Patents

Literature

1520 results about "Reaper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reaper is a farm implement or person that reaps (cuts and often also gathers) crops at harvest when they are ripe. Usually the crop involved is a cereal grass. The first documented reaping machines were Gallic reaper that was used in modern-day France during Roman times. The Gallic reaper involved a comb which collected the heads, with an operator knocking the grain into a box for later threshing.

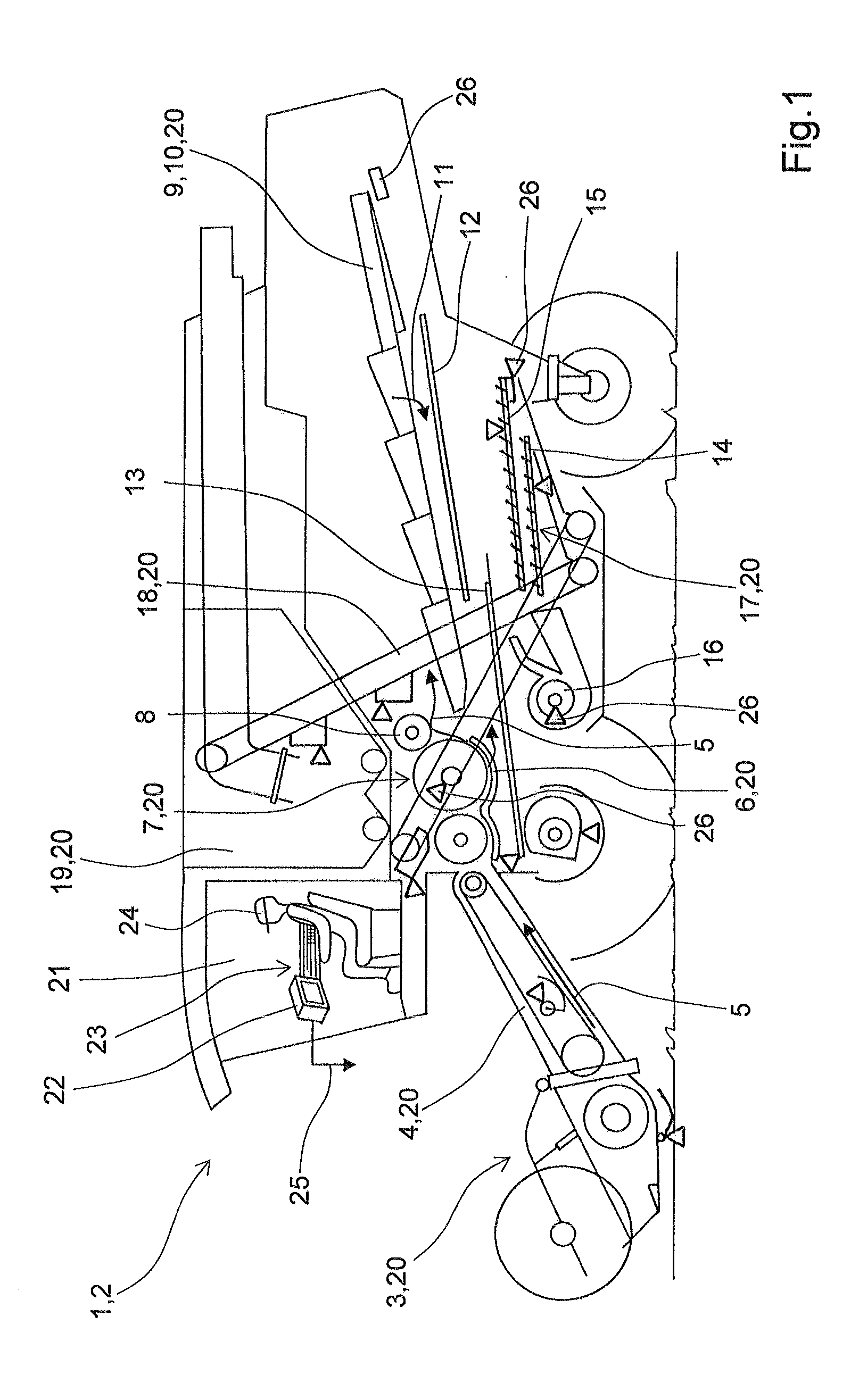

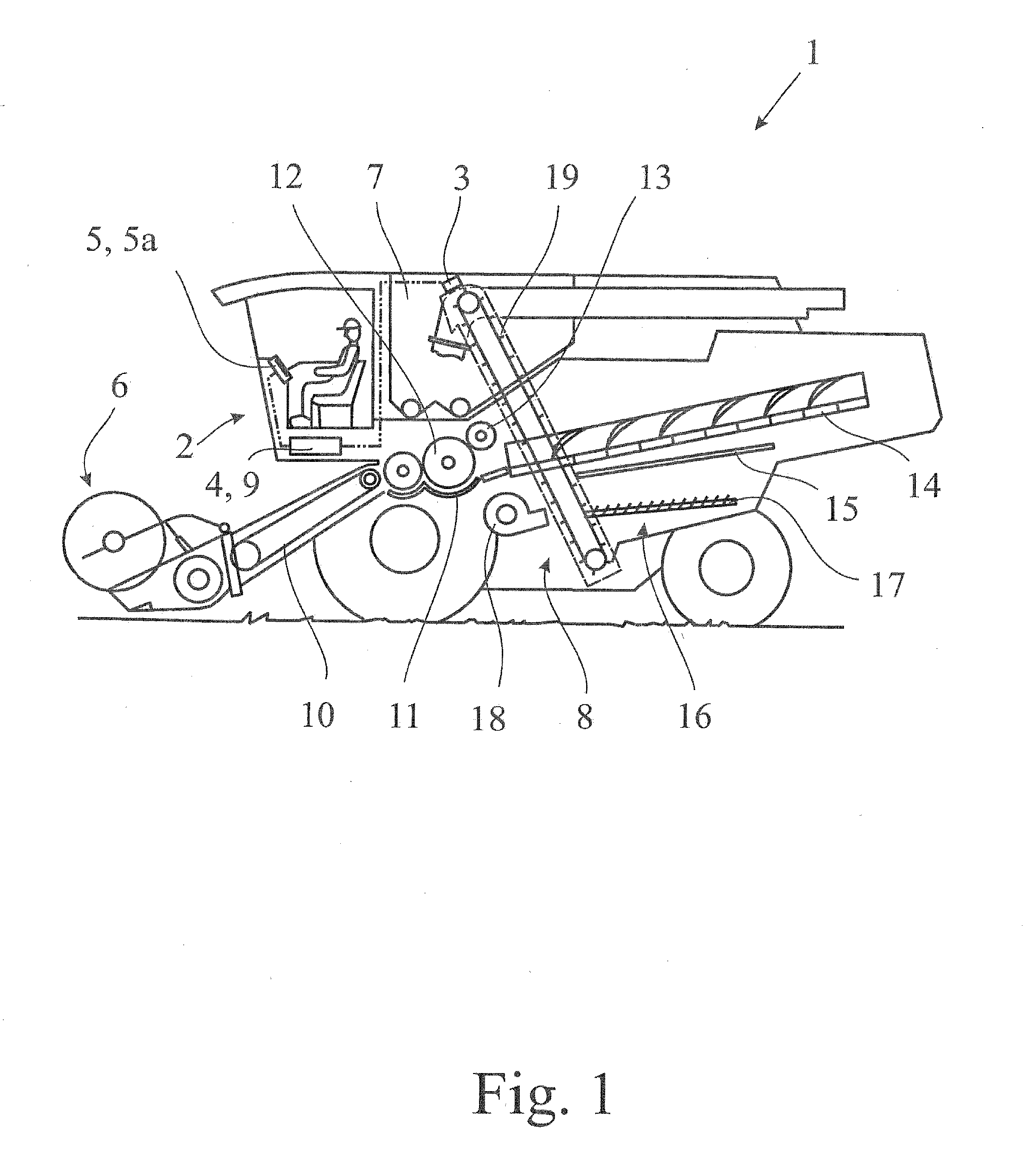

Agricultural working machine

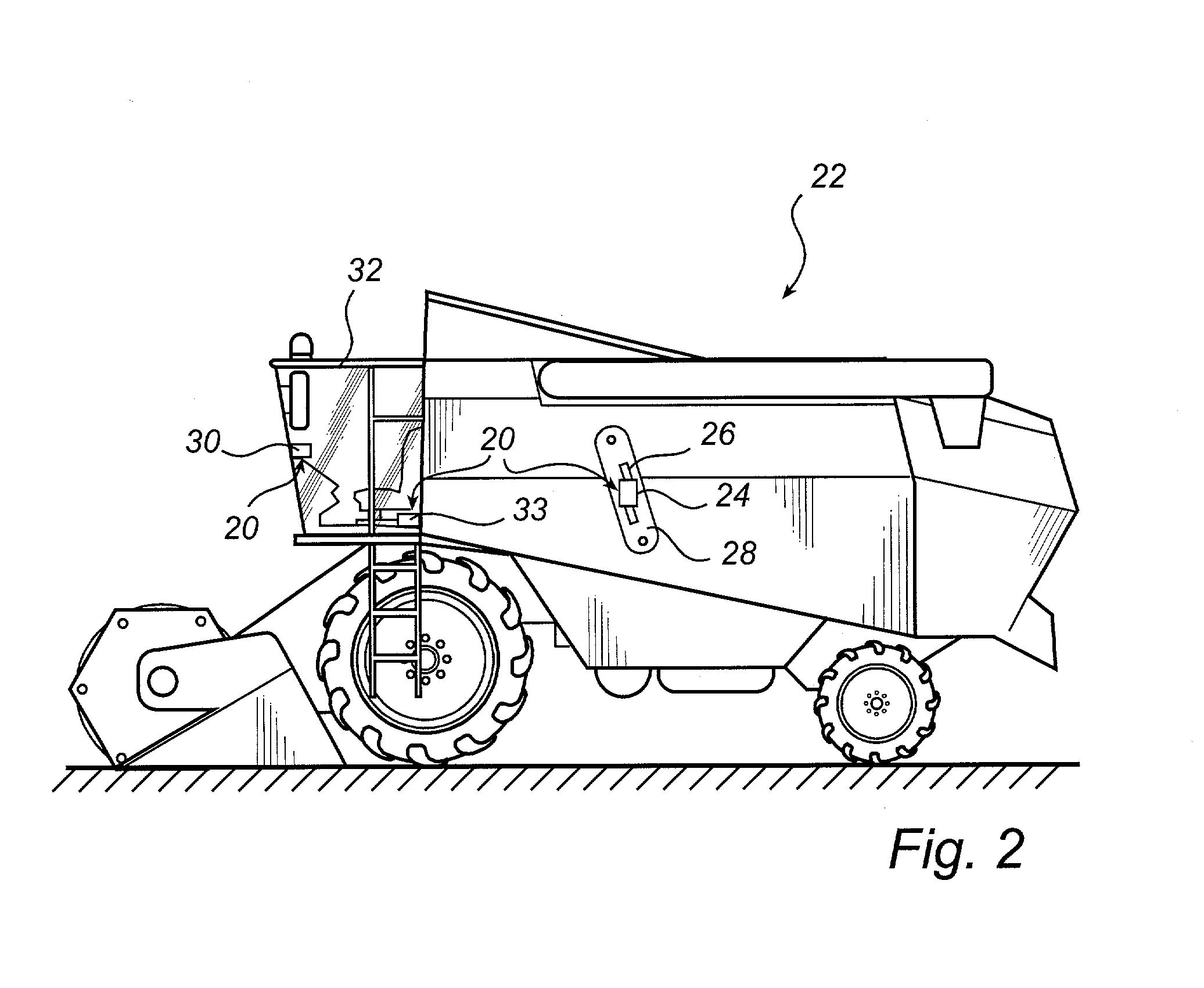

InactiveUS20090044505A1Improving visibility conditionIncrease awarenessMowersPicking devicesAgricultural scienceForage harvester

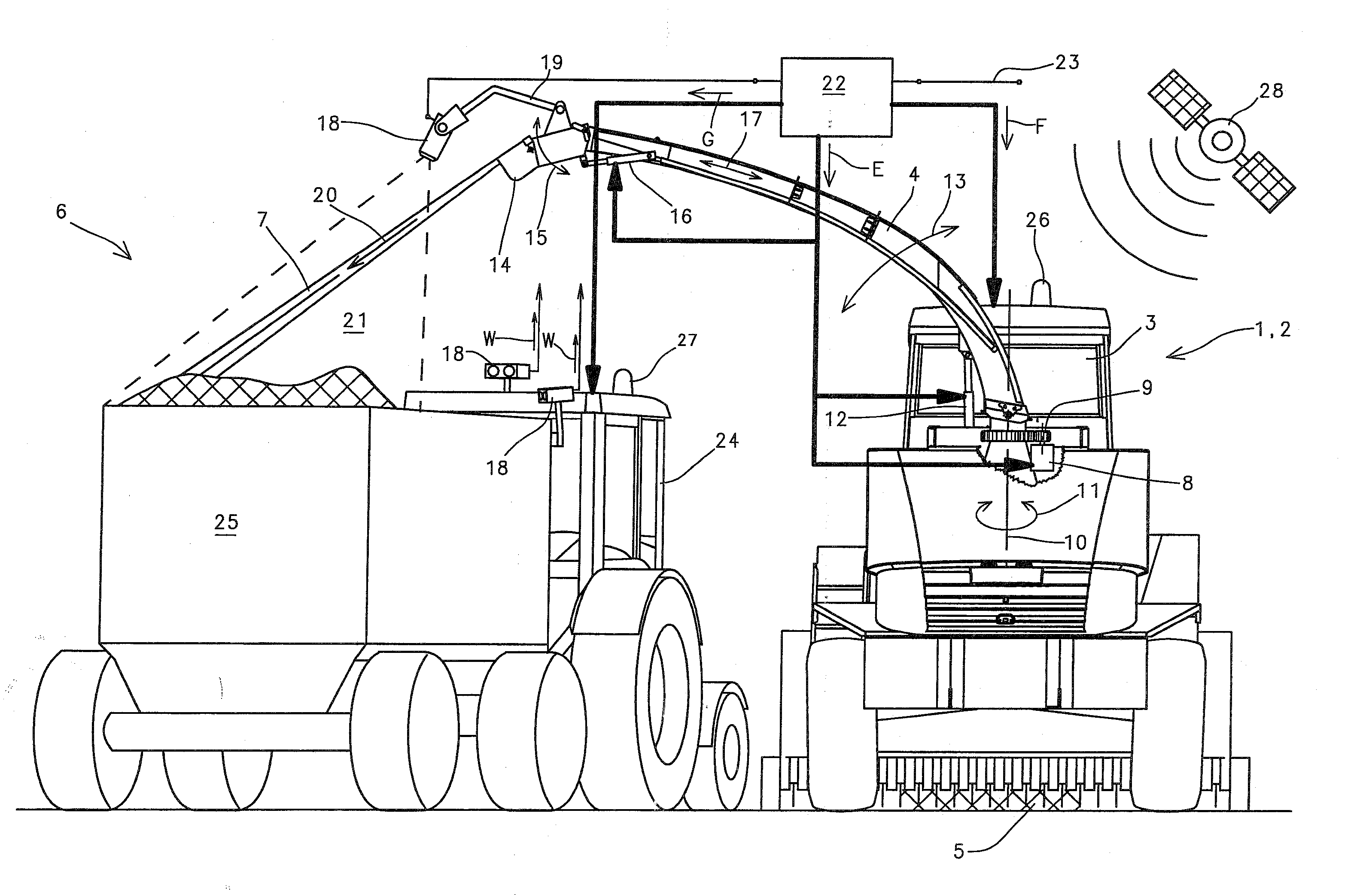

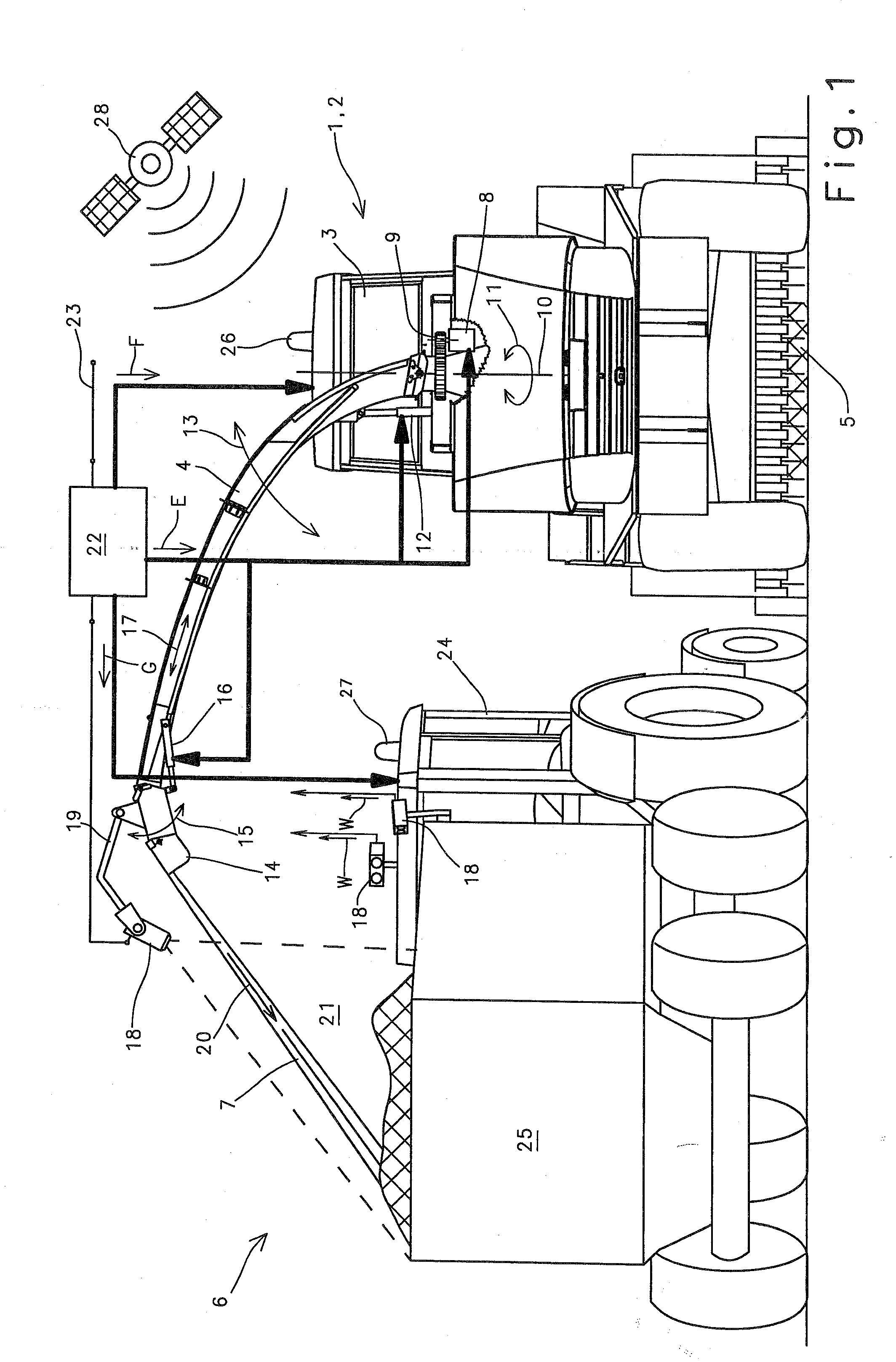

The invention relates to an agricultural working machine (1), in particular a forage harvester (2), with at least one spout (4) for conveying received and processed crop (7) to a transport vehicle (6, 25), wherein an electro-optical device (18) is provided for the direction control of the spout (4) at least during the process of conveying to the transport vehicle (6, 25), and wherein the electro-optical device (18) detects characteristic parameters (30) of the spout (4) and characteristic parameters (30) of the transport vehicle (6) and / or the agricultural working machine (1). This ensures that a control of a spout (4) of agricultural working machines (1, 2) is provided which almost completely relieves the operator of the agricultural working machine (1, 2) of the task of monitoring the spout.

Owner:AGROCOM & AGRARSYST

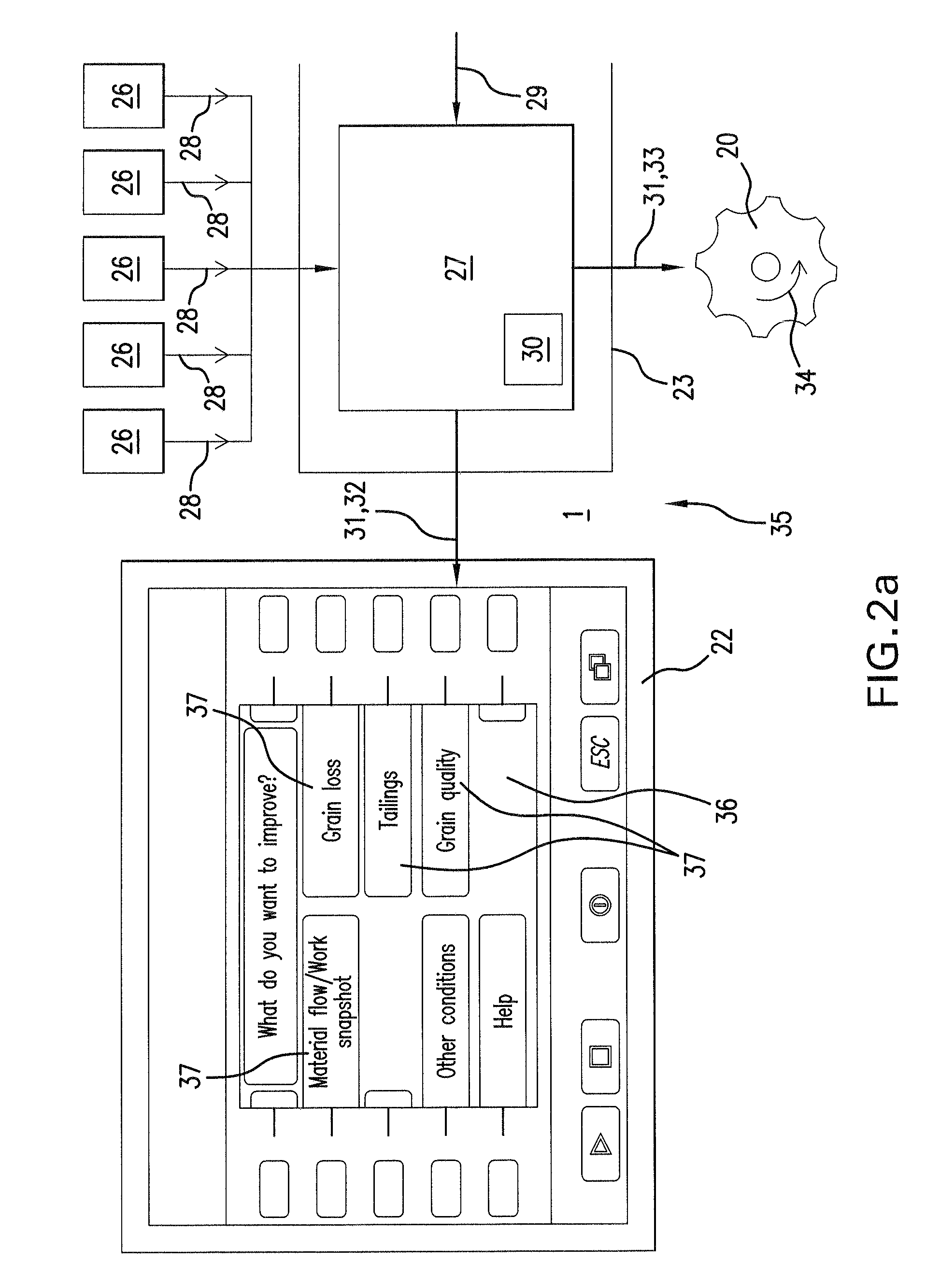

Driver assistance system for agricultural working machines

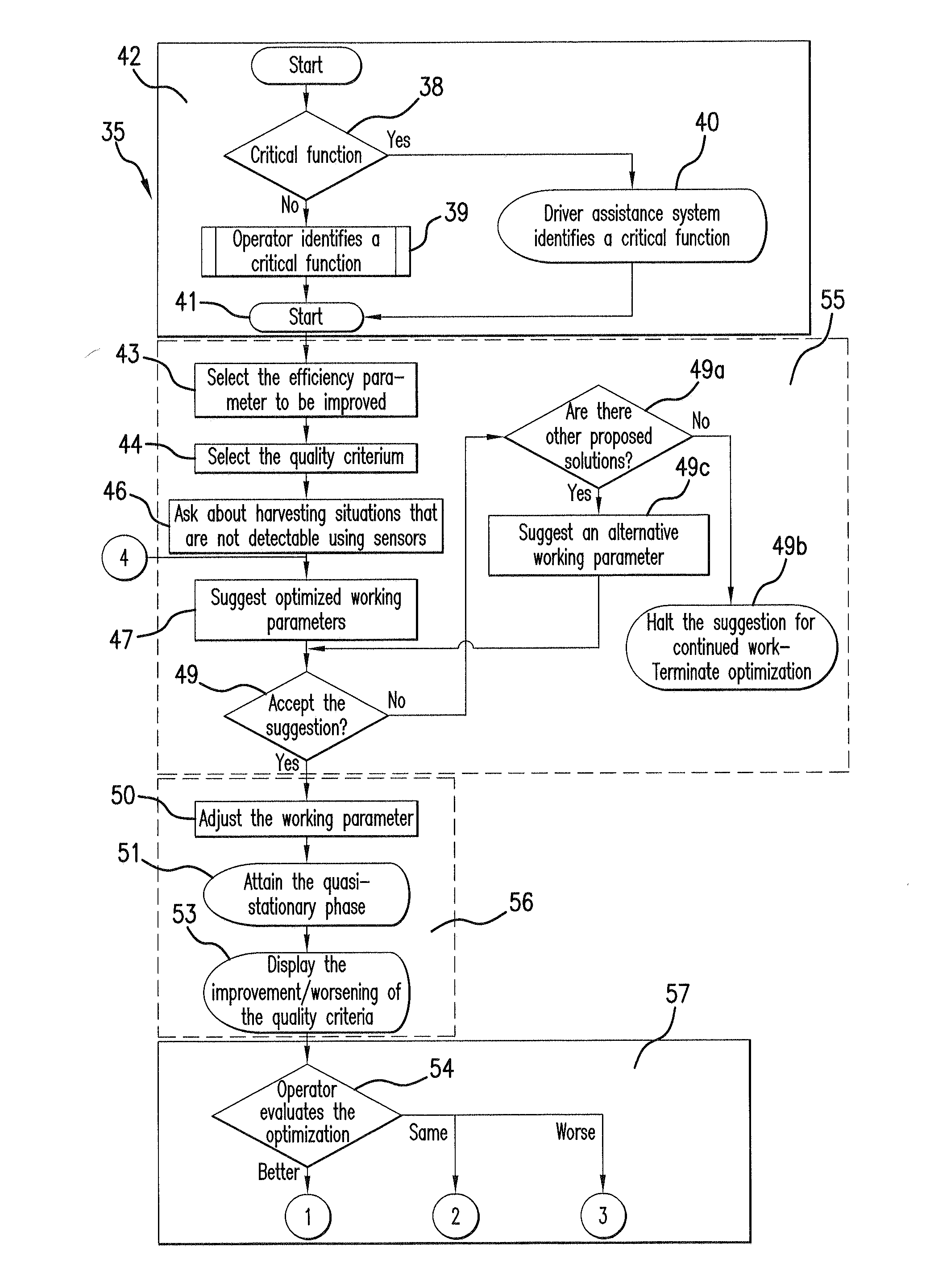

ActiveUS20100217474A1Improve efficiencyVehicle testingAnalogue computers for trafficArithmetic logic unitDriver/operator

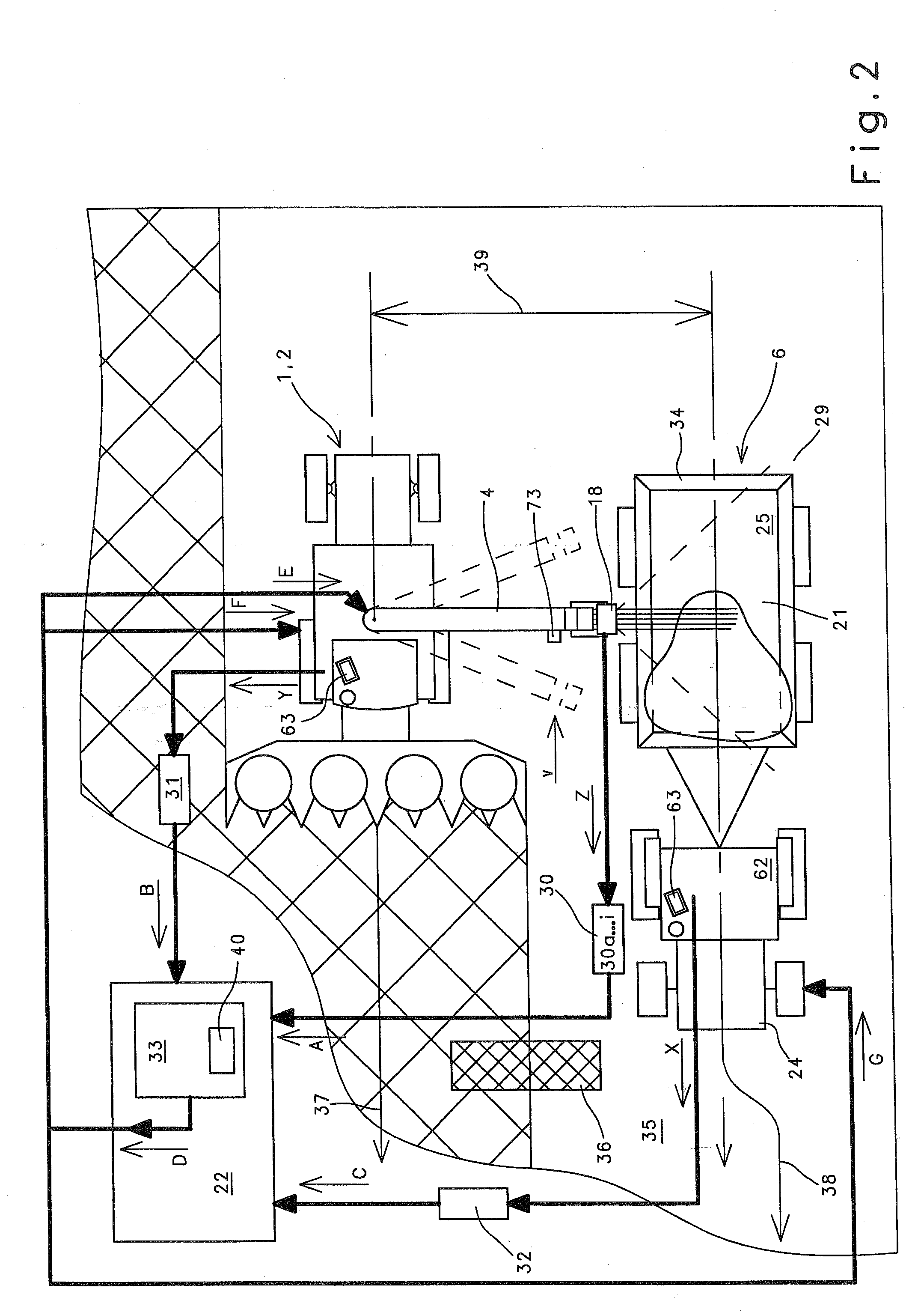

A driver assistance system for an agricultural working machine, in particular a combine harvester has a large number of working mechanisms, an arithmetic logic unit, and at least one display unit, in which the arithmetic logic unit may process information generated by machine-internal sensor systems, external information, and information that is storable in the arithmetic logic unit, and in which the driver assistance system overcomes—with consideration for at least a selection of the available information—critical functions of the agricultural working machine in that efficiency parameters of the agricultural working machine are optimized via interactive, natural-language communication between the operator of the agricultural working machine and the driver assistance system.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

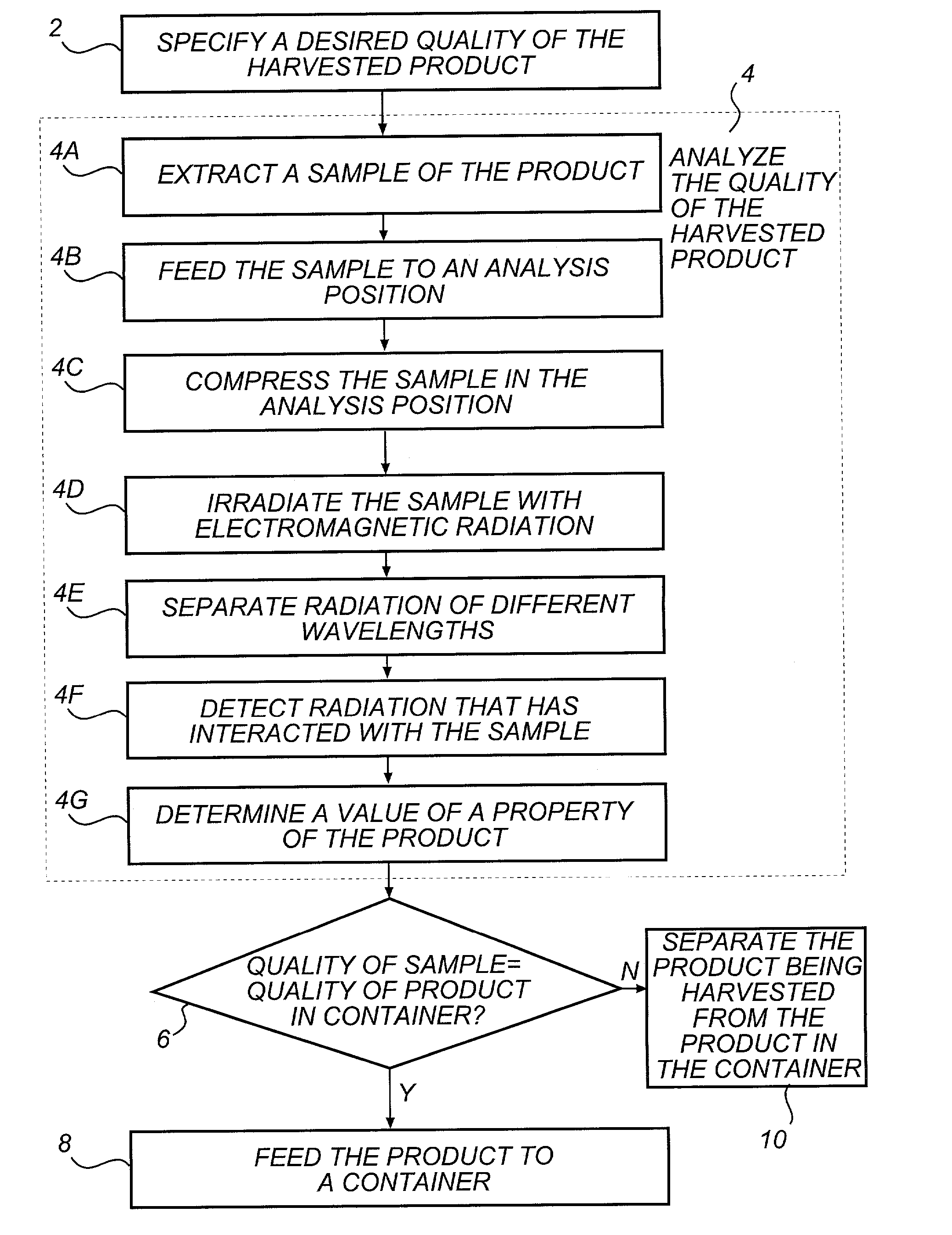

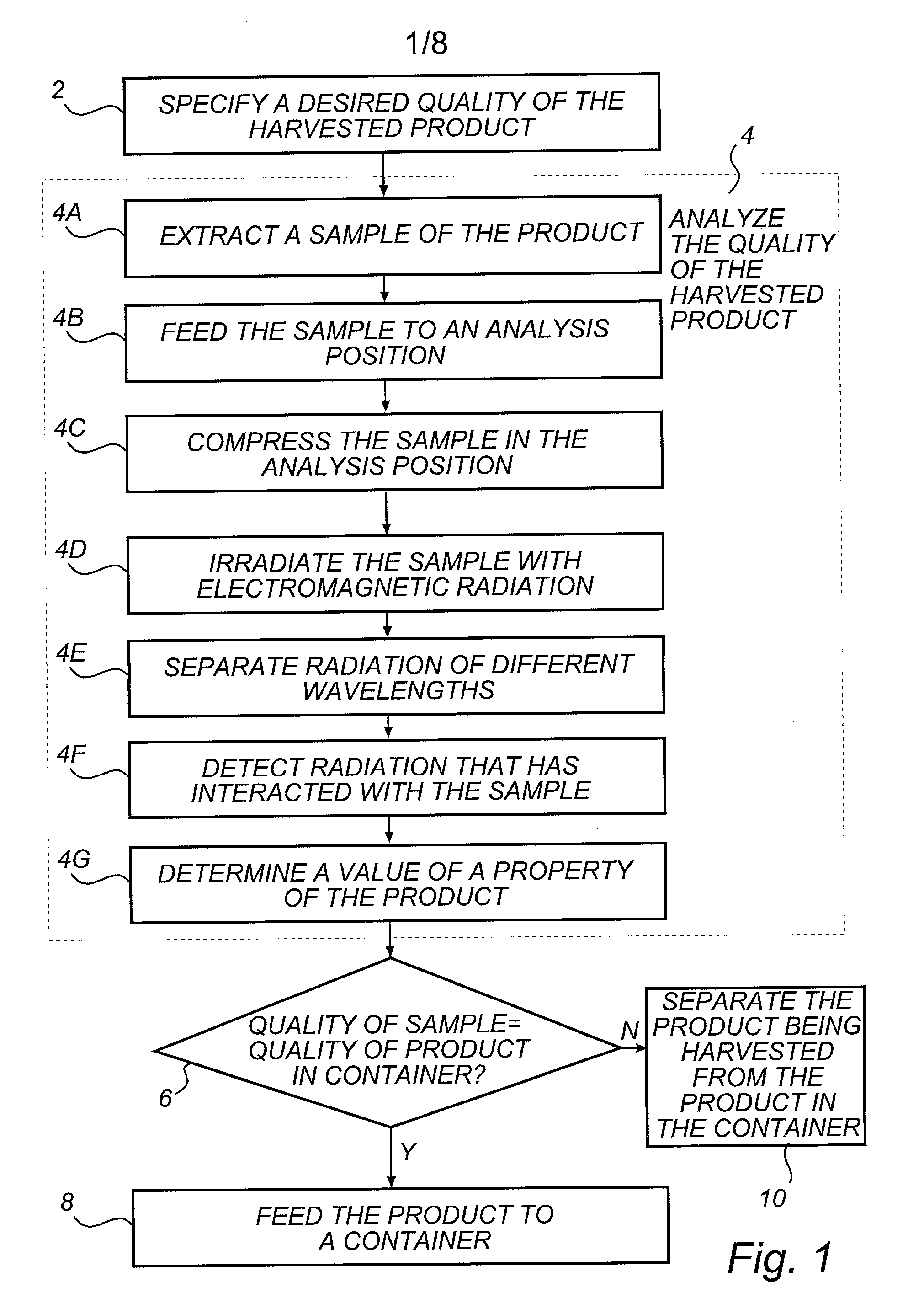

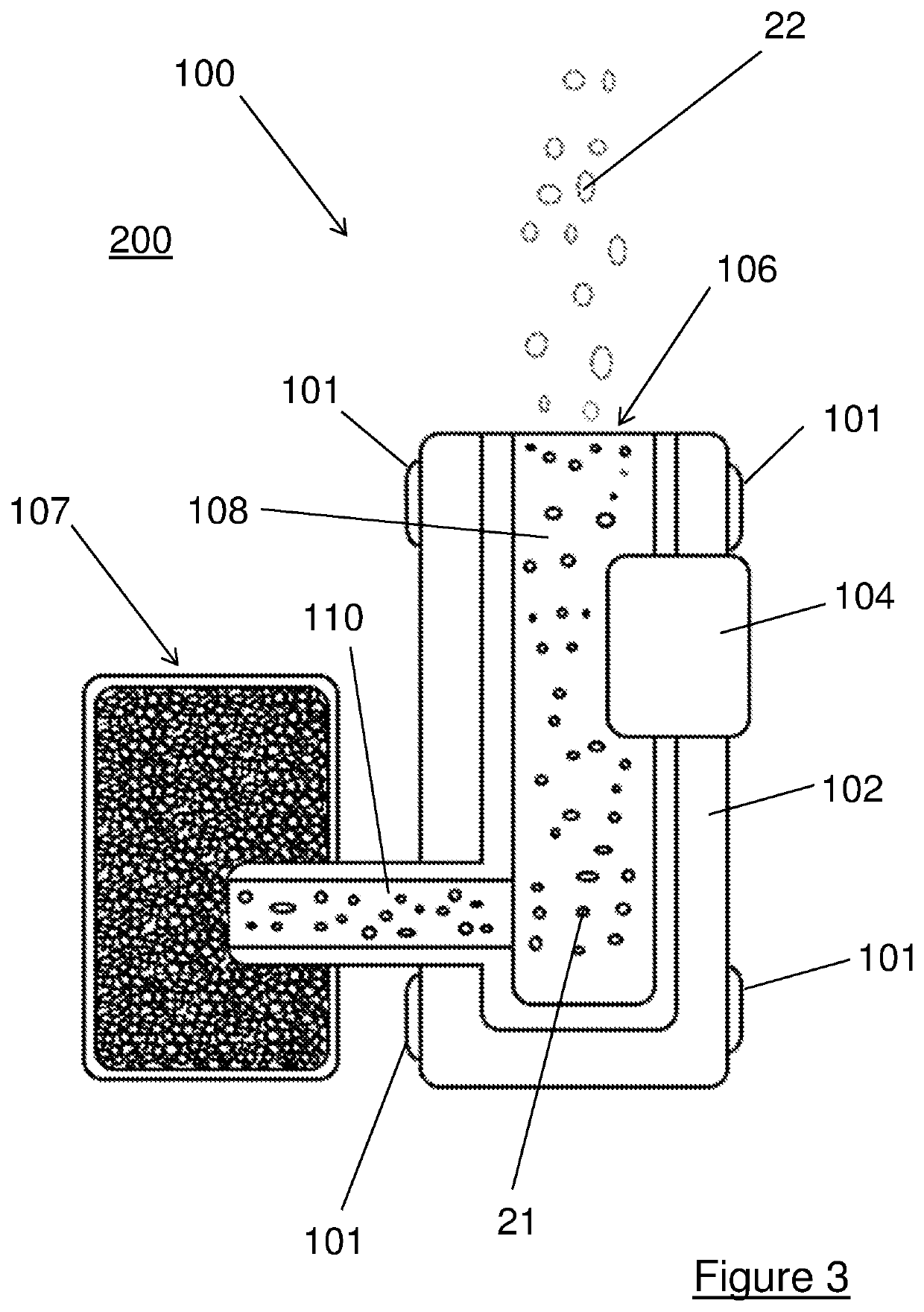

Sorting grain during harvesting

A method for segregating qualities of an agricultural product during processing of the product comprises the step of setting a desired range of a measurement value (2). The measurement value represents a property of the product and defines a first quality of the product for which the measurement value is inside the range and a second quality of the product for which the measurement value is outside the range. The method further comprises the step of analyzing (4) the quality of the product that is being processed. The step of analyzing comprises the steps of continuously extracting samples of the product (4a), irradiating each sample by electromagnetic radiation (4d), spatially separating electromagnetic radiation of different wavelengths (4e), and detecting electromagnetic radiation emitted from the sample (4f). The step of detecting produces intensity signals indicative of detected electromagnetic radiation of different wavelengths. The step of analyzing further comprises the steps of determining a sample value of said property of the product from the intensity signals, and determining a measurement value (4g) from at least one sample value. The method further comprises the step of separating the product of said first quality from the product of said second quality on the combine.

