Online liquid level monitoring method and system for oil-immersed transformer

An oil-immersed transformer and liquid level monitoring technology, applied in the field of transformers, can solve the problems of time-consuming and labor-intensive oil level monitoring, inability to determine whether the oil level gauge is working normally, inaccurate measurement, etc. Timeliness and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

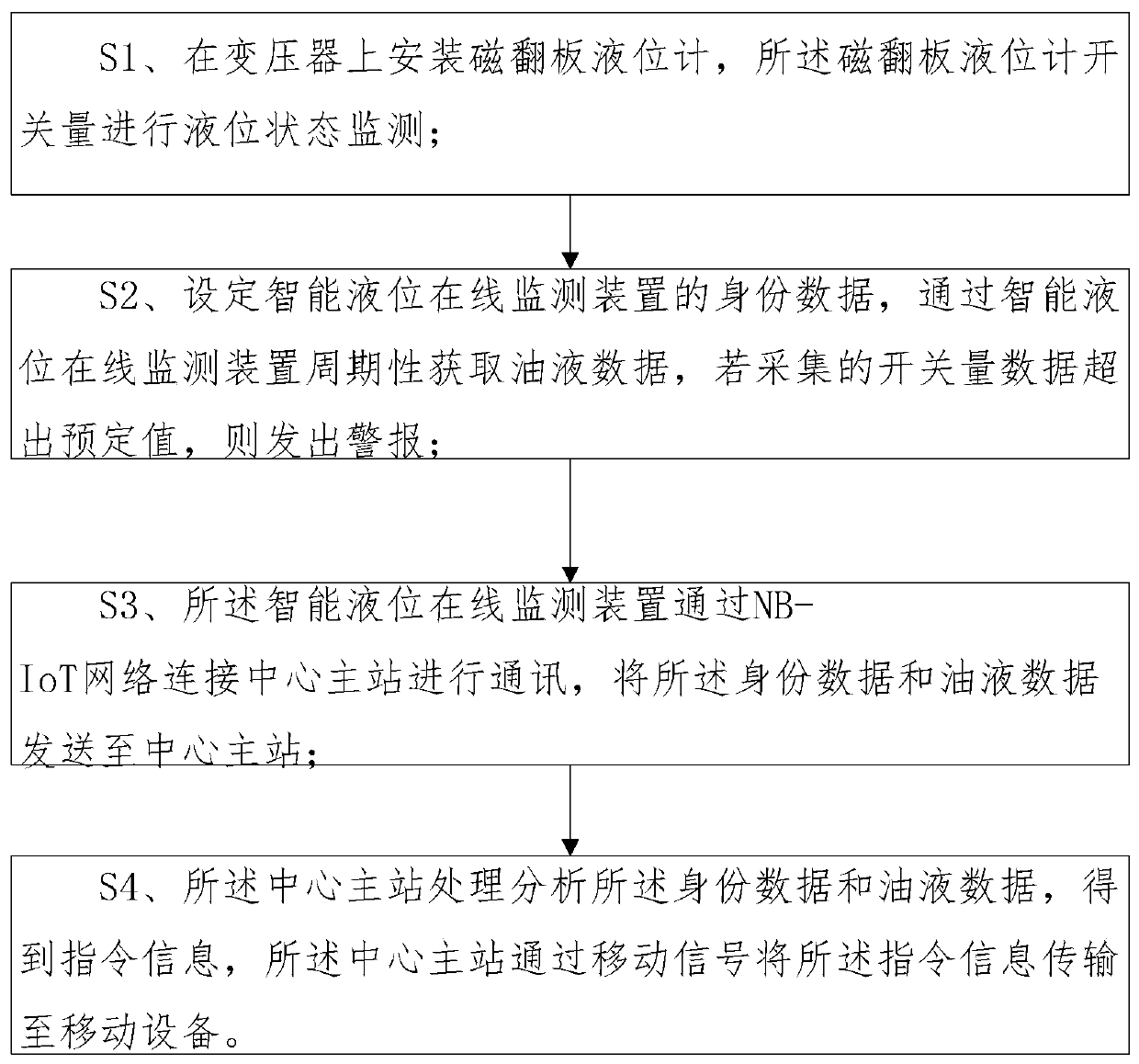

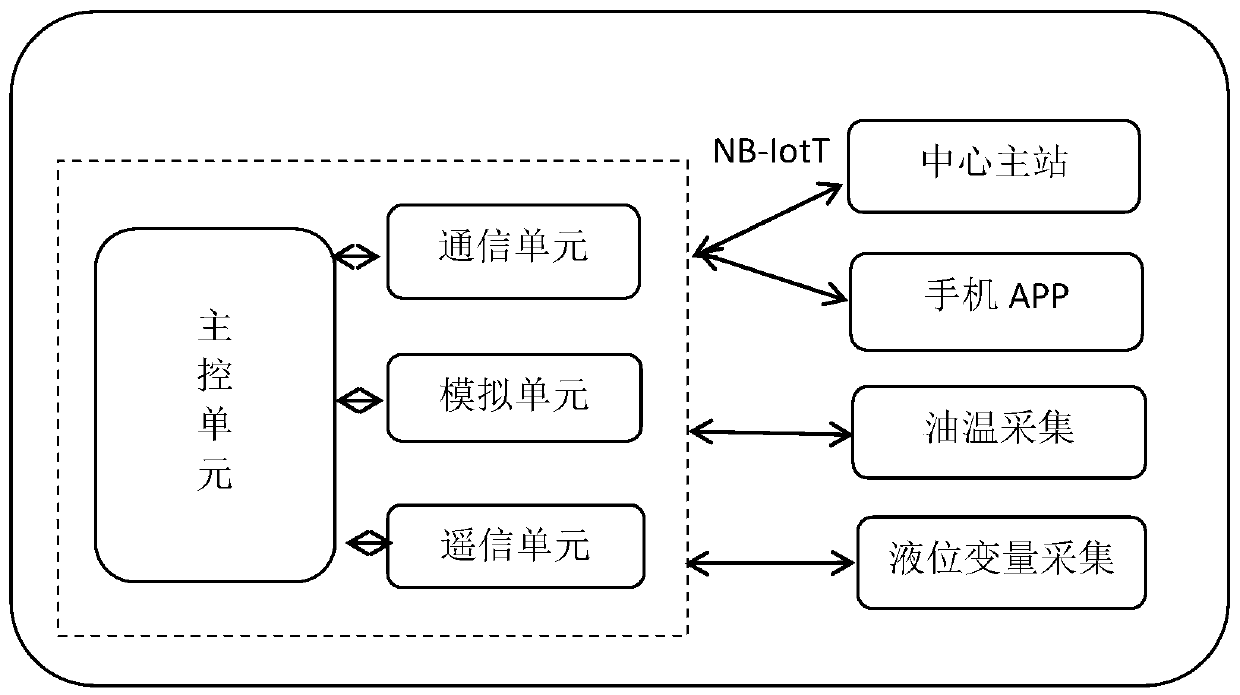

[0039] Embodiment 1: as Figure 1-2 As shown, an oil-immersed transformer online liquid level monitoring method is characterized in that it comprises the following steps:

[0040] S1. Install a magnetic flap liquid level gauge on the transformer, and the switching value of the magnetic flap liquid level gauge monitors the liquid level state;

[0041] S2. Set the identity data of the intelligent liquid level online monitoring device, and periodically obtain the oil data through the intelligent liquid level online monitoring device. If the collected switch data exceeds the predetermined value, an alarm will be issued;

[0042] S3. The intelligent liquid level online monitoring device communicates with the central master station through the NB-IoT network, and sends the identity data and oil data to the central master station;

[0043] S4. The central master station processes and analyzes the identity data and oil data to obtain instruction information, and the central master st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com