Patents

Literature

241results about How to "Easy to bag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

Tundish dry ribration material for continuous casting and its preparation method

InactiveCN1651352ANo irritating smellEasy constructionMelt-holding vesselsPolyvinyl alcoholRefractory

A lining material of tundish for conticasting is prepared from 6 primary raw materials including sintered magnesium sand, electrosmelted magnesium sand, forsterite, light forsterite, etc and 9 secondary raw materials including water glass, sodium tripolyphosphate, dextrin, starch, etc through proportionally mixing, stirring, loading in mould, vibrating, baking at 150-400 deg.C and demoulding.

Owner:WUHAN UNIV OF SCI & TECH

Lining material of tundish for conticasting

InactiveCN1382541AHigh strengthImprove slag erosion resistanceMelt-holding vesselsSoft clayRefractory

A lining material of tundish for conticasting contains magnesium sand (80-95 wt.%), alumina (1-10 wt.%), soft clay (1-5 wt.%) and thermoplastic organic compound (2-15 wt.%). Its advantages are high strnegth, anticorrosion power, and high conticasting productivity.

Owner:朱德智

Tundish magnesium dry-type stock adding aluminum hydroxide

The invention discloses a magnesia-based dry material for a tundish with aluminum hydroxide, which belongs to a refractory material. The magnesia-based dry material for the tundish with the aluminum hydroxide comprises the following compositions in percentage by weight: 1 to 15 percent of aluminum hydroxide fine powder, 82 to 89 percent of magnesia, and 1.5 to 6.5 percent of bonding agent. During the baking and use, the aluminum hydroxide fine powder is decomposed to produce activated alumina and vapor, the vapor moistens the surfaces of particles inside the dry material to ensure that the surfaces of the magnesia and silica fume in the dry material are hydrated, and the bonding agent is partially dissolved and diffused to bond with the surface of the magnesia. The generated activated alumina has a spinel reaction with magnesia fine powder at a temperature higher than 900 DEG C to form a large quantity of fine magnesium aluminate spinels, which remarkably improves the penetration-resistant action of the dry material on molten steel and steel slag and plays a role in ceramic bonding. The dry material does not depend on carbon-containing bonding agents such as phenolic resin, asphalt, which avoids the carburization to molten steel of low carbon steel and also reduces the poisonous fume emission. The construction of the magnesia-based dry material adopts a dry-press process, and then the dry material is subjected to heat conduction through the heating on a metal mold to make the bonding agent fused or solidified to form a fixed tundish working lining for receiving the molten steel.

Owner:江苏苏嘉集团新材料有限公司

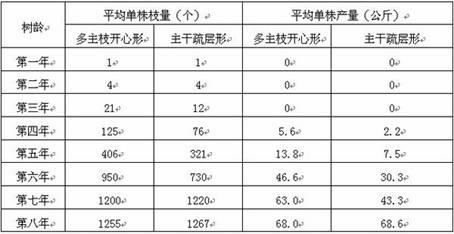

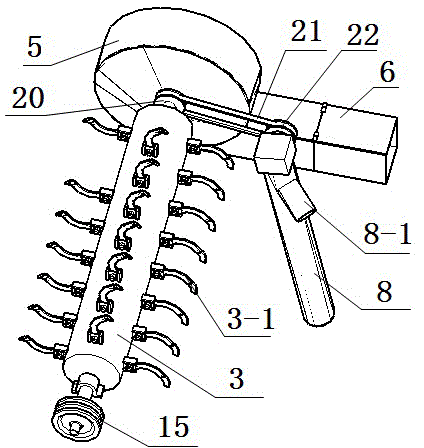

Multi-main-branch open center tree shape of pear tree and pruning method for pear tree

The invention discloses a multi-main-branch open center tree shape of a pear tree, and belongs to the field of pruning of fruit trees. The trunk height of the tree shape is 0.7 to 0.9 meter, the central trunk height is 1.7 to 1.9 meters, 7 to 9 main branches are uniformly grown on the central trunk, and medium and small branch groups are directly grown on the main branches; the angle between each main branch and the central trunk is 70 to 80 degrees; and the thickness of a leaf curtain is 1.8 to 2.3 meters, and the height of the tree is 2.2 to 2.7 meters. The intervals of the medium branch groups on the main branches are 50 to 70 centimeters, and the intervals of the small branch groups are 10 to 20 centimeters. The tree shape has the advantages of simplicity and convenience in pruning, quickness in formation, earliness in fruiting, convenience in management, good ventilation and light transmission conditions and the like.

