Wheat-threshing and cornstalk-cutting machine

A technology for cutting stalks and wheat, applied in threshing equipment, cutters, harvesters, etc., to achieve the effect of convenient operation, reasonable design of power parameters and small body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

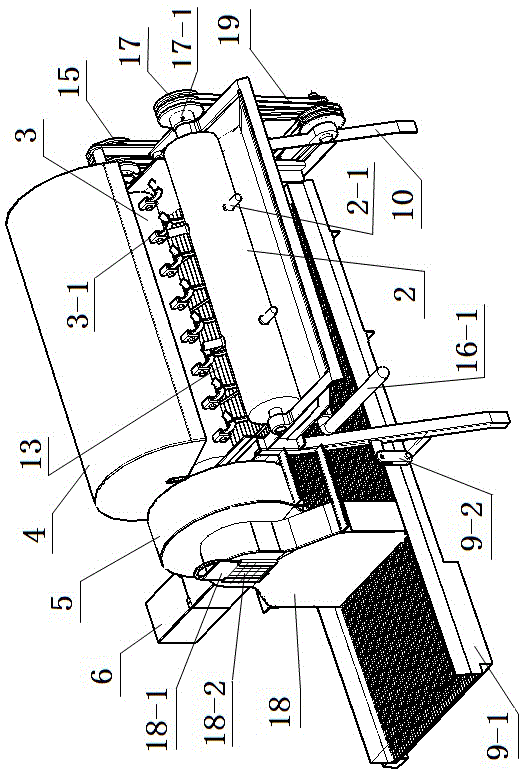

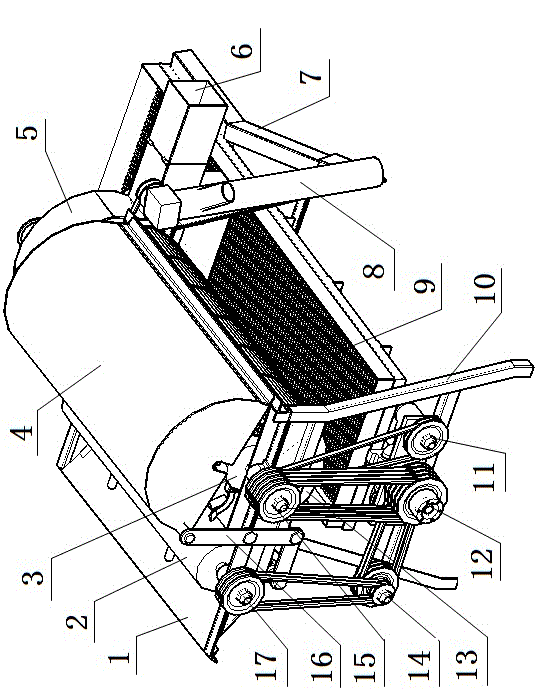

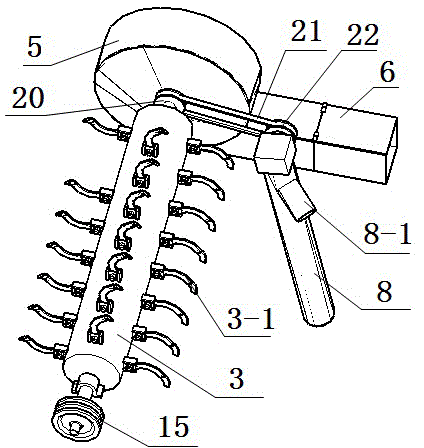

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a frame 10 and a feeding table 1 arranged on the frame 10 , a crushing and threshing bin, a vibrating screen mechanism, an air draft mechanism 5 , and an auger conveyor 8 . Said feeding platform 1 is arranged at the front upper part of the crushing and threshing bin, the bottom of the crushing and threshing bin is provided with a vibrating screen mechanism, the upper part of the rear half of the vibrating screen mechanism and the left side of the crushing and threshing bin are provided with an exhaust mechanism 5, and the rear part of the crushing and threshing bin is provided with a vibrating screen mechanism. There are 8 auger conveyors.

[0024] Said feeding platform 1 is fixed on the frame 10, and the feeding port of feeding platform 1 is provided with retractable rake conveying roller 2, and conveying roller 2 is connected with feeding roller wheel 17 through clutch 17-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com