Full-automatic mechanical production equipment for tourist shoe processing and method

A production equipment, fully automatic technology, applied in the direction of cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc., can solve the problems of increased manufacturing cost, poor cleaning effect, troublesome operation, etc., to improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

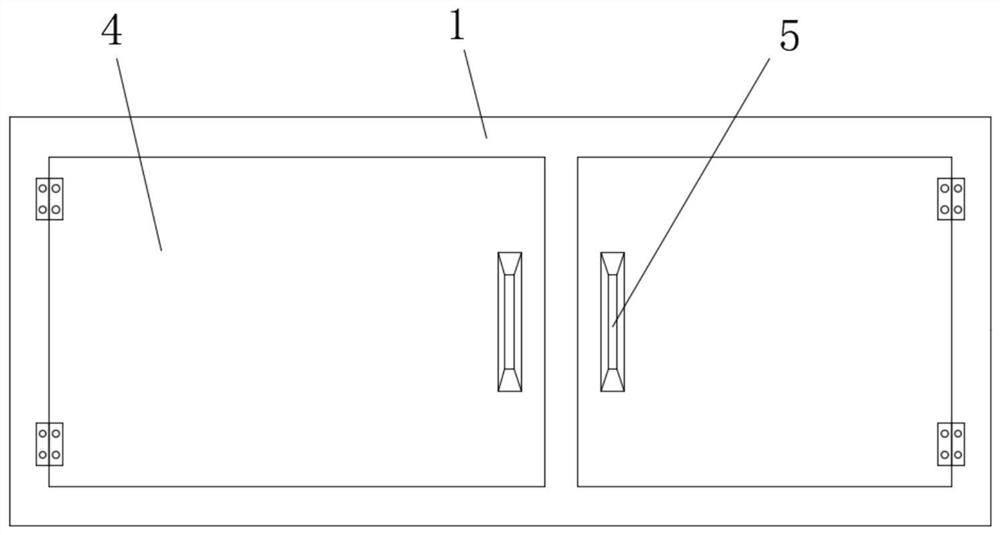

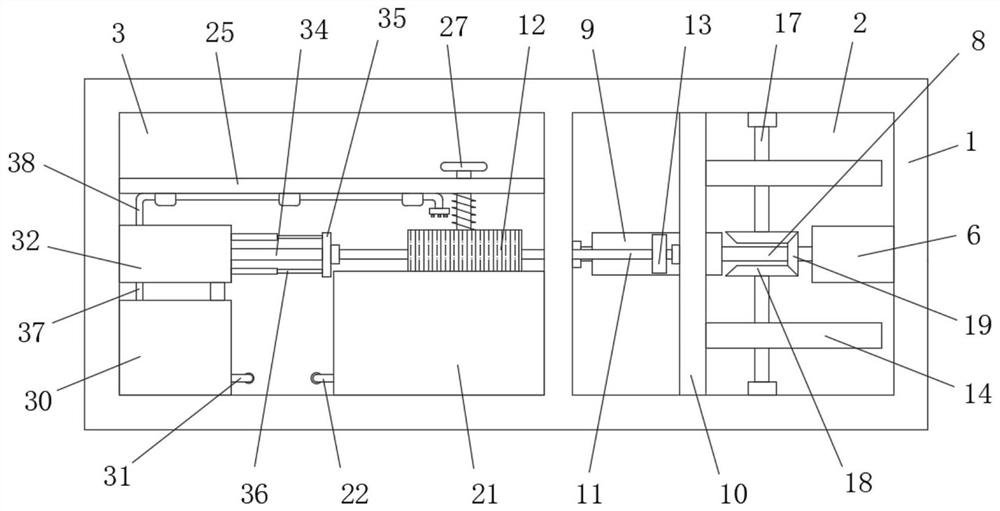

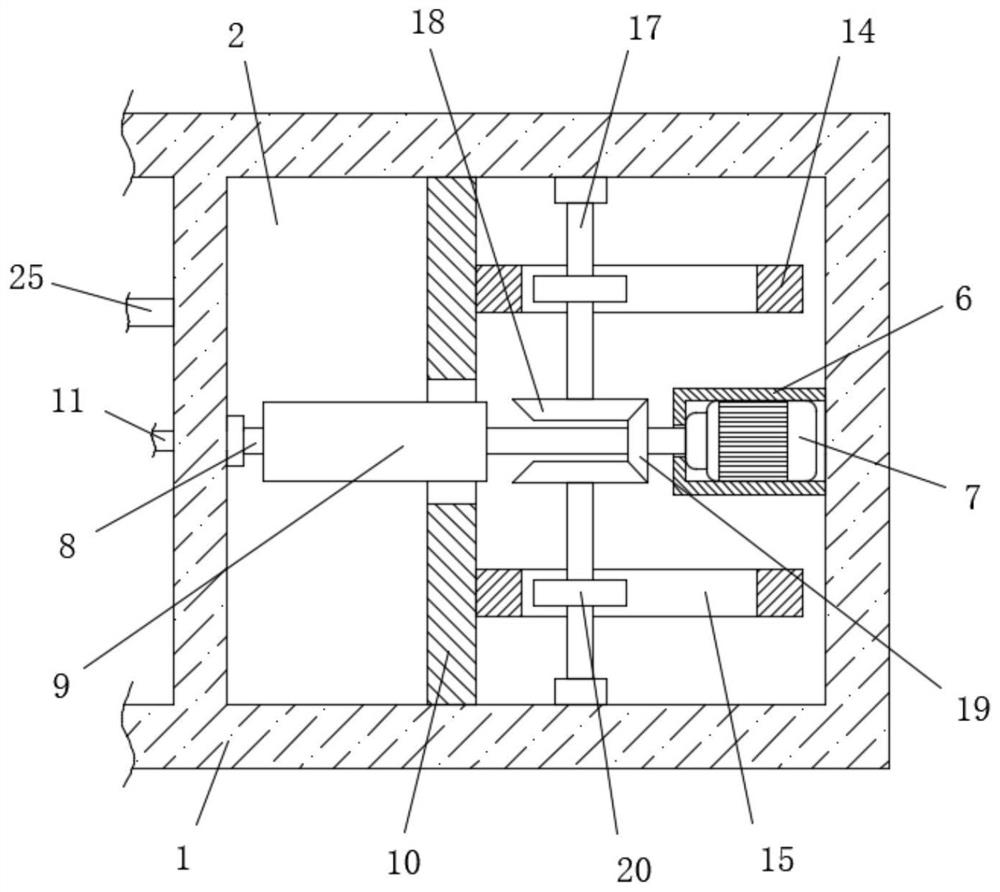

[0032] refer to Figure 1-7 , a fully automatic mechanical production equipment for the processing of tourist shoes, comprising a box body 1, the inside of the box body 1 is respectively provided with a drive chamber 2 and a cleaning chamber 3, and the outsides of the drive chamber 2 and the cleaning chamber 3 are hinged Chamber door 4 is arranged, and the outside of two chamber doors 4 is all provided with handle 5, and drive chamber 2 is fixedly connected with installation box 6 on the side inner wall away from cleaning chamber 3, and drive motor 7 is fixedly installed in installation box 6, drives The output shaft of the motor 7 is fixedly connected with the first rotating rod 8, and one end of the first rotating rod 8 extends to the outside of the installation box 6 and is connected with the inner wall of the side of the driving chamber 2 close to the cleaning chamber 3 for rotation. One side of the rod 8 is covered with a slide plate 10, and the top and bottom of the slide ...

Embodiment 2

[0034] Further improved on the basis of embodiment one:

[0035] In this embodiment, the two groups of cleaning components include two second rotating rods 11 that are rotationally connected to one side of the slide plate 10 horizontally and symmetrically. One side of the two second rotating rods 11 both extends into the cleaning chamber 3 and is fixed Roller hair brush 12 is provided, two second rotating rods 11 are positioned at one side in driving chamber 2 and are all fixedly set with moving gear 13, and one side of first rotating rod 8 is fixedly sleeved with long gear 9, and long One side of the gear 9 moves through one side of the slide plate 10 and meshes with two moving gears 13 respectively. The drive motor 7 drives the first rotating rod 8 to rotate, and the meshing movement between the long gear 9 and the moving gear 13 can drive the second Two rotating rods 11 rotate, and then drive roller brush 12 to rotate, realize the effect of cleaning with this.

[0036] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com