Owner:SHIJIAZHUANG POMOLOGY INST OF HEBEI ACADEMY OF AGRI & FORESTRY SCI

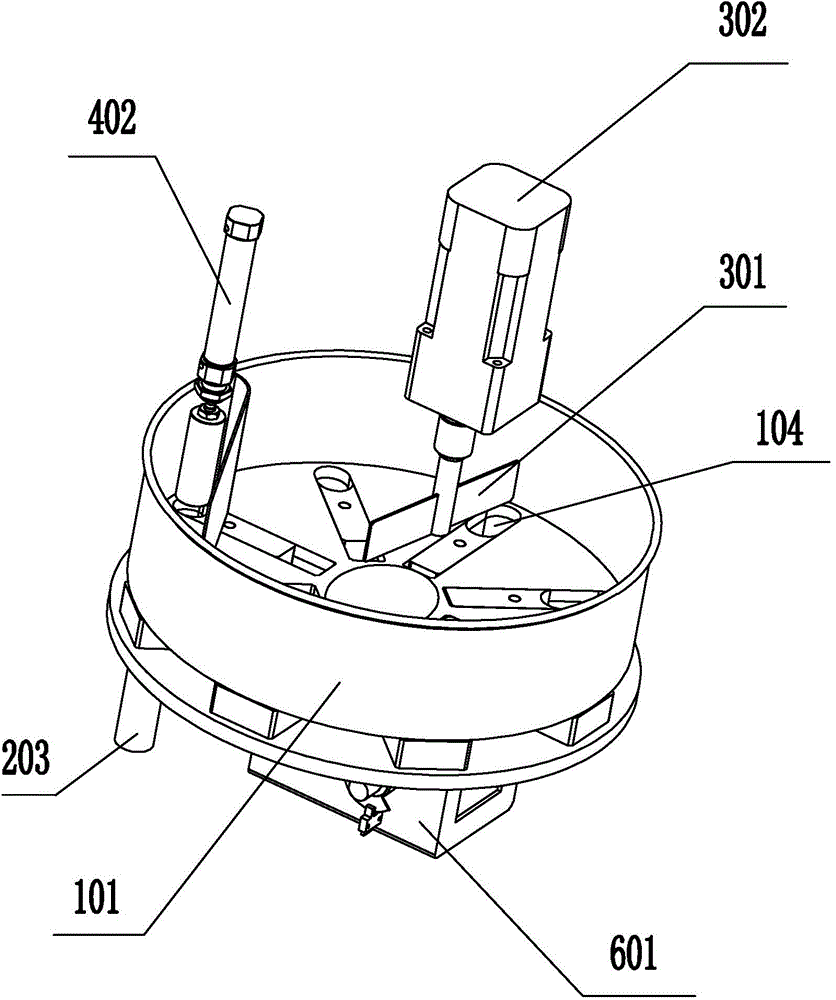

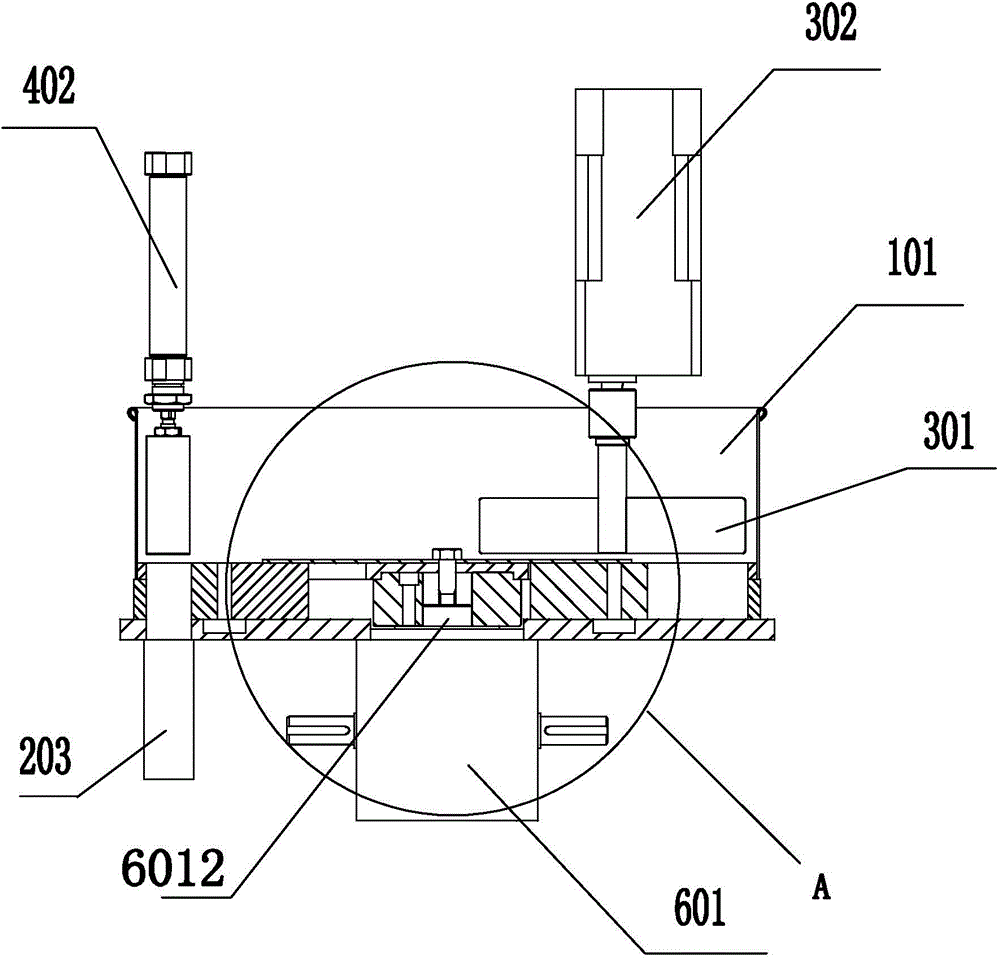

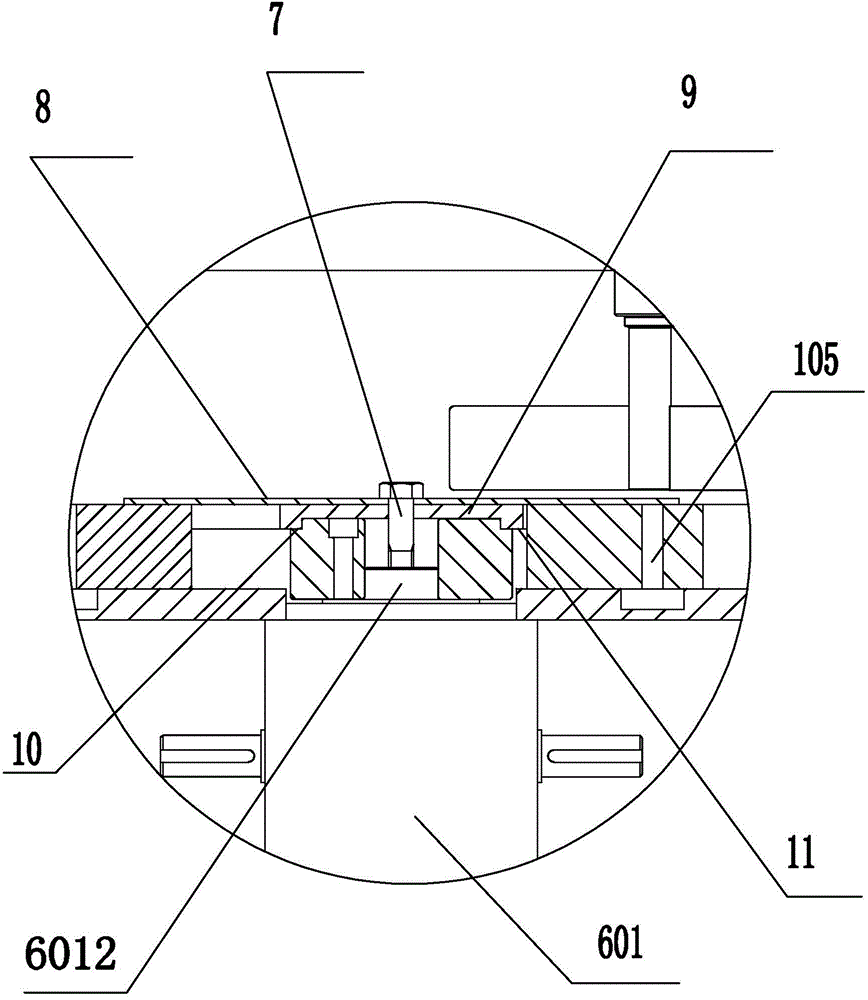

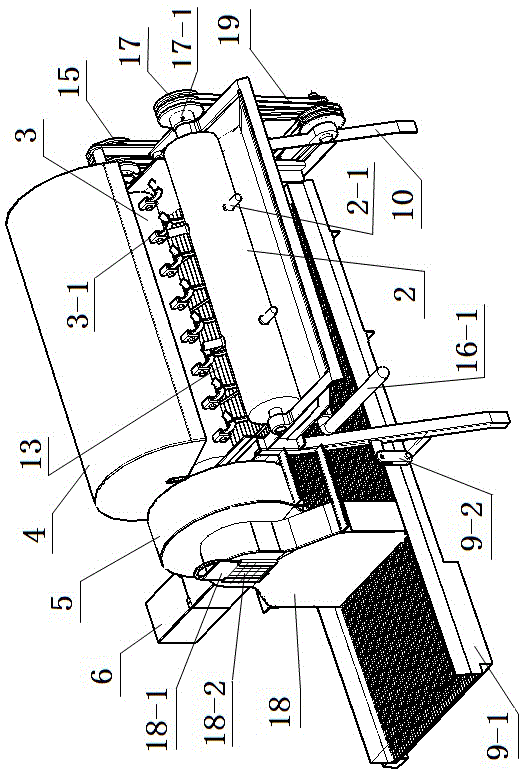

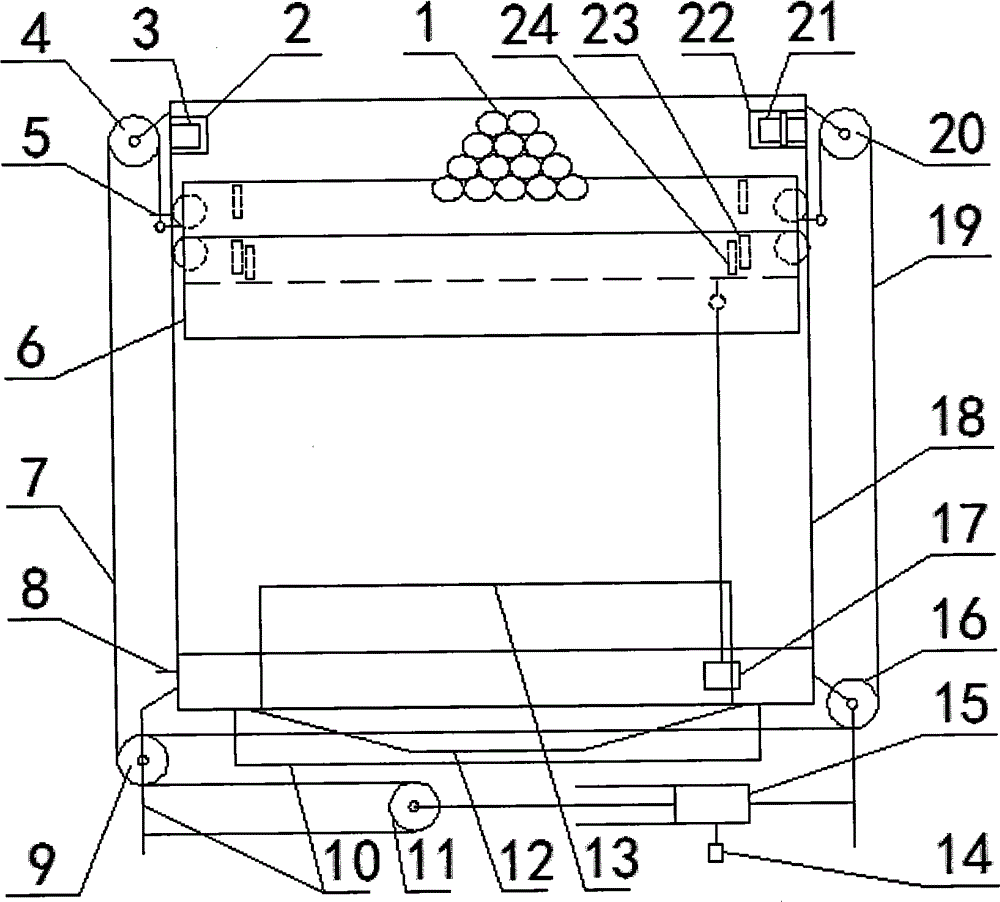

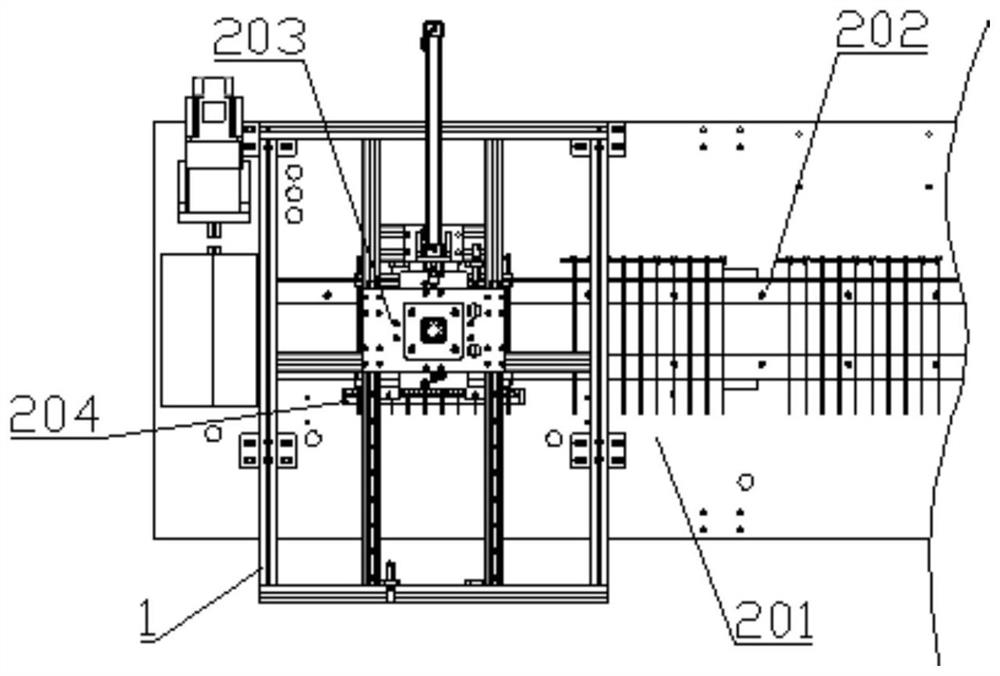

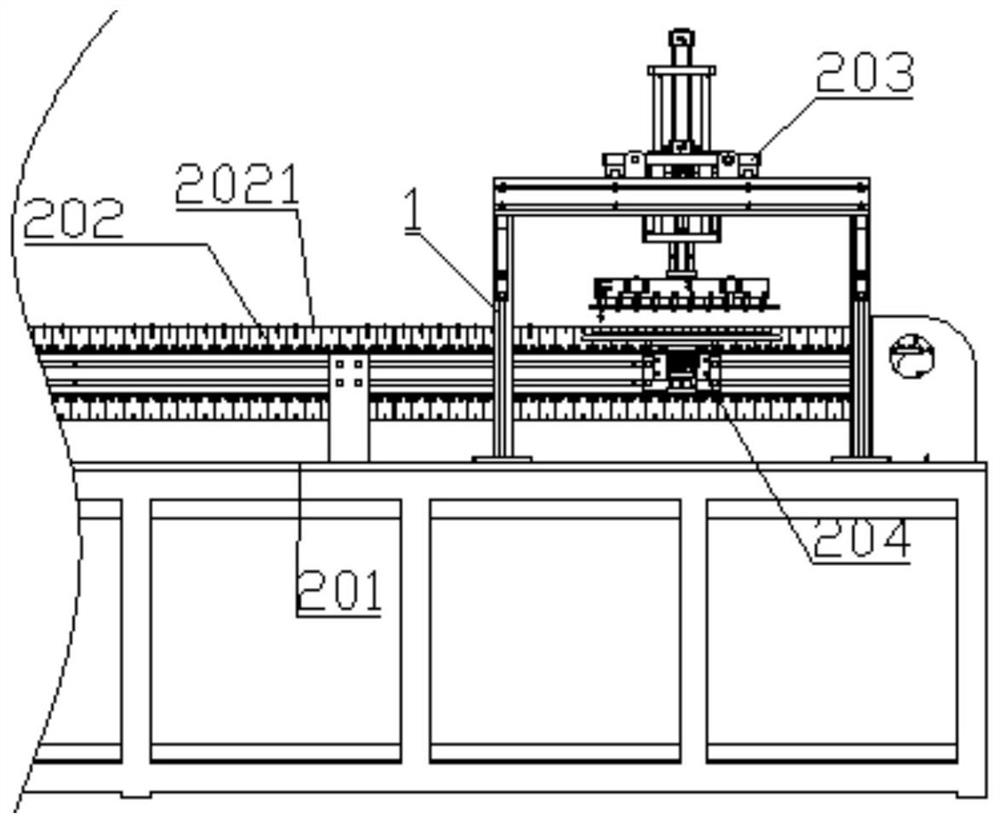

Disc cam type packaged food metering device

ActiveCN104528004AImprove the degree of automated productionIncrease productivitySolid materialEngineeringCam

The invention provides a disc cam type packaged food metering device and belongs to the field of composite leisure food packaging metering techniques. The disc cam type packaged food metering device comprises a rack, a cylindrical turntable composite structure, a disc cam and a stirring paddle. The cylindrical turntable composite structure comprises a cylindrical turntable, 6-18 fixed metering cups, 6-18 sliding blocks and 6-18 bearings, the cylindrical turntable comprises a bottom and 6-18 bottom slots, a fixed metering cup slot is formed in the middle of each fixed metering cup, the bottom slots and the fixed metering cup slots are stacked in an upper and lower mode to form 6-18 sliding block slots, and 6-18 movable metering cups are formed between inwards concave semicircles of the sliding blocks and outwards concave semicircles of the sliding block slots; the disc cam comprises a cam groove and is arranged below the fixed metering cups; each bearing comprises a bearing head, the bearing heads are arranged in the cam groove and can rotate along the cam groove, and the sliding blocks can slide in the sliding block slots forwards or backwards; the stirring paddle is horizontally arranged. The disc cam type packaged food metering device has the advantages that metering is precise, the automated production degree is high, production efficiency is high, and materials are easy to put in.

Owner:RUIAN GUCHUAN PACKAGING MACHINERY CO LTD

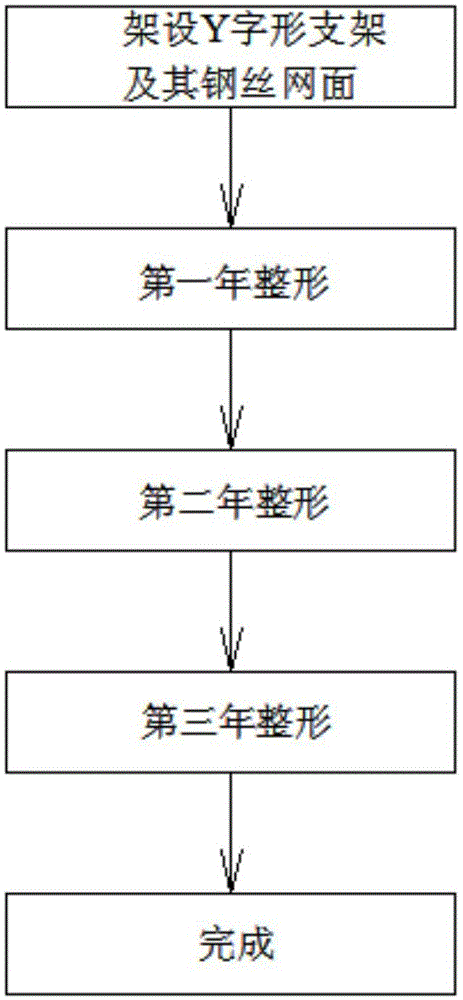

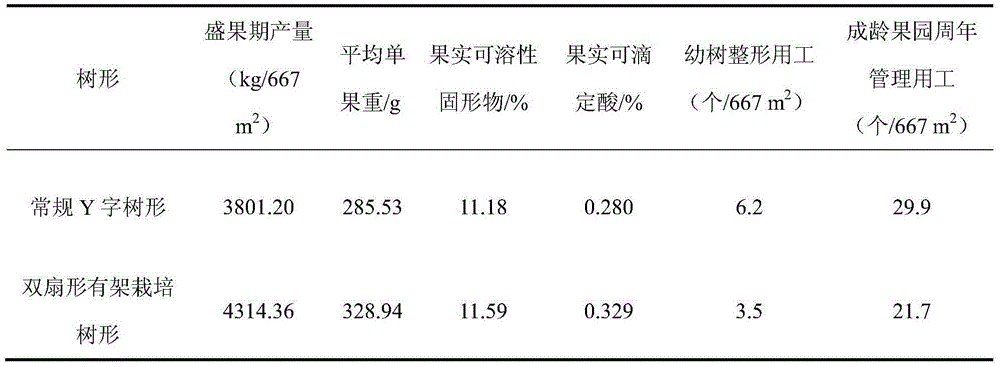

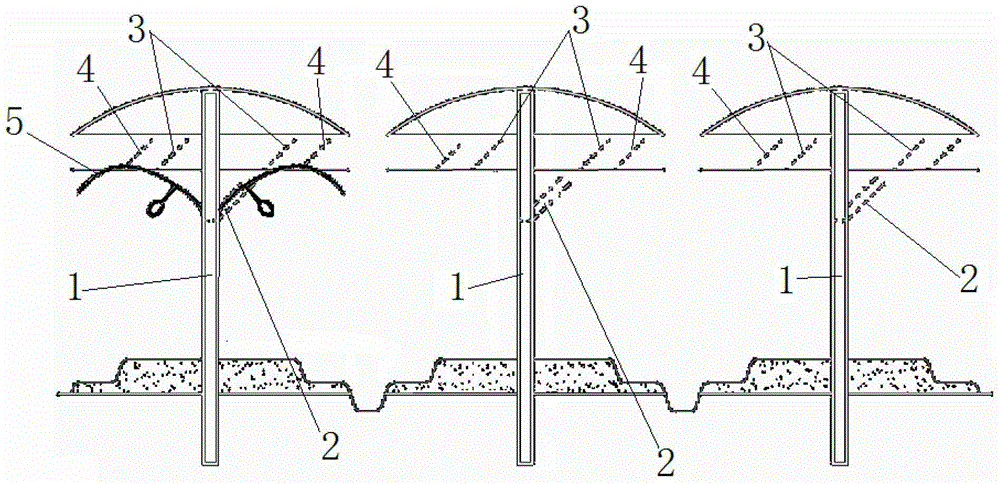

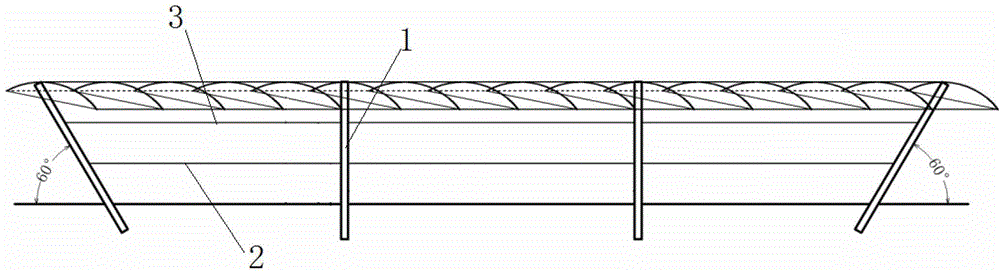

Double-sector trellis cultivation type pear tree form and shaping method thereof

ActiveCN105028105ALess branchedOrderly rowsCultivating equipmentsHorticulture methodsFruit treeWire gauze

The invention belongs to the field of fruit tree cultivation and fruit tree ecology and relates to a double-sector trellis cultivation type pear tree form and a shaping method thereof. Only two principal branches are reserved on a pear tree, a 90-degree included angle is formed between the two principal branches which are fixed to a Y-shaped support, and the two principal branches are symmetrically spread towards the space between lines; a base lateral branch is arranged on each of the two sides of the base of each principal branch, and a plurality of monopodium non-pruning type bearing branch groups are evenly arranged on and above the middle portion of each principle branch in a stagger mode; a 90-degree side angle is formed between each base lateral branch and the corresponding principal branch; a 90-degree base angle is formed between each monopodium non-pruning type bearing branch group and the corresponding principle branch, and the monopodium non-pruning type bearing branch groups are spread in parallel in the line direction; lateral branch bearing branch groups are formed on the base lateral branches through bud carving and non-pruning; weak shoots are taken as the main part of each principal branch, and the crown is spread to be sectors on the two sides of the Y-shaped support. The shaping method comprises the steps of erecting the Y-shaped support and a steel wire gauze surface, shaping at the first year, shaping at the second year and shaping at the third year. The method is convenient to operate and remarkable in effect.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

Grape cultivation method and special rack for cultivation method

InactiveCN103329774AImprove fruit setting rateImprove qualityCultivating equipmentsViticultureBiology

The invention discloses a grape cultivation method and a special rack for the cultivation method. The cultivation method is characterized in that grape branches are cultivated to an M-shaped growth trend. The special rack for the grape cultivation method comprises an upright; a first pulling rope for binding a main vine is arranged at a part, 1.4-1.6m from the ground, of the upright; second pulling ropes for binding new shoots sprouting from the main vine are arranged on the two sides of the first pulling rope on the upright respectively; a third pulling rope for breaking a side shoot and allowing the branches to grow in a falling manner is arranged on one side of each second pulling rope on the upright; a distance between each second pulling rope and the ground is greater than that between the first pulling rope and the ground; and a distance between each third pulling rope and the ground is not less than that between each second pulling rope and the ground. According to the grape cultivation method and the special rack for the cultivation method, after the new shoots grow horizontally and the branches are broken, front ends grow in a falling manner, so that apical dominance of grapes is inhibited, and the quality of the grapes is improved; light rays directly illuminate leaves, and the branches and the shoots are not crossed mutually, so that a photosynthesis effect is improved; and bearing branches are fixed on the pulling ropes according to the distances, and fruit clusters are not abraded mutually, so that the production quality of the grapes is uniform.

