Patents

Literature

149results about How to "Facilitate standardized management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large-seed directional seeding device

ActiveCN102918959AIncrease production capacityEasy to manageSingle grain seedersThrottleReciprocating motion

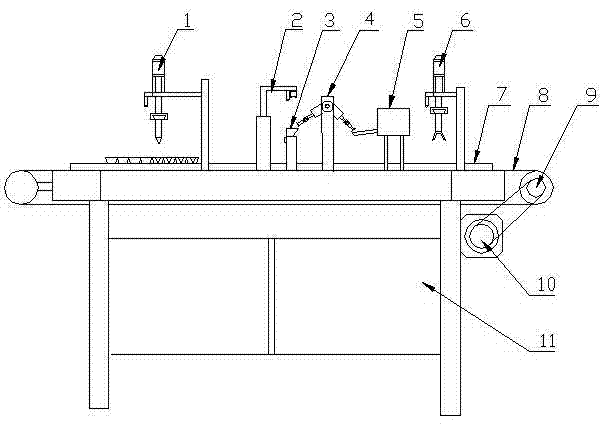

The invention relates to a large-seed directional seeding device, comprising an operating platform, a conveying mechanism, a seedling disc, a hole pressing mechanism, a camera shooting detection mechanism, a seeding mechanism, a seed box, a guide plate, a direction adjusting mechanism, a correcting mechanism and a control box, wherein the operating platform comprises a rack and an operating platform surface; the conveying mechanism, the hole pressing mechanism, the camera shooting detection mechanism, a seed absorbing mechanism, the direction adjusting mechanism and the correcting mechanism are connected with a control system in the control box; and the camera shooting detection mechanism is a computer which is externally connected with the control system in the control box and is internally equipped with image processing software. According to the large-seed directional seeding device provided by the invention, a sensor accurately detects and feeds back a working process, a conveying speed is controlled by virtue of frequency modulation of a stepping motor, bidirectional throttle valves and one-way throttle valves are adopted for regulating speed during the reciprocating motion of a hole pressing cylinder and a correcting cylinder and a gas collecting tube connecting suction needle motion, and directional planting with consistent germination point orientation after planting is realized.

Owner:NORTHWEST A & F UNIV

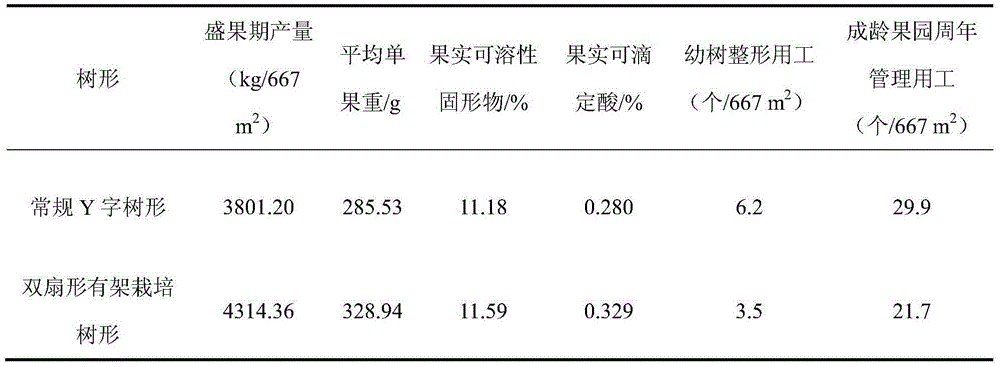

Double-sector trellis cultivation type pear tree form and shaping method thereof

ActiveCN105028105ALess branchedOrderly rowsCultivating equipmentsHorticulture methodsFruit treeWire gauze

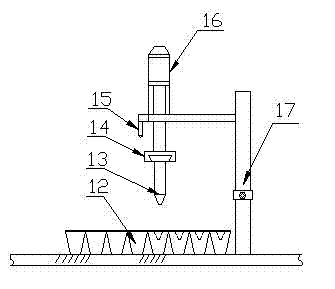

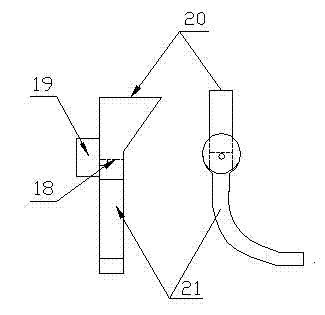

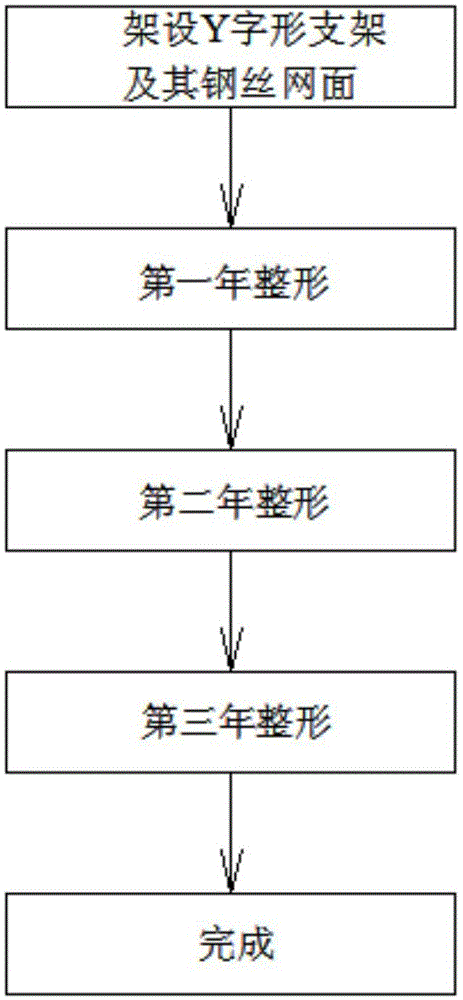

The invention belongs to the field of fruit tree cultivation and fruit tree ecology and relates to a double-sector trellis cultivation type pear tree form and a shaping method thereof. Only two principal branches are reserved on a pear tree, a 90-degree included angle is formed between the two principal branches which are fixed to a Y-shaped support, and the two principal branches are symmetrically spread towards the space between lines; a base lateral branch is arranged on each of the two sides of the base of each principal branch, and a plurality of monopodium non-pruning type bearing branch groups are evenly arranged on and above the middle portion of each principle branch in a stagger mode; a 90-degree side angle is formed between each base lateral branch and the corresponding principal branch; a 90-degree base angle is formed between each monopodium non-pruning type bearing branch group and the corresponding principle branch, and the monopodium non-pruning type bearing branch groups are spread in parallel in the line direction; lateral branch bearing branch groups are formed on the base lateral branches through bud carving and non-pruning; weak shoots are taken as the main part of each principal branch, and the crown is spread to be sectors on the two sides of the Y-shaped support. The shaping method comprises the steps of erecting the Y-shaped support and a steel wire gauze surface, shaping at the first year, shaping at the second year and shaping at the third year. The method is convenient to operate and remarkable in effect.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

Injection mold manufacturing method based on CAD/CAE/CAM and products

The invention relates to an injection mold manufacturing method based on CAD / CAE / CAM. The method includes the steps of a, designing a mold, to be more specific, using three-dimensional software to build 3D models of the structural parts of the mold, and manufacturing the general assembly drawing of the mold; b, manufacturing the engineering drawing of each part and setting a mold tolerance standard; c, manufacturing the injection mold, to be more specific, CAM tool path programming and importing a CNC manufacturing process, an EEM manufacturing process, a WEEM manufacturing process and a grinding process; d, soaking the mold in special plant oil for more than 24 hours; e, detecting the mold. The method has the advantages that a mold prototype drawing CAD design link can avoid problems in actual machining according to graphic simulation analysis, overall mold design is further optimized, and subsequent processes can be implemented reliably; due to the fact that the mold is soaked in the plant oil for more than 24 hours, the precision of the mold can be increased evidently, the service life of the mold is prolonged evidently, and the yield of injection molding products is increased evidently.

Owner:DONGGUAN KONKA MOLD PLASTIC

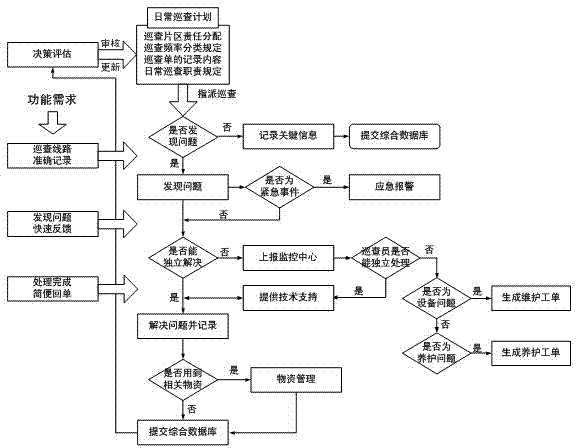

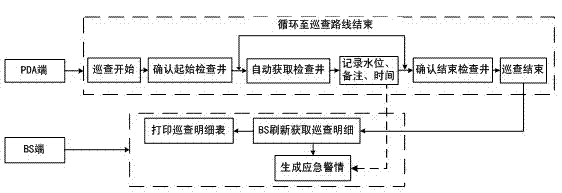

Inspection managing method for municipal drainage pipeline network

InactiveCN102768740AGuarantee scientific and effectiveTo achieve a virtuous circleResourcesComputer science

The invention relates to an inspection managing method for a drainage pipeline network, which can realize the intelligentization of the management of the inspection of the drainage pipeline network, the correct record and convenient recheck of the inspection tracks and the record and feedback of the event processing information and meet the requirements of the inspection staff and a monitoring center to communicate information effectively and timely. The method effectively avoids the problems that inspection points in the inspection of the drainage pipeline network are omitted, the management of the inspection is ineffective, and the inspection efficiency is low, and the method can achieve the real-time convenient collection of different kinds of data and comprehensive management; the inspection managing method for municipal drainage pipeline network is characterized by carrying out the inspection process of the pipeline network through a pipeline network inspection system; and the network inspection system is established by adopting combination of an M / S mode and a B / S mode and comprises an M / S inspection management sub-system and a B / S inspection management sub-system.

Owner:北京清控人居环境研究院有限公司

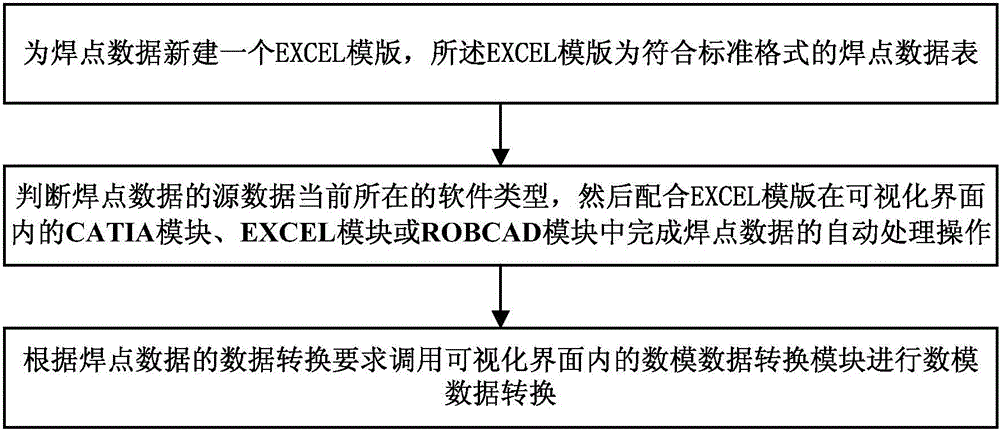

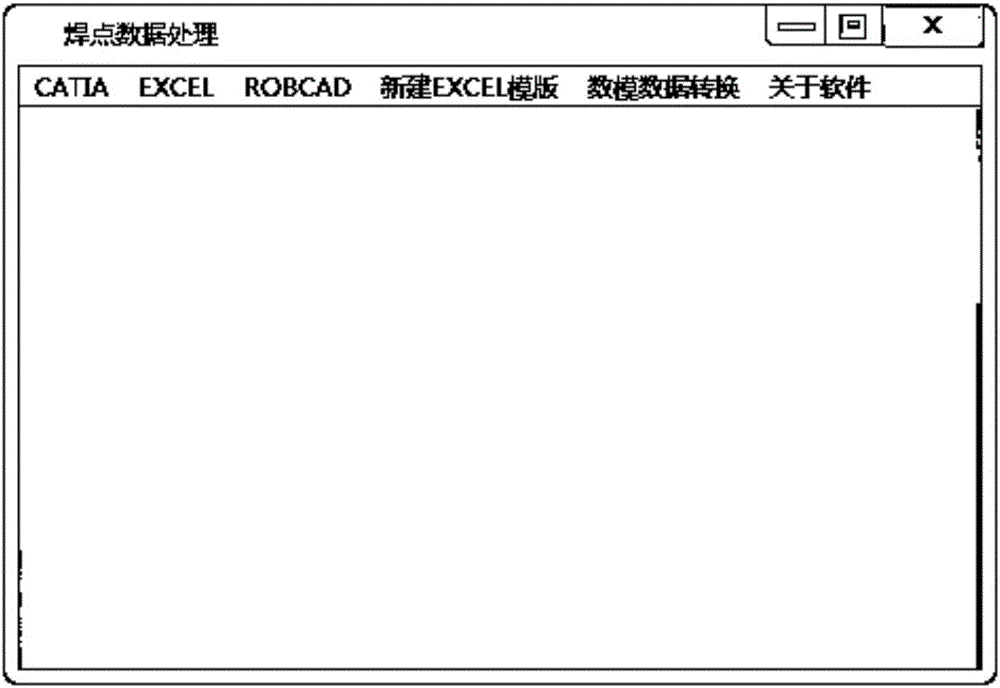

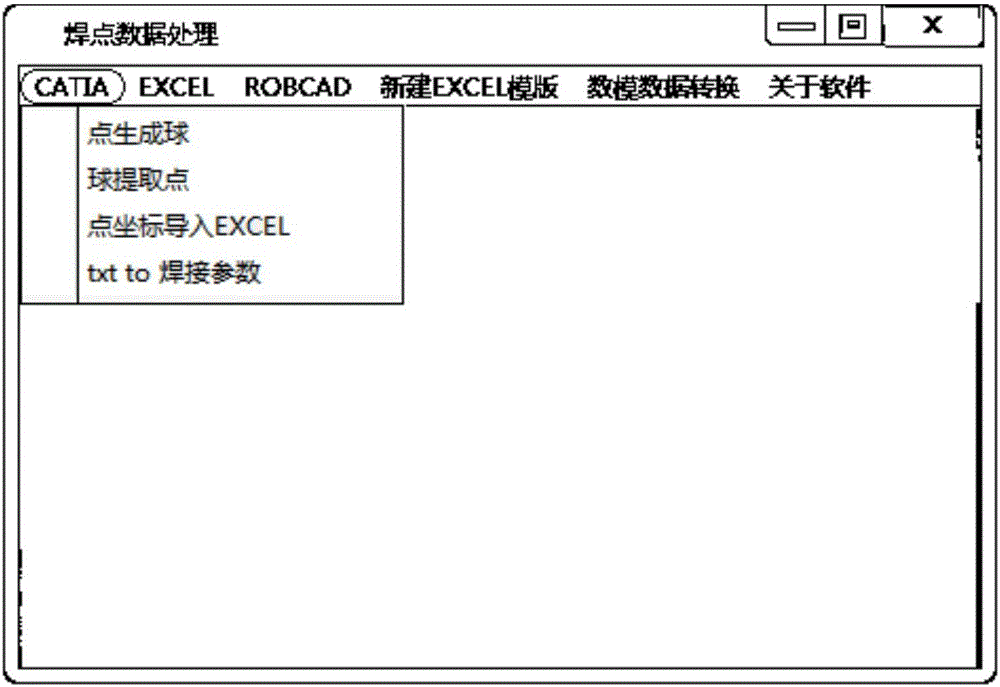

Welding spot data processing method and system

ActiveCN106202022AFacilitate standardized managementNo professional skills requiredData processing applicationsText processingTechnical standardSoftware engineering

The invention discloses a welding spot data processing method and system. The method comprises the following steps of: establishing an EXCEL template for welding spot data, wherein the EXCEL template is a welding spot data table which conforms to a standard format; judging the type of software where the source data of the welding spot data is positioned at present, then, cooperating with the EXCEL template to finish the automatic processing operation of the welding spot data in a CATIA (Computer-graphics Aided Three-dimensional Interactive Application) module, an EXCEL module or a ROBCAD module in a visual interface; and according to the data conversion requirement of the welding spot data, calling a digital-analog data conversion module in the visual interface to carry out digital-analog data conversion. The method fills up the blank of welding spot data processing software development, is favorable for the standardized management of the welding spot data, functionally contains requirements on processing the welding spot data in general design and simulation, is more comprehensive, provides the good visual interface for users, is high in universality and interaction, and is convenient in use. The method can be widely applied to the fields of welding data processing and computer application.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

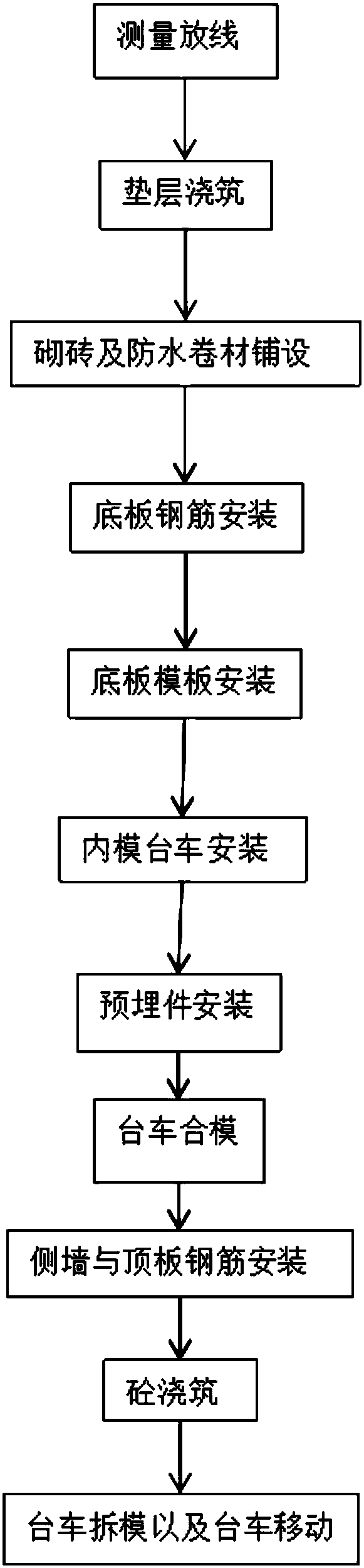

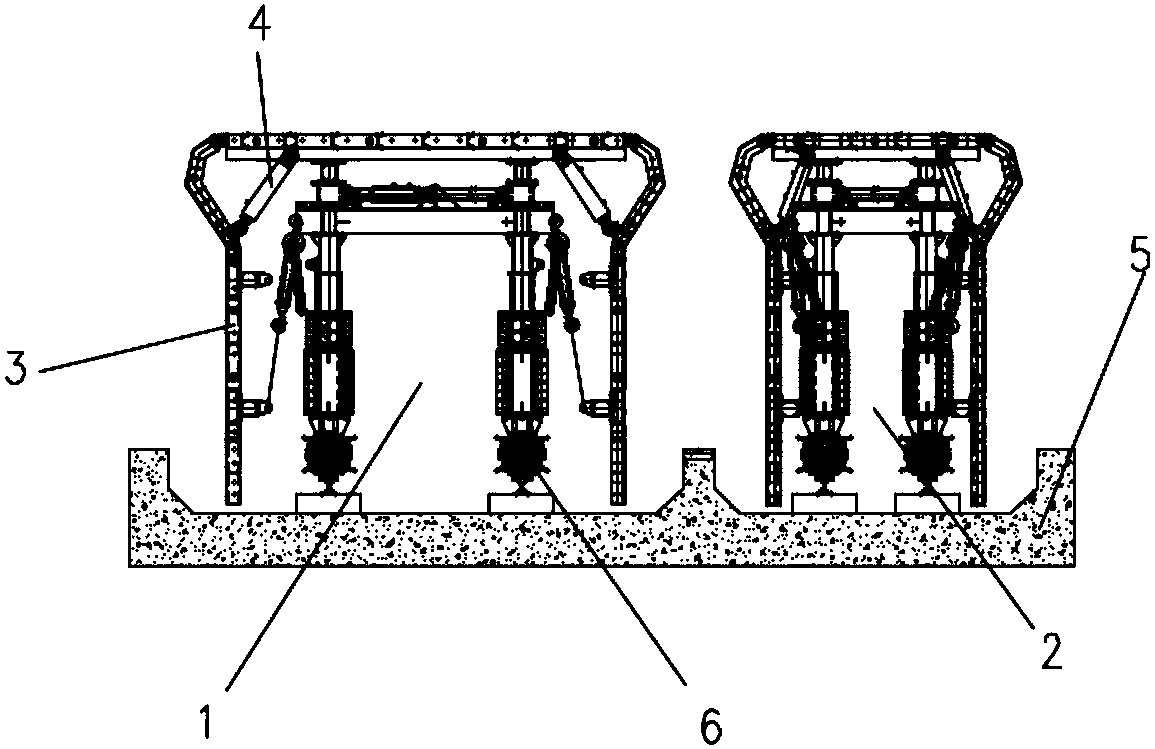

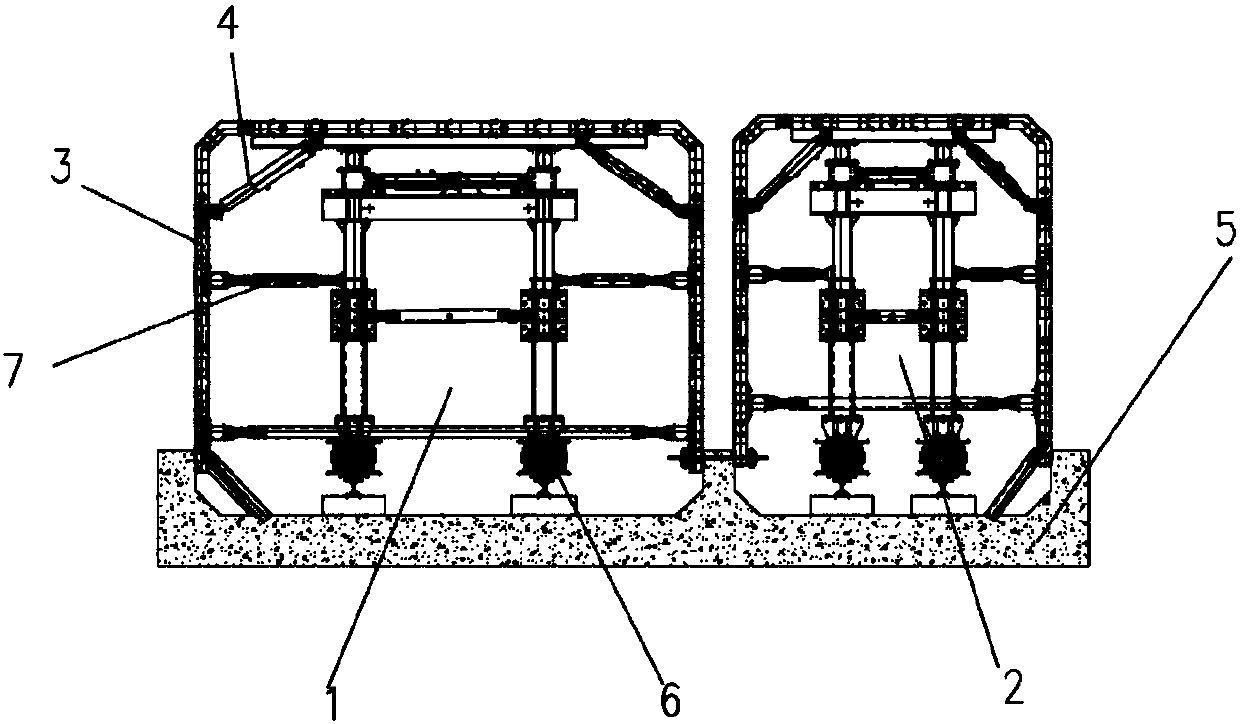

Construction method for support formwork integrated hydraulic inner formwork trolley of comprehensive pipe gallery

