Large-seed directional seeding device

A sowing device and seed technology, applied in the direction of single-seed seeder, etc., can solve the problem of inconsistency in the orientation of the germination point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

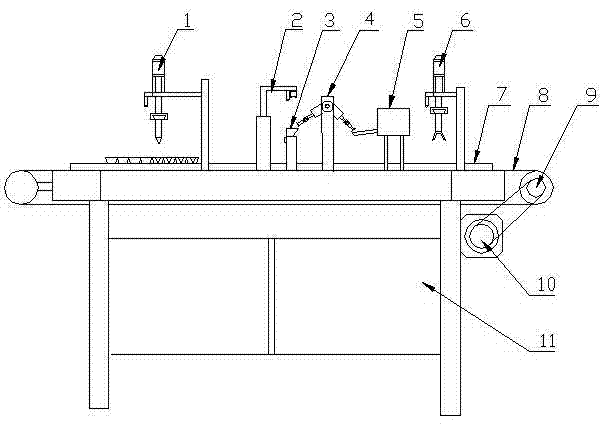

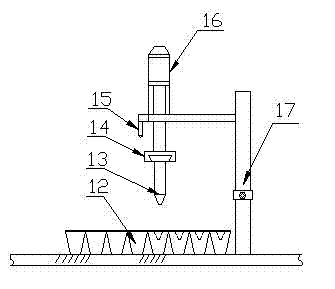

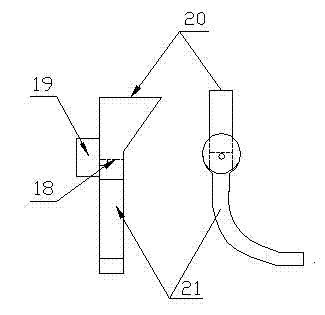

[0026] see figure 1 , a device for directional sowing of large seeds, consisting of a hole pressing mechanism 1, a camera detection mechanism 2, a direction adjustment mechanism 3, a seed suction mechanism 4, a seed box 5, a correction mechanism 6, a guide plate 7, a control box 11, a seedling tray 12, etc. The composition is characterized in that: according to the workflow of the assembly line, the frame of the workbench is respectively fixed with a pressure-cavity mechanism 1, a camera detection mechanism 2, a direction adjustment mechanism 3, a seed suction mechanism 4, a seed box 5, and a correction mechanism 6. A control box 11 is installed under the workbench. Conveying mechanism is made up of stepper motor 10, belt pulley 9, conveyer belt 8, and stepper motor 10 is installed on the side of the output end of workbench seedling disc 12, passes belt pulley 9

[0027] Drive and be installed on the workbench conveyer belt 8 transmissions, two guide plates 7 that width can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com