Owner:ANHUI WUHU RUIKANG AGRI TECH DEV

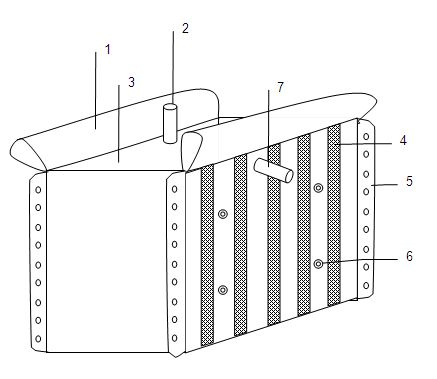

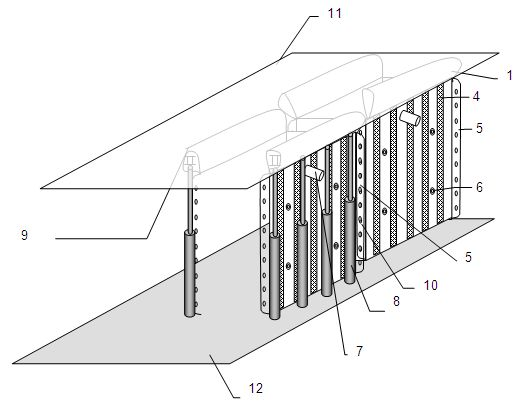

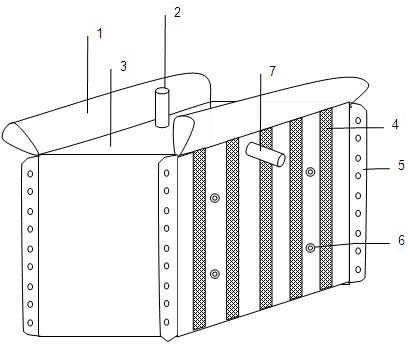

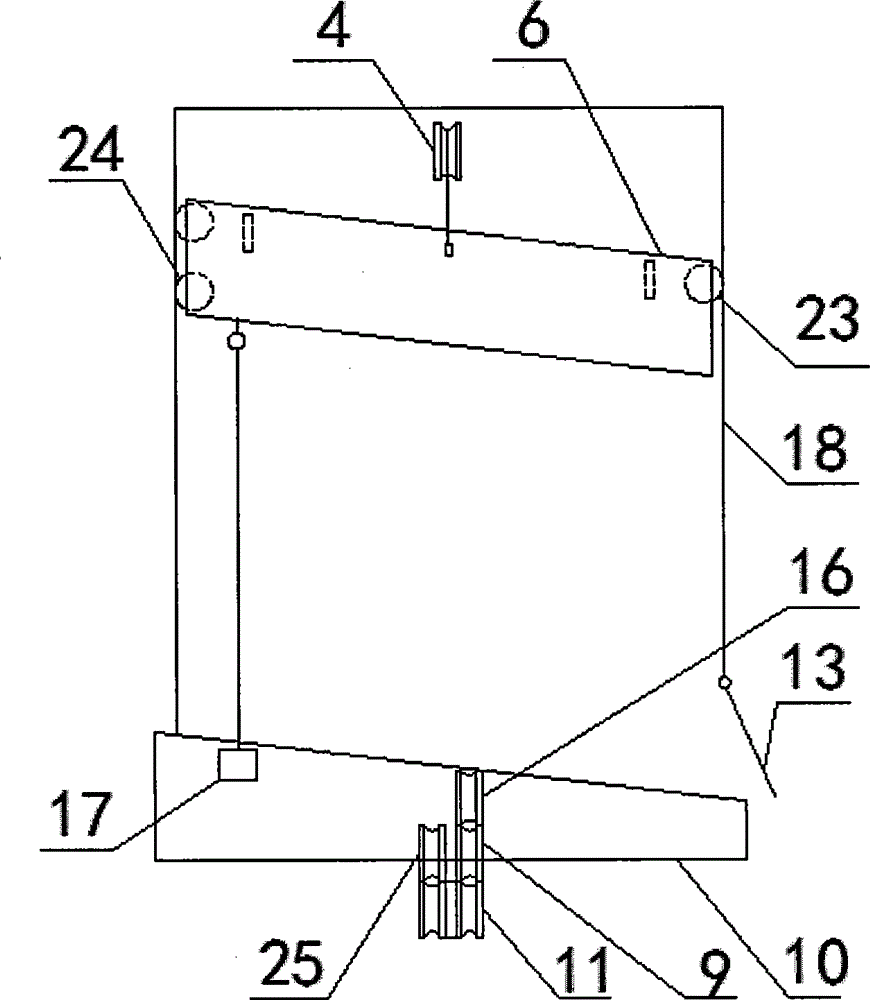

Gob-side entry retaining concrete partition wall construction mold bag and construction method thereof

InactiveCN101929342AGuaranteed sealing performanceEasy to bagUnderground chambersTunnel liningEavesEngineering

The invention discloses a gob-side entry retaining concrete partition wall construction mold bag and a construction method thereof. The mold bag is a bag with a closed structure; and the mold bag structurally comprises a fixed lug cylinder, a pouring exhaust hole, a mold bag top, a reinforcing rib, connecting feather eaves, an anchor bar hole and a concrete grouting duct. The construction method comprises the following steps of: penetrating a rigid beam into the fixed lug cylinder, jacking the rigid beam to a top plate by using a strut and fixing the rigid beam; penetrating a rope into a connecting hole of the connecting feather eaves to connect and position the adjacent mold bag; then penetrating an anchor bar and controlling a concrete pumping device; and finally, pumping concrete to fill the whole mold bag till the mold bag is full to the top. The mold bag is adaptive to the pouring of a gob-side entry retaining masonry partition wall of a coal mine, has a simple structure and high construction speed, and can be widely applied in quick masonry of the gob-side entry retaining partition wall of the mine and water conservancy, war industry and other civil engineering industries.

Owner:XIAN UNIV OF SCI & TECH

Tundish magnesia coating material prepared by using waste magnesium aluminum spinel as raw material and method

ActiveCN110282991ASolve the problem that it is difficult to turn over the bag and the color is blackSolve problems such as easy peelingCeramic materials productionClaywaresBrickPlasticizer

The invention belongs to the technical field of unshaped refractory materials, and specifically relates to a tundish magnesia coating material prepared by using waste magnesium aluminum spinel as a raw material and a method. The waste magnesium aluminum spinel is obtained in two ways: waste magnesium aluminum spinel bricks or preformed units produced in a production process of a refractory material enterprise are prepared into the waste magnesium aluminum spinel with the particle diameter of 3-0 mm through sorting and crushing; waste magnesium aluminum spinel bricks or preformed units after use by steel mills are prepared into the waste magnesium aluminum spinel with the particle diameter of 3-0 mm through deslagging, sorting and crushing; the waste magnesium aluminum spinels obtained through the two ways are mixed according to the ratio of (1.5:1) to (1:1.5), and then are sieved to obtain waste magnesium aluminum spinel particles of two kinds of particle diameters of 3-1 mm and 1-0 mm; the waste magnesium aluminum spinel particles are taken as a raw material to be added with a binder, a plasticizer, a water reducer, an anti-knock agent, and the like at the same time to develop the tundish coating material which is stable in performance, high in strength, excellent in construction performance and low in cost; the cyclic utilization of waste refractory materials is realized; the enterprise production cost is lowered.

Owner:瑞泰马钢新材料科技有限公司

Biomass fertilizer drying device

InactiveCN107906921AAchieve reusePlay the role of energy savingManure dryingDrying gas arrangementsPulp and paper industryAir compressor

A biomass fertilizer drying device, comprising a body, the top of the body is provided with a feeding port, the top of the feeding port is fixedly connected with a constant-speed material cylinder, and the top of the interior of the body is fixedly connected with a suction plate, One end of the suction plate is fixedly connected with a circulation pipe, one end of the circulation pipe is fixedly connected with a dehumidifier, one end of the dehumidification box is fixedly connected with a hot air blower through the circulation pipe, and one end of the hot air blower is fixedly connected with a compressor. machine. The biomass fertilizer drying device is equipped with a suction plate, a dehumidifier, a hot air blower and a compressor, and the heat absorption of the suction plate is used to remove moisture through the dehumidifier, and then through the hot air blower and the compressor through the circulating cylinder to the body. The interior is dried, and then passes through the suction plate, which realizes the reuse of the heat in the high-temperature gas, plays a role in energy saving, and thus achieves the purpose of heat circulation.

Owner:建始惠万农生物科技有限公司

Intelligent garbage sorting device based on principle of big data comparison

InactiveCN110436087AAccurate classificationImplement automatic classificationWaste collection and transferRefuse receptaclesEngineeringIntelligent equipment

The invention relates to the technical field of intelligent equipment, and discloses an intelligent garbage sorting device based on the principle of big data comparison. The device includes a box body, the top of the box body is fixedly connected with a cover plate, the bottom of the cover plate is connected with an image recognition device, the inside of the cover plate is provided with grippers,the two sides of the box body are located below a conveying belt and movably connected with collection boxes, the front end of the box body is fixedly connected with an integrated control end, and the box body is internally and uniformly provided with a recyclable area, a hazardous area, a dry waste area and a wet waste area. According to the intelligent garbage sorting device based on the principle of big data comparison, when the conveying belt carrying garbage passes through the recyclable area, the hazardous area, the dry waste area and the wet waste area, the integrated control end controls the gripper of the corresponding area to grip the garbage to the corresponding area, the sorting result is sent to a mobile phone of a user, automatic sorting is achieved, and meanwhile, the usercan learn scientific garbage sorting knowledge.

