Construction method for support formwork integrated hydraulic inner formwork trolley of comprehensive pipe gallery

A construction method and technology of integrated pipe gallery, which can be applied to artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of unguaranteed appearance and quality of embedded parts, poor economic benefits of underground comprehensive pipe gallery construction, etc., to achieve Save turnover materials and labor costs, facilitate standardized management, and achieve remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

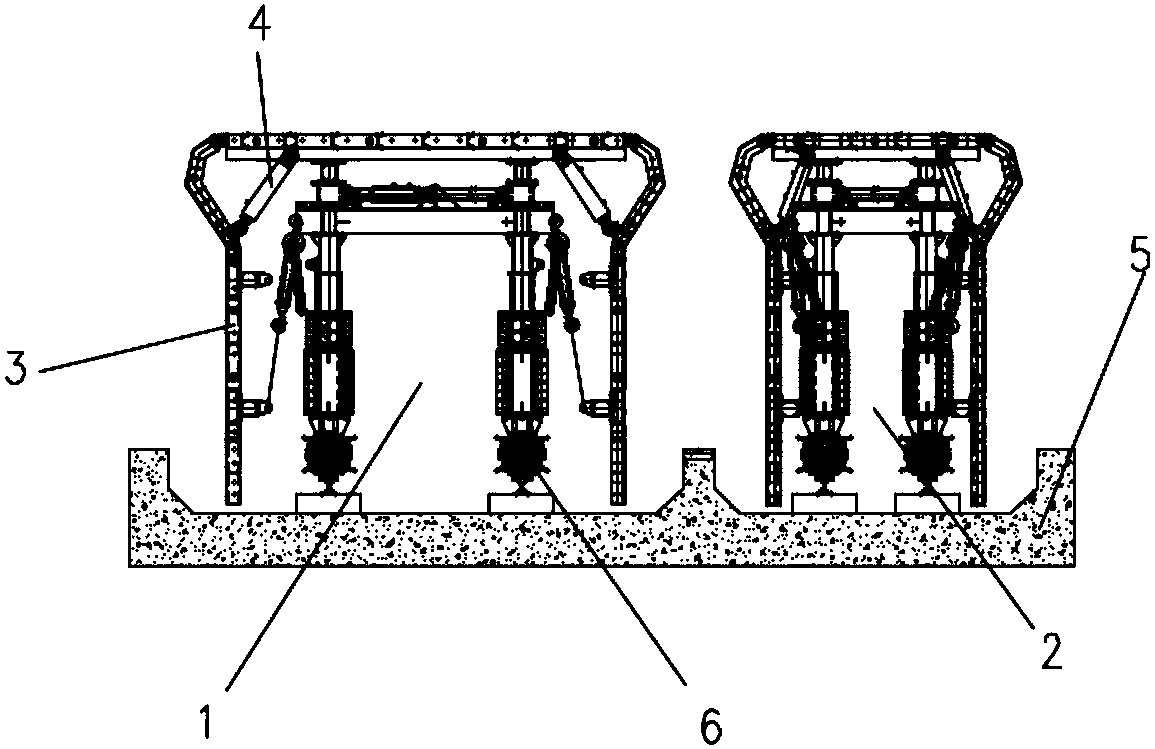

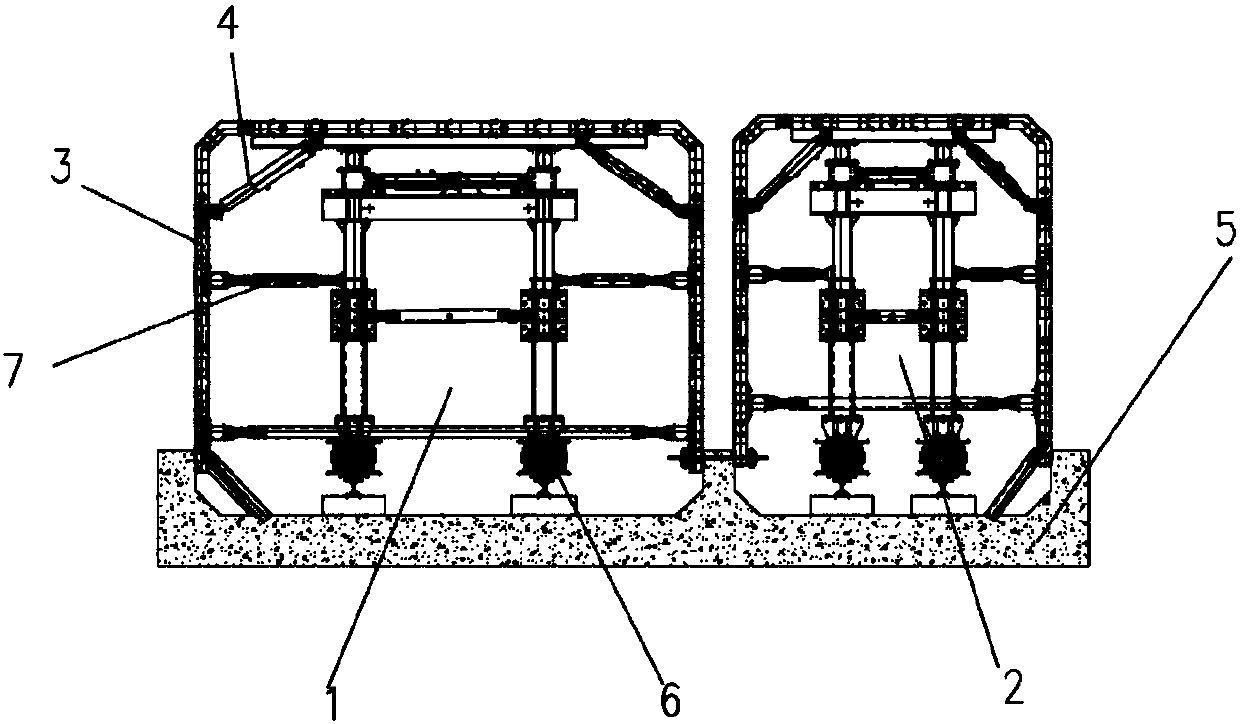

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

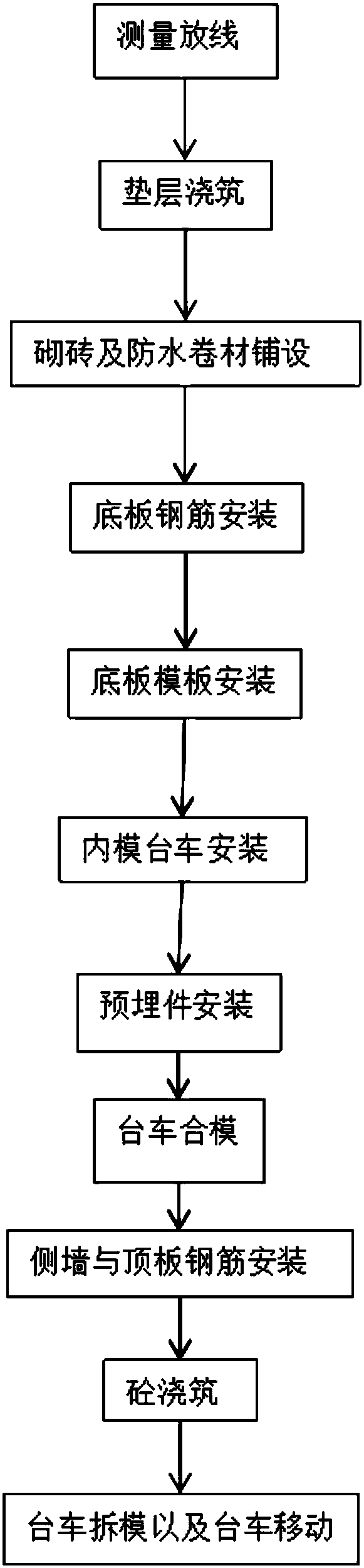

[0032] A construction method of an integrated hydraulic internal formwork trolley for integrated pipe gallery support and formwork, comprising the following steps:

[0033] Step 1: Measurement and setting out: Stake out according to the size and elevation of the cushion and the main structure. The main cross-section of the standard section of the pipe gallery is 7.35m wide and 3.9m high. It is divided into pipeline warehouses and power warehouses. The middle partition wall is 25cm, the thickness of the bottom plate of the double warehouse is 40cm, the thickness of the roof plate of the pipeline warehouse is 40cm, and the thickness of the roof plate of the power warehouse is 35cm. The cushion layer is made of 30cm thick 1:1 gravel sand + 10cm thick C15 plain concrete, which is lengthened by 2 to 3m according to the length of the main structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com