Owner:FOSS ANALYTICAL AB (SE)

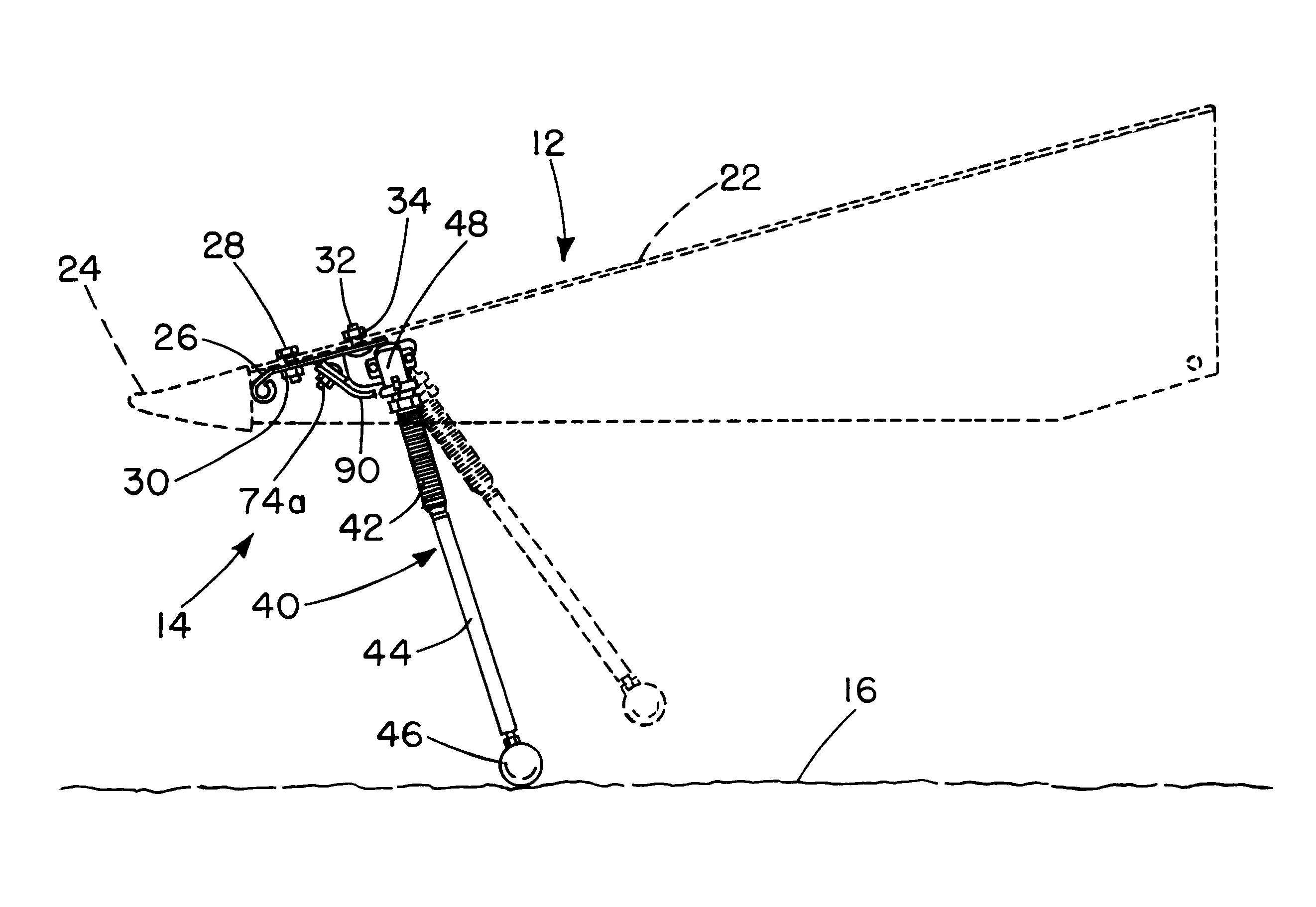

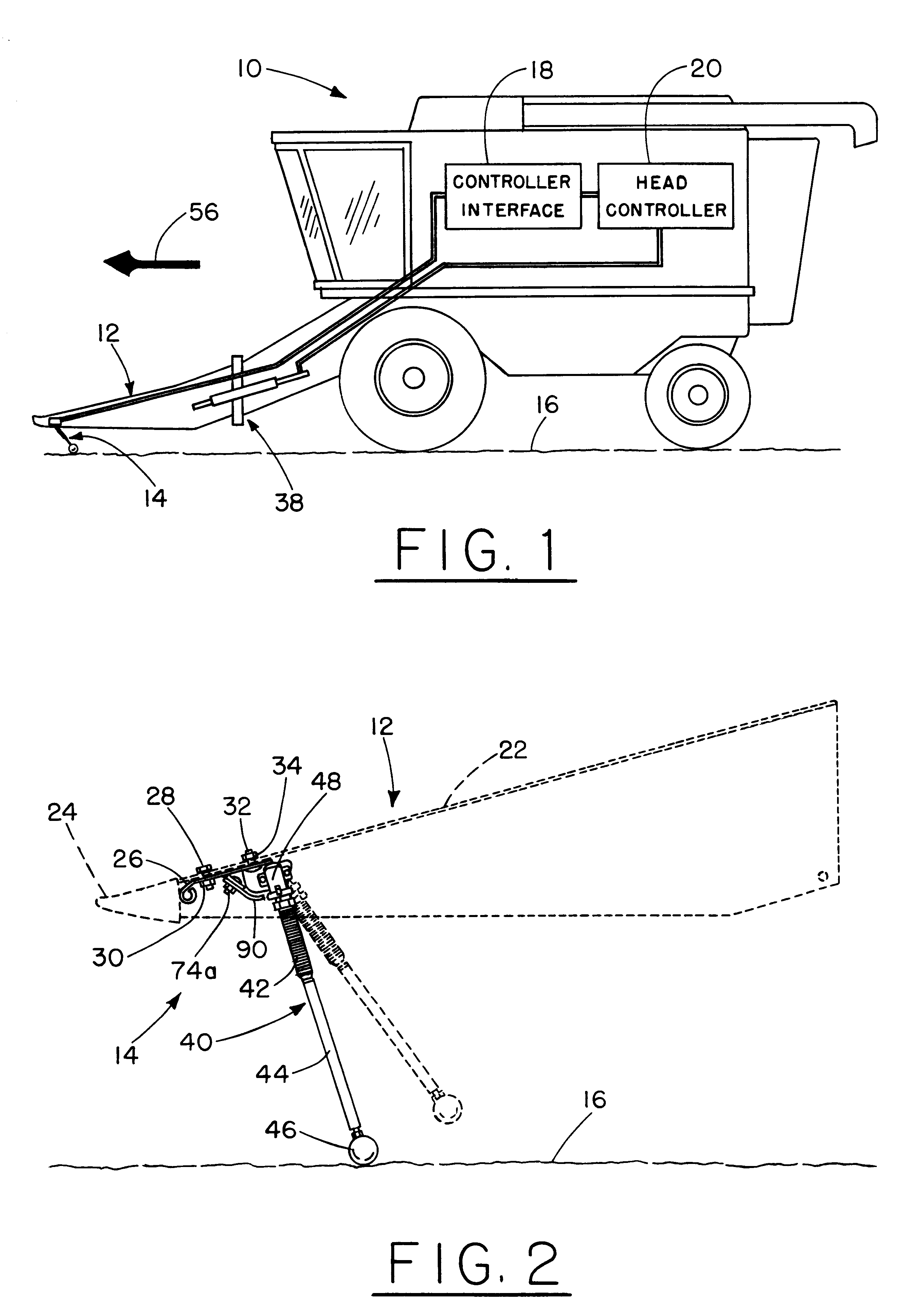

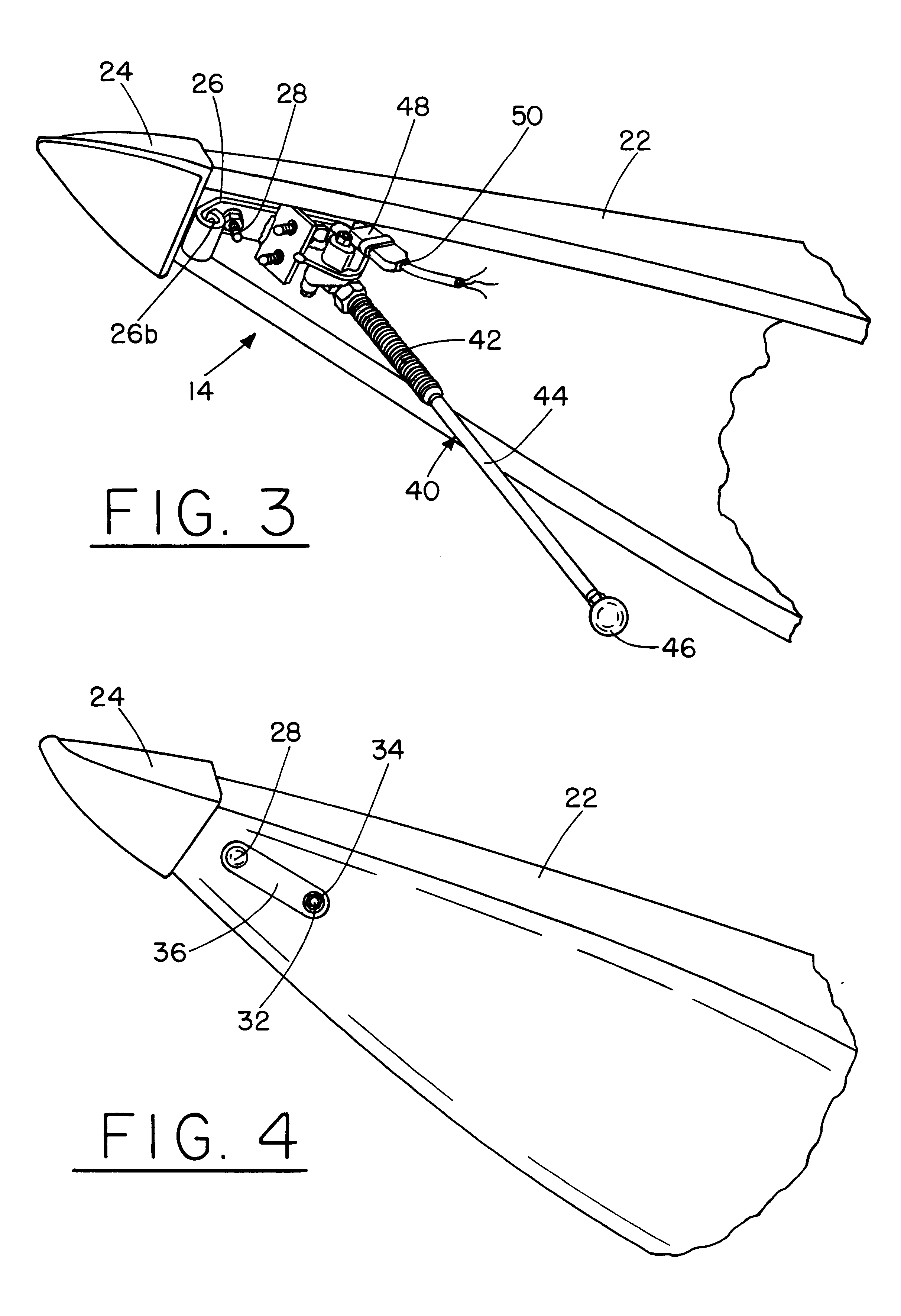

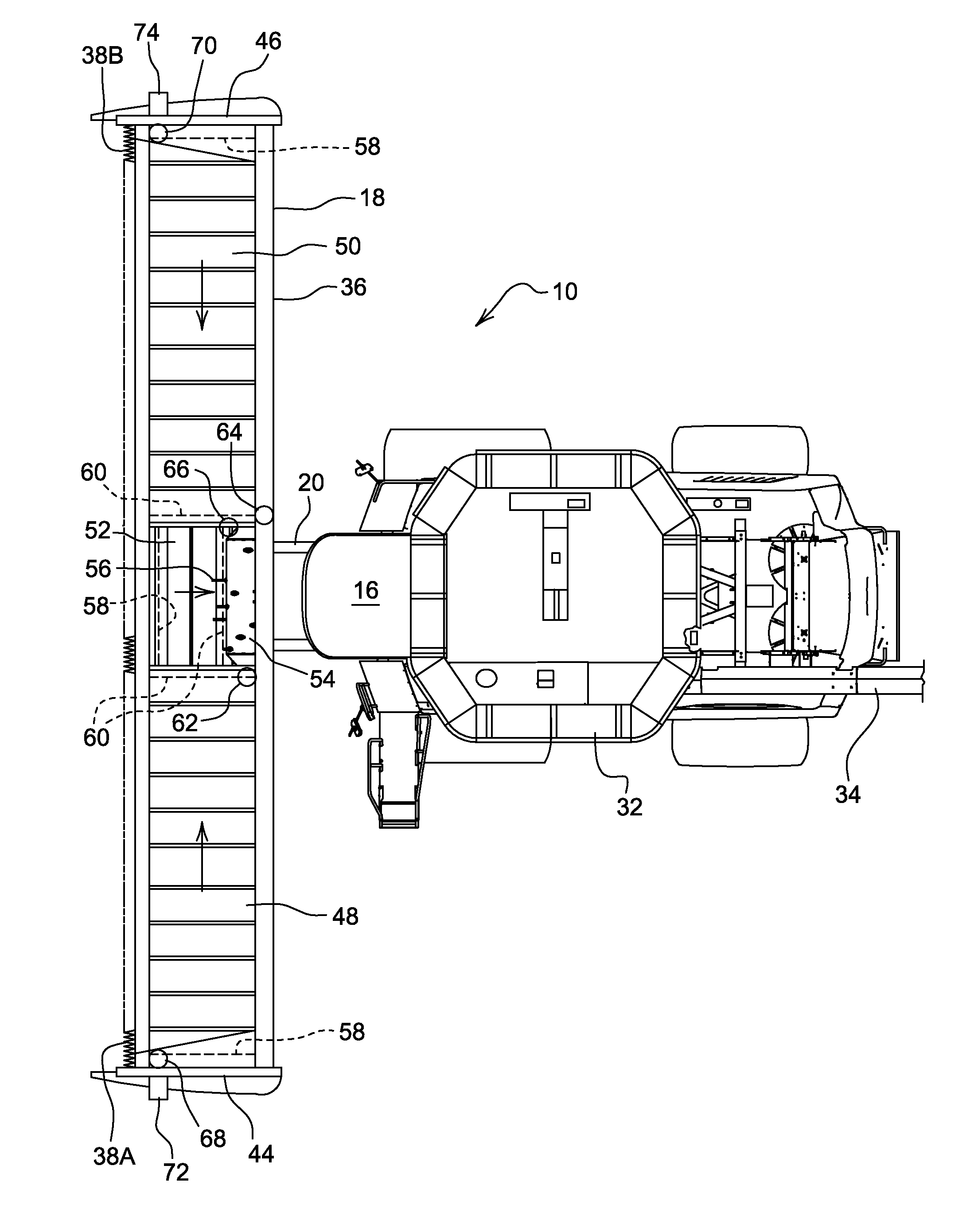

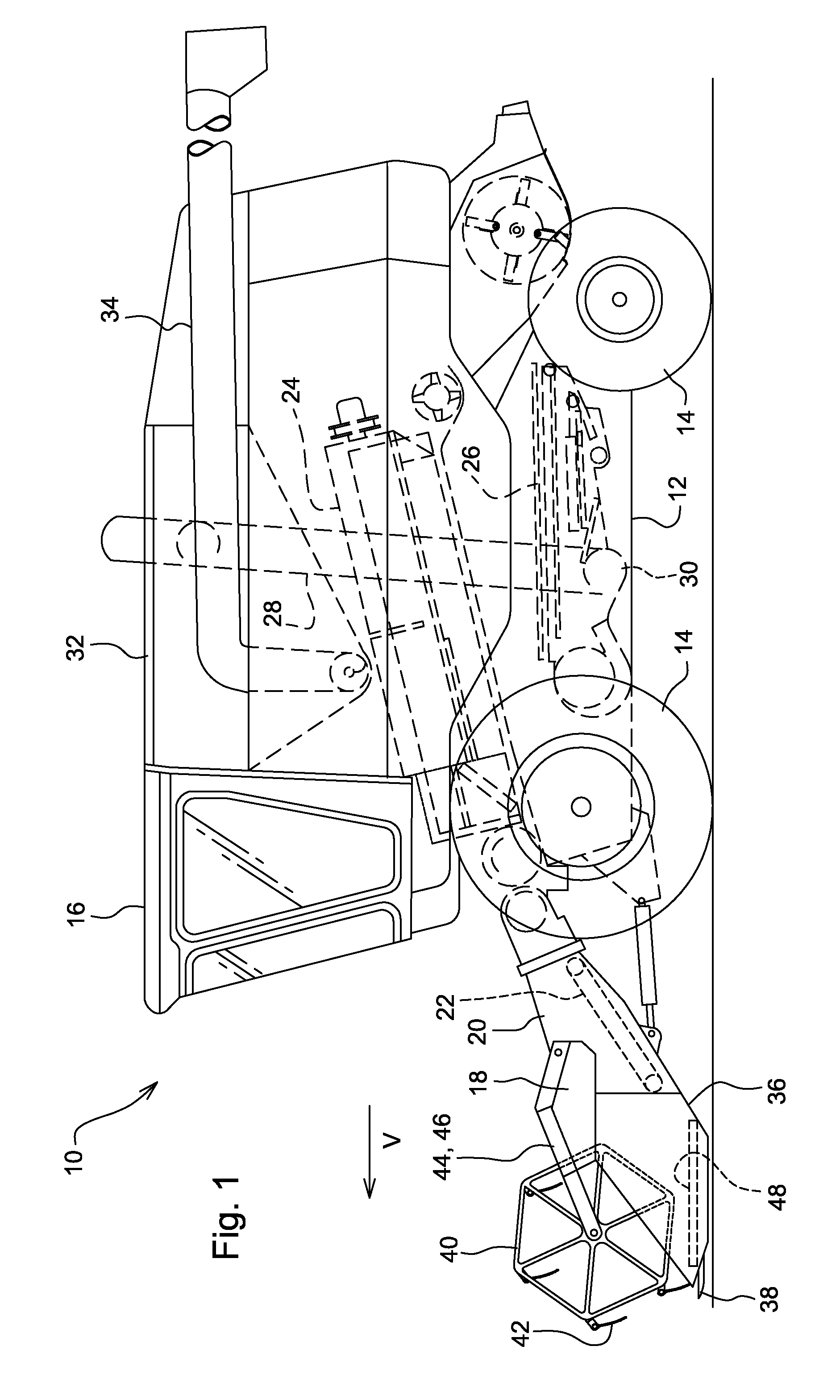

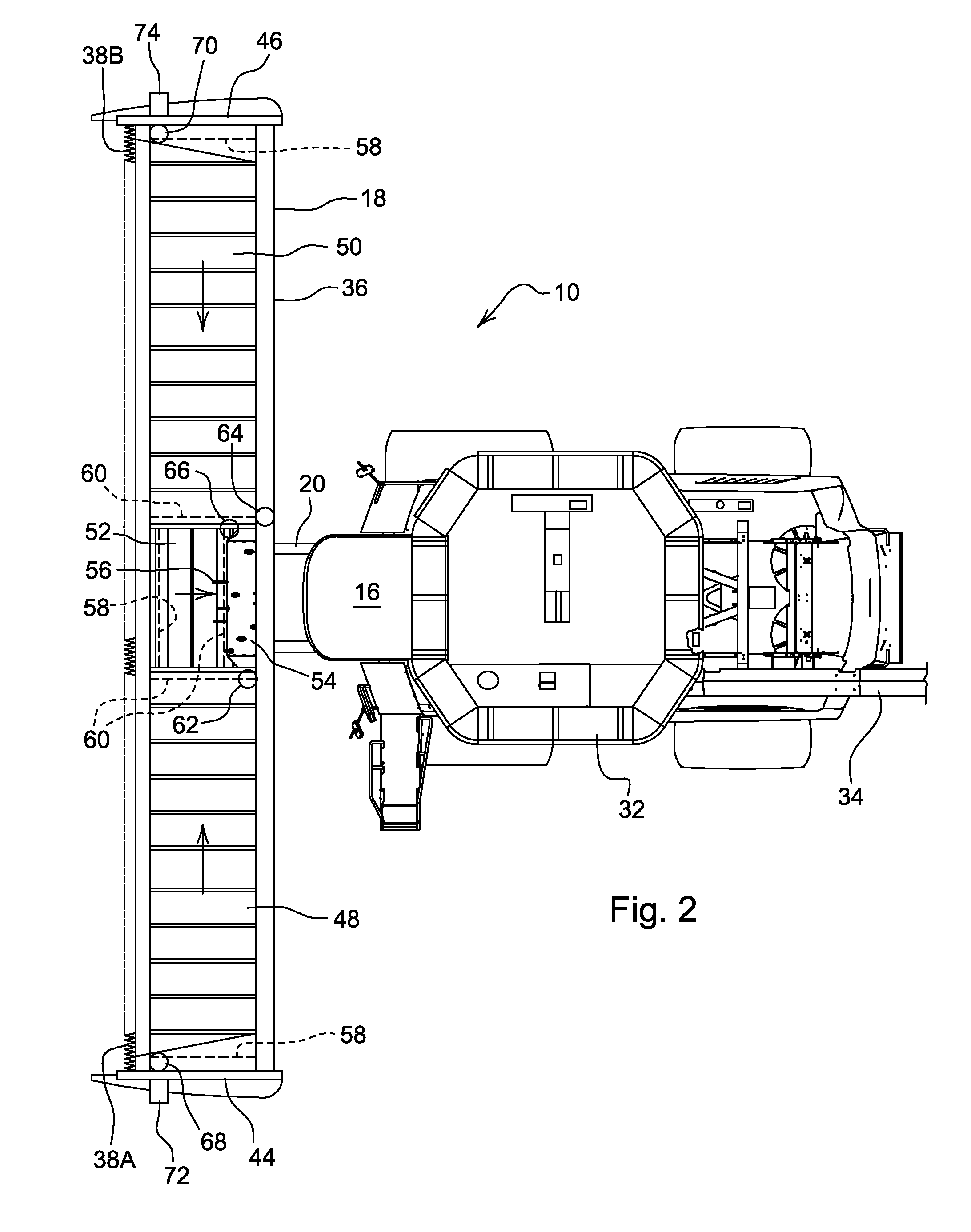

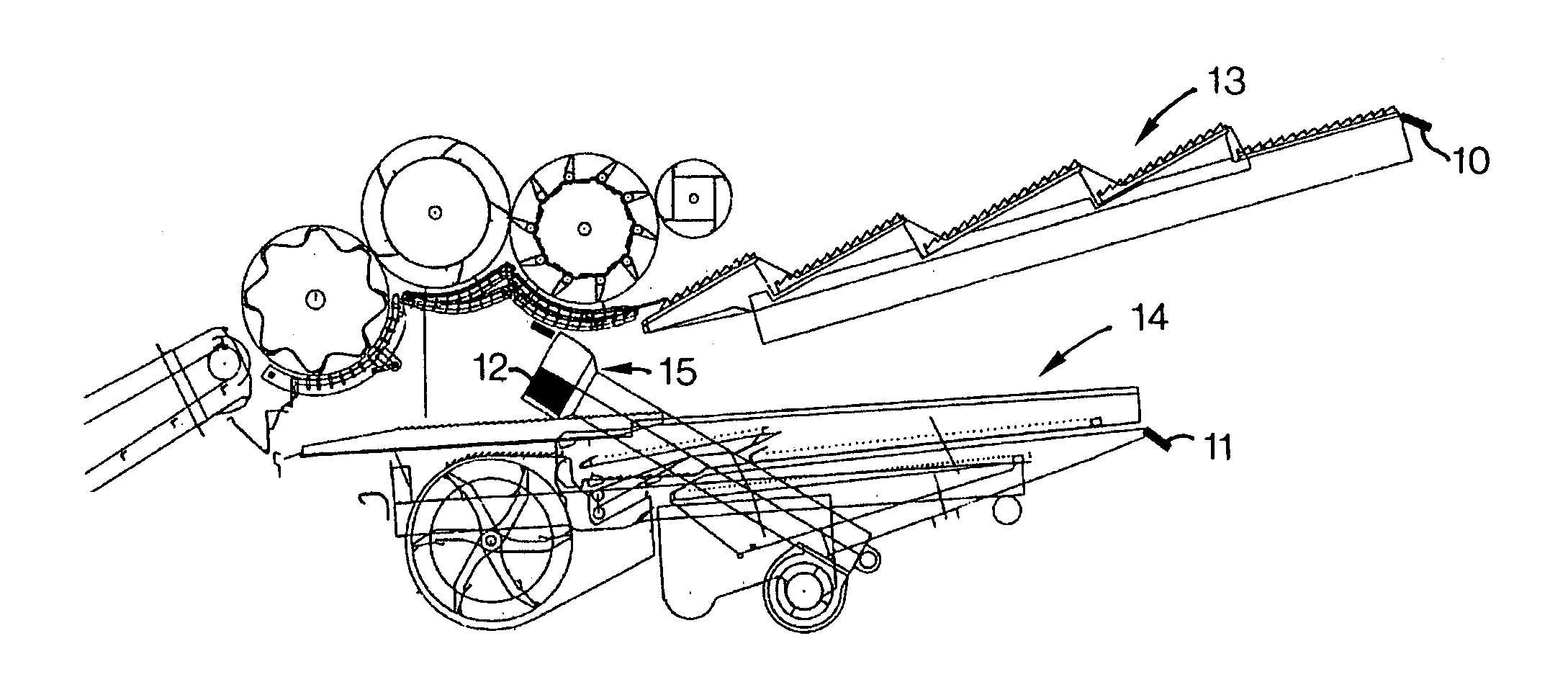

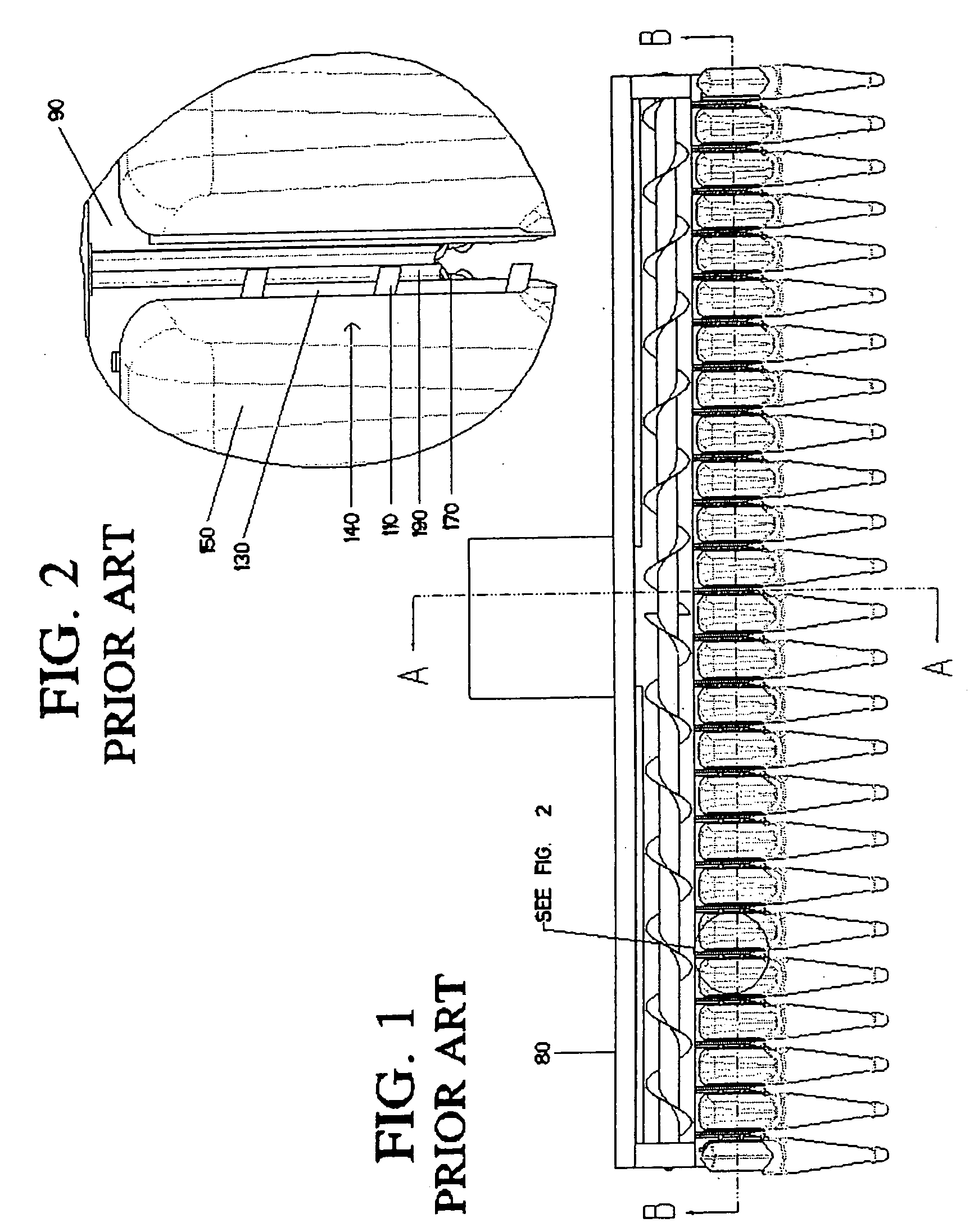

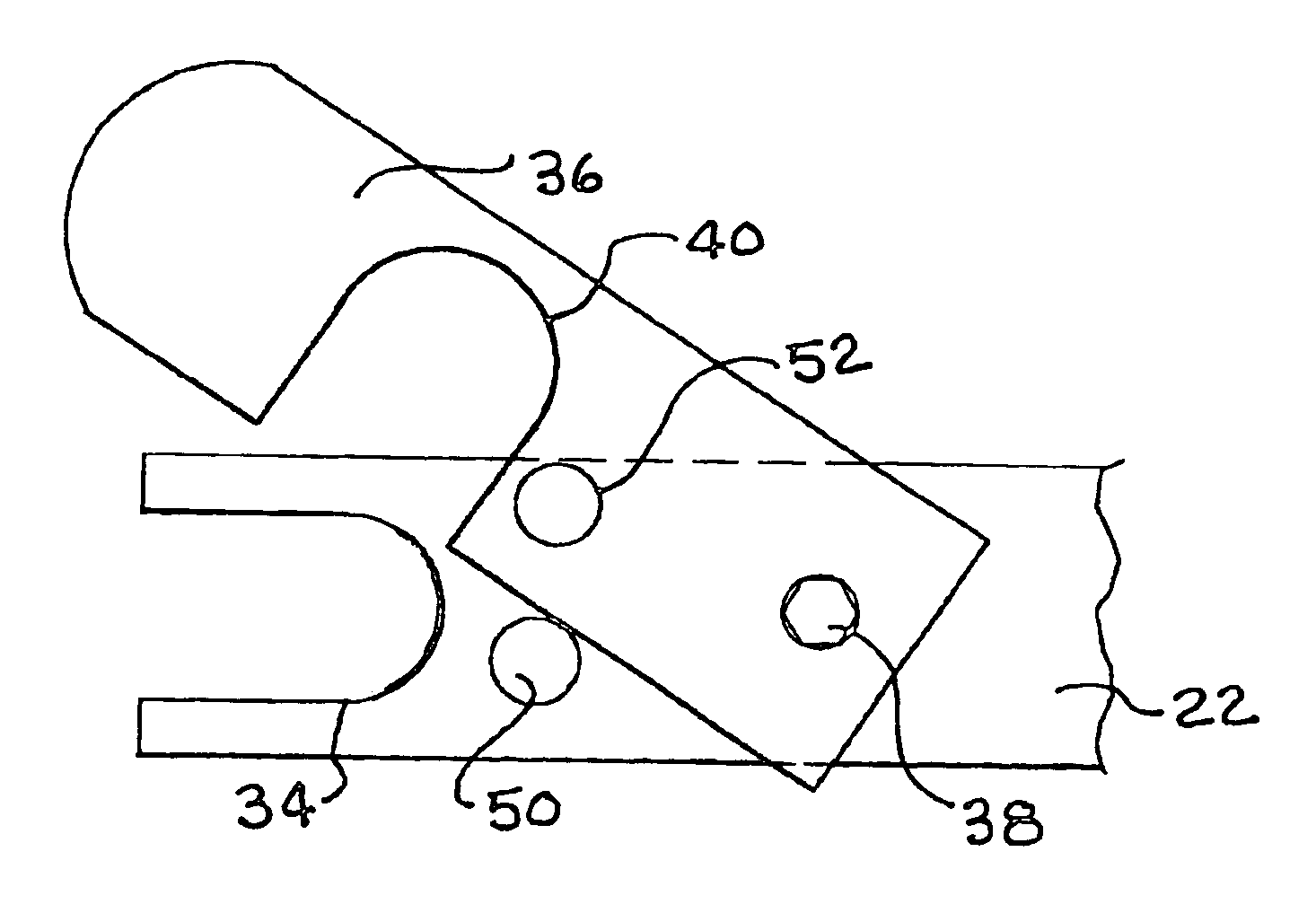

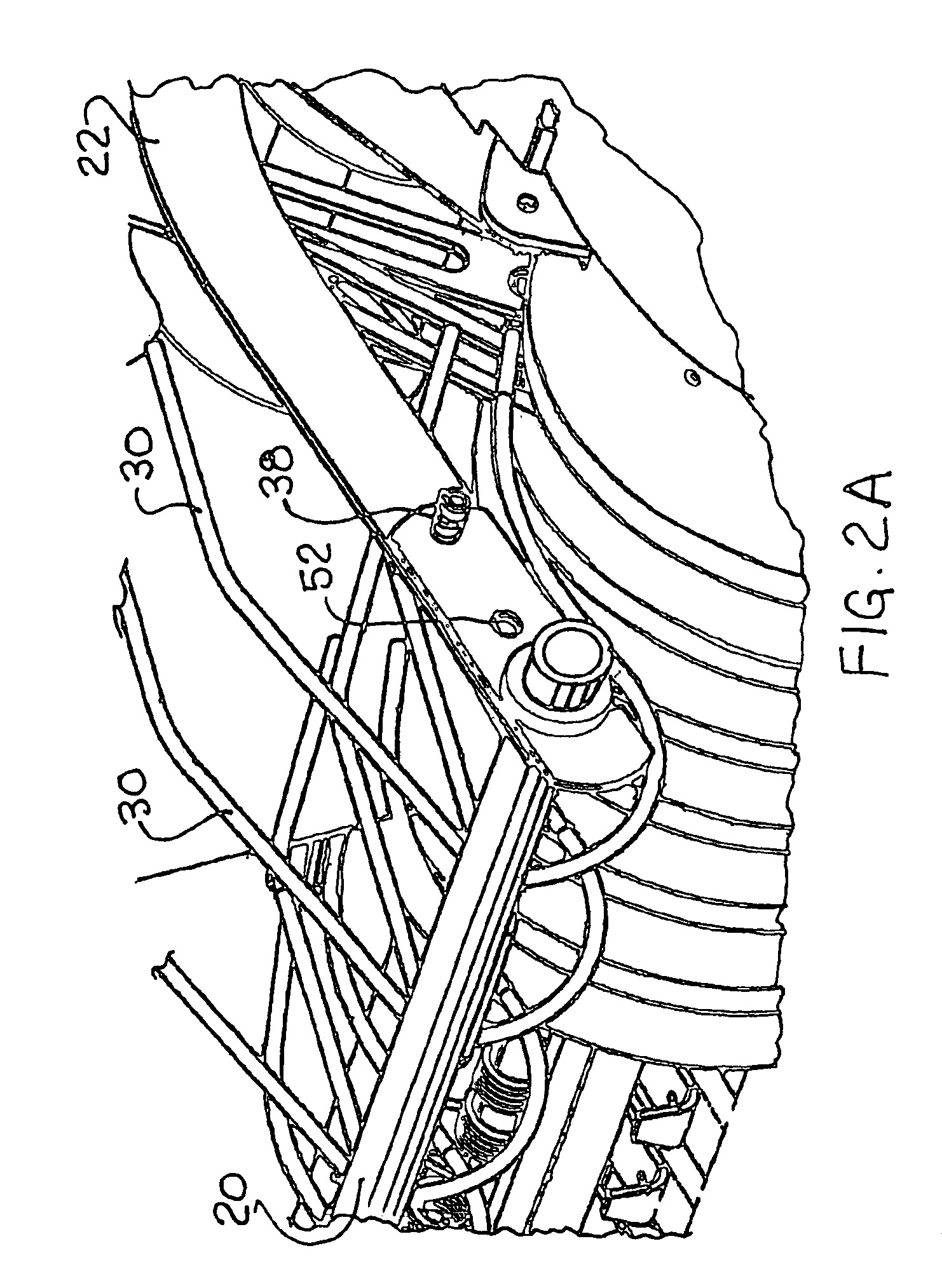

Combine header height control

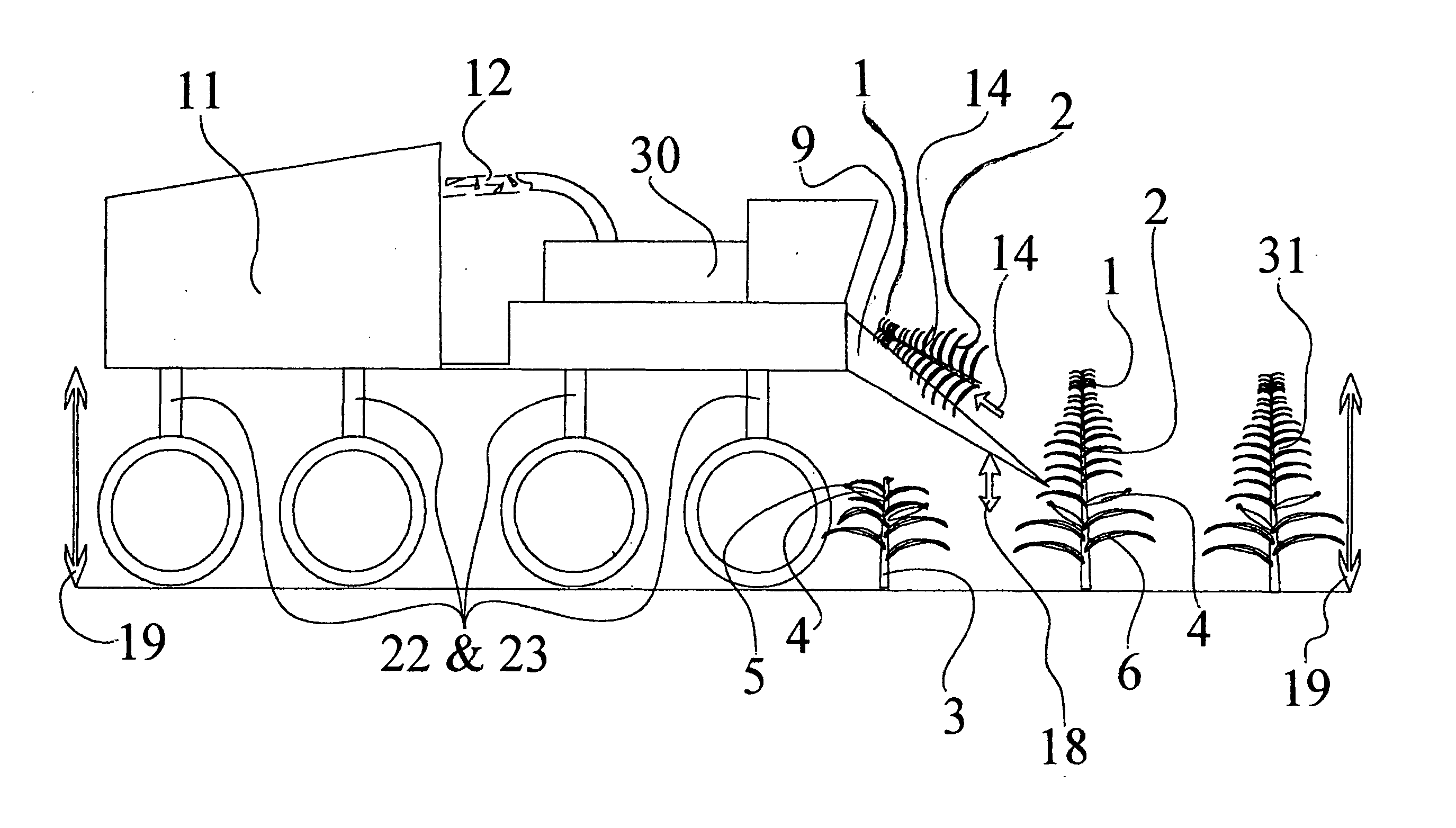

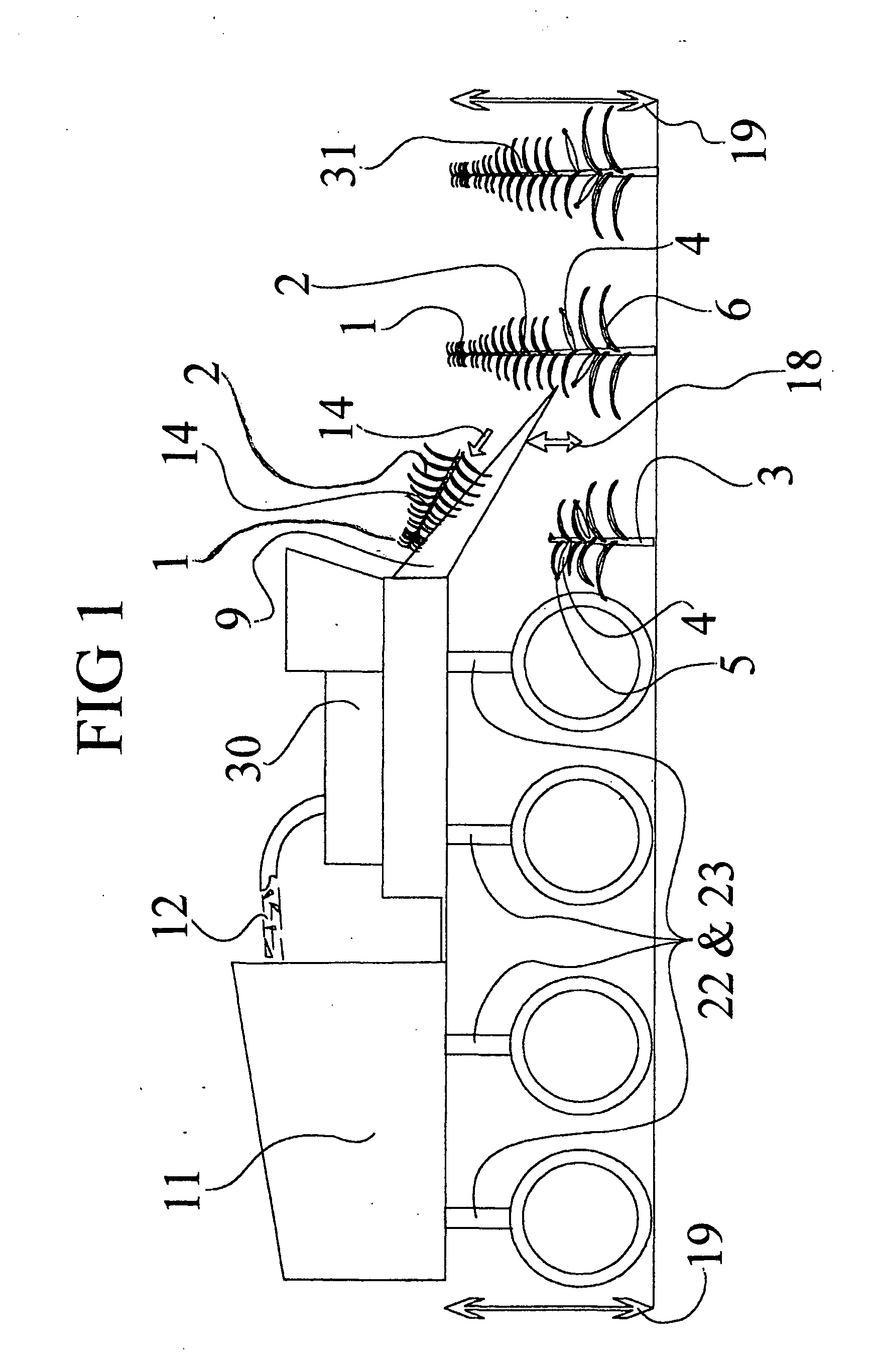

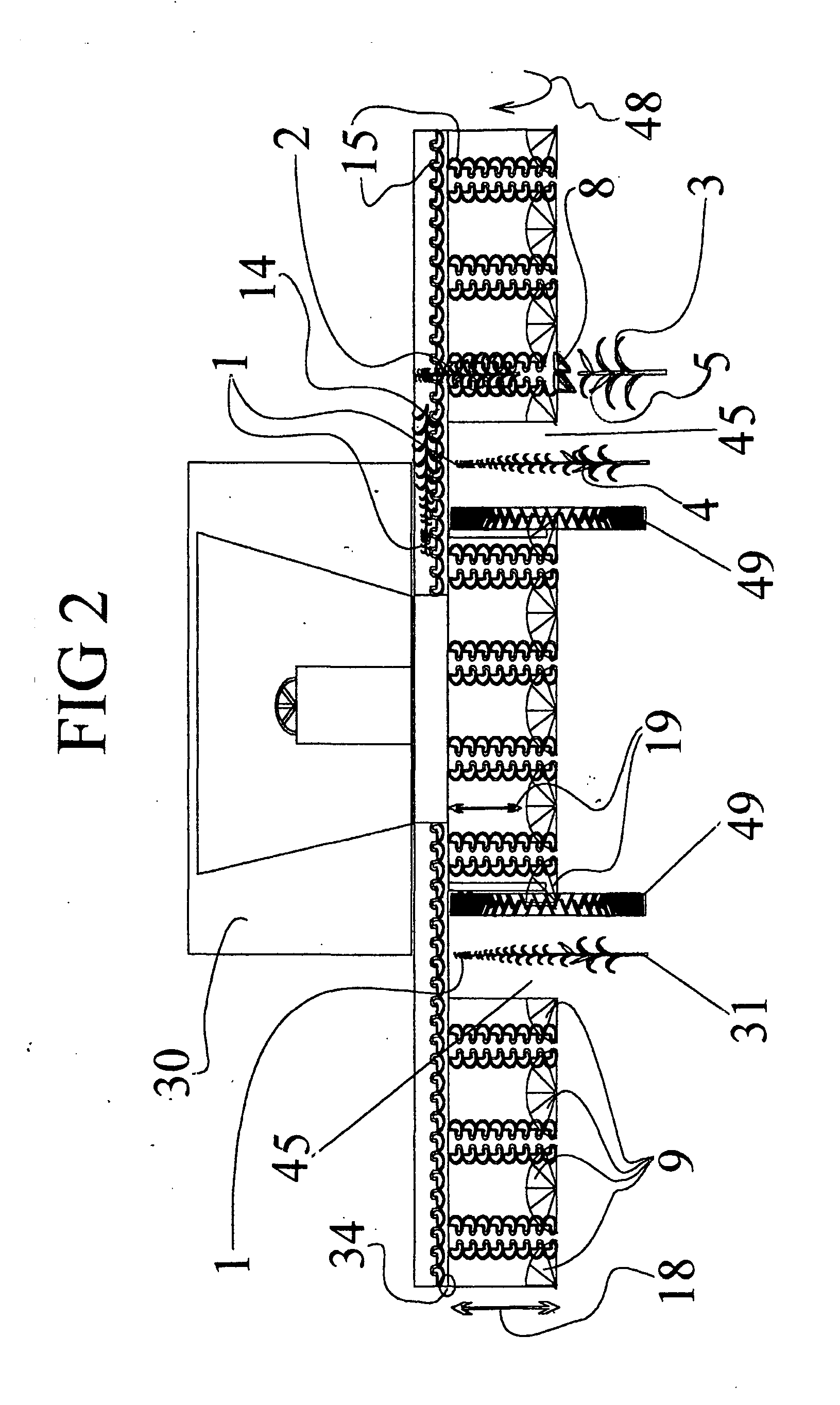

InactiveUS6202395B1Accurate height positioningReduce combine ingestionAgricultural machinesMowersCoil springEngineering

An arrangement for controlling the height above or depth below an irregular surface of a body moving over or below the surface includes a rotation sensor coupled to a controller responsive to an angular deflection signal output by the rotation sensor. The rotation sensor and controller are mounted to a vehicle moving over the surface such as an agricultural vehicle traversing a field. A semi-rigid, flexible arm has a first end coupled to the rotation sensor with a ground engaging member attached to a second opposed end of the arm. In one embodiment, the flexible arm includes an elongated coil spring attached to a rigid shaft and the ground engaging member is a spherical ball attached to the shaft's distal end. The coil spring is pre-loaded to a selected bending or flexure force and permits the ground engaging member to impact obstructions in the field without damage to the rotation sensor. The coil spring also prevents damage to the rotation sensor when the vehicle is reversed in direction. The flexible arm may be urged downwardly to ensure that the ground engaging member contacts the soil