Owner:新昌县知行智能科技有限公司

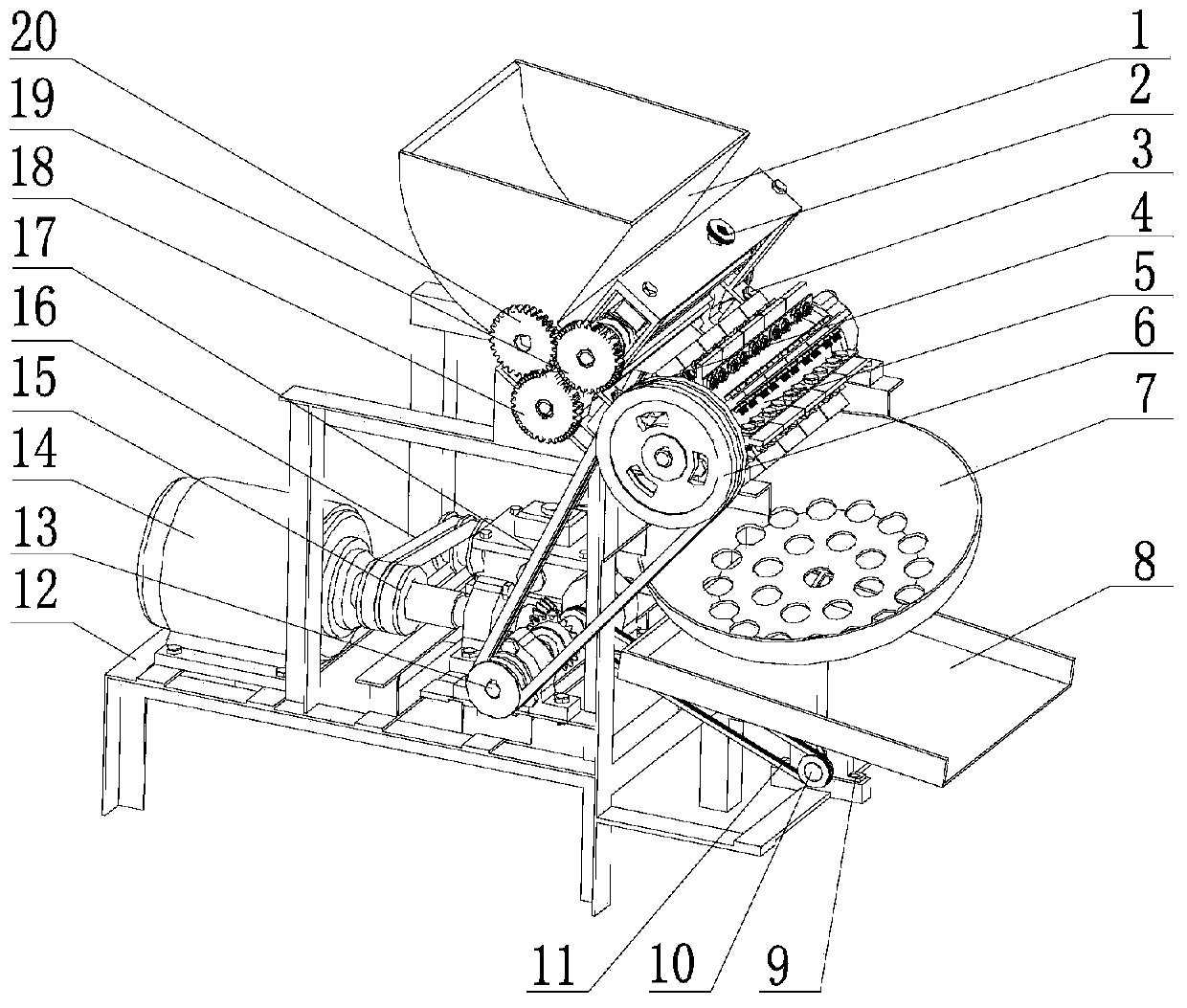

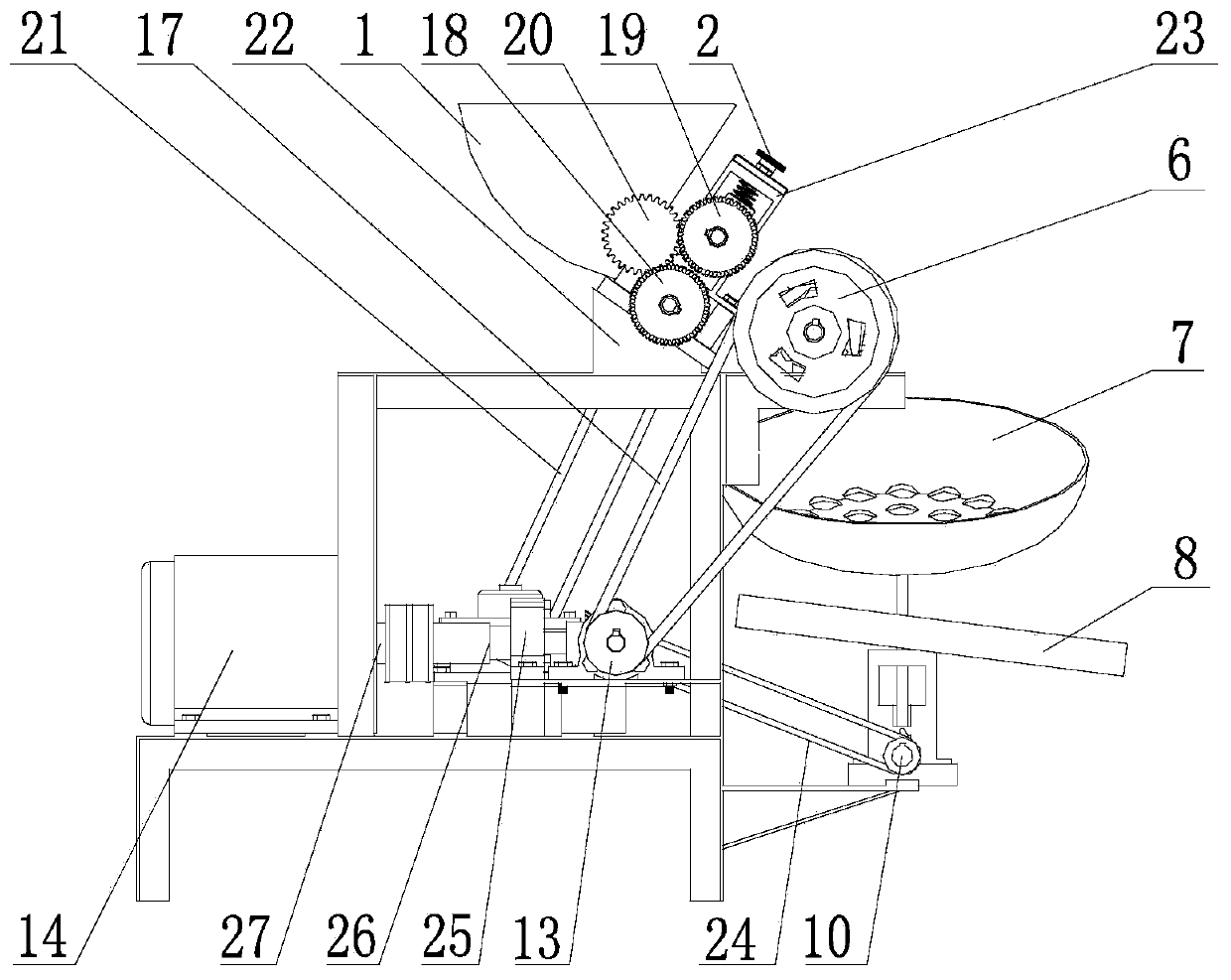

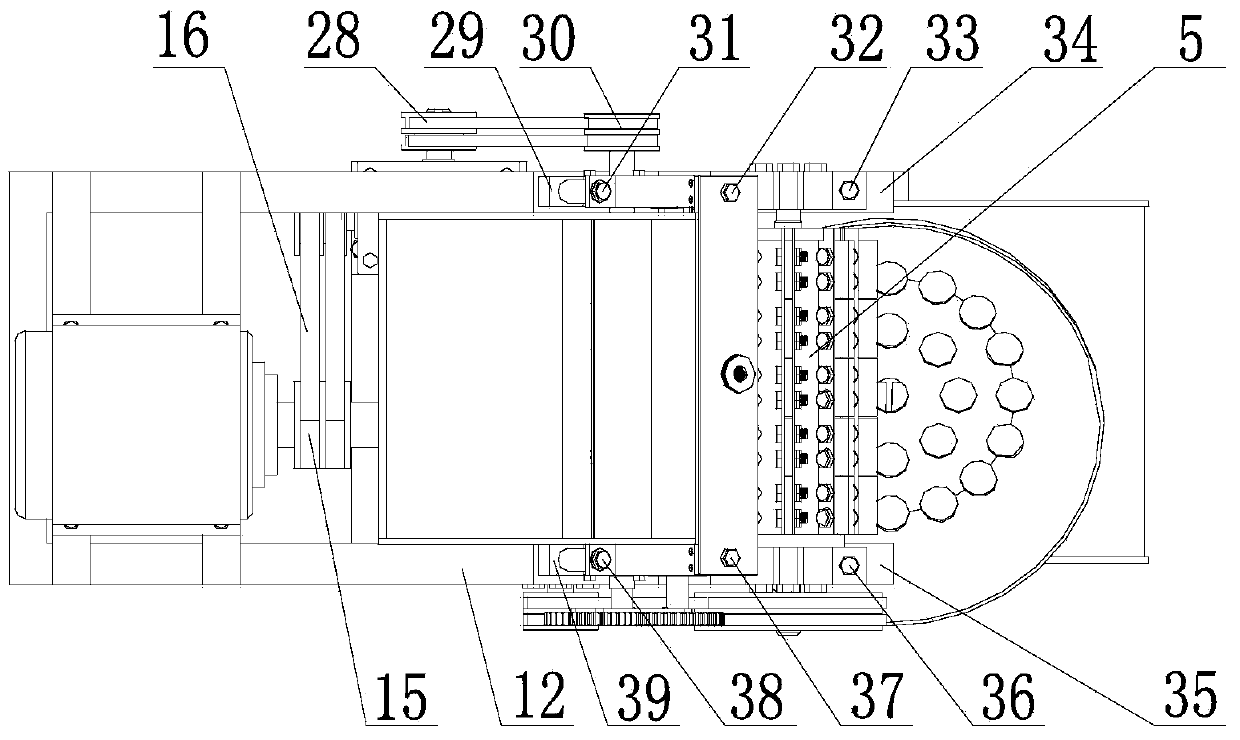

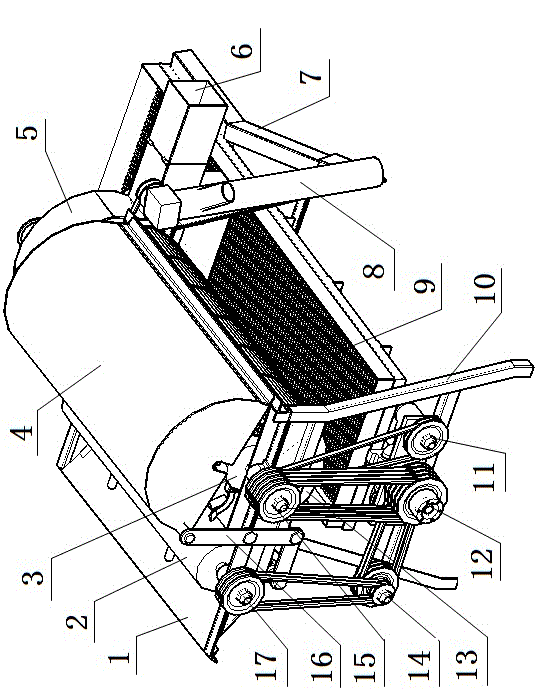

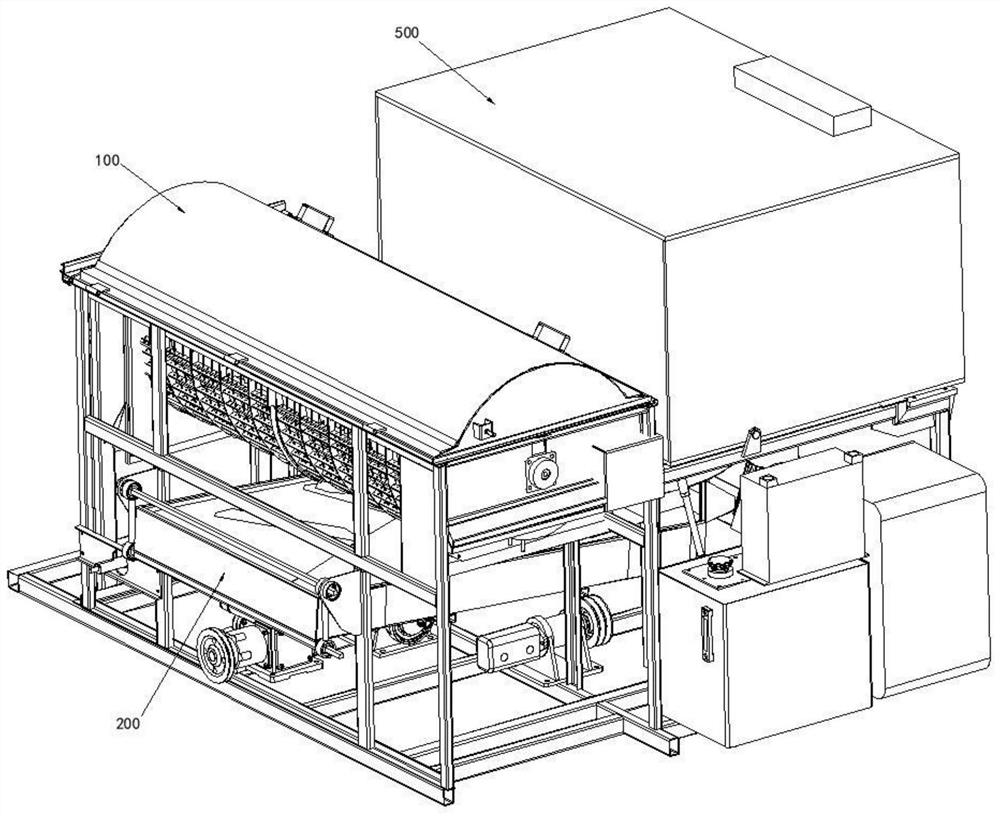

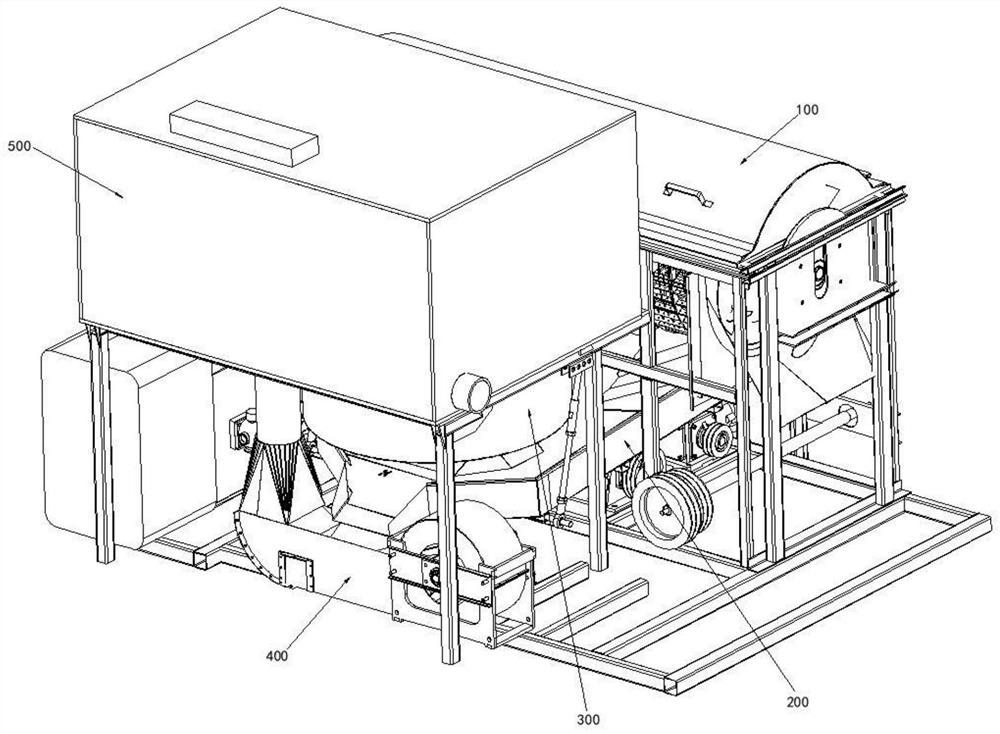

Automatic Chinese chestnut huller

An automatic Chinese chestnut huller comprises a power transmission mechanism, an automatic regulating device, a hulling roller cutter and a screening mechanism. The power transmission mechanism is formed by a driving shaft and a driven part; the power transmission mechanism is connected with a lower roller of the automatic regulating device through a third belt wheel, an upper roller and the lower roller are driven to rotate simultaneously through a gear mechanism, and Chinese chestnut shells are fractured; the power transmission mechanism is connected with the hulling roller cutter through a first driven belt wheel, the hulling roller cutter is driven to rotate, and the Chinese chestnut shells are removed; the power transmission mechanism is connected with a crank of the screening mechanism through a second driven belt wheel, the screening mechanism is driven to conduct reciprocating motion upwards and downwards, and the Chinese chestnut shells and Chinese chestnuts can be separated. The automatic Chinese chestnut huller enables the Chinese chestnut shells to be separated from the Chinese chestnuts better, fills the vacancy of automatic Chinese chestnut hullers at the current market, and is suitable for families, Chinese chestnut planting bases and other occasions.

Owner:GUANGXI UNIV

Dry material and method for building ladle lining by using same

ActiveCN102126864APrevents the problem of easy hydrationReduce inclusionsMelt-holding vesselsHydration reactionDolomite

The invention provides a dry material and a method for building a middle lining by using the same. The dry material consists of the following raw materials in percentage by mass: 35-55 percent of aggregate with the particle size of between 5 millimeters and 1 millimeter, 15-30 percent of aggregate with the particle size of between 0 millimeter and 1 millimeter, 20-35 percent of powder with the particle size of less than or equal to 0.088 millimeters, 3-7 percent of solid phenolic resin and 1-2 percent of additive. In the method, dolomite serving as a rich resource can be fully utilized and calcined into clinker dolomite, and calcium in the clinker dolomite is directly added in the form of calcium oxide. When the calcium oxide with molten steel cleaning function is applied to a tundish lining, the deposition of aluminum oxide in the tundish can be reduced, phosphor removal and sulfur removal are performed, and inclusions in molten steel are reduced. Meanwhile, hydration-proof treatment is performed on the surface of the constructed tundish lining, so that the dry material is effectively isolated from the air, hydration reaction of the clinker dolomite caused by absorption of moisture in the air is avoided, the clinker dolomite is resistant to flushing and erosion in a using process, the clinker dolomite is easily separated from a flame retardant coating after being used.

