Intelligent control system for large-scale structural component automatic production line

A technology for automated production lines and large structural parts, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of difficulty in improving parts processing efficiency, insufficient resource guarantee, etc., to ensure processing quality, reduce production costs, The effect of improving the efficiency of production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

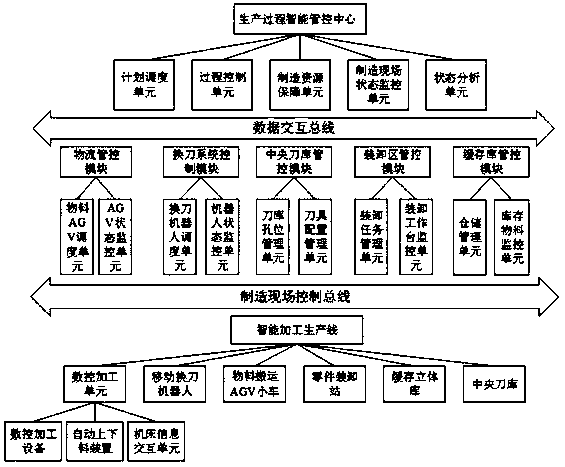

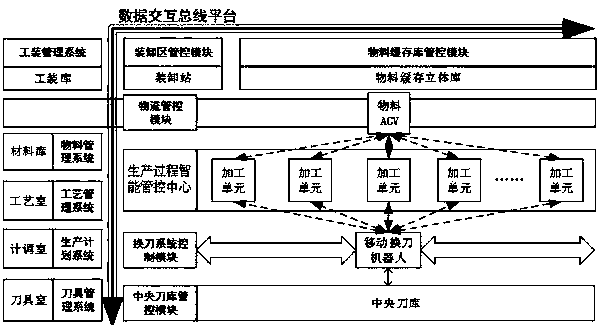

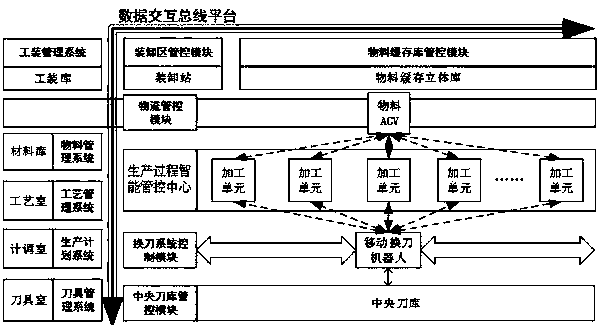

[0047] Such as figure 1 As shown, an intelligent management and control system for an automatic production line of large-scale structural parts is characterized in that it includes an intelligent processing production line, an intelligent production process management and control center, a logistics management and control module, a tool change system control module, a central tool magazine management and control module, a loading and unloading area management and control module, Material cache warehouse control module, tooling management system, material management system, process management system, production planning system and tool management system;

[0048] The production process intelligent management and control center, logistics management and control module, tool change system control module, central tool magazine management and control module, loading and unloading area management module and material cache warehouse management and control module are based on the data ...

Embodiment 2

[0092] The production process intelligent management and control center includes: production line production process management software and monitoring equipment; the production process intelligent management and control center production management software includes: planning scheduling unit, process control unit, manufacturing resource guarantee unit, manufacturing site status monitoring unit, State analysis unit; the planning and scheduling unit completes the reception of the production line production tasks, and uses the scheduling algorithm based on artificial intelligence to perform dynamic scheduling of the processing units according to the production line manufacturing resources and the production line in-progress task execution status; the process The control unit drives the product manufacturing process according to the product manufacturing process regulations, and realizes the connection of processing, logistics, and inspection production processes; the manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com