and upward and downward rotation stops may be provided to limit rotation of the rotation sensor and flexible arm combination. When a plurality of rotation sensors and flexible arms are employed such as along the length of a combine header, each rotation sensor may be individually calibrated by rotating the sensor relative to the head unit to which it is mounted to permit all sensors to uniformly measure the height above or depth below the soil surface.

Owner:GRAMM RICHARD

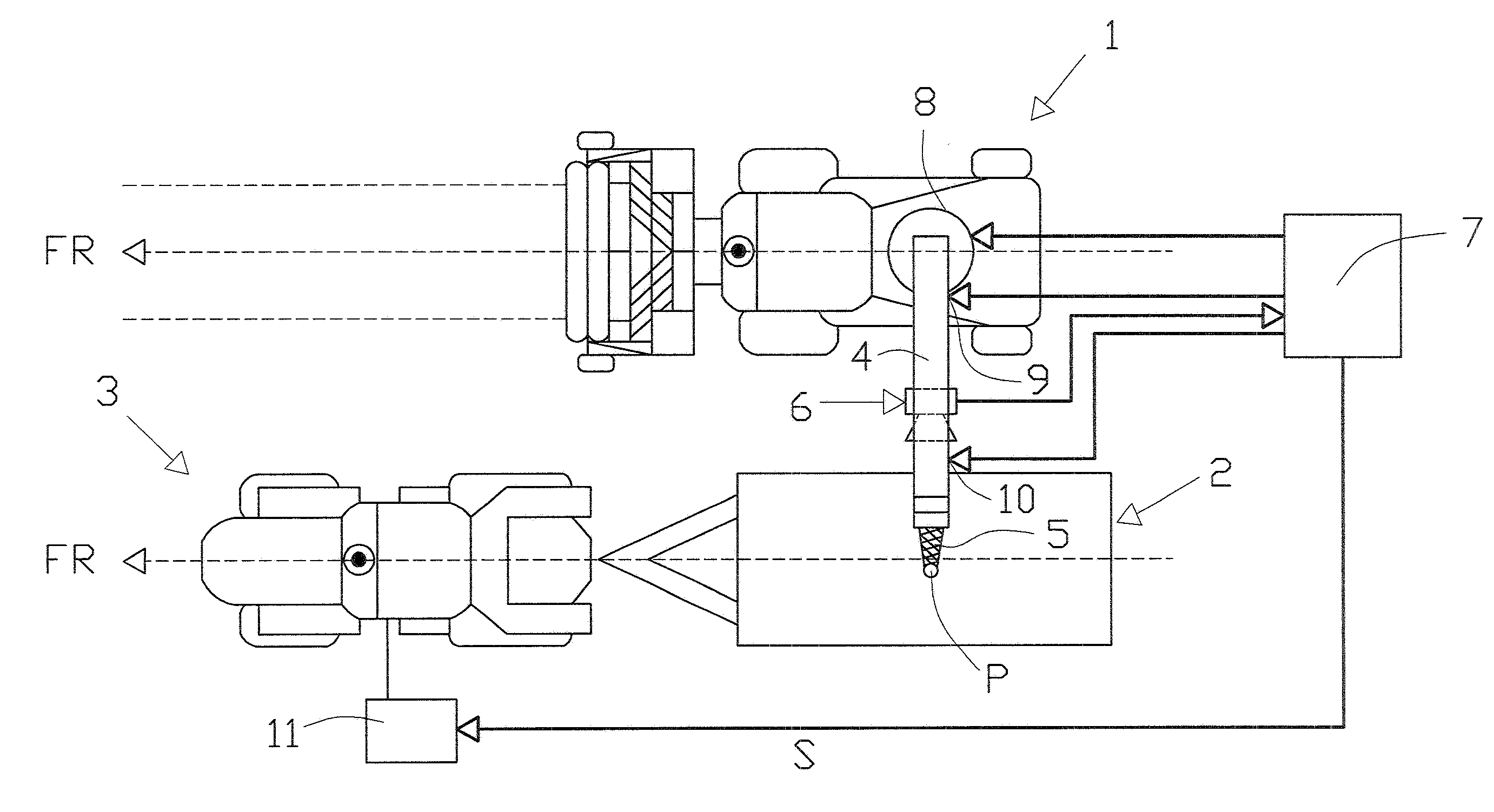

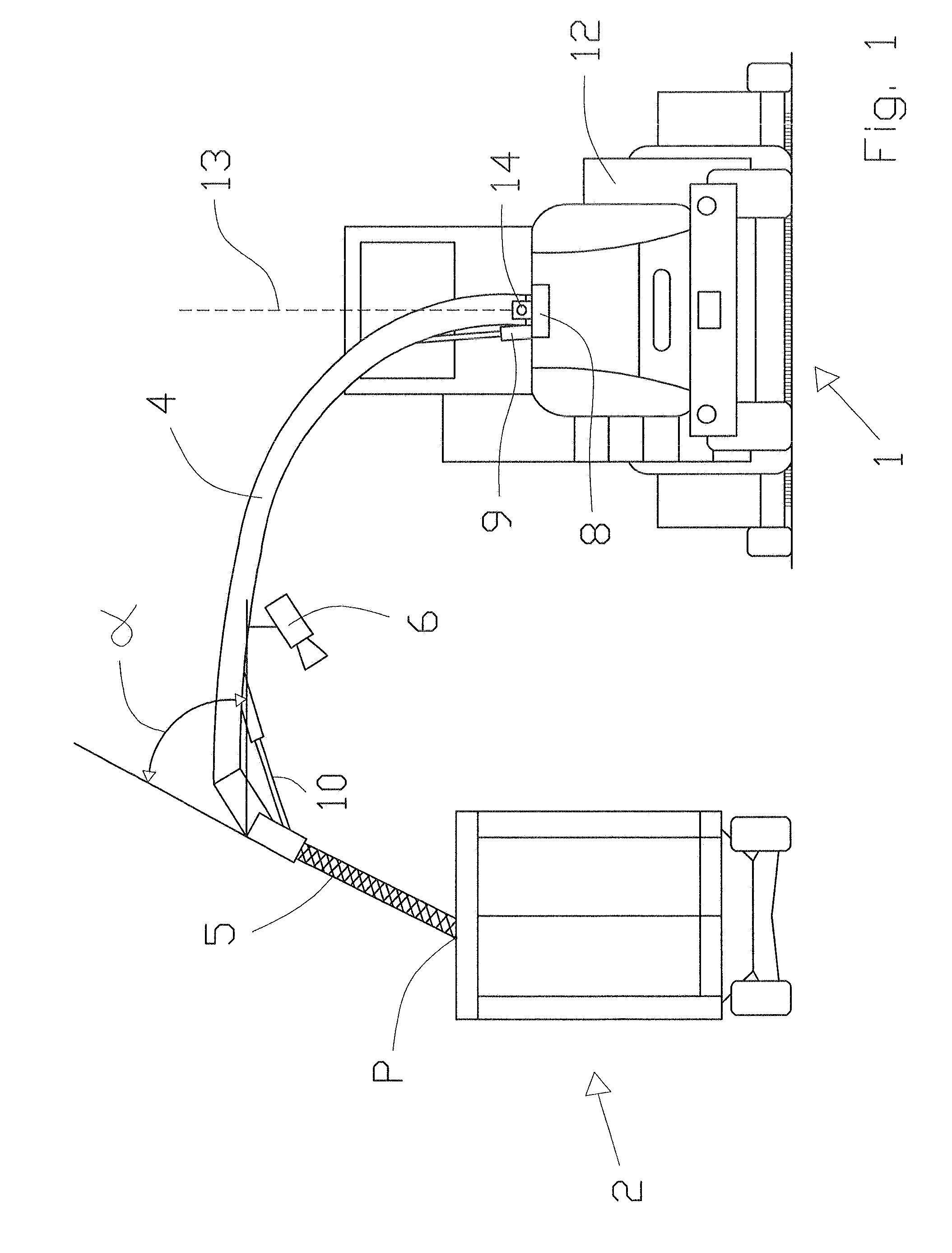

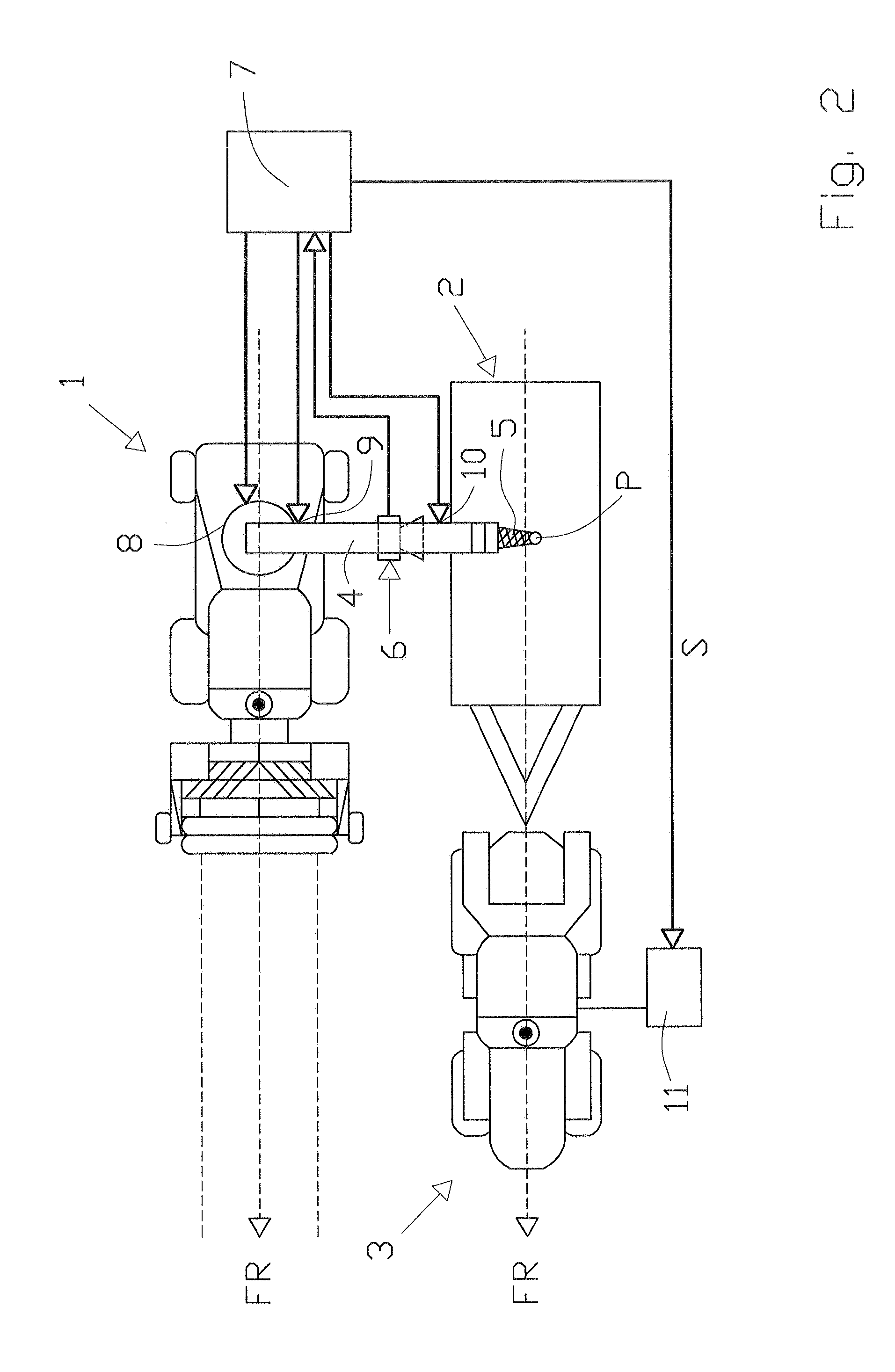

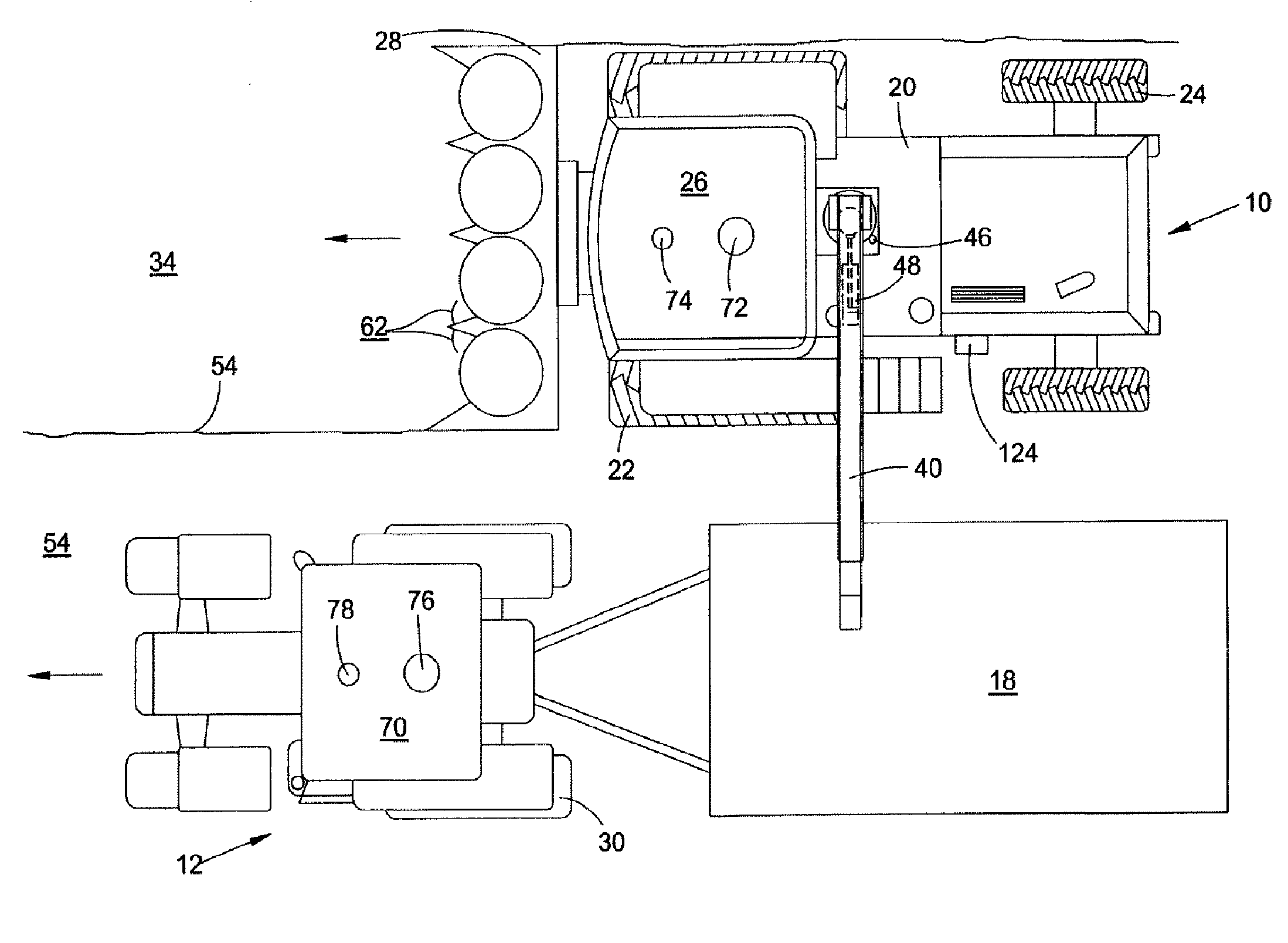

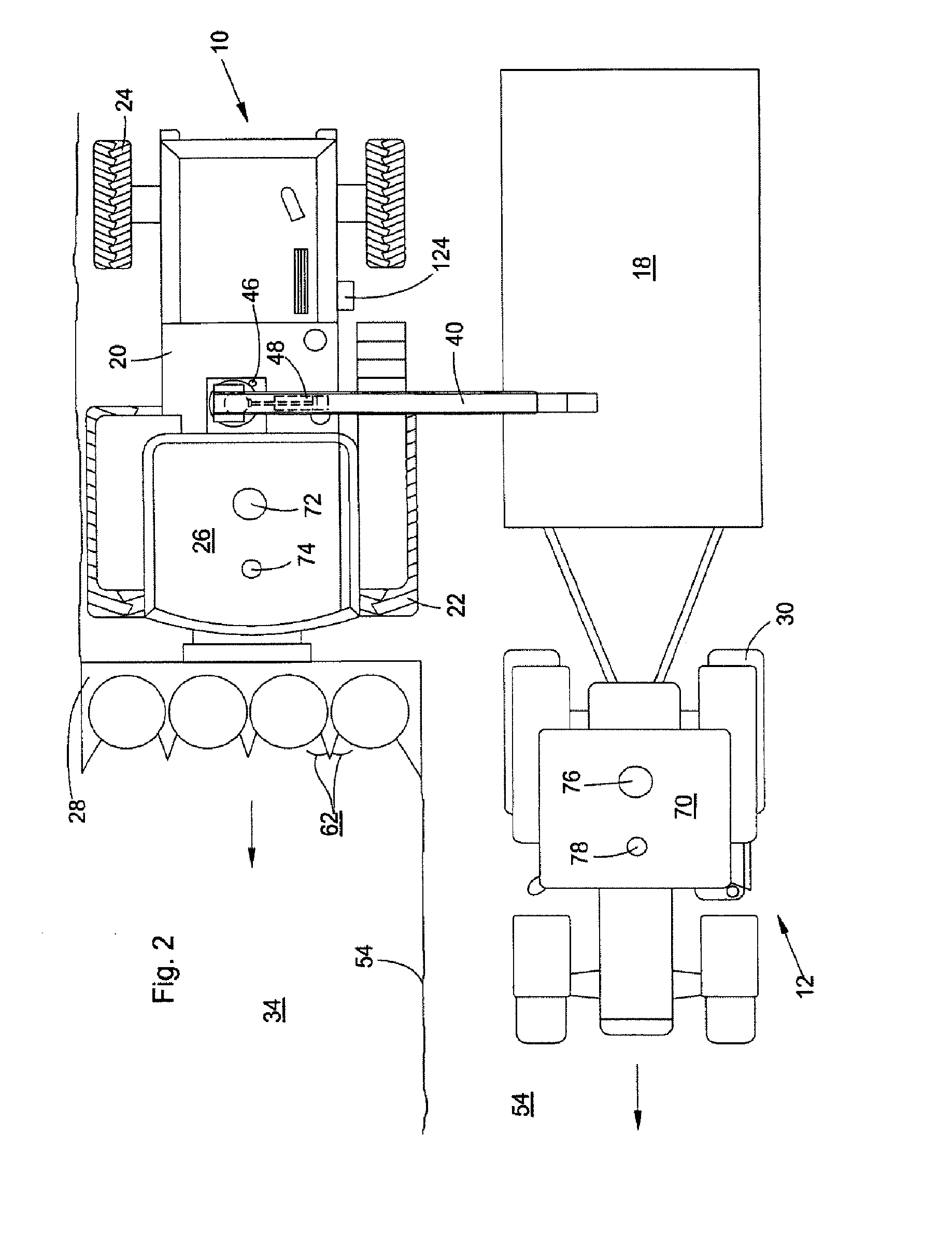

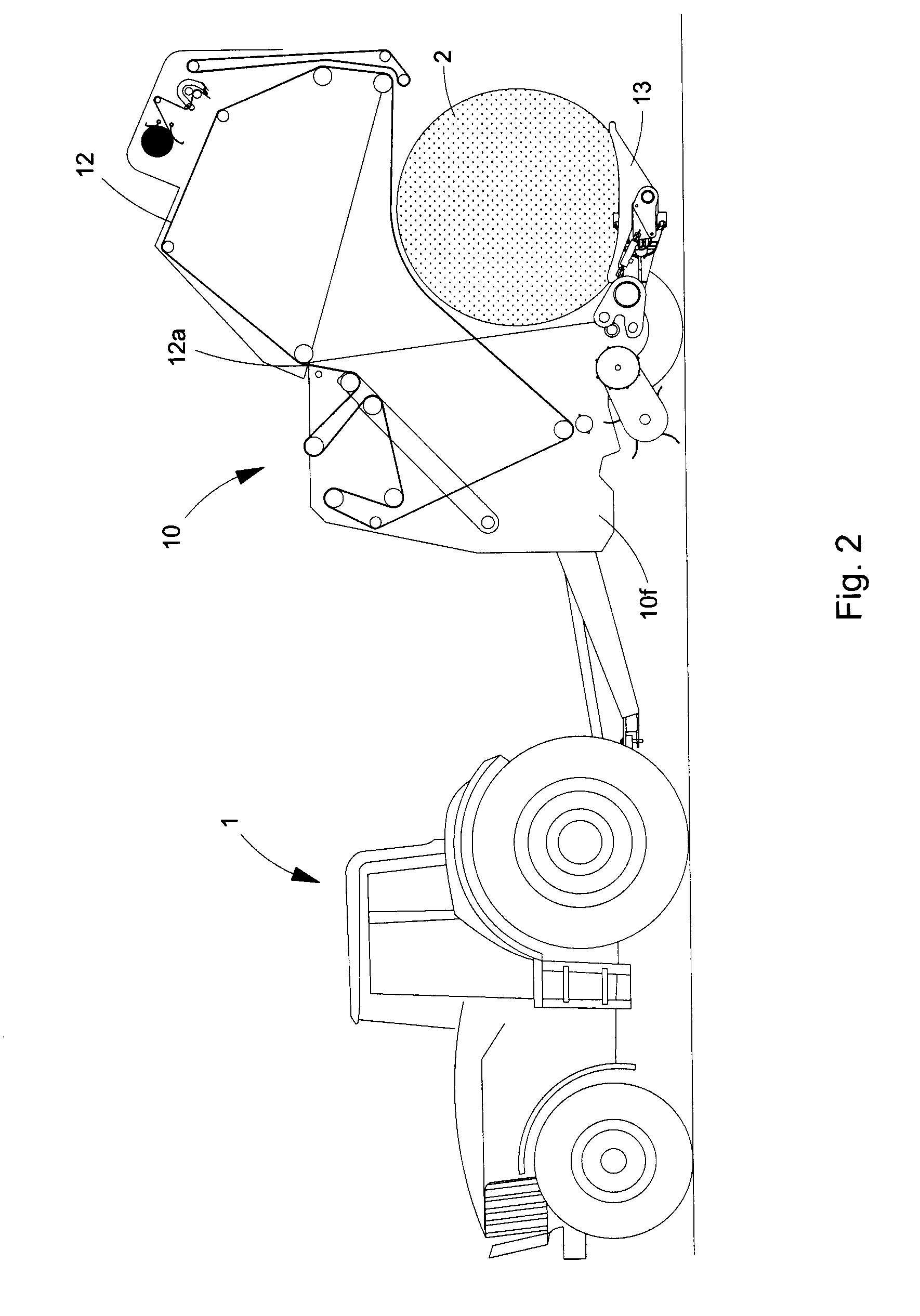

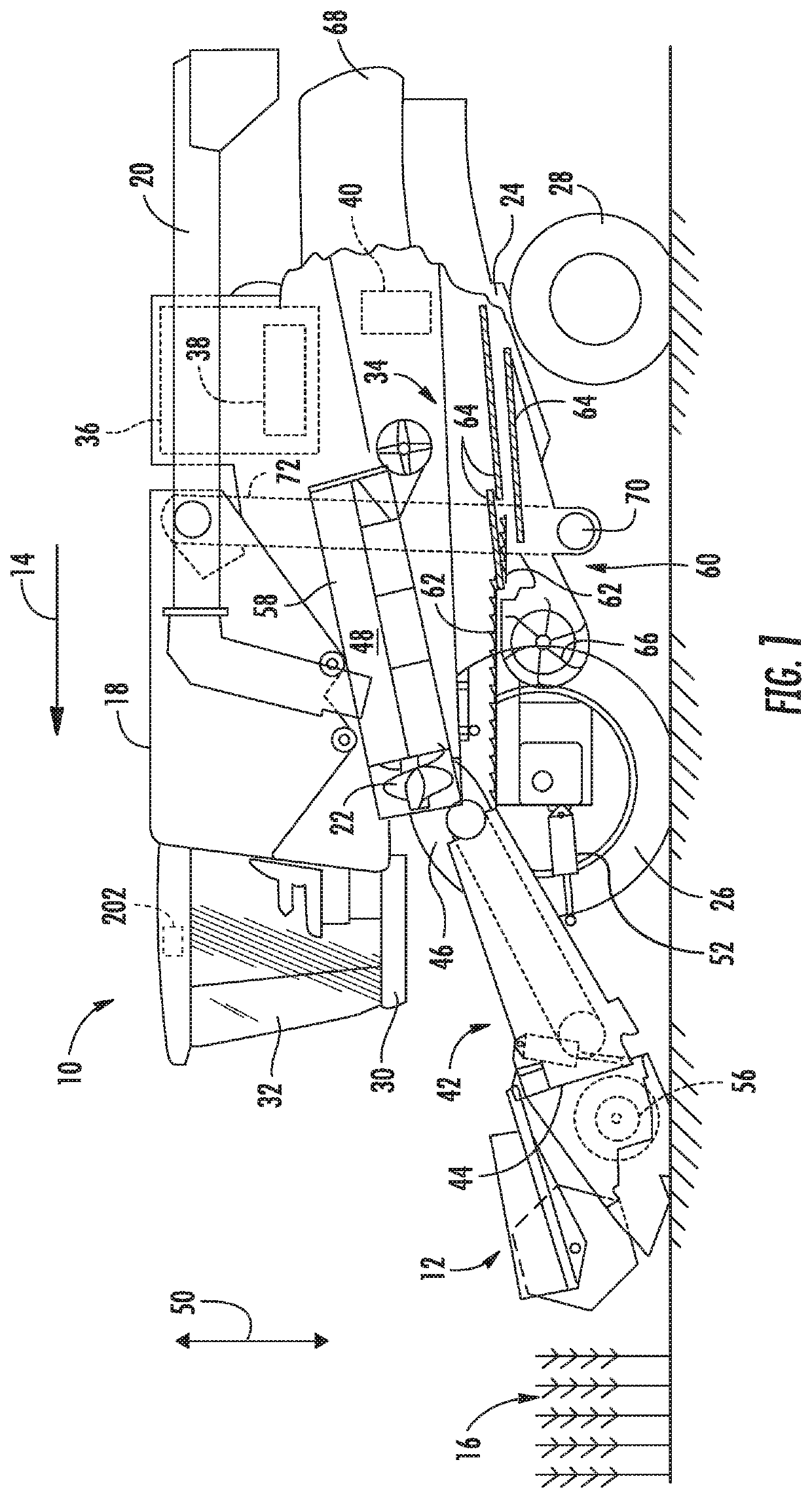

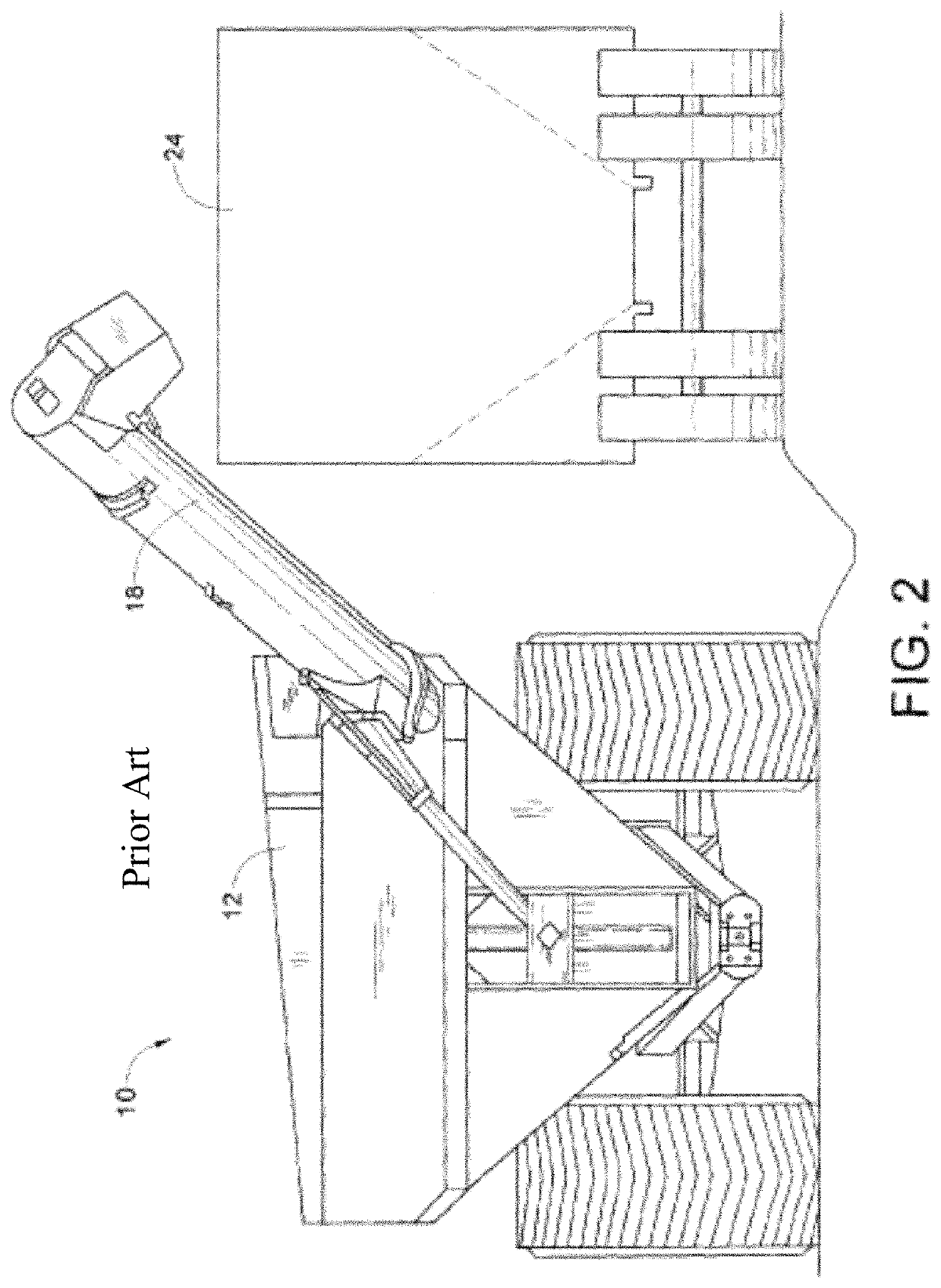

System and method for controlling crop transfer

InactiveUS20120263560A1Good reliefFast influenceMowersStorage devicesAgricultural scienceControl signal

A system for controlling crop transfer from a self-propelled agricultural harvesting machine into the loading container of a hauling vehicle includes a transfer device assigned to the harvesting machine from which the crop emerges in the form of a crop discharge flow and a detection device which detects the position of the loading container relative to the harvesting machine and transmits it to a control unit. The control unit actuates at least one actuator assigned to the transfer device in such a way that the crop discharge flow lands within the loading container in order to fill it with crop. The control unit generates a control signal (S) for the hauling vehicle that specifies a position of the hauling vehicle relative to the harvesting machine that is suitable for transfer into the loading container.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