ActiveCN107905254AImprove flatnessLess labor requiredArtificial islandsUnderwater structuresSocial benefitsVehicle frame

The invention provides a construction method for a support formwork integrated hydraulic inner formwork trolley of a comprehensive pipe gallery. The construction method comprises the following steps of surveying and setting out, pouring of a cushion layer, bricking and waterproof roll laying, mounting of base plate rebars, mounting of base plate formwork plates, mounting of the inner formwork trolley, mounting of embedded parts, formwork closing of the trolley, mounting of side wall and top plate rebars, concrete pouring, formwork removal of the trolley and moving of the trolley. According tothe construction method, dimensions of the support formwork integrated hydraulic inner formwork trolley are customized according to internal space dimensions of the pipe gallery; the support formworkintegrated hydraulic inner formwork trolley is composed of a walking system, a trolley frame, steel formwork plates, a formwork plate vertical and side-direction extending-and-contracting system, a hydraulic system and an electrical control system; the formwork plates are rapidly combined through rapid locating of the trolley and removed rapidly after pouring is completed; after pouring of a pipegallery main body is completed, locating of a subsequent pipe gallery main body can be completed by moving the trolley through the walking system; and after concrete pouring is completed, the surfaceis good in flatness and appearance quality, and good social benefits are achieved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

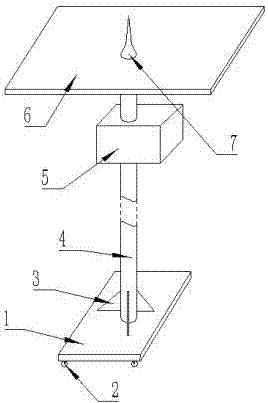

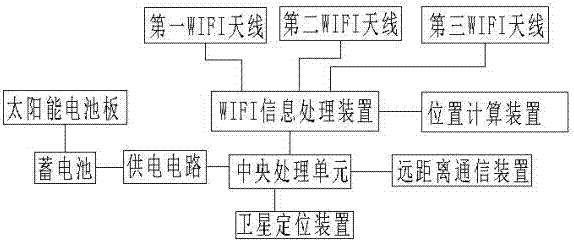

Electronic fence positioning pile for bicycle sharing

PendingCN106980107AAccurate parkingFacilitate standardized managementPosition fixationTowersClose rangeReal-time computing

The invention discloses an electronic fence positioning pile for bicycle sharing, which comprises a fixed device positioning communication system (5), and is characterized in that the positioning communication system (5) comprises a central processing unit, an energy device, a positioning device and a remote communication device, the energy device, the positioning device and the remote communication device are in signal connection with the central processing unit; and the positioning device comprises a close-range high-precision positioning device and a satellite positioning device. Through setting an electronic fence, accurate parking of shared bicycles can be realized, standardized management of the shared bicycles is improved, the management cost is reduced, and the service quality is improved. Through adopting various fixing modes, the installation cost of the electronic fence can be saved to the maximum extent, and the economic benefits are improved. The electronic fence is arranged by adopting a movable mode, so that adjustment can be performed on a parking area, and optimum setting for the electronic fence is realized. Riding information of the bicycles can be transmitted to the company through setting the remote communication device.

Owner:CHENGDU WENGWENG TECH CO LTD

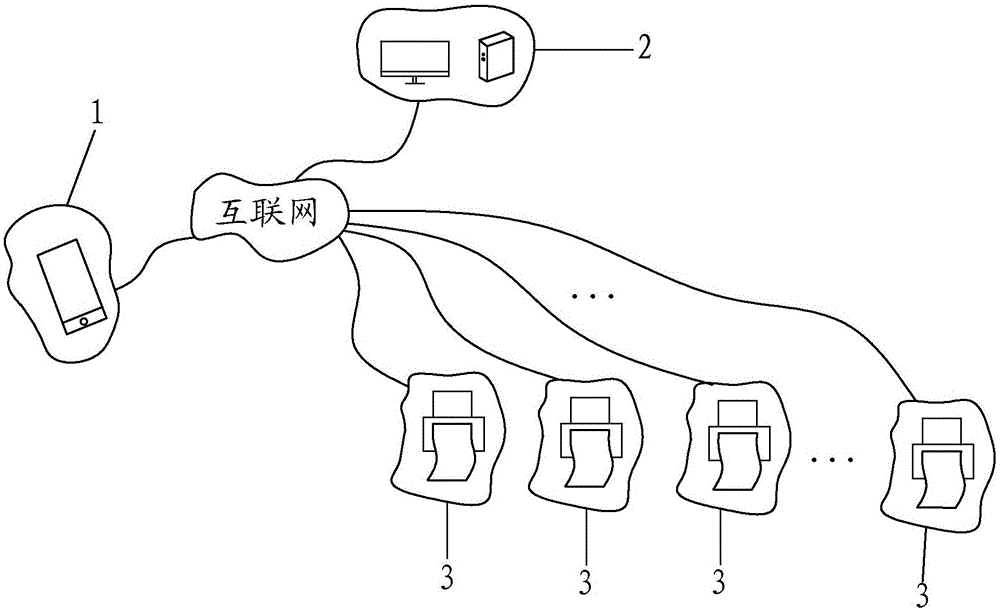

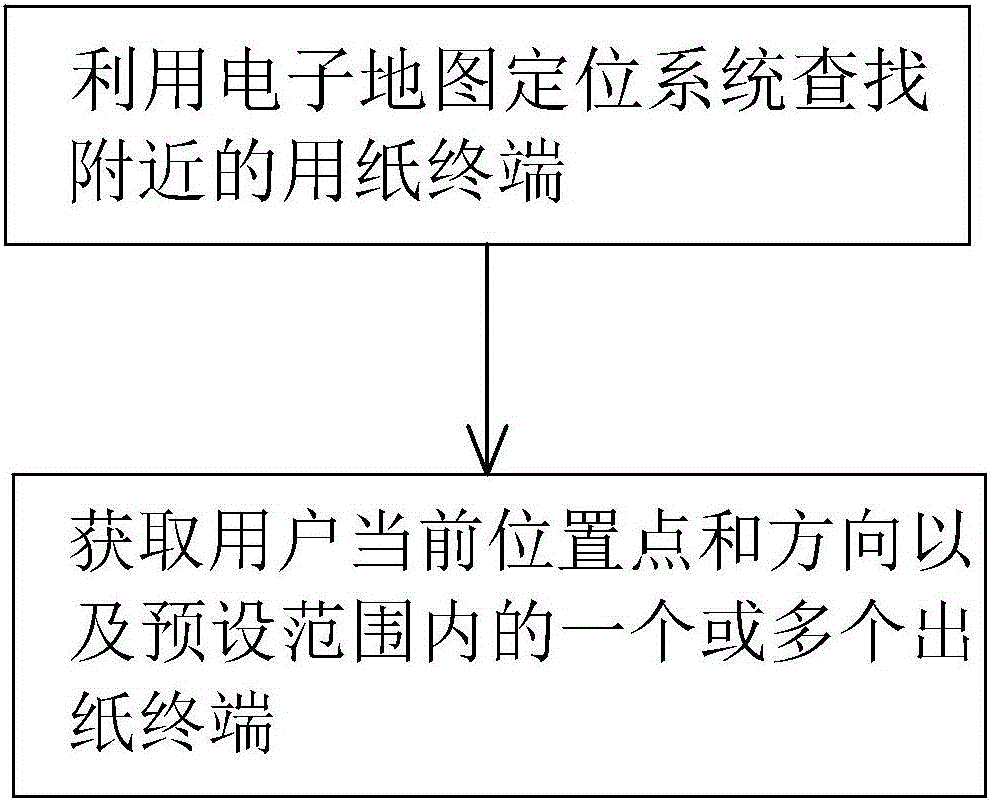

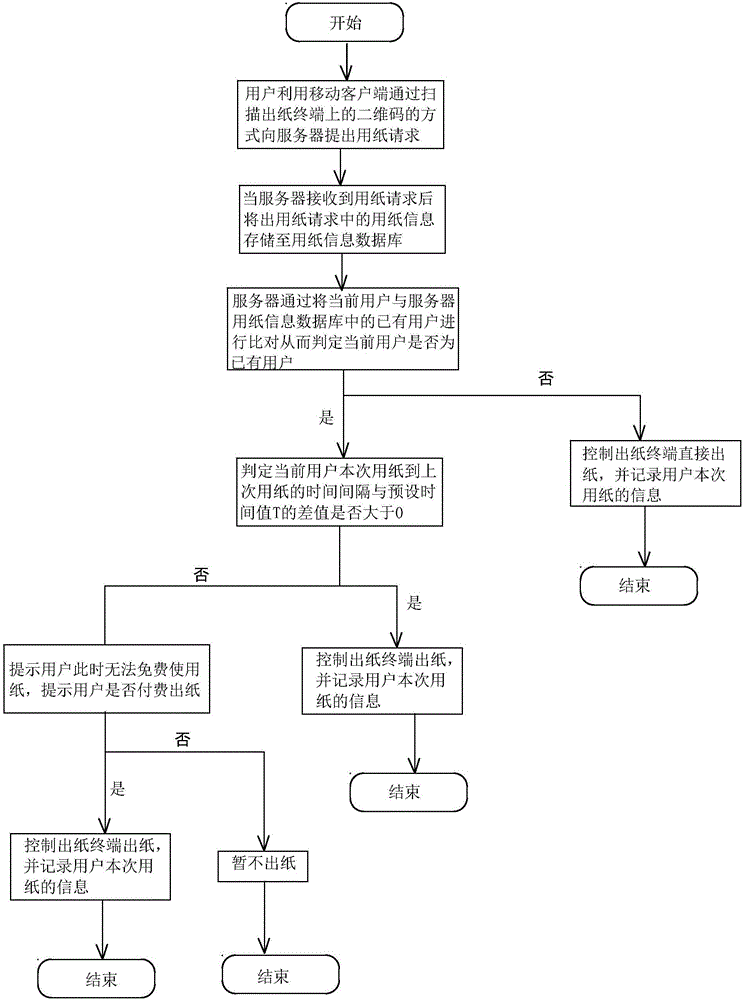

Intelligent saving toilet paper paper-out method and system for public toilet

InactiveCN106296541AFacilitate standardized managementQuick responseData processing applicationsDomestic applicationsPublic toiletMobile client

The present invention provides an intelligent saving toilet paper paper-out method and system for a public toilet. The method comprises the following steps: a paper-out platform is built in advance, wherein the paper-out platform includes a server, a communication network, a mobile client, a paper-out machine terminal and a detector, and the server includes a first determination module configured to determine whether the users are existing users or not; a second determination module is configured to determine whether the existing users can use paper for free or not; after the server receives the paper using request, the server determines whether the users are existing users according to the user paper-out information, and if the users are not existing users, the papers are directly taken out; and if the users are existing users, the server compares the time interval from paper using at the last time to this time with a presetting time value T, and it is controlled whether the papers are taken out or not and the paper-out state according to the comparison value. The server controls the paper delivery of each paper-out machine terminal so as to greatly improve the paper using standardization management, put an end to take more papers by people who are greedy for small gains and ensure that everybody can use the papers.

Owner:苏州托尔斯自动化有限公司

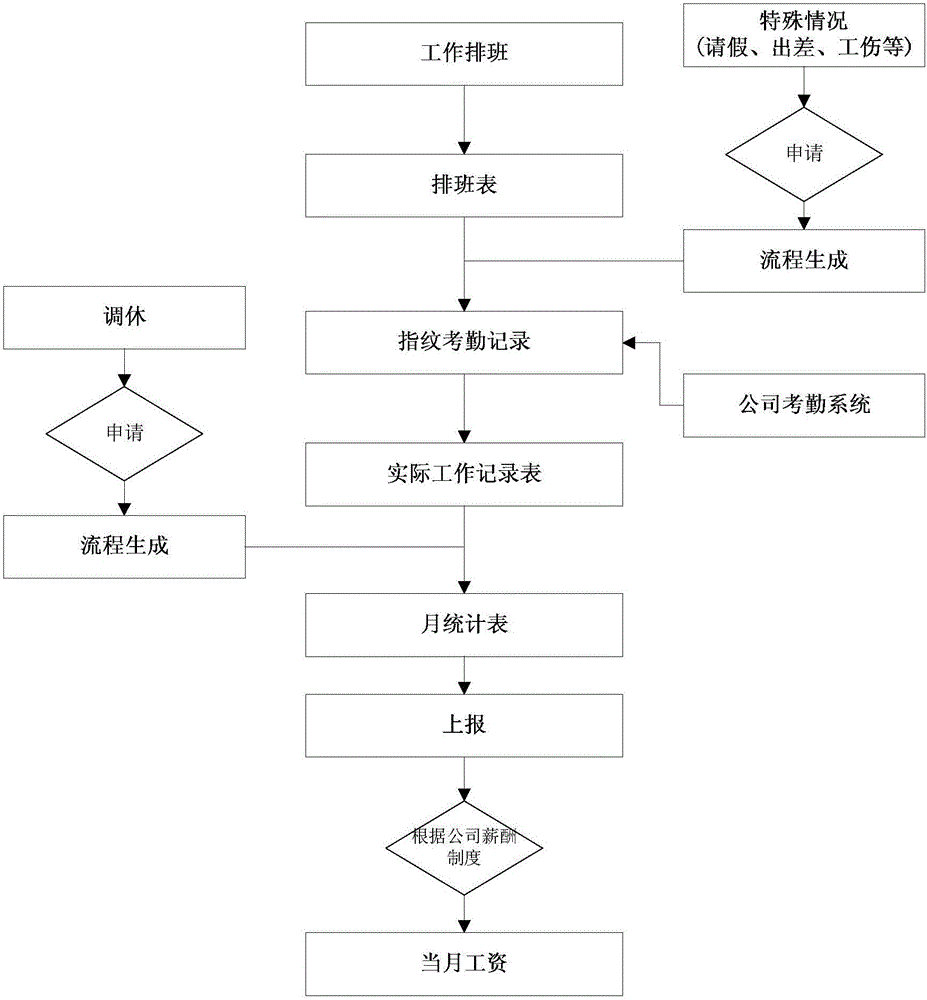

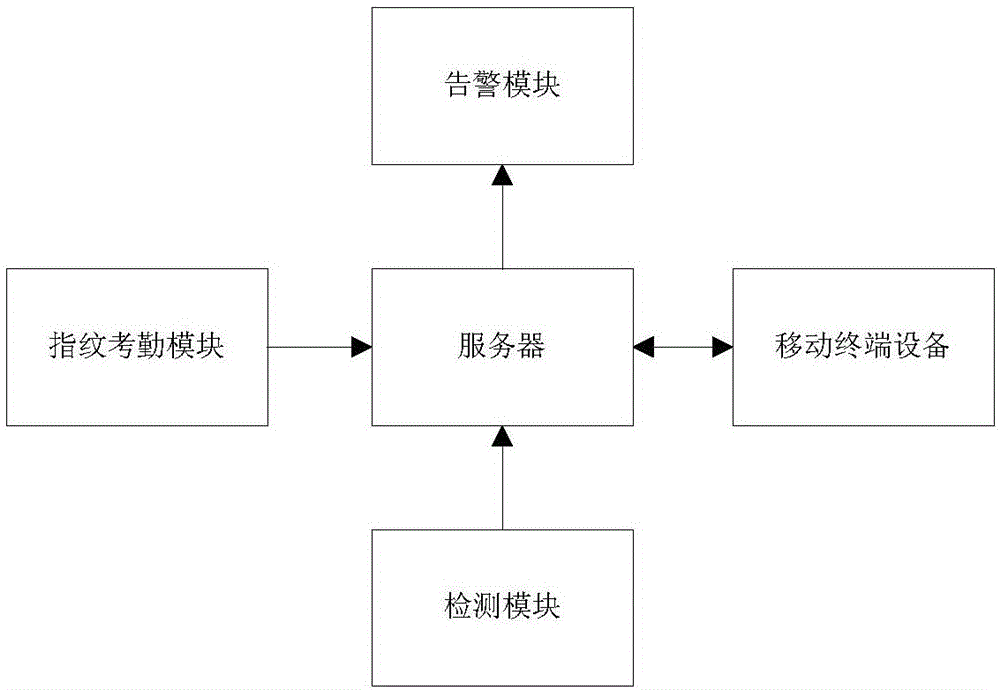

Attendance management method and system

InactiveCN106447156ARealize standardized managementRealize unified managementRegistering/indicating time of eventsResourcesWorkloadComputer science

The present invention provides an attendance management method and system. The method comprises that a. a scheduling table is set, staff attendance information is collected, and the attendance information is uploaded to a server, wherein the attendance information comprises identity information, fingerprint information and scheduling information; b. according to the attendance information, the server collects statistics of the actual work record of staff, and dynamically assigns experimental test tasks through the fingerprint attendance condition of the test staff and the experiment workload; and c. the actual salary of the staff is automatically obtained by matching a pre-established salary system with the actual work record. According to the attendance management method and system provided by the present invention, a digital experiment and digital management platform is established, so that on one hand, assignment of experimental test tasks can be facilitated, efficiency in the experiment process can be improved, and the progress and result of the overall experiment can be ensured, and one the other hand, standardized management to the staff can be facilitated, and the salary system is combined, so that the cost of manual accounting is reduced, and the efficiency of the enterprise is improved.

Owner:LONCIN MOTOR

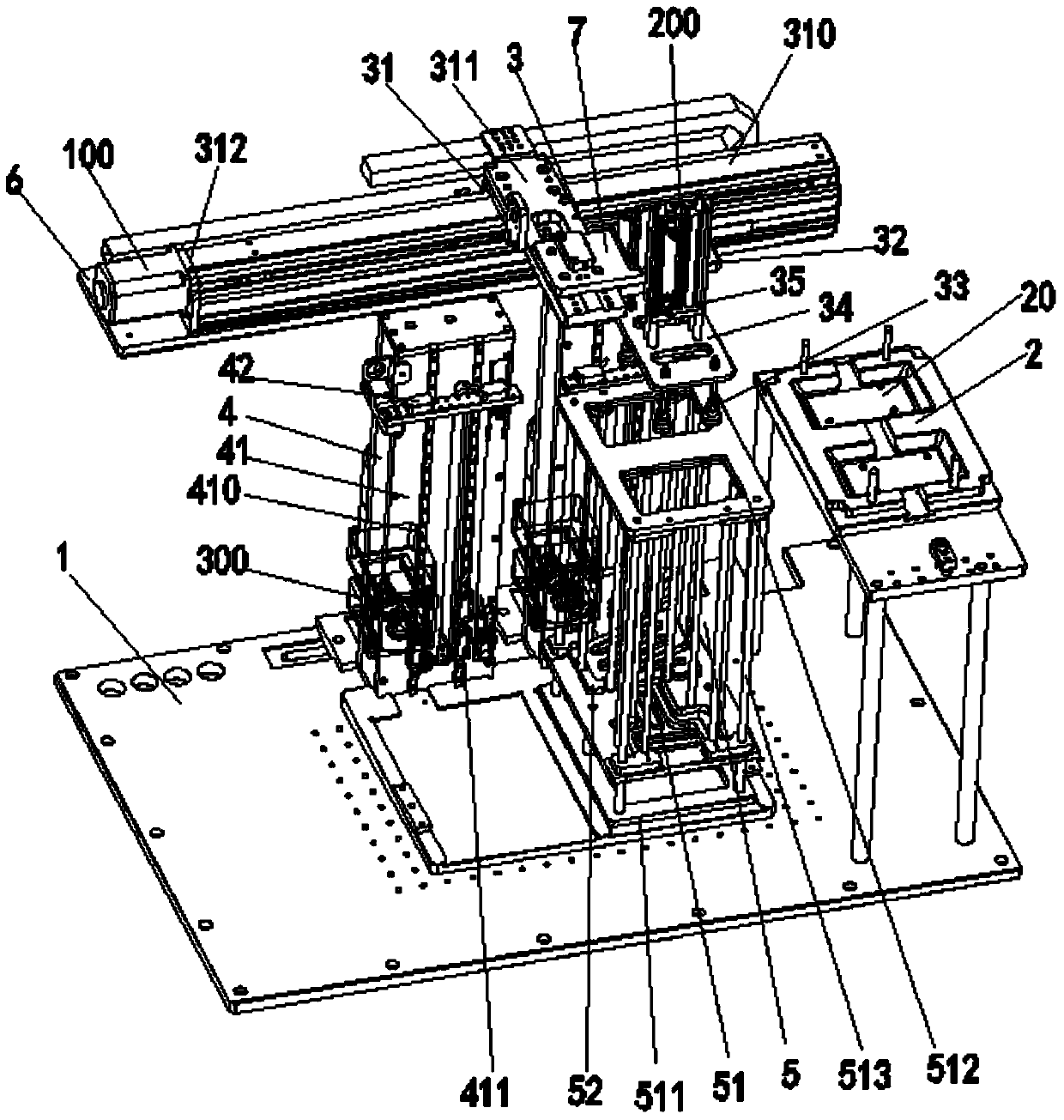

Automatic feeding device applied to in-mold injection molding inserts

ActiveCN104191544AReduce downtimeFacilitate standardized managementInjection molding processProcess engineering

The invention discloses an automatic feeding device applied to in-mold injection molding inserts, belonging to the field of production and manufacturing of digital devices. The automatic feeding device comprises a base, a positioning component, a taking and placing component, a stacking component and a supply component, wherein the positioning component is arranged on the base; the taking and placing component is used for taking inserts out and placing the inserts on the positioning component; the stacking component is used for limiting and stacking the inserts; the supply component is used for supplying the inserts to the taking and placing component; the taking and placing component mainly comprises a grabber, a transverse feeding mechanism and a longitudinal feeding mechanism; the grabber is fixedly arranged on the longitudinal feeding mechanism; the supply component mainly comprises a precise guide rail, a servo motor and a sensing device; the servo motor is arranged at the bottom part of the precise guide rail; the sensing device is arranged at the upper part of the precise guide rail. By virtue of the automatic feeding device applied to the in-mold injection molding inserts, the manual operation of taking and placing the inserts is fully replaced; the automatic feeding device and an injection molding machine mechanical arm cooperate for placing the inserts into a mold, so that the full-automatic operation of the whole in-mold injection molding process is truly achieved; the labor cost is greatly reduced; the production efficiency is improved; meanwhile, the standardized management of a workshop is facilitated.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

