Pneumatic conveying type edible bean combine harvester

A combined harvester and pneumatic conveying technology, which is applied to harvesters, applications, cutters, etc., can solve the problems of difficult discharge of storage bins and easy blockage of the discharge mechanism, and achieve simple structure, convenient operation, and convenient bagging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

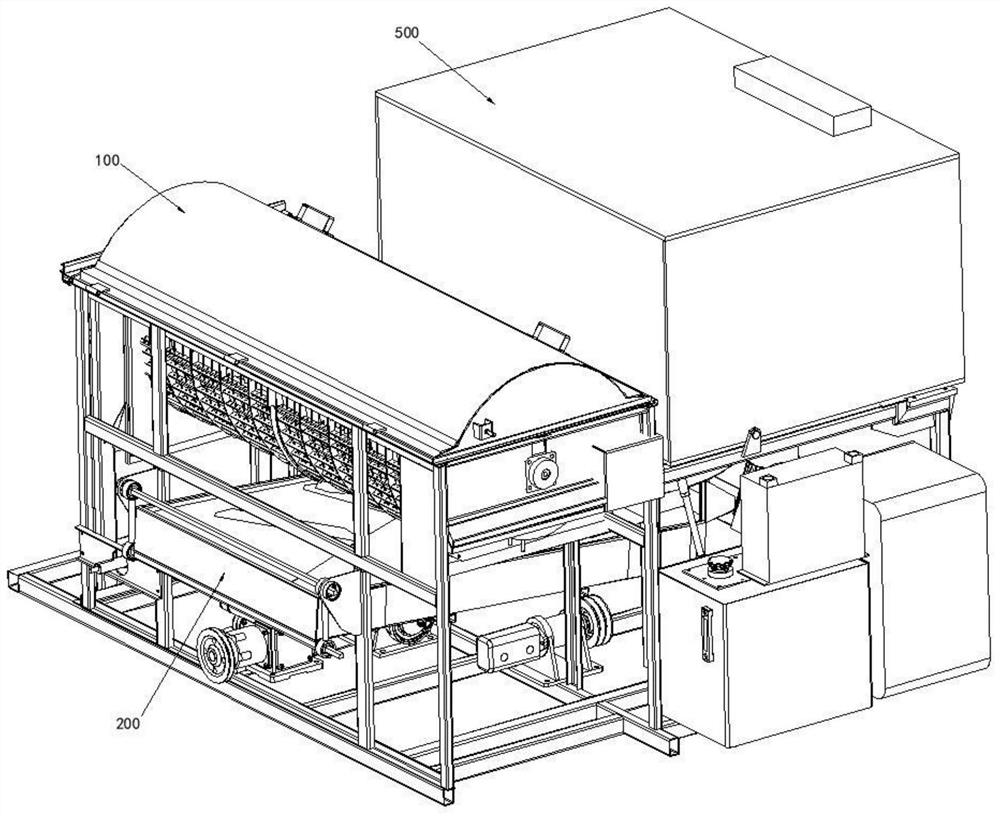

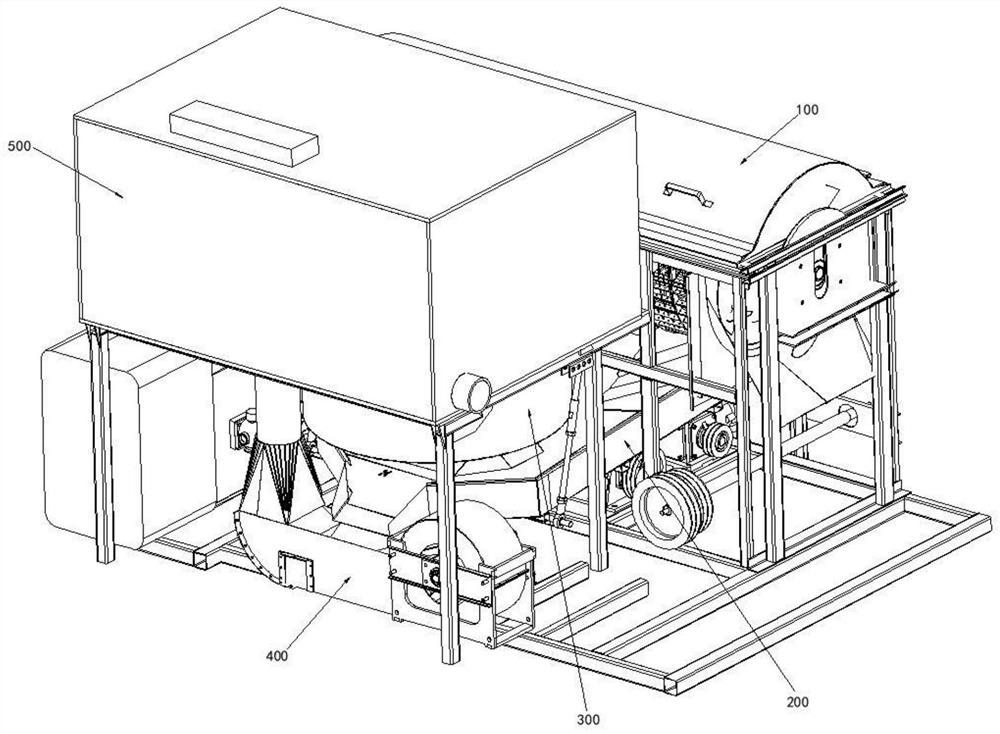

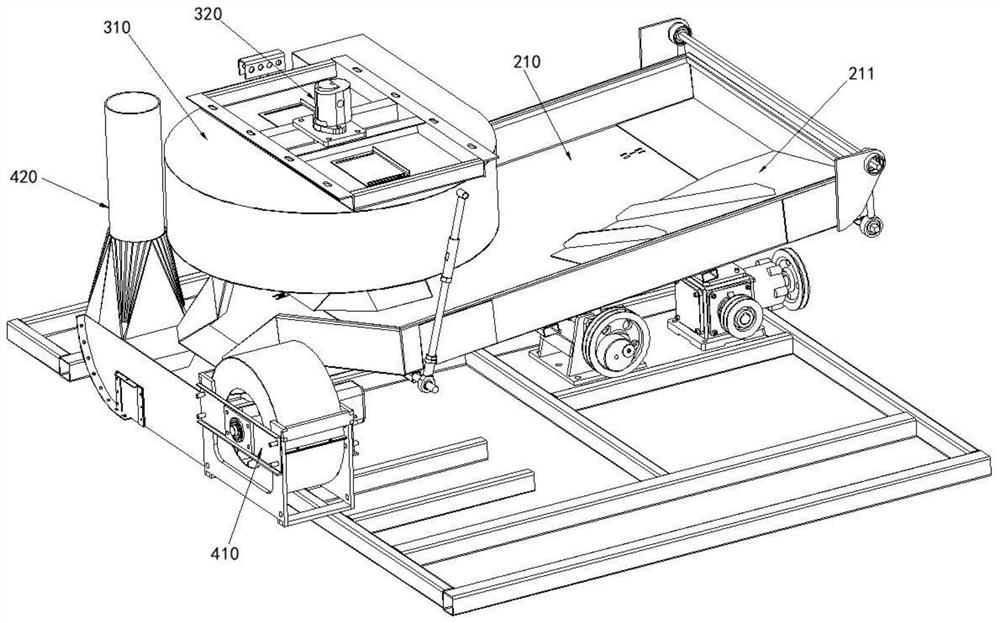

[0031] Such as figure 1 As shown, the pneumatically conveyed edible bean combine harvester of this embodiment includes a traveling mechanism, a cutting mechanism, a conveying mechanism, a threshing mechanism 100, a cleaning mechanism 200, a discharge mechanism 300, a lifting mechanism 400 and a storage bin 500;

[0032] The traveling mechanism loads all parts, and the two ends of the conveying mechanism are connected to the cutting mechanism and the threshing mechanism 100 respectively. The cutting mechanism harvests the edible beans in the field, and the conveying mechanism transports the harvested pods to the threshing mechanism 100. The threshing mechanism 100 utilizes the threshing mechanism The drum kneads the pods so that the pod shells and the bean grains are separated; the traveling mechanism, the conveying mechanism, the threshing mechanism 100 and the cutting mechanism in this embodiment all belong to the prior art. mechanism;

[0033]The lifting mechanism 400 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com