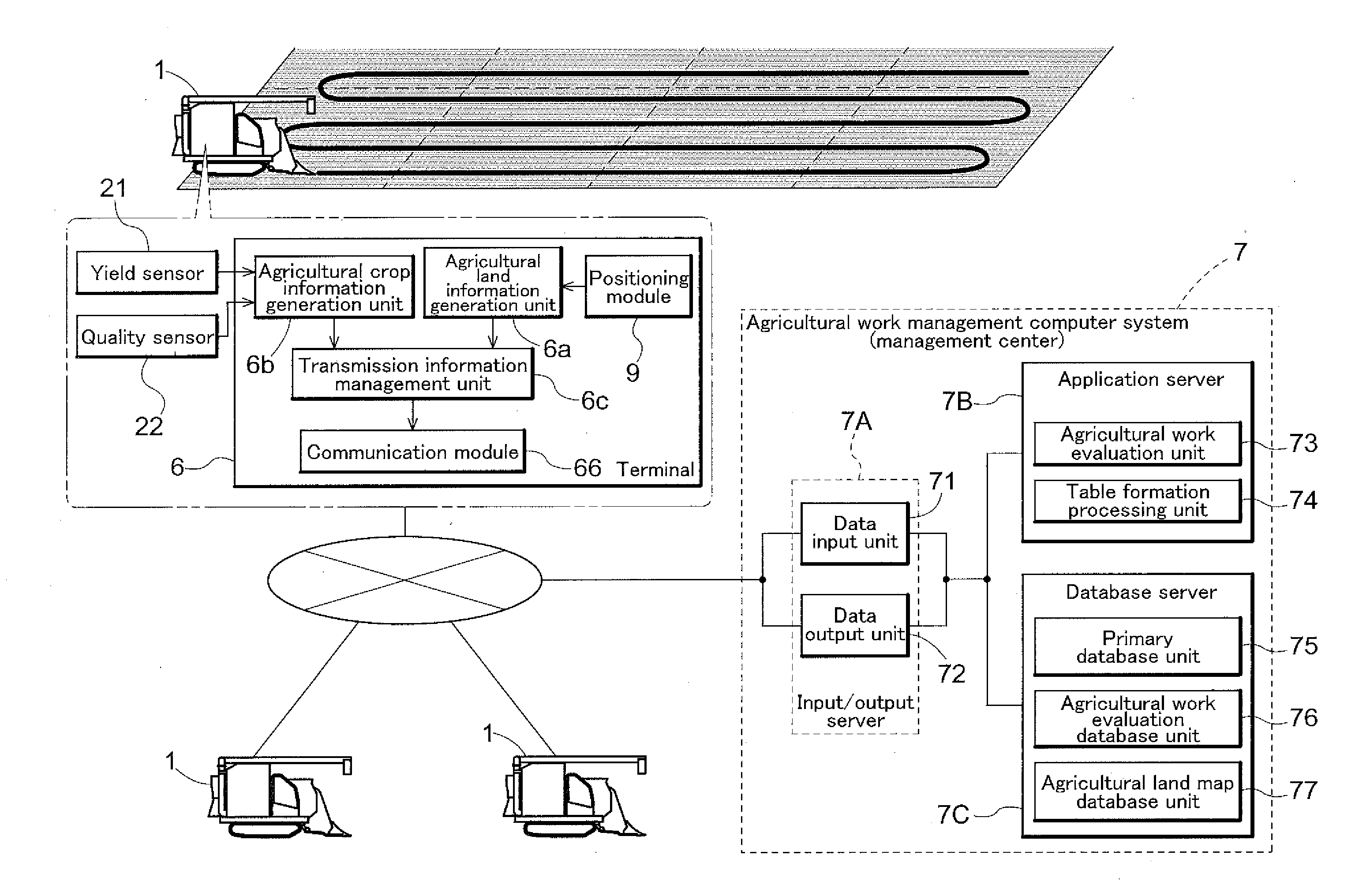

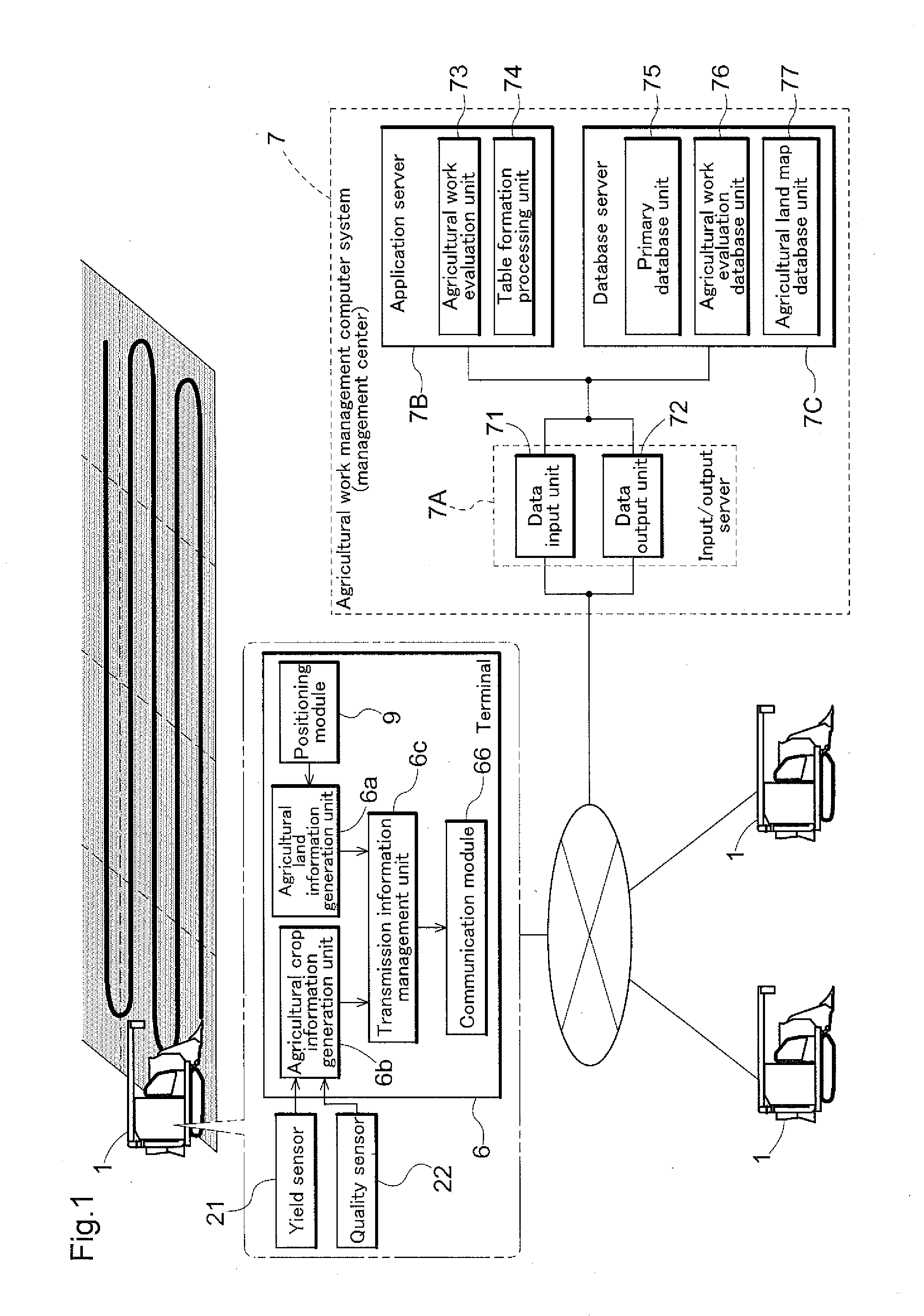

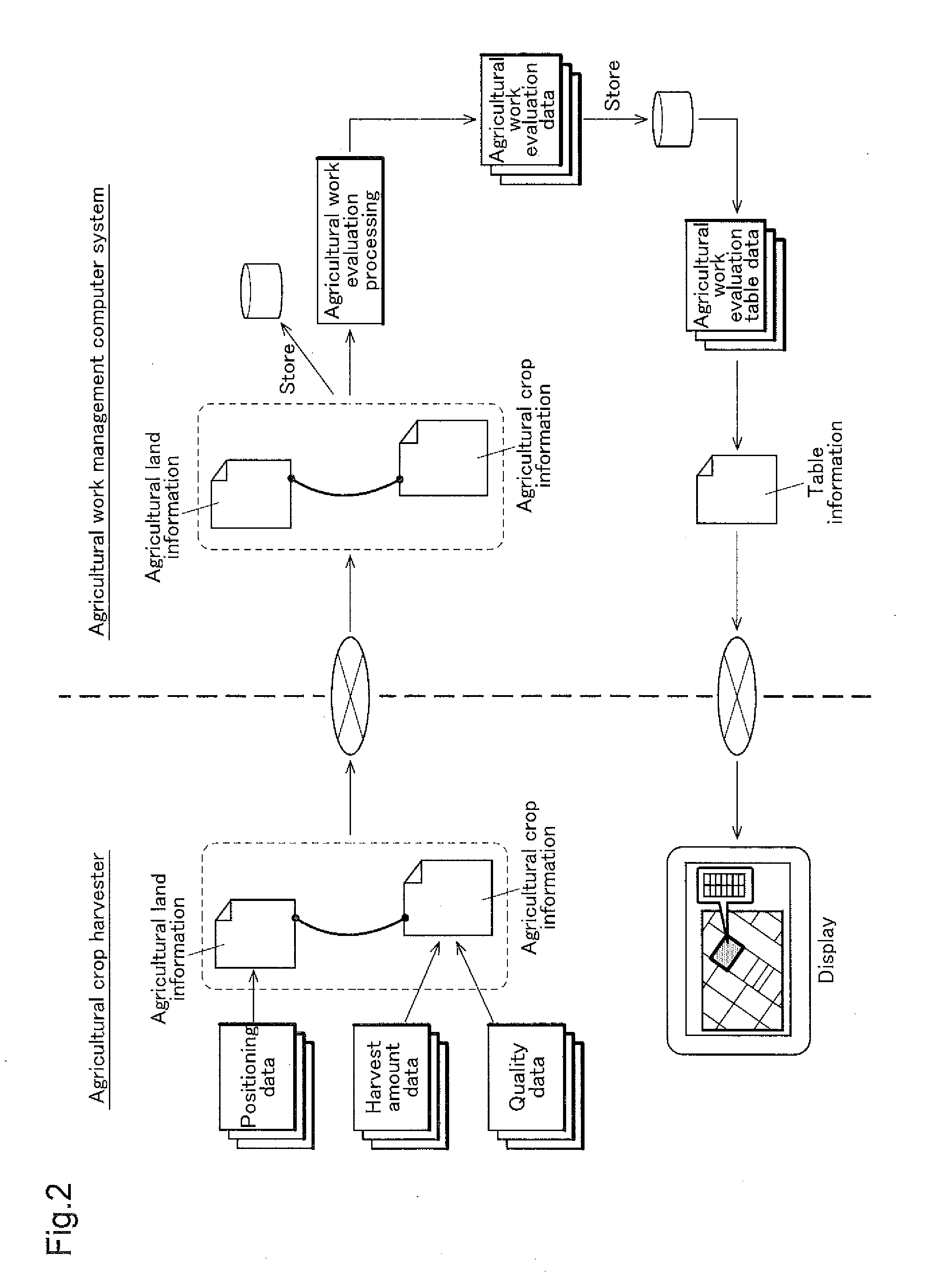

Agricultural Work Management System and Crop Harvester

ActiveUS20150242799A1Easy to useEasy to measureParticular environment based servicesMowersAgricultural landQuality data

An agricultural work management system includes: a data input unit configured to receive, from an agricultural crop harvester, harvesting position data indicating a harvesting work position as agricultural land information, harvest amount data indicating a harvest amount of the agricultural crop harvested in the agricultural land, and quality data indicating the quality thereof as agricultural crop information; a database server configured to store the agricultural land information and the agricultural crop information such that they can be associated with each other; an agricultural work evaluation unit configured to perform agricultural work evaluation on the agricultural land based on the agricultural land information and the agricultural crop information; and a data output unit configured to send out the agricultural work evaluation data generated by the agricultural work evaluation unit.

Owner:KUBOTA LTD

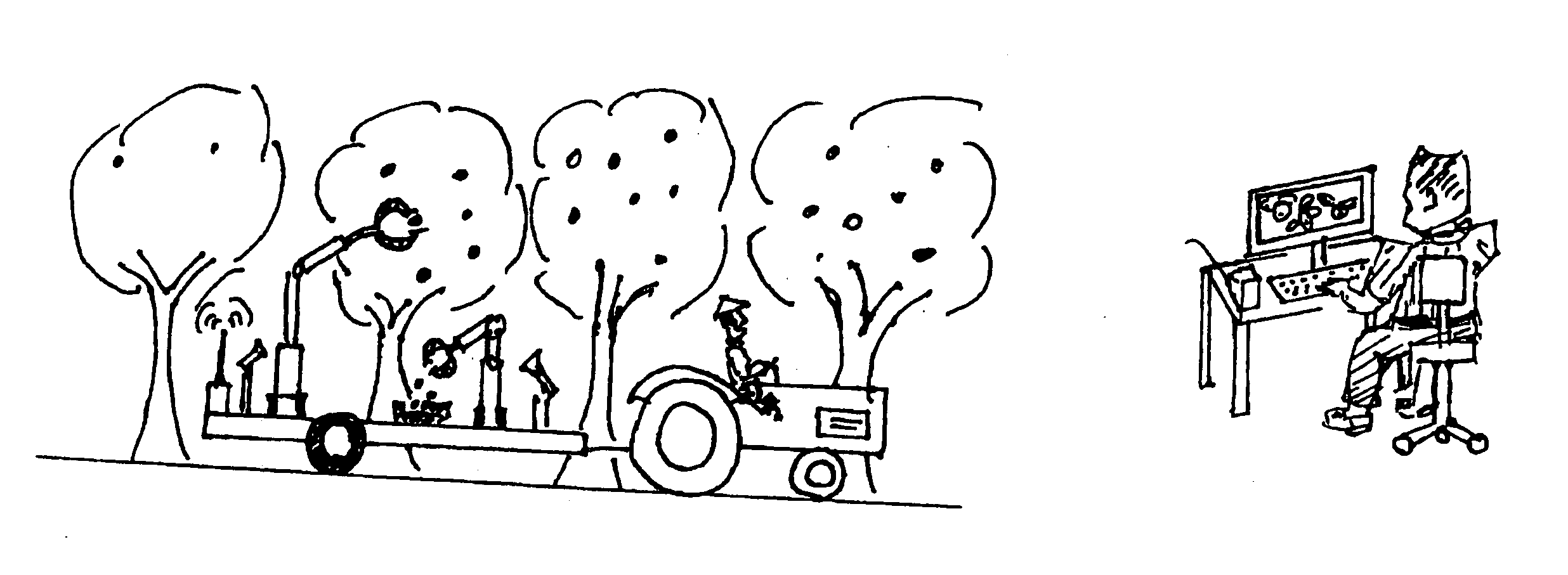

Method and apparatus for remotely assisted harvester

The present invention provides methods for remotely assisted harvesting. Additionally, the present invention provides a harvester that is assisted by a remote operator. The apparatus is designed to be moved through a field harvesting agricultural products. Cameras of the apparatus image the objects to be harvested. The image is sent through a set of antennas and cables to a remote operator who can command the camera pointing, view the crop, and selected fruit to be harvested. The objects are harvested with flexible arms and a collection device. The cameras, harvester arms, collectors, and communication equipment are controlled by a computer on the harvesting apparatus. The object selection information is transmitted to the harvester from the remote operator. The harvester computer uses the selection information to guide the collectors to a location near the object to be harvested. The harvester computer then uses sensors on the collector to precisely locate the object. The collector then collects the object.

Owner:STIMMANN ERIC

Control arrangement for controlling the transfer of agricultural crop from a harvesting machine to a transport vehicle

A control arrangement and method for controlling the transfer of agricultural crop from a harvesting machine to a transport vehicle comprises a loading container. The control arrangement is able to be operated to automatically deposit the crop during the harvesting mode successively at different points in the loading container, following a predetermined loading strategy, by means of a discharging device of the harvesting machine, where the loading strategy may be changed and / or a choice may be made between different loading strategies.

Owner:DEERE & CO

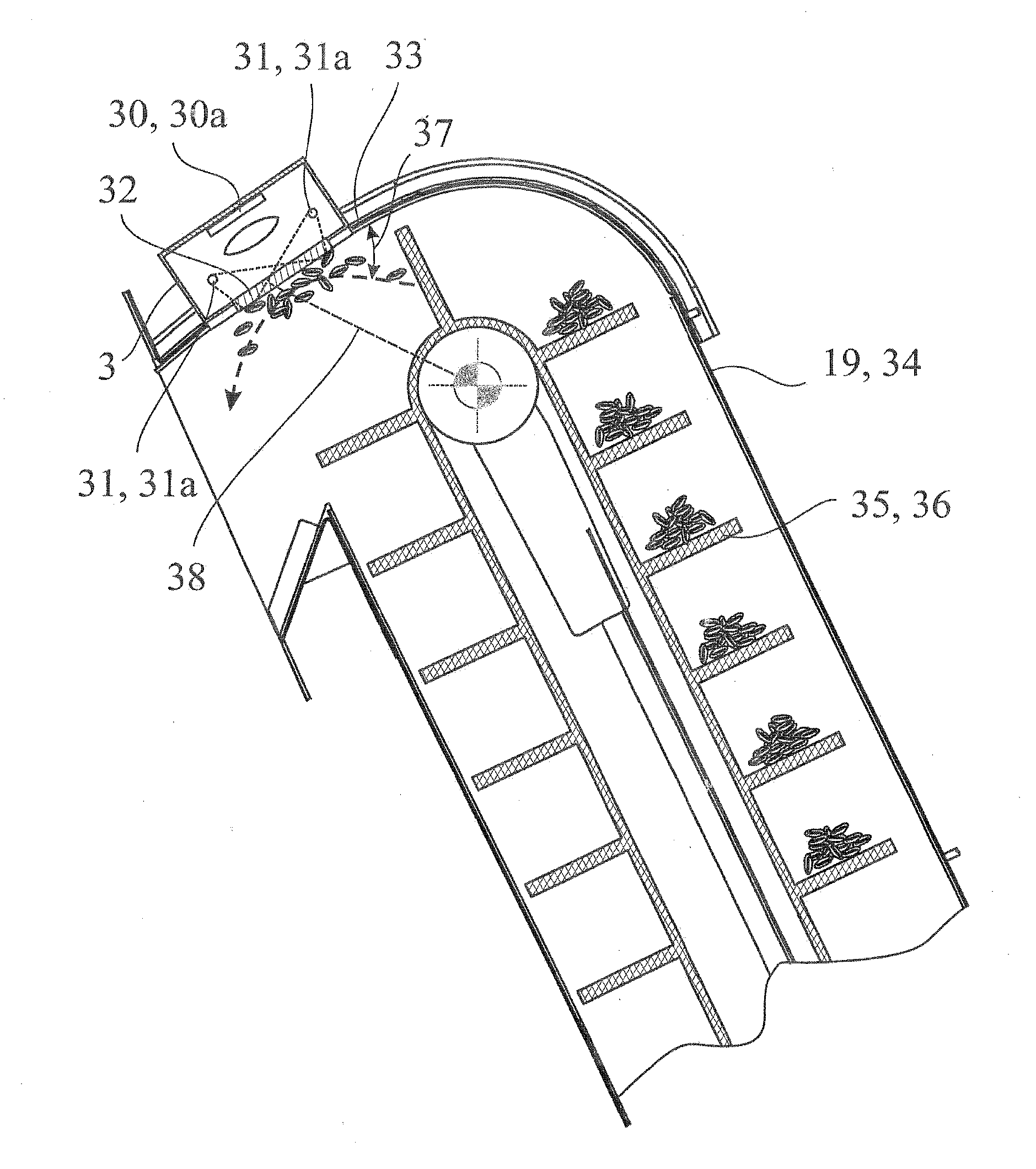

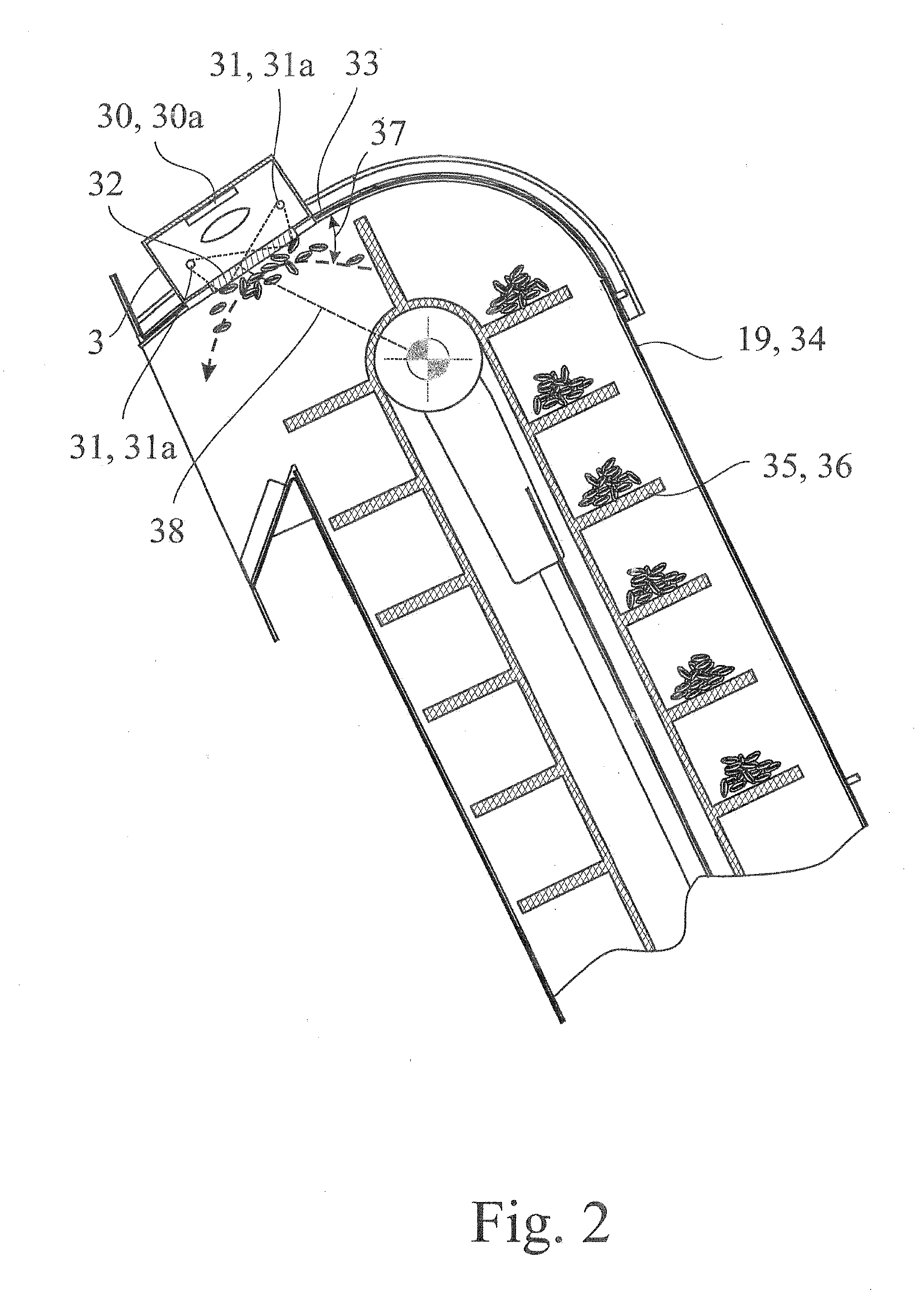

Agricultural harvesting machine

ActiveUS20150009328A1Accurately and rapidly estimatedEasy to identifyMowersColor television detailsAgricultural scienceImaging analysis

An agricultural harvesting machine has a control arrangement including an optical sensor device for recording image series of a continuous main crop stream, an evaluation device for ascertaining a portion of damaged grain, a portion of non-grain in the main crop stream or both, on the basis of an image analysis of the recorded image series and a visualization device for displaying the portion of damaged grain and / or the portion of non-grain. The control arrangement cyclically records image series of the continuous main crop stream and, within a predetermined processing time after an image series has been recorded, displays a current portion of damaged grain, a current portion of non-grain or both, based on the image series.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

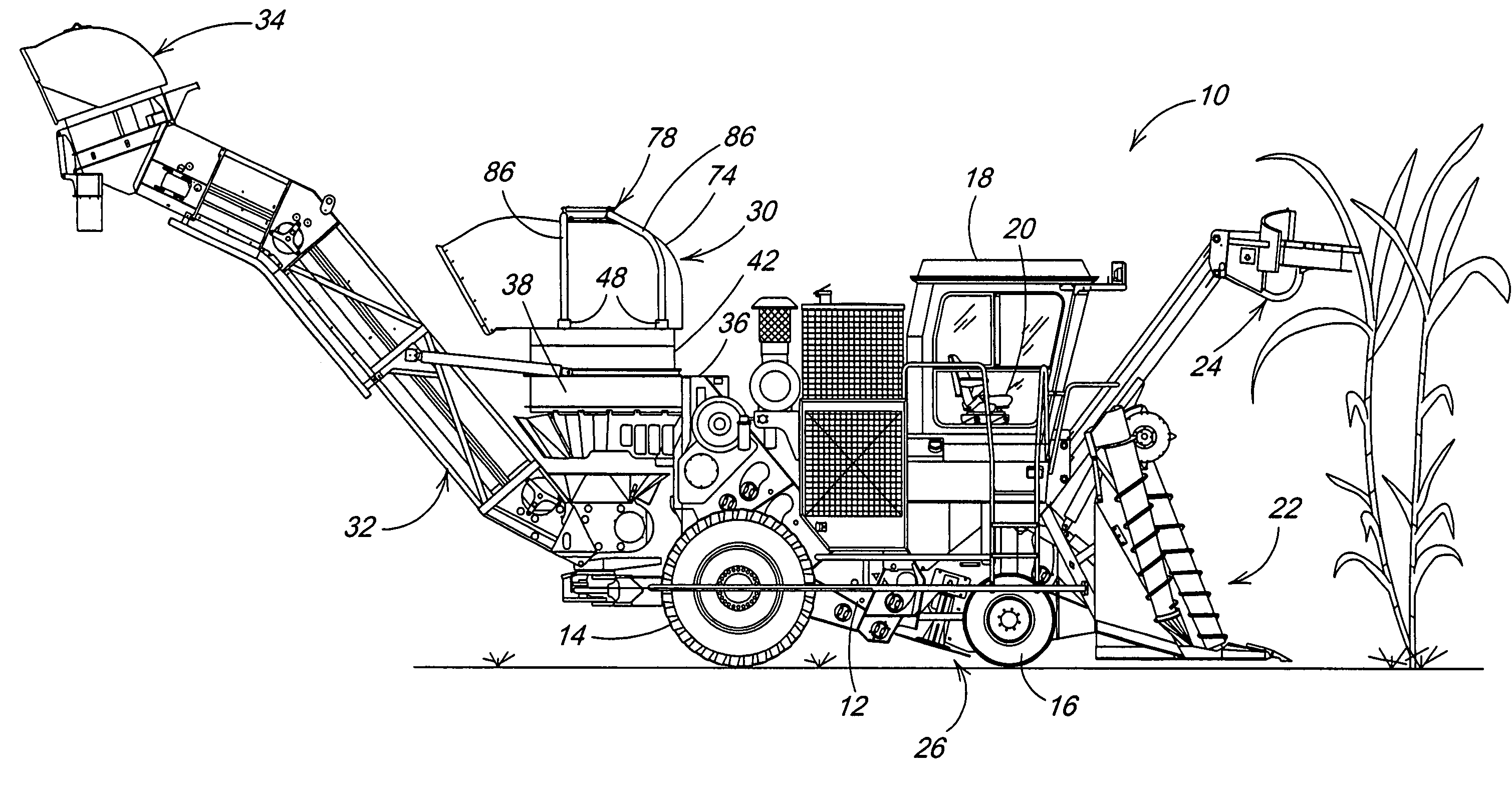

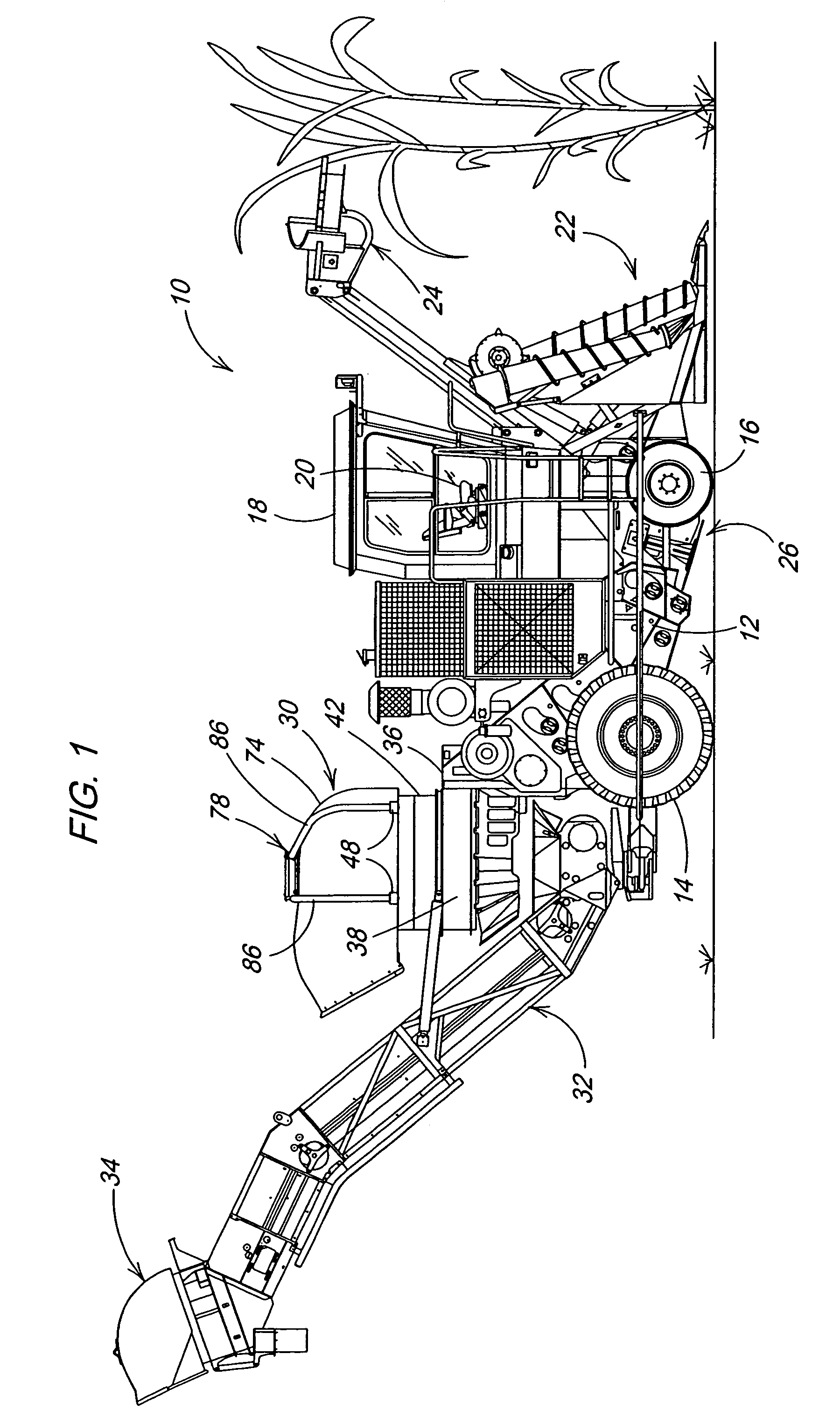

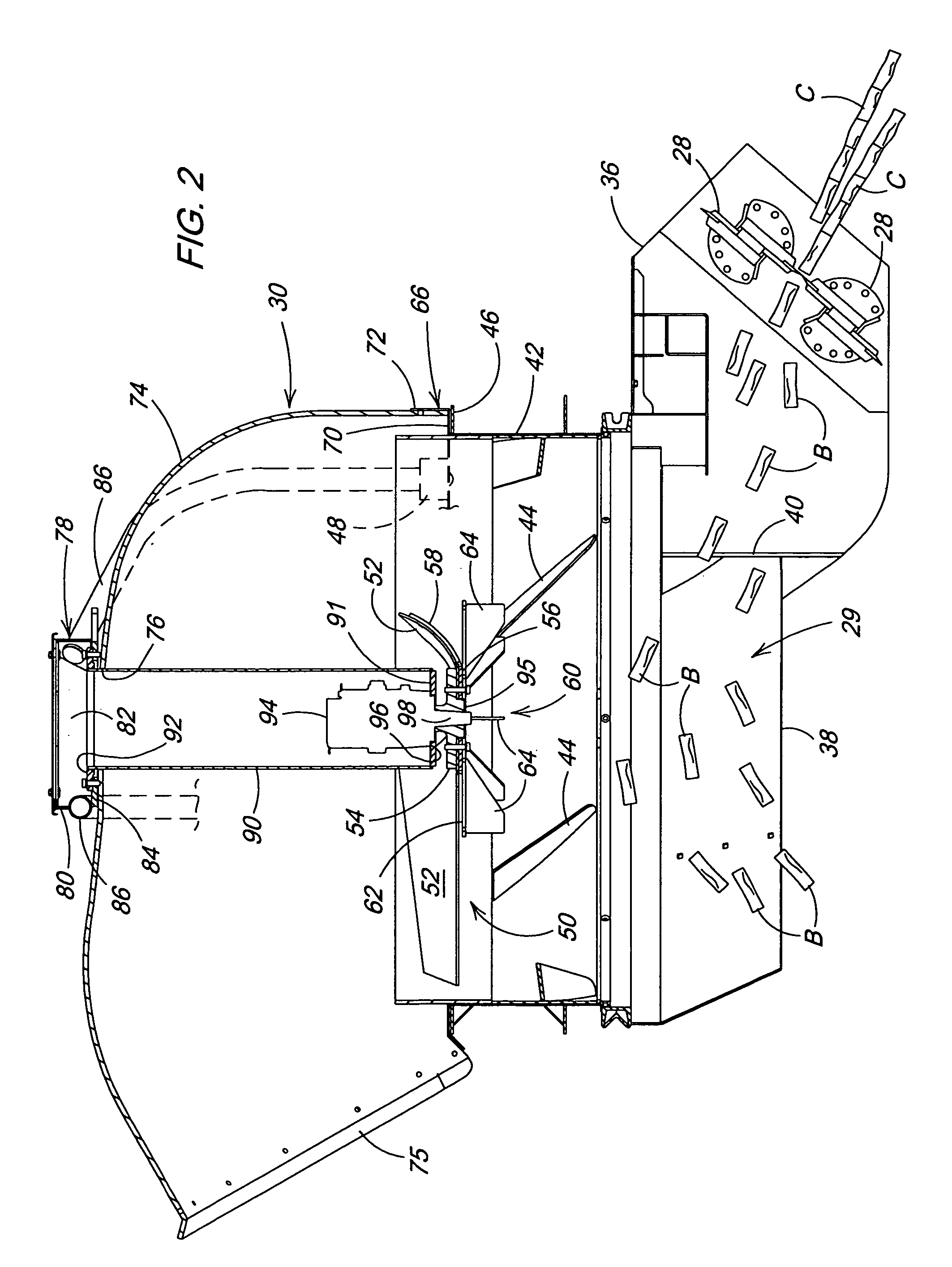

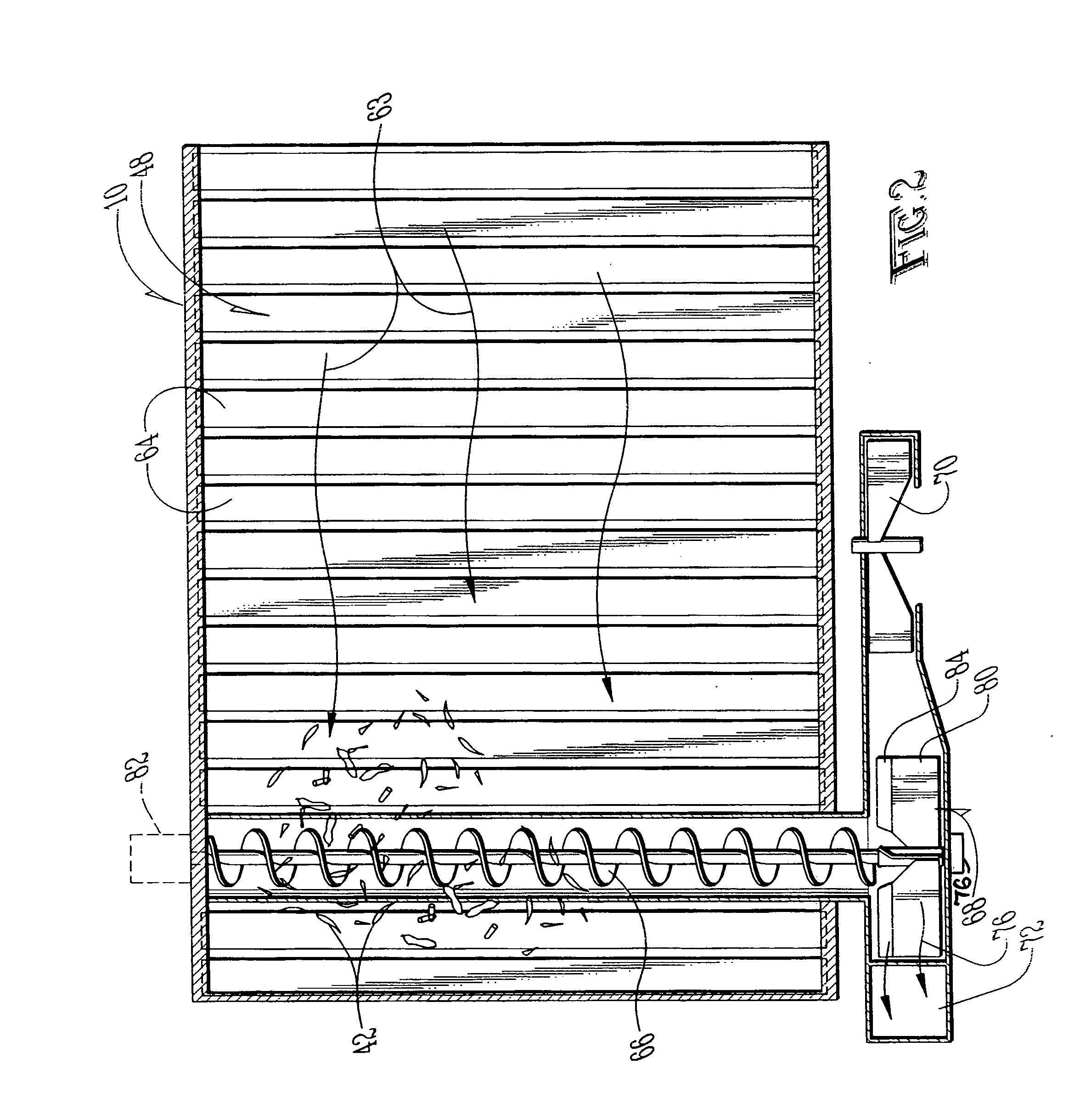

Cleaning chamber and method for a sugarcane chopper harvester

A sugarcane chopper harvester is equipped with a cleaning chamber for cleaning extraneous leafy matter and dirt from harvested and chopped cane delivered to the chamber. Located within the chamber is an axial flow fan for effecting an upward flow of air including a high-velocity, outer, ring-shaped upwardly flowing air stream. Mounted to the bottom of the axial flow fan is a blower wheel for creating an upwardly and outwardly flowing air stream beneath the center of the axial flow fan such that leafy matter and dirt passing into the middle of the cleaning chamber below the axial flow fan is caused to be directed outwardly to the high-velocity, ring-shaped stream of air.

Owner:DEERE & CO

Collecting kernels of corn and cobs

ActiveUS20080261668A1Reduces corn cob lossReduce cloggingSievingScreeningImpellerAgricultural engineering

A combine is provided with an improved system for collecting agricultural material, such as stover, from an agricultural field. The combine is provided with an impeller to assist in driving stover through a duct and into a container. The combine separates and cleans the stover and any seed before directing the stover and seed into separate containers provided on the combine.