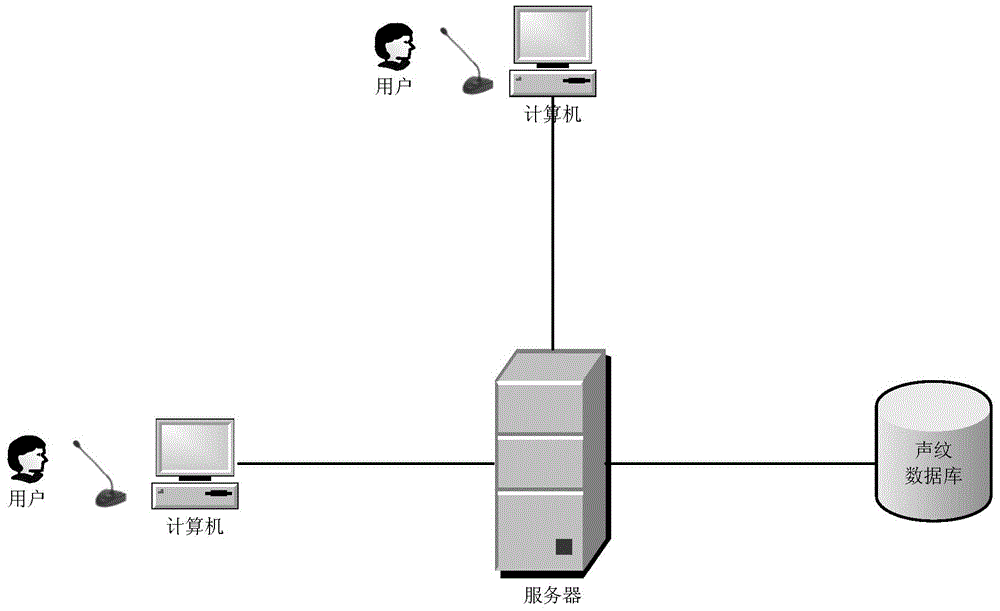

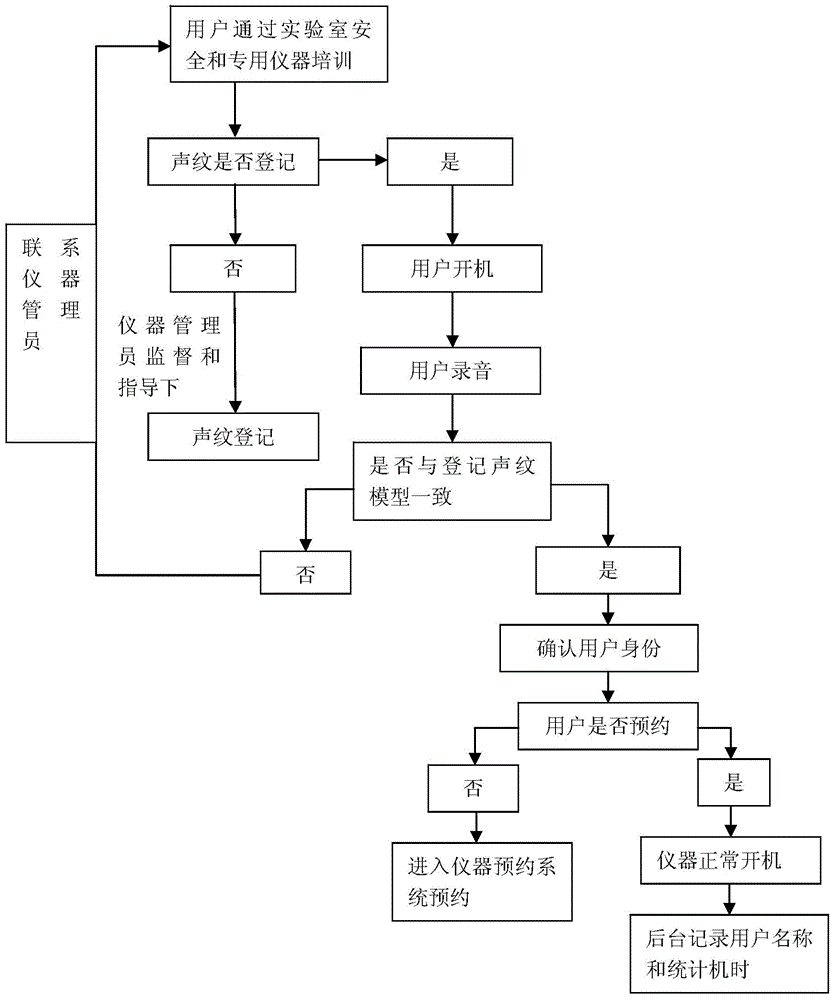

Sharing instrument platform management method based on voiceprint recognition technology

InactiveCN104392723AFacilitate standardized managementEasy to useSpeech analysisUser needsActive time

A sharing instrument platform management method based on a voiceprint recognition technology relates to identity authorization with the biological recognition technology. The voice-recording is carried out via a microphone; a user reads characters on a computer screen and the voiceprint feature values are acquired and a system prompts the user to finish the voice-recording after the active time; the voiceprint model is registered after the system detects the voice and the screen displays the successful voiceprint registration; when the user needs to use the instrument, a voice verification program is started automatically, the user reads the characters on the screen via the microphone and the system prompts the user to finish the voice-recording after the active time; the system judges whether the user's voiceprint is consistent with the registered voiceprint model, identifies whether the user's identity is an authorized user, verifies whether the authorized user has been appointed on an instrument appointment system and obtains the authorization of an instrument administrator; if the user is an appointed user, the instrument can be started normally, the user can use the instrument normally and the backstage records user information and counts running time; if the authorized user is a non-appointed user, the system prompts the user to enter the appointment system for appointment; if the user is a non-authorized user, the instrument cannot be started normally, the user cannot use the instrument and can contact with the instrument administrator to report the existing problem.

Owner:XIAMEN UNIV

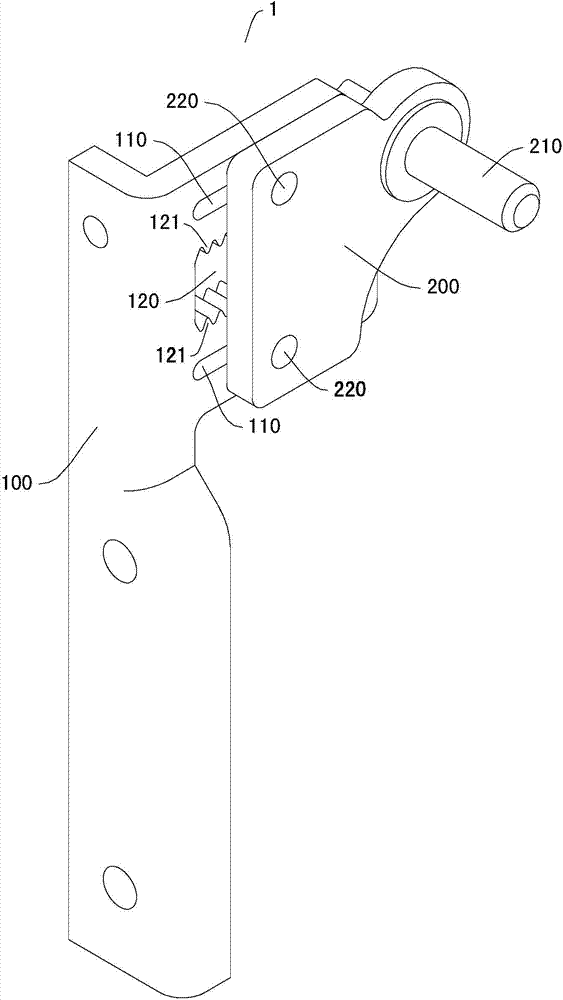

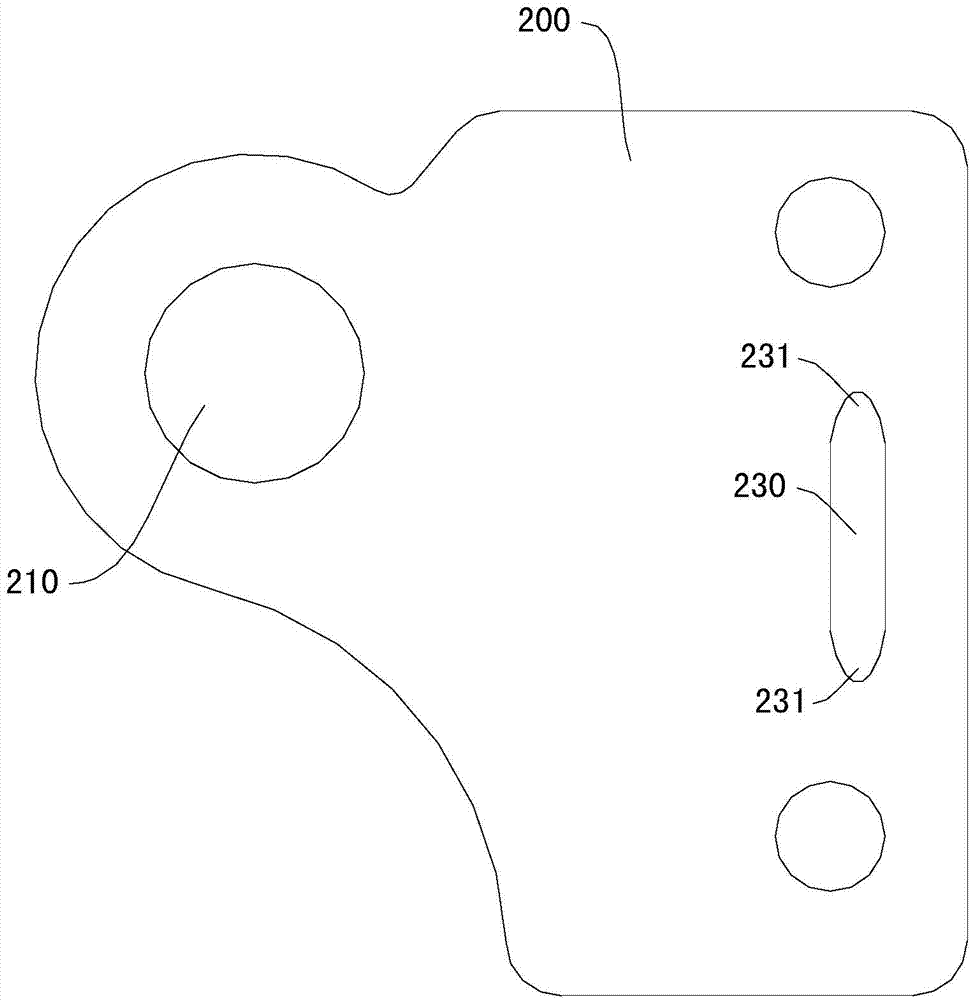

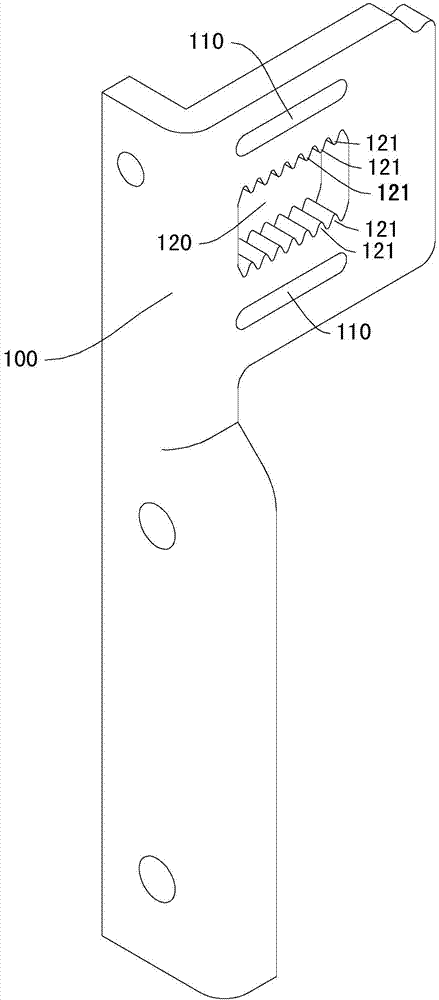

Hinge and refrigerator with hinge

ActiveCN103670094AImprove applicabilityEasy to standardize managementHingesFastenerAerospace engineering

The invention discloses a hinge and a refrigerator with the hinge. The hinge comprises a hinge base, a hinge frame and a fastening part. A central shaft is arranged on the hinge frame, the hinge frame is movably arranged on the hinge base, and the fastening part is used for fixing the hinge frame on the hinge base. The hinge which can meet the assembly requirements of different refrigerators has the advantages of facilitating standardization management, being low in mold development cost and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

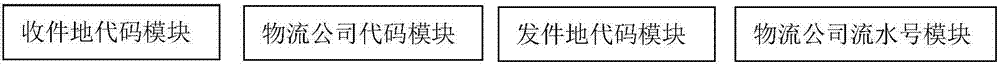

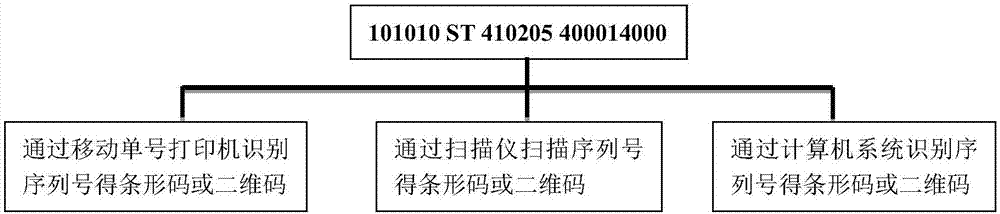

Computer logistics management method based on tracking number coding rules

The invention discloses tracking number coding rules and a computer logistics management method based on the tracking number coding rules. The tracking number coding rules are disclosed, and a tracking number comprises a receipt place code, a logistics company code, a sending place code and a logistics company running number; the receipt place code and the sending place code are generated according to administrative region zip codes of a receipt place and a sending place; the logistics company code is generated according to Pinyin letters of a logistics company name, or an English name for short or other codes different from those of other logistics companies; the logistics company running number includes but not limited to a preset regional running number, a mail types code, a date code, an encryption cryptograph code and a check code, moreover, the tracking number coding rules are for the computer logistics management method of a computer management system and the computer logistics management method for a non-computer management system. The method is advantaged in that coding rules of all logistics system tracking numbers are unified, and standardized management, information collection, data processing, query and statistics are facilitated.

Owner:周惠君

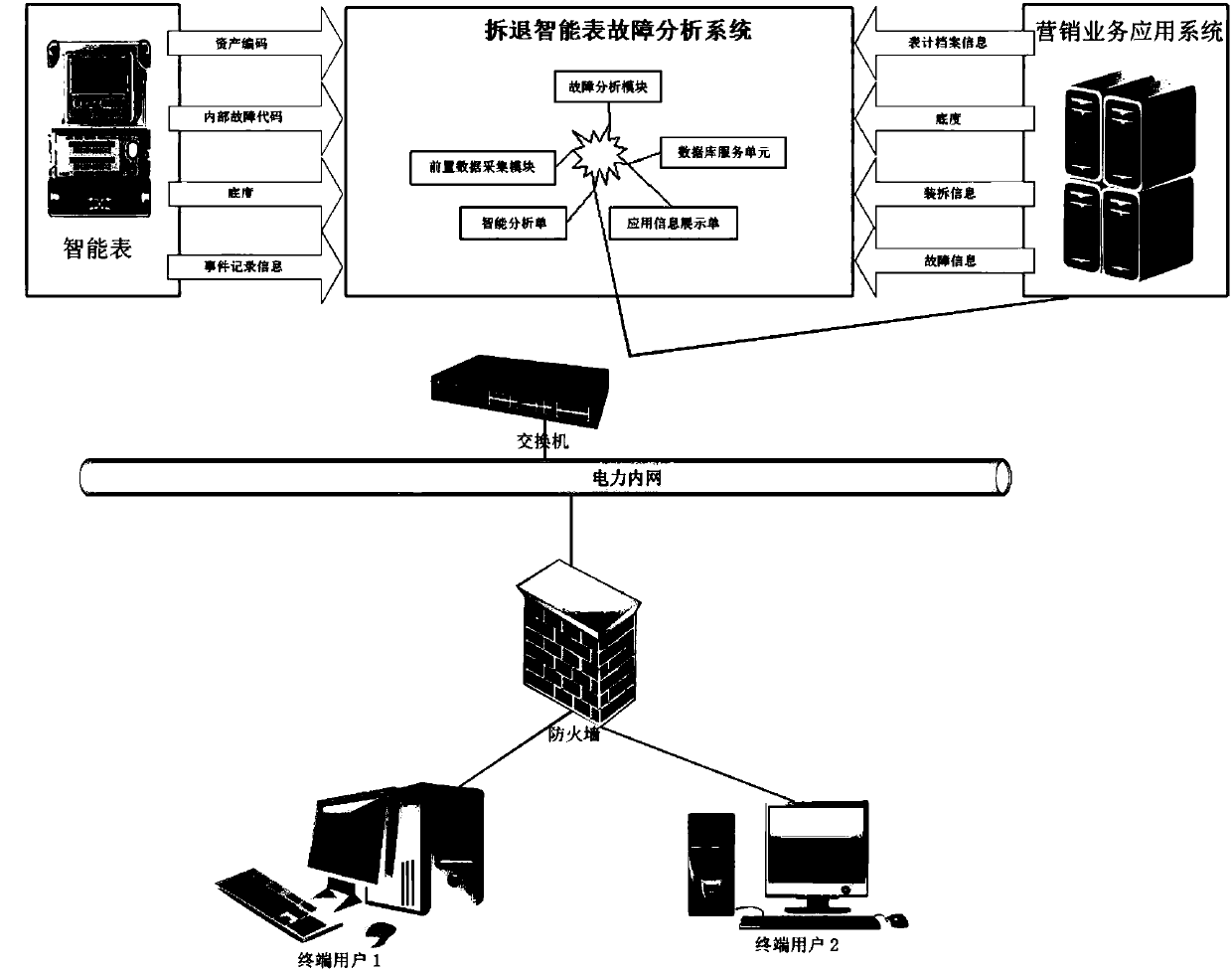

Quality supervision and management platform based on dismounted and returned intelligent meter assembly line device

PendingCN107730074ARealize intelligent managementSolid data supportSustainable waste treatmentResourcesData informationData access

The invention discloses a quality supervision and management platform based on a dismounted and returned intelligent meter assembly line device. The quality supervision and management platform comprises a marketing service application system, terminal users and a dismounted and returned intelligent meter failure analysis system, wherein the dismounted and returned intelligent meter failure analysis system acquires corresponding intelligent meter data information of an intelligent meter and in the marketing service application system, the dismounted and returned intelligent meter failure analysis system is used for completing data access of each system, performing intelligent analysis and providing failure data sources, and the dismounted and returned intelligent meter failure analysis system comprises a pre-positioned data acquisition module, a failure analysis module, a database service unit, an intelligent analysis unit and an application information display unit. The quality supervision and management platform can realize automatic study and judgment of various failure types. Through carrying out appearance judgment, reading meter record information, event codes, failure codes,mounting and dismounting information and original readings, and performing error detection and analysis, the quality supervision and management platform realizes automatic failure diagnosis.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

