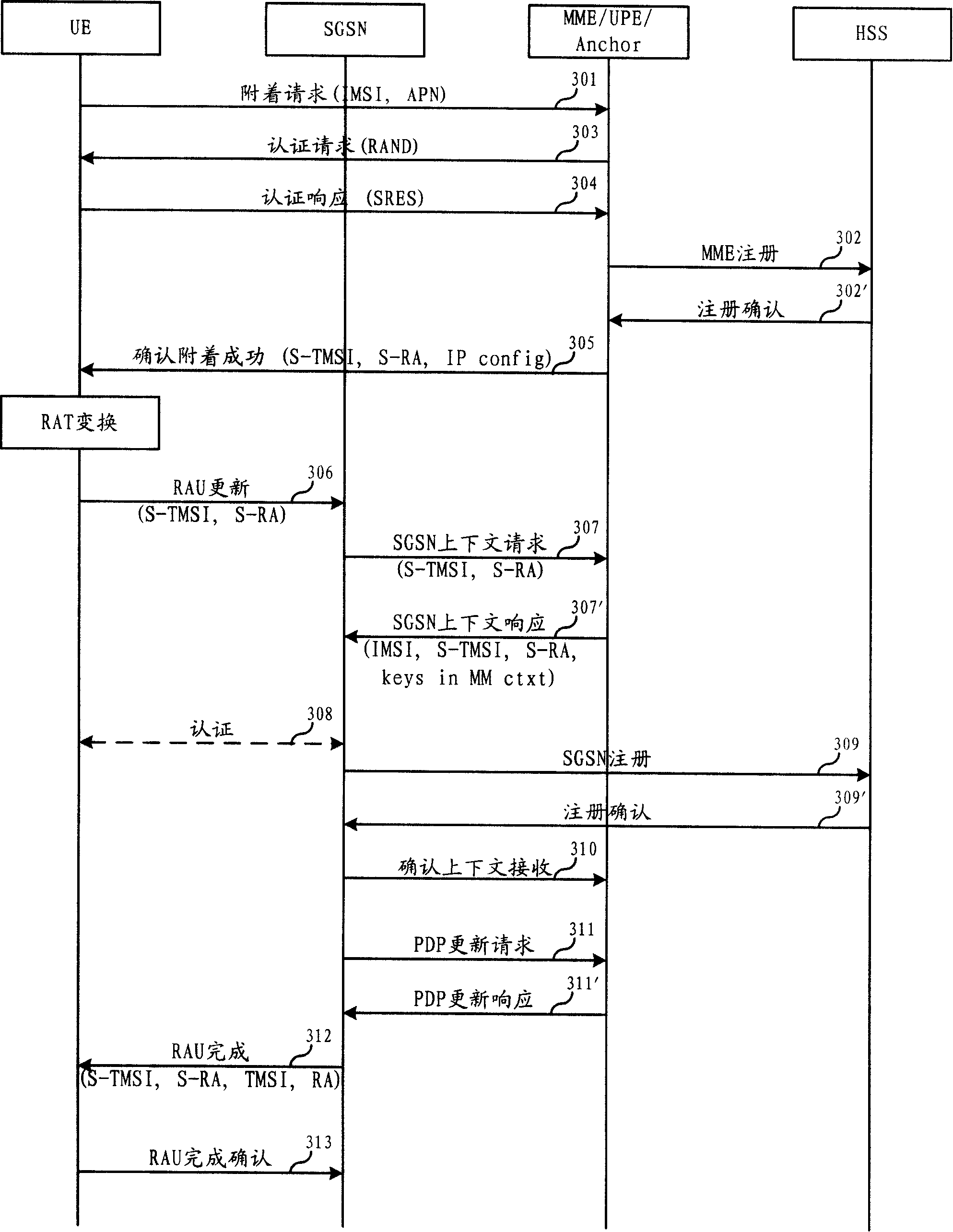

Method for user facility to attach to network and system thereof

InactiveCN101179561AReduce stepsEasy to handleData switching networksSecurity arrangementTelecommunicationsBiological activation

A method, system and device for an user equipment attaching to a network. During the course that an UE is attaching to a network, if the UE and / or the network side does not meet the basic conditions for an UE to access to an evolution network, namely the UE has no ability to access to an evolution network, or the UE has no demand to access to an evolution network, or the UE has no permission to access to an evolution network, or the network side has no ability to access to an evolution network, the activation process of a PDP context is forbidden to perform.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com