Owner:COBCO MFG

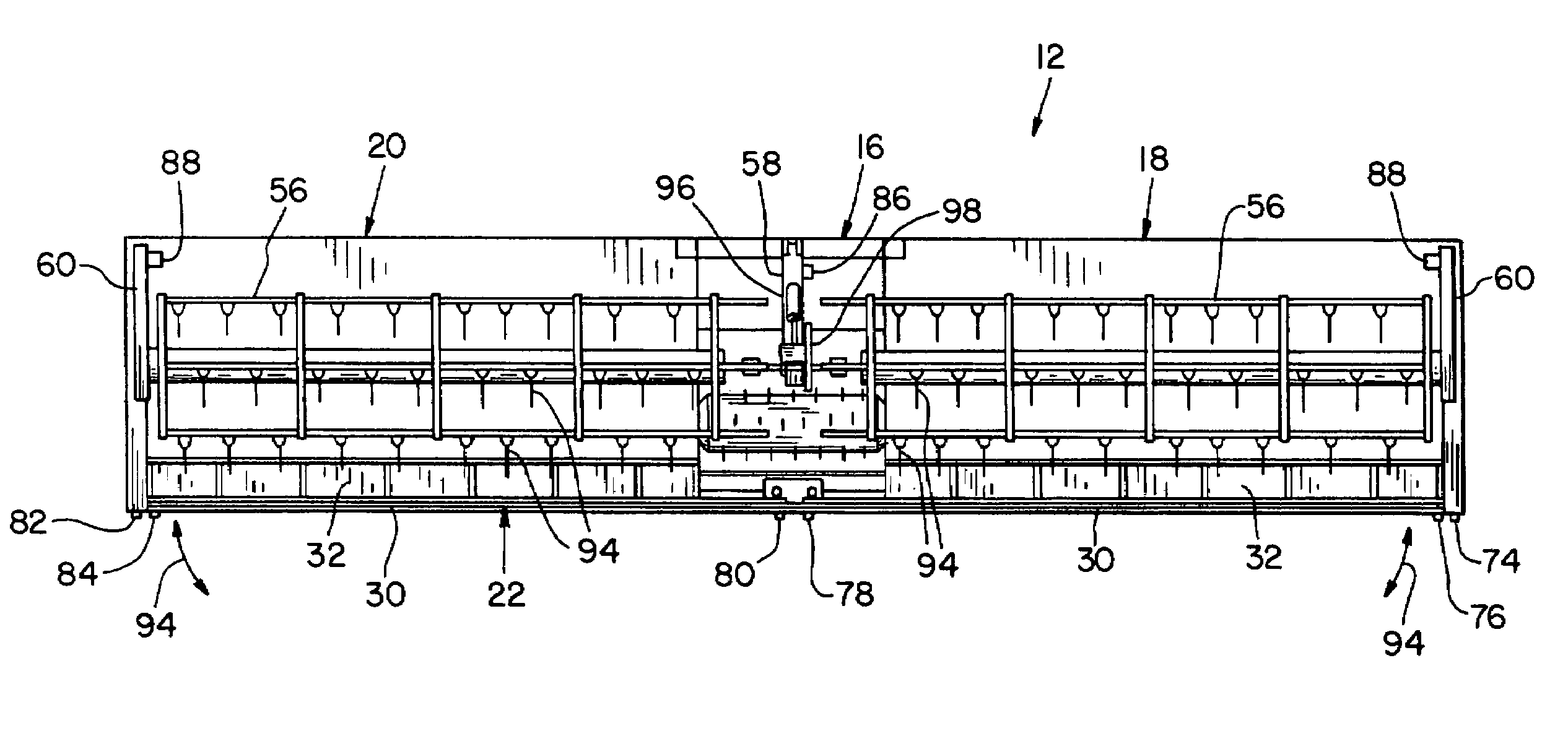

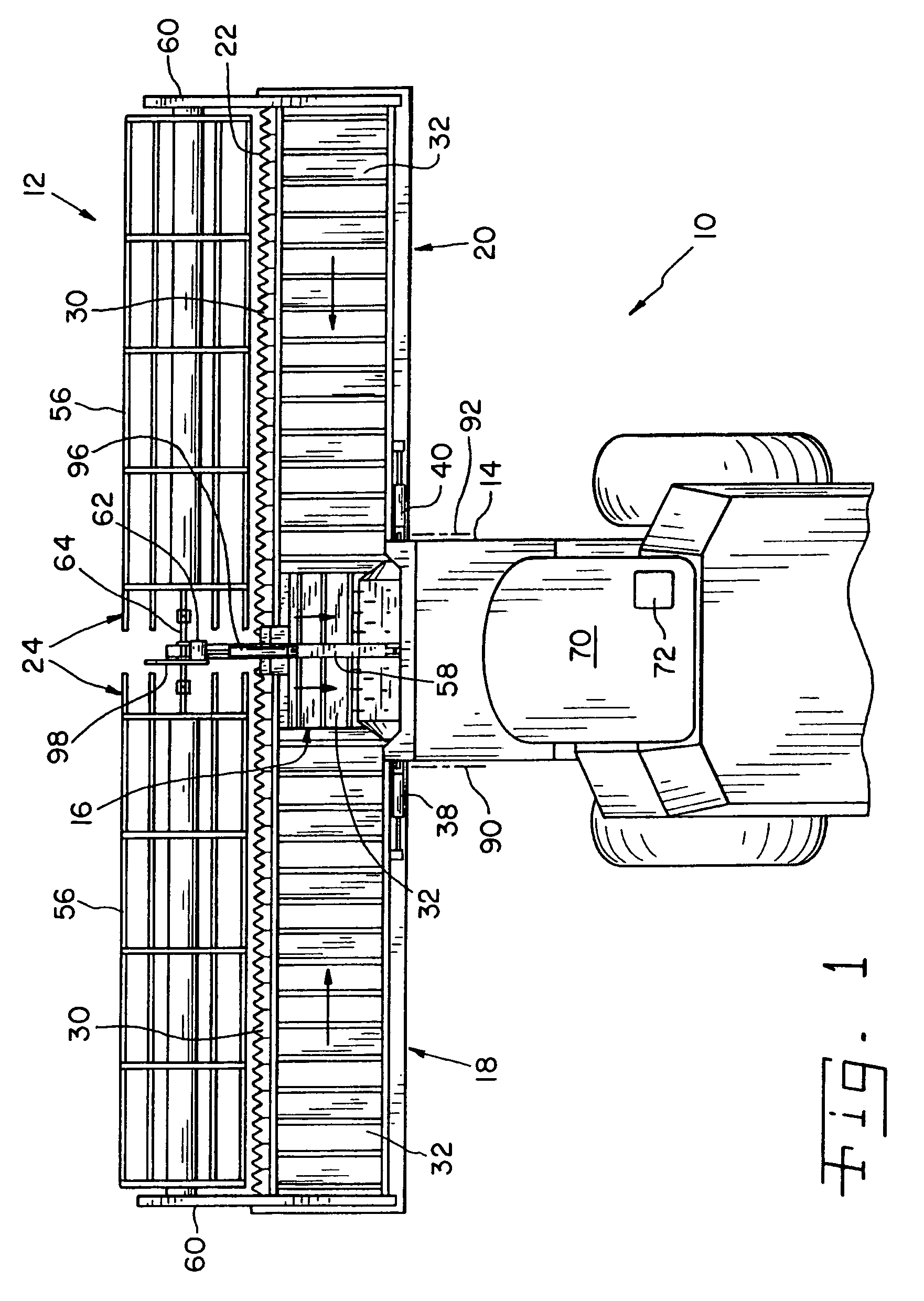

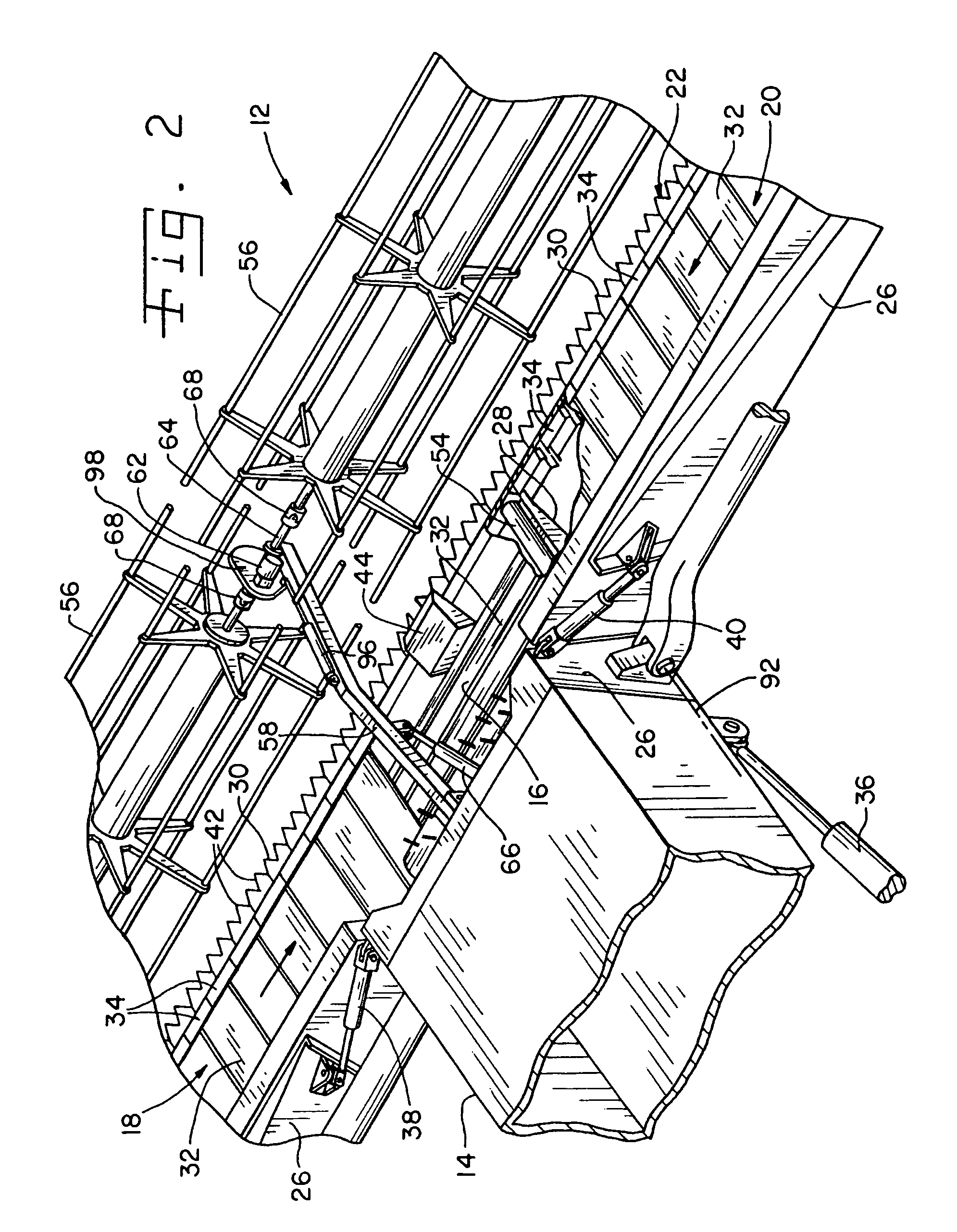

Agricultural Combine And Draper Header

ActiveUS20110270494A1Analogue computers for trafficMowersAgricultural scienceAgricultural engineering

An agricultural combine with draper header includes left and right conveyors, and a microprocessor-based controller coupled to the conveyors to determine whether one of the conveyors is overloaded or slipping.

Owner:DEERE & CO

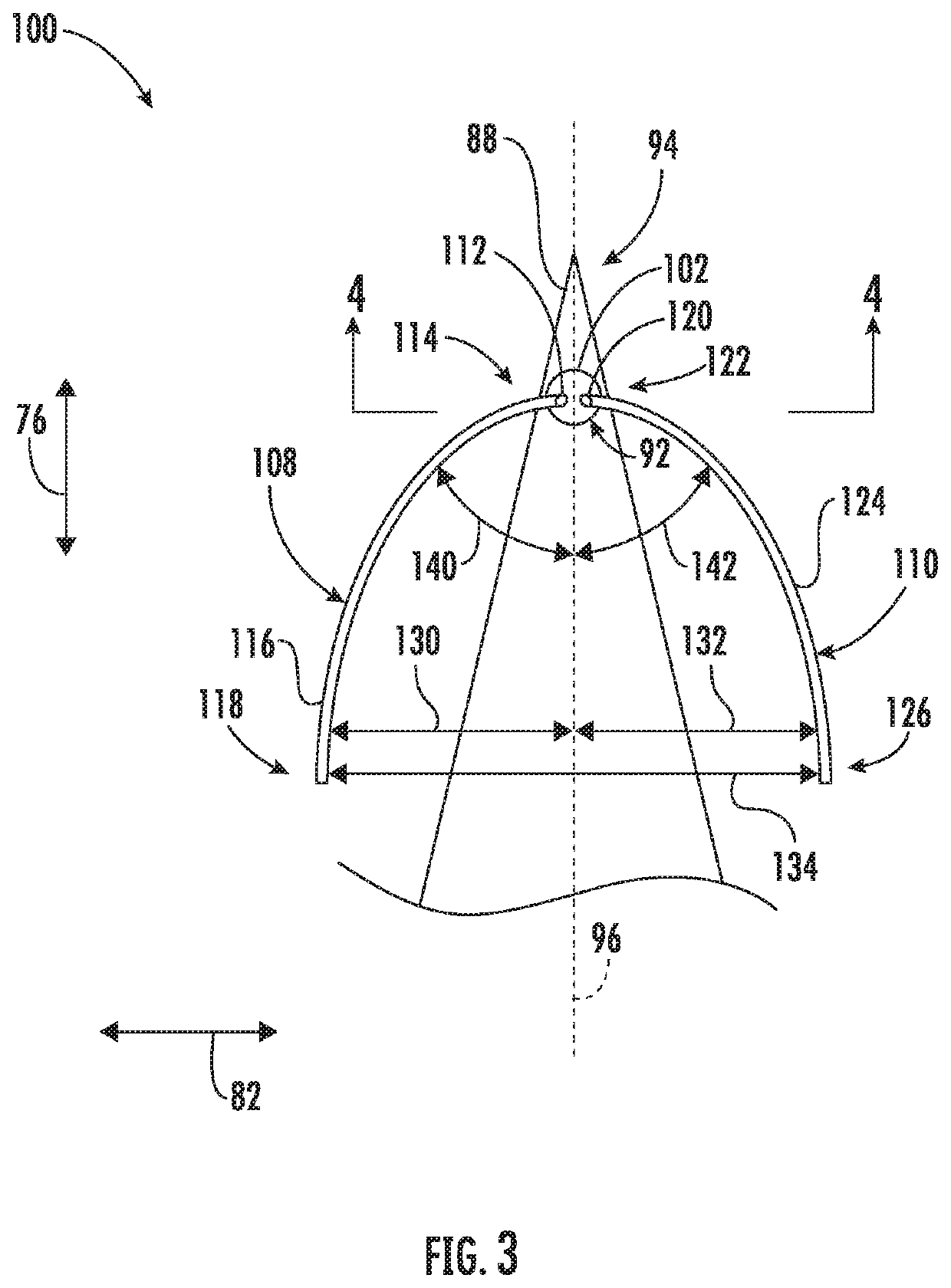

Independent center reel position adjustment for an agricultural harvesting machine

A cutting platform for use with an agricultural harvesting machine includes a first platform section and a second platform section pivotally coupled together about a first axis. A first reel and a second reel are positioned in end-to-end juxtaposed relation to each other above the first platform and the second platform. A reel support arm is positioned between and carries each of the first reel and the second reel. The reel support arm is movable toward and away from the first platform section and the second platform section.

Owner:DEERE & CO

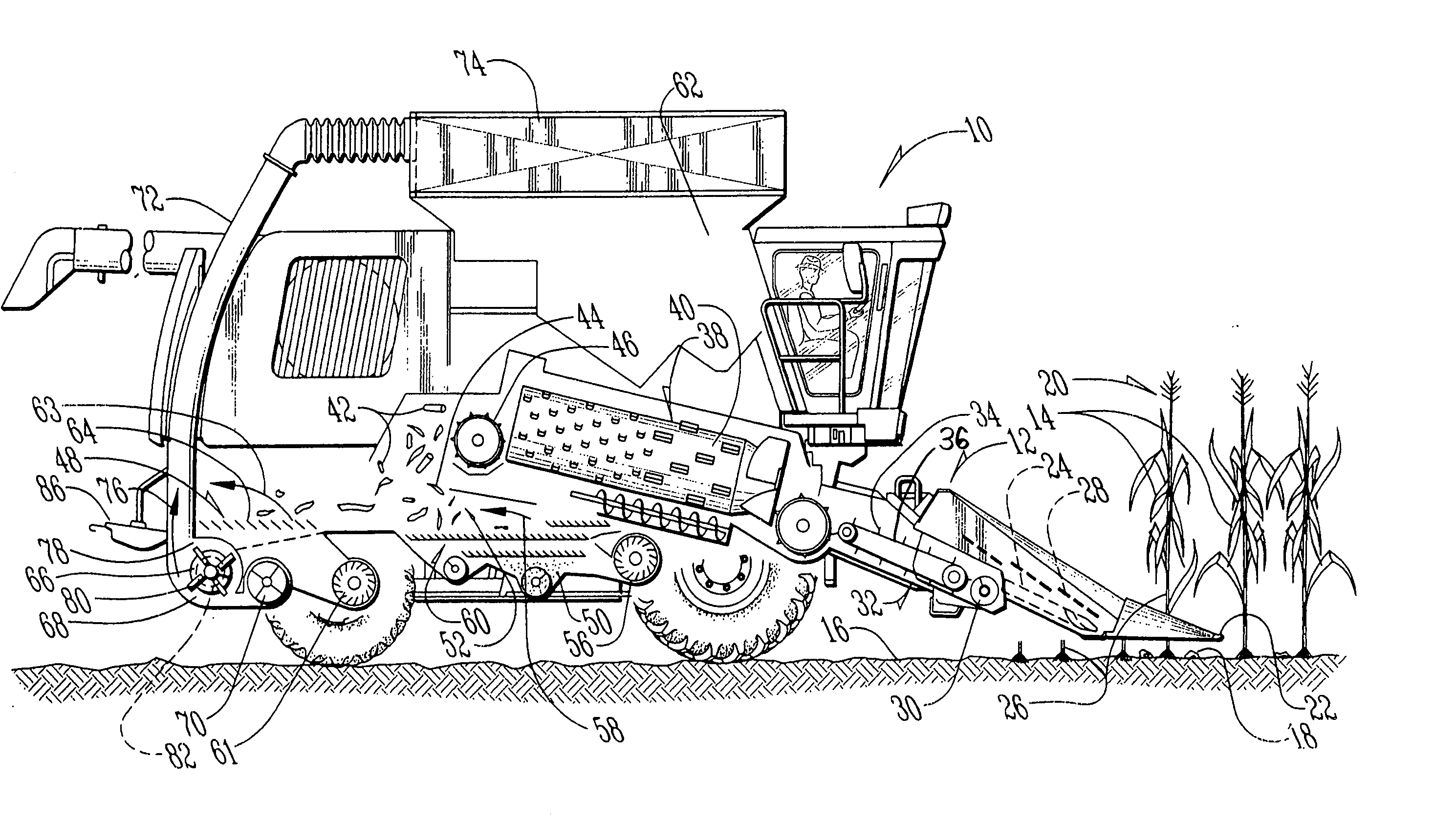

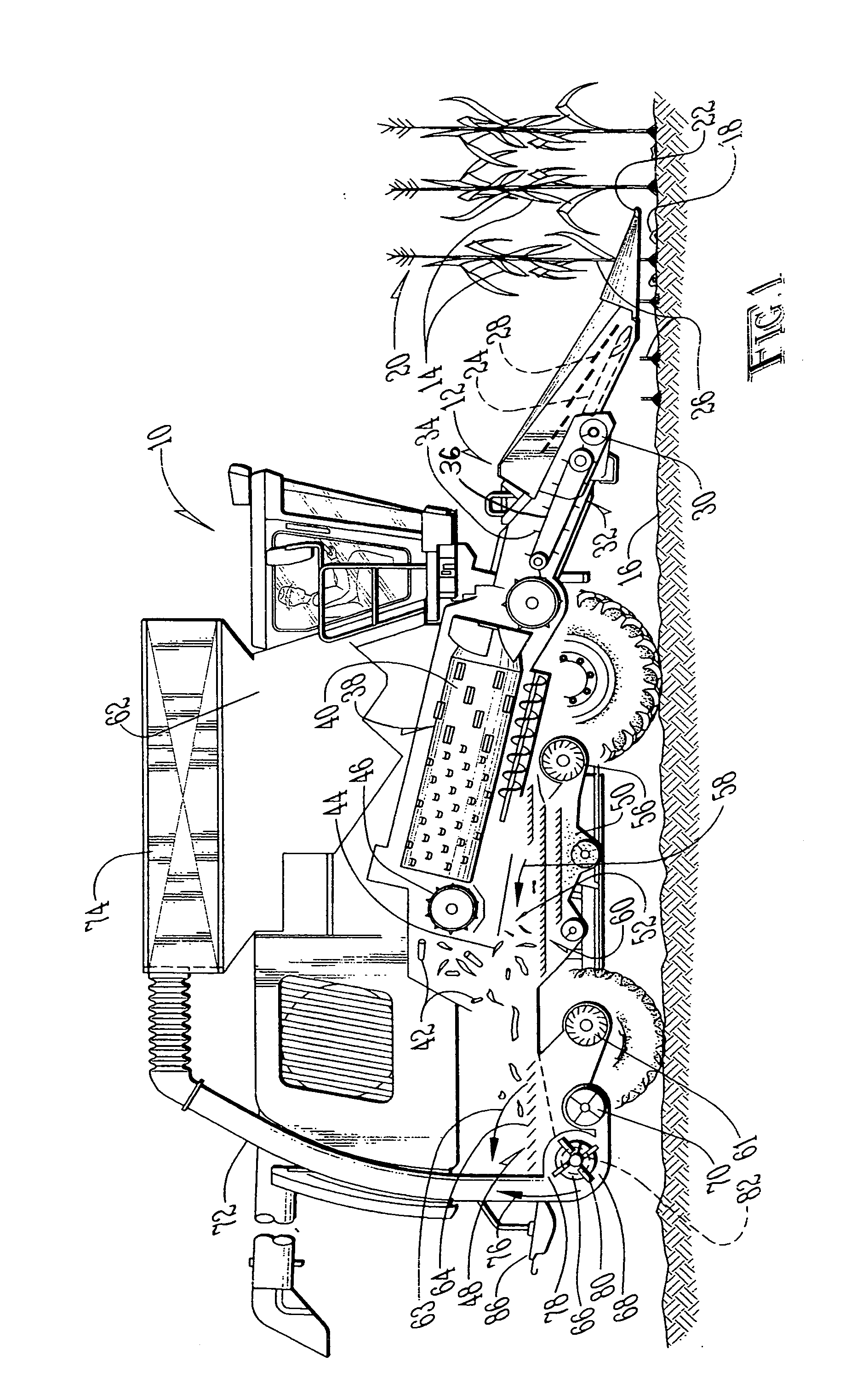

Air movement unit for biomass conveyance, separation, or combine performance enhancement

InactiveUS20090113867A1Reducing static air pressureReduce pressureLoadersMowersAir movementPerformance enhancement

A harvesting machine includes a self-propelled vehicle adapted for separating grain from non-grain material, a cleaning shoe and a fan for controlling air flow. The fan is positioned downstream of the cleaning shoe and the fan having an air inlet for providing air to the fan and an aspiration outlet for providing air from the fan. The fan assists in reducing static air pressure within the harvesting machine. The fan may be a centrifugal fan. The harvesting machine may further include a chopper operatively connected to the vehicle and adapted for receiving the non-grain material and chopping the non-grain material and a blower adapted for assisting in conveying the non-grain material from the chopper such as for collection in a collection container.

Owner:IOWA STATE UNIV RES FOUND

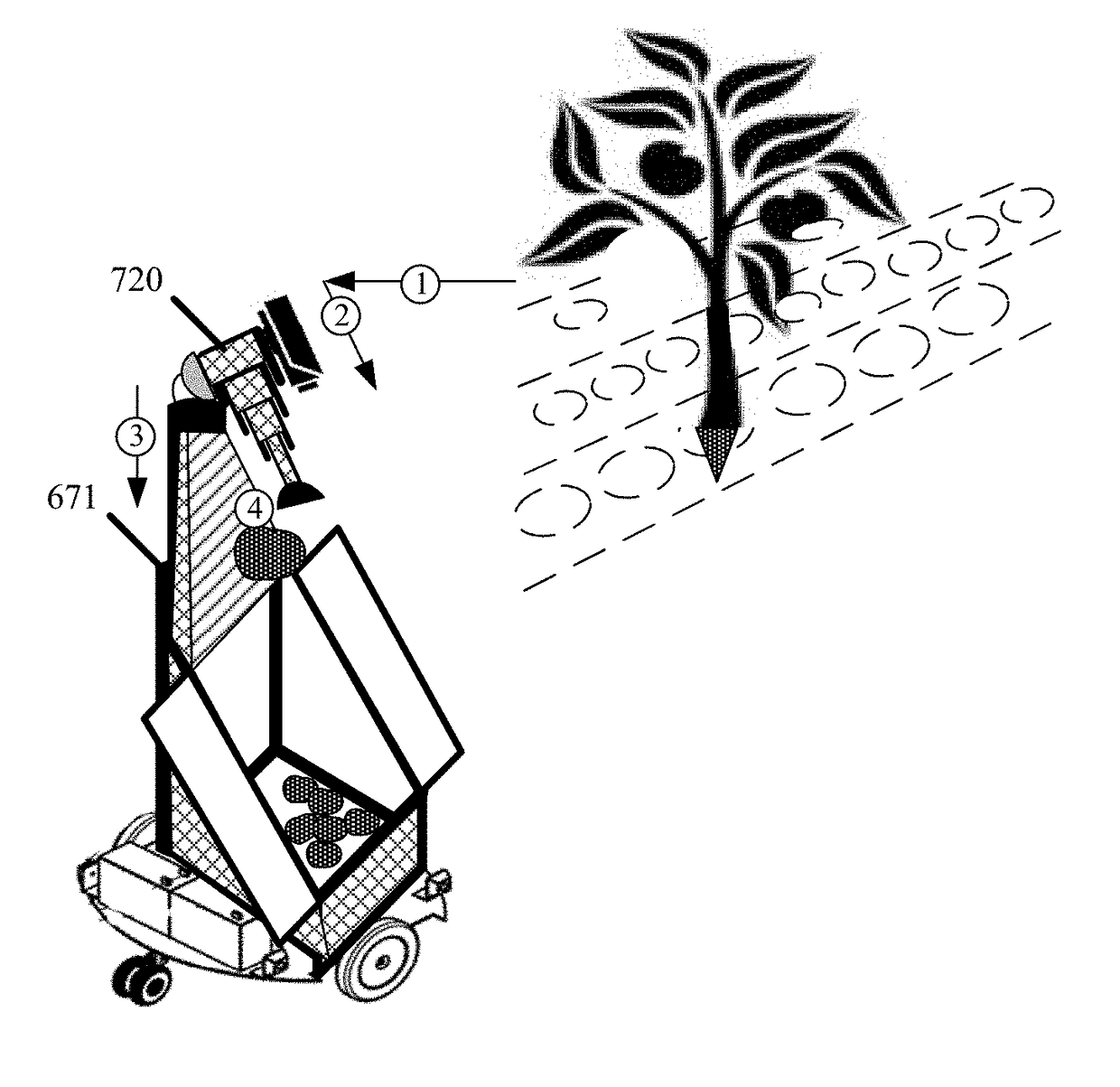

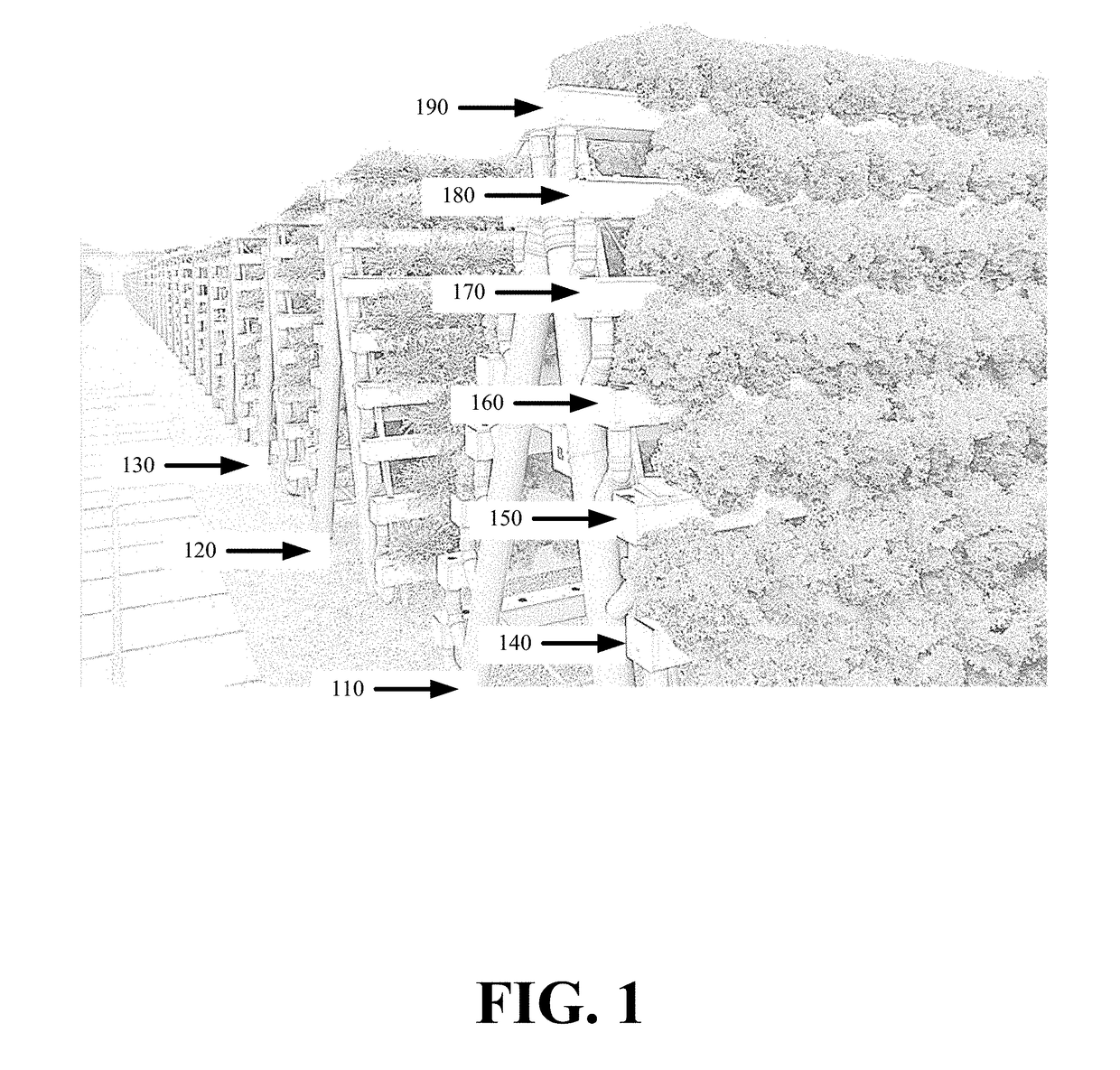

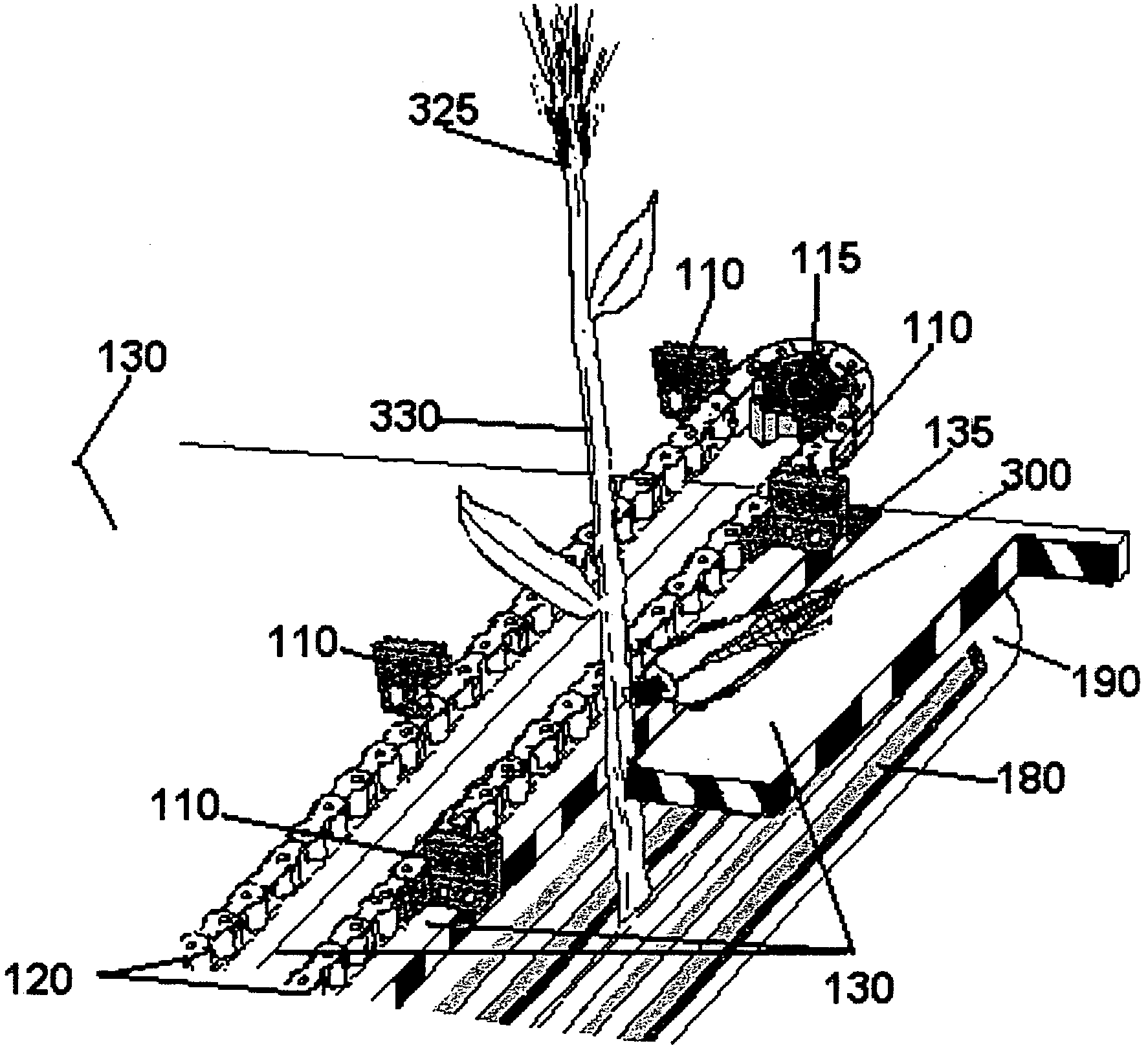

Harvesting Robots for Hydroponics

Robots for autonomous harvesting of hydroponically grown organic matter with different harvesters are disclosed. The autonomous harvesting involves using one or more robots to (1) navigate a hydroponics arrangement or environment to arrive at locations of harvestable organic matter, (2) identify mature organic matter for harvesting from under-ripe or over-ripe organic matter using the robot's sensors, (3) identify the irregular positions and the irregular extraction points at which the mature organic matter is to be correctly harvested using the robot's sensors, (4) harvest the organic matter at the identified positions using the robot harvester, and (5) place the extracted organic matter into a storage bay for delivery to a packaging or shipment station. The harvester includes one or more of a vacuum, gripper, cutting saw, or clipping shears disposed about a distal end of an extendable or mechanical arm mounted atop a lift.