Owner:KUNMING IRON & STEEL GRP CO LTD

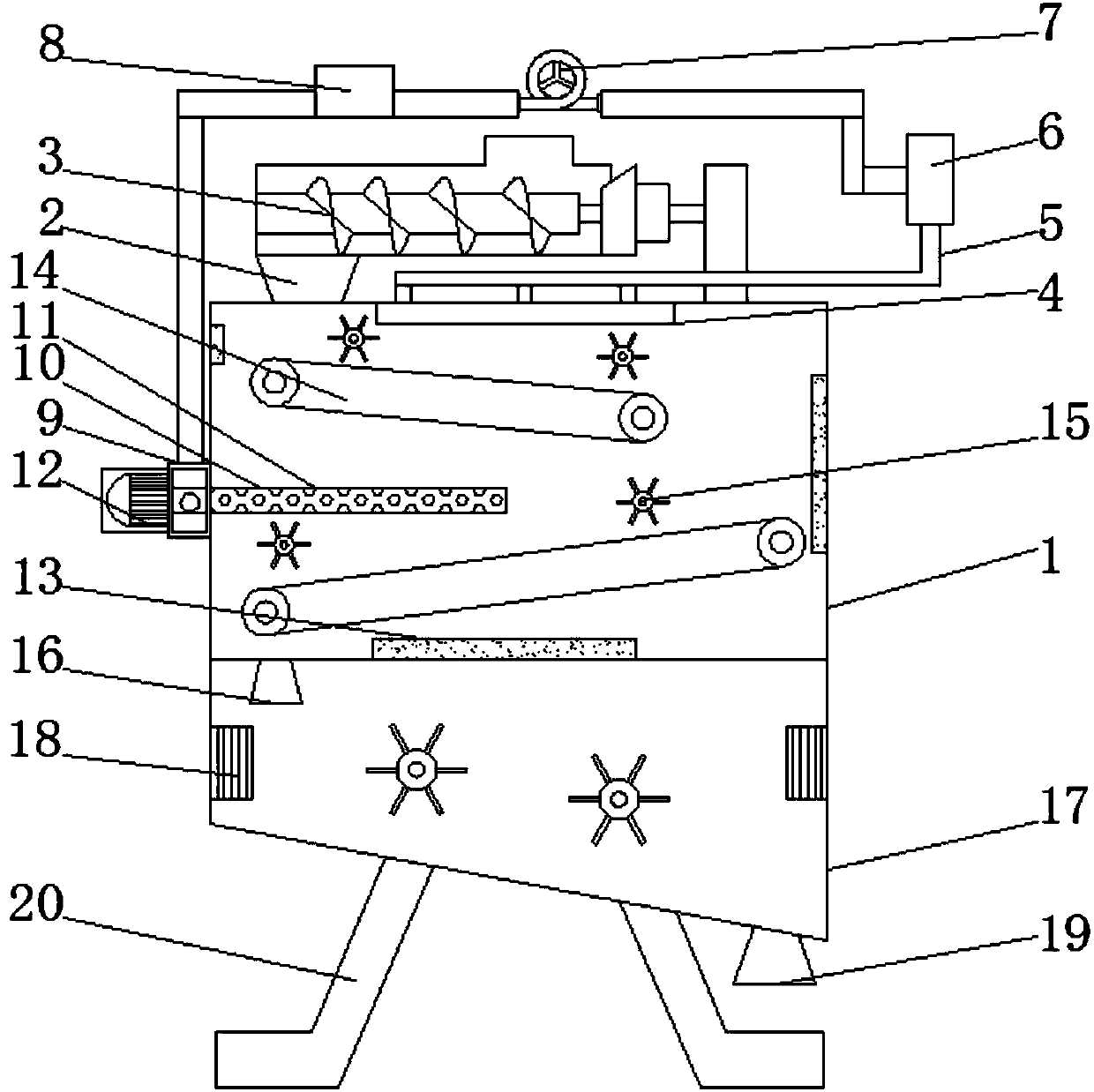

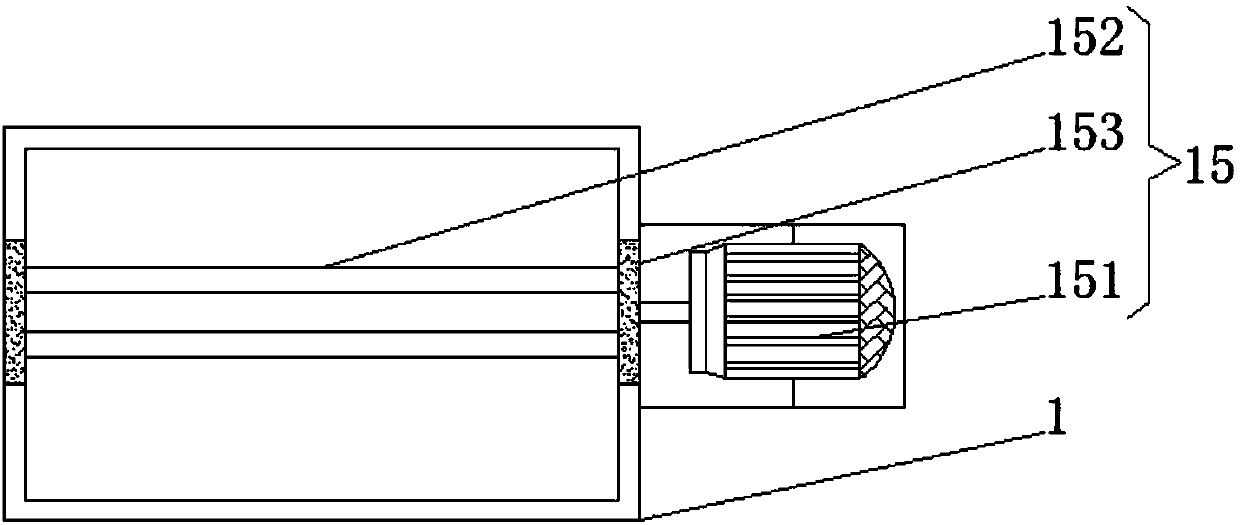

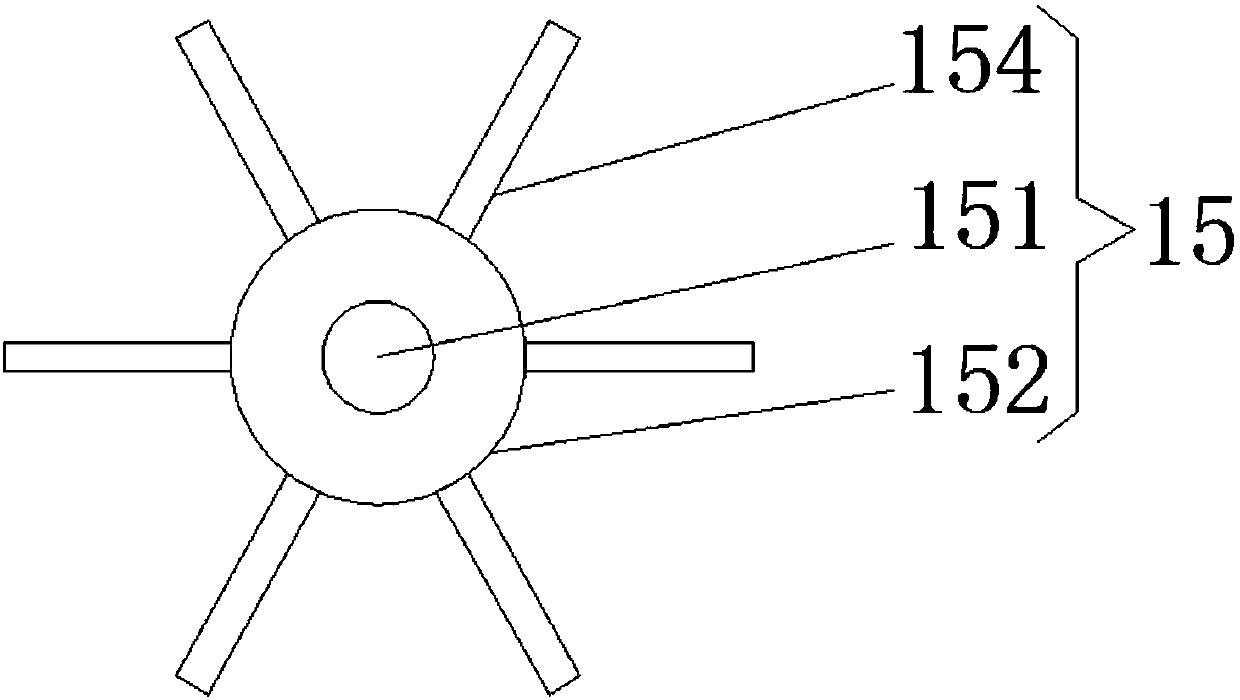

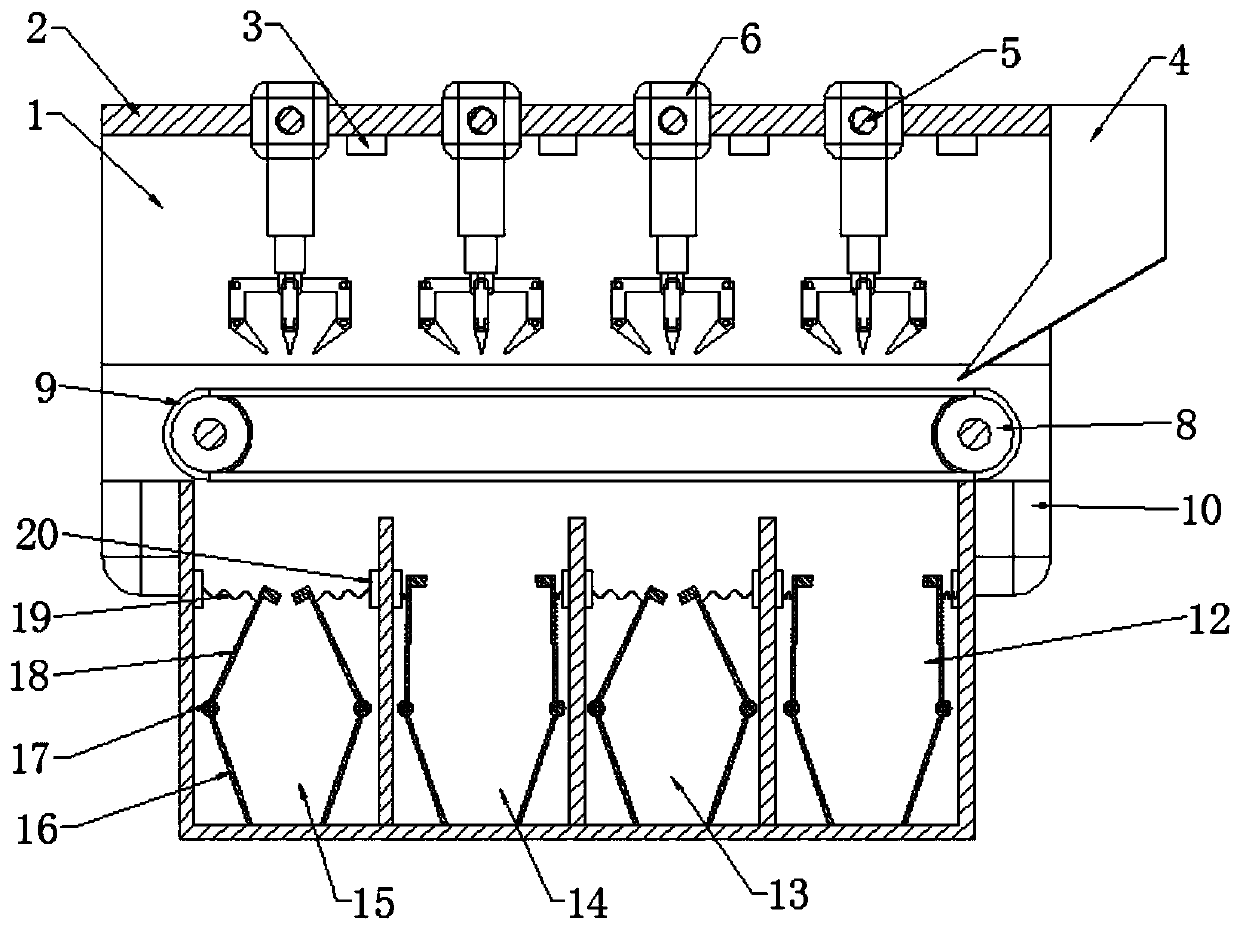

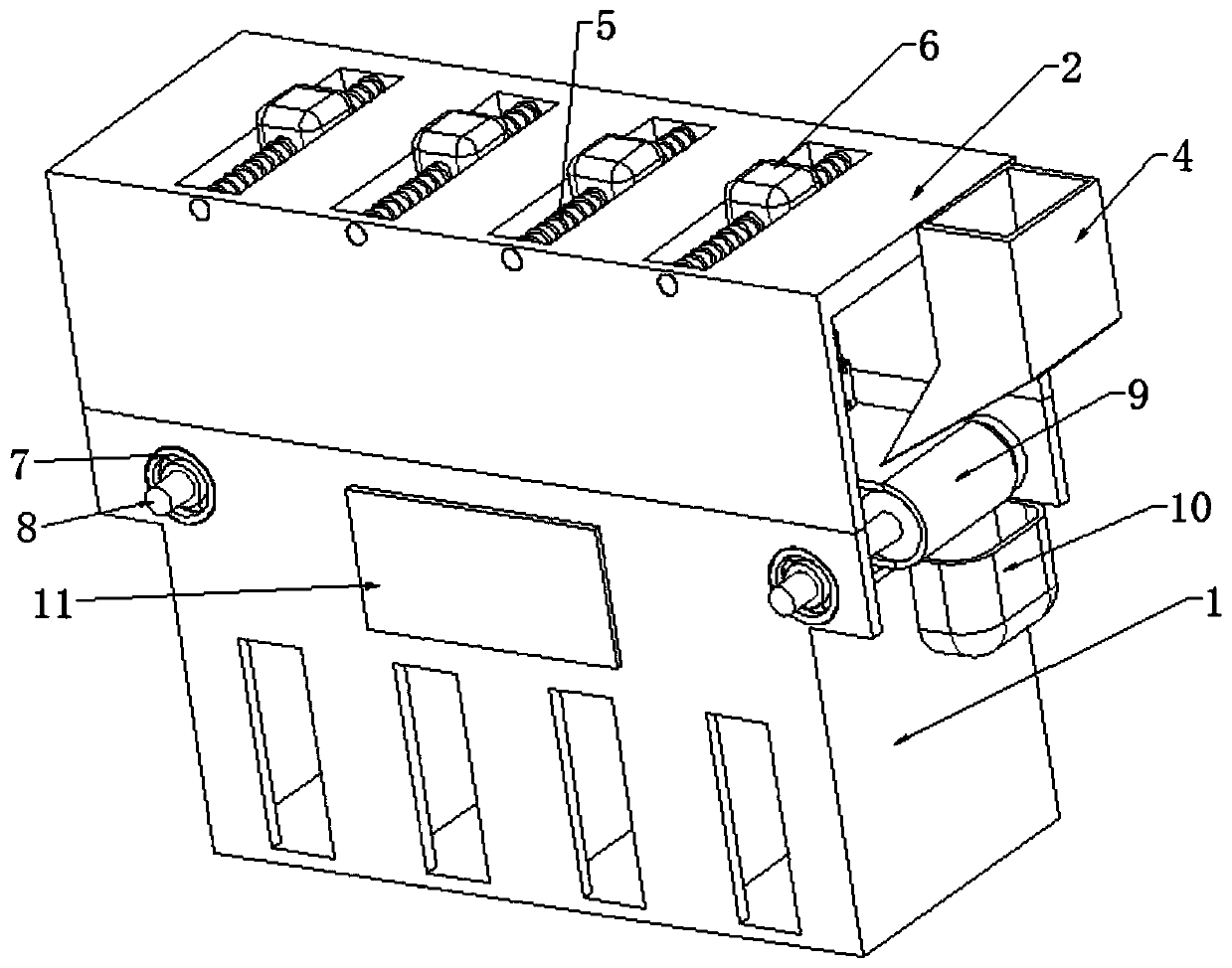

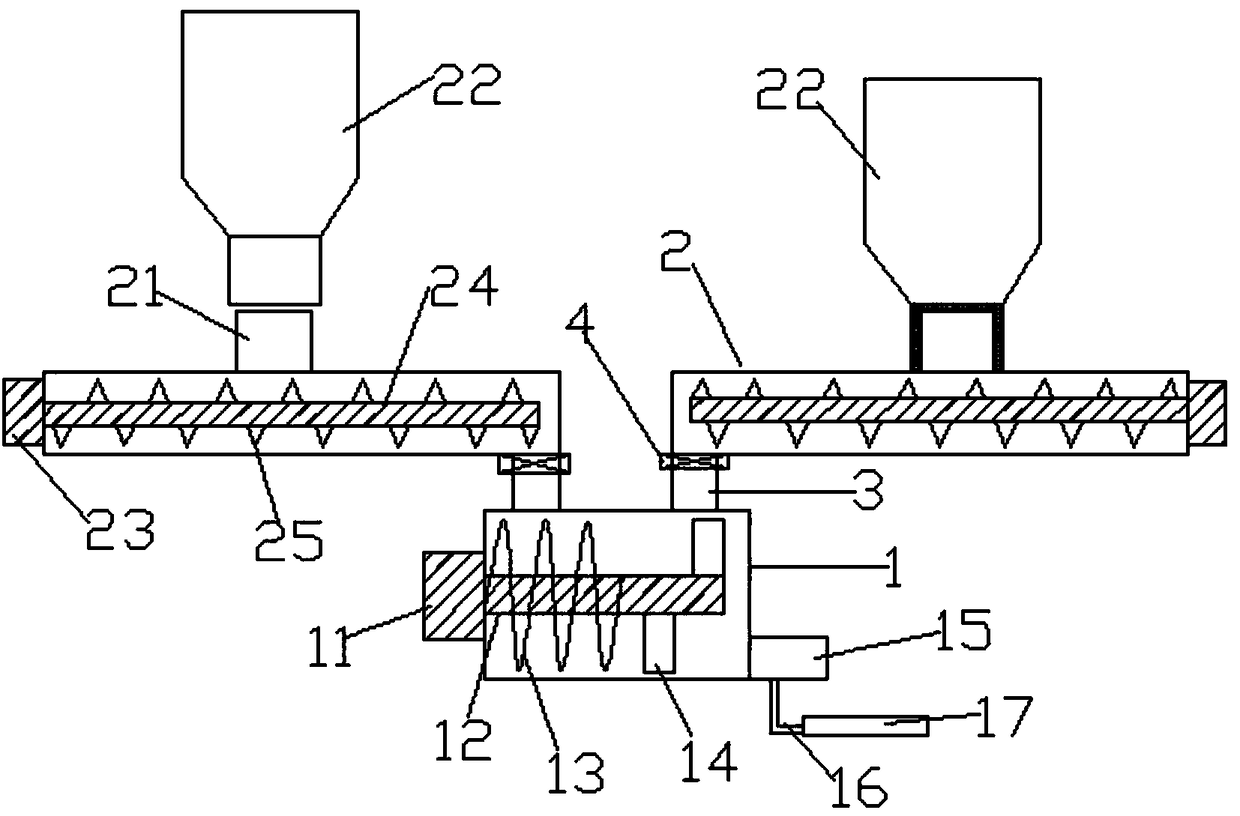

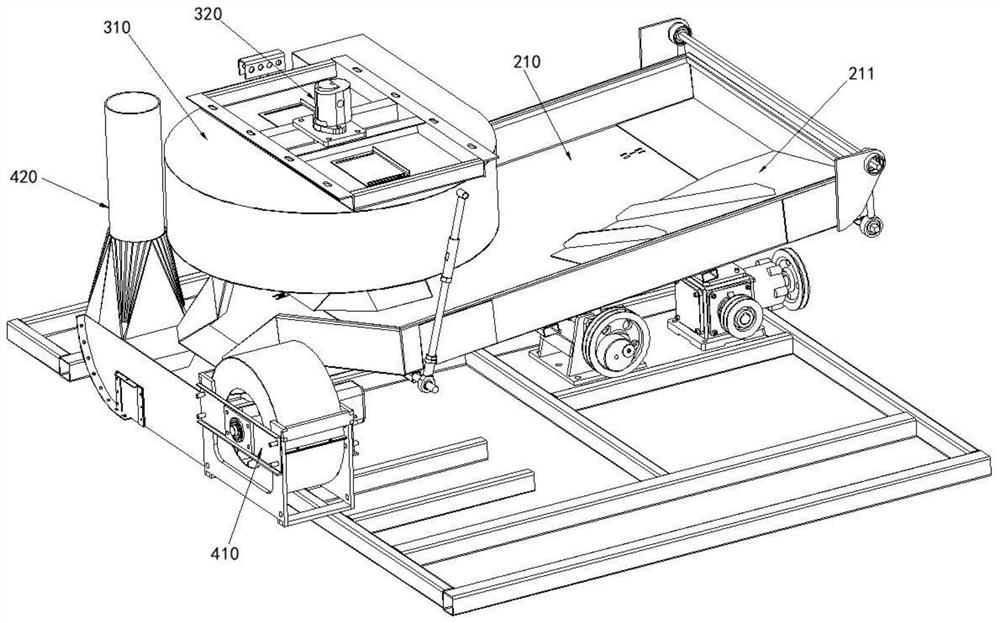

Automatic raw material processing equipment

InactiveCN108212410AWell mixedEasy to bagFeeding-stuffRotary stirring mixersProcess engineeringMaterial distribution

The invention discloses automatic raw material processing equipment. The automatic raw material processing equipment comprises a mixing device, pulverizing devices, a material passing pipe and a valve, wherein the pulverizing devices are respectively arranged on the two sides of the upper end of the mixing device and are symmetrical with each other; the mixing device is communicated with the pulverizing devices through the material passing pipe and the valve is arranged on the material passing pipe; each of the pulverizing devices comprises a feeding hole, a raw material bin, a motor No.1, arotating shaft No.1 and a cutting die; the corresponding feeding hole is formed in the center of the upper end of the corresponding pulverizing device; the corresponding raw material bin is arranged at the corresponding feeding hole; the sizes of the raw material bins are different, and the weight of the raw materials in the all raw material bins can be immobilized; the corresponding motor No.1 isarranged on the left side of the corresponding pulverizing device; the corresponding rotating shaft No.1 is arranged in the corresponding pulverizing device; the corresponding cutting die is arrangedon the corresponding rotating shaft No.1. The automatic raw material processing equipment disclosed by the invention has the advantages of reasonable design and convenience in using; moreover, the phenomena of less materials and more materials are avoided, so that material distribution is more convenient, the labor power is reduced, and the working efficiency is improved.