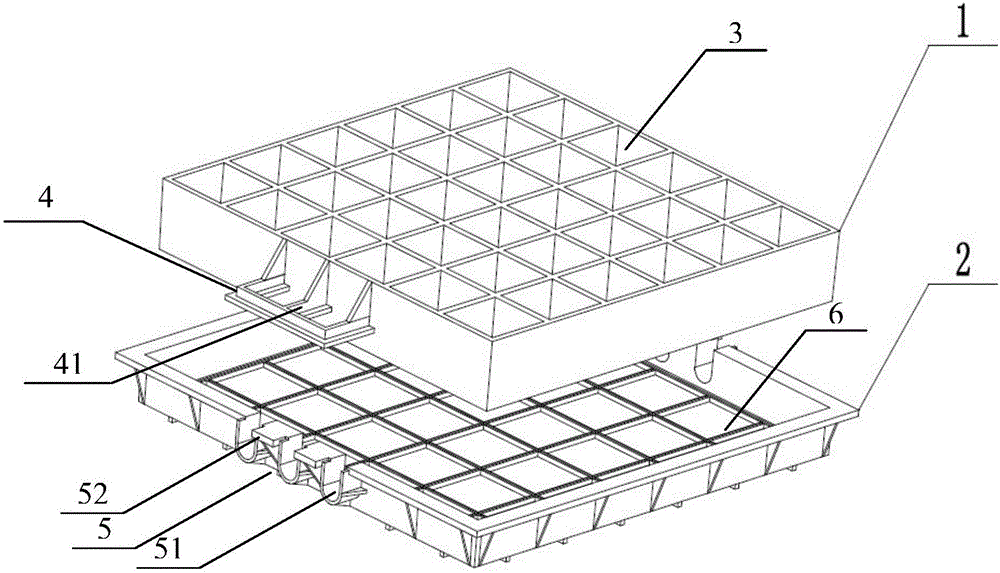

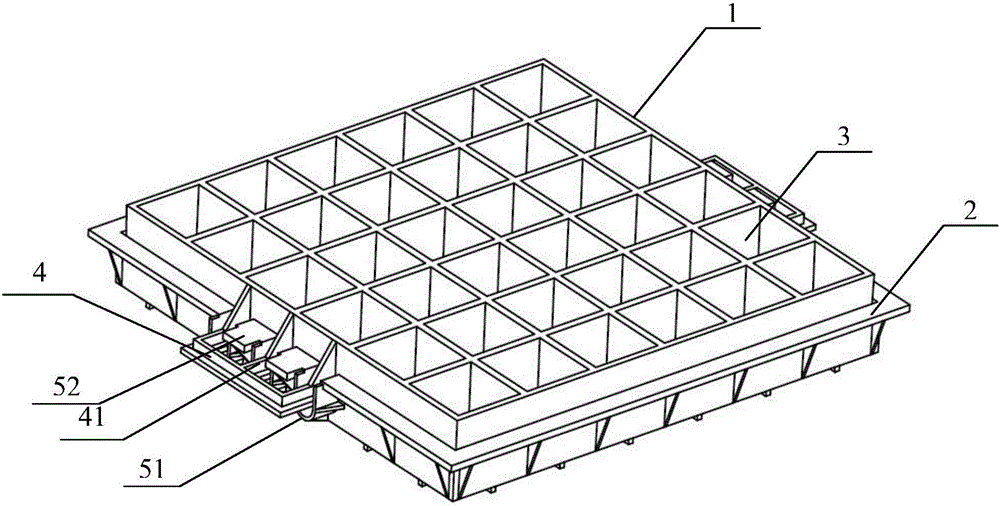

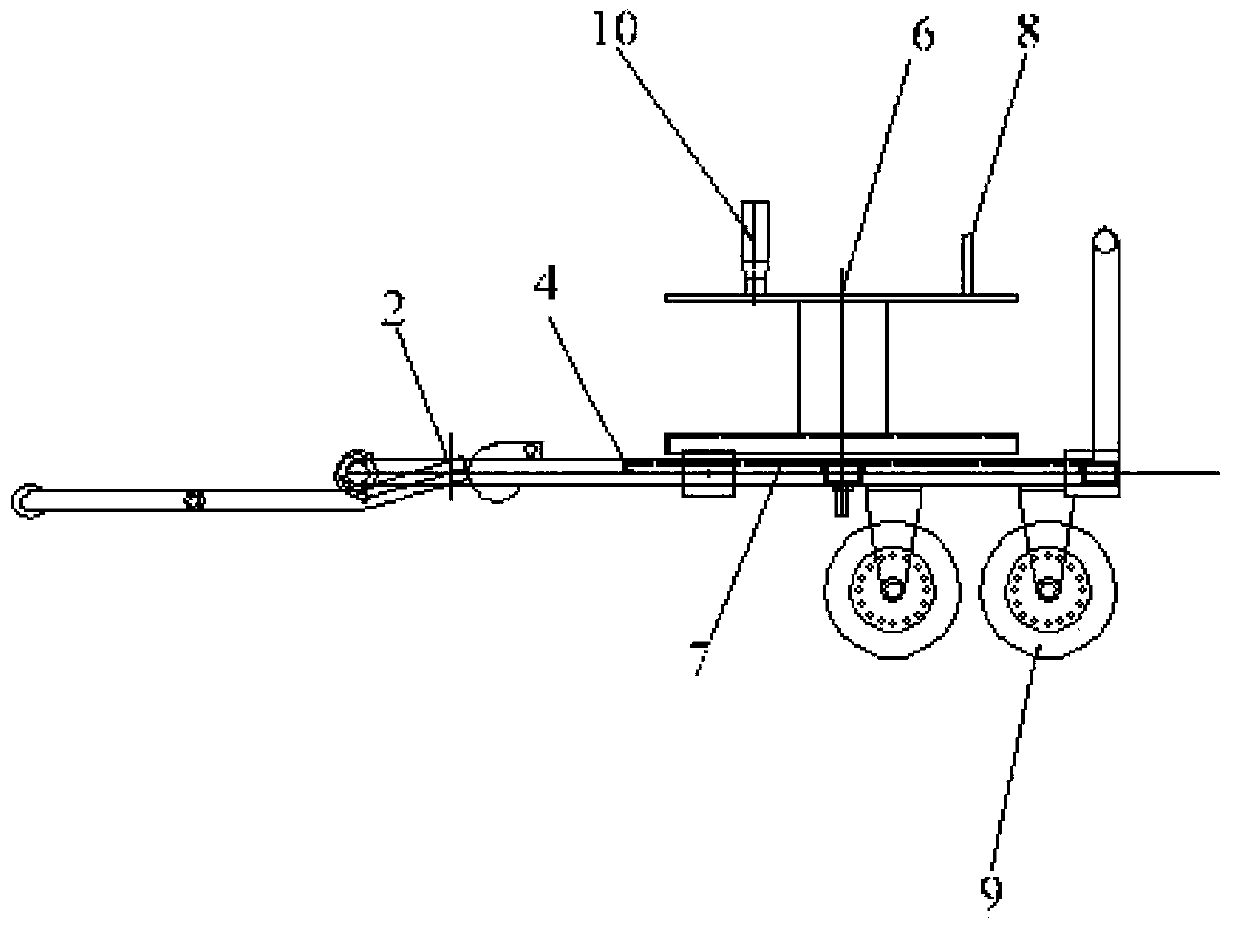

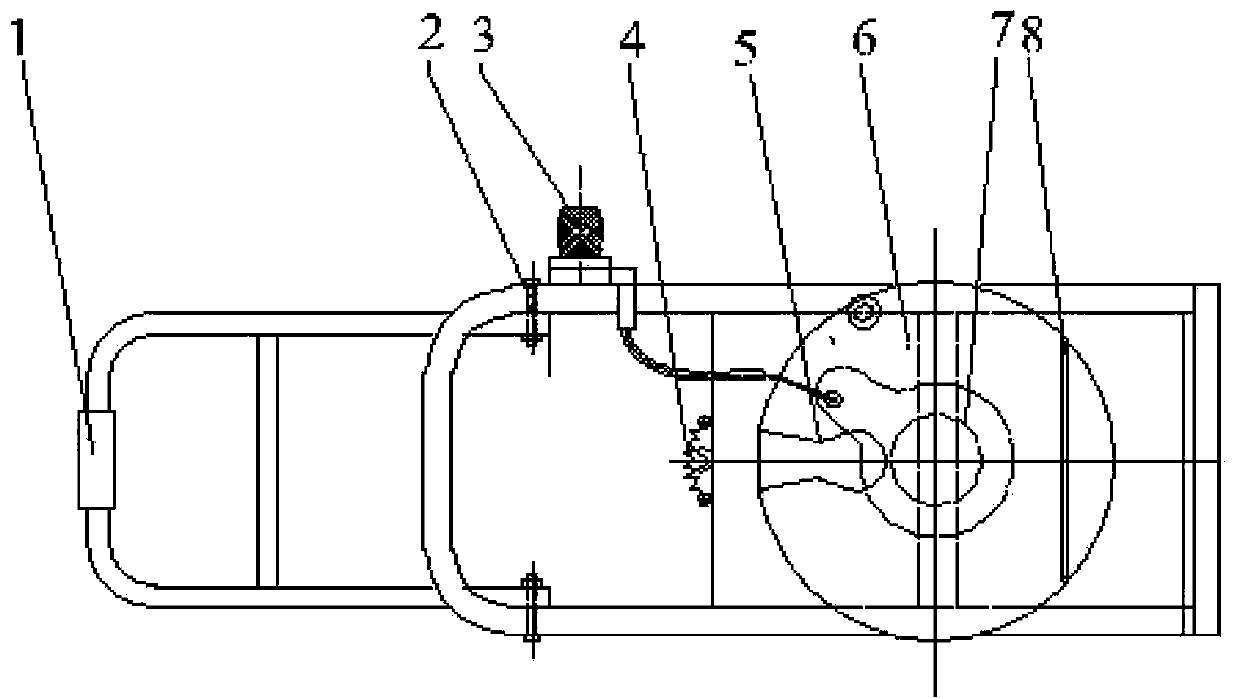

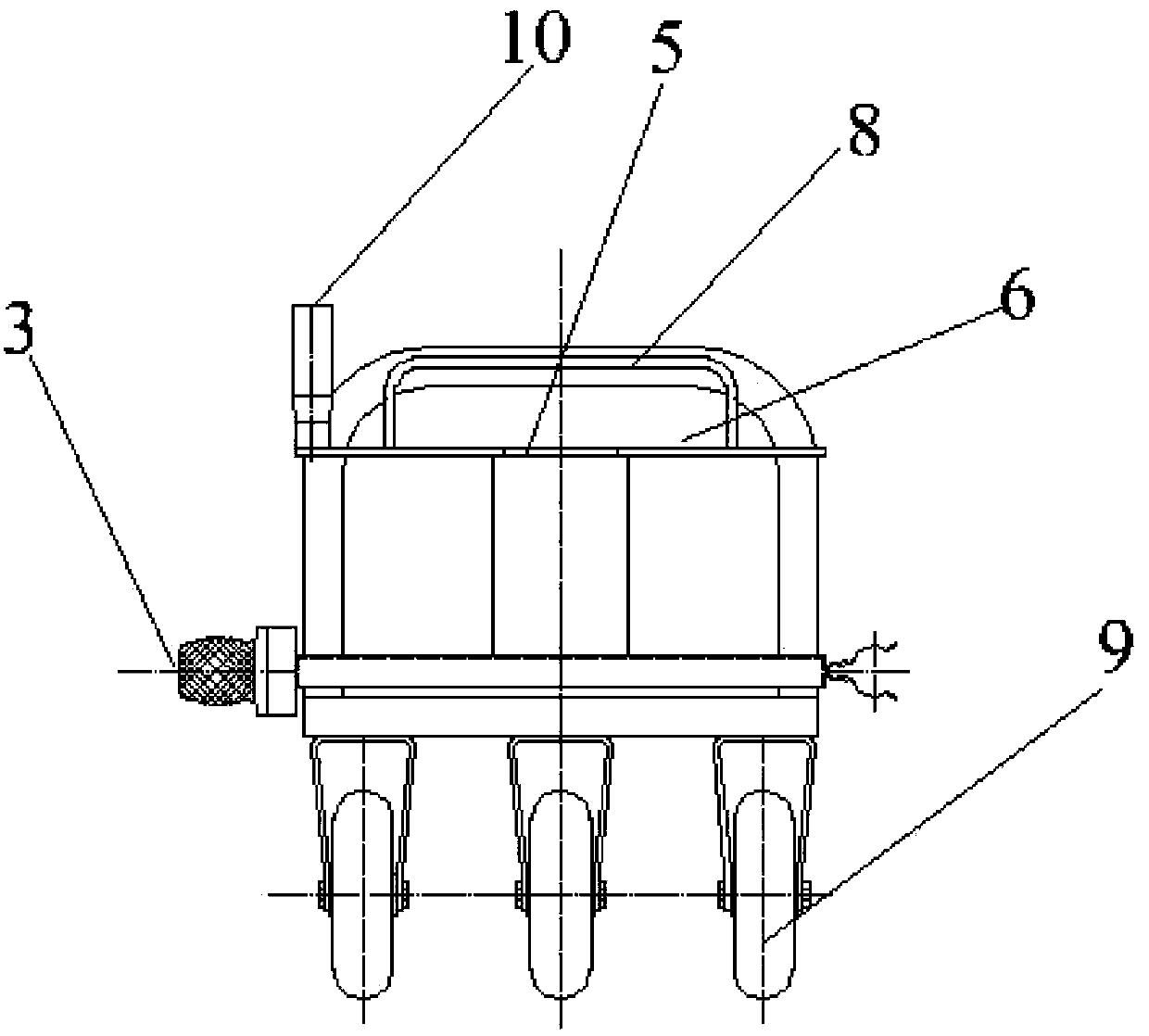

Seedling transplanting method and special matched equipment thereof

ActiveCN105724038AEasy to transportFacilitate standardized managementCultivating equipmentsPlant cultivationUltimate tensile strengthBiology

The invention relates to a seedling transplanting method and special matched equipment thereof. The special matched equipment comprises a combined hole tray and a full-automatic transplanter. By means of the combined hole tray, seedlings can be conveniently transported, and seedlings can be conveniently taken with an air-blowing method in the transplanting process; in combination with the full-automatic transplanter carrying an air-blowing type seedling taking device, seedlings can be continuously and rapidly taken and put in the transplanting process, the labor intensity in the transplanting process is relieved, working efficiency is high, seedling damage caused in the traditional seedling transplanting process can be reduced, and the seedling taking success rate is high. The special matched equipment is high in automation degree, low in manufacturing cost, easy to popularize and beneficial to achieving mechanical and automatic transplanting, facilitates standardized field management and achieves increasing of the yield and income.

Owner:CHINA AGRI UNIV

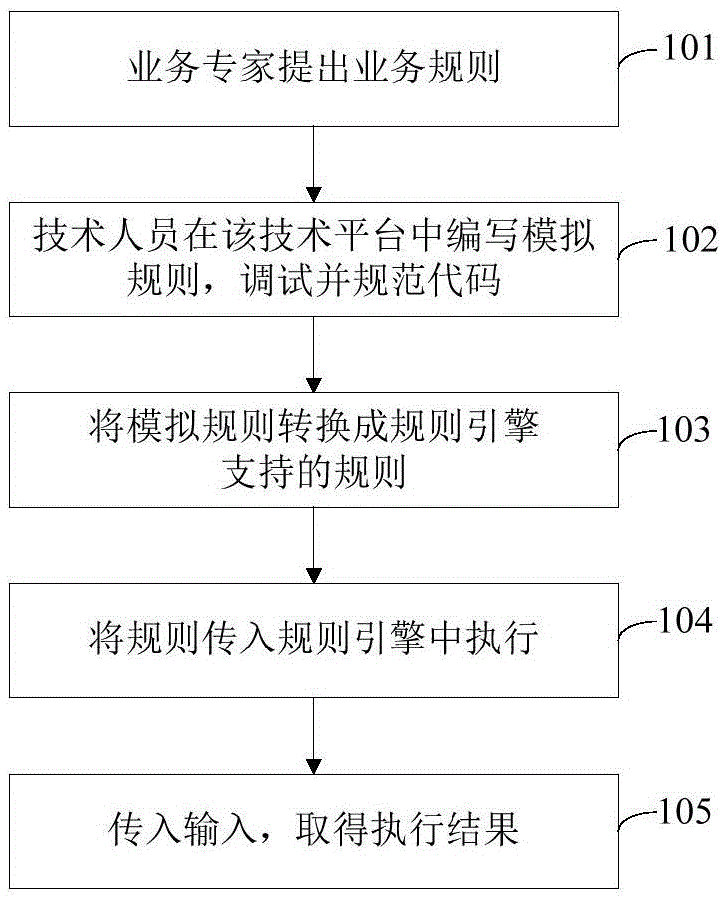

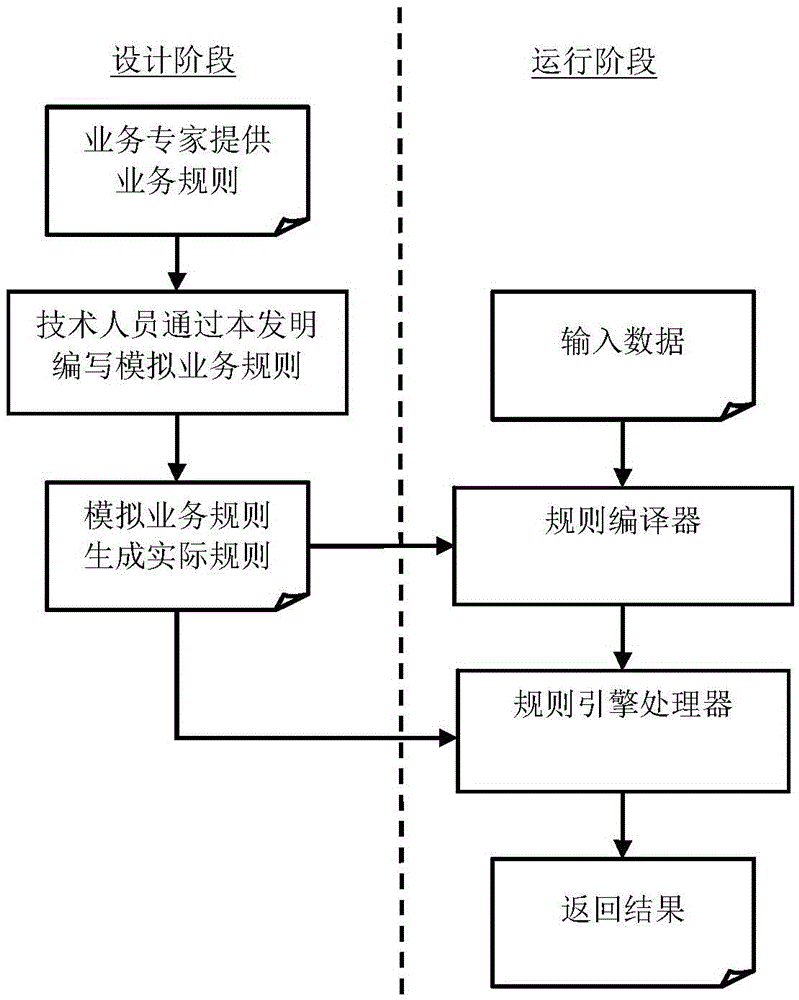

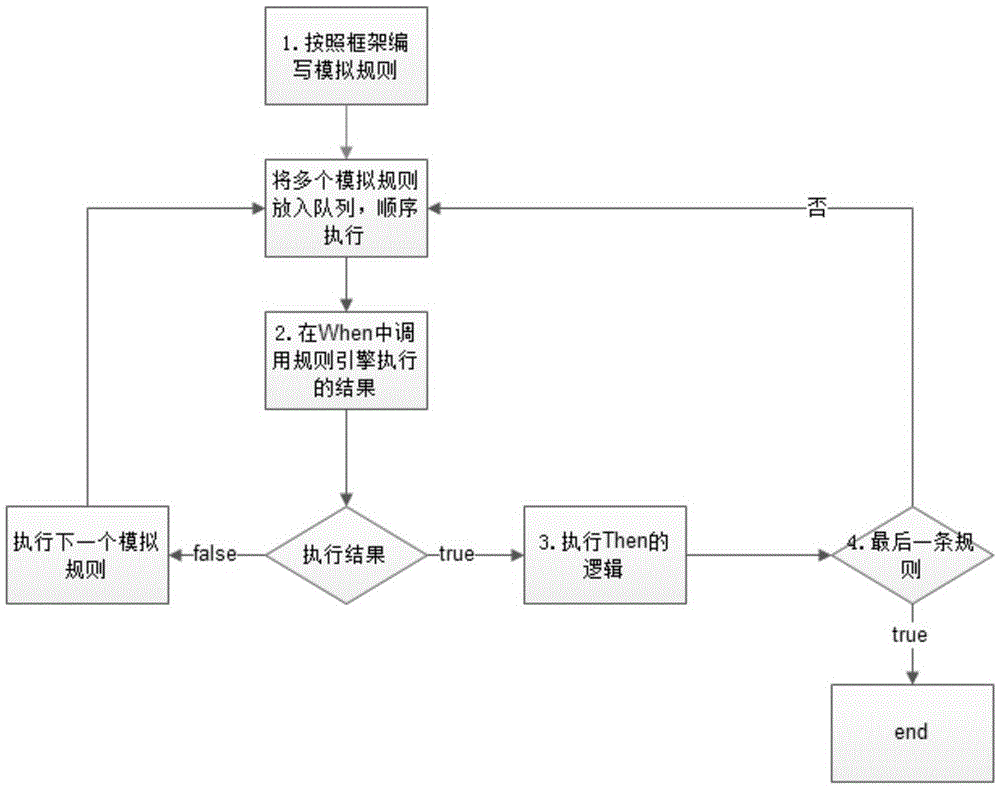

Rule engine debugging method and rule engine debugging system

InactiveCN105653268AFacilitate standardized managementEasy to writeModel driven codeSpecific program execution arrangementsBusiness ruleProgramming language

The invention discloses a rule engine debugging method, which comprises the following steps of compiling a simulation rule in advance according to a business rule provided by a business expert; converting the simulation rule into a rule supported by a rule engine; transferring the rule into the rule engine to be executed; and obtaining the execution result. The invention also discloses a rule engine debugging system, and provides a technology for compiling, debugging and verifying a JBoss Drools rule. Through the embodiment of the invention, technicians can conveniently perform rule compiling and debugging and can perform standardized management on codes, so that the development efficiency is improved, and the rule running correctness is also ensured.

Owner:TRAVELSKY

Special vehicle for ground wire

InactiveCN103863902AAvoid operabilityAvoid the problem of easy damage to the ground wireGround lineRoad condition

The invention relates to a special vehicle for a ground wire. The special vehicle is used for paving the ground wire under various road conditions and comprises a vehicle body, wherein a handle is arranged at the front end of the vehicle body in a connecting manner; wheels are arranged at the bottom of the vehicle body; a winding turnplate with a crank and a wire compressor are arranged on the vehicle body in a connecting manner; a winding guider and a fixer are also arranged on the winding turnplate; the ground wire is compressed by the wire compressor; the fixer is used for fixing the position of the ground wire; the winding guide is used for controlling the winding state of the ground wire on the winding turnplate and realizing uniform retraction and release of the ground wire. A brake is arranged between the vehicle body and the winding turnplate; a brake handle is arranged at the front part of the vehicle body; the brake is connected with the brake handle through a brake cable and is used for controlling the rotating speed of the winding turnplate. The wheels are dislocated shaft rotating wheels arranged at the rear end of the vehicle body. The handle is connected with the vehicle body by folding bolts for controlling the folding of the handle.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

