Method and apparatus to reduce stalk shear

a technology of stalk shear and apparatus, applied in the field of corn harvesting machinery, can solve the problems of reducing the efficiency of the stalk, affecting the harvesting equipment, and affecting the harvesting efficiency of corn, so as to reduce the intake of trash and increase the harvesting ground speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]

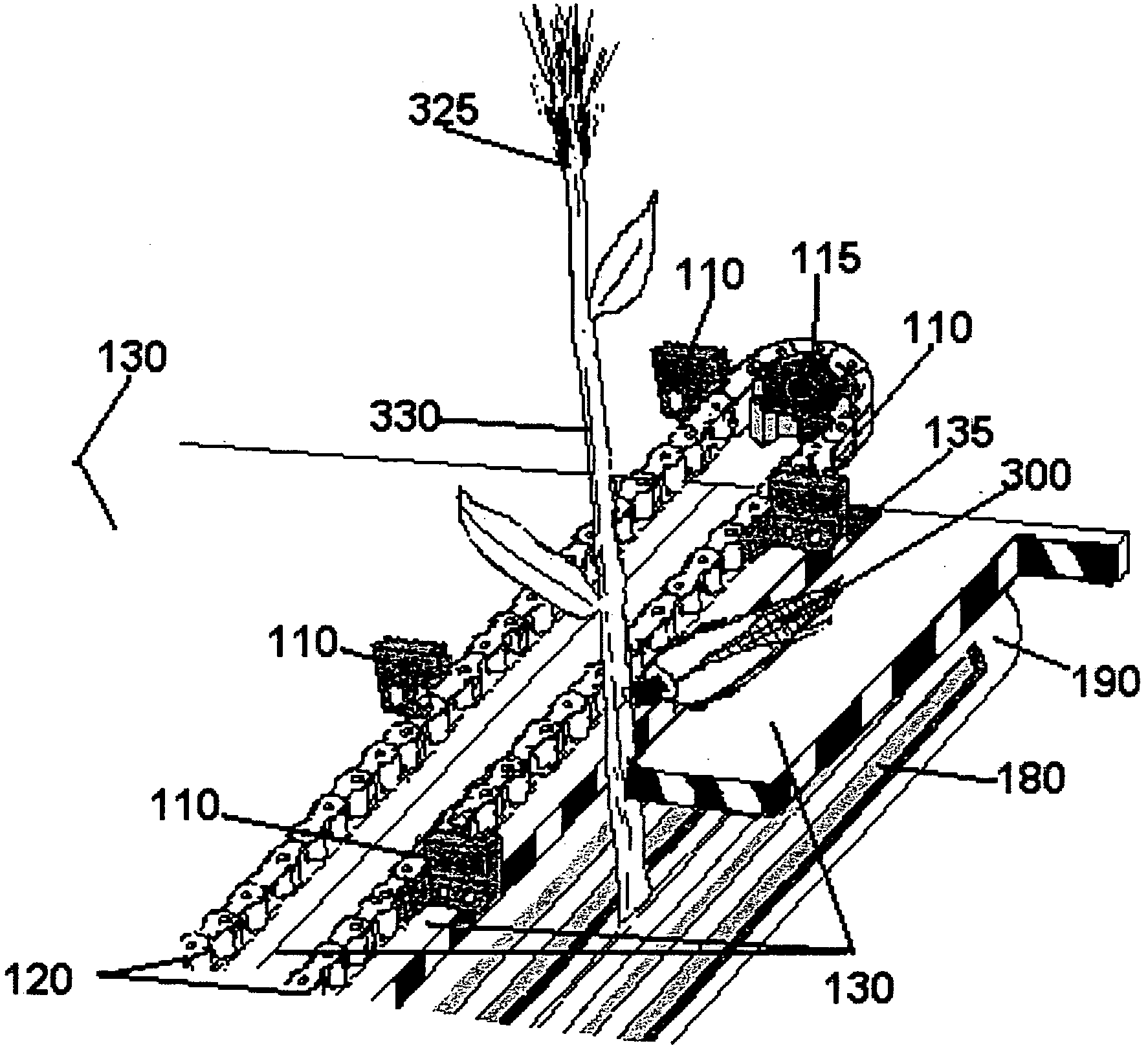

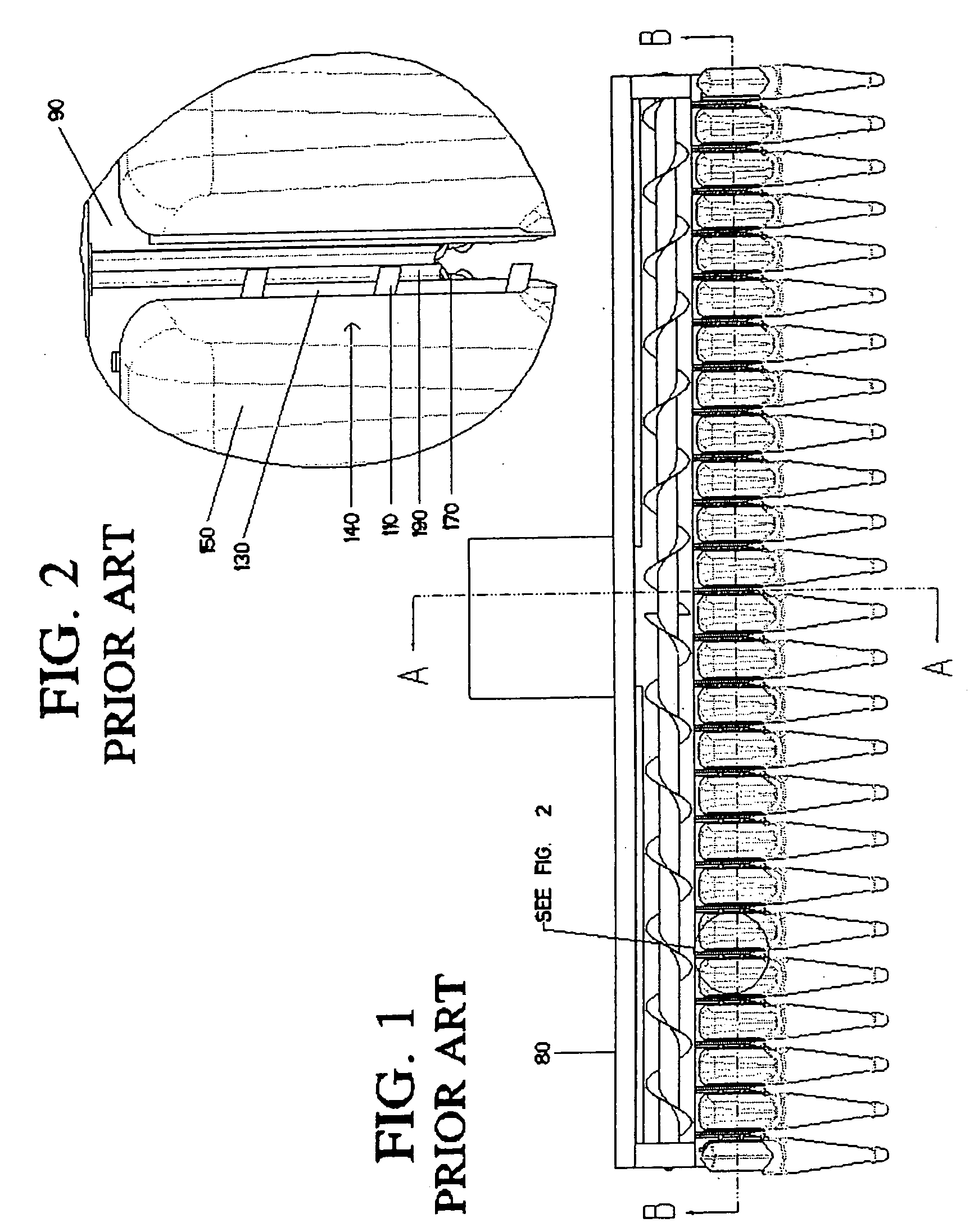

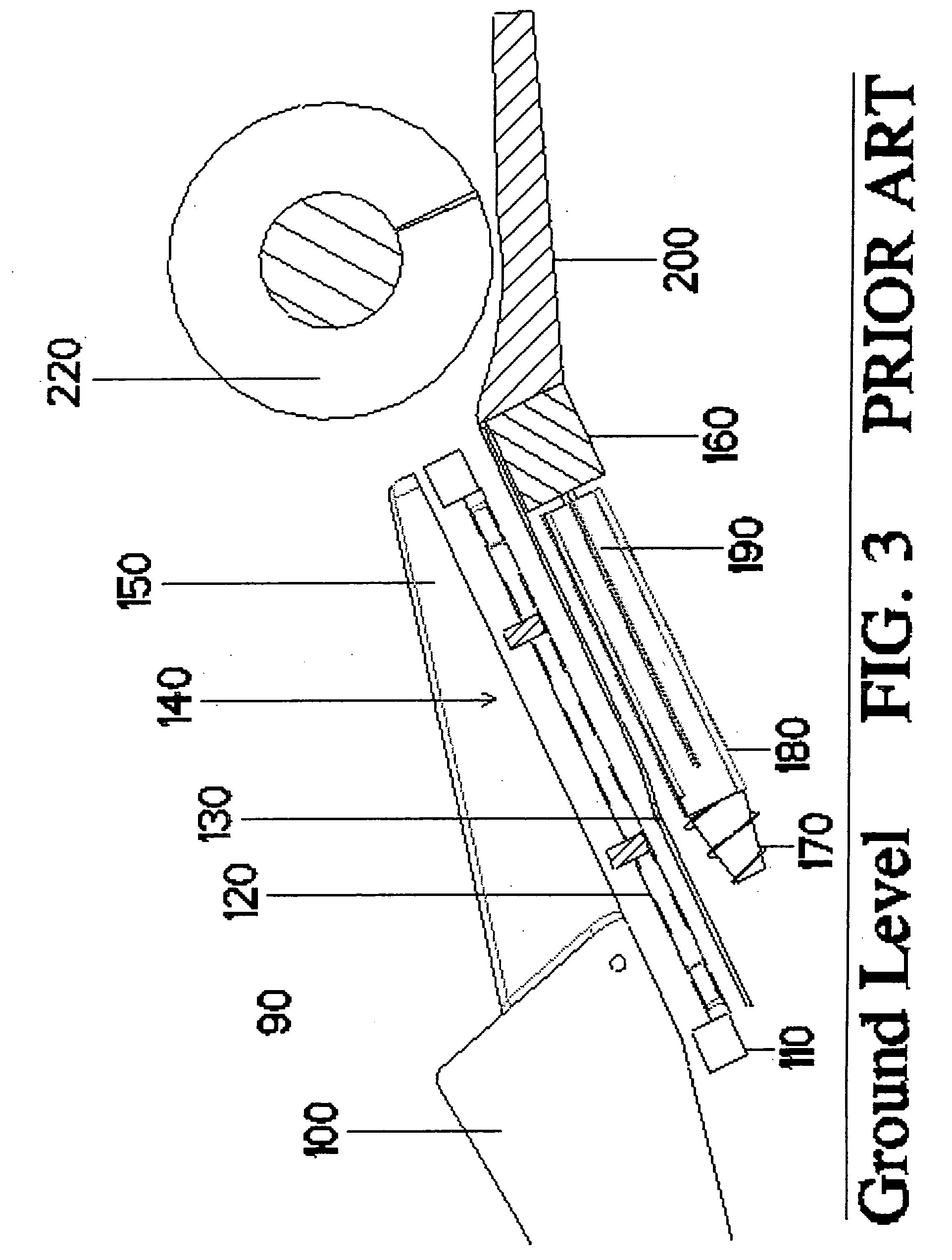

Listing of the ElementsDescriptionNumberCorn head80Row unit90Row unit dividers100Gathering chain paddles1108 tooth gathering chain drive sprocket (Prior Art)1125 tooth gathering chain drive sprocket115Gathering chain120Stripper plates130Row unit shear point135Ear Separation Chamber140Row unit covers150Gearbox160Transport vanes170Stalk Roll flutes180Stalk rolls190Cross Auger Trough200Cross Auger220Corn plant ear300Upper Portion of Corn Plant Stalk325Lower Portion of Corn Plant Stalk330

[0046] The general operation of corn heads incorporating this invention in FIGS. 1 through 9 are similar to that of the operation of corn heads of the prior art as illustrated in FIGS. 1, 2 and 3. As shown in FIG. 1, corn heads are provided with several row crop dividers 100 for retrieving, lifting, and directing the rows of corn stalks toward there respective ear separation chambers 140. In FIGS. 1 and 3 the corn stalks are lifted and guided toward the row unit 90 by row unit dividers 100. Row un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com