Owner:INVIA ROBOTICS INC

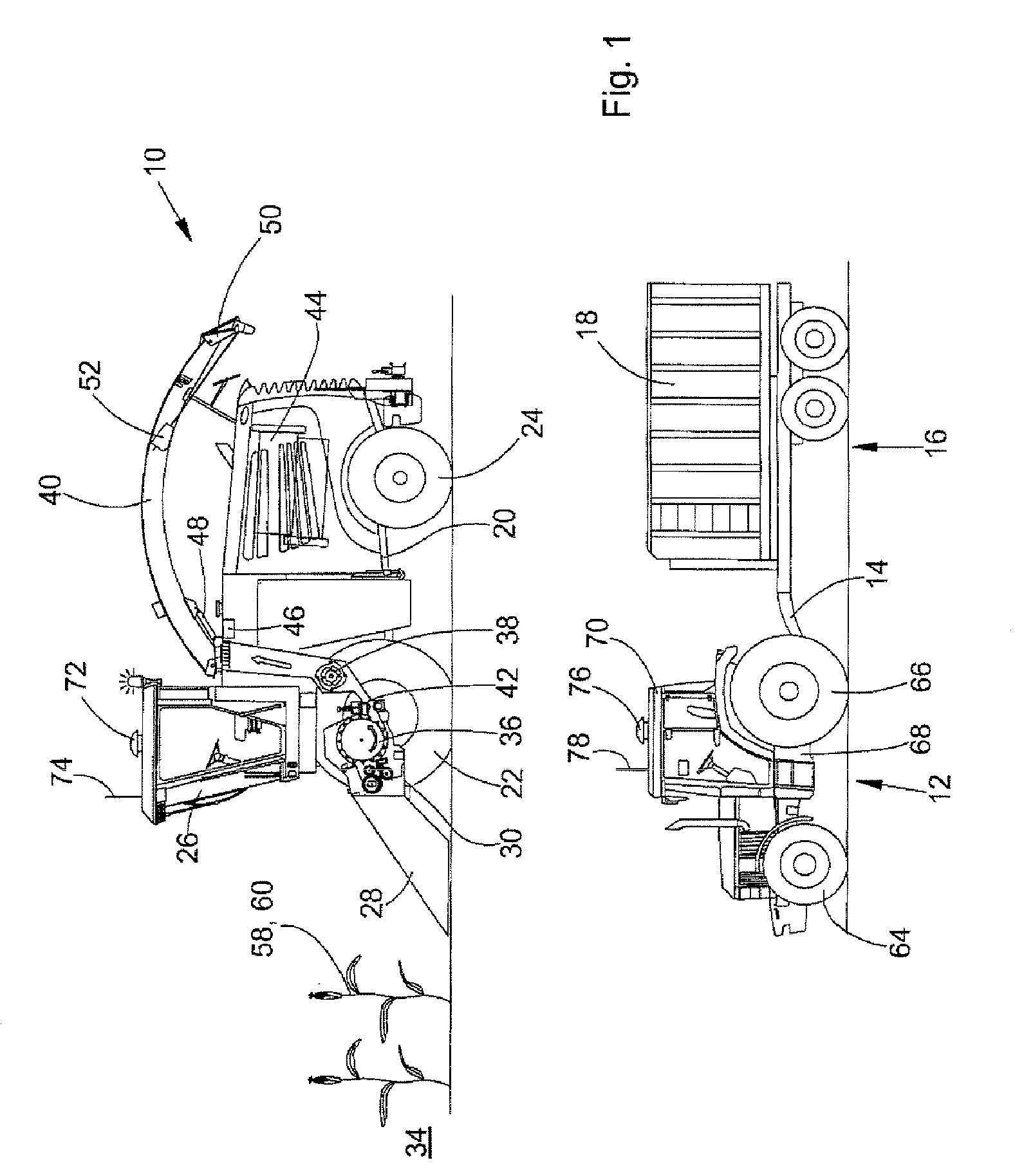

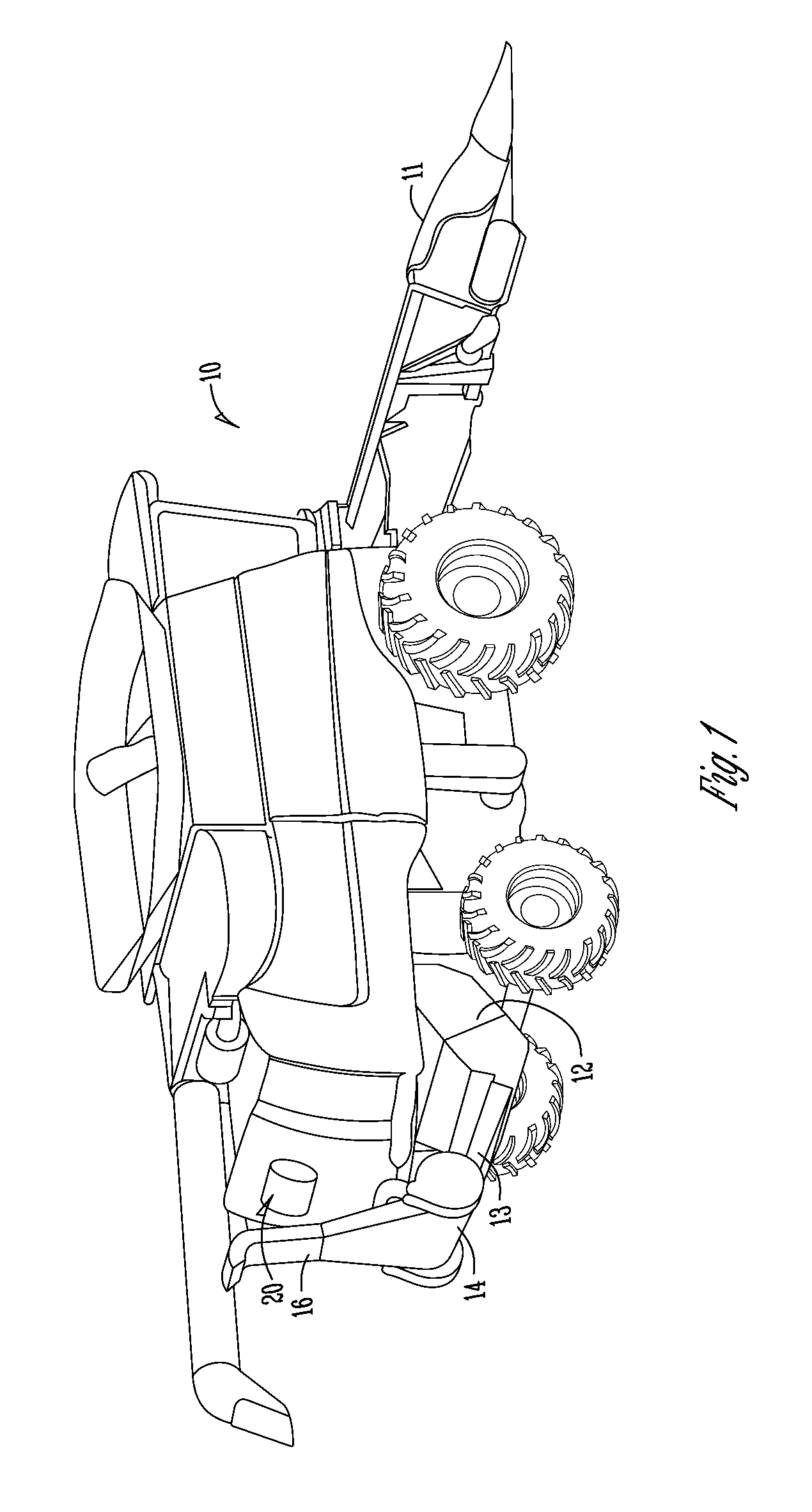

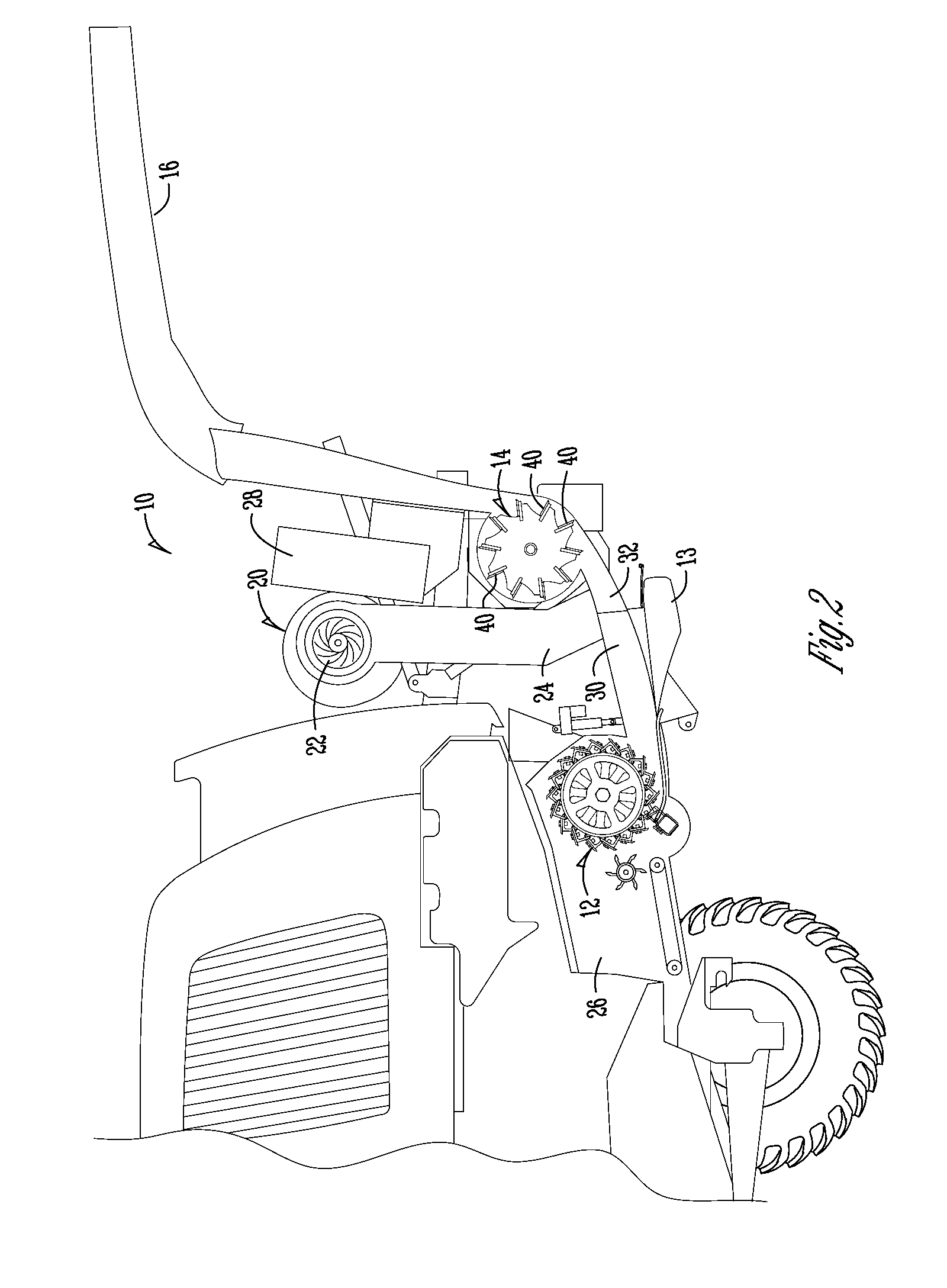

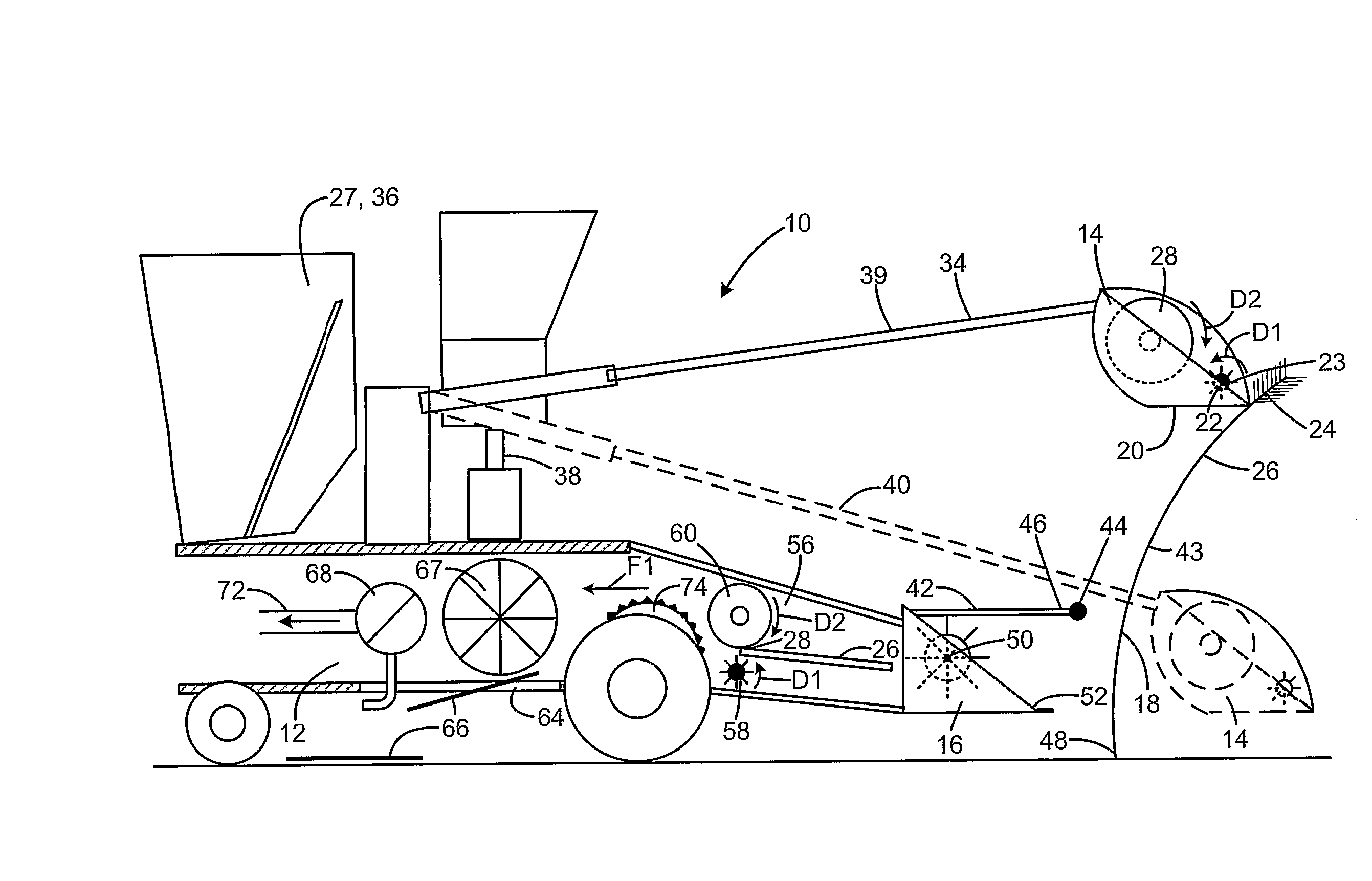

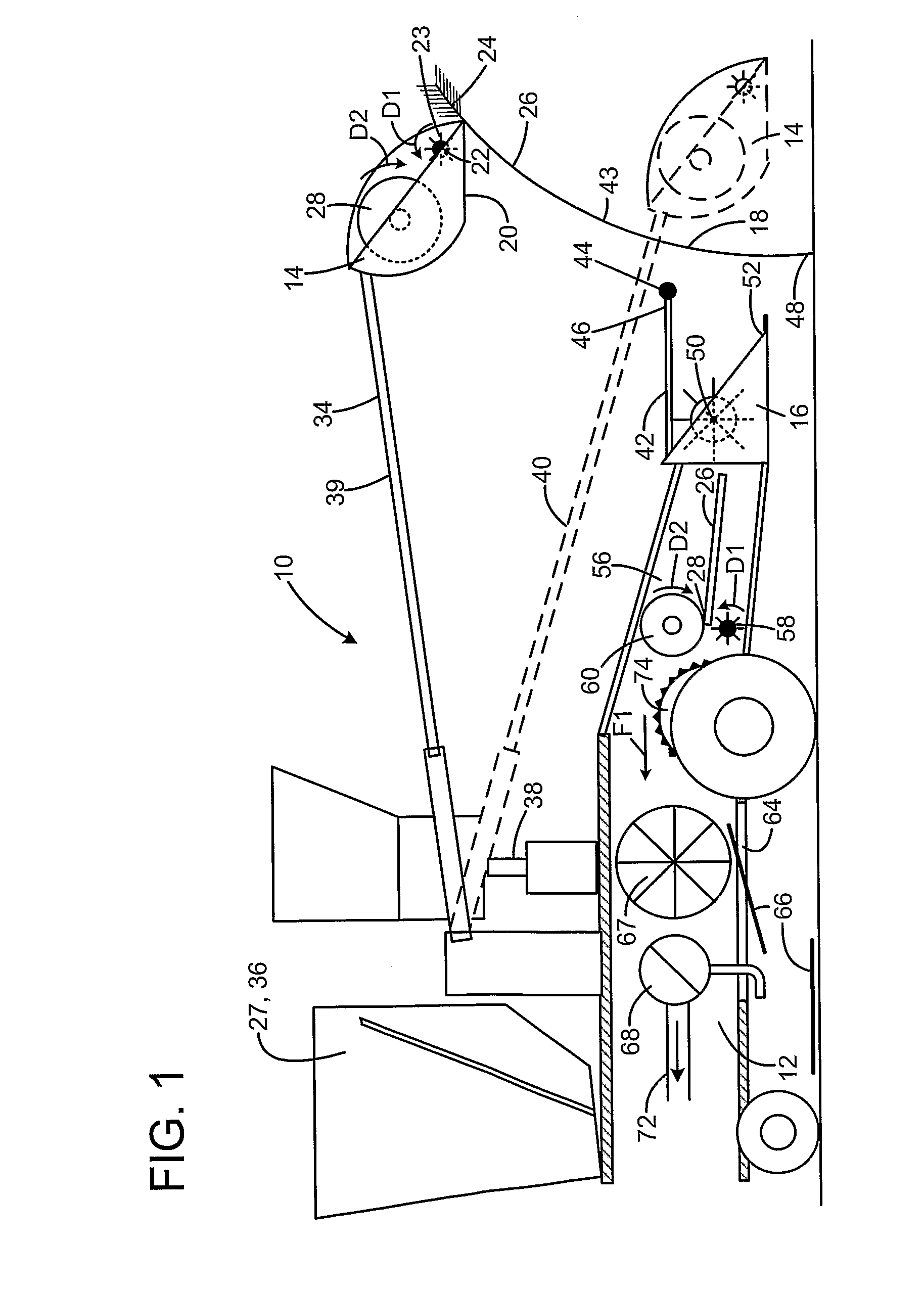

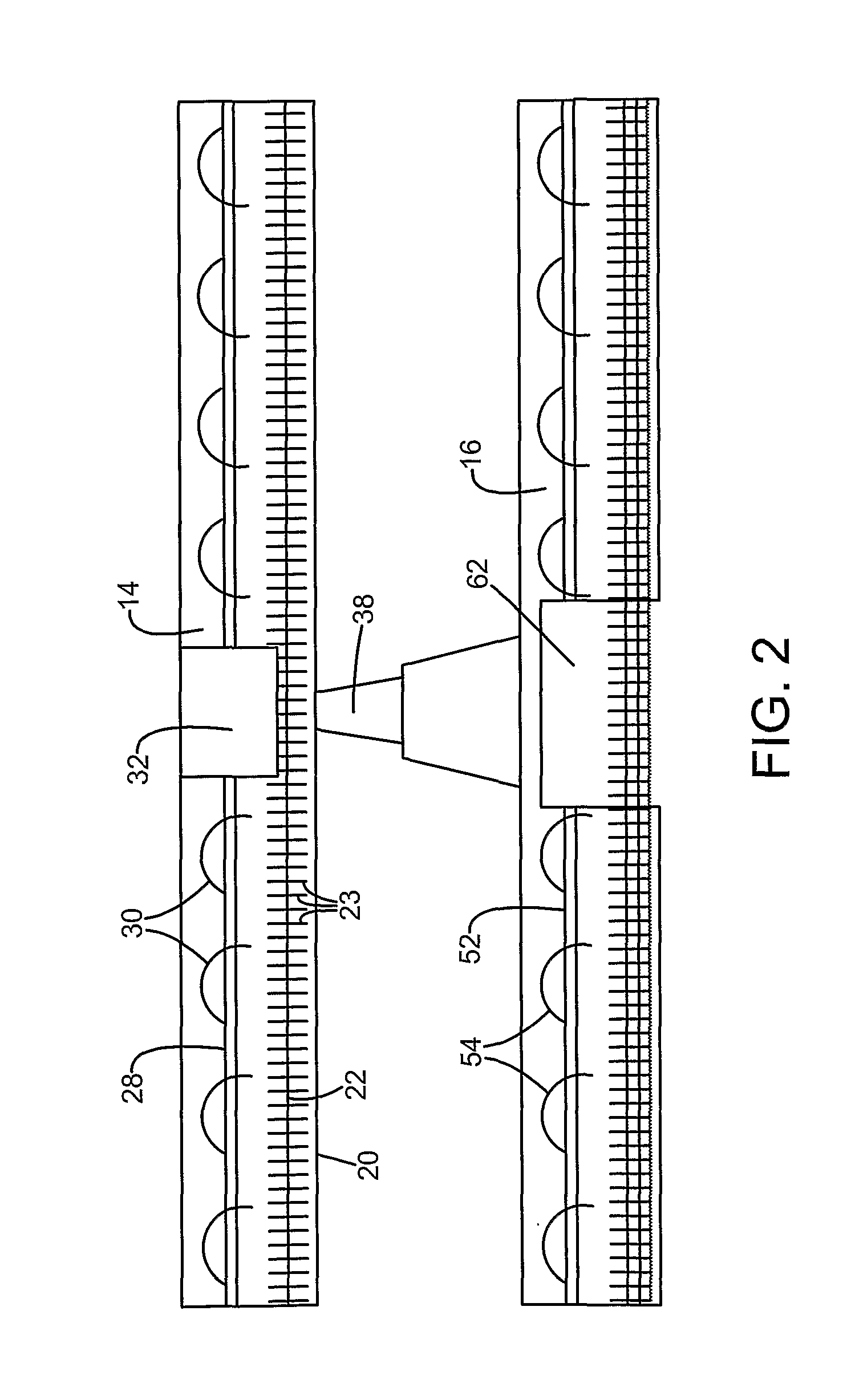

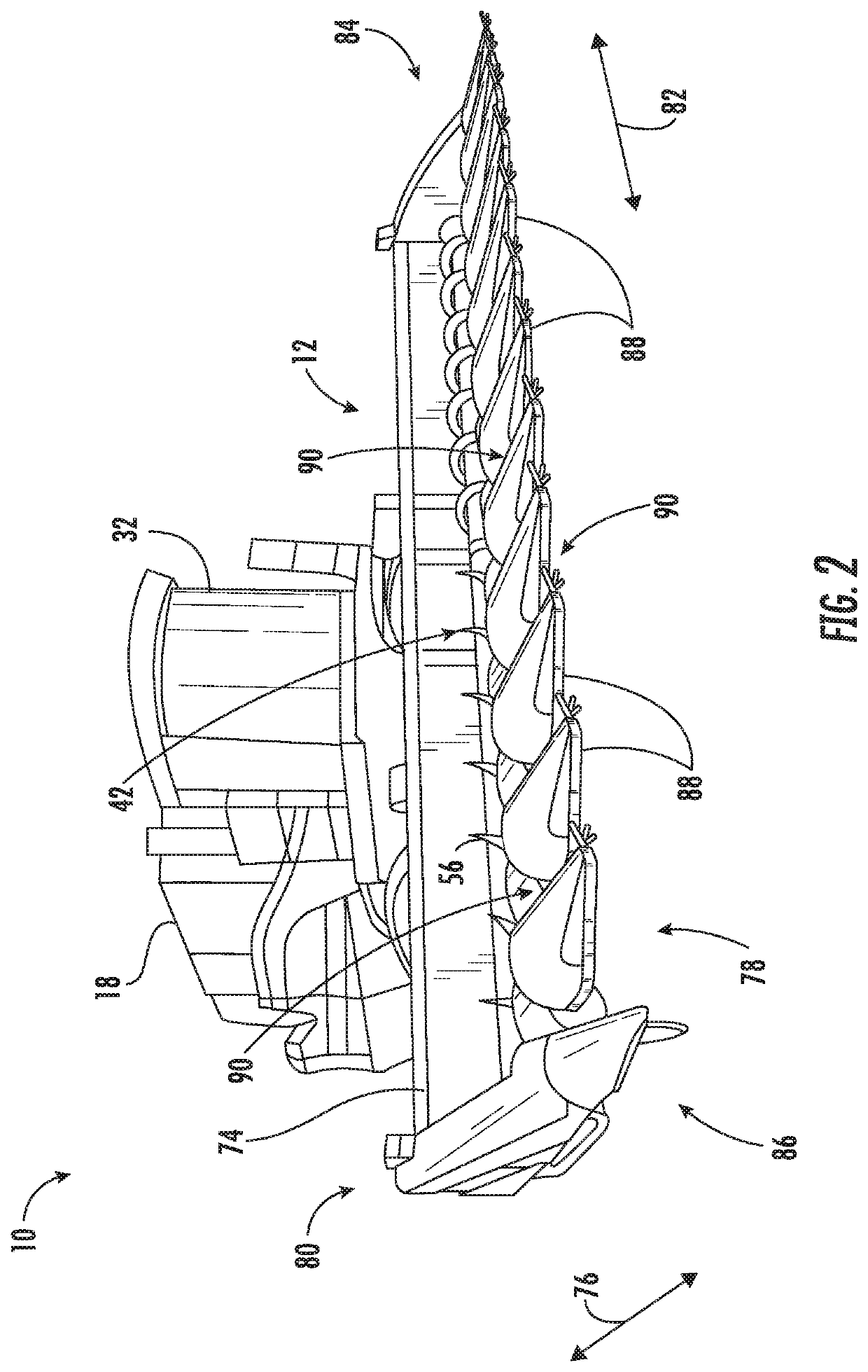

Harvesting device

The method is for harvesting a crop. A harvesting device (10) is provided that has an upper harvesting device (16) and a lower harvesting device (16). The upper harvesting device is in front of the lower harvesting device. The upper harvesting device detaches crop sections (24) of stalk sections (26) of crops (18). An intermediate engagement member (42) bends the stalk sections forwardly and the lower harvesting device cuts root sections (28) of the crops.

Owner:MALMROS DAN +3

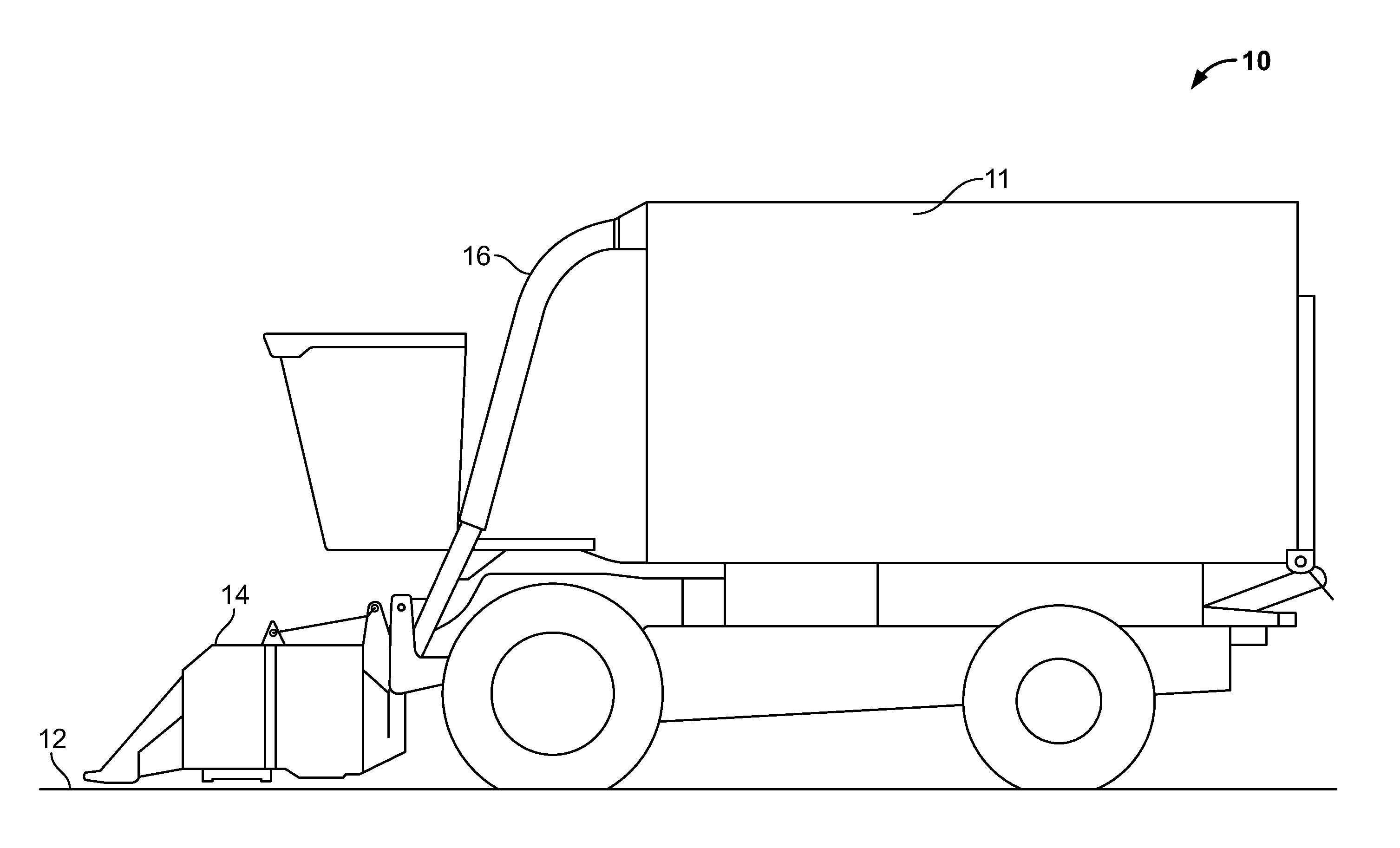

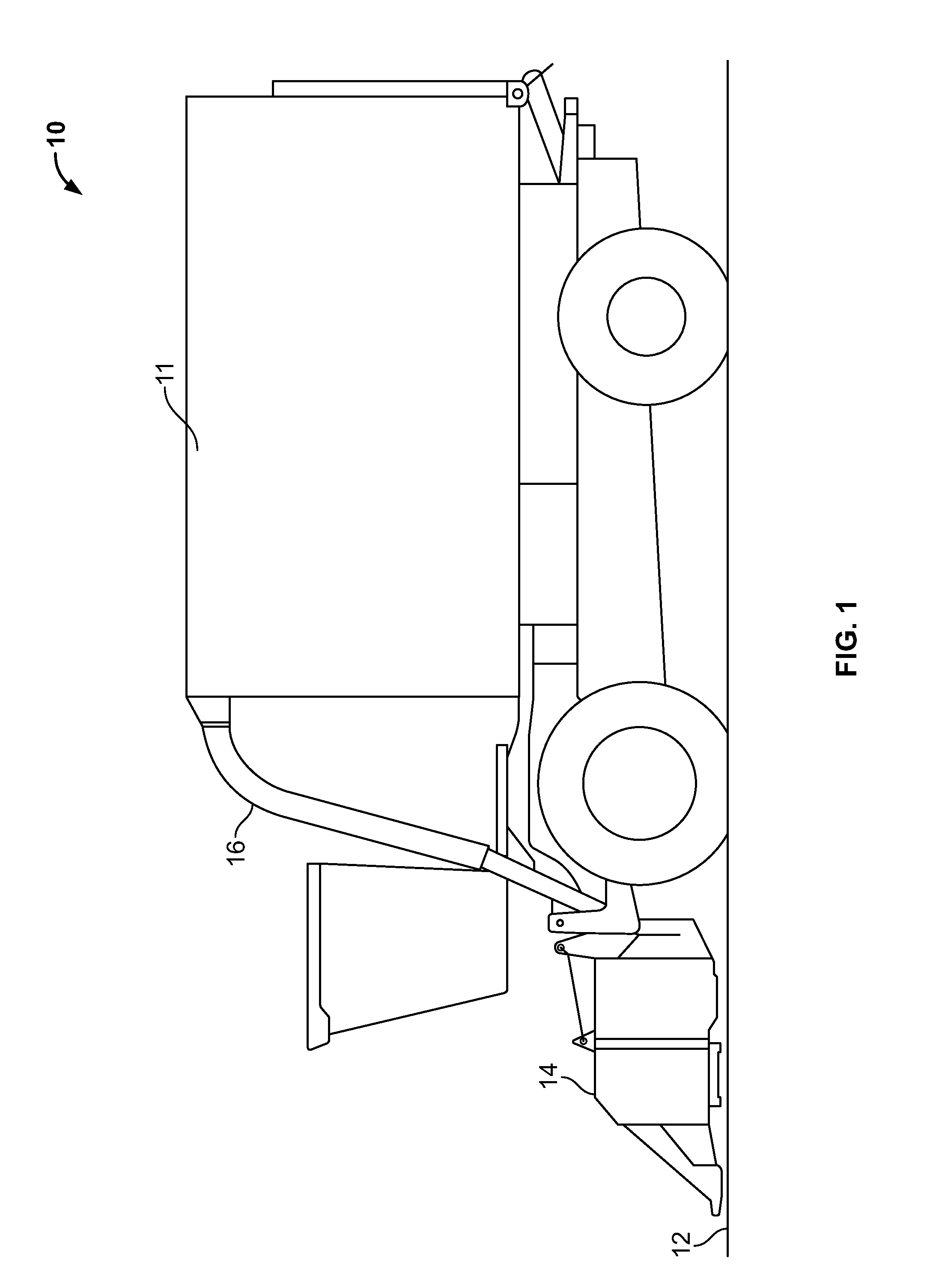

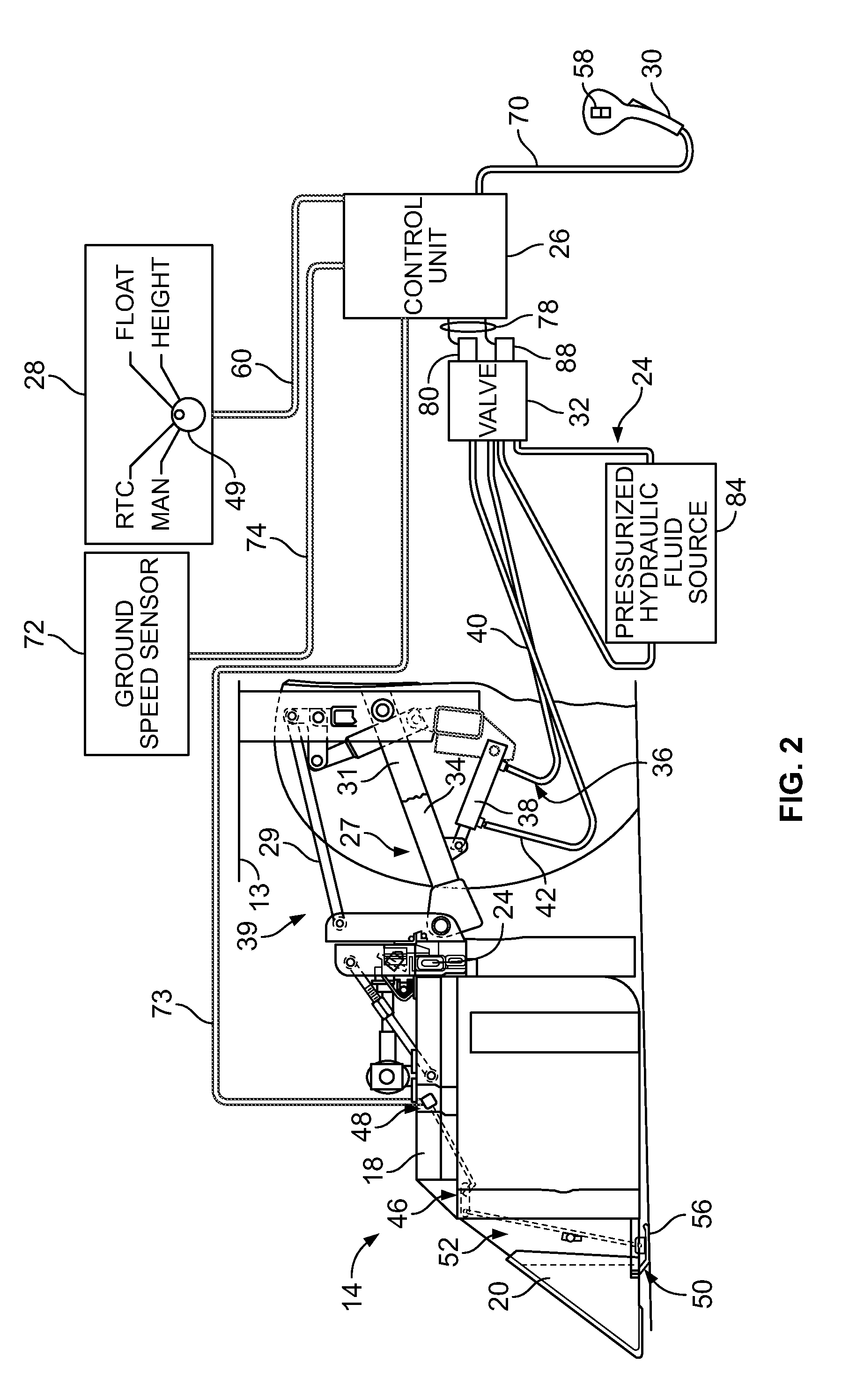

Implement height control adjustment on agricultural vehicles

ActiveUS20100287900A1Unnecessary strain is reducedReduce strainAnalogue computers for trafficMowersControl systemEngineering

An adjustable height implement system for an agricultural vehicle. A harvesting implement has an adjustable height. A control system is operably connected in a first operating mode to the harvesting implement to adjust the height of the harvesting implement with respect to the ground. The control system is operably connected in a second operating mode to the harvesting implement to maintain at least a predetermined distance between the harvesting implement and the ground. The second operating mode is engaged in response to the agricultural vehicle satisfying at least one predetermined vehicle operating parameter.

Owner:BLUE LEAF I P

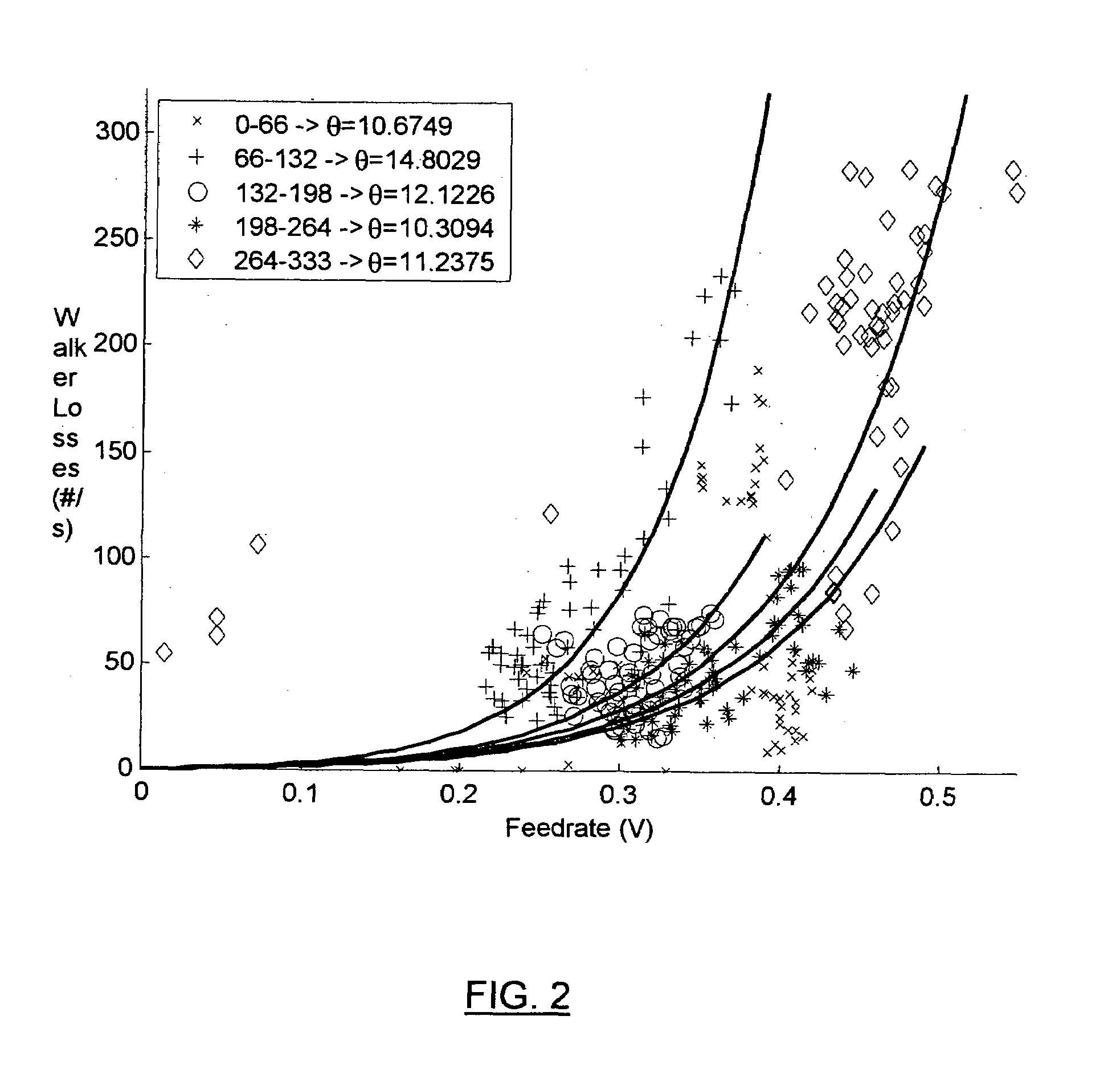

Methods of optimizing stochastic processing parameters in crop harvesting machines

Owner:BLUE LEAF I P INC

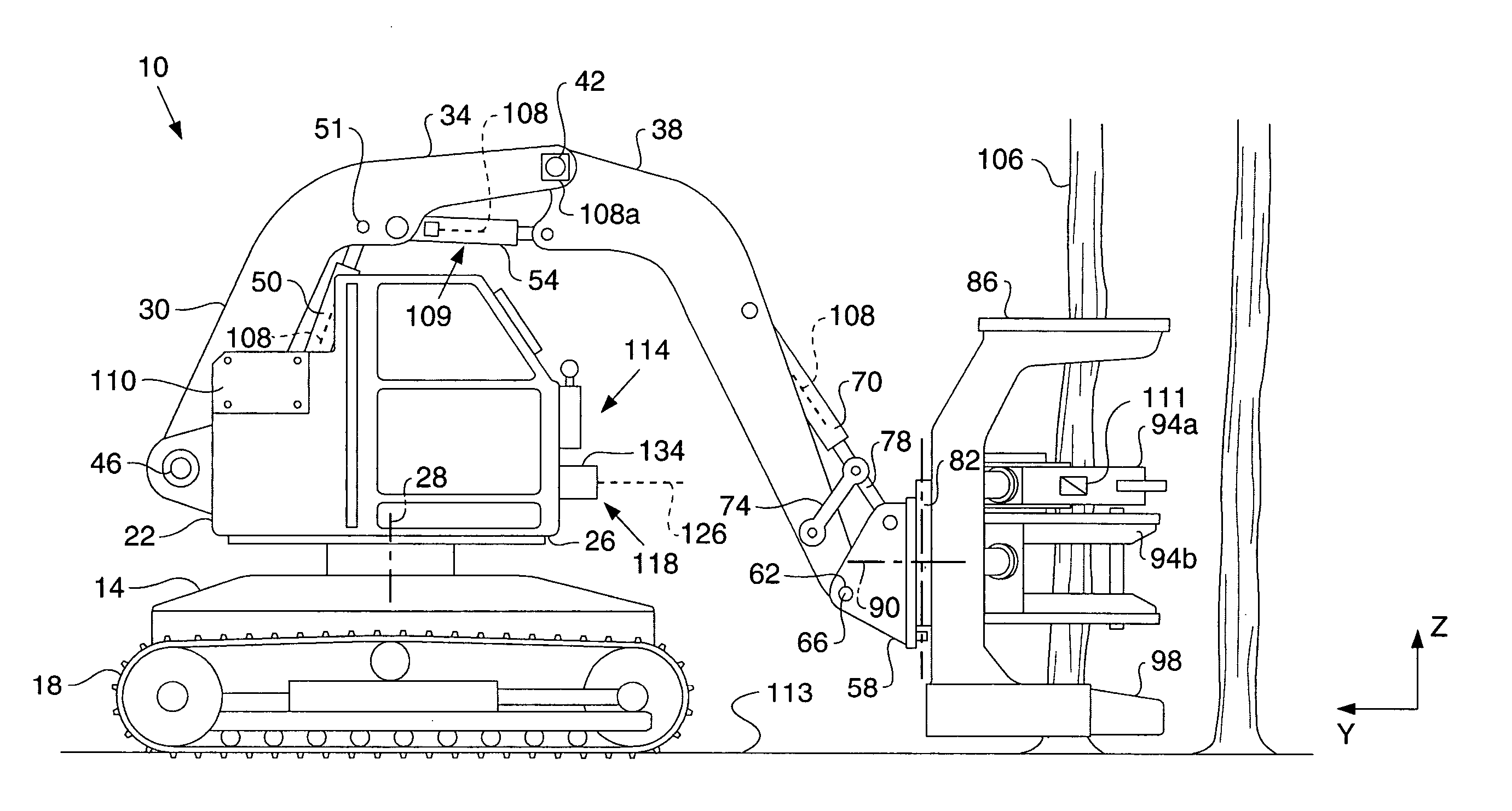

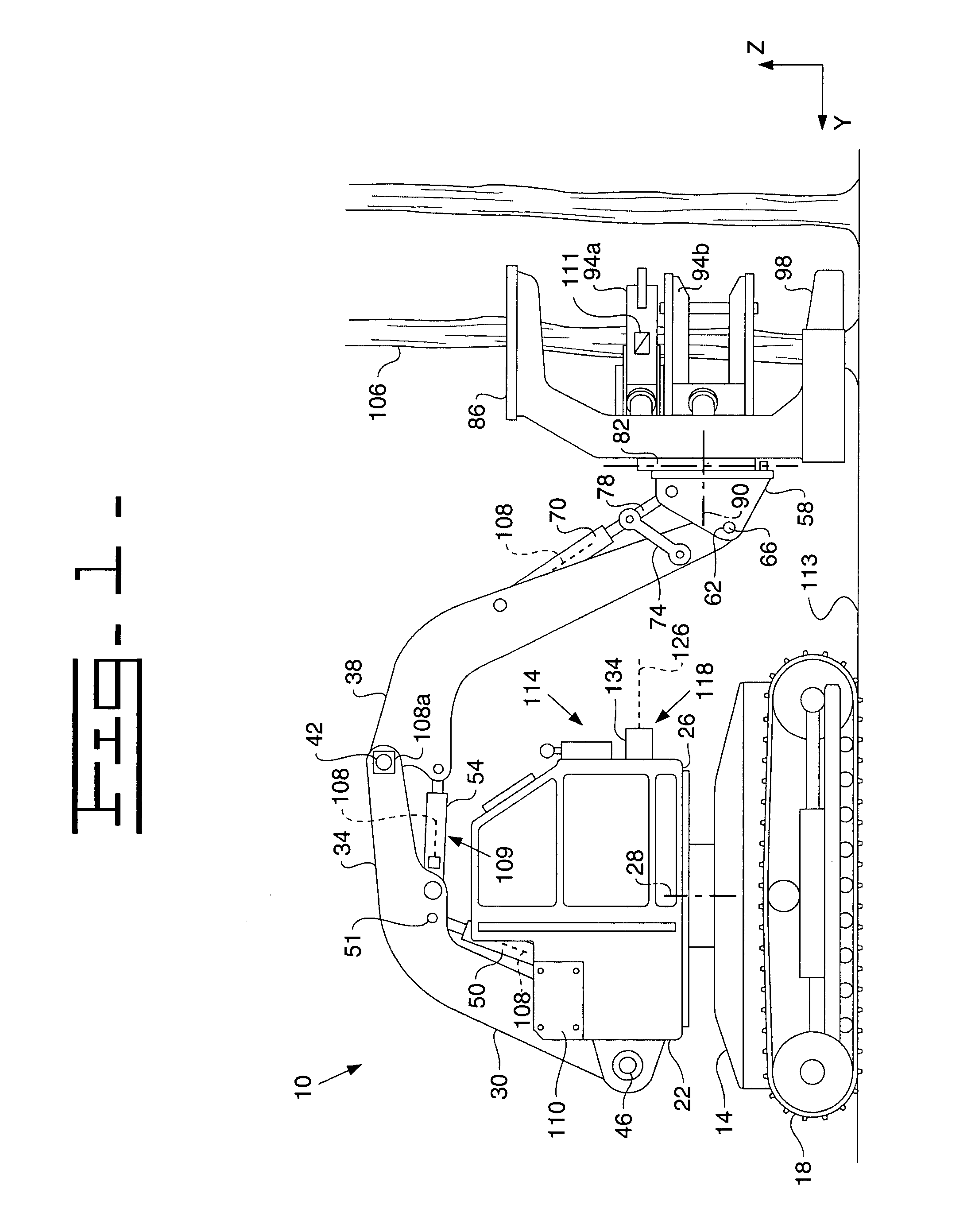

Tree harvester

InactiveUS20050133115A1Automatic control devicesPrecision positioning equipmentControl signalTheoretical computer science

A method and system for operating a tree harvesting machine including a tree harvesting tool are provided. The method may include identifying a tree to be harvested, generating one or more tree position signals indicative of a position of the tree, and controlling movement of the tree harvesting tool toward the tree as a function of the one or more tree position signals. The system may include a tree position sensor operable to generate one or more tree position signals indicative of a position of a tree. The system may further include a controller operable to receive the one or more tree position signals. The controller may be further operable to generate one or more tool control signals for controlling movement of the tree harvesting tool toward the tree as a function of the one or more tree position signals.