Owner:SUZHOU JU SHENG ELECTROMECHANICAL EQUIP ENG CO LTD

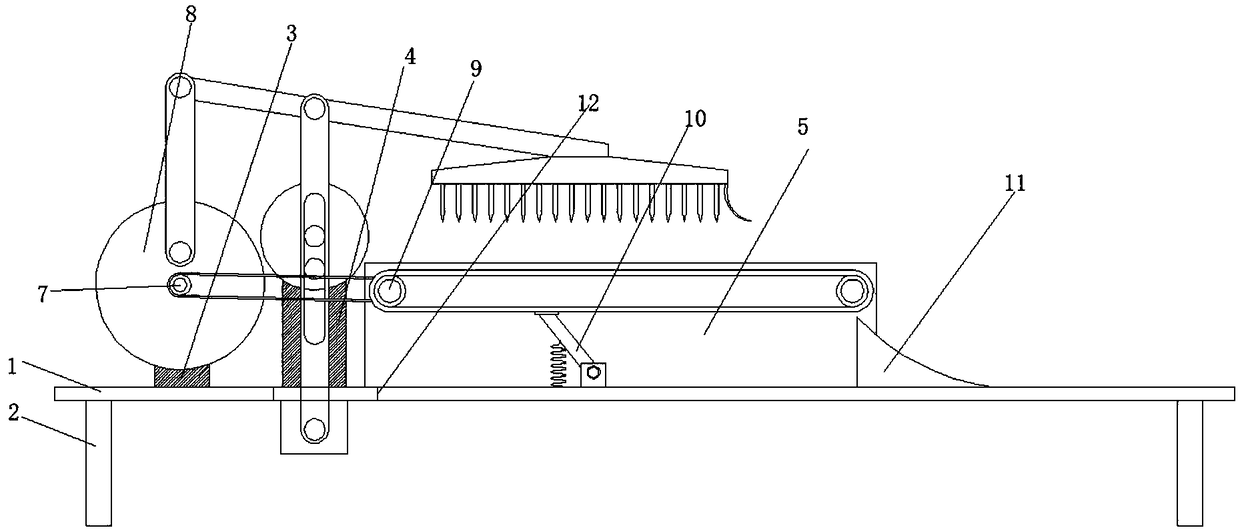

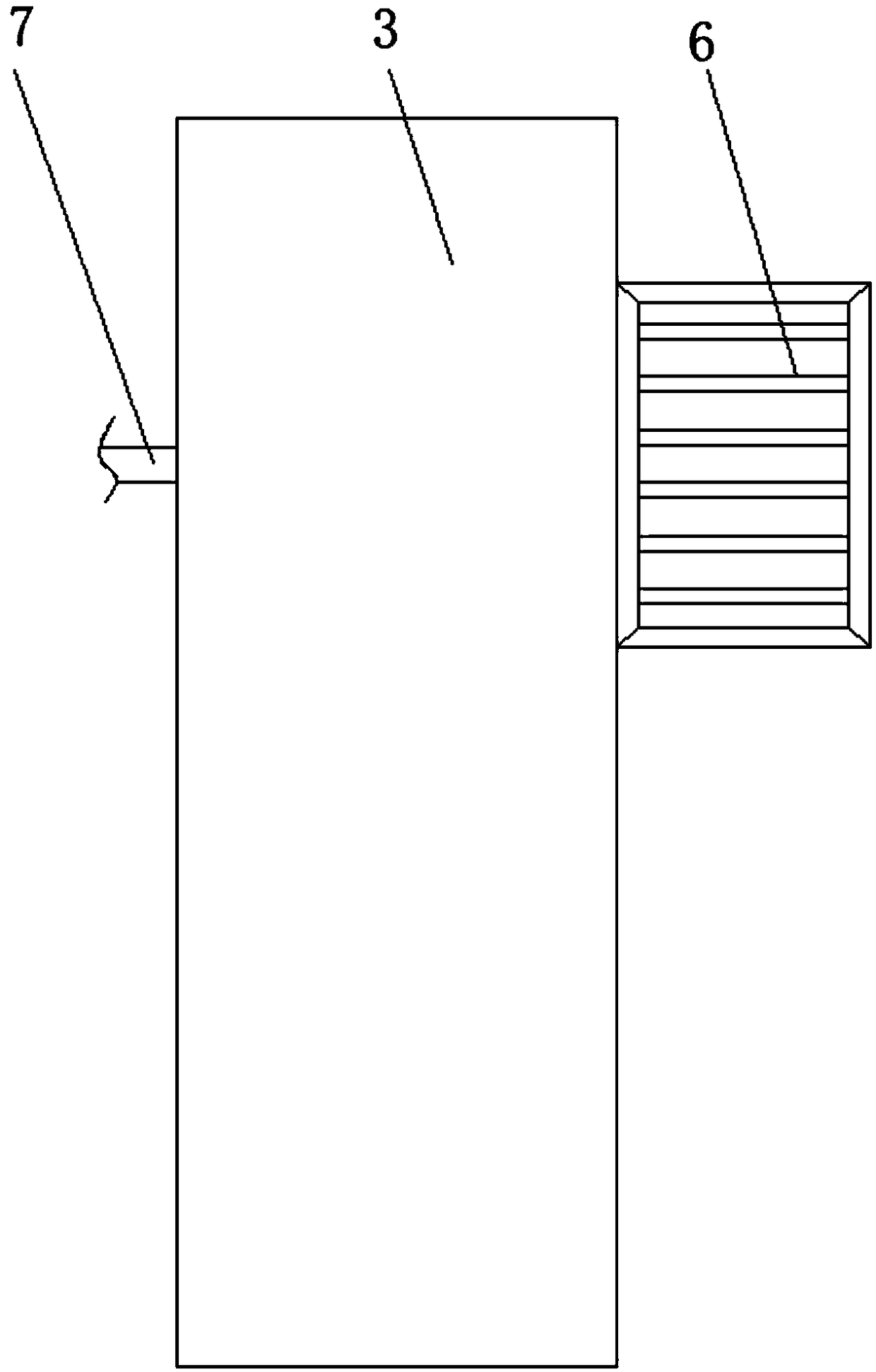

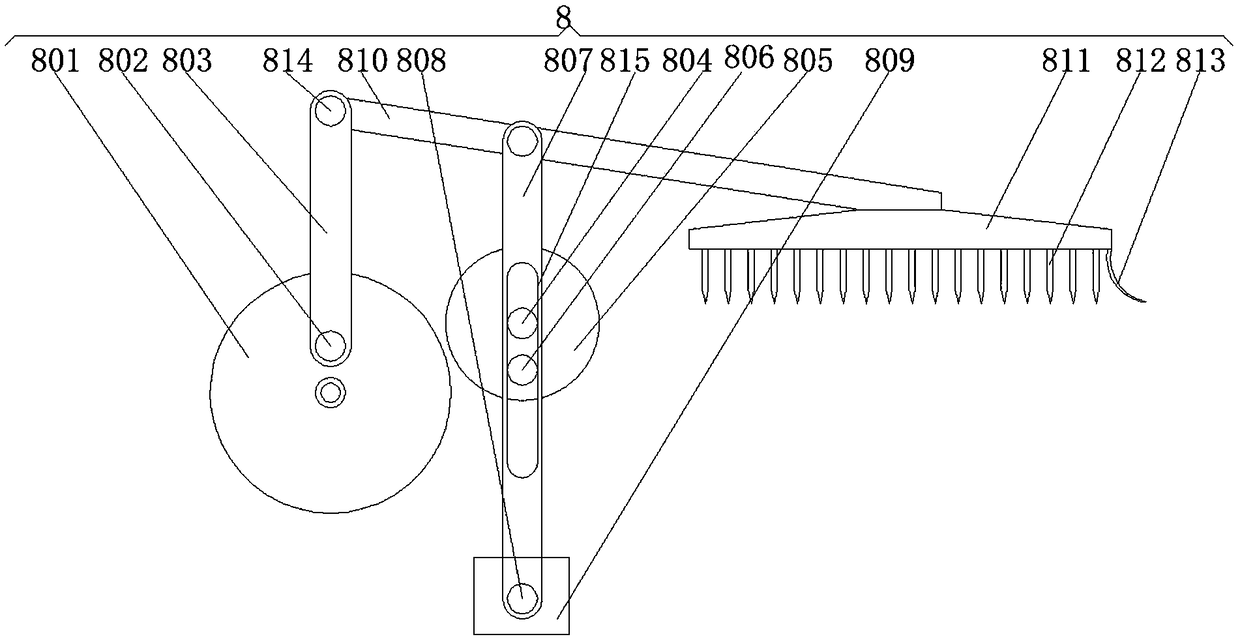

Wheat-threshing and cornstalk-cutting machine

InactiveCN104969728AEasy to bagWon't fly backMowersThreshersAgricultural engineeringAgricultural machinery

The invention relates to a grain-threshing and stalk-cutting machine in agricultural machinery, specifically to a wheat-threshing and cornstalk-cutting machine. A conventional wheat-threshing machine can only smash and thresh sundried wheat and has the disadvantages of single function, complex and cumbersome structure, and largely-required power. The wheat-threshing and cornstalk-cutting machine provided by the invention comprises a frame, and a feeding table, a smashing-threshing cabin, a vibration screen mechanism, an air exhausting mechanism and a packing auger conveyer which are arranged on the frame, wherein the feeding table is arranged in the front and upper part of the smashing-threshing cabin; the lower part of the smashing-threshing cabin is provided wtih the vibration screen mechanism; the air exhausting mechanism is arranged above the rear half part of the vibration screen mechanism and at the left side of the smashing-threshing cabin; and the rear part of the smashing-threshing cabin is provided with the packing auger conveyer. The wheat-threshing and cornstalk-cutting machine provided by the invention has the advantages of compact structure, light weight, low cost, small equipped power, clean separation of grain and stalk powder, convenient bagging of grain, no air pollution, timely halt and rescue treatment, no need of wheat sundrying treatment and capablities of cutting and smashing cornstalks.

