Integrated bridge girder erection machine for prefabricated bridge pier-beamand construction method thereof

A construction method and bridge erecting machine technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to consider the continuity of bridge structures, high land acquisition costs, and inconvenient transportation, etc., to protect the natural environment and farmland , reduce construction road leveling, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

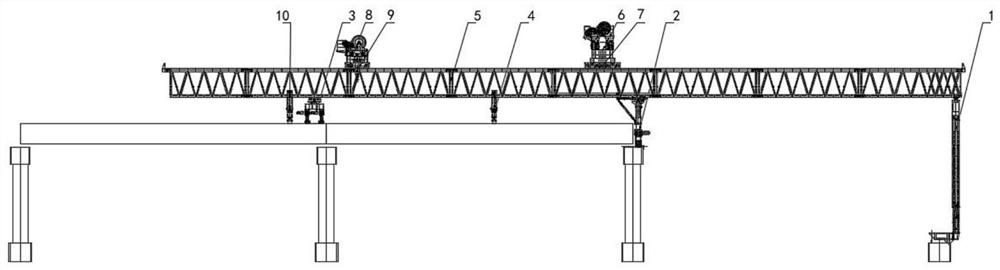

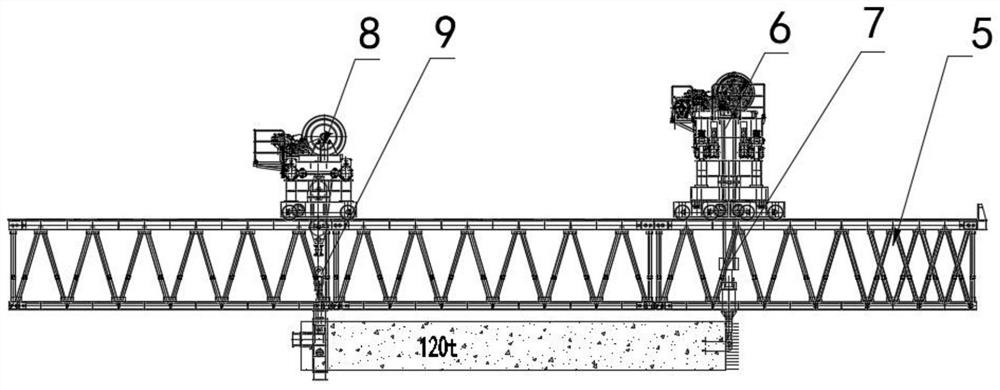

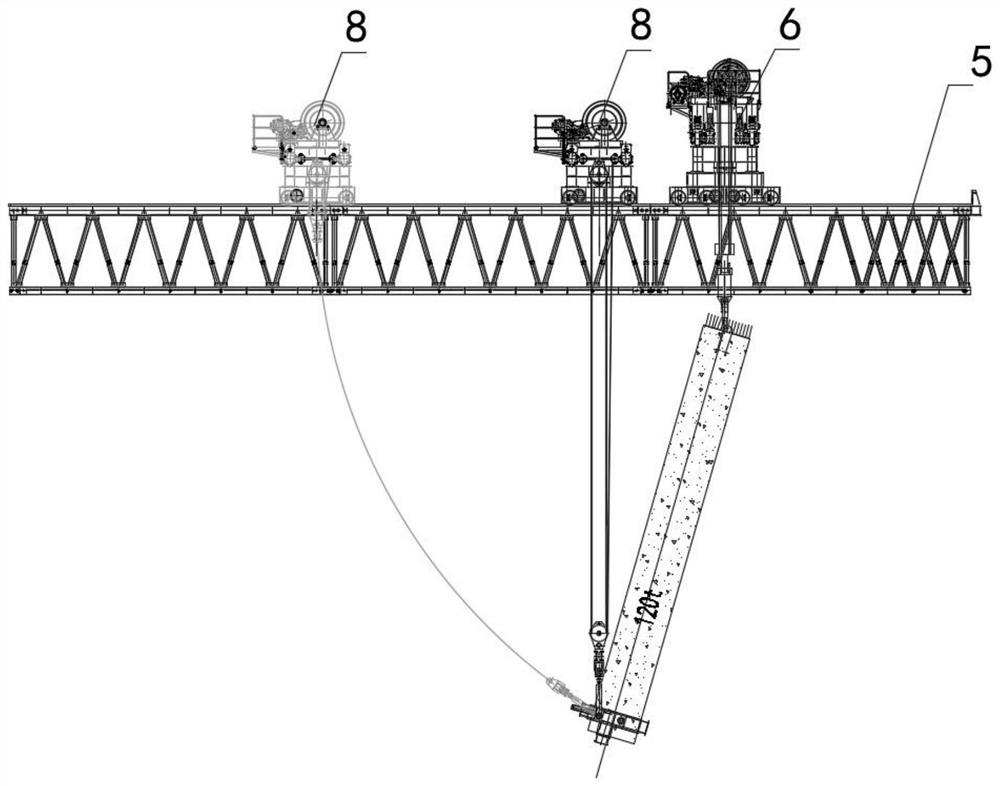

[0046]Such asFigure 1-15As shown, the prefabricated bridge pier girder integrated bridge machine, including the main truss 5, the first starting car 6, the second starting car 8, the main leg 1, the main carrier 2, the side is heavy legs 3, the first Auxiliary leg 4 and second auxiliary leg 10; the first starting carriage 6 and the second starting vehicle 8 slide to be connected to the top of the main truss 5, and the first lifting vehicle 6 is provided with a first hanger 7, second start A second hanger 9 is provided on the heavy driving 8; the main leg 1, the main contract is heavy leg 2, the side loaded leg 3, the first auxiliary leg 4 and the second auxiliary leg 10 detachable connected to the main truss 5 bottom.

[0047]The main truss 5 is horizontally disposed, and the top of the main truss 5 is formed with a track that is adapted to the first starting and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com