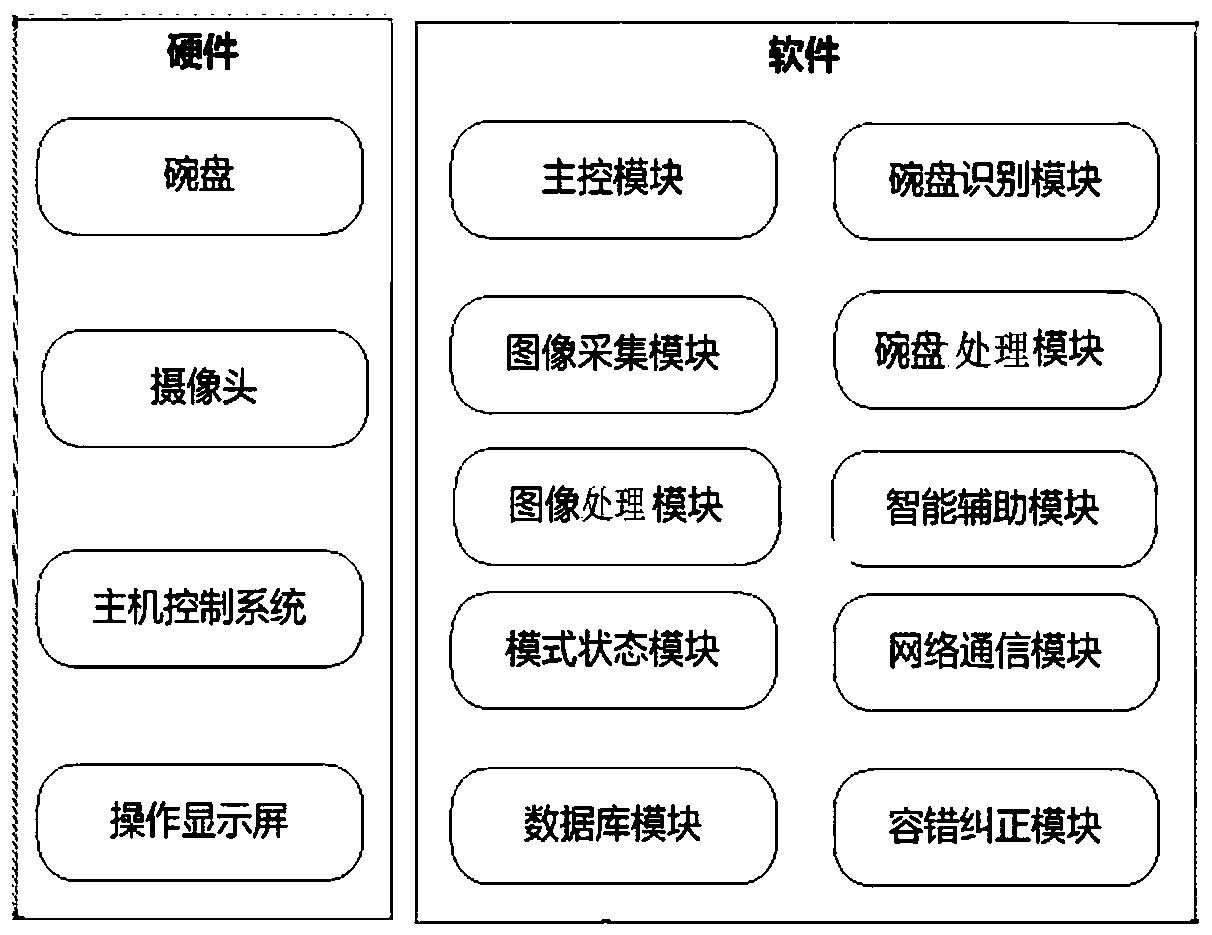

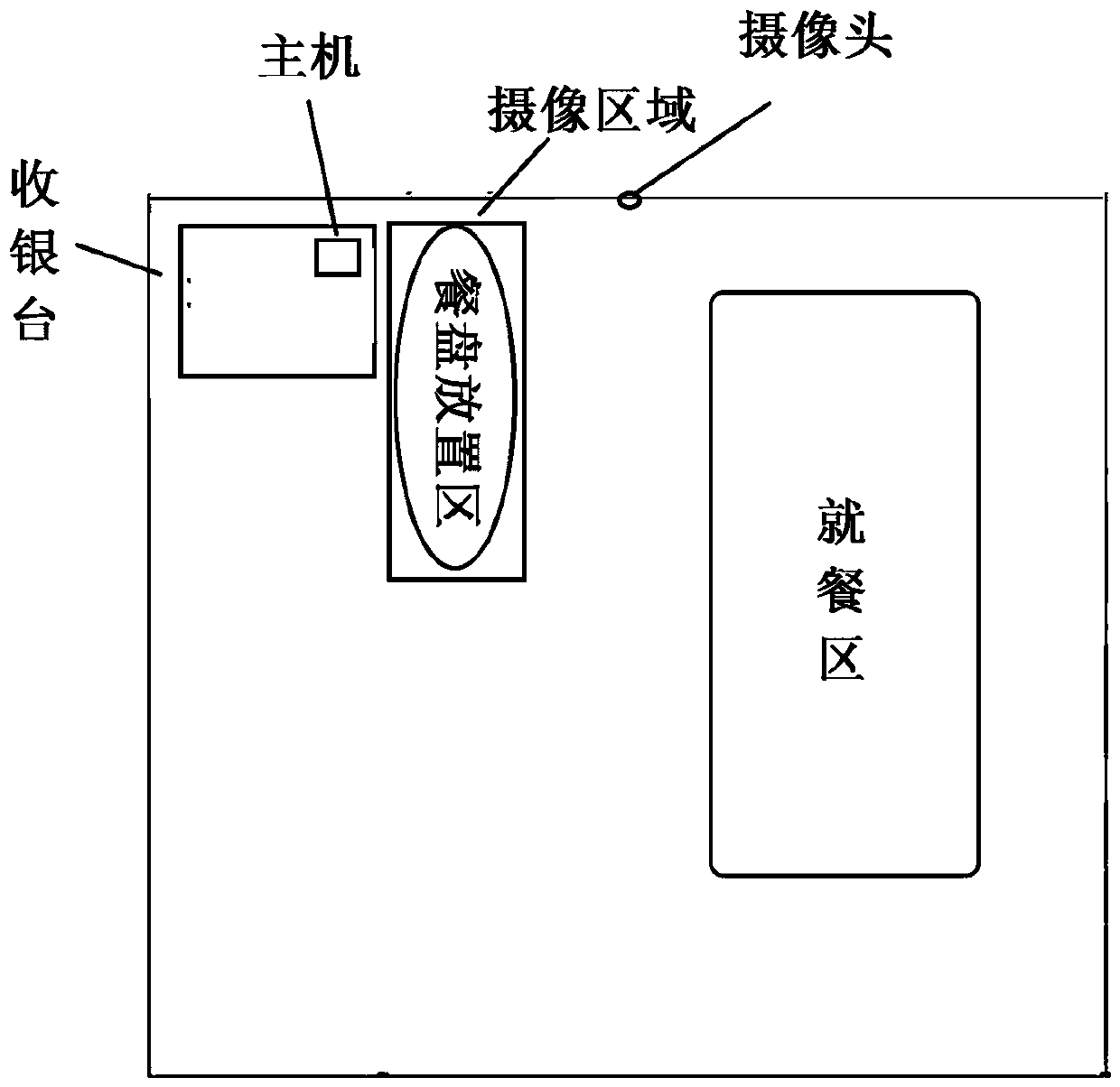

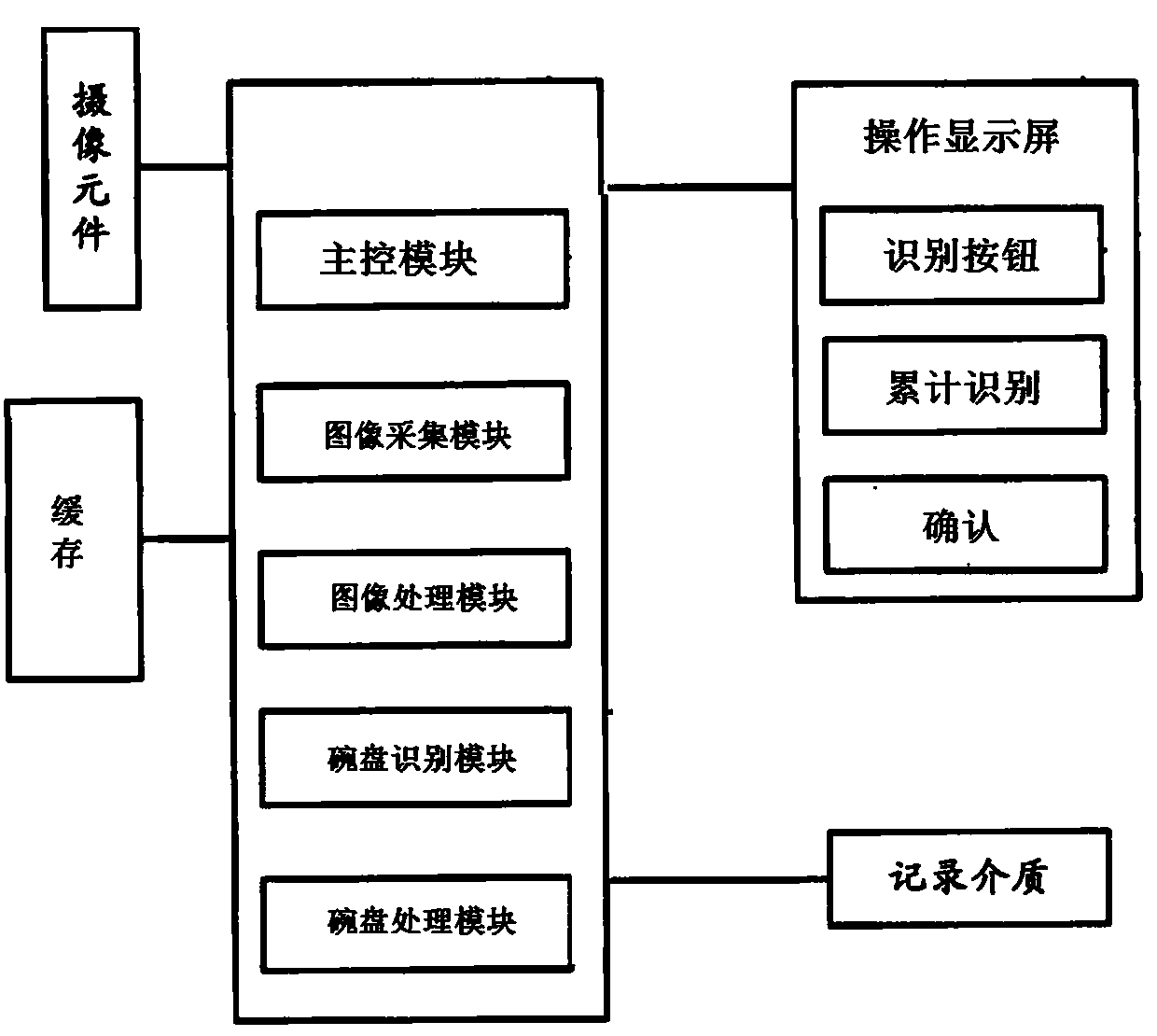

A fast food cashier system based on intelligent bowl and dish recognition

PendingCN109740579ASolve industry problemsLower performance requirementsCharacter and pattern recognitionCash registersPattern recognitionImaging processing

The invention discloses a fast food cashier system based on intelligent recognition of bowls and dishes. The device is used for canteens / restaurants / fast food restaurants and the like. The system comprises a main control module, an image acquisition module, an image processing module, a bowl and dish recognition module, a bowl and dish processing module, an intelligent auxiliary module, a mode state module, a network communication module, a database module and a fault-tolerant correction module, and is used for recognizing bowls and dishes with different types, different colors and different shapes and sizes and containing a breakfast / lunch / supper / night food multi-mode; according to the fast food cashier system based on intelligent recognition of bowls and dishes, intelligent recognition and manual input can be combined, application is flexible, different client requirements are met, and by means of the fast food cashier system based on intelligent recognition of bowls and dishes and dish classification management, a large amount of settlement cashier time is saved, and the queuing waiting time of users is shortened; meanwhile, a good solution is provided for restaurant standardized management, reduction of cashier requirements and rapid training on work.

Owner:上海柏珍信息科技有限公司

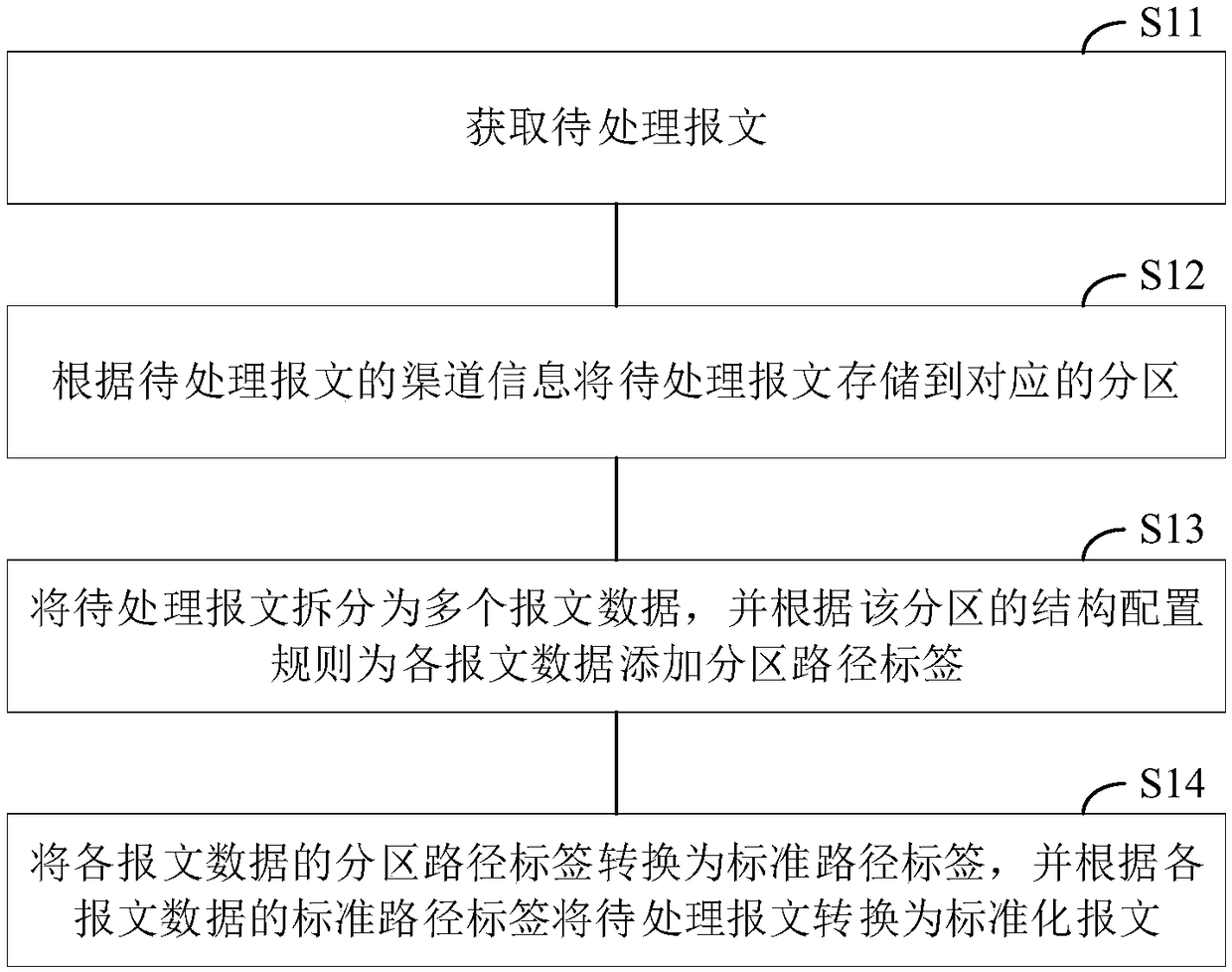

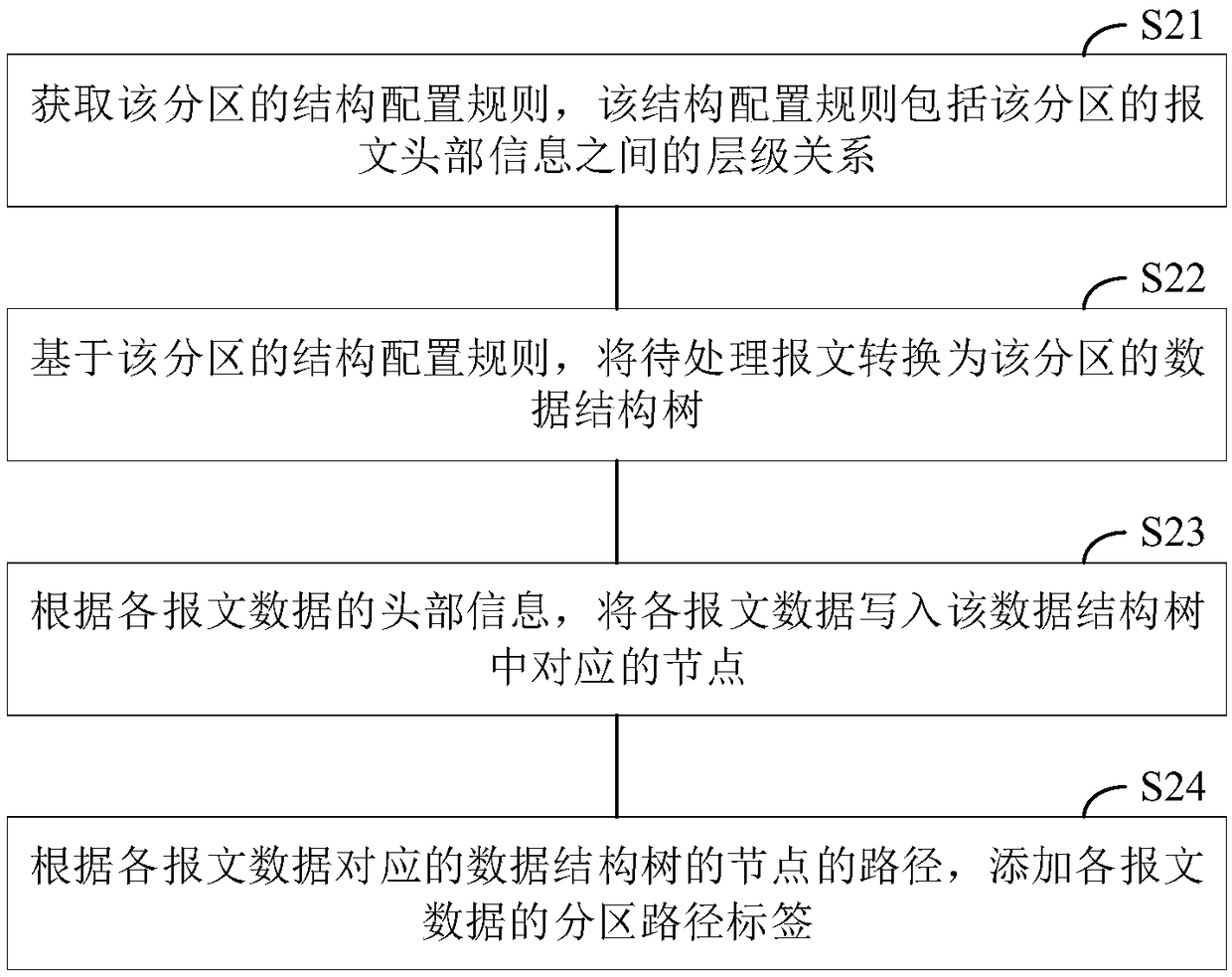

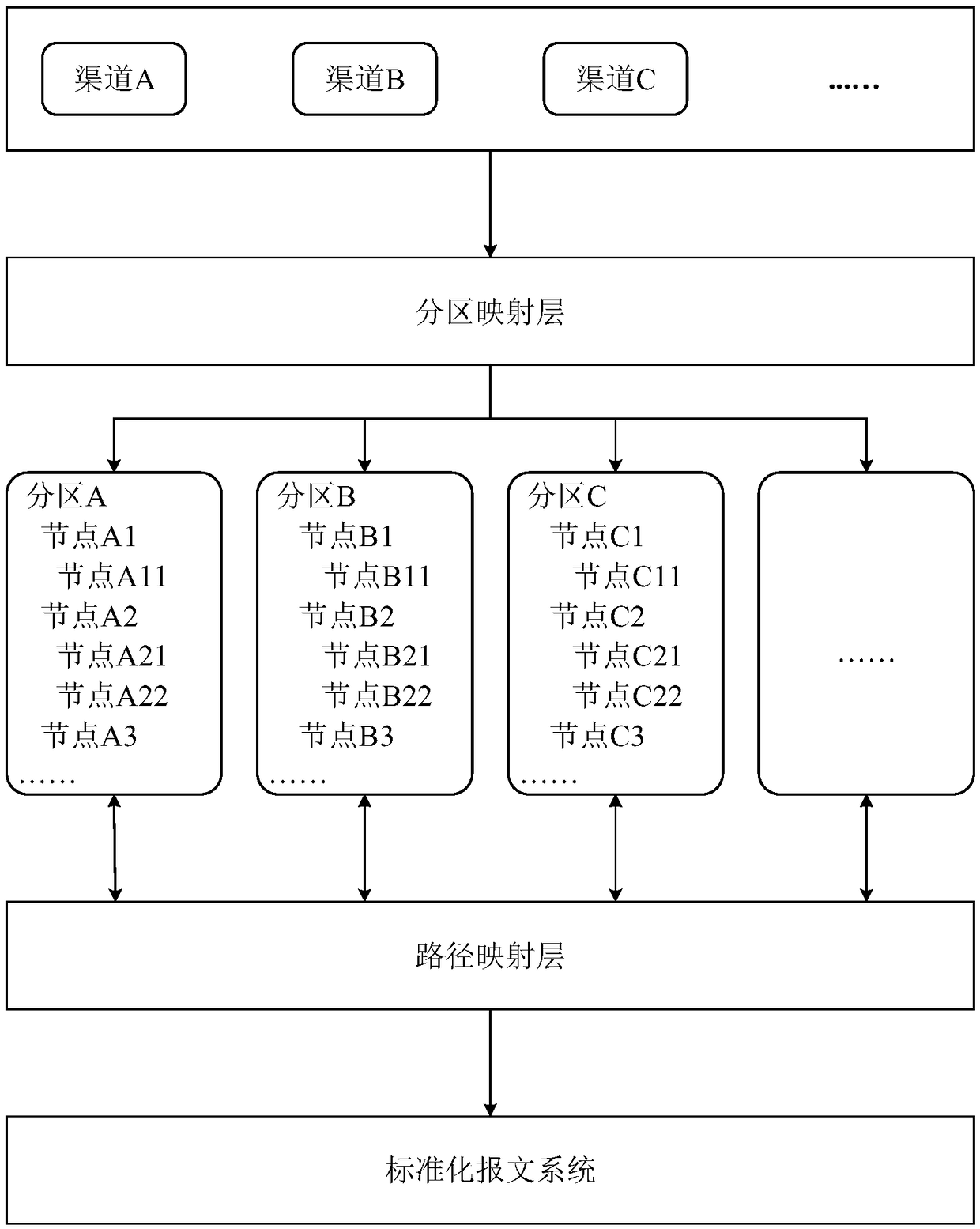

Message conversion processing method and device, electronic equipment and storage medium

ActiveCN109495392AFacilitate standardized managementFlexible handlingData switching networksComputer hardwareTechnical standard

The invention provides a message conversion processing method and device, electronic equipment and a computer readable storage medium, and belongs to the technical field of computers and communication. The method comprises the following steps of acquiring a message to be processed; storing the message to be processed into a corresponding partition according to channel information of the message tobe processed; splitting the message to be processed into multiple message data, and adding a partition path label for each piece of message data according to a structure configuration rule of the partition; and converting the partition path label of each piece of message data into a standard path label, and converting the message to be processed into a standardized message according to the standard path label of each piece of message data. The message to be processed can be split and converted, the processing method is more flexible, analysis codes do not need to be specially written every time, the labor cost is saved, and the processing efficiency is improved.