Owner:穆合塔尔·图尔荪

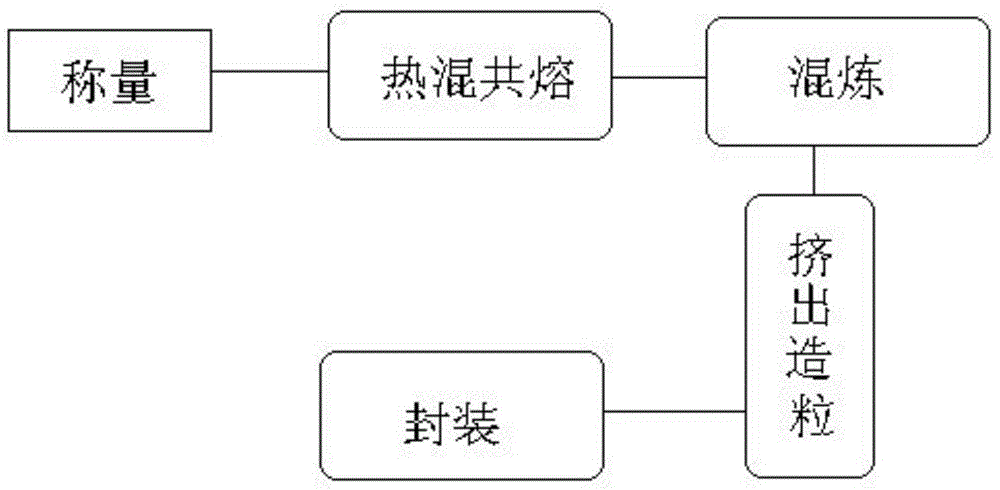

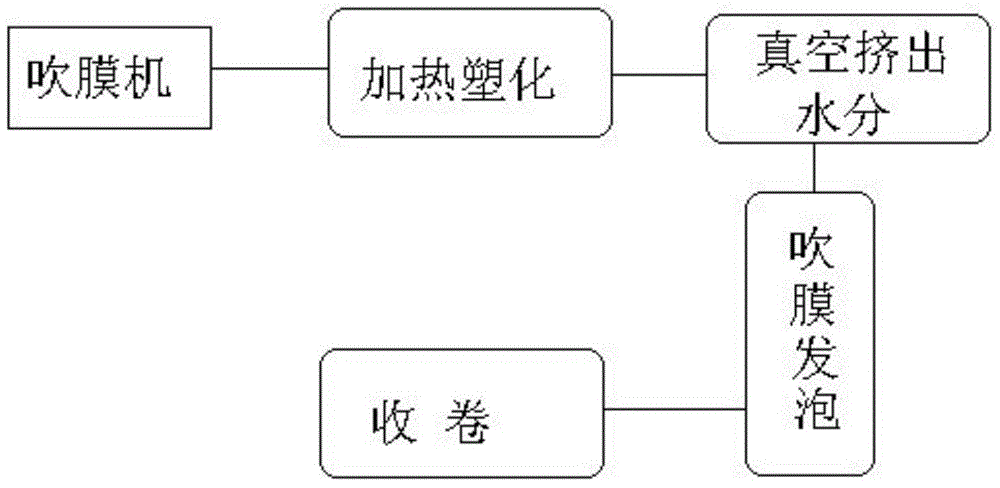

Preservative film for short-term storage of fruits and vegetables, preparation method of preservative film and prepared preservative bag

InactiveCN104309903ASlow down the rate of ripening and decayExtended decay timeFlexible coversWrappersSurface layerDecomposition

The invention discloses a preservative film for short-term storage of fruits and vegetables. A micro-foamed film body with a surface layer for slowing down water loss and adsorbing ethylene is formed on the preservative film, and the density of the film body is 0.5-0.9 g / cm<3>. The invention further discloses a preparation method of the preservative film for short-term storage of the fruits and the vegetables. The invention further discloses a preservative bag produced by using the components and the preparation method. By adopting the technical scheme of the invention, the film has sufficient adsorption capacity for ethylene gas wrapped in the film, and the adsorption capacity cannot be reduced obviously under natural ambient conditions, so that the speed of maturing and decaying the fruits and the vegetables wrapped by using the preservative film is effectively reduced, the decomposition time of the fruits and the vegetables is prolonged, the freshness of the fruits and the vegetables is guaranteed, and the decomposition of matured fruits and vegetables is also avoided; through the addition of catalysts, micro foams on the surface of the film body are promoted, the freshness of the fruits and the vegetables is guaranteed, and the maturity and decomposition of the fruits and vegetables cause by the concentration of the ethylene gas are also avoided.

Owner:ZHONGSHAN ZHENHONG PACKAGING TECH

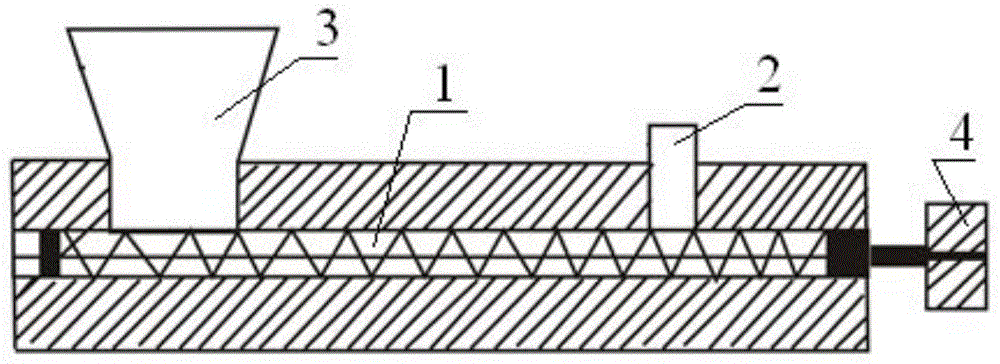

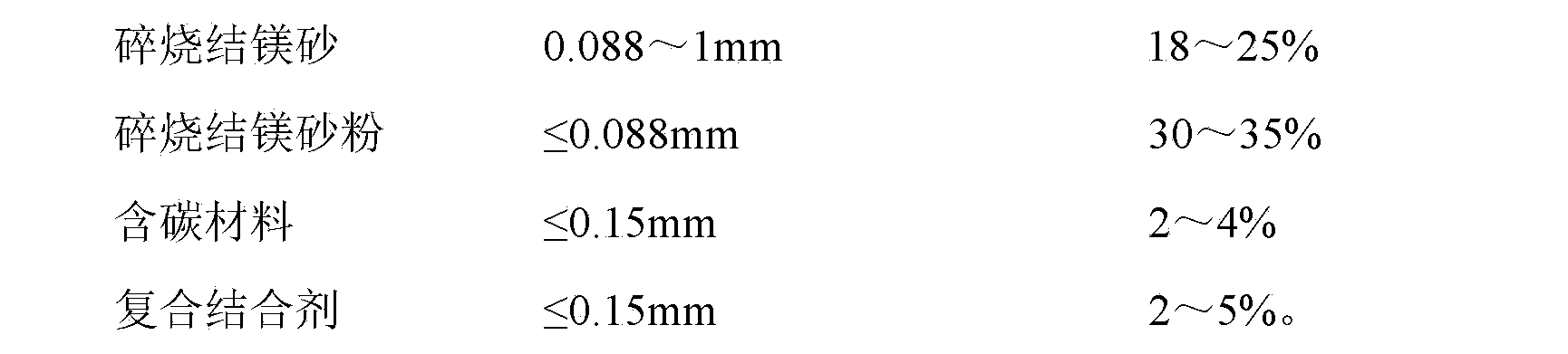

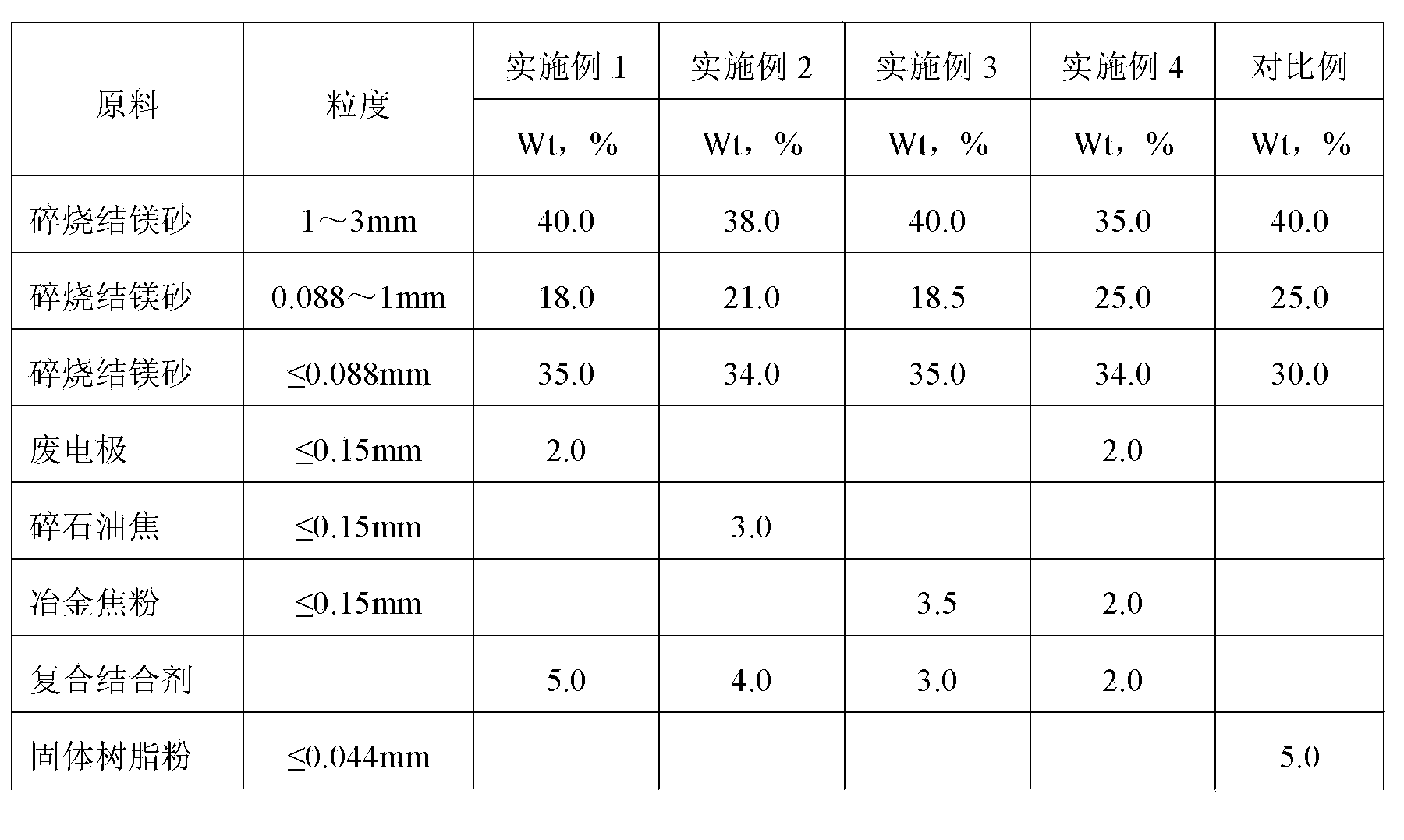

Non-sticking tundish dry material and production method thereof

The present invention discloses a non-sticking tundish dry material adopting broken sintered magnesia and a low cost carbon-containing material as main raw materials, and a production method thereof. The used technical scheme is that the non-sticking tundish dry material comprises, by weight, 35-40% of 1-3 mm broken sintered magnesia, 18-25% of 0.088-1 mm broken sintered magnesia, 30-35% of broken sintered magnesia with a particle size of less than or equal to 0.088 mm, and 2-4% of a carbon-containing material with a particle size of less than or equal to 0.15 mm, the amount of a composite binding agent is 2-5% of the total weight of the main material, and the composite binding agent comprises 20-40% by weight of dextrin and 60-80% by weight of solid resin powder. The preparation method comprises screening, grinding, material preparing, mixing, inspection, packaging, and other processes. According to the present invention, the used aggregate is the broken sintered magnesia, such that the prices is low; and the carbon-containing material is introduced so as to significantly improve sintering resistance of the magnesia dry material, and avoid difficult tundish disassembly caused by adhesion of the work lining on the permanent lining due to sintering after tundish off-line.

Owner:廊坊森德科技有限公司

Method for producing vacuum packed potted silver carp head

InactiveCN1748578AGuaranteed freshnessKeep it authenticFood preservationFood preparationSilver carpEngineering

The production process of vacuum packed potted silver carp head includes the following steps: washing silver carp head and eliminating fishy smell, frying, adding seasoning and stewing, separately vacuum packing silver carp head and fish soup, high temperature sterilizing, preparing seasoning packet, and final outer packing. The present invention is convenient in eating, and before being served, the silver carp head and fish soup are boiled in pot and the seasoning is added to form the delicious potted silver carp head. The product needs no freezing, and is convenient in transport and maintenance.

Owner:臧小荣

Fruit cultivation bag paper with multilayer compound structure, as well as manufacturing method of fruit cultivation bag paper

ActiveCN104711903ALow investment costEasy to bagSpecial paperWater-repelling agents additionCompound structurePulp and paper industry

The invention belongs to the technical field of fruit cultivation bags, and relates to fruit cultivation bag paper with a multilayer compound structure, as well as a manufacturing method of the fruit cultivation bag paper. The paper achieves the compounding of multilayer structures, which means that the paper achieves the function of compounding multiple types of independent and separate paper in the prior art. The manufacturing method comprises the following steps: each wet paper sheet layer is respectively manufactured; all the wet paper sheet layers are then superposed, so as to form a wet paper sheet with a multilayer structure; the wet paper sheet with the multilayer structure is finally subjected to pressing dewatering and drying dewatering, so as to obtain the fruit cultivation bag paper with the multilayer structure. All the layers in the paper structure have different performance, so that the fruit cultivation bag paper achieves the effect of a double-layer or three-layer fruit cultivation bag manufactured from the multiple types of paper.

Owner:北京丽阳盛兴科贸有限公司

Dry vibration mix for tundish and preparation method thereof

InactiveCN107226683ARaw material environmental protectionEasy to unpackMelt-holding vesselsUltimate tensile strengthImpurity

The invention provides a dry vibration mix for a tundish and a preparation method thereof. Based on the total mass of the dry vibration mix for a tundish, the dry vibration mix for a tundish is prepared from the following components in percentage by mass: 45-65% of fused magnesite, 15-25% of binding agent, 5-10% of aluminum hydroxide micropowder, 5-10% of calcium carbonate powder and the balance of impurity. The dry vibration mix finished product for a tundish is favorable in various technical performance indices; the raw materials are green and environmentally friendly, and can purify molten steel; the dry vibration mix realizes easy tundish removal and tundish turning, lowers the work intensity, increases the service life and saves the cost; and the dry vibration mix is simple in preparation process and is formed by a dry method during construction, thereby realizing a favorable construction environment.

Owner:浙江欣辉耐火材料股份有限公司

Sesame seed candy dicing device transforming rotating force into reciprocating cutter type

ActiveCN108908434AEasy to transportWon't cause a stuck situationMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of the sesame seed candy dicing devices, in particular to a sesame seed candy dicing device transforming rotating force into reciprocating cutter type. Thefour corners of the bottom of a workbench are fixedly connected with angle steel bases, the back face of the workbench is fixedly connected with a vertical plate A, a vertical plate B and a verticalplate C from left to right in sequence, the top of the workbench is provided with a square groove located directly under the vertical plate B, and the back face of the vertical plate A is fixedly connected with a servo motor. The sesame seed candy dicing device transforming the rotating force into the reciprocating cutter type has the advantages that the servo motor works, a rotating shaft A rotates, so that the rotation of the rotating shaft A drives a reciprocating dicing mechanism to reciprocate vertically to dice sesame seed candy; a transportation mechanism performs transportation from left to right, thereby facilitating the transportation of the sesame seed candy, so that the sesame seed candy can be diced continuously, and the sesame sticking to a transport belt falls off and is shaken through the vibration of a shaking mechanism.

Owner:浙江启博知识产权运营有限公司

Packaging bag sorting device

The invention relates to a packaging bag sorting device comprising a workbench, a guide-in roller, a pulling force roller, an air ejecting pipe and a brush roller, wherein the air nozzle of the air ejecting pipe is aligned with the guide-in roller and used for initially blowing flat a packaging bag delivered from the workbench and guided in by the guide-in roller, and the brush roller is used for leveling and spreading the packaging bag blown flat by the air ejecting pipe. The packaging bag sorting device provided by the technical scheme of the invention can sort packaging bags flatly and regularly and is convenient to load and open bags, thereby realizing automatic filling of the packaging bags.

