Automatic blood taking needle packaging equipment

A technology for automatic packaging and blood collection needles, which is applied in the directions of packaging, transportation and packaging, packaging/bundling items, etc., and can solve the problems of poor coil stability of blood collection needles, low work efficiency, and no blood collection needle reclaiming device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0142] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

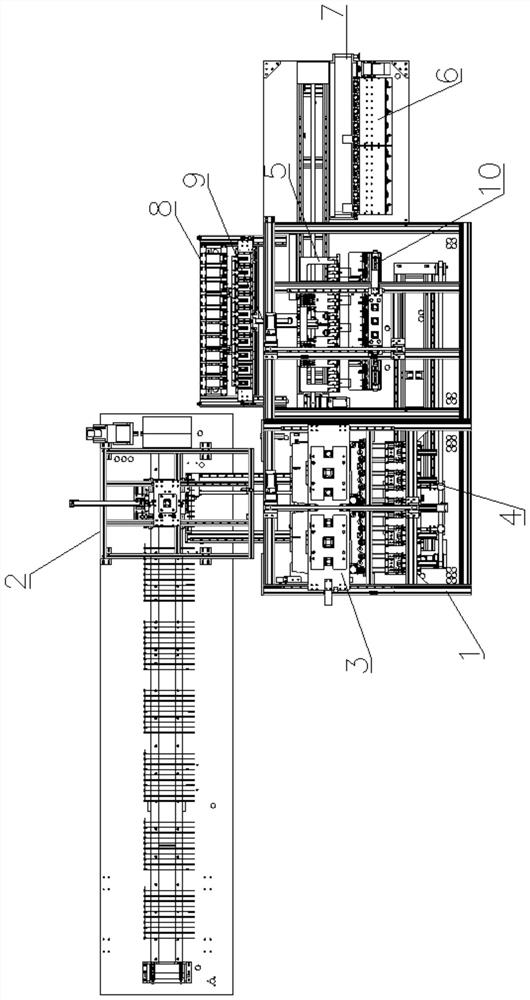

[0143] Such as Figure 1-53 In the shown embodiment, an automatic packaging equipment for blood collection needles includes a frame 1, a material-taking and distance-changing device 2 installed on the frame 1, a winding device 3, a storage transfer device 4, a packaging bag processing production line, and a packaging Bag sealing transfer device 5, heat welding device 6 and output device 7, wherein:

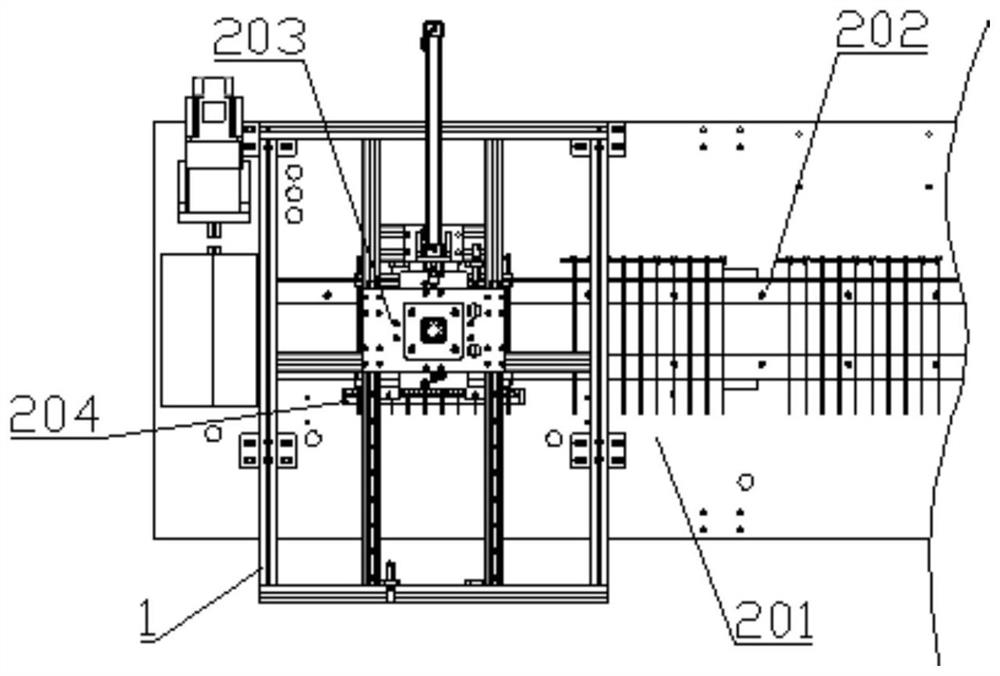

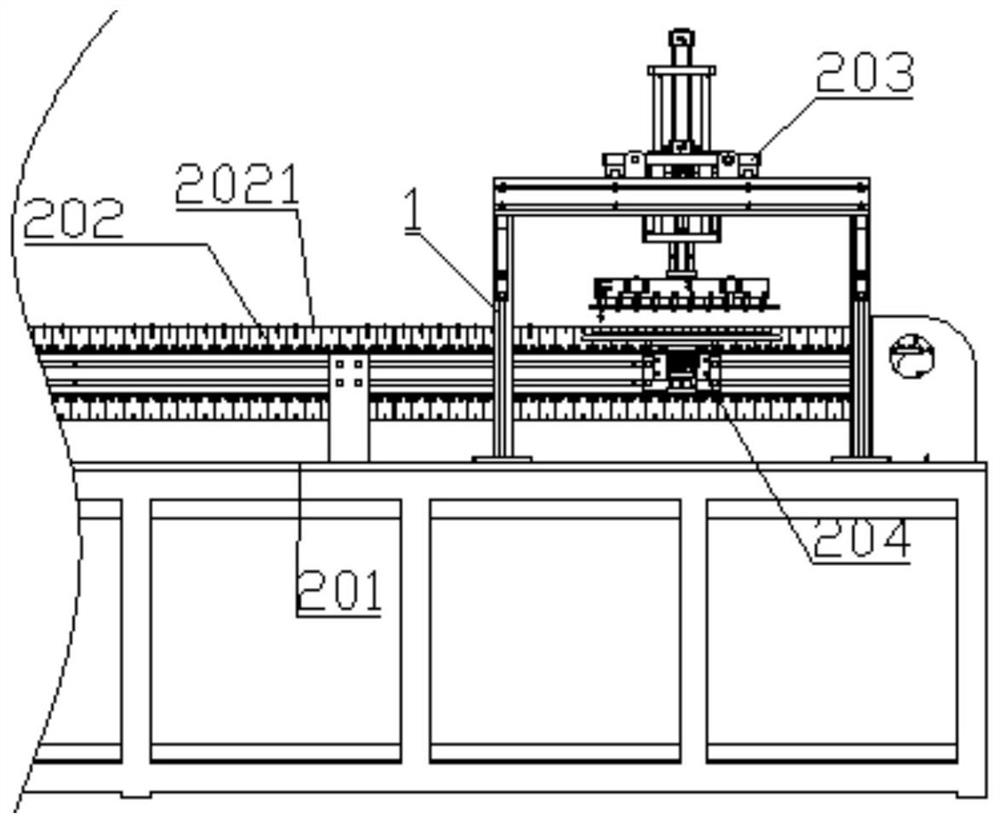

[0144] The material taking and distance changing device 2 includes an operating platform 201 arranged on the frame 1, a lancet conveyor 202 arranged on the operating platform 201, and a lancet retrieving mechanism arranged on the frame 1 above the operating platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com