Owner:CATERPILLAR INC

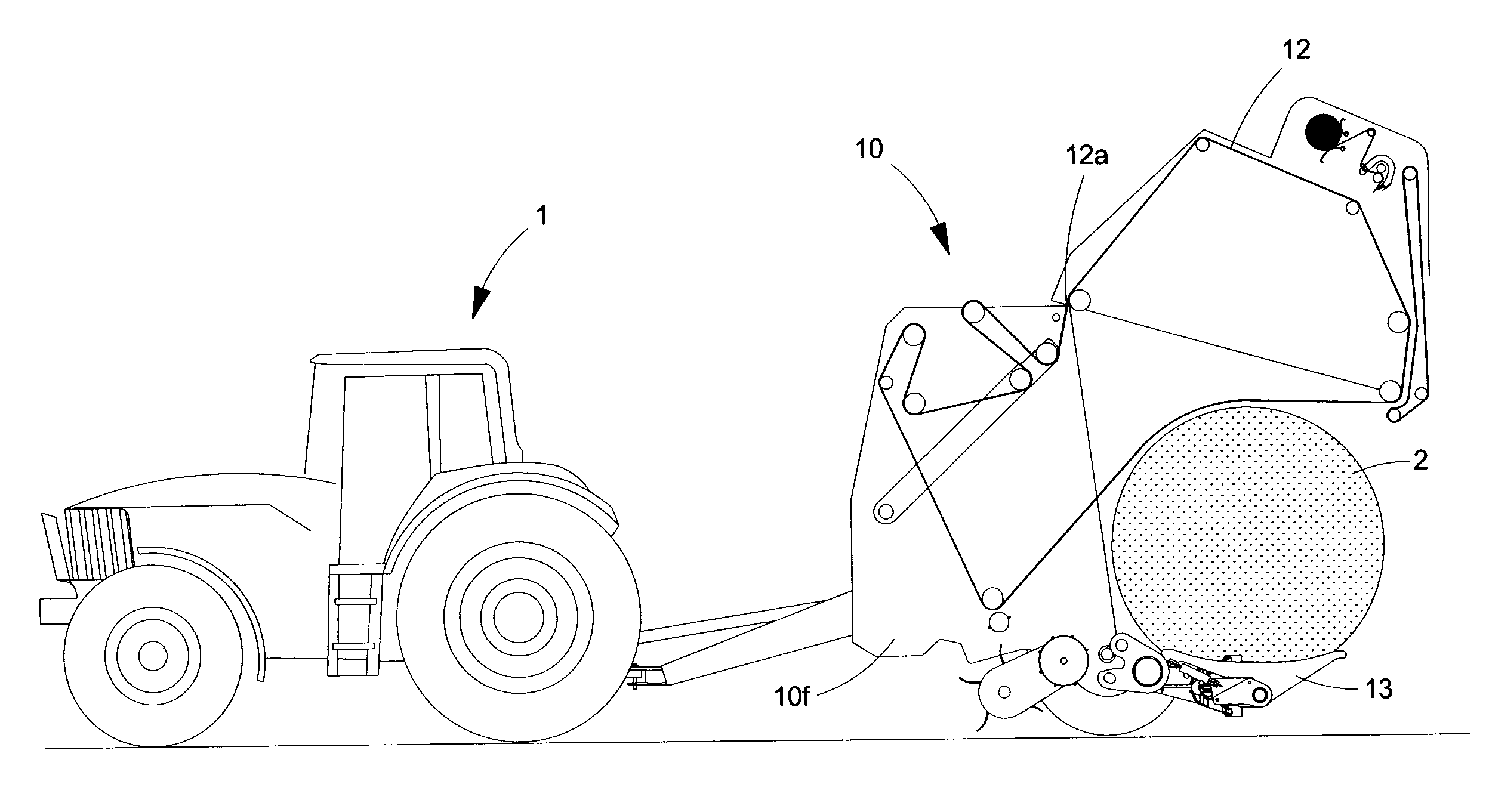

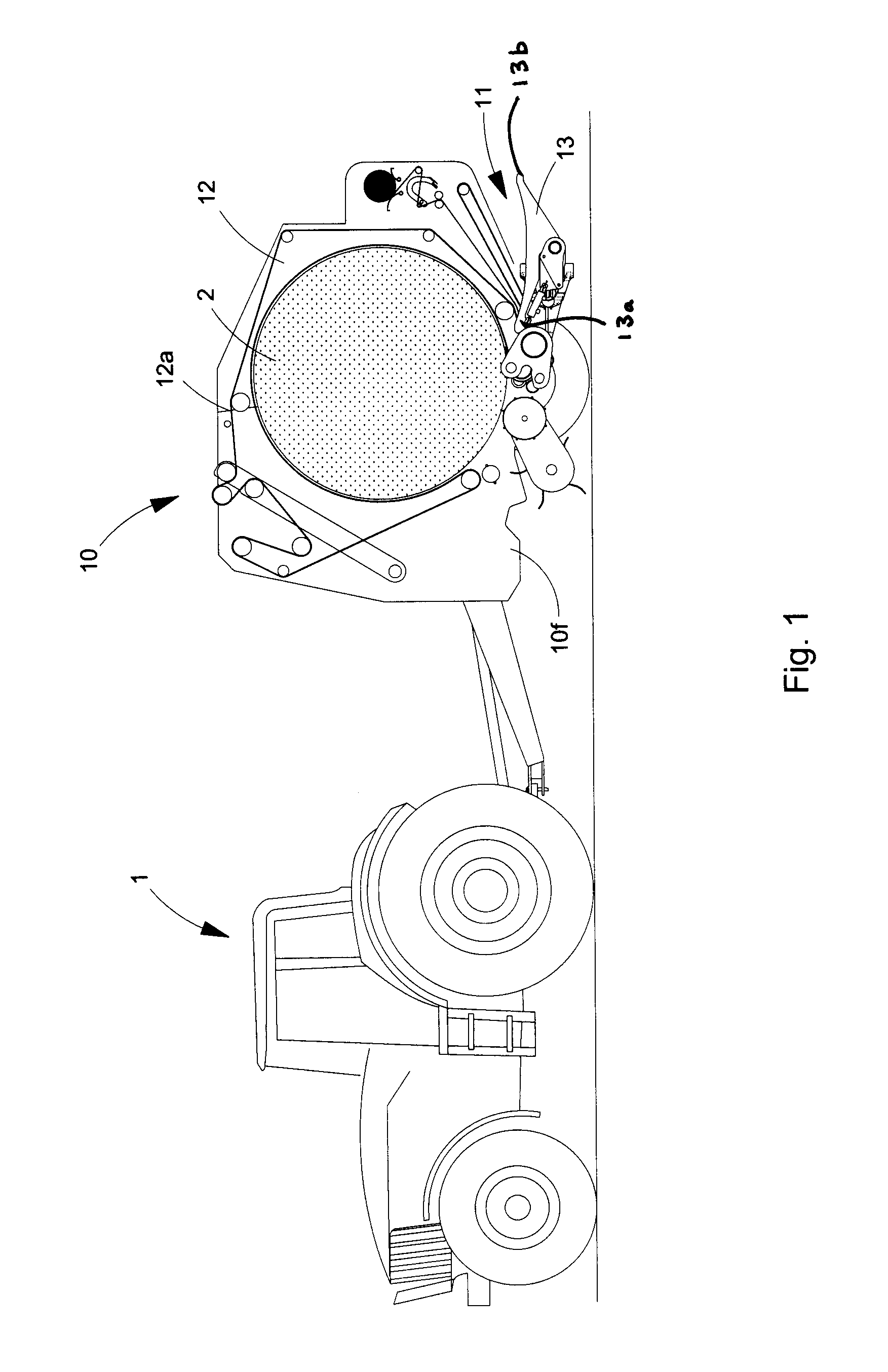

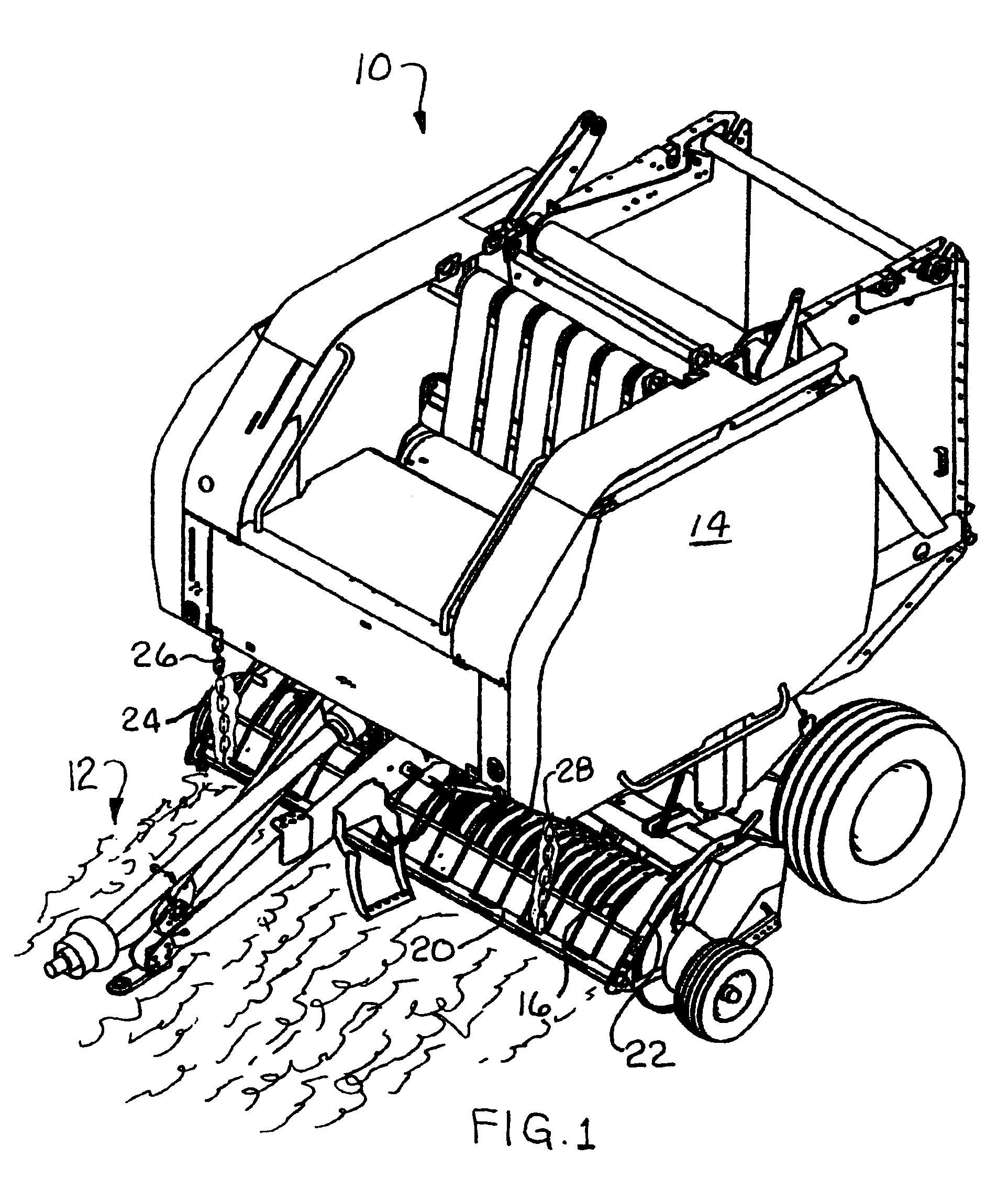

Baler Attachment for Optionally Changing the Orientation of Bales Being Released From a Baler

A bale turning apparatus for attachment to a baler to generally align the cylindrical of the bales in each row as the bales are released from the baler. Using the disclosed invention, the bales are essentially turned ninety degrees from the orientation of bales from the position that they are typically released from a round baler. By accomplishing this general alignment of the cylindrical axis of each bale in each row, when baling corn stover or other row crops, the bale loading operation can later be done more efficiently by driving down the rows in the same direction as the combine and baler have traveled.

Owner:VERMEER MFG CO

System for Coordinating the Relative Movements of an Agricultural Harvester and a Cart

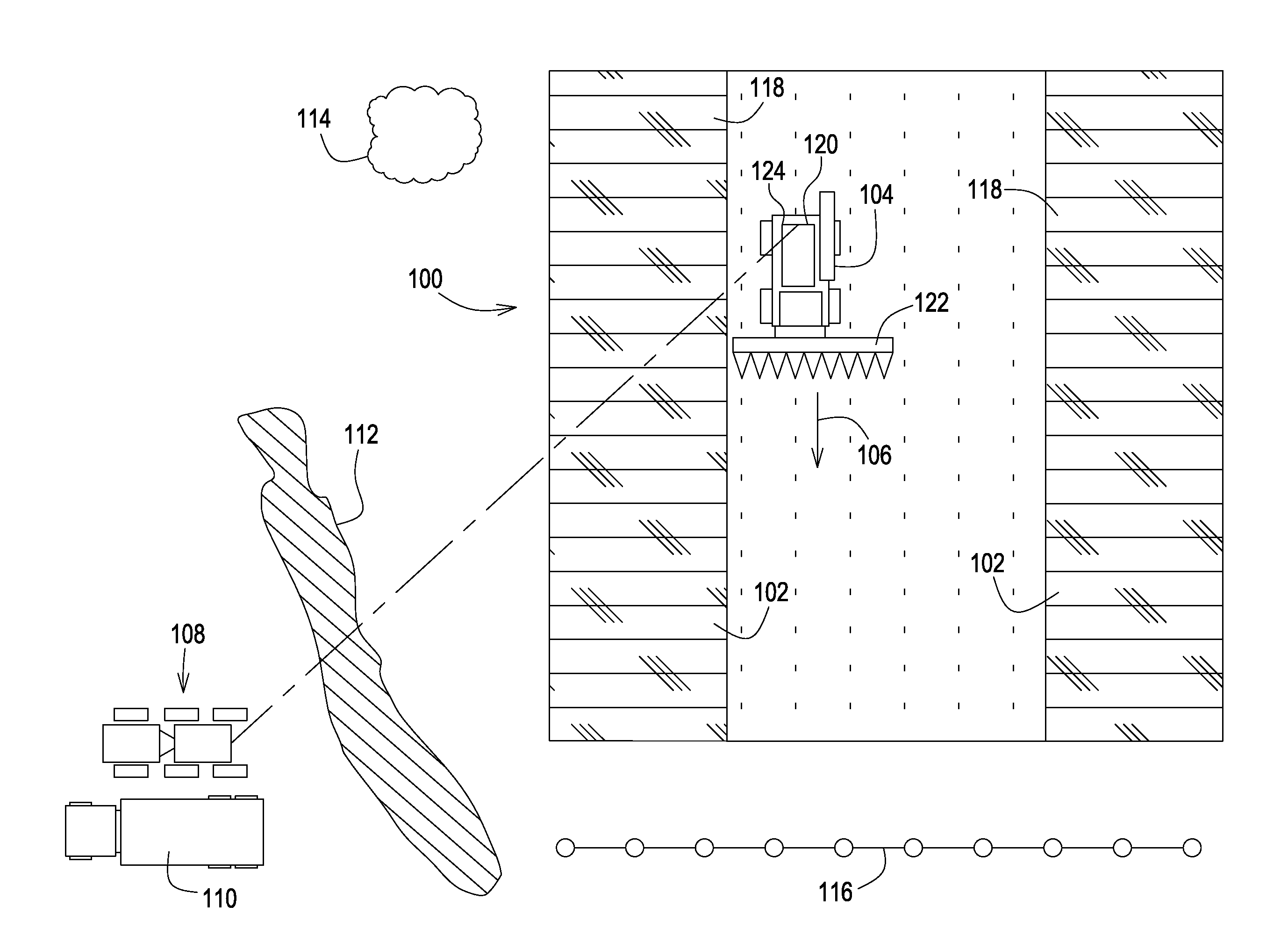

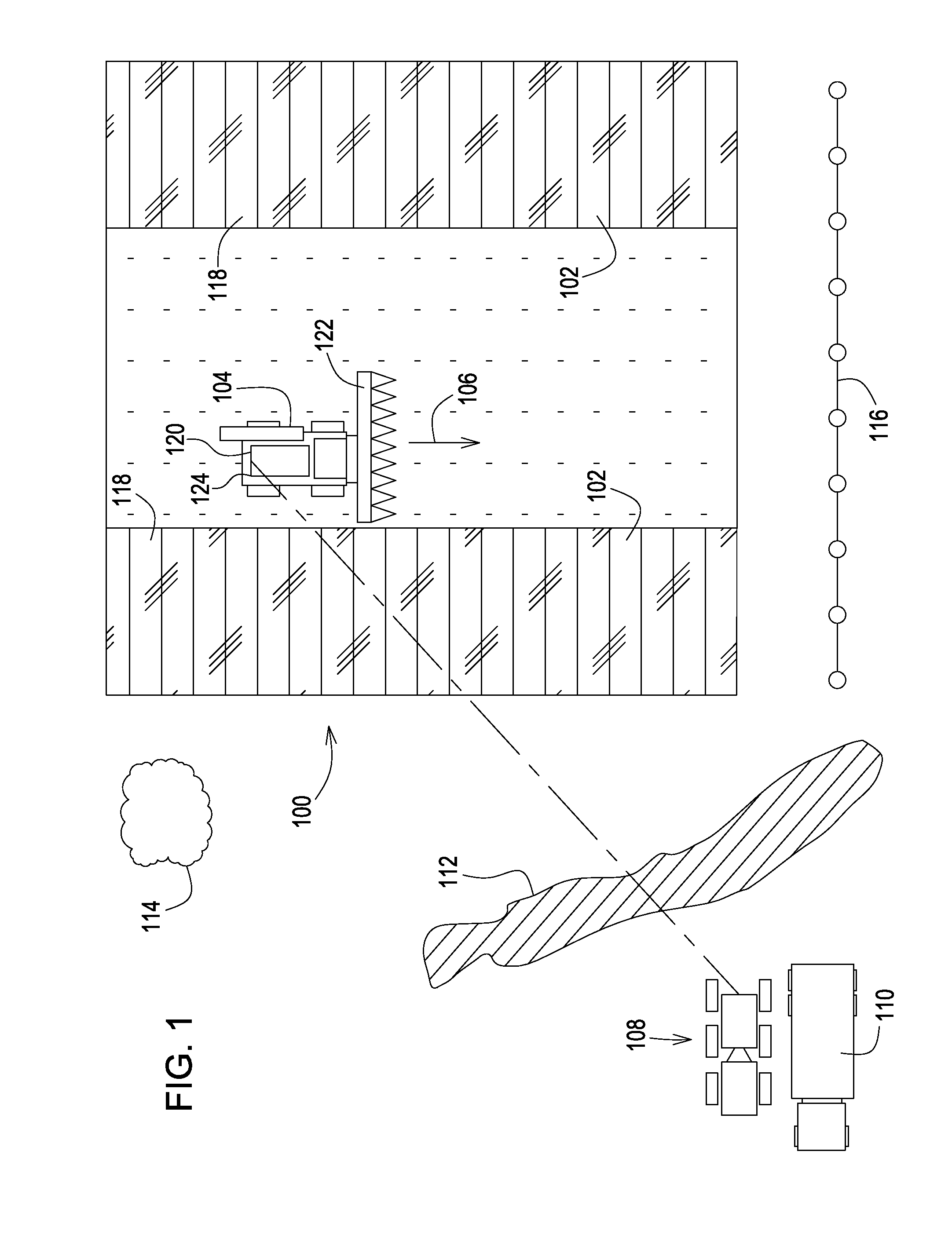

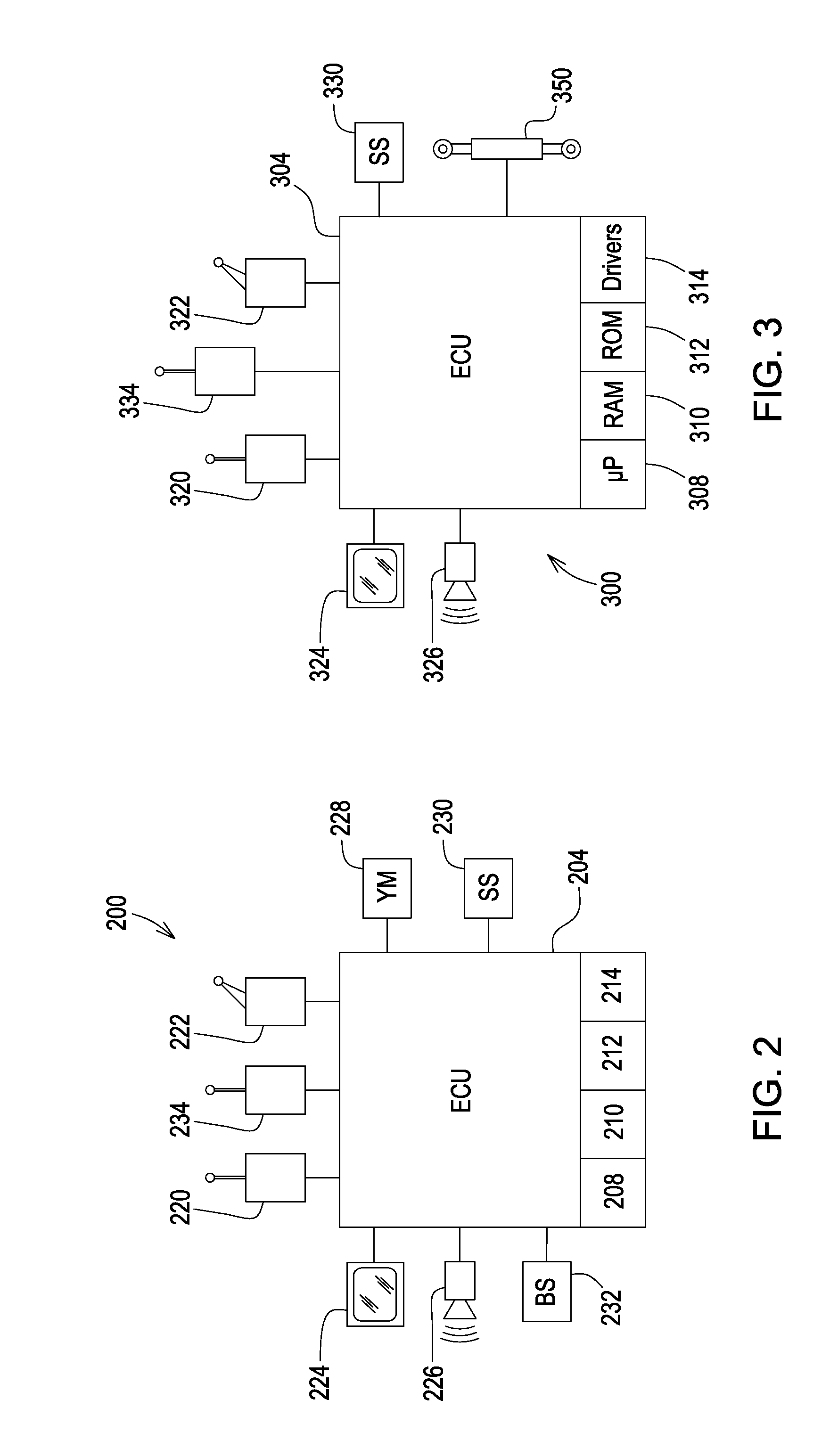

InactiveUS20140121882A1Analogue computers for trafficNavigation instrumentsAgricultural engineeringReaper

A system for coordinating the relative movements of an agricultural harvester (104) and a cart (108) by electronically estimating an unload position at which it the agricultural harvester (104) should be unloaded, and electronically calculating a path for the cart (108) to follow to arrive at that unload position.

Owner:DEERE & CO

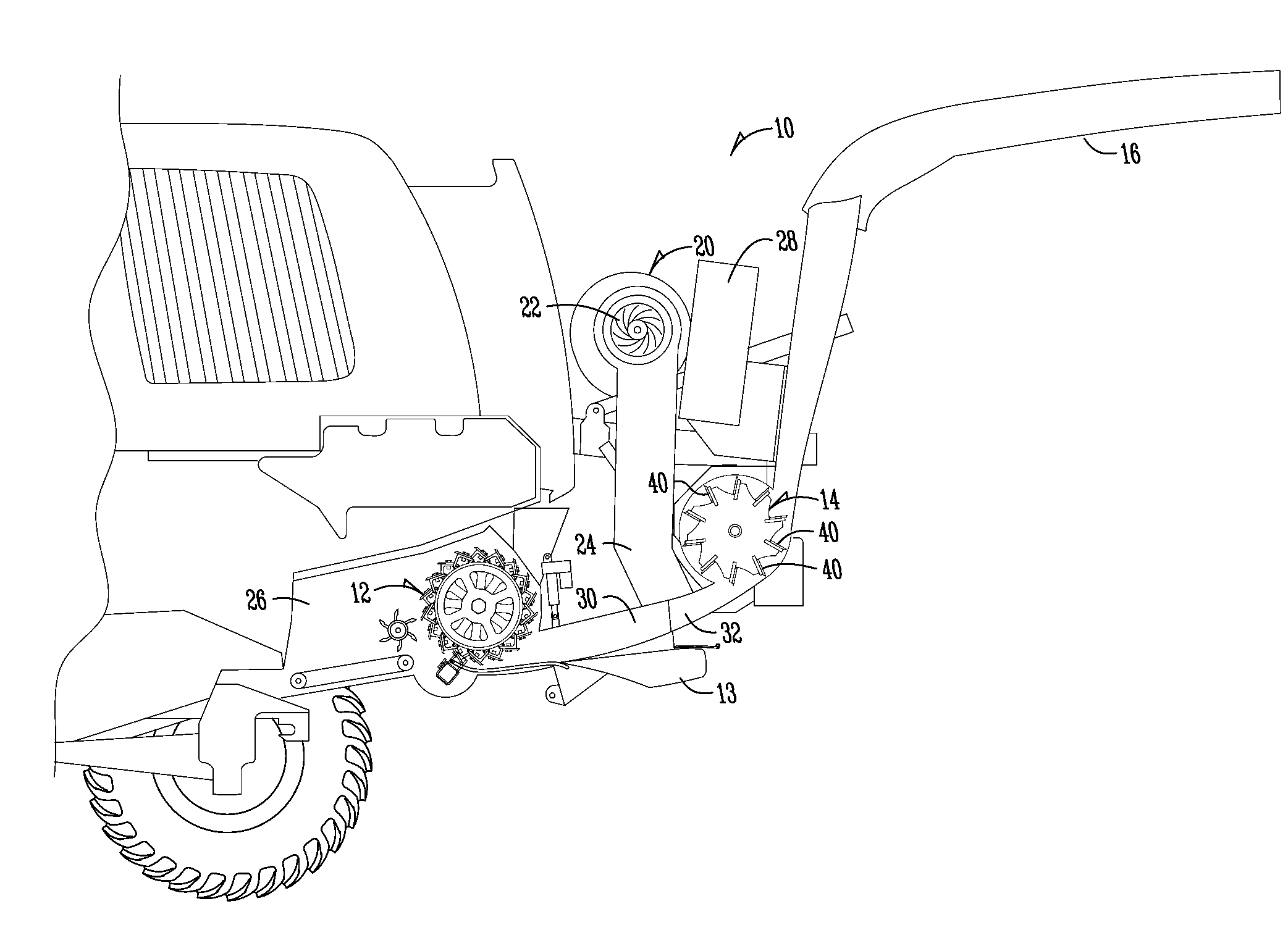

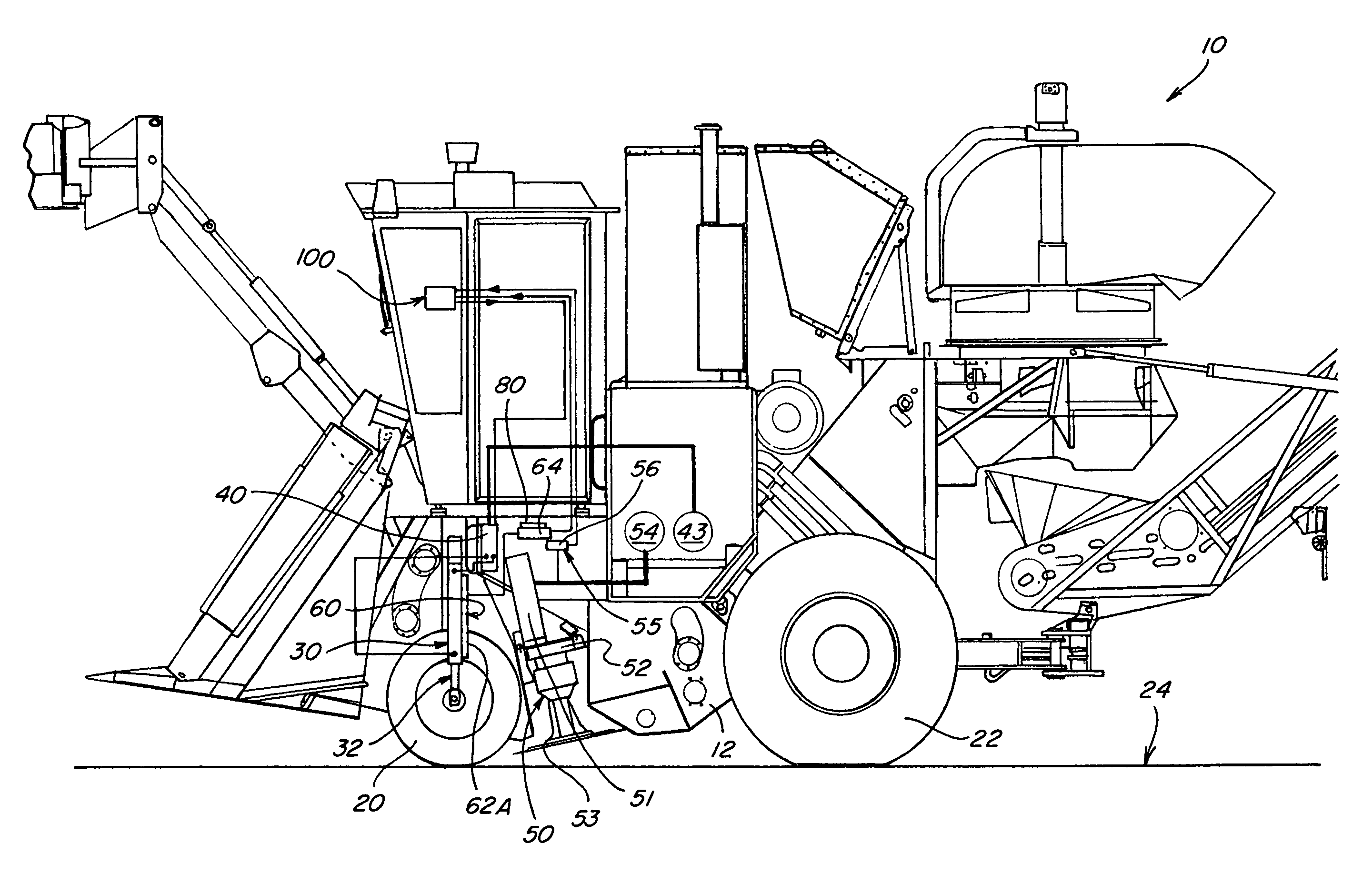

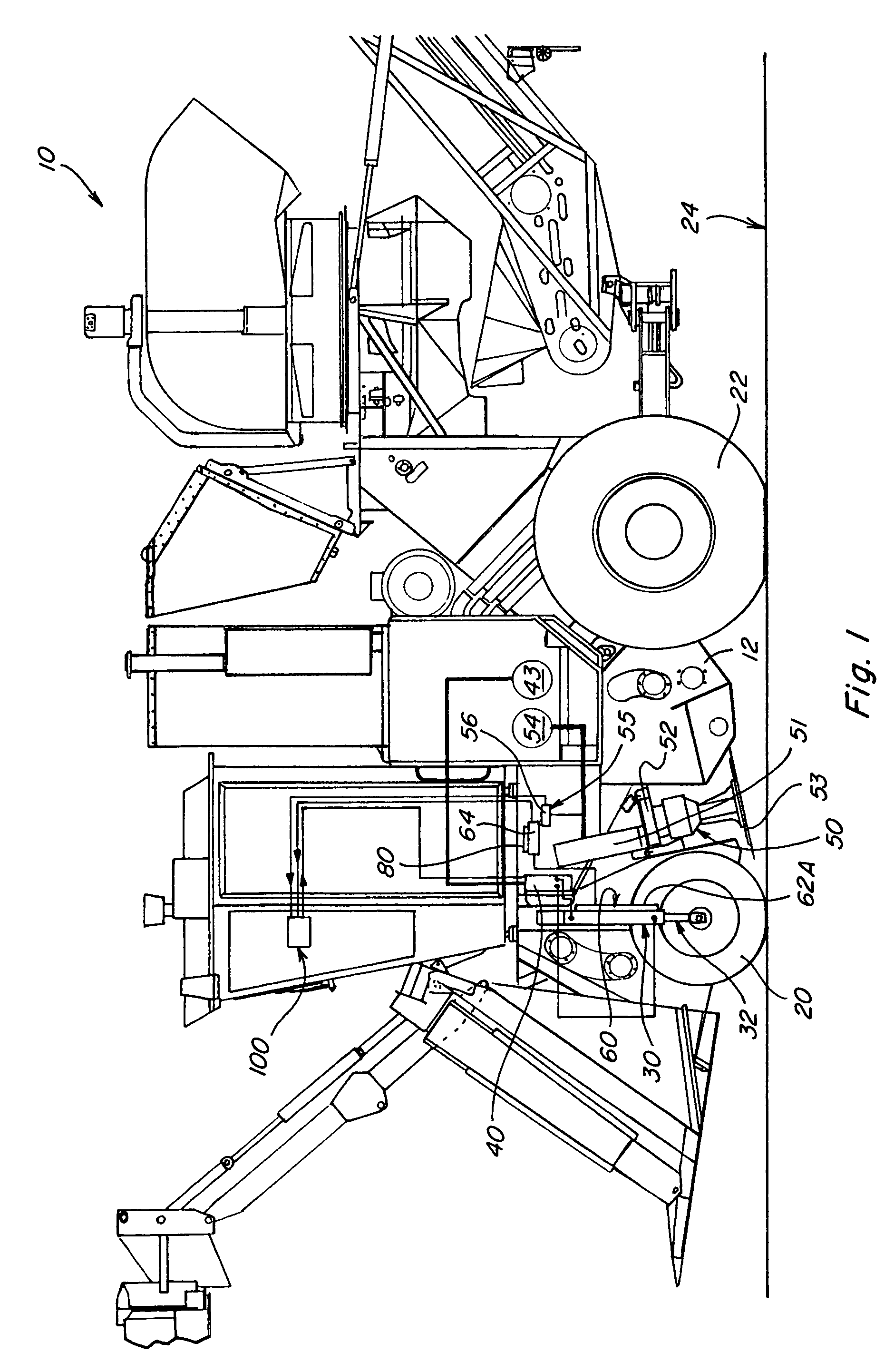

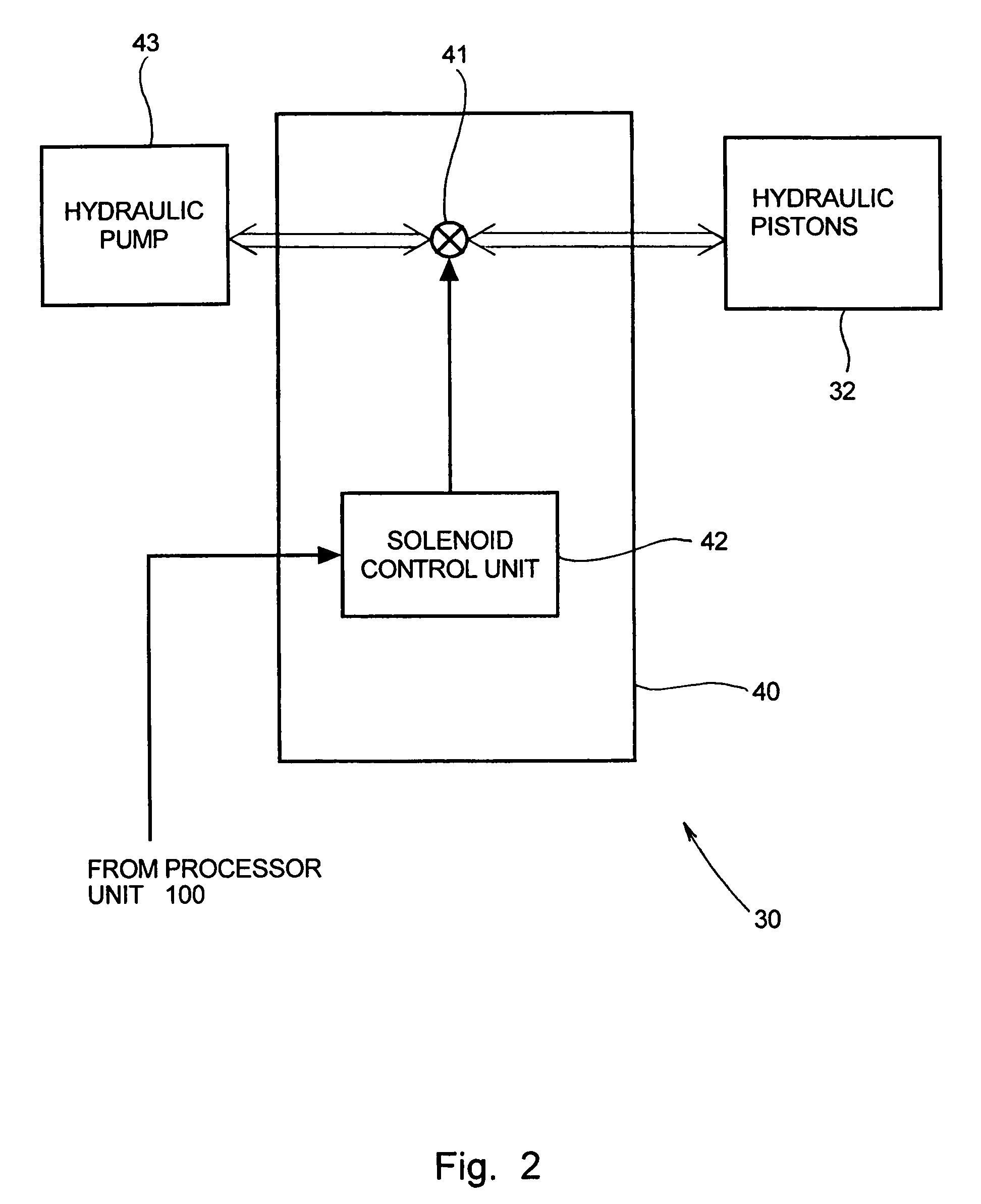

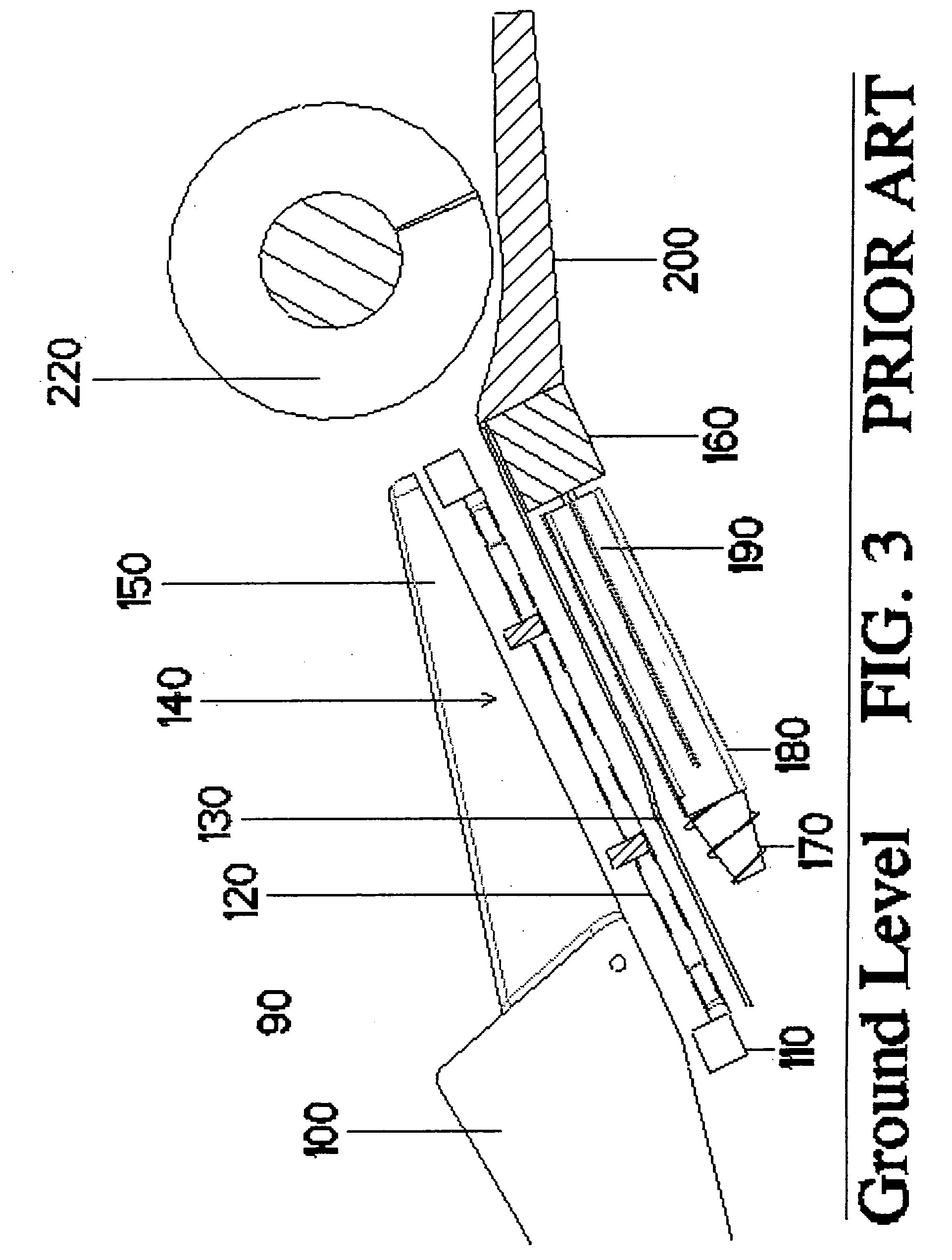

System and method for controlling the base cutter height of a sugar cane harvester

ActiveUS7401455B1Quick responseReduce the overall heightMowersPicking devicesAutomatic controlControl system

Owner:BLUE LEAF I P INC

A crop monitoring system and method

A harvester monitoring system configured to determine one or more parameters associated with harvested items, the system comprising: a camera module having a field of view and configured to generate image data associated with the harvested items; a mounting bracket configured to secure the camera module to a harvester such that a conveyor of the harvester is within the field of view of the camera module; a location sub-system configured to determine and output location data representative of a geographical location of the harvester monitoring system; and a processing unit configured to receive the image data and the location data, to determine one or more parameters associated with the harvested items, and to record the one or more parameters in association with the location data on a computer readable medium.