Owner:JIANGSU WANLE COMPOSITE MATERIAL

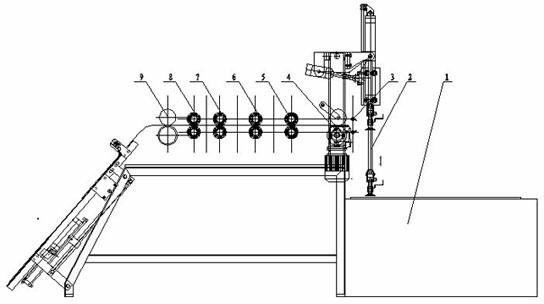

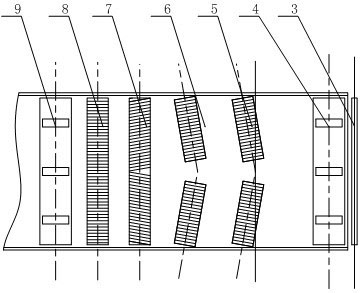

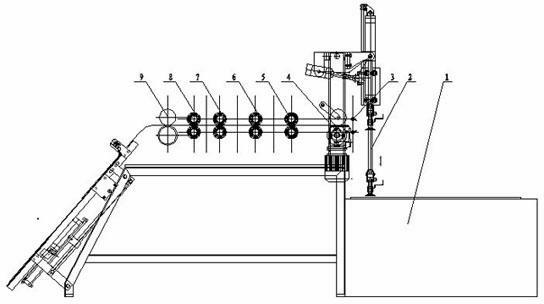

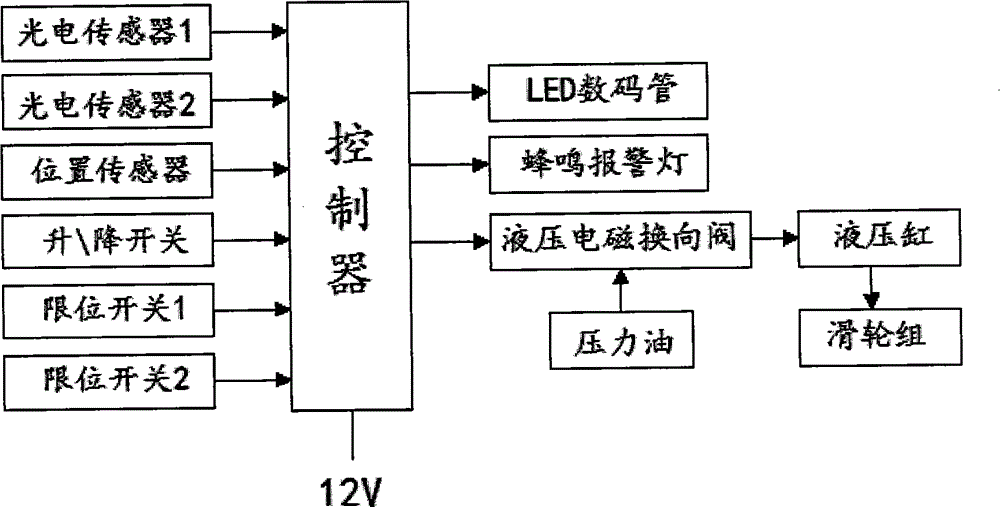

Novel potato harvesting and collecting device

InactiveCN104663107ASolving the Potato ProblemReal-time detection and collectionDigger harvestersHydraulic cylinderDriver/operator

The invention relates to a novel potato harvesting and collecting device which is composed a detection device, a control device, a hydraulic device, a pulley component, a potato collecting box and a rack. The box wall of the potato collecting box is fixed on the rack, a movable box bottom is placed obliquely in the box wall, a discharging port is arranged in the downmost middle of the box wall on the rear side, a front photoelectric sensor and a rear photoelectric sensor in the detection device are mounted at the upper edge of the box wall on each of the left side and the right side, each photoelectric sensor is provided with a protecting cover, a position sensor is mounted between the movable box bottom and the rack, a fixed pulley in the pulley component is fixed on the rack, a movable pulley is fixed at an extending end of a hydraulic cylinder, the hydraulic cylinder is mounted on the rack below the potato collecting box, one end of a steel wire rope is connected with the movable box bottom while the other end of the same is fixed on the rack, and the control device is mounted in a cab. The novel potato harvesting and collecting device can automatically control potato falling height within a safe range and is convenient for bagging, the problem of causing damage to potatoes is solved effectively during potato collecting, and working intensity of drivers is reduced greatly.

Owner:NORTHWEST A & F UNIV

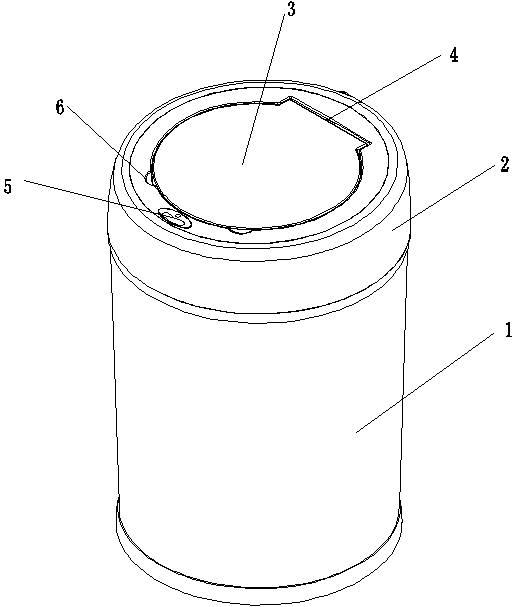

Intelligent induction garbage can convenient in bag changing

The invention discloses an intelligent induction garbage can convenient in bag changing. The garbage can comprises a garbage can body and a garbage can cover connected with the garbage can body. A movable cover plate is disposed on the garbage can cover. The movable cover plate is hinged to the garbage can cover through a garbage can cover shaft. An infrared sensor is disposed in front of the cover plate. An actuator triggering and controlling device is connected below the garbage can cover shaft and electrically connected with the infrared sensor. A garbage bag storage box is disposed at the inner bottom of the garbage can body. Waved patterns are formed on the inner wall of the garbage bag storage box. A garbage bag pulling out hole is formed in the garbage bag storage box. A plurality of hooks are mounted on the upper portion of the inner side of the garbage can body. The intelligent induction garbage can has the advantages the garbage can cover is opened through infrared induction, and bacteria contact is prevented; by the garbage bag storage box, garbage bag changing is facilitated; by the hooks disposed on the inner side of the garbage can body, the garbage bag is prevented from sliding down into the garbage can body, and garbage bag nesting is facilitated.

Owner:芜湖欣荣管业科技有限公司

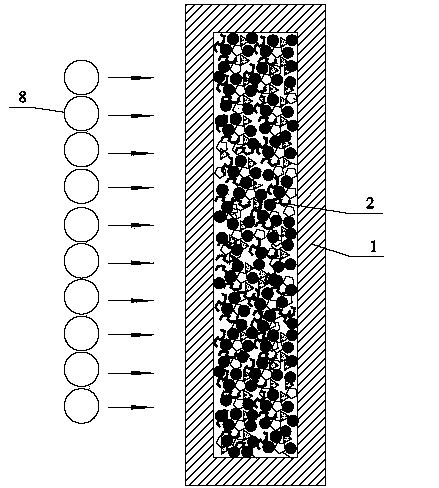

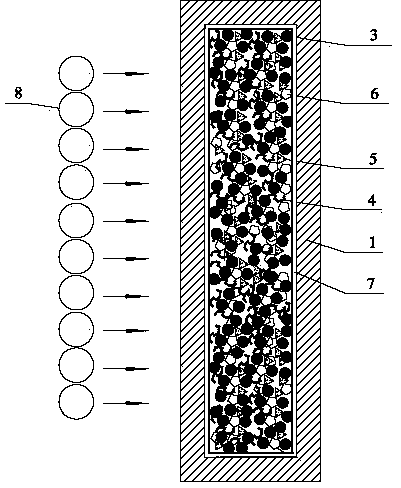

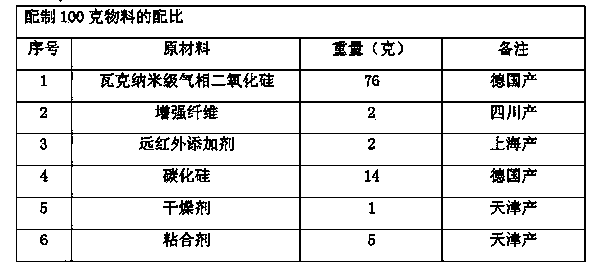

Nano-scale insulation board and manufacturing method thereof

ActiveCN102828563BGood heat insulationSmall conduction heat transfer effectClimate change adaptationInsulation improvementCrack resistanceThermal insulation

The invention discloses a nano-scale insulation board and a manufacturing method thereof. The board body is manufactured by coating a thermal insulation material in a non-woven fabric and packaging the thermal insulation material in a packaging bag in a vacuum seal mode. The thermal insulation material comprises the following raw materials in percentage by weight: 70 to 80 percent of nano-scale fumed silica, 1 to 3 percent of reinforced fiber, 1 to 3 percent of far infrared additive, 12 to 18 percent of silicon carbide, 0.8 to 1.2 percent of drying agent and 5 to 10 percent of adhesive, wherein the heat conductivity coefficient is less than or equal to 0.008W / (m.K). Due to detection, the heat conductivity coefficient of the product is less than 0.008W / (m.K), the heat preservation and heat insulation performances are high, the product is light, the defects that the traditional wall heat preservation building materials have poor fireproof performance, poor heat preservation and heat insulation performances and low crack resistance can be overcome, and the nano-scale insulation board can be widely applied to heat preservation and heat insulation roofs of buildings, outer-wall external thermal insulation and outer-wall internal thermal insulation construction.

Owner:王胜怀

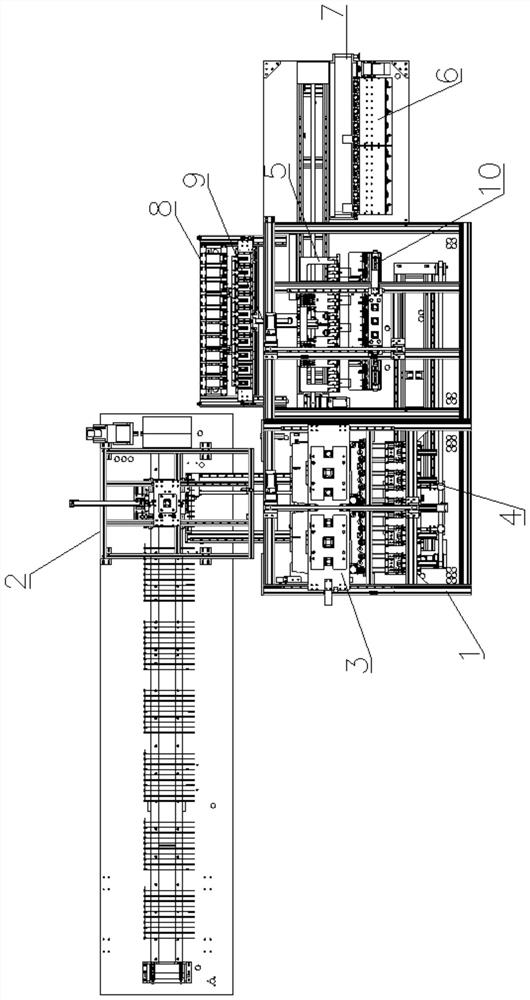

Automatic blood taking needle packaging equipment

ActiveCN112249410AAvoid damageImprove operational efficiencyWrappingPackaging under vacuum/special atmosphereProduction lineProcess engineering

The invention relates to the technical field of blood taking needle packaging equipment, in particular to automatic blood taking needle packaging equipment. The automatic blood taking needle packagingequipment comprises a rack and also comprises a material taking and distance changing device, a winding device, a material storing and transferring device, a packaging bag processing production line,a packaging bag sealing and transferring device, a hot welding device and an output device which are arranged on the rack, wherein the packaging bag processing production line comprises a packaging bag taking and aligning device, a packaging bag pre-opening device and a packaging bag opening device. According to the automatic blood taking needle packaging equipment, blood taking needles can be efficiently and accurately taken, wound and fed into a packaging bag, and then the packaging bag is smoothly moved to the hot welding device to be subjected to hot welding sealing, so that the automation degree of blood taking needle packaging is greatly improved.

Owner:YANTAI KAIBO AUTOMATION TECH

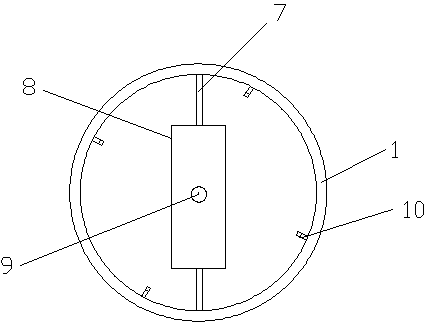

Pneumatic conveying type edible bean combine harvester

ActiveCN113597877ADoes not affect normal rotationEasy to bagMowersAgricultural engineeringStructural engineering

The invention discloses a pneumatic conveying type edible bean combine harvester which comprises a walking mechanism, a cutting mechanism, a conveying mechanism, a threshing mechanism, a cleaning mechanism, a discharging mechanism, a lifting mechanism and a storage bin. The walking mechanism loads all parts, the lifting mechanism is connected with the cleaning mechanism and the storage bin, the storage bin comprises a bin body, an inner cylinder, an outer cylinder, a rotating rod and a sealing plate, a discharging cylinder is arranged on a side plate of the bin body, the outer cylinder is vertically fixed to a bottom plate of the bin body, the bottom end of the inner cylinder is inserted into the outer cylinder and penetrates through the bottom plate of the bin body, and the inner cylinder can rotate in the outer cylinder. A first round hole is formed in the surface of the outer cylinder, and a second round hole which is the same as the first round hole in size and flush with the first round hole in height is formed in the surface of the inner cylinder. According to the combine harvester, the rotatable inner cylinder is arranged in the storage bin, the inner cylinder is matched with the outer cylinder, beans are conveyed to the discharging cylinder through airflow generated by the lifting mechanism, and a traditional dumping type storage bin is replaced; the structure is simpler, and bean bagging is facilitated.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Environment-friendly type multifunctional granular high-efficiency ladle covering agent

InactiveCN101190455AGood spreadabilityMelting fastProcess efficiency improvementChemical compositionSlag

The invention provides an environmental-friendly multifunctional grain-shaped high-efficiency ladle covering agent. The invention is characterized in that the chemical composition of the invention according to weight percentage is 5 to 20 of CaO, 36 to 72 of SiO2, 4 to 14 of MgO, 5 to 11 of Al2O3, 3 to 8 of Fe2O3, 0 to 20 of C (fixed) and residual quantity of H2O. The invention has the advantages of good extension, heat insulation and heat preservation, good slag adsorption performance, easy turnover, fast melting on steel liquid surface, no leakage of steel liquid surface, no incrustation of the slag layer, reducing the heat loss and temperature reduction of molten steel in ladle, good capability for dissolving and adsorbing sundries in the molten steel, improving the purity of the molten liquid, reducing the slagging of ladle mouth, being beneficial for slag removal and prolonging the service life of the ladle.

Owner:吕安明

Environment-friendly dry material for continuous casting tundish and preparation method thereof

The invention belongs to the technical field of refractory materials, and particularly relates to an environment-friendly dry material for a continuous casting tundish and a preparation method thereof. The dry material is characterized by comprising the following components in percentage by weight: 12%-16% of 5-3 mm waste magnesia-alumina-carbon particles, 32%-36% of 3-1 mm waste magnesia-alumina-carbon particles, 14%-22% of 1-0 mm waste magnesia-alumina-carbon particles, 5%-9% of 180-mesh waste prefabricated brick powder, 14%-18% of 240-mesh fused magnesite, 5%-10% of 1000-mesh active causticcalcined magnesite, 3.5%-5.5% of composite binder, and 0.5%-1% of a sintering agent. The dry material disclosed by the invention is put into a continuous casting tundish for use, can be used for morethan 60 furnaces, is used normally from the conditions of a permanent layer after use and the residual condition of a casting residual surface, is excellent in performance, and is easy to turn over;waste recycling is achieved, and the dry material has important significance in energy conservation, consumption reduction and environmental protection.

Owner:瑞泰马钢新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com