Owner:TAIKANG LIFE INSURANCE CO LTD +1

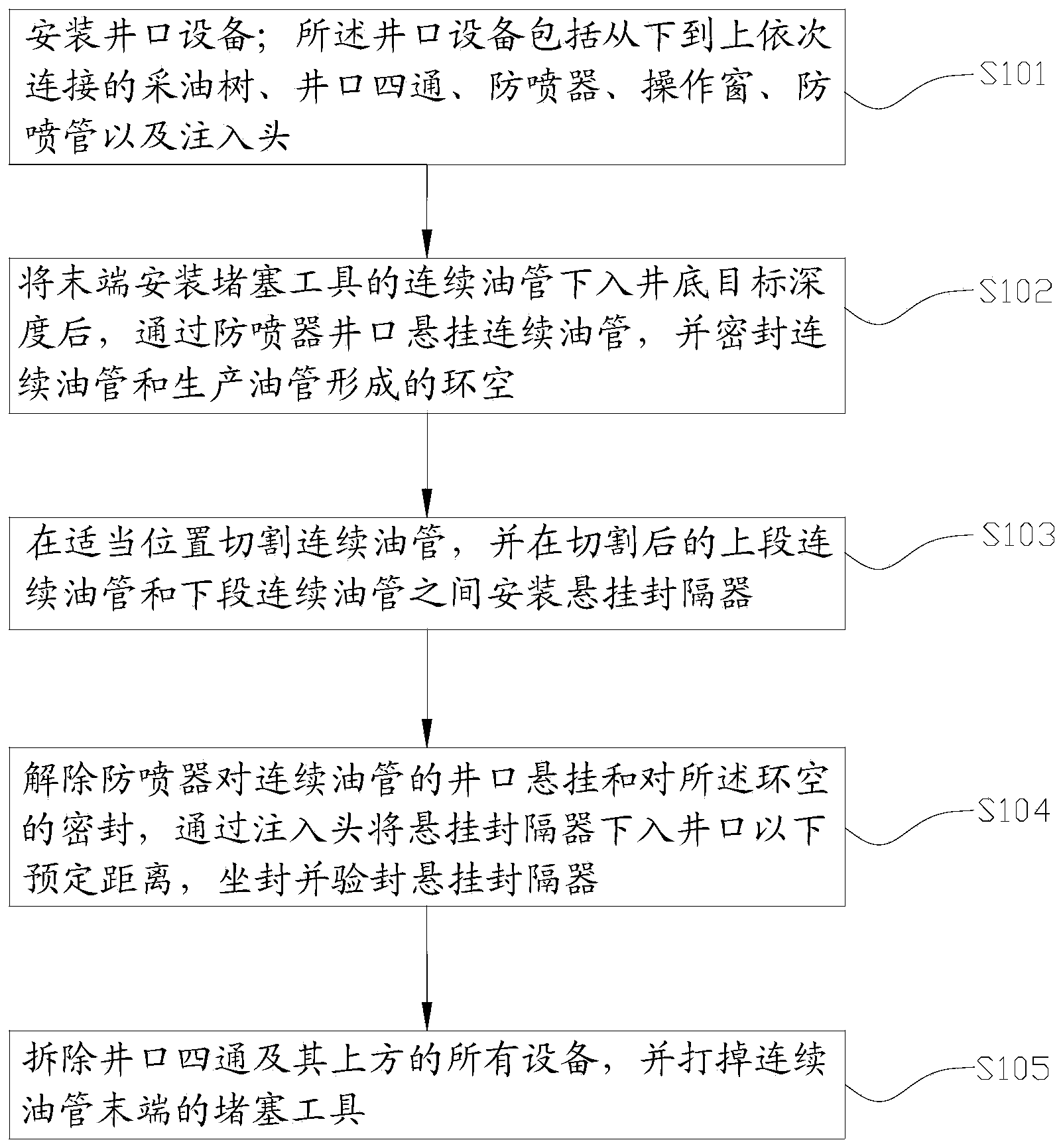

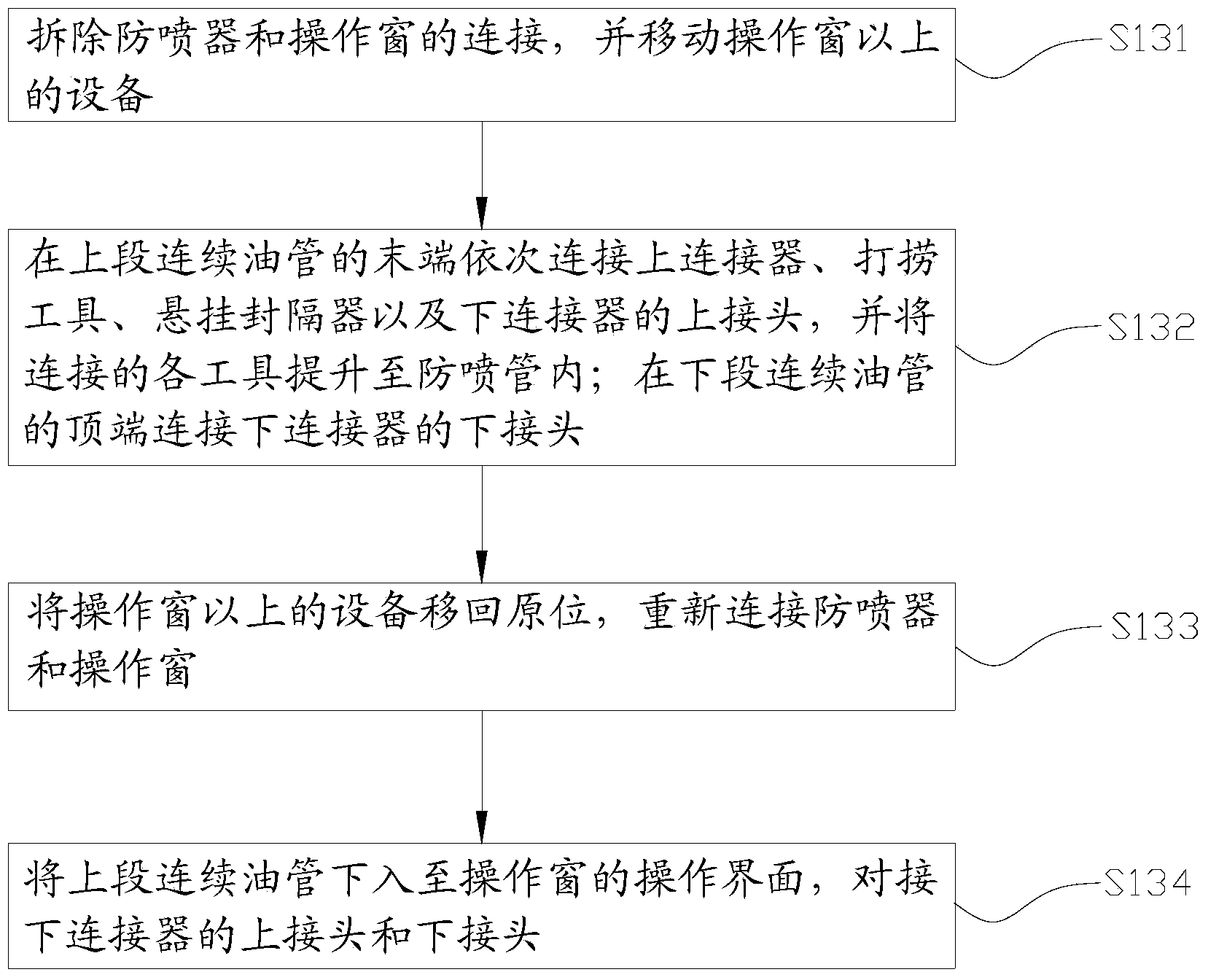

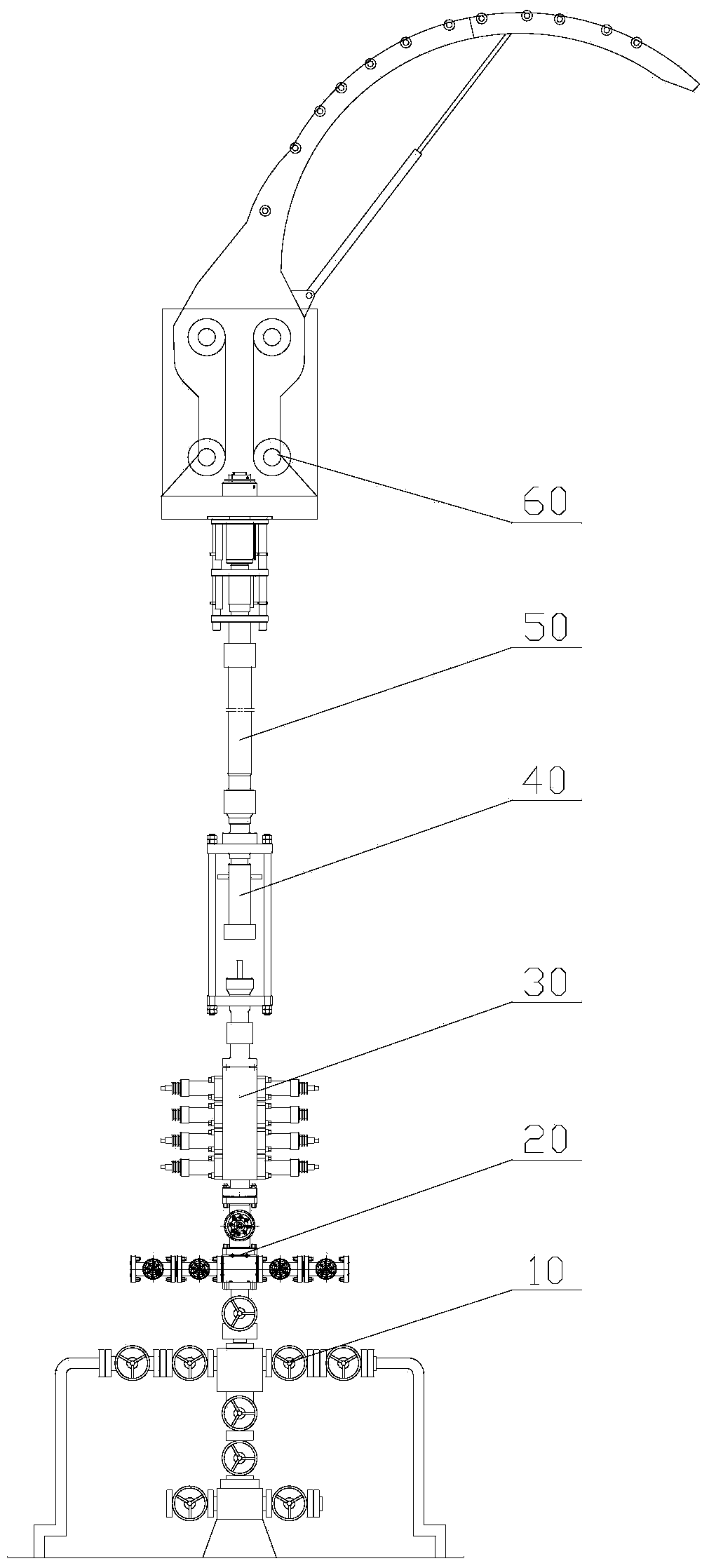

Method for suspending speed tubular column of continuous oil tube

ActiveCN104018796AReduce workloadReduce construction costsBorehole/well accessoriesCoiled tubingBlowout preventer

The invention discloses a method for suspending a speed tubular column of a continuous oil tube. The method includes the following steps that wellhead equipment is installed; the wellhead equipment comprises a Christmas tree, a wellhead cross joint, a blowout preventer, an operating window, a blowout prevention tube and an injection head which are sequentially connected from bottom to top; after the continuous oil tube with a plugging tool at the tail end is placed into a target depth of a downhole, the continuous oil tube is suspended at a wellhead through the blowout preventer, and an annular cavity formed by the continuous oil tube and a production oil tube is sealed; the continuous oil tube is cut at a proper position, and a suspension packer is installed between an upper continuous oil tube section and a lower continuous oil tube section after the continuous oil tube is cut; wellhead suspension for the continuous oil tube through the blowout preventer and sealing for the annular cavity are eliminated, the suspension packer is placed in a preset distance below the wellhead through the injection head, and setting and examining seal are conducted on the suspension packer; the wellhead cross joint and all equipments above the wellhead cross joint are detached, and the plugging tool is knocked off. According to the method, an original producing well pattern does not need to be changed, workloads are relieved, and construction cost is reduced.

Owner:BEIJING ORION ENERGY TECH DEV

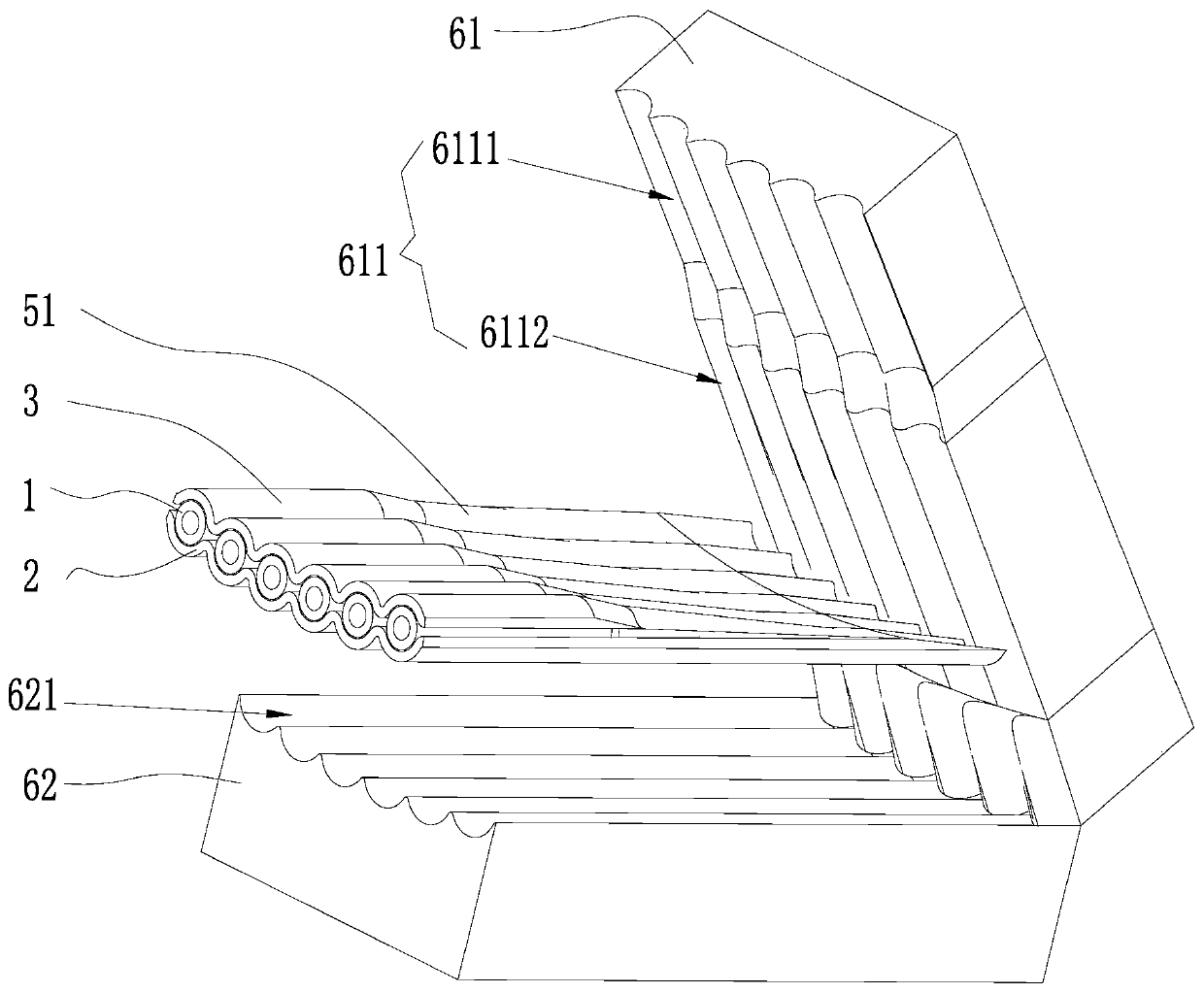

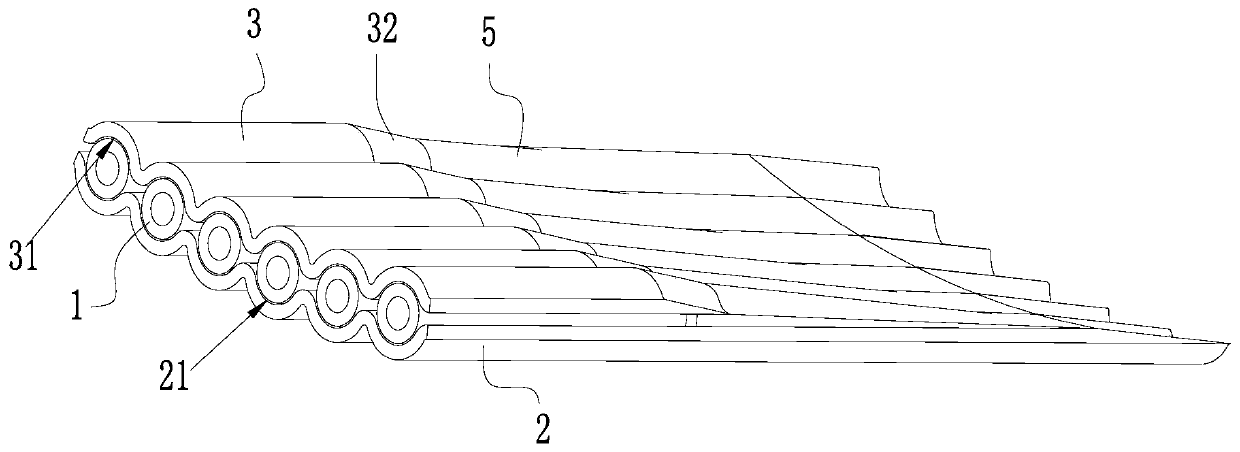

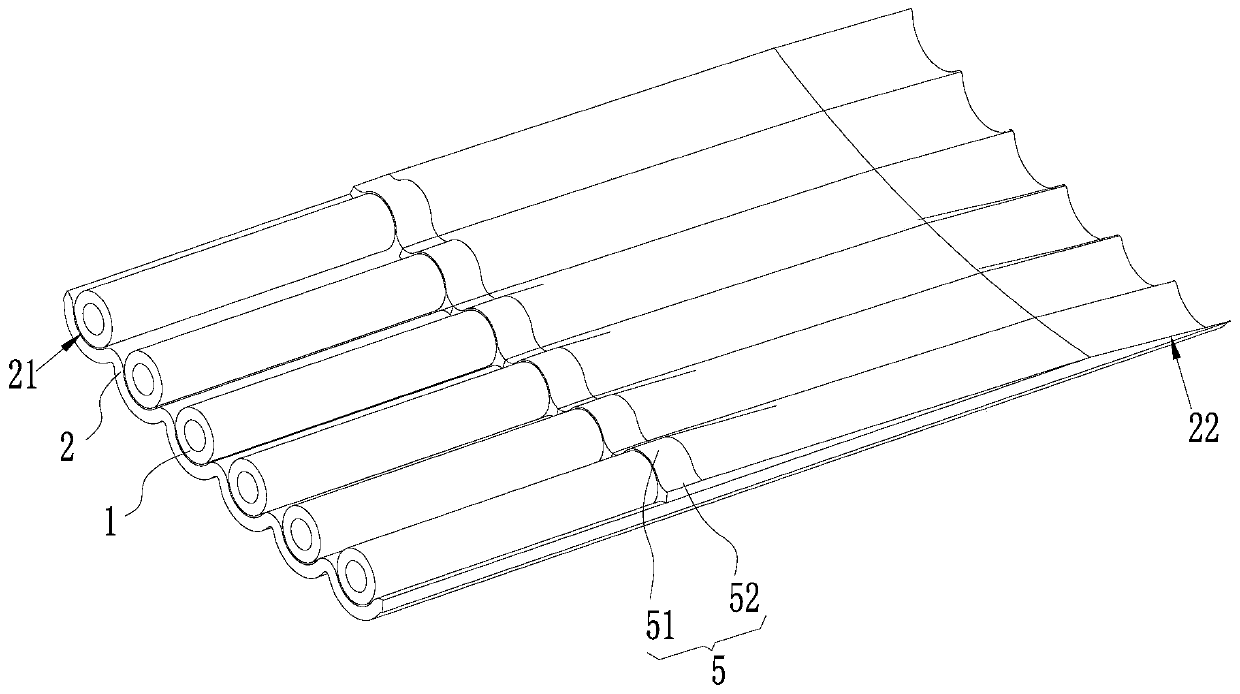

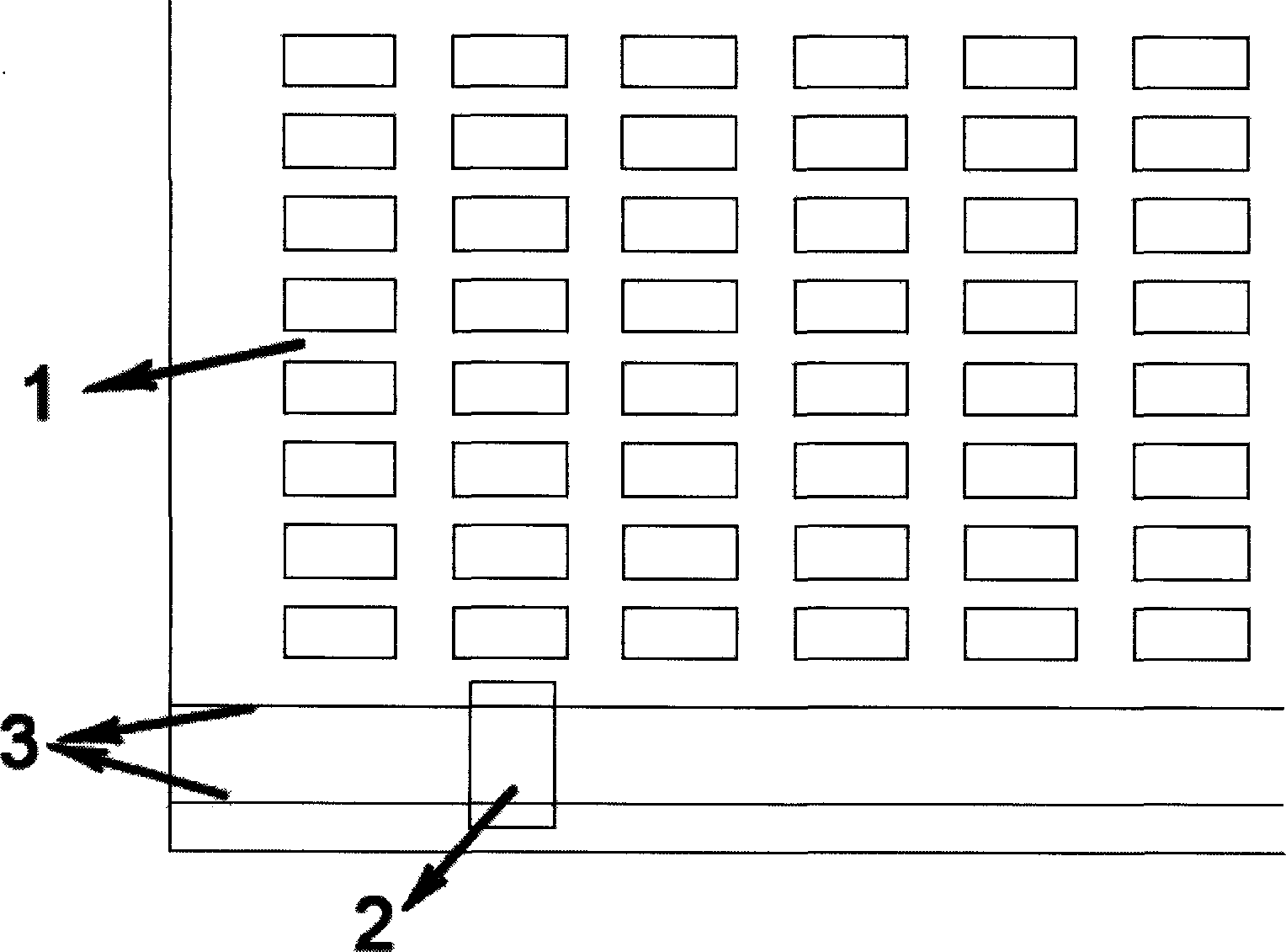

Prefabricated part of wind power blade root, blade root part, blade and manufacturing method thereof

PendingCN111022248AReduce difficultyShorten the timeFinal product manufactureMachines/enginesFiberStructural engineering

The invention provides a prefabricated part of a wind power blade root, a blade root part, a blade and a manufacturing method thereof. A plurality of prefabricated parts of a blade root of the wind power blade are manufactured; outer-layer fiber fabric is laid in the blade root mold, the multiple prefabricated parts are arranged on the outer-layer fiber fabric, and the adjacent prefabricated partsare spliced; an inner-layer fiber fabric is laid on the spliced prefabricated part; pouring into the blade root mold is performed, and molding is achieved to obtain the blade root. A part of the laying layers are prefabricated in advance, assembled and formed and then placed into the blade root mold to be integrally formed with the remaining laying layers, difficulty and the time for later pouring forming can be reduced, a block overlapping mode is adopted in the thickness direction, multiple sections of prefabricated parts are spliced in the circumferential direction, and assembling difficulty can be greatly reduced. Standardized and modular production is adopted, manufacturing can be conducted in advance, defects are easy to check and control, risks are reduced, production efficiency can be further improved, universality of different types can be achieved, and standardized management is facilitated.