Owner:B HIVE INNOVATIONS LTD

System and method for operating an agricultural harvester

In one aspect, a system for operating an agricultural harvester may include a sensor assembly configured to detect a parameter indicative of an operating line of the harvester. The system may also include a controller configured to monitor the operating line of the harvester based on measurement signals received from the sensor assembly when the harvester is operated in a first operating mode. The controller may also be configured to determine a differential between the operating line and a predetermined guidance line of the harvester. Furthermore, the controller may be configured to update a stored correction value based on the determined differential. Additionally, when the harvester is switched from the first operating mode to a second operating mode, the controller may be configured to adjust a location of the predetermined guidance line based on the stored correction value.

Owner:BLUE LEAF I P INC

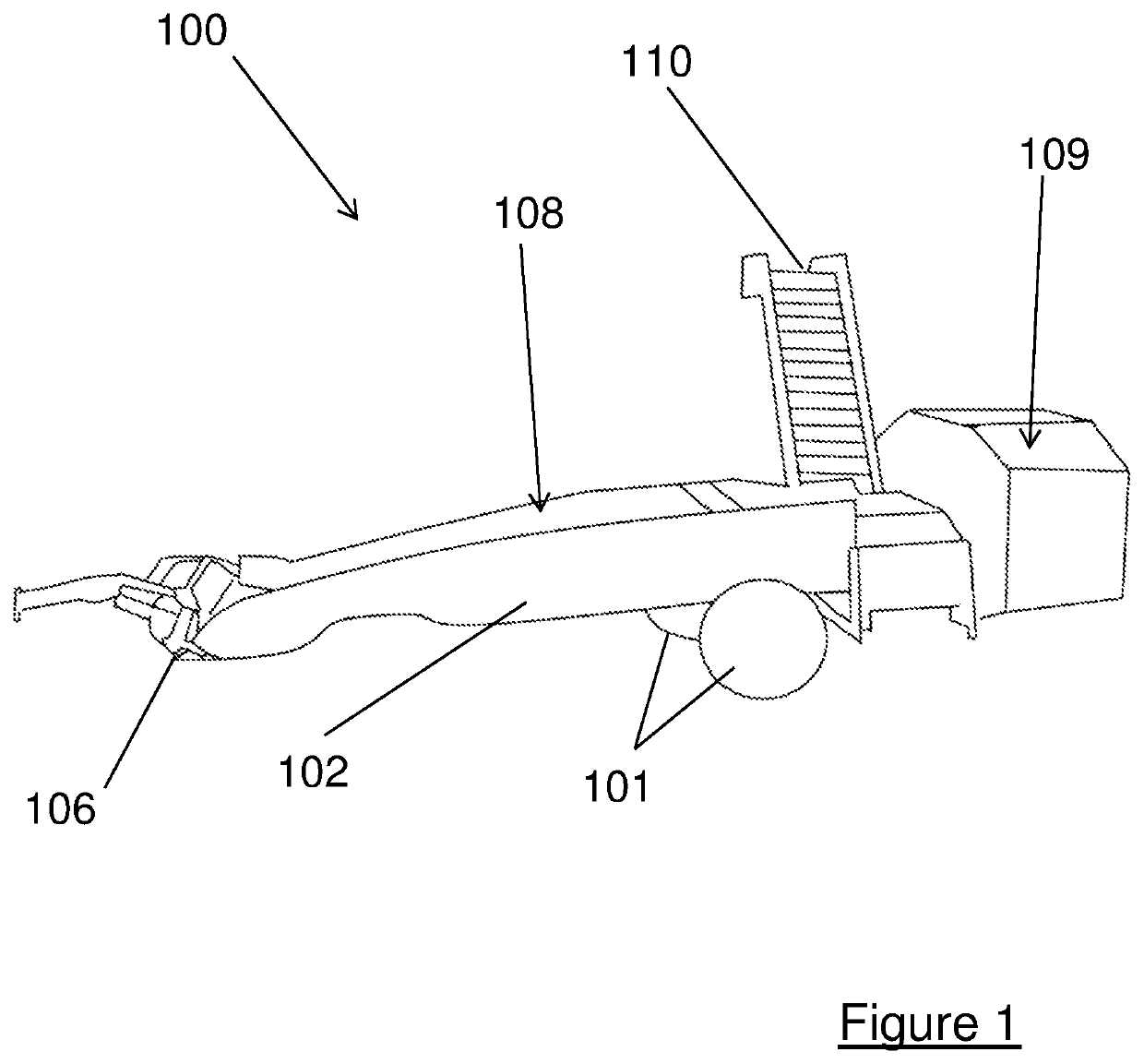

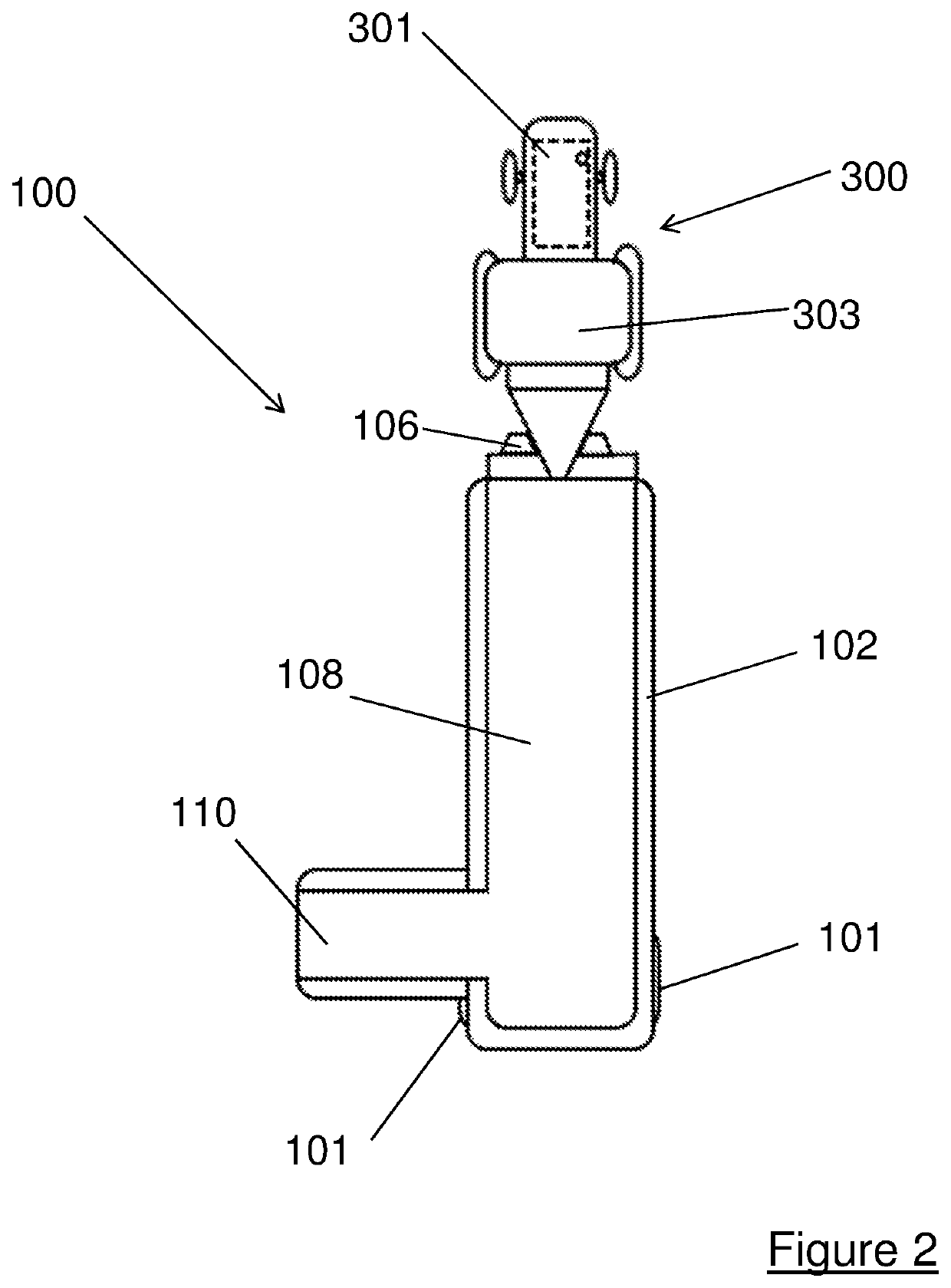

Corn Stalk Harvester

An apparatus for the harvesting and collecting of plant materials from the tops of the plants, such as a corn plant, or other types of crops, above the ear(s), either before, during or after pollination, sweet corn harvesting time or at the black layer, while the stalk is still alive, and has most of its moisture, or at any advantageous time in the growing cycle and collect such plant materials for livestock feed, fuels, sugars or other nutrients, and or for any other useful purpose.

Owner:DOERSCHER SR ARTHUR CHARLES

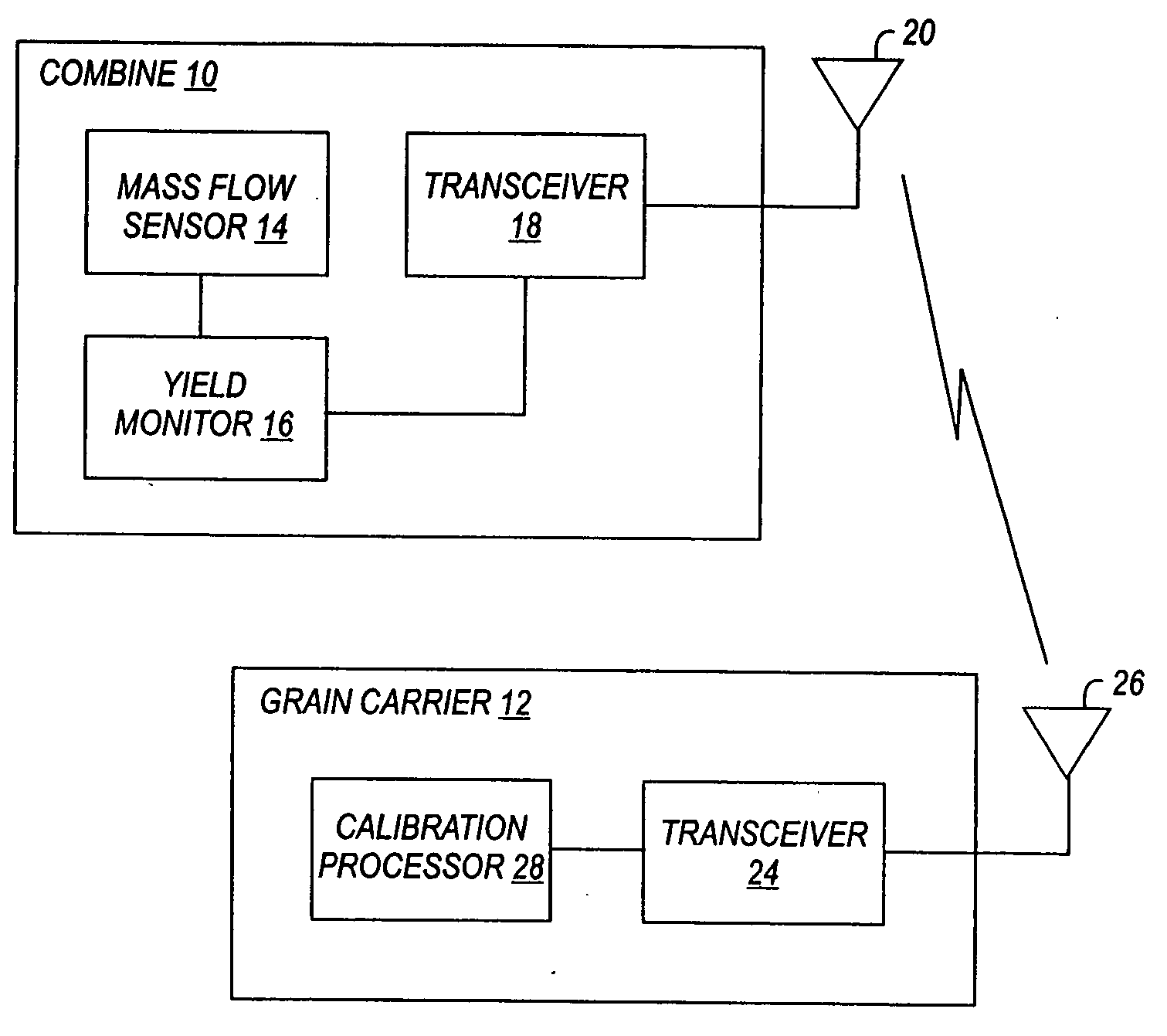

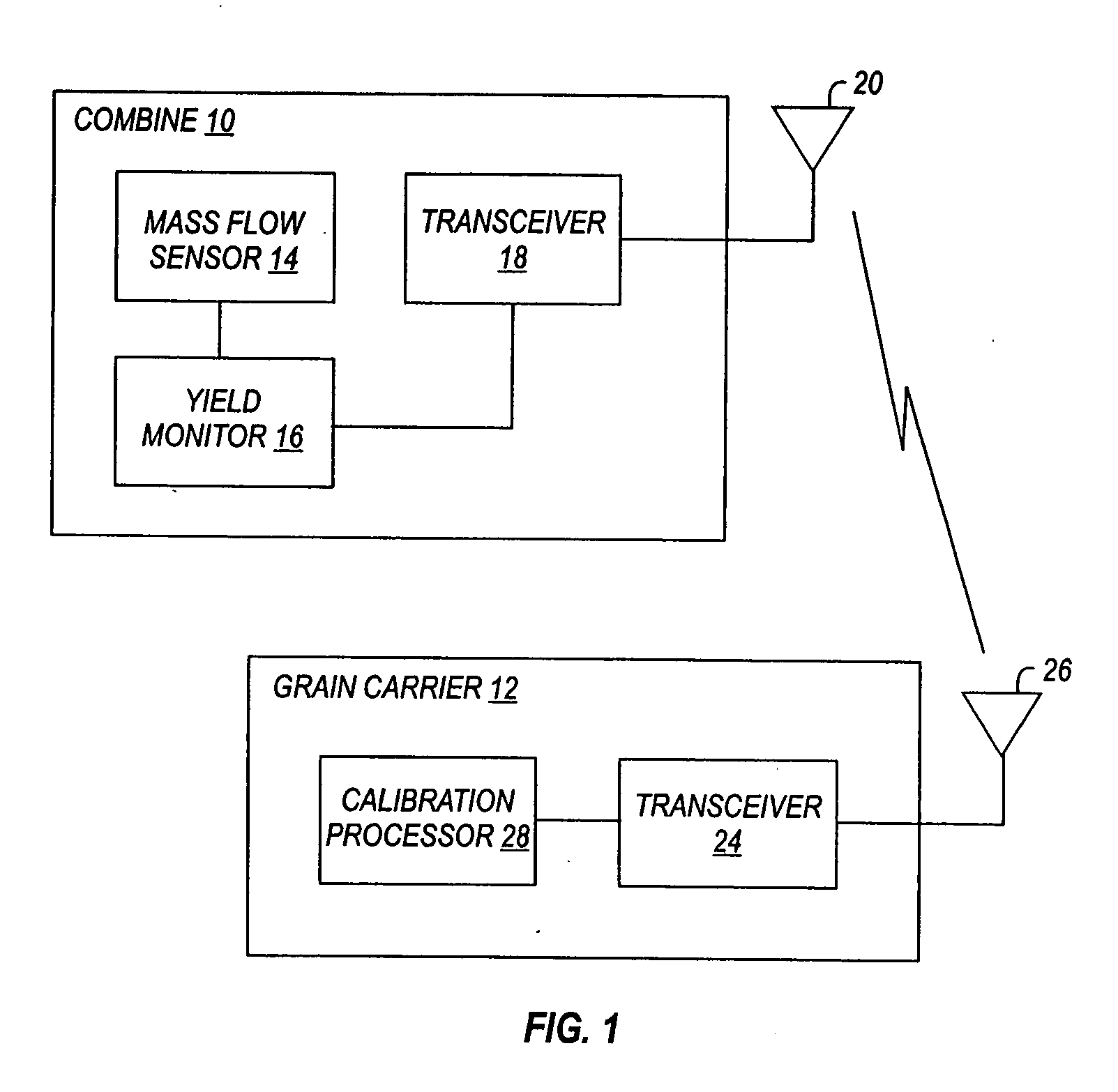

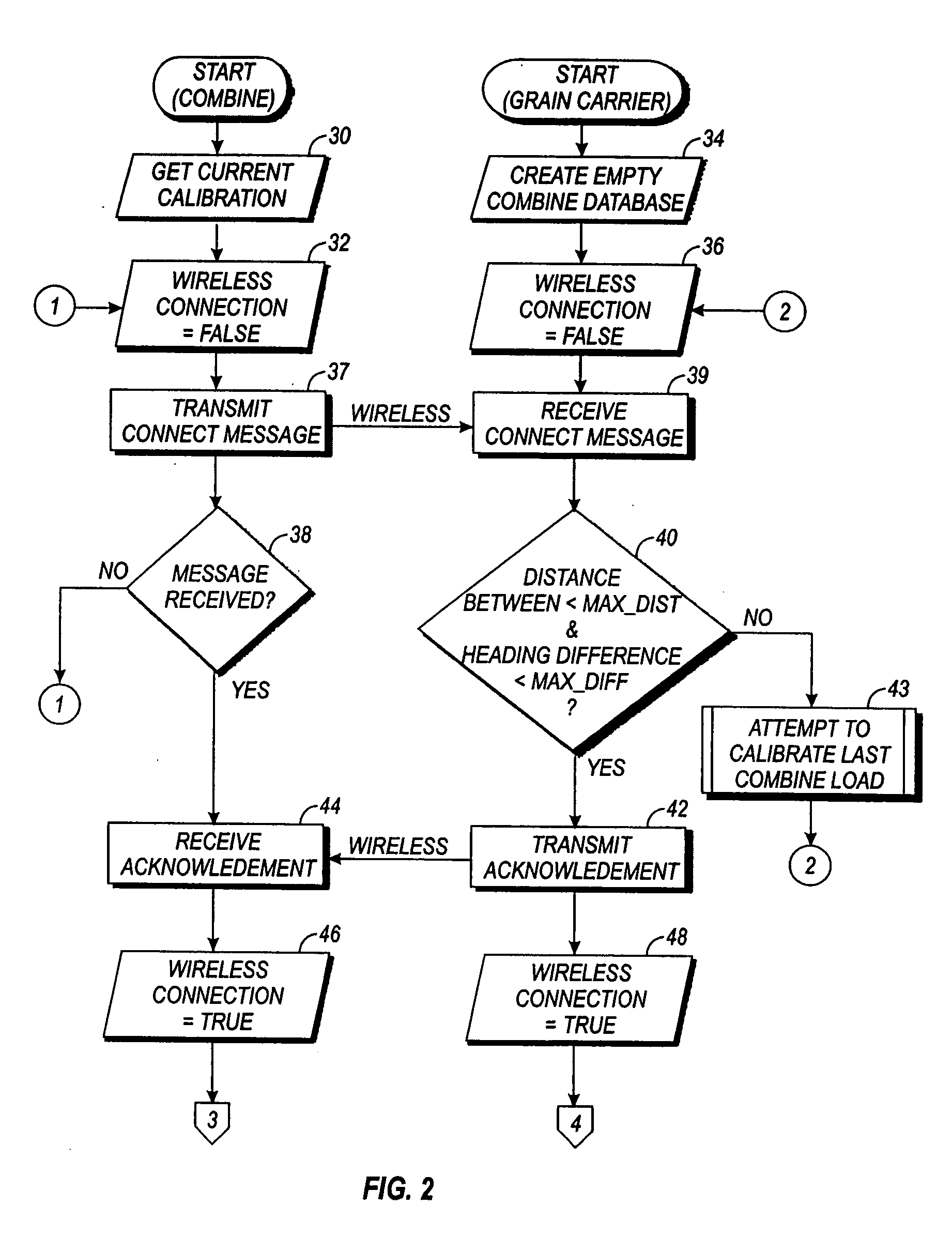

Automatic mass-flow sensor calibration for a yield monitor

A system and method is provided for remotely and automatically calibrating a mass-flow sensor in a yield monitor of a combine. The invention uses a wireless communication device installed on a combine and a remote wireless communication device installed on a grain carrier or truck carrier. Once an actual weight is obtained, calibration information is sent to the combine to calibrate the mass-flow sensor.

Owner:DEERE & CO

System and method for measuring grain cart weight

ActiveUS10760946B2Compensation effectIncrease diversityLoadersBeacon systems using radio wavesAccelerometerAgricultural engineering

Owner:BITSTRATA SYST INC

Method and apparatus to reduce stalk shear

The invention provides four (4) methods to reduce stalk shear in a corn head row unit that utilizes a non-variable or dependent drive system. The four methods described include altering the gearbox ratio, increasing the lengths of the fluted portion of the stalk roll, increasing stalk roll diameter or reducing the size of the gathering chain drive sprocket. The invention allows for a more balanced application of multi directional energy to be applied to the corn plant. The resultant effect is to reduce stalk shear which reduces trash intake to the harvester. This novel idea provides the first means and method to which genetically improved taller and healthier corn plants can be harvested with minimal amounts of material other than ears ultimately being transferred to the threshing unit.

Owner:CALMER MARION

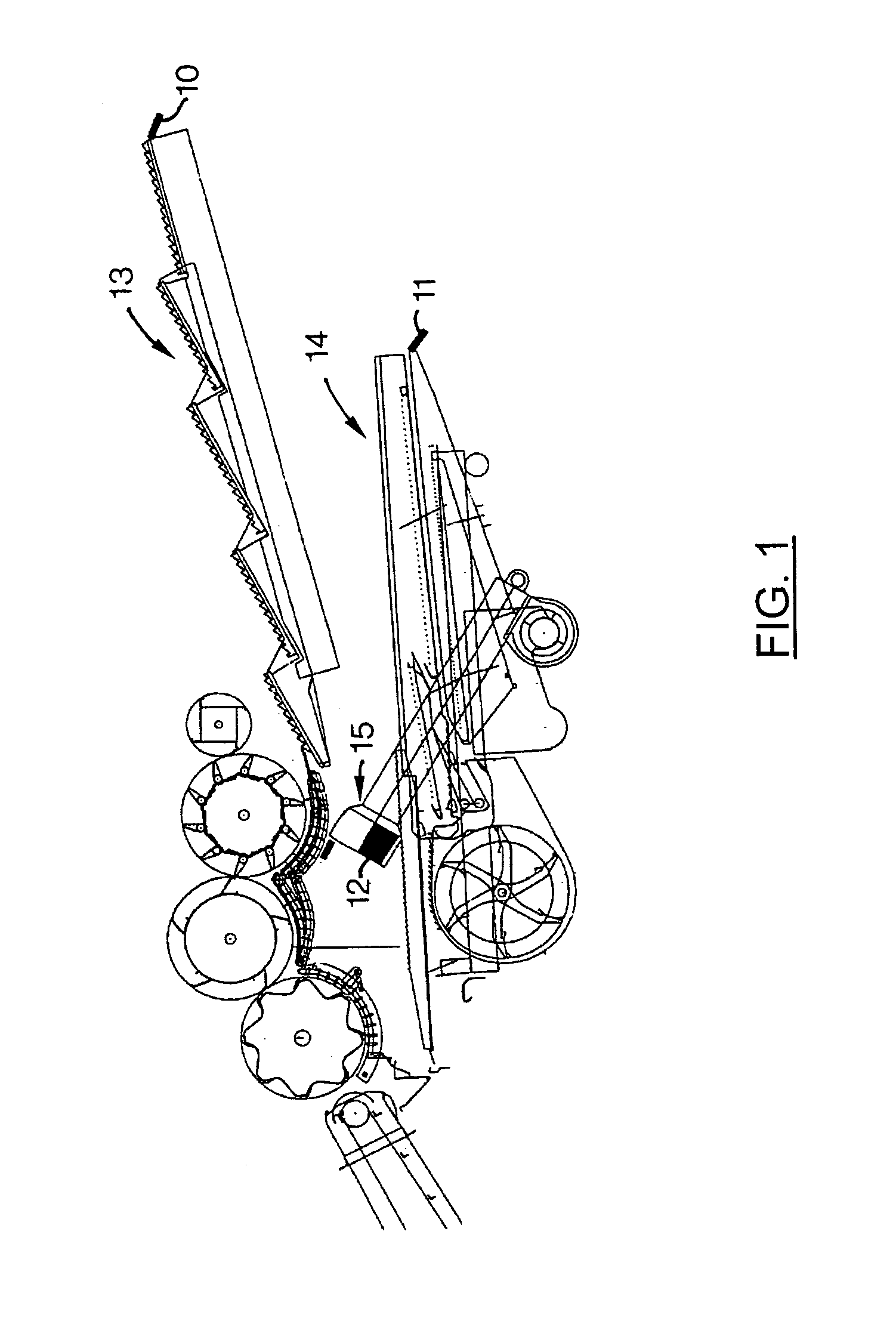

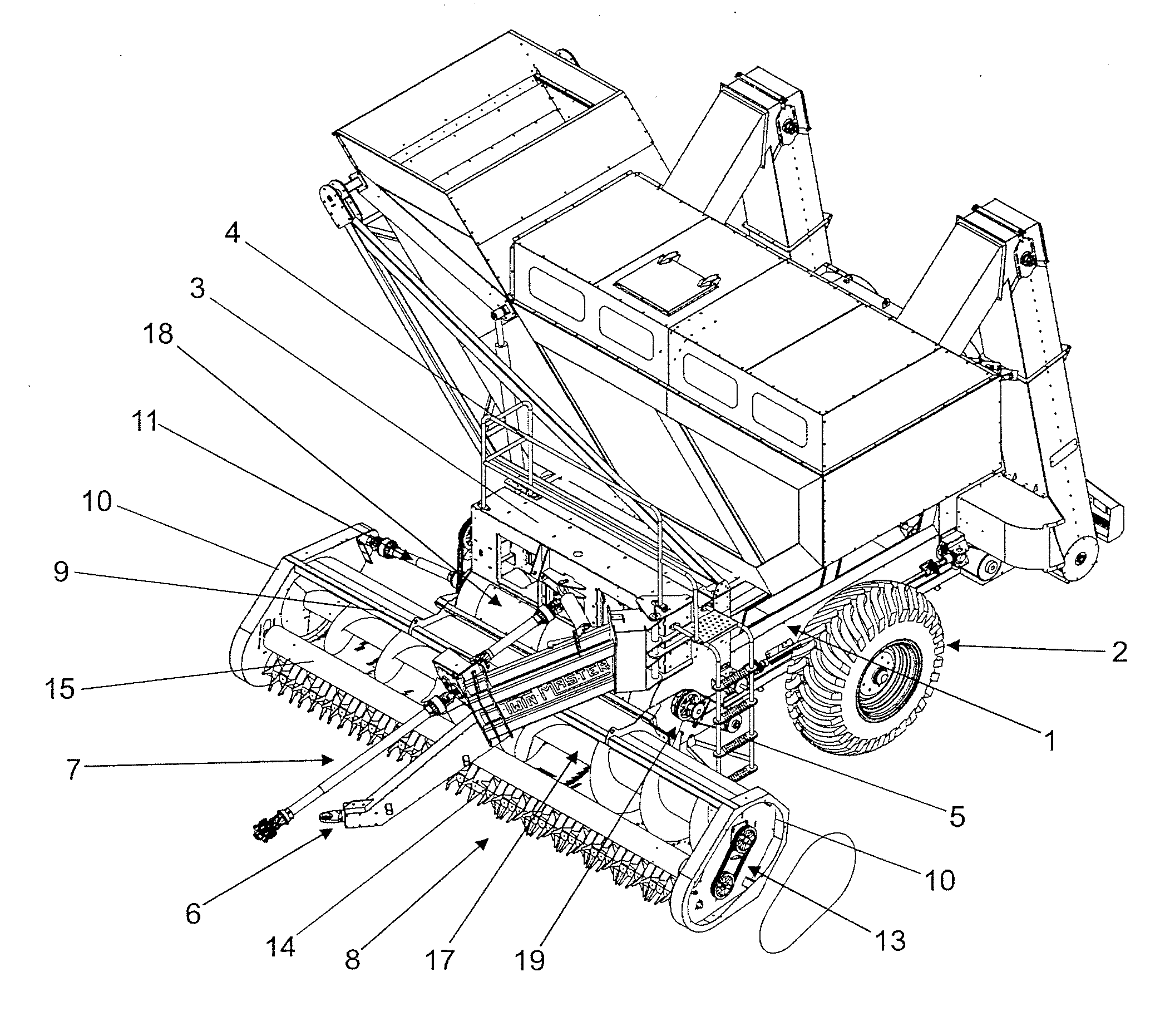

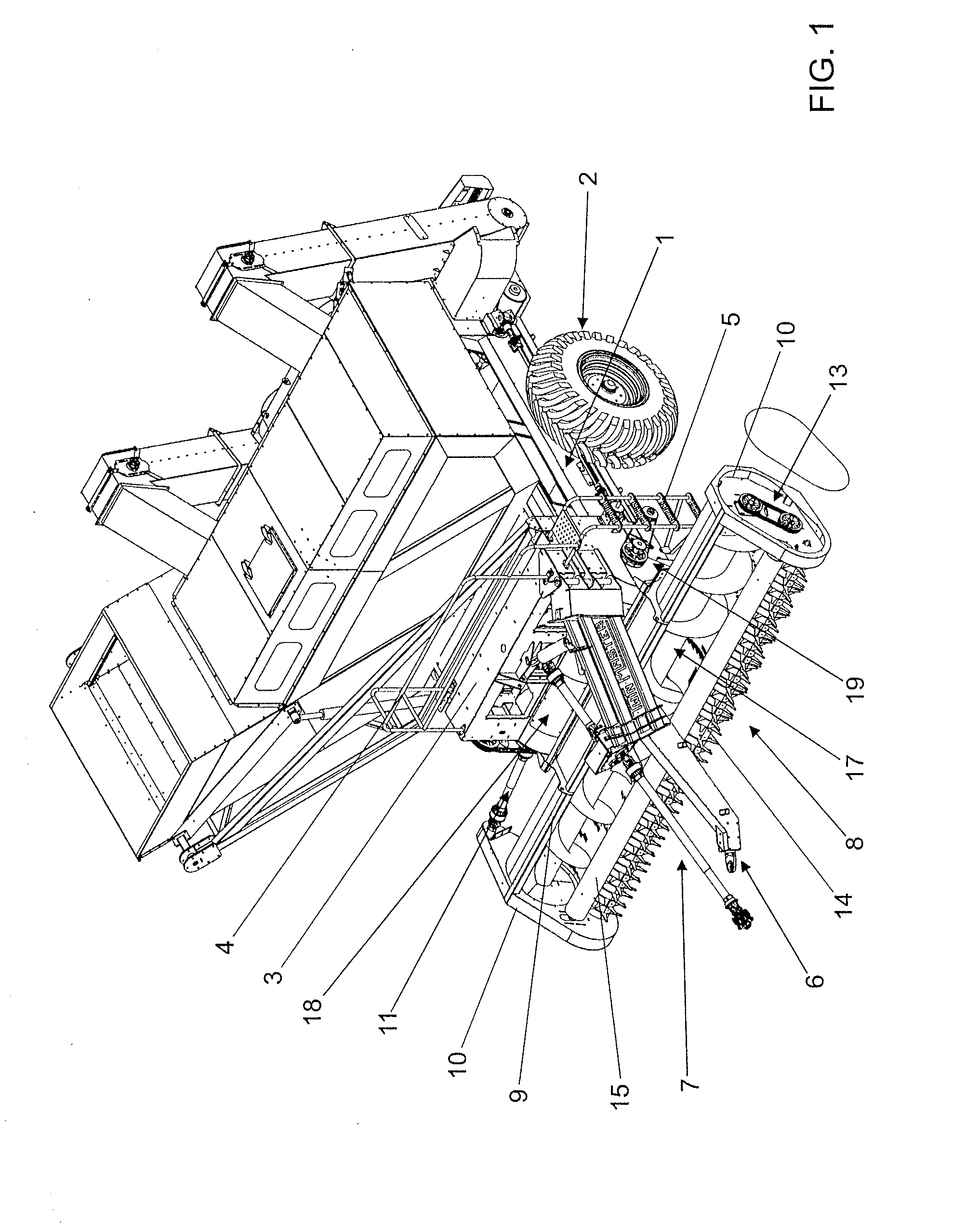

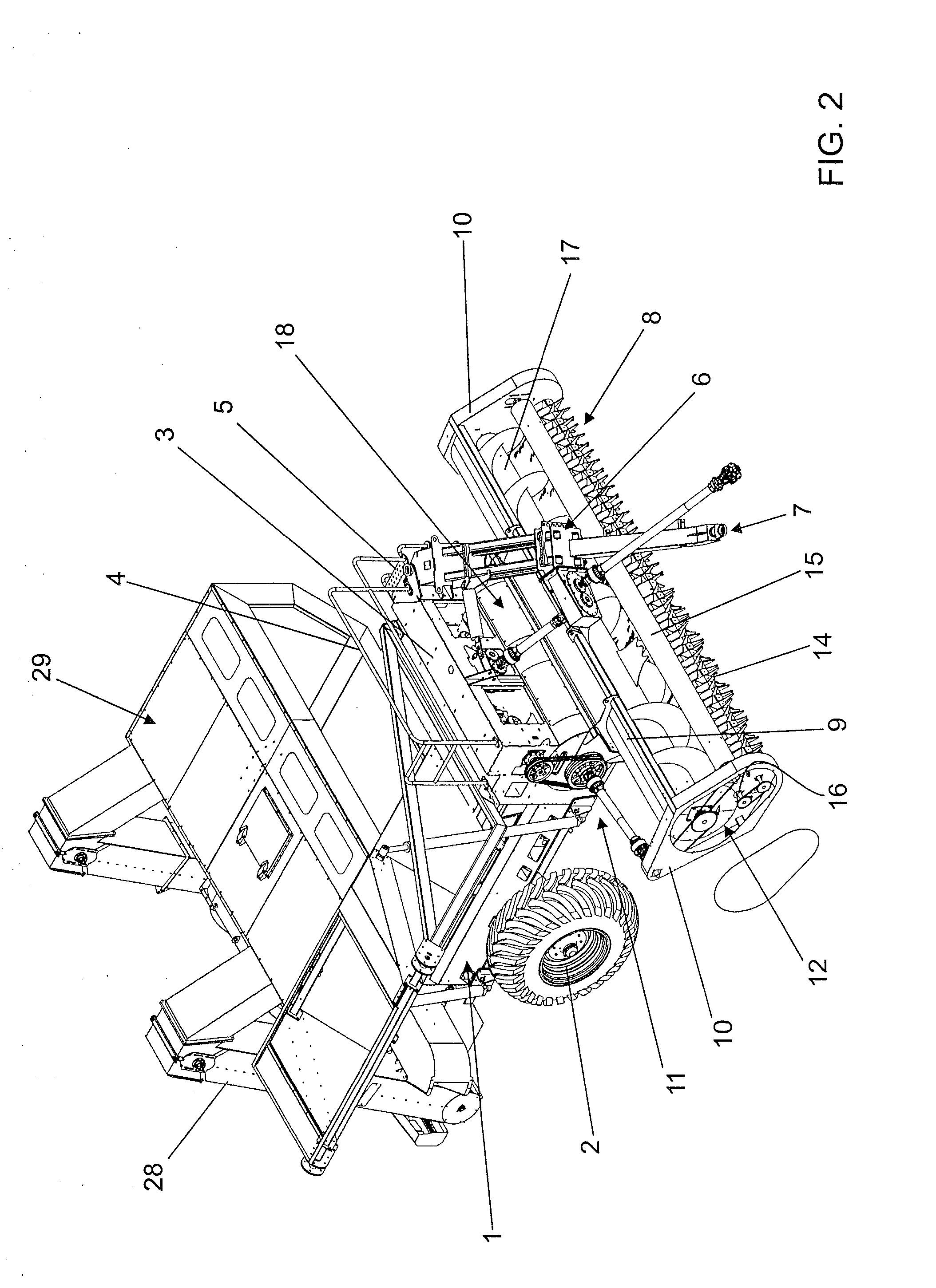

Grain reaper

ActiveUS20080295476A1The process is simple and fastWork resistanceMowersDigger harvestersEngineeringReaper

The present invention relates to a reaper for grains, specially for the bean grains. More specifically, the present invention refers to technical and functional improvements specially developed and introduced which configures a bean reaper that is classified as a trailer to carry out two different operations, the first one of which is gathering various plants, such as bean plants, peanuts and other grains, plants which are previously plucked and aligned, whereas the second function of which is to perform a whole cleaning process by separating the grains (seeds) from the remaining unwanted parts.

Owner:IND REUNIDAS COLOMBO LTD

Wind guard latch retainer

ActiveUS6935094B1Reliable constructionReduce manufacturing costLoadersMowersEngineeringAgricultural crops

Owner:CNH IND AMERICA LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com