Owner:SINOMATECH WIND POWER BLADE

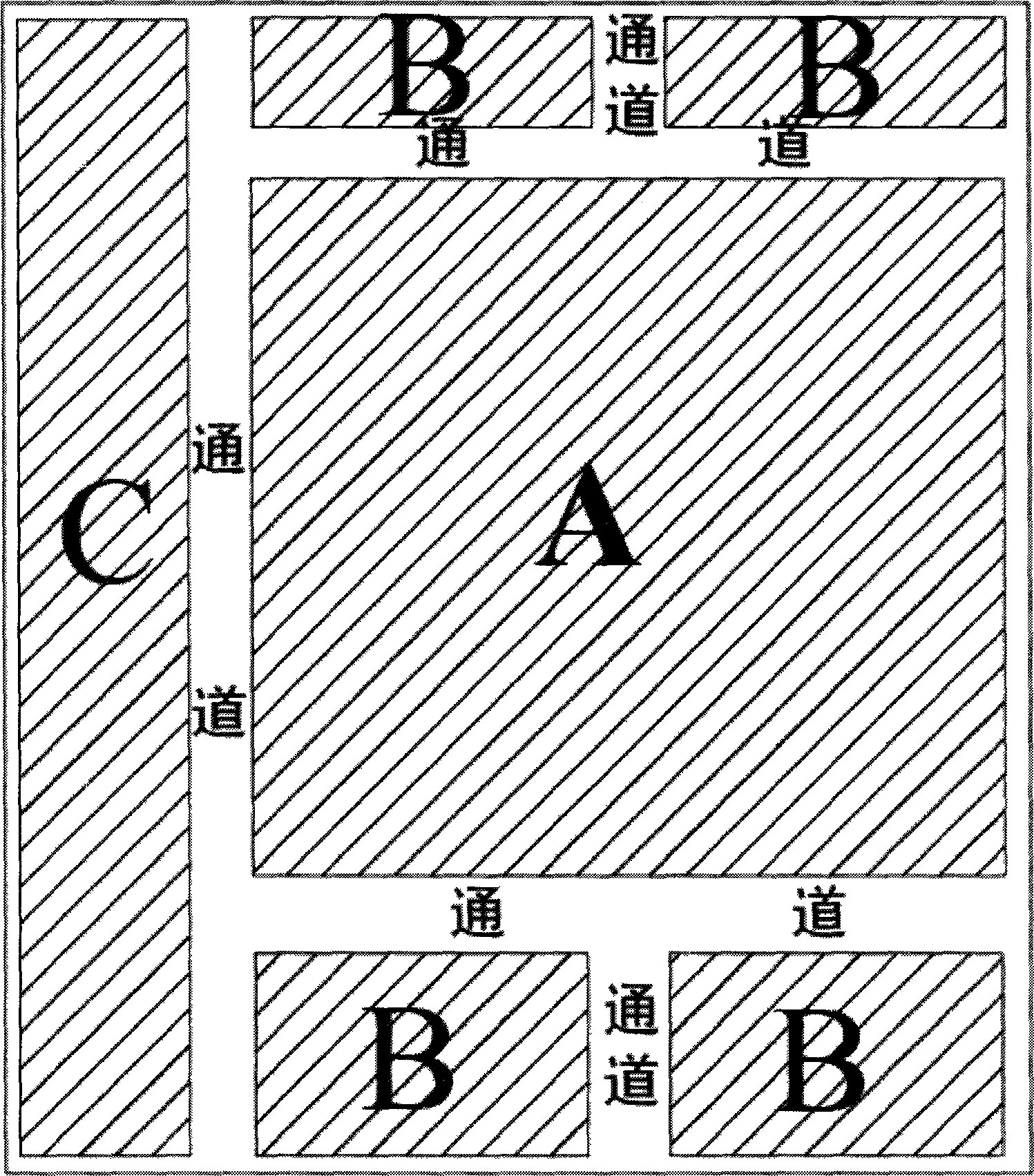

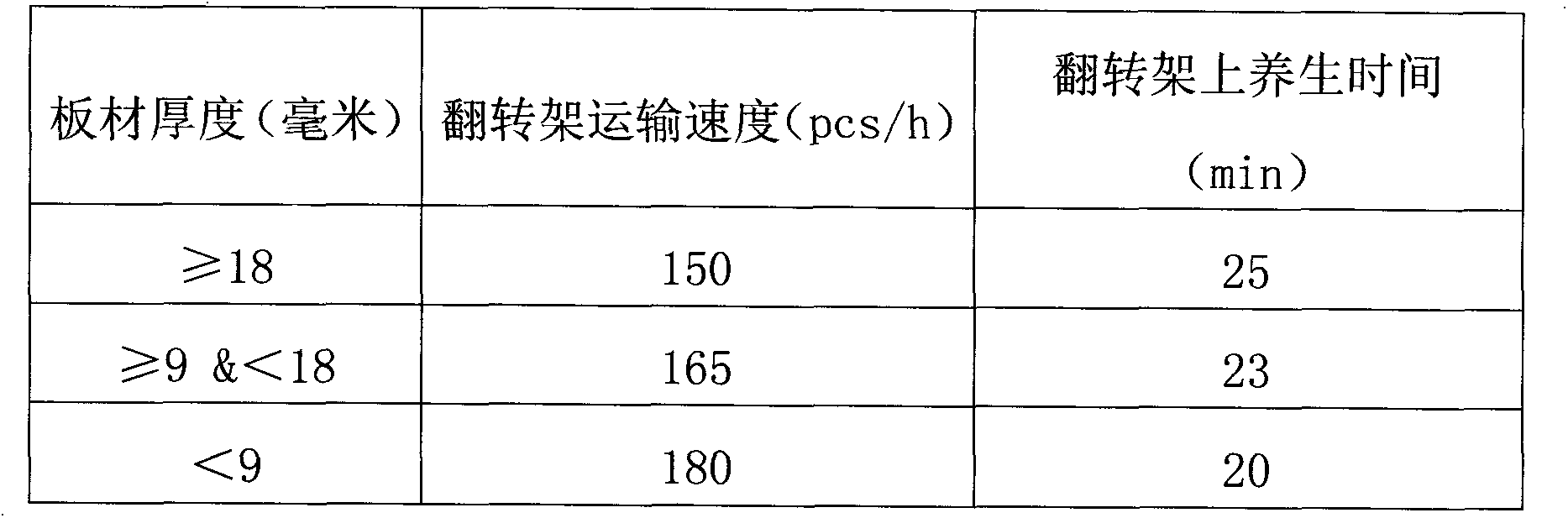

Preserving technology for decorative boards

InactiveCN104060786ATo achieve the effect of healthOptimize layoutCovering/liningsProduction lineEngineering

The invention provides a preserving technology for decorative boards. The preserving technology comprises an on-line preserving process, a packaging preserving process, a storage preserving process and a delivery preserving process. According to the on-line preserving process provided by the invention, an on-line roll-over stand is mounted at the tail end of a hot press; a production line is prolonged to realize the preserving effect rapidly; unpowered rollers, a hydraulic propulsion device and a guide rail are arranged in the storage preserving process; the unpowered rollers are mounted on the ground of a storage area in parallel at certain intervals; the hydraulic propulsion device and the guide rail are mounted at the same ends of the unpowered rollers; when produced decorative boards are stacked at one ends of the unpowered rollers through conveying tools and the hydraulic propulsion device is moved to a to-be pushed position for propulsion, therefore, to-be preserved decorative boards are stacked on the rollers; decorative boards satisfying preserving time are arranged at the other ends of the unpowered rollers and can be conveyed for use. According to the preserving technology for the decorative boards, the layout is simple, the field utilization rate is high, the ventilating effect is good, the storage and taking are convenient and fast, the high efficiency, low energy consumption and environmental protection are achieved and the standardized management is facilitated.

Owner:广州易福诺木业有限公司

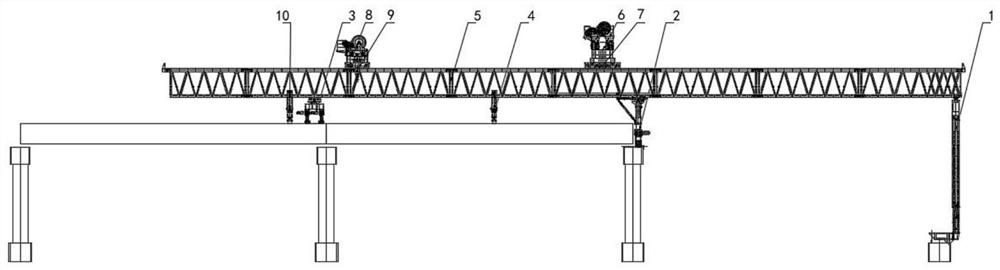

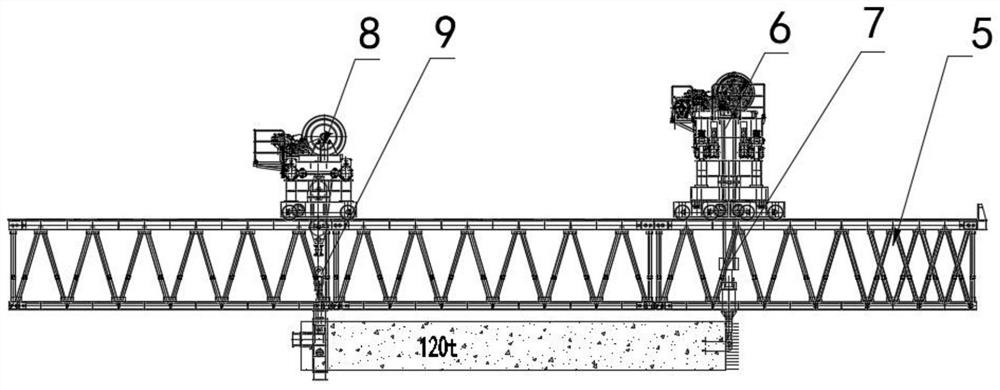

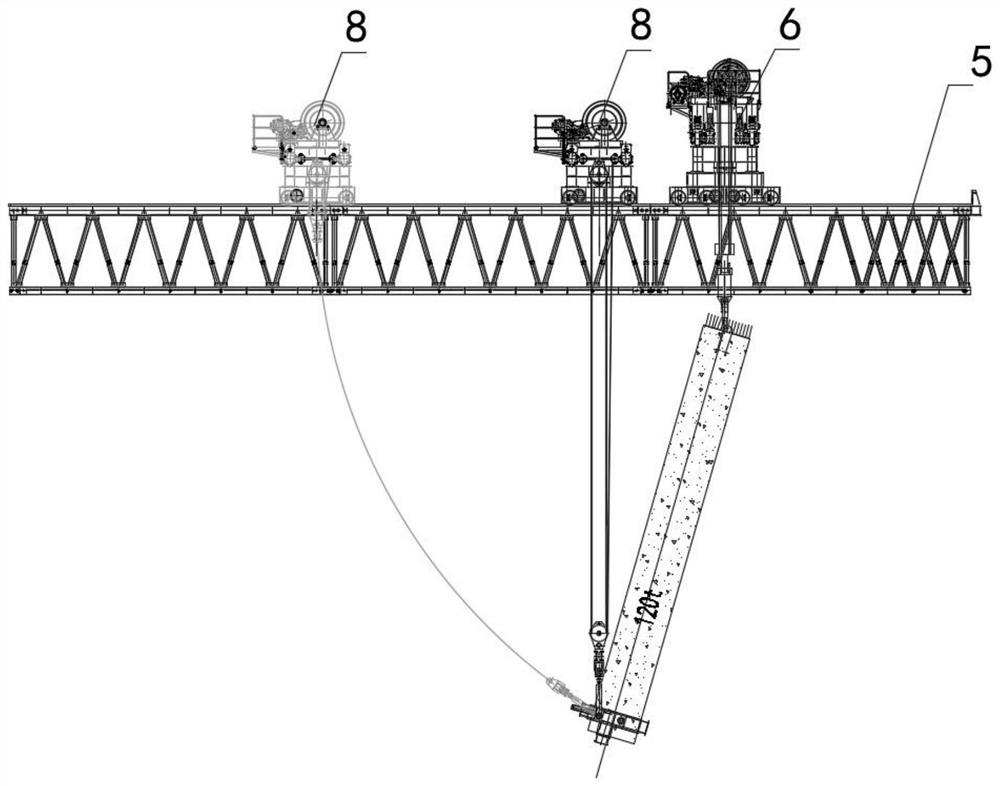

Integrated bridge girder erection machine for prefabricated bridge pier-beamand construction method thereof

PendingCN112854008AImprove construction efficiencyReduce the process of changing spreadersBridge erection/assemblyPierArchitectural engineering

An integrated bridge girder erection machine for a prefabricated bridge pier beam comprises a main truss, a first crane, a second crane, a main supporting leg, a main bearing supporting leg, an auxiliary bearing supporting leg, a first auxiliary supporting leg and a second auxiliary supporting leg. The first crane and the second crane are connected to the top of the main truss in a sliding manner, a first lifting appliance is arranged on the first crane, and a second lifting appliance is arranged on the second crane; and the main supporting leg, the main bearing supporting leg, the auxiliary bearing supporting leg, the first auxiliary supporting leg and the second auxiliary supporting leg are detachably connected to the bottom of the main truss. Compared with the prior art, the advanced and novel integrated bridge girder erection machine is adopted for erecting the upper structure and the lower structure, different components can be hoisted at the same time through hoisting tools of the first crane trolley and the second crane trolley, the hoisting tool replacing procedures are reduced, meanwhile, the multi-stage telescopic function of the main supporting legs can adapt to erection of bridges with different heights, equipment replacement is reduced, and the erection construction efficiency is improved.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

Walnut big container-growing seedling breeding method

The invention discloses a walnut big container-growing seedling breeding method. The method is high in planting survival rate; during cultivation, the root system of the nursery stock always grows in a container; during the seedling lifting and planting process, the root system and the root system roll are not destroyed, the seedling continuously grows, there is no rejuvenation period, the seedling can be planted in four seasons, and the survival rate reaches 100%. Early-stage nutrition growth is completed in the container, fruiting is started, and the seedling directly enters into the initial fruit period after the seedlings are planted. Labor-saving cultivation is facilitated, the young tree shaping has been completed, the tree shape framework is unified, the young tree period management is saved, tree body pruning in the fruiting period is simplified, and meanwhile the mechanical management is facilitated; big container-growing seedlings are uniform in specification, the orchard uniformity is high and standardization management is facilitated. Firstly, fruits are seen and then the trees are planted, the quality of the variety can be identified in advance, the inferior variety is removed, the problem of fine-variety mixing is solved, and the realization of the 'one-orchard one-product' is facilitated, the commodity rate and the economic benefit are improved, transportation and cultivation are facilitated, and the method has the popularization and application values.

Owner:洞口县丰胜林木科技有限公司

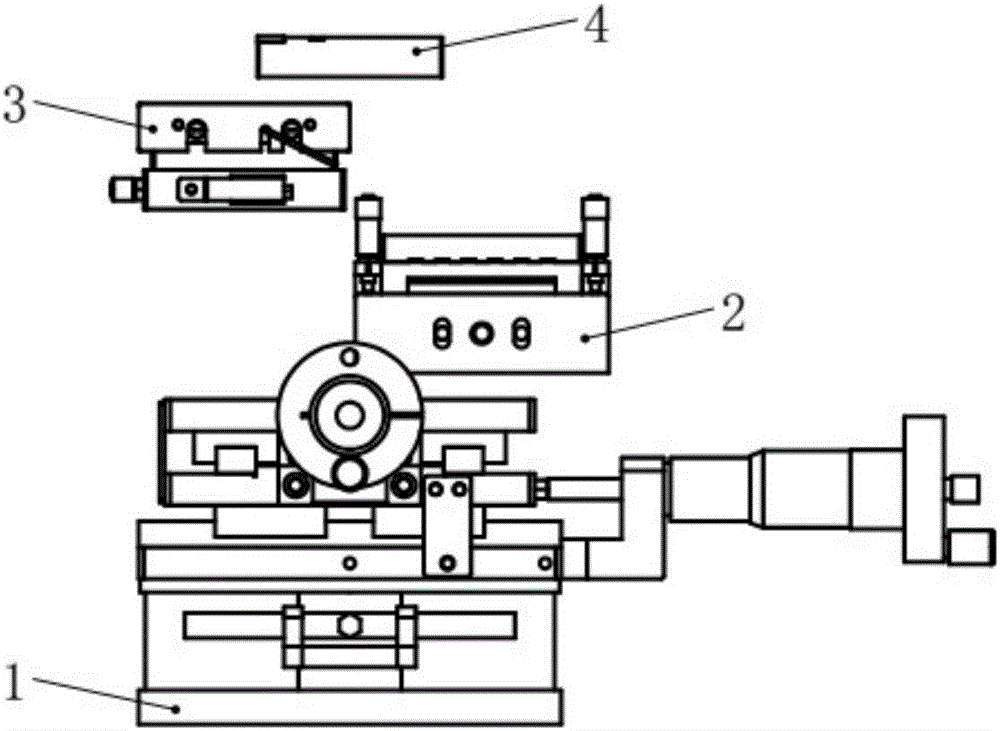

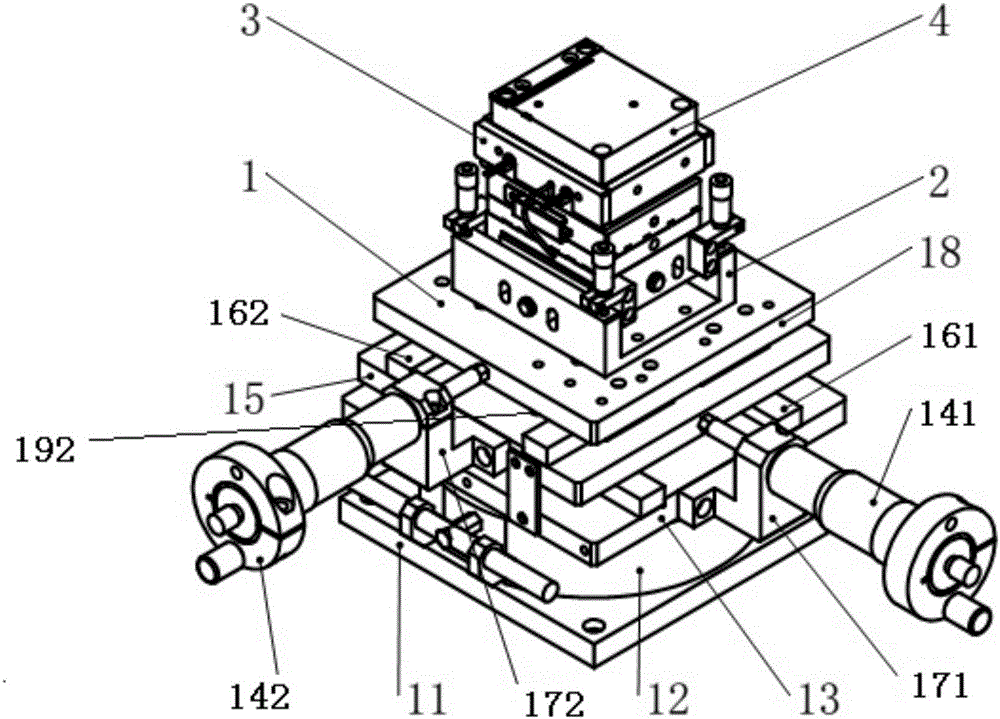

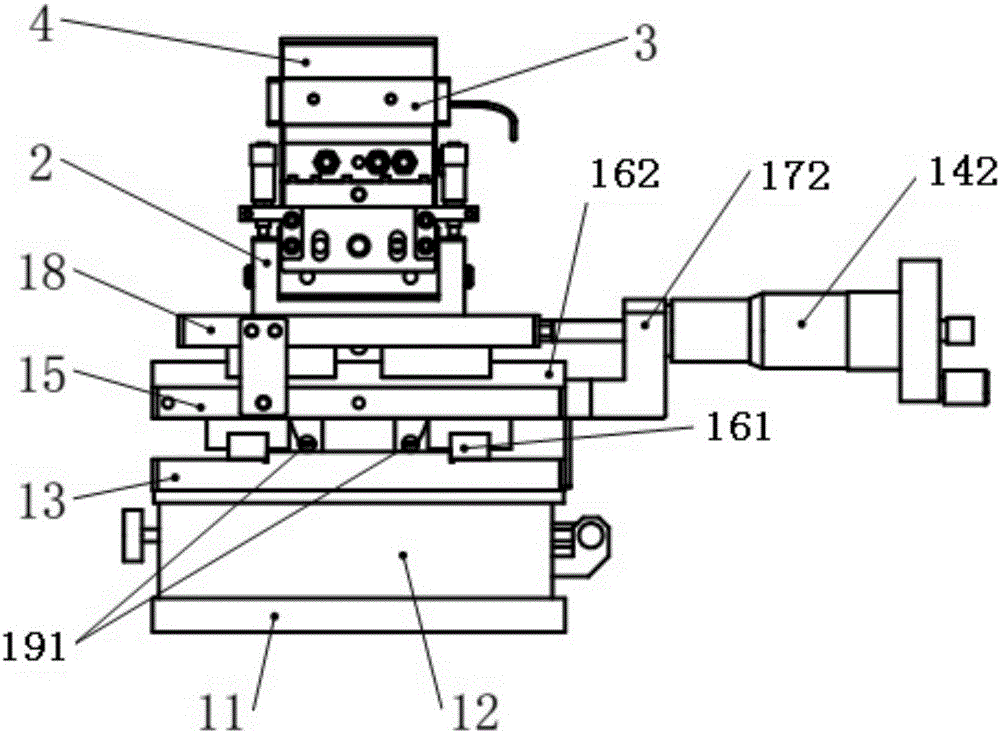

Modularly-design multi-functional heating table mechanism

ActiveCN105097572AImprove interactivityImprove interchangeabilitySemiconductor/solid-state device manufacturingState of artModularity

The invention relates to a modularly-designed multi-functional heating table mechanism which comprises a movement base table (1) and a jig (4), wherein the jig (4) is arranged on the movement base table (1), a workpiece matched with the jig (4) is placed on the jig (4), the movement base table (1) comprises a fixed bottom plate (11), a Theta-axis sliding table (12), a first carrying platform (13), a second carrying platform (15) and a third carrying platform (18), the Theta-axis sliding table (12) is arranged on the fixed bottom plate (11) and does Theta-direction rotation movement around a Z-axis, the first carrying platform (13), the second carrying platform (15) moving along a y-axis and the third carrying platform (18) moving along an x-axis are sequentially arranged on the Theta-axis sliding table (12) from bottom to top, during working, the Theta-axis sliding table (12), the second carrying platform (15) and the third carrying platform (18) are respectively adjusted, the jig (4) is moved onto an appointed station, and the workpiece on the jig is processed. Compared with the prior art, the modularly-designed multi-functional heating table mechanism has the advantages of multiple functions, high processing accuracy, low manufacturing cost and the like.

Owner:SHANGHAI WEISONG IND AUTOMATION

Seedling-raising medium production method

InactiveCN104402581ARaw materials are uniqueSolve the problem of incomplete fermentationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiseasePhosphate

The invention relates to a seedling-raising medium, and especially relates to a seedling-raising medium production method. The method is characterized in comprising the following steps: a, waste furfural residue is composted and fermented, wherein urea is added before fermentation for adjusting a carbon-nitrogen ratio to 25:1; during fermentation, turning time and frequency are determined according to fermentation temperature; b, fermented and composted furfural residue is subjected to sunlight exposure; c, the fermented and composted furfural residue, perlite, vermiculite, furnace slag, urea, monoammonium phosphate, potassium sulfate, carbendazim and the like are weighed according to a certain ratio, and are well mixed, such that the seedling-raising medium is obtained. The seedling-raising medium has unique raw materials. With the seedling-raising medium, the soilless cultivation yield is high, the cost is saved, pest and disease seldom occur, the production period is short, weather and season influences are low, and vegetable products are provided with good flavors and quality. The medium and the method facilitate the realization of agricultural mechanization and automation, and facilitate standardized management.

Owner:NINGXIA KOCEL BIOLOGICAL CHEM

Pain patient quality management platform and out-hospital follow-up surveying system

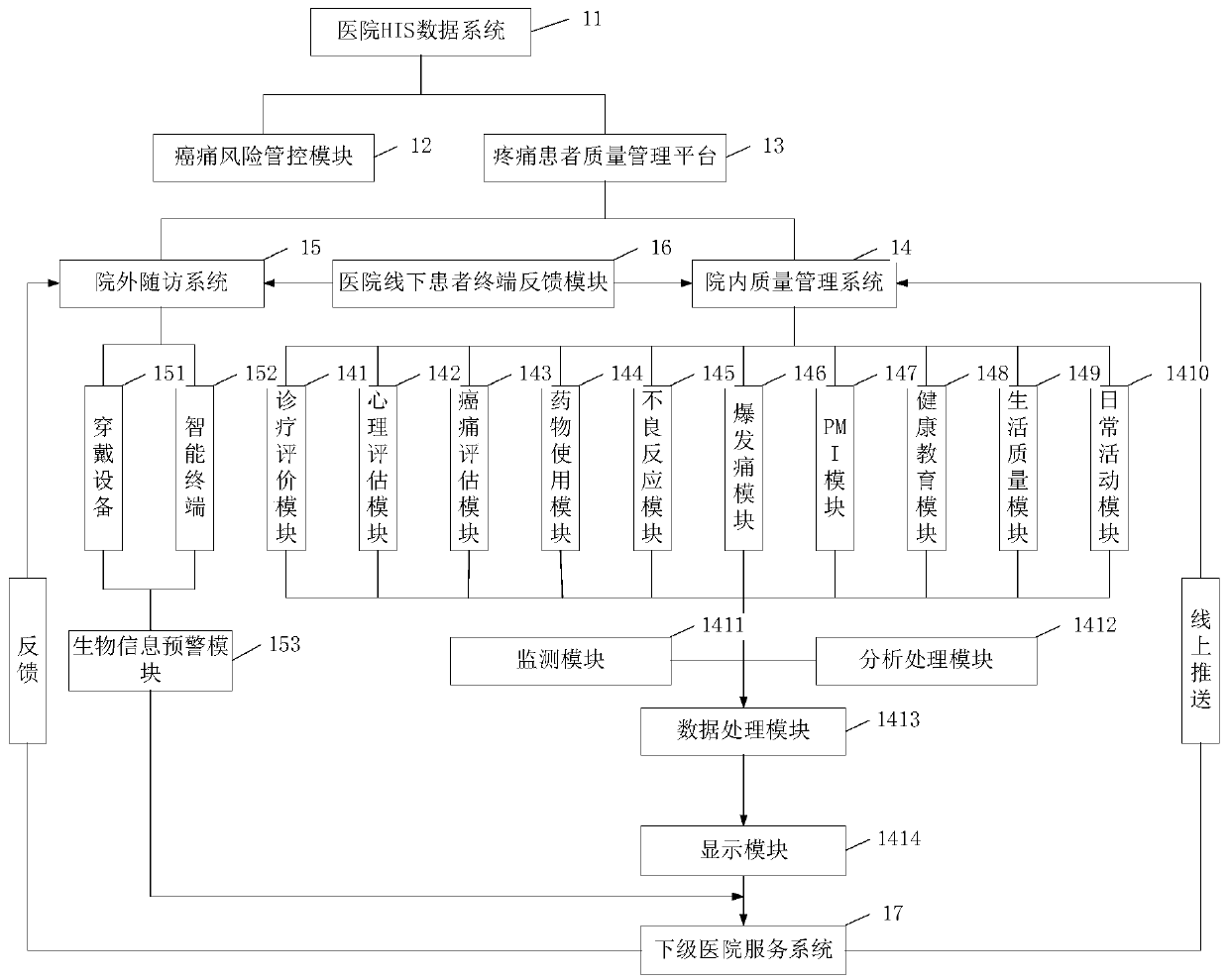

PendingCN110097972AFacilitate standardized managementGuarantee data qualityMedical communicationHealth-index calculationData systemSurveyor

The invention provides a pain patient quality management platform and out-hospital follow-up surveying system. The pain patient quality management platform and out-hospital follow-up surveying systemcomprises a hospital HIS data system, a cancer pain risk control module, a pain patient quality management platform, an in-hospital quality management system, an out-hospital follow-up surveying system, a hospital offline patient terminal feedback module and a lower-grade hospital service system. According to the invention, the open and intelligent pain patient quality management platform and out-hospital follow-up surveying system is established, thereby supplying the open intelligent interactive platform with functions such as pain data uploading, pain difficult case consultation diagnosis and quality evaluation to the low-grade hospital and citizens in the constructing area, and facilitating implementation of public health data standard management.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

Two-trunk flat net rack and grape shaping method applying same

ActiveCN103444488AReduce labor intensityUniform growthCultivating equipmentsHorticulture methodsAgricultural engineeringPest control

The invention discloses a two-trunk flat net rack, comprising a flat net rack body, wherein a part which is 20-40cm below a main reinforcement iron wire at the lower part of a rack surface of the flat net rack body is provided with a main branch fixed iron wire. The invention has the beneficial effects that the two-trunk flat net rack has the advantages that the height of trunks is lowered, the labor intensity of producers is greatly relieved, and the working efficiency is improved; the shaping method has the advantages that main branches are order in sprouting, young sprouts are consistent in growth and are uniformly distributed on the rack surface of the flat net rack, light is fully received, after grapes shaped through the shaping method are sprouted, the phonological periods are consistent, and standard management can be conveniently carried out on production links such as flower tidying, particle scattering, bagging, binding and pest control in the growth period of the grapes.

Owner:盖南南

Online liquid level monitoring method and system for oil-immersed transformer

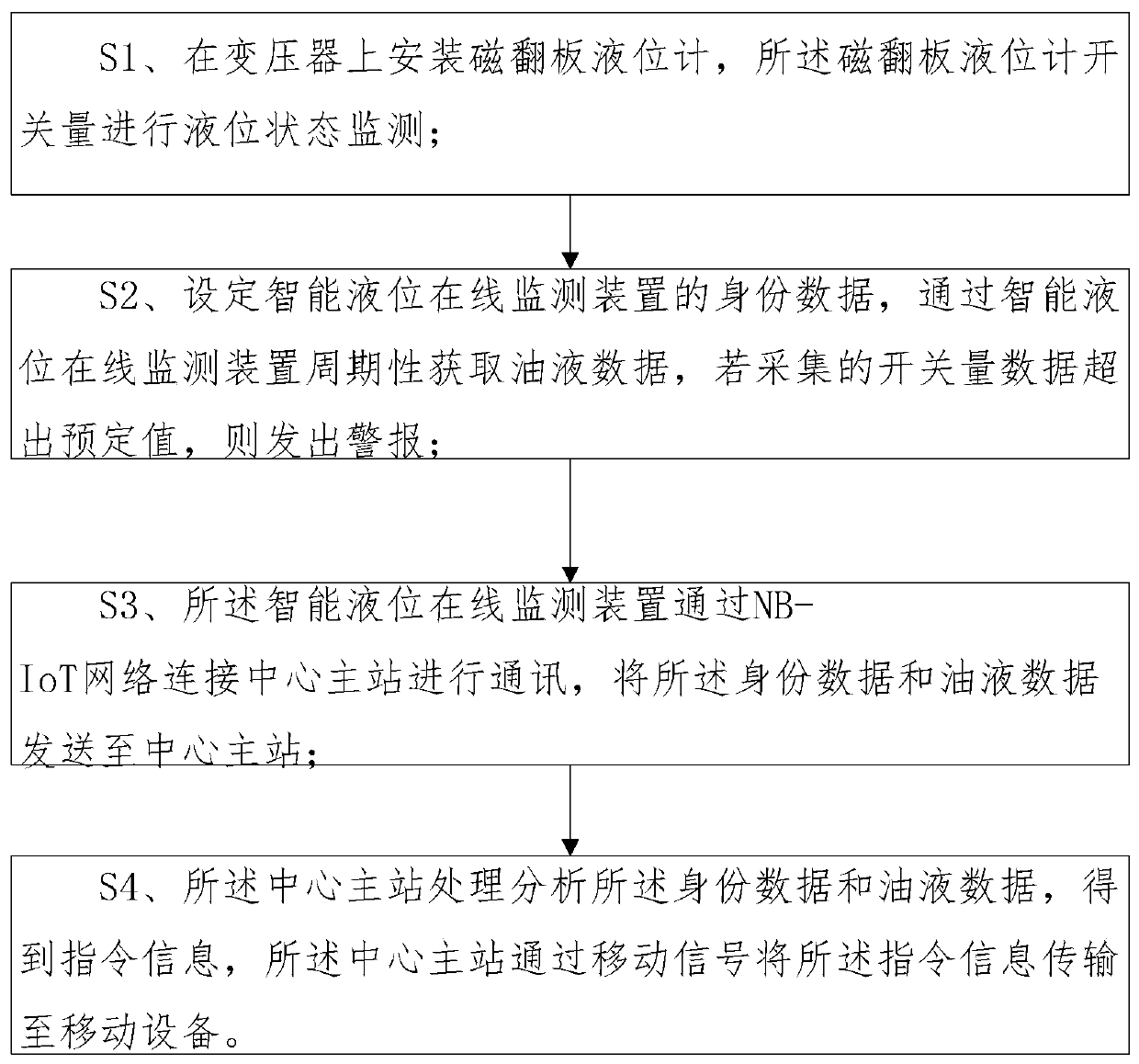

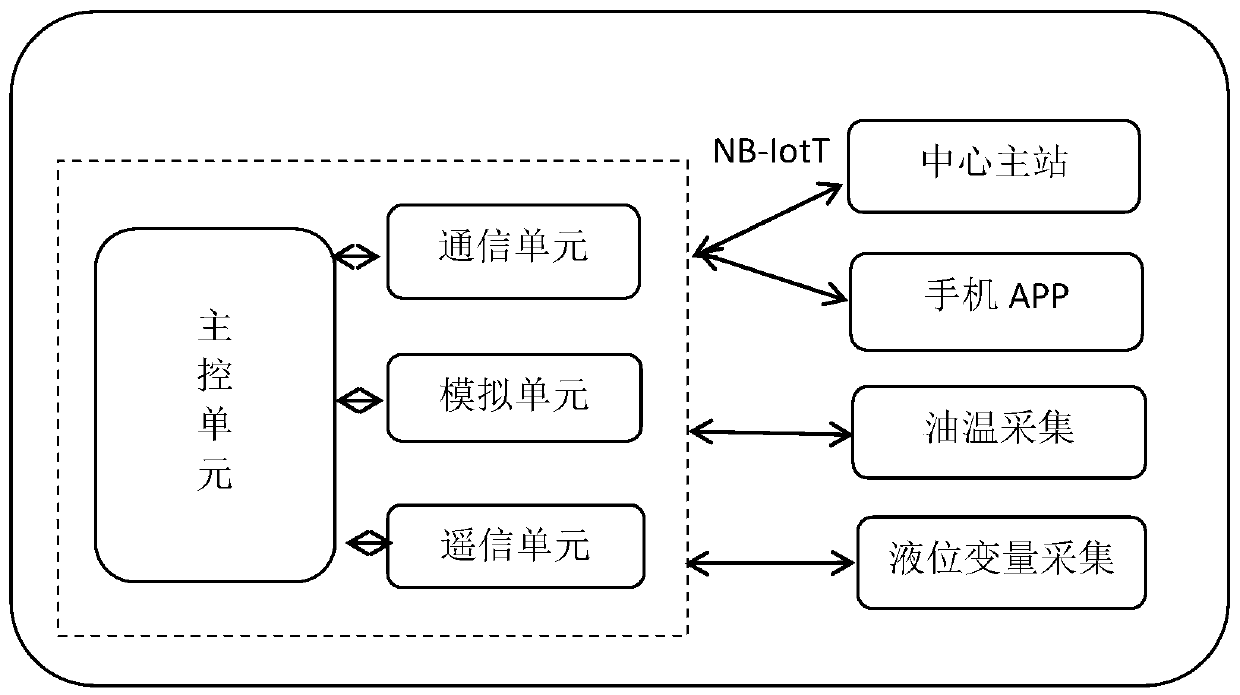

InactiveCN110987127AImprove convenienceImprove accuracyTransmission systemsTemperature measurement of flowing materialsCommunication unitControl engineering

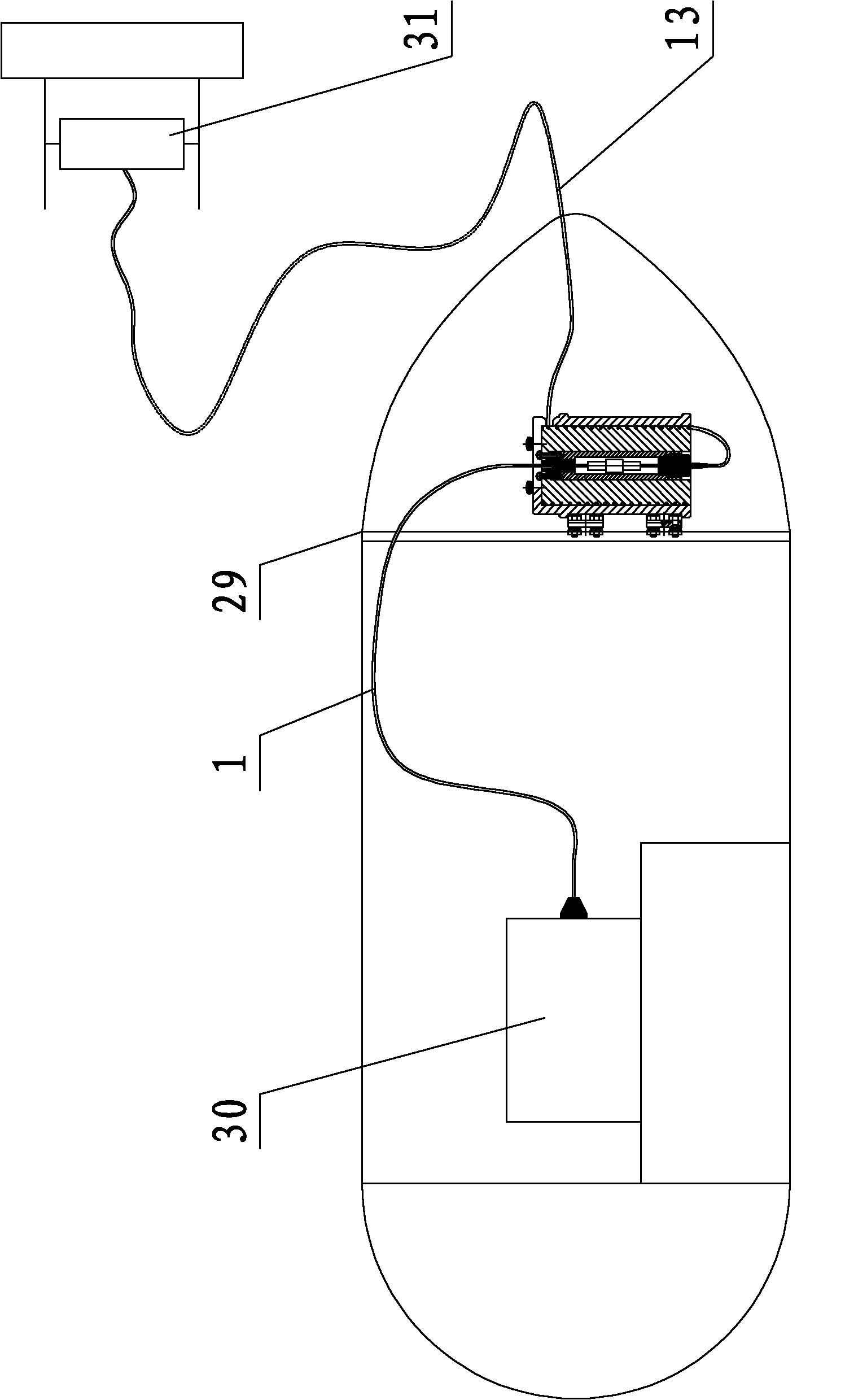

The invention provides an online liquid level monitoring method for an oil-immersed transformer. The method comprises the following steps: S1, installing a magnetic turning plate liquid level meter ona transformer, and monitoring a liquid level state; S2, setting identity data of an intelligent liquid level online monitoring device, and periodically acquiring oil liquid data; S3, carrying out communication with a central main station through an NB-IoT network by the intelligent liquid level online monitoring device; S4, processing and analyzing the identity data and the oil liquid data and transmitting the identity data and the oil liquid data to mobile equipment by the central main station. In addition, an online liquid level monitoring system for an oil-immersed transformer comprises asimulation unit, a remote signaling unit, a communication unit, a main control unit and a power supply; the simulation unit is used for collecting the oil temperature of transformer oil; the remote signaling unit is used for performing liquid level variable acquisition on the transformer oil; the communication unit is connected with the central master station through an NB-IoT network and transmits the oil liquid data and the identity data to the central main station; the main control unit is used for data processing; the power supply is used for system power supply. Therefore, technical problems that traditional oil level monitoring consumes time and labor, whether an oil level gauge works normally or not cannot be judged, and measurement is inaccurate are solved.

Owner:XIAN DAYI ELECTRONICS SCI & TECH CO LTD

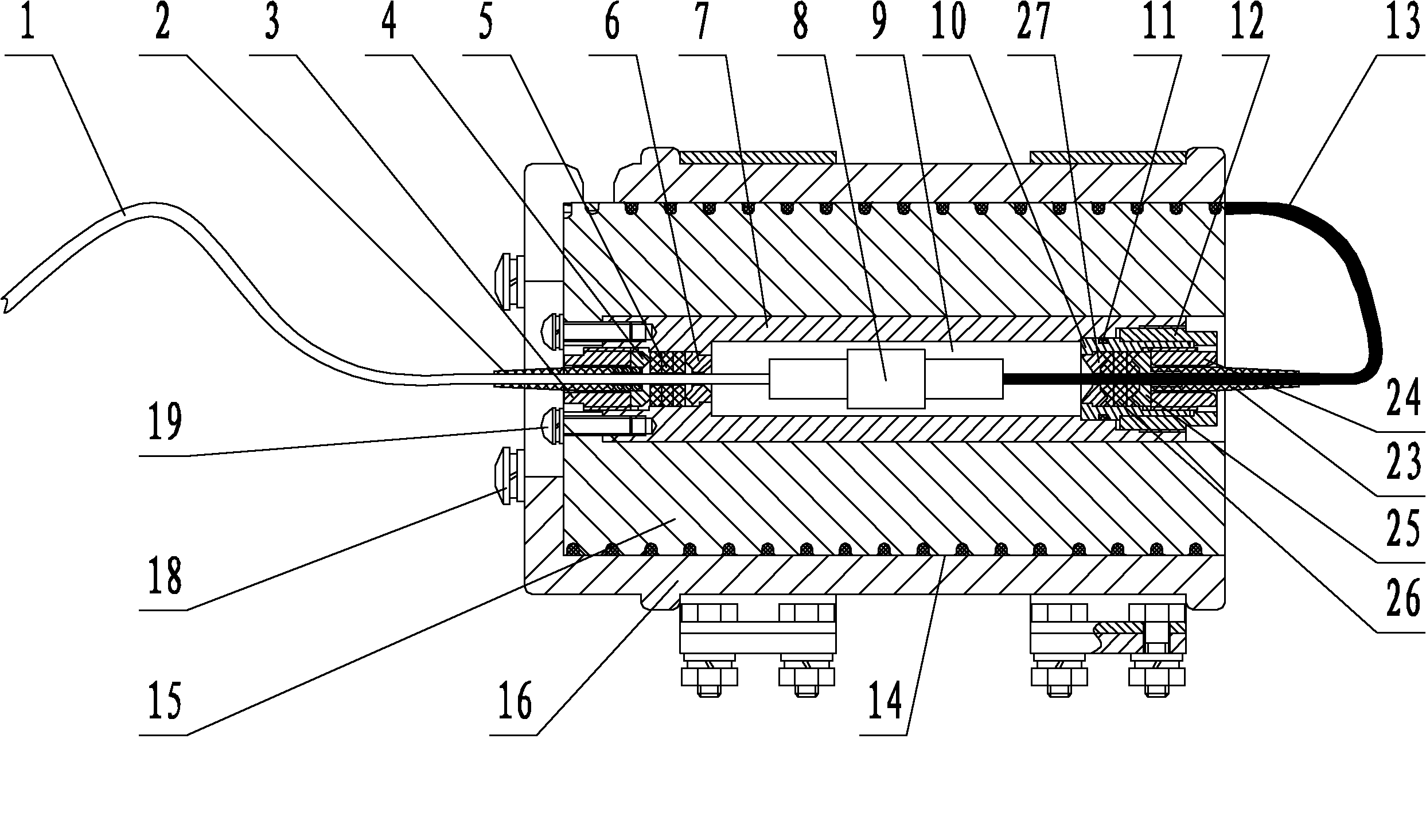

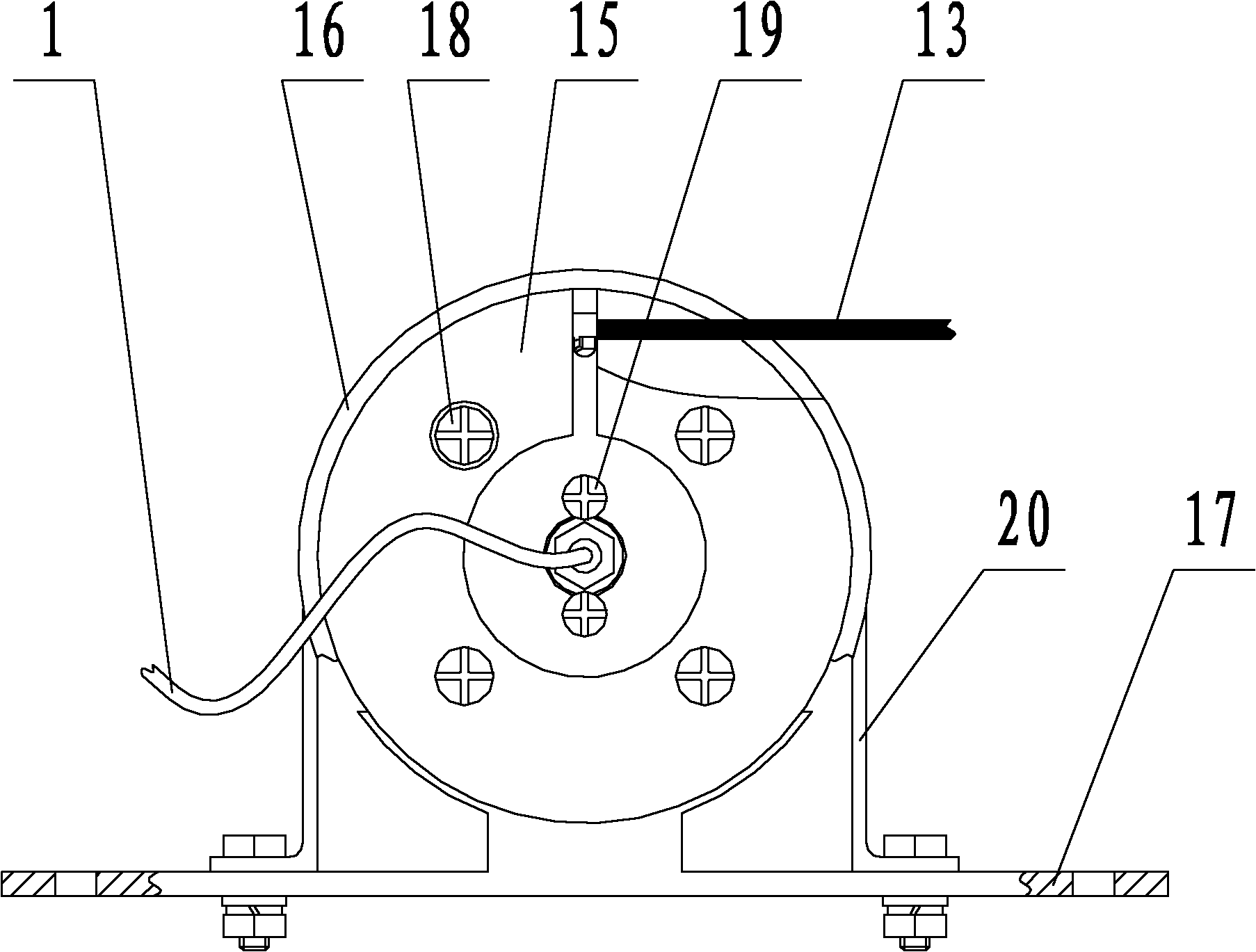

Underwater robot optical micro-cable spiral winding device capable of bearing tension

ActiveCN102590964AAvoid seal failureGuaranteed tightnessFibre mechanical structuresUnderwater equipmentKeelEngineering

The invention relates to an underwater robot device, specifically an underwater robot optical micro-cable spiral winding device capable of bearing tension. A translation sealed cabin is installed in an optical spiral sleeve. Sealing assemblies are hermetically connected at both ends of the translation sealed cabin respectively. An optical translation terminal is in the translation sealed cabin. Both ends of the optical translation terminal are respectively connected with one ends of section A and section B of the optical micro-cable. The other end of the section A of the optical micro-cable is connected with a control cabin of the underwater robot through the sealing assemblies. The other end of the section B of the optical micro-cable is winded on the external surface of the optical spiral sleeve through the translation sealing assemblies. An optical compression sleeve is sleeved outside the optical spiral sleeve and compresses the section B of the optical micro-cable. The other end of the section B of the optical micro-cable is extracted by the optical compression sleeve and connected to a water surface optical reeling and unreeling device. The device disclosed by the invention translates the tension of the optical micro-cable to a carrier keel frame of the underwater robot so as to avoid the problem of failed sealing caused by the tension at the sealing position of the optical micro-cable and